Haier Network Air Conditioner

Two by One Room Air Conditioner

AB212BCBAA

CONTENTS

Before Use

Operation Points

Name of Parts

Safety Precautions

*********** 1-2

************* 3-4

********** 5-6

Operation Instruction

Fan Operation

************** 7

Auto, Cooling, Dehumidifying,

Heating operation

Swing Operation

Sleep Function

Timer On/Off Function

Timer On-Off Function

Usersí Attention

************ 8

************ 9

************* 10

******** 11

******** 12

************ 13

Maintenance

Maintenance

Troubleshooting

*************14-18

*********** 19-20

Installation of Indoor Unit

Installation Instruction

****** 21

22

*

Installation Procedure

*

No.

0010571570

Please read this manual carefully before using

Please keep this manual for future use

****** 23*36

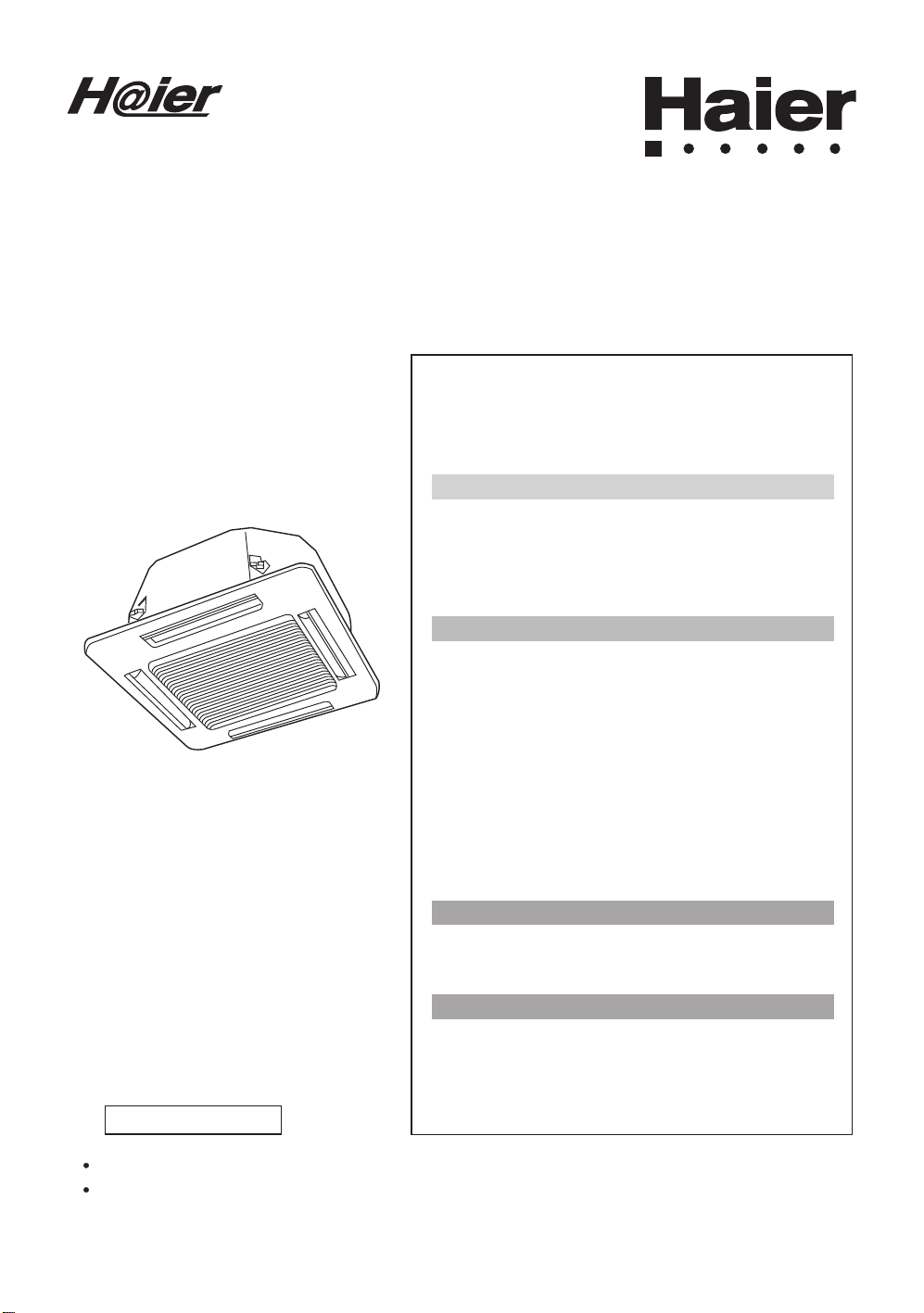

Characteristics of Products

Characteristics of Products

1.Free combination multi-split.

2.Four-direction air sending, more even temperature adjustment.

3.Inner hidden type installation, space-saving; harmonized with the ceiling, exquisite

and beautiful.

4.Powerful circular air volume, quick temperature adjustment.

5.This air conditioner has POWER FAILURE RESUME FUNCTION.

6.Anti-bacteria mildew resistant air filter, fresher air creates more healthy.

This unit has the function of far distance monitoring. Through the telephone

network, it can be effectively controlled in any other far-distance place. (Only

after equipped with the ìfar distance detectorî made by our company can this

function be fulfilled.)

7.This unit has the function of far distance monitoring. Through the telephone network,

it can be effectively controlled in any other far-distance place. (Only after equipped

with the ìfar distance detectorî made by our company can this function be fulfilled.)

Far distance monitoring

There is a pre-set far distance control communication interface on the control

panel of indoor unit. After installing the peripheral equipment according to the

manual attached with the Haier made far distance control detector, the computer

management or other place monitoring can be achieved to the air conditioner.

Operation points

Operation of air conditioner

When the ambient humidity is too high,

in COOLING or DEHUMIDIFYING

mode, there may be water dropped

in the air outlet.

3-minute protection function

If start the unit immediately only after

it is turned off, the compressor will start

after 3 minutes have elapsed to protect the

compressor.

Change of fan speed

In COOLING mode, the air sending is set at AUTO, when the indoor

temperature is near the set temperature,

the fan speed will lower automatically.

In HEATING mode, when room

temperature reaches the set temperature,

the compressor will stop running, and

the fan will change to LOW FAN or stop.

In DEHUMIDIFYING mode, the fan speed

will change automatically.

Far distance monitoring

There is a pre-set far distance control communication interface on the

control panel of indoor unit. After installing the peripheral equipment

according to the manual attached with the Haier made far distance

control detector, the computer management or other place monitoring

can be achieved to the air conditioner.

1

Operation points

Anti-cold air blowing out

During Heating operation, after

starting the unit, the indoor fan

motor will not rotate immediately

to prevent cold air from blowing out.

Defrosting function

During Heating operation, when frost formed

on the heat exchanger of outdoor unit, the air

conditioner will defrost automatically for

several minutes. During defrosting, both

the fan of indoor and outdoor unit do not

run. After finishing defrosting, the air

conditioner will automatically resume operation.

Hint

When the air conditioner is in Heating mode,

it absorbs heat from outside and release to

indoors. So the outdoor temperature may

affect the Heating effect.

Please wait

?

Power failure resume function

(please set and use this function according to actual condition)

After setting power failure resume function, if there is a sudden power

failure during unit operation, when power on for again, the unit will

resume the previous state.

Setting method: when the wire controller is in ON state (except for

TIMER and FAN mode), press the SLEEP button for 10 times in 5

seconds, after the buzzer sounds 4 times, the unit will change to

POWER FAILURE RESUME function.

Cancellation method: press the SLEEP button 10 times in 5 seconds, after

the buzzer 2 times, the POWER FAILURE RESUME function is cancelled.

Note: After the unit is set POWER FAILURE RESUME function, if there

is a sudden power failure in using, during this period of time if there is no

need to use the unit for a long time, please cut off power to prevent the air

conditioner from automatically resuming to the previous setting if power

failure resumes, or press the ON/OFF button to turn off the unit after power

failure resumes.

2

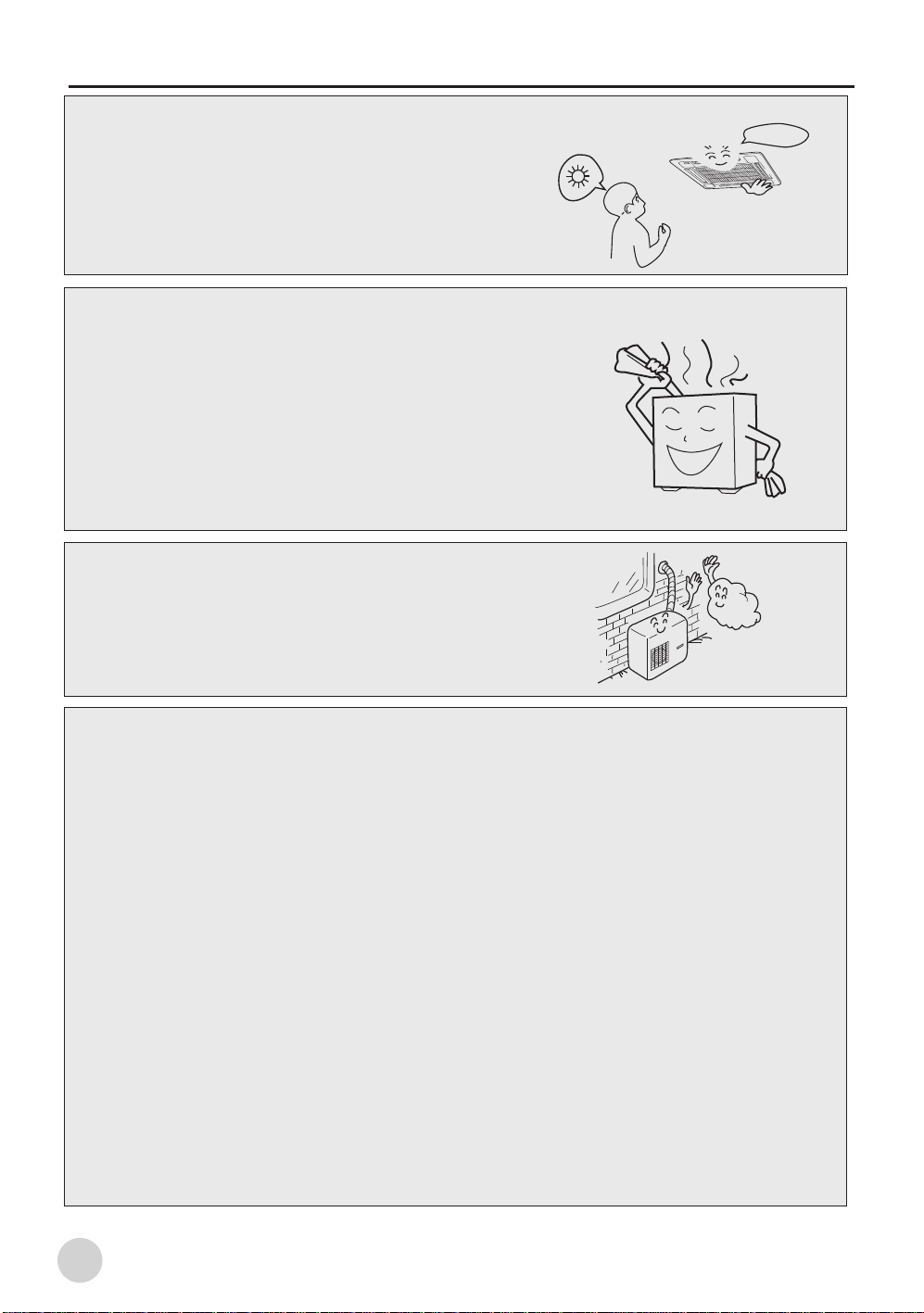

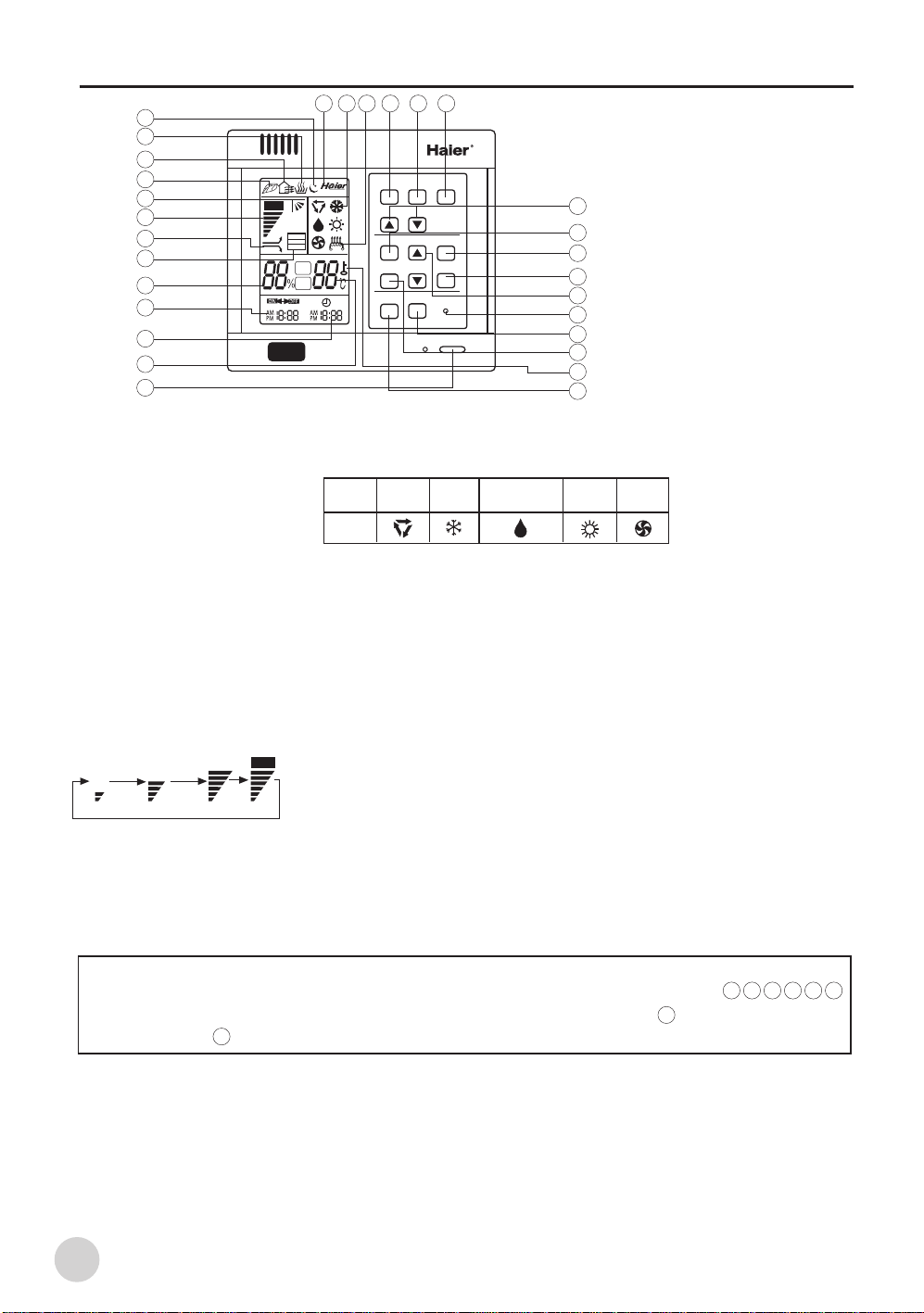

Name of Parts

Indoor Unit

Drain hose Louver

Louver

(inside of air outlet)

Air outlet

Air filter

(inside of air inlet grille)

Wire Controller

Connection pipes

and electric wire

Air inlet grille

** ** **

AUTO

**

**

**

**

**

**

****

**

**

**

**/**

3

Name of Parts

Wire Controller

13

12

11

10

9

8

7

6

5

4

3

2

1

AUTO

**

**

1.ON/OFF button

Used to turn on/off unit

2.Temperature display

3.Clock display

4.Timer ON/OFF display

5.Humidity display

6.Air filter cleaning display

When there is too much dust

collected on the air inlet, the

wire controller will show

this display to remind the

user to clean the air inlet.

After cleaning and installation,

just press the air filter reset button.

*

17.Operation mode button

7.Super/Soft operation display

8.Fan speed display

Auto

Low Fan Med Fan High Fan Auto

9.Auto Swing display

10.Health state display

11.Fresh air state display

12.Humidifying state display

Note:

1.This model does not have the following related display and function

2.Non-electric heating type, there is no electric heating button and electric heating

display

16

14 15 16 17 18

** ** **

**

**

**

**/**

19

**

**

**

****

**

13.Sleep state display

14.Network control display

15.Working mode display

Working

Auto

Cooling

mode

Wire

controller

operation

operation

Dehumidifying

operation

16.Electric heating display

Used to set working mode:

Auto, Cooling, Dehumidifying,

Heating, Fan

18.Fan speed button

Used to set fan speed: Low

Fan, Med Fan, High Fan, Auto

19.Swing button

Used to set Auto Swing or

Fixed air sending direction

20.Temperature Setting button

Used to set temperature,

temperature range: 16*~30*

21.Clock button

Used to calibrate the time of

timer and clock

20

21

22

23

24

25

26

27

28

29

Heating

operation

22.Setting button

Used to confirm

the time of timer

and clock

23.Sleep button

Used to set Sleep

state or Power

Failure Resume

Function

24.Time Adjusting

button

Used to adjust the

time of timer and

clock

25.Reset button

Fan

operation

When the wire

controller appears

abnormal condition,

use a sharp-pointed

article to press this

button to make the

wire controller

resume normal

26.Air Filter Reset

button

After cleaning the

air inlet, press this

button, the unit

can start to operate

27.Timer button

Used to set the

mode of timer

28.Lock state display

29.Electric heating button

* * 10 11 12 28

29

Calibration of clock

When turning on the unit for the first time, the clock should be calibrated. The

method of calibration is:

1.Press “Clock” button, the Clock display “AM” “PM” will flash.

2.Press * or * to adjust time. For each press, the time will increase or*decrease 1

*minute. If depressing the button, the time will increase or decrease*rapidly.

3.After confirming the time, press “Set” button, “AM” or “PM” will stop flashing,

*the clock will begin to work.

4

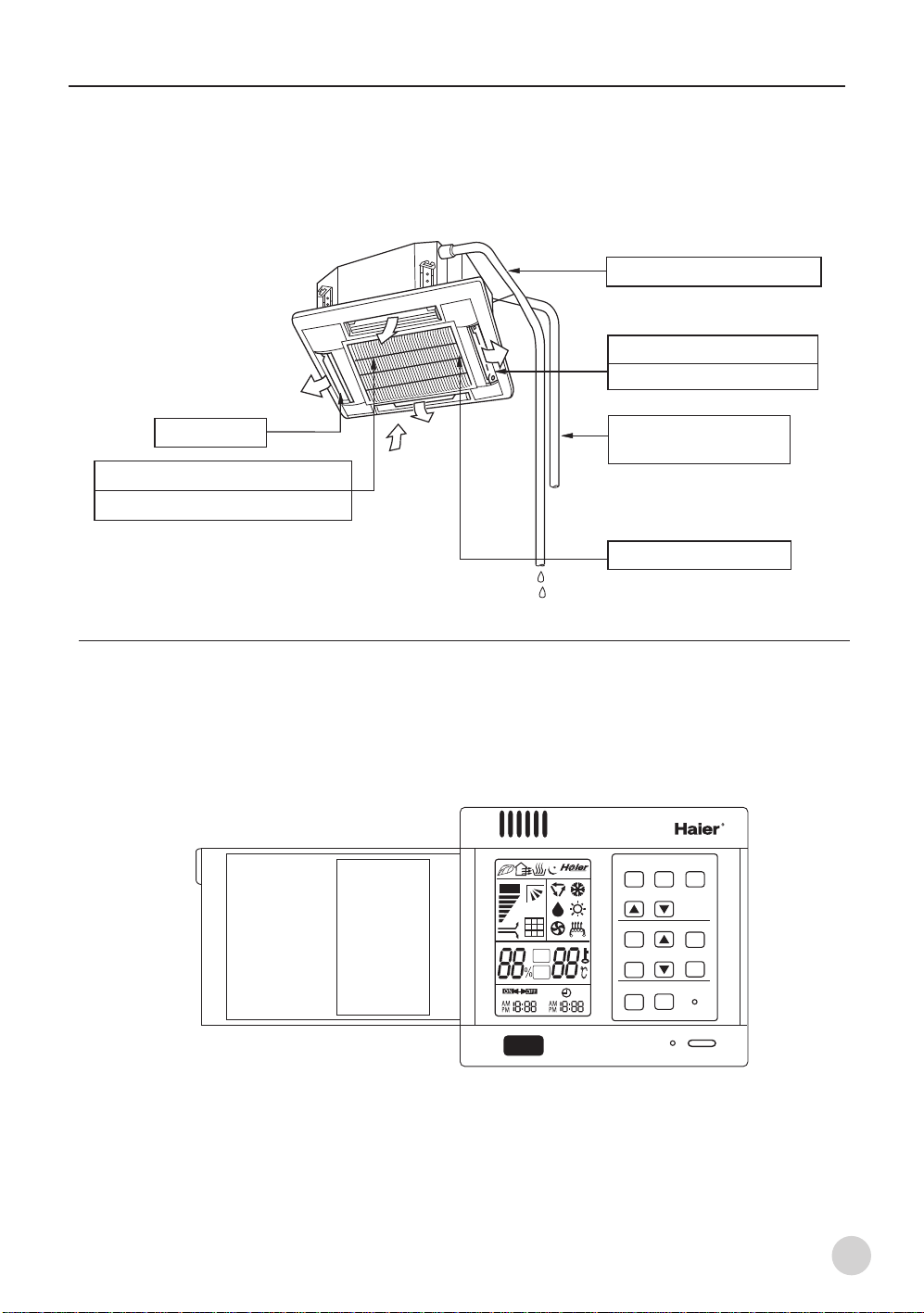

Safety Precautions

Please read the following Safety Precautions carefully and use the

air conditioner properly.

The following lists four kinds of safety precaution items and suggestions:

!

Warning: Improper use may cause death or serious injury.

!

Notice: Improper use may cause body hurt or unit damage; in some

circumstance, it may cause serious results.

*

Those contents marked with “Prohibition” are definitely prohibited

action, otherwise, it may cause unit damage or risk to users’ safety.

* Those contents marked with “Forced” are definitely forced action,

otherwise, it may cause unit damage or risk to users’ safety.

The following safety precautions must be observed.

This safety precautions should keep in hand for reference.

If the air conditioner is given to a new user, this manual should be attached with

unit to the new user.

Warning

!

If finding abnormal phenomenon

(e.g. smell of firing), please cut off

the power first, and contact the

after-sales service worker

for treatment.

Under this

circumstance,

Cut off

power

if continue using

the air conditioner,it may be

damaged, it may also cause electric

shock or fire accident.

When repair is needed, please ask

the after-sales service worker for

help.

Improper repair and maintenance

may cause water leakage,

electric shock

and fire.

During unit operation, do not insert

fingers or other objects into air inlet,

air outlet and louver.

Because high

rotation speed

fan is dangerous,

it may cause injury.

Ask after-sales service worker to take

measure to prevent refrigerant from

leaking.

If the leaked refrigerant exceeds a

certain density, it will cause

lack of oxygen. If the room

installed with air conditioner

is too small, do take enough

measure in order to avoid lack of

oxygen even if refrigerant leaks.

When have to dismantle and reinstall

the air conditioner, please ask the

after-sales service worker to perform

the work.

Improper installation may

cause water leakage,

electric shock or fire.

5

Safety Precautions

Notice

Do not use wet hands to operate the

air conditioner.

Otherwise, it may

cause electric shock.

Only use the proper specified fuse.

Do not use cable or

other materials to

replace the fuse,

otherwise it may

cause fire and

other trouble.

Do not put the fire devices in the

places, which the air from the air

conditioner can directly blow.

It may cause the

fire devices

cannot burn

completely.

Do not put or use any spray near the

air conditioner,

otherwise it

may cause

fire.

Do not use water to

clean air conditioner,

otherwise

may cause

electric shock.

Connected with the grounding wire.

The grounding wire shouldn’t be

connected with gas pipe, tap water pipe,

lightning rod or

telephone line.

Improper grounding

may cause electric shock accident.

The drain hose should be

arranged properly to have a

smooth drainage.

If the drain hose is

not arranged properly, the leaked

drain water may damage the

furniture or other articles alike.

Do not install the air conditioner

in a place where the inflammable

gas maybe exists.

The inflammable gas around the

air conditioner may cause fire

accident.

The Creepage breaker should

be equipped.

If not equipped

with Creepage breaker, it may

cause Creepage.

Only after cutting off the power, can

the cleaning of the air conditioner be

performed to

avoid leading

to electric

shock or

injury.

6

Not in

operation

When using indoor smoky type

pesticide, do not use air

conditioner.

Otherwise, it

may cause the

chemicals

accumulate

in the unit, result in

doing harm to the people’s health

who is extremely sensitive to

these chemicals.

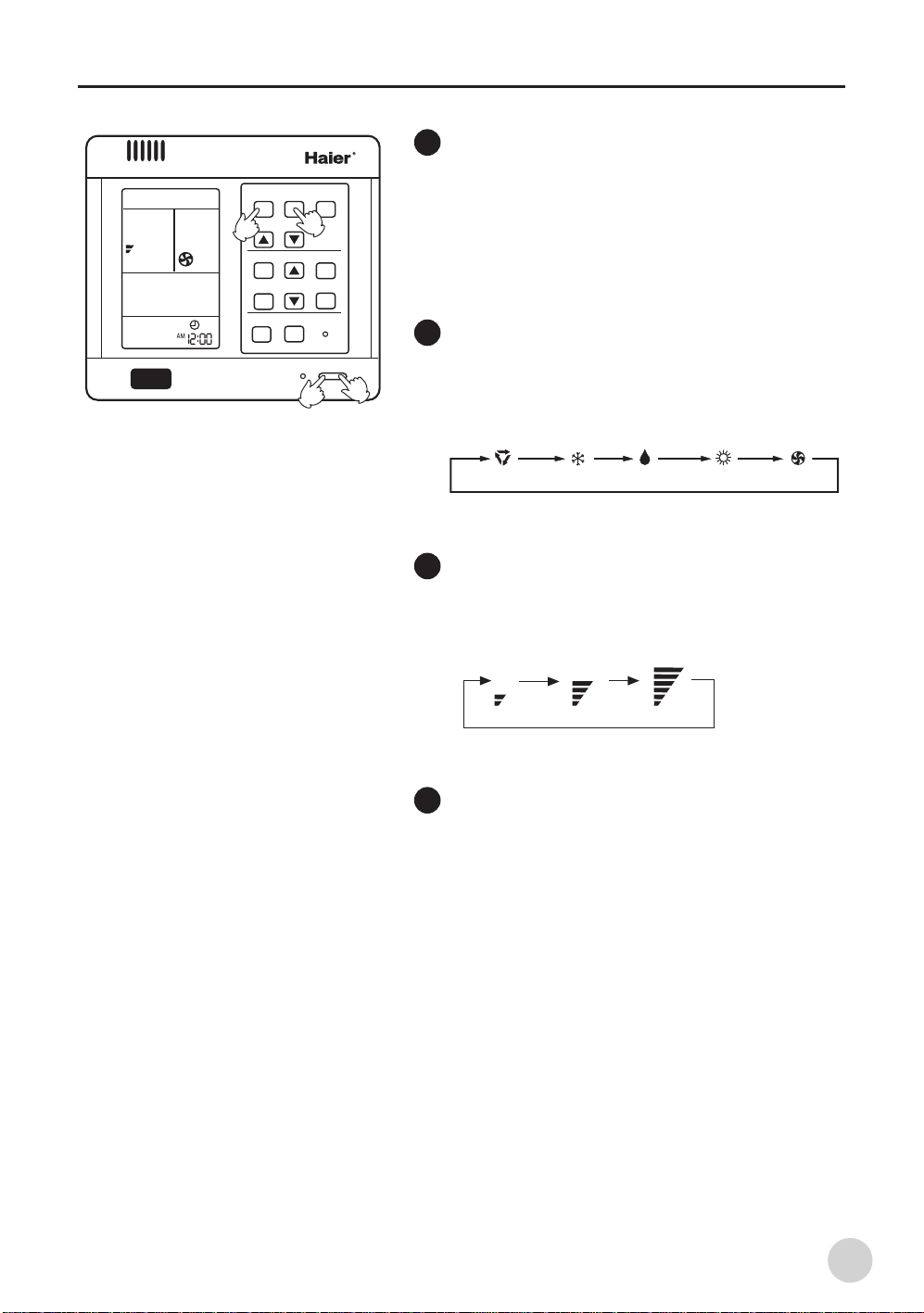

Operation instruction

** ** **

**

2

**

3

**

**

**/**

****

**

**

**

4

1

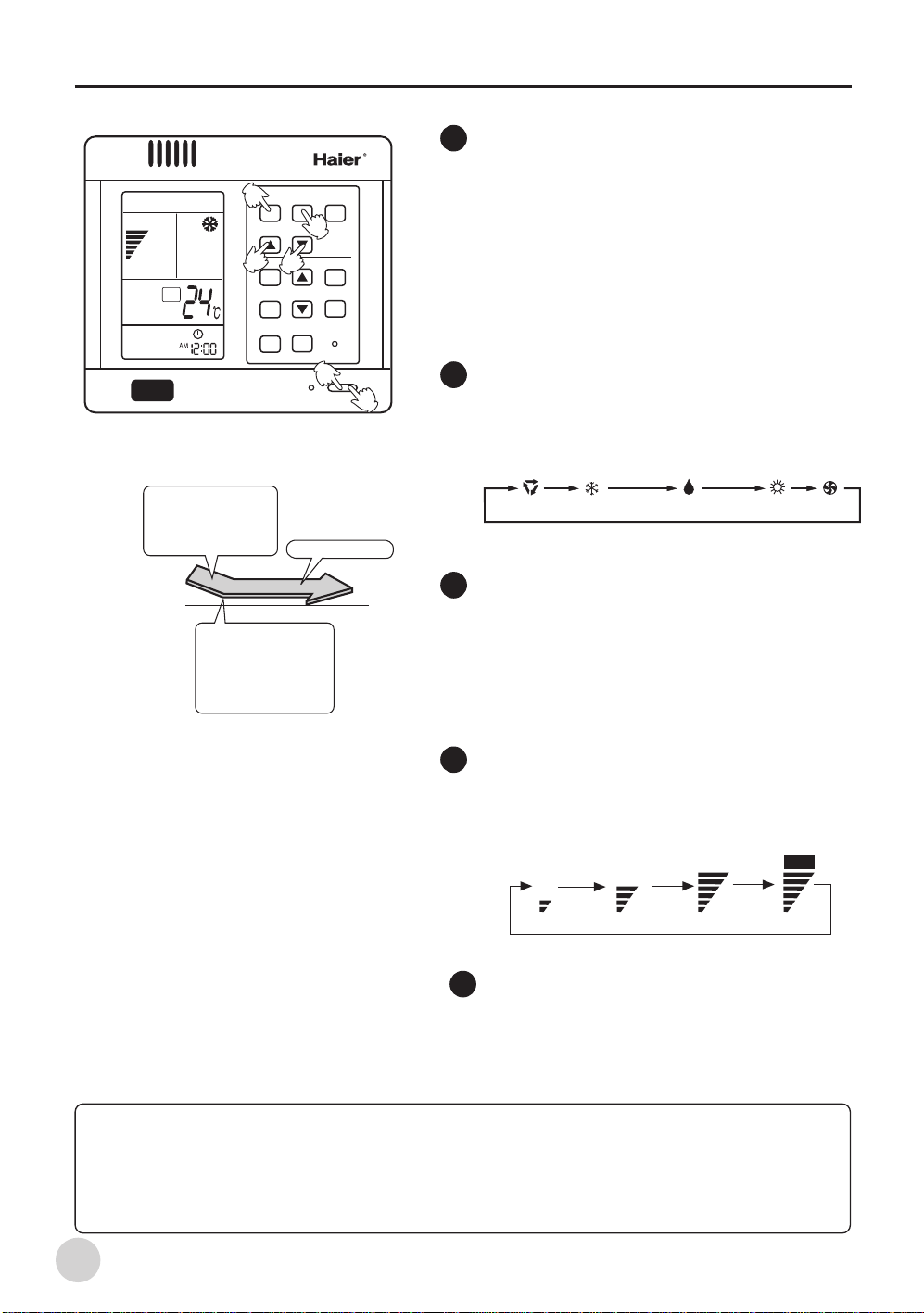

Fan operation

1

Turn on the unit

Press the ON/OFF button to turn on the

unit The LCD display of the wire controller

will show the previous working state

(except for Timer, Sleep, Swing mode), the

operation indicator light on the wire controller

will light up.

2

Choose of working mode

Press MODE button, each press the

working mode will change as the

following sequence:

.

AUTO

COOLING

DEHU

HEATING

choose FAN operation

Adjusting FAN SPEED

3

Press the FAN SPEED button to change fan

speed:

LOW FAN MED FAN HIGH FAN

Choose the desired fan speed

4

Turn off the unit

Press the ON/OFF button to turn off the

unit.

The wire controller only shows the clock and

room temperature.

About FAN operation:

FAN operation refers the air conditioner does not perform COOLING and

HEATING operation, but FAN operation. In this mode, the air conditioner

cannot perform AUOT FAN operation, and does show the temperature

value on the wire controller.

FAN

7

Operation instruction

2

** ** **

4

**

3

**

**

**

**

3

****

**

**

**

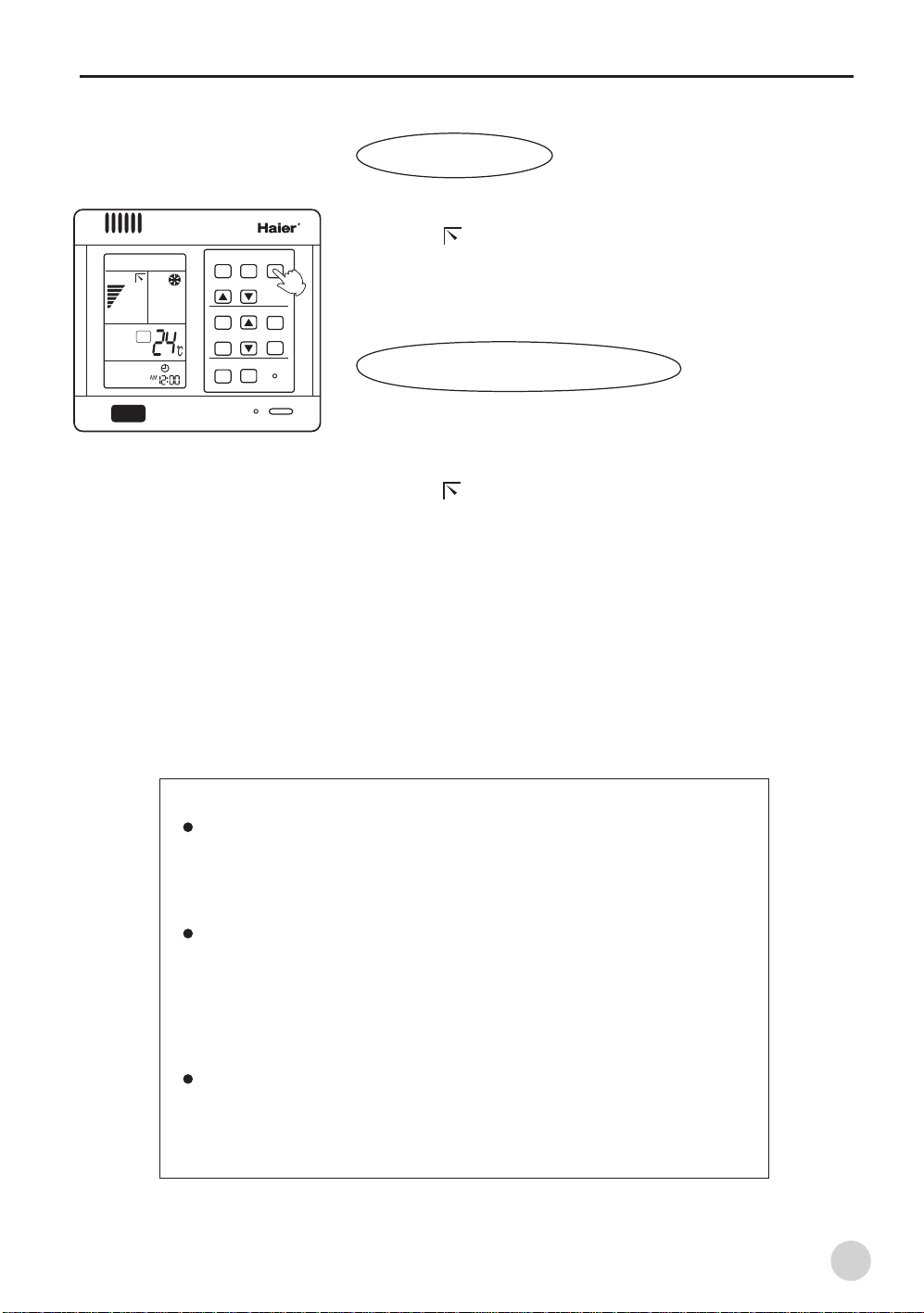

Auto/Cooling/Dehumidifying/Heating operation

1

Turn on the unit

Press the ON/OFF button to turn on the

unit The LCD display of the wire

controller will show the previous

working state (except for TIMER,

SWING, SLEEP mode). The operation

indicator light on the wire controller

will light up.

**/**

5

1

2

Choose of working mode

Press MODE button, each press the

working mode will change as the

following sequence:

When room temperature

is higher than set

temperature, unit in

COOLING operation.

Set temperature + 2*

Set temperature

Ultra-low air flow

When room temperature

reaches set temperature

+ 2*, the unit will

operate in mild

dehumidifying

operation.

3

AUTO COOLING DEHUMIDIFYING HEATING FAN

then choose AUTO, COOLING,

DEHUMIDIFYING, HEATING operation.

Set temperature

Press the TEMP. SET button

*Each press , the set temperature will

increase 1 degree.

*Each press, the set temperature will

decrease 1 degree.

Set the desired temperature.

Adjusting FAN SPEED

4

Press the FAN SPEED button, for each

press, the fan speed will change as the

In Heating operation, after start

following sequence:

the unit, the air conditioner will

sending warm air a moment

later to prevent the cold air

blowing out. In Dehumidifying,

when the room temperature drops

2* higher than the set

temperature, regardless the set fan

speed, the air conditioner will

intermittently operate in low fan

speed.

5

LOW FAN MED FAN HIGH FAN AUTO

Choose the desired fan speed.

Turn off the unit

Press the ON/OFF button to turn off

the unit.

The wire controller only shows the clock

and room temperature.

Hints:

The wire controller can memorize the working condition of each time. When

start the unit for the second time, just need to press ON/OFF button, the air

conditioner will work according to the previous working mode. (except for

Timer, Sleep and Swing)

AUTO

8

Operation instruction

Press SWING button, the LCD of the wire controller

display “ ”, the louver of the air conditioner begins

** ** **

**

**

**

**

**

**

**

****

**

**/**

automatic swing and air sending.

When the Auto SWING of the air conditioner swings

to an appropriate angle, press SWING button, the

display “ ” on the LCD of the wire controller will

disappear, the air sending direction is fixed.

When fixing the air sending direction, the louver

should be kept in the following position:

In COOLING and DEHUMIDIFYING, it is better to

be upward.

In HEATING, it is better to be downward.

Swing

Auto swing

Fixed air sending direction

Always use the SWING button of the wire controller to

adjust the louver. If adjust the louver manually, it may

damage the louver.

During COOLING and DEHUMIDIFYING, do not make

the louver downwards for a long time. Because the vapor

around the air outlet grille may be condensed and may

have drop of water.

When the infant, children, ages and the patients use the

air conditioner, please pay attention to the set

temperature.

9

Operation instruction

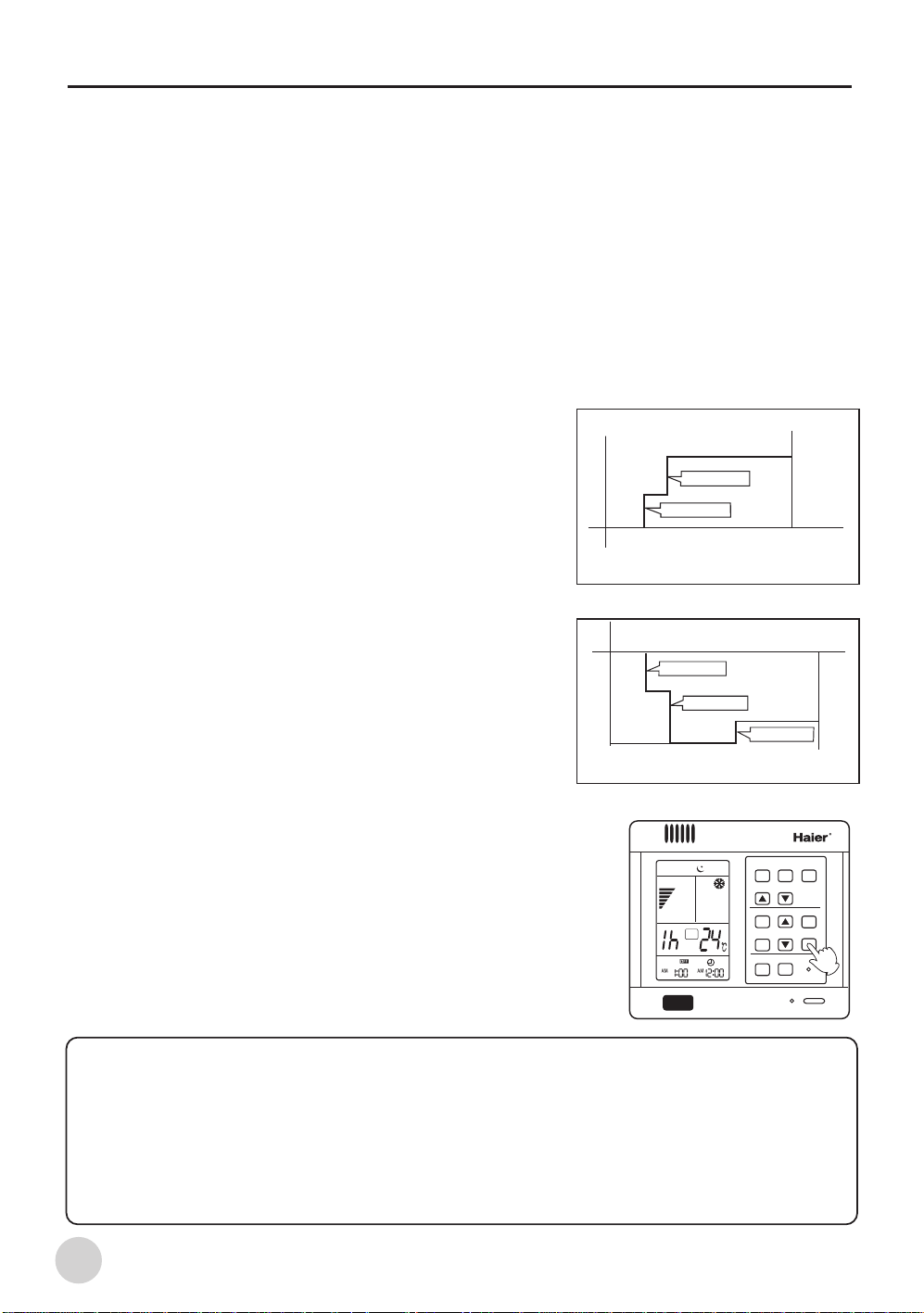

Sleep operation

Before going to bed, you can press the SLEEP button, the air conditioner will

operate in comfort sleep mode to make you have a sound sleep.

Before using this function, you should calibrate the clock first, otherwise, the SLEEP

function will be out of order.

Use of SLEEP function

After turning on the unit, setting the working mode, then press SLEEP button to

make the air conditioner have the previous Sleep time (powered on for the first

time or after performing Sleep is 1h). The Sleep symbol will appear. Press time

*/* button, you can choose between 1~8h. Each press, it may increase/decrease

1h and will display in the humidity area with “xh”, and display “Timer Off” in

Timer Off area and the time to turn off; press Sleep button again to cancel Sleep

function. The Sleep symbol disappears.

Operation modes

1.In COOLING, DEHUMIDIFYING operation

1 hour later in SLEEP operation, the temperature

will increase 1* from the set temperature, another

1 hour later increase another 1*, then the unit will

operate continuous for 6 hours, then it turns off

automatically. The temperature is higher than set

SLEEP operation starts

increase 1*

1 hour

increase 1*

1 hour

Set temperature

in COOLING* DEHUMIDIFYING operation

SLEEP operation stops

about 6 hours

turn off

temperature to prevent you from getting a cold.

2.In HEATING operation

1 hour later in SLEEP operation, the temperature

will decrease 2* from the set temperature, another

1 hour later increase another 2*, then the unit will

operate continuous at this temperature for 3 hours,

then it increases 1*, after operating at this

Set temperature

1 hour

decrease 2*

1 hour

SLEEP operation starts

in HEATING operation

decrease 2*

3 hours

about 3 hours

increase 1*

SLEEP operation stops

temperature for another 3 hours, the unit will turn

off automatically. The temperature is lower than set

temperature to prevent you from feeling

uncomfortable during sleep.

3.In AUTO operation

The air conditioner will perform the relative SLEEP

operation according to automatically chosen operation

**

** ** **

**

**

**

**

****

**

**

**

mode.

4.In FAN operation

Cannot use SLEEP function

**/**

Note:

lAfter setting Sleep function, it is not permitted to adjust clock.

lThe Sleep time is less than 8h, after reaching the set time, the unit will automatically stop.

lSet Sleep function after setting “Timer Off” function, the air conditioner will perform

Sleep function.

lAfter setting Sleep function, the Timer function cannot be set.

lSet Sleep function after setting “Timer On” function, the Sleep function can only be set

in the set time of Timer On.

turn off

10

Operation instruction

** ** **

**

**

**

**

**

**/**

****

**

**

**

Timer On/Off function

Before using TIMER function, calibrate the

clock first (referring to page 4). When you

wake up in the morning, before going back

to home after work or after going to bed, you

can let your air conditioner automatically turn

on or turn off.

1.Turn on the unit

After turning on the unit, set the desired

working mode.

The LCD of the wire controller will show

working mode. (except for Timer, Sleep, Swing)

2.Set of TIMER mode

Press the TIMER button to change the

TIMER mode, each press the TIMER

mode will change as the following

sequence:

OFFON OFFON

AM

TIMER ON TIMER OFF TIMER ON-OFF

PM

AM

PM

Blank

Then choose the timer mode as you need

(TIMER ON or TIMER OFF.)

" " " "

At this time the or will flash.

ON

3.Set time

Press the time adjusting button

* Each press, the set time increases 10 minutes. If depress the button, the

time will increase rapidly.

*Each press, the set time decreases 10 minutes. If depress the button, the time will

decrease rapidly.

This LCD will show the time set, the time can be adjusted within 24h.

(AM stands for morning, PM stands for afternoon).

4.Confirm the time

After calibration of the clock, press SET button to confirm time.

At this time, the* *or* *will not flash.

ON

OFF

OFF

The time displayed is: at x o’clock x minutes the unit will be turned on

(TIMER ON) or turned off (TIMER OFF).

Cancel TIMER

Press the TIMER button several times until the TIMER mode display

disappears.

Hints:.

*

After power failure, the clock should be calibrated again.

The wire controller has memory function, when you use this function for the

second time, if the time set is the same as the previous one, you just need to

choose the TIMER mode then press the SET button to confirm.

11

Operation instruction

** ** **

**

**

**

**

**

**/**

****

**

**

6

5

**

Timer On-Off function

1.Turn on the unit

After turning on the unit, set the desired

working mode.

The LCD of the wire controller will show

working mode. (except for Timer, Sleep, Swing)

2.Set of TIMER mode

Press the TIMER button to change the

TIMER mode, each press the TIMER

mode will change as the following

sequence:

OFFON OFFON

AM

TIMER ON TIMER OFF TIMER ON-OFF

PM

AM

PM

Blank

Then choose the TIMER ON-OFF mode.

At this time the" "will flash.

3.Set time

Press the time adjusting button

* Each press, the set time increases 10 minutes. If depress the button, the

time will increase rapidly.

*Each press, the set time decreases 10 minutes. If depress the button, the time will

decrease rapidly.

This LCD will show the time set, the time can be adjusted within 24h.

(AM stands for morning, PM stands for afternoon).

4.Confirm the time

After adjusting time, press SET button to confirm time.

At this time, the" "will not flash ," "begins to flash.

ON

OFF

ON

The time displayed is: at x o’clock x minutes the unit will be turned on.

5.Set the TIMER OFF time

Press the TIME button, the adjustment method is the same as the one of

setting TIMER ON time.

6.Confirm the time of TIMER OFF

After adjusting time, press SET button to confirm time.

At this time, the" "will not flash.

The time displayed is: at x o’clock x minutes the unit will be turned off.

OFF

Cancel TIMER

Press the TIMER button several times until the TIMER mode display

disappears.

According to the sequence of TIMER ON & TIMER OFF setting, you can realize

turning on unit first, then turning off unit.

12

Users’ Attention

Do not press tightly with the LCD part of

the wire controller to avoid damage of it.

Set proper room temperature

Not too low or high and make every people in the

room

feel

Cooling is

26~28*

Heating is

18~23*

comfortable.

Do not let the cold air blows directly to

human body for a long time and do not

make the room temperature drop too

low.

Otherwise, it may

cause uncomfortable

or bad to your health.

The airflow cannot directly blow

to the pets and plants.

Otherwise, pets

and plants

may be hurt.

The room should often ventilate.

After a long-time

of using air

conditioner, the

room must be

ventilated.

Do not keep the doors and windows

open

Otherwise, it

may lower the

efficiency of

the air conditioner.

Television, radio and acoustics, etc.

equipment should keep over 1m from

indoor unit and wire controller.

Otherwise, they may

disturb the image

and cause noise.

Do not put any drying

devices under

the indoor unit.

The heat may cause

the deformation of

indoor unit.

If do not use the air conditioner

for a long time, it is necessary to

cut off power.

If do not cut

off power, the

Cut off

power

unit may consume

power. In order to protect the unit,

before using the air conditioner

again, turning on the power at least

12 hours in advance.

The windows should be hung

with curtains or blinds.

Do not let the sun

shine directly shine

in the room; do not

let the outdoor air

enter room.

The articles must keep dry cannot

be put under the indoor unit.

When the humidity

is over 80% or

the drainage

outlet is blocked,

the indoor unit may drop water.

Do not put articles around the

air inlet and outlet.

This kind of obstacle can lower the

efficiency of the air conditioner or

cause unit trouble.

The air conditioner can only be used

in air conditioning. It can not be

used in other purpose.

Do not use the air conditioner in some

specific purpose, such as storage or

protect food, animals, plants, precise

instrument and

artwork,

otherwise,

the quality

of them may

be declined.

13

Maintenance

Notice

The repair can only be performed

by the professional workers.

Only after turning off the unit and

cutting off the power can the

cleaning of the unit be performed.

Otherwise, it may cause electric

shock or injury.

Daily maintenance

Don’t in

operation

Before touch the wire connection

device, cut off the power first.

Notice

Do not use water to clean the air

conditioner.

Otherwise, it

may cause

electric

shock

Use stable stand support.

Please pay high attention when

cleaning the unit

Clean the air filter

Instructions:

When not for cleaning, do not dismantle the air filter, otherwise it may

cause trouble.

When the air conditioner is used in a dusty environment, the air filter

should be cleaned more often

(generally once every two weeks).

1.Open air inlet grille

Pull the two handles at the same time,

slowly draw them out.

(when closing it, the

procedure

is reversed.)

14

Open

Maintenance

Clean the air filter

2.Dismantle the air filter

Pull the two side handles

at the back of the air inlet

grille, lift the air filter to

dismantle it.

3.Clean

Notice

Do not use the hot water over 50* to clean to avoid discoloration

or deformation.

Do not dry the unit on fire, the filter may be burnt.

Use cleaner or water to clean to remove dust.

Open and remove

*A*Use cleaner to remove dust.

* B *When the dust is too much, use

soft brush and neutral detergent.

( C ) Throw the water off, then put it

in the shadow for airing.

4. Install air filter

(1) Put the air filter into those extruding

parts at the top of the air inlet grille.

(2) Draw the handles at the back of the

air inlet grille inwards to fix the air

filter.

5. Close air inlet grille

Referring to procedure 1.

15

Maintenance

Clean the air inlet grille

1. Open air inlet grille

Pull the two handles at the

same time, slowly draw

them out. (when closing

it, the procedure is

reversed.)

2. Remove air filter

Referring to “Clean the air filter”.

3. Remove the air inlet grille

Open the air inlet grille for 45o, the lift it up.

4. Clean

Notice

Open

Do not use the hot water over 50* to clean to avoid discoloration

or deformation.

Use soft brush, water and neutral

detergent to clean, then throw the water off.

Instruction

*When there is too much dust*

Use ventilation fan or directly spray the detergent special

for kitchen ware on the air inlet grille, 10 minutes later

use water to clean.

5. Install air inlet grille

Referring to procedure 3.

6. Install the air filter

Referring to “Clean the air filter”

7. Close air inlet grille

Referring to procedure 1.

16

Maintenance

Clean the air outlet and casing

Notice

Do not use gasoline, benzene, diluent, polish powder or liquid

pesticide to clean.

Do not use the hot water over 50* to clean to avoid discoloration

or deformation.

Use soft dry cloth to clean.

If cannot remove the dust, use water or neutral detergent.

If the louver of the air conditioner is too dirty, it may be dismantled

(as the following described) for cleaning.

Dismantle and install louver

1. Fix the louver at the lowest position.

Referring to SWING.

2. Dismantle louver

Notice

When use water to clean the louver, do not clean it to hard,

otherwise the fuzz on the surface maybe fall off.

Loosen the screws at

the two ends of the louver.

3. Install louver

Slightly rotate the louver, the

extruding edges at the ends

of the air inlet can be inserted

into the louver groove, then

tighten the screws.

Instruction

For details, please consult the

after-sales service worker.

17

Maintenance

Maintenance before and after the using season.

Before using season

1.Check the following items:

If the air inlet and outlet of indoor and outdoor unit are blocked.

If the earth wire is proper.

If the wire connection is proper.

If there is abnormal phenomenon, please ask the after-sale

service staffs for help.

2.Cleaning the air filter or air inlet and casing

After cleaning the air filter, it must be reinstalled.

3.Turn on the power

After using season

1.In a sunny day, perform half-a-day Fan operation to make the

inner of the unit dry.

2.Cut off the power

If do not cut off power, the unit will consume power. Power

cutoff can save power.

3.Cleaning the air filter or air inlet and casing

After cleaning the air filter, it must be reinstalled.

For the details of cleaning, please refer to Maintenance.

18

Troubleshooting

The following phenomena are not troubles

Symptom Cause

The unit does

not work

The unit

blows out

mist.

The unit

gives out

noise

The unit

blows out dust

The unit

gives out

smells.

In DEHUMIDIFYING, no air sent

out or cannot change the fan speed.

Immediately operate the unit

after its stop.

In COOLING operation, when

the ambient humidity is too

high. (the content of oil or

dust is too much in the room.)

After finishing DEFROSTING,

the HEATING operation starts.

In COOLING or

DEFROSTING, there is

continuous “Si, Si” noise.

When the unit is started,

stopped and when

DEFROSTING starts or stops,

there is the “Si, Si” sound.

In operation or after operation,

there is a continuous “Si, Si”

sound.

In operation or after operation,

a “GaZi” sound is generated.

After a long-time out of use,

the unit is started.

In operation.

3 minutes later, the unit will

automatically operate.

When the inner of the indoor

unit is not clean, the temperature

fluctuation may occur.

The removed frost rises in vapor

state.

This is the refrigerant gas

flowing sound in the air

conditioner.

It is generated when the

refrigerant stops flow or

changes flow.

It is the operation sound of the

drainage system. (in COOLING

operation, the drainage system

drains in indoor side.)

Because of the temperature

change, It is caused by the hot

expansion and cold shrink of the

resin parts.

The dust in the indoor unit

assembly is blown out.

The smells or the cigarette smell

absorbed in indoor unit are blown

out.

In DEHUMIDIFYING operation, when

the room temperature is 2 higher than

the set temperature, despite of the set

FAN SPEED the air conditioner will

operate in LOW FAN SPEED.

In HEATING, even after stopping

operation, the indoor unit still

In order to remove the remained heat,

after automatic stop, the indoor fan will

continue operating for a period of time.

19

When Troubles Occur

Before contacting the commissioned repair center for after-sales service,

please check your air conditioner according to the following items.

Symptom

The unit does not operate. The fuse is blown out or the breaker is open. Change the fuse or close the breaker.

Once the unit operates,

it stops immediately.

Abnormal of COOLING

or HEATING.

The air inlet or air outlet of indoor or outdo

or unit is blocked.

The air inlet or air outlet of indoor or outdo

or unit is blocked.

Improper set temperature Referring to page 8

The fan speed is set too low Referring to page 8

Incorrect swing direction Referring to page 9

The doors or windows are open

Direct sunshine Hang the curtain or blinds before

Too much people in room

Too many heat sources in room

Trouble display

Phenomenon of

outdoor unit trouble

The trouble of outdoor ambient

temperature sensor

The trouble of outdoor coil

temperature sensor

Over electric current protection

CT wire breaks

The communication trouble

between indoor and outdoor unit

Phenomenon of indoor

unit trouble

The trouble of indoor ambient

temperature sensor

The trouble of indoor coil

temperature sensor

The trouble of outdoor ambient

temperature sensor

The trouble of outdoor coil

temperature sensor

The trouble of electric current

overload

The communication trouble

between panel and indoor panel

The communication trouble

between indoor panel and

outdoor panel

The trouble of water pump

After checking the above items and treating the air conditioner, it still cannot

normally work, or find the following troubles occur, please stop the unit and

cut off power, then contact the after-sales service worker.

The fuse and creepage breaker are often blown out;

In Cooling or Dehumidifying operation, there is water leakage;

Abnormal operation or abnormal sound can be heard.

The screen on the wire controller shows trouble code (E1, …E0), which

indicates the air conditioner has trouble.

20

Cause Solution

Remove the obstacles.

Remove the obstacles.

Close them

windows

The flashing time of indicator light

on outdoor control panel

1 (A, B systems indicate together)

2 (A and B system indicate individually)

5 (A and B system indicate individually)

6 (A and B system indicate individually)

8 (A and B system indicate individually)

Trouble indication on remote

control type indoor unit

The compressor indicator light flashes 1

time in 0.2S/time frequency

The compressor indicator light flashes 2

time in 0.2S/time frequency

The compressor indicator light flashes 3

time in 0.2S/time frequency

The compressor indicator light flashes 4

time in 0.2S/time frequency

The compressor indicator light flashes 5

time in 0.2S/time frequency

The compressor indicator light flashes 8

time in 0.2S/time frequency

The compressor indicator light flashes 9

time in 0.2S/time frequency

The compressor indicator light flashes 10

time in 0.2S/time frequency

Indoor control

panel indication

E3

E4

E5

E5

E8

Trouble code on wire

control type indoor unit

E1

E2

E3

E4

E5

E8

E9

E0

Installation instruction

Before installing, do read this “Safety precautions” carefully to guarantee the proper installation.

The below attentive matters are divided into “ Warning” and “ Note” two parts. When the wrong

installation occur, it is very possible death and severe injury and other serious accidents will happen. For

those items are listed in “ Warning” part. But even the items listed in “ Note” part can also cause serious

accidents. Above all, both the two parts are very important contents related to safety, so they must be obeyed.

After finishing the installation work, do test run to verify everything is normal. After that please explain the

using and maintenance methods to the user. Additionally, give this installation manual and operation manual

to the user and ask them to keep it properly.

Warning

The commissioned repair center shall do the installation work. If you do the installation work by yourself,

the improper installation will cause water leakage, electric shock fire and other accidents.

The installation work shall be in line with what the installation manual specified. If installation is not

proper, water leakage, electric shock, fire and other accidents will occur.

Install the air conditioner to a place where can definitely stand its weight. The air conditioner can not be

installed on a nonmetal bracket (such as theft guard net). Places not firm enough will cause drop down of

unit resulting in body hurt.

The installation work shall be preventive to typhoon and earthquake. If the installation work is not met

with the requirements, overturn of the unit will occur resulting in accidents.

Using the specified cable to do wiring work and connecting firmly and properly. Fix the connecting part

of the terminals to prevent it from the external force. Improper connection and fixing will cause heating

and fire etc. accidents.

Wiring shall be kept in correct shape avoiding extrusion. After installation, the electric box cover and the

external panel shall not nip the wire. Improper installation will cause heating and fire etc. accidents.

When setting or moving the air conditioner do not let the air and things alike get into the refrigeration

system except the specified refrigerant (R22). If air and other things enter, abnormal high pressure will

occur, which easily cause break and body injuries etc. accidents.

When installing, do use the accessories or specified parts. If not using the parts specified by our company,

water leakage, electric shock, fire and refrigerant leakage will occur.

Do not lead the drain hose to drain where the sulfur gas may be involved. Otherwise, the poisonous gas

will enter into the indoor.

During installation, if refrigerant leakage occurs, do the ventilation work immediately. As soon as the

refrigerant gas meets fire, poisonous gas will be produce.

After installation, confirm there is no leakage of refrigerant. If the refrigerant gas enters into room and

meet the air blowing heater, heater or stove etc. fire source, the poisonous gas may be produced.

Do not install the unit in a place where the combustible gas may be leaked. In any case the combustible gas

leaks and accumulated around the unit, fire accident will occur.

The drain hose should be correctly installed according to the installation manual to ensure smooth drainage,

and take proper heat preservation measure to prevent from dew. Improper pipe installation may cause water

leakage result in wet the indoor articles.

Do heat insulation work to the refrigerant gas pipes and liquid pipes to reach the purpose of heat preservation.

If the heat insulation measure is not sufficient, water generated by condensing dew will drip leading to wet

the floor and indoor articles.

Note

Do grounding work. Do not connect the grounding wire to gas pipe, tap, lighting rod or telephone line.

Improper grounding will cause electric shock.

In some places the creepage breaker shall be installed. If do not install the breaker, electric shock may occur.

After electric installation, power on them to do electric leakage test.

21

Installation instruction

Notice

This manual can not include all kinds of conditions, if you have new

requirements and questions, please contact with local Haier Sales Center.

Warning

Before installing the unit, please read this manual carefully. Improper

installation may cause accidents and make unit damage or death.

Installation tools

1. Screwdriver 2. Steel saw 3. 60, 70mm diameter drill

4. Spanner (diameter 17,27mm) 5. Spanner (14, 17, 19, 27mm)

6. Pipe cutter 7. Pipe flarer 8. Knife

9. Pincers 10. Leakage detector/soap water

Accessories attached with the unit

The following is the manual mentioned standard accessories, please check them by

yourself. As the following figure shown

No.

Shape &

name

Amount

No.

Shape &

name

Amount

1

Wire controller

(signal wire)

** ** **

AUTO

**

**

**

******

**

**

****

**

**/**

1

7

Drain hose

1

2

Signal

wire

1

8

Seal cushion

4

3

Install

1

9

Gasket

8

4

Little wire

clamp

6

10

Buckle

1

5

Big wire

clamp

2

11

Screw

3

6

Thermal

insulation

pipe

2

12

Manual

1

22

Installation procedure

Install indoor unit

1. Before installation [Before finishing installation, do not throw the attached

parts installation needs]

Confirm the way to move the unit to the installation place.

Before moving the unit to the installation place, do not remove their packages.

When have to remove the package, use a soft material or protection board with

rope to lift the unit assembly to avoid unit damage or bumping a scrape.

2. Choose installation place

(1)The chosen installation place should meet the following requirements and

get the user’s consent.

Place ensures ideal airflow distribution.

The passage of airflow has no obstacles.

The condensate water can be drained smoothly.

Place can stand the weight of indoor unit.

Place ensures enough space for maintenance.

The pipe length between indoor and outdoor unit is in the permitted limit

(referring to outdoor unit installation part).

The indoor unit, outdoor unit, electric wire and connection wire is at least

1m away from television and radio. This is to avoid the image disturbance

and noise caused by the above-mentioned home appliance. (Even if 1m

away, if the electromagnetic wave is too strong, it can also cause noise.)

(2)The height of ceiling

The indoor unit can install on the ceiling, which height is no more than 2.7m.

(3)Install and use the hoisting screw. Check if the installation place can bear the

weight of unit assembly. If not certain, strengthen it before install the unit.

(The installation gaps are marked on the installation paper panel. Refer to

the paper panel to find those points needing to fixing.)

280

Ceiling

Over 1500

Air

discharging

hole

Over 1500

Air

Air inlet

Over 1000

Obstacle

Not exceeding 2700 from the ground

discharging

hole

Space installation needed (unit: mm)

Over 1500

Over 1500

Over 1500

Over 1500

23

Installation procedure

Install indoor unit

3.Preparation before installation

The position relation among ceiling opening and hoisting screws (unit: mm)

(Instruction)

The dimension of the ceiling

Refrigerant pipe

opening with the mark of *

can reach 910mm, but the

overlap part between ceiling

and decorative panel should

keep over 20mm.

Hoisting angel iron

A direction

Over20

950 (Decorative panel)

780 (The distance betwe

890*(Ceiling opening)

-en hoisting screws)

840 (Indoor unit assembly)

890*(Ceiling opening)

780 (The distance betw

-een hoisting screws)

840 (Indoor unit assembly)

950 (Decorative panel)

Hoisting screw

Ceiling

Before hanging the indoor unit, please choose the installation position after

A

considering the connection pipes and connection wire inside the ceiling and

decide the out direction of the connection pipe.

* When using the original ceiling, before hanging the unit, put the refrigerant

pipe, drain hose, indoor unit connection wire and wire control wire in the

position of the connection pipe and connection wire.

* Confirm the dimension of indoor unit by using the attached installation

paper panel to make the indoor unit accord with the dimension of ceiling

opening and its position.(Use the attached 4 M5x12 screws to fix the

installation paper panelunder the indoor unit.)

Ceiling opening and the installation of hoisting screw

Treatment to ceiling

About the treatment of dismantling ceiling. In order to prevent the ceiling

from vibration, it is very important to strengthen the base of ceiling and insure

level of the previous ceiling.

*Cut and remove the base of the ceiling.

*Strengthen the cut surface of the ceiling base. Increase the ends and edges

of the ceiling to fix the ceiling base.

Install the hoisting screw

Use M8 or M10 hoisting screw (4, prepare on site) (When the height of

hoisting screw is more than 0.9m, you must use M10), their gaps refer to the

dimension of air conditioner, according to the original structure and the

following method to install.

Wood structure

Frame wood

Hoisting screw

Beam

Put up the frame wood on the beam

and mount the hoisting screws.

New cement panel

Use embedded parts and

24

foot screw, etc to mount.

(Knife type

embedded part)

(Louver type

embedded part)

Iron

Foot screw

(hoisting foot screw for

connection pipe)

Installation procedure

Original cement panel

Use the in hole hinge, in hole plug or in hole screw.

Steel structure

Directly use angle steel or new angle steel for support.

Suspending of indoor unit

Adjust the position of screw cap

(underside) to make the gap between

the attached washer (underside) and

the ceiling is 135mm.

*.Installation of indoor unit

Tighten the screw cap of the hoisting screw and suspend them on the T

groove of the unit suspending part.

Use gradienter to keep the level degree of the unit within 5mm.

Use installation paper panel to confirm and adjust the position relation

between unit and ceiling opening and the suspending height of the unit.

(shows the using direction of the installation paper panel)

*The bottom of indoor unit is 43mm away from the bottom of ceiling.

(4 corners)

*The side of the indoor unit leaves 25mm gaps from ceiling.

M10 screw

135mm

Install indoor unit

Suspending bolt

Hoisting screw

Hoisting screw

Screw cap (upside)

Ceiling

Angle steel for support

Attached washer

(The suspending part of the unit)

Screw cap (underside)

Gradienter

Indoor unit

Ceiling

4 edges together

Suspending bolt (M8 or M10)

Screw cap (M8 or M10)

Hoisting screw

Suspending pole

Installation paper panel

The fittings should be prepared on site except for M10 flat washer

M10 or M8 flat washer

M10 or M8 flat washer

In order to prevent the bolt from breaking off

(safety), they must be installed blow the sus

pending parts as this figure shown.

Screw cap (M8 or M10)

43mm

25mm

25

Installation procedure

5.

Refrigerant pipe

Install indoor unit

[The proper thermal insulation must be treated to gas pipe and liquid pipe. If not,

it may cause water leakage.]

The outdoor unit is not charged with refrigerant.

When connecting the pipes to unit or dismantling the pipes from the unit, do

proceed as the figure shown, use spanner and torque pincers together.

For the dimension of the cone-shaped screw nut, please referring to Table 1.

When connecting pipes, both the inner or the outside of the cone-shaped screw

nut should pasted with refrigerant oil. Use hands to twist it for 3~4 circles, then

tighten it.

According to Table 1 to confirm the fasten torque. (fasten too tight may damage

the screw nut leading to leakage)

After check if the connection pipes leaks, then perform thermal insulation

treatment, as the following figure shown.

Only use seal cushion to bind the joint between gas pipe and the insulation parts.

Paste refrigerant oil here

Torque spanner

Spanner

Pipe joint

Cone-shaped screw nut

Medium seal cushion (accessory)

(use seal cushion to bind the pipe joint)

Clamp

Gas pipe

Liquid pipe

Thermal insulation part (accessory)

(for liquid pipe)

Thermal insulation part (accessory)

(for gas pipe)

Table 1

Specification of pipe (mm)

9.52

15.88

Torque

3270*3990 N.cm

(333*407 kgf.cm)

6180*7450 N.cm

(630*770 kgf.cm)

Dimension of cone A (mm)

45 2

12.0 *12.4

90 0.5

18.6*19.0

Cone

R0.4~0.8

A

6. Installation of drain hose

(1)Install the drain hose

The diameter of the drain hose should be larger than or equal to the

diameter of connection pipe.

(Polyethylene pipe, dimension: 25mm, external diameter:32mm)

Material of connection pipe

Material of thermal insulation

26

Stiff PVC pipe VP 31.5mm (inside diameter)

Foam polyethylene pipe, thickness over 10mm

Installation procedure

Install indoor unit

The indoor side drain hose and the parts connected with indoor unit should be

thermal insulated. Improper thermal insulation may cause dew-forming

phenomenon.

The drain hose should be as short as possible. The droop slant degree at least

should be 1/100 to avoid forming of gas bag.

If cannot make the drain hose have an enough slant degree, a drainage

enhancing hose should be equipped.

In order not to let the drain hose bend, a 1~1.5m distance should be kept

between suspending frame.

1m*1.5m

Droop slant degree over

1/100 Support frame

Thermal insulation material

(customer self-provided)

***

S-shaped bend

As large as possible (about 10cm)

Droop slant degree over

VP30

1/100 Support frame

Hose

Hose buckle

Thermal insulation treatment:

Use thermal insulation material, as figure shown, to bind

the hose and the hose buckle to the bottom of the indoor

unit without any gaps.

Hose

Accessorial thermal

insulation material

Thermal insulation material

Stiff PVC pipe

The hose can be used to adjust the radius and angle of stiff PVC pipe.

*Directly stretch the hose to perform work, do not make it deform.

*The soft end of the hose must be fixed by the hose buckle.

*Please use the hose in the level part.

Radius adjustment

(Max 20mm)

20mm

<The attentive matters of drainage enhancing pipe>

*

45* bend(Max)

45*

Hose

Hose buckle

Hose

Indoor unit

The installation height of the drainage enhancing pipe should be less than 530mm.

The drainage enhancing pipe should be vertical to the unit and no more than 300mm away

from the unit.

Within 300mm

Drain hose

(accessory)

Wire clamp (accessory)

1-1.5m

Hoisting foot

Drainage enhancing pipe

Below 530

220

Below 750

Drain hose

(accessory)

Below 75

Below 750

Instruction)

*The slant of the accessory drain hose should be within 75mm to make the drain faucet not

bear too much excessive external force.

*If many drain hoses join together, please install according to the following procedure.

Over 100

The specification of the chosen joined drain hoses should be applicable to the operation capacity of the unit.

T-joint joined drain hose

27

Installation procedure

Install indoor unit

Test of drainage system

(a)After finishing the electric work, perform the test to the drainage system.

(b)During test, confirm the water flow properly passes the hose and there is no leakage

at the joint.

(c)If the house is new, perform test before installing ceiling.

(d)Even if installing in the season needing to make heating, the test also must be

performed.

Procedure

(a)Through the air outlet and use water pump to provide the equipment with about

1000cc water.

(b)In COOLING operation, check the drainage system.

Maintenance cover

Drain hose The drainage

outlet for maintenance

(with a rubber stop)

(use this outlet to discharge

the water in the drain pan)

Checking hole

Connected with

outdoor unit

Terminals block

of the power

The PC board of

the indoor unit

Terminals block

of the power

100mm

Plastic watering pot

(the pipe should be

about 100mm long)

(Charge through the checking hole)

(discharge through the

air discharging hole)

Electric box cover

7.Electric circuit

All the provided parts, material and electric work should be complied with

the local regulation.

Must use cooper core cable.

When performing electric work, please refer to the wiring diagram on the

unit.

All the wiring work should be done by the qualified electrician.

A breaker which can cut off the power of the whole circuit must be equipped.

For the specification of the power cable connected with the outdoor unit, the capacity

of breaker and switch and the guide of circuit, etc. please refer to the configuration

of the power supply.

28

Installation procedure

Install indoor unit

<The wiring method of the connection of the unit>

Connect the unit

Remove the electric box cover (1), draw the wire in the rubber lining, use wire

clamp A to clamp it together with other wires, and connect the wire of the

relative polarity to the inner power terminal block.

After proper connection, press the wire clamp A tight.

Bind the seal cushion on the wire. (it must be bound tight to avoid dew-forming)

After proper connection, reinstall the electric box cover (1).

Power terminal

block

Wire clamp A

Power

terminal block

Grounding wire end

Electric box cover (1)

Rubber lining

This part must be sealed to prevent water from entering

Rubber lining

(inside)

Attached with seal cushion

Instruction: Use seal cushion to bind

*****tight not leaving any gap.

Seal cushion (little size)

bind the wire

(outside)

Wiring on site

29

Installation procedure

Install wire controller

1.Remove the upper cover of wire controller

The PC board is installed on the back cover of

Upper cover of

wire controller

Switch

Screw hole

wire controller. When remove the upper cover,

pay attention not to damage PC board.

Back cover of

wire controller

2.Install wire controller

**Drill 2 wall holes according to the position of the 2 screw holes on the back

*cover of wire controller, then hit wood in the wall holes. Put the 2 screw holes

*on the back cover of wire controller properly to its corresponding wood, then

*use wood screws to fix the back cover on the wall.

Note:

Install the back cover of wire controller on the even wall as possible as can.

When tightening the wood screw , do not use to tight force, otherwise the wire

controller may be damaged.

Switch

Mark

1

2

3

4

ON

3 grades fan speed

Have rise and drop

Swing

The collection

temperature of

main panel

Under this series, the switch is set as:

OFF

2 grades fan speed

No rise and drop

Not Swing

The collection

temperature of

panel

Note:

When connecting wire, please keep a

certain distance between signal wire and

electric wire. (over 10mm)

Dimension of signal wire:

Type of wire

Dimension

Shield wire (4 cords)

0.33mm

2

1.ON 2. OFF 3. OFF 4.OFF

3.Indoor unit wire connection

Connect the terminals (A, B, C, D,) on the wire

controller to the terminals on the indoor PC

panel (A, B, C, D,) respectively.

Arrange wire from this part

AB CD

Back cover

wire controller

Upper cover

of wire

controller

The connection between indoor unit

and wire controller and indoor unit

and outdoor unit should use shield

wire. And the two ends of the shield

wire should be grounded,

otherwise, the disturbance will

cause unit abnormal operation.

Shield wire

Grounded

Grounded

Note:

Confirm the connection part of terminals is firm and will not touch shield wire.

4. Cover the wire controller upper cover

Pay attention not to press the connection wire.

Note: Do not touch PC board by hand.

30

Installation procedure

Install the decorative panel

1. Preparation of decorative panel

The treatment of decorative panel

The decorative panel cannot be put down with the front downwards,

cannot lean on the wall and cannot be put on the extruding objects.

Do not touch louver or force on it, otherwise the louver may have trouble.

(1) Dismantle the air inlet grille from the decorative panel

Pull the pole of the air inlet grille inwards, then lift one end of the pole

(referring to Figure 1).

Lift the air inlet grille for about 45*, dismantle the air inlet grille from the

decorative panel. Then tear off the adhesive tape to fixing the air filter on

the back of the air inlet grille (referring to Figure 2).

45

Adhesive tape (2 positions)

Pole

Figure 1

Figure 2

(2) Dismantle the corner cover

Tear off the fixing adhesive tape on the corner

cover. When the corner cover can slide,

dismantle the corner cover (referring to Figure

3).

Note: When the air conditioner is under use, the fixing

adhesive tape can be removed, not use any longer.

Slide

**

2.The installation of the decorative panel on the indoor unit.

As Figure 4 shown, make the position of the louver motor of the

decorative panel and the position of nozzle of the indoor unit face to face, then

install the decorative panel on the indoor unit.

31

Installation procedure

Louver motor

3

2

Hoisting ring

The position of nozzle

4

Install the decorative panel

1

2

Figure 4

(1)Install decorative panel

1

Temporarily hang the hoisting ring opposite to the louver motor of the decorative panel on

the hoisting ring fixing piece (2 pieces) of the indoor unit.

2

Temporarily hang the other 2 hoisting rings on the hoisting ring fixing pieces at the side of

the indoor unit (be careful not to stick to wire of the louver motor into the sealing material).

3

Screw all the 4 hexagon screws under the hoisting ring into about 5mm (the decorative

panel will rise).

4

T wist in the direction as Figure 4 shown, adjust the decorative panel to make it totallycover

the ceiling opening.

5

Fasten the screw to make the thickness of the sealing material between

decorative panel and the indoor unit compressed to 5~8mm.

Indoor unit

Ceiling material

Notice

If fastening the screws improperly, it may

cause the trouble as Figure 5 shown.

The screw should be fastened properly.

If after fastening the screw, there still is gap

between decorative panel and ceiling, please

readjust the height of the indoor unit (referring

to Figure 6).

If the indoor unit keeps horizontal and the

drain hose is not affected, adjust the height

of the indoor unit through those holes at the

corner of the decorative panel.

32

Sealing material

5~8mm

Decorative panel

Leakage

Leak air from the roof

Pollution

Gap is not permitted

Moist forming and drop

Figure 5

Figure 6

Installation procedure

Install the decorative panel

(3)The circuit of the decorative panel

6

Connect the wire end of the louver motor installed on the decorative panel

(referring to Figure 7).

Figure 7

Side of indoor unit

<The indication diagram of circuit>

(different from the actual condition)

3.Installation of air inlet grille and corner cover

*(1)Install the air inlet grille

*The reversed procedure to the “the preparation of decorative panel” part.*****

When installing the air inlet grille, be careful not

to wrap the wire of the louver motor.

(2)Install the corner cover on the corner

1

**As Figure 8 shown, tie the rope of the corner cover on the cleat of the decorative

panel.

2

* Install the corner cover on the decorative panel (referring to Figure 9).

Cleat

Slide the 5 buckles to install the

corner cover and make it meet with

the holes in the decorative panel

Figure 8

Figure 9

33

Installation procedure

Connection of pipe

1. Connection of pipe**

For the specific max length and the max fall

of connection pipe, please refer to the manual

of outdoor unit.

In order to guarantee the efficiency, the pipe

should be as short as possible.

Daub the refrigerant oil on the joint and the

flared nut.

When bending the pipes, give the roundness

as large as possible, to avoid crashing the pipes.

T o connect the pipe, fit the center and use hand

to screw the nut, then use spanner to tighten

the nut, as shown in figure.

Pay attention not to let alien matters, such as

sand, vapor get into the pipe.

The connection of indoor unit pipe must be

performed by using two spanners.

2. Dimension of connection pipe

Liquid pipe

Gas pipe

Pipe diameter

15.88mm

Joint

Spanner

If do not fit the center and

screw the nut hard, the screw

thread may be damaged,

which will cause refrigerant

leakage.

Fasten torque

9.52mm

32.7~39.9 N.m

61.8~74.5 N.m

Nut

Spanner

3. The additional charging amount of refrigerant

The additional charging of refrigerant (R407C) should be complied with the

installation manual of outdoor unit. It must use measurer to quantificationally

charge. The additional charging amount must be complied with the specified

amount.

Requirements: Both excessive charging and less charging of refrigerant will cause the

compressor trouble. It must be complied with the specified amount.

4.Discharging of pipe

**For details, please refer to the pipe installation part in the manual of outdoor unit.

5.Leakage detection

Use leakage detector or soap water to check if the connected part of the connection

pipe and the valve cap leak.

6.Thermal insulation treatment

The thermal insulation of connection pipe should be performed at both gas side

and liquid side. In COOLING, both liquid side and gas side are in low temperature,

in order to prevent dew from forming, thermal insulation should be done.

The thermal insulation material at the gas side must use the material with the heat

resistant temperature over 120*.

The connected parts of indoor unit connection pipe should be thermal insulated.

34

Installation procedure

Electric wiring

Note:

*All the wires should be copper core wires.

*The power cable of indoor unit should be equipped according to the operation

manual of indoor unit.

*Before finishing vacuumizing the refrigerant pipe system, do not supply

power to outdoor unit.

*The connection of power cable should be complied with local wiring

regulation.

*When connecting the wire of indoor and outdoor unit, check the number on the indoor

and outdoor terminal blocks, the same number uses one wire to connect.

*Incorrect wiring easily damage the controller of the air conditioner, or the unit cannot

work normally.

Wiring method

1.The wiring method of orbicular terminal

For the connection wire which end is orbicular

terminal, its wiring method is as the right figure

shown. Dismantle the screw and put it through

the ring at the end of the connection wire, then

connect it to the terminal block and tighten the

screw.

The wiring method of orbicular terminal

2.The wiring method of straight terminal

For those connection wires whose end are not orbicular terminals, their

wiring method is:

Loosen the connecting screw, insert the end of the wire directly into the terminal

block, and then tighten screw. Pull the wire outwards slightly to confirm it is held

tightly.

3.Pressing method of connection wire:

After wiring, the connection wire must be

Correct pressing

Terminal block

pressed with wire holding clamp. The wire

holding clamp should press on the out co-

Wire holding clamp

ver of the connection wire. As the right fi gure shown:

Connect wire between indoor &

outdoor unit

As the wiring diagram show to arrange the

Indoor terminal block

(A system)

(Sketch map)

1 2 3

connection wire (note: the two ends of

connection wire is different, do not connect

them reversedly).

L

A(L)

N

Outdoor terminal block

Power supply

1PH, 220V*, 50Hz

A(C)A(N)

Note: The terminal block’s mark at the two ends of the connection wire should be

corresponding one by one, otherwise the air conditioner cannot work normally.

Wrong pressing

Indoor terminal block

(B system)

1 2 3

B(C)B(N)B(L)

35

Installation procedure

Other instruction

1.Power supply

The air conditioner must use a special power circuit and special air switch

(40A). The wiring should be done by a qualified electrician according to

the wiring rules specified by national standard

An creepage breaker should be installed.

The grounding wire and null wire of receptacle should be strictly separated.

It is incorrect to connect the null wire with grounding wire.

The connection method of power cord is Y connection. If the power cable is

damaged, in order to avoid danger, it must be replaced by the manufacturer

or its specified repair center of the same qualified worker.

2. Cut and flaring method

Use pipe cutter to cut the pipe, the burrs must be removed.

After inserting the flarer, perform flared nut.

Flarer

A

Correct

Connent pipe

Liquid pipe

Slant

Flaring dimensions as follows:

Pipe diameter

9.52mm (3/8")

Gas pipe

19.05mm (3/4")

Broken

Burrs Too long

Dimension A (mm)

1.0-1.2

1.4-2.2

Incorr

Uncompleted

Test run

The following items must be noticed carefully during installation. After finishing

installation, performing checking.

After installing the refrigerant pipe, drain hose and electric wire properly , perform test

run to ensure the system not have trouble.

Perform test run before installing decorative panel

(1)Open the stop valve of gas pipe.

(2)Open the stop valve of liquid pipe.

(3)Use remote controller to set to COOLING operation, press ON/OFF button to start

operation.

(4)After finishing operation, cut off the general power supply.

Perform test run after installing decorative panel

(1) Open the stop valve of gas pipe.

(2) Open the stop valve of liquid pipe.

Note: The wiring diagram of this model is pasted inside of the unit.

36

Loading...

Loading...