Page 1

Multi-Zone Technical Overview

ENGLISH

Table of Contents

Introduction ..................................................................................................................................... 2-11

Nomenclature ....................................................................................................................................................... 2

Specications .....................................................................................................................................................3-5

Safety Overview .................................................................................................................................................6-7

Functions & Controls....................................................................................................................................... 8-11

Outdoor Unit Technical Overview ................................................................................................... 12-33

Components ................................................................................................................................................. 12-18

Operations .................................................................................................................................................... 19-25

Testing ........................................................................................................................................................... 26-28

Error Codes ................................................................................................................................................... 29-33

Indoor Unit Technical Overview - Wall Mount ..................................................................................34-43

Components ................................................................................................................................................. 34-39

Testing ........................................................................................................................................................... 40-41

Error Codes ................................................................................................................................................... 42-43

Indoor Unit Technical Overview - Cassette ..................................................................................... 44-51

Components ................................................................................................................................................. 44-47

Testing ........................................................................................................................................................... 48-51

Indoor Unit Technical Overview - Slim Duct .................................................................................... 52-57

Components ................................................................................................................................................. 52-55

Testing ........................................................................................................................................................... 56-57

Wired Controller ............................................................................................................................ 58-64

Wireless Remote Controller ...........................................................................................................65-68

References......................................................................................................................................69-121

Troubleshooting,Resistance Values, Error Detection, Piping Length Limits ............................................ 69-72

Component Ratings ............................................................................................................................................ 73

Ductwork Installation ......................................................................................................................................... 74

Wiring ............................................................................................................................................................. 75-89

Piping Installation Dimensions ..................................................................................................................... 90-95

Flow Charts.................................................................................................................................................. 96-109

Sensors ...................................................................................................................................................... 101-121

TECHNICAL OVERVIEW

PAGE 1

Page 2

ENGLISH

1 U 18 LC 2 V H A

1 U 18 ES 2 V H A

Unit Type

A = Indoor Unit

1 = Single Zone Outdoor

2 = Two Zone Outdoor

3 = Three Zone Outdoor

4 = Four Zone Outdoor

NOMENCLATURE - Model Name Explanation

Nomenclature

Product Revision

Unit Type

U = Outdoor

B = Cassette Type Indoor

D = Slim Duct Type Indoor

M = Mid Static Duct Type Indoor

H = High Static Duct Type Indoor

W = Wall Mount Type Indoor

Nominal Capacity

In Btu/hr (x 1000)

Product Family

- MS

- LC

- SL

- SC

System Type

H = Heat Pump

C = Cool Only

Compressor Speed

V = Variable Speed

Voltage

1 = 115V

2 = 230V

PAGE 2

INTRODUCTION

Page 3

SPECIFICATIONS

Multi-Zone Indoor

ENGLISH

INTRODUCTION

PAGE 3

Page 4

ENGLISH

SPECIFICATIONS

Multi-Zone Indoor

PAGE 4

INTRODUCTION

Page 5

SPECIFICATIONS

Multi-Zone Outdoor

ENGLISH

INTRODUCTION

PAGE 5

Page 6

SAFETY OVERVIEW

Read These Safety Precautions

Be sure to read the safety precautions before conducting work. The items are classied into “Warning” and “Caution.” The

“Warning items are especially important since they can lead to death or serious injury if not followed closely. The “Caution”

items can also lead to serious accidents under some conditions if they are not followed. Therefore, be sure to observe all safety

ENGLISH

precautions listed here.

∆ This symbol means be careful when doing this procedure or touching this equipment.

ᴏ This symbol indicates a prohibited action.

• This symbol means that an action must be taken; the action will be listed next to the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment operates properly;

explain the safety precautions for operating the equipment to the customer.

Warning

Disconnect the power cable from electrical socket

before disassembling equipment for repair. Working

on equipment that is connected to a power supply

can cause an electrical shock.

If the refrigerant gas discharges during the repair

work DO NOT touch the discharging refrigerant gas.

The refrigerant gas can cause frostbite.

Before disconnecting the suction or discharge pipe

of the compressor at the welded section, recover

the refrigerant gas in a well-ventilated area. If

refrigerant gas remains inside the compressor, the

refrigerant gas or the refrigerating machine oil will

discharge when the pipe is disconnected and may

cause injury.

If the refrigerant gas leaks during the repair work,

ventilate the area. The refrigerant gas can generate

toxic gases when it contacts ames.

The step-up capacitor supplies high-voltage

electricity to the electrical components of the

outdoor unit. Be sure to discharge the capacitor

completely before conducting repair work. A

charged capacitor can cause electrical shock.

Be sure to use parts listed in the service parts

of the applicable model and appropriate tools to

conduct repair work. Never attempt to modify

the equipment. The use of inappropriate parts or

tools can cause electrical shock, excessive heat

generation, or re.

When relocating the equipment make sure that

the new installation site has sucient strenght to

withstand the weight of the equipment. If the new

installation site does not have sucient strength

and if the installation work is not conducted

securely, the equipment can fall and cause injury.

Be sure to install the product correctly by using the

standard installation frame provided. Incorrect use

of the installation frame and improper installation

can cause equipment to fall, resulting in injury.

Do not repair the electrical components with wet

hands. Working on equipment with wet hands can

cause electrical shock.

Do not clean the equipment by splashing water.

Washing the unit with water can cause an electrical

shock.

Make sure that the unit is grounded when reparing

the equipment in a wet or humid place to avoid

electrical shocks.

Be sure to turn o the power switch when cleaning

the equipment; the internal fan rotates at a high

speed and may cause injury.

Do not tilt the unit when removing it. Water inside

the unit can spill, wetting the oor.

Be sure to check that the refrigeration cycle section

has cooled down suciently before conducting

repair work. Working on the unit when the

refrigerating cycle is hot can cause burns.

Use the welder in a well-ventilated place. Using

the welder in an enclosed room can cause oxygen

deciency.

Be sure to use a dedicated power circuit for the

equipment; follow appropriate technical standards

for the electrical equipment, the internal wiring

regulations, and the instruction manual for

installation when conducting electrical work.

Insucient power circuit capacity and improper

electrical work can cause an electrical shock or re.

PAGE 6

INTRODUCTION

Page 7

SAFETY OVERVIEW

Read These Safety Precautions

Be sure to use the specied cable to connect

between the indoor and outdoor units. Make the

connections securely and route the cable properly

so that there is no force pulling the cable at the

connection terminals.

When connecting the cable between the indoor and

outdoor units make sure that the terminal cover

does not lift o or dismount because of the cable.

If the cover is not mounted properly, the terminal

connection section can cause an electrical shock,

excessive heat generation, or re.

Do not damage or modify the power cable.

Damaged or modied power cables can cause

electrical shock or re. Placing heavy items on the

power cable and heating or pulling the power cable

can damage the cable.

Do not mix air or gas other than the specied

refrigerant (R=4 10A/R22) in the refrigerant system.

If air enters the refrigerant system, an excessively

high pressure results, causing equipment damage

and injury.

If the refrigerant gas leaks, be sure to locate the leak

and repair it before charging the refrigerant. If the

leak cannot be located and the repair work cannot

be stopped, be sure to perform pump-down and

close the service valve to prevent the refrigerant

gas from leaking into the room. The refrigerant gas

itself is harmless, but it can generate toxic gases

when it contacts ames, such as fan and other

heaters or stoves and ranges.

When replacing the remote control battery, be sure

to safely dispose of the battery to prevent children

from swallowing it.

Do not install the equipment in a place where

there is a possibility of combustable gas leaks. If

combustible gas leaks and remains near the unit, it

may cause a re.

Be sure to install the packing and seal on the

installation frame correctly. If the packing and

seal are not properly installed, water can spill out,

wetting furniture and the oor.

ENGLISH

Replace power cables and lead wires if they are

scratched or deteriorated. Damaged cable and

wires can cause electrical shock, excessive heat

generation, or re.

Check to see if the parts are mounted correctly,

that the wires are connected correctly, and that

connections at soldered or crimped terminals are

secure. Improper installation and connections can

cause excessive heat generation, electrical shock,

and re.

If the installation platform or frame has deteriorated

or corroded, replace it. Corroded platform or frames

can cause the unit to fall, resulting in injury.

Check to make sure that the equipment is grounded.

Repair it if it is not properly grounded. Improper

grounding can cause an electrical shock.

Be sure to measure the installation resistance of

the repair. Be sure that the resistance is 1 M ohm

or higher. Faulty installation can cause an electric

shock.

Be sure to check the drainage of the indoor unit

after the repair. Faulty drainage can cause the water

to spill, wetting the furniture and the oor.

Important Safety Related

Installation Information

Indoor Clearances: If noncompliant may lead to temperature

control complaints.

Wire Sizing: If noncompliant may lead to communication errors

and inverter irregular operation.

Splices in Field Wiring: Splices between the wires that connect

between the outdoor and indoor unit should be avoided.

Communication errors may occur if noncompliant.

Sealing Penetrations: If penetrations at back of unit are not

sealed, unconditioned air may be drawn into the back of the

indoor wall mount unit. Temperature control and capacity

complaints may occur.

INTRODUCTION

PAGE 7

Page 8

OVERVIEW & INTRODUCTION

Functions and Controls

Auto Mode

When the running mode is turned to auto after starting the

ENGLISH

system, the system will rst determine the running mode

according to the current room temperature and then will

run according to the determined mode: Tr means room

temperature; Ts means temperature setting; Tp means

temperature of indoor coil pipe

Tr≥73°F Choose Cooling Mode

Tr<73°F Choose Heating Mode

After turning to the auto mode, the running mode will be

switched between cooling mode, fan mode, and heating mode

according to the change of the indoor ambient temperature.

There is a 15 minute delay between mode changes.

Cooling operation mode

Temperature control range: 60°F---86°F

Temperature dierence: ±2°F

* Control features: When Tr (input airow)>Ts (set

temperature) °F, the indoor fan will operate at the set speed,

the mode signal will be sent to the outdoor system, and

the compressor will start. When Tr (input airow)< Ts (set

temperature)°F, the indoor fan will operate at the set speed,

and the mode signal will be sent to the outdoor system, and

the compressor will stop. The system will keep the original

status if Tr= Ts.

Airow speed control: (temperature dierence ±2°F)

Automatic:

When Tr≤Ts +4°F high speed.

When Ts+2°F≤Tr<Ts+5°F, medium speed

When Tr<Ts+2°F, low speed

When the sensor is o, low speed

When the airow speed has no delay from the high to low

switching, the speed should be delayed for 3 minutes (remain

at high speed for 3 minutes.) before the next switch.

When the system is operating, you can set the high, medium

or low speed manually. (When the sensor is on or o, the

system will change the speed 2 seconds after receiving the

signal.)

*Louver control: the location for the louver can be set

according to your needs.

*Defrosting function: preventing the frosting on the indoor

heat exchanger (when cooling or dehumidifying). When the

compressor works continuously for 1 to 6 minutes (adaptable

in EEPROM) and the temperature of the indoor coils has been

below 32°F for 10 seconds, the compressor will be stopped

and the malfunction will be recorded in the malfunction list.

The indoor system will continue to run. When the temperature

of the indoor coil is raised to 45°F, the compressor will be

restarted again (the requirement of 3 minutes’ delay should

be satised.)

Dry Mode (Dehumidifying mode)

* temperature control range: 60---86°F

* temperature dierence: ±2°F

Control feature: Send the dehumidifying signal to the outdoor

system.

When Tr>Ts+4°F, the compressor will be turned on, the indoor

fan will operate at the set speed. When Tr is between the

Ts and Ts+4°F, the outdoor system will operate at the high

dehumidifying frequency for 10 minutes and then at the low

dehumidifying mode for six minutes. The indoor fan will

operate at low speed.

When Tr< Ts, the outdoor system will be stopped, the indoor

fan will be stopped for 3 minutes and then turned to the low

speed option.

All the frequency conversions have a ±2°F dierence.

* Wind speed control: Automatic:

When Tr≥ Ts+ 9°F, high speed.

When Ts+5°F≤Tr< Ts+9°F, medium speed.

When Ts+4°F≤Tr< Ts+5°F, low speed.

When Tr<Ts+4°F, light speed.

If the outdoor fan is stopped, the indoor fan will be paused for

3 minutes.

If the outdoor fan is stopped for more than 3 minutes and the

outdoor system still operates, the system will be changed into

light speed mode.

When the airow speed has no delay from the high to low

switching, the speed should be delayed for 3 minutes (remain

at high speed for 3 minutes.) before the next switch.

When the sensor is o or Tr< Ts+5°F, the manual operation can

not be made. (obligatory automatic operation.)

*Louver location control: the location for the louver can be set

according to your needs.

*Defrosting function: preventing the frosting on the indoor

heat exchanger (when cooling or dehumidifying). When the

compressor works continuously for 16 minutes (adaptable in

EEPROM) and the temperature of the indoor coils has been

below 32°F for 10 second, the compressor will be stopped and

the malfunction will be recorded in the malfunction list. The

indoor system will continue to run. When the temperature

of the indoor coil is raised to 45°F, the compressor will be

restarted again (the requirement of 3 minutes’ delay should

be satised.)

PAGE 8

INTRODUCTION

Page 9

OVERVIEW & INTRODUCTION

Functions and Controls

Heat Mode mode.

* temperature control range: 60---86°F

* temperature dierence: ±2°F

Control feature: the temperature compensation is

automatically added and the system will send the heating

signals to the outdoor system.

If Tr≤Ts, the outdoor compressor is turned on, the indoor

fan will be at the cold air proof mode.

If Tr>Ts+, the outdoor system is turned o, the indoor fan

will be at the heat residue sending mode.

If Tr<Ts+, the outdoor system will be turned on again, the

indoor fan will be in the cold air proof mode.

Indoor fan control

Manual Control: You can choose high, medium, low and

automatic speed control. Automatic:

When Tr<Ts, high speed.

When Ts≤Tr≤Ts+4°F, medium speed.

When Tr> Ts+4°F, low speed.

When the airow speed has no delay from the high to low

switching, the speed should be delayed for 3 minutes (remain

at high speed for 3 minutes.) before the next switch.

*Louver location control: the location for the louver can be set

according to your needs.

Cold air-proof operation

ENGLISH

4. During the cold air proof operation, the indoor system

will continuously send ‘indoor high speed’ signals to the

outdoor system.

* Residue heat sending. The indoor fan will send the

residue heat at a low speed for 12 seconds.

If other conditions are satised, when the compressor stops,

the indoor system will operate at a light speed. The indoor

fan will stop when the coil temperature is below the heat start

temp 4’.

* Defrosting. When the system receives the defrosting

signal from outdoors, the indoor fan will stop and the indoor

temperature display won’t change. At thistime, any indoor coil

malfunctions will be neglected. When the outdoor defrosting

nishes, the coil malfunction will still be neglected until the

compressor has been started up for 30 seconds. The indoor

temperature display will not change and the system operates

at the cold air proof mode.

* Automatic heating temperature compensation:

when the system enters the heating mode, the temperature

compensation (4) will be added. When the status is switched

o, the compensation will be erased.

Timing

You can set 24 hours on/o timing. After setting, the timing

indicator will be displayed. Also, the light will turn o after the

timing is set. The followings are several timing methods:

1. The indoor operation within 4 minutes after the start

up is as the following diagram, the air speed can be raised only

after the speed has reached a certain level.

2. 4 minutes after the start up of the indoor fan, the

light airow and the low airow will be turned to the set speed

airow.

3. In the cold air proof operation, the fan won’t stop

after the start up.

1. System ON timing: The timing indicator will be

displayed and the indoor system is under the waiting mode.

The light will be turned o when the timing is nished and the

rest of the system will operate under a normal condition. The

timing starts since the last reception of the timing signal.

2. System /OFF timing: When the system is turned on,

the timing indicator will be displayed; the rest of the system

will operate under normal conditions. When the set time

expires, the indicator display will turn o and the system will

turn o. If you have set the dormant functions, the order

of your settings will be operated according to the timing

settings.

3 . System ON/OFF timing: The settings will be

completed according to the settings.

INTRODUCTION

PAGE 9

Page 10

OVERVIEW & INTRODUCTION

Indoor Unit Operating Mode Conicts

Indoor System Mode Conict

The indoor unit is trying to operate in a mode that is opposite

ENGLISH

of the mode the outdoor unit is currently operating in. Change

the operating mode to either heat or cool, or the indoor unit

will shut o.

Abnormality conrmation approaches

1. Indoor temperature sensor abnormality:

Under the operation, the normal temperature ranges from

120°F to -30°F. When the temperature goes beyond this

range, the abnormality can be conrmed. If the temperature

goes back into the range, the system will automatically

resume.

2. Indoor heat interaction sensor abnormality:

Under the operation, the normal temperature ranges from

120°F to -30°F. When the temperature goes beyond this

range, the abnormality can be conrmed. If the temperature

goes back into the range, the system will automatically

resume.

Low Load Protection Control

In order to prevent the frosting of the indoor heat interaction

device, the outdoor system will be stopped if the indoor heat

interaction temperature is 32°F for 5 minutes, but the fan will

continue to operate. The outdoor system will be started again

when the heat interaction temperature is above 108°F, and the

system has been stopped for 3 minutes. The malfunction will

be stored in the malfunction resume and will not be revealed.

High Load Protection Control

The outdoor system will be stopped if the coil temperature is

above 149°F for 2 minutes. The indoor fan will be controlled by

the thermostat. The outdoor system can be restarted when

the coil temperature is below 108°F and the system has been

stopped for 3 minutes. The malfunction will be stored in the

malfunction resume and will not be revealed.

3. Indoor/Out door malfunction: When the indoor system

receives the outdoor malfunction codes, it will store the code

into E2 for the malfunction list resume. The indoor system

will continue to operate according to the original status, the

malfunction code will not be revealed or processed.

4. Transmission abnormality:

If the indoor system can’t receive the outdoor system for 8

minutes, the communication abnormality can be conrmed

and reported and the outdoor system will be stopped.

PAGE 10

INTRODUCTION

Page 11

OVERVIEW & INTRODUCTION

Multi-Zone Outdoor

When the compressor rst starts

The compresor will start in low frequency. After a brief time

delay, the compressor will come up to operating speed to

meet the demand requirement for capacity.

The outdoor fan control (exchange fan)

When adjusting the fan speed, the unit should remain at each

speed for 30+ seconds to avoid speed-change malfunctions.

In Cooling Mode, the wait time between speed levels should

be 15 seconds.

The outdoor fan control when in cooling or dehumidifying

mode

Five seconds after compressor starts, the outdoor fan will

start running at medium speed. After 30 seconds, it begins

to control the fans peed according to the temperature

conditions of the outdoor environment.

Multi-Zone Outdoor

The Control of the Outdoor Unit Expansion Valve

When unit starts, the EEV valves will energize and change to a

standard opening. When operation starts, the EEV will change

position to keep the suction vapor superheat level at around

10°F.

When the unit is shut o the opening size of the expansion

valve of the indoor unit is 5 steps;

Four-way valve control

For the details of defrosting four-way valve control, see the

defrosting process.

Under heating mode, the four-way valve opens. If the

compressor does not start or changes to a non-heating

mode, the compressor will be stopped for 2 minutes, and then

the four-way valve will shift.

ENGLISH

Over-temperature Heat Mode Indoor Coil

The over-temperature routine will protect the system from excessive high indoor coil temperature during heat mode operation.

The routine will initiate if the indoor coil temperature sensor reads temperatures in excess of 131F. Conditions that cause high

indoor coil temperature include indoor fan failure, dirty indoor coil and operating the system in heat mode when outdoor air

temperatures exceed operating limit. (Too warm outside)

Should this routine be initiated, the system will reduce compressor frequency until the indoor coil temperature reaches 117F.

Once this is achieved, the system will return to normal operation.

149°F

138°F

131°F

124°F

117°F

INTRODUCTION

PAGE 11

Page 12

Outdoor Unit Technical Overview

Outdoor Unit Technical Overview

The outdoor unit features a variable speed rotary type compressor that delivers refrigerant ow to up to 4 individual

ENGLISH

indoor units. The system uses R-410A refrigerant mixed with

PVE oil. The system is rated to operate at 208/230 volts single

phase 60 Hz power.

Indoor units compatible with this model include high wall type,

slim duct type and cassette type.

The indoor cassette unit can be controlled by either a remote

control or a wired controller. The indoor high wall unit is controlled by infrared remote. The slim duct unit is controlled by

wired controller only.

All indoor units must operate together in either heat mode,

or cool mode. The indoor units will not automatically switch

between heat and cool modes of operation. The rst unit that

is turned on and set to provide comfort, will set the operating

mode of the system. All other indoor units must now operate

in the same mode as the rst unit that was energized.

Introduction - Overview

Circuit Boards

The Circuit Boards

There are 4 control boards located in the outdoor unit. To access the boards, remove the top cover and the cover located to the

right of the outdoor fan motor opening. The boards are the Electronic Control Unit (ECU), Module Circuit Board (MCB), Power

Circuit Board (PCU) and Service Monitor Board (SMB).

Service Monitor Board (SMB)

Service Monitor Board (SMB)

The SMB has important features, including DIP Switches

that aect system operation, Digital Error Code Displays, Compressor Operating Frequency Display and

Diagnostic capability.

1

The SMB is connected to the ECU via Plugs CN-2

and CN-3.

2

The SMB DIP switch SW-1 should have all 4

switches in the OFF position. This setting will congure

the system for normal operation with variable speed

inverter control.

3

1

2

4

3

The digital display will indicate operating frequency of the compressor when no error code is present. If a system error

code occurs, the code will be displayed here.

4

There are 4 GREEN LED indicators that indicate the status of the wiring and communication links between the outdoor

unit and indoor unit. When lit GREEN, the wiring is correct.

PAGE 12

TECHNICAL OVERVIEW

Page 13

TECHNICAL OVERVIEW

Electronic Control Unit Circuit Board (ECU)

Electronic Control Unit Circuit

Board (ECU)

The Electronic Control Unit

operates the outdoor fan motor,

crankcase heater, EEV stepper

motors and the 4-way valve.

This board also controls the

general operation of the system

and makes all of the diagnostic

decisions. The ECU is connected

via communication cables to

the Module Circuit Board, Power

Circuit Board and the Service

Monitor Board.

1

Voltage to operate the

ECU is provided by the PCB on

terminals ACN and ACL.

2

When this power is present, the GREEN LED on the ECU should be lit.

11

12

ENGLISH

6

14

10

9

15

8

7

13

3

2

4

1

16

5

3

The communication cables to the PCB and MCB boards

connect via Plugs CN6 and CN-9.

4

The SMB connects to plugs CN-23 and CN-8. When

these cables are connected to the SMB, the SMB digital display should be illuminated.

5

Plug CN-21 connects the data path between each

indoor unit and the outdoor unit ECU board. The connections

from this plug terminate at the Number 3 terminal at the voltage connection terminal strips for the indoor units.

6

The Outdoor Fan Motor is a DC voltage variable speed

type that connects to the ECU at terminal Plug CN-11.

7

The 4-Way Valve is energized by line voltage from a

connection via Plug CN-5. This valve is energized in HEAT

MODE.

8

The Crankcase Heater is energized via a connection at

terminals CON-9 and CON-8 on the ECU.

9

The EEV Stepper Motors are controlled via connections

at terminals CN-15 through CN-20. These EEV Stepper Motor

connections include the connection for the HEAT MODE EEV

located at the outdoor coil.

10

Each EEV has a set of temperature sensors that monitor

the temperature of the exiting liquid and entering vapor from

each evaporator circuit. These sensors are mounted in a group

near the center of the circuit board.

11

There are 6 system temperature sensors that monitor

refrigerant line temperature and outdoor air temperatures.

These sensors plug into the ECU via 2 Plugs CN-14 and CN-7.

12

The system has two refrigerant pressure switches, a Low

Pressure Switch and a High Pressure Switch. These switches

are connected to the ECU via Plugs CN-12 and CN-13.

13

There are 3 sets of DIP Switches located on the circuit

board. They are SW-7. (Factory Settings Only), SW-5 (Defrost

Adjustments) and SW-6 (Not Currently Used).

14

There are 4 surface mounted buttons located next to

SW-5 and SW-6. These buttons are for factory use only.

15

The ECU board has two LED Indicators, a GREEN power

indicator and a RED Diagnostic Indicator LED. When power is

present, both the GREEN and RED LED lights are lit.

16

A 15A 250V rated ceramic fuse is located on the ECU. This

fuse will open if excessive current occurs or if a power surge is

present. This fuse is eld replaceable.

TECHNICAL OVERVIEW

PAGE 13

Page 14

Technical - OverviewOUTDOOR UNIT TECHNICAL OVERVIEW

Module Circuit Board (MCB)

Module Circuit Board (MCB)

1

ENGLISH

The Module Circuit Board generates 3 phase DC power

to operate the variable speed compressor. The compressor is

connected to the MCB via terminals CN-5. CN-6 and CN-7.

2

A Reactor Coil is connected to the MCB at terminals

CN-3 and CN-4. The Reactor Coil will lter out electrical noise

generated at high frequency operation. The ltering out of

electrical noise will prevent pin holes from being burned into

the compressor motor windings during high speed operation.

3

The MCB has 3 surface mounted LED indicators to aid

in diagnostics. The indicator LED colors are GREEN for Power/

Status, Red and Yellow for Diagnostic Codes.

4

The MCB generates heat that is transferred to a heat

sink located on the back of the board. The heat sink transmits this heat to the outdoor air. A temperature sensor Tm is

attached to the inverter semi-conductor chip.

5

The temperature sensor is connected to the MCB via

terminal CN-11. If excessive heat is detected by this sensor,

the system will stop operation and generate an Error Code 38.

The RED Diagnostic LED indicator located on MCB will ash 14

times. When the sensor cools o, the system will re-start and

the diagnostic error codes will clear.

6

There is a communication cable connected to the MCV

via Plug CN-9. The wire from this plug goes to a connection on

the ECU board. If this plug is disconnected or loose, the RED

Diagnostic LED located on the MCB will ash 14 times and the

system will shut o on an Error Code 04.

1

2

6

3

LEDs

4

5

Temperature Sensor

(located under board)

PAGE 14

TECHNICAL OVERVIEW

Page 15

Technical OverviewOUTDOOR UNIT TECHNICAL OVERVIEW

Power Circuit Board (PCB)

Power Circuit Board (PCB)

The purpose of the Power Circuit Board is to lter out potential electrical noise before it reaches the outdoor unit electronic circuits. All voltage to operate the outdoor unit circuits

must pass through the PCB.

1

A replaceable 25A 250V rated ceramic fuse protects

the outdoor unit electronics. The fuse would open if a power

surge or internal short in the outdoor unit occurred. This fuse

is eld replaceable.

2

The Power Circuit Board (PCB) receives line voltage

from the building power supply via a connection between the

Line Power terminal on the outdoor unit and the terminals P1

and P2 of the PCB.

3 4

connects to terminals P3 and P4. The Electronic Control Unit

receives power to operate via connections at terminals P5

and P6. The Compressor Module board receives power via

connections at terminals P7 and TERMINAL 3.

When power is available to the Electronic Control Board and

the Compressor Module board, their respective GREEN LED

indicators will be ashing if the unit is in standby, or continuously lit if the system is running. If the GREEN LED is not lit,

there may not be power to either the PCB or the board receiving power from the PCB. (The Power Control Board does not

have a power indicating LED.)

6

There is a communication plug labeled CN-1 on the

PCB. This plug connects from the PCB to the Electronic

Control Unit (ECU). If this cable is disconnected or loose, the

system will generate a Code 6 module low or high voltage

error. This error will not be displayed in memory on the indoor

unit wired controller.

5

The voltage that powers the indoor units

ENGLISH

6

6

Ground

2

1

5

25A 250V

4

Fuse

3

TECHNICAL OVERVIEW

PAGE 15

Page 16

ENGLISH

OUTDOOR UNIT TECHNICAL OVERVIEW

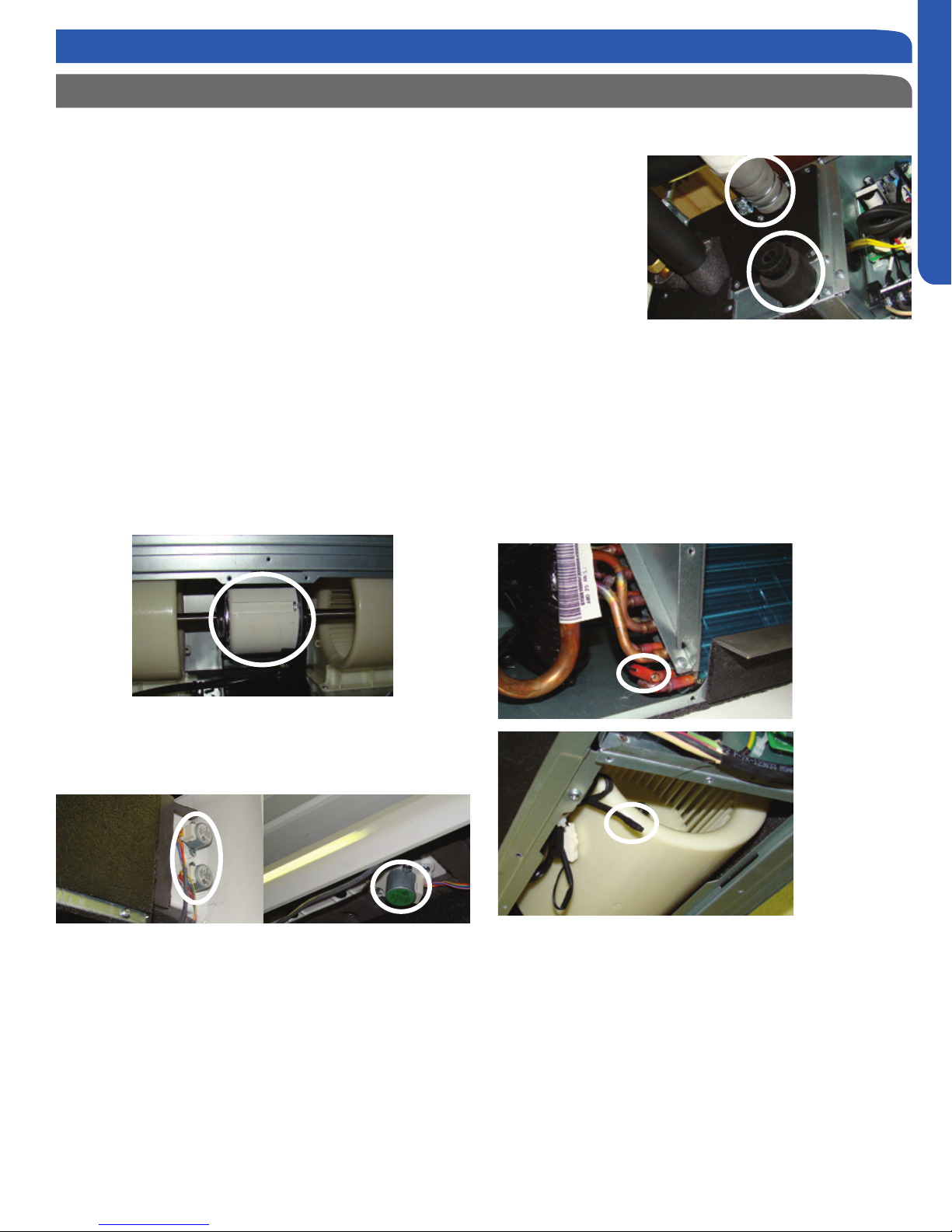

Outdoor Unit Components

4 Way Valve

Outdoor

Fan Motor

Outdoor Fan Motor

The Outdoor Fan Motor is a variable speed motor. The motor

is energized via a connection plug on the ECU. The motor

is powered by line voltage from the ECU. The motor has a

PWM circuit that feeds back voltage to the ECU. The ECU will

control the speed of the motor by a DC voltage applied to the

yellow wire of the connection plug. The feedback PWM signal

from the fan motor is applied to the ECU via the blue wire on

the connection plug.

Low

Pressure

Switch

4 Way Valve

The 4 Way Valve is energized during heating mode operation.

The valve is energized with 230 volts via a connection plug on

the ECU. When energized, the valve directs the compressor

hot gas to the indoor coil.

During Cooling mode and Defrost mode operation, the valve

is de-energized. When de-energized, the valve will direct the

compressor hot gas to the outdoor coil.

High

Pressure

Switch

Low Pressure Switch

The system has a Low Pressure Switch that will shut down

system operation if abnormally low refrigeration circuit

pressure is detected. This switch is connected to the ECU

via an electrical plug. During normal operation this switch

will be closed.

If the switch were to open during a call for cooling or heating

mode operation, the system will shut o the compressor

and display an error code. If the pressure rises to re-close

the switch, the compressor will re-start and continue on

with normal operation. Multiple cycles of opening and

closing the switch will cause the system to lock out and

display an Error Code 43.

Causes of low refrigerant pressure include leaks,

undercharging, restrictions, EEV failure and cold room air

temperatures/dirty indoor coils/restricted airow at indoor

unit.

PAGE 16

High Pressure Switch

The system has a High Pressure Switch that will shut down

system operation if abnormally high refrigeration circuit

pressure is detected. This switch is connected to the ECU via

an electrical plug. During normal operation this switch will be

closed.

If the switch were to open during a call for cooling or heating

mode operation, the system will shut o the compressor and

display an error code. If the pressure drops to re-close the

switch, the compressor will re-start and continue on with

normal operation. Multiple cycles of opening and closing the

switch will cause the system to lock out and display an Error

Code 42.

Causes of high refrigerant pressure include overcharging,

restrictions, EEV failure, and dirty outdoor coil.

TECHNICAL OVERVIEW

Page 17

OUTDOOR UNIT TECHNICAL OVERVIEW

Outdoor Unit Components

Compressor

The compressor is a variable speed dual rotary type compressor. The compressor has a built in accumulator to protect

against liquid oodback during running operation. A factory

supplied crankcase heater will protect the compressor from

o cycle liquid migration. Additionally, there is an oil separator

located in the outdoor unit that will aid in the return of compressor oil during both cooling and heating modes of opera-

tion.

The normal operating frequency of the compressor is between 20-95 RPS.

ENGLISH

When a call for cooling or heating occurs, the EEV will be positioned to a starting position. The starting position is based

upon the Outdoor Ambient Air Temperature. For example,

in cooling mode, at outdoor air temperature above 68°F, the

starting position of the valve will be 250 pulses. If the Outdoor

Air Temperature is lower than 68°F, the valve will be opened to

a position equal to 210 pulses.

The actual starting position of the valve is not something a

service technician can use to aid in solving a diagnostic problem. It is however, good to understand how these systems

fundamentally work.

When the compressor starts and the cooling or heating cycle

starts, the position of the EEV will be adjusted based upon the

Liquid and Gas Temperature Sensors that are associated with

each EEV. The EEV open position will be adjusted to try and

maintain around 10F of suction vapor superheat.

The ECU may also make an open or close adjustment to the

EEV based upon the temperature of the compressor hot gas

discharge line. If the line becomes too hot, or cool, the position of the EEV may be altered to ensure the compressor is

not damaged by a lack of refrigerant ow or liquid oodback.

The operation of the compressor is monitored by the ECU for

starting operation, suction line temperature and discharge

line temperature. Should an abnormal condition be detected,

the ECU will in some instances adjust the operational frequency of the compressor or may shut down system operation and display an appropriate Error Code.

EEV Valves

The metering devices used in the outdoor unit are EEV type

valves. The valve positions are controlled by electronic pulses

received from the ECU. These valves have potentially 500

steps. Each indoor unit has an EEV for cooling mode operation. The outdoor unit has 1 EEV that is used for heating mode

operation.

Crankcase Heater

The system has an option for a compressor crankcase heater.

The heater is powered by line voltage via a connection plug on

the ECU. The purpose of the heater is to keep the compressor

oil warm during o cycle periods. Warming the compressor

oil prevents liquid refrigerant from migrating into the compressor shell and mixing with the oil during periods where the

compressor is o.

The heater is energized during o cycle periods when the outdoor air temperature is below 90°F. During running operation,

the heater will be o.

TECHNICAL OVERVIEW

PAGE 17

Page 18

OUTDOOR UNIT TECHNICAL OVERVIEW

Outdoor Unit Components

Temperature Sensors Outdoor Unit

The outdoor unit has two groups of temperature sensors. The rst group of sensors are Liquid and Gas Sensors that are asso-

ENGLISH

ciated with each indoor unit EEV. These sensors monitor the leaving liquid temperature from the EEV and the returning Suction

Vapor temperature from the indoor units. The dierence between the two temperatures is used to calculate the operational

suction vapor superheat level of each calling indoor unit. These sensors are labeled Tc1 and Tc2 on the schematic drawing. They

plug into the ECU unit on a series of plugs located near the center of the circuit board.

The second group of sensors monitor key temperatures in the refrigeration circuit and outdoor unit. The sensors associated

with the refrigeration circuit include compressor discharge line temperature, compressor suction line temperature, outdoor

coil entering gas temperature, outdoor coil temperature cooling mode and outdoor coil heat mode temperature (Defrost). The

ambient outdoor air temperature is monitored by sensor Ta. The temperature of the heat sink attached to the Module Board is

monitored by Sensor Tm. These sensors connect to the ECU via plugs CN-7 and CN-14.

Outdoor Coil

Entering Gas

Temperature

Sensor

Compressor

Discharge Line

Temperature

Sensor

Outdoor Coil Cooling

Temperature Sensor

Outdoor coil

Heat Mode

Temperature

Sensor

(Defrost)

Module

Heat Sink

Temperature

Sensor

Compressor

Suction Line

Temperature

Sensor

PAGE 18

TECHNICAL OVERVIEW

Page 19

OUTDOOR UNIT SEQUENCE OF OPERATION

The outdoor unit is capable of controlling up to 4 individual indoor units. The outdoor unit will vary compressor capacity and

outdoor fan motor speed to match the demand requirement from the indoor units. All capacity and diagnostic decisions are controlled by the outdoor unit ECU. During any period where the outdoor unit is running, all indoor units must be in the same mode

of operation. If any unit is energized in a mode that opposes the rst indoor unit that was turned on and set to provide cooling or

heating, the opposing unit’s request will be ignored.

Throughout a call for either heating or cooling operation, the temperature sensors in the indoor and outdoor units will provide

critical temperature points to the outdoor unit ECU. If the temperatures being sensed are abnormal or trending to a level that is

potentially going to create overheating of the compressor or freezing of the indoor unit.

The frequency adjustments or system responses to temperature sensors readings are explained in the section Temperature

Sensor Responses.

Cooling Mode Sequence of Operation

Outdoor

heat

exchanger

temp.

sensor

EEV O

Low pressure

switch

Accumulator

Pipe sensor

Toci

Strainer

2

FAN-OUT

Distributor

4

Outdoor

ambient

temp.

sensor

Defrost

sensor

4-way valve coil:

OFF

ON

Indoor

heat

exchanger

temp.

sensor

FAN-IN

Indoor

ambient

temp.

sensor

Refrigerant flow in cooling

Refrigerant flow in heating

Indoor unit A

Indoor unit B

Indoor unit C

Indoor unit D

Indoor unit A

Unit A gas pipe temp. sensor

Unit B gas pipe temp. sensor

Indoor unit B

Unit C gas pipe temp. sensor

Indoor unit C

Unit D gas pipe temp. sensor

Indoor unit D

5

Unit A liquid pipe temp. sensor

Unit B liquid pipe temp. sensor

Unit C liquid pipe temp. sensor

Unit D liquid pipe temp. sensor

Strainer

Strainer

Strainer

Strainer

7

Suction temp.

sensor

Compressor

Discharge temp.

sensor

6

Gas stop valve

Oil

separator

High pressure

switch

5/8

1

Capillary tube

φ2.7*φ1.0*55in

4-way valve

3

EEV A

EEV C

EEV D

B VEE

Liquid stop vavle

3/8

valve

Receiver

Check valve

ENGLISH

On a call for cooling, the indoor unit will send the room temperature and set-point requirement to the outdoor unit ECU

via the data signal wire path. The data travels from the indoor

unit to the outdoor unit via the wire located on terminal 3.

The indoor unit’s louver will open and the indoor fan motor will

start.

The outdoor unit will energize the EEV’s that are controlling

refrigerant ow to the calling indoor units. The position of the

EEV valves will be set to a beginning position based upon the

outdoor air temperature.

The 4-way valve will be de-energized. After a 3 minute time

delay, the outdoor fan motor will be energized. Shortly after

the outdoor fan motor turns on, the compressor will start in

low frequency. The operating frequency of the compressor

will be displayed on the Service Monitor Board Display.

The refrigerant in the system will begin to ow. The compressor will discharge hot gas into the oil separator. Oil will be

trapped in the separator and returned to the suction inlet of

the compressor via the capillary tube assembly low pressure

path.

1

Temperature Sensor Td

The temperature of the compressor discharge hot gas will be

monitored by the Discharge Temperature Sensor. If the sensor

reads too hot or cool, the frequency/status of the operation will

potentially be altered.

The hot gas will leave the oil separator and enter the 4 way

OPERATIONS

PAGE 19

Page 20

OUTDOOR UNIT SEQUENCE OF OPERATION

Cooling Mode Sequence of Operation

valve. The 4 way valve will direct the hot gas to the outdoor

coil. The refrigerant will condense in the outdoor coil and be

slightly subcooled. The refrigerant is now in a liquid state.

ENGLISH

2

Temperature Sensor Toci

The temperature of the hot gas leaving the 4 way valve will be

monitored by the Toci Temperature Sensor. This temperature

should be near the temperature of the compressor discharge

gas temperature. If it is not, there is a problem with the 4 way

valve. The ECU will detect the temperature dierence and generate an Error Code.

3

Temperature Sensor Tc

This sensor monitors the temperature of the outdoor coil during

condensing operation. If abnormal condensing temperature is

detected this sensor, the outdoor fan motor speed or compressor frequency may be adjusted.

4

Temperature Sensor Ta

The outdoor air temperature will be monitored by the ECU. If the

outdoor air temperature rises or falls, the speed of the outdoor

fan/positions of the EEV’s may be changed.

The vapor refrigerant will then enter the 4 way valve and be

directed to the Compressor suction accumulator. The accumulator will trap any liquid refrigerant that may enter the

compressor and potentially damage it.

The vapor will exit the accumulator and enter the compressor.

The refrigeration cycle will continually repeat until the demand for cooling ends.

7

Temperature Sensor Ts

The temperature of the suction gas entering the compressor

is monitored by the Suction Temperature Sensor. If abnormal

temperature either hot or cool is detected, the frequency of the

compressor may be adjusted or the system may stop operation

to protect the compressor.

During the call for cooling, the indoor air temperature will get

closer to setpoint and demand will ease. The compressor will

reduce frequency as the demand decreases. Should an additional indoor unit call for cooling, the demand will increase and

the compressor speed will increase.

The refrigerant liquid will exit the outdoor coil and enter a

strainer where debris is trapped. The refrigerant liquid leaves

the strainer and bypasses the outdoor coil EEV via a path

through the check valve.

The refrigerant liquid now enters a receiver where excess

refrigerant will store. The required liquid leaves the outdoor

liquid receiver and passes through the Liquid Stop Valve.

After the liquid leaves the stop valve, it will enter the restriction of the CALLING INDOOR UNIT’s EEV. The EEV will drop

the pressure of the liquid to low pressure low temperature.

5

Temperature Sensor Tc2

The EEV associated Liquid Pipe Sensor will monitor the temperature of the refrigerant leaving the EEV to calculate system

superheat.

The low pressure low temperature refrigerant will enter the

mixed phase liquid line and travel to the indoor unit. Heat from

the air passing across the indoor unit evaporator will ash o

the cold refrigerant into a cold vapor.

The cold vapor will travel down the vapor line and return to the

outdoor unit via a path through the Gas Stop Valve.

When the temperature setpoint of the indoor units is met, the

indoor units will continue to run but the outdoor unit will shut

o. This is normal operation.

6

Temperature Sensor Tc1

The EEV Gas Pipe Sensor will monitor the temperature of the

suction gas to calculate the dierence between Liquid Pipe

Temperature and Gas Pipe Temperature. This calculation is the

suction vapor superheat. If a change in EEV port opening size is

needed, the EEV will make a small adjustment.

PAGE 20

OPERATIONS

Page 21

OUTDOOR UNIT SEQUENCE OF OPERATION

4-way valve coil:

OFF

ON

3

Indoor

heat

exchanger

temp.

sensor

FAN-IN

Indoor

ambient

temp.

sensor

Refrigerant flow in cooling

Refrigerant flow in heating

Indoor unit A

Indoor unit B

Indoor unit C

Indoor unit D

Heating Mode Sequence of Operation

Unit A gas pipe temp. sensor

Indoor unit A

Unit B gas pipe temp. sensor

Indoor unit B

Unit C gas pipe temp. sensor

Indoor unit C

Unit D gas pipe temp. sensor

Indoor unit D

4

Unit A liquid pipe temp. sensor

Unit B liquid pipe temp. sensor

Unit C liquid pipe temp. sensor

Unit D liquid pipe temp. sensor

Strainer

Strainer

Strainer

Strainer

ENGLISH

Outdoor

heat

exchanger

temp.

sensor

EEV O

Low pressure

switch

Accumulator

Pipe sensor

Toci

Strainer

6

FAN-OUT

Distributor

Outdoor

ambient

temp.

sensor

Defrost

sensor

5

7

Suction temp.

sensor

Compressor

Discharge temp.

sensor

2

Gas stop valve

EEV A

B VEE

EEV C

EEV D

Liquid stop vavle

Oil

separator

High pressure

switch

5/8

valve

3/8

Receiver

1

Capillary tube

φ2.7*φ1.0*55in

4-way valve

Check valve

On a call for heating, the indoor unit will send the room

temperature and set-point requirement to the outdoor unit

ECU via the data signal wire path. The data travels from the

indoor unit to the outdoor unit via the wire located on terminal

3. The indoor unit’s louver will open the indoor fan will remain

o.

EEV valves serving indoor circuits will step to a FULL OPEN

BYPASS position. Outdoor EEV valve serving outdoor coil

will step open to a pre-set metering position based upon the

temperature of the outdoor air.

The outdoor unit 4 way valve will be energized. Equalization

noise will be heard.

The outdoor fan motor will start.

The compressor will start in low RPS speed and gradually

speed up.

Indoor fan will begin to operate at slow speed and gradually

increase speed.

With the compressor operating, refrigerant will begin to ow

throughout the refrigeration circuit.

The operating frequency of the compressor will be displayed

on the Service Monitor Board Display.

When the compressor starts, the compressor will discharge

hot gas into the oil separator. Oil will be trapped in the

separator and returned to the suction inlet of the compressor

via the capillary tube assembly low pressure path.

1

Temperature Sensor Td

The temperature of the compressor discharge hot gas will be

monitored by the Discharge Temperature Sensor. If the sensor

reads too hot or cool, the frequency/status of the operation will

potentially be altered.

The hot gas will leave the oil separator and enter the 4 way

valve. The 4 way valve will direct the hot gas to ALL of the

indoor coils.

Note: Any indoor unit that is in heating mode will have it’s louver

open and indoor fan running. Non-calling indoor units will receive hot

gas but their fans will remain on very low speed with the louver open.

When demand for heat increases, the indoor fan will speed up to

meet the increased demand.

2

Temperature Sensor Tc1 and 3Indoor Heat Exchanger

Temperature Sensor

The temperature of Tc1 should now be hot. This will indicate

the 4 way valve is directing hot gas to the indoor coils. If it is not,

there is a problem with the 4 way valve. The ECU will detect the

temperature dierence and generate an Error Code.

OPERATIONS

PAGE 21

Page 22

OUTDOOR UNIT SEQUENCE OF OPERATION

Heating Mode Sequence of Operation

The indoor heat exchanger temperature sensor will monitor

the temperature of the indoor coil to ensure it is hot enough to

ENGLISH

prevent blowing cold air. Once adequately warm temperature is

sensed at the indoor coil, the ECU will energize the indoor fan to

a higher speed.

The hot gas entering the indoor coil will condense into a

saturated mix and then be subcooled. The refrigerant will

return to the outdoor unit via the mixed phase small line.

is monitored by the Suction Temperature Sensor. If abnormal

temperature either hot or cool is detected, the frequency of the

compressor may be adjusted or the system may stop operation

to protect the compressor.

During the call for heating, the indoor air temperature will

get closer to setpoint and demand will ease. The compressor

will reduce frequency as the demand decreases. Should an

additional indoor unit call for heating, the demand will increase

and the compressor speed will increase.

4

Temperature Sensor Tc2

This sensor monitors the temperature of the refrigerant liquid

returning from the indoor coil. If abnormally warm liquid is

sensed, the ECU will make inverter or indoor fan motor speed

changes to compensate.

The liquid will enter the Liquid Line Strainer and will pass

through the OPEN EEV

The refrigerant liquid now enters a receiver where excess

refrigerant will store.

After the liquid leaves the Liquid Receiver, it will enter the

restriction of the OUTDOOR UNIT’s EEV. The EEV will drop

the pressure of the liquid to low pressure low temperature.

Heat from the outdoor air will boil o the cold refrigerant.

The outdoor coil absorbs heat from the outdoor air. The

refrigerant vapor boiling from the liquid refrigerant in the

outdoor coil exits the outdoor coil.

5

Temperature Sensor Te

The outdoor coil temperature will be sensed by the Defrost

Sensor. The sensor will use this temperature to maintain EEV

position/superheat adjustment and to calculate when a defrost

cycle is necessary.

When the temperature setpoint of the indoor units is met, the

indoor units will continue to run but the outdoor unit will shut

o. This is normal operation.

6

Temperature Sensor Toci

This temperature sensor is now sensing the suction line

temperature of the refrigerant vapor leaving the outdoor coil.

This temperature is used in calculation of the required position

of the OUTDOOR UNIT EEV for proper superheat adjustments.

The vapor refrigerant will then enter the 4 way valve and

be directed to the Compressor suction accumulator. The

accumulator will trap any liquid refrigerant that may enter the

compressor and potentially damage it.

The vapor will exit the accumulator and enter the compressor.

The refrigeration cycle will continually repeat until the demand

for heating ends.

7

Temperature Sensor Ts

The temperature of the suction gas entering the compressor

PAGE 22

OPERATIONS

Page 23

OUTDOOR UNIT TEMPERATURE SENSOR RESPONSES

Outdoor Unit Control Information

10.2.1 Outdoor frequency control

A. The compressor running frequency is range is 20-95 RPS.

10.2.2 Electronic expansion valve (EEV) control

A: EEV SPECIFICATION: Maximum open angle is 500 pulses.

Driving speed is PPS.

B: Start-up EEV Conditional state

When the system is in the Cool/Dry mode, the standard open

angle of the EEV will be set at a position that is determined

by the temperature of the outdoor air. When the outdoor air

temperature is greater than 68°F, the initial setting of the EEV

will be 250 pulse open. If the outdoor air temperature is less

than 68°F, the EEV will open 210 pulses.

In Heating mode, the standard open position will be 250

pulses when the ambient air temperature outdoors is greater

than 50°F. If the air temperature outdoors is less than 50°F, the

open pulse rate is set to 210.

During running operation, the EEV position may be adjusted if

the compressor discharge gas temperature indicates a need

to supply more or less refrigerant to the evaporator circuit.

ENGLISH

10.2.4 Crankcase Heater Control

The crankcase heater is controlled by the ECU. The heater

keeps the compressor oil warm to prevent liquid refrigerant

from migrating to the oil during periods where the system is

not running. The heater will operate during o cycle periods

when the outdoor air temperature is below 80.6°F. When the

outdoor air temperature is greater than 90°F, the heater will

not be energized. When the compressor is running, the heater

will not be energized.

10.2.5 On Demand Defrost Logic

The system defrost function during heat mode is a demand

type system. Two temperatures are monitored by the ECU

to determine if defrosting is needed, they are Outdoor air

temperature Sensor Ta and Outdoor coil temperature Sensor

Te.

To enter a defrost cycle on demand, the system must be in

heat mode and the compressor must have run for 10 minutes

continuously and 45 minutes of compressor run time in heat

mode must have accumulated. If the following conditions

have been met for at least 5 continuous minutes, the system

will enter a demand defrost cycle:

Here are the control responses and EEV positional changes

that can occur due to either hot or cool discharge gas

temperature:

Valve Adjustments

Valve Adjustments Due To Hot Gas Discharge Temperature

Limits

If the discharge gas temperature rises above 212°F, the EEV

will open to its widest allowed position to try and reduce the

temperature of the compressor.

If the discharge temperature is greater than 194°F, but less

than 212°F, the EEV will not be adjusted.

If the discharge line temperature drops below 194°F, the EEV

will reduce its size to reduce refrigerant ow.

10.2.3 4-way valve control during heating mode

If the 4 way valve fails to switch the hot gas ow to the indoor

coil during a call for heat, the system will enter a protection

routine. If the indoor coil average temperature is below 59°F,

10 minutes after the compressor has started, and stays there

for at least 1 minute, the system will lock out and display a

4-way valve protection fault error code.

Sensor Te must sense a temperature that is less than or equal

to:

Te< CxTa-a

C is calculated as follows:

If Ta < 32°F then C=.8 If Ta> 32°F then C=.6

a is set by SW5-2 switch Factory setpoint is 8

Opposite Switch setting is 6

If the system is in an area that is easy to frost, it is

recommended to set the SW5-2 switch to opposite setting

and change the value of a to 6.

Example: Te = 26°F Ta = 44°F C=.8 a = 8

Solution: 26°F 44 x .8= 35.2-8=27.2 26°F is colder than

27.2°F so the system defrost cycle starts.

The system can only remain in defrost for up to 10 continuous

minutes of run time. The defrost cycle will terminate if sensor

Te reaches 44.6°F for a period of 60 seconds or 53.6°F for

a period of 30 seconds. In either case, the defrost cycle will

terminate after 10 minutes.

OPERATIONS

PAGE 23

Page 24

(Td)

is too high

Co

de

s

g

e

p

1.0 I

0.95I

0.93I

0.90I

0.88I

0.85I

Stop immediately, if abnormal stop 3 times in 1 hour, the

unit will stop and alarm.

Reduce FQY rapidly 2HZ/S

Reduce FQY rapidly 1HZ/S

Reduce FQY slowly 1HZ/10S

Remain FQY

Increase FQY slowly 1HZ/10S

OUTDOOR UNIT TEMPERATURE SENSOR RESPONSES

Forced Defrost Operation

10.2.6 Forced Defrost Operation

The system can be placed into a forced defrost cycle from the

wired controller. The system will remain in defrost until sensor

ENGLISH

Te has sensed 53.6°F for at least 1 minute or until the defrost

cycle has reached 10 minutes total runtime.

A forced defrost cycle can be initiated with the compressor

o. The system will enter a 3 minute time delay prior to

energizing the compressor.

10.2.7 Defrosting Time Flowchart

beginning end

fixed frequency indicated FQY 60s defrosting FQY 80 Hz(E) 60s soft startup

compressor

outdoor motor ON send defrosting signal to indoor Auto

4-way valve ON

all EEVs auto open angle auto open angle

all indoor motors ON

10.2.8 Frequency Control and Compressor Discharge Line

Temperature

If the temperature of the discharge line gets too high, and

the EEV adjustment cannot correct the problem, the ECU will

make frequency adjustment to the speed of the compressor

in an attempt to cool it down. The chart here shows the

adjustment steps versus the discharge line temperature.

Multi:

248 ℉

239 ℉

230℉

Discharging temp. TD

221℉

212℉

203℉

0HZ 0HZ

OFF

OFF 15s

OFF anti-cold air func tion

5s

450-pulse 450-pulse

350-pulse(E)

If keeping for 10s, the unit stops, 3 minutes later, the unit can

re-startup. If in 60 minutesthe unit occurs alarm for 3 times, the

failure can be eliminated.

Reduce FQY rapidly 2HZ/S

Reduce FQY rapidly 1HZ/S

Reduce FQY slowly 1HZ/10S

Remain FQY

Increase FQY slowly 1HZ/10S

10.2.8 Frequency Control when there is CT Over-current

Protection

Stop immediately, if abnormal stop 3 times in 1 hour, the

1.0 I

0.95I

0.93I

0.90I

0.88I

0.85I

unit will stop and alarm.

Reduce FQY rapidly 2HZ/S

Reduce FQY rapidly 1HZ/S

Reduce FQY slowly 1HZ/10S

Remain FQY

Increase FQY slowly 1HZ/10S

10.2.9 High Pressure Protection

If abnormally high refrigerant circuit condensing pressure is

detected, the high pressure switch will open. The outdoor unit

will initiate an Error Code and stop compressor operation. If

the system pressure drops enough to re-close the switch the

system will re-start. If the failure occurs 3 times, the system

will lock out and display the appropriate Error Code.

High condensing temperature can also cause high pressure.

The ECU will monitor the temperature of the condensing coil

in both heating and cooling modes of operation. Frequency

adjustments will be made to the compressor speed in an

attempt to manage high pressure that can be caused by dirty

condensing coils and high heat loading. The chart below shows

the ECU frequency response at high condenser temperatures.

(Indoor Coil Heat Mode, Outdoor Coil Cool Mode)

Keep for 5 seconds, stop to alarm, after 3-minute standby, the

unit can restartup. In 60 minutes it occurs 3 times continously,

156℉

154℉

.

m

t

151℉

in

n

147℉

n

144℉

140℉

unit will stop to alarm and the failure can be resumed after being

electrified again.

Reduce FQY rapidly 2HZ/S

Reduce FQY rapidly 1HZ/S

Reduce FQY slowly 1HZ/10S

Remain FQY

Increase FQY slowly 1HZ/10S

10.2.10 Low Pressure Protection

The system low pressure switch is normally closed. The

switch will open when the refrigerant pressure gets too low.

Typical causes are refrigerant leaks/undercharging and low

evaporator heat loading. The system will auto re-start if the

switch re-closes after opening. If the switch opens 3 times in

60 minutes of running, the system will display an error code.

PAGE 24

The low pressure switch is checked even when the system

is o. This protects the compressor against operating with a

great loss of refrigerant when the system has been o for a

long time.

OPERATIONS

Page 25

OUTDOOR UNIT TEMPERATURE SENSOR RESPONSES

·When unit stops, the reason that system still checks the low pressure : in a long time stop, make

protection for the compressor on the condition of great refrigerant leakage.

·The reason that low pressure switch action time is 30 seconds: when compressor stops, low pressure

does not change, so it will be shorter than the set time in operation.

(3) When compressor starts up, in 8 minutes, low pressure switch signal will be shielded.

(4) In defrosting, low pressure switch will be shielded.

(5) In oil return procedure, low pressure switch will be shielded.

(6) In the refrigerant discharging procedure after the oil return in cooling is over, low pressure switch will

be shielded.

In addition, the system will control low pressure through the evaporator temp. TE to realize the low

pressure protection function.

Forced Defrost Operation

10A, the frequency of the compressor decreases at the speed

of 0.1HZ/second.

ENGLISH

There are times when the switch is not active. The periods of

inactive switch operation are:

1. When the compressor starts up the switch will be o

for 8 minutes.

2. When the system is defrosting the switch is not

active.

3. In the oil return cycles the switch is not active.

4. In the refrigerant discharging procedure after the oil

return in cooling is over the switch is not active.

The system will recognize cold evaporator temperatures as a

likely condition where the low pressure switch may open. The

ECU uses the Te sensor in heat mode and the Tc2 sensor in

cooling mode to monitor the temperature of the evaporator

circuit. If abnormally cold coil temperatures are detected,

the ECU will reduce the compressor operating frequency to

prevent potential low pressure switch trips. The charts below

show the frequency versus evaporator circuit temperature

relationships.

In cooling, confirm through Tc2AVE:

-13℉

-22℉

TinAVE

-31℉

-40℉

-49℉

In heating, confirm through defrosting temp. Te:

Te

-22℉

-31℉

-40℉

-49℉

-58℉

Normal operation

Min. running FQY 20HZ

SV2 OFF & 20HZ

SV2 ON & 20HZ

Keep for 5 seconds, unit stops and alarm

occurs. 3 minutes later, restart up. If i

occurs 3 times in 1 hour, it will always

alarm and stop, electrify again a nd failure

will be cleared.

Normal operation

Min. running FQY 20HZ

SV2 OFF & 20HZ

SV2 ON & 20HZ

Keep for 5 seconds, unit stops and

alarm occurs. 3 minutes later, restart

up. If it occurs 3 times in 1 hour, it will

always alarm and stop, electrify again

and failure will be cleared.

Preventing Compressor Overcurrent

During compressor start-up, if the AC current is greater

than 9A, the frequency of the compressor increases at the

prohibited speed.

During compressor start-up, if the AC current is greater than

8A, the frequency of the compressor increases at the speed

of no faster than 0.1HZ/second.

The protection function of AC current:

• During the starting process of the compressor, if the AC

current is greater than 15A, the frequency of the

compressor decreases at the speed of 1HZ/second.

• During the starting process of the compressor, if the AC

current is greater than 13A, the frequency of the

compressor decreases at the speed of 0.1HZ/second.

• During the starting process of the compressor, if the AC

current is greater than 11A, the frequency of the

compressor increases at the prohibited speed.

• During the starting process of the compressor, if the AC

current is greater than 10A, the frequency of the compressor

increases at the speed of no faster than 0.1HZ/second.

When the outdoor ambient temperature is high, there’s

compensation for AC current protection.

t

When the outdoor ambient temperature is higher than 104°F,

AC current protection value decreases by 10AD

When the outdoor ambient temperature is higher than 115°F,

AC current protection value decreases by 15AD

When the outdoor ambient temperature is higher than 122°F,

AC current protection value decreases by 20AD

Antifreezing protection of the indoor heat exchanger

Prevents freeze-up of the indoor coil.

During compressor start-up, if the current of the compressor

is greater than 17A for 3 seconds, the compressor will stop

and alarm. After 3 minutes, the compressor will restart. If this

occurs 3 times in 20 minutes the compressor will stop, lock

out, and display an error code. Power must be removed from

the system to clear the code.

During compressor start-up, if the AC current is greater than

12A, the frequency of the compressor decreases at the speed

of 1HZ/second.

During compressor start-up, if the AC current is greater than

OPERATIONS

Outdoor coil

Heat Mode

Temperature

Sensor

(Defrost)

PAGE 25

Page 26

OUTDOOR UNIT TESTING PROCEDURES

Blue Viole t Yellow O range Red

Blue 47 Ω 46 Ω 46 Ω 46 Ω

Viol et 92 Ω 92 Ω 92 Ω

Yellow 91 Ω 91 Ω

Oran ge 91 Ω

Red

EEV Stepper Motor Resistance Values

Compressor Testing

If the compressor fails to start, the compressor may have an

internal electrical failure, the compressor may be seized mechanically, or the Module Control Board (MCB) may be bad.

ENGLISH

To test for a bad failed compressor, perform the following test:

EEV testing

The EEV metering devices are stepper type valves that have

up to 500 potential positional changes. The electrical coil that

is installed on the end of the EEV body rotates a magnetic

eld that opens and closes the valve. If the valve has failed, it

is either stuck in position or the electrical coil has an internal

problem.

1. Disconnect power and allow 10 minutes. Restore

power and call for normal operation. If the compress sor starts, the system may have been in a protection

mode that prevented the compressor from running.

If the compressor does not start, continue on with

testing.

2. Disconnect power. Wait 10 minutes for the capacitors

on the MCB to electrically discharge.

3. Unplug the compressor motor windings terminals

from the MCB.

4a-4d. Ohm the windings through each combination of leads

to determine if there is an open winding. If a winding is

open, replace the compressor. If the windings are

good, check each motor winding lead for a short to

ground. If the compressor winding is shorted to

ground, replace the compressor. If the motor checks

out good, continue on with testing.

3

4a

To test for an electrical coil problem, perform the following

test:

1. Disconnect power to the outdoor unit.

2. Unplug the suspect EEV coil from the connection plug

at the ECU.

3. Using an ohmmeter, check the ohms of all combina tions of windings.

4. Compare measured Ohms against the chart shown

below.

5. Replace the EEV coil if the ohm range is not correct.

6. If the OHM range is correct, yet the EEV does not

click/pulse open or closed when it should, check for a

mechanically stuck EEV.

7. Move the EEV coil to another EEV circuit to see if the

coil will operate the other EEV. If it works, the EEV

valve is stuck and must be replaced.

8. Always reset power when working with EEV valves

to reset any temperature sensor logic that may be

keeping the EEV from being energized during normal

operation. (Freezing etc.)

2

4b

4c

4d

PAGE 26

3

4

TESTING

Page 27

OUTDOOR UNIT TESTING PROCEDURES

Outdoor Fan Motor Testing

If the outdoor unit fan motor does not run or the Service Monitor board indicates an error code of