Hach-Lange POCKET Colorimeter II User Manual [en, de, es, fr, it]

DOC022.98.90061

POCKET COLORIMETER

TM

II -

Formaldehyde/Formaldehyd/

Aldéhyde formique/Formaldehido/

Formaldeide/

LCK 325

APPLICATION INSTRUCTION

PROGRAMMIERANLEITUNG

INSTRUCTIONS DE FONCTIONNEMENT

INSTRUCCIONES DE APLICACIÓN

ISTRUZIONI APPLICATIVE

GEBRUIKSAANWIJZING

INSTRUKTIONSHANDBOK

April 2008, Edition 1

April 2008, Ausgabe 1

Avril 2008, édition 1

Abril 2008, Edición 1

Aprile 2008, edizione 1

April 2008, Editie 1

April 2008, Utgåva 1

Table of contents

Section 1 General information .....................................................................17

1.1 Safety information ..................................................................................... 17

1.1.1 Use of hazard information .............................................................. 17

1.2 General product information ..................................................................... 17

Section 2 Installation ......................................................................................19

2.1 Packing list ................................................................................................ 19

2.2 Insert the adapter ......................................................................................19

2.3 Replace the instrument cap ......................................................................19

Section 3 System start up .............................................................................21

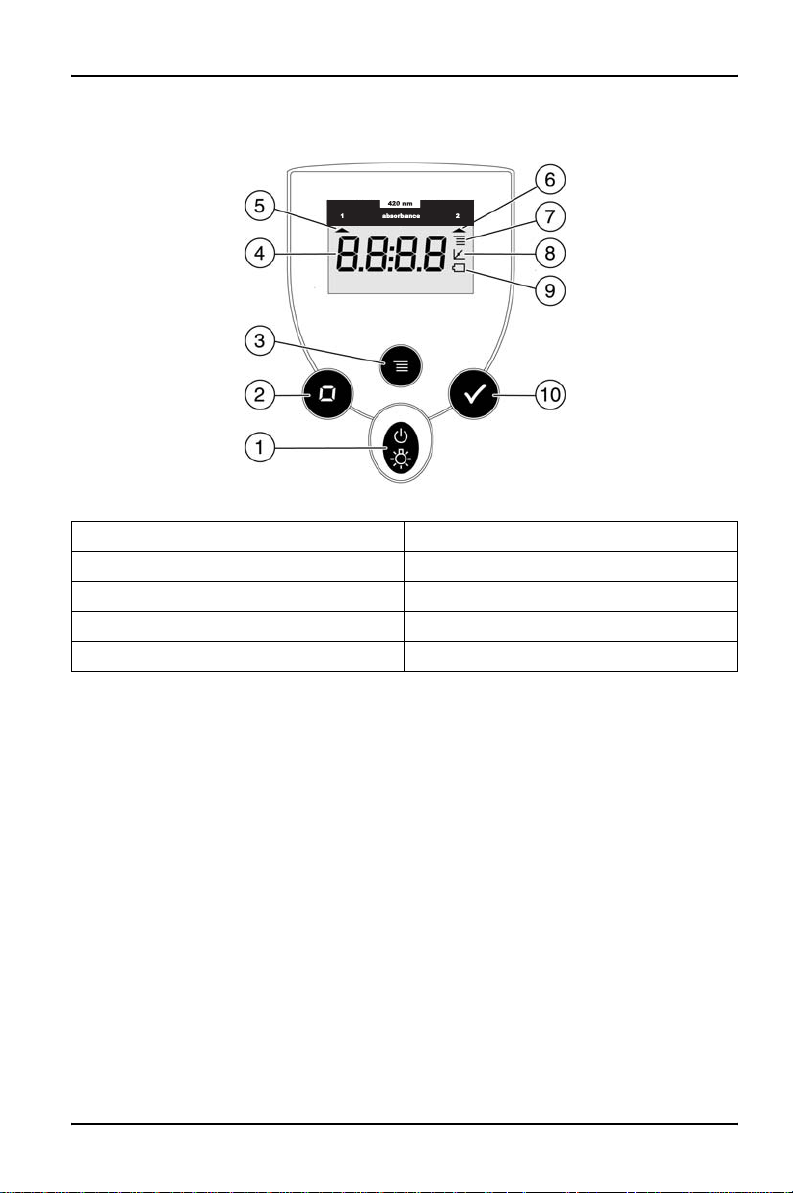

3.1 Instrument keys and display ..................................................................... 21

3.1.1 Key-Functions .................................................................................21

3.2 Enter calibration data of LANGE Cuvette Test .........................................21

3.2.1 Overview .........................................................................................21

3.2.2 Data table ....................................................................................... 22

3.3 Programming procedure ...........................................................................22

3.3.1 LCK 325 Formaldehyde H

3.4 Check entered data ..................................................................................23

3.5 Overwrite stored calibration data ..............................................................24

3.5.1 Retrieve the factory calibration ....................................................... 24

Section 4 Operation ........................................................................................ 25

4.1 Analyse Formaldehyde with LANGE Cuvette Test ............................ ....... 25

4.2 Quality assurance ..................................................... .. ... ...........................25

4.3 Evaluate LANGE Formaldehyde Cuvette Test ........................................25

Section 5 Replacement Parts and Accessories ....................................27

5.1 Replacement Parts ................................................................................... 27

5.2 Accessories .............................................................................................. 27

Section 6 Warranty, liability and complaints ........................................... 29

CO ....................................................... 22

2

3

4

Inhalt

Abschnitt 1 Allgemeine Informationen ......................................................31

1.1 Sicherheitsinformationen .......................................................................... 31

1.1.1 Bedeutung der Hinweise ................................................................31

1.2 Allgemeine Produkt informationen ......................................................... .. ..31

Abschnitt 2 Installation ................................................................................... 33

2.1 Verpackungsliste ...................................................................................... 33

2.2 Küvettenadapter einsetzen .......................................................................33

2.3 Austausch der Instrumentenkappe ...........................................................33

Abschnitt 3 Inbetriebnahme .........................................................................35

3.1 Gerätetasten und Display .......... ...............................................................35

3.1.1 Tasten-Funktionen .......................................................................... 35

3.2 Eingabe der Kalibrierdaten für LANGE Küvetten-Test ..............................36

3.2.1 Überblick .........................................................................................36

3.2.2 Datentabelle ...................................................................................36

3.3 Programmierung ....................................................................................... 36

3.3.1 LCK 325 Formaldehyd H

3.4 Dateneingabe kontrollieren ....................................................................... 38

3.5 Überschreiben gespeicherter Kalibrierdaten .............................................38

3.5.1 Grundeinstellung wieder herstellen ................................................38

Abschnitt 4 Betrieb .......................................................................................... 39

4.1 Analyse von Formaldeyd mit dem LANGE Küvetten-Test .................... .. ..39

4.2 Qualitätssicherung .................................................................................... 39

4.3 Auswertung des LANGE Formaldeyd Küvetten-Tests .............................. 39

Abschnitt 5 Ersatzteile und Zubehör ......................................................... 41

5.1 Ersatzteile ................................................................................................. 41

5.2 Zubehör ....................................................................................................41

Abschnitt 6 Gewährleistung, Haftung und Reklamationen ................43

CO ......................................................... 37

2

5

6

Sommaire

Section 1 Informations générales ...............................................................45

1.1 Consignes de sécurité .............................................................................. 45

1.1.1 Utilisation des informations relatives aux risques ........................... 45

1.2 Informations générales relatives au produit ..............................................45

Section 2 Installation ......................................................................................47

2.1 Liste d’expédition ......................................................................................47

2.2 Insertion de l’adaptateur ........................................................................... 47

2.3 Réinstallation du capuchon de l’instrument ..............................................47

Section 3 Démarrage du système ..............................................................49

3.1 Écran et touches de l’instrument ............................................................... 49

3.1.1 Fonctions des touches ....................................................................49

3.2 Saisie des données d'étalonnage de test en cuve LANGE ...................... 50

3.2.1 Vue d’ensemble .............................................................................. 50

3.2.2 Tableau de données ....................................................................... 50

3.3 Procédure de programmation ...................................................................50

3.3.1 LCK 325 aldéhyde formique H

3.4 Vérification des données saisies ...............................................................52

3.5 Écrasement des données d'étalonnage stockées ....................................52

3.5.1 Récupération de l'étalonnage usine ...............................................52

Section 4 Fonctionnement ............................................................................53

4.1 Analyse d‘aldéhyde formique à l’aide de test en cuve LANGE .................53

4.2 Assurance qualité ..................................................................................... 53

4.3 Évaluation de test en cuve aldéhyde formique LANGE ...........................53

Section 5 Pièces de remplacement et accessoires ..............................55

5.1 Pièces de remplacement ..........................................................................55

5.2 Accessoires .............................................................................................. 55

Section 6 Garantie, responsabilité et réclamations ..............................57

CO .................................................50

2

7

8

Índice de contenido

Sección 1 Información general ...................................................................59

1.1 Indicaciones de seguridad ........................................................................59

1.1.1 Utilización de las indicaciones de peligro ....................................... 59

1.2 Información general del producto .............................................................59

Sección 2 Instalación .....................................................................................61

2.1 Lista de embalaje ......................................................................................61

2.2 Insertar el adaptador .................................................................................61

2.3 Reemplazar la tapa del instrumento .........................................................61

Sección 3 Arranque del sistema ................................................................. 63

3.1 Teclas y pantalla del instrumento ........................................................... ..63

3.1.1 Funciones de tecla ......................................... .. ..............................63

3.2 Introduzca los datos de calibración de la cubeta test de LANGE .............63

3.2.1 Vista general ...................................................................................63

3.2.2 Tabla de datos ................................................................................64

3.3 Procedimientos de programación .............................................................64

3.3.1 LCK 325 Formaldehido H

3.4 Controlar los datos introducidos. ..............................................................65

3.5 Sobreescribir los datos de calibración almacenados. ...............................66

3.5.1 Recuperación de calibración por defecto .......................................66

Sección 4 Operación ......................................................................................67

4.1 Análisis de formaldehido con la cubeta test de LANGE ........................... 67

4.2 Aseguramiento de calidad ........................................................................ 67

4.3 Evaluación de formaldehido de LANGE Cubeta test ............................... 67

Sección 5 Piezas de repuesto y accesorios ........................................... 69

5.1 Piezas de repuesto ...................................................................................69

5.2 Accesorios ................................................................................................69

Sección 6 Garantía, responsabilidad y reclamaciones .......................71

CO ........................................................ 64

2

9

10

Indice

Capitolo 1 Informazioni generali .................................................................73

1.1 Istruzioni di sicurezza ................................................................................73

1.1.1 Utilizzo delle informazioni di sicurezza ........................................... 73

1.2 Informazioni generali sul prodotto .............................................................73

Capitolo 2 Installazione .................................................................................75

2.1 Distinta di imballaggio ...............................................................................75

2.2 Inserimento dell’adattatore ........................................................................75

2.3 Inserimento del coperchio Hach Lange ....................................................75

Capitolo 3 Messa in esercizio del sistema ..............................................77

3.1 Tasti e display dello strumento ................................................................. 77

3.1.1 Funzioni dei tasti ................................. ............................................77

3.2 Inserimento dei dati di calibrazione dei test in cuvetta LANGE ................78

3.2.1 Panoramica strumentale .................................................................78

3.2.2 Tabella dati di calibrazione .............................................................78

3.3 Procedura di programmazione ..................................................................78

3.3.1 LCK 325 Formaldeide H

3.4 Controllo dei dati inseriti ............................................................................ 80

3.5 Come sovrascrivere i dati di calibrazione memorizzati ............................. 80

3.5.1 Come richiamare la calibrazione di fabbrica ...................................80

Capitolo 4 Esercizio ........................................................................................ 81

4.1 Analisi formaldeide con test in cuvetta LANGE ........................................81

4.2 Garanzia di qualità ....................................................................................81

4.3 Test in cuvetta LANGE formaldeide ......................................................... 81

Capitolo 5 Parti di ricambio e accessori ...................................................83

5.1 Parti di ricambio .................................................. ... ... ................................83

5.2 Accessori .................................................................................................. 83

Capitolo 6 Garanzia, responsabilità e reclami .......................................85

CO .......................................................... 78

2

11

12

Inhoud

Deel 1 Algemene informatie .........................................................................87

1.1 Veiligheidsinformatie ................................................................................. 87

1.1.1 Gebruik van gevareninformatie .......................................................87

1.2 Algemene productinformatie ..................................................................... 87

Deel 2 Installatie ..............................................................................................89

2.1 Paklijst ......................................................................................................89

2.2 De adapter insteken ..................................................................................89

2.3 De kap van het instrument terug aanbrengen. ..........................................89

Deel 3 Het systeem opstarten .....................................................................91

3.1 Instrumenttoetsen en display .................................................................... 91

3.1.1 Toets-functies ................................................................................. 91

3.2 De kalibratiedata van LANGE kuvettentesten invoeren ............................91

3.2.1 Overzicht ........................................................................................ 91

3.2.2 Datatabel ........................................................................................92

3.3 Programmeerprocedure ............................................................................ 92

3.3.1 LCK 325 Formaldehyde H

3.4 De ingevoerde data controleren ................................................................93

3.5 Opgeslagen kalibratiedata overschrijven .................................................. 94

3.5.1 De fabriekskalibratie herstellen ....................................................... 94

Deel 4 Bedrijf ....................................................................................................95

4.1 Formaldehyde met Lange kuvettentest analyseren ..................................95

4.2 Kwaliteitsborging .......................................................................................95

4.3 LANGE formaldehyde kuvettentest ..........................................................95

Deel 5 Reservedelen en toebehoren ........................................................97

5.1 Reservedelen ............................................................................................97

5.2 Accessoires .............................................................................................. 97

Deel 6 Garantie, aansprakelijkheid en klachten .................................... 99

CO ....................................................... 92

2

13

14

Innehåll

Sektion 1 Allmän information .....................................................................101

1.1 Säkerhetsinformation .............................................................................. 101

1.1.1 Så här används säkerhetsinformationen ......................................101

1.2 Allmän produktinformation ......................................................................101

Sektion 2 Installation ....................................................................................103

2.1 Packlista ................................................................................................. 103

2.2 Installera adaptern ..................................................................................103

2.3 Byta ut instrumentlocket .......................................................................... 103

Sektion 3 Systemstart ..................................................................................105

3.1 Instrumenttangenter och display .............................................................105

3.1.1 Funktionstangenter ....................................................................... 105

3.2 Mata in kalibreringsdata för LANGE kyvett-tester ................................... 105

3.2.1 Översikt ........................................................................................105

3.2.2 Datatabell .....................................................................................106

3.3 Programmeringsprocedur ....................................................................... 106

3.3.1 LCK 325 Formaldehyd H

3.4 Kontrollera indata ....................................................................................107

3.5 Skriv över sparade kalibreringsdata ........................................................107

3.5.1 Återgå till först fabrikskalibreringen ............................................... 108

Sektion 4 Användning ..................................................................................109

4.1 Analysera formaldehyd med LANGE kyvett-test .....................................109

4.2 Kvalitetssäkring .......................................................................................109

4.3 Utvärdering LANGE formaldehyd kyvett-test .........................................109

Sektion 5 Reservdelar och tillbehör ......................................................... 111

5.1 Reservdelar ............................................................................................111

5.2 Tillbehör .................................................................................................. 111

Sektion 6 Garanti, ansvar och reklamationer .......................................113

CO ....................................................... 106

2

15

16

Section 1 General information

1.1 Safety information

Please read this entire application instruction and the POCKET COLORIMETERTM II

instruction manual before unpacking, setting up, or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use

or install this equipment in any manner other than that specified in this manual.

1.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not

avoided, could result in death or serious injury.

Important Note: Information that requires special emphasis.

Note: Information that supplements points in the main text.

1.2 General product information

This application instruction describes how to evaluate LANGE Cuvette Tests on a

single-wavelength POCKET COLORIMETER II.

17

18

Section 2 Installation

Important Note: This application instruction is only valid in conjunction with the

POCKET COLORIMETERTM II instruction manual and the applied LCK working

procedure. Please read this entire application instruction and the entire POCKET

COLORIMETER II instruction manual before unpacking, setting up or operating the

instrument.

2.1 Packing list

• POCKET COLORIMETER II 420 nm, Cat. No. 5870042

• Instrument cap with HACH LANGE label, Cat. No. LZV 759

• Cuvette adapter 1 cm, Cat. No. 5954600

• Application instruction DOC022.98.90061

2.2 Insert the adapter

Remove the instrument cap and carefully position the cuvette adapter into the cell

holder with the arrow pointing downward. Fix it by pressing it down.

2.3 Replace the instrument cap

Use the instrument cap with the HACH LANGE label when evaluating LANGE

cuvettes.

19

20

Section 3 System start up

3.1 Instrument keys and display

Figure 1 Instrument keys and display

1 POWER/BACKLIGHT 6 Channel indicator (2)

2 ZERO/SCROLL (BLUE key)7Menu indicator

3MENU 8Calibration adjusted indicator

4 Numeric display 9 Battery low indicator

5 Channel indicator (1) 10 READ/ENTER (GREEN key)

3.1.1 Key-Functions

ZERO/SCROLL (BLUE key) : In measurement mode, sets the instrument to zero. In

menu mode, scrolls through menu options. Also scrolls numbers when entering or

editing a value.

READ/ENTER (GREEN key) : In measurement mode, initialize s s ample

measurement. In menu mode, selects a menu option. When entering numbers,

moves one space to the right. Confirm the function when the entry is complete.

3.2 Enter calibration data of LANGE Cuvette Test

3.2.1 Overview

Each POCKET COLORIMETER II has two channels in which measurements can be

made. Each channel will accept user-defined calibration data.

This application instruction contains the calibration data of the LANGE Cuvette Test

for Formaldehyde:

21

System start up

• LCK 325: 0.5-10.0 mg/l Formaldehyde

Each programming procedure has only to be followed once prior to the first test

evaluation.

For detailed information please read the POCKET COLORIMETER II instruction

manual.

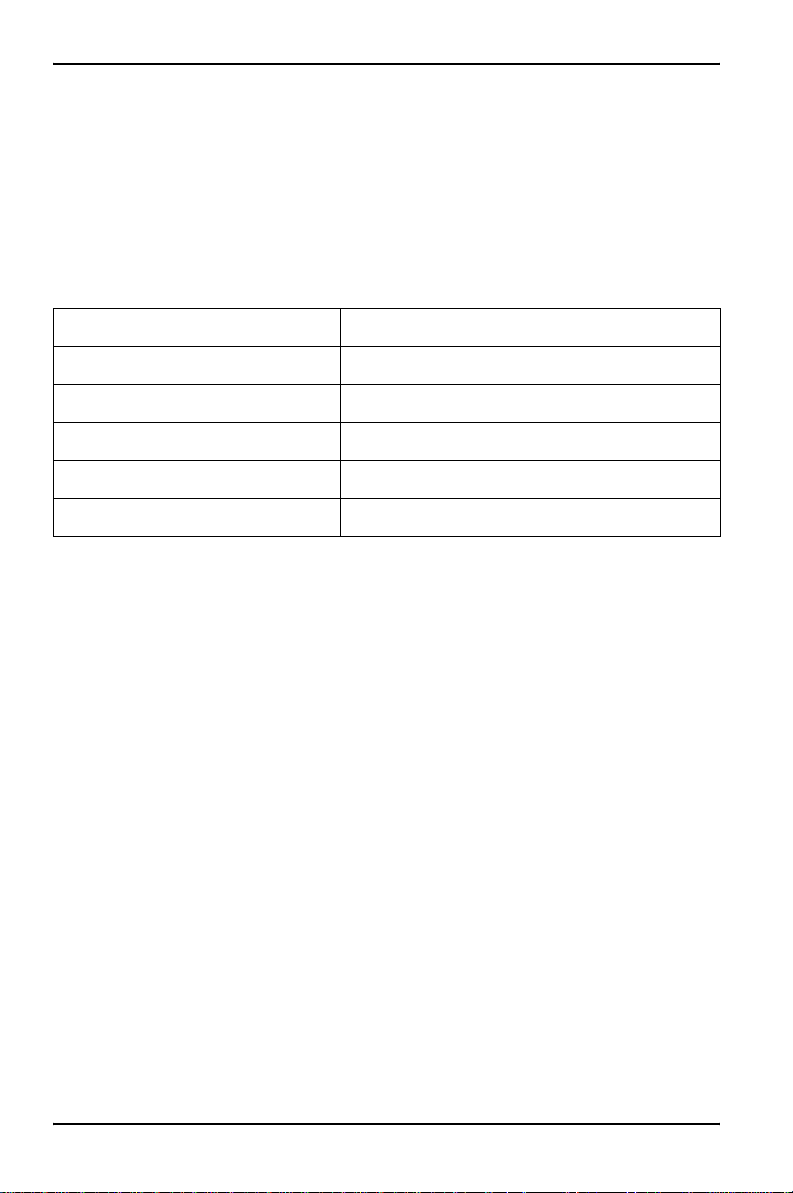

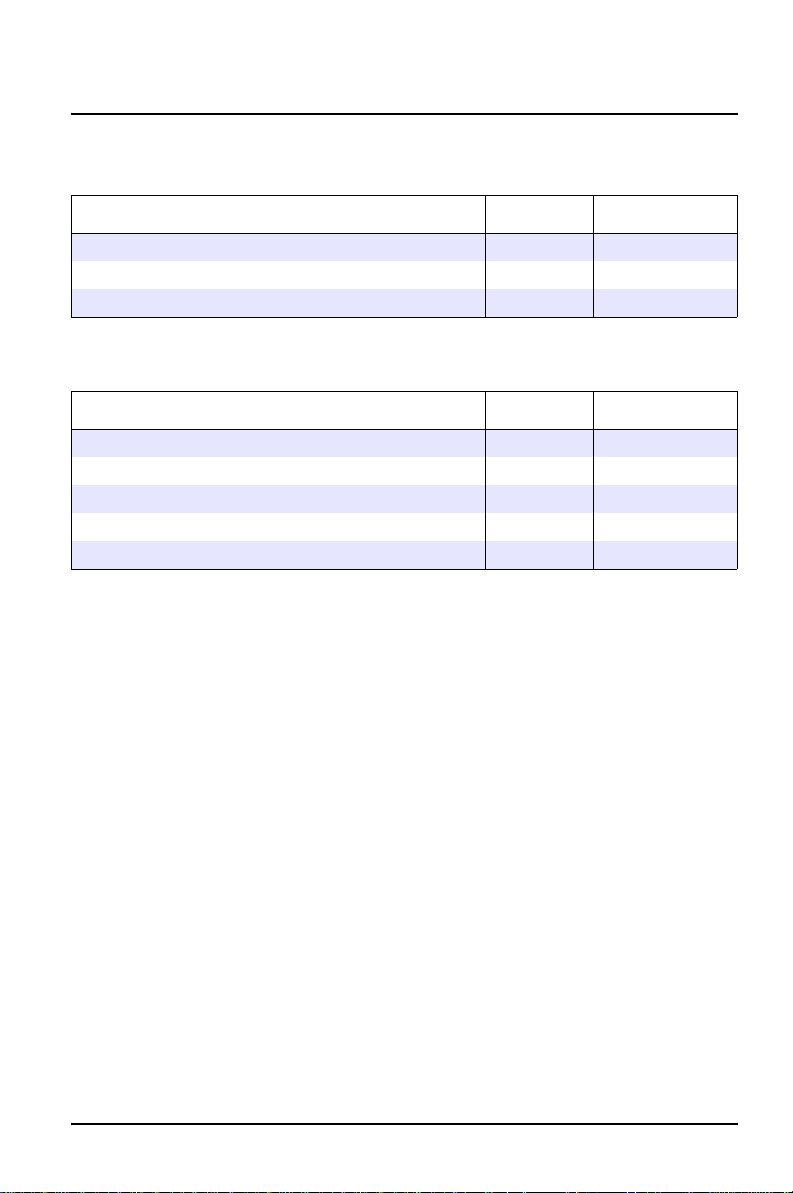

3.2.2 Data table

3.2.2.1 Evaluation as Formaldehyde Table 1 Evaluation as Formaldehyde

LCK 325

RES (resolution)

S0 (standard 0)

A0 (absorbance 0)

S1 (standard 1)

A1 (absorbance 1)

--.--

00.50

0.046

10.00

0.993

3.3 Programming procedure

Note: Each programming procedure has only to be followed once prior to the first test

evaluation.

Note: After programming the calibration data, it could be helpful to mark the channel(s) 1

and/or 2 accordingly with a label.

3.3.1 LCK 325 Formaldehyde H2CO

1. Press POWER to switch on the instrument.

2. Press MENU. "SEL" is displayed. A flashing arrow indicates the current channel

(1 or 2).

3. Select channel 1 for LCK 325 (0.5-10.0 mg/l H

Note: Press GREEN key to toggle between channels.

4. Press MENU for about five seconds until "USER" followed by "CAL" is

displayed.

5. Press BLUE key until "Edit" is displayed. Press GREEN key. " RES" is

displayed.

6. Press GREEN key. "-.---" is displayed.

7. Press BLUE key until "--.--" is displayed. Press GREEN key. "S0" is displayed.

8. Press GREEN key until "A0" is displayed.

9. Press GREEN key until "S1" is displayed.

CO).

2

22

System start up

10. Press GREEN key. Enter "10.00" by using BLUE key to change value and

GREEN key to move to the next space. Press GREEN key until "A1" is

displayed.

11. Press GREEN key. Enter "0.993" by using BLUE key to change value and

GREEN key to move to the next space. Press GREEN key until "Add" is

displayed.

12. Press MENU until "Edit" is displayed. Press GREEN key until „S0“ is displayed.

13. Press GREEN key. Enter "00.50" by using BLUE key to change value and

GREEN key to move to the next space. Press GREEN key until "A0" is

displayed.

14. Press GREEN key. Enter "0.046" by using BLUE key to change value and

GREEN key to move to the next space. Press GREEN key until „S1“ is

displayed.

15. Press MENU until "Edit" is displayed to check the entered data. Press GREEN

key. „RES“ is displayed.

16. Press BLUE key to scroll through the entries. Compare the entries with the data

shown in the table below.

Table 2 Calibration data of LCK 325 Formaldehyde

RES --.--

S0 0.50

A0 0.046

S1 10.00

A1 0.993

17. After comparing the entries press MENU two times to enter the measuring

mode. See 4.3 Evaluate LANGE Formaldehyde Cuvette Test on page 25.

Note: In case of any mistake retrieve the factory calibration first. See 3.5.1 Retrieve the factory

calibration on page 24. After retrieving the factory calibration, start the programming procedure

again. If the instrument is shut-off or loses power during data entry, all edits will be lost.

Automatic shut-off is 60 minutes.

3.4 Check entered data

To avoid erroneous measurements it is recommended to check the data after

completing the programme procedure.

1. Press MENU for about five seconds until "USER" followed by "CAL" is

displayed.

2. Press BLUE key to scroll to "Edit". Press GREEN key.

3. "RES" is displayed. Press BLUE key to scroll through the entries. Compare the

entries with the figures in the 3.2.2.1 Evaluation as Formaldehyde on page 22.

In case a value was not stored correctly, retrieve the factory calibration first. See 3.5.1

Retrieve the factory calibration on page 24. After retrieving the factory calibration,

start the programming procedure again.

23

System start up

3.5 Overwrite stored calibration data

With the POCKET COLORIMETER II it is possible to overwrite stored calibration

data. Before overwriting calibration data it is recommended to retrieve the factory

calibration first. After retrieving the factory calibration, you can program new

calibration data.

In case of any mistake retrieve the factory calibration first.

3.5.1 Retrieve the factory calibration

1. Press MENU. "SEL" is displayed. A flashing arrow indicates the current channel

(1 or 2). Press GREEN key to toggle between channels. Select channel

retrieving the factory calibration.

2. Press MENU for about five seconds until "USER" followed by "CAL" is

displayed.

3. Press BLUE key to scroll to "dFL". Press GREEN key.

24

Section 4 Operation

4.1 Analyse Formaldehyde with LANGE Cuvette Test

DANGER

Handling chemical samples, standards and reagents can be dangerous. Users

of this product are advised to familiarize themselves with safety procedures

and the correct use of chemicals, and to carefully read all relevant material

safety data sheets.

To analyse formaldehyde follow the working procedure enclosed in the according

Cuvette Test LCK 325.

4.2 Quality assurance

The measurement results must be subjected to plausibility checks (dilute and/or

spike the sample).

4.3 Evaluate LANGE Formaldehyde Cuvette Test

Note: Make sure that the instrument is programmed with the corresponding calibration data,

see 3.4 Check entered data on page 23.

1. Press POWER to switch on the instrument.

2. Make sure that channel 1 is selected!

Otherwise press MENU. "SEL" is displayed. A flashing arrow indicates the

current channel (1 or 2). Press GREEN key to select channel 1. Press MENU to

get back to the measuring mode.

3. Insert the zero-solution into the cell holder equipped with the cuvette adapter

1cm.

Note: Make sure that the cuvette adapter is positioned correctly.

4. Place the instrument cap with the HACH LANGE label over the cell holder to

cover the cuvette.

5. Press BLUE key. "0.00" is displayed.

6. Remove the instrument cap and insert the sample cuvette.

7. Place the instrument cap over the cell holder to cover the cuvette.

8. Press GREEN key.

9. The result is displayed in mg/l Formaldehyde.

Note: In case the formaldehyde concentration is out of the selected measuring range the

value for the lowest or highest concentration is displayed and flashes. Repeat the test

diluting your sample.

Note: A new zero measurement should be performed prior to each individual test series.

25

26

Section 5 Replacement Parts and

Accessories

5.1 Replacement Parts

Description Quantity Cat. Number

POCKET COLORIMETERTM II 420 nm 1 5870042

Instrument cap with HACH LANGE label 1 LZV 759

Cuvette adapter 1 cm 1 5954600

5.2 Accessories

Description Quantity Cat. Number

Formaldehyde Cuvette Test (0.5-10.0 mg/l H2CO) 1 pk/24 pc LCK 325

Pipette 0.2-1 ml 1 BBP 078

Pipette tips for BBP 078 1 pk/100 pc BBP 079

Cuvette Stand for LANGE cuvettes 1 LYW 915

Thermostat LT 200 1 LTV082.99.51002

27

28

Section 6 Warranty, liability and

complaints

The manufacturer warrants that the product supplied is free of material and

manufacturing defects and undertakes the obligation to repair or replace any

defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out

within 6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the

lack of assured properties as follows: all those parts that can be demonstrated to

have become unusable or that can only be used with significant limitations due to a

situation present prior to the transfer of risk, in particular due to incorrect design, poor

materials or inadequate finish will be improved or replaced, at the supplier's

discretion. The identification of such defects must be notified to the supplier in writing

without delay, however at the latest 7 days after the identification of the fault. If the

customer fails to notify the supplier, the product is considered approved despite the

defect. Further liability for any direct or indirect damages is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be

performed within the warranty period by the customer (maintenance) or by the

supplier (servicing) and these requirements are not met, claims for damages due to

the failure to comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or

incorrect use are excluded from this clause.

29

30

Loading...

Loading...