Page 1

DOC023.98.93060

Ultrapure Conductivity Module

10/2013, Edition 3

User Manual

Benutzerhandbuch

Manuale d'uso

Manuel d'utilisation

Manual de usuario

Manual do utilizador

Gebruikershandleiding

Instrukcja obsługi

Käyttäjän käsikirja

Руководство пользователя

用户手册

Page 2

English..............................................................................................................................3

Deutsch..........................................................................................................................22

Italiano............................................................................................................................43

Français.........................................................................................................................63

Español..........................................................................................................................83

Português....................................................................................................................105

中文...............................................................................................................................126

Nederlands.................................................................................................................143

Polski............................................................................................................................164

Suomi............................................................................................................................184

Русский........................................................................................................................204

2

Page 3

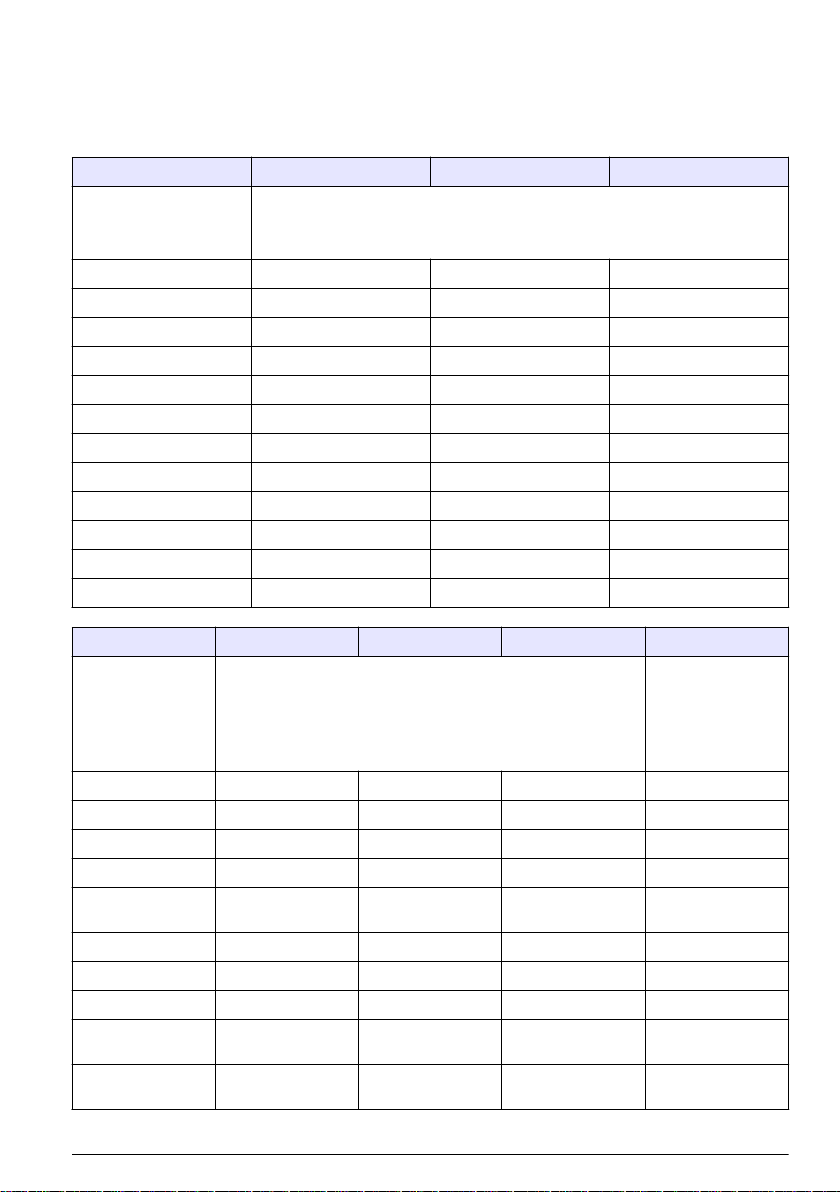

Specifications

Specifications are subject to change without notice.

Contacting conductivity sensors

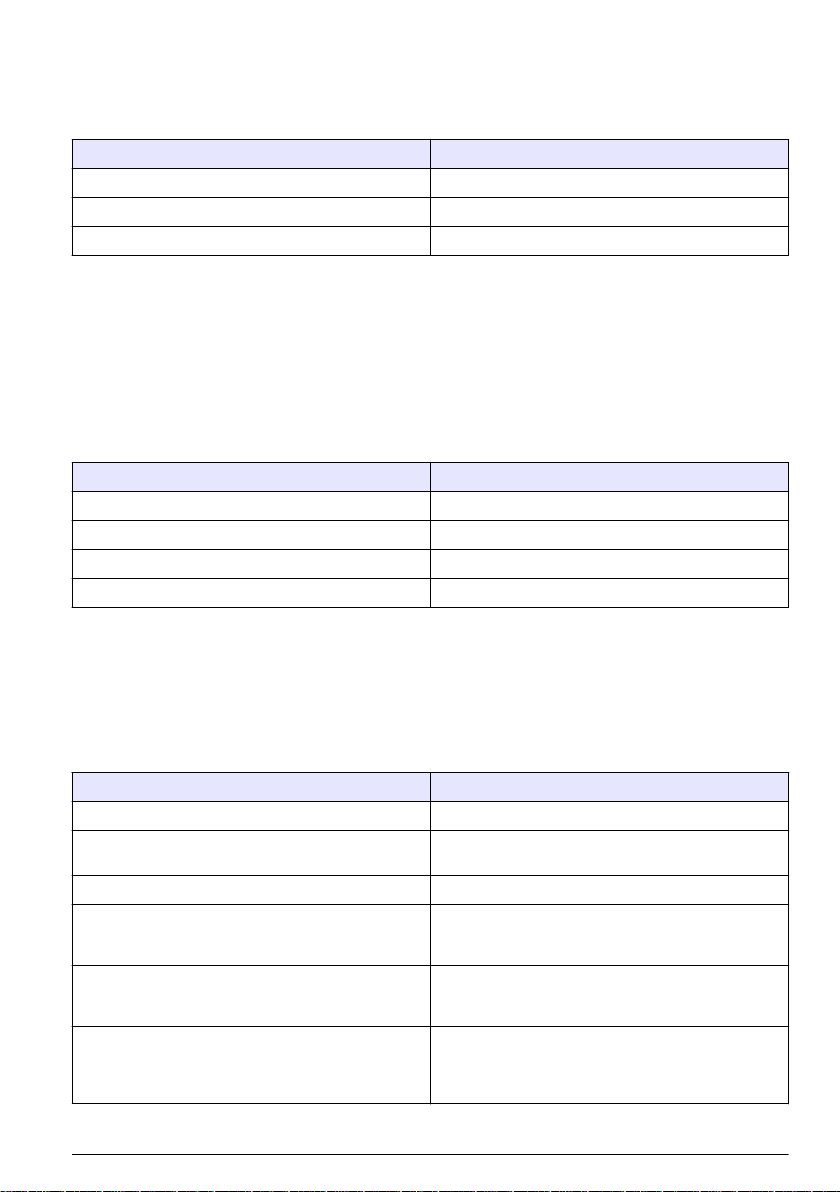

Specification 8310 8311 8312

Drinking water and wastewater treatment

Application

Body material Black PSU Black PSU Black PSU

Internal electrode SS 316L SS 316L Graphite

External electrode SS 316L SS 316L Graphite

Insulator PSU PSU PSU

Connector Glass polyester (IP65) Glass polyester (IP65) Glass polyester (IP65)

Cell constant K 0.01 (cm-1) 0.1 (cm-1) 1.0 (cm-1)

Accuracy < 2% < 2% < 2%

Measurement range 0.01—200 μS.cm

Temperature response < 30 seconds < 30 seconds < 30 seconds

Maximum temperature 125 °C 125 °C 125 °C

Maximum pressure 10 bars 10 bars 10 bars

Sample connection ¾ inch NPT ¾ inch NPT ¾ inch NPT

Specification 8315 8316 8317 8394

Application

Body material SS 316L SS 316L SS 316L SS 316L

Internal electrode SS 316L SS 316L Graphite SS 316L

External electrode SS 316L SS 316L Graphite SS 316L

Insulator PES PES PES PEEK

Connector Glass polyester

Cell constant K 0.01 (cm-1) 0.1 (cm-1) 1.0 (cm-1) 0.01 (cm-1)

Accuracy < 2% < 2% < 2% < 2%

Measurement range 0.01—200 μS.cm-10.1 μS—2 mS.cm-11 μS—20 mS.cm-10.01—200 μS.cm

Temperature

response

Maximum

temperature

Process water monitoring (condensates, cleaning cycles, heat

(IP65)

< 30 seconds < 30 seconds < 30 seconds < 30 seconds

150 °C 150 °C 150 °C 150 °C

-1

Pure water production

exchangers)

Glass polyester

Chemical processes

Demineralized and softened water

0.1 μS—2 mS.cm

(IP65)

-1

Glass polyester

(IP65)

1 μS—20 mS.cm

Monitoring of

ultrapure water in

pharmaceutical and

food industries

Suitable for CIP-SIP

processes

Glass polyester

(IP65)

-1

-1

English 3

Page 4

Specification 8315 8316 8317 8394

Maximum pressure 25 bars 25 bars 25 bars 25 bars

Sample connection ¾ inch NPT ¾ inch NPT ¾ inch NPT

Tri-Clamp 1½ or

2 inch

Inductive conductivity sensors

Specification 8398 series 8332

Application Corrosive and fouling applications Measurement in harsh conditions

Material PEEK PVDF

Cell constant K 2.35 (cm-1) 10 (cm-1)

Accuracy ± 2 % ± 2 %

Measurement range 0—2000 mS/cm 100 μS/cm—10 S/cm

Conductivity response < 1 second < 1 second

Temperature response < 2 minutes < 2 minutes

Maximum pressure 18 bars 7.5 bars

Maximum temperature 140 °C 120 °C

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

4 English

D A N G E R

W A R N I N G

C A U T I O N

Page 5

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary

statement.

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems. In conformity with European local and national regulations, European electrical equipment

users must now return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Product overview

The module, when installed in an sc200 or a Polymetron 9500 controller, allows an analog sensor to

connect to the controller.

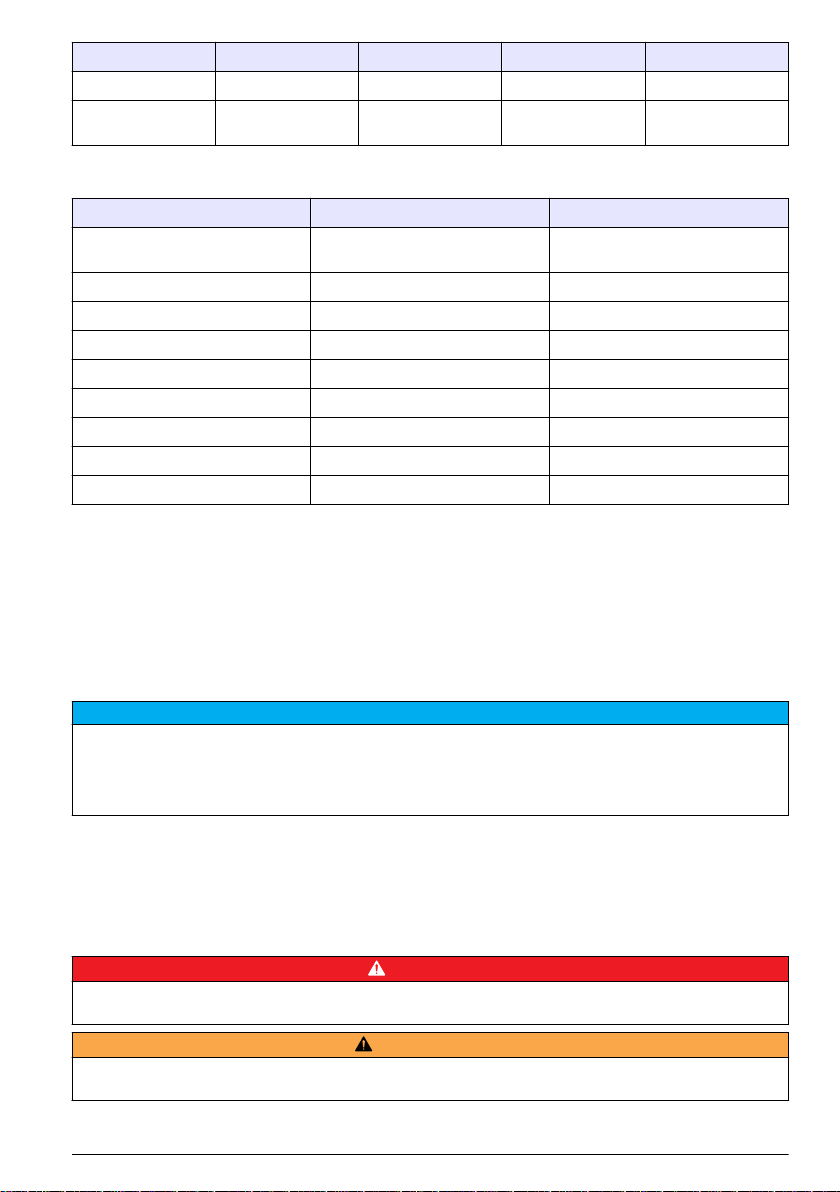

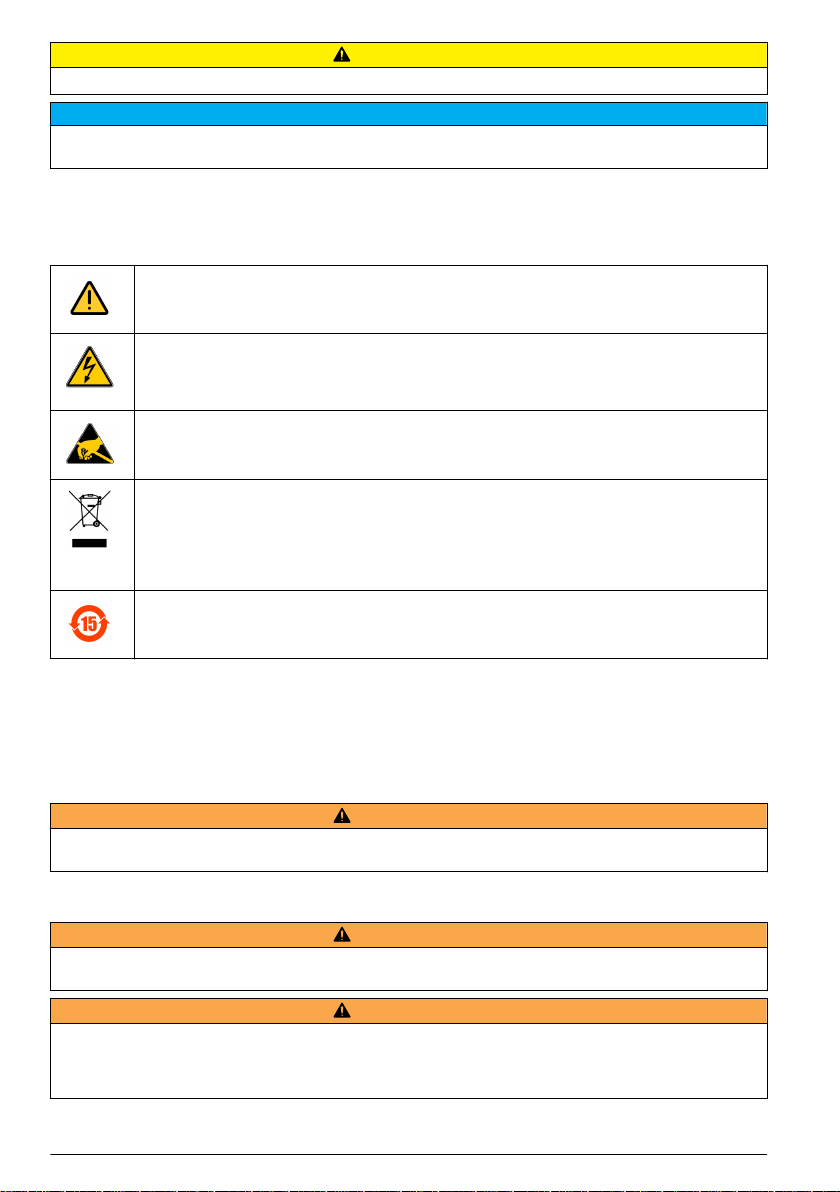

Installation

W A R N I N G

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the document.

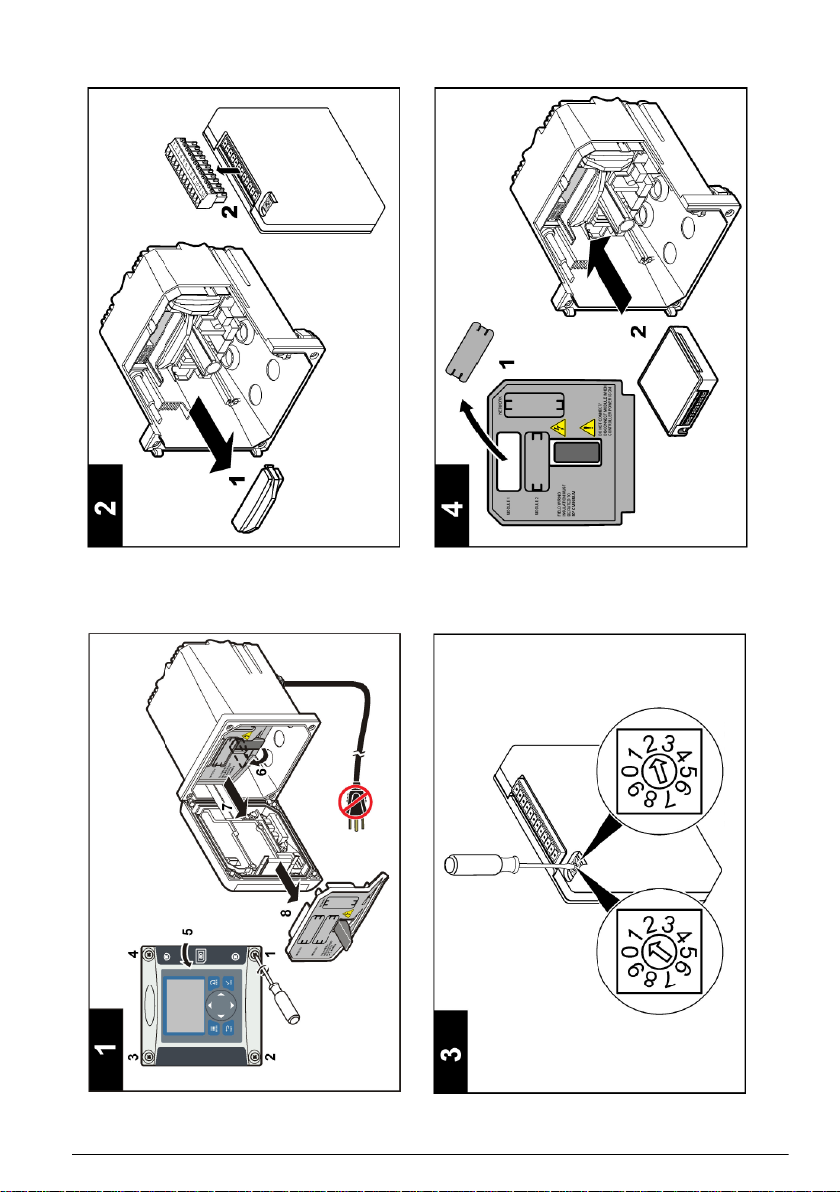

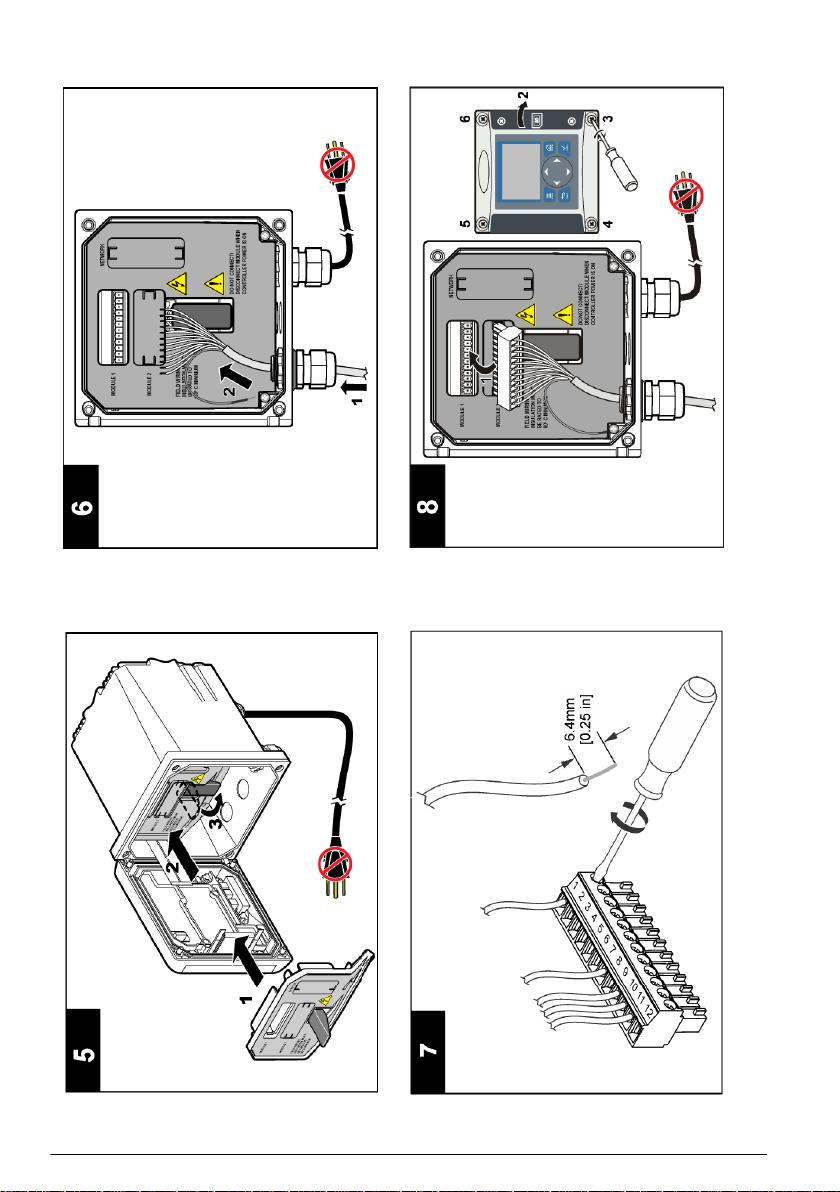

Connect the sensor to the module

Potential electrocution hazard. Always disconnect power to the controller when making electrical connections.

Electrocution hazard. High voltage wiring for the controller is conducted behind the high voltage barrier in the

controller enclosure. The barrier must remain in place except when installing modules, or when a qualified

installation technician is wiring for power, relays or analog and network cards.

Potential instrument damage. Delicate internal electronic components can be damaged by static electricity,

resulting in degraded performance or eventual failure.

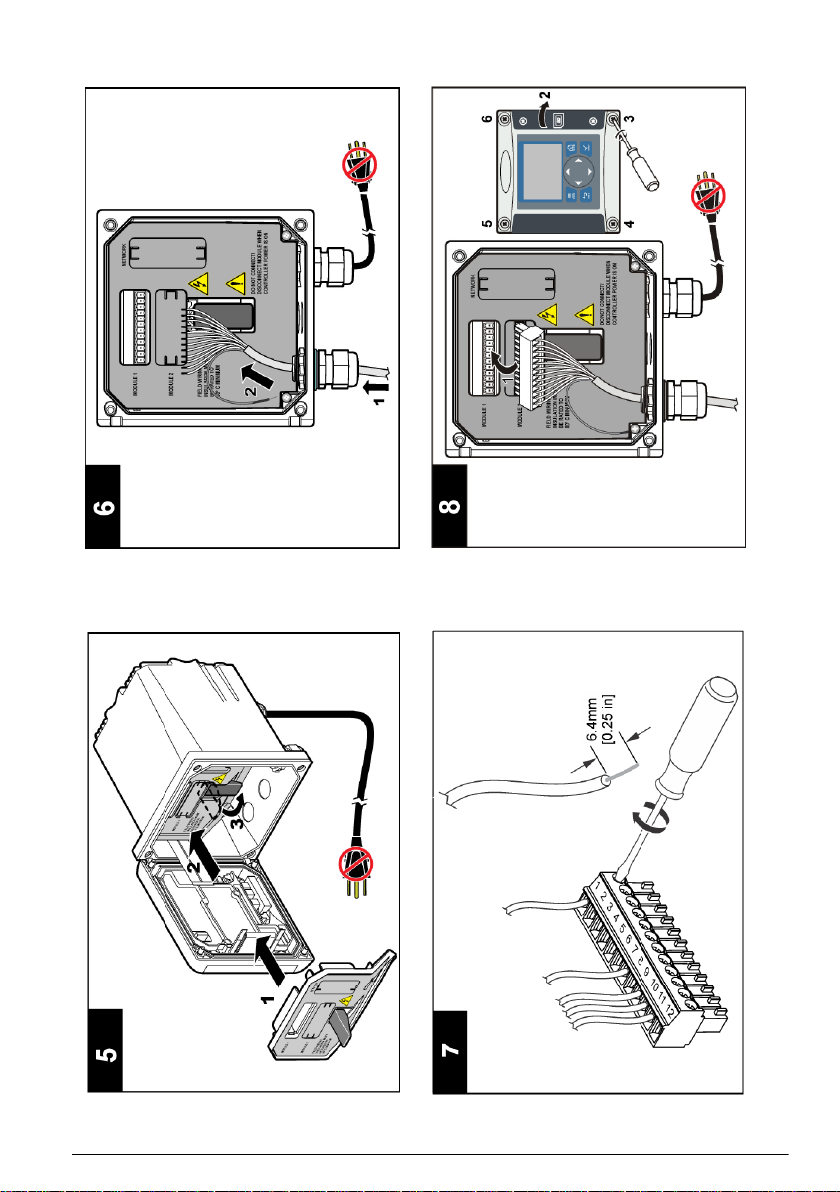

To install the module and connect the sensor, refer to the illustrated steps that follow and the wiring

table.

Be sure to connect all sensor ground/shield wires to the controller enclosure grounding screws.

W A R N I N G

W A R N I N G

N O T I C E

English

5

Page 6

Note: If the sensor cable is not long enough to reach the controller, an interconnect cable (model 150727,10000)

and junction box (model 08335=A=6000) should be used to extend the distance.

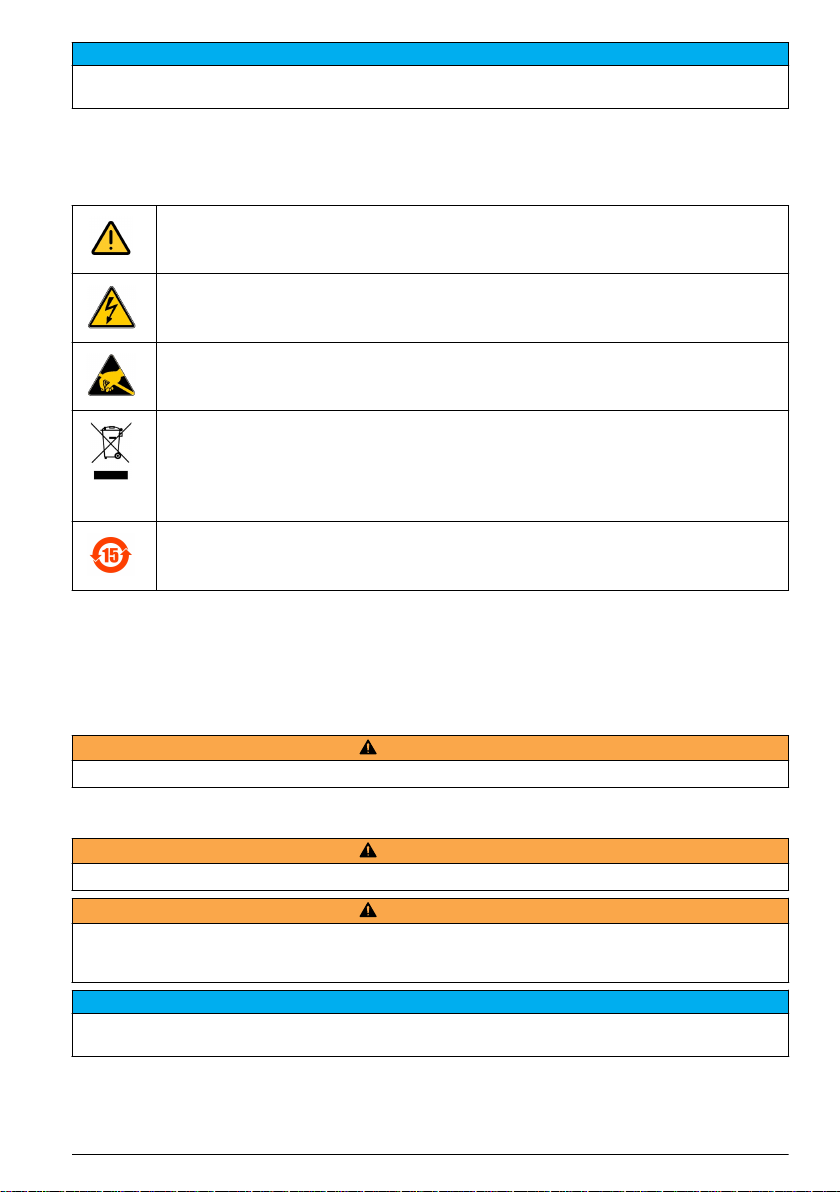

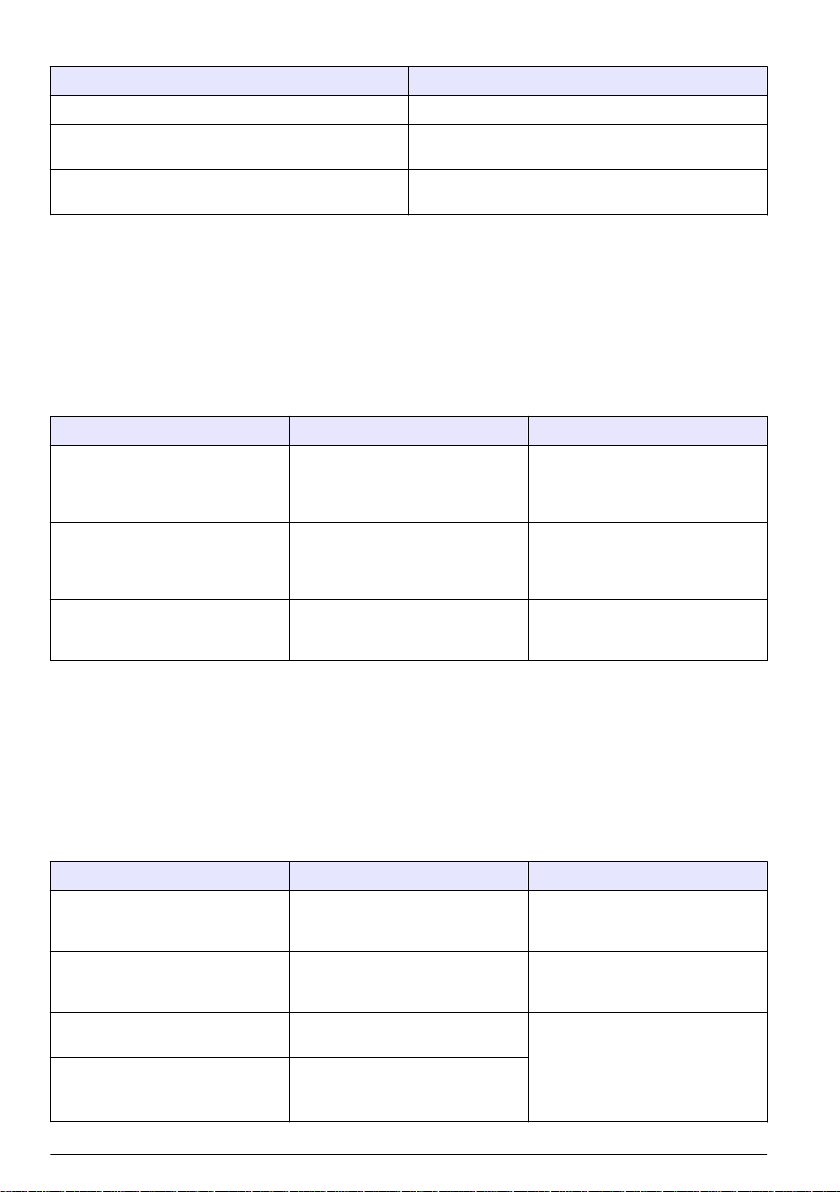

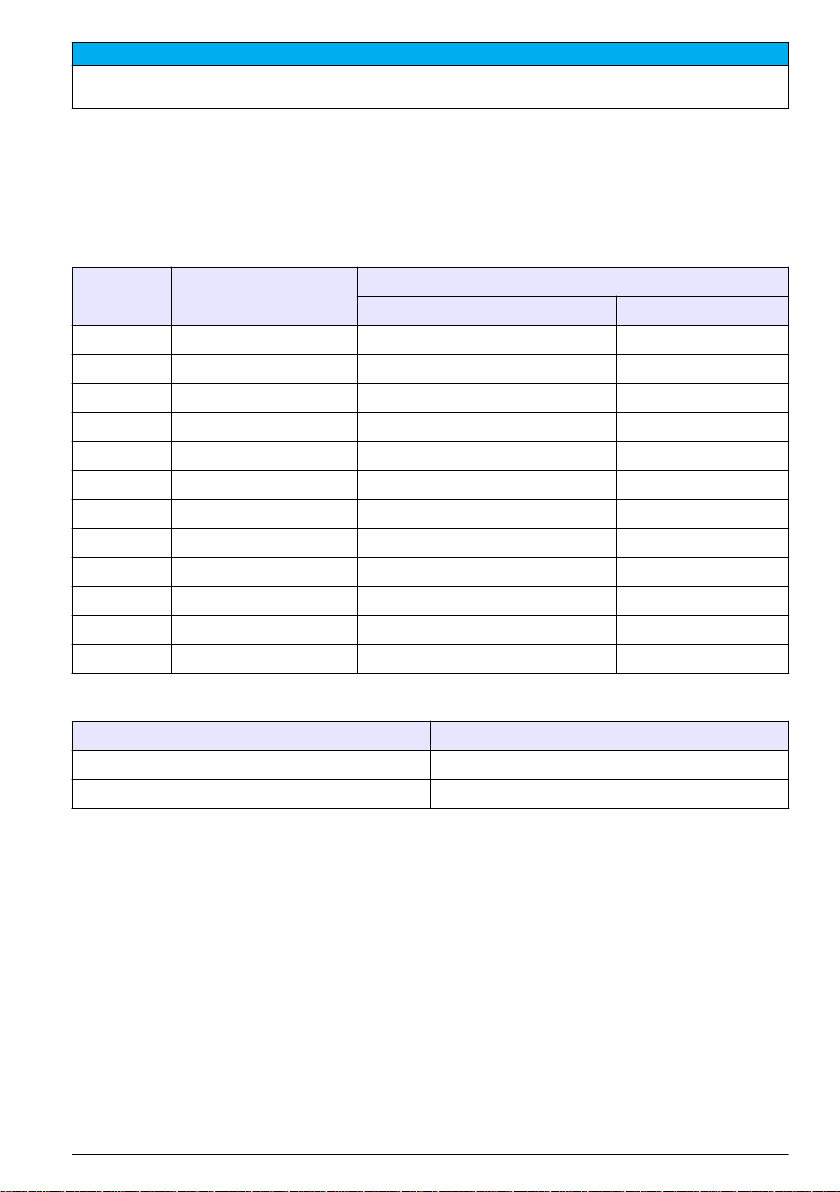

Table 1 Conductivity sensor wiring

Terminal Description Sensor

8398 831x and 8394

1 Inner electrode White (white cable) White

2 Inner electrode Black (white cable) —

3 Ground — Green

4 — — —

5 — — —

6 — — —

7 Temp - Green Black

8 — — —

9 — — —

10 Temp + Yellow Yellow

11 Outer electrode Brown (brown cable) Red

12 Outer electrode Black (brown cable) —

In Step 3 of the following sequence, set the switch as follows:

Switch Setting Description

Setting 1 Contacting conductivity sensor

Setting 2 Inductive conductivity sensor

6 English

Page 7

English 7

Page 8

8 English

Page 9

Operation

User navigation

Refer to the User interface and navigation section of the controller documentation for keypad

description and navigation information.

Sensor configuration

Contacting conductivity sensor configuration

Use the CONFIGURE menu to enter identification information for the sensor and to change options

for data handling and storage.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CONFIGURE.

2. Select an option and push enter. To enter numbers, characters or punctuation, push and hold the

up or down arrow keys. Push the right arrow key to advance to the next space.

Option Description

EDIT NAME Changes the name that corresponds to the sensor on the top of the measure screen.

SENSOR S/N Allows the user to enter the serial number of the sensor, limited to 16 characters in any

SELECT MEASURE Changes the measured parameter to CONDUCTIVITY (default), TDS (total dissolved

DISPLAY FORMAT Changes the number of decimal places that are shown on the measure screen. When

MEAS UNITS Changes the units for the selected measurement—select the unit from the list

TEMP UNITS Sets the temperature units to °C (default) or °F.

T-COMPENSATION Adds a temperature-dependent correction to the measured value:

The name is limited to 16 characters in any combination of letters, numbers, spaces or

punctuation. Only the first 12 characters are displayed on the controller.

combination of letters, numbers, spaces or punctuation.

solids), SALINITY or RESISTIVITY. All other configured settings are reset to the

default values.

Note: If SALINITY is selected, the measurement unit is defined as ppt (parts per

thousand) and cannot be changed.

set to auto, the number of decimal places changes automatically with changes in the

measured value.

available.

• NONE—Temperature compensation not required

• USP—Set the alarm level for the standard USP definition table

• ULTRA PURE WATER—Not available for TDS. Set the compensation type

according to the sample characteristics—Select NaCl , HCl, AMMONIA or ULTRA

PURE WATER

• USER—Select BUILT IN LINEAR, LINEAR or TEMP TABLE:

• BUILT IN LINEAR—Use the pre-defined linear table (slope defined as 2.0%/°C,

reference temperature as 25 °C)

• LINEAR—Set the slope and reference temperature parameters if different from

the built-in parameters

• TEMP TABLE—Set the temperature and multiplication factor points (refer to

Configure user tables on page 11)

• NATURAL WATER—Not available for TDS

CONFIG TDS TDS only—changes the factor that is used to convert conductivity to TDS: NaCl

CABLE PARAM Sets the sensor cable parameters to improve measurement accuracy when the sensor

(0.49 ppm/µS) or CUSTOM (enter factor between 0.01 and 99.99 ppm/µS).

cable is extended or shortened from the standard 5 m. Enter the cable length,

resistance and capacitance.

English 9

Page 10

Option Description

TEMP ELEMENT Sets the temperature element to PT100 or PT1000 for automatic temperature

FILTER Sets a time constant to increase signal stability. The time constant calculates the

LOG SETUP Sets the time interval for data storage in the data log—5, 30 seconds, 1, 2, 5, 10,

RESET DEFAULTS Sets the configuration menu to the default settings. All sensor information is lost.

compensation. If no element is used, the type can be set to MANUAL and a value for

temperature compensation can be entered.

average value during a specified time—0 (no effect) to 60 seconds (average of signal

value for 60 seconds). The filter increases the time for the sensor signal to respond to

actual changes in the process.

15 (default), 30, 60 minutes.

Inductive conductivity sensor configuration

Use the CONFIGURE menu to enter identification information for the sensor and to change options

for data handling and storage.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CONFIGURE.

2. Select an option and push enter. To enter numbers, characters or punctuation, push and hold the

up or down arrow keys. Push the right arrow key to advance to the next space.

Option Description

EDIT NAME Changes the name that corresponds to the sensor on the top of the measure screen.

SENSOR S/N Allows the user to enter the serial number of the sensor, limited to 16 characters in any

SELECT MEASURE Changes the measured parameter to CONDUCTIVITY (default), RESISTIVITY,

DISPLAY FORMAT Changes the number of decimal places that are shown on the measure screen. When

MEAS UNITS Changes the units for the selected measurement—select the unit from the list

TEMP UNITS Sets the temperature units to °C (default) or °F.

T-COMPENSATION Adds a temperature-dependent correction to the measured value:

The name is limited to 16 characters in any combination of letters, numbers, spaces or

punctuation. Only the first 12 characters are displayed on the controller.

combination of letters, numbers, spaces or punctuation.

SALINITY, TDS (total dissolved solids) or CONCENTRATION. All other configured

settings are reset to the default values.

Note: If SALINITY is selected, the measurement unit is defined as ppt (parts per

thousand) and cannot be changed.

set to auto, the number of decimal places changes automatically with changes in the

measured value.

available.

• LINEAR—Set the slope and reference temperature parameters

• NATURAL WATER—Not available for TDS or CONCENTRATION

• TEMP TABLE—Set the temperature and multiplication factor points (refer to

Configure user tables on page 11)

• NONE—Temperature compensation not required

CONFIG TDS TDS only—changes the factor that is used to convert conductivity to TDS: NaCl

(0.49 ppm/µS) or CUSTOM (enter factor between 0.01 and 99.99 ppm/µS).

10 English

Page 11

Option Description

CONFIG CONC CONCENTRATION only—sets the type of concentration table to use.

• BUILT-IN—Set the CHEMICAL that is measured:

• H2SO4 0-30%

• HNO3 0-28%

• HCl 0-18%

• NaOH 0-16%

Note: Although the range is shown as 0-16%, the tables can be more accurately

defined as 0-10% for all temperatures.

• NaCl 0-25%

• H3PO4 0-40%

• USER TABLE—Set the conductivity and concentration% points (refer to Configure

user tables on page 11)

TEMP ELEMENT Sets the temperature element to PT100 or PT1000 for automatic temperature

FILTER Sets a time constant to increase signal stability. The time constant calculates the

LOG SETUP Sets the time interval for data storage in the data log—5, 30 seconds, 1, 2, 5, 10,

RESET DEFAULTS Sets the configuration menu to the default settings. All sensor information is lost.

compensation. If no element is used, the type can be set to MANUAL and a value for

temperature compensation can be entered.

average value during a specified time—0 (no effect) to 60 seconds (average of signal

value for 60 seconds). The filter increases the time for the sensor signal to respond to

actual changes in the process.

15 (default), 30, 60 minutes.

Configure user tables

Depending on the type of sensor and the type of measurement required, user-defined tables can be

selected during sensor configuration. The following explains how to configure a user-defined table.

Concentration tables

By default, this table contains only 2 points (P1 and P2) that define the minimum and maximum

limits. When P1 and P2 have been defined, additional points can be inserted between them. As an

example to define the minimum conductivity and concentration as zero, and the maximum

conductivity as 750 with a maximum concentration of 30. proceed as follows:

1. From the USER TABLE option select P1>EDIT POINT.

2. Enter the minimum conductivity (X) as 0.0 and push enter.

3. Enter the minimum concentration% (Y) as 0.0 and push enter.

4. Select SAVE CHANGES? and push enter.

5. From the USER TABLE option select P2>EDIT POINT.

6. Enter the maximum conductivity (X) as 750.0 and push enter.

7. Enter the maximum concentration% (Y) as 30.0 and push enter.

8. Select SAVE CHANGES? and push enter.

The following table has been defined:

Conductivity Concentration%

P1 0 0

P2 750 30

To insert an additional point with a conductivity of 250 and a concentration of 15, select the point with

a conductivity value immediately above the value to insert. In this example select P2. The new

conductivity value of 250 will then become P2 and the existing P2 will become P3 as follows:

English

11

Page 12

1. From the USER TABLE option select P2>INSERT POINT.

2. Enter the conductivity (X) as 250.0 and push enter.

3. Enter the concentration% (Y) as 15.0 and push enter.

4. Select SAVE CHANGES? and push enter.

The table will now be defined as:

Conductivity Concentration%

P1 0 0

P2 250 15

P3 750 30

Additional points can be inserted up to a maximum of P10.

Note: The conductivity value taken into account is temperature compensated according to the temperature

compensation option configured.

Temperature tables

The process is the same as described for the concentration tables, but the X value refers to

temperature and the Y value is a factor used to multiply against the non-compensated conductivity

value to obtain a temperature compensated conductivity value.

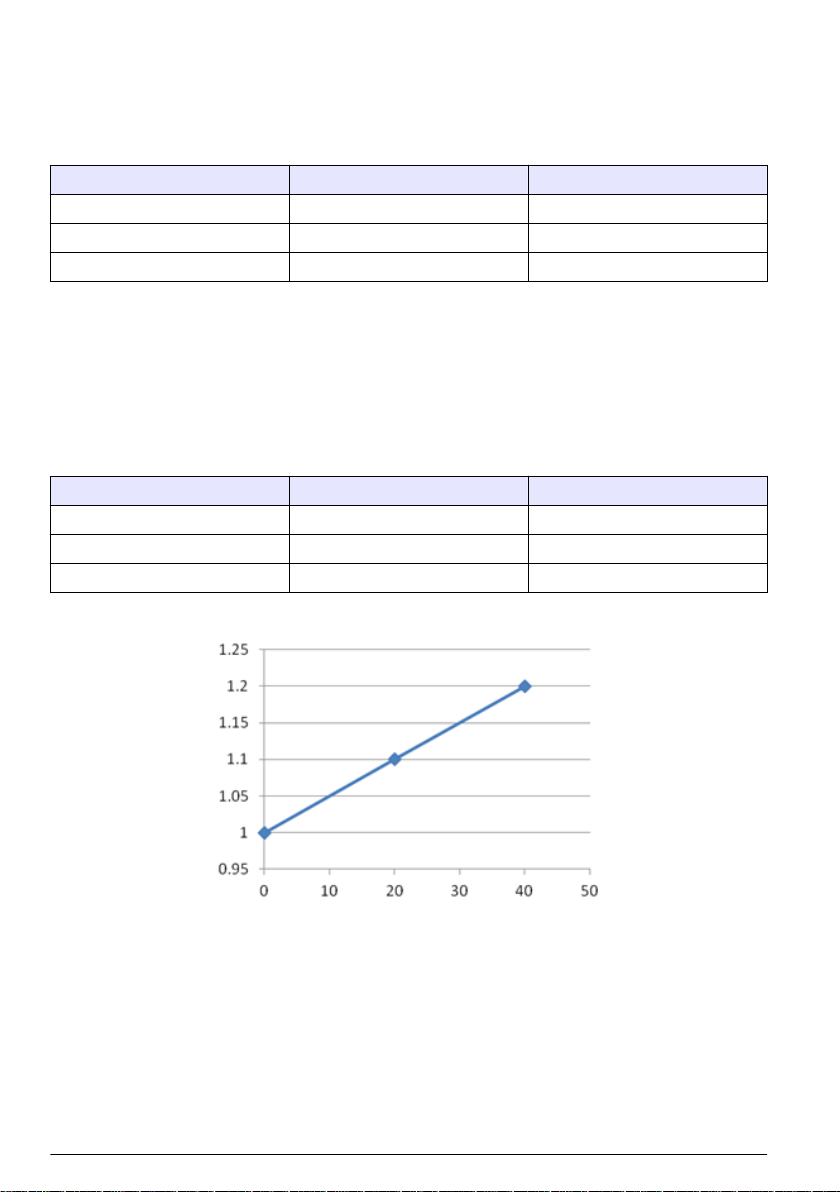

For example, if the temperature table was configured as follows:

Temperature Value

P1 0 1

P2 20 1.1

P3 40 1.2

This can be displayed graphically as:

This shows that a temperature of 10° corresponds to a factor of 1.05. Therefore, a non-compensated

conductivity value of 10 mS/cm at 10° will give a temperature compensated value of 10.5 mS/cm (i.e.

10 mS/cm multiplied by a factor of 1.05).

Calibrate the sensor

About sensor calibration

The sensor characteristics slowly shift over time and cause the sensor to lose accuracy. The sensor

must be calibrated regularly to maintain accuracy. The calibration frequency varies with the

application and is best determined by experience.

12

English

Page 13

Contacting conductivity sensors: Use air (zero calibration) and the process sample to define the

calibration curve. When the process sample is used, the reference value must be determined with a

certified secondary verification instrument.

Inductive conductivity sensors: Use air (zero calibration) and a reference solution or process

sample to define the calibration curve. A reference solution calibration is recommended for best

accuracy. When the process sample is used, the reference value must be determined with a certified

secondary verification instrument.

Calibration limits

A calibration will fail if the value is ± 10% of the target value.

Cell constant

Before making a calibration make sure the sensor cell parameters are correct.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select CELL CONSTANT and push enter.

4. Contacting conductivity sensors: Select the cell K range for the sensor (0.01, 0.1 or 1.0) then

enter the actual K value as printed on the label attached to the sensor.

Inductive conductivity sensors: Enter the actual K value as printed on the label attached to the

sensor.

Zero calibration procedure

Use the zero calibration procedure to define the unique zero point of the sensor.

1. Remove the sensor from the process. Wipe with a clean towel to make sure the sensor is dry.

2. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

3. If the pass code is enabled in the security menu for the controller, enter the pass code.

4. Select ZERO CAL and push enter.

5. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

6. Place the sensor in air, push enter.

7. Review the calibration result:

• PASS—the sensor is calibrated and ready to measure samples.

• FAIL—the calibration is outside of accepted limits. Clean the sensor and retry. Refer to

Troubleshooting on page 18 for more information.

8. If the calibration passed, push enter to continue.

9. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 17.

10. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

NO The sensor was calibrated previously with this controller.

the preset value.

calibration curves for the sensor are reset.

English 13

Page 14

11. Return the sensor to the process and push enter. The output signal returns to the active state

and the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

Calibration with the process sample

The sensor can remain in the process sample, or a portion of the process sample can be removed

for calibration.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select SAMPLE CAL and push enter.

4. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

5. With the sensor in the process sample, push enter. The measured value is shown. Wait for the

value to stabilize and push enter.

6. Measure the conductivity value with a certified secondary verification instrument. Use the arrow

keys to enter this value if different from the value displayed and push enter.

7. Review the calibration result:

• PASS—the sensor is calibrated and ready to measure samples.

• FAIL—the calibration is outside of accepted limits. Clean the sensor and retry. Refer to

Troubleshooting on page 18 for more information.

8. If the calibration passed, push enter to continue.

9. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 17.

10. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

NO The sensor was calibrated previously with this controller.

11. Return the sensor to the process and push enter. The output signal returns to the active state

and the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

the preset value.

calibration curves for the sensor are reset.

Calibration with a reference solution (inductive conductivity sensors)

Calibration adjusts the sensor reading to match the value of a reference solution. Use a reference

solution that is at the same value or higher than the expected measurement readings.

Note: If the sensor is calibrated for the first time, be sure to complete the zero calibration first.

1. Thoroughly rinse the clean sensor in deionized water.

2. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

3. If the pass code is enabled in the security menu for the controller, enter the pass code.

4. Select SOLN CAL and push enter.

14

English

Page 15

5. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

the preset value.

6. Put the sensor in the reference solution. Make sure that the sensing area is fully immersed in the

solution. Stir the sensor to remove bubbles.

7. Wait for the sensor and solution temperature to equalize. This can take 30 minutes or more if the

temperature difference between the process and reference solution is significant.

8. With the sensor in the reference solution, push enter.

9. Use the arrow keys to enter the reference solution temperature and push enter.

10. Use the arrow keys to enter the reference solution slope and push enter. The measured value is

shown. Wait for the value to stabilize.

11. Use the arrow keys to enter the reference value and push enter.

12. Review the calibration result:

• PASS—the sensor is calibrated and ready to measure samples. The new cell constant K value

is shown.

• FAIL—the calibration slope or offset is outside of accepted limits. Clean the sensor and retry

with a fresh reference solution. Refer to Troubleshooting on page 18 for more information.

13. If the calibration passed, push enter to continue.

14. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 17.

15. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

calibration curves for the sensor are reset.

NO The sensor was calibrated previously with this controller.

16. Return the sensor to the process and push enter. The output signal returns to the active state

and the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

Resistor calibration (contacting conductivity sensors)

This type of calibration is sometimes referred to as an electrical calibration and is used to verify the

electrical connection rather than the sensor itself.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select RESISTOR CAL and push enter.

4. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

the preset value.

English 15

Page 16

5. Disconnect the sensor from the sensor cable and push enter. Connect a 50 kΩ, 5 kΩ, 500 Ω, or

50 Ω NIST resistor (accuracy ±0.05%) on pins 2-3 of the sensor cable and push enter. Use the

arrow keys to enter the value of the resistor and push enter.

6. Review the calibration result:

• PASS—the calibration is successful.

• FAIL—the cell constant is outside of accepted limits. Clean the sensor and retry. Refer to

Troubleshooting on page 18 for more information.

7. If the calibration passed, push enter to continue.

8. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 17.

9. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

calibration curves for the sensor are reset.

NO The sensor was calibrated previously with this controller.

10. Reconnect the sensor, return it to the process and push enter. The output signal returns to the

active state and the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

Resistor calibration (inductive conductivity sensors)

This type of calibration is sometimes referred to as an electrical calibration and is used to verify the

electrical connection rather than the sensor itself.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

3. Select RESISTOR CAL and push enter.

4. Select the option for the output signal during calibration:

Option Description

ACTIVE The instrument sends the current measured output value during the calibration procedure.

HOLD The sensor output value is held at the current measured value during the calibration procedure.

TRANSFER A preset output value is sent during calibration. Refer to the controller user manual to change

5.

the preset value.

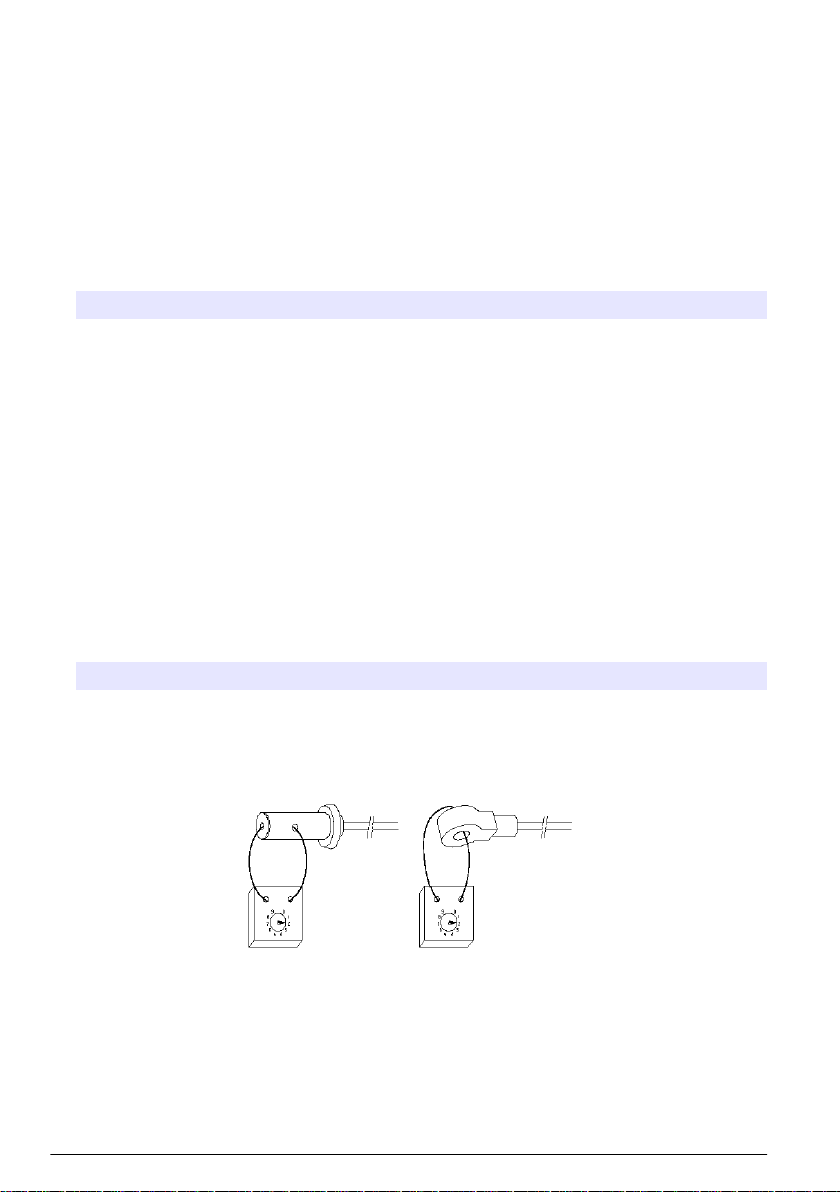

Remove the sensor from the sample. Place a 5 kΩ, 500 Ω, 50 Ω, or 5 Ω resistor loop through the

sensor and push enter. Push enter when the displayed resistor value is stable. Use the arrow

keys to enter the actual value of the resistor and push enter.

6. Review the calibration result:

• PASS—the calibration is successful.

• FAIL—the calibration slope or offset is outside of accepted limits. Clean the sensor and retry.

Refer to Troubleshooting on page 18 for more information.

16

English

Page 17

7. If the calibration passed, push enter to continue.

8. If the option for operator ID is set to YES in the CAL OPTIONS menu, enter an operator ID. Refer

to Change calibration options on page 17.

9. On the NEW SENSOR screen, select whether the sensor is new:

Option Description

YES The sensor was not calibrated previously with this controller. The days of operation and previous

calibration curves for the sensor are reset.

NO The sensor was calibrated previously with this controller.

10. Reconnect the sensor, return it to the process and push enter. The output signal returns to the

active state and the measured sample value is shown on the measure screen.

Note: If the output mode is set to hold or transfer, select the delay time when the outputs return to the active

state.

Temperature calibration

The temperature sensor has been calibrated at the factory. However, it is recommended to always

calibrate the temperature sensor before calibrating the measurement sensor.

1. Put the sensor in a container of water that is at a known temperature. Measure the temperature of

the water with an accurate thermometer or independent instrument.

2. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

3. If the pass code is enabled in the security menu for the controller, enter the pass code.

4. Select 1 PT TEMP CAL and push enter.

5. The raw temperature value is displayed. Push enter.

6. Enter the correct value if different from that displayed and push enter.

7. Push enter to confirm the calibration.

Exit calibration procedure

If the back key is pushed during a calibration, the user can exit the calibration.

1. Push the back key during a calibration. Three options are shown:

Option Description

QUIT CAL Stop the calibration. A new calibration must start from the beginning.

BACK TO CAL Return to the calibration.

LEAVE CAL Exit the calibration temporarily. Access to other menus is allowed. To return to the

calibration, push the menu key and select SENSOR SETUP.

2. Use the arrow keys to select one of the options and push enter.

Change calibration options

The user can set a calibration reminder or include an operator ID with calibration data from this

menu.

1. Push the menu key and select SENSOR SETUP>[Select Sensor]>CALIBRATE.

2. If the pass code is enabled in the security menu for the controller, enter the pass code.

English

17

Page 18

3. Select CAL OPTIONS and push enter.

4. Use the arrow keys to select an option and push enter.

Option Description

CAL REMINDER Sets a reminder for the next calibration in days, months or years—select the required

OP ID ON CAL Includes an operator ID with calibration data—YES or NO (default). The ID is entered

delay from the list.

during the calibration.

Troubleshooting

Intermittent data

During calibration, data is not sent to the datalog which will result in the datalog having areas where

the data is intermittent.

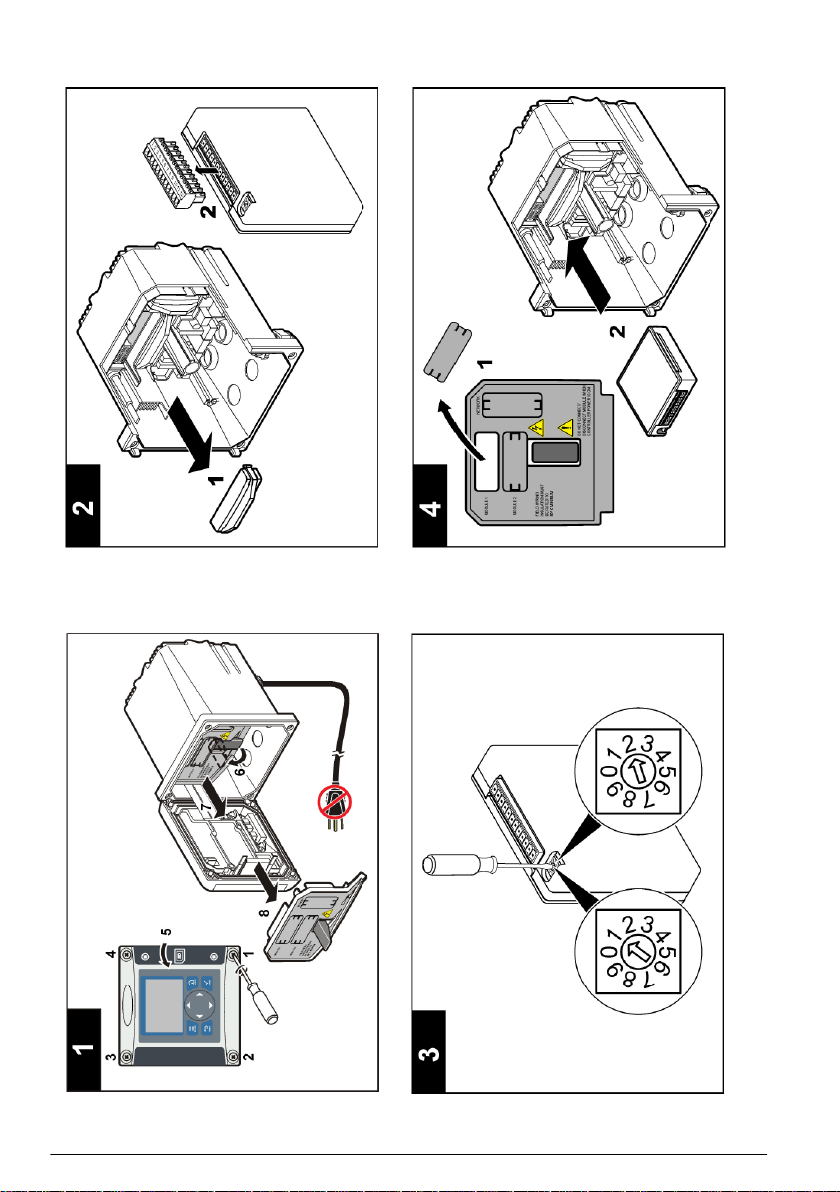

Test the contacting conductivity sensor

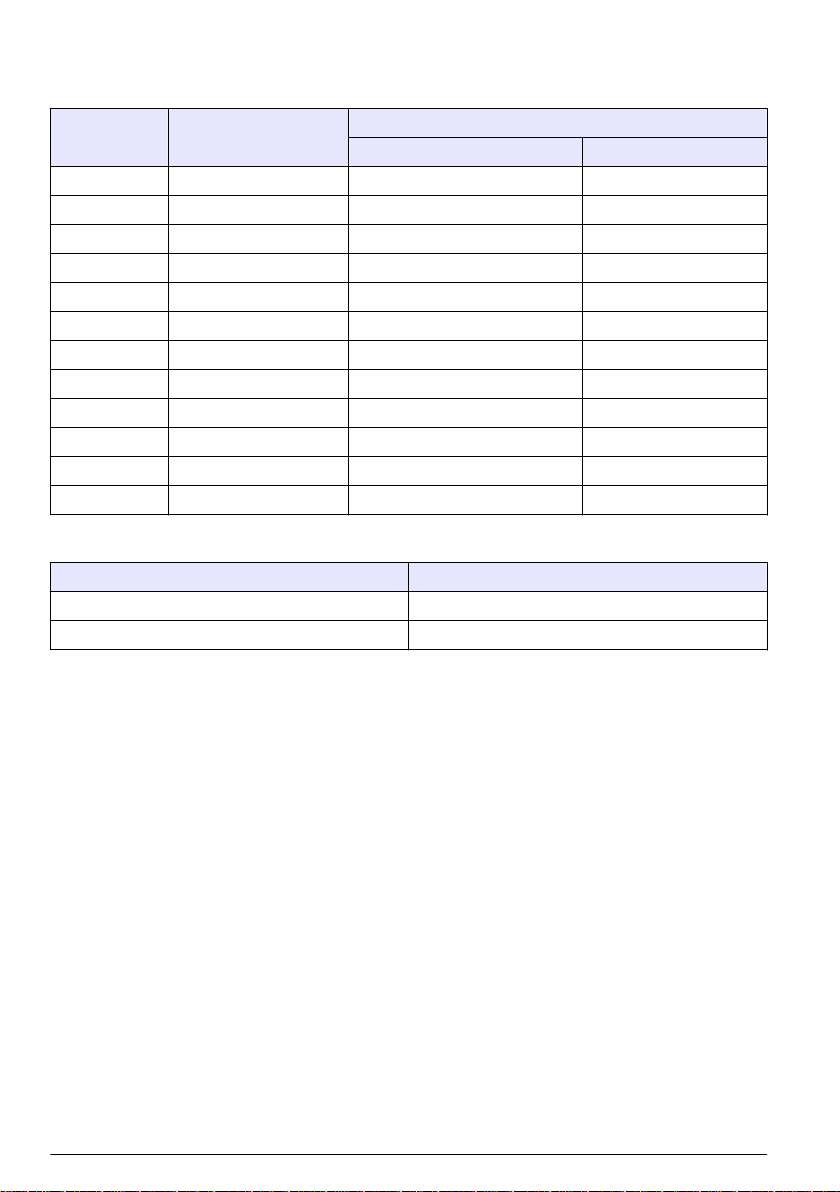

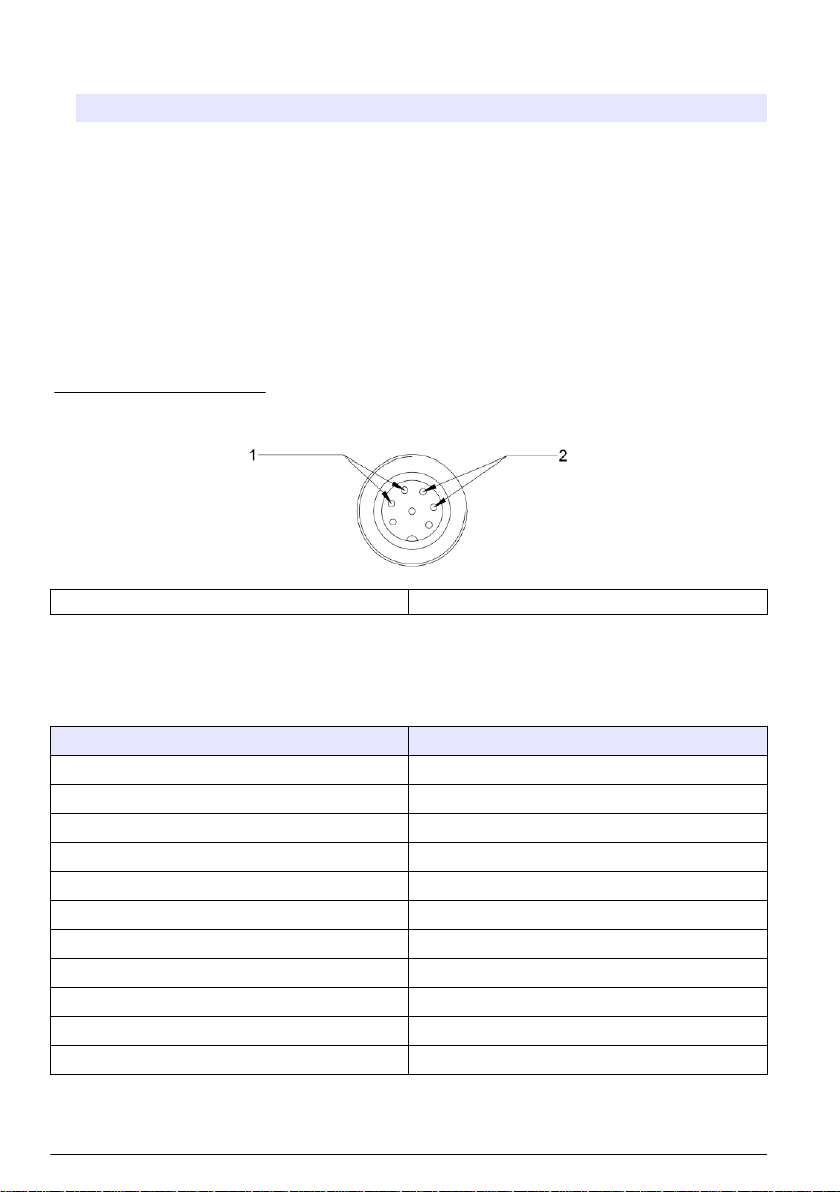

Figure 1 Sensor connector

1 Electrodes 2 Pt100

1. Disconnect the sensor from the module.

2. Electrodes: Check the insulation between the two electrodes. There should be an infinite

resistance when the sensor is dry and exposed to air.

3. Pt100: Compare the resistance measured directly on the connector with the values below:

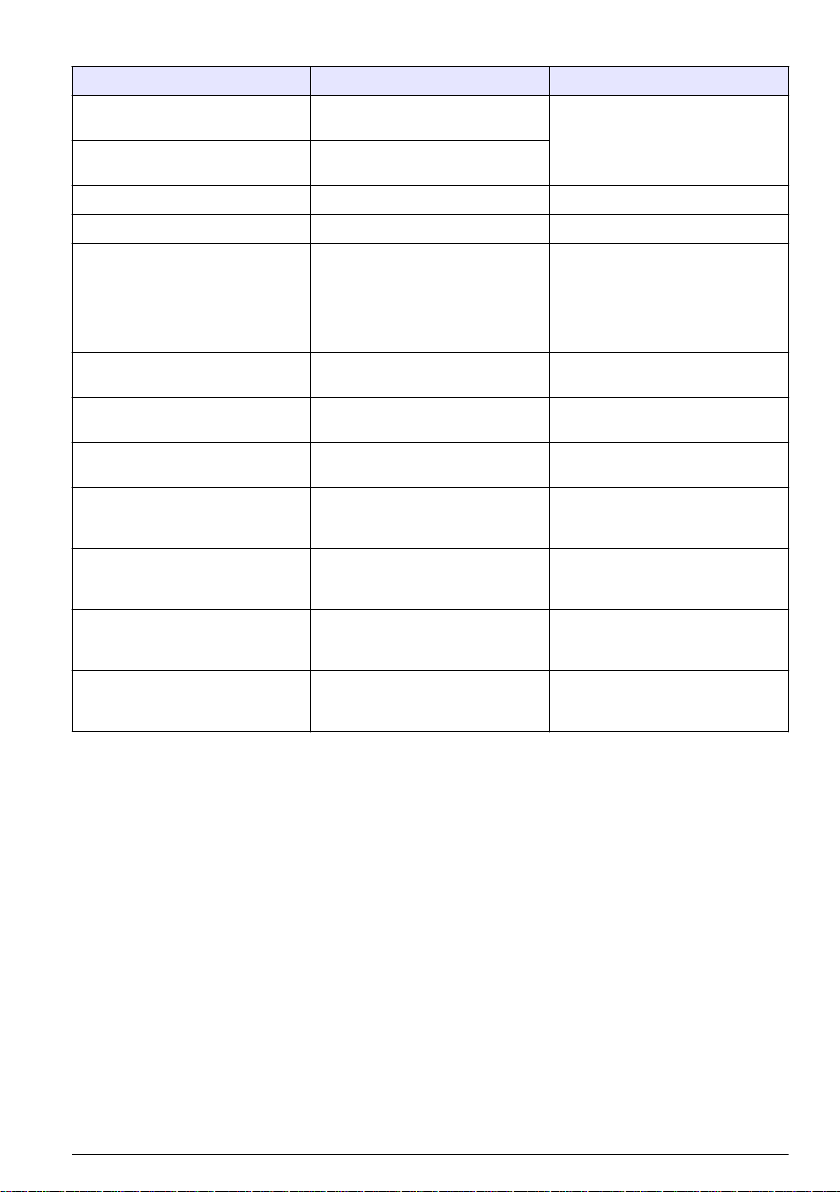

Temperature (°C) Resistance (Ω)

0 100.00

10 103.90

20 107.70

30 111.67

40 115.54

50 119.40

60 123.24

70 127.07

80 130.89

90 134.70

100 138.50

18 English

Page 19

Test the inductive conductivity sensor

If there is a doubt concerning the operation of the sensor, disconnect it from the controller but leave it

in place in your sample process. Check the following resistance values across the terminals indicated

(refer also to the wiring table Table 1 on page 6):

Wiring connections Resistance

Terminals 7-10 (Temperature sensor Pt100) ≈ 110 Ω (at 25 °C)

Terminals 1-2 (Secondary coil) ≈ 1—2 Ω

Terminals 11-12 (Primary coil) ≈ 1—2 Ω

If the checks do not generate any erroneous resistance values, the sensor can be considered to be

working properly.

If the measurement is still not satisfactory proceed as follows:

1. Set T-COMPENSATION to NONE (see Inductive conductivity sensor configuration on page 10).

2. Perform a ZERO CALIBRATION of the sensor (see Zero calibration procedure on page 13).

3. Perform a RESISTOR CALIBRATION of the sensor (see Resistor calibration (inductive

conductivity sensors) on page 16).

4. Check the following:

Displayed conductivity (K = 2.35) Simulated resistance

470 μS/cm 5 kΩ

4.7 mS/cm 500 Ω

47 mS/cm 50 Ω

470 mS/cm 5 Ω

Sensor diagnostic and test menu

The sensor diagnostic and test menu shows current and historical information about the instrument.

Refer to Table 2.

To access the sensor diagnostic and test menu, push the menu key and select SENSOR

SETUP>[Select Sensor]>DIAG/TEST.

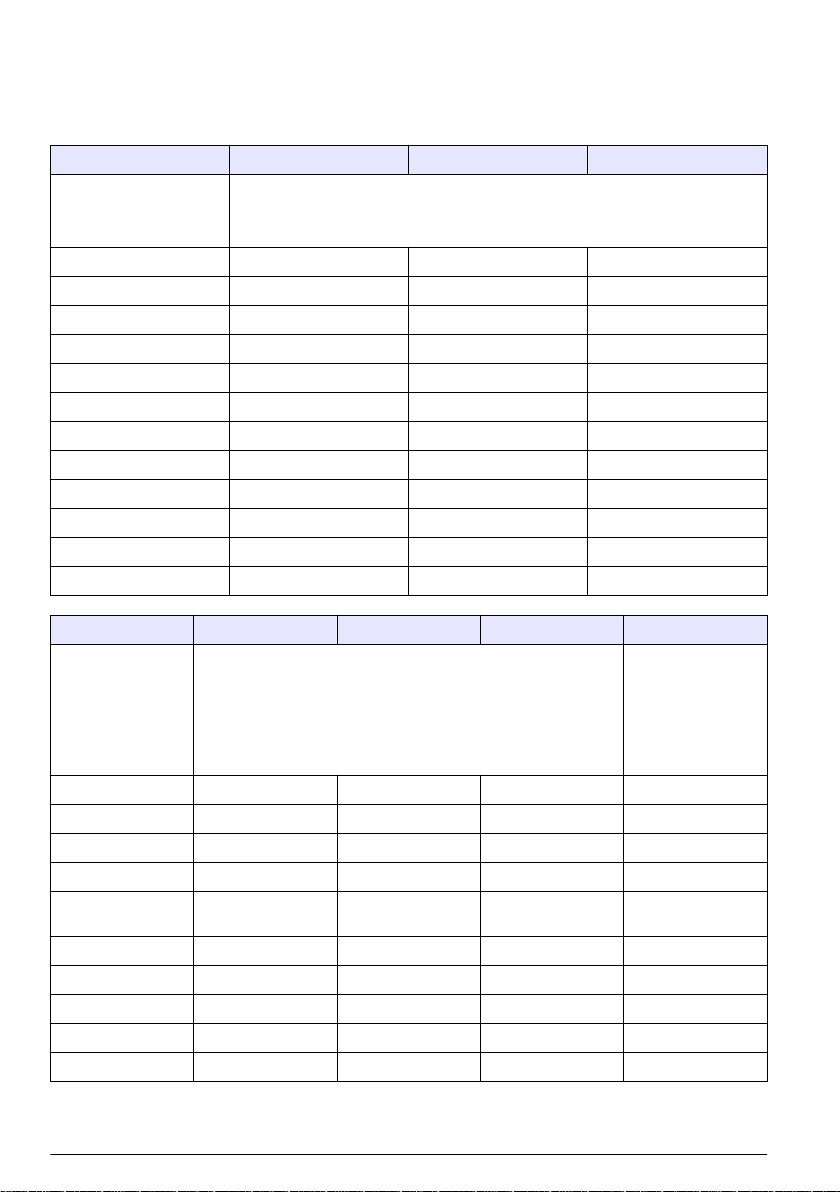

Table 2 Sensor DIAG/TEST menu

Option Description

MODULE INFORMATION Shows information about the sensor module.

SENSOR INFORMATION Shows the name and serial number that was entered

CAL DAYS Shows the number of days since the last calibration.

CAL HISTORY Shows a list of all calibrations by date/time stamp. Use

RESET CAL HISTORY Resets the calibration history for the sensor (requires

POLARIZATION Contacting conductivity sensors only. Shows

by the user.

the arrows keys to select a calibration and push enter

to view the details.

service-level passcode). All previous calibration data is

lost.

information about the electrode polarization, the cable

capacitance and the time before the next

measurement.

English 19

Page 20

Table 2 Sensor DIAG/TEST menu (continued)

Option Description

SENSOR SIGNALS Shows the current sensor signal information.

SENSOR DAYS Shows the number of days that the sensor has been in

RESET SENSOR Resets the number of days that the sensor has been in

operation.

operation and resets all calibration data to defaults.

Error list

Errors may occur for various reasons. An error icon consists of an exclamation point within a circle.

When an error occurs, the error icon and the measurement screen flash alternately in the main

display. All outputs are held when specified in the controller menu. To view errors, push the menu

key and select DIAGNOSTICS. Then select the device to view any problems associated with that

device.

A list of possible errors is shown in Table 3.

Table 3 Error list for conductivity sensors

Error Description Resolution

ADC FAILURE The analog to digital conversion

failed

SENSOR MISSING The sensor is missing or

disconnected

SENS OUT RANGE The sensor signal is outside of the

accepted limits (2 S/cm)

Make sure that the sensor module is

fully inserted into the controller

connector. Replace the sensor

module.

Examine the wiring and connections

for the sensor and for the module.

Make sure that the terminal block is

fully inserted into the module.

Make sure that the display format is

set for the correct measurement

range.

Warning list

A warning icon consists of an exclamation point within a triangle. Warning icons appear on the right

of the main display below the measurement value. A warning does not affect the operation of menus,

relays and outputs. To view warnings, push the menu key and select DIAGNOSTICS. Then select

the device to view any problems associated with that device. The warning icon will no longer be

displayed once the problem has been corrected or acknowledged.

A list of possible warnings is shown in Table 4.

Table 4 Warning list for conductivity sensors

Warning Description Resolution

MEAS TOO HIGH The measured value is > 2 S/cm,

1,000,000 ppm, 200% or 20,000 ppt

MEAS TOO LOW The measured value is < 0 μS/cm,

0 ppm, 0% or 0 ppt

ZERO TOO HIGH The zero calibration value is too

high

ZERO TOO LOW The zero calibration value is too low

20 English

Make sure that the display format is

set for the correct measurement

range

Make sure that the sensor is

configured for the correct cell

constant.

Make sure that the sensor is held in

air during zero calibration and is not

located near radio frequency or

electromagnetic interference. Make

sure that the cable is shielded by

metal conduit.

Page 21

Table 4 Warning list for conductivity sensors (continued)

Warning Description Resolution

TEMP TOO HIGH The measured temperature is >

200 °C

TEMP TOO LOW The measured temperature is <

-20 °C

CAL OVERDUE The Cal Reminder time has expired Calibrate the sensor.

NOT CALIBRATED The sensor has not been calibrated Calibrate the sensor.

REPLACE SENSOR The sensor has been in operation >

365 days

CAL IN PROGRESS A calibration was started but not

completed

OUTPUTS ON HOLD During calibration, the outputs were

set to hold for a selected time.

WRONG LINEAR TC The user-defined linear temperature

compensation is out of range

WRONG TC TABLE The user-defined temperature

compensation table is out of range

WRNG USER CONC TABLE The concentration measurement is

outside of the range of the user

table

WRNG BLT-IN TEMP TABLE The measured temperature is

outside of the range of the built-in

temperature compensation table

WRNG BLT-IN CONC TABLE The concentration measurement is

outside of the range of the built-in

concentration table

Make sure that the sensor is

configured for the correct

temperature element.

Calibrate the sensor with a

reference solution and reset the

sensor days. Refer to Sensor

diagnostic and test menu

on page 19. If the calibration fails,

call technical support.

Return to calibration.

The outputs will become active after

the selected time period.

The value must be between 0 and

4%/°C; 0 to 200 °C.

The temperature is above or below

the temperature range defined by

the table.

Make sure that the user table is set

for the correct measurement range.

Make sure that the temperature

compensation is configured

correctly.

Make sure that the concentration

measurement is configured for the

correct chemical and range.

English 21

Page 22

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen.

Kontakt-Leitfähigkeitssensoren

Spezifikation 8310 8311 8312

Trink- und Abwasseraufbereitung

Anwendung

Entmineralisiertes und enthärtetes Wasser

Gehäusematerial PSU schwarz PSU schwarz PSU schwarz

Innere Elektrode SS 316L SS 316L Graphit

Äußere Elektrode SS 316L SS 316L Graphit

Isoliermaterial PSU PSU PSU

Stecker Glas Polyester (IP65) Glas Polyester (IP65) Glas Polyester (IP65)

Zellkonstante K 0,01 (cm-1) 0,1 (cm-1) 1,0 (cm-1)

Genauigkeit < 2% < 2% < 2%

Messbereich 0,01—200 μS.cm

Temperaturverhalten < 30 Sekunden < 30 Sekunden < 30 Sekunden

Max. Temperatur 125 °C 125 °C 125 °C

Max. Druck 10 bar 10 bar 10 bar

Probenanschluss NPT ¾ Zoll NPT ¾ Zoll NPT ¾ Zoll

Spezifikation 8315 8316 8317 8394

Anwendung

Gehäusematerial SS 316L SS 316L SS 316L SS 316L

Innere Elektrode SS 316L SS 316L Graphit SS 316L

Äußere Elektrode SS 316L SS 316L Graphit SS 316L

Isoliermaterial PES PES PES PEEK

Stecker Glas Polyester

Zellkonstante K 0,01 (cm-1) 0,1 (cm-1) 1,0 (cm-1) 0,01 (cm-1)

Genauigkeit < 2% < 2% < 2% < 2%

Messbereich 0,01—200 μS.cm-10,1 μS—2 mS.cm-11 μS—20 mS.cm-10,01—200 μS.cm

Temperaturverhalten < 30 Sekunden < 30 Sekunden < 30 Sekunden < 30 Sekunden

Max. Temperatur 150 °C 150 °C 150 °C 150 °C

Prozesswasserüberwachung (Kondensat, Reinigungszyklen,

(IP65)

-1

Reinwasserproduktion

Wärmetauscher)

Glas Polyester

Chemische Prozesse

0,1 μS—2 mS.cm

(IP65)

-1

Glas Polyester

(IP65)

1 μS—20 mS.cm

Überwachung von

Reinstwasser in der

Pharma- und

Lebensmittelindustri

e

Für CIP-/ SIP-

Prozesse geeignet

Glas Polyester

(IP65)

-1

-1

22 Deutsch

Page 23

Spezifikation 8315 8316 8317 8394

Max. Druck 25 bar 25 bar 25 bar 25 bar

Probenanschluss NPT ¾ Zoll NPT ¾ Zoll NPT ¾ Zoll

Tri-Clamp 1½ oder

2 Zoll

Induktive Leitfähigkeitssensoren

Spezifikation Serie 8398 8332

Anwendung Fouling- und

Korrisionsschutzanwendungen

Material PEEK PVDF

Zellkonstante K 2,35 (cm-1) 10 (cm-1)

Genauigkeit ± 2 % ± 2 %

Messbereich 0—2000 mS/cm 100 μS/cm—10 S/cm

Leitfähigkeitsverhalten < 1 Sekunde < 1 Sekunde

Temperaturverhalten < 2 Minuten < 2 Minuten

Max. Druck 18 bar 7,5 bar

Max. Temperatur 140 °C 120 °C

Messungen unter erschwerten

Bedingungen

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führt.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

G E F A H R

W A R N U N G

Deutsch 23

Page 24

V O R S I C H T

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

H I N W E I S

Aufkleber mit Vorsichtshinweisen

Bitte lesen Sie alle auf dem Produkt angebrachten Etiketten und Hinweise. Die Nichtbeachtung kann

zu Verletzungen an Personen oder einer Beschädigung des Produkts führen. Im Handbuch werden

auf die am Gerät angebrachten Symbole in Form von Warnhinweisen verwiesen.

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen darf.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Elektrische Geräte, die dieses Symbol aufweisen, dürfen in Europa nicht als Haushaltsabfall

entsorgt werden. Den lokalen und nationalen europäischen Bestimmungen gemäß müssen

Benutzer von Elektrogeräten diese nun zur für den Benutzer kostenlosen Entsorgung an den

Hersteller zurückgeben.

Hinweis: Mit der Wiederverwertung, der stofflichen Verwertung oder anderen Formen der Verwertung von

Altgeräten leisten Sie einen wichtigen Beitrag zum Schutz unserer Umwelt.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Produktübersicht

Nach seiner Installation in einen sc200 oder Polymetron 9500 Controller ermöglicht das Modul den

Anschluss eines analogen Sensors an den Controller.

Installation

W A R N U N G

Mehrere Gefahren. Die in diesem Abschnitt des Handbuchs beschriebenen Eingriffe dürfen ausschließlich von

qualifiziertem Personal vorgenommen werden.

Sensor an das Instrument anschließen

Potenzielle Stromschlaggefahr! Stellen Sie stets die Spannungsversorgung am Controller ab, wenn elektrische

Anschlüsse durchgeführt werden.

Gefahr von Stromschlägen. Die Hochspannungsleitungen für den Controller verlaufen hinter der

Hochspannungssperre im Controllergehäuse. Die Schutzabdeckung darf nicht entfernt werden, außer beim

Anschluss von Spannungsversorgung, Relais, oder Analog- und Netzwerkkarten durch einen qualifizierten

Techniker.

24 Deutsch

W A R N U N G

W A R N U N G

Page 25

H I N W E I S

Möglicher Geräteschaden. Empfindliche interne elektronische Bauteile können durch statische Elektrizität

beschädigt werden, wobei dann das Gerät mit verminderter Leistung funktioniert oder schließlich ganz ausfällt.

Um das Modul einzubauen und den Sensor anzuschließen, siehe nachfolgende Zeichnungen und

Anschlusstabelle.

Stellen Sie sicher, alle Erdleiter/Beilauflitzen des Sensors mit den Erdungsschrauben des

Controllergehäuses verbunden zu haben.

Hinweis: Wenn das Sensorkabel nicht bis zum Controller reicht, ist ein Verbindungskabel (Modell 150727,10000)

mit Anschlusskasten (Modell 08335=A=6000) erforderlich, um die Entfernung zu überbrücken.

Tabelle 1 Verkabelung des Leitfähigkeitssensors

Kontakt Beschreibung Sensor

8398 831x und 8394

1 Innere Elektrode Weiß (weißes Kabel) Weiß

2 Innere Elektrode Schwarz (weißes Kabel) —

3 Masse — Grün

4 — — —

5 — — —

6 — — —

7 Temp - Grün Schwarz

8 — — —

9 — — —

10 Temp + Gelb Gelb

11 Äußere Elektrode Braun (braunes Kabel) Rot

12 Äußere Elektrode Schwarz (braunes Kabel) —

In Schritt 3 der folgenden Sequenz stellen Sie den Schalter wie folgt ein:

Schaltereinstellung Beschreibung

Einstellung 1 Kontakt-Leitfähigkeitssensor

Einstellung 2 Induktiver Leitfähigkeitssensor

Deutsch 25

Page 26

26 Deutsch

Page 27

Deutsch 27

Page 28

Betrieb

Benutzernavigation

Siehe Abschnitt Benutzerschnittstelle und Navigation der Anleitung zum Controller bzgl. der

Tastaturbeschreibung und Navigationsinformationen.

Sensorkonfigurierung

Kontakt-Leitfähigkeitssensor konfigurieren

Verwenden Sie das Konfigurationsmenü CONFIGURE, um eine Identifizierungsinformation für den

Sensor einzugeben und die Optionen für die Datenverwaltung und -speicherung zu ändern.

1. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CONFIGURE

(Sensoreinstellung>Sensor wählen>Konfigurieren) auswählen.

2. Wählen Sie eine Option aus und drücken Sie dann ENTER. Zur Eingabe der Zahlen, Zeichen

oder Satzzeichen die Pfeiltasten nach oben oder nach unten drücken und halten. Mit der

rechten Pfeiltaste zum nächsten Feld gehen.

Option Beschreibung

EDIT NAME Definiert den dem Sensor zugewiesenen Namen, der oben in der Messanzeige

SENSOR-S/N Ermöglicht dem Benutzer die Eingabe einer Sensor-Seriennummer. Die Nummer kann

SELECT MEASURE Stellt für den Messparameter die Optionen CONDUCTIVITY (Leitfähigkeit = Standard),

DISPLAY FORMAT Ändert die Anzahl der Dezimalstellen, die auf der Messanzeige dargestellt werden. Bei

MEAS UNITS Ändert die Einheiten für die gewählte Messung - wählen Sie eine Einheit aus der

TEMP UNITS Legt für die Temperatureinheit die Einstellung °C (Standard) oder °F fest.

T-COMPENSATION Addiert eine temperaturabhängige Korrektur zu dem gemessenen Wert.

erscheint. Der Name kann maximal 16 Zeichen bestehen und Buchstaben, Zahlen,

Leerzeichen und Satzzeichen enthalten. Nur die ersten 12 Zeichen werden auf dem

Controller angezeigt.

maximal aus 16 Zeichen bestehen und Buchstaben, Zahlen, Leerzeichen und

Satzzeichen enthalten.

TDS (vollständig gelöste Feststoffe), SALINITY (Salzgehalt) oder RESISTIVITY

(Resistivität) ein. Alle anderen konfigurierten Einstellungen werden auf die

Standardwerte zurückgestellt.

Hinweis: Bei der Auswahl der Option SALINITY (Salzgehalt) wird für die Messeinheit

automatisch ppt (parts per thousand) eingestellt. Diese Einstellung kann nicht

verändert werden.

der Einstellung "Auto" wird die Anzahl der Dezimalstellen automatisch mit den

Änderungen der gemessenen Werte geändert.

vorhandenen Liste aus.

• NONE—Temperaturkompensation nicht erforderlich

• USP—Einstellen des Alarmniveaus für die USP-Standarddefinitionstabelle

• ULTRA PURE WATER (Ultrareines Wasser) - Nicht für TDS verfügbar. Stellt die

Kompensierungsart in Abhängigkeit von den Probeneigenschaften ein—Wählen Sie

NaCl , HCl, AMMONIA oder ULTRA PURE WATER

• USER—BUILT IN LINEAR, LINEAR oder TEMP TABLE wählen:

• BUILT IN LINEAR—Die vordefinierte lineare Wertetabelle verwenden (Steigung

2,0%/°C, Referenztemperatur 25 °C)

• LINEAR—Einstellen der Steigungs- und Referenztemperaturparameter weicht

von den integrierten Parametern ab

• TEMP TABLE—Definiert die Temperatur und die Punkte für die

Multipliaktionsfaktoren (siehe Benutzertabellen konfigurieren auf Seite 30).

• NATURAL WATER—Nicht für TDS verfügbar

28 Deutsch

Page 29

Option Beschreibung

CONFIG TDS Nur TDS—ändert den Faktor, der zur Umwandlung der Leitfähigkeit zu TDS verwendet

CABLE PARAM Einstellen der Sensorkabelparameter, um die Messgenauigkeit zu verbessern, wenn

TEMP ELEMENT Stellt für das Temperaturelement PT100 oder PT1000 für die automatische

FILTER Definiert eine Zeitkonstante zur Verbesserung der Signalstabilität. Die Zeitkonstante

LOG SETUP Legt das Zeitintervall für die Datenspeicherung im Datenprotokoll fest— 5 oder

RESET DEFAULTS Setzt das Konfigurationsmenü auf die Standardeinstellungen zurück. Alle

wird: NaCl (0,49 ppm/µS) oder CUSTOM (Faktor zwischen 0,01 und 99,99 ppm/µS

eingeben).

das Sensorkabel über die 5 m Standardlänge hinaus verlängert oder gekürzt wird.

Geben Sie die Kabellänge, den Widerstand und die Leitfähigkeit ein.

Temperaturkompensation ein. Wenn kein Element verwendet wird, kann hier die

Einstellung MANUAL eingestellt werden, um einen Wert für die

Temperaturkompensation einzugegeben.

berechnet den Durchschnittswert innerhalb eines festgelegten Zeitraums -0 (No Effect)

bis 60 Sekunden (Durchschnitt des Signalwerts für 60 Sekunden). Der Filter erhöht die

Ansprechzeit des Sensorsignals auf aktuelle Prozessänderungen.

30 Sekunden und 1, 2, 5, 10, 15 (Standard), 30 oder 60 Minuten.

Sensorinformationen gehen verloren.

Induktiven Leitfähfigkeitssensor konfigurieren

Verwenden Sie das Konfigurationsmenü CONFIGURE, um eine Identifizierungsinformation für den

Sensor einzugeben und die Optionen für die Datenverwaltung und -speicherung zu ändern.

1. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CONFIGURE

(Sensoreinstellung>Sensor wählen>Konfigurieren) auswählen.

2. Wählen Sie eine Option aus und drücken Sie dann ENTER. Zur Eingabe der Zahlen, Zeichen

oder Satzzeichen die Pfeiltasten nach oben oder nach unten drücken und halten. Mit der

rechten Pfeiltaste zum nächsten Feld gehen.

Option Beschreibung

EDIT NAME Definiert den dem Sensor zugewiesenen Namen, der oben in der Messanzeige

SENSOR-S/N Ermöglicht dem Benutzer die Eingabe einer Sensor-Seriennummer. Die Nummer kann

SELECT MEASURE Stellt für den Messparameter die Optionen CONDUCTIVITY (Leitfähigkeit = Standard),

DISPLAY FORMAT Ändert die Anzahl der Dezimalstellen, die auf der Messanzeige dargestellt werden. Bei

MEAS UNITS Ändert die Einheiten für die gewählte Messung - wählen Sie eine Einheit aus der

TEMP UNITS Legt für die Temperatureinheit die Einstellung °C (Standard) oder °F fest.

erscheint. Der Name kann maximal 16 Zeichen bestehen und Buchstaben, Zahlen,

Leerzeichen und Satzzeichen enthalten. Nur die ersten 12 Zeichen werden auf dem

Controller angezeigt.

maximal aus 16 Zeichen bestehen und Buchstaben, Zahlen, Leerzeichen und

Satzzeichen enthalten.

RESISTIVITY (Resistivität), SALINITY (Salzgehalt), TDS (vollständig gelöste

Feststoffe) oder CONCENTRATION (Konzentration) ein. Alle anderen konfigurierten

Einstellungen werden auf die Standardwerte zurückgestellt.

Hinweis: Bei der Auswahl der Option SALINITY (Salzgehalt) wird für die Messeinheit

automatisch ppt (parts per thousand) eingestellt. Diese Einstellung kann nicht

verändert werden.

der Einstellung "Auto" wird die Anzahl der Dezimalstellen automatisch mit den

Änderungen der gemessenen Werte geändert.

vorhandenen Liste aus.

Deutsch 29

Page 30

Option Beschreibung

T-COMPENSATION Addiert eine temperaturabhängige Korrektur zu dem gemessenen Wert.

• LINEAR—Einstellen der Steigungs- und Referenztemperaturparameter

• NATURAL WATER—Nicht für TDS oder CONCENTRATION verfügbar

• TEMP TABLE—Definiert die Temperatur und die Punkte für die

Multipliaktionsfaktoren (siehe Benutzertabellen konfigurieren auf Seite 30).

• NONE—Temperaturkompensation nicht erforderlich

CONFIG TDS Nur TDS—ändert den Faktor, der zur Umwandlung der Leitfähigkeit zu TDS verwendet

CONFIG CONC Nur CONCENTRATION —Definiert die zu verwendende Konzentrationstabelle.

TEMP ELEMENT Stellt für das Temperaturelement PT100 oder PT1000 für die automatische

FILTER Definiert eine Zeitkonstante zur Verbesserung der Signalstabilität. Die Zeitkonstante

LOG SETUP Legt das Zeitintervall für die Datenspeicherung im Datenprotokoll fest— 5 oder

RESET DEFAULTS Setzt das Konfigurationsmenü auf die Standardeinstellungen zurück. Alle

wird: NaCl (0,49 ppm/µS) oder CUSTOM (Faktor zwischen 0,01 und 99,99 ppm/µS

eingeben).

• BUILT-IN—Definiert die CHEMICAL (Chemikalie), die gemessen wird:

• H2SO4 0-30%

• HNO3 0-28%

• HCl 0-18%

• NaOH 0-16%

Hinweis: Auch wenn hier ein Bereich von 0-16% angezeigt wird, können die

Tabellen auch genauer für 0-10% für alle Temperaturen definiert werden.

• NaCl 0-25%

• H3PO4 0-40%

• USER TABLE—Definiert die Punkte für die Leitfähigkeit und die Konzentration

(siehe Benutzertabellen konfigurieren auf Seite 30).

Temperaturkompensation ein. Wenn kein Element verwendet wird, kann hier die

Einstellung MANUAL eingestellt werden, um einen Wert für die

Temperaturkompensation einzugegeben.

berechnet den Durchschnittswert innerhalb eines festgelegten Zeitraums -0 (No Effect)

bis 60 Sekunden (Durchschnitt des Signalwerts für 60 Sekunden). Der Filter erhöht die

Ansprechzeit des Sensorsignals auf aktuelle Prozessänderungen.

30 Sekunden und 1, 2, 5, 10, 15 (Standard), 30 oder 60 Minuten.

Sensorinformationen gehen verloren.

Benutzertabellen konfigurieren

Je nach erforderlichem Sensor- und Messungstyp können während der Sensorkonfigurierung

benutzerdefinierte Tabellen ausgewählt werden. Im Folgenden wird erklärt , wie eine

benutzerdefinierte Tabelle konfiguriert wird.

Konzentrationstabellen

Standardmäßig enthält diese Tabelle nur zwei Punkte (P1 und P2), die den oberen und unteren

Grenzwert definieren. Nachdem P1 und P2 definiert wurden, können zusätzliche Punkte im

Zwischenbereich eingegeben werden. Um z. B. für die Leitfähigkeit und die Konzentration den

Mindestwert null und für die Leitfähigkeit den Höchstwert 750 bei einer maximalen Konzentration von

30 zu definieren, verfahren Sie wie folgt:

1. Wählen Sie in der Option USER TABLE (Benutzerdefinierte Tabelle) die Funktion P1>EDIT

POINT (Punkt bearbeiten).

2. Geben Sie einen Mindestleitfähigkeitswert (X) in dem Format 0.0 ein und bestätigen Sie mit

Enter.

3. Geben Sie einen Mindestkonzentrationswert in Prozent (Y) in dem Format 0.0 ein und bestätigen

Sie mit Enter.

30

Deutsch

Page 31

4. Wählen Sie SAVE CHANGES? (Änderungen speichern?) und bestätigen Sie mit Enter.

5. Wählen Sie in der Option USER TABLE (Benutzerdefinierte Tabelle) die Funktion P2>EDIT

POINT (Punkt bearbeiten).

6. Geben Sie einen Höchstleitfähigkeitswert (X) in dem Format 750.0 ein und bestätigen Sie mit

Enter.

7. Geben Sie einen Höchstkonzentrationswert in Prozent (Y) in dem Format 30.0 ein und bestätigen

Sie mit Enter.

8. Wählen Sie SAVE CHANGES? (Änderungen speichern?) und bestätigen Sie mit Enter.

Folgende Tabelle wurde definiert:

Leitfähigkeit Konzentration%

P1 0 0

P2 750 30

Um einen zusätzlichen Punkt mit einer Leitfähigkeit von 250 und einer Konzentration von

15 einzufügen, wählen Sie den Punkt mit dem Leitfähigkeitswert, der sich direkt über dem

einzufügenden Wert befindet. In diesem Beispiel wählen Sie P2: Der Wärmleitfähigkeitswert 250 wird

dann P2 und der vorhandene Punkt P2 wird P3:

1. Wählen Sie in der Option USER TABLE (Benutzerdefinierte Tabelle) die Funktion P2>INSERT

POINT (Punkt einfügen).

2. Geben Sie einen Leitfähigkeitswert (X) in dem Format 250.0 ein und bestätigen Sie mit Enter.

3. Geben Sie einen Konzentrationswert in Prozent (Y) in dem Format 15.0 ein und bestätigen Sie

mit Enter.

4. Wählen Sie SAVE CHANGES? (Änderungen speichern?) und bestätigen Sie mit Enter.

Die Tabelle ist jetzt wie folgt definiert:

Leitfähigkeit Konzentration%

P1 0 0

P2 250 15

P3 750 30

Sie können maximal bis P10 zusätzlich Punkte einfügen.

Hinweis: Der berücksichtigte Leitfähigkeitswert ist die in Übereinstimmung mit der konfigurierten Option für die

Temperaturkompensierung kompensierte Temperatur.

Temperaturtabellen

Der Prozess ist identisch mit dem für die Konzentrationstabellen beschriebenen, mit der

Einschränkung, dass sich der X-Wert hier auf die Temperatur bezieht, während der Y-Wert ein

Faktor ist, der für die Multiplikation des nicht kompensierten Leitfähigkeitswerts verwendet wird, um

einen temperaturkompensierten Leitfähigkeitswert zu ermitteln.

Die Temperaturtabelle wurde z. B. wie folgt konfiguriert:

Temperature Wert

P1 0 1

P2 20 1,1

P3 40 1,2

Das kann graphisch folgendermaßen dargestellt werden:

Deutsch

31

Page 32

Das heißt, dass eine Temperatur von 10° einem Faktor von 1,05 entspricht. Folglich ergibt sich aus

einem nicht kompensierten Leitfähigkeitswert von 10mS/cm bei einer Temperatur von 10° ein

kompensierter Temperaturwert von 10,5mS/cm (d. h. 10 mS/cm multipliziert mit einem Faktor von

1,05).

Sensor kalibrieren

Hinweise zur Sensorkalibrierung

Im Laufe der Zeit verändert sich die Sensoreigenschaften, wodurch der Sensor an Genauigkeit

verliert. Um die gewünschte Genauigkeit zu erhalten, muss der Sensor regelmäßig kalibriert werden.

Die Häufigkeit der Kalibrierung hängt von der Anwendung ab und sollte anhand der praktischen

Erfahrungen bestimmt werden.

Kontakt-Leitfähigkeitssensoren: Verwenden Sie Luft (Null-Kalibrierung) und die Prozessprobe für

die Bestimmung der Kalibrierungskurve. Wenn die Prozessprobe verwendet wird, muss der

Referenzwert mit einem zweiten zertifizierten Prüfgerät geprüft werden.

Induktive Leitfähigkeitssensoren: Verwenden Sie Luft (Null-Kalibrierung) und eine Referenzlösung

oder die Prozessprobe für die Bestimmung der Kalibrierungskurve. Für eine optimale Genauigkeit

wird eine Kalibrierung mit einer Referenzlösung empfohlen. Wenn die Prozessprobe verwendet wird,

muss der Referenzwert mit einem zweiten zertifizierten Prüfgerät geprüft werden.

Kalibrierungsgrenzen

Eine Kalibrierung schlägt fehl, wenn der Wert ± 10% unter dem Zielwert liegt.

Zelle konstant

Vor der Kalibrierung sicherstellen, dass die Sensorzellenparameter richtig sind.

1. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CALIBRATE

(Sensoreinstellung>Sensor auswählen>Kalibrieren) auswählen.

2. Wenn der Pass Code im Sicherheitsmenü des Controllers aktiviert wurde, geben Sie den Pass

Code ein.

3. Wählen Sie CELL CONSTANT (Zellkonstante) und drücken Sie Enter.

4. Kontakt-Leitfähigkeitssensoren: Wählen Sie den Bereich für die Zellkonstante K für den

Sensor (0,01, 0,1 oder 1,0). Geben Sie dann den aktuellen K-Wert, wie er auf dem Schild auf

dem Sensor angegeben ist, ein.F

Induktiver Leitfähigkeitssensor: Geben Sie den aktuellen K-Wert, wie er auf dem Schild auf

dem Sensor angegeben ist, ein.

Null-Kalibrierungsverfahren

Nutzen Sie die Nullpunkt-Kalibrierung, um den eindeutigen Nullpunkt des Sensors festzulegen.

32

Deutsch

Page 33

1. Entfernen Sie den Sensor aus dem Prozess. Mit einem sauberen Tuch abwischen, um

sicherzustellen, dass der Sensor trocken ist.

2. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CALIBRATE

(Sensoreinstellung>Sensor auswählen>Kalibrieren) auswählen.

3. Wenn der Pass Code im Sicherheitsmenü des Controllers aktiviert wurde, geben Sie den Pass

Code ein.

4. Wählen Sie ZERO CAL (Nullkalibrierung) und drücken Sie Enter.

5. Wählen Sie die Option für das Ausgangssignal während der Kalibrierung:

Option Beschreibung

ACTIVE Das Gerät übermittelt während der Kalibrierung den aktuellen Messwert.

HOLD Das Gerät hält den aktuellen Messwert während der Kalibrierung.

TRANSFER Das Gerät sendet während der Kalibrierung einen vorher eingestellten Ausgangswert. Für die

Änderung des voreingestellten Wertes beziehen Sie sich bitte auf das Benutzerhandbuch des

Controllers.

6. Den Sensor in die Luft halten und Enter drücken.

7. Kontrollieren Sie das Kalibrierungsergebnis:

• PASS—der Sensor ist kalibriert und zur Messung von Proben bereit.

• FAIL—die Kalibrierung ist außerhalb der zugelassenen Grenzwerte. Reinigen Sie den Sensor

und wiederholen Sie den Vorgang. Für detaillierte Informationen beziehen Sie sich bitte auf

Fehlerbehebung auf Seite 38.

8. Nach erfolgter Kalibrierung bitte Enter drücken, um fortzufahren.

9. Ist die Option für die Bediener-ID im Menü CAL OPTIONS (Kalibrierungsoptionen) auf YES

eingestellt, geben Sie eine Bediener-ID ein. Beziehen Sie sich auf Kalibrierungsoptionen ändern

auf Seite 38.

10. In der Bildschirmanzeige NEW SENSOR legen Sie fest, ob der Sensor neu ist:

Option Beschreibung

YES Der Sensor wurde vorher nicht an diesem Controller kalibriert. Die Betriebsdauer in Tagen und die

vorherigen Kalibrierungskurven für den Sensor werden zurückgesetzt.

NO Der Sensor wurde vorher an diesem Controller kalibriert.

11. Sensor in den Prozess zurückführen und Enter drücken. Das Ausgangssignal kehrt wieder in den

aktiven Zustand zurück und der Messwert der Probe wird in der Messungsanzeige angezeigt.

Hinweis: Wenn der Ausgangsmodus auf Halten oder Ersatzwert eingestellt war, wählen Sie eine

Verzögerungszeit, nach deren Ablauf die Ausgänge wieder in den aktiven Zustand zurückkehren sollen.

Kalibrierung mit einer Prozessprobe

Der Sensor kann in der Prozessprobe verbleiben, oder ein Teil der Prozessprobe kann für die

Kalibrierung entnommen werden.

1. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CALIBRATE

(Sensoreinstellung>Sensor auswählen>Kalibrieren) auswählen.

2. Wenn der Pass Code im Sicherheitsmenü des Controllers aktiviert wurde, geben Sie den Pass

Code ein.

3. Wählen Sie SAMPLE CAL (Probenkalibrierung) und drücken Sie Enter.

4. Wählen Sie die Option für das Ausgangssignal während der Kalibrierung:

Option Beschreibung

ACTIVE Das Gerät übermittelt während der Kalibrierung den aktuellen Messwert.

Deutsch 33

Page 34

Option Beschreibung

HOLD Das Gerät hält den aktuellen Messwert während der Kalibrierung.

TRANSFER Das Gerät sendet während der Kalibrierung einen vorher eingestellten Ausgangswert. Für die

Änderung des voreingestellten Wertes beziehen Sie sich bitte auf das Benutzerhandbuch des

Controllers.

5. Mit dem Sensor in der Prozessprobe Enter drücken. Der gemessene Wert wird angezeigt. Wenn

der Wert konstant ist, Enter drücken.

6. Messen Sie den Leitfähigkeitswert mit einem zweiten zertifizierten Prüfgerät. Geben Sie diesen

Wert mit den Pfeiltasten ein, wenn er von dem angezeigten Wert abweicht und drücken Sie

Enter.

7. Kontrollieren Sie das Kalibrierungsergebnis:

• PASS—der Sensor ist kalibriert und zur Messung von Proben bereit.

• FAIL—die Kalibrierung ist außerhalb der zugelassenen Grenzwerte. Reinigen Sie den Sensor

und wiederholen Sie den Vorgang. Für detaillierte Informationen beziehen Sie sich bitte auf

Fehlerbehebung auf Seite 38.

8. Nach erfolgter Kalibrierung bitte Enter drücken, um fortzufahren.

9. Ist die Option für die Bediener-ID im Menü CAL OPTIONS (Kalibrierungsoptionen) auf YES

eingestellt, geben Sie eine Bediener-ID ein. Beziehen Sie sich auf Kalibrierungsoptionen ändern

auf Seite 38.

10. In der Bildschirmanzeige NEW SENSOR legen Sie fest, ob der Sensor neu ist:

Option Beschreibung

YES Der Sensor wurde vorher nicht an diesem Controller kalibriert. Die Betriebsdauer in Tagen und die

vorherigen Kalibrierungskurven für den Sensor werden zurückgesetzt.

NO Der Sensor wurde vorher an diesem Controller kalibriert.

11. Sensor in den Prozess zurückführen und Enter drücken. Das Ausgangssignal kehrt wieder in den

aktiven Zustand zurück und der Messwert der Probe wird in der Messungsanzeige angezeigt.

Hinweis: Wenn der Ausgangsmodus auf Halten oder Ersatzwert eingestellt war, wählen Sie eine

Verzögerungszeit, nach deren Ablauf die Ausgänge wieder in den aktiven Zustand zurückkehren sollen.

Kalibrierung mit einer Referenzlösung (induktiver Leitfähigkeitssensor)

Bei der Kalibrierung wird der Sensormesswert an den Wert einer Referenzlösung angepasst.

Verwenden Sie eine Referenzlösung mit einem gleichen oder höheren Wert als die erwarteten

Messwerte.

Hinweis: Wenn der Sensor zum ersten Mal kalibriert wird, muss zuerst die Nullpunkt-Kalibrierung ausgeführt

werden.

1. Spülen Sie den sauberen Sensor gründlich mit entionisiertem Wasser ab.

2. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CALIBRATE

(Sensoreinstellung>Sensor auswählen>Kalibrieren) auswählen.

3. Wenn der Pass Code im Sicherheitsmenü des Controllers aktiviert wurde, geben Sie den Pass

Code ein.

4. Wählen Sie SOLN CAL und drücken Sie Enter.

5. Wählen Sie die Option für das Ausgangssignal während der Kalibrierung:

Option Beschreibung

ACTIVE Das Gerät übermittelt während der Kalibrierung den aktuellen Messwert.

HOLD Das Gerät hält den aktuellen Messwert während der Kalibrierung.

TRANSFER Das Gerät sendet während der Kalibrierung einen vorher eingestellten Ausgangswert. Für die

34 Deutsch

Änderung des voreingestellten Wertes beziehen Sie sich bitte auf das Benutzerhandbuch des

Controllers.

Page 35

6. Geben Sie den Sensor in die Referenzlösung. Stellen Sie sicher, dass der Erfassungsbereich

komplett in die Lösung eingetaucht wurde. Rühren Sie mit dem Sensor um, damit sich eventuelle

Blasen auflösen.

7. Warten Sie, bis sich die Sensortemperatur der Lösung angeglichen hat. Bei größeren

Unterschieden zwischen Prozessmedium und Referenzlösung kann dies 30 Minuten und mehr in

Anspruch nehmen.

8. Mit dem Sensor in der Referenzlösung Enter drücken.

9. Mithilfe der Pfeiltasten die Temperatur der Referenzlösung eingeben und dann Enter drücken.

10. Mithilfe der Pfeiltasten die Steigung der Referenzlösung eingeben und dann Enter drücken. Der

gemessene Wert wird angezeigt. Warten Sie, bis der Wert konstant ist.

11. Mithilfe der Pfeiltasten den Referenzwert eingeben und dann Enter drücken.

12. Kontrollieren Sie das Kalibrierungsergebnis:

• PASS—der Sensor ist kalibriert und zur Messung von Proben bereit. Der neue Wert der

Zellkonstante wird angezeigt.

• FAIL—Kalibrierungssteigung, bzw. Offset außerhalb der zugelassenen Grenzwerte. Reinigen

Sie den Sensor und wiederholen Sie den Vorgang mit einer neuen Referenzlösung. Für

detaillierte Informationen beziehen Sie sich bitte auf Fehlerbehebung auf Seite 38.

13. Nach erfolgter Kalibrierung bitte Enter drücken, um fortzufahren.

14. Ist die Option für die Bediener-ID im Menü CAL OPTIONS (Kalibrierungsoptionen) auf YES

eingestellt, geben Sie eine Bediener-ID ein. Beziehen Sie sich auf Kalibrierungsoptionen ändern

auf Seite 38.

15. In der Bildschirmanzeige NEW SENSOR legen Sie fest, ob der Sensor neu ist:

Option Beschreibung

YES Der Sensor wurde vorher nicht an diesem Controller kalibriert. Die Betriebsdauer in Tagen und die

vorherigen Kalibrierungskurven für den Sensor werden zurückgesetzt.

NO Der Sensor wurde vorher an diesem Controller kalibriert.

16. Sensor in den Prozess zurückführen und Enter drücken. Das Ausgangssignal kehrt wieder in den

aktiven Zustand zurück und der Messwert der Probe wird in der Messungsanzeige angezeigt.

Hinweis: Wenn der Ausgangsmodus auf Halten oder Ersatzwert eingestellt war, wählen Sie eine

Verzögerungszeit, nach deren Ablauf die Ausgänge wieder in den aktiven Zustand zurückkehren sollen.

Widerstandskalibrierung (Kontakt-Leitfähigkeitssensor)

Diese Kalibrierung wird manchmal auch als elektrische Kalibrierung bezeichnet. Sie wird nicht für die

Sensoren, sondern für die Prüfung der elektrischen Anschlüsse verwendet.

1. Die Menü-Taste drücken und SENSOR SETUP>[Select Sensor]>CALIBRATE

(Sensoreinstellung>Sensor auswählen>Kalibrieren) auswählen.

2. Wenn der Pass Code im Sicherheitsmenü des Controllers aktiviert wurde, geben Sie den Pass

Code ein.

3. Wählen Sie RESISTOR CAL (Widerstandskalibrierung) und drücken Sie Enter.

4. Wählen Sie die Option für das Ausgangssignal während der Kalibrierung:

Option Beschreibung

ACTIVE Das Gerät übermittelt während der Kalibrierung den aktuellen Messwert.

HOLD Das Gerät hält den aktuellen Messwert während der Kalibrierung.

TRANSFER Das Gerät sendet während der Kalibrierung einen vorher eingestellten Ausgangswert. Für die

5. Trennen Sie den Sensor von dem Sensorkabel und drücken Sie Enter. Schließen Sie einen

50 kΩ, 5 kΩ, 500 Ω, oder 50 Ω NIST Widerstand (Genauigkeit ±0,05%) an die Stifte 2-3 des

Änderung des voreingestellten Wertes beziehen Sie sich bitte auf das Benutzerhandbuch des

Controllers.

Deutsch

35

Page 36

Sensorkabels an und drücken Sie Enter. Geben Sie den Wert des Widerstands mit den

Pfeiltasten ein und drücken Sie Enter.

6. Kontrollieren Sie das Kalibrierungsergebnis:

• PASS—Die Kalibrierung war erfolgreich.

• FAIL—Die Zellkonstante ist außerhalb der zulässigen Grenzwerte. Reinigen Sie den Sensor