Page 1

DOC026.52.00797

si792 D

si792x D

si792x D-FF

si792x D-PA

Dissolved Oxygen

2-Wire Transmitters

USER MANUAL

December 2007, Edition 1

© HACH Company, 2007. All rights reserved. Printed in Germany

Page 2

2

Page 3

Table of Contents

Section 1 Specifications ......................................................... 5

Section 2 General Information...........................................11

2.1 Safety information ....................................................................11

2.1.1 Use of hazard information ................................................. 11

2.1.2 Precautionary labels.......................................................... 11

2.2 General product information..................................................... 13

2.2.1 Product overview............................................................... 13

2.2.2 FDA 21 CFR part 11 Compliance (HART only)................. 13

2.2.2.1 Electronic signatures for si792(x) D transmitters ....... 14

2.2.2.2 Audit trail for si792(x) D transmitters.......................... 14

Section 3 Installation ..............................................................15

3.1 Hazardous location................................................................... 16

3.2 Unpacking the transmitter ........................................................16

3.3 Mechanical installation ............................................................. 18

3.3.1 Transmitter assembly........................................................ 18

3.3.2 Mounting ........................................................................... 18

3.3.2.1 Wall mount ................................................................. 18

3.3.2.2 Panel or pipe mount (optional) ................................... 18

3.4 Wiring Safety Information......................................................... 20

3.5 Electrical installation................................................................. 21

3.5.1 Wire preparation................................................................ 21

3.5.2 Power and communication connections............................ 23

3.5.2.1 si792(x) D (4–20 mA/HART) wiring............................ 24

3.5.2.2 si792x D-FF and si792x D-PA wiring .........................25

3.5.3 Sensor wire connection..................................................... 25

3.5.3.1 Oxygold G/Oxyferm sensor—si792(x) D (4–20 mA/

HART) ................................................................................. 26

3.5.3.2 Oxygold G/Oxyferm sensor—si792x D-FF or si792x D-

PA .......................................................................................27

3.5.3.3 Oxysens sensor—si792(x) D (4–20 mA/HART)......... 28

3.5.3.4 Oxysens sensor—si792x D-FF and si792x D-PA ......29

3.6 HART communication connection............................................ 30

1

Page 4

Table of Contents

Section 4 Interface and navigation .................................. 31

4.1 si792(x) D (4–20 mA/HART) interface...................................... 31

4.2 si792x D-FF and si792x D-PA interface ................................... 32

4.3 Display...................................................................................... 33

Section 5 Operation—si792(x) D

(4–20 mA/HART) .........................................................................35

5.1 Measure mode .........................................................................35

5.2 Configuration............................................................................ 35

5.2.1 Output configuration.......................................................... 36

5.2.1.1 Output range ..............................................................38

5.2.1.2 Time averaging filter...................................................38

5.2.1.3 Output signal during errors......................................... 38

5.2.1.4 Output signal during HOLD ........................................ 39

5.2.2 Temperature sensor configuration ....................................40

5.2.3 Correction menu configuration ..........................................40

5.2.4 Calibration mode configuration.......................................... 41

5.2.5 Alarm settings configuration .............................................. 41

Section 6 Operation—Foundation Fieldbus................ 43

6.1 Configuration............................................................................ 43

6.1.1 Configuration steps ...........................................................43

6.1.2 Configuration menu........................................................... 44

6.2 Foundation Fieldbus communication........................................ 46

6.2.1 Standard resource block (RB)........................................... 46

6.2.2 Standard analog input block (AI)....................................... 49

6.2.2.1 Operating modes........................................................ 49

6.2.2.2 Set the parameter and units....................................... 49

6.2.2.3 Data processing .........................................................50

6.2.2.4 Alarms ........................................................................ 50

6.2.2.5 Bus parameters for the analog input block.................51

6.2.2.6 Cyclic measured value status..................................... 54

6.2.2.7 Measured value limits—limit bits................................54

6.2.3 Transducer block...............................................................55

6.2.4 Calibration via Foundation Fieldbus.................................. 63

2

Page 5

Table of Contents

Section 7 Operation—Profibus PA...................................65

7.1 Configuration............................................................................ 65

7.1.1 Configuration steps ...........................................................65

7.1.2 Configuration menu........................................................... 66

7.2 Profibus PA communication .....................................................67

Section 8 Calibration .............................................................. 71

8.1 Calibration ................................................................................ 71

8.1.1 Zero calibration ................................................................. 72

8.1.2 DO calibration (default) .....................................................73

8.1.2.1 Calibration in air (recommended)............................... 73

8.1.2.2 Calibration in water .................................................... 74

8.1.3 Gas calibration (volume concentration)............................. 74

8.1.4 Calibration by comparison................................................. 75

8.2 Temperature sensor adjustment ..............................................76

Section 9 Maintenance........................................................... 77

9.1 Cleaning the instrument ...........................................................77

9.2 Sensor maintenance ................................................................77

Section 10 Troubleshooting ................................................79

10.1 Sensoface ..............................................................................79

10.2 Sensocheck............................................................................79

10.3 Error codes.............................................................................80

10.4 Calibration errors....................................................................82

10.5 Diagnostic functions ............................................................... 83

Section 11 Parts and accessories .................................... 85

11.1 si792 D series versions .......................................................... 85

11.2 Accessories............................................................................ 85

Section 12 Contact information......................................... 87

Section 13 Limited warranty ............................................... 90

Appendix A Passcode editor .............................................. 93

3

Page 6

Table of Contents

4

Page 7

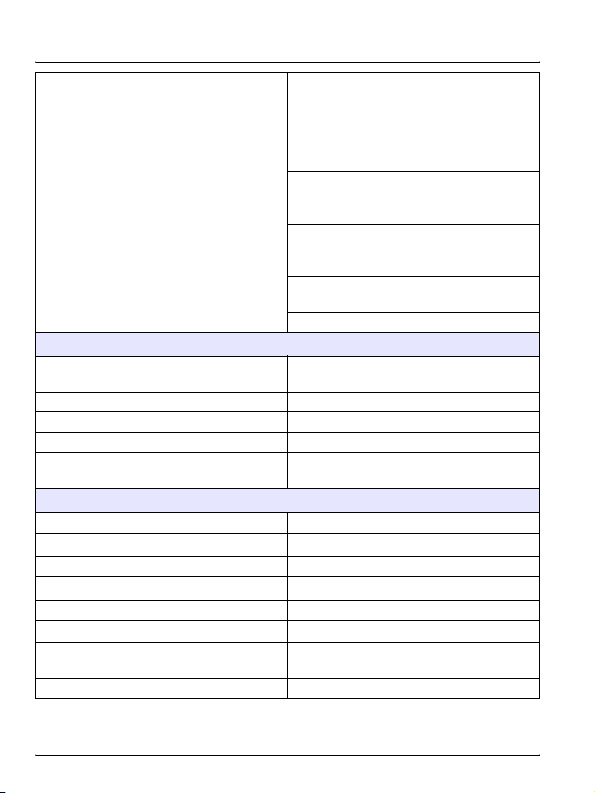

Section 1 Specifications

Specifications are subject to change without notice.

Transmitter

Composition PBT (polybutylene terephthalate)

Display LCD

Fittings

Power Requirements—HART

Power requirements—FF and

Profibus PA

Loop current—HART

Current consumption—FF and

Profibus PA

Maximum current in case of fault

(FDE)—FF and Profibus PA

Measurement error

1

3 knockouts for M20 x 1.5 strain reliefs

2 knockouts for ½ inch NPT or rigid

metallic conduit

12–30 VDC (30 VDC maximum)

100 mA maximum

0.8 W maximum (Ex)

FISCO bus supply: 9 to 17.5 VDC

Linear barrier: 9 to 24 VDC

4–20 mA floating;

3.80–22.00 mA specifiable

<13.2mA

<17.6mA

<0.3% current value + 0.05 mA

5

Page 8

Specifications

US:

si792 D

FM listed for:

Class I, Division 2

si792x D; si792x D-FF; si792x D-PA

FM listed for:

Class I, Division 1, Groups A, B, C, D

Class II, Division 1, Groups E, F,

Class III, Division 1

Class I, Zone 0, AEx ia, Group IIC T4

Enclosure: Type 2

Canada:

si792 D CSA certified to:

Certification (may not apply to all

sensors. Refer to the control drawing or

listing for certification information for

the sensor that is used)

Lightning protection EN 61000-4-5

Output averaging time constant (HART) 0–120 seconds

Output span allowed

Storage Temperature –20 to 70 °C (–4 to 158 °F)

Operating Temperature –20 to 55 °C (–4 to 131°F)

Class I, Division 2

si792x D CSA certified and

si792x C-FF; si792x D-PA cFMus

certified to:

Class I, Division 1, Groups A, B, C, D

Class I, Division 2, Groups A, B, C, D

Sensor: Class I, Zone 0, Group IIC

Transmitter: Class I, Zone 1, Group IIC

EU: si792x P; si792x D-FF;

si792x D-PA

ATEX Certification:

II 2 (1) G EEx ib (ia) IIC T6

Enclosure: Type 2

EU: CE Marked to:

EMC Directive 2004/108/EC

ATEX Directive 94/9/EC

Enclosure: IP65

2%–500%

200–9999 µg/L (ppb)

0.5–50 mg/L (ppm)

6

Page 9

Specifications

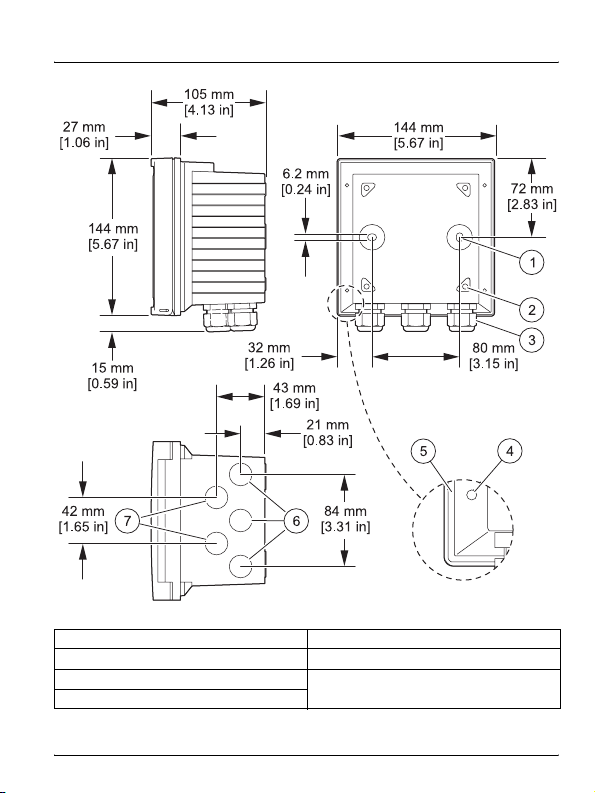

Weight Approximately 1 kg

Dimensions H 144 mm, W 144 mm, D 105 mm

Data retention

Passcodes

Sensocheck

Probe monitor

Communications

HART communication

Foundation Fieldbus (FF_H1)

Parameters and calibration data

>10 years (EEPROM)

Modifiable according to FDA 21 CFR

Part 11 “Electronic Signatures”

Automatic monitoring for short circuits

or open circuits (can be disabled).

Delay: 30 seconds.

Direct display of uncorrected sensor

signal (sensor current/temperature)

Digital communication by FSK

modulation of loop current, reading of

device identification, measured values,

status and messages, reading and

writing of parameters, start of product

calibration, signaling of configuration

changes according to FDA 21 CFR

Part 11.

Bus-powered device with constant

current consumption. Cyclic and acyclic

data exchange. 1 resource block,

1 transducer block, 3 analog input

function blocks (switchable: O

saturation, O

temperature, zero, slope, volume

concentration)

Execution time: 50 ms

Certified to ITK 4.6

Physical interface: to IEC 1158-2

Address range: 017 to 246

concentration,

2

2

7

Page 10

Specifications

Bus-powered device with constant

current consumption. Cyclic and acyclic

data exchange. Physical block,

2 analog input function blocks,

2 discrete input blocks, logbook block,

alarm block.

PNO directive: PROFIBUS-PA,

Profibus-PA (DPV1)

Temperature Input

Probe

Range –20.0 to 150.0 °C (–4 to 302 °F)

Adjustment range 10 K

Resolution 0.1 °C; 0.1 °F

Measurement error

Dissolved oxygen input

Type A sensor

Type B sensor

Measuring current 0–1200 nA; resolution: 20 pA

Measurement error

Temperature coefficient 0.005 nA/K

Permitted guard current

Polarization voltage

Range, percent saturation 0–199.9%/200–500% (–10 to 80 °C)

1,2

3

3

1,2

Profile for Process Control Devices,

Version 3.0

Physical interface: MBP-IS

(Manchester Bus Powered-Intrinsically

Safe) to IEC 1158-2 (DIN-EN 61158-2)

Connection: via segment coupler to

SPC, PC, PCS

Address range: 1 to 126

NTC 30 kΩ/NTC 22 kΩ (selectable),

2-wire connection

<0.5 K

(<1 K at T >100 °C)

Oxyferm, Oxysens (Hamilton)

Oxygold G (Hamilton)

0.5% measured value + 0.05 nA

≤ 20 µA

400–1000 mV; resolution:

approximately 3 mV

8

Page 11

Specifications

Range, concentration (–10 to 80 °C)

Range, volume concentration in gas

Process pressure 0–9.999 bars (0–999.9 kPa/0–145 PSI)

Pressure correction 0–9.999 bars (0–999.9 kPa/0–145 PSI)

Salinity correction 0–45 g/kg

Probe calibration

Type A sensor

Range, Type B sensor

Calibration timer 0 to 9999 hours

1

IEC 746 Part 1, at nominal operating conditions

2

(± 1 count plus sensor error)

3

Sensor specifications given in Table 1.

4

si792(x) D and si792x D-FF only

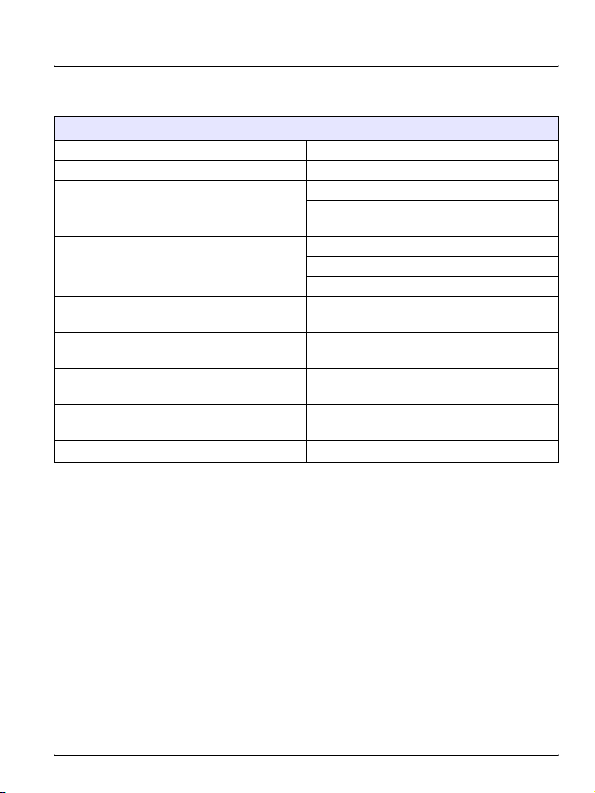

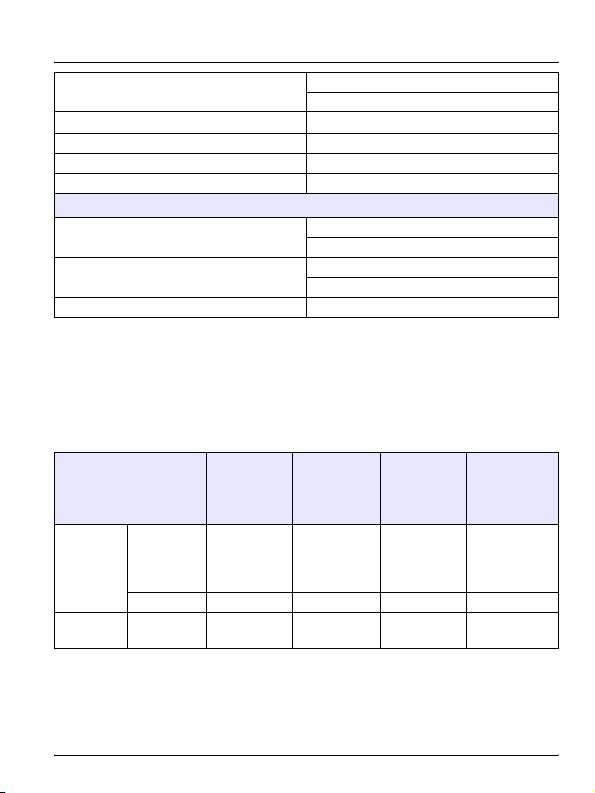

Table 1 Sensor specifications

Sensor type Screw cap

5 meter,

Type A

sensor

Type B

sensor

Oxysens

Oxyferm VP 40–80 nA 0.01 ppm 22 NTC

Oxygold G VP 180–400 nA 0.001 ppm 22 NTC

fixed cable

with stripped

ends

0–50.00 mg/L; 0–50.00 ppm

0–9999 µg/L; 0–9999 ppb

4

0–9999 ppm; 0–120.0% (–10 to 80 °C)

Slope 25–130 nA (25 °C, 1013 mbars)

Zero point ± 2 nA

Slope 200–550 nA (25 °C, 1013 mbars)

Zero point ± 2 nA

Sensor

current

in air

(25 °C)

40–80 nA 0.04 ppm 22 NTC

Detection

limit

Temperature

sensor

9

Page 12

Specifications

10

Page 13

Section 2 General Information

2.1 Safety information

Please read this entire manual before unpacking, setting up, or

operating this equipment. Pay attention to all danger and caution

statements. Failure to do so could result in serious injury to the operator

or damage to the equipment.

To ensure that the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner other than

that specified in this manual.

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

Important Note: Information that requires special emphasis.

Note: Information that supplements points in the main text.

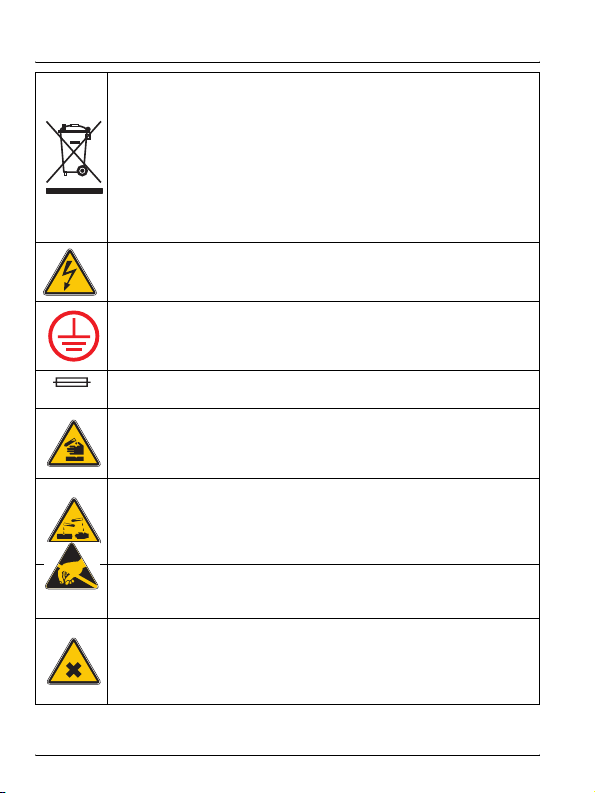

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol, if

noted on the instrument, will be included with a danger or caution

statement in the manual.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

11

Page 14

General Information

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU

Directive 2002/96/EC), European electrical equipment users must

now return old or end-of life equipment to the Producer for disposal

at no charge to the user.

Note: For return for recycling, please contact the equipment

producer or supplier for instructions on how to return end-of-life

equipment, producer-supplied electrical accessories, and all auxiliary

items for proper disposal.

This symbol, when noted on a product enclosure or barrier, indicates

that a risk of electrical shock and/or electrocution exists.

This symbol, when noted on the product, identifies the location of the

connection for Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a

fuse or current limiting device.

This symbol, when noted on the product, identifies a risk of chemical

harm and indicates that only individuals qualified and trained to work

with chemicals should handle chemicals or perform maintenance on

chemical delivery systems associated with the equipment.

This symbol, when noted on the product, identifies the presence of a

strong corrosive or other hazardous substance and a risk of chemical

harm. Only individuals qualified and trained to work with chemicals

should handle chemicals or perform maintenance on chemical

delivery systems associated with the equipment.

This symbol, when noted on the product, indicated the presence of

devices sensitive to Electro-static Discharge (ESD) and indicated

that care must be taken to prevent damage with the equipment.

This symbol, when noted on the product, identifies the presence of a

strong corrosive or other hazardous substance and a risk of chemical

harm. Only individuals qualified and trained to work with chemicals

should handle chemicals or perform maintenance on chemical

delivery systems associated with the equipment.

12

Page 15

General Information

2.2 General product information

2.2.1 Product overview

The si792 D and si792x D transmitters are used for continuous

dissolved oxygen and temperature measurement. Applications include

biotechnology, chemical, pharmaceutical and food processing as well

as environmental monitoring and sewage treatment. This manual

describes the installation, operation and maintenance for standard and

EU models of the si792 D series transmitters.

The transmitter accepts various amperometric sensors, for example:

• Hamilton Oxysens, Oxyferm, Oxygold G

The molded transmitter enclosure can be attached to a panel, wall, post

or pipe railing. The optional hood (see Accessories on page 87)

provides protection against direct weather exposure and mechanical

damage.

Three communication options are available for the si792 transmitter:

• 4–20 mA/HART—si792 D and si792x D (si792(x) D)

• Foundation Fieldbus—si792x D-FF

• Profibus PA—si792x PD-PA

This user manual includes instructions for all three protocols.

Important Note: An ‘x’ in the model number is an indication of an

instrinsically safe (IS) instrument.

2.2.2 FDA 21 CFR part 11 Compliance (HART only)

In the directive “Title 21 Code of Federal Regulations, 21 CFR Part 11,

Electronic Records; Electronic Signatures“ the US American health

agency FDA (Food and Drug Administration) regulates the production

and processing of electronic documents for pharmaceutical

development and production. The features described in section 2.2.2.1

and section 2.2.2.2 make the transmitter compliant with the

requirements of FDA 21 CFR Part 11.

13

Page 16

General Information

2.2.2.1 Electronic signatures for si792(x) D transmitters

Device functions are protected by passcode access, which prevents

unauthorized modification of device settings or manipulation of

measurement results. Passcodes may be used as electronic

signatures. Passcodes can be edited with the passcode editor

(Appendix A on page 93).

2.2.2.2 Audit trail for si792(x) D transmitters

The si792(x) D can automatically track all changes to the device

settings. Each change is tagged with a Configuration Change flag,

which is documented using HART communication. Altered device

settings or parameters can be retrieved from the transmitter using

HART communication.

14

Page 17

Section 3 Installation

DANGER

Explosion hazard. Trained personnel only must install or

commission the equipment.

DANGER

Explosion hazard. Never connect items to the transmitter that are

not specified on the control drawing. Do not connect or

disconnect any equipment unless power has been switched off or

the area is known to be non-hazardous.

DANGER

Explosion hazard. The safety of the transmitter may be impaired if

any of the following conditions have occurred:

• visible damage

• storage above 70 °C for prolonged periods

• exposure to severe transport stresses

• previous installation

• failure to operate properly

If any of these conditions have occurred, return the device to the

manufacturer for recertification.

The si792 and si792x transmitters differ in hazard classification. The

si792 transmitter is designed for non-hazardous or Class I, Division 2,

Groups A, B, C, D hazardous locations. The si792x transmitter is

designed for Class I, Division 1, Groups A, B, C, D hazardous locations.

Refer to the control drawing or listing applicable to the site location.

For outdoor installation, use of a protective hood or sunshield is

recommended (section 11.2 on page 87).

Installation of the si792x in an outdoor hazardous location per FM or

CSA control drawings requires a suitable enclosure and must follow

NEC guidelines. Refer to NEMA 250 to determine enclosure needs.

15

Page 18

Installation

3.1 Hazardous location

Before installation, review the applicable Hazardous Location Control

Drawings or ATEX EC-type Examination certificate included with the

instrument and on the provided documentation CD. Follow all

regulations specified for the installation location.

Refer to the documentation CD for manuals provided in

other languages.

3.2 Unpacking the transmitter

Check the shipment for transport damage and make sure all

components have been shipped complete. The package includes:

• Display module • Bag of hardware and fasteners

• Back enclosure • Test report and user manual

16

Page 19

Installation

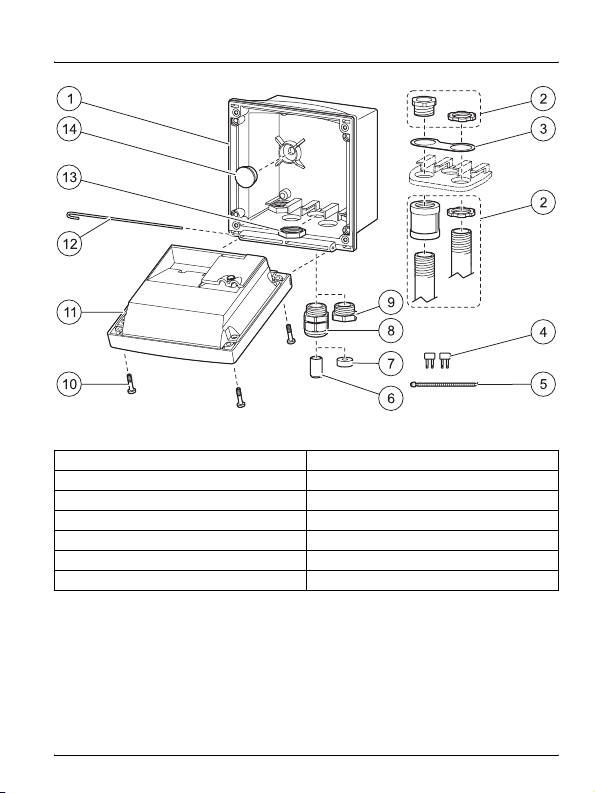

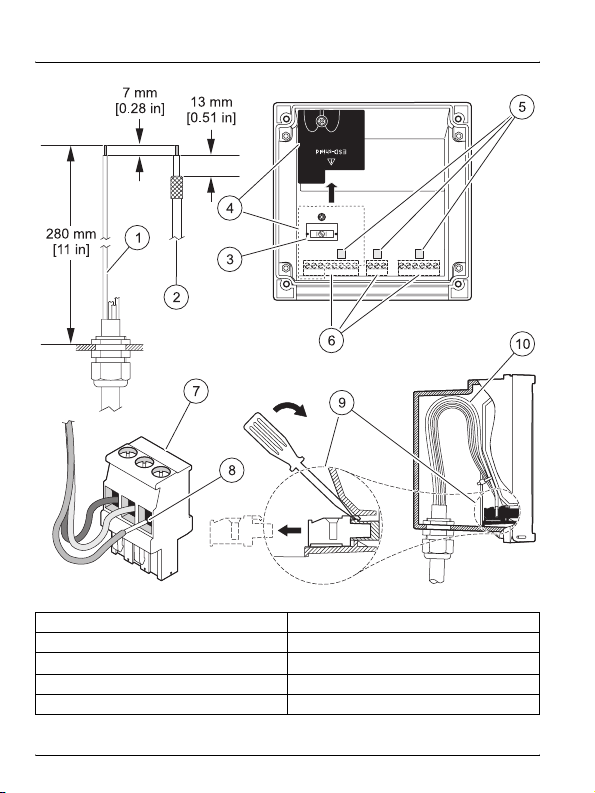

Figure 1 Instrument Components

1 Back enclosure 8 Strain relief (3x)

2 Optional conduit hardware 9 Filler plug (3x)

3 Conduit washer 10 Enclosure screw (4x)

4 Jumper (2x) 11 Display module

5 Cable tie (3x) 12 Hinge pin

6 Sealing insert 13 Hex nuts (5x)

7 Rubber reducer 14 Sealing plug (2x)

17

Page 20

Installation

3.3 Mechanical installation

3.3.1 Transmitter assembly

Refer to Figure 1 and the following instructions to assemble the

transmitter.

1. Insert the strain relief fittings in the holes of the back enclosure and

secure with the hex nuts (Figure 2).

2. Insert the conduit hardware or plugs in the back enclosure and

secure with the hex nuts.

3. Attach the display module to the back enclosure using the hinge pin.

3.3.2 Mounting

Refer to the following sections to mount the transmitter on a wall, panel

or pipe.

3.3.2.1 Wall mount

1. Use a punch to open the two wall-mount holes in the back enclosure

(Figure 2).

2. Drill holes in the wall suitable for the user-supplied mounting bolts.

3. Attach the back enclosure to the wall using two customer-supplied

bolts.

4. Insert the clear plastic plugs into the mounting holes.

3.3.2.2 Panel or pipe mount (optional)

Refer to Figure 2 and the instructions supplied with the panel and pipe

mounting kits (see Accessories on page 85).

18

Page 21

Installation

Figure 2 Wall attachment dimensions

1 Breakout for wall mounting (2x) 5 Groove for panel mount gasket

2 Hole for pipe mounting (4x) 6 Strain relief opening (3x)

3 Strain relief (3x)

4 Breakout for panel mounting

7 Strain relief or ½ inch conduit opening

(2x) Ø 21.5 mm [0.85 in]

19

Page 22

Installation

3.4 Wiring Safety Information

When making any wiring connections to the instrument, the following

warnings and notes must be adhered to, as well as any warnings and

notes found throughout the individual installation sections. For more

safety information refer to section 2.1 on page 11.

DANGER

Always disconnect power to the instrument when making any

electrical connections.

Electrostatic Discharge (ESD) Considerations

To minimize hazards and ESD risks, maintenance procedures not

requiring power to the analyzer should be performed with power

removed.

Delicate internal electronic components can be damaged by static

electricity, resulting in degraded instrument performance or eventual

failure.

The manufacturer recommends taking the following steps to prevent

ESD damage to the instrument:

• Before touching any electronic components (such as printed circuit cards

and the components on them) discharge static electricity from the body by

touching an earth-grounded metal surface such as the chassis of an

instrument or a metal conduit or pipe.

• To reduce static build-up, avoid excessive movement. Transport static-

sensitive components in anti-static containers or packaging.

• To discharge static electricity from the body and keep it

discharged, wear a wrist strap connected by a wire to earth

ground.

• Handle all static-sensitive components in a static-safe area. If

possible, use anti-static floor pads and work bench pads.

20

Page 23

Installation

3.5 Electrical installation

DANGER

Explosion hazard. Do not connect any components that are not

specified for the device. Always defer to the Hazardous Location

Control Drawing.

DANGER

Hamilton dissolved oxygen sensors are ATEX certified. The

combination of Hamilton dissolved oxygen sensors and the

si792 D transmitter are FM C1D1 certified. The Hamilton sensors

are not certified by CSA for use in Canadian hazardous locations.

See CSA control drawings for approved sensor options

Prerequisites:

• Review the applicable control drawing or ATEX certificate

• Review the electrical code regulations

• Review the regulations for electrical installations in hazardous

locations as needed (e.g. EN 60079-10/EN60079-14; 94/9/EC

directive; NEC; CEC; Profibus Technical Guidelines 2.091).

• Remove power or confirm non-hazardous status before making

any connections

• Confirm that the intrinsic safety of the device is maintained when

connected to other equipment such as a power supply unit.

3.5.1 Wire preparation

To remove the terminal blocks from the transmitter for sensor wiring:

1. Insert a flat screwdriver between the terminal block and the

transmitter body.

2. Use the screwdriver as a lever to lift the terminal block off the

connectors (see Figure 3 on page 22).

21

Page 24

Installation

Figure 3 Wire preparation and insertion

1 Stripping lengths for cables 6 Terminals (vary by model number)

2 Stripping lengths for coaxial cables 7 Typical terminal

3 Cable shield connector

4 ESD shield removed 9 Removing terminal with screwdriver

5 Areas for screwdriver to pry terminal 10 Cable loop position in housing

1

Not used for si792x D-ff and si792x D-PA transmitters.

1

8 Seat insulation against connector

22

Page 25

Installation

3.5.2 Power and communication connections

DANGER

Explosion hazard. The AC power source for the power supply unit

cannot exceed 250 VAC. Do not connect the transmitter directly to

an AC power source.

DANGER

Explosion hazard. The output voltage of the power supply unit

cannot exceed 30 VDC. The si792x transmitter must be connected

to an appropriately certified explosion-proof power supply unit.

Refer to "associated apparatus" in the control drawing or to the

EC-Type Examination Certificate for input ratings.

Prerequisites

• Trained personnel only must install or commission the

equipment.

• Follow the instructions in this user manual and the applicable

local and national codes.

• Observe the technical specifications and input ratings during

installation.

• Disconnect all power sources during wiring and installation.

• Use single wires/flexible leads up to 2.5 mm (AWG 14) for

connection to terminals.

• Do not damage the wire when stripping the insulation.

• All parameters must be set by a system administrator (Authority

Having Jurisdiction) before commissioning.

23

Page 26

Installation

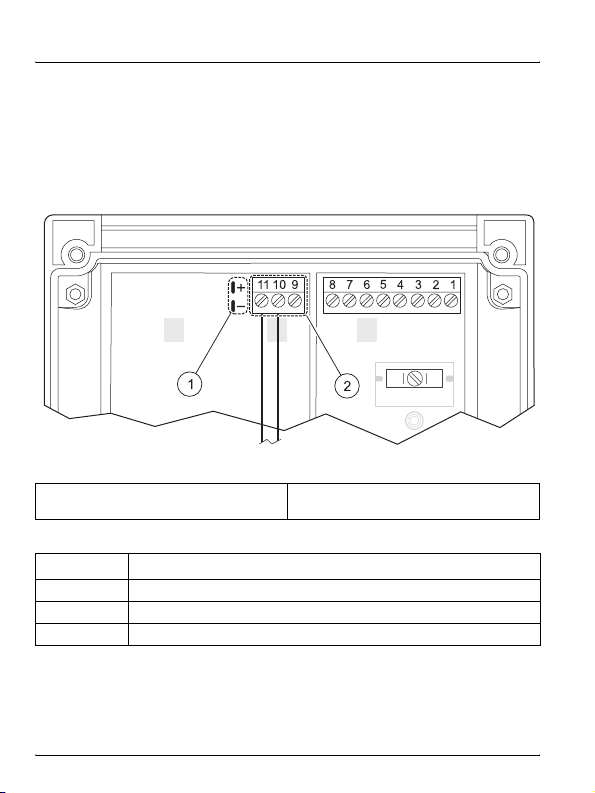

3.5.2.1 si792(x) D (4–20 mA/HART) wiring

DANGER

Explosion hazard. Never connect items to the transmitter that are

not specified on the control drawing/ATEX EC-Type certificate.

Refer to Figure 6 and Table 2 and the following steps to connect the

power supply to the si792(x) D transmitter.

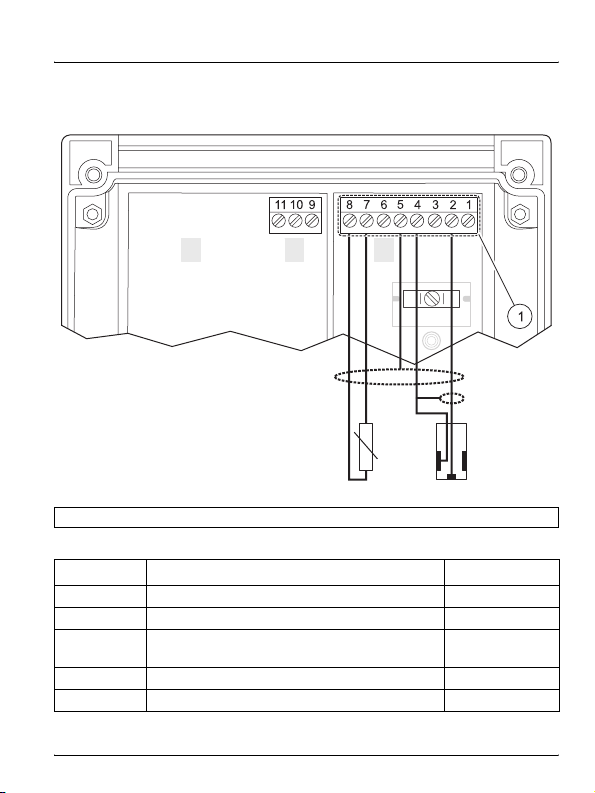

Figure 4 si792(x) D (4–20 mA/HART) wiring

1 HART connection (see warnings in

section 3.6 on page 30)

Table 2 Terminal assignments—si792(x) D

Terminal No. Assignment

9 Equipotential bonding for ATEX. Do not connect for FM and CSA.

10 4–20 mA output (–)

11 4–20 mA output (+)

2 Wiring terminals—see Table 4

24

Page 27

Installation

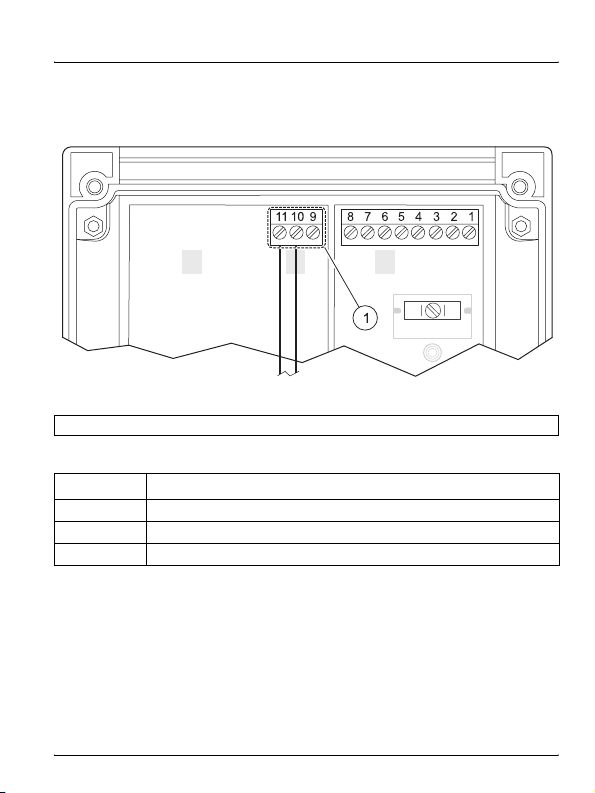

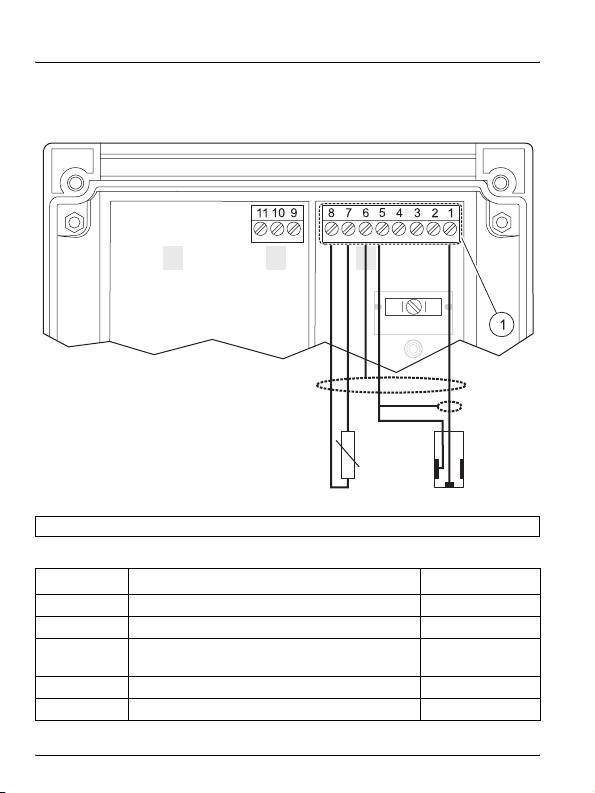

3.5.2.2 si792x D-FF and si792x D-PA wiring

Refer to Figure 5 and Table 3 to connect power and communications

to the si792x D-FF or si792x D-PA transmitters.

Figure 5 si792x D-FF and si792x D-PA wiring

1 Wiring terminals—see Table 3

Table 3 Terminal assignments—si792x D-FF and si792x D-PA

Terminal No. Assignment

9 Equipotential bonding for ATEX. Do not connect for FM and CSA.

10 Connection from FF or Profibus PA (–)

11 Connection from FF or Profibus PA (+)

3.5.3 Sensor wire connection

Important Note: Do not connect earth ground to the shield connector in the

transmitter. Connect the cable shields to the shield connector.

Refer to the following sections to connect the transmitter to a sensor:

• Oxygold G/Oxyferm sensor (si792(x) D, section 3.5.3.1)

• Oxygold G/Oxyferm sensor (si792x D-FF/si792x D-PA, section 3.5.3.2)

• Oxysens sensor (si792(x) D, section 3.5.3.3)

• Oxysens sensor (si792x D-FF/si792x D-PA, section 3.5.3.4)

25

Page 28

Installation

3.5.3.1 Oxygold G/Oxyferm sensor—si792(x) D (4–20 mA/HART)

Use Figure 6 and Table 4 to wire the sensor to the transmitter.

Figure 6 Oxygold G/Oxyferm sensor (VP connector)—si792(x) D

1 Wiring terminals—see Table 4

Table 4 Terminal assignments—Oxygold G or Oxyferm sensor

Ter min al No.

1

With VP cable LZY079, LZY353 and LZY354. Blue and gray are not used.

Assignment

1 Cathode (coaxial center wire) clear

5 Anode (coaxial shield) shield/red

Cable shield connection

6

Note:

Do not connect to earth ground.

7 RTD (resistive temperature device) green

8 RTD (resistive temperature device) white

Wire color

shield/yellow-

green

1

26

Page 29

Installation

3.5.3.2 Oxygold G/Oxyferm sensor—si792x D-FF or si792x D-PA

Use Figure 7 and Table 5 to wire the sensor to the transmitter.

Figure 7 si792x D-FF and si792x D-PA wiring for Oxygold G/Oxyferm

1 Wiring terminals—see Table 5

Table 5 Terminal assignments—Oxygold G or Oxyferm sensor

Ter min al No.

1

With VP cable LZY079, LZY353 and LZY354. Blue and gray are not used.

Assignment

2 Cathode receive high clear

4 Anode shield/red

Cable shield connection

5

Note:

Do not connect to earth ground.

7 RTD (resistive temperature device) green

8 RTD (resistive temperature device) white

Wire color

shield/yellow-

green

1

27

Page 30

Installation

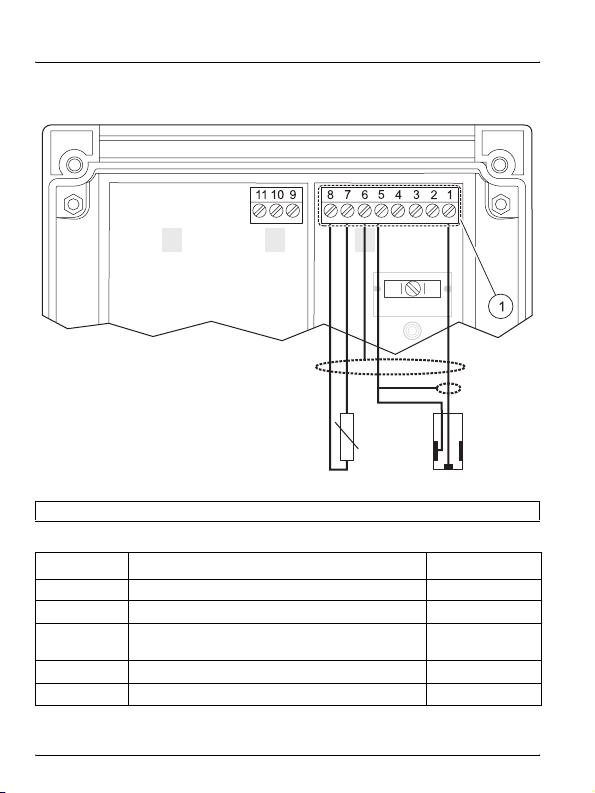

3.5.3.3 Oxysens sensor—si792(x) D (4–20 mA/HART)

Use Figure 8 and Table 6 to wire the sensor to the transmitter.

Figure 8 si792(x) D wiring example for Oxysens sensor (fixed cable)

1 Wiring terminals—see Table 6

Table 6 Terminal assignments—Oxysens sensor

Ter min al No.

Assignment Wire color

1 Cathode (coaxial center wire) clear

5 Anode brown

Cable shield connection

6

Note:

Do not connect to earth ground.

7 RTD (resistive temperature device) yellow

8 RTD (resistive temperature device) blue

shield

28

Page 31

Installation

3.5.3.4 Oxysens sensor—si792x D-FF and si792x D-PA

Use Figure 9 and Table 7 to wire the sensor to the transmitter.

Figure 9 si792x D-FF and si792x D-PA wiring example for Oxysens

(fixed cable)

1 Wiring terminals—see Table 7

Table 7 Terminal assignments—Oxysens sensor

Ter min al No.

Assignment Wire color

2 Cathode receive high clear

4 Anode brown

Cable shield connection

5

Note:

Do not connect to earth ground.

7 RTD (resistive temperature device) yellow

8 RTD (resistive temperature device) blue

shield

29

Page 32

Installation

3.6 HART communication connection

DANGER

Explosion hazard. Never connect items to the transmitter that are

not specified on the control drawing. Do not connect or

disconnect any equipment unless power has been switched off or

the area is known to be non-hazardous.

DANGER

The si792x transmitter must be used with an explosion-proof

HART communication device. Refer to the appropriate control

drawing for the location of the HART (Rosemount) device.

The handheld HART communication device can only be connected to

the transmitter in US Class I, Division 1 classified locations (permitted

only by FM). Do not connect the handheld Hart communication device

to the transmitter in any Zone or Canadian Class I, Division 1 classified

location. Refer to Figure 4 on page 24 for the connector location.

30

Page 33

Section 4 Interface and navigation

The si792 transmitter user interface contains a display, indicators and

keys for navigation and menu selection.

4.1 si792(x) D (4–20 mA/HART) interface

Use the arrow and enter keys to scroll through the menu and change

settings. Use the indicators to identify which mode the transmitter is in.

Refer to Figure 10 to identify the keys and indicators of the si792(x) D.

Figure 10 User interface—si792(x) D

1 Calibration key 7 Wash mode indicator (not available)

2 Configure key 8 Configuration mode indicator

3 Measure mode indicator 9 Up arrow key

4 Calibration mode indicator 10 Right arrow key

5 Alarm indicator

6 Display

11 Enter key

31

Page 34

Interface and navigation

4.2 si792x D-FF and si792x D-PA interface

Refer to Figure 11 to identify the keys and indicators of the si792x D-FF

and the si792x D-PA.

Figure 11 User interface—si792x D-FF and si792x D-PA

1 Measure key 7 Communication indicator

2 Calibration key 8 Configuration mode indicator

3 Measure mode indicator 9 Up arrow key

4 Calibration mode indicator 10 Right arrow key

5 Alarm indicator 11 Enter key

6 Display 12 Configuration mode

32

Page 35

Interface and navigation

4.3 Display

Figure 12 identifies all of the possible icons and symbols that may be

seen in the si792 transmitter display.

Figure 12 Display

1 Passcode 13 Secondary display

2 Temperature 14 Alarm mode

3 4–20 mA output (HART) 15 Manual temperature on

4 Limit values (FF and Profibus PA) 16 Calibration mode

5 Alarm 17 Hold mode active

6 Sensocheck—sensor error 18 Hourglass

7 Calibration active 19 Measure mode active

8 Calibration interval 20 Calibration complete

9 Parameter display 21 Calibration—zero or first point

10 Enter prompt 22 Calibration—second point

11 Configuration mode

12 Main display

23 Sensofaces

33

Page 36

Interface and navigation

34

Page 37

Section 5 Operation—si792(x) D

(4–20 mA/HART)

The following section describes how to navigate and operate the

si792(x) D transmitters.

5.1 Measure mode

In the measure mode the display shows the dissolved oxygen value

and the temperature. The status bar is shown above the measure mode

indicator.

• To return to the measure mode from the configure menu, press

CONF and then ENTER.

• To return to the measure mode from the calibration menu, press

CAL and then ENTER.

Note: The waiting time for the stabilization of the measured value is

approximately 20 seconds.

5.2 Configuration

Use the configuration mode to specify the sensor, range and other

parameters for the system as shown in Table 8.

1. Press CONF and enter 1200 to enter the configuration mode.

2. Use the arrow and enter keys to change the settings. All settings

and options are shown in section 5.2.1, section 5.2.2, section 5.2.3,

section 5.2.4 and section 5.2.5.

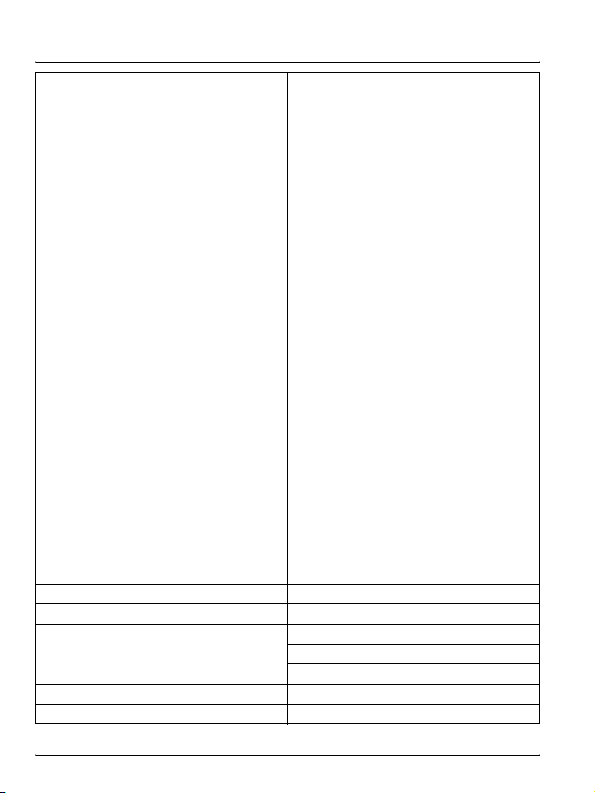

Table 8 Configuration menu

Code Setting Passcode

35

Page 38

Operation—si792(x) D (4–20 mA/HART)

Table 8 Configuration menu

o1 4–20 mA current output

tc Temperature sensor

Corr

CAL Calibration setup

AL Alarm settings

To exit the configuration mode at any time, press

ENTER. The output current will be held for 20 seconds and the

measured value will be displayed.

Note: During configuration the transmitter remains in the Hold mode for

safety reasons. The loop current is frozen at the value specified in the

o1.HoLD menu option. The Sensoface icon is inactive. The

configuration mode indicator is displayed (Figure 12 on page 33).

5.2.1 Output configuration

Select the parameter

o1. FCT

Select the sensor type

o1.SnSR

Select the units

o1.UniT

Correction for pressure,

salinity, polarization voltage.

1200

CONF and then

Table 9 Output setup menu—out.1MNU

DO (concentration by weight; default)

GAS (concentration by volume)

Type A (standard; default) examples: Oxysens, Oxyferm

Type B (trace measurements) example: Oxygold G

SAt % (percent saturation; default)

Conc µg/L

DO (default)

GAS

Conc mg/L

Conc ppb

Conc ppm

GAS % (default)

GAS ppm

36

Page 39

Operation—si792(x) D (4–20 mA/HART)

Table 9 Output setup menu—out.1MNU (Continued)

Specify the value for the 4 mA signal (section 5.2.1.1)

o1. 4mA Enter the minimum DO or GAS value (default: 0%)

Specify the value for the 20 mA signal (section 5.2.1.1)

o1.20mA Enter the maximum DO or GAS value (default: 500%)

Set time averaging filter for reducing noise (section 5.2.1.2)

o1.Ftme Enter the time in seconds (0 to 120 seconds; default: 0 seconds)

Send a 22 mA signal during errors (section 5.2.1.3)

o1.FAil

Specify the value to send during HOLD periods (section 5.2.1.4)

o1.HoLD

Press

values. Press

acceptable range, “Err” will be displayed and the value will not be

accepted. To exit the menu and return to the measurement mode, press

CONF and then ENTER.

Example: Set the 4 mA current output signal to 2 mg/L O

1. Press

Conf and then out.1MNU.

2. Press

show o1.UniT.

3. Press

show o1.4mA.

4. Use the

03.00 mg/L. Press

o1.20mA.

5. Press

On

Off (default)

LAST measured value (default)

FIXed Enter the value in mA (0 to 22 mA; default: 21 mA)

ENTER to access a menu item. Use the ARROW KEYS to edit

ENTER to save the settings. If a value is outside of the

.

2

CONF, enter passcode: 1200, ENTER. The display will show

ENTER to access the output setup menu. The display will

ENTER, ENTER to show the 4 mA submenu. The display will

UP ARROW and RIGHT ARROW to edit the value to

ENTER to save the value. The display will show

CONF and then ENTER to exit the configuration menu.

37

Page 40

Operation—si792(x) D (4–20 mA/HART)

5.2.1.1 Output range

The upper and lower end of the dissolved oxygen range should

correspond to the 4 mA and 20 mA signals. For example, to set a range

of 3–10 mg/L O

20 mA signal to a value of 10 mg/L O

5.2.1.2 Time averaging filter

An averaging filter is available to reduce noise in the output signal. The

filter averages readings over a specified time interval. The time interval

can be set from 0 to 120 seconds (default: 0 seconds).

When set to 0 seconds, there is no noise reduction and the signal is the

same before and after the filter. When set to 120 seconds, the signal

after the filter will be averaged over 120 seconds. Increase the time

interval to reduce the noise in the output signal.

Note: The filter acts on the output signal but not on the displayed value.

5.2.1.3 Output signal during errors

When an error condition occurs, a 22 mA output signal can be sent as

a notification (default: off).

, set the 4 mA signal to a value of 3 mg/L and the

2

.

2

38

Page 41

Operation—si792(x) D (4–20 mA/HART)

5.2.1.4 Output signal during HOLD

The output signal during hold periods can be maintained at the last

measured value (Figure 13) or fixed at a specified value (Figure 14).

The allowable range for the fixed value is 3.8 to 22 mA.

Figure 13 Output signal during HOLD—last value

1 Output signal during HOLD 2 HOLD mode

Figure 14 Output signal during HOLD—fixed value

1 Output signal during HOLD 2 HOLD mode

39

Page 42

Operation—si792(x) D (4–20 mA/HART)

5.2.2 Temperature sensor configuration

An overview of the temperature compensation setup menu is shown in

Table 10.

Table 10 Temperature sensor setup menu—tc

Select temperature unit

tc.UnIT

Select temperature sensor

tc.rTD

Press

values. Press

°C (default)

°F

22NTC (default)

30NTC

ENTER to access a menu item. Use the ARROW KEYS to edit

ENTER to save the settings. If a value is outside of the

acceptable range, “Err” will be displayed and the value will not be

accepted. To exit the menu and return to the measurement mode, press

CONF and then ENTER.

5.2.3 Correction menu configuration

An overview of the corrections menu is shown in Table 11.

Table 11 Corrections setup menu—Corr MNU

Specify the polarization voltage

Co.UPoL Enter the polarization voltage (400–1000 mV; default: 675 mV)

Select pressure units

Bar (default)

Co.UniT

Specify the correction for process pressure (for % saturation only)

Co.PrES Enter the process pressure (default: 1.013 Bar)

Specify the correction for salinity

Co. SAL

1

ppt—parts per thousand (corresponds to g/kg)

KPa

PSI

Enter the salinity value of the sample (0–45.00 ppt

MNU

1

; default: 0 ppt)

40

Page 43

Operation—si792(x) D (4–20 mA/HART)

5.2.4 Calibration mode configuration

An overview of the calibration setup menu is shown in Table 12. Refer

to Appendix A on page 95 for buffer tables.

Table 12 Calibration mode setup menu—CAL

Select calibration units

CA. MOD

Enter calibration timer interval

CA.tiME Enter the time interval for calibration (0 to 9999 hours; default: 0 h)

SAt (default)

Conc

5.2.5 Alarm settings configuration

An overview of the alarm setup menu is shown in Table 13.

Table 13 Output setup menu for alarm settings—ALrt MNU

Select Sensocheck on or off

AL.SnSO

Enter alarm delay

AL.dLY 0010 sec (default) Range: 0000–0600 sec

LED in Hold mode

AL.LED

CHECK ON

CHECK OFF (default)

HOLD ON LED blinks during hold

HOLD OFF LED off during hold

Continuous evaluation of sensor function

MNU

41

Page 44

Operation—si792(x) D (4–20 mA/HART)

42

Page 45

Section 6 Operation—Foundation

Fieldbus

The following section describes how to navigate and operate the

si792x D-FF. The transmitter can be operated as follows:

• Direct interface with the transmitter (section 6.1)

• Foundation Fieldbus communication (section 6.2 on page 46)

6.1 Configuration

Use the configuration mode to specify the sensor, range and other

parameters for the system.

6.1.1 Configuration steps

Complete the following steps to configure the si792 transmitter.

1. Press MEAS + CAL and enter 1200 to enter the configuration

mode.

2. Use the arrow and enter keys to change the settings. All settings

and options are shown in section 6.1.2.

To exit the configuration mode at any time, press MEAS + CAL and

ENTER. The Hold mode will be active for 20 seconds and then the

then

measured value will be displayed.

Note: During configuration the transmitter remains in the Hold mode for

safety reasons. The Sensoface icon is inactive. The configuration mode

indicator is displayed (Figure 10 on page 31).

43

Page 46

Operation—Foundation Fieldbus

6.1.2 Configuration menu

Select signal level

ln.rnGE

Select the sensor

ln.SnSR

Select process medium (O2 dissolved (DO) / gas (GAS)

ln.FCT

Select filter time

ln.FtME 0000–0120 SEC (default: 0000 SEC)

Select temperature unit

tc.UnIT

Select temperature sensor

tc.rTD

Select polarization voltage

Co.UPOL –1000–0 mV (default: –0675 mV)

Select pressure unit

Co.UnIT

Select pressure correction

Hi level (default)

Lo level

Type A (default). See Table 1 on page 9.

Type B. See Table 1 on page 9.

DO (default) ln.UnIT

GAS ln.UnIT

°C (default)

°F

22 NTC (default)

30 NTC

BAR (default)

kPa

PSI

% (default)

mg/L

µg/L

ppm

ppb

ppm (default)

%

44

Page 47

Operation—Foundation Fieldbus

6.1.2 Configuration menu (continued)

Co.PrES

Select salinity correction

Co.SAL 0.00–45.00 mg/L (default: 0.00 mg/L)

Select calibration mode

Ca.MOD

Select calibration interval

CA.tiME 0000–9999 h (default 0000 h)

Select Sensocheck

AL.SnSO

LED in Hold mode

AL.LED

Select Fieldbus address (optional)

FF.ADR 0017–0031 BUS (default: 0026 BUS)

1

Use only when there is no bus connection. The transmitter will restart and set all

parameters to default values. Individual settings must be entered once more.

0.000–9.999 BAR (default: 1.013 BAR)

999.9 kPa / 145.0 PSI (not in sensor)

SAt (default)

Conc

CHECK ON

CHECK OFF (default)

HOLD ON LED blinks during hold

HOLD OFF (default) LED off during hold

Continuous Sensocheck evaluation of

sensor function

1

45

Page 48

Operation—Foundation Fieldbus

6.2 Foundation Fieldbus communication

Use the Foundation Fieldbus specification to set up and configure the

si792 transmitter. The communication parameters are listed in the

following sections. The sensor can be calibrated as described in

section 6.2.4 on page 63.

6.2.1 Standard resource block (RB)

The standard resource block describes the transmitter characteristics

(manufacturer, device name, operating status, global status). The

resource block must be in automatic mode for any of the other blocks to

operate. The bus parameters for the standard resource block (RB) are

shown in Table 14.

Table 14 Bus parameters—resource block (RB)

Parameter Description Default R/W

ST_REV Static revision 0 R

TAG_DESC TAG description ‘ R/W

STRATEGY Strategy 0 R/W

ALERT_KEY Alert key 0 R/W

Ta rg e t

MODE_BLK

BLOCK_ERR Block error R

RS_STATE Resource state 1 R

TEST_RW Test R/W

DD_RESOURCE DD resource ‘ R

MANUFAC_ID Manufacturer ID 0x001D6D for Hach R

DEV_TYPE Device type 0x0064 R

DEV_REV Device revision 1 R

DD_REV DD revision 1 R

Actual —

Permitted OOS, Auto

Normal Auto

(out of service)

OOS

R/W

46

Page 49

Operation—Foundation Fieldbus

Table 14 Bus parameters—resource block (RB) (continued)

Parameter Description Default R/W

GRANT_DENY

HARD_TYPES Hardware type 1 R

RESTART Restart R/W

FEATURES Feature supported Reports/ Soft W Lock R

FEATURES Feature selected Reports/ Soft W Lock R/W

CYCLE_TYPE Cycle type

CYCLES_SEL Cycle selected

MIN_CYCLE_T Min cycle time

MEMORY_SIZE Memory size R

NV_CYCLE_T Non-volatile cycle time R

FREE_SPACE Free space R

FREE_TIME Free time R

SHED_RCAS R/W

SHED_ROUT R/W

FAULT_STATE Fault state R

SET_FSTATE Set fault state 1 R/W

CLR_FSTATE Clear fault state 1 R/W

MAX_NOTIFY Max notifications 20 R

LIM_NOTIFY Limit of notification 8 R/W

CONFIRM_TIME Confirmation time

WRITE_LOCK Write locking 1 (Unlocked) R/W

UPDATE_EVT

Grant 0 R/W

Deny 0 R/W

Scheduled/

Block Execution

Scheduled/

Block Execution

1

1600

/32 ms (50ms)

1

/32 ms

640000

Unacknowledged 0 R/W

Update state 0 R

Time stamp 0 R

Static revision 0 R

Relative index 0 R/W

R

R/W

R

R/W

47

Page 50

Operation—Foundation Fieldbus

Table 14 Bus parameters—resource block (RB) (continued)

Parameter Description Default R/W

Unacknowledged R/W

BLOCK_ALM

ALARM_SUM

ACK_OPTION

WRITE_PRI Write priority 0 R/W

WRITE_ALM

ITK_VER ITK_version 4 R

DEVICE_LOCK

Alarm state R

Time stamp R

Sub-code R

Val ue R

Current R

Unacknowledged R

Unreported R

Disabled R/W

Automatic acknowledge

option

Unacknowledged R/W

Alarm state R

Time stamp R

Sub-code R

Val ue R

Locks the device for local

access.

1 byte

Data type = uns8

Range:

0 (Unlocked)

1 (Locked)

0 (Disabled) R/W

0 (Unlocked) R/W

48

Page 51

Operation—Foundation Fieldbus

6.2.2 Standard analog input block (AI)

Three Analog Input Function Blocks provide for cyclic transmission of

measured values (currently measured value with status, alarm limits,

freely selectable process parameter).

6.2.2.1 Operating modes

Use the MODE_BLK parameter to set the following operating modes:

• OOS—out of service. If not write-protected, access to all

parameters is allowed.

• MAN—manual

• Auto—online, normal state

6.2.2.2 Set the parameter and units

Use CHANNEL to set the measured parameter and units (Table 15).

The corresponding measurement unit is selected in the UNITS

subparameter of XD_SCALE (Table 16 on page 51).

Table 15 Measurement parameters and units

Channel Parameter Unit Unit value

1 Saturation % (percent) 1342

mg/l 2001

2 Concentration

3 Temperature

4 Zero A 2003

5 Slope A 1587

Volume

6

concentration

μg/l 2002

ppm 1423

ppb 1424

°C 1001

°F 1002

% percent 1342

ppm 1423

49

Page 52

Operation—Foundation Fieldbus

6.2.2.3 Data processing

Use the L_TYPE parameter to apply a linearization function to the data.

• Direct—data is sent directly from the TB to the AI without

processing. The units for the XD_SCALE and OUT_SCALE

parameters must be identical.

• Indirect—data from the TB is linearly scaled from the input scale

(XD_SCALE) to the output scale (OUT_SCALE).

• Indirect square root—data is rescaled from the input scale

(XD_SCALE) and recalculated using a root function. Then the

value is linearly scaled to the output scale (OUT_SCALE).

6.2.2.4 Alarms

The AI block can generate block alarms and limit alarms. Use the

ACK_OPTION parameter to specify if an alarm must be acknowledged.

When the measured value status is “bad”, the AI block BLOCK_ERR

parameter indicates an Input Failure.

• Block alarms—a block error will be reported via the

BLOCK_ERR parameter (simulate active, input failure, block

configuration error, out of service (OOS)). The BLOCK_ALM

parameter sends the alarm status to the control system.

• Limit alarms—the measured value OUT falls outside of the limit

values (HI_HI_LIM, HI_LIM, LO_LIM, LO_LO_LIM).

If an alarm occurs, evaluate the following bus parameters:

• OUT parameter (currently measured value) in the Al block

• LAST_ERROR parameter in the transducer block

• SENSOFACE_STATUS parameter in the transducer block

50

Page 53

Operation—Foundation Fieldbus

6.2.2.5 Bus parameters for the analog input block

The bus parameters for the analog input function block (AI) are shown

in Table 16.

Table 16 Bus parameters/analog input blocks (AI)

Parameter Description Default R/W

ST_REV Static Revision 0 R

TAG_DESC TAG Description R/W

STRATEGY Strategy 0 R/W

ALERT_KEY Alert Key 0 R/W

Target OOS

MODE_BLK

BLOCK_ERR Block Error R

PV

OUT

SIMULATE

XD_SCALE

OUT_SCALE

Actual —

Permitted OOS, Auto

Normal Auto

Process Value R

Status R

Measured Value R

Status R

Simulate Status R/W

Simulate Value R/W

Transducer Status R

Transducer Value R

Simulate Enable / Disable R/W

High Range 100 R/W

Low Range 0 R/W

Units Index 0 R/W

Decimal Point 0 R/W

High Range 100 R/W

Low Range 0 R/W

Units Index 0 R/W

Decimal Point 0 R/W

R/W

51

Page 54

Operation—Foundation Fieldbus

Table 16 Bus parameters/analog input blocks (AI) (continued)

Parameter Description Default R/W

GRANT_DENY

IO_OPTS IO Block Options 0 R/W

STATUS_OPTS Status Options

CHANNEL Channel 1 R/W

L_TYPE Linearization Type 0 R/W

LOW_CUT Low Cut Off 0 R/W

PV_TIME Filter Time 0 R/W

FIELD_VAL

UPDATE_EVT

BLOCK_ALM

ALARM_SUM

ACK_OPTION

AlARM_HYS Alarm Hysteresis 0.50% R/W

HI_HI_PRI High High Priority 0 R/W

HI_HI_LIM High High Limit INF R/W

HI_PRI High Priority 0 R/W

HI_LIM High Limit INF R/W

LO_PRI Low Priority 0 R/W

Grant 0 R/W

Deny 0 R/W

Percent Value R

Status R

Unacknowledged 0 R/W

Update State 0 R

Time Stamp 0 R

Static Revision 0 R

Relative Index 0 R

Unacknowledged 0 R/W

Alarm State 0 R

Time Stamp 0 R

Sub-code 0 R

Current 0 R

Unacknowledged 0 R

Unreported 0 R

Disabled 0 R/W

Automatic Acknowledge

Option

0R/W

52

Page 55

Operation—Foundation Fieldbus

Table 16 Bus parameters/analog input blocks (AI) (continued)

Parameter Description Default R/W

LO_LIM Low Limit –INF R/W

LO_LO_PRI Low Low Priority 0 R/W

LO_LO_LIM Low Low Limit –INF R/W

Unacknowledged 0 R/W

HI_HI_ALM

HI_ALM

LO_ALM

LO_LO_ALM

Alarm State 0 R

Time Stamp 0 R

Sub-code 0 R

Value 0 R

Unacknowledged 0 R/W

Alarm State 0 R

Time Stamp 0 R

Sub-code 0 R

Value 0 R

Unacknowledged 0 R/W

Alarm State 0 R

Time Stamp 0 R

Sub-code 0 R

Value 0 R

Unacknowledged 0 R/W

Alarm State 0 R

Time Stamp 0 R

Sub-code 0 R

Value 0 R

53

Page 56

Operation—Foundation Fieldbus

6.2.2.6 Cyclic measured value status

The cyclic measured value status is shown in Table 17.

Table 17 Cyclic measured value status

Priority Quality Sub-status

Low

Good

Uncertain

Bad

High Out of Service 00 01 11 xx 0 x 1C

Good Non-Specific 10 00 00 00 0 x 80

Good Active Advisory Alarm 10 00 10 xx 0 x 88

Good Active Critical Alarm 10 00 11 xx 0 x 8C

Uncertain Non-Specific 01 00 00 xx 0 x 40

Last Usable Value (LUV) 01 00 01 xx 0 x 44

Substitute-Set 01 00 10 xx 0 x 48

Initial Value 01 00 11 xx 0 x 4C

Sensor Conversion Not Accurate 01 01 00 xx 0 x 50

Engineering Unit Violation 01 01 01 xx 0 x 54

Sub-Normal 01 01 10 xx 0 x 58

Non-Specific 00 00 00 xx 0 x 00

Sensor Failure 00 01 00 xx 0 x 10

Device Value 00 00 11 xx 0 x 0C

Bin-coding

(no limit bits)

6.2.2.7 Measured value limits—limit bits

The respective status bit is set when a condition occurs (Table 18). The

status bit is reset when the condition no longer exists.

Table 18 Limit bit description

Bin coding of limit bits Description

00 OK

01 Low-limited

10 High-limited

11 Constant

Hexcoding

54

Page 57

Operation—Foundation Fieldbus

Range

The revision value is

incremented every

time a static

parameter in the

block is changed.

Data

type

6.2.3 Transducer block

The transducer block provides for acyclic data transmission. Calibration, configuration, and

maintenance commands coming from the control station are processed in the Transducer

Table 19 Transducer block bus parameters

Block. The bus parameters for the transducer block (TB) are shown in Table 19 (default values

are in bold type).

R2

The revision of the static data

associated with the function

block. Used by the host to

Parameter Description R/W Bytes

ST_REV

determine when to re-read the

R/W 32 Default: Text

static data.

The user description of the

intended application of the

TAG -DE SC

block.

R/W 2 Default: 0

The strategy field can be used

to identify a grouping of blocks.

STRATEGY

Can be used for any purpose

by the user.

Identification number that may

R/W 1 Default: 0

be used by the host system to

sort alarms and other device

information.

ALERT_KEY

55

Page 58

Operation—Foundation Fieldbus

Available modes:

Automatic, Out Of

Service

Range

Data

type

(OOS), Manual

Default: 0

Default: 0

56

Allows the user to set the

Target, Permitted, and Normal

111

R/WRR/W

device mode. Displays the

1

R/W

Actual mode.

Target

Actual

Permitted

Normal

Reflects the error status

associated with the hardware or

11822

R2

software of the block. It is a bit

string so multiple errors may be

shown.

Unacknowledged Update State

R

Time Stamp Static Rev Relative

Index

11821

R

Unacknowledged Alarm State

Time Stamp Subcode Value

Table 19 Transducer block bus parameters (continued)

Parameter Description R/W Bytes

MODE_BLK

BLOCK_ERR

UPDATE_EVENT

BLOCK_ALM

Page 59

Range

Data

type

Operation—Foundation Fieldbus

Default: 65535 =

other

0 = LO_LEVEL

1 = HI_LEVEL

0 = Standard

1 = Traces

R4

Directory that specifies the

number and the starting indices

of the transducers in the

transducer block.

R1 Default: 0

A transducer block sub-code.

XD_ERROR contains the

highest priority alarm that has

been activated in the

TB_DETAILED_STATUS

parameter.

A directory that specifies the

R36

number, starting indices, and

DD item of IDs of the data

collection in each transducer

within a transducer block. Used

by the host for efficient transfer

R/W 2 uns16

of information.

Selects the connection of the

sensor

Table 19 Transducer block bus parameters (continued)

TRANSDUCER_

DIRECTORY

Parameter Description R/W Bytes

TRANSDUCER_TYPE Identifies the transducer type. R 2

XD_ERROR

COLLECTION_

DIRECTORY

Output

INPUT_RANGE

POLARIZATION_VOLTAGE Sets the polarization voltage R/W 4 float –1000–0

SENSOR_TYPE Selects the used sensor type. R/W 2 uns16

57

Page 60

Operation—Foundation Fieldbus

0 = Dissolved

oxygen

1 = Measurement in

Range

Data

type

gases

0 = DO_%

1 = DO_mg/l

2 = DO_μg/l

3 = DO_ppm

4 = DO_ppb

5 = GAS_ppm

6 = GAS_%

DS_65

4

1

0–120

Default: 0s

58

Selects the measurement

R/W 2 uns16

method

R

(DO/ GAS)

Shows the primary value and

status

Val ue

Status

Selects the displayed primary

value depending

R/W 2 uns16

on the selected measuring

method in APPLICATION

R/W 2 uns16

R4 float

R4 float

parameter

Sets the filter time of the input

filter

Shows the impedance of the

sensor

Shows the momentary current

of the sensor

Table 19 Transducer block bus parameters (continued)

APPLICATION

Parameter Description R/W Bytes

PRIMARY_VALUE

PRIMARY_VALUE_TYPE

FILTER_TIME

IMPEDANCE

SENSOR_CURRENT

Temperature

Page 61

Operation—Foundation Fieldbus

Range

Data

type

4

R

Process temperature value and

status

DS_65

1001 = °C

1002 = °F

1000 = NTC30

1002 = NTC22

1

R

R/W 2 uns16

R/W 2 uns16

Val ue

Status

Degree C or degree F. Changes

the unit of temperature being

displayed and transmitted.

Type of temperature sensor.

The value entered must

correspond to the temp. sensor

being used.

Sets the wire impedance of the

R/W 4 float Default: 0Ω

temp. sensor. Typically 0 unless

the wire of the sensor gets too

long

–10–10K

Default: 0

1133 = kPA

1137 = BAR

114 1 = PSI

R/W 4 float

Desired temperature reading,

used for temperature

measurement calibration.

R/W 2 uns16

Selects the process pressure

measurement unit

Table 19 Transducer block bus parameters (continued)

SECONDARY_VALUE_2

Parameter Description R/W Bytes

SECONDARY_VALUE_

UNIT_2

TEMP_SENSOR_TYPE

TEMP_WIRE_IMPEDANCE

TEMP_SENSOR_CAL

Concentration/Saturation

PROCESS_PRESSURE_

UNIT

59

Page 62

Operation—Foundation Fieldbus

0–9.999 BAR

0–999.9 kPa

0–145 PSI

Default: 1.013 BAR

0–45 g/kg

Default: 0 g/kg

0 = Sat

1 = Conc

30–110 Sensor A

220–525 Sensor B

Default: 60 E-9A

–2–2

Ampere

Default: 0 E-9A

R/W 4 float

The zero offset resulting from a

calibration in Ampere

Range

Data

type

R/W 4 float

The slope of the Oxy sensor in

Table 19 Transducer block bus parameters (continued)

R4 floatDefault: 0 s

Shows the settling time in

seconds

R4 float

Shows the relative humidity in

R4 float

%

Shows the temperature which

was used during calibration

60

PROCESS_PRESSURE Sets the process pressure R/W 4 float

Parameter Description R/W Bytes

SALINITY Sets the salinity value R/W 4 float

Calibration

CALIBRATION_MODE Sets the calibration mode R/W 1 uns8

CAL_HIGH

CAL_ZERO

CAL_SETTLINGTIME

CAL_RH

CAL_PRESSURE Shows the pressure R 4 float

CAL_TEMP

Page 63

Operation—Foundation Fieldbus

000–9999h

Default: 0000 h =

disable

0 = Nop

1 = Sample

Default: 0 if step 1 of

product calibration

product calibration.

Shows the stored value of the

was not started

Rfloat

first step of Oxy product

calibration

Range

Data

type

R4 float

Shows the value of saturation

calibration

Shows the value of

R4 float

concentration calibration

Sets the calibration timer (time

R/W 4 float

R/W 1 uns8

in which the device should be

calibrated).

Starts the 1st part of Oxy

Table 19 Transducer block bus parameters (continued)

0 = Off

1 = On

0 = Off

1 = On

0 = Off

1 = On

0...100

Default: 0 = None

R/W 4 float

Sets the value for the 2nd part

of Oxy product calibration.

R/W 1 uns8

Enables or disables

Sensocheck.

CAL_VALUE_SAT

CAL_VALUE_CONC

CALIBRATION_TIMER

CAL_SAMPLE_PRD

CAL_SAMPLE_PRD_

STORED_VAL

CAL_PRODUCT

Alert

HOLD Sets the device to HOLD mode. R/W 1 uns8

SENSOCHECK

ALARM_LED_MODE Sets the LED to HOLD mode. R/W 1 uns8

Parameter Description R/W Bytes

LAST_ERROR Shows the last error. R 2 uns16

61

Page 64

Operation—Foundation Fieldbus

0 = Good

2 = Bad

Range

Data

type

R 1 uns8

Shows the current status of the

Sensoface.

Table 19 Transducer block bus parameters (continued)

62

SENSOFACE_STATUS

Identification and local parameter setting

SW_REV_LEVEL Software revision number R 2 uns16

Parameter Description R/W Bytes

HW_REV_LEVEL Hardware revision number R 1 uns8

Page 65

Operation—Foundation Fieldbus

6.2.4 Calibration via Foundation Fieldbus

The transmitter can be calibrated via Foundation Fieldbus using the

comparison or grab sample method.

1. Make sure the system is configured for the value that is measured:

• Dissolved oxygen:

PRIMARY_VALUE_TYPE = DO_mg/l, DO_ppm, DO_µg/l,

DO_ppb or DO_%

APPLICATION = Dissolved oxygen

CALIBRATION_MODE = Conc or Sat

• Gaseous oxygen:

PRIMARY_VALUE_TYPE = GAS_ppm or GAS_%

APPLICATION = Measurement in gases

CALIBRATION_MODE = Conc or Sat

2. Collect a grab sample and set CAL_SAMPLE_PRD to sample. The

measured value of the sample is stored. After writing, the parameter

is automatically reset to NOP (no operation).

3. Read the parameter CAL_SAMPLE_PRD_STORED_VAL. It

contains the stored value.

4. Measure the grab sample and write the lab value in

CAL_PRODUCT. The device is now calibrated.

CAL_SAMPLE_PRD_STORED_VAL is reset to zero.

Note: The calibration values can also be entered directly in the

parameters CAL_ZERO and CAL_HIGH.

63

Page 66

Operation—Foundation Fieldbus

64

Page 67

Section 7 Operation—Profibus PA

The following section describes how to navigate and operate the

si792x D-PA transmitter. The transmitter can be operated as follows:

• direct interface with the transmitter (section 7.1)

• remote operation from the control station (section 7.2 on

page 67)

Note: Calibration must be completed by direct interface with the

transmitter.

7.1 Configuration

Use the configuration mode to specify the sensor, range and other

parameters for the system.

7.1.1 Configuration steps

1. Press MEAS + CAL and enter 1200 to enter the configuration

mode.

2. Use the arrow and enter keys to change the settings. All settings

and options are shown in section 7.1.2.

To exit the configuration mode at any time, press MEAS + CAL and

ENTER. The Hold mode will be active for 20 seconds and then the

then

measured value will be displayed.

Note: During configuration the transmitter remains in the Hold mode for

safety reasons. The Sensoface icon is inactive. The configuration mode

indicator is displayed (Figure 12 on page 33).

65

Page 68

Operation—Profibus PA

7.1.2 Configuration menu

Select the sensor

Type A (standard; default). See Table 2 on page 24.

Type B (trace measurements). See Table 2 on page 24.

Select the range

Lo-Level

Hi-Level (default)

Select the units

µg/L

Lo-Level

Hi-Level

Select the temperature unit

Auto °C (default)

Auto °F

man °C

man °F

Bus °C –20–150 °C

Bus °F –4–302 °F

If Auto is selected >select the temperature sensor

NTC 22 kΩ (default)

NTC 30 kΩ

Select the pressure measurement unit

BAR (default)

KPA

PSI

Enter the process pressure

0–9.999 bar (default: 1.013 BAR)

ppb

mg/L

ppm

% (default)

mg/L

ppm

% (default)

66

Page 69

Operation—Profibus PA

m

T

7.1.2 Configuration menu (continued)

Enter the salinity

0–45.00 SAL (default: 00.00)

Enter polarization voltage

U-Pol 0 mV to 800 mV (default: 675 mV, 0mV = Off)

Select Sensocheck

CHECK ON

CHECK OFF (default)

Select the calibration mode

CAL

Enter cal timer interval

Enter Profibus address

Edit 0001–0126 (default: 0126)

Saturation (Sat)

Concentration (Conc) (default)

0000–9999 h (default: 0000 h (Off))

Continuous Sensocheck

evaluation of sensor function

7.2 Profibus PA communication

Profibus PA uses a master/slave data exchange technique. The master

(typically a PLC) generates queries to individual slaves. The slaves, in

turn, reply back with a response to the master. A Profibus message

contains the information required to send a query or request, including

the slave address, function code, data, and a checksum. See Table 20

on page 67 for Profibus communication parameters.

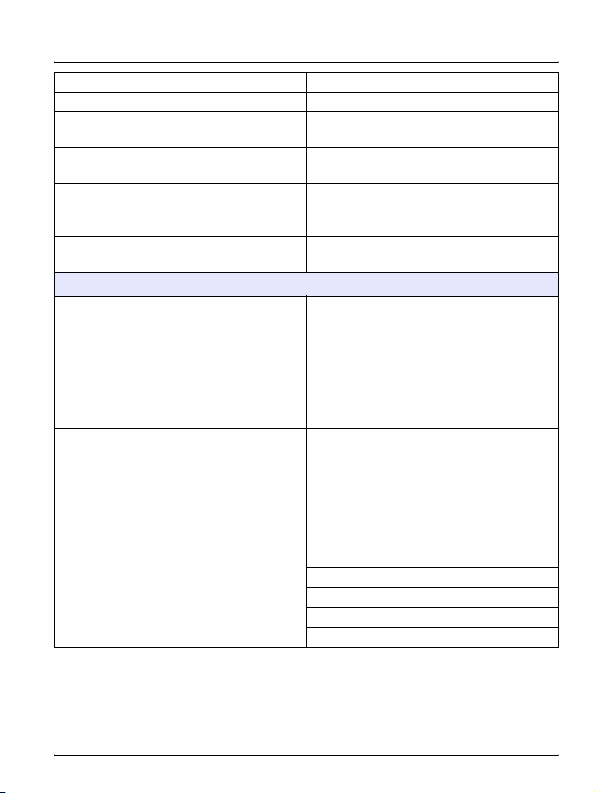

Table 20 PROFIBUS PA communication

Cause

Factory settings

defective

Configuration data

defective, Gaincheck

No. of

binary

message

1 0000 11xx Failure ERR SYSTEM

2 0000 11xx Failure ERR PARAME

Analog input

status

Physical Block

(PB)

Global status

Text of binary

(default)

67

Page 70

Operation—Profibus PA

Logbook

(default)

Text of binary message

(default)

Failure ERR SAT VALUE Yes

Failure ERR CONC VALUE Yes

Failure ERR TEMP VALUE Yes

0100 0111

0100 1111

0100 0111

0100 1111

5

6

Table 20 PROFIBUS PA communication (continued)

Physical Block

Analog input

No. of

(PB)

Global status

status

binary

message

0100 0111

0100 1111

3 0000 11xx Failure ERR MEMORY Yes

4

CHK ZERO/SLOPE Yes

CHK EL. RESPONSE Yes

CAL REQUIRED Yes

Failure ERR SENSOCHECK Yes

Maintenance

req.

Maintenance

req.

Maintenance

req.

Function check CAL RUNNING Yes

0100 0111

0100 1111

10 0101 00xx

0100 0111

0100 1111

68

Cause

Memory error

(RAM, ROM,

EPROM)

Measurement range

violation

Measurement range

violation

Temp range violation

Temperature sensor

Membrane defective 7

Zero point/Slope 8 0101 00xx

Sensor response time 9 0101 00xx

Calibration timer

Cal prompt

Calibration 9

Configuration 10 1010 00xx Function check CONF RUNNING Yes

Page 71

Table 20 PROFIBUS PA communication (continued)

Logbook

Text of binary message

Physical Block

No. of

(default)

(default)

(PB)

Analog input

status

binary

Global status

message

Operation—Profibus PA

HI_HI_LIMIT OXY

HI_LIMIT OXY

LO_LIMIT OXY

LO_LO_LIMIT OXY

HI_HI_LIMIT TEMP

HI_LIMIT TEMP

LO_LIMIT TEMP

LO_LO_LIMIT TEMP

Function check HOLD Yes

Limit 1

Bit 1

Limit 1

Bit 2

Limit 1

Bit 3

Limit 1

Bit 4

Limit 2

Bit 1

Limit 2

Bit 2

Limit 2

Bit 3

Limit 2

Bit 4

0100 0111

0100 1111

11

14 1000 1110

15 1000 1010

16 1000 1001

17 1000 1101

18 1000 1110

19 1000 1010

20 1000 1001

21 1000 1101

Cause

HOLD

(Device state =

Maintenance)

HI_HI_LIM

FB analysis

HI_LIM

FB analysis

LO_LIM

FB analysis

LO_LO_LIM

FB analysis

HI_HI_LIM

FB temperature

HI_LIM

FB temperature

LO_LIM

FB temperature

LO_LO_LIM

FB temperature

Logbook empty 22 Function check EMPTY LOGBOOK

69

Page 72

Operation—Profibus PA

70

Page 73

Section 8 Calibration

8.1 Calibration

The transmitter is adjusted to the sensor through the calibration. The

available calibration methods are shown in Table 21. Calibrate the

sensor in air when the sensor can be removed from the process. The

sensor will stabilize more quickly in air.

When the sensor cannot be removed from the process (e.g. sterile

processes), the process medium must be aerated during calibration

(e.g. after sterilization).

Table 21 Calibration methods and passcodes

Method Passcode

Zero calibration 1001

Temperature probe adjustment 1015

Zero/slope display 0000

Calibration in air or water 1100

Calibration by product comparison 1105

During calibration the transmitter remains in the Hold mode for safety

reasons. The loop current is frozen at the value specified in the

o1.HoLD menu option. The Sensoface icon is inactive. The calibration

mode indicator is displayed (Figure 12 on page 33).

To exit the calibration mode at any time, press

The output current will be held for 20 seconds and the measured value

will be displayed.

Note: Calibrations must be performed by trained personnel. Incorrectly

set parameters may result in errors in sample measurements.

CAL and then ENTER.

71

Page 74

Calibration

8.1.1 Zero calibration

Perform a zero calibration as the first point whenever a 2-point

calibration is required.

Note: The DO sensor models SE 704, SE 705 and InPro6000 have a

very low zero current. Therefore a zero calibration is only

recommended for measurement of oxygen traces.

Allow the sensor to stabilize in the calibration medium for at least 10 to

30 minutes (InPro6900 at least 60 minutes). A drift check will not be

made. The zero current of a properly functioning sensor is notably less

than 0.5% of the current in air.

The display will not change until an input current is entered for the zero

point. When measuring in an oxygen-free medium, the displayed

current can be taken directly.

Complete the following steps to set the zero point.

1. Press

2. Place the sensor in an oxygen-free medium.

3. Press

4. The slope of the sensor will be shown in the main display. The new

5. Return the sensor to the process. The oxygen value will be shown in

CAL, enter passcode: 1001, ENTER. The main display will

show CAL ZRO and then the entered value (in nA) for the zero

point. The secondary display shows the measured current.

ENTER to accept the value or correct the value and then

ENTER.

press