Hafler VRM 1 0 S, VRM 1 0 S C E, VRM 1 2 S, VRM 1 2 S C E, VRM 1 5 S Owner's Manual

...

VRM10S

VRM

10S CE

VRM12S

VRM

12S CE

VRM15S

VRM

15S CE

SUBWOOFER

SYSTEMS

®

Declaration of Conformity

Application of Council Directive: 73/23/EEC (Low Voltage Directive)

89/336/EEC (EMC Directive)

Standard(s) to which Conformity is Declared: EN55103-1

EN55103-2

EN60065

Manufacturer’s Name: Hafler

Manufacturer’s Address: 546 South Rockford Drive, Tempe, Arizona 85281

Importer’s Name:

Importer’s Address:

Type of Equipment:

Amplified Subwoofer

Model No:

VRM10sCE VRM12sCE VRM15sCE

Year of Manufacturing: 1999 2000 2001 2002 2003

Serial Number:

I, the undersigned, hereby declare that the equipment specified above conforms

to the above Directive(s) and Standard(s)

Place: Hafler

Date: 12/01/98 James C. Strickland, VP Engineering

– i –

25Hz-100Hz, ±2dB

>115dB (w/music @ 2m)

<3%, 25Hz (90dB @ 2m)

12” (305mm) Cellulose Fibre Cone

Santoprene Rubber Surround

2.5” (63.5mm) 4-Layer Voice Coil

102 oz. Magnet

1.8ft3(50.4Liter) Bass Reflex Down Firing

16.75”(H) x 18.50”(W) x 19.50”(D)

(46.35cm x 49.53cm x 49.21cm)

Black Ebony Ash Vinyl

74 lbs. (33.6kg)

Free Field Frequency Response

Peak Acoustic Output

Total Harmonic Distortion (THD)

Low Frequency Driver

Dimensions

Cabinet Finish

Net Weight

27Hz-100Hz, ±2dB

>112dB (w/music @ 2m)

<3%, 30Hz (90dB @ 2m)

10”(254mm) Cellulose Fibre Cone

Santoprene Rubber Surround

2” (51mm) 4-Layer Voice Coil

30 oz. Magnet

1.0ft3(28 Liter) Bass Reflex Down Firing

14.75”(H) x 16.0”(W) x 17.50”(D)

(37.46cm x 40.64cm x 40.64cm)

Black Ebony Ash Vinyl

51 lbs. (23.2kg)

SUBWOOFER MODEL

VRM10S

VRM12S

22Hz-100Hz, ±2dB

>118dB (w/music @ 2m)

<3%, 22Hz (90dB @ 2m)

15” (381mm) Cellulose Fibre Cone

Santoprene Rubber Surround

2.5” (63.5mm) 4-Layer Voice Coil

153 oz. Magnet

2.5ft3(70 Liter) Bass Reflex Down Firing

18.75”(H) x 20.0”(W) x 21.0”(D)

(46.35cm x 49.53cm x 49.21cm)

Black Ebony Ash Vinyl

88 lbs. (40kg)

VRM15S

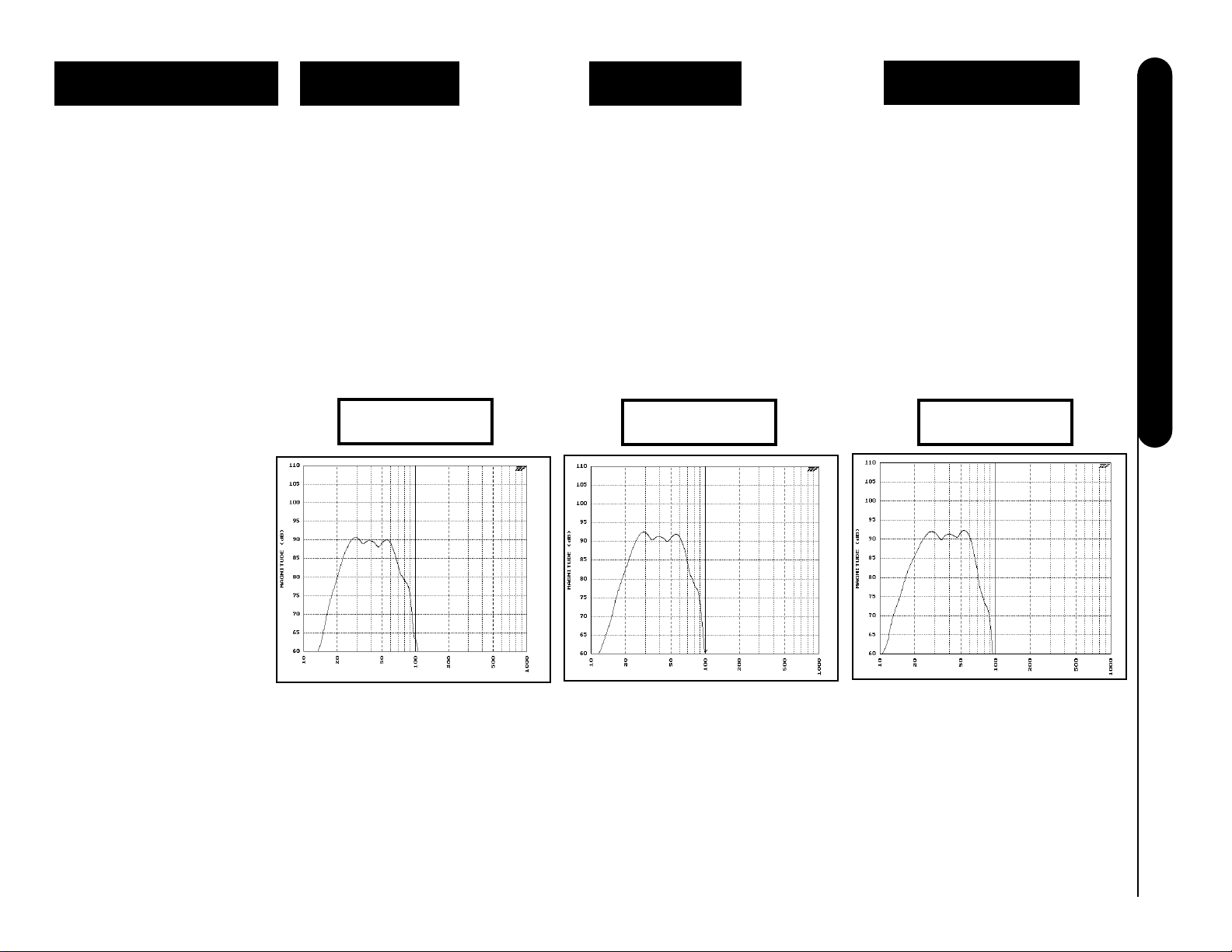

Frequency Response @ 2m*

Frequency Response @ 2m*

VRM10s

Frequency Response

Specifications are subject to change without notice.

Performance Specifications

VRM12s

Frequency Response

VRM15s

Frequency Response

Frequency Response @ 2m*

– ii –

Power Rating

Signal-to-Noise

CMRR

Input Impedance

Input Sensitivity Range

Maximum Input

Gain

Crossover Frequency Variable from 40Hz~140Hz

Crossover Slope 24dB/octave (4th order) Linkwitz-Riley

Subsonic Filter 12dB/octave (-3dB @ 18Hz)

Specifications are subject to change without notice.

Idle Power: 11W / 150mA @ 120 VAC

Idle Power: 11W / 90mA @ 230 VAC

Normal Operation: 66W / 380mA @ 230VAC

Full Power: 330W / 3.3A @ 120VAC

Full Power: 315W / 1.7mA @ 230VAC

Unbalanced RCA Inputs

Gain Control (30dB range)

Low Pass Crossover (variable 40Hz~140Hz)

Phase DIP Switches (0°, -90°, -180°, -270°)

200W RMS @ 4 ohms

>100dB

>70dB typical @ 60Hz

47kΩ per phase balanced, 47kΩ unbalanced

RCA Input: 160mV to 5V RMS

Speaker Input: 50mV to 45W (receivers that

drive nominal 8Ω speaker loads)

RCA Input: 10V RMS

Speaker Input: 180W (receivers that drive

nominal 8Ω speaker loads)

+45dB max. to +15dB min.

Performance Specifications - Amplifier Section

Power Consumption

Rear Panel

Low -Pass Crossover Section

– iii –

PERFORMANCE SPECIFICATIONS

Frequency Response Graphs i

INTRODUCTION 1

TECHNICAL DESIGN FEATURES 1

DESIGN FEATURES 4

INSTALLATION

Location 5

Typical Studio Installations 5

Home Theater Installations 5

Input Switch 6

XLR Wiring Configurations 7

OPERATION

Auto Turn-On/Sleep Mode 8

Input Sensitivity 8

Low-Pass Crossover 8

Phase Control 9

Set-up Procedure 9

AC Line 10

LED Indicator 10

Break-In and Warm Up 10

Cleaning and Maintenance 10

SERVICE POLICY &LIMITED WARRANTY 11

SAFETY PRECAUTIONS 12

Table of Contents

– 1 –

The VRM10s/VRM12s/VRM15s monitors utilize a specially designed amplifier featuring our innovative Trans•ana circuitry. This topology, with its unique input-to-output configuration (derived from

our patented Trans•nova circuit), employs power gain in the MOSFET output stage that result in

superior sound quality.

The amplifier features an auto turn-on/off circuit that eliminates the need for a conventional power

switch. Input signals can be fed into the amplifier via Un-Balanced RCA jacks or Speaker level input

jacks. Each pair of inputs is combined into a mono-summed signal before being fed into a 4th order

Linkwitz-Riley low-pass crossover, adjustable from 40Hz~140Hz. If selected, the signal is then fed

into the Phase Control that allows the phase of the signal to be adjusted at 90˚, 180˚, or 270˚ increments.

The VRM10s is a 10” (254mm) low frequency transducer that features a 2” (51mm) voice coil and is

driven by a 30 oz. magnet. The VRM12s is a 12” (305mm) low frequency transducer that features a

2.5” (63.5mm) voice coil and is driven by a 102 oz. magnet. The VRM15s is a 15” (381mm) low frequency transducer that features a 2.5” (63.5mm) voice coil and is driven by a 153 oz. magnet. All

VRM transducers feature Cellulose Fiber cones for accurate sound reproduction and Santoprene

Rubber Surrounds that are immune to temperature fluctuations. This specialized rubber surround

controls woofer damping and reduces 2nd harmonic distortions for a very wide and flat frequency

response. The VRM series voice coils are 4-layers of copper wound on aluminum formers.

Aluminum voice coil formers provide excellent heat dissipation that provides higher power handling

versus plastic or Kapton type formers used by other manufacturers.

Introduction

Technical Design Features

Thank you and congratulations on your purchase of the HAFLER series of Subwoofer, the world's

finest brand in professional audio equipment.

The VRM series is comprised of three modules; the VRM10s, VRM12s, and VRM15s. The VRM10s

is an amplified 10" subwoofer. The VRM12s is an amplified 12" subwoofer and the VRM15s is an

amplified 15" subwoofer. All VRM series are designed and engineered for Home Theater Systems.

For ease of use, this manual is organized into two main sections: Installation and Operation.

"Installation" covers the set-up of your new HAFLER equipment in the system. "Operation" covers

the controls and how to use them for optimum performance.

– 2 –

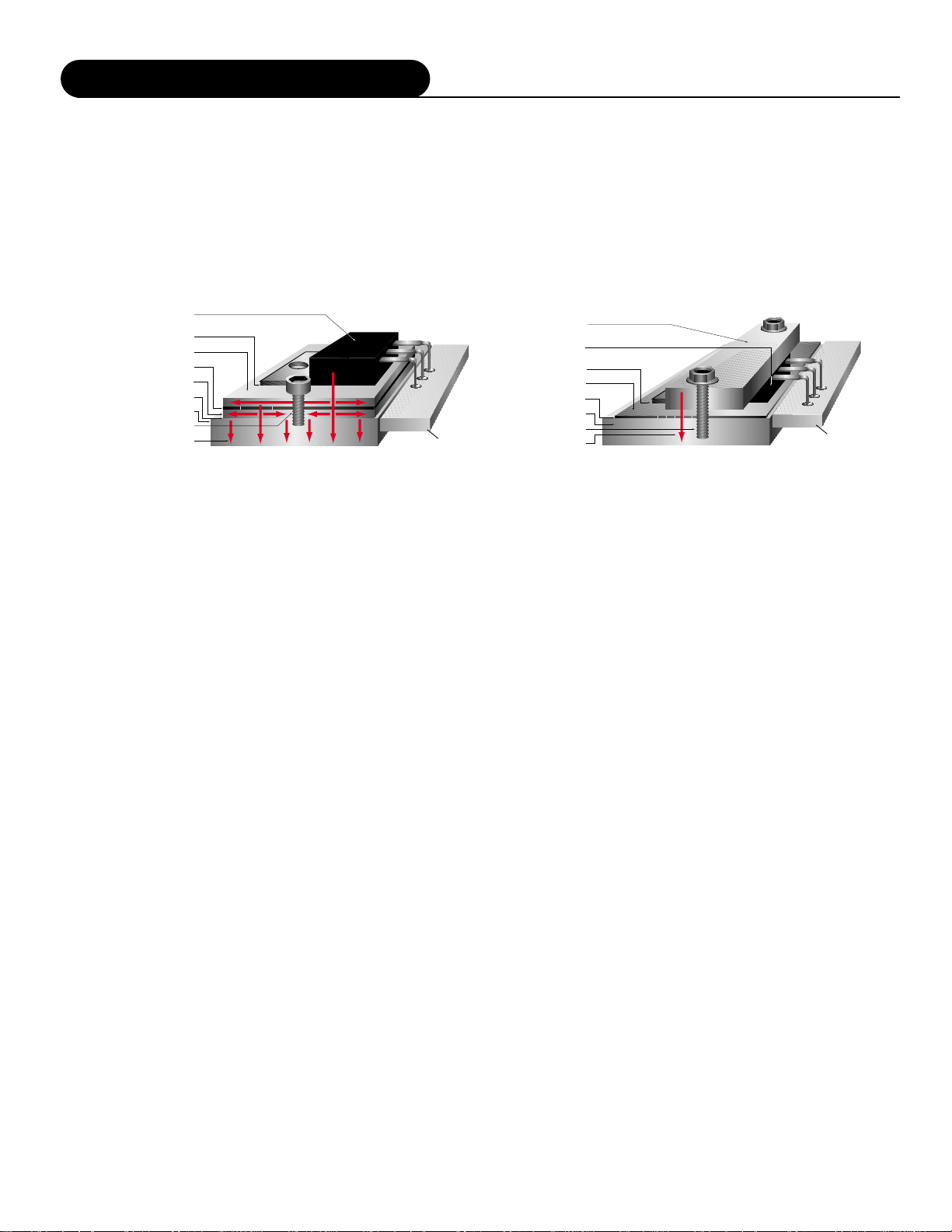

MEHSA

(Maximum Efficiency HeatSink Application) MEHSA is a proprietary process that yields up to 5 times

better heat transfer than traditional FET mounting techniques using the exact same components. A

multi-layer insulated metal substrate operating with minimal thermal resistance spreads heat both

downward and outward to quickly dissipate heat from each device across the heatsink. This process

combined with our DSM technology and MOSFET devices allows us to squeeze more watts per cubic

inch from every output device as well as provide consistent thermal stability.

The Result: Better reliability through faster heat dissipation.

Trans•ana

Trans•ana (TRANSconductance Active Nodal Amplifier) is a circuit that allows the audio signal to pass

through the amplifier at low voltage. The signal is directly level-shifted to the fixed high voltage rails

via a pair of driver transistors. Signal linearity is assured by an active node formed by the driver transistors at ultrasonic frequencies. This allows amplifier performance similar to Trans•nova which is highly

stable and linear while utilizing the advantages of a non-floating power supply.

The Result: An extended frequency band width accurately supplied to the output stages of the

amplifier.

MOSFET Devices

HAFLER is one of the few manufacturers in the sound community to utilize MOSFET devices in the

amplifier output stage. MOSFET (Metal Oxide Semiconductor Field Effect Transistor) devices offer several important inherent advantages over older bi-polar designs. These advantages include: thermal stability, fast switching speed, ultra low output impedance and wide bandwidth linearity. In addition,

MOSFETs operate very similarly to vacuum tubes in that they are more linear than bipolar transistors.

However, MOSFETs can deliver the midrange clarity without the limitations of transient response and

high frequency phase shifting normally associated with tube

operation.

The Result: Thermal stability, fast switching speed, ultra low output impedance and wide bandwidth

linearity.

The MEHSA Way The Old Way

Technical Design Features

Heat Monster:

High output MOSFET device

Solder

Copper heat spreader

Dielectric layer

Base Layer - aluminum

Thermal grease

Heat sink

Screw, no pressure on component!

Multiple heat paths

PC Board

Heat generating component

(typically a power MOSFET or

Clamp Bar

bipolar semiconductor)

Thermal grease

Mica

Thermal grease

Heat sink

Screw

Heat path

PC Board

– 3 –

Subsonic Filter

The VRM series uses a Subsonic Filter to prevent the woofer from reproducing inaudible frequencies.

Subsonic frequencies (known as infrasonic frequencies) are signals below the normal human hearing

range.The subsonic filter reduces the energy of these frequencies and restrains the woofer from operating outside its optimum linear excursion. This type of electronic control eliminates the mechanical distortion caused by a woofer traveling beyond its XMAX, improves power handling, increases reliability

and improves sonic performance.

The Result: Improved power handling, increased reliability and improved sonic performance.

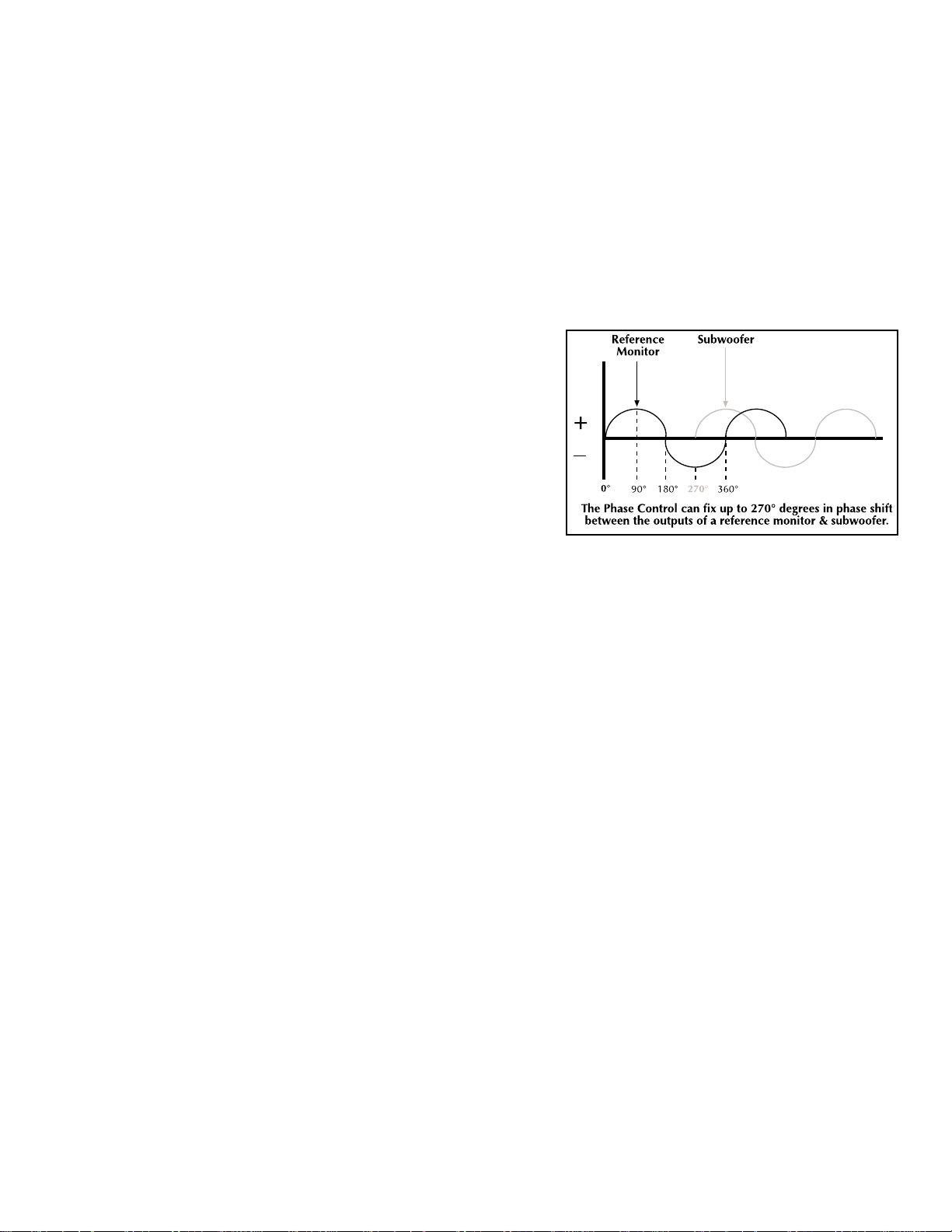

Phase Control

The Phase Control is used to align the arrival time of the subwoofer’s output information with satellite monitors. Aligning

both signals will insure that both Subwoofer and reference

monitor information arrive at the listening position at the same

time. This eliminates the possibility of acoustical cancellation

and improves the reproduction of transients in the crossover

region.

The Result: Eliminates phase cancellation and improves transient response.

Speaker Level Inputs

Does your receiver have only speaker level outputs? No problem! Hafler’s Speaker Level Input circuitry

converts the speaker line outputs (high level) from your receiver into pre-amp line inputs (low level) for

your VRM amplifier. This allows compatibility with a variety of receivers as well as the ability to retrofit

your new Hafler subwoofer into existing systems without the need for external adapters.

Santoprene Rubber Surround

Santoprene is a very durable and temperature tolerant material which provides a consistent support

necessary for the linear motion of the speaker cone. In addition, the damping capabilities eliminate

the transmission of sonic disturbances between the cone and the frame of the speaker. This greatly

improves the accuracy of the woofer’s low frequency response.

The Result: Improves woofer’s low frequency response.

Aluminum Voice Coil Former

The transducers voice coil former is black anodized aluminum for highly efficient thermal transfer.

Another method of producing voice coils is with Kapton® formers. Although this material is very resistant to heat, any heat generated by the transducer is “trapped” on the copper voice coil windings.

HAFLER uses aluminum voice coil formers because aluminum acts like a “heat sink” and helps dissipate heat away from the voice coil. This allows winding high temperature copper wire in multiple layers for improved efficiency.

The Result: Improves power handling by efficiently dissipating heat.

Loading...

Loading...