Haier AE122FCBKA, AE242FCBKA, AE142FCBKA, AE182FCBKA, AE072FCAMA Operation And Installation Manual

...

Please read this operation manual before using the air conditioner.

Please keep this manual carefully and safely.

CEILING CONCEALED TYPE AIR CONDITIONER

Operation & Installation

Manual

No. 0010573668

A

Table of Contents

Cautions

Important Points of Safety

Trouble Shooting

When Fault Occurs

Notice to Users

Installation Precautions

Installation Procedure

Installation Check and Trial Run

1-2

3-5

6-7

8

9

10-11

12-17

18

18

Installation Check and Trial Run

Check if the drain pipe and connection wires are arranged properly.

The drain pipe shall be put below. The connection wire shall be put above. Be sure to wrap

the drain pipe (especially the indoor part and the part inside the machine) with thermal insulating materials.

The drain pipe shall be made into slope. Avoid bulging up or down or phenomena shown

right figure in the run.

Installation check

* Do the supply voltage meet the requirement?

* Could the drainage water completely discharged to outdoor

*Are the power cord and the indoor/outdoor

* Is there any gas leakage at the pipe joints?

*Connection wire connected properly?

* Are the wires pressed firmly?

*Is the noise too big?

*Do the terminal numbers of the indoor/outdoor connection wire coincide with each other?

*Is the pipe connection part thermally insulated?

*Is the indoor unit mounted firmly and reliably?

Trial operation

The installation serviceman must conduct a trial operation and check:

* Does the temperature regulator work normally?

* Does the installation location selection meet the related requirements?

Wrap with the protective plastic tape

Wrap the connection pipe, the drain pipe and the connection wire

together with PVC tape.

Caution:

The connection pipe must be wrapped individually with insulating material from down to up.

1

Cautions

17

Installation Procedure

Vacuum pumping

With a vacuum pump, create vacuum from the stop valve of the outdoor unit.

Emptying with refrigerant sealed in the outdoor unit is absolutely forbidden.

Open all valves

Open all the valves on the outdoor unit.

Gas leakage detection

Check with a leakage detector or soap water that if there is gas leakage at the pipe

connections and bonnets.

Insulation treatment

Conduct insulation treatment on both the gas side and liquid side of pipes respectively.

During cooling operation, both the liquid and gas sides are cold and thus shall be insulated

so as to avoid dew generation.

The notch upward (Attached detail view)

Indoor unit

Subsidiary insulation tube

Field piping side

2

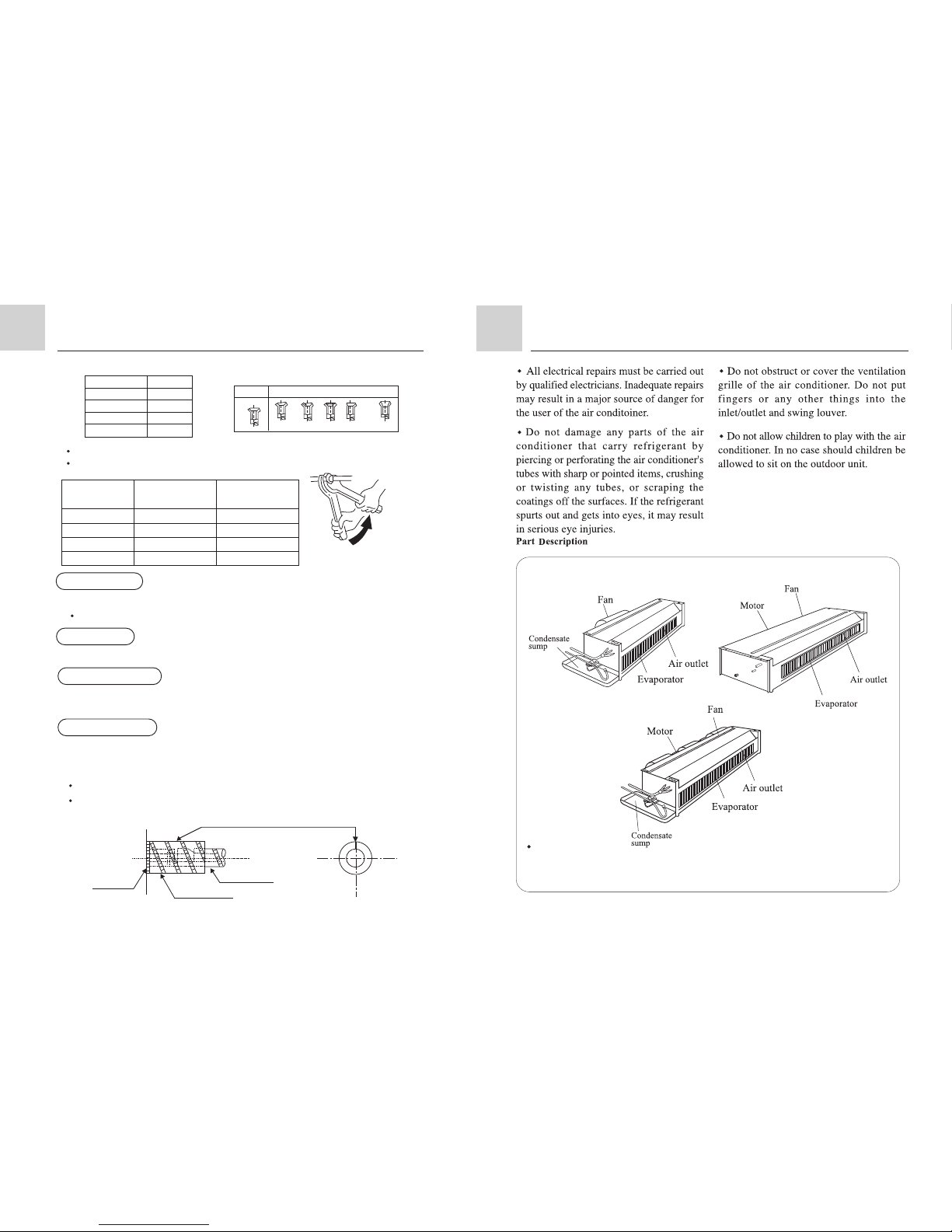

When the unit have the Return air box (see the following picture) when shipping

from the factory and they are of back-side return air type.

R22:

Series 07

R22:

Series 24

R22:

Series 09-21

R407C:

Series 07-24

Cautions

NOTE

The insulating material at gas side shall be resistant to a temperature above 120*.

The indoor unit pipe connection part shall be insulated.

The connection of indoor unit pipes must use double spanners.

The installing torque shall be as given in the following table.

Double-spanner

operation

Connecting pipe

O.D.(mm)

ÿ6.35

ÿ9.52

ÿ12.70

ÿ15.88

Installing torque

(N-m)

11.8 (1.2kgf-m)

24.5 (2.5kgf-m)

49.0 (5.0 kgf-m)

78.4 (8.0 kgf-m)

Increased installing

torque (N-m)

13.7 (1.4 kgf-m)

29.4 (3.0 kgf-m)

53.9 (5.5 kgf-m)

98.0 (10.0 kgf-m)

Pipe expansion dimensions as follows:

Slope Damage Bur Partial Overlong

Correct

Incorrect

6.35 mm (1/4") 0.8 ~ 1.5

9.52 mm (3/8") 1.0 ~ 1.8

12.7 mm (1/2") 1.2 ~ 2.0

15.88 mm (5/8") 1.4 ~2.2

Pipe diameter ÿ Size A (mm)

Loading...

Loading...