Page 1

SERVICE MANUAL

Orde r NO . TL14 03S006V1. 1

Automatic Washing Machine

Model NO

HLP24E

WARNING

This service information is d es ig ne d f or experienced repair technicians onl y a n i s n or de si gn ed for use by the general

public. It does n ot co nt ai n w ar ni ng s or cautions to advise non-technical in di vi du al s of potential dangers in attempting t o

service a product. Pro du ct s p ow er ed by electricity should be serviced or r ep ai re d only by experienced p ro fe ss io na l

technicians. Any a tt em pt to se rv ic e or re pa ir the products dealt wi th in t hi s s er vi ce inf or ma ti on by anyone else could

c year(Full name of t he co mp an y w ho is su es th e serv ic e i nf or ma ti on ).

All rights reserved. Una ut ho ri ze d c op yi ng and distribution is a vi ol at io n of law.

Haier Group

Page 2

Service Manual

Order No. TL1001S001V0

Chapter 1: General Infromation

1-1. Table of Contents

Issue

Rev.

Document control

Chapter 1. General Information ............................................................................... 2

1-1. Table of Contents 2

1-2. General Guidelines 3

1-3. Caution and Warning symbols 3

1-4. Function indication symbols 3

Chapter 2. Product Feature

2-1. Features 4

2-2. Specifications 5

Chapter 3. Safety Precautions

3-1.

Safety 6

3-2. Warning and cautions 7

3-3. Net Dimensins 8

Chapter 4. Installation and accessory parts

4-1. Key points in installation

4-2. Installation the button plate

4-3. Adjustment of the installation position

4-6. Usage of operation buttons

4-7. Product briefs

4-8. Key points in disassembly

Chapter 6. Maintenance service and trouble shooting

Trouble alarm

6-1.

6-2. Trouble shooting charts

6-2-1. No action(the indicator is off)

6-2-2. No water filling

6-2-3. No rotation in washing or(rotate to one direction)

6-2-4. No draining

6-2-5. Keep filling water

6-2-6. No spinning

6-2-7. Too much spinning noise

6-2-8. Too much noise in washing

6-2-9. The tub rotates to one direction(in washing)

6-2-10. Brake time out

.........................................................................................................

.......................................................................................

.......................................................................................

.....................................................................

.....................................................................

....................................................................................... 4

.......................................................................................

.......................................................................................

.......................................................................................

.........................................................................................................

.......................................................................................

.......................................................................................

.............................................................

.......................................................................................

.......................................................................................

.....................................................................

.......................................................................................

.........................................................................................................

.......................................................................................

.............................................

and solve

.......................................................................................

metho

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

d

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

11

12

13

17

17

18

18

19

19

20

20

21

21

22

22

23

1

6

8

8

8

9

Chapter 7. Wiring diagram

.........................

.................................................................24

Page 3

Service Manual

Order No. TL1001S001V0

Issue

Rev.

1-2. General Guidelines

When servicing,observe the original lead dress.If a short circuit is found, replace all parts which are

overheated or damaged by the short circuit.After servicing ,see to it that all the protective devices such as

insulation barriers ,insulation papers shields are properly installed .Confirm that the screws,parts and wiring

which were removed in order to service are put in the original positions, or whether there are the portions

which are deteriorated around the service places serviced or not. And be sure safety of that.

1-3. Caution and Warning symbols

(You will see them in Matters needing attention )

Any instructions in this service manual with this Warning sign must be followed strictly.

To prevent damage to the washing machine, any instructions in this manual with this

Stop sign must be followed strictly.

1-4. Function indication symbols

(You will see them in the specification table)

Signify the washing machine has this function.

<

Signify the washing machine doesn t have this function.

X

3

Page 4

Service Manual

Order No. TL1001S001V1.1

Chapter 2: General Infromation

2-1 FEATURES

Soak wash make cleaner wash.

Fashionable appearance, transparent top lid

Efficaciously reduce noise

Automaticly power off function

Self-adjustment to unbalance of laundry in spinning

Fuzzy computer control, self-program function, more

convenient washing

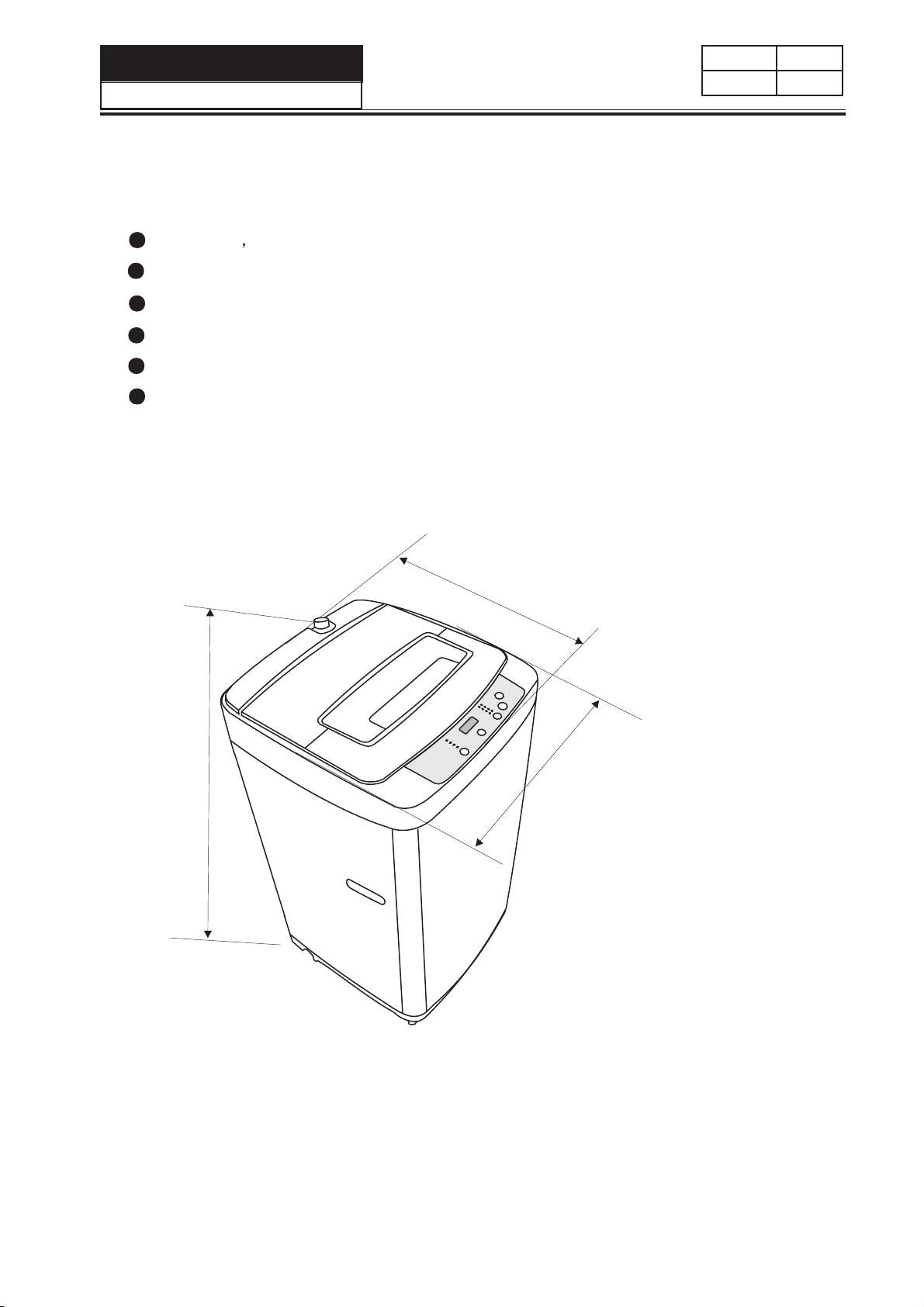

2-2 Net Dimension

Issue

Rev.

902

510

500

Unit:mm

4

Page 5

Service Manual

Order No. TL1001S001V0

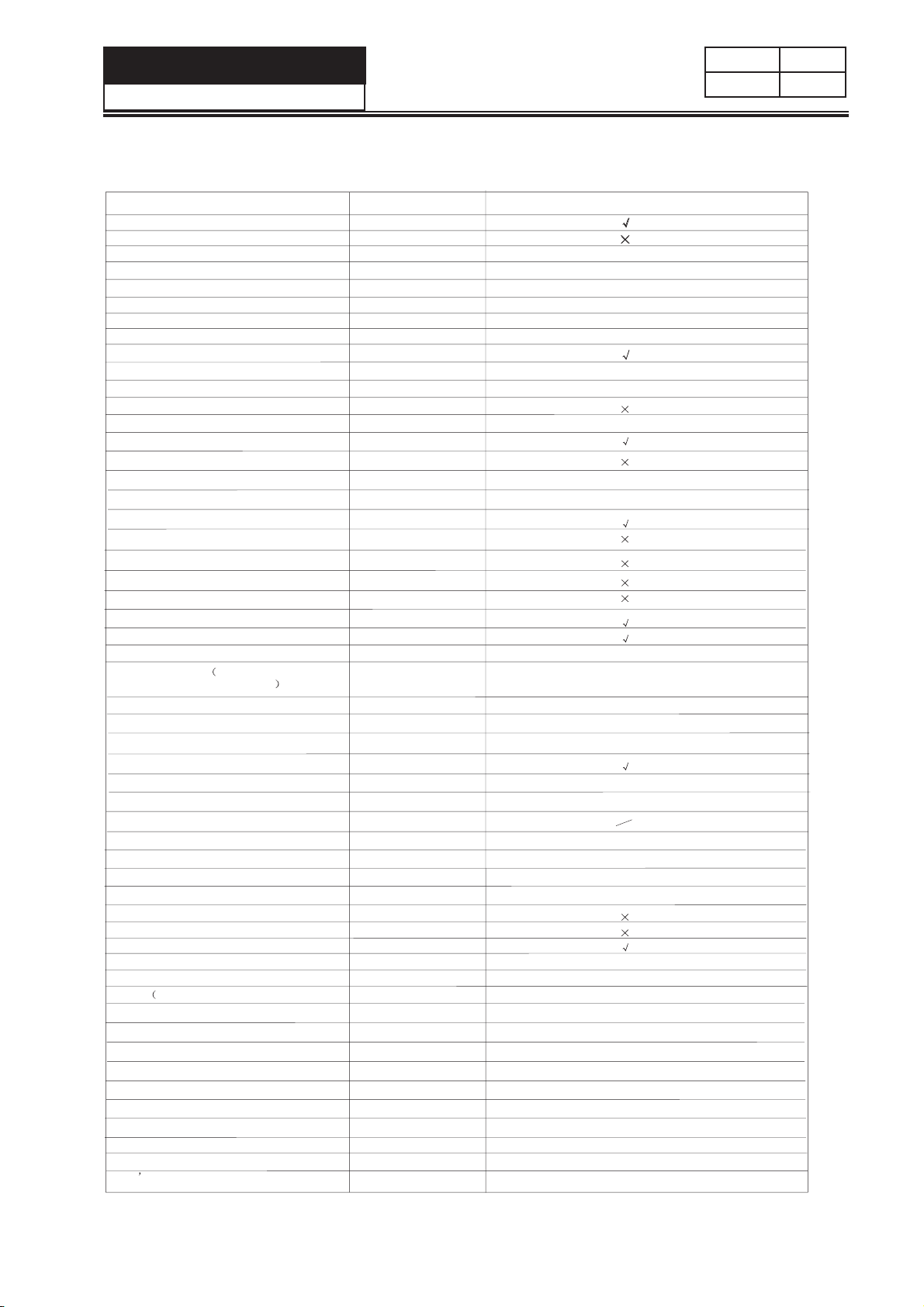

2-2 SPECIFICATIONS

Issue

Rev.

Model

Free standing

Built under

EAN code

Energy efficiency class

Features for use

Wash capacity

Spin capacity

Level/Volume

Preset

Residual dampness

Control model

Controller

Normal computerized

Fuzzy computerized

Frequency conversion

Service features

Programs

Short cycle

Inlet water select

Heating selection

Spinning cycle (selector)

Spinning cycle (variable)

Start/Pause

Automatic balancing

Aesthetics

Cabinet material P=Plastic/Z=Zincking

/C=Cold rolled stainless steel )

Inner drum (stainless steel=s / plastic=p)

Drain type

Door (glass=g / plastic=p)

Adjustable feet

Technical data

Voltage/frequency

Energy consumption

Water consumption

Wash power

Spin power

Special function

Air-Bubble

Feet wheel

Spray current

Dimensions (measurements)

Height / built under

Width include drain pipe)

Depth / with open door

Dimensions packed ( measurements packed)

Height

Width

Depth

Net weight

Gross weight

20'Container load

40'Container load

40H Container load

Kg

Kg

L

H

%

V/Hz

kwh/kg

L/kg

w

w

mm

mm

mm

mm

mm

mm

kg

kg

Sets

Sets

Sets

HLP24E

7704353033123

-

5.0

5.0

Small/Medium/Large/Super

<115

8

C

S

Drain up

G

120/60

24

325

255

902

500

510

986

582

582

28

30

60

120

168

5

Page 6

Service Manual

Order No. TL1001S001V0

Chapter 3. Safety Precautions

3-1. Safety

Issue

Rev.

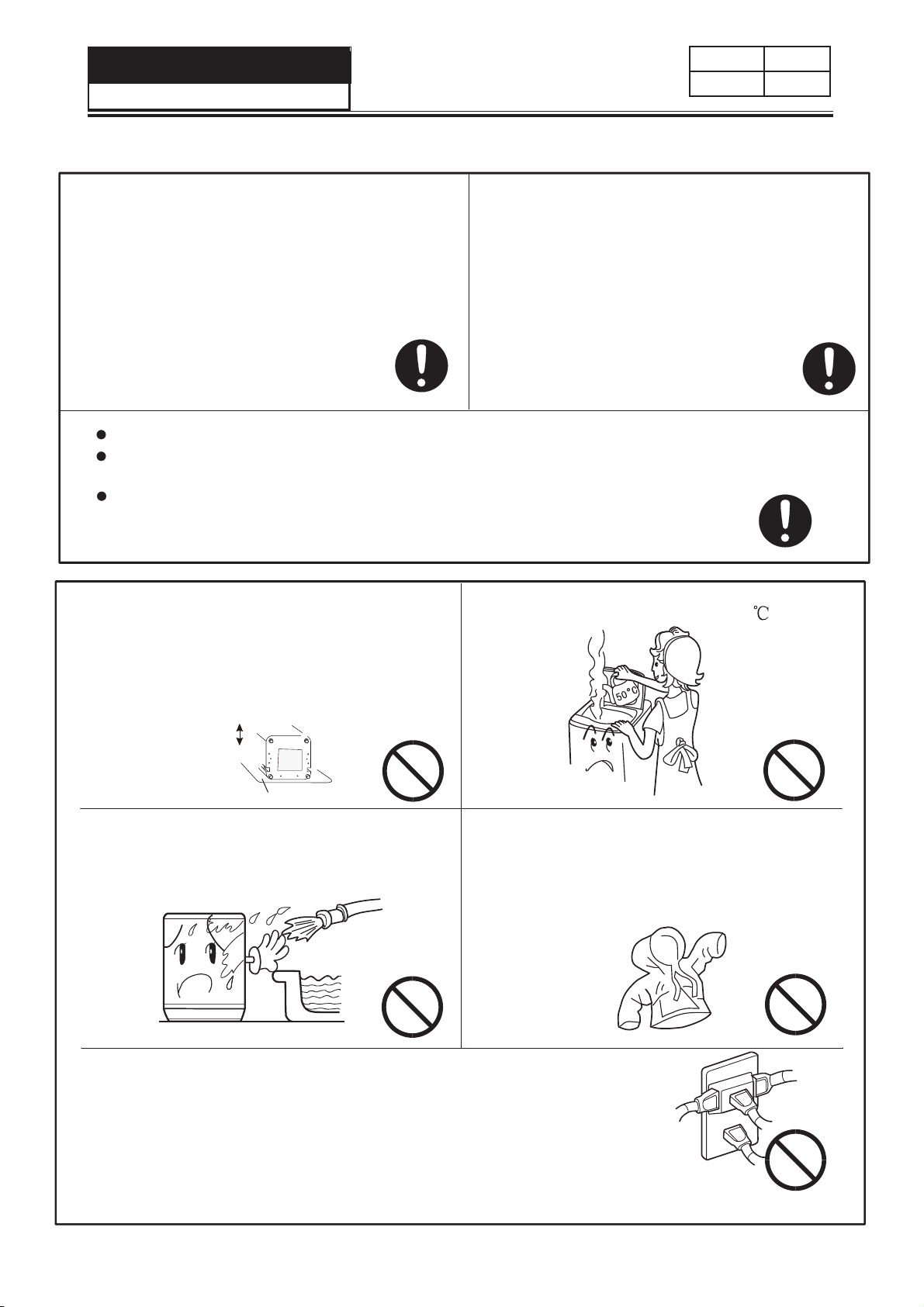

Please plug the power plug on special

receptacle. Be sure to use three-pins

power receptacle. Ensure that the earthing

prong of the power receptacle is earthed

reliably. Use leakage protector if possible.

The washing machine must be positioned

so that the plug is accessible. Be sure to pull

the plug off and close the water faucet in

following cases: power failure, delivering

the machine, setting the machine idle or

cleaning the machine.

Do not plug or pull the

power plug with wet

hand.

Do not bend ,extend, twist, bind by force. Do not press or nip it with weight.

Keep the pin of the power plug clean, if the power plug is polluted with dust,

please wipe with dry cloth carefully.

If the supply cord is damaged, it must be replaced by

the manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

In case the washing machine is installed

Do not use water hotter than 50 .

on ground with carpet, do not block the

ventilation hole with carpet.

Ensure carpet does not

obstruct the

opening in

the bases.

Front

Back

Carpet

Do not put the machine at damp place

like the bathroom. Never wash it with

water. Do not put wet laundries on the

control panel.

Do not wash water-proof laundries like

the raincoat, bike covers etc. to avoid

abnormal vibrations in spinning.Wash

the clothes that can float on the water

surface easily,please be careful

especially,for

fear damage.

Do not let the machine share one receptacle with other

electric appliances. If the plugging into the receptacles

loose, do not use the plug any more.

6

Page 7

Service Manual

Order No. TL1001S004V0

3-2.Warning and Cautions

Issue

Rev.

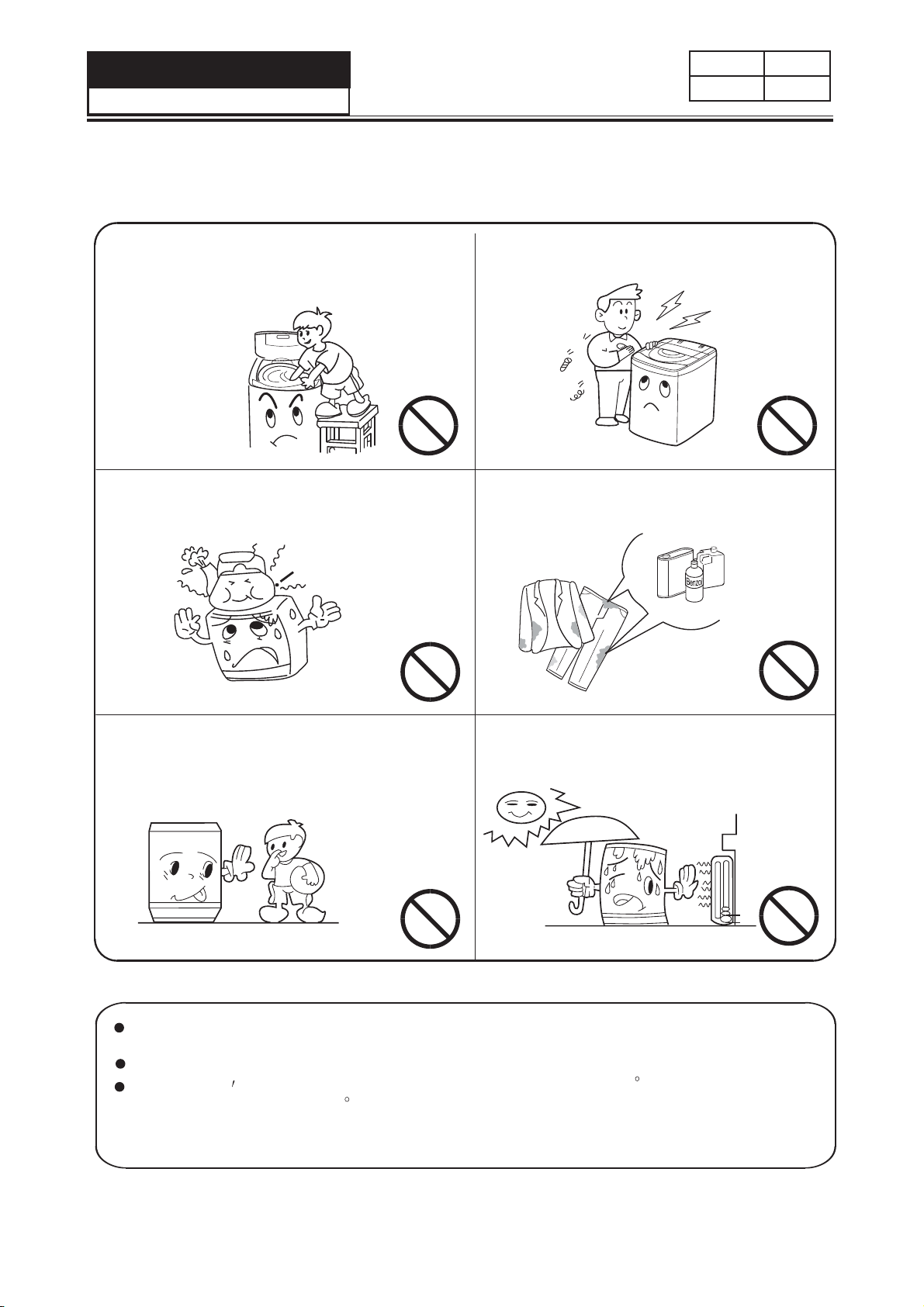

Do not stretch hands into the working

machine. It is dangerous even if the

rotation is slow. Take special care of

the children.

Do not put any hot or heavy items (such

as the kettle with hot water ) on the

washing machine.

Do not decompose, repair or alter the

machine by yourself.

Do not wash laundries with volatile

materials (such as thinner, petrol etc.)

Thinn

er

Petrol

The children shall not approach

the working washing machine.

Keep the machine away from direct

sunlight and heat source like the heater.

Please check if the water faucet is open, and if the connection of the

water inlet pipe is proper.

It is suggested to use foamless washing powder.

Please don t use the washer in the environment below 0 C; if the washer

has been stored below 0 C, please be sure to ensure the washer is placed

under the room temperature more than 2 hours and then use otherwise

the washing effects may be lowered or the washer may be damaged.

7

Page 8

Service Manual

Order No. TL1001S001V1.1

Issue

Rev.

Chapter4 Installation and accessory parts

4-1.Key points in installation

Please install and adjust the machine according to the requirement of the mannual.

It is very important to your security and correct operating the machine.

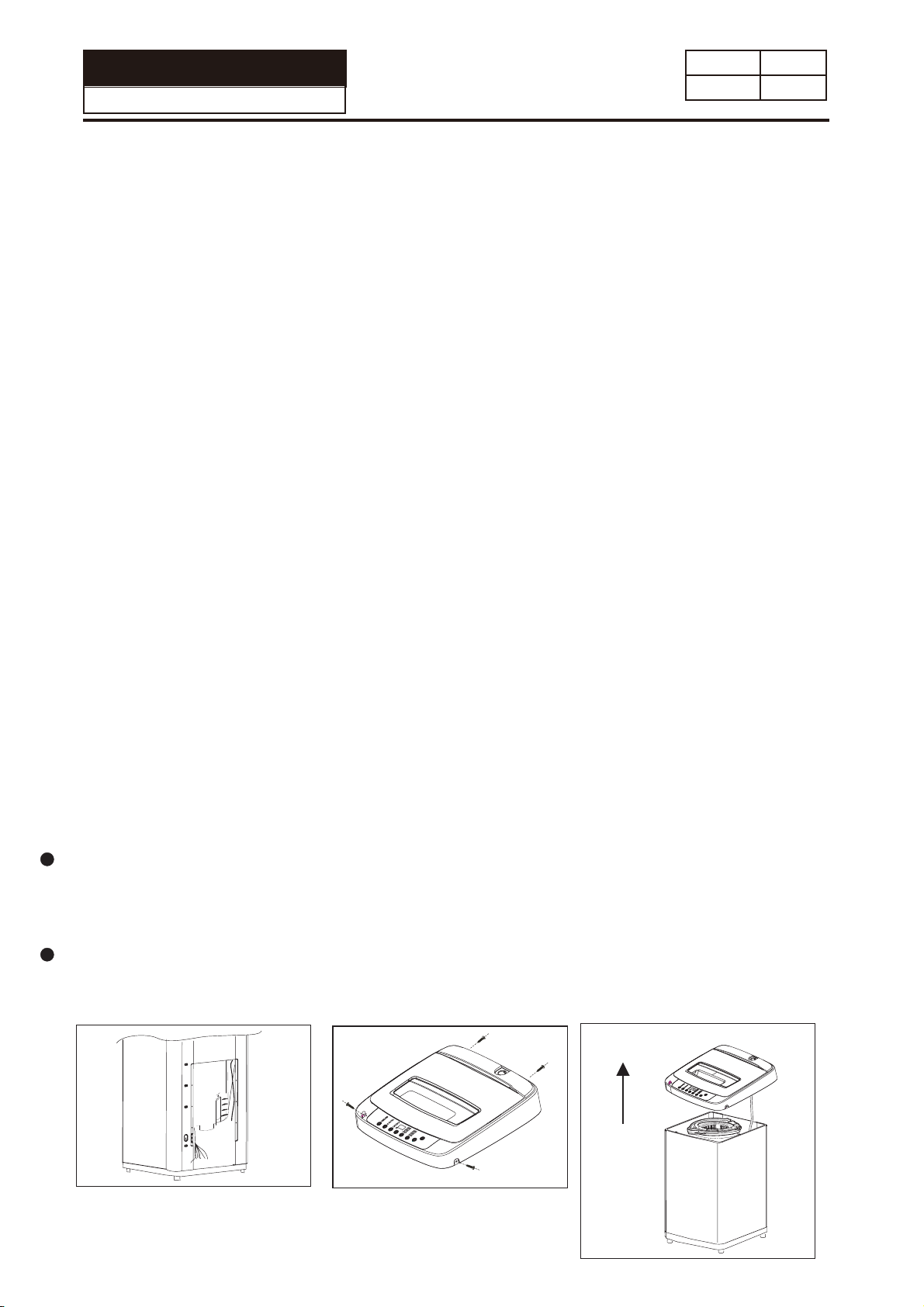

4-2 Adjustment of the installation position

The washing machine away from wall should be overrun 20mm. The largest

allowable slope of the shank base of the machine is 2 The slanting or rough

ground will result in unstable running or stoppage of the machine. Please adjust

it with following methods:

Confirm it's horizontal:

Hang the lead line to check if it is horizontal.

Adjust the adjustable leg:

Please lift up the side of the leg slightly,

twist the adjustable leg, make sure to keep the

washing machine in balance

High

Adjustable leg

low

8

Page 9

Service Manual

Order No. TL1001S001V0

4-4.Usage of operation buttons

Issue

Rev.

WASH CYCLE BUTTON

Use this button to select the desired cycle for your wash load.

Ţ

The standard default settings of each cycle will be displayed; the default

Ţ

settings can be changed by using the Setting button - Water Level.

There are 6 cycles to choose from:

Ţ

Heavy Duty - Use this cycle for heavily soiled durable garments. This cycle

can also be used for towels, sports gear, children’s clothes, etc.

Normal - Use this cycle for normally soiled cottons and mixed fabric loads.

Delicate - Use this cycle to wash lightly soiled garments and delicate clothes

that need gentle washing.

Quick - Use this cycle to wash small, lightly soiled loads that are needed in a

hurry.

Rinse & Spin - Use this cycle for removing excess detergent and refreshing

clean garments.

Spin Only - Use this cycle to extract water from sink washed or clean wet

garments.

SETTING BUTTON

Water Level Button

Use this button to select an appropriate water level for your load. Small is

Ţ

the lowest water level and Super is the highest.

9

Page 10

Service Manual

Order No. TL1001S003V0

Issue

Rev.

DELAY START BUTTON

Press this button to delay the start of your wash cycle between 1 - 24 hours

Ţ

in one hour increments.

Use this button to select a delayed start of the washer. The number of hours

Ţ

will be shown in the Estimated Time Remaining Display. Each press of the

Delay Start Button will increase the time by 1 hour.

One button press after 24 will cancel the Delay Start feature. You can also

Ţ

POWER Button.

The START/PAUSE Button must be selected to begin the countdown.

Ţ

ESTIMATED TIME REMAINING DISPLAY

The Estimated Time Remaining Display shows the estimated cycle time in

Ţ

minutes.

When the Delay Start option is being used, the Estimated Time Remaining

Ţ

Display will show the delay time in hours.

START/PAUSE BUTTON

Press this button to start a selected cycle or to pause an operating cycle.

Ţ

NOTE: After starting the wash cycle, you must pause the operating cycle to

change the Water Level setting.

POWER BUTTON

Press the POWER button to turn on the washer.

Ţ

NOTE: If the washer is turned on, but START/PAUSE is not pressed, the power

10

Page 11

Service Manual

Order No. TL1001S003V1.1

Issue

Rev.

4-5 Product Brief

1)Computer sequencer

It adopts pouring seal with polyurethane on the surface. The light-emitting diode

is sealed with insulation bushing to avoid humidit

of computer plate and box and the operation components of the control panel seat

are coated with control panel film.

2)Structure of the top lid

The top lid adopts transparent view window structure. If the top lid is closed, you

can observe the running of the washing machine through the transparent lid.

3)Power transmission system

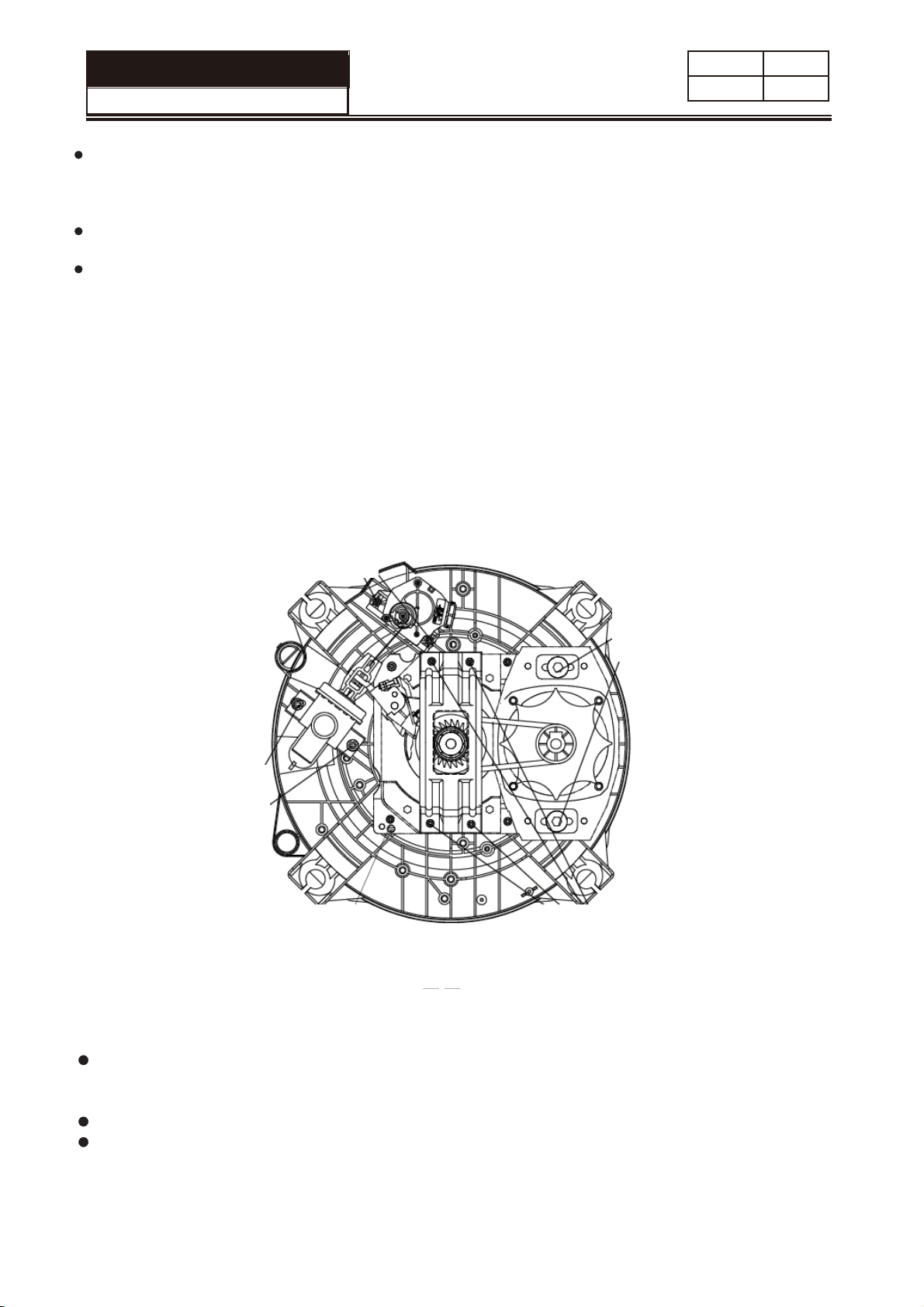

During washing, the rotation of Motor 1 is transferred to Follower 6 from Drive

Wheel 2 through Belt 3. Meanwhile, the puller makes the first action. The brake

belt is departed. Pawl 9 and 10 brake the Ratchet 5 and 8 by the action of spring.

y

To avoid splashing, the surface

.

The force will be transferred to Center Gear11, and then be retarded and

transferred to Tie-rod 13 through a planetary gear mechanism consisting of Center

Gear 11, Planet Gear 12 and Spin Shaft 4 (inner gear), then Tie-rod 13 is

connected to Pulsator 14 via a spline shaft. The Pulsator 14 will move along with

the clockwise and counterclockwise rotation of the Motor 1. The Spin tub 15

rotates to the opposite direction against the pulsator by the action of the retarder

planetary gear mechanism.

During spinning, the rotation of Motor 1 is transferred to Follower 6 from Drive

Wheel 2 through Belt 3. Meanwhile, the puller will make the second action. The

Pawl 9 and 10 will leave Ratchet 5 and 8 by the action of the puller. Clutch Reed 7

is twisted tightly on the down part of Spin Shaft 4. The Spin 15 and Spin shaft 4

adopt flange connection. The movement of Motor 1 is retarded by V-belt 3, and

make Spin tub 15 spin through Spin shaft 4.

4)Damping system

Please pay attention in installation of the hangers that the spring of the hanger

at the motor side (two) is different from those installed on the other hangers (two).

11

Page 12

Se r vice Manual

Model No: TL1001S003V0

Issue

Rev.

Key points in disassembly

General attention

Be sure to pull off the power plug in disassembly or maintenance

Use stipulated crimo terminals in connecting the wires between the

conducting wires as far as possible ,and fix with suitable tools ,and insulate

with insulation tape completely .

In inserting the conducting wires ,be sure to plug the pins to the root and

make it hard to be pulled out .

If welding is needed ,be careful not to touch the plastic or other insulation

parts and the parts with the iron .

When connecting the wires ,be sure not to make the wire touch the mobile

parts like the belt ,radiating pulley and jib ect.,and the sharp protruding

parts and the parts with high temperature (motor ). Connect and fix the wires

as per their original mode .

If there is metal object at the wire fixing point,be sure to insulate with in

sulation materials,

Retain the dismantled screws of future usage in installation ,

Points of attention in usage of electic components

In case that the power is on ,the earthing circuit of the computer sequencer

can have 120V voltage to earth.Take care not to get electric shock .

Store the computer sequencer and driver under 4 degree to 30 degree ,

Avoid direct sunlight .

In trouble -shooting ,it may require hot-line work .Please be extremely .

1.Method of opening panel seat

A.Open the back cover .Loosen the locking belt fixed on the cabinet(used

inner wiring ),to loosen the inner wiring

B. Loosen the four screws used to install the control panel seat (rear and side)

C.Lift the rear upwards.Loosen the control panel seat from the inlay of

Attention :

Do not lift the control panel seat by force ,otherwise the safety switch control

rod may get transformed.and the jointer part of the connecting pipe of the

water level sensor may be loosened ,therefore influence the normal

operation of the microswitch and water level sensor .

After opening the control panel seat ,hold it with one hand or lean it on

supporter like the wall .Do not put it down .

First loosen the screws when dismantling the computer controller .

12

Page 13

vice Manual

r

Se

Model No: TL1001S003V1.1

Attention :

Do not lift the control panel seat by force ,otherwise the safety switch control rod may get

transformed.and the jointe

loosened ,therefore influence the normal operation of the microswitch and water level

sensor .

After opening the control panel seat ,hold it with one hand or lean it on supporter like the

wall .Do not put it down .

First loosen the screws when dismantling the computer controller .

3)Method cabinet and outer tub of disassembling

A.Loosen the two motor bolt unit to dismantle the motor.To adjust the

tension of the blet ,loosen the bolts and move the motor left and right .

B.Loosen the four fastening screws to dismantle the delivery shield .

C.Loosen the three fastening screws to dismantle the drain motor .

D.dismantle the drain pipe ,

E.In dismantling the inner tub ,first take offthe outer tub cover ,then

dismantle the pulsator ,finally dismantle the inner tub .Handle with care

when taking the inner tub off from th

r part of the connecting pipe of the water level sensor may be

e outer tub

.

Issue

Rev.

4)Points of attention in assembly

In installation of thedrain pipe ,please smear a piece of 801 glue at the connection

part between the drain pipe and outer tub and between the overflow hose and drain

hose to guarantee that the drain pipe will not leak .

In fastening the screws ,make it tight without sliding .

Take care not to scratch the cabinet and influence the appearance of the machine .

13

Page 14

Service Manual

Model No: TL1001S003V0

Chaper5.PARTS AND FUNCTIONS

Front Vie w

2

Issue

Rev.

1

3

6

1.

Top Lid

Control Panel

2.

Washer Cab inet

3.

Adjustable Leg

4.

Back View

11

9

10

4

5. Cab inet

5

Handle

(loca ted on

bo th

sidesof thewasher)

6.Drain bushing

7. Screw co ver

8

7

14

12

8. Water inlet valve

9. Water absorption cushion

10. Power cord(120Volt/60Hz)

13

11. Back cover

12. Fixed foot

13. Adjustable foot film

14. Hanging hole

14

Page 15

Service Manual

Order No. TL1001S003V0

Issue

Rev.

Chapter. 6 MAINTENANCE SERVICE AND TROUBLE SHOOTING

Phenomena The reason How to settle

The digitron displays dO. The top lid is open during

reserve procedure.

The drainage cannot

work, or is too slow. The

digitron displays Ld.

It stops running in

midway. The digitron

displays

The safety switch acts,

and the spinning cannot

work. The digitron

displays

not work, or is slow, the

digitron displays

The digitron displays FA. The water level sensor is bad. Please contact the after-sales service

The

machine

does not

act

dO.

uL.

LF.

Not wash Is there power failure?

Not spin

Is the drain hose blocked?

The top lid is not closed.

When using the child lock function,

if the top cover is opened, the

machine will stop and display dO

alarm. After 5 minutes the machine

will automatic drainage

Are the laundries put slantingly?

Is the machine slanting?

Is the water tap opened, or is

there water supply failure?

Is the water inlet valve blocked?

Is the water pressure too low?

Is the power plug inserted tightly?

Is the water level reached preset

position?

Is the power plug inserted tightly?

Is the top lid closed reliably?

Close the top lid.

Put down the drain hose . Open and

close the top lid once.

Clean the foreign material. Open and

close the top lid once.

Close the top lid.

clear the dO alarm, please close the top

cover and press the START/PAUSE ”

button. Then dO alarm will be cleared.

Reorder the laundries. Close the top lid.

Place the machine horizontally, open

and close the top lid once.

Open the water tap. Open and close the

top lid once.

Clean the water inlet valve then open

and close the top lid once.

Use after the water pressure is normal.

department.

Please use it when there s power

supply.

Insert the power plug tightly.

Fill water to the preset position.

Insert the power plug tightly.

Close the top lid.

There is abnormal sound

inside the machine

The water tap leaks

Is the machine slanting?

Are the laundries put slantingly in

spinning?

Are there any foreign materials?

Is the screw of the jointer of water

inlet hose loose or awry?

Adjust the machine to be even

Reorder t he laundries and close the top

lid.

Remove the foreign materials.

Fasten the screw of the jointer properly.

noitanalpxEanemonehP

The spinning is intermittent when it starts. Balance the laundries to avoid slanting.

Push the spin” button to select Spin”, but it doesn t

work.

There may be some water flowing out of the drain hose

in the first use of the machine.

The wash procedure is paused .

The pulsator pauses during water inlet in wash

and rinse.

When the power plug is inserted,computer board

indicator is switched on, and the machine starts

working.

The program is setting the drain time. Some time is

needed before it starts spinning.

It is the water remained in the factory inspection of

performance.

The cloth sensor is checking the cloth, it will add

water after 48 seconds.

It is to avoid splashing during water inlet.

It is the special resume function. In the case of power

failure or the power plug is

machine can save the running program, and resume

the program after the power supply is recovered. You

do not need to set the program again.

loose during washing, the

15

Page 16

Service Manual

Order No. TL1001S003V1.1

Issue

Rev.

6-2 Trouble-shooting charts

If you replace the computer sequencer without checking the other components carefully ,

the computer sequencer may be damaged again .Therefore,please first check if the other

components working normally before replacing the computer sequencer in maintenance .

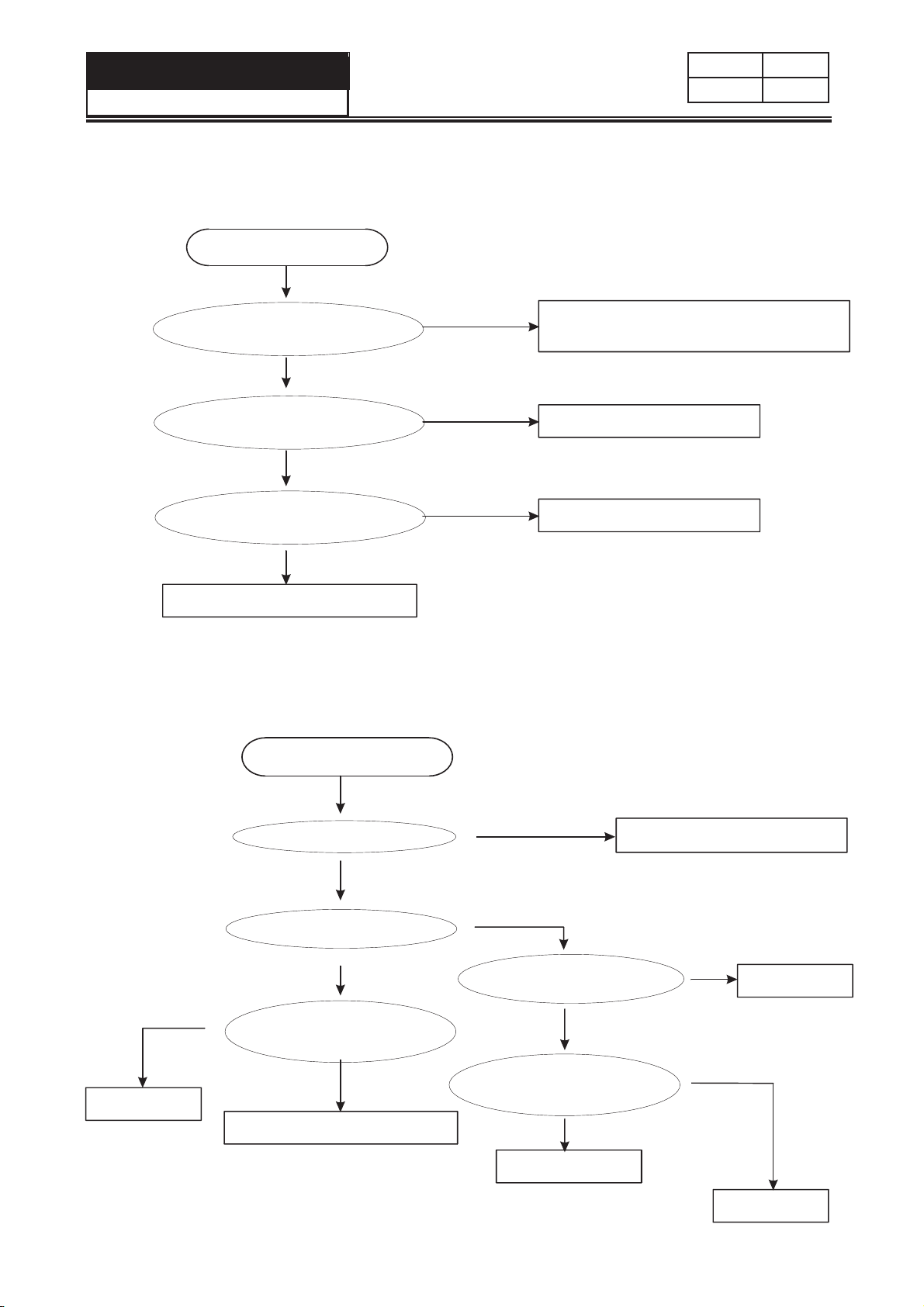

6-2-1 No acting (The indicator is off )

Confirm that there is no power failure ,

and the power plug is inserted reliably.

The power switch is at ON mode.

Measure the voltage

of the two ends of the power input

of the sequencer

Pull off

the power

plug

Measure the resistance

between the light blue wire

terminal in the white plug on

top of the wire unit and the N pin

on the power receptacle .

The resistance

is 0.

Measure the resistance

between the brown wire terminal

in the white plug on top of the wire

unit and the brown wire of

the lower part

No

exist

The resistance

is 0.

Infinite

Exist

Replace the sequencer

Infinite

Measure the resistance

between the light blue wire terminal

in the end plug on top of the wire

unit and the light blue wire of

the lower part .

The resistance

is 0.

Replace the

power cord

Infinite

Replace the wire unit .

Check if the fuse is burnt?

No

Check if the connection

between the fuse and the wires

of the two ends are well

Connect the fuse and the

wires of the two ends.

Yes

Replace the fuse

Yes

Replace the computer

sequencer.

16

At this time please check if the other

electric components work normally .

Page 17

Service Manual

Order No. TL1001S003V1.1

6-2-2

No water filling

Switch on the power .Push

the START button

Issue

Rev.

6-2-3

Confirm the action sound

of the water inlet valve ?

There is no sound

Measure the voltage

of the two ends of the water

inlet valve ?

There is no voltage

Measure the voltage

of the two ends of the computer

sequencer?

There is no voltage

Replace the computer sequencer

No rotation in washing (or rotate to one direction only)

Start the test without water.

Enter no-water washing.

There is sound

There is voltage

There is voltage

At this time please check if the water inlet valve

works normally.

Remove the foreign materials of the water

inlet valve filter screen or raise the water

pressure to 0.03Mpa-1Mpa before use

Replace the water inlet valve.

Replace the wire unit

Replace the wire unit

Exist

Replace the

wire unit.

Check the action of the motor.

No exist

Measure the voltage

of the two ends of the motor

No exist

Measure the voltage

of the two ends of output of

the computer sequencer.

No exist

Replace the computer sequencer.

At this time please check if the

capacitor and motor works normally.

17

Acts

Exist

If the motor overheat

protector acts?

No

If the capacitor has brocken

circuit or short circuit?

No

Replace the motor

Please check the transmission

system carefully.

If it is normal of the bearing part

locking the clutch.

Yes

Please check

the reason.

Replace the

capacitor

Yes

Page 18

Service Manual

Order No. TL1001S003V1.1

Issue

Rev.

6-2-4

6-2-5

No draining

Keep filling water

Open the water faucet

without switching on the power.

Set rinse or spin start

the machine.

Check if the drain motor acts?

Replace the computer sequencer.

No

Measure the voltage

of the two ends of the

drain motor.

No Exist

Measure the voltage

of the two ends of the output

of the computer

sequencer.

No Exist

Roll up normally

Exist

Exist

Check the drain system like the

drain pump etc.

Check the drain motor.

Check the wire unit.

If the water can fill into the

water inlet valve.

Switch on the power.Do not

push the START button.

If the water can fill into the

water inlet valve.

Check if the wire

connecting the computer board to

the water level sensor is bad?

Select 1 to 2 water level

and start the machine to

check if the gas cell has

water.

Yes

Yes

Yes

Yes

Replace the water inlet valve.

Replace the computer sequencer.

At this time please check if the

water inlet valve is well.

Replace the wire unit.

It weaks gas.Please check and

repair the gas guide system.

Please smear 801 glue in installation

of the connecting pipe.

Please smear 801 glue in installation

of the gas cell cover.

Check if the gas guide

system is blocked?

Replace the water level switch.

Yes

18

Clear various factors like

the foreign materials.

Blow form the connecting pipe to the

water level sensor and gas cell to see

if there is blocked.

Page 19

Service Manual

Order No. TL1001S003V1.1

Issue

Rev.

6-2-6

6-2-7

No spinning

Too much spinning noise

The washing and draining

are normal.

Check the On/off point of

the microswtich and stop

switch.

Normal

Check if the clutch pawl is

pulled enough.

Yes

Replace the retarder clutch.

If the washing machine is

set horizontally?

No

If the hanger is wrong used?

No

No On/Off point

No

At this time please check if the

drain motor is well.

Yes

Yes

Replace the microswitch or stop

switch.

Replace the drain motor.

Set the machine horizontally.

Replace the hanger is

If the noise of the motor

is too much?

No

If the motor is fastened tightly?

Yes

If the bearing of the retarder is

well?

Yes

If the departing of the

ratchet and pawl is well?

No

If the machine body

vibrate resonantly with the

cabinet?

No

If the balance ring is rubbing

the outer tub cover?

Yes

No

No

Yes

Yes

Yes

Replace the motor

Fasten the motor

Replace the retarder.

Adjust the angle or the distance of

the ratchet and pawl. The distance

between the ratchet and the pawl is

above 2mm.

Adjust the cabinet to acquire

balance.

Adjust the gap between the

balance ring and the outer tub.

No

If the connecting pipe or

the wire unit bumps

the outer tub?

No

The hanger seat is lack of oil,

Inject oil at the hanger seat.

19

Yes

Fix the connecting pipe and

the wire unit.

Page 20

Service Manual

Order No. TL1001S003V1.1

Too much noise in washing

6-2-8

Issue

Rev.

If the noise of the motor

is too much?

No

If the motor fastened tightly?

Yes

The pulsator is rubbing the

bottom of the inner tub

6-2-9. The tub rotates to one direction (in washing)

Start the no-water test

program;do no-water washing

Check if the drain motor works

Y

Adjust the paw spring

Y

Check if the paw

spring is unlocked

N

Adjust the

connecting arm of

the paw

Y

inserted into the two ratchet

Check if

the two paws are

simultaneously

N

Adjust the retracting

spring

Y

Check if the

retracting spring of the

retarder is

loose

Yes

No

Replace the motor.

Fasten the motor.

Add pulsator gasket.

Check

N

purple,blue and yellow

legwire of HMwire are inlayed to

the corresponding 1,2,3

if the

terminals of the drain

motor

N

Inlay the HMwire again

Y

the voltage between the 1,2

Measure

terminals of the drain

motor

Exist

Replace drain motor

Not exist

Measure

the voltage between

the purple and blue terminals of

the computer

sequencer

Exist

Replace the wire unit

Not exist

Adjust the

adjusting screw of

the brake lever

N

Replace the computer sequencer

Check if

Y

the gap between

the adjusting screw of the

retarder brake lever and the baffle

plate of the paw connecting

arm is too small

At this time please confirm if the drain motor works normally

N

Replace the retarder

20

Page 21

Se r vice Manual

Model No: TL1001S003V1.1

6-2-10

9. Brake time out

Issue

Re v.

Is the brake moment of the retarder

lower than 6N.m?

No

Is the reset spring of the retarder loose?

No

Is the gap between the connecting arm block

and the brake arm of retarder less

than 0.8mm?

No

Replace the retarder.

Yes

Yes

Yes

Adjust the brake moment.

Adjust the reset spring.

Check if the pawl can leave the ratchet for 2mm

up during spinning. If not, adjust the position of

the brake arm.

21

Page 22

Service Manual

Order No. TL1001S003V0

Chapter 7 WIRING DIAGRAM

Issue

Rev.

Black

Green

Blue

Blue

Blue

White

Motor

Red

Blue

Blue

Fuse

Hote Water

inlet valve

Cold Water

inlet valve

Retractor

Drain Pump

Red/White

Black

White

Pink

Grey

White

L

Yellow

Red

Program controller

Yellow

Yellow

Red/White

Red/White

Orange

Orange

Cover Switch

Stop Switch

Water Level

Sensor

Actual Circuit Diagram

Control panel seat

Computer sequencer

Cabinet

Wate

rl

e

vel senso

r

Re

O

O

r

r

d

a

a

/

nge

ng

Wh

e

i

te

Red/White

Red/White

D

ra

in Pum

p

Blue

R

e

d

/

W

h

i

t

e

Blue

Stop s

wi

tc

h

Ye

l

l

o

w

Mi

c

r

os

wi

t

c

h

Y

e

l

l

o

w

Retractor

White

motor

H

ot

e

Wat

er l

e

v

el

v

al

v

e

Black

Grey

Yellow

Blue

Blue

C

ol

DW

a

t

er

lev

e

l

val

v

e

White

Red

Red

White

ca

p

a

ci

t

o

r

22

White

Black

Page 23

Sincere Forever

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...