Page 1

CAUTION

READ THIS MANUAL CAREFULLY TO

DIAGNOSE TROUBLE CORRECTLY

Refrigerator

SERVICE MANUAL

Features:

1. Spacercraft insulation technology saving

2. Digital temperature with VFD disply

3. full-out fridge tray

4. Ice and water dispenser

5. Super freezing

6. Direct current vairable-frequency

7. Direct current vairable-frequency blower fan

8.Deluxe bar ,ice machine

9. Cold drink outside access design

10. Deluxe deep bottle holderr

11.Detachable door seal

Haier Group

BEFORE OFFERING SERVICE .

MODEL: HRF-661FF/ASS

1

Page 2

Model HRF-661FF/ASS,HRF-661FF/A

Part1.Specifications

Model HRF-661FF/ASS HRF-661FF/A

Cavity Supply(V/Hz) 220~240/50 220~240/50

Power

Consumption(Kw.h/year)

Unit Dimensions (WDH

WDH/mmXmmXmm)

Unit Weight(Kg) 138 132

Box

Dimensions(WDH/mmXmmX

mm)

Box Weight(Kg) 156 156

Container Quantity(40’Hc) 36 36

Specifications are subject to change without prior notice.

537 537

770*890*1768 770*890*1768

960*770*1894 960*770*1894

2

Page 3

3

Page 4

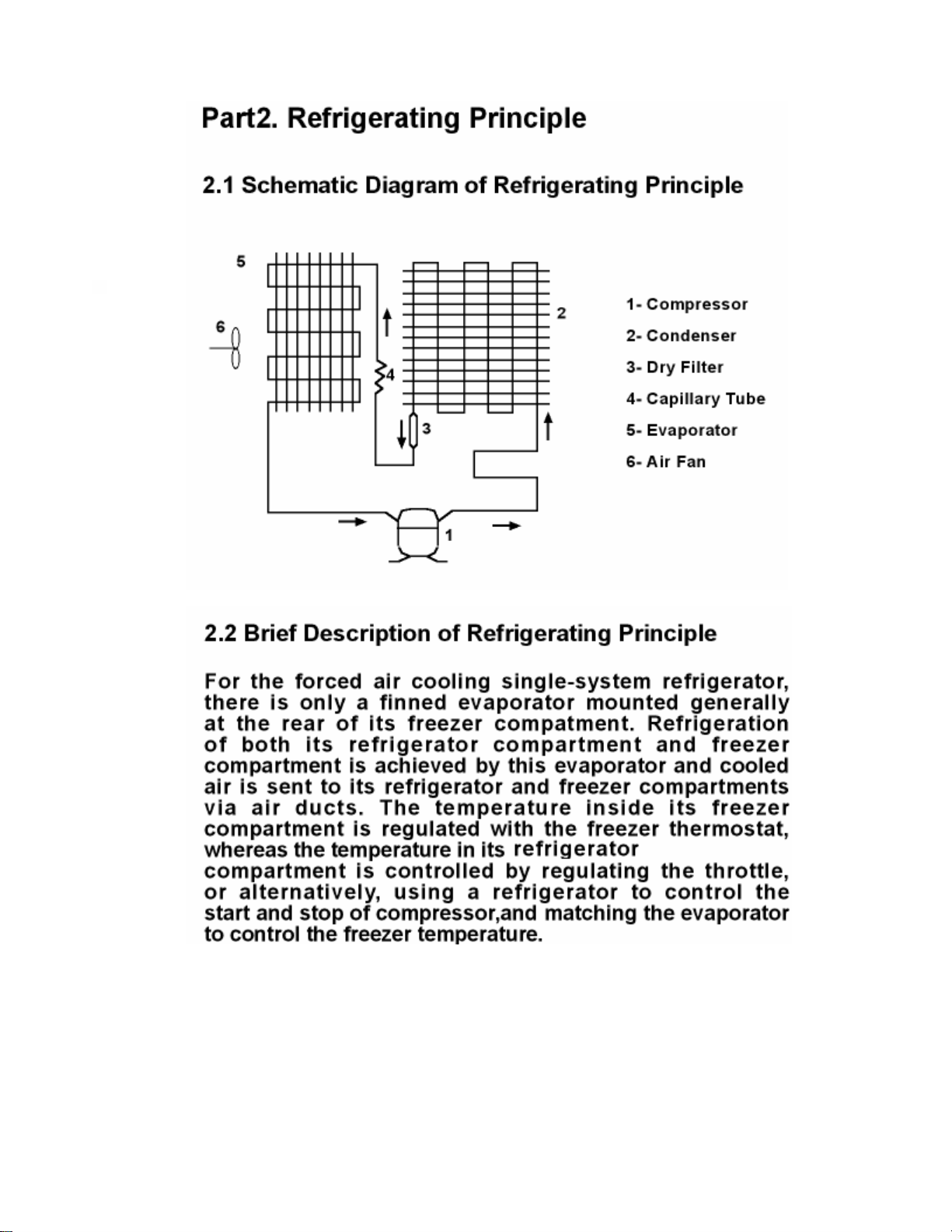

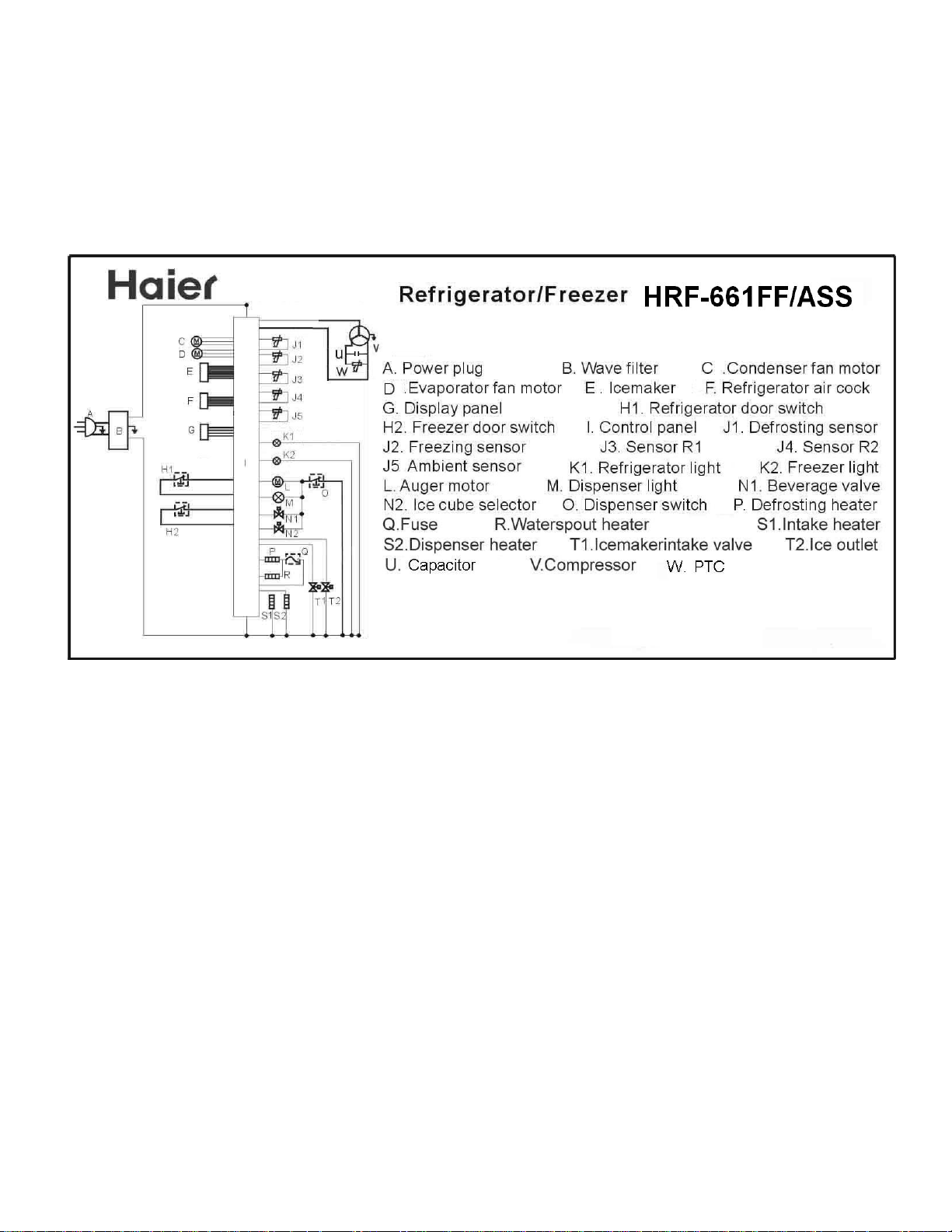

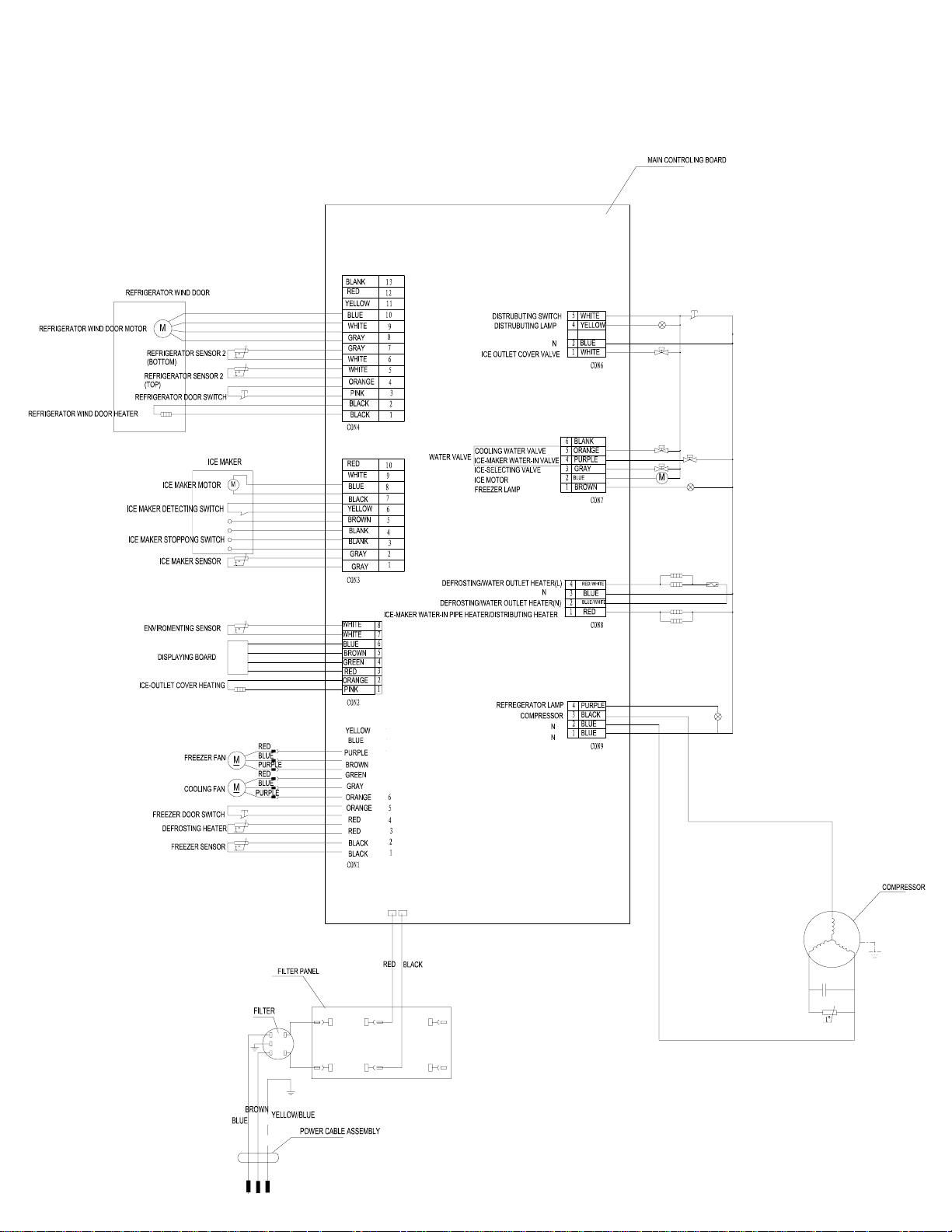

Part3. Principle of Electric Control

Schematic Circuit Diagram

Brief Description of Control Principle

HRF-661FF/ASS , HRF-661FF/A , is the forced air cooling

refrigerator with two doors(side by side). A mechanical type of all the

control is generally adopted. The thermostat directly controls the

start and stop of compressor, and hence the refrigerator

temperature.

Low Temperature Compensation in the above schematic

diagram,

be closed and the heating will work, thus ensuring the normal start,

and operation of refrigerator at lower ambient temperature, in such case,

the freezer compartment temperature can reach a good point.

when the ambient is below the set temperature, the switch will

4

Page 5

Part4. Assembly figure

6

Page 6

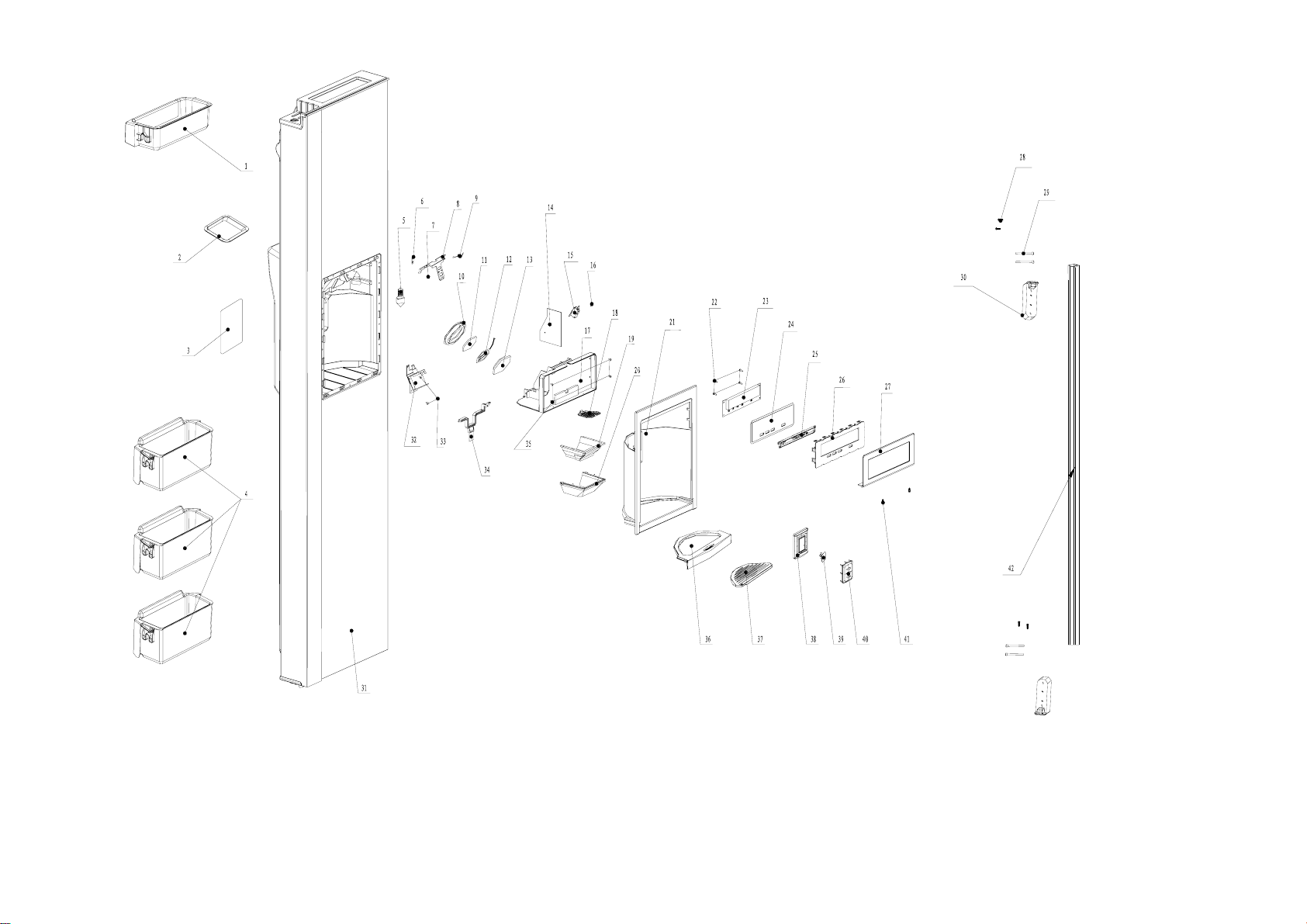

Part 5. Exploded view

8

Page 7

9

Page 8

10 11 112

Page 9

Page 10

Page 11

REFRIGERATOR

Model:

HRF-661FF/ASS

Product code:BC0JX0E0500

general assembly

No. In the

exploded

Spare parts

number

view

1 0060821750 fridge foamed door assembly HRF-661FF/ASS 1 0.05% 0.05% *

2 0060822301 freezer foaming door assembly HRF-661FF/ASS 1 0.00% 0.00%

3 0060821346 lower vegetable box assembly HRF-661FF/ASS 1 0.00% 0.00%

4 0060219817 right slide way of lower vegetable box HRF-661FF/ASS 1 0.00% 0.00%

5 0060600097 screw HRF-661FF/ASS 4 0.00% 0.00% *

6 0060219580 left slide way of lower vegetable box HRF-661FF/ASS 1 0.01% 0.01% *

7 0060818005 freezer drawer cover board HRF-661FF/ASS 1 0.00% 0.00%

8 0060818006 freezer shelf HRF-661FF/ASS 2 0.00% 0.00% *

9 0060818598 ice-crushed box assembly HRF-661FF/ASS 1 0.01% 0.01% *

10 0060214369 freezer lampshade cover HRF-661FF/ASS 1 0.00% 0.00%

11 0060214368 freezer lampshade HRF-661FF/ASS 1 0.00% 0.00% *

12 0060212618 ice-crushed box slide way HRF-661FF/ASS 2 0.00% 0.00%

13 0060600097 screw HRF-661FF/ASS 4 0.00% 0.00%

14 0060204650 ice box HRF-661FF/ASS 1 0.00% 0.00% *

15 0064000955 ice box motor HRF-661FF/ASS 1 0.00% 0.00%

16 0060600097 screw HRF-661FF/ASS 4 0.00% 0.00%

17 0060205021 fixing nut HRF-661FF/ASS 4 0.00% 0.00% *

18 0060214376 ice-maker supporter HRF-661FF/ASS 1 0.00% 0.00%

19 0060214386 ice-crushed motor box HRF-661FF/ASS 1 0.00% 0.00%

20 0060205614 ice-crushed motor box right slide way HRF-661FF/ASS 4 0.00% 0.00% *

21 0060600097 screw HRF-661FF/ASS 4 0.00% 0.00% *

22 00608010087 screw HRF-661FF/ASS 2 0.00% 0.00%

23 00604050121 anti-heat and glisten patch gasket HRF-661FF/ASS 4 0.00% 0.00%

24 0060161498 anti-heat and glisten patch HRF-661FF/ASS 1 0.21% 0.21%

25 00606040080 lamp HRF-661FF/ASS 1 0.00% 0.00%

26 0060818587 bottom freezer air tower assembly HRF-661FF/ASS 1 0.00% 0.00%

27 0060600097 screw HRF-661FF/ASS 4 0.00% 0.00% *

28 00602160304 screw cover HRF-661FF/ASS 2 0.00% 0.00%

29 0064098047 screw HRF-661FF/ASS 2 0.00% 0.00% *

30 0060401479 ice-crushed motor box cable HRF-661FF/ASS 1 0.00% 0.00%

31 0060818586 top freezer air tower assembly HRF-661FF/ASS 1 0.00% 0.00%

32 0060818729 defrost waterspout assembly HRF-661FF/ASS 1 0.00% 0.00%

33 0060818585 freezer air shutter assembly HRF-661FF/ASS 1 0.00% 0.00%

34 0064082811 screw HRF-661FF/ASS 5 0.00% 0.00% *

35 0060207845 fan motor cover HRF-661FF/ASS 1 0.00% 0.00%

36 0060301218 damping rubber I HRF-661FF/ASS 1 0.00% 0.00%

37 0060207848 fan vane HRF-661FF/ASS 1 0.00% 0.00%

38 0064000459 DC fan motor HRF-661FF/ASS 1 0.00% 0.00% *

39 0060215338 damping rubber II HRF-661FF/ASS 1 0.00% 0.00%

40 0060818584 freezer motor assembly HRF-661FF/ASS 1 0.00% 0.00%

41 0060818624 evaporator assembly HRF-661FF/ASS 1 0.00% 0.00%

42 0060214973 motor cable cover HRF-661FF/ASS 1 0.00% 0.00%

43 0060801032 screw HRF-661FF/ASS 1 0.00% 0.00%

44 0060215938 down decorating strip assembly HRF-661FF/ASS 1 0.00% 0.00%

45 0060818824A left below hinge assembly HRF-661FF/ASS 1 0.00% 0.00%

Spare parts description in English Model Qty Failure rate

The proportion

of the spare

part stock

Remark

related

technical

bulletin ID

number

Page 12

No. In the

exploded

Spare parts

number

view

46 00609380509 adjustable foot assembly HRF-661FF/ASS 2 0.00% 0.00%

47 0060801032 screw HRF-661FF/ASS 7 0.00% 0.00% *

48 0060215014 seal strip I HRF-661FF/ASS 1 0.00% 0.00%

49 0060215015 seal strip II HRF-661FF/ASS 1 0.00% 0.00%

50 0060801032 screw HRF-661FF/ASS 4 0.00% 0.00% *

51 0060818345 compressor bracket assembly HRF-661FF/ASS 1 0.00% 0.00%

52 0060703449 connection tube for exhaust HRF-661FF/ASS 1 0.00% 0.00% *

53 0060806084 valve HRF-661FF/ASS 1 0.00% 0.00%

54 0060400035 cable of valve HRF-661FF/ASS 1 0.00% 0.00%

55 0060210199 rubber grommet HRF-661FF/ASS 4 0.00% 0.00%

56 0060803303 compressor bolt HRF-661FF/ASS 4 0.00% 0.00% *

57 0060732586 compressor HRF-661FF/ASS 1 0.00% 0.00%

58 0060700768 injection tube HRF-661FF/ASS 1 0.00% 0.00% *

59 0060703455 condenser assembly HRF-661FF/ASS 1 1.79% 1.79%

60 0060801032 screw HRF-661FF/ASS 4 0.00% 0.00%

61 0060214381 water tray HRF-661FF/ASS 1 0.00% 0.00%

62 0060818623

63 0060801032 screw HRF-661FF/ASS 1 0.00% 0.00%

64 0060215338 damping rubber II HRF-661FF/ASS 1 0.00% 0.00%

65 0064000460 DC fan motor HRF-661FF/ASS 1 0.00% 0.00%

66 0060301218 damping rubber I HRF-661FF/ASS 1 0.00% 0.00%

67 0060214385 fan motor cover HRF-661FF/ASS 1 0.00% 0.00%

68 0064082808 screw HRF-661FF/ASS 2 0.00% 0.00%

69 0060208240 fan vane HRF-661FF/ASS 1 0.00% 0.00%

70 0060109707 compressor cover HRF-661FF/ASS 1 0.00% 0.00% *

71 0060801032 screw HRF-661FF/ASS 6 0.00% 0.00% *

72 0060214899 tanker water inlet protect pipe HRF-661FF/ASS 1 0.00% 0.00%

73 0060205753 water pipe fixup nip HRF-661FF/ASS 1 0.00% 0.00% *

74 0060801032 screw HRF-661FF/ASS 1 0.00% 0.00%

75 0060205757 water leader HRF-661FF/ASS 1 0.00% 0.00%

76 0064000967 enter water pipe of ice maker assembly HRF-661FF/ASS 1 0.00% 0.00% *

77 0060214635 elbow of enter water pipe HRF-661FF/ASS 1 0.00% 0.00%

78 0060161557 ice maker pipe fixup board HRF-661FF/ASS 1 0.00% 0.00%

79 0060161089 freezer top hinge HRF-661FF/ASS 1 0.00% 0.00%

80 0060600251 screw HRF-661FF/ASS 4 0.00% 0.00%

81 0060214961 freezer top hinge box HRF-661FF/ASS 1 0.00% 0.00%

82 0060818535 main control box supporter HRF-661FF/ASS 1 0.00% 0.00% *

83 0060600097 screw HRF-661FF/ASS 3 0.00% 0.00% *

84 0064001169 control panel HRF-661FF/ASS 1 0.00% 0.00% *

85 00606020090 filter HRF-661FF/ASS 1 0.00% 0.00% *

86 00606110135 power cable HRF-661FF/ASS 1 0.00% 0.00%

87 0060210244 control panel box cover HRF-661FF/ASS 1 0.03% 0.03%

88 0060600097 screw HRF-661FF/ASS 4 0.00% 0.00%

89 0060600097 screw HRF-661FF/ASS 2 0.00% 0.00%

90 0060214959 fridge top hinge box HRF-661FF/ASS 1 0.00% 0.00% *

91 0060600251 screw HRF-661FF/ASS 4 0.00% 0.00%

92 0060161090 fridge top hinge HRF-661FF/ASS 1 0.00% 0.00%

93 0060818126 refrigerator wind passage assembly HRF-661FF/ASS 1 0.00% 0.00%

94 00609340017 electric wind door HRF-661FF/ASS 1 0.00% 0.00%

95 0060214734 front foamed of refrigerator wind passage HRF-661FF/ASS 1 0.00% 0.00%

Spare parts description in English Model Qty Failure rate

cooling fan assembly

HRF-661FF/ASS 1

0.00% 0.00%

The proportion

of the spare

part stock

Remark

related

technical

bulletin ID

number

Page 13

No. In the

exploded

Spare parts

number

view

96 0060818127 refrigerator wind passage cover assembly HRF-661FF/ASS 1 0.00% 0.00%

97 00606040084 lamp HRF-661FF/ASS 1 0.00% 0.00%

98 0060600097 screw HRF-661FF/ASS 2 0.00% 0.00%

99 0060214630 refrigerator top lampshade HRF-661FF/ASS 1 0.00% 0.00% *

100 0060215432 dryer fix slip HRF-661FF/ASS 1 0.01% 0.01%

101 0060207543 egg rack HRF-661FF/ASS 1 0.00% 0.00%

102 00606050061 lamp switch HRF-661FF/ASS 1 0.00% 0.00% *

103 0060214565 fridge shelf HRF-661FF/ASS 2 0.00% 0.00%

104 0060821776 foamed cabinet assembly HRF-661FF/ASS 1 0.12% 0.12% *

105 0060214565 fridge shelf HRF-661FF/ASS 1 0.00% 0.00%

106 0060818319 vegetable container cover HRF-661FF/ASS 1 0.00% 0.00% *

107 0060214963 sensor cover assembly HRF-661FF/ASS 1 0.00% 0.00%

108 0060214384 deodorization box HRF-661FF/ASS 1 0.00% 0.00%

109 0060819042 cold water jug assembly HRF-661FF/ASS 1 0.00% 0.00%

110 0060214735 foam block HRF-661FF/ASS 1 0.00% 0.00% *

111 0060818825A fridge bottom hinge assembly HRF-661FF/ASS 1 0.00% 0.00% *

112 0060600097 screw HRF-661FF/ASS 1 0.02% 0.02%

113 0060818589 top drawer assembly HRF-661FF/ASS 1 0.00% 0.00%

114 0060818315 right slide way of top drawer HRF-661FF/ASS 1 0.00% 0.00% *

115 0060818314 left slide way of top drawer HRF-661FF/ASS 1 0.00% 0.00%

116 00609380554 right slide way of lower drawer HRF-661FF/ASS 1 0.00% 0.00%

117 00609380553 left slide way of lower drawer HRF-661FF/ASS 1 0.00% 0.00%

118 0060818590 lower drawer assembly HRF-661FF/ASS 1 0.06% 0.06%

119 0060818314 left slide way of top vegetable box HRF-661FF/ASS 1 0.00% 0.00%

120 0060600097 screw HRF-661FF/ASS 1 0.00% 0.00% *

121 0060818315 right slide way of top vegetable box HRF-661FF/ASS 1 0.00% 0.00%

122 0060818292 top vegetable box assembly HRF-661FF/ASS 1 0.00% 0.00%

123 0060512560 manual instruction HRF-661FF/ASS 1 0.00% 0.00%

124 0060512939 packing HRF-661FF/ASS 1 0.00% 0.00%

Spare parts description in English Model Qty Failure rate

The proportion

of the spare

part stock

fridge foamed door assembly

No. In the

exploded

Spare parts

number

view

1 0060818999 fridge top bottle seat assembly HRF-661FF/ASS 1 0.02% 0.02% *

2 0060818348 fridge center bottle seat assembly HRF-661FF/ASS 3 0.01% 0.01%

3 0060818349 fridge bottom bottle seat assembly HRF-661FF/ASS 1 0.00% 0.00%

4 0060821749 fridge foam door HRF-661FF/ASS 1 0.00% 0.00%

5 0064098047 screw HRF-661FF/ASS 4 0.00% 0.00% *

6 0064082803 screw HRF-661FF/ASS 4 0.00% 0.00%

7 0060219681 handle seat HRF-661FF/ASS 2 0.06% 0.06% *

8 0060163046 handle HRF-661FF/ASS 1 0.00% 0.00%

0060821749S fridge door seal assembly

9

Spare parts description in English Model Qty Failure rate

HRF-661FF/ASS 1 0.00% 0.00%

The proportion

of the spare

part stock

freezer foaming door assembly

No. In the

exploded

Spare parts

number

view

1 0060818280 freezer top bottle seat assembly HRF-661FF/ASS 4 0.00% 0.00%

2 0060214607 cover of filler HRF-661FF/ASS 1 0.00% 0.00%

3 0064000156 lamp HRF-661FF/ASS 1 0.00% 0.00%

4 0060103988 press patch of filler bracket HRF-661FF/ASS 1 0.00% 0.00%

5 0064082811 cross groove self attach screw HRF-661FF/ASS 1 0.00% 0.00%

6 0064000270 lamp switch HRF-661FF/ASS 1 0.00% 0.00%

Spare parts description in English Model Qty Failure rate

The proportion

of the spare

part stock

Remark

Remark

Remark

related

technical

bulletin ID

number

related

technical

bulletin ID

number

related

technical

bulletin ID

number

Page 14

No. In the

exploded

Spare parts

number

view

7 0060600070 spring of filler bracket HRF-661FF/ASS 1 0.00% 0.00% *

8 0060300256 seal ring of leaking mouth HRF-661FF/ASS 1 0.12% 0.12%

9 0060300254 sponge tray of filler HRF-661FF/ASS 1 0.00% 0.00%

10 00606040068 cover heater of filler mouth HRF-661FF/ASS 1 0.00% 0.00% *

11 0060205622 filler cover HRF-661FF/ASS 1 0.00% 0.00%

12 0060214992 switch plywood HRF-661FF/ASS 1 0.00% 0.00%

13 0060600096 jiggling switch HRF-661FF/ASS 1 0.00% 0.00%

14 0064082811 cross groove self attach screw HRF-661FF/ASS 1 0.00% 0.00% *

15 0060214609 bracket of control board HRF-661FF/ASS 1 0.00% 0.00%

16 0060301125 protection cover tray of filler HRF-661FF/ASS 1 0.00% 0.00% *

17 0060818937 dispenser outsider bucket HRF-661FF/ASS 1 0.00% 0.00% *

18 0060819075F display panel I HRF-661FF/ASS 1 0.00% 0.00%

19 0064001168A display panel II HRF-661FF/ASS 1 0.00% 0.00%

20 0064098047 screw HRF-661FF/ASS 4 0.00% 0.00%

21 0064082803 screw HRF-661FF/ASS 4 0.06% 0.06% *

22 0060219681 handle seat HRF-661FF/ASS 2 0.06% 0.06% *

23 0060821528 freezer foamed door HRF-661FF/ASS 1 0.00% 0.00%

24 0060806082 electromagnetism valve HRF-661FF/ASS 1 0.00% 0.00% *

25 0060600097 cross groove self attach screw HRF-661FF/ASS 3 0.00% 0.00%

26 0060214613 bracket of touch switch HRF-661FF/ASS 1 0.00% 0.00%

27 0060600097 cross groove self attach screw HRF-661FF/ASS 4 0.00% 0.00%

28 0060214599 big water tray HRF-661FF/ASS 1 0.00% 0.00%

29 0060214600 small water tray HRF-661FF/ASS 1 0.00% 0.00% *

30 0064082855 cross groove self attach screw HRF-661FF/ASS 1 0.00% 0.00%

31 0060163046 handle HRF-661FF/ASS 1 0.00% 0.00%

32 0060821528S freezer foamed door seal HRF-661FF/ASS 1 0.02% 0.02%

Spare parts description in English Model Qty Failure rate

The proportion

of the spare

part stock

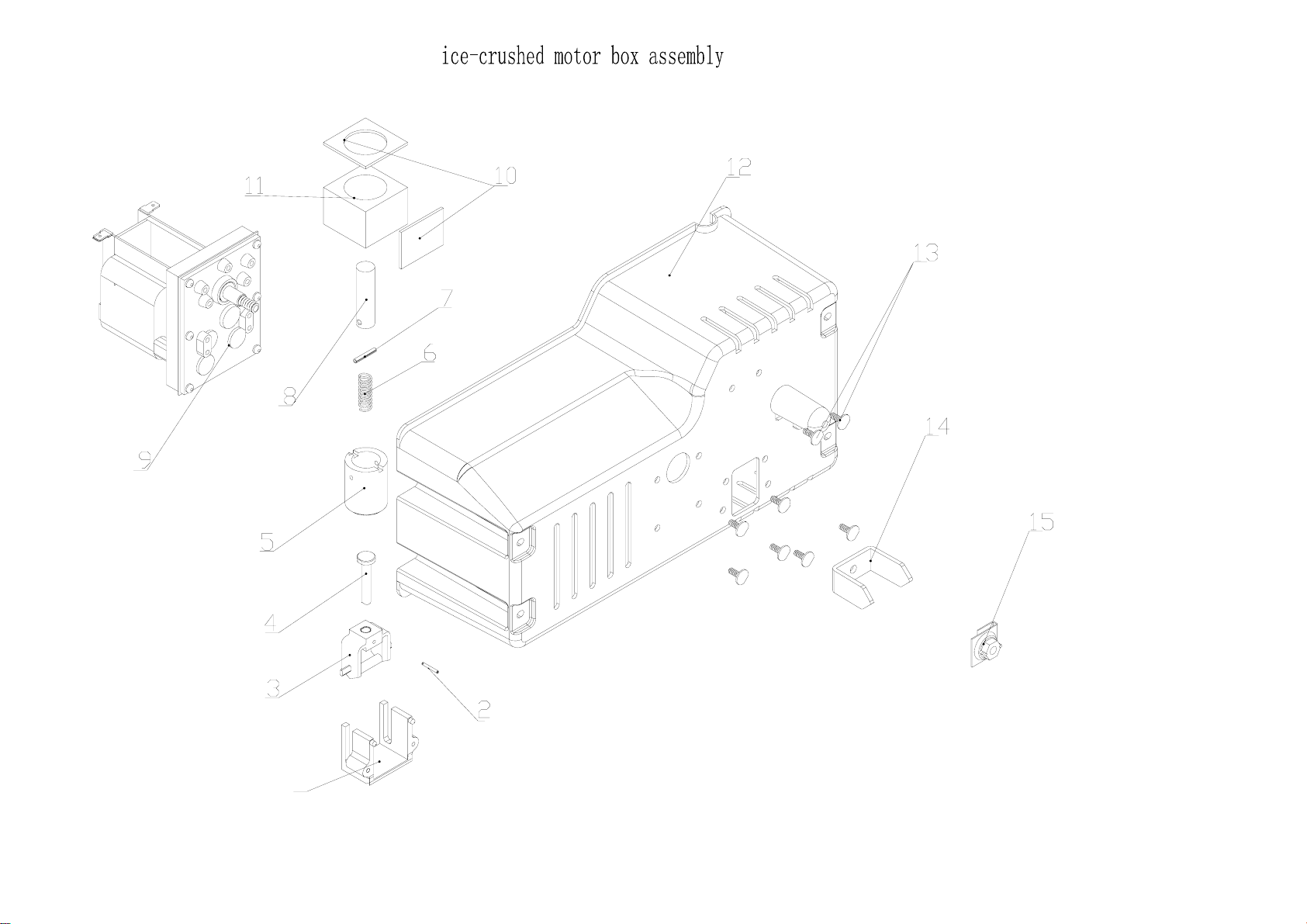

ice-crushed motor box assembly

No. In the

exploded

view

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Spare parts

number

0060205637 slide seat HRF-661FF/ASS

0060600075 spring column pin HRF-661FF/ASS

0060205638 slide block HRF-661FF/ASS

0060205640 connecting guide HRF-661FF/ASS

0060205639 connecting cover HRF-661FF/ASS

0060600074 compressed spring HRF-661FF/ASS

0060600076 spring column pin HRF-661FF/ASS

0060806081 electromagnetism valve HRF-661FF/ASS

0064000955 ice-crushed motor HRF-661FF/ASS

0067270041 double tape HRF-661FF/ASS

0060300257 eliminating noise foam block HRF-661FF/ASS

0060214386 ice-crushed box HRF-661FF/ASS

0060600091 stainless cross tray bolt HRF-661FF/ASS

0060600077 dial fork HRF-661FF/ASS

0060600078 fitting screw HRF-661FF/ASS

Spare parts description in English Model Qty Failure rate

1 0.00% 0.00%

1 0.00% 0.00% *

1 0.06% 0.06%

1 0.00% 0.00%

1 0.00% 0.00% *

1 0.00% 0.00%

1 0.00% 0.00%

1 0.01% 0.01% *

1 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00% *

2 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00%

The proportion

of the spare

part stock

ice-crushed box assembly

No. In the

exploded

view

1

2

Spare parts

number

0060214377 ice store box HRF-661FF/ASS

0060300270 ice box seal ring HRF-661FF/ASS

Spare parts description in English Model Qty Failure rate

1 0.00% 0.00%

1 0.00% 0.00%

The proportion

of the spare

part stock

Remark

Remark

Remark

related

technical

bulletin ID

number

related

technical

bulletin ID

number

related

technical

bulletin ID

number

Page 15

No. In the

exploded

1.If the color of the Spare parts number is red,it means that the number has been changed,it should be paid more attention when you place the Spare Parts

order to us.

2,The failer rate and the proportion of the spare-part stock are regarded as the reference of the stock for spare-parts;The first time should be stocked

accorded with the proportion of the spare-parts,and it should be adjusted with the actual quantity 3 months later.

Spare parts

number

view

0060205623 shaft cover of push shaft HRF-661FF/ASS

3

0060161361 ice push screw HRF-661FF/ASS

4

0060600067 wrest spring of dial pole HRF-661FF/ASS

5

0060103727 bracket of dial pole HRF-661FF/ASS

6

00608010087 screw HRF-661FF/ASS

7

0060103725 block patch of push ware HRF-661FF/ASS

8

0060161948 dial pole of push tongue HRF-661FF/ASS

9

0060205605 roller of push HRF-661FF/ASS

10

00608010087 screw HRF-661FF/ASS

11

0060161303 ice-crushed clapboard HRF-661FF/ASS

12

0060103724 No.3 circumrotate skates HRF-661FF/ASS

13

0060205607 No.1 skates tray HRF-661FF/ASS

14

0060103721 No.2 fixup skates HRF-661FF/ASS

15

0060205609 fitting block of skates HRF-661FF/ASS

16

0060205608 No.2 states tray HRF-661FF/ASS

17

0060103723 No.2 circumrotate skates HRF-661FF/ASS

18

0060205607 No.1 skates tray HRF-661FF/ASS

19

0060103720 No.1 fixup skates HRF-661FF/ASS

20

0060205608 No.2 states tray HRF-661FF/ASS

21

0060600082 spring column pin HRF-661FF/ASS

22

0060103722 No.1 circumrotate skates HRF-661FF/ASS

23

0060205604 fitting screw HRF-661FF/ASS

24

0060600072 living tongue wrest spring HRF-661FF/ASS

25

0060205606 wrest spring of ice box HRF-661FF/ASS

26

0060205616 skate seal HRF-661FF/ASS

27

0060600083 pin of living tongue HRF-661FF/ASS

28

0060600091 screw HRF-661FF/ASS

29

0060600069 round tray HRF-661FF/ASS

30

0060600071 spring tray HRF-661FF/ASS

31

0060214378 front lid of ice box HRF-661FF/ASS

32

Spare parts description in English Model Qty Failure rate

1 0.06% 0.06%

1 0.00% 0.00% *

1 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00%

1 0.01% 0.01%

1 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00% *

1 0.00% 0.00%

1 0.06% 0.06% *

4 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00% *

1 0.00% 0.00%

1 0.00% 0.00%

1 0.00% 0.00%

1 0.06% 0.06%

1 0.00% 0.00% *

1 0.00% 0.00%

1 0.00% 0.00% *

1 0.00% 0.00%

1 0.01% 0.01%

1 0.00% 0.00%

1 0.00% 0.00%

3 0.00% 0.00%

1 0.00% 0.00% *

1 0.06% 0.06%

1 0.00% 0.00% *

The proportion

of the spare

part stock

Remark

related

technical

bulletin ID

number

3,easy-damaged;The spare-part which is often damaged and the customer must stock in the spare-parts warehouse,and should be marked with"*"

4,possible damaged:The spare-part which is not often damaged like the easy damaged one and the customer may stock in the spare-part warehouse

accord with the actual case,should be marked with " ".

5,not need provided :The spare-part which is seldom damaged or the maintenance man could not maitmains.The spare parts may be air freighted by the

factory if they were damaged.The customer nees not stock in the spare-part warehouse,should be marked with " x ".

6,Above should be improved accord with the reply of the market half a year per time.

Page 16

Part6. Troubleshooting and Repair

6.1 Normal Phenomena—Not Troubles for Refrigerators

In a domestic refrigerator, there is not only a complicated electric control system,

but also a refrigerating system that is difficult to discern whether it is in a good

working condition. Both the systems are related and affect each other. If a certain

part of a refrigerator works abnormally .Its refrigerating efficiency will decrease,

operation properties will become unstable, or even it cannot be used normally for

those serious cases.

Refrigerators are generally of larger volume, once troubles appear, to send

them to a service department is really a tough thing, if such is the case, the user

will always be in suspense, sometimes, normal phenomena will be erroneously

regarded as troubles. Therefore, before we deal with the topics of frequently

occurring troubles of refrigerators and their remedies, we should firstly give a

brief account of some normal phenomena which are not troubles .In case any

one of such phenomena occurs, there is no need to worry about it, and the user

can use it at total ease.

1). When the compressor of a refrigerator has just stopped running, a rumbling

sound can be heard from inside its evaporator. This is a sound caused by the

flowing of refrigerant in the evaporator tubing. Because the pressure difference is

still greater after the compressor has just stopped running, the refrigerant will flow

for a certain time; therefore, this sound is a normal phenomenon.

2). A click sound can often be heard from the refrigerator. This is a normal sound

produced by the pull-in or release of the armature of a current deadweight start

relay when starting the compressor .The compressor motor will produce a slight

and uniform sound while it is running. This sound is not easy to be heard in the

daytime, but of course it can be heard distinctly at night.

3).The compressor consists of an electric motor and a compressing

apparatus .During its normal operation ,the motor’s stator core and windings will

rise to a temperature in the range of 100℃~110℃ ,and the temperature of the

piston and cylinder of the compressing mechanism can also reach as above

100℃ due to the heat produced when compressing refrigerant .Most of the heat

radiates to the air through the compressor casing ,therefore ,its casing is generally

at a temperature between 85℃~90℃ ,it is very hot ,particularly in summer when

the ambient temperature is higher .All these are normal phenomena .

4). For the forced air cooling refrigerator, a kind of irregular crack sound can be

often heard when the compressor is running for a certain period of time or has just

stopped its running. The stress relief due to expansion and contraction causes this

21

Page 17

sound when temperature changes, and will not affect the normal application of

refrigerator.

6.2 Common Troubles in Refrigerators and Their Remedies

Causes for troubles occurring in refrigerators are closely related to the quality of

components and workmanship in assembling by manufacturers as whether

refrigerators are properly used and maintained .The parameters generally used to

express the working conditions of a refrigerator include the temperature inside the

refrigerator, operation rate, electric power consumption, noise level, and other

functional indexes .If any one of these parameters is beyond its permissible range,

this indicates that there is a fault or trouble in the refrigerator.

During the whole service life of a refrigerator, the probability of troubles occurring

within a union time is called its failure rate. Making a comparison between the

control circuit system of a refrigerator and its refrigerating system, we can find that

the failure rate of the former is higher, and that of the thermostat is the highest. In

troubleshooting, the first thing you must do is to determine where the trouble

comes from --- the control system or the refrigerating system. There is general no

trouble indicating instrument mounted on the domestic refrigerator, locations and

natures of troubles should be determined according to their respective features,

therefore, experience in servicing is very important to troubleshooting. Service

technicians with rich experience can correctly locate them and take reasonable

remedy measures based on their comprehensive analysis of trouble

characteristics as well as operating conditions for various kinds of refrigerators.

Three Essentials for Checkup

1) Look

a) Check the tubing of refrigerating system for cracks and various welding

points for leaks; if leakage occurs, an oil stain can be seen definitely .

b) Check the suction and exhaust pressure values (high pressure and low

pressure) of compressor to see whether they are normal.

c) Check the conditions of frost attached to its evaporator and gas return

tube .It is abnormal if frost has formed on part of the evaporator or there is no frost

22

Page 18

attached to it. (This criterion is not applicable to the evaporator of refrigerator

compartment.)

d) Pay attention to the speed of temperature drop inside both the refrigerator

compartment and freezer compartment .It is abnormal if the speed of temperature

drop is obviously slower than the corresponding normal speed.

e) Check the environment to see whether it is suitable for placing a

refrigerator.

f) Check refrigerator door seal, case, and table surface and heat insulation

layer.

2) Listen

a) Listen to the noises produced when the compressor is running

Hums from a fully enclosed aggregate unit is the sound caused by overload

indicating that the motor cannot be started normally, meanwhile, a clattering

sound can be heard from inside the start relay, which is produced because the

start contacts cannot be released normally whistling sound is caused by the high

pressure gas flowing out of the crack of the pressure tube inside the compressor,

and clucks are the sound of striking after the suspended spring inside the

compressor has broken.

During the normal operation of compressor, a slight and uniform hum sound due

to undulation of electric current can be heard generally, this is a normal

phenomenon. However, if it sounds like “tong, tong…”, i.e., an impact sound

inside the compressor, this means that a large quantity of wet vapor of refrigerant

or refrigerating oil has come into the compressor cylinder; if it sounds like “dang,

dang…”, a striking sound of metal parts inside the compressor ,this means that

some moving parts have loosened (note to differentiate this sound from those

formed during starting or stopping the compressor).

b) Listen to the sound caused by the flowing of gas in the evaporator

Open the refrigerator door while the compressor is in operation , incline your ear

and listen attentively the gas flow sound inside the evaporator .If it sounds like

gentle whistling accompanied by a sound similar to water flowing ,this is the sound

produced by the normal circulation of refrigerant within the evaporator .In case

only the gas flowing sound can be heard and there is no water flowing sound ,this

indicates that the refrigerant has already percolated .If neither the flowing sound

nor the gas sounds from the evaporator can be heard ,this means that the filter or

capillary has been clogged .

3) Touch and Feel

a) Feel the compressor when running ,its temperature should be generally

less than 90℃ in the normal state (it may exceed 90℃ in case of running for a

longer period of time ).

b) After the compressor has operated normally for 5~10 minutes, touch and

feel the condenser, the temperature of its upper part should be higher than that of

23

Page 19

its lower part (or its right part is hotter than its left part, depending on the type of

condenser coil), this indicates that the refrigerant is circulating. If the condenser is

not hot, this means the leakage of refrigerant, In case the condenser radiates heat

for only several minutes and then cools down, this means that the filter and

capillary have been clogged. As for the forced air cooling condenser, hot air will

be blown out of it; this means that the system is out of order.

c) Feel the filter’s temperature. During the normal operation of refrigerating

system, the temperature on the filter’s surface should be a little higher than the

ambient temperature; if you touch it with your hand, you will have a sense of slight

heat. In case dew condensation appears due to the fact that its temperature is

obviously lower than the ambient temperature, this means that most meshes of its

screen has been clogged, resulting in an obstructed flowing of refrigerant, thus

causing a drop in temperature due to throttling.

d) Feel the temperature of exhaust gas from the refrigerating system .the

exhaust gas should be very hot and this is the normal working state. For those

refrigerator with enclosed type of compressor refrigerating system, no frost or dew

drop will from on the gas suction tube, otherwise, there is something wrong in the

system (Frosting and dew condensation may appear for a very short time period

when just starting the machine, this is a normal phenomenon).

Because a refrigerator is a combination of several components, they are related

and have influence on each other .In case an abnormal phenomenon has been

found through the above-mentioned checkups, you need not to make a hasty

conclusion based on only one abnormal phenomenon .It is advisable to find out

two or more abnormal phenomenon, or conduct troubleshooting comprehensively

with the aid of instruments or other ways, because several kinds of troubles may

share a common abnormal phenomenon, and two or more abnormal phenomena

may occur simultaneously due to a certain trouble .With this method , you can

reject some suspicious troubles and finally make a correct judgment .

6.3 Analysis of Troubles and Troubleshooting

A. Poor Refrigerating Effect

The so-called “poor refrigerating effect “ refers to the fact that the refrigerator can

operate and refrigerator normally, but the temperature in the refrigerator cannot

drop to the prescribed value under the stipulated working conditions. In view of

there are many causes for this phenomenon, we are going to discuss and analyze

it in the following 7 aspects:

1) Leakage of refrigerant

Analysis of Trouble

The leakage of refrigerant in the system will result in an insufficient refrigerating

capacity, the resulting phenomena are its lower gas suction pressure and exhaust

pressure as well as higher exhaust gas temperature. The exhaust tube feels

24

Page 20

rather hot, and a continuous gas flowing sound louder than usual can be heard at

the outlet of the capillary, and no frost or a smaller quantity of loose frost appears

on the evaporator. After shut down, the balance pressure in the system is usually

lower than the saturation pressure corresponding to the same ambient

temperature.

Remedy

In case there is leakage of refrigerant from the system, do not hurry to recharge it

with refrigerant, manage to find out leak points immediately, and make a note of

from where it leaks ---welding points and parts. After having them repaired,

recharge refrigerant.

There are so many joints and sealed surfaces in a refrigerator, accordingly, quite

a lot potential leak points do exist in the system. In troubleshooting, pay attention

to those parts that are liable to leak, check main connection points for oil seepage

and tubing for cracks. If there is no severer leak point, charge the system with

nitrogen and detect leak points with the commonly adopted method, repair them,

evacuate, charge the system with refrigerant, and then turn on the refrigerator to

make a test run.

2) Too much refrigerant charged into the system

Analysis of Trouble

a) In case the amount of refrigerant charged into the system exceeds its

nominal capacity, the superfluous refrigerant will of course take some space of the

evaporator, thus reducing its heat-dissipation area and hence the refrigerating

efficiency of the system. The abnormal phenomena caused by this reason are as

follows: the gas suction and exhaust pressures are generally higher than their

respective normal values, the temperature of its condenser is higher and the

electric current of the compressor rises, loose frost forms on the evaporator, the

refrigerator temperature drops slowly, and frost appears on the gas return tube .

b) In case excessive refrigerant has been charged, the liquid refrigerant that

can not evaporates in the evaporator will return to the compressor, and thus a

phenomenon of “liquid striking” will occur. The liquid refrigerant evaporates and

effervesces as soon as it flows into the refrigerating oil at the bottom of

compressor .If the condition is severe, foams will fill all over inside the compressor

housing and be sucked by the piston, causing damage to the components of

compressor.

Remedy

According to the operating procedures, it is mandatory to turn the machine off,

and several minutes later, open the refrigerant charging tube and let the

refrigerant escape from it, replace the dry filter, recharge refrigerant after

evacuating, and then seal the charging port.

3) There is air left in the refrigerating system

25

Page 21

Analysis of Trouble

Residual air in the refrigerating system will reduce its refrigerating efficiency .The

prominent phenomena are the increase in its gas suction and exhaust pressures

(however, the gas exhaust pressure will not exceed its rated value), obvious

increase in temperature in the segment from the compressor outlet to the

condenser inlet. Because there is air in the system, both the gas exhaust pressure

and temperature will rise, and moreover, the gas flowing sound is intermittent and

obviously louder.

Remedy

After shut down for several minutes, open the tubing, evacuate it and then

recharge the system with refrigerant.

4) Low efficiency of compressor

Analysis of Trouble

Low efficiency of a refrigerating compressor refers to the actual reduction of gas

discharge capacity, and hence the corresponding reduction of refrigerating

capacity, under the condition that the refrigerant in the system is unchanged. This

phenomenon occurs mostly when the compressor has been used for quite a long

time, its moving parts have worn to a considerable degree, fit clearance between

various parts have increased and sealing property of its gas valve has

deteriorated, resulting in an decrease in its actual gas discharge capacity.

Methods of Judgment

Measure the high and low pressures with pressure gauges to see whether they

are normal. If an abnormal sound comes from the compressor or the temperature

of its causing is too high, cut the discharge port open and operate the compressor,

feel it if there is pressure at the discharge port with your finger (For a normal

compressor, its discharge port is difficult to be blocked with your finger if you just

apply a little effort).

5) Refrigerating oil left in evaporator tubing

Analysis of Trouble

During the process of refrigerating cycles, a little refrigerating oil may remain in

the evaporator tubing, and after a longer time of operation, if there is considerable

refrigerating oil left in the evaporator, the heat conduction effect will be severely

affected, thus causing a poor refrigerating effect.

Remedy

It is quite difficult to determine whether this trouble is caused by the refrigerating

oil left in the evaporator tubing, because this kind of phenomenon and other

several trouble are tends to be confused. Generally speaking, you can make a

judgment based on the frost formed on the evaporator. If the frost does not cover

26

Page 22

the evaporator, and moreover, it is loosely formed, you can make a judgment that

the deterioration of refrigerating effect is due to the accumulation of refrigerating

oil left in the evaporator tubing in case no other troubles have been found. To

clear off refrigerating oil left in the evaporator, dismantle the evaporator, purge it

thoroughly and then dry it. In case it is difficult to dismantle it, charge refrigerant

from the evaporator inlet to wash it several times, then purge and dry it with

nitrogen.

6) Flowing obstructed in refrigerating system

Analysis of Trouble

Because the refrigerating system was originally not purged thoroughly, some of

the filter screen meshes have been clogged by dirt accumulated in the filter after

using it for a certain time of period, thus resulting in a decrease in flow rate, and

hence a poorer refrigerating effect.

The abnormal phenomena caused by this kind of slight clogging in the system are

as follows: the gas discharge pressure is lower, the temperature of discharged

gas drops down, the position clogged has a temperature lower than that in normal

conditions, and for a severe clogging, even dew condensation as frosting may

appear.

Remedy

Purge the tubing, and after replacing the dry filter with a new one or clearing it

thoroughly, recharge the system with refrigerant and seal the charging port.

B. No Refrigerating

The phenomenon that the compressor runs normally, but no frost (or only a little

frost) appears on the evaporator, and the refrigerator temperature does not drop

down is called “no refrigerating”. There are many causes for this trouble and it is

relatively complicated, too. In servicing, special attention to finding direct causes

for this phenomenon. Three main potential causes for this trouble are analyzed

below:

1) All refrigerant in the system has leaked out

Analysis of Trouble

Leak points in the refrigerating system have not been found and repaired timely,

thus resulting in the total escape of refrigerant. There are two kinds of leakage: I)

slow leakage for instance, when we want to use a refrigerator that has been put

out of quite a long time, we find the leakage of refrigerant, or in the course of its

operation, we have found that the refrigerator is gradually becoming not so cold

and finally no refrigerating cab be achieved; ii) fast leakage in that case, all the

refrigerant will escape swiftly due to abrupt rupture of system tubing.

27

Page 23

Symptoms of total leakage of refrigerant are mainly as follows: the compressor

can be started easily (if there is no damage to the compressor parts) and its

operating current becomes low, its gas suction pressure is high and discharge

pressure is lower, the gas discharge tube feels rather cold, no sound of gas

eruption from the liquid in the evaporator can be heard, and no will gush out of the

process tube if you cut it open after shutdown.

Remedy

Check the whole machine, particularly those locations, which are liable to leak.

After leak points have been found, repair them or replace them with new parts

according to specific circumstances, then evacuate the system and finally charge

refrigerant.

2) Refrigerating system has been clogged

a) Clogged with Ice

Analysis of Trouble

The dryness treatment for the major parts in the refrigerating system has been

performed improperly, the effect of air purging for the whole system is not good ,or

the water content in the refrigerant is out of standard ,all these will cause the

expansion valve to be clogged with ice .The symptom for this trouble are as

follows :the refrigerator sometimes can refrigerate and sometimes cannot :the

refrigerator compartment works normally at the beginning ,but after working for a

certain period of time ,frosting begins at the clogged position ,evaporation

temperature reaches below 0℃, water will accumulate at the narrow part of the

capillary and clog it gradually ,then frost begins to melt at the evaporator ,no gas

flowing sound can be heard ,and the gas suction pressure assumes a state of

vacuum .Note that these phenomena will appear intermittently ; sometimes ,the

refrigerator works well ,and sometimes not well .In order to determine whether it is

clogged with ice ,heat the suspicious points with hot water to make ice melt ,and

after a while if a gas flowing sound resulting from an abrupt gush is heard and the

gas suction pressure rises as well ,it can be confirmed that the trouble is caused

by ice clogging .

Remedy

If there is too much moisture in the refrigerating system, it is advisable to release

the refrigerant, purge the tubing with nitrogen, and then charge the system with

the filtered refrigerant. However, the commonly adopted method is to connect a

filter with moisture absorbers (such as silica-gel, anhydrous calcium chloride) to

the refrigerating system so as to filter out the moisture from the system, then

replace the filter, evacuate it again and finally charge the system with refrigerant.

b) Clogged with dirt in capillary

28

Page 24

Analysis of Trouble

The capillary inlet is a place where coarse-grained dirt or refrigerant oil in the

system will tend to settle down and clog it. In case considerable dirt accumulates

there, the whole filter screen may be blocked totally, making the refrigerant unable

to go through. Clogging with dirt exhibits the same symptoms as that with ice,

namely, higher gas suction pressure, lower temperature of discharged gas, and

no gas flowing sound from the evaporator. The difference between the both is as

follows: if the clogging is caused by dirt, tapping the suspicious clogged point

(generally in the capillary or the connection joint of the filter) may cause the

refrigerant to flow through partially, resulting in some corresponding change,

whereas in that case if you heat it with a hot towel, no reaction will happen, no

flowing sound can be heard, moreover, there is no periodic change. After rejecting

the possibility of ice clogging, it can be generally considered as the clogging due

to dirt.

Remedy

Dismantle the system, remove the dry filter from it, purge the tubing with nitrogen,

install a new filter, then evacuate it and finally charge it with refrigerant.

C) Clogging in filter

Analysis of Trouble

Total clogging of a filter is rarely to occur. The paste-like matter formed from the

substances filled into the system mostly causes this trouble or other dust after the

refrigerator has been used for a longer time, or by the dirt accumulated gradually

inside the filter. Sometimes, tapping the filter nay cause a passage for flowing,

Touching it with your hand, you will feel that it is cooler compared with its

temperature in the normal state.

Remedy

The same as described in the capillary clogging with dirt.

3) Troubles of Compressor

a) Breakage of gas suction and discharge valve blocks

Analysis of Trouble

The compressor works by means of the opening and closing of gas suction valve

and discharge valve to suck and discharge the refrigerant. If the valve block is

broken, the refrigerant can not be discharged, and hence no refrigerating can be

achieved.

Method for making judgement

It is quite difficult to differentiate this trouble from others because they often have

similar symptoms. In repairing, firstly, hear attentively if there is some abnormal

29

Page 25

sound coming from the compressor (sometimes, the broken pieces of valve block

may strike against the cylinder), and feel the compressor casing with your hand to

ascertain whether it is too hot, this is also helpful to the troubleshooting; secondly,

measure the pressures at the high and low pressure ports of the compressor with

pressure gauges, if the gas suction valve block is broken, the suction pressure

gauge pointer will swing violently and the suction pressure is very high, whereas

when the gas discharge valve block is broken , the discharge pressure gauge

pointer will swing drastically and the discharge pressure is very high. In the both

cases, stop the compressor at once, and if technique is available, open the

cylinder cover and check up the valve block, repair it, or replace it with a new one,

C. Sudden stop of Compressor during Its Running

The cause of sudden stop of a compressor during its running is mostly that the

gas suction pressure and/or discharge pressure exceed their respective

prescribed ranges, thus making a pressure-operated protective relay shut off the

power to the compressor and stop it. In the following we discuss mainly the

reasons for causing excessively high gas discharge pressure and low suction

pressure.

1) Stoppage due to excessively high gas discharge pressure

A) Too much refrigerant charged into the system

Analysis of Trouble

The phenomenon, such as loose frosting and poor refrigerating effect, may occur

if excessive refrigerant has been charged into the system. Superfluous refrigerant

will occupy a certain space of the evaporator, thus reduce its heat dissipating area,

and the phenomenon of “liquid striking” may occur, too. Meanwhile, dew or frost

condensation may occur on the gas return tube, and the gas discharge pressure

will obviously rise, when it reaches the threshold value, the protective relay will

actuate and shut off the power supply to the compressor.

Remedy

Open the tubing, re-evacuate and then charge the system with a proper quantity

of refrigerant.

b) Air left in the system

Analysis of Trouble

The residual air in the system will circulate together with the refrigerant in the

system. The major symptoms caused by this residual air is higher gas discharge

pressure, higher discharged gas temperature (the gas discharge tubing is

considerably hot when you feel it with your hand), and poorer refrigerating effect.

Furthermore, the gas discharge pressure will exceed its normal value when the

30

Page 26

compressor has run for a period not too long, thus making the protective relay

actuate and bring to a stoppage.

Remedy

Check up how the air has been left in the refrigerating system. Generally, there

are two possibilities: one is that the air has been sucked into the system when

repairing due to carelessness, or it has not been purged out totally when

evacuating the system; the other is that there are leak points at the low pressure

end of the refrigerating system. Leak points appear mostly in those low

temperature parts or assemblies, because the evaporation temperature is lower

for such low temperature devices, especially at the low pressure end, it is easier

for the air goes into the system. Once it has been ascertained that air does exist in

the system, you have to open the tubing, re-evacuate it and then charge it with

refrigerant.

2) Stoppage due to electric troubles

a) Thermostat is out of control

Analysis of Trouble

In case the thermostat does not work in its good order or its temperature sensor

has not been installed properly, frequent stoppage is also likely to occur.

Remedy

Try to adjust the temperature sensor’s position until the compressor can be

started and stopped normally. If this cannot be achieved, and the stoppage still

occurs repeatedly, it is most likely that the mechanical parts or contacts are out of

order, disassemble the thermostat, make a thorough checkup and repair it.

b) Overload of electric motor

Analysis of Trouble

Probably, too many things have been put into the refrigerator, and hence the

thermal load exceeds its refrigerating capacity; or in case the power supply

voltage drops considerably, the current flowing through the motor will increase

drastically making the thermal protector actuate and the fuse blown, and hence

the motor stops running. If the motor is still running continuously in such a case,

its windings will be burned out.

Remedy

Reduce the thermal load; pay attention to the variation in voltage of the power

supply.

c) Abnormal thermal protection

31

Page 27

Analysis of Trouble

The compressor current is within its normal range, but the thermal protector

actuates repeatedly.

Remedy

Replace the thermal protector with a new one.

3) Sudden stoppage due to other causes

Normal Stoppage

A thermostat generally controls start and stop of the compressor. When the

temperature in the refrigerator reaches its desired value, the thermostat will shut

down the compressor automatically. Never take this normal operation as a trouble,

care should be taken to differentiate it from other real troubles in servicing.

D. Compressor won 't start

In case the compressor cannot be started, you must find out the origins of this

trouble through checkup step by step, because probably there are many causes,

including those electrical and mechanical.

1) Inspect the power supply to see whether it is connected to the compressor

circuit.

Analysis of Trouble

In case the compressor cannot be started, this will generally exhibit in the power

supply circuit, for instance, power failure, poor contact of switch, and blown fuse.

Make a comprehensive analysis of these phenomena, find out its real cause and

take correct measures to remove this trouble.

Remedy

a) Check the input power circuit to see whether where is voltage of the power

supplies, namely, the circuit which is connected to the knife switch. This can be

determined with an avometer or a test pencil. If a blown fuse is found, ascertain

and remove its cause, then replace it with a new one of the same specifications.

b) Check the compressor accessories, including its thermal protector and relay. In

case the thermal protector is damaged, the compressor cannot be powered on. If

the relay is out of order, the motor will not run and hum sound can be heard from it

after the compressor is turned on, in that case, shut it down immediately,

otherwise, the motor windings will be burned out in case this condition lasts longer.

c) Check the relay contacts and plugs to see if they are perfect and work reliably.

Poor contact may cause the motor not running or humming.

2) Check the circuit voltage to see whether it is normal.

32

Page 28

Analysis of trouble

If the circuit voltage is obviously lower than its rated value, it will be difficult to start

the motor, and a hum sound can be heard from it.

Remedy

Measures the voltage with a voltmeter, if it is really too low, give directions to the

user for buying a stabilizer so as to step up the voltage, thus normal operation can

be achieved.

3) Check the thermal relay to see whether its contacts are closed.

Analysis of Trouble

The contacts of thermal relay sometimes may be open due to the leakage of

temperature sensing agent from the temperature sensor.

Remedy

Remove the relay cover to check up its contacts, if they are open, this means that

the original setting is not properly set or temperature sensing agent has leaked out

of the temperature sensor. Try to turn the adjusting stem of this value in the

direction of the lower temperature graduation, then check the contacts to see

whether they are closed. If they are still not closed, dismantle the temperature

sensing disc and then immerse it into warm water to see whether the contacts

actuate, if not, it can be preliminarily determine that temperature sensing agent

has leaked out, and it must be replaced with a new thermostat.

4) Motor troubles and other electric faults

a) Motor windings have been burned or short-circuited between turns

Analysis of Trouble

When motor windings have been burned or short-circuited between turns, the fuse

will be blown repeatedly, and the blowout occurs particularly at the instant when

you close the knife switch.

Remedy

Check the terminals and the outer casing to see whether they are short-circuited,

and measure the resistance of each phase with an avometer. If short circuit

occurs or the resistance of a certain phase is low, this means that short circuit

does exist in the windings and/or between turns, and insulation layers have been

burned or deteriorated. A megametre can be used in this inspection, too. If the

insulation resistance is lower than 2 MΩ, this means that the insulation layer is

already breakdown. If the motor has been burned, repair it or replaced it with a

new one.

b) Fault of control relay

33

Page 29

Analysis of Trouble

Overheat, burnout or wear of control relay contacts may occur generally. All these

will cause poor contact in electricity.

Remedy

Dismantle it to repair, or replace it with a new one.

c) Poor electric contractor in thermostat

Analysis of Trouble

Burnout of contractor and leakage of temperature sensing agent may occur

generally.

Remedy

Replace the old with a new one.

d) Check the terminals for loose connection and electric circuits for other

abnormal phenomena.

5) Mechanical faults of compressor

a) Seizing of shaft

This phenomenon is caused mostly by poor lubrication, such as insufficient

quantity of lubricant, clogging in the lubricant oil line, or intermittent lubricant oil

supply. Dirt and other impurities in the lubricant oil will increase its viscosity and

cause the shaft to be seized. Copper plating may also result in seizing of shaft.

b) Seizing of piston

This is caused by too small fit clearance between the piston and cylinder or

expansion due to heat.

Judgement of seizing shaft and piston:

After the refrigerator has been powered on,

the compressor will not start and run, but a slight hum sound can be heard, and

several seconds later, thermal protective relay will actuate and make the contacts

open; this process will occur repeatedly, but the compressor cannot be started.

E. Compressor won’t stop

Sometimes, the compressor will run continuously (for several hours or run without

end), If the food placed in the refrigerator is not too much, there may be the

following two situations: I) the refrigerator very low, this means that the control

34

Page 30

system is probably out of order; ii) the control system works normally, and there

are troubles in the refrigerating system or other parts.

1) Temperature is set improperly

a) The temperature control knob is set to the “coldest” position. This position is

to be used for fast freezing or continuous running, its temperature for power off

is too low, therefore, the compressor won’t stop and the temperature in the

refrigerator becomes lower and lowers.

b) Inspection method: check the temperature control knob to see whether it is

set in the position “coldest”.

2) Thermostat is malfunctioning and makes the compressor running continuously

Analysis of Trouble

When the thermostat doesn’t work normally, it will make the compressor run

continuously, and hence very low temperature will be achieved in the refrigerator.

The fault is generally due to the fact that the contacts of the thermostat cannot be

released.

Remedy

Dismantle the thermostat and make a through checkup, if it is totally out of

functioning, replace it with a new one.

3) evaporation temperature is too high in refrigerating system, resulting in

lower refrigerating capacity and hence continuous running of compressor

Analysis of Trouble

Leakage of refrigerant and clogging in a refrigerating system will directly affect its

refrigerating capacity. Due to the reduction in its refrigerating capacity, the

refrigerator temperature cannot reach its rated value, the thermostat won’t work,

and thus the compressor runs continuously. When the evaporation temperature in

the system is too high, the temperature-sensing agent in the temperature sensor

is also hotter, therefore, the thermostat is unable to cut off the power supply to the

compressor and stop it.

Remedy

If it has been found that the refrigerant in the system is insufficient in quantity,

recharge it with refrigerant. In case clogging occurs, disassemble the part where it

is blocked. If the evaporation temperature is too high, settle this problem with an

appropriate quantity of refrigerant.

4) No stoppage of compressor due to damaged heat-insulation layer inside

case body and/or door seal

35

Page 31

Analysis of Trouble

When the heat-insulation layer inside the case body deteriorates or the door seal

is not closely touches the doorframe, the temperature in the refrigerator will rise

and makes the compressor running continuously.

Remedy

Check the heat-insulation layer for its damaged parts; repair it to improve its heatinsulation property. If the door has deformed or the door seal is not tightly sealed

against the case body, repair them, respectively.

5) Too much food is placed in the refrigerator, or is placed too densely,

resulting in poor ventilation or poor conditions for temperature sensing, and

hence no stoppage of the compressor.

6) Too high ambient temperature, poorer ventilation and heat dissipation

makes the compressor running without stop.

F. Electric leakage of refrigerator

1) Slight electric leakage

Electric insulation has deteriorated due to being affected with damp, thus resulting

in slight electric leakage.

2) Serious electric leakage

Refrigerator case has become live due to faults occurred in some electric devices

or the erroneous wiring in installing power cord plug or outlet by the user. This is

very dangerous.

3) Electric leakage test

a) Slight electric leakage

A tingle sense will be experienced as soon as you touch the metal parts of the

refrigerator with your hand. When you test them with a test pencil, its neon lamp

will come on .In that case, the first thing you need to do is to determine whether

the grounding is perfect .If the grounding is no problem, turn off the refrigerator

immediately, then check the insulation of electric circuits with an avometer.

b) Serious electric leakage

Never touch the case body of the refrigerator, its door handle or other metal parts

with your hand. Test the refrigerator with a test pencil, it will

light up intensively ;measure the resistance between the power cord plug and the

case body with an avometer ,the reading will be zero (0Ω); in the worst case ,the

fuse will be blown .Check the 3-prong outlet to see whether the live wire and the

36

Page 32

null line are inversely connected ,this makes the ground protection lead-out from

the power cord plug being connected to the live wire .Another possibility is that the

live wire and null line of the outdoor power supply circuit have been inversely

connected accordingly ,this makes the null line become a live wire .

G. Stronger vibration and loader noise

1) Refrigerator placed improperly

a) Uneven ground

Uneven ground will cause the refrigerator to be placed unsteadily, causing

stronger vibration and noise during its operation.

b) Leveling screws not properly adjusted

If the leveling screws on refrigerator legs have not been adjusted properly,

vibration and noise will still occur even if the refrigerator has been placed on a

level ground.

2) Abnormal noise from compressor

Three suspended spring inside the compressor case are out of balance, and

strike against the case, moreover, the wear of compressor parts may cause noise

sometimes.

3) Resonance of tubing and loosening of parts

Improper and compact laying of tubes or the loosening of parts may cause

vibration and noise.

4)Large noise of the fan

a)The fan motor is loose;

b)Noise is produced by normal operation of the fan.

c)The impellers are not tightly fixed or eccentrically assembled.

Remedy:

For reason a): Fasten the fan motor.

For reason b) or c): Replace the fan motor or impellers.

5)Inspection method

To find the sources of noise, press the vibration spot with your hand while the

refrigerator is in operation and listen attentively whether the vibration becomes

weaker or vanishes. If the refrigerator has not been levelly placed, put a level

meter on its top table and adjust the leveling screws on its legs. In case noise

occurs from the compressor, strike different locations on the side surface of its

case using a rubber hammer or hand hammer with a wood block in-between so as

to determine whether the suspended springs are out of balance or being seized.

37

Page 33

Loading...

Loading...