Page 1

CEILING CONCEALED TYPE AIR CONDITIONER INDOOR UNIT

Household MRV

Ceiling Concealed Type Room Air Conditioner

AE092FCAJA

AE182FCAJA

Health and power failure compensation function

AE182FCBJA

AE182FCBJA

5

8

14

0010572352

Installation precautions

15-16

17Fault occurs

18

19-20

21-33

34

Page 2

1

Page 3

AE092FCAJA,AE182FCAJA

21*/18*

AE092FCBJA,AE182FCBJA

21*/15.5*

2

Page 4

R407C:AE092FCBJA AE182FCBJA

R22: AE092FCAJA AE182FCAJA

Operation

Buttons of the wire controller.

5

6

FAN

SWING

AUTO

%

ON OFF

AM

PM

11

12

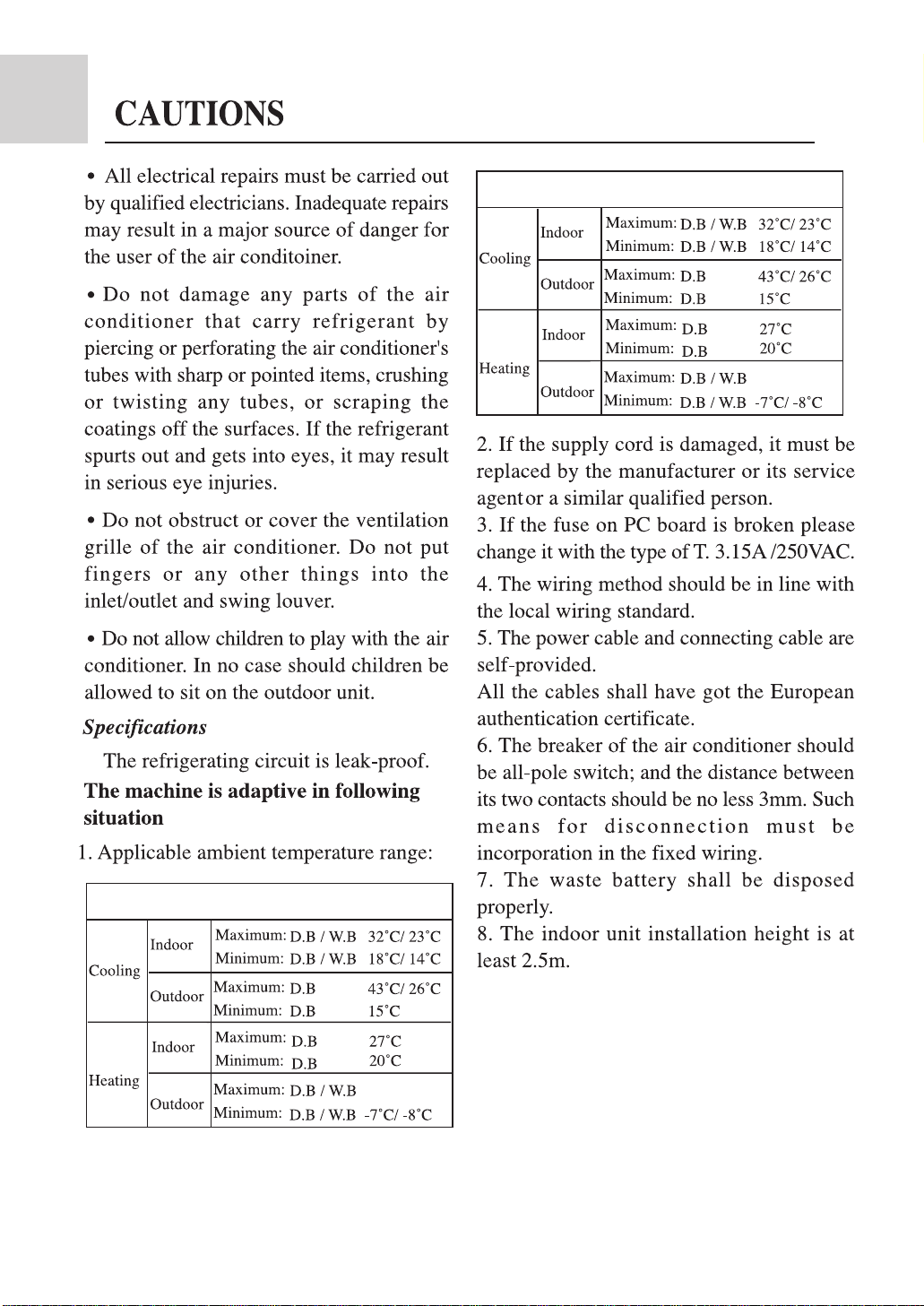

1.MODE

Used to select AUTO

RUN, COOL, DRY,

HEAT and FAN

operation.

2.FAN SPEED

Used to select fan

speed: LO, MED, HI,

AUTO

3.HEALTH

Use to control oxygen-make

function and negative ion function.

(If both of these functions exist,

use ìhealth buttonî to control both

of them)

4.TEMP

Used to select your

desired temp.

5.CLOCK

Used to set correct time.

Note:

1.In outdoor unit without oxygen bar function or non-negative ion air conditioner, there

is no health function mentioned in the third item function.

2.The "Swing" function are not available on the models mentioned in this manual;

3.Actual products may vary slightly from the ones show in the manual, due to the continuous

development.

MODE

HEALTH

TEMP

CLOCK SET

SET

TIMER SLEEP

ROOM

*

FILTER RESET

AM

PM

RESET

ON/OFF

6.TIMER

Used to select

TIMER ON,

TIMER OFF,

TIMER ON/OFF.

7.SET

Used to confirm Timer

and Clock settings.

8.TIME

Used to set clock and

timer setting.

9.SLEEP

Used to select sleep

mode.

10.Power ON/OFF

Used for unit start and

stop.

11.

Receiver

R

eceiver

remote controller.

window

the signal from

Buttons of the remote controller.

4

TIMP

7

8

9

10

SWING

10

1

3

5

6

8

12

ON

OFF

MODE SLEEP

NEW FAN

HEALTH

CLOCK

TIMER

RESET

FAN SPEED

SET

LOCK

**

12.RESET

Press with a pointed

article to reset value if

abnormal operation

occurs.

13.LOCK

Used to lock press

button,Press LOCK

button again to cancel

lock function.

4

2

9

7

13

3

Page 5

Operation

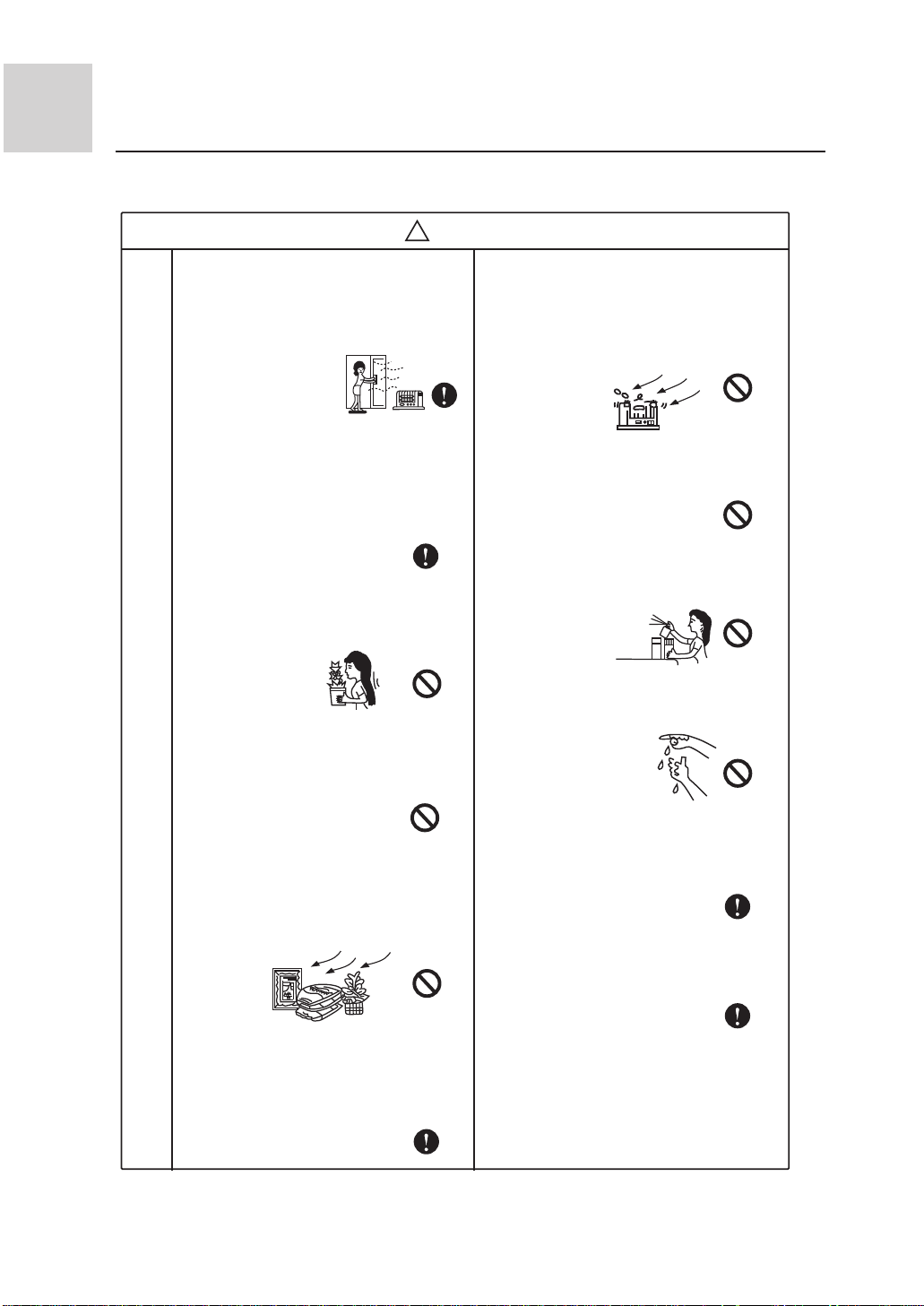

Display of the wire controller and remote controller.

4

6

AUTO

ON OFF

AM

PM

7

8

9

10

1.AUTO

2.COOL

3.DRY

4.HEAT

5.FAN OPERATION

6.SLEEP

FAN

MODE

HEALTH

TEMP

CLOCK SET

SET

TIMER SLEEP

ROOM

%

*

FILTER RESET

AM

PM

RESET

ON/OFF

8.TIMER ON

9.TIMER OFF

10.CLOCK

11.OPERATING LAMP

12.TEMP.

13.LOCK.

1

2

3

4

5

13

11

12

7

8

9

SWING

TIMP

ON

OFF

MODE SLEEP

NEW FAN

HEALTH

CLOCK

TIMER

RESET

FAN SPEED

SET

LOCK

**

5

6

12

13

10

7.FNA SPEED

Note:The above information is the explanation of the displayed information therefore

varies with those displayed in actual operation.

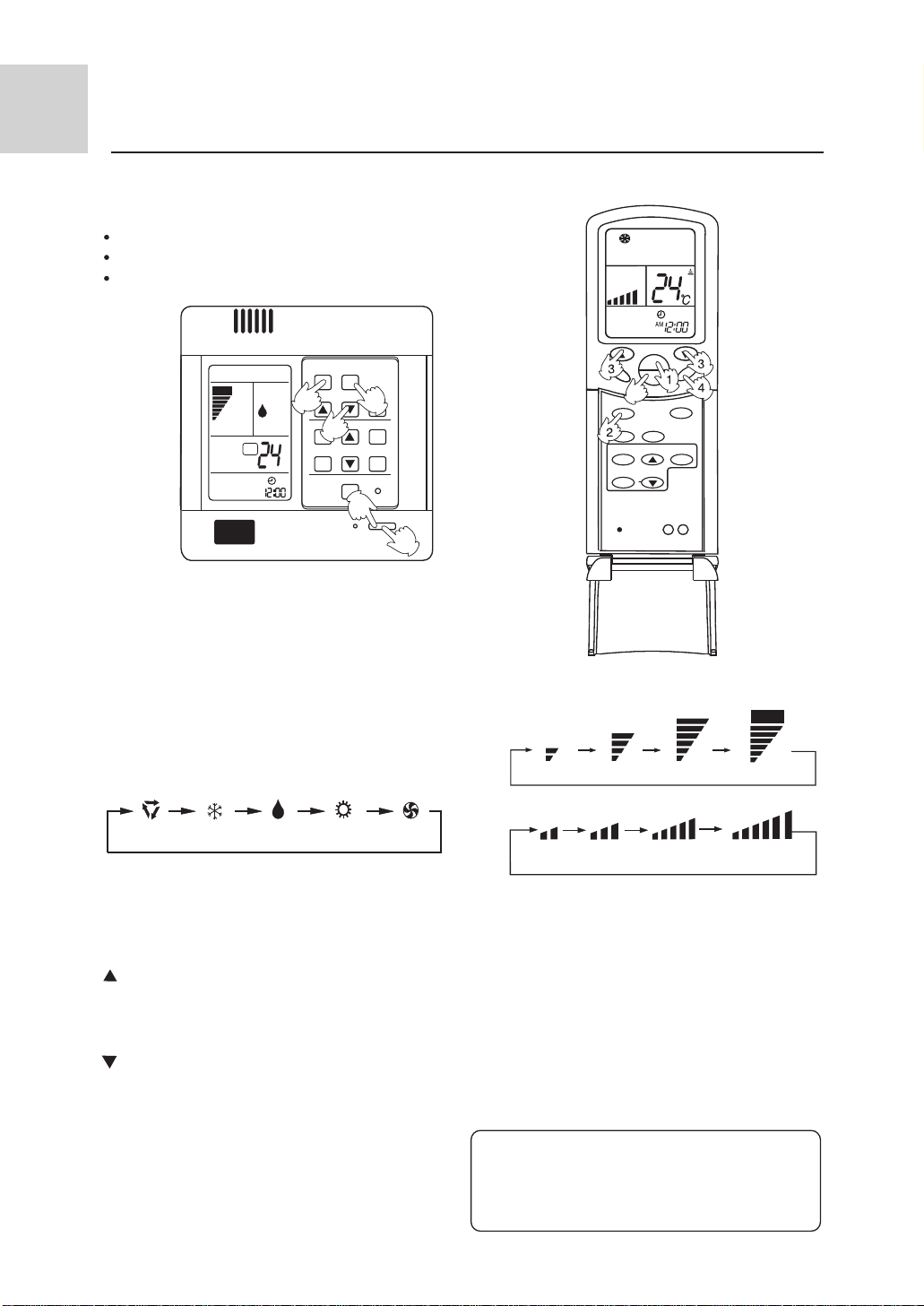

Clock set

When unit is started for the first time, clock should be adjusted as follows:

Press CLOCK button, "AM"or "PM" flashes.

Press or to set correct time. Each press will increase or decrease 1min. If the

button is kept depressed, time will change quickly.

After time setting is confirmed, press SET, "AM "and "PM" stop flashing, while clock

starts working.

Remote controller

SWING

FAN

(Operation of remote controller)

1.When using remote controller, first point it to the receiving

window of wire controller, and then operate remote controller.

A ìtickî tone will be uttered to indicate a right acceptance.

2.All the buttons except the sleeping button is no effective

after wire controller received lock signal from remote controller.

4

MODE

AUTO

SET

ROOM

%

ON OFF

AMPMAM

PM

HEALTH

TEMP

CLOCK SET

TIMER SLEEP

*

FILTER RESET

RESET

ON/OFF

Page 6

*

Make sure that the remote controller is used within 7 meters from receiver window

of the wire controller and there are no obstructions in between.

*

The remote controller or wire controller should be handled with care.

*

When operating the remote controller in an area where electronically controlled lights

are installed or wireless handsets are used, move closer to the indoor unit as the function

of the remote controller might be affected by signals from this equipment.

Battery loading

Batteries are fitted as follows:

Remove the battery compartment lid

Slightly press and disengage the battery compartment lid marked with ì î and then hold

the remote controller by the upper section and then remove the battery compartment lid by

pressing in the direction of the arrow as shown in the figure above.

Loading the battery

Ensure that batteries are correctly placed in the compartment as required for positive and

negative terminals.

Replacing the battery compartment lid

The battery compartment lid is reinstalled in the reverse sequence.

Display review

Press the button to see if batteries are properly fitted. If no display appears, refit the batteries.

Caution:

If the remote controller does not operate as designed after fitting new batteries of the same

type, press the Reset button (marked ) with a pointed article.

Note:

It is recommended that the batteries be removed from the compartment if the remote

controller is not used for an extended period.

The remote controller is programmed for automatic test of operation mode after the

batteries are replaced. When the test is conducted, all icons will appear on the screen

and then disappear if the batteries are properly fitted.

NOTE:The wired remote controller is supplied by factory along with the

indoor unit,but the remote controller should be purchased separately.

5

Page 7

Important Points of Safety

The following four important points of safety and suggestions should be paid great attention:

!

Warning: Misuse may cause fatal result such as death or serious injury etc.

!

Attention: Misuse may cause human injury or damage of machine, in some case

fatal results.

: Content marked with this ìforbiddenî sign should be absolutely forbid den, otherwise may cause damage of machine and human injury of the

user.

: Content marked with this ìcompulsoryî sign should be executed comp-

!

ulsively, otherwise may cause damage of machine and human injury of

the user.

Comply with the following important points of safety.

Put these important points of attention and suggestions nearby and convenient for reference in need.

Hand over this instruction manual to new user if you resell this machine.

!

Warning

l Entrusted Installation

Installation of the machine should

be entrusted to certified person of

after service. Unauthorized install-

Warning for installation

ation may cause water leakage,

electric shock or fire hazard for

improper operation.

l To prevent leakage of refrigerant,

let certified person of after service

do it.

Leakage of refrigerant over certain

consistence may result in shortage

of oxygen. Enough precautions

MUST be done to avoid oxygen

shortage in case of refrigerant lea king if the room where the air conditioner is installed is small.

l The power supply must be fitted with

earth line to ensure valid earthing of

the air-conditioner. No or incomplete

earthing connection may cause the

risk of electric shock.

l Test run

!

After indoor units are installed,all

cassettes hinded models should be

tested.when the units are confirmed

to be normal,other fitments can be

installed.

!

!

!

6

Page 8

Important Points of Safety

Warning

!

l Avoid your body being blown

Warning for use

directly by cold wind for long

period, otherwise your health

may be affected.

l Donít extend your fingers or

any other article into the inlet

or outlet during operation of

the machine for touching re volving fans may cause human

injury or damage of machine.

Warning for move and repair

l When you have to disassemble

and reinstall the machine, entrust

it to after service. Improper inst allation may cause fire hazard,

electric shock or damage of ma chine.

l If something abnormal (e.g.: burnt

smell etc.) occurs, stop running the

machine, shut down the manual

power switch and contact after

service. Continuous operation in

disorder may cause fire hazard or

electric shock etc.

l Unauthorized alteration or repair

work is strictly forbidden. Impr oper alteration or maintenance

may cause fire hazard, electric

shock or water leakage. Repair

work should be entrusted to cert ified person of after service.

!

!

Attention points for installation

l Ensure the drainage hose work

normally during installation.

Improper installation of drainage

can cause water leakage and

damp articles.

l DO NOT install the machine in

place where flammable gas

releases easily to avoid fire

hazard.

Attention

!

l Ensure electric leakage breaker

being installed. Electric leakage

breaker MUST be installed,

otherwise electric shock may be

caused.

! !

l If the power supply cord is

damaged, call a certified

electrician of the manufacturer

or other maintenance department

to replace it.

7

Page 9

Important Points of Safety

Attention

!

* Ensure ventilation of the room

if the machine is used with

burning facilities. Deficient

ventilation can cause oxygen

shortage.

* Check whether installation

bench of the machine is

damaged after a long period

of use. Machine on damaged

bench may fall down and cause

human injury or other damage.

Attention points for use

* In place where winds produced

by the machine can reach, donít

lay any animals or plants which

may be hurt otherwise.

* Donít put vases containing water

or other else on the unit assembly .

Otherwise, the machine may be

immersed internally and result in

bad electric insulation causing

electric shock.

* The is machine CANNOT be

used for the purpose of prese rving food, animals, plants,

precision instruments and

artwork etc., which may be

destroyed otherwise.

* DONíT lay any burning facilities

in place where winds produced by

the machine can reach. Incomplete

combustion of burning facility may

be caused otherwise.

* DONíT clean the machine with

water. Electric shock may occur

otherwise.

* DONíT put flammable spray

articles nearby or spray them to

the machine. Fire hazard may

occur otherwise.

* DONíT operate switch with wet

hand. Electric shock may occur

otherwise.

* Stop operation and shut down

manual power switch before

cleaning and maintenance.

* The power supply MUST be of

rated voltage and connected with

special electrical supply circuit.

* DONíT replace fuse with ma terial other than fuse of proper

capacity. Replacing fuse with

metal wire or copper etc. can

cause fire hazard or other faults.

8

Page 10

Operating instructions

The air conditioner has the function of POWER

FAILURE RESUME.

FAN

MODE

HEALTH

TEMP

TIMER SLEEP

FILTER RESET

4

ON/OFF

3

TIMP

ON

OFF

SWING

RESET

1

MODE SLEEP

HEALTH

CLOCK

TIMER

RESET

FAN

NEW FAN

SET

LOCK

**

(3) Fan

Press wire controller FAN button. For

each press,fan speed changes as

follows:

LOW

MID HIGH

Press remote controller FAN button.

For each press,fan speed changes as

follows:

2

CLOCK SET

ROOM

*

AM

Fan operation

Enjoy yourself by just a

gentle press.

(1) Unit start

Press ON/OFF button, unit starts.

Previous operation status appears on display.

(Not Timer setting)

Power indicator lights up.

(2) Select operation mode

Press MODE button. For each press, operation

mode changes as follows:

AUTO COOL DRY FAN

HEAT

Unit will run in selected mode.

stop display at " " FAN.

Hints

Wire controller can memorize settings in each operation mode. To run it next time just select

the operation mode and it will start with the previous setting.

No reselecting is needed.(TIMER ON/OFF needs reselecting)

In FAN mode, temp. can't be set.

LOW

MID HIGH

Unit will run at selected fan speed.

(4) Unit stop

Press ON/OFF button.

Only time and room temp remains on

LCD.All indicators go out.

9

Page 11

Operating instructions

AUTO RUN, COOL,HEAT and DRY operation

Recommendations

Use COOL in summer.

Use HEAT in winter.

Use DRY in spring,autumn and in damp climate.

TIMP

FAN

MODE

AUTO

SET

2

*

AM

TEMP

CLOCK SET

3

TIMER SLEEP

FILTER RESET

HEALTH

4

RESET

5

ON/OFF

1

(1) Unit start

Press ON/OFF button, unit starts.

Previous operation status appears on display

(Not Timer setting). Power indicator lights up.

(2) Select operation mode

Press MODE button. For each press, operation mode

changes as follows:

Press FAN button. For each press,

fan speed changes as follows:

Wire controller

LOW

ON

OFF

SWING

5

MODE SLEEP

NEW FAN

HEALTH

CLOCK

TIMER

RESET

MID HIGH

FAN SPEED

SET

LOCK

**

AUTO

AUTO

Remote controller

AUTO COOL DRY FANHEAT

Unit will run in operation mode displayed on LCD.

Stop display at your desired mode.

(3) Select temp. setting

Press TEMP button

Every time the button is pressed, temp. setting

increases 1*.

If button is kept depressed, temp.setting will

increase quickly.

Every time the button is pressed, temp. setting

decreases 1*.

If button is kept depressed, temp. setting will

decrease quickly.

(5) Unit stop

Press ON/OFF button.

Only time and room temp remains on LCD.

All indicators go out.

Vertical flap closes automatically.

Unit will start running to reach the temp. setting

on LCD.

(4) Fan speed selection

10

A

U

T

O

LOW

MID

HIGH

AUTO

Unit runs at the speed displayed on LCD.In HEAT

mode, warm air will blow out after a short period

of time due to cold-draft prevention function.

In DRY mode, when room temp. becomes 2*higher

than temp. setting, unit will run intermittently at

LOW speed regardless of FAN setting.

Hints

Wire controller can memorize each operation status.

When starting it next time, just press ON/OFF button

and unit will run in previous status.

Page 12

Operating instructions

FAN

MODE

TEMP

HEALTH

CLOCK SET

*

2

TIMER SLEEP

FILTER RESET

ON/OFF

ON

OFF

4

RESET

3

1

(3)Timer setting

Press TIME button.

Every time the button is pressed, time increases 10min.

If button is kept depressed, time will change quickly.

Every time the button is pressed, time decreases 10min.

If button is kept depressed, time will change quickly.

Time will be shown on LCD. It can be adjusted within

24hours.

(4)Confirming your setting

blank

After setting correct time, press SET button to confirm

"ON" or "OFF" stops flashing.

Time displayed: Unit starts or stops at x hour x min (ON

or OFF).

Timer mode indicator lights up.

SET

ON

AM AM

TIMER operation

Set Clock correctly before starting Timer operation.

You can let unit start or stop automatically at following time: Before

you wake up in the morning, or get back from outside or after you

fall asleep at night.

TIMER ON/OFF

(1)After unit start, select your desired

operation mode.

Operation mode will be displayed on LCD.

Power indicator lights up.

(2)TIMER mode selection

Press TIMER button to change TIMER mode.

Every time the button is pressed, display changes

as follows:

ON

Select your desired TIMER mode (ON or OFF)

OFF

SWING

HEALTH

CLOCK

2

TIMER

RESET

TIMP

ON

OFF

MODE SLEEP

NEW FAN

FAN SPEED

1

SET

4

3

LOCK

**

To cancel TIMER mode

Just press TIMER button several times until TIMER mode disappears.

Hints:

Wire controller possesses memory function, when use TIMER mode next time, just

press SET button after mode selecting if timer setting is the same as previous one.

Please close health function first before set Timer, then you can do the TIMER ON

operation.Please do not use the health function when in TIMER ON state.

1 1

Page 13

Operating instructions

FAN

MODE

TEMP

HEALTH

3

CLOCK SET

SET

ON OFF

PM

TIMER ON-OFF

(1)After unit start, select your desired

operation mode

Operation mode will be displayed on LCD.

Power indicator lights up.

2

TIMER SLEEP

*

FILTER RESET

4

AM

ON/OFF

6

RESET

5

1

SWING

HEALTH

CLOCK

2

TIMER

RESET

TIMP

ON

OFF

MODE SLEEP

NEW FAN

4

FAN SPEED

1

COMFORT

3

SET

LIGHT

6

5

LOCK

**

(2) Press TIMER button to change TIMER

(4) Time confirming for TIMER ON

mode

Every time the button is pressed, display changes as follows:

ON

ON

Select .

OFF

OFF

ON

OFF

blank

(3)Time setting for TIMER ON

Press TIME button.

Every time the button is pressed, time increases 10min.

If button is kept depressed, time will change quickly.

Every time the button is pressed, time decreases 10min.

If button is kept depressed, time will change quickly.

Time will be shown on LCD.

It can be adjusted within 24hours.

AM refers to morning and PM to afternoon.

After time setting, press TIMER button to confirm.

"ON" stops blinking, While "OFF" starts blinking.

Time displayed: Unit starts at Xhour X min.

(5)Time setting for TIMER OFF

Follow the same procedures in "Time setting for

TIMER ON".

(6)Time confirming for TIMER OFF

After time setting, press SET button to confirm

"OFF" stops flashing.

Time displayed: Unit stops at X hour X min.

To cancel TIMER mode

Just press TIMER button several times until TIMER mode disappears.

According to the Time setting sequence of TIMER ON or TIMER OFF, either Start-Stop or Stop-Start can

be achieved.

12

Page 14

Operating instructions

Comfortable Sleep

At night, before going to bed you

can press down the SLEEP button

on the controller and the airconditioner will run by the

comfortable sleeping mode to

SET

*

OFF

AM

AM

FAN

MODE

TEMP

CLOCK SET

TIMER SLEEP

FILTER RESET

TIMP

ON

HEALTH

RESET

OFF

SWING

FAN

MODE SLEEP

HEALTH

COMFORT

SET

CLOCK

TIMER

LOCK

LIGHT

RESET

make you sleep more comfortable.

ON/OFF

In cooling, dehumidifying mode

One hour after sleeping operation start, the temp. is 1* higher than the setting one. After another

hour the temp. rises 1* and then run continuously for another 6hrs' and then close. The actual

temp. is higher than the setting one which is to prevent from being too cool to your sleep.

In heating mode

One hour after start up, the temp. decrease 2* lower than the setting one. After another hour

decrease by more 2*.

The temperature will automatically rise by 1* after another 3hrs' operation, and then automatically

close after 3hrs' continuous operation. The actral temperature is lower than the setting one which

is to prevent from being too hot to your sleep.

Note:

In AUTO mode, unit will run in SLEEP function according to the operation mode.

After setting SLEEP function, it is forbidden to calibrate clock.

If the set sleep-time does not reach 8 hours, the unit will stop operation automatically after set

time is complete.

Set "TIMER-OFF" function first, then set SLEEP, and the sleep-set is performance; set TIMER-

ON function first, the sleep function can only be set before TIMER-ON; if set theSLEEP function

first, the TIMER function can not be set.

SETTING T

1 hr

decrease 2*

1 hr

decreases 2*

about 3 hrs

3 hrs

SLEEP RUN BEGINS SLEEP RUN STOPS

increase1*

Heat mode

SHUT DOWN

SLEEP RUN BEGINS

SETTING T

1 hr

1 hr

increase 1*

Cooling mode

SLEEP RUN STOPS

about 6 hrs

increase 1*

SHUT DOWN

13

Page 15

Operating instructions

1.How to use the health function (only for units

with this function)

After set the right function mode, press health button,

FAN

MODE

HEALTH

TEMP

CLOCK SET

SET

OFF

AM

TIMER SLEEP

*

FILTER RESET

AM

RESET

ON/OFF

TIMP

ON

OFF

SWING

MODE SLEEP

COMFORT

HEALTH

CLOCK

TIMER

LIGHT

RESET

conditioner has the negative ion function simultaneous, when press the health button, negative ion function could

still be operated. When the temperature of the outdoor unit is higher than 6*, oxygen pump could automatically

resume to oxygen-make function.

Power Failure Compensation (to be applied for a necessary situation)

After the power failure compensation is set, if power failure suddenly occurs while the air conditioner is working, it

will resume the previous working state when the power is supplied again.

Setting Method: When the remote controller is on (excluding timer mode and fan mode),

press the "Sleeping" button on the remote controller 10 times within 5 seconds, and after the buzzer rings 4 times,

the air conditioner will enter the state of power failure compensation.

Cancel Method: Press the "Sleeping" button on the remote controller 10 times within 5 seconds, and after the buzzer

rings 2 timer, the power failure compensation mode will be cancelled.

Notes: When a power failure suddenly occurs during the air conditioner is working after the power failure

compensation is set, if the air conditioner will not be used for a long time, please cut off the power supply to prevent

its operation from being resumed after the power is supplied again, or press the "Switch On/Off" button after the

power comes again.

Indoor unit malfunction display code of wire remote controller

Display code

Indoor unit

malfunction

Display code

Indoor unit

malfunction

Display code

Indoor unit

malfunction

Float switch or water

motor abnormal

Gas temperature

sensor is abnormal

The communication between the wire

remote controller and indoor unit

control board is abnormal

E0 E1

Outdoor unit

abnormal

E4 E5 E7

The communication between indoor 846

chip and communication chip is abnormal

E8

Outdoor unit malfunction display code of wire remote controller

(When the wire remote controller display E1,can check the indoor unit control board LED1 or the outdoor unit control

board LED1(AU242)*Outdoor unit control board LED(ALARMA or ALARMB)*AU422*.

LED flaching

Outdoor unit

malfunction

Display code

Outdoor unit

malfunction

Display code

Outdoor unit

malfunction

flaching once

Outdoor unit defrost

temp. sensor is abnormal

Outdoor unit AC

over-current protection

Compressor Discharge

temperature overheat

protection

Outdoor unit environment

temp. sensor is abnormal

flaching 7 timersflaching 6 timers flaching 10 timersflaching 9 timers

Outdoor unit DC voltage

is insufficient protection

The communication between

outdoor unit 857 and communication

chip is abnormal

remote controller or wire controller displays ì î,

oxygen pump or negative ion generator starts up to apply

FAN

oxygen or negative ion to indoor unit. Press the button

again,the sign ì î disappeared and negative ion generator

SET

stops working. After all health function of the indoor unit

being fully canceled, oxygen pump stopped.

LOCK

CAUTION:

When the temperature of the outdoor unit is lower than 4*,

oxygen pump is automatically stopped, if press health button

just then, oxygen pump could not start up. But if the air

:

E2

Setting running mode is different

with outdoor running mode

The communication with electronic

expansion box is abnormal

E9

The communication

between indoor and

outdoor unit is abnormal

flaching twice flaching 4 timersflaching 3 timers

Outdoor unit suction

temp. sensor is abnormal

IPM protection

flaching 12 timersflaching 11 timers flaching 13 timers

Outdoor unit system over-high

pressure protection

Liquid temperature

sensor is abnormal

Water temp. sensor

is abnormal

Outdoor unit discharge

temp. sensor is abnormal

Outdoor unit

EEPROM abnormal

E3

EB

14

Page 16

Troubleshooting

The following cases are not troubles.

Water flow sound is heard.

"Hua-Hua"

A sound of "Pi-Pa" is generated.

Smells are given off.

During operation, mist or steam are

blown out.

During operation, the air conditioner may

sometimes exhibit a sound of "clatter" or

"rumble". This is the common sound of

refrigerant flow but not a trouble.

This is caused by the thermal expansion

or cold shrinkage of plastics.

Sometimes there are smells in the air flow

from the indoor unit. This is caused by the

smell of cigarettes or paint coatings inside

the unit.

During COOL or DRY operation, the unit

may blow out a thin mist. This is the condensate water mist caused by sudden cooling of the indoor air blown out from the

indoor unit.

During COOL operation, it automatically

changes to FAN mode.

The system couldnt be re-started immediately

after turning off.The unit can't start?

In order to prevent frost accumulation on

the heat exchanger in the indoor unit,

sometimes it will automatically transfers

to FAN mode, but soon will return to

COOL mode.

This is due to the systems self-protection

function, which prevents it from restarting

in 3 min after stops.

Please wait

for 3 min.

15

Page 17

Troubleshooting

During DRY operation, there is no air

sent out or fan speed cant be changed.

In HEAT mode, the outdoor unit

generates water or steam.

This occurs during removal of the frost

(in defrosting operation) on the radiator

of outdoor unit.

Defrost operation

In HEAT mode, the indoor fan still

keeps running even the unit operation

stops.

After the unit stops, the indoor fan will

continue to run for a while to eliminate

residual heat.

Before asking for after-service to an authorized service center, please check your air

conditioner for the following items

Is power on/off switched on?

ON

OFF

The power on/off switch is

not at position of "ON".

The system couldnt start

Is the power supply line

normal?

Power

failure?

16

Is current leakage breaker

triggered?

Please do immediately

cut off power supply and

contact the authorized

service center.

Page 18

When fault occurs

Poor cooling or heating

Is the operation controller

adjusted as required?

Is there any other heat

source in the room?

Are there any obstructs

before the air inlet or outlet?

Poor cooling

Is there any direct sunlight

into the room?

Is there any door or window

left open?

Are there too many people

in the room?

When the air conditioner does not operate properly after you have checked the above mentioned items or when the

following phenomenon is observed, stop the operation of the air conditioner and contact your sales dealer.

The fuse or breaker often shuts down.

Water drops off during cooling operation.

There is a irregularity in operation or abnormal sound is audible.

When the CHECK lamp flickers, an irregularity has occurred in the air conditioner.

17

Page 19

Notice to users

Notice to users

l To ensure proper operation of the system, the user shall follow this instruction manual

to install the unit.

l When handling the air conditioner, please be care not to scratch the case surface.

l This instruction manual describes the installation method aided with the installation

tools specified by manufacturer .

l The maximum length of connection pipe is 50 m, and the maximum difference between

levels of indoor unit and outdoor unit shall be 30 m.

l Please keep the installation instruction manual well for reference in maintenance or

changing installation position.

Information about application

Adjust your desired air flow direction Avoid direct sunlight and gas flow

Keep appropriate room temperature

Too cool or too warm wont benefit

to your health, but causes an increased energy consumption.

Maximum

temperature

Caution: After installation, please confirm no refrigerant leaks.

Effectively use the timer Using

TIMER mode you can enjoy a

comfortable room temperature

when wake up or come back home.

18

Page 20

Installation precautions

Before installing, do read this"Safety precautions" carefully to guarantee the proper installation.

The below attentive matters are divided into"

wrong installation occur, it is very possible death and severe injury and other serious accidents will

happen. For those items are listed in

part can also cause serious accidents. Above all, both the two parts are very important contents

related to safety, so they must be obeyed.

After finishing the installation work, do test run to verify everything is normal. After that please

explain the using and maintenance methods to the user. Additionally, give this installation manual

and operation manual to the user and ask them to keep it properly.

Warning

!

The distributing shop, where you bought the air conditioner, or the specified shops shall do the

installation work. If you do the installation work by yourself, the improper installation will cause

water leakage, electric shock fire and other accidents.

The installation work shall be in line with what the installation manual specified. If installation

is not proper, water leakage, electric shock, fire and other accidents will occur.

Install the air conditioner to a place where can definitely stand its weight. Places not firm enough

will cause drop down of unit resulting in body hurt.

The installation work shall be preventive to typhoon and earthquake. If the installation work is

not met with the requirements, overturn of the unit will occur resulting in accidents.

The wiring work shall be done by a qualified person and referred to the" technical standard of

electric equipment", "indoor wiring regulation"and what the manual specified. Do use

special circuit. If the capacity of the circuit is not enough or bad work, electric shock, fire and other

accidents will happen.

Using the specified cable to do wiring work and connecting firmly and properly. Fix the connecting

part of the terminals to prevent it from the external force.Improper connection and fixing will cause

heating and fire etc. accidents.

Wiring shall be kept in correct shape avoiding extrusion. After installation, the electric box cover

and the external panel shall not nip the wire. Improper installation will cause heating and fire etc.

accidents.

When setting or moving the air conditioner do not let the air and things alike get into the

refrigeration system except the specified refrigerant (R407C). If air and other things enter, abnormal high pressure will occur, which easily cause break and body injuries etc. Accidents.

When installing, do use the accessories or specified parts. If not using the parts specified by our

company, water leakage, electric shock, fire and refrigerant leakage will occur.

Do not lead the drainpipe to drain where the sulfur gas may be involved. Otherwise, the poisonous

gas will enter into the indoor.

During installation, if refrigerant leakage occurs, do the ventilation work immediately. As soon as

the refrigerant gas meets fire, poisonous gas will be produce. If the refrigerant gas enters into room

and meet the air blowing heater, heater or stove etc. fire source, the poisonous gas may be produced.

After installation, confirm there is no leakage of refrigerant.

Do not install the unit in a place where the combustible gas may be leaked. In any case the

combustible gas leaks and accumulated around the unit, fire accident will occur.

Do heat insulation work to the refrigerant gas pipes and liquid pipes to reach the purpose of heat

preservation. If the heat insulation measure is not sufficient, water generated by condensing dew

will drip leading to wet the floor and indoor articles.

!

Do grounding work.Do not connect the grounding wire to gas pipe,tap,lighting rod or telephone

line.Improper grounding will cause electric shock.

After electric installation,power on them to do electric leakage test.

!

Warning

"!Warning"

Note

" and "

part. But even the items listed in "

!

two parts. When the

Note"

!

Note"

19

Page 21

Installation precautions

! Attention

This description does not address to all possible cases. For new requirement and query, please

consult the regional sales center of Haier Air Conditioner General Co., Ltd.

! Warning

This instruction manual must be read carefully before beginning of installation, improper installation may cause accidents and thus bring about machine damage and personal casualty.

Installing tools

1. Screw driver 6. Pipe cutter 10. Leakage detector or soap water

2. Hacksaw 7. Pipe expander 11. Measuring tape

3. Driller of 70mm diameter 8. Knife 12. Scraper

4. Spanner (diameter 17, 27mm) 9. Pinchers 13. Refrigeration oil

5. Spanner (14, 17, 19, 27mm)

20

Page 22

Installation procedure

Electrical requirements

l The power supply shall be connected from the outdoor side. (For models with electric-aided

heating function, the power supply to the indoor unit shall be connected at the indoor side

The power cord size is 3 G(1.0-1.5)mm2, type of H05RN-F).

l A separate power circuit shall be supplied and connected by a qualified electrician according

to the wiring rules specified in the corresponding national standard.

l A current leakage breaker must be installed.

l The connection method of power cord is " Y " type. If the power flexible cord is damaged, it

shall be replaced by the manufacturer or its service department or similar qualified technician

so as to avoid risks.

l Power cord plug: L should be connected to the live wire, N should be connected to the neutral

wire and to the ground wire.

l Connection wire size: 3 G (1.0-1.5) mm2, type of H05RN-F.

l Signal transmission wire size:H05RN-F 2 x (0.75-1.5) mm2 (shielded wire).

l Power cord, connection wire and signal wire shall be provided by the user.

Pipe expansion dimensions as follows:

Specification

Liquid pipe

Liquid pipe

Gas pipe

Gas pipe

Pipe diameter ÿ Size A (mm)

6.35 mm (1/4") 0.8 ~ 1.5

9.52 mm (3/8") 1.0 ~ 1.8

12.7 mm (1/2") 1.2 ~ 2.0

15.88 mm (5/8") 1.4 ~2.2

Pipe cutting and expanding

If the pipe is too long or the flare is damaged,

it needs to be cut or expanded.

1. Pipe cutting 2. Removing burrs

Correct

3.Insertion nut 4. Pipe expansion

A

Pipe expander

Incorrect

Slope Damage Bur Partial Overlong

21

Page 23

Installation procedure

Choosing the installation location

! Caution

Please do not install the unit in places where flammable gases may be leaked. In case

that gas is leaked and accumulated around the unit, it may cause dangers of fire etc.

The indoor unit shall be installed at locations where cold and hot air could evenly circulated.

The following locations should be avoided:

l Places with rich saline matters (seaside regions).

l Places with plenty of gas sulfides (mainly in warm spring areas where the copper tube and

braze weld is prone to corrosion).

l Locations with much oil (including mechanical oil) and steam.

l Locations using organic solvents.

l Places where there are machines generating HF electromagnetic waves.

l Positions adjacent to door or window in contact with high-humidity external air. (Easy to

generate dew).

l Locations frequently using special aerosols.

l Less than 2.7 meters above the floor for air outlet opening.

Indoor unit

1. Select suitable places the outlet air can be sent to the

entire room, and convenient to lay out the connection

pipe, connection wire and the drainage pipe to outdoor.

2. The ceiling structure must be strong enough to support

the unit weight.

3. The connecting pipe, drain pipe and connection wire

shall be able to go though the building wall to connect

between the indoor and outdoor units.

4. The connecting pipe between the indoor and outdoor

units as well as the drain pipe shall be as short as possible.

(See Figure 1)

5. If its necessary to adjust the filling amount of the

refrigerant, please refer to the installation manual

attached with the outdoor unit.

6. The connecting flange should be provided by the user

himself.

Important

An access port must be provided during installation of indoor unit for maintenance.

Fig 1

22

Page 24

Installation procedure

! Warning

Installation of indoor unit

l The unit shall be installed at locations enough

to support the unit. If not, the air conditioner

may fall down and cause personal injury.

After selecting the unit installation location, proceed the following steps:

1. Drill a hole in the wall and insert the connecting pipe and wire through a PVC wall-through tube

purchased locally. The wall hole shall be with a outward down slope of at least 1/100. (See

Figure 2)

2. Before drilling check that there is no pipe or reinforcing bar just behind the drilling position.

Drilling shall avoid at positions with electric wire or pipe.

3. Mount the unit on a strong and horizontal building roof. If the base is not firm, it will cause

noise, vibration or leakage (see Figure 6).

4. Support the unit firmly.

5. Change the form of the connection pipe, connection wire and drain pipe so that they can go

through the wall hole easily.

l The unit shall be installed according to the

specifications to resist to strong wind and

earthquake. Improper installation may cause

dangers of unit falling down etc.

Figure showing installation dimensions: (unit:mm)

650

223

Fig 2

223

1100

AE092FCAJA

AE092FCBJA

AE182FCAJA

AE182FCBJA

23

Page 25

Installation procedure

Installation of indoor unit

l When installing the ceiling concealed type indoor unit, a specially designed return air

bellows shall be installed, as shown in Figure 3, Figure 4.

Figure 3

Figure 4

Ceiling

Air outlet grille

Installing building roof

*0.5mor*5m

Air supply

Air outlet duct

Unit

Detail A

A

Return air bellows

Return air

Return air bellows

Air supply

No obstacles

within 1 m

Unit

Return air

Each air return and supply duct should fix to the floor precast slab by using an iron stand. Use glue to

l

seal the interface closely. Recommend the distance between the air return duct and the wall is more than

150mm.

The distance between air duct outlet and air conditioner outlet is according to the length of actually installed

l

air duct and in service behavior of the static pressure terminal: Installation sketch map for long and short air

duct is showed below, when connect to short air duct, using low static terminal (terminal color is write), the

distance between air duct outlet and air conditioner outlet is no more than 0.5m; when connect to long air duct,

using high static terminal (terminal color is red), the distance between air duct outlet and air conditioner outlet

could be within 5m at this point.

sling dog

drain piping

air return duct

air return shutter

Drain piping of condensed water should keep a downhill grade of 1% or more. Use insulating pipe to cover

l

transition

air duct

air outlet

duct

air diffuser

joint of air diffuser

the drain piping of condensed water to keep warmth.

As figure shown, suspend and install the unit.

l

M8 broad foundation bolt

M8 suspension screw

M8 broad lock ring

M8 nut

Figure 5

Unit

24

Page 26

Installation procedure

Installation of indoor unit

Installation for air duct of indoor unit

1. Installation for air supply duct

This type of unit uses circular air duct with its caliber of 180mm.

An additional transitive air duct is necessary for the circular air duct to connect to the air

supply inlet. It should be also connected to its respective air diffuser separately. See

Fig.1. Adjust the wind speed of each air diffuser outlet to keep in line on the whole, so

as to meet a demand of the air conditioner in the room.

Indoor unit

flexible joint

or static pressure box

Fig1: Duct connected

transitive air duct

circular air duct

joint of air diffuser

air diffuser

*** mm

2. Installation for air return duct

Use rivets to connect the air return duct to the air return inlet of the indoor unit. The

other end connects to the air return shutter. as shown in Fig.2.

air return

shutter

air return

duct

Fig2: Duct return connected

indoor unit

rivet

3. Air duct insulation

Insulation layer is needed for air supply and return duct. First, paste a glue nail to the

air duct, and then attach the insulation cotton that has a tinfoil layer and use the glue

nail cover to fix. Finally, seal the air duct interface with tinfoil adhesive tape closely.

as shown in Fig3.

galvanized

board

glue nail

insulating

fabric

tinfoil

glue nail cover

Fig3

25

adhesive tape

Page 27

Installation procedure

Installation of indoor unit

Installing the suspension screw:

Use M8 or M10 suspension screws (4, prepared in the field) (when the suspension screw

height exceeds 0.9 m, M10 size is the only choice). These screws shall be installed as

follows with space adapting to air conditioner overall dimensions according to the original

building structures.

Wooden structure

A square wood shall be supported by the beams and then set the suspension screws.

Square wood

Suspension

screw

New concrete slab

To set with embedded parts, foundation bolts etc.

Knife embedded part

Guide plate embedded part Pipe suspension foundation bolt

Original concrete slab

Use hole hinge, hole plunger or hole bolt.

Steel reinforcement structure

Use steel angle or new support steel angle directly.

Beam

Iron reinforcement

Foundation bolt

Hanging bolt

Suspension screw

Support steel angle

Hanging of the indoor unit

l Fasten the nut on the suspension screw and then hang the suspension screw in the T

slot of the suspension part of the unit.

l Aided with a level meter, adjust level of the unit within 5 mm2.

26

Page 28

Installation procedure

1. Remove upper part of wire controller

Installation of remote controller

Upper part of wire

controller

Remove upper part of wire controller

by press.

Lower part of wire

PCB is mounted on lower part of wire

controller

controller, be careful not to damage it.

2. Install wire controller

(1) For exposed installation,

use 2 wood screws (accessory).

(2) For recessed installation,

use 2 wood screws (accessory).

Note

Try as far as possible a flat surface for installation.

Don't use excessive force when tightening screws,

or lower part might got deformed.

3. Indoor unit wiring

Connect terminals (A,B,C,D) on lower part of wire controller to terminals (A,B,C,D) on

PCB of indoor unit.

No

1

2

3

4

Symbol

A

B

C

D

colour

White or Green

Red

Yellow

control

contents

12V

Grd

COM

control

Hint

When make wiring, please keep a distance

between wires and power supply cord.

Wire size

Use shielede wires for telecommunication

Cord kind

Size

Shield wire (4 core) (refer to Hint 3,4)

0.33mm

2

between wire controller and indoor unit;

indoor unit and outdoor unit. Ground the

shield on one side.

Otherwise misoperation because of noise

Hint

Tread surface of the terminal well so that

shielding may not contact other part.

may occur.

Signal wire is self-provided.

4. Replace the upper part of wire controller

Be careful not to press the wiring.

ground

Upper part of

wire

wiring from

A

C

B

D

Lower part of

wire

Shielded wire

Hint

1. Switch box and cord for wiring are not supplied.

2. Don't touch PCB with hand.

27

Page 29

Installation procedure

Drain pipe

! Caution

l In order to drain water normally, the drain pipe shall be processed as specified in

the installation manual and shall be thermal insulated to avoid dew generation.

Improper hose connection may cause indoor water leakage.

Requirements

l The indoor drain pipe shall be thermal insulated.

l The connection part between the drain pipe and the indoor unit shall be insulated so as to

prevent dew generation.

l The drain pipe shall be slant downwards (greater than 1/100). The middle part shall not be

of S type elbow, otherwise abnormal sound will be produced.

l The horizontal length of the drain pipe shall be less than 20 m. In case of long pipe, suppo rts shall be provided every 1.5 ñ 2m to prevent wavy form.

l Central piping shall be laid out according to the following figure.

l Take care not to apply external force onto the drain pipe connection part.

1.5m~2m

Insulation

(supplied by the user)

To the largest (app. 10cm)

Down slope above 1/100

Support

Down slope

above 1/100

VP30

S type elbow

Pipe and insulation material

Pipe

Insulation

Rigid PVC pipe VP31.5mm (internal diameter)

Foamed PE with thickness above 7mm

Hose

Drain pipe size: ÿ19.05mm2 (3/4") PVC pipe

The hose is used for adjusting the off-center and angle of the rigid PVC pipe.

l Directly stretch the hose to install without making any deformation.

l The soft end of the hose must be fastened with a hose clamp.

l Please apply the hose on horizontal part

Hose Hose clamp

Insulation treatment:

l Wrap the hose and its clamp until to the

indoor unit without any clearance with

insulating material, as shown in the figure.

Wall

Outside

Slant

Drain pipe (supplied

by the user)

Drain confirmation

Subsidiary insulation

Insulation

Rigid PVC pipe

During trial run, check that there is no leakage at the pipe connection part during water

draining even in winter.

28

Page 30

Installation procedure

Refrigerant piping

! Caution

l In installation, if there is refrigerant gas leakage, please take ventilation measures

immediately. The refrigerant gas will generate poisonous gas upon contacting fire.

l After installation, please verify that there is no refrigerant leakage. The leaked re frigerant gas will produce poisonous gas when meeting fire source such as heater

and furnace etc.

Allowable pipe length and drop

These parameters differ according to the outdoor unit. See the instruction manual attached

with the outdoor unit for details.

Pipe material and size

Pipe material

Model

Pipe size

(mm)

Supplementary refrigerant

R22*AE182FCAJA*AE182FCAJA

R407C*AE182FCBJA*AE182FCBJA

The refrigerant supplementation shall be as specified in the installation instructions

attached with the outdoor unit. The added refrigerant shall be R407CorR22.

The adding procedure shall be aided with a measuring meter for a specified amount

of supplemented refrigerant

Requirement

l Overfilling or underfilling of refrigerant will cause compressor fault. The amount of the

added refrigerant shall be as specified in the instructions.

Connection of refrigerant pipe

Conduct flared connection work to connect all refrigerant pipes.

l The connection of indoor unit pipes must use double spanners.

l The installing torque shall be as given in the following table.

Phosphorus deoxidized copper seamless pipe (TP2) for air conditioner

Gas side

Liquid side

AE092FCAJA

AE092FCBJA

ÿ9.52

ÿ6.35

AE182FCAJA

AE182FCBJA

ÿ15.88

ÿ9.52

Connecting pipe

O.D.(mm)

ÿ6.35

ÿ9.52

ÿ12.70

ÿ15.88

Installing torque

(N-m)

11.8 (1.2kgf-m)

24.5 (2.5kgf-m)

49.0 (5.0 kgf-m)

78.4 (8.0 kgf-m)

Increased installing

torque (N-m)

13.7 (1.4 kgf-m)

29.4 (3.0 kgf-m)

53.9 (5.5 kgf-m)

98.0 (10.0 kgf-m)

29

Double-spanner

operation

Page 31

Installation procedure

Vacuum pumping

With a vacuum pump, create vacuum from the stop valve of the outdoor unit.

l Emptying with refrigerant sealed in the outdoor unit is absolutely forbidden.

Open all valves

Open all the valves on the outdoor unit.

Gas leakage detection

Check with a leakage detector or soap water that if there is gas leakage at the pipe

connections and bonnets.

Insulation treatment

Conduct insulation treatment on both the gas side and liquid side of pipes respectively.

During cooling operation, both the liquid and gas sides are cold and thus shall be insulated

so as to avoid dew generation.

l The insulating material at gas side shall be resistant to a temperature above 120*.

l The indoor unit pipe connection part shall be insulated.

Refrigerant piping

Indoor unit

The notch upward (Attached detail view)

Field piping side

Subsidiary insulation tube

30

Page 32

Installation procedure

! Warning

l The electric wiring work shall be conducted by qualified electricians according to the install ation instructions. A separate power circuit shall be used. Insufficient power cord amperage

or improper wiring will cause danger of electric shock or fire.

Electric wiring

!

l During wiring connection, the power cord shall be of the specified cable and reliably fastened

so that external forces applied to the cable wouldnt transfer to the terminals. Improper conne ction or fastening will cause danger of heating, fire etc.

The power cord must be fitted with a grounding wire.

l Grounding shall be made as specified. Unreliable grounding will cause electric shock. The g rounding wire shall not be connected to the gas pipeline, water pipeline, thunder arrestor and

telephone wire

!

!

! Caution

!

l A current leakage breaker shall be installed, otherwise it electric shock would happen easily.

l If the power cord is damaged, it must be replaced by the manufacturer or its service center or

similar personnel to avoid risks. The power supply to the indoor unit shall be laid in comply ing with the operational instruction manual.

l The electric wiring shall avoid contacting with the high temperature part of the piping so as

to prevent the cable insulation melts and cause dangers.

l After connected on the terminal block, the wires shall be bent to U form and then fastened

with wire clip.

l The control wiring and refrigerant piping may be laid and fastened together.

l Before completion of vacuum pumping of the refrigerant pipe system, do not electrify the in-

door unit.

l The power cord of the indoor unit and connection wiring between indoor and outdoor units

shall be laid out according to the operational instruction manual of the indoor unit.

l The connection of the power cord shall comply with the local regulations.

31

Page 33

Installation procedure

Electric wiring

Wiring connection method : (the wiring diagram is attached inside the machine)

1) Ring terminal connection method

If there is a ring at the end of the connection wire,

the wire connection method is as shown in the right

figure. Remove the terminal screw and insert it

through the ring at the connection wire end, then

connect to the terminal board and fasten the screw.

2) Straight terminal connection method

If there isnt a ring at the end of the connection wire,

the connection method shall be: loosen the terminal

screw, insert the connection wire end completely

into the terminal board and fasten the screw. Pull the

connection wire outwards slightly to confirm it is

clamped tightly.

3) Clamping method of the connection wire

After wire connection is finished, the connection wire

must be pressed tightly with wire clips, which shall

apply to the outer sheath of the connection wire.

Connection method

for ring terminal

Wire connection for built-in indoor unit

l Insert from outside the connection wire and signal transmission wire through the wall hole

with pipeline already arranged.

l Pull out the front ends of connection wire and signal wire and make a circle on the signal

wire.

l Connect the connection wire according to the connection method and indoor and outdoor

wiring diagram.

l Pull the connecting conductor outwards slightly to confirm it is clamped tightly.

l Connect the plug for connecting the signal wire with the plug of the signal wire connected

from the indoor unit.

l After wire connection is finished, install wire clips using the same method for connection

wire clamping.

Note: When connecting the indoor unit and the outdoor unit, please do connect the wires

with the same color terminals.

Notes:

l Before connecting the conductors between indoor unit and outdoor unit, check for the nu mber on the indoor and outdoor units connecting terminals. Connect the terminals with the

same color and number with a wire.

l Wrong connection would damage the controller of the air conditioner or the machine cou ldnt operate.

l Do not connect the connection wire and signal wire with the same cable. They shall be co nnected respectively to ensure system normal operation.

32

Page 34

Installation procedure

Field setting

Field setting

Field setting the unit number

In order to realize central control of the MRV air conditioning system, its necessary to set

the indoor unit number (control address).

Indoor unit number setting

Indoor unit number setting switch and confirmation of the settings.

There is a 4-position dial switch for setting the indoor unit number on the computer board

of the indoor unit.

Setting way is as follows:

Before connecting the power supply, please set the indoor unit number manually according

to the following table

Matrix of the dial switch and indoor unit number

Position 1 Position 2 Position 3 Representing unit number

Example:

Setting for No. 2 indoor unit Disabled

0 0 0 1

1 0 0 2

0 1 0 3

1 1 0 4

0 0 1 5

1 0 1 6

1 0 0

Pos.1

Pos.2 Pos.3 Pos.4

: 0

: 1

33

Page 35

Wrap the connection pipe, the drain pipe and the connection wire together with PVC tape.

Loading...

Loading...