Page 1

DOC023.52.90447

RTC112 SD-Module

Real Time Control System for Sludge Dewatering

User manual

07/2013, Edition 1A

© HACH-LANGE GmbH, 2013. All rights reserved. Printed in Germany.

Page 2

Page 3

Table of contents

Section 1 Technical data ........................................................................................................................ 7

Section 2 General information............................................................................................................... 9

2.1 Safety information............................................................................................................................... 9

2.1.1 Hazard notices in this manual.................................................................................................... 9

2.1.2 Warning labels ........................................................................................................................... 9

2.2 Areas of application .......................................................................................................................... 10

2.3 Scope of delivery .............................................................................................................................. 10

2.4 Instrument overview.......................................................................................................................... 11

2.5 Theory of operation........................................................................................................................... 12

2.5.1 Theory of operation of the RTC Module................................................................................... 12

2.5.2 Input signals............................................................................................................................. 12

2.5.3 Parameters for configuration.................................................................................................... 12

2.5.4 Operating modes ..................................................................................................................... 13

Section 3 Installation............................................................................................................................ 17

3.1 Installation of the RTC Module ......................................................................................................... 17

3.1.1 Supply voltage of the RTC Module ..........................................................................................17

3.2 Connection of process measurement instruments for the TSS concentration.................................. 17

3.2.1 Power supply of the sc sensors and the sc1000 controller...................................................... 17

3.3 sc1000 controller connection ............................................................................................................ 17

3.4 Connection to the automation unit on the plant side.........................................................................18

Section 4 Parameterization and operation ......................................................................................... 21

4.1 Operating the sc controller................................................................................................................ 21

4.2 sc1000 setup .................................................................................................................................... 21

4.3 Menu structure.................................................................................................................................. 21

4.3.1 DIAGNOSIS............................................................................................................................. 21

4.4 Configuration of RTC112 SD-Module parameters on the sc1000 controller .................................... 21

4.4.1 RTC112 SD-Module open and closed-loop controller ............................................................. 21

4.5 Select sensors .................................................................................................................................. 26

4.6 PRESELECT PROG......................................................................................................................... 29

4.6.1 POLYMER DOSING CONTROL.............................................................................................. 29

4.6.2 FEED FLOW CONTROL .........................................................................................................29

4.6.3 CLOSED-LOOP EFFLUENT CONTROL................................................................................. 29

4.6.4 CLOSED-LOOP FILTRATE CONTROL .................................................................................. 29

3

Page 4

Table of contents

4.7 CONTROL PARAMETER .................................................................................................................30

4.7.1 FACTOR POLYMER DOSING.................................................................................................30

4.7.2 POLYMER CONCENTRATION ...............................................................................................30

4.7.3 MANUAL POLYMER DOSING.................................................................................................30

4.7.4 MANUAL FEED FLOW ............................................................................................................30

4.7.5 MAX DECREASE CLOSED L ..................................................................................................30

4.7.6 MAX INCREASE CLOSED L ...................................................................................................30

4.7.7 SET-POINT TSS ......................................................................................................................30

4.7.8 P GAIN TSS .............................................................................................................................31

4.7.9 INTEGRAL TIME TSS..............................................................................................................31

4.7.10 DERIVATIVE TIME TSS ........................................................................................................31

4.7.11 SET-POINT FILT....................................................................................................................31

4.7.12 P GAIN FILT...........................................................................................................................31

4.7.13 INTEGRAL TIME FILT ...........................................................................................................31

4.7.14 DERIVATIVE TIME FILT........................................................................................................31

4.8 INPUT/OUTPUT LIMITS ...................................................................................................................31

4.8.1 FEED FLOW LOW ...................................................................................................................31

4.8.2 FEED FLOW HIGH ..................................................................................................................32

4.8.3 FEED FLOW SMOOTHING .....................................................................................................32

4.8.4 LIMIT TSS IN LOW ..................................................................................................................32

4.8.5 LIMIT MAX TSS IN HIGH.........................................................................................................32

4.8.6 TSS IN SMOOTHING...............................................................................................................32

4.8.7 LIMIT TSS OUT LOW ..............................................................................................................32

4.8.8 LIMIT TSS OUT HIGH..............................................................................................................32

4.8.9 TSS OUT SMOOTHING...........................................................................................................33

4.8.10 POLYMER DOSING MINIMUM .............................................................................................33

4.8.11 POLYMER DOSING MAXIMUM ............................................................................................33

4.9 INPUTS .............................................................................................................................................33

4.9.1 MIN FEED FLOW.....................................................................................................................33

4.9.2 MAX FEED FLOW....................................................................................................................33

4.9.3 0/4...20 mA...............................................................................................................................33

4.9.4 MIN POLYMER FLOW.............................................................................................................33

4.9.5 MAX POLYMER FLOW............................................................................................................33

4.9.6 0/4...20 mA...............................................................................................................................34

4.10 OUTPUTS .......................................................................................................................................34

4.10.1 MIN FEED FLOW...................................................................................................................34

4.10.2 MAX FEED FLOW..................................................................................................................34

4.10.3 0/4...20 mA.............................................................................................................................34

4.10.4 MIN POLYMER FLOW...........................................................................................................34

4.10.5 MAX POLYMER FLOW..........................................................................................................34

4.10.6 0/4...20 mA.............................................................................................................................34

4.10.7 CONTROL CYCLE.................................................................................................................34

4.10.8 MIN RUNTIME .......................................................................................................................34

4

Page 5

Table of contents

4.11 Displayed measurement values and variables ............................................................................... 34

Section 5 Maintenance ......................................................................................................................... 37

5.1 Maintenance schedule...................................................................................................................... 37

Section 6 Troubleshooting................................................................................................................... 39

6.1 Error messages ................................................................................................................................ 39

6.2 Warnings........................................................................................................................................... 39

6.3 Wear parts ........................................................................................................................................ 39

Section 7 Replacement parts and accessories.................................................................................. 41

7.1 Replacement parts............................................................................................................................ 41

Section 8 Contact information............................................................................................................. 43

Section 9 Warranty and liability........................................................................................................... 45

Appendix A MODBUS address setting ............................................................................................... 47

Appendix B Configuration of the network modules.......................................................................... 49

B.1 RTC112 SD-Module Profibus/MODBUS telegram .......................................................................... 49

Index ...................................................................................................................................................... 51

5

Page 6

Table of contents

6

Page 7

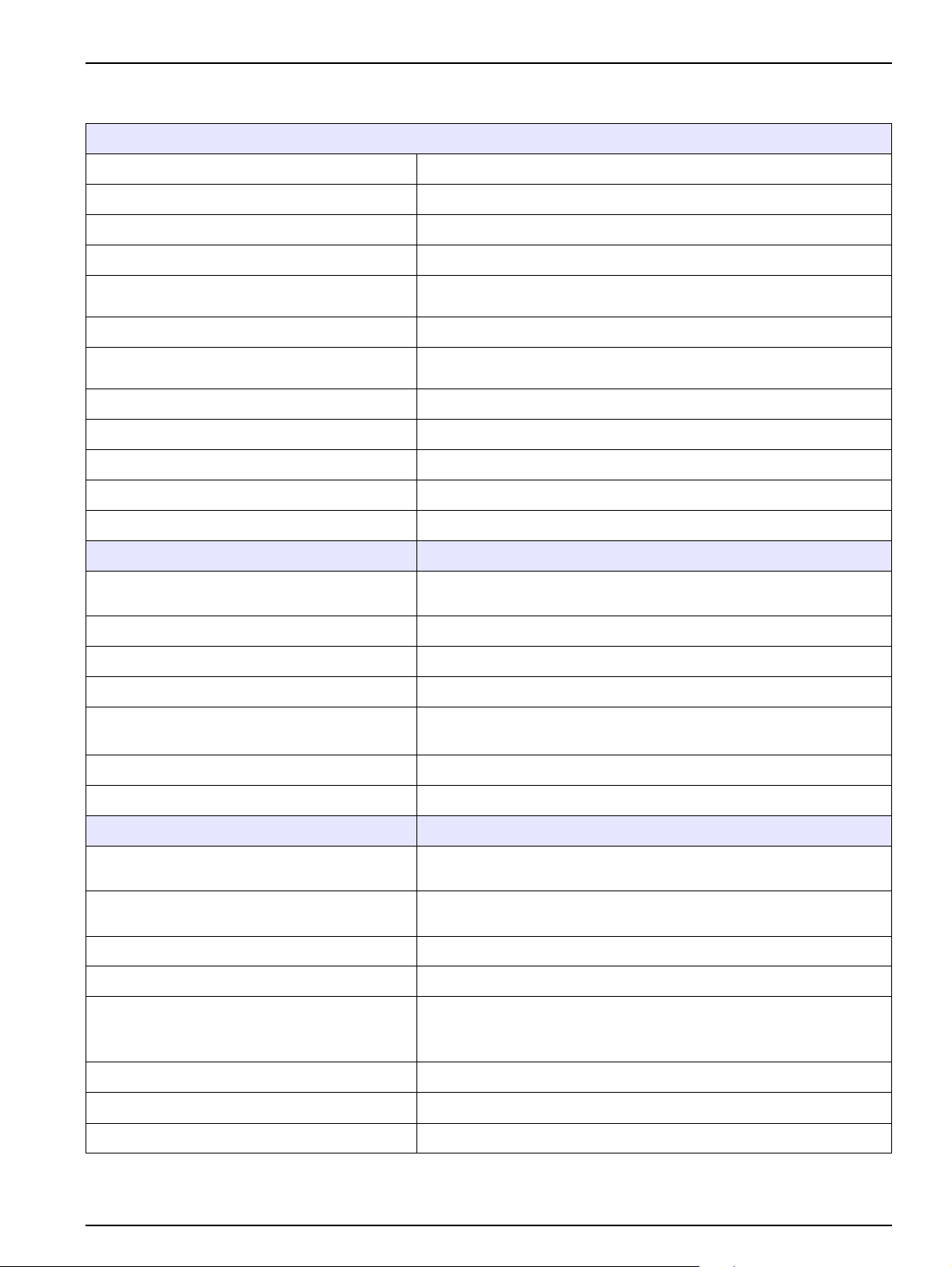

Section 1 Technical data

These are subject to change without notice.

Embedded PC (compact industrial PC)

Processor

Flash memory 2 GB compact flash card

Internal working memory 256 MB DDR-RAM (not expandable)

Interfaces 1× RJ 45 (Ethernet), 10/100 Mbit/s

Diagnostic LED

Expansion slot 1× CompactFlash type II slot with ejector mechanism

Clock

Operating system Microsoft Windows

Control software TwinCAT PLC Runtime or TwinCAT NC PTP Runtime

System bus 16 bit ISA (PC/104 standard)

Power supply Via system bus (through power supply module CX1100-0002)

Max. power loss 6 W (including the system interfaces CX1010-N0xx)

Analog inputs 0/4 to 20 mA for input of the feed flow rate and the polymer flow rate

Number of inputs

Internal resistance 80 ohm + diode voltage 0.7 V

Pentium®1, MMX compatible, 500 MHz clock rate

1× power, 1× LAN speed, 1× LAN activity, TC status,

1× flash access

Internal, battery-buffered clock for time and date (battery can be

replaced)

®2

CE or Microsoft Windows Embedded Standard

One-channel: 2 (KL3011)

Two-channel: 4 (KL3011)

Signal current 0/4 to 20 mA

Common mode voltage (U

Measurement error (for entire measurement

range)

Voltage surge resistance 35 V DC

Electrical isolation 500 V

Analog outputs Output of the polymer dosing, output of the feed flow rate

Number of outputs

Supply voltage

Signal current 0/4 to 20 mA

Working resistance <500 ohm

Measurement error

Resolution 12 bit

Conversion time Approximately 1.5 ms

) 35 V max.

CM

< ± 0.3 % (from end value of measurement range)

One-channel: 2 (KL4012)

Two-channel: 4 (KL4012)

24 V DC via the power contacts

(Alternatively, 15 V DC with bus termination KL9515)

± 0.5 LSB linearity error

± 0.5 LSB offset error

± 0.1 % (relative to the measuring range end value)

(K-bus/signal voltage)

eff

Electrical isolation 500 V

(K-bus/field voltage)

eff

7

Page 8

Technical data

Digital outputs Control of polymer pump: feed flow rate and fault messages

Number of outputs

One-channel: 4 (KL2134)

Two-channel: 8 (KL2408)

Nominal load voltage 24 V DC (–15 % / +20 %)

Load type ohmic, inductive lamp load

Max. output current 0.5 A (short-circuit proof) per channel

Reverse polarity protection Yes

Electrical isolation 500 V

(K-bus/field voltage)

eff

Equipment properties

Dimensions (W × H × D)

One-channel: 191 × 120 × 96 mm (7.52 × 4.72 × 3.78 in)

Two-channel: 227 × 120 × 96 mm (8.94 × 4.72 × 3.78 in)

Mass Approximately 0.9 kg (approximately 1.98 lb)

Environmental conditions

Working temperature 0 to 50 °C (32 to 122 °F)

Storage temperature –25 to +85 °C (–13 to 185 °F)

Relative humidity 95 %, non-condensing

Miscellaneous

Pollution Degree

Protection Class

Installation Category

Maximum Altitude

2

1

II

2000 m (6,562 ft.)

Protection class IP20

Installation DIN rail EN 50022 35 × 15.0

1

Pentium is a registered trademark of the Intel Corporation.

2

Microsoft Windows is a brand name for operating systems of the Microsoft Corporation.

1.

8

Page 9

Section 2 General information

2.1 Safety information

Please read the entire manual carefully before unpacking, assembling or operating the

instrument. Pay attention to all hazard and warning notices. Failure to do so could result in

serious injury to the operator or damage to the instrument.

To prevent damage to or impairment of the device's protection equipment, the device may

only be used or installed as described in this manual.

2.1.1 Hazard notices in this manual

DANGER

Indicates a potentially or imminently hazardous situation that, if not avoided, can result in death or

serious injury.

WARNING

Indicates a potentially or imminently dangerous situation that, if it is not avoided, can lead to

death or to serious injuries.

CAUTION

Indicates a possible dangerous situation that can have minor or moderate injuries as the result.

Indicates a situation that, if it is not avoided, can lead to damage to the device. Information that

requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Warning labels

Observe all labels and tags attached to the instrument. Failure to do so may result in

personal injury or damage to the instrument.

This symbol may be attached to the device and refers to operation and/or safety notes in the user manual.

This symbol may be found on an enclosure or barrier within the product and indicates a risk of electric shock

and/or death by electrocution.

Electrical equipment marked with this symbol may no longer be disposed of in unsorted domestic or industrial

waste in Europe after August 12, 2005. In conformity with the provisions in force (EU Directive 2002/96/EC),

consumers in the EU must return old electrical devices to the manufacturer for disposal from this date, at no

charge to the consumer.

Note: You obtain instructions on the correct disposal of all (marked and not marked) electrical products that

were supplied or manufactured by Hach-Lange at your relevant Hach-Lange sales office.

NOTICE

9

Page 10

General information

2.2 Areas of application

The RTC112 SD-Module (Real Time Controller for Sludge Dewatering) is an open and

closed-loop control unit for universal applications. It can be used by mechanical sludge

dewatering devices, such as centrifuges in wastewater treatment plants.

The RTC112 SD-Module

• Optimizes polymer consumption

• Uniformly manages the concentration of solids in dewatered sludge

1-channel Open/closed-loop controller for one dewatering system

2-channel Open/closed-loop controller for two dewatering systems

The use of an RTC Module does not release the operator from the responsibility of maintaining

the system. No guarantees as to the functionality or operational safety of the system.

In particular, the operator must make sure that instruments connected to the RTC

open/closed-loop controller are always fully functional.

To make sure these instruments supply correct, reliable measurement values, regular

maintenance work (for example, cleaning of the sensor and laboratory comparative

measurements) is essential! (Refer to the user manual for the relevant instrument.)

Table 1 Versions of the RTC112 SD-Module

NOTICE

2.3 Scope of delivery

The combination of pre-assembled components supplied by the manufacturer does not represent

a standalone functional unit. In accordance with EU guidelines, this combination of

pre-assembled components is not supplied with a CE mark, and there is no EU declaration of

conformity for the combination.

However, the conformity of the combination of components with the guidelines can be proved

through technical measurements.

Each RTC Module is supplied with:

• SUB-D connector (9 pin)

• User manual

• Ferrite core

Check that the order is complete. All listed components must be present. If anything is

missing or damaged, contact the manufacturer or distributor immediately.

NOTICE

10

Page 11

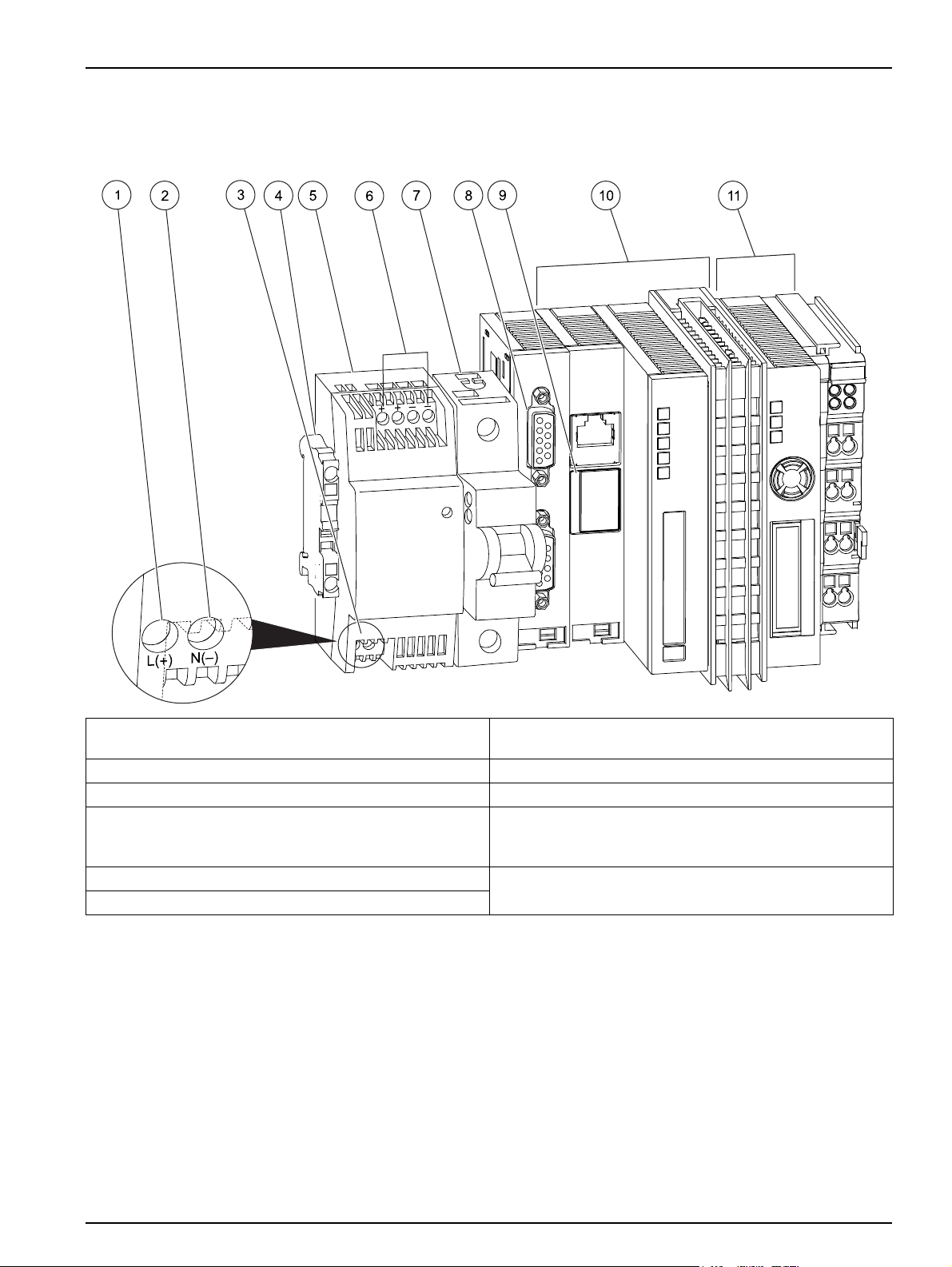

2.4 Instrument overview

Figure 1 Base module RTC 100-240 V version

General information

1 L(+) 7 Automatic circuit breaker (ON/OFF switch for item 10

and 11 without fuse function)

2 N(–) 8 sc1000 connection: RS485 (CX1010-N041)

3 Input AC 100–240 V / Input DC 95 V–250 V 9 Battery compartment

4 PE (protective earth) 10 CPU base module, consisting of Ethernet port with

battery compartment (CX1010-N000), CPU module with

CF card (CX1010-0021) and passive aeration element

5 24 V transformer (Specification section 3.1.1, page 17) 11 Power supply module, consisting of bus coupler

6 Output DC 24 V, 0,75 A

Note: All components are pre-wired.

(CX1100-0002) and terminal module 24V.

11

Page 12

General information

2

1

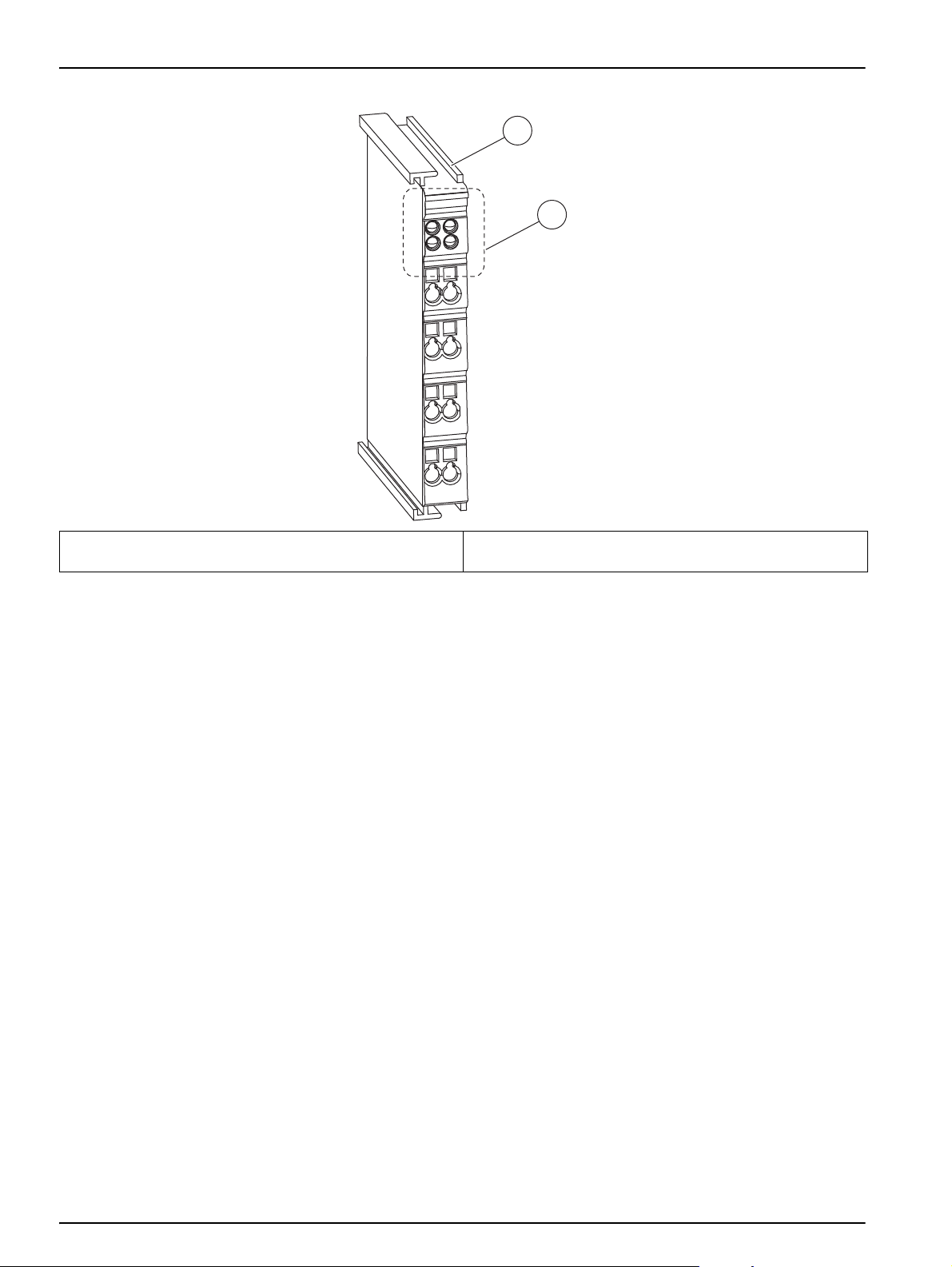

Figure 2 Design of the analog and digital input and output modules

1 Input- or Output- Module or Bus Termination Module

analog or digital

Note: The number of green LEDs indicates the number of channels.

2 LED area with installed LEDs or free LED installation

2.5 Theory of operation

2.5.1 Theory of operation of the RTC Module

The RTC112 SD-Module outputs analog (0/4–20 mA) and digital (0/24 V) signals for the

polymer dosing rate or the feed flow rate of mechanical sludge dewatering devices. Digital

fieldbus signals from sc1000 communication cards can also be used.

2.5.2 Input signals

The most important input signals are:

• Sludge influent TSS concentration (concentration of solids)

2.5.3 Parameters for configuration

• Feed flow rate of the dewatering system

• Thickened sludge TSS concentration (optional)

• Status of the thickened sludge pump (on/off)

spaces

12

The most important parameters for configuration are:

• The required specific polymer dosing [g polymer/kg TSS]

• The target TSS concentration in dewatered sludge or

• The target TSS concentration in centrate

Page 13

In a closed-loop circuit, TSS measurement is required in centrate or dewatered sludge. The

program of the RTC112 SD-Module has to be adjusted to the type of measurement location that

is being used for the closed loop part of the RTC. This is done by executing *.bat files on the CF

card of the RTC. Make_Filtrate.bat has to be executed for applications where centrate TSS is

measured and Make_Effluent for applications where dewatered/thickened sludge is measured.

Note: Never retrieve the CF-card from the RTC unit while power is on!

2.5.4 Operating modes

The RTC112 SD-Module can be operated as a combined open-loop and closed-loop

controller. Several variants can be configured.

1. Configuration of a fixed polymer rate [L/h] with a fixed feed flow rate [m

2. Configuration of a specific polymer dosing rate [g polymer/kg TSS]. One of the

following settings is adjusted:

a. The polymer flow rate according to the TSS concentration and the feed flow rate

• Based on the actual feed flow rate [L/h] and TSS concentration [g/L] in the feed

General information

NOTICE

3

/h].

(Figure 3).

flow, the polymer dosing rate [L/h] is calculated for the required specific dosing

rate.

Or:

b. The feed flow rate according to the specified polymer dosing rate and the

measured TSS concentration of the influent (Figure 4).

• Based on the measurement value of the TSS concentration from the influent [g/L]

and the configurable specified polymer dosing rate [L/h], the feed flow rate [m

is calculated such that it corresponds to the pre-defined specific polymer dosing

rate [g/kg].

3. Both variants 2a and 2b can be combined with one of the closed-loop controllers

described below:

a. Closed-loop control of the TSS concentration in the dewatered sludge

• The specific polymer dosing rate is adjusted according to the difference between

the target and actual TSS concentration in the dewatered sludge. Higher TSS

concentrations lead to a reduction of the dose and lower concentrations will lead

to higher dose rates than preset in the open-loop part of the RTC.

b. Closed-loop control of the TSS concentration in the centrate or filtrate

• The specific polymer dosing rate is adjusted according to the difference between

the target and actual TSS concentration in the centrate. Higher TSS

concentrations lead to an increase of the dose and lower concentrations will lead

to a decrease of the dose rates preset in the open-loop part of the RTC.

3

/h]

13

Page 14

General information

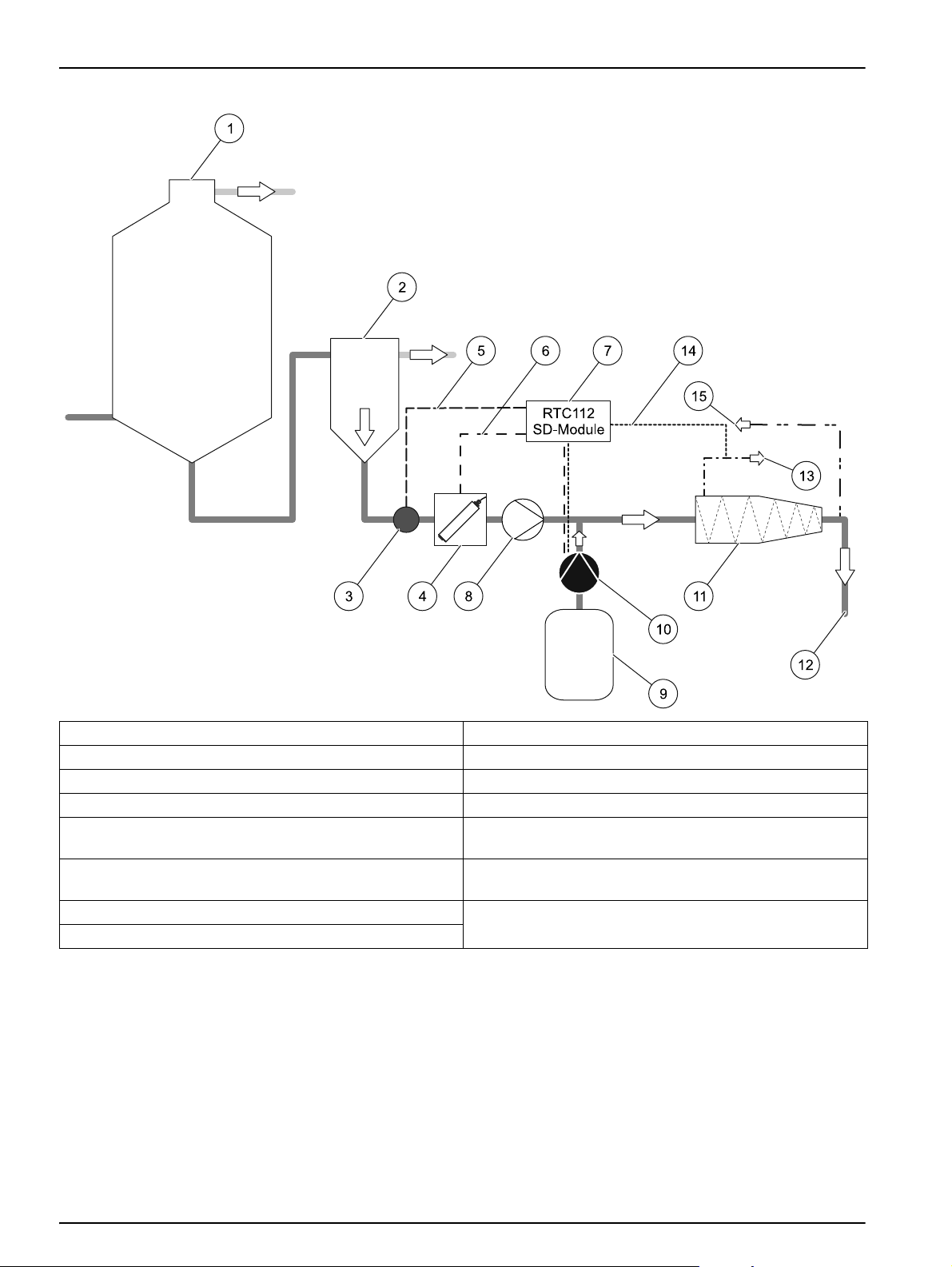

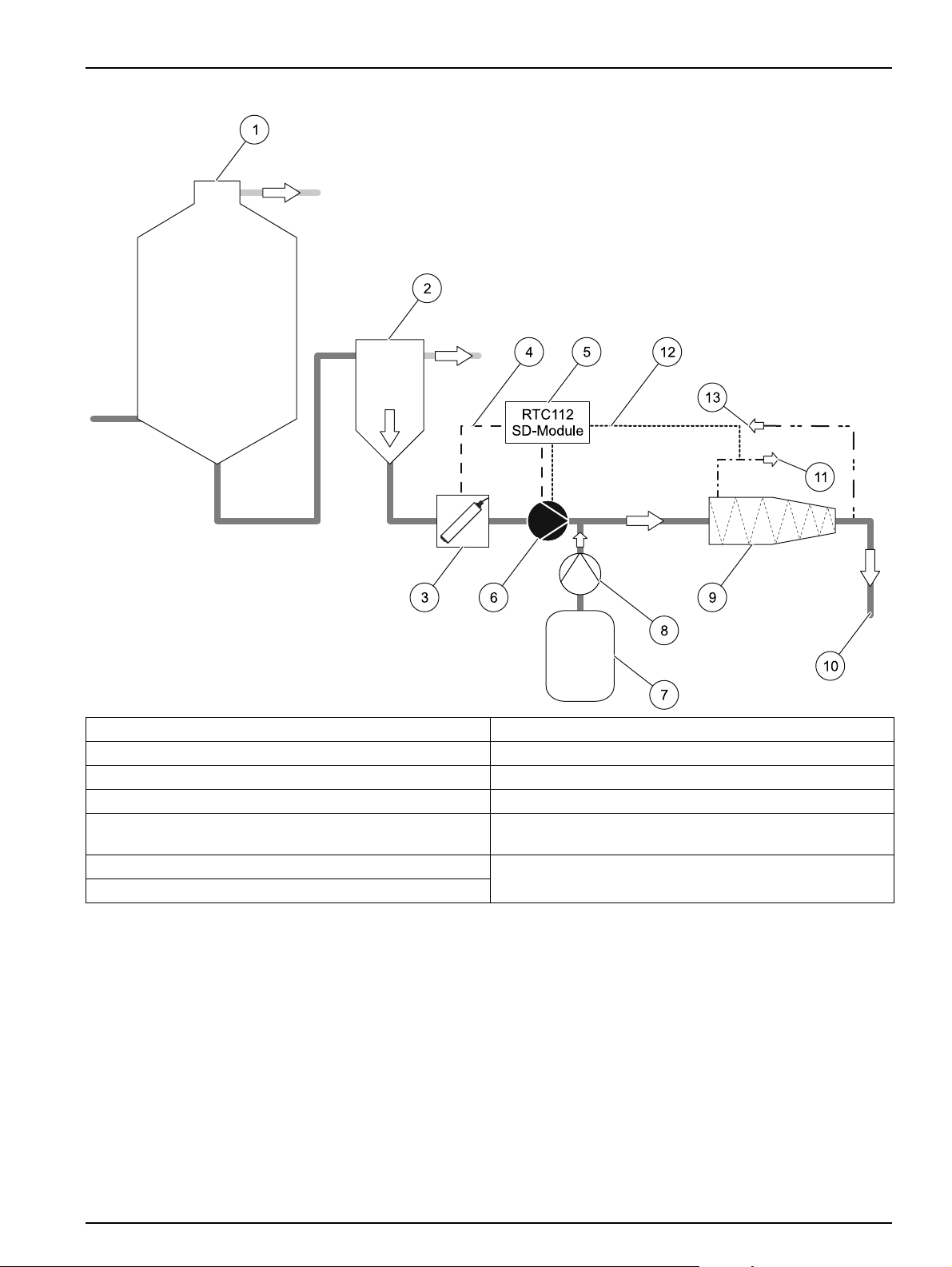

Figure 3 Adjustment of the polymer dosing rate to the influent TSS load

1 Digester 9 Polymer supply

2 Static thickener 10 Pump for open-loop control of the polymer dosing rate

3 Measurement of the feed flow rate 11 Mechanical sludge dewatering device

4 TSS measurement from the influent 12 Dewatered sludge

5 Open-loop control of the polymer dosing rate (feed flow

rate measurement value)

6 Open-loop control of the polymer dosing rate (influent

TSS concentration measurement value)

7 RTC112 SD-Module 15 Option: Measurement of the TSS concentration in the

8 Pump for the feed flow rate (constant)

13 Centrate

14 Option: Measurement of the TSS concentration in the

centrate

dewatered sludge instead of centrate

14

Page 15

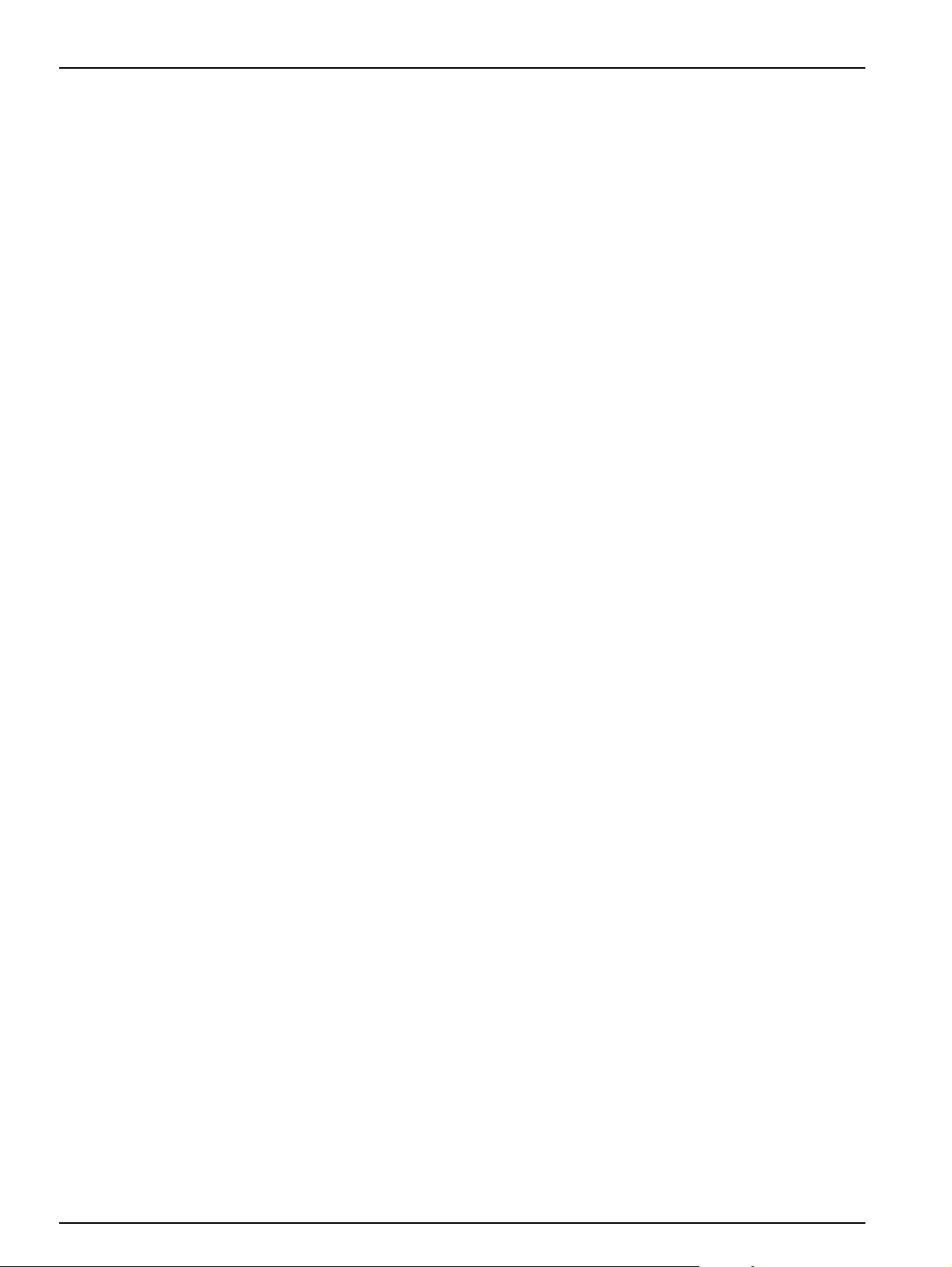

Figure 4 Adjustment of the feed flow rate to fixed polymer dosing rate

General information

1 Digester 8 Pump for polymer dosing (constant)

2 Static thickener or sludge storage 9 Mechanical sludge dewatering device

3 TSS measurement from the influent 10 Dewatered sludge

4 Open-loop control for the feed flow rate 11 Centrate

5 RTC112 SD-Module 12 Option: Measurement of the TSS concentration in the

centrate

6 Pump for open-loop control of the feed flow rate 13 Option: Measurement of the TSS concentration in the

7 Polymer supply

dewatered sludge instead of centrate

15

Page 16

General information

16

Page 17

Section 3 Installation

Only qualified experts may perform the tasks described in this section of the manual, while

adhering to all locally valid safety regulations.

Always lay cables and hoses so that they are straight and do not pose a tripping hazard.

Before the power supply is switched on, refer to the instructions in the relevant manuals.

3.1 Installation of the RTC Module

Only install the RTC Module on a DIN rail. The module must be attached horizontally, with

at least 30 mm (1.2 in.) space at the top and bottom to make sure that the passive

aeration element can function correctly.

When used indoors, the RTC Module must be installed in a control cabinet. When used

outdoors, the RTC Module requires a suitable enclosure that provides the technical

specifications indicated in Section 1.

DANGER

CAUTION

CAUTION

The RTC Module is operated via the sc1000 controller (see the user manual for the

sc1000 controller).

Note: The software version of the sc1000 controller must be V3.20 or above.

3.1.1 Supply voltage of the RTC Module

Table 2 Supply voltage of the RTC Module

Voltage 24 V DC (–15 % / +20 %), max. 25 W

Recommended fuse C2

With 110–230 V option 110–230 VAC, 50-60 Hz, approximately 25 VA

Note: An external deactivation switch is recommended for all installations.

3.2 Connection of process measurement instruments for the TSS concentration

The measurement signals of the sc sensors for the measurement of the concentration of

solids (e. g. SOLITAX sc) are provided to the RTC112 SD-Module via the RTC

communication card (YAB117) in the sc1000 probe module.

3.2.1 Power supply of the sc sensors and the sc1000 controller

See operating instructions of the respective sc sensors and the sc1000 controller.

3.3 sc1000 controller connection

Connect the SUB-D plug supplied to a dual-core, sheathed data cable (signal or bus

cable). For additional information regarding the data cable connection, refer to the

enclosed assembly instructions.

17

Page 18

Installation

3.4 Connection to the automation unit on the plant side

The one-channel and two-channel versions of the RTC112 SD-Module are equipped with

various modules that must be connected to the plant automation system.

• The feed flow rate must be provided to the RTC112 SD-Module as a 0/4 to 20 mA

signal.

• The polymer flow rate must be provided (on both versions) to the RTC112 SD-Module

as a 0/4 to 20 mA signal.

• The polymer pump can be operated in pulse/pause mode (PWM).

• The status signals and fault indications are output as 0 V/24 V signals.

• Measurement errors are shown 5 minutes after the error occurs. In the event of a new

startup (return of power supply), the unit is set back to ON (24 V) after approximately

1 minute and 40 seconds if there are no measurement errors.

• In the event of a new startup (return of power supply), the RTC operating signal is set

back to ON (24 V) after approximately 1 minute and 25 seconds.

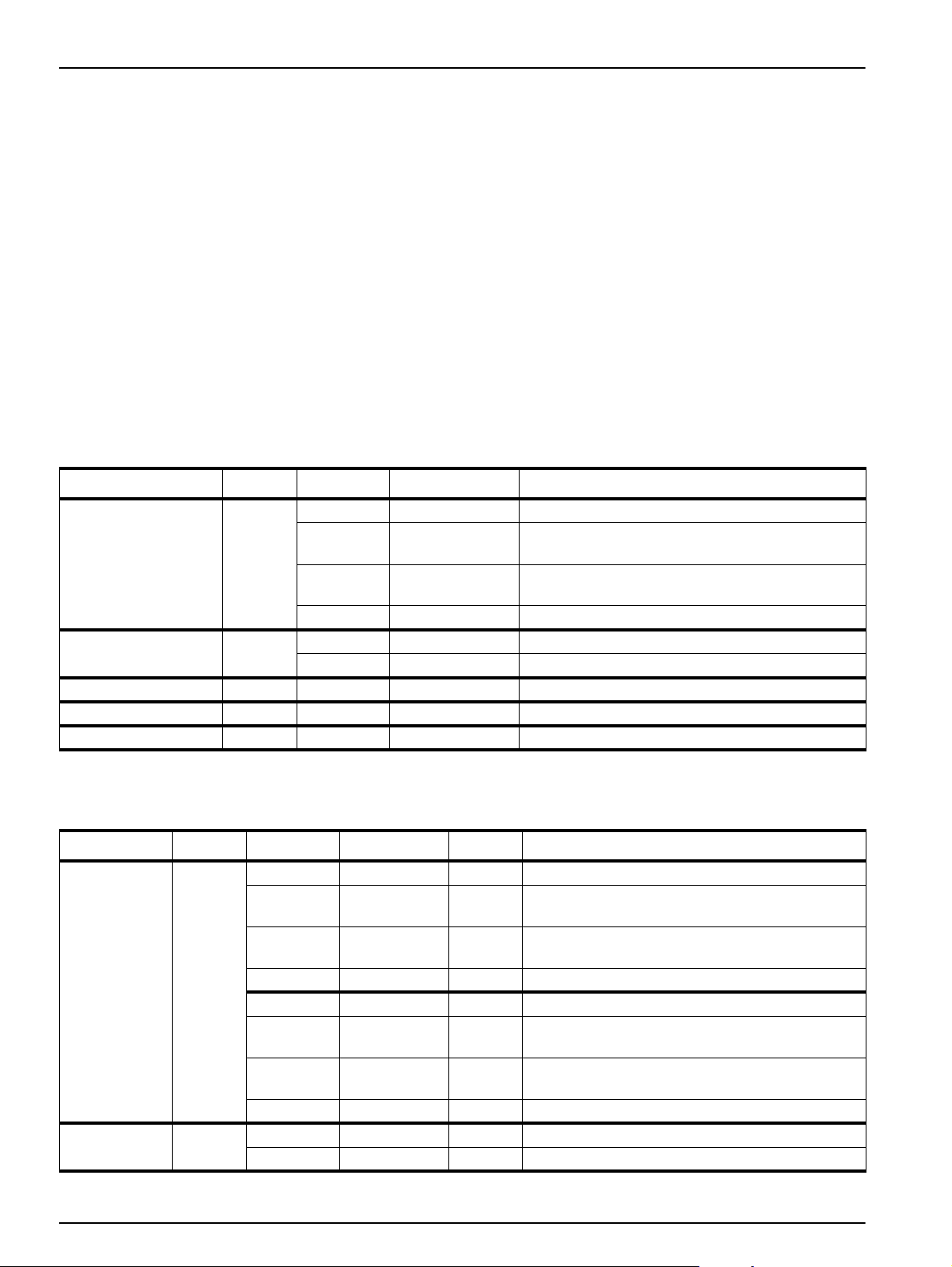

Table 3 Connections for the 1-channel RTC112 SD-Module

Module Name Connection Signal Function

1 +24 V/0 V Polymer pump on/off (24 V/0 V); (LED a)

5 +24 V/0 V

4x digital output

2x analog output KL4012

1x analog input KL3011 1(+) - 2(-) 0/4 to 20 mA Input of the feed flow rate

1x analog input KL3011 1(+) - 2(-) 0/4 to 20 mA Input of the polymer flow rate

Bus termination KL9010 Bus termination

1

KL2134

4 +24 V/0 V

8 +24 V/0 V RTC operational (24 V), RTC faulty (0 V), (LED d)

1(+) - 3(-) 0/4 to 20 mA Output of the polymer pump flow rate

5(+) - 7(-) 0/4 to 20 mA Output of the feed flow rate

Closed-loop control of the feed flow rate

active/inactive (24 V/0 V); (LED c)

Input signals OK (24 V), input signal faulty (0 V);

(LED b)

1

Ground to connection 3 and 7 or to the supply voltage connections

Table 4 Connections for the 2-channel RTC112 SD-Module

Module Name Connection Signal Channel Function

1 +24 V/0 V 1 Polymer pump on/off (24 V/0 V) (LED a)

Closed-loop control of the feed flow rate

active/inactive (24 V/0 V) (LED e)

Input signals OK (24 V), input signal faulty (0 V)

(LED b)

Closed-loop control of the feed flow rate

active/inactive (24 V/0 V) (LED g)

Input signals OK (24 V), input signal faulty (0 V)

(LED d)

8x digital

1

output

2x analog

output

KL2408

KL4012

5 +24 V/0 V 1

2 +24 V/0 V 1

6 +24 V/0 V 1 RTC operational (24 V), RTC faulty (0 V) (LED f)

3 +24 V/0 V 2 Polymer pump on/off (24 V/0 V) (LED c)

7 +24 V/0 V 2

4 +24 V/0 V 2

8 +24 V/0 V 2 RTC operational (24 V), RTC faulty (0 V) (LED h)

1(+) - 3(-) 0/4 to 20 mA 1 Output of the polymer pump flow rate

5(+) - 7(-) 0/4 to 20 mA 1 Output of the feed flow rate

18

Page 19

Table 4 Connections for the 2-channel RTC112 SD-Module

Module Name Connection Signal Channel Function

2x analog

output

1x analog input KL3011 1(+) - 2(-) 0/4 to 20 mA 1 Input of the feed flow rate

1x analog input KL3011 1(+) - 2(-) 0/4 to 20 mA 1 Input of the polymer flow rate

1x analog input KL3011 1(+) - 2(-) 0/4 to 20 mA 2 Input of the feed flow rate

1x analog input KL3011 1(+) - 2(-) 0/4 to 20 mA 2 Input of the polymer flow rate

Bus termination KL9010 Bus termination

1

Ground to connection to the supply voltage connections

KL4012

1(+) - 3(-) 0/4 to 20 mA 2 Output of the polymer pump flow rate

5(+) - 7(-) 0/4 to 20 mA 2 Output of the feed flow rate

Installation

19

Page 20

Installation

Figure 5 Connections and corresponding LEDs for digital output card KL2408 (2 channel option

only)

a LED a e LED e

b LED b f LED f

c LED c g LED g

d LED d h LED h

1 Connector 1 9 Connector 5

2 Connector 2 10 Connector 6

3 Connector 3 11 Connector 7

4 Connector 4 12 Connector 8

20

Page 21

Section 4 Parameterization and operation

4.1 Operating the sc controller

The RTC Module can only be operated via the sc1000 controller

in conjunction with the RTC communication card. Before the RTC

Module is used, the user must be familiar with the functionality of

the sc1000 controller. Learn how to navigate through the menu

and perform the relevant functions.

4.2 sc1000 setup

1. Open the MAIN MENU.

2. Select

3. Select

4. Select

RTC MODULES / PROGNOSYS and confirm.

RTC MODULES and confirm.

RTC and confirm.

4.3 Menu structure

4.3.1 DIAGNOSIS

DIAGNOSIS

RTC

ERROR LIST

WARNING LIST

REMINDER LIST

Possible error messages:

RTC MISSING, RTC CRC, CHECK CONFIG, RTC FAILURE

Possible warning messages:

MODBUS ADDRESS, PROBE SERVICE

Note: Refer to Section 6 Troubleshooting, page 39 for a list of all

possible error and warning messages together with a description of all

necessary countermeasures to be taken.

4.4 Configuration of RTC112 SD-Module parameters on the sc1000 controller

The following menu items are in the SC1000 SETUP menu.

4.4.1 RTC112 SD-Module open and closed-loop controller

RTC MODULES / PROGNOSYS

RTC MODULES

RTC

CONFIGURE

SELECT SENSOR

Select the sensors installed for the open/closed-loop controller

(refer to section 4.5, page 26).

21

Page 22

Parameterization and operation

4.4.1 RTC112 SD-Module open and closed-loop controller (Continued)

RTC MODULES / PROGNOSYS

RTC MODULES

RTC

PRESELECT PROG.

CHANNEL 1

Based on the feed flow rate [m³/h] and measured TSS

POLYMER DOSING

CONTROL

FEED FLOW CONTROL

CLOSED-LOOP EFFLUENT

CONTROL

CLOSED-LOOP FILTRATE

CONTROL

CHANNEL 2 As per channel one

CONTROL PARAMETER

CHANNEL 1

FACTOR POLYMER

DOSING

POLYMER CONCENTRATION

MANUAL POLYMER

DOSING

MANUAL FEED FLOW

concentration [g/L] from the influent, the polymer dosing rate

[L/h] is calculated such that it corresponds to the target specific

polymer dosing rate [g/kg].

Based on the measured TSS concentration [g/L] and a fixed

polymer dosing rate [L/h], the feed flow [m

that it corresponds to the specific polymer dosing rate [g/kg].

If activated, the specific polymer dosing rate FACTOR

POLYMER DOSING is adjusted based on the difference

between the target and actual TSS concentration in the

dewatered sludge.

The change in the specific dosing rate affects the polymer

dosing rate [L/h] in the POLYMER DOSING CONTROL module

or affects the feed flow rate in the FEED FLOW CONTROL

module.

If activated, the specific polymer dosing rate FACTOR

POLYMER DOSING is adjusted based on the difference

between the target and actual TSS concentration in the

filtrate/centrate.

The change in the specific dosing rate affects the polymer

dosing rate [L/h] in the POLYMER DOSING CONTROL module

or affects the feed flow rate in the FEED FLOW CONTROL

module.

Note: Activation and deactivation of CLOSED-LOOP

EFFLUENT CONTROL and CLOSED-LOOP FILTRATE

CONTROL have to be prepared by executing the relevant

*bat-files on the RTC CF-card (see section 2.5.3).

Required specific polymer dosing [g/kg]. This parameter

determines how many grams of polymer per kilogram of TSS

are fed by the machine.

Polymer concentration [g/L] fed via the polymer pump. g/L

The RTC outputs the polymer flow rate [L/h] if

• FEED FLOW CONTROL is activated

• No open-loop control mode (see above) is activated

• The TSS measurement from the influent reports an error, or

• The flow measurement from the influent reports an error.

The RTC outputs the feed flow rate [m³/h] if

• POLYMER DOSING CONTROL is activated

• No open-loop control mode (see above) is activated

• The TSS measurement from the influent reports an error, or

• The flow measurement from the influent reports an error

3

/h] is calculated such

Activation/

deactivation

Activation/

deactivation

Activation/

deactivation

Activation/

deactivation

g/kg

L/h

m³/h

22

Page 23

Parameterization and operation

4.4.1 RTC112 SD-Module open and closed-loop controller (Continued)

RTC MODULES / PROGNOSYS

RTC MODULES

RTC

MAX DECREASE CLOSED

L

MAX INCREASE CLOSED L

SET-POINT TSS

P GAIN TSS

INTEGRAL TIME TSS

DERIVAT IVE TIME TSS

SET-POINT FILT

P GAIN FILT

INTEGRAL TIME FILT

This value defines the maximum decrease of the specific

polymer dosing rate FACTOR POLYMER DOSING [g/kg] if

CLOSED-LOOP EFFLUENT CONTROL is selected.

This value defines the maximum increase of the specific

polymer dosing rate FACTOR POLYMER DOSING [g/kg] if

CLOSED-LOOP EFFLUENT CONTROL is selected.

Required setpoint of the TSS concentration in the thickened

sludge.

Note: This parameter is only considered if CLOSED-LOOP

EFFLUENT CONTROL is activated.

Proportional gain for the PID closed-loop controller for the TSS

concentration in the thickened sludge.

Note: This parameter is only considered if CLOSED-LOOP

EFFLUENT CONTROL is activated.P GAIN TSS [L/g] is divided

by 100 before it is multiplied by the deviation of the actual TSS

concentration [g/L] from the required TSS setpoint [g/L] .

Integral time for the PID closed-loop controller for the TSS

concentration in the thickened sludge.

Note: This parameter is only considered if CLOSED-LOOP

EFFLUENT CONTROL is activated. INTEGRAL TIME TSS is set

to "0" to deactivate the integral part of the PI open-loop

controller.

Derivative time for the PID closed-loop controller for the TSS

concentration in the thickened sludge.

Note: This parameter is only considered if CLOSED-LOOP

EFFLUENT CONTROL is activated.

Required setpoint of the TSS concentration in the

centrate/filtrate.

Note: This parameter is only considered if CLOSED-LOOP

FILTRATE CONTROL is activated.

Proportional gain for the PID closed-loop controller for the TSS

concentration in the centrate/filtrate.

Note: This parameter is only considered if CLOSED-LOOP

EFFLUENT CONTROL is activated.

P GAIN FILT [L/g] is divided by 100 before it is multiplied by the

deviation of the actual TSS concentrat ion fr om the requ ire d TSS

setpoint.

Integral time for the PID closed-loop controller for the TSS

concentration in the centrate/filtrate.

Note: This parameter is only considered if CLOSED-LOOP

EFFLUENT CONTROL is activated.

INTEGRAL TIME TSS is set to "0" to deactivate the integral part

of the PID open-loop controller.

g/kg

g/kg

g/L

L/g

min

min

g/L

L/g

min

23

Page 24

Parameterization and operation

4.4.1 RTC112 SD-Module open and closed-loop controller (Continued)

RTC MODULES / PROGNOSYS

RTC MODULES

RTC

Derivative time for the PID closed-loop controller for the TSS

DERIVATIVE TIME FILT

CHANNEL 2 As per channel one

INPUT/OUTPUT LIMITS

CHANNEL 1

FEED FLOW LOW

FEED FLOW HIGH

FEED FLOW SMOOTHING

LIMIT TSS IN LOW

LIMIT MAX TSS IN HIGH

TSS IN SMOOTHING

LIMIT TSS OUT LOW

LIMIT TSS OUT HIGH

TSS OUT SMOOTHING

POLYMER DOSING

MINIMUM

POLYMER DOSING

MAXIMUM

CHANNEL 2 As per channel one

concentration in the centrate/filtrate.

Note: This parameter is only considered if CLOSED-LOOP

FILTRATE CONTROL is activated.

3

Feed flow rate input signals below this value [m

this value (to avoid low flow peaks).

Feed flow rate input signals above this value [m3/h] are set to

this value (to avoid high flow peaks).

Feed flow measurement values are smoothed in line with this

parameter.

TSS measurement values from the influent that are below this

value [g/L] are set to this value (to avoid low peaks).

TSS measurement values from the influent that are above this

value [g/L] are set to this value (to avoid high peaks).

The TSS measurement values from the influent are smoothed in

line with this parameter.

The TSS values of the dewatered sludge or centrate sludge that

are below this value [g/L] are set to this value (to avoid low

peaks).

The TSS values of the dewatered sludge or centrate sludge that

are above this value [g/L] are set to this value (to avoid high

peaks).

The TSS measurement values from the effluent are smoothed in

line with this parameter.

When FEED FLOW CONTROL is activated, measurement

values for the polymer dosing rate that are below this value

[m³/h] are set to this value (to avoid low peaks in the dosing

flow).

Any RTC calculation above this value [g/L] is set to this value

and delivered to the polymer pump.

When FEED FLOW CONTROL is activated, measurement

values for the polymer dosing rate that are above this value

[m³/h] are set to this value (to avoid high peaks in the dosing

flow).

/h] are set to

min

m

m

min

g/L

g/L

min

g/L

g/L

min

L/h

L/h

3

/h

3

/h

24

Page 25

Parameterization and operation

4.4.1 RTC112 SD-Module open and closed-loop controller (Continued)

RTC MODULES / PROGNOSYS

RTC MODULES

RTC

INPUTS

CHANNEL 1

MIN FEED FLOW

MAX FEED FLOW

0/4...20mA

MIN POLYMER FLOW

MAX POLYMER FLOW

0/4...20mA

CHANNEL 2 As per channel one

OUTPUTS

CHANNEL 1

MIN FEED FLOW Minimum feed flow rate [m³/h] in accordance with 0/4 mA. m³/h

MAX FEED FLOW Maximum feed flow rate [m³/h] in accordance with 20 mA. m³/h

0/4...20mA

MIN POLYMER FLOW

MAX POLYMER FLOW

0/4...20mA

CONTROL CYCLE

MIN RUNTIME

CHANNEL 2 As per channel one

Minimum flow rate [m³/h] from the influent in accordance with

the 0/4 mA measurement signal.

Maximum flow rate [m³/h] from the influent in accordance with

the 20 mA measurement signal.

Transfer range of 0/4 to 20 mA current loop (as set in connected

flow measuring instrument).

Minimum polymer dosing in [L/h] in accordance with the 0/4 mA

measurement signal.

Maximum polymer dosing in [L/h] in accordance with the 20 mA

measurement signal.

Transfer range of 0/4 to 20 mA current loop (as set on

connected flow measuring instrument).

Transfer range of 0/4 to 20 mA current loop (as set on

connected flow measuring instrument).

Minimum polymer pump delivery rate in accordance with

0/4 mA.

Maximum polymer pump delivery rate in accordance with

20 mA.

Transfer range of 0/4 to 20 mA current loop (as set on

connected flow measuring instrument).

Pulse/pause mode for the polymer pump open-loop control for

dosing rates beneath the minimum polymer flow rate (MIN

POLYMER FLOW). The on/off duration in pulse/pause mode

can be affected by the duration of the CONTROL CYCLE. For

example, with a CONTROL CYCLE of 100 seconds and a

dosing control value of 60 %, the polymer pump is regularly

switched on for 60 seconds and switched off for 40 seconds.

Short cycle times increase the switching frequency but enable

more precise adaptation to individual requirements. CONTROL

CYCLE should be divisible by MIN RUNTIME and produce a

whole number.

The minimum ON time in pulse/pause dosing mode. The pump

is not activated for periods shorter than this. The MIN RUNTIME

must be shorter than the duration of the CONTROL CYCLE.

m³/h

m³/h

L/h

L/h

L/h

L/h

s

s

25

Page 26

Parameterization and operation

4.4.1 RTC112 SD-Module open and closed-loop controller (Continued)

RTC MODULES / PROGNOSYS

RTC MODULES

RTC

MODBUS

ADDRESS

DATA ORDER

DATALOG INTRVL Indicates the interval in which the data is saved in the log file. [min]

SET DEFAULTS Restores the factory settings.

MAINTENANCE

RTC DATA

RTC MEASUREMEN

RT C AC TUAT VAR

DIAG/TEST

EEPROM Hardware test

RTC COMM TO Communication time-out

RTC CRC Communication check sum

MODBUS ADDRESS

Start address of an RTC within the MODBUS network. Default

setting: 41–61

Specifies the register order within a double word. Presetting:

NORMAL

Specifies the value measured by the RTC, e. g. the influent

measurement.

Specifies the variable calculated by the RTC, e. g. whether the

aeration should be switched on or off.

Address displayed where the communication actually takes

place. Presetting: 41

4.5 Select sensors

1. To select sensors and their sequence for the RTC Module,

press RTC > CONFIGURE > SELECT SENSOR.

26

Page 27

Figure 6 Select sensor

Parameterization and operation

1ENTER — Saves the setting and returns to the

CONFIGURE menu.

2 CANCEL — Returns to the CONFIGURE menu without

saving.

3ADD — Adds a new sensor to the selection.

2. Press

A selection list of all subscribers to the sc1000 network

opens.

3. Press the required sensor for the RTC Module and confirm

by pressing

Sensors in black type are available for the RTC Module.

Sensors in red type are not available for the RTC Module.

Note: Sensors marked (p) are available for PROGNOSYS if these

sensors have been selected in conjunction with an RTC (refer to the

PROGNOSYS user manual).

4 DELETE — Removes a sensor from the selection.

5UP/DOWN — Moves the sensors up or down.

ADD (Figure 6, item 3).

ENTER below the selection list.

27

Page 28

Parameterization and operation

4. The selected sensor is shown in the sensor list.

Press

ADD (Figure 6, item 3) to open the selection list again.

5. Select the second sensor for the RTC Module and confirm

by pressing

Note: Previously selected sensors are shown in gray.

ENTER below the selection list.

The selected sensors are shown in the sensor list.

6. To sort the sensors in the order specified for the RTC

Module, press the sensor and use the arrow keys to move it

(Figure 6, item 5).

Press

DELETE (Figure 6, item 4) to remove an incorrect

sensor from the sensor list again.

7. Press ENTER (Figure 6, item 1) to confirm the list once it is

finished.

28

Page 29

4.6 PRESELECT PROG

4.6.1 POLYMER DOSING CONTROL

4.6.2 FEED FLOW CONTROL

Parameterization and operation

Based on the measured feed flow rate [m³/h] and the measured

TSS concentration [g/L] from the influent, the polymer dosing rate

[L/h] is calculated such that the setpoint corresponds to the

specific polymer dosing rate [g/kg].

Note: This open-loop control mode can only be activated if FEED FLOW

CONTROL is deactivated.

Note: The polymer flow rate is controlled via the RTC.

Based on the measured TSS concentration [g/L] and the

specified polymer dosing rate [L/h], the feed flow rate is

calculated such that it corresponds with the specific polymer

dosing rate [g/kg] (FACTOR POLYMER DOSING).

Note: This open-loop control mode can only be activated if POLYMER

DOSING CONTROL is deactivated.

Note: The feed flow rate is controlled via the RTC.

4.6.3 CLOSED-LOOP EFFLUENT CONTROL

If activated, the specific polymer dosing rate FACTOR POLYMER

DOSING is adjusted based on the difference between the target

and actual TSS concentration in the dewatered sludge.

If FEED FLOW CONTROL is activated, the TSS load fed with the

sludge thickening is adjusted based on the difference between

the target and actual TSS concentration in the filtrate.

Note: This closed-loop control can only be activated if POLYMER

DOSING CONTROL (section 4.6.1) or FEED FLOW CONTROL

(section 4.6.2) is activated.

4.6.4 CLOSED-LOOP FILTRATE CONTROL

If activated, the specific polymer dosing rate FACTOR POLYMER

DOSING is adjusted based on the difference between the target

and actual TSS concentration in the filtrate/centrate.

The change in the specific dosing rate affects the polymer dosing

rate [L/h] in the POLYMER DOSING CONTROL module or

affects the feed flow rate in the FEED FLOW CONTROL module.

Note: Activation and deactivation of CLOSED-LOOP EFFLUENT

CONTROL and CLOSED-LOOP FILTRATE CONTROL have to be

prepared by executing the relevant *bat-files on the RTC CF-card (see

section 2.5.3).

29

Page 30

Parameterization and operation

4.7 CONTROL PARAMETER

4.7.1 FACTOR POLYMER DOSING

4.7.2 POLYMER CONCENTRATION

4.7.3 MANUAL POLYMER DOSING

Required specific polymer dosing [g/kg]. This parameter

determines how many grams of polymer per kilogram of TSS are

fed by the system.

Polymer concentration [g/L] fed via the polymer pump.

The RTC outputs the polymer dosing rate [L/h] if

• FEED FLOW CONTROL is activated

• No open-loop control mode (section 4.6.1 to section 4.6.3) is

activated

• The TSS measurement from the influent reports an error, or

• The flow measurement from the influent reports an error.

4.7.4 MANUAL FEED FLOW

4.7.5 MAX DECREASE CLOSED L

4.7.6 MAX INCREASE CLOSED L

4.7.7 SET-POINT TSS

The RTC outputs the feed flow rate [m3/h] if

• POLYMER DOSING CONTROL is activated

• No open-loop control mode (section 4.6.1 to section 4.6.3) is

activated

• The TSS measurement at the inlet reports an error, or

• The flow measurement from the influent reports an error.

This value defines the maximum decrease of the specific polymer

dosing rate FACTOR POLYMER DOSING [g/kg] if

CLOSED-LOOP EFFLUENT CONTROL is selected.

This value defines the maximum increase of the specific polymer

dosing rate FACTOR POLYMER DOSING [g/kg] if

CLOSED-LOOP EFFLUENT CONTROL is selected.

Required setpoint of the TSS concentration in the dewatered

sludge.

30

Note: · This parameter is only considered if CLOSED-LOOP EFFLUENT

CONTROL (section 4.6.3) is activated.

Page 31

4.7.8 P GAIN TSS

4.7.9 INTEGRAL TIME TSS

4.7.10 DERIVATIVE TIME TSS

4.7.11 SET-POINT FILT

Parameterization and operation

Proportional gain for the PID closed-loop controller for the TSS

concentration in the dewatered sludge.

Note: P GAIN TSS [L/g] is divided by 100 before it is multiplied by the

deviation of the actual TSS concentration from the required TSS

setpoint.

Integral time for the PID closed-loop controller for the TSS

concentration in the dewatered sludge.

Note: INTEGRAL TIME TSS is set to "0" to deactivate the integral part of

the PI open-loop controller.

Derivative time for the PID closed-loop controller for the TSS

concentration in the dewatered sludge.

Required setpoint of the TSS concentration in the centrate/filtrate.

4.7.12 P GAIN FILT

4.7.13 INTEGRAL TIME FILT

4.7.14 DERIVATIVE TIME FILT

Note: This parameter is only considered if CLOSED-LOOP FILTRATE

CONTROL is activated.

Proportional gain for the PID closed-loop controller for the TSS

concentration in the centrate/filtrate.

Note: This parameter is only considered if CLOSED-LOOP EFFLUENT

CONTROL is activated.

P GAIN FIL T [L/g] is divided by 100 before it is multiplied by the deviation

of the actual TSS concentration from the required TSS setpoint.

Integral time for the PID closed-loop controller for the TSS

concentration in the centrate/filtrate.

Note: This parameter is only considered if CLOSED-LOOP EFFLUENT

CONTROL is activated.

INTEGRAL TIME TSS is set to "0" to deactivate the integral part of the

PID open-loop controller.

Derivative time for the PID closed-loop controller for the TSS

concentration in the centrate/filtrate.

4.8 INPUT/OUTPUT LIMITS

4.8.1 FEED FLOW LOW

Note: This parameter is only considered if CLOSED-LOOP FILTRATE

CONTROL is activated.

Feed flow rate input signals below this value [m3/h] are set to this

value. This means that very low feed flow rates can be avoided.

31

Page 32

Parameterization and operation

4.8.2 FEED FLOW HIGH

4.8.3 FEED FLOW SMOOTHING

Feed flow rate input signals above this value [m3/h] are set to this

value. This avoids load peaks.

Feed flow measurement values are smoothed in line with this

parameter.

SMOOTHING = 1: The signal for the flow rate measurement

is not smoothed.

SMOOTHING = 2: Smoothing is performed over 3 minutes.

SMOOTHING = 3: Smoothing is performed over 5 minutes.

SMOOTHING = 5: Smoothing is performed over 12 minutes.

SMOOTHING = 10: Smoothing is performed over

25 minutes.

Example:

With the setting SMOOTHING = 2, it takes 3 minutes for the

smoothed value to reach 95 % of the final value after an abrupt

change in the feed flow rate.

4.8.4 LIMIT TSS IN LOW

4.8.5 LIMIT MAX TSS IN HIGH

4.8.6 TSS IN SMOOTHING

4.8.7 LIMIT TSS OUT LOW

TSS measurement values from the influent that are below this

value [g/L] are set to this value (to avoid low peaks).

Measurement values from the influent that are above this value

[g/L] are set to this value (to avoid high peaks).

TSS measurement values from the influent are smoothed in line

with this parameter.

SMOOTHING = 1: The signal is not smoothed.

SMOOTHING = 2: Smoothing is performed over 3 minutes.

SMOOTHING = 3: Smoothing is performed over 5 minutes.

SMOOTHING = 5: Smoothing is performed over 12 minutes.

SMOOTHING = 10: Smoothing is performed over

25 minutes.

TSS measurement values for the dewatered sludge or centrate

that are below this value [g/L] are set to this value (to avoid low

peaks).

4.8.8 LIMIT TSS OUT HIGH

32

TSS measurement values for the dewatered sludge or centrate

that are above this value [m

peaks).

3

/h] are set to this value (to avoid high

Page 33

4.8.9 TSS OUT SMOOTHING

4.8.10 POLYMER DOSING MINIMUM

Parameterization and operation

TSS measurement values from the effluent are smoothed in line

with this parameter.

SMOOTHING = 1: The signal is not smoothed.

SMOOTHING = 2: Smoothing is performed over 3 minutes.

SMOOTHING = 3: Smoothing is performed over 5 minutes.

SMOOTHING = 5: Smoothing is performed over 12 minutes.

SMOOTHING = 10: Smoothing is performed over

25 minutes.

RTC calculations below this value [g/L] are set to this value and

transferred to the polymer pump.

4.8.11 POLYMER DOSING MAXIMUM

4.9 INPUTS

4.9.1 MIN FEED FLOW

4.9.2 MAX FEED FLOW

4.9.3 0/4...20 mA

Note: When FEED FLOW CONTROL is activated, measurement values

for the polymer dosing rate that are below this value [m

value (to avoid low peaks in the dosing flow).

RTC calculations above this value [g/L] are set to this value and

transferred to the polymer pump.

Note: When FEED FLOW CONTROL is activated, measurement values

for the polymer dosing rate that are above this value [m

value (to avoid high peaks in the dosing flow).

Minimum flow rate [m³/h] from the influent in accordance with the

0/4 mA measurement signal.

Maximum flow rate [m³/h] from the influent in accordance with the

20 mA measurement signal.

3

/h] are set to this

3

/h] are set to this

4.9.4 MIN POLYMER FLOW

4.9.5 MAX POLYMER FLOW

Transfer range of the 0/4 to 20 mA current loop (as set in

connected flow measuring instrument).

Minimum polymer dosing in [L/h] in accordance with the 0/4 mA

measurement signal.

Maximum polymer dosing in [L/h] in accordance with the 20 mA

measurement signal.

33

Page 34

Parameterization and operation

4.9.6 0/4...20 mA

4.10 OUTPUTS

4.10.1 MIN FEED FLOW

4.10.2 MAX FEED FLOW

4.10.3 0/4...20 mA

4.10.4 MIN POLYMER FLOW

Transfer range of the 0/4 to 20 mA current loop (as set in

connected flow measuring instrument).

Minimum feed flow rate [m³/h] in accordance with 0/4 mA.

Maximum feed flow rate [m³/h] in accordance with 20 mA.

Transfer range of 0/4 to 20 mA current loop (as set in connected

flow measuring instrument).

Minimum polymer pump delivery rate in accordance with 0/4 mA.

4.10.5 MAX POLYMER FLOW

4.10.6 0/4...20 mA

4.10.7 CONTROL CYCLE

4.10.8 MIN RUNTIME

Maximum polymer pump delivery rate in accordance with 20 mA.

Transfer range of 0/4 to 20 mA current loop (as set in connected

flow measuring instrument).

Pulse/pause mode for the polymer pump open-loop control for

dosing rates beneath the minimum polymer flow rate (MIN

POLYMER FLOW). The on/off duration in pulse/pause mode can

be affected by the duration of the CONTROL CYCLE. For

example, with a CONTROL CYCLE of 100 seconds and a dosing

control value of 60 %, the polymer pump is switched on for

60 seconds and switched off for 40 seconds. Short cycle times

increase the switching frequency but enable more precise

adaptation to individual requirements.

Note: CONTROL CYCLE must be divisible by MIN RUNTIME and

produce a whole number.

Minimum ON time in pulse/pause dosing mode. The pump is

activated for this runtime at the very least. The MIN RUNTIME

must be shorter than the duration of the CONTROL CYCLE.

4.11 Displayed measurement values and variables

The following measurement values and variables are shown on

the sc1000 display and transferred via fieldbus (refer to

section Appendix B).

34

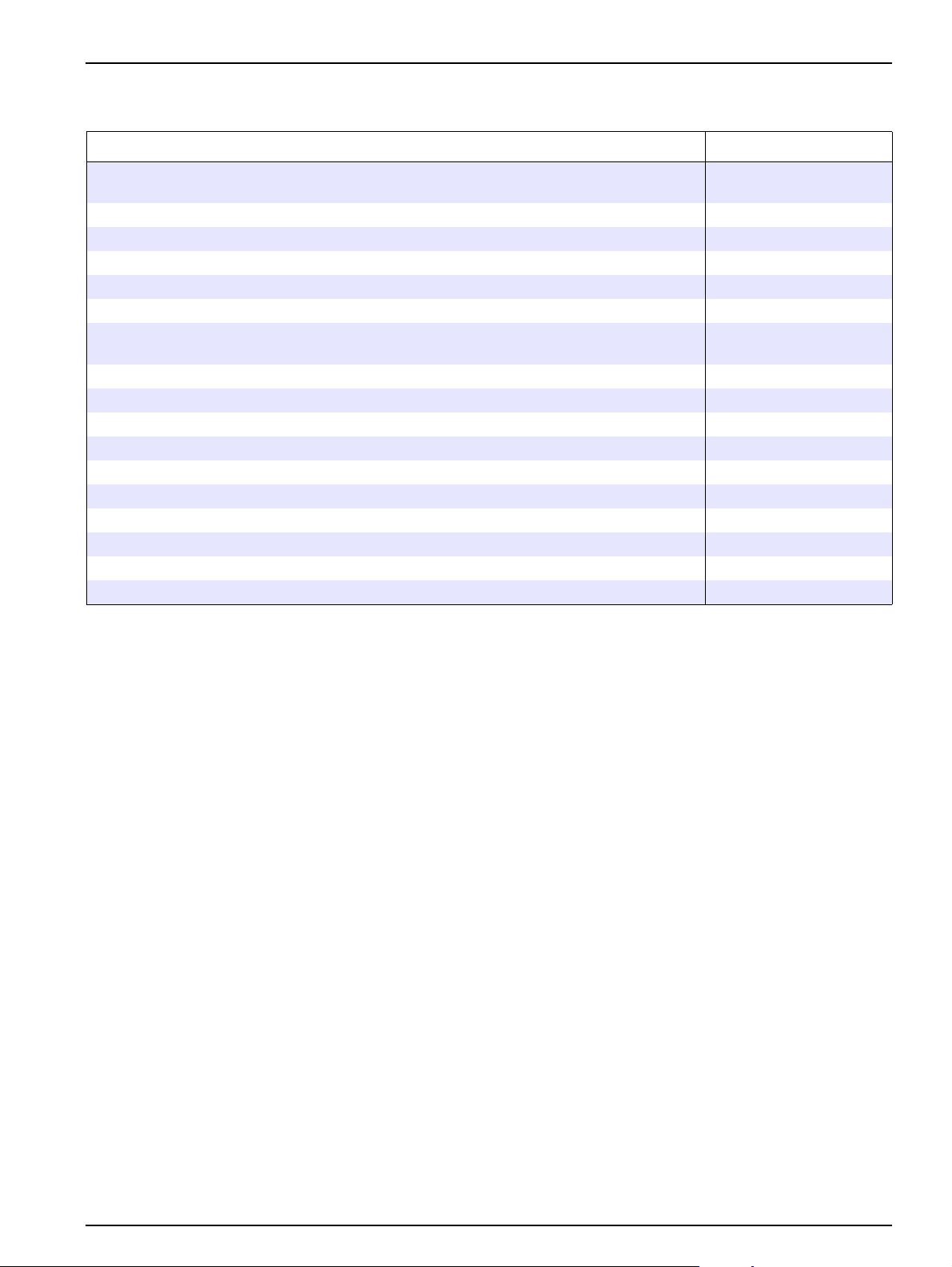

Page 35

Parameterization and operation

RTC112 SD-Module,

one-channel

Measurement 1 Qin 1 m

Measurement 2 Qavg 1 m

Parameter Unit Description

3

/h Flow rate from the influent

3

/h Average flow rate

Measurement 3 Qdos1 L/h Polymer flow rate

Measurement 4 TSin 1 g/L TSS concentration from the influent

Measurement 5 TSef 1 g/L TSS concentration from the effluent

Actuat var 6 Pdos1 L/h Polymer dosing

Actuat var 7 Fact 1 g/kg Specific polymer dosing

3

Actuat var 8 Feed 1 m

RTC112 SD-Module,

two-channel

Parameter Unit Description

Measurement 1 Qin 1 m

Measurement 2 Qavg 1 m

/h Feed flow rate

3

/h Flow rate from the influent 1

3

/h Average flow rate

Measurement 3 Qdos 1 L/h Polymer flow rate 1

Measurement 4 TSin 1 g/L TSS concentration from the influent 1

Measurement 5 TSef 1 g/L TSS concentration in the effluent 1

3

Measurement 6 Qin 2 m

Measurement 7 Qavg 2 m

/h Flow rate from the influent 2

3

/h Average flow rate

Measurement 8 Qdos 2 L/h Polymer flow rate 2

Measurement 9 TSin 2 g/L TSS concentration from the influent 2

Measurement 10 TSef 2 g/L TSS concentration in the effluent 2

Actuat var 11 Pdos 1 L/h Polymer dosing 1

Actuat var 12 Fact 1 g/kg Specific polymer dosing 1

3

Actuat var 13 Feed 1 m

/h Feed flow rate 1

Actuat var 14 Pdos2 L/h Polymer dosing 2

Actuat var 15 Fact 2 g/kg Specific polymer dosing 2

3

Actuat var 16 Feed 2 m

/h Feed flow rate 2

35

Page 36

Parameterization and operation

36

Page 37

Section 5 Maintenance

Multiple hazards

Only qualified personnel must conduct the tasks described in this section of the manual.

5.1 Maintenance schedule

Interval Maintenance task

DANGER

Visual inspection

Battery 5 years

Application-specific Check for contamination and corrosion

Replacement by manufacturer's service department (Section 8,

page 43)

37

Page 38

Maintenance

38

Page 39

Section 6 Troubleshooting

6.1 Error messages

Possible RTC errors are displayed by the sc controller.

Displayed errors Cause Resolution

Supply RTC with voltage

RTC MISSING

RTC CRC

CHECK CONFIG

RTC FAILURE

INFLOW1 NOT G. Influent measurement signal faulty Test sensor, check cable connections

INFLOW2 NOT G. Influent measurement signal faulty Test sensor, check cable connections

No communication between RTC and RTC

communication card

Interrupted communication between RTC and

RTC communication card

The sensor selection of the RTC was deleted

by deleting or selecting a new sc1000

participant.

Brief general read/write error on the CF card,

mostly caused by a brief interruption to the

power supply.

Test connection cable

Reset the sc1000 and the RTC (switch so it is

completely voltage free and switch back on)

Make sure +/- connections of the connector

cable between RTC and RTC communication

card in the sc1000 are installed correctly.

From MAIN MENU > RTC MODULES /

PROGNOSYS > RTC MODULES > RTC >

CONFIGURE > SELECT SENSOR, select the

correct sensor for the RTC again and confirm.

Acknowledge error. If this message is shown

frequently, eliminate the cause of the power

disruptions. If necessary, inform the service

team of the manufacturer (Section 8, page 43).

6.2 Warnings

Possible RTC sensor warnings are displayed by the sc controller.

Displayed warnings Cause Resolution

The RTC menu SET DEFAULTS was opened.

MODBUS ADDRESS

PROBE SERVICE A configured sensor is in service status. The sensor must exit service status.

This deleted the MODBUS address of the RTC

in the sc1000.

Go to MAIN MENU > RTC MODULES /

PROGNOSYS > RTC MODULES > RTC >

CONFIGURE > MODBUS > ADDRESS and

set the correct MODBUS address.

6.3 Wear parts

Designation Quantity Service life

Battery 1

~5 years

39

Page 40

Troubleshooting

40

Page 41

Section 7 Replacement parts and accessories

7.1 Replacement parts

Description Cat. No

DIN rail NS 35/15, punched according to DIN EN 60715 TH35, made of galvanized steel.

Length: 35 cm (13.78 in.)

Transformer 90–240 V AC/24 V DC 0.75 A, module for DIN rail assembly LZH166

Terminal for 24 V connection without power supply LZH167

Terminal for protective earth LZH168

SUB-D connector LZH169

C2 circuit breaker LZH170

CPU base module with Ethernet port, passive ventilation element. (CX1010-0021) and

RS422/485 connection module (CX1010-N031)

Power supply module, consisting of a bus coupler and a 24 V terminal module (CX1100-0002) LZH172

Digital output module 24 V DC (4 outputs) (KL2134) LZH174

Analog output module (2 outputs) (KL4012) LZH176

Analog input module (1 input) (KL3011) LZH177

Digital input module 24 V DC (2 inputs) (KL1002) LZH204

Digital output module 24 V DC (8 outputs) (KL2408) LZH205

Bus termination module (KL9010) LZH178

RTC communication card YAB117

CF card type RTC-Module LZY748-00

Ferrite core LZH216

LZH165

LZH171

41

Page 42

Replacement parts and accessories

42

Page 43

Section 8 Contact information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Că

minului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE SPAIN S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Bizkaia

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

43

Page 44

Contact information

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

44

Page 45

Section 9 Warranty and liability

The manufacturer warrants that the supplied product is free of material and manufacturing

defects, and undertakes to repair or to replace any defective parts without charge.

The warranty period is 24 months. If a maintenance contract is taken out within 6 months

of purchase, the warranty period is extended to 60 months.

With the exclusion of further claims, the supplier is liable for defects, including the lack of

assured properties, as follows: all parts that, within the warranty period calculated from the

day of the transfer of risk, can be demonstrated to have become unusable or that can only

be used with significant limitations owing to circumstances prior to transfer of risk, in

particular due to incorrect design, substandard materials or inadequate finish, shall be

repaired or replaced at the supplier's discretion. The identification of such defects must be

reported to the supplier in writing as soon as possible, but no later than 7 days after the

discovery of the fault. If the customer fails to notify the supplier, the product is considered

approved despite the defect. Further liability for indirect or direct damages is not accepted.

If device-specific maintenance- or inspection work prescribed by the supplier is to be

performed within the guarantee period by the customer (maintenance) or by the supplier

(inspection) and these requirements are not met, claims for damages that result from

non-observance of these requirements are void.

Further claims, in particular for consequential damages, cannot be made.

Wear and damage caused by improper handling, incorrect installation or non-designated

use are excluded from this clause.

The process instruments of the manufacturer have proven their reliability in many

applications and are therefore often used in automatic control loops to enable the most

economical and efficient operation of the relevant process.

To avoid or limit consequential damage, it is therefore recommended that the control loop

be designed such that an instrument malfunction results in an automatic changeover to

the backup control system. This guarantees the safest operating condition both for the

environment and the process.

45

Page 46

Warranty and liability

46

Page 47

Appendix A MODBUS address setting

The same slave address must be set for MODBUS communication on the sc1000

controller display and in the RTC module. Since 20 slave numbers are reserved for

internal purposes, the following numbers are available for assignment:

1, 21, 41, 61, 81, 101…

The start address 41 is preset at the factory.

NOTICE

If this address is to be or must be changed because, for example, it has already been allocated

for another RTC, the changes must be made both on the sc1000 controller and on the CF card of

the RTC module.

This can only be done by the manufacturer service department (Section 8)!

47

Page 48

48

Page 49

Appendix B Configuration of the network modules

B.1 RTC112 SD-Module Profibus/MODBUS telegram

Table 5 RTC112 SD-Module, one-channel

Register Parameter Unit Description

3

MEASUREMENT 1 Qin 1 m

MEASUREMENT 2 Qavg 1 m

MEASUREMENT 3 Qdos1 L/h Polymer flow rate

MEASUREMENT 4 TSin 1 g/L TSS concentration in the inflow

MEASUREMENT 5 TSef 1 g/L TSS concentration in the outflow

ACTUAT VAR 6 Pdos1 L/h Polymer dosing

ACTUAT VAR 7 Fact 1 g/kg Specific polymer dosing

AC TUAT VAR 8 Fee d 1 m

Table 6 RTC112 SD-Module, two-channel

Register Parameter Unit Description

MEASUREMENT 1 Qin 1 m3/h Flow rate in inflow 1

MEASUREMENT 2 Qavg 1 m

MEASUREMENT 3 Qdos 1 L/h Polymer flow rate 1

MEASUREMENT 4 TSin 1 g/L TSS concentration in inflow 1

MEASUREMENT 5 TSef 1 g/L TSS concentration in outflow 1

MEASUREMENT 6 Qin 2 m

MEASUREMENT 7 Qavg 2 m

MEASUREMENT 8 Qdos 2 L/h Polymer flow rate 2

MEASUREMENT 9 TSin 2 g/L TSS concentration in inflow 2

MEASUREMENT 10 TSef 2 g/L TSS concentration in outflow 2

ACTUAT VAR 11 Pdos 1 L/h Polymer dosing 1

ACTUAT VAR 12 Fact 1 g/kg Specific polymer dosing 1

ACTUAT VAR 13 Feed 1 m

ACTUAT VAR 14 Pdos2 L/h Polymer dosing 2

ACTUAT VAR 15 Fact 2 g/kg Specific polymer dosing 2

ACTUAT VAR 16 Feed 2 m

/h Flow rate in the inflow

3

/h Average flow rate

3

/h Feed flow rate

3

/h Average flow rate

3

/h Flow rate from the influent 2

3

/h Average flow rate

3

/h Feed flow rate 1

3

/h Feed flow rate 2

49

Page 50

50

Page 51

Index

Numerics

1-channel version ..................................................... 18

2-channel version ..................................................... 18

A

Address setting ........................................................ 47

aeration element ...................................................... 11

B

Battery compartment ................................................ 11

C

Closed-loop controller behavior ............................... 12

Concentration of solids

SOLITAX sc .......................................................... 17

TSS ....................................................................... 17

Control cycle ............................................................ 25

D

DIN rail ..................................................................... 17

E

Embedded PC ............................................................ 7

Error messages ........................................................ 39

Ethernet port ............................................................ 11

Expansion slot ............................................................ 7

F

Feed flow rate ............................................................ 7