Haier Hr48c1var Owner's Manual

HAIER

COMMERCIAL

AIR CONDITIONER

Service Manual

Part # AC-8888-108

HAIER TRADING COMPANY, LLC

www.haieramerica.com

1

Commercial Air Conditioning

SERVICE MANUAL

●Features

High efficiency design

Models

HR18C1VAR HR24C1VAR

HR30C1VAR HR36C1VAR

HR42C1VAR HR48C1VAR

HR60C1VAR

Hermetic compressor design

Haier Hi-Efficiency fin and copper tube design

Compact design of outdoor unit

Convenient for installation and maintenance

Heat pump, 12SEER

Manual code: SYJS----AM-----003-04---Rev.2

Edition: 2005-03-22

Commercial Air Conditioner Model: heat pump, 12SEER UNITS

CONTENTS

1. DESCRIPTION OF PRODUCTS & FEARURES……………………..3

2.PHYSICAL AND ELECTRICAL SPECIFICATIONS………………..…5

3.SAFETY PRECAUTION…………………………………………….……7

4.SYSTEM COMPONENTS AND FUNCTIONS …………………………7

5.ELECTRICAL CONTROL DEVICES…………………………….……..9

6.APPLICATION…………………..……………………………………..….10

7.INSTALLATION INSTRUCTIONS………………………....……………12

8.MAINTENANCE INSTRUCTIONS………………………………..……..29

9.SERVICE AND TROUBLESHOOTING ……………………...…………30

10.WIRING DIAGRAMS……………………………….……………………41

11. EXPLOSIVE DIAGRAM AND SPARE PARTS LIST ……………42

2

Commercial Air Conditioner Model: heat pump, 12SEER UNITS

1. DESCRIPTION OF PRODUCTS & FEARURES

1.1 Air conditioner

This manual discusses “split” central air conditioning ,indoor coils, .”Split” refers to the physical location

of the major air conditioning components that are not in the same box ,as in a “packaged” system.

10 SEER(“Seasonal Energy Efficiency Ratio”), families of split system air conditioning are

manufactured to rigid standards of quality and performance. They meet or exceed the standards

imposed by efficiency legislated and therefore represent both good value today and for years to come.

The current families of the air conditioning now use scroll and reciprocating compressors. This gives

the air conditioning a much more durable compressor needing less external protection while

increasing the unit efficiency in cooling mode.

1.2 NOMENCLATURE FOR MODEL NUMBE

Example

.

H C 24 A 1 V A R

Nominal

Haier System type

Brand

symb

ol :H:

Haier

Table 1-1

C: Air

Conditioner;

R: Heat

Pump

capacity in

(1000) Btuh

24:

24000BTU/h;

60:

60000BTU/h

SEER

designation

A:10SEER;

B:11SEER;

C:12SEER;

D:13SEER

E:14SEER;

F:15SEER;

G:16SEER;

H:17SEER

I:18SEER

Design

series

1:1st

Generatio

2:2nd

Generatio

n;

n

Electric Designation Body style

Y:575V-3Ph-60Hz;

V:208/230V-1Ph-60

Hz;

C:208/230V-3Ph-60

Hz;

D:460V-3Ph-60Hz;

A:115V,1 Ph,60Hz

A:

standard

style

Reserved

1.3 ENGINEERING FEATURES:

COPPER TUBE/ALUMINUM FIN COILS Both indoor and outdoor coils are designed to optimize heat

transfer, minimize size and cost, and increase durability and reliability.

Fig.1-1

3

Commercial Air Conditioner Model: heat pump, 12SEER UNITS

CABINETS-Constructed of powder painted and galvanized steel providing protection to the outdoor

unit and a durable finish.

Fig.1-2

SERVICE VALVES-Facilitates unit servicing and provides a reliable and safe access to measure unit

pressures .

Fig.1-3

FLOWCHECK DISTRIBUTORS-Outdoor units use the Flowcheck Distributor to act as an open check

valve in the cooling mode. BASE PAN-.

This deep-drawn and sturdy base keeps the bottom of the coil

out of harms way. The base has weep holes to allow the water from rain to flow away from the unit.

Fig.1-4

ACCESSORIES

LOW AMBIENT CONTROL- This allows low temperature operation in the cooling cycle down to 0

℉,outdoor temperature .This control should be installed in units that operate in cooling in outdoor

ambient temperatures below 65℉, and is recommended for all commercial applications.

START COMPONENTS – Offer additional starting torque covering a wide range of voltage and

pressure variations .Usually required on reciprocating compressors with flowcheck piston metering .

4

Commercial Air Conditioner Model: heat pump, 12SEER UNITS

2.Physical and Electrical Specifications

12 SEER

Model Number

Comments 1.5-Ton Outdoor HP 2-Ton Outdoor HP 2.5-Ton Outdoor HP 3-Ton Outdoor HP 3.5-Ton Outdoor HP 4-Ton Outdoor HP 5-Ton Outdoor HP

Model Status New Model New Model New Model New Model New Model New Model New Model

Performance

with Matching Indoor Unit

Cooling Capacity (Btu/h)

Net Sensible Capacity (Btu/h)

Net Latent Capacity (Btu/h) 5,040 6,720 8,400 9,800 11,760 13,020 15,680

SEER 12.0 12.0 12.0 12.0 12.0 12.0 12.0

Total Input Watts (Cooling) 1,800 2,400 3,099 3,357 4300 4609 5560

Heating Capacity (Btu/h) (8.3℃)

Heating COP (8.3℃)

Heating HSPF 7.3 7.3 7.3 7.3 7.3 7.3 7.3

Total Input Watts (Heating) 1550.0 2000.0 2660.0 2970.0 3670.0 4000.0 5230.0

Outdoor Rated Airflow (CFM) 1950 2200 2700 2700 2700 2900 3200

Electrica

Voltage - Phase - Frequency (Hz) 208/230 - 1 - 60 208/230 - 1 - 60 208/230 - 1 - 60 208/230 - 1 - 60 208/230 - 1 - 60 208/230 - 1 - 60 208/230 - 1 - 60

Minimum Circuit Amps 9.4 13.4 16.1 17.7 21.2 34.7 38.6

Maximum Fuse Size(A) 15.0 20.0 25.0 30.0 35.0 60 60

Compresso

Type / Maker Reciprocating Reciprocating Reciprocating Reciprocating Reciprocating Scroll Scroll

Model Number H20J173ABCA H20J223ABCA H20J293ABCA H20J323ABCA H20J403ABCA H23R483ABCA H20R583ABCA

RLA (Rated Load Amps) 6.8 9.6 11.7 13.0 15.8 26.6 28.9

LRA (Locked Rotor Amps) 48.0 60.0 73 85.0 90 155 165

Input Watts 1550 2030 2550 2810 3510 4185 5080

Internal Overload Protection Yes Yes Yes Yes Yes Yes Yes

Crankcase Heater Yes Yes Yes Yes Yes Yes Yes

Fan Motor

RLA (Rated Load Amps) 0.86 1.4 1.43 1.43 1.43 1.4 2.5

Rated House Power (hp) 1/8 1/5 1/3 1/3 1/3 1/3 1/2

Nominal RPM 1000 1075 1075 1075 1075 1075 1075

Input Watts 90.0 180.0 300 300 300 350 500

Fan

Diameter (In) 18.0 18.0 22 22 22 22 24

No. of Blade 3 3 33333

Fan Material Zinc-Coated Steel Zinc-Coated Steel ALUMINIUM ALUMINIUM ALUMINIUM ALUMINIUM ALUMINIUM

Condenser coi

Number or Rows 1 1 1 1 222

Tube spacings (V x H) (In) 1 x 0.85 1 x 0.85 1 x 0.85 1 x 0.85 1 x 0.85 1 x 0.85 1 x 0.85

Fins per Inch - FPI 21 21 21 21 16 16 17

Fin Type Enhanced fins Enhanced fins Enhanced fins Enhanced fins Enhanced fins Enhanced fins Enhanced fins

Tube OD and Type 3/8" Grooved 3/8" Grooved 3/8" Grooved 3/8" Grooved 3/8" Grooved 3/8" Grooved 3/8" Grooved

Gross Finned Face Area (Sq Ft) 12.65 12.65 16.0 18.4 16.0 18.4 20.85

Number of Circuits (In/Out) 4/4 4/4 4/4 5/5 4/4 7/7 9/9

Exterior Appearance

Cabinet color White White White White White White White

Top cover Stamped sheet metal Stamped sheet metal Stamped sheet metal Stamped sheet metal Stamped sheet metal Stamped sheet metal Stamped sheet metal

Basepan Deep Drawn, Elevated Deep Drawn, Elevated Deep Drawn, Elevated Deep Drawn, Elevated Deep Drawn, Elevated Deep Drawn, Elevated Deep Drawn, Elevated

Service panel Easy Access Easy Access Easy Access Easy Access Easy Access Easy Access Easy Access

Body style / Coil guard

5

Feature

Galvanized Steel Cabinet Yes Yes Yes Yes Yes Yes Yes

Coil Design Haier Enhanced Coil Haier Enhanced Coil Haier Enhanced Coil Haier Enhanced Coil Haier Enhanced Coil Haier Enhanced Coil Haier Enhanced Coil

l

r

l

Full metal jacket Optioanal Optioanal Optioanal Optioanal Optioanal Optioanal Optioanal

Wire grill Yes Yes Yes Yes Yes Yes Yes

Plastic mesh Yes Yes Yes Yes Yes Yes Yes

s

HP HR18C1VAR HR24C1VAR HR30C1VAR HR36C1VAR HR42C1VAR HR48C1VAR HR60C1VAR

HB2400VC1M20 HB2400VC1M20 HB3600VA1M20 HB3600VC1M25 HB4800VA1M25 HB4800VA1M25 HB6000VC1M25

18,000 24,000 30,000 35,000 42,000 46,500 56,000

12960 17280 21600 25200 30240 33480 40320

17,500 22,500 30,000 33,500 42,000 48,000 58,000

3.3 3.3 3.3 3.3 3.4 3.4 3.3

Haier Commercial Air Conditioning Model: heat pump, 12SEER UNITS

3.SAFETY PRECAUTIONS

CAUTION: To ensure proper installation and operation, completely read all instructions prior to

attempting to assemble ,install ,operate, maintain or repair the product.

WARNING:THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR DEFECT

TO THE AIR CONDITIONER CAUSED BY THE ATTACHMENT OR USE OF ANY

COMPONENTS,ACCESSORIES OR DEVICES(OTHER THAN THOSE AUTHORIZED BY THE

MANUFACTURER)INTO,ONTO OR IN CONJUNCTION WITH THE HEAT PUMP.BE AWARE THAT

THE USE OF UNAUTHORIZED COMPONENTS,ACCESSORIES OR DEVICES MAY ENDANGER

LIFE AND PROPERTY.THE MANUFACTURER DISCLAIMS ANY RESPONSIBILITY FOR SUCH LOSS

OR INJURY RESULTING FROM THE USE OF SUCH UNAUTHORIZED

COMPONENTS,ACCESSORIES OR DEVICES.

● Always use good industry-recognized service practices in the maintenance, adjustment and repair of

the products covered in this manual to protect the technician and the customer.

● Always wear safety glasses when handling refrigerant and brazing materials.

● Follow the manufacturer’s instructions when making repairs and installing replacement parts and

assemblies.

● Use only authorized parts to ensure that the equipment operates at the efficiency and useful life that

the manufacturer built into the product.

4.SYSTEM COMPONENTS AND FUNCTIONS

This section describes the various air conditioning components, their purpose and operation. This

section is only a guide and does not consider all components that could be found on an air conditioner in

the field.

COMPRESSORS

The heart of any refrigerant system is the compressor .It is a pump causing refrigerant to flow. There are

several different types of compressors ,but all use electricity to turn an electric motor to drive a pump.

Air conditioners use two types of compressors. The first is the enhanced reciprocating compressor .It

operates with an offset crankshaft and pistons, and resembles an internal combustion engine. The

driving force is supplied by an electric motor turning the crankshaft and forcing the pistons into the

cylinders where valves control the flow of refrigerant. The valves provide a seal between high and low

pressure sides of the system. If the valves are damaged ,the compressor’s reliability, efficiency and

effectiveness are reduced or eliminated

Reciprocating type compressor Scroll type compressor

Fig.4-1

Generally, liquid refrigerant is suspected if valve damage occurs. Some compressors can tolerate the

presence of small amounts of liquid refrigerant in the returning gas, but none are designed to withstand it

continually. Returning refrigerant cools the compressor motor. Surrounding the motor with low pressure

gas gives it the name of “low-side” shell compressor.

The scroll compressor used a helix (similar in shape to a snail shell)

within a similar stationary helix, the moving helix rotates so that the space between the two constantly

decreases as the gas moves toward the center of the Scrolls. The returning refrigerant gas first cools the

motor, then flows into the suction intake of the compressor scroll. The discharge gas leaves from the

center of the helix and exits the compressor. The lower part of the shell should be cool to the touch.

All current single phase units use two types of compressors .In construction, the two compressors are

quite different. In function they are identical. Scroll units do not need start components or crankcase

heaters. The reciprocating compressor may need both. Both types benefit from using a time-delay. This

7

to move refrigerant. When placed

Haier Commercial Air Conditioning Model: heat pump, 12SEER UNITS

prevents thermostat short cycling and momentary power interruptions ,from damaging the compressor.

Both compressor types are protected against over-current and over-temperature conditions. Some scroll

compressors have an additional thermostat mounted externally in series electrically with the contactor

coil.

FAN AND BLOWER MOTORS

The outdoor unit of split systems contains an outdoor fan motor. These PSC(permanent split

capacitor )motors are single speed motors driving a propeller fan. The motor mounts to the unit top with

the shaft down. The fan pulls outdoor air through the outdoor coil.

Fan motor

Fig.4-2

To access the motor, carefully remove the unit top to avoid damaging the blade or motor.

WARNING: WHEN SERVICING THIS MOTOR,TURN OFF THE ELECTRICAL POWER TO THE OUTDOOR UNIT.

The indoor air handler also has a motor . This blower motor is a PSC motor and usually has more than

one fan speed

.

Fan and motor assembly

Fig4-3

METERING DEVICES

Flow-Check Pistons

One air conditioning metering device is the flow-check piston. It has two functions. First it acts as a

refrigerant metering device controlling refrigerant flow into the evaporator. Second, it acts as an open

check valve when refrigerant flows in the opposite direction.

When refrigerant enters the device from the nut end, the piston seats and forces all refrigerant through

the center of the piston. It functions as a metering device controlling the amount of refrigerant flow. With

flow in the opposite direction, pressure moves the piston off the seat and liquid refrigerant flows around

the piston.

PROPER MATCH OF UNIT AND PISTON SIZES

Split air conditioning indoor and outdoor units must be properly matched in accordance with the

manufacturer’s specification sheets and installation manuals.

Combinations for indoor and outdoor units using a distributor and flowcheck are shown in the application

table 6-2.

Using too small a piston starves the coils of refrigerant .A piston that is too large floods coils.

Mismatching indoor and outdoor units of split systems affects performance, efficiency, charging and

reliability.

8

Haier Commercial Air Conditioning Model: heat pump, 12SEER UNITS

Distributor assy

Fig.4-4

REFRIGERANT CIRCUIT

There are two types of outdoor coil circuiting: single and multi-circuited.

The 12 series are all multi –circuits.

Fig.4-5

SERVICE VALVES

There are two types of service valve used on the air conditioning .They are the service port valve or

“Schrader valve” and the refrigerant line valve. The Schrader valve is like a tire valve in an automobile.

The stem or core is removable with a flexible seal at its base held closed with a spring. Schrader valves

allow a technician to connect gages to the system with a minimum loss of charge. Use a cap with an

inner seal to prevent leakage and keep dirt and moisture out..

The refrigerant control valve lets the system be isolated into two separate sections. In split system,

These valves hold the charge in the outdoor section from the time of manufacture until the unit is

connected to the indoor section by the installer.

5.ELECTRICAL CONTROL DEVICES

THERMOSTATS

Thermostats are the most obvious control in the air conditioning ,since these controls are accessible by

the consumer. Contact the local distributor for information on part numbers of various manual

changeover, auto changeover and set-back thermostats or see the thermostat and subbase selection

information found in the wiring diagram booklet.

In the cooling mode, the thermostat calls for cooling by energizing the compressor contactor and the

indoor blower control. The indoor blower can operate continuously by setting the thermostat subbase fan

switch to the “ON” position.

PROTECTION DEVICES

Protection for the unit begins with the installation of appropriate fuses or circuit breakers by the installing

contractor. Breaker or fuse size is governed by local codes and the National Electrical Code. Current

requirements for each unit are found in the unit specifications.

OVERLOADS AND LIMITS

Overloads protect against over-current or over-temperature conditions. Those located in the outdoor unit

include the automatic reset internal overload in the fan motor and the compressor automatic reset

internal overload. Such controls are not serviceable but their operation may influence service

troubleshooting .For example ,the compressor internal overload may stay open for several hours .A

technician may incorrectly diagnose an open compressor winding.

There are similar overloads in the indoor air handling portion with the electric resistance heaters. The

indoor blower motor has an internal overload. The electric elements use two types of protectors ,both

replaceable. Some electric heat section use fusible links. They are a one time over-temperature

protector and must be replaced upon opening. Limit controls are thermal discs that automatically

reset .Normally, limit open and stop a heat rise before the fusible links open.

NOTE: Never disconnect or wire around a safety device .First determine why it opened, then replace it

with a properly rated part.

HIGH PRESSURE CUT OUT SWITCH (optional)

The high pressure cut-out is a pressure activated switch. It opens an electrical circuit when the

refrigerant pressure exceeds a pre-determined limit of 440 to 460 p.s.i.g. When pressure becomes

9

Haier Commercial Air Conditioning Model: heat pump, 12SEER UNITS

normal,it can restore automatically.

Fig.1-10

RELAYS

Relays provide control switching .The voltages controlled may be either low(24V.A.C.)or line voltage. It is

usually 24 volts. Contact voltage may be either low or line voltage.

COMPREESSOR CONTACTOR

The compressor contactor is a large relay. The coil uses 24 volts but the contacts carry line voltage .The

contactor controls compressor and the outdoor fan operation. Some contactor use single pole

contacts ,while others use 2-pole or 3-pole contacts.

Single-pole contacts break power to only one side of the compressor and outdoor fan .The other side

remains hot with voltage. The 2-pole or 3-pole contactor breaks power to all sides of the compressor and

outdoor fan.

CAUTION:WITH A SINGLE POLE CONTACTOR,ONE SIDE OF A 240 V.A.C.CIRCUIT IS ALWAYS

HOT.THIS MEANS ALL WIRING IN THE HIGH VOLTAGE CIRCUIT MAY HAVE A POTENTIAL OF 120

V.A.C.TO GROUD.BEFORE SERVICING THE UNIT ALWAYS TURN OFF POWDER AT THE UNIT

DISCONNECT SWITCH.

OPTIONAL RELAYS AND KITS

A Time-Delay in the compressor contactor low-voltage circuit allows time for system pressure to equalize

before re-starting the compressor.

This delay user solid state circuitry to measure the time since the power was interrupted. It is set for up to

3 minutes .It is not field adjustable. It is a delay on break timer.

Compressor delay PCB

Fig.5-1

START KITS(OPTIONAL)

This special relay uses the EMF generated by

the compressor start windings to take a start capacitor

out of the circuit. The relay and its companion capacitor can start the compressor at low voltages and

against higher pressure, such as those caused by non-bleed port expansion valves.

Start kits are not normally required with scroll compressors. The operating characteristics of the scroll

compressor make a start kit unnecessary.

6.APPLICATION

Before specifying any air conditioning equipment, a survey of the structure and a heat gain calculation

must be made. A heat gain calculation involves identifying all surfaces and openings that gain heat

from the surrounding air and quantifying that heat gain. It also calculates the extra heat load caused by

sunlight and by humidity removal. These factors must be considered before selecting an air conditioning

system to provide year round comfort. The Air Conditioning Contractors of America (ACCA) J Manual

method of load calculation is one recognized procedure for determining the cooling load.

10

Haier Commercial Air Conditioning Model: heat pump, 12SEER UNITS

The cooling load calculation determines the unit size. There are two capacities that enable the

equipment to provide comfort. The first is sensible capacity. How much sensible heat can the unit

remove? Sensible heat is the heat energy measured on the dry bulb thermometer.

The second form of heat is called latent or hidden heat. This is heat held in the humidity in the air.

Removing this heat does not affect a thermometer. However, removing the heat held in the moisture in

the air greatly increase comfort. A properly sized unit removes both forms of heat, producing a

comfortable living space. An oversized system cycles on and off too quickly and does not properly

remove humidify , producing an uncomfortable living space. Select the indoor and outdoor equipment

combination based on the manufacturer’s engineering data.

After the proper equipment combination has been selected, satisfying both sensible and latent

conditioning requirements, the system must be properly installed. Only then can the unit provide the

comfort the manufacturer built into it.

There are several factors that installers must consider.

● Outdoor unit location

● Proper equipment evacuation

● Outdoor unit refrigerant charge

● Indoor unit air flow

● Indoor unit blower speed

● Supply and return air duct design and sizing

● System air balancing

● Diffuser and return air grille location and sizing

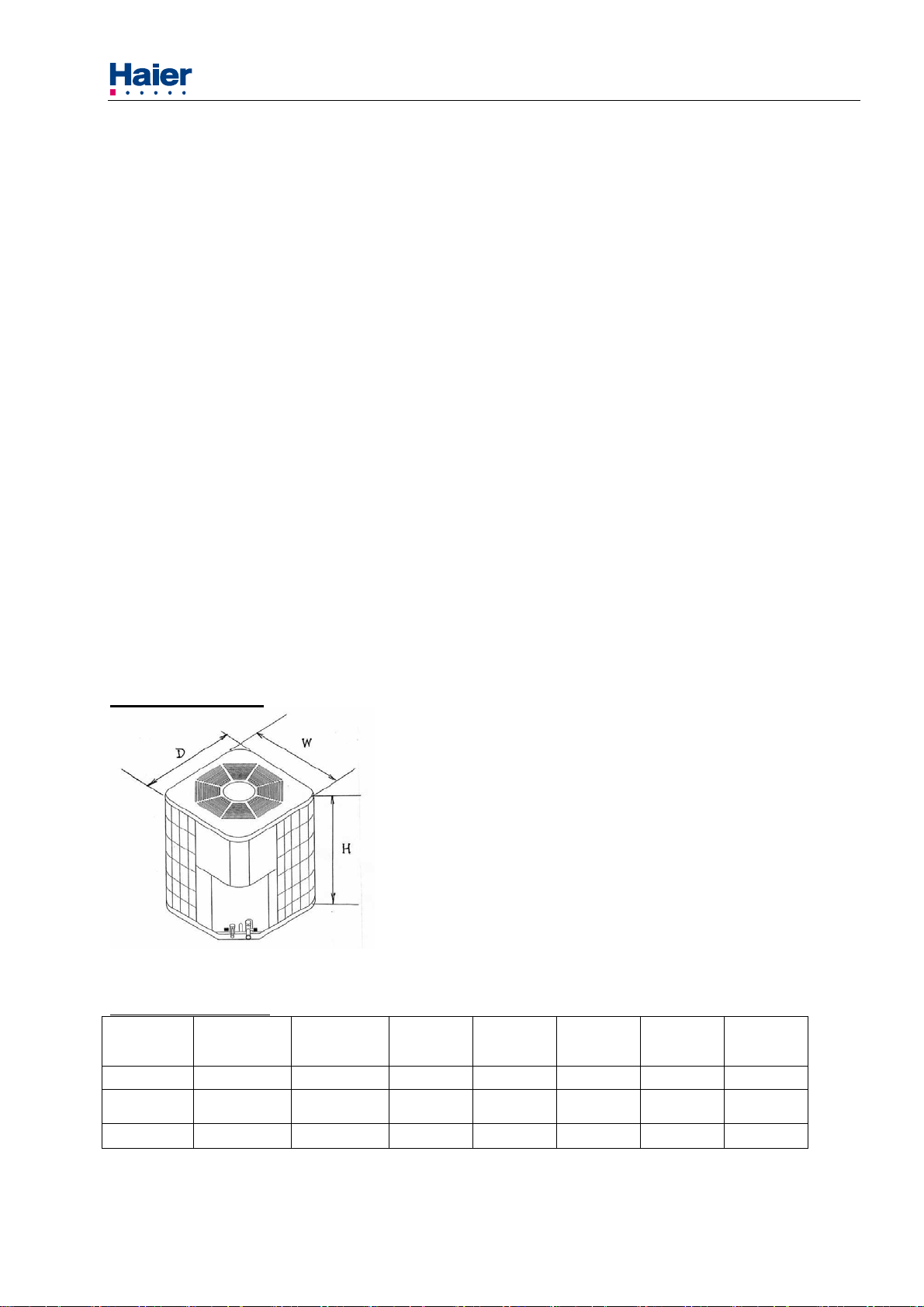

Unit Dimensions

Model:HR18-60C1VAR

----C1VAR HR18 HR24 HR30 HR36 HR42 HR48 HR60

D 23[585] 23[585] 30 1/4[770] 30 1/4[770] 30 1/4[770] 30 1/4[770] 30 1/4[770]

W 23[585] 23[585] 30 1/4[770] 30 1/4[770] 30 1/4[770] 30 1/4[770] 30 1/4[770]

H 31 1/2[802] 31 1/2[802] 27 1/2[698] 31 1/2[798] 27 1/2[698] 31 1/2[798] 35 1/2[898]

[ ] Designates Metric Conversions

Table 6-1

11

Haier Commercial Air Conditioning Model: heat pump, 12SEER UNITS

piston sizes:

Note: the piston placed in the outdoor unit packaging box is used for indoor unit when cooling.

Piston

Size(placed

in package

bag)

Outdoor unit

Indoor coil model

Piston Size

(Installed in

outdoor)

HR18C1VAR

HR24C1VAR

HR30C1VAR

HR36C1VAR

HR42C1VAR

HR48C1VAR

HR60C1VAR

Table 6-2 Piston size

The air distribution system has the greatest effect. The duct system is totally in the control of the

contractor. The industry can only recommend the correct procedure.

The correct air quantity is critical on air conditioning system. Proper operation ,efficiency, compressor life

and humidity control depend on the correct balance between indoor load and outdoor unit capacity .High

indoor air flow increases the possibility of high humidity problems in cooling. Low indoor air flow reduces

total capacity, and causes coil icing. Serious harm can be done to the compressor in either condition.

Air conditioning requires a specified air flow. Each ton of air conditioning requires 400 cubic feet of air

per minute(400CFM/TON).

Duct design and construction should be carefully done. System performance can be lowered

dramatically through bad planning or workmanship. In cooling ,a hot attic can cause a temperature gain

of 3°in the return duct and 4°in the supply duct. This can reduce the cooling capacity of an air

conditioning system by as much as 30%.This means a loss of almost one ton of cooling capacity from a

three ton system.

Air leakage of only 3% in a return duct can cause a 5% loss in system capacity. 3% leakage on a three

ton system is only 30 CFM. Two or three unsealed joints can cause this leak. Sealing the return and

supply ducts pays dividends in increased system capacity and lower operating costs.

Effective duct insulation is essential to prevent loss of capacity and sweating ducts in the cooling mode.

Duct systems installed in the conditioned space can be left uninsulated , but a dense 1/2” fiberglass duct

liner reduces blower and air noises, and prevents sweating ducts when humidity levels are high.

Supply and return duct systems in attics and crawl spaces require a minimum 1” of dense duct liner or 2”

fiberglass wrap with a sealed vapor barrier. A leaky vapor barrier results in duct sweating, causing wet

insulation.

Wet insulation does not insulated .Heat transfer through poorly insulated systems can result in over 50%

loss in operating capacity. Sweating ducts also promote rusting ducts resulting in premature duct failure.

Other duct materials have been successfully used. Carefully follow the duct manufacturers’ installation

instructions. The duct system is only as good as the planners and installers construct.

Air supply diffusers must be selected and located carefully. They must be sized and positioned to deliver

treated air along the perimeter of the space. If they are too small for their intended air flow the become

noisy. If they are not located properly they cause drafts on the occupants in the rooms. Return air grilles

must be properly sized to carry air back to the blower. If they are too small they also cause noise. The

installers should balance the air distribution system to ensure proper air flow to all rooms in the home.

This ensures a comfortable living space.

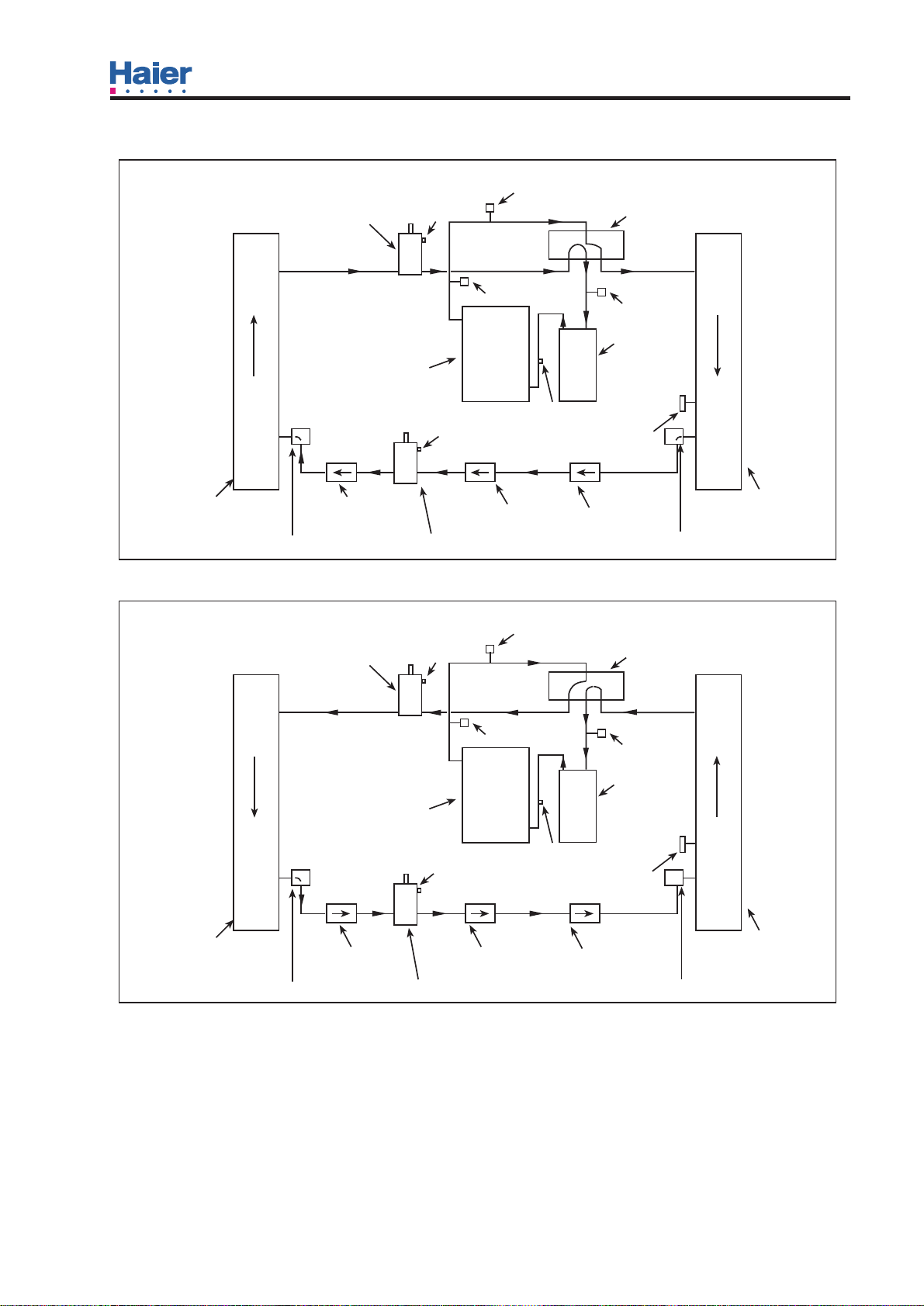

Refrigerant system diagram refer figure below

HB2400VC1M20

HB2400VC1M20

HB3600VA1M20

HB3600VC1M25

HB4800VA1M25

HB4800VA1M25

HB6000VC1M25

0.068

0.071

0.074

0.078

0.078

0.081

0.081

0.078

0.071

0.081

0.085

0.117

0.108

0.117

7. INSTALLATION INSTRUCTIONS

! WARNING

These instructions are intended as an aid to qualified, licensed service personnel for proper installation,

adjustment and operation of this unit. Read these instructions thoroughly before attempting installation or

operation. Failure to follow these instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical shock, property damage, personal

12

Commercial Air Conditioner Model: heat pump, 12SEER UNITS

Figure

Cooling

INDOOR COIL

Heat Pump Refrigerant Circuit

SERVICE VALVE

EVAPORATOR

CHECK VALVE

ORIFICE

DISTRIBUTOR

SERVICE PORT

COMPRESSOR

SERVICE VALVE

DISCHARGE TEMP. SENSOR

HIGH PRESSOR

SERVICE PORT

SERVICE PORT

DRYER

DEFROSED SENSOR

CHECK VALVE ORIFICE

REVERSING VALVE

LOW PRESSOR

ACCUMULATOR

CONDENSER

OUTDOOR COIL

DISTRIBUTOR

Heating

INDOOR COIL

SERVICE VALVE

CONDENSER

CHECK VALVE

ORIFICE

DISTRIBUTOR

SERVICE PORT

COMPRESSOR

SERVICE VALVE

DISCHARGE TEMP. SENSOR

HIGH PRESSOR

SERVICE PORT

SERVICE PORT

DEFROSED SENSOR

DRYER

CHECK VALVE ORIFICE

REVERSING VALVE

LOW PRESSOR

ACCUMULATOR

EVAPORATOR

OUTDOOR COIL

DISTRIBUTOR

Loading...

Loading...