Haier BD-519GB Service Manual

Order No. Ref0902S003V0

200◎ 8(HAIER ELECTRICAL APPLIANCES COR. LTD)

All right reserved. Unauthorized copying and distribution is a violation of law。

Chest Freezer

SERV ICE MANUAL

MODEL:BD-519GB

Haier Group

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It

dose not contain warnings and cautions to advice non-technical individuals of potential dangers in attempting to service a product.

Product powered by electricity should by serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

WARNING

SERVICE MANUAL

Model: BD-519GB

2

Issue 2009-02-03

Rev.

Ref0902S003V0

Contents

Table of Contents ·········································································································· 2

1. General Information ································································································ 3

1-1. General guideline ····························································································· 3

1-2. Insurance Test ·································································································· 3

1-3. How to read this Service Manual ······································································ 4

2. Product Feature ·········································································································

2-1. Specifications ··································································································· 5

2-2. External views ·································································································· 6

3.

Installation, adjustments and maintenance ··················································· 7

3-1. Installation ········································································································ 7

3-2.

Defrosting and draining ···················································································· 7

3-3. Cleaning your freezer ······················································································· 8

4. Disassembly ············································································································ 9

4-1. Door assembly (Door, hinge, hinge cover) ······················································· 9

4-2. Compartment Grill assembly ············································································ 9

4-3. Control panel assembly (Panel, cover board, knob, indicator light) ················ 10

4-4. Thermostat assembly ······················································································ 10

5. Control and display system ··················································································· 11

5-1. Control and display panel ··············································································· 11

5-2. Starting the Freezer ························································································ 11

6. System flow principle ····························································································· 12

6-1. Refrigeration flow chart ··················································································· 12

6-2.

Refrigeration flow scenograph ········································································ 13

7. Circuit diagram ········································································································ 14

7-1. Brief principle diagram ···················································································· 14

8. Trouble shooting ····································································································· 15

8-1. Normal phenomena ························································································· 15

8-2. Abnormal phenomena ····················································································· 17

8-2-1. Compressor doesn’t start ····································································· 17

8-2-2. Poor cooling ·························································································· 18

SERVICE MANUAL

Model: BD-519GB

3

Issue 2009-02-03

Rev.

Ref0902S003V0

Chapter 1 General Information

1-1. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts which

have been overheated or damaged by the short circuit. After servicing, see to it that all the protective

devices such as insulation barriers, insulation papers shields are properly installed. After servicing,

make the following leakage current checks to prevent the customer from being exposed to shock

hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatic Sensitive

1-2. Insurance Test

1. Check if there is any leak of current.

2. Cut out the power supply before the repair to avoid an electrical shock hazard.

3. In the case of a live-line test, insulating gloves should be worn to avoid potential electrical

shock.

4. Confirm the rated current, voltage and capacity before testing with any kinds of instruments.

5. Watch if the upper door is open when you check something at a lower position.

6. Take out every part in the cabinet before moving the machine, especially things like panels

(e.g. glass shelf).

7. Please wear intact cotton gloves when repair any parts of the evaporator, so that scratches

by the sharp fins can be avoided.

8. If there is a breakdown with the refrigeration system, please surrender the machine to the

service center, else the leaked refrigerant may pollute the atmosphere.

9. The refrigerator use AC of 220V with a frequency of 50Hz.

10. A big fluctuation of voltage (exceed the range 187~242V) may cause a start failure of the

refrigerator, a burn-out of the control panel and compressor, or an abnormal sound from the

compressor in operation.

11. Take care not to damage the supply line. Don’t yank at the line; pull the plug out gently from

the receptacle. Don’t press the line under the cabinet or step on it. Take care not to roll on or

damage the supply line when moves the machine from the wall.

12. In the case of leakage of inflammable gases like carbon monoxide, open the door and

windows. Don’t pull out or insert the plugs of the appliance.

13. Don’t touch the refrigeration surface of the freezing compartment when the refrigerator is in

operation, especially when your hand is wet, else you may be glued to the surface.

14. Pull out the plug of power supply during clearance or power outage. Wait at least five

minutes to resume the power supply in order to prevent damage to the compressor caused by

SERVICE MANUAL

Model: BD-519GB

4

Issue 2009-02-03

Rev.

Ref0902S003V0

continuous restart.

Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of products, which

may differ from your products in some way.

1-3. How to read this Service Manual

1-3-1. Using Icons

The meaning of each icon is described in the table below:

Note:

A “note” provides information that is not indispensable.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation, may

damage equipment, loose data, get an unexpected result or has to restart (part of) a procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides to find additional information on a specific topic.

SERVICE MANUAL

Model: BD-519GB

5

Issue 2009-02-03

Rev.

Ref0902S003V0

Chapter 2 Product Feature

2-1. SPECIFICATIONS

Superfast freeze function.

Adjustable temperature control with power indicator.

High pressure and microbiological foam filled door for energy

conservation.

Convenient water drain.

Hi-temp indicator.

External controls.

Type Model BD-519GB

Commercial brand

Haier-Thermocool

Product description

Chest Freezer

Type of appliance (FS=free standing / BI= built-in)

FS

Climate class (N=16-32℃ ST=16-38℃ T=18-43℃)

T

Key features

Gross capacity L

519

Total net capacity L

519

Energy consumption/year kWh/year

494

Defrosting (Manual-Automatic)

Manual

Kind of coolant (R134a/R600a)

R600a

Foaming components (R141b/C-P)

C-P

Technical data

Voltage / frequency V/Hz

220~ / 50

Input power / currency W /A

170/1.6

Length of cable / incl. plug cm

150/155

Temperature range (from>to) °C

≤ -18

Cooling system: (K=Compressor / A=Absorption)

K

Maximum noise level dB(A)

55

Aesthetics

Door

round edges

Chest

round edges

Colours:

white

Cabinet

white

Top

white

Door frame

white

Control panel / Handle (w/b/g/s)

●/●

Equipment & accessories

Product classification (Super eco/Eco/Standard)

Standard

Lid (Number/Handle/Lock)

1/●/●

SERVICE MANUAL

Model: BD-519GB

6

Issue 2009-02-03

Rev.

Ref0902S003V0

Type of lid (Hinge/Counter balanced/Sliding)

Hinge(metal )

Inside walls (Stainless steel/Aluminum/Synthetic mat.)

Aluminum

Insulation Lid thickness mm

70

Walls thickness mm

60

Baskets number n°

2 (metal)

Defrost drain

●

Interior light

●

Adjustable thermostat

●

Fast freeze lamp (yellow)

●

On light (green)

●

Breakdown light (red)

●

Fast freeze switch

●

Product net dimensions

Unit dimensions (H / W / D) mm

1650/745/845

Net weight kg

76

Packing dimensions & load ability

Packing dimensions (H / W / D) mm

1710/775/895

Gross weight kg

86

40 ' High cube container load pcs

62

Service

User instruction (languages)

ENGLISH

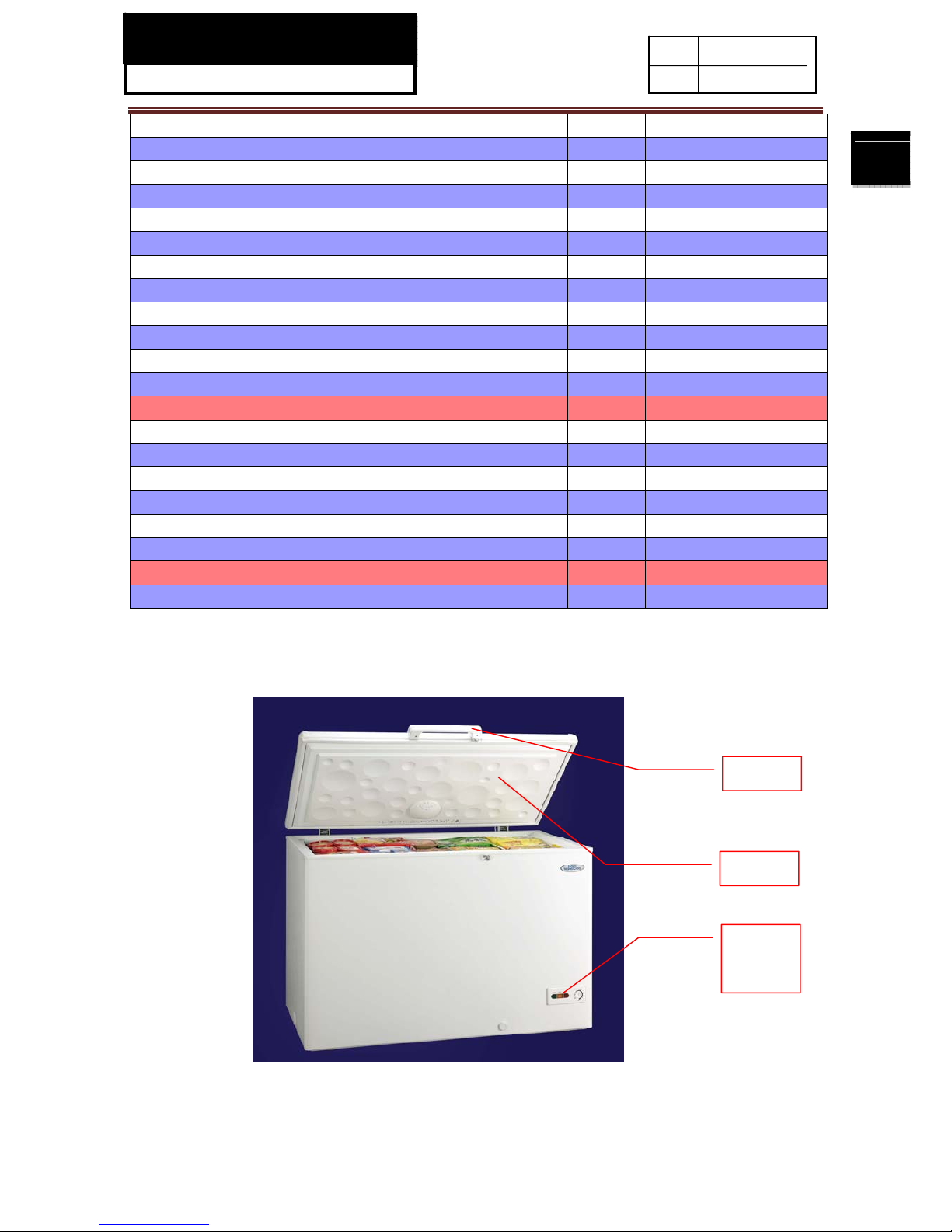

2-2. External views

Handle

Lid

Control

panel

Loading...

Loading...