Page 1

DOC026.52.80437

SD900 Portable Sampler

03/2014, Edition 1

User Manual

Page 2

Page 3

Table of Contents

Specifications..............................................................................................................3

General information..................................................................................................4

Safety information........................................................................................................5

Use of hazard information....................................................................................5

Precautionary labels.............................................................................................5

Certification........................................................................................................... 5

Product overview.........................................................................................................6

Product components....................................................................................................7

Installation.....................................................................................................................8

Confined space precautions........................................................................................8

Mechanical installation

Site installation guidelines....................................................................................8

Install the sampler in a manhole...........................................................................9

Install the distributor or full-bottle shutoff (optional)..............................................9

Prepare the sampler.............................................................................................9

Clean the sample bottles...............................................................................9

Install a single bottle......................................................................................9

Install the first bottle for multiple sample collections.....................................9

Install multiple bottles..................................................................................10

Plumb the sampler......................................................................................11

Electrical installation..................................................................................................12

Controller connections........................................................................................12

Connect a flow meter.......................................................................................... 13

Connect a PC or communications network........................................................13

Connect an SDI-12 device.................................................................................. 14

Connect the sampler to power............................................................................ 14

Calculate the pump cycle time............................................................................ 15

Close the cover..........................................................................................................16

................................................................................................. 8

Set the power to on.................................................................................................16

User interface and navigation............................................................................16

Operation.....................................................................................................................17

Main menu overview..................................................................................................17

Configure the system settings...................................................................................17

Configure the SDI-12 device..............................................................................18

Set up a sampling program........................................................................................ 19

Time based collection.........................................................................................21

Use variable volume....................................................................................21

Do not use variable volume.........................................................................21

Flow based collection.........................................................................................21

Use counts for the flow source....................................................................21

Use 4–20 mA input for the flow source.......................................................22

Review or modify program settings....................................................................22

Save or load programs.......................................................................................22

Restore the default settings................................................................................22

Constant Time Variable Volume (CTVV) sampling............................................23

1

Page 4

Table of Contents

Start or stop a program..............................................................................................24

View the program status............................................................................................24

Manual operation.......................................................................................................24

Collect a grab sample.........................................................................................24

Move the distributor arm.....................................................................................25

Start or stop the pump........................................................................................25

View data...................................................................................................................25

View the sample history...................................................................................... 25

View the event log..............................................................................................26

Event log information

Erase the event log.....................................................................................26

View data from SDI-12 devices..........................................................................26

Volume calibration.....................................................................................................27

Calibrate the liquid sensor..................................................................................27

Restore the default calibration............................................................................27

Calibrate the sample volume with the liquid sensor...........................................27

Calibrate the sample volume manually............................................................... 28

Verify the sample volume...................................................................................28

Full bottle shutoff.......................................................................................................28

Activate the full bottle shutoff.............................................................................. 29

Enable the full bottle shutoff...............................................................................29

Full bottle shutoff in non-continuous mode.........................................................29

Full bottle shut off in continuous mode...............................................................29

Full bottle shutoff and timed bottle mode....................................................30

Full bottle shutoff exception conditions............................................................... 30

................................................................................... 26

Advanced sampling................................................................................................30

Send output signal at program completion................................................................30

Send output signal with sample cycle (special output)..............................................31

Operate from an external signal (setpoint sample)....................................................31

Use an SDI-12 device for setpoint sampling .....................................................31

Set multiple start and stop times................................................................................ 32

Collect first flush stormwater samples.......................................................................33

Set variable intervals.................................................................................................33

Timed bottle sets.......................................................................................................34

Maintenance...............................................................................................................34

Clean the instrument.................................................................................................. 35

Replace the desiccant...............................................................................................35

Pump maintenance....................................................................................................36

Replace the pump tubing.................................................................................... 36

Clean the rotor....................................................................................................38

Replace the distributor arm tube................................................................................ 39

Fuse replacement......................................................................................................39

Troubleshooting.......................................................................................................39

General troubleshooting............................................................................................39

Error messages.........................................................................................................40

Diagnostic tests.........................................................................................................42

Replacement parts and accessories...............................................................42

2

Page 5

Specifications

Specifications are subject to change without notice.

SD900 Portable Sampler

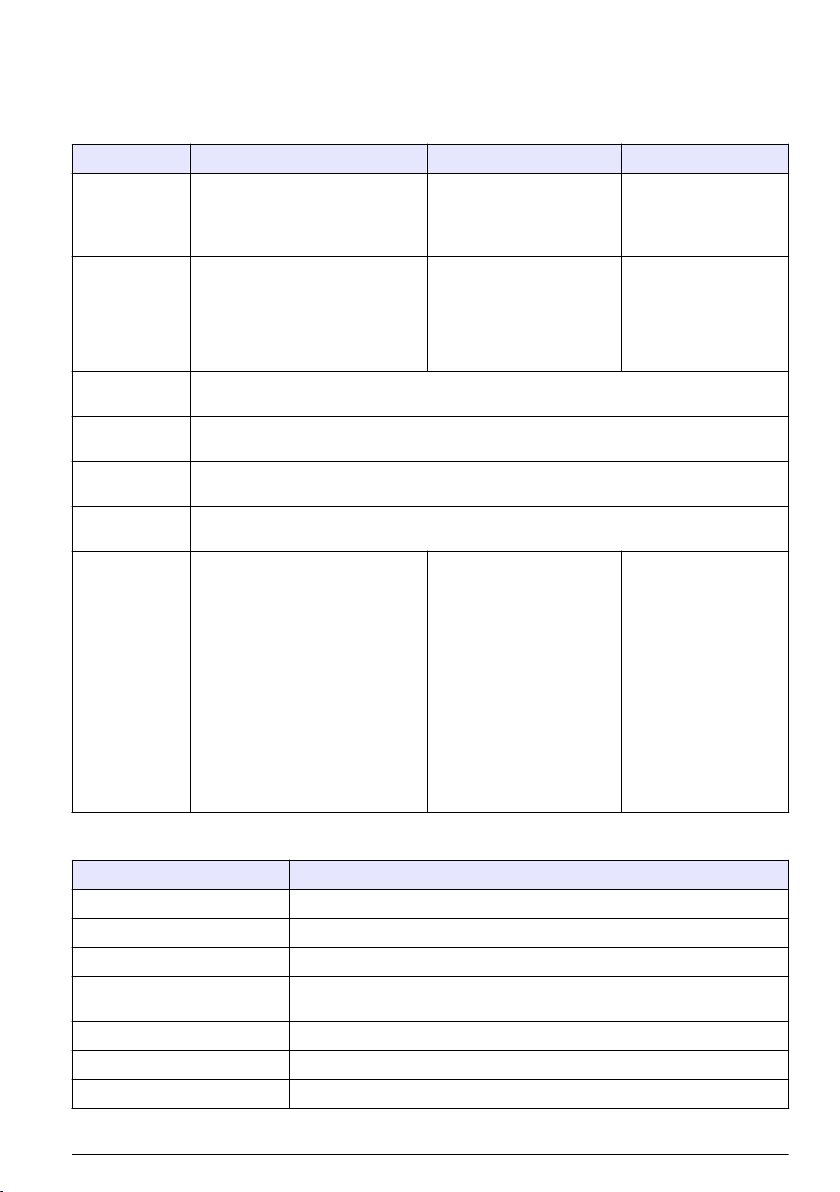

Specification Standard base Compact base Composite base

Dimensions Diameter: 50.5 cm (19.9 in.)

Height: 69.4 cm (27.3 in.)

Weight 15 kg (35.6 lb) with 1-L

Enclosure Impact-resistant ABS, 3-section construction; double-walled base with 2.54 cm (1 in.)

Sample

temperature

Strainers 316 stainless steel in standard size, high velocity or low profile for shallow depth applications

Sample intake

tubing

Sample bottle

capacity

polyethylene bottles (24x)

14.8 kg (32.6 lb) with 10-L (2.5 gal)

polyethylene container (1x)

insulation—direct bottle contact with ice.

0–60 °C (32–140 °F)

and Teflon® or 316 stainless steel in standard size

9.5 mm (3/8 in.) I.D. vinyl or Teflon-lined polyethylene

1-L (0.26 gal) polyethylene and/or

350-mL (11.83 oz) glass bottles

(24x)

2.3-L (0.6 gal) polyethylene and/or

1.9-L (0.5 gal) glass bottles (8x)

3.8-L (1 gal) polyethylene and/or

3.8-L (1 gal) glass bottles (4x)

3.8-L (1 gal) polyethylene and/or

3.8-L (1 gal) glass bottles (2x)

21-L (5.5 gal) or 15-L (4 gal)

polyethylene composite container

or 20-L (5.25 gal) polyethylene or

10-L (2.5 gal) polyethylene or 10-L

(2.5 gal) glass (1x)

Diameter: 44.1 cm (17.4 in.)

Height: 61 cm (24 in.)

12.2 kg (27 lb) with 575-mL

(19.44 oz) polyethylene

bottles (24x)

12.9 kg (28.3 lb) with 10-L

(2.5 gal) polyethylene

container (1x)

575-mL (19.44 oz)

polyethylene bottles (24x)

950-mL (32.12 oz) glass

bottles (8x)

10-L (2.5 gal) polyethylene

bottle (1x)

10-L (2.5 gal) glass bottle

(1x)

Diameter: 50.28 cm

(19.8 in.)

Height: 79.75 cm

(31.4 in.)

15 kg (36 lb) with 950mL (32.12 oz) glass

bottles (12x)

21-L (5.5 gal)

polyethylene bottle (1x)

SD controller

Specification Details

Dimensions (W x H x D) 29.2 x 17.1 x 26.4 cm (11½ x 6¾ x 103/8 in.)

Weight 4.2 kg (9.26 lb)

Enclosure PC/ABS blend, NEMA 4X, 6, IP 67

Power requirements 15 VDC supplied by a 8754500 power supply; 15 VDC supplied by an integral

Overload protection 7 A, DC line fuse for the pump

Operating temperature 0 to 50 °C (32 to 122 °F)

Storage temperature –30 to 60 °C (–22 to 140 °F)

power supply

English 3

Page 6

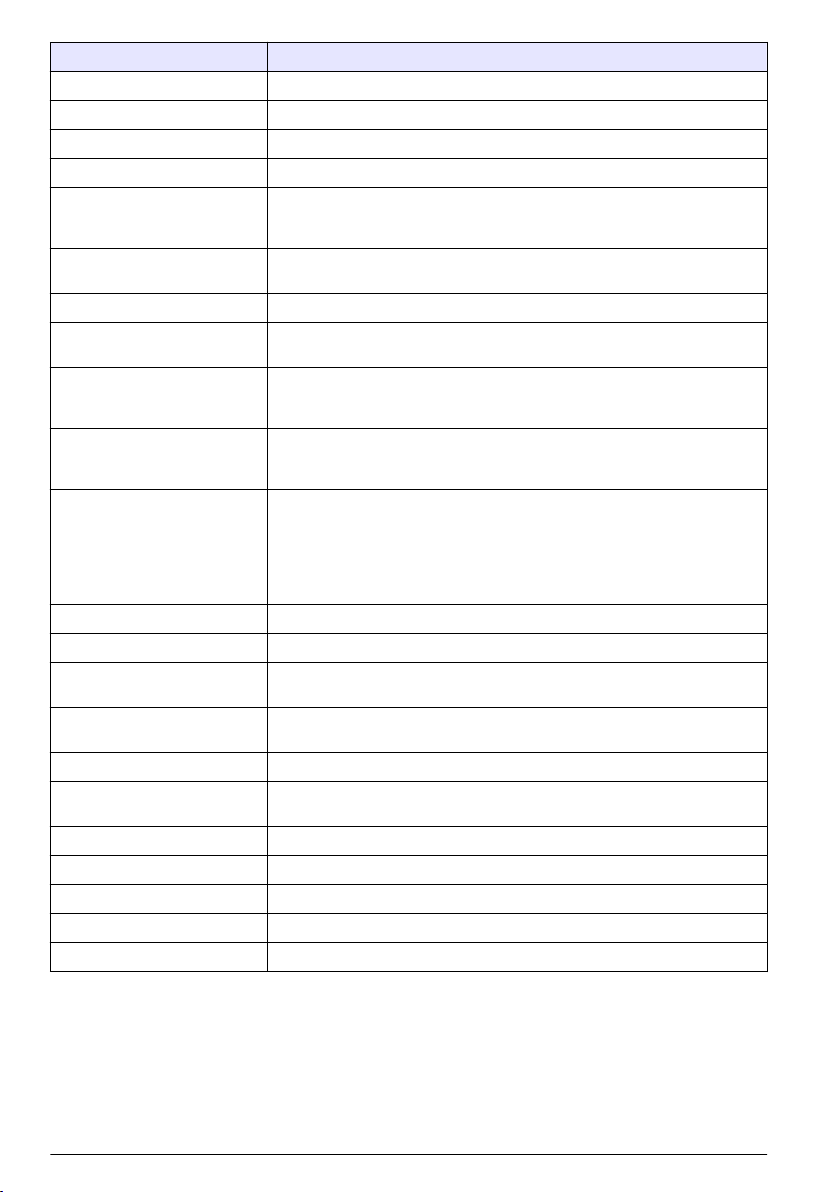

Specification Details

Storage/operating humidity 100% condensing

Pump Peristaltic high speed, with spring-mounted Nylatron rollers

Pump enclosure IP37

Pump tubing 9.5 mm ID x 15.9 OD mm (3/8 in. ID x 5/8 in. OD) silicone

Pump tubing life 20,000 sample cycles with: 1 L (0.3 gal) sample volume, 1 rinse, 6 minute

Vertical sample lift Maximum 8.5 m (28 ft) for: 8.8 m (29 ft) of 3/8-in. vinyl intake tube at sea level

Pump flow rate 4.8 L/min (1.25 gpm) at 1 m (3 ft) vertical lift with 3/8-in. intake tube typical

Sample volume Programmable in 10-mL (0.34 oz) increments from 10 to 10,000 mL (3.38 oz

Sample volume repeatability

(typical)

Sample volume accuracy

(typical)

Sampling modes Pacing: Time-fixed, flow-fixed, time-variable, flow-variable, constant time

Run modes Continuous or non-continuous with user-entered number of samples

Multiple programs Stores up to three sampling programs

Transfer velocity (typical) 0.9 m/s (2.9 ft/s) with: 4.6 m (15 ft) vertical lift, 4.9 m (16 ft) of 3/8-in. vinyl

Liquid sensor Ultrasonic. Body: Ultem® NSF ANSI standard 51 approved, USP Class VI

Sample history Up to 510 records

Air purge Air purged automatically before and after each sample. The duration

Event log 510 records

Connections Power, auxiliary, serial communications, distributor, SDI-12

Wetted materials Stainless steel, polyethylene, Teflon, Ultem, silicone

Communications RS232, Modbus, SDI-12

Warranty 1 year

pacing interval, 4.9 m (16 ft) of 3/8 in. intake tube, 4.6 m (15 ft) of vertical lift,

21 °C (70 °F) sample temperature

at 20–25 °C (68–77 °F)

to 2.6 gal)

±5% of 200 mL sample volume using uncalibrated liquid detect with: 4.6 m

(15 ft) vertical lift, 4.9 m (16 ft) of 3/8-in. vinyl intake tube, single bottle, full

bottle shut-off at room temperature and 1524 m (5000 ft) elevation

±10% of 200 mL sample volume using uncalibrated liquid detect with: 4.6 m

(15 ft) vertical lift, 4.9 m (16 ft) of 3/8-in. vinyl intake tube, single bottle, full

bottle shut-off at room temperature and 1524 m (5000 ft) elevation

variable volume (CTVV).

Refer to Constant Time Variable Volume (CTVV) sampling on page 23.

Distribution: Single bottle composite, multi-bottle composite, multi-bottle

discrete, bottles per sample, samples per bottle, combination of bottles per

sample, samples per bottle

intake tubing, 21 °C (70 °F) and 1524 m (5000 ft) elevation

compliant

automatically compensates for varying intake tube lengths.

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

4 English

Page 7

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential

injury. If on the instrument, refer to the instruction manual for operation or safety information.

D A N G E R

W A R N I N G

C A U T I O N

N O T I C E

This symbol indicates a potential pinch hazard.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public

disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Certification

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

English 5

Page 8

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

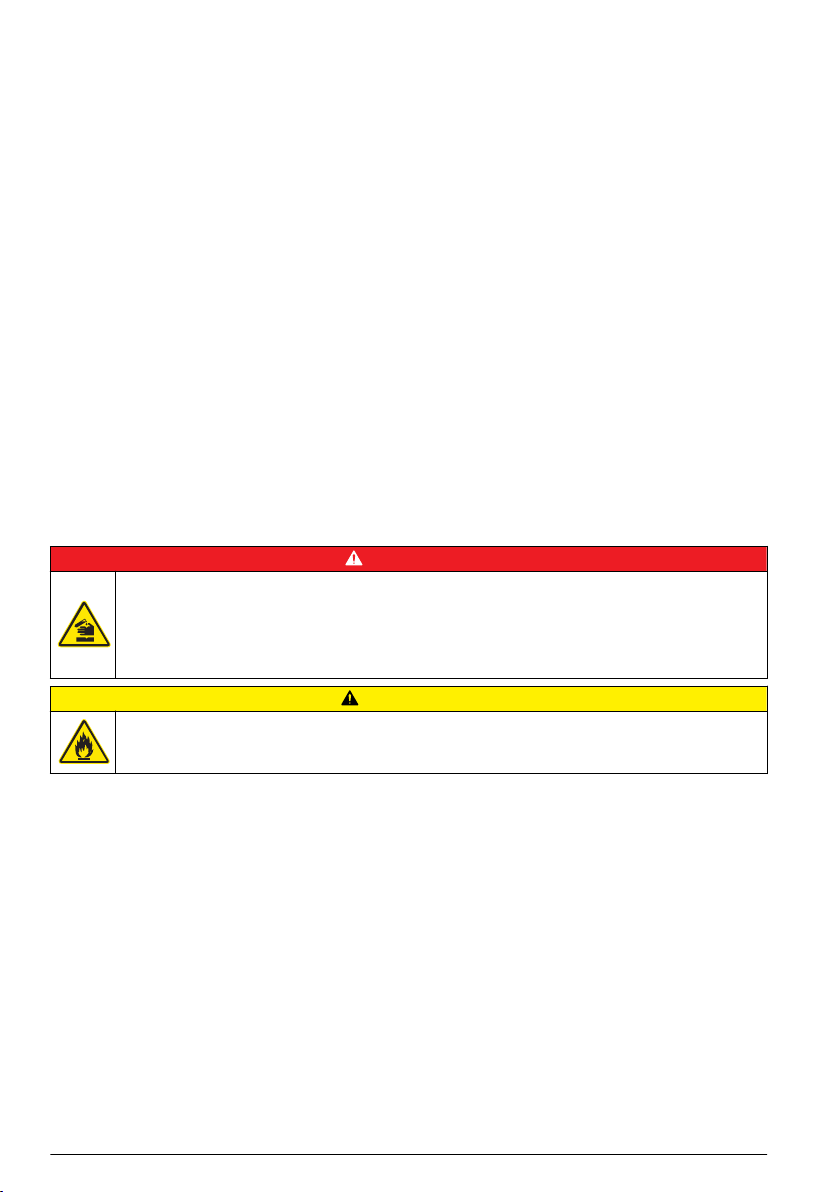

Product overview

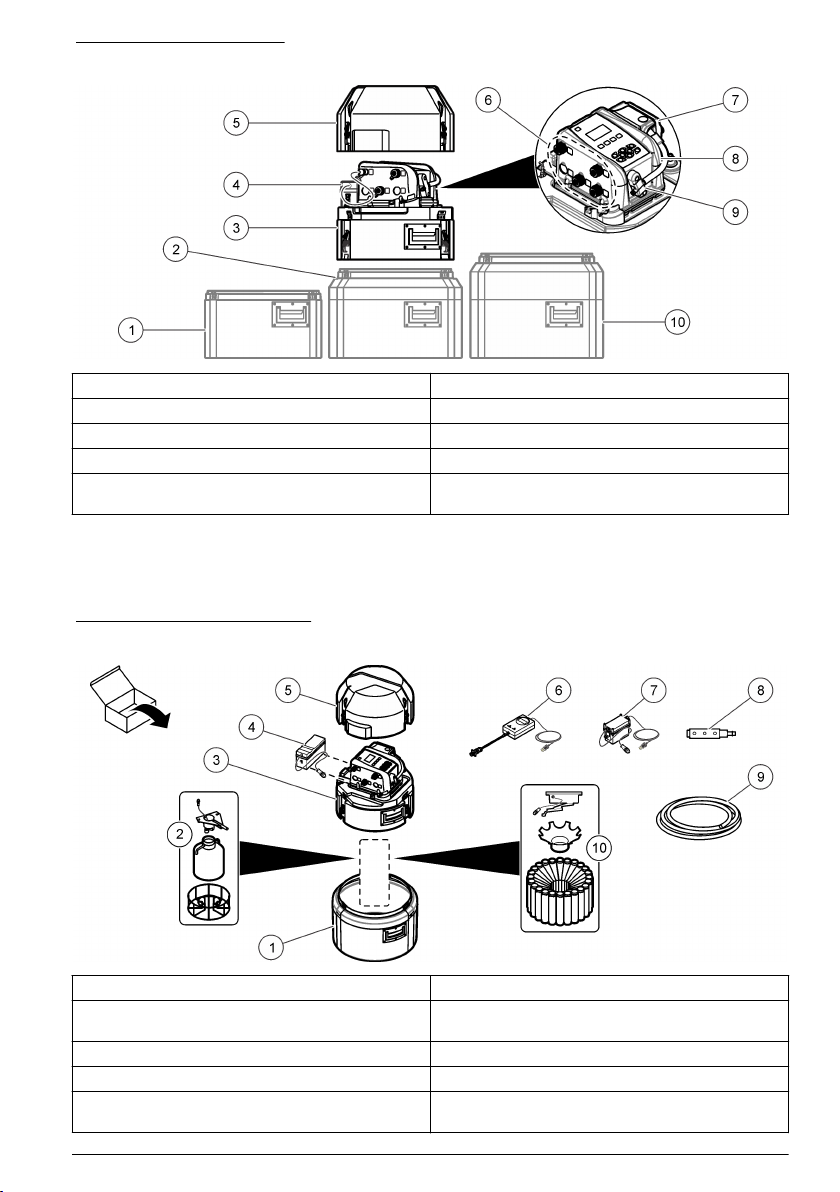

D A N G E R

Chemical or biological hazards. If this instrument is used to monitor a treatment process and/or

chemical feed system for which there are regulatory limits and monitoring requirements related to

public health, public safety, food or beverage manufacture or processing, it is the responsibility of the

user of this instrument to know and abide by any applicable regulation and to have sufficient and

appropriate mechanisms in place for compliance with applicable regulations in the event of malfunction

of the instrument.

C A U T I O N

Fire hazard. This product is not designed for use with flammable liquids.

The SD900 Portable Sampler collects liquid samples at specified intervals and keeps the samples in

bottles or containers. Use the sampler for a wide variety of aqueous applications and for toxic

pollutants and suspended solids. Set up

the sampler with different retainers, bottles or containers.

Refer to Figure 1.

6 English

Page 9

Figure 1 Product overview

1 Compact base 6 Controller connections

2 Standard insulated base 7 Pump

3 Center section 8 Controller

4 Power source 9 Liquid sensor

5 Top cover 10 Standard insulated base for 21-L (5.5 gal)

container

Product components

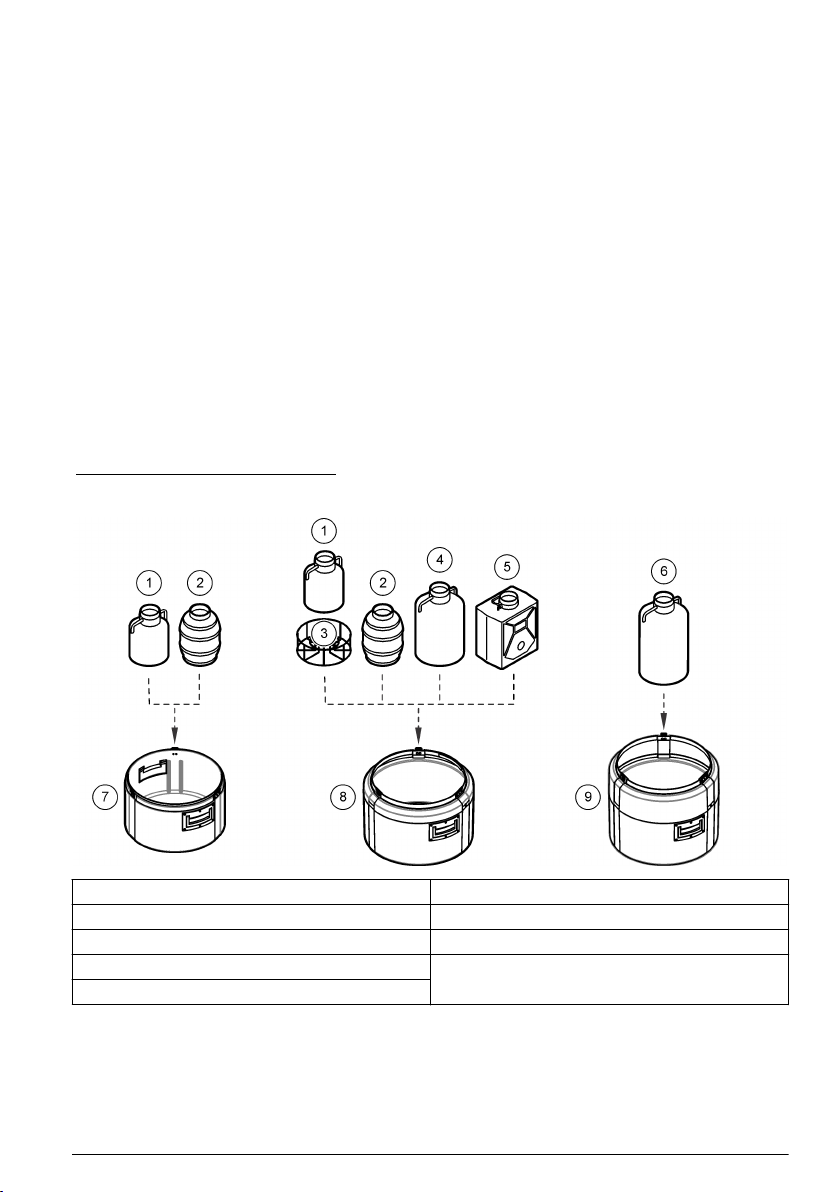

Make sure that all components have been received. Refer to Figure 2. If any items are missing or

damaged, contact the manufacturer or a sales representative immediately.

Figure 2 Product components

1 Base (Standard, compact or composite) 6 Battery charger (optional)

2 Components for a single-bottle option (bottle and

support can change)

3 Center section with controller 8 Strainer

4 Battery (optional) 9 Intake tubing, vinyl or Teflon-lined

5 Top cover 10 Components for a multiple-bottle option (bottles

7 AC power supply (optional)

and retainers can change)

English 7

Page 10

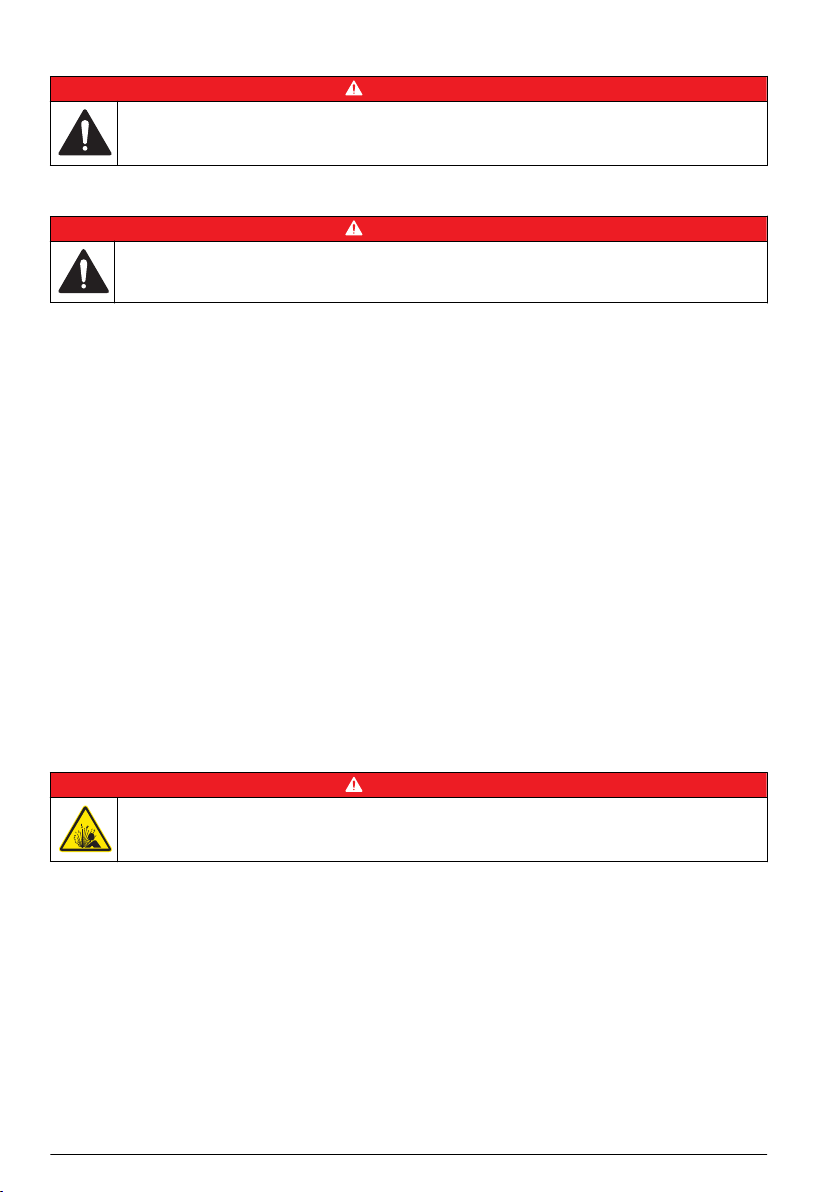

Installation

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

Confined space precautions

D A N G E R

Explosion hazard. Training in pre-entry testing, ventilation, entry procedures, evacuation/rescue

procedures and safety work practices is necessary before entering confined spaces.

The information that follows is supplied to help users understand the dangers and risks that are

associated with entry into confined spaces.

On April 15, 1993, OSHA's final ruling on CFR 1910.146, Permit Required Confined Spaces, became

law. This standard directly affects more than 250,000 industrial sites in the United States and was

created to protect the health and safety of workers in confined spaces.

Definition of a confined space:

A confined space is any location or enclosure that has (or has the immediate potential for) one or

more of the following conditions:

• An atmosphere with an oxygen concentration that is less than 19.5% or more than 23.5% and/or a

hydrogen sulfide (H2S) concentration that is more than 10 ppm.

•

An atmosphere that can be flammable or explosive due to gases, vapors, mists, dusts or fibers.

• Toxic materials which upon contact or inhalation can cause injury, impairment of health or death.

Confined spaces are not designed for human occupancy. Confined spaces have a restricted entry

and contain known or potential hazards. Examples of confined spaces include manholes, stacks,

pipes, vats, switch vaults and other similar locations.

Standard safety procedures must always be obeyed before entry into confined spaces and/or

locations where hazardous gases, vapors, mists, dusts or fibers can be present. Before entry into a

confined space, find and read all procedures that are related to confined space entry.

Mechanical installation

Site installation guidelines

D A N G E R

Explosion hazard. The instrument is not approved for installation in hazardous locations.

Refer to the guidelines that follow for the site location evaluation.

• Obey all the safety precautions if the sampler is installed in a confined space. Refer to Confined

space precautions on page 8.

• Make sure that the temperature at the location is in the specification range. Refer to Specifications

on page 3.

• Install the sampler on a level surface or hang the sampler with the suspension harness, the

support bracket or the spanner bar. Refer to Install the sampler in a manhole on page 9 and to

the applicable installation documentation.

• As near the sample source as possible to decrease analysis delay. Refer to Plumb the sampler

on page 11.

• For limitations on transport velocity and maximum vertical lift, refer to Specifications on page 3.

8 English

Page 11

Install the sampler in a manhole

Install the sampler above the sample water in a manhole. Install the sampler

support bracket. Install the spanner bar inside the manhole. The spanner bar is supported by

pressure against the walls. The support bracket has the same width as the manhole cover. Install the

support bracket directly below the cover for support. Refer to Replacement parts and accessories

on page 42. Refer to the documentation supplied with the accessories to install the sampler.

with a spanner bar or a

Install the distributor or full-bottle shutoff (optional)

The distributor or full-bottle shutoff assembly is typically installed at the factory. Refer to the

distributor or full-bottle shutoff documentation for installation.

Prepare the sampler

Clean the sample bottles

Clean the sample bottles and caps with a brush, water and a mild detergent. Flush the containers

with fresh water followed by a distilled water rinse.

Install a single bottle

Use a single bottle to collect one composite sample. When the bottle is full, the full bottle shut-off

stops the sample program.

1. Clean the sample bottles. Refer to Clean the sample bottles on page 9.

2. Install the sample bottle as shown in Figure 3.

Figure 3 Single bottle installation

1 Polyethylene bottle, 10 L (2.5 gal) (1918) 6 Polyethylene bottle, 21 L (5.5 gal) (6494)

2 Glass bottle, 10 L (2.5 gal) (6559) 7 Compact base (8975)

3 Support (1502) 8 Standard insulated base (8976)

4 Polyethylene bottle, 15 L (4 gal) (1367) 9 Standard insulated base for 21 L (5.5 gal) bottle

5 Polyethylene bottle, 19 L (5 gal) (6498)

(8561)

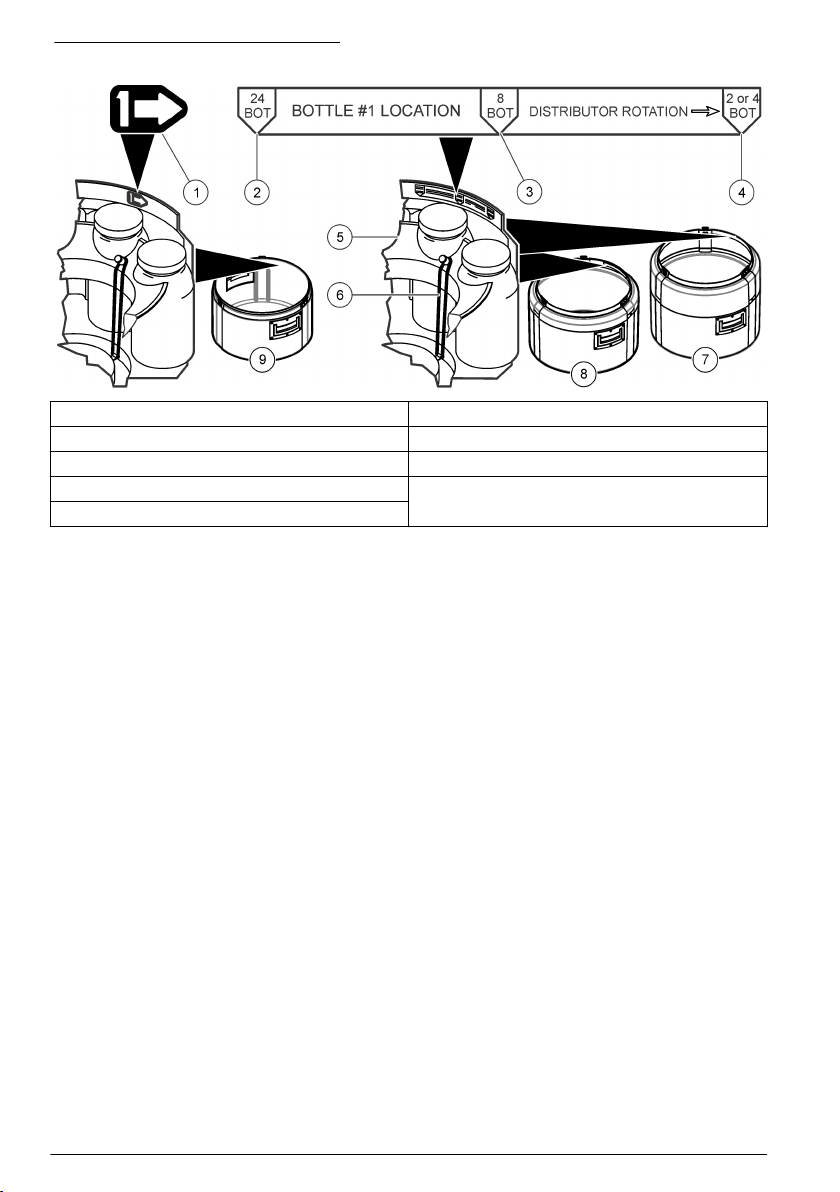

Install the first bottle for multiple sample collections

Use multiple bottles to collect samples into separate bottles or into more than one bottle. The

distributor moves the sample tube above each bottle. Install the bottles in the sampler base as shown

in Figure 4. Install the first sample bottle (number 1) below the label in the sampler base. Install the

remaining bottles in increasing numbers in the direction shown by the label. Refer to Figure 5

on page 11 for a diagram of necessary components.

9

English

Page 12

Figure 4 Bottle number 1 installation

1 Bottle number 1 location (compact base) 6 Elastic straps

2 Bottle number 1 location for 24 bottles 7 Standard insulated base for 21 L (5.5 gal) bottle

3 Bottle number 1 location for 8 bottles 8 Standad insulated base

4 Bottle number 1 location for 2 or 4 bottles 9 Compact base

5 Retainer

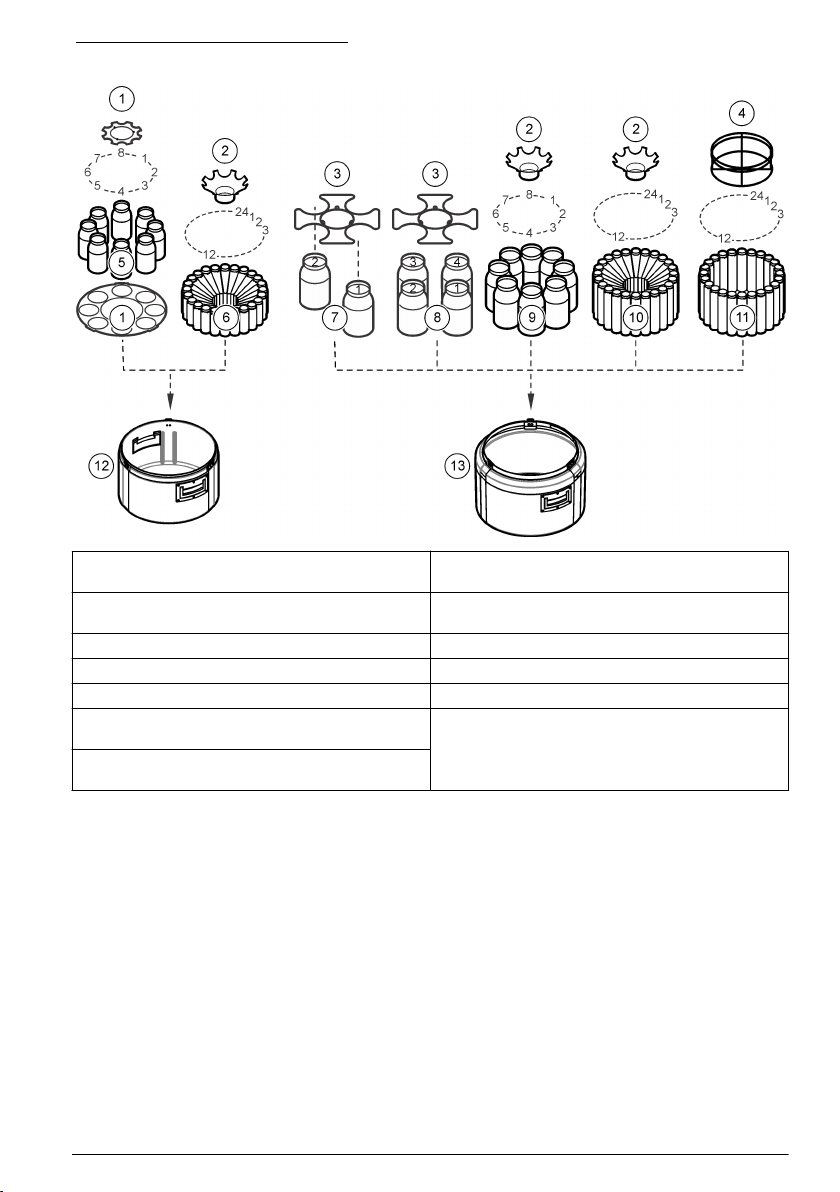

Install multiple bottles

When multiple bottles are installed, a distributor arm moves the sample tube over each bottle.

Sample collection automatically stops when the specified number of samples have been collected.

1. Clean the sample bottles. Refer to Clean the sample bottles on page

9.

2. Install the first sample bottle (number 1) below the label in the sampler base. Refer to Install the

first bottle for multiple sample collections

on page 9.

3. Assemble the sample bottles as shown in Figure 5. For eight or more bottles, make sure that the

first bottle goes next to the bottle one indicator in the clockwise direction.

4. Put the bottle assembly in the sampler. For eight or more bottles, align the wires in the slots in the

bottom tray.

10 English

Page 13

Figure 5 Multiple bottle installation

1 Positioner/retainer (2347) 8 Glass bottles, 3.8 L (1 gal), (4x) (2216) or

2 Retainer (1422) 9 Glass bottles, 1.9 L (0.5 gal), (8x) (1118) or

3 Retainer (2190) 10 Polyethylene bottles, 1 L (0.26 gal), (24x) (737)

4 Retainer (2189) 11 Glass bottles, 350 mL (11.83 oz), (24x) (732)

5 Glass bottles, 950 mL (32.12 oz) (8x) (2348) 12 Compact base (8975)

6 Polyethylene bottles, 575 mL (19.44 oz), (24x)

(1369)

7 Glass bottles, 3.8 L (1 gal), (2x) (2214) or

polyethylene bottles, 3.8 L (1 gal), (2x) (2215)

polyethylene bottles, 3.8 L (1 gal), (4x) (2217)

polyethylene bottles, 2.3 L (0.61 gal), (8x) (657)

13 Standard base (8976)

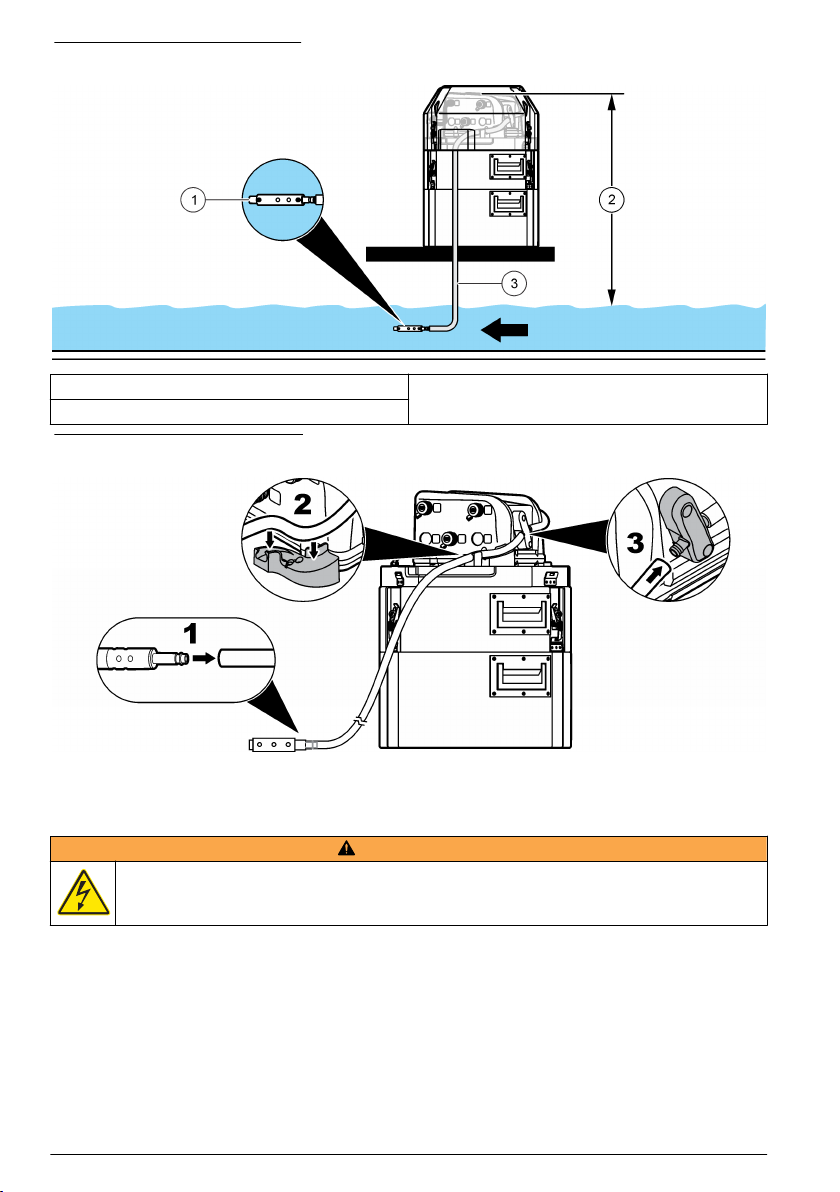

Plumb the sampler

Install the strainer in the middle of the sample stream (not near the surface or the bottom) to make

sure that a representative sample is collected. Refer to Figure 6. Refer to Figure 7 for the intake tube

installation.

1. Connect the tubing to the sampler as shown in Figure 7.

Note: Use connection kit 2186 if Teflon-lined tubing is used.

2. Install the intake tube and strainer in the main stream of the sample source where the water is

turbulent and well-mixed.

• Make the intake tube as short as possible.

•

Keep the intake tube at a maximum vertical slope so that the tube drains completely between

samples.

Note: If a vertical slope is not possible or if the tube is pressurized, disable the liquid sensor. Calibrate the

sample volume manually. Refer to Calibrate the sample volume manually on page 28.

• Make sure that the intake tube is not pinched.

English 11

Page 14

Figure 6 Instrument installation

1 Strainer 3 Intake tube

2 Vertical lift

Figure 7 Intake tube installation

Electrical installation

Controller connections

W A R N I N G

Electrical shock hazard. Externally connected equipment must have an applicable country safety

standard assessment.

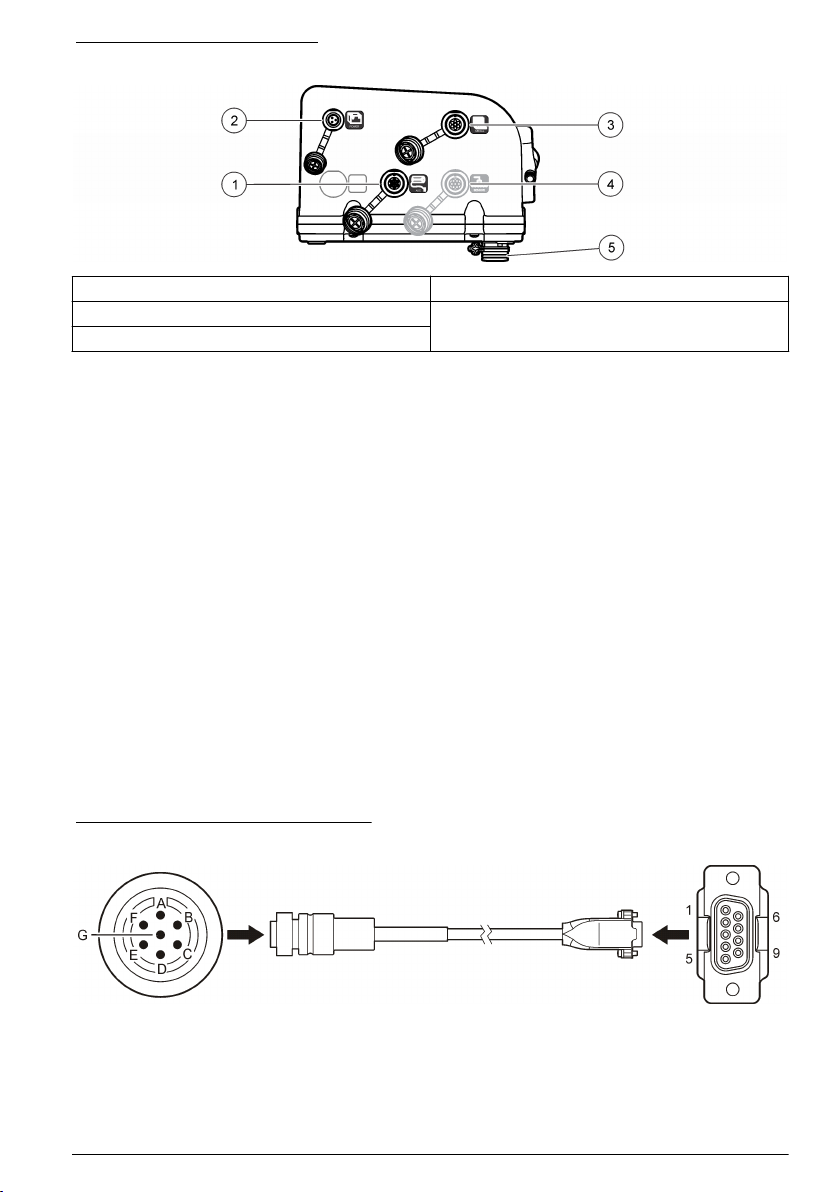

Figure 8 shows the connections that can be made to the controller.

12 English

Page 15

Figure 8 Controller connectors

1 Auxiliary device 4 SDI-12 device option

2 Power supply 5 Distributor/full bottle shut-off

3 Serial communications

Connect a flow meter

Connect a flow meter to the controller to start or stop the sampler when the sample flow goes above

or below a specified value.

Items to collect:

• Multi-purpose full cable for Sigma flow meters (or 980 half cable for the model 980 flow meter).

•

Optional splitter for additional connections. Two or more splitters can be connected in series.

1. Connect one end of the cable to the flow meter. For the model 980 flow meter, refer to the model

980 flow meter user manual.

2. Connect the other end of the cable to the auxiliary device connector on the controller.

Note: If the flow meter has a 6-pin cable, use the 6-pin to 7-pin adapter cable.

Connect a PC or communications network

Connect a PC or a communications network to the controller to transfer data or to configure the

sampler.

Items to collect:

• Serial cable, 7-pin RS232 to DB-9 (refer to Figure 9). Connections: B to 5 (signal ground); D to

3 (RCD); F to 2 (TXD); G (ground).

1. Connect one end of the serial cable to the communications device or network.

2. Connect the other end of the cable to the serial communications connector on the controller.

Figure 9 Serial communications cable

English 13

Page 16

Connect an SDI-12 device

N O T I C E

Measurement errors can occur due to electrical transients from sources such as lightning or large electrical

motors. These errors can cause unexpected sample acquisition or a missed sample when the controller is

programmed for setpoint sampling based on sonde measurements. Use a power line filter or connect the

controller to a different branch circuit to reduce the possibility of transients.

The controller supplies power to the SDI-12 device. Use the 15 m (50 ft) cable or the 30 m (100 ft)

cable to connect a sonde to the controller. Refer to Figure 10.

Note: A separate power supply for the sonde is necessary for data logging by the sonde.

The SDI-12 interface is enabled only when a connected device is found by the controller. The scan

for a sensor occurs automatically. The address that is assigned to the SDI-12 device is automatically

detected by the controller.

Figure 10 Sonde connection

1 Sonde 4 SDI-12 connector

2 Sonde bulkhead connector 5 15 or 30 m (50 or 100 ft) cable

3 6-pin cable connector

Connect the sampler to power

Electrocution hazard. If this equipment is used outdoors or in potentially wet locations, a Ground Fault

Circuit Interrupt (GFCI/GFI) device must be used for connecting the equipment to its main power

source.

Fire hazard. Install a 15 A circuit breaker in the power line. A circuit breaker can be the local power

disconnect, if located in close proximity to the equipment.

Electrocution hazard. Protective Earth Ground (PE) connection is required.

Electrocution hazard. Make sure that there is easy access to the local power disconnect.

14 English

D A N G E R

D A N G E R

D A N G E R

W A R N I N G

Page 17

W A R N I N G

Electric shock hazard. The power supply can overheat when the time between pump cycles is too

short.

N O T I C E

Make sure that the pump cycle time will not cause the power supply to overheat. Refer to Calculate the pump

cycle time on page

15.

Connect the sampler to a battery or to an AC power supply. Refer to the illustrated steps that follow.

Calculate the pump cycle time

The pump must stay off for a minimum time period between sample cycles so that the power supply

does not overheat.

1. Calculate the total amount of time that the pump will run continuously during a sample cycle.

Include all stages: pre-purge, intake rinse, sample, sample retries and post-purge.

2. Find the minimum amount of time that the pump must stay off between sample cycles from

Figure 11.

3. Make sure that the pacing or time interval in the sampler program lets the pump stay off between

sample cycles for the minimum amount of time.

English 15

Page 18

Figure 11 Pump on and off times at 50 °C (122 ºF)

1 Time (in minutes) that the pump must stay off 3 Example: if the pump is on continuously for

2 Time (in minutes) that the pump is on continuously

5 minutes, the pump must stay off for 15 minutes.

Close the cover

To close the cover, align the latch plates as shown in Figure 12 and close the latches.

Figure 12 Latch plates alignment

Set the power to on

Push the power button to set the power to on or off. Make sure that the power supply (AC power or

battery power) is correctly installed.

User interface and navigation

The controller keypad is shown in Figure 13. Use the MENU key to set up sampling programs,

configure the controller settings or complete the diagnostic tests. Use the arrows, ENTER and BACK

keys to scroll through the menu, make selections and enter values. Look for arrows on the bottom or

side of the display screen to know when more options are available.

16 English

Page 19

Figure 13 Controller keypad

1 POWER 5 MENU 9 STATUS

2 VOLUME CALIBRATION 6 ENTER 10 RUN/HALT PROGRAM

3 STOP 7 BACK 11 MANUAL OPERATION

4 LED 8 ARROW KEYS

Operation

Main menu overview

The main menu contains four options for sampler operation, monitoring or data management.

Table 1 Sampler menu overview

Menu option Description

Program setup Create, review or set up a sampling program

Status Display the status of the current program

Diagnostics Review and manage data or test the operation of components

System setup Change the controller settings or calibrate the liquid sensor

Configure the system settings

1. Push MENU.

2. Go to SYSTEM SETUP.

3. Change the applicable options.

Option Description

Time/date setup Set the time (24-hour format) and date.

Communication Select the baud rate (19200, 38400, 57600 or 115200) and protocol (Modbus RTU or

ASCII) for the serial port.

English 17

Page 20

Option Description

Setup base Select the sampler base (All weather refrigerated, refrigerated, portable standard or

Language Select the language of the controller.

Liq sensor cal Calibrate the liquid sensor or set to default.

Set contrast Adjust the contrast of the LCD screen.

Pump duty cycle Change the pump duty cycle. Range: 50% to 100% (default: 100%).

Password setup Set up a password to control access to the program setup and the system setup menus.

Tubing life Set a reminder when the pump tubing is to be changed. Go to ENABLE>RESET

SDI–12 (optional) Configure the operation of an SDI–12 device. This option is shown only when a device is

portable compact).

Select ENABLE>YES to set a new password or ENABLE>NO to activate the current

password. If the password is set for the first time, use 900900 as the current password.

CYCLES to reset the pump cycle count to 0. Go to ENABLE>CYCLE LIMIT to change

the number of pump cycles that is used for the reminder. Go to ENABLE>STATUS to

show the current number of pump cycle counts.

found.

Configure the SDI-12 device

A sensor such as a sonde can connect to the optional SDI-12 interface. The controller can get up to

nine measurements from one SDI-12 sensor. The sensor data can then be used as a trigger in

setpoint sampling applications. Configure the parameter type and unit, and set how often the

SDI-12 device is scanned for new measurement data.

1. Select Menu>System Setup>SDI-12.

Note: The SDI-12 option is only shown when an SDI-12 device is found by the controller.

2. Select one of the options:

Option Description

DISPLAY SONDE Shows information about the device such as the vendor name, model name,

CFG PARAMETERS Gives a name and measurement unit to the SDI-12 channel. Each channel is initially

SCAN INTERVAL Sets the time interval when measurement data is refreshed in the controller. Short

SDI-12 address, protocol version, number of available measurements and the warmup time.

shown with a generic reference indicator in the same order that is set in the

SDI-12 device. Table 2 shows the measurements that are supported by the controller.

Note: It may be necessary to configure the SDI-12 interface for the sonde.

time intervals decrease the battery life.

Dissolved oxygen (DO) mg/L, % saturation x.xx

18 English

Table 2 Supported measurements

Measurement Unit Resolution

Ammonia (NH3) mg/L-N x.xx

Ammonium (NH4+) mg/L-N, mV x.xxxx

Chloride (Cl-) mg/L-N, mV x.xxxx

Chlorophyll µg/L, V x.xx

Conductivity mS/cm, µS/cm x.xxx

Ext. Sonde Pwr V, % x.xxxx

HOCl ppm, V x.xxxx

1

Page 21

Table 2 Supported measurements (continued)

Measurement Unit Resolution

Int. Sonde Pwr V, % x.xxxx

Level m, ft, psi x.xxx

NH3+NH4 mg/L-N x.xxxx

Nitrate (NO3-) mg/L-N, mV x.xx

ORP mV x

PAR µE/S/n2 x.xxxx

pH pH unit x.xx

Phycocyanin cells/mL, mV x.xx

Phycoerythrin cells, mV x.xx

raw TDG mV x.xxxx

ref PAR µE/S/n2 x.xxxx

Resistivity kΩ/cm x.xxx

Rhodamine ppb, V x.xx

Salinity ppt x.xxxx

Total Dissolved Solids g/L x.xx

Temperature C, F, K x.xx

Total Dissolved Gas mmHg, psi x.xxxx

Transmission %, V, %660 nm, v660 nm x.xxxx

Turbidity NTU, V x.x

1

The number of decimal places shown on the controller display

1

Set up a sampling program

A sampling program includes all of the parameters that are necessary to collect samples

automatically. Collect the samples at regular intervals or when the sampling program is complete.

1. Push MENU.

2. Go to PROGRAM SETUP>MODIFY ALL. The first screen is shown.

3. Select or enter the values for each parameter. Use the left and right arrow keys to move left or

right. Use the up and down arrow keys to change a value. Change the units if necessary (gal or

mL) with the arrow keys.

Option Description

Bottles Bottle quantity: the number of bottles in the sampler (1, 2, 4, 8 or 24).

Full BTL shutoff: Enabled/Disabled. If enabled, the controller checks for bottle

overflow conditions.

Bottle volume: the volume capacity of each bottle. Range: 50–65000 mL (0.01 -

17.17 gal)

English 19

Page 22

Option Description

Intake tubing Tubing length: the length of the intake tubing from the strainer to the liquid sensor.

Range: 100–3000 cm or 3–99 ft. An accurate length is necessary to get an accurate

sample volume.

Intake tube type: the diameter and material of the intake tubing (¼ in. vinyl, 3/8 in.

vinyl or 3/8 in. Teflon).

Program delay Enable/disable: when enabled, the sampling program starts at a specified time or

number of counts. Date and time: the date and time when the program starts (24hour format). Counts: the number of counts or pulses from a flow meter when the

program will start (1 to 9999 counts). If the sample pacing is later set to time, the

program delay will be disabled.

Sample

pacing/collection

Time based—Refer to Time based collection on page 21.

Note: When CTVV is used:

• The liquid sensor is always enabled.

• The sample distribution is composite.

• The run mode is non-continuous.

• The first sample is taken after the interval.

• Flow source is always 4–20 mA input.

Flow based—Refer to Flow based collection on page 21.

Sample distribution Deliver samples to all>YES

Each sample is delivered to all bottles. End after last: program stops after the last

sample (1–999). Continuous: program continues until it is stopped manually.

Deliver samples to all>NO

Samples are delivered to a subset of bottles (Figure 14). Samples/bottle: the number

of samples to be collected in each bottle (1–999). Bottles/sample: The number of

bottles that will contain the same sample.

Liquid sensor Enable or disabled. If disabled, the sample volume must be calibrated by time.

Sample volume The volume of each sample in mL (1 gal = 3785.4 mL). If bottles/sample mode is

used, each bottle receives a full sample volume (10–10,000 mL). Make sure that the

sample volume does not exceed the bottle volume. Sample volumes are rounded to

the nearest 10 mL.

Intake rinses The number of intake tube rinses before a sample is collected (0–3).

Sample retries The number of sampling tries after a sampling failure occurs (0–3).

Site ID The name for the sampling location (up to 12 characters). The site ID is used as the

preset name if the program is saved.

Advanced sampling Goes to the advanced sampling menu. If necessary, configure the options in the

Advanced Sampling menu.

Run program The creation of the basic sampling program finishes. The sampler prompts the user

to start or cancel the program.

Figure 14 Two samples per bottle (left) versus two bottles per sample (right)

20 English

Page 23

Time based collection

1. Select or enter the values for each option.

Option Description

Pacing interval Collect samples at regular time intervals, in hours and minutes (0:01–999:00).

Take first sample The program starts immediately or after the first interval.

Variable volume Specify whether the sample volumes vary (flow based). If yes, refer to Use variable

Use variable volume

Sample pacing is constant time variable volume (CTVV).

1. Select or enter the values for each option.

Option Description

Select unit Select the flow units to use.

Map 4 mA input Enter the flow rate that agrees with 4 mA input.

Map 20 mA input Enter the flow rate that agrees with 20 mA input.

Average flow rate Specify the average flow rate for the site (1–999,999). The units are specified by

Time volume desired Specify the total volume to be collected during the sample program

Collection period Specify the total collection period in hours and minutes (0:01–999:00).

Minimum sample volume If the flow volume is not sufficient to collect this minimum volume, the sample is

volume on page 21. If no, refer to Do not use variable volume on page 21.

the units selected above.

(10–10,000 ml).

skipped (10–10,000 ml).

Do not use variable volume

1. Select or enter the values for the option.

Option Description

Take first sample Select whether the program starts immediately or after the first time interval has passed.

Flow based collection

Specify the flow source for flow based sampling:

• Counts—Refer to Use counts for the flow source

• 4–20 mA input—Refer to Use 4–20 mA input for the flow source on page 22.

Use counts for the flow source

1. Select or enter the values for each option.

Option Description

Take sample every Collect samples at regular flow intervals, in counts (1–9999 counts).

Overrride time Collect a sample if the flow volume is very low.

on page 21.

English 21

Page 24

Option Description

Time The maximum time between samples (0:01–999:00). The timer starts again after each

Take first sample The program starts immediately or after the first time interval.

sample is collected.

Use 4–20 mA input for the flow source

1. Select or enter the values for each option.

Option Description

Select unit Selects the flow units to use.

Map 4 mA input Enter the flow rate that would agree with the 4 mA input.

Map 20 mA input Enter the flow rate that would agree with the 20 mA input.

Take sample every Enter the total flow after which the sample has to be drawn.

Override time Select enable to push a sample to be collected if the flow volume is unusually low.

Time The maximum time between samples (0:01–999:00). The timer starts again after each

Sample volume Enter the volume to be collected per sample. If bottles/sample mode is selected, each

sample is collected.

bottle receives a full sample volume (100–10,000 mL). This option is skipped if variable

volume is selected.

Review or modify program settings

To review or change Individual settings for an existing sampling program:

1. Push MENU.

2. Go to PROGRAM SETUP. Select one of the options.

Option Description

Modify selected Change any of the program settings.

Review Review the program settings.

Save or load programs

Up to three sampling programs can be saved as presets for later use. If any changes are made to a

preset program after it is loaded, the program must be saved again to keep the changes.

1. Push MENU.

2. Go to PROGRAM SETUP>PRESETS.

3. Select one of the preset numbers (P1, P2 or P3).

Note: If a program is already stored, the site ID for that program is shown to the right of the preset number. If

no program is stored, the preset field is empty.

4. Select one of the options.

Option Description

STORE CURRENT Store the current program as a preset.

LOAD PROGRAM Open the selected preset program.

Restore the default settings

The restore option sets all of the program parameters to the default settings.

22 English

Page 25

1. Push MENU.

2. Go to PROGRAM SETUP>RESTORE.

3. Select YES.

Constant Time Variable Volume (CTVV) sampling

CTVV samples are taken at user-specified constant (fixed) time intervals. However, the actual

volume of each sample is based on the:

• Known average flow rate of the site

•

Actual metered flow rate at the time of sampling

• Total sample volume desired

• User-specified collection period

• Specified sampling interval

The volume of individual sampling can vary and depends on the flow volumes of the stream at

various intervals within the collection period. The total sample collected during the entire period can

be slightly above or below the necessary total volume. For these reasons, the manufacturer

recommends that a sampling container is used that has a larger volume than the necessary total

volume. When CTVV is used for sampling:

• Sample distribution menus are not available when CTVV is selected, only composite sampling is

supported.

• The liquid sensor is always enabled.

• The sample distribution is composite.

• The run mode is non-continuous.

• The first sample is taken after the interval.

• Flow source is always 4–20 mA input.

The instrument finds the sample volume, based on user inputs and actual metered flow volume. For

example, the entered values are:

• Average flow rate (historical, site specific): 150 gph

• Sampling interval: 2 minutes

• Total sample volume desired: 1500 mL

• Collection period: 30 minutes

Calculation 1: Total number of samples

Collection period ÷ Sampling interval = 30 minutes ÷ 2 minutes = 15 samples

Calculation 2: Average sample volume

Total sample volume desired ÷ Total number of samples = 1500 mL ÷ 15 Samples = 100 mL/sample

Calculation 3: Sample volume per unit of flow rate

Average sample volume ÷ Average flow rate = (100 mL/sample) ÷ 150 gph = 0.66 mL/gph

Calculation 4: Collect actual sample volume

• If the 4–20 mA flow source is used and the flow rate measured is 140 gph, use sample volumes

per unit of flow rate x actual metered flow rate.

0.66 mL/gph x 140 gph = 92.4 mL. The sampler will pull a 90 mL sample (rounded off from

92.4 mL).

• If the flow pulses are used and every pulse count is 2 gallons and 2 counts are received in

2 minutes, the flow rate is 120 gph.

Sample volumes per unit of flow rate x actual metered flow rate

0.66 mL/gph x 120 gph = 79.2 mL. The sampler will pull a 80 mL sample (rounded off from

79.2 mL).

English 23

Page 26

Start or stop a program

Use the RUN/HALT PROGRAM key to start or stop a program. Up to 12 user-defined start/stop

times/dates can be set. A program must be stopped before the program or system setup can be

changed.

The status reads RUNNING (while a program runs) or HALTED (when temporarily stopped by the

user). Use the RIGHT arrow to get information about the program while it runs.

• Power supply voltage

•

Inhibit mode (none, setpoint trigger, program delay, user start, storm trigger, full bottle and setpoint

delay)

• Sample summary (number of samples tried, missed and remaining)

• Next sample information (sample number and the bottle number of the next sample)

• Flow information when variable volume is enabled (current flow and the flow since the program

started)

• Time before the next sample

• Program the start time

1. Push RUN/HALT PROGRAM.

2. Select one of the options.

Option Description

Start Starts the currently loaded program. The status changes to RUNNING.

Halt Stops the program temporarily. The status changes to HALTED.

Resume The program resumes from the point at which it was halted. The status changes to

Start over The program starts from the beginning. The status changes to RUNNING.

End program Stops the currently running program. The status changes to COMPLETE.

RUNNING.

View the program status

The current status of main and/or stormwater programs and of SDI-12 measurements can be shown.

1. Push STATUS or select STATUS from the main menu.

2. If multiple programs are in operation, select one of the programs. The program status is shown.

3. Review the program status. Push the right arrow to see additional information.

Status Description

READY The program is ready to start. The power supply voltage and the current time are shown.

RUNNING The program is in operation.

HALTED The program was stopped temporarily by the user.

COMPLETE All of the programmed sample cycles are complete, or the program was stopped by the user.

Manual operation

Use manual operation to collect a grab sample, move the distributor arm or operate the pump.

Collect a grab sample

Collect a grab sample to make sure that the sample volume is correct or to bypass the sample

program.

1. Put the tubing from the outlet side of the pump into a sample container.

2. Put the intake tubing into the sample water.

24 English

Page 27

3. Push MANUAL OPERATION.

4. Select GRAB SAMPLE.

5. Enter the volume to collect and push ENTER.

Note: The grab sample volume can only be changed if the liquid sensor is enabled.

The intake tubing is purged and then the specified volume of sample is collected. The intake tube

is purged again.

Move the distributor arm

Move the distributor arm manually to put a grab sample in a specific bottle or to make sure that the

distributor arm position is correct.

1. Push MANUAL OPERATION.

2. Select MOVE DISTRIB. The current bottle number is shown.

3. Enter the number of the bottle over which the distributor arm will be moved.

4. Push ENTER. The distributor arm moves to the selected bottle.

Note: To stop the distributor arm at any time, push STOP.

Start or stop the pump

The pump can be operated manually to collect a sample or purge the intake tubing.

1. Push MANUAL OPERATION.

2. Select OPERATE PUMP.

3. Select the direction:

Option Description

Run forward The pump operates in the forward direction to collect a sample and deposit the sample in a

Run backward The pump operates in the reverse direction to purge the intake tubing.

4. Push STOP to stop the pump.

sample container.

View data

Data can be viewed from one of the status screens or from the diagnostics menu.

View the sample history

The sample history shows the sample number, bottle number, sample volume, result and time/date

for each sample.

get the additional information, download the sample history with the SampleView program. If a

program is in operation or has been halted, the sample history is shown for the current program. If

the program is complete, the sample history is shown for the most recently completed sampling

program. The sample history is automatically erased when a new program is started.

The following results can be shown:

• Success—the sample was drawn successfully.

• Bottle full—the full bottle shut-off was activated.

• Rinse error—an error occurred during the rinse cycle.

• User abort—a user pushed the STOP key to end the sample cycle.

• Arm faulty—the distributor arm did not move correctly.

• Pump fault—a fault occurred when the pump was operating.

• Purge fail—an error occurred during the purge cycle.

• Sample time out—liquid was not detected within the timeout period.

• Power fail—a power failure occurred during sampling.

• Low flow—sample was missed due to insufficient flow.

Flow information is recorded when a sampler program is run with CTVV pacing. To

English 25

Page 28

1. Select DIAGNOSTICS>SAMPLE HISTORY from the main menu to view the sample history.

2. The sample history shows the sample numbers, bottle numbers and brief result for each sample.

Select a sample from the list and push ENTER to view the complete details.

View the event log

View the event log to see details about the events that have been recorded.

1. Go to DIAGNOSTICS>EVENT LOG.

2. Select DISPLAY. The event log shows the date and event.

3. Select an event from the list, then push ENTER to see the complete details.

The top bar shows the event number and the total number of events in the event log. For

example, 01/80 will be shown for event number 1 and a total number of 80 events. The time/date,

event description and any additional data for the selected event is shown.

Event log information

The event log records information on these events:

•

Power on—power was connected to the controller.

• Power fail—power was intentionally or unintentionally disconnected from the controller without first

turning the power off.

• Firmware update—a new version of firmware was installed.

• Pump fault—a fault occurred when the pump was operating.

• Arm faulty—the distributor arm did not move correctly.

• Low memory battery—the internal battery should be replaced.

• User on—a user turned the power on using the power key.

• User off—a user turned the power off using the power key.

• Program start—the sample program was started.

• Program resume—a program was resumed from the halt state.

• Program halt—a program was halted.

• Program complete—a program was completed.

• Grab sample—a grab sample was taken.

• Change tube—the maximum pump cycle counts have expired.

• SDI-12 timeout—indicates a communication error on the SDI-12 interface.

• High setpoint on—indicates that a user-specified high setpoint is activated, the measurement

channel of interest and the current measurement value.

• High setpoint off—indicates that a user-specified high setpoint is cleared, the measurement

channel of interest and the current measurement value.

• Low setpoint on—indicates when a user-specified low setpoint is activated, the measurement

channel of interest and the current measurement value.

• Low setpoint off—indicates when a user-specified low setpoint is cleared, the measurement

channel of interest and the current measurement value.

Erase the event log

Erase the event log after event details have been reviewed to reduce the number of entries that are

shown.

1. Select DIAGNOSTICS>EVENT LOG from the main menu to erase the event log.

2. Select ERASE.

3. Select YES to confirm the deletion.

View data from SDI-12 devices

If a sonde is detected on the SDI-12 interface and the sonde provides measurement data, the user

can view the current status of these measurements. Push STATUS or select STATUS in the main

menu.

26 English

Page 29

The measurement status screen shows current measurement of each channel on the sonde which

includes the measurement name and unit assigned to each specific channel. The measurements will

be updated based on the user-defined scan interval. Navigation arrows on the screen indicate

whether additional channel information is available. CH0..CHX indicates the current position within

the available channels.

Volume calibration

The sample volume can be calibrated automatically with the liquid sensor or manually. When the

liquid sensor is used for volume calibration, the sensor is adjusted to accurately measure all

programmed volumes. If the liquid sensor is disabled, the volume for samples, rinses and stormwater

must be calibrated manually.

For typical applications, tap water can be used for the volume calibration. If the sample composition

is significantly different from typical water samples, calibrate the sampler with the liquid to be

collected. All programs must be stopped before calibration.

Calibrate the liquid sensor

The accuracy of the liquid sensor varies with the type of liquid that is sampled. For example, the

volume of a highly turbid sample may not be as accurate as that of clear water. The liquid sensor can

be calibrated with the sample water to improve volume accuracy.

1. Put the intake tubing into the sample water.

2. Push MENU.

3. Go to PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>ENABLE to make sure that

the liquid sensor is enabled.

4. Go to SYSTEM SETUP>LIQ SENSOR CAL.

5. Select PERFORM CAL.

6. Select START. The pump operates in reverse to purge the intake tube. The pump then operates

in the forward direction.

7. Look at the sample flow in the intake tube to make sure that the sample goes through the liquid

sensor.

8. When the sample goes through the liquid sensor and no bubbles are present, push STOP. The

intake tube is automatically purged. The liquid sensor calibration is complete.

9. Select DONE to exit or REPEAT to do the calibration again.

Restore the default calibration

The volume calibration for the liquid sensor can be returned to the default factory settings.

1. Select PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>ENABLE to make sure that

the liquid sensor is enabled.

2. Push VOLUME CALIBRATION and select RESET CAL. The volume calibration is set to the

default settings. The message “value has been reset to 0” will be shown.

Calibrate the sample volume with the liquid sensor

Calibrate the sample volume with the liquid sensor enabled to adjust sample volumes slightly.

1. Go to PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>ENABLE to make sure that

the liquid sensor is enabled.

2. Put the intake tubing into the sample water or tap water.

Note: Use the sample water for best accuracy.

3. Put the tubing from the outlet side of the pump into a graduated cylinder.

4. Push VOLUME CALIBRATION and select CALIBRATION.

5. Select START. The pump operates in reverse to purge the intake tube. The pump then operates

in the forward direction and collects the sample volume that is specified in the sampling program.

The pump operates in reverse to purge the intake tube.

English 27

Page 30

6. When the sample has been collected, select DONE. Compare the volume of the sample in the

graduated cylinder with the sample volume that is entered in the program setup menu.

7. If the volume that was collected is different from the sample volume in the current program, enter

the volume that was actually collected. Push ENTER. The sensor is adjusted to accurately

measure all programmed volumes.

8. Select START to start the sampling program or CANCEL to exit the volume calibration menu.

Calibrate the sample volume manually

When the liquid sensor is disabled, all volumes must be calibrated manually by time. The sample

volume is calibrated for the volume specified in the current program. If the sample volume is changed

in the program, the sample volume must be calibrated again for the new volume.

1. Select PROGRAM SETUP>MODIFY SELECTED>LIQUID SENSOR>DISABLE to make sure that

the liquid sensor is disabled.

2. Put the intake tubing into the sample water or tap water.

3. Put the tubing from the outlet side of the pump into a graduated cylinder.

4. Push VOLUME CALIBRATION. If more than one volume is shown, select one of the volumes for

calibration.

5. Select START. The pump operates in reverse to purge the intake tube. The pump then operates

in the forward direction and starts to collect the sample.

6. Stop the pump at the selected volume or rinse location:

• Sample volume: push STOP

collected.

• Rinse: push STOP when the liquid in the intake tubing gets to the liquid detector.

• Storm volume: push STOP when the volume specified in the stormwater program is collected.

7. Select DONE to go to the next volume calibration or REPEAT to do the calibration again.

8. When all volumes have been calibrated, select DONE.

9. Connect the outlet tubing to the tube fitting on the sampler.

10. Select START to start the sampling program or CANCEL to exit.

when the volume that is specified in the main program is

Verify the sample volume

To make sure that the sample volume is accurate, take a grab sample. Do not go back into

calibration to check the volume since the volume compensation is reset to zero at the start of a

calibration.

1. Push MANUAL OPERATION.

2. Select GRAB SAMPLE.

3. Put the intake tubing into the sample water.

4. Put the tubing from the outlet side of the pump into a graduated cylinder.

5. If the liquid sensor is enabled, enter the volume to be verified.

6. If the liquid sensor is disabled, enter the volume that is specified in the program.

7. Push ENTER. The pump cycle starts (purge-sample-purge).

8. Compare the volume that was collected in the graduated cylinder to the expected volume. If the

collected volume is not correct, do the volume calibration again.

Full bottle shutoff

Programs can sometimes cause bottles to overflow. If the full bottle shutoff option is activated and

enabled, a program stops when one or more bottles is close to an overflow condition. The program

will not run again until the full bottle condition is reset.

28 English

Page 31

Activate the full bottle shutoff

The full bottle shutoff option must be activated before it can be enabled. After activation, the option

remains available until the controller firmware is upgraded. After a firmware upgrade, the full bottle

option must be activated again.

1. If necessary, push any key on the controller to take it out of sleep mode.

2. Push and hold the MENU key for more than 30 seconds. The display shows FB SHUTOFF

AVAILABLE.

Enable the full bottle shutoff

1. Push MENU.

2. Select PROGRAM SETUP>MODIFY SELECTED>BOTTLE.

3. Select the BOTTLE QUANTITY and confirm.

4. In the list of FULL BTL SHUTOFF options, select ENABLE.

To disable full bottle shutoff, select DISABLE.

Full bottle shutoff in non-continuous mode

In non-continuous mode, sample collection is not monitored while the program runs. The controller

tries to find possible overflow conditions before the program starts. Table 3 gives the specified check

criteria for different configurations.

Table 3 Configuration and controller checks

Configuration Check criteria

Multiple composite sampling (deliver samples

to all bottles)

Samples per bottle distribution The number of samples per bottle multiplied by the sample

Storm water enabled The first flush (FF) sample volume is less than the bottle

Storm water enabled with first flush bottles set

to 1

Storm water enabled with multiple first flush

bottles and distribution set to samples per

bottle

Timed bottle (TB) set is enabled and

configured to run in non-continuous mode

The number of samples multiplied by the sample volume is less

than the bottle volume.

volume is less than the bottle volume.

volume.

The number of FF samples to collect multiplied by the FF

sample volume is less than the bottle volume.

The number of FF samples per bottle multiplied by the FF

sample volume is less than the bottle volume.

The number of samples per TB multiplied by the sample volume

is less than the bottle volume.

If any of the checks fail, the display shows an INVALID PROGRAM message and the program will

not run. Navigate to MENU>MODIFY ALL to correct the program, or disable the full bottle shutoff.

If the results of the necessary checks are satisfactory or the full bottle shutoff is disabled, the

program will run.

Full bottle shut off in continuous mode

In continuous mode, sample collection is monitored while the program runs. The controller does not

do any checks before the program is started.

If the bottle capacity is one sample volume less than the maximum capacity, the sample collection is

halted. An event is recorded in the event log with a date and time stamp. The display shows a

HALTED BOTTLE FULL? message and the program enters the PROGRAM HALT state.

Push a key on the controller to clear the warning message. The program stays in the halted state to

let bottles be emptied and replaced as necessary.

Push RUN/HALT PROGRAM to start the program again. Select from four options:

English 29

Page 32

• RESUME—Continue the program from where it halted

• START OVER—Start the program from the beginning

•

END PROGRAM—Stop the program

• CANCEL—Stay in the halted state

If RESUME is selected, the display shows a BOTTLES EMPTIED? message. Select YES or NO:

• YES—The controller starts to monitor the sample collection again.

Note: The controller acts as if the bottles are now empty even if they are not.

• NO—The program does not resume sample collection but stays in the HALTED state if the bottle

full condition was detected earlier.

Full bottle shutoff and timed bottle mode

In order to use the full bottle shutoff when timed bottle is enabled, the timed bottle run mode must be

set to END AFTER LAST.

If an attempt is made to run timed bottle in continuous mode, a NOT ALLOWED error screen shows

TB CONTINUOUS NOT POSSIBLE WITH FULL BTL.

If this error occurs, push ENTER to acknowledge the message. In the TB MODE screen that shows,

select END AFTER LAST.

If it is necessary to run timed bottle in continuous mode, disable the full bottle shutoff.

Full bottle shutoff exception conditions

Full bottle shutoff does not prevent bottles from being over or under filled when certain exception

conditions occur. Such conditions can occur if:

• The liquid sensor is disabled and the manual calibration is incorrect.

• The liquid sensor is enabled but does not operate correctly or has bad calibration.

• Bottles are emptied but the program is not halted (controller does not know bottles are empty and

activates full bottle shut off too soon).

• The program is halted but the user gives incorrect feedback:

• Bottles are empty but the user selects NO in the BOTTLES EMPTIED? screen.

• Bottles are not empty but the user selects YES in the BOTTLES EMPTIED? screen.

Advanced sampling

Send output signal at program completion

A 12 VDC signal can be sent through pin F of the auxiliary connector at the completion of a sampling

program or when the full bottle shut-off is activated. The signal stays on for 61 seconds.

The output signal can be used to:

• Start another sampler. Cascading samplers require a cascading cable (8757300). The slave

sampler must enable setpoint sampling and start on an external trigger.

• Activate a relay or other device when the program is complete.

To transfer the sample history to an external Sigma 950 flow meter, program complete must be

disabled. In addition, the special output must be enabled and configured to assert after the sample

cycle is complete.

1. Select PROGRAM SETUP>MODIFY SELECTED>ADV SAMPLING from the main menu.

2. Select PGM COMPLT O/P>ENABLE. The message “Bottle number output disabled on pin F” will

be shown. The bottle number output to send sample history to a Sigma 950 flow meter will be

disabled.

3. Select ENTER to activate the output signal.

30 English

Page 33

Send output signal with sample cycle (special output)

The special output option sends a 12 VDC signal through pin E of the auxiliary connector during or

after a sample cycle.

There are five possible configurations:

• After cycle—4-second pulse at the end of each sample cycle. This option is used to signal an

external device that a sample cycle is complete.

•

Entire cycle—during the entire sample cycle, includes all purge and rinse cycles.

• During sample—during the sample intake portion of the cycle only, ignores all purges and rinse

cycles.

• Missed sample—4-second pulse in the event of a missed sample. A missed sample can be

caused by a distributor error, purge fail, rinse fail, sample timeout, full bottle or pump fault.

• Trouble output—4-second pulse when a low main battery or low memory battery error occurs.

Two configurations are necessary to transfer sample history to an external flow meter:

• First, the program complete output needs to be disabled to enable the bottle number output. The

bottle number output transmits whether the sample was taken successfully or not and which bottle

received the sample.

• Second, the special output needs to be enabled and configured to assert "After Each Sample".

The sample history will be transferred to the external Sigma 950.

1. Select PROGRAM SETUP>MODIFY SELECTED>ADV SAMPLING from the main menu.

2. Select SPECIAL OUTPUT>ENABLE.

3. Select one of the output options:

• AFTER CYCLE—at the completion of each sample cycle

• ENTIRE CYCLE—during the entire sample cycle

• DURING SAMPLE—during the sample intake

• MISSED SAMPLE—in the event of a missed sample

• TROUBLE OUTPUT—when a low main battery or low memory battery error occurs

Operate from an external signal (setpoint sample)

The setpoint sample option starts and stops the sampler after a signal is received from an external

device such as a flow meter. The current program status shows when the sample program is

inhibited by an external device.

Note: Setpoint and stormwater sampling cannot be enabled at the same time.

1. Select PROGRAM SETUP>MODIFY SELECTED>ADV SAMPLING from the main menu.

2. Select SETPT SAMPLE>SETPT TRIGGER>EXT TRIGGER >ENABLE.

3. Select SETPT SAMPLE>SETPT CONTROL and select one of the setpoint options:

Option Description

START ON SETPT The sampling program operates until the program is complete.

START/STOP The sampling program operates until the external signal is no longer received.

4. To use a setpoint delay, enter a delay time in hours and/or minutes. The delay time starts when

the external signal is received. The program starts when the delay time expires.

Use an SDI-12 device for setpoint sampling

When an SDI-12 device is connected to the controller, the measurements can be used as setpoint

sampling triggers (in addition to the external inhibit). A maximum of one measurement trigger can be

enabled that is independent of the external trigger. If multiple triggers are enabled, the program starts

from at least one trigger and stops when all triggers are cleared.

English 31

Page 34

Each trigger can be defined as a high or low setpoint. Additionally, an optional deadband value can

be set. A deadband prevents the trigger from rapidly changing between active and inactive states

when the measurement value is near the setpoint. Refer to Figure 15.

1. Go to PROGRAM SETUP>MODIFY SELECTED>ADV SAMPLING>SETPT SAMPLE>SETPT

TRIGGER.

2. Select a measurement channel.

Note: A check mark is shown when a channel is enabled as a trigger.

3. Enter a setpoint trigger within the range that is shown.

4. Enter an optional deadband value.

5. Select ENABLE.

6. Select SETPT CONTROL to define how the sample program will operate.

Option Description

START ON SETPT The sampling program operates until the program is complete.

START/STOP The sampling program operates until the trigger is cleared.

7. To use a setpoint delay, enter a delay time in hours and/or minutes. The delay time starts when

the setpoint trigger becomes active. The program starts when the delay time expires.

Note: Setpoint control and delay options are global settings that are applied to all triggers.

Figure 15 High setpoint example

1 Channel value 3 Setpoint trigger off 5 Setpoint value

2 Setpoint trigger on 4 Deadband 6 Scan intervals

Set multiple start and stop times

A sampling schedule can be set up to start sampling at a specified start time and stop at a specified

stop time. Up to twelve start and stop times can be specified.

1. Select PROGRAM SETUP>MODIFY SELECTED>ADV SAMPLING from the main menu.

2. Select STRT/STOP TIME>ENABLE.

3. If the sample program is configured for multiple bottles, select the distribution option.

Option Description

ENABLE Put the first sample in bottle 1 at each start time.