Page 1

R410A MULTI SPLIT SERIES ROOM AIR CONDITIONER

OUTDOOR UNIT

INSTALLATION MANUAL

AU282XHERA

AU342XHERA

NO.0010577255

A

Please read this manual carefully before installing the units.

Please keep this manual safely for future use.

Page 2

Contents

Cautions .......................................................................................................................

Safety precautions........................................................................................................

Installation accessories..................................................................................................

Choose the installation place.........................................................................................

Installation dimensions(mm)..........................................................................................

Installation drawings of indoor and outdoor units........................................................

Matching of the indoor and outdoor units

Power source.................................................................................................................

Limitations on the installation

Refrigerant piping work...........................................................................................

Purging method: to use vacuum pump.........................................................................

......................................................................................

......................................................................

10-11

1-2

3-4

4

4

4

5

6-7

8

8-9

12

Wiring work...............................................................................................................

Test running..................................................................................................................

Items to confirm...........................................................................................................

Trouble shooting...........................................................................................................

13-15

16

16

17

Page 3

Cautions

Disposal of the old air conditioner

Before disposing an old air conditioner that goes

out of use, please make sure it's inoperative and

safe. Unplug the air conditioner in order to avoid

the risk of child entrapment.

It must be noticed that air conditioner system

contains refrigerants, which require specialized

waste disposal. The valuable materials contained

in a air conditioner can be recycled. Contact your

local waste disposal center for proper disposal of

an old air conditioner and contact your local

authority or your dealer if you have any question.

Please ensure that the pipework of your air

conditioner does not get damaged prior to being

picked up by the relevant waste disposal center,

and contribute to environmental awareness by

insisting on an appropriate, anti-pollution method

of disposal.

Disposal of the packaging of your new air

conditioner

All the packaging materials employed in the

package of your new air conditioner may be

disposed without any danger to the environment.

Consult your local authorities for the name and

address of the waste materials collecting centers and

waste paper disposal services nearest to your house.

Safety Instructions and Warnings

Before starting the air conditioner, read the

information given in the User's Guide carefully. The

User's Guide contains very important observations

relating to the assembly, operation and maintenance

of the air conditioner.

The manufacturer does not accept responsibility for

any damages that may arise due to non-observation

of the following instruction.

Damaged air conditioners are not to be put into

operation. In case of doubt, consult your supplier.

Use of the air conditioner is to be carried out in

strict compliance with the relative instructions set

forth in the User's Guide.

Installation shall be done by professional people,

don't install unit by yourself.

The cardboard box may be broken or cut into

smaller pieces and given to a waste paper disposal

service. The wrapping bag made of polyethylene

and the polyethylene foam pads contain no

fluorochloric hydrocarbon.

All these valuable materials may be taken to a waste

collecting center and used again after adequate

recycling.

For the purpose of safety, the air conditioner must

be properly grounded in accordance with

specifications.

Always remember to unplug the air conditioner

before opening inlet grill. Never unplug your air

conditioner by pulling on the power cord. Always

grip plug firmly and pull straight out from the outlet.

1

Page 4

Cautions

All electrical repairs must be carried out by

qualified electricians. Inadequate repairs may result

in a major source of danger for the user of the air

conditoiner.

Do not damage any parts of the air conditioner

that carry refrigerant by piercing or perforating the

air conditioner's tubes with sharp or pointed items,

crushing or twisting any tubes, or scraping the

coatings off the surfaces. If the refrigerant spurts

out and gets into eyes, it may result in serious eye

injuries.

Do not obstruct or cover the ventilation grille of

the air conditioner. Do not put fingers or any other

things into the inlet/outlet and swing louver.

Do not allow children to play with the air

conditioner. In no case should children be allowed

to sit on the outdoor unit.

4. The wiring method should be in line with the local

wiring standard.

5. The power cable and connecting cable are selfprovided. All the cables shall have got the local

authentication certificate. During installation, when

the connecting cables break off, it must be assured

that the grounding wire is the last one to be broken

off.

6. The breaker of the air conditioner should be allpole switch; and the distance between its two contacts

should be no less 3mm. Such means for disconnection

must be incorporation in the fixed wiring.

7. The waste battery shall be disposed properly.

Specifications

The refrigerating circuit is leak-proof.

The machine is adaptive in following

situation

1. Applicable ambient temperature range:

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

2. If the supply cord is damaged, it must be replaced

by the manufacturer or its service agentor a similar

qualified person.

3. If the fuse on PC board is broken please change it

with the type of T 3.15A /250VAC or T 25A/250VAC.

Please check the circuit diagram about the fuse

replaced.

Maximum:D.B/W.B 32 C/23 C

Minimum:D.B/W.B

Maximum:D.B 43 C/26 C

Minimum:D.B

Maximum:D.B 27 C

Minimum:D.B

Maximum:D.B/W.B 24 C/18 C

Minimum:D.B/W.B

18 C/14 C

10 C/6 C

20 C

-15 C

2

Page 5

Safety precautions

To ensure proper installation, please read this safety precautions carefully before the installation. After

installation, start the unit correctly and ensure that you show the customer how to operate and maintain

the units.

WARNING!

CAUTION!

Installation work must be carried out by professional qualified people, do not install the unit by

yourself. Incorrect installation will cause water leakage, electric shock and potentially fire.

Install the unit as per the manual. Incorrect installation will cause water leakage, electric

shock or fire risk.

Be sure to use specified accessories and parts. Otherwise, water leakage, electric shock, fire risk

or unit falling down may occur .

Mounting position must be strong enough to hold the unit. Or, the unit will potentially fall down

causing injuries.

When installing the unit, take in consideration storms and high winds. Incorrect installation may

cause the unit to fall down.

All electric work should be carried out by experienced personnel as per current regulations and

this manual. Incorrect installation or undersized electric cable may cause electric shock or fire risk.

All circuits must be earthed. Ensure that no external forces will affect the terminal block and electric

cable. Poor wiring and installation may cause fire risk.

Arrange wire connection between connecting the indoor and outdoor power supply correctly. Fix

terminal cover firmly to avoid overheating, electric shock or even fire risk.

In the case of a refrigerant leakage during unit installation, keep the room well ventilated.

Check the unit upon installation. Be sure there is no leakage. Refrigerant will induce a poisonous

gas subject to heat.

Isolate power supply before touching terminal block.

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

WARNING

WARNING

All units shall be earthed. The earth must not be connected to a gas pipe, water pipe, or telephone

line. Poor earthing could cause electric shock.

Be sure to install a circuit breaker to avoid electric shock.

Arrange water drainage according to this manual. Cover pipe with insulation materials to prevent

condensation occuring. Improper installation of water drainage will cause water leakage.

To maintain good picture or reduce noise, keep the unit at least 1m from T.V. or radio,

when installing the communication wire and power supply. (If the radio wave is relatively strong,

1m is not enough to reduce the interference).

Do not install the unit in following places:

(a) Oil mist or oil gas exists, such as kitchen, or, plastic parts may age, or water leakage.

(b) Where there is corrosive gas. Copper tube and welded part may be damaged due to corrosion

causing leakage.

3

Page 6

580

185

185

Safety precautions

(c) Where there is strong radiation. It will affect the unit's control system, causing malfunction of the unit.

(d) Where there are flammable gas, dirt, and volatile matter (thinner, gasoline) exist, these items will cause

a fire risk.

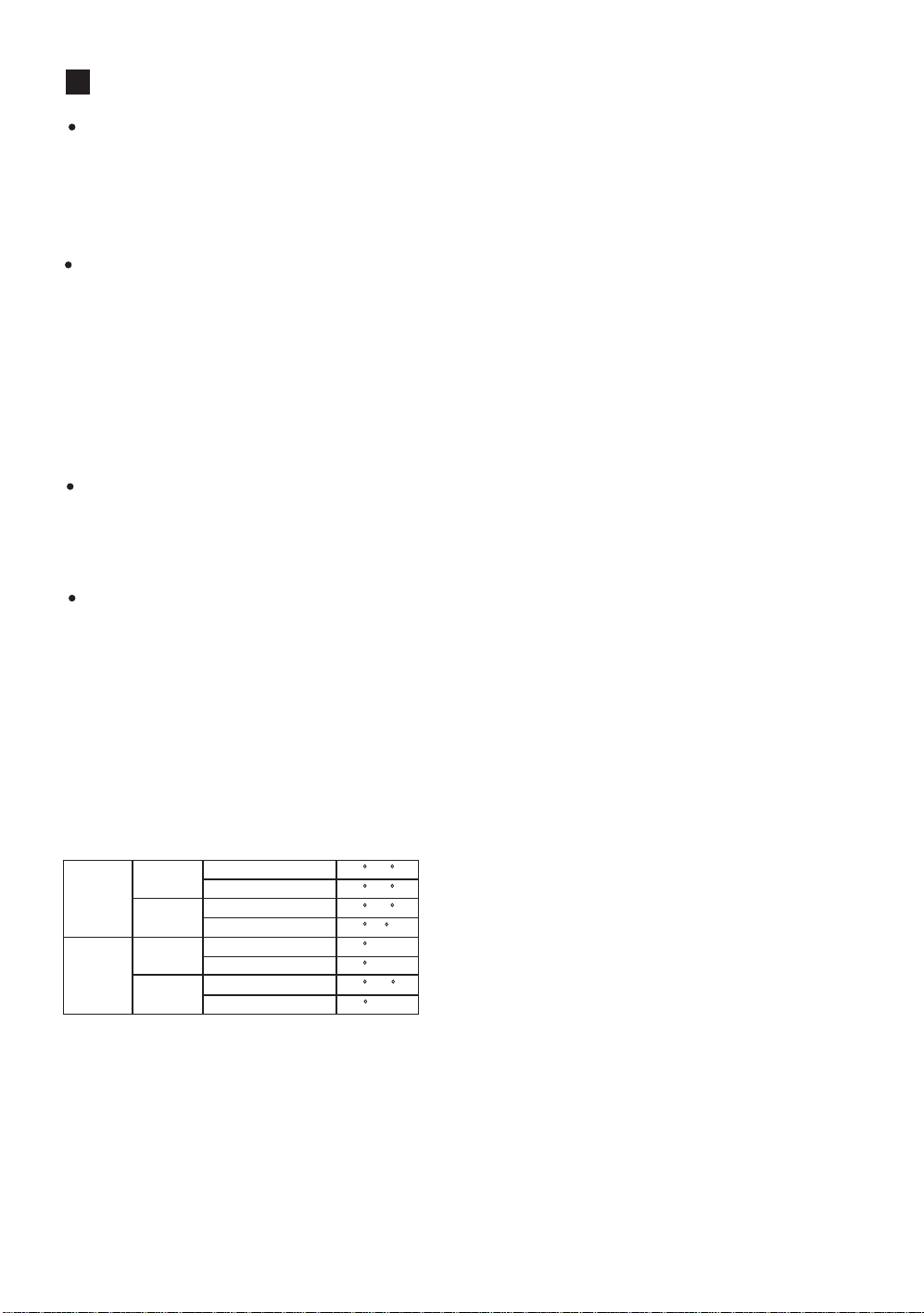

Installation accessories

The following accessories are supplied together with the outdoor unit.

No.

1

2

3

Drawing

Name of parts

Drainage elbow

Rubber cushion

Clap

Quantity

1

4

1

Choose the installation place

Place, robust not causing vibration, where the body can be supported sufficiently.

Place, not affected by heat or steam generated in the vicinity, where inlet and outlet of the unit are not

disturbed.

Place, possible to drain easily, where piping can be connected with the outdoor.

Place,where cold air can be spread in a room entirely.

Place, nearby a power receptacle, with enough space around.(Refer to drawings).

Place, where the distance of more than 1m from televisions, radios, wireless apparatuses and fluorescent

lamps can be left.

In the case of fixing the remote controller on a wall, place where the indoor unit can receive signals when

the fluorescent lamps in the room are lightened.

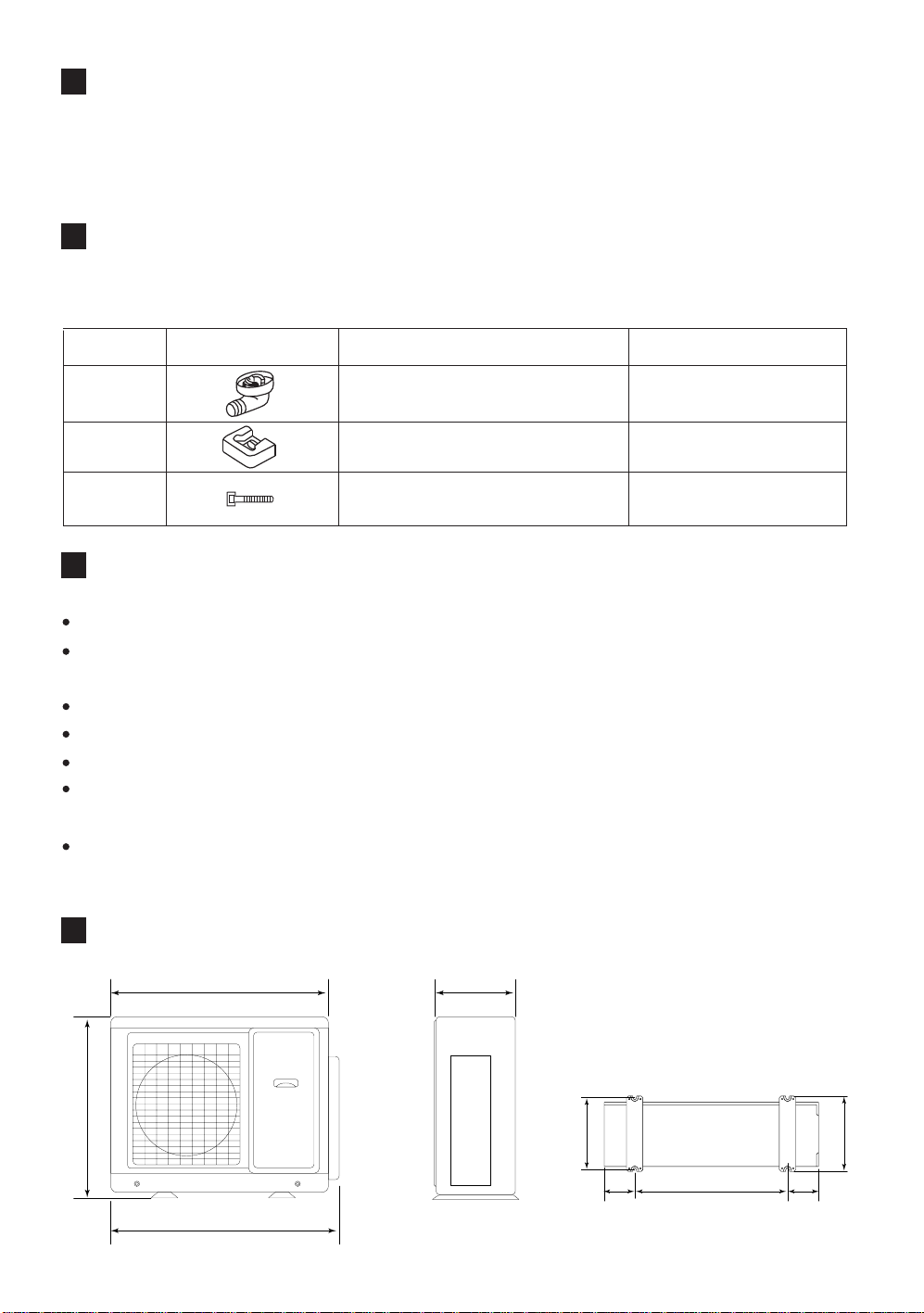

Installation dimensions(mm)

830

950

1068

340

4

380

416

Page 7

Installation drawings of indoor and outdoor units

1. Do not connected the embedded branch piping and the outdoor unit when only carrying out piping work

without connecting the indoor unit in ordor to add another indoor unit later. Make sure no dirt or mositure

gets into eigher side of the embedded branch piping.

2.It is impossible to connect the indoor unit for one room only. Be sure to connect at least 2 rooms.

Arrangement of piping directions

Rear left

Rear right

Right

Below

More than 10cm

Wrap the insulation pipe with the finishing

tape from bottom to top.

Left

More than 5cm

Cut thermal insulation pipe to an

appropriate length and wrap it with tape,

making sure that no gap is left in the

insulation pipe's cut line.

more than 10cm

more than 60cm

more than 10cm

more than 25cm

Attention must be

paid to the rising up

of drain hose

If there is the danger of the unit falling or overturning, fix the unit with foundation bolts, or with wire or

other means.

If the location does not have good drainage, place the unit on a level mounting base(or a plastic pedestal).

Install the outdoor unit in a level position. Failure to do so may result in water leakage or accumulation.

5

Page 8

Matching of the indoor and outdoor units

WARNING!

Combinations those marked * would not be applied where the temperature in winter is too low and in

summer is too higher to avoid bad heating or cooling effect.

For AU282XHERA

Combination

1:2

1:3

1:4

A

07

09

12

12

14

14

18

07

07

07

07

07

07

07

09

09

09

09

09

09

12

12

12

12

12

14

07

07

07

07

07

07

07

07

07

07

07

07

07

09

09

09

09

09

09

B

18

18

14

18

14

18

18

07

07

07

09

09

09

09

09

09

09

09

12

12

12

12

12

14

14

14

07

07

07

07

07

07

07

07

07

09

09

09

09

09

09

09

09

09

12

C

-

-

-

-

-

-

12

14

18

09

12

14

18

09

12

14

18

12

14

12

14

18

14

18

14

07

07

07

07

07

09

09

09

09

09

09

09

09

09

09

09

12

12

12

6

D

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

07

09

12

14

18

09

12

14

18

09

12

14

18

09

12

14

12

14

12

Remark

-

-

-

-

-

-

*

-

-

-

-

-

-

*

-

-

-

*

*

*

*

*

*

*

*

-

-

*

*

-

*

*

*

*

*

*

*

*

*

*

*

Page 9

Matching of the indoor and outdoor units

For AU342XHERA

Combination

1:2

1:3

1:4

A

12

14

14

18

07

07

07

07

07

09

09

09

09

09

09

12

12

12

12

12

14

14

07

07

07

07

07

07

07

07

07

07

07

07

07

07

07

07

07

09

09

09

09

09

09

09

12

B

18

14

18

18

07

07

09

09

09

09

09

09

09

12

12

12

12

12

14

14

14

14

07

07

07

07

07

07

07

07

07

07

07

09

09

09

09

09

09

09

09

09

09

09

09

12

12

C

-

-

-

14

18

12

14

18

09

12

14

18

12

14

12

14

18

14

18

14

18

07

07

07

07

09

09

09

09

12

12

14

09

09

09

09

12

12

09

09

09

09

12

12

12

12

D

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

09

12

14

18

09

12

14

18

12

14

14

09

12

14

18

12

14

09

12

14

18

12

14

12

12

Remark

-

-

*

-

-

-

-

-

-

-

*

-

*

*

*

*

*

*

*

-

-

*

-

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

7

Page 10

Power source

Before inserting power plug into receptacle, check the voltage without fail. The power source is the

same as the corresponded name plate.

Install an exclusive branch circuit of the power.

A receptacle shall be set up in a distance where the power cable can be reached. Do not extend the

cable by cutting it.

Limitations on the installation

1.Precautions on installation

Check the strength and level of the installation ground so that unit will not cause any operating vibration

or noise after installation.

In accordance with the foundation drawing in fix the unit securely by means of the foundation bolts.

It is best to screw in the foundation bolts unit their length are 20 mm from the foundation surface.

2.Selecting a location for installation of the indoor units

The maxinum allowable length of refrigerant piping, and the maxmum allowable height

difference between the outdoor and indoor units, are listed below.

(The shorter the refrigerant piping, the better the performance. Connect so that the

piping is as short as possible. Shortest allowable length per room is 3m)

Outdoor unit capacity class

Piping to each indoor unit

Total length of liquid piping between all units

AU282XHERA AU342XHERA

25m max.

60m max.

8

Page 11

Limitations on the installation

3. Limitations values on the piping work .

L1

L2

A

h

B

H +

L3

L4

The piping length information, please refer the following table.

Item

A, B, C,D liquid pipe

A, B, C,D Gas pipe

L1 (one way)

L2 (one way)

L3 (one way)

L4 (one way) m Pipe length when the compressor connects only one indoor unit

L1+L2+L3+L4 m

h

H +

H -

Unit

mm

Size of the liquid side connection pipe

mm

Size of the gas side connection pipe

m

Pipe length when the compressor connects with two indoor units

m

Pipe length when the compressor connects with two indoor units

m

Pipe length when the compressor connects only one indoor unit

Total liquid piping length(It is no need to charge additional

refrigerant within this value)

m

Drop between every two indoor units

m

Drop between the outdoor unit and the indoor unit

m

Drop between the outdoor unit and the indoor unit

Descriptions

C

D

Standard

6.35

9.52

10

10

10

10

40

1

5

5

H -

Maximum

/

/

25

25

25

25

60

5

15

10

9

Page 12

Refrigerant piping work

1. Selection of pipe

To this unit, both liquid and gas pipes shall be insulated as they become low temperature in operation.

Use optional parts for piping set or pipes covered with equivalent insulation material.

Liquid pipe

Gas pipe

2. Connection of pipe

Apply refrigerant oil on half union and flare nut.

To bend a pipe, give the roundness as large as possible not to crush the pipe.

Connecting the pipe of gas side firstly makes working easier.

Forced fastening without careful centering may damage the threads and cause a

leakage of gas.

6.35mm ( 1/4'' ) x 0.8mm

9.52mm ( 3/8'' ) x 0.8mm

Flare nutHalf union

Torque wrenchSpanner

Pipe Diameter ( )

Liquid Side 6.35mm (1/4'')

Gas Side 9.52mm (3/8'') 50N.m

3. Attaching Drain-Elbow

If the drain-elbow is used, please attach it as figure.

Fastening Torque

18N.m

10

Page 13

Refrigerant piping work

4.Cutting and Flaring work of piping

Pipe cutting is carried out with a pipe cutter and burs must be removed.

After inserting the flare nut, flaring work is carried out.

A

Pipe diameter*

Liquid side

Gas side

Flare tooling die

Correct

Incorrect

Lean Damage of flare Crack Partial Too outside

5.On drainage

Please install the drain hose so as to be downward slope without fail.

Please don't do the drainage as shown below.

6.35mm(1/4")

9.52mm(3/8")

Less than 5cm

Size A (mm)

0.8~1.5

1.0~1.5

It becomes high midway. The end is immersed in

water

It waves. It gap with the ground

ts too small.

There is the bad smell

from a ditch.

Please pour water in the drain pan of the indoor unit, and confirm that drainage is carried out serely

to outdoor.

In case that the attached drain hose is in a room, please apply heat insulation to it without fail.

11

Page 14

Purging method: to use vacuum pump

Liquid stop valve

1 .Detach the service portis cap of 3-way valve, the valve

rod's cap for 2-way valve and 3-way valves, connect the

service port into the projection of charge hose (low) for

gaugemanifold. Then connect the projection of charge

hose (center) for gaugemanifold into vacuum pump.

2 .Open the handle at low in gaugemanifold, operate

vacuum pump. If the scale-moves of gause (low) reach

vacuum condition in a moment, check 1 again.

3 .Vacuumize for over 15min. And check the level gauge

which should read -0.1MPa (-76 cm Hg) at low pressure

side. After the completion of vacuumizing, close the

handle 'Lo' in the vacuum pump. Check the condition of

the scale and hold it for 1-2min. If the scale-moves back

in spite of tightening, make flaring work again, then

return to the beginning of 3 .

4 .Open the valve rod for the 2-way valve to and an angle

of anticlockwise 90 degree. After 6 seconds, close the 2way valve and make the inspection of gas leakge.

5 .No gas leakage?

In case of gas leakage, tighten

parts of pipe connection. If

leakage stops, then proceed 6

steps.

6 .Detach the charge hose from the service port, open 2way valve and 3-way. Turn the valve rod anticlockwise

until hitting lightly.

7 .To prevent the gas leakage, turn the service ports cap,

the valve rodis cap for 2-way valve and 3-way's a little

more than the point where the torque increases suddenly.

8 .Take the same steps from 1 to 7 for each ways to

ensure a completely vacuum for the whole system.

CAUTION: If the refrigerant of the air conditioner leaks,

it is necessary to make all the refrigerant out. Vacuumize

first, then charge the liquid refrigerant into air conditioner

according to the amount marked on the name plate.

12

2 way valve

3 way valve

Open

Close

2 way valve

If it does not stop gas leakage, discharge

whole refrigerants from the service port.

After flaring work again and vacuumize,

fill up prescribed refrigerant from the gas

cylinder.

2 way valve

3 way valve

2 way valve

3 way valve

3 way valve

2 way valve

3 way valve

2 way valve

3 way valve

2 way valve

3 way valve

2 way valve

Gas stop valve

Gauge maifold(R410A)

Vacuum pump(R410A)

0

90

Service port cap

9.52mm

(3/8")

6.35mm

(1/4")

9.52mm

(3/8")

6.35mm

(1/4")

9.52mm

(3/8")

6.35mm

(1/4")

9.52mm

(3/8")

6.35mm

(1/4")

3 way valve

Service port

0

90

for 6 sec.

6

6

Valve rod cap

Valve rod cap

To indoor unit A

To indoor unit B

To indoor unit C

To indoor unit D

Page 15

Wiring work

1. Electric wiring

Note:

The air conditioner must use special circuit , and wiring by the qualified electrician according to the wiring

rules specified in national standard.

The grounding wire and the neutral wire shall be strictly separated. Connect the neutral wire with grounding

wire is incorrect.

The electric leakage breaker must be installed.

All the electric wire must be copper wire.When wiring,there shall keep a proper distance between the

power line and communication wire to avoid twist together. Otherwise,signal disturbance will occur,and

the air conditioner can not operate normally. Power supply: 1PH, 220-230V~, 50Hz.

The wiring method of power line is Y connection. If the power line is damaged, in order to avoid risk

of electric shock, it must be replaced by the manufacturer or its repair center or other similar qualified

person.The connecting cable must be shielded.

Fuse: T3.15A 250VAC T25A 250VAC (Please check with the outdoor unit wiring diagram.)

Please check the circuit diagram about the fuse replaced.

2. Wiring method

Wiring method of orbicular terminals

For the connection wire with orbicular terminals, its wiring method is as shown in

the right figure: remove the connecting screw, put the screw through the ring on the

end of the wire, then connect to the terminal block and fasten screw.

Wiring method of straight terminals

For the connection wire without orbicular terminals, its wiring method is: loosen

the connection screw, and insert the end of the connection wire completely into the Terminal block, then

fasten the screw. Slightly pull the wire outwards to confirm it is firmly held.

Correct Pressing

Wrong Pressing

Terminal

block

Wiring Method for

Ring Terminal Block

Pressing

Clamps

Crimp connection method for wires without terminals

Connect the wire with

same diameter to the

two sides of the terminal

Do not connect the

wire with same diameter

to the same side

13

Do not connect the

wire with different

diameters

Page 16

Wiring work

Crimp connection method for connection wire

After connection,the wire must be fastened by wire cover. The wire cover shall press on the protection

coat of the connection wire,as shown in right top figure.

Note:When connecting the wiring,confirm the terminal number of indoor and outdoor units carefully.

Incorrect wiring will damage the controller of air conditioner or the unit can not operate.

3. Wiring method of outdoor unit:

Power line

Remove the repair board of the outdoor unit and loosen the wire cover A,then put the live wire, neutral

wire and grounding wire through the wire cover ,and connect them to terminal block correspon

dingly. After connection, fasten wire cover to its previous state.

Communication wire of indoor unit.

Loosen wire cover , put the communication wire through the wire cover B, and connect them to

terminal block correspondingly. After connection, fasten wire cover B to its previous state.

Note: Power line and communication wire are provided by consumers themselves.

Terminal block

Cord anchorage A

Cord anchorage B

Valve cover

4. Wiring method of indoor unit

Loosen wire cover and connect the power line and communication wire of indoor unit to the

terminal correspondingly.

Note:

When connecting power line to power supply terminal, please pay attention to the following items:

Do not connect the power line with different dimensions to the same connection wire end.

Improper contact will cause heat generation.

Do not connect the power line with different dimensions to the same grounding wire end.

Improper contact will affect protection.

Keep a proper distance between the communication wire and the power line. Otherwise, abnormal

communication will occur because of disturbance. And also, the communication wires should be

shielded wire, and the shield cover should be grounded on the outdoor unit.

Do not connect the power line to the connecting end of communication wire.

Incorrect connection will cause damage to the connected unit.

14

Page 17

Wiring work

5. Example wiring diagram.

Indoor unit D

Power supply cable:

H05RN-F 3G (5.0~8.0)mm

Communication cable (Shield

wire):

H05RN-F 2 X (0.75~1.5)mm

Indoor unit C

QP2(N)1(L)

1(L) 2(N) C1 C2

Indoor unit B

4

2(N)1(L)

2

2

(P) (Q)

C2C1

3

L

N

Indoor unit A

1(L) 2(N)

4

3

Connecting cable:

H05RN-F 3G (1.5~2.5)mm

2

30A

Outdoor unit

1PH, 220-230V~, 50Hz

Please refer to the indoor unit installation manual to find detailly how to set and check the communication

address.

Incorrect address setting will cause abnormal to the system.

6. After installation, please fill in the following table for easy daily maintenance:

Indoor unit NO.

Model of indoor unit Serial no.Room name

A

B

C

D

15

Page 18

Test running

Before starting the test running, please confirm the following works have been done successfully.

1) Correct piping work;

2) Correct wiring work;

3) Correct match of indoor and outdoor unit;

4) Proper recharge of refrigerant if needed;

5) Correct indoor unit addresses setting.

Make sure that all the stop valves are fully open.

Check the voltage supplied to the outdoor and indoor units, please cinfirm that is 230V.

Test running.

1) If the temperature is lower than 16 OC, it is impossible to test cooling with remote controller, and also

when the temperature is higher than 30 OC, it is impossible to test heating.

2) To test cooling, set the lowest temperature at 16 OC. To test heating,set the highest temperature, at

30OC.

3) Please check both cooling and heating operation of each unit individually and then also check the

simultaneous operation of all indoor units.

4) After ruuning the unit for about 20 minutes, check the indoor unit outlet temperature.

5) After the unit is stopped, or working mode changed, the system will not start again for about 3 minutes.

6) During cooling operation, frost may ocur on the indoor unit or pipes, this is normal.

7) Operate the unit according to the operation manual. Please kindly explain to our customers how to

operate through the instruction manual.

Items to confirm

Check items for test run, put mark " in ".

Gas leakage from pipe connection?

Heat insulation treatment of pipe connection?

Are the connection wiring of indoor and outdoor unit firmly inserted into the terminal block?

Is the connection wiring of indoor and outdoor firmly fixed?

Is drainage securely arranged?

Is the ground wire securely and firmly connected?

Is power supply voltage abided by electric code?

Is there any noise?

Does cooling perform normally?

Does room temperature regulator operate normally?

16

Page 19

Trouble shooting

FAILURE

CODE

1 Faulty defrost sensor Te Sensor disconnected, or broken, or short circuit

5

6

9

10

11

13

14

15

16

24

25

26

27

28

29

30

31

Take of f the plastic cover on the right side of the unit, you can find the LEDs near the communication terminal.

Symbol means the LED is ON, and symbol means the LED is OFF.

STATE OF

LED 5-4-3-2-1

TROUBLE

SHOOTING

Faulty sensor Tao Sensor disconnected, or broken, or short circuit2

Faulty sensor Ts Sensor disconnected, or broken, or short circuit3

Faulty sensor Td Sensor disconnected, or broken, or short circuit4

Over current of the system, or broken of the current

Input overcurrent

Abnormal communication

between indoor and outdoor

units

System high pressure

protection

System low pressure

protection

IPM protection

EEPROM fault Faulty outdoor unit PCB12

Over hot protection of

compressor

Over hot protection of SPDU

(or ISPM)

DC fan motor fault

Faulty 4-way valve

switching on

Faulty sensor Tc Sensor disconnected, or broken, or short circuit17

Faulty sensor Toci Sensor disconnected, or broken, or short circuit21

Low voltage protection VDC<194V, too low voltage from power source23

High voltage protection

Abnormal communication

between main PCB and

SPDU(or ISPM)

Compressor be locked Faulty compressor or SPDU(or ISPM)

Compressor vibration too big

Compressor lose position Faulty SPDU(or ISPM)

Faulty compressor start Faulty compressor or SPDU(or ISPM)

Faulty position checking

circuit

Compressor broken Faulty compressor or SPDU(or ISPM)

sensor,or malfunction with indoor or outdoor fan

motors, or faulty PCB.

Wrong connection, or the wires be disconnected, or

wrong address setting of indoor units, or faulty

PCB, or faulty power supply

High pressure switch is disconnected, or high

pressure switch worked, or Tc too high and faulty

outdoor fan motor when cooling, or faulty indoor

fan motors when heating, or refrigerant

overabundance

Low pressure switch is disconnected, or low

pressure switch worked, or Te too low and faulty

outdoor fan motors when heating, or faulty indoor

fan motor when cooling, or refrigerant shortage

IPM over current, or short circuit, or IPM

temperature too high, or IPM input voltage too

low,or faulty SPDU(or ISPM).

Serious lack of refrigerant of the system, or the

ambient temperature too high, or PMVs be

blocked

Ambient tempreatrue too high, or outdoor fan be

blocked, or bad air circulation of outdoor unit

Fan is blocked, or the terminal is disconnected

from the PCB

Coil of 4-way valve is disconnected, or faulty

outdoor PCB

VDC>400V, too high voltage from power source

Communication cables broken, or not be well

connected, or faulty main PCB, or faulty SPDU(or

ISPM)

Faulty compressor

Faulty SPDU(or ISPM)

17

POSSIBLE REASONS

Page 20

HAIER GROUP

Qingdao Haier Air Conditioner Electric Co., Ltd.

Address: Haier Garden, Qianwangang Road, Economic Development Zone,

Qingdao, Shandong 266555, P.R.China

Web Site: http://www.haier.com

Loading...

Loading...