Page 1

DOC273.52.00161

Power connection box for sc analyzers

Mounting instruction

07/2013, Edition 3A

© HACH-LANGE GmbH, 2013. All rights reserved. Printed in Germany

Page 2

Page 3

Installation

Safety information

Read the entire instruction sheet carefully before unpacking, setting up or operating this

device. Pay attention to all danger and warning statements. Failure to do so could result in

serious injury to the operator or damage to the device.

To make sure that the protection provided by this device is not impaired, do not use or

install this device in any manner other than that specified in this instruction sheet.

Danger notes in this instruction sheet

Indicates a potentially or imminently hazardous situation that, if not avoided, can result in death or

serious injury.

Indicates a potentially or imminently dangerous situation that, if it is not avoided, can lead to

death or to serious injuries.

Indicates a possible dangerous situation that can have minor or moderate injuries as the result.

DANGER

WARNING

CAUTION

If shown on the device, this symbol references the user manual for operation and/or for safety information.

This symbol may be shown on a product enclosure or barrier and indicates a risk of electric shock and/or a risk of

death by electrocution.

Electrical devices marked with this symbol may no longer be disposed of in unsorted domestic or industrial waste in

Europe after August 12, 2005. In conformity with the provisions in force (EU Directive 2002/96/EC), consumers in

the EU must return old electrical devices to the manufacturer for disposal from this date. This is free for the

consumer.

Note: Contact the manufacturer or supplier for instructions on how to return end-of-life devices,

manufacturer-supplied electrical accessories, and all auxiliary items for proper disposal.

Introduction

NOTICE

Indicates a situation that, if it is not avoided, can lead to damage to the device. Information that

requires special emphasis.

Warning labels

Read all labels and tags attached to the device. Failure to do so could result in personal

injury or damage to the device. Symbols shown on the device are noted in this instruction

sheet with a danger or caution statement.

In this instruction sheet, the assembly and installation of the power connection box

(catalog number LQV155.99.0000x) is described.

The power connection box serves to connect sc analyzers to a power supply. It offers a

power connection, fuses and power sockets for two sc analyzers.

DANGER

Risk of electric shock. The procedures described in this instruction sheet may only be performed

by qualified personnel.

3

Page 4

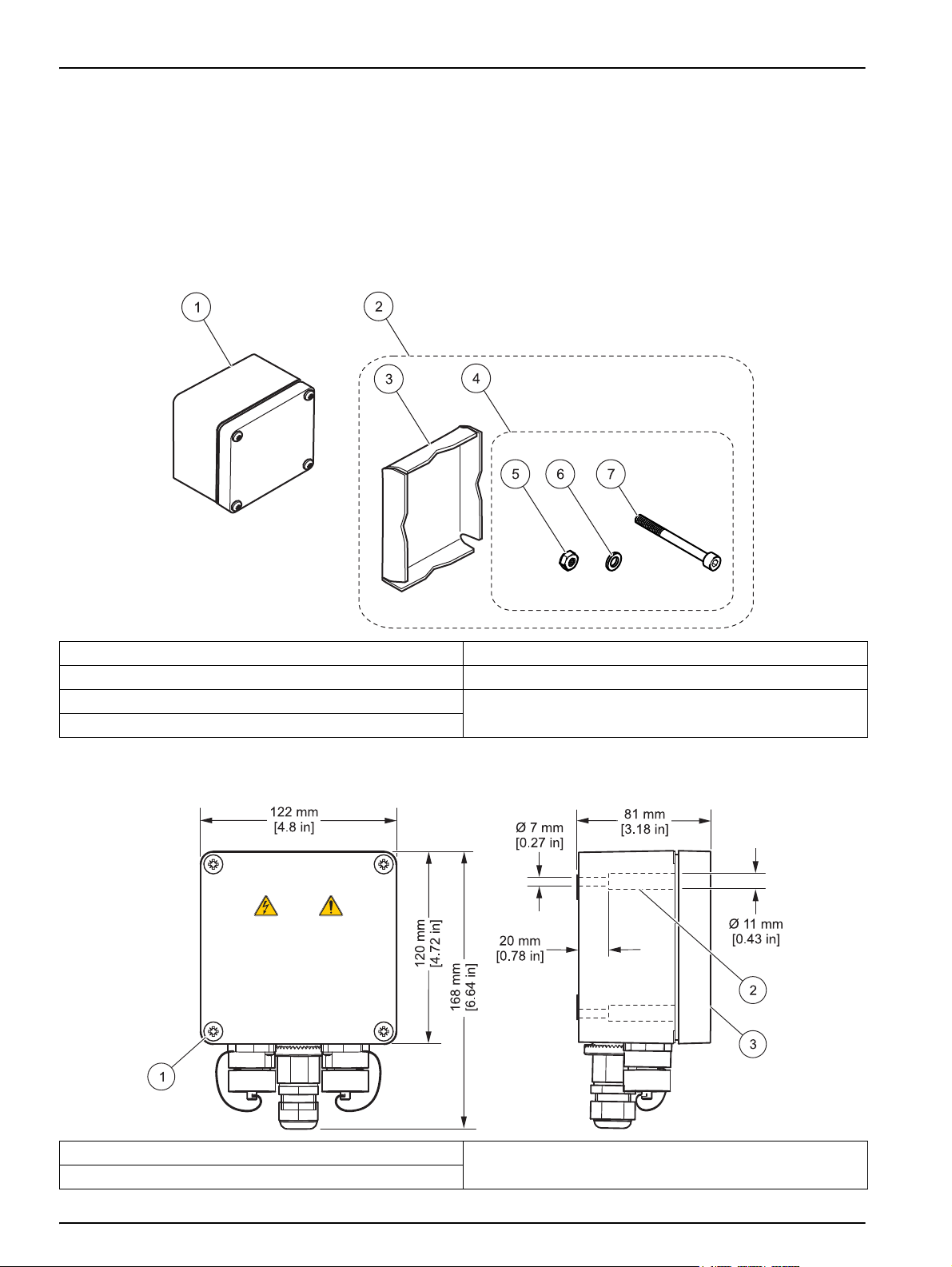

The parts included in the scope of delivery for the power connection box are listed in

Figure 1, page 4. Under some circumstances, not all supplied parts are required.

Therefore the only parts listed are those mentioned in this instruction sheet.

The dimensions of the installation are shown in Figure 2, page 4.

Note: Important note: Leave underneath the power connection box (i.e. 50–100 mm) for

cables and connectors.

Figure 1 Parts included in the scope of delivery for the power connection box (LQV155.99.0000x)

1 Power connection box 5 Nut, M6 (4x) (LZQ058)

2 Assembly kit for the rail or pole assembly (LZQ059) 6 Washer for M6 (4x) (LZQ058)

3 Clamping plate for LZQ060 (LZQ059) 7 Hexagons socket screw, M6 x 100 mm (4x) (LZQ058)

4 Screw set for LZQ058 (LZQ059)

Figure 2 Dimensions

1 Lid screw (4x) 3 Lid

2 Screw hole (4x)

4

Page 5

Assembly

Risk of electric shock.

This device may only be connected to a single-phase power supply at 100–240 V~, which is

protected with a 15 A fuse or a current breaker.

Risk of electric shock.

The wire connection of the power supply must always contain a 2-pin disconnect switch available

on site. The disconnect switch must meet the applicable regulations. This disconnect switch must

be installed in the immediate vicinity of the device and be easily accessible; it must also be

labeled as a disconnect switch. Before opening the power supply cover, disconnect the system

electrically via the disconnect switch.

Installation location

The power connection box can be installed on a wall, a vertical pole or on horizontal rails.

During the installation of the power connection box, read the user manuals for the sensor and for

the controller. Pay particular attention to all safety instructions and danger notes.

DANGER

DANGER

NOTICE

Leave sufficient space underneath the power connection box (i.e. 50–100 mm) for cables and

connectors.

Note: Always make sure that all parts of the system can be accessed without hindrances when the

installation location is selected.

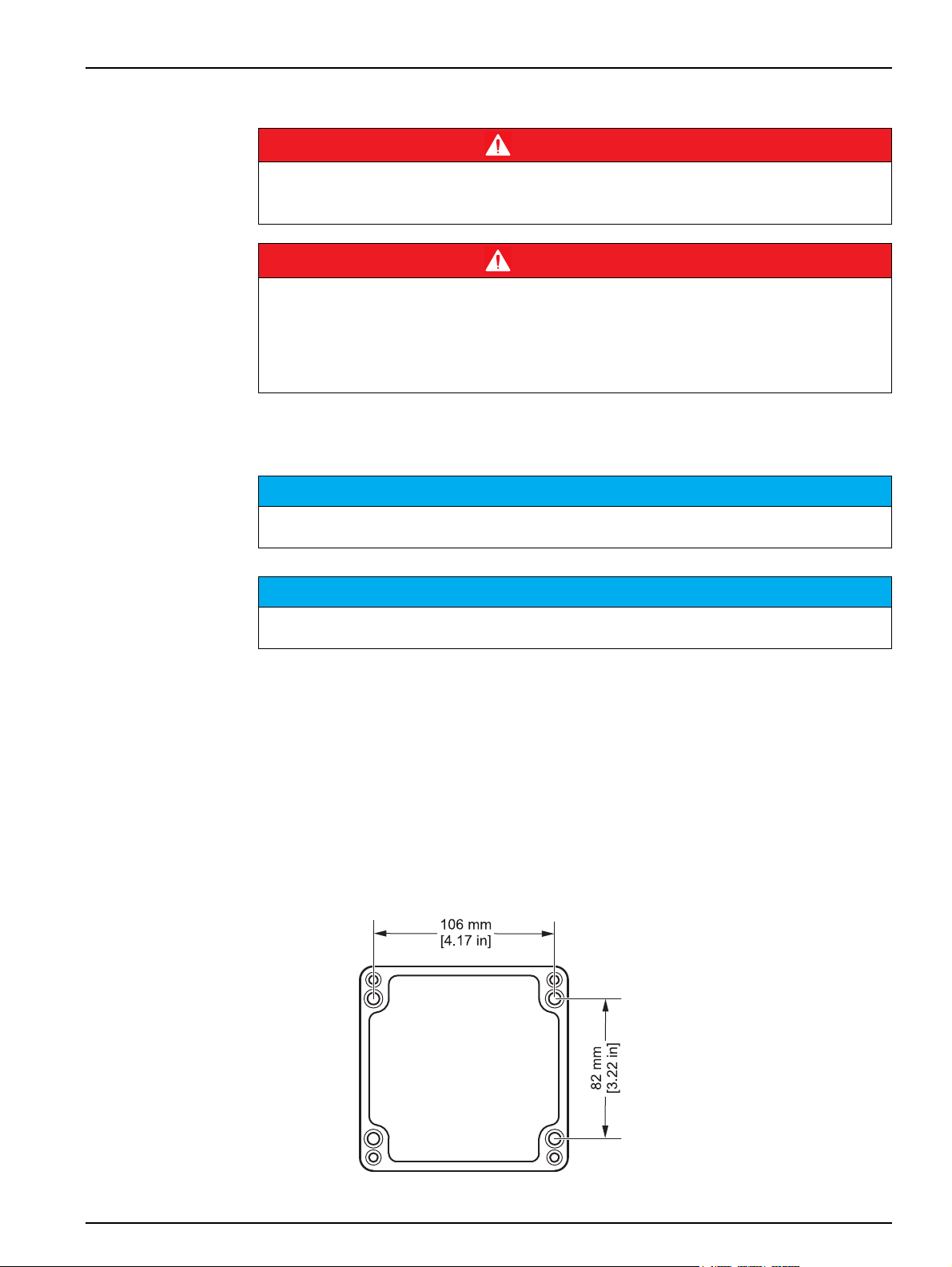

Wall assembly

1. Loosen the four lid screws and remove the lid (refer to Figure 2, page 4).

2. Secure the housing with the four screws provided to the wall (refer to Figure 1,

page 4 and Figure 2, page 4). The dimensions required for assembly can be found in

Figure 3, page 5.

Figure 3 Dimensions

NOTICE

5

Page 6

Rail or pole assembly

Note: Make sure that the diameter of the rail or of the pole is between 35 and 55 mm.

Note: Instructions on how to secure the housing with the clamping plate can be found in Figure 4,

page 6 or Figure 5, page 6.

Figure 4 Assembly on a horizontal rail

1 Washer for M6 4 Rail

2 Nut 5 Power connection box

3 Clamping plate 6 Hexagon socket screw, M6 x 100 mm

Figure 5 Pole assembly

1 Washer for M6 4 Rail

2 Nut 5 Power connection box

3 Clamping plate 6 Hexagon socket screw, M6 x 100 mm

6

Page 7

Electrical connections

Risk of electric shock. For installation in wet areas or areas in which wetness can occur, a

residual-current circuit breaker must always be installed with this socket. For assembly in outdoor

areas, overvoltage protection is required. For fixed wire connections (cable conduit), a clearly

labeled 2-pin disconnect switch must be installed on site next to the socket, in accordance with

the applicable regulations. For the wire connection to the on-site disconnect switch, disconnect

the power supply to the socket.

With fixed wiring, a disconnecting device (local interruption) must be integrated into the supply

line. The disconnecting device must meet the applicable standards and regulations. It must be

installed near the device, be able to be reached easily by the operator and labeled as a

disconnecting device.

If the connection is established using a mains connection cable that is permanently connected to

the power supply, the plug of the mains connection cable can serve as local interruption.

Electrical dangers and fire hazards. Use only the supplied power cable.

Only qualified experts may perform the tasks described in this section of the manual, while

adhering to all locally valid safety regulations.

DANGER

DANGER

WARNING

NOTICE

Use only earthed sockets for the connection of this device to the power supply.

If you are not sure if the sockets are earthed, have this checked by a qualified electrician.

The power plug serves in addition to the power supply to isolate the device quickly from the

mains where necessary.

This is recommended for long-term storage and can prevent potential dangers in the event of a

fault.

Therefore make sure that the sockets to which the device is connected are easy to reach by each

user at all times.

DANGER

The products of the manufacturer for use outdoors have a comprehensive protection against the

penetration of moisture and dust. If these products are connected to a mains socket of the main

power line via a cable with plug instead of fixed-installation wire connections, the plug and socket

are considerably more susceptible to the penetration of moisture and dust.

It lies in the responsibility of the operator to protect plug and socket in a way that the connection

has an adequate protection against the penetration of moisture and dust and fulfils the local

safety conditions.

When the device is used outdoors, it should be connected only via a suitable socket that has at

least protection rating IP44 (protection against spray water from all directions).

The power connection box is available with and without a pre-assembled power cable. If

no pre-assembled power cable is provided, the power connection box can be connected

to the mains power via a fixed wire connection or a power cable with suitable strain relief.

The wire connection is established via the same connection terminals for a fixed wire

connection and a cable wire connection.

For the wire connection, proceed as follows (refer to Figure 6, page 9):

1. Make sure that the housing is well secured.

2. Remove the four screws and the socket lid (component 8).

7

Page 8

3. Unscrew the nut of the strain relief (component 5).

4. Remove the cap of the strain relief (component 4).

5. Strip off the insulation of all three conductors of the power cable (phase, neutral

conductor and earth conductor) over a length of 8 mm. The connection terminals are

designed for solid or stranded conductors (18 – 16 AWG).

6. Feed the cables through the strain relief or cable guide. If strain relief is used, feed

the power cable through the strain relief nut (component 5), the cap (component 4)

and the cable gland (component 3).

7. If strain relief is used, insert the cap (component 4) into the cable gland (component

3) and screw the nut (component 5) onto the cable gland. Do not tighten the nut.

NOTICE

Leave the bridges between the terminals 1 and 2 as well as 3 and 4. Both the conductors of the

power cable and the bridges must be connected to the corresponding terminals.

8. Open the fuse holder of terminal 1 — to do this, push the fuse holder down (refer to

Figure 7, page 9).

9. Connect the phase to terminal 1 (refer to Figure 8, page 10) and tighten the screw.

10. Insert the fuse holder again.

11. Open the fuse holder of terminal 4.

12. Connect the neutral conductor to terminal 4 and tighten the screw.

13. Insert the fuse holder again.

DANGER

Risk of electric shock.

A good ground connection to this product is required to make sure that this and all other

connected devices fulfill the safety standards and safety provisions.

NOTICE

The terminal block for the ground connection has several terminals. The outer screws (top and

bottom screw) are intended for the front terminals.

14. Connect the front ground cable to terminal 5 and tighten the top screw.

15. For wire connections with a power cable, tighten the nut of the cable gland

(component 3 in Figure 6, page 9), so that the cable sits firmly in the strain relief. Do

not tighten the inner conductors of the power cable too tightly under tension (instead

leave a small loop for service work).

16. Position the socket lid again and tighten the four screws.

8

Page 9

Figure 6 Cable connections

1 Cable guide 6 Power socket

2 Sealing ring

3 Cable gland Observe the output voltage at the power sockets.

The output voltage supplied by the power connection box to

the power sockets corresponds to the country-specific mains

voltage to which the power connection box is connected.

Never connect consumers with a lower input voltage to the

power connection box, if the power connection box is

operated at a higher mains voltage.

4 Cap 7 Lid

5 Nut 8 Power connection box

Note

Figure 7 Fuse holder

1 Fuse 2 Fuse holder

9

Page 10

Figure 8 Circuit diagram (see inside of the lid)

1 Phase, line (live) 7 Black for left power socket

2 Connection to terminal 1 via bridge 8 Black for right power socket

3 Connection to terminal 4 via bridge 9 White for left power socket

4 Neutral conductor 10 White for right power socket

5 Protective ground (two terminals) 11 Fuse, T 5 A H, 250 V (4x)

6 Protective ground for left and right power socket 12 Lid protective ground

Clean the power connection socket

Risk of electric shock.

Disconnect the power connection socket from the power supply before it is cleaned in order to

avoid electric shocks.

Wipe the outside of the housing with a damp cloth. Make sure that the connector is well

sealed with the sealing cap. Use a mild cleaning agent if required. Solvents must not be

used.

Replace the fuse

Risk of electric shock.

The procedures described in this section of the instruction sheet may only be performed by

qualified personnel.

Risk of electric shock.

An incorrect fuse can lead to injuries and damage. The fuse must always be replaced with a fuse

of the same type and with the same nominal values.

DANGER

DANGER

DANGER

10

1. Make sure that the power connection box is disconnected from the power supply.

Page 11

2. Loosen the screws and remove the lid.

3. Open the fuse holder (there are two fuses for each analyzer connection: one for the

phase and another for the neutral conductor — refer to Figure 7, page 9) and replace

damaged fuses with fuses of the same type and with the same nominal values (T

5 A, time-lag, H, 250 V). Close the fuse holder (component 11, Figure 8, page 10).

4. Position the lid again and tighten the screws.

Connect the sc analyzer

Risk of electric shock.

If a power socket (component 4 in Figure 9, page 11) is not to be used, make sure that the power

socket is well sealed with the cap (component 2 in Figure 9, page 11).

1. Remove the sealing cap from the connector.

2. Connect the analyzer to the power socket.

3. Secure the connector of the analyzer to the power socket.

4. Connect the sealing caps of the connector (component 1) and of the power socket

(component 2) securely together.

Figure 9 Connections of the analyzer

DANGER

1 Sealing cap for the analyzer connector 3 Analyzer connector

2 Sealing cap for the power socket 4 Power socket of the analyzer

11

Page 12

Technical data

Subject to change.

General information

Power supply 100–240 V~, + 10 %–15 %; 50/60 Hz; maximum 1000 VA

Installation category II

Pollution degree II

Fuses T 5 A (time-lag) H, 250 V (4x)

Dimensions

Weight 1250 g

Housing protection rating IP56 (with protective caps or connectors assembled)

Certifications CE, cTUVus

(H x W x T) housing: 168 mm x 122 mm x 80 mm

Assembled: (free space for the cables) x width x (free space for the hardware)

Assembly

Cable gland

Environmental conditions

Ambient temperature –20 °C to +45 °C, 95 % relative humidity, non-condensing

Materials

Enclosure Aluminum with powder coating

Wall, pole or rail (with supplied assembly kit LZQ059):

Ø 35 mm–55 mm

Strain relief: water resistant, 8–13 mm

Cable guide: 1,3 cm (0,5 inches)

Conductors: maximum 1,5 mm2 (AWG 16)

Replacement parts and accessories

Description Quantity Catalog number

Clamping plate 1LZQ060

Cable guide 1 LZX981

Fuse set (4x, T 5 H/250 V) 1 LZY460

Assembly kit for rail or pole assembly 1LZQ059

Screws set 1 LZY058

12

Page 13

Warranty and liability

The manufacturer warrants that the product supplied is free of material and manufacturing

defects and undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out within

6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the lack

of assured properties as follows: all those parts that, within the warranty period calculated

from the day of the transfer of risk, can be demonstrated to have become unusable or that

can only be used with significant limitations due to a situation present prior to the transfer

of risk, in particular due to incorrect design, poor materials or inadequate finish will be

improved or replaced, at the supplier's discretion. The identification of such defects must

be notified to the supplier in writing without delay, however at the latest 7 days after the

identification of the fault. If the customer fails to notify the supplier, the product is

considered approved despite the defect. Further liability for any direct or indirect damages

is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be

performed within the warranty period by the customer (maintenance) or by the supplier

(servicing) and these requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or incorrect use

are excluded from this clause.

The manufacturer process instruments are of proven reliability in many applications and

are therefore often used in automatic control loops to provide the most economical

possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control

loop such that a malfunction in an instrument results in an automatic change over to the

backup control system; this is the safest operating state for the environment and the

process.

13

Page 14

Contact Information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

Repair Service in

Latin America, the Caribbean,

the Far East, Indian

Subcontinent, Africa, Europe, or

the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE SPAIN S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Bizkaia

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava – Vajnory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

14

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE SU

ANALİZ SİSTEMLERİ LTD . ŞTİ.

Ilkbahar mah. Galip Erdem Cad.

616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE MAROC SARLAU

Villa 14 – Rue 2 Casa Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

Loading...

Loading...