Page 1

DOC023.52.00032.Mrz05

sc100

User Manual

Page 2

© HACH LANGE GmbH, 2005. All rights reserved. Printed in Germany

Page 3

DOC023.52.00032.Mrz05

sc100

User Manual

© HACH LANGE GmbH, 2005. All rights reserved. Printed in Germany

Page 4

Page 5

Table of Contents

Section 1 Specifications .............................................................................................................................................. 3

Section 2 General Information .................................................................................................................................... 5

2.1 Safety Information .............................................................................................................................................. 5

2.1.1 Use of Hazard Information........................................................................................................................ 5

2.1.2 Precautionary Labels................................................................................................................................ 5

2.2 General Product Information .............................................................................................................................. 5

Section 3 Installation.................................................................................................................................................... 7

3.1 Mechanical Installation....................................................................................................................................... 8

3.1.1 Controller Dimension Illustrations............................................................................................................. 8

3.1.2 Mounting the Controller .......................................................................................................................... 10

3.2 Wiring Safety Information................................................................................................................................. 12

3.2.1 Electrostatic Discharge (ESD) Considerations ....................................................................................... 12

3.3 Electrical Installation ........................................................................................................................................ 12

3.3.1 Installation in Conduit ............................................................................................................................. 13

3.3.2 Installation Using a Power Cord ............................................................................................................. 13

3.3.3 Wiring for Power at the Controller .......................................................................................................... 14

3.4 Alarms and Relays ........................................................................................................................................... 17

3.4.1 Connecting the Relays ........................................................................................................................... 17

3.4.2 Connecting the Analog Outputs.............................................................................................................. 18

3.5 Connecting/Wiring the sc Sensor..................................................................................................................... 19

3.5.1 Connecting the sc Sensor in a Non-hazardous Location ....................................................................... 19

3.6 Wiring the Digital Gateway............................................................................................................................... 22

3.7 Connecting the Optional Digital Output............................................................................................................ 22

Section 4 Operation.................................................................................................................................................... 25

4.1 Using the Keypad............................................................................................................................................. 25

4.2 Controller Display Features ............................................................................................................................. 26

4.2.1 Important Key Presses ........................................................................................................................... 26

4.3 System Setup ................................................................................................................................................. 27

4.3.1 Adjusting Display Contrast ..................................................................................................................... 27

4.3.2 Specifying the Displayed Language ....................................................................................................... 27

4.2.2 Software Text Abbreviations................................................................................................................... 27

4.3.3 Setting the Time and Date...................................................................................................................... 28

4.4 Setting up System Security .............................................................................................................................. 29

4.4.1 Setting the Passcode.............................................................................................................................. 29

4.4.2 Editing the Passcode.............................................................................................................................. 29

4.5 Output Options ................................................................................................................................................. 30

4.5.1 Navigating to the Output Options Menu ................................................................................................. 30

4.5.2 Hold/Transfer Outputs ............................................................................................................................ 30

4.5.3 Release Outputs..................................................................................................................................... 31

4.6 Relay Options .................................................................................................................................................. 31

4.6.1 Navigating to the Relay Options Menu ................................................................................................... 31

4.7 Data Event Logging Options ............................................................................................................................ 31

4.8 Digital Network Options ................................................................................................................................... 32

4.9 System Setup Menu......................................................................................................................................... 32

4.10 Test/Maint Menu ............................................................................................................................................ 36

I

Page 6

Table of Contents

Section 5 Maintenance ............................................................................................................................................... 37

5.1 Cleaning the Controller..................................................................................................................................... 37

5.2 Fuse Replacement ........................................................................................................................................... 37

Section 6 Replacement Parts ................................................................................................................................... 39

6.1 Replacement Items........................................................................................................................................... 39

6.2 Accessories ...................................................................................................................................................... 39

Section 7 Warranty, liability and complaints ............................................................................................................ 41

7.1 Immunity ........................................................................................................................................................... 42

7.2 Emissions ......................................................................................................................................................... 42

Section 8 Contact ....................................................................................................................................................... 43

Index............................................................................................................................................................................. 53

II

Page 7

Section 1 Specifications

Specifications are subject to change without notice.

Component Description

Controller Operating

Tem per atur e

Controller Storage Temperature –20 to 70 °C (–4 to 158 °F); 95 % relative humidity, non-condensing

Enclosure NEMA 4X/IP66 metal enclosure with a corrosion-resistant finish

Power Requirements

Pollution Degree/

Installation Category

Outputs

Relays

Controller Dimensions ½ DIN—144 × 144 × 150 mm (5.7 × 5.7 × 5.9 inches)

Controller Weight 1 ,6 kg (3.5 lb)

Certifications

Microprocessor-controlled measuring unit with measured value display, temperature display,

and menu-driven system

–20 to 60 °C (–4 to 140 °F); 95 % relative humidity, non-condensing with sensor/network

card load <7 W; –20 to 40 °C (–4 to 104 °F) with sensor /network card load <25 W

AC Powered sc100 model: 100–230 V AC ±10 %, 50/60 Hz; Power 15 W with 7 W

sensor/network card load, 37 W with 25 W sensor/network card load

24 V DC powered sc100 model: 24 V DC –15 % / +20 %; Power 16 W with 7 W

sensor/network card load, 34 W with 25 W sensor/network card load

II; II

Two (Analog (4–20 mA)) outputs, maximum impedance 500 Ohm. Optional digital network

connection. IrDA digital connection.

Three SPDT, user-configured contacts rated 100–230 V AC, 5 Amp resistive maximum for the

ac powered sc100 and 24 V DC, 5 A resistive maximum for the dc powered sc100.

CE approved (with all sensor types)

Listed for use in general locations to UL and CSA safety standards by ETL

(with all sensor types)

Specifications

3

Page 8

Specifications

Specifications

4

Page 9

Section 2 General Information

2.1 Safety Information

Please read this entire manual before unpacking, setting up, or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use or install this

equipment in any manner other than that specified in this manual.

2.1.1 Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Important Note: Information that requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth

(ground).

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems

after 12 August of 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the

Producer for disposal at no charge to the user.

Note: For all electrical products (marked or unmarked) which are supplied or produced by Hach-Lange, please contact

the local Hach-Lange sales office for instructions for proper disposal.

General Information

5

Page 10

General Information

2.2 General Product Information

The controller enclosure is NEMA4X/IP66-rated and has a corrosion-resistant finish designed to

withstand corrosive environmental constituents such as salt spray and hydrogen sulfide. The

controller display shows the current reading plus a secondary measurement such as temperature

if connected to a single sensor, or two readings with their corresponding secondary measurement

readings when two sensors are connected.

Installation instructions for the controller are presented in this manual. If a system with a sensor

and a controller has been purchased, complete information for installation and operation is also

presented in the sensor system manual.

General Product Information

6

Page 11

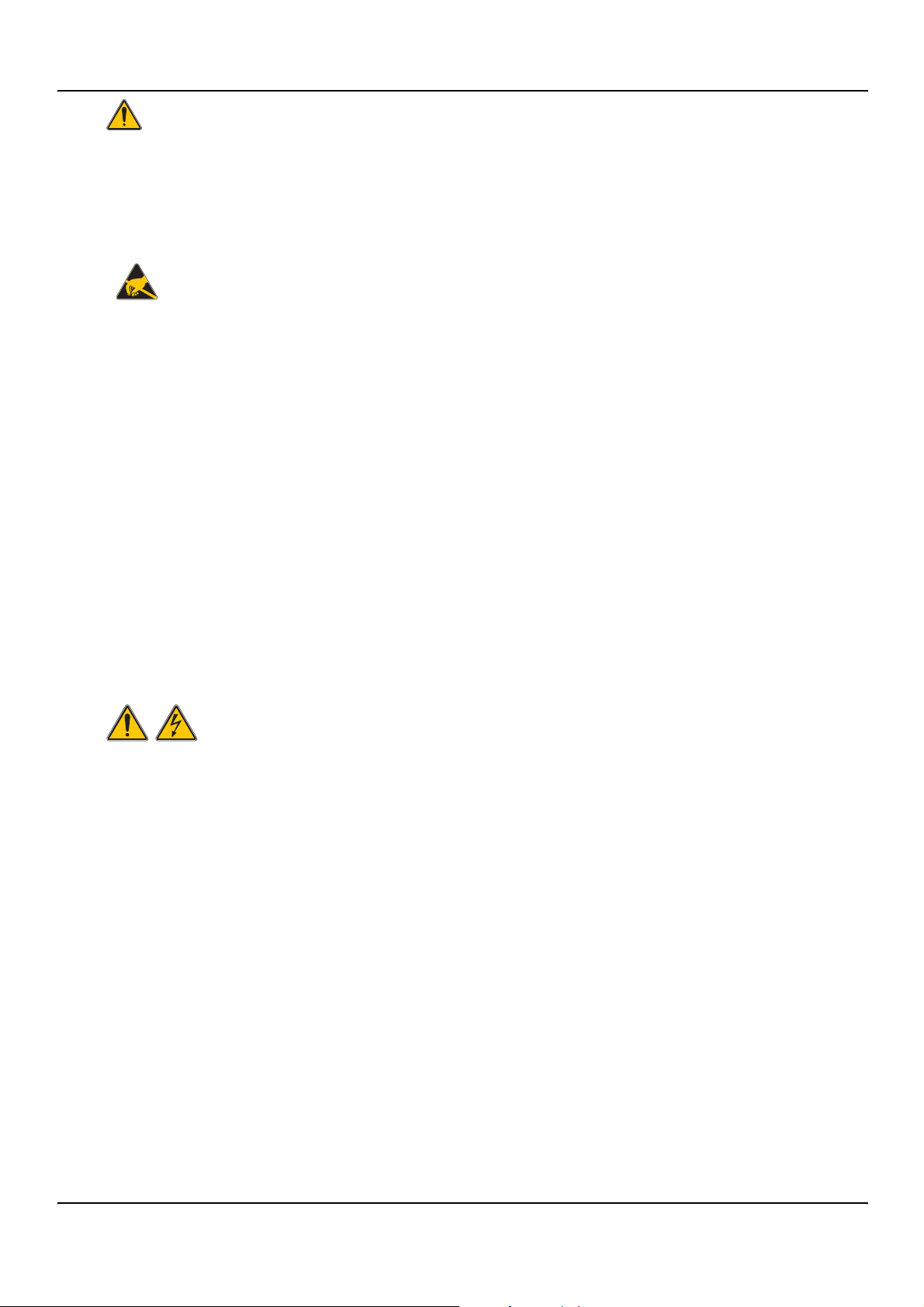

Section 3 Installation

DANGER

Only qualified personnel should conduct the installation tasks described in this section of

the manual.

DANGER

Do not replace any component unless power has been switched off or the area is known to

be non-hazardous.

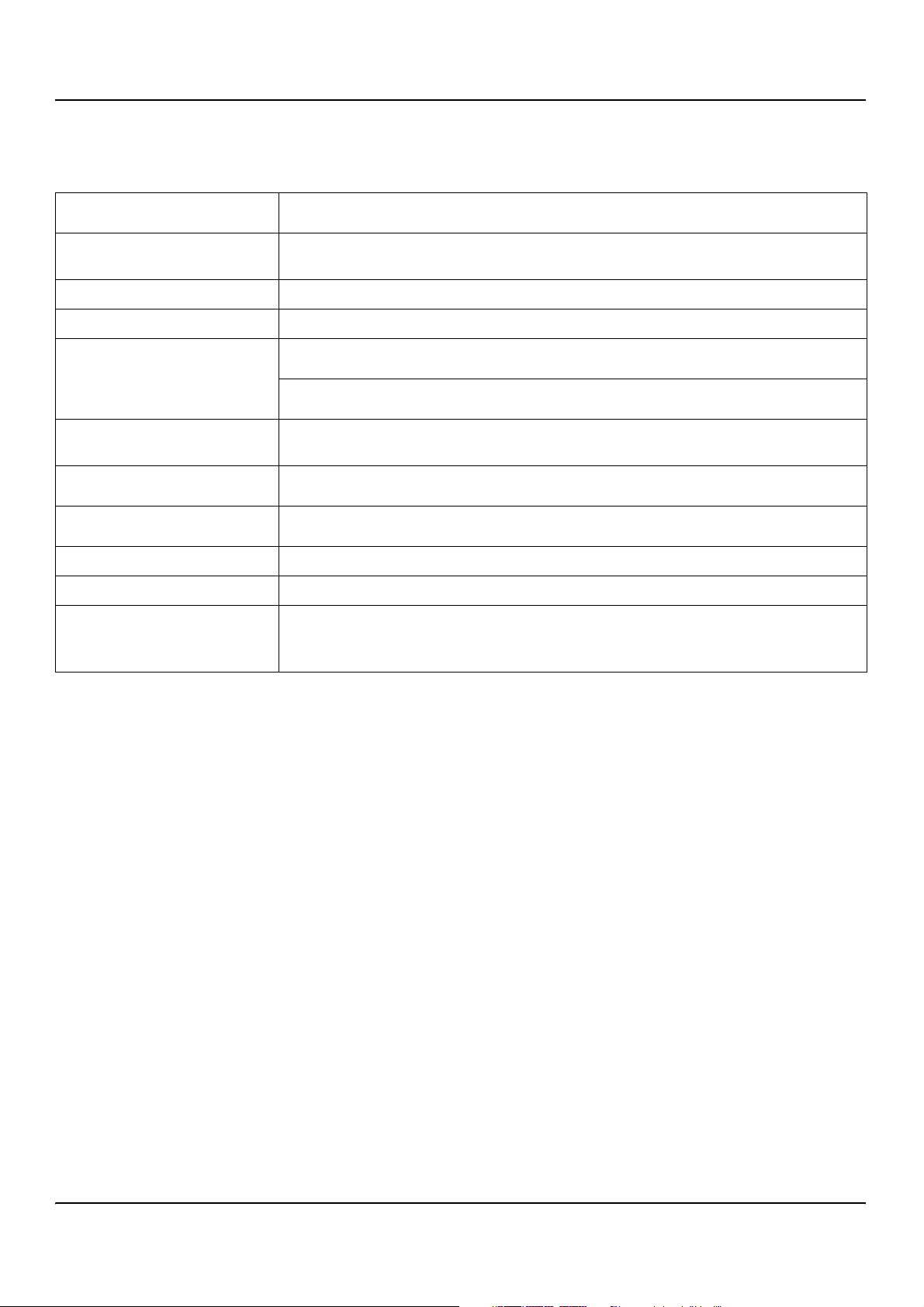

Figure 1 Components of a Basic System

1

sc100

1. Controller 6. Lock washer, ¼-inch I.D. (4), Cat. No. 8H1336

2. Mounting foot for panel mounting (2), Cat. No. 1000B4F3222 7. Flat washer, ¼-inch I.D. (4), Cat. No. 8H1346

3. Bracket for panel & pipe mounting,

Cat. No. 1000C4F3217-101

4. Gasket for panel mounting, Neoprene,

Cat. No. 1000A4F3249-101

5. Hex nut, M6 (4), Cat. No. 5867300 10. Pan head screws (4), M6 x 1,0 x 150 mm,

3

2

4

8. Pan head screws (4), M6 x 1,0 x 20 mm,

Cat. No. 5867400

9. Pan head screws (4), M6 x 1,0 x 100 mm,

Cat. No. 5867500

Cat. No. 5867600

5

6

7

8

9

10

Table 1 Customer-supplied Items

Item

14-AWG wire for electrical power connections in conduit or 115 or 230 V ac power cord plus a IP65 / NEMA 4X-rated strain

relief

High-quality, shielded instrumentation cable for connecting the analog outputs plus a IP65 / NEMA 4X-rated strain relief.

Mounting hardware for the sensor (available from the manufacturer, order separately). See the sensor manual.

Sun shield for mounting configurations where the sun strikes the front of the display.

Common hand tools

Installation

7

Page 12

Installation

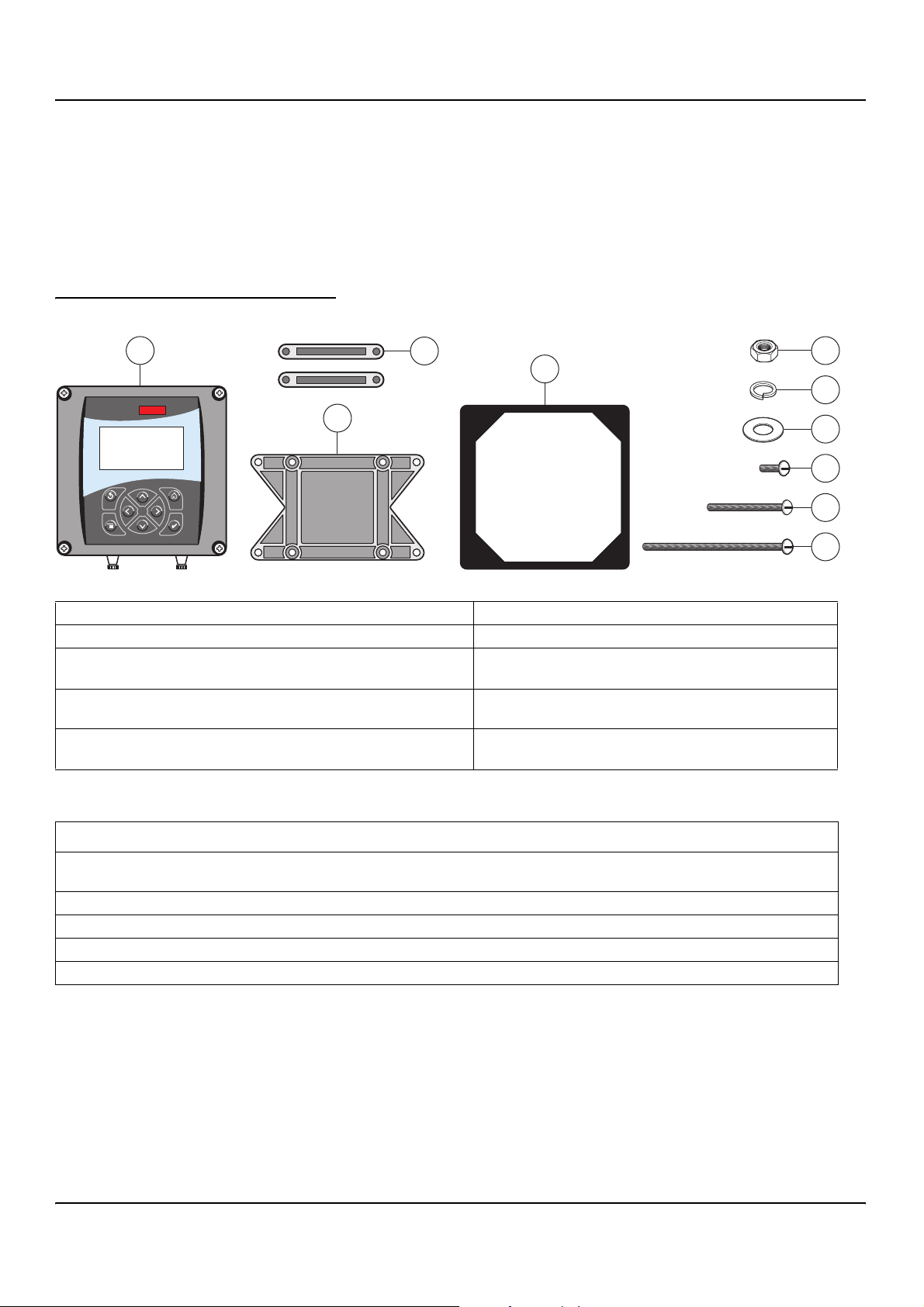

3.1 Mechanical Installation

Install in an environment that is protected from corrosive fluids.

3.1.1 Controller Dimension Illustrations

Figure 2 Controller Dimensions

144.0 mm (5.67 inches) 150.0 mm (5.91 inches)

sc100

Figure 3 Controller Mounting Dimensions

144.02 mm (5.67 inches)

72.01 mm

(2.84 inches)

72.01 mm

(2.84 inches)

144.02 mm

(5.67 inches)

144.0 mm (5.67 inches)

40.14 mm

(1.58 inches)

80.27 mm

(3.16 inches)

40.14 mm (1.58 inches)

Mechanical Installation

8

M6 x 1.0

80.27 mm

(3.16 inches)

Page 13

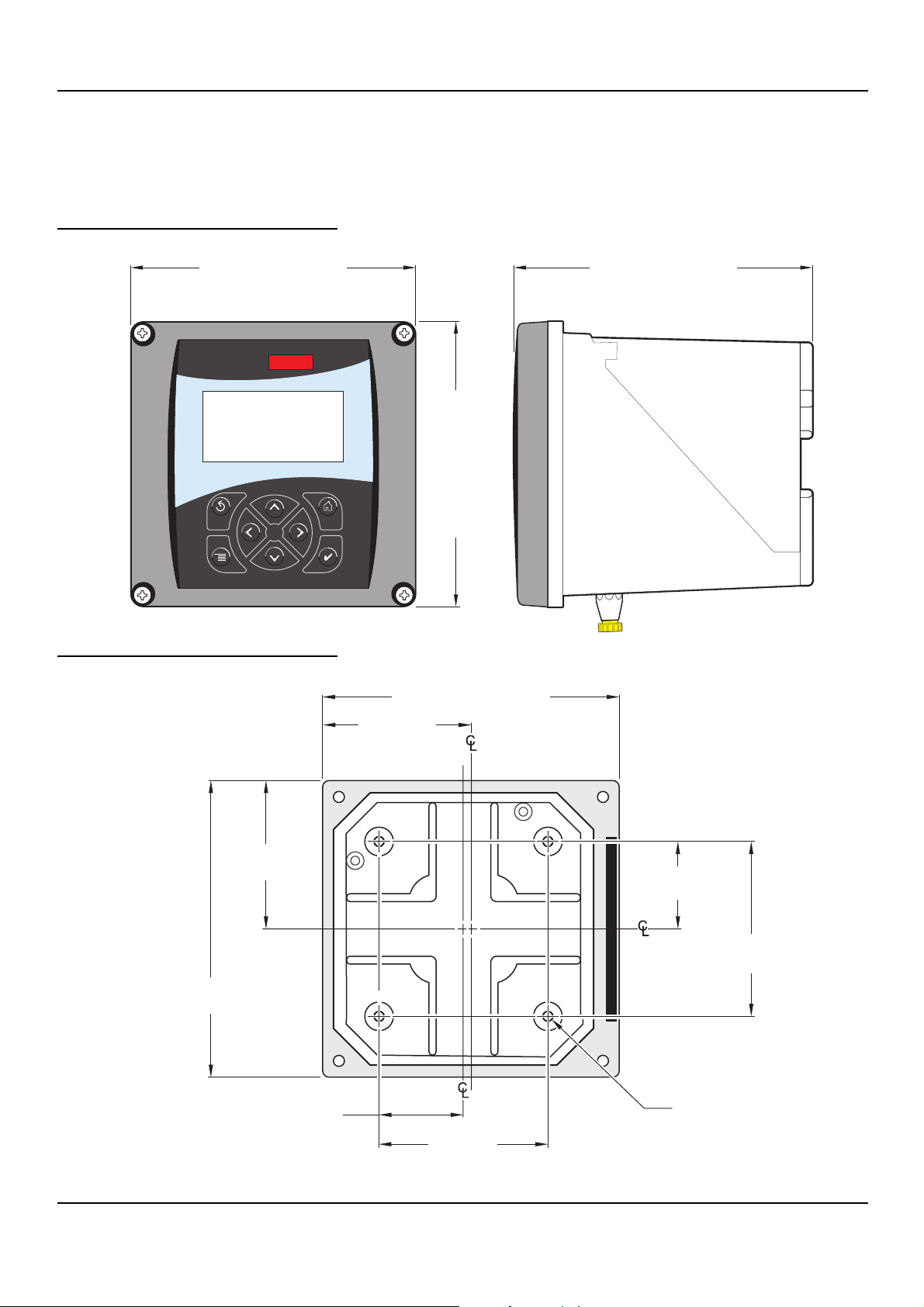

Figure 4 Panel Mount Cut-out Dimensions

75 mm (2.955 )inches

(ref only)

Installation

144 mm (5.67 )inches

ref only()

144 mm

(5.67 )

inches

()

ref only

72 mm

(2.835 )inches

ref only()

66.67 mm (2.625 )inches

Figure 5 Conduit Hole Dimensions

75.07 mm (2.955 inches)

28.57 mm (1.125 inches)

135 mm

(5.31 )inches

67.4 mm

(2.65 )inches

133 mm (5.25 )inches

144 mm (5.67 inches)

68.96 mm (2.715 inches)

28.57 mm (1.125 inches)

25.4 mm (1.00 inch)

25.4 mm (1.00 inch)

99.31 mm

(3.91 inches)

50.8 mm

(2.00 inches)

6.35 mm (0.25 inch)

15.24 mm (0.60 inch)

(5.00 inches)

Mechanical Installation

150 mm

(5.91 inches)

(ref only)

127 mm

9

Page 14

Installation

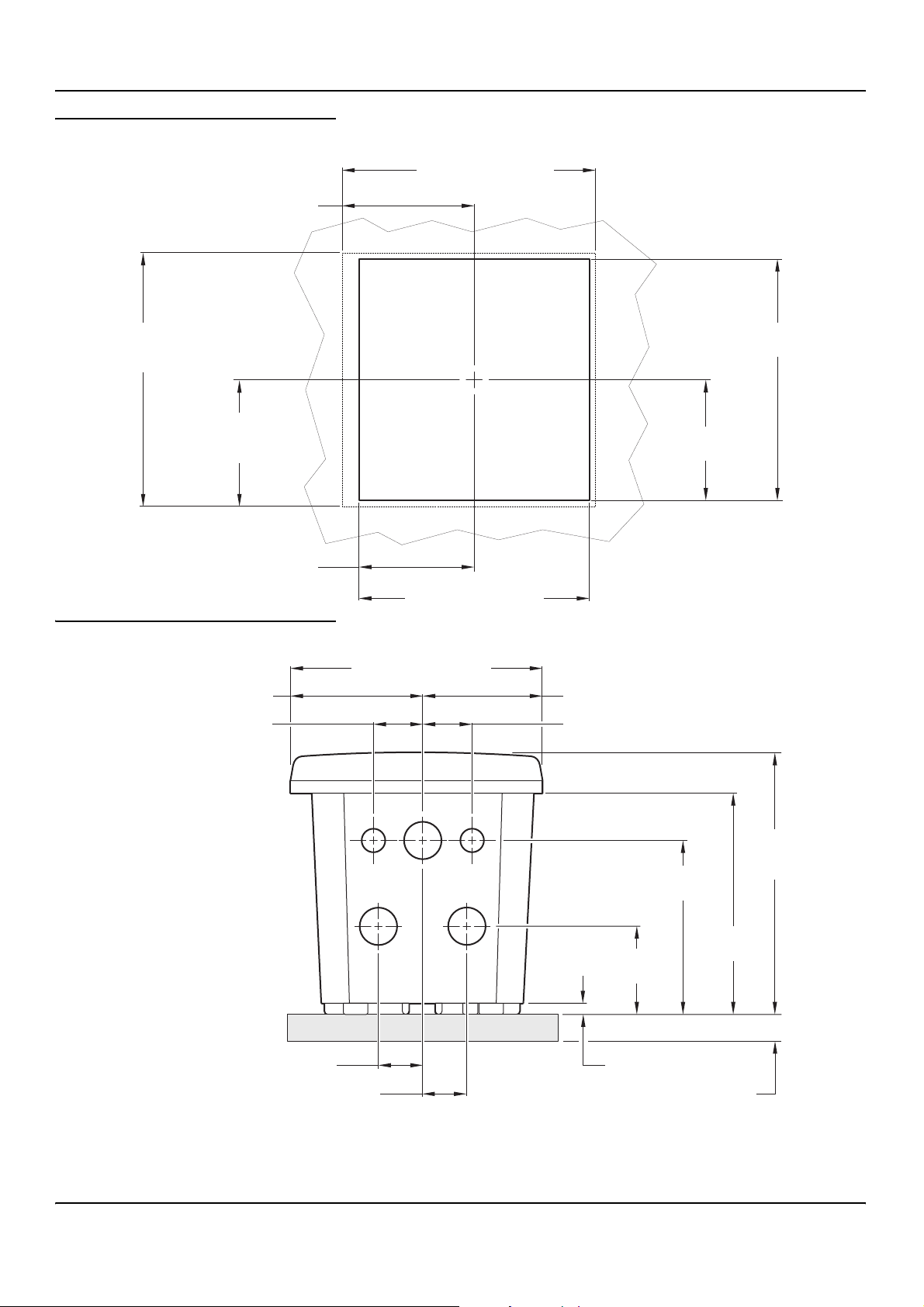

3.1.2 Mounting the Controller

Attach the controller to a rail or wall or mount it in a panel. Supplied mounting hardware is shown in

Figure 6, Figure 7, and Figure 8.

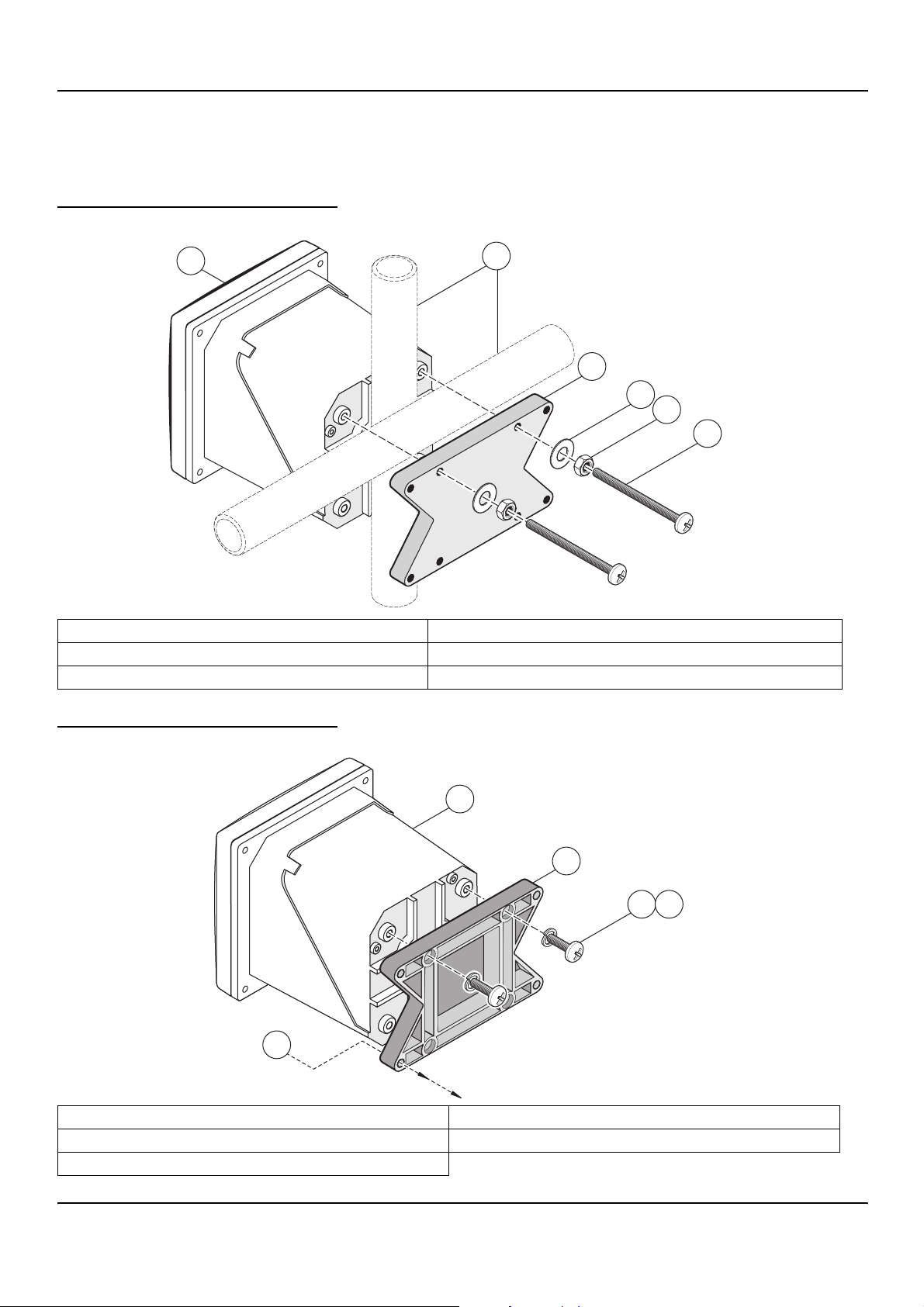

Figure 6 Vertical or Horizontal Pipe Mounting the Controller

1

1. Controller 4. Flat washer, ¼-inch I.D. (4), Cat. No. 8H1346

2. Pipe (vertical or horizontal) 5. Hex nut, M6 (4), Cat. No. 5867300

3. Bracket, pipe mounting, Cat. No. 1000C4F3217-101 6. Pan head screw, M6 x 1,0 x 100 mm (4), Cat. No. 5867400

2

3

4

5

6

Figure 7 Wall Mounting the Controller

1

2

3

4

5

1. Controller 4. Pan head screw, M6 x 1,0 x 20 mm (4), Cat. No. 5867400

2. Bracket, Cat. No. 1000C4F3217-101 5. Customer-supplied hardware for wall mounting

3. Lock washer, ¼-inch I.D., Cat. No. 8H1336

Mechanical Installation

10

Page 15

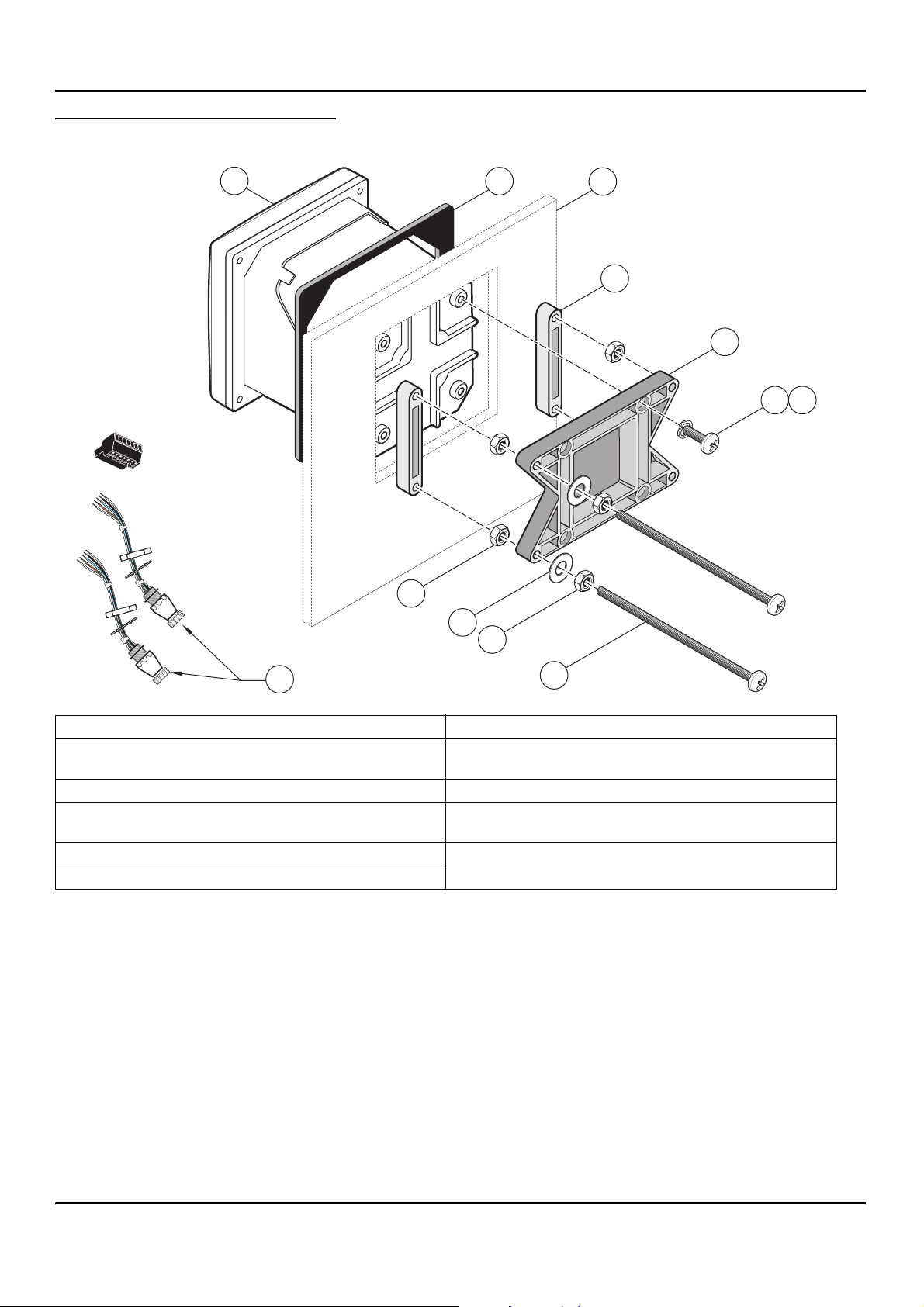

Figure 8 Panel Mounting the Controller

Installation

1

8

2

9

8

3

4

5

6

7

11

1. Controller 7. Lock washer, ¼-inch I.D., (4) Cat. No. 8H1336

2. Gasket, Neoprene, panel mount,

Cat. No. 1000A4F3249-101

3

3. Panel (maximum thickness is 9,5 mm (

4. Mounting Foot (2), Cat. No. 1000B4F3222 10. Pan head screw, M6 x 1,0 x 150 mm (4),

5. Mounting bracket, controller, Cat. No. 1000C4F3217-101 11. It may be necessary to remove the sensor connectors.

6. Pan head screw (4), Cat. No. 5867400

/8 inch)) 9. Flat washer (4), Cat. No. 8H1346

8. Hex nut (4), Cat. No. 5867300

Cat. No. 5867600

see procedure below.

10

To remove the sensor connectors before inserting the controller enclosure into the panel cut-out:

1. Disconnect the wires at terminal block J5, see Figure 19 on page 21.

2. Loosen and remove the nut securing the sensor connector inside the enclosure. Remove the

sensor connector and wires. Repeat step 1 and 2 for the other sensor connector.

3. After the controller is in place in the panel, reinstall the sensor connectors and reconnect the

wiring to terminal J5 as shown in Figure 19 on page 21.

Mechanical Installation

11

Page 16

Installation

3.2 Wiring Safety Information

When making any wiring connections to the sc100 Controller, the following warnings and must be

adhered to, as well as, any warnings and notes found throughout the individual installation

sections. For more safety information refer to Safety Information on page 5.

DANGER

Always disconnect power to the instrument when any making electrical connections.

3.2.1 Electrostatic Discharge (ESD) Considerations

Important Note: To minimize hazards and ESD risks, maintenance procedures not requiring

power to the analyzer should be performed with power removed.

Delicate internal electronic components can be damaged by static electricity, resulting in degraded

instrument performance or eventual failure.

The manufacturer recommends taking the following steps to prevent ESD damage to

your instrument:

• Before touching any instrument electronic components (such as printed circuit cards and the

components on them) discharge static electricity from your body. This can be accomplished by

touching an earth-grounded metal surface such as the chassis of an instrument, or a metal

conduit or pipe.

• To reduce static build-up, avoid excessive movement. Transport static-sensitive components in

anti-static containers or packaging.

• To discharge static electricity from your body and keep it discharged, wear a wrist strap

connected by a wire to earth ground.

• Handle all static-sensitive components in a static-safe area. If possible, use anti-static floor

pads and work bench pads.

3.3 Electrical Installation

High-voltage wiring for the controller is conducted behind the high voltage barrier in the controller

enclosure. The barrier must remain in place unless a qualified installation technician is installing

wiring for power, alarms, or relays. See Figure 9 for barrier removal information.

Wiring Safety Information

12

Page 17

Installation

RELAYA

+

DATA

+

OUT 2

+

V

+

OUT 1

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYARELAYA

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

J1

J2

J4

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

S1

Figure 9 Removing Voltage Barrier

J1

S1

J2

U5

J4

U9

NETWORK

INTERFACE

CARD

1. High voltage barrier 2. Unsnap the barrier latch then pull out to remove the barrier.

J3

1

+

DATA

– DATA

2

SERVICE REQUEST

3

4

+

5

6

1

2

3

4

5

NCNCNC

NONO

COMCOMCOM

RELAYCRELAYBRELAYA

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

V

GND

F1

+

OUT 2

– OUT 2

SHIELD/CHASSIS GND

+

OUT 1

– OUT 1

NO

F2

PROBES

J5

PCB

CONNECTOR

DANGER - EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

J6

DANGER - RISQUE D'EXPLOSION

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

ANALOG OUTPUTS

1

2

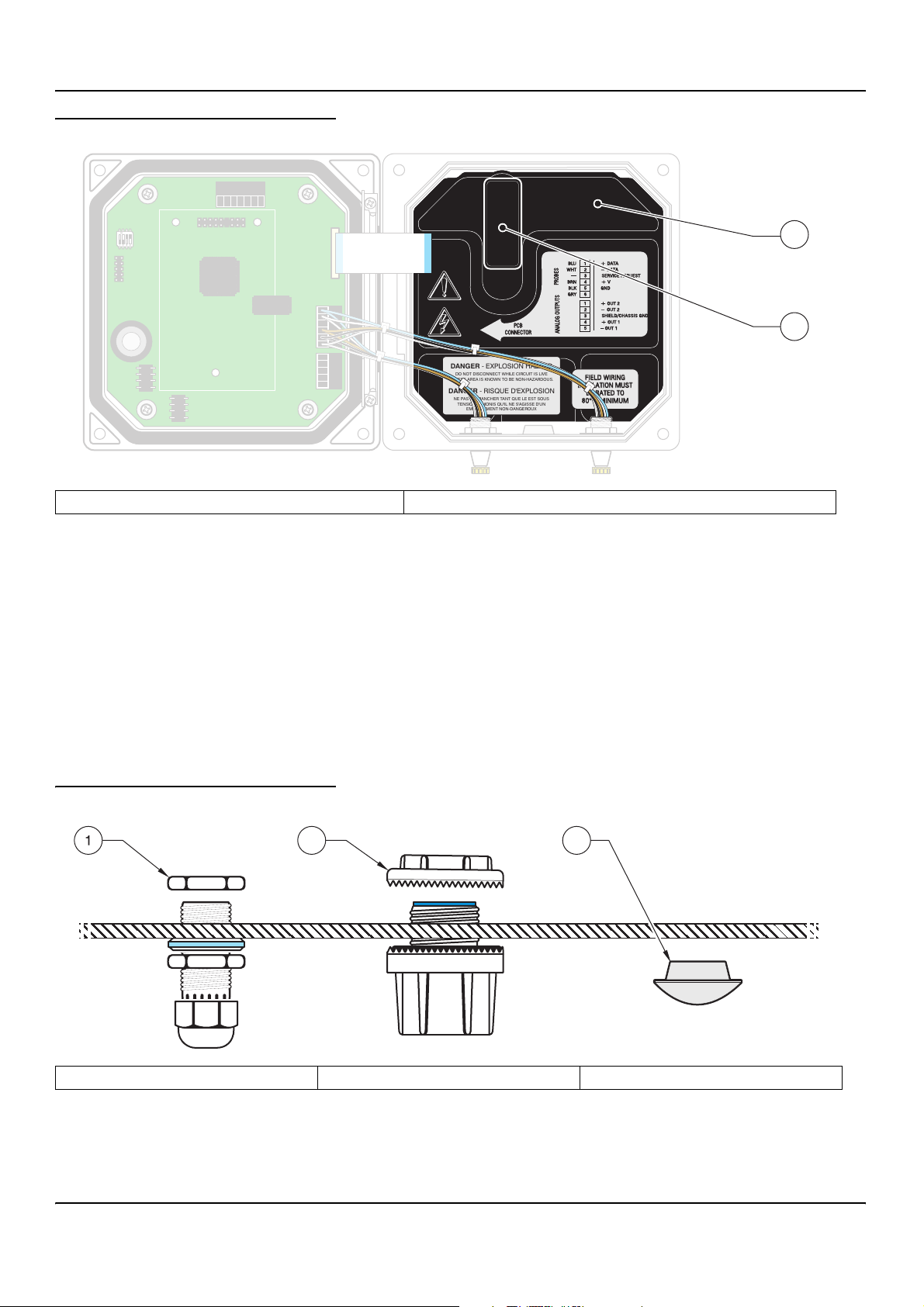

3.3.1 Installation in Conduit

In hard-wired electrical applications, the power and safety ground service drops for the instrument

must be 18 to 12 AWG. See Figure 10 on page 13 for strain relief and conduit opening sealing plug

information. See section 3.3.3 on page 14 for wiring information.

3.3.2 Installation Using a Power Cord

A sealing-type strain relief to maintain the NEMA 4X/IP66 environmental rating and a power cord

less than 3 meters (10 feet) in length with three 18-gauge conductors (including a safety ground

wire) can be used, see Replacement Parts on page 39. See Figure 10 on page 13 for strain relief

and conduit opening sealing plug assembly. See section 3.3.3 on page 14 for wiring information.

Figure 10 Using the Optional Strain Relief and Conduit Plug

2

3

1. Power cord strain relief 2. Conduit strain relief 3. Conduit opening sealing plug

Electrical Installation

13

Page 18

Installation

3.3.3 Wiring for Power at the Controller

DANGER

Explosion hazard. Do not connect or disconnect electrical components or circuits to the

equipment unless power has been switched off or the area is known to be non-hazardous.

DANGER

Do not connect AC power to a sc100 24 V DC powered model.

The sc100 can be purchased as either an 100–230 V AC powered model or a 24 V DC powered

model. Follow the appropriate wiring instructions per the purchased model.

Important Note: A protective earth (PE) ground connection is required by the sc100 for both

100–230 V AC and 24 V DC wiring applications. Failure to connect a good PE ground connection

can result in shock hazards and poor performance due to electromagnetic interferences. ALWAYS

connect a good PE ground to the sc100 terminal.

The controller can be wired for line power by hard-wiring in conduit or wiring to a power cord.

Regardless of the wire used, the connections are made at the same terminals. A local disconnect

designed to meet local electrical code is required and must be identified for all types of installation.

See Figure 13 and Figure 14 on page 16 for suggested local disconnect configurations.

1. Obtain appropriate fittings with NEMA 4X/IP66 environmental rating.

2. Loosen the screws using a phillips-head screwdriver and open the hinged controller cover.

3. Remove the high-voltage barrier (see Figure 9 on page 13).

4. Insert the wires through the strain relief fitting or conduit hub located in the right-rear access

hole in the bottom of the enclosure. Tighten the strain relief if used, to secure the cord.

5. Properly prepare each wire (Figure 11) and insert each wire into the terminal according to

Table 2 or Table 3. Tug gently after each insertion to ensure the connection is secure.

6. Seal any unused openings in the controller box with conduit opening sealing plugs.

7. Reinstall the high-voltage barrier and latch to secure.

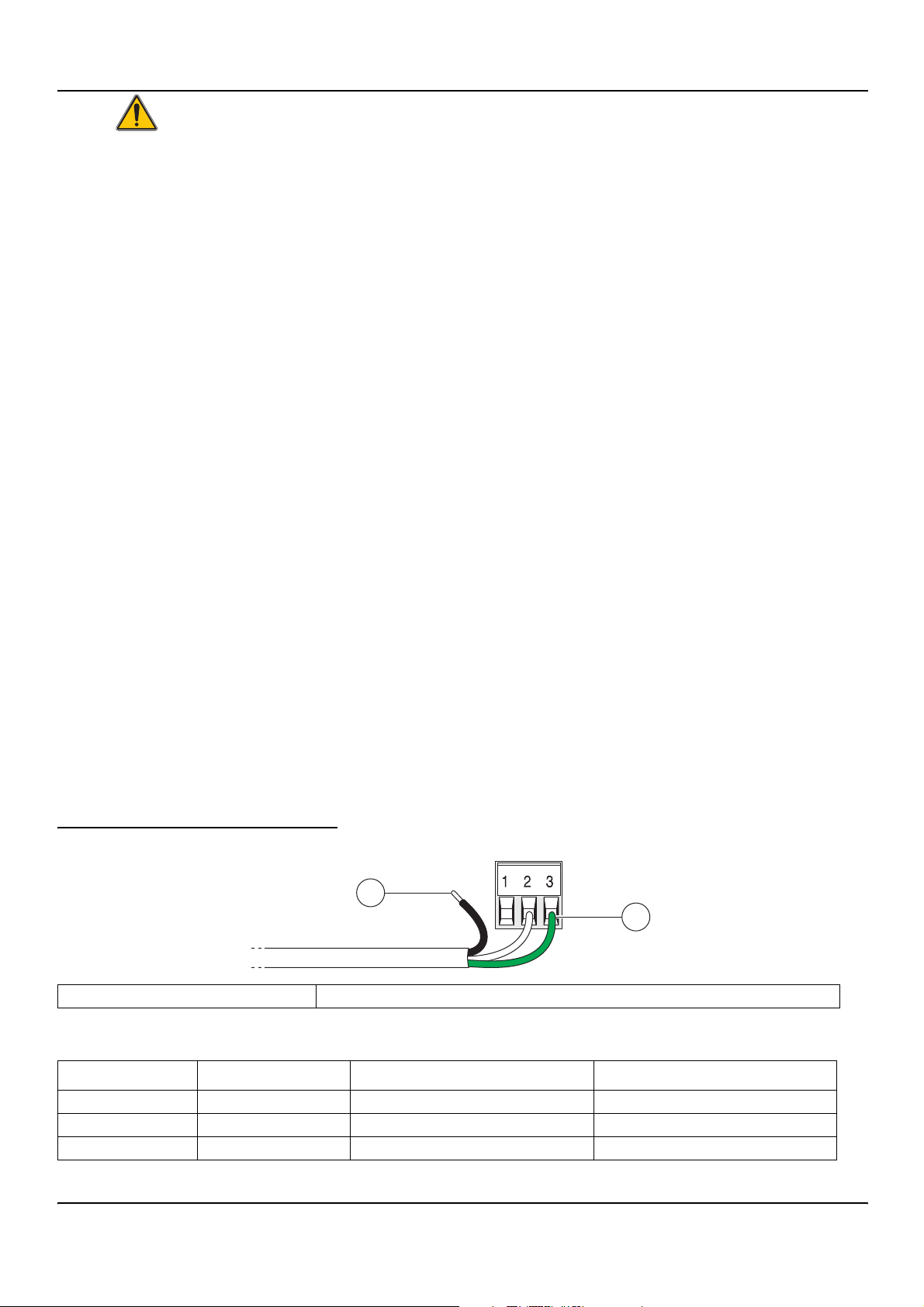

Figure 11 Proper Wire Preparation and Insertion

1

2

1. Strip ¼-inch of insulation. 2. Seat insulation against connector with no bare wire exposed.

Table 2 AC Power Wiring Information (sc100 AC powered model only)

Terminal Number Terminal Description Wire Color Code for North America Wire Color Code for Europe

1 Hot (L1) Black Brown

2 Neutral (N) White Blue

3 Protective Earth (PE) Green Green w/yellow tracer

Electrical Installation

14

Page 19

Table 3 DC Power Wiring Information (sc100 24 V DC powered model only)

RELAYA

+24

VDC

–24

VDC

Terminal Number Terminal Description Wire Color Code for North America Wire Color Code for Europe

1 +24 V dc Red Red

2 24 V dc return Black Black

3 Protective Earth (PE) Green Green w/yellow tracer

The DC power source that supplies power to the 24 V DC powered sc100 must maintain voltage

regulation within the specified 24 V DC –15 % / +20 % voltage limits. The DC power source must

also provide adequate protection against line transients.

Figure 12 sc100 Wiring Connections

312

45

J1

J3

14

S1

J2

Installation

CARD

U5

U9

11 10

F1

J5

NONO

J6

F2

NCNCNC

NO

COMCOMCOM

RELAYCRELAYBRELAYA

–24 VDC

+24 VDC

89

13

12

J4

NETWORK

INTERFACE

1. J1—Network connector 8. Sensor connector

2. J2—Header for optional network interface card 9. Sensor connector

3. J5—Relay A connector 10. J6—Analog output (4–20 mA) connector

4. J6—Relay B connector 11. J5—Sensor connector for hard-wiring

5. J7—Relay C connector 12. Position for network interface card

6. Fuses (F1, F2) 13. Service port

7. J8—Power connections 14. Sensor terminator selector/service port configuration

a. AC Power connection (AC powered sc100 model only)

b. DC Power connection (24 V DC sc100 model only)

6

7

7a

7b

Electrical Installation

15

Page 20

Installation

RELAYA

Figure 13 Local Disconnect for Power Cord

J1

S1

J2

J3

1

CARD

U5

U9

J5

J6

F1

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

J4

NETWORK

INTERFACE

1. Power terminal 2. Power cord strain relief

Figure 14 Local Disconnect for Hard-wired Line Power

J1

S1

J2

J3

F2

2

1

CARD

U5

U9

J5

NCNCNC

NONO

COMCOMCOM

RELAYCRELAYBRELAYA

J6

J4

NETWORK

INTERFACE

1. Power terminal 2. Conduit strain relief

Electrical Installation

16

F1

F2

2

NO

Page 21

3.4 Alarms and Relays

DANGER

Explosion hazard. Do not connect or disconnect electrical components or circuits to the

equipment unless power has been switched off or the area is known to be non-hazardous.

DANGER

Exposure to some chemicals may degrade the sealing properties of materials used in the

following devices: Relays K1, K2, and K3. Periodic inspection of these devices is

recommended to check for degradation.

The controller is equipped with three unpowered relays rated 100–230 V AC, 50/60 Hz, 5 Amp

resistive maximum. See the sensor manual for relay setup details.

3.4.1 Connecting the Relays

DANGER

Relay loads must be resistive. User must externally limit current to the relays to 5 Amps by

use of a fuse or breaker.

DANGER

Power and relay terminals are designed for only single wire termination. Do not use more

than one wire in each terminal.

Installation

The relay connector accepts 18–12 AWG wire (as determined by load application). Wire gauge

less than 18 AWG is not recommended.

The Normally Open (NO) and Common (COM) relay contacts will be connected when an alarm or

other condition is active. The Normally Closed (NC) and Common relay contacts will be connected

when an alarm or other condition is inactive or when power is removed from the controller.

AC Line (100–230 V) Powered sc100’s

AC line powered sc100 controllers contain three relays designed for use with high voltage (greater

than 30 V-RMS, 42,2 V-PEAK or 60 V DC). Refer to Figure 15 for connection information. The

relay wiring compartment is not designed for voltage connections below these levels. Relays must

not be powered from the same wiring used to power the controller.

24 V DC Powered sc100

The 24 V DC sc100 controller contains three relays designed for use with only low voltage (less

than 30 V-RMS, 42,2 V-PEAK or 60 V DC). Refer to Figure 15 for connection information. The

wiring compartment is not designed for voltage connections above these levels. Relay must not be

powered from the same wiring used to power the controller.

Alarms and Relays

17

Page 22

Installation

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYA

J1

J2

J4

S1

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

J5J5

Figure 15 Alarm and Relay Connections

J1

S1

J4

J2

U5

U9

J3

J5J5

J5

NC COM NO

J5 J6 J7

3

2

1

RELAY A RELAY B RELAY C

F1

F2

NETWORK

INTERFACE

CARD

J6

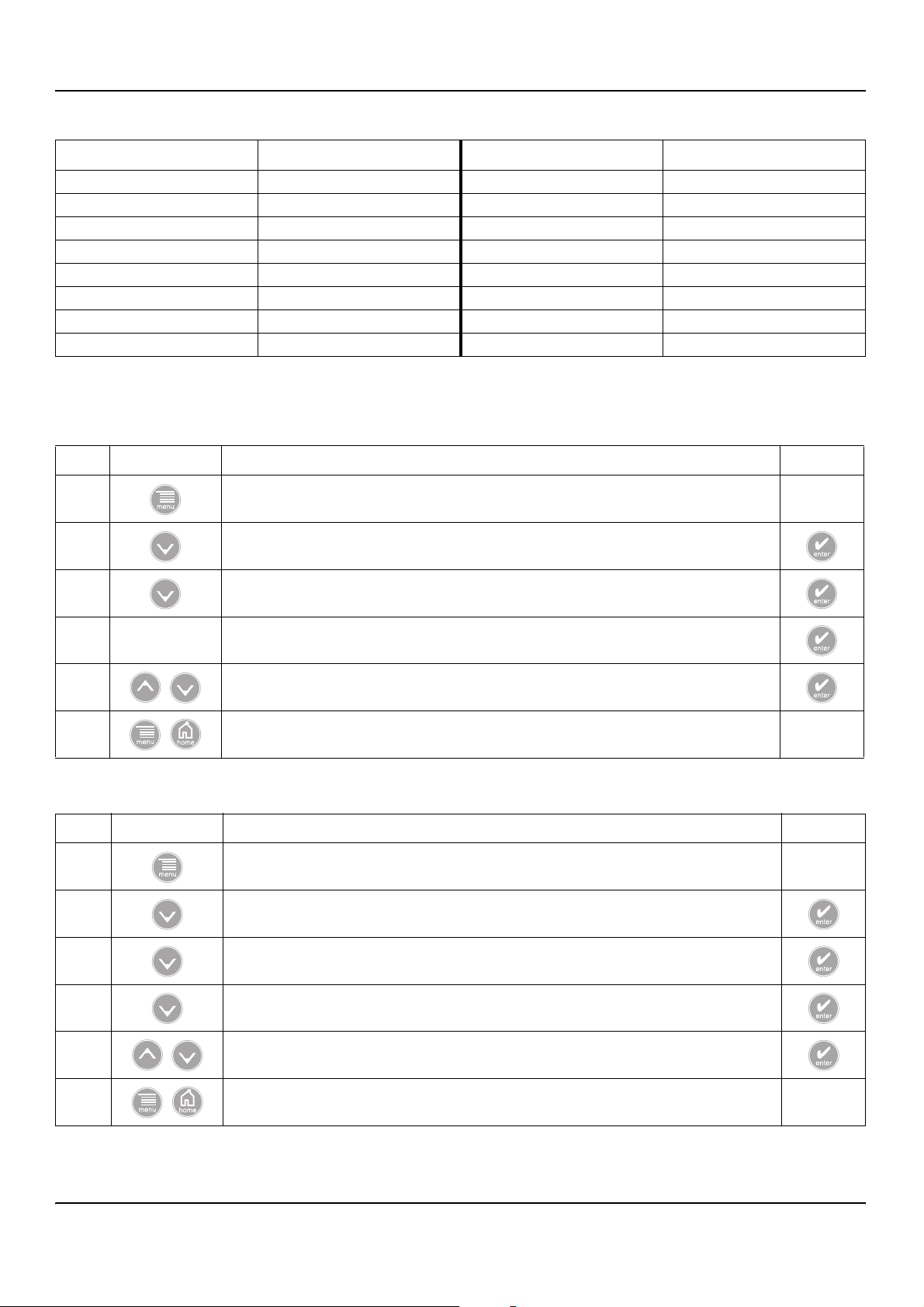

3.4.2 Connecting the Analog Outputs

DANGER

Explosion hazard. Do not connect or disconnect electrical components or circuits to the

equipment unless power has been switched off or the area is known to be non-hazardous.

Two isolated analog outputs (1 and 2) are provided, see Figure 16. Each output can be set to 0–20

or 4–20 mA, and can be assigned to represent the measured parameter or secondary

measurement such as temperature. Make connections with twisted-pair shielded wire and connect

the shield at the controlled component end or at the control loop end. Do not connect the shield

at both ends of the cable. Use of non-shielded cable may result in radio frequency emission or

susceptibility levels higher than allowed. Maximum loop resistance is 500 Ohm. Refer to the

sensor manual for output software setup.

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

Disconnect

Power

Alarms and Relays

18

Make wiring connections at the analyzer end as shown in Figure 16.

Table 4 Output Connections at Terminal Block J6

Recorder Wires Circuit Board Position

Output 2 + 1

Output 2 – 2

Shield 3

Output 1 + 4

Output 1 – 5

Page 23

Figure 16 Analog Output Connections

+

DATA

+

OUT 2

+

V

+

OUT 1

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYA

J1

J2

J4

S1

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTSANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

J5J5

J1

S1

J2

U5

J4

U9

NETWORK

INTERFACE

CARD

J3

J5J5

J5

J6

Installation

1

+

DATA

– DATA

2

SERVICE REQUEST

3

4

+

5

6

1

2

3

4

5

NCNCNC

NONO

COMCOMCOM

RELAYCRELAYBRELAYA

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

V

GND

F1

+

OUT 2

– OUT 2

SHIELD/CHASSIS GND

+

OUT 1

– OUT 1

NO

F2

PROBES

PCB

CONNECTOR

DANGER - EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

DANGER - RISQUE D'EXPLOSION

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

ANALOG OUTPUTS

1

2

3

4

5

J6

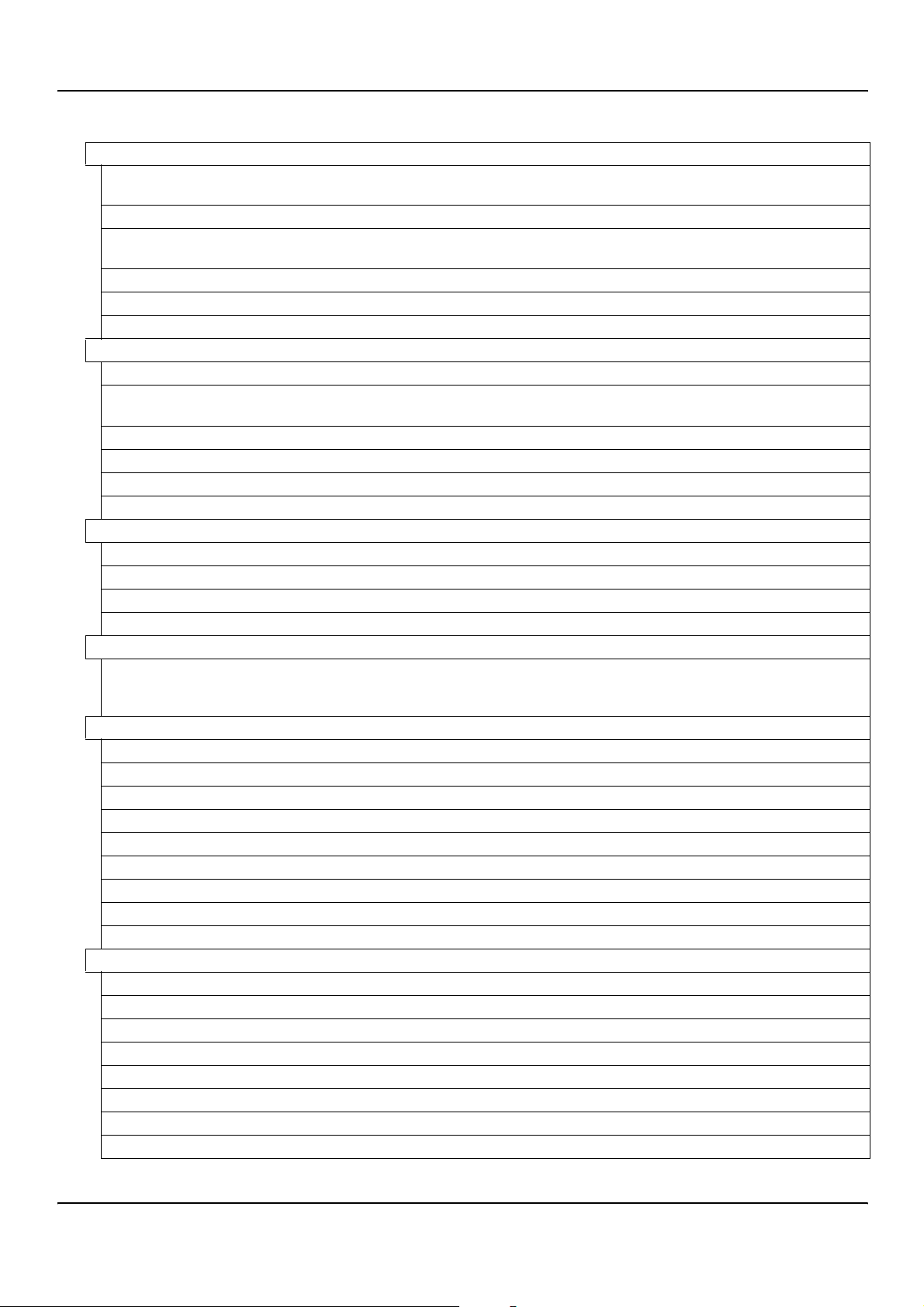

3.5 Connecting/Wiring the sc Sensor

DANGER

Explosion hazard. Do not connect or disconnect electrical components or circuits to the

equipment unless power has been switched off or the area is known to be non-hazardous.

3.5.1 Connecting the sc Sensor in a Non-hazardous Location

3.5.1.1 Attaching a sc Sensor with a Quick-connect Fitting

The sensor cable is supplied with a keyed quick-connect fitting for easy attachment to the

controller, see Figure 17. Retain the connector cap to seal the connector opening in case the

sensor must be removed. Optional extension cables may be purchased to extend the sensor cable

length. If the total cable length exceeds 100 m (300 ft), a termination box must be installed. When

used with the termination box, the maximum cable length is 400 m (1300 ft). See the Replacement

Parts section in the sensor manual for part number information.

Connecting/Wiring the sc Sensor

19

Page 24

Installation

Figure 17 Attaching the Sensor using the Quick-connect Fitting

sc100

Figure 18 Quick-connect Fitting pin assignment

5

4

3

Item Designation Wire Color

1 Pin 1 (+12 V DC) Brown

2 Pin 2 (Circuit Common) Black

3 Pin 3 (Data (+)) Blue

4 Pin 4 (Data (–)) White

5 Pin 5 (Shield) Shield (grey wire in existing quick-disconnect fitting)

6Groove

3.5.1.2 Hard-wiring a sc Sensor to the Controller

6

1

2

1. Open the controller cover.

2. Disconnect and remove the existing wires between the quick connect and terminal block J5,

see Figure 19 on page 21.

3. Remove the quick connect fitting and wires and install the threaded plug on the opening to

maintain the environmental rating.

Connecting/Wiring the sc Sensor

20

Page 25

4. Strip the insulation on the cable back 1-inch. Strip ¼-inch of each individual wire end.

+

DATA

+

OUT 2

+

V

+

OUT 1

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

+

DATA

+

OUT 2

+

V

+

OUT 1

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTSANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAY3RELAY 2RELAY1

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTSANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

J1

J2

J4

NETWORK

INTERFACE

CARD

J3

U5

U9

S1

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

5. Pass the cable through conduit and a conduit hub or a strain relief fitting and an available

access hole in the controller enclosure. Tighten the fitting.

6. Wire as shown in Table 5.

7. Close and secure the cover.

Figure 19 Hard-wiring the sensor

J1

S1

J4

NETWORK

INTERFACE

CARD

J2

U5

J5J5

J5

U9

J5

J6

Installation

J3

1

1

+

DATA

+

DATA

– DATA

– DATA

2

2

SERVICE REQUEST

SERVICE REQUEST

3

3

4

4

+

V

+

5

5

GND

GND

6

6

1

1

+

+

– OUT 2

– OUT 2

2

2

SHIELD/CHASSIS GND

SHIELD/CHASSIS GND

3

3

4

4

+

+

5

5

– OUT 1

– OUT 1

NCNCNC

NONO

COMCOMCOM

RELAY3RELAY 2RELAY1

FIELD WIRING

FIELD WIRING

INSULATION MUST

INSULATION MUST

BE RATED TO

BE RATED TO

80° C MINIMUM

80° C MINIMUM

V

F1

F2

OUT 2

OUT 2

OUT 1

OUT 1

NO

PCB

PCB

CONNECTOR

CONNECTOR

DANGER - EXPLOSION HAZARD

DANGER - EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

DANGER - RISQUE D'EXPLOSION

DANGER - RISQUE D'EXPLOSION

NE PAS DEBRANCHER TANT QUE LE EST SOUS

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

EMPLACEMENT NON-DANGEROUX

PROBES

PROBES

ANALOG OUTPUTS

ANALOG OUTPUTS

From Probe

Table 5 Wiring the Sensor at Terminal Block J5

Terminal Number Terminal Designation Wire Color

1 Data (+) Blue

2 Data (–) White

3 Service Request No Connection

4 +12 V dc Brown

5 Circuit Common Black

6 Shield Shield (grey wire in existing quick disconnect fitting)

Disconnect

Power

Connecting/Wiring the sc Sensor

21

Page 26

Installation

3.6 Wiring the Digital Gateway

The digital gateway is designed to provide a digital interface to the sc100 controller (or other

appropriate digital controller). The non-sensor end is connected to the controller as described in

section 3.5.1 on page 19 for non-hazardous locations.

3.7 Connecting the Optional Digital Output

DANGER

Explosion hazard. Do not connect or disconnect electrical components or circuits to the

equipment unless power has been switched off or the area is known to be non-hazardous.

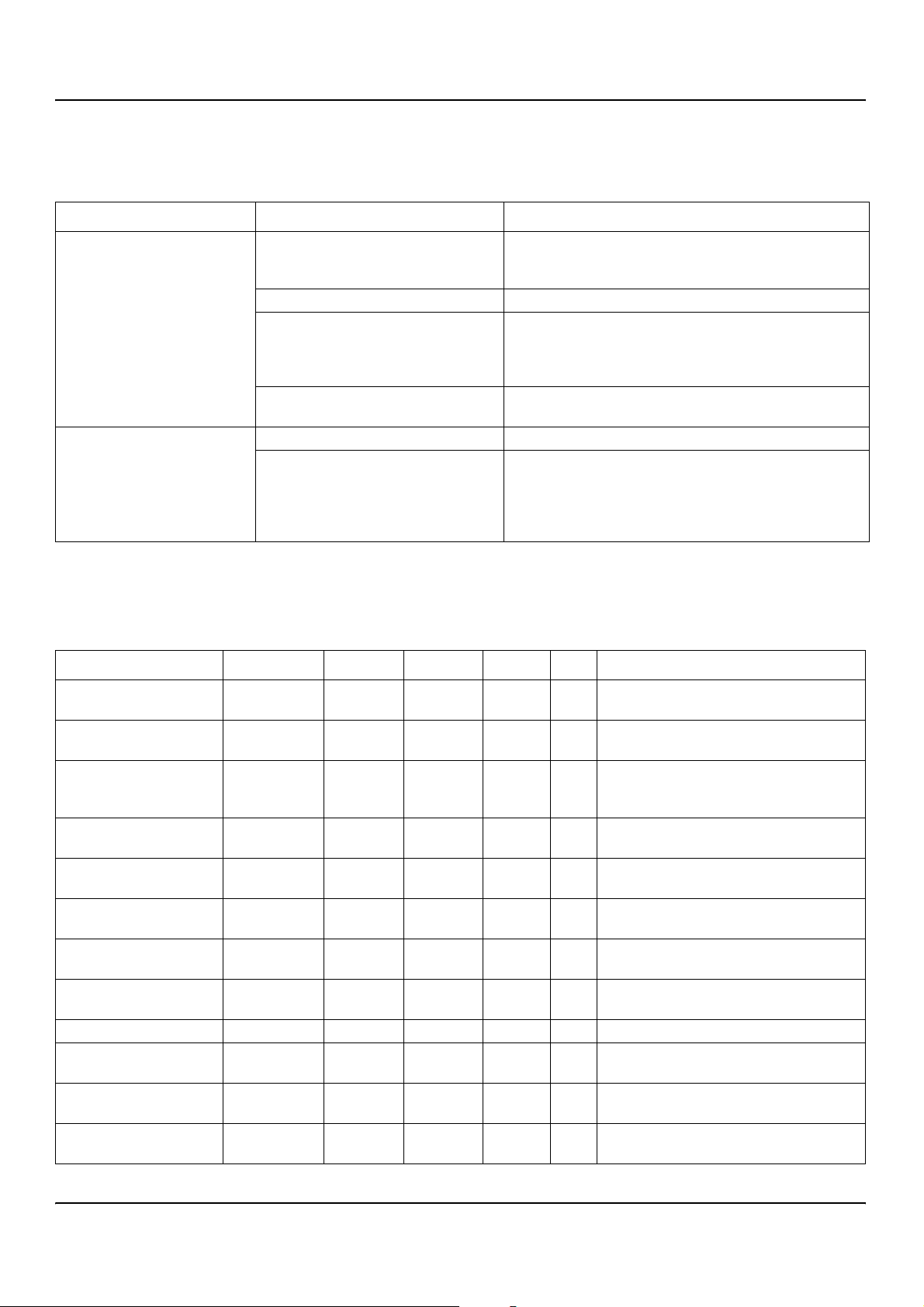

At this time, the manufacturer supports Modbus RS485, Modbus RS232, and Profibus DP

communication protocols. The optional digital output card is installed in the location indicated in

Figure 21 on page 23. Terminal block J1 provides user connection to the optional network card.

The terminal connection is based on the selected network card. Refer to the instructions supplied

with the network card for more details.

Note: The sc100/1720E system also supports the AquaTrend Network.

Surge Protection Recommendation for Profibus DP

Many industrial environments are vulnerable to power transients and lightning. Water and

wastewater plants are notorious lightning targets. Lightning has become a leading cause of

instrument failure at these facilities. Surge protectors limit the magnitude of over-voltage transients

and protect equipment from damage. To be effective on Data lines, at a minimum, a surge

protector should provide two stages of protection with sub-nanosecond response time. Data line

surge protection should be installed on a Profibus DP network where it might be susceptible to

lightning or transients. The purpose of the surge protector is to protect the device (instrument) it is

located next to, not the network cable.

For the best performance/protection connect the surge protector as close as possible to the device

to be protected and connect the device (instrument) ground connection through the surge

protector’s ground to the local protective earth ground. Contact your local Profibus network

component supplier for their recommendation as to which surge protectors may be best for your

system.

Table 6 Digital Output Terminal Assignments

Terminal

Number

1 Network A D+ RD+ Rx A1– (out)

2 Network B D– RD– No connection B1+ (out)

3 Network A No connection TD+ Tx A2– (in)

4 Network B No connection TD– No connection B2+ (in)

5 No connection Common Common Common Common

6 No connection No connection No connection No connection No connection

7 Shield Shield Shield Shield Shield

1

The AquaTrend Network only applies to sc100/1720E systems

AquaTrend

Network

1

Modbus RS485

2-wire

Modbus RS485

4-wire

Modbus RS232 Profibus DP

Wiring the Digital Gateway

22

Page 27

Installation

RELAYA

+

DATA

+

OUT 2

+

V

+

OUT 1

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYARELAYA

J1

J2

J4

S1

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

J5J5

Figure 20 RS232 Connection to Customer-supplied Computer 9-pin D Subminiature Connector

Common 5

Not used 4

Rx 3

Tx 2

Not used 1

Figure 21 Network Card Position in the Controller

21

J1

S1

J2

U5

J4

U9

NETWORK

INTERFACE

CARD

J3

J5J5

J5

DANGER - EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

J6

DANGER - RISQUE D'EXPLOSION

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

PCB

CONNECTOR

EMPLACEMENT NON-DANGEROUX

PROBES

ANALOG OUTPUTS

1

2

3

4

5

6

1

2

3

4

5

NCNCNC

NONO

COMCOMCOM

RELAYCRELAYBRELAYA

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

+

DATA

– DATA

SERVICE REQUEST

+

V

GND

F1

+

OUT 2

– OUT 2

SHIELD/CHASSIS GND

+

OUT 1

– OUT 1

NO

9

8

7

6

F2

3

4

5

1. J2—Network card header 4. Mounting hole (3)

2. J2 Pin 1 5. Network card placement

3. J1 Terminal

Connecting the Optional Digital Output

23

Page 28

Installation

Connecting the Optional Digital Output

24

Page 29

Section 4 Operation

4.1 Using the Keypad

The front of the controller is shown in Figure 22. The keypad consists of the eight keys described in

Tab le 7 .

Figure 22 Front of the Controller

1

sc100

5

2

3

4

1. Instrument display 5. IrDA Port

2. BACK key 6. HOME key

3. MENU key 7. ENTER key

4. RIGHT, LEFT, UP and DOWN keys

Table 7 Controller Key Functions/Features

Number Key Function

2 Moves back one level in the menu structure.

3

Moves to the main menu from other menus. This key is not active in menus where a selection or other

input must be made.

6

7

4 Navigates through the menus, changes settings, and increments and decrements digits.

6

7 Accepts an input value, updates, or accepts displayed menu options.

Moves to the Main Measurement screen from any other screen. This key is not active in menus where a

selection or other input must be made.

Operation

25

Page 30

Operation

4.2 Controller Display Features

When a sensor is connected and the controller is in measurement mode, the controller

automatically identifies the connected sensors and displays associated measurements.

The display will flash on startup, when a sensor error has occurred, when the hold outputs function

has been activated, and when a sensor is being calibrated. An active system warning will cause

the warning icon (a triangle with an exclamation point inside) to be displayed on the right side of

the display. See Figure 23.

Figure 23 Display Example

1

2

3

1. Status bar. Indicates the sensor name and status of relays. The relay

letter is displayed when the relay is energized.

2. Main measurement 5. Warning icon area

3. Secondary measurement (if applicable) 6. Measurement units

SENSOR NAME:

7.00

pH

TEMP: 23.0°C

4. Parameter

4.2.1 Important Key Presses

• Press HOME then RIGHT or LEFT to display two readings when two sensors are connected.

Continue to press

RIGHT or LEFT to toggle through the available display options:

4

5

6

• Press

display the secondary measurement (temperature) and output information.

• When in Menu mode, an arrow may appear on the right side of the display to indicate that

more menus are available. Press UP or DOWN (corresponding to the arrow direction) to

display additional menus.

MAIN MENU

SENSOR DIAG

SENSOR SETUP

SYSTEM SETUP

TEST/MAINT

Controller Display Features

26

UP and DOWN to toggle the status bar at the bottom of the measurement display to

SENSOR NAME:

7.00

TEMP: 23.0°C

SYSTEM SETUP

OUTPUT SETUP

RELAY SETUP

NETWORK SETUP

DISPLAY SETUP

SENSOR NAME:

7.00

OUTPUT1: 12.00 mA

SYSTEM SETUP

DISPLAY SETUP

SECURITY SETUP

LOG SETUP

CALCULATION

SENSOR NAME:

pH pHpH

7.00

pH

OUTPUT2: 12.00 mV

pHpH

SYSTEM SETUP

SECURITY SETUP

LOG SETUP

CALCULATION

ERROR HOLD MODE

Page 31

Operation

4.2.2 Software Text Abbreviations

Abbreviation Meaning Abbreviation Meaning

Adj Adjust P/F Pass/Fail

Cal Calibration Pass Password

Cont Continue Preped Prepared

Dflt Default SN Serial Number

Diag Diagnostic Std Standard

Freq Frequency Temp Temperature

Int Internal Vers Version

Meas Measurement Xfer Transfer

4.3 System Setup

4.3.1 Adjusting Display Contrast

Step Select Menu Level/Instructions Confirm

1

2

3

4

— ADJUST CONTRAST

5

6

Main Menu or Main Measurement Screen —

MAIN MENU —

SYSTEM SETUP

DISPLAY SETUP

(+0–50)

4.3.2 Specifying the Displayed Language

Step Select Menu Level/Instructions Confirm

1

2

MAIN MENU —

SYSTEM SETUP

3

4

5

6

Select the language from displayed options.

Main Menu or Main Measurement Screen —

DISPLAY SETUP

LANGUAGE

System Setup

27

Page 32

Operation

4.3.3 Setting the Time and Date

4.3.3.1 Setting the Time (24-hr format)

Step Select Menu Level/Instructions Confirm

1

2

3

4

5

MAIN MENU —

SYSTEM SETUP

DISPLAY SETUP

SET DATE/TIME

Highlight TIME

Select the character to edit.

6

Scroll to appropriate number.

7

Main Menu or Main Measurement Screen —

4.3.3.2 Setting the Date Format and Date

Step Select Menu Level/Instructions Confirm

1

2

3

4

5

6

— Highlight DATE FORMAT

Choose the appropriate date format from the displayed options.

7

MAIN MENU —

SYSTEM SETUP

DISPLAY SETUP

SET DATE/TIME

Highlight DATE

Select the character to edit. —

8

Scroll to the appropriate number.

9

Main Menu or Main Measurement Screen —

System Setup

28

Page 33

Operation

4.4 Setting up System Security

The passcode feature of the sc100 restricts unauthorized access to configuration and calibration

settings. The passcode is factory set to sc100 (the five digits must be followed by a space to

remove the trailing asterisk). The following two options are available:

Disabled: All configuration settings and calibrations can be changed. This is the default setting.

Enabled: Certain calibration and Test/Maint settings/operations cannot be accessed without

the passcode. If the passcode is enabled, it may be edited (see section 4.4.2). The passcode can

consist of up to six digits (alpha and/or numeric and available characters). If the instrument is reset

using the Configure/Default Setup menu selection, the passcode will return to the factory default. If

a changed passcode is forgotten, obtain the Master passcode from the Technical Consulting

Services Department.

4.4.1 Setting the Passcode

Step Select Menu Level/Instructions Confirm

1

2

3

4

— SET PASSCODE

5

6

Main Menu or Main Measurement Screen —

MAIN MENU —

SYSTEM SETUP

SECURITY SETUP

Highlight ENABLE

4.4.2 Editing the Passcode

Step Select Menu Level/Instructions Confirm

1

2

3

Highlight SECURITY SETUP

MAIN MENU —

SYSTEM SETUP

4

5

EDIT PASSCODE select character (shown in brackets) —

ENTER PASSCODE

EDIT PASSCODE

6

EDIT PASSCODE move to the next character

7

Main Menu or Main Measurement Screen —

Setting up System Security

29

Page 34

Operation

4.5 Output Options

Refer to the System Setup on page 27 for more information on the output options menu.

4.5.1 Navigating to the Output Options Menu

Step Select Menu Level/Instructions Confirm

1

2

3

4

5

6

Main Menu or Main Measurement Screen when Output options are configured. —

Customize the options, refer to System Setup on page 27.

MAIN MENU —

SYSTEM SETUP

OUTPUT SETUP

SELECT OUTPUT

The analyzer provides two isolated analog outputs (Output 1 and Output 2).

4.5.2 Hold/Transfer Outputs

During normal measurement operation, the analog outputs can be held at the last measured value

or transferred to a preset value. To hold or transfer the output until released:

Step Select Menu Level/Instructions Confirm

1

2

3

4

5

6

7

8

9

10

MAIN MENU —

TEST/MAINT

HOLD OUTPUTS

SET OUTMODE

Select HOLD OUTPUTS or XFER OUTPUTS

SET CHANNELS

Select ALL or one of the connected sensors. —

ACTIVATION

Select LAUNCH

Main Menu or Main Measurement Screen

reading will

flash

Output Options

30

Page 35

Operation

During calibration, analog outputs can remain active, held, or transferred to a preset mA value.

4.5.3 Release Outputs

Step Select Menu Level Confirm

1

2

3

4

5

6

Main Menu or Main Measurement Screen —

MAIN MENU —

TEST/MAINT

HOLD OUTPUTS

ACTIVATION

RELEASE

4.6 Relay Options

Refer to System Setup on page 27 for more information on the relay options menu.

4.6.1 Navigating to the Relay Options Menu

Step Select Menu Level/Instructions Confirm

1

MAIN MENU —

2

3

4

5

6

Main Menu or Main Measurement Screen when Relay options are configured. —

Customize the options, refer to System Setup on page 27.

4.7 Data Event Logging Options

The sc100 provides three data logs (one for each sensor and one for calculated values) and three

event logs (one for each sensor and one for the controller). The data logs store the measurement

data at selected intervals. The event log stores a variety of events that occur on the devices such

as configuration changes, alarms, and warning conditions. The data logs are stored in a packed

binary format and the event logs are stored in a CSV format. The logs can be downloaded through

the digital network port or through the service port using the service cable LZX887.

SYSTEM SETUP

RELAY SETUP

SELECT RELAY

Relay Options

31

Page 36

Operation

4.8 Digital Network Options

The sc100 provides two digital communication methods with the controller (the digital network port

and the IrDA port). Either of the digital ports can be used to access setup data, measurement data,

or data/event logs. For the features available for each individual digital network port, refer to the

instruction sheet supplied with the selected network card.

4.9 System Setup Menu

OUTPUT SETUP (see section 4.5.1 on page 30 for expanded menu information)

SELECT OUTPUT 1 OR 2

SELECT SOURCE

Press

ENTER to access a list of all connected sensors and select the sensor that will drive the output.

SET PARAMETER

Press ENTER to select from the displayed parameters. Highlight the appropriate displayed parameter and press ENTER.

SET FUNCTION

Select LINEAR CONTROL for current output to track the measurement valve. Select PID CONTROL for the sc100 to operate

as a PID controller.

SET TRANSFER

Each analog output is normally active, responding to the measured value of its assigned parameter. However, during

calibration, each output can be transferred to this preset transfer value.

SET FILTER

Average measurements over time (0–999 seconds). Default is 0 seconds. The higher the value, the longer the sensor signal

response time will be to a change in the actual process value.

SCALE 0 mA/4 mA

Select 0 mA or 4 mA for minimum current (outputs will be set to 0–20 mA or 4–20 mA).

ACTIVATE

Dependent on Function selected previously. See section 4.5.1 on page 30 for additional information.

FUNCTION set to LINEAR CONTROL

If LINEAR CONTROL was selected in SET FUNCTION, set the low and the high values for the current output here.

FUNCTION set to PID CONTROL

1. SET MODE: AUTO or MANUAL

2. PHASE: DIRECT or REVERSE controller operation.

3. SET SETPOINT: enter the setpoint the PID control will control the process to.

4. PROP BAND: control the proportional band for the PID control.

5. INTEGRAL: control the integral action time period in minutes.

6. DERIVATIVE: control the settings for the rate control.

Digital Network Options

32

Page 37

Operation

4.9 System Setup Menu (continued)

RELAY SETUP

Select Relay A, B, or C

SELECT SOURCE

Select from none, a connected sensor, or the real time clock (RTC)

SET PARAMETER

ENTER to select from the displayed parameters.

Press

SET FUNCTION

Source set to sensor

Alarm: Operates relays in response to the measured parameter. Contains separate High and Low Alarm points, deadbands,

and ON/OFF delay.

Feeder Control: Operates in response to the measured parameter. Can be set for phasing, setpoint, deadband, overfeed

timer, and ON/OFF delay.

Event Control: Controls a cleaning system (or equivalent) on a timed basis.

Warning: Activated when the analyzer detects a sensor warning.

PWM Control: Allows the relay to provide a duty cycled output.

Freq Control: Allows the relay to cycle at a frequency between the minimum pulse per minute and maximum pulse per minute.

Source set to RTC

Timer: Sets the timer for a cleaning system (or equivalent). Controls the output hold, interval, duration, and off delay.

SET TRANSFER

Sets the relay to Energize or De-energize (user-selectable). Normally, each control or alarm relay is active, responding to the

measured value of its assigned parameter. During calibration, however, the relay can be transferred to a preset on/off state to

suit the application requirements. Select Energize or De-energize and press ENTER.

FAILSAFE

Allows the user to create a state where the normal condition is energized. The relay is de-energized when an error condition is

experienced. Select YES (Energized) or NO (De-energized) and press ENTER. YES sets the relay normal condition to

energized resulting in the relay becoming de-energized when an error condition is experienced.

ACTIVATION

Function set to ALARM

LOW ALARM—Sets the value where the relay will turn on in response to decreasing measured value. For example, if the low

alarm is set for 1,0 and the measured value drops to 0,9, the relay will be activated.

HIGH ALARM—Sets the value where the relay will turn on in response to increasing measured value. For example, if the

high alarm is set for 1,0 and the measured value increases to 1,1 the relay will be activated.

LOW DEADBAND—Sets the range where the relay remains on after the measured value increases above the low alarm

value. Default is 5 % of the range. For example, if the low alarm is set for 1,0 and the low deadband is set for 0,5, then the

relay remains on between 1,0 and 1,5.

HIGH DEADBAND—Sets the range where the relay remains on after the measured value decreases below the high alarm

value. Default is 5 % of the range. For example, if the high alarm is set for 4,0 and the high deadband is set for 0,5, then the

relay remains on between 3,5 and 4,0.

OFF DELAY—Sets a time (0–300 seconds) to delay the relay from normally turning off.

ON DELAY—Sets a time (0–300 seconds) to delay the relay from normally turning on.

LOW ALARM—Sets the value where the relay will turn on in response to decreasing measured value. For example, if the low

alarm is set for 1,0 and the measured value drops to 0,9, the relay will be activated.

System Setup Menu

33

Page 38

Operation

4.9 System Setup Menu (continued)

Function set to FEEDER CONTROL

PHASE—“High” phase assigns the relay setpoint to respond to an increasing measured value; conversely, a “Low” phase

assigns the relay setpoint to respond to a decreasing measured value.

SET SETPOINT—Sets the value where the relay will turn on.

DEADBAND—Sets the range where the relay remains on after the measured value decreases below the setpoint value (high

phase relay) or increases above the setpoint value (low phase relay).

OVERFEED TIMER—Sets the time (0–999,9 minutes) to limit how long the relay can remain on.

OFF DELAY—Sets a time (0–999 seconds) to delay the relay from normally turning off.

ON DELAY—Sets a time (0–999 seconds) to delay the relay from normally turning on.

Function set to EVENT CONTROL

SET SETPOINT—Sets the value where the relay will turn on.

DEADBAND—Sets the range where the relay remains on after the measured value decreases below the setpoint value (high

phase relay) or increases above the setpoint value (low phase relay).

OnMax TIMER—Sets the time (0–999 minutes) to limit the time the relay can remain on.

OffMax TIMER—Sets a time (0–999 minutes) to delay the relay from normally turning off.

OnMin TIMER—Sets the time (0–999 minutes) to limit the time the relay can remain on.

OffMin TIMER—Sets the time (0–999 minutes) to limit the time the relay can remain off.

Function set to TIMER (RTC selected in SELECT SOURCE)

HOLD OUTPUTS—Set OUTMODE to select output hold operation and select channels that cause the outputs to be held.

INTERVAL—Set the off time for the relay.

DURATION—Set the on time for the relay.

OFF DELAY—Set the time for additional hold/output time after the relay has been turned off.

Function set to WARNING CONTROL

WARNING LEVEL—Set the warning level that will trigger a relay. Range: 0–32. For example: If warnings 1–9 are active on

the instrument, set the warning level to 0 to allow all warnings to trigger the relay; set the warning level to 5 to allow warnings

6 and above to trigger the relay. Set the warning level to 9 or greater to not trigger the relay on any warning.

Function set to PWM CONTROL

SET MODE—Auto or Manual

PHASE—Direct or Reverse

SET SETPOINT—Control Setpoint

DEAD ZONE—Zone around setpoint where output is off

PERIOD—3–60 second PMW period

MIN WIDTH—Minimum pulse width in 0,1 seconds

MAX WIDTH—Maximum pulse width in 0,1 seconds

PROP BAND—Proportional control band

INTEGRAL—Integral control setting (minutes)

Function set to FREQ CONTROL

SET MODE—Auto or Manual

PHASE—Direct or Reverse

SET SETPOINT—Control Setpoint

DEAD ZONE—Zone around setpoint where output is off

MIN WIDTH—0,001–200 pulses per minute

MAX WIDTH—0,001–200 pulses per minute

PROP BAND—Proportional control band (this is outside of the dead zone)

INTEGRAL—Integral control setting (minutes)

System Setup Menu

34

Page 39

4.9 System Setup Menu (continued)

NETWORK SETUP (this menu appears only if a network card is installed in the controller)

SET MODE

Auto or Manual

MODBUS ADDRESS

Highlight sc100 Analyzer, or either connected sensor then press

(each source must have a different address) then press

BAUD RATE

Select a baud rate of 9600, 19200, 38,4 K, 57,6 K, or 115,2 K. Default: 19200

STOP BITS

Select 1 or 2 stop bits. Default: 1

MODBUS MODE

Select RTU or ASCI. Default: RTU

DATA ORDER

Select Normal or Swapped. Default: Swapped

DISPLAY SETUP

ENTER.

ENTER. Choose a number between 1 and 247 as the address

Operation

ADJUST CONTRAST

Use the UP and DOWN keys to increase or decrease the contrast, see section 4.3.1 on page 27.

LANGUAGE

The default is English. Choose Spanish, German or French to allow all menus to appear in the selected language.

SET DATE/TIME

Use this menu to select the date format and to set the date and time (24-hour (military) format), see section 4.3.3 on page 28.

SECURITY SETUP (Enter a 6-digit passcode)

SET PASSCODE

DISABLE

Disables system security. See section 4.4 on page 29.

ENABLE

Enables system security. See section 4.4 on page 29.

LOG SETUP

DATALOG SETUP

Setup datalogging of displayed sensor measurements

CALCULATION

SET VARIABLE X

Select the sensor corresponding to the variable set as “X”.

SET VARIABLE Y

Select the sensor corresponding to the variable set as “Y”.

SET PARAMETER

Select the parameter to be associated with the variable.

SET FORMULA

Select the formula of the calculation to be performed on “X” and “Y”.

System Setup Menu

35

Page 40

Operation

4.9 System Setup Menu (continued)

ERROR HOLD MODE

HOLD OUTPUTS

Holds outputs when unable to communicate with the sensor.

XFER OUTPUTS

Goes to transfer state when unable to communicate with the sensor.

4.10 Test/Maint Menu

STATUS

Indicates the status of each relay and indicates which sensors are connected to the controller.

OUTPUT CAL

SELECT OUTPUT 1 OR 2

Calibrate Analog Output by specifying values to correspond to 4 mA and 20 mA using the

HOLD OUTPUTS

SET OUTMODE

Choose Hold Outputs or Xfer Outputs

SET CHANNELS

Choose any individual attached sensor or all attached sensors to be held or transferred.

ACTIVATION

Select Launch or Release.

OVERFEED RESET

Reset the overfeed time out.

TEST OUTPUT

SELECT OUTPUT 1 OR 2

Set the analog output to a desired current level. Range: 0–20

TEST RELAY

SELECT RELAY A, B, OR C

Energize or de-energize the selected relay.

RESET CONFIG

UP and DOWN arrow keys.

Reset to default configuration

SIMULATION

SELECT SOURCE, SET PARAMETER, SET SIM VALUE

Simulate sensor measurement value for testing the outputs and relays.

SCAN SENSORS

Manually scans for sensors to determine if sensors have been added or removed.

MODBUS STATS

Indicates the communication statistics for use with an external network.

CODE VERSION

Indicates the controller software version.

Test/Maint Menu

36

Page 41

Section 5 Maintenance

DANGER

Only qualified personnel should conduct the maintenance tasks described in this section

of the manual.

DANGER

Do not replace any component unless power to all electrical circuits to the Controller have

been switched off and the area is known to be non-hazardous.

5.1 Cleaning the Controller

With the enclosure securely closed, wipe the exterior with a damp cloth.

5.2 Fuse Replacement

The instrument contains two mains fuses. Failed fuses are an indication that an equipment

problem could exist. Problem resolution and fuse replacement should be performed only by

qualified service personnel. Refer to Figure 24 and the following steps to replace the fuses:

1. Disconnect power to the controller (including power to relays and other components,

if powered).

2. Open the hinged controller cover by completely loosening all four captive screws in the cover.

3. Remove the high voltage barrier; pull out on the lever of the captive fastener then pull straight

out on the barrier. Set the barrier aside for reinstallation.

4. Remove the fuses and install new fuses of the same type and rating:

• AC Powered sc100: T, 1,6 A, 250 V, slow blow

• 24 V DC powered sc100: T, 3 A, 250 V, slow blow

5. Reinstall the high voltage barrier.

6. Close the controller cover and hand-tighten the four screws.

7. Reconnect power to the instrument.

Maintenance

37

Page 42

Maintenance

RELAYC

Figure 24 Fuse Replacement

J1

S1

J4

NETWORK

INTERFACE

J2

U5

U9

CARD

1. Fuses F1 and F2.

AC powered, T, 1,6A, 250 V, slow blow

DC powered, T, 3A, 250 V, slow blow

1

J3

F1

J5

NONO

RELAYBRELAYA

J6

F2

NCNCNC

NO

COMCOMCOM

RELAYC

Fuse Replacement

38

Page 43

Section 6 Replacement Parts

6.1 Replacement Items

Description Quantity Catalog Number

Controller Installation Kit each 58672-00

Fuse, T, 3A, 250 V, slow blow each 41060

Fuse, T, 1,6 A, 250 V, slow blow each 52083-00

Instruction manual, English each

6.2 Accessories

Description Quantity Catalog Number

Digital output card for Modbus RS232 communication each 59200-00

Digital output card for Modbus RS485 communication each 59200-01

Locknut each 1059612

Plug, conduit opening each 58687-00

Power cord with strain relief, 115 V each 54488-00

Power cord with strain relief, 230 V each 54489-00

Sealing Washer each 1033814

Strain relief, Heyco each 16664

Sun Shield each LZX961

DOC023.52.00032.XXXXX

XXXXX= Date of Revision

Replacement Parts

39

Page 44

Replacement Parts

Accessories

40

Page 45

Section 7 Warranty, liability and complaints

HACH LANGE GmbH warrants that the product supplied is free of material and manufacturing

defects and undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out within 6 months

of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the lack of

assured properties as follows: all those parts that can be demonstrated to have become unusable

or that can only be used with significant limitations due to a situation present prior to the transfer of

risk, in particular due to incorrect design, poor materials or inadequate finish will be improved or

replaced, at the supplier's discretion. The identification of such defects must be notified to the

supplier in writing without delay, however at the latest 7 days after the identification of the fault. If

the customer fails to notify the supplier, the product is considered approved despite the defect.

Further liability for any direct or indirect damages is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be performed

within the warranty period by the customer (maintenance) or by the supplier (servicing) and these

requirements are not met, claims for damages due to the failure to comply with the requirements

are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or incorrect use are

excluded from this clause.

HACH LANGE GmbH process instruments are of proven reliability in many applications and are

therefore often used in automatic control loops to provide the most economical possible operation

of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control loop

such that a malfunction in an instrument results in an automatic change over to the backup control

system; this is the safest operating state for the environment and the process.

Warranty, liability and complaints

41

Page 46

Warranty, liability and complaints

7.1 Immunity

This equipment was tested for Industrial level EMC per:

EN 61326 (EMC Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use)

compliance by Hach Company.

Standards include:

IEC 1000-4-2:1995 (EN 61000-4-2:1995) Electrostatic Discharge Immunity (Criteria B)

IEC 1000-4-3:1995 (EN 61000-4-3:1996) Radiated RF Electromagnetic Field Immunity

(Criteria A)

IEC 1000-4-4:1995 (EN 61000-4-4:1995) Electrical Fast Transients/Burst (Criteria B)

IEC 1000-4-5:1995 (EN 61000-4-5:1995) Surge (Criteria B)

IEC 1000-4-6:1996 (EN 61000-4-6:1996) Conducted Disturbances Induced by RF Fields

(Criteria A)

IEC 1000-4-11:1994 (EN 61000-4-11:1994) Voltage Dip/Short Interruptions (Criteria B)

Additional Immunity Standard/s include:

ENV 50204:1996 Radiated Electromagnetic Field from Digital Telephones (Criteria A)

per 89/336/EEC EMC: Supporting test records by Hach Company, certified

7.2 Emissions

This equipment was tested for Radio Frequency Emissions as follows:

Standards include:

EN 61000-3-2 Harmonic Disturbances Caused by Electrical Equipment

EN 61000-3-3 Voltage Fluctuation (Flicker) Disturbances Caused by Electrical Equipment

Additional Emissions Standard/s include:

EN 55011 (CISPR 11), Class “A” emission limits

Per 89/336/EEC EMC: EN 61326:1998 (Electrical Equipment for measurement, control and

laboratory use—EMC requirements) Class “A” emission limits. Supporting test records by

Hewlett Packard, Fort Collins, Colorado Hardware Test Center (A2LA # 0905-01) and certified

compliance by Hach Company.

Immunity

42

Page 47

Section 8 Contact

HACH LANGE GmbH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0) 211- 52 88 - 0

Fax +49 (0) 211- 52 88 - 143

info@hach-lange.de

www.hach-lange.de

DR. BRUNO LANGE

GES. MBH

Industriestraße 12

A-3200 Obergrafendorf

Tel. +43 (0) 2747 - 74 12

Fax +43 (0) 2747 - 42 18

info@hach-lange.at

www.hach-lange.de

DR. LANGE NEDERLAND B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)3 44 63 11 30

Fax +31(0)3 44 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE LTD

Pacific Way

Salford

Manchester, M50 1DL