Page 1

Installation Manual of Room Air Conditioner

Preparation

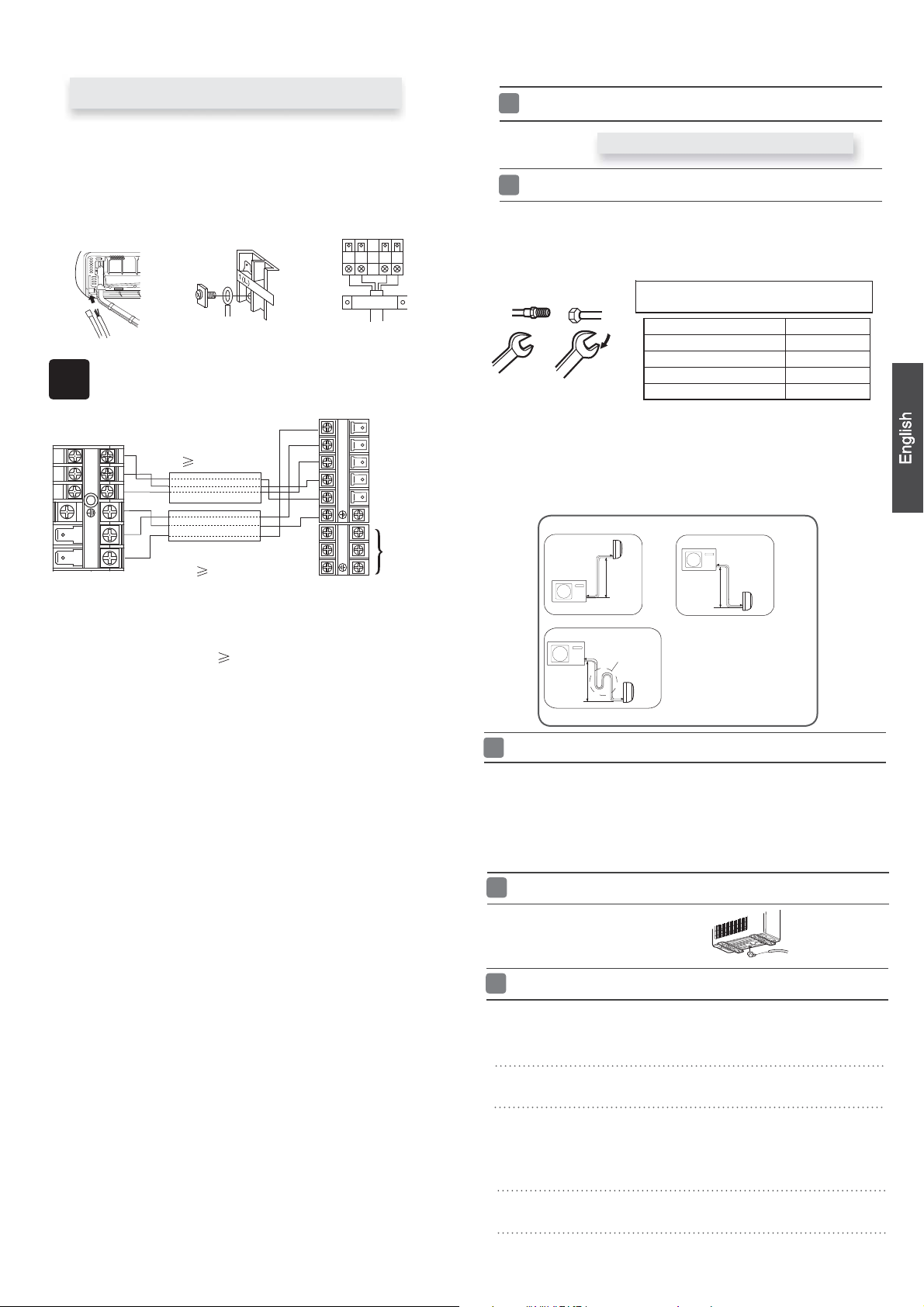

Necessary Tools for Installation

Tor que wr ench

Driverƽ

Nipperƽ

Hacksawƽ Pipe cutterƽ

Hole core drillƽ Flaring toolƽ

Spanner(17,19 and 26mm)ƽ Knifeƽ

Gas leakage detector orƽ

soap-and-water solution

ƽ

(17mm,2 2mm,2 6mm)

Measuring tapeƽ

Reamerƽ

Power Source

ƽ

Before inserting power plug into receptacle, check the voltage without fail.

The power

Install an exclusive branch circuit of the power.

ƽ

Areceptacleshallbesetupin a distancewherethepowercablecanbe

ƽ

reached.

sourceisthesameasthe

Donotextendthecablebycuttingit.

corresponding name plate.

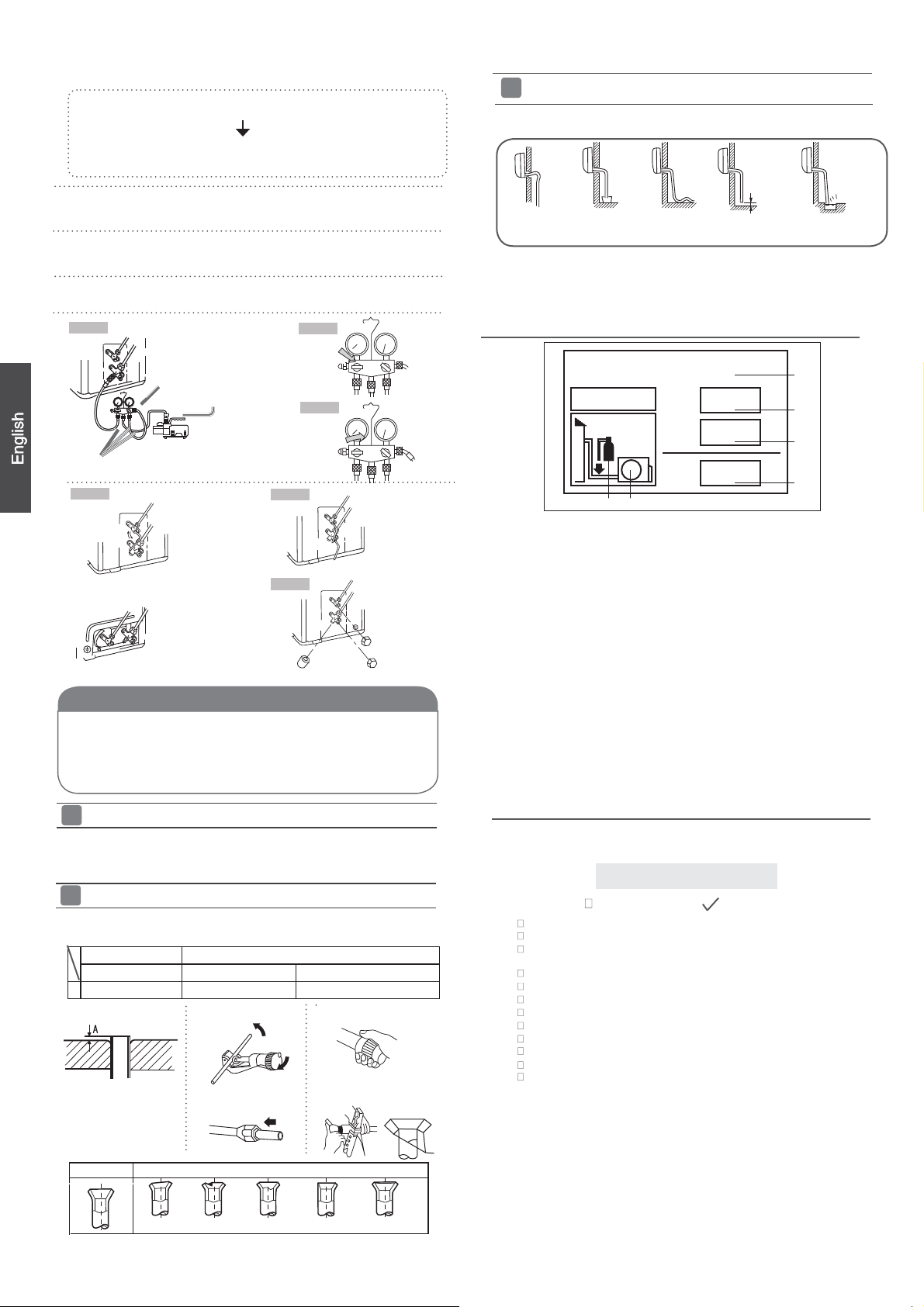

Drawing for the installation of indoor and outdoor units

ThemodelsadoptHFCfreerefrigerantR410A

more than 5cm

more than

10cm

Selection of Installation Place

Indoor Unit

Place, robust not causing vibration, where the body can be supported sufficiently.ƽ

Place, not affected by heat or steam generated in the vicinity, where inlet and outlet of the

ƽ

unit are not disturbed.

Place, possible to drain easily, where piping can be connected with the outdoor unit.ƽ

Place,wherecoldaircanbespreadin a roomentirely.ƽ

Place, nearby a power receptacle, with enough space around. (Refer to drawings).ƽ

Place where the distance of more than lm from televisions, radios, wireless apparatuses

ƽ

and fluorescent lamps can be left.

In the case of fixing the remote controller on a wall, place where the indoor unit can

ƽ

receive signals when the fluorescent

lampsintheroomarelightened.

Outdoor Unit

Place, which is less affected by rain or direct sunlight and is sufficiently ventilated.ƽ

Place,possibletobeartheunit,wherevibrationandnoisearenotincreased.ƽ

Place, where discharged wind and noise do not cause a nuisance to the neighbors.ƽ

Place, where a distance markedƽ

Attention must be paid to

the rising up of drain hose

is available as illustrated in the above figure.

Optional parts for piping

Non-adhesive tape

A

Adhesive tape

B

Saddle (L.S) with screws

G

C

Connecting electric cable

D

for indoor and outdoor

E

Drain hose

Heating insulating material

F

G

Piping hole cover

Arrangement of piping

directions

Rear left

Left

Below

The marks from to

ƽ

G

in the figure are the

parts numbers.

Thedistancebetween

ƽ

the indoor unit and the

floor should be more

than 2m.

A

Rear

right

Right

more than 10cm

more than

60cm

more than 10cm

A

more than

10cm

more than15cm

F

C

Floor fixing dimensions of the

outdoor unit (Unit:mm)

113.5

633

043

113.5

Fixing of outdoor unit

Fix the unit to concrete or blockƽ

with bolts (10mm) and nuts firmly

and horizontally.

When fitting the unit to wall

ƽ

surface, roof or rooftop, fix

D

E

asupportersurelywithnails

orwiresinconsideration of

earthquakeandstrongwind.

If vibration may affect the

ƽ

house, fix the unit by attaching a

vibration-proof mat.

Please be subject to the actual product purchased , the above picture is just for your reference.

Read this manual before installation

Explain sufficiently the operating means to the user according to this manual.

NO.0010526881

Page 2

Accessory parts

Installation of the Indoor Unit

Remote controller (1)

R-03 dry battery (2)

Mounting plate (1)

Plastic cap (4)

Ø4X25 Screw

(4)

Drain hose (1)

Cushion (4)

Drain-elbow (1)

Pipe supporting plate (1)

Selection of pipe

Liquid pipe (Ø)

Gas pipe (Ø)

NOTE˖The thickness of the pipe must be 0.8mm at least.

6.35mm(1/4”)

15.88mm(5/8”)

Indoor unit

FittingoftheMountingPlateand

Whenthemountingplateisfirstfixed

1. Carry out, based on the neighboring pillars or lintels, a

tobefixedagainstthewall,then

2. Make sure once more the proper level of the plate, by

weight from the central top of the plate, then fasten securely the plate with the

attachment steel nail.

3. Find the wall hole location A using a measuring tape

temporarily fasten the plate with one steel nail.

Positioning of the wall Hole

proper leveling for the plate

hanging a thread with a

Drawing of pipe

[ Rear piping ]

Drawpipesandthedrainhose,thenfastenthemwiththeadhesivetape

ƽ

[Left・Left-rear piping ]

ƽ

In case of left side piping, cut away, with a nipper, the lid for left piping.

In case of left-rear piping, bend the pipes according to the piping direction to

ƽ

themark of holeforleft-rearpipingwhichismarkedonheatinsulationmaterials.

1. Insert the drain hose into the dent of heat insulation

2. Insert the indoor/outdoor electric cable from backside of

outonthefrontside,thenconnect them.

3.Coattheflaringsealfacewithrefrigerantoilandconnect

Cover the connection part with heat insulation materials closely, and make sure

fixingwithadhesivetape

Heat insulation

material

Lid for right

piping

Lid for under piping pipe

Fixwithadhesivetape

ƽ

Indoor/outdoorelectriccableanddrainhosemustbeboundwithrefrigerant

piping by protecting tape.

Lid for left piping

Drain hose

materials of indoor unit.

indoor unit, and pull it

pipes.

Indoor/outdoor electric cable

Piping

Pipe supporting

plate

[ Other direction piping ]

ƽ

Cut away, with a nipper, the lid for piping according to the piping direction and

thenbendthepipeaccordingtotheposition of wallhole.Whenbending,be

careful not to crash

ƽ

Connect beforehand the indoor/outdoor electric cable,

connected to the heat insulation of connecting part specially.

pipes.

andthenpulloutthe

B= 70mm

A=150mm

When the mounting plate is fixed side bar and lintel

Fix to side bar and lintel a mounting bar, Which is separately sold, and then

ƽ

fasten the plate to the fixed mounting bar.

Refer to the previous article, “ When the mounting plate is

ƽ

position of wall hole.

Making a Hole on the Wall and Fitting the Piping Hole Cover

Make a hole of 70 mm in diameter, slightly descending to outside the wall.

ƽ

Installpipingholecoverandsealit offwithputty afterinstallation

ƽ

Wall hole

first fixed “, for the

35mm

Fixing the indoor unit body

Hang surely the unit body onto the upper notches of the

ƽ

mounting plate. Move the body from side to side to verify its

secure fixing.

Inordertofixthebodyontothemountingplate,holdup

ƽ

thebodyaslantfromtheundersideandthenputitdown

perpendicularly.

Unloading of indoor unit body

When you unload the indoor unit,please use

ƽ

your hand to arise the body to leave agraffe,

then lift the bottom of the body outward

slightly and lift the unit aslant until it

leaves the mounting plate.

agraffe

Connecting the indoor/outdoor Electric Cable

Removing the wiring cover

Remove terminal cover at right bottom corner of indoor unit, then takeƽ

offwiringcoverbyremovingitsscrews.

mounting plate

mounting plate

Ø70mm

When connecting the cable after installing the indoor unit

Indoor side

(Section of wall hole)

Thickness of wall

Piping hole pipe

G

Outdoor side

1. Insert from outside the room cable into left side of the wall

hole,inwhichthepipehasalreadyexisted.

2. Pull out the cable on the front side, and connect the cable

making a loop.

2

Page 3

When connecting the cable before installing the indoor unit

Outdoor unit

Installation of Outdoor Unit

Insert the cable from the backƽ

ƽ

Loosen the screws and insert

tighten the screws.

ƽ

Pull the cable slightly to

tightened.

After the cable connection,

ƽ

wiring cover.

When connecting the cable, confirm the terminal number of indoor and

Note

outdoor units carefully. If wiring is not correct, proper operation can not

be carried out and will cause defect.

connecting wiring:

45

3

2

1

Indoor unit

Power cable:

side of the unit, then pull it out

the cable ends fully into

make sure the cables have

never fail to fasten the connected cable with the

3X0.75mm

connecting wiring:

3G0.75mm

2

2

terminal block, then

been properly inserted and

Outdoor unit

HSU-24HEK03/R2

HSU-24HEA03/R2

3G2.5mm

2

on the front side.

1

2

3

4

5

L

N

POWER

Install according to Drawing for the installation of indoor and

Connection of pipes

ƽ

To bend a pipe, give the roundness as large as possible not to crush the pipe ,

andthebendingradiusshouldbe30to40

ƽ

Connecting the pipe of gas side first makes working easier.

TheconnectionpipeisspecializedforR410A.ƽ

Half union

Spanner

Becarefulthatmatters,suchaswastesofsands,etc.shallnotenterthepipe.

Thestandardpipelengthis5m.Ifitisover7m,thefunctionoftheunitwillbe

affected.Ifthepipehastobelengthened,therefrigerantshouldbecharged,

accordingto20g/m.Butthechargeofrefrigerantmust

sionalairconditionerengineer.Beforeaddingadditionalrefrigerant,performair

purging from the refrigerant pipes and indoor unit using a vacuum pump,then

charge additional refrigerant.

Flare nut

Torque wrench

CAUTION

B

Outdoor unit

Outdoor unit

A

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Liquid side6.35mm(1/4") 18N.m

Liquid/Gas side9.52mm(3/8") 42 N.m

Gas side 12.7mm(1/2") 55N.m

Gas side 15.88mm(5/8") 60 N.m

Indoor unit

A

Oil trap

B

Indoor unit

mm or longer.

Pipe Diameter(ǿ) Fastening torque

Outdoor unit

B

Indoor unit

A

Max.Elevation:

●

In case the elevation A is more●

than 5m, oil trap shoud be

installed every 5~7m

●

Max. Length:

In case the pipe length B is●

more than 7m, the refrigerant

should be charged, according

to 20 g/m.

Amax=15m

Bmax=25m

outdoor units

be conducted by profes-

1.Ifthesupplycordisdamaged,itmustbereplacedbythemanufacturerorits

service agent or a similar qualified person. The type of connecting wire is H05RN-F

or H07RN-F.

2. If the fuse on PC board is broken please change it with the

3.Thewiringmethodshouldbeinlinewiththelocalwiringstandard.

4. After installation, the power plug should be easily reached.

5. A breakershouldbeincorporatedintofixedwiring.Thebreakershouldbeall-pole

switch and the distance between its two contacts should be not less than 3mm.

type of T. 3.15A/250V.

Connection

Use the same method on indoor unit. Loosen the screws onƽ

insert the plugs fully into terminal block, then tighten the screws.

ƽ

Insert the cable according to terminal number in the same manner as the indoor

unit.

If wiring is not correct, proper operation can not be carried out and controller

ƽ

may be damaged.

Fix the cable with a clamp.ƽ

Attaching Drain-Elbow

If the drain-elbow is used,ƽ

please attach it as figure. (Note:

Only for heat pump unit.)

Purging Method:To use vacuum pump

Detach the service port’s cap of

1.

and 3-way’s, connect the service port into the

for gaugemanifold.

gemanifold

2.

Open the handle at Iow in

moves of gause (Iow) reach vacuum condition in a moment, check 1. again.

Vacuumize for over 15min.And check the level gauge which should read -0.1MPa

3.

(76 cm Hg) at Iow

handle ‘Lo’ in gaugemanifold and stop the operation of the vacuum pump. Check

condition of the scale and hold it for 1-2min. If the scale-moves back in spite of

tightening, make flaring work again, the return to the beginning of 3 .

Openthevalverodforthe2-wayvalvetoanangle of4.

After 6 seconds, close the

Then connect

into vacuum pump.

pressure side. After the

3-wayvalve,thevalverod’scapfor2-wayvalve

the projection of charge hose (center) for gau-

gaugemanifold, operate

2-way valve and make the

projection of charge hose (Iow)

vacuum pump. If the scale-

completion of vacuumizing, close the

anticlockwise 90 degrees.

inspection of gas leakage.

terminal block and

3

Page 4

No gas leakage?5.

In case of gas leakage, tighten parts of pipe connection. If

leakage stops, then proceed 6. steps

If it does not stop gas leakage, discharge whole refrigerants

port.Afterflaring workagainandvacuumize,fillupprescribed

Detachthechargehose6.

the valve rod anticlockwise until hitting lightly.

To prevent the gas

7.

valve and 3-way’s a little more

After attaching the each

8.

refrigerant from the gas cylinder.

from the service port,

leakage, turn the service

than the point where the torque increases suddenly.

caps, check the gas

open 2-way valve and 3-way. Turn

port’s cap, the valve

leakage around the caps.

from the service

rod’s cap for 2-way

On Drainage

Pleaseinstallthedrainhosesoastobedownwardslopewithoutfail.

ƽ

Please don’t do the drainage as shown below.

ƽ

Less than

5cm

It becomes

high midway.

Pleasepourwaterinthedrainpan of theindoorunit,and

ƽ

is carried out surely to outdoor.

In case that the attached drain hose is in a room, please

ƽ

it without fail.

The end is immersedinwater.

It waves.

The gap with the

ground is too small.

confirm that drainage

apply heat insulation to

There is the bad

smell from a ditch

Step 1.

Tube(for R410A)

Step 4.

O

Open 90

2-way valve

2-way valve Liquid Side

3-wayvalveGasSide

Gaugemanifold(for

Anti countercurrent joint

Vacuum pump(for R410A)

2-way valve

3-way valve

3-way valve

R410A)

Step 2.

Open

Step 3.

Close

Step 6.

Step 7.

Service port cap

2-way valve

3-way valve

2-way valve

3-way valve

Valve ro d c ap

Valve ro d c ap

CAUTION

ƽ

If the refrigerant of the air conditioner leaks, it is necessary to discharge all the

refrigerant. Vacuumize first, then

neraccordingtotheamountmarkedonthenameplate.

ƽ

Please do not let other cooling medium, except specified one (R410A), or air

enter into the cooling circulation system. Otherwise, there will be abnormal

highpressureinthesystemtomakeitcrackandleadtopersonalinjuries.

Power Source Installation

ƽ

The power source must be exclusively used for air

ƽ

In the case of installing an air conditioner in a moist place,

rth leakage breaker.

ƽ

For installation in other places, use a circuit breaker as far

Cutting and Flaring Work of Piping

ƽ

Pipe cutting is carried out with a pipe cutter and burs must

After inserting the flare nut, flaring work is carried out.

ƽ

FlaretoolforR410A Conventionalflaretool

Clutch-type clutch-type(Rigid-type) Wing-nut type (Imperial-type)

A 0~ 0.5mm 1.0~1.5mm 1.5~2.0mm

Flare tooling die

chargetheliquidrefrigerantintoairconditio-

conditioner. (Over 15A)

please install an ea-

as possible.

be removed.

1.Cut pipe

3.Inserttheflarenut

2.Remove burs

4.Flare pipe

Refrigerant charge labelƵ

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

R410A

2

1=

2=

1

1+2=

FE

kg

kg

kg

A

B

C

D

This product contains fluorinated greenhouse gases covered by

the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type:R410A

GWP* value:1975

GWP=global warming potential

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field and

• 1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the stop value cover).

A contains fluorinated greenhouse gases covered by the Kyoto

Protocol

B factory refrigerant charge of the product: see unit name plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

Check for Installation and Test Run

Ƶ

Please kindly explain to our customers how to operate

Ƶ

through the instruction manual.

CheckItemsforTestRun

Put check mark

Gasleakfrompipeconnecting?

Heat insulation of pipe connecting?

Are the connecting wirings of indoor and outdoor firmly

inserted to the terminal block?

Istheconnectingwiring of indoorandoutdoorfirmlyfixed?

Is drainage securely carried out?

Is the earth line securely connected?

Is the indoor unit securely fixed?

Ispowersourcevoltageabidedbythecode?

Is there any noise?

Isthelampnormallylighting?

Arecoolingandheating(wheninheatpump)performednormally?

Is the operation of room temperature regulator normal?

in boxes

Correct Incorrect

Lean

Damage of flare Crack Partial Too outside

4

Page 5

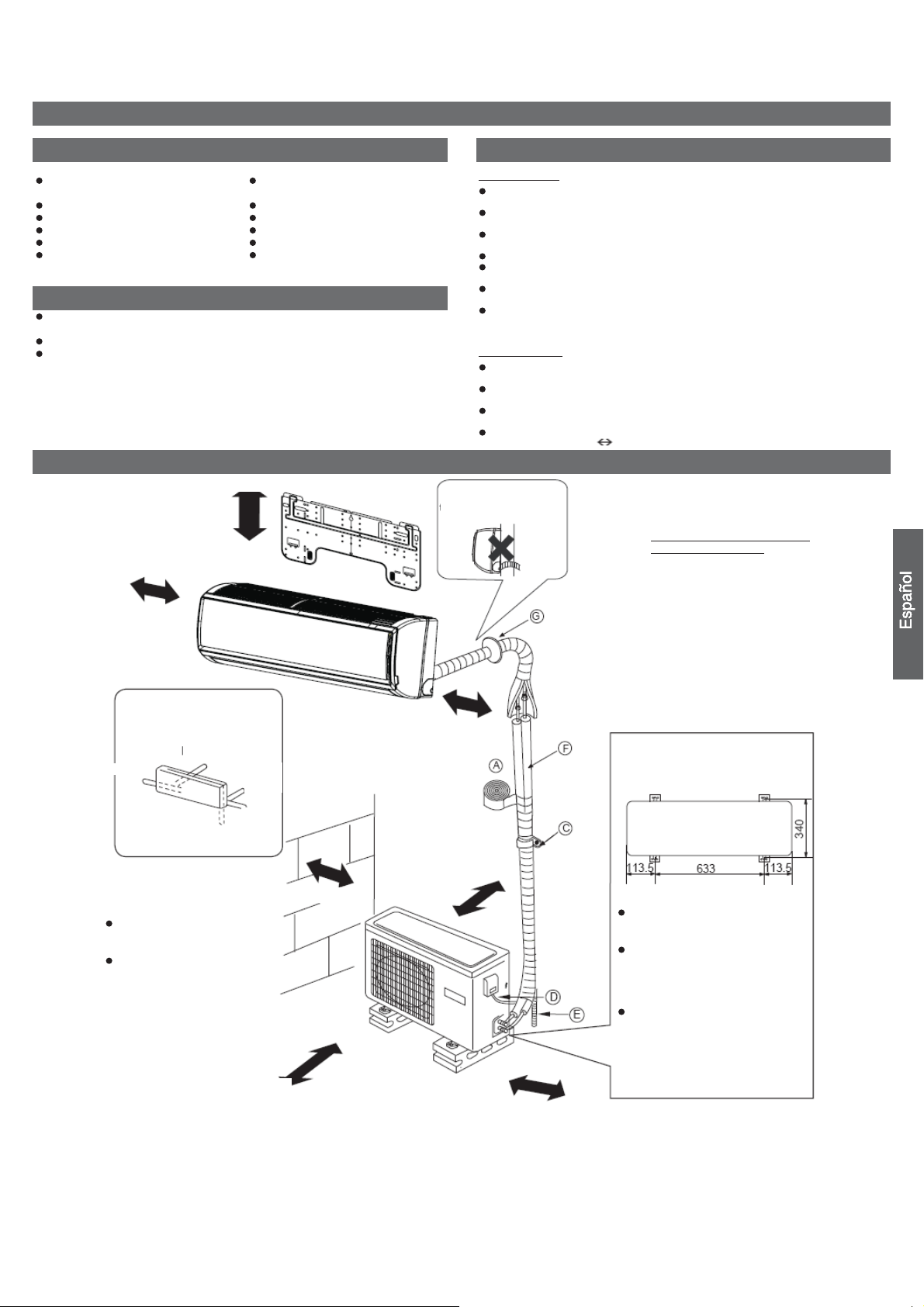

Manual de instalación de aparato de aire acondicionado

r

Preparación

Herramientas necesarias para realizar la instalación

Destornillador Llave dinamométrica (17mm, 22mm,

Alicate Sierra de tubos

Sierra para metales Herramienta de conicidad

Broca de tubo Cuchilla

Llave (17, 19 y 26 mm) Metro

Detector de fugas de gas o agua

jabonosa

26mm)

Avellanador

Fuente de alimentación

Antes de insertar el enchufe de alimentación en la toma, compruebe que el voltaje

no falla. La fuente de alimentación es la que figura en la placa de datos nominales.

Instale el aparato en un circuito dedicado de alimentación.

Debe existir una toma al alcance del cable de alimentación. No prolongue el cable

cortándolo.

Diagrama para la instalación de aparatos interiores y exteriores

Los modelos cumplen la norma R410A sobre refrigerantes libres de HFC

más de 5cm

más de 10cm

Unidad interior

Coloque la unidad sobre una superficie que pueda soportarla correctamente y no

provoque vibraciones.

Asegúrese de que el lugar no se ve afectado por calor o vapor generado en las

cercanías y donde las tomas de entrada y salida no estén obstruidas.

Asegúrese de que el lugar permita un drenaje sencillo y en el que puedan

conectarse los tubos a la unidad exterior.

Asegúrese de que el aire frío pueda distribuirse uniformemente por la sala.

Coloque la unidad interior cerca de una toma de suministro eléctrico con espacio

suficiente alrededor. (Consulte los diagramas).

Coloque la unidad interior de modo que se encuentre a más de 1m de televisiones,

radios, aparatos inalámbricos y lámparas fluorescentes.

En el caso de fijar el control remoto a una pared, colóquelo donde la unidad interior

pueda recibir su señal mientras estén encendidas las lámparas fluorescentes de la

sala.

Unidad exterior

Seleccione el lugar menos afectado por la lluvia o la luz solar directa y

suficientemente ventilado.

Elija un lugar que permita soportar el peso de la unidad y que no amplifique el

ruido y las vibraciones.

Seleccione un lugar en el que los residuos y el viento generado por la unidad no

cause una molestia a los vecinos.

Coloque la unidad en un lugar en el que pueda disponerse de la distancia de

separación marcada

Debe prestarse atención a la

pendiente de la manguera

de drenaje

Selección del lugar de instalación

en la figura anterior.

Componentes opcionales para la

instalación de los tubos

A Cinta no adhesiva

ƻ

B Cinta adhesiva

ƻ

C Soporte (L.S) con tornillos

ƻ

D Conexión de cable eléctrico

ƻ

para interior y exterior

E Manguera de drenaje

ƻ

F Material aislante de calor

ƻ

G Cubierta de orificio de

ƻ

entubación

Organización de la dirección

de los tubos

Izquierda trasera

Izquierda

Inferio

Las marcas de ƻA a ƻG

que se muestran en la figura

representan los componentes.

La distancia entre la unidad

interior y el suelo debe ser

superior a 2m.

Recuerde que la ilustración anterior podría no reflejar fielmente el producto adquirido y debe utilizarse únicamente como referencia.

Lea este manual antes de la instalación

Explique el uso del aparato al usuario siguiendo las instrucciones de este manual.

Derecha

trasera

Derecha

más de 60cm

más de 10cm

más de 10cm

más de 10cm

más de15cm

Dimensiones de fijación al suelo de

la unidad exterior (Unidad:mm)

Fijación de la unidad exterior

Fije la unidad a un bloque de

cemento con pernos (10mm) y

tuercas firme y horizontalmente.

Si instala la unidad sobre una

pared, techo o tejado, instale un

soporte con clavos o cables

considerando la posibilidad de

terremotos o viento fuerte.

Si la vibración afectase a la casa,

fije la unidad instalando una

alfombra de absorción de

vibraciones.

5

Page 6

Accesorios

r

r

)1( ejanerd ed areugnaM )1( otomer lortnoC

Batería seca R-03 (2) Acolchado (4)

Placa de montaje (1) Codo de drenaje (1)

Tapón de plástico (4)

Tornillo

ø4X25 (4)

Placa de soporte del tubo (4)

Selección de tubo

Tubo de líquido

(Ø)

Tubo de gas (Ø) 15,88mm (5/8")

NOTA: El grosor del tubo debe ser, al menos, de 0,8mm.

6,35mm (1/4")

Unidad interior

Instalar la placa de montaje y ubicar el orificio en la pared

Al fijar por primera vez la placa de montaje

1. Nivele correctamente la placa a fijar contra la pared basándose en pilares o

dinteles cercanos y fije temporalmente la placa con un clavo de acero.

2. Asegúrese de nuevo de que la placa se encuentre bien nivelada colgando una

plomada desde el punto superior central de la placa. Una vez comprobado, fije la

placa con el clavo de acero de fijación.

3. Busque la ubicación del orificio de pared A utilizando un metro.

1. Pase la manguera aislante a través del hueco de los materiales de aislamiento de

calor de la unidad interior.

2. Inserte los cables eléctricos de interior / exterior a través de la parte trasera de la

unidad interior y tire de ellos desde la parte delantera. A continuación, conéctelos.

3. Cubra la cara de sellado con aceite refrigerante y conecte los tubos.

Cubra la conexión con material aislante de calor y asegúrese de fijarla con cinta

adhesiva.

Material aislante

de calor

izquierda

Manguera de

drenaje

Cubierta de

entubación inferior

Cubierta de entubación derecha

Fijación con cinta adhesiva

Los cables eléctricos de interior/exterior deben conectarse a la entubación del

refrigerante utilizando cinta protectora.

[Entubación en otra dirección]

Corte con una cuchilla la cubierta de entubación de acuerdo con la dirección de

entubación y doble los tubos de acuerdo con la posición del orificio en la pares.

Tenga cuidado de no romper los tubos al doblarlos.

Conecte previamente el cable eléctrico de interior / exterior y tire de la conexión al

aislante de calor del componente de conexión.

Cubierta de entubación

Cable eléctrico de interior/exterior

Entubación

Placa de soporte del

tubo

Fijación de la unidad interior

Cuelgue con seguridad la unidad de las muescas

superiores de la placa de montaje. Mueva el bastidor

hacia los lados para verificar que la fijación se haya

realizado de la forma correcta.

Para fijar el bastidor a la placa de montaje, sostenga

el aislante del bastidor por debajo y colóquelo en

posición perpendicular.

placa de montaje

Al montar la placa de montaje fijándola a una

barra lateral y un dintel

Fije una barra de montaje (se vende por separado) a la barra lateral y el dintel, y

asegure la placa a la barra de montaje fijada.

Consulte la sección anterior "Al fijar por primera vez la placa de montaje" para más

información acerca del orificio de la pared.

Practicar un orificio en la pared e instalar la cubierta del orificio de entubación

Practique un orificio de 70mm de diámetro con pendiente ligeramente

descendiente hacia el exterior de la pared.

Instale la cubierta del orificio de entubación y séllela con masilla después de la

instalación.

Orificio de pared

Cara interio

(Sección del orificio de pared) ƻG Tubo del orificio de entubación

Grosor de la pared

Cara exterio

Instalación de la unidad interior

Extracción de los tubos

Descarga de la unidad interior

Al descargar la unidad interior, utilice

la mano para levantar el bastidor.

Levante entonces la parte inferior

del bastidor llevándolo hacia fuera

ligeramente y levante la unidad

hasta que se separe de la placa de

gancho

placa de montaje

montaje.

Conexión de los cables eléctricos de interior/exterior

Extraer la cubierta del cableado

Extraiga la cubierta de los terminales situada en la esquina inferior

derecha de la unidad interior. Extraiga entonces la cubierta del

cableado desenroscando los tornillos.

Al conectar el cable después de instalar la unidad de interior

1. Inserte desde fuera el cable en la sala a través del lado izquierdo

del orificio de la pared en el que ya se encuentra el tubo.

2. Tire del cable desde el lado delantero y conecte el cable creando

un bucle.

Al conectar el cable antes de instalar la unidad de interior

Inserte el cable desde la parte trasera de la unidad y tire desde la parte delantera.

Afloje los tornillos e inserte los extremos del cable en el bloque de terminales.

Apriete entonces los tornillos.

Tire ligeramente del cable para asegurarse de que los cables han quedado

correctamente insertados y apretados.

Después de conectar el cable, no olvide fijar el cable conectado con la cubierta de

cable.

[ Entubación trasera ]

Extraiga los tubos y la manguera de drenaje y fíjelos con cinta adhesiva

[Izquierda

En caso de realizar la entubación por el lado izquierdo, corte con una cuchilla la

cubierta de la entubación izquierda.

En caso de realizar la entubación a través de la parte trasera izquierda, doble los

tubos de acuerdo con la dirección de entubación que figura en la marca del orificio

de entubación trasera izquierda, ubicada sobre los materiales aislantes.

Entubación trasera izquierda]

6

Page 7

Nota

r

A

2

Al conectar el cable, confirme el número de terminales de las unidades

interior y exterior detenidamente. Si el cableado no se ha realizado

correctamente no se podrá utilizar el aparato correctamente,

provocándose un defecto.

PRECAUCIÓN

Unidad exterior

Unidad interior

Unidad interior

Cable de alimentación:

ı3×0,75mm

Cable de alimentación:

ı3×0,75mm

HSU-24HEK03/R2

HSU-24HEA03/R2

2

2

LIMENTACIÓN

Unidad exterio

cableado de conexión: ı3×2,5mm

1. Si el cable de alimentación está dañado deberá ser reemplazado por el fabricante,

agente de servicio o profesional cualificado. El tipo de cable de conexión es

H05RN-F o H07RN-F.

2. Si el fusible de la placa PC está roto, cámbielo por otro de tipo T. 3.15A/250V.

3. El método de cableado debe satisfacer los requisitos de las normas locales de

cableado.

4. Después de la instalación, el enchufe de alimentación debe encontrarse ubicado

en un lugar fácilmente accesible.

5. Debe instalarse un interruptor en el cableado fijo. El interruptor deberá ser de tipo

omnipolar y la distancia entre los dos contactos no deberá ser inferior a 3mm.

Unidad exterior

Instalación de la unidad exterior

Instale la unidad exterior de acuerdo con el diagrama de instalación de unidades

interiores y exteriores.

Conexión de los tubos

Para doblar un tubo, intente hacer la curva lo más suave posible para no aplastar el

tubo. El radio de doblado debe ser de entre 30 y 40mm o superior.

Será más sencillo conectar en primer lugar el tubo de gas.

El tubo de conexión es especial para el tipo R410A.

Media unión

Llave

Procure que no penetren materiales, como residuos o arena, en el tubo.

La longitud estándar del tubo es de 5m. Si el tubo tiene más de 7m, se verán

afectadas las funciones de la unidad. Si es necesario alargar el tubo, deberá cargarse

refrigerante adicional a razón de 20 g/m. No obstante, la carga de refrigerante deberá

ser realizada por un ingeniero profesional en aire acondicionado. Antes de añadir

refrigerante adicional, realice una purga de aire desde los tubos refrigerantes y la

unidad interior utilizando una bomba de vacío y cargue después el refrigerante

adicional.

Tuerca cónica

Llave dinamométrica

Si se fuerza la fijación sin aplicar centrado podrían dañarse los

tubos y provocarse una fuga de gas.

Diámetro del tubo (ø)

Lado de líquido 6,35 mm (1/4") 18N.m

Lado de líquido/gas 9,52mm (3/8") 42 N.m

Lado de gas 12,7mm (1/2") 55N.m

Lado de gas 15,88mm (5/8") 60 N.m

Par de

apriete

Unidad interior

Unidad exterior

Unidad exterior

Filtro de aceite

Unidad interior

Elevación máx. Amáx=15m

En caso de que la elevación A sea

superior a 5m, el filtro de aceite deb e

instalarse cada 5 ~7 m.

Longitud máx.: Bmáx =25m

En caso de que la longitud del tubo B

sea superior a 7m, deberá cargarse el

refrigerantearazónde20g/m.

Conexión

Utilice el mismo método con la unidad interior. Afloje los tornillos del bloque de

terminales e inserte los tapones completamente en los mismos. Apriete entonces

los tornillos.

Inserte el cable de acuerdo con el número del terminal, de la misma forma que hizo

con la unidad interior.

Si el cableado no es correcto, no podrá alcanzarse la orientación correcta y el

controlador podría resultar dañado.

Fije el cable con una pinza.

Instalación del codo de drenaje

Si utiliza un codo de drenaje, instálelo como indica la figura.

(Nota: sólo para unidades con bomba de calor).

Método de purgado: para utilizar una bomba de vacío

1. Retire el tapón del puerto de mantenimiento de la válvula de 3 vías (G), el tapón

del vástago de la válvula de 2 vías (L) y 3 vías (G). Conecte entonces la

manguera de proyección de carga (central) del colector a la bomba de vacío.

2. Abra la espita inferior del colector y accione la bomba de vacío. Si el indicador

de la escala (inferior) alcanza la condición de vacío por un momento,

compruebe de nuevo el punto 1.

3. Succione durante 15 minutos. Compruebe el nivel medido, que deberá ser de

-0.1MPa (76 cm Hg) en el lado de baja presión. Tras finalizar la succión, cierre

la espita inferior del colector y detenga la bomba de vacío. Compruebe el

funcionamiento de las escala y manténgala durante 1-2 min. Si la escala

retrocede a pesar de ajustarse, realice de nuevo los trabajos de conicidad y

vuelva al punto 3.

4. Abra el vástago de la válvula de 2 vías 90 grados hacia la izquierda. Después

de 6 segundos, cierre la válvula de 2 vías e inspeccione si existen fugas de gas.

5. ¿No existen fugas de gas?

En caso de que exista una fuga de gas, apriete las conexiones de los tubos. Si la fuga

Si la fuga de gas no se detiene, descargue todo el refrigerante a través del puerto de

mantenimiento. Después de realizar de nuevo la operación de conicidad y succión,

rellene con el refrigerante especificado desde el cilindro de gas.

6. Desconecte la manguera de carga del puerto de mantenimiento y abra las

válvulas de 2 y 3 vías. Gire el vástago de la válvula hacia la izquierda.

7. Para evitar fugas de gas, gire el tapón del puerto de mantenimiento y el tapón

del vástago de las válvulas de 2 y 3 vías un poco por encima del punto en el

que la torsión aumenta súbitamente.

8. Después de instalar los tapones, compruebe si existen fugas de gas a su

alrededor.

se detiene, proceda al paso 6.

7

Page 8

Paso 1.

Tubo (para R410A)

Paso 4.

Abrir 90e

Lateral de líquido de la válvula de 2 vías

Lateral de gas de la válvula de 3 vías

Colector (para R410A)

Junta de retención de contracorriente

Bomba de vacío (para R410A)

Válvula de 2 vías

Válvula de 3 vías

Paso 6.

Paso 2.

Abrir

Paso 3.

Cerrar

Válvula de 2 vías

Válvula de 3 vías

Menos de

5cm

Se alza por la

mitad.

Deposite agua en la bandeja de drenaje de la unidad interior y confirme que el

drenaje se realiza correctamente hacia fuera.

En caso de que la manguera de drenaje se encuentre en una sala, asegúrese de

aplicar aislante de calor.

El extremo está

sumergido en agua.

Está ondulado.

La separación con el

suelo es demasiado

pequeña

Se aprecia mal olor de

una acequia

Etiqueta de carga de refrigerante

Contiene gases fluorados de efecto invernadero

regulados por el Protocolo de Kyoto.

Paso 7.

Válvula de 2 vías

Si existen fugas de refrigerante en el aire acondicionado, será necesario

descargar todo el refrigerante. Succione primero, y cargue líquido refrigerante en

el acondicionador de aire de acuerdo con la cantidad marcada en la placa de

valores nominales.

No permita que penetren otros medios de refrigeración (excepto el especificado,

R410A) o aire en el sistema de circulación del refrigerante. Si ocurriese, se

acumularía una presión anormalmente alta en el sistema que podría provocar

roturas y lesiones personales.

Válvula de 3 vías

Tapa del puerto de mantenimiento

PRECAUCIÓN

Válvula de 2 vías

Válvula de 3 vías

Tapa del vástago de válvula

Tapa del vástago de válvula

Instalación de la fuente de alimentación

La fuente de alimentación debe utilizarse exclusivamente con el aparato de aire

acondicionado. (Más de 15A)

En caso de instalar el aire acondicionado en un lugar húmedo, instale un interruptor

de fugas de masa.

Para realizar la instalación en otro lugar, utilice un interruptor de circuito situado lo

más lejos posible.

Trabajos de corte y conicidad de los tubos

El corte del tubo se realiza con un cortador de tubos. Deberán eliminarse las

rebabas.

Después de insertar la tuerca cónica deberá procederse a realizar los trabajos de

conicidad.

Herramienta de

conicidad para R410A

De tipo acoplamiento

A 0~0,5mm 1,0~1,5mm 1,5~2,0mm

Cuchilla de conicidad

1. Cortar el tubo

3. Insertar la tuerca

cónica

Herramienta de conicidad convencional

De tipo acoplamiento

(tipo rígido)

De tipo palometa (tipo

2. Eliminar las rebabas

4. Tubo cónico

imperial)

Este producto contiene gases fluorados de efecto invernadero regulados por el

Protocolo de Kyoto. No los libere libremente a la atmósfera.

Tipo de refrigerante: R410A

Valor GWP*: 1975

GWP = Potencial de contribución al calentamiento global

Escriba con tinta indeleble:

• 1 La carga de refrigerante que contiene el producto de fábrica

• 2 La cantidad de refrigerante adicional cargada durante la instalación y

• 1+2 La carga total de refrigerante

en la etiqueta de carga de refrigerante suministrada con el producto.

Una vez escritos los datos correspondientes, la etiqueta deberá adherirse cerca de la

conexión de carga del producto (por ejemplo, sobre la parte interna de la cubierta de

la válvula de retención).

A

Contiene gases fluorados de efecto invernadero regulados por el Protocolo de

Kyoto.

B Carga de refrigerante que contiene el producto de fábrica: consulte la placa de

características de la unidad.

C Cantidad de refrigerante adicional cargada durante la instalación.

D Carga total de refrigerante.

E Unidad exterior.

F Botella de refrigerante y colector de carga.

Prueba de instalación y ejecución de la prueba

Explique al cliente cómo utilizar el aparato utilizando el manual de instrucciones.

Compruebe los siguientes puntos de prueba

¿Existe una fuga de gas en la conexión del tubo?

¿Aislamiento de calor de la conexión del tubo?

¿Están los cables de conexión interiores y exteriores firmemente insertados en el

bloque de terminales?

¿Están los cables de conexión interior y exterior fijados firmemente?

¿Se ha realizado el drenaje correctamente?

¿Está la línea de tierra conectada con seguridad?

¿Está la unidad interior fijada con seguridad?

¿Cumple la normativa la fuente de voltaje?

¿Se aprecian ruidos?

¿Está la lámpara iluminada normalmente?

¿Se realizan normalmente las operaciones de calentamiento (con la bomba de calor)

y refrigeración?

¿Funciona correctamente el regulador de temperatura de la sala?

Escriba una marca en los cuadros

otcerrocnI otcerroC

Delgado Daño de conicidad Grieta Parcial Demasiado fuera

Durante el drenaje

Instale la manguera de drenaje formando una pendiente descendiente.

No practique el drenaje como se muestra a continuación.

8

Page 9

Manuale d’ installazione del Condizionatore

Preparazione

Attrezzi necessari per l’’installazione

Cacciavite Chiave dinamometrica (17mm,

Pinza Tagliatubi

Seghetto Allargatubi

Carotatore Lama

Chiave per bulloni (17, 19 e 26mm) Metro

Rilevatore di perdite del gas oppure

soluzione d’acqua saponata

22mm, 26mm)

Alesatrice

Origine d'alimentazione

Prima di collegare la spina alla presa di corrente, accertarsi che la tensione sia

corretta. L’alimentazione deve essere uguale a quella dell’etichetta corrispondente.

Installare un circuito derivato della corrente.

Ad una certa distanza deve essere installato un ricettacolo dove poter raggiungere il

cavo d’alimentazione. Non allungare il cavo tagliandolo.

Schema per l’installazione dell’unità interna ed esterna

I modelli adottano il refrigerante senza HFC R410A

Deve essere prestata

Più di 5cm

Più di 10cm

sollevamento del tubo di

attenzione al

scarico

Selezione del luogo d’installazione

Unità interna

Installare in un luogo solido, senza vibrazioni, in grado di supportare il peso

dell’unità.

Luogo, non soggetto a calore o vapore generato nelle vicinanze, dove le prese e

gli scarichi dell’unità non sono disturbati.

Luogo, dove lo scarico è semplice, dove le tubature possono essere collegate

all'unità esterna.

Luogo da dove l’aria fredda può essere diffusa in tutta la stanza.

Luogo, vicino ad una presa di corrente, con sufficiente spazio libero attorno. (Fare

riferimento alle immagini)

Luogo ad una distanza superiore ad 1 m da dove si trovano televisori, radio,

apparati wireless e lampade fluorescenti.

Quando si installa il telecomando su parete, accertarsi di collocarlo in una

posizione da cui l’unità interna possa ricevere i segnali quando sono accese le

lampade fluorescenti della stanza.

Unità da esterno

Luogo meno interessato dalla pioggia e dalla luce diretta del sole e che sia

sufficientemente ventilato.

Luogo, in grado di sostenere il peso dell’unità, dove le vibrazioni ed il rumore non

siano aumentati.

Luogo, dove l’aria di scarico ed il rumore non provocano disturbo ai vicini di casa.

Luogo, dove sia disponibile una distanza contrassegnata da

precedente.

Parti optional per le tubature

A Nastro non adesivo

○

B Nastro adesivo

○

C Supporto (L.S) con viti

○

D Collegamento del cavo elettrico

○

per interno ed esterno

E Tubo di drenaggio

○

F Materiale isolante termico

○

G Coperchio foro tubatura

○

nella figura

Disposizione della direzione delle

tubature

Posteriore sinistra

Inferiore

Posteriore

destra

Destra

Più di 60cm

Più di 10cm

Sinistra

I contrassegni da Aa G nella

figura indicano i numeri delle

parti

La distanza tra l’unità interna

ed il pavimento deve essere

superiore ai 2 m.

Attenersi al prodotto acquistato: le immagini sono solo per riferimento.

Leggere questo manuale prima dell’installazione

Spiegare all’utente in modo esauriente il funzionamento e l’uso del condizionatore in base alle istruzioni di questo manuale.

Più di 10cm

Più di 10cm

Più di 15cm

Dimensioni fissaggio a pavimento

dell’unità esterna (unità di misura: mm)

Fissaggio dell’unità esterna

Fissare l’unità alla pavimentazione o

al blocco di cemento stringendo bene

dadi e bulloni (10mm) ed accertarsi

che l’unità sia a livello orizzontale.

Quando si installa l’unità su pareti,

tetti o tettoie, fissare in sicurezza un

supporto usando chiodi o cavi

tenendo in considerazione i terremoti

ed i forti venti.

Se la vibrazione può avere influenza

sulla casa, fissare l’unità usando un

pannello antivibrazione.

9

Page 10

Parti accessorie

gg

Telecomando (1) Tubo di scarico (1)

Batteria a secco R-03 (2) Cuscino (4)

Installazione dell’unità interna

Schema della tubatura

Piastra di montaggio (1) Giunto a gomito dello scarico (1)

Coperchio di plastica (4)

Viti Ø4X25 (4)

Piastra di supporto tubature (1)

Selezione dei tubi

Tubo per liquidi (Ø) 6.35mm (1/4”)

Tubo per gas (Ø) 15,88mm (5/8”)

NOTA: Lo spessore del tubo deve essere di almeno 0.8mm.

Condizionatore

Regolazione della piastra di montaggio e collocazione del foro su parete

Prima installazione della piastra di montaggio

1. Eseguire, in base ai pilastri o architravi nelle vicinanze, un appropriato livellamento

della piastra da fissare alla parete, poi bloccare temporaneamente la piastra

usando un chiodo d’acciaio.

2. Controllare di nuovo che il livellamento della piastra sia appropriato attaccando un

filo a piombo alla parte centrale superiore della piastra, poi fissarla in sicurezza

usando il chiodo d’acciaio.

3. Trovare la posizione del foro su parete A usando un metro

[Tubatura posteriore]

Passare le tubature e lo scarico, poi fissarli con nastro adesivo

[Tubatura sinistra – sinistra posteriore]

Se la tubatura è a sinistra, tagliare con una pinza, il coperchio della tuba

tubatura sinistra.

Se la tubatura è posteriore sinistra, piegare i tubi seguendo la direzione delle

tubature verso il contrassegno del foro per la tubatura sinistra posteriore che è

stampigliato sui materiali d'isolamento termico.

1. Inserire il tubo di scarico nella scanalatura dei materiali d’isolamento dell’unità

interna.

2. Inserire il cavo elettrico interno/esterno dal retro dell’unità interna ed estrarlo dal lato

frontale, poi collegarli.

3. Coprire la superficie svasata dell’attacco con olio refrigerante e collegare i tubi.

Coprire bene la parte di collegamento con materiale d’isolamento ed assicurarsi di

fissare con nastro adesivo

Coperchio per

tubatura destra

Coperchio per tubatura

inferiore

Fissare con nastro

adesivo

Coperchio per

tubatura sinistra

Materiale

termicamente isolante

Tubo di

drena

io

Cavo elettrico

interno/esterno

Tubazione

Piastra di supporto della

tubazione

Cavo elettrico interno/esterno e tubo di scarico devono essere uniti alla tubatura

refrigerante usando nastro protettivo.

[Tubature con altre direzioni]

Tagliare, usando una pinza, il coperchio della tubatura in base alla direzione

delle tubature e poi piegare il tubo in base alla posizione del foro su parete.

Quando si piega, prestare attenzione e non spaccare i tubi.

Connettere prima il cavo elettrico interno/esterno, quindi estrarre la parte

connessa all'isolante termico della parte di connessione speciale.

Installazione della piastra di montaggio su barra

laterale ed architrave

Fissare una barra di montaggio, venduta separatamente, alla barra laterale ed

all’architrave e poi fissare la piastra alla barra di montaggio.

Fare riferimento alla sezione precedente “Prima installazione della piastra di

montaggio” per la posizione de foro.

Perforamento del muro ed installazione del coperchio foro tubatura

Fare un buco di 70mm di diametro, leggermente inclinato verso la parete

esterna.

Installare il coperchio foro tubatura e sigillarlo con stucco dopo l’installazione

Buco della parete

Lato interno

Spessore della parete

(Sezione del foro su parete) G Tubo del foro tubatura

Lato esterno

Fissaggio del corpo dell’unità interna

Appendere in sicurezza il corpo dell’unità alle tacche

superiori della piastra di montaggio. Spostare il

corpo da un lato all’altro per verificare che sia fissato

in sicurezza.

Per fissare il corpo alla piastra di montaggio, tenere

il corpo inclinato sulla parte inferiore e poi

appoggiarlo perpendicolarmente.

Scaricamento del corpo dell’unità da interno

Quando si smonta

l’unità interna, usare

le mani per sollevare il

corpo, poi sollevare

leggermente la parte

inferiore del corpo su

un lato ed infine

sollevare l’unità finché

si stacca dalla piastra

di montaggio.

Gancio

Collegamento del cavo elettrico interno/esterno

Rimozione della copertura dei cavi

Rimuovere la copertura terminali nell’angolo in basso a

destra dell’unità interna, poi estrarre la copertura dei cavi

rimuovendo le viti.

piastra di

montaggio

piastra di

montaggio

Collegamento del cavo dopo avere installato l’unità interna

1. Inserire dall’esterno il cavo della stanza nella sinistra del foro su

parete, nel quale è già stato installato il tubo.

2. Estrarre il cavo sulla parte frontale e collegarlo facendo un anello.

10

Page 11

Collegamento del cavo prima di avere installato

A

A

l’unità interna

Inserire il cavo dal lato posteriore dell’unità e poi estrarlo sul lato frontale.

Allentare le viti ed inserire completamente le estremità del cavo nel blocco

terminali, poi stringere le viti.

Tirare leggermente il cavo per accertarsi che i cavi siano stati inseriti e fissati in

modo appropriato.

Dopo avere collegato i cavi, non dimenticare mai di stringere i cavi collegati con

la copertura dei cavi.

Nota Quando si collegano i cavi, controllare con attenzione i numeri di

1. Se il cavo d'alimentazione è danneggiato, deve essere sostituito dal produttore, il

suo rappresentante o persona similarmente qualificata. Il tipo di cavo di

collegamento è H05RN-F o H07RN-F.

2. Se il fusibile della scheda PC è saltato, sostituirlo con uno di tipo T. 3. 3,15A/250V.

3. Il metodo di cablaggio deve essere in linea con le normative di cablaggio locali.

4. Dopo l'installazione, la spina deve essere facilmente raggiungibile.

5. Nel cablaggio fisso deve essere incorporato un interruttore di circuito. L’ interruttore

di circuito deve essere un interruttore di tutti i poli e la distanza fra i suoi due contatti

non deve essere inferiore a 3mm.

terminale dell’unità interna ed esterna. Se il cablaggio non è corretto, non

sarà possibile eseguire in modo appropriato le operazioni e si

provocheranno danni.

Condizionatore

Cavo d’ alimentazione:

≥ 3G× 0.75mm

Cavo d’ alimentazione:

≥ 3G× 0.75mm

Cavi di collegamento: ≥ 3G

2

2

HSU-24HEK03/R2

HSU-24HEA03/R2

Unità da

esterno

× 2.5mm

LIMENTAZIONE

2

Unità da esterno

Installazione dell’unità esterna

Installare attenendosi allo schema per l’installazione dell’unità interna ed esterna

Collegamento dei tubi

Per piegare i tubi, curvarli con un raggio molto ampio per non spaccarli, il raggio

deve essere compreso tra 30 e 40 mm o più.

Collegando prima il tubo del gas rende il lavoro più facile.

Il tubo di collegamento è apposito per R410A.

Unione di mezzo

Chiave per bulloni

Prestare attenzione che materiali, come scarti di sabbia, non entrino nel tubo.

La lunghezza standard del tubo è 5m. Se eccede i 7m, il funzionamento dell’unità sarà

compromesso. Se il tubo deve essere allungato, deve essere caricato il refrigerante, in

base a 20 g/m. Tuttavia, il caricamento del refrigerante deve essere eseguito da

personale professionista. Prima di aggiungere altro refrigerante, eseguire lo sfiato

dell’aria dalle tubature del refrigerante e dall’unità interna usando una pompa a vuoto,

poi caricare il refrigerante.

VVERTENZA

Unità da esterno

Unità da esterno

Dado svasato

Chiave dinamometrica

Condizionatore

Trappola per l’olio

Condizionatore

La stretta forzata eseguire una centratura accurata può

danneggiare le filettature e provocare perdite di gas.

Diametro del tubo (ǿ) Coppia di serraggio

Lato liquidi 6.35mm (1/4") 18N.m

Lato liquidi/gas 9.52mm (3/8") 42 N.m

Lato gas 12.7mm (1/2") 55N.m

Lato gas 15,88mm (5/8") 60 N.m

Unità da esterno

Condizionatore

Elevazione massima: A massimo =

15m

Se l’elevazione A è superiore ai 5m, un

raccoglitore dell’olio deve essere

installato ogni 5~7m

Lunghezza massima: B massimo =

25m

Se la lunghezza del tubo B è superiore

ai 7m, deve essere caricato il

refrigerante, in base a 20 g/m.

Connessione

Usare lo stesso metodo usato per l’unità interna Allentare le viti ed inserire

completamente le spine nel blocco terminali, poi stringere le viti.

Inserire il cavo in base la numero del terminale allo stesso modo usato per l’unità

interna.

Se il cablaggio non è corretto, non sarà possibile eseguire in modo appropriato le

operazioni e si provocheranno danni.

Fissare il cavo con un morsetto.

Attaccare l’attacco a gomito dello scarico

Se si usa l’attacco a gomito dello scarico, attaccarlo come

mostrato nella figura. (Nota: Solo per unità con pompa di

calore.)

Metodo di scarico: Uso della pompa a vuoto

1. Staccare il coperchio della porta di servizio della valvola a 3 vie, il coperchio della

valvola a stelo della valvola a 2 vie e della valvola a stelo della valvola a 3 vie,

collegare la porta di servizio nella protuberanza del tubo di carico (basso) del

gruppo monometrico. Poi collegare la protuberanza del tubo di carico (centrale) alla

pompa a vuoto.

2. Aprire a livello basso la manopola del gruppo monometrico, operare la pompa a

vuoto. Se l'indicatore (basso) raggiunge la condizione di vuoto immediatamente,

controllare di nuovo il punto 1.

3. Operare per oltre 15min. Controllare l'indicatore che deve indicare -0.1MPa (76 cm

Hg) sul lato della bassa pressione. Dopo avere completato la procedura di scarico,

chiudere la manopola in posizione "Lo" del gruppo manometrico ed arrestare il

funzionamento della pompa a vuoto. Controllare le condizioni dell'indicatore ed

attendere 1-2min. Se l’indicatore si sposta, malgrado la chiusura, far funzionare di

nuovo il degassamento e tornare al principio del punto 3 .

11

Page 12

4. Aprire la valvola a stelo della valvola a 2 vie girandola in senso antiorario di 90

A

A

A

gradi. Dopo 6 secondi, chiudere la valvola a 2 vie ed eseguire un'ispezione per

accertarsi che non ci siano perdite di gas.

5. Non ci sono perdite di gas?

Se ci sono perdite di gas, stringere i giunti del tubo. Se la perdita di arresta, procedere

al punto 6.

otterrocSotterroC

Inclinato Danno della svasatura Rottura Parziale Troppo esterno

Se la perdita non si arresta, scaricare tutto il refrigerante usando la porta di servizio.

Dopo avere attivato di nuovo il degassamento ed aspirato l'aria, riempire con

refrigerante raccomandato usando la bombola del gas.

6. Staccare il tubo di carico dalla porta di servizio, aprire la valvola a 2 vie ed a 3 vie.

Girare l'asta della valvola in senso antiorario delicatamente.

7. Per prevenire la perdita di gas, girare ancora un po' il coperchio della porta di

servizio, il coperchio della valvola a stelo della valvola a 2 vie e della valvola a 3

vie oltre il punto in cui la coppia aumenta improvvisamente.

8. Dopo avere attaccato ciascun coperchio, controllare che non ci siano perdite di

gas attorno ai coperchi.

Fase 6.

Fase 7.

Fase 2.

perto

Fase 3.

Chiuso

Valvola a 2 vie

Valvola a 3 vie

Valvola a 2 vie

Valvola a 3 vie

Coperchio valvola a stelo

Coperchio valvola a stelo

Fase 1.

Tubo (per R410A)

Fase 4.

Valvola a 2 vie Valvola a 3 vie

Valvola a 2 vie lato liquidi

perto 90°

Valvola a 3 vie lato gas

Gruppo monometrico (per R410A)

Giunto anti-controcorrente

Pompa a vuoto (per R410A)

Valvola a 2 vie

Valvola a 3 vie

Coperchio porta di servizio

AVVERTENZA

Se c'è una perdita di refrigerante del condizionatore, è necessario scaricare tutto il

refrigerante. Per prima cosa aspirare, poi caricare il refrigerante liquido nel

condizionatore in base alla quantità indicata sull'etichetta.

Non permettere ad altri liquidi refrigeranti, fatta eccezione per quello specificato

(R410A), o all'aria di entrare nel sistema di circolazione. Diversamente ci sarà

un'alta pressione anomala nel sistema che provocherà la rottura e possibili lesioni

alle persone.

Installazione della sorgente d'alimentazione

La sorgente d'alimentazione deve essere usata esclusivamente per il

condizionatore. (Oltre 15A)

Se il condizionatore è installato in un luogo umido, installate un interruttore di

circuito con messa a terra.

Per l'installazione in altri luoghi, usare un interruttore di circuito il più lontano

possibile.

Taglio e svasatura dei tubi

Il taglio dei tubi si esegue con un tagliatubi e le fresature devono essere

rimosse.

Dopo avere inserito il dado svasato, si esegue il lavoro di svasatura.

Attrezzo per

svasatura per

R410A

Tipo a frizione

Attrezzo convenzionale per svasatura

Tipo a frizione (tipo

rigido)

Tipo dado ad alette (tipo

imperiale)

A 0~0.5mm 1.0~1.5mm 1.5~2.0mm

Profilo attrezzo per svasatura

1. Tagliare il tubo

3. Inserire il dado svasato

2. Rimuovere le fresature

4. Svasare il tubo

Sullo scarico

Installare il tubo di scarico in modo che sia inclinato correttamente verso il

basso.

Non installare lo scarico come mostrato di seguito.

Inferiore a

5cm

mezza via si

solleva.

L'estremità è immersa

nell'acqua.

È ondulato.

Lo spazio tra l'estremità

ed il terreno è troppo

piccolo.

Ci sono cattivi odori che

provengono da uno scolo

Versare dell'acqua nel raccoglitore dell'unità interna che sarà scaricata in

sicurezza all'esterno.

Se il tubo di scarico collegato si trova in una stanza, isolarlo in modo

appropriato.

Etichetta di caricamento del refrigerante

Questo prodotto contiene gas serra fluorinato,

trattato nel Protocollo di Kyoto

Questo prodotto contiene gas serra fluorinato, oggetto del Protocollo di Kyoto. Non

lasciar sfogare nell'atmosfera.

Tipo di refrigerante:R410A

Valore GWP* :1975

GWP=global warming potential

Inserire, con inchiostro indelebile,

• 1 il carico di refrigerante del prodotto inserito in fabbrica

• 2 il quantitativo aggiuntivo di refrigerante caricato sul campo e

• 1+2 il totale di refrigerante caricato sull'etichetta di caricamento del refrigerante

fornita col prodotto.

L'etichetta compilata deve essere attaccata accanto alla porta di caricamento del

prodotto (es. all'interno del coperchio con il valore di arresto).

A Questo prodotto contiene gas serra fluorinato, trattato nel Protocollo di Kyoto

B Carico di refrigerante del prodotto inserito in fabbrica: vedere la piastra con il nome

dell'unità

C quantitativo aggiuntivo di refrigerante caricato sul campo

D carico di refrigerante totale

E unità da esterno

F cilindro di refrigerante e collettore per la carica

Controllo dell'installazione e collaudo

Spiegare accuratamente al cliente come funziona e come si usa il condizionatore

in base alle istruzioni del manuale d'uso.

Elenco di controllo per il collaudo

Mettere il segno nelle caselle

Perdita di gas sui collegamenti dei tubi?

Isolamento termico sui collegamenti dei tubi?

I cavi di collegamento dell'unità interna ed esterna sono inseriti in sicurezza nel

blocco terminali?

I cavi di collegamento dell'unità interna ed esterna sono ben fissati?

Lo scarico è stato e seguito correttamente?

La messa a terra è collegata in sicurezza?

L'unità interna à fissata in sicurezza?

La tensione della sorgente d'alimentazione è regolamentare?

Ci sono dei rumori?

Gli indicatori luminosi si illuminano in modo normale?

Le funzioni di raffreddamento e riscaldamento (per i modelli con pompa di calore)

sono eseguite in modo normale?

Il funzionamento del regolatore della temperatura d'ambiente è normale?

12

Page 13

Manuel d'installation d'un climatiseur de pièce

A

A

Outillage requis pour l'installation

Clé Clé dynamométrique (17 mm, 22 mm,

Pince Coupe-tube

Scie à métaux Outil d'évasement

Perceuse Couteau

Clé à ergot (17,19 et 26 mm) Rubans à mesurer

Détecteur de fuite de gaz ou solution à

base d'eau savonneuse

Source d'alimentation

Avant de brancher la fiche dans la prise, vérifiez que la tension est sans faille. La source

d'alimentation correspond aux informations sur la plaque signalétique.

Installez un circuit d'alimentation auxiliaire exclusive.

Une prise doit être installée de manière à ce que le câble d'alimentation puisse être branché

facilement. Ne pas prolonger le câble en le coupant.

Les modèles utilisent le réfrigérant R410A sans HFC

plus de 5 cm

26 mm)

Alésoir

Schéma de l'installation des unités intérieures et extérieures

Préparation

Unité intérieure

L'emplacement doit être solide sans vibration et offrir un support suffisant.

L'emplacement ne doit pas être affecté par de la chaleur ou de la vapeur générées dans les

environs et doit garantir que l'entrée et la sortie de l'unité ne seront pas gênées.

L'emplacement doit permettre une vidange facile avec la tuyauterie connectée à l'unité

extérieure.

L'emplacement doit permettre de répartir l'air froid dans toute la pièce.

L'emplacement doit disposer d'une prise d'alimentation avec suffisamment d'espace autour. (Voir

les schémas).

Sélectionnez un emplacement à une distance d'au moins (1) m par rapport aux postes de

télévision, radio, appareils sans fil et lampes fluorescentes.

En cas de fixation de la télécommande sur un mur, sélectionnez l'emplacement de sorte que

l'unité intérieure puisse recevoir les signaux lorsque les lampes fluorescentes sont allumées

dans la pièce.

Unité extérieure

Sélectionnez un emplacement qui ne soit pas exposé à la pluie ou à la lumière du jour et qui soit

suffisamment ventilé.

Sélectionnez un emplacement capable de supporter l'unité où les vibrations et le bruit

n'augmentent pas.

Sélectionnez un emplacement où le vent et le bruit ne risquent pas de gêner les voisins.

Choisir un endroit dans lequel les distances marquées ↔ illustrées dans le schéma ci-dessus

sont disponibles.

Il faut faire particulièrement

attention au soulèvement du

tuyau de vidange.

Sélection de l'emplacement pour l'installation

plus de 10 cm

Disposition des directions de la

tuyauterie

rrière gauche

Gauche

En bas

Les marques de A à G sur la

figure représentent les références

de pièce.

La distance entre l'unité intérieure

et le sol est de 2 m minimum.

plus de 60 cm

rrière

droite

Droite

plus de 10 cm

plus de 10 cm

plus de 10 cm

Pièces en option pour la tuyauterie

A

Ruban non adhésif

○

B

Ruban adhésif

○

C

Selle (L.S) avec vis

○

D

Raccordement du câble électrique

○

entre unités intérieures et

extérieures

E

Tuyau de vidange

○

F

Matériau d'isolation thermique

○

G

Cache trou de tuyauterie

○

Dimensions de fixation au sol de l'unité

extérieure (Unité:mm)

Fixation de l'unité extérieure

Fixez l'unité horizontalement et

solidement sur le béton ou un bloc de

béton avec des boulons (10 mm) et

des écrous

Lorsque l'unité doit être installée sur

un mur, un toit ou la toiture, fixez un

support avec des clous ou des fils en

tenant compte des séismes et vents

forts.

Si des vibrations risquent d'affecter la

maison, fixez l'unité avec un tapis

anti-vibration

L'illustrati

on ci-dessus est indiquée à titre de référence uniquement, vous devez tenir compte des particularités du modèle acheté.

Lisez ce manuel avant de procéder à l'installation

Communiquez à l'utilisateur suffisamment d'informations sur l'exploitation de l'unité selon ce manuel.

plus de 15 cm

13

Page 14

Accessoires

Installation de l'unité intérieure

)1( egnadiv ed uayuT )1( ednammocéléT

Batterie sèche R-03 (2) Coussinet (4)

)1( egnadiv ed eduoC )1( noitaxif ed euqalP

Capuchon en plastique (4)

Vis Ø4X25 (4)

Plaque de support de tuyau (1).

Sélection du tuyau

Tuyau de liquide (Ø) 6.35mm (1/4 po)

Tuyau de gaz (Ø) 15,88mm (5/8 po)

REMARQUE: L'épaisseur du tuyau doit être de 0,8 mm minimum.

Unité intérieure

Installation de la plaque de fixation et positionnement du trou dans le mur

Lorsque la plaque de fixation est installée pour

la 1e fois

1. Localisez en fonction des piliers ou des linteaux autour, un endroit de fixation contre le mur, puis

attachez la plaque temporairement avec un clou en acier.

2. Assurez-vous à nouveau que le niveau de la plaque est approprié en suspendant un fil avec un

poids du dessus central de la plaque, puis fixez solidement la plaque avec le clou en acier.

3. Localisez le trou A dans le mur avec un ruban à mesurer

Schéma de la tuyauterie

[Tuyauterie arrière]

Acheminez les tuyaux et le tuyau de vidange que vous fixez ensuite avec du ruban adhésif.

[Gauche - Tuyauterie arrière gauche]

Dans le cas d'une tuyauterie à gauche, découpez, avec une pince, le couvercle pour la

tuyauterie gauche.

Pour une tuyauterie à l'arrière gauche, cintrez les tuyaux selon le sens de la tuyauterie jusqu'à la

marque du trou pour une tuyauterie arrière-gauche qui est marquée sur les matériaux d'isolation

thermique.

1. Insérez le flexible d'évacuation dans l'encoche des matériaux d'isolation thermique de l'unité

intérieure.

2. Introduisez le câble électrique de l'unité intérieure/extérieure de l'endos de l'unité intérieure et

sortez-le par l'avant puis effectuez la connexion.

3. Enduisez le joint évasé avec de l'huile réfrigérante et connectez les tuyaux.

Enduisez la pièce de connexion avec des matériaux d'isolation thermique et fixez avec du ruban

adhésif.

Câble électrique des unités intérieures/extérieures

Matériau d'isolation

thermique

Couvercle pour

tuyauterie de

droite

Couvercle de dessous

Fixez avec du ruban adhésif

Le câble des unités intérieures/extérieures et le tuyau de vidange doivent être fixé au tuyau de

réfrigérant avec un ruban protecteur.

Couvercle pour

tuyauterie de

gauche

Tuyau de vidange

[Tuyauterie dans une autre direction].

A l'aide d'une pince, découpez le couvercle pour la tuyauterie en fonction de la direction de la

tuyauterie et cintrez ensuite le tuyau selon la position du trou dans le mur. Lors du cintrage, prenez

soin de ne pas écraser les tuyaux.

Connectez au préalable le câble des unités intérieures/extérieures et recouvrez ensuite les

câbles connectés avec l'isolation.

Tuyauterie

Plaque de

support de tuyau

Lorsque la plaque de fixation est installée sur

une barre latérale ou un linteau

Installer une barre de fixation (vendue séparément) à la barre latérale et au linteau puis

resserrez la plaque à la barre de fixation fixe.

Voir la position du trou dans le mur dans la section précédente intitulée Lorsque la plaque de

fixation est installée pour la 1e fois.

Faire un trou dans le mur et installer le cache-trou de tuyauterie

Faites un trou de 70 mm de diamètre, descendant légèrement vers l'extérieur du mur.

Installez le cache trou de tuyauterie et scellez avec du mastic après l'installation

Trou dans le mur

Ø70 mm

Côté intérieur

(Section du trou dans le mur)

Epaisseur de la paroi

Tuyau pour le trou de tuyauterie

Côté extérieur

Fixation de l'unité intérieure

Suspendez l'unité sur les encoches supérieures de la plaque de

fixation. Déplacez l'unité d'un côté vers l'autre pour vérifier la fixation.

Pour fixer le corps sur la plaque de fixation, soutenez le corps du

dessous et reposez-le perpendiculairement.

Déballage de l'unité intérieure

Lorsque vous déballez l'unité intérieure,

utilisez vos mains pour soulever le corps

puis sortez la partie inférieure du corps

légèrement vers l'extérieur et soulevez

ensuite l’unité jusqu'au dégagement de la

plaque de fixation.

Crochet

Connexion du câble des unités intérieures/extérieures

Dépose du cache-câble

Enlevez le cache-borne en bas à droite de l'unité intérieure et séparez le

couvercle du câblage en desserrant les vis.

Connexion du câble après l'installation de

l'unité intérieure

1. Insérez le câble de l'extérieur de la pièce dans le côté gauche du trou dans

le mur dans lequel se trouve le tuyau.

2. Tirez le câble sur le côté avant et connectez-le en formant une boucle.

Plaque de fixation

Plaque de

fixation

14

Page 15

Connexion du câble avant l'installation de

A

A

l'unité intérieure

Unité extérieure

Installation de l’unité extérieure

Insérez le cordon depuis l'arrière de l'unité et sortez par l'avant.

Desserrez les vis et enfoncez bien les extrémités du câble dans le bornier. Serrez les vis.

Tirez légèrement sur le câble pour garantir qu'il a été correctement enfoncé et serré.

Après avoir raccordé le câble, placez le cache-câble sur le câble connecté.

Remarque

Unité intérieure

Lors de la connexion du câble, confirmez le numéro de la borne des unités

intérieures et extérieures. Si le câblage est incorrect, le fonctionnement sera

incorrect et entraînera des dommages.

Câblage de connexion :

3× 0,75 mm

Câblage de connexion :

2

3G0,75 mm

LIMENTATION

2

Unité extérieure

Effectuez l'installation selon le schéma d'installation des unités intérieures et extérieures

Raccords de tuyauterie

Lorsque vous cintrez un tuyau, prenez soin de ne pas écraser le tuyau. Le rayon de cintrage doit

être entre 30 et 40 mm ou plus long.

Connectez d'abord le côté gaz pour faciliter la suite des travaux.

Le tuyau de raccordement est réservé à R410A.

Demi-raccord

Clé

Faites attention que des particules telles que les déchets. le sable, etc. ne rentrent pas dans le tuyau.

La longueur standard du tuyau est de 5 m. Au delà de 7 m, l'unité ne fonctionnera pas correctement.

S'il faut rallonger le tuyau, le réfrigérant doit être chargé selon 20 g/m. Toutefois, la charge de

réfrigérant doit être exécuté par un professionnel de la climatisation. Avant d'ajouter du réfrigérant,

purgez l'air des tuyaux de réfrigération et de l'unité intérieure avec pompe à vide. Chargez ensuite le

réfrigérant supplémentaire.

Ecrou

d'évasement

Clé

dynamométrique

Le serrage forcé sans prêter attention au centrage peut

endommager les filets et entraîner des fuites de gaz.

Diamètre du tuyau (Ø) Couple de serrage

Côté liquide 6,35 mm (1/4 po) 18N.m

Côté liquide/gaz 9,52 mm

(3/8 po)

Côté gaz 12.7mm (1/2 po) 55N.m

Côté gaz 15.88mm (5/8 po) 60 N.m

42N.m

VERTISSEMENT

Unité extérieure

Unité

intérieure

Unité

intérieure

Câble électrique: ≥3G2,5mm

1. Si le cordon d'alimentation est endommagé, il doit être remplacé par le fabricant, un de ses

agents d'entretien ou une personne qualifiée. Le type du fil de connexion est H05RN-F ou

H07RN-F.

2. Si le fusible sur la carte PC a fondu, remplacez-le avec le type T. 3.15A/ 250V.

3. La méthode de câblage doit être conforme aux normes locales de câblage.

4. Après installation, la prise de courant doit être d'accès facile.

5. Un disjoncteur doit être incorporé au câblage fixe. Le disjoncteur doit être omnipolaire et la

distance entre ses deux contacts ne doit pas être inférieure à 3 mm.

2

Unité extérieure

Hauteur max: A1max=15m

Unité extérieure

Piège dl'huile

Unité

intérieure

Si la hauteur A dépasse les 5m, installez

un piège à huile tous les 5 à 7 m

Longueur max: Bmax=25m

Si la longueur du tuyau B dépasse les 7

m, le réfrigérant doit être chargé à 20

g/m.

Raccordement

Procédez selon la même méthode que pour l'unité intérieure. Desserrez les vis sur le bornier et

insérez totalement les fiches dans le bornier puis resserrez les vis.

Insérez le câble selon le numéro de la borne (tel que pour l'unité intérieure).

Si le câblage est incorrect, le fonctionnement sera incorrect et le contrôleur risque de subir des

dommages.

Fixez le câble avec un serre-câble.

Fixation d'un drain coudé

Si vous utilisez un drain coudé, procédez à la fixation selon

l'illustration. (Remarque : (uniquement pour la pompe thermique)

Méthode de purge: avec une pompe à vide:

1. Enlevez le capuchon de l'orifice d'entretien de la vanne à 3 voies, le capuchon du robinet de la

vanne à 2 voies et à 3 voies. Connectez ensuite l'orifice d'entretien dans la projection du tuyau

de charge (bas) pour le collecteur à manomètre. Connectez ensuite la projection du tuyau de

charge (centre) pour le collecteur à manomètre dans la pompe à vide.

2. Ouvrez la poignée du collecteur à manomètre au niveau bas. Mettez la pompe à vide en marche.

Si l’indicateur se déplace (bas), précipitez l'état de vide et vérifiez 1 à nouveau.

3. Mettez sous vide pendant plus de 15 min Vérifiez également le manomètre qui doit indiquer

-0.1MPa (76 cm Hg) sur le côté basse pression. Après avoir effectué le vide, fermez la poignée

Lo dans le collecteur à manomètre et arrêtez l'opération de la pompe à vide. Inspectez

l’indicateur et observez pendant 1 à 2 minutes. Si l’indicateur revient en dépit du serrage,

reprenez l'opération d'évasement en revenant au début de l'étape 3.

4. En tournant dans le sens antihoraire, ouvrez le robinet de la vanne à 2 voies à un angle de

90 degrés. Environ 6 secondes plus tard, fermez la vanne à 2 voies et inspectez afin de détecter

toute fuite de gaz.

15

Page 16

5. Pas de fuite de gaz?

Si elle n'a pas été maîtrisée, videz le réfrigérant de l'orifice d'entretien. Après avoir effectué

6. Détachez le tuyau de charge de l'orifice d'entretien, ouvrez la vanne à 2 et 3 voies. Tournez le

robinet de la vanne dans le sens antihoraire.

7. Pour empêcher toute fuite de gaz, tournez le capuchon de l'orifice d'entretien, le capuchon du

robinet des vannes à 2 et 3 voies un peu au-delà du point où le couple augmente brusquement.

8. Après avoir fixé les capuchons, inspectez-en le tour pour détecter toute trace de fuite.

Étape 1.

En cas de fuite de gaz, resserrez les pièces de connexion du

tuyau. Lorsque la fuite est maîtrisée, passez à l'étape 6

l'évasement et le vide, remplissez de réfrigérant indiqué de la bouteille.

Vanne à 2 voies, côté liquide.

Vanne à 3 voies, côté gaz

Collecteur à manomètre (pour le

modèle R410A)

Joint anti-contre-courant

Étape 2.

Ouvrir

Étape 3.

Vidange

Installez le tuyau de vidange de manière à ce que la pente soit descendante.

Ne pas effectuer la vidange telle qu'illustrée ci-dessous.

Moins de 5cm

Il est surélevé à

mi-chemin.

Versez de l'eau dans le bac de vidange de l'unité intérieure et vérifiez qu'il soit dirigé vers

l'extérieur.

Si le tuyau de vidange est dans une pièce, utilisez une isolation thermique.

L'extrémité est

immergée dans

l'eau.

Il ondule :

L'intervalle au sol

est trop petit.

Il y a une odeur

nauséabonde de la

fosse

■ Etiquette de charge de réfrigérant

Contient des gaz à effet de serre fluorés

couverts par le protocole de Kyoto.

Étape 6.

Étape 7.

Fermer

Vanne à 2 voies

Vanne à 3 vo ies

Vanne à 2 voies

Vanne à 3 voies

Capuchon du robinet

de vanne

Capuchon du robinet

de vanne

Tube (pour le modèle R410A)

Étape 4.

Ouvert à 90°

Vanne à 2 voies

Pompe à vide (pour le modèle R410A)

Vanne à 2 voies

Vanne à 3 voies

Vanne à 3 voies

Capuchon de l'orifice d’entretien

AVERTISSEMENT

Si le réfrigérant du climatiseur fuit, il faut vidanger tout le réfrigérant. Mettez d'abord

sous vide, puis chargez le réfrigérant liquide dans le climatiseur d'air jusqu'à la quantité

indiquée sur la plaque signalétique.

Ne laissez pas les autres moyens de réfrigération, sauf pour celui spécifié (R410A) ou

l'air entrer dans le système de circulation du produit de refroidissement. Toute entrée

entraînerait une pression élevée dans le système au point de le faire craquer et blesser

les individus.

Installation du bloc d'alimentation

La source d'alimentation doit être utilisée exclusivement par le climatiseur. (Plus de 15A)