Page 1

DOC023.52.90351

PROGNOSYS

05/2014, Edition 7

User Manual

Page 2

Page 3

Table of Contents

General information..................................................................................................3

Safety information........................................................................................................3

Use of hazard information....................................................................................3

Precautionary labels.............................................................................................3

Product overview.........................................................................................................4

Product components....................................................................................................4

Installation.....................................................................................................................4

PROGNOSYS communication card............................................................................4

Install the RTC/PROGNOSYS communication card

.................................................... 4

User interface and navigation..............................................................................4

Keypad description......................................................................................................4

Startup............................................................................................................................. 5

Add a sensor................................................................................................................ 5

Sort the sensors (RTC modules only)..................................................................6

Delete a sensor from the list.................................................................................7

Operation.......................................................................................................................7

PROGNOSYS indicator bars.......................................................................................7

Display description....................................................................................................... 8

Measurement value indicator....................................................................................... 9

Service indicator..........................................................................................................9

See the message lists.................................................................................................. 9

Configure the general settings...................................................................................10

Configure the sensor.................................................................................................11

Service and measurement value indicator messages.............................11

AMTAX sc and PHOSPHAX sc.................................................................................11

NITRATAX plus sc.....................................................................................................13

ANISE sc/AISE sc/NISE sc........................................................................................ 13

SOLITAX sc...............................................................................................................15

LDO Probe, Model 2..................................................................................................16

Troubleshooting.......................................................................................................17

Replacement parts...................................................................................................18

Warranty.......................................................................................................................18

PROGNOSYS register............................................................................................18

Index...............................................................................................................................21

1

Page 4

Table of Contents

2

Page 5

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety

information.

D A N G E R

W A R N I N G

C A U T I O N

N O T I C E

This symbol indicates that a risk of electrical shock and/or electrocution exists.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public

disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

English 3

Page 6

Product overview

PROGNOSYS (Prognosis System) is a software package used to monitor and show the reliability of

measurement values and to identify pending maintenance tasks. This software is available for sc

sensors. The sc1000 controller operates and configures the software.

The controller display will show horizontal bars as a measurement value indicator and as a service

indicator for the remaining time until the next maintenance task. The green, yellow and red indicators

show and identify the status of each sensor. Each sensor has an individual screen.

The service indicator is a prediction about future maintenance and service tasks, which are based on

the current sensor status. The service messages supply information on maintenance tasks that the

user must complete (e.g., to clean the sensor or replace the reagents). In addition, service tasks are

shown that the service technician must complete. All service messages have a countdown period

with sufficient time to contact a service technician or to order a replacement part.

Product components

Make sure that all components have been received. If any items are missing or damaged, contact the

manufacturer or a sales representative immediately.

PROGNOSYS can only be used with an sc1000 controller that has an RTC communication card or a

PROGNOSYS card installed. The PROGNOSYS files for the different sc sensors are kept on the

sc1000 controller.

To use PROGNOSYS without an RTC module, install a PROGNOSYS communication card on an

sc1000 controller. Refer to Replacement parts on page 18

.

Installation

PROGNOSYS communication card

If a PROGNOSYS communication card is installed, the controller display shows RTC

MODULES/PROGNOSYS in the main menu.

Install the RTC/PROGNOSYS communication card

Install an RTC or a PROGNOSYS communication card on an sc1000 controller with the software

version 3.20 or higher.

The controller operates a maximum of three communication cards at the same time. Each

PROGNOSYS communication card manages a maximum of eight sensors.

Refer to the applicable documentation for the RTC or PROGNOSYS communication card installation.

User interface and navigation

Keypad description

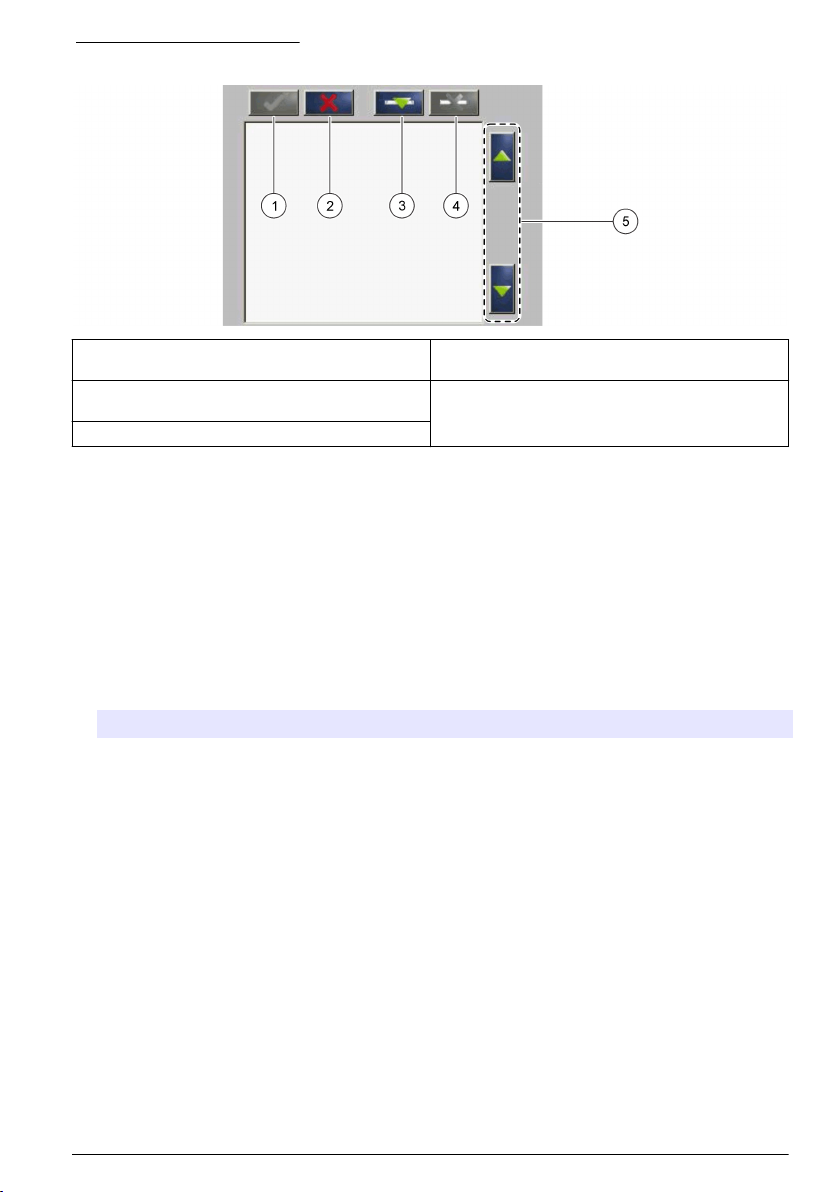

Refer to Figure 1 for the keypad description and navigation information.

4 English

Page 7

Figure 1 Keypad description

1 Enter: Saves the setting and exits the current

screen to the CONFIGURE menu

2 Cancel: Exits the current screen to the

CONFIGURE menu without saving the setting

3 Add: Adds a new sensor to the selection

4 Delete: Removes a sensor from the selection

5 UP and DOWN arrows: Moves the sensors up or

down the list

Startup

Add a sensor

Note: PROGNOSYS is not available for all sensors. Only newer sensor models can use the PROGNOSYS

function.

Note: Make sure that an RTC or a PROGNOSYS communication card is installed in the sc1000 sensor module.

When an RTC or PROGNOSYS communication card is installed, PROGNOSYS files are available

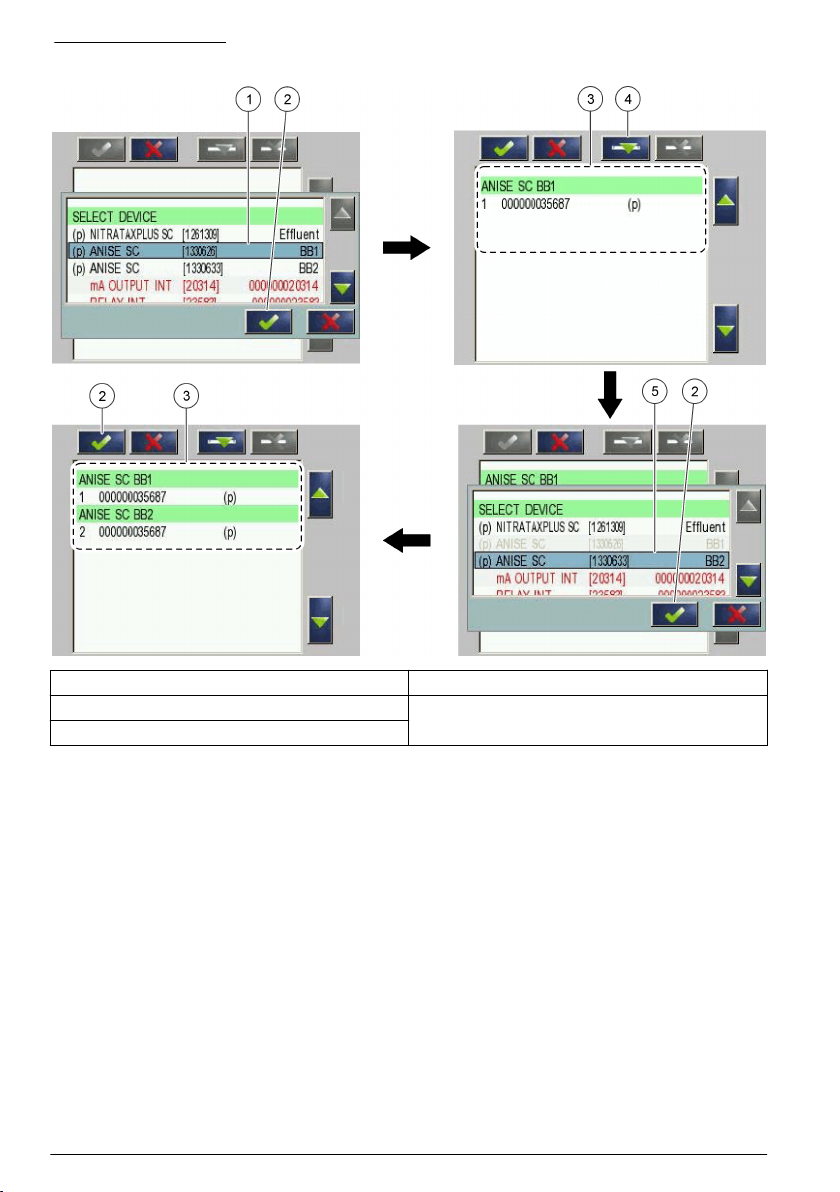

for different sc sensors. Do the steps that follow to add a sensor. Refer to Figure 2.

1. Connect the controller. Refer to the controller documentation.

2. Select an option.

Option Description

For

RTC/PROGNOSYS

card

For PROGNOSYS

card

3. Push Add. A list with all network connections opens.

4. Select the applicable sensor for the RTC or PROGNOSYS module and push Enter. The sensor is

shown in the sensor list.

Note: Sensor names with black font are available for an RTC module. Sensor names with red font are not

available for an RTC module. A sensor name identified with a "(p)" is available for PROGNOSYS.

5. Push Add to add more sensors from the list.

Sensors that are selected before are shown in gray. Refer to Figure 3

on page 7 to put in order or delete a sensor.

6. Push Enter to accept the list.

Select MAIN MENU>RTC MODULES/PROGNOSYS>RTC

MODULES>RTC>CONFIGURE>SELECT SENSOR

Select MAIN MENU>RTC

MODULES/PROGNOSYS>PROGNOSYS>CONFIGURATION>PROGNOSYS>SELECT

SENSOR

on page 7 or Figure 4

English 5

Page 8

Figure 2 Add sensors

1 Select sensor 4 Add

2 Accept 5 Select additional sensor

3 Sensor list

Sort the sensors (RTC modules only)

The sensor sequence is programmed in the RTC module for the measurement values. To sort the

sensors in the order specified for the RTC module, move the selected sensor with the UP and

DOWN arrows. Refer to Figure 3.

6 English

Page 9

Figure 3 Sort the sensors

1 Select sensor 2 UP and DOWN arrows

Delete a sensor from the list

To delete a selected sensor from the list, push Delete. Refer to Figure 4.

Figure 4 Delete a sensor

1 Select sensor 3 Delete the sensor

2 Go back without changes

Operation

PROGNOSYS indicator bars

If PROGNOSYS is installed, two additional horizontal bars show in the top right-hand corner of the

measurement screen. The top bar is the measurement value indicator. The bottom bar is the service

indicator. If no bars show up, refer to Troubleshooting on page 17

the value in the indicator identifies the sensor status. Refer to Table 1.

. The position of the cursor and

English 7

Page 10

Table 1 Color definitions

Color Definition

Green The sensor is in operation with no warnings, errors or reminders.

Yellow The sensor is in operation with active warnings or reminders.

Red The measurement value is invalid or immediately complete a service task.

Blank (background

color)

The measurement indicator (top bar) shows a possible measurement value deviation,

but the value is still within the permitted tolerance.

The service indicator (bottom bar) shows an upcoming maintenance task which

includes a countdown period. Set the countdown period between 7 and 14 days.

No data is available or the RTC/PROGNOSYS communication card was removed.

Display description

The measurement value indicator is not a linear degrading indicator because of the sensor special

model based calculation.

Measurement zone Range

Green zone 100 to 75%

Yellow zone <75 to 50%

Red zone <50 to 0%

The exact status shows with an additional vertical cursor. A maximum of four measurement values

show if multiple sensors are installed on the sc1000. The indicators are shown for each installed

sensor in the top right-hand corner.

If only a frame around the background color shows and no traffic light colors, no data is available for

the sensor. If no bars are shown, refer to Troubleshooting on page

Figure 6 for examples shown on the display.

17. Refer to Figure 5 and

Figure 5 Display overview for one sensor

1 Symbol for the service indicator 3 Cursor with exact status of the measurement value

2 Symbol for the measurement value indicator 4 Cursor with exact status of the service indicator

indicator

8 English

Page 11

Figure 6 Display overview for four sensors

1 Sensor 1 3 Sensor 3

2 Sensor 2 4 Sensor 4

Measurement value indicator

If the sensor condition changes, the measurement value indicator changes. A deterioration of the

measurement value indicator level in the top bar can change the color in the bottom service bar.

Pending maintenance tasks do not have an immediate effect on the measurement value indicator

(e.g., to replace the reagents).

A change in color from green to yellow shows that the reliability of the measurement value

decreased. There can be a deviation in the measurement value, but the value is still within the

permissible tolerance.

The top bar shows the measurement value indicator in [%].

If the vertical cursor is in the red area (<50%), the measurement value indicator is not in the

permitted range. These measurement values must not be used for control purposes in processes.

Refer to Service and measurement value indicator messages on page

When the errors are successfully solved, the color automatically changes from red to green.

11 for troubleshooting.

Service indicator

The service indicator shows the maintenance status of the sensor. The bottom bar shows the

number of days that remain until a maintenance task must be completed. The date and time for the

next maintenance task (e.g., cleaning or calibration is calculated). Service tasks with no countdown

show immediately and change the color from green to red (e.g., an interruption of communication

over a prolonged period or moisture in the sensor).

The number of days until the next maintenance tasks is shown in the applicable message list. Refer

to Configure the sensor on page 11.

See the message lists

The messages in the measurement value indicator list show the type of incident with a percentage

value. The percentage shows the influence degree on the probability that the measurement value is

correct. The measurement value indicator is the product of the first incident multiplied by the average

of all possible incidents. Notice that incidents with 100% are not shown in the list but are part of the

calculation.

Refer to Service and measurement value indicator messages on page 11 for a general overview of

the instrument-specific messages.

English 9

Page 12

Example: A probe has 10 possible indicators. Three parameters show indicators of 75%, 90% and

90%. The hidden indicators have a value of 100%. The worst incident is changed to a decimal

number: 0.75. The average of the other incidents is 0.98. The overall indicator is 0.75 × 0.98 = 0.73.

The overall indicator for the example is 73%. Refer to Table 2.

The message list specifies the type of the maintenance task with the number of days left until the

maintenance must be completed. The example shows to replace the cleaning solution today. The

reagents should be used up in six days. Refer to Table 3.

1. Push PROGNOSYS to access the applicable menu.

2. Push the top bar.

The measurement value indicator message list shows.

3. Push the bottom bar.

The service indicator message list shows.

Table 2 Example of a measurement value indicator list

Measurement indicator Measurement value indicator value in %

Insufficient light 75

Analysis: too cold 90

Analysis: moisture 90

Table 3 Example of a service indicator list

Service indicator Time in days

clean Solu days 1 day

Reagent days 6 days

Configure the general settings

Configure service messages to send emails to the manufacturer telemetry service and to a maximum

of four freely-configured email address(es). This email gives information about important changes in

the measurement indicator and about pending maintenance tasks.

In addition, the length of the "YELLOW PHASE" of the service indicator can be configured. The

yellow phase setting applies to all sensors connected to the controller that are monitored by

PROGNOSYS. The setting specifies the duration of the yellow maintenance countdown phase in

days. For maintenance tasks that are not often necessary, the user can extend the yellow phase to

operate on a self-sufficient basis.

1. Push MAIN MENU>SERVICE>PROGNOSYS.

2. Select an option.

Option Description

SERVICE

MESSAGE

YELLOW PHASE Sets the number of days that remain of the yellow phase to complete the next

Sets the number of days to send an email before a color change in the service indicator

will occur. Range: –1 to –14 days (default = –7 days)

maintenance task (when the color changes from yellow to red). Range: 1 to 14 days

(default = 14 days)

10 English

Page 13

Configure the sensor

Use the PROGNOSYS menu to monitor specific settings or to change the blink mode.

1. Push MAIN MENU>RTC MODULES/PROGNOSYS>PROGNOSYS.

2. Select the applicable sensor.

3. Select an option.

Option Description

MEAS. INDICATOR Shows the measurement indicator bar in %.

DETAILS Shows the message list for the measurement indicator. Example: R<M—shows if

SERVICE INDICATOR Shows the number of days that remain until a maintenance task must be completed.

DETAILS Shows the message list for the service indicator. Example: replace the wiper profile:

DEVICE Shows the sensor name.

LOCATION Shows the location name where the sensor is used.

PROGNOSYS VERS. Shows the PROGNOSYS software version.

BLINK MODE MEAS< Enters the measurement indicator value in %. The measurement indicator bar

BLINK MODE SERV< Enters individual number of days for a maintenance task. The service indicator bar

the reference signal is smaller than the measurement signal in %. MEAS EXT—

shows the absorbance value in %.

1 day or replace the seals: 42 days

flashes when the value decreases below the given value. Make sure to enter a

higher value when the measurement is related to a control system or a sensitive

parameter. Range: 0 to 100% (default = 0%)

flashes when the value decreases below the given value. Range: 0 to 200 days

(default = 0 days)

Service and measurement value indicator messages

W A R N I N G

For safe use of the instrument, obey the precautions and the instructions in the sensor documentation.

This list gives a general overview for the service and measurement value indicator messages. Refer

to the sensor documentation for a more detailed list of maintenance messages.

AMTAX sc and PHOSPHAX sc

Message Possible cause Solution

Instrument error The instrument caused an error

Instrument

warning

Warm-up phase The inside of the instrument is too

Cooling down The instrument is overheated and

message.

The instrument caused a warning

message.

cold (e.g., the enclosure door was

open at low external

temperatures).

is cooling-down. If the instrument

version has a filter probe, the

compressor is deactivated in this

phase.

Examine the error message on the controller. Refer to

the sensor documentation for solutions. Make sure that

the error is shown in the service menu and push

START.

Wait until the warm-up phase is completed. If the startup temperature was higher, the warm-up phase can

vary from a few minutes to an hour.

• Wait until the cooling-down phase is completed.

•

Make sure that no blockage of the vent is caused.

• Clean or change the air filter.

• Complete a function test on the fan.

• Specify the correct operating temperature.

English 11

Page 14

Message Possible cause Solution

Pump piston

replacement

If 0 day is shown, the time for the

pump piston is expired.

• Contact technical support immediately to replace the

pump piston, so that the instrument operates

correctly.

• Set the counter when the pump piston is replaced.

Air filters clean The maintenance for the air filter

Reagent days Shows the days that remain to

clean Solu days Shows the days that remain to

Standards days

(AMTAX sc only)

Electrolyte days

(AMTAX sc only)

Compressor

replacement

is necessary.

replace the reagent.

replace the cleaning solution.

Shows the days that remain to

replace the calibration standard.

Shows the days that remain to

change the electrolyte in the

electrode and the membrane cap.

The time for the compressor is

expired. For instruments with a

filter probe only.

• Examine the air filter condition.

• Rinse the air filter with water or replace it.

• Examine and clean the air inlet and outlet on the

back of the instrument.

• Use tweezers to remove contamination from the air

filter support.

• Complete the air filter maintenance task correctly so

that the instrument does not overheat.

• Set the counter when the maintenance task is

completed.

• Replace the reagents on time.

• Set the counter when the maintenance task is

completed.

• Replace the cleaning solution on time.

• Set the counter when the maintenance task is

completed.

• Replace the calibration solution on time.

• Set the counter when the maintenance task is

completed.

• Change the electrolyte in the electrode and the

membrane cap on time.

• Set the counter when the maintenance task is

completed.

• Replace the compressor.

• Set the counter when the maintenance task is

completed.

Clean filtration

modules

Humidity probe % Humidity is in the enclosure.

Service filter

probe required

Shows the days that remain to

clean the filtration modules. For

instruments with a filter probe

only.

Shows the time that remains to

replace the filter probe.

Shows the days that remain to

replace the pump membrane in

the filter probe.

12 English

• Clean the filtration modules. Replace the filtration

module if the cleaning is not sufficient.

• Set the counter when the maintenance task is

completed.

Contact technical support immediately for the filter

probe maintenance and desiccant replacement, so that

the instrument operates correctly.

• Contact technical support immediately for the filter

probe maintenance and pump membrane

replacement, so that the instrument operates

correctly.

• Set the counter when the pump membrane is

replaced.

Page 15

NITRATAX plus sc

Message Possible cause Solution

Sensor,

Application

check

R<M

The signal level is too low. The sensor

possibly has a dirty window. The selected

path length is too long (if applicable). The

solid concentration or the turbidity in the

measurement medium can be too high.

• Clean sensor window fully.

• Examine the wiper.

• Examine the measuring medium with a

diluted sample.

• Contact technical support.

meas ext The measurement absorbance is too high.

ref ext The path length is too long. The wiper does

Wiper blocked The wiper is mechanically blocked. The

Wiper position

unknown

Moist Moisture in the sensor is over limit: the

R too high The automatic zeroing is not correct. Contact technical support for a zero point

Replace

shaftseals

Replace profile The time for wiper profile cycles is expired.

Motor cycle The time for motor cycles is expired. Contact technical support to replace the wiper

Flash lamp

replace

Replace seals The annual change of the sensor enclosure

Error Collective error message Examine the error message on the controller.

Warning Collective warning message

The measurement range is too high because

the signal level is too low. The sensor

possibly has a dirty window. Interferences

can be caused by other substances.

not operate correctly. The absorbance is too

high because of nitrate concentration or other

UV-absorbing materials.

measurement window is not clean anymore.

No sample is pulled in the instrument. The

wiper is possibly in front of the window.

desiccant is expired. There is possibly a

problem with the gasket set for the sensor

sleeve or the wiper axle.

The time for the wiper axle gasket cycles is

expired.

The time for flashes is expired. Contact technical support to replace the flash

gasket is necessary.

• Clean sensor window fully.

• Examine the wiper.

• Examine the solid content of sample.

• Use a cuvette test to examine the nitrate

concentration. If the EM/ER values are

>2.74, use a smaller path length.

• Contact technical support.

• Examine and clean the measurement

window fully.

• Complete a wiper test and do a stop position

test.

• Contact technical support.

Contact technical support immediately to

replace the gasket, so that the instrument

operates correctly.

calibration.

Contact technical support to replace for a wiper

axle gasket.

• Replace the wiper profile.

• Set the counter when the maintenance task

is completed.

motor.

lamp.

Contact technical support to replace the sensor

enclosure gasket.

Refer to the sensor documentation for

solutions.

ANISE sc/AISE sc/NISE sc

1

Message

Instrument error The instrument caused an

Instrument warning The instrument caused a

Possible cause Solution

error message.

warning message.

Examine the error message on the controller. Refer to

the sensor documentation for solutions.

English 13

Page 16

Message

1

Possible cause Solution

RFID-Data not valid The RFID calibration data for

the cartridge could not be

read.

Reference potential

uncertain

The data supplied by the

reference system for the

cartridge is not reliable.

Initial matrix

correction required

When a new cartridge is

installed, a matrix correction is

necessary after 24 hours.

Matrix correction

NH4 necessary

Matrix correction

NO3 necessary

A matrix correction for NH4 is

necessary.

A matrix correction for NO3 is

necessary.

Replace cartridge The time (one year) for the

cartridge is expired.

no contact Ref1 Problem with the contact

no contact Ref2

between sensor and reference

system.

no contact NH4

no contact NO3

no contact K+

no contact Cl-

Humidity cartridge

contacts

There is humidity between the

sensor and the cartridge.

Enter the sensor code for the temporary sensor

operation manually, then replace the cartridge.

Examine the measurement values and if necessary,

replace the cartridge.

Complete a one-point matrix correction for NH4-N and

NO3-N. Complete a one-point matrix correction for a

higher measurement accuracy for small values for NH4N

+K and NO3N +Cl.

Complete a one-point matrix correction (MX1) or value

correction (VC1) for NH4. If the calibration is good in

comparison to the laboratory value, use the

measurement value as the calibration value when a

calibration is started.

Complete a one-point matrix correction (MX1) or value

correction (VC1) for NO3. If the calibration is good in

comparison to the laboratory value, use the

measurement value as the calibration value when

calibration is started.

Examine the measurement values and replace the

cartridge as soon as possible.

• Remove the cartridge.

• Examine and clean the contacts.

• Examine the spring action of the contacts in the

sensor and replace the spring insert if necessary.

• Contact technical support to examine and replace the

electronics if necessary.

• Replace the cartridge if necessary.

• Make sure that the cartridge screws are tightened

correctly.

• Examine the gasket.

• Dry the contact area.

• Contact technical support to replace the gold spring

contacts if necessary.

• Replace the gasket.

• Replace cartridge and gasket.

Ref electrode aged The yellow plug is still on the

reference system. The time of

the reference system is

expired (membrane pores are

blocked) and can not operate

correctly.

14 English

• Remove the yellow plug from the reference system.

• Carefully try to clean the outlet of the reference

system from the cartridge mechanically. Carefully

remove any objects with a toothbrush or a similar

object.

• Carefully apply a drop of hydrochloric acid (5%) only

onto the reference system. If it foams, repeat until the

foaming stops. If this is not successful, replace the

cartridge.

Page 17

1

Message

NH4 electrode

damaged

NO3 electrode

damaged

K+ electrode

damaged

CL- electrode

damaged

NH4 MX2: high

Temp. diff. P1 P2

NH4: High temp.

diff. to MX

NO3 MX2: high

Temp. diff. P1 P2

NO3: High temp.

diff. to MX

1

AISE: All messages except for NO3 and Cl electrodes. NISE: All messages except for NH4 and K electrodes.

Possible cause Solution

The NH4 electrode is

damaged.

The NO3 electrode is

damaged.

The K+ electrode is damaged.

The Cl- electrode is damaged.

The temperature difference

between the two correction

points of a matrix correction

(MX2) or value correction

(VC2) for NH4 is more than

7.5 °C (45.5 °F).

The temperature difference

between the correction point of

a one-point matrix correction

(MX1) or value correction

(VC1) is more than 7.5 °C

(45.5 °F) for NH4.

The average temperature of

the two-point matrix correction

(MX2) or value correction

(VC2) and the actual

temperature of the medium is

more than 7.5 °C (45.5 °F) for

NH4.

The temperature difference

between the two correction

points of a matrix correction

(MX2) or value correction

(VC2), for NO3 is more than

7.5 °C (45.5 °F).

The temperature difference

between the correction point of

a one-point matrix correction

(MX1) or value correction

(VC1) is more than 7.5 °C

(45.5 °F) for NO3.

The average temperature of

the correction points of a twopoint matrix correction (MX2)

or value correction (VC2) and

the actual temperature of the

medium is more than 7.5 °C

(45.5 °F) for NO3.

• Replace the cartridge.

• Examine if the cartridge was in contact (through

vibrations) with the wall or other objects.

• Do not hit the cartridge during removal from the basin.

• Do not touch the ground with the cartridge.

Select a two-point matrix correction (MX2) or value

correction (VC2) for within a temperature difference of

7.5 °C (45.5 °F).

Make sure to put the sensor fully in the medium.

Complete new MX1 or MX2 (VC1 or VC2) near to the

temperature of the medium during operation.

Select the correction points for MX2 (VC2) within a

temperature difference of 7.5 °C (45.5 °F).

Make sure to put the sensor fully in the medium.

Complete a new MX1 or MX2 (VC1 or VC2) near to the

temperature of the medium during operation.

SOLITAX sc

Message Possible cause Solution

Service required The counter for maintenance is expired. Contact technical support.

Replace wiper

blade

The counter for wiper cycles is expired. Replace the wiper profile.

English 15

Page 18

Message Possible cause Solution

Check wiper

function

Wiper position

unknown

The wiper is mechanically blocked. The

measurement window is not clean anymore.

No sample is pulled in the instrument. The

wiper is possibly in front of the window.

• Examine and clean the measurement

window fully.

• Complete a wiper test and do a stop

position test.

• Contact technical support.

Replace wiper

motor

Calibration data

faulty

Instrument error The instrument caused an error message. Examine the error message on the

Instrument

warning

Humidity probe Moisture in the sensor is over limit: the

LED faulty LED intensity is too low. Contact technical support.

Replace gasket The time for the wiper axle gasket cycles is

The counter for wiper motor is expired. Contact technical support to replace the

The factory calibration data is lost. Contact technical support.

The instrument caused a warning message.

desiccant is expired. There can be a problem

with the gasket set for the sensor sleeve or

the wiper axle.

expired.

wiper motor.

controller. Refer to the sensor

documentation for solutions.

Contact technical support immediately to

replace the gasket, so that the instrument

operates correctly.

Contact technical support to replace for a

wiper axle gasket.

LDO Probe, Model 2

Message Possible cause Solution

Red amplitude error No sensor cap is installed. Refer to the LDO manual to install the sensor

The red LED is defective. Contact technical support.

Blue amplitude error No sensor cap is installed. Refer to the LDO manual to install the sensor

The blue LED is defective. Contact technical support.

Temp <0°C/32°F The sample temperature is less than

the specified value.

The thermistor system is defective. Contact technical support.

Temp >50°C/122°F The sample temperature is more than

the specified value.

The thermistor system is defective. Contact technical support.

cap. If the cap is already installed, replace the

sensor.

cap. If the cap is already installed, replace the

sensor.

Make sure that the sample temperature is >

0°C (32°F). Move the sensor to another

position.

Make sure that the sample temperature is <

50°C (122°F). Move the sensor to another

position.

16 English

Page 19

Message Possible cause Solution

Red amplitude low The sensor cap surface is damaged or

worn. The reflection is not correct.

Red amplitude high The sensor cap surface is damaged or

worn. The sensor is received too much

ambient light.

Blue amplitude low The sensor cap surface is damaged or

worn. The reflection is not correct.

Blue amplitude high The sensor cap surface is damaged or

worn. The sensor is received too much

ambient light.

Clean sensor The "Clean sensor" timer is expired. Clean the sensor cap. Set the "Clean sensor"

Replace sensor cap The sensor cap is expired. Replace the sensor cap.

Calibration in progress The sensor is calibrating. Complete the sensor calibration and go back

Default cap lot The factory calibration is not complete. Contact technical support.

Examine the sensor cap for damage or wear.

Replace the sensor cap.

timer (default: off) again.

to main menu.

Troubleshooting

Problem Possible cause Solution

The sensor is selected

from the RTC

communication card, but

no bars are shown.

The bars do not show

RED, YELLOW or

GREEN. Only the

background color is

shown.

The

RTC/PROGNOSYS

communication card

is not installed

correctly.

No sensor data is

available. The

RTC/PROGNOSYS

communication card

is not installed

correctly.

Make sure that the RTC/PROGNOSYS communication card is

installed correctly. Select MAIN MENU>RTC

MODULES/PROGNOSYS>PROGNOSYS>ALLOCATION

MAP. Refer to the communication card installation

documentation for more information.

• Make sure that the RTC/PROGNOSYS communication

card is installed correctly. Select MAIN MENU>RTC

MODULES/PROGNOSYS>PROGNOSYS>ALLOCATION

MAP. Refer to the communication card installation

documentation for more information.

• Examine if the installation/configuration is setup correctly in

the SC1000 SETUP menu.

The maintenance task

was completed or the

error was resolved, but

the corresponding bar is

still in the red area.

The error message

E33 is shown.

In the

PROGNOSYS>SELECT

SENSOR menu, no

PROGNOSYS-enabled

sensors are shown.

Error is not reset

automatically or a

new error shows.

Instrument-specific

software files are

missing.

Instrument-specific

software files are

missing.

• Reset the error manually. Refer to the applicable sensor

manual.

• Once an error is resolved, the parameters are calculated

again. Examine the error list if a new error is shown.

Contact technical support.

• A sensor name identified with a "(p)" is available for

PROGNOSYS.

• Contact technical support.

English 17

Page 20

Replacement parts

W A R N I N G

Personal injury hazard. Use of non-approved parts may cause personal injury, damage to the

instrument or equipment malfunction. The replacement parts in this section are approved by the

manufacturer.

Note: Product and Article numbers may vary for some selling regions. Contact the appropriate distributor or refer to

the company website for contact information.

Replacement parts

Description Item no.

Telemetry-inspection contract Available on request

PROGNOSYS communication card LZY885.99.00001

Warranty

The manufacturer warrants that the supplied product is free of material and manufacturing defects,

and undertakes to repair or to replace any defective parts without charge.

The warranty period is 24 months. If a maintenance contract is taken out within 6 months of

purchase, the warranty period is extended to 60 months.

With the exclusion of further claims, the supplier is liable for defects, including the lack of assured

properties, as follows: all parts that, within the warranty period calculated from the day of the transfer

of risk, can be demonstrated to have become unusable or that can only be used with significant

limitations owing to circumstances prior to transfer of risk, in particular due to incorrect design,

substandard materials or inadequate finish, shall be repaired or replaced at the supplier's discretion.

The identification of such defects must be reported to the supplier in writing as soon as possible, but

no later than 7 days after the discovery of the fault. If the customer fails to notify the supplier, the

product is considered approved despite the defect. Further liability for indirect or direct damages is

not accepted.

If device-specific maintenance- or inspection work prescribed by the supplier is to be performed

within the guarantee period by the customer (maintenance) or by the supplier (inspection) and these

requirements are not met, claims for damages that result from non-observance of these requirements

are void.

Further claims, in particular for consequential damages, cannot be made.

Wear and damage caused by improper handling, incorrect installation or non-designated use are

excluded from this clause.

The process instruments of the manufacturer have proven their reliability in many applications and

are therefore often used in automatic control loops to enable the most economical and efficient

operation of the relevant process.

To avoid or limit consequential damage, it is therefore recommended that the control loop be

designed such that an instrument malfunction results in an automatic changeover to the backup

control system. This guarantees the safest operating condition both for the environment and the

process.

PROGNOSYS register

Table 4 shows PROGNOSYS parameters that are available from the RTC/PROGNOSYS

communication card. These parameters can be sent to a superordinate programmable open loop

control or to a computer via a fieldbus card such as Profibus or Modbus TCP/IP.

Each communication card gives parameters for a maximum of 15 sensors. The sequence for the

sensors or allocation of sensor parameters is controlled by the allocation of the sensors on the

applicable communication card. Refer to Add a sensor on page

18 English

5.

Page 21

Refer to the applicable fieldbus card documentation for information on the installation and

configuration.

Table 4 PROGNOSYS register

Tag name Contents Modbus register Data Length

PrognosysMeasIndicator1 MEAS INDICAT 1 40171 Unsigned Integer 1

PrognosysServiceStat1 SERVICE STAT 1 40172 Unsigned Integer 1

PrognosysMeasIndicator2 MEAS INDICAT 2 40173 Unsigned Integer 1

PrognosysServiceStat2 SERVICE STAT 2 40174 Unsigned Integer 1

PrognosysMeasIndicator3 MEAS INDICAT 3 40175 Unsigned Integer 1

PrognosysServiceStat3 SERVICE STAT 3 40176 Unsigned Integer 1

PrognosysMeasIndicator4 MEAS INDICAT 4 40177 Unsigned Integer 1

PrognosysServiceStat4 SERVICE STAT 4 40178 Unsigned Integer 1

PrognosysMeasIndicator5 MEAS INDICAT 5 40179 Unsigned Integer 1

PrognosysServiceStat5 SERVICE STAT 5 40180 Unsigned Integer 1

PrognosysMeasIndicator6 MEAS INDICAT 6 40181 Unsigned Integer 1

PrognosysServiceStat6 SERVICE STAT 6 40182 Unsigned Integer 1

PrognosysMeasIndicator7 MEAS INDICAT 7 40183 Unsigned Integer 1

PrognosysServiceStat7 SERVICE STAT 7 40184 Unsigned Integer 1

PrognosysMeasIndicator8 MEAS INDICAT 8 40185 Unsigned Integer 1

PrognosysServiceStat8 SERVICE STAT 8 40186 Unsigned Integer 1

PrognosysMeasIndicator9 MEAS INDICAT 9 40187 Unsigned Integer 1

PrognosysServiceStat9 SERVICE STAT 9 40188 Unsigned Integer 1

PrognosysMeasIndicator10 MEAS INDICAT 10 40189 Unsigned Integer 1

PrognosysServiceStat10 SERVICE STAT 10 40190 Unsigned Integer 1

PrognosysMeasIndicator11 MEAS INDICAT 11 40191 Unsigned Integer 1

PrognosysServiceStat11 SERVICE STAT 11 40192 Unsigned Integer 1

PrognosysMeasIndicator12 MEAS INDICAT 12 40193 Unsigned Integer 1

PrognosysServiceStat12 SERVICE STAT 12 40194 Unsigned Integer 1

PrognosysMeasIndicator13 MEAS INDICAT 13 40195 Unsigned Integer 1

PrognosysServiceStat13 SERVICE STAT 13 40196 Unsigned Integer 1

PrognosysMeasIndicator14 MEAS INDICAT 14 40197 Unsigned Integer 1

PrognosysServiceStat14 SERVICE STAT 14 40198 Unsigned Integer 1

PrognosysMeasIndicator15 MEAS INDICAT 15 40199 Unsigned Integer 1

PrognosysServiceStat15 SERVICE STAT 15 40200 Unsigned Integer 1

English 19

Page 22

20 English

Page 23

B

Bar color code

Bar indicator, Bar color code ............................7

Blink mode ......................................................11

..................................................8

Index

P

PROGNOSYS communication card .................4

C

Communication card ........................................4

M

Measurement value indicator ...........................9

Message list ...................................................... 9

R

RTC communication card ................................. 4

S

Service indicator ...............................................9

21

Page 24

Page 25

Page 26

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

©

Hach Company/Hach Lange GmbH, 2011–2014.

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

All rights reserved. Printed in Germany.

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

Loading...

Loading...