Page 1

DOC024.98.93034

POLYMETRON Model

9240 Multi-Channel Sodium

Analyzer

09/2013, Edition 5

Basic User Manual

Manuale dell'utente di base

Manuel d'utilisation de base

Manual básico del usuario

Temel Kullanıcı Kılavuzu

Osnovni uporabniški priročnik

Basishandbuch

Page 2

English..............................................................................................................................3

Deutsch..........................................................................................................................24

Italiano............................................................................................................................47

Français.........................................................................................................................70

Español..........................................................................................................................93

Türkçe...........................................................................................................................116

Slovenski.....................................................................................................................138

2

Page 3

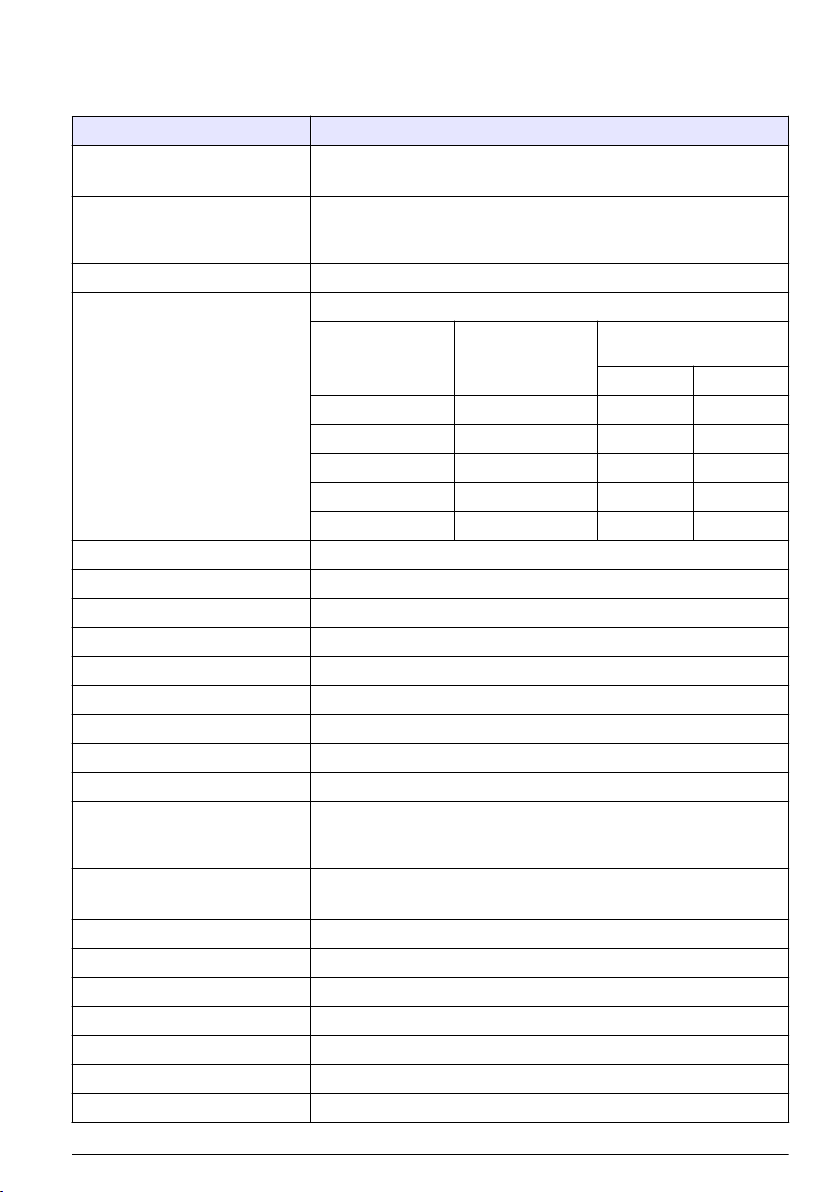

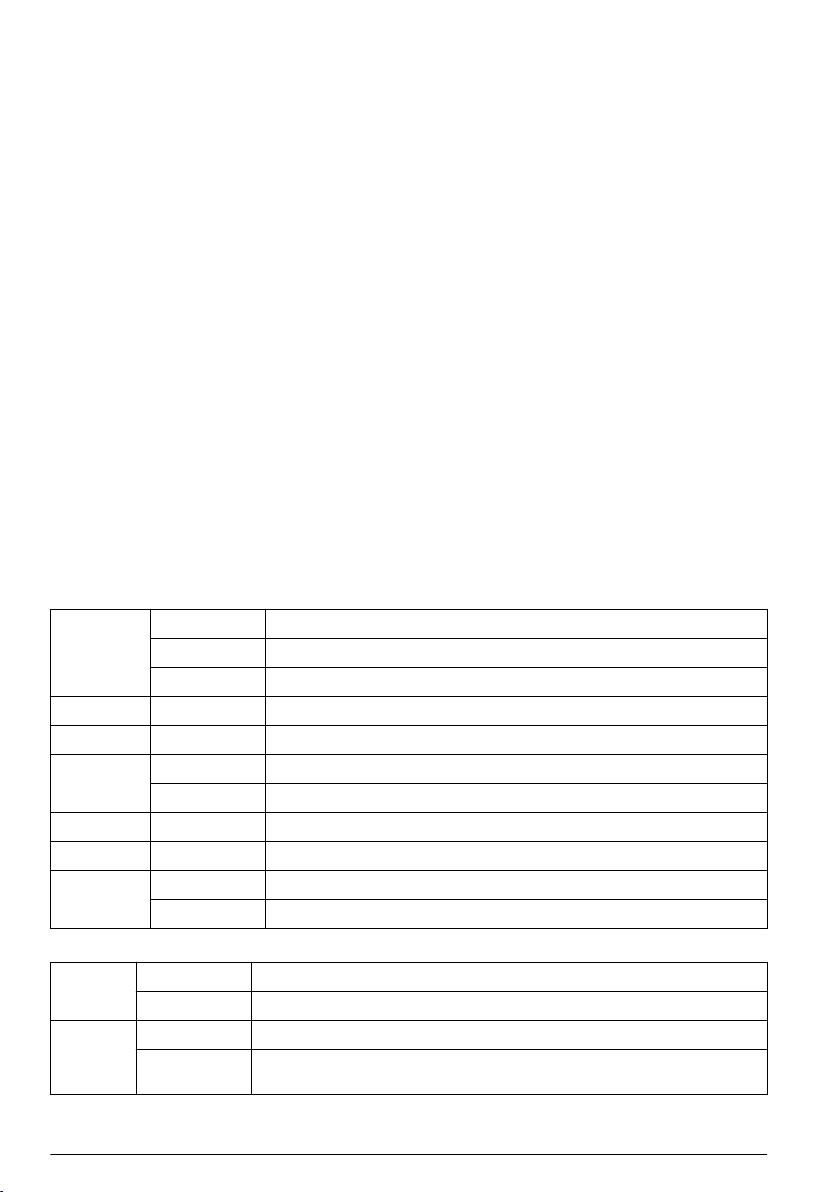

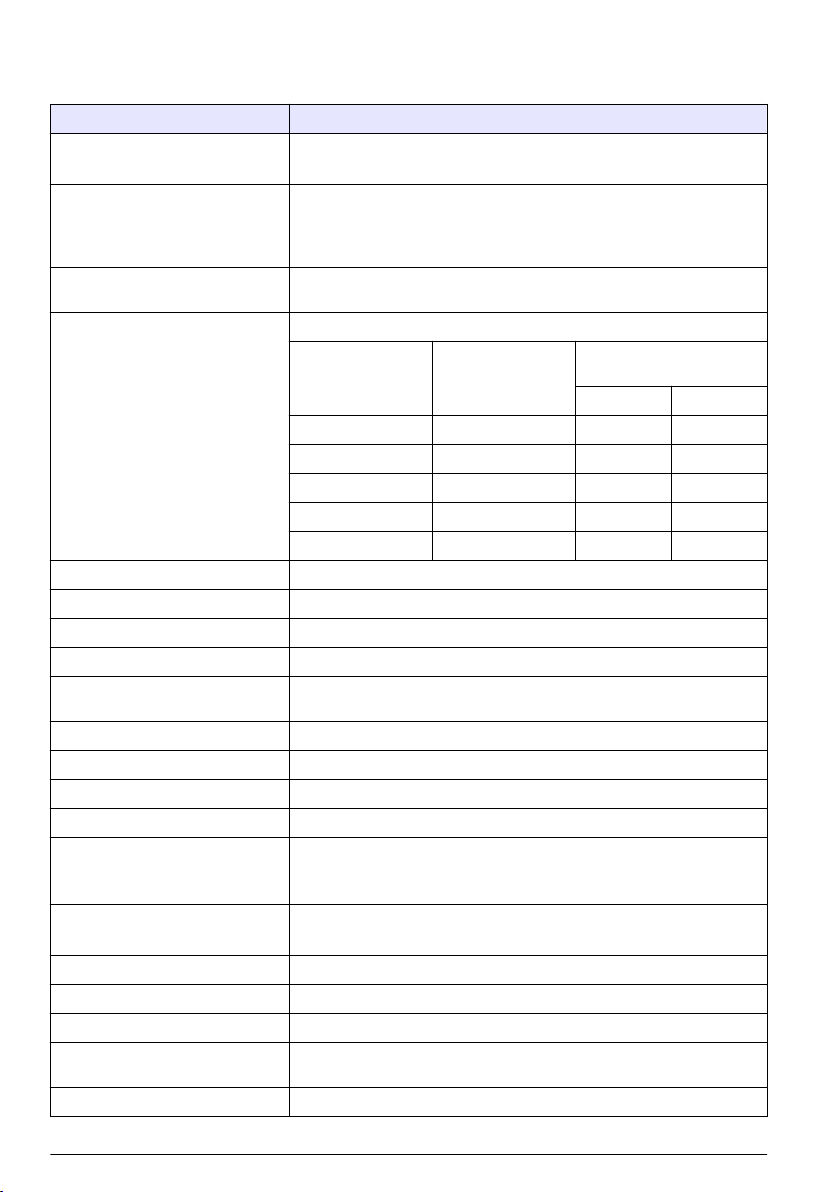

Specifications

Specifications are subject to change without notice.

Specification Details

Measuring range 0 to 10,000 ppb freely programmable

0 to 200 ppm with K-Kit option

Accuracy Non-cationic application: ± 0.1 ppb or ± 5% of reading, whichever is

Repeatability < 0.02 ppb or 1.5% reading, whichever is greater within 10°C variation

Average response times at 25°C

with a maximum ΔT =15°C between

channels

Electrode type pH glass electrode

Number of channels 1 to 4

Interference phosphate 10 ppm Measurement variation less 0.1 ppb

Sample temperature interference < 0.5% / °C

Typical environment Power station / indoor / demineralized water plant or instrumentation room

Suspended solids < 2 NTU, no oil, no grease

Temperature range for storage -20 to 60°C (2 to 140°F)

Relative humidity 10 to 80%

Ambient temperature 5 to 50°C (41 to 122°F)

Sample temperature variation Stabilization in 10 mins from 15°C to 30°C

pH range of sample Non-cationic application: 6 to 10 pH

Flow rate 6 to 9 L/hour

Pressure 0.2 to 6 bar (3 - 87 psi)

Acidity Less than 250 ppm (equivalent CaCO3)

Power supply voltage fluctuation ± 10%

Over voltage category 2 (according to standard EN 61010-1)

Pollution degree 2 (according to standard CEI 664)

Altitude < 2000 m

greater

Cationic application: ± 2 ppb or 5% reading, whichever is greater

T90% ≤ 10 min

Concentration step

from one channel to

another

0.1 ↔ 5 ppb 3 9 min 27 min

0.1 ↔ 50 ppb 3 11 min 41 min

0.1 ↔ 200 ppb 3 9 min 45 min

< 0.1 ↔ 1 ppb 3 29 min 36 min

0.1 ↔ 50 ppb 15 11 min 41 min

Use the static heat exchanger system when the temperature difference

between samples is higher than 15°C

Cationic application: 2 to 10 pH

Max. temp variation

(°C)

Time to reach accuracy

0.1 ppb or 5%

up down

English 3

Page 4

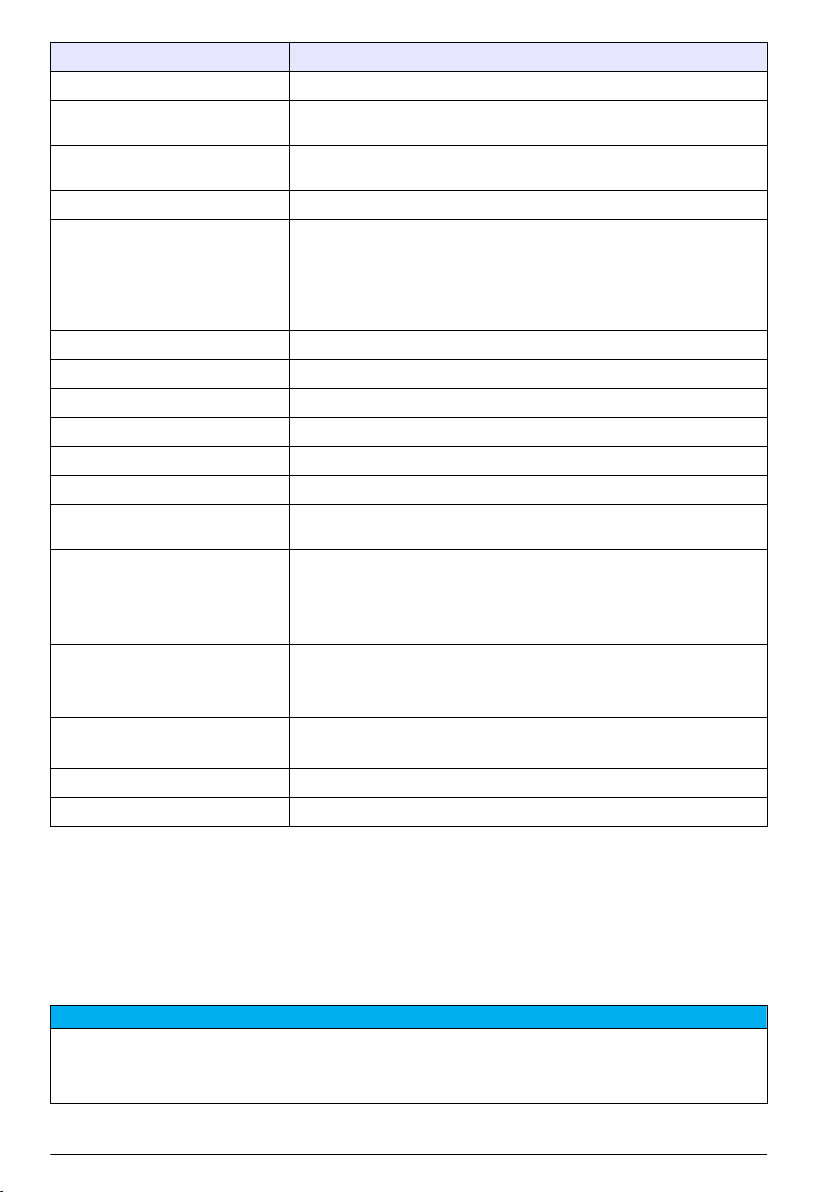

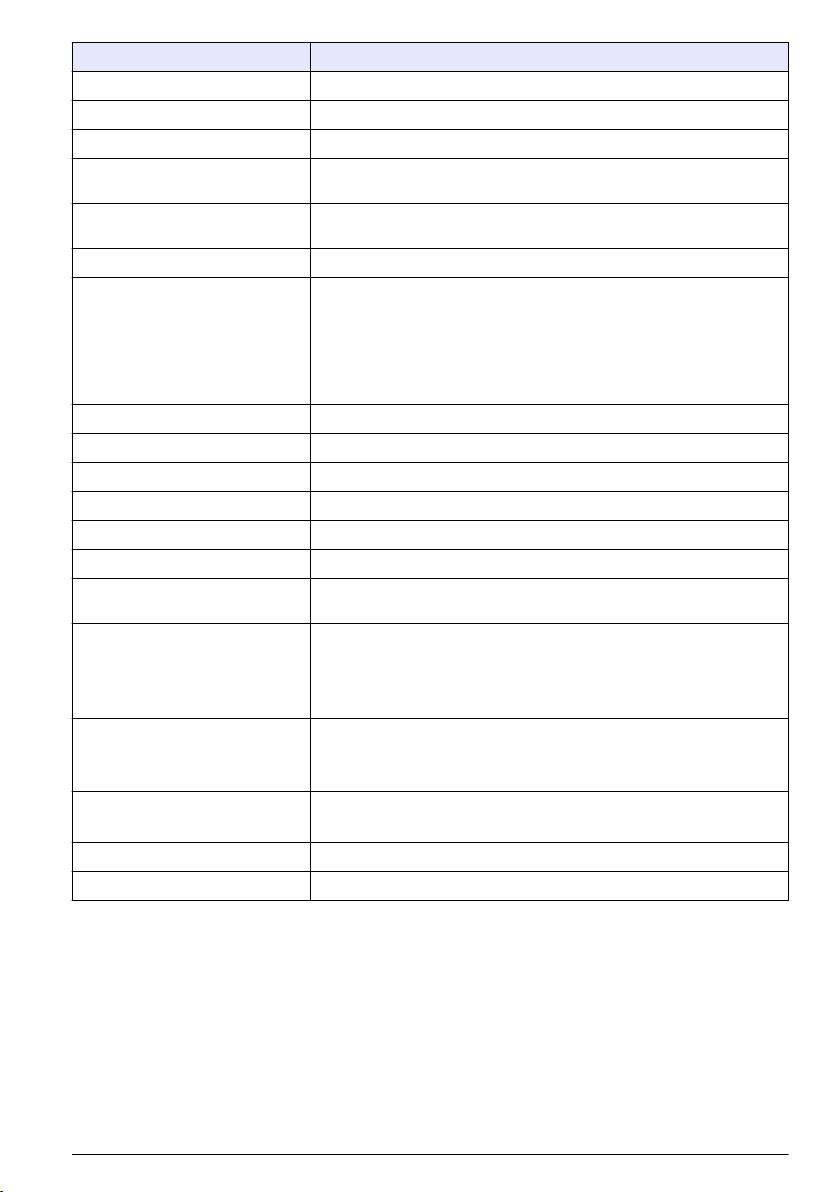

Specification Details

Measurement category Cat II, Class 1 (overvoltage < 1500V)

Maximum panel dimension (H x L xD)850 x 450 x 252.5mm [33.46 x 17.71 x 9.94in]

Inlet Simple fittings for 6 mm O.D. tubing or ¼" O.D. in PE-low density. ¼" OD

Outlet Barbed stem for 12 mm (½" I.D.) hose

Protection rate Transmitter: IP65 (NEMA 4)

Cell PMMA - compact (minimum tubing)

Flame rate Conform UL

Maximum weight 15 - 30 Kg

Mains power supply 100 - 240 VAC, 50-60 Hz, ± 10%, automatic switching

Max. consumption 80 VA

Fuse 5 x 20 cartridge T2AL-250V following CEI127

Display Curve trend, Last Cal Date, Historical, Concentration, Temperature,

Analog outputs Number: 6

Relays 4 x Relay (conc)

Logic input Active / Inactive channels

European standards EN 61326 Class A for EMC; EN 601010-1 for low voltage safety

International standards cETLus

in PHED-PTFE-SS as option

Panel: IP50 (dust protection)

Optional Enclosure: IP54 (splash water proof)

Instrument is designed to avoid DIPA vapor inside the enclosure. All DIPA

vapor is collected and sent to the instrument drain

Potential

4-20 or 0-20 mA (650 ohms)

Linear / Dual / Logarithm

Event indication

1 x Warning

1 x System

Remote AutoCal

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

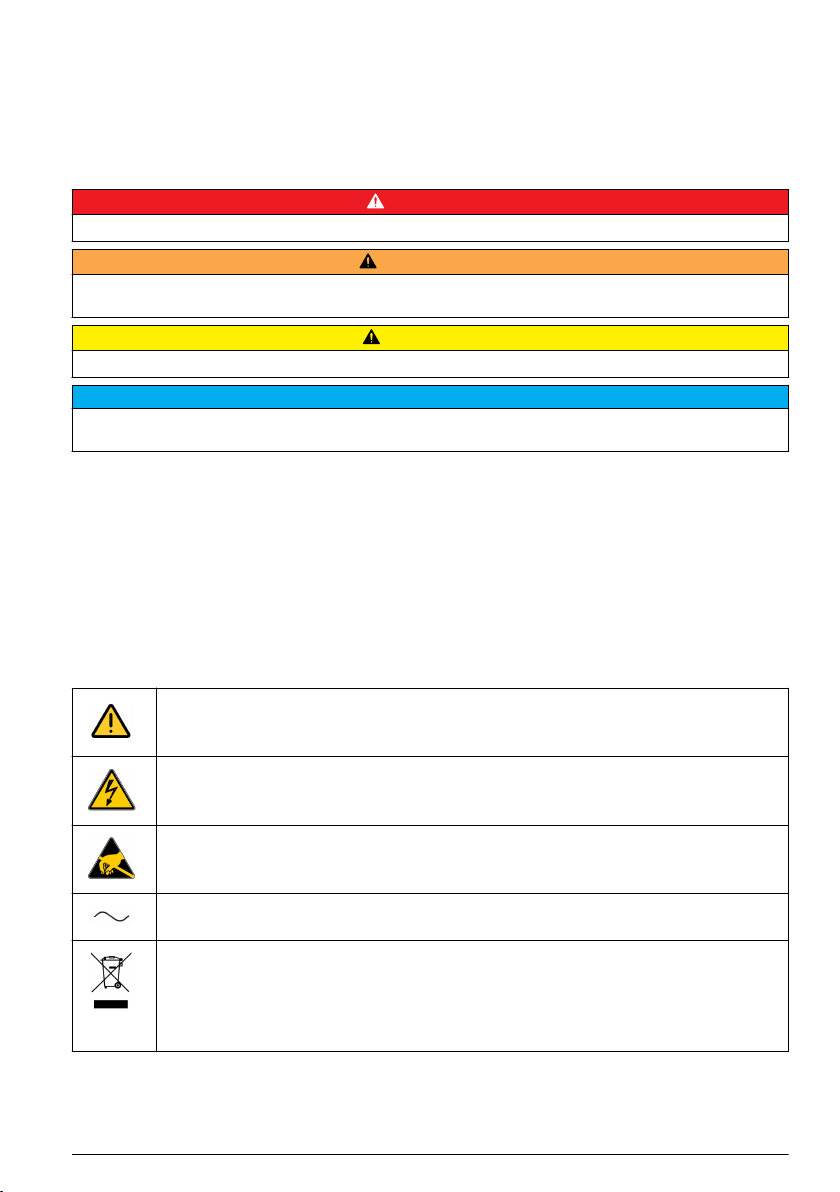

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

4 English

Page 5

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

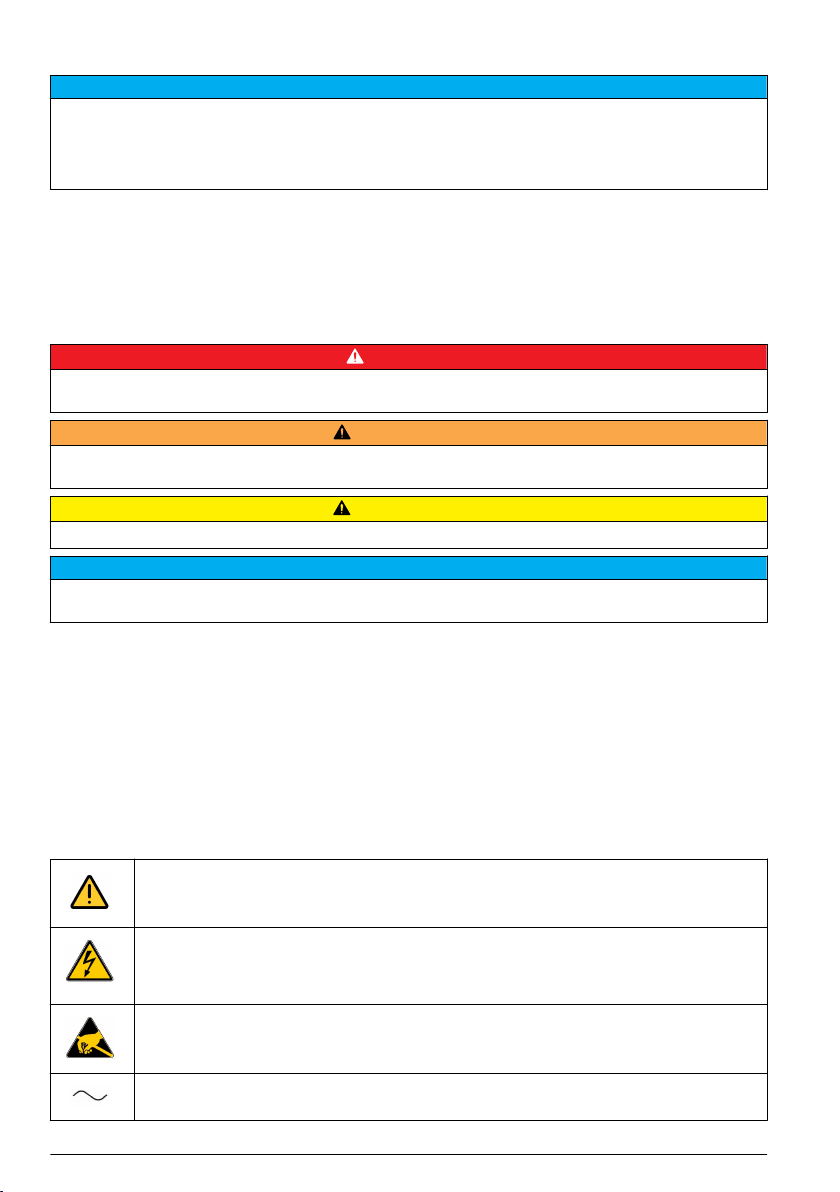

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

W A R N I N G

C A U T I O N

N O T I C E

Potential safety hazards

The following potential safety hazards are associated with operating the analyzer:

• Electrical (line voltage)

• Potentially hazardous chemicals

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary

statement.

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on a product, indicates the instrument is connected to alternate current.

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems. In conformity with European local and national regulations, European electrical equipment

users must now return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

English 5

Page 6

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Products marked with this symbol indicates that the product conforms to relevant South Korean

EMC standards.

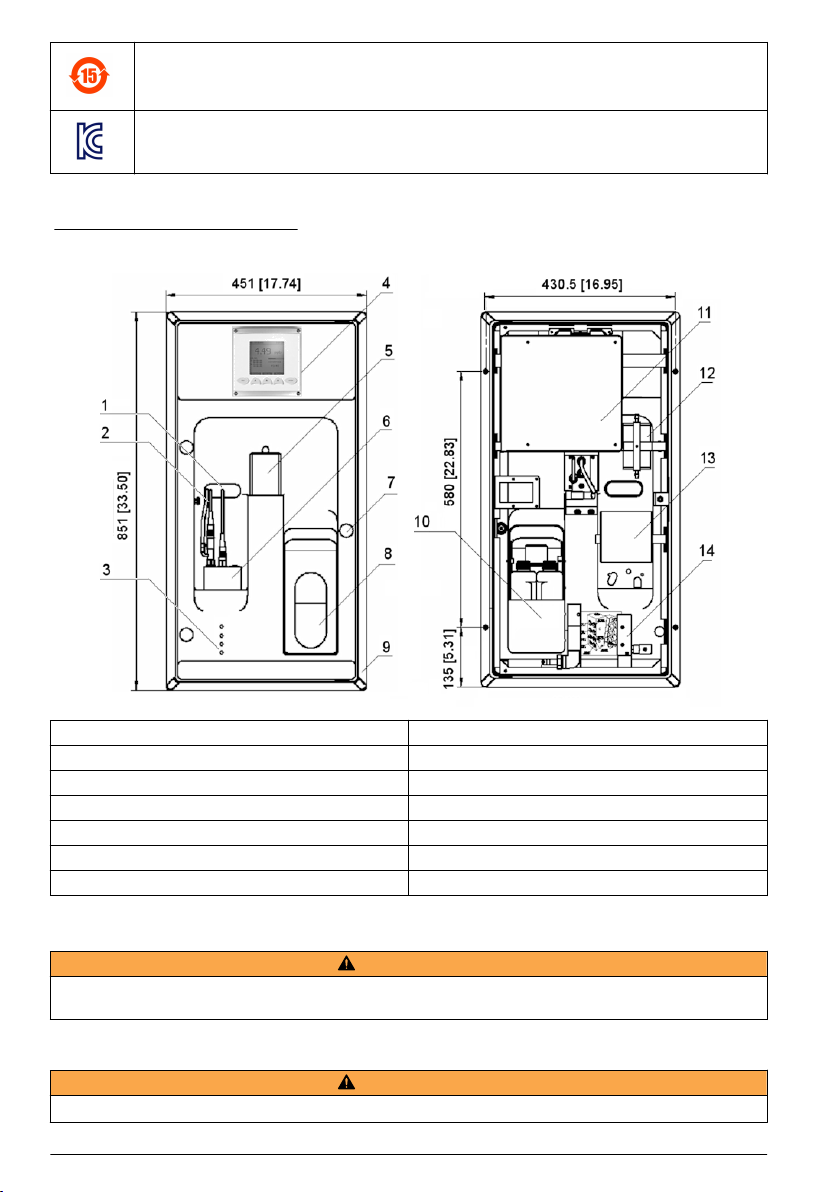

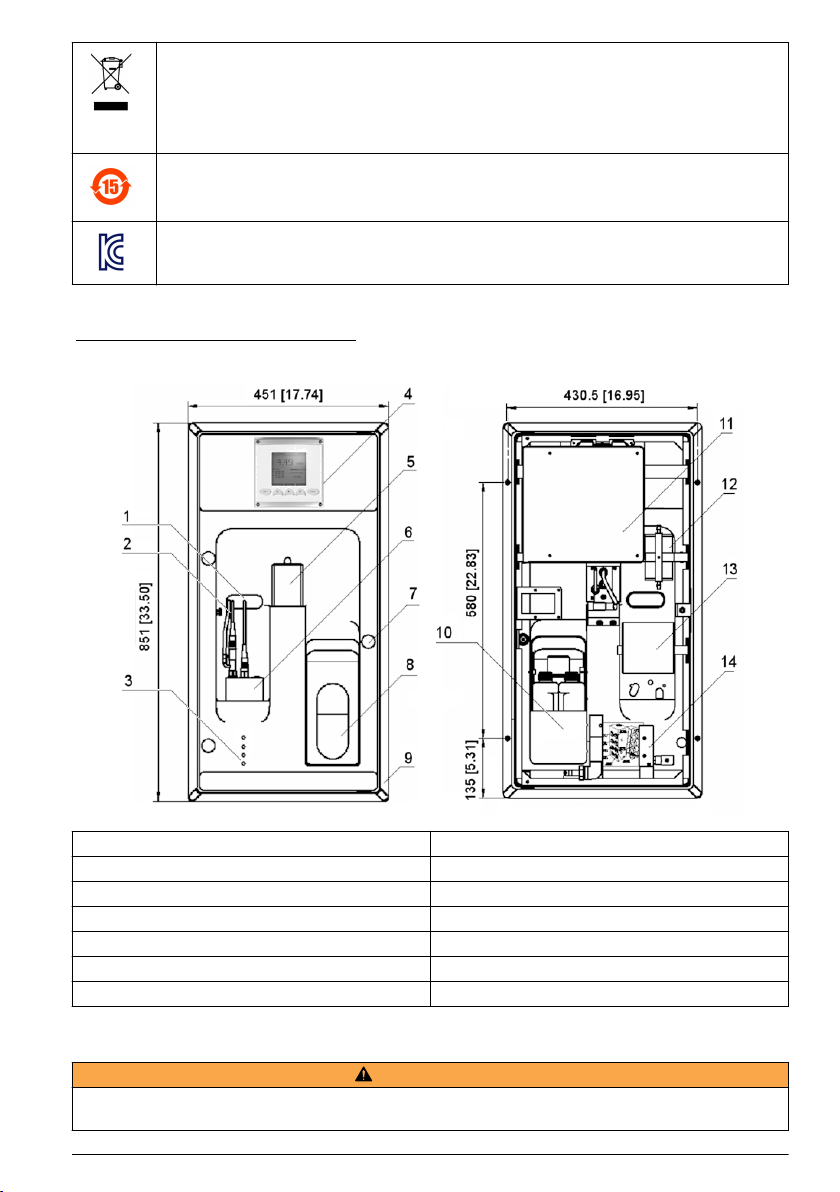

Overview

Figure 1 Front and rear panels

1 Sodium ion selective electrode 8 Reagent shelf

2 Reference electrode 9 Frame for panel mounting

3 Flow rate adjustment for each channel 10 Reagent canister holder

4 User interface 11 Local controller box

5 Overflow vessel 12 Electrolyte reservoir

6 Measuring cell 13 Pump box

7 Door lock 14 Sample inlet valves

Installation

W A R N I N G

The analyzer should only be assembled by qualified staff. Mains power should only be connected once

installation has been completed and checked

Mounting the analyzer

Do not connect power prior to mounting and plumbing the instrument.

6 English

W A R N I N G

Page 7

C A U T I O N

Personal injury hazard. Instruments or components are heavy. Use assistance to install or move. Make sure that

the wall mounting is able to hold 4 times the weight of the equipment.

Wherever the analyzer is to be mounted, it is important to note that it must be placed in an upright position with

the transmitter at the top. It is recommended to use a spirit level to ensure that the analyzer is correctly positioned

and not leaning to one side or forward. This is essential to guarantee the accuracy of the analyzer.

C A U T I O N

Panel mounting

Mount the analyzer using the fixation holes located around the outside of the analyzer.

Wall mounting

Use the wall mounting kit to fix the instrument to the wall. The distance between the two pieces is

460 mm.

C A U T I O N

It is extremely important to respect this gap of 460 mm to avoid bending the cabinet out of shape while fitting.

Mains power connection

W A R N I N G

No intervention should be made on the instrument without first switching off the power.

The electrical installation should be carried out by duly qualified personnel. A supply voltage of

100-240 VAC is acceptable without changing the configuration. The power supply terminals can be

removed from their housing to make connection easier.

For safety reasons, it is imperative to respect the working procedure below:

• Use a three-wire power cable (live + neutral + earth), sized for supplying the required power.

• The instrument should be connected to the mains via a circuit-breaker or fuse whose value should

be less or equal to 20 A. It should be located in proximity and be identified. This connection should

cut-off the live and the neutral when electrical problems occur or when the user wishes to

intervene inside the instrument. On the other hand, the earth conductor should always be

connected.

The main cabinet should be open with access to the interior.

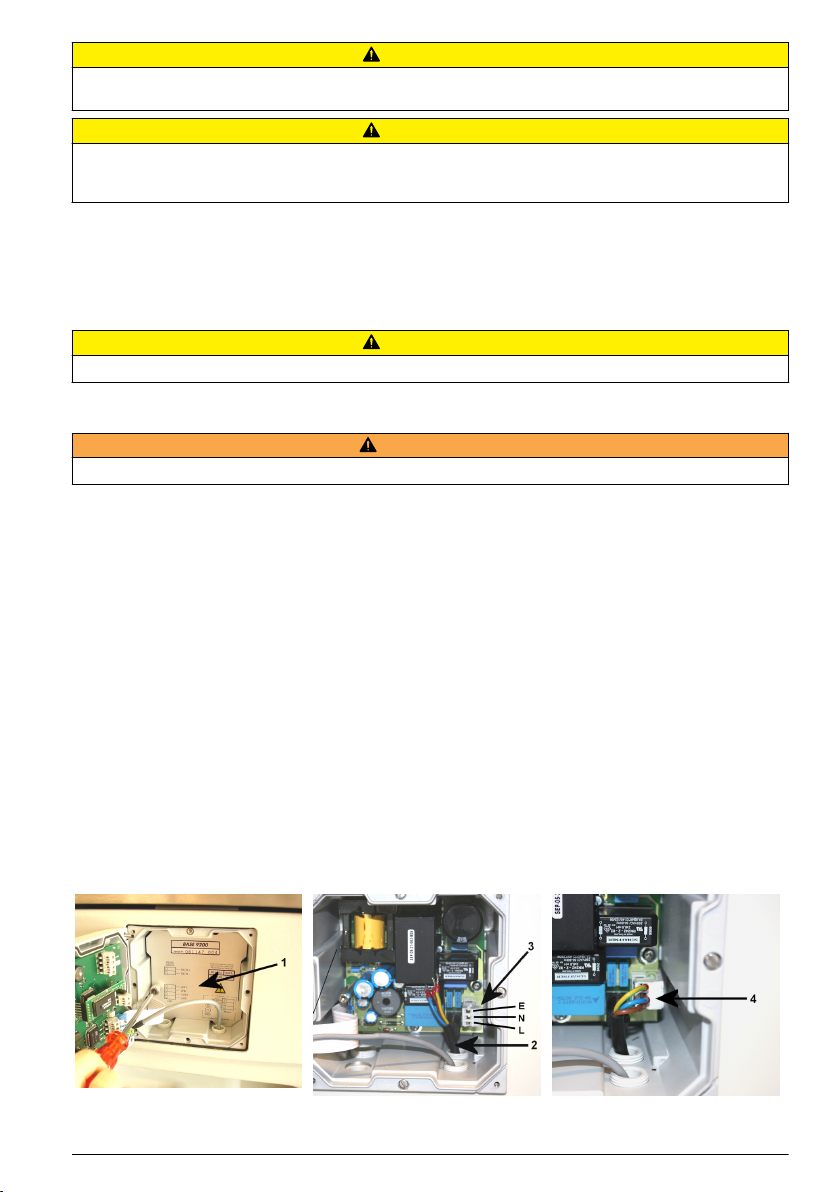

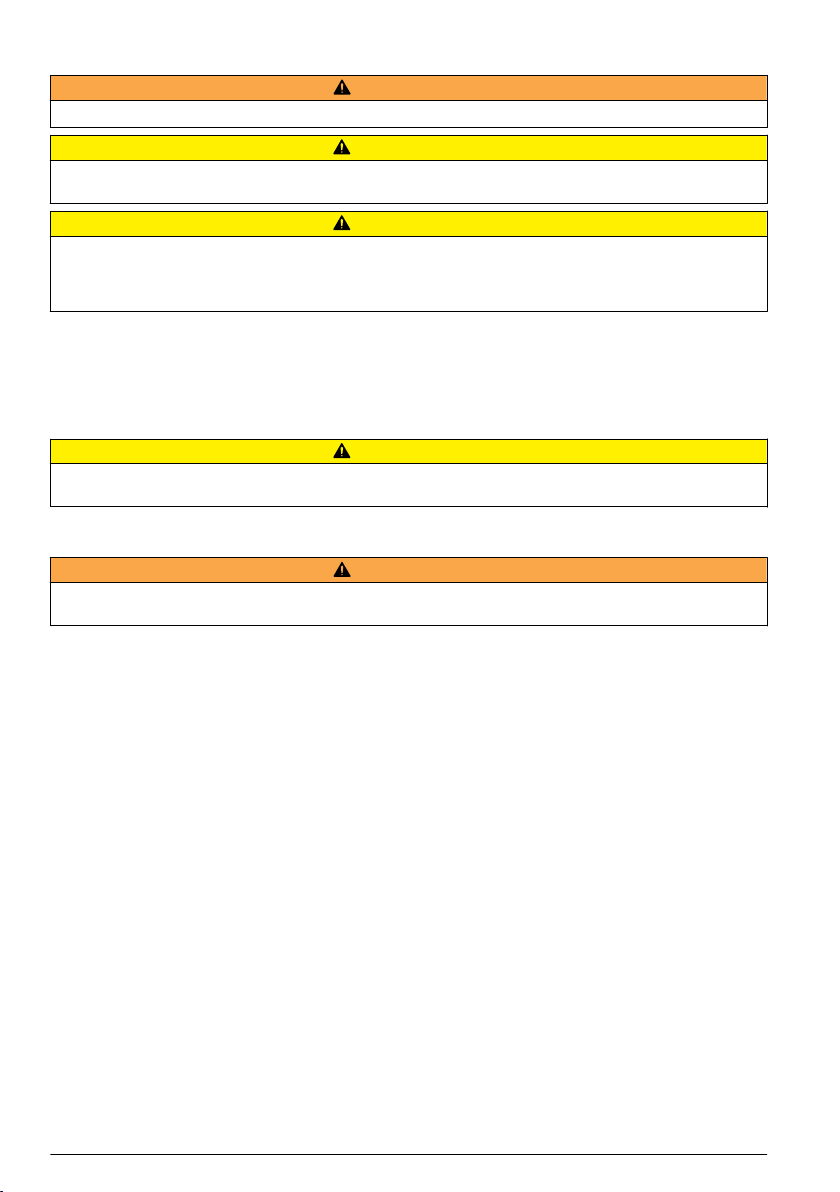

1. Pass the power cable through the cable gland located at the back left of the bottom of the

cabinet.

2. Open the back of the local controller box (No. 11 in Figure 1 on page 6) by unscrewing the

6 screws.

3. Unscrew the two holding screws on the upper left and right side of the box, and allow it to rotate

down to reveal the back of the transmitter. The cable gland for the power cable is located left and

nearest to you.

English

7

Page 8

4. Unscrew the cable gland nut, pass the power cable through it, and then up through the cable

gland and into the transmitter (No. 2). Screw back the cable gland nut to secure the power cable.

5. Open the transmitter front door by unscrewing the four holding screws.

6. Swing open the door (it is hinged to the left) to reveal the inside of the transmitter.

7. Remove the metallic shielding plate (No. 1) protecting access to the main board.

8. Remove the power supply connector (No. 3) and note where the earth, neutral and live (E, N, L)

must be connected.

9. Connect the power supply cables to the connector.

10. Put the connector back in place (No. 4).

11. Replace the metallic shielding plate, ensuring it is in front of the power cable just installed.

External communications connection

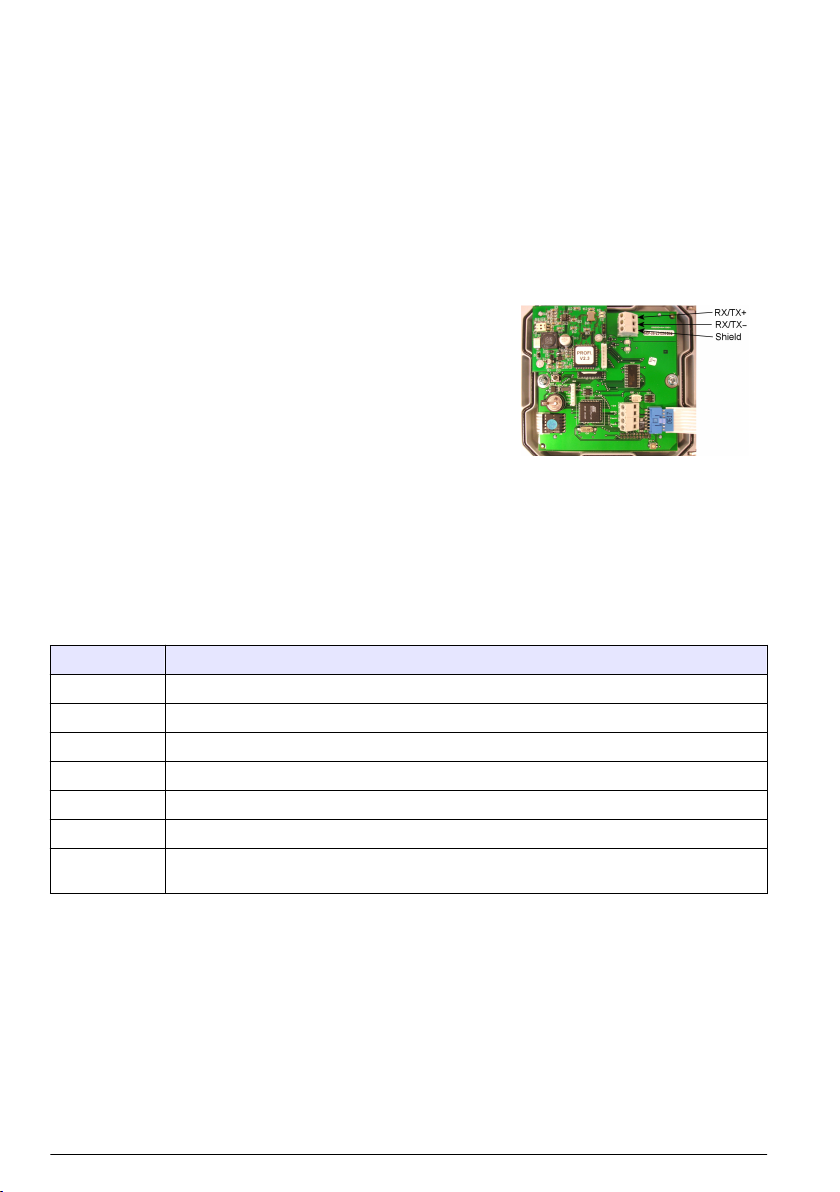

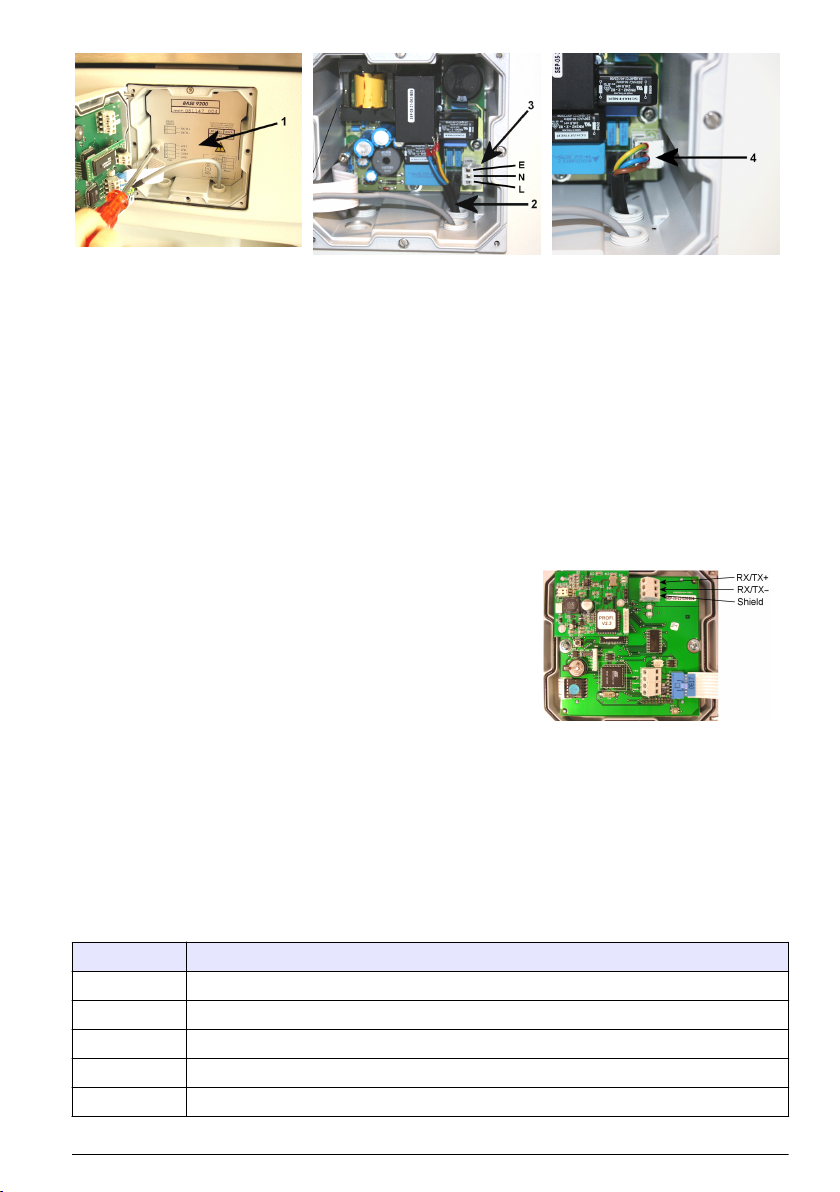

1. Run the communications cable through an external cable gland on

the bottom of the cabinet, and into the analyzer.

2. Pass it through the cable gland located right and farthest from you

on the base of the transmitter, so it appears inside the transmitter

through the left front cable gland.

3. Connect the communication cable as indicated. Connection is the

same on the CPU board for both the JBUS/ MODBUS and

PROFIBUS options.

4. Close the transmitter door and secure in place with the 4 screws.

5. Put the local controller box back in its normal position and secure in

place with the 2 holding screws.

Input/Output connections

Before using any of the cable glands, perforate first with a screwdriver. To ensure a good seal, the

external diameter of the cables should be between 5 and 7 mm. The nomenclature given in the

connections column of the following table refers to the same nomenclature that is printed on the I/O

board against each available connection.

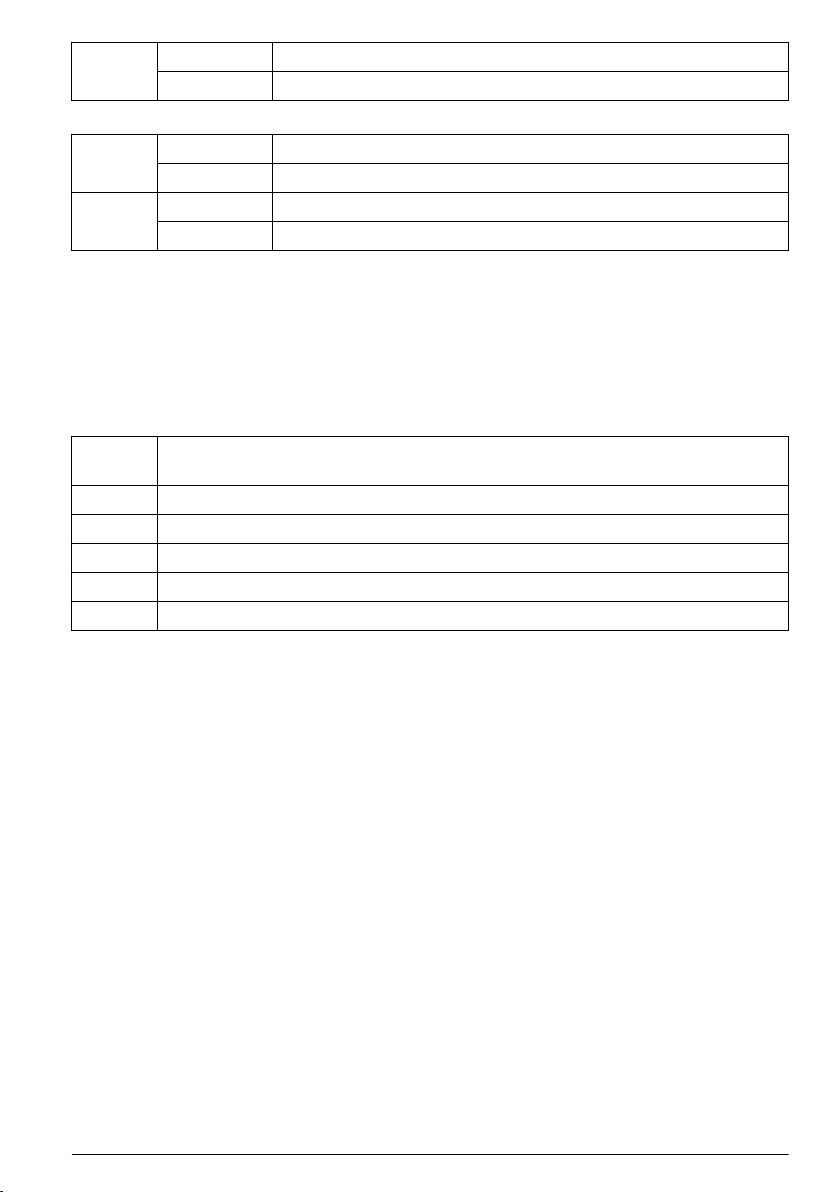

Connections Function

Re1 to Re6 User relays - see Alarms on page 16 for more information on the relays

Re7 Warning alarm

Re8 System alarm

In2 For remote calibration

In4 to In7 By-pass channel measurement (channel 4 - 1 respectively)

Iout0 Used for the current measurement signals

Iout1 to Iout7 Can be freely linked to different parameters like measurement, temperature - refer to the

section entitled mA outputs on page 17 for details

On completion, close the local controller box (No. 11 in Figure 1 on page 6) and secure in place with

the 6 screws.

Sample tubes installation

Connecting the sample

Use new tubes for connections during installation

• Exterior Ø: 6 mm exactly (or ¼'')

• Material: polyethylene or PTFE or FEP

• Flow rate: 6 to 9 L/hour

8

English

Page 9

• Pressure: 0.2 to 6 bar (8-100 psig)

• Sample acidity: sample acidity should not be more than 300 ppm CaCO

3

• Temperature: 5 to 45°C

At this stage of the installation, make sure that the flow valve is closed. Connect the pipes by

inserting them into the quick release connections found on the bottom of the analyzer under the

sampling block (No. 14 in Figure 1 on page 6). Be sure that the sample line is correctly flushed

before any connection to avoid particle injection into the hydraulic system. If particulate matter is

present in the sample, pre-filtration is necessary. A filter should be inserted in the sample line. One is

available as an option. Connect one inlet and one outlet per channel.

Connecting the drain tube

The drain outlet is located on the bottom of the analyzer. A 12 x 17 mm pipe is delivered with the

analyzer and should be connected to the drain outlet at one end and the other fed to a drain for

sample evacuation.

Reagents installation

The canisters are installed in the canister holder (No. 10 in Figure 1 on page 6).

1. Prepare the reagents.

2. Install and connect the conditioning solution (diisopropylamine).

3. Install and connect the reactivation solution (blue R label).

4. If you have this option, install and connect the auto calibration solution

(yellow CAL label).

Magnetic stirrer installation

1. On the front of the panel, remove the plastic bag from the overflow vessel (No. 5 in Figure 1

on page 6).

2. Remove the magnetic stirrer from the bag and install it in the overflow vessel.

Reagents volume declaration

Note: As you will now be using the analyzer menus to input data, it may be useful to familiarize yourself with the

data entry procedures by reading the section entitled User interface on page 12.

1. Open the sample valve and check that there is no leakage in the hydraulic path.

2. Power on the analyzer.

3. Select the Menu option from the display.

4. Select MAINTENANCE/DIAG. from the main menu and press Enter.

5. Select the REAGENT CHANGES option and press Enter.

6. Set the BOTTLES FULL parameter to Yes and press Enter.

7. Press Esc to return to the MAINTENANCE/DIAG. menu.

Flow rate adjustment

1. From the MAINTENANCE/DIAG. menu select START UP and press Enter.

2. First, the system automatically primes both the calibration and reactivation tubes.

3. Check that there are no air bubbles in the reagent tubes for reactivation and auto calibration.

4. The next step allows you to regulate the sample flow rate on each measurement channel. The

name of the channel to regulate is displayed.

5. The analyzer automatically empties and refills the overflow vessel to determine the flow rate

which is displayed on screen.

English

9

Page 10

6. The flow rate for each channel should be 6 to 9 L/hour.

7. Using a screwdriver, regulate the channel’s sample flow (No. 3 in Figure 1 on page 6) by turning

counter-clockwise to increase the flow rate or clockwise to decrease the flow rate.

8. The process is repeated until the flow is correctly regulated for the channel. At this point select

OK.

9. The system then allows you to regulate the next channel until all flow rates have been set for the

configured channels.

10. Once all flow rates for the configured channels have been set, an Action completed message

will be displayed. Select Esc to exit.

Sample pH conditioning check

Non-cationic applications

1. Install a calibrated pH sensor in the center position of the measurement chamber which is

normally used for the ISE sodium electrode (No. 1 in Figure 1 on page 6).

2. On the analyzer, press Start on the main menu to start the measurement process.

3. For each channel, check that the pH value of the sample after conditioning is greater than 10.5. If

not, check the quality of the conditioning product used.

Cationic applications

1. With a calibrated pH sensor, measure the pH of the sample for each channel outside of the

analyzer.

2. The analyzer measurement sequence will be factory set depending on the number of configured

channels (e.g. 1 2 3 4 * for a 4-channel analyzer or 1 2 * for a 2-channel analyzer). Verify this

sequence is correctly setup (see Sequence on page 18 for more details).

3. Set the following measurement timings (see Measure steps on page 15):

• CYCLE TIME to 11 min

• ON LINE MEAS to 8 min

• SEARCH STAB to No

4. For each channel, determine the gas injection time ratio depending on the sample pH. Enter this

value into the analyzer as described in Total gas/water ratio (cationic applications only)

on page 15. The standard values are:

• pH = 2.0 - Tgas/Twater ratio = 180%

• pH = 2.3 - Tgas/Twater ratio = 80%

• pH = 2.6 - Tgas/Twater ratio = 50%

• pH = 2.9 - Tgas/Twater ratio = 30%

• pH = 3.5 - Tgas/Twater ratio = 15%

• pH = 4.0 - Tgas/Twater ratio = 10%

5. Install the same pH sensor in the center position of the measurement chamber (No. 2 in Figure 1

on page 6).

6. On the analyzer, press Start on the main menu to start the measurement process.

7. For each channel, measure the pH in the conditioned sample to check if the pump ratios are

efficient enough to obtain a pH of around 11.0. If necessary, update the ratio to maintain a final

constant pH of 11.0 ± 0.2.

10

English

Page 11

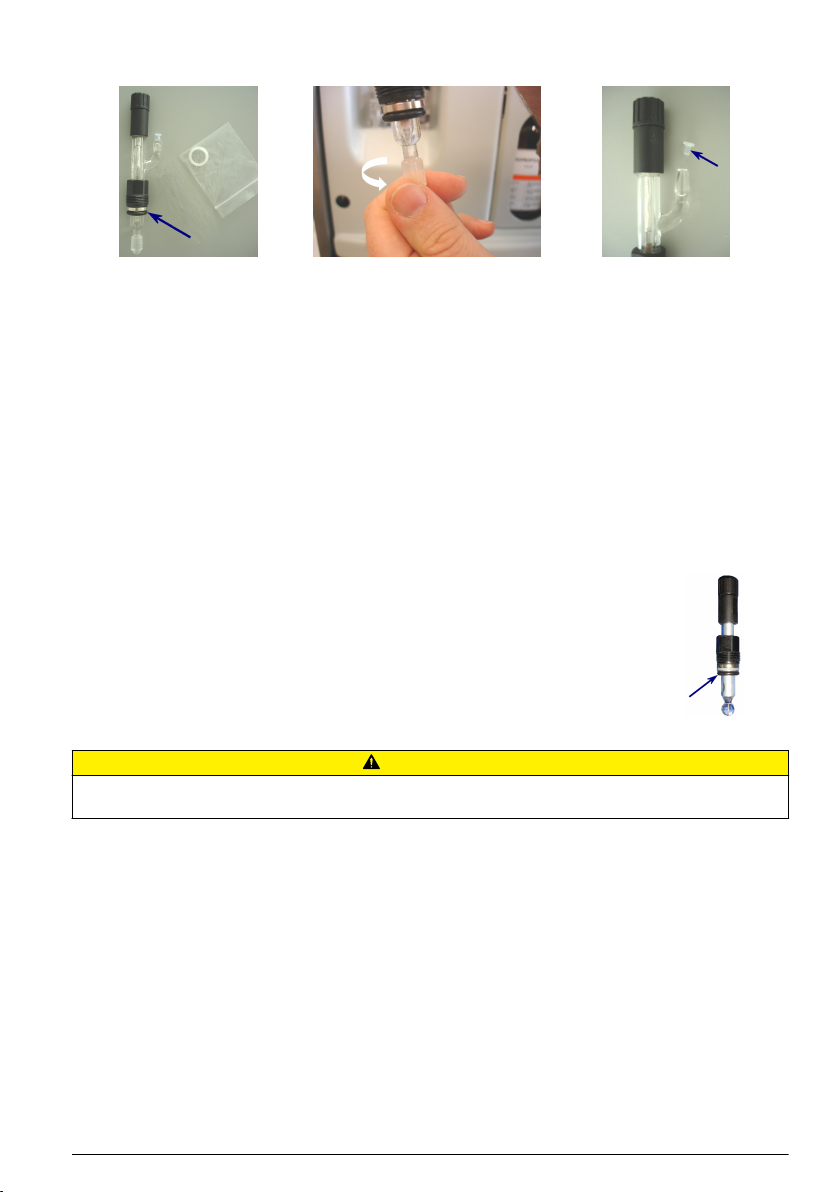

Reference electrode installation

1. Remove the reference sensor from its box.

2. Remove the plastic reservoir from the bottom (the storage solution is KCl 3M) and install the O-

ring as shown.

3. With care, turn the bottom electrolyte tube ferrule with a maximum ¼ turn to lock it.

4. Remove the plastic plug on the entry port.

5. Install the reference electrode in the extreme left measurement chamber (No. 2 in Figure 1

on page 6).

6. Connect the reference cable (the one without the blue label on it) to the reference electrode.

7. Connect the electrolyte tube to the entry port on the reference electrode.

Sodium ion selective electrode installation

Note: It is critical to preserve the integrity of the sodium ion selective electrode as much as possible. This is why

this electrode must be installed at the very last moment after all other adjustments.

1. Remove the sodium ion selective sensor from its box.

2. Remove the plastic reservoir from the bottom (the storage solution is standard tap

water) and shake gently (as you would a thermometer) to dispose of any bubbles.

3. Install the O-ring as indicated right.

4. Install the ISE in the center position of the measurement chamber (No. 1 in Figure 1

on page 6).

5. Connect the AS7 cable (with the blue label) to the electrode.

C A U T I O N

After the electrodes installation, it is very important that none of the electrode heads are touching the bottom part

of the measuring cell.

Fill electrolyte reservoir

The electrolyte reservoir is located at the back of the analyzer (No. 12 in Figure 1 on page 6).

1. Take the KCl electrolyte bottle and insert the tip of the tapered spout into the reservoir inlet tube

as far as it will go but without exerting any extra pressure.

2. Squeeze on the bottle as many times as necessary to fill the reservoir to about 3/4 of its capacity.

If you have any difficulty filling the reservoir, raise the spout of the bottle very slightly to avoid an

airlock.

3. Using thumb and forefinger, pump on the electrolyte tube between the reservoir and the

reference electrode to remove any air bubbles that may have formed.

4. If necessary, clean any KCl drops from the analyzer and the reservoir.

English

11

Page 12

Analyzer stabilization

At this stage the analyzer has been completely installed, but needs to run for a period of time to

stabilize.

1. Press Start on the main menu to start the measurement process.

2. Leave the system to run for a couple of hours before starting any calibrations.

User interface

Function keys

The display panel has 5 function keys (illustrated below) to allow menu option selection, field

selection, and data entry options.

• The Esc key cancels data input or goes back to the previous screen.

• The Enter key validates the input and goes on to the next step

• The Up Arrow keys select the option displayed immediately above them on the screen.

When a screen requiring data entry is displayed, the first editable field is always highlighted. To

select other fields on the screen, scroll through them by pressing the Up Arrow function key under

the Select option. As each field is selected, the data element available for update is highlighted.

The same is also true when a menu is displayed. In this case, the first available option is always

highlighted. Scroll to the required option by pressing the Up Arrow function key under the Select

option.

Data entry is effected in a variety of ways depending on the characteristics of the data field being

accessed.

Numeric fields

These fields require that the user enter one or more numeric values into a field. The type of field

determines the available input. In some fields only digits 0 through 9 would be available to select

whereas in other fields the decimal point and/or minus sign may also be available.

1. For data elements such as these, press the function key under either the Up Arrow or Down

Arrow options to initiate data entry.

2. The first digit will then be highlighted, and a new Right Arrow option replaces the Select option

at the bottom of the screen.

3. Press the function key under the Up Arrow option to increase the value of the field by 1.

4. Press the function key under the Down Arrow option to decrease the value of the field by 1.

5. Press the function key under the Right Arrow option to accept the currently displayed digit and

move one digit to the right.

6. Press the Enter function key to accept the data and move to the next input field.

Alphanumeric fields

These fields require that the user enter one or more alphanumeric values into a field. The type of

field determines the available input. In some fields only upper case alpha characters may be allowed,

in others upper and lower case alphanumeric characters my be allowed, etc.

1. Press the function key under either the Up Arrow or Down Arrow options to initiate data entry.

2. The first character will then be highlighted, and a new Right Arrow option replaces the Select

option at the bottom of the screen.

12

English

Page 13

3. Press the function key under the Up Arrow or Down Arrow option to scroll through the list of

available characters.

4. Press the function key under the Right Arrow option to accept the currently displayed character

and move to the next character.

5. Press the Enter function key to accept the complete field and move to the next data input field.

List element fields

This type of data entry is where a pre-defined list of available data values are available to the user

who must select the one which is applicable. Free-format text is not allowed.

1. For data elements such as these, press the function key under the Up Arrow option to scroll

forward through the pre-defined list or press the function key under the Down Arrow option to

scroll backward through the list.

2. When the required list element is displayed press the Enter function key to accept the data and

move to the next data input field.

Incremental value fields

These are fields where a value is displayed on the screen and the user has the option of increasing

or decreasing the value.

1. Use the Up Arrow function keys under the plus or minus symbols to adjust the value by 1.

2. On completion press the Enter function key, to accept the new value.

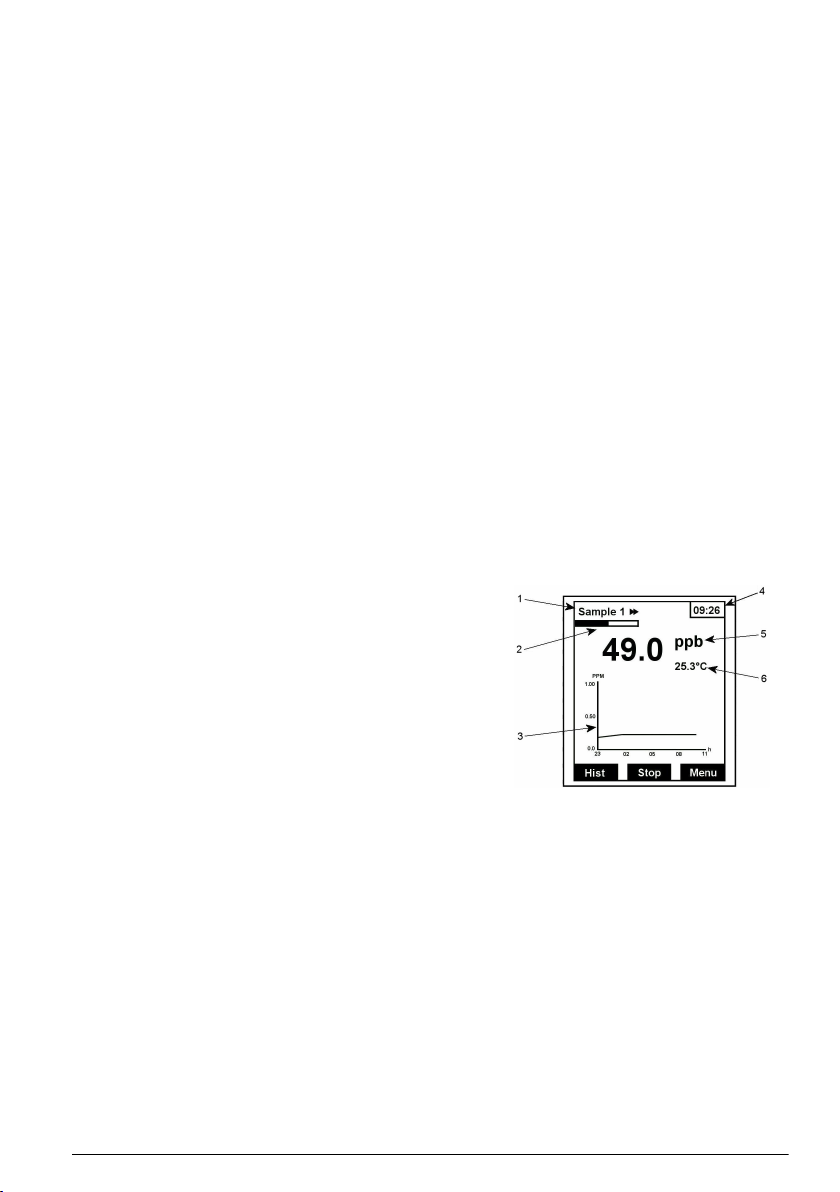

Measurement screens

Principal display

1. Sample being measured

2. Bar graph of measurement progress

3. Current measurement graph

4. Time

5. Current measurement and unit

6. Temperature

The options at the bottom of the screen will include three of the following:

• Hist - Selecting this option will show the most recent measurements along with the last grab

sample and verification details.

• Stop - Select this option to stop the current process on the analyzer. This could be a

measurement, verification or grab sample process. The option is only available when one of these

processes is currently running. You will be asked for confirmation (YES or NO) that you want to

stop the process.

• Start - Select this option to start the analyzer measurement process. This option is only available if

the analyzer has been stopped.

• Menu - This will bring up the main menu screen.

• Alarm - This option will appear flashing on the screen if any alarms have been set. Selecting this

option will take you to the alarms screen.

English

13

Page 14

Main menu

The main menu is accessible from any one of the measurement screens. To access the main menu

screen press the Up Arrow function key under the Menu option.

Note: Access to the Main Menu will require a password if a PROGRAMMING password has been set (see

Passwords on page 14).

The first option in the menu will always be highlighted by default. To scroll to the option required,

press the Up Arrow function key under the Select option. Detailed information on each of the main

menu options is available elsewhere in this manual as follows:

• VERIFICATION - See section entitled VERIFICATION on page 21

• GRAB SAMPLE - See section entitled GRAB SAMPLE on page 22

• CALIBRATION - See section entitled CALIBRATION on page 18

• MAINTENANCE/DIAG. - See section entitled MAINTENANCE/DIAG. on page 22

• USER SETUP - See section entitled USER SETUP on page 15

• SYSTEM SETUP - See section entitled SYSTEM SETUP on page 14

SYSTEM SETUP

Date and time

1. Select the DATE/TIME option to access the date/time sub-menu.

2. Scroll to the required day and press the Enter function key.

3. Enter the day, month, and year.

4. Enter the time in HH:MM:SS format (24 hour clock).

5. On completion press Esc to return to the main System Setup menu.

Display options

1. Select the DISPLAY option to set up the display parameters.

2. Select the LANGUAGE, CONC. UNIT and TEMPERATURE UNIT fields in turn, and set your

preferences by scrolling through the available options.

Passwords

1. Select the PASSWORDS option to set passwords for access to programming, calibration and

system setup options.

2. Each password is a 4-digit numeric field. Enter the required value for each of the three

passwords. A value of 0000 signifies no password is required to gain access to those menu

options.

Default values

1. Select the DEFAULT VALUES option to erase all the previously set user parameters and load

the default values. A warning message is displayed and confirmation of this action is required.

2. To exit from the screen without loading the default values, press the Esc function key.

3. To load the default values, select the Yes option.

Adjust mA output

1. Select the ADJUST mA OUTPUT option to access the analyzer’s analog output parameters.

2. Select the mA output you wish to change to display the next screen.

14

English

Page 15

3. The option to increase or decrease the low end value (0 mA or 4 mA depending on your setting)

is displayed. Change the value up or down by selecting the Minus or Plus indicators at the

bottom of the screen.

4. On completion press the Enter function key and the display changes to 20 mA.

5. Enter the adjustment value in the same way as for the low end value. On completion press the

Enter function key, and the display reverts back to the main ADJUST mA OUTPUT screen, to

allow you to select the next output to adjust.

USER SETUP

Measurement

Targeted pH (non-cationic applications only)

Select the pH option and enter the target pH value for your application. The measured pH value of

the sample in the measuring cell should be within ±0.2 pH of the target.

Total gas/water ratio (cationic applications only)

1. For each channel, enter the ratio of gas to water to minimize the DIPA consumption. This is part

of the installation procedure and is explained in more detail in the installation section of the full

user manual.

Measure steps

1. Select the MEASURE STEPS option to set up the measurement timings.

Measure steps - single channel

1. The on line measurement time defines the measurement time of the sample and how often the

measurement values are stored in memory. For a single channel configuration, it is

recommended to leave this time at the default value of 10 minutes.

2. If smart rinsing is required after a calibration, grab sample or sensor reactivation, set this

parameter to Yes and define the maximum rinse time.

Measure steps - multi channel

1. The on line measurement time is the time when the analyzer displays the true sodium

measurement. This value must be at least 1 minute and less than the cycle time.

2. If smart rinsing is required after a calibration, grab sample or sensor reactivation, set this

parameter to Yes and define the maximum rinse time.

3. The cycle time is the total measurement time for each channel and cannot be less than

10 minutes.

4. After a change of measurement channel, for a manual mode with a fixed cycle time, set the

search stability mode to No. For an automatic mode which minimizes the cycle time, set this

parameter to Yes.

Reactivation frequency

1. Select the ACTIVAT. FREQ option to set the time period between electrode reactivation. When

this time period expires, the electrode is reactivated automatically with an injection of a small

amount of reactivation solution.

2. Set the reactivation mode to either a Frequency or a fixed date.

3. If set to frequency, the recommended time period is 24 hours so that the electrode is reactivated

on a daily basis.

English

15

Page 16

Note: If this value is set to zero, then no electrode reactivation will take place during the calibration process and

as such the calibration may be inaccurate. It is highly recommended to set this parameter to 24.

4. If set to a fixed date, define the day and time of the week when reactivation takes place. Set the

day of the week to an asterisk if reactivation is not to take place on that day.

Datalogger setup

1. Select the VIEW DATA option to display the requested data.

2. All information matching the parameters selected in the VIEW SETUP option is displayed on the

screen. If the data covers more than one screen, an Arrow key will be displayed at the bottom.

Use this key to scroll through the data.

3. Select the VIEW SETUP option to define the parameters for the data you wish to view.

4. The FROM data field is the date (DD/MM/YY) from which you want to start viewing data.

5. The AT data field is the time (HH:MM:SS format) from which you want to start viewing the data.

6. The CH field defines the channel for which you want to view the data.

7. If you wish to see the ALARMS information (both system and warning alarms), select Yes in this

field, or No if alarm information is not required.

Graph time base

For graphical displays, enter the number of hours as the base line for the graph.

Alarms

1. Select the ALARMS option to set up the parameters for all the alarms including the system and

warning alarms.

2. Select the alarm to set up.

3. General alarms:

Limit Trigger the alarm when the measurement is above or below a pre-defined limit

Mode

Attributes Channel n Defines the channel number on which the alarm is triggered

Limit nnnn Define the limit when the alarm should be triggered

Direction

Delay nnn seconds The delay before the alarm is activated

Hysteresis nn% Hysteresis %

Relay

4. Warning alarm:

Alarm

Accept

Sample flow Trigger the alarm when the sample flow rate is too low

Active channel Trigger the alarm when the channel is active

Up Trigger alarm when measurement is above the limit

Down Trigger alarm when measurement is below the limit

N.O. Normally open

N.C. Normally closed

Yes Activate the warning alarm

No Deactivate the warning alarm

Manual When the alarm is triggered, turn it off by pressing the Enter function key

Auto

When the alarm is triggered, it will turn itself off only when the reason for the

alarm being triggered is no longer valid

16 English

Page 17

Relay

N.O. Normally open

N.C. Normally closed

5. System alarm:

Alarm

Relay

Yes Activate the system alarm

No Deactivate the system alarm

N.O. Normally open

N.C. Normally closed

mA outputs

1. Select the mA OUTPUTS option to set up the parameters for all the analog outputs.

2. From the list available, select the mA output you wish to set.

Output parameters

1. Analog output parameters:

Attribute

Type Choose either a 0-20 mA or 4-20 mA analog output

Mode Select the mode. This parameter is only selectable if the attribute is set to a measurement channel

Low The value corresponding to the low end of the scale

Middle The value corresponding to the mid-point of the scale (only available in dual mode)

High The value corresponding to the high end of the scale

Choose the attribute that triggers the analog output.

Note: The attribute variable cannot be applied to Output 0, which is reserved for the continuous live output signal.

Event indication

1. Select the EVENT INDICATION option in the mA Outputs menu to display the options available

for event setting.

2. Select the option for which you want to set an event.

3. Define the attribute for the event. This is one of the outputs or None.

4. The MODE can be either a Preset val or Frozen.

5. If a preset value is chosen, you will be required to enter the value of the analog output that will be

forced, when that event occurs.

Test

This option allows you to enter a value into the mA field. Press the Enter function key to force this

value on all the analog outputs. The value can then be verified with the use of a multimeter

connected to the analyzer.

RS485 (or PROFIBUS)

Note: If the PROFIBUS option has been installed, then the menu option will show PROFIBUS rather than RS485,

and the PROFIBUS parameters will need to be installed.

1. Select the RS485 option to set up the parameters for the communications protocol.

2. Press the Enter function key to accept each data element.

3. On completion, press the Esc function key to return to the user setup screen.

English

17

Page 18

Sample channels

Select the SAMPLE CHANNELS option to set up the channel parameters.

Number of channels

1. If the number of channels parameter is changed, an activation key will be required before the

additional channel is recognized.

Channel activation

Using the Up and Down Arrow keys, define whether the channel is active (Activ) or inactive

(Inactiv).

Sequence

The sequence defines the channel order in which samples are measured.

1. Only configured channels can be used in the sequence. For example for a 3-channel analyzer

only values 1,2 and 3 are available.

2. Up to 12 sequences can be defined. If a channel has been deactivated, but is still in the

sequence, it is simply ignored and the next channel in sequence is measured.

3. If there is no sample on a programmed channel, the analyzer will detect this and after 3 minutes

move on to the next channel in sequence. The channel on which the sample is missing will be

assigned the alarm sample x flow < min (where sample x is the name of the channel).

4. If the analyzer is stopped manually from the keyboard, it restarts from the same place in the

sequence.

5. In the event of a power failure, when restarted the analyzer with start at the beginning of the

sequence.

Channel names

Define the name of the channel with free-format alphanumeric text up to a maximum of 8 characters.

CALIBRATION

The instrument cannot be calibrated until at least one complete measurement cycle has been

successfully performed. An attempt to calibrate the instrument before this will result in a “Not

authorized” message being displayed.

In order to obtain accurate measurement results, the analyzer should be calibrated on a regular

basis. Two basic methods of calibration are available:

• Manual calibration - The user can manually perform a calibration on an ad-hoc basis.

• Automatic calibration - Parameters can be set up so that the analyzer will perform a calibration

automatically on pre-defined days at a pre-defined time (see Automatic calibration setup

on page 20). This type of calibration is always done using known calibration solution

concentrations.

Note: Before starting a calibration It is very important to ensure that the Reactivation Frequency parameter (see

Reactivation frequency on page 15) is greater than zero. If set to zero, the electrode reactivation process will not

take place during calibration and as such the measurement results may well be out of limits.

Calibration solution concentrations

N O T I C E

The maximum concentration value for any calibration solution cannot be greater than 2000 ppm. Any value

superior to this is outside the analyzer specifications and cannot be processed.

Manual calibration

For a manual calibration, the calibration solutions must be between 100 ppb and 2000 ppm and

must respect the following rules:

18

English

Page 19

• LOW CAL SOL must be ≥ sample concentration of Na+ and a minimum of 100 ppb

• HIGH CAL SOL = (LOW CAL SOL x 10)

Example 1: sample concentration of Na+ = 20 ppb

→ LOW CAL SOL = minimum value = 100 ppb Na

→ HIGH CAL SOL = (100 ppb x 10) = 1000 ppb Na

+

+

Example 2: sample concentration of Na+ = 450 ppb

→ LOW CAL SOL = ≥ sample concentration of Na+ = 500 ppb Na

→ HIGH CAL SOL = (500 ppb x 10) = 5000 ppb Na

Note: The values LOW CAL SOL and HIGH CAL SOL must be entered into the system (see One point calibration

on page 20 or Two point calibration on page 20).

+

+

Automatic calibration

For an automatic calibration, the calibration solution must be between 10 ppm and 2000 ppm and

must respect the following rules:

• CAL SOL minimum = 10 ppm

• CAL SOL = (sample concentration of Na+ x 1000)

Example 1: sample concentration of Na+ = 0.1 ppb

→ CAL SOL = minimum value = 10 ppm Na

+

Example 2: sample concentration of Na+ = 1 ppm

→ CAL SOL = (1 ppm x 1000) = 1000 ppm Na

Note: The value CAL SOL must be entered into the system (see Automatic calibration setup on page 20)

+

Start calibration

Select the START CALIBRATION option to calibrate the analyzer manually.

Calibrate known addition

1. Select the CAL.KNOWN ADDITION option to calibrate the analyzer by mixing the sample with a

known concentration of calibration solution. The concentration of the calibration solution is

defined in Automatic calibration setup on page 20.

2. The instrument first checks that the volume of calibration solution remaining is enough. If not, a

warning alarm is activated and the instrument returns to normal measurement with the original

parameters.

3. If the volume of solution is OK, the background point measurement (P0) to be used as the base

measurement value is taken. This is the measurement against the sample before any additions of

the calibration solution have been made.

4. The measurement must be stable and less than 1 per thousand of the calibration solution

concentration, otherwise the instrument returns to normal measurement with the original

parameters. Provided the measurement is OK, the P0 measurement details are displayed on

screen.

5. If the reactivation frequency parameter is not zero (as is highly recommended), the electrode will

be reactivated.

6. When the reactivation process is complete, the overflow vessel is rinsed to remove all traces of

sample.

7. After rinsing, the overflow vessel is re-filled with sample plus 2mL of the calibration solution.

8. The sample is then measured and the details displayed against P1.

9. When the measurement is stable, the details are displayed at the top of the screen against

measurement P1.

10. The overflow vessel is then rinsed and re-filled with sample plus 20mL of the calibration solution.

11. This sample is then measured and the details displayed against P2.

12. Once the final measurement is stable, the offset and slope for this calibration are calculated.

English

19

Page 20

13. The default values of the offset and slope are displayed along with the calculated values for the

last and current calibration.

14. A message is displayed indicating the success or failure of the calibration.

One point calibration

This process requires that a calibration solution of known sodium concentration is available. Refer to

Calibration solution concentrations on page 18 for information regarding the concentration of the

calibration solution.

1. Select the MAN.OFFSET CAL option to start the one point calibration process.

2. If necessary, enter the concentration of the calibration solution, and select START to initiate the

calibration process. Then, provided the reactivation frequency parameter is not zero (as is highly

recommended), the electrode is reactivated. On completion this is followed by a rinsing of the

overflow vessel.

3. When prompted, fill the overflow vessel with the calibration solution and select OK to start the

measurement.

4. The calibration solution is measured and the results displayed.

5. Once the final measurement is stable, the offset for the calibration is calculated.

6. A message is displayed indicating the success or failure of the calibration.

Two point calibration

This process requires that two calibration solutions of known sodium concentrations are available.

Refer to Calibration solution concentrations on page 18 for information regarding the concentrations

of the calibration solution.

1. Select the MAN.OFFSET+SLOPE CAL option to start the two point calibration process.

2. If necessary, enter the concentrations of the calibration solution, and select START to initiate the

calibration process. Then, provided the reactivation frequency parameter is not zero (as is highly

recommended), the electrode is reactivated. On completion this is followed by a rinsing of the

overflow vessel.

3. The process is then very similar to the one-point calibration above, except after the instrument

measures the low value calibration solution, the overflow vessel will be rinsed and you will be

asked to fill it with the high value calibration solution.

4. A message is displayed indicating the success or failure of the calibration.

Automatic calibration setup

This allows the analyzer to be automatically calibrated at pre-defined and regular intervals.

The process is the same as described in Calibrate known addition on page 19 except it is initiated

automatically at the pre-defined time.

1. Select the AUTO. CAL. SETUP option to access its sub-menu and set the calibration

parameters.

2. Turn the automatic calibration on or off by selecting Yes or No as appropriate. Note that even if

this is set to Yes, it is still possible to calibrate the analyzer manually if required.

3. CAL.SOL defines the concentration of the calibration solution. Refer to Calibration solution

concentrations on page 18 for information regarding the concentration of the calibration solution.

4. MODE can either be set up to a fixed date or to a specified Frequency.

5. If the mode is set to fixed date, enter the day(s) of the WEEK when the calibration will be

performed. Set the day to an asterisk to skip that day.

6. Set the HOUR field (HH:MM:SS format on a 24 hour clock) to the time the automatic calibration

should start.

20

English

Page 21

7. If the mode is set to frequency, then the week and hour data fields will be replaced by a TIME

PERIOD field. Enter the calibration frequency in hours into this field.

8. Finally, in the CALIB ON field, select the channel to be used for calibration. The number of

channels available will depend on the number of channels configured for the instrument. The

sample concentration being measured on this channel must be less than 1 per thousand of the

calibration solution concentration, otherwise an error is signalled during calibration.

Calibration results

After the slope and offset have been calculated, the default parameters, last calibration details and

current calibration details are displayed, along with a “Calibration ok” or “Calibration error”

message. The criteria for accepting or rejecting the calibration is as follows:

• The slope must be within ± 10% of the standard slope

• The offset must be within ± 59 mV from the reference point

If the calibration is accepted, the parameters are updated and the instrument returns to the normal

measurement mode after a short delay.

If the calibration is rejected an alarm is set and the parameters remain unchanged. After a short

delay the analyzer returns to the normal measurement mode.

For details of the calibration results, select the calibration loggings option as described below.

Calibration loggings

1. Select the CALIBRATION LOGGINGS option to view historical information about previous

calibrations.

2. Use the Arrow key to scroll through the data.

Custom adjustment

1. Where the analyzer displays values that are slightly above or below the expected value, the

CUSTOM.ADJ option can be used to manually adjust the measurement value.

2. Enter a positive or negative value which will be added to the measurement value. This option can

only be used to make minor adjustments. The allowable adjustment value is between -0.1 ppb

and +0.1 ppb.

3. If the displayed and expected values differ significantly, the analyzer should be recalibrated.

Temperature calibration

1. Select the TEMPERATURE CALIB. option to calibrate the temperature electrode.

2. The measured temperature reading is displayed in the raw temp field.

3. Take a temperature reading with a certified thermometer and press OK to continue.

4. Then enter this temperature reading into the CAL.TEMP. field.

5. Press OK to calibrate.

VERIFICATION

This option allows you to verify the measurement using a solution of known sodium concentration.

Concentration of the known solution should be higher than 20 ppb (100 ppb is recommended) to

ensure a preparation step in a range with lower risks of contamination.

1. First enter the concentration of the verification solution in the VALID. SOL field.

2. Select START to commence the process.

3. The first step of this cycle allows the reactivation of the electrode. The message SENSOR

ACTIVATION is displayed. Select Yes to reactivate the sensor. Select No if time is more

important than accuracy.

English

21

Page 22

4. The reactivation process is automatically followed by a rinsing of the overflow vessel and

measuring cell using the process sample. Upon completion of the rinsing step, the analyzer is

ready for the first manual step in the cycle.

5. Place the lid of the overflow vessel on the side and pour approximately 200 mL of the solution

into the overflow vessel, as prompted on screen. Manual introduction is complete when the

sample overflows at the back of the overflow vessel.

6. Place the lid back on top of the overflow vessel and select OK to start the measurement. The

display switches back to the main measurement screen and displays the measurement value.

7. Once measurement of the solution is complete, the measured value and time will be displayed

against verif. s. This should be almost identical to the value entered in the VALID. SOL field

previously.

The value displayed in gap, will be the percentage difference between the concentration of the

verification solution entered in the VALID. SOL field, and the concentration measured by the

instrument. If this value is too high, then a calibration of the analyzer is recommended.

8. Once the cycle is complete, the analyzer automatically reverts back to standard measurement

mode.

9. Select Main to go back to the main measurement screen.

GRAB SAMPLE

Similar to the verification process, this option allows measurement of a sample of your choice. Before

starting this process, ensure you have a sample of approximately 200 mL to measure.

Note: It is recommended that the grab sample should have a concentration of > 10 ppb and should be at the same

temperature as during calibration for better accuracy. Under these conditions, measurement with manual

introduction gives 5% accuracy from 10 ppb to 10 ppm at a temperature which is within ± 5 °C of the temperature

during calibration.

1. The first step of this cycle allows the reactivation of the electrode. The message SENSOR

ACTIVATION is displayed. Select Yes to reactivate the sensor. Select No if time is more

important than accuracy.

2. The reactivation process is automatically followed by a rinsing of the overflow vessel and

measuring cell using the process sample. Upon completion of the rinsing step, the analyzer is

ready for the first manual step in the cycle.

3. Place the lid of the overflow vessel on the side and pour approximately 200 mL of the solution

into the overflow vessel, as prompted on screen. Manual introduction is complete when the

sample overflows at the back of the overflow vessel.

4. Place the lid back on top of the overflow vessel and select OK to start the measurement. The

display switches back to the main measurement screen and displays the measurement value.

5. Once measurement of the solution is complete, the measured value and time will be displayed

against grab s.

6. Once the cycle is complete, the analyzer automatically reverts back to standard measurement

mode.

7. Select Main to go back to the main measurement screen.

MAINTENANCE/DIAG.

Reagent changes

This procedure is applicable to each change of reagent solution. It allows the regulation of the

volumes of solutions in the bottles. The analyzer consistently checks the consumption of these

solutions, triggering an alarm when these levels get too low. This option must be selected each time

a solution is refilled or changed to reset the measurement parameters.

Note: The conditioning reagent and electrolyte consumption are approximate measurements, so a discrepancy

between measurement and actual consumption may occur. The conditioning solution consumption has been

measured for a pH of 11.2 at an ambient temperature of 25°C.

22

English

Page 23

Adjust bottle volumes

This option should be used to set the default values of reagents or when bottles are being used that

are not full (see Bottles full on page 23).

1. Select the ADJUST BOTTLE VOLS. option to set the reagent volumes.

2. Enter the volumes for the conditioning solution, reactivation solution, calibration solution and

electrolyte in milliliters.

3. Press Select to move from one field to another to keep the value displayed, or press Enter on

completion of a field to move to the next.

4. Press the Esc function key on completion.

Priming tubes

1. After refilling the bottles (reference electrolyte, calibration solution and reactivation solution)

and/or after exchanging the empty bottle of conditioning reagent with a new one, select the

PRIMING TUBES option. This will set off the process to purge and refill the tubes.

2. Press the Esc function key at any time to abort the process and return to the menu.

Bottles full

1. If the bottles of reagent are full, select Yes and the default values for the volumes will be set.

These values can be viewed and modified by selecting the ADJUST BOTTLE VOLS. option in

the menu. If you select No to this option, you will manually have to enter the correct values using

the ADJUST BOTTLE VOLS. option.

Test accessories

This option allows you to check that a number of accessories, as well as the alarm relays and logical

inputs are functioning correctly.

Sensor reactivation

Usually, the electrode is reactivated automatically based on the time delay set in Reactivation

frequency on page 15. This option allows for a manual reactivation.

Extended stop

If the instrument is not to be used for an extended period of time, select this option to shut the

analyzer down in a controlled manner.

1. Place all the tubes in demineralized water for cleaning.

2. Press OK to continue.

3. A progress bar will be displayed whilst the shut down is being performed.

4. On completion, you will be informed to remove and store the electrodes.

5. Press ESC to exit.

Startup

This process guides you through various steps required to set the instrument up for initial

measurements, or to restart after a long period of inactivity. This includes regulating the sample flow

and purging the pumps of reagent.

1. Regulate the flow of the sample to ensure a slight overflow into the overflow vessel.

2. Select OK to continue. You will then be required to regulate the flow on the next configured

channel.

3. On completion, an Action completed message will be displayed. Select Esc to exit.

English

23

Page 24

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen.

Spezifikation Details

Messbereich 0 bis 10.000 ppb frei programmierbar

0 bis 200 ppm mit Option K-Kit

Genauigkeit Nicht kationische Anwendungen: ± 0,1 ppb oder ± 5% der Anzeige, je

Wiederholbarkeit < 0,02 ppb oder 1,5% der Anzeige, je nachdem, welcher Wert größer ist,

Durchschnittliche Reaktionszeiten

bei 25°C mit max. ΔT = 15°C

zwischen den Kanälen

Elektrodentyp pH-Glaselektrode

Anzahl der Kanäle 1 bis 4

Interferenz Phosphat 10 ppm Messvariation weniger als 0,1 ppb

Interferenz Probentemperatur < 0,5% / °C

Typische Umgebung Kraftwerk / Innenbereich / Anlage für entmineralisiertes Wasser oder

Gelöste Festkörper < 2 NTU, kein Öl, kein Fett

Temperaturbereich für die Lagerung -20 bis 60°C (2 bis 140°F)

Relative Feuchtigkeit 10 bis 80%

Umgebungstemperatur 5 bis 50°C (41 bis 122°F)

Variation der Probentemperatur Stabilisierung in 10 Minuten von 15°C bis 30°C

pH-Bereich der Probe Nicht kationische Anwendungen: 6 bis 10 pH

Flussrate 6 bis 9 l/Stunde

Druck 0,2 bis 6 bar (3 - 87 psi)

Säuregrad Weniger als 250 ppm (entspricht CaCO3)

Spannungsschwankung der

Stromversorgung

Überspannungskategorie 2 (gemäß Standard EN 61010-1)

nachdem, welcher Wert größer ist

Kationische Anwendung: ± 2 ppb oder ± 5% der Anzeige, je nachdem,

welcher Wert größer ist

innerhalb einer Variation von 10°C

T90% ≤ 10 min

Konzentrationsschrit

t von einem Kanal

zum nächsten

0.1 ↔ 5 ppb 3 9 Min 27 Min

0.1 ↔ 50 ppb 3 11 Min 41 Min

0.1 ↔ 200 ppb 3 9 Min 45 Min

< 0.1 ↔ 1 ppb 3 29 Min 36 Min

0.1 ↔ 50 ppb 15 11 Min 41 Min

Instrumentenraum

Verwenden Sie den statischen Wärmeaustauscher, wenn der

Temperaturunterschied zwischen den Proben höher als 15°C ist.

Kationische Anwendung: 2 bis 10 pH

± 10%

Max.

Temperaturveränd.

(°C)

Zeit Erreichen d. Präz.

0,1 ppb oder 5%

auf ab

24 Deutsch

Page 25

Spezifikation Details

Verschmutzungsgrad 2 (gemäß Standard CEI 664)

Höhe < 2000 m

Messkategorie Kat. II, Klasse 1 (Überspannung < 1.500V)

Max. Paneelabmessungen (H x L xT)850 x 450 x 252,5 mm [33,46 x 17,71 x 9,94in]

Einlass Einfache Anschlüsse für 6 mm A.D.-Leitungen oder ¼" A.D. aus LDPE ¼"

Auslass Bajonettanschluss 12 mm (½" I.D.) Schlauch

Schutzgrad Transmitter: IP65 (NEMA 4)

Zelle PMMA - kompakt (min. Leitungen)

Flammpunkt gemäß UL

Max. Gewicht 15 - 30 kg

Stromversorgung 100 - 240 VAC, 50-60 Hz, ± 10%, automatische Umschaltung

Max. Verbrauch 80 VA

Sicherung 5 x 20 Patronen T2AL-250V gemäß CEI127

Anzeige Kurventrend, letztes Kal-Datum, Historie, Konzentration, Temperatur,

Analoge Ausgänge Nummer: 6

Relais 4 x Relais (Konz.)

Logikeingang Aktive / inaktive Kanäle

Europäische Standards EN 61326 Klasse A (EMV); EN 601010-1 Niederspannungssicherheit

Internationale Standards cETLus

AD aus PHED-PTFE-SS optional

Paneel: IP50 (Staubschutz)

Optionales Gehäuse: IP54 (Spritzwasserschutz)

Das Instrument wurde so entwickelt, dass keine DIPA-Dämpfe im

Gehäuseinneren auftreten. Alle DIPA-Dämpfe werden gesammelt und zum

Ablass des Instruments geleitet.

Potenzial

4-20 oder 0-20 mA (650 Ohm)

Linear / Dual / Logarithmus

Ereignisanzeige

1 x Warnung

1 x System

Remote AutoCal

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Deutsch

25

Page 26

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

G E F A H R

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

W A R N U N G

V O R S I C H T

H I N W E I S

Potenzielle Gefahren für die Sicherheit

Der Einsatz des Analysators weist die folgende potenziellen Gefahren für die Sicherheit auf:

• Elektrische Gefahr (Leitungsspannung)

• Potenziell gefährliche Chemikalien

Aufkleber mit Vorsichtshinweisen

Bitte lesen Sie alle auf dem Produkt angebrachten Etiketten und Hinweise. Die Nichtbeachtung kann

zu Verletzungen an Personen oder einer Beschädigung des Produkts führen. Im Handbuch werden

auf die am Gerät angebrachten Symbole in Form von Warnhinweisen verwiesen.

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen darf.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Dies Symbol weist darauf hin, dass das Gerät an Wechselstrom angeschlossen ist.

26 Deutsch

Page 27

Elektrische Geräte, die dieses Symbol aufweisen, dürfen in Europa nicht als Haushaltsabfall

entsorgt werden. Den lokalen und nationalen europäischen Bestimmungen gemäß müssen

Benutzer von Elektrogeräten diese nun zur für den Benutzer kostenlosen Entsorgung an den

Hersteller zurückgeben.

Hinweis: Mit der Wiederverwertung, der stofflichen Verwertung oder anderen Formen der Verwertung von

Altgeräten leisten Sie einen wichtigen Beitrag zum Schutz unserer Umwelt.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Produkte, die mit diesem Symbol gekennzeichnet sind, zeigen an, dass sie den EMC-Standards

Südkoreas entsprechen.

Übersicht

Abbildung 1 Vorder- und Rückseite

1 Der Natriumionen-selektiven Elektrode 8 Reagenzlösungsregal

2 Referenzelektrode 9 Rahmen für Paneelmontage

3 Flussrateneinstellung für jeden Kanal 10 Halterung für den Reagenzlösungskanister

4 Benutzeroberfläche 11 Lokales Steuerungsgehäuse

5 Überflussgefäß 12 Elektrolytreservoir

6 Messzelle 13 Pumpengehäuse

7 Türschloss 14 Probeneinlassventile

Installation

W A R N U N G

Der Analysator sollte ausschließlich von qualifiziertem Personal montiert werden. Die Stromversorgung darf erst

angeschlossen werden, nachdem die Installation abgeschlossen und überprüft worden ist.

Deutsch 27

Page 28

Installation des Analysators

W A R N U N G

Schließen Sie die Stromversorgung nicht an, bevor das Instrument montiert und verplombt worden ist

Verletzungsgefahr. Geräte oder Komponenten sind schwer. Bewegen oder installieren Sie diese nicht allein.

Vergewissern Sie sich, dass die Wandbefestigung das vierfache Gewicht der Ausrüstung tragen kann.

Unabhängig davon, ob der Analysator in einem Paneel oder an der Wand montiert wird, muss darauf geachtet

werden, dass er aufrecht mit dem Transmitter oben installiert wird. Wir empfehlen, eine Wasserwaage zu

verwenden, um sicherzustellen, dass der Analysator ordnungsgemäß montiert wird und nicht zu einer Seite

geneigt ist. Dies ist von wesentlicher Bedeutung für die Gewährleistung der Präzision des Analysators.

V O R S I C H T

V O R S I C H T

Paneelmontage

Befestigen Sie den Analysator. Verwenden Sie Bohrungen auf der Außenseite des Geräts.

Wandmontage

Verwenden Sie für die Befestigung des Instruments an der Wand den Wandmontagekit. Der Abstand

zwischen den beiden Teilen beträgt 460 mm.

V O R S I C H T

Dieser Abstand von 460 mm muss unbedingt eingehalten werden, damit sich das Gehäuse bei der Befestigung

nicht verbiegt.

Anschluss der Stromversorgung

W A R N U N G

Es dürfen keinerlei Eingriffe am Instrument vorgenommen werden, ohne dass zuvor die Stromversorgung

abgeschaltet wird.

Die elektrische Installation sollte von qualifiziertem Personal vorgenommen werden. Ohne Änderung

der Konfigurierung an eine Stromversorgung von 100-240 VAC angeschlossen werden. Die Kontakte

der Stromversorgung können zur Vereinfachung der Anschlussarbeiten aus ihrem Gehäuse

entnommen werden.

Die folgenden Arbeitsverfahren müssen aus Sicherheitsgründe eingehalten werden:

• Verwenden Sie ein dreiadriges Netzkabel (Phase + Nullleiter + Erde), das der erforderlich Leistung

angemessen ist.

• Das Instrument sollte über eine Unterbrechungsstelle oder eine Sicherung an die

Stromversorgung angeschlossen werden, deren Werte über 20 A liegen. Diese sollten sich in der

Nähe des Instruments befinden und gekennzeichnet werden. Dieser Anschluss muss die Phase

und den Nullleiter bei elektrischen Problemen oder bei Eingriffen im Inneren des Instruments

unterbrechen. Der Erdunsleiter muss jedoch immer angeschlossen bleiben.

Das Hauptgehäuse sollte offen sein.

1. Führen Sie das Netzkabel durch den Kabeldurchlass links unten am Boden des Gehäuses.

2. Die rückwärtige Abdeckung des lokalen Steuerungsgehäuses (Nr. 11 in Abbildung 1 auf Seite 27)

öffnen. Dazu die 6 Schrauben lösen.

3. Die beiden Halteschrauben rechts und links auf der Oberseite des Gehäuses lösen und das

Gehäuse nach unten drehen, um auf die Rückseite des Transmitters zugreifen zu können. Die

Kabeldurchführung für das Stromkabel befindet sich links und liegt Ihnen am nächsten.

28

Deutsch

Page 29

4. Schrauben Sie die Mutter der Kabeldurchführung ab, führen Sie das Kabel hindurch und dann

hinauf durch die Kabeldurchführung und in den Transmitter (Nr. 2). Schrauben Sie die Mutter der

Kabeldurchführung wieder auf, um das Stromkabel zu sichern.

5. Öffnen Sie die Fronttür des Transmitters durch Abschrauben der 4 Halterungsschrauben.

6. Öffnen Sie die Tür (sie ist links angeschlagen), um zum Inneren des Transmitters zu gelangen.

7. Entfernen Sie die Abschirmungsplatte aus Metall (Nr. 1), die den Zugang zum Mainboard schützt.

8. Entfernen Sie den Stecker des Stromkabels (Nr. 3) und überprüfen Sie, wo Erde, Nullleiter und

Phase (E, N, L) angeschlossen werden müssen.

9. Schließen Sie die Leiter des Stromkabel an den Anschluss an.

10. Setzen Sie den Anschluss wieder ein (Nr. 4).

11. Bringen Sie die Abschirmplatte aus Metall wieder an und stellen Sie sicher, dass sie sich vor dem

soeben installiert Stromkabel befindet.

Anschluss der externen Kommunikation

1. Das Kabel für die Datenübertragung durch die äußere Kabelführung

am Gehäuseboden und anschließend in den Analysator führen.

2. Führen Sie es durch die Kabeldurchführung auf der rechten Seite

auf der Basis des Transmitters, die am weitesten von Ihnen entfernt

ist, so dass es durch die linke vordere Kabeldurchführung in den

Transmitter gelangt.

3. Schließen Sie das Kommunikationskabel wie angegeben an. Der

Anschluss ist der selbe, wie an der CPU-Karte für die beiden

Optionen JBUS/MODBUS und PROFIBUS.

4. Die Abdeckung für den Transmitter einsetzen und mit den

4 Schrauben sichern.

5. Das lokale Steuerungsgehäuse wieder einsetzen und mit den

beiden Halteschrauben fixieren.

Anschlüsse für Eingang/Ausgang

Durchstechen Sie die Kabeldurchführungen vor der Benutzung mit einem Schraubenzieher. Zur

Gewährleistung einer guten Abdichtung sollte der Außendurchmesser der Kabel 5 bis 7 mm

betragen. Die Nomenklatur in der Spalte Anschlüsse der folgenden Tabelle beziehen sich auf die

gleiche Nomenklatur, die auf der E/A-Karte der verfügbaren Anschlüsse aufgedruckt ist.

Anschlüsse Funktion

Re1 bis Re6 Bediener-Relais - siehe Alarme auf Seite 38 für detaillierte Informationen über die Relais

Re7 Warnalarm

Re8 Systemalarm

In2 Für Fernkalibrierung

In4 bis In7 Bypass-Kanal-Messung (Kanal 4 bis 1)

Deutsch 29

Page 30

Anschlüsse Funktion

Iout0 Wird für die aktuellen Messsignale verwendet

Iout1 bis Iout7 Kann frei mit unterschiedlichen Parametern wie Messung, Temperatur verknüpft werden, für

detaillierte Informationen beziehen Sie sich bitte auf Abschnitt mA-Ausgänge auf Seite 39.

Abschließend das lokale Steuerungsgehäuse (Nr. 11 in Abbildung 1 auf Seite 27) schließen und mit

den 6 Schrauben fixieren.

Installation der Probenleitungen

Probe anschließen

Verwenden Sie bei der Installation für alle Anschlüsse neue Leitungen.

• Außen Ø: 6 mm exakt (oder ¼'')

• Material: Polyäthylen, PTFE oder FEP

• Flussrate: 6 bis 9 l/Stunde

• Druck: 0,2 bis 6 bar (8-100 psig)

• Säuregrad der Probe: Der Säuregrad der Probe sollte 300 ppm CaCO3 nicht übersteigen

• Temperatur: 5 bis 45°C

Stellen Sie sicher, dass das Flussventil in dieser Phase der Installation geschlossen ist. Die

Leitungen anschließen. Diese dazu in die Schnellanschlüsse, die sich auf der Unterseite des

Analysators unter dem Problenblock (Nr. 14 in Abbildung 1 auf Seite 27) befinden, einführen. Stellen

Sie sicher, dass die Probenleitung vor dem Anschließen ordnungsgemäß durchgespült worden ist,

um zu verhindern, dass Partikel in das Hydrauliksystem des gelangen. Falls Partikel in der Probe

vorhanden sind, ist eine Vorfilterung erforderlich. In die Probenleitung sollte ein Filter eingesetzt

werden. Ein Filter kann als Option geliefert werden. Schließen Sie einen Einlass und einen Auslass

pro Kanal an.

Abflussleitung anschließen

Der Auslass befindet sich am Boden des Analysators. Mit dem Analysator wird eine Leitung 12 x

17 mm geliefert; ein Ende sollte am Auslass angeschlossen und das andere zum Abfluss der Probe

geführt werden.

Installation der Reagenzlösungen

Die Kanister werden in die Kanisterhalterung (Nr. 10 in Abbildung 1 auf Seite 27)

eingesetzt.

1. Die Reagenzlösungen vorbereiten.

2. Installieren Sie die Konditionierungslösung (Di-Isopropylamin) und schließen

Sie sie an.

3. Installieren Sie die Reaktivierungslösung (blaues Etikett R) und schließen Sie

sie an.

4. Installieren Sie die Auto-Kalibrierungslösung (gelbes Etikett CAL) und

schließen Sie sie an, falls diese Option vorhanden ist.

Installation des Magnetrührwerks

1. Entfernen auf der Front des Paneels den Kunststoffbeutel vom Überflussgefäß (Nr. 5 in

Abbildung 1 auf Seite 27).

2. Entnehmen Sie das Magnetrührwerk aus dem Beutel und installieren Sie es im Überflussgefäß.

Angabe des Reagenzlösungsvolumens

Hinweis: Da Sie jetzt die Menüs des Analysators für die Dateneingabe verwenden werden, empfiehlt es sich, dass

Sie sich zuvor mit den Verfahren für die Dateneingabe vertraut machen und dazu den Abschnitt

Benutzeroberfläche auf Seite 33.

30

Deutsch

Page 31

1. Öffnen Sie das Probenventil und stellen Sie sicher, dass die Hydraulikleitungen keine Lecks

aufweisen.

2. Schalten Sie die Stromversorgung des Analysators ein.

3. Wählen Sie die Option Menü auf der Anzeige.

4. Wählen Sie WARTUNG/DIAG. aus dem Hauptmenü und drücken Sie Enter.

5. Wählen Sie die Option WECHSEL REAGENZLÖSUNG und drücken Sie Enter.

6. Stellen Sie den Parameter FLASCHEN VOLL auf Ja ein und drücken Sie Enter.

7. Drücken Sie Esc, um zum Menü WARTUNG/DIAG. zurückzukehren.

Einstellung der Flussrate

1. Wählen Sie im Menü WARTUNG/DIAG. NEUSTART und drücken Sie Enter.

2. Zuerst bereitet das System automatisch die Kalibrierungsleitung und die Reaktivierungsleitung

vor.

3. Stellen Sie sicher, dass keine Luftblasen in den Reagenzlösungsleitungen für die Reaktivierung

und die Auto-Kalibrierung vorhanden sind.

4. Mit dem nächsten Schritt können Sie den Probenfluss für jeden Messkanal einstellen. Der Name

des Kanals, der reguliert werden soll, wird angezeigt.

5. Der Analysator leert und füllt das Überflussgefäß automatisch, um die Flussrate, die auf dem

Bildschirm angezeigt wird, zu ermitteln.

6. Die Flussrate für jeden Kanal sollten 6 bis 9 l/Stunde.

7. Für die Einstellung des Probenflusses in dem betreffenden Kanal (Nr. 3 in Abbildung 1

auf Seite 27) drehen Sie einen Schraubenzieher gegen den Uhrzeigersinn, um die Flussrate zu

erhöhen und im Uhrzeigersinn, um die Flussrate zu senken.

8. Wiederholen Sie den Vorgang, bis die Flussrate für den Kanal korrekt eingestellt ist. Wählen Sie

dann OK.

9. Jetzt können Sie den nächsten Kanal einstellen. Wiederholen Sie den Vorgang, bis alle

Flussraten für die konfigurierten Kanäle eingestellt sind.

10. Nachdem alle Flussraten für die konfigurierten Kanäle eingestellt wurden, erscheint eine Meldung

Durchfluss einstellen beendet . Wählen Sie zum Verlassen Esc.

Kontrolle der Konditionierung des pH-Werts der Probe

Nicht kationische Anwendungen

1. Installieren Sie einen kalibrierten ph-Sensor in der mittleren Position der Messkammer, die

normalerweise für die ISE-Natriumelektrode verwendet wird (Nr. 1 in Abbildung 1 auf Seite 27).

2. Drücken Sie auf dem Analysator im Hauptmenü Start, um den Messvorgang zu starten.

3. Prüfen Sie für jeden Kanal, ob der pH-Wert der probe nach der Konditionierung größer als

10,5 ist. Andernfalls prüfen Sie die Qualität des Produkts, das für die Konditionierung verwendet

wird.

Kationische Anwendungen

1. Messen Sie mit einem kalibrierten pH-Sensor den pH-Wert der Proben für jeden Kanal außerhalb

des Analysators.

2. Die Messsequenz des Analysators wird werkseitig eingestellt und ist abhängig von der Anzahl

der konfigurierten Kanäle (z. B. 1 2 3 4 * für 4-Kanal Analysatoren oder 1 2 * für 2-KanalAnalysatoren). Prüfen Sie, ob diese Sequenz korrekt eingestellt ist (siehe Sequenz auf Seite 40

für weitere Informationen).