Page 1

DOC026.98.80437

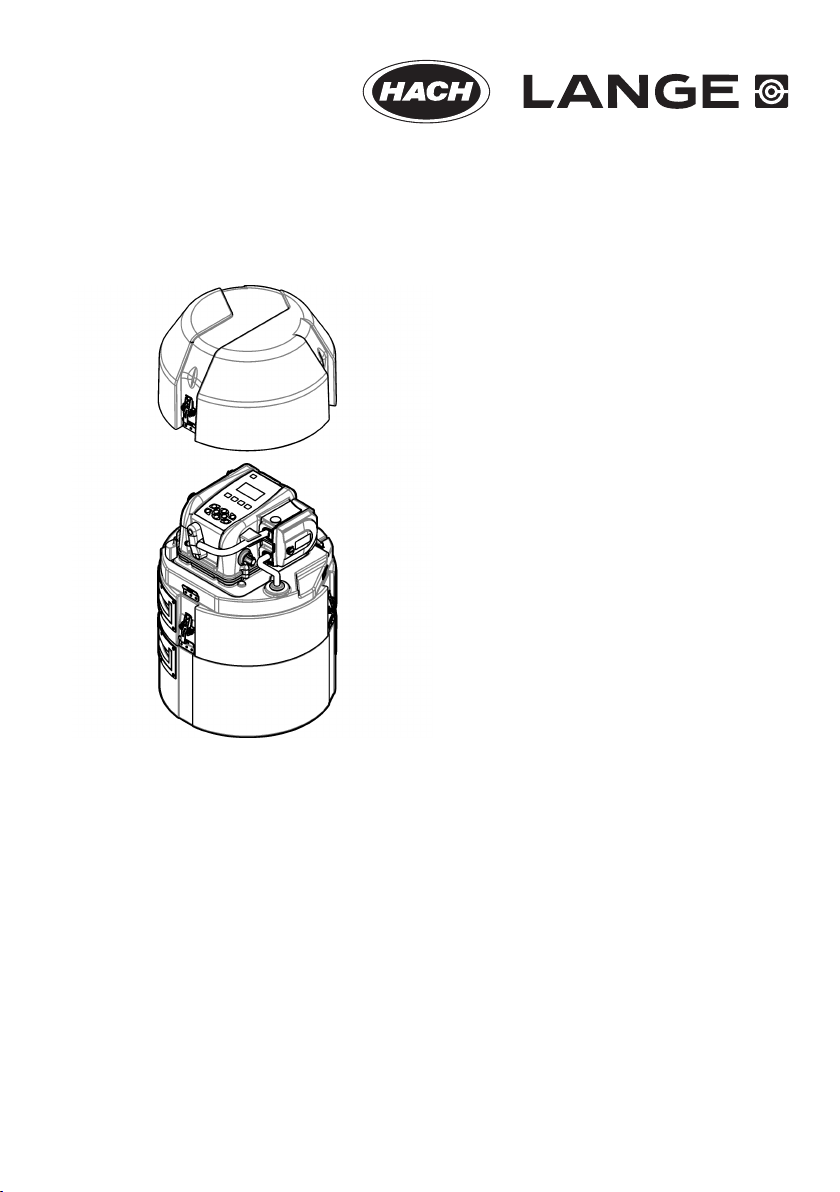

SD900 Portable Sampler

03/2014, Edition 1

Basis-Bedienungsanleitung

Manuale di base per l'utente

Manuel d'utilisation de base

Manual básico del usuario

Basisgebruikershandleiding

Podstawowa instrukcja obsługi

Alapvető felhasználói útmutató

Manual de utilizare de bază

Základný návod na použitie

Osnovni uporabniški priročnik

Osnovni korisnički priručnik

Βασικό εγχειρίδιο λειτουργίας

Basic User Manual

Základní návod k použití

Temel Kullanım Kılavuzu

Page 2

English..............................................................................................................................

Deutsch..........................................................................................................................28

Italiano............................................................................................................................54

Français.........................................................................................................................80

Español........................................................................................................................106

Čeština.........................................................................................................................132

Nederlands.................................................................................................................157

Polski............................................................................................................................183

Magyar.........................................................................................................................209

Română.......................................................................................................................235

Türkçe...........................................................................................................................260

Slovenský jazyk.........................................................................................................285

Slovenski.....................................................................................................................311

Hrvatski........................................................................................................................336

3

Ελληνικά......................................................................................................................362

2

Page 3

Table of contents

Specifications on page 3 Operation on page 17

General information on page 5 Maintenance on page 23

Installation on page 8

Additional information

Additional information is available on the manufacturer's website.

Specifications

Specifications are subject to change without notice.

SD900 Portable Sampler

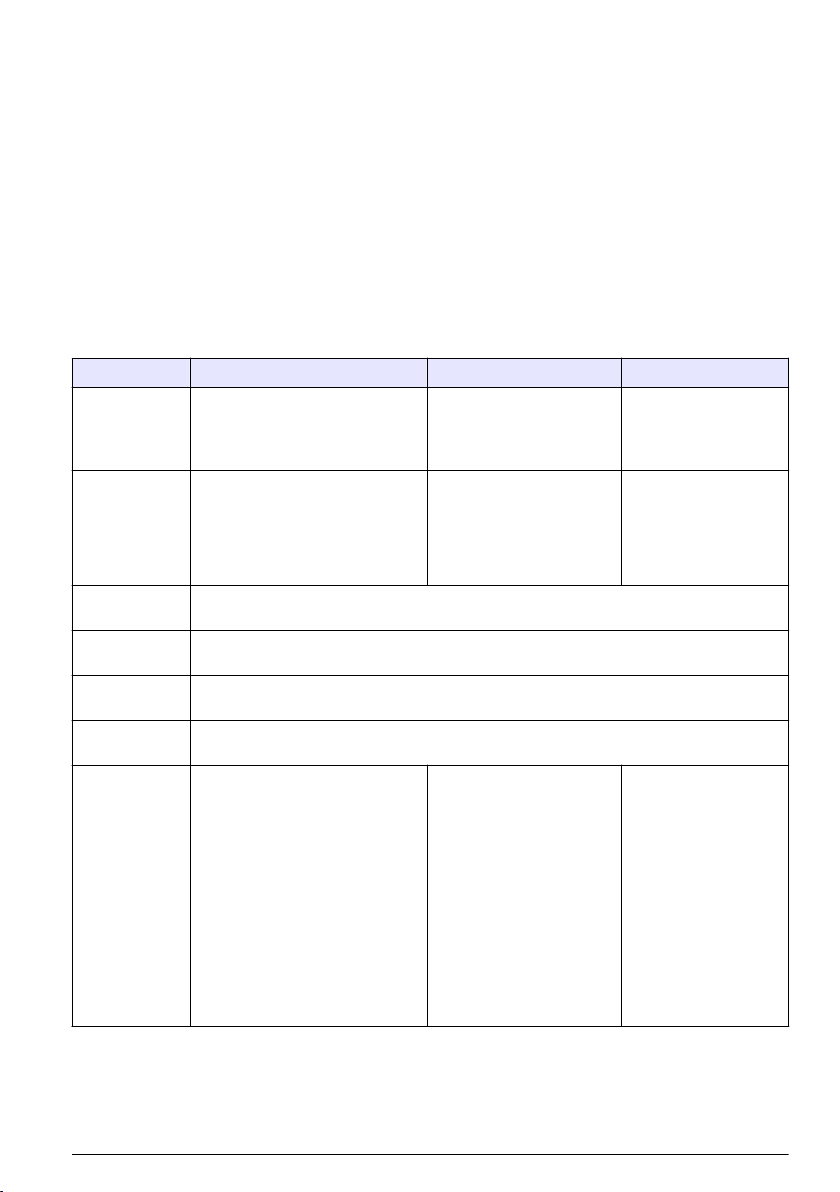

Specification Standard base Compact base Composite base

Dimensions Diameter: 50.5 cm (19.9 in.)

Height: 69.4 cm (27.3 in.)

Weight 15 kg (35.6 lb) with 1-L

Enclosure Impact-resistant ABS, 3-section construction; double-walled base with 2.54 cm (1 in.)

Sample

temperature

Strainers 316 stainless steel in standard size, high velocity or low profile for shallow depth applications

Sample intake

tubing

Sample bottle

capacity

polyethylene bottles (24x)

14.8 kg (32.6 lb) with 10-L (2.5 gal)

polyethylene container (1x)

insulation—direct bottle contact with ice.

0–60 °C (32–140 °F)

and Teflon® or 316 stainless steel in standard size

9.5 mm (3/8 in.) I.D. vinyl or Teflon-lined polyethylene

1-L (0.26 gal) polyethylene and/or

350-mL (11.83 oz) glass bottles

(24x)

2.3-L (0.6 gal) polyethylene and/or

1.9-L (0.5 gal) glass bottles (8x)

3.8-L (1 gal) polyethylene and/or

3.8-L (1 gal) glass bottles (4x)

3.8-L (1 gal) polyethylene and/or

3.8-L (1 gal) glass bottles (2x)

21-L (5.5 gal) or 15-L (4 gal)

polyethylene composite container

or 20-L (5.25 gal) polyethylene or

10-L (2.5 gal) polyethylene or 10-L

(2.5 gal) glass (1x)

Diameter: 44.1 cm (17.4 in.)

Height: 61 cm (24 in.)

12.2 kg (27 lb) with 575-mL

(19.44 oz) polyethylene

bottles (24x)

12.9 kg (28.3 lb) with 10-L

(2.5 gal) polyethylene

container (1x)

575-mL (19.44 oz)

polyethylene bottles (24x)

950-mL (32.12 oz) glass

bottles (8x)

10-L (2.5 gal) polyethylene

bottle (1x)

10-L (2.5 gal) glass bottle

(1x)

Diameter: 50.28 cm

(19.8 in.)

Height: 79.75 cm

(31.4 in.)

15 kg (36 lb) with 950mL (32.12 oz) glass

bottles (12x)

21-L (5.5 gal)

polyethylene bottle (1x)

English 3

Page 4

SD controller

Specification Details

Dimensions (W x H x D) 29.2 x 17.1 x 26.4 cm (11½ x 6¾ x 103/8 in.)

Weight 4.2 kg (9.26 lb)

Enclosure PC/ABS blend, NEMA 4X, 6, IP 67

Power requirements 15 VDC supplied by a 8754500 power supply; 15 VDC supplied by an integral

Overload protection 7 A, DC line fuse for the pump

Operating temperature 0 to 50 °C (32 to 122 °F)

Storage temperature –30 to 60 °C (–22 to 140 °F)

Storage/operating humidity 100% condensing

Pump Peristaltic high speed, with spring-mounted Nylatron rollers

Pump enclosure IP37

Pump tubing 9.5 mm ID x 15.9 OD mm (3/8 in. ID x 5/8 in. OD) silicone

Pump tubing life 20,000 sample cycles with: 1 L (0.3 gal) sample volume, 1 rinse, 6 minute

Vertical sample lift Maximum 8.5 m (28 ft) for: 8.8 m (29 ft) of 3/8-in. vinyl intake tube at sea level

Pump flow rate 4.8 L/min (1.25 gpm) at 1 m (3 ft) vertical lift with 3/8-in. intake tube typical

Sample volume Programmable in 10-mL (0.34 oz) increments from 10 to 10,000 mL (3.38 oz

Sample volume repeatability

(typical)

Sample volume accuracy

(typical)

Sampling modes Pacing: Time-fixed, flow-fixed, time-variable, flow-variable, constant time

Run modes Continuous or non-continuous with user-entered number of samples

Multiple programs Stores up to three sampling programs

Transfer velocity (typical) 0.9 m/s (2.9 ft/s) with: 4.6 m (15 ft) vertical lift, 4.9 m (16 ft) of 3/8-in. vinyl

Liquid sensor Ultrasonic. Body: Ultem® NSF ANSI standard 51 approved, USP Class VI

Sample history Up to 510 records

Air purge Air purged automatically before and after each sample. The duration

Event log 510 records

power supply

pacing interval, 4.9 m (16 ft) of 3/8 in. intake tube, 4.6 m (15 ft) of vertical lift,

21 °C (70 °F) sample temperature

at 20–25 °C (68–77 °F)

to 2.6 gal)

±5% of 200 mL sample volume using uncalibrated liquid detect with: 4.6 m

(15 ft) vertical lift, 4.9 m (16 ft) of 3/8-in. vinyl intake tube, single bottle, full

bottle shut-off at room temperature and 1524 m (5000 ft) elevation

±10% of 200 mL sample volume using uncalibrated liquid detect with: 4.6 m

(15 ft) vertical lift, 4.9 m (16 ft) of 3/8-in. vinyl intake tube, single bottle, full

bottle shut-off at room temperature and 1524 m (5000 ft) elevation

variable volume (CTVV).

Refer to Constant Time Variable Volume (CTVV) sampling in the expanded

version of this manual.

Distribution: Single bottle composite, multi-bottle composite, multi-bottle

discrete, bottles per sample, samples per bottle, combination of bottles per

sample, samples per bottle

intake tubing, 21 °C (70 °F) and 1524 m (5000 ft) elevation

compliant

automatically compensates for varying intake tube lengths.

4 English

Page 5

Specification Details

Connections Power, auxiliary, serial communications, distributor, SDI-12

Wetted materials Stainless steel, polyethylene, Teflon, Ultem, silicone

Communications RS232, Modbus, SDI-12

Warranty 1 year

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

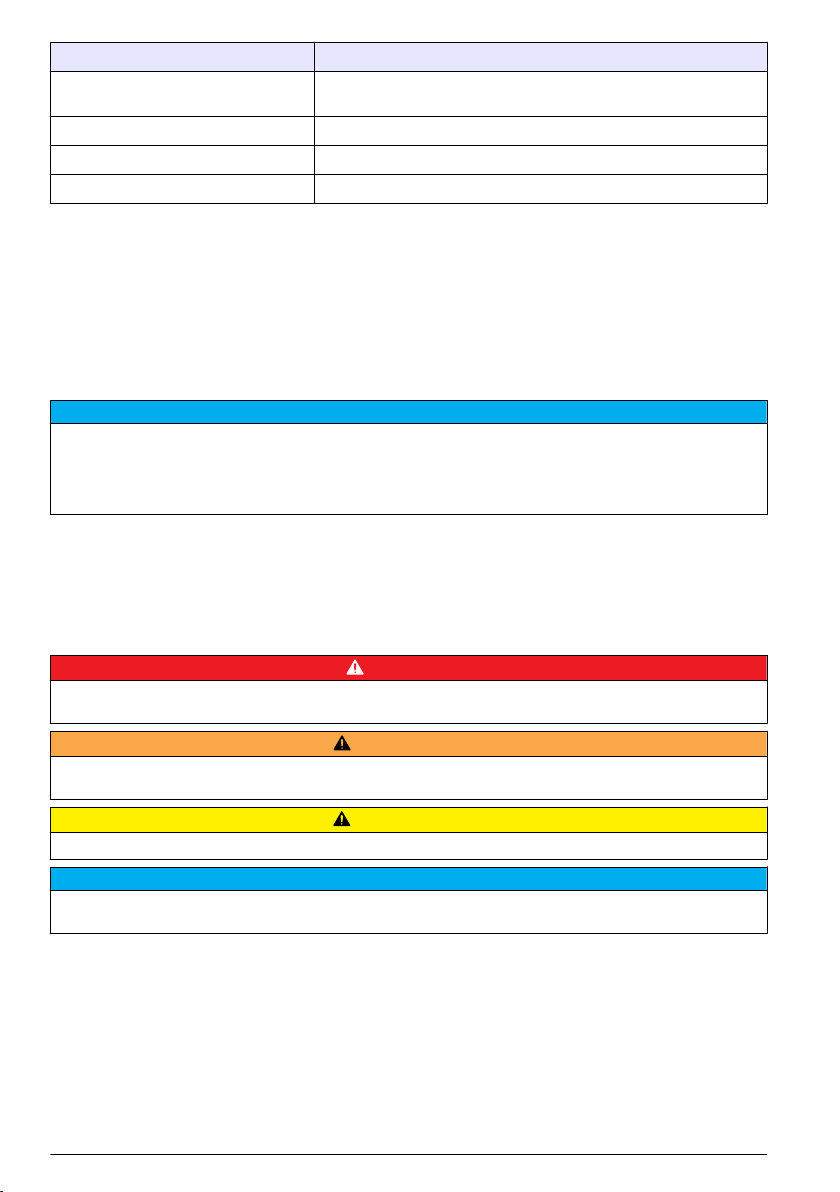

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

D A N G E R

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

C A U T I O N

N O T I C E

English 5

Page 6

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential

injury. If on the instrument, refer to the instruction manual for operation or safety information.

This symbol indicates a potential pinch hazard.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public

disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Certification

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

6 English

Page 7

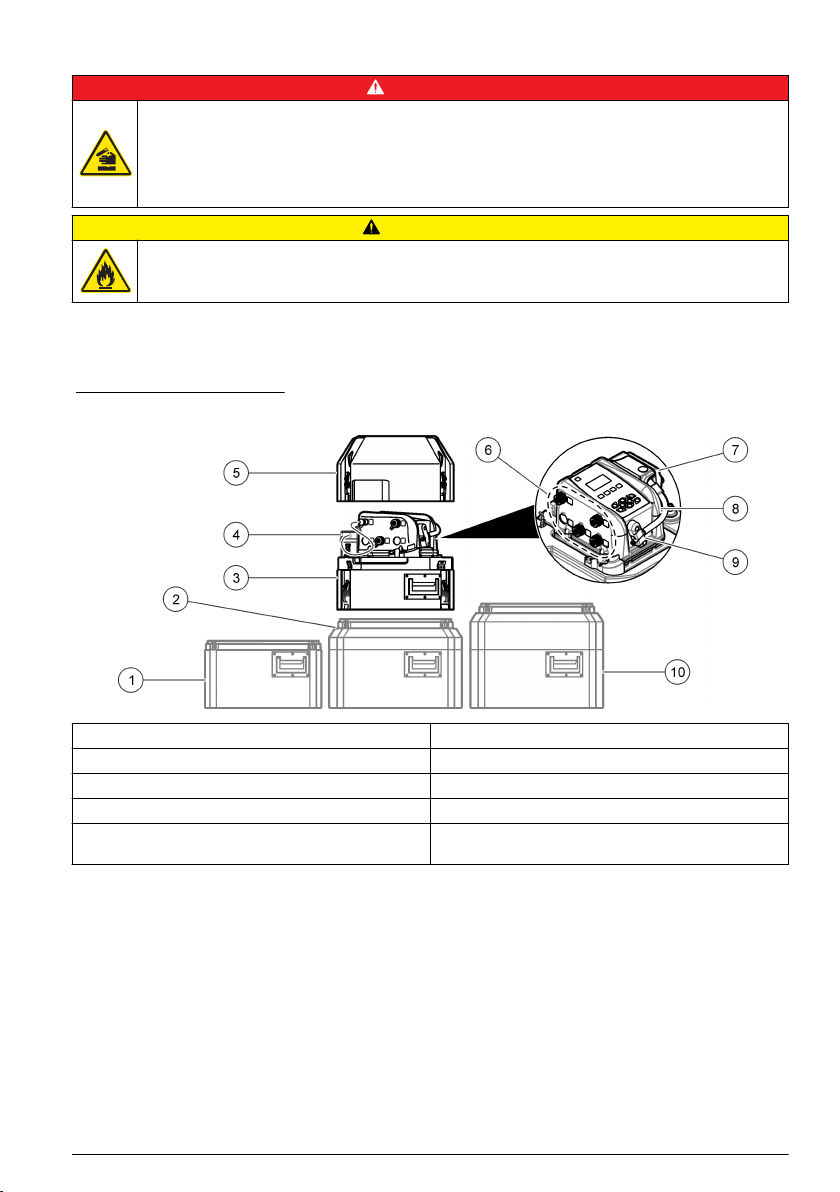

Product overview

Chemical or biological hazards. If this instrument is used to monitor a treatment process and/or

chemical feed system for which there are regulatory limits and monitoring requirements related to

public health, public safety, food or beverage manufacture or processing, it is the responsibility of the

user of this instrument to know and abide by any applicable regulation and to have sufficient and

appropriate mechanisms in place for compliance with applicable regulations in the event of malfunction

of the instrument.

Fire hazard. This product is not designed for use with flammable liquids.

D A N G E R

C A U T I O N

The SD900 Portable Sampler collects liquid samples at specified intervals and keeps the samples in

bottles or containers. Use

the sampler for a wide variety of aqueous applications and for toxic

pollutants and suspended solids. Set up the sampler with different retainers, bottles or containers.

Refer to Figure 1.

Figure 1 Product overview

1 Compact base 6 Controller connections

2 Standard insulated base 7 Pump

3 Center section 8 Controller

4 Power source 9 Liquid sensor

5 Top cover 10 Standard insulated base for 21-L (5.5 gal)

container

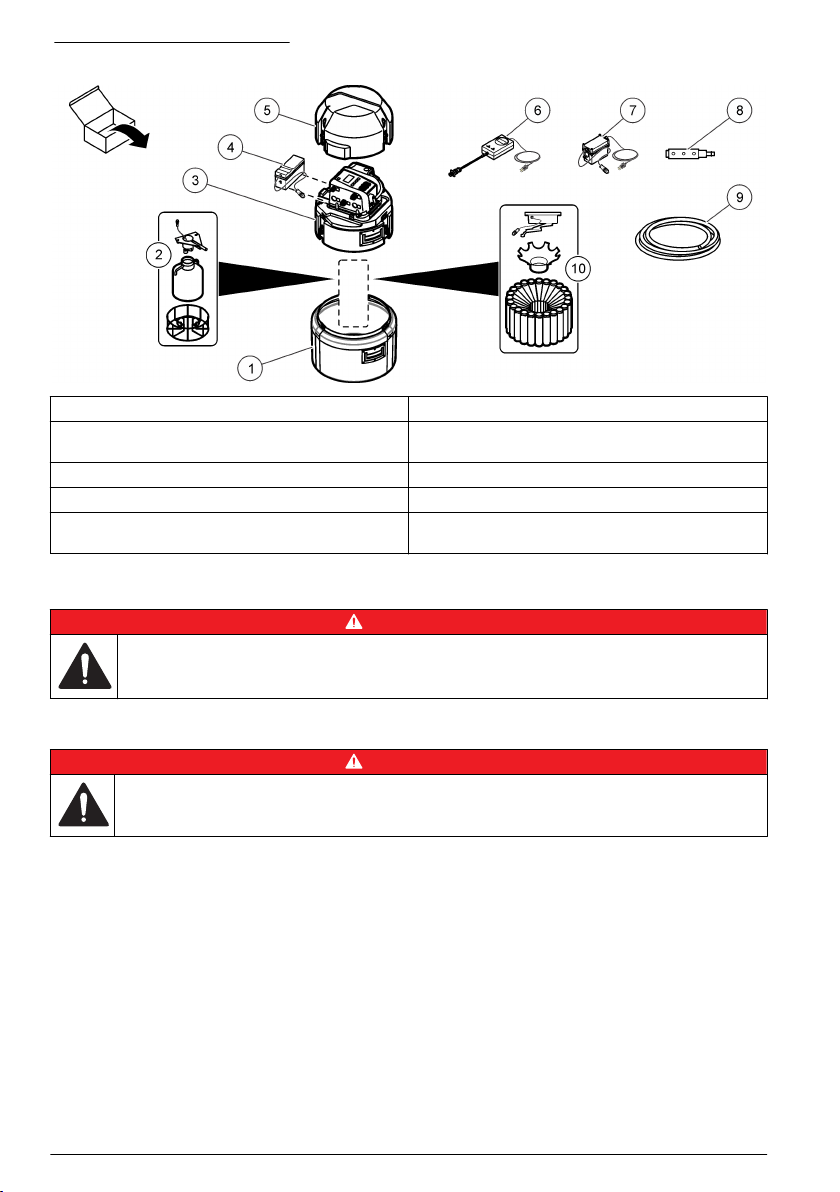

Product components

Make sure that all components have been received. Refer to Figure 2. If any items are missing or

damaged, contact the manufacturer or a sales representative immediately.

English 7

Page 8

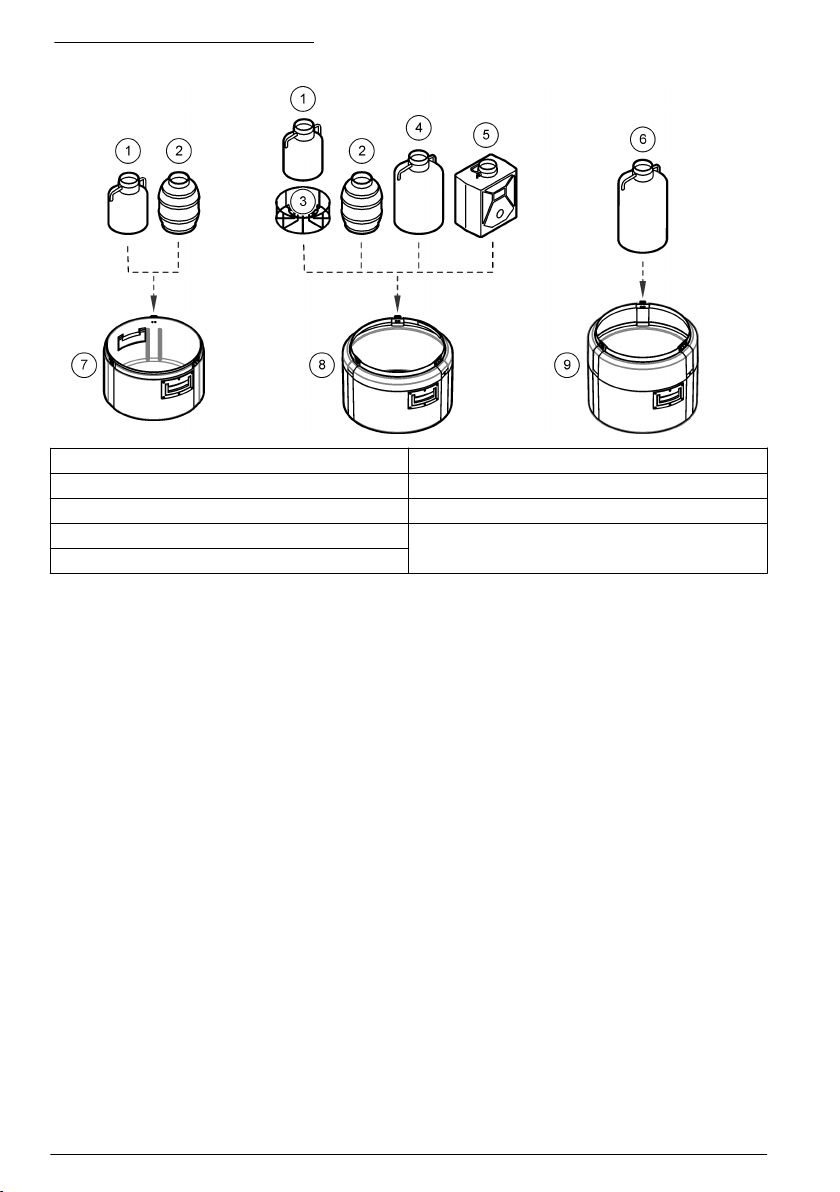

Figure 2 Product components

1 Base (Standard, compact or composite) 6 Battery charger (optional)

2 Components for a single-bottle option (bottle and

support can change)

3 Center section with controller 8 Strainer

4 Battery (optional) 9 Intake tubing, vinyl or Teflon-lined

5 Top cover 10 Components for a multiple-bottle option (bottles

7 AC power supply (optional)

and retainers can change)

Installation

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

Confined space precautions

D A N G E R

Explosion hazard. Training in pre-entry testing, ventilation, entry procedures, evacuation/rescue

procedures and safety work practices is necessary before entering confined spaces.

The information that follows is supplied to help users understand the dangers and risks that are

associated with entry into confined spaces.

On April 15, 1993, OSHA's final ruling on CFR 1910.146, Permit Required Confined Spaces, became

law. This standard directly affects more than 250,000 industrial sites in the United States and was

created to protect the health and safety of workers in confined spaces.

Definition of a confined space:

A confined space is any location or enclosure that has (or has the immediate potential for) one or

more of the following conditions:

An atmosphere with an oxygen concentration that is less than 19.5% or more than 23.5% and/or a

•

hydrogen sulfide (H2S) concentration that is more than 10 ppm.

• An atmosphere that can be flammable or explosive due to gases, vapors, mists, dusts or fibers.

• Toxic materials which upon contact or inhalation can cause injury, impairment of health or death.

8 English

Page 9

Confined spaces are not designed for human occupancy. Confined spaces have a restricted entry

and contain known or potential hazards. Examples of confined spaces include manholes, stacks,

pipes, vats, switch vaults and other similar locations.

Standard safety procedures must always be obeyed before entry into confined spaces and/or

locations where hazardous gases, vapors, mists, dusts or fibers can be present. Before entry into a

confined space, find and read all procedures that are related to confined space entry.

Mechanical installation

Site installation guidelines

D A N G E R

Explosion hazard. The instrument is not approved for installation in hazardous locations.

Refer to the guidelines that follow for the site location evaluation.

Obey all the safety precautions if the sampler is installed in a confined space. Refer to Confined

•

space precautions on page 8.

• Make sure that the temperature at the location is in the specification range. Refer to Specifications

on page 3.

• Install the sampler on a level surface or hang the sampler with the suspension harness, the

support bracket or the spanner bar. Refer to Install the sampler in a manhole on page 9 and to

the applicable installation documentation.

• As near the sample source as possible to decrease analysis delay. Refer to Plumb the sampler

on page 12.

• For limitations on transport velocity and maximum vertical lift, refer to Specifications on page 3.

Install the sampler in a manhole

Install the sampler above the sample water in a manhole. Install the sampler with a spanner bar or a

support bracket. Install the spanner bar inside the manhole. The spanner bar is supported by

pressure against the walls. The support bracket has the same width as the manhole cover. Install the

support bracket directly below the cover for support.Refer to the expanded manual on the

manufacturer's website.Refer to the documentation supplied with the accessories to install the

sampler.

Install the distributor or full-bottle shutoff (optional)

The distributor or full-bottle shutoff assembly is typically installed at the factory. Refer to the

distributor or full-bottle shutoff documentation for installation.

Prepare the sampler

Clean the sample bottles

Clean the sample bottles and caps with a brush, water and a mild detergent. Flush the containers

with fresh water followed by a distilled water rinse.

Install a single bottle

Use a single bottle to collect one composite sample. When the bottle is full, the full bottle shut-off

stops the sample program.

1. Clean the sample bottles. Refer to Clean the sample bottles on page 9.

2. Install the sample bottle as shown in Figure 3.

English 9

Page 10

Figure 3 Single bottle installation

1 Polyethylene bottle, 10 L (2.5 gal) (1918) 6 Polyethylene bottle, 21 L (5.5 gal) (6494)

2 Glass bottle, 10 L (2.5 gal) (6559) 7 Compact base (8975)

3 Support (1502) 8 Standard insulated base (8976)

4 Polyethylene bottle, 15 L (4 gal) (1367) 9 Standard insulated base for 21 L (5.5 gal) bottle

5 Polyethylene bottle, 19 L (5 gal) (6498)

(8561)

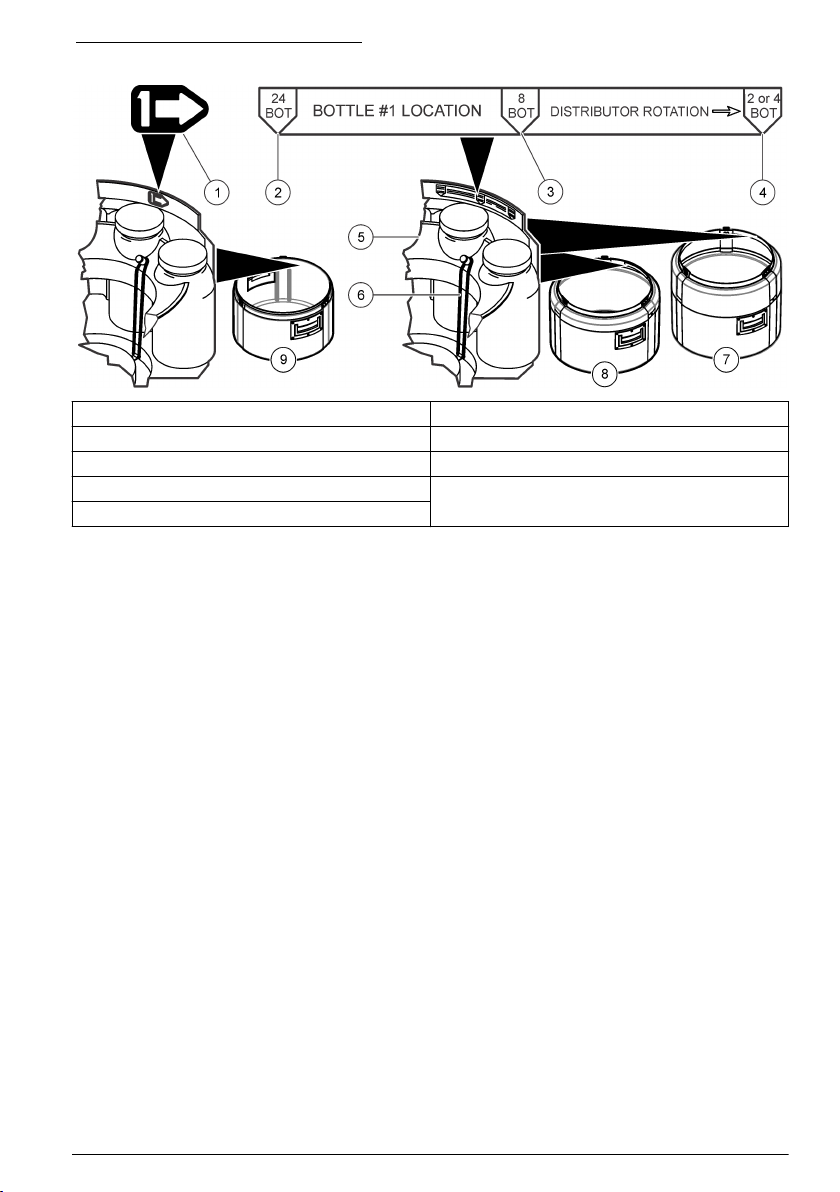

Install the first bottle for multiple sample collections

Use multiple bottles to collect samples into separate bottles or into more than one bottle. The

distributor moves the sample tube above each bottle. Install the bottles in the sampler base as shown

in Figure 4. Install the first sample bottle (number 1) below the label in the sampler base. Install the

remaining bottles in increasing numbers in the direction shown by the label. Refer to Figure 5

on page

12 for a diagram of necessary components.

10 English

Page 11

Figure 4 Bottle number 1 installation

1 Bottle number 1 location (compact base) 6 Elastic straps

2 Bottle number 1 location for 24 bottles 7 Standard insulated base for 21 L (5.5 gal) bottle

3 Bottle number 1 location for 8 bottles 8 Standad insulated base

4 Bottle number 1 location for 2 or 4 bottles 9 Compact base

5 Retainer

Install multiple bottles

When multiple bottles are installed, a distributor arm moves the sample tube over each bottle.

Sample collection automatically stops when the specified number of samples have been collected.

1. Clean the sample bottles. Refer to Clean the sample bottles on page

9.

2. Install the first sample bottle (number 1) below the label in the sampler base. Refer to Install the

first bottle for multiple sample collections on page 10.

3. Assemble the sample bottles as shown in Figure 5. For eight or more bottles, make sure that the

first bottle goes next to the bottle one indicator in the clockwise direction.

4. Put the bottle assembly in the sampler. For eight or more bottles, align the wires in the slots in the

bottom tray.

English 11

Page 12

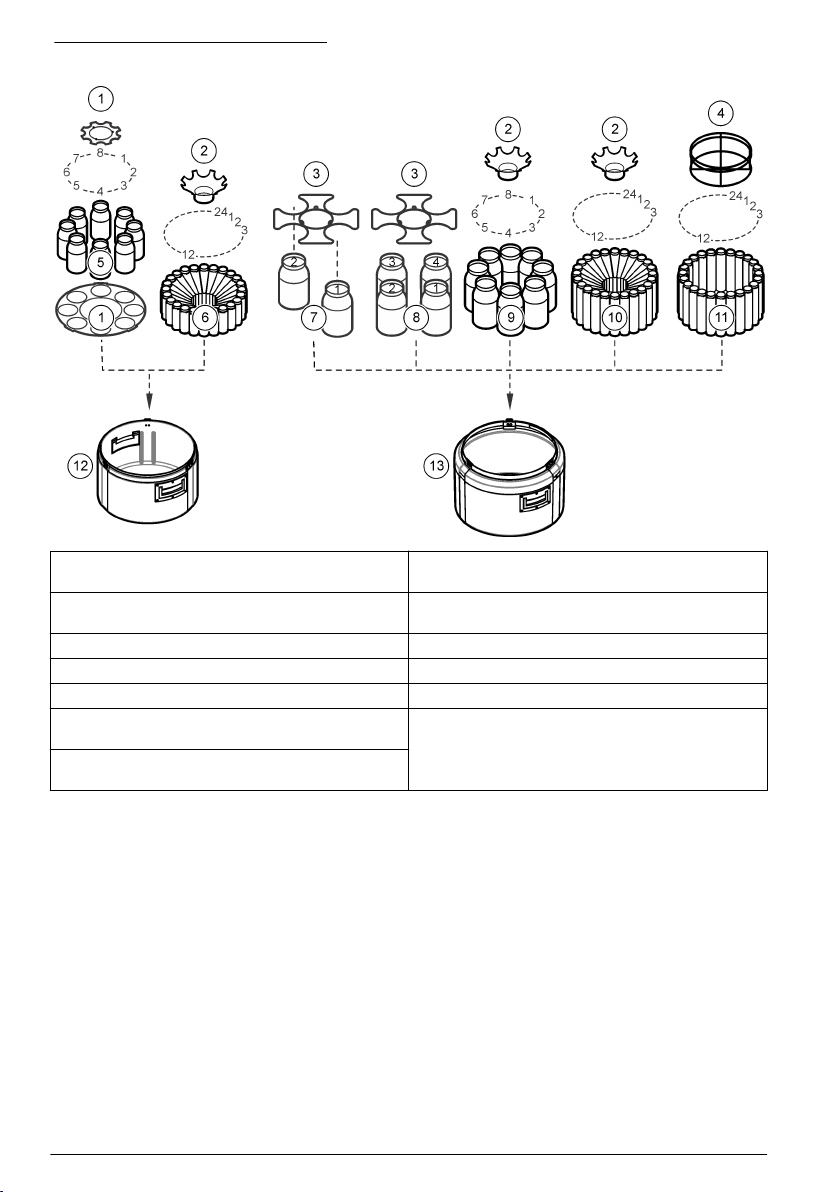

Figure 5 Multiple bottle installation

1 Positioner/retainer (2347) 8 Glass bottles, 3.8 L (1 gal), (4x) (2216) or

2 Retainer (1422) 9 Glass bottles, 1.9 L (0.5 gal), (8x) (1118) or

3 Retainer (2190) 10 Polyethylene bottles, 1 L (0.26 gal), (24x) (737)

4 Retainer (2189) 11 Glass bottles, 350 mL (11.83 oz), (24x) (732)

5 Glass bottles, 950 mL (32.12 oz) (8x) (2348) 12 Compact base (8975)

6 Polyethylene bottles, 575 mL (19.44 oz), (24x)

(1369)

7 Glass bottles, 3.8 L (1 gal), (2x) (2214) or

polyethylene bottles, 3.8 L (1 gal), (2x) (2215)

polyethylene bottles, 3.8 L (1 gal), (4x) (2217)

polyethylene bottles, 2.3 L (0.61 gal), (8x) (657)

13 Standard base (8976)

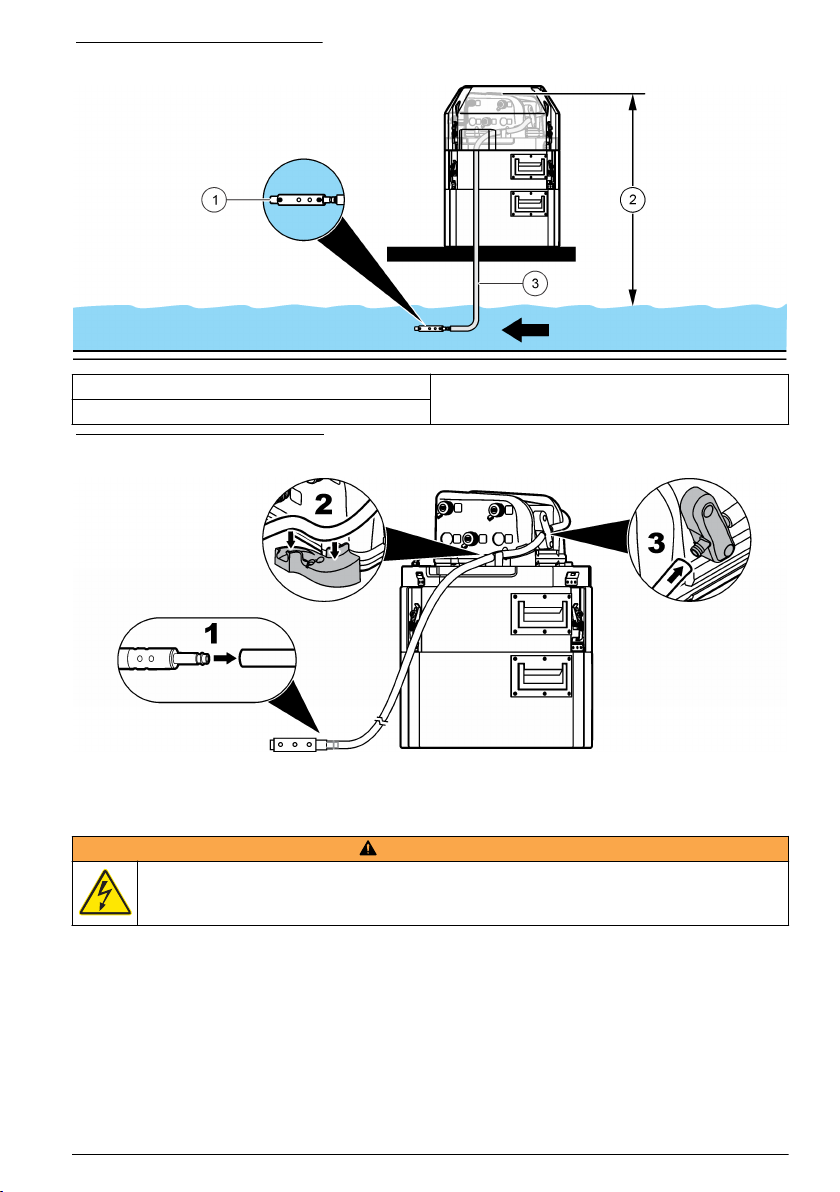

Plumb the sampler

Install the strainer in the middle of the sample stream (not near the surface or the bottom) to make

sure that a representative sample is collected. Refer to Figure 6. Refer to Figure 7 for the intake tube

installation.

1. Connect the tubing to the sampler as shown in Figure 7.

Note: Use connection kit 2186 if Teflon-lined tubing is used.

2. Install the intake tube and strainer in the main stream of the sample source where the water is

turbulent and well-mixed.

•

Make the intake tube as short as possible.

• Keep the intake tube at a maximum vertical slope so that the tube drains completely between

samples.

Note: If a vertical slope is not possible or if the tube is pressurized, disable the liquid sensor. Calibrate the

sample volume manually. Refer to Calibrate the sample volume manually on page 22.

• Make sure that the intake tube is not pinched.

12 English

Page 13

Figure 6 Instrument installation

1 Strainer 3 Intake tube

2 Vertical lift

Figure 7 Intake tube installation

Electrical installation

Controller connections

W A R N I N G

Electrical shock hazard. Externally connected equipment must have an applicable country safety

standard assessment.

Figure 8 shows the connections that can be made to the controller.

English 13

Page 14

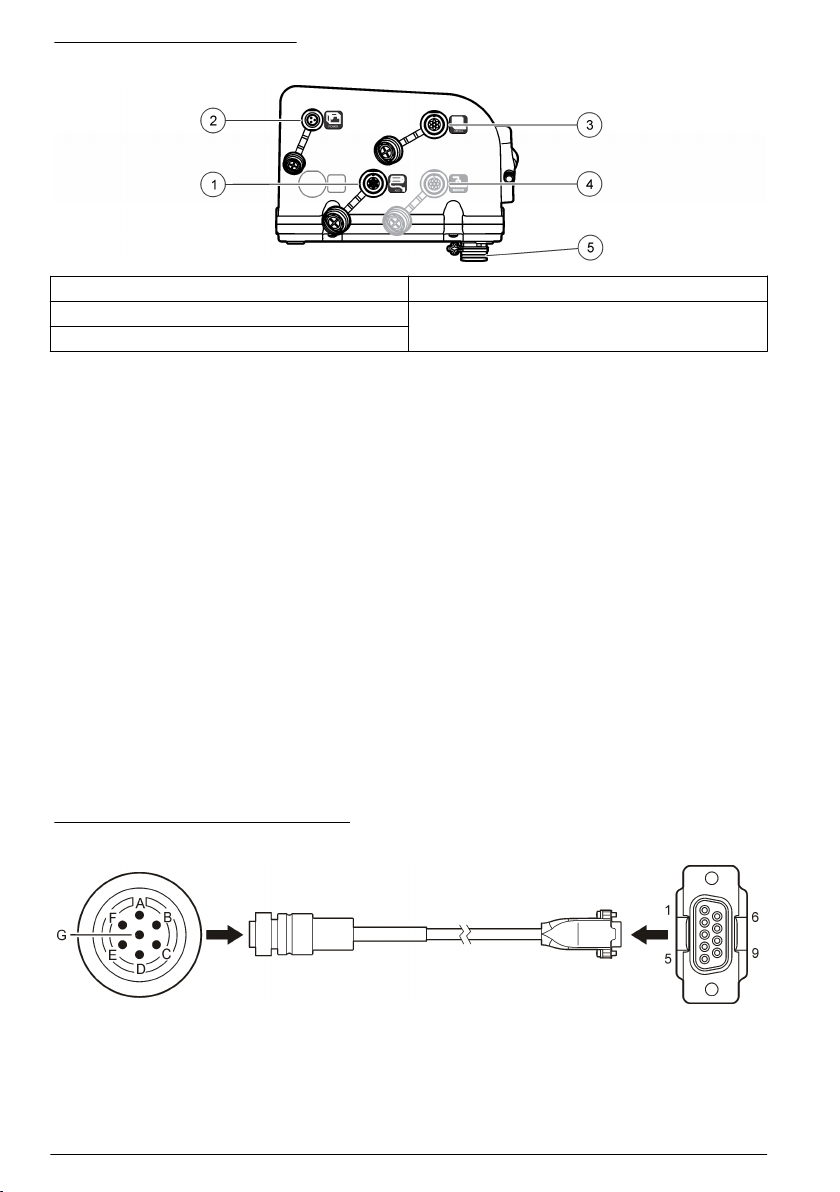

Figure 8 Controller connectors

1 Auxiliary device 4 SDI-12 device option

2 Power supply 5 Distributor/full bottle shut-off

3 Serial communications

Connect a flow meter

Connect a flow meter to the controller to start or stop the sampler when the sample flow goes above

or below a specified value.

Items to collect:

•

Multi-purpose full cable for Sigma flow meters (or 980 half cable for the model 980 flow meter).

• Optional splitter for additional connections. Two or more splitters can be connected in series.

1. Connect one end of the cable to the flow meter. For the model 980 flow meter, refer to the model

980 flow meter user manual.

2. Connect the other end of the cable to the auxiliary device connector on the controller.

Note: If the flow meter has a 6-pin cable, use the 6-pin to 7-pin adapter cable.

Connect a PC or communications network

Connect a PC or a communications network to the controller to transfer data or to configure the

sampler.

Items to collect:

• Serial cable, 7-pin RS232 to DB-9 (refer to Figure 9). Connections: B to 5 (signal ground); D to

3 (RCD); F to 2 (TXD); G (ground).

1. Connect one end of the serial cable to the communications device or network.

2. Connect the other end of the cable to the serial communications connector on the controller.

Figure 9 Serial communications cable

14 English

Page 15

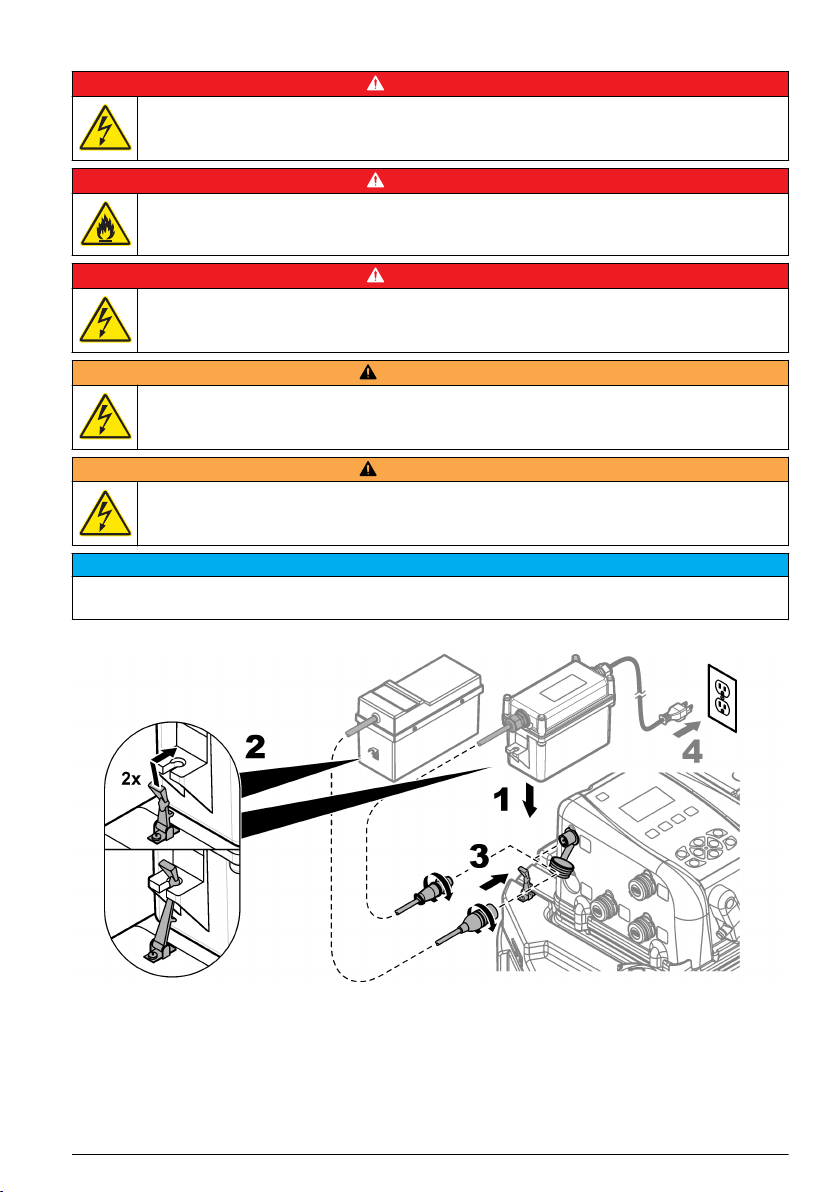

Connect the sampler to power

D A N G E R

Electrocution hazard. If this equipment is used outdoors or in potentially wet locations, a Ground Fault

Circuit Interrupt (GFCI/GFI) device must be used for connecting the equipment to its main power

source.

Fire hazard. Install a 15 A circuit breaker in the power line. A circuit breaker can be the local power

disconnect, if located in close proximity to the equipment.

Electrocution hazard. Protective Earth Ground (PE) connection is required.

Electrocution hazard. Make sure that there is easy access to the local power disconnect.

Electric shock hazard. The power supply can overheat when the time between pump cycles is too

short.

Make sure that the pump cycle time will not cause the power supply to overheat. Refer to Calculate the pump

cycle time on page

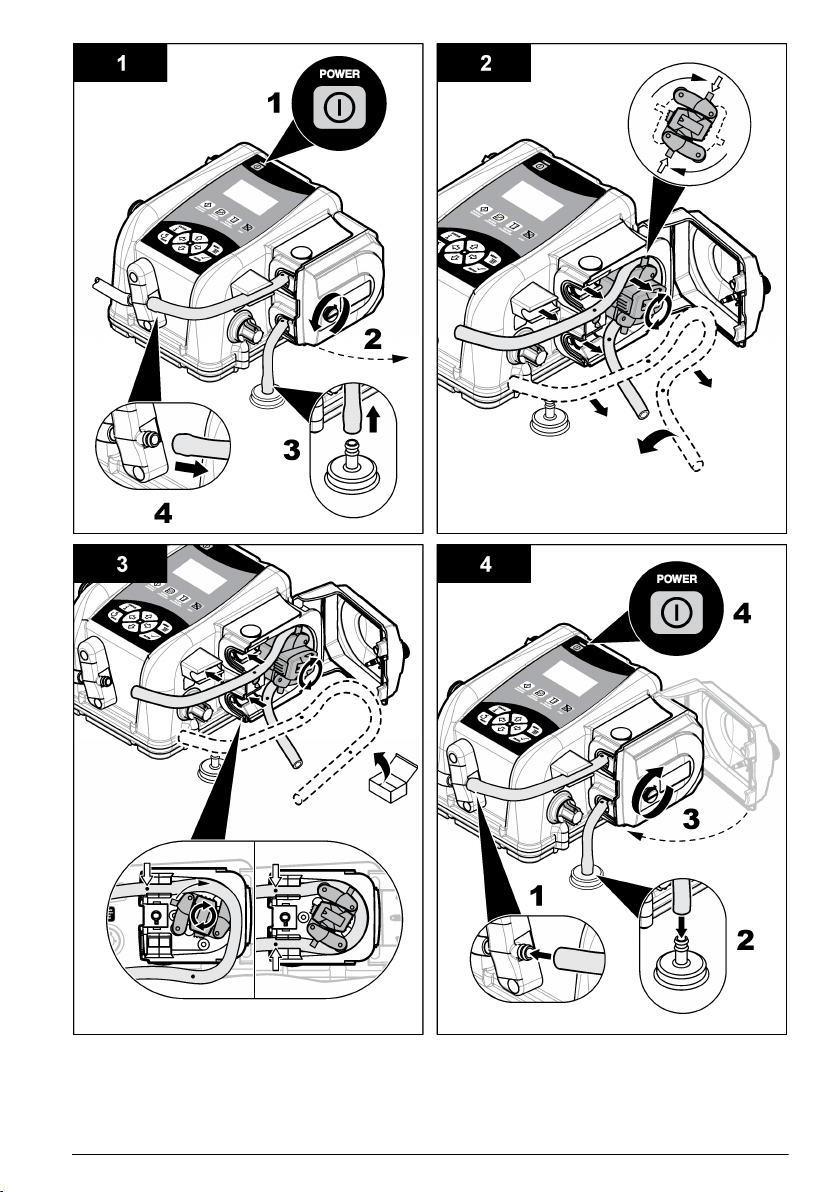

Connect the sampler to a battery or to an AC power supply. Refer to the illustrated steps that follow.

16.

D A N G E R

D A N G E R

W A R N I N G

W A R N I N G

N O T I C E

English 15

Page 16

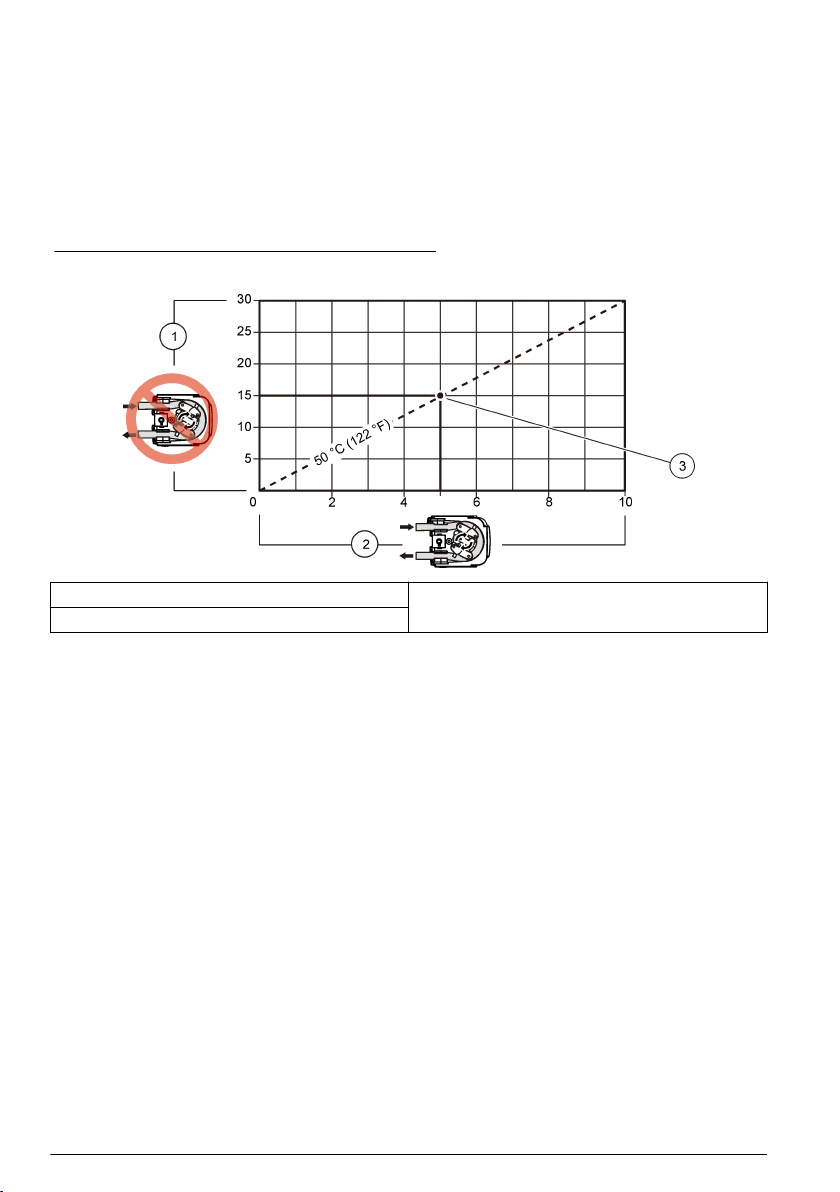

Calculate the pump cycle time

The pump must stay off for a minimum time period between sample cycles so that the power supply

does not overheat.

1. Calculate the total amount of time that the pump will run continuously during a sample cycle.

Include all stages: pre-purge, intake rinse, sample, sample retries and post-purge.

2. Find the minimum amount of time that the pump must stay off between sample cycles from

Figure 10.

3. Make sure that the pacing or time interval in the sampler program lets the pump stay off between

sample cycles for the minimum amount of time.

Figure 10 Pump on and off times at 50 °C (122 ºF)

1 Time (in minutes) that the pump must stay off 3 Example: if the pump is on continuously for

2 Time (in minutes) that the pump is on continuously

5 minutes, the pump must stay off for 15 minutes.

Set the power to on

Push the power button to set the power to on or off. Make sure that the power supply (AC power or

battery power) is correctly installed.

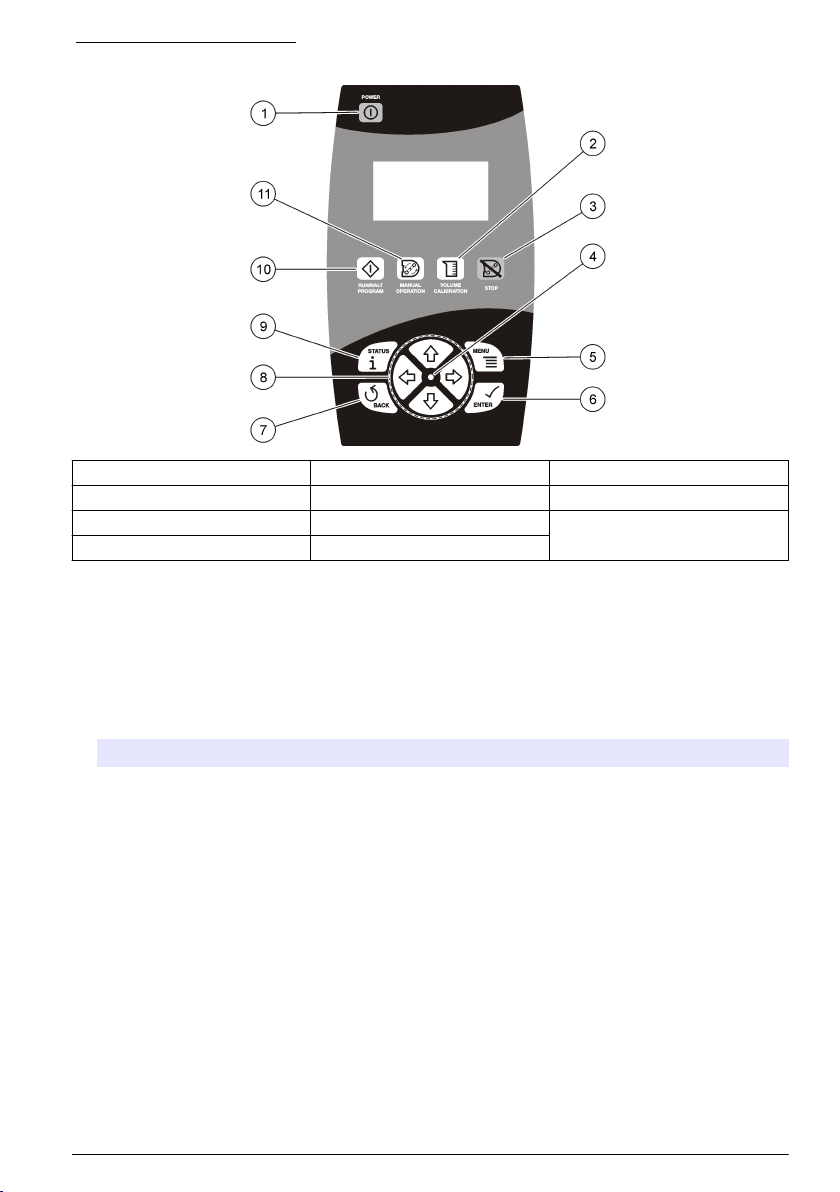

User interface and navigation

The controller keypad is shown in Figure 11. Use the MENU key to set up sampling programs,

configure the controller settings or complete the diagnostic tests. Use the arrows, ENTER and BACK

keys to scroll through the menu, make selections and enter values. Look for arrows on the bottom or

side of the display screen to know when more options are available.

16 English

Page 17

Figure 11 Controller keypad

1 POWER 5 MENU 9 STATUS

2 VOLUME CALIBRATION 6 ENTER 10 RUN/HALT PROGRAM

3 STOP 7 BACK 11 MANUAL OPERATION

4 LED 8 ARROW KEYS

Operation

Configure the system settings

1. Push MENU.

2. Go to SYSTEM SETUP.

3. Change the applicable options.

Option Description

Time/date setup Set the time (24-hour format) and date.

Communication Select the baud rate (19200, 38400, 57600 or 115200) and protocol (Modbus RTU or

Setup base Select the sampler base (All weather refrigerated, refrigerated, portable standard or

Language Select the language of the controller.

Liq sensor cal Calibrate the liquid sensor or set to default.

Set contrast Adjust the contrast of the LCD screen.

Pump duty cycle Change the pump duty cycle. Range: 50% to 100% (default: 100%).

Password setup Set up a password to control access to the program setup and the system setup menus.

ASCII) for the serial port.

portable compact).

Select ENABLE>YES to set a new password or ENABLE>NO to activate the current

password. If the password is set for the first time, use 900900 as the current password.

English 17

Page 18

Option Description

Tubing life Set a reminder when the pump tubing is to be changed. Go to ENABLE>RESET

SDI–12 (optional) Configure the operation of an SDI–12 device. This option is shown only when a device is

CYCLES to reset the pump cycle count to 0. Go to ENABLE>CYCLE LIMIT to change

the number of pump cycles that is used for the reminder. Go to ENABLE>STATUS to

show the current number of pump cycle counts.

found.

Set up a sampling program

A sampling program includes all of the parameters that are necessary to collect samples

automatically. Collect the samples at regular intervals or when the sampling program is complete.

1. Push MENU.

2. Go to PROGRAM SETUP>MODIFY ALL. The first screen is shown.

3. Select or enter the values for each parameter. Use the left and right arrow keys to move left or

right. Use the up and down arrow keys to change a value. Change the units if necessary (gal or

mL) with the arrow keys.

Option Description

Bottles Bottle quantity: the number of bottles in the sampler (1, 2, 4, 8 or 24).

Full BTL shutoff: Enabled/Disabled. If enabled, the controller checks for bottle

overflow conditions.

Bottle volume: the volume capacity of each bottle. Range: 50–65000 mL (0.01 -

17.17 gal)

Intake tubing Tubing length: the length of the intake tubing from the strainer to the liquid sensor.

Program delay Enable/disable: when enabled, the sampling program starts at a specified time or

Sample

pacing/collection

Range: 100–3000 cm or 3–99 ft. An accurate length is necessary to get an accurate

sample volume.

Intake tube type: the diameter and material of the intake tubing (¼ in. vinyl, 3/8 in.

vinyl or 3/8 in. Teflon).

number of counts. Date and time: the date and time when the program starts (24hour format). Counts: the number of counts or pulses from a flow meter when the

program will start (1 to 9999 counts). If the sample pacing is later set to time, the

program delay will be disabled.

Time based—Refer to Time based collection on page 19.

Note: When CTVV is used:

• The liquid sensor is always enabled.

• The sample distribution is composite.

• The run mode is non-continuous.

• The first sample is taken after the interval.

• Flow source is always 4–20 mA input.

Flow based—Refer to Flow based collection on page 20.

Sample distribution Deliver samples to all>YES

Liquid sensor Enable or disabled. If disabled, the sample volume must be calibrated by time.

Each sample is delivered to all bottles. End after last: program stops after the last

sample (1–999). Continuous: program continues until it is stopped manually.

Deliver samples to all>NO

Samples are delivered to a subset of bottles . Samples/bottle: the number of samples

to be collected in each bottle (1–999). Bottles/sample: The number of bottles that will

contain the same sample.

18 English

Page 19

Option Description

Sample volume The volume of each sample in mL (1 gal = 3785.4 mL). If bottles/sample mode is

Intake rinses The number of intake tube rinses before a sample is collected (0–3).

Sample retries The number of sampling tries after a sampling failure occurs (0–3).

Site ID The name for the sampling location (up to 12 characters). The site ID is used as the

Advanced sampling Goes to the advanced sampling menu. If necessary, configure the options in the

Run program The creation of the basic sampling program finishes. The sampler prompts the user

used, each bottle receives a full sample volume (10–10,000 mL). Make sure that the

sample volume does not exceed the bottle volume. Sample volumes are rounded to

the nearest 10 mL.

preset name if the program is saved.

Advanced Sampling menu.

to start or cancel the program.

Time based collection

1. Select or enter the values for each option.

Option Description

Pacing interval Collect samples at regular time intervals, in hours and minutes (0:01–999:00).

Take first sample The program starts immediately or after the first interval.

Variable volume Specify whether the sample volumes vary (flow based). If yes, refer to Use variable

Use variable volume

Sample pacing is constant time variable volume (CTVV).

volume on page 19. If no, refer to Do not use variable volume on page 20.

1. Select or enter the values for each option.

Option Description

Select unit Select the flow units to use.

Map 4 mA input Enter the flow rate that agrees with 4 mA input.

Map 20 mA input Enter the flow rate that agrees with 20 mA input.

Average flow rate Specify the average flow rate for the site (1–999,999). The units are specified by

the units selected above.

Time volume desired Specify the total volume to be collected during the sample program

(10–10,000 ml).

English 19

Page 20

Option Description

Collection period Specify the total collection period in hours and minutes (0:01–999:00).

Minimum sample volume If the flow volume is not sufficient to collect this minimum volume, the sample is

skipped (10–10,000 ml).

Do not use variable volume

1. Select or enter the values for the option.

Option Description

Take first sample Select whether the program starts immediately or after the first time interval has passed.

Flow based collection

Specify the flow source for flow based sampling:

•

Counts—Refer to Use counts for the flow source on page 20.

• 4–20 mA input—Refer to Use 4–20 mA input for the flow source on page 20.

Use counts for the flow source

1. Select or enter the values for each option.

Option Description

Take sample every Collect samples at regular flow intervals, in counts (1–9999 counts).

Overrride time Collect a sample if the flow volume is very low.

Time The maximum time between samples (0:01–999:00). The timer starts again after each

Take first sample The program starts immediately or after the first time interval.

sample is collected.

Use 4–20 mA input for the flow source

1. Select or enter the values for each option.

Option Description

Select unit Selects the flow units to use.

Map 4 mA input Enter the flow rate that would agree with the 4 mA input.

Map 20 mA input Enter the flow rate that would agree with the 20 mA input.

Take sample every Enter the total flow after which the sample has to be drawn.

Override time Select enable to push a sample to be collected if the flow volume is unusually low.

Time The maximum time between samples (0:01–999:00). The timer starts again after each

Sample volume Enter the volume to be collected per sample. If bottles/sample mode is selected, each

sample is collected.

bottle receives a full sample volume (100–10,000 mL). This option is skipped if variable

volume is selected.

Restore the default settings

The restore option sets all of the program parameters to the default settings.

20 English

Page 21

1. Push MENU.

2. Go to PROGRAM SETUP>RESTORE.

3. Select YES.

Start or stop a program

Use the RUN/HALT PROGRAM key to start or stop a program. Up to 12 user-defined start/stop

times/dates can be set. A program must be stopped before the program or system setup can be

changed.

1. Push RUN/HALT PROGRAM.

2. Select one of the options.

Option Description

Start Starts the currently loaded program. The status changes to RUNNING.

Halt Stops the program temporarily. The status changes to HALTED.

Resume The program resumes from the point at which it was halted. The status changes to

Start over The program starts from the beginning. The status changes to RUNNING.

End program Stops the currently running program. The status changes to COMPLETE.

RUNNING.

Manual operation

Use manual operation to collect a grab sample, move the distributor arm or operate the pump.

additional information, refer to the expanded version of this manual.

For

Volume calibration

The sample volume can be calibrated automatically with the liquid sensor or manually. When the

liquid sensor is used for volume calibration, the sensor is adjusted to accurately measure all

programmed volumes. If the liquid sensor is disabled, the volume for samples, rinses and stormwater

must be calibrated manually.

For typical applications, tap water can be used for the volume calibration. If the sample composition

is significantly different from typical water samples, calibrate the sampler with the liquid to be

collected. All programs must be stopped before calibration.

Calibrate the liquid sensor

The accuracy of the liquid sensor varies with the type of liquid that is sampled. For example, the

volume of a highly turbid sample may not be as accurate as that of clear water. The liquid sensor can

be calibrated with the sample water to improve volume accuracy.

1. Put the intake tubing into the sample water.

2. Push MENU.

3. Go to PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>ENABLE to make sure that

the liquid sensor is enabled.

4. Go to SYSTEM SETUP>LIQ SENSOR CAL.

5. Select PERFORM CAL.

6. Select START. The pump operates in reverse to purge the intake tube. The pump then operates

in the forward direction.

7. Look at the sample flow in the intake tube to make sure that the sample goes through the liquid

sensor.

8. When the sample goes through the liquid sensor and no bubbles are present, push STOP. The

intake tube is automatically purged. The liquid sensor calibration is complete.

9. Select DONE to exit or REPEAT to do the calibration again.

English 21

Page 22

Restore the default calibration

The volume calibration for the liquid sensor can be returned to the default factory settings.

1. Select PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>ENABLE to make sure that

the liquid sensor is enabled.

2. Push VOLUME CALIBRATION and select RESET CAL. The volume calibration is set to the

default settings. The message “value has been reset to 0” will be shown.

Calibrate the sample volume with the liquid sensor

Calibrate the sample volume with the liquid sensor enabled to adjust sample volumes slightly.

1. Go to PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>ENABLE to make sure that

the liquid sensor is enabled.

2. Put the intake tubing into the sample water or tap water.

Note: Use the sample water for best accuracy.

3. Put the tubing from the outlet side of the pump into a graduated cylinder.

4. Push VOLUME CALIBRATION and select CALIBRATION.

5. Select START. The pump operates in reverse to purge the intake tube. The pump then operates

in the forward direction and collects the sample volume that is specified in the sampling program.

The pump operates in reverse to purge the intake tube.

6. When the sample has been collected, select DONE. Compare the volume of the sample in the

graduated cylinder with the sample volume that is entered in the program setup menu.

7. If the volume that was collected is different from the sample volume in the current program, enter

the volume that was actually collected. Push ENTER. The sensor is adjusted to accurately

measure all programmed volumes.

8. Select START to start the sampling program or CANCEL to exit the volume calibration menu.

Calibrate the sample volume manually

When the liquid sensor is disabled, all volumes must be calibrated manually by time. The sample

volume is calibrated for the volume specified in the current program. If the sample volume is changed

in the program, the sample volume must be calibrated again for the new volume.

1. Select PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>DISABLE to make sure that

the liquid sensor is disabled.

2. Put the intake tubing into the sample water or tap water.

3. Put the tubing from the outlet side of the pump into a graduated cylinder.

4. Push VOLUME CALIBRATION. If more than one volume is shown, select one of the volumes for

calibration.

5. Select START. The pump operates in reverse to purge the intake tube. The pump then operates

in the forward direction and starts to collect the sample.

6. Stop the pump at the selected volume or rinse location:

•

Sample volume: push STOP when the volume that is specified in the main program is

collected.

• Rinse: push STOP when the liquid in the intake tubing gets to the liquid detector.

• Storm volume: push STOP when the volume specified in the stormwater program is collected.

7. Select DONE to go to the next volume calibration or REPEAT to do the calibration again.

8. When all volumes have been calibrated, select DONE.

9. Connect the outlet tubing to the tube fitting on the sampler.

10. Select START to start the sampling program or CANCEL to exit.

22 English

Page 23

Verify the sample volume

To make sure that the sample volume is accurate, take a grab sample. Do not go back into

calibration to check the volume since the volume compensation is reset to zero at the start of a

calibration.

1. Push MANUAL OPERATION.

2. Select GRAB SAMPLE.

3. Put the intake tubing into the sample water.

4. Put the tubing from the outlet side of the pump into a graduated cylinder.

5. If the liquid sensor is enabled, enter the volume to be verified.

6. If the liquid sensor is disabled, enter the volume that is specified in the program.

7. Push ENTER. The pump cycle starts (purge-sample-purge).

8. Compare the volume that was collected in the graduated cylinder to the expected volume. If the

collected volume is not correct, do the volume calibration again.

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

D A N G E R

Electrocution hazard. Remove power from the instrument before doing maintenance or service

activities.

W A R N I N G

Biohazard exposure. Obey safe handling protocols during contact with sample bottles and sampler

components.

W A R N I N G

Multiple hazards. The technician must make sure that the equipment operates safely and correctly

after maintenance procedures.

Clean the instrument

C A U T I O N

Fire hazard. Do not use flammable agents to clean the instrument.

N O T I C E

Do not clean the controller compartment heater with liquids of any kind.

If water is not sufficient to clean the controller and the pump, disconnect the controller and move the

controller away from the sampler. Allow sufficient time for the controller and pump to dry before the

parts are re-installed and put back into service.

Clean the sampler as follows:

Sampler enclosure—Clean the internal and external surfaces with a damp cloth and a mild

•

detergent. Do not use abrasive cleaners or solvents.

English 23

Page 24

• Sample bottles—Clean the bottles with a brush and water and a mild detergent. Rinse with fresh

water and then with distilled water. Use an autoclave to clean glass bottles if necessary.

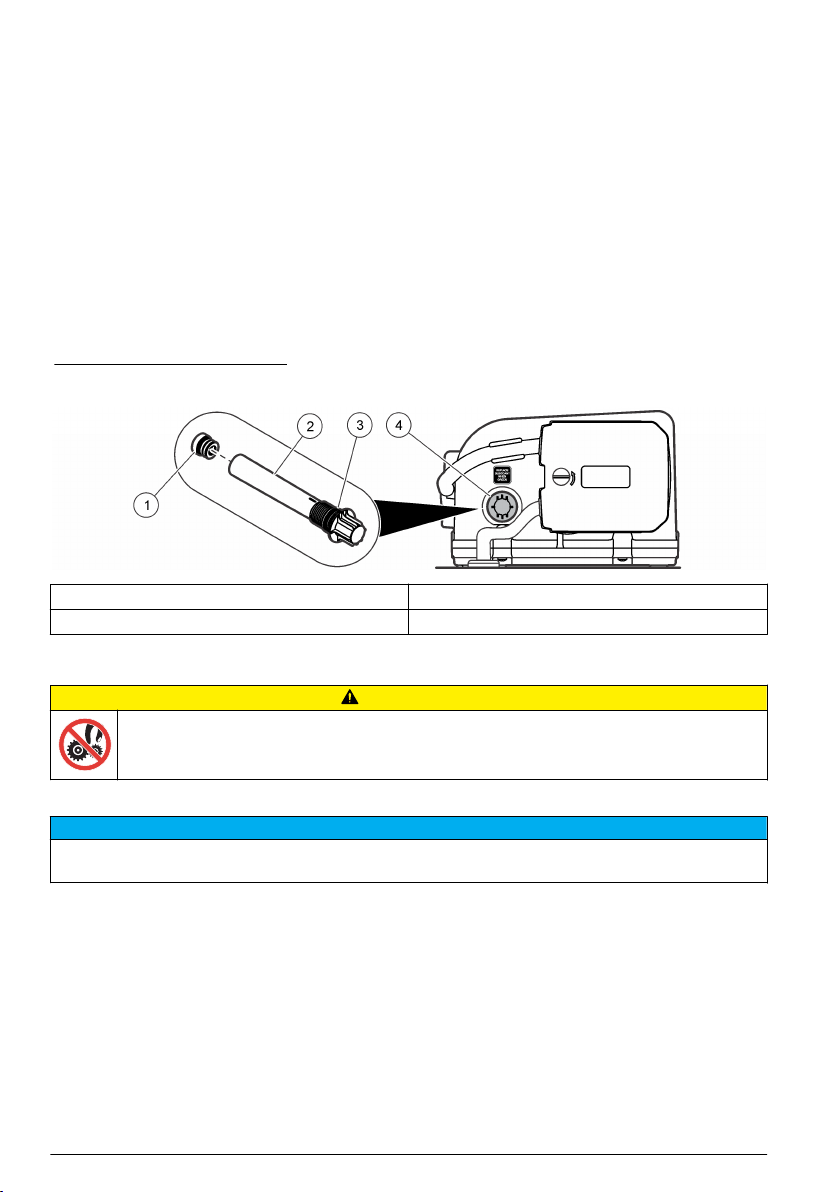

Replace the desiccant

A desiccant cartridge in the controller absorbs moisture and prevents corrosion. Monitor the

desiccant color through the window (Figure 12). Fresh desiccant is yellow. When the color is green,

replace the desiccant.

1. Unscrew and remove the desiccant cartridge (Figure 12).

2. Remove the plug and discard the spent desiccant.

3. Fill the desiccant tube with fresh desiccant.

4. Install the plug.

5. Apply grease to the O-ring.

6. Install the desiccant tube in the controller.

Figure 12 Desiccant cartridge

1 Plug 3 O-ring

2 Desiccant tube 4 Desiccant window

Pump maintenance

C A U T I O N

Pinch hazard. Remove power from the instrument before maintenance or service activities are done.

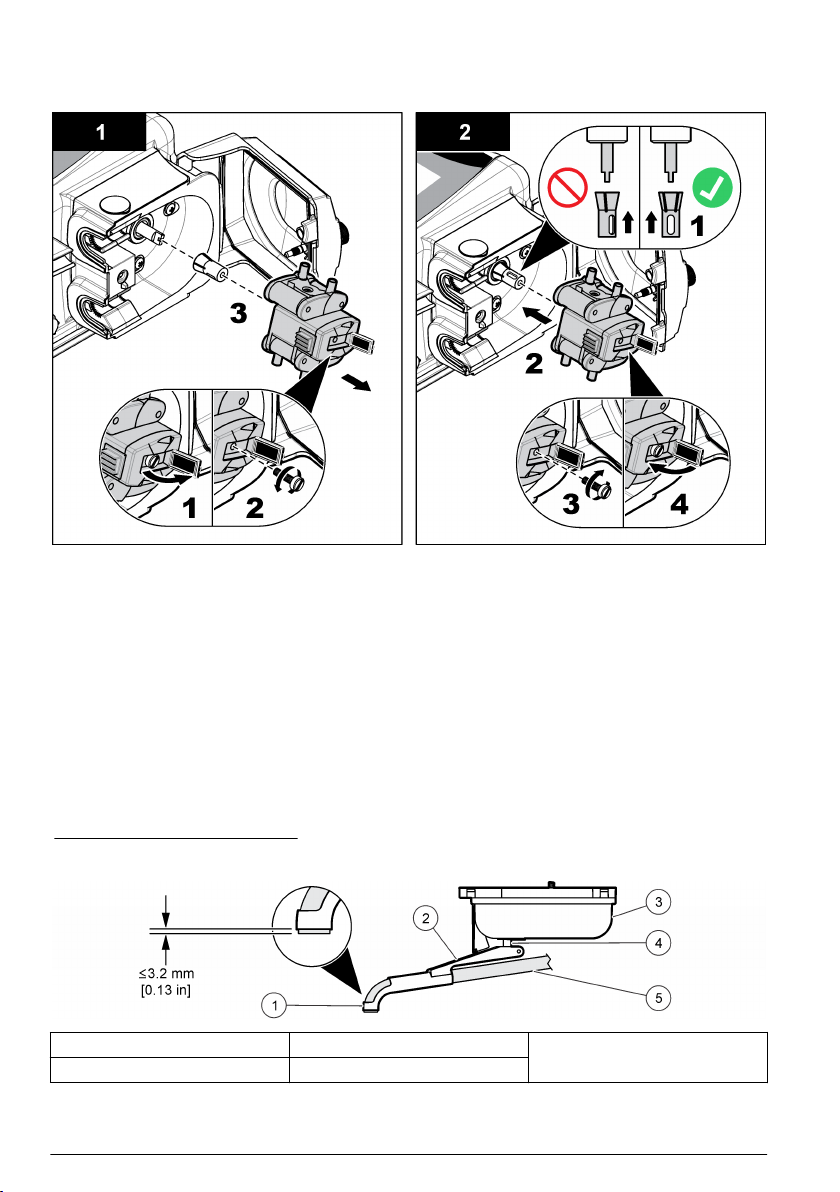

Replace the pump tubing

N O T I C E

Use of tubing other than that supplied by the manufacturer can cause excessive wear on mechanical parts and/or

poor pump performance.

Examine the pump tubing for wear where the rollers rub against the tubing. Replace the tubing when

the reminder message is shown or when the tubing shows signs of wear.

Pre-requisites:

Pump tubing—pre-cut or bulk 4.6 m or 15.2 m (15 ft or 50 ft)

•

1. Disconnect the power to the controller.

2. If the bulk tubing is used, cut the tubing and add alignment dots. Refer to the expanded manual

on the manufacturer's website.

3. Remove the pump tubing as shown in the illustrated steps that follow.

4. Clean the silicone residue from the interior of the pump housing and from the rollers.

5. Install the new pump tubing as shown in the illustrated steps that follow.

24 English

Page 25

English 25

Page 26

Clean the rotor

Clean the rotor, pump tube tracks and pump housing with a mild detergent. Refer to Replace the

pump tubing on page

24 and the illustrated steps that follow.

Replace the distributor arm tube

The distributor arm moves over each bottle during multiple bottle sampling. Replace the tube in the

distributor arm when the tube is worn. Make sure that the correct tube is used for the correct

distributor and distributor arm.

Note: The distributor tubing is not the same as the pump tubing. The pump tubing installed in the distributor

assembly can damage the distributor. Also, samples can be missed because the distributor arm cannot move

easily.

1. Remove the tube from the distributor arm and from the ceiling of the

center section.

2. Insert the new tube into the distributor arm. Make sure that the tube is aligned with the

dimensions shown in Figure 13.

3. Insert the other end of the tube into the fitting on the ceiling of the center section.

4. Complete the diagnostic test for the distributor to make sure that the operation is correct.

Figure 13 Distributor assembly

1 Nozzle 3 Distributor motor 5 Distributor tube

2 Distributor arm 4 Shaft

26 English

Page 27

Fuse replacement

The fuse is a not a user-serviceable item. Contact technical support. A blown fuse can be an

indication that

the sampler has a problem and that service is necessary.

English 27

Page 28

Inhaltsverzeichnis

Technische Daten auf Seite 28 Betrieb auf Seite 42

Allgemeine Informationen auf Seite 30 Wartung auf Seite 49

Installation auf Seite 33

Zusätzliche Informationen

Zusätzliche Informationen finden Sie auf der Website des Herstellers.

Technische Daten

Änderungen vorbehalten.

Transportabler Probenehmer SD900

Technische Daten Standard-Unterteil Kompakt-Unterteil Mischproben-

Abmessungen Durchmesser: 50.5 cm (19.9")

Höhe: 69.4 cm (27.3")

Gewicht 15 kg mit 1-Liter-PE-Flaschen

(24x)

14,8 kg mit 10-Liter-PE-Behälter

(1x)

Gehäuse Schlagfestes ABS-Gehäuse, 3-teilige Konstruktion; doppelwandiges Unterteil

(2,54 cm). Isolierung: direkter Kontakt der Flaschen mit Eis.

Probentemperatur 0–60°C (32–140 °F)

Saugköpfe Aus Edelstahl 316 in Standardgröße, mit Hochgeschwindigkeit oder mit flacher

Bauform zur Anwendung in seichten Gewässsern sowie Teflon® oder Edelstahl

316 in Standardgröße

Schlauch für Probenahme 9,5 mm I.D.-Vinyl oder PE mit Teflonbeschichtung

Probenflaschenkapazität 1-Liter-PE-Flaschen und/oder

350-ml-Glasflaschen (24x)

2,3-Liter-PE-Flaschen und/oder

1,9-Liter-Glasflaschen (8x)

3,8-Liter-PE-Flaschen und/oder

3,8-Liter-Glasflaschen (4x)

3,8-Liter-PE-Flaschen und/oder

3,8-Liter-Glasflaschen (2x)

21-Liter-PE-Verbundbehälter

oder 15-Liter-PEVerbundbehälter oder 20-LiterPE-Behälter oder 10-Liter-PEBehälter oder 10-LiterGlasbehälter (1x)

Durchmesser: 44.1 cm

(17.4")

Höhe: 61 cm (24")

12,2 kg mit 575-ml-PEFlaschen (24x)

12,9 kg mit 10-Liter-PEBehälter (1x)

575-ml-PE-Flaschen

(24x)

950-ml-Glasflaschen

(8x)

10-Liter-PE-Flaschen

(1x)

10-Liter-Glasflasche (1x)

Unterteil

Durchmesser:

50,28 cm (19,8")

Höhe: 79.75 cm

(31.4")

15 kg mit 950-mlGlasflaschen (12x)

21-Liter-PE-Flasche

(1x)

SD-Steuerung

Technische Daten Details

Größe (B x H x T) 29,2 x 17,1 x 26,4 cm

Gewicht 4.2 kg (9.26 lb)

28 Deutsch

Page 29

Technische Daten Details

Gehäuse PC/ABS-Mischung, NEMA 4X, 6, IP 67

Stromversorgung 15 V Gleichstrom von einem 8754500 Netzteil; 15 V Gleichstrom von

Überlastungsschutz 7 A, Gleichstrom-Leitungssicherung für die Pumpe

Betriebstemperatur 0 bis 50 °C (32 bis 122 °F)

Lagertemperatur -30 bis 60 °C (-22 bis 140 °F)

Luftfeuchtigkeit Lagerung/Betrieb 100%, kondensierend

Pumpe Hochgeschwindigkeits-Peristaltikpumpe mit gefederten Nylatron-

Pumpengehäuse IP37

Pumpenschläuche 9,5 mm Innendurchmesser x 15,9 mm Außendurchmesser (3/8 Zoll

Betriebsdauer der Pumpenschläuche 20.000 Probenzyklen mit: 1 l Probenvolumen, 1 Spülung, 6 Minuten

Saughöhe Maximal 8,5 m für: 8,8 m 3/8 Zoll Vinyl-Ansaugschlauch auf der

Pumpendurchflussrate 4,8 l/min bei 1 m Saughöhe mit 3/8 Zoll Ansaugschlauch typisch

Probenvolumen Programmierbar in 10-ml-Schritten von 10 bis 10.000 ml

Wiederholbarkeit des Probenvolumens

(typisch)

Genauigkeit des Probenvolumens

(typisch)

Probenahmemodi Probentakt: feste Zeit, fester Durchfluss, variable Zeit, variabler

Ausführungsmodi Kontinuierlich oder diskontinuierlich mit einer vom Benutzer

Mehrere Programme Speichert bis zu drei Programme für die Probenahme

Übertragungsgeschwindigkeit (typisch) 0,9 m/s mit: 4,6 m Saughöhe, 4,9 m 3/8 Zoll Vinyl-Ansaugschlauch,

Flüssigkeitssensor Ultraschall. Gehäuse: Ultem® entspricht der NSF ANSI Richtlinie 51,

Probenprotokoll Bis zu 510 Datensätze

Druckluftreinigung Automatische Druckluftreinigung vor und nach jeder Probenahme. Die

Ereignisprotokoll 510 Datensätze

einem integrierten Netzteil

Rollen

Innendurchmesser x 5/8 Zoll Außendurchmesser) Silikon

Taktintervall, 4,9 m 3/8 Zoll Ansaugschlauch, 4,6 m Saughöhe, 21 °C

Probentemperatur

Meereshöhe bei 20–25 ˚C

±5% bei einem Probenvolumen von 200 ml unter Verwendung nicht

kalibrierter Flüssigkeitserkennung mit einer Saughöhe von 4,6 m,

4,9 m 3/8 Zoll Vinyl-Ansaugschlauch, Einzelflasche, Abschaltung bei

voller Flasche bei Raumtemperatur und 1524 m über NN

±10 % bei einem Probenvolumen von 200 ml unter Verwendung nicht

kalibrierter Flüssigkeitserkennung mit einer Saughöhe von 4,6 m,

4,9 m 3/8 Zoll Vinyl-Ansaugschlauch, Einzelflasche, Abschaltung bei

voller Flasche bei Raumtemperatur und 1524 m über NN

Durchfluss, konstante Zeit/variables Volumen (CTVV).

Siehe Probenahme bei konstanter Zeit/variablem Volumen (CTVV) in

der erweiterten Version dieses Handbuchs.

Verteilung: Gemischt eine Flasche, gemischt mehrere Flaschen,

diskret mehrere Flaschen, Flaschen pro Probe, Proben pro Flasche,

Kombination aus Flaschen pro Probe und Proben pro Flasche

eingegebenen Probenanzahl

21 °C und 1524 m über NN

USP Klasse VI konform

Dauer wird automatisch an unterschiedliche Ansaugschlauchlängen

angepasst.

Deutsch 29

Page 30

Technische Daten Details

Anschlüsse Netzanschluss, Zusatzanschluss, serielle Datenschnittstelle, Verteiler,

Medienberührte Materialien Rostfreier Stahl, Polyethylen, Teflon, Ultem, Silikon

Datenübertragung RS232, Modbus, SDI-12

Garantie 1 Jahr

SDI-12

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führt.

G E F A H R

W A R N U N G

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

V O R S I C H T

H I N W E I S

30 Deutsch

Page 31

Warnhinweise

Lesen Sie alle am Gerät angebrachten Aufkleber und Hinweise. Nichtbeachtung kann Verletzungen

oder Beschädigungen des Geräts zur Folge haben. Im Handbuch werden auf die am Gerät

angebrachten Symbole in Form von Warnhinweisen verwiesen.

Dies ist das Sicherheits-Warnsymbol. Befolgen Sie alle Sicherheitshinweise im Zusammenhang mit

diesem Symbol, um Verletzungen zu vermeiden. Wenn es am Gerät angebracht ist, beachten Sie die

Betriebs- oder Sicherheitsinformationen im Handbuch.

Dieses Symbol weist auf eine mögliche Quetschgefahr hin.

Mit diesem Symbol gekennzeichnete elektrische Geräte dürfen europaweit nicht mehr im unsortierten

Haus- oder Gewerbemüll entsorgt werden. Geben Sie Altgeräte an den Hersteller zurück, der sie

kostenlosen für den Benutzer entsorgen muss.

Zertifizierung

Kanadische Vorschriften zu Störungen verursachenden Einrichtungen, IECS-003, Klasse A:

Entsprechende Prüfprotokolle hält der Hersteller bereit.

Dieses digitale Gerät der Klasse A erfüllt alle Vorgaben der kanadischen Normen für Interferenz

verursachende Geräte.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Teil 15, Beschränkungen der Klasse "A"

Entsprechende Prüfprotokolle hält der Hersteller bereit. Das Gerät entspricht Teil 15 der FCCVorschriften. Der Betrieb unterliegt den folgenden Bedingungen:

1. Das Gerät darf keine Störungen verursachen.

2. Das Gerät muss jegliche Störung, die es erhält, einschließlich jener Störungen, die zu

unerwünschtem Betrieb führen, annehmen.

Änderungen oder Modifizierungen an diesem Gerät, die nicht ausdrücklich durch die für die

Einhaltung der Standards verantwortliche Stelle bestätigt wurden, können zur Aufhebung der

Nutzungsberechtigung für dieses Gerät führen. Dieses Gerät wurde geprüft, und es wurde

festgestellt, dass es die Grenzwerte für digitale Geräte der Klasse A entsprechend Teil 15 der FCCVorschriften einhält. Diese Grenzwerte sollen einen angemessenen Schutz gegen

gesundheitsschädliche Störungen gewährleisten, wenn dieses Gerät in einer gewerblichen

Umgebung betrieben wird. Dieses Gerät erzeugt und nutzt hochfrequente Energie und kann diese

auch abstrahlen, und es kann, wenn es nicht in Übereinstimmung mit der Bedienungsanleitung

installiert und eingesetzt wird, schädliche Störungen der Funkkommunikation verursachen. Der

Betrieb dieses Geräts in Wohngebieten kann schädliche Störungen verursachen. In diesem Fall

muss der Benutzer die Störungen auf eigene Kosten beseitigen. Probleme mit Interferenzen lassen

sich durch folgende Methoden mindern:

1. Trennen Sie das Gerät von der Stromversorgung, um sicherzugehen, dass dieser die Störungen

nicht selbst verursacht.

2. Wenn das Gerät an die gleiche Steckdose angeschlossen ist wie das gestörte Gerät, schließen

Sie das störende Gerät an eine andere Steckdose an.

3. Vergrößern Sie den Abstand zwischen diesem Gerät und dem gestörten Gerät.

4. Ändern Sie die Position der Empfangsantenne des gestörten Geräts.

5. Versuchen Sie auch, die beschriebenen Maßnahmen miteinander zu kombinieren.

Deutsch 31

Page 32

Produktübersicht

Chemische und biologische Risiken. Wird das Gerät dazu verwendet, ein Verfahren und/oder eine

chemische Zuleitung zu überwachen, für das vorgeschriebene Grenzwerte und

Überwachungsvorschriften im Bereich der öffentlichen Sicherheit, der Gesundheit oder im Bereich der

Lebensmittel- oder Getränkeherstellung bestimmt wurden, so unterliegt es der Verantwortung des

Benutzers des Geräts, alle solche Bestimmungen zu kennen und diese einzuhalten und für

ausreichende und entsprechende Vorsorgemaßnahmen zur Einhaltung der für den Fall einer

Fehlfunktion des Geräts bestehenden Bestimmung zu sorgen.

Brandgefahr. Dieses Produkt ist nicht für den Gebrauch mit entzündbaren Flüssigkeiten geeignet.

G E F A H R

V O R S I C H T

Der transportable Probenehmer SD900 entnimmt in festgesetzten Intervallen flüssige Proben und

sammelt diese in Flaschen oder Behältern. Der

der Probennehmer ist geeignet für eine Vielzahl von

Anwendungen mit wässrigen Medien sowie für toxische Schadstoffe und Schwebstoffe. Bauen Sie

der Probennehmer mit verschiedenen Haltern, Flaschen oder Behältern auf. Siehe Abbildung 1.

Abbildung 1 Produktübersicht

1 Kompakt-Unterteil 6 Steuergerätanschlüsse

2 Isoliertes Standard-Unterteil 7 Pumpe

3 Mittelteil 8 Steuergerät

4 Stromquelle 9 Flüssigkeitssensor

5 Obere Abdeckung 10 Isoliertes Standard-Unterteil für 21-Liter-Behälter

Produktkomponenten

Stellen Sie sicher, dass Sie alle Teile erhalten haben. Siehe Abbildung 2. Wenn Komponenten fehlen

oder beschädigt sind, kontaktieren Sie bitte den Hersteller oder Verkäufer.

32 Deutsch

Page 33

Abbildung 2 Produktkomponenten

1 Unterteil (Standard, kompakt oder gemischt) 6 Ladegerät (optional)

2 Komponenten bei Verwendung nur einer Flasche

(Flasche und Halterung sind variabel)

3 Mittelteil mit Steuergerät 8 Saugkopf

4 Batterie (optional) 9 Ansaugschlauch, Vinyl oder mit Teflonbeschichtung

5 Obere Abdeckung 10 Komponenten bei Verwendung mehrerer Flaschen

7 Wechselstromversorgung (optional)

(Flaschen und Halter sind variabel)

Installation

G E F A H R

Mehrere Gefahren. Nur qualifiziertes Personal sollte die in diesem Kapitel des Dokuments

beschriebenen Aufgaben durchführen.

Vorsichtsmaßnahmen in geschlossenen Räumen

G E F A H R

Explosionsgefahr. Personen, die in begrenzten Räume arbeiten, müssen zuvor in Verfahren bezüglich

Betreten, Belüftung und Zugang, Evakuierungs-/Rettungsverfahren und sicherer Arbeitspraxis geschult

worden sein.

Die nachfolgenden Informationen sollen Benutzern helfen, die Gefahren und Risiken beim Betreten

geschlossener Räume zu verstehen.

Am 15. April 1993 wurde die endgültige Entscheidung von der OSHA (Occupational Safety and

Health Administration) zu der Regelung CFR 1910.146, Permit Required Confined Spaces

(Erforderliche Erlaubnis für geschlossene Räume), als Gesetz erlassen. Dieser Standard im Sinne

des Schutzes der Gesundheit und der Sicherheit für Arbeiter in geschlossenen Räumen betrifft mehr

als 250.000 Industriestandorte in den USA.

Definition eines geschlossenen Raums:

Ein geschlossener Raum ist ein Ort oder eine umschlossene Räumlichkeit, bei der eine oder

mehrere der folgenden Bedingungen erfüllt sind bzw. die unmittelbare Möglichkeit besteht, dass eine

oder mehrere Bedingungen erfüllt werden könnten:

Eine Atmosphäre mit einer Sauerstoffkonzentration von weniger als 19,5 % oder mehr als 23,5 %

•

und/oder einer Schwefelwasserstoff (H2S)-Konzentration von mehr als 10 ppm.

Deutsch 33

Page 34

• Eine Atmosphäre, die durch das Vorkommen von Gasen, Dämpfen, Nebel, Staub oder Fasern

leicht entzündlich oder explosiv sein könnte.

•

Toxische Materialien, die durch körperlichen Kontakt oder durch Einatmen zu Verletzungen, zur

Schädigung der Gesundheit oder zum Tod führen können.

Geschlossene Räume sind nicht geeignet für den Aufenthalt von Menschen. Geschlossene Räume

unterliegen der Zugangsbeschränkung und enthalten bekannte oder potenzielle Gefahren. Beispiele

für geschlossene Räume sind Kanalschächte, Schornsteine, Rohre, Fässer, Schaltschränke und

andere ähnliche Orte.

Vor dem Betreten solcher geschlossener Räume und/oder Orte, an denen gefährliche Gase,

Dämpfe, Nebel, Staub oder Fasern vorhanden sein können, müssen immer alle

Standardsicherheitsmaßnahmen beachtet werden. Vor dem Betreten eines geschlossenen Raums

müssen alle Verfahren im Bezug auf das Betreten von geschlossenen Räumen in Ermittlung

gebracht und gelesen werden.

Mechanische Montage

Richtlinien für Standortinstallation

G E F A H R

Explosionsgefahr. Das Gerät ist nicht für den Einsatz in explosionsgefährdeten Bereichen zugelassen.

Beachten Sie für die Standortbewertung die folgenden Richtlinien.

Befolgen Sie alle Sicherheitshinweise, wenn der der Probennehmer in einem geschlossenen

•

Raum installiert ist. Siehe Vorsichtsmaßnahmen in geschlossenen Räumen auf Seite 33.

• Stellen Sie sicher, dass sich die Standorttemperatur innerhalb des spezifizierten Bereichs befindet.

Siehe Technische Daten auf Seite 28.

• Installieren Sie der Probennehmer auf einem ebenen Untergrund oder hängen Sie der

Probennehmer mit dem Aufhängegürtel, der Halterung oder der Spannvorrichtung auf. Siehe

Installation der Probennehmer in einem Kanalschacht auf Seite 34 und die entsprechende

Installationsdokumentation.

• So nah wie möglich an der Probenquelle, um Verzögerungen bei der Analyse zu verringern. Siehe

Anschließen des Probennehmers auf Seite 37.

• Angaben zu Transportgeschwindigkeitsgrenzen und maximalem Hub finden Sie in Technische

Daten auf Seite 28

Installation der Probennehmer in einem Kanalschacht

Installieren Sie der Probennehmer in einem Kanalschacht oberhalb des Probenwassers. Installieren

Sie der Probennehmer mit einer Spannvorrichtung oder einer Halterung. Installieren Sie die

Spannvorrichtung im Kanalschacht. Die Spannvorrichtung wird zwischen den Wänden eingeklemmt

und durch den Druck, den sie auf die Wände ausübt, gehalten. Die Halterung ist genauso breit wie

die Abdeckung des Kanalschachts. Installieren Sie die Halterung direkt unterhalb der

Abdeckung.Weitere Angaben finden Sie in der ausführlichen Bedienungsanleitung auf der Website

des Herstellers.Befolgen Sie bei der Installation der Probennehmer die Anweisungen in der mit dem

Zubehör gelieferten Dokumentation.

Installation des Verteilers / der Abschaltung bei max. Flaschenfüllstand (optional)

Die Baugruppe für Verteiler / Abschaltung bei max. Flaschenfüllstand wird normalerweise werksseitig

installiert. Befolgen Sie die Installationsanweisungen in der Dokumentation von Verteiler /

Abschaltung bei max. Flaschenfüllstand.

Vorbereiten des Probennehmers

Reinigen der Probenflaschen

Reinigen Sie die Probenflaschen und Kappen mit einem Pinsel, Wasser und milden

Reinigungsmittel. Spülen Sie die Sammelbehälter zuerst mit Frischwasser und danach mit

destilliertem Wasser.

34 Deutsch

Page 35

Installieren einer Einzelflasche

Verwenden Sie eine Einzelflasche, um eine Mischprobe zu nehmen. Wenn die Flasche voll ist, wird

das Probennahmeprogramm gestoppt.

1. Reinigen der Probenflaschen. Siehe Reinigen der Probenflaschen auf Seite 34.

2. Installieren Sie die Probenflasche wie in Abbildung 3 gezeigt.

Abbildung 3 Installation des Einzelflaschengeräts

1 PE-Flasche, 10 Liter (1918) 6 PE-Flasche, 21 Liter (6494)

2 Glasflasche, 10 Liter (6559) 7 Kompakt-Unterteil (8975)

3 Halterung (1502) 8 Isoliertes Standard-Unterteil (8976)

4 PE-Flasche, 15 Liter (1367) 9 Isoliertes Standard-Unterteil für 21 Liter (8561)

5 PE-Flasche, 19 Liter (6498)

Installation der ersten Flasche bei Entnahme mehrerer Proben

Bei Mehrflaschengeräten können Sie Proben auf separate Flaschen oder eine Probe auf mehr als

eine Flasche aufziehen. Der Verteiler führt den Probenschlauch über jede Flasche. Setzen Sie die

Flaschen wie in Abbildung 4 gezeigt in das Unterteil des Probenehmers ein. Positionieren Sie die

erste Probenflasche (Nr. 1) unter der entsprechenden Markierung im Unterteil des Probenehmers.

Setzen Sie die verbleibenden Flaschen mit steigender Nummerierung in der auf der Markierung

angegebenen Richtung ein. Eine Darstellung der erforderlichen Komponenten finden Sie in

Abbildung 5 auf Seite 37.

Deutsch 35

Page 36

Abbildung 4 Installation von Flasche Nr. 1

1 Position von Flasche Nr. 1 (Kompakt-Unterteil) 6 Elastische Riemen

2 Position von Flasche Nr. 1 bei 24 Flaschen 7 Isoliertes Standard-Unterteil für 21-Liter-Flasche

3 Position von Flasche Nr. 1 bei 8 Flaschen 8 Isoliertes Standard-Unterteil

4 Position von Flasche Nr. 1 bei 2 oder 4 Flaschen 9 Kompakt-Unterteil

5 Halter

Installieren mehrerer Flaschen

Wenn mehrere Flaschen installiert sind, bewegt der Verteilerarm den Probenschlauch über die

einzelnen Flaschen. Die Probennahme wird automatisch gestoppt, wenn die festgelegte Anzahl an

Proben genommen wurde.

1. Reinigen der Probenflaschen. Siehe Reinigen der Probenflaschen auf Seite 34.

2. Positionieren Sie die erste Probenflasche (Nr. 1) unter der entsprechenden Markierung im

Unterteil des Probenehmers. Siehe Installation der ersten Flasche bei Entnahme mehrerer

Proben auf Seite

35.

3. Bauen Sie die Probenflaschen wie in Abbildung 5 gezeigt zusammen. Stellen Sie bei acht oder

mehr Flaschen sicher, dass die erste Flasche neben der Anzeige für Flasche eins und alle

anderen im Uhrzeigersinn eingesetzt werden.

4. Setzen Sie die Flaschenbaugruppe in den Probennehmer ein. Verlegen Sie bei acht oder mehr

Flaschen die Kabel unten in den Schlitzen der Flaschenablage.

36 Deutsch

Page 37

Abbildung 5 Installation des Mehrflaschengeräts

1 Positionierer/Halter (2347) 8 Glasflaschen 3,8 Liter, (4x) (2216) oder PE-

2 Halter (1422) 9 Glasflaschen 1,9 Liter, (8x) (1118) oder PE-

3 Halter (2190) 10 PE-Flaschen, 1 Liter, (24x) (737)

4 Halter (2189) 11 Glasflaschen, 350 ml, (24x) (732)

5 Glasflaschen, 950 ml, (8x) (2348) 12 Kompakt-Unterteil (8975)

6 PE-Flaschen, 575 ml, (24x) (1369) 13 Standard-Unterteil (8976)

7 Glasflaschen 3,8 Liter, (2x) (2214) oder PE-

Flaschen, 3,8 Liter, (2x) (2215)

Flaschen, 3,8 Liter, (4x) (2217)

Flaschen, 2,3 Liter, (8x) (657)

Anschließen des Probennehmers

Installieren Sie den Saugkopf in der Mitte des Probenstroms (nicht in der Nähe der Oberfläche oder

des Bodens), um sicherzustellen, dass eine repräsentative Probe genommen wird. Siehe

Abbildung 6. Informationen zur Installation des Ansaugschlauchs finden Sie in Abbildung 7.

1. Schließen Sie die Schläuche wie in Abbildung 7 gezeigt an den Probennehmer an.

Hinweis: Verwenden Sie Anschlusskit 2186, wenn Schläuche mit Teflonbeschichtung verwendet werden.

2. Setzen Sie den Ansaugschlauch und den Saugkopf in den Hauptstrom der Probenquelle ein, wo

das Wasser turbulent und gut durchmischt ist.

•

Halten Sie den Ansaugschlauch so kurz wie möglich.

• Halten Sie den Ansaugschlauch nahezu senkrecht, sodass der Schlauch zwischen Proben

vollständig geleert werden kann.

Hinweis: Wenn eine nahezu senkrechte Position nicht möglich ist oder der Schlauch unter Druck steht,

deaktivieren Sie den Flüssigkeitssensor. Manuelles Kalibrieren des Probenvolumens. Siehe Manuelles

Kalibrieren des Probenvolumens auf Seite 48.

• Vergewissern Sie sich, dass der Ansaugschlauch nicht eingeklemmt ist.

Deutsch 37

Page 38

Abbildung 6 Geräteinstallation

1 Saugkopf 3 Ansaugschlauch

2 Saughöhe

Abbildung 7 Installation des Ansaugschlauchs

Elektrische Installation

Steuergerätanschlüsse

W A R N U N G

Stromschlaggefahr. Extern angeschlossene Geräte müssen über eine entsprechende

Sicherheitsnormenbeurteilung des jeweiligen Landes verfügen.

Abbildung 8 zeigt die Anschlüsse, die am Steuergerät möglich sind.

38 Deutsch

Page 39

Abbildung 8 Steuergerätstecker

1 Zusatzgerät 4 SDI-12-Geräteoption

2 Netzteil 5 Abschalten Verteiler/volle Flasche

3 Serielle Kommunikation

Anschließen eines Durchflussmessgeräts

Schließen Sie ein Durchflussmessgerät an die Steuerung an, um den Probennehmer zu starten oder

zu stoppen, wenn der Probenfluss einen festgelegten Wert über- oder unterschreitet.

Zusätzlich erforderliche Artikel:

•

Mehrzweck-Vollkabel für Durchflussmessgeräte vom Typ Sigma (oder 980er Halbkabel für

Durchflussmessgerät, Modell 980).

• Optionaler Splitter für zusätzliche Verbindungen. Sie können zwei oder mehr Splitter in Reihe

schalten.

1. Verbinden Sie ein Ende des Kabels mit dem Durchflussmessgerät. Für das Durchflussmessgerät

vom Modell 980 siehe die Bedienungsanleitung für das Modell 980.

2. Verbinden Sie das andere Kabelende mit dem Anschluss für das Zusatzgerät an der Steuerung.

Hinweis: Wenn das Durchflussmessgerät ein 6-poliges Kabel hat, verwenden Sie das 6-Pol-zu-7-PolAdapterkabel.

Verbinden mit einem PC oder Kommunikationsnetzwerk

Verbinden Sie die Steuerung mit einem PC oder Kommunikationsnetzwerk, um Daten zu übertragen

oder den Probennehmer zu konfigurieren.

Zusätzlich erforderliche Artikel:

• Serielles Kabel, 7-polig RS232 zu DB-9 (siehe Abbildung 9). Anschlüsse: B zu 5 (Signalmasse); D

zu 3 (RCD); F zu 2 (TXD); G (Masse).

1. Schließen Sie ein Ende des seriellen Kabels an das Kommunikationsgerät oder das Netzwerk an.

2. Verbinden Sie das andere Kabelende mit dem seriellen Kommunikationsanschluss an der

Steuerung.

Abbildung 9 Serielles Kommunikationskabel

Deutsch 39

Page 40

Anschluss der Probennehmer an eine Stromquelle

G E F A H R

Lebensgefahr durch Stromschlag. Wenn dieses Gerät im Freien oder an potenziell feuchten Standorten

eingesetzt wird, muss eine Fehlerstrom-Schutzeinrichtung zum Anschluss an die Netzversorgung

verwendet werden.

Brandgefahr. Installieren Sie einen 15 A-Leitungsschutzschalter in der Netzleitung. Ein

Leitungsschutzschalter kann die örtliche Netzabschaltung sein, wenn sie sich in nächster Nähe zur

Ausrüstung befindet.

Lebensgefahr durch Stromschlag. Es ist eine Schutzerdung erforderlich.

Lebensgefahr durch Stromschlag. Stellen Sie sicher, dass die örtliche Netzabschaltung leicht

zugänglich ist.

Gefahr von elektrischen Schlägen. Die Stromversorgung kann sich überhitzen, wenn die Zeit zwischen

den Pumpzyklen zu kurz ist.

Stellen Sie sicher, dass die Pumpenzykluszeit nicht zu einer Überhitzung der Stromversorgung führt. Siehe

Berechnen der Pumpendurchlaufzeit auf Seite 41

Schließen Sie der Probennehmer an eine Batterie oder eine Wechselstsromquelle an. Siehe die

folgenden bebilderten Schritte.

G E F A H R

G E F A H R

W A R N U N G

W A R N U N G

H I N W E I S

.

40 Deutsch

Page 41

Berechnen der Pumpendurchlaufzeit

Zwischen Probenzyklen muss die Pumpe für eine Mindestzeit ausgeschaltet bleiben, damit die

Stromversorgung nicht überhitzt.

1. Berechnen Sie, wie lange die Pumpe während eines Beprobungszyklus insgesamt kontinuierlich

läuft. Beziehen Sie dabei alle Stufen mit ein: Vorspülen, Spülen des Ansaugschlauchs,

Ansaugversuche und Nachspülen.

2. Entnehmen Sie die Zeit, die die Pumpe zwischen Probenzyklen ausgeschaltet bleiben muss, aus

Abbildung 10.

3. Stellen Sie sicher, dass die Schrittsteuerung oder das Zeitintervall im Probennehmerprogramm

der Pumpe erlauben, zwischen Probenzyklen für den Mindestzeitraum ausgeschaltet zu bleiben.

Abbildung 10 Ein- und Ausschaltzeiten der Pumpe bei 50 °C

1 Zeit (in Minuten), während der die Pumpe

ausgeschaltet bleiben muss

2 Zeit (in Minuten), während der die Pumpe ohne

Unterbrechung läuft

3 Beispiel: Wenn die Pumpe 5 Minuten ohne

Unterbrechung läuft, muss die Pumpe 15 Minuten

lang ausgeschaltet bleiben.

Einschalten

Drücken Sie die Einschalttaste, um das Messgerät ein- oder auszuschalten. Vergewissern Sie sich,

dass die Stromversorgung (Netzstrom oder Batteriebetrieb) korrekt installiert ist.

Benutzerschnittstelle und Navigation

Die Tastatur der Steuerung ist in Abbildung 11 dargestellt. Verwenden Sie die Taste MENU, um

Probennahmeprogramme einzurichten, die Steuerungseinstellungen zu konfigurieren oder die

Diagnosetests durchzuführen. Verwenden sie die Pfeile, ENTER- und BACK-Tasten, um durch die

Menüs zu blättern, Auswahlen zu treffen und Werte einzugeben. Pfeile am unteren Rand oder an der

Seite des Bildschirms zeigen an, dass weitere Optionen zur Verfügung stehen.

Deutsch 41

Page 42

Abbildung 11 Tastatur der Steuerung

1 POWER 5 MENÜ 9 STATUS

2 VOLUME CALIBRATION

(VOLUMENKALIBRIERUNG)

3 STOP (STOPP) 7 ZURÜCK 11 MANUAL OPERATION

4 LED 8 ARROW KEYS (PFEILTASTEN)

6 ENTER 10 RUN/HALT PROGRAM

(PROGRAMM

STARTEN/ANHALTEN)

(MANUELLER BETRIEB)

Betrieb

Konfigurieren der Systemeinstellungen

1. Drücken Sie auf MENU (MENÜ).

2. Gehen Sie zu SYSTEMKONFIGURATION.

3. Ändern Sie die entsprechenden Optionen.

Optionen Beschreibung

Zeit/Datum einstellen Einstellen der Uhrzeit (24-Stunden-Format) und des Datums.

Kommunikation Auswählen der Datenübertragungsgeschwindigkeit (19200, 38400, 57600 oder

Unterteil einrichten Auswählen des Probennehmer-Unterteils (wetterfest gekühlt, gekühlt, tragbares

Sprache Auswählen der Sprache der Steuerung

Flüss.Sens.Ka Kalibrierung des Flüssigeitssensors oder Übernahme der Standardeinstellungen.

Kontrast einst Einstellen des Kontrasts auf dem LCD-Bildschirm.

Pumpenbetriebszyklus Ändern des Pumpenbetriebszyklus Bereich: 50 % bis 100 % (Standardwert:

42 Deutsch

115200) und des für den seriellen Anschluss verwendeten Protokolls (Modbus

RTU oder ASCII)

Standard-Unterteil oder tragbares Kompakt-Unterteil).

100 %).

Page 43

Optionen Beschreibung

Kennwort-Setup Einrichten eines Kennworts zur Steuerung des Zugriffs auf die

Schlauchzyklus Einstellen einer Erinnerung zum Austauschen des Pumpenschlauchs. Gehen Sie

SDI-12 (optional) Konfigurieren der Bedienung eines SDI-12-Geräts. Diese Option wird nur

Programmkonfiguration und die Systemkonfigurationsmenüs. Wählen Sie

AKTIVIEREN>JA, um ein neues Kennwort festzulegen, oder AKTIVIEREN>NEIN,

um das aktuelle Kennwort zu aktivieren. Wenn zum ersten Mal ein Kennwort

festgelegt wird, verwenden Sie 900900 als aktuelles Kennwort.

zu AKTIVIEREN>ZYKLEN ZURÜCKSETZEN, um den Zähler des Pumpenzyklus

auf 0 zu setzen. Gehen Sie zu AKTIVIEREN>ZYKLUSGRENZWERT, um die

Anzahl der Pumpenzyklen zu ändern, die als Erinnerung verwendet werden.

Gehen Sie zu AKTIVIEREN>STATUS, um die aktuelle Zahl im Zähler des

Pumpenzyklus anzuzeigen.

angezeigt, wenn ein Gerät gefunden wurde.