Haier A2FE635CFJRU, C2FE636CWJRU, C2FE637CXJRU, C2FE636CFJRU, A2FE637CXJRU Service Manual

...

Order No.Ref0902S006V0

◎2009(HAIER ELECTRICAL APPLIANCES COR. LTD)

All right reserved. Unauthorized copying and distribution is a violation of law。

SERV ICE MANUAL

MODEL: A2FE635CFJRU

C2FE636CWJRU

C2FE636CFJRU

C2FE636CSJRU

A2FE637CXJRU

C2FE637CXJRU

This service information is designed for experienced repair technicians

only and is not designed for use by the general public. It does not contain

warnings and cautions to advice non-technical individuals of potential

dangers in attempting to service a product. Product powered by electricity

should by serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the product or products dealt

with in this service information by anyone else could result in serious injury

or death.

WARNING

SERVICE MANUAL

Model:

2

Issue

Rev.

Contents

Table of Contents ··········································································································· 1

1. General Information ·································································································· 4

1-1.General guidelines ······························································································ 4

1-2. Important notice·································································································· 4

1-3. How to read this Service Manual ········································································ 6

2. Product Feature ········································································································ 7

2-1. Specifications ·········································································································· 7

2-2. External views ········································································································· 11

2-3. Major features ·········································································································· 14

3.Installation, adjustments and maintenance ···························································· 15

3-1. Door (Refrigerator door, Freezer door) ···································································· 15

3-2.Adjustable foot ·········································································································· 18

3-3. Maintenance ······································································································· 18

4. Disassembly ·············································································································· 20

4-1. A2FE635CFJRUFreezer door assembly ································································· 20

4-2. Display screen assembly ···················································································· 21

4-3. Air passage assembly ························································································ 21

4-4. Compressor assembly························································································ 23

4-5. Disassembly method of heating wire for defrosting ············································ 24

5. Control and display system ····················································································· 25

5-1. Control and display panel ························································································ 25

5-2. Function adjustment ··························································································· 25

5-3. Error code display and sensor positions ···························································· 28

6. Control principle of electronic component ···························································· 32

6-1. Fan cooling system ·································································································· 32

6-2. Ice maker system ······························································································· 32

6-3. Defrost function ·································································································· 32

SERVICE MANUAL

Model:

3

Issue

Rev.

6-4. Electromagnetic valve ························································································ 33

7. System flow principle ······························································································· 34

7-1. Refrigeration flow chart ····················································································· 34

7-2. Refrigeration flow scenograph ·········································································· 35

7-3. Air flow scenograph ·························································································· 36

7-4. Water supply flow scenograph ·········································································· 36

8. Circuit diagram·········································································································· 37

8-1. Brief principle diagram ······················································································ 37

8-2. Main control PCB diagram ················································································ 38

9. Quick check ··············································································································· 39

9-1. Self test model ·································································································· 39

9-2. PCB checkout ································································································· 40

10. Trouble shooting····································································································· 43

10-1.Abnormal phenomena ·····················································································43

SERVICE MANUAL

Model:

4

Issue

Rev.

Chapter 1 General Information

1-1. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts which

have been overheated or damaged by the short circuit. After servicing, see to it that all the protective

devices such as insulation barriers, insulation papers shields are properly installed. After servicing,

make the following leakage current checks to prevent the customer from being exposed to shock

hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatic Sensitive

1-2. Important notice

1-2-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to open the

units and disassemble the units. For example, we need to describe properly how to avoid the

possibility to get electrical shock from the live power supply or charged electrical parts (even the

power is off).

This symbol indicates that high voltage is present inside. It is dangerous to make any

king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance instructions in

the literature accompanying the appliance.

1-2-2. Be careful to the electrical shock

To prevent damage which might result in electric shock or fire, do not expose this component to rain

or excessive moisture. This component must not be exposed to dripping or splashing water, and

objects filled with liquid, such as vases, must not be place on top of or above the component

1-2-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. The following techniques

should be used to help reduce the incidence of component damage caused by electro static

discharge (ESD).

1-2-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the consumer

products industry at large to be environmentally responsible. Lead-free solder must be used in the

servicing and repair of this product.

SERVICE MANUAL

Model:

5

Issue

Rev.

1-2-5. Use the genewing parts (specified parts)

Special parts which have purposes of fire retardant (resistors), high-quality sound (capacitors), low

noise (resistors), etc. are used.When replacing any of components, be sure to use only

manufacture's specified parts shown in the parts list.

Safety Component

● Components identified by mark have special characteristics important for safety.

1-2-6. Safety Check after Repairmen

Confirm that the screws, parts and wiring which were removed in ordertoservice are put in the original

positions, or whether there are the portions which are deteriorated around the serviced places

serviced or not. Check the insulation between the antenna terminal or external metal and the AC cord

plug blades. And be sure the safety of that.

Insuration Test

1. Check if there is any leak of current.

2. Cut out the power supply before the repair to avoid an electrical shock hazard.

3. In the case of a live-line test, insulating gloves should be worn to avoid potential electrical

shock.

4. Confirm the rated current, voltage and capacity before testing with any kinds of instruments.

5. Watch if the upper door is open when you check something at a lower position.

6. Take out every part in the cabinet before moving the machine, especially things like panels

(e.g. glass shelf).

7. Please wear intact cotton gloves when repair any parts of the evaporator, so that scratches

by the sharp fins can be avoided.

8.

If there is a breakdown with the refrigeration system, please surrender the machine to

the service center, else the leaked refrigerant may pollute the atmosphere

.

9. The refrigerator use AC of 220~240V with a frequency of 50Hz.

10. A big fluctuation of voltage (exceed the range 220~240V) may cause a start failure of the

refrigerator, a burn-out of the control panel and compressor, or an abnormal sound from the

compressor in operation. In this condition an automatic voltage regulator over 750W should be added.

11. Take care not to damage the supply line. Don’t yank at the line; pull the plug out gently from

the receptacle. Don’t press the line under the cabinet or step on it. Take care not to roll on or damage

the supply line when moves the machine from the wall.

12. In the case of leakage of inflammable gases like carbon monoxide, open the door and

windows. Don’t pull out or insert the plugs of the appliance.

13. Don’t touch the refrigeration surface of the freezing compartment when the refrigerator is in

operation, especially when your hand is wet, else you may be glued to the surface.

SERVICE MANUAL

Model:

6

Issue

Rev.

14. Pull out the plug of power supply during clearance or power outage. Wait at least five

minutes to resume the power supply in order to prevent damage to the compressor caused by

continuous restart.

1-2-7. Photo used in this manual

The illustration and photos used in this Manual may not base on the finaldesignof products, which

may differ from your products in some way.

1-3. How to read this Service Manual

1-3-1. Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each icon

is described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable to the

reader, such as tips and tricks.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation, may

damageequipment, loosedata, get an unexpectedresultorhas to restart (part of) a procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides the reader to other places in this binder or in this manual, where he/she will find

additional informationonaspecific topic.

SERVICE MANUAL

Model:

7

Issue

Rev.

Chapter 2 Product Feature

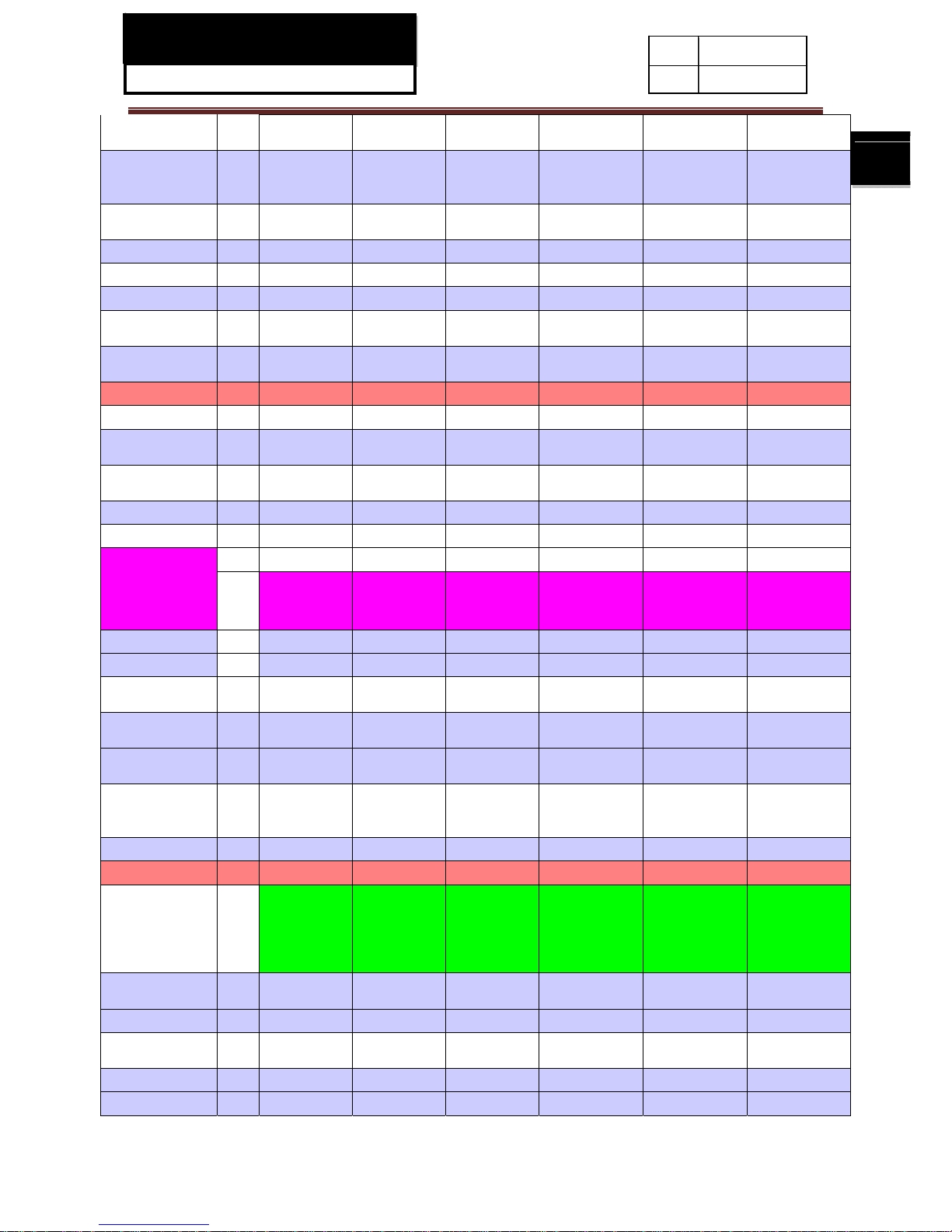

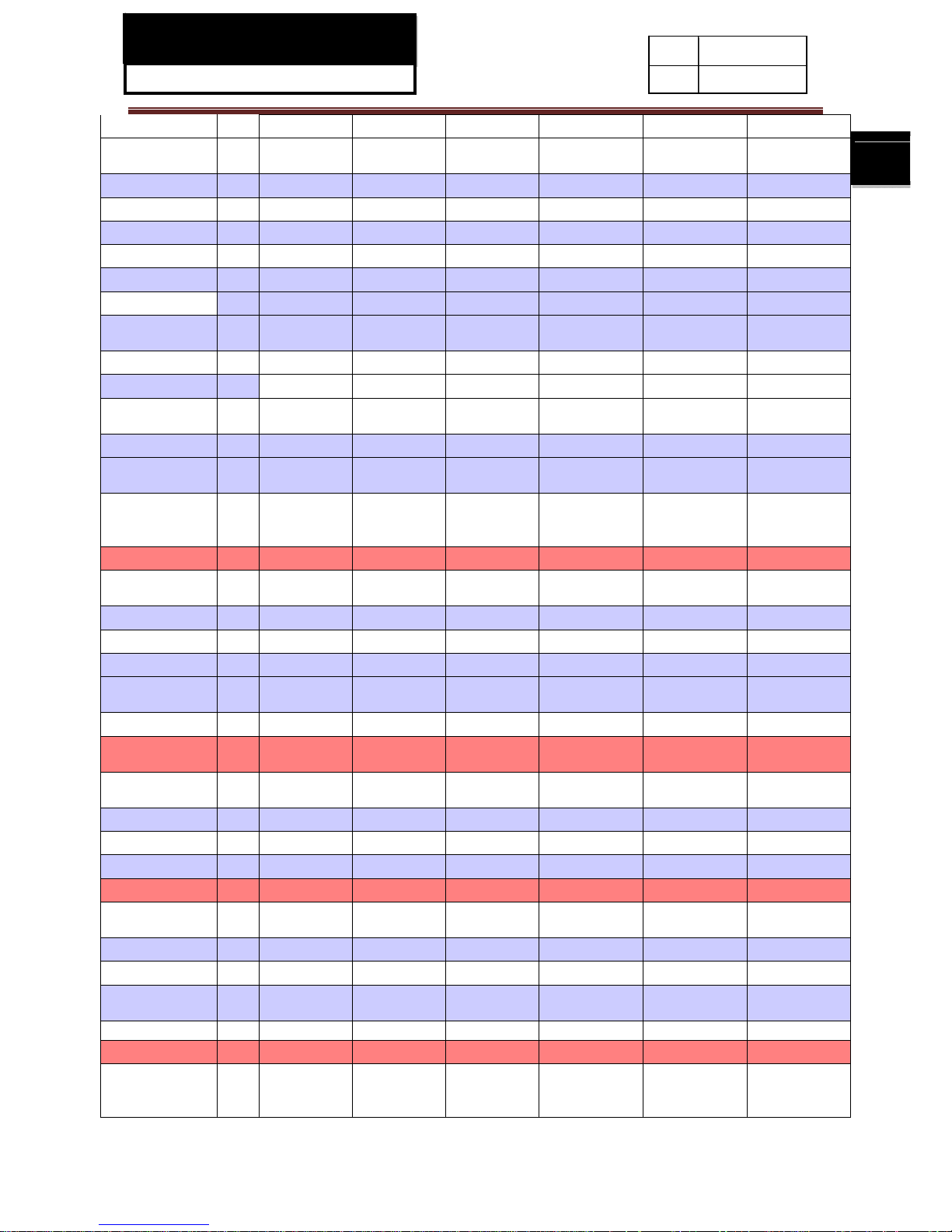

2-1. Specifications

Pictures

Model

A2FE635CFJRU C2FE636CFJRU C2FE636CSJRU C2FE636CWJRU A2FE637CXJRU C2FE637CXJRU

BEST GOOD GOOD GOOD

BEST GOOD

Product Properties

Product description

(Refrigerator/Freezer)

Refrigerator Refrigerator Refrigerator Refrigerator

Refrigerator Refrigerator

Type of appliance

(FS= freestanding /

BI= built-in)

FS FS FS FS

FS FS

Type of cooling

system(NF=no frost/

S=static)

NF NF NF NF

NF NF

Enegey Class A+ A+ A+ A+

A+ A+

Unit dimensions

( H / W / D)

mm 1905/595/670 1905/595/670 1905/595/670 1905/595/670

1998/595/672 1998/595/672

Total net capacity L 347 352 352 352

369 374

Climate class* SN/T SN/T SN/T SN/T

SN/T SN/T

Freezer compartment /

Star rating

4* 4* 4* 4*

4* 4*

Approvals

(VDE / TÜV / IMQ / NF

/ ÖVE / DEMKO etc.)

TÜV/GS (Rhl.) TÜV/GS (Rhl.) TÜV/GS (Rhl.) TÜV/GS (Rhl.)

- -

PCT PCT PCT PCT

PCT

PCT

Certifications

( CE / ISO 9001/2)

CE / ISO 9001 CE / ISO 9001 CE / ISO 9001 CE / ISO 9001

CE / ISO 9001 CE / ISO 9001

Rohs Y Y Y Y

Y Y

Key features

Gross capacity L 400 /400 400 400

Total net capacity L 347 352 352 352

369 374

Net capacity

refrigerator

compartment

L

201 201 201 201

223 223

My zone compartment L 47

47 47 47

47 47

Freezing capacity

kg/24h

12 12 12 12

12 12

Energy

consumption/year

kwh 348 353 353 353

376 381

SERVICE MANUAL

Model:

8

Issue

Rev.

Max storage time at

breackdown Freezer

Hours

13 13 13 13

13 13

Defrosting:

(M=manual;A=automati

c)

A A A A

A A

Ventilated fan motor in

Refrigerator

N N N N

N N

Frost free system Y Y Y Y

Y Y

Defrost water outlet Y Y Y Y

Y Y

Air circulating ventilator Y Y Y Y

Y Y

Kind of coolant

(R134a/R600a)

R600a R600a R600a R600a

R600a R600a

Foaming components

(R141b / R134a / C-P)

PU/ C-P C-P C-P C-P

C-P C-P

Technical data

Voltage / frequency V/Hz 220~240/ 50 220~240/ 50 220~240/ 50 220~240/ 50

220~240/ 50 220~240/ 50

Input power / mains

fuse minimum

W /A 120/ (DC) 120/ (DC) 120/ (DC) 120/ (DC)

120/ (DC) 120/ (DC)

Temperature range

(from>to)

°C

Refrigerator 2~8°C 2~8°C 2~8°C 2~8°C

2~8°C 2~8°C

Vegetable Crisper 2~8°C 2~8°C 2~8°C 2~8°C

2~8°C 2~8°C

My zone

(3

mode :Thaw ;Q,cool;Ch

iller)

yes/no

Y Y Y Y

Y Y

Tem -2~+3° -2~+3° -2~+3° -2~+3°

-2~+3° -2~+3°

Chiller

yes/no

Y Y Y Y

Y Y

Chiller °C -2~+3° -2~+3° -2~+3° -2~+3°

-2~+3° -2~+3°

Freezer

-16

~-24°C

-16 ~-24°C -16 ~-24°C -16 ~-24°C -16 ~-24°C

-16 ~-24°C -16 ~-24°C

Features:

(DIN 8950 resp. 8953)

Energy consumption

(EN 153) per / 24h

kWh 0.95 0.96 0.96 0.96

1.030136986 1.043835616

Cooling system:

K=Compressor /

In=Inverter compressor

In In In In

In In

Max noise level

dB(A)

40 42 42 42

40 42

Aesthetics

Colours: W=white

S=silver

B=Obsidian

X=stainless steel

F=SS looking

F F S W

x x

Cabinet / Door / Top /

Frame (w / c)

S/F/B/B S/F/B/B S/S/S/S W/W/W/W

S/x/S/S S/x/S/S

Door:

F= flat / R= rounded /

S= streamline

R R R R

R R

Inside colour W W W W

w w

Bottle compartment n° 3 3 3 3

4 4

SERVICE MANUAL

Model:

9

Issue

Rev.

Hinged (r =right l =left) /

reversible

R/R R/R R/R R/R

R/R R/R

Lock

yes/no

N N N N

N N

Freezing compartment

integrated with door

Y N N N

Y N

Shelves:

Number Fridge /

Freezer

3/ - 3/ - 3 / - 3 / -

3 / - 3 / -

Type (gr=grill / g=glass

/ p=plastic)

g g g g

g g

Colourw-white / b=blue

/ g=green / t=transpar.

t t t t

t t

Adjustable (Y=yes /

N=not)

yes/no

N N N N

Y Y

Foldable Shelf

yes/no

N N N N

Y Y

Bottle Rack

yes/no

N N N N

Y N

Drawers:

Plastic drawers (fully

freezing comp.)

n°. 2 4 4 4

2 4

half freezing comp n°.

Colour of drawer

(w=white/t=transp./g=gr

een)

w w w w

w w

Crisper:

Chiller / Meat (salad

crisper) transparent

/ white

t t t t

t t

Vegetable crisper(s)

transparent / white

t t t t

t t

Equipment &

accessories

Control panel:

Power on/off Y Y Y Y

Y Y

Interior / exterior Exterior Exterior Exterior Exterior

Exterior Exterior

Display type

Display on door Display on door Display on door Display on door

Display on door Display on door

Control Type LED LED LED LED

LED LED

Control lamps

green& yellow / white

white white white white

white white

Over temperature

alarm freezer LED /

Acoustic

- - - -

- -

Door open alarm fridge

LED / Acoustic

A A A A

A A

Fast freeze switch

/-function

Y Y Y Y

Y Y

Fast cooling Y Y Y Y

Y Y

Holiday function Y Y Y Y

Y Y

Deodorizing N N N N

N N

UV-light N N N N

N N

Icon-sliver N N N N

N N

SERVICE MANUAL

Model:

10

Issue

Rev.

Antibacteoria N N N N

N N

VC(Vitamin C,keep

fresh longer)

N N N N

N N

Interior light W

LED light

Type

Full Top Points Top Points Top Points

Top Points Top Points

Freeze pack(s) n° 2 3 3 3

2 3

ice maker N N N N

N N

Ice cube tray(s) n° 1 1 1 1

1 1

Water dispenser N N N N

N N

Water dispenser

with/without gas

N N N N

N N

Butter holder N N N N

Egg trays Y Y Y Y

Y Y

Adjustable feet front /

rear

n° 2 / - 2 / - 2 / - 2 / -

2 / - 2 / -

Castors front / rear -/x -/x -/x -/x

-/x -/x

Length of cable/incl.

plug

cm 200 200 200 200

200.000 200.000

Condenser

Backwall / Integrated /

Under

U U U U

U U

Product dimensions

Unit dimensions

( H / W / D)

mm 1905/595/670 1905/595/670 1905/595/670 1905/595/670

1998/595/670 1998/595/670

Depth Without handle mm 670 670 670 670

672 672

Depth with open door mm 1204 1204 1204 1204

1204.0 1204.0

Door open angle n° >125 >125 >125 >125

>125 >125

Crisper fully extension

with door open angle

n° >125 >125 >125 >125

>125 >125

Net weight kg 84 80 80 80

86 83

Packing dimensions

& loadability

Packing dimensions

(H / W / D)

cm 200/66.3/74.1 200/66.3/74.1 200/66.3/74.1 200/66.3/74.1

210/66.3/74.1 210/66.3/74.1

Gross weight kg 92 88 88 88

96.0 93.0

40 ' Container load pcs 54 54 54 54

54 54

40 ' HC Container load pcs 71 71 71 71

54 54

Recycling symbols

Packing materials /

Recycling simbols (RS)

RS RS RS RS RS

RS RS

Cartonweight in gr 8Kg 8Kg 8Kg 8Kg

8kg 8kg

Polystyreneweight in gr 06 1.6 Kg 1.6 Kg 1.6 Kg 1.6 Kg

1.6kg 1.6kg

Polyethylene foil

weight in gr

04 0.3 Kg 0.3 Kg 0.3 Kg 0.3 Kg 0.3 Kg 0.3 Kg

Wood weight in kg - 0.000 0.000 0.000 0.000 0.000 0.000

Service

Users instruction

(languages)

D / F / I / GB / E /

P /

NL/PL/RO/CZ/HU

D / F / I / GB / E /

P /

NL/PL/RO/CZ/HU

D / F / I / GB / E /

P /

NL/PL/RO/CZ/HU

D / F / I / GB / E / P /

NL/PL/RO/CZ/HU

RUSSIAN RUSSIAN

SERVICE MANUAL

Model:

11

Issue

Rev.

SERVICE MANUAL

Model:

12

Issue

Rev.

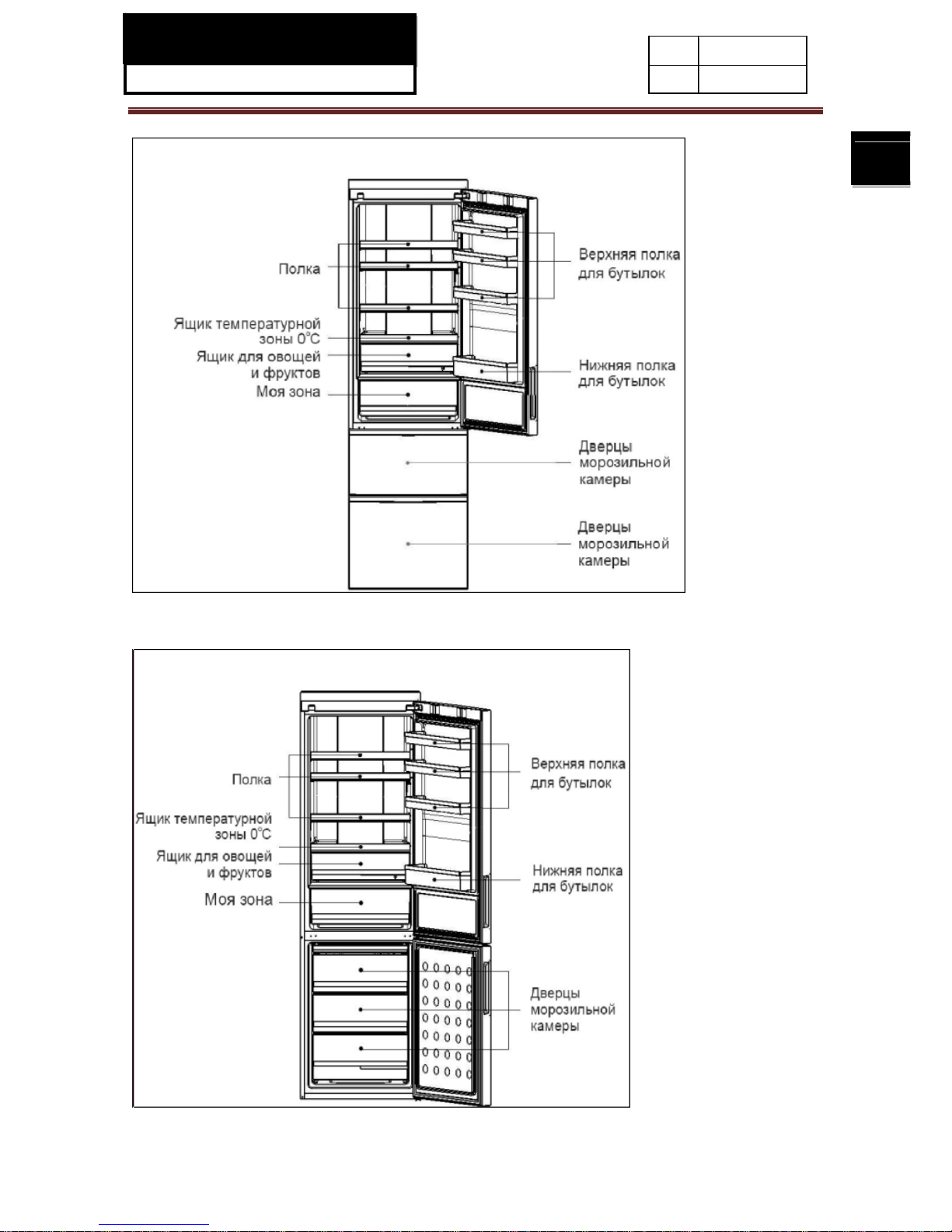

2-2. External views

2-2-1.A2FE635CFJRU

2-2-2.C2FE636CFJRU /C2FE636CSJRU/C2FE636CWJRU

SERVICE MANUAL

Model:

13

Issue

Rev.

2-2-3.A2FE637CXJRU

2-2-4.C2FE637CXJRU

SERVICE MANUAL

Model:

14

Issue

Rev.

2-3. Major features

2-3-1.Features

1. New appearance of three stainless steel doors, fashionable and luxurious, satisfies the

demands of the modern high-income families. Fully closed freezing system and drawer storage

can avoid food tainting, keep cold and are energy-saving. As warm air can't easily enter into the

storage area when opening the door.

2. Fully frequency control: it integrates the techniques of frequency conversion, de-noise,

energy-saving and quick-freezing which can benefit mutually to make better performance. The

refrigerator can automatically adjust the working efficiency of the frequency conversion

compressor by comparing the inside temperature with the setting temperature and keeps the

refrigerator in the optimized status all the time.

3. Two functions are added to the Chiller chamber: defrost(D-Frost)、quick cool(Q-Cool), when

defrost function works, the temperature of the Chiller chamber will reach to +1℃; When quick cool

function works, the temperature of the Chiller chamber is -1℃。

4. Cool wind but no frost: adopting fully air cooled refrigeration system, deep cooling and quick

freezing.

5. Quick cool function: the refrigerating chamber can be adjusted to quick cool status, after

being at this status, it will automatically turn on the function of quick cool and make the food go

through the max ice crystal zone and thus effectively reserve the nutrition.

6. Holiday function: when you are out for holiday, refrigerator will run at the low energy

consumption to make sure there's no odor in the refrigerating chamber and guarantee soft

freezing and the normal storage of frozen food.

7. LED display: adopting dynamic LED to display the operational situation of refrigerator.

8. Sliding shelf, folding bottlerack: there are designs of sliding shelf and folding bottlerack for the

refrigerating chamber to make storing and taking articles easier.

9. LED light guide plate illumination: adopting the technique of light guide plate illumination, the

light is soft, even, bright and no illumination dead angle.

10. Double-drawer freezing door body: the freezing chamber adopts the double-drawer door

body which can be opened straightly and completely. It makes storing and taking food easier. The

imported slide rail with automatic door closing device can save labor as well as electric power.

SERVICE MANUAL

Model:

15

Issue

Rev.

2-3-2.Explanation of The Models

A2 F E 7

35

PRODUCT FAMILY

COOLING

TECHNOLOGY

USER

INTERFACE CLASS

VOLUME

A1 = 3D Gen 1

F= FULL NO

FROST

M= Mechanical

9= A++++

05 = 45-54 lt

A2 = 3D Gen 2

S= DIRECT

COOLING

S= Semi

Electronical

8=A+++

14 = 135-144 lt

C1 = 2D Gen 1

T= HYBRID

E= Electronic

(= display on

the door)

7=A++

21 = 195-204 lt

C2 = 2D Gen 2

6=A+

31 = 305-314 lt

D1= Double doors Gen 1

32 = 315-324 lt

33= 325-334 lt

35 = 345-354 lt

36 = 355-364 lt

C X J

SPECIAL FEATURES COLOUR HANDLES

A = Without chiller

W = White J= Recessed/integrated

C = Chiller

T = Titanium T= External

I = Automatic Ice Device / ice maker

with water tank in the fridge

S = Silver E= Easy handles

T = ATD (Adj. T° Drawer)

X = Inox (Stainless steel)

W = Water through the door

G = Glass (Transparent

Door)

GW = Glass white

GR = Glass red

GB = Glass black

GS= Glass stainless steel

N = Black SS (VCM)

A = Aluminium SS (VCM)

B = Obsidian

F = Inox looking

SERVICE MANUAL

Model:

16

Issue

Rev.

Chapter 3 Installation, adjustments and maintenance

3-1. Door (Refrigerator door, Freezer door)

3-1-1.Removing and replacing the right door of refrigerator compartment

3-2. Water pipe

3-3. Water supplied time

A) Unscrew the four screws which secure the front panel

located at the top;

B) Push the front panel upward to withdraw the front panel;

C) Pull the hinge cover upward;

D) Disconnect the two connected terminals of electric cable;

E) Push the small cover on the right side of the front panel by

one hand to withdraw the small cover;

SERVICE MANUAL

Model:

17

Issue

Rev.

A) Remove the top hinge from the refrigerator door;

B) With the aid of pliers, unscrew and remove the

screws on the top of the hinge, then loosen and remove

the pin on the bottom of the hinge; then re-install the

A) transfer the display cable located in the slit above

the refrigerator door from left to right, always keeping

it inside the slit, and connect it to the electric cable

which is extending from the cabinet above the cabinet;

A) Click-fit the hinge cover, firstly to clip the electric

cable into the hinge cover, then clip it to the hinge;

B) install the small cover to the right side of the front

panel from bottom to top direction;

C) Click-fit the front panel from top to bottom

direction, applying pressure on several points to secure

the bottom clips being inserted into the slit of the

cross beam;

D) secure it with four screws;

E) fit the clips on the left sides(previously removed);

F) Click-fit the front panel onto the refrigerator door;

SERVICE MANUAL

Model:

18

Issue

Rev.

3-1-2.Removing and replacing the right door of freezer compartment

(For C2FE636CFJRU /C2FE636CSJRU/C2FE636CWJRU/C2FE637CXJRU)

Directions on how to dismantle and install the middle and lower hinges

⑴ Detach the 3 screws affixed to the middle hinge and remove the hinge. Unscrew the hinge

axis and then screw it from the reversed direction.

⑵ Remove the upper and lower doors separately. Dismantle the stop blocks on the bottom of

the doors. Turn them by 180 degrees and refit them on the other side.

⑶ Tilt the refrigerator to the required angle. Detach the screws fixing the lower hinge and

remove the hinge.

⑷ Fix the lower hinge to the bottom of the other side of the cabinet. Then, mount the lower door

on the lower hinge.

⑸ Take out the 3 hole plugs on the other side of the cabinet.

Turn the middle hinge by 180 degrees and install it on the other side of the cabinet. Attach the 3

screws removed in step 1. Mount the 3 hole plugs into the holes where the hinge is seated

originally.

Note: For 3-door refrigerators, the operation concerning the lower hinge is not needed.

Middle hinge

Screws affixed to

the middle hin

g

e

Middle hinge

axis

Hole plug

Screws affixed to

the lower hinge

lower hinge

Before change

Refrigerator

After change

SE

RV

Model:

3-2. Ad

Level the

placed on

foam pac

k

shorten t

h

3-3 Ma

i

3-3-1.D

e

Def

r

Thefre

Cle

a

There

f

safety,un

p

Clean

t

Drywa

t

Alway

s

Th

da

ro

cpro

D

o

si

mdet

D

m

e

Wbre

3-3-2.M

e

Even

i

ICE

M

justable

cabinet. Th

an uneven

ing materi

a

e adjustabl

e

ntenan

c

frosting a

n

ostingt

h

ezer defros

t

ning

rigerator

lugthepow

e

herefrigerat

erdroplets

o

keepthedo

o

erefrigerato

magethe fl

o

kingittoavo

i

Donotspra

y

perty.

notcleanwi

t

ilarorganic

ergent toa

v

onot touc

h

talparts.

hencleanin

g

akduetosu

d

asures o

n

nsummer,f

o

AN

U

foot

e refrigerat

o

surface, fl

a

l as a pe

d

feet of the

e

dcleaning

efreez

e

sautomatic

a

should

b

cordbefor

e

orwitha soft

ntherefrige

r

r gasketcl

e

r isvery

h

or.Keep t

h

ddamageto

or flus

h

h hardbrus

solutions

,

oiddamage

thecoldm

, donotcle

den tempe

r

power in

t

odmay be

s

AL

r should b

e

t strong an

estal. If th

e

refrigerator

r

lly. Noman

u

ecleaned

r

e

cleaningth

e

clothor spo

n

ator surfac

e

an

.

eavy.Whe

ner

efrigerat

o

the floor.

therefriger

a

h, wirebrus

acidor

a

or warm w

a

etalparts

w

anthecoldgl

aturechan

g

erruption

tored inthe

r

placed on

d fire- resis

refrigerat

o

by turning

t

al operatio

gularlytopr

e

efrigerator.

gewithwar

m

swith adry

s

youaremo

v

r uprightd

u

torwithwat

e

h, deterge

n

lkalinesolu

ter and a

m

ithwethand

ass shelv

e

eandcause

efrigerator

a flat and

s

tant materi

a

r is slightl

y

hem clock

w

nisneeded.

ventbadst

o

water(mild

oft cloth.

ingitforclea

n

ringmoving

toavoidim

p

tpowder, g

a

tions.Pleas

e

ild deturge

n

s;otherwise

y

swithwarm

w

personal in

j

f

or afewho

u

I

s

R

olid surfac

e

ls must be

unstable,

ise or antic

l

red

f

detergent

m

ingorrepair

s

.Donotmov

e

actonitsele

c

soline,am

y

cleanwith

t.

ourskinma

ater. Oth

e

ury orprop

e

rsafterapo

w

sue

ev.

. If the refr

i

used. Nev

e

you can le

n

ockwise.

oododors.

ay be add

e

,takecaren

the refrige

tricalinsula

lacetate, a

c

special r

e

ystick ont

h

rwisethegl

a

rtyloss

er interru

p

gerator is

r use the

gthen or

For

d).

ot to

rator by

tion

etoneand

frigerator

e cold

ssmay

tion. If a

19

SE

RV

Model:

poweri

Donot

p

fewtim

Ifprior

n

somei

c Asto

3-3-3.St

o

Ifthe r

e

water

s

Keept

h

badod

o

To

etur

3-3-4. B

e

Ifleavi

n

waitfo

r

anyfo

o

dropb

e

syste

m

jointbr

e

3-3-5. M

o

Unplu

g

Remo

v

Secur

e

mova

b

Donot

t

refrige

Donot

m

Ne

v

ICE

M

nterruption

o

utaddition

a

esas possi

b

oticeofapo

w

eandputitin

stemperatu

rageperiod

a

pping us

e

frigeratorw

i

ource,and

ce r

efriger

a

rs.

nsurethes

e

ned off unl

e

fore leavi

gonanexte

n

thefrostto

dremaining

i

low0oC,ple

a

.Otherwise

s

aks.

ve the re

f

therefriger

a

eallfood.

theshelves

a

leparts inth

e

iltthe

ratingsyste

m

ovethe ref

erplacethe

AN

U

ccurs, plea

s

lfoodintoth

e

le.

erinterrupt

i

acontaineri

n

eintherefri

g

ndedible q

u

llnotbeuse

d

leanitwithth

tor doorop

e

rvicelifeof

t

ss itisnece

s

ng for a h

o

ded vaca

t

melt. Aft

e

nthe comp

a

seaska

eriousprop

rigerator

tor.

ndcrisperi

n f

reezer wi

t

refrigera

t

.

igerator by

i

refrigeratin

g

AL

ecall thep

o

refrigerator

onis given

the topofth

e

eratorwill

ality offoo

d

for anexten

emethodde

s

n topreve

n

herefrigera

t

sary.

liday or v

a

ion,please

d

rwards,cle

a

rtment fro

m

ertylossma

y

thefridgest

o

h adhesive

t

ormoretha

n

tshandleto

a

horizontall

y

wercompa

n

duringap

o

andtheinte

fridgestor

a

riseduring

a

willbereduc

ded period,

cribed abo

v

tanyfoodre

or, itis re

c

cation

isconnectth

nanddryth

e

producing

qualifieds

e

becausedd

ragecomp

a

ape. Close

t

45degrees

(

voidpropert

down.

ytoaskabo

u

wer interr

u

rruptiondur

a

gecompart

m

power i

n

ed.

pleaseunpl

e.

mainingin

t

ommende

d

e powera

n

interior, a

n

badodors. I

rviceperso

n

ueto ov

e

tmentasw

e

hedoor and

angle

damageor

I

s

R

tthe interru

p

ptionandtr

y

tionis ove

r

ent.

terruptiono

r

ugthepowe

r

hecompart

m

thatthere

f

dwatersour

c

dkeepthe

f

theroomte

m

todrainthe

w

rflowofwat

e

ll asth

e

securewith

tovertic

a

personalinj

u

sue

ev.

tionduratio

n

toopen th

e

24 hours,

m

otherfailure

s

cord, disco

n

ent fromp

r

igerator n

o

e. Remo

v

dooropen

peratureis

aterinthew

a

rif thew

a

shelvesan

d

adhesiveta

p

l)toavoidd

a

ry.

.

door as

ake

,the

nect the

oducing

tbe

eanyfood;

toprevent

expected

tersupply

terpipeor

other

e.

magingthe

20

SERVICE MANUAL

Model:

21

Issue

Rev.

Chapter 4 Disassembly

4-1.A2FE635CFJRU/A2FE637CXJRU Freezer doorassembly

4-1-1. Disassembly of the freezer’s upper door body

① ②③

① Open upper drawer of the

freezer;

② Make the front-ends of the

drawer and the tray lean

upward a little according to

illustration ②;

③ Take out the drawer and

the tray from the side;

④⑤⑥⑦

④Turn the decoration caps of

the slide rail outward, and

then take off the 2 decoration

caps;

⑤ Use Phillips screwdriver to

take off the left and right

screws.

⑥ As shown in illustration ⑦,

catch and pluck the bracket

from the slide rail, , then take

off the door body;

4-1-2. Disassembly of the freezer’s bottom door body

①

②③④

①Open the bottom drawer of

freezer;

② As shown in the

illustration, make the front-end

of the tray lean upward a little,

then take off the tray from the

top;

③ As shown in illustration ④,

make the back of the drawer

lean upward, then take off the

drawer from the top;

⑤ Use Phillips screwdriver to

take off the left and right

screws.

⑥ As shown in illustration ⑦,

catch and pluck the bracket

from the slide rail, then take

SERVICE MANUAL

Model:

22

Issue

Rev.

⑤⑥⑦

off the bottom door body,;

4-2. Display screen assembly

①②③④

Press a sucker onto the

middle of the display screen

gently, and take off the display

screen from the door body of

the refrigerating chamber, and

then take apart the terminal.

4-3.Air passage assembly

4-3-1. Disassembly of the air duct of refrigerating chamber

① ②③

① Carefully take down the

lampshade;

② Use Phillips screwdriver to

take off the 2 screws on the

top of the refrigerating air

duct;

③ Unplug the terminal

connectedwith the

refrigerating air duct and take

off the refrigerating air duct.

4-3-2. Disassembly of the air duct of the chiller chamber

①②

① Use Phillips screwdriver to

take off the left and right

screws of the air duct of the

chiller chamber;

② Unplug the 2 terminals

connected with the air duct of

the chiller chamber and take

off the air duct of the chiller

chamber.

4-3-3. Disassembly of the air door

SERVICE MANUAL

Model:

23

Issue

Rev.

① ②

① Take the air duct of the

chiller chamber out of the cover

board;

② Unplug the terminal of the

air door and take off the air

door.

4-3-4. Disassembly of the air duct of the freezer

①②③④

① Use Phillips screwdriver to

take off the 5 screws of the air

duct of the freezer;

② Pull out 4 slide rails and

uplift the bottom of the air duct

slightly, make the right side

onward a little and take off the

air duct of the freezer a little;

③ Unplug the 2 terminals

connected with the air duct of

the freezer;

④ Make the air duct of the

freezer slide from the bottom.

4-3-5. Disassembly of the freezer fan

①

① Prize up the upper and

down cover boards of the

air duct of the freezer

gently from the side;

②

② Take out the fan cable,

open the claw of the fan gently

and take off the freezer fan.

SERVICE MANUAL

Model:

24

Issue

Rev.

4-4. Compressor assembly

Illustration of the compressor chamber components:

Material list:

No. Name of material Specific No. Qty.

1

Self-tapping screw 0060112284 3

2

Compressor NX1116Y(Include Capacity ) 0060702332 1

3

Supporting plate assembly of compressor 0060830615 1

4

SCREW 0060600186 1

5

Evaporating utensil 0060222122 1

6

DAMPING MAT 0060220107 1

7

Heating pipe of evaporating utensil 0060703847 1

8

POWER CORD FIXING RUBBER 0060405012 1

SERVICE MANUAL

Model:

25

Issue

Rev.

4-5.Disassembly of the heating wire for defrosting

①②③

① Take out the 2 plug

terminals connected with the

defrosting cable in the red

circles;

② As the red circle shown in

illustration ② , gently break

apart the 2 chips which are

used to fix the defrosting and

heating wire, and then get the

defrosting and heating wire to

go through the right chip;

③ Make the defrosting and

heating wire go through the

left chip.

SERVICE MANUAL

Model:

26

Issue

Rev.

Chapter 5 Control and display system

5-1. Control and display panel

5-2. Function adjustment

Fridgestorage temperaturesetup

Press key A1 repeatedly until indicators B inlluminates; press A2 to set the refrigerator

temperature. ,corresponding indicators B and D begin to flash simultaneously. The temperature

increases by 1℃ by each single press; The refrigerator setting position sequences through

“2”-“3”-“4”-“5”-“6”-“7”-“8”-“2”. The refrigerator temperature range is from a minimum value of 2℃

to a maximum value of 8℃. Stop to press A2 to confirm the set temperature.

Freezerstoragetemperaturesetup

Press key A1 repeatedly until indicators C inlluminates; press A2 to set the freezer temperature.

corresponding indicators C and D begin to flash simultaneously. The temperature reduces by 1℃

by each single press; The freezersetting sequences through “-16”- “-17”- “-18”- “-19”- “-20” -

“-21” -22”- “-23”-“-24”-“-16”. The freezer temperature ranges from a minimum value of -24℃ to a

maximum value of -16℃. Stop to press A2 to confirm the set temperature.

Supercool

SERVICE MANUAL

Model:

27

Issue

Rev.

Press key A3 repeatedly until indicators E begin to flash; press A4 to confirm the activation of the

Super Cooling function. This function can be disabled by repeating the activation procedure

manually. This function will be automatically disabled when temperature drops below minimum

level.

In this mode, the Super Cool function will be disabled by the operation of setting the refrigerator

temperature.

SuperFreeze

Press key A3 repeatedly until indicators G begin to flash; press A4 to confirm the activation of the

Super Freeze function. This function can be disabled by repeating the activation procedure

manually. This function will be automatically disabled after 56 hours.

In this mode, the Super Freeze function will be disabled by the operation of setting the freezer

temperature.

HolidayFunction

Press key A3 repeatedly until indicators I begin to flash; press A4 to confirm the activation of the

Holiday Function. This function can be disabled by repeating the activation procedure manually. In

Holiday mode, the refrigerator compartment operates at a temperature of 17℃ automatically.

In this mode, the Holiday Function will be disabled by the operation of setting the refrigerator

temperature.

My Zone Q-cool Function

Press key A3 repeatedly until indicators F begin to flash; press A4 to confirm the activation of the

My Zone Q-cool Function. This function can be automatically disabled by choosing the other

functions of My Zone box.

My Zone D-Frost Function

Press key A3 repeatedly until indicators H begin to flash; press A4 to confirm the activation of My

Zone D-Frost function. This function can be automatically disabled by choosing the other

functions of My Zone compartment.

My Zone Chiller Function

Press key A3 repeatedly until indicators J begin to flash; press A4 to confirm the activation of My

Zone Chiller Function. This function can be automatically disabled by choosing the other functions

of My Zone compartment.

Note: Among the three functions of My Zone compartment, one of the functions must be

activated.

SERVICE MANUAL

Model:

28

Issue

Rev.

DisplayControl

Thedisplayscreen willturnoff automatically 30 seconds after anoperationisfinished.Itwillbelitup by

openingthe dooror pressinganykey. (Alarmdoesnotlightupthedisplayscreen)

Door

OpeningAlarm

Whentherefrigeratordooris open formorethan3minutes, thebuzzerwillsoundbeepsall the time.

Thebuzzercanbesilencedbyclosingthedoor or pressing any keys. If the refrigerator door is left open

for over 7 minutes, the internal light automatically switches off.

Turningoff/on theRefrigerator

When the refrigerator is working, if you press key A4 for 5 seconds, the whole refrigerator will

be switched off. The buzzer will begin to beep after pressing key A3 for 5 seconds. The whole

refrigerator will stop to work after the beep.

When the refrigerator is switched off, if you press key A4 for 5 seconds, the relevant indicator

lights up, the refrigerator begins to operate.

Note: The refrigerator needs to be emptied before operating this function; this operation does

not equivalent to tuning off the power.

SERVICE MANUAL

Model:

29

Issue

Rev.

5-3. Error code display and sensor positions

When the refrigerator runs abnormally, it can enter into the mode of malfunction check by manually

adjusting the display board.

Entering method: Open the refrigerator door,after the display board is lighted, press the key of “Temp

Zone”, and at the same time press the key of “Temp Set” 5 times to enter into the mode of malfunction

code and sensor temperature display. After entering into this mode, it will display the malfunction code

in the temperature display area according to display priority level. Press the key of “Temp Set” to

display next code. After the malfunction code is displayed, every time you press the key of “Temp Set”,

it will display AT SNR, R SNR, S SNR, F SNR, D SNR practical temperatures one by one. Notes: if no

malfunction, then it will display the practical temperatures of each sensor directly after entering. The

following table shows the display methods of each sensor:

Sensor Display method Displayed icon

RT SNR

All the icons in the temperature

display area are dark.

R SNR

The R area is lighted among all

the icons in the temperature

display area.

S SNR

The R area is lighted and

flashing among all the icons in

the temperature display area.

F SNR

The F area is lighted among all

the icons in the temperature

display area.

D SNR

All the icons are lighted in the

temperature display area.

SERVICE MANUAL

Model:

30

Issue

Rev.

Notes: when checking the practical temperature of each sensor, distinguish the name of the presently

displayed sensor according to the above table. The temperature display area of “-88” displays the

integer figures of the practical temperature of the current sensor. One decimal figure of the practical

temperature is displayed through 4 functional icons as shown in the following table:

Represent

ative No.

Displayed icon Lighted

icon

Represent

ative No.

Displayed icon Lighted icon

0.0

None

0.5

S-Cool + D-Frost

0.1

S-Cool

0.6

Q-Cool + D-Frost

0.2

Q-Cool

0.7

S-Frz.+ D-Frost

0.3

S-Frz.

0.8

S-Cool + S-Frz. +

D-Frost

0.4

D-Frost

0.9

Q-Cool + S-Frz. +

D-Frost

Log-out method: after entering into this mode, press the key of “Temp Zone” again for 3seconds to log

out from this mode. If there’s no key press operation for 2minutes after entering into this mode, it will

log out automatically.

SERVICE MANUAL

Model:

31

Issue

Rev.

Correspondence table of refrigerator malfunction codes:

NO. Item Code Content

Position of

sensor

1 RT SNR error F2 RT SNR short circuit or open circuit Door body

2 R SNR error F3 R SNR short circuit or open circuit

Air duct of

refrigerating

chamber

3 F SNR error F4 F SNR short circuit or open circuit

Air duct of

freezerchamb

er

4 S SNR error F5 S SNR short circuit or open circuit

Air duct of

chiller

chamber

5 D SNR error F6 D SNR short circuit or open circuit Evaporator

6 Communication error E0

No signal,More than 2 minutes

/

7 F FAN error E1

No signal,More than 10 seconds

/

8 C FAN error E2

No signal,More than 10 seconds

/

9 Defrosting error Ed

D SNR Can’t reach 8℃,90 minutes

/

SERVICE MANUAL

Model:

32

Issue

Rev.

Graphic display of the sensor location

Name of sensors Distance to the

top (mm)

Distance to the right

side (mm)

Distance to the

left side (mm)

Environment temperature sensor

13 286 309

Refrigerating sensor

390 194 401

Freezing sensor

1270 112 483

Chiller sensor

912.5 203 392

Defrosting sensor

1275 461 134

Fridge storage

temperature sensor

Ambient

temperature sensor

Freezer storage

tem

p

erature sensor

Defrosting

temperature sensor

Chiller

temperature sensor

SERVICE MANUAL

Model:

33

Issue

Rev.

Chapter 6 Control principle of electronic component

6-1. Fan cooling system

(1)Air escaper’s open and close is controlled by fridge sensor R SNR.

(2)Air escaper is closed firstly and then opened once, then open or close of air escaper is controlled

according condition (1).

(3)If air escaper is closed more than an hour, it will be opened at a time. Then open or close of air

escaper is controlled according fridge sensor R SNR.

6-2. Ice maker system

6-3. Defrost function

Refrigerator will start defrosting for the 1st time after 8 hours of the initial operation.

After refrigerator runs normally, the refrigerator will start defrosting after 30 hours’ operation when the

environment temperature is over 28℃; or after 49hours’operation when the environment temperature

is not over 28℃.

When the refrigerator runs normally, the compressor continuously runs for 90minutes, or after

defrosting, the compressor continuously runs for 180minutes, or the air door of the refrigerating

chamber continuously opens for 60minutes, or the temperature of the freezing sensor is over -5℃ and

the temperature of the refrigerating sensor is equal or higher than the sum of the set refrigerating

temperature and 6℃, when the environment temperature is over 28℃, the refrigerator will start

defrosting after 12hours’ operation. When the environment temperature is equal or lower than 28℃,

the refrigerator will start defrosting after 25hours’ operation.

During the process of turning on the compressor, the air door of the refrigerating chamber never

reaches to the turning off point, and then the refrigerator will start defrosting after 8hours.

When the temperature of the defrosting sensor reaches to 8℃ during defrosting, the refrigerator will

log out of defrosting mode.

The compressor is stop and fridge air escaper is close when defrosting.

If the defrosting time is over 90minutes, the refrigerator will start defrosting control after 5hours’

operation, until the temperature of the defrosting sensor reaches to 8℃ in 90minutes, then the

refrigerator starts defrosting control normally.

The product can enter into defrosting mode, and exit defrosting mode after the defrosting time is more

SERVICE MANUAL

Model:

34

Issue

Rev.

than 90 minutes, when the defrosting sensor malfunction (short circuit or open circuit).

If defrosting time is more than 90 minutes and the defrosting sensor temperature can’t reach 8ºC, the

product will disconnect defrosting heater, and display ED on fridge display area under malfunction

mode until in some defrosting cycle the defrost sensor temperature reach 8 ºC.

If the product is set to enter into fast freezer or fast fridge, the icon of fast freezer or fast fridge will light,

but the defrosting process will go on, fast freezer or fast fridge mode will not execute until finishing this

defrosting cycle. The surplus defrosting time is not reckoned in the time of fast freezer or fast fridge.

6-4. Electromagnetic valve

SERVICE MANUAL

Model:

35

Issue

Rev.

Chapter 7 System flow principle

7-1. Refrigeration flow chart

The refrigeration system of direct cooling single-system cooler belongs to the category of a

single-temperature and single-control refrigerating system with one evaporators and is controlled by a

single temperature control.

SERVICE MANUAL

Model:

36

Issue

Rev.

7-2. Refrigeration flow scenograph

SERVICE MANUAL

Model:

37

Issue

Rev.

7-3. Air flow scenograph

7-4. Water supply flow scenograph

None

SERVICE MANUAL

Model:

38

Issue

Rev.

Chapter 8 Circuit diagram

8-1. Brief principle diagram

A.Power plug

B. Refrigerator sensor C. Chiller sensor D. Freezer sensor E .Defrost sensor

F.Ambient sensor G.Display panel H. Refrigerator lamp I.Hall IC J.Damper

K.Freezer Fan Motor L. Fuse1 M. Defrost Heater N. Fuse2 O. Heater near water

drain hole

P. Over load protector Q. Compressor R. PTC S.Capacitor T.Control board

SERVICE MANUAL

Model:

39

Issue

Rev.

8-2. Main control PCB diagram

SERVICE MANUAL

Model:

40

Issue

Rev.

Chapter 9 Quick check

9-1. Self test model

Entering method of TEST function: Open the refrigerator door,press the keys of “Func.Set” and “OK” at

the same time, press the key of “OK” and press the key of “Func.Set” for 10times at the same time to

enter the TEST function mode.

TEST adjustment: after entering into the TEST function mode, every time pressing the key of

“Func.Set”, TEST mode will go from T1→T2→T3→T4→Log out, controlling the operation normally.

TEST1:For testing the capability of cooling, “T1” will show on the display screen and force appliance

to cool down immediately: during this time the compressor run at a high speed, F FAN motor run at a

middle speed. Air door of the refrigerating chamber is normally turn on and off according to previous

set mode, the air door of the temperature adjusting chamber is opened by 30° and turned on and off

normally according to the set mode. And defrost heater is switched off.

TEST2:Under TEST1 MODE, press“Func.Set” key ,“T2” will show on the display screen and force

appliance to defrost immediately: during this time the compressor and fan motor are switching off,

defrost heater is switching on. Power of the defrost heater should be 205±5W here.

When temperature around defrost sensor above 8 degree, appliance will exit “T2”mode.after heater

working 1 minute! When temperature around defrost sensor below 8 degree, heater will work

continually until reach 8 degree, appliance then exit “T2”!

TEST3:Under TEST2 MODE, press “Func.Set” key, “T3” will show on the display screen. The

refrigerator enters into normal operation and non-defrosting control until manual adjustment to log out

of “T3” mode.

TEST4: Under TEST3 MODE, press“Func.Set” key, “T4” will show on the display screen. The

refrigerator loads are all turned off at this mode, and the refrigerator will log out of TEST mode after

30seconds, and then runs normally.

SERVICE MANUAL

Model:

41

Issue

Rev.

9-2. PCB checkout

9-2-1. PCB diagram

SERVICE MANUAL

Model:

42

Issue

Rev.

9-2-2. PCB photo

9-2-3. PCB connection technical data

Connector

NO.

Connection Testing part Testing part location Normal data

CN1

1.NULL

2.NULL

3.NULL

/ / /

CN2

1.Black

2.Orange

3. Brown

Evaporating Fan

motor

The inside of the air duct of

the freezer

Working volt

8V-13V

4.White

5.Blue

6.Yellow

7. Red

Damper motor The inside of the air duct of

the chiller chamber

Working volt 12V

8.Purple

9. Green

Refrigerating LED The top of the refrigerating

chamber

Working volt 12V,

power 2W

CN3

1.Pink

2.Black

3. Grey

Switch of the

refrigerating chamber

door

The door body of the

refrigerating chamber

Working volt 5V

4.Grey

5. Black

Frequency signal wire Connect to the frequency

conversion board

Working volt 5V

SERVICE MANUAL

Model:

43

Issue

Rev.

6.Green

7.Red

8.Brown

9.Blue

10-12 NULL

Display board of the

door body

The outside of the door

body of the refrigerating

chamber

Working volt 5V

CN14

1.White

2.White

Environment

temperature sensor

The door body of the

refrigerating chamber

Working volt 0-5V

3.Orange

4. Orange

Defrosting sensor Liquid storage bag of the

evaporating utensil

Working volt 0-5V

5.Grey

6. Grey

Chiller sensor The air duct of the

temperature adjusting

chamber

Working volt 0-5V

7.Pink

8. Pink

Freezing sensor The air duct of the freezer Working volt 0-5V

9.Yellow

10.Yellow

Refrigerating sensor The air duct of the

refrigerating chamber

Working volt 0-5V

CN5

1.Red

2.blue

Heating wire for

defrosting

Under the evaporating

utensil

Working volt

220-240V

3.Brown

4.Blue

5-6 NULL

Power supply of

frequency conversion

board

The end of the power

supply of the frequency

conversion board

Working volt

220-240V

SERVICE MANUAL

Model:

44

Issue

Rev.

Chapter 10 Trouble shooting

10-1.Abnormal phenomena

Symptom:food in the fridge storage compartment is frozen

Check:

1) Verify that the temperature in the fridge storage compartment is too low and the food is

frozen there;

2) Disconnect the connection wires of the damper and the LED lamps. Take out the air

door-foam assembly. Tear the adhesive tape wrapped around the foam and separate the

foam. Check if the seal between the damper and the foam is tight.

3) If the seal is tight, check if the fridge storage temperature sensor R SNR is OK.

4) If the R SNR sensor R is OK, then the main control panel is probably malfunctioning.

5)If the wiring of the damper is OK, check the circuit from the connector of the main control

panel to the connector in the cabinet. If there is no problem in this circuit, the damper is

malfunctioning.

Solutions:

1) If the seal between the damper and the foam is found to be not tight, please affix seal strip

on the interface between the damper and the foam;

2) If the R SNR sensor is malfunctioning, please replace it with a new one;

3) If the main control panel is malfunctioning, please replace it with a new one;

4) If the connector of the damper is connected with reverse polarity, please reconnect it

correctly;

5) If the damper is malfunctioning, please replace it with a new one.

Symptom:no defrosting

Check:

1) Entering into “T2” mode by manually pressing keys on the display board. Then, check if the

temperature of the defrosting heating wire is rising.If the temperature of the heating wire

does not change, remove the fan cover plate to check if all the connectors are connected

properly and test if there is 220V voltage output across the terminals of the heating wire.

2) Measure the resistance of the heating wire with a multimeter. It should be around 268Ω.

3) Measure the resistance of the defrosting fuse. If it is zero, the fuse is OK. If it is infinite, the

fuse is malfunctioning.

4) If no malfunction is found in the above checks, please test the defrosting temperature

sensor with a multimeter.

SERVICE MANUAL

Model:

45

Issue

Rev.

Symptom:neither displaying nor starting when powering on

Check:

1) Check if the power supply is connected properly.

2) Remove the main control panel and examine its back side carefully to see if there are

solder skips or open soldering;

3) Check if the connector of the freezer door hinge is connected properly.

4) Verify the display panel to see if the refrigerator is in OFF state. If so, press and hold the

button on the power board for 5s to turn it on.

Solutions:

1) If there is dry soldering or open soldering on the control panel, resolder it with an electrical

iron.

2) If any connector is not connected properly, replug it firmly.

3) Press and hold the button on the power board for 5s to turn the refrigerator on.

Symptom:poor freezing effect accompanied by loud noise

Check:

1) Check if there is apparent abnormal sound in the freezer storage compartment. Remove

the fan cover plate, close the refrigeration air door, and check if the freezer fan is operating

normally. (The fan does not operate when the refrigeration air door is open. Please first

eliminate the possibility of improper installation of the door on-off)

2) If the freezer fan does not run, remove it and check if its connector and the cabinet

connector are connected properly. Test if there is approximately 12VDC voltage across

pin1 and pin 3 of CN2. If there is no 12VDC voltage, the main control panel can generally

be determined to be malfunctioning. If there is 12VDC voltage, the freezer fan can

generally be determined to be malfunctioning.

3) If the fan rotates abnormally, the fan is malfunctioning.

Solutions:

1)If there is apparent abnormal sound in the freezer storage compartment, check if the fan

base is firmly fixed, if the fan vanes are installed properly, and if they intervene with the

wires. If any of these problems is found, please remove the fan and reinstall it properly.

2)If the fan connector is not installed properly, disconnect the terminals and reinstall the

connector。

3)If the main control panel or the fan is malfunctioning, replace the malfunctioning one with a

good spare part.

SERVICE MANUAL

Model:

46

Issue

Rev.

Sincere forever

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...