Service Manual

Commercial Air Conditioning

14 18 Universal Outdoor Fixed Frequency Series

AC142ACBEA+AU142AFBEA

AD142AMBEA+AU142AFBEA

AB142ACBEA+AU142AFBEA

AC182ACBEA+AU182AFBEA

AD182AMBEA+AU182AFBEA

AB182ACBEA+AU182AFBEA

Features

Fixed frequency

Auto-restart function

Group control(if with a group controller)

Auto-changeover

The Outdoor unit can match with cassette \convertible\duct indoor

Weekly timing(if with a weekly timer)

With new environment friendly refrigerant R407C

Haier Group

MANUAL CODE: SYJS-007 rev.0

CONTENTS

CONTENTS

Contents

1. Description of Products & Features…………...…….1

2. Specifications…………………. ………………...……3

3. Mechnical Data………………..…...………………. 7

4. Electrical Data…… …......…....…..… 36

5.Performance Curves ………...….…………. ………..45

6. Charts …………………….........……..…… ..………47

7. Electrical Control Functions …..........………………56

8.Diagnostic Information (Trouble Shooting) ...............62

9. Installation Instructions and Maintenance ….......…67

10. Exploded Views and Parts lists...............…. ……102

- 1 -

DESCRIPTION OF PRODUCTS & FEATURES

1 DESCRIPTION OF PRODUCTS & FEATURES

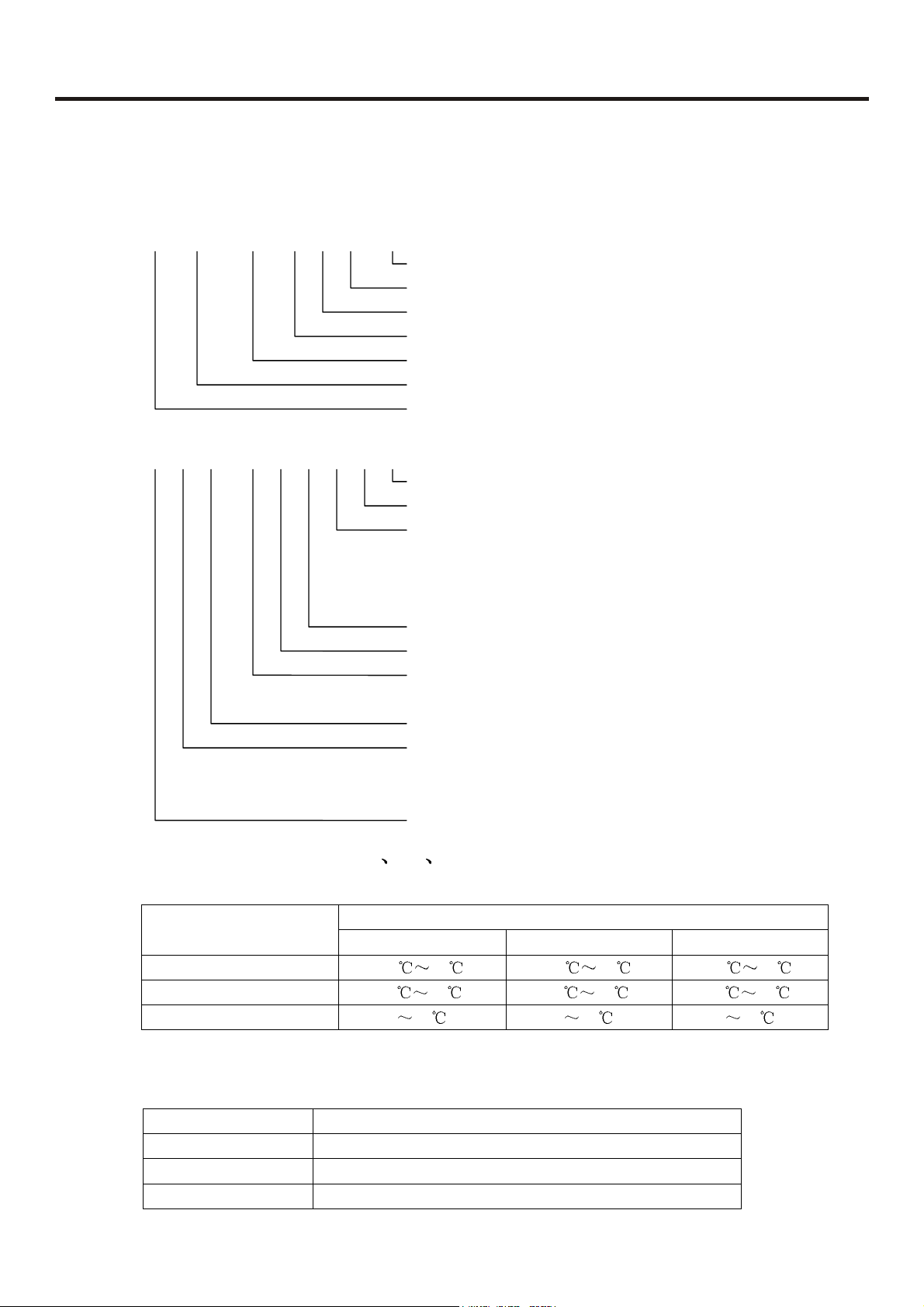

1.1 Products coding direction

Old code

H BU – 14 H A 03/ R1

Refers to HFC refrigerant, fixed frequency

Power: 03(230V/50Hz).04(240V/50Hz).12(115V/60Hz).13(230v/60Hz)

Design series number

“H” refer to cooling and heating, ”C” refer to cooling only

Nominal cooling capacity (BTU/h), 14=14000BTU/h

Indoor unit code: "B" Cassette type; "C" convertible "D" Duct type

“H” means “Haier”

New code

A B 14 2 A C B E A

Climate type: T1 (see table 1)

Design number (E stands for fixed frequency heat pump air conditioner)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407

M stands for cool only type, refrigerant is R22

N stands for cool only type, refrigerant is R407

Appearance character

Product series: one wall-mounted split type

Applicable voltage: 2 stands for 220-240V/50Hz,4 stands for 220v/60Hz

N stand for 380V/50Hz

Cooling / Heating capacity,14=14000BTU/h

Product type : “B” stands for cassette type, “C” stands for convertible

type, ”D” stands for duct, “S” stands for split type, ”Q” stands for chiller

Air conditioner

system, "E" stands for ceiling concealed type, “U” stands for outdoor unit

1.2 Brief Introduction to T1 T2 T3 working condition

Table 1

Type of Air Conditioner

Climate type

T1 T2 T3

Cool only

Heat pump

Electricity heating

18

-7

43 10 35 21 52

43 -7 35 -7 52

43 35 52

1.3 Operating Range of air conditioners

Normal condition

Operation Operation Range Outside / Inside

Cooling

Drying

Heating

150C – 43oC

150C – 43oC

-7oC – 18oC

NEW

NEW

NEW

DESCRIPTION OF PRODUCTS & FEATURES

1.4 Products characteristic

The outdoor unit can match with different indoor unit

The indoor unit can be cassette type\convertible type and duct type. Due to its compact size it

neither breaks the harmonization of indoor decoration nor occupies the indoor spaces. The stylish

appearance of air conditioner allows it to blend right into ceiling.

Superbly efficient healthy filter

Superbly efficient antibiotic materials are utilized and can prevent germs from breeding efficiently.

Flexible and easy installation

Slim design with machine body, completely ceiling concealed and portable shape, all make it

greatly easier to install. Moreover, it occupies least constructional spaces, which help to reduce

constructional cost prices. It also features a specific drainage system with up to 600mm lift, which

allows reducing installation spaces and ensures to drain smoothly. Thanks to its "smudge-free"

mobile outlet grill, the ceiling can be protected from pollution effectively and allow the airflow to fit

people's comfortable need much more.

ESP can be from 0Pa to 50Pa; in the meantime, the duct unit is equipped with a filter and air return

box.

Auto-Restart function

When meeting a power failure during running, no matter how long it will be, once the power is

restored, air conditioner will automatic restart with the previous status.

Safety and reliable control due to various signal controls

1.Inputting with press buttons on the panel

2.Inputting with temperature sensors (indoor ambient temperature sensors, indoor coil pipe

temperature sensors)

3.Piping pressure signals

4.Compressor current signals

5.Testing signals

6.System time-shorten signal

7.Water overflowing signal

8.Communication signals between indoor unit and front plate or between indoor unit and outdoor

unit.

Universal convenient remote-controller

When using remote-controlling mode, it is comfortable and convenient to operate. The remote

controller is used as new style; it looks like a phone, very compact. It is a universal controller and

can be used for any unit such as single unit, multi free unit, MRV, etc. compatible with the old ones.

New wired controller

One wired controller can control 16 indoor units without any other device such as detector.

Silent design

The use of radial outward flow turbine fan produces large airflow volume and acts to significantly

decrease operating noise.

Low ambient temperature cooling function (optional)

Equipped with high/low pressure protection switch

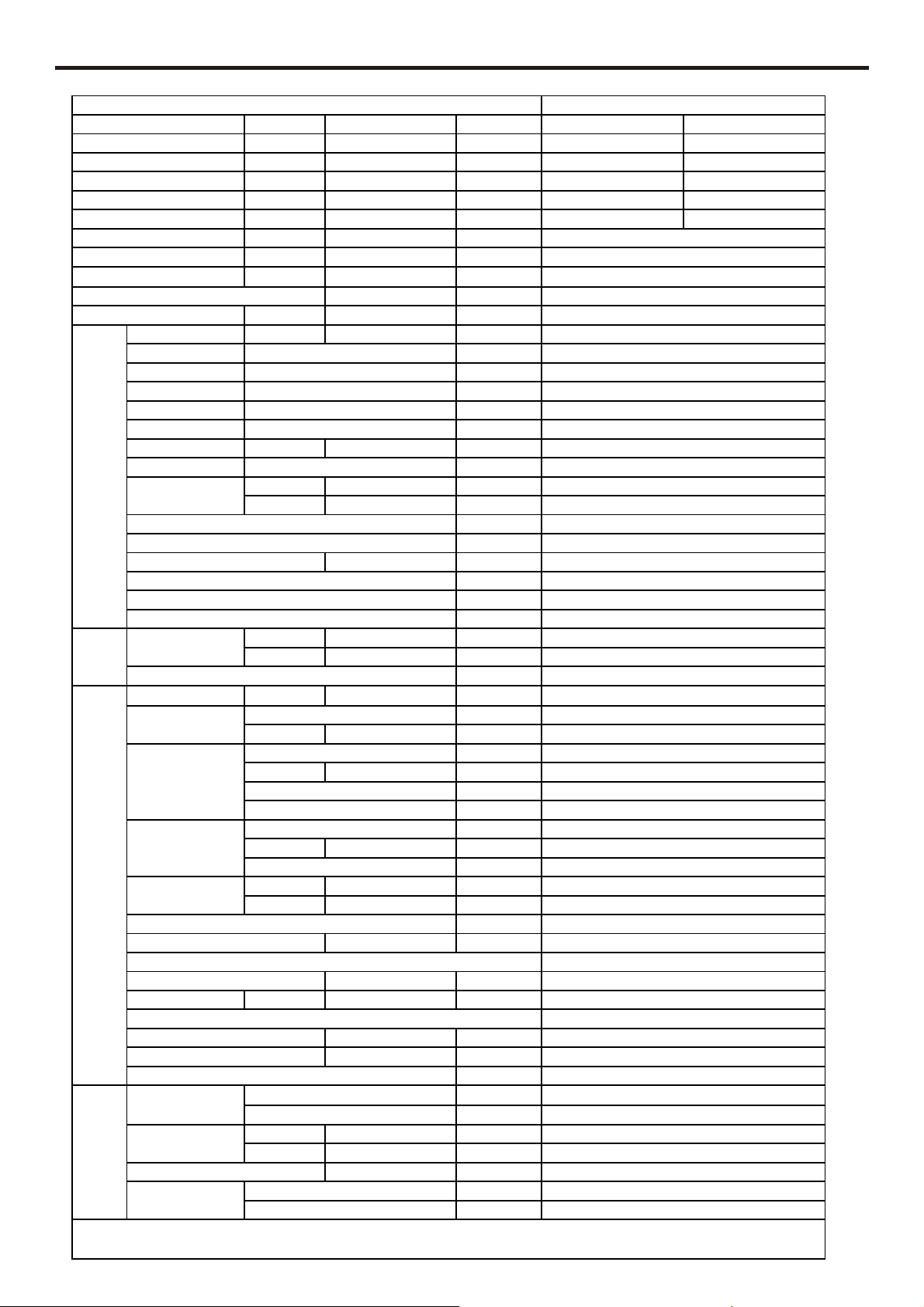

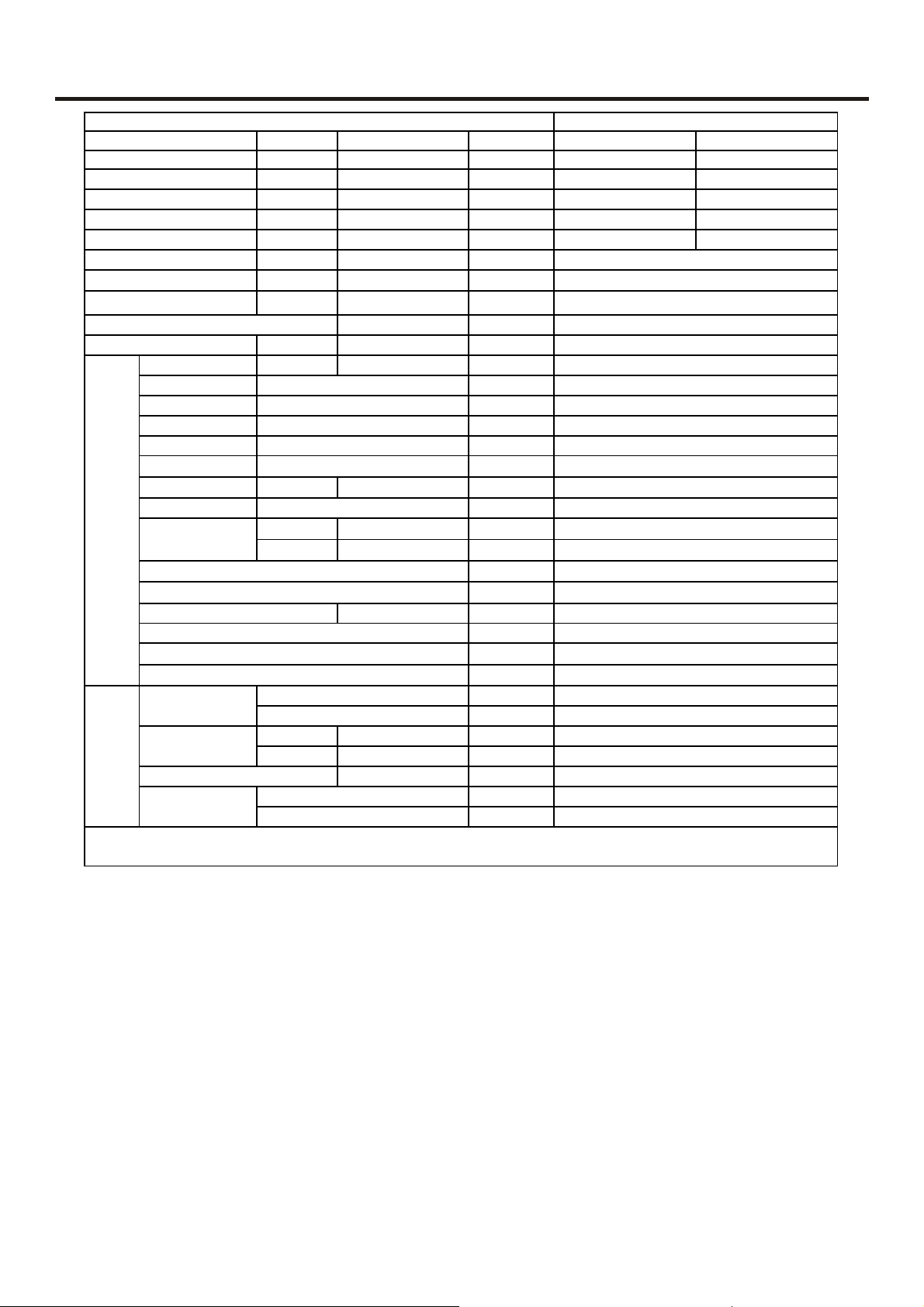

2 SPECIFICATIONS

item Model

Function

Capacity KW

Capacity BTU/h

Total power input W

Max. power input W

EER

or COP

Dehumidify capacity

Power cable

Power source

Running /Max.Running current A / A

Start current A

Unit model (color)

Fan type×number

speed (H-M-L) r/min

Fan motor output power W

Air-flow(H-M-L) m³/h

Heat exchanger

Type / Diameter

Total Area

Temp. scope

Dimension

indoor unit

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired)

Fresh air hole dimension mm

Electricity Heater

Noise level (H-M-L)

Weight (Net / Shipping)

Dimension

Panel

Weight (Net / Shipping)

External

Package

External

Package

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

W/W

10‐³×m³/h

N,V,Hz

mm

m²

℃

mm×mm×mm

mm×mm×mm

kW

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

Unit model (color)

Compressor

Model / Manufacture

Type

Type × Number

Fan

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Heat exchanger

Dimension

Outdoor unit

Drainage pipe (material , I.D./O.D.) mm

Total area m²

Temp. scope

External

Package

(L×W×H)

(L×W×H)

℃

mm×mm×mm

mm×mm×mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

Connecting Method

PIPING

Between I.D &O.

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop

MAX.Piping length

kg / kg

m

m

AU142AFBEA/AB142ACBEA

cooling heating

4.10 4.39

14000 15000

1550 1450

1800 1800

2.65 3.03

2.95

2X2.0+2X0.75

1PH 220V-230V 50HZ

cooling:7.8/8.5 heating:6.8/8.5

40

AB142ACBEA (grey)

centrifugal×1

900±30/850±30/750±30/610/540

20

1100/1000/900

9.52

653*200*65

5-10

700*570*276

775*715*361

PVC、26/32

remote

100

0

53.5/51.5/49.8

26/28

630*630*93

685*685*155

4.2/6.3

AU142AFBEA(WHITE)

PG260X2CS-4KT1 toshiba

rotary

Axial-flow

820±30

35

2300

TP2M/9.52

0.92

43-60

780x650x250

903x714x343

/

main: 1.7*400,auxiliary:2.0*140

auto

/

58/--/50

/

XPE

/

41/43

R407C 1600

50

6.35

12.7

flared

20

30

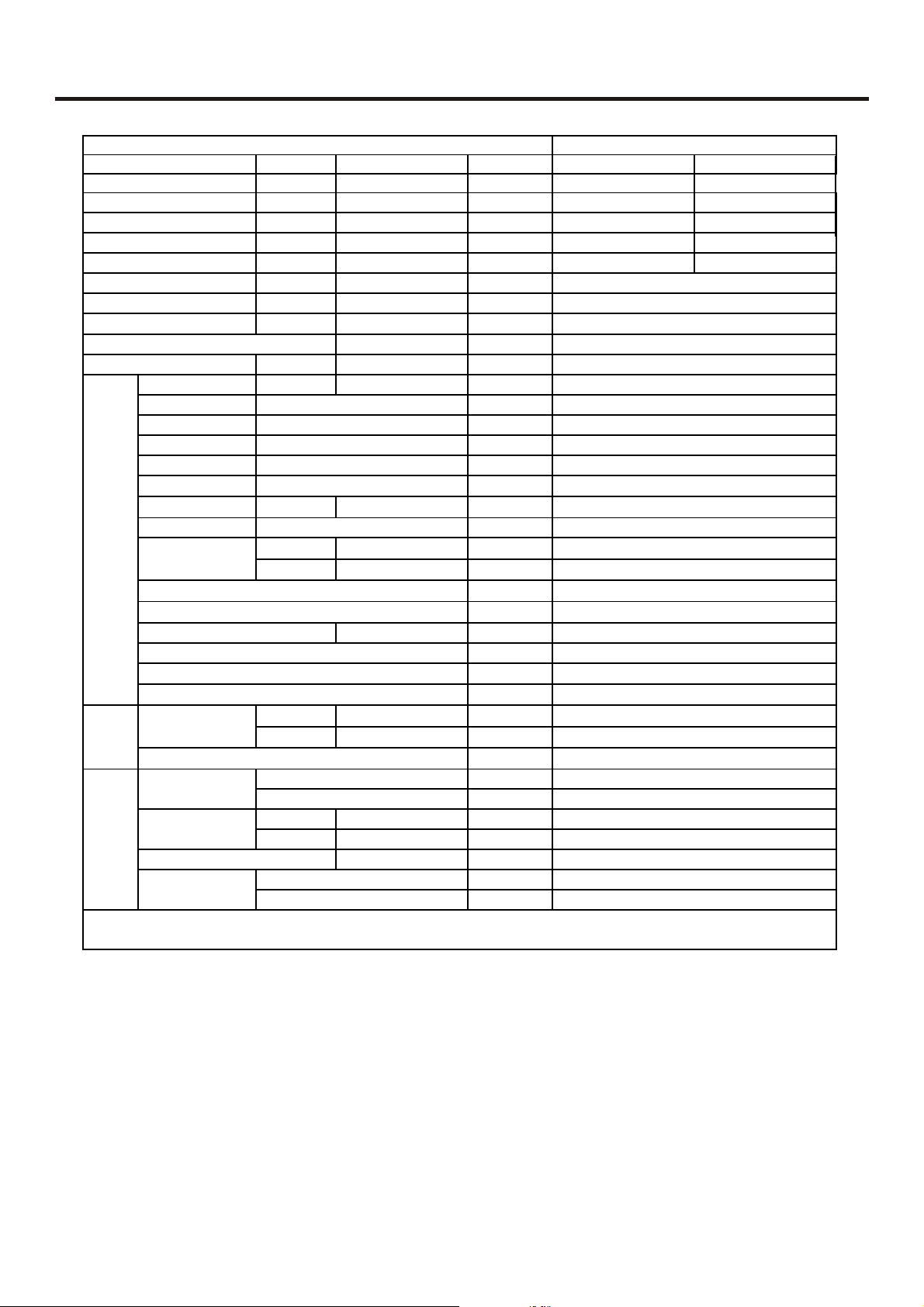

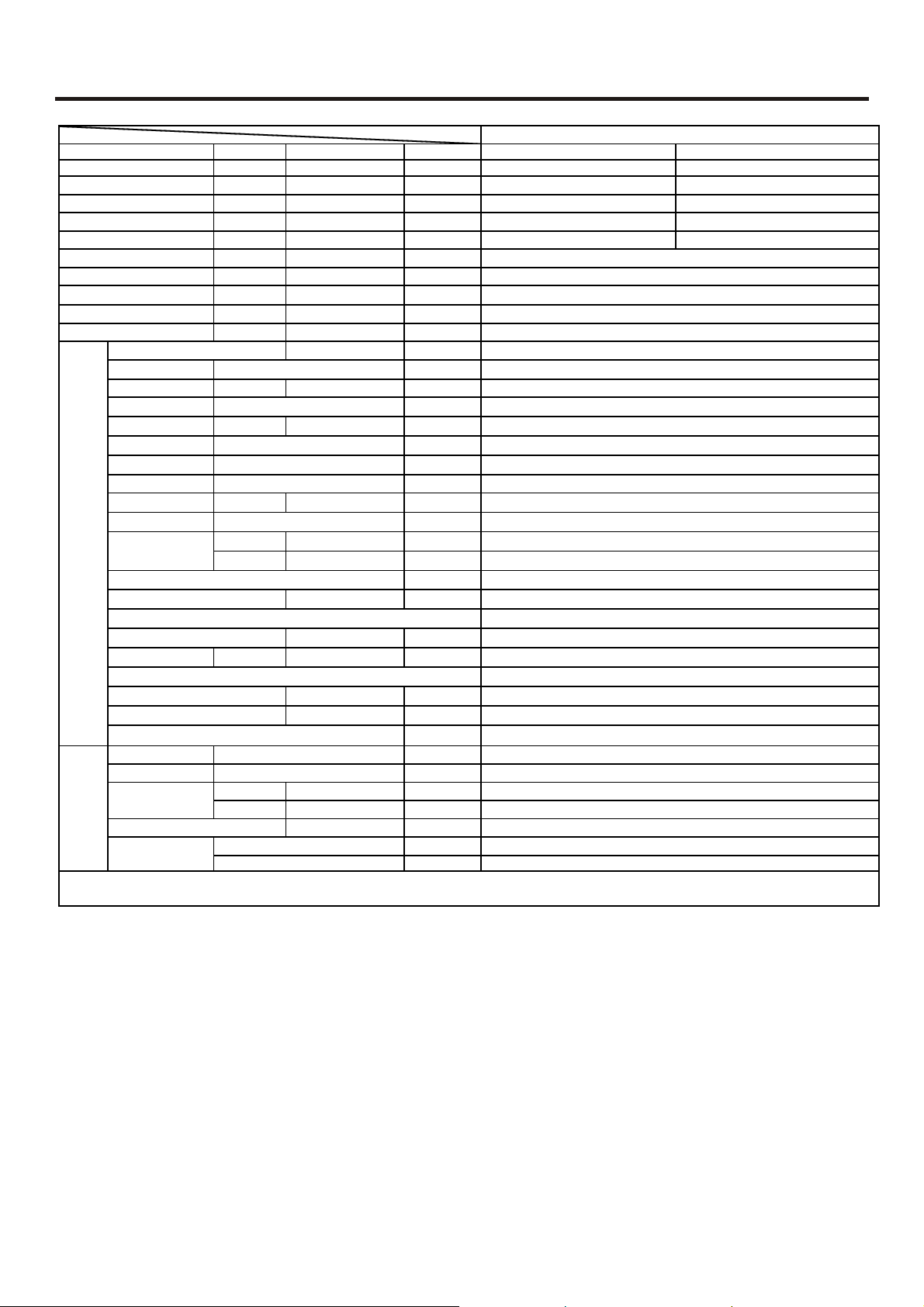

item Model

Function

Capacity KW

Capacity BTU/h

Total power input W

Max. power input W

or COP

EER

Dehumidify capacity

W/W

10‐³×m³/h

Power cable

Power source

N,V,Hz

Running /Max.Running current A / A

Start current A

Unit model (color)

Fan type×number

speed (H-M-L) r/min

Fan motor output power W

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

Total Area m²

Dimension

indoor unit

Temp. scope

External

Package

(L×W×H)

(L×W×H)

℃

mm×mm×mm

mm×mm×mm

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired)

Fresh air hole dimension mm

Electricity Heater /

Noise level (H-M-L)

Weight (Net / Shipping)

Dimension

Panel

Weight (Net / Shipping)

External

Package

(L×W×H)

(L×W×H)

kW

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

Unit model (color)

Compressor

Model / Manufacture

Type

Type × Number

Fan

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Heat exchanger

Dimension

Outdoor unit

Drainage pipe (material , I.D./O.D.) mm

Total area m²

Temp. scope

External

Package

(L×W×H)

(L×W×H)

℃

mm×mm×mm

mm×mm×mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop 20

D

MAX.Piping length 30

kg / kg

m

m

AU142AFBEA/AC142ACBEA

cooling heating

4.10 4.39

14000 15000

1550 1450

1800 1800

2.65 3.03

2.95

2X2.0+2X0.75

1PH 220V-230V 50HZ

cooling:7.8/8.5 heating:6.8/8.5

40

AC142ACBEA (white)

centrifugal×2

1350±30/1280±30/1210±30

20W

1100/1000/900

9.52

653*200*65

5-10

830*450*225

976*526*288

PVC、26/32

remote

/

53.5/51.5/49.8

20/22

/

/

/

AU142AFBEA(WHITE)

PG260X2CS-4KT1 toshiba

rotary

Axial-flow

820±30

35

2300

TP2M/9.52

0.92

43-60

780x650x250

903x714x343

/

main: 1.7*400,auxiliary:2.0*140

auto

/

58/--/50

/

XPE

/

41/43

R407C 1600

50

6.35

12.7

flared

Norminal condition: indoor temperature (cooling): 27 ℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7 ℃DB/6℃WB

item Model

Function

Capacity KW

Capacity BTU/h

Total power input W

Max. power input W

EER

Dehumidify capacity

Power cable

Power source

Running /Max.Running current A / A

Start current A

AU142AFBEA/AD142AMBEA

cooling heating

4.10 4.39

14000 15000

1550 1450

1800 1800

or COP

W/W

2.65 3.03

10‐³×m³/h

N,V,Hz

1PH 220V-230V 50HZ

cooling:7.8/8.5 heating:6.8/8.5

Unit model (color)

AD142AMBEA (white)

Fan type×number

speed (H-M-L) r/min

1290±30/1220±30/940±30/710±40

Fan motor output power W

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

Total Area m²

Temp. scope

Dimension

indoor unit

External

Package

(L×W×H)

(L×W×H)

℃

mm×mm×mm

mm×mm×mm

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired)

Fresh air hole dimension mm

Electricity Heater /

Noise level (H-M-L)

Weight (Net / Shipping)

Dimension

Panel

Weight (Net / Shipping)

External

Package

(L×W×H)

(L×W×H)

Unit model (color)

Compressor

Model / Manufacture

Type

kW

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

AU142AFBEA(WHITE)

PG260X2CS-4KT1 toshiba

Type × Number

Fan

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Heat exchanger

Dimension

Outdoor unit

Drainage pipe (material , I.D./O.D.) mm

Refrigerant control method mm/mm

Total area m²

Temp. scope

External

Package

(L×W×H)

(L×W×H)

℃

mm×mm×mm

mm×mm×mm

main: 1.7*400,auxiliary:2.0*140

Defrosting

Volume of Accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop 20

D

MAX.Piping length 30

kg / kg

m

m

2.95

2X2.0+2X0.75

40

centrifugal×2

20W

950/850/770

9.52

653*200*65

5-10

830*450*225

980*543*305

PVC、18/21

remote

/

40/38/36

25/28

/

/

/

rotary

Axial-flow

820±30

35

2300

TP2M/9.52

0.92

43-60

780x650x250

903x714x343

/

auto

/

58/--/50

/

XPE

/

41/43

R407C 1600

50

6.35

12.7

flared

Norminal condition: indoor temperature (cooling): 27 ℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7 ℃DB/6℃WB

item Model

Function

Capacity KW

Capacity BTU/h

Total power input W

Max. power input W

EER or COP

Dehumidify capacity

Power cable

Power source

Running /Max.Running current A / A

Start current A

Unit model (color)

Fan type×number

speed (H-M-L) r/min

Fan motor output power W

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

Total Area m²

Temp. scope

Dimension

indoor unit

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired)

Fresh air hole dimension mm

Electricity Heater

Noise level (H-M-L)

Weight (Net / Shipping)

Dimension

Panel

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.D

Norminal condition: indoor temperature (cooling): 27 ℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7 ℃DB/6℃WB

External

Package

External

Package

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop

MAX.Piping length

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

WW

10‐³×m³/h

N,V,Hz

℃

mm×mm×mm

mm×mm×mm

kW

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

m

m

cooling heating

18000 20000

cooling: 10/12 heating: 9.5/14

AB182ACBEA

5.27 5.86

2000 1900

2400 2800

2.64 3.08

1.2

4X0.75

1PH 220V-230V 50HZ

50

AB182ACBEA(WHITE)

CENTRIFUGAL*1

500±30/450±40/380±50

0.04

1050/945/790

TP2M/7

0.199

2-7

750×750×280

900×900×460

PVC 26/32

remote

/

/

43/42/40

29/39

750x750x80

800x800x180

3.5/5.8

R407C 1950

30

6.35

15.88

flared

20

30

item Model

Function

Capacity KW

Capacity BTU/h

Total power input W

Max. power input W

EER or COP

Dehumidify capacity

Power cable

Power source

Running /Max.Running current A / A

Start current A

Unit model (color)

Fan type×number

speed (H-M-L) r/min

Fan motor output power W

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

Total Area m²

Temp. scope

Dimension

indoor unit

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired)

Fresh air hole dimension mm

Electricity Heater

Noise level (H-M-L)

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.D

Norminal condition: indoor temperature (cooling): 27 ℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7 ℃DB/6℃WB

External

Package

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop

MAX.Piping length

(L×W×H)

(L×W×H)

W/W

10‐³×m³/h

N,V,Hz

℃

mm×mm×mm

mm×mm×mm

kW

dB(A)

kg / kg

m

m

cooling heating

18000 20000

cooling: 10/12 heating: 9.5/14

AC182ACBEA

5.27 5.86

2000 1900

2400 2800

2.64 3.08

2.1

4X0.75

1PH 220V-230V 50HZ

50

AC182ACBEA(WHITE)

CENTRIFUGALX2

1070+30/1000+40/940+50

0.04

900/840/790

TP2M/9.52

0.199

2-7

1990×655×199

1150×750×300

PVC 18/20

remote

/

/

48/44/38

30/39

R407C 1950

30

6.35

15.88

flared

20

30

item Model

Function

Capacity KW

Capacity BTU/h

Total power input W

Max. power input W

EER or COP

Dehumidify capacity

Power cable

Power source

Running /Max.Running current A / A

Start current A

Unit model (color)

Fan type×number

speed (H-M-L) r/min

Fan motor output power W

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

Total Area m²

Temp. scope

Dimension

indoor unit

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired)

Fresh air hole dimension mm

Electricity Heater

Noise level (H-M-L)

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.D

Norminal condition: indoor temperature (cooling): 27 ℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7 ℃DB/6℃WB

External

Package

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop

MAX.Piping length

(L×W×H)

(L×W×H)

WW

10‐³×m³/h

N,V,Hz

cooling: 10/12 heating: 9.5/14

℃

mm×mm×mm

mm×mm×mm

kW

dB(A)

kg / kg

m

m

AD182AMBEA

cooling heating

5.27 5.86

18000 20000

2000 1900

2400 2800

2.64 3.08

1.2

4X0.75

1PH 220V-230V 50HZ

50

AD182AMBEA(WHITE)

CENTRIFUGALx2

780+30/710+30/630+50

0.13

850/770/680

TP2M/9.52

0.199

2-7

990×650×300

1137×800×320

PVC 26/32

wired+remote

/

/

33/31/28

38/55

R407C 1950

30

6.35

15.88

flared

20

30

g

g

y

ping

item Model

Function

Capacit

Capacity BTU/h

Total power input

Max. power input

EER or COP

Dehumidifying capacity

Power cable

Power source

Running /Max.Running

Start Current A

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

Total area m²

Temp. scope

Dimension

Outdoor unit

Drainage pipe (material , I.D./O.D.) mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant Type / Charge g

Pipe

PIPING

Connecting Method

Between I.D &O.

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

External

Package

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop 20

MAX.Pi

(L×W×H)

(L×W×H)

length 30

KW

W

W

W/W

10‐³×m³/h

N,V,Hz

A / A

℃

mm×mm×mm

mm×mm×mm

kg / kg

m

m

Coolin

5.27 5.86

18000 20000

2000 1900

2400 2800

2.64 3.08

cooling: 10/12 heating: 9.5/14

PG330X2CS-4KU1 Toshiba

Main capillary2.0x450;Sub-capillary2.0x200

AU182AFBEA

1PH 220V-230V 50HZ

AU182AFBEA(WHITE)

810x288x680

960x406x760

R407C 1950

Heatin

2.1

4X0.75

50

Rotary

Axial-flow

820±30

35

2000

TP2M/9.52

0.72

43-60

/

Auto

/

52/--/46

/

XPE

/

59/66

30

6.35

15.88

Flare

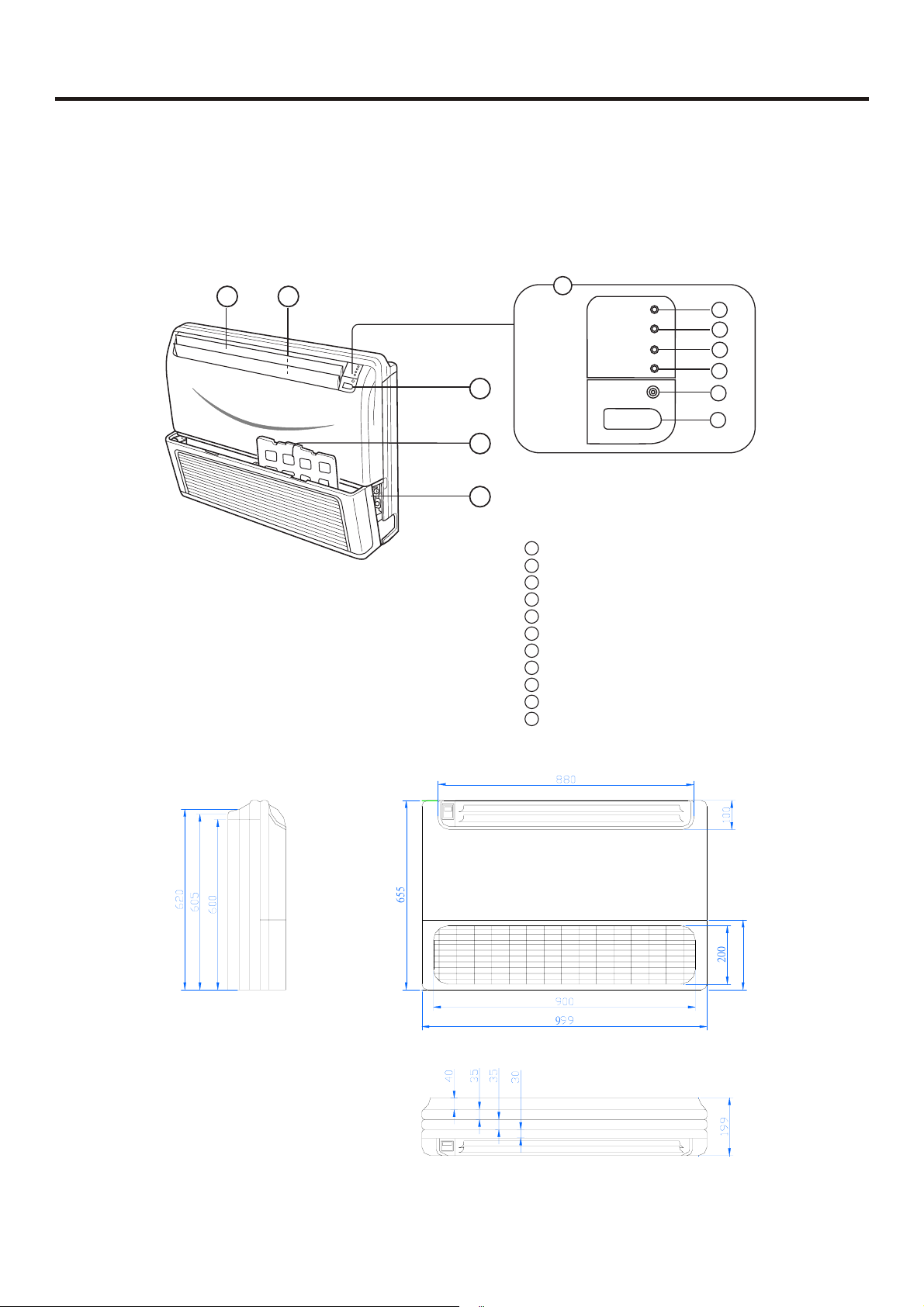

3 MECHANICAL DATA

3.1 Drawings / Dimensions

3.1.1 Cassette Indoor unit

Swing louver

(Air flow direction can be adjusted by using

the SWING button on the remote controller)

Electrical Components Case

Air Inlet Grille

3.1.2 outdoor unit

Air Filter (Inside of the Inlet Grille)

Air inlet

Compressor(inside of unit)

Air outlet

18 series

Dimension

(Ceiling opening hole)

e

l

e

c

t

r

i

c

a

l

b

o

x

)

e

l

o

h

g

n

i

n

e

p

o

g

)

n

i

置

l

i

位

e

C

挂

(

悬

(

400

190

65

75

N

I

M

110

150

.

N

I

M

M

I

N

.

.

M

I

N

.

Needed minimum position

480

265

30

170

200

220

680

100 100

810

580

288

Convertible type

Fig.1

Dimension

Fig.2

1

POWER

OPER

TIMER

COMP

EMER

4

5

6

7

2

3

1110

3

9

8

Fig.1 Indoor Unit

1 Operating Control Panel (Fig.2)

2 Emergency switch

3 Remote Control Signal Receiver

4 Power Indicator Lamp (Red)

5 OPERATION Indicator Lamp (Green)

6 TIMER Indicator Lamp (Yellow)

7 Compressor Run Lamp (Green)

8 Intake Grill (Fig.3)

9 Air Filter

10

UP/DOWN Air Direction Flaps

11

RIGHT/LEFT Air Direction Louvers

(behind UP/DOWN Air Direction Flaps)

5

5

6

0

0

2

240

9

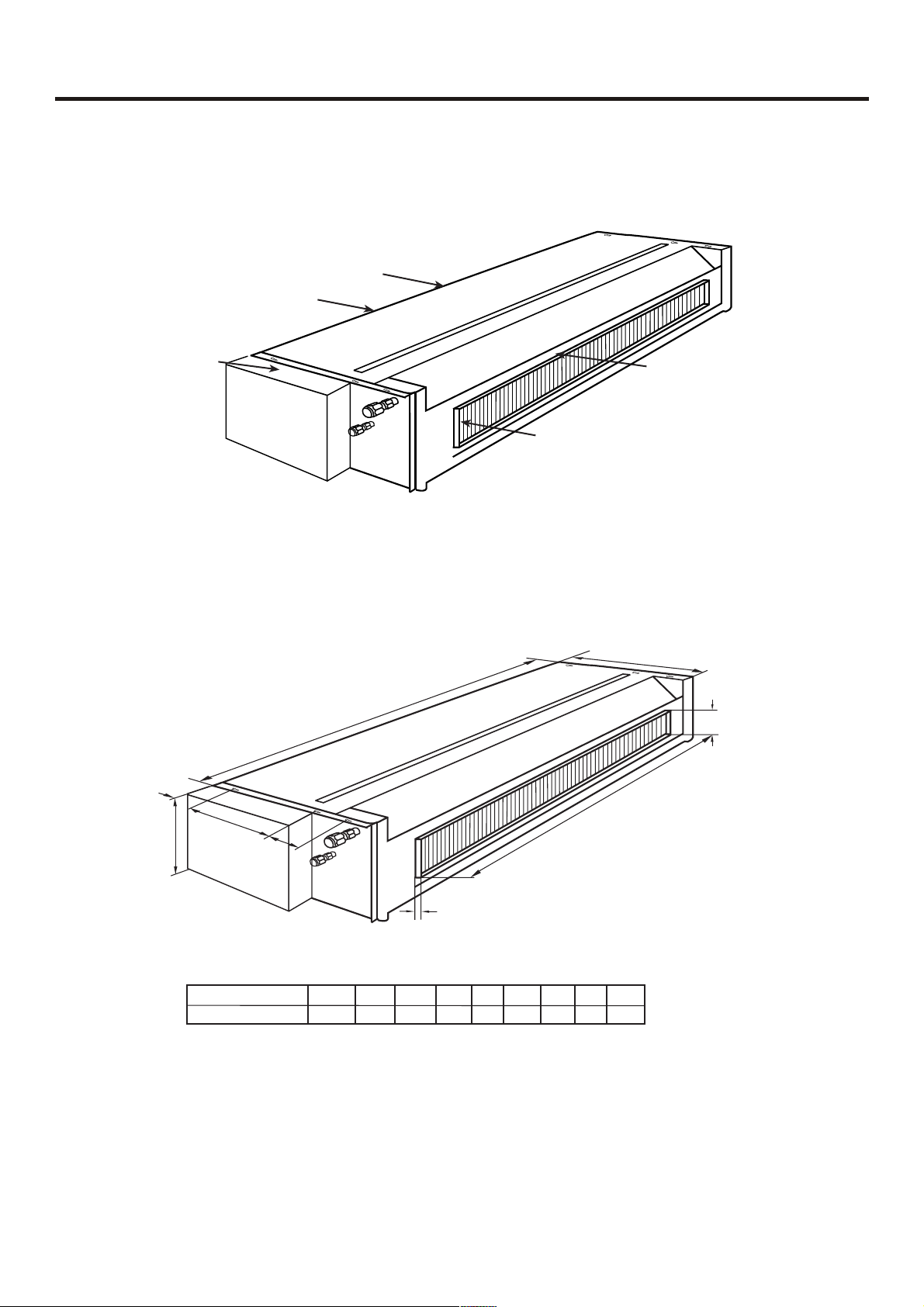

ceiling concealed type Indoor unit

fan inside

motor inside

electric control box

C

B

air duct

evaporator

A

@

G

D

?

E

9JLM?HH?MGKJ BGICJLGKJ4 +=JGM4 II,

<>;8

57.1/5:685

?@ABCDEFG

2-- 30- 12- //2 3- //2 ./0 // .--

F

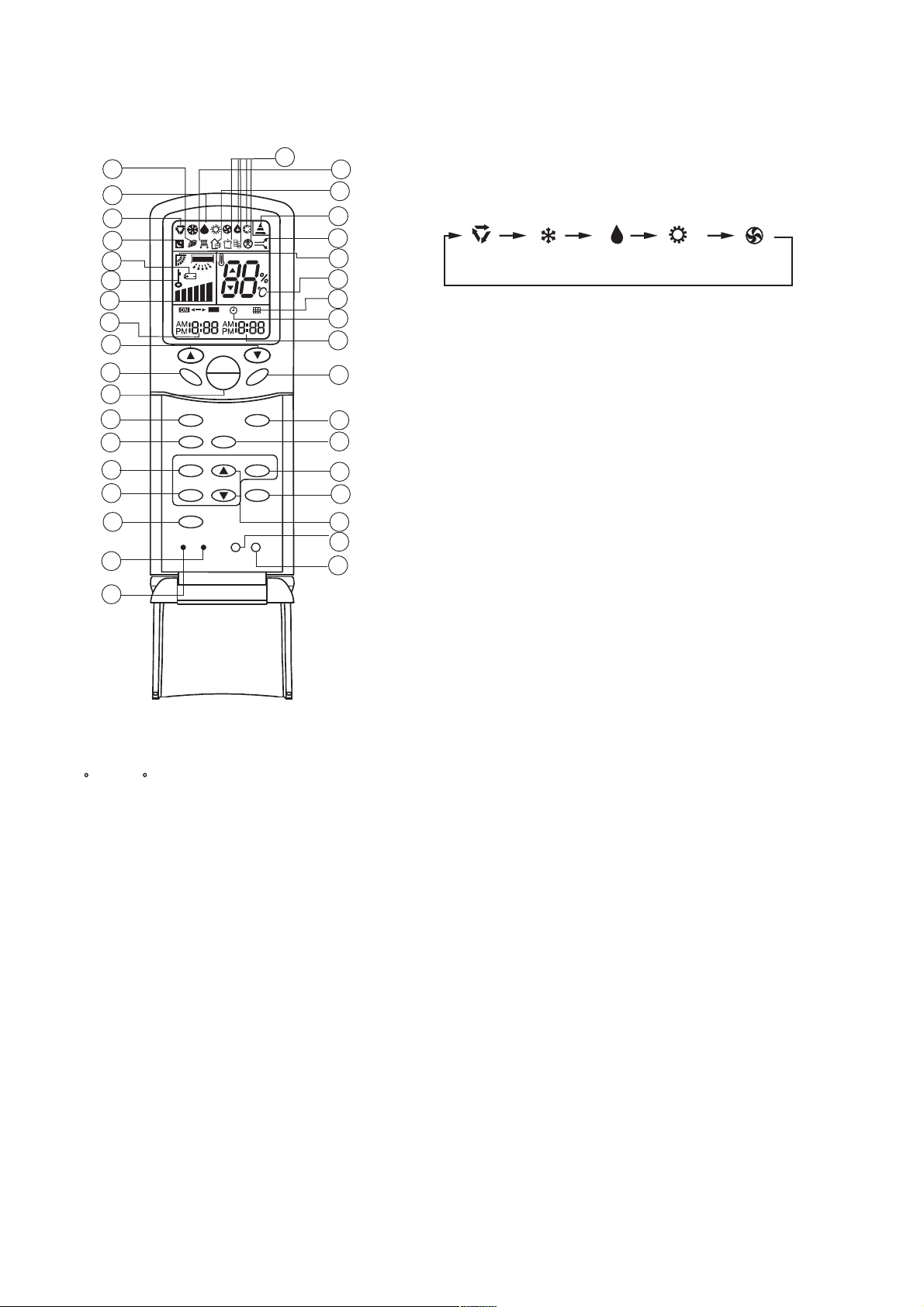

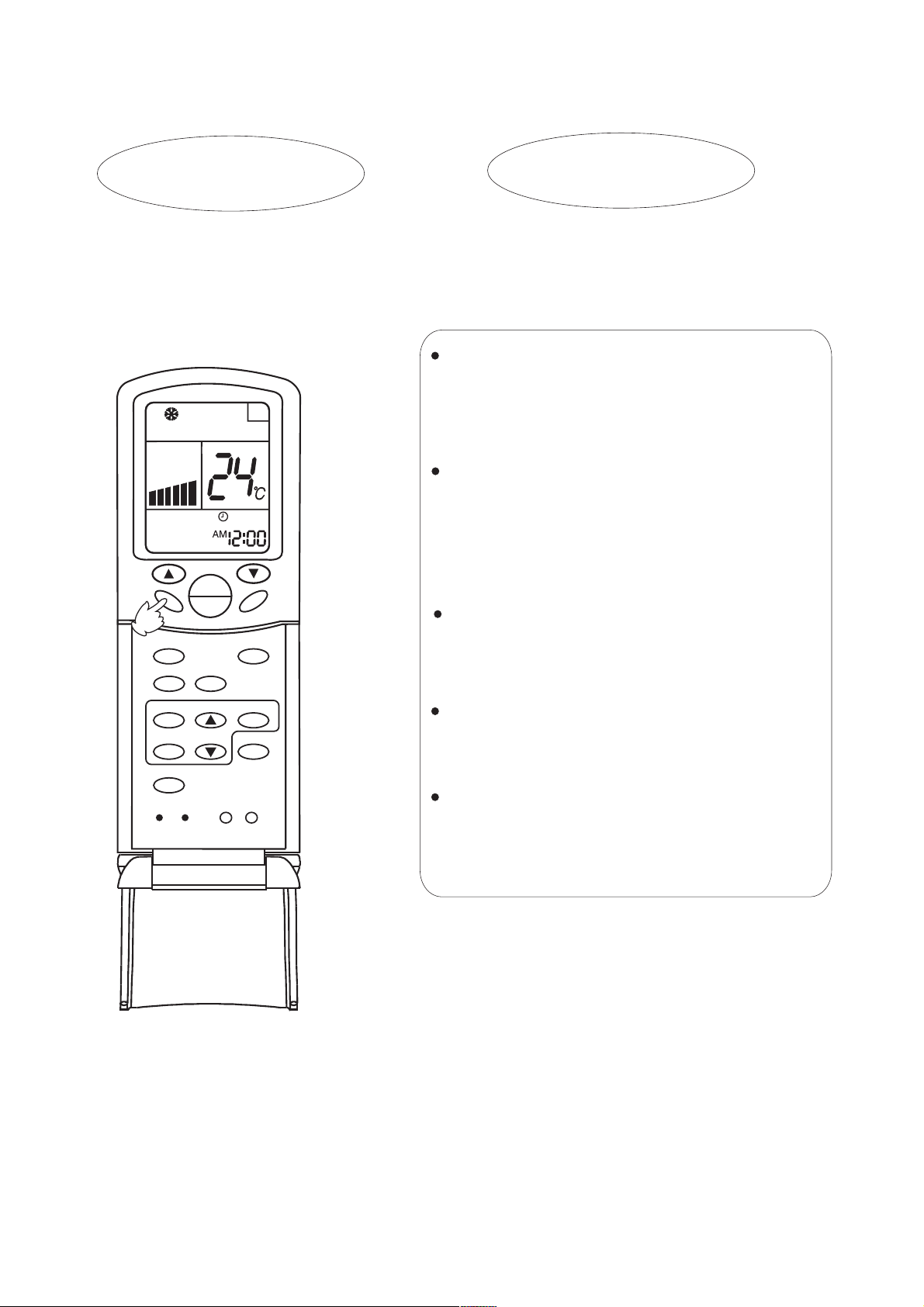

7.Remote controller functions

Remote controller

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

SWING

RESET

M D

MODE

HEALTH

CLOCK

TIMER

FILTER

CODE

A

U

T

O

OFF

TEMP

ON

OFF

FRESH

LIGHT

SLEEP

HIGH/SO

LOCK

SET

4.Operation MODE

28

B

A

FAN

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

Used to select operation mode.

Every time you press MODE button, operation mode

changes according to following sequence:

AUTO

COOL

DRY

HEAT

FAN

5.HEALTH Button

Used to set health mode, if the unit has the negative ion function

and oxygen bar function.

6.CLOCK Button

Used to set correct time.

7.CLOCK Button

Used to select TIMER ON, TIMER OFF.

(Note: if time of TIMER ON is the same as TIMER

OFF ,TIMER ON/OFF cannot be set)

8. FILTER Button

Used to set up/down function of filter.

9. CODE Button

Used to select code A or B, for this unit, the code is A.

10

1.TEMP Setting Button

(Used to set temperature. Setting ranges:

16 C to 30 C)

In Up/Down function, for controlling up and

down filter.

2.SWING Button

If you press this button once, auto swing will

be activated.

If you press this button again, the louver will

fix in the present position.

3.Power ON/OFF Button

Used for unit start and stop

After power on, the LCD of remote controller

will display the previous operation state (except

for TIMER,SLEEP and SWING state).

10.RESET Button

Press this button by using a sharp article to resume

the correct operation of the remote controller in case

of need, i.e. for example in case of malfunctions due

to electromagnetic noise.

11.LOCK Button

Used to lock operation button and LCD display

contents: by pressing this button, other buttons comes

out of function and lock state display appears; if you press

it again, lock state will be no more active and lock state

display will disappear.

12.LIGHT Button

Used to light the control panel (only for cabinet unit)

13.Up and down Button

Used to set TIMER and CLOCK up or down.

14.HIGH/SO Button

Used to select HIGH or SOFT operation.

15.SET Button

Used to confirm TIMER and CLOCK settings.

16.FRESH Button

Used to set fresh mode, the unit will draw in fresh air.

17.SLEEP Button

(The clock must be corrected before setting sleep

function)

Used to set sleep mode.

NOTE: 1.Cooling only air conditioner does not have the displays and functions related to heating.

2.HIGH/SO button

This button is activated in Cooling/Heating mode, the fan speed is in AUTO mode after pressing it and "high

functon" will be cancelled automatically after 15 minutes running.

18.FAN Button

Used to select fan speed:LOW,MID,HIGH,AUTO.

19.TIMER OFF Display

20.CLOCK Display

21.FILTER Display

22.TEMPERATURE Display

23.AUTO SWING Display

24.HIGH/SO Display

25.SIGNAL SENDING Display

26.FRESH AIR Display

27.ELECTRICAL HEATING Display

28.Some other buttons

All these functions are not available now.

29.HEALTH Display

Displays when healthy run function is set.

30.DEHUMIDIFICATION Display

31.Operation MODE Display

AUTO RUN

COOL RUN

DRY RUN

HEAT RUN

FAN RUN

32.SLEEP State Display

33.BATTERY Energy Display

Notify the user when it is time to change

the batteries.

34.LOCK State Display

35.FAN SPEED Display

LO

MID

The distance between the remote controller and the receiver

should be max 7m and there should be no obstacle between them.

Do not throw the remote controller; prevent it from being

damaged.

When operating the remote controller in an area where

electronically controlled lights are installed or wireless handsets

are used, please move closer to the indoor unit as the function

of the remote controller might be affected by signals emitted

by the above mentioned equipments.

Battery loading

Battery loading

Batteries are fitted as follows:

Remove the battery compartment lid

Slightly press and disengage the battery compartment lid marked

with ì

section and then remove the battery compartment lid by pressing

in the direction of the arrow as shown in the figure above.

î and then hold the remote controller by the upper

Loading the battery

Ensure that batteries are correctly placed in the compartment

as required for positive and negative terminals.

Replacing the battery compartment lid

The battery compartment lid is reinstalled in the reverse

sequence.

Display review

Press the button to see if batteries are properly fitted. If

no display appears, refit the batteries.

Confirmation indicator

If no indication is displayed after press ON/OFF button,

reload the batteries.

Caution:

* *

* *

HI

AUTO

AUTO

If the remote controller does not operate as designed after

fitting new batteries of the same

type, press the Reset button (marked ) with a pointed article.

Note:

36.TIMER ON Display

Remote Controller' Operation

When in use, direct signal transmission

head to the receiver placed on the indoor

unit

It is recommended that the batteries be removed from the

compartment if the remote controller is not used for an extended

period.

The remote controller is programmed for automatic test of

operation mode after the batteries are replaced. When the test

is conducted, all icons will appear on the screen and then

disappear if the batteries are properly fitted.

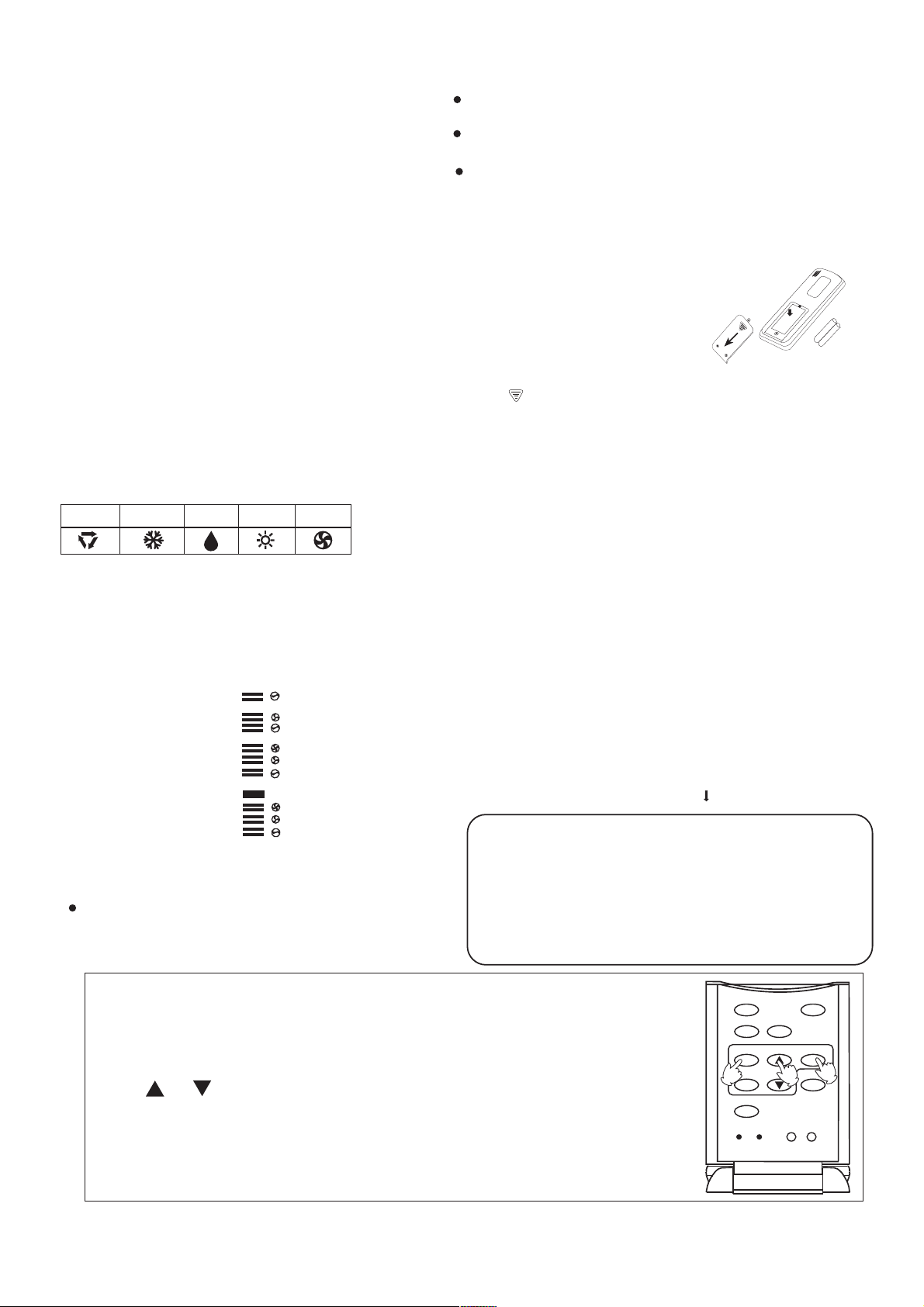

Clock Set

When unit is started for the first time and after replacing batteries in remote

controller, clock should be adjusted as follows:

1.Press CLOCK button, clock indication of " AM " or " PM " flashes.

2.Press or to set correct time. Each press will increase or decrease

1 min. If the button is kept pressed, time will increase or decrease quickly.

3.After time setting is confirmed, press "SET" : AM or PM stop flashing,

while clock starts working.

Note:AM means morning and PM means afternoon.

1

RESET

HEALTH

CLOCK

TIMER

FILTER

CODE

FRESH

2

LIGHT

SLEEPMODE

SET

HIGH/SO

LOCK

3

Fan Operation

1.Unit start

Press ON/OFF button to start your air conditioner.

Previous operation status appears on LCD (except for

TIMER, SLEEP, and SWING setting).

2.Select operating mode

Press MODE button. At each press, operation mode

changes as follows:

A

SWING

MODE

HEALTH

2

CLOCK

TIMER

FILTER

RESET

4

CODE

A

U

T

O

TEMP

ON

OFF

FRESH

1

LIGHT

FAN

SLEEP

SET

HIGH/SO

LOCK

AUTO

FANHEATCOOL DRY

Then select FAN

3. Adjust fan speed

Press FAN button. At each press, fan speed changes as

3

follows:

LOW

MID

HIGH

Air conditioner will run at the selected fan speed.

When in AUTO mode, unit will adjust fan speed

according to room temperature automatically.

4. Unit stop

Press ON/OFF button to stop unit.

About FAN mode

When the air conditioner runs in F AN mode,

it is not possible to select AUTO FAN or to

set temperature.

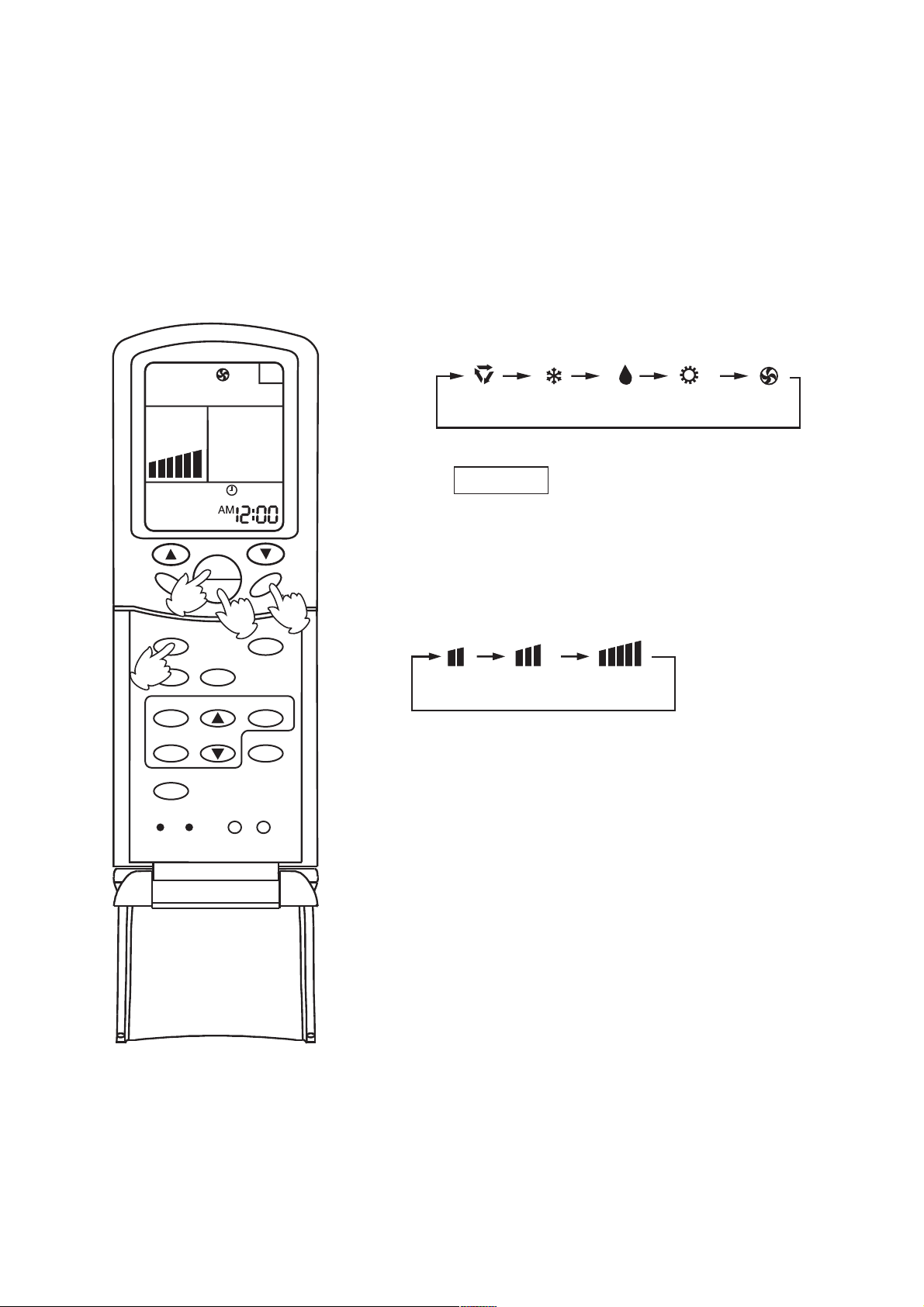

AUTO, COOL , HEAT and DRY Operation

3

SWING

MODE

HEALTH

2

CLOCK

TIMER

FILTER

RESET

5

CODE

A

U

T

O

TEMP

ON

OFF

FRESH

LIGHT

1

SLEEP

HIGH/SO

SET

LOCK

A

FAN

4

1. Unit start

Press ON/OFF button,unit starts.

Previous operation status appears on LCD (except for TIMER,

SLEEP and SWING setting)

2.Select operation mode

Press MODE button. At each press, operation mode changes

as follows:

3

AUTO

FANHEATCOOL DRY

Then select AUTO run or select COOL operation or

select DRY operation or select HEAT operation

3.T emperature setting

Press TEMP button.

Every time the button is pressed, temp. setting increases

1 C; if the button is kept pressed, temp. setting will increase

quickly .

Every time the button is pressed, temp. setting decreases

1 C, if the button is kept pressed, temp. setting will decrease

quickly .

Set proper temperature

4.Adjust FAN button

Press F AN button. At each press, fan speed changes as follows:

A

U

T

O

COOL operation starts

when room temp.is

higher than temp.

setting.

Temp. setting +2 C

Temp.setting

Ultra-low air flow

On reaching temp.setting

+2 C, unit will run in mild

DRY mode.

AUTO

Air conditioner will run at the selected fan speed.

5. Unit stop

Press ON/OFF button,unit stops.

LOW

In ATUO mode, the temperature setting is not displayed on LCD. In this mode, during running air conditioner

will select COOL, HEAT or FAN mode automatically according to the room temperature.

In DRY mode, when room temperature becomes 2 C higher than temperature setting, unit will run intermittently

at LOW speed regardless of FAN setting. When room temperature is lower than temperature setting, unit will

only run F AN operation.

In HEAT mode,warm air will blow out after a short period of time due to cold-draft prevention function.

MID HIGH

Adjusting air flow direction

AUTO SWING

Press SWING button.

Up and down airflow varies upwards

and downwards. Left and right airflow

varies left and right sides.

A

A

U

T

O

TEMP

ON

SWING

OFF

MODE

FAN

SLEEP

AUTO SWING

When the automatic swing louver moves to the proper

angle, press SWING button can fix the airflow direction.

Always use SWING button on the remote

controller to adjust flaps. Adjusting them by hand

may result in air conditioner's abnormally running.

In COOL or DRY mode, do not leave the louver in

downward position for a long time, as the water

vapor close to the grille may condense and water

may drop from the air conditioner.

Please carefully set temperature when children,

old or infirm people ues the air conditioner.

FRESH

HEALTH

LIGHT

SET

HIGH/SO

LOCK

In case of great humidity, If the vertical flaps

are completely turned towards left or right, the

louver will drop water.

Never adjust the louver directly by hand, as this

CLOCK

TIMER

FILTER

RESET

CODE

could make it work abnormally .If the louver work

abnormally , stop unit, restart and adjust the louver

by remote controller.

After unit stops:

Displays on the LCD disappear.

All indicators on the indoor unit go out.

Swing louver automatically close the air outlet.

Hints:

As in COOL mode air flows downwards, adjusting airflow horizontally will be much more helpful

for a better air circulation

As in HEAT mode air flows upwards, adjusting airflow downward will be much more helpful for

a better air circulation.

Be careful not to catch a cold when cold air blows downward directly.

Sleep Function

Before going to bed you can press down the SLEEP button and the air conditioner will run so as to make

you sleep more comfortably.

Before using this function, the clock must be set.

Use of SLEEP function

After the unit's start, set running mode and then press SLEEP button once to make the air conditioner

have the previous-set sleep time (first power-on is "1h"). The sleep symbol will appear. Press time button

/ : you can choose the time in 1~8 hours. Each time the button is pressed, the time increases/decreases 1

hour: "xh" and "OFF" indications appear on the display.

Operation Mode

1.In COOL, DRY mode

One hour after sleeping operation start, the temperature

is 1 C higher than the setting one. After another hour,

temperature rises 1 C: sleep run continuously for another

6 hours and then stops. The actual temperature is higher

than the setting one which is to prevent from being too

cold to your sleep.

2.In HEAT mode

One hour after sleeping operation start, the temperature

is 2 C lower than the setting one. After another hour,

temperature decreases by 2 C more. Temperature will

automatically rise by 1 C after another 3 hours'

continuous operation. The actual temperature is lower

than the setting one which is to prevent from being too

hot to your sleep.

3.In AUTO mode.

The air conditioner will run in corresponding sleep

operation according to the automatically selected

operation mode.

SLEEP RUN BEGINS

1 hrs

SETTING T

In COOL,DRY mode

SETTING T

1 hrs

1 hrs

SLEEP RUN BEGINS

In HEAT mode

SLEEP RUN STOPS

about 6 hrs

increase 1 C

increase 1 C

decrease 2 C

decrease 2 C

about 6 hrs

3 hrs

SLEEP RUN STOPS

SHUT DOWN

SHUT DOWN

increase 1 C

Notes:

After setting SLEEP function, it is not possible to set clock.

If set-sleep time does not reach 8 hours, unit will automatically stop operation

after set time is reached.

Set " TIMER ON " or " TIMER OFF "In COOL,DRY mode function first,

then set SLEEP. After set SLEEP function, the TIMER function cannot be

set.

SWING

RESET

MODE

HEALTH

CLOCK

TIMER

FILTER

A

A

U

T

O

OFF

TEMP

ON

OFF

FAN

SLEEP

FRESH

SET

HIGH/SO

LOCK

LIGHT

CODE

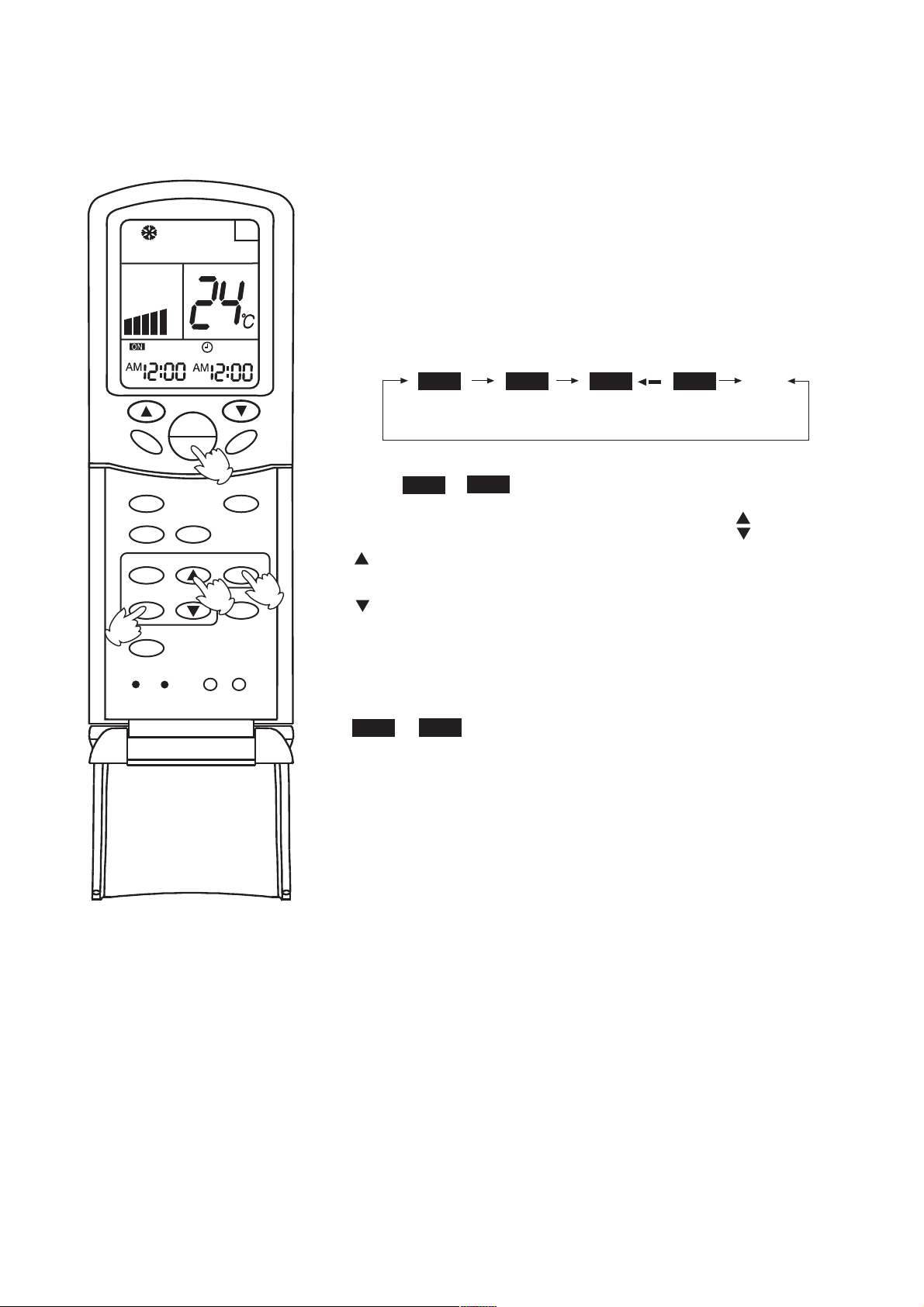

Timer ON/OFF Function

Set clock correctly before starting TIMER operation

1.Unit start

A

After unit start, select your desired operation mode (operation

mode will be displayed on LCD)

2.TIMER mode selection

Press TIMER button on the remote controller to change TIMER

mode. Every time the button is pressed, display of TIMER mode

changes as follows:

SWING

MODE

HEALTH

CLOCK

TIMER

2

FILTER

RESET

CODE

TEMP

ON

OFF

FRESH

LIGHT

1

3

FAN

SLEEP

SET

HIGH/SO

LOCK

ON OFF ON OFF

AM

12:00

TIMER ON

PM

12:00

TIMER OFF

AM

12:00

TIMER ON-OFF

PM

12:00

blank

Then select TIMER mode as needed (TIMER ON or TIMER OFF).

Now or will flash.

ON

OFF

3.TIMER setting (press time adjust buttons )

Every time the button is pressed, time increases 10 minuts.

If the button is kept pressed, time changes quickly.

4

Every time the button is pressed, time decreases 10 minuts.

If the button is kept pressed, time changes quickly.

It can be adjusted within 24 hours at will.

4.Confirm setting

After setting correct time, press SET button to confirm time. Now

or stop flashing.

ON

OFF

Time displayed: unit starts or stops at X hour X min (TIMER ON

or TIMER OFF)

5.Cancel TIMER mode

Just press TIMER button several times until TIMER mode disappears.

Hints:

After replacing batteries or if a power failure occurs, TIMER setting

must be reset.

Remote controller has memory function. When you use TIMER

mode next time, just press SET button after mode selection if timer

setting is the same as the previous one.

Note:

After setting TIMER function, the remote controller displays TIMER time. If you want to see clock time,

just press CLOCK button once: clock time will be displayed (if you press the button again continuously ,you

can adjust clock). 5 seconds later, the display will show TIMER time again.

Timer ON-OFF Function

Set clock correctly before starting TIMER operation

1.Unit start

After unit start, select your desired operation mode (operation

mode will be displayed on LCD)

SWING

2

MODE

HEALTH

CLOCK

TIMER

FILTER

4

RESET

5

CODE

OFF

TEMP

ON

OFF

FRESH

LIGHT

1

3

A

FAN

SLEEP

SET

HIGH/SO

LOCK

2.TIMER mode selection

Press TIMER button on the remote controller to change TIMER

mode. Every time the button is pressed, display of TIMER mode

changes as follows:

ON

AM

12:00

TIMER ON

OFF

PM

12:00

TIMER OFF

AM

ON

12:00

Then select TIMER ON-OFF mode.

OFF

PM

12:00

TIMER ON-OFF

ON

will flash.

blank

3.Time setting for TIMER ON

Press time button

Every time the button is pressed, time increases 10 minuts.

If the button is kept pressed, time will changes quickly.

Every time the button is pressed, time decreases 10 minuts.

6

If the button is kept pressed ,time will changes quickly.

It can be adjusted within 24 hours at will.

AM refers to morning and PM refers to afternoon.

4.Timer confirming for TIMER ON

After setting correct time, press TIMER button to confirm time. Now

stops to flash, while

ON

starts flashing.

OFF

Time displayed : unit starts at X hour X min.

5.Timer setting for TIMER OFF

Press time buttons and follow the same procedures in " Time setting

for TIMER ON"

6.Time confirming for TIMER OFF

After time setting, press SET button to confirm time.

Time displayed: unit starts at X hour X min.

stops to flash.

OFF

7.Canel TIMER mode

Just press TIMER button several times until TIMER mode disappears.

According to the time setting sequence of TIMER ON and TIMER OFF,

either start-stops or stops-start can be realized.

If the time setting of TIMER ON is the same as TIMER OFF, TIMER

ON-OFF function cannot be set.

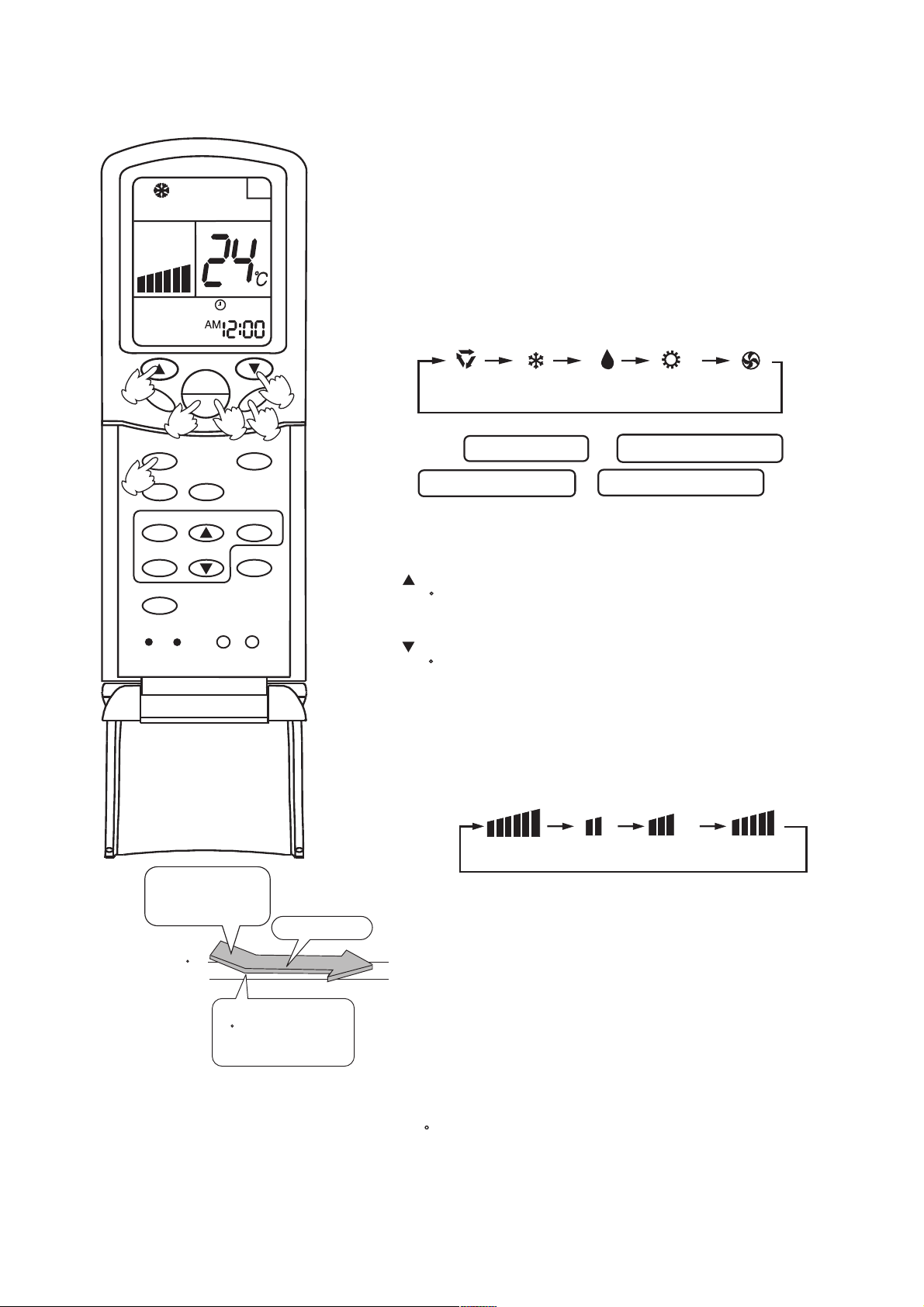

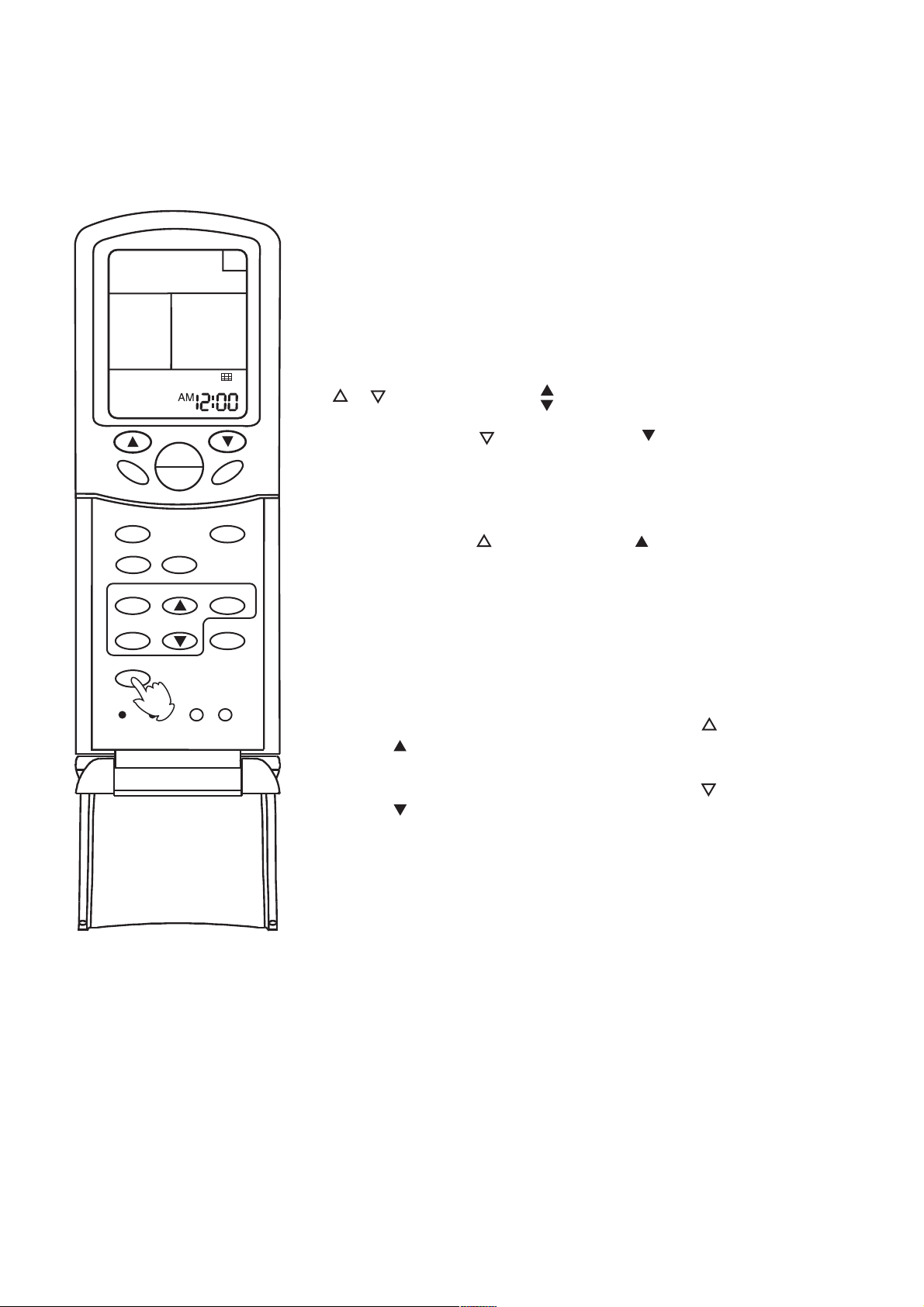

Filter Up/Down

(Only for AB182ACBEA)

A

After the air conditioner has operated for a certain period, dust has

accumulated on the filter, and the filter up/down function can be used

to clean it.

1.Whether unit starts or stops, continuously press FILTER

button for 3 seconds, and enter the filter up/down waiting

status (when unit stops, the yellow TIMER indicator flashes,

and filter and clock indication are displayed on the remote

controller . Only the FILTER button, the temperature buttons

" " " " and time buttons are active).

SWING

MODE

HEALTH

CLOCK

TIMER

FILTER

RESET

CODE

1

TEMP

ON

OFF

FRESH

LIGHT

FAN

SLEEP

SET

HIGH/SO

LOCK

2.Press temperature button or time button in filter

" "

" "

up/down waiting status: the up/down mechanism makes

the filter moving downward and does not stop until it has

reached the maximum limit.

3.Press temperature button or time button in filter

" "

" "

up/down waiting status: the up/down mechanism makes

the filter to moving upward till near the surface board and

then automatically adjusts it to reset (when adjusting to reset,

it will not be controlled by the remote controller till the adju stment is finished).

4.During moving downward, press temperature button

or time button: moving stops.

" "

5.During moving downward, press temperature button

or time button: moving stops.

" "

" "

" "

6.Continuously press FILTER button 3 seconds again to

cancel the filter up/down waiting mode (unit stops, the

yellow timer indicator stops flashing, the filter goes back to

the original position, the remote controller goes back to off

status and only clock is displayed).

Note:

If the filter does not thoroughly go back to the original position, only needs to

operate several times repeatedly.

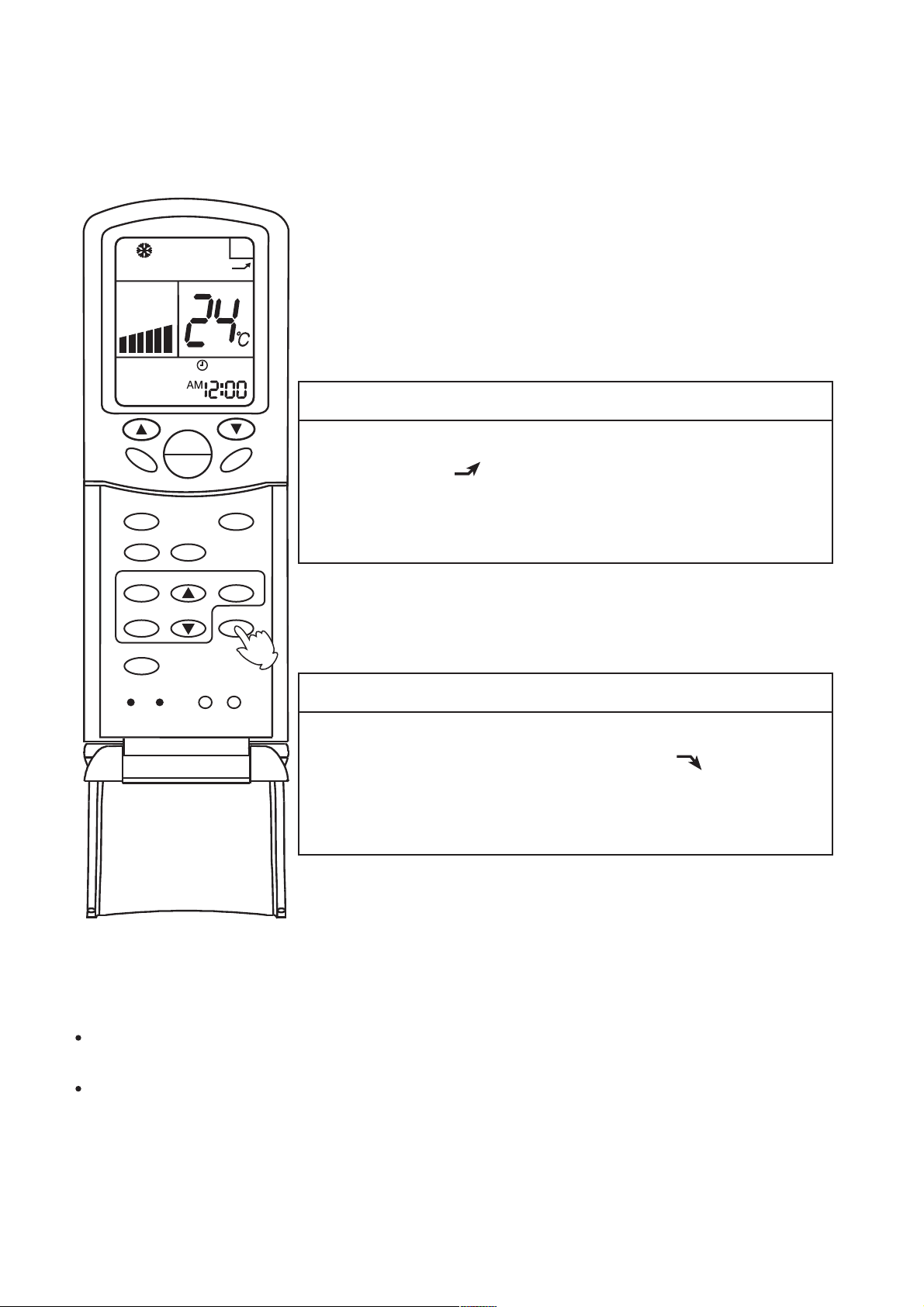

" High mode " Operation

A

A

U

T

O

TEMP

ON

SWING

MODE

HEALTH

OFF

FRESH

FAN

SLEEP

Outline of operation in "High Mode"

This function is suitable when the set temperature must be

reached in the shortest delay.

The button "HIGH/SO", referred to this function, is effective

in Cooling/Heating mode (not in Auto/Dry/Fan modes).

ON

Press the HIGH/SO button noce

The indication appears on the display of the remote

controller and operation in "High Mode" starts.

The AUTO fan speed is automatically set and the corresponding

indication is also displayed.

LIGHT

SET

HIGH/SO

1

LOCK

OFF

CLOCK

TIMER

FILTER

RESET

CODE

Press the HIGH/SO button twice

If the button is pressed once, the indication is displayed

on the remote controller. If you press the button once again,

the indication disappears, regular operation is restored and fan

speed goes back to the mode set before "High Mode" operation.

NOTICE:

When the air conditioner is operating in " High Mode " , unevenness of room air temperature

may occur due to the intensive operation in a short time.

Anyway, operation in "High Mode", does not last for more than 15 minutes, then regular

operation is automatically restored.

" Soft mode " Operation

A

A

U

T

O

OFF

TEMP

ON

SWING

MODE

HEALTH

CLOCK

TIMER

OFF

FRESH

FAN

SLEEP

SET

HIGH/SO

Outline of operation in "Soft Mode"

Operation in "Soft Mode", more silent, is suitable when noises

should be reduced, e.g.. for reading or sleeping.

The button "HIGH/SO", referred to this operation, is effective

in Cooling/Heating mode (not in Auto/Dry/Fan modes).

ON

Press the HIGH/SO button twice

The indication appears on the display of the remote

controller and operation in "Soft Mode" starts.

The AUTO fan speed is automatically set and the corresponding

indication is also displayed.

FILTER

RESET

CODE

LIGHT

1

LOCK

OFF

Press the HIGH/SO button twice

If the button is pressed once, the indication is disappears

from the remote controller's display. If you press the button

once again, regular operation is restored and fan speed goes

back to the mode set before "Soft Mode" operation.

NOTICE:

When the air conditioner is operating in " High Mode " , unevenness of room air temperature

may occur due to the intensive operation in a short time.

Anyway, operation in "High Mode", does not last for more than 15 minutes, then regular

operation is automatically restored.

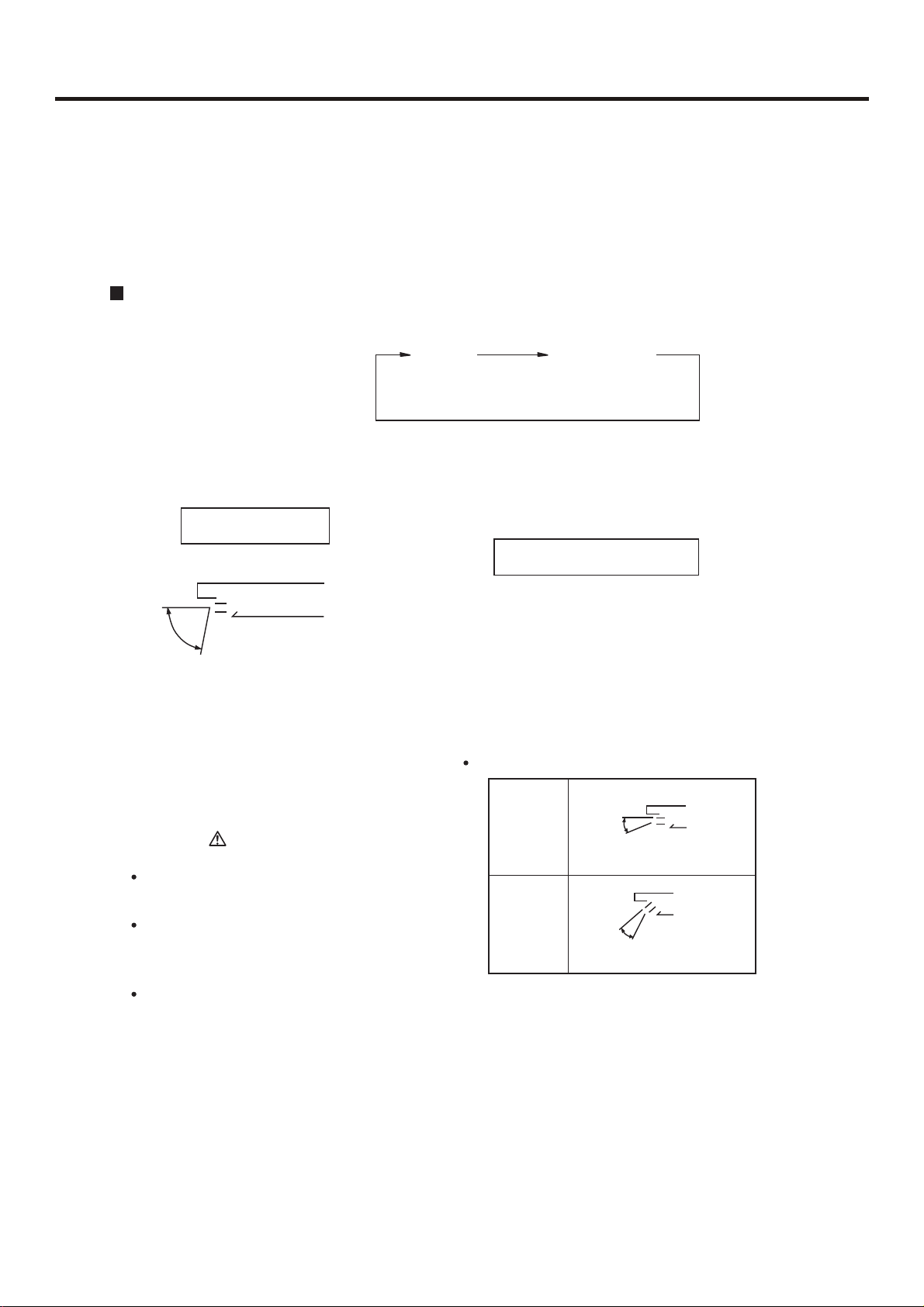

AIR FLOW DIRECTION ADJUSTMENT PROCEDURE-Cassette type

Adjusting up/down air flow direction

Up/down direction can be adjusted by using the SWING button on the remote

controller.

Each time pressing this button, the mode changes in the following sequence.

SWING

Change to the AIRFLOW mode.

SWING

Louver moves in upward and

downward directions continuously.

No indication

(louver stopped)

LOUVER STOPPED

When the LOUVER button is

pushed during SWING mode,

it stops swinging at the just

angle.

CAUTION

Avoid direct air flow to the body for many hours.

Avoid downward blowing operation of cooling mode for many hours.

Do not touch the swing louver during swing operation.

AIR FLOW DIRECTION ADJUSTMENT PROCEDURE-Convertible type

Adjusting up/down air flow direction

Up/down direction can be adjusted by using the SWING button on the remote controller.

Each time pressing this button, the mode changes in the following sequence.

Change to the AIRFLOW mode.

SWING

Louver moves in upward and

downward directions continuously.

CAUTION

Avoid direct air flow to the body

for many hours.

Avoid downward blowing operation of cooling mode for many

hours.

Do not touch the swing louver

during swing operation.

SWING

No indication

(louver stopped)

LOUVER STOPPED

When the LOUVER button is

pushed during SWING mode,

it stops swinging at the just

angle.

Recommendable stopping angle of the louver

COOL

and

DRY

(Horizontal Blowing)

HEAT

(Downward Blowing)

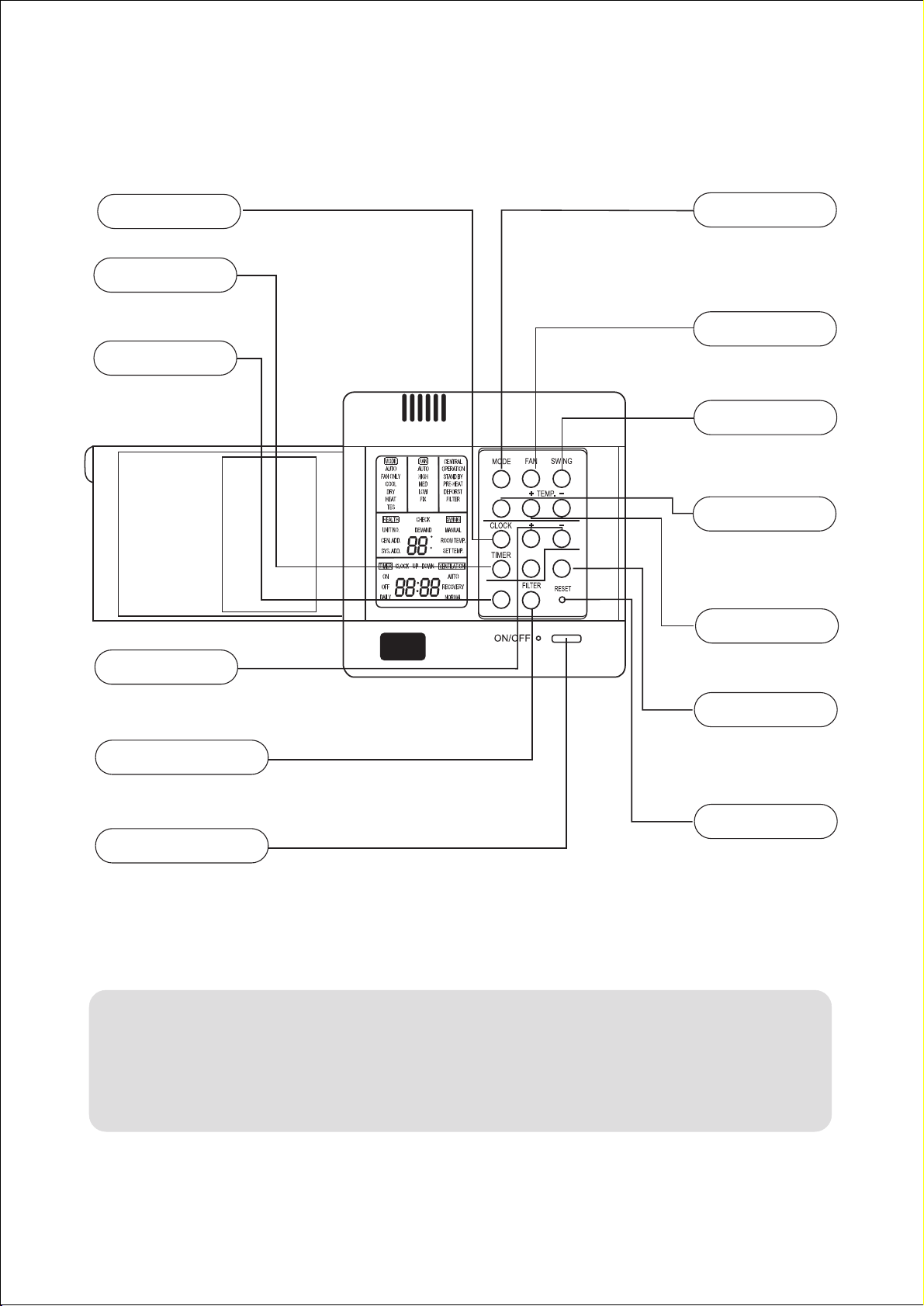

Wired controller functions:

Buttons and functions of the wired controller

CLOCK

Used to adjust time.

TIMER

Used to set timer

mode.

CHECK

Auto-diagnostic

button.

+ -

stands for time plus/minus,

used to adjust time.

FILTER

Filter-cleaned button.

MODE

Used for select

indoor operation

mode.

FAN SPEED

Used for select indoor

air flow.

SWING

Used for setting

indoor swing mode.

HEALTH

HEALTH

C

F

SET RECOVERY

CHECK

Used for setting

indoor health

function.

TEMP + -

Used for changing

set temperature.

RECOVERY

used to switch

over airexchanging mode.

POWER ON/OFF

Used for unit start and

stop.

Cautions:

On cooling only unit, heating

mode is not available.

RESET

Reset correct

mode button.

Note:

The above information is the explanation of

the displayed information therefore varies

with those displayed in actual operation.

Buttons function:

MODE:used for select indoor operation mode.

FAN:used for select indoor air flow.

SWING:used for setting indoor swing mode.

HEALTH:used for setting indoor health function.

TEMP + -:used for changing set temperature.

CLOCK:used to adjust time.

+、-:stands for time plus/minus, used to adjust time.

TIMER:used to set timer mode.

RECOVERY:used to switch over air-exchanging mode.

CHECK:auto-diagnostic button.

FILTER:filter-cleaned button.

RESET:reset correct mode button.

Display description:

[MODE] [AUTO]:auto operation mode

[MODE] [FAN ONLY]:air-throwing mode

[MODE] [COOL]:Cooling operation mode

[MODE] [DRY]:Dehumidification mode

[MODE] [HEAT]:Heating operation mode

[MODE] [HEAT] [TES]:In heating mode, auxiliary electric heater is running. Only when the unit

with auxiliary electric heater is in auxiliary electric heating mode, it will display.

[FAN] [AUTO]:auto fan running

[FAN] [HIGH]:high fan speed

[FAN] [MED]: medium fan speed

[FAN] [LOW]: low fan speed

[FAN] [FIX]: fixed fan speed, it will display only when fixed fan speed is requested to main indoor

unit.

[CENTRAL]: central control mode

[OPERATION] :running mode

[STAND BY] : waiting mode

[PRE-HEAT] : pre-heating mode

[DEFROST]: defrosting mode

[FILTER] : request of filter to be cleaned

[HEALTH]:health function

[UNIT NO.]

[CEN.ADD]:central control address, the address number will display on “88”

[SYS.ADD.]:system address, the address number will display on “88”

[CHECK]:auto-diagnostic, trouble shooting

[DEMAND]:compulsory operation function, when it works, [CENTRAL] will flash

[SWING]:swing mode

[ROOM TEMP.]:indoor ambient temperature

[SET TEMP.]:set admired temperature

[TIMER][ON] :timer function is on, it will switch over in the sequence below:

[ON][OFF] → [ON][OFF][DAILY] →[ ]

[TIMER][OFF] :timer function is off

[TIMER][ON][OFF] :timer function ON-OFF

[TIMER][ON][OFF][DAILY]:timer ON-OFF will switch over in turn daily

[CLOCK]:clock display, the displaying time is the current time of the clock.

[UP]、[DOWN]:indicator of filter elevating

[VENTILATION][AUTO]:auto ventilation mode

[VENTILATION][RECOVERY]:fully heat exchanging ventilation mode

[VENTILATION][NORMAL]:normal ventilation mode

FAN ONLY OPERATION:

1)Start up operation: press the button of ON/OFF, the system will start up, and will display

[MODE][AUTO];[FAN][AUTO];[ROOM TEMP.]+“24℃”;[CLOCK]+”12:00”.

2) Select MODE: press the MODE button, then you will see in the display section [MODE] switch

over in below sequence:[FAN ONLY]→[COOL]→[DRY]→[HEAT]→[AUTO]→[FAN ONLY].

Select [FAN ONLY].

3)Select fan speed: press FAN button, then you see in the display section [FAN] switch over in

below sequence: [HIGH]→[MED]→[LOW]→[HIGH]. Select proper fan speed.

4)Power off: press ON/OFF button, indoor unit will be powered off, there are only time and the

ambient temperature in the screen.

AUTO operation, COOLING, HEATING and DEHUMIDIFICATION operation

1) Start up operation: press the button of ON/OFF, the system will start up, and will display

[MODE][AUTO];[FAN][AUTO];[ROOM TEMP.]+“24℃”;[CLOCK]+”12:00”.

2) Select MODE: press the MODE button, then you will see in the display section [MODE] switch

over in below sequence:[FAN ONLY]→[COOL]→[DRY]→[HEAT]→[AUTO]→[FAN ONLY]. Select

[FAN ONLY].

3) Change set temperature: press TEMP + or – every time, [SET] will display, and set

temperature will increase/reduce 1℃(F).

4) Select fan speed: press FAN button, then you see in the display section [FAN] switch over in

below sequence: [HIGH]→[MED]→[LOW]→[HIGH]. Select proper fan speed.

5) Select [SWING]: press [SWING] button,swing function is valid. Press again, swing function is

invalid.

6) Set [HEALTH]: used to set the indoor health function. Press it once, [HEALTH] will display in

the display section, then indoor health function is valid. Press it again, [HEALTH] will disappear,

then the health function is invalid.

This function is valid only for the unit with health function.

7) Power off: press ON/OFF button, indoor unit is powered off. There are only time and the

ambient temperature in the screen.

Set TIMER operation:

Adjust clock: when powered on, for the first time to set timer function, the clock will be adjusted.

Press “CLOCK” button, and set the current clock. Now, “CLOCK” will flash at the frequency of

2Hz every minute. Press the clock +/- button; the current clock can be adjusted. Until the proper

time comes, press [SET].

TIMER ON operation:

Press TIMER button, and keep pressing it, in the display section [TIMER] will switch over in below

sequence: [ON]→[OFF]→[ON][OFF] → [ON][OFF][DAILY] →[ ]. Select [TIMER] [ON], then

[TIMER] [ON] flashes, press the clock +/- button to adjust the time of TIMER ON, press [SET]

button.

TIMER OFF operation:

Press TIMER button, and keep pressing it, in the display section [TIMER] will switch over in below

sequence: [ON]→[OFF]→[ON][OFF] → [ON][OFF][DAILY] →[ ]. Select [TIMER] [OFF], then

[TIMER] [OFF] flashes, press the clock +/- button to adjust the time of TIMER OFF, press [SET]

button.

TIMER ON-OFF operation:

Press TIMER button, and keep pressing it, in the display section [TIMER] will switch over in below

sequence: [ON]→[OFF]→[ON][OFF] → [ON][OFF][DAILY] →[ ]. Select [TIMER] [ON] [OFF].

Firstly, [TIMER][ON] flashes, press the clock +/- button to adjust the time of TIMER ON, press

[SET]. [TIMER][ON] will be constant on. Then [TIMER] [OFF] flashes, press the clock +/- button

to adjust the time of TIMER OFF, press [SET]. The time sequence of timer on and timer off will

determine the mode is [TIMER] [ON] →[OFF] or [TIMER] [OFF] →[ON].

Note: 1. If the two times are the same, the unit will adjust the state after set time arrives according

to the current state. If current state is in running mode, after set time arrives the unit will switch to

“power off“ state. If current state is in “power off” mode, after set time arrives, the unit will switch to

running mode.

2. When in TIMER setting state, if you do not input any button in continuous 10 seconds, the unit

will think [SET] pressed.

Cancel TIMER operation:

In the timer operation state, press [TIMER] button, the unit will quit from the current timer

operation state, and the set data will be memorized, then enter the next timer mode.

After timer be set, press ON/OFF to cancel timer mode. When in running again, timer mode will

be continuous (without timer).

[FILTER] function

When the wired controller receives the filter-cleaned signal from indoor unit, [FILTER] will display.

After finishing clean, press [FILTER], the sign [FILTER] disappears, and the controller will send

the filter reset signal to indoor unit.

When the sign [FILTER] not display, it is invalid to press [FILTER] in short time.

FILTER ELEVATING function: (only for the unit with elevating function)

In power off state, press [FILTER] for 5 seconds to enter filter elevating set state. In this state, the

sign [FILTER] will flash at the frequency of 2Hz. By pressing [+] TEMP [-], filter can go up or down.

Press TEMP [+], in timer section [UP] will display, while press TEMP [-], in timer section [DOWN]

will display. Press [FILTER] button to quit the mode.

DEMAND operation function:

In the stop state of cooling mode, press [ON/OFF] button for 5 seconds to enter [DEMAND]

cooling operation state, the sign [DEMAND] will display. In the 7-segmet liquid crystal screen of

set temp. section, “0” will display in first position, which shows that No. 0 indoor unit has enter

demand operation. In the second position, “L” will display, in the meantime, [COOL] will flash,

[FAN][AUTO] is constant on. Press TEMP [+] [-] to set different indoor unit. Press [ON/OFF] to

cancel [DEMAND] operation.

In the stop state of heating mode, press [ON/OFF] button for 5 seconds to enter [DEMAND]

heating operation state, the sign [DEMAND] will display. In the 7-segmet liquid crystal screen of

set temp. section, “0” will display in first position, which shows that No. 0 indoor unit has enter

demand operation. In the second position, “H” will display, in the meantime, [HEAT] will flash,

[FAN][AUTO] is constant on. Press TEMP [+] [-] to set different indoor unit. Press [ON/OFF] to

cancel [DEMAND] operation.

VENTILATION mode (only for the unit with fresh air function or heat recovery function)

Press [RECOVERY] button, then the unit will switch over the ventilation mode:

[ ] → [VENTILATION][AUTO] → [VENTILATION][RECOVERY] → [VENTALATION][NORMAL]

→[ ], please select appropriate ventilation mode.

Query indoor malfunction history:

In the state of power on or power off, press [CHECK] button, enter the malfunction-querying

mode of all indoor units in the group. Then [CHECK] and [UNIT NO.] will display, and the actual

indoor numbers will be displayed in some sequence (unit number is in decimals). At the same

time, in the time region, there will be the current malfunction and the latest time malfunction, the

displaying format is [XX:YY], in which XX stands for the current malfunction, if normal, it will

display “――”; YY stands for the latest time malfunction. The failure code of every unit will display

for 3 seconds. After the failure codes of all indoor units in the whole group are displayed, the

mode will quit automatically.

Clear abnormal state and malfunction history:

In normal state, press [CHECK] button for 5 seconds to clear abnormal states, at the same time,

wired controller will send the data of “clear abnormal state”, but the malfunction history still

retains.

In normal state, press [CHECK] button for 15 seconds, except for malfunction states, the

malfunction history in wired controller will be cleared.

Query indoor performance state:

In normal state, press both buttons of [CHECK] and [FILTER] for 5 seconds, in the set

temperature region in the screen, [XX] will display, XX is indoor number, which can be selected by

pressing [TEMP] [+] [-]. In the timer region in the screen, [YZZZ] will display, in which Y stands for

data type, ZZZ stands for the corresponding data. which can be selected by pressing [CLOCK] [+]

[-].

Y ZZZ Type

A Indoor capacity (W) Nominal cooling

capacity/10, decimal

B Request of indoor capacity(Hz) Actual value, decimal

C Temperature of indoor ambient

temp. sensor TA

d Temperature of indoor gas pipe

sensor TC1

E Temperature of indoor liquid pipe

sensor TC2

F Open degree of indoor PMV Actual value, decimal

g Preset ―――

H Outdoor total capacity Actual value, decimal

Actual value, decimal

Actual value, decimal

Actual value, decimal

In check mode, press [CHECK] to quit the check mode, and go into normal running mode.

How to change the function switches?

No. Type State of

Function description

switch

J01

J02

J06

J07

J03

SW01

①

SW01

②

D1

D2

Changeover of Wired

controller and central

controller

Changeover of type of

wired controller

Selection of room temp.

sensor

Auto reset after power

failure

Display of room

temperature

Changeover of master or

slave controller

℃ or ℉

Shorten time function

Compulsorily defrost

Connected Central controller

Cut off Wired controller

Connected Set as simple controller

Cut off Set as standard controller

Connected Use the sensor in the wired

controller

Cut off Use the sensor in the indoor unit

Connected Common control

Cut off Auto reset after power failure

Connected Yes

Cut off No

ON Set as slave controller

OFF Set as master controller

ON

OFF

Connected Indoor unit in shorted time

Cut off Common control

Connected Send compulsorily defrost signal

Cut off Common control

℉

℃

function

to indoor unit

Note: The switches in grey can be operated after opening the cover of wired

controller.

Electrical functions of wired controller:

1.Switch over method: wired control master unit/wired control slave

unit/remote control unit

Control method

Socket

/jumper

CN23 Short circuit Not short circuit Not short circuit

CN30 Short circuit Short circuit Not short circuit

CN21 Blank Blank To remote receiver

J19 Short circuit Short circuit Cut circuit

Signal terminal block A,B,C connected

Function difference between master wired controller and slave one:

Contrastive items Master wired controller Slave wired controller

Function All of functions Only with below functions:

Wired control

master unit

Wired control

slave unit

B,C connected to

to wired controller

wired controller

Remote control unit

board

A,B,C not connected

to wired controller

ON/OFF, MODE, FAN SPEED,

SET TEMP., SWING

2. Wiring connections of wired controller:

A

indoor 1 indoor 2

wired controller

B

indoor 1

wired controller

1

A

wired controller

2

B

wired controller

C

3

polar wire

C

indoor N

wired controller wired controller

indoor 1

wired controller

123

polar wire

ABC

wired controller

indoor 15

polar wire

ABC

wired controller

indoor 16

(master unit)

wired controller

control wiring of wired controller, polar.

ABC

wired controller

There are three methods to connection wired controller and the indoor

units:

A. One wired controller can control max. up to 16 sets of indoor units, and

1

3 pieces of polar wire must connect the wired controller and the master

unit (the indoor unit connected with wired controller directly), the others

connect with the master unit through 2 pieces of polar wire.

B. One wired controller controls one indoor unit, and the indoor unit

connects with the wired controller through 3 pieces of polar wire.

C. Two wired controllers control one indoor unit. The wired controller

connected with indoor unit is called master one, the other is called slave

one. Master wired controller and indoor unit; master and slave wired

controllers are all connected through 3 pieces of polar wire.

3. Communication wiring:

The wired controller is equipped with special communication wiring in the

accessories. 3-core terminal (1-white 2-yellow 3-red) is connected with the

terminal A、B、C of wired controller respectively.

The communication wiring is 4 meter long; if the actual length is more than

it, please distribute wiring according to below table:

Communication wiring length(m) Dimensions of wiring

<100 0.3mm2X3-core shielded wire

≥100 and <200 0.5mm2X3-core shielded wire

≥200 and <300 0.75mm2X3-core shielded wire

≥300 and <400 1.25mm2X3-core shielded wire

≥400 and <600 2mm2X3-core shielded wire

※ One side of the shielded sheet of communication wire must be earthed.

3.4 Refrigerant Diagram

Piping Systematic Diagram for Cooling/Heating Type Air Conditioner

Indoor Unit

Capillary Tube

Cooling Operation

Stop

Valve

Heat Exchanger

Stop

Valve

Heating Operation

Quieter

Outdoor Unit

Filter

One-way Valve

Reversing Valve

Heat Exchanger

Compressor

4 ELECTRICAL DATA

2HP cassette type wiring diagram

2HP convertible type wiring diagram

14000BTU/h mid ESP duct type wiring diagram

Note:

1.Dashed parts are not available

2.Central controller is optional

3.P16 and P17 are used for room card function

18000BTU/h mid ESP duct wiring diagram

Note:

1.Dashed parts are not available in duct type

2.Central controller is optional

3. P16 and P17 are used for room card function

Outdoor wiring diagram

2HP OUTDOOR UNIT WIRING DIRGRAM

TRANS.

BL

7

8

W

5

3

NONOCOM

COM

642

W

B

1

RELAY

NC

NC

GR

FAN MOTOR

SPEED

CONTROLLER

2

HIGH PRESSURE SWITCH

P

LOW PRESSURE SWITCH

1

OUTDOOR AMBINENT SENSOR

OUTDOOR PIPING SENSOR

COMPRESSOR VENT SENSOR

R:RED W:WHITE GR:GRAY

BL:BLUE B:BLACK Y/G:YELLOW/GREEN

CN1

CN2

CN10

CN3

CN12

CN11

S

TO INDOOR UNIT

CIRCUIT

DETECTOR

CN4

Y/G

BWR

Y/G

N3

FAN

N2

ST

HB

N1

C

A

V

E

0

S

3

4

NOTE:

1. Dashed parts

2. Dashed parts is optional for Low Ambient Temp.

Cooling,and there is no relay in only Cooling type

5

U

2

F

/

A

5

1

.

3

N

T

FAN MOTOR CAP.

W

B

BL

4-WAY VAVLE

BL

WIND

CRANK

HEATER

W

R

R

B

S

Y/G

C

M

COMPRESSOR

is not available for only Cooling type

M

FAN MOTOR

Circuit for 14000BTU/h, 18000BTU/h outdoor unit:

54321

6

N

250

D

250

L1

4007

62K/3W

D1

R4

S

250

C

CT 1

0057W

B

CN3

XHB2B

2

1

2

1

PIP ROOM

CN12

XHB2B

A

1 2 3 4 56

C16

22uF/250V

R1

200K

D2

4007

R2

62K/3W

R3

62K/3W

D3

4007

R15

10K/0.5W

D4

4007

R16

10K/0.5W

CN10

VHB2B

CN2

VHB2 B

+5

D5

4148

D14D15

D13D12

R13

470

RW

102

R24

5.1K

+5

R25

5.1K

C20

104

C3

103

R5

33K

IC1

R6

C2

2.2K

103

2

1

2

1

R10

R11

1K

1K

C21

470UF/16V

C17

4.7UF/50V

C22

4.7UF/50V

+5

3

C7

104

TLP371

IC2

C27 103

C10 103

C12 103

C11 103

C6

104

+5

R27

10K

Vout

TLP521-1

R17

10K

RG1 7 8 05

GND

2

+5

+5

R7

10K

R8

1K

103

C4

R19

R18

10K

+5

Vin

R20

10K

10K

TEST

4MHz

OSC1

R23

560

+12 1

1

C8

104

2200UF/35V

D8 D11

C1

1

IRQ

2

PTA0

3

R9

LED1

1M

VSS

4

OSC1

5

OSC2/PTA6

6

PTA1

7

VDD

8

PTA2

9

PTA3

10

PTB7

11

PTB6

12

PTB5

13

PTD7

14

PTD6

D10D9 L1

R12

560

IC3

MC68HC908JL3ECP

CN1

XHB2P3

1

2

RST

PTA5

PTD4

PTD5

PTD2

PTA4

PTD3

PTB0

PTB1

PTD1

PTB2

PTB3

PTD0

PTB4

CN11

XHB2B

CN4

RTB- 1 . 5 - 2 P

D

D4

+12

4004

+5

C5

104

28

27

26

25

24

23

22

21

20

19

18

10K

17

R21

16

15

R26

C25

47K

104

2

1

1

2

3

4

5

6

+5

IC4

ULN2003A

A1

A2

A3

A4

A5

A6

A77Q7

GND8VCC

16

Q1

15

Q2

14

Q3

13

Q4

12

Q5

11

Q6

10

9

D4

4004

JK5

JTN1S-TMP-F-DC12V

JK2

JQ1A

JK7

OJE-SS-112DM

FAN

N2

N1

HB

YJ

ST

N3

C

B

FUSE

T3.15A/250V

2

0.1UF/250V

LX102

LX1

C23

C24

VR

S1 4 K 3 5 0

0.1UF/250V

250

Title

AU242ACBEA

Number RevisionSiz e

B

Date: 13-Nov-2003 Sheet of

File:

250

N

0010451493

A

0010451167 PCB information – circuit diagram

XT1

INOUT

2200uF

LED5

2

E1

1

VDD

R8 10

8.00M

D17

1N4148

D1-D4

C34

104

D12

4148

D13

4148

103

C24

R63

LED4

27K

D15

4148

D14

4148

1K

4.7uF

R141KR15

E6

R7 10

R25

4

R13

1K

D16

4148

2.4K

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

4.7K

R27

4.7K

R26

C14 103

C15 103

C16 103

R61 20K

R62 20K

R60 20K

4.7uF

E7

+5

1

CN6

CN20

CN19

VDD

IC1

2003

104

C32

IC2

2003

104

C31

N5

9013

N4

9013

1

4

CN4

1

CN5

A

B

C

12345

12345

16

15

14

13

12

11

10

9

+12

16

15

14

13

12

11

10

9

+12

C35

104

C36

104

T1

TRAN1-2

C20

103

0.1UF/275V

LB1

CN1

C2

+12

RL6

JQ1AP-A

JQ1P-A

JQ1P-A

RL5

JQ1AP-A

RL4

JQ1AP-A

RL3

JQ1AP-A

RL2

JQ1AP-A

RL1

JQ1AP-1

BUZ1

100

R67

+5

R65

200K

R20

1K

2.2uF

4.7K

R35

220

IC8

R9

E8

TLP521-1

J1 J2 J3 J4 J5 J6 J7 J8 J9 J10

0.1UF/275V

RL8

RL7

+12

680

R6

1N4007

D11

C1

FUSE1

100K/1W

187

T3.15A/250V

187

187

187

RC3

0.033uF+120

187

RC1

0.033uF+120

187

RC2

0.033uF+120

187

187

187

187

187

R1

187

1 P2-P6

RV1

1 P1

1 P14

1 P13

1 P12

1 P11

1 P10

1 P9

1 P8

1 P7

CN7

1

1

P16

1

P17

P15

187

D10

1N4007

+5V

GND

CN17

CN16

CN12

CN11

CN15

R43

10K

R39 10K

R22 1K

AB32

+5

CGMXFC

VDDAREF

C33

104

N1 9013

OSC1

OSC2

VSSA

VDDA

VREFH

NOP

AVss

NOP

SW1

+5

470uF/16V

N3

9013

N2

9013

E3

R11

R32

4.7K

R33

1K

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

C12

103

103

R5 33K

R2

10K/0.5W

LED3

10K/0.5W

R3

1

CN23

1

2

2.2K

D9

CN14

+12

4

+5

1

R53 10K

+5

CN13

1

7

2

1

D19

4148

+12

DL1

2

DL2

1

+5

+5

1

2

1

1

R4

R54

N8

9013

R19

9013

N10

5

6

7

8

R44

R45

R46

CN22

2

1

C3

1K

103

10K

LED1

R12

1K

C6

102

R57

IC4 MAX487

DI4GND

DE

A

/RE

B

RO

VCC

C25 104

10K

10K

10K

C4 103

1

23

R58

N6

N7

560

4.7K

3

2

1

1K

R18

1K

R17

1K

R16

IC6

TLP371

6

5

1

2

LED2

IC7TLP521

4

9013

4.7K

R28

9013

4.7K

R29

1K

R23

C23

103

C26 104

IC5

1

2

3

4

C17

103

C18

103

C19

103

1

24

CN10

R36

10K

24C01A

EEPROM

RB1