SERVICE MANUAL

X MULTI SERIES

4-WAY CASSETTE INDOOR UNIT

CONVERTIBLE INDOOR UNIT

CONSOLE INDOOR UNIT

DUCT INDOOR UNIT

WALL MOUNTED INDOOR UNIT

OUTDOOR UNIT

Haier Commercial Air Conditioner

Version: 200708

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-2-

CONTENT

1.General information --------------------------------------------------------------------------------------------- 3

1.1 X Multi series line up -----------------------------------------------------------------------------------------

-

3

1.2 Operation temperature range -----------------------------------------------------------------------------

-

3

1.3 Product features ----------------------------------------------------------------------------------------------

-

4

2.Specifications ---------------------------------------------------------------------------------------------------- 6

3.Dimension --------------------------------------------------------------------------------------------------------

-

17

4.Pipe and wiring installation ----------------------------------------------------------------------------------- 21

4.1 Conbination of indoor and outdoor units ---------------------------------------------------------------

-

21

4.2 Wiring connection --------------------------------------------------------------------------------------------

-

31

4.3 Limitation on the installation ------------------------------------------------------------------------------- 34

4.4 Outdoor unit installation ------------------------------------------------------------------------------------

-

37

4.5 Cassette type installation ----------------------------------------------------------------------------------

-

44

4.6 Convertible type installation -------------------------------------------------------------------------------

-

51

4.7 Duct type installation ----------------------------------------------------------------------------------------

-

64

4.8 Console type installation -----------------------------------------------------------------------------------

-

74

4.9 Wall mounted type installation ----------------------------------------------------------------------------

-

81

5.PCB photo,wiring diagram and function description ---------------------------------------------------

-

85

5.1 Outdoor unit ----------------------------------------------------------------------------------------------------

-

85

5.1.1 Outdoor PCB photo ---------------------------------------------------------------------------------------

-

85

5.1.2 Outdoor wiring diagram ----------------------------------------------------------------------------------

-

86

5.1.3 PCB function description --------------------------------------------------------------------------------

-

90

5.2 Indoor unit ------------------------------------------------------------------------------------------------------

-

90

5.2.1 Cassette and duct type PCB photo -------------------------------------------------------------------

-

90

5.2.2 Cassette and duct type wiring diagram --------------------------------------------------------------

-

98

5.2.3 Convertible type PCB photo ----------------------------------------------------------------------------

-

100

5.2.4 Convertible type wiring diagram -----------------------------------------------------------------------

-

101

5.2.5 Converible type PCB function description ----------------------------------------------------------- 102

5.2.6 Console type PCB ----------------------------------------------------------------------------------------- 108

5.2.7 Console type wiring diagram ---------------------------------------------------------------------------

-

109

5.2.8 Console type PCB function description --------------------------------------------------------------

-

110

5.2.9 Wall mounted type PCB photo -------------------------------------------------------------------------

-

111

5.2.10 Wall mounted type wiring diagram ------------------------------------------------------------------

-

112

5.2.11 Wall mounted type PCB function description -----------------------------------------------------

-

114

6.Diagnostic code -------------------------------------------------------------------------------------------------

-

117

6.1.1 Outdoor unit diagnostic code ---------------------------------------------------------------------------

-

117

6.1.2 Cassette type and convertible type diagnostic code ---------------------------------------------

-

118

6.1.3 Duct type diagnostic code -------------------------------------------------------------------------------

-

119

6.1.4 Console type diagnostic code --------------------------------------------------------------------------

-

121

6.1.5 Wall mounted type diagnostic code ------------------------------------------------------------------- 122

6.2 Trouble shooting ---------------------------------------------------------------------------------------------

-

123

7.Assistant software ----------------------------------------------------------------------------------------------

-

126

8.Performance curves -------------------------------------------------------------------------------------------

-

127

9. Indoor air velocity and temperature distribution---------------------------------------------------------

-

133

9.1 AB092-182XCERA -------------------------------------------------------------------------------------------

-

133

9.2 AC142-182XCERA -------------------------------------------------------------------------------------------

-

135

9.3 AF092-122XCERA -------------------------------------------------------------------------------------------

-

139

9.4 Wall mounted type -------------------------------------------------------------------------------------------- 141

10. Air flow and static pressure chart -------------------------------------------------------------------------

-

142

-3-

.9773:1506 -5: .9825;5983:

JK@IB[LNVJ

JKABB[LNVJ

JKADB[LNVJ

JKAHB[LNVJ

JLADB[LNVJ

JLAHB[LNVJ

JM@IB[SNVJ

JMABB[SNVJ

JMADB[SNVJ

JMAHB[SNVJ

JO@IB[LNVJ

JOABB[LNVJ

JW@GB[YNVJ

JW@IB[YNVJ

JWABB[YNVJ

JWAHB[YNVJ

A?C Ug`h\jbfe j`dg`h\jkh` h\ea`

JXAHB[ONVJ

JXBBB[ONVJ

Lffcbea

Q`\jbea

Re_ffh

fkj_ffh

V\j`_ T\nbdkd Tbebdkd

BG CB AE

AI BC AD

CE DC >E

BD BF F

B@ BG A@

AD?E >> >>

G BC >A@

FAH >>

MK L

ZK L

MK L

ZK L

Re_ffh

fkj_ffh

MK L

ZK L

MK L

ZK L

bel`hj`h ibeac` kebj= ikg`h cfm \d]b`ej j`dg? ^ffcbea

JXBEB[PNVJ

JXBHB[QNVJ

JXCDB[QNVJ

JXCFB[QNVJ

,+ /383:06 5849:70;598

A?A rpqvtus i`hb`i cbe` kg

Commercial Air Conditioner

1 .3 Product features

High efficienct, universal outdoor unit

The outdoor unit can match with cassette type ,duct type, convertible type, console type and wall mounted

type indoor unit. Outdoor unit can match with multiple indoor units. Even when you have already installed

the air conditioner, if you want to add or reduce one unit, go ahead freely as long as your operation

complies with our design. Greatly convenient for designer and installer.

Total indoor load can be up to 135% than the standard match

The total capacity of all indoor units can be 135% more than the nominal cooling capacity, but the total

indoor cooling capacity will not be increased.

Newly designed V- appearance indoor unit

The wall mounted type indoor unit adopts the newly designed V appearance, more fashion, more beautiful.

The unit is designed with the health airflow and sterilize function, which will make the air more healthy.

Also the air blow direction can be set as step or stepless control, much convenient to control.

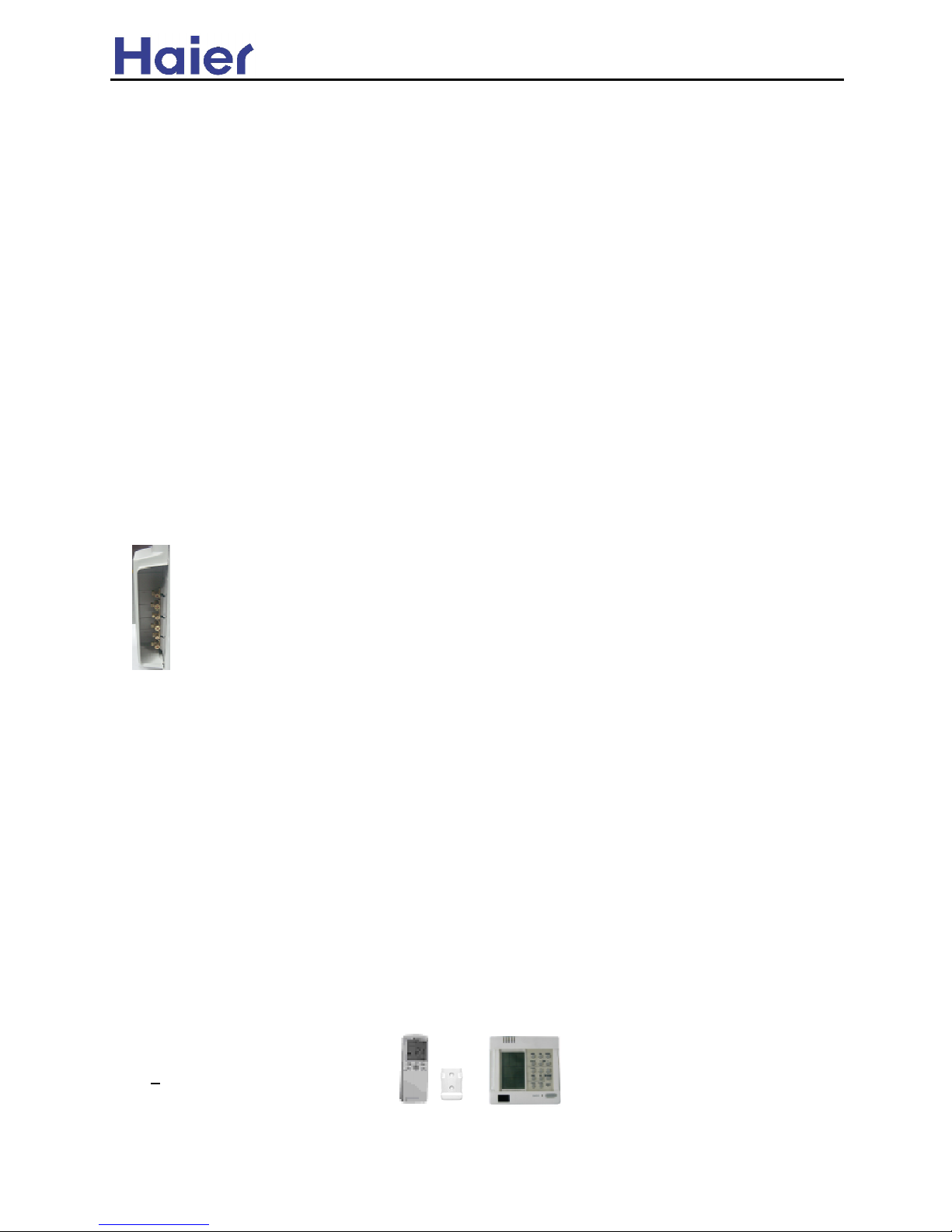

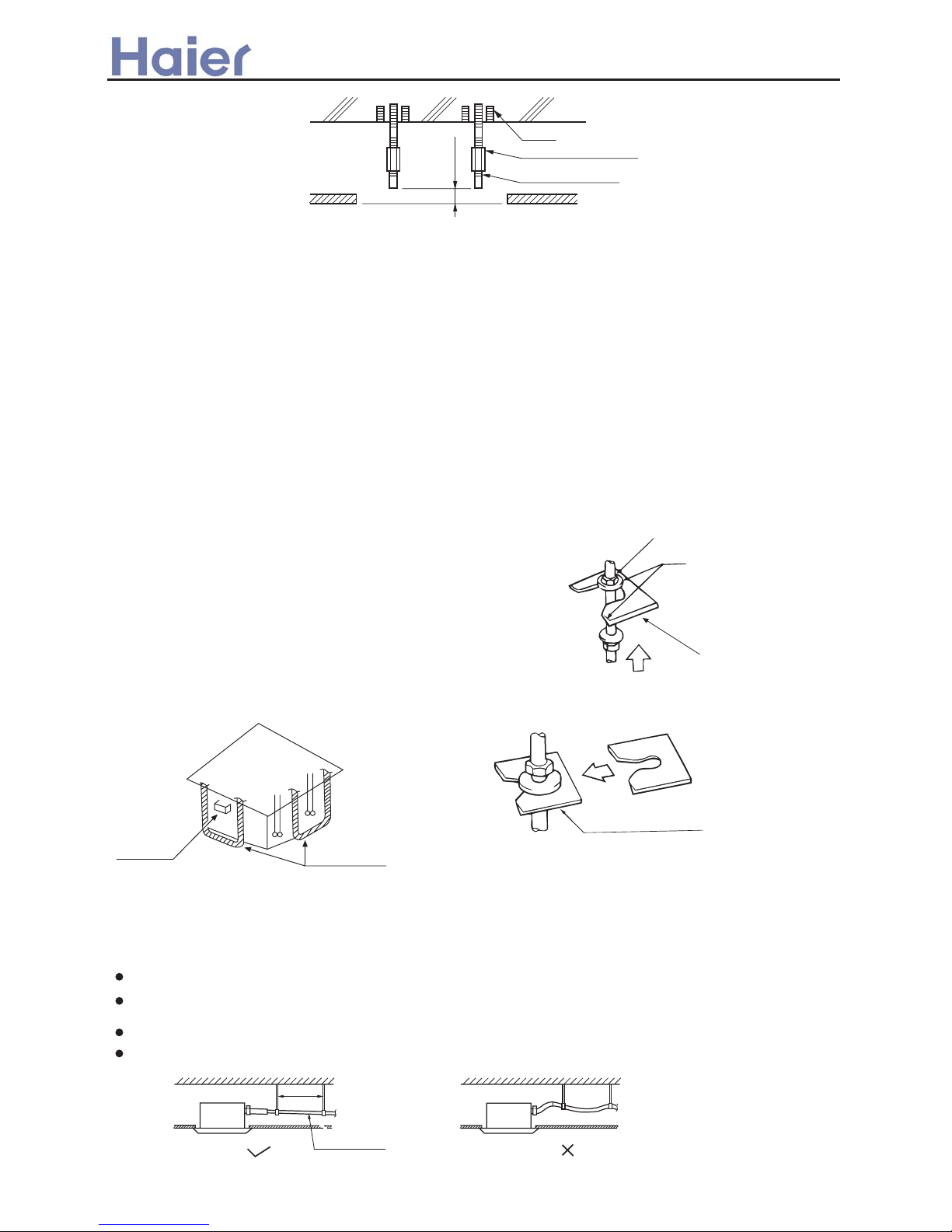

Newly designed guarding plate of valve

In order to protect the valve against the dust, the rain or the snow, etc. we add a guarding plate to the

valve.

Adopt the much friendlier refrigerant R410a

The air conditioner system adopts the greatly friendly refrigerant R410a, which is protective for the ozone

layer and is good to avoid the earth getting warmer. Benefit for the environment.

Adopt the advanced DC inverter technology

The system adopts the advanced DC inverter technology, which can consume less power energy to realize

the equal efficiency, saving money for you.

With air inlet filter, enhance the air quality

The high efficiency filter can collect the dirt and remove the bacterium, which can be installed on the

easy-to-unload place, convenient to be cleaned.

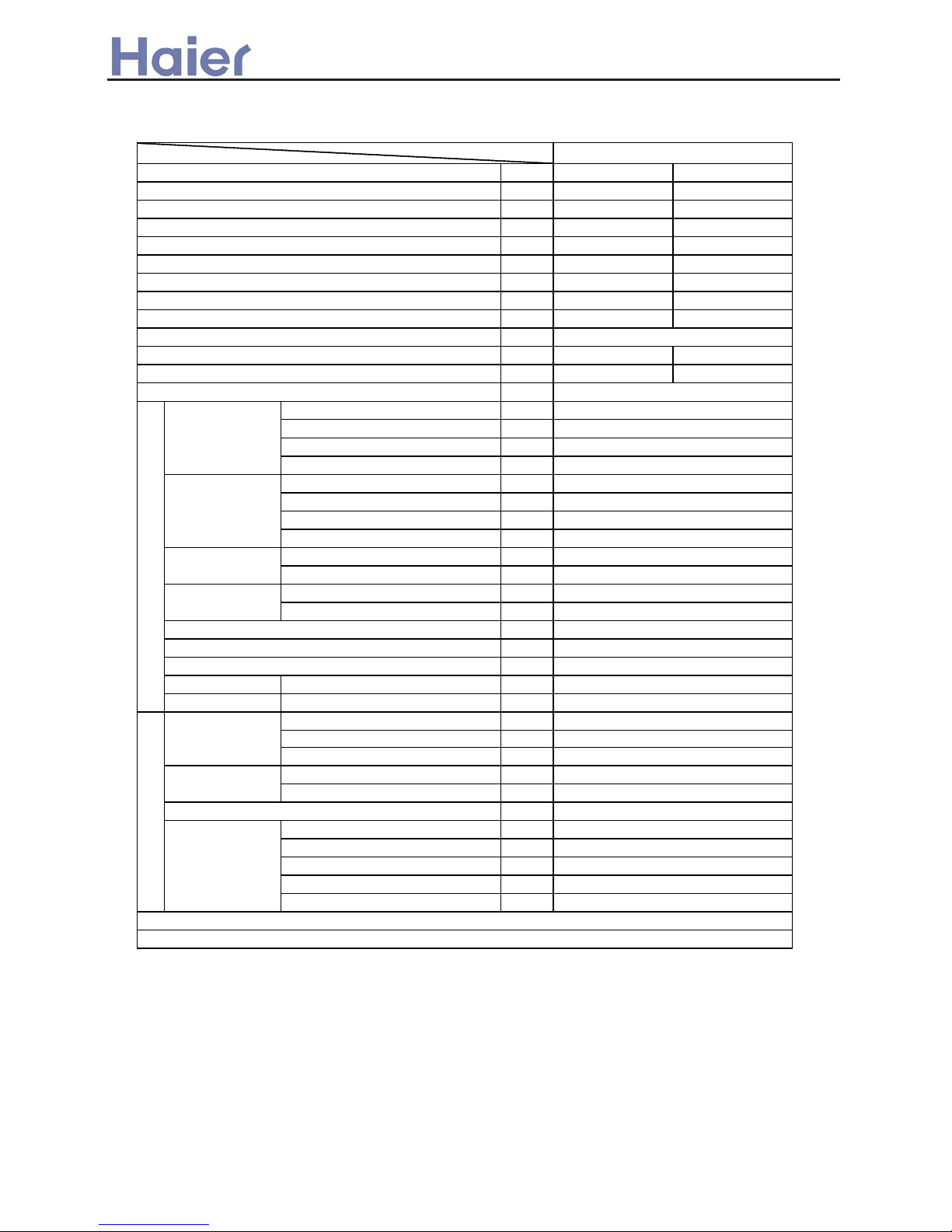

Convenient infrared remote controller

This remote controller YR-H65 can realize the healthy air flow and sterilize function, it is mobile type

appearance, so smart and compact. And the infrared controller can be equipped with the controller holder,

convenient to fix the remote controller.

Auto

restart function (optional)

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will

automatically recover the previous running mode once the power supply is on.

-4-

Commercial Air Conditioner

Self-diagnostic function

In the course of operation, if the failure occurs, the failure code will display on the wired controller

or on the operation panel. Then according to the failure code chart, you can eliminate the failure soon.

Central control function, if connected with a detector and a central controller

That is convenient for building management.

Adjustable heating temperature compensation

In heating mode, the temperature compensation can be adjusted by the remote controller. If you do not

want the compensation, you can set the compensation as 0 degree.

Software for diagnostic installation

After installation, you can use file "X-MULTI Setup Assistant " to know the installation is OK or

not, if system has error, software will give you trouble shooting.

-5-

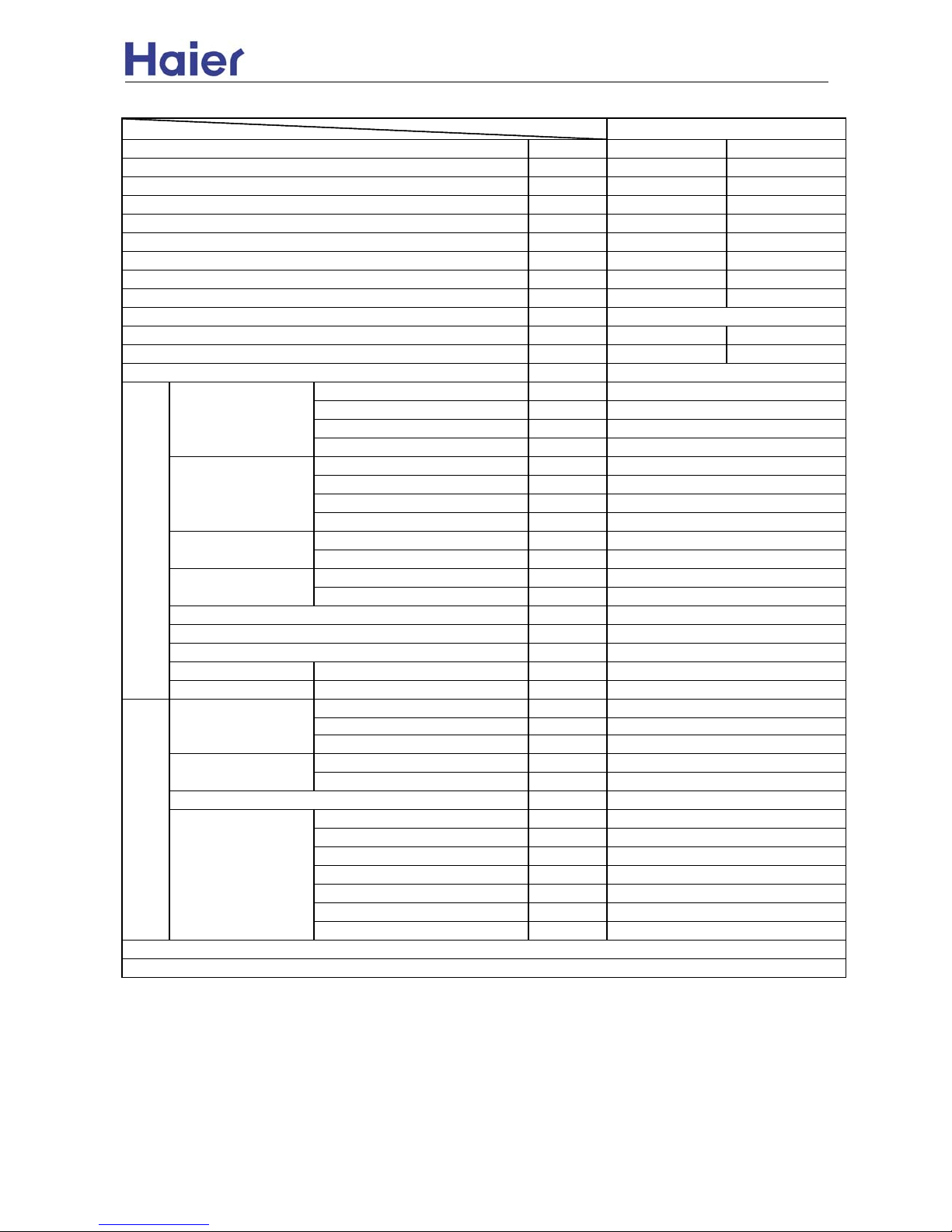

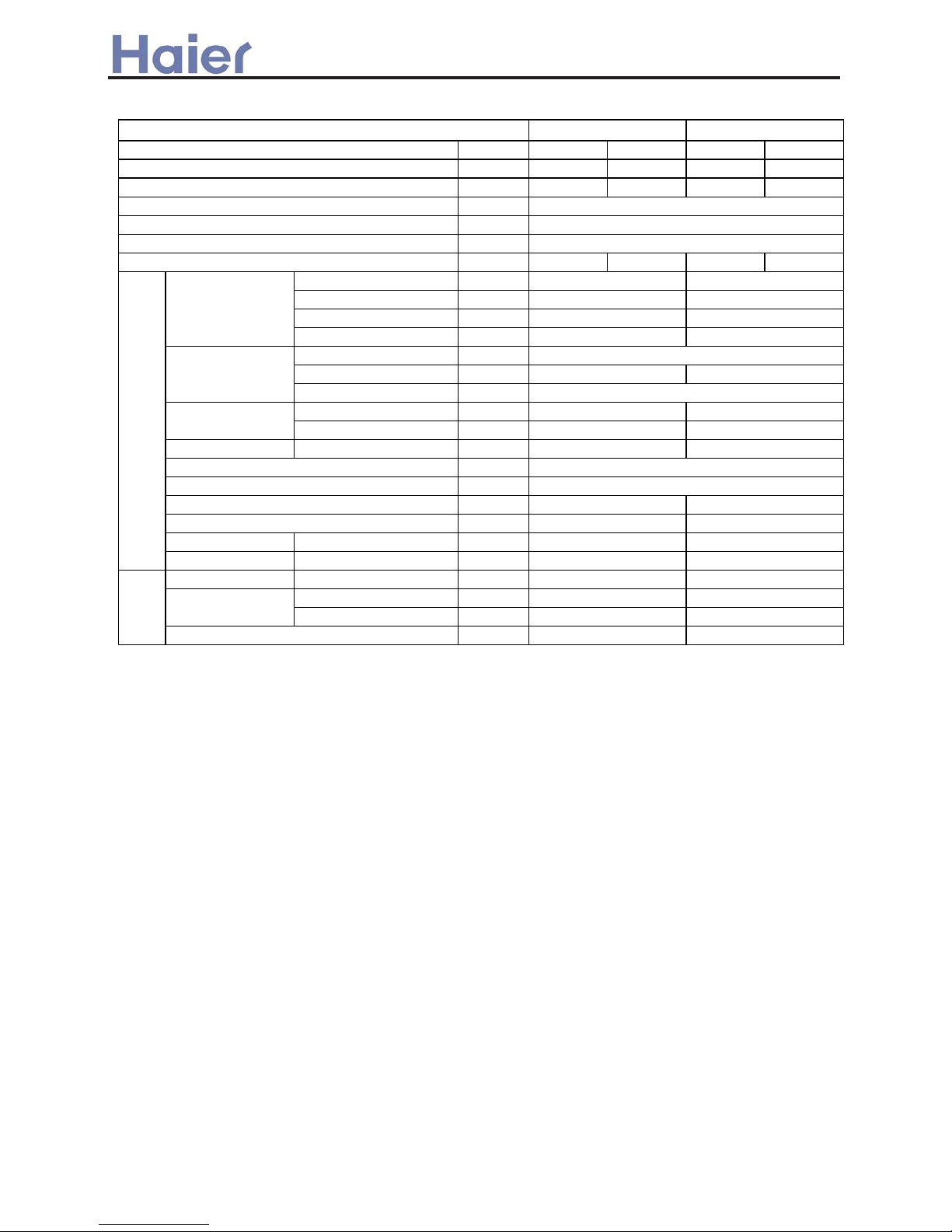

2. Specifications

-6-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating

W 5300 7000

W 1650 1800

A 7.3 8.0

W/W

3.21 3.89

W 1500 1800

W 500 500

W

5800 7300

W

2300 2300

——

A / A 10.2 10.2

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Max.Drop between IU & OU m

Max.Drop between IU & OU m

Max.Drop between indoor units m

Max.Piping length between IU & OU m

Max.Total liquid piping length

m

2. Large drop and long piping installation will obviously reduce the totao capacity.

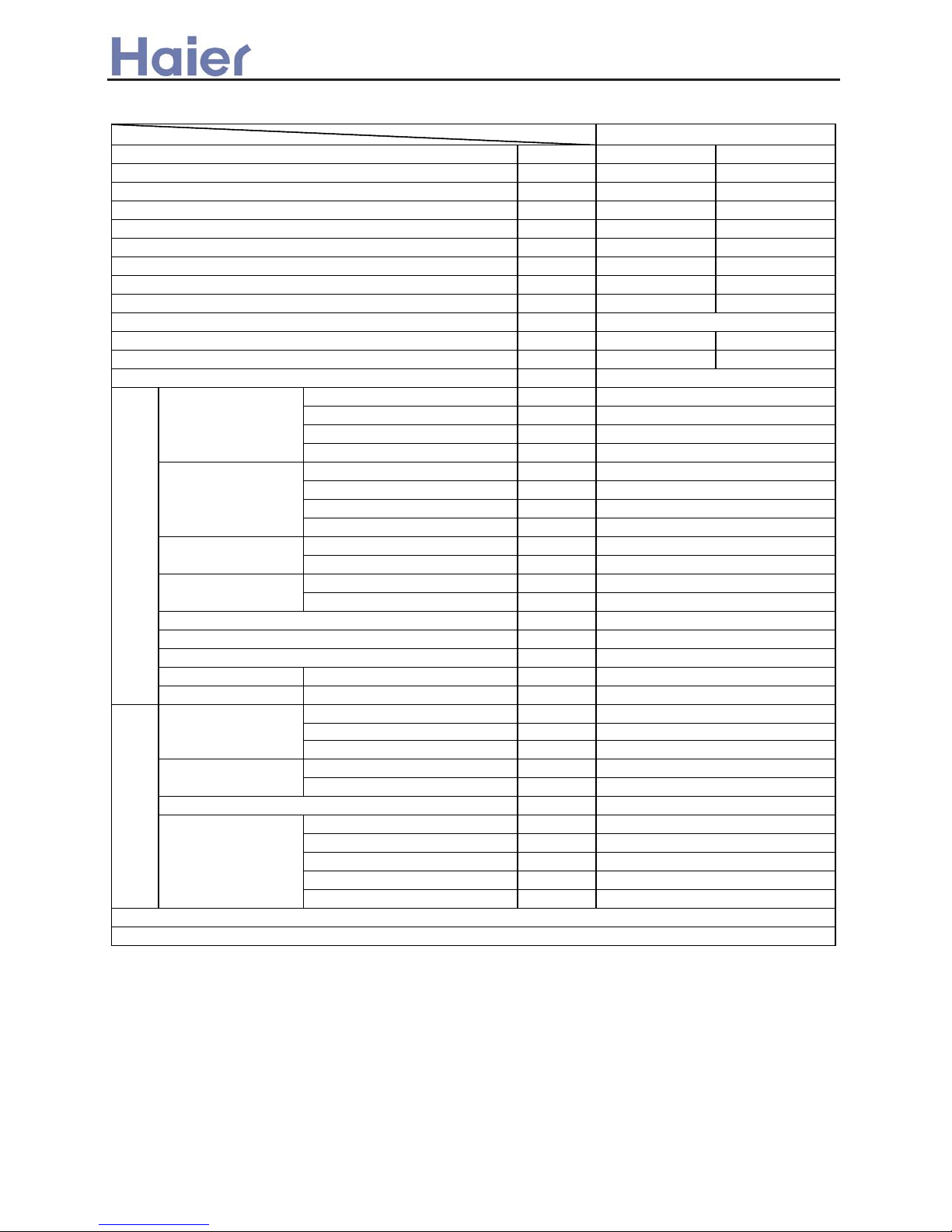

1. The above performance data are from the combination of AU182XFERA+2*AS092XVERA+AS122XVERA.

51/-/-

54 / 60

Piping

Refrigerant R410A / 2.0

Connecting method

Flared

30

20

10(indoor unit lower than outdoor unit)

25

15 (indoor unit higher than outdoor unit)

5

Pipe 3* Φ6.35

3* Φ9.52

45

35

Refrigerant control method PMVs

Defrosting method Automatic by reversible cycle

Axial × 1

870CC, MEL 56

928/288/680

1015/405/760

850 / 700 / 500

35/85

about 3000

TP2M / 7.0

about 0.52

Compressor

Dimension

(WxDxH)

Heat exchanger

Crankcase heater power

TNB175FLBM / MELCO

Twin Rotary (DC inverter)

1

25

Item Model AU182XFERA

Function

Power source 1PH, 220-230V~, 50Hz

Rating capacity

Maximum capacity

Power input (indoor + outdoor)

EER / COP

Between I.U &O.U

Power input (indoor + outdoor)

Minimum capacity

Power input

Power facor(under rating power input)

Max.Running current (indoor + outdoor)

Current input (indoor + outdoor)

Fan

Fuse size (recommended size)

Outdoor unit

-7-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating

W 6400 7300

W 2100 2000

A 9.3 8.9

W/W

3.04 3.65

W 1500 1800

W 500 500

W

6800 7500

W

2900 2900

——

A / A 12.9 12.9

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Max.Drop between IU & OU m

Max.Drop between IU & OU m

Max.Drop between indoor units m

Max.Piping length between IU & OU m

Max.Total liquid piping length

m

2. Large drop and long piping installation will obviously reduce the totao capacity.

Between I.D &O.D

5

25

45

1. The above performance data are from the combination of AU222XFERA+AS092XVERA+2*AS122XVERA.

Connecting method

Flared

10(indoor unit lower than outdoor unit)

15 (indoor unit higher than outdoor unit)

55/-/-

54 / 60

Piping

Refrigerant R410A / 2.0

30

20

Pipe 3* Φ6.35

3* Φ9.52

Defrosting method

Automatic by reversible cycle

Crankcase heater power 35

Dimension

(WxDxH)

928/288/680

1015/405/760

Refrigerant control method PMVs

about 3200

Heat exchanger TP2M / 7.0

about 0.52

Outdoor unit

Compressor

TNB175FLBM / MELCO

870CC, MEL 56

Twin Rotary (DC inverter)

1

Fan

Axial × 1

960 / 700 / 500

35/100

Max.Running current (indoor + outdoor)

Power facor(under rating power input)

Fuse size (recommended size)

25

Maximum capacity

Power input (indoor + outdoor)

Power source

1PH, 220-230V~, 50Hz

Power input (indoor + outdoor)

EER / COP

Minimum capacity

Power input

Current input (indoor + outdoor)

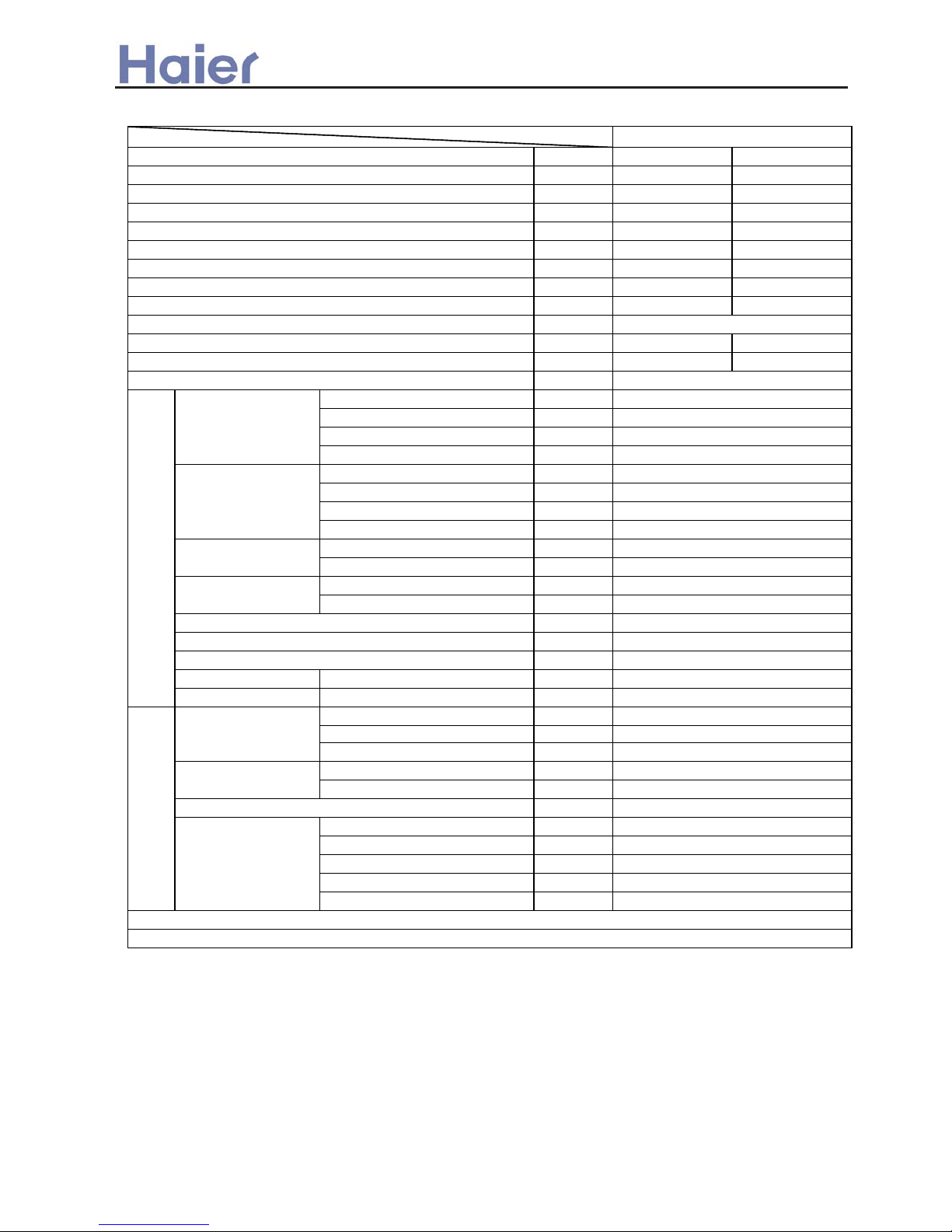

Item Model AU222XFERA

Function

Rating capacity

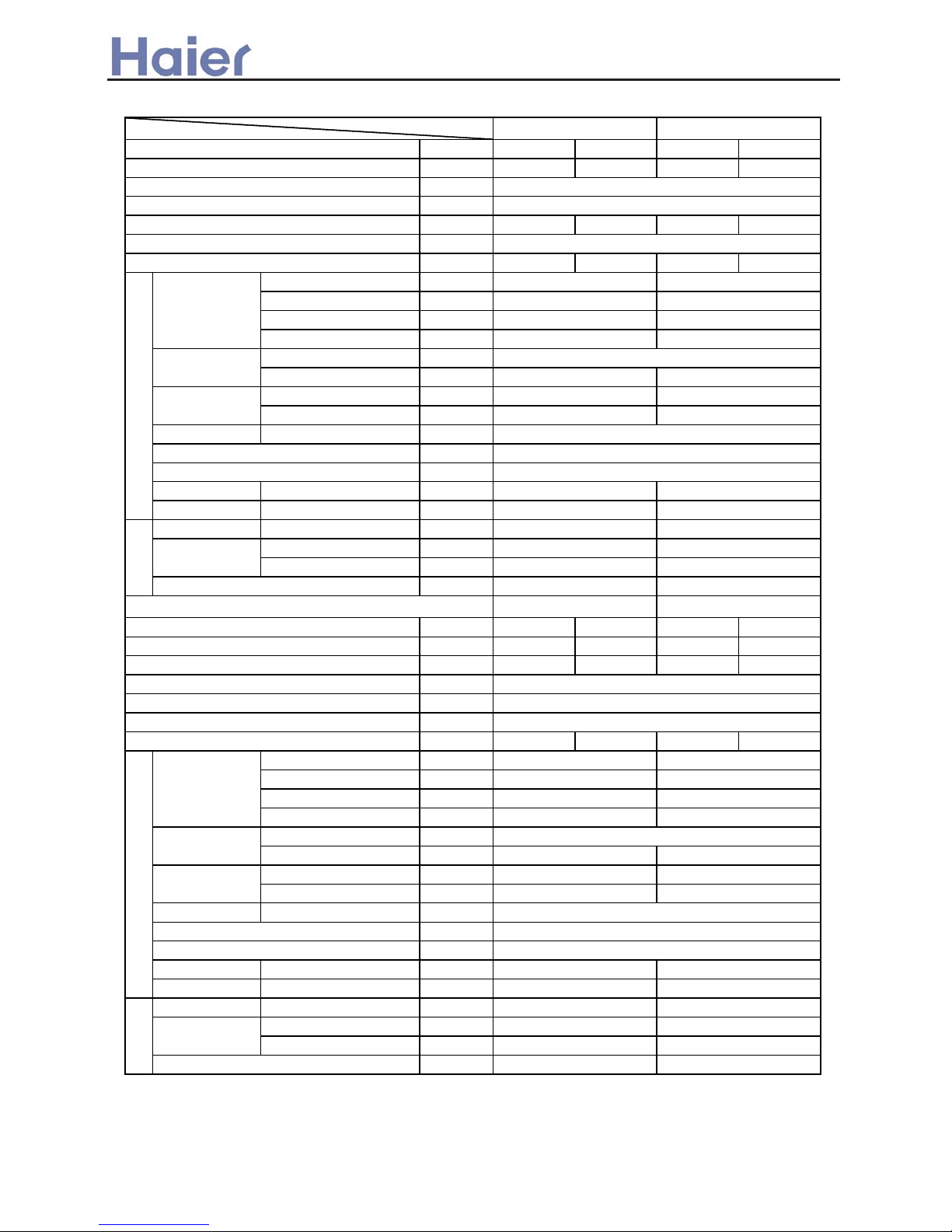

——

Cooling Heating

W 7250 8000

W 2250 2200

A 10.4 10.4

W/W

3.22 3.64

W 1500 1800

W 500 500

W

8200 9000

W

3200 3000

——

A / A 14.3 13.5

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Max.Drop between IU &OU m

Max.Drop between IU & IU m

Max.Drop between IU & OU

m

Max.Piping length between IU & OU m

Max.Total length

m

Item Model AU252XGERA

Function

Rating capacity

Power input (indoor + outdoor)

Current input (indoor + outdoor)

EER / COP

Minimum capacity

Power input

Maximum capacity

Power input (indoor + outdoor)

Power source

1PH, 220-230V~, 50Hz

Max.Running current (indoor + outdoor)

Power facor(under rating power input)

Fuse size (recommended size)

30

Outdoor unit

Compressor

TNB175FLBM / MELCO

870CC

DC TWIN ROTARY

1

Fan

Axial × 1

930 / 700 / 500

98/200

about 3400

Heat exchanger TP2M / 7.0

about 0.67

Dimension

(WxDxH)

976/335/732

1065/420/815

Refrigerant control method PMVs

Defrosting method Automatic by reversible cycle

Crankcase heater power 35

1. The above performance data are from the combination of AU252XGERA+3*AD092XLERA

2. Large drop and long piping installation will obviously reduce the total capacity.

Connecting method

Flared

5

Piping

Refrigerant

60

Pipe 4* Φ6.35

Between I.D &O.D

15 (indoor unit higher than outdoor unit)

57/-/-

58 / 64

R410A / 2.5

30

20

4* Φ9.52

25

10(indoor unit lower than outdoor unit)

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-8-

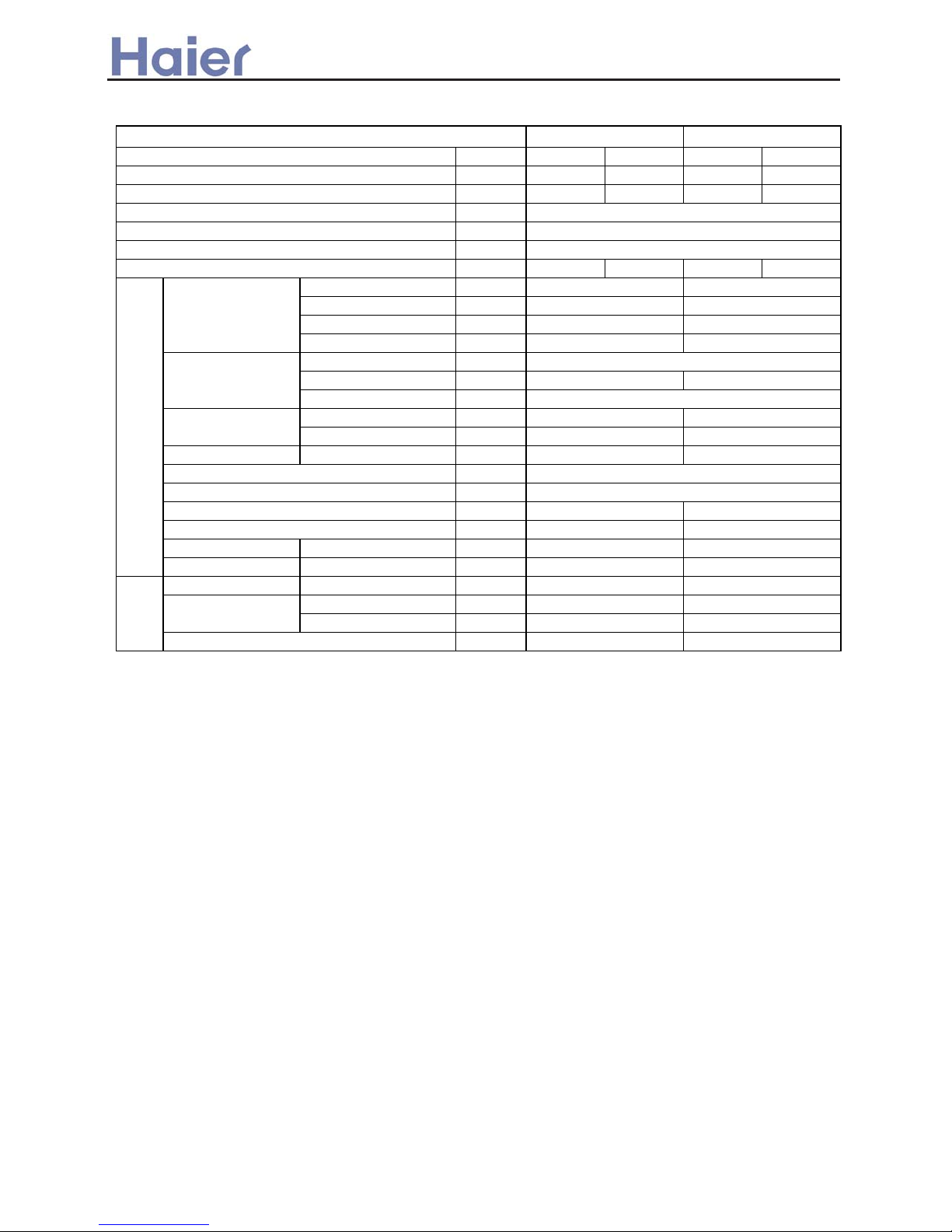

-9-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating

W 8000 10000

W 2480 2700

A 11.0 11.9

W/W

3.22 3.70

W 1500 1800

W 550 550

W

9500 11000

W

3800 3800

——

A / A 16.8 16.8

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Max.Drop between IU &OU m

Max.Drop between IU & IU m

Max.Drop between IU & OU

m

Max.Piping length between IU & OU m

Max.Total length

m

1. The above performance data are from the combination of AU282XHERA+2*AS092XVERA+2*AS122XVERA.

2. Large drop and long piping installation will obviously reduce the total capacity.

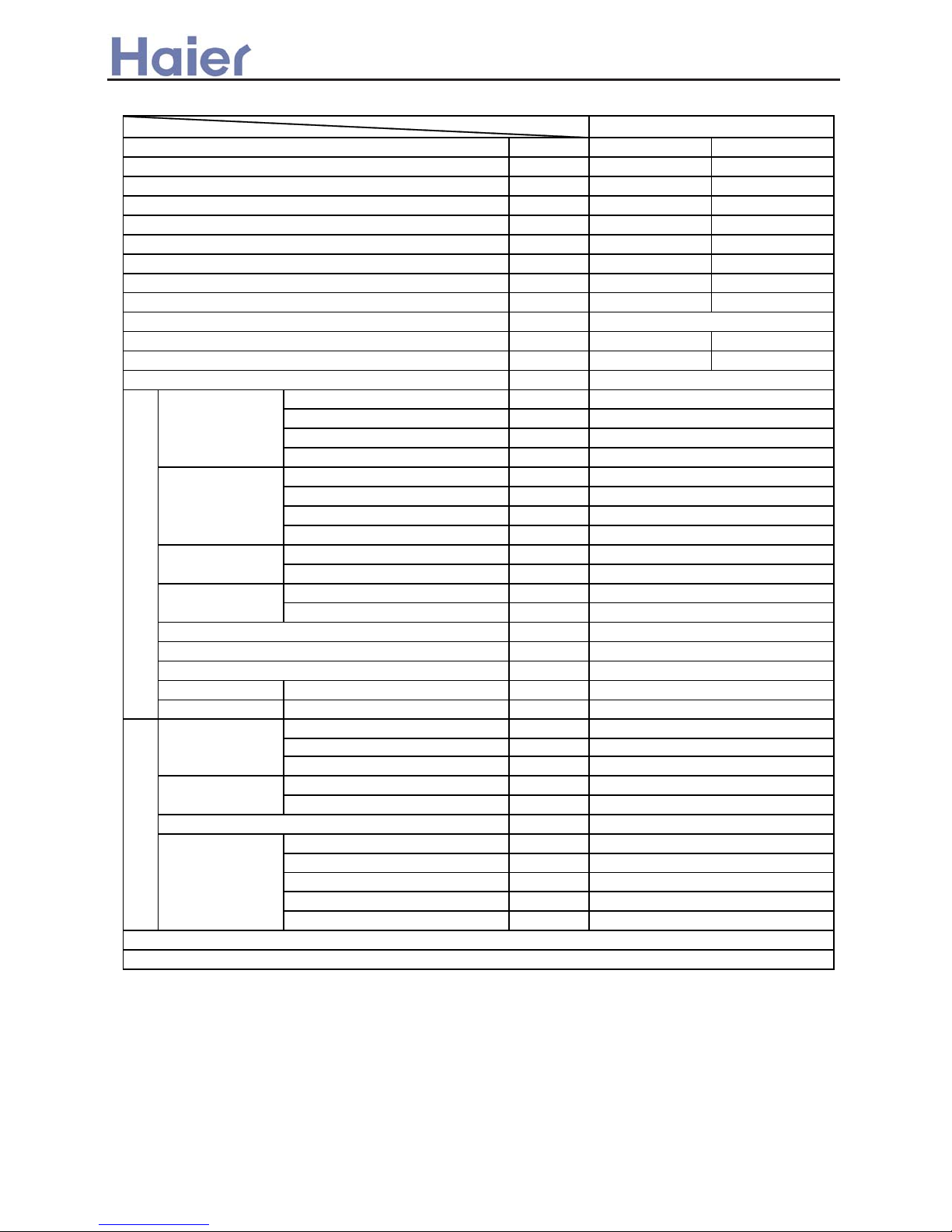

Item Model AU282XHERA

Function

Rating capacity

Power input (indoor + outdoor)

EER / COP

Minimum capacity

Power input

Maximum capacity

Power input (indoor + outdoor)

Power source

1PH, 220-230V~, 50Hz

Max.Running current (indoor + outdoor)

Power facor(under rating power input)

Fuse size (recommended size)

30

Compressor

TNB220FLBM / MELCO

870CC

Twin Rotary (DC inverter)

1

about 4000

Heat exchanger TP2M / 7.0

about 0.75

Fan

Axial × 1

850 / 700 / 500

60/150

Dimension

(WxDxH)

1068x340x830

1100x440x979

Refrigerant control method

PMVs

Defrosting method

Automatic by reversible cycle

Crankcase heater power

35

74 / 89

Piping

Refrigerant R410A / 2.6

40

20

Pipe 4* Φ6.35

4* Φ9.52

Outdoor unit

Between I.D &O.D

Current input (indoor + outdoor)

Connecting method

Flared

5

10(indoor unit lower than outdoor unit)

15 (indoor unit higher than outdoor unit)

25

60

58/-/-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-10-

——

Cooling Heating

W 10000 11000

W 3200 3200

A 14.3 14.3

W/W

3.13 3.44

W 1500 1800

W 550 550

W

11000 11500

W

4000 4000

——

A / A 18.1 18.1

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Drop between IU & OU

m

Piping length between IU & OU

m

Total liquid piping length

m

Max.Drop between IU &OU m

Max.Drop between IU & IU m

Max.Piping length between IU & OU m

Max.Total length

m

Item Model AU342XHERA

Function

Rating capacity

Power input (indoor + outdoor)

Current input (indoor + outdoor)

EER / COP

Minimum capacity

Power input

Maximum capacity

Power input (indoor + outdoor)

Power source

1PH, 220-230V~, 50Hz

Max.Running current (indoor + outdoor)

Power facor(under rating power input)

Fuse size (recommended size)

30

Outdoor unit

Compressor

TNB220FLBM / MELCO

870CC

Twin Rotary (DC inverter)

1

Fan

Axial × 1

990/ 840/ 590

130/300

about 4300

Heat exchanger TP2M / 7.0

about 0.75

Dimension

(WxDxH)

1068x340x830

1100x440x979

Refrigerant control method PMVs

60

Defrosting method

Automatic by reversible cycle

Crankcase heater power 35

Pipe 4* Φ6.35

4* Φ9.52

25

10(indoor unit lower than outdoor unit)

1. The above performance data are from the combination of AU342XHERA+2*AD092XLERA+2*AD122XLERA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Connecting method

Flared

Between I.D &O.D

≤5

≤10

≤40

Piping

Refrigerant

15 (indoor unit higher than outdoor unit)

59/-/-

74 / 89

R410A / 3.0

40

20

——

Cooling Heating

W 10000 11000

W 3200 3200

A 14.3 14.3

W/W

3.13 3.44

W 1500 1800

W 550 550

W

11000 11500

W

4000 4000

——

A / A 18.1 18.1

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Drop between IU & OU

m

Piping length between IU & OU

m

Total liquid piping length

m

Max.Drop between IU &OU m

Max.Drop between IU & IU m

Max.Piping length between IU & OU m

Max.Total length

m

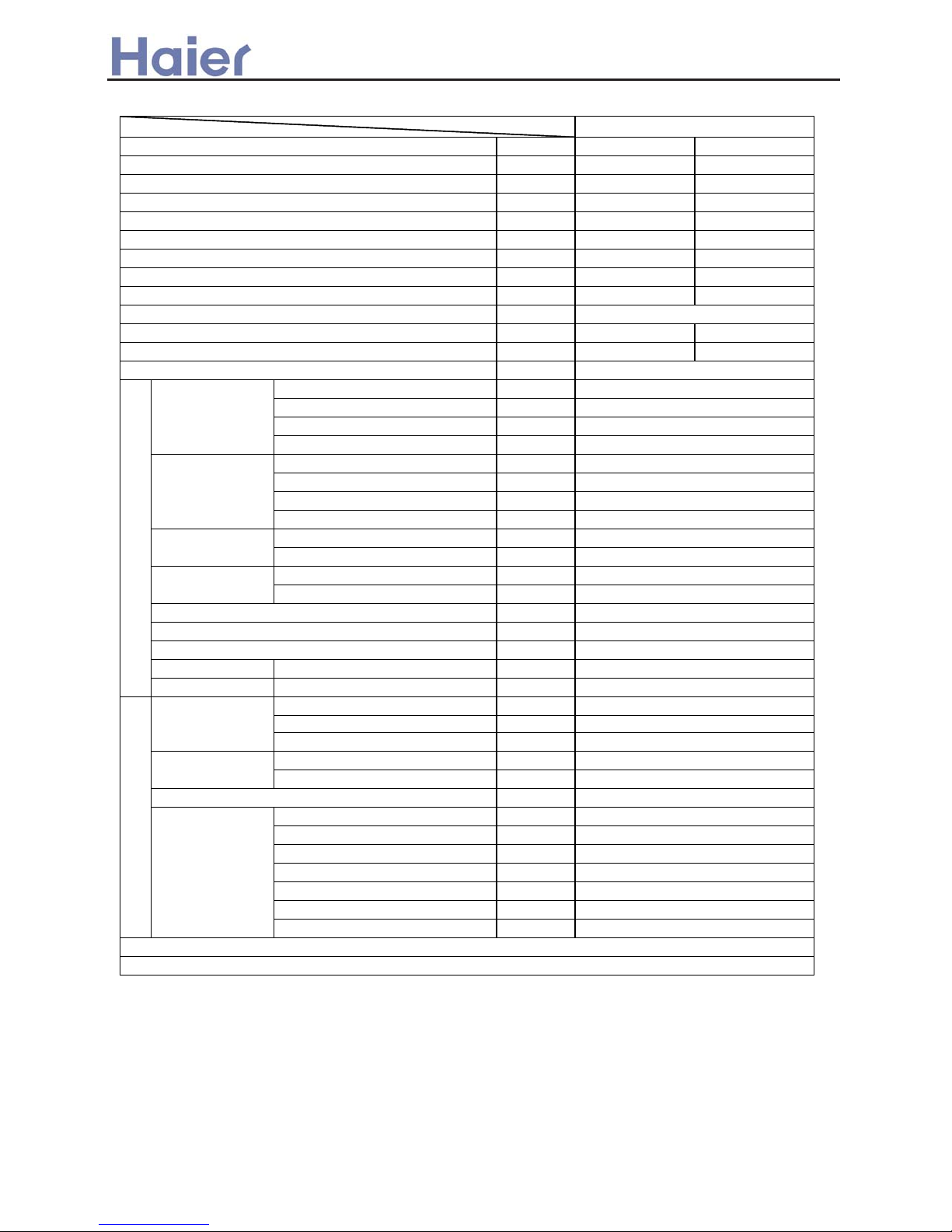

Item Model AU362XHERA

Function

Rating capacity

Power input (indoor + outdoor)

Current input (indoor + outdoor)

EER / COP

Minimum capacity

Power input

Maximum capacity

Power input (indoor + outdoor)

Power source

1PH, 220-230V~, 50Hz

Max.Running current (indoor + outdoor)

Power facor(under rating power input)

Fuse size (recommended size)

30

Outdoor unit

Compressor

TNB220FLBM / MELCO

870CC

Twin Rotary (DC inverter)

1

Fan

Axial × 1

990/ 840/ 590

130/300

about 4300

Heat exchanger TP2M / 7.0

about 0.75

Dimension

(WxDxH)

1068x340x830

1100x440x979

Refrigerant control method PMVs

60

Defrosting method

Automatic by reversible cycle

Crankcase heater power 35

Pipe 5* Φ6.35

5* Φ9.52

25

10(indoor unit lower than outdoor unit)

1. The above performance data are from the combination of AU362XHERA+2*AD092XLERA+2*AD122XLERA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Connecting method

Flared

Between I.D &O.D

≤5

≤10

≤40

Piping

Refrigerant

15 (indoor unit higher than outdoor unit)

59/-/-

74 / 89

R410A / 3.0

40

20

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-11-

-12-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating Cooling Heating

W

2000 2300 2500 2900

——

——

10‐³×m³/h

1.0 / 1.0 /

N, V, Hz

A / A 0.15 0.15 0.15 0.15

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

Drainage pipe material, diameter mm

——

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

——

Cooling Heating Cooling Heating

W

3200 3800 5000 5500

10‐³×m³/h

1.6 / 2.0 /

——

——

N, V, Hz

A / A 0.15 0.15 0.25 0.25

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H-M-L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

Drainage pipe material, diameter mm

——

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

Piping

Pipe

Connecting method

7.6/10.6

R410A

Flared

Refrigerant control

PMV on outdoor unit

12/15

Fan

Heat exchanger

Dimension

(L×W×H)

Controller type

962*365*312

Controller type

TP2M / 7×0.35

16/40 25/40

39/36/33 42/40/37

PVC, 11.4/16.4

795×197×265

870*225*305

880×315×330

Infrared (YR-H65)

1250/1150/1050 1200/1050/950

550/480/430 600/550/500

1, 220~230, 50

CROSS×1 CROSS×1

Running current

Fan

Heat exchanger

Dimension

(L×W×H)

about 0.20 about 0.20

Function

Capacity

Dehumidifying capacity

Power source

Power cable

6.35

9.52

Item

AS122XVERA AS182XVERA

Piping

Pipe

Connecting method

6.35

9.52

PMV on outdoor unit

7.6/10.6 7.6/10.6

36/33/30 38/34/31

Item Model

16/40

480/430/380 520/450/390

Power source

1,220-230~, 50

Running current

CROSS×1 CROSS×1

1150/1050/950

R410A R410A

Capacity

Dehumidifying capacity

about 0.15 about 0.15

TP2M / 7×0.35

880×315×330

PVC, 11.4/16.4

Refrigerant control

795*197*265 795×197×265

880×315×330

Function

AS072XVERA AS092XVERA

1200/1100/1000

16/40

Flared

R410A

6.35 6.35

9.52 12.7

3 × (1.0~1.5mm2 )

Communication cable

2x(0.75~1.25mm2 ), must be shieled

Power cable

3 × (1.0~1.5mm2 )

Communication cable

2x(0.75~1.25mm2 ), must be shieled

Flared Flared

Infrared (YR-H65)

-13-

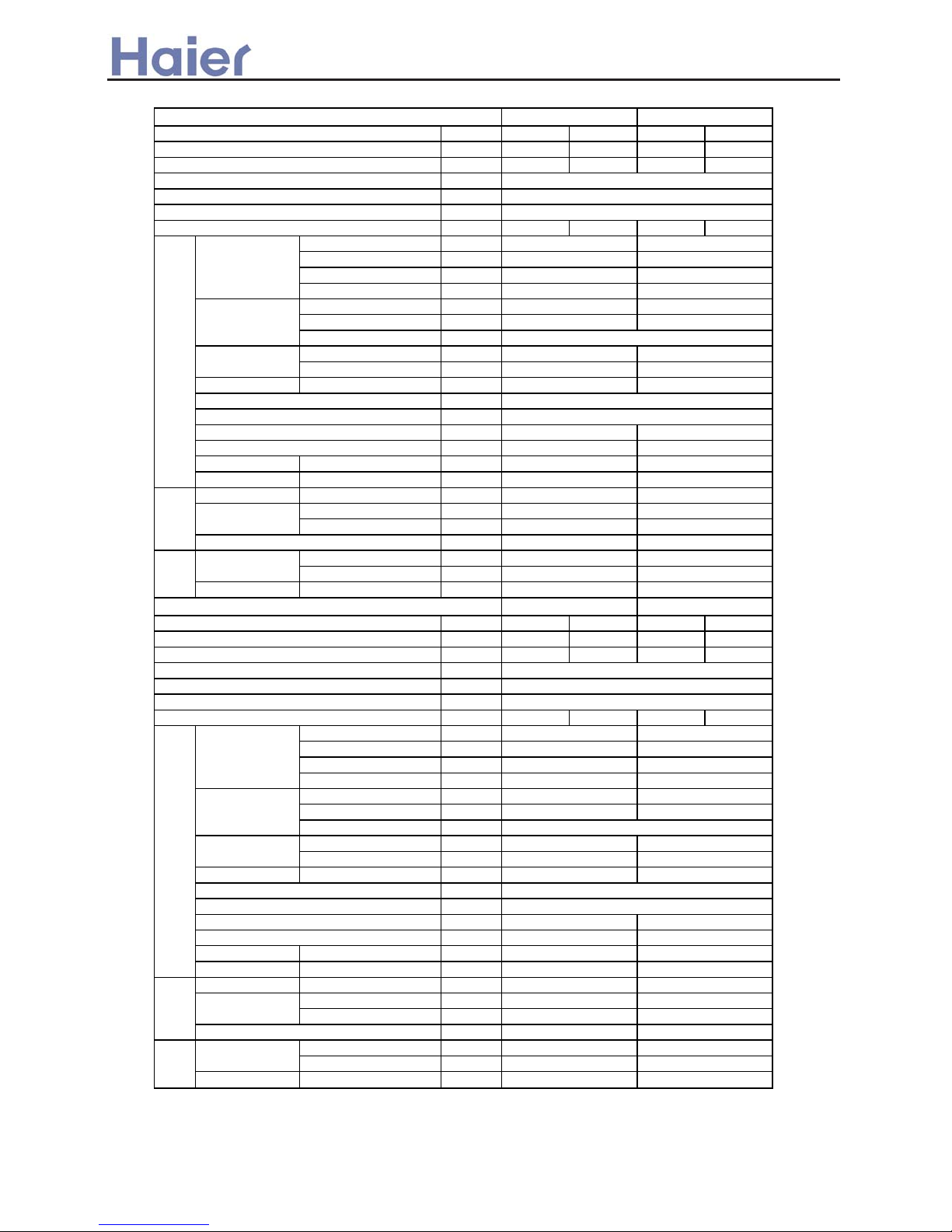

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating Cooling Heating

W

2500 2900 3500 3800

10‐³×m³/h

1.0 / 1.2 /

——

——

N, V, Hz

A 0.45 0.45 0.45 0.45

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

External mm

Package mm

Weight Net / Shipping

kg / kg

——

Cooling Heating Cooling Heating

W

4100 4600 5000 5500

10‐³×m³/h

1.6 / 2 /

——

——

N, V, Hz

A 0.45 0.45 0.45 0.45

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

External mm

Package mm

Weight Net / Shipping

kg / kg

* o.d.=outer diameter; i.d.=inner diameter

Connecting method Flared Flared

Panel

Dimension 700/700/60 700/700/60

740/750/115 740/750/115

2.8/4.8 2.8/4.8

19/23.5 19/23.5

Piping

R410A R410A

Pipe 6.35 6.35

12.7 12.7

Electricity Heater / /

44/40/37 44/40/37

PMV on outdoor unit

Fresh air hole dimension 100 100

570/570/260

718/680/380 718/680/380

PVC, 32/26(o.d./I.d.*) PVC, 32/26(o.d./I.d.*)

670/600/550

Heat exchanger 7 7

about 0.273 about 0.273

cooling: 6~7 / heating: 43~60

CENTRIFUGAL × 1

750/650/540 750/650/540

38/95 38/95

Running current

Fan CENTRIFUGAL × 1

670/600/550

Dimension

(L×W×H)

570/570/260

Controller type Infrared YR-H71 or wired YR-E12

Refrigerant control

3 × 0.75mm

2

Communication cable

2x(0.75~1.25mm2 ), must be shieled

Power source 1, 220~230, 50

Function

Capacity

Dehumidifying capacity

Power cable

2.8/4.8

Item Model

AB142XCERA AB182XCERA

Connecting method Flared Flared

Panel

Dimension

(L×W×H)

700/700/60 700/700/60

740/750/115 740/750/115

2.8/4.8

17/20 17/20

Piping

R410A R410A

Pipe 6.35 6.35

9.52 9.52

Electricity Heater / /

41/39/38 44/40/37

PMV on outdoor unit

Fresh air hole dimension 100 100

570/570/260

718/680/380 718/680/380

PVC, 32/26(o.d./I.d.*) PVC, 32/26(o.d./I.d.*)

670/600/550

Heat exchanger 7 7

about 0.273 about 0.273

cooling: 6~7 / heating: 43~60

CENTRIFUGAL × 1

650/570/520 750/650/540

38/95 38/95

Running current

Fan CENTRIFUGAL × 1

620/560/530

Dimension

(L×W×H)

570/570/260

Controller type Infrared YR-H71 or wired YR-E12

Refrigerant control

Communication cable

2x(0.75~1.25mm2 ), must be shieled

Power source 1, 220~230, 50

Capacity

Dehumidifying capacity

Power cable

3 × (1.0~1.5mm2 )

Item Model

AB092XCERA AB122XCERA

Function

-14-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating Cooling Heating

W

2500 2900 3500 3800

10‐³×m³/h

1.0 / 1.2 /

——

——

N, V, Hz

A 0.35 0.35 0.35 0.35

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

——

Cooling Heating Cooling Heating

W 4100 4600 5000 5500

10‐³×m³/h

1.6 / 2.0 /

——

——

N, V, Hz

A 0.85 0.85 0.85 0.85

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

* o.d.=outer diameter; i.d.=inner diameter

Item Model AD092XLERA AD122XLERA

Function

Capacity

Dehumidifying capacity

Power cable

3 × (1.0~1.5mm2 )

Communication cable 2x(0.75~1.25mm

2

), must be shieled

Power source

1, 220~230, 50

Running current

Fan CROSS × 1

550/500/450/400

Dimension

(L×W×H)

610×500×220

Controller type

Wired controller YR-E12

Refrigerant control

CROSS × 1

1050/950/850/750 1050/950/850/750

30/75 30/75

550/500/450/400

Heat exchanger 7 7

about 0.12 about 0.12

cooling: 6~7 / heating: 43~60

610×500×220

695/536/265 695/536/265

(o.d./I.d.*) (o.d./I.d.*)

PMV on outdoor unit

Fresh air hole dimension

//

Electricity Heater

//

43/40/38/35 43/40/38/35

14/16 14/16

Piping

R410A R410A

Pipe 6.35 6.35

9.52 9.52

Item Model AD142XLERA AD182XLERA

Connecting method

Flared Flared

Function

Capacity

Dehumidifying capacity

Power cable

3 × 0.75mm

2

Communication cable 2x(0.75~1.25mm

2

), must be shieled

Power source

1, 220~230, 50

Running current

Fan CROSS × 2

780/700/650/600

Dimension

(L×W×H)

1090×500×220

Controller type

Wired YR-E12

Refrigerant control

CROSS × 2

1270/1160/1020/900 1270/1160/1020/900

80/200 80/200

780/700/650/600

Heat exchanger 7 7

about 0.23 about 0.23

cooling: 6~7 / heating: 43~60

Fresh air hole dimension

//

1090×500×220

1161/536/269 1161/536/269

(o.d./I.d.*) (o.d./I.d.*)

Flared

25/29 25/29

PMV on outdoor unit

Electricity Heater

//

46/44/40/38 46/44/40/38

Piping

R410A R410A

Pipe 6.35 6.35

12.7 12.7

Connecting method

Flared

-15-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating Cooling Heating

W

4100 4600 5000 5500

10‐³×m³/h

1.6 / 2 /

——

——

N, V, Hz

A 0.45 0.45 0.45 0.45

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

* o.d.=outer diameter; i.d.=inner diameter

Piping

R410A R410A

Pipe 6.35 6.35

12.7 12.7

Connecting method

Flared

Electricity Heater

//

48/45/41 48/45/41

Flared

28.3/34.3 28.3/34.3

PMV on outdoor unit

Fresh air hole dimension

//

990/655/199

1150/750/300 1150/750/300

PVC, 20/18(o.d./I.d.*) PVC, 20/18(o.d./I.d.*)

700/640/580

Heat exchanger TP2M / 7×0.35

about 0.49 about 0.49

cooling: 6~7 / heating: 43~60

CENTRIFUGAL × 2

1150/1050/850 1150/1050/850

28/80 28/80

Running current

Fan CENTRIFUGAL × 2

700/640/580

Dimension

(L×W×H)

990/655/199

Controller type

Infrared YR-H71 or wired YR-E12

Refrigerant control

Communication cable

2x(0.75~1.25mm2 ), must be shieled

Power source

1, 220~230, 50

Capacity

Dehumidifying capacity

Power cable

3 × 0.75mm

2

Item Model AC142XCERA AC182XCERA

Function

-16-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

——

Cooling Heating Cooling Heating

W

2500 2900 3500 3800

10‐³×m³/h

1.0 / 1.2 /

——

——

N, V, Hz

A 0.45 0.45 0.45 0.45

Type × Number ——

Speed r/min

Motor output/input power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Type ——

Liquid mm

Gas mm

——

* o.d.=outer diameter; i.d.=inner diameter

Item Model AF092XCERA AF122XCERA

Function

Capacity

Dehumidifying capacity

Power cable

3 × (1.0~1.5mm2 )

Communication cable 2x(0.75~1.25mm

2

), must be shieled

Power source

1, 220~230, 50

Running current

Fan CROSS × 2

480/420/370

Dimension

(WxDxH)

720/205/630

Controller type

Infrared YR-H71

Refrigerant control

CROSS × 2

1000/900/800 1050/950/850

50/100 50/100

510/450/400

Heat exchanger TP2M / 7×0.35

about 0.25 about 0.25

cooling: 6~7 / heating: 43~60

Fresh air hole dimension

//

720/205/630

780/280/690 780/280/690

PVC, 16.4/11.4(o.d./I.d.*) PVC, 16.4/11.4(o.d./I.d.*)

Flared

17/20.7 17/20.7

PMV on outdoor unit

Electricity Heater

//

40/38/36 41/39/37

Piping

R410A R410A

Pipe 6.35 6.35

9.52 9.52

Connecting method

Flared

-17-

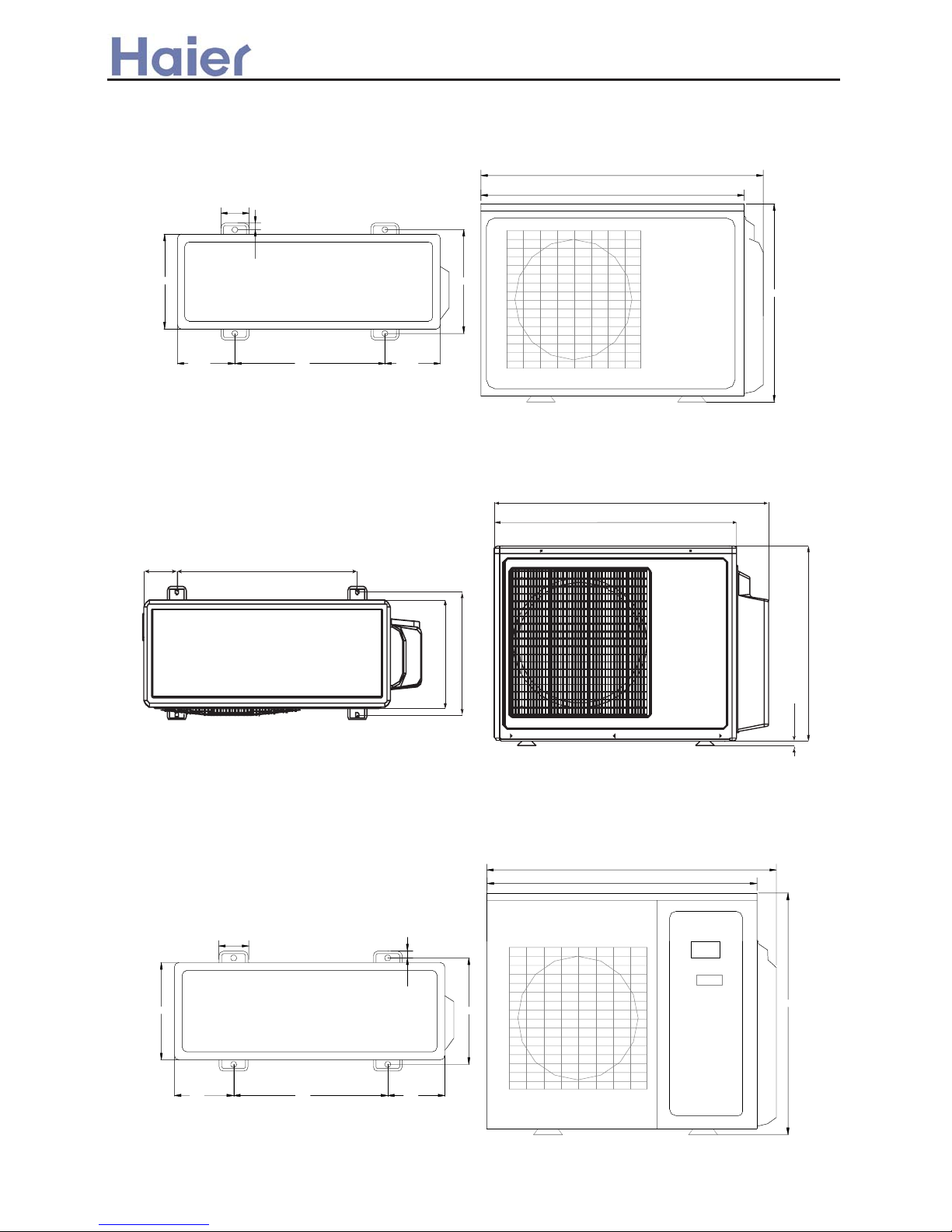

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

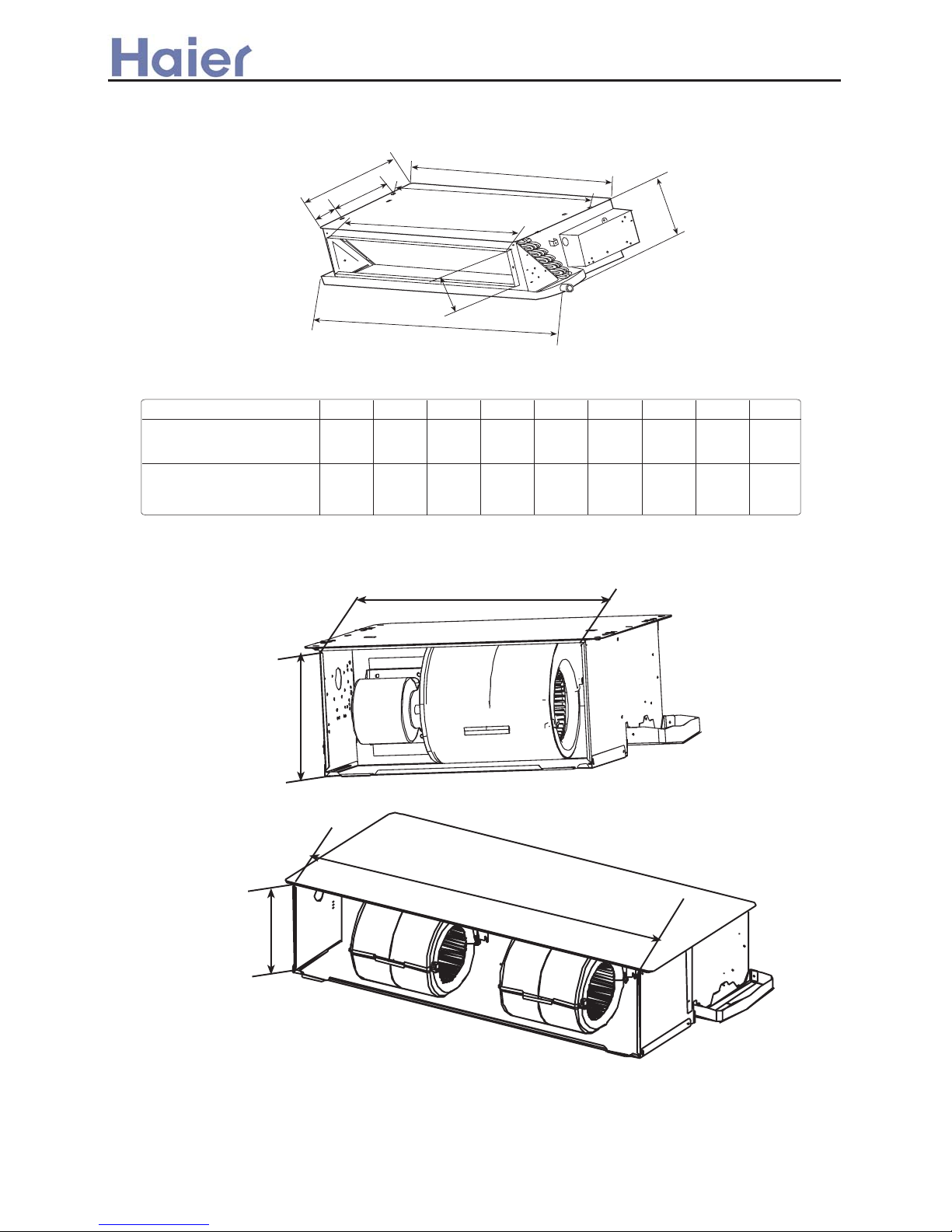

AU182XFERA,AU222XFERA

3. Dimension

AU282XHERA:

583

288

113.5

680

319.5

113.5

50

928

810

18

18

950

70

185

380

830

185

340

580

1068

48,.,965743

++.

-..

-*1

/-*

,.

0-*

1/*

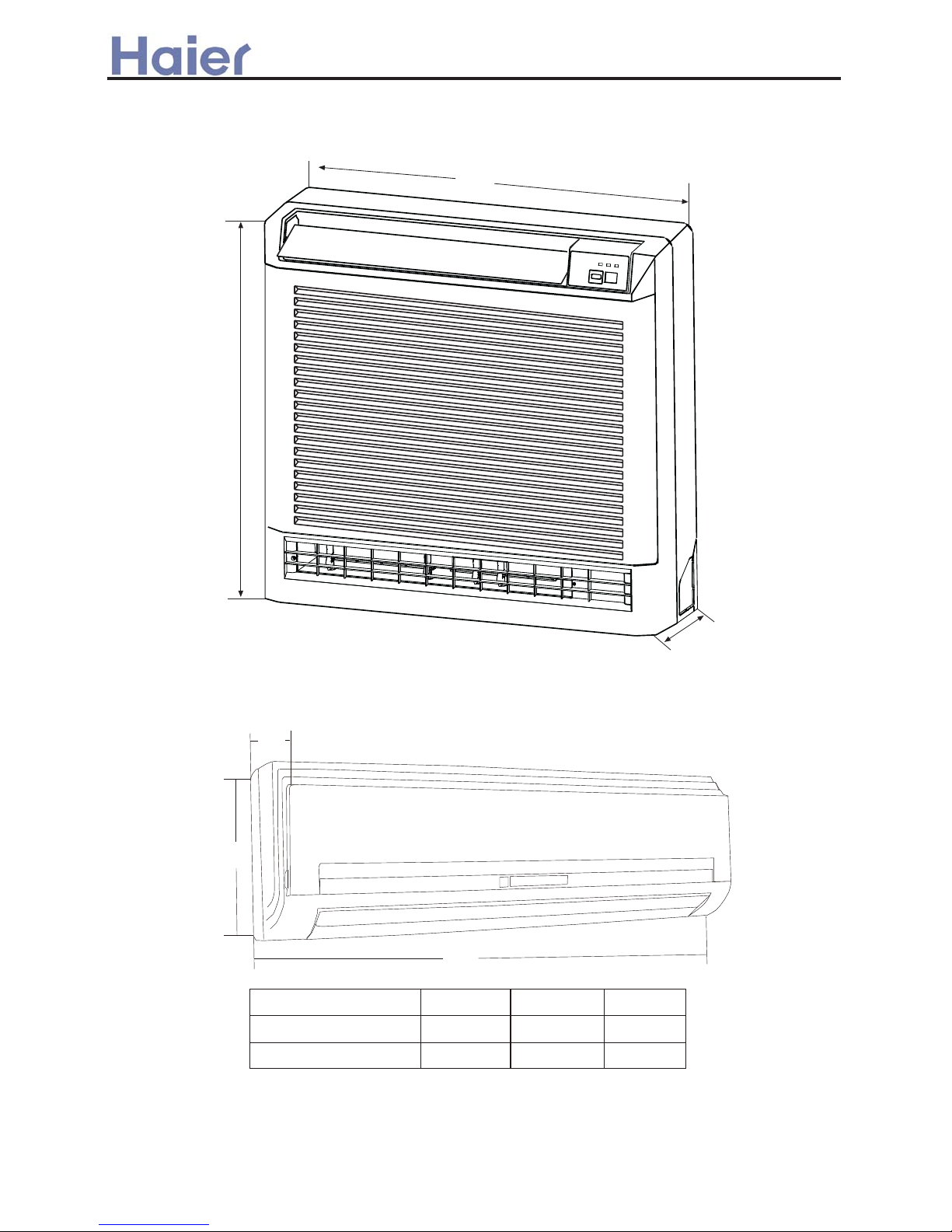

20/

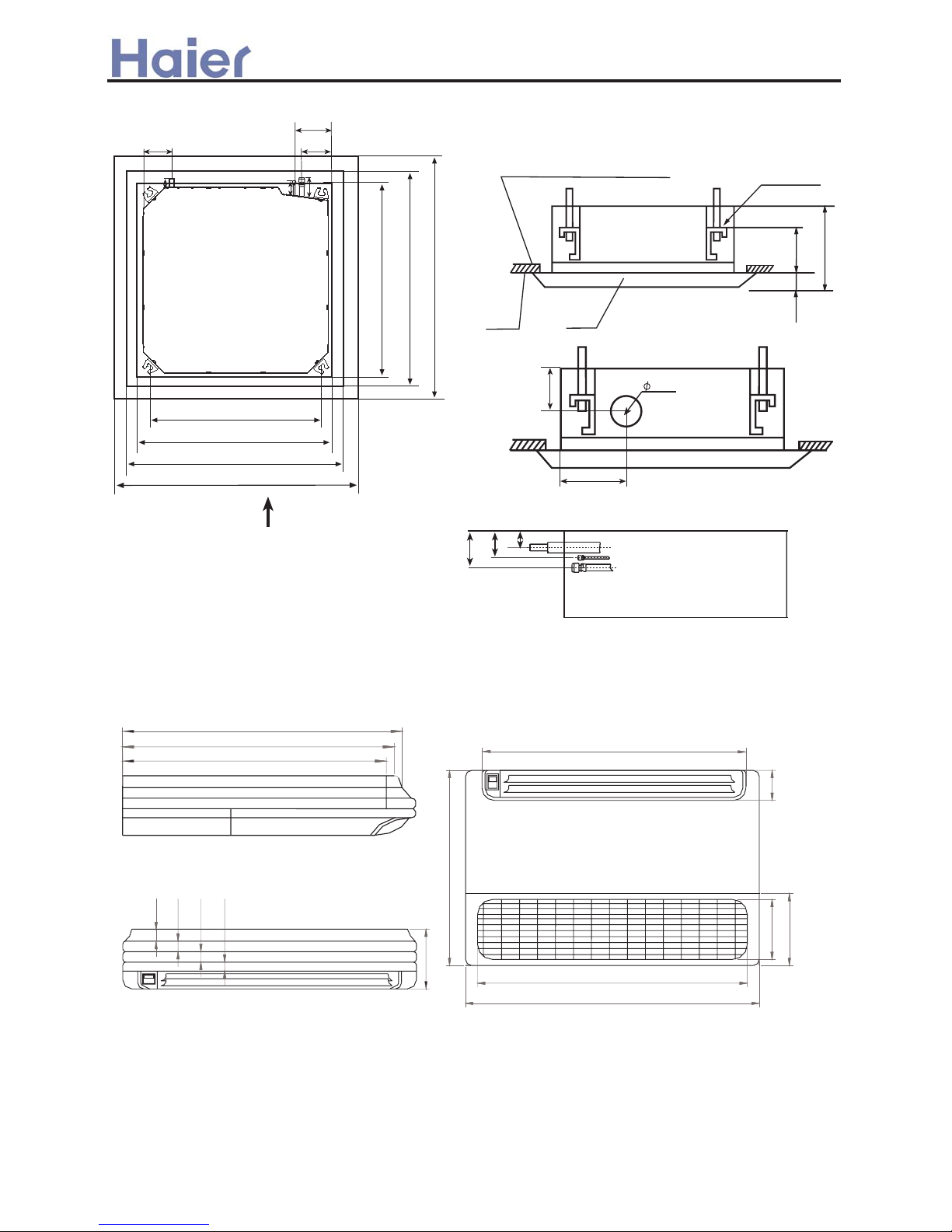

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

B9

A9

:;9

HGFI D

><>TT 7KN[^NNU Z\ZWNUZRVU WVSNZ8

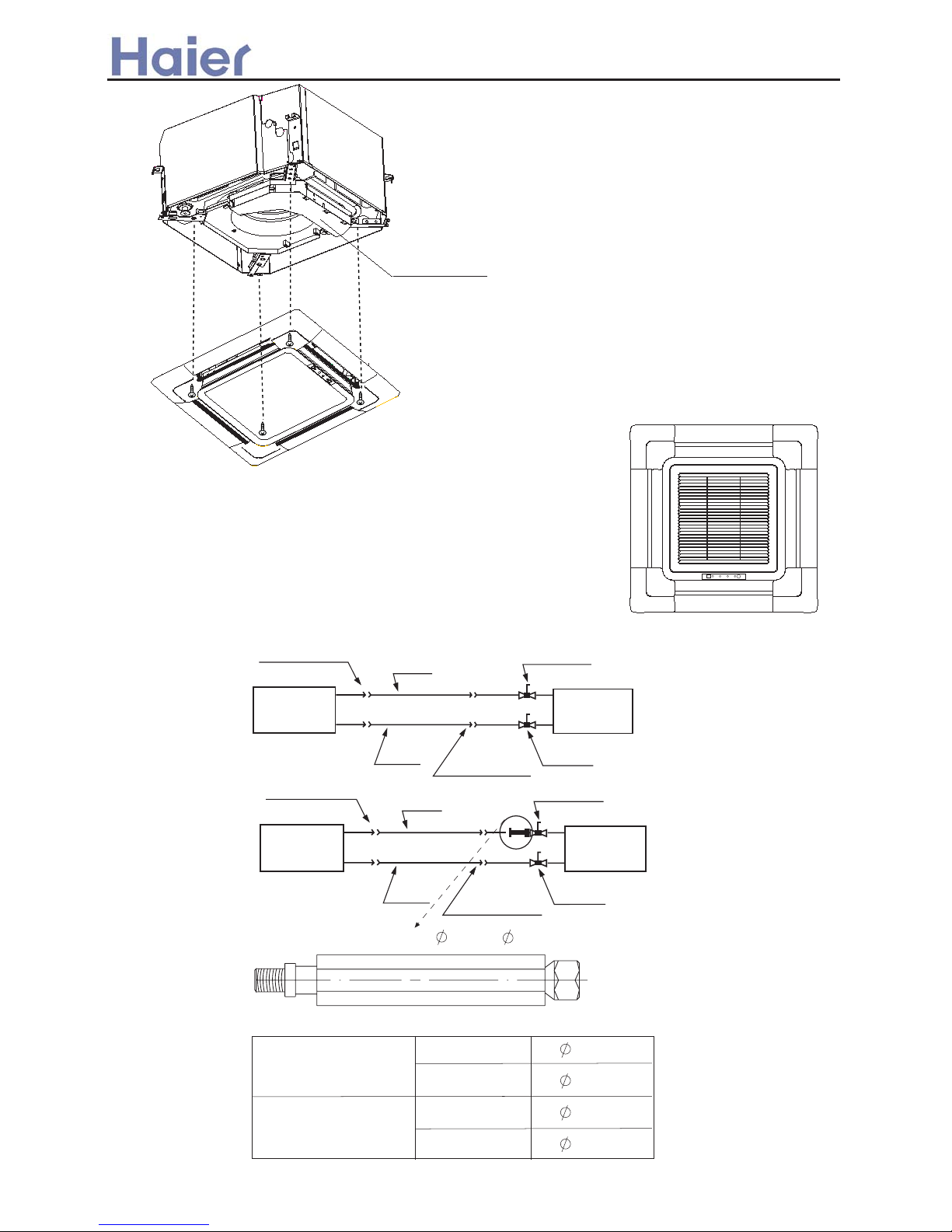

MYJRUJPN WRWN

PJZ WRWN

SRX\RM WRWN

>@9TT 7RUMVVY \UR[ MRTNUZRVU8

?>9TT 7LNRSRUP VWNURUP MRTNUZRVU8

@99TT 7WJUNS MRTNUZRVU8

>@9TT 7RUMVVY \UR[ MRTNUZRVU8

?>9TT 7LNRSRUP VWNURUP MRTNUZRVU8

@99TT 7WJUNS MRTNUZRVU8

HGFI D

B>

:=9

:A9

OYNZQ JRY QVSN

Z\ZWNUZRVU QVSMNY

<;9TT

:>9TT

?9TT

V]NYSJWNM MRZ[JULN KN[^NNU [QN LNRSRUP

JUM [QN WJUNSC ;>TT

LNRSRUP

WJUNS

>@

@>

?>

A9

:99

:=>

EJZZN[[N \UR[C

5;:?7<=8697 >:8=4

-/+

,++

3++

33+

100

-++

22+

1-+

1+0

1++

/+ .0 .0 .+

,33

-18-

=MPQBKKBQJNM EJLFMPJNM8+LL,

@MJQ LNEFK

9;/20A><?9

9;/60A><?9

9;/00A><?9

9;.70A><?9

B

/..0

316

C

261-3

261-3

D

/1/

/1/

E

//.3

4/.

F

033

033

G

/.3

/.3

H

66.

2/6

I

75.

3.6

J

00.

00.

T

U

V

W

X

Y

Z

[

\

72.

00.

9;/20A><?9

9;/60A><?9

256

00.

9;.70A><?9

9;/00A><?9

:FJKJMH DNMDFBKFE QSOF RMJQ8

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

- -19

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

Console type unit:

/+*

.,*

+*-

C

B

A

C

model

A B

AS07/09/122XVERA

AS182XVERA

197 265

795

225

305

870

Wall Mounted Type

- -20

G

G

G

4. Pipe and wiring installation

- 1-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

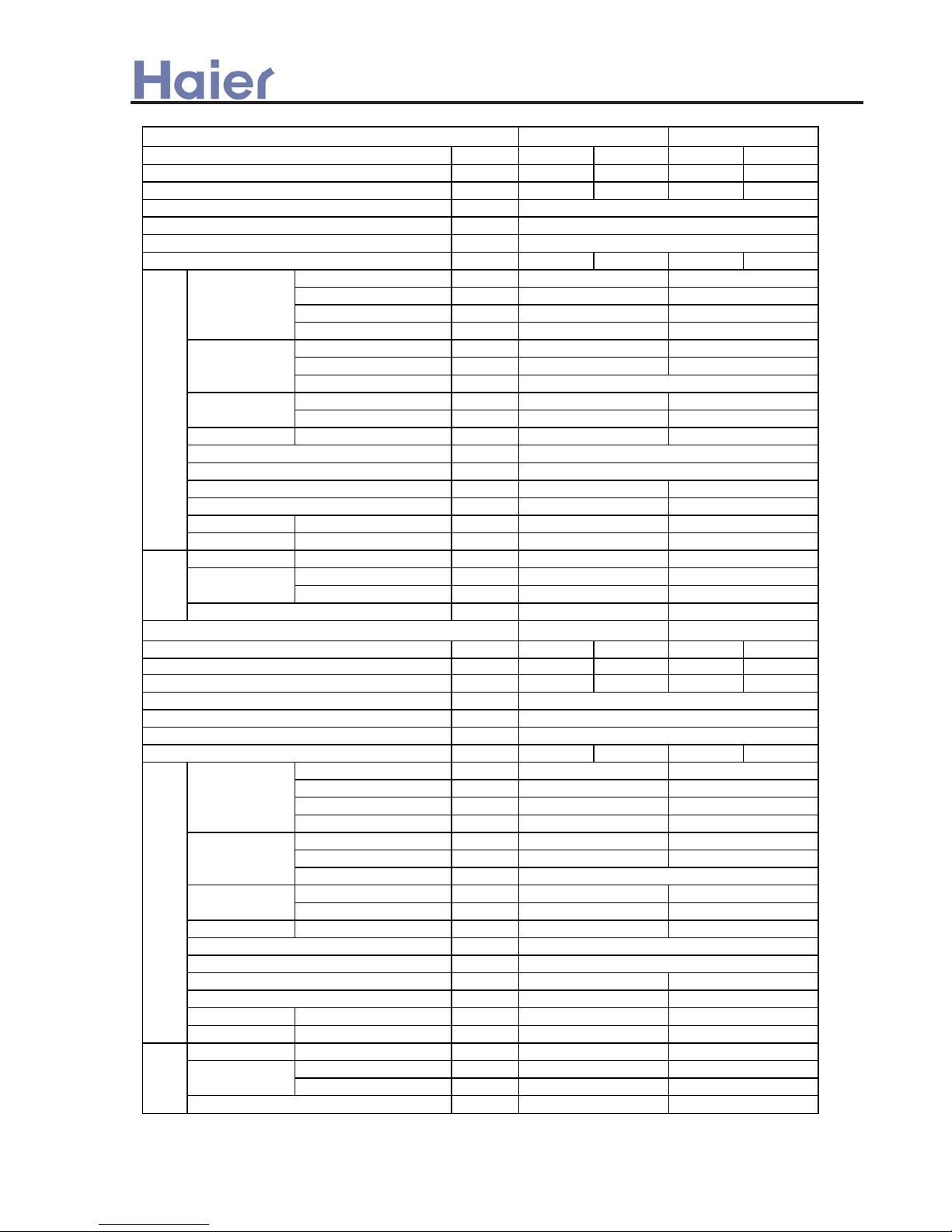

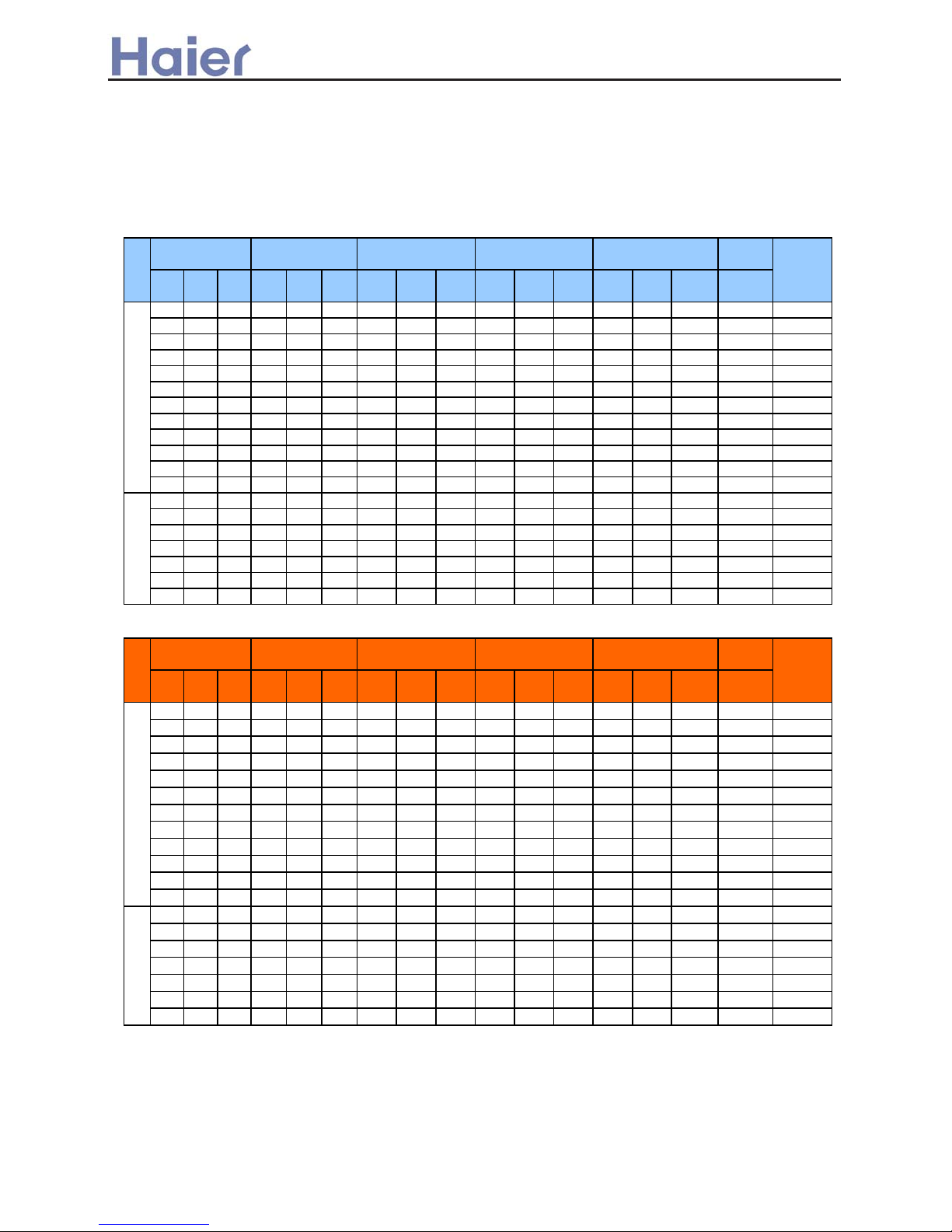

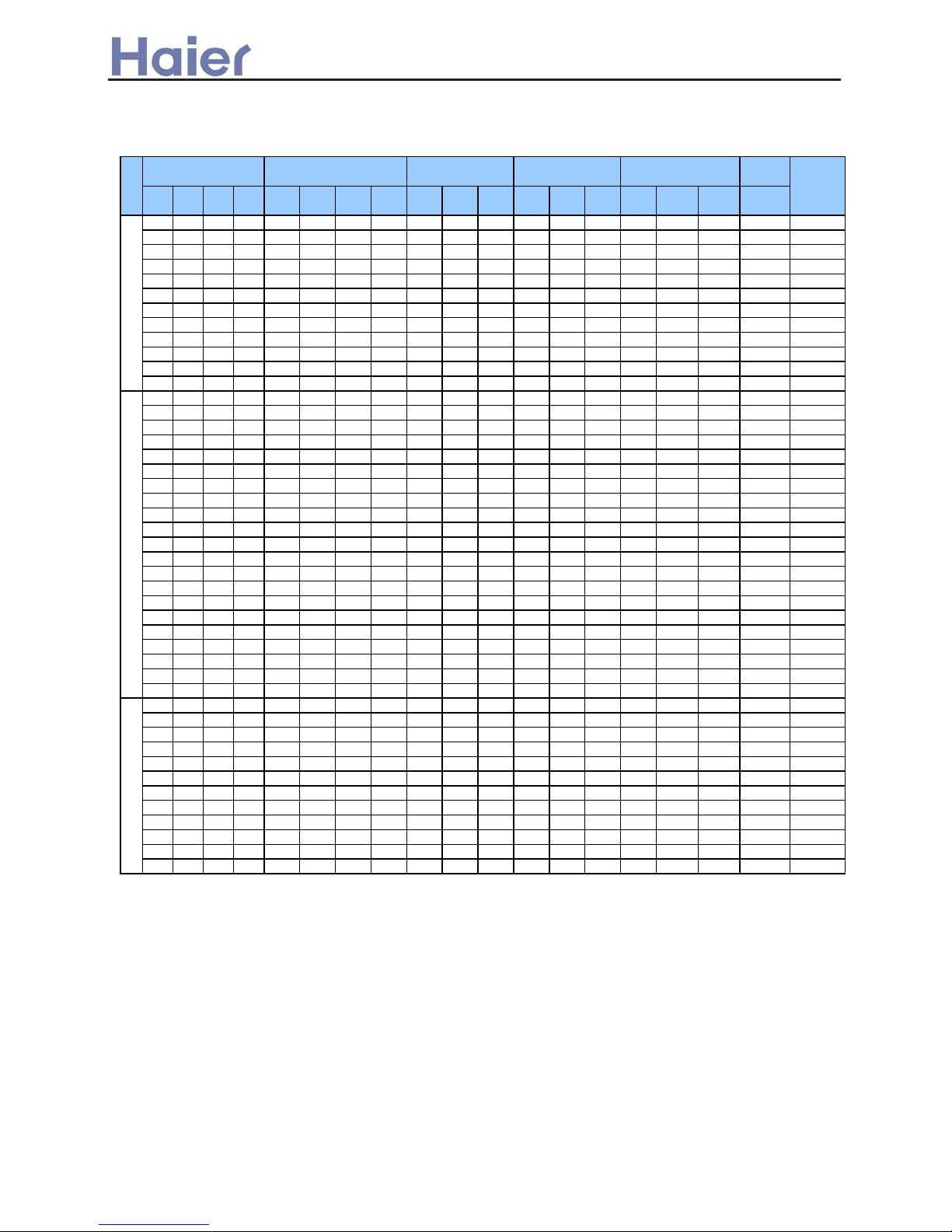

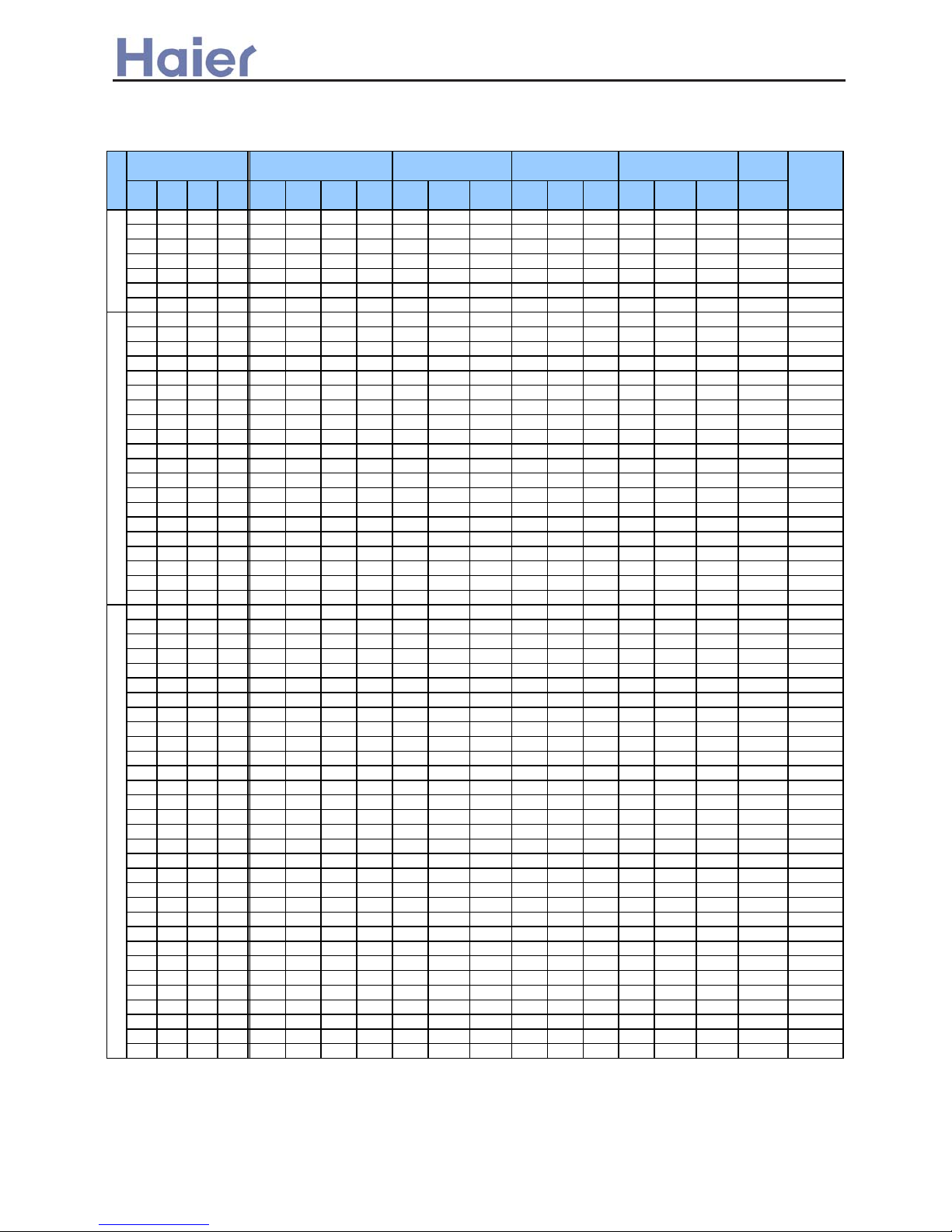

AU182XFERA combination and the data

COOLING

EER

(W/W)

UnitAUnitBUnitCUnitAUnitBUnit

C

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 7 — 2.0 2.0 — 1.00 4.00 4.40 0.47 1.60 2.30 2.15 7.80 10.20 2.50 E

7 9 — 2.0 2.5 — 1.00 4.50 4.90 0.47 1.75 2.30 2.15 7.80 10.20 2.57 E

7 12 — 2.0 3.2 — 1.00 5.20 5.80 0.47 1.75 2.30 2.15 7.80 10.20 2.97 C

7 14 — 1.73 3.47 — 1.00 5.20 5.80 0.55 1.85 2.30 2.50 8.30 10.20 2.81 C

7 18 — 1.48 3.72 — 1.00 5.20 5.80 0.55 1.85 2.30 2.50 8.30 10.20 2.81 C

9 9 — 2.5 2.5 — 1.00 5.00 5.40 0.47 1.75 2.30 2.15 7.80 10.20 2.86 C

9 12 — 2.3 2.9 — 1.00 5.20 5.80 0.47 1.75 2.30 2.15 7.80 10.20 2.97 C

9 14 — 2.0 3.2 — 1.00 5.20 5.80 0.55 1.85 2.30 2.50 8.30 10.20 2.81 C

9 18 — 1.73 3.47 — 1.00 5.20 5.80 0.55 1.85 2.30 2.50 8.30 10.20 2.81 C

12 12 — 2.6 2.6 — 1.00 5.20 5.80 0.47 1.75 2.30 2.15 7.80 10.20 2.97 C

12 14

— 2.42 2.78 — 1.00 5.20 5.80 0.55 1.85 2.30 2.50 8.30 10.20 2.81 C

12 18

— 2.18 3.12 — 1.00 5.30 5.80 0.55 1.85 2.30 2.50 8.30 10.20 2.86 C

7 7 7 1.73 1.73 1.73 1.50 5.20 5.80 0.50 1.70 2.30 2.29 7.62 10.20 3.06 B

7 7 9 1.60 1.60 2.00 1.50 5.20 5.80 0.50 1.70 2.30 2.29 7.62 10.20 3.06 B

7 7 12 1.39 1.39 2.42 1.50 5.20 5.80 0.50 1.70 2.30 2.29 7.62 10.20 3.06 B

7 9 9 1.48 1.86 1.86 1.50 5.20 5.80 0.50 1.70 2.30 2.29 7.62 10.20 3.06 B

7 9 12 1.30 1.63 2.27 1.50 5.20 5.80 0.50 1.65 2.30 2.29 7.62 10.20 3.15 B

9 9 9 1.73 1.73 1.73 1.50 5.20 5.80 0.50 1.65 2.30 2.29 7.62 10.20 3.15 B

9 9 12 1.56 1.56 2.18 1.50 5.30 5.80 0.50 1.65 2.30 2.29 7.40 10.20 3.21 A

HEATING

COP

(W/W)

UnitAUnitBUnitCUnitAUnitBUnit

C

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 7 — 2.30 2.30 — 1.20 4.60 5.00 0.55 1.85 2.30 2.50 9.10 10.20 2.49 F

7 9 — 2.30 2.90 — 1.20 5.20 5.70 0.55 2.05 2.30 2.50 9.10 10.20 2.54 F

7 12 — 2.30 3.80 — 1.20 6.10 6.50 0.55 1.90 2.30 2.50 8.43 10.20 3.21 C

7 14 — 2.30 4.60 — 1.30 6.90 7.30 0.60 1.95 2.30 2.65 8.65 10.20 3.54 B

7 18 — 2.10 4.90 — 1.30 7.00 7.30 0.60 1.95 2.30 2.65 8.65 10.20 3.59 B

9 9 — 2.90 2.90 — 1.20 5.80 6.50 0.55 1.90 2.30 2.50 8.43 10.20 3.05 C

9 12 — 2.80 3.80 — 1.20 6.60 6.80 0.55 1.90 2.30 2.50 8.43 10.20 3.47 B

9 14 — 2.70 4.30 — 1.30 7.00 7.30 0.60 2.00 2.30 2.65 8.65 10.20 3.50 B

9 18 — 2.40 4.60 — 1.30 7.00 7.30 0.60 2.00 2.30 2.65 8.65 10.20 3.50 B

12 12 — 3.50 3.50 — 1.20 7.00 7.30 0.55 1.95 2.30 2.50 8.43 10.20 3.59 B

12 14

— 3.20 3.80 — 1.30 7.00 7.30 0.60 2.00 2.30 2.65 8.65 10.20 3.50 B

12 18

— 2.85 4.15 — 1.30 7.00 7.30 0.60 2.00 2.30 2.65 8.65 10.20 3.50 B

7 7 7 2.30 2.30 2.30 1.50 6.90 6.90 0.55 2.05 2.30 2.50 8.21 10.20 3.37 C

7 7 9 2.15 2.15 2.70 1.50 7.00 7.30 0.55 2.00 2.30 2.50 8.21 10.20 3.50 B

7 7 12 1.95 1.95 3.10 1.50 7.00 7.30 0.55 1.95 2.30 2.50 8.21 10.20 3.59 B

7 9 9 2.00 2.50 2.50 1.50 7.00 7.30 0.55 1.95 2.30 2.50 8.21 10.20 3.59 B

7 9 12 1.80 2.25 2.95 1.50 7.00 7.30 0.55 1.90 2.30 2.50 8.21 10.20 3.68 A

9 9 9 2.30 2.30 2.30 1.50 6.90 7.30 0.55 1.85 2.30 2.50 8.21 10.20 3.73 A

9 9 12 2.10 2.10 2.80 1.50 7.00 7.30 0.55 1.80 2.30 2.50 7.99 10.20 3.89 A

TRI (1x3)

capacity(kW)

(Nom. heating)

total heating

capacity(kW)

ENERGY

LABEL

BI (1x2)

total current

(A)@230V

total power input

(kW)

Co

mb.

Combinations

ENERGY

LABEL

BI (1x2)TRI (1x3)

capacity(kW)

(Nom. cooling)

total cooling

capacity(kW)

total power input

(kW)

total current

(A)@230V

Combinations

Co

mb.

4.1 Multi combination and the data

2

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

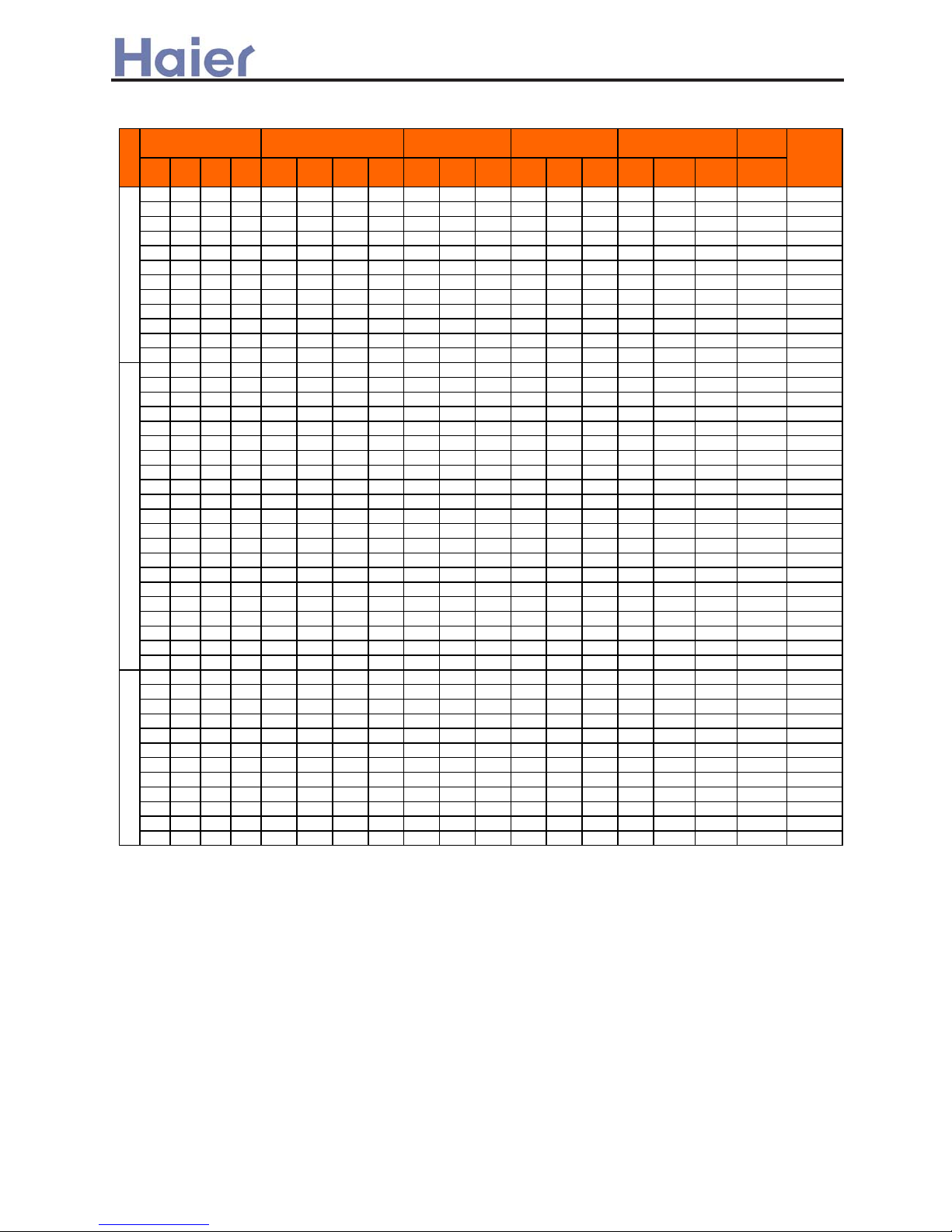

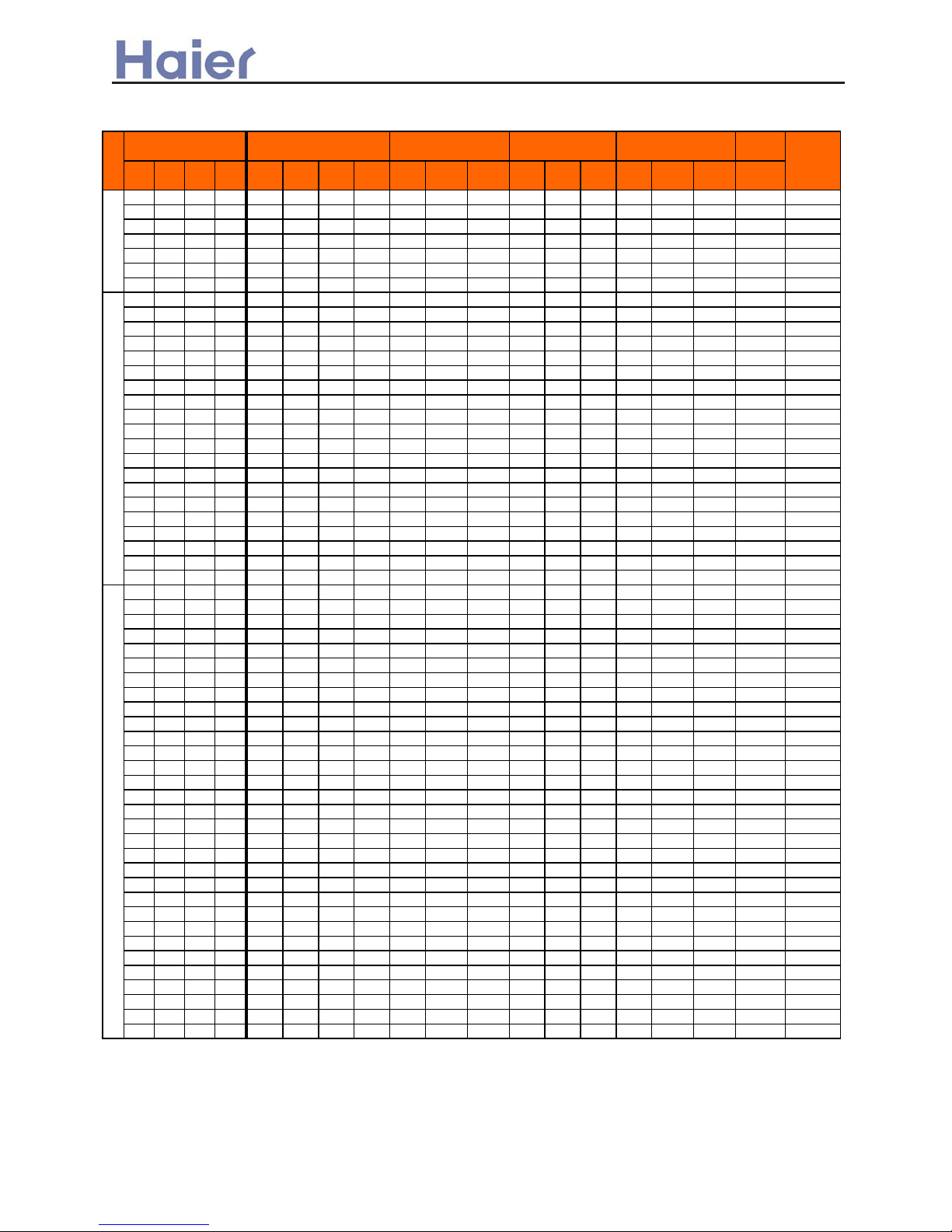

AU222XFERA combination and the data

COOLING

EER

(W/W)

UnitAUnitBUnitCUnitAUnitBUnit

C

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 9 — 2.00 2.50 — 1.00 4.50 4.90 0.47 1.75 2.90 2.20 7.76 12.90 2.57 E

7 12 — 2.00 3.20 — 1.00 5.20 5.60 0.47 1.75 2.90 2.20 7.76 12.90 2.97 C

7 14 — 2.00 4.10 — 1.00 6.10 6.50 0.47 2.20 2.90 2.20 9.76 12.90 2.77 D

7 18 — 1.85 4.55 — 1.20 6.40 6.50 0.55 2.20 2.90 2.50 9.76 12.90 2.91 C

9 9 — 2.50 2.50 — 1.00 5.00 5.40 0.55 1.75 2.90 2.50 7.76 12.90 2.86 C

9 12 — 2.50 3.20 — 1.00 5.70 6.10 0.47 2.00 2.90 2.20 8.87 12.90 2.85 C

9 14 — 2.40 4.00 — 1.00 6.40 6.50 0.47 2.20 2.90 2.20 9.76 12.90 2.91 C

9 18 — 2.15 4.25 — 1.20 6.40 6.50 0.55 2.20 2.90 2.50 9.76 12.90 2.91 C

12 12 — 3.20 3.20 — 1.00 6.40 6.50 0.47 2.20 2.90 2.20 9.76 12.90 2.91 C

12 14

— 2.80 3.60 — 1.20 6.40 6.50 0.55 2.25 2.90 2.50 9.98 12.90 2.84 C

12 18

— 2.50 3.90 — 1.20 6.40 6.50 0.55 2.25 2.90 2.50 9.98 12.90 2.84 C

7 7 7 2.00 2.00 2.00 1.50 6.00 6.60 0.50 2.15 2.90 2.30 9.54 12.90 2.79 D

7 7 9 2.00 2.00 2.40 1.50 6.40 6.80 0.50 2.15 2.90 2.30 9.54 12.90 2.98 C

7 7 12 1.80 1.80 2.80 1.50 6.40 6.80 0.50 2.15 2.90 2.30 9.54 12.90 2.98 C

7 7 14 1.60 1.60 3.20 1.50 6.40 6.80 0.55 2.15 2.90 2.50 9.54 12.90 2.98 C

7 7 18 1.45 1.45 3.50 1.50 6.40 6.80 0.55 2.15 2.90 2.50 9.54 12.90 2.98 C

7 9 9 1.70 2.35 2.35 1.50 6.40 6.80 0.50 2.15 2.90 2.30 9.54 12.90 2.98 C

7 9 12 1.65 2.10 2.65 1.50 6.40 6.80 0.50 2.15 2.90 2.30 9.54 12.90 2.98 C

7 9 14 1.50 1.90 3.00 1.50 6.40 6.80 0.60 2.15 2.90 2.65 9.54 12.90 2.98 C

7 12 12 1.60 2.40 2.40 1.50 6.40 6.80 0.60 2.15 2.90 2.65 9.54 12.90 2.98 C

9 9 9 2.10 2.10 2.10 1.50 6.30 6.80 0.50 2.15 2.90 2.30 9.54 12.90 2.93 C

9 9 12 1.95 1.95 2.50 1.50 6.40 6.80 0.50 2.15 2.90 2.30 9.54 12.90 2.98 C

9 9 14 1.75 1.75 2.90 1.50 6.40 6.80 0.60 2.10 2.90 2.65 9.32 12.90 3.05 B

9 12 12 1.80 2.30 2.30 1.50 6.40 6.80 0.50 2.10 2.90 2.30 9.32 12.90 3.05 B

HEATING

EER

(W/W)

UnitAUnitBUnitCUnitAUnitBUnit

C

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 9 — 2.30 2.90 — 1.20 5.20 5.40 0.50 1.90 2.90 2.30 8.65 12.90 2.74 E

7 12 — 2.30 3.80 — 1.20 6.10 6.50 0.50 1.95 2.90 2.30 8.43 12.90 3.13 C

7 14 — 2.30 4.60 — 1.20 6.90 7.30 0.50 2.20 2.90 2.30 8.65 12.90 3.14 C

7 18 — 2.15 5.15 — 1.20 7.30 7.50 0.55 2.20 2.90 2.50 8.65 12.90 3.32 C

9 9 — 2.90 2.90 — 1.20 5.80 6.20 0.55 1.95 2.90 2.50 9.09 12.90 2.97 D

9 12 — 2.90 3.80 — 1.20 6.70 7.10 0.50 2.00 2.90 2.30 9.09 12.90 3.35 C

9 14 — 2.80 4.50 — 1.20 7.30 7.50 0.50 2.25 2.90 2.30 9.32 12.90 3.24 C

9 18 — 2.50 4.80 — 1.20 7.30 7.50 0.55 2.25 2.90 2.50 9.32 12.90 3.24 C

12 12 — 3.65 3.65 — 1.20 7.30 7.50 0.55 2.20 2.90 2.50 9.09 12.90 3.32 C

12 14

— 3.30 4.00 — 1.20 7.30 7.50 0.55 2.15 2.90 2.50 9.54 12.90 3.40 C

12 18

— 2.95 4.35 — 1.20 7.30 7.50 0.55 2.15 2.90 2.50 9.76 12.90 3.40 C

7 7 7 2.30 2.30 2.30 1.50 6.90 7.50 0.55 2.05 2.90 2.50 8.21 12.90 3.37 C

7 7 9 2.25 2.25 2.80 1.50 7.30 7.50 0.55 2.10 2.90 2.50 9.32 12.90 3.48 B

7 7 12 2.10 2.10 3.10 1.50 7.30 7.50 0.55 2.10 2.90 2.50 9.32 12.90 3.48 B

7 7 14 1.85 1.85 3.60 1.50 7.30 7.50 0.60 2.15 2.90 2.65 9.54 12.90 3.40 C

7 7 18 1.70 1.70 3.90 1.50 7.30 7.50 0.60 2.15 2.90 2.65 9.54 12.90 3.40 C

7 9 9 2.10 2.60 2.60 1.50 7.30 7.50 0.55 2.10 2.90 2.50 9.32 12.90 3.48 B

7 9 12 1.95 2.30 3.05 1.50 7.30 7.50 0.55 2.10 2.90 2.50 9.32 12.90 3.48 B

7 9 14 1.75 2.15 3.40 1.50 7.30 7.50 0.60 2.10 2.90 2.65 9.32 12.90 3.48 B

7 12 12 1.70 2.80 2.80 1.50 7.30 7.50 0.60 2.10 2.90 2.65 9.32 12.90 3.48 B

9 9 9 2.40 2.40 2.40 1.50 7.20 7.50 0.55 2.10 2.90 2.50 9.32 12.90 3.43 B

9 9 12 2.18 2.18 2.84 1.50 7.20 7.50 0.55 2.05 2.90 2.50 9.09 12.90 3.51 B

9 9 14 2.05 2.05 3.20 1.50 7.30 7.50 0.60 2.10 2.90 2.65 9.54 12.90 3.48 B

9 12 12 2.10 2.60 2.60 1.50 7.30 7.50 0.55 2.00 2.90 2.50 8.87 12.90 3.65 A

BI (1x2)TRI (1x3)

Co

mb.

ENERGY

LABEL

Rated capacity(kW)

(Nom. heating)

total heating

capacity(KW)

total power input

(W)

total current

(A)@230V

ENERGY

LABEL

Rated capacity(Kw)

(Nom. cooling)

BI (1x2)TRI (1x3)

Combinations

Combinations

Co

mb.

total cooling

capacity(kW)

total power input

(kW)

total current

(A)@230V

-22-

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

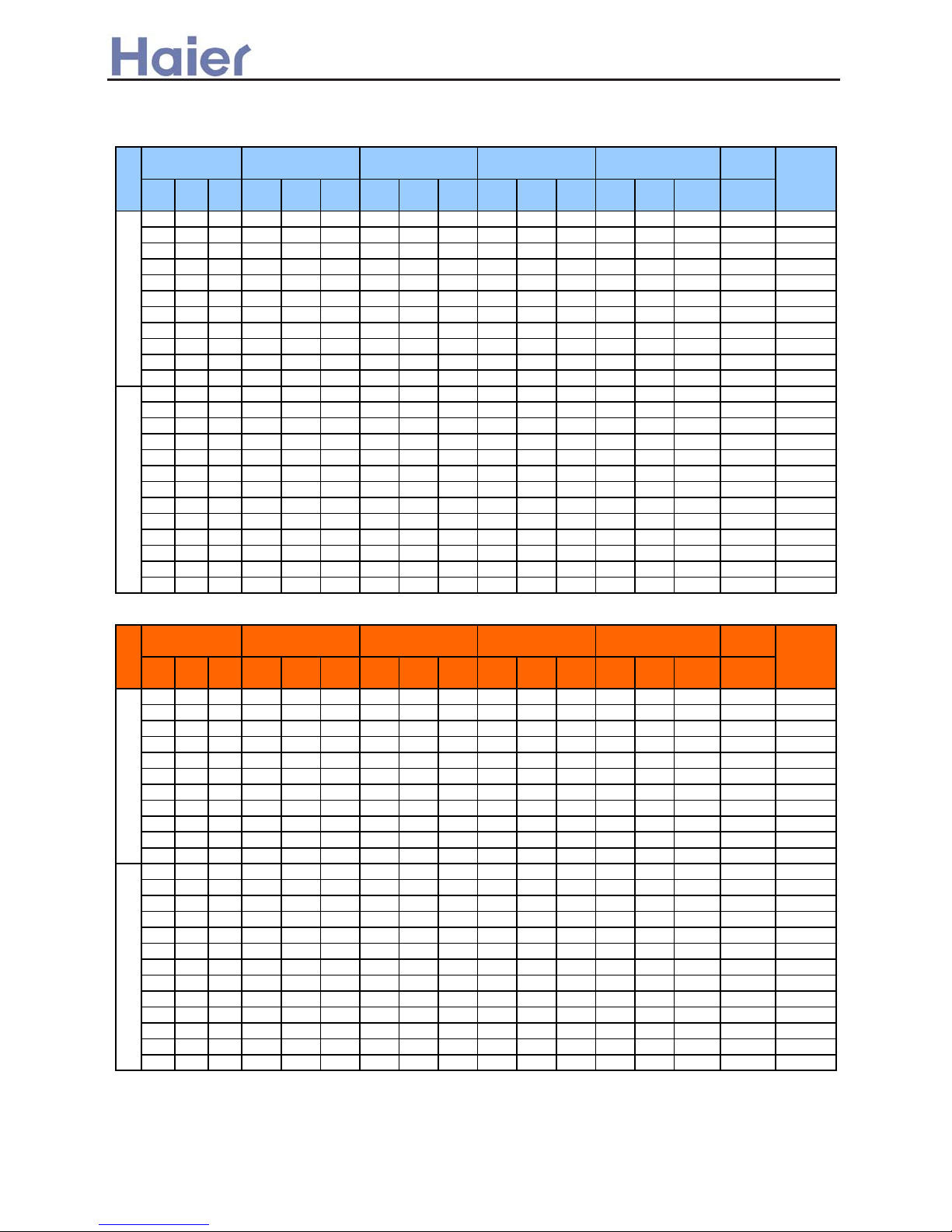

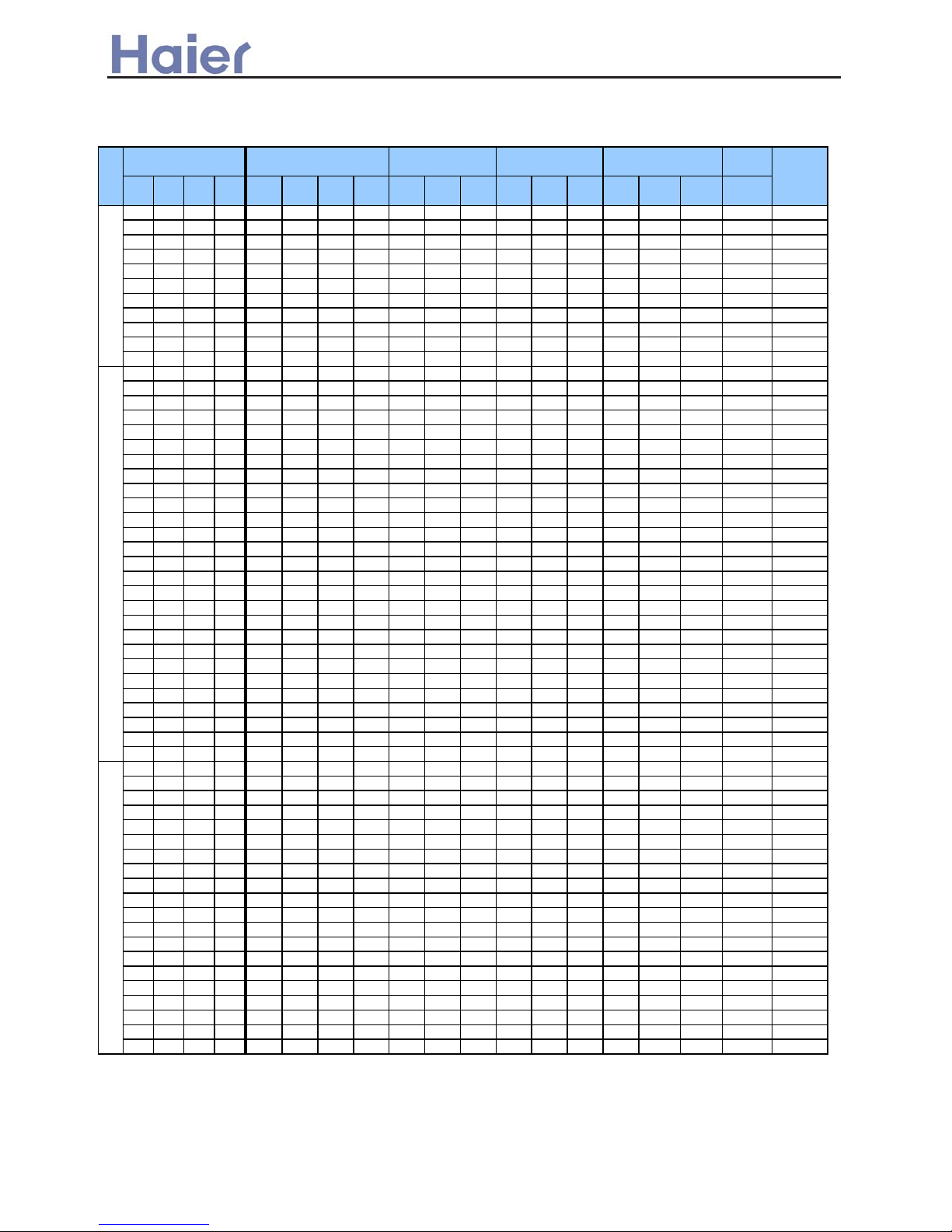

AU252XGERA combination and the data

COOLING

EER

(W/W)

UnitAUnitBUnitCUnitDUnitAUnitBUnitCUnit

D

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 12 — — 2.00 3.50 — — 1.00 5.50 5.90 0.47 2.06 3.20 2.09 9.76 14.50 2.67 D

7 14 — — 2.00 4.10 — — 1.00 6.10 6.50 0.50 2.37 3.20 2.22 11.22 14.50 2.57 E

7 18 — — 2.00 5.00 — — 1.00 7.00 7.40 0.50 2.34 3.20 2.22 11.09 14.50 2.99 C

9 12 — — 2.50 3.50 — — 1.20 6.00 6.40 0.47 2.16 3.20 2.09 10.20 14.50 2.78 D

9 14 — — 2.50 4.10 — — 1.00 6.60 7.00 0.50 2.34 3.20 2.22 11.09 14.50 2.82 C

9 18 — — 2.43 4.87 — — 1.00 7.3 7.90 0.50 2.44 3.20 2.22 11.54 14.50 2.99 C

12 12 — — 3.50 3.50 — — 1.00 7.00 7.40 0.47 2.44 3.20 2.09 11.54 14.50 2.87 C

12 14

— — 3.36 3.94 — — 1.20 7.3 8.00 0.50 2.49 3.20 2.22 11.80 14.50 2.93 C

12 18

— — 3.03 4.27 — — 1.00 7.3 8.00 0.50 2.48 3.20 2.22 11.76 14.50 2.94 C

14 14

— — 3.65 3.65 — — 1.20 7.3 8.00 0.55 2.48 3.20 2.44 11.71 14.50 2.95 C

14 18

— — 3.31 3.99 — — 1.20 7.3 8.00 0.55 2.46 3.20 2.44 11.62 14.50 2.97 C

18 18

— — 3.65 3.65 — — 1.20 7.3 8.00 0.55 2.44 3.20 2.44 11.54 14.50 2.99 C

7 7 7 — 2.00 2.00 2.00 — 1.50 6.00 6.60 0.55 2.44 3.20 2.44 11.54 14.50 2.46 E

7 7 9 — 2.00 2.00 2.50 — 1.50 6.50 7.10 0.55 2.42 3.20 2.44 11.45 14.50 2.69 D

7 7 12 — 1.95 1.95 3.41 — 1.50 7.3 8.10 0.55 2.40 3.20 2.44 11.36 14.50 3.04 B

7 7 14 — 1.83 1.83 3.65 — 1.50 7.3 8.20 0.60 2.34 3.20 2.66 11.09 14.50 3.11 B

7 7 18 — 1.63 1.63 4.03 — 1.50 7.3 8.20 0.60 2.33 3.20 2.66 11.00 14.50 3.14 B

7 9 9 — 2.00 2.50 2.50 — 1.50 7.00 7.60 0.55 2.42 3.20 2.44 11.45 14.50 2.89 C

7 9 12 — 1.83 2.31 3.17 — 1.50 7.3 8.20 0.55 2.39 3.20 2.44 11.31 14.50 3.05 B

7 9 14 — 1.73 2.11 3.46 — 1.50 7.3 8.20 0.60 2.33 3.20 2.66 11.00 14.50 3.14 B

7 9 18 — 1.54 1.92 3.84 — 1.50 7.3 8.20 0.60 2.30 3.20 2.66 10.87 14.50 3.18 B

7 12 12 — 1.63 2.83 2.83 — 1.50 7.3 8.20 0.55 2.44 3.20 2.44 11.54 14.50 2.99 C

7 12 14 — 1.54 2.59 3.17 — 1.50 7.3 8.20 0.60 2.39 3.20 2.66 11.31 14.50 3.05 B

7 12 18 — 1.44 2.40 3.46 — 1.50 7.3 8.20 0.60 2.39 3.20 2.66 11.31 14.50 3.05 B

9 9 9 — 2.43 2.43 2.43 — 1.50 7.3 8.20 0.62 2.39 3.20 2.75 11.31 14.50 3.05 B

9 9 12 — 2.16 2.16 2.98 — 1.50 7.3 8.20 0.55 2.39 3.20 2.44 11.31 14.50 3.05 B

9 9 14 — 2.02 2.02 3.27 — 1.50 7.3 8.20 0.60 2.34 3.20 2.66 11.09 14.50 3.11 B

9 9 18 — 1.83 1.83 3.65 — 1.50 7.3 8.20 0.60 2.34 3.20 2.66 11.09 14.50 3.11 B

9 12 12 — 1.92 2.69 2.69 — 1.50 7.3 8.20 0.55 2.39 3.20 2.44 11.31 14.50 3.05 B

9 12 14 — 1.83 2.50 2.98 — 1.50 7.3 8.20 0.60 2.34 3.20 2.66 11.09 14.50 3.11 B

9 12 18 — 1.68 2.31 3.31 — 1.50 7.3 8.20 0.60 2.34 3.20 2.66 11.09 14.50 3.11 B

12 12 12 — 2.43 2.43 2.43 — 1.50 7.3 8.20 0.55 2.39 3.20 2.44 11.31 14.50 3.05 B

12 12 14 — 2.31 2.31 2.69 — 1.50 7.3 8.20 0.60 2.34 3.20 2.66 11.09 14.50 3.11 B

77771.83 1.83 1.83 1.83 1.80 7.3 8.20 0.60 2.33 3.20 2.66 11.00 14.50 3.14 B

77791.73 1.73 1.73 2.11 1.80 7.3 8.20 0.60 2.33 3.20 2.66 10.87 14.50 3.13 B

7 7 7 12 1.54 1.54 1.54 2.69 1.80 7.3 8.20 0.60 2.33 3.20 2.66 10.78 14.50 3.13 B

7 7 7 14 1.44 1.44 1.44 2.98 1.80 7.3 8.20 0.62 2.35 3.20 2.75 10.65 14.50 3.11 B

77991.63 1.63 2.02 2.02 1.80 7.3 8.20 0.60 2.33 3.20 2.66 10.78 14.50 3.13 B

7 7 9 12 1.44 1.44 1.83 2.59 1.80 7.3 8.20 0.60 2.33 3.20 2.66 10.74 14.50 3.13 B

7 7 9 14 1.39 1.39 1.73 2.79 1.80 7.3 8.20 0.62 2.35 3.20 2.75 10.65 14.50 3.11 B

7 7 12 12 1.34 1.34 2.31 2.31 1.80 7.3 8.20 0.60 2.32 3.20 2.66 10.65 14.50 3.15 B

79991.54 1.92 1.92 1.92 1.80 7.3 8.20 0.60 2.32 3.20 2.66 10.65 14.50 3.15 B

7 9 9 12 1.39 1.73 1.73 2.45 1.80 7.3 8.20 0.60 2.30 3.20 2.66 10.56 14.50 3.17 B

99991.83 1.83 1.83 1.83 1.80 7.3 8.20 0.60 2.28 3.20 2.66 10.65 14.50 3.21 A

9 9 9 12 1.68 1.68 1.68 2.26 1.80 7.3 8.20 0.60 2.25 3.20 2.66 10.56 14.50 3.24 A

Rated capacity(Kw)

(Nom. cooling)

TRI (1x3) BI (1x2)

total cooling

capacity(kW)

total power input

(kW)

total current

(A)@230V

QUADRI(1x4)

Co

mb.

Combinations

ENERGY

LABEL

-23-

HEATING

COP

(W/W)

UnitAUnitBUnitCUnitDUnitAUnitBUnitCUnit

D

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 12 — — 2.30 3.80 — — 1.00 6.10 6.70 0.47 2.11 3.20 2.09 9.98 14.50 2.89 D

7 14 — — 2.30 4.60 — — 1.00 6.90 7.60 0.50 2.39 3.20 2.22 11.31 14.50 2.89 D

7 18 — — 2.30 5.50 — — 1.00 7.80 8.50 0.50 2.39 3.20 2.22 11.31 14.50 3.26 C

9 12 — — 2.90 3.80 — — 1.20 6.70 7.30 0.47 2.16 3.20 2.09 10.20 14.50 3.11 C

9 14 — — 2.90 4.50 — — 1.00 7.40 8.10 0.50 2.39 3.20 2.22 11.31 14.50 3.10 C

9 18 — — 2.83 5.37 — — 1.00 8.2 9.00 0.50 2.39 3.20 2.22 11.31 14.50 3.43 B

12 12 — — 3.80 3.80 — — 1.00 7.60 8.00 0.47 2.34 3.20 2.09 11.09 14.50 3.24 C

12 14

— — 3.71 4.49 — — 1.20 8.2 9.00 0.50 2.39 3.20 2.22 11.31 14.50 3.43 B

12 18

— — 3.38 4.82 — — 1.00 8.2 9.00 0.50 2.39 3.20 2.22 11.31 14.50 3.43 B

14 14

— — 4.10 4.10 — — 1.20 8.2 9.00 0.55 2.48 3.20 2.44 11.76 14.50 3.30 C

14 18

— — 3.76 4.44 — — 1.20 8.2 9.00 0.55 2.47 3.20 2.44 11.67 14.50 3.33 C

18 18

— — 4.10 4.10 — — 1.20 8.2 9.00 0.55 2.47 3.20 2.44 11.67 14.50 3.33 C

7 7 7 — 2.30 2.30 2.30 — 1.50 6.90 7.50 0.55 2.44 3.20 2.44 11.54 14.50 2.83 D

7 7 9 — 2.30 2.30 2.90 — 1.50 7.50 8.10 0.55 2.42 3.20 2.44 11.45 14.50 3.10 C

7 7 12 — 2.25 2.25 3.71 — 1.50 8.2 9.00 0.55 2.40 3.20 2.44 11.36 14.50 3.42 B

7 7 14 — 2.07 2.07 4.05 — 1.50 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

7 7 18 — 1.64 1.64 4.92 — 1.50 8.2 9.00 0.60 2.33 3.20 2.66 11.00 14.50 3.53 B

7 9 9 — 2.30 2.90 2.90 — 1.50 8.10 8.90 0.55 2.42 3.20 2.44 11.45 14.50 3.35 C

7 9 12 — 2.12 2.60 3.47 — 1.50 8.2 9.00 0.55 2.39 3.20 2.44 11.31 14.50 3.43 B

7 9 14 — 1.93 2.41 3.86 — 1.50 8.2 9.00 0.60 2.33 3.20 2.66 11.00 14.50 3.53 B

7 9 18 — 1.83 2.22 4.15 — 1.50 8.2 9.00 0.60 2.30 3.20 2.66 10.87 14.50 3.57 B

7 12 12 — 1.93 3.14 3.14 — 1.50 8.2 9.00 0.55 2.44 3.20 2.44 11.54 14.50 3.36 C

7 12 14 — 1.78 2.89 3.52 — 1.50 8.2 9.00 0.60 2.39 3.20 2.66 11.31 14.50 3.43 B

7 12 18 — 1.64 2.60 3.96 — 1.50 8.2 9.00 0.60 2.39 3.20 2.66 11.31 14.50 3.43 B

9 9 9 — 2.73 2.73 2.73 — 1.50 8.2 9.00 0.62 2.39 3.20 2.75 11.31 14.50 3.43 B

9 9 12 — 2.33 2.33 3.54 — 1.50 8.2 9.00 0.55 2.39 3.20 2.44 11.31 14.50 3.43 B

9 9 14 — 2.41 2.41 3.38 — 1.50 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

9 9 18 — 2.03 2.03 4.15 — 1.50 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

9 12 12 — 2.41 2.89 2.89 — 1.50 8.2 9.00 0.55 2.39 3.20 2.44 11.31 14.50 3.43 B

9 12 14 — 2.12 2.75 3.33 — 1.50 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

9 12 18 — 1.93 2.56 3.71 — 1.50 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

12 12 12 — 2.73 2.73 2.73 — 1.50 8.2 9.00 0.55 2.39 3.20 2.44 11.31 14.50 3.43 B

12 12 14 — 2.56 2.56 3.09 — 1.50 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

77772.05 2.05 2.05 2.05 1.80 8.2 9.00 0.60 2.34 3.20 2.66 11.09 14.50 3.50 B

77791.93 1.93 1.93 2.41 1.80 8.2 9.00 0.60 2.30 3.20 2.66 10.87 14.50 3.57 B

7 7 7 12 1.78 1.78 1.78 2.85 1.80 8.2 9.00 0.60 2.30 3.20 2.66 10.87 14.50 3.57 B

7 7 7 14 1.64 1.64 1.64 3.28 1.80 8.2 9.00 0.62 2.27 3.20 2.75 10.74 14.50 3.61 A

77991.83 1.83 2.27 2.27 1.80 8.2 9.00 0.60 2.30 3.20 2.66 10.87 14.50 3.57 B

7 7 9 12 1.69 1.69 2.12 2.70 1.80 8.2 9.00 0.60 2.30 3.20 2.66 10.87 14.50 3.57 B

7 7 9 14 1.59 1.59 1.93 3.09 1.80 8.2 9.00 0.62 2.27 3.20 2.75 10.74 14.50 3.61 A

7 7 12 12 1.54 1.54 2.56 2.56 1.80 8.2 9.00 0.60 2.27 3.20 2.66 10.74 14.50 3.61 A

79991.83 2.12 2.12 2.12 1.80 8.2 9.00 0.60 2.27 3.20 2.66 10.74 14.50 3.61 A

7 9 9 12 1.59 1.93 1.93 2.75 1.80 8.2 9.00 0.60 2.25 3.20 2.66 10.65 14.50 3.64 A

99992.05 2.05 2.05 2.05 1.80 8.2 9.00 0.60 2.25 3.20 2.66 10.65 14.50 3.64 A

9 9 9 12 1.93 1.93 1.93 2.41 1.80 8.2 9.00 0.60 2.25 3.20 2.66 10.65 14.50 3.64 A

total power input

(W)

total current

(A)@230V

ENERGY

LABEL

BI (1x2)

Co

mb

.

Combinations

Rated capacity(kW)

(Nom. heating)

total heating

capacity(KW)

QUADRI(1x4) TRI (1x3)

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-24-

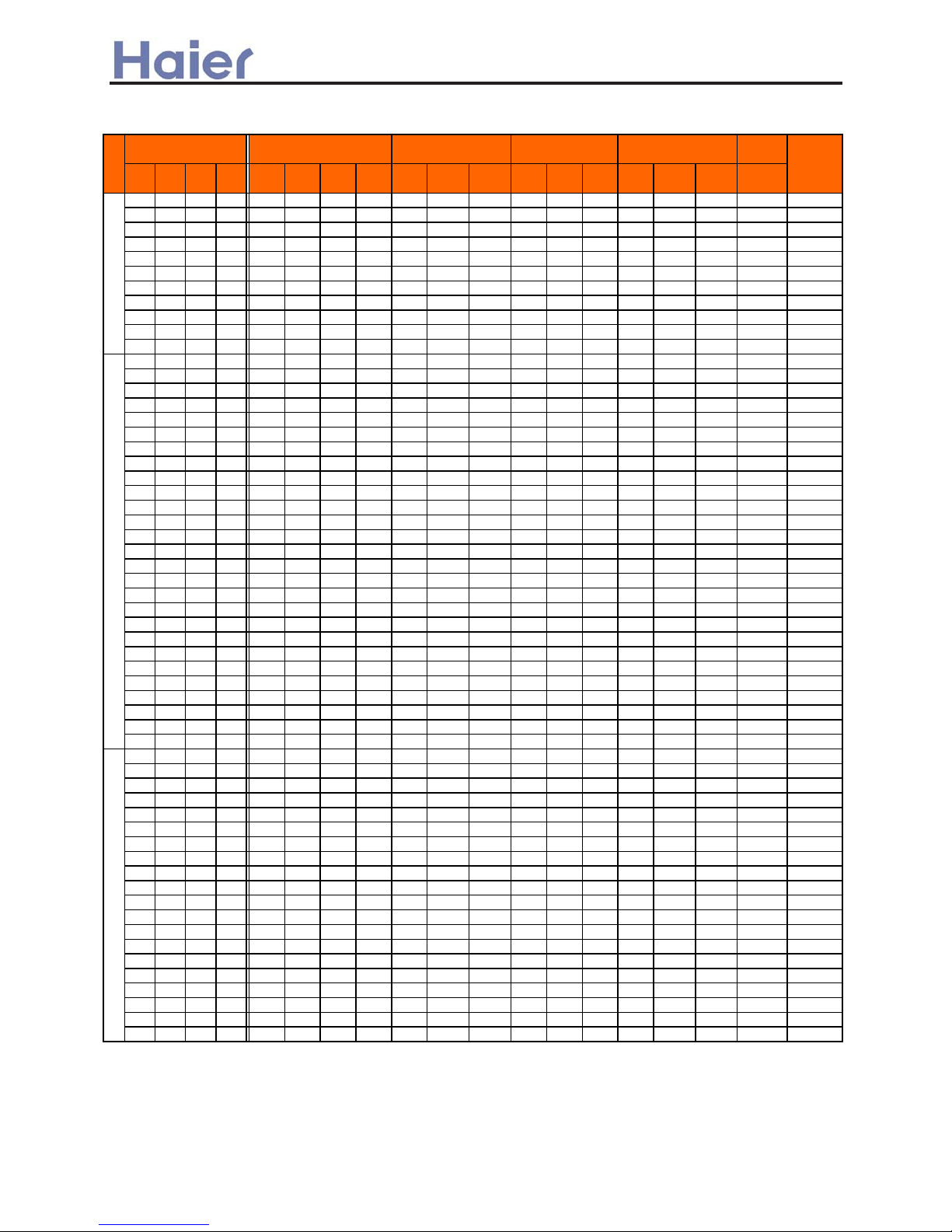

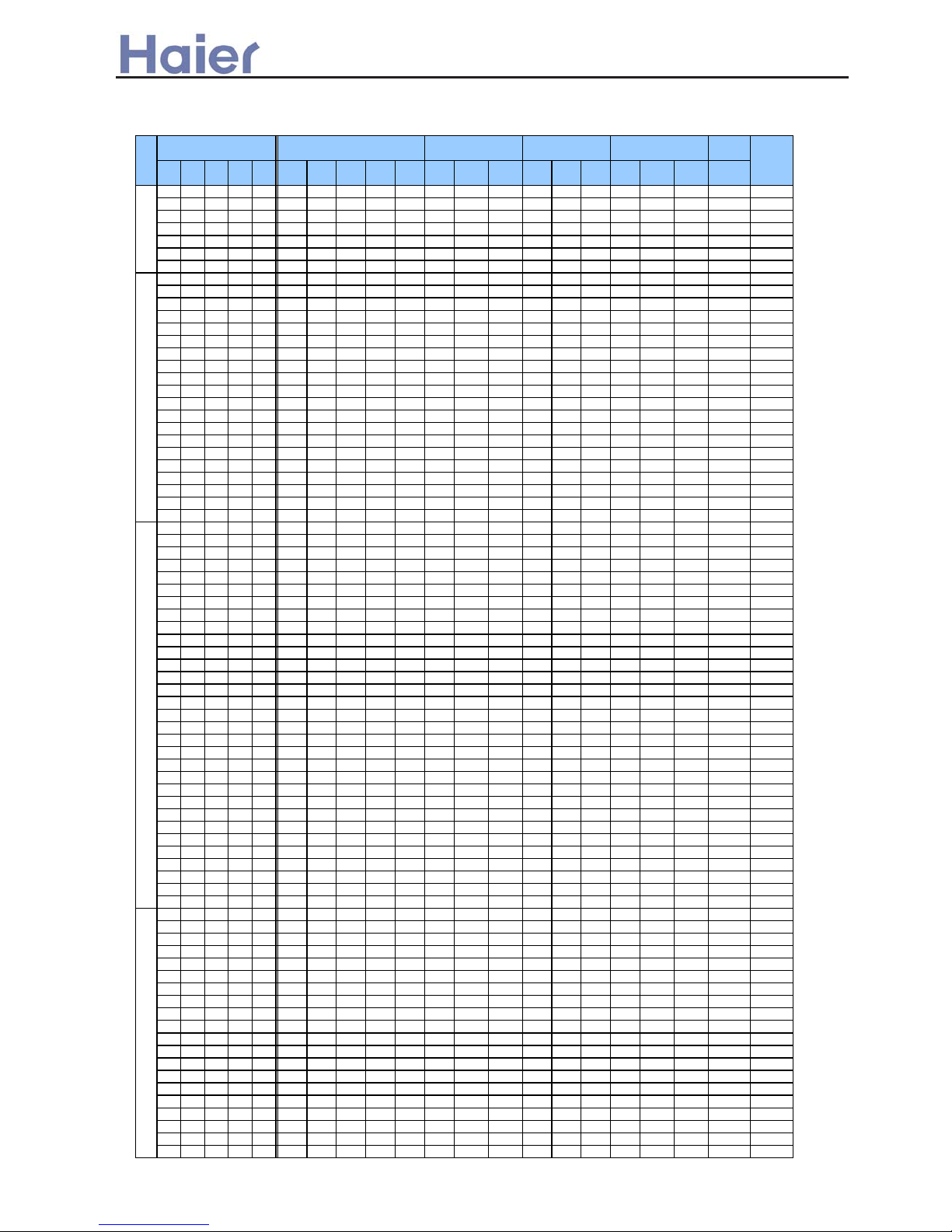

AU282XHERA combination and the data

COOLING

EER

(W/W)

UnitAUnitBUnitCUnitDUnitAUnitBUnitCUnit

D

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 14 — — 2.00 4.10 — — 1.00 6.10 6.50 0.50 2.20 3.80 2.15 9.76 16.80 2.77 D

7 18 — — 2.00 5.00 — — 1.00 7.00 7.40 0.50 2.45 3.80 2.15 10.87 16.80 2.86 C

9 12 — — 2.50 3.50 — — 1.00 6.00 6.40 0.50 2.35 3.80 2.15 10.43 16.80 2.55 E

9 14 — — 2.50 4.10 — — 1.00 6.60 7.00 0.50 2.20 3.80 2.15 9.76 16.80 3.00 B

9 18 — — 2.50 5.00 — — 1.00 7.50 7.90 0.50 2.50 3.80 2.15 11.09 16.80 3.00 B

12 12 — — 3.50 3.50 — — 1.00 7.00 6.80 0.50 2.25 3.80 2.15 9.98 16.80 3.11 B

12 14

— — 3.50 4.10 — — 1.00 7.60 8.00 0.50 2.60 3.80 2.15 11.54 16.80 2.92 C

12 18

— — 3.05 4.95 — — 1.00 8.00 8.40 0.50 2.60 3.80 2.15 11.54 16.80 3.08 B

14 14

— — 4.00 4.00 — — 1.00 8.00 8.60 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

14 18

— — 3.50 4.50 — — 1.00 8.00 8.60 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

18 18

— — 4.00 4.00 — — 1.00 8.00 8.60 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

7 7 7 — 2.00 2.00 2.00 — 1.50 6.00 6.60 0.55 2.70 3.80 2.50 11.98 16.80 2.22 F

7 7 9 — 2.00 2.00 2.50 — 1.50 6.50 7.10 0.55 2.70 3.80 2.50 11.98 16.80 2.41 E

7 7 12 — 2.00 2.00 3.50 — 1.50 7.50 8.10 0.55 2.70 3.80 2.50 11.98 16.80 2.78 D

7 7 14 — 2.00 2.00 4.00 — 1.50 8.00 8.70 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

7 7 18 — 1.75 1.75 4.50 — 1.50 8.00 8.80 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

7 9 9 — 2.00 2.00 2.50 — 1.50 6.50 7.10 0.55 2.70 3.80 2.50 11.98 16.80 2.41 E

7 9 12 — 2.00 2.50 3.50 — 1.50 8.00 8.60 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

7 9 14 — 1.90 2.30 3.80 — 1.50 8.00 8.70 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

7 9 18 — 1.70 2.10 4.20 — 1.50 8.00 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

7 12 12 — 1.85 3.05 3.05 — 1.50 7.95 8.60 0.55 2.70 3.80 2.50 11.98 16.80 2.94 C

7 12 14 — 1.70 2.90 3.40 — 1.50 8.00 8.70 0.55 2.70 3.80 2.50 11.98 16.80 2.96 C

7 12 18 — 1.60 2.60 3.80 — 1.50 8.00 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

7 14 14 — 1.55 3.20 3.20 — 1.50 7.95 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.00 B

71418

— 1.40 3.00 3.60 — 1.50 8.00 8.90 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 9 9 — 2.5 2.5 2.5 — 1.50 7.50 8.10 0.55 2.65 3.80 2.50 11.76 16.80 2.83 C

9 9 12 — 2.44 2.44 3.12 — 1.50 8.00 8.60 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 9 14 — 2.20 2.20 3.60 — 1.50 8.00 8.70 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 9 18 — 2.0 2.0 4.0 — 1.50 8.00 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 12 12 — 2.26 2.87 2.87 — 1.50 8.00 8.60 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 12 14 — 2.05 2.60 3.35 — 1.50 8.00 8.70 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 12 18 — 1.80 2.50 3.70 — 1.50 8.00 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9 14 14 — 1.90 3.05 3.05 — 1.50 8.00 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

9

14 18

— 1.70 2.90 3.40 — 1.50 8.00 8.90 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

12 12 12 — 2.65 2.65 2.65 — 1.50 7.95 8.50 0.55 2.65 3.80 2.50 11.76 16.80 3.00 B

12 12 14 — 2.45 2.45 3.10 — 1.50 8.00 8.70 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

12 12 18 — 2.20 2.20 3.60 — 1.50 8.00 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.02 B

12 14 14 — 2.25 2.85 2.85 — 1.50 7.95 8.80 0.55 2.65 3.80 2.50 11.76 16.80 3.00 B

77772.02.02.02.01.80 8.00 9.20 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

77791.90 1.90 1.90 2.30 1.80 8.00 9.20 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 7 12 1.75 1.75 1.75 2.75 1.80 8.00 9.20 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 7 14 1.60 1.60 1.60 3.20 1.80 8.00 9.30 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 7 18 1.45 1.45 1.45 3.65 1.80 8.00 9.50 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

77991.75 1.75 2.25 2.25 1.80 8.00 9.20 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 9 12 1.70 1.70 2.10 2.50 1.80 8.00 9.20 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 9 14 1.50 1.50 1.90 3.10 1.80 8.00 9.30 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 9 18 1.40 1.40 1.70 3.50 1.80 8.00 9.50 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 7 12 12 1.45 1.45 2.55 2.55 1.80 8.00 9.20 0.65 2.55 3.80 2.85 11.31 16.80 3.14 B

7 7 12 14 1.40 1.40 2.40 2.80 1.80 8.00 9.30 0.65 2.55 3.80 2.85 11.31 16.80 3.14 B

79991.70 2.10 2.10 2.10 1.80 8.00 9.20 0.65 2.60 3.80 2.85 11.54 16.80 3.08 B

7 9 9 12 1.60 2.00 2.00 2.40 1.80 8.00 9.20 0.65 2.55 3.80 2.85 11.31 16.80 3.14 B

7 9 9 14 1.45 1.80 1.80 2.95 1.80 8.00 9.30 0.65 2.55 3.80 2.85 11.31 16.80 3.14 B

7 9 12 12 1.40 1.70 2.45 2.45 1.80 8.00 9.20 0.65 2.50 3.80 2.85 11.09 16.80 3.20 B

7 9 12 14 1.30 1.65 2.30 2.75 1.80 8.00 9.30 0.65 2.50 3.80 2.85 11.09 16.80 3.20 B

99992.00 2.00 2.00 2.00 1.80 8.00 9.20 0.65 2.55 3.80 2.85 11.31 16.80 3.14 B

9 9 9 12 1.90 1.90 1.90 2.30 1.80 8.00 9.20 0.65 2.50 3.80 2.85 11.09 16.80 3.20 B

9 9 9 14 1.70 1.70 1.70 2.90 1.80 8.00 9.30 0.65 2.50 3.80 2.85 11.09 16.80 3.20 B

9 9 12 12 1.65 1.65 2.05 2.65 1.80 8.00 9.40 0.65 2.50 3.80 2.85 11.09 16.80 3.20 B

Co

mb.

ENERGY

LABEL

Rated capacity Output/kW

(Nom. cooling)

total cooling

capacity(kW)

total power input

(kW)

BI (1x2)TRI (1x3)QUADRI(1x4)

Combinations

total current

(A)@230V

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-25-

HEATING

EER

(W/W)

UnitAUnitBUnitCUnitDUnitAUnitBUnitCUnit

D

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 14 — — 2.30 4.60 — — 1.20 6.90 7.50 0.50 2.80 3.80 2.15 12.42 16.80 2.46 F

7 18 — — 2.30 5.50 — — 1.20 7.80 8.40 0.50 2.90 3.80 2.15 12.87 16.80 2.69 E

9 12 — — 2.90 3.80 — — 1.20 6.70 7.30 0.50 2.90 3.80 2.15 12.87 16.80 2.31 G

9 14 — — 2.90 4.60 — — 1.20 7.50 8.20 0.50 3.00 3.80 2.15 13.31 16.80 2.50 F

9 18 — — 2.90 5.50 — — 1.20 8.40 9.20 0.50 3.00 3.80 2.15 13.31 16.80 2.80 D

12 12 — — 3.80 3.80 — — 1.20 7.60 8.20 0.50 2.95 3.80 2.15 13.09 16.80 2.58 F

12 14

— — 3.80 4.60 — — 1.20 8.40 9.10 0.50 2.90 3.80 2.15 12.87 16.80 2.90 D

12 18

— — 3.80 5.50 — — 1.20 9.30 10.20 0.50 3.10 3.80 2.15 13.75 16.80 3.00 C

14 14

— — 4.60 4.60 — — 1.20 9.20 10.20 0.55 3.00 3.80 2.50 13.31 16.80 3.07 C

14 18

— — 4.60 5.40 — — 1.20 10.00 10.50 0.55 3.00 3.80 2.50 13.31 16.80 3.33 C

18 18

— — 5.00 5.00 — — 1.20 10.00 11.00 0.55 3.00 3.80 2.50 13.31 16.80 3.33 C

7 7 7 — 2.30 2.30 2.30 — 1.50 6.90 7.80 0.55 2.85 3.80 2.50 12.64 16.80 2.42 F

7 7 9 — 2.30 2.30 2.90 — 1.50 7.50 8.40 0.55 2.85 3.80 2.50 12.64 16.80 2.63 E

7 7 12 — 2.30 2.30 3.80 — 1.50 8.40 9.30 0.55 2.85 3.80 2.50 12.64 16.80 2.95 D

7 7 14 — 2.30 2.30 4.60 — 1.50 9.20 10.20 0.55 2.80 3.80 2.50 12.42 16.80 3.29 C

7 7 18 — 2.30 2.30 5.40 — 1.50 10.00 10.50 0.55 2.80 3.80 2.50 12.42 16.80 3.57 B

7 9 9 — 2.30 2.90 2.90 — 1.50 8.10 10.50 0.55 2.90 3.80 2.50 12.87 16.80 2.79 E

7 9 12 — 2.30 2.90 3.80 — 1.50 9.00 10.50 0.55 2.90 3.80 2.50 12.87 16.80 3.10 C

7 9 14 — 2.30 2.90 4.60 — 1.50 9.80 10.50 0.55 2.80 3.80 2.50 12.42 16.80 3.50 B

7 9 18 — 2.15 2.70 5.15 — 1.50 10.00 11.00 0.55 2.85 3.80 2.50 12.64 16.80 3.51 B

7 12 12 — 2.30 3.80 3.80 — 1.50 9.90 10.80 0.55 2.90 3.80 2.50 12.87 16.80 3.41 B

7 12 14 — 2.15 3.55 4.30 — 1.50 10.00 11.00 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

7 12 18 — 2.00 3.25 4.75 — 1.50 10.00 11.00 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

7 14 14 — 2.00 4.00 4.00 — 1.50 10.00 11.00 0.55 2.85 3.80 2.50 12.64 16.80 3.51 B

71418

— 1.90 3.70 4.40 — 1.50 10.00 11.00 0.55 2.85 3.80 2.50 12.64 16.80 3.51 B

9 9 9 — 2.90 2.90 2.90 — 1.50 8.70 10.50 0.55 2.90 3.80 2.50 12.87 16.80 3.00 C

9 9 12 — 2.90 2.90 3.80 — 1.50 9.60 10.50 0.55 2.90 3.80 2.50 12.87 16.80 3.31 C

9 9 14 — 2.75 2.75 4.50 — 1.50 10.00 10.50 0.55 2.85 3.80 2.50 12.64 16.80 3.51 B

9 9 18 — 2.50 2.50 5.00 — 1.50 10.00 11.50 0.55 2.80 3.80 2.50 12.42 16.80 3.57 B

9 12 12 — 2.80 3.60 3.60 — 1.50 10.00 11.50 0.55 2.80 3.80 2.50 12.42 16.80 3.57 B

9 12 14 — 2.55 3.35 4.10 — 1.50 10.00 11.50 0.55 2.80 3.80 2.50 12.42 16.80 3.57 B

9 12 18 — 2.40 3.10 4.50 — 1.50 10.00 11.50 0.55 2.85 3.80 2.50 12.64 16.80 3.51 B

9 14 14 — 2.40 3.80 3.80 — 1.50 10.00 11.50 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

9

14 18

— 2.25 3.55 4.20 — 1.50 10.00 11.50 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

12 12 12 — 3.35 3.35 3.35 — 1.50 10.05 11.50 0.55 2.95 3.80 2.50 13.09 16.80 3.41 B

12 12 14 — 3.10 3.10 3.80 — 1.50 10.00 11.50 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

12 12 18 — 2.90 2.90 4.20 — 1.50 10.00 11.50 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

12 14 14 — 2.90 3.55 3.55 — 1.50 10.00 11.50 0.55 2.90 3.80 2.50 12.87 16.80 3.45 B

77772.30 2.30 2.30 2.30 1.80 9.20 10.50 0.65 2.90 3.80 2.85 12.87 16.80 3.17 C

77792.30 2.30 2.30 2.90 1.80 9.80 10.50 0.65 2.90 3.80 2.85 12.87 16.80 3.38 C

7 7 7 12 2.15 2.15 2.15 3.55 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

7 7 7 14 2.00 2.00 2.00 4.00 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

7 7 7 18 1.85 1.85 1.85 4.45 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

77992.20 2.20 2.80 2.80 1.80 10.00 11.50 0.65 2.90 3.80 2.85 12.87 16.80 3.45 B

7 7 9 12 2.05 2.05 2.55 3.35 1.80 10.00 11.50 0.65 2.90 3.80 2.85 12.87 16.80 3.45 B

7 7 9 14 1.90 1.90 2.40 3.80 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

7 7 9 18 1.75 1.75 2.20 4.30 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

7 7 12 12 1.90 1.90 3.10 3.10 1.80 10.00 11.50 0.65 2.90 3.80 2.85 12.87 16.80 3.45 B

7 7 12 14 1.75 1.75 2.90 3.60 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

79992.10 2.65 2.65 2.65 1.80 10.05 11.50 0.65 2.90 3.80 2.85 12.87 16.80 3.47 B

7 9 9 12 1.95 2.45 2.45 3.15 1.80 10.00 11.50 0.65 2.90 3.80 2.85 12.87 16.80 3.45 B

7 9 9 14 1.80 2.25 2.25 3.70 1.80 10.00 11.50 0.65 2.85 3.80 2.85 12.64 16.80 3.51 B

7 9 12 12 1.95 2.25 2.90 2.90 1.80 10.00 11.50 0.65 2.80 3.80 2.85 12.42 16.80 3.57 B

7 9 12 14 1.70 2.15 2.80 3.35 1.80 10.00 11.50 0.65 2.80 3.80 2.85 12.42 16.80 3.57 B

99992.50 2.50 2.50 2.50 1.80 10.00 11.50 0.65 2.75 3.80 2.85 12.20 16.80 3.64 A

9 9 9 12 2.30 2.30 2.30 3.10 1.80 10.00 11.50 0.65 2.75 3.80 2.85 12.20 16.80 3.64 A

9 9 9 14 2.20 2.20 2.20 3.40 1.80 10.00 11.50 0.65 2.75 3.80 2.85 12.20 16.80 3.64 A

9 9 12 12

2.15 2.15 2.85 2.85

1.80 10.00 11.50 0.65 2.70 3.80 2.85 11.98 16.80 3.70 A

ENERGY

LABEL

Rated capacity Output/kW

(Nom. heating)

total heating

capacity(KW)

total power input

(W)

total current

(A)@230V

BI (1x2)TRI (1x3)QUADRI(1x4)

Combinations

Co

mb.

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-26-

AU342XHERA combination and the data

COOLING

EER

(W/W)

UnitAUnitBUnitCUnitDUnitAUnitBUnitCUnit

D

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 18 — — 2.00 5.00 — — 1.00 7.00 7.50 0.50 2.85 4.00 2.15 12.64 18.10 2.46 E

9 18 — — 2.50 5.00 — — 1.00 7.50 8.00 0.50 2.90 4.00 2.15 12.87 18.10 2.59 E

12 14

— — 3.50 4.10 — — 1.00 7.60 8.10 0.50 2.90 4.00 2.15 12.87 18.10 2.62 D

12 18

— — 3.50 5.00 — — 1.00 8.50 9.00 0.50 3.30 4.00 2.15 14.64 18.10 2.58 E

14 14

— — 4.10 4.10 — — 1.00 8.20 8.80 0.50 3.30 4.00 2.15 14.64 18.10 2.48 E

14 18

— — 4.10 5.00 — — 1.00 9.10 9.70 0.50 3.50 4.00 2.15 15.53 18.10 2.60 D

18 18

— — 5.00 5.00 — — 1.00 10.00 10.50 0.50 3.50 4.00 2.15 15.53 18.10 2.86 C

7 7 12 — 2.00 2.00 3.50 — 1.50 7.50 8.10 0.55 3.10 4.00 2.50 13.75 18.10 2.42 E

7 7 14 — 2.00 2.00 4.10 — 1.50 8.10 8.80 0.55 3.20 4.00 2.50 14.20 18.10 2.53 E

7 7 18 — 2.00 2.00 5.00 — 1.50 9.00 9.80 0.55 3.25 4.00 2.50 14.42 18.10 2.77 D

7 9 9 — 2.00 2.50 2.50 — 1.50 7.00 7.60 0.55 3.10 4.00 2.50 13.75 18.10 2.26 F

7 9 12 — 2.00 2.50 3.50 — 1.50 8.00 8.60 0.55 3.10 4.00 2.50 13.75 18.10 2.58 E

7 9 14 — 2.00 2.50 4.10 — 1.50 8.60 9.30 0.55 3.15 4.00 2.50 13.98 18.10 2.73 D

7 9 18 — 2.00 2.50 5.00 — 1.50 9.50 10.20 0.55 3.40 4.00 2.50 15.08 18.10 2.79 D

7 12 12 — 2.00 3.50 3.50 — 1.50 9.00 9.60 0.55 3.40 4.00 2.50 15.08 18.10 2.65 D

7 12 14 — 2.00 3.50 4.10 — 1.50 9.60 10.20 0.55 3.40 4.00 2.50 15.08 18.10 2.82 C

7 12 18 — 1.90 3.30 4.80 — 1.50 10.00 10.50 0.55 3.40 4.00 2.50 15.08 18.10 2.94 C

9 9 9 — 2.50 2.50 2.50 — 1.50 7.50 8.10 0.55 3.40 4.00 2.50 15.08 18.10 2.21 F

9 9 12 — 2.50 2.50 3.50 — 1.50 8.50 9.10 0.55 3.40 4.00 2.50 15.08 18.10 2.50 E

9 9 14 — 2.50 2.50 4.10 — 1.50 9.10 9.80 0.55 3.35 4.00 2.50 14.86 18.10 2.72 D

9 9 18 — 2.50 2.50 5.00 — 1.50 10.00 10.50 0.55 3.35 4.00 2.50 14.86 18.10 2.99 C

9 12 12 — 2.50 3.50 3.50 — 1.50 9.50 10.20 0.55 3.40 4.00 2.50 15.08 18.10 2.79 D

9 12 14 — 2.45 3.45 4.10 — 1.50 10.00 10.50 0.55 3.38 4.00 2.50 15.00 18.10 2.96 C

9 12 18 — 2.30 3.20 4.50 — 1.50 10.00 10.50 0.55 3.38 4.00 2.50 15.00 18.10 2.96 C

12 12 12 — 3.33 3.33 3.33 — 1.50 10.00 10.50 0.55 3.40 4.00 2.50 15.08 18.10 2.94 C

12 12 14 — 3.15 3.15 3.70 — 1.50 10.00 10.50 0.55 3.38 4.00 2.50 15.00 18.10 2.96 C

12 12 18 — 2.90 2.90 4.20 — 1.50 10.00 10.50 0.55 3.38 4.00 2.50 15.00 18.10 2.96 C

77772.00 2.00 2.00 2.00 1.80 8.00 8.80 0.65 3.25 4.00 2.85 14.42 18.10 2.46 E

77792.00 2.00 2.00 2.50 1.80 8.50 9.30 0.65 3.25 4.00 2.85 14.42 18.10 2.62 D

7 7 7 12 2.00 2.00 2.00 3.50 1.80 9.50 10.30 0.65 3.25 4.00 2.85 14.42 18.10 2.92 C

7 7 7 14 1.95 1.95 1.95 4.10 1.80 9.95 10.80 0.65 3.30 4.00 2.85 14.64 18.10 3.02 B

7 7 7 18 1.85 1.85 1.85 4.45 1.80 10.00 11.00 0.65 3.30 4.00 2.85 14.64 18.10 3.03 B

77992.00 2.00 2.50 2.50 1.80 9.00 9.80 0.65 3.25 4.00 2.85 14.42 18.10 2.77 D

7 7 9 12 2.00 2.00 2.50 3.50 1.80 10.00 10.50 0.65 3.25 4.00 2.85 14.42 18.10 3.08 B

7 7 9 14 1.85 1.85 2.35 3.95 1.80 10.00 10.80 0.65 3.30 4.00 2.85 14.64 18.10 3.03 B

7 7 9 18 1.75 1.75 2.15 4.35 1.80 10.00 11.00 0.65 3.30 4.00 2.85 14.64 18.10 3.03 B

7 7 12 12 1.80 1.80 3.20 3.20 1.80 10.00 10.80 0.65 3.25 4.00 2.85 14.42 18.10 3.08 B

7 7 12 14 1.70 1.70 3.00 3.60 1.80 10.00 10.90 0.65 3.30 4.00 2.85 14.64 18.10 3.03 B

7 7 12 18 1.60 1.60 2.80 4.00 1.80 10.00 11.00 0.65 3.30 4.00 2.85 14.64 18.10 3.03 B

79992.00 2.50 2.50 2.50 1.80 9.50 10.30 0.65 3.25 4.00 2.85 14.42 18.10 2.92 C

7 9 9 12 1.90 2.40 2.40 3.30 1.80 10.00 10.80 0.65 3.28 4.00 2.85 14.55 18.10 3.05 B

7 9 9 14 1.80 2.25 2.25 3.70 1.80 10.00 10.90 0.65 3.25 4.00 2.85 14.42 18.10 3.08 B

7 9 9 18 1.70 2.10 2.10 4.10 1.80 10.00 11.00 0.65 3.25 4.00 2.85 14.42 18.10 3.08 B

7 9 12 12 1.75 2.15 3.05 3.05 1.80 10.00 10.80 0.65 3.25 4.00 2.85 14.42 18.10 3.08 B

7 9 12 14 1.65 2.05 2.90 3.40 1.80 10.00 10.90 0.65 3.22 4.00 2.85 14.29 18.10 3.11 B

7 9 12 18 1.55 1.95 2.70 3.80 1.80 10.00 11.00 0.65 3.20 4.00 2.85 14.20 18.10 3.13 B

7 12 12 12 1.60 2.80 2.80 2.80 1.80 10.00 11.00 0.65 3.22 4.00 2.85 14.29 18.10 3.11 B

7 12 12 14 1.55 2.70 2.70 3.05 1.80 10.00 11.00 0.65 3.22 4.00 2.85 14.29 18.10 3.11 B

99992.50 2.50 2.50 2.50 1.80 10.00 11.00 0.65 3.30 4.00 2.85 14.64 18.10 3.03 B

9 9 9 12 2.30 2.30 2.30 3.10 1.80 10.00 11.00 0.65 3.25 4.00 2.85 14.42 18.10 3.08 B

9 9 9 14 2.15 2.15 2.15 3.55 1.80 10.00 11.00 0.65 3.24 4.00 2.85 14.37 18.10 3.09 B

9 9 9 18 2.00 2.00 2.00 4.00 1.80 10.00 11.00 0.65 3.23 4.00 2.85 14.33 18.10 3.10 B

9 9 12 12 2.10 2.10 2.90 2.90 1.80 10.00 11.00 0.65 3.20 4.00 2.85 14.20 18.10 3.13 B

9 9 12 14 2.00 2.00 2.75 3.25 1.80 10.00 11.00 0.65 3.17 4.00 2.85 14.06 18.10 3.15 B

9 9 12 18 1.85 1.85 2.60 3.70 1.80 10.00 11.00 0.65 3.15 4.00 2.85 13.98 18.10 3.17 B

9 12 12 12 1.90 2.70 2.70 2.70 1.80 10.00 11.00 0.65 3.17 4.00 2.85 14.06 18.10 3.15 B

9 12 12 14 1.85 2.50 2.50 3.15 1.80 10.00 11.00 0.65 3.17 4.00 2.85 14.06 18.10 3.15 B

12 12 12 12 2.50 2.50 2.50 2.50 1.80 10.00 11.00 0.65 3.17 4.00 2.85 14.06 18.10 3.15 B

TRI (1x3)QUADRI(1x4)

total power input

(kW)

total current

(A)@230V

ENERGY

LABEL

BI (1x2)

Co

mb

.

Combinations

Rated capacity Output/kW

(Nom. cooling)

total cooling

capacity(kW)

>_]]VbTZR\ <Zb >_^UZdZ_^Vb

-27-

HEATING

EER

(W/W)

UnitAUnitBUnitCUnitDUnitAUnitBUnitCUnit

D

min.

data

rated

data

max.

data

min.

data

rated

data

max.

Data

min.

data

rated

data

max.

Data

rated

capacity

7 18 — — 2.30 5.50 — — 1.20 7.80 7.50 0.50 2.95 4.00 2.15 12.64 18.10 2.64 E

9 18 — — 2.90 5.50 — — 1.20 8.40 8.40 0.50 3.00 4.00 2.15 12.87 18.10 2.80 D

12 14

— — 3.80 4.60 — — 1.20 8.40 7.30 0.50 3.00 4.00 2.15 12.87 18.10 2.80 D

12 18

— — 3.80 5.50 — — 1.20 9.30 8.20 0.50 3.30 4.00 2.15 14.64 18.10 2.82 D

14 14

— — 4.60 4.60 — — 1.20 9.20 9.20 0.50 3.30 4.00 2.15 14.64 18.10 2.79 E

14 18

— — 4.60 5.50 — — 1.20 10.10 8.20 0.50 3.45 4.00 2.15 15.53 18.10 2.93 D

18 18

— — 5.50 5.50 — — 1.20 11.00 9.10 0.50 3.45 4.00 2.15 15.53 18.10 3.19 C

7 7 12 — 2.30 2.30 3.80 — 1.20 8.40 10.20 0.55 2.95 4.00 2.50 13.75 18.10 2.85 D

7 7 14 — 2.30 2.30 4.60 — 1.20 9.20 10.20 0.55 2.90 4.00 2.50 14.20 18.10 3.17 C

7 7 18 — 2.30 2.30 5.50 — 1.20 10.10 10.50 0.55 2.95 4.00 2.50 14.42 18.10 3.42 B

7 9 9 — 2.30 2.90 2.90 — 1.20 8.10 11.00 0.55 2.95 4.00 2.50 13.75 18.10 2.75 E

7 9 12 — 2.30 2.90 3.80 — 1.50 9.00 7.80 0.55 2.95 4.00 2.50 13.75 18.10 3.05 C

7 9 14 — 2.30 2.90 4.60 — 1.50 9.80 8.40 0.55 3.00 4.00 2.50 13.98 18.10 3.27 C

7 9 18 — 2.30 2.90 5.50 — 1.50 10.70 9.30 0.55 3.05 4.00 2.50 15.08 18.10 3.51 B

7 12 12 — 2.30 3.80 3.80 — 1.50 9.90 10.20 0.55 2.95 4.00 2.50 15.08 18.10 3.36 C

7 12 14 — 2.30 3.80 4.60 — 1.50 10.70 10.50 0.55 3.00 4.00 2.50 15.08 18.10 3.57 B

7 12 18 — 2.10 3.60 5.30 — 1.50 11.00 10.50 0.55 3.05 4.00 2.50 15.08 18.10 3.61 A

9 9 9 — 2.90 2.90 2.90 — 1.50 8.70 10.80 0.55 3.00 4.00 2.50 15.08 18.10 2.90 D

9 9 12 — 2.90 2.90 3.80 — 1.50 9.60 11.00 0.55 3.05 4.00 2.50 15.08 18.10 3.15 C

9 9 14 — 2.90 2.90 4.60 — 1.50 10.40 11.00 0.55 3.10 4.00 2.50 14.86 18.10 3.35 C

9 9 18 — 2.80 2.80 5.40 — 1.50 11.00 11.00 0.55 3.10 4.00 2.50 14.86 18.10 3.55 B

9 12 12 — 2.90 3.80 3.80 — 1.50 10.50 11.00 0.55 3.05 4.00 2.50 15.08 18.10 3.44 B

9 12 14 — 2.70 3.80 4.50 — 1.50 11.00 11.00 0.55 3.10 4.00 2.50 15.00 18.10 3.55 B

9 12 18 — 2.55 3.55 4.90 — 1.50 11.00 10.50 0.55 3.15 4.00 2.50 15.00 18.10 3.49 B

12 12 12 — 3.66 3.66 3.66 — 1.50 11.00 11.50 0.55 3.45 4.00 2.50 15.08 18.10 3.19 C