Page 1

BD-478A

Freezer

Service Manual

BD-478A

●Features

●Door lock for safety storage

●High pressure foam cover for efficient Temperature

preservation.

●Adjustable thermostat.

●Superior insulation.

●Efficient defrosted storage

●Designed for cafeterias restaurants and hotels

Haier Group

Manual No.:BD-478A Edition:20051201

PDF created with pdfFactory trial version www.pdffactory.com

Page 2

2

Contents

1. Contents……………………………………………………………………….……1

2. Product Code Illumination and Series Introduction……………………………

3. Features …………………………………………………………………………... 3

4. Specifications………………………………………………………………………4

5. Safety Precautions(including Warning and Cautions)………………………...5

6. Net Dimension……………………………………………………………… …....7

7. Installation and Accessory Parts ………………………………………………. 8

8. Parts and Functions …………………………………………………………… 12

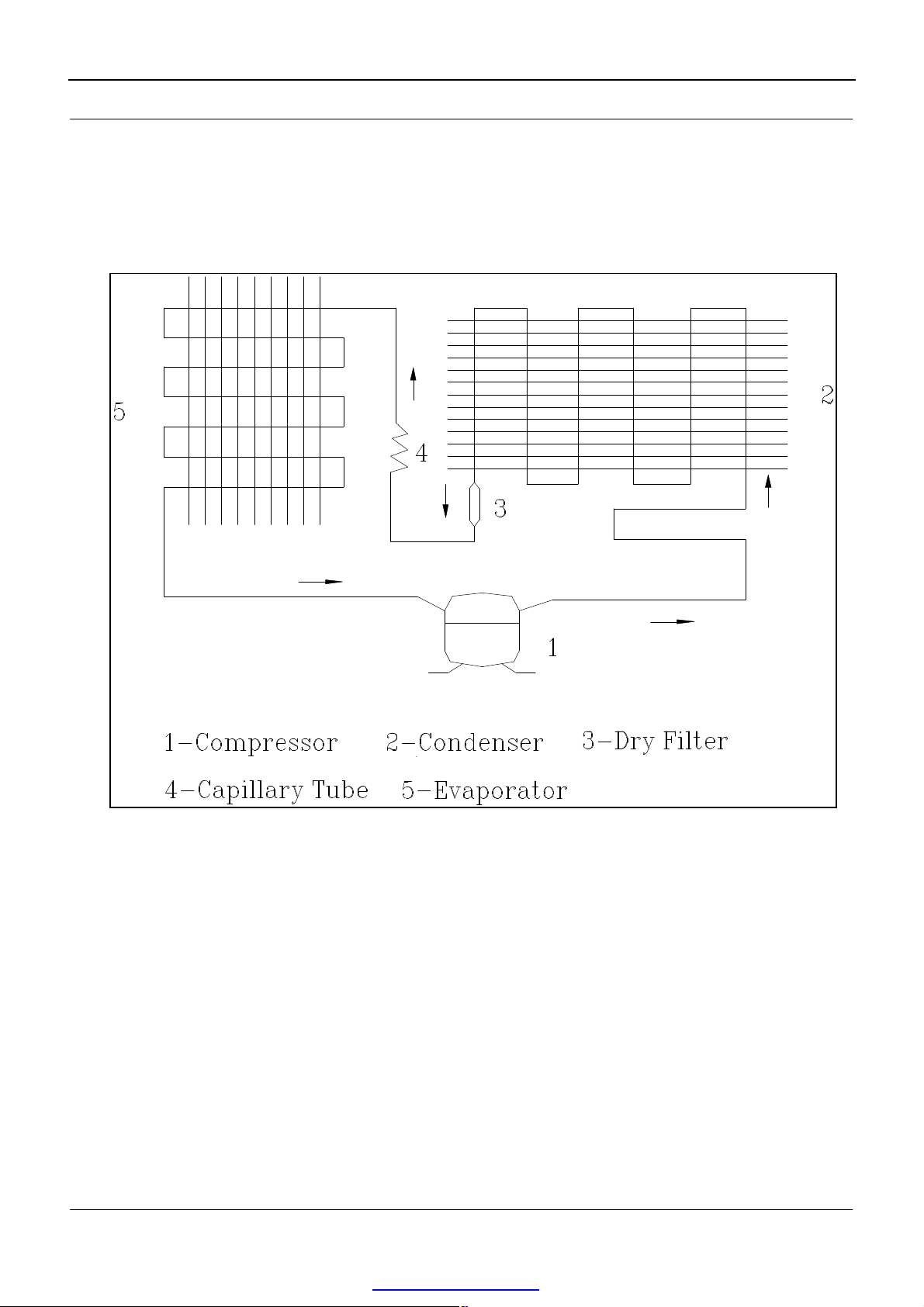

9. System Flow Chart………………………………………………………………13

10. Function Schedule……………………………………………………………… 14

11. Circuit Diagram ………………………………………………………………… 15

12. Maintenance Service and Trouble Shooting

1. System Troubleshooting…………………………………………………16

2. Common freezer problems………………………………………………28

3. Service and technical requirements of R134a freezer ……………… 30

4. Application and maintenance of freezer ……………………………… 33

5. Procedure and tools required for evacuation and Charging …………38

6. Freezers Noise…………………………………………………………… 40

7. National Standard for noise………………………………………………49

8. Measuring technology of freezer performance parameter……………51

13. Exploded View……………………………………………………………………58

14. List of Parts………………………………………………………………………59

1

PDF created with pdfFactory trial version www.pdffactory.com

Page 3

PRODUCT CODE ILLUMINNATION AND SERIES INTRODUCTION

Product Code Illumination and Series Introduction

B D -- □ □

A B C D

A: The first letter of “FREEZER” in Chinese spelling.

B: The first letter of “FREEZER” in Chinese spelling.

C: Capacity. (Unit: litre).

D: Improve Series Number.

2

PDF created with pdfFactory trial version www.pdffactory.com

Page 4

Features

●Door lock for safety storage

●High pressure foam cover for efficient Temperature

preservation.

●Adjustable thermostat.

●Superior insulation.

●Efficient defrosted storage

FEATURES

●Designed for cafeterias restaurants and hotels

● Low power consumption 20% less than the other similar

freezers

● Imported high quality compressor and condenser, large

freezing capacity, 1.5 times more then regular freezers

Freezing quick and deep freeze functions are 2 times faster then

regular freezers

3

PDF created with pdfFactory trial version www.pdffactory.com

Page 5

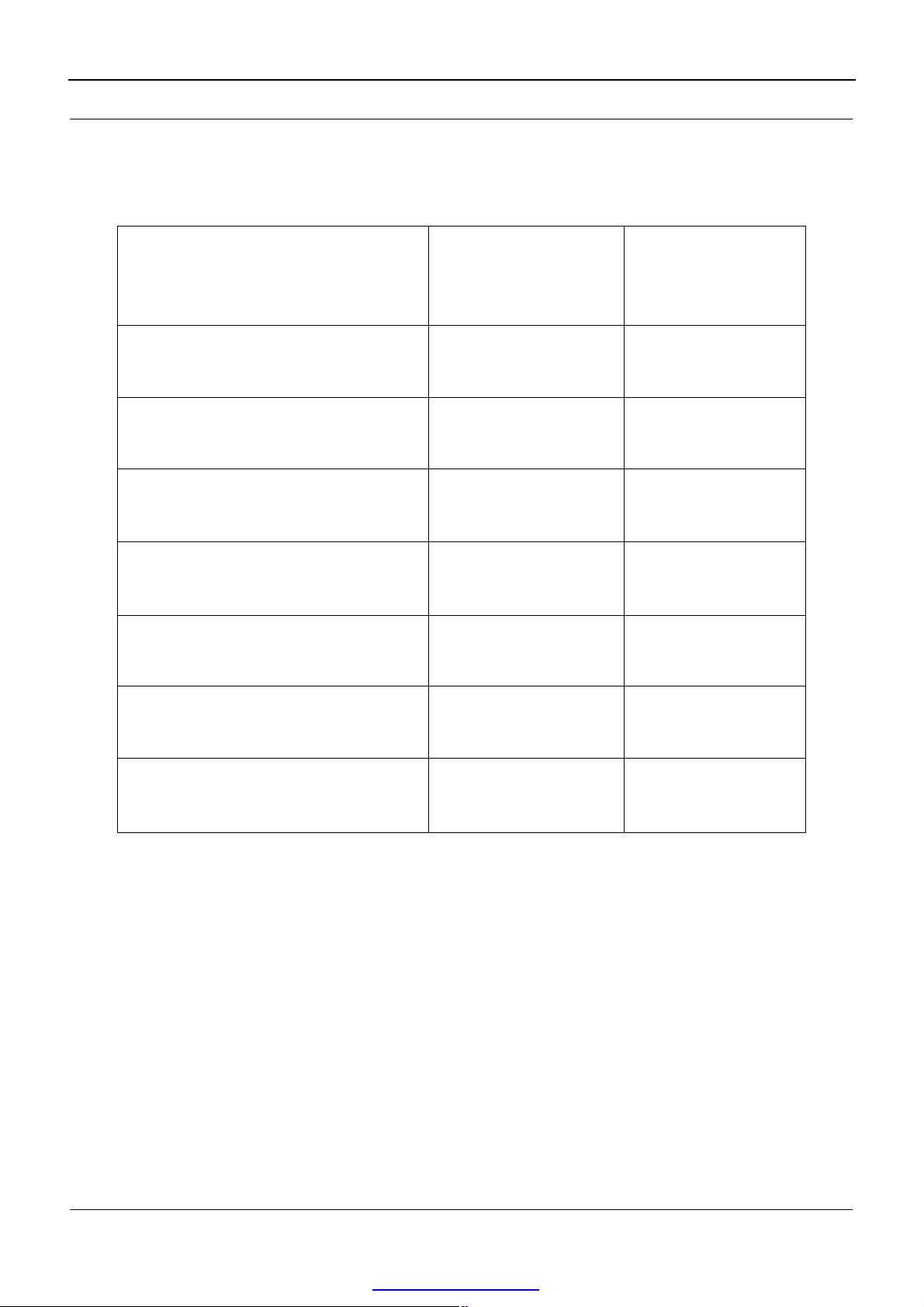

Specifications

Model BD-388A BD-478A

SPECIFICATIONS

Capacity (L)

Power Supply (V/Hz)

Unit Dimension (W*D*H)

Unit Weight (Kg)

Box Dimensions (W*D*H)

Box Weight (Kg)

Container Quantity (40HC’)

388 478

220V~ /50Hz 220V~ /50Hz

1420*715*810 1690*715*810

72 78

1495*765*870 1765*765*870

84 91

66 57

4

PDF created with pdfFactory trial version www.pdffactory.com

Page 6

SAFETY PRECAUTIONS

Safety Precautions

Read all of the instructions before using this appliance. When using

this appliance, always exercise basic safety precautions, including the

following:

1. Use this appliance only for its intended purpose as described in this

uses and care guide.

2. This freezer must be properly installed in accordance with the

installation section. Instructions before it is used, See grounding

instructions in the installation section.

3. Never unplug your freezer by puling on the power cord, Always

grasp the plug firmly and pull straight out from the outlet.

4. Repair or replace immediately, all electric service cords that have

become frayed or otherwise damaged, Do not use a cord that

shows cracks or abrasion damage along its length, the plug or the

connector end.

5. Unplug your freezer before cleaning or before making any repairs,

Note: If for any reason this product requires service, we strongly,

recommend that a certified technician perform the service.

6. If your old freezer is not being used, we recommend that you

remove the door and leave the shelves in place; this will reduce the

possibility of danger to children.

5

PDF created with pdfFactory trial version www.pdffactory.com

Page 7

SAFETY PRECAUTIONS

Safety Precautions

7. This freezer should not be recessed or built-in an enclosed

Cabinet. It is designed for freestanding installation only

8. Do not operate your freezer in the presence of explosive fumes.

9. Do not refreeze foods, which have been thawed completely.

10.Do not use any electrical device or any sharp instrument in

defrosting your freezer.

6

PDF created with pdfFactory trial version www.pdffactory.com

Page 8

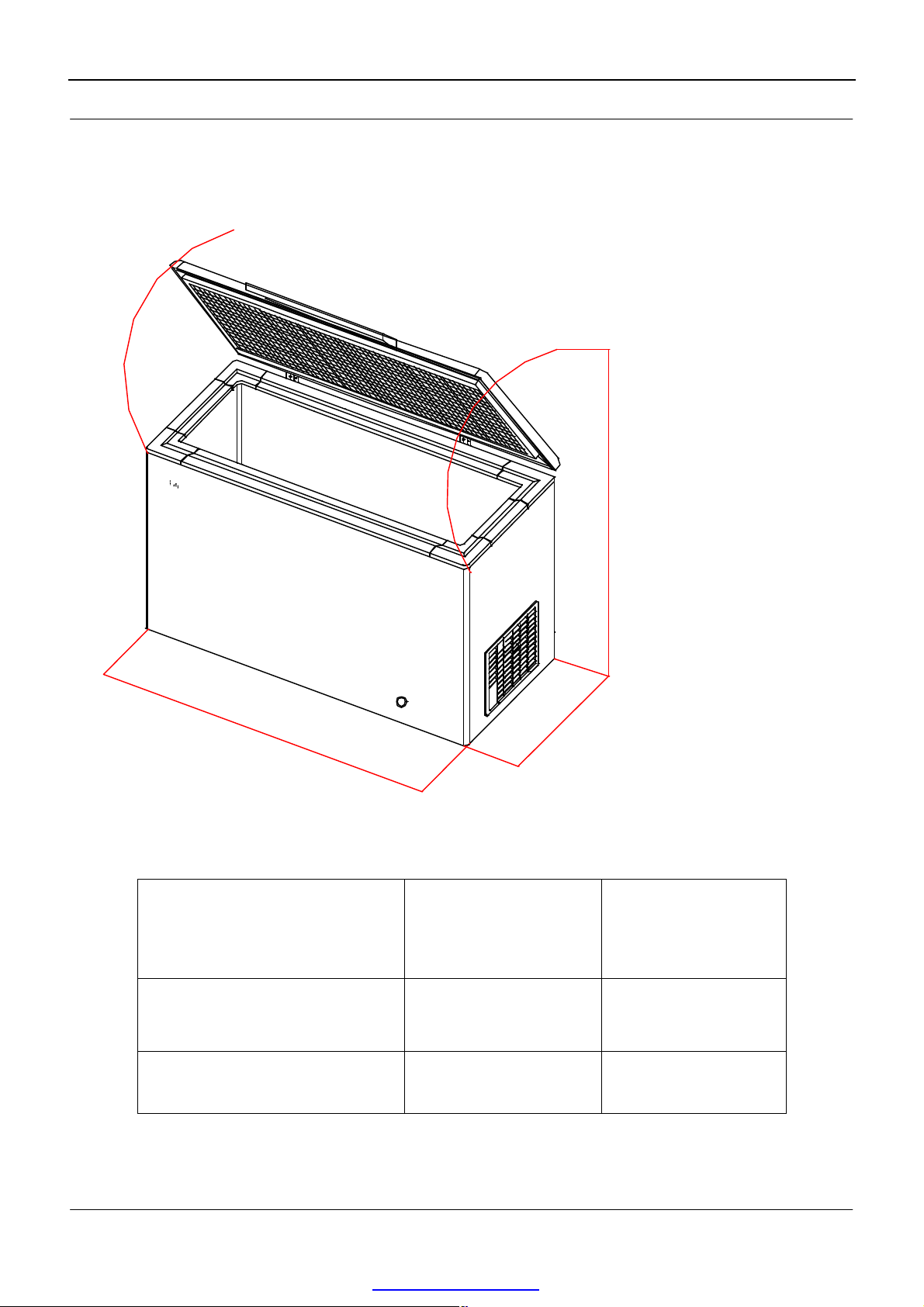

Net Dimension

H

a

NET DIMENSION

H

L

W

Model BD-388A BD-478A

Unit Dimension (W*D*H)

Dimension (Door open)

1420*715*810 1690*715*810

1420*715*1470 1690*715*1470

7

PDF created with pdfFactory trial version www.pdffactory.com

Page 9

INSTALLATION AND ACCESSORY PARTS

Installation and Accessory Parts

Unpacking Your Freezer

1.Remove all packaging material; this includes the foam base and all adhesive

tape holding the freezer accessories inside and outside.

2.Inspect and remove any remains of packing, tape or printed materials before

powering on the freezer.

Adjusting Your Freezer

1.Your freezer is designed for freestanding installation only. It should not be

recessed or built-in.

2.Place the freezer on a floor strong enough to support it fully loaded.

3.When moving the freezer, never tilt it more than a 45-degree angle. This could

damage the compressor and the sealed system.

4.If the freezer is tilted let it stand in an upright position for at least 24 hours prior

to plugging. This is to allow the refrigerant to settle.

·Proper Air Circulation

l To assure your freezer works at the maximum efficiency it was designed for,

you should install it in a location where there is proper air circulation,

l Plumbing and electrical connections.

l The following are recommended clearances around the freezer:

Sides…………..2”(50mm)

Top. ……………2”(50mm)

Back…………..2”(50mm)

8

PDF created with pdfFactory trial version www.pdffactory.com

Page 10

INSTALLATION AND ACCESSORY PARTS

Installation and Accessory Parts

l Do not over fill freezer for proper internal air circulation.

Electrical Requirement

l Make sure there is a suitable power Outlet (220V) with proper grounding to

power the freezer.

l Avoid the use of cutting off the third grounding , this is a dangerous practice

since it provides no effective grounding for the freezer and may result in

shock hazard.

Install Limitations

l Do not install your freezer in any location not properly insulated or heated e.g.

garage etc,

l Select a suitable location for the freezer on a hard even surfaces away from

direct sunlight or heat source e.g. radiators, baseboard heaters, cooking

appliances etc, Any floor unevenness should be corrected.

9

PDF created with pdfFactory trial version www.pdffactory.com

Page 11

Operating Your Freezer

INSTALLATION AND ACCESSORY PARTS

Installation and Accessory Parts

Once the freezer is in its proper place, plug it in an electrical outlet having 220

volts.

Set the temperature, on the temperature contrail knob.”1”being the warmest and

“6”being the coldest. Initially set the temperature on”3”. Place food inside the

freezer After using the freezer for 24 hours set the freezer to your desired

setting.

In case you unplug your freezer or experience an electrical outage, allow 5

Minutes before plugging it back in.

(Note: If the freezer has been placed in a horizontal or tilted position for any

period of time wait 24 hours before plugging the unit in.)

Adjustable temperature dial:

Your freezer will automatically maintain the temperature level you select. The

temperature level you select. The temperature control dial has 6 settings plus

0.”1”is the warmest,”6”is the coldest. Turning the dial to 0 stops cooling the

freezer. Set the dial to “3”and allow 24 hours to pass before adjusting the

temperature to your needs.

10

PDF created with pdfFactory trial version www.pdffactory.com

Page 12

INSTALLATION AND ACCESSORY PARTS

Installation and Accessory Parts

Food Storage Basket

Your Freezer has 1 or 2 removable basket. It allows you to store food more

accessibly or you can remove it if not needed.

Defrosting and Draining The Freezer

·Defrost whenever the frost becomes 5MM thick. Never use a sharp or

metallic instrument to remove the frost as it may damage the cooling

coils.(A punctured coil will void the warranty)

·Turn the temperature control to 0 position and unplug the unit. For draining,

place a tray beneath the outer drain plug. Pull out the drain dial and rotate it

so that the arrow points down ward. This will let the water flow out into the

tray.

·Remove the drain plug from the inside of the freezer. Defrosting usually

takes a few hours. To defrost faster keep the freezer door open. When done,

push the drain dial in and turn the arrow to the up position. Re-plug the

drain plug inside the freezer compartment. Note: monitor the container

under the drain to avoid overflow.

·Wipe the interior of the freezer and replace the electrical plug in the

electrical outlet.

·Rest the temperature control to the desired setting.

11

PDF created with pdfFactory trial version www.pdffactory.com

Page 13

System Flow Chart

SYSTEM FLOW CHART

The refrigeration system of direct cooling single-system freezers

belongs to the category of a single-temperature and single-control

refrigerating system with only one evaporator and is controlled by a

single temperature control.

12

PDF created with pdfFactory trial version www.pdffactory.com

Page 14

FUNCTION SCHEDULE

Function Schedule

Set the temperature, on the temperature contrail knob.”1”being the

warmest and “6”being the coldest. Initially set the temperature on”3”.

Place food inside the freezer .After using the freezer for 24 hours set

the freezer to your desired setting.

In case you unplug your freezer or experience an electrical outage,

allow 5

minutes before plugging it back in.

(Note: If the freezer has been placed in a horizontal or tilted position for

any period of time wait 24 hours before plugging the unit in.)

Adjustable temperature dial:

Your freezer will automatically maintain the temperature level you

select. The temperature level you select. The temperature control dial

has 6 settings plus 01.”1”is the warmest,”6”is the coldest. Turning the

dial to 0 stops cooling the freezer. Set the dial to “3”and allow 24 hours

to pass before adjusting the temperature to your needs.

13

PDF created with pdfFactory trial version www.pdffactory.com

Page 15

Circuit Diagram

Brief description of principle about BD-318A/428A:

CIRCUIT DIAGRAM

Brief description of principle about Thermostat:

When the temperature in the freezer is higher and reaches the

value for starting the machine, the thermostat will be closed, the

compressor will run; When the temperature in the freezer is lower and

reaches the value for closing the machine, the thermostat will be open,

thus the compressor will be stop running.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.1 System Trouble shooting

14

PDF created with pdfFactory trial version www.pdffactory.com

Page 16

12.1.1 Servicing freezer

(1)Check the whole circuit of freezer, if there are wire connections

came off, any wires broken, or a short circuit.

(2) Check the insulation of the whole freezer. At normal situation,

the resistance is greater than 2 mebohms; if it is less than 2

mebohms, please make a further check of the freezer resistance.

Set the voltmeter to R1 Ohm position, put the two voltmeter leads

pencils into L and N terminals respectively, watch the indication

of odometer. The normal value is several Ohm to tens of ohm. If

the resistance is zero, means that there is a short in the freezer

circuit or there is a short caused by a bad compressor or fan

motor. The reason should be found out and repaired. If the

resistance is too big or infinite, this means that there is broken

circuit, please check and solve it.

After the above checks, the freezer will not have any

electrical problem and you can switch power on for further

completely check.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.1.2 Reasons of electricity leakage of freezer

15

PDF created with pdfFactory trial version www.pdffactory.com

Page 17

(1) Leakage of compressor: mainly because of serious vibration,

the motor coil of compressor contacts with the shell, the coat of

enameled wire will come off some where and connect with shell.

Other reasons may be over voltage, insufficient of voltage,

adverse circumstances (temperature too high, ventilation and

heat radiation to bad) for freezer, thermal protection unit out of

order, etc. They will make the motor coil over temperature,

insulation material loose, insulation is damaged then electricity

will occur.

(2) Leakage of motor connection terminals: the connection

terminals of fully enclosed compressor are made from high

temperature soda glass sintered ceramics, around the terminals

are filled with a high polymer. The terminals and insulation

material must have the same linear expansion coefficient, the for

requirement between terminals and the shell is more than 0.5

million ohm. The reason of terminal leakage is that soda glass is

broken or there are conductive materials such as water, dirt, etc.,

adhered to terminals.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

If electricity leakage occurs outside the compressor, please use

16

PDF created with pdfFactory trial version www.pdffactory.com

Page 18

tetra chloromethane or alcohol to clean it. If the leakage occurs in

the inner of compressor, it needs to be changed.

(3) Leakage of temperature controller: because of too long a

period of service or too high temperature, or too much dirt, or too

high humidity, there may be electricity leakage. If it has been

defined that there is leakage of temperature controller, please

change.

(4) Leakage of starting relay: during mounting and repairing,

screw of relay lead is easy to contact the shell and leakage will

then occur. If you suspect the relay is bad, check it. If there is

leakage, please make the connections again and leave a piece of

insulation paper under the screw.

(5) Leakage of fan: because of too high humidity of freezer

environment or a bad fan controlling unit, the fan is burned after

long time operation and thus causes leakage. Using voltammeter

to measure the insulation resistance between each respective

connection terminal and the freezer body, if the resistance is too

little, means there is leakage caused by humidity; if the resistance

Is zero, means the fan coil is burned or short-circuited. Please

change the fan.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.1.3 Troubleshooting observation

17

PDF created with pdfFactory trial version www.pdffactory.com

Page 19

(1) At normal operation conditions, the temperature around the

surface of freezer evaporator is nearly the same; the thickness of

frost layer is similar. If there is no frost at the surface of

evaporator (bed type freezer at all of its inner wall), or only a small

part at the upper, conclusion can be made that the operation of

refrigeration system is not normal, the refrigerant is insufficient or

there is leakage.

(2) Check the system tubing and make sure there is no leakage,

especially at the joint connections. Refrigerant has good

permeability, and it also contains a little refrigerant oil. If there is

leak, there will be traces of oil at the leak points.

12.1.4 Troubleshooting by sounds

(1) When the freezer is working normal, high-pressure liquid

refrigerant flows into the low-pressure evaporator via

acapillarytube, a gas flowing sound and water flowing sound can

be heard. Open the freezer door and access to the evaporator, you

can hear the sound. If there is no sound or there is sound a little

now and then, there must be leakage of system refrigerant or

insufficient charge.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(2) After switching on power, Listen to the running sound of the

compressor whether it is normal or not. Whether or not hear

18

PDF created with pdfFactory trial version www.pdffactory.com

Page 20

normal running sounds. If there is heavy buzz that means the

motor has not been started normally. If there is bump sound, this

means that the suspended spring in the compressor is broken

and the compressor is running in tilt. When these matters occur,

please change compressor.

12.1.5 troubleshooting by touch

(1) Touch the cover of condenser, after continuous operation,

the upper part of the cover is the warmest; the temperature of

lower part is similar to room temperature. Its temperature is

relative to environment temperature. The temperature in winter is

low and the condenser’s temperature is low too, and there is only

a small part warm. In summer, the temperature is high and the

temperature of condenser cover is high too, and the whole

condenser is warm.

(2) The temperature of high-pressure exhaust pipe is high, when

touching with your hand, in summer it is hot; in winter it is also

hot. The temperature of low-pressure gas inlet pipe is low. In

summer there is dew at the pipe wall and it will feel cool when

touching; when touching in winter, it will feel cooler.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(3) The cover temperature of The evaporator can be as low as

-30℃it will feel sticky when touching. If you’d like to touch,

19

PDF created with pdfFactory trial version www.pdffactory.com

Page 21

please move your hand over it quickly, otherwise your hand will

be stuck.

(4) At normal operation of freezer, the temperature of filter dryer

cover is similar to room temperature, only a little warmer. If the

cover temperature is much higher or lower than that of

environment, and there is frost, there must be problem with the

refrigeration system.

Touching the above mentioned parts, if there is big temperature

difference compared with normal, there must be problem and

further decision should be made.

12.1.6 System noise repair

Normally there are two kinds of freezer noise, one is the natural

noise of compressor and fan, and the other is the resonance

noise or structural noise. The natural noise of compressor and

fan is controlled within a standard range, if the range is exceeded,

the compressor or fan needs to be repaired or changed. The

resonance or structural noise can be handled as follows:

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(1) If the freezer is not level, or if the floor is loose, please adjust

the base cover or fasten the floor.

20

PDF created with pdfFactory trial version www.pdffactory.com

Page 22

(2) If noise is caused by tighten loose of screw between the base

cover and freezer body, please make it tight.

(3) If the reason for noise is the aging rubber cushion of

compressor or a loose fastening clip, please change rubber

cushion, or secure clip.

(4) If tubing bumps against freezer body, or against each other,

make adjustments accordingly to remove noise.

(5) If fan blade is blocked and thus causes noise, please clear the

obstacles around the fan, or adjust fan blades.

(6) If the fan supporter is loose and noise is caused, please

tighten.

12.1.7 Poor freezing effect analysis and solutions

(1) Check the position of temperature control dial, if it is set at

“weak” position, please change to “middle” or close to strong

position.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(2) Check the rear side and the top of freezer, if it is too close to

the wall or not; if the freezer is under sunlight directly or if it is

21

PDF created with pdfFactory trial version www.pdffactory.com

Page 23

near thermal source or not; if the room temperature is too high or

not; if the condenser is blocked by cloth pieces or paper or dirt or

not. Any one of these matters will affect heat radiation of

condenser and refrigeration ability will be reduced.

(3) Check if there are too much food stored in the freezer, if hot

food has been put in or not, Too full of food is not good for cold

air circulation. Hot foodstuff can only be put in when it gets cool.

(4) Check if the freezer door has been closed well, if the door seal

bar is too dirty and the door cannot be sealed well. Remove dirt

and put on a little talcum powder.

(5) Frequent opening and extended opening of freezer door will

reduce refrigeration ability.

12.1.8 How to handle the seal bar for poor sealing

If there is too much dirt and the sealing effect is not well, please

take a rag and dip in warm water and clean the seal bar. After

cleaned, put on a little talcum powder. If there is still seam, you

can put an electrical blower outside the seal bar and make it warm,

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

keep the temperature at 50-60℃, press the bar to make it recover,

and press the bar around by hand, so that it can recover. If this is

22

PDF created with pdfFactory trial version www.pdffactory.com

Page 24

not effective, take a piece of sponge with about 10mm wide, 5mm

thick, a little longer than the seam and put it inside the seal bar,

i.e., the place between the bottom of seal bar and the door

cushion. This will make the seam place higher and adhere to

freezer body the same as other places.

12.1.9 Why freezer cannot be used at low temperature

environment

When environment temperature is below zero, the lubrication

ability of freezing oil in freezer compressor will decrease, the

compressor will be difficult to start or cannot be started, or

Compressor damage may occur.

12.1.10 How to know there is problem with compressor

motor

It is easy to find out motor problem by checking the resistance of

coil. The method is to connect the terminals of “common” and

“run” using ohm- meter, the coil resistance can then be

determined. Using terminals “common” and “start” can measure

the resistance of starting coil. If the value is infinite, the coil must

be open. If the resistance is much less than the value the motor

has, there must be short circuit problem inside the motor or the

windings are burned.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.1.11 Freezer problem analysis and service

23

PDF created with pdfFactory trial version www.pdffactory.com

Page 25

unit jump

compressor is blocked, please

Problems Reasons Removing methods

Compressor

can not be

started

Compressor

starts too

frequent,

operation

time too long,

but

temperature

drop in

freezer is too

slow

Compressor

runs without

stop,

temperature

in freezer is

too low

Compressor

buzzes and

cannot be

started,

thermal

protection

1. Fuse is broken

2. The contact of plug, socket, and cable

is not good. Cable broken.

3. The voltage is too low, 10-15% less

than rated voltage

4. The knob of temperature controller is at

“rest” position.

5. The temperature controller is out of

order.

6. Starting relay or thermal protection unit

is out of order or broken.

7. Wire broken of motor starting coil or

operation coil.

8. The compressor motor is burned or

rotator and stator are blocked to dead.

9. There is leakage of high-pressure gas

valve or the shaft is embraced to dead.

1. The distance between temperatures

sensing tube of temp. Controller and

evaporator are too big.

2. The temperature controller is out of

order.

3. Food stuffs in the freezer too much,

door opens too frequent and open time

too long.

4. The environment temperature is too

high, humidity too high, airflow is

impeded.

5. The frost layer at the evaporator is too

thick.

6. The refrigerant is insufficient or

leakage.

7. Compressor efficiency is reduced.

8. The drying filter is blocked.

1.The knob of temperature controller has

been set to “over cooling” position.

2.The contacting point of temperature

controller is adhered.

3.The temperature sensing probe of

controller is not placed well, and causes

maladjustment

4.Compressor efficiency reduced.

1. Voltage is too low.

2. Starting relay out of order.

3. The starting coil of starting motor is

broken.

4. Compressor does not run.

1. Check if there is short circuit and

solve it, if not, change capable fuse

2. Check and connect tightly, or

change.

3. Use till voltage rises to rated

value or attach a stabilizer.

4. Rotate the knob to wanted

position for suitable temperature.

5. Change the controller.

6. Change starting relay or thermal

protection unit.

7. Measure using R×1 position of

avometer, if there is wire broken,

change compressor.

8. Change compressor.

9. Change compressor.

1 Adjust and make it close to

evaporator cover.

2.Change the temperature

controller.

3.Reduce them.

4.Put the freezer to suitable place

and make air circulate well.

5.Remove frost regularly.

6.Check or supplement refrigerant.

7.Change compressor.

8.Change new drying filter.

1. Change the position to

moderate.

2. Repair or change.

3. Adjust to suitable position,

normally contact tightly with

evaporator cover.

4.Change compressor.

1. Supplement a stabilizer, adjust

to rated value.

2. Change starting relay.

3. Change compressor.

4.The shaft and piston in the

24

PDF created with pdfFactory trial version www.pdffactory.com

Page 26

Please let or make food dry

repeatedly. change.

After short

time of

operation,

over load

protection

unit cuts off

Too much

noise when

compressor

runs

There is no

frost at

evaporator

Frost at

evaporator is

not full

1. The voltage is too high.

2. Over load protection unit is not good, it

jumps earlier.

3. Starter contacting point is adhered.

4. There is short circuit in compressor.

5. There is mechanical problem in the

compressor.

6. Temperature around compressor is too

high.

1. The floor is loose.

2. The freezer body is not stable and in

level.

3. When compressor runs, friction

between tubes and freezer body causes

resonance.

4. Compressor fixing screw is loose.

5. The vibration absorption cushion for

compressor fixing is too tight, or too

loose or ageing.

6. Compressor inside noise is too big or

vibration absorption suspending spring

is broken.

1. There is serious leakage of

refrigerant.

2. There is dirt blocked the capillary or

system.

1. There is some leakage of refrigerant.

2. There is dirt block, but not serious.

3. Refrigeration quantity of compressor

is reduced.

1. Supplement a stabilizer and

adjust its value to rated.

2. Change over load protection

unit.

3. Change starting relay.

4. Change compressor.

5. Change compressor.

6.Increase heat radiation space.

1. Reinforce the floor.

2. Make the freezer body stable.

3. Move the tube a little away to

avoid friction.

4. Make the screw tight.

5. Adjust the degree of tight or

loose of vibration absorption

cushion, or change cushion.

6. Change compressor.

1. Check leakage, make welding

repair, and fill refrigerant again.

2. Clean the capillary or change

filter.

1. Check leakage, make welding

repair, and fill refrigerant again.

2Clean the capillary and filter.

3.Change compressor.

Evaporator

frosts too

rapid, frost

layer too thick

or frozen to

1. Food put into freezer contains water.

2. Too much food has been stored.

1.

after cleaning, then store it.

2. Store only corrects quantity of

food.

ice

Electricity

leakage of

freezer body,

you will feel

tingle when

touching by

hand

Electricity

leakage of

fan

Fan too noisy

1. Freezer body has not been connected

to the ground.

2. The compressor terminal contacts body

shell and causes short circuit.

3. When the components of electrical

system get wet, insulation ability is

dropped, electricity leaks.

1. Environment temperature too high or

insulation ability of insulator is dropped.

2. There is short circuit between fan

coils or the fan coil is burned.

1. The blade of fan is blocked or fan

supporter is loose.

2. The clearance of fan axle is too big.

25

1. Make the ground connection as

stipulated.

2. Change compressor.

3. Check carefully step by step, if

insulation is seriously damaged,

please change; remove wet parts

and put them into drying box to

make them dry.

1. Change fan.

2.Change fan.

1. Clear obstacles around the fan

or tighten the supporter.

2. Change the fan.

PDF created with pdfFactory trial version www.pdffactory.com

Page 27

The fan

doesn’t run

Electricity

leakage of

temperature

controller

Temperature

controller out

of order

The probe of

temperature

sensing tube

doesn’t

contact

evaporator

well

1. Check if any connection has come off.

2. Check is the fan is burned.

1. The service time is too long.

2. The environment is too dirty.

3. Humidity is too high.

1. There is leakage of temperature

sensing medium.

2. Damage of cam of contacting point

spring, etc.

It has not been mounted to position or

changed during transportation.

12.1.12 Procedure for fan change

1. Change the fan.

2. Change the fan.

1. Change temperature controller.

2. Use brush to remove dust.

3. Make the temperature dry and

control the environment humidity.

Change temperature controller.

Mount it again.

(1) Switch off power and open the fan protection cover.

(2) Remove the fan bolts by using fork wrench or universal tool.

(3) Loose the fan blade and take it out.

(4) Take the fan out from the space between compressor and tubes.

(5) Mount new fan from the space between the compressor and tubes, put

blade onto position and secure it by using a fork wrench or universal

tool.

(6) Make a test run; check if the operation is normal, if there is any blocking

of blade.

(7) Make sure not to bend or damage tubing during removal and

installation.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.1.13 Procedure for temperature controller change

26

PDF created with pdfFactory trial version www.pdffactory.com

Page 28

(1) Switch off power.

(2) Remove side protection cover.

(3) Unscrew fastening nut.

(4) Hold the base end of temperature sensing tube and the controller, pull

out downward.

(5) Change with new temperature controller.

12.2 Common freezer problems

12.2.1 Freezer cannot be started

When switching on power, the freezer cannot be started. Determine first

that the failure is caused by inside or outside factors. The factors may be:

(1) Outside factors

① The fuse is burned, or the contact of plug and socket is not well, or the

voltage is too low.

② The knob of temperature controller is set to off position.

(2) In side factors

① Electrical problem of freezer (normally caused by connection terminals

coming off or not in good contact).

② Temperature controller out of order (contact point are burned or switch

element is damaged, etc.).

③ The start capacitor is bad.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

④ The starter relay or overload protector is bad. A bad starter normally is

caused by a burn a contact points or the welded point has come off; a

27

PDF created with pdfFactory trial version www.pdffactory.com

Page 29

bad thermal protection unit is normally caused by burn contact points or

a bad heating wire.

⑤ The motor winding are burned.

⑥ The compressor shaft is broken and blocking the cylinder.

12.2.2 Operation of freezer is not normal

Freezer starts when power is switched on, but after a few seconds or 1-2

minutes, it stops automatically and will start again in several minutes. It

stops again within a very short time period after starting. If it runs like this

Continuity and can not work normally; there are several reasons for this

matter:

(1) Big fluctuation of voltage

The voltage required for proper operation is 220V olts. If the voltage is too

high, the current flowing through the starter will increase accordingly.

When it exceeds the permissible value, the starting contact point will keep

in connection state for a long time and cannot be released in time (at

normal situation, the motor starting coil will cut off in about 1s after

starting). This will make the coil temperature rising rapidly, and then the

thermal protection unit cuts off the circuit and stop operation. When power

is cut off, the temperature of thermal protection unit reduces quickly and

will switch power on when reaching the reset temperature. At this time, if

the contact point has not been released, the starting contact point could

not contact tightly and it is in false connection. This will make the

compressor tremble; thermal protection unit will open after a short time.

(2) Operating amperage too high

Freezer operation current is too big and will not operate normally. There are

two reasons way:

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

First, the freezer stops automatically after a few seconds after starting,

28

PDF created with pdfFactory trial version www.pdffactory.com

Page 30

several minutes later it starts again and stops automatically again. With in

cycles like this and the motor, or starter, and thermal protection unit will

burn up after a long time. The main reason is: the motor coil is shorted at

some parts.

Second, the freezer operates a certain time after starting, but it will stop

automatically before the temperature reduces before the desired

temperature is reached. After several minutes, it will start again, and the

electricity consumption increases bad. The reason is that the insulation

around the motor windings bad.

12.3 Service and technical requirements of a R134a freezer

12.3.1 Refrigeration equipment requirements

The compressor, condenser, evaporator, drying filter must be special for

R134a freezer and not be confused.

12.3.2 Repair equipment Requirements

(1) The evacuation and fill machine is special only for R134a use.

(2) Other equipment (such as pressure gauge) has no special requirements,

but once it is used for R134a freezer, it can be no longer for other use.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.3.3 Service procedure

29

PDF created with pdfFactory trial version www.pdffactory.com

Page 31

(1) Operation method of repairing equipment (please see instruction

manual).

(2) Special requirements

① The time interval from opening of compressor to the beginning of

evacuation can not exceed 10 minutes.

② The evacuation time shall not be less than 45 min.

③ In case there is leakage of freezer, if leakage occurs at high-pressure end,

it is repairable. Please blow high purity N2 before welding. If leakage

occurs at low-pressure end, Check system pressure, if the system has

no pressure, the freezer has to be scrapped and change with new one, if

there is pressure, it is repairable.

12.3.4 Changing procedure of R134a compressor

(1) Switch power off:Open the protection cover by using cross screwdriver

or universal

(2) Screwdriver.

(3) Remove electrical parts of compressor.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(4) Remove the four mounting bolts of compressor by using fork wrench or

universal tool.

30

PDF created with pdfFactory trial version www.pdffactory.com

Page 32

(5) Remove the compressor.

(6) Install new compressor and new filter dryer and weld them. The open

time of system shall not be more than 10 min.

(7) Connect the R134a recovery unit to the low sideline of the compressor,

and then evacuate. The evacuation time shall not be less than 45 min.

(8) Fill system with R134a according to its original quantity.

(9) Check if there is any leakage at welded point by using soapsuds.

(10) Use clean gauze to wipe away welding powder and flux.

(11) Connect the electrical controlling unit of compressor.

(12) Mount and adjust temperature controller.

(13) Switch on power for test run, check unit operation.

12.3.5 Compressor installation and brazing procedures

(1) Install new compressor.

(2) Compressor is not allowed to suck in air directly for check or other test.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(3) When changing with new compressor during service, the seal plug shall

be opened last and make the brazing and evacuation immediately.

31

PDF created with pdfFactory trial version www.pdffactory.com

Page 33

(4) When seal plug of compressor is removed, if there is no gas flowing

sound (no pressure), the compressor shall not be used.

(5) Compressor has no seal plug it cannot be used.

(6) There should be no grease adhered to service operator’s hands.

(7) The unpacking of the filter dryer of freezer should be opened right

before use.

12.4 Application and maintenance of freezer

12.4.1 Product characters

(1) Completely green environmental bed type freezer uses R134a as the

refrigerant, which is recognized internationally. It has an ozonosphere

depletion coefficient ODP=0.

New climate type design: commercial freezer uses wide temperature zone

design. At 38℃(100°F) high temperature, the freezer can start and stop

freely.

(2) New refrigeration system design: it takes dual direction refrigeration

system, thus increases refrigeration speed and prolongs compressor

life.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.4.2 Notice for use

(1) The freezer should level, the tilting angle when moving shall not be

32

PDF created with pdfFactory trial version www.pdffactory.com

Page 34

greater than 45°, so that the sliding door could not move out from its

guiding slot and other accident will not happen.

(2) The clearance between freezer and other objects should be more than

30 cm for ventilation and heat radiation.

(3) Please don’t leave the freezer at humid or corrosive gas area.

(4) Freezer should be placed at a place with proper ventilation, away from

heat source, and avoiding direct sunlight.

At the first application, please wait some time for operation (in summer 6

hours, in winter, 4 hours), when the temperature inside the freezer has

(5) reached to -15℃ and below, then you can put food in. If food is put in

too early, it may get damaged, as the temperature is still high.

(6) Do not over pack refrigerator.

(7) Place food by reasonable sorts, try to power open door frequency and

time so as to reduce the loss of refrigeration and reduce consumption.

(8) There are four wheels at the bottom of freezer, but it can only be used

for short distance and on level road movement. If it is required to move

frequently, please put the freezer onto a strong trolley base.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(9) As this type freezer is often used outdoors, please make sure that the

plug is firm, so that unnecessary loss caused by infirm plug can be

avoided.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 35

(10) Cold drinks and snacks, which contain much milk and needs to be

stored at low temperature, please try to put them at lower part of freezer.

(11) When the freezer is used outdoors, please keep unit away from direct

sun light. Frequently clean the inside and outside of freezer especially

the cabin part including condenser, compressor, etc.

12.4.3 Safety notice of product

(1) The freezer needs to be on a separate ground circuit with a 5A minimum

carrying capacity.

(2) If the electrical cable needs to be extended, the cross section of

extending wire should not be less than 1.5mm2.

(3) There must be reliable ground connection for the freezer; ground line is

not allowed to connect to water pipe, gas pipe, etc.

(4) Once the freezer is cut off, at least 5 minute must be waited for starting

again, otherwise the compressor or refrigeration system will be

damaged.

(5) Explosive, flammable and volatile substance, liquid filled glass

containers, alkalis or corrosive acids are not or be stored in freezer.

(6) Do not let children play in freezer compartment so as to avoid

suffocation or damage to freezer.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.4.4 Maintenance

Frost removal: At the inner container, there will be frost layer after using

some time. If the layer is too thick, it will affect refrigeration and increase

34

PDF created with pdfFactory trial version www.pdffactory.com

Page 36

electricity consumption.

(1) At a regular period, when the frost layer reaches about 5mm, please

remove it by plastic shovel.

(2) When removing frost, switch power off, take out stored food and place

in a cool place. In order to accelerate frost-removing speed, containers

with warm water can be put into compartment.

(3) When frost buildup has melted, pull out the drainage plug wipe freezer

so water can drain out. Compartment down with a dry cloth.

(4) Cleaning: For safety reason, please disconnect before cleaning so as to

avoid electrical shock or damage to unit.

(5) When cleaning the freezer, please use soft cloth or sponge and dip in

water or soap water (non-corrosive neutral detergent is available). After

cleaning please make it dry by using cloth so as to avoid rust.

(6) Please clean the condenser, compressor in the cabin and dust proof

element by using soft brush regularly, so as to keep good refrigeration

effect. (Dust proof element 2-3 days)

(7) Down time: If the freezer has extended down time, please disconnect

power supply, and wipe unit clean according to the above-mentioned

methods. Open the door, till it is dry and then seal for storage.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.4.5 Standard procedure of maintenance

(1) Cleaning unit cabinet: Take a cross screwdriver, remove the cabinet

board and rear protection cover. Take a brush and wipe away dust from

35

PDF created with pdfFactory trial version www.pdffactory.com

Page 37

condenser, fan, compressor and temperature controller. Wipe clean and

avoid damaging pipes and electrical parts.

(2) Switch on power and check the freezer operation. If not normal, check

and repair.

(3) Check all brazing connections. If the black paint has peeled off and

there is rust, please grind the surface slightly using No.0 grinding paper.

When the rust is removed, wipe it with clean towel. Then take a brush

and dip in alcoholic paint and paint the welded points and pipes.

(4) Check the casters and change if there is any damage.

(5) Check the power cord, if there is any wear or damage, please change.

(6) Take an avometer and check if the resistance of ground resistor is

normal.

(7) Check the insulation by using, if it is abnormal; please check the circuit

and various components.

(8) If the trademark is damaged or lost, please change with new Haier

trademark.

(9) Wipe the inside and outside of freezer clean. If freezer will be off for a

long time, wipe water away, and put the freezer into a plastic bag and

leave it at a dry warehouse with good air convection and a level floor.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.5

36

PDF created with pdfFactory trial version www.pdffactory.com

Page 38

12.5.1 Freezer repair tool and equipment

(1) Recovery machine

(2) N2 container, O2 container, acetylene container and torch kit.

(3) Thermometer.

(4) Voltmeter.

(5) Test pencil.

(6) Manifold gauges

(7) Flathead screw driver.

(8) Philip screwdriver.

(9) Needle nose pliers, notch pliers, sealing pliers.

(10) Hansen valve.

(11) Tube cutters.

12.5.2 Notice for use

R134a filling equipment can only be used specially for R134a refrigerant,

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(1) It is not allowed to fill R134a by R12 filling equipment.

37

PDF created with pdfFactory trial version www.pdffactory.com

Page 39

(2) Please keep the pliers, pipe cutting unit and Hansen valve clean, and

keep them away from grease dirt.

12.5.3 Procedure for filling equipment

(1) Preparation before use

① Visually inspect recovery machine for abnormalities, etc.

② Keep all valves closed to equipment until really to proceed.

(2) Evacuation

① Connect recovery machine hoses to system fittings

② Switch on power.

③ Switch on motor.

④ Open all related valves.

⑤ Observe the pointer of vacuum meter when it is accessing the mark –1.

⑥ Evacuation time shall not be less than 45 min.

⑦ After evacuation close valves.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

⑧ Switch off motor.

38

PDF created with pdfFactory trial version www.pdffactory.com

Page 40

(3) Filling

① Determine the filling quantity first according to the freezer being

repaired. (Each small mark of the liquid tube is 25g, each big mark is 100g).

② Open all related valves.

③ When the liquid level has reached filling quantity, close valves.

(4) Test run

① After filling, turn on power to freezer for test run. Observe the unit

operation.

② Switch off power.

12.6 Freezer noise

12.6.1 Freezer noise sources

Freezer noise comes from the expanding with heat and contracting with

cold of compressor, evaporator or condenser; from the contacting or

resonance of pipes; from the flowing of refrigerant; or from the vibration of

freezer because the floor is not level, etc.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.6.2 Compressor

39

PDF created with pdfFactory trial version www.pdffactory.com

Page 41

Freezer noise mainly comes from the compressor. The Compressor

generates various sounds. There are continuous and not continuous,

periodic and not periodic. Their frequencies may be from tens of Hertz to

thousands of Hertz. Reasons for compressor noise are:

(1) There are two pieces thin elastic steel slice inside the compressor (gas

in valve and gas out valve), when the freezer starts, each steel slice will

open and close about 47 times per second, this will cause vibration

sound. At the same time, the open and close of steel slice will contacts

other parts and also make sound. The continuous buzz we heard is this

kind of sound.

(2) When compressor is produced, there must be clearance between

components. When freezer is running, the existing of clearance will make

some components touch and gives out sound. Especially, at starting and

stopping, the forces acted on compressor components changes greatly

and bigger sound will be generated.

(3) Noise of flowing liquid

The running process of compressor is a continuous gas in and out

process.

If the pressure of refrigerant gas breathed in or exhausted out changes

suddenly, vibration sound will be generated.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(4) Resonance sound of compressor components

40

PDF created with pdfFactory trial version www.pdffactory.com

Page 42

Compressor parts, such as compressor body, exhaust tube, noise

eliminator in compressor, supporting spring, etc., will cause resonance

sometimes and give out sound.

(5) Collision between body and shell

Compressor body is suspended by three pieces of spring or supported by

spring in the shell. At starting or stopping, forces acted on compressor

changes greatly and sometimes make the body contact its shell and makes

sound. This situation is of shore duration.

(6) The electromagnetic sound a hermetically sealed motor, is relatively

small

12.6.3 How is the sound of water flowing generated?

Answer: When liquid refrigerant is flowing especially through the

evaporator, there will sound like water flowing. This sound is different, for

the evaporator used and assembly technologies during producing are

different. If there is not this sound at freezer operation, and evaporator

cannot make refrigeration, condenser is not hot, this means there is

restriction or there is a refrigerant leak.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.6.4 Gas flowing sound

41

PDF created with pdfFactory trial version www.pdffactory.com

Page 43

At operation of compressor, it breathes in and exhausts out gas

continuously. When liquid refrigerant flows through capillary, there will be

gas jet and makes sound of gas flowing. This is normal sound and may be

different for various freezers as compressors and evaporators used are

different.

12.6.5 Why there is sudden “cluck” sound or “pattering”

sound from freezer?

Answer: This is the sound of expanding with heat and contracting with cold

of condenser and evaporator, or the sound of ice at evaporator surface

because of sudden heat or cold. This sound may occur at the following

situations:

(1) Newly bought freezer, the internal stress of materials has not been

eliminated. With time going on, the stress of materials will disappear

and it is less possible to make this sound.

(2) Temperature in the freezer is not uniform just after frost melting.

(3) When open door and take out food, the evaporator feels hot suddenly.

(4) Temperature changes greatly of condenser and evaporator several

minutes after starting or stopping of freezer.

Expand with heat and contract with cold is natural law, and this sound is

normal.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.6.6 Why the freezer’s noise increases after using

42

PDF created with pdfFactory trial version www.pdffactory.com

Page 44

sometime?

Answer: After half a year or one year’s use, clearance will increase because

of wear of inner components, and compressor’s noise will increase

accordingly. Then it will get stable till the whole life of freezer.

12.6.7 Why freezer’s noise increases after stop use for

sometime?

Answer: After long time stop of freezer, the crankshaft of compressor may

be blocked by dirt brought in by lubrication oil or blocked by freezing

lubrication oil because of low temperature. For this reason, compressor

cannot be started, or noise will increase after starting, and the wear of

crankshaft will increase too. It is better that freezer doesn’t stop use.

Sometimes newly bought freezer also has this characteristic. After a period

operation, it will get normal.

12.6.8 How to reduce freezer’s noise?

At present, all kinds of freezers have the problem of noise. Scientists have

been seeking a method to solve it but to little effect. The final solution

depends on new improvements and developments in technology.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.6.9 why freezer noise changes greater at night?

43

PDF created with pdfFactory trial version www.pdffactory.com

Page 45

Answer: This is because the affection of freezer noise to people is relative

to the level of environmental sound. In noisy city or shops, people feel the

noise is little, while in countryside or quiet living room will feel the same

noise greater. This is the reason that people feel the freezer gets noisier at

home than at shop.

12.6.10 What are the national stipulations for freezer

noise?

Answer: Regarding the side effect of noise to people’s health and the

technological level freezer industry can reach at present, standardized

stipulations for freezer noise is made in national standard GB8059.1-87:

family use freezer with the volume below 250L, noise≤52 dB(A) sound

power level. The noise at offices we stay everyday or other public places is

much higher than this freezer noise.

12.6.11 Why freezer noise measured at home is incorrect?

Answer: Because at home there is not the environment conditions for

freezer noise measuring, and the value measured is not effective. The

conditions for noise measuring are stipulated in national standard as the

followings:

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(1) In semi-sound eliminating room or in sound eliminating room without

sound wave reflection.

PDF created with pdfFactory trial version www.pdffactory.com

44

Page 46

(2) Put freezer onto 5-10mm elastic cushion.

(3) Freezer must be empty and running at least 30 minutes before

measuring. If normal stop happens, please make the measurement 3

minutes after freezer starting again.

(4) 4 measuring positions are required, they are 1m away from freezer at

front, back, front left, front right respectively. The height is 1/2 of freezer;

the instrument is accurate sound level meter (A weighted).

12.6.12 What’s the different between national noise

standard 52dB(A) and ministry of light industry standard

42dB?

Answer: The noise of 52dB(A) in national standard is the sound power level.

Under the measuring conditions stipulated in national standard, measure

the freezer noise at four points, take the average of indicated reading at

greater noise situation, calculate the arithmetic average value of the four

points. This value is the average sound pressure level of noise, the

calculation formula is:

Lw=(LPA-2)+10LgS

where: LW—sound power level, dB

LPA-average sound pressure level of measuring surface, dB

S—the envelope area of measuring surface, m

2

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

The standard 42dB of the ministry of light industry is the noise pressure

level measured 1m away from freezer door. This value plus 10 is the

45

PDF created with pdfFactory trial version www.pdffactory.com

Page 47

approximate value of sound power level.

The restriction to noise in national standard is more strict and scientific. At

present, freezer noise is required to take sound power level stipulated in

national standard.

12.6.13 Why the noises of it type freezers are different?

Answer: The noise of each qualified freezer ex-factory is within the range of

national standard. Different types of freezers have different powers,

compressors used are not the same neither, and so their noises are

different. Even for same type freezers, as the noise of compressors are

different, their differences to national standard 52dB(A) are not the same,

and the noises are different.

12.6.14 Why there are greater noises at starting and

stopping of freezer?

Answer:

(1) At the starting of freezer, starting relay will make sound. The

acceleration of motor will cause vibration of compressor and makes sound.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(2) When freezer stops, because of inertial rotation, there will be vibration

sound from compressor.

46

PDF created with pdfFactory trial version www.pdffactory.com

Page 48

(3) When freezer stops, the compressor decelerates, high pressure and low

pressure at gas exhausting tube and returning tube will get balance, thus

causes sound of compressor.

(4) At the starting of compressor, if the voltage is low, the hammer

type-starting relay will make loud sound. Even if stabilizer is equipped with,

measurement should be made in time. If it cannot reach the requirement of

stabilizing, there must be quality problem with it, please don’t use in case

the voltage output is low.

For the previous reasons, freezer makes sound at starting and stopping.

12.6.15 Why sometimes noise at far distance is greater

than at near distance?

Answer: Because the transfer of freezer noise has relations with freezer

position, room space, etc. The sound wave giving out at freezer operation

will reflect when it touches wall or furniture. So it is possible that at a far

distance, it is noisier than near distance. So it is not correct to make

decision of big sound just by it can be heard meters away.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.6.16 How to determine that the sound is noise or

normal?

47

PDF created with pdfFactory trial version www.pdffactory.com

Page 49

Answer: Normally speaking, freezer noise within the range of national

standard is normal. But if there is continuous sound of metal contacting

from compressor, please check and solve the problem in time.

12.7 National standard for noise

There are stipulations in Items 6.5.7.1 and 6.3.6.1.of GB/T 8059.3-1995.

12.7.1 When freezer is running for freezing, there will be no

obvious noise?

The noise of sound power level of freezer with the volume 250L and below,

measuring according to the stipulations in item 6.3.6.1, will not greater than

52dB(A).

Sound power level noise of freezing freezer with fan

300L below ≤55dB(A)

300-400L(including 400L) ≤60dB(A)

401-500L(including 500L) ≤63dB(A)

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.7.2 Noise test

At the geometrical center of measuring field, put the freezing freezer onto

an elastic base (5-6mm thick elastic rubber cushion). The freezer should be

48

PDF created with pdfFactory trial version www.pdffactory.com

Page 50

empty. Turn the knob of temperature controller to middle or near to strong

position and close the door or cover. Make the measurement at least 30 min.

after freezer operation.

During test, if the freezer reaches the temperature the knob stipulated, and

the freezer stops, the measurement must be interrupted and resume 3min.

after the freezer starts again.

The test environment is semi-sound-eliminating-room. Other test field must

comply with the stipulations in GB4214.

The test of noise is carried out as shown in figure 8. Put sound transfer

units to measurement point 1,2,3,4, measure the sound level by sound level

meter (A weighted). Take the greater readings and calculate the average

value. The arithmetic average value of these four points is taken as the

average sound pressure level noise.

According to the testing result, sound power level of the freezer being

measured can be calculated out.

LW=(LPA-2)+10LgS

Where: LW--A sound power level, dB (datum value is 1PW);

LPA --average sound pressure level of measuring surface,

dB(datum value is 20μPa);

S—measuring surface enveloped area, m2

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

Assume l1, l2, l3 is the length, width, height of freezer respectively, unit is

m.

49

PDF created with pdfFactory trial version www.pdffactory.com

Page 51

A=l1/2 +d b=l2/2 +d c=l3/2 +d

Take d=1m

Then S=4(ab+bc+ac)

The positions of measuring points are shown in table 4.

12.8Measuring technology of freezer performance

parameter

12.8.1 Measuring content

The measuring technology of freezer includes measurement of refrigeration

property and measurement of safety requirement of electrical parts. The

following items must be done before ex-factory: (1) appearance

requirement; (2) cooling speed; (3) leakage of current; (4) insulation

resistor (cool state); (5) electrical intensity; (6) starting performance; (7)

ground resistor; (8) sealing performance of refrigeration system; (9)

documents and accessories.

Spot tests for ex-factory are: (10) store temperature; (11) insulation resistor

(wet state and hot state); (12) electrical intensity (wet state and hot state);

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(13) Electricity consumption; (14) noise and vibration; (15) electroplated

parts; (16) painting cover; (17) protection of anti-electric shock; (18) cables;

(19) door opening force; (20) freezing ability; (21) rising up speed of

50

PDF created with pdfFactory trial version www.pdffactory.com

Page 52

temperature with load.

Type tests include items (1), (2), (8), (9), (10), (13), (17), (18), (20), (21) and

the followings: (22) total effective volume; (23) ice producing ability; (24)

frost melting performance; (25) heat insulation performance and anti dew;

(26) gas tightness of door seal; (27) duration of door bar and handle; (28)

strength of supporting bracket and similar parts; (29) internal freezer

material and smell; (30) firmness of freezer and transportation test.

12.8.2 Test method and instrument

12.8.2.1 Sealing performance test of refrigeration system

In this test, freezer is put to positive pressure room, temperature is 16-32℃.

Leakage inspection instrument is set to 0.5g of yearly leakage, check every

position of refrigeration system. Leakage at any point shall not greater than

0.5g. Leakage inspection instrument normally used includes H-25 of

American GE product and Halogen instrument HLD4000 made by a German

company.

12.8.2.2 Insulation resistor

This test is to check the insulation performance of freezer. The resistance is

measured with a voltage of 500V DC added to live parts and accessible

metal parts. The resistance must be not less than 2 million ohm.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.8.2.3 Electrical intensity

This test is to check the electrical intensity of live parts and all accessible

metal parts. The testing equipment is flashover and breakdown unit,

51

PDF created with pdfFactory trial version www.pdffactory.com

Page 53

voltage is 1650V (50Hz) for 2s. At the test, there will not flashover and

breakdown occurring.

12.8.2.4 Ground resistor

Check the voltage drop between freezer ground connection point and

accessible metal parts, using AC power of load empty voltage not over 12V

and 10A current. Calculate the resistance according to the current and

voltage drop. Ground connection resistance shall not exceed 0.1 ohm.

12.8.2.5 Leakage of current

When testing, give 1.06 times rated voltage to the freezer, and make the test

at operation status. The test complies with GB4706.1-84, the leakage

current testing instrument is made in accordance with the stipulations. The

leakage current measured shall not exceed 1.5mA.

12.8.2.6 Noise test

This test is carried out at semi sound eliminating room. The freezer is put

to the geometrical center of room, on a 5-10mm thick elastic cushion. The

freezer should be empty when testing. Turn the knob of temperature

controller to middle or near to strong position and close the door. Test after

the freezer has running more than 30 minutes. The freezer noise power

level, 250L and below, ≤52dB(A); 250L above ≤55dB(A)

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

12.8.2.7 Test method of refrigeration performance

(1) 4 or 6 freezers can be tested simultaneously at the test room. The

52

PDF created with pdfFactory trial version www.pdffactory.com

Page 54

material of enclosure structure of test room is made up of 10mm thick

polyurethane or polystyrene, which has good insulation. There are air

re-treatment motor sets in the test room. Air comes into the room from

the ceiling of porous plate with uniform pressure, so as to assure

airflow speed in the room not over 0.25m/s and thus keep the room

temperature uniformly.

The temperature of test room is adjustable within the range of 10-43℃.

(2) Temperature requirements for different climate freezers please refer to

table 6-1.

Each test point shall keep the stipulated environment temperature, the

fluctuation range is +-0.5K. Within the range of 2m heights away from the

test platform, the vertical temperature gradient shall not exceed 2K/m.

Table 6-1 Different climate sorts for freezers

Climate types Symbols Suitable

temperature (℃)

Sub-temperate

zone

Temperate zone

Sub-tropical

zone

Tropical zone

SN

N

ST

T

10-32

16-32

18-38

18-43

Measuring

temperature (℃)

25

25

25

32

(3) Environmental humidity: normally the relative humidity is 45-75%.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(3) Test pack: Use the rectangle packs of following dimensions as the load

of freezer.

(4) Table 6-2 Test packs for freezer performance

53

PDF created with pdfFactory trial version www.pdffactory.com

Page 55

Dimensions (mm) Mass (g)

Small

Middle

Big

25×50×100

50×100×100

50×100×200

125

500

1000

In the geometrical center of 5oog

pack, there is a thermal element;

this pack is called M pack.

Note

The contents of test packs are (take 1000g pack as the datum):

hydroxyethlmethylcellulose 230g; water 764.2g; sodium chloride 5g;

parachlorometacresol 0.8g. The freezing point of filling of pack is -1℃, its

thermal property is similar to lean beef.

(5) Temperature measuring gauge: The measuring of temperature normally

use platinum resistor. There are two types:

Put the platinum resistor directly into test pack (M pack) when measuring

a. Its temperature;

b. Insert the platinum resistor into the center of four tin electroplated

copper columns, the diameter and height of column is the same 15.2mm.

The measuring equipment is temperature-measuring bridge with the

accuracy of +-0.3K.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(6) Humidity measuring instrument: the measurement of relative humidity

is wet and dry bulb method. Put the dry bulb thermometer and wet bulb

thermometer (enclose 1.5-2 layers of degreased gauze at the temperature

54

PDF created with pdfFactory trial version www.pdffactory.com

Page 56

sensing parts of thermometers, and put the bottom end of gauze into

distilled water) under the blowing of wind with the speed of 2.5-3m/s.

Record the temperature of dry bulb thermometer, and calculate the relative

humidity using the <<Relative humidity referring table for environment

test>> GB6999-86.

(7) Cooling speed

Leave the freezer at test room, room temperature is 32℃ , the inner

temperature of freezer gets balance with room temperature (temperature

difference +-1K). Close freezer door and let the freezer running

continuously. Record the time needed for storage temperature tm to reach

tm(max) in accordance with table 13-3, cooling temperature tm to reach +14

℃, and the time the freezing temperature reaches the corresponding star

level. According to standard, 250L below freezer will not exceed 2h;

250L-500L freezers will not exceed 3h.

(8) Freezing ability

The freezing ability of freezer shall not be less than 90% of rated ability.

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Maintenance Service and Trouble Shooting

(9) Electricity consumption

Leave the freezer at test room, climate temperatures are: SN, N, and ST

55

PDF created with pdfFactory trial version www.pdffactory.com

Page 57

types 25℃; T type 32℃.

Test time is 24h. The consumption of storage freezer and storage and

freezing freezer shall be less than 115% of rated; freezing freezer is less

than 110% of rated.

Other tests to be done: the measurement of temperature of storage

(10) Freezer and freezing freezer; test of storage temperature, ice

producing ability, etc.

Table 6-3 Storage temperature of freezer

type

erate

e

tropical

Climat

e type

SN

N

ST

T

Environme

nt

temp(℃)

10 Sub-temp

32

16 Temperat

32

18 Sub38

18 Tropical

43

Storage Cabin Climate

t1,t2,t3 tm max

-1≤t1,t2,t3≤10

0≤t1,t2,t3≤10

0≤t1,t2,t3≤12 7

7

5

Cooling

cabin

8≤tcm≤14

Freezing

cabin

Complies

with

One star≤-6

Two stars ≤

-12

three stars≤

-18

Exploded View

56

PDF created with pdfFactory trial version www.pdffactory.com

EXPLODED VIEW

Page 58

Exploded View

Edition:2005 12 01

Marketing model: BD-388A/478A

CARTON

USER MANAUL

LIST OF PARTS

Parts list

57

PDF created with pdfFactory trial version www.pdffactory.com

Page 59

Spare parts description in

proportion of

the

Spare parts

No.

1

2

3

4

5

6

number

0070803227 Lock

0070804794 Handle

0070810207

0072040003 Top hinge cover

0072040011 Bottom hinge cover

0077050002

Door

Screw

7

0078090002

8

0072040402

9

0072060009

10

0077050051

11

0070102849

12

0070810205

13

0070201812

0070800197 Castor

14

15

0070503876

16

0070401608 power Wire

0071150025 Lock nose

17

0077050051 Screw

18

0070200676 Drain stopper

19

0070504852 LOGO

20

21

0072040012

0070504220A

22

0070504926A

23

0070202887

24

0070202886

25

0075050003

26

0075050008

27

0072040202

Hinge

Insolution fill cap(small)

Lamp cover

Screw

Food basket

Outer cabinet

Insolution fill cap(large)

Use manual

Drain plug

Carton

control knob

panel cover

yellow light

Green light

Light cover

english

Model QTY. Price list

BD-388A/478A

BD-388A/478A

BD-388A

BD-478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

1

1

1

1

2

2

16

2

BD-388A

BD-478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A

BD-478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A

BD-478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

BD-388A/478A

2

2

2

2

1

1

1

6

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Failure

rate

the

spare-part

stock

0.931%

0.168%

0.490%

0.490%

1.400%

0.200%

0.500%

0.500%

0 0.050%

0 0.050%

0 0

0.140%

0.140%

0.280%

0.280%

0 0

0 0

0.007% 0.007%

0.189% 0.189%

0.189% 0.189%

0 0

0.168% 0.200%

0 0

0.056% 0.056%

0 0.010%

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0.010% 0.020%

0.010% 0.020%

0 0

Remark

*

X

X

X

X

X

X

X

X

X

X

X

X

X

X

*

X

*

X

X

X

X

X

X

X

X

X

*

*

*

58

PDF created with pdfFactory trial version www.pdffactory.com

Page 60

28

0070202885

29

0075040013 Thermostat

30

0072070010 Thermostat protecting-bag

31

0070102761

32

0077010062 Screw

33

0075020333 Capacitor

34

0075020357 Terminal cover

35

0075020335 Over load over heat protector

36