Page 1

Document Number 221=183=000

POLYMETRON 83xx

2 Electrode Conductivity Probes

USER MANUAL

September 2010, Version B

Page 2

Page 3

Restriction of hazardous substances (RoHS)

The European Union RoHS Directive and subsequent regulations

introduced in member states and other countries limits the use of six

hazardous substances used in the manufacturing of electrical and

electronic equipment.

Currently, monitoring and control instruments do not fall within the

scope of the RoHS Directive, however Hach Lange has taken the

decision to adopt the recommendations in the Directive as the target

for all future product design and component purchasing.

Note: The following only applies to exports of this product into the

People’s Republic of China.

Plastic sensor

(8310, 8311, 8312)

Stainless steel sensor

(8314, 8394)

Digital sensor PCB O

Glass electrode O

O:

X:

O

O

Page 4

Page 5

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

SUMMARY

1. Overview ................................................................. 5

General.......................................................................................5

Principle of electrolytic conductivity............................................5

Influence of the temperature ......................................................6

2. Technical specifications........................................ 9

Chemical resistance.................................................................10

3. Installation and start-up....................................... 13

Cable connection......................................................................13

Programming of the transmitter................................................14

Probe calibration ......................................................................16

Probe installation......................................................................17

4. Maintenance and cleaning................................... 25

Spares parts.............................................................................27

5. Precautionary Labels........................................... 29

621=183=000 Issue B 09/2010 Page 1

Page 6

Page 7

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Any use that does not comply with that described in this manual may

lead to risks for the user. Furthermore, this latter cannot change any of

the sensor or transmitter’s components. Only Hach Lange staff, or its

approved representative, is authorised to repair the system and only

components explicitly approved by the manufacturer can be used.

Any attempts to repair the instrument that go against these principles

may cause damage to the equipment or to the person performing the

repairs.

It also cancels the guarantee and may compromise the instrument’s

safety, electrical integrity or EC compliance.

Warning !

621=183=000 Issue B 09/2010 Page 3

Page 8

Page 9

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

1. Overview

General

The probes for which the electrochemical

exchanges take place directly between the

electrode and the solution are called

"contacting" probes or "kohlrausch" probes.

They consist of two conductor electrodes

(chemically inert in relation to the solution),

insulated from each other, in a particular and

known geometrical form (cell constant), on

which an alternating voltage is applied.

Therefore a mechanism of exchange exists at

the interface of the liquid and the electrodes

and only the use of an alternating voltage with

an optimum frequency avoids saturating the

surface of the electrodes (formation of an

insulating layer reducing the flow of current, a

phenomenon known under the term of

"polarisation").

It is the total quantity of ions present in the

solution that is measured and not the type of

ion as such.

Principle of electrolytic conductivity

Ohm’s law specifies that the current circulating

in the dipole is proportional to the difference in

potential and resistance of this dipole:

I = E / R.

621=183=000 Issue B 09/2010 Page 5

Page 10

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

E, potential

R, resistance of the dipole such as:

the resistance of a homogenous

environment depends on the geometry of

the resitivity (characteristic of the material):

R = r. l/S where r = R/K (Ω.cm) where

C=

K

(S.cm-1)

R

K depending solely on the geometry of the

probe is (in the case of the two flat electrodes

face to face) the relation between the distance

separating the electrodes divided by their

surfaces and expressed in cm

I= E/R= C.E/K

-1

.

Influence of the temperature

The conductivity of a solution depends both on

the ionic concentration and the mobility of these

ions (size, weight, charge, viscosity). The

temperature of the solution has an influence on

these two factors (the temperature favours the

dissociation of the molecules and therefore the

ionic concentration, and increases the mobility).

In order to allow the comparison between

measurements made at different temperatures,

this measurement needs to be brought back to

a reference temperature (generally 25 °C).

Page 6 09/2010 621=183=000 Issue B

Page 11

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

= C T [1 + " (T - T

C

Tref

ref

)]-1

: Conductivity compensated to the

C

Tref

reference temperature

C

: Conductivity measured at T

T

T

: Reference temperature

ref

(generally 25°C)

" : Temperature coefficient of the solution

(% / °C)

• For the sufficiently concentrated solutions

(natural waters, process…) the coefficient

is constant and is situated around 2 %.

• For slightly concentrated solutions, the

concentration of H+ protons and hydroxyl

OH- ions (stemming from the weak

dissociation of the water [H+] = [OH-] =

-7

mol/l to 25°C) can no longer be

10

neglected in the presence of the product,

this therefore leads to a non-linear

variation (compensation curve NaCI and

HCI).

621=183=000 Issue B 09/2010 Page 7

Page 12

Page 13

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

2. Technical specifications

Model 8310 and 8315 8311 and 8316 8312 and 8317 8394

Applications : Pure or high purity

K (cm-1) 0.01 0.1 1 0.01

Precision K < 2 % < 2 % < 2 % < 2 %

Measurement

range (9125)

Temperature

response

Pt100 (t 90 %)

Materials in contact

with the liquid:

Temperature max

(°C)

P max (bars) 10 (8310)

Process

connection

waters

0.01 à 200 µS.cm-1 0.1 µS à 2 mS.cm-1 1 µS à 20 mS.cm-1 0.01 à 200 µS.cm-1

< 30 s < 45 s < 3 mn < 45 s

Electropolished

stainless steel +

Psu (8310)

Electropolished

stainless steel +

PES 30 %

glassfiber + viton

(8315)

125 (8310)

150 (8315)

25 (8315)

¾’’NPT ¾’’NPT ¾’’NPT Tri clamp 1.5 et 2’’

Meanly

conductived

solutions

Stainless steel +

Psu (8311)

Stainless steel +

PES 30 %

glassfiber + viton

(8316)

125 (8311)

150 (8316)

10 (8311)

25 (8316)

Worm water,

process

Graphite + Psu

(8312)

Stainless steel +

graphite + viton

(8317)

125 (8312)

150 (8317)

10 (8312)

25 (8317)

Food and

pharmaceutical

industries

(sterilizable)

Electropolished

stainless steel +

PEEK + EPDM

« FDA », Ra < 0.4

150

25

621=183=000 Issue B 09/2010 Page 9

Page 14

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

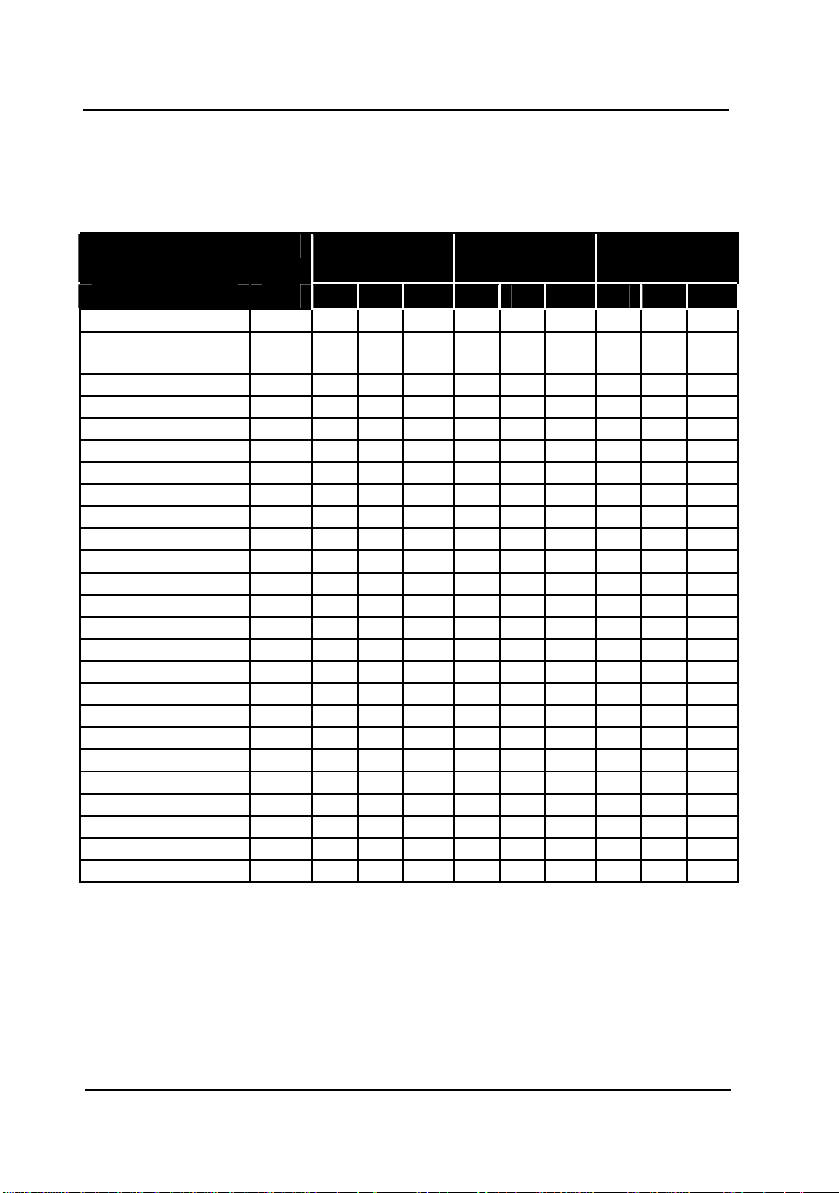

Chemical resistance

O = yes ; - = no

X = momentarily

°C/% 20 60 100 20 60 100 20 60 100

Sulphuric acid 10 0 X X 0 0 X 0 X X

Hydrochloric acid 1

Citric acid < 25 0 X - 0 - - 0 X Phosphoric acid < 25 0 0 0 0 0 0 0 0 0

Hydrofluoric acid 40 - - - X - - - - Acetic acid 10 0 0 X 0 0 0 X X Citric acid 50 0 0 - 0 0 - 0 0 Potassium hydroxide 50 0 x x - - - x x Sodium hydroxide 10 0 0 X 0 0 X 0 X Ammoniac 10 0 0 X 0 0 X - - Zinc chloride 50 x x x 0 0 0 x x x

Iron chloride 50 - - - 0 0 0 - - Sodium sulphite Sat 0 0 0 0 0 0 0 0 Potassium chloride Sat 0 x x 0 0 0 0 x x

Sodium sulphite Sat 0 0 0 0 0 0 0 0 0

Calcium chloride Sat 0 0 x 0 0 0 0 0 x

Sodium chloride Sat x x x 0 0 0 x x x

Sodium nitrate 50 x x x 0 0 0 x x x

Aluminium chloride Sat - - - 0 0 0 - - Sodium hypochlorite 50 x x x 0 0 x x x x

Ethanol 80 0 x - 0 x - 0 x Cyclohexane - - - - - - - - Toluene - - - - - - - - Trichloroethane - - - - - - - - Water 0 0 0 0 0 0 0 0 0

8310/8311

0 - - - - - 0 0 0 0 0 0 0 - - - -

10

8312

8315/8316

-

Page 10 09/2010 621=1 83=000 Issue B

Page 15

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

O = yes ; - = no

X = momentarily

°C/% 20 60 100 20 60 100

Sulphuric acid 10 0 X X 0 X X

Hydrochloric acid 1

Citric acid < 25 0 X - 0 - Phosphoric acid < 25 0 0 0 0 0 0

Hydrofluoric acid 40 - - - - - Acetic acid 10 0 0 0 X X Citric acid 50 0 0 - 0 0 Potassium hydroxide 50 0 x x - - Sodium hydroxide 10 0 0 X 0 X Ammoniac 10 0 0 X - - Zinc chloride 50 x x x x x X

Iron chloride 50 - - - - - Sodium sulphite Sat 0 0 0 0 0 Potassium chloride Sat 0 x x 0 x X

Sodium sulphite Sat 0 0 0 0 0 0

Calcium chloride Sat 0 0 x 0 0 X

Sodium chloride Sat x x x x x X

Sodium nitrate 50 x x x x x x

Aluminium chloride Sat - - - - - Sodium hypochlorite 50 x x - x x X

Ethanol 80 0 x - 0 x Cyclohexane - - - - - Toluene - - - - - Trichloroethane - - - - - Water 0 0 0 0 0 0

8394 8317

0 - - - - - 0 - - - -

10

-

621=183=000 Issue B 09/2010 Page 11

Page 16

Page 17

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

3. Installation and start-up

Cable connection

WARNING

Connect the cable quickly to avoid any risk

of humidifying the connector

L = 5, 10 or 20 m

L = 5/10 ou 20 m

Figure 3-1 - Connections

1. External shielding

2. Internal shielding

3. Internal electrode

4. External electrode

5. Pt100

6. Pt100

The cable reference :

08319=A=0005/0010/0020 (depending on

length 5, 10 or 20 m) must be connected in

compliance with the following table:

N° Colour Function Transmitter

6 Blue Pt100 TEMP + 14 (19) 10

5 Black Pt100 TEMP - 15 (20) 11

4 Red External electrode OUT 17 (22) 13

3 White

(Yellow tip)

2 White

(Orange tip)

1 White

(red tip)

Internal electrode IN 18 (23) 12

Internal shielding GND 16 (21) 14

External shielding EARTH BOX EARTH BOX EARTH BOX

9125

Transmitter

8920

Transmitter

8925

621=183=000 Issue B 09/2010 Page 13

Page 18

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Programming of the transmitter

REMARK

To obtained detailed information, please

refer to the operating manuals of our

transmitters.

Setting the type of measurement:

9125: Check that both switches of the

conductivity module have been correctly

configured on K (2 electrodes).

Setting the frequency in function with the

conductivity:

K (cm-1) Low

conductivity

0.01 0.01…0.1 µS 0.1 µS…20 µS 20 µS…200 µS

0.1 0.1….1 µ S 1 µS…200 µS 200µS…2 mS

1 1 … 10 µ S 10 µS…2 mS 2…20 mS

It is preferable, whenever possible, to operate

in the "Average conductivity" zone (and

therefore to choose the type of sensor well).

Average

conductivity

High

conductivity

• « Low conductivity » zone:

Do not combine a long length of cable with

a high measurement frequency, to avoid

provoking a parallel capacitance

(measurement of conductivity too high).

If one uses a long cable (> 20 m), adjust to

a frequency of 70 Hz.

Page 14 09/2010 621=183=000 Issue B

Page 19

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

• « Average conductivity » zone:

No particular precautions in this zone:

choose f = 1 kHz.

• « High conductivity » zone:

When the measurement frequency is low,

the surface of the electrodes will very

quickly saturate (formation of an insulating

layer reducing the flow of current, a

phenomenon known as "polarisation").

Choose f > 1 kHz

REMARK

9125 : select the "automatic frequency"

mode, in order to automatically set the best

frequency according to the measurement

range.

Definition of the cell constant value:

Enter real cell constant value of the probe (this

value is indicated in the certificate, it is

determined with a precision < 2 % in

compliance with ASTM D 1125 and ISO7888

standards).

Definition of the temperature

compensation mode:

Programm the mode of temperature

compensation of the transmitter according to

the characteristics of the process (see & 1,

influence of the temperature).

621=183=000 Issue B 09/2010 Page 15

Page 20

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Probe calibration

Whenever possible, we advise proceeding in

the following order:

• Temperature calibration

¾ It's an indispensable operation during

the commission for taking into account

the resistivity of the cable and offset

probe Pt100.

¾ Immerse the probe in a solution for

about 10 mn.

¾ Record the temperature of the solution

with a thermometer (precision < ± 0.1°C).

¾ Programm the transmitter in process

calibration mode.

¾ Adjust the value of the temperature read

with that of the thermometer.

• Conductivity calibration

First method (recommended) :

¾ Programm the transmitter in electrical

calibration mode. Choose the resistance

the closest possible to your process

(see table on the following page).

¾ First point: Remove the probe from the

liquid or unscrew the connector (Infinite

resistance, taking into account the

capacity of the cable).

¾ Second point: Connect the resistance

(precision < 0,1 %) of the value

programmed at the IN/OUT terminals of

the conductivity module.

Page 16 09/2010 621=183=000 Issue B

Page 21

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Conductivity solution :

Resistivity solution :

R connected for K= 0.01 cm-1

R connected for K= 0.1 cm-1 R connected for K= 1 cm-1 -

0.1 µS.cm-1

10 MΩ.cm

100 kΩ 1 kΩ

0.1 MΩ.cm

-1

10 µS.cm

10 kΩ 100 Ω

100 kΩ 1 kΩ 100 Ω

1 mS.cm-1

1 kΩ.cm

10 mS.cm-1

100 Ω.cm

- -

-

- : unadapted measurement

Second method :

¾ Programm the transmitter in "process"

calibration mode.

¾ Make sure that the value recorded is

stabilised before adjusting it with that of

a precision calibration solution

(conductivity close to that of the

process).

Probe installation

On piping:

Entirely immerse the internal electrode in the

process (take into account the dimensions on

the following page in the event of a 90°

installation):

621=183=000 Issue B 09/2010 Page 17

Page 22

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Figure 3-2 - Dimensions of electrodes

Figure 3-3 - Dimensions of electrodes

Figure 3-4 - Diameters of electrodes

MODEL h max

(mm)

8310/11 40 80 DN40 ou 1.5’’

8312 50 75 DN20 ou ¾’’

8315 28 117 DN90 ou 4’’

8316 28 80 DN50 ou 2’’

8317 28 90 DN75 ou 3’’

8394 21.5 65.5 DN50 ou 2’’

H min

(mm)

D min

(standard piping)

Page 18 09/2010 621=183=000 Issue B

Page 23

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

EXEMPLES OF INSTALLATIONS :

• 8315 :

h > 28 mm

h < 28 mm

Figure 3-5 - Electrode 8315

A Very good installation:

Perfect immersion of the electrode surfaces.

B Correct installation:

Satisfactory immersion of the electrode surfaces.

C Poor installation:

Incomplete immersion of the electrodes, the

conductivity will be too low.

The direction indicates the direction of flow.

REMARK

621=183=000 Issue B 09/2010 Page 19

Page 24

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

• 8394 :

This one installs perfectly in all short reduced

triclamp Tee "3A" Tri-clover® starting from

1.5” (A), and also in short standard bent Ts at

90° "3A" starting from 2” (B).

Figure 3-6 - 8394 electrode

A Very good installation:

Perfect immersion of the electrode surfaces.

B Correct installation:

Satisfactory immersion of the electrode surfaces.

C Poor installation:

Incomplete immersion of the electrodes, the

conductivity will be too low.

The direction indicates the direction of flow.

REMARK

In bypass

The flow-through chambers, are designed not

to retain air bubbles. To encourage the

extraction of the bubbles, use a minimum

flowrate of 20 l/hr (ideally 60 l/hr).

Page 20 09/2010 621=183=000 Issue B

Page 25

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

REMARK

The progressive accumulation of bubbles on

the surface of the probe:

¾ reduces its active surface,

¾ increases the cell constant,

¾ leads to a too low measure of conductivity.

Figure 3-7 - Circulation chamber

A Very good installation:

Perfect immersion of the electrode surfaces.

B Correct installation:

Satisfactory immersion of the electrode surfaces.

C Poor installation:

Incomplete immersion of the electrodes, the

conductivity will be too low.

The direction indicates the direction of flow.

REMARK

621=183=000 Issue B 09/2010 Page 21

Page 26

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Specifications of flow-through

chamber :

Reference : 08313=A=0001 08318=A=0001

Material: PVC 316 L SS

Tmax (°C) 60 150

Pressure (bar) 10 (at 25°C) 25

Sensor connection ¾’’NPT ¾’’NPT

Process connections (I/O) ¾’’NPT ¼’’NPT

Reference : 08394=A=8200 08394=A=8150

Material: 316 L SS 316 L SS

Tmax (°C) 150 150

Pressure (bar) 25 25

Sensor connection Clamp 2’’ Clamp 1.5’’

Process connections (I/O) ¼’’NPT ¼’’NPT

REMARK

Make sure the NPT fittings are leak free by adding

some waterproof material (PTFE thread seal tape,

sealant compound, etc.) onto the male thread.

Recommended waterproof material :

Flow-through

chamber

08313=A=0001 PTFE thread seal tape PTFE thread seal tape

08318=A=0001 PTFE thread seal tape Loctite 577

08394=A=8200 PTFE thread seal tape Loctite 577

08394=A=8150 PTFE thread seal tape Loctite 577

Sensor

8310/8311/8312

Sensor

8315/8316/8317/8394

Page 22 09/2010 621=183=000 Issue B

Page 27

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Dimensions :

08313=A=0001 08318=A=0001 08394=A=8200 08394=A=8150

Figure 3-8 - Dimensions of flow-through chamber

621=183=000 Issue B 09/2010 Page 23

Page 28

Page 29

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

4. Maintenance and cleaning

Conductivity probes are extremely reliable and

not very demanding in matters of calibration.

However, if you observe an erroneous

measurement, we advise you to proceed with

the following checks:

A Check the wiring (see Chapter 3 -

page 13)

B Check the programming of the transmitter

(see Chapter 3 - page 14)

C Check the installation of the probe (see

Chapter 3 - page 17)

D Check the probes (Pt100 and electrodes):

Figure 4-1 - Connecter view

Pt100: Compare the resistance

measured directly on the conductor with

the values below:

Temperature°C

Resistance (Ω)

0 10 20 30 40 50

100.00 103.90 107.70 111.67 115.54 119.40

Temperature°C

Resistance (Ω)

60 70 80 90 100

123.24 127.07 130.89 134.70 138.50

621=183=000 Issue B 09/2010 Page 25

Page 30

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Electrodes: Check the insulation

between the two electrodes (R infinite

when probe exposed to air and dry).

Pay attention to the maintenance of

the probes!

E The difficult conditions in which the

conductivity probes are often used makes

a periodic cleaning programm almost

obligatory.

This will contribute towards avoiding

accumulation at the surface of the

electrode of insulating layers leading to a

too weak reading of conductivity.

Ö In most uses, washing in hot water

with a household washing up liquid is

sufficient.

Ö Greasy or oily layers can be

eliminated with methanol or ethanol.

Ö With solutions containing bacteria or

algae, use a chlorinated cleaning

product such as bleach.

Ö In the case of deposits of metallic

hydroxide, soak the probe for 10 mn in

a 20 % nitric acid solution.

F Carefully recalibrate the measurement

loop (See Chapter 3 - Calibration)

Page 26 09/2010 621=183=000 Issue B

Page 31

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

Spares parts

• Probes :

Reference Description

08310=A=0000 2 electrodes conductivity sensor k=0,01 3/4NPT Thread

08311=A=0000 2 electrodes conductivity sensor k=0,1 3/4NPT Thread

08312=A=0000 2 electrodes conductivity sensor k=1 3/4NPT Thread

08315=A=0000 2 electrodes conductivity sensor k=0,01 3/4NPT Thread

08315=A=0002 2 electrodes conductivity sensor k=0,01 (8315.2 for

08315=A=1111 2 electrodes conductivity sensor k=0,01 ¾"G thread

08316=A=0000 2 electrodes conductivity sensor k=0,1 3/4NPT Thread

08317=A=0000 2 electrodes conductivity sensor k=1 3/4NPT Thread

08394=A=1500 2 electrodes conductivity sensor (k=0,01),

08394=A=1511 2 electrodes conductivity sensor (k=0,01),

08394=A=2000 2 electrodes conductivity sensor (k=0,01),

08394=A=2011 2 electrodes conductivity sensor (k=0,01),

Yokogawa flow chamber)

(8315.1)

1,5" (38 mm) clamp

1,5"(38 mm) clamp with certificates of conformity

2" (51 mm) clamp

2" (51 mm) clamp with certificates of conformity

• Cables :

Reference Description

08319=A=0000 Female connector 6+T with connexion drawing

08319=A=0005 5 m cable and IP65 connector for 2 electrodes

08319=A=0010 10 m cable and IP65 connector for 2 electrodes

08319=A=0020 20 m cable and IP65 connector for 2 electrodes

588800,29050 Shielded 4 conductor cable (per meter)

91010=A=0144 30 m cable and IP65 connector for 2 electrodes

conductivity sensor (8319.5)

conductivity sensor (8319.10)

conductivity sensor (8319.20)

conductivity sensor

621=183=000 Issue B 09/2010 Page 27

Page 32

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

• Flow-through chamber :

Reference Description

08313=A=0001 PVC flow chamber with 3 X ¾ FNPT bores

08318=A=0001 SSt flow-chamber with 1 X ¾ FNPT bore + 2 X ¼ FNPT

08394=A=8150 Kit for 8394 1,5" clamp probe with EPDM gasket, clamp

08394=A=8200 Kit for 8394 2" clamp probe with EPDM gasket, clamp and

bores (8318,1 model)

and 316L SS flow-through chamber

316LL flow-through chamber

• Fittings :

Reference Description

08394=A=0380 Kit for 8394 1,5" clamp probe with EPDM gasket, clamp

08394=A=0510 Kit for 8394 2" clamp probe with EPDM gasket, clamp and

and 316L SS welding ferrule (H = 13mm)

316L SS welding ferrule (H = 13mm)

• Spare part :

Reference Description

429=500=380 EPDM gasket for 1,5" clamp fastening device

429=500=510 EPDM gasket for 2" clamp fastening device

• Documentation :

Reference Description

621=083=000 User manual of 2 electrodes conductivity sensors in

621=183=000 User manual of 2 electrodes conductivity sensors in

621=283=000 User manual of 2 electrodes conductivity sensors in

621=483=000 User manual of 2 electrodes conductivity sensors in

621=583=000 User manual of 2 electrodes conductivity sensors in

french

english

german

italian

spanish

Page 28 09/2010 621=183=000 Issue B

Page 33

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

5. Precautionary Labels

Read all labels and tags attached to the

instrument.

Personal injury or damage to this instrument

could occur if not observed.

!

Note: For return for recycling, please contact the equipment

producer or supplier for instructions on how to return end-of-life

equipment for proper disposal.

Important document. Retain with product records.

This symbol, if noted on the instrument,

references the instruction manual for operation

and / or safety information.

Electrical equipment marked with this symbol

may not be disposed of in European public

disposal systems after 12 August of 2005. In

conformity with European local and national

regulations (EU Directive 2002/96/EC),

European electrical equipment users must

now return old or end-of life equipment to the

Producer for disposal at no charge to the user.

621=183=000 Issue B 09/2010 Page 29

Page 34

2 ELECTRODES CONDUCTIVITY PROBE - INSTRUCTION MANUAL

The information contained in this manual (and its associated

documentation) is as complete and accurate as possible at the

time of their printing. If the behaviour of this product while

operating is different from this written manual, our documentation

may be out-of-date. In this case, contact the representative of the

Hach Lange product line to solve the problem.

Hach Lange reserves the right to make improvements and

changes in the hardware and software associated to the product

described.

Page 30 09/2010 621=183=000 Issue B

Page 35

Page 36

Loading...

Loading...