Page 1

DOC023.98.93065

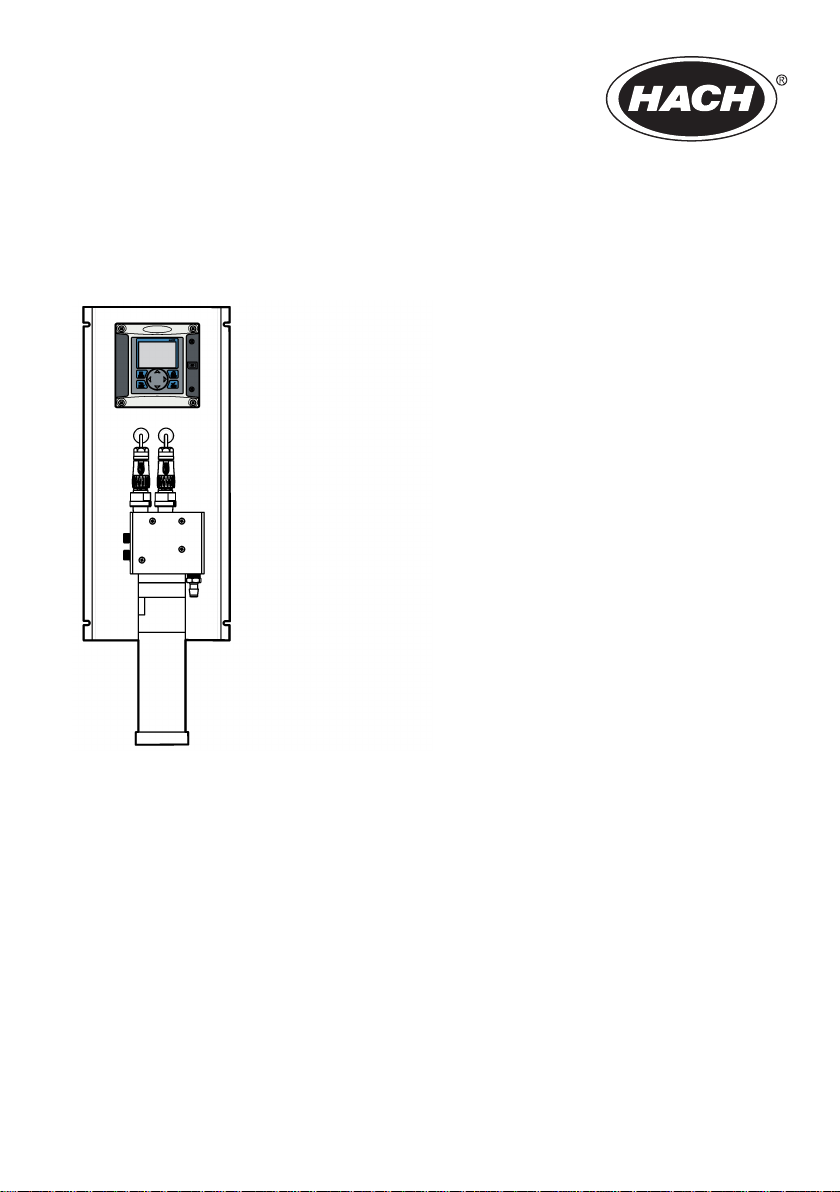

Polymetron 9523 pH Calculator

11/2013, Edition 3

Basic User Manual

Manuale dell'utente di base

Manuel d'utilisation de base

Manual básico del usuario

Manual de operações básicas

Basisgebruikershandleiding

Podstawowa instrukcja obsługi

Начальное руководство пользователя

Basishandbuch

基本用户手册

Peruskäyttöohje

Page 2

English..............................................................................................................................3

Deutsch..........................................................................................................................25

Italiano............................................................................................................................48

Français.........................................................................................................................71

Español..........................................................................................................................94

Português....................................................................................................................118

中文...............................................................................................................................141

Nederlands.................................................................................................................160

Polski............................................................................................................................184

Suomi............................................................................................................................207

Русский........................................................................................................................229

2

Page 3

Table of contents

Specifications on page 3 Operation on page 18

General information on page 5 Maintenance on page 22

Installation on page 8

User interface and navigation on page 17

Additional information

Additional information is available on the manufacturer's website.

Specifications

Specifications are subject to change without notice.

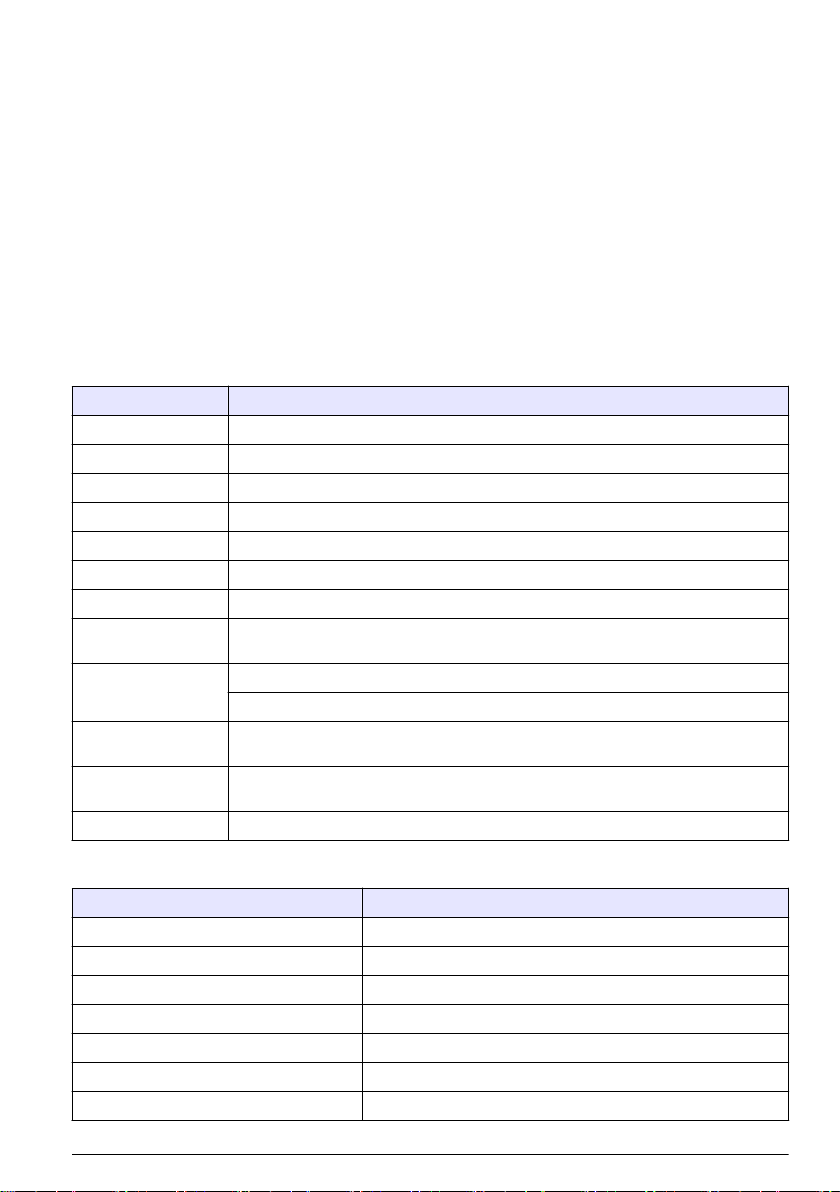

Analyzer

Specification Details

Dimensions 748 x 250 x 236 mm (29.4 x 9.8 x 9.3 in.)

Weight 7 kg (15.4 lb)

Sample flow rate 5—20 liters/hour

Ambient temperature 0—60 °C (32—140 °F)

Relative humidity 10—90%

Temperature sensor Pt100

Accuracy ± 1% of displayed value; temperature < ± 0.2 °C

Calculated pH

Display range

Display resolution Conductivity/resistivity: automatic point drift (minimum resolution 0.001 μS/cm) < 0.1 °C

Sample tubing

Certifications EN 61326-1: 2006; EN 61010-1: 2010

Accuracy on conductivity measurement: ± 2%; Maximum difference calculated-theoretical

value: 0.1 pH

NH3; 7 < pH < 10; 2.8 μS/cm < C1 < 28 μS/cm; C2 < 0.5 μS/cm

NaOH; 7 < pH < 10.7; 2.5 μS/cm < C1 < 125 μS/cm; C2 < 100 μS/cm

Polyethylene or PTFE or FEP; 0.2 to 6 bars (3 to 90 psi); 5 to 50 °C (40 to 120 °F); Input:

6-mm (standard) or 1/4-inch (with adapter); Output: 12-mm or 1/2-inch

Sensor

Specification Details

Sensor body material Black PSU

Conductivity electrodes, internal and external Stainless steel 316L

Cell constant K 0.01 (cm-1)

Conductivity range 0.01—200 μS.cm-1; Resistivity range: 5k Ω.cm—100 MΩ.cm

Maximum pressure 10 bar

Maximum temperature 125 °C (257 °F)

Accuracy < 2%

English 3

Page 4

Specification Details

Temperature response < 30 seconds

Insulator PSU

Connector Glass polyester (IP65)

Controller

Specification Details

Component description Microprocessor-controlled and menu-driven controller that operates the sensor and

Operating temperature -20 to 60 ºC (-4 to 140 ºF); 95% relative humidity, non-condensing with sensor load

Storage temperature -20 to 70 ºC (-4 to 158 ºF); 95% relative humidity, non-condensing

Enclosure

1

Power requirements AC powered controller: 100-240 VAC ±10%, 50/60 Hz; Power 50 VA with 7 W

Altitude requirements Standard 2000 m (6562 ft) ASL (Above Sea Level)

Pollution

degree/Installation

category

Outputs Two analog (0-20 mA or 4-20 mA) outputs. Each analog output can be assigned to

Relays Four SPDT, user-configured contacts, rated 250 VAC, 5 Amp resistive maximum for

Dimensions ½ DIN—144 x 144 x 180.9 mm (5.7 x 5.7 x 7.12 in.)

Weight 1.7 kg (3.75 lb)

Compliance information2CE approved (with all sensor types). Listed for use in general locations to UL and

Digital communication Optional Modbus, RS232/RS485, Profibus DPV1 or HART network connection for

Data logging Secure Digital Card (32 GB maximum) or special RS232 cable connector for data

Warranty 2 years

1

Units that have the Underwriters Laboratories (UL) certification are intended for indoor use only and do not

have a NEMA 4X/IP66 rating.

2

DC powered units are not listed by UL.

displays measured values.

<7 W; -20 to 50 ºC (-4 to 104 ºF) with sensor load <28 W

NEMA 4X/IP66 metal enclosure with a corrosion-resistant finish

sensor/network module load, 100 VA with 28 W sensor/network module load

(optional Modbus, RS232/RS485, Profibus DPV1 or HART network connection).

24 VDC powered controller: 24 VDC—15%, + 20%; Power 15 W with 7 W

sensor/network module load, 40 W with 28 W sensor/network module load (optional

Modbus, RS232/RS485, Profibus DPV1 or HART network connection).

Polution Degree 2; Installation Category II

represent a measured parameter such as pH, temperature, flow or calculated

values. Optional module supplies three additional analog outputs (5 total).

the AC powered controller and 24 VDC, 5A resistive maximum for the DC powered

controller. Relays are designed for connection to AC Mains circuits (i.e., whenever

the controller is operated with 115 - 240 VAC power) or DC circuits (i.e., whenever

the controller is operated with 24 VDC power).

CSA safety standards by ETL (with all sensor types).

Certain AC mains powered models are listed for use in general safety locations to

UL and CSA safety standards by Underwriters Laboratories (with all sensor types).

data transmission

logging and performing software updates. The controller will keep approximately

20,000 data points per sensor.

4

English

Page 5

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

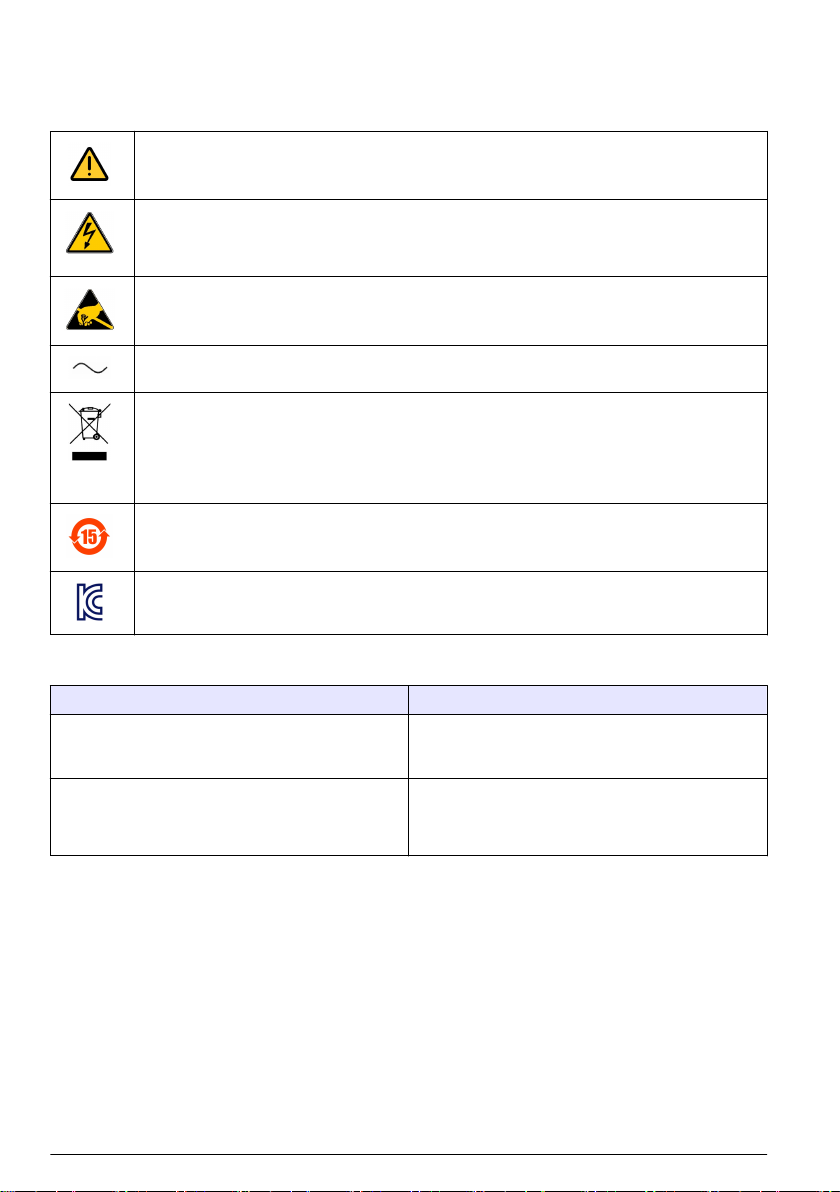

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary

statement.

D A N G E R

W A R N I N G

C A U T I O N

N O T I C E

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on a product, indicates the instrument is connected to alternate current.

English 5

Page 6

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems. In conformity with European local and national regulations, European electrical equipment

users must now return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Products marked with this symbol indicates that the product conforms to relevant South Korean

EMC standards.

EMC compliance statement (Korea)

Type of equipment Additional information

A 급 기기

( 업무용 방송통신기자재 )

Class A equipment

(Industrial Broadcasting and Communication

Equipment)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또

는 사용자는 이 점을 주의하시기 바라며, 가정외의 지역

에서 사용하는 것을 목적으로 합니다.

This equipment meets Industrial (Class A) EMC

requirements. This equipment is for use in industrial

environments only.

Certification

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

6

English

Page 7

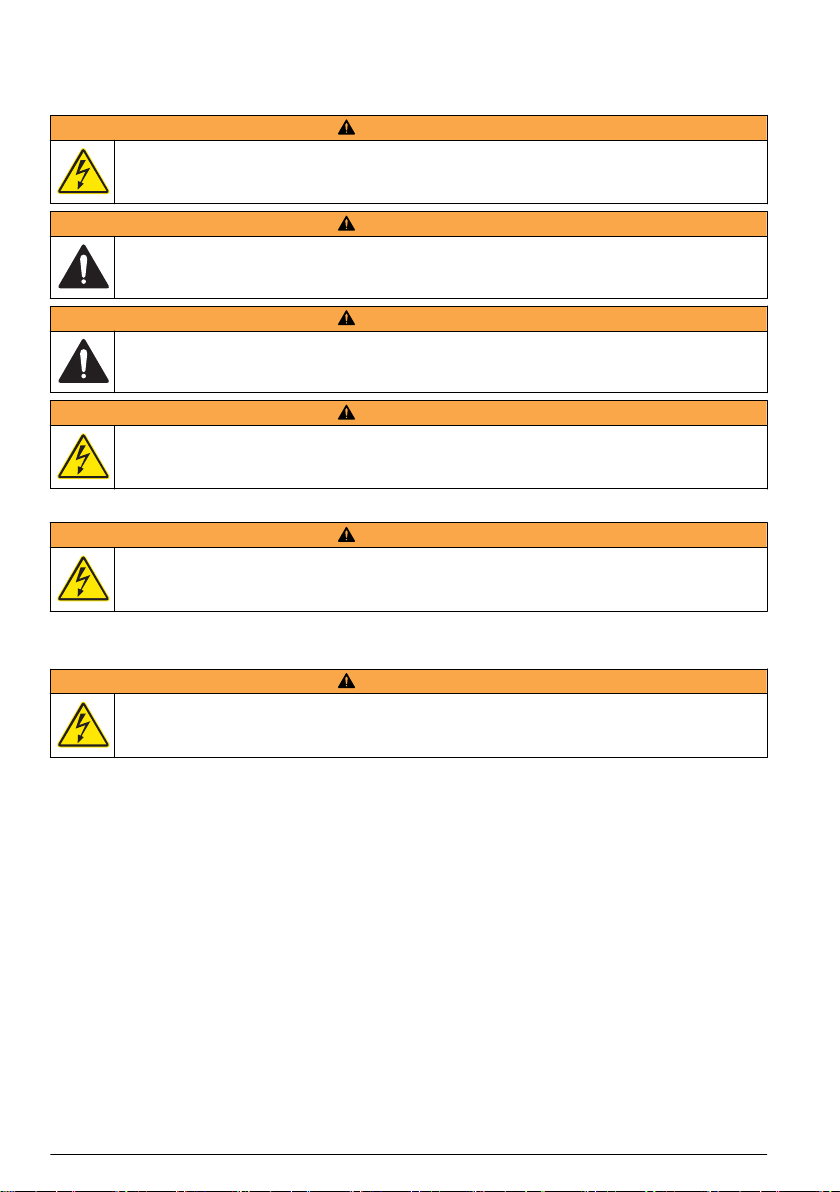

Product components

Make sure that all components have been received. If any items are missing or damaged, contact the

manufacturer or a sales representative immediately.

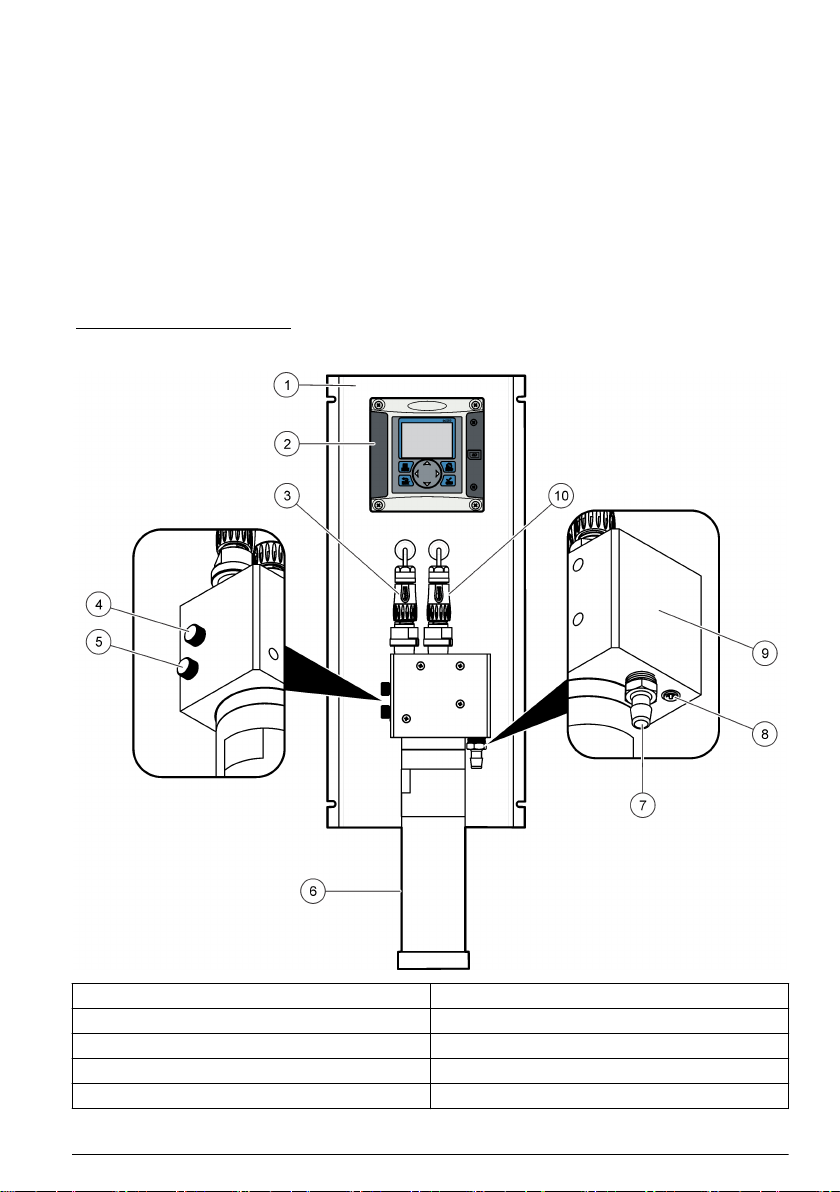

Product overview

The analyzer measures conductivity and calculates the pH in low-conductivity applications. The

system can include the controller as shown in Figure 1 or the controller can be installed as an

external component.

The system can be configured to function in numerous applications in the following industry sectors:

• Measurement in pure and ultrapure water, power plants, semiconductor industry, pharmaceutical

• Drinking water

• Industrial processes (chemistry, paper mills, sugar refineries, etc.)

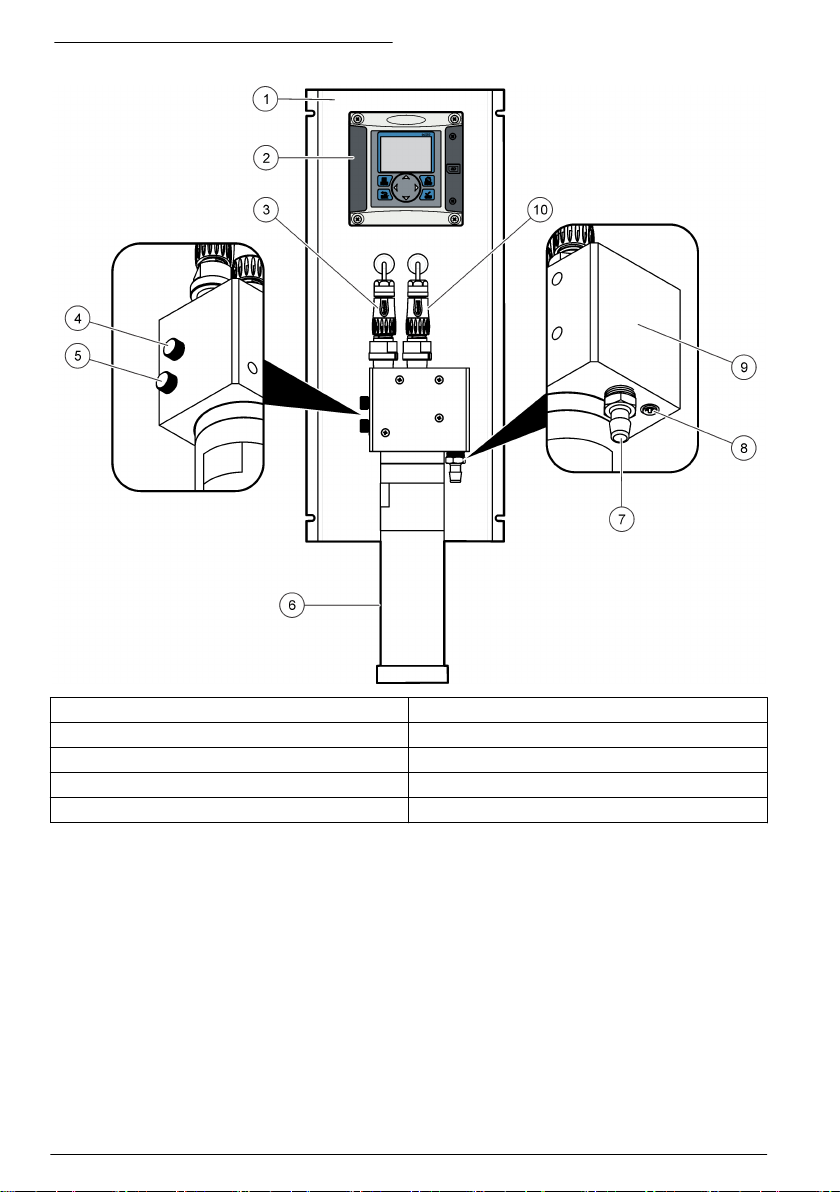

Figure 1 Analyzer overview

1 Mounting panel 6 Cationic resin cartridge

2 Controller 7 Sample output

3 Channel 1 conductivity probe 8 Sample input

4 Degassing valve 9 Measurement cell

5 Sample flow adjustment valve 10 Channel 2 conductivity probe

English 7

Page 8

Principle of operation (pH calculation)

The 9523 analyzer adheres to the recommendations contained in the guidelines for feedwaters,

boiler water and steam quality for power and industrial plants.

The pH calculations can only be applied under the following strict chemical conditions:

• The sample must only contain an alkaline agent (ammonia, sodium hydroxide or ethanolamine)

• Any impurity is principally NaCl (sodium chloride)

• The concentration of impurity must be negligible in comparison to the alkaline agent

Installation

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

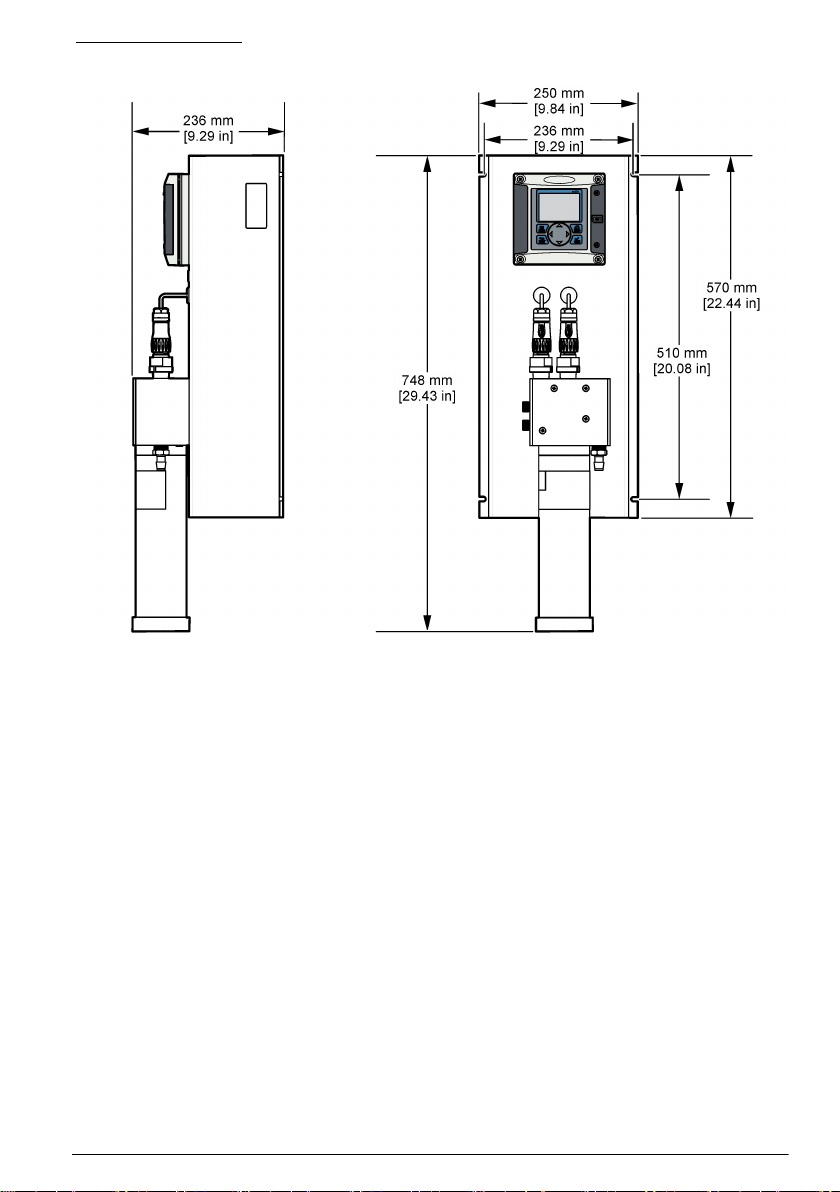

Analyzer mounting

Attach the analyzer to a stable, vertical surface. Refer to the guidelines that follow and Figure 2.

Note: If an external controller is used, refer to the controller documentation for mounting instructions.

• Put the instrument in a location that has access for operation, service and calibration.

• Make sure that there is good view of the display and controls.

• Keep the instrument away from a heat source.

• Keep the instrument away from vibrations.

• Keep the sample tubing as short as possible to minimize the response time.

• Make sure that there is no air in the sample supply line.

8 English

Page 9

Figure 2 Dimensions

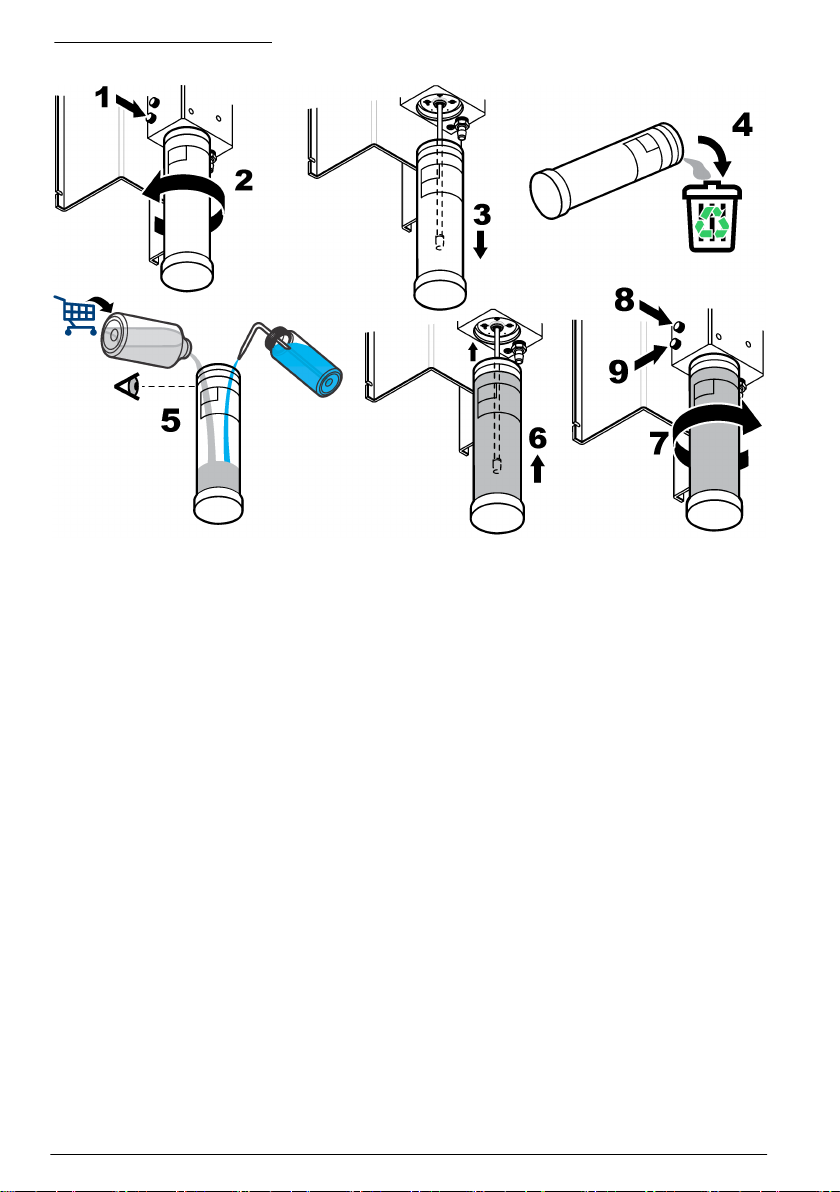

Resin cartridge installation

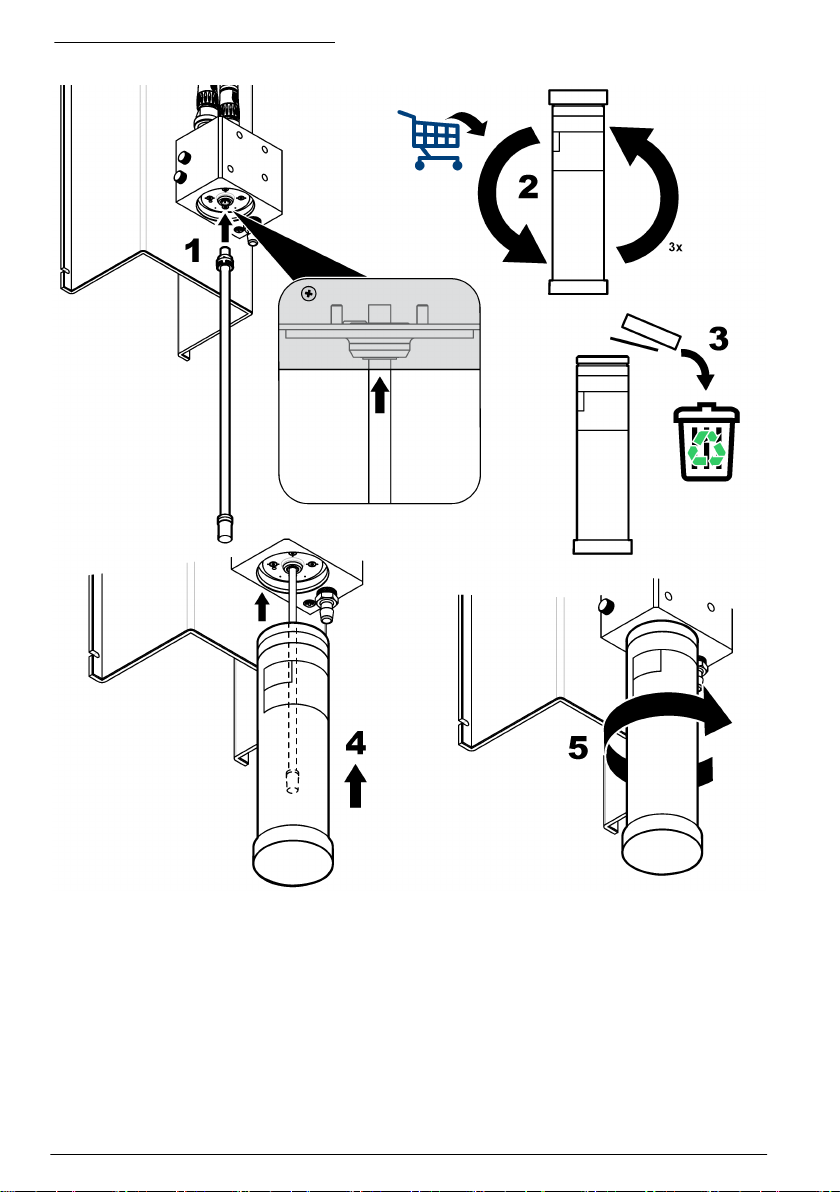

Refer to the steps that follow and Figure 3 to install the resin cartridge.

1. Insert the steel tube into the quick lock connector.

2. Push the steel tube as far as possible into the measuring cell.

3. Take the resin cartridge and turn it upside down 2 or 3 times until the resin comes away from the

sides of the cartridge and settles at the bottom, at the opposite end to the marker line.

4. Unscrew the cap off the top of the cartridge, by the marker line. Discard this cap and the flat black

sealing cap following the safety and disposal information for used cartridges.

5. Place the end of the steel tube into the center of the cartridge.

6. Slowly raise the cartridge to the measuring cell and screw into place to obtain an airtight and

watertight fitting.

English

9

Page 10

Figure 3 Resin cartridge installation

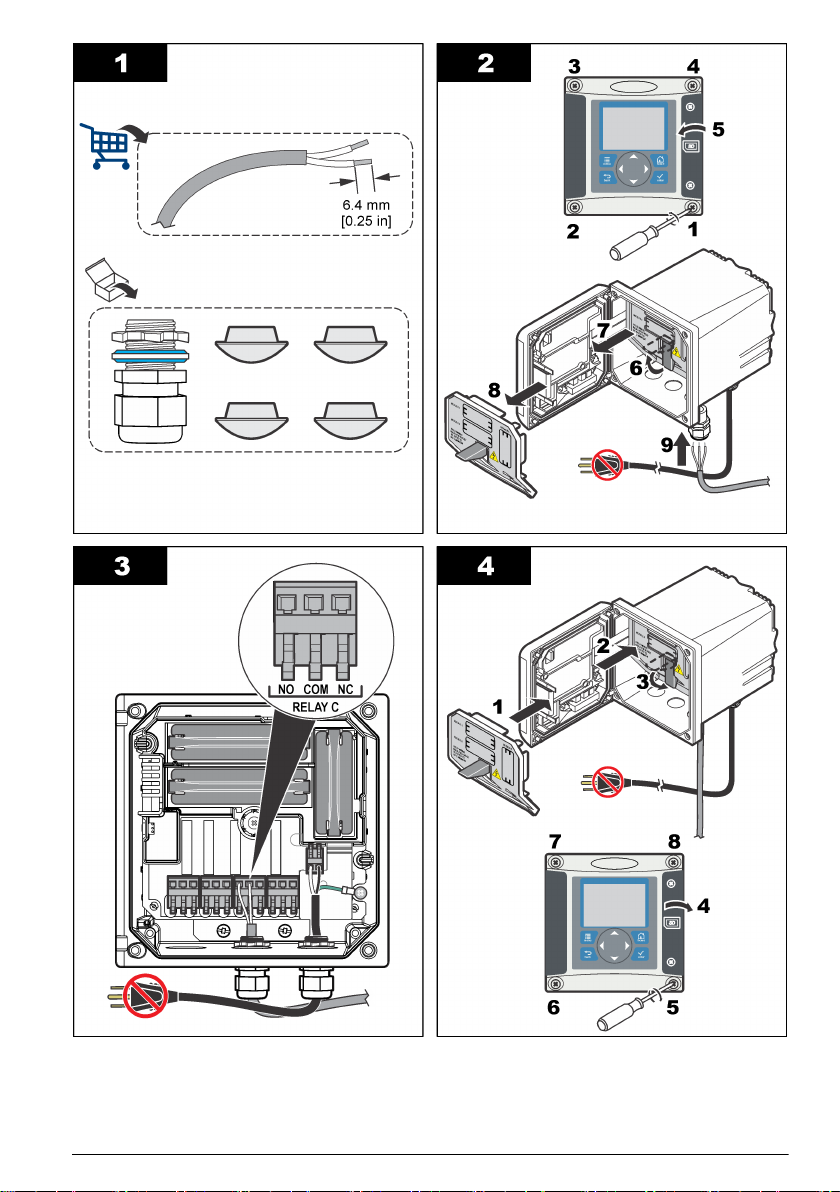

Wiring overview

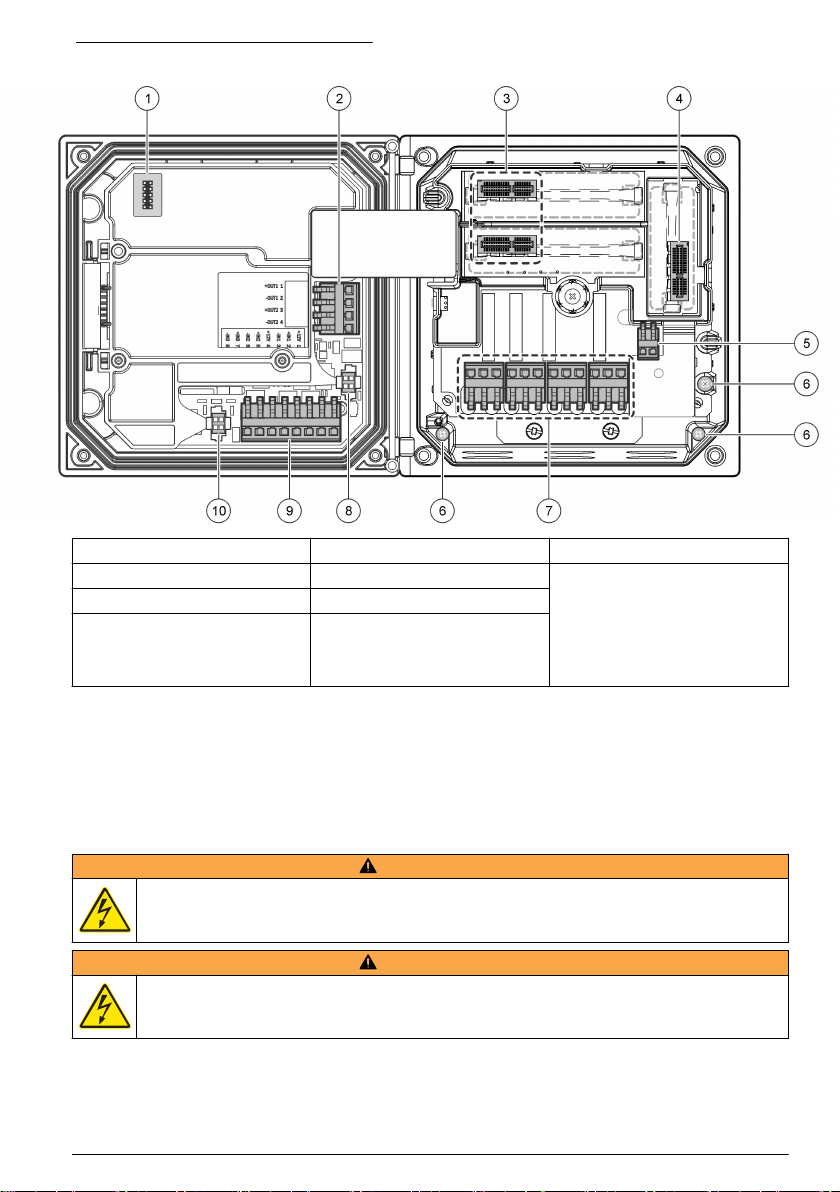

Figure 4 shows an overview of the wiring connections inside the controller with the high voltage

barrier removed. The left side of the figure shows the back side of the controller cover.

Note: Remove connector caps from the connectors before module installation.

10

English

Page 11

Figure 4 Wiring connections overview

1 Service cable connection 5 AC and DC power connector

2 4-20 mA output

3 Sensor module connector 7 Relay connections

4 Communication module

connector (e.g., Modbus,

Profibus, HART, optional

4-20 mA module, etc.)

1

Terminals can be removed for improved access.

1

6 Ground terminals 10 Digital sensor connector

1

8 Digital sensor connector

1

9 Discrete input wiring connector

1

1

High-voltage barrier

High-voltage wiring for the controller is located behind the high-voltage barrier in the controller

enclosure. The barrier must remain in place except when installing modules or when a qualified

installation technician is wiring for power, alarms, outputs or relays. Do not remove the barrier while

power is applied to the controller.

Wiring for power

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical

connections.

W A R N I N G

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially wet locations, a

Ground Fault Interrupt device must be used for connecting the equipment to its mains power source.

1

English 11

Page 12

D A N G E R

Electrocution Hazard. Do not connect AC power to a 24 VDC powered model.

W A R N I N G

Potential Electrocution Hazard. A protective earth (PE) ground connection is required for both

100-240 VAC and 24 VDC wiring applications. Failure to connect a good PE ground connection can

result in shock hazards and poor performance due to electromagnetic interferences. ALWAYS connect

a good PE ground to the controller terminal.

Install the device in a location and position that gives easy access to the disconnect device and its operation.

N O T I C E

The controller can be purchased as either a 100-240 VAC powered model or a 24 VDC powered

model. Follow the appropriate wiring instructions for the purchased model.

The controller can be wired for line power by hard-wiring in conduit or wiring to a power cord.

Regardless of the wire used, the connections are made at the same terminals. A local disconnect

designed to meet local electrical code is required and must be identified for all types of installation. In

hard-wired applications, the power and safety ground service drops for the instrument must be 18 to

12 AWG.

Notes:

• The voltage barrier must be removed before making any electrical connections. After making all

connections, replace the voltage barrier before closing the controller cover.

• A sealing type strain relief and a power cord less than 3 meters (10 feet) in length with three 18gauge conductors (including a safety ground wire) can be used to maintain the NEMA

4X/IP66 environmental rating.

• Controllers can be ordered with AC power cords pre-installed. Additional power cords may also be

ordered.

• The DC power source that supplies power to the 24 VDC powered controller must maintain

voltage regulation within the specified 24 VDC-15% +20% voltage limits. The DC power source

must also provide adequate protection against surges and line transients.

Wiring procedure

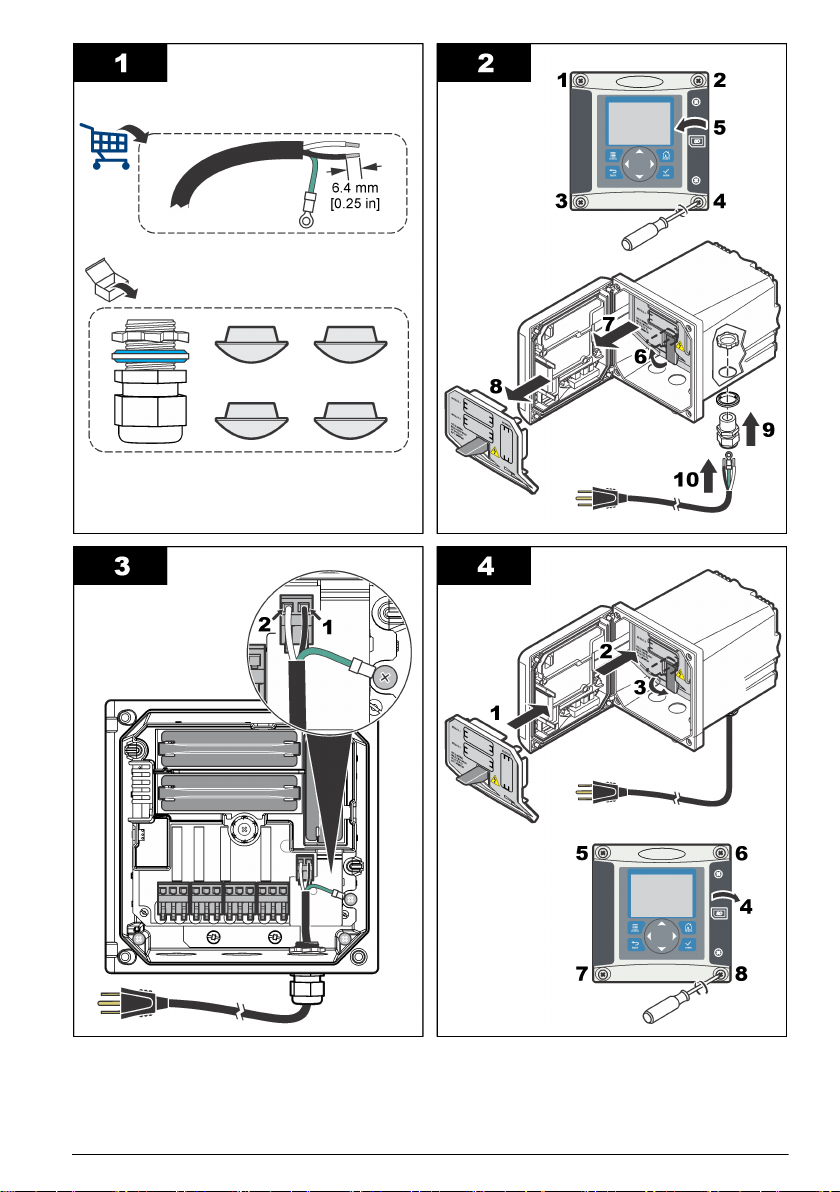

Refer to the illustrated steps that follow and Table 1 or Table 2 to wire the controller for power. Insert

each wire into the appropriate terminal until the insulation is seated against the connector with no

bare wire exposed. Tug gently after insertion to make sure that there is a secure connection. Seal

any unused openings in the controller box with conduit opening sealing plugs.

Table 1 AC power wiring information (AC powered models only)

Terminal Description Color—North America Color—EU

1 Hot (L1) Black Brown

2 Neutral (N) White Blue

— Protective Earth (PE) Ground lug Green Green with yellow stripe

Table 2 DC power wiring information (DC powered models only)

Terminal Description Color—North America Color—EU

1 +24 VDC Red Red

2 24 VDC return Black Black

— Protective Earth (PE) Ground lug Green Green with yellow stripe

12 English

Page 13

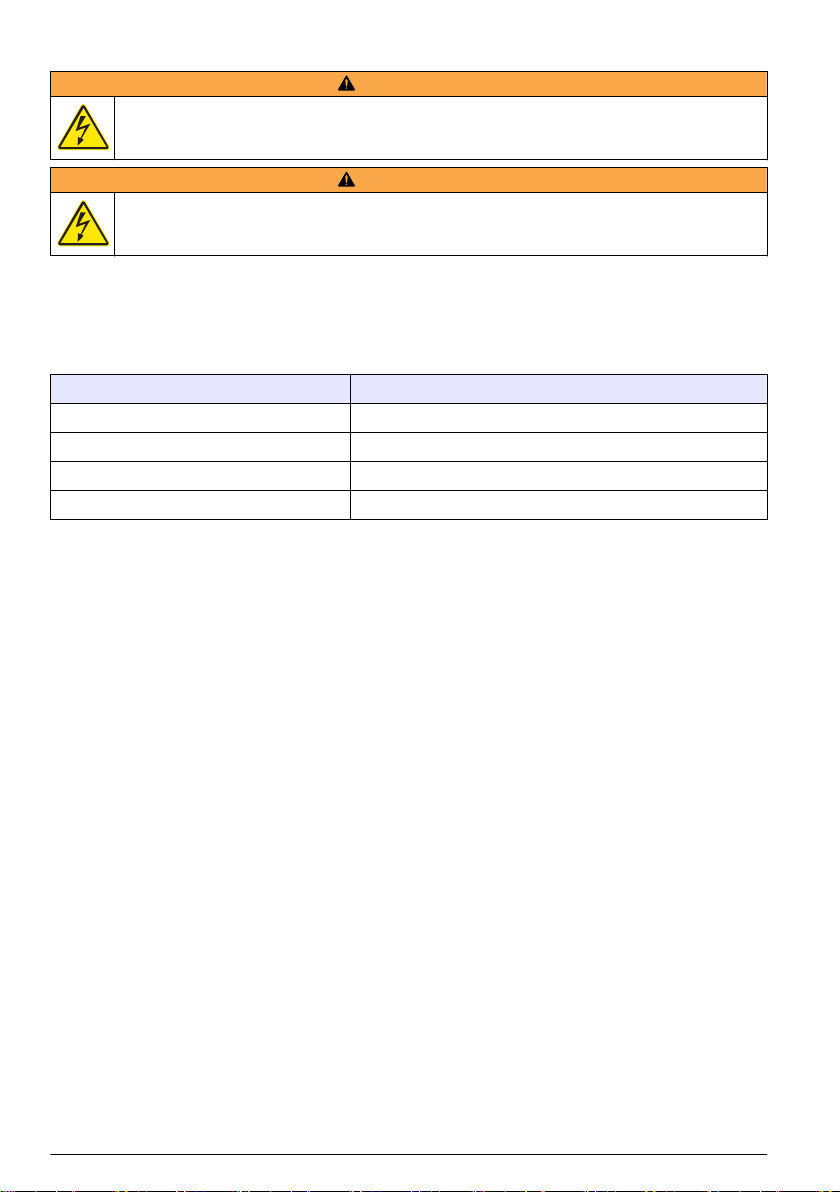

Alarms and relays

The controller is equipped with four unpowered, single pole relays rated 100-250 VAC, 50/60 Hz,

5 amp resistive maximum. Contacts are rated 250 VAC, 5 amp resistive maximum for the AC

English

13

Page 14

powered controller and 24 VDC, 5A resistive maximum for the DC powered controller. The relays are

not rated for inductive loads.

Wiring relays

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical

connections.

W A R N I N G

Potential fire hazard. The relay contacts are rated 5A and are not fused. External loads connected to

the relays must have current limiting devices provided to limit current to < 5 A.

W A R N I N G

Potential fire hazard. Do not daisy-chain the common relay connections or jumper wire from the mains

power connection inside the instrument.

W A R N I N G

Potential electrocution hazard. In order to maintain the NEMA/IP environmental ratings of the

enclosure, use only conduit fittings and cable glands rated for at least NEMA 4X/IP66 to route cables in

to the instrument.

AC line (100—250 V) powered controllers

Potential electrocution hazard. AC mains powered controllers (115 V–230 V) are designed for relay

connections to AC mains circuits (i.e., voltages greater than 16 V-RMS, 22.6 V-PEAK or 35 VDC).

The wiring compartment is not designed for voltage connections in excess of 250 VAC.

24 VDC powered controllers

Potential electrocution hazard. 24 V powered controllers are designed for relay connections to low

voltage circuits (i.e., voltages less than 16 V-RMS, 22.6 V-PEAK or 35 VDC).

W A R N I N G

W A R N I N G

The 24 VDC controller relays are designed for the connection to low voltage circuits (i.e., voltages

less than 30 V-RMS, 42.2 V-PEAK or 60 VDC). The wiring compartment is not designed for voltage

connections above these levels.

The relay connector accepts 18–12 AWG wire (as determined by load application). Wire gauge less

than 18 AWG is not recommended.

The Normally Open (NO) and Common (COM) relay contacts will be connected when an alarm or

other condition is active. The Normally Closed (NC) and Common relay contacts will be connected

when an alarm or other condition is inactive (unless the Fail Safe is set to Yes) or when power is

removed from the controller.

Most relay connections use either the NO and COM terminals or the NC and COM terminals. The

numbered installation steps show connection to the NO and COM terminals.

14

English

Page 15

English 15

Page 16

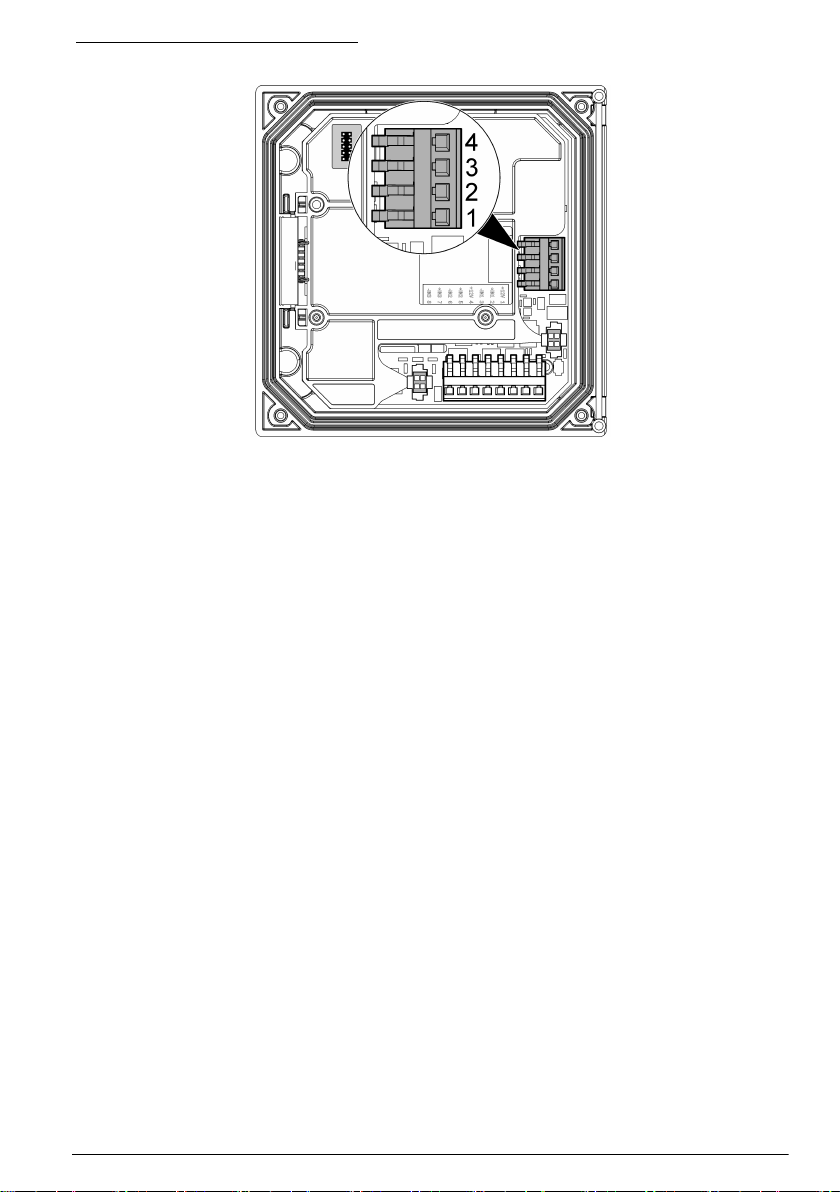

Analog output connections

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical

connections.

W A R N I N G

Potential electrocution hazard. In order to maintain the NEMA/IP environmental ratings of the

enclosure, use only conduit fittings and cable glands rated for at least NEMA 4X/IP66 to route cables in

to the instrument.

Two isolated analog outputs (1 and 2) are provided (Figure 5). Such outputs are commonly used for

analog signaling or to control other external devices.

Make wiring connections to the controller as shown in Figure 5 and Table 3.

Note: Figure 5 shows the back of the controller cover and not the inside of the main controller compartment.

Table 3 Output connections

Recorder wires Circuit board position

Output 2– 4

Output 2+ 3

Output 1– 2

Output 1+ 1

1. Open the controller cover.

2. Feed the wires through the strain relief.

3. Adjust the wire as necessary and tighten the strain relief.

4. Make connections with twisted-pair shielded wire and connect the shield at the controlled

component end or at the control loop end.

• Do not connect the shield at both ends of the cable.

• Use of non-shielded cable may result in radio frequency emission or susceptibility levels higher

than allowed.

• Maximum loop resistance is 500 ohm.

5. Close the controller cover and tighten the cover screws.

6. Configure outputs in the controller.

16

English

Page 17

Figure 5 Analog output connections

Connect the optional digital communication output

The manufacturer supports Modbus RS485, Modbus RS232, Profibus DPV1 and HART

communication protocols. The optional digital output module is installed in the location indicated by

item 4 in Figure 4 on page 11. Refer to the instructions supplied with the network module for more

details.

For information about Modbus registers, go to http://www.hach-lange.com or http://www.hach.com

and search Modbus registers or go to any sc200 product page.

Plumb the sample and drain lines

After the panel is attached to a wall, connect the sample and drain lines to the fittings on the panel.

Make sure that the tubing meets the Specifications on page 3. Refer to the steps that follow and

Figure 1 on page 7.

1. Insert the sample tubing into the input quick-connect fitting under the flow chamber (Figure 1

on page 7).

2. Connect a drain line to sample output fitting. Keep the drain line as short as possible to prevent

back-pressure.

Analyzer startup

1. Open the degassing valve.

2. Open the sample flow adjustment valve and ensure everything is watertight and there are no

leaks.

3. Close the degassing valve when the measuring cell is free of air.

4. Set the sample flow to the required rate (between 5 and 20 L/h).

5. Pass about 10 liters of sample through the resin to thoroughly rinse it and prepare the analyzer

for measurements.

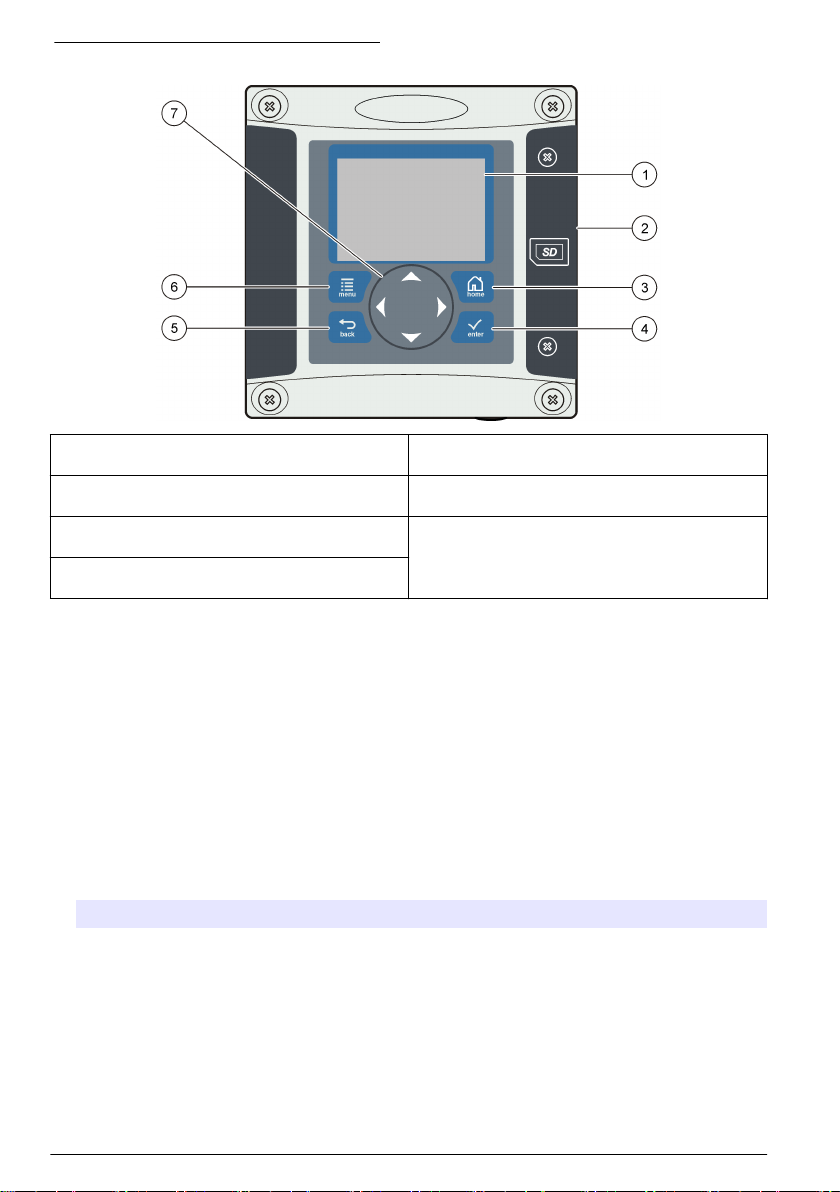

User interface and navigation

User interface

The keypad has four menu keys and four directional keys as shown in Figure 6.

English

17

Page 18

Figure 6 Keypad and front panel overview

1 Instrument display 5 BACK key. Moves back one level in the menu

2 Cover for secure digital memory card slot 6 MENU key. Moves to the Settings Menu from other

3 HOME key. Moves to the Main Measurement

screen from other screens and submenus.

4 ENTER key. Accepts input values, updates, or

displayed menu options.

structure.

screens and submenus.

7 Directional keys. Used to navigate through the

menus, change settings, and increment or

decrement digits.

Inputs and outputs are set up and configured through the front panel using the keypad and display

screen. This user interface is used to set up and configure inputs and outputs, create log information

and calculated values, and calibrate sensors. The SD interface can be used to save logs and update

software.

Operation

Contacting conductivity sensor configuration

Use the CONFIGURE menu to enter identification information for the sensor and to change options

for data handling and storage.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CONFIGURE.

2. Select an option and push enter. To enter numbers, characters or punctuation, push and hold the

up or down arrow keys. Push the right arrow key to advance to the next space.

Option Description

EDIT NAME Changes the name that corresponds to the sensor on the top of the measure screen.

SENSOR S/N Allows the user to enter the serial number of the sensor, limited to 16 characters in any

SELECT MEASURE Changes the measured parameter to CONDUCTIVITY (default), TDS (total dissolved

The name is limited to 16 characters in any combination of letters, numbers, spaces or

punctuation. Only the first 12 characters are displayed on the controller.

combination of letters, numbers, spaces or punctuation.

solids), SALINITY or RESISTIVITY. All other configured settings are reset to the

default values.

Note: If SALINITY is selected, the measurement unit is defined as ppt (parts per

thousand) and cannot be changed.

18 English

Page 19

Option Description

DISPLAY FORMAT Changes the number of decimal places that are shown on the measure screen. When

MEAS UNITS Changes the units for the selected measurement—select the unit from the list

TEMP UNITS Sets the temperature units to °C (default) or °F.

T-COMPENSATION Adds a temperature-dependent correction to the measured value:

set to auto, the number of decimal places changes automatically with changes in the

measured value.

available.

• NONE—Temperature compensation not required

• USP—Set the alarm level for the standard USP definition table

• ULTRA PURE WATER—Not available for TDS. Set the compensation type

according to the sample characteristics—Select NaCl , HCl, AMMONIA or ULTRA

PURE WATER

• USER—Select BUILT IN LINEAR, LINEAR or TEMP TABLE:

• BUILT IN LINEAR—Use the pre-defined linear table (slope defined as 2.0%/°C,

reference temperature as 25 °C)

• LINEAR—Set the slope and reference temperature parameters if different from

the built-in parameters

• TEMP TABLE—Set the temperature and multiplication factor points (refer to the

conductivity module documentation)

• NATURAL WATER—Not available for TDS

CONFIG TDS TDS only—changes the factor that is used to convert conductivity to TDS: NaCl

CABLE PARAM Sets the sensor cable parameters to improve measurement accuracy when the sensor

TEMP ELEMENT Sets the temperature element to PT100 or PT1000 for automatic temperature

FILTER Sets a time constant to increase signal stability. The time constant calculates the

LOG SETUP Sets the time interval for data storage in the data log—5, 30 seconds, 1, 2, 5, 10,

RESET DEFAULTS Sets the configuration menu to the default settings. All sensor information is lost.

(0.49 ppm/µS) or CUSTOM (enter factor between 0.01 and 99.99 ppm/µS).

cable is extended or shortened from the standard 5 m. Enter the cable length,

resistance and capacitance.

compensation. If no element is used, the type can be set to MANUAL and a value for

temperature compensation can be entered.

average value during a specified time—0 (no effect) to 60 seconds (average of signal

value for 60 seconds). The filter increases the time for the sensor signal to respond to

actual changes in the process.

15 (default), 30, 60 minutes.

Resin option

Use the RESIN option to view and change the parameters related to the resin cartridge. These

parameters must be defined before the analyzer is used for the first time.

1. Push the menu key and select TEST/MAINT>RESIN.

2. To monitor the status of the resin select the TRACK option and push enter.

Option Description

YES Monitor the resin status. When the life expectancy of the resin is less than 10 days a warning

message is triggered. When the life expectancy reaches 0 days a system error is triggered.

NO The resin is not monitored.

English 19

Page 20

3. To view the current status of the resin select the STATUS option and push enter. The date the

resin was last changed and the current life expectancy are displayed. Push back to return to the

menu or enter to reset the parameters.

4. To reset the resin parameters select PARAMETERS and push enter. Based on the values input,

the life expectancy of the resin is recalculated.

Option Description

CAPACITY Use the arrow keys to enter the resin exchange capacity (0.5 to 5.0 mole/liter).

VOLUME Use the arrow keys to enter the volume of resin (0.5 to 20 liters).

FLOW Use the arrow keys to enter the sample flow rate through the cartridge (2 to

CONCENTRATION Use the arrow keys to enter the resin concentration (0 to 20 ppm).

20 liters/hour).

Calibration

About sensor calibration

The sensor characteristics slowly shift over time and cause the sensor to lose accuracy. The sensor

must be calibrated regularly to maintain accuracy. The calibration frequency varies with the

application and is best determined by experience.

Use air (zero calibration) and the process sample to define the calibration curve. When the process

sample is used, the reference value must be determined with a secondary verification instrument.

Cell constant

Before making a calibration make sure the sensor cell parameters are correct.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select CELL CONSTANT and push enter.

4. Contacting conductivity sensors: Select the cell K range for the sensor (0.01, 0.1 or 1.0) then

enter the actual K value as printed on the label attached to the sensor.

Inductive conductivity sensors: Enter the actual K value as printed on the label attached to the

sensor.

Temperature calibration

It is recommended to calibrate the temperature sensor once a year. Calibrate the temperature sensor

before calibrating the measurement sensor.

1. Measure the temperature of the water with an accurate thermometer or independent instrument.

2. Push the menu key and select SENSOR SETUP>CALIBRATE.

3. If the pass code is enabled in the security menu for the controller, enter the pass code.

4. Select 1 PT TEMP CAL and push enter.

5. The raw temperature value is displayed. Push enter.

6. Enter the correct value if different from that displayed and push enter.

7. Push enter to confirm the calibration. The temperature offset is displayed.

Zero calibration procedure

Use the zero calibration procedure to define the unique zero point of the sensor.

1. Remove the sensor from the process. Wipe with a clean towel to make sure the sensor is dry.

2. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

3. If the pass code is enabled in the security menu for the controller, enter the pass code.

4. Select ZERO CAL and push enter.

20

English

Page 21

5. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

the preset value.

6. Place the sensor in air, push enter.

7. Review the calibration result:

• PASS—the sensor is calibrated and ready to measure samples.

• FAIL—the calibration is outside of accepted limits. Clean the sensor and retry. Refer to

Troubleshooting on page 24 for more information.

8. If the calibration passed, push enter to continue.

9. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 22.

10. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

calibration curves for the sensor are reset.

NO The sensor was calibrated previously with this controller.

11. Return the sensor to the process and push enter. The output signal returns to the active state

and the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

Calibration with the process sample

The sensor can remain in the process sample.

1. Push the menu key and select SENSOR SETUP>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select SAMPLE CAL and push enter.

4. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

the preset value.

5. With the sensor in the process sample, push enter. The measured value is shown. Wait for the

value to stabilize and push enter.

6. With a certified secondary verification instrument measure the concentration value of the sample.

To avoid impurities in the sample take the measurement before the sample enters the flow

chamber. Use the arrow keys to enter this value if different from the value displayed and push

enter.

7. Review the calibration result:

• PASS—the sensor is calibrated and the calibration factor is displayed.

• FAIL—the calibration is outside of accepted limits. Clean the sensor and retry. Refer to

Troubleshooting on page 24 for more information.

English

21

Page 22

8. If the calibration passed, push enter to continue.

9. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 22.

10. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

calibration curves for the sensor are reset.

NO The sensor was calibrated previously with this controller.

11. With the sensor still in the process push enter. The output signal returns to the active state and

the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

Change calibration options

The user can set a calibration reminder or include an operator ID with calibration data from this

menu.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select CAL OPTIONS and push enter.

4. Use the arrow keys to select an option and push enter.

Option Description

CAL REMINDER Sets a reminder for the next calibration in days, months or years—select the required

OP ID ON CAL Includes an operator ID with calibration data—YES or NO (default). The ID is entered

delay from the list.

during the calibration.

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the document.

Service schedule

The following table shows the recommended service schedule:

Validation (check with referenced measure) X X X X

Calibration (measure) X X

Calibration (temperature) X

22 English

Every 3 Months Every 6 Months Yearly As Needed

Page 23

Cleaning the controller

D A N G E R

Always remove power from the controller before performing maintenance activities.

Note: Never use flammable or corrosive solvents to clean any part of the controller. Use of these solvents may

degrade the environmental protection of the unit and may void the warranty.

1. Make sure the controller cover is securely closed.

2. Wipe the controller exterior with a cloth dampened with water, or with a mixture of water and mild

detergent.

Replace the resin

C A U T I O N

Chemical exposure hazard. Dispose of chemicals and wastes in accordance with local, regional and

national regulations.

The cartridge of resin can be replaced with a new cartridge, or as an alternative, keep the cartridge

and replace only the resin. In order to take advantage of the full system specifications, we

recommend the use of nuclear grade cationic resin.

1. Stop the sample flow using the sample flow adjustment valve.

2. Replace the cartridge or resin:

• Cartridge—refer to Resin cartridge installation on page 9.

• Resin—refer to Figure 7. Make sure to add deionized water at regular intervals when new resin

is added to compact the resin.

3. Open the degassing valve.

4. Open the sample flow adjustment valve and ensure everything is watertight and there are no

leaks.

5. Close the degassing valve when the measuring cell is free of air.

6. Set the sample flow to the required rate (between 5 and 20 L/h).

7. Reset the resin options. Refer to Resin option on page 19.

English

23

Page 24

Figure 7 Resin replacement

Troubleshooting

Additional information

Additional information is available on the manufacturer's website.

24

English

Page 25

Inhaltsverzeichnis

Spezifikationen auf Seite 25 Betrieb auf Seite 41

Allgemeine Informationen auf Seite 27 Wartung auf Seite 46

Installation auf Seite 31

Benutzeroberfläche und Navigation auf Seite 41

Zusätzliche Informationen

Zusätzliche Informationen finden Sie auf der Website des Herstellers.

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen.

Analysator

Spezifikation Details

Abmessungen 748 x 250 x 236 mm (29.4 x 9.8 x 9.3 Zoll)

Gewicht 7 kg / 15.4 lb

Probenflussrate 5—20 l/h

Umgebungstemperatur 0—60 °C (32—140 °F)

Relative Feuchtigkeit 10—90%

Temperatursensor Pt 100

Genauigkeit ± 1% des angezeigten Werts; Temperatur < ± 0,2°C

Berechneter pH-Wert

Anzeigebereich

Anzeigeauflösung

Probenleitung

Zertifikationen EN 61326-1: 2006; EN 61010-1: 2010

Genauigkeit der Leitfähigkeitsmessung: ±2 %; Maximale Abweichung von´m

errechneten theoretischen Wert: 0,1 pH

NH3; 7 < pH < 10; 2,8 μS/cm < C1 < 28 μS/cm; C2 < 0,5 μS/cm

NaOH; 7 < pH < 10,7; 2,5 μS/cm < C1 < 125 μS/cm; C2 < 100 μS/cm

Leitfähigkeit/Resistivität; automatische Punktverschiebung (Mindestauflösung

0,001 μS/cm) < 0,1 °C

Polyethylen oder PTFE oder FEP; 0,2 bis 6 bar (3 bis 90 psi); 5 bis 50 °C; Eingang:

6 mm (Standard) oder 1/4 Zoll (mit Adapter); Ausgang: 12 mm oder 1/2 Zoll

Sensor

Spezifikation Details

Material des Sensorgehäuses PSU schwarz

Leitfähigkeitselektroden, intern und extern Edelstahl 316L

Zellkonstante K 0,01 (cm-1)

Leitfähigkeitsbereich 0,01 - 200 μS.cm-1; Resistivitätsbereich: 5 kΩ.cm - 100 MΩ.cm

Max. Druck 10 bar

Max. Temperatur 125 °C (257 °F)

Genauigkeit < 2%

Deutsch 25

Page 26

Spezifikation Details

Temperaturverhalten < 30 Sekunden

Isoliermaterial PSU

Stecker Glas Polyester (IP65)

Controller

Technische Daten Details

Beschreibung der Komponenten Mikroprozessor- und menügesteuerter Controller, der Sensoren

Betriebstemperatur –20 bis 60 °C (–4 bis 140 °F); 95 % relative Luftfeuchtigkeit, nicht

Lagertemperatur –20 bis 70 ºC (-4 bis 158 ºF); 95 % relative Luftfeuchtigkeit, nicht

1

Gehäuse

Stromversorgung Controller mit Wechselspannungsversorgung:100-240 V~ ±10 %,

Aufstellungshöhe Standardmäßig 2000 m ü. M. (über Meeresspiegel)

Verschmutzungsgrad/Einbaukategorie Verschmutzungsgrad 2; Einbaukategorie II

Ausgänge Zwei Analogausgänge (0-20 mA oder 4-20 mA). Jeder analoge Ausgang

Relais Für SPDT, benutzerkonfigurierte Kontakte, mit folgenden Nennwerten:

Abmessungen ½ DIN—144 x 144 x 180,9 mm (5,7 x 5,7 x 7.12 Zoll)

Gewicht 1.7 kg (3.75 lbs)

Einhaltungsinformationen

2

Digitale Kommunikation Optionaler Modbus-, RS232/RS485-, Profibus DPV1- oder HART-

ansteuert und Messwerte anzeigt.

kondensierend mit Sensorleistung <7 W; –20 bis 50 °C (–4 bis 104 °F)

mit Sensorleistung <28 W

kondensierend

Metallgehäuse, Schutzart NEMA 4X/IP66, mit korrosionsbeständiger

Oberfläche

50/60 Hz; Leistung 50 VA bei Sensor-/Netzwerkmodullast von 7 W,

100 VA bei Sensor-/Netzwerkmodullast von 28 W (Modbus-,

RS232/RS485-, Profibus DPV1- oder HART-Netzwerkverbindung

optional).

Controller mit 24-Volt-Gleichstromversorgung:24 V= -15 % + 20 %;

Leistung 15 W bei Sensor-/Netzwerkmodullast von 7 W, 40 W bei

Sensor-/Netzwerkmodullast von 28 W (Modbus-, RS232/RS485-,

Profibus DPV1- oder HART-Netzwerkverbindung optional).

lässt sich Messgrößen wie pH, Temperatur, Durchfluss oder

berechneten Werten zuordnen. Das optionale Modul wendet drei

zusätzliche analoge Ausgänge an (insgesamt 5).

250 V~, max. Schaltlast 5 A bei wechselstrombetriebenen Controllern

bzw. 24 V=, max. Schaltlast 5 A bei gleichstrom betriebenen Controllern.

Relais sind für den Anschluss an das Stromnetz (bei Betrieb des

Controllers mit 115 - 240 V~) oder eine Gleichspannungsversorgung (bei

Betrieb des Controllers mit 24 V=) ausgelegt.

CE-Zulassung (alle Sensortypen). UL- und CSA-Zulassung für den

Einsatz an allgemeinen Aufstellungsorten durch ETL (alle Sensortypen).

Bestimmte Modelle mit Anschluss an das Stromnetz werden für den

Einsatz an allgemeinen Sicherheitsstandorten mit UL- und CSAZulassung von Underwriter Laboratories aufgeführt (alle Sensortypen).

Netzwerkanschluss für die Datenübertragung

26 Deutsch

Page 27

Technische Daten Details

Datenprotokollierung Secure Digital-Speicherkarte (maximal 32 GB) oder spezieller RS(232-

Gewährleistung 2 Jahre

1

Geräte mit einer Zertifizierung von Underwriters Laboratories (UL) eignen sich nur zur Verwendung in

geschlossenen Räumen und verfügen nicht über die Schutzart NEMA 4X/IP66.

2

Geräte mit Gleichstromversorgung werden nicht von UL aufgeführt.

Kabelanschluss für Datenprotokollierung und Software-Updates. Der

Controller speichert ca. 20.000 Datenpunkte pro Sensor.

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führt.

G E F A H R

W A R N U N G

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

V O R S I C H T

H I N W E I S

Deutsch 27

Page 28

Warnaufkleber

Bitte lesen Sie alle Aufkleber und Schilder, die am Produkt angebracht sind. Die Nichtbeachtung

kann zu Verletzungen von Personen oder Beschädigungen des Produkts führen. Im Handbuch

werden auf die am Gerät angebrachten Symbole in Form von Warnhinweisen verwiesen.

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen sollte.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Dieses Symbol weist darauf hin, dass das Instrument an Wechselstrom angeschlossen werden

muss.

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in der Europäischen Union nicht

als Haushaltsabfall entsorgt werden. Den lokalen und nationalen europäischen Bestimmungen

gemäß müssen Benutzer von Elektrogeräten diese jetzt an den Hersteller zurückgeben. Dieser

Rücknahmeservice ist für den Benutzer kostenlos.

Hinweis: Bitte wenden Sie sich für Anweisungen zur Rücklieferung für die ordnungsgemäße Entsorgung von alten

oder nicht mehr benutzten elektrischen Geräten an den Hersteller oder Händler.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Produkte, die mit diesem Symbol gekennzeichnet sind, entsprechen den EMV-Standards

Südkoreas.

EMV-Konformitätserklärung (Korea)

Gerätetyp Zusätzliche Informationen

A 급 기기

( 업무용 방송통신기자재 )

Geräteklasse A

(Industrielle Übertragungs- und Kommunikationsgeräte)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또

는 사용자는 이 점을 주의하시기 바라며, 가정외의 지역

에서 사용하는 것을 목적으로 합니다.

Dieses Gerät ist mit den Anforderungen der EMVRichtliniene für industrielle Geräte (Klasse A) konform.

Dieses Gerät ist ausschließlich für den industriellen

Gebrauch bestimmt.

Zertifizierungen

Kanadische Vorschriften zu Störungen verursachenden Einrichtungen, IECS-003, Klasse A:

Entsprechende Prüfprotokolle hält der Hersteller bereit.

Dieses digitale Gerät der Klasse A erfüllt alle Vorgaben der kanadischen Normen für Interferenz

verursachende Geräte.

FCC Teil 15, Beschränkungen der Klasse "A"

Entsprechende Prüfprotokolle hält der Hersteller bereit. Das Gerät entspricht Teil 15 der FVVVorschriften. Der Betrieb unterliegt den folgenden Bedingungen:

1. Das Gerät darf keine Störungen verursachen.

2. Das Gerät muss jegliche Störung, die es erhält, einschließlich jener Störungen, die zu

unerwünschtem Betrieb führen, annehmen.

28

Deutsch

Page 29

Änderungen oder Modifizierungen an diesem Gerät, die nicht ausdrücklich durch die für die

Einhaltung der Standards verantwortliche Stelle bestätigt wurden, können zur Aufhebung der

Nutzungsberechtigung für des Geräts führen. Dieses Gerät wurde geprüft, und es wurde festgestellt,

dass es die Grenzwerte für digitale Geräte der Klasse A entsprechend Teil 15 der FCC-Vorschriften

einhält. Diese Grenzwerte bieten beim Einsatz der Ausrüstung in gewerblichen Umgebungen einen

ausreichenden Schutz gegen Verletzungen. Dieses Gerät erzeugt und nutzt hochfrequente Energie

und kann diese auch abstrahlen, und es kann, wenn es nicht in Übereinstimmung mit der

Bedienungsanleitung installiert und eingesetzt wird, schädliche Störungen der Funkkommunikation

verursachen. Der Betrieb dieses Geräts in Wohngebieten kann schädliche Störungen verursachen.

In diesem Fall muss der Benutzer die Störungen auf eigene Kosten beseitigen. Probleme mit

Interferenzen lassen sich durch folgende Methoden mindern:

1. Trennen Sie das Gerät von der Stromversorgung, um sicherzugehen, dass dieser die Störungen

nicht selbst verursacht.

2. Wenn das Gerät an die gleiche Steckdose angeschlossen ist wie das gestörte Gerät, schließen

Sie das störende Gerät an eine andere Steckdose an.

3. Vergrößern Sie den Abstand zwischen diesem Gerät und dem gestörten Gerät.

4. Ändern Sie die Position der Empfangsantenne des gestörten Geräts.

5. Versuchen Sie auch, die beschriebenen Maßnahmen miteinander zu kombinieren.

Produktkomponenten

Stellen Sie sicher, dass Sie alle Teile erhalten haben. Wenn Komponenten fehlen oder beschädigt

sind, kontaktieren Sie bitte den Hersteller oder Verkäufer.

Produktübersicht

Der Analysator misst Leitfähigkeit und berechnet den pH-Wert in Anwendungen mit geringer

Leitfähigkeit. Das System kann einen Controller wie in Abbildung 1 gezeigt umfassen. Alternativ kann

der Controller als externe Komponente installiert werden.

Das System kann für den Betrieb in zahlreichen Anwendungen in den folgenden Branchen

konfiguriert werden:

• Messung in Rein- und Reinstwasser, Kraftwerken, Halbleiterindustrie, pharmazeutische Industrie.

• Trinkwasser

• industrielle Prozesse (chemische Industrie, Papierfabriken, Zuckerraffinerien usw.)

Deutsch

29

Page 30

Abbildung 1 Übersicht über den Analysator

1 Montagepaneel 6 Patrone kationisches Harz

2 Controller 7 Probenauslass

3 Kanal 1 Sonde Leitfähigkeit 8 Probeneinlass

4 Entlüftungsventil 9 Messzelle

5 Probenflusseinstellventil 10 Kanal 2 Sonde Leitfähigkeit

Betriebsweise (pH-Wertberechnung)

Der Analysator 9523 entspricht den Empfehlungen der Richtlinien für Speisewasser, Boilerwasser

und Dampfqualität für Kraftwerke und Industrieanlagen.

Die pH-Wertberechnung kann nur unter den folgenden strengen chemischen Bedingungen erfolgen:

• Die Probe darf ausschließlich alkaline Arbeitsstoffe (Ammoniak, Natriumhydroxid oder

Äthanolamin) enthalten.

• Bei eventuellen Verunreinigungen handelt es sich überwiegend um NaCl (Natriumchlorid).

• Die Konzentration der Verunreinigung muss im Vergleich zu dem alkalinen Arbeitsstoff

vernachlässigbar sein

30

Deutsch

Page 31

Installation

V O R S I C H T

Mehrere Gefahren. Nur qualifiziertes Personal sollte die in diesem Kapitel des Dokuments

beschriebenen Aufgaben durchführen.

Montage des Analysators

Bringen Sie den Analysator auf einer stabilen, vertikalen Oberfläche an. Beachten Sie die folgenden

Anweisungen und Abbildung 2.

Hinweis: Wenn ein externer Controller verwendet wird, entnehmen Sie die Montageanweisungen der

Dokumentation für den Controller.

• Stellen Sie das Gerät an einem Ort auf der ausreichend Platz für den Betrieb, die Wartung und die

Kalibrierung bietet.

• Vergewissern Sie sich, dass die Anzeige und die Bedienelement gut sichtbar sind.

• Halten Sie das Instrument von Wärmequellen fern.

• Setzen Sie das Instrument keinen Vibrationen aus.

• Halten Sie die Probenleitung so kurz wie möglich, um die Reaktionszeit so kurz wie möglich zu

halten.

• Vergewissern Sie sich, dass sich keine Luft in der Probezufuhrleitung befindet.

Abbildung 2 Abmessungen

Deutsch 31

Page 32

Harzpatrone installieren

Beachten Sie die folgenden Schritte und Abbildung 3 zum Installieren der Harzpatrone.

1. Setzen Sie das Stahlrohr in die Schnellkupplung ein.

2. Schieben Sie das Stahlrohr so weit wie möglich in die Messzelle ein.

3. Nehmen Sie die Harzpatrone und drehen Sie deren Oberseite 2 bis 3 Mal nach unten, damit sich

der Harz von den Seitenwänden der Patrone löst und auf dem Boden auf der

gegenüberliegenden Seite der Markierung absetzt.

4. Lösen Sie den Deckel auf der Oberseite der Patrone an der Markierung. Entsorgen Sie den

Deckel und die schwarze flache Dichtungskappe wie in den Informationen zur Sicherheit und

Entsorgung für gebrauchte Patronen beschrieben.

5. Setzen Sie das Ende des Stahlrohrs in die Mitte der Patrone.

6. Schieben Sie die Patrone vorsichtig in die Messzeile und verschrauben Sie diese dann so, dass

sie luft- und wasserdicht abschließt.

32 Deutsch

Page 33

Abbildung 3 Harzpatrone installieren

Verdrahtungsübersicht

Abbildung 4 zeigt einen Überblick über die Kabelverbindungen im Innenraum des Controllers bei

abgenommener Schutzabdeckung. Auf der linken Seite wird die Rückseite der Controller-Abdeckung

dargestellt.

Hinweis: Entfernen Sie vor der Installation von Modulen die Kappen von den Anschlüssen.

Deutsch

33

Page 34

Abbildung 4 Übersicht der Drahtanschlüsse

1 Servicekabelanschlüsse 5 Anschluss für Wechsel- und

2 Ausgang 4-20 mA

3 Anschluss für Sensormodul 7 Relaiskontakte

4 Anschluss für

Kommunikationsmodul (Modbus,

Profibus, HART, optionales

4-20-mA-Modul usw.)

1

Die Anschlüsse können für besseren Zugang entfernt werden.

1

Gleichspannungsversorgung

6 Masseklemmen 10 Anschluss für Digitalsensor

1

8 Anschluss für Digitalsensor

9 Klemmen für die diskreten

1

Eingänge

1

1

Hochspannungs-Schutzabdeckung

Die Hochspannungskabel für den Controller befinden sich im Controllergehäuse hinter der

Hochspannungs-Schutzabdeckung. Die Schutzabdeckung darf nicht entfernt werden, außer beim

Einbau von Modulen oder beim elektrischen Anschluss von Spannungsversorgung, Alarmen,

Ausgängen oder Relais durch einen qualifizierten Techniker. Die Schutzabdeckung darf nicht

entfernt werden, während Spannung am Controller anliegt.

Kabelbelegung für die Stromversorgung

W A R N U N G

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn

elektrische Anschlüsse durchgeführt werden.

W A R N U N G

Potenzielle Stromschlaggefahr. Wenn dieses Gerät im Freien oder an potenziell feuchten Standorten

eingesetzt wird, muss ein FI-Schutzschalter zum Anschluss an die Netzversorgung verwendet werden.

1

34 Deutsch

Page 35

G E F A H R

Gefahr durch elektrischen Schlag. Schließen Sie ein mit 24 VDC betriebenes Modell nicht an

Wechselstrom an.

W A R N U N G

Potenzielle Stromschlaggefahr. Bei 100-240 VAC- und 24 VDC-Geräten muss ein Erdungsschutzleiter

(PE) angeschlossen werden. Ohne ausreichenden Erdungsschutz besteht Stromschlaggefahr, und das

Gerät kann wegen elektromagnetischer Störungen nicht richtig funktionieren. Schließen Sie IMMER

einen Erdungsschutzleiter an der Steuerungsklemme an.

Installieren Sie das Gerät an einem Standort und in einer Position, wo es zur Bedienung und zum

Abschalten/Abklemmen gut zugänglich ist.

H I N W E I S

Der Controller ist entweder als Modell mit einem auf 100–240 V ausgelegten

Wechselstromanschluss oder als Modell mit einem 24-V-Gleichspannungsanschluss erhältlich.

Folgen Sie den für das von Ihnen erworbene Modell zutreffenden Verkabelungsanweisungen.

Sie können den Controller entweder über ein Netzanschlusskabel an die Spannungsversorgung

anschließen oder ihn in Kabelführungsrohren fest verdrahten. Der Anschluss erfolgt unabhängig vom

Kabeltyp immer an denselben Klemmen. Für alle Installationsarten ist eine entsprechend den

örtlichen elektrischen Vorschriften ausgelegte externe Abschaltmöglichkeit anzubringen. Bei

Anwendungen mit fester Verkabelung der Spannungsversorgung des Geräts muss ein Schutzleiter

mit 18 bis 12 AWG verwendet werden.

Anmerkungen:

• Die Hochspannungs-Schutzabdeckung muss entfernt werden, bevor elektrische Kabel

angeschlossen werden können. Nachdem alle Kabel angeschlossen wurden, muss die

Schutzabdeckung vor dem Schließen der Controller-Abdeckung wieder angebracht werden.

• NEMA-Schutzart 4X/IP66 kann durch eine dichtende Zugentlastung und ein Netzkabel mit einer

maximalen Länge von 3 m und drei Leitern mit einem Querschnitt von 0,80 mm² (AWG 18)

(einschließlich Schutzkontaktleiter) erzielt werden.

• Controller können mit vorinstalliertem Wechselstromnetzkabel bestellt werden. Darüber hinaus

können zusätzliche Netzkabel bestellt werden.

• Die Gleichspannungsquelle, die den mit 24 V Gleichspannung betriebenen Controller versorgt,

muss den Spannungsabfall innerhalb der spezifizierten Schranken von 24 VDC –15% + 20%

halten können. Außerdem muss die Gleichspannungsquelle einen angemessenen Schutz vor

Überspannungen und Stromstößen bieten.

Verdrahtung

Siehe die folgenden illustrierten Schritte und Tabelle 1 oder Tabelle 2, um den Controller an eine

Stromquelle anzuschließen. Stecken Sie die einzelnen Leiter in die entsprechende Klemme, bis die

Isolierung an der Klemme anliegt und kein blanker Leiter sichtbar ist. Ziehen Sie nach dem

Einstecken vorsichtig, um sicherzustellen, dass die Verbindung sicher ist. Versehen Sie alle nicht

benötigten Verschraubungen mit Blindstopfen.

Tabelle 1 Klemmenbelegung bei Wechselspannungsversorgung (nur für Modelle mit

Wechselstromanschluss)

Kontakt Beschreibung Farbe – Nordamerika Farbe - EU

1 Phase (L1) Schwarz Braun

2 Nullleiter (N) Weiß Blau

— Kabelschuh für Schutzerde Grün Grün mit gelben Streifen

Deutsch 35

Page 36

Tabelle 2 Klemmenbelegung bei Gleichstromversorgung (nur für DC-Modelle)

Kontakt Beschreibung Farbe – Nordamerika Farbe - EU

1 +24 VDC Rot Rot

2 24 VDC-Rückführung Schwarz Schwarz

— Kabelschuh für Schutzerde Grün Grün mit gelben Streifen

36 Deutsch

Page 37

Alarme und Relais

Der Controller verfügt über vier potenzialfreie, einpolige Relais-Kontakte 100–250 V~, 50/60 Hz, 5 A

maximal. Die Kontakte haben folgende Nennwerte: 250 V~, max. Schaltlast 5 A bei

wechselstrombetriebenen Controllern bzw. 24 V=, max. Schaltlast 5 A bei gleichstrom betriebenen

Controllern. Die Relais sind nicht für induktive Lasten vorgesehen.

Verdrahtung der Relais

W A R N U N G

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn

elektrische Anschlüsse durchgeführt werden.

W A R N U N G

Potenzielle Brandgefahr Die Relaiskontakte haben einen Nennstrom von 5 A und besitzen keine

Sicherung. Externe Lasten, die an den Relais angeschlossen werden, müssen eine Strombegrenzung

aufweisen, die den Strom auf < 5 A begrenzt.

Potenzielle Brandgefahr Gemeinsame Relaisverbindungen oder der Brückendraht vom

Stromnetzanschluss im Innern des Geräts dürfen nicht verkettet werden.

Potenzielle Stromschlaggefahr. Um die NEMA/IP-Umweltbedingungen des Gehäuses zu wahren,

benutzen Sie zur Verlegung von Kabeln im Geräteinnern nur Rohranschlussstücke und

Kabeldurchführungen, die mindestens NEMA 4X/IP66 erfüllen.

Controller mit Wechselspannungsversorgung (100–250 V)

W A R N U N G

W A R N U N G

Deutsch

37

Page 38

W A R N U N G

Potenzielle Stromschlaggefahr! Die Relais von Controllern mit Anschluss an das Stromnetz (115 230 V) sind für den Anschluss an das Stromnetz (d. h. Spannungen oberhalb von 16 V

Effektivspannung, 22,6 V Spitzenspannung bzw. 35 V Gleichspannung) ausgelegt.

Das Anschlussfach ist nicht für Spannungen über 250 VAC ausgelegt.

DC-Controller (24 V)

W A R N U N G

Potenzielle Stromschlaggefahr! Die Relais von mit 24 Volt Gleichspannung betriebenen Controllern

sind für den Anschluss an Niederspannungskreise (d. h. Spannungen unterhalb von 16 V

Effektivspannung, 22,6 V Spitzenspannung bzw. 35 V Gleichspannung) ausgelegt.

Die Relais von mit 24 Volt Gleichspannung betriebenen Controllern sind für den Anschluss an

Niederspannungskreise ausgelegt (Spannungen unterhalb von 30 V Effektivspannung, 42,2 V

Spitzenspannung bzw. 60 V Gleichspannung). Das Anschlussfach ist nicht für Spannungen

ausgelegt, die darüber liegen.

Die Anschlussklemmen für die Relaiskontakte sind für Kabelquerschnitte von 0,8 bis 3 mm² (18 bis

12 AWG) ausgelegt. Von Kabelgrößen unter 18 AWG wird abgeraten.

Die Relaiskontakte NO (Normally Open) und COM (Common) werden angeschlossen, wenn ein

Alarm oder eine andere Bedingung vorliegen. Die Relaiskontakte NC (Normally Closed) und COM

(Common) werden miteinander verbunden, wenn kein Alarm und keine andere Bedingung vorliegen

(es sei denn, für die Ausfallsicherung (Fail Safe) wurde die Option Yes eingestellt) oder wenn die

Stromversorgung des Controllers ausgeschaltet wird.

Die meisten Relaisanschlüsse verwenden die Kontakte NO und COM bzw. NC und COM. In den

nummerierten Installationsschritten werden die Anschlüsse bei Verwendung der Kontakte NO und

COM beschrieben.

38 Deutsch

Page 39

Anschlüsse des analogen Ausgangs

W A R N U N G

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn

elektrische Anschlüsse durchgeführt werden.

W A R N U N G

Potenzielle Stromschlaggefahr. Um die NEMA/IP-Umweltbedingungen des Gehäuses zu wahren,

benutzen Sie zur Verlegung von Kabeln im Geräteinnern nur Rohranschlussstücke und

Kabeldurchführungen, die mindestens NEMA 4X/IP66 erfüllen.

Zwei isolierte Analogausgänge (1 und 2) stehen zur Verfügung (Abbildung 5). Solche Ausgänge

werden häufig für Analogsignale oder zur Steuerung anderer externer Geräte verwendet.

Erstellen Sie die Anschlüsse für den Controller wie in Abbildung 5 und Tabelle 3 beschrieben.

Hinweis: Abbildung 5 zeigt die Rückseite der Controllerabdeckung, nicht das Innere des Hauptgehäuses des

Controllers.

Tabelle 3 Belegung der Ausgänge

Verdrahtung Aufzeichnungsgerät Position Schaltplatte

Ausgang 2– 4

Ausgang 2+ 3

Ausgang 1– 2

Ausgang 1+ 1

1. Öffnen Sie die Abdeckung des Controllers.

2. Führen Sie die Drähte durch die Zugentlastung.

3. Längen Sie die Drähte nach Bedarf ab, und ziehen Sie die Zugentlastung fest.

Deutsch

39

Page 40

4. Verwenden Sie für den Anschluss abgeschirmte Twisted-Pair-Kabel, und schließen Sie den

Schirm entweder am Ende der geregelten Komponente oder am Ende des Regelkreises an.

• Schließen Sie den Schirm NICHT an beiden Kabelenden an!

• Die Verwendung nicht abgeschirmter Kabel kann zu unzulässig hohen

Hochfrequenzemissionen oder Störempfindlichkeiten führen.

• Der maximale Schleifen-Widerstand beträgt 500 Ohm.

5. Schließen Sie die Abdeckung des Controllers, und ziehen Sie die Schrauben fest.

6. Konfigurieren Sie die Ausgänge im Controller.

Abbildung 5 Anschlüsse des analogen Ausgangs

Anschließen des optionalen digitalen Kommunikationsausgangs

Der Hersteller unterstützt die Kommunikations-Protokolle Modbus RS485, Modbus RS232, Profibus

DPV1 und HART. Das optionale Digitalausgangsmodul wird an der Position eingebaut, die in

Abbildung 4 auf Seite 34 mit 4 angegeben ist. Weitere Einzelheiten finden Sie in den Anweisungen,

die mit dem Netzwerkmodul mitgeliefert werden.

Informationen zu Modbus-Registern finden Sie auf http://www.hach-lange.com oder

http://www.hach.com, indem Sie nach Modbus-Register suchen, oder auf jeder sc200-Produktseite.

Verlegen der Proben- und Ablaufleitungen

Nachdem das Paneel an der Wand montiert wurde, verbinden Sie die Proben- und Ablaufleitungen

mit den Anschlüssen am Paneel. Vergewiessern Sie sich, dass die Schläuche die Spezifikationen

auf Seite 25 erfüllen. Beachten Sie die folgenden Schritte und Abbildung 1 auf Seite 30.

1. Setzen Sie die Probenleitung in den Schnellanschluss unter der Durchflusskammer ein

(Abbildung 1 auf Seite 30).

2. Verbinden Sie eine Ablaufleitung mit dem Probenauslassanschluss. Sorgen Sie dafür, dass die

Ablaufleitung so kurz wie möglich ist, sodass kein Gegendruck entstehen kann.

Analysator starten

1. Öffnen Sie das Entlüftungsventil.

2. Öffnen Sie das Probenflusseinstellventil und stellen Sie sicher, dass alles wasserdicht ist und

keine Undichtigkeiten vorhanden sind.

3. Schließen Sie das Entlüftungsventil, wenn keine Luft mehr in der Messzelle ist.

40

Deutsch

Page 41

4. Stellen Sie den Probenfluss auf den erforderlich Durchsatz ein (zwischen 5 und 20 l/h).

5. Lassen Sie ca. 10 Liter Probe durch das neue Harz fließen, um es auszuspülen und um den

Analysator für die Messungen vorzubereiten.

Benutzeroberfläche und Navigation

Benutzeroberfläche

Das Tastenfeld umfasst vier Menütasten und vier Pfeiltasten (siehe Abbildung 6).

Abbildung 6 Überblick über das Tastenfeld und die Frontplatte des Controllers

1 Instrumentenanzeige 5 BACK-Taste. Führt in den Menüebenen um eine

2 Abdeckung des Steckplatzes für SD-Speicherkarten 6 MENU-Taste. Hiermit navigieren Sie von einem

3 HOME-Taste. Hiermit kehren Sie von einem

beliebigen Bildschirm oder Untermenü wieder zum

Haupt-Messbildschirm zurück.

4 ENTER-Taste. Durch Drücken dieser Taste werden

eingegebene Werte, Aktualisierungen oder

angezeigte Menüoptionen übernommen.

Stufe zurück.

beliebigen Bildschirm oder Untermenü zum

Einstellungsmenü.

7 Pfeiltasten. Hiermit können Sie durch die Menüs

navigieren, Einstellungen ändern oder den Wert von

Ziffern vergrößern und verkleinern.

Die Einrichtung und Konfiguration der Ein- und Ausgänge erfolgt über das Tastenfeld und das

Display an der Frontplatte. Über diese Benutzeroberfläche können Ein- und Ausgänge eingerichtet

und konfiguriert, Protokolldaten und berechnete Werte erstellt sowie Sensoren kalibriert werden.

Über die SD-Speicherkartenschnittstelle können Protokolle gespeichert und SoftwareAktualisierungen durchgeführt werden.

Betrieb

Kontakt-Leitfähigkeitssensor konfigurieren

Verwenden Sie das Konfigurationsmenü CONFIGURE, um eine Identifizierungsinformation für den

Sensor einzugeben und die Optionen für die Datenverwaltung und -speicherung zu ändern.

Deutsch

41

Page 42

1. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CONFIGURE

(Sensoreinstellung>Sensor wählen>Konfigurieren) auswählen.

2. Wählen Sie eine Option aus und drücken Sie dann ENTER. Zur Eingabe der Zahlen, Zeichen

oder Satzzeichen die Pfeiltasten nach oben oder nach unten drücken und halten. Mit der

rechten Pfeiltaste zum nächsten Feld gehen.

Option Beschreibung

EDIT NAME Definiert den dem Sensor zugewiesenen Namen, der oben in der Messanzeige

SENSOR-S/N Ermöglicht dem Benutzer die Eingabe einer Sensor-Seriennummer. Die Nummer kann

SELECT MEASURE Stellt für den Messparameter die Optionen CONDUCTIVITY (Leitfähigkeit = Standard),

DISPLAY FORMAT Ändert die Anzahl der Dezimalstellen, die auf der Messanzeige dargestellt werden. Bei

MEAS UNITS Ändert die Einheiten für die gewählte Messung - wählen Sie eine Einheit aus der

TEMP UNITS Legt für die Temperatureinheit die Einstellung °C (Standard) oder °F fest.

T-COMPENSATION Addiert eine temperaturabhängige Korrektur zu dem gemessenen Wert.

erscheint. Der Name kann maximal 16 Zeichen bestehen und Buchstaben, Zahlen,

Leerzeichen und Satzzeichen enthalten. Nur die ersten 12 Zeichen werden auf dem

Controller angezeigt.

maximal aus 16 Zeichen bestehen und Buchstaben, Zahlen, Leerzeichen und

Satzzeichen enthalten.

TDS (vollständig gelöste Feststoffe), SALINITY (Salzgehalt) oder RESISTIVITY

(Resistivität) ein. Alle anderen konfigurierten Einstellungen werden auf die

Standardwerte zurückgestellt.

Hinweis: Bei der Auswahl der Option SALINITY (Salzgehalt) wird für die Messeinheit

automatisch ppt (parts per thousand) eingestellt. Diese Einstellung kann nicht

verändert werden.

der Einstellung "Auto" wird die Anzahl der Dezimalstellen automatisch mit den

Änderungen der gemessenen Werte geändert.

vorhandenen Liste aus.

• NONE—Temperaturkompensation nicht erforderlich

• USP—Einstellen des Alarmniveaus für die USP-Standarddefinitionstabelle

• ULTRA PURE WATER (Ultrareines Wasser) - Nicht für TDS verfügbar. Stellt die

Kompensierungsart in Abhängigkeit von den Probeneigenschaften ein—Wählen Sie

NaCl , HCl, AMMONIA oder ULTRA PURE WATER

• USER—BUILT IN LINEAR, LINEAR oder TEMP TABLE wählen:

• BUILT IN LINEAR—Die vordefinierte lineare Wertetabelle verwenden (Steigung

2,0%/°C, Referenztemperatur 25 °C)

• LINEAR—Einstellen der Steigungs- und Referenztemperaturparameter weicht

von den integrierten Parametern ab

• TEMP TABLE—Die Temperatur- und Multiplikationsfaktorpunkte festlegen (siehe

die Dokumentation für das Leitfähigkeitsmodul)

• NATURAL WATER—Nicht für TDS verfügbar

CONFIG TDS Nur TDS—ändert den Faktor, der zur Umwandlung der Leitfähigkeit zu TDS verwendet

CABLE PARAM Einstellen der Sensorkabelparameter, um die Messgenauigkeit zu verbessern, wenn

TEMP ELEMENT Stellt für das Temperaturelement PT100 oder PT1000 für die automatische

FILTER Definiert eine Zeitkonstante zur Verbesserung der Signalstabilität. Die Zeitkonstante

wird: NaCl (0,49 ppm/µS) oder CUSTOM (Faktor zwischen 0,01 und 99,99 ppm/µS

eingeben).

das Sensorkabel über die 5 m Standardlänge hinaus verlängert oder gekürzt wird.

Geben Sie die Kabellänge, den Widerstand und die Leitfähigkeit ein.

Temperaturkompensation ein. Wenn kein Element verwendet wird, kann hier die

Einstellung MANUAL eingestellt werden, um einen Wert für die

Temperaturkompensation einzugegeben.

berechnet den Durchschnittswert innerhalb eines festgelegten Zeitraums -0 (No Effect)

bis 60 Sekunden (Durchschnitt des Signalwerts für 60 Sekunden). Der Filter erhöht die

Ansprechzeit des Sensorsignals auf aktuelle Prozessänderungen.

42 Deutsch

Page 43

Option Beschreibung

LOG SETUP Legt das Zeitintervall für die Datenspeicherung im Datenprotokoll fest— 5 oder

RESET DEFAULTS Setzt das Konfigurationsmenü auf die Standardeinstellungen zurück. Alle

30 Sekunden und 1, 2, 5, 10, 15 (Standard), 30 oder 60 Minuten.

Sensorinformationen gehen verloren.

Harz-Option

Die Option RESIN (Harz-Option) wird verwendet, um die Parameter der Harzpatrone anzuzeigen und

zu ändern. Diese Parameter müssen vor der Erstinbetriebnahme des Analysators definiert werden.

1. Die Menü-Taste drücken und TEST/MAINT>RESIN (Test>Wartung>Harz) auswählen.

2. Zur Überwachung des Harzstatus wählen Sie die Option TRACK (Nachverfolgen) und drücken

dann Enter.

Option Beschreibung

YES Harzstatus überwachen. Liegt die erwartete Nutzungsdauer des Harzes unter 10 Tagen, wird eine

Warnmeldung ausgegeben. Liegt die erwartete Nutzungsdauer des Harzes bei 0 Tagen, wird ein

Systemfehler ausgegeben.

NO Harzstatus nicht überwachen.

3. Für die Anzeige des aktuellen Harzstatus wählen Sie die Option STATUS und drücken dann

Enter. Jetzt werden das Datum, an dem der Harz zuletzt gewechselt wurde, und die erwartete

Nutzungsdauer angezeigt. Drücken Sie auf Back, um zum Menü zurückzukehren oder Enter, um

die Parameter zurückzusetzen.

4. Zur Rückstellung der Harzparameter wählen Sie PARAMETER und drücken Enter. Ausgehend

von den Eingabewerten wird die erwartete Nutzungsdauer des Harzes berechnet.

Option Beschreibung

CAPACITY Mithilfe der Pfeiltasten die Harzaustauschkapazität (0,5 bis 5,0 mol/l) eingeben.

VOLUME Mithilfe der Pfeiltasten das Harzvolumen (0,5 bis 20 l) eingeben.

FLOW Mithilfe der Pfeiltasten die Veränderung Probenflussrate durch die Kartusche (2 bis

CONCENTRATION Mithilfe der Pfeiltasten die Harzkonzentration (0 bis 20 ppm) eingeben.

20 l/h) eingeben.

Kalibrierung

Hinweise zur Sensorkalibrierung

Im Laufe der Zeit verändert sich die Sensoreigenschaften, wodurch der Sensor an Genauigkeit

verliert. Um die gewünschte Genauigkeit zu erhalten, muss der Sensor regelmäßig kalibriert werden.