Page 1

No. 0150502676

Please read this manual carefully before using this air conditioner

Please keep this manual safely for future use

DUCT TYPE 20Pa

INDOOR UNIT

ON-OFF

INVERTER

AD122ALERA

AD182ALERA

AD242ALERA

OPERATION MANUAL

INSTALLATION MANUAL

EN

MANUALE DI ISTRUZIONI

MANUALE DI INSTALLAZIONE

IT

MANUEL D’INSTRUCTIONS

MANUEL D’INSTALLATION

FR

BEDIENUNGSANLEITUNG

INSTALLATIONSANLEITUNG

DE

MANUAL DE INSTRUCCIONES

MANUAL DE INSTALACIÓN

ES

R410A UNITARY SMART

ALEAA

AD182ALEAA

AD242ALEAA

AD122

Page 2

Page 3

AD122ALEAA AD182ALEAA AD242ALEAA AD122ALERA AD182ALERA AD242ALERA

CE

Tutti i prodotti sono conformi alle seguenti normative europee:

- Direttiva 73/23/EEC Basso Voltaggio

- Direttiva 2006/95/EC Basso Voltaggio

- Direttiva 89/336/EEC Compatibilità elettromagnetica

ROHS

Il prodotto è conforme alla normativa 2002/95/EEC sulla restrizione d’uso di

sostanze inquinanti negli apparecchi elettrici ed elettronici.

WEEE

Informativa al consumatore come previsto dalla normativa europea

2002/96/CE riguardante i rifiuti di apparecchiature elettriche ed elettroniche.

SPECIFICHE DI SMALTIMENTO:

Il climatizzatore è contrassegnato con questo simbolo,

ciò significa che i prodotti elettrici ed elettronici non

possono essere smaltiti insieme ai rifiuti domestici non

differenziati. Non cercare di demolire il sistema da soli:

la demolizioni dei sistemi di condizionamento, nonché il

recupero del refrigerante, dell’olio e di qualsiasi altra

parte devono essere eseguiti da un installatore qualifi-

cato in conformità alla legislazione locale e nazionale

vigente in materia.I climatizzatori devo essere trattati presso una struttura specializzata nel riutilizzo, riciclaggio e recupero dei materiali. Il corretto smaltimento del prodotto eviterà le possibili conseguenze negative all’ambiente e alla

salute dell’uomo. Per maggiori informazioni contattare l’installatore o le autorità locali. Le batterie devono essere tolte dal telecomando e smaltite separatamente conformemente alla legislazione locale e nazionale vigente in materia.

CONFORMITÀ ALLE DIRETTIVE EUROPEE PER I MODELLI:

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

IT

AD122ALEAA AD182ALEAA AD242ALEAA AD122ALERA AD182ALERA AD242ALERA

CE

All the products are in conformity with the following European provision:

- Low Voltage Directive 73/23/EEC

- Low Voltage Directive 2006/95/EC

- Electromagnetic CompatibilitY 89/336/EEC

ROHS

The products are fulfilled with the requirements in the directive 2002/95/EEC of the

European parliament and of the council on the Restriction of the use of Certain Hazardous Substances in Electrical and Electronic Equipment (EU RoHS Directive)

.

WEEE

In accordance with the directive 2002/96/CE of the European parliament,

herewith we inform the consumer about the disposal requirements of the

electrical and electronic products.

DISPOSAL REQUIREMENTS:

Your air conditioning product is marked with this sym-

bol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dis-

mantling of the air conditioning system, treatment of

the refrigerant, of oil and of other part must be done

by a qualified installer in accordance with relevant

local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use,

recycling and recovery. By ensuring this product is disposed of correctly, you

will help to prevent potential negative consequences for the environment and

human health. Please contact the installer or local authority for more information. Battery must be removed from the remote controller and disposed of

separately in accordance with relevant local and national legislation.

EUROPEAN REGULATIONS CONFORMITY FOR THE MODELS:

EN

AD122ALEAA AD182ALEAA AD242ALEAA AD122ALERA AD182ALERA AD242ALERA

CE

Tous les produits sont conformes aux directives européennes suivantes:

- Directive 73/23/CEE Basse tension

- Directive 2006/95/CE Basse tension

- Directive 89/336/CEE Compatibilité électromagnétique

ROHS

L'appareil est conforme à la directive 2002/95/CEE relative à la limitation de

l'utilisation de certains substances dangereuses dans les équipements électriques et électroniques.

DEEE (WEEE)

Information au consommateur comme le prévoit la directive européenne

2002/96/CE relative aux déchets d'équipements électriques et électroniques.

SPECIFICATIONS POUR L'ELIMINATION:

Ce pictogramme, apposé sur le climatiseur, signifie

que les équipements électriques et électroniques ne

peuvent pas être éliminés avec les déchets ménagers

non triés. Ne pas essayer de démanteler l'équipement

soi-même: le démantèlement des systèmes de clima-

tisation, ainsi que la récupération du frigorigène, de

l'huile et de toute autre partie doivent être effectués

par un installateur qualifié conformément à la législation locale et nationale en vigueur en la matière. Les climatiseurs doivent être

traités dans un centre spécialisé dans la réutilisation, le recyclage et la valorisation des matériaux. L'élimination correcte de ces appareils permet d'éviter les effets nocifs sur l'environnement et la santé humaine. Pour plus de

renseignements contacter l'installateur ou les autorités locales. Les piles doivent être retirées de la télécommande et éliminées séparément, conformément à la législation locale et nationale en vigueur en la matière.

CONFORMITÉ AUX DIRECTIVES EUROPÉENNES POUR LES MODÈLES:

FR

Page 4

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

AD122ALEAA AD182ALEAA AD242ALEAA AD122ALERA AD182ALERA AD242ALERA

CE

Alle Produkte erfüllen die folgenden europäischen Richtlinien:

- Niederspannungsrichtlinie 73/23/EWG

- Niederspannungsrichtlinie 2006/95/EG

- EMV-Richtlinie 89/336/EWG

ROHS

Das Produkt erfüllt die Richtlinie 2002/95/EWG zur Beschränkung der Verwendung bestimmter gefährlicher Stoffe in Elektro- und Elektronikgeräten.

WEEE

Verbraucherinformation laut europäischer Richtlinie 2002/96/EG zu Elektround Elektronik-Altgeräten.

HINWEISE ZUR ENTSORGUNG:

Das Klimagerät ist mit diesem Symbol gekennzeich-

net, das darauf hinweist, dass Elektro- und Elektronik-

geräte getrennt vom Hausmüll entsorgt werden müs-

sen. Verschrotten Sie die Anlage nicht selbst: die Ver-

schrottung von Klimaanlagen, sowie die Rückgewin-

nung des Kältemittels, des Öls und aller sonstigen Tei-

le müssen durch einen qualifizierten Installateur in

Übereinstimmung mit den einschlägigen geltenden

örtlichen und nationalen Vorschriften erfolgen. Die Klimageräte müssen bei

einem Unternehmen entsorgt werden, das auf die Verwertung, das Recycling

und die Rückgewinnung der Materialien spezialisiert ist. Die richtige Entsorgung des Produkts hilft negative Auswirkungen auf Umwelt und Gesundheit

zu vermeiden. Für weitere Informationen wenden Sie sich bitte an den Installateur oder die örtlichen Behörden. Die Batterien müssen aus der Fernbedienung entfernt und in Übereinstimmung mit den einschlägigen geltenden örtlichen und nationalen Vorschriften getrennt entsorgt werden.

ÜBEREINSTIMMUNG MIT DEN EUROPÄISCHEN RICHTLINIEN FÜR DIE MODELLE:

DE

AD122ALEAA AD182ALEAA AD242ALEAA AD122ALERA AD182ALERA AD242ALERA

CE

Todos los productos están en conformidad con las siguientes Normativas

Europeas:

- Bajo Voltaje directiva 73/23/EEC

- Bajo Voltaje directiva 2006/95/EC

- Compatibilidad electromagnética 89/336/EEC

ROHS

Los productos cumplen los requisitos de la directiva 2002/95/EEC del parlamento Europeo y el consejo regulador Del uso de materiales peligrosos en

equipamientos eléctricos Y electrónicos. (EU RoHS Directiva).

WEEE

De acuerdo con la directiva 2002/96/CE del parlamento Europeo, Informamos al consumidor acerca del reciclage de los productos Electrónicos y

eléctricos.

REQUISITOS PARA LA ELIMINACIÓN:

Su acondicionador de aire está marcado con este

símbolo. Esto significa que los productos eléctricos y

electrónicos no deben mezclarse con el resto de resi-

duos domésticos no clasificados.

No intente desmontar el sistema usted mismo: El des-

mantelamiento del acondicionador de aire, así como

el tratamiento del refrigerante, aceite y otros compo-

nentes, debe ser efectuado por un instalador competente de acuerdo con las normas locales y nacionales aplicables. Los acondicionadores de aire deben ser tratados en instalaciones especializadas para

su reutilización, reciclaje y recuperación. Al asegurarse de desechar este producto de la forma correcta, està contribuyendo a evitar posibles consecuencias negativas para el entorno y para la salud de las personas. Contacte, por

favor, con el instalador o con las autoridades locales para obtener más información. Las pilas del control remoto deben extraerse y eliminarse por separado y de acuerdo con la normativa local y nacional aplicable.

CONFORMIDAD EUROPEA DE LAS REGULACIONES PARA LOS MODELOS:

ES

Page 5

Questo prodotto contiene gas fluorurati ad effetto serra inclusi nel Protocollo

di Kyoto. Non liberare tali gas nell’atmosfera.

Tipo di refrigerante: R410A

Valore GWP*: 1975

*

GWP = potenziale di riscaldamento globale

Compilare con inchiostro indelebile,

• 1 la carica di refrigerante di fabbrica del prodotto

• 2 la quantità di refrigerante aggiuntiva nel campo e

• 1+2 la carica di refrigerante totale

sull’etichetta di carica del refrigerante fornita con il prodotto

L’etichetta compilata deve essere collocata in prossimità della portata di carica del prodotto (ad esempio, nell’interno del coperchio della valvola d’intercettazione).

A contiene gas fluorurati ad effetto serra inclusi nel protocollo di Kyoto

B carica di refrigerante di fabbrica del prodotto: vedi targhetta con il nome

dell’unità

C quantità di refrigerante aggiuntiva nel campo

D carica di refrigerante totale

E unità esterna

F cilindro del refrigerante e collettore di carica

INFORMAZIONI IMPORTANTI SUL REFRIGERANTE UTILIZZATO

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

This product contains fluorinated greenhouse gases covered by the Kyoto

Protocol. Do not vent into the atmosphere.

Refrigerant type: R410A

GWP* value: 1975

*

GWP = global warming potential

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field and

• 1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product charging

port (e.g. onto the inside of the stop valve cover).

A contains fluorinated greenhouse gases covered by the Kyoto Protocol

B factory refrigerant charge of the product: see unit name plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

IT

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

EN

Ce produit contient des gaz à effet de serre fluorés encadrés par le protocole de Kyoto. Ne pas laisser les gaz s’échapper dans l’atmosphère.

Type de réfrigérant: R410A

Valeur GWP*: 1975

*

GWP = potentiel de réchauffement global

Prière de compléter à l’encre indélébile,

• 1 la charge de réfrigérant d’usine du produit

• 2 la quantité de réfrigérant supplémentaire chargée sur place et

• 1+2 la charge de réfrigérant totale

sur l’étiquette de charge de réfrigérant fournie avec le produit.

L’étiquette complétée doit être apposée à proximité de l’orifice de recharge

du produit (par ex. à l’intérieur du couvercle de la vanne d’arrêt).

A contient des gaz à effet de serre fluorés encadrés par le protocole de

Kyoto

B charge de réfrigérant d’usine du produit: voir plaquette signalétique de

l’unité

C quantité de réfrigérant supplémentaire chargée sur place

D charge de réfrigérant totale

E unité extérieure

F cylindre de réfrigérant et collecteur de recharge

INFORMATION IMPORTANTE RELATIVE AU RÉFRIGÉRANT UTILISÉ

FR

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

A

R410A

2

1=

2=

1

1+2=

FE

kg

B

kg

C

kg

D

Page 6

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

Dieses Produkt enthält fluorierte Treibhausgase, die durch das Kyoto-Protokoll abgedeckt werden. Lassen Sie Gase nicht in die Atmosphäre ab.

Kältemitteltyp: R410A

GWP* Wert: 1975

*

GWP = Treibhauspotential

Bitte füllen Sie am Kältemittelbefülletikett, das im Lieferumfang des Gerätes

enthalten ist, mit abriebfester Tinte wie folgt aus:

• 1 die werkseitige Kältemittelbefüllung des Produktes

• 2 die am Montageort befüllte zusätzliche Kältemittelmenge und

• 1+2 die gesamte Kältemittelbefüllung

Das ausgefüllte Etikett muss in der Nähe der Kältemittel-Einfüllöffnung angehängt werden (z. B. auf der Innenseite der Absperrventilabdeckung).

A Enthält fluorierte Treibhausgase, die durch das Kyoto-ProtoKoll abge-

deckt werden

B werkseitige Kältemittelbefüllung des Produktes: siehe Typenschild der

Einheit

C zusätzliche am Montageort befüllen Kältemittelmenge

D gesamte Kältemittelbefüllung

E Außeneinheit

F Kältemittelzylinder und Sammelleitung für die Befüllung

WICHTIGE INFORMATIONEN HINSICHTLICH DES VERWENDETEN KÄLTEMITTELS

DE

Este producto contiene los gases fluorados de efecto invernadora regulados

por el Protocolo de Kioto. No vierta gases a la atmósfera.

Tipo de refrigerante: R410A

Valor GWP*: 1975

*

GWP = Potencial de calentamiento global

Rellene con tinta indeleble,

• 1 la carga de refrigerante de fábrica del producto

• 2 la cantidad adicional de refrigerante cargado en campo y

• 1+2 la carga total de refrigerante

En la etiqueta de carga de refrigerante suministrada con el producto.

La etiqueta rellenada debe pegarse cerca de la conexión de carga del producto (p.ej. en el interior de la cubierta de la válvula de tope).

A Contiene los gases fluorados de efecto invernadora regulados por el

Protocolo de Kioto

B Carga de refrigerante de fábrica del producto: véase placa de especifi-

caciones técnicas de la unidad

C Cantidad adicional de refrigerante cargado en campo

D Carga total de refrigerante

E Unidad exterior

F Cilindro del refrigerante y dosificador de carga

INFORMACIÓN IMPORTANTE EN RELACIÓN AL REFRIGERANTE UTILIZADO

ES

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

A

R410A

2

1=

2=

kg

kg

1

1+2=

FE

kg

B

C

D

Page 7

DUCT TYPE AIR CONDITIONER

OPERATION MANUAL

INSTALLATION MANUAL

On-Off

AD122ALEAA

AD182ALEAA

AD242ALEAA

Please read this operation manual before using the air conditioner.

Please keep this manual carefully and safely.

AD122ALERA

AD182ALERA

AD242ALERA

Inverter

Page 8

Contents

Cautions

Safety Precautions

Parts and Functions

Operation

Heating Mode

Care and Maintenance

Troubleshooting

Precauton for Installation

Is The Unit Installed Correctly

Installation Procedure

3

4

6

9

12

13

14

18

19

20

2

Page 9

Cautions

Disposal of the old air conditioner

Before disposing an old air conditioner that goes out of use, please make sure it's inoperative and safe. Unplug the air conditioner

in order to avoid the risk of child entrapment.

It must be noticed that air conditioner system contains refrigerants, which require specialized waste disposal. The valuable

materials contained in an air conditioner can be recycled. Contact your local waste disposal center for proper disposal of an old

air conditioner and contact your local authority or your dealer if you have any question. Please ensure that the pipework of your

air conditioner does not get damaged prior to being picked up by the relevant waste disposal center, and contribute to environmental

awareness by insisting on an appropriate, anti-pollution method of disposal.

Disposal of the packaging of your new air conditioner

All the packaging materials employed in the package of your new air conditioner may be disposed without any danger to the

environment.

The cardboard box may be broken or cut into smaller pieces and given to a waste paper disposal service. The wrapping bag

made of polyethylene and the polyethylene foam pads contain no fluorochloric hydrocarbon.

All these valuable materials may be taken to a waste collecting center and used again after adequate recycling.

Consult your local authorities for the name and address of the waste materials collecting centers and waste paper disposal

services nearest to your house.

Safety Instructions and Warnings

Before starting the air conditioner, read the information given in the User's Guide carefully. The User's Guide contains very

important observations relating to the assembly, operation and maintenance of the air conditioner.

The manufacturer does not accept responsibility for any damages that may arise due to non-observation of the following

instruction.

Damaged air conditioners are not to be put into operation. In case of doubt, consult your supplier.

Use of the air conditioner is to be carried out in strict compliance with the relative instructions set forth in the User's Guide.

Installation shall be done by professional people, don't install unit by yourself.

For the purpose of safety, the air conditioner must be properly grounded in accordance with specifications.

Always remember to unplug the air conditioner before opening inlet grill. Never unplug your air conditioner by pulling on the

power cord. Always grip plug firmly and pull straight out from the outlet.

All electrical repairs must be carried out by qualified electricians. Inadequate repairs may result in a major source of danger for

the user of the air conditioner.

Do not damage any parts of the air conditioner that carry refrigerant by piercing or perforating the air conditioner's tubes with

sharp or pointed items, crushing or twisting any tubes, or scraping the coatings off the surfaces. If the refrigerant spurts out

and gets into eyes, it may result in serious eye injuries.

Do not obstruct or cover the ventilation grille of the air conditioner. Do not put fingers or any other things into the inlet/outlet

and swing louver.

Do not allow children to play with the air conditioner. In no case should children be allowed to sit on the outdoor unit.

3

Page 10

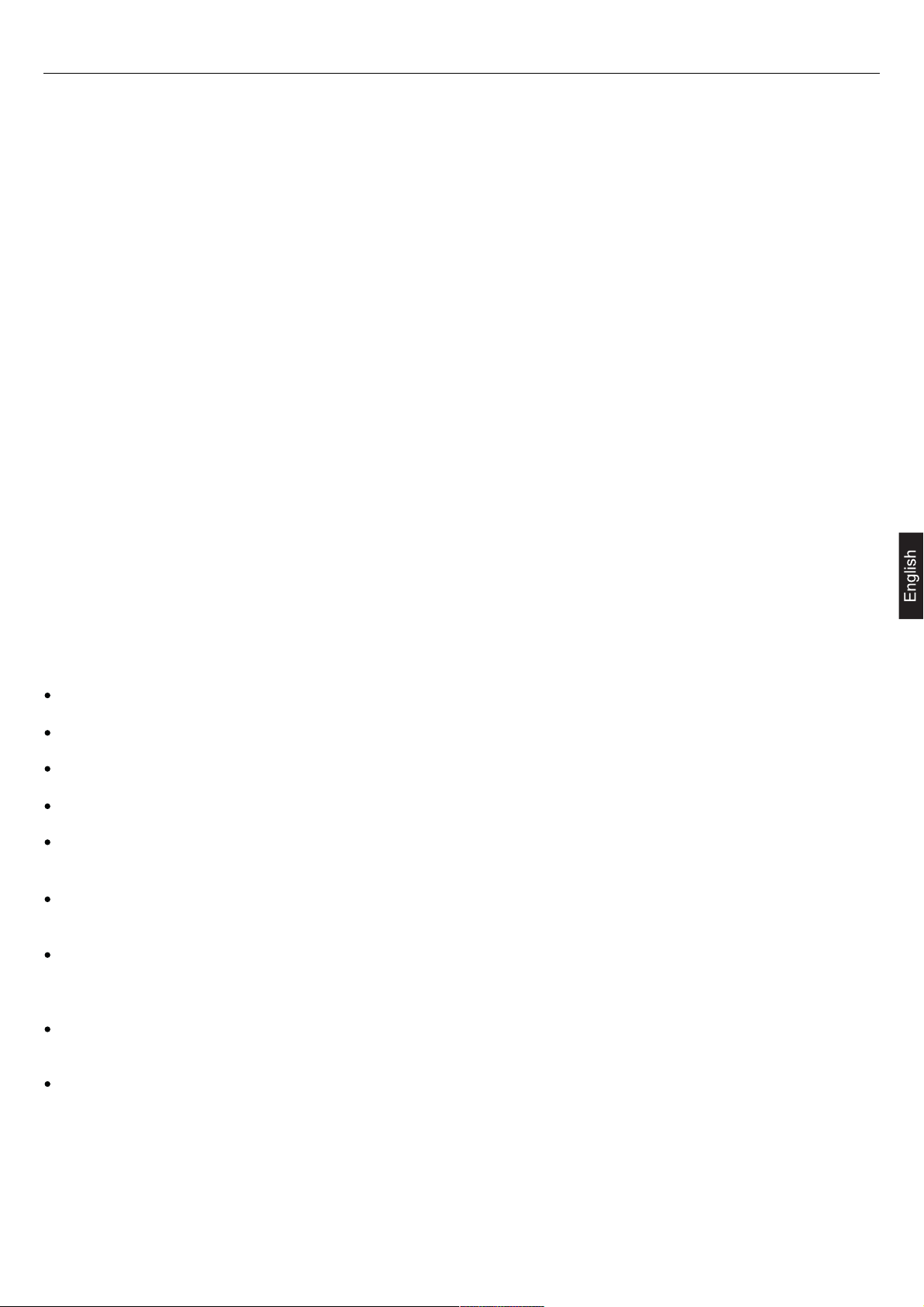

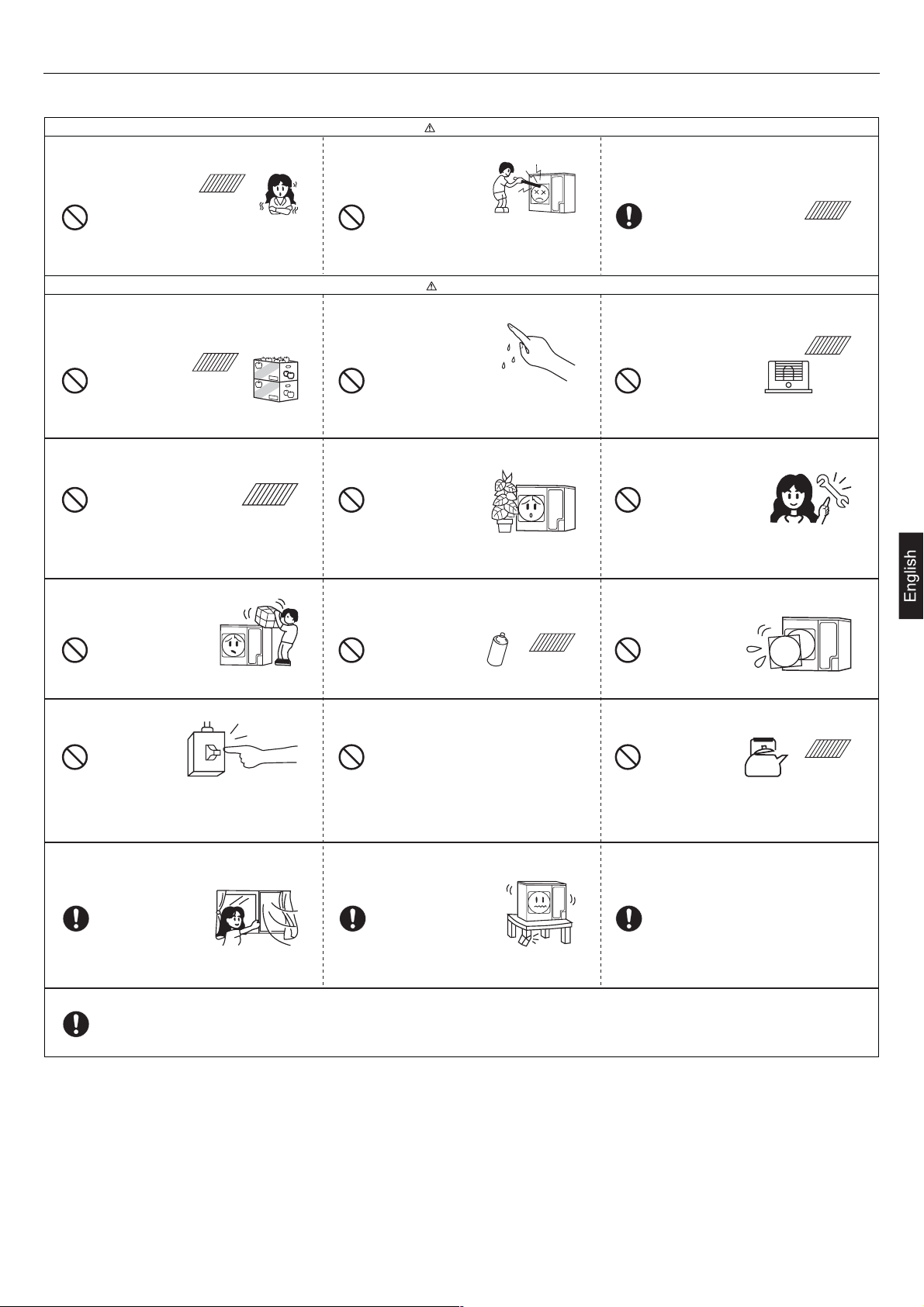

Safety Precautions

Before starting to use the system, read carefully this "SAFETY PRECAUTIONS" to ensure a proper operation of the system.

Safety precautions described here are classified to " WARNING" and " CAUTION". Precautions which are shown

in the column of " WANING" means that an improper handing could lead to a grave result like a death, serious injury,

etc. However, even if precautions are shown in the column of " CAUTION", a very serious problem could occur depending

on situation. Make sure to observe these safety precautions faithfully because they are very important information to ensure

the safety.

Symbols which appear frequently in the text have following meanings.

Strictly prohibited.

Observe instructions faithfully.

Provide a positive grounding.

When you have read through the manual, keep it always at hand for read consultation. If the operator is replaced, make

sure to hand over this manual to the new operator.

CAUTIONS FOR INSTALLATION

WARNING

The system should be applied to places as office,

restaurant, residence and the like.

Application to inferior environment such as an

engineering shop, could cause equipment

malfunction and serious injury or death.

Do not install nearby the place where may have

leakage of flammable gas.

If the gas leakes and gathers around, it may cause

the fire.

Where strong winds may prevail, the system

should be fixed securely to prevent a collapse.

The system should be installed by your dealer or

a professional installer.

Installation by yourself is not encouraged because

it could cause such problems as water leakage,

electrical shock or fire accident by some improper

handing.

CAUTION

Depending on the place of installation, a circuit

breaker may be necessary.

ON

OFF

Unless the circuit breaker is installed, it could cause

elecrical shocks.

Install on the place where can endure the weight

of air conditioner.

When you need some optional devices such as a

humidifier, electric heater, etc., be sure to use the products

which are recommended by us. These devices should

be attached by a professional installer.

Installation by yourself is not encouraged because it could

cause such problems as water leakage, electrical shock

or fire accident by some improper handing.

Drain pipe should be arranged to provide a positive

draining.

If the pipe is arranged improperly, furniture or the

likes may be damaged by leaked water.

Make sure the system is grounded.

Bodily injury could result by a collapse. Bodily injury could result by a careless installation. Grounding cable should never be connected to

a gas pipe, city water pipe, lightning conductor

rod or grounding cable of telephone. If the

grounding cable is not set properly, it could cause

electric shocks.

CAUTIONS FOR TRANSFER OR REPAIR

WARNING

Modification of the system is strictly prohibited. When the system needs a

repair, consult your dealer.

Improper practice of repair could cause water leakage, electric shock or

fire.

When the air conditioner is relocated, contact your dealer or a professional

installer.

Improper practice of installation could cause water leakage, electric shock

or fire.

4

Page 11

Safety Precautions

CAUTIONS FOR OPERATION

You should refrain from exposing your body directly

to cool wind for a long time.

WARNING

Do not poke the air inlet or outlet with a bar, etc. When any abnormal condition (scorching smell or

others) is found, stop the operation immediately

and turn off the power switch. Then consult your

dealer.

It could affect your physical condition or cause

some health problems.

The system should never be used for any other

purposes than intended such as for preservation

of food, flora and fauna, precision devices or work

of art.

problems.

Do not wash the air conditioner with water.

It could cause electric shocks. It will not be good for their health. Use of steel or copper wire in place of a fuse is

Neither stand on the air conditioner nor

place something on it.

object.

Do not use the power switch to turn on or off the

system.

It could cause a fire or water leakage. There is a risk of injury. If the system is operated at the vicinity of such

When operating the system simultaneously with

a combustion apparatus, indoor air must be

ventilated frequently.

ON

OFF

Since the internal fan is operating with a high

speed, it could cause an injury.

CAUTION

Do not handle switches with a wet hand. Combustion apparatus should not be placed

It could cause electric shocks.It could cause deterioration of food or other

Do not install the system where the air outlet

reaches directly the flora and fauna.

It is strictly prohibited to place a container of

combustible gas or liquid near the air conditioner

or to spray it directly with the gas or liquid.

Do not touch the air outlet section while the swing

louver is operating.

Check occasionally the support structure of the

unit for any damage after a use of long period of

time.

If you continue the operation without removing the

cause, it could result in a trouble, electric shock

or fire.

allowing a direct exposure to wind of air conditioner.

Incomplete combustion could occur on the

apparatus.

Make sure to use a fuse of proper electric rating.

strictly prohibited because it could result in a trouble

or fire accident.

Do not operate the system while the air outlet grill

is removed.

There is a risk of injury.It could cause a fire accident.There are risks of falling or injury by collapsed

Do not use such equipment as a water heater, etc.

around the indoor unit or the wire controller.

equipment which generates steam, condensed

water may drip during cooling operation or it could

cause a fault current or short-circuit.

When cleaning the system, stop the operation and

turn off the power switch.

Insufficient ventilation could cause an oxygen

deficiency accident.

Do not put water containers on the unit such as a flower vase, etc.

If the water enters into the unit and damages the electric insulation material, it may cause electric shock.

If the structure is not repaired immediately, the

unit could topple down to cause a personal injury.

Cleaning should never be done while the internal

fans are running with high speed.

5

Page 12

Safety Precautions

The machine is adaptive in following situation

1. Applicable ambient temperature range:

ON-OFF Inverter

Cooling

Heating

2. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similar qualified person.

3. If the fuse on PC board is broken please change it with the type of T 3.15A /250VAC.

4. The wiring method should be in line with the local wiring standard.

5. The power cable and connecting cable are self-provided.

For series 122, 182, the power cable should be H05RN-F 3G 2.5mm

For series 242, the power cable should be H05RN-F 3G 4.0mm

For 122, 182(*EAA), the connecting cable should be H05RN-F 3G 2.0mm

For the others the connecting cable should be H05RN-F 4G 0.75mm

All the cables shall have got the European authentication certificate. During installation, when the connecting cables break off,

it must be assured that the grouding wire is the last one to be broken off.

6. The breaker of the air conditioner should be all-pole switch, and the distance between its two contacts should be no less than

3mm. Such means for disconnection must be incorporation in the fixed wiring.

7. The indoor unit installation height is at least 2.5m.

8. The distance between its two terminal blocks of indoor unit and outdoor unit should not be over 5m. If exceeded, the diameter

of the wire should be enlarged according to the local wiring standard.

9. The waste battery shall be disposed properly.

Indoor temperature

Outdoor temperature

Indoor temperature

Outdoor temperature

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

32/23 C

18/14 C

43/26 C

10/6 C

27 C

15 C

24/18 C

-7 C

2

.

32/23 C

18/14 C

43/26 C

-5 C

24/18 C

-10 C

2

.

2

+ 1x0.75mm2.

2

.

27 C

15 C

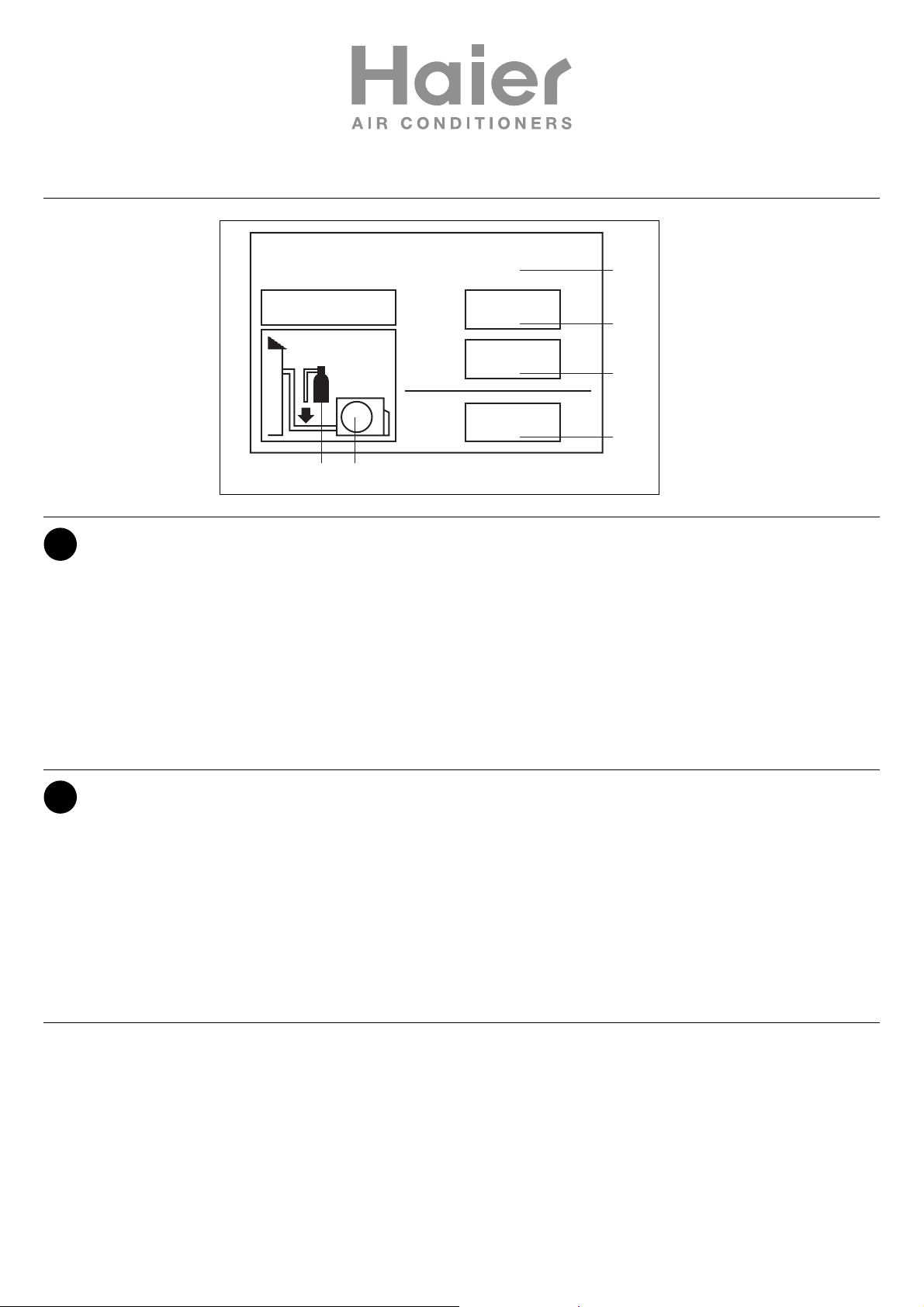

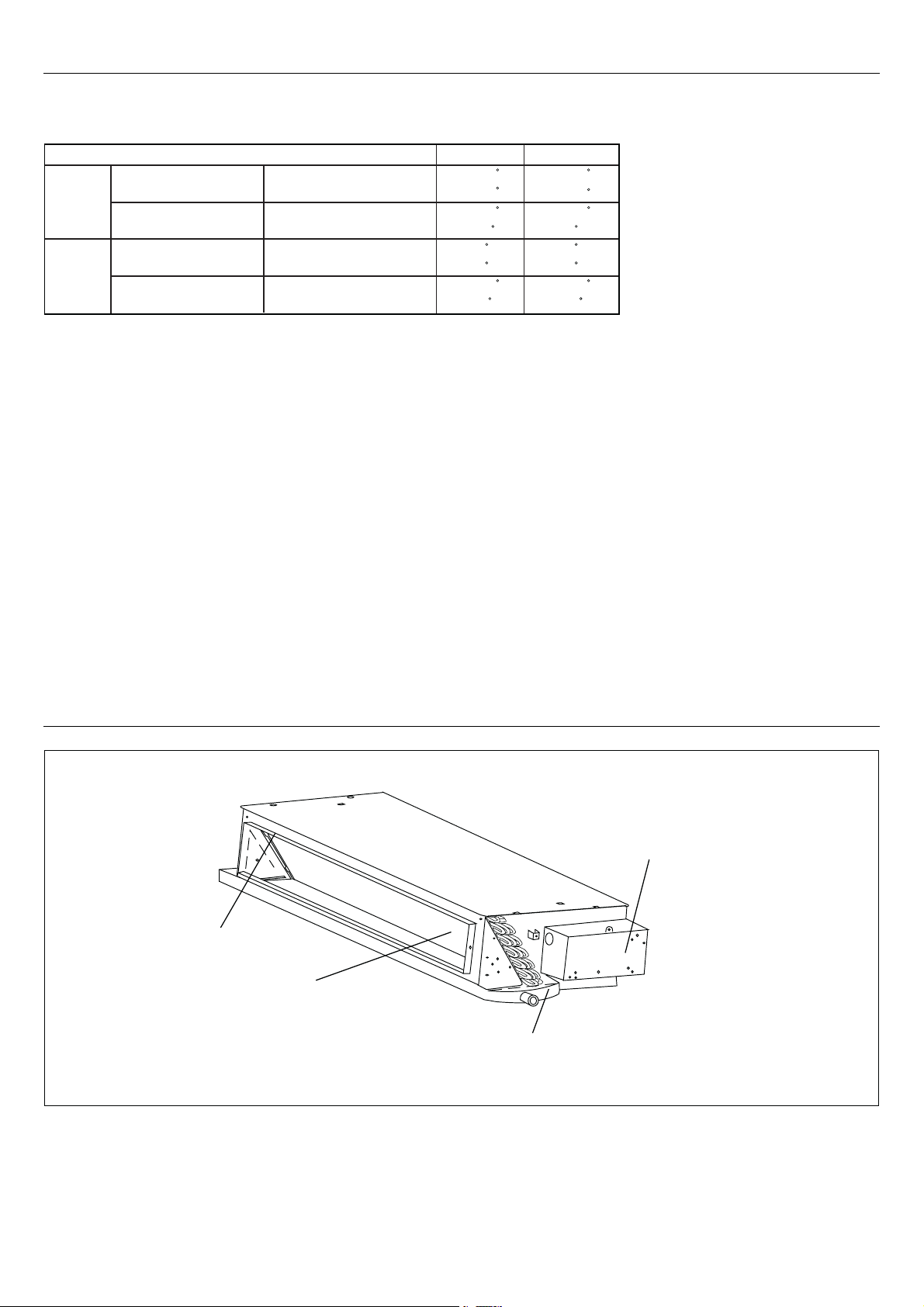

Parts and Functions

Air outlet frame

Evaporator

Electrical components Case

Drain pan

6

Page 13

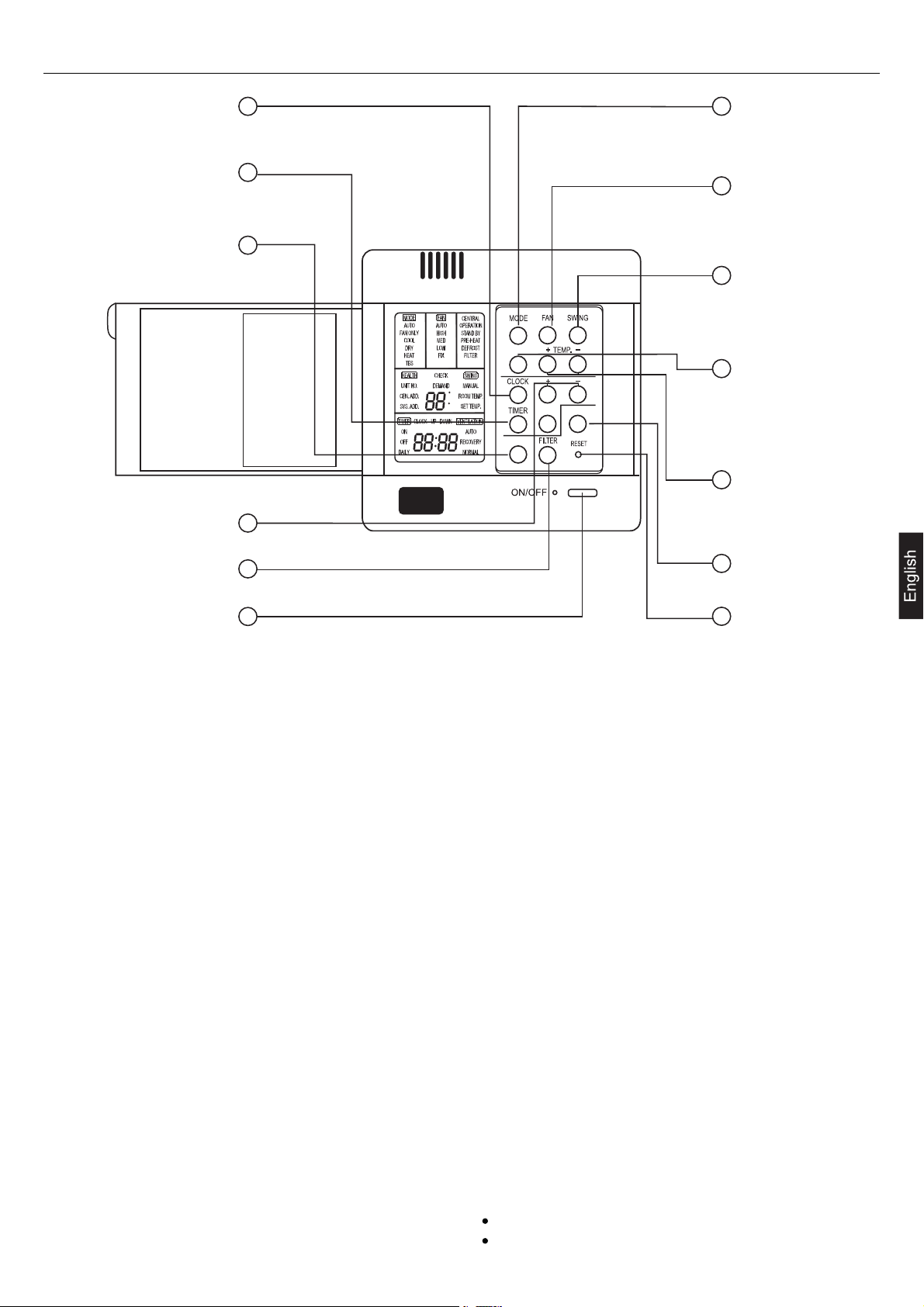

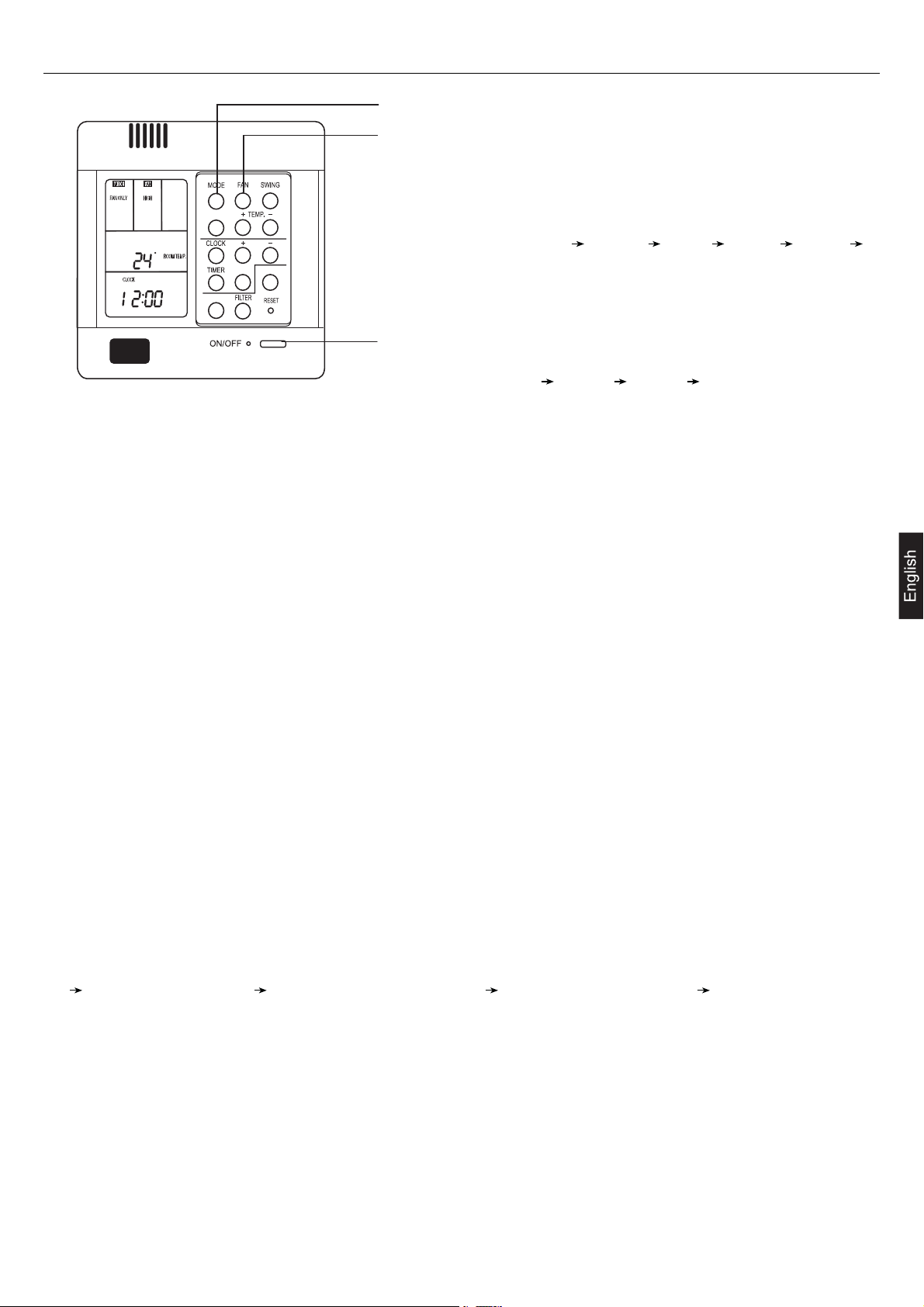

Parts and Functions

1

2

3

HEALTH

C

F

4

SET RECOVERY

CHECK

7

8

9

10

11

5

6

1.CLOCK button

Used to adjust time.

2.TIMER button

Used to set timer mode.

3.CHECK button

Auto-diagnostic button.

4.+ and - button

Stands for time plus/minus, used to adjust time.

5.FILTER button

Filter-cleaned button.

6.POWER ON/OFF button

Used for unit to start and stop.

12

13

8.FAN button

Used to select indoor air flow.

9.SWING button

Used for setting indoor swing mode.

10.HEALTH button

Used for setting indoor health function.

11.TEMP + and - button

Used for changing set temperature.

12.RECOVERY button

used to switch over air-exchanging mode.

13.RESET button

Reset correct mode button.

7.MODE button

Used to select indoor operation mode.

Note:

The above information is the explanation of the displayed

information. Therefore it varieswith those displayed in

actual operation.

Cautions:

On cooling only unit, heating mode is not available.

The functions 5,9,10 are not available for these units.

7

Page 14

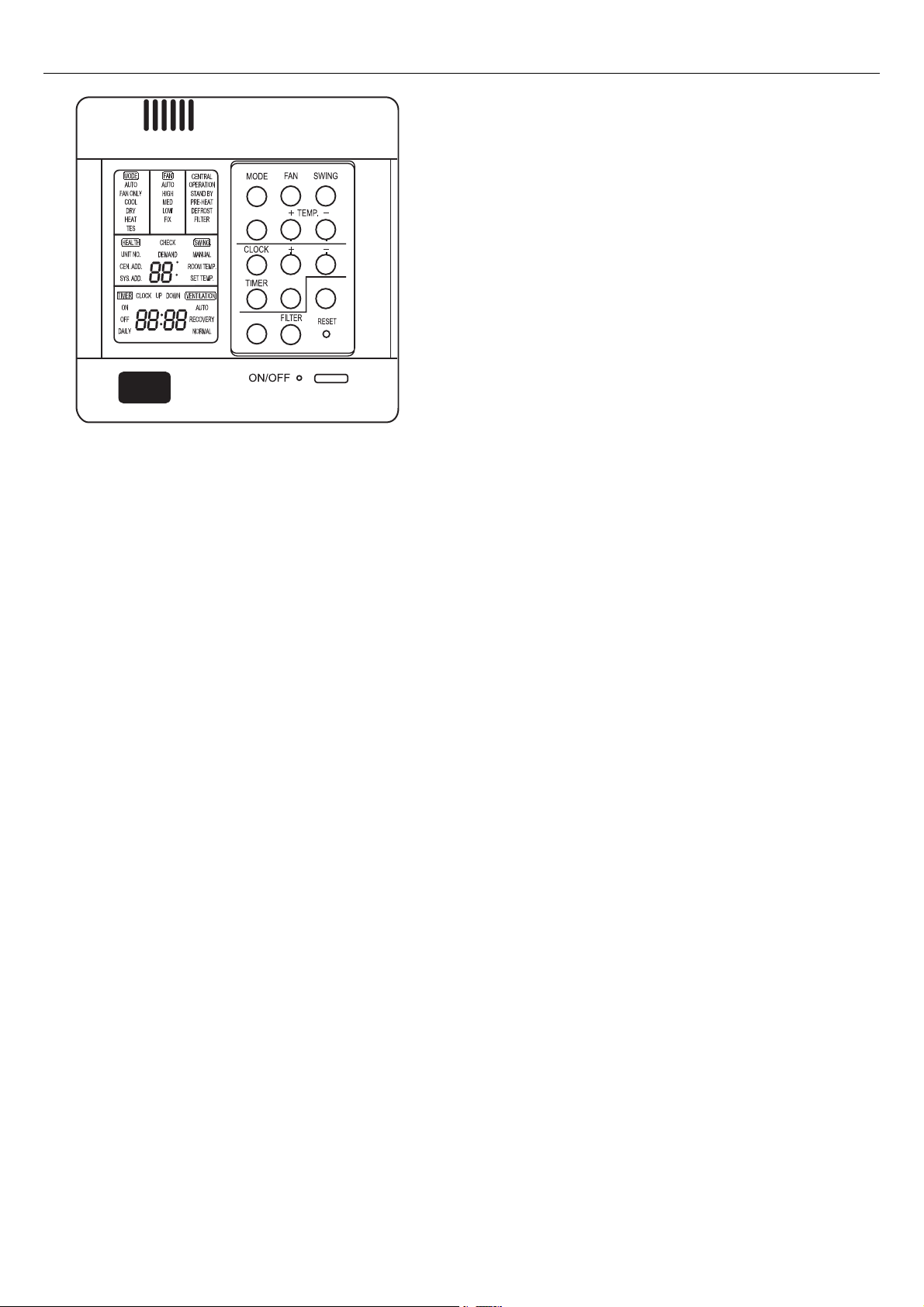

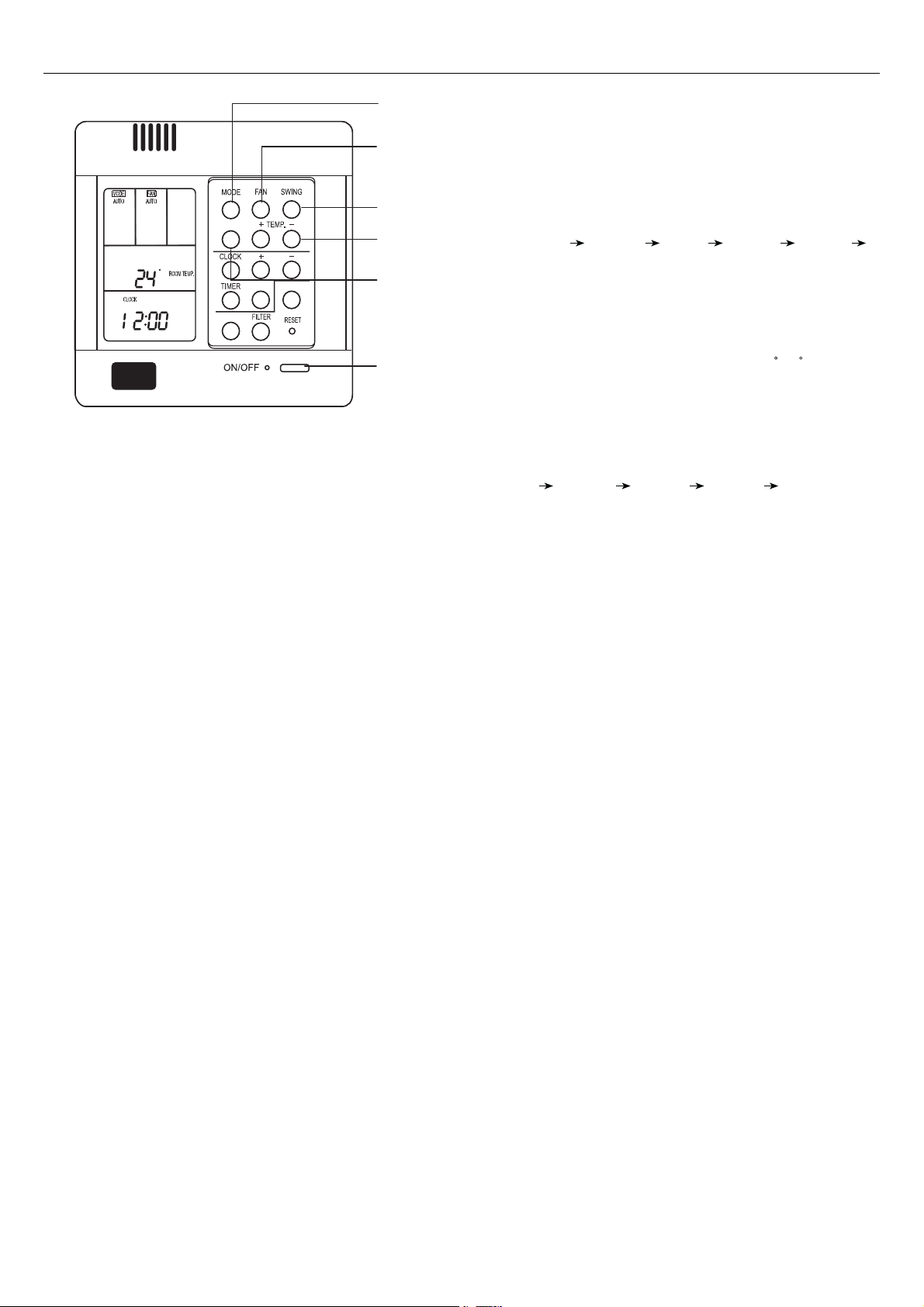

Parts and Functions

HEALTH

C

F

SET RECOVERY

CHECK

[MODE]

[AUTO]:Auto operation mode.

[FAN ONLY]:Air-throwing mode.

[COOL]:Cooling operation mode.

[DRY]:Dehumidification mode.

[HEAT]:Heating operation mode.

[TES]:In heating mode, auxiliary electric heater is running.

Only when the unit with auxiliary electric heater is in

auxiliary electric heating mode, it will display.

[FAN]

[AUTO]:Auto fan running.

[HIGH]:High fan speed.

[MED]:Medium fan speed.

[LOW]:Low fan speed.

[FIX]:Fixed fan speed, it will display only when fixed fan

speed is requested to main indoor unit.

[CENTRAL]:Central control mode.

[OPERATION]:Running mode.

[STAND BY]: Waiting mode.

[PRE-HEAT]: Pre-heating mode.

[DEFROST]: Defrosting mode.

[FILTER]: Request of filter to be cleaned.

[HEALTH]:Health function.

[CEN.ADD]:Central control address, the address number

will display on "88".

[SYS.ADD.]:System address, the address number will

display on "88".

[CHECK]:Auto-diagnostic, trouble shooting.

[DEMAND]:Compulsory operation function, when it works,

[CENTRAL] will flash.

[SWING][MANUAL]:Swing mode.

[ROOM TEMP.]:Indoor ambient temperature.

[SET TEMP.]:Set admired temperature.

[TIMER]

[ON]:Timer function is on.

[OFF] :Timer function is off.

[ON][OFF] :Timer function is ON-OFF.

[ON][OFF][DAILY]:Timer ON-OFF will switch over in turn

daily.

[CLOCK]:Clock display, the displaying time is the current

time of the clock.

[UP],[DOWN]:Indicator of filter elevating.

[VENTILATION]

[AUTO]:Auto ventilation mode.

[NORMAL]:Normal ventilation mode.

[RECOVERY]:Fully heat exchanging ventilation mode.

8

Page 15

Operation

Fan Only

2

(1)Start up operation:

Press the ON/OFF button. The system will start up and the

3

display will be on LCD.

(2)Select operation mode :

HEALTH

Press the MODE button. Each press, operation mode in

the [MODE] display section changes as follows:

C

SET RECOVERY

[FAN ONLY] [COOL] [DRY] [HEAT] [AUTO]

[FAN ONLY].

Select [FAN ONLY].

CHECK

(3)Select fan speed:

1, 4

Press the FAN button. Each press, fan speed in the [FAN]

display section changes as follows:

[HIGH] [MED] [LOW] [HIGH].

Select proper fan speed.

(4)Power off:

Press the ON/OFF button. Indoor unit will be powered off,

and there are only the time and the ambient temperature

in the screen.

VENTILATION mode

(only for the unit with fresh air function or heat recovery function)

Press the RECOVERY button, then the unit will switch over the ventilation mode:

[ ] [VENTILATION][AUTO] [VENTILATION][RECOVERY] [VENTILATION][NORMAL] [ ]

Please select appropriate ventilation mode.

9

Page 16

Operation

Auto, Cool, Heat, and Dry

2

(1) Start up operation:

Press the ON/OFF button. The system will start up and the

4

display will be on LCD.

(2) Select operation mode:

5

HEALTH

3

C

SET RECOVERY

CHECK

6

Press the MODE button. Each press, operation mode in

the [MODE] display section changes as follows:

[FAN ONLY] [COOL] [DRY] [HEAT] [AUTO]

[FAN ONLY].

Select operation mode ([COOL],[DRY],[HEAT],or [AUTO]).

(3) Set temperature:

Press the TEMP + or - button. Each press, setting

1, 7

temperature will increase or decrease by 1 C ( F). [SET

TEMP.] appears on the display.

(4) Select fan speed:

Press the FAN button. Each press, fan speed in the [FAN]

display section changes as follows:

[AUTO] [HIGH] [MED] [LOW] [AUTO].

Select proper fan speed.

(5) Select SWING function:

Press the SWING button once, [SWING] will display and

swing function is valid. Press again, [SWING] will disappear

and swing function is invalid.

(6) Set HEALTH operation:

Press the HEALTH button to set the indoor health function.

Press it once, [HEALTH] will display in the display section,

and indoor health function is valid. Press it again, [HEALTH]

will disappear, and the health function is invalid. This function

is valid only for the unit with health function.

(7) Power off:

Press the ON/OFF button. Indoor unit will be powered off,

and there are only the time and the ambient temperature

in the screen.

10

Page 17

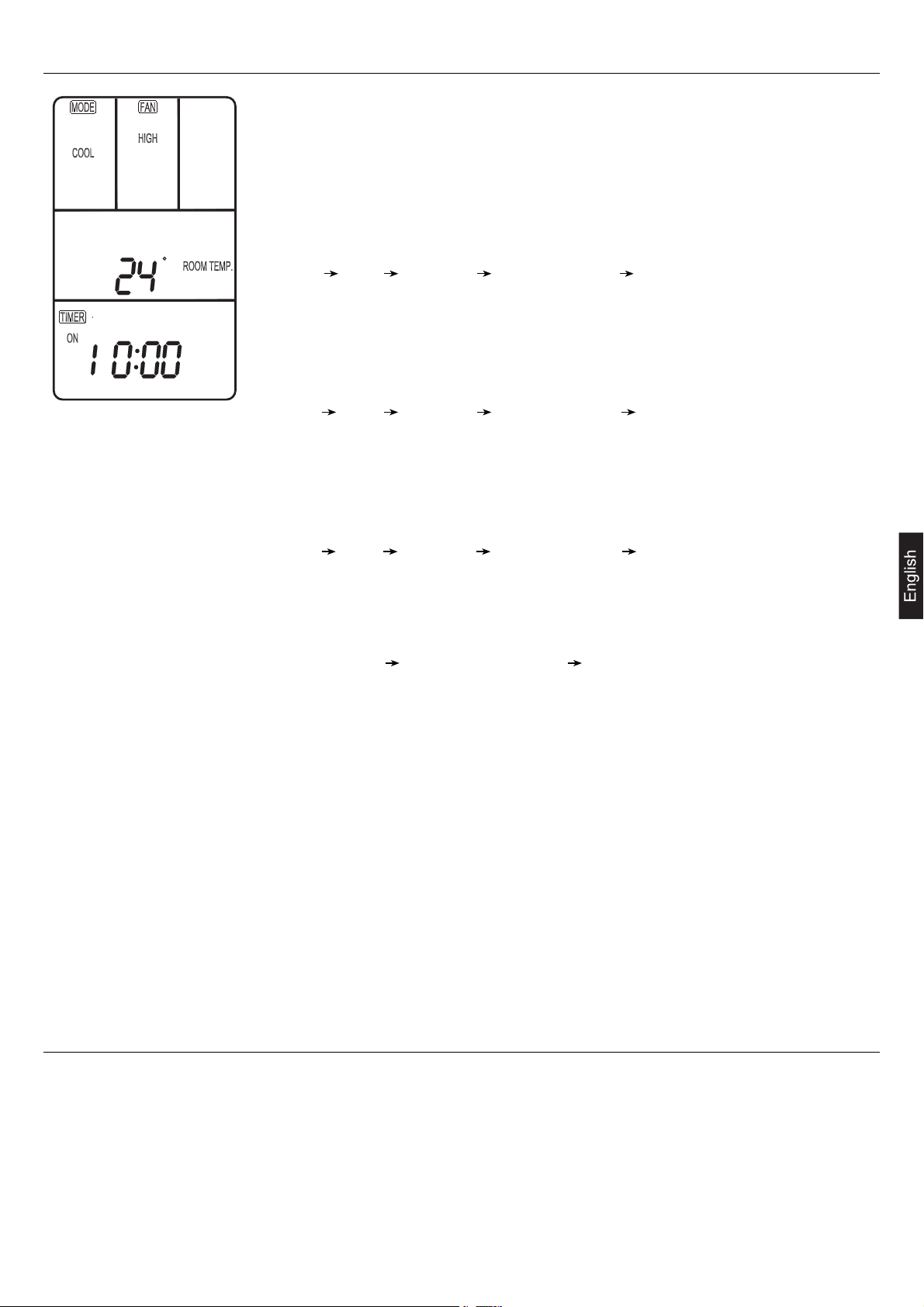

Operation

C

Timer Function

Clock set

Before setting timer mode, set the clock to the correct time.

Press the CLOCK button. "CLOCK" will begin flashing at the frequency of 2Hz. Press

the clock +/- button to adjust the current time. Then press the SET button to confirm

until the proper time comes.

TIMER ON operation:

Press the TIMER button. Each time the button is pressed, TIMER mode in the [TIMER]

display section changes as follows:

[ON] [OFF] [ON][OFF] [ON][OFF][DAILY] [ ].

Select [TIMER] [ON], and then [TIMER] [ON] flashes. Press the clock +/- button to adjust

the time of TIMER ON, and press the SET button to confirm.

TIMER OFF operation:

Press the TIMER button. Each time the button is pressed, TIMER mode in the [TIMER]

display section changes as follows:

[ON] [OFF] [ON][OFF] [ON][OFF][DAILY] [ ].

Select [TIMER] [OFF], and then [TIMER] [OFF] flashes. Press the clock +/- button to

adjust the time of TIMER OFF, and press the SET button to confirm.

TIMER ON-OFF operation:

Press the TIMER button. Each time the button is pressed, TIMER mode in the [TIMER]

display section changes as follows:

[ON] [OFF] [ON][OFF] [ON][OFF][DAILY] [ ].

Select [TIMER] [ON] [OFF], and then [TIMER][ON] flashes. Press the clock +/- button

to adjust the time of TIMER ON, and then press the TIMER button to confirm. [TIMER][ON]

will be constant on and [TIMER] [OFF] flashes.

Press the clock +/- button to adjust the time of TIMER OFF, and press the SET button

to confirm. The time sequence of timer on and timer off will determine the mode is

[TIMER] [ON] [OFF] or [TIMER] [OFF] [ON]. If you want the current time, press

the CLOCK button once, current time will display; Press again, [CLOCK] will flash, and

press clock + / - button to adjust the time.

Note:

1.

If the two times are the same, the timer state which is set later will flash, in this case,

timer can not be set.

When entering TIMER setting state, if you do not input any button in continuous 10

2.

seconds, the unit will quit from the TIMER mode.

Cancel TIMER operation:

In the timer operation state, press the TIMER button, the unit will quit from the current

timer operation state, and the set data will be memorized, then enter the next timer

mode. When [TIMER] does not display, the timer will be cancelled.

Operation

Query indoor malfunction history:

In the state of power on or power off, press the CHECK button to enter the malfunction-querying mode of all indoor units

in the group. Then [CHECK] and [UNIT NO.] will display, and the actual indoor numbers will be displayed in some sequence

(unit number is in decimals). At the same time, in the time region, there will be the current malfunction and the latest time

malfunction, the displaying format is [XX:YY], in which XX stands for the current malfunction, if normal, it will display "--";

YY stands for the latest time malfunction. The failure code of every unit will display for 3 seconds. After the failure codes

of all indoor units in the whole group are displayed, the mode will quit automatically.

11

Page 18

Heating Mode

"HOT KEEP" function

"HOT KEEP" is operated in the following cases.

When heating is started:

In order to prevent blowing out of cool wind, the indoor unit fan stopped according to the room temperature which heating

operation is started. Wait for approx. 2 to 3 minute, and the operation will be automatically changed to the ordinary heating

mode.

Defrosting operation (in the heating mode):

When it is liable to frost, the heating operation is stopped automatically for 5 to 12 minutes once per approx. one hour,

and defrosting is operated. After defrosting is completed, operation mode is automatically changed to ordinary heating

operation.

When the room thermostat is actuated:

When room temperature increases and room temperature controller actuates, the fan speed is automatically changed to

stop under low temperature condition of indoor heat exchanger. When room temperature decreases, air conditioner

automatically changes over to ordinary heating operation.

Warming operation

Heat pump type warming

With the heat pump type warming, the mechanism of heat pump that concentrate heat of outdoor air with the help of

refrigerant to warm the indoor space, is utilized.

Defrosting operation

When a room is warmed with a heat pump type air conditioner, frost accumulates on the heat exchanger of outdoor unit

along with the drop of indoor temperature. Since the accumulated frost reduces the effect of warming, it is necessery to

automatically switch the operation to the defrosting mode. During the defrosting operation, heating operation is interrupted.

Atmospheric temperature and warming capacity

Warming capacity of heat pump type air conditioner decreases along with the drop of outdoor temperature.

When the warming capacity is not sufficient, it is recommended to use another heating implement.

Period of warm-up

Since the heat pump type air conditioner employs a method to circulate warm winds to warm

the entire space of a room, it takes time before the room temperature rises.

It is recommendable to start the operation a little earlier in a very cold morning.

12

Page 19

Care and Maintenance

Points to observe

Turn off the power supply switch. Do not touch with wet hand. Do not use hot water or volatile liquid.

ON

OFF

CAUTION

Do not open the inlet grill until fan stops completely.

Fan will continue rotating for a while by the law of inertia after operation is being stopped.

Cleaning the air filter

1.Clean the air filter by lightly tapping it or with the cleaner. It is more effective to clean

the air filter with water.

If the air filter is very dirty, dissolve neutral detergent in the lukewarm water (approx. 30 C),

rinse the air filter in the water, and thoroughly wash off the detergent on the air filter

in the plain water.

2.After drying the air filter, set it up on the air conditioner.

Thinner

Do not

use!

Benzine

Tooth powder

CAUTION

Do not dry the air filter with fire.

Do not run the air conditioner without the air filter.

Care and Cleaning of the unit

Clean with soft and dry cloth.

If it is very dirty, dissolve neutral detergent in the lukewarm water and make the cloth wet with the water. After wiping,

clean off the detergent using clean water.

Post-Season Care

Operate the unit with FAN mode on a fair day for about half a day to dry the inside of the unit well.

Stop operation and turn off the power supply switch. Electric power is consumed even if the air conditioner is in stop.

Clean the air filter and set it in the place.

Pre-Season Care

See that there are no obstacles blocking the air inlet and air outlet of both indoor and outdoor units.

Make sure that the air filter is not dirty.

Turn on the power supply switch 12 hours before starting run.

13

Page 20

Troubleshooting

Please check the following things about your air conditioner before making a service call.

Unit fails to start

Is the power source switch

adjust cut in?

ON

OFF

Power supply switch is not

ON.

Is city supply power in normal? Isn't the signal receiving

section exposed to the direct

sunlight or strong illumination?

Power

stoppage?

Isn't the earth leakage breaker

in action?

It is dangerous. Turn off the

power supply switch

immediately and contact the

sales dealer.

Cooling or heating is not sufficient

Is the thermostat adjusted as

required?

Isn't the air filter dirty? Isn't any doors or windows left

open?

Doesn't any obstacle exist at

the air inlet or outlet?

Cooling is not sufficient

Isn't sun-shine invading direct? Isn't any unexpected heating

load generated?

Isn't the room much crowded? The wind does not blow during

heating operation.

Isn't it warming up?

When the air conditioner does not operate properly after you have checked the above mentioned items or when the following

phenomenon is observed, stop the operation of the air conditioner and contact your sales dealer.

The fuse or breaker often shuts down.

Water drops off during cooling operation.

There is an irregularity in operation or abnormal sound is audible.

14

Page 21

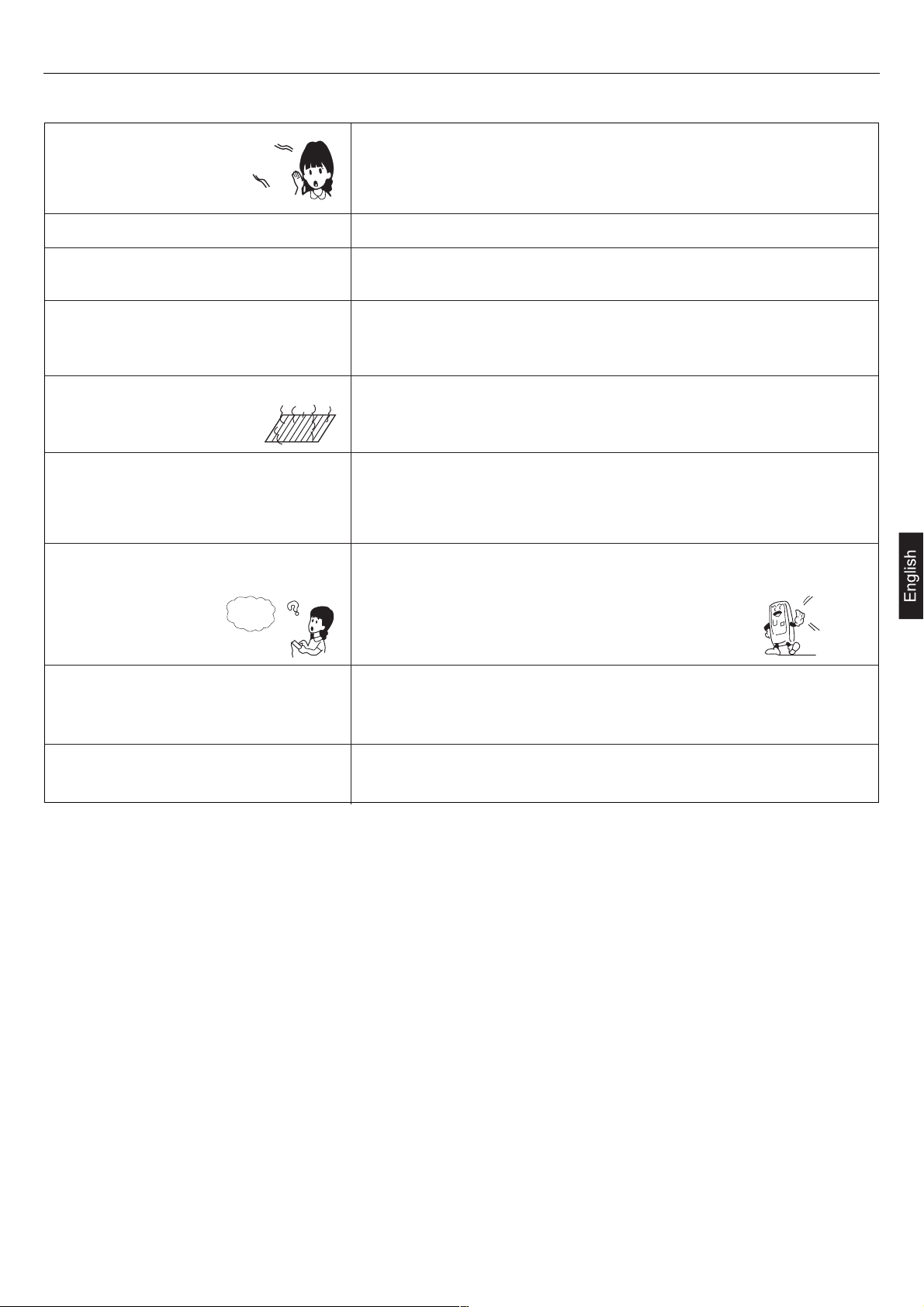

Troubleshooting

The followings are not malfunction

Water flowing sound is heard.

Shuru

Shuru

When the air conditioner is started, when the compressor starts or stops during

operation or when the air conditioner is stopped, it sometimes sounds "shuru

shuru" or "gobo gobo". It is the flowing sound of the refrigerant, and it is not a

trouble.

This is caused by heat expansion or contraction of plastics.Cracking sound is heard.

It smells. Air which blows out from the indoor unit sometimes smells. The smell results

from residents of tobacco smoke or cosmetics stuck inside of unit.

During operation, white fog comes out of

indoor unit.

When the air conditioner is used at restaurant etc. where dense edible oil fume

is always exists, white fog sometimes blows out of air outlet during operation.

In this case consult sales dealer for cleaning the heat exchanger.

It is switched into the FAN mode during

cooling.

To prevent frost from being accumulated on the indoor unit heat exchanger, it

is sometimes automatically switched to the FAN mode but it will soon return

to the cooling mode.

The air conditioner can not be restarted soon

after it stops.

Even if the operation switch is turned on, cooling, dehumidifying or heating is

not operable for three minutes after the conditioner is stopped. Because the

protecting circuit is activated.

(During this time air conditioner operates in fan mode.)

Air does not blow or the fan speed can not be

changed during dehumidifying

Unit does

not start

When it is excessively cooled during dehumidifying, the blower automatically

repeats reducing and lowering the fan speed.

Wait for

three

minutes

During operation, operation mode has changed

over automatically.

Water or steam generates from the outdoor

unit during heating.

Isn't the AUTO mode selected?

In the case of AUTO mode, operation mode is changed automatically from

cooling to heating or vise-versa according to the room temperature.

This results when frost accumulated on the outdoor unit is removed (during

defrosting operation).

15

Page 22

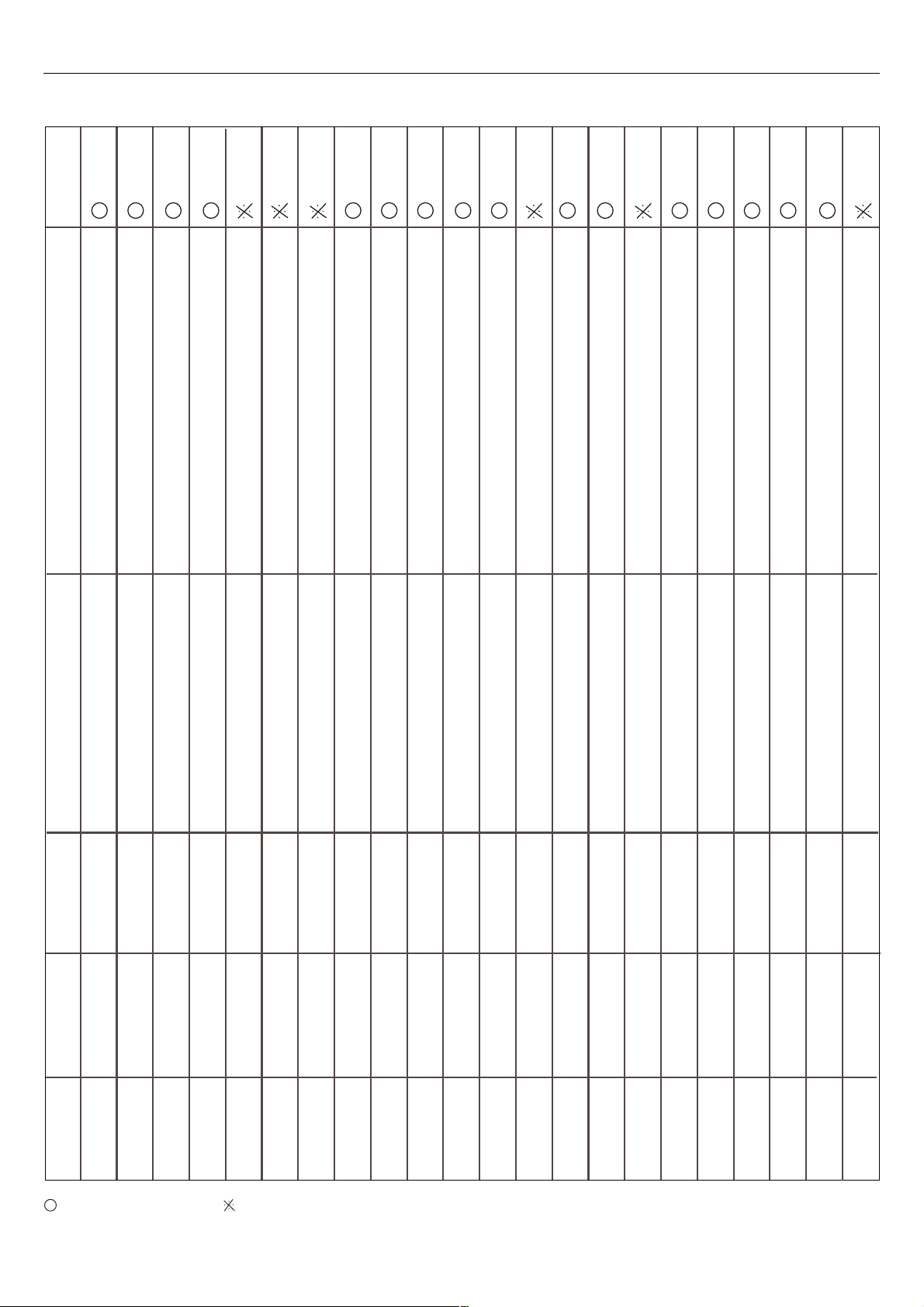

Troubleshooting

Diagnosis for inverter models

Remarks

Resumable

if lower than

100 degree

Reason

Sensor broken down or short circuit for more than 2m continuously

Sensor broken down or short circuit for more than 2m continuously

Sensor broken down or short circuit for more than 2m continuously

Sensor broken down or short circuit for more than 2m continuously

CT check abnormal 3 times in 30m

Failure description

Indoor ambient temp. sensor failure

Indoor coil temp. sensor failure

Outdoor ambient temp. sensor failure

Outdoor coil temp. sensor failure

Over-current protection

Failure code

for central control

01D

02D

11D

12D

10D

Fault phase, short of phase, out of balance greatly

High pressure switch acts 3 times in 30m

High pressure abnormal

14D

Communication abnormal for more than 4m continuously

Power supply abnormal

Communication between wired controller

and indoor abnormal

22D

06D

Communication abnormal for more than 4m continuously

Float switch broken down for more than 25m continuously

Outside signal broken down for more than 10s

Sensor broken down or short circuit for more than 2m continuously

Solenoid valve act incorrectly 3 times continuously

Sensor broken down or short circuit for more than 2m continuously

EEPROM data missing

Low pressure switch acts in normal running

The discharging temperature is higher than 120degree

Communication between indoor and outdoor abnormal

Drainage system abnormal

Outside alarm signal input

Gas pipe temp. sensor abnormal

Temperature protection malfunction

Discharging temp. sensor abnormal

EEPROM abnormal

Pressure abnormal(low pressure)

Compressor overheat

05D

21D

30D

20D

31D

15D

17D

26D

15D

Indoor operation mode is different with the running indoor unit.

Sensor broken down or short circuit for more than 2m continuously

Sensor broken down or short circuit for more than 2m continuously

Spdu module temperature is too high

Outdoor DC motor abnormal or cooling & heating abnormal

Abnormal mode

Outdoor coil B(suction temp sensor-for MRV II)

Outdoor discharging B(oil temp sensor-for MRV II)

SPDU module temperature protection

Outdoor DC motor failure or system failure

23D

18D

15D

07D

08D

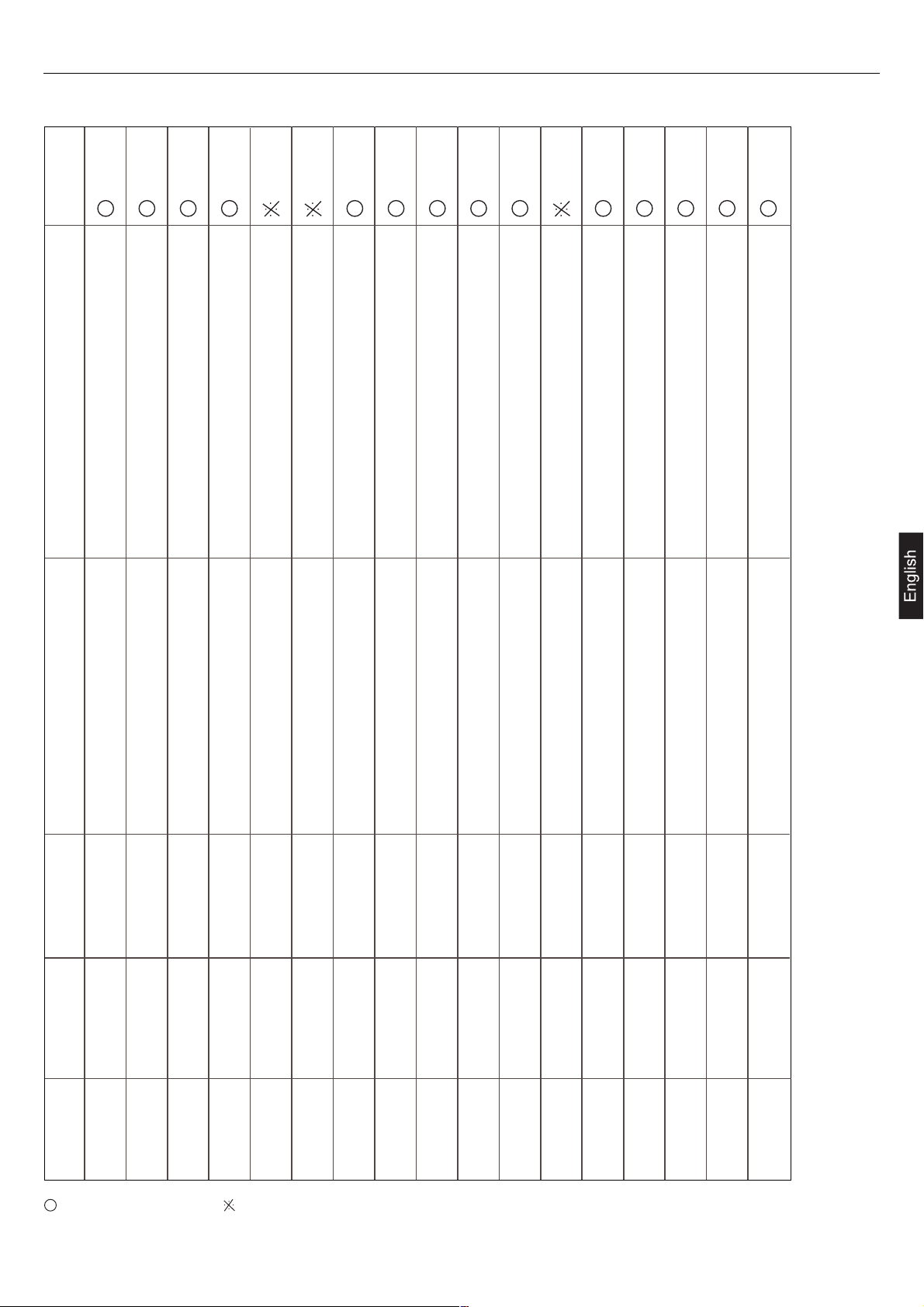

01(01H)

02(02H)

74(4AH)

73(49H)

72(48H)

83(53H)

71(47H)

07(07H)

06(06H)

Failure code

on wired controller

Flash times

for remote type

1

2

3

4

5

6

7

8

shows resumable fault, shows it is not resumable fault.

08(08H)

9

10

16

11(0BH)

11

03(03H)

12

13(0DH)

13

76(4CH)

14

05(05H)

15

84(54H)

16

80(50H)

17

12(0CH)

18

75(4BH)

19

77(4DH)

20

20(32D)

21

36(54D)

22

Page 23

Troubleshooting

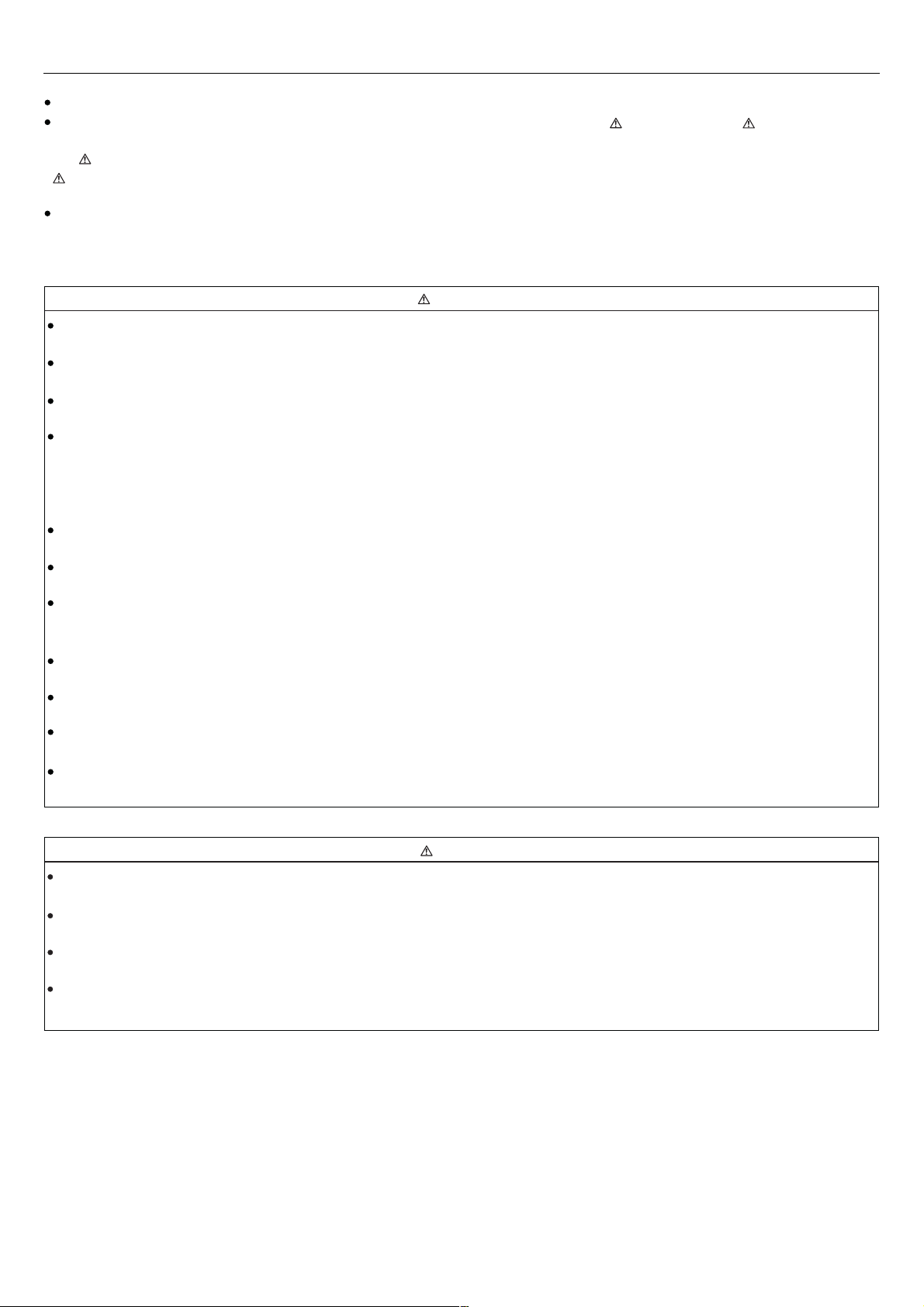

Diagnosis for On-Off models

Remarks

Resumable

if lower than

100 degree

Sensor broken down or short circuit for more than 2m

continuously

Sensor broken down or short circuit for more than 2m

continuously

Sensor broken down or short circuit for more than

2m continuously

Sensor broken down or short circuit for more than

2m continuously

CT check abnormal 3 times in 30m / Fault phase,

short of phase,out of balance greatly

Failure description Reason

Indoor ambient temp. sensor failure

Indoor coil temp. sensor failure

Outdoor ambient temp. sensor failure

Outdoor coil temp. sensor failure/ Compressor

discharging temp. sensor abnormal

Over-current protection / Power supply

abnormal

Failure code

for central control

01D

02D

11D

12D

10D

High pressure switch acts 3 times in 30m/Low pressure

switch acts in normal running

Communication abnormal for more than 4m continuously

Communication abnormal for more than 4m continuously

Float switch broken down for more than 25m continuously

Outside signal broken down for more than 10s

Sensor broken down or short circuit for more than 2m

continuously

Solenoid valve act incorrectly 3 times continuously

High/Low pressure abnormal

Communication between wired controller and

indoor abnormal

Communication between indoor and outdoor

abnormal

Drainage system abnormal

Outside alarm signal input

Gas pipe temp. sensor abnormal

Temperature protection malfunction

14D

06D

05D

21D

30D

20D

31D

EEPROM data missing

The discharging temperature is higher than 120degree

Indoor operation mode is different with the running

indoor unit.

Sensor broken down or short circuit for more than 2m

continuously

Sensor broken down or short circuit for more than 2m

continuously

EEPROM abnormal

Compressor overheat

Abnormal mode

Outdoor coil B(suction temp sensor-for MRV II)

Outdoor discharging B(oil temp sensor-for

MRV II)

17D

15D

23D

18D

15D

01(01H)

02(02H)

74(4AH)

73(49H)

72(48H)

83(53H)

07(07H)

Failure code

on wired controller

Flash times

for remote type

1

2

3

4

5

6

shows resumable fault, shows it is not resumable fault.

06(06H)

8

9

08(08H)

10

17

11(0BH)

11

03(03H)

12

13(0DH)

13

05(05H)

15

80(50H)

17

12(0CH)

18

75(4BH)

19

77(4DH)

20

Page 24

Precaution for Installation

Please read these "Safety Precautions" first and then accurately execute the installation work.

Though the precautionary points indicated herein are divided under two headings, and , those

points which are related to the strong possibility of an installation done in error resulting in death or serious injury are listed in

WARNING

the section. However, there is also a possibility of serious consequences in relationship to the points listed in the

CAUTION

section as well. In either case, important safety related information is indicated, so by all means, properly observe

all that is mentioned.

After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please explain

operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner's manual.

Moreover, ask the customer to keep this sheet together with the owner's manual.

WARNING

This system should be applied to places as office, restaurant, residence and the like. Application to inferior environment such

as engineering shop could cause equipment malfunction.

Please entrust installation to either the company which sold you the equipment or to a professional contractor. Defects from

improper installations can be the cause of water leakage, electric shocks and fires.

Execute the installation accurately, based on following the installation manual. Again, improper installations can result in water

leakage, electric shocks and fires.

When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned countermeasure for

the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration. In regards to preparing this

countermeasure, consult with the company from which you perchased the equipment, and make the installation accordingly.

In the rare event that a refrigerant leakage and exceeding of threshold concentration does occur, there is the danger of a

resultant oxygen deficiency accident.

For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insufficient, injury can

result from a falling of the unit.

Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons and hurricanes,

etc. Improper installations can result in accidents due to a violent falling over of the unit.

For electrical work, please see that a licensed electrician executes the work while following the safety standards related to

electrical equipment, and local regulations as well as the installation instructions, and that only exclusive use circuits are used.

Insufficient power source circuit capacity and defective installation execution can be the cause of electric shocks and fires.

Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to the terminal

connection part, through properly securing it. Improper connection or securing can result in heat generation or fire.

Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation can also result

in heat generation or fire.

When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated refrigerant

within the refrigeration cycle. Rupture and injury caused by abnormal high pressure can result from such mixing.

Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this company can

result in water leakage, electric shock, fire and refrigerant leakage.

WARNING

CAUTION

CAUTION

Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone ground

wire. Improper placement of ground wires can result in electric shock.

The installation of an earth leakage breaker is necessary depending on the established location of the unit. Not installing an

earth leakage breaker may result in electric shock.

Do not install the unit where there is a concern about leakage of combustible gas. The rare event of leaked gas collecting

around the unit could result in an outbreak of fire.

For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to prevent

condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

18

Page 25

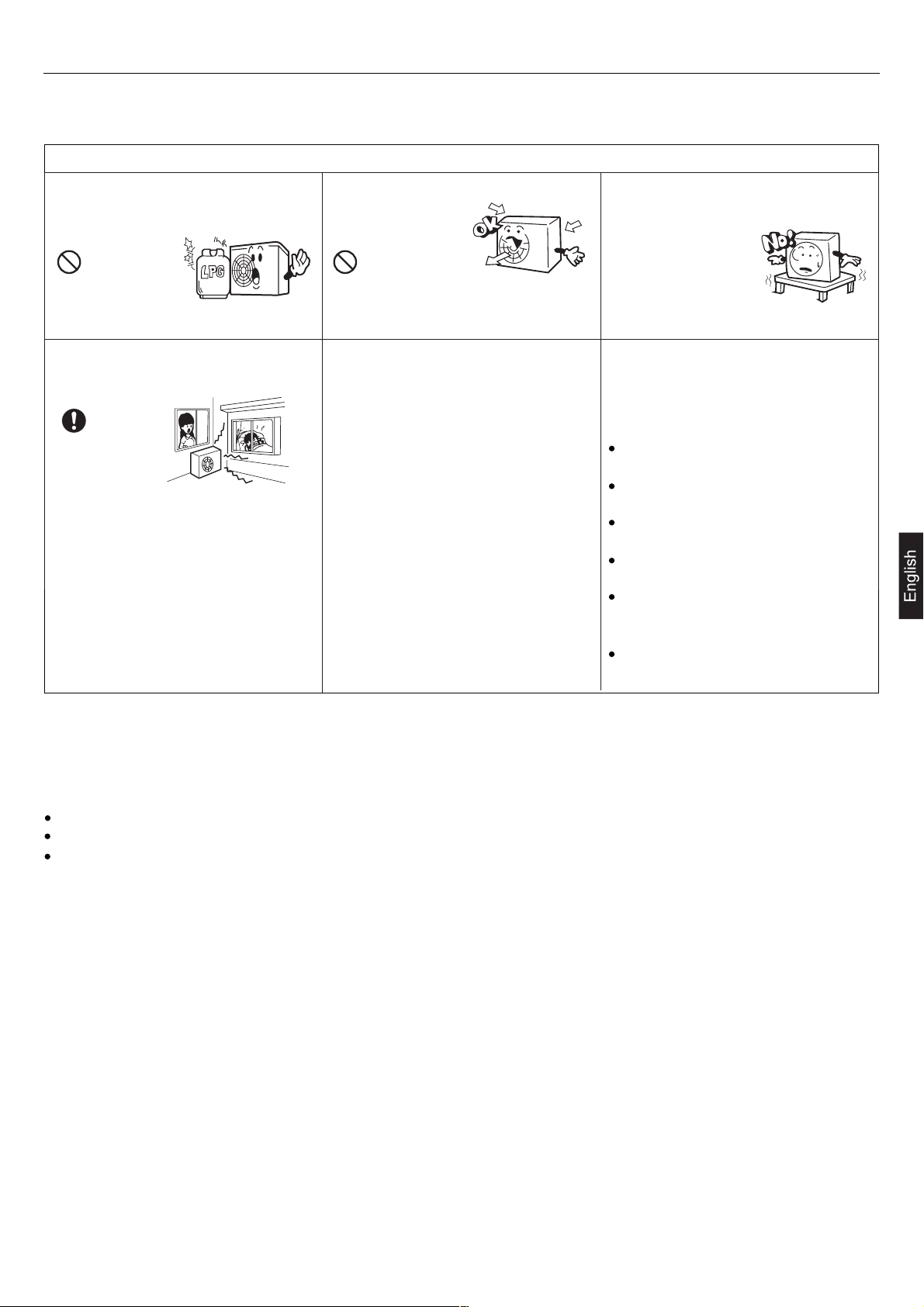

Is The Unit Installed Correctly

Confirm the following items for safe and comfortable use of air conditioner.

The installation work is to be burden on the sales dealer, and do not conduct it by yourself.

Installation place

Avoid installing the air conditioner near

the place where possibility of inflammable

gas leakage exists.

Select the place so as not to annoy

neighbor with the hot air or noise.

Install the unit at well ventilated place. Install the air conditioner firmly on the

foundation that can fully support the

weight of the unit.

If some obstacle exist, it may cause

capacity reduction or noise increase.Explosion (Ignition) may occur.

Snow protection work is necessary where

outdoor unit is blocked up by snow.

For details consult your sales dealer.

If not, it may cause vibration or noise.

It is advisable not to install the air

conditioner at the following special place.

It may cause malfunction, consult the

sales dealer when you have to install the

unit on such a place.

The place where corrosive gas

generates (Hot spring area etc.)

The place where salt breeze blows

(Seaside etc.)

The place where dense soot smoke

exists

The place where humidity is

extraordinarily high

The place where near the machine

which radiates the electromagnetic

wave

The place where voltage variation is

considerably large

Electric work

The electric work must be burden on the authorized engineer with qualification for electric work and grounding work, and the

work must be conducted in accordance with electric equipment technical standard.

The power source for the unit is to be of exclusive use.

An earth leakage breaker should be installed. This is necessary to prevent electric shock.

The unit must be grounded.

When you change your address or the installation place

Special technology is required for removal or reinstallation of air conditioner, consult the sales dealer. Besides, construction

expense is charged for removal or reinstallation.

For inspection and maintenance

The capacity of air conditioner will decrease by contamination of inside of unit when it is used for about three years although

depending upon the circumstances under which it is used, and so in addition to the usual maintenance service, special

inspection/maintenance service is necessary. It is recommended to make a maintenance contract (charged) by consulting your

sales dealer.

In the place with much dust, the condenser is easy to be blocked, which will result in the low cooling efficiency. So please clean

in period.

19

Page 26

Installation Procedure

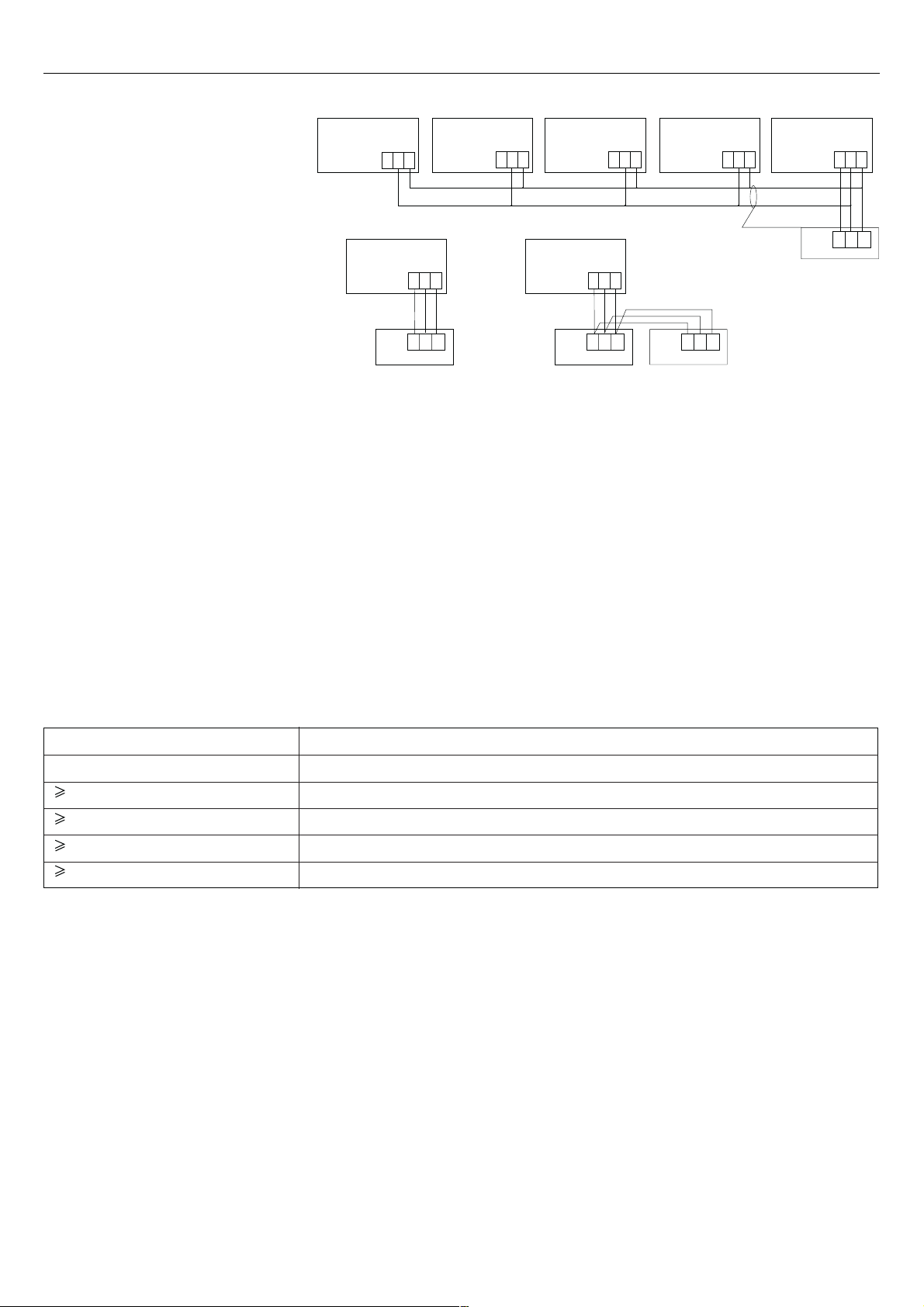

Wiring connections of wired controller

A

Wired controller Wired controller Wired controller Wired controller Wired controller

Wired controller

Indoor 16Indoor 15Indoor NIndoor 2Indoor 1

(master unit)

1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

BC

Indoor 1

Wired controller

Poler wire

Wired controller

1 2 3

A B C

Indoor 1

Wired controller

Poler wire

Wired controller

1 2 3

Poler wire

A B C

Wired controller

Control wiring of wired

controller, polar.

A B C

A B C

Wired controller

There are three methods to connect wired controller and the indoor units:

A.One wired controller can control max. up to 16 sets of indoor units. In this case, 3 pieces of polar wire must connect

the wired controller and the master unit (the indoor unit connected with wired controller directly), the others connect with

the master unit through 2 pieces of polar wire.

B. One wired controller controls one indoor unit. The indoor unit connects with the wired controller through 3 pieces

of polar wire.

C. Two wired controllers control one indoor unit. The wired controller connected with indoor unit is called master one,

the other is called slave one. Master wired controller and indoor unit; master and slave wired controllers are all connected

through 3 pieces of polar wire.

Note:

The method A needs to set the PCB function switch. The method C needs to set the controller function switch.

Communication wiring

The wired controller is equipped with special communication wiring in the accessories. 3-core terminal (1-white 2-yellow

3-red) is connected with the terminal A, B, C of wired controller respectively.

The communication wiring is 4 meter long. If the actual length is more than it, please distribute wiring according to below

table:

Communication wiring length(m) Dimensions of wiring

< 100 0.3mm

100 and <200 0.5mm

200 and <300 0.75mm

300 and <400 1.25mm

400 and <600 2mm

2

x 3-core shielded wire

2

x 3-core shielded wire

2

x 3-core shielded wire

2

x 3-core shielded wire

2

x 3-core shielded wire

*One side of the shielded sheet of communication wire must be earthed.

20

Page 27

Installation Procedure

CAUTION

Please do not install the unit in places where flammable gases may be leaked. In case that gas is leaked and accumulated

around the unit, it may cause dangers of fire etc.

The indoor unit shall be installed at locations where cold and hot air could evenly circulated. The following locations

should be avoided

Places with rich saline matters (seaside regions).

Places with plenty of gas sulfides (mainly in warm spring areas where the copper tube and braze weld is prone to corrosion).

Locations with much oil (including mechanical oil) and steam.

Locations using organic solvents.

Places where there are machines generating HF electromagnetic waves.

Positions adjacent to door or window in contact with high-humidity external air. (Easy to generate dew).

Locations frequently using special aerosols.

Selecting the mounting position to install the indoor units

Select suitable places where the outlet air can be sent to the entire room, and convenient to lay out

the connection pipe, connection wire and the drainage pipe to outdoor.

The ceiling structure must be strong enough to support the unit weight.

The connecting pipe, drain pipe and connection wire shall be able to go though the building wall

to connect between the indoor and outdoor units.

The connecting pipe between the indoor and outdoor units as well as the drain pipe shall be as

short as possible.

If it is necessary to adjust the filling amount of the refrigerant, please refer to the installation manual

attached with the outdoor unit.

The connecting flange should be provided by the user himself.

The indoor unit has two water outlets one of which is obstructed at the factory (with a rubber cap). Only the outlet not obstructed

(liquid inlet and outlet side) will be generally used during installation. If applicable, both the outlets should be used together.

An access port must be provided during installation of indoor unit for maintenance.

Indoor Unit

After selecting the unit installation location, proceed the following steps:

1. Drill a hole in the wall and insert the connecting pipe and wire through a PVC wall-through tube

purchased locally. The wall hole shall be with a outward down slope of at least 1/100.

2. Before drilling check that there is no pipe or reinforcing bar just behind the drilling position.

Drilling shall avoid at positions with electric wire or pipe.

3. Mount the unit on a strong and horizontal building roof. If the base is not firm, it will cause noise,

vibration or leakage.

4. Support the unit firmly.

5. Change the form of the connection pipe, connection wire and drain pipe so that they can go through the wall hole easily.

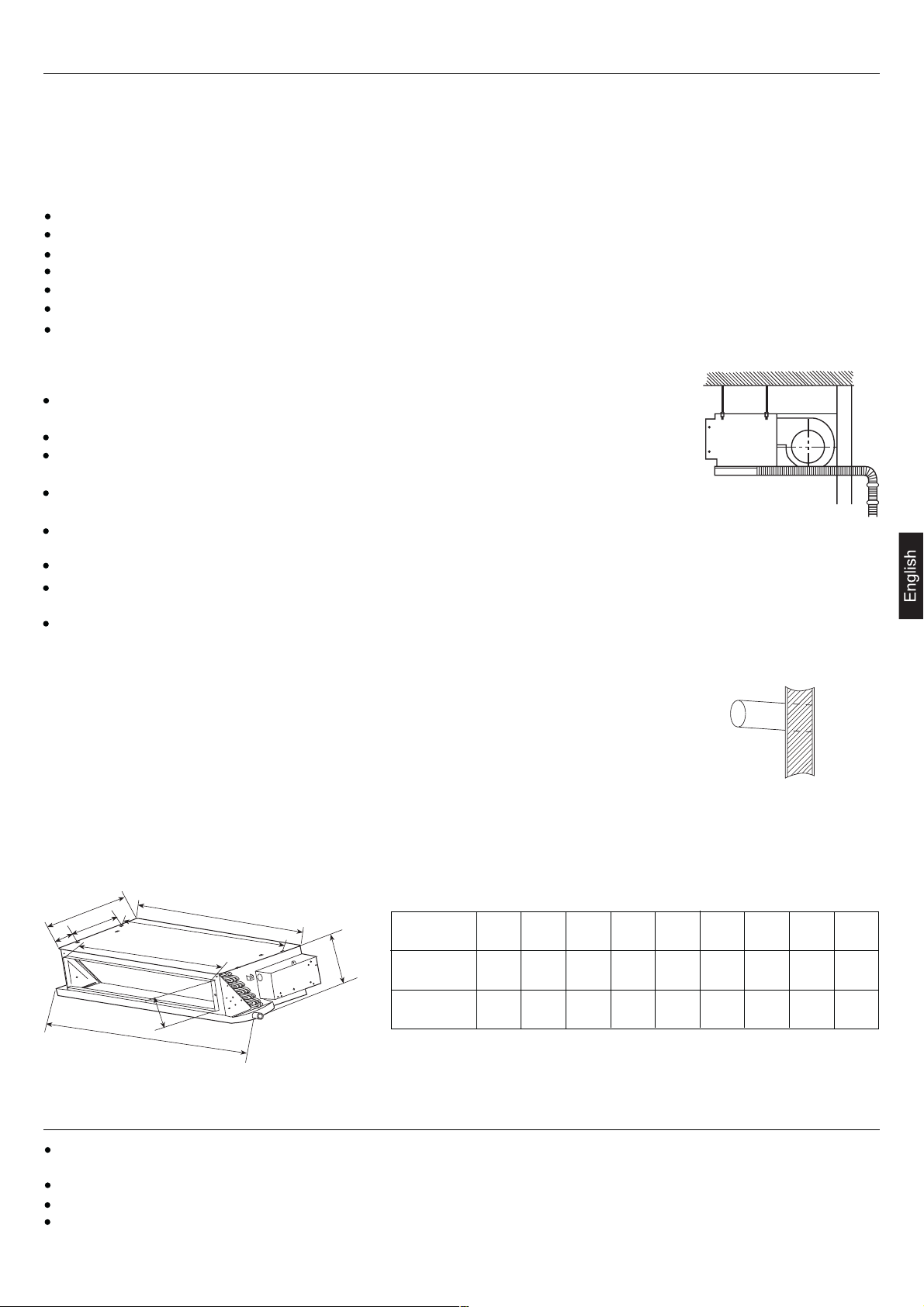

Installation dimension

b

e

f

g

c

d

a

h

i

Installation Procedure

Indoor unit dimensions(unit:mm)

Unit model a

182, 242

1002

538

b

483.5

483.5

c

131

131

d

610

1105

e

255

255

f

105

105

g

418

880

h

508

970

Air Duct

i

220122

220

Each of the air sending duct and air return duct shall be fixed on the prefabricated panel of the floor by the iron bracket. The

recommended distance between the edge of the air return duct and the wall is over 150mm.

The gradient of the condensate water pipe shall keep over 1%.

The condensate water pipe shall be thermal insulated.

When installing the ceiling Concealed type indoor unit, the air return duct must be designed and installed as figure shown.

21

Page 28

Installation Procedure

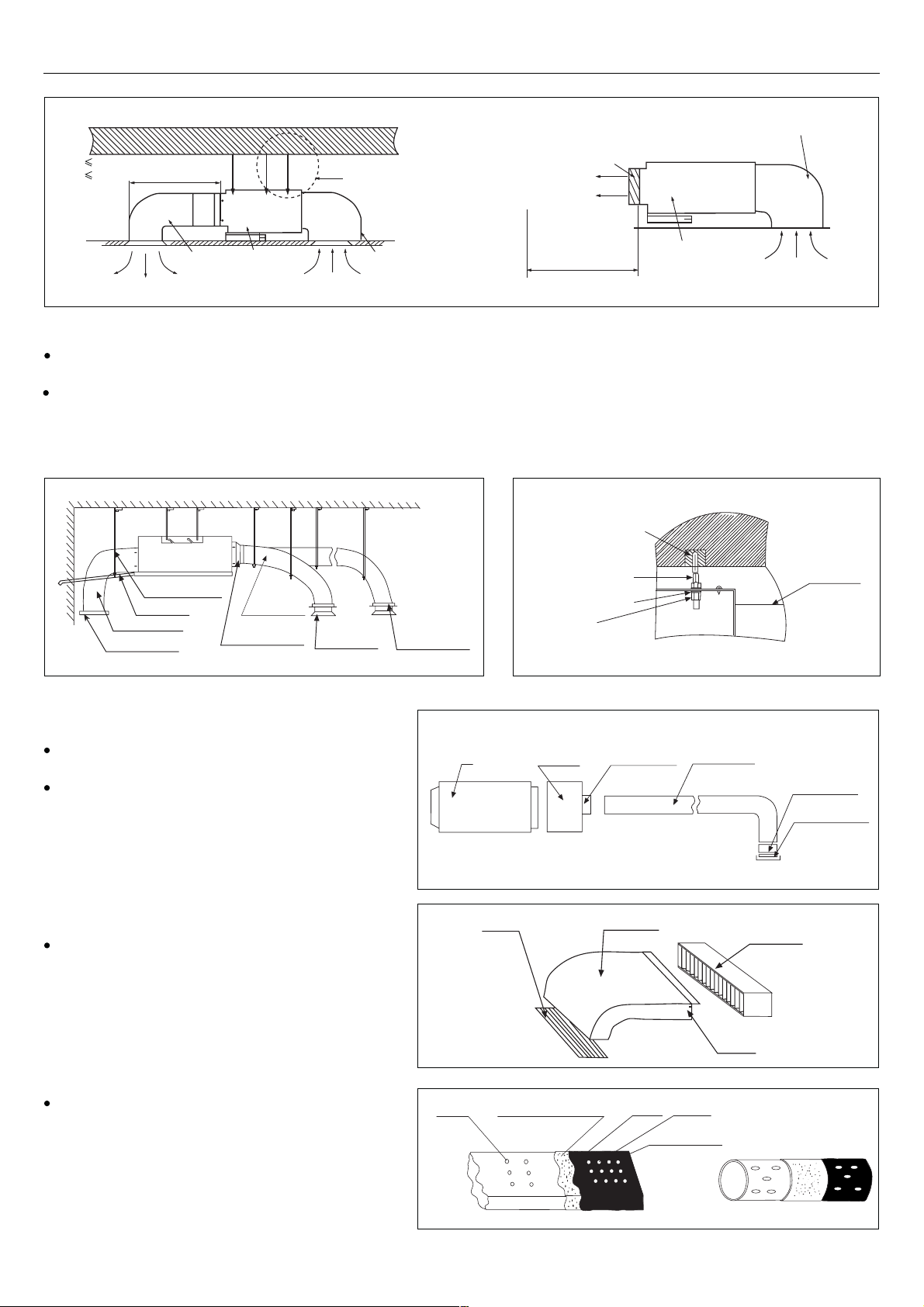

Air Duct

Building roof of installation

0.5m (use white motor plug)

2.0m (use red motor plug)

Ceiling

Air supply

Unit

A

Return air box

Return air

Air outlet grille

Air supply

There should

be no obstacles

within 1m

Unit

Note:

When connecting the short ducts, use the low static terminals, which color is white.

The distance L from the air outlet of the duct to the air outlet of the air conditioner shall be no more than 0.5 m.

When connecting the long ducts, use the middle static terminals, which color is red.

The distance L from the air outlet of the duct to the air outlet of the air conditioner shall be no more than 2.0 m.

The sketch map of long duct

M8 wide expansion bolt

Return air box

Return air

Suspending hook

Drain pipe

Air return duct

Air return blind

Air out duct

Transition duct

Air distributary

1. Installation of air sending duct

This unit uses rounded duct, the diameter of the duct

is 180mm.

The rounded duct needs to add a transition duct to

connect with the air-sending duct of indoor unit, then

connect with respective separator. As Figure shown,

all the fan speed of any of the separator's air outlet

shall be adjusted approximately the same to meet

the requirement for the room air conditioner.

2. Installation of air return duct

Use rivet to connect the air return duct on the air

return inlet of the indoor unit, then connect the other

end with the air return blind as Figure shown.

Tie-in of air

distributary

Indoor unit

M8 suspender screw

M8 wide lock washer

M8 screw nut

Soft connection

or static box

Air return blind

Air conditioner

Transition duct Rounded duct

Tie-in of air

distributary

Air distributary

Unit: mm

Air return duct

Indoor unit

3.Thermal insulation of duct

Air-sending duct and air return duct shall be thermally

insulated. First stick the gluey nail on the duct, then

attach the heat preservation cotton with a layer of

tinfoil paper and use the gluey nail cap to fix. Finally

use the tinfoil adhesive tape to seal the connected

part. As Figure shown.

rivet

gluey nail gluey nail cap

tinfoilheat preservation cotton

adhesive tape

22

Page 29

Installation Procedure

Air Duct

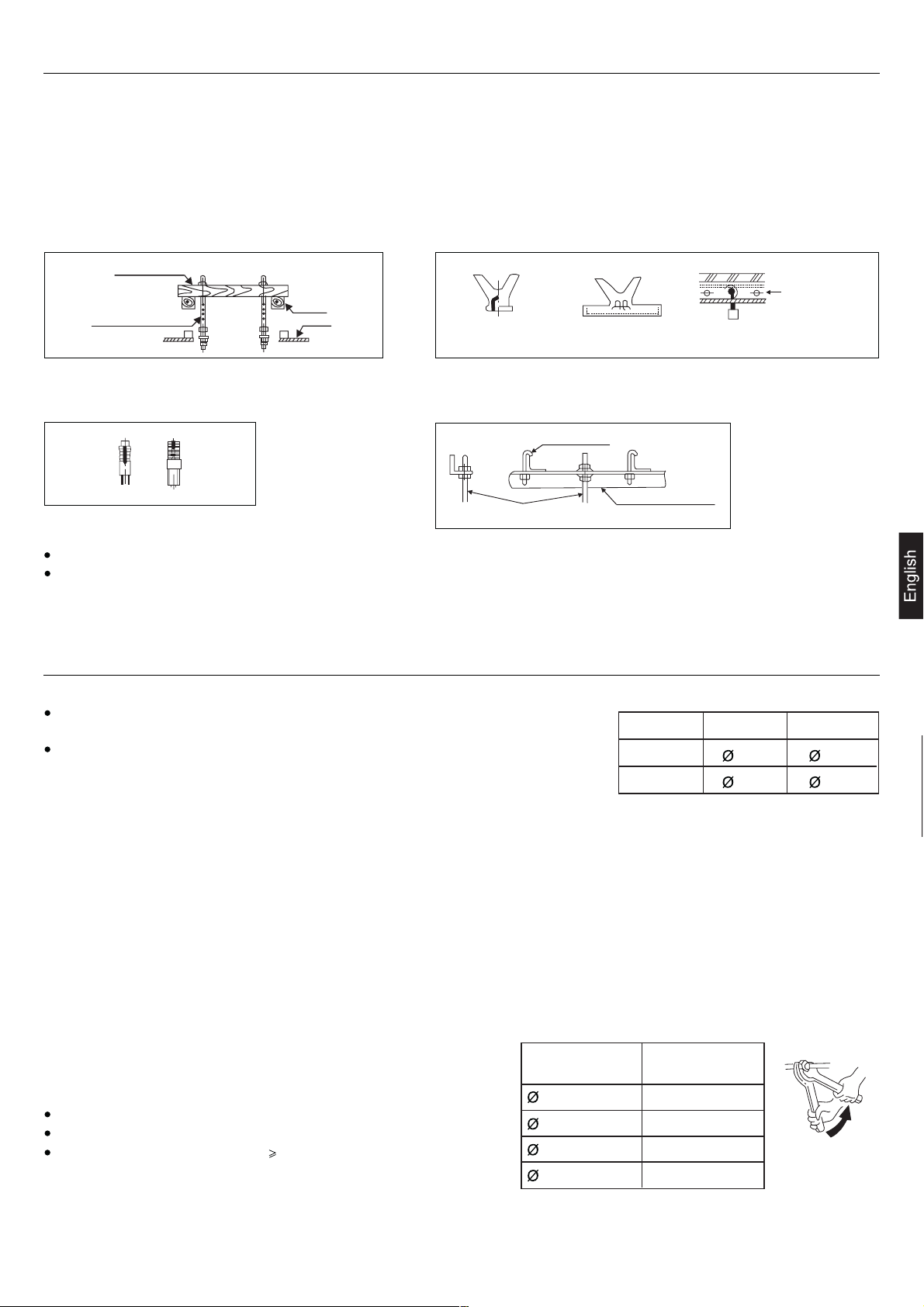

Installing the suspension screw

Use M8 or M10 suspension screws (4, prepared in the field) (when the suspension screw height exceeds 0.9m, M10 size is the

only choice). These screws shall be installed as follows with space adapting to air conditioner overall dimensions according to

the original building structures.

Wooden structure

A square wood shall be supported by the beams and

New concrete slab

To set with embedded parts, foundation bolts etc.

then set the suspension screws.

Square wood

Iron reinforcement

Suspension screw

Beam

Original concrete slad

Use hole hinge, hole plunger or hole bolt.

Knife embedded part Guide plate embedded part Pipe suspension foundation bolt

Steel reinforcement structure

Use steel angle or new support steel angle directly.

Hanging bolt

Support steel angle

Suspension screw

Foundation bolt

Hanging of the indoor unit

Fasten the nut on the suspension screw and then hang the suspension screw in the T slot of the suspension part of the unit.

Aided with a level meter, adjust level of the unit within 5mm

Installation Procedure

Caution

In installation, if there is refrigerant gas leakage, please take ventilation measures

immediately. The refrigerant gas will generate poisonous gas upon contacting fire.

After installation, please verify that there is no refrigerant leakage. The leaked

Pipe size (unit :mm)

Model

122, 182

Refrigerant Pipe

Gas side Liquid side

12.70

6.35

refrigerant gas will produce poisonous gas when meeting fire source such as

heater and furnace etc.

242

15.88

9.52

Pipe material

Phosphorus deoxidized copper seamless pipe (TP2M) for air conditioner.

Allowable pipe length and drop

These parameters differ according to the outdoor unit. See the instruction manual attached with the outdoor unit for details.

Supplementary refrigerant

The refrigerant supplementation shall be as specified in the installation instructions attached with the outdoor unit.

The adding procedure shall be aided with a measuring meter for a specified amount of supplemented refrigerant.

Note:

Overfilling or underfilling of refrigerant will cause compressor fault. The amount of the added refrigerant shall be as specified in

the instructions.

Connection of refrigerant pipe

Conduct flared connection work to connect all refrigerant pipes.

The connection of indoor unit pipes must use double spanners.

The installing torque shall be as given in the following table.

Wall thicknessof connection pipe 0.8mm

Connecting pipe

O.D.(mm)

6.35

9.52

12.70

15.88

Installing torque

(N-m)

11.8 (1.2kgf-m)

24.5 (2.5 kgf-m)

49.0 (5.0 kgf-m)

78.4 (8.0 kgf-m)

Double-spanner

operation

Creating vacuum

With a vacuum pump, create vacuum from the stop valve of the outdoor unit. Emptying with refrigerant sealed in the outdoor

unit is absolutely forbidden.

23

Page 30

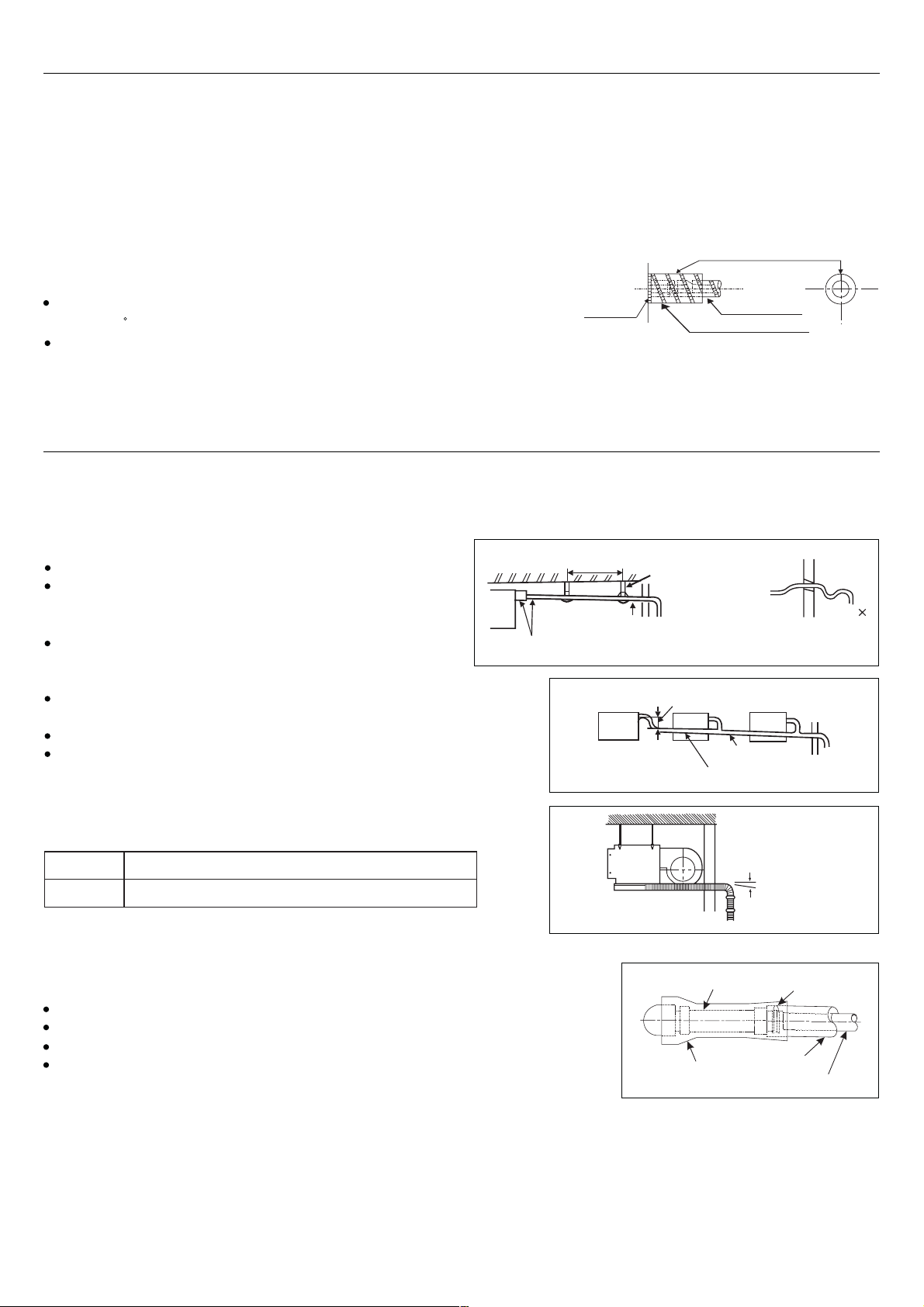

Installation Procedure

Open all valves

Open all the valves on the outdoor unit.

Gas leakage detection

Check with a leakage detector or soap water if there is gas leakage at the pipe connections and bonnets.

Insulation treatment

Conduct insulation treatment on both the gas side and liquid side of pipes respectively.

During cooling operation, both the liquid and gas sides are cold and thus shall be insulated

so as to avoid dew generation.

The insulating material at gas side shall be resistant to a temperature

Indoor unit

above 120 C

The indoor unit pipe connection part shall be insulated.

The notch upward(Attached detail view)

Field piping side

Subsidiary insulation tube

Refrigerant Pipe

Installation Procedure

Drain Pipe

Caution

In order to drain water normally, the drain pipe shall be processed as specified in the installation manual and shall be thermal

insulated to avoid dew generation. Improper hose connection may cause indoor water leakage.

Requirements

The indoor drain pipe shall be thermal insulated.

1.5m~2m

Support

The connection part between the drain pipe and

the indoor unit shall be insulated so as to prevent

dew generation.

The drain pipe shall be slant downwards (greater

Insulation (supplied by the user)

Down slope above 1/100

S type elbow

than 1/100). The middle part shall not be of S type

elbow, otherwise abnormal sound will be produced.

The horizontal length of the drain pipe shall be less than 20 m. In case of

To the largest (app. 10cm)

long pipe, supports shall be provided every 1.5 _ 2m to prevent wavy form.

Central piping shall be laid out according to the right figure.

Take care not to apply external force onto the drain pipe connection part.

Pipe and insulation material

Pipe

Insulation

Rigid PVC pipe VP20 mm (internal diameter)

Foamed PE with thickness above 7 mm

Down slope above 1/100

VP30

Wall

Outside

Slant

Drain pipe (supplied

by the user)

Hose

Drain pipe size: (3/4") PVC pipe

The hose is used for adjusting the off-center and angle of the rigid PVC pipe.

Hose Hose clamp

Directly stretch the hose to install without making any deformation.

The soft end of the hose must be fastened with a hose clamp.

Please apply the hose on horizontal part Insulation treatment.

Wrap the hose and its clamp up to the indoor unit without any

Subsidiary insulation

clearance with insulating material, as shown in the figure.

Drain confirmation

During trial run, check that there is no leakage at the pipe connection part during water draining even in winter.

24

Insulation

Rigid PVC pipe

Page 31

Installation Procedure

WARNING

DANGER OF BODILY INJURY OR DEATH

TURN OFF ELECTRIC POWER AT CIRCUIT BREAKER OR POWER SOURCE BEFORE MAKING ANY ELECTRIC

CONNECTIONS. GROUND CONNECTIONS MUST BE COMPLETED BEFORE MAKING LINE VOLTAGE CONNECTIONS.

Precautions for Electrical wiring

Electrical wiring work should be conducted only by authorized personnel.

Do not connect more than three wires to the terminal block. Always use round type crimped terminal lugs with insulated grip on

the ends of the wires.

Use copper conductor only.

Selection of size of power supply and interconnecting wires

Select wire sizes and circuit protection from table below. (This table shows 20 m length wires with less than 2% voltage drop.)

Model

122, 182

242

Item

Phase

Circuit breaker

Switch breaker

(A)

Overcurrent protector

rated capacity (A)

Power source

wire size

(minimum)

(mm

2

)

Earth leakage breaker

breaker(A)

Electrical wiring

Switch

Leak

current(mA)

301 40 26 2.5 40

301 40 26 4.0 40

Wiring connection

Make wiring to supply power to the outdoor unit, so that the power for the indoor unit is supplied by terminals.

AD182ALERA

AD242ALERA

AD242ALEAA

Make wiring to supply power to the indoor unit, so that the power for the outdoor unit is supplied by terminals.

AD122ALEAA

AD122ALERA

AD182ALEAA

Indoor unit

terminal block

Outdoor unit

terminal block

Power supply :1PH, 220-230V~, 50Hz

Outdoor unit

terminal block

Indoor unit

terminal block

123

12 3NL

12 3NL

Y/G

123LN

Y/G

Y/G

Y/G

Power supply:1PH, 220-230V~, 50Hz

25

Page 32

Page 33

IST HA082 Rev. 00-2007

• Si prega di leggere il presente manuale di istruzioni prima di utilizzare il climatizzatore

• Conservare il presente manuale per ogni futura evenienza.

CLIMATIZZATORE UNITARY SMART

CANALIZZATO 20Pa

MANUALE DI ISTRUZIONI

MANUALE DI INSTALLAZIONE

On-Off

EAA

Inverter

AD122ALERA

AD182ALERA

AD242ALERA

AD182ALEAA

AD242ALEAA

AD122AL

Page 34

Indice

Precauzioni per l'uso 3

Denominazione dei componenti 5

Tasti e display del comando a filo 6

Funzionamento 8

Manutenzione 13

Guida alla ricerca dei guasti 14

Diagnostica 16

Precauzioni per l'installazione 18

Installazione del comando a filo 20

Installazione dell'unità interna 21

2

Page 35

• Si prega di leggere il presente manuale di istruzioni prima di

utilizzare il climatizzatore.

• Le precauzioni di sicurezza di seguito elencate si

suddividono in PERICOLO e ATTENZIONE. La voce

PERICOLO riguarda precauzioni che, se non seguite,

possono portare a serie conseguenze, quali morte, gravi

lesioni, ecc. Tuttavia, anche la voce ATTENZIONE riguarda

precauzioni che, se non osservate, possono causare seri

problemi, a seconda della situazione.

• Tenere le Precauzioni di sicurezza sempre a portata di

mano, affinché possano essere consultate in qualsiasi

momento.

PERICOLO

Non dirigere il flusso d'aria fredda

direttamente sulle persone, e non lasciar