Page 1

DOC023.98.90241

Transmitters si627 P

Manual

Bedienungsanleitung

Manual

Manuel d’utilisateur

Manuale di istruzioni

05/2010, Edition 1

05/2010, Heft 1

05/2010, Edición 1

05/2010, Edition 1

05/2010, Edizione 1

© HACH LANGE GmbH, 2010, All rights reserved. Printed in Spain

si627 P_HACH_LANGE_Ed.0510.indd IND:1si627 P_HACH_LANGE_Ed.0510.indd IND:1 20/5/10 10:50:4220/5/10 10:50:42

Page 2

si627 P_HACH_LANGE_Ed.0510.indd IND:2si627 P_HACH_LANGE_Ed.0510.indd IND:2 20/5/10 10:50:4220/5/10 10:50:42

Page 3

ENGLISHDEUTSCHESPAÑOLFRANÇAISITALIANOCONTACT

si627 P_HACH_LANGE_Ed.0510.indd IND:3si627 P_HACH_LANGE_Ed.0510.indd IND:3 20/5/10 10:50:4220/5/10 10:50:42

Page 4

si627 P_HACH_LANGE_Ed.0510.indd IND:4si627 P_HACH_LANGE_Ed.0510.indd IND:4 20/5/10 10:50:4220/5/10 10:50:42

Page 5

Table of contents

1. Technical specifications . . . . . . . . . . . . . . . . . . . 3

1.1. Dimensions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. General information

2.1. Safety information

2.1.1. Use of hazard information

2.2. General product information

2.3. Items supplied

3. Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1. si627 P

3.1.1. Assembly

3.1.2. Connections

3.2. Electrode cable

4. Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1. Description

4.2. Setting up

4.3. Quick guide

4.4. Programming to measure pH

4.5. Programming to measure ORP

4.6. Operation of 4 to 20 output and relays

. . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . 5

. . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . 13

. . . . . . . . . . . 14

. . . 15

4.7. Calibration of pH electrode . . . . . . . . . . 16

4.8. Recognized Buffers and Redox standard

4.9. Measurement

5. Maintenance

5.1. Cleaning

6. Error messages

. . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. 17

ENGLISH

7. Replacement parts

8. Warranty and liability

. . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . 21

Contact information

1

si627 P_HACH_LANGE_Ed.0510.indd ANG:1si627 P_HACH_LANGE_Ed.0510.indd ANG:1 20/5/10 10:50:4220/5/10 10:50:42

Page 6

si627 P_HACH_LANGE_Ed.0510.indd ANG:2si627 P_HACH_LANGE_Ed.0510.indd ANG:2 20/5/10 10:50:4220/5/10 10:50:42

Page 7

1. Technical specifications

Measuring ranges

pH –2.00 to 16.00

mV –1500 to 1500

°C –20.0 to 150.0

Measurement error

≤ 0.02 pH, ≤ 1 mV, ≤ 0.5 °C (± 1 digit)

Reproducibility

± 0.01 pH, ± 1 mV, ± 0.1 °C (± 1 digit)

Automatic temperature compensation

With temperature probe Pt 1000 or by keypad

pH calibration options

Default access password: 100

With 1,2 or 3 buffer solutions

Automatic buffer recognition

T echnical (at 25 °C) pH 2.00, 4.01, 7.00, 9.21

and 10.90

Criteria to accept calibration

Slope 85 to 103 %.

Asymmetry potential ≤ 60 mV

Language

English, German, Spanish, French, Italian,

Portuguese

Keypad

LCD, alphanumeric, backlit,

2 lines of 16 characters

Inputs and outputs

Electrode, BNC connector

ATC, Pt 1000 or Pt 100, terminal strip connection

Analogic signal, galvanically isolated

• 4 to 20 mA for measurement (R max.= 500 Ohm)

• 21 mA or the last mA value measured for the

instrument in hold

• 22 mA for the alarm

Maximum cable length

≤ 25 m

Power supply

230 or 24 VAC ±10 %, 45-65 Hz,

(115 VAC under demand)

Consumption 4 VA

Protection: Class II

Overvoltage category: II

EC Directives

Electrical security according to 2006/95/EC

Electromagnetic compatibility according to

2004/108/EC

Environmental conditions

Working temperature: 0 to 50 °C (32 to 122 °F)

Storage temperature: –20 to 65 °C (–4 to 149 °F)

Relative humidity < 80 % (non condensing)

Max. height 2.000 m. at 230 V; 3.000 at 24 V

Enclosure

si627 P : Noryl, protection IP54.

Flame rating FV-1

Weight

600 g

Dimensions

96 x 96 x 100 mm (3.8 x 3.8 x 3.9 in.)

Warranty

Instruments: 2 years

Specifications are subject to change without

notice.

ENGLISH

3

si627 P_HACH_LANGE_Ed.0510.indd ANG:3si627 P_HACH_LANGE_Ed.0510.indd ANG:3 20/5/10 10:50:4220/5/10 10:50:42

Page 8

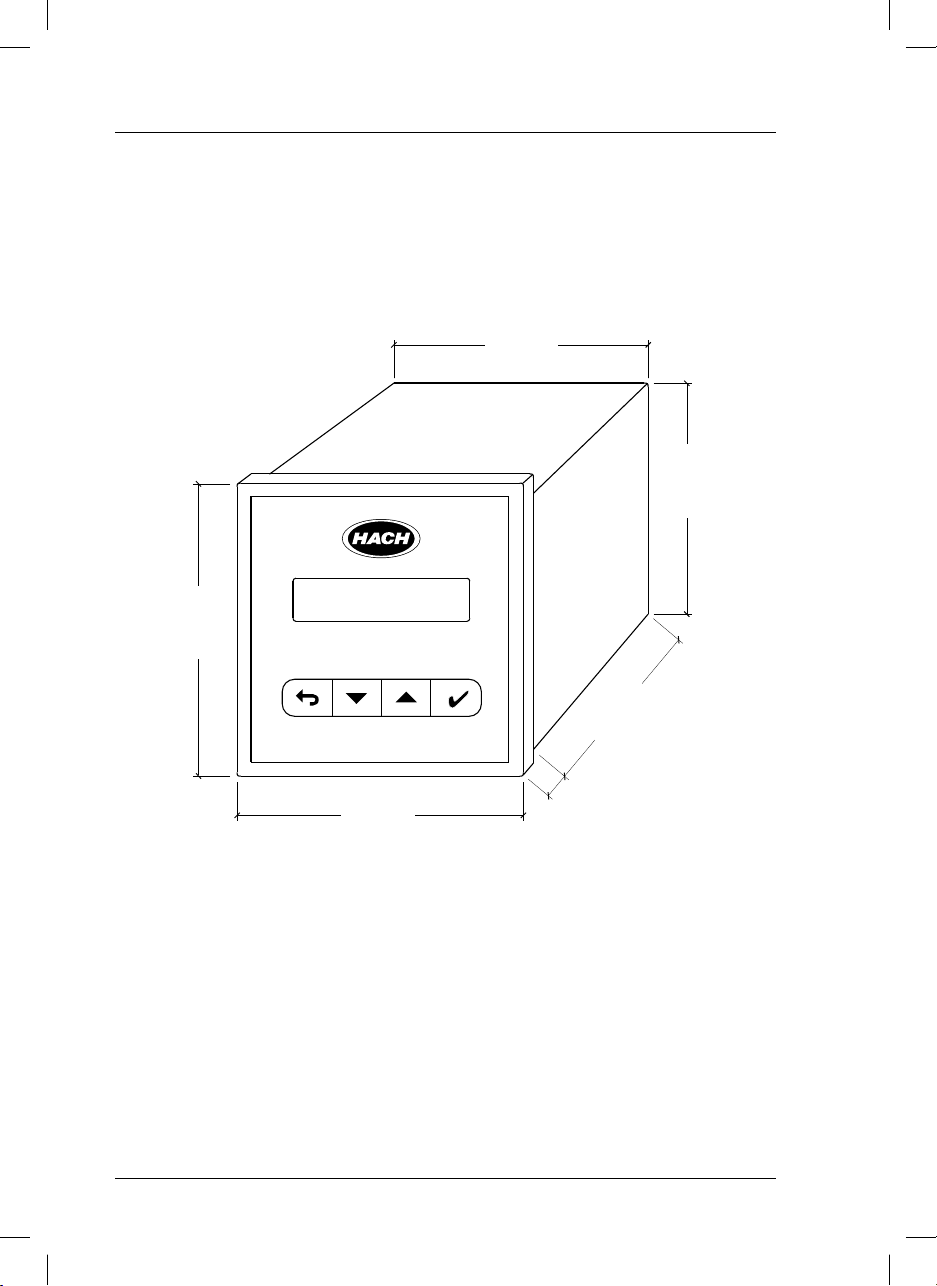

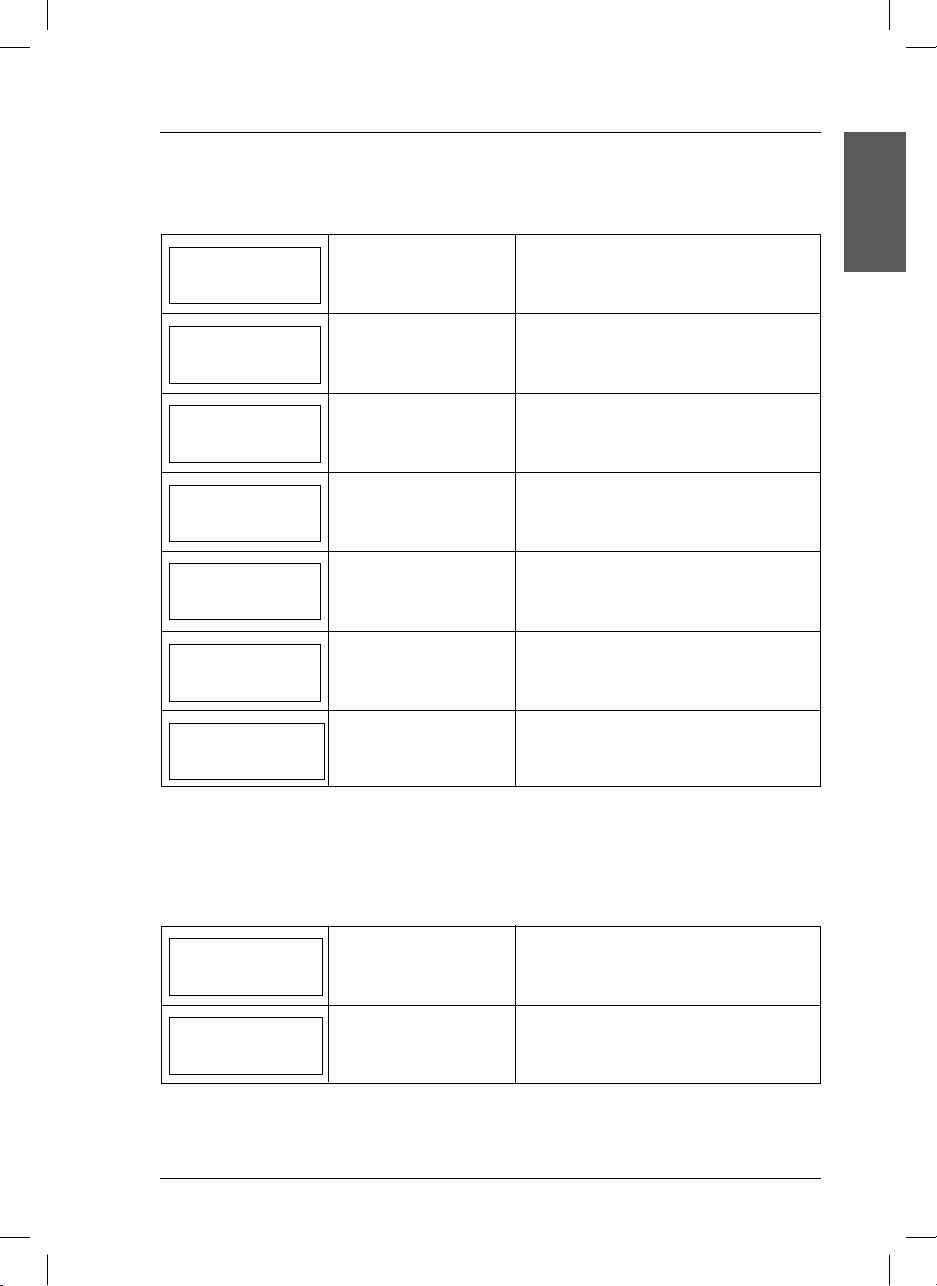

1. Technical specifications

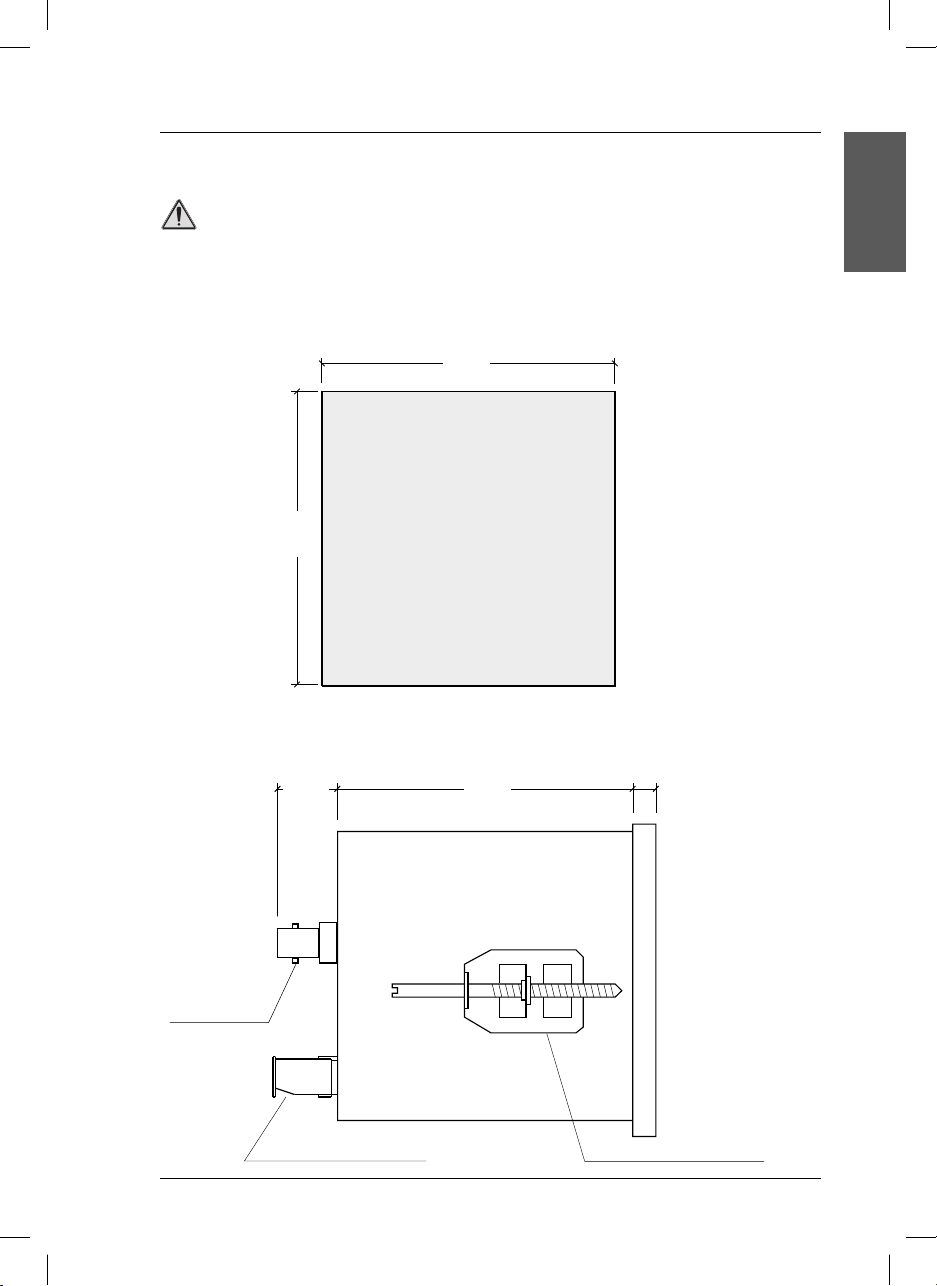

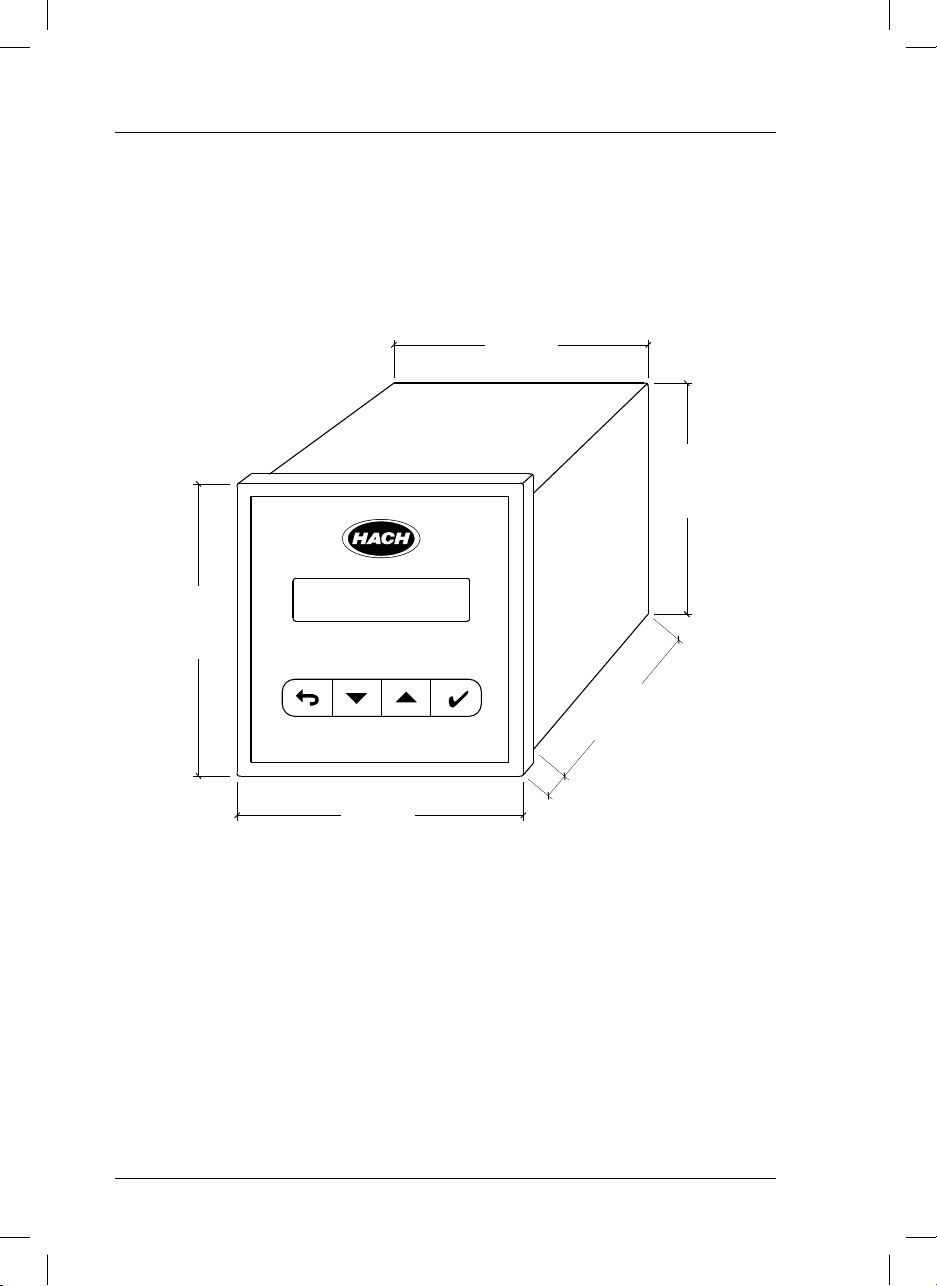

1.1. Dimensions

si627 P

3.8 in

96 mm

90 mm

3.5 in

3.5 in

90 mm

80 mm

3.1 in

96 mm

3.8 in

4

si627 P_HACH_LANGE_Ed.0510.indd ANG:4si627 P_HACH_LANGE_Ed.0510.indd ANG:4 20/5/10 10:50:4220/5/10 10:50:42

7 mm

0.3 in

Page 9

2. General information

As a result of constant improvements to our products sometimes differences may exist between this manual

and the instructions supplied with the instrument.

ENGLISH

2.1. Safety information

Please, read carefully this information before installing and using the instrument !

Pay attention to all danger and caution statements.

2.1.1. Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation that, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation that, if not avoided, may result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

Important note

Indicates a situation that, if not avoided, could lead to damage to the instrument. Important information that requires special emphasis.

Note

Information that supplements points in the main text.

Precautionary labels

Read carefully all labels and tags attached to the instrument.

This symbol references the instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock or electrocution exists.

This symbol indicates the connection for Protective Earth.

This symbol indicates ground connection.

This symbol identifies a fuse.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after 12 August of 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the

Producer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how

to return end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper

disposal.

5

si627 P_HACH_LANGE_Ed.0510.indd ANG:5si627 P_HACH_LANGE_Ed.0510.indd ANG:5 20/5/10 10:50:4220/5/10 10:50:42

Page 10

2. General information

DANGER

• Remember that the voltage across accessible

parts of the open instrument, may be dangerous

to life. Do not open the instrument when it is

connected to the power supply, there are areas

whose voltage could cause death.

• Always disconnect power to the instrument

before it is opened.

• Repair or adjustment of an opened instrument

under voltage shall be carried out only by

a qualified technician who is aware of the

hazards involved.

• Never work in an environment subject to

explosion hazards. The housing of the

instrument is not gas tight.

• The Company will not be responsible for any

physical damage caused by non authorised

work or manipulation.

• It is the responsibility of whoever uses this

instrument to consult and establish appropriate

safety and health practices and determine the

applicability of regulatory limitations prior to use.

• Before connecting the instrument to a power

supply unit, make sure that the mains voltage

lies within the range:

230 or 24 V AC ±10%, 45-65 Hz (standard

version).

115 V AC ±10%, 45-65 Hz (under demand).

Important notes

• Read carefully the manual of the instrument.

• Avoid direct sunlight over the instrument.

• Exclude the following environmental influences:

- vibrations

- atmospheric humidity higher than 80 %

- corrosive gases present

- temperature < 0 °C, or > 50 °C (< 32 °F, or >

122 °F).

- powerful electric and magnetic fields.

• Only use original accessories and spare parts.

• Have the instrument serviced only by the

Company Service.

2.2. General product information

Proper use

The si627 P is used for pH or redox potential and temperature measurement in the chemical industry, food

process and waste-water treatment.

2.3. Items supplied si627 P

• Instrument (with strips for connections).

• BNC connector.

• Clamps to fix to the panel.

• User manual.

6

si627 P_HACH_LANGE_Ed.0510.indd ANG:6si627 P_HACH_LANGE_Ed.0510.indd ANG:6 20/5/10 10:50:4420/5/10 10:50:44

Page 11

3. Installation

3.1. si627 P

DANGER

Only qualified personnel should conduct the tasks described in this section of the manual.

ENGLISH

3.1.1. Assembly

For the si627 P mounting a drill hole is required according to the diagram.

92 mm

3.7 in

3.7 in

92 mm

After putting the instrument in the panel, it must be fitted using two clamps as indicated in the figure.

21 mm

0.8 in

Drill hole

Panel

80 mm

3.1 in

7 mm

0.3 in

BNC connector

for electrode

Plug-in screw connector Clamp to fix to the panel

si627 P_HACH_LANGE_Ed.0510.indd ANG:7si627 P_HACH_LANGE_Ed.0510.indd ANG:7 20/5/10 10:50:4420/5/10 10:50:44

Side view

7

Page 12

3. Installation

When making any wiring connections to the instrument, any warnings and notes found throughout the

manual must be adhered to. For more safety information see “Safety information” on page 5.

DANGER

Always disconnect power to the instrument when making any electrical connections.

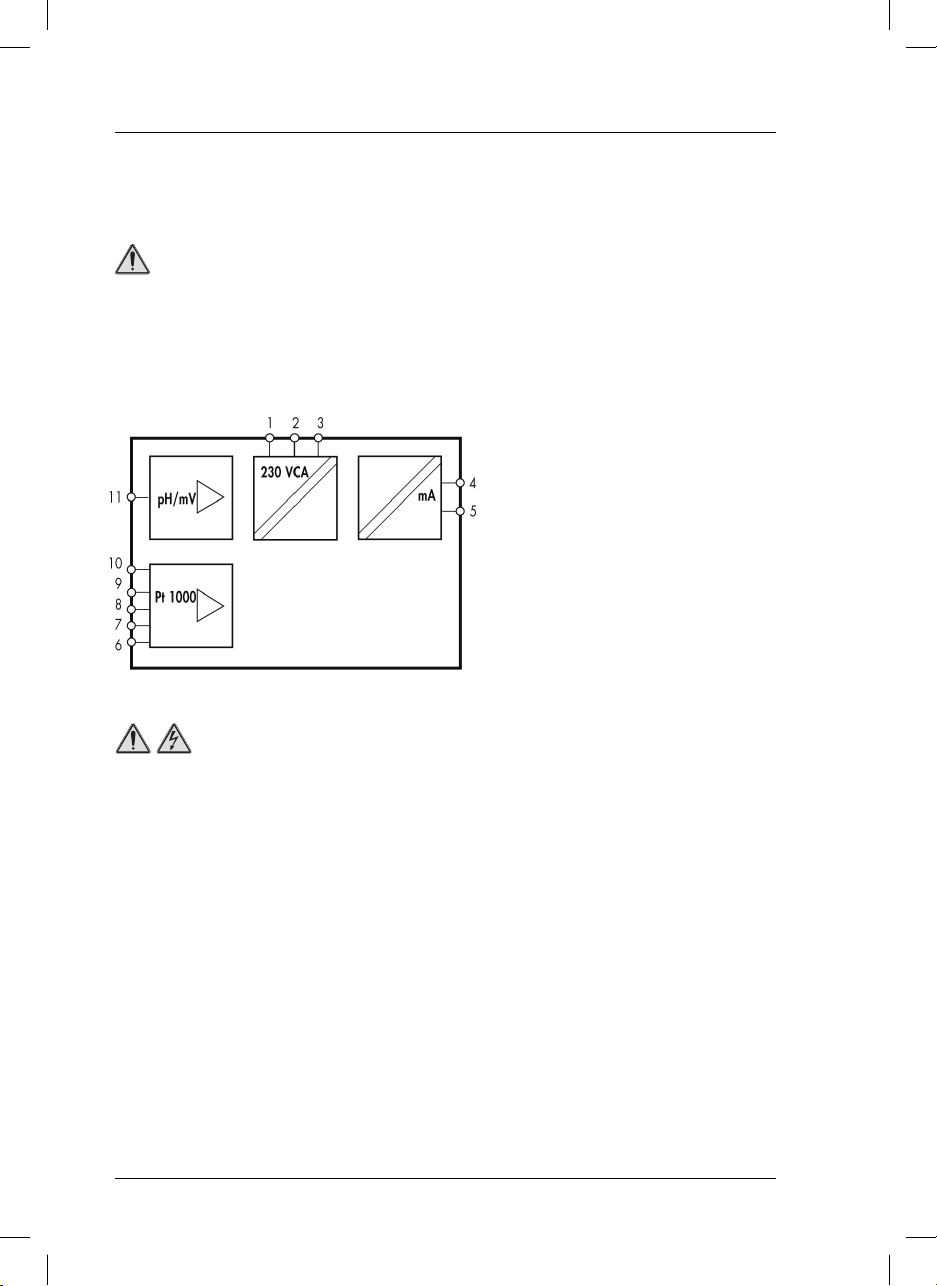

3.1.2. Connections

System functions

1 Ground connection.

See Important notes (page 9).

2,3 Power supply 230 VAC ± 10%.

(24 or 115 VAC under demand).

4,5 Current output 4-20 mA (pH or mV).

6...9 Temperature probe input.

10 Shield for temperature probe.

11 pH or redox electrode input.

High-voltage wiring for the instrument is protected by a protective casing. The protective casing

DANGER

must remain in place unless a qualified installation technician is installing wiring for power.

8

si627 P_HACH_LANGE_Ed.0510.indd ANG:8si627 P_HACH_LANGE_Ed.0510.indd ANG:8 20/5/10 10:50:4420/5/10 10:50:44

Page 13

3. Installation

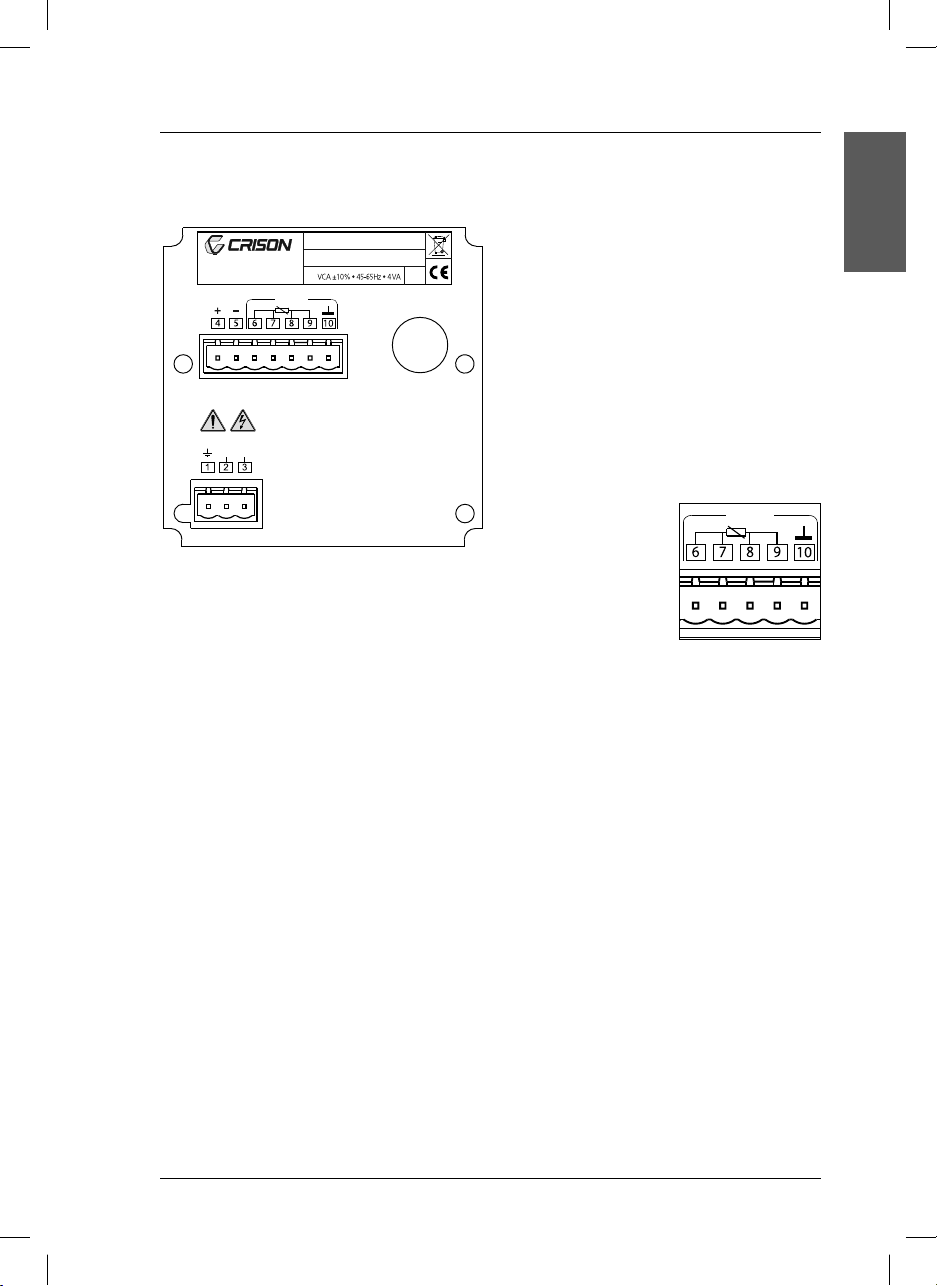

Terminal assignment (rear panel)

CRISON INSTRUMENTS, S.A.

E-08328 ALELLA - Barcelona

Made in Spain

4-20 mA Pt 1000

VCA

Transmitter si627 P

S/N:

ELECTRODE

IP 54

pH / mV

Important notes:

ENGLISH

• The si627 P does not require ground connection (terminal 1).

• In environments with interference problems it

is recommended to connect the instrument to

ground in terminal 1.

It is also recommended to use shielding cable,

both for the electrode signal (triaxial cable) and

the temperature probe.

The external shield of the triaxial cable and the

probe cable must be connected to terminal 10.

• If the temperature probe has a 2-wire cable instead of a 4-wire, fit

a jumper between ter-

Pt 1000

minals 6 and 7 and

another one between

8 and 9, as indicated

in the scheme.

9

si627 P_HACH_LANGE_Ed.0510.indd ANG:9si627 P_HACH_LANGE_Ed.0510.indd ANG:9 20/5/10 10:50:4520/5/10 10:50:45

Page 14

3. Installation

3.2. Electrode cable

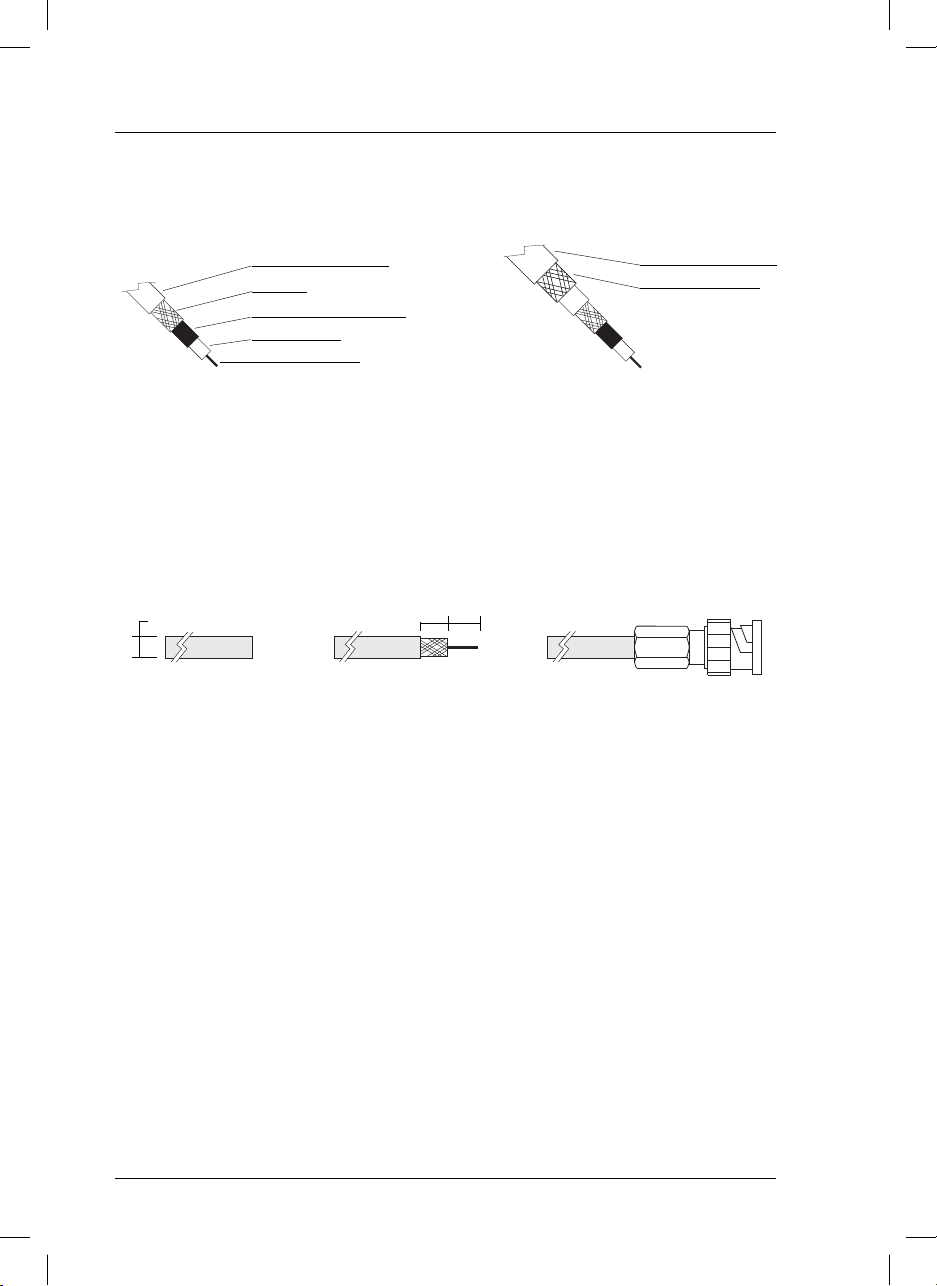

Coaxial cable

PVC protector Ø 5 mm.

Shielding

Plastic conductor (black).

PE insulation.

Triaxial cable

PVC protector Ø 7 mm.

Additional shielding.

(See Important notes

page 9).

Inner conductor.

Installation of BNC connector to the cable

The instrument is supplied with a BNC connector, to be screwed directly (without weldings) to the coaxial

cable. To assemble it, the cable must be prepared and the connector screwed (see diagram below).

7 mm

5 mm

Ø

0,2 in

0,3 in

7 mm

0,3 in

Coaxial cable Cable preparation Cable with connector already screwed

Using a triaxial cable the connector is assemblied in the same way as with the coaxial cable, leaving

the “additional” shielding and the outer protector out of the connector. The additional shielding must be

connected to ground.

10

si627 P_HACH_LANGE_Ed.0510.indd ANG:10si627 P_HACH_LANGE_Ed.0510.indd ANG:10 20/5/10 10:50:4520/5/10 10:50:45

Page 15

4. Operation

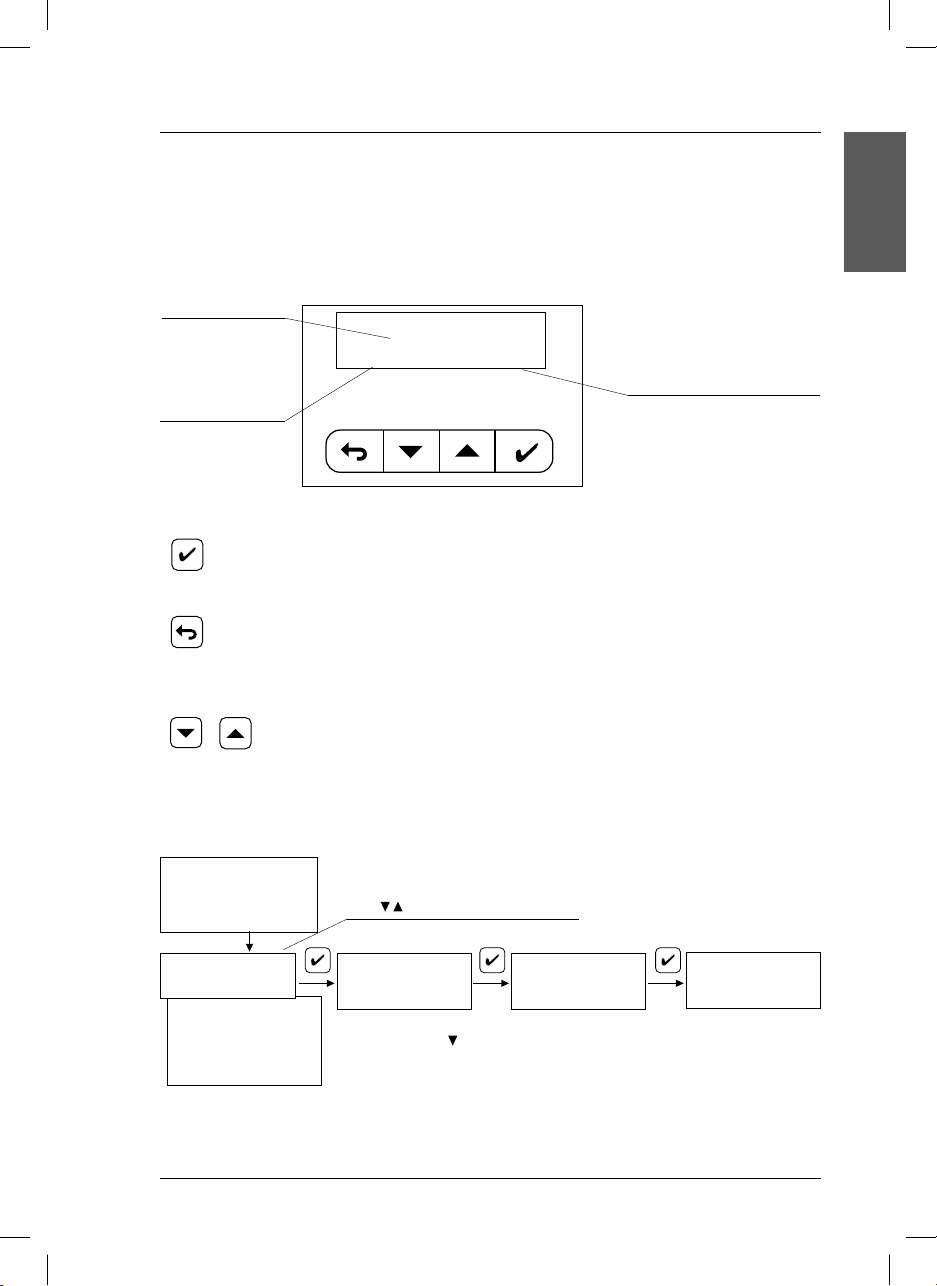

4.1. Description

Display

si627 P have an alphanumeric display that explains itself. One of the most significant screens is described below as an example:

Measured value.

ENGLISH

MEASURE

pH 7.34 25.2 °C

Sample temperature

Measuring unit.

Resolution:

1 °C manual selection.

0.1°C measuring with Pt1000.

Teclas

ENTER.

• Horizontal movements to move forward in the “diagram”.

• Acceptance of numerical values.

ESCAPE.

• Horizontal movements to move back in the “diagram”.

• Vertical movements to move back in the “diagram”.

• To erase numerical values.

• Modification of numerical values.

• Cursor “>” movements on the screen.

4.2. Setting-up

Connect the si627 P to mains. At power up the first time only the following screens will appear:

si627_P

V1.0

IDIOMA >Español

Italiano

Français

English

Deutsch

Português

Instrument is already measuring pH, with the following factory settings::

• Current output: 4 mA = pH 0, 20 mA = pH 14.

To modify this configuration see pages 13 and 14.

si627 P_HACH_LANGE_Ed.0510.indd ANG:11si627 P_HACH_LANGE_Ed.0510.indd ANG:11 20/5/10 10:50:4520/5/10 10:50:45

Possibility to select other language

with keys.

MEASURE : >pH

mV MEASURE pH & °C

Attention. Possibility to

change to mV with

key.

MEASURE

PH 7.34 25.2 °C

11

Page 16

4. Operation

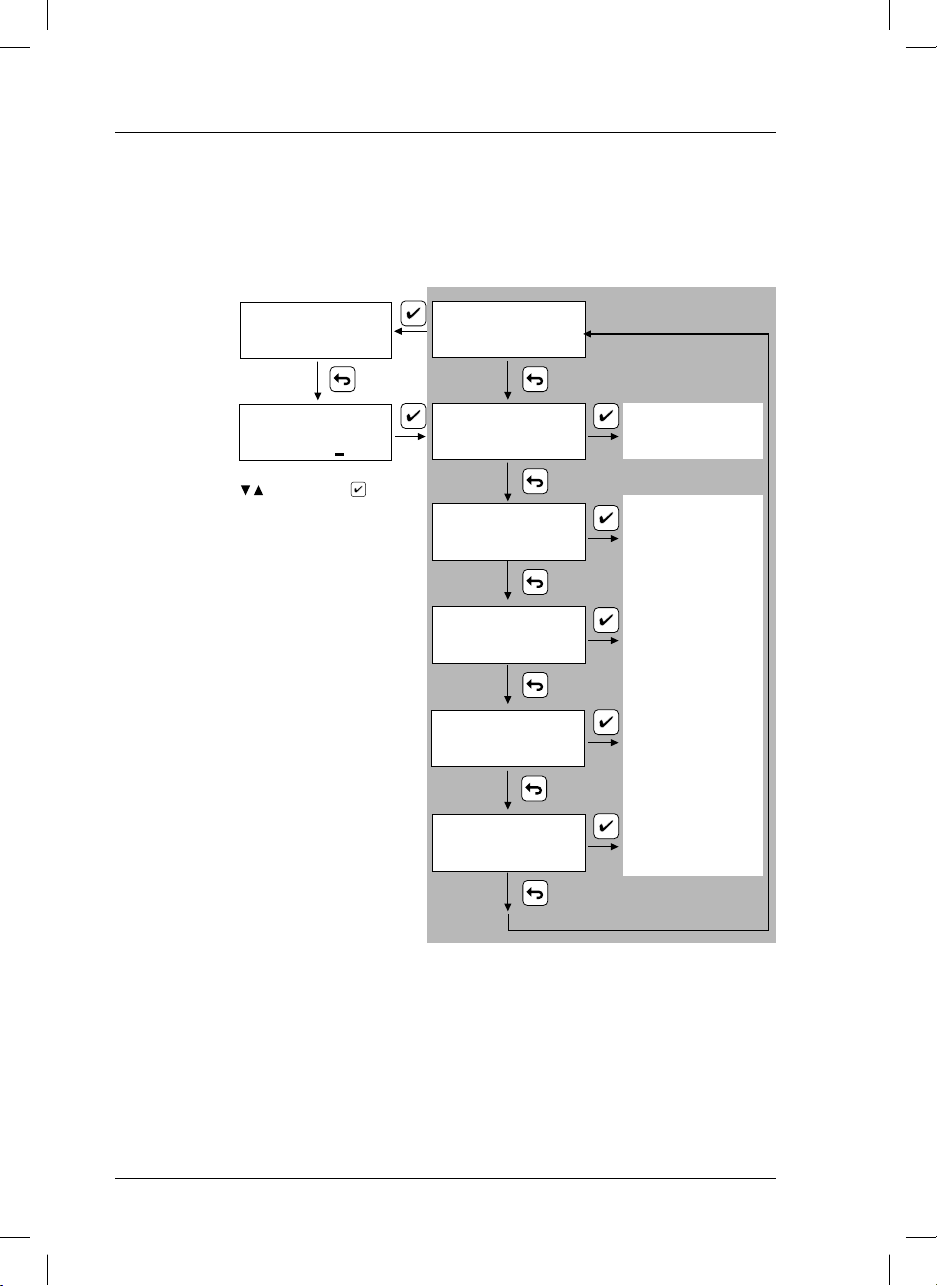

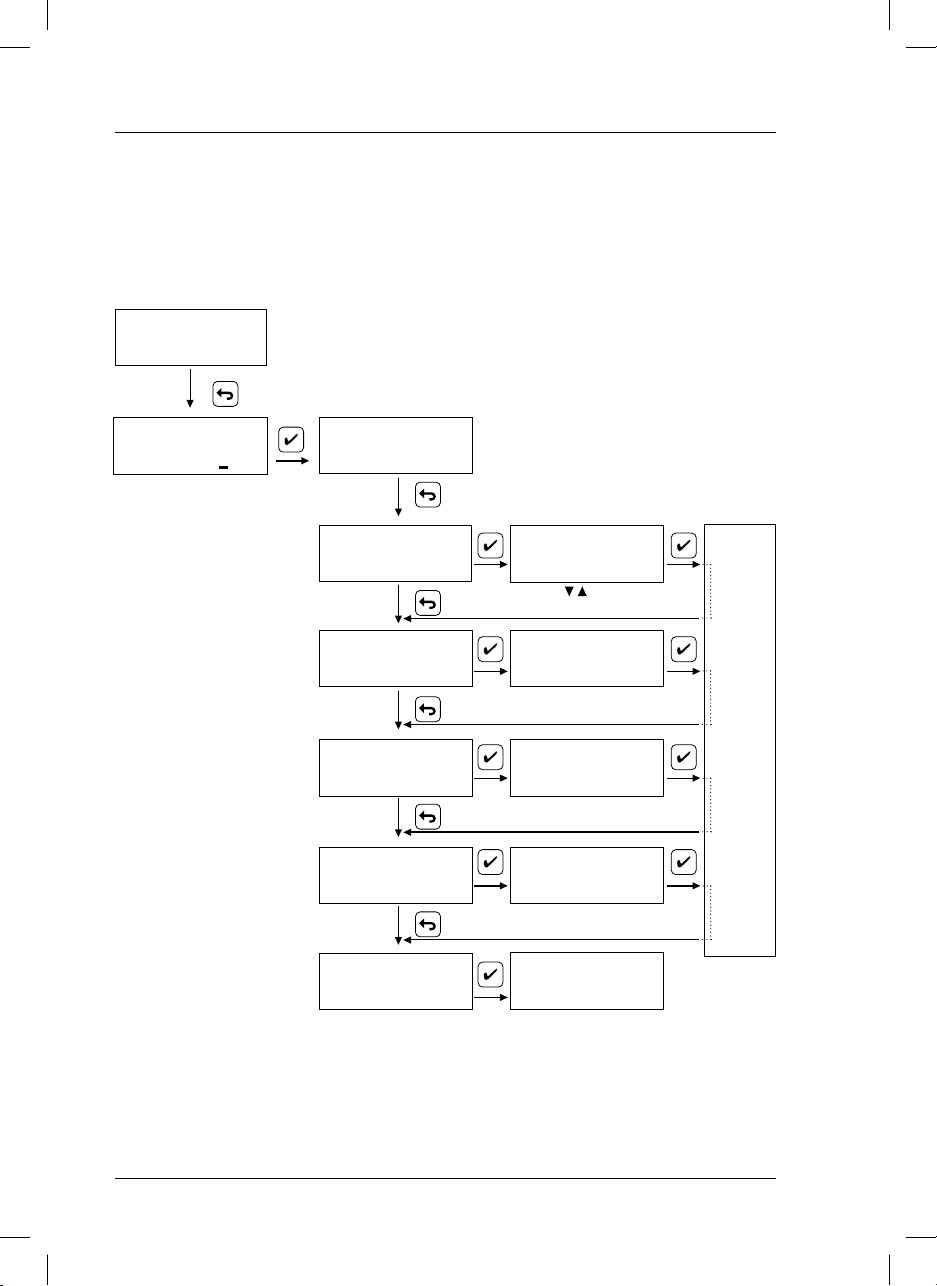

4.3. Quick guide

This page shows the instrument’s operation by blocks. It is intended to provide a quick idea about all the

instrument’s capabilities and how to gain access to them.

MEASURE

pH 7.34 25.2 °C

MEASURE pH & °C

Security access

code.

It limits the access to calibration or programming of the ins trument by non au-

CODE 000

Vary the underlined digit with

and accept with .

Authorised code = 100.

CALIBRATE

TYPE OF MEASURE

thorised people.

When the “Code” screen has been shown for

more than 30 sec. the instrument will automatically return to MEASURE.

OUTPUT 4-20 mA

LANGUAGE

See “calibration“

(page 16)

See “programming ...”

(pages 13-14)

HOLD

Instrument in hold state.

When being in the grey zone, the instrument is in hold state:

• According to the configuration the current output is frozen at 21 mA or at the mA corresponding

to the last measured value.

To quit the hold state it is necessary to return to MEASURE. The Current output 4 to 20 and the Relays

will activate in 10 sec.

12

si627 P_HACH_LANGE_Ed.0510.indd ANG:12si627 P_HACH_LANGE_Ed.0510.indd ANG:12 20/5/10 10:50:4620/5/10 10:50:46

Page 17

4. Operation

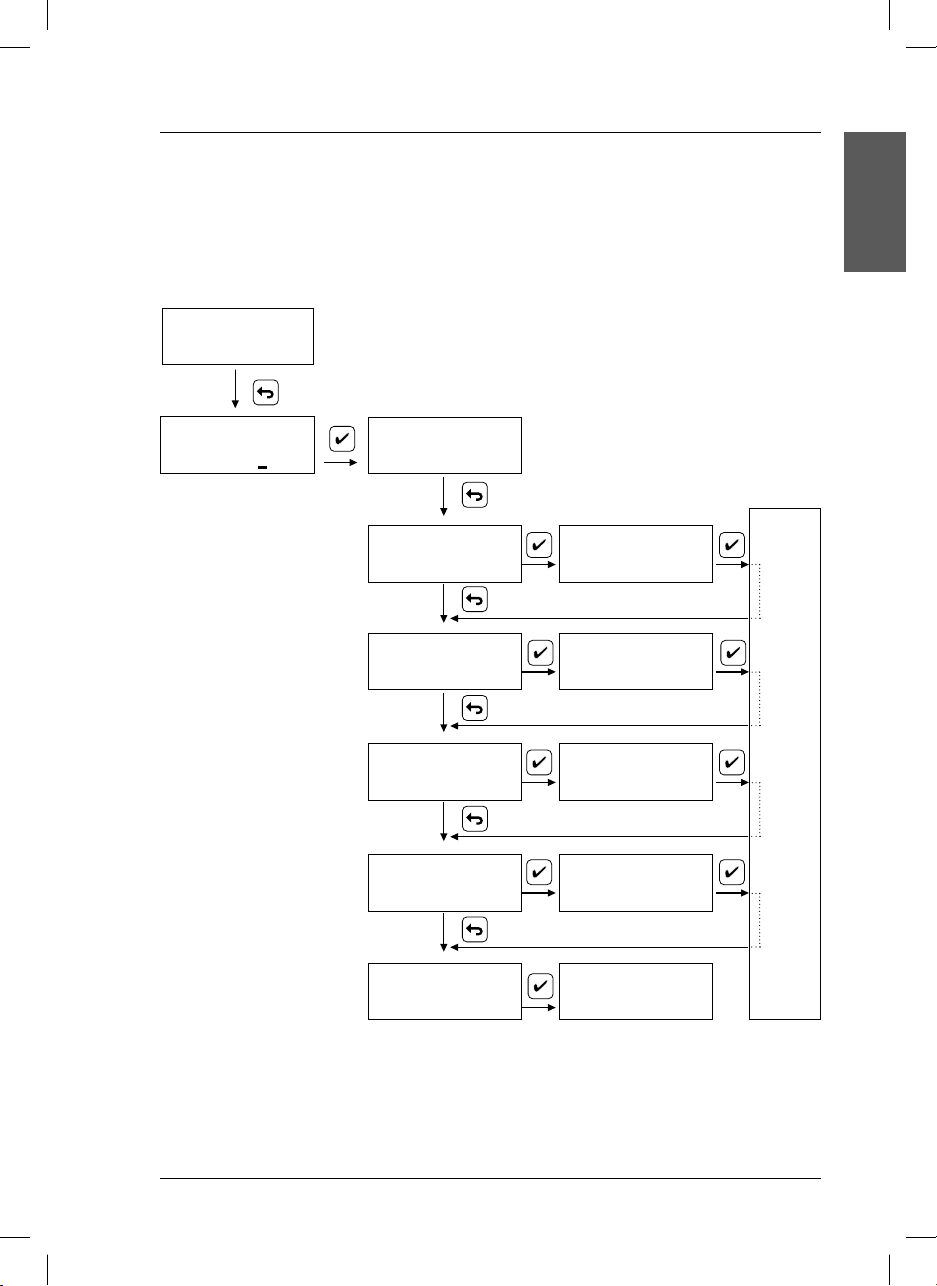

4.4. Programming to measure pH

This instrument is supplied programmed as a pH transmitter-controller with the configuration indicated

in the Setting up, at the end of page 11.

To modify the default configuration and adapt it to specific applications follow the diagram below.

MEASURE

pH 7.34 25.2 °C

CODE

000

Introduce the code 100

CALIBRATE

ENGLISH

TYPE OF MEASURE

Output current.

Selection of pH values corresponding to 4 mA and 20 mA.

Selectable values between

pH 0.0 and 14.0.

Hold.

Selection of the current output

when the instrument is in hold,

fixed at 21 mA or equivalent to

the last value

Language.

Selection of the working

language: English, German,

Spanish, French, Italian or

Portuguese.

MEASURE pH & °C

OUTPUT 4-20 mA

HOLD

LANGUAGE

UNITS: > pH

mV

4 mA 20 mA

pH: 0.0 pH: 14.0

> 21 mA

LAST

Language > Español

Italiano

MEASURE

pH 7.34 25.2 °C

STORING DATA

13

si627 P_HACH_LANGE_Ed.0510.indd ANG:13si627 P_HACH_LANGE_Ed.0510.indd ANG:13 20/5/10 10:50:4620/5/10 10:50:46

Page 18

4. Operation

4.5. Programming to measure ORP (redox). mV range

The instrument is supplied programmed to measure pH. To change the measuring unit (pH) to mV go to Settingup, after selecting the language, see page 12, or follow the diagram below until TYPE OF MEASURE.

MEASURE

pH 7.34 25.2 °C

CODE

000

Introduce the code 100

Output current.

Selection of mV values corresponding to 4 mA and 20 mA.

Selectable values between

± 1500 mV.

Hold.

Selection of the current output

when the instrument is in hold,

fixed at 21 mA or equivalent to

the last value

Language.

Selection of the working language:

English, German, Spanish, French,

Italian or Portuguese.

CALIBRATE

TYPE OF MEASURE

OUTPUT 4-20 mA

HOLD

LANGUAGE

MEASURE pH & °C

UNITS

: pH

> mV

Variar con

4 mA 20 mA

-500 mV +500 mV

> 21 mA

LAST

Language > Español

Italiano

MEASURE

pH 7.34 25.2 °C

STORING DATA

14

si627 P_HACH_LANGE_Ed.0510.indd ANG:14si627 P_HACH_LANGE_Ed.0510.indd ANG:14 20/5/10 10:50:4720/5/10 10:50:47

Page 19

4. Operation

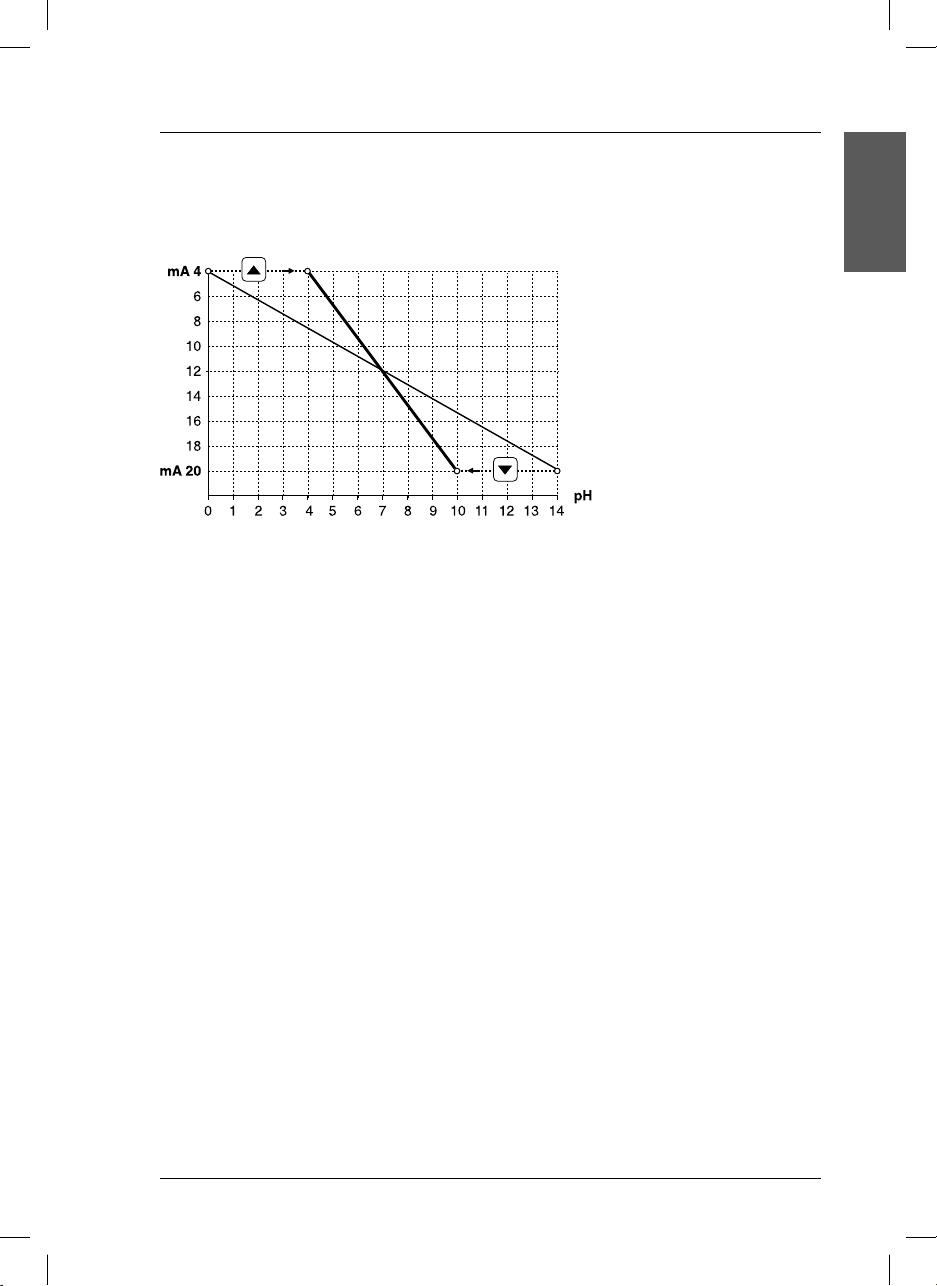

4.6. Operation of 4 to 20 outputs and Relays

Current output 4 to 20 mA depending on the pH

a b

a = Factory default values

b = Example of values user-programmed

The analogic output offers 3 levels of different currents:

• 4 to 20 mA for measurement signal (pH or mV).

• 21 mA frozen, or the last mA value measured, when the instrument is in Hold state.

• 22 mA frozen, with the message OUT OF RANGE on display during 1 minute or more. Alarm.

ENGLISH

15

si627 P_HACH_LANGE_Ed.0510.indd ANG:15si627 P_HACH_LANGE_Ed.0510.indd ANG:15 20/5/10 10:50:4820/5/10 10:50:48

Page 20

4. Operation

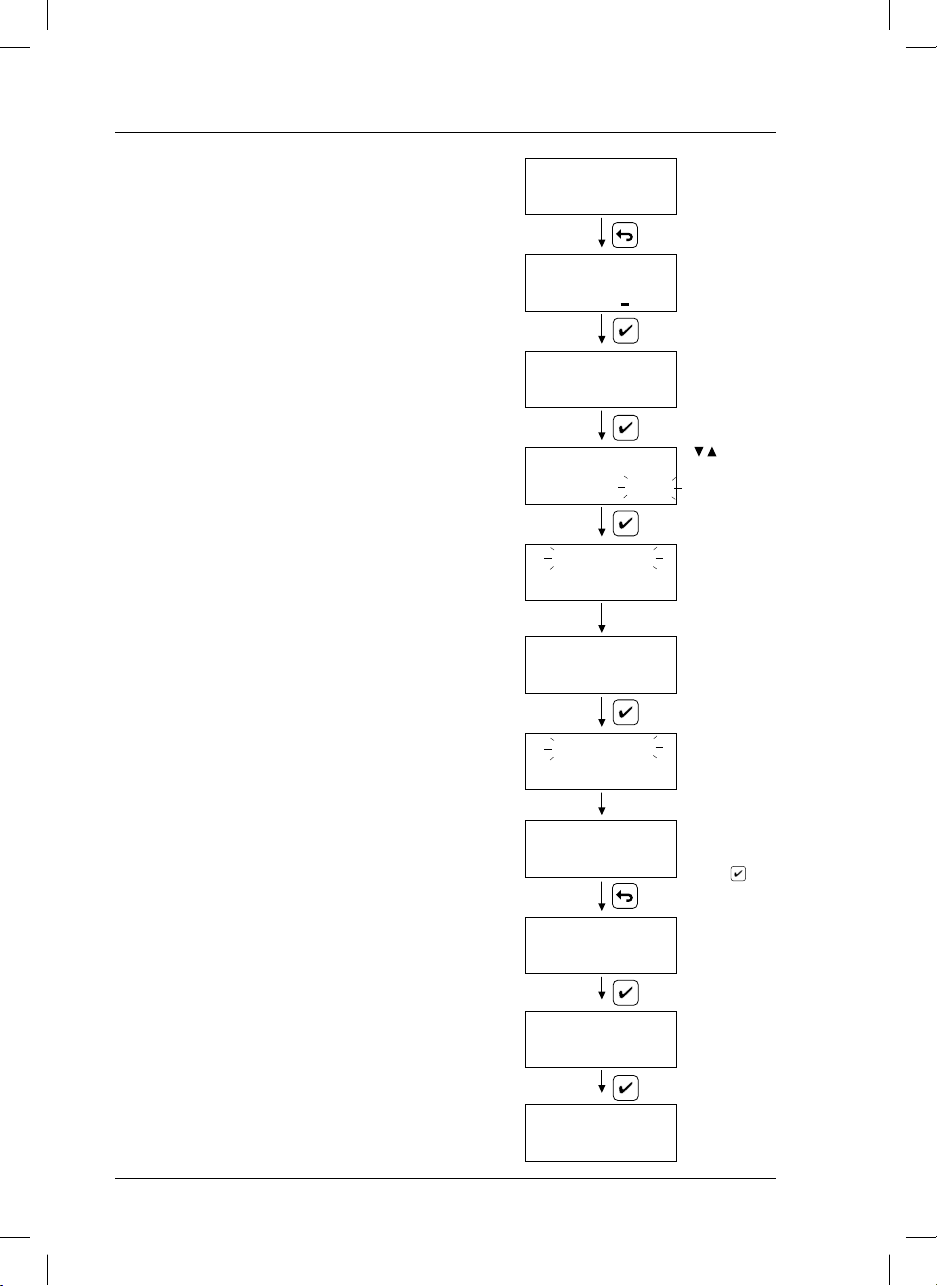

4.7. Calibration of pH electrode

To measure pH correctly, the electrode and instrument set

MEASURE

pH 7.34 25.2 °C

needs to be calibrated regularly with buffer solutions.

The instrument is capable of one-, two- and three-point calibration. The calibration parameters are stored in the memory until a new calibration is performed.

CODE 000

If an anomaly occurs during calibration an error message

will appear on-screen (see page 19).

One-point calibration

CALIBRATE

This form of calibration is acceptable when pH values

around that of the buffer used are being measured.

One-point calibration only corrects the asymmetry potential

of the electrode.

INSERT 1 st BUFFER

25°C

Two-point calibration

This is the most common type of calibration. We recommend pH 7 for the first buffer, and pH 4 or 9 for the second,

depending on whether you will be working in the acid or

CALIBRATING

pH 7.02 19°C

alkaline region.

In addition to asymmetry potential, calibration with two

buffers also compensates the electrode slope or sensitivity

loss.

INSERT 2 nd BUFFER

Three-point calibration

This type of calibration is recommended when measurements

are made across the entire pH scale. It is also used when a

great deal of accuracy is required in a certain region.

CALIBRATING

pH 4.00 19°C

For the first point pH 7 is recommended. For the second and

third points, two of the remaining values must be chosen (pH

2.00, 4.01, 9.21, 10.90, at 25˚C).

Three-point calibration compensates the asymmetry of the

INSERT 3d BUFFER

electrode and its sensitivity in acid and alkaline regions.

During calibraTIOn instrument is in hold state:

Notes:

• Current output is frozen at 21 mA or at last value.

To quit the

Press ESC to quit the calibration, from any screen, without

storing data.

For practical reasons, CRISON recommeds to select

temperature manually during calibraTIOn, even if you have

an ATC probe connected (Pt 1000)

hold state it is necessary to return to mEASURE.

59.26 mV/pH

ASYMMETRY POT.

0 mV

CALIBRATION OK

SLOPE

Introduce the

code 100

The buffer

temperature

can be introduced by the

, keys.

The display

shifts automatically when

the reading is

stable.

Press

to perform a

3-point calibration.

16

si627 P_HACH_LANGE_Ed.0510.indd ANG:16si627 P_HACH_LANGE_Ed.0510.indd ANG:16 20/5/10 10:50:4820/5/10 10:50:48

Page 21

4. Operation

4.8. Recognized Buffers

Table of values according to temperature.

Values stored in the si627 P

°C pH

0 2.01 4.01 7.12 9.52 11.45

10 2.01 4.00 7.06 9.38 11.20

20 2.00 4.00 7.02 9.26 11.00

25 2.00 4.01 7.00 9.21 10.90

30 2.00 4.01 6.99 9.16 10.81

40 2.00 4.03 6.97 9.06 10.64

50 2.00 4.06 6.97 8.99 10.48

60 2.00 4.10 6.98 8.93 10.23

70 2.01 4.16 7.00 8.88 10.19

80 2.01 4.22 7.04 8.83 10.06

90 2.01 4.30 7.09 8.79 9.93

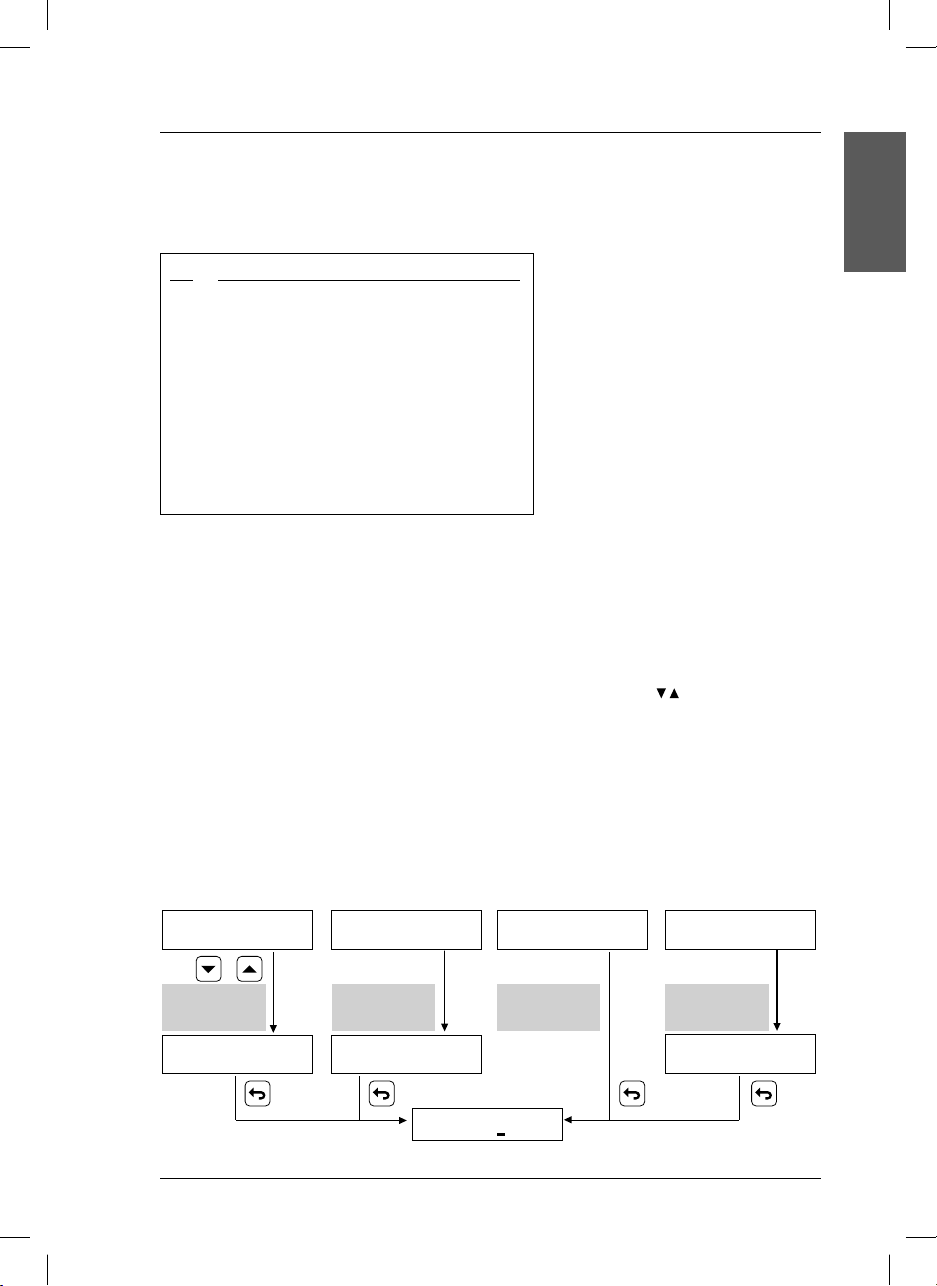

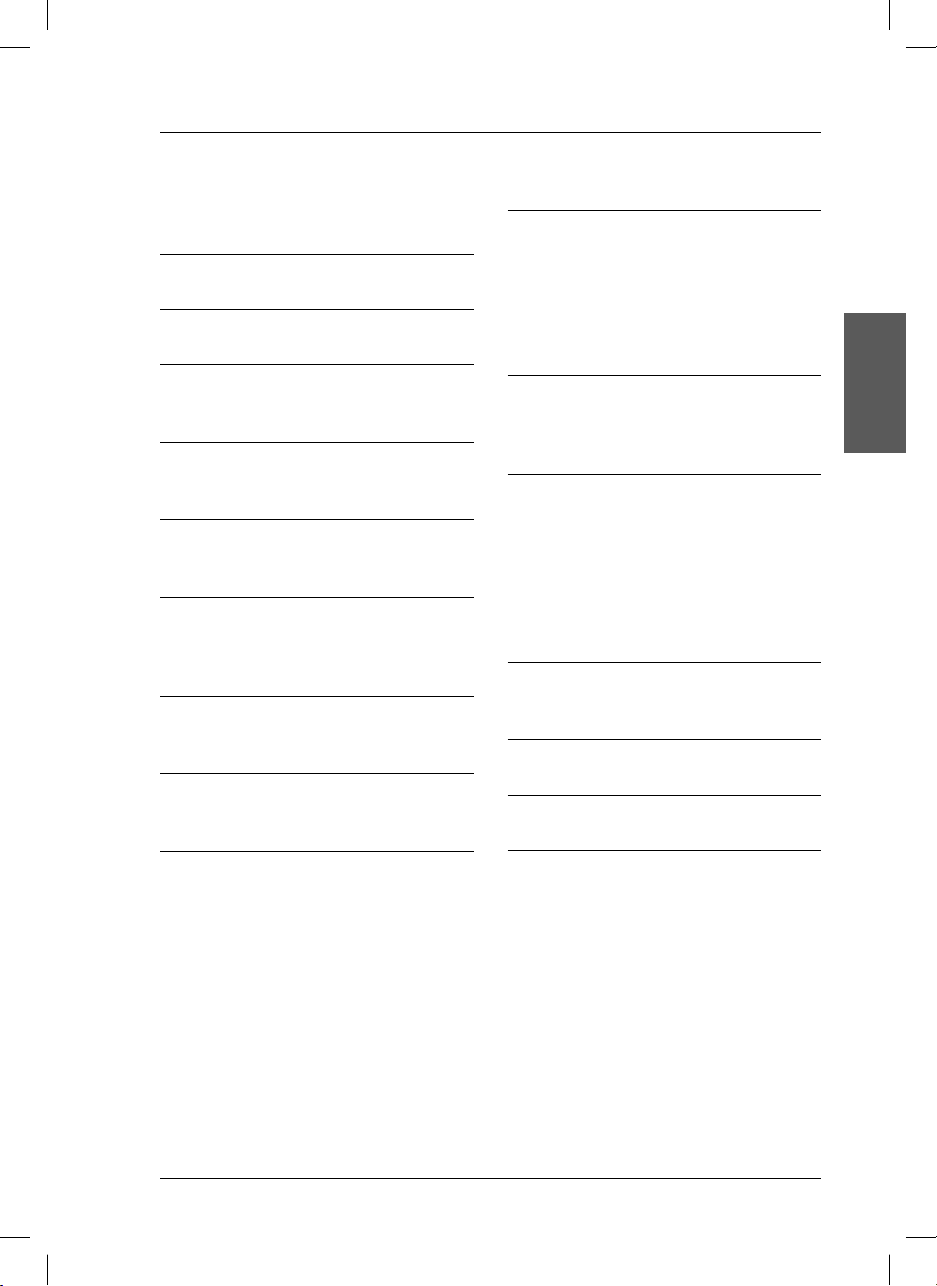

4.9. Measurement

pH and temperature measurement

The pH value and the temperature in °C appear simultaneously on the display. The instrument is usually

measuring pH (see page 13).

The temperature is measured when an A.T.C. Pt 1000 is connected. Otherwise, it is necessary to inform

the instrument about the temperature of the measured solution using the keys

.

ENGLISH

ORP (redox) measurement. mV range

To measure redox potential the instrument must be programmed to measure mV (see page 14).

The temperature is measured when an A.T.C. Pt 1000 is connected.

The redox potential (mV) of the solutions is affected by temperature. Nevertheless the instrument does not

carry out any compensation. Hence it is impossible to introduce the process temperature manually.

pH measurement... mV measurement...

...without A.T.C. Pt 1000 ...with A.T.C. Pt 1000 ...without A.T.C. Pt 1000 ...with A.T.C. Pt 1000

MEASURE

pH 7.34 25 °C

Temperature

selected

manually

MEASURE

pH 7.34 17 °C

MEASURE

pH 7.34 25.2 °C

Temperature

measured

automatically

MEASURE

pH 7.34 25.1 °C

MEASURE

375 mV

Temperature

not indicated

CODE 000

si627 P_HACH_LANGE_Ed.0510.indd ANG:17si627 P_HACH_LANGE_Ed.0510.indd ANG:17 20/5/10 10:50:4820/5/10 10:50:48

MEASURE

375 mV 21.3 °C

Temperature

totally

independent

MEASURE

375 mV 21.4 °C

17

Page 22

5. Maintenance

5.1. Clean the measuring instrument and accessories

Important note: Never use cleaning such as turpentine, acetone or similar products to clean the instrument

including the display and accessories.

Only clean the housing and accessories using a soft, damp cloth. Mild soap solution may also be used. Dry

the cleaned parts carefully with a soft cotton cloth.

CAUTION

When using chemicals or solvents, comply with the instructions of the producer and the general

safety rules.

18

si627 P_HACH_LANGE_Ed.0510.indd ANG:18si627 P_HACH_LANGE_Ed.0510.indd ANG:18 20/5/10 10:50:4820/5/10 10:50:48

Page 23

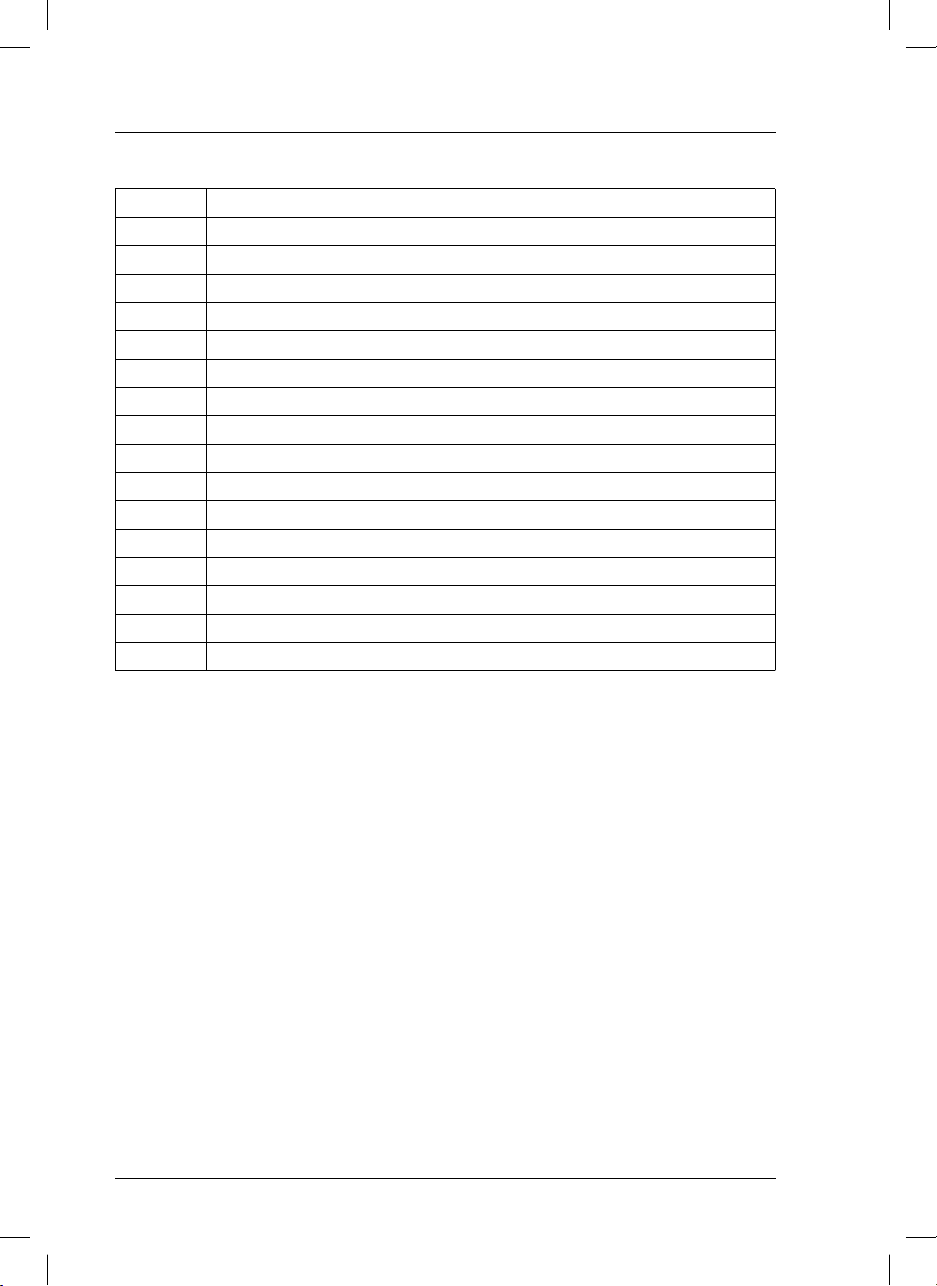

6. Error messages

During calibration

On display Problem Possible causes

Asymmetry Potential

> 60 mV

Electrode asymmetry

potential > 60 mV.

Electrode “worn out”.

Buffer solutions contaminated.

ENGLISH

Sensitivity

< 85 %

Sensitivity

> 103 %

Buffer solutions at

different temperature

Unstable reading

more than 1 min

SAME BUFFER

SOLUTIONS

UNKNOWN

BUFFER SOLUTION

Electrode slope < 85 % of

theoretical value.

Electrode slope > 103 % of

theoretical value.

Buffers temperature.

Unstable reading for more

than 60 seconds.

1st and 2nd buffer solutions

are the same.

Incorrect buffer solution.

Electrode “worn out”.

Buffer solutions contaminated.

Electrode “worn out”.

Buffer solutions contaminated.

The temperature difference between both buffer

solutions used in calibration is > 3 °C.

Press ESC to quit.

Electrode defective or dirty, see miscellaneous solutions. Variation of buffer solution temperature.

(i.e. when stored previously in the refrigerator).

Same standard was used for both calibration steps.

Electrode is broken or cable defective.

Press ESC to quit.

Same standard was used for both calibration steps.

Electrode is broken or cable defective.

Press ESC to quit.

Other messages

On display Problem Possible causes

Measured value out of

OUT OF RANGE

°C OUT OF RANGE

si627 P_HACH_LANGE_Ed.0510.indd ANG:19si627 P_HACH_LANGE_Ed.0510.indd ANG:19 20/5/10 10:50:4920/5/10 10:50:49

range.

Measured temperature out

of range.

pH value < -2 or > 16, mV < –1500 or > 1500.

The current output will be frozen at 22 mA.

(Alarm).

Pt 1000 broken or temperature < –20 or >

. The current output will be frozen at 22

150°C

mA. (Alarm)

19

Page 24

7. Replacement parts

P/N Description

LZU1004.99 Clamps to fix si629 P (only panel mount).

LZU9106.99 BNC connector, straight, for coaxial cable Ø 5 (manual assembly, without special tools).

LZU9188.99 BNC Connector, L-shaped, for coaxial cable (manual assembly, without special tools).

LZU1003.99 Coaxial cable with AS9 connector, 3 m.

LZU1005.99 Coaxial cable with AS9 connector, 5 m.

LZU1010.99 Coaxial cable with AS9 connector, 10 m.

LZU1015.99 Coaxial cable with AS9 connector, 15 m.

LZU1020.99 Coaxial cable with AS9 connector, 20 m.

LZU1025.99 Coaxial cable with AS9 connector, 25 m.

LZW9463.99 pH buffer solution 4.01, with certificate of analysis, 250 ml flask.

LZW9466.99 pH buffer solution 4.01, with certificate of analysis, 1000 ml flask.

LZW9464.98 pH buffer solution 7.00, with certificate of analysis, 250 ml flask.

LZW9467.98 pH buffer solution 7.00, with certificate of analysis, 1000 ml flask.

LZW9465.99 pH buffer solution 9.21, with certificate of analysis, 250 ml flask.

LZW9468.99 pH buffer solution 9.21, with certificate of analysis, 1000 ml flask.

LZW9400.99 Standard redox solution of 220 mV, 250 ml flask.

LZW9401.99 Standard redox solution of 220 mV, 1000 ml flask.

For electrodes please ask for specific brochure.

20

si627 P_HACH_LANGE_Ed.0510.indd ANG:20si627 P_HACH_LANGE_Ed.0510.indd ANG:20 20/5/10 10:50:4920/5/10 10:50:49

Page 25

8. Warranty and liability

The manufacturer warrants that the product supplied is free of material and manufacturing defects and

undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out within 6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the lack of assured properties as follows: all those parts that, within the warranty period calculated from the day of the transfer of

risk, can be demonstrated to have become unusable or that can only be used with significant limitations

due to a situation present prior to the transfer of risk, in particular due to incorrect design, poor materials or

inadequate finish will be improved or replaced, at the supplier’s discretion. The identification of such defects

must be notified to the supplier in writing without delay, however at the latest 7 days after the identification

of the fault. If the customer fails to notify the supplier, the product is considered approved despite the defect.

Further liability for any direct or indirect damages is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be performed within the

warranty period by the customer (maintenance) or by the supplier (servicing) and these requirements are not

met, claims for damages due to the failure to comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or incorrect use are excluded

from this clause.

The manufacturer process instruments are of proven reliability in many applications and are therefore often

used in automatic control loops to provide the most economical possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control loop such that

a malfunction in an instrument results in an automatic change over to the backup control system; this is the

safest operating state for the environment and the process.

ENGLISH

21

si627 P_HACH_LANGE_Ed.0510.indd ANG:21si627 P_HACH_LANGE_Ed.0510.indd ANG:21 20/5/10 10:50:4920/5/10 10:50:49

Page 26

si627 P_HACH_LANGE_Ed.0510.indd ANG:22si627 P_HACH_LANGE_Ed.0510.indd ANG:22 20/5/10 10:50:4920/5/10 10:50:49

Page 27

Inhalt

1. Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1. Abmessungen

2. Allgemeine Informationen . . . . . . . . . . . . 5

2.1. Sicherheitshinweise

2.1.1. Bedeutung von Gefahrenhinweisen

2.2. Allgemeine Produktinformationen

2.3. Inhalt

. . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . 5

5

. . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . 6

3. Installation

3.1. si627 P

3.1.1. Montage

3.1.2. Anschlüsse

3.2. Elektrodenkabel

4. Bedienung und Funktion

4.1. Beschreibung

4.2. Inbetriebnahme

4.3. Kurzanleitung

4.4. Programmierung für die pH-Messung

4.5. Programmierung für die ORP-Messung

4.6. Betrieb des Ausgangs 4 bis 20 mA

4.7. Kalibrierung der pH-Elektrode

4.8.

4.9. Messung

5. Wartung

5.1. Reinigung des Geräts und des Zubehörs

6. Fehlermeldungen

7. Ersatzteile

8. Gewährleistung und Haftung

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . 13

. . . . 14

. . . . . . 15

. . . . . . . . . . . . 16

Geeignete pH-Puffer . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . 18

. . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . 21

Kontaktdaten

DEUTSCH

1

si627 P_HACH_LANGE_Ed.0510.indd ALE:1si627 P_HACH_LANGE_Ed.0510.indd ALE:1 20/5/10 10:50:4920/5/10 10:50:49

Page 28

si627 P_HACH_LANGE_Ed.0510.indd ALE:2si627 P_HACH_LANGE_Ed.0510.indd ALE:2 20/5/10 10:50:4920/5/10 10:50:49

Page 29

1. Technische Daten

Messbereiche

pH: –2,00 bis 16,00

mV: –1500 bis 1500

°C: –20,0 bis 150,0

Messfehler

≤ 0,02 pH, ≤ 1 mV, ≤ 0,5 °C (±1 Stelle)

Reproduzierbarkeit

±0,01 pH, ±1 mV, ±0,1 °C (±1 Stelle)

Automatische Temperaturkompensation

Mit Temperatursensor (Pt 1000) oder

Dateneingabe über Tastatur

Kalibrierungsoptionen (pH)

Zugangscode (Festcode): 100

Mit 1, 2 oder 3 Puffern

Automatische Puffererkennung

Technischer pH 2,00, 4,01, 7,00, 9,21 und

10,90 (bei 25 °C).

Kriterien für die Annahme der

Kalibrierung

Steilheitsbereich: 85 bis 103 %

Asymmetriepotential: ≤ 60 mV

Sprachen

Englisch, Deutsch, Spanisch, Französisch,

Italienisch, Portugiesisch

Display

LCD, alphanumerisch, von hinten beleuchtet,

2 Zeilen zu je 16 Buchstaben

Eingänge und Ausgänge

Elektrode, BNC-Stecker

Temperatursensor, Typ Pt 1000,

Klemmleistenanschluss

Galvanisch isolierter Analogausgang

• 4 bis 20 mA für die Messung (R max.= 500 Ω)

• 21 mA oder mA-Wert entsprechend dem

letzten Messwert für den Haltemodus (Hold)

• 22 mA für Alarm

Maximale Kabellänge

≤ 25 m

Spannungsversorgung

230 oder 24 VAC ±10 %, 45–65 Hz,

Standardausführungen

(115 VAC auf Anfrage)

Leistungsaufnahme: 4 VA

Schutzklasse II

Überspannungskategorie II

EG-Richtlinien

Gemäß Niederspannungsrichtlinie 2006/95/EG

Elektromagnetische Verträglichkeit gemäß

Richtlinie 2004/108/EG

Umgebungsbedingungen

Betriebstemperatur:

0 bis 50 °C (32 bis 122 °F)

Lagertemperatur:

-20 bis 65 °C (-4 bis 149 °F)

Relative Feuchtigkeit: < 80 % (nicht kondensiert)

Max. Höhe 2.000 m bei 230 V; 3.000 m bei

24 V

Gehäuse

si627 P Noryl, frontseitiger Schutz IP54.

Brennbarkeit: FV-1

Gewicht

600 g

Abmessungen

96 x 96 x 100 mm

Garantie

Geräte: 2 Jahre

Technische Daten können jederzeit ohne Vorankündigung geändert werden.

DEUTSCH

3

si627 P_HACH_LANGE_Ed.0510.indd ALE:3si627 P_HACH_LANGE_Ed.0510.indd ALE:3 20/5/10 10:50:4920/5/10 10:50:49

Page 30

1. Technische Daten

1.1. Abmessungen

si627 P

3.8 in

96 mm

90 mm

3.5 in

3.5 in

90 mm

80 mm

3.1 in

96 mm

3.8 in

4

si627 P_HACH_LANGE_Ed.0510.indd ALE:4si627 P_HACH_LANGE_Ed.0510.indd ALE:4 20/5/10 10:50:4920/5/10 10:50:49

7 mm

0.3 in

Page 31

2. Allgemeine Informationen

Da wir unsere Geräte laufend verbessern, können Unterschiede zwischen den Informationen in dieser

Bedienungsanleitung und dem von Ihnen erworbenen Gerät nicht ausgeschlossen werden.

2.1. Sicherheitshinweise

Lesen Sie die vorliegende Bedienungsanleitung vor der Montage und Installation des Geräts vollständig

durch.

Beachten Sie alle Warnetiketten.

2.1.1. Bedeutung von Gefahrenhinweisen

GEFAHR

Weist auf eine potenzielle oder unmittelbare Gefahrensituation hin, deren Nichtbeachtung zu

ernsthaften Verletzungen oder sogar zum Tod führt.

WARNUNG

Weist auf eine potenzielle oder unmittelbare Gefahrensituation hin, deren Nichtbeachtung zu

ernsthaften Verletzungen oder sogar zum Tod führen kann.

VORSICHT

Weist auf eine mögliche Gefahrensituation hin, die zu leichten bis mittelschweren Verletzungen

führen kann.

Wichtiger Hinweis: Weist auf eine Situation hin, die zu Schäden am Gerät führen kann. Wichtige

Information, die beim Umgang mit dem Gerät besonders zu beachten ist.

Hinweis: Zusätzliche Information über den Umgang mit dem Gerät.

DEUTSCH

Warnetiketten

Beachten Sie alle am Gerät angebrachten Etiketten, Schilder und Aufkleber.

Dieses Symbol verweist auf Bedienungs- und/oder Sicherheitshinweise in der Bedienungsanleitung.

Dieses Symbol weist auf Verletzungs- oder Lebensgefahr durch einen Stromschlag hin.

Dieses Symbol bezeichnet die Anschlussstelle für die Schutzerde.

Dieses Symbol bezeichnet die Erdung.

Dieses Symbol bezeichnet die Lage der Sicherung.

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen nach dem 12. August 2005 in Europa nicht im normalen öffentlichen Abfallsystem entsorgt werden, sondern müssen gesondert gesammelt

werden. Nach den Maßgaben der EU-Richtlinie 2002/96/EG müssen Elektro- und Elektronik-Altgeräte

von den Nutzern kostenlos zur Entsorgung an den Hersteller zurückgegeben werden können.

Hinweis: Zur Rücknahme zwecks Recycling wenden Sie sich bitte an den Hersteller oder Lieferanten des

Geräts. Bitten Sie ihn um Informationen zur Rückgabe von Elektro- und Elektronik-Altgeräten, von durch

den Hersteller geliefertem Elektrozubehör und von allen Zusatzkomponenten für die ordnungsgemäße

Entsorgung.

5

si627 P_HACH_LANGE_Ed.0510.indd ALE:5si627 P_HACH_LANGE_Ed.0510.indd ALE:5 20/5/10 10:50:4920/5/10 10:50:49

Page 32

2. Allgemeine Informationen

GEFAHR

• Das Gerät darf nicht geöffnet werden, wenn es

an das Stromnetz angeschlossen ist. Hierdurch

werden spannungsführende Teile freigelegt,

deren Berührung zum Tod führen kann.

• Wenn es unbedingt nötig ist, das Gerät zu öffnen,

muss dieses zuvor von allen Spannungsquellen

getrennt werden.

• Arbeiten am Geräteinneren dürfen nur von

entsprechend geschulten Technikern durchgeführt

werden, die mit den möglichen Gefahren beim

Umgang mit dem Gerät vertraut sind.

• Das Gerät darf nicht in einer Umgebung mit

Explosionsgefahr verwendet werden. Das

Gehäuse des Geräts ist nicht gasdicht.

• Hach Company kann nicht für gesundheitliche

Schäden haftbar gemacht werden, die durch

nicht fachgerechte Arbeiten am Gerät verursacht

werden.

• Der Benutzer hat selbst für ausreichende

Vorkehrungen zum Schutz seiner Sicherheit

und seiner Gesundheit zu sorgen. Vor der

Nutzung des Geräts sind die entsprechenden

Verwendungsbeschränkungen darüber hinaus

vom Benutzer selbst zu bestimmen.

• Vor dem Anlegen von Spannung an das Gerät

ist sicherzustellen, dass diese in folgendem

Bereich liegt:

230 oder 24 VAC ±10 %, 45–65 Hz

(Standardausführungen)

115 VAC ±10 %, 45–65 Hz (auf Anfrage).

Wichtige Hinweise

• Lesen Sie die Anweisungen zum Umgang mit

dem Gerät sorgfältig durch.

• Entfernen Sie Spritzer sofort. Das Gerät ist nicht

wasserdicht.

• Folgende Beanspruchungen sind zu vermeiden:

- Erschütterungen

- atmosphärische Feuchtigkeit über 80 %

- korrosive Gase

- Temperaturen < 0 °C oder > 50 °C (< 32 °F

oder > 122 °F)

- starke magnetische und elektrische Felder

• Verwenden Sie nur Original-Ersatzteile und

-Zubehör.

• Für Geräteprüfungen ist der Technische

Kundendienst von Hach Company zuständig.

2.2. Allgemeine Produktinformationen

Bestimmungsgemäßer Gebrauch

Das si627 P wird zur Messung von pH- und Redoxwerten in Industrie und Umwelt, bei der Lebensmittelverarbeitung und für Abwasser eingesetzt.

2.3. Inhalt si627 P

• Gerät (einschließlich Klemmleisten für die Anschlüsse)

• BNC-Stecker

• Klammer zur Befestigung an der Schalttafel

• Bedienungsanleitung

6

si627 P_HACH_LANGE_Ed.0510.indd ALE:6si627 P_HACH_LANGE_Ed.0510.indd ALE:6 20/5/10 10:50:5120/5/10 10:50:51

Page 33

3. Montage und Installation

3.1. si627 P

GEFAHR

In diesem Kapitel beschriebene Arbeiten dürfen nur von qualifiziertem Fachpersonal vorgenommen werden.

3.1.1. Montage und Installation

Zur Installation des si627 P in einer Schalttafel ist eine der Zeichnung entsprechende Vorbohrung

erforderlich.

92 mm

3.7 in

DEUTSCH

3.7 in

92 mm

Bohrung

Schalttafel

Das in die Schalttafel eingesetzte Gerät wird mit zwei Klammern befestigt (s. Abbildung).

21 mm

0.8 in

80 mm

3.1 in

7 mm

0.3 in

BNC-Stecker

Elektrode

Montierte Klemmleiste Klammer zur Befestigung an

Seitenansicht

der Schalttafel

7

si627 P_HACH_LANGE_Ed.0510.indd ALE:7si627 P_HACH_LANGE_Ed.0510.indd ALE:7 20/5/10 10:50:5120/5/10 10:50:51

Page 34

3. Montage und Installation

Beim Anschließen des Geräts sind alle Sicherheitsempfehlungen in dieser Bedienungsanleitung zu beachten. Das Kapitel „Sicherheitshinweise“ auf Seite 5 der vorliegenden Bedienungsanleitung sollte unbedingt

durchgelesen werden.

GEFAHR

Beim Herstellen elektrischer Anschlüsse muss das Gerät vom Stromnetz getrennt sein.

3.1.2. Anschlüsse

Blockschaltbilder

1 Erdung.

Siehe Wichtige Hinweise auf S. 9.

2,3 Versorgung mit 230 VAC ±10 %

(24 VAC oder 115 VAC auf Anfrage)

4,5 Ausgangsstrom 4 - 20 mA

(pH oder mV).

6...9 Eingang für Temperaturfühler

10 Abschirmung des Temperaturfühlers

11 Eingang für pH- oder Redox-Elektrode

GEFAHR

Die Klemmleiste für den Netzanschluss ist durch ein Gehäuse geschützt. Dieses darf nur für die

Montage- und Installationsarbeiten durch qualifiziertes Fachpersonal entfernt werden.

8

si627 P_HACH_LANGE_Ed.0510.indd ALE:8si627 P_HACH_LANGE_Ed.0510.indd ALE:8 20/5/10 10:50:5120/5/10 10:50:51

Page 35

3. Montage und Installation

Klemmenbelegen (hintere Klemmleiste)

CRISON INSTRUMENTS, S.A.

E-08328 ALELLA - Barcelona

Made in Spain

4-20 mA Pt 1000

VCA

Transmitter si627 P

S/N:

ELECTRODE

IP 54

pH / mV

Wichtige Hinweise:

• Der si627 P-Transmitter benötigt keine Erdung

(Klemme 1).

• In Umgebungen, in denen es zu Interferenzen

kommen kann, empfiehlt es sich, das Gerät an

der Klemme 1 zu erden und das Triaxialkabel

zu verwenden; der Zusatzschirm wird an der

Klemme 1 angeschlossen.

Ist kein Erdungsanschluss verfügbar, so sollte

DEUTSCH

die Klemme 1 frei gelassen und der Zusatzschirm des Triaxialkabels an der Klemme 10

(Abschirmung für Pt 1000) angeschlossen

werden.

• Ist das Kabel des Temperaturfühlers 2-adrig

(statt 4-adrig), so ist eine Brücke zwischen

den Klemmen 6

Pt 1000

und 7 sowie

zwischen den

Klemmen 8 und

9 notwendig

(s. Plan).

9

si627 P_HACH_LANGE_Ed.0510.indd ALE:9si627 P_HACH_LANGE_Ed.0510.indd ALE:9 20/5/10 10:50:5120/5/10 10:50:51

Page 36

3. Montage und Installation

3.2. Elektrodenkabel

Koaxialkabel

PVC-Schutz, Ø 5 mm

Schirm

Leitfähiger Kunststoff (schwarz)

PE-Isolierung

Innenleiter

Triaxialkabel

PVC-Schutz, Ø 7 mm

Zusatzschirm

(Siehe Wichtige Hin-

weise

auf S. 9).

Montage des BNC-Steckers am Kabel

Im Lieferumfang ist ein BNC-Stecker enthalten, der direkt (ohne Löten) am Koaxialkabel angebracht werden kann.

Zur Montage wird das Kabelende (gemäß Abbildung) vorbereitet und der Stecker auf das Kabel aufgedreht.

5 mm

Ø

0,2 in

7 mm

0,3 in

7 mm

0,3 in

Koaxialkabel Vorbereitetes Kabel Kabel mit aufgedrehtem Stecker

Bei einem Triaxialkabel wird der Stecker auf die gleiche Art montiert; der Zusatzschirm und der Außenschutz bleiben jedoch außerhalb des Steckers. Der Zusatzschirm muss geerdet werden.

10

si627 P_HACH_LANGE_Ed.0510.indd ALE:10si627 P_HACH_LANGE_Ed.0510.indd ALE:10 20/5/10 10:50:5220/5/10 10:50:52

Page 37

4. Bedienung und Funktion

4.1. Beschreibung

Display

Die Transmitter der Serie si627 P haben ein alphanumerisches Display. Das Display ist selbsterklärend.

Nachstehend wird das Display für die pH-Messung als Beispiel beschrieben.

Messwert

MISST...

pH 7,34 25,2 °C

Probentemperatur

Maßeinheit

Tasten

ENTER

• Horizontale Vorwärtsbewegung innerhalb des „Organigramms“

• Bestätigen von numerischen Werten

ESCAPE

• Horizontale Rückwärtsbewegung innerhalb des „Organigramms“

• Vertikale Bewegung innerhalb des „Organigramms“

• Löschen von numerischen Werten

Auflösung:

1 °C manuelle Auswahl

0,1 °C Messung mit Pt 1000

DEUTSCH

• Ändern von numerischen Werten

• Bewegung des Cursors > auf dem Display

4.2. Inbetriebnahme

Schließen Sie den si627 P-Transmitter an das Stromnetz an. Bei der ersten Inbetriebnahme erscheint folgender

Schriftzug im Display:

si627_P

V1.0

SPRACHE >Español

Das Gerät misst bereits den pH-Wert mit folgenden Einstellungen:

• Stromausgang 4 mA = pH 0, 20 mA = pH 14

Auf den Seiten

si627 P_HACH_LANGE_Ed.0510.indd ALE:11si627 P_HACH_LANGE_Ed.0510.indd ALE:11 20/5/10 10:50:5220/5/10 10:50:52

Italiano

Français

English

13-14 erfahren Sie, wie Sie die werkseitigen Einstellungen ändern können.

Mit den Tasten kann eine andere Sprache gewählt werden.

MESSUNG VON:

>pH

mV

Hinweis: mV kann auch

mit der Taste

geändert werden.

MESSUNG pH

und °C

MISST…

PH 7,34 25,2 °C

11

Page 38

4. Bedienung und Funktion

4.3. Kurzanleitung

Auf den folgenden Seiten wird die Software des Geräts erläutert. Die Beschreibung ist in logische Einheiten

gegliedert. Dies erleichtert die Einarbeitung und den Zugriff auf die verfügbaren Funktionen.

MISST…

pH 7,34 25,2 °C

MESSUNG pH und °C

Zugriffscode

Der Zugriffscode

verhindert die

Beendigung des

Messvorgangs

CODE 000

Unterstrichene Ziffer mit

ändern und mit

Autorisierter Code = 100

bestätigen.

und den Zugriff

auf die Kalibrierung und Programmierung des

Geräts durch unbefugtes Personal.

Wenn die Verweildauer auf der Displayseite

„Code“ 30 Sekunden überschreitet, kehrt das

Gerät automatisch zu MISST... zurück.

KALIBRIERUNG

MESSART

OUTPUT 4-20 mA

HOLD

SPRACHE

Siehe „Kalibrierung…“

(Seite 16)

Siehe „Programmie-

rung…“

(S. 13-14)

Displayseiten bei Haltemodus (Hold)

Beim Zugriff auf die Displayseiten im grauen Bereich bleibt das Gerät im Haltemodus:

• Die Relaiskontakte sind offen.

• Je nach Hold-Programmierung bleibt der Stromausgang unverändert bei 21 mA oder beim mA-Wert

entsprechend dem letzten Messwert.

Um den Haltemodus zu beenden, müssen Sie zu MISST… zurückkehren. Bei der Rückkehr zur Messung

bleibt das Gerät 10 Sekunden im Haltemodus.

12

si627 P_HACH_LANGE_Ed.0510.indd ALE:12si627 P_HACH_LANGE_Ed.0510.indd ALE:12 20/5/10 10:50:5220/5/10 10:50:52

Page 39

4. Bedienung und Funktion

4.4. Programmierung für die pH-Messung

Das Gerät wurde werkseitig als pH-Transmitter/Controller programmiert. Die Originaleinstellungen

finden Sie im Kapitel Inbetriebnahme (Seite 11 unten).

Um die werkseitige Programmierung zu ändern und an konkrete Anwendungen anzupassen, folgen

Sie dem Diagramm.

MISST…

pH 7,34 25,2 °C

DEUTSCH

CODE 000

Code 100 eingeben.

Stromausgang Auswahl der mVWerte entsprechend 4 mA und

20 mA .

Werte wählbar im Bereich

pH 0,0 und 14,0.

Hold Auswahl des Stromausgangs, wenn sich das Gerät im

Haltemodus befindet: unverändert

bei 21 mA oder beim mA-Wert

entsprechend dem letzten Messwert.

Sprache Auswahl der

Arbeitssprache (Englisch, Deutsch,

Spanisch, Französisch, Italienisch

oder Portugiesisch).

MESSUNG pH und °C

KALIBRIERUNG

MESSART

OUTPUT 4-20 mA

HOLD

SPRACHE

MESSUNG VON: >

pH

mV

4 mA 20 mA

pH: 0,0 pH: 14,0

> 21 mA

Letzter

SPRACHE >

Deutsch

Italiano

MISST…

pH 7,34 25,2 °C

SPEICHERT DATEN

13

si627 P_HACH_LANGE_Ed.0510.indd ALE:13si627 P_HACH_LANGE_Ed.0510.indd ALE:13 20/5/10 10:50:5320/5/10 10:50:53

Page 40

4. Bedienung und Funktion

4.5. Programmierung für die ORP-Messung( Redox) – mV-Skala

Das Gerät wurde werkseitig für die pH-Messung programmiert. Die Änderung der Maßeinheit (pH) auf mV ist

bei der Inbetriebnahme nach der Sprachauswahl möglich (siehe S. 12). Alternativ folgen Sie dem nachstehenden Organigramm bis MESSART.

MISST…

pH 7,34 25,2 °C

CODE 000

Code 100 eingeben.

Stromausgang

Auswahl der mV-Werte

entsprechend 4 mA und 20 mA.

Werte wählbar im Bereich

±1500 mV.

Hold Auswahl des Stromausgangs, wenn sich das Gerät im

Haltemodus befindet: unverändert

bei 21 mA oder beim mA-Wert

entsprechend dem letzten Messwert.

Sprache Auswahl der Arbeitssprache (Englisch, Deutsch,

Spanisch, Französisch oder Italienisch).

MESSUNG mV und °C

KALIBRIERUNG

MESSART

OUTPUT 4-20 mA

HOLD

SPRACHE

MESSUNG VON

:

pH

> mV

Ändern mit

4 mA 20 mA

-500 mV +500 mV

> 21 mA

Letzter

SPRACHE >

Deutsch

Italiano

MISST…

375 mV 25,2 °C

SPEICHERT DATEN

14

si627 P_HACH_LANGE_Ed.0510.indd ALE:14si627 P_HACH_LANGE_Ed.0510.indd ALE:14 20/5/10 10:50:5420/5/10 10:50:54

Page 41

4. Bedienung und Funktion

4.6. Betrieb des Ausgangs 4 bis 20 mA

Stromausgang 4 bis 20 mA

a b

a = werkseitig programmierte Werte

b = Beispiel für benutzerprogrammierte

Werte

DEUTSCH

Der Analogausgang liefert 3 verschiedene Strompegel:

• 4 bis 20 mA für das Messsignal (pH oder mV).

• Unverändert 21 mA oder letzter Messwert, wenn sich das Gerät im Haltemodus (Hold) befindet.

• Unverändert 22 mA, wenn auf dem Display 1 Minute oder länger die Meldung „Außerhalb des Messbereichs“ erscheint. Alarm.

15

si627 P_HACH_LANGE_Ed.0510.indd ALE:15si627 P_HACH_LANGE_Ed.0510.indd ALE:15 20/5/10 10:50:5420/5/10 10:50:54

Page 42

4. Bedienung und Funktion

4.7. Kalibrierung der pH-Elektrode

Für eine korrekte ph-Messung ist eine regelmäßige Kalibrie-

MISST…

pH 7,34 25,2 °C

rung von Gerät und Elektrode erforderlich.

Die Kalibrierung kann mit einem, zwei oder drei Punkten

erfolgen. Die Kalibrierungsparameter werden bis zur

Durchführung einer neuen Kalibrierung gespeichert.

CODE 000

Wenn bei der Kalibrierung ein Fehler auftritt, erscheint

eine Fehlermeldung (siehe Seite 19).

Kalibrierung mit einem Punkt

KALIBRIERUNG

Diese Kalibrierung kann für Messwerte im Pufferbereich

eingesetzt werden.

Bei der Kalibrierung mit einem Punkt wird lediglich die

Asymmetrie der Elektrode korrigiert.

Puffer 1 einführen

25°C

2-Punkt-Kalibrierung

Dies ist die am häufigsten verwendete Kalibrierungsmethode. Es sollte zuerst mit einem Puffer mit pH 7 und dann

mit einem zweiten Puffer mit pH 4 oder 9 kalibriert werden.

KALIBRIERT…

pH 7,02 19°C

Bei der Kalibrierung mit zwei Puffern wird außer dem

Asymmetriepotential die Steilheit oder der Empfindlichkeitsverlust der Elektrode ausgeglichen.

Puffer 2 einführen

3-Punkt-Kalibrierung

Diese Kalibrierung ist zu empfehlen, wenn gewöhnlich im

gesamten pH-Bereich gemessen wird, oder wenn eine hohe

Genauigkeit in einem bestimmten Bereich erforderlich ist.

Als erster Puffer empfiehlt sich pH 7. Als zweiter und dritter

KALIBRIERT…

pH 4,00 19°C

Punkt müssen zwei der übrigen Werte gewählt werden (pH

2,00, 4,01, 9,21, 10,90 bei 25˚C).

Bei der 3-Punkt-Kalibrierung wird sowohl die Asymmetrie

der Elektrode als auch ihre Empfindlichkeit im sauren sowie

Puffer 3 einführen

im alkalinen Bereich korrigiert.

STEILHEIT

Hinweise: Während der Kalibrierung befindet sich das Gerät

im Haltemodus:

• Die Relaiskontakte sind offen.

• Der Stromausgang bleibt unverändert bei 21 mA.

Um „Hold“ zu beenden, müssen Sie zu MISST… zurückkehren.

Um die Kalibrierung ohne Datenspeicherung abzubrechen,

drücken Sie auf einer beliebigen Displayseite auf ESC.

Aus praktischen Gründen empfiehlt es sich, die Temperatur

bei der Kalibrierung

Temperatursensor (Pt 1000) angeschlossen ist.

manuell zu wählen – auch wenn ein

59,26 mV/pH

ASYMMETRIEPOTENTIAL

0 mV

KALIBRIERUNG OK

Code 100

eingeben.

Die Temperatur der

Puffer mit den

Tasten

eingeben.

Der Wechsel

der Displayseite erfolgt

automatisch,

sobald sich

der Messwert

stabilisiert

hat.

Drücken Sie

, um

mit 3 Punkten zu

kalibrieren.

16

si627 P_HACH_LANGE_Ed.0510.indd ALE:16si627 P_HACH_LANGE_Ed.0510.indd ALE:16 20/5/10 10:50:5420/5/10 10:50:54

Page 43

4. Bedienung und Funktion

4.8. Geeignete pH-Puffer

Die Werte in der folgenden Tabelle sind abhängig von der Temperatur angegeben.

Sie sind im Speicher des si627 P-Transmitters abgelegt.

SDgrC pH

0 2,01 4,01 7,12 9,52 11,45

10 2,01 4,00 7,06 9,38 11,20

20 2,00 4,00 7,02 9,26 11,00

25 2,00 4,01 7,00 9,21 10,90

30 2,00 4,01 6,99 9,16 10,81

40 2,00 4,03 6,97 9,06 10,64

50 2,00 4,06 6,97 8,99 10,48

60 2,00 4,10 6,98 8,93 10,23

70 2,01 4,16 7,00 8,88 10,19

80 2,01 4,22 7,04 8,83 10,06

90 2,01 4,30 7,09 8,79 9,93

DEUTSCH

4.9. Messung

pH- und Temperaturmessung

Der pH-Wert und die Temperatur (in °C) werden gleichzeitig am Display angezeigt.

Das Gerät misst normalerweise den pH-Wert, sofern es für die pH-Messung programmiert wurde (siehe S. 13).

Die Temperatur kann ebenfalls gemessen werden, wenn zuvor ein Temperatursensor vom Typ Pt 1000 angeschlossen wurde. Andernfalls muss die Temperatur der Messlösung über die Tasten eingegeben werden.

ORP-Messung (Redox) – mV-Skala

Zur Messung von Redoxpotentialen muss das Gerät für die mV-Messung programmiert sein (siehe S. 14).

Die Temperatur kann ebenfalls gemessen werden, wenn zuvor ein Temperatursensor vom Typ Pt 1000 angeschlossen wurde.

Das Redoxpotential (mV) einer Lösung wird von der Temperatur beeinflusst; das Gerät führt jedoch

keine Art von Ausgleich durch. Aus diesem Grund ist es nicht möglich, die Prozesstemperatur manuell

auszuwählen.

... ohne Pt-1000-Fühler ... mit Pt-1000-Fühler ... ohne Pt-1000-Fühler ... mit Pt-1000-Fühler

MISST…

pH 7,34 25 °C

Temperatur

manuell

ausgewählt

MISST…

pH 7,34 17 °C

si627 P_HACH_LANGE_Ed.0510.indd ALE:17si627 P_HACH_LANGE_Ed.0510.indd ALE:17 20/5/10 10:50:5520/5/10 10:50:55

pH-Messung ... mV-Messung ...

MISST…

pH 7,34 25,2 °C

Temperatur

automatische

Messung

MISST…

pH 7,34 25,1 °C

MISST…

375 mV

Temperatur

nicht angegeben

unabhängig

375 mV 21,4 °C

CODE 000

MISST…

375 mV 21,3 °C

Temperatur

völlig

MISST…

17

Page 44

5. Wartung

5.1. Reinigung des Geräts und des Zubehörs

Wichtiger Hinweis: Verwenden Sie zur Reinigung des Geräts (einschließlich des Displays und des Zubehörs)

keine Reinigungsmittel wie Terpentin, Aceton oder ähnliche Produkte.

Reinigen Sie das Gehäuse und das Zubehör nur mit einem weichen, feuchten Tuch. Sie können auch

eine milde Seifenlösung verwenden. Trocknen Sie die gereinigten Teile vorsichtig mit einem weichen

Baumwolltuch ab.

VORSICHT

Beachten Sie die Gefahrenhinweise, die allgemeinen Sicherheitsvorschriften und die sonstigen Hinweise der Hersteller von Reagenzien.

18

si627 P_HACH_LANGE_Ed.0510.indd ALE:18si627 P_HACH_LANGE_Ed.0510.indd ALE:18 20/5/10 10:50:5520/5/10 10:50:55

Page 45

6. Fehlermeldungen

Während der Kalibrierung

Auf dem Display Problem Mögliche Ursachen

Asymmetrie Pot.

> 60 mV

Empfindlichkeit

< 85 %

Empfindlichkeit

> 103 %

Puffer mit

Temp-Differenz

Instab. Messung > 1

Minute

GLEICHE PUFFER

P. NICHT GEEIGNET

Asymmetriepotential der

Elektrode > 60 mV.

Steilheit der Elektrode

< 85 % des theoretischen

Werts.

Steilheit der Elektrode

< 103 % des theoretischen

Werts.

Temperatur der Puffer.

Messwert länger als 60 s

instabil.

Puffer 1, 2 und 3 haben den

gleichen Wert.

Pufferlösung wird

vom Gerät nicht erkannt.

Elektrodenverschleiß.

Pufferlösungen kontaminiert.

Elektrodenverschleiß.

Pufferlösungen kontaminiert.

Elektrodenverschleiß.

Pufferlösungen kontaminiert.

Der Temperaturunterschied zwischen den beiden

Puffern ist > 3 °C.

Drücken Sie auf ESC , um die Kalibrierung zu

beenden.

Elektrode schadhaft oder verschmutzt, siehe verschiedene Lösungen.

Puffer wurde dem Kühlschrank entnommen.

Identischer Puffer an den beiden Kalibrierungspunkten.

Elektrode defekt oder Kabel schadhaft. Drücken Sie

auf ESC , um die Kalibrierung zu beenden.

Der verwendete Puffer ist nicht im Gerät gespeichert (entspricht nicht pH 7,00, 4,01 oder 9,21

bei 25 °C).

Drücken Sie auf ESC , um die Kalibrierung zu

beenden.

DEUTSCH

Sonstige Meldungen

Auf dem Display Problem Mögliche Ursachen

AUSSERHALB DES

Messwert außerhalb des

Messbereichs

MESSBEREICHS

°C AUSSERHALB DES

Temperaturmesswert außerhalb der Skala

MESSBEREICHS

si627 P_HACH_LANGE_Ed.0510.indd ALE:19si627 P_HACH_LANGE_Ed.0510.indd ALE:19 20/5/10 10:50:5520/5/10 10:50:55

Messwert pH < 0 oder > 14, mV < -1500 oder

> 1500. Wenn diese Meldung 1 Minute oder

länger auf dem Display angezeigt wird, bleibt der

Stromausgang unverändert bei 22 mA (Alarm).

Pt-1000-Fühler defekt oder Temperatur < -20 oder

> 150 °C Wenn diese Meldung 1 Minute oder

länger auf dem Display angezeigt wird, bleibt der

Stromausgang unverändert bei 22 mA (Alarm).

19

Page 46

7. Ersatzteile

Code Beschreibung

LZU1004.99 Befestigungsklammern für si627 P.

LZU9106.99 Gerader BNC-Stecker,

LZU9188.99 Abgewinkelter BNC-Stecker, für Koaxialkabel (manuelle Montage ohne Spezialwerkzeug).

LZU1003.99 Koaxialkabel mit AS9-Stecker, 3 m.

LZU1005.99 Koaxialkabel mit AS9-Stecker, 5 m.

LZU1010.99 Koaxialkabel mit AS9-Stecker, 10 m.

LZU1015.99 Koaxialkabel mit AS9-Stecker, 15 m.

LZU1020.99 Koaxialkabel mit AS9-Stecker, 20 m.

LZU1025.99 Koaxialkabel mit AS9-Stecker, 25 m.

LZW9463.99 Pufferlösung pH 4,01, mit Analysezertifikat, 250-ml-Flasche.

LZW9466.99 Pufferlösung pH 4,01, mit Analysezertifikat, 1000-ml-Flasche.

LZW9464.98 Pufferlösung pH 7,00, mit Analysezertifikat, 250-ml-Flasche.

LZW9467.98 Pufferlösung pH 7,00, mit Analysezertifikat, 1000-ml-Flasche.

LZW9465.99 Pufferlösung pH 9,21, mit Analysezertifikat, 250-ml-Flasche.

LZW9468.99 Pufferlösung pH 9,21, mit Analysezertifikat, 1000-ml-Flasche.

LZW9400.99 Redox-Standardlösung 220 mV, 250-ml-Flasche.

LZW9401.99 Redox-Standardlösung 220 mV, 1000-ml-Flasche.

Für Ersatzelektroden Prospekt anfordern.

für Koaxialkabel Ø 5 mm (manuelle Montage ohne Spezialwerkzeug).

20

si627 P_HACH_LANGE_Ed.0510.indd ALE:20si627 P_HACH_LANGE_Ed.0510.indd ALE:20 20/5/10 10:50:5520/5/10 10:50:55

Page 47

8. Gewährleistung und Haftung

Der Hersteller leistet Gewähr dafür, dass das gelieferte Produkt frei von Material- und Herstellungsfehlern ist,

und verpflichtet sich, etwaige fehlerhafte Teile kostenlos zu reparieren oder auszutauschen.

Die Garantiezeit für Geräte beträgt 24 Monate. Bei Abschluss eines Wartungsvertrags innerhalb der ersten

6 Monate nach Kauf verlängert sich die Garantiezeit auf 60 Monate.

Für Mängel, zu denen auch das Fehlen zugesicherter Eigenschaften zählt, haftet der Lieferer unter Ausschluss weiterer Ansprüche wie folgt: Alle diejenigen Teile, die innerhalb der Garantiezeit vom Tage

des Gefahrenüberganges an gerechnet nachweisbar infolge eines vor dem Gefahrenübergang liegenden

Umstandes, insbesondere wegen fehlerhafter Konstruktion, minderwertiger Werkstoffe oder mangelhafter

Ausführung, unbrauchbar werden oder deren Brauchbarkeit erheblich beeinträchtigt ist, werden nach Wahl

des Lieferers unentgeltlich ausgebessert oder ausgetauscht. Die Feststellung solcher Mängel muss dem

Lieferer unverzüglich, jedoch spätestens 7 Tage nach Feststellung des Fehlers, schriftlich gemeldet werden.

Unterlässt der Kunde diese Anzeige, gilt die Leistung trotz Mangels als genehmigt. Eine darüber hinausgehende Haftung für unmittelbare oder mittelbare Schäden besteht nicht.

Wenn vom Lieferer vorgegebene gerätespezifische Wartungs- oder Inspektionsarbeiten innerhalb der Garantiezeit durch den Kunden selbst (Wartung) oder durch den Lieferer (Inspektion) durchzuführen sind und

diese Anforderungen nicht eingehalten werden, erlöschen Ansprüche für Schäden, die sich aus der Nichtbeachtung dieser Anforderungen ergeben.

Weitergehende Ansprüche, insbesondere für Folgeschäden, können nicht geltend gemacht werden.

DEUTSCH

Verschleißteile und Beschädigungen, die durch unsachgemäße Handhabung, nicht ordnungsgemäße Installation oder nicht bestimmungsgemäßen Gebrauch entstehen, sind von dieser Bestimmung ausgeschlossen.

Die Prozessgeräte des Herstellers haben ihre Zuverlässigkeit in vielen Anwendungen unter Beweis gestellt

und werden daher häufig in automatischen Regelkreisen eingesetzt, um die wirtschaftlich günstigste Betriebsweise für den jeweiligen Prozess zu ermöglichen.

Zur Vermeidung bzw. Begrenzung von Folgeschäden empfiehlt es sich daher, den Regelkreis so zu konzipieren, dass die Störung eines Gerätes automatisch eine Umschaltung auf das Ersatz- Regelungssystem

bewirkt. Dadurch wird der für die Umwelt und den Prozess sicherste Betriebszustand hergestellt.

21

si627 P_HACH_LANGE_Ed.0510.indd ALE:21si627 P_HACH_LANGE_Ed.0510.indd ALE:21 20/5/10 10:50:5520/5/10 10:50:55

Page 48

si627 P_HACH_LANGE_Ed.0510.indd ALE:22si627 P_HACH_LANGE_Ed.0510.indd ALE:22 20/5/10 10:50:5520/5/10 10:50:55

Page 49

Índice

1. Especificaciones técnicas . . . . . . . . . . . . . . . . . . 3

1.1. Dimensiones

2. Información general . . . . . . . . . . . . . . . . . 5

2.1. Información de seguridad

2.1.1. Uso de avisos de peligro

2.2. Información general del producto

2.3. Contenido

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . 5

. . . . . . . . . 5

. . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Instalación

3.1. si627 P

3.1.1. Montaje

3.1.2. Conexiones

3.2. Cable del electrodo

4. Funcionamiento

4.1. Descripción

4.2. Puesta en marcha

4.3. Guía rápida

4.4. Programación para medir pH

4.5. Programación para medir P.O.R.

4.6. Funcionamiento de salida 4 a 20 mA

4.7. Calibración del electrodo de pH

4.8.

4.9. Medida

5. Mantenimiento

5.1. Limpieza de instrumento y accesorios

6. Mensajes de error

7. Piezas de recambio

8. Garantía y responsabilidad

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . 13

. . . . . . . . . 14

. . . . 15

. . . . . . . . . 16

Soluciones buffer de pH reconocidos . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . 21

Contact information

ESPAÑOL

1

si627 P_HACH_LANGE_Ed.0510.indd ESP:1si627 P_HACH_LANGE_Ed.0510.indd ESP:1 20/5/10 10:50:5520/5/10 10:50:55

Page 50

si627 P_HACH_LANGE_Ed.0510.indd ESP:2si627 P_HACH_LANGE_Ed.0510.indd ESP:2 20/5/10 10:50:5620/5/10 10:50:56

Page 51

1. Especificaciones técnicas

Escalas de medida

pH –2.00 a 16.00

mV –1500 a 1500

°C –20.0 a 150.0

Error de medida

≤ 0.02 pH, ≤ 1 mV, ≤ 0.5 °C (± 1 dígito)

Reproducibilidad

± 0.01 pH, ± 1 mV, ± 0.1 °C (± 1 dígito)

Compensación automática de temperatura

Con sonda C.A.T. (Pt 1000) o entrada datos por

teclado

Posibilidades en calibración pH

Código de acceso fijo: 100

Con 1, 2 ó 3 soluciones buffer

Reconocimiento automático de soluciones

buffer

Técnicos pH 2.00, 4.01, 7.00, 9.21 y 10.90 (a

25 °C).

Criterios de aceptación de calibración

Pendiente 85 a 103 %

Potencial de asimetría ≤ 60 mV

Idiomas

Inglés, Alemán, Español, Francés, Italiano,

Portugués

Pantalla

LCD, alfanumérica retroiluminada,

2 líneas de 16 caracteres

Entradas y Salidas

Electrodo, conector BNC

CAT, tipo Pt 1000, conexión en regleta

Salida analógica aislada galvánicamente

• 4 a 20 mA para la medida (R máx.= 500 Ω)

• 21 mA o el valor en mA equivalente al último

valor medido para instrumento en suspenso

(hold)

• 22 mA para situación de alarma

Longitud máxima cable

≤ 25 m

Alimentación

230 ó 24 VCA ±10 %, 45-65 Hz, versiones

estándar

(115 VCA bajo pedido)

Consumo 4 VA

Protección: Clase II

Categoría de sobretensión: II

Directivas CE

Según norma 2006/95/EC

Compatibilidad electromagnética según norma

2004/108/EC

Condiciones ambientales

Temperatura de trabajo:

0 a 50 °C (32 a 122 °F)

Temperatura almacenamiento:

–20 a 65 °C (–4 a 149 °F)

Humedad relativa < 80 % (no condensada)

Altitud máx. 2.000 m. at 230 V; 3.000 at 24 V

Contenedor

si627 P Noryl, protección frontal IP54. Clase de

inflamabilidad FV-1

Peso

600 g

Dimensiones

96 x 96 x 100 mm (3.8 x 3.8 x 3.9 in.)

Garantía

Instrumentos: 2 años

Especificaciones sujetas a cambio sin previo aviso.

ESPAÑOL

3

si627 P_HACH_LANGE_Ed.0510.indd ESP:3si627 P_HACH_LANGE_Ed.0510.indd ESP:3 20/5/10 10:50:5620/5/10 10:50:56

Page 52

1. Especificaciones técnicas

1.1. Dimensiones

si627 P

3.8 in

96 mm

90 mm

3.5 in

3.5 in

90 mm

80 mm

3.1 in

96 mm

3.8 in

4

si627 P_HACH_LANGE_Ed.0510.indd ESP:4si627 P_HACH_LANGE_Ed.0510.indd ESP:4 20/5/10 10:50:5620/5/10 10:50:56

7 mm

0.3 in

Page 53

2. Información general

La continua mejora de nuestros instrumentos puede provocar diferencias entre la información descrita en

el presente manual y el instrumento adquirido.

2.1. Información de seguridad

Por favor asegúrese de leer completamente el siguiente manual antes de instalar el instrumento.

Esté atento a todos los símbolos de seguridad.

2.1.1. Uso de avisos de peligro

PELIGRO

Indica una situación inminente o potencialmente peligrosa que, de no evitarse, provocará la

muerte o lesiones graves.

ADVERTENCIA

Indica una situación inminente o potencialmente peligrosa que, de no evitarse, podría provocar

la muerte o lesiones graves.

ATENCIÓN

Indica una situación potencialmente peligrosa que, de no evitarse, puede provocar lesiones leves

o menos graves.

Nota importante: Indica una situación que, de no evitarse, podría averiar el instrumento. Información importante que el usuario debe tener en cuenta al manejar el instrumento.

Nota: Información adicional para el usuario sobre el manejo del instrumento.

ESPAÑOL

Símbolos de seguridad

Leer detenidamente los símbolos y etiquetas que hay en el instrumento.

Hace referencia al manual de instrucciones, para operación del instrumento o seguridad.

Indica riesgo de electrocución o choque eléctrico.

Indica la localización del tierra.

Indica la conexión a tierra.

Identifica la localización del fusible.

El equipo eléctrico marcado con este símbolo no puede ser desechado en los sistemas públicos europeos de desechos desde el 12 de agosto de 2005. Conforme a los reglamentos locales y nacionales

europeos (directiva de la UE 2002/96/EC), los usuarios de equipos eléctricos en Europa deben

devolver al productor todo equipo viejo o cuya vida útil haya terminado para que sea desechado sin

cargo para el usuario.

Nota: Para devolver equipos para su reciclaje, contáctese con el fabricante o distribuidor para así obtener instrucciones acerca de cómo devolverlos y desecharlos correctamente. Esto se aplica a equipos

que hayan alcanzado el término de su vida útil, accesorios eléctricos suministrados por el fabricante

o distribuidor y todo elemento auxiliar.

5

si627 P_HACH_LANGE_Ed.0510.indd ESP:5si627 P_HACH_LANGE_Ed.0510.indd ESP:5 20/5/10 10:50:5620/5/10 10:50:56

Page 54

2. Información general

PELIGRO

•

No abrir el instrumento si está conectado a

la red ya que quedan expuestas zonas cuyo

voltaje puede ser causa de muerte.

• Si es inevitable abrir el instrumento, primero se

desconectará de todas las fuentes de voltaje.

• Cualquier manipulación interna la efectuará

únicamente una persona especialmente

preparada que conozca los peligros inherentes

a la operación.

• No trabajar nunca en un ambiente sujeto a

peligro de explosión. La carcasa del instrumento

no es hermética a la penetración de gases.

• La empresa no se hace responsable de ningún

daño físico ocasionado por la manipulación del

instrumento por personal no autorizado.

• El usuario tiene la responsabilidad de tomar

las medidas suficientes para su seguridad y su

salud, así como de determinar las limitaciones

correspondientes antes de su utilización

• Antes de dar tensión al instrumento, asegúrese

de que el voltaje esté entre:

230 ó 24 V CA ±10%, 45-65 Hz (versiones

estándar)

115 V CA ±10%, 45-65 Hz (bajo pedido).

Notas Importantes

• Leer cuidadosamente las instrucciones de

manejo del instrumento.

• En caso de salpicaduras limpiar inmediatamente.

El instrumento no es impermeable.

• Evitar las siguientes perturbaciones sobre el

instrumento:

- vibraciones

- humedad atmosférica superior al 80%

- gases corrosivos

- temperaturas < 0 °C, ó > 50 °C (< 32 °F, ó >

122 °F).

- campos magnéticos o eléctricos fuertes.

• Utilizar sólo recambios y accesorios originales.

• Para su revisión envíe el instrumento al Servicio

Técnico de la empresa.

2.2. Información general del producto

Uso adecuado

Los si627 P se utilizan para medir pH o redox y temperatura en la industria, en el medioambiente, en

procesos alimentarios y en las aguas residuales.

2.3. Contenido si627 P

• Instrumento (con regletas para conexiones).

• Connector BNC.

• Grapa para fijación a panel

• Manual.

6

si627 P_HACH_LANGE_Ed.0510.indd ESP:6si627 P_HACH_LANGE_Ed.0510.indd ESP:6 20/5/10 10:50:5720/5/10 10:50:57

Page 55

3. Instalación

3.1. si627 P

PELIGRO

Las tareas descritas en esta sección del manual del usuario sólo deben ser realizadas por personal cualificado.

3.1.1. Montaje

Para la instalación del si627 P en panel se requiere un taladro previo según el esquema.

92 mm

3.7 in

3.7 in

92 mm

Taladro

ESPAÑOL

Panel

Una vez colocado el instrumento en el panel es necesario fijarlo utilizando las dos grapas indicadas en

la figura.

21 mm

0.8 in

Conector BNC

electrodo

80 mm

3.1 in

7 mm

0.3 in

Regleta instalada Grapa para fijación a panel

si627 P_HACH_LANGE_Ed.0510.indd ESP:7si627 P_HACH_LANGE_Ed.0510.indd ESP:7 20/5/10 10:50:5720/5/10 10:50:57

Vista lateral

7

Page 56

3. Instalación

Durante el conexionado del instrumento deben cumplirse todas las recomendaciones de seguridad que

aparecen en este manual. Es necesario leer el apartado ““Información de seguridad” en la página 5 del

presente manual.

PELIGRO

Mientras se efectúen conexiones eléctricas es necesario mantener el instrumento desconectado de

la red.

3.1.2. Conexiones

Diagramas de bloques

1 Conexión para tierra.

Ver Notas importantes (pág. 9).

2,3 Alimentación 230 VCA ± 10%.

(24 VCA ó 115 VCA bajo pedido).

4,5 Salida de corriente 4-20 mA

(pH o mV).

6...9 Entrada para sonda de temperatura.

10 Blindaje de la sonda de temperatura.

11 Entrada para electrodo de pH o redox.

PELIGRO

La regleta de conexión a red va protegida por una carcasa protectora. No eliminar dicha

carcasa excepto para que personal cualificado efectúe las tareas de instalación.

8

si627 P_HACH_LANGE_Ed.0510.indd ESP:8si627 P_HACH_LANGE_Ed.0510.indd ESP:8 20/5/10 10:50:5720/5/10 10:50:57

Page 57

3. Instalación

Asignación de los bornes (panel posterior)

CRISON INSTRUMENTS, S.A.

E-08328 ALELLA - Barcelona

Made in Spain

4-20 mA Pt 1000

VCA

Transmitter si627 P

S/N:

IP 54

pH / mV

ELECTRODE

Notas importantes:

• El si627 P no requiere conexión a tierra

(borne 1).

• En ambientes con problemas de interferencias

se recomienda conectar el instrumento a tierra

en el borne 1 y utilizar el cable triaxial, conectando la pantalla adicional en el borne 1.

Si la toma de tierra no está disponible, se

aconseja dejar libre el borne 1 y conectar la

pantalla adicional del cable triaxial al borne

10 (blindaje Pt 1000).

• Si el cable de la sonda de temperatura es

de 2 hilos, y no de

4, se debe realizar

Pt 1000

un puente entre los

bornes 6 y 7 y otro

entre el 8 y el 9,

tal como se indica

en el esquema.

ESPAÑOL

9

si627 P_HACH_LANGE_Ed.0510.indd ESP:9si627 P_HACH_LANGE_Ed.0510.indd ESP:9 20/5/10 10:50:5820/5/10 10:50:58

Page 58

3. Instalación

3.2. Cable del electrodo

Cable coaxial

Protector PVC Ø 5 mm.

Pantalla.

Plástico conductor (negro).

Aislamiento PE.

Cable triaxial

Protector PVC Ø 7 mm.

Pantalla adicional.

(Ver Notas importantes

en pág. 9).

Conductor interno.

Instalación del conector BNC al cable

El instrumento se suministra con un conector BNC, directamente “roscable” (sin soldaduras) al cable coaxial.