MRV Intelligent Network Cassette Type

Air Conditioner Indoor Unit

INSTALLATION MANUAL

No.0010570459

B

Please read this manual carefully before using.

Please keep this manual carefully and safely.

AB072FDAHA

AB092FDAHA

AB122FDAHA

AB162FDAHA

AB182FDAHA

AB242FDAHA

AB282FDAHA

AB072FDBHA

AB092FDBHA

AB122FDBHA

AB162FDBHA

AB182FDBHA

AB242FDBHA

AB282FDBHA

Contents

Safety cautions 1

Indoor unit installation 2 7

Refrigerant piping 8 9

Electrical wiring & Application control 10 14

Trial operation 15

Troubleshooting 16 17

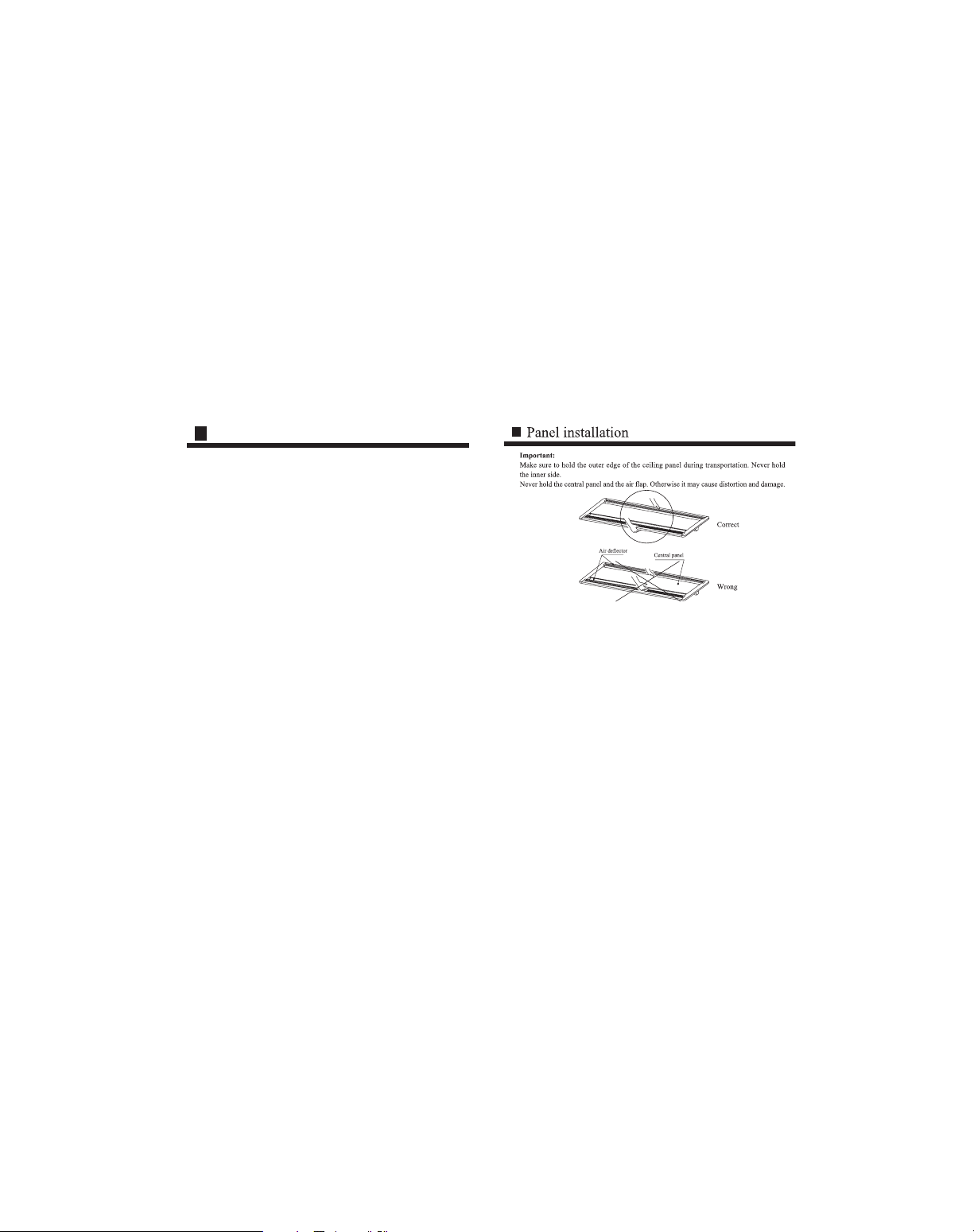

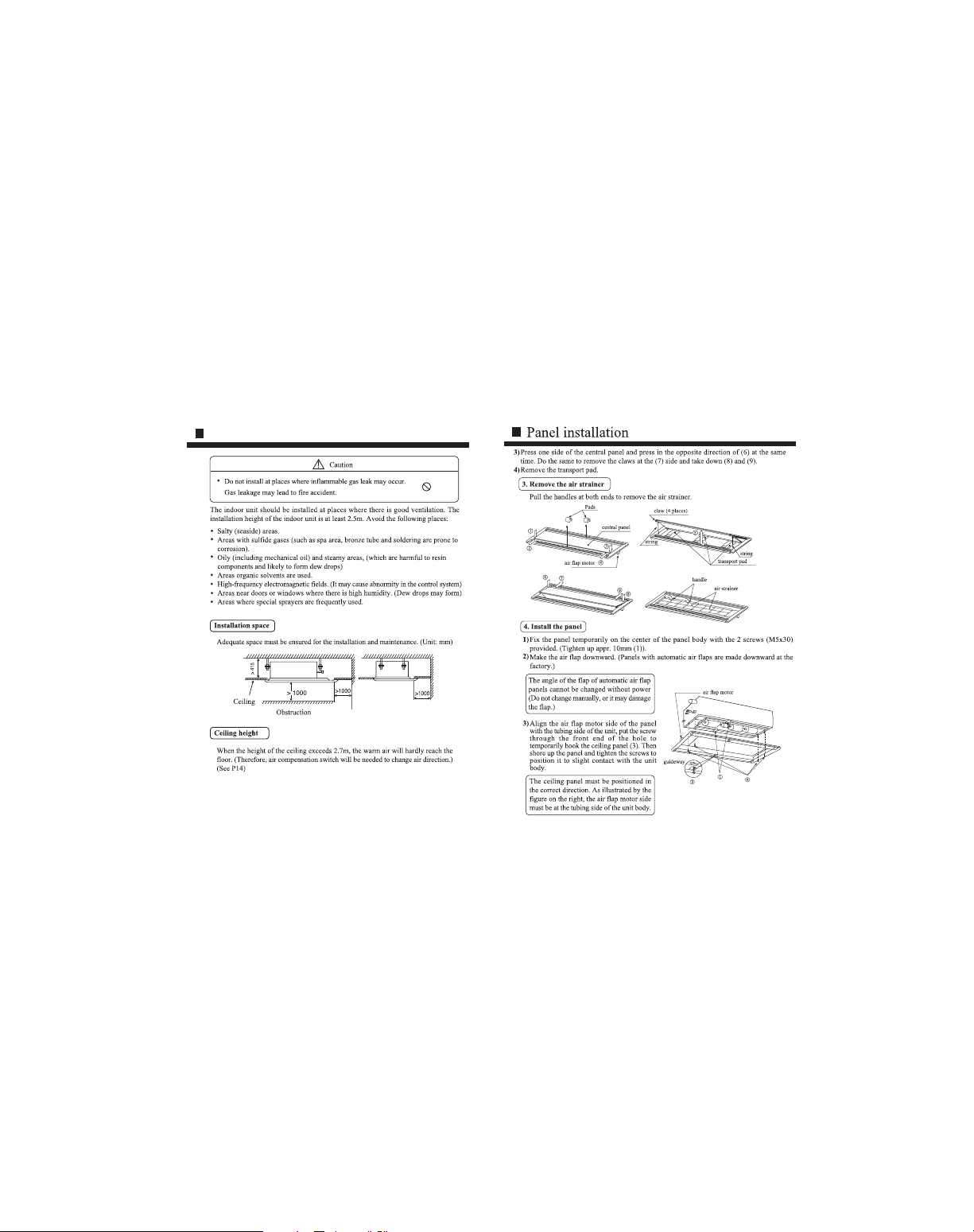

Panel installation 18 21

Caution

Auto Restart function for C MRV models

Haier Auto Restart function when the unit power drops down suddenly, the unit

microprocessor will store the previous working condition and when the power is on again,

the unit will run as this memory

Auto Restart function is designed basically on the MRV whole system, but it is suitable

for each indoor unit individually

If some of indoor units power cut down, but the outdoor unit and the other indoor units

still work, maybe problems will happen such as freezing at cooling mode and overload

protection at heating mode on those indoor units without power

Reason

When one or some indoor units power drops down and the other indoor units are still

work, the indoor units without the power, will keep the previous working condition before

the power is off And expansion valve keeps open at a kind of opening rate condition as

the previous requirement, so there is refrigerant flowing in the exchanger, but the indoor

fan stops working If the units work at cooling mode, the indoor units without the power

will maybe make freezing If the unit works at heating mode, maybe the outdoor unit

compressor will stop because of the pressure or temperature protection This is our design

basically on Auto Restart function currently

Haier, Herewith, solemnly informs our customers, installers, distributors, etc when making

installation, please make sure when the power is shut down whether artificially or

accidentally, the whole system including outdoor unit and all the indoor units must

be off. If you do not make the installation as our indication, Haier will not be responsible

for any problem resulting from this.

21

20

Safety Cautions

1

The following safety measures must be strictly followed

Keep these safety measures close at hand for timely references

After installation, trial run must be made to ensure normal operation Familiarize the user with the use

and maintenance through this manual

If the air conditioner is transferred to a new user, this manual should also be transferred

Please pay attention to the following:

Warning: Inappropriate use may lead to fatal or serious injuries

Caution: Inappropriate use may lead to bodily harm or mechanical damage; it may lead to serious

consequences in some cases

Any instructions with the sign of ì NOî shall be strictly followed, otherwise, it may cause me

chanical damage or endanger the safety of the user

Any instructions with the sign of ì STOPî shall be strictly followed, otherwise, it may cause me

chanical damage or endanger the safety of the user

Entrusted ins allation

Ins allation should be entrusted with after sale

servicemen Self installation is likely to cause

water leakage, shock and fire, etc

Ins allation should be done according to this install

ation manual Inappropriate installation may lead to

water leakage, shock and fire, etc

Connection of the earth wire

The earth wire should not be connected to gas pipes,

water pipes, lightning rods or telephone wires Poor

earth may lead to shocks

After sale servicemen shou d take measures to avoid

refrigerant eakage

Refrigerant leak may cause anox a when a certain

density is reached If the room is small, make sure o

have sound safety measures to avoid anox a acciden s

The installation of the elec ric part should be con

ducted by qualified professionals and done accord

ing to the installation manual Special return circuit

must be used Insufficient capacity return circuit and

inappropriate installation may lead to fire accidents

Installation site

The site must be firm enough to withstand the weight

of the air conditioner to prevent falling

During installation, if refrigerant leakage occurs,

ventilation measures must be taken When refrig

erant meets with fire, hazardous gas will be produced

After installation, make sure that there is no refriger

ant leakage

Refrigerant, if meeting with heaters and stoves, etc

in the room, may produce hazardous gas

Specific cables should be used for the wiring To avoid

external tension of the cables, the terminals should

be firmly fixed Inappropriate connection and fix ure

may lead to fire accidents

In order to discharge the condensed water, the

installation of the drainpipe should be done in

accordance with the manual instructions The

drainp pe should be treated for heat isolation

Inappropriate treatment may lead to water leak

age in the room

Electric leak breaker should be installed

Wi hout t, shock accidents may occur

Do not install at places where inflammable gas leak

may occur

Gas eakage may lead to fire accident

Caution

Warning

2

Indoor unit installation

19

18 3

Indoor unit installation

4

Indoor unit installation

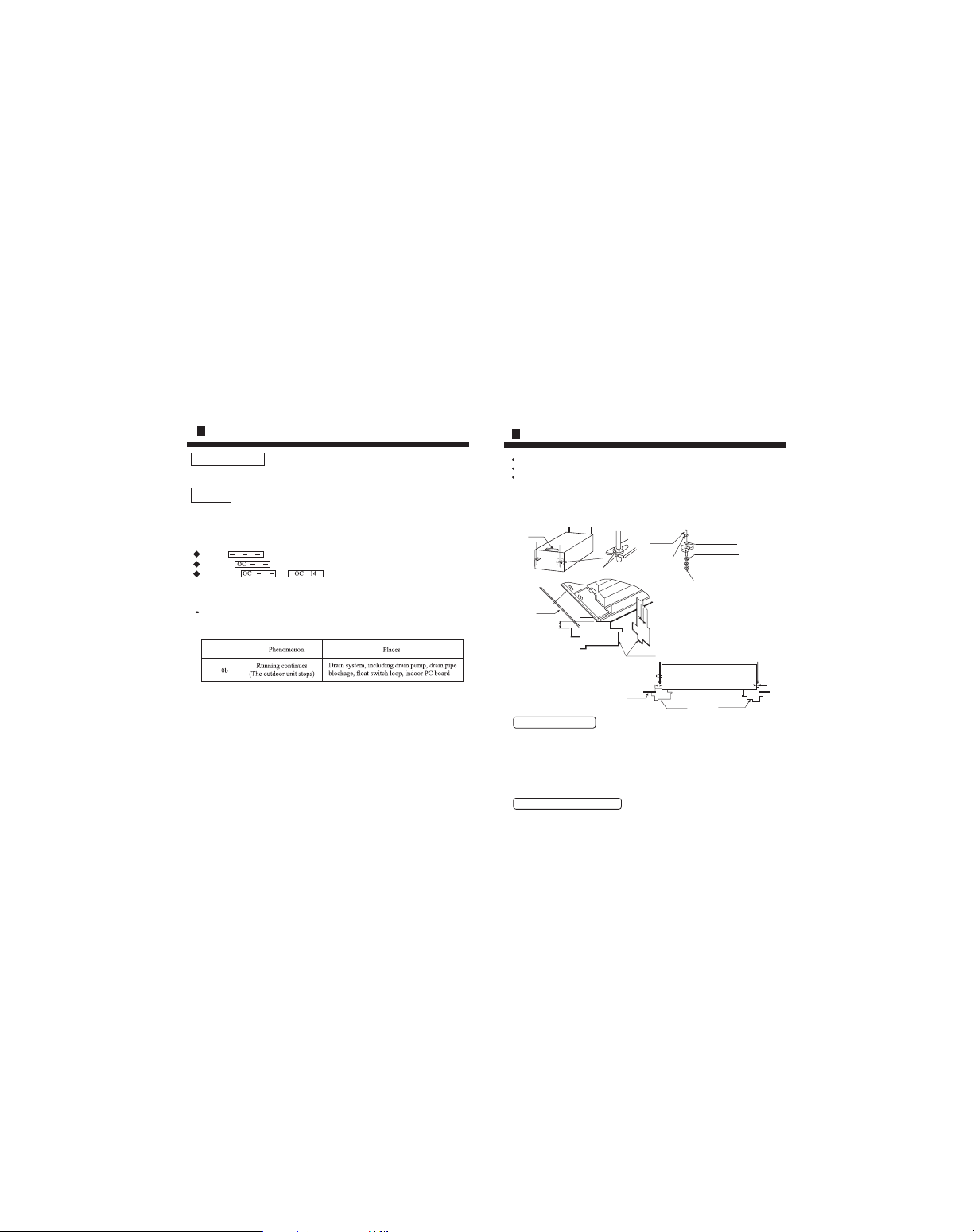

Troubleshooting

17

93/94

11

12

14

17

18

1C

1d

1F

21

b5

b6

97

98

99

0C

Phenomenon

Running

continues

Running

continues

All stop

Running continues

All stop

All stop

All stop

All stop

All stop

All stop

All stop

Running continues

All stop

Running continues

Running continues

Stops

Runs

Outdoor interlocked input, including outdoorl unit and indoor PC board

Room temperature sensor (TA) circuit, including Room temperat

ure seasor (TA), indoor PC board

Indoor heat exchanger temperature sensor circuit (TC1/TC2), including indoor

heat exchanger temperature sensor (TC1/TC2) and indoor PC board

Indoor fan system, including revolution detecting circuit, indoor fan mo

tor and indoor PC board

Indoor unit, including PC board (EEPROM and peripheral circuit)

Converter overcurrent protection circuit, including G Tr, outdoor PC

board, converter wiring and compressor

Current sensor circuit, including current detecting circuit and outdoor

converter PC board

Outdoor defrosting sensor circuit, including outdoor defrosting sensor (TE)

and outdoor converter PC board

Outdoor unit, including outdoor interface control (I/F) PC board

Compressor system, including compressor lock and phase absence

Current detecting circuit, including power pressure and overload of refrig

erant circulation

High presure switch circuit, including high pressure switch and overload

of refrigerant circulation

Setting of indoor unit number and remote controller

Connecting wire, indoor PC board and remote controller

Center controlled address setting, including address setting (SW02),

central remote controller and indoor PC board

Center controlled communication circuit, including communication wire,

centralized controller, indoor power and indoor PC board

Outdoor abnormal input, including outdoor unit and indoor PC board

Fault

code

Reasons

Fault codes and reason

Troubleshooting

16

Confirm and verify

1 Press the ì Checkî switch on the remote controller for 1 2 seconds, ì Checkî will appear, and

the unit number and the error code will be displayed on the remote controller

2 The displayed number is the error unit number

3 Example is listed as follows:

Normal:

One error:

Two errors:

The signs will be displayed for a very short time If not seen clearly, press the ì Checkî switch again

When failure occurs, use the remote controller to display the corresponding error code

Checking

Fault codes and error place

Fault code

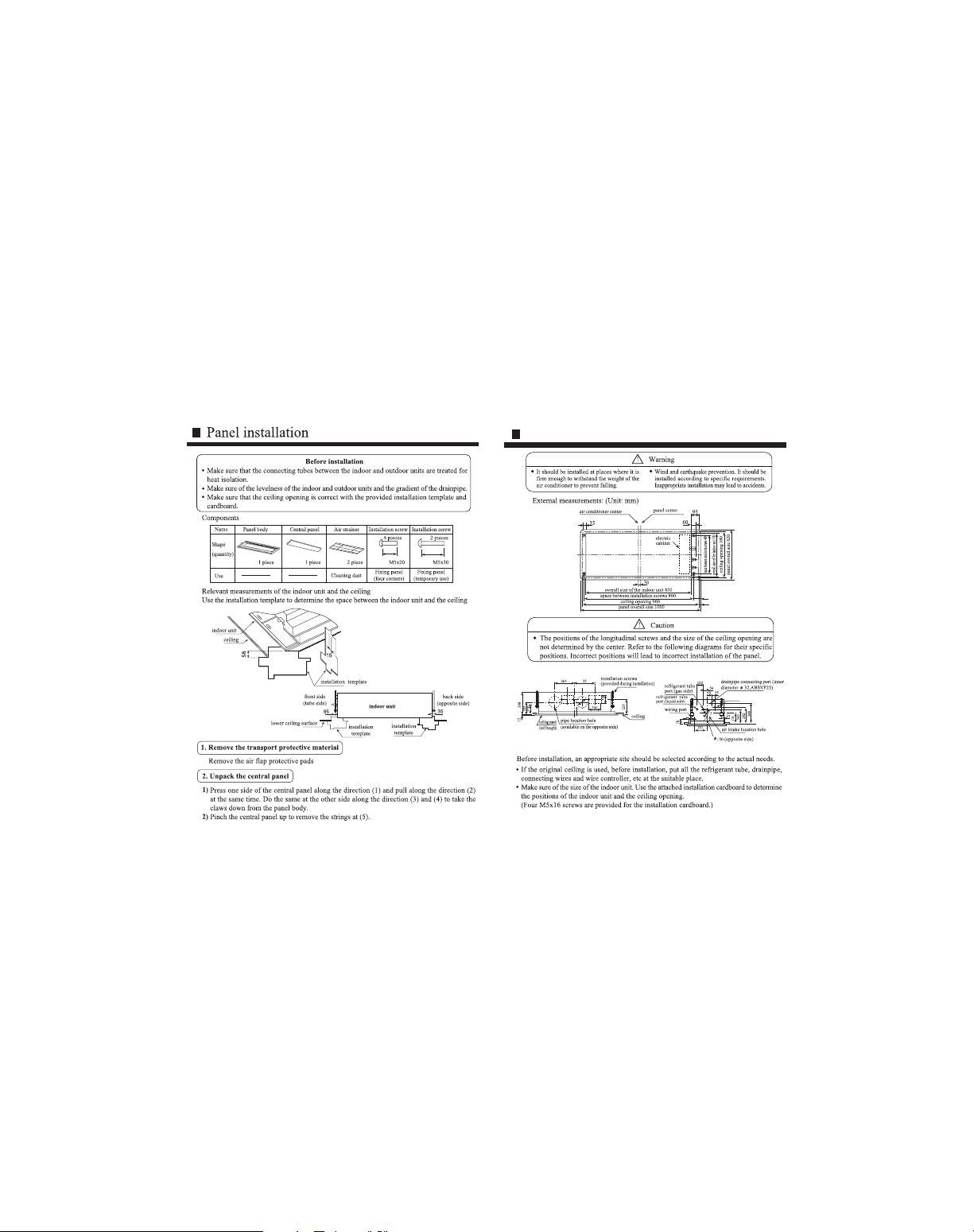

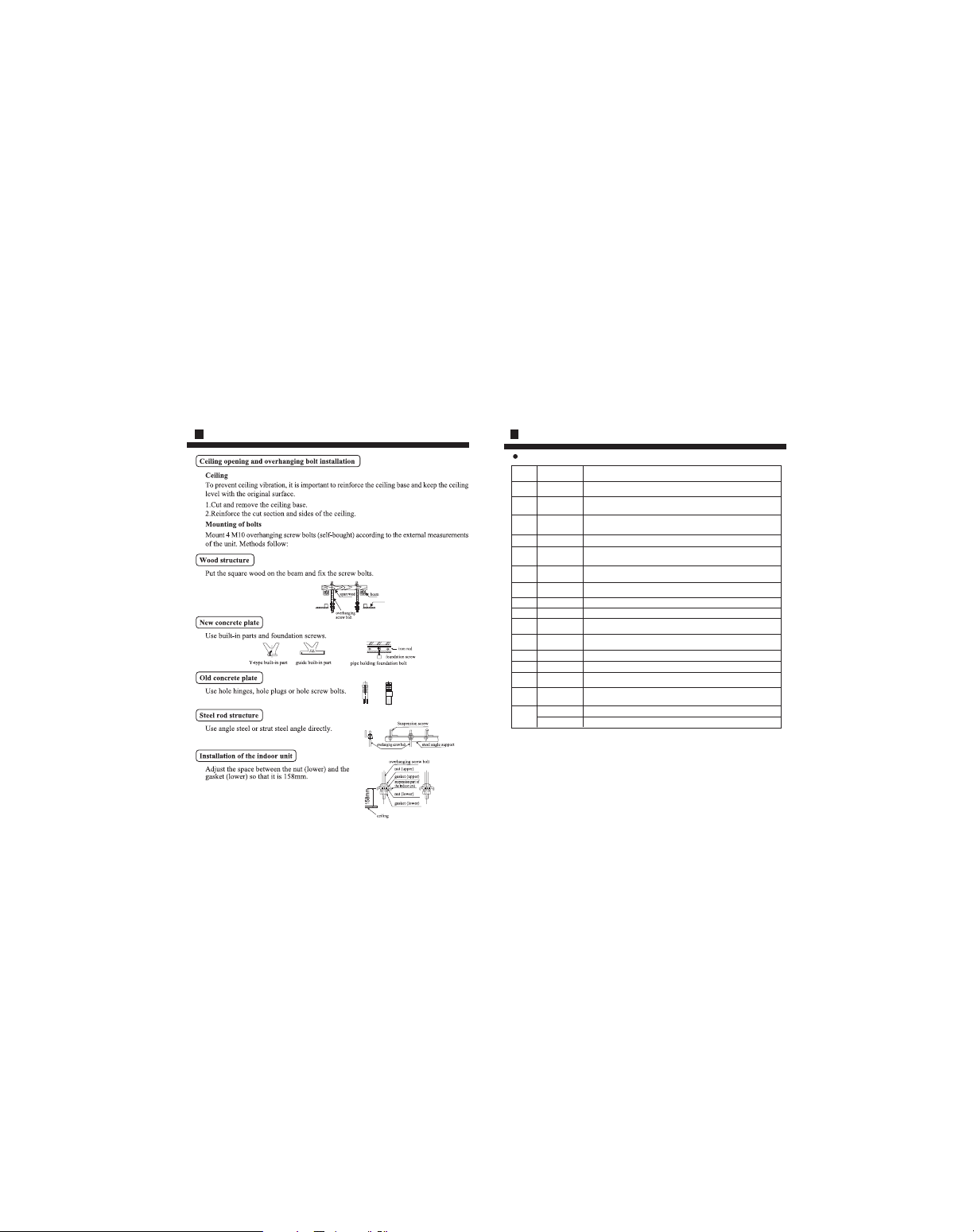

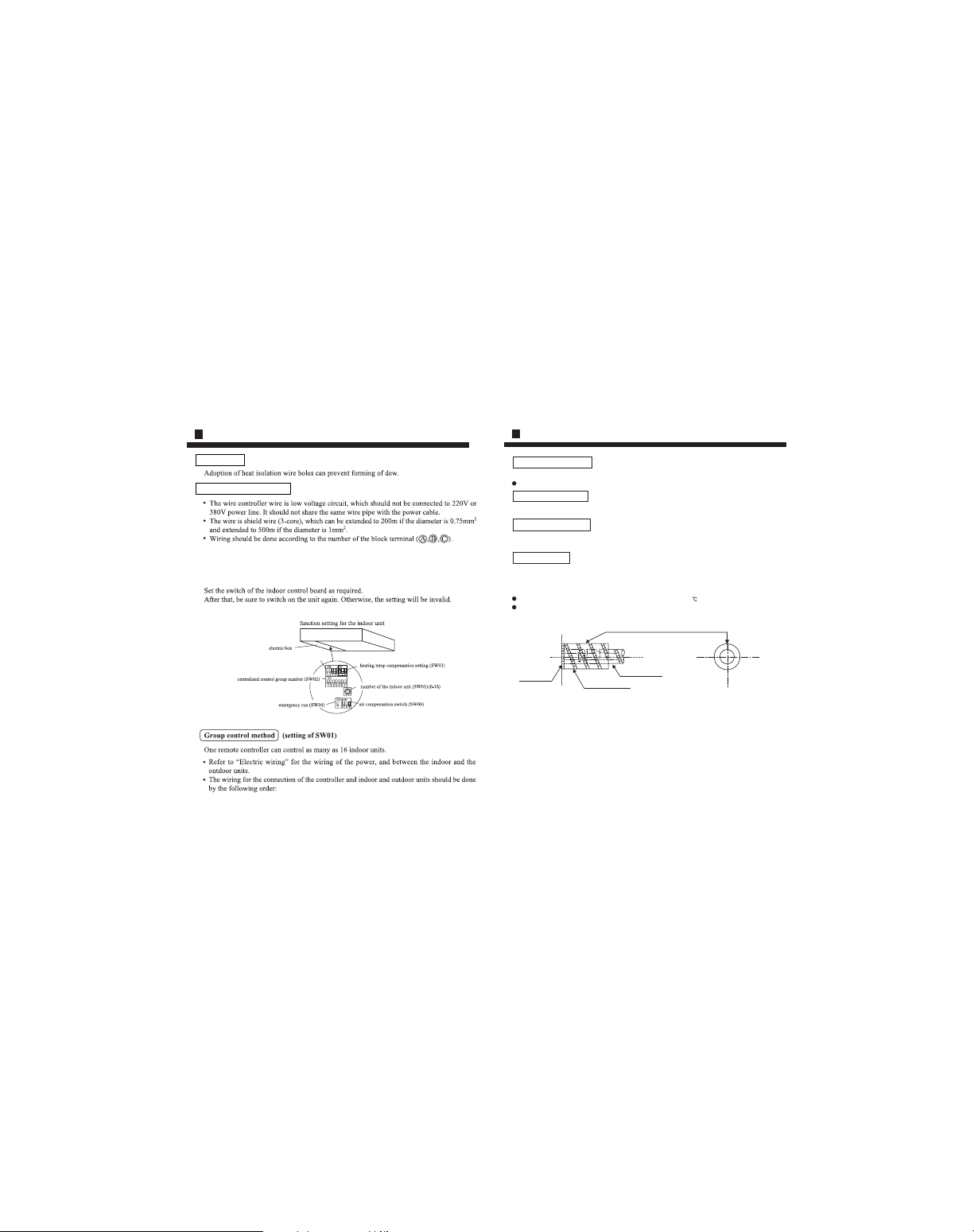

Put the nut on the screw bolt and suspend it on the T slot of the suspension part of the unit

Keep level of the body (within 5mm) with a gradoenter

Make sure and adjust the positions of the unit and the ceiling opening as well as the height

of the unit with the installation template

1 The bottom of the unit is 58mm from the lower ceiling surface (four corners)

2 Make sure that the front side of the indoor unit (tube side) is 95mm from the ceiling and the

back side of the unit (opposite side) is 35mm from the ceiling with the template

Installation of the panel

Mount the panel after tubing and wiring installation

Please refer to P18 21 of this manual for the panel installation

Before installation, make sure that the positions of the indoor unit and the ceiling opening

are correct

Requirements:

There is no space between the panel and the ceiling and between the panel and the indoor

unit, otherwise, dew or water leak may occur

Installation of remote controller

58

15

indoor unit

ceiling

installation template

front side

(tube side)

95

lower

ceiling

surface

indoor unit

35

back side

(opposite

s de)

Tighten the upper nut to fix the indoor unit

insta lation template

installation template

Please refer to the installation manual for the installation of the remote controller

5

Indoor unit installation

suspension screw

(M10)

tighten up w th a nut

gradienter

nut (M10)

parts other than M10 flat gasket a e

provided during installation

M10 flat gasket

M10 flat gasket

for safety, please mount according

to his diagram

nut (M10)

The indoor drainpipe should be treated for heat isolation

The indoor connections must have heat isolation Inappropriate isolation may lead to

dew forming

The drainpipe must have a falling gradient (above 1/100) and should not be made into

an ì Sî form, otherwise, it will produce noises

The horizontal length of the pipe should be shorter than 20m If the pipe is long, one

support should be set up for every 1 5 2m Avoid undulation of the pipe

Centralized piping is installed according to the following diagram

Never apply external forces on the connections of the drainpipe

To enable normal discharge of water, use drainpipes according to the installation manual To

avoid forming of dewdrops, it must be treated for heat isolation Inappropriate tubing may

lead to water leakage in the room

Caution

Requirements:

Pipe material

*

1.

5m~2m

solation

material

"S" shaped p pe

VP30

as large as possible(about 10 cm)

falling gradient

above 1/100

support

falling

gradient

(above 1/100)

Pipe material and isolation material

Unit attached parts

Isolation material

Hard PVC pipe 31 5mm (inner diameter)

Foam polyethylene thickness above 10mm

6

Indoor unit installation Trial operation

15

Before operation

Heating mode

Set the running mode to ì Heatî

Press the ON/OFF button till a blinking ì Hî and an ì Autoî sign appear on the wire controller Now

the unit enters into heating trial run

During forced trial run, working modes cannot be changed through the wire controller

After trial run, press the ON/OFF button to stop the unit

Trial operation

Refer to the service manual for the running procedure

When the unit fails to start under room temperature, try forced trial run by the following steps

Cooling mode

Set the running mode to ì Coolî

Press the ON/OFF button till an ì Lî blinks at the ì Setting Tempî area on the wire

controller LCD and ì Autoî is displayed at the fan speed area Now the unit enters

into cooling trial run

Before the unit is turned on, test the resistance between the power block terminal (L, N terminals) and

the earth If it is below 1M , it can't allowed running

Turn on the outdoor unit To protect the compressor during start up, it should be switched on 12 hours

in advance

Never operate the electromagnetic contactor manually for forced trial run (It is dangerous when the

protection device does not work )

14

Electrical wiring & Application control

7

Indoor unit installation

8

Warning

During installation, if refrigerant gas leakage occurs, ventilation measures must be taken When

refrigerant gas meets with fire, hazardous gas will be produced

After installation, make sure that there is no refrigerant leak

Refrigerant, if meeting with heaters and stoves, etc in the room, may produce hazardous gas

Allowable tube length and allowable height difference

Different units have different limits Refer to the attached manual

Pipe material and size

Material

Model

Pipe size

Gas side

Liquid side

Air conditioner used deoxidized phos copper (TP

2)

series 072 162

model

Refill refrigerant

Refer to the installation manual for the refilling of refrigerant A special meter should

be used for the filling of refrigerant and the filling must be in strict accordance with the specifications

R22:AB072 282FDAHA

R407:AB072 282FDBHA

Requirements:

Overfilling or underfilling may lead to compressor trouble The filling must be done

in strict accordance with the specifications

Connection of refrigerant pipes

Connect all refrigerant tubes before connection of the flare tube

Use two spanners for the indoor connection

Refer to the following table for the installation torque

Torque increase (N m)

Pipe external

diameter (mm)

Torque (N m)

series 182 282

model

Refrigerant piping

13

remote contro ler

D

Electrical wiring & Application control

()mm

15 88

9 52

12 70

6 35

6 35

11 8(1 2kgf m) 13 7(1 4kgf m)

9 52

15 88

24 5(2 5kgf m)

78 4(8 0kgf m)

29 4(3 0kgf m)

98 0(10 0kgf m)

12 70 490(5 0kgf m) 53 9(5 5kgf m)

19 05

98 0(10 0kgf m) 117 7(12 0kgf m)

12

Set capacity (SW05)

Electrical wiring & Application control

Wiring hole

Remote controller wiring

Application control

9

Vacuum evacuation

Open all the valves

Open all the valves of the outdoor unit

Evacuate from the outdoor cut off valve with a vacuum pump

Never use encapsulated refrigerant in the outdoor unit for evacuation

Check the gas leaking

Check the joints and valve caps with a leakage detector or with soapsuds for gas leaks

Heat insulation

All the liquid and gas tubes must have separate isolation

During cooling run, temperature at both the liquid side and the gas side is low To prevent

dew forming, heat isolation must be made

Materials used for the tube isolation at the gas side must withstand 0 temperature

The joints should be treated for heat isolation

With cut edge up (Attached diagram)

Field tubing side

Auxiliary isolated tube

Indoor unit

Refrigerant piping

10

Caution

The specifications of the power circuit are listed in the table below Smaller capacity may cause

overheat or burnout

Power specifications

Electric leak breaker should be installed Without it, shock accidents may occur

To avoid danger, damaged cable must be replaced by professionals of cable makers or the like Wires

used by the indoor unit should be selected according to the installation manual

Never connect the block terminal in the control circuit (A, B, C, P, Q, X and Y) to a 220 230V or a

380 400V power line Otherwise, it may lead to mechanical damage or personal injury

Avoid contact of electric wires with high temperature pipes to prevent melting of the outer isolation

Wires should be made into a ì Uî shape after connected to the block terminal, and fixed with clips

Controlling wires may be laid and fixed together with the refrigerant tubes

If the supply cord is damaged,it must be replaced by the manufaturer or its service agent or a similar

qualified person

The wiring method should be in line with the local wiring standard

All the cables shall have got the European authentication certificate

The breaker of the air conditioner should be all pole switch,and the distance between its two contacts

should be no less 3mm Such means for disconnection must be incorporation in the fixed wiring

The power cable and connecting cable are self provided

Electrical installation should be entrusted with qualified servicemen and done in accordance with the

installation manual Special return circuit must be used Insufficient capacity return circuit and

inappropriate installation may lead to fire accidents

Specific cables should be used for the wiring To avoid external tension of the cables, the terminals

should be firmly fixed Inappropriate connection and fixture may lead to fire accidents

The unit must be earthed

The unit should be earthed properly Poor earth may lead to shocks The earth wire should not be

connected to gas pipes, water pipes, lightning rods or telephone wires

Warning

1) The type of connecting wire is shielded wire The type of the power cord is H07RN F(3G)

2) The wiring diagram refer to the wiring diagram on the indoor and outdoor units

NOTE:

AB072 282

FDAHA

AB072 282

FDBHA

Indoor un t

power

15A

H05RN F

3G1 5mm

2

5A/

250

V

AC

AC

220

230V

50Hz

2

500m<

1000m

2 5mm

2

L 50m

Manual

sw tch

23

< 500m

1 5mm

2

< 500m

1 5mm

2

< 200m

0 75mm

2

200m<

500m

1mm

2

Item

Model

Fuse

Connecting cable

Power w re (L)

Cent al contro ler

holding wire

Indoor & outdoor

commun cat on w re

Remote controller w re

Number of

cores

Core sec

tional area

Number of

cores

Core sec

tional area

Number of

cores

Core sec

tional a ea

Electrical wiring & Application control

11

Wiring should be done according to the number of the

block terminal,inappropriate connetction may lead to error

Indoor power wiring

The indoor and outdoor units should use separate special power lines

If several indoor units connect the same outdoor unit, the leak breakers and

switches of the indoor units should use the same power

Centralized controller communication wiring

The centralized controller communication wire are

non polarity 2 core wires (Fig 1)

To prevent electromagnetic disturbance, please use shielded wires

Remote controller wiring

The remote controller remote is polarized 3 core wires

The grouped wire controller wire (between the indoor and indoor

units) is polarized 2 core wires (Fig 2)

380 400V3N 50Hz

outdoor power

junc ion box

indoor un t

1PH 220 230V 50Hz

ea th

communica ion wire

shielding layer ear h

The shie d ng layer should be

connected together

(

shie d ng layer as isolation

)

leak b eaker manual witch

emo e cont o ler

grouped control

(

shielding layer as isolation

)

(

shielding layer as isolation

)

(

shielding layer as isolation

)

ndoor unit

shielding layer should be

connected ogether

central zed control signal w re earth

cen ralized con rol s gnal wire

(centralized cont o ler)

communication w re

leak breaker manual switch

ndoor power

1PH 220 230V 50Hz

ndoor unit

(cen ralized

controller)

spec ally used

by he power

remote controller

Wiring of indoor unit and outdoor unit

remote

con ro ler

Electrical wiring & Application control

Loading...

Loading...