Page 1

DOC022.98.00743.NOV05

Piston pipette

with tip ejector system

Kolbenhubpipette

mit Spitzen-Auswurfsystem

Pipette à piston

avec dispositif d’éjection des cônes

Pipeta de émbolo

con sistema de expulsión de puntas

Pipetta a pistone

con sistema di espulsione del puntale

Page 2

Page 3

DOC022.98.00743.NOV05

Piston pipette

Kolbenhubpipette

Pipette à piston

Pipeta de émbolo

Pipetta a pistone

USER MANUAL

BEDIENUNGSANLEITUNG

MODE D’EMPLOI

MANUAL DEL USUARIO

MANUALE UTENTE

November 2005, Edition 1

© Hach Company, 2005. All rights reserved. Printed in Germany

CK/SK

Page 4

2

Page 5

Table of Contents

Section 1 Description of the piston pipette ....13

1.1 Pipette tips ..................................................... 14

Section 2 Using the pipette ..............................15

2.1 Setting the volume ......................................... 15

2.2 Tip ejection ..................................................... 15

2.3 Pipetting techniques ....................................... 16

Section 3 Standard technique .........................17

Section 4 Daily check .......................................18

Section 5 Maintenance .....................................19

5.1 Opening the pipettes (0.2–1.0 mL) ................ 19

5.2 Opening the pipette (1–5 mL) ........................ 21

Section 6 Calibration ........................................22

6.1 Checking the calibration ................................. 22

Section 7 Recalibration ....................................24

Section 8 Troubleshooting ...............................25

Section 9 Warranty, liability and complaints ..26

3

Page 6

Table of Contents

4

Page 7

Inhaltsverzeichnis

Kapitel 1 Beschreibung der

Kolbenhubpipette ..............................................27

1.1 Pipettenspitzen .............................................. 28

Kapitel 2 Pipettenbedienung ...........................29

2.1 Volumeneinstellung ........................................ 29

2.2 Spitzenauswurf .............................................. 29

2.3 Pipettiertechniken .......................................... 30

Kapitel 3 Standard-Technik ..............................31

Kapitel 4 Pipettieren von Vollblut ....................32

Kapitel 5 Tägliche Prüfung ..............................33

Kapitel 6 Wartungsarbeiten .............................34

6.1 Öffnen der Pipetten (0,2–1,0 mL) .................. 34

6.2 Öffnen der Pipette (1–5 mL) .......................... 36

Kapitel 7 Kalibrierung .......................................37

7.1 Prüfen der Kalibrierung .................................. 37

Kapitel 8 Rekalibrierung ...................................39

Kapitel 9 Fehlersuche .......................................40

Kapitel 10 Gewährleistung, Haftung und

Beanstandungen ................................................41

5

Page 8

Inhaltsverzeichnis

6

Page 9

Table des matières

Section 1 Description de la pipette à piston ..43

1.1 Pointes de pipette .......................................... 44

Section 2 Utilisation de la pipette ...................45

2.1 Réglage du volume ........................................ 45

2.2 Ejection de la pointe ....................................... 45

2.3 Techniques de pipetage ................................. 46

Section 3 Technique standard .........................47

Section 4 Pipetage de sang complet ..............48

Section 5 Contrôle quotidien ...........................49

Section 6 Entretien ...........................................50

6.1 Pour ouvrir la pipette (0,2–1,0 mL) ................ 50

6.2 Pour ouvrir la pipette (1–5 mL) ...................... 52

Section 7 Etalonnage .......................................53

7.1 Vérification de l'étalonnage ............................ 53

Section 8 Recalibrage ......................................55

Section 9 Recherche de problèmes ................56

Section 10 Garantie, responsabilité et

réclamations .......................................................57

7

Page 10

Table des matières

8

Page 11

Índice

Sección 1 Descripción de la pipeta de

émbolo ................................................................59

1.1 Puntas de pipeta ............................................ 60

Sección 2 Utilización de la pipeta ...................61

2.1 Ajuste del volumen ......................................... 61

2.2 Expulsión de la punta .....................................61

2.3 Técnicas de pipeteado ................................... 62

Sección 3 Técnica estándar .............................63

Sección 4 Pipeteado de sangre completa ......64

Sección 5 Control diario ..................................65

Sección 6 Mantenimiento .................................66

6.1 Abrir las pipetas (0,2–1,0 mL) ........................ 66

6.2 Abrir la pipeta (1–5 mL) ................................. 68

Sección 7 Calibración ......................................69

7.1 Comprobación de la calibración ..................... 69

Sección 8 Recalibración ..................................71

Sección 9 Localización y resolución de

fallos ...................................................................72

Sección 10 Garantía, responsabilidad y

reclamaciones ....................................................73

9

Page 12

Índice

10

Page 13

Indice

Sezione 1 Descrizione della pipetta a pistone 75

1.1 Puntali per pipette .......................................... 76

Sezione 2 Uso della pipetta .............................77

2.1 Regolazione del volume ................................. 77

2.2 Espulsione del puntale ................................... 77

2.3 Tecniche di pipettatura ................................... 78

Sezione 3 Tecnica standard .............................79

Sezione 4 Pipettare sangue intero ..................80

Sezione 5 Controllo quotidiano .......................81

Sezione 6 Manutenzione ..................................82

6.1 Apertura delle pipette (0,2–1,0 mL) ............... 82

6.2 Apertura della pipetta (1–5 mL) ..................... 84

Sezione 7 Calibrazione .....................................85

7.1 Controllo della calibrazione ............................ 85

Sezione 8 Ricalibrazione ..................................87

Sezione 9 Diagnostica ......................................88

Sezione 10 Garanzia, responsabilità e

reclami ................................................................89

11

Page 14

Indice

12

Page 15

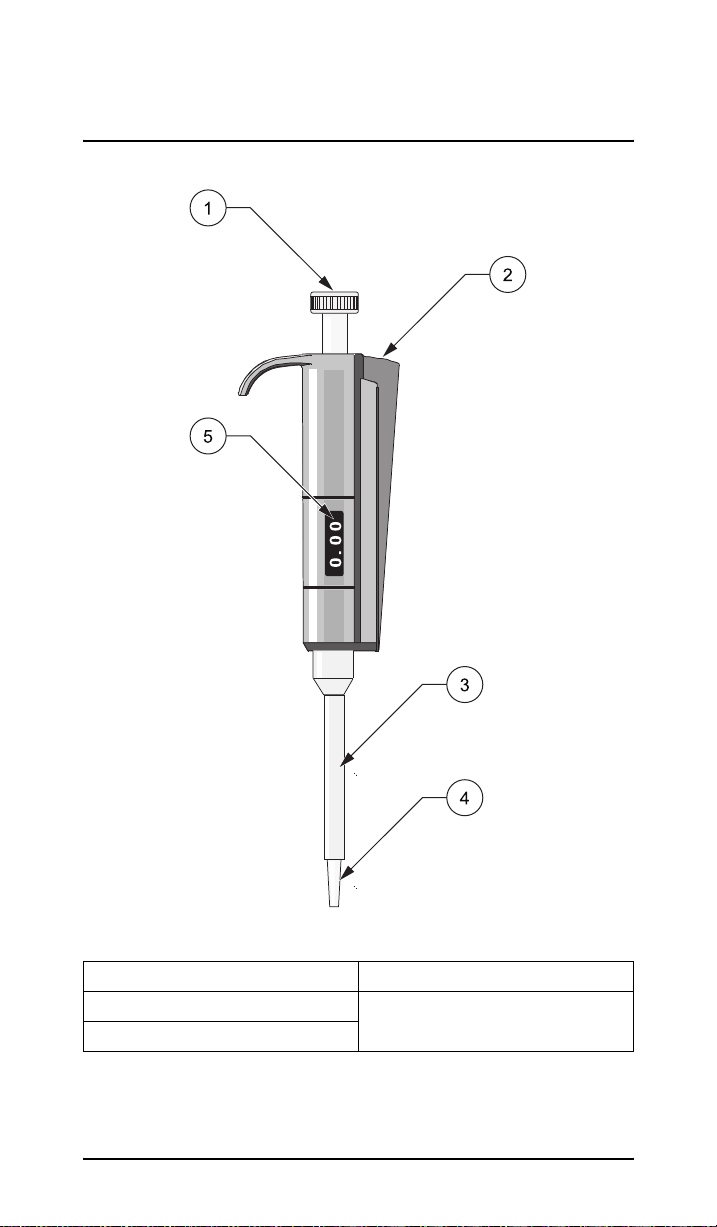

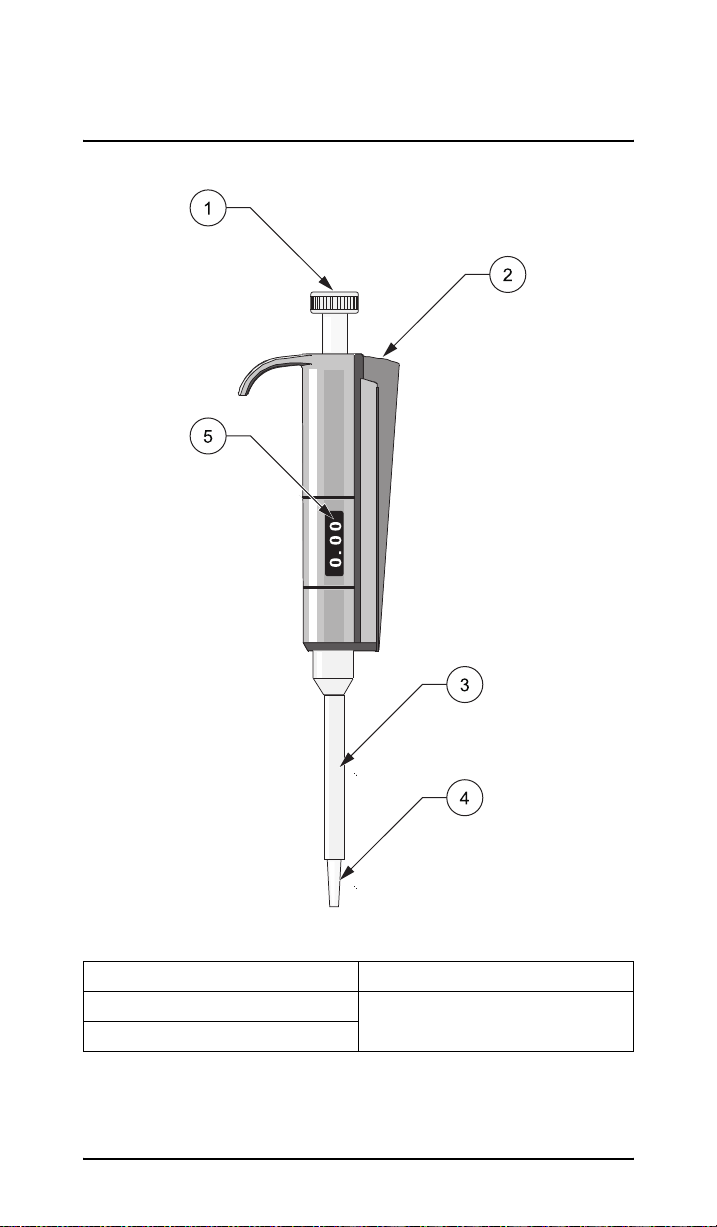

Section 1 Description of the

piston pipette

Figure 1 Description of the piston pipette

1 Push button 4 Cone

2 Ejector button 5 Volume scale

3 Tip ejector

13

Page 16

Description of the piston pipette

The piston pipette is a handy, general-purpose microliter

pipette for transferring exact volumes of liquid. It operates on

the principle of air expulsion, making use of disposable tips.

The volume that is to be pipetted is shown in a clearly visible

display on the pipette handle. All piston pipettes are fitted with

a mechanical tip ejector system.

1.1 Pipette tips

We recommend the use of original HACH pipette tips when

working with the piston pipette. The pipette tips are made of

polypropylene and can be autoclaved at 121 °C/250 °F.

14

Page 17

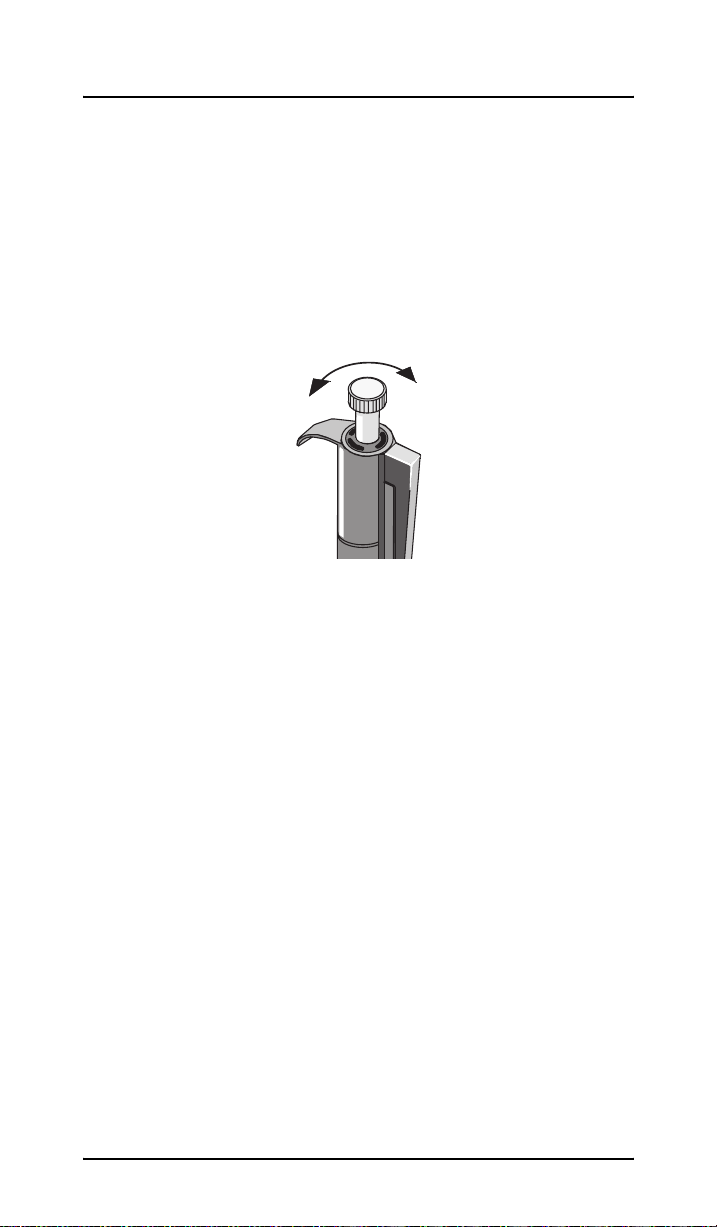

Section 2 Using the pipette

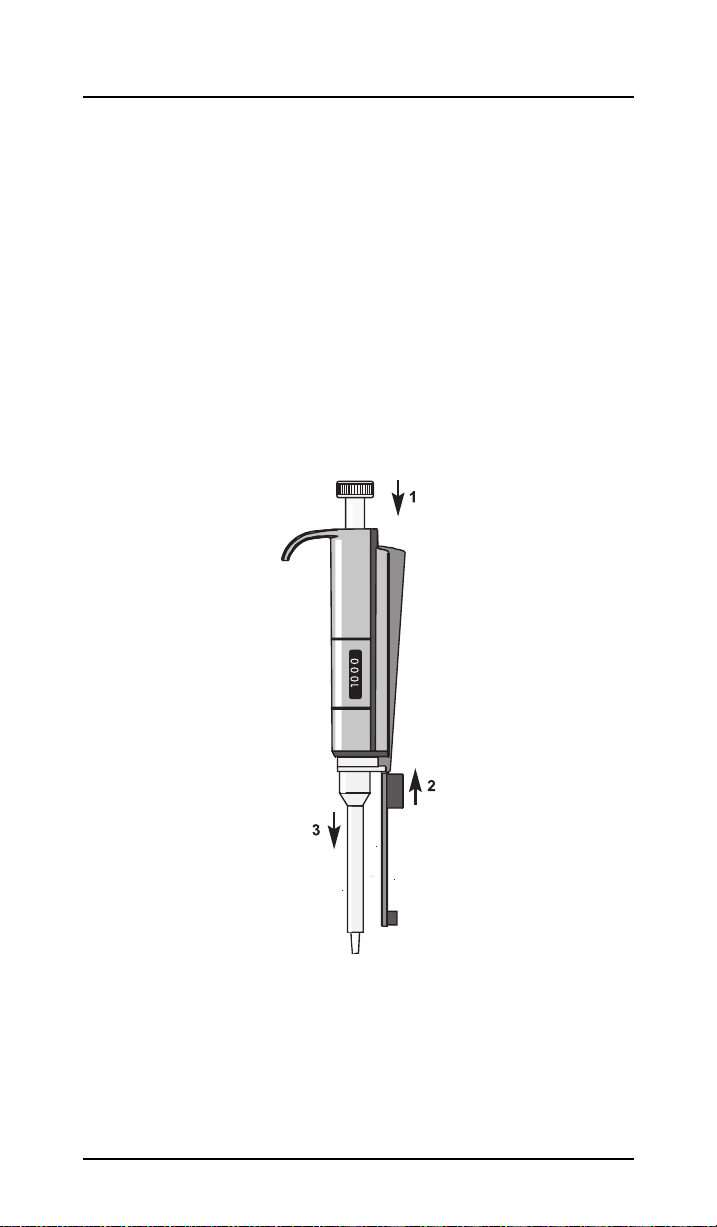

2.1 Setting the volume

(only for variable piston pipettes)

The pipette volume is set with the push button at the end of the

handle. Turn the button anticlockwise to increase the volume

and clockwise to decrease it. Make sure that the volume

setting is correct (clicks into place) and the volume shown in

the display is completely visible.

Figure 2 Setting the volume

Important Note: The given precision and accuracy only apply

for the volume range specified on the pipette. Do not set the

volume to a value outside of this range. Do not use force to

turn the push button to a volume that is outside of the specified

range. This could damage the pipette.

2.2 Tip ejection

Each piston pipette is fitted with a tip ejection system to

prevent possible contamination. Press thumb down on ejector

button and remove tip from tip cone.

15

Page 18

Using the pipette

2.3 Pipetting techniques

The pipette is operated by means of the push button at the

end of the handle.

Maximum accuracy can be achieved by carrying out the

following steps:

1. Move the piston up or down slowly and evenly. (especially

when pipetting highly viscous liquids)

2. Do not allow the push button to spring back into its original

position.

3. Use light pressure to fit a new tip to the cone, turning the

tip slightly as you do so.

4. Make sure that the tip is firmly in position on the tip cone

and there are no foreign bodies between the tip and the

cone.

5. Wet the tips with the liquid by repeatedly filling and

emptying them.

6. Hold the pipette almost vertical (no more than 10° from the

vertical) while liquid is being drawn into the tip.

7. The temperature of the pipette and the tip should match

that of the liquid.

16

Page 19

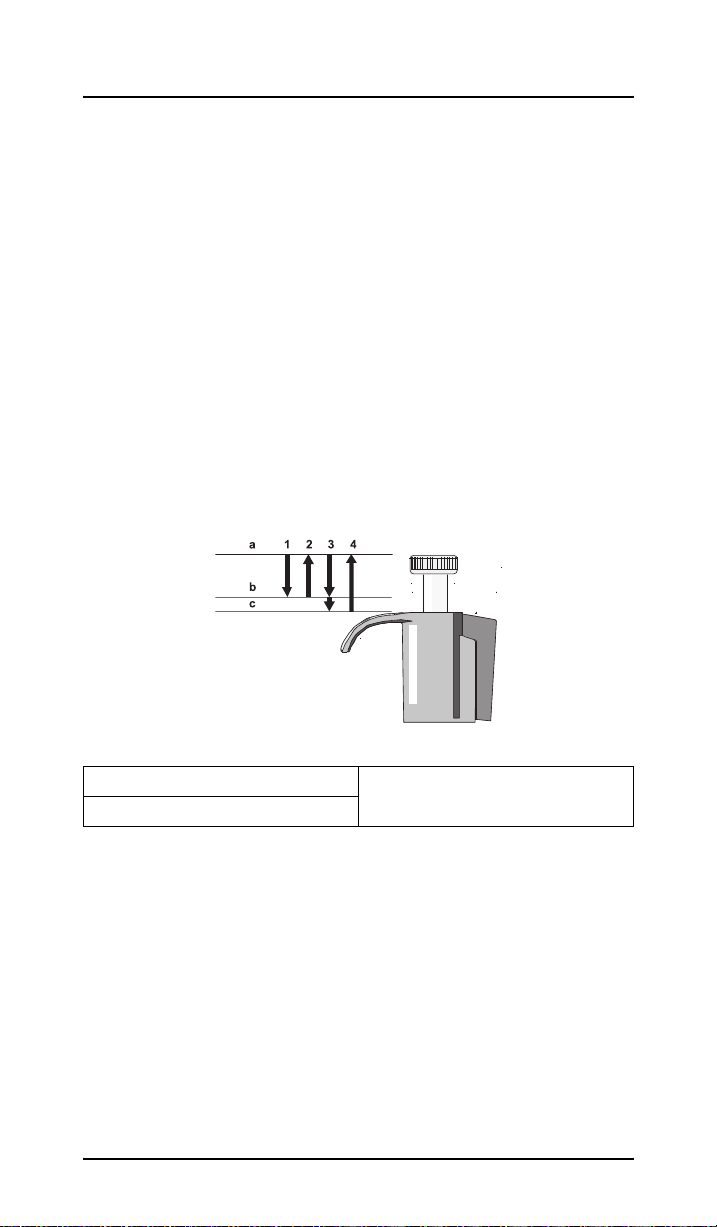

Section 3 Standard technique

1. Press the push button to the first pressure point.

2. Dip the pipette tip under the surface of the liquid (2–3 mm)

and slowly release the push button. Take the tip out of the

liquid and touch it against the inside wall of the vessel to

remove excess liquid.

3. Place the tip against the inside wall of the vessel and

press lightly and evenly on the push button until the first

pressure point is reached. Hold the pipette in this position.

After about one second, press the push button until the

second pressure point is reached. This completely

empties the tip.

4. Allow the push button to return to its rest position.

Figure 3 Standard technique

a Rest position c Second pressure point

b First pressure point

Important Note: After use change pipette tip!

17

Page 20

Section 4 Daily check

Check the pipette daily for dust and external soiling before

starting work or after finishing work. Pay special attention to

the tip cone. Clean the pipette with 70% alcohol. Do not use

any other solvents to clean the pipette.

18

Page 21

Section 5 Maintenance

If the pipette is used each day, maintenance should be carried

out at least twice each year. Maintenance can be carried out

in your laboratory. Carry out the steps described below:

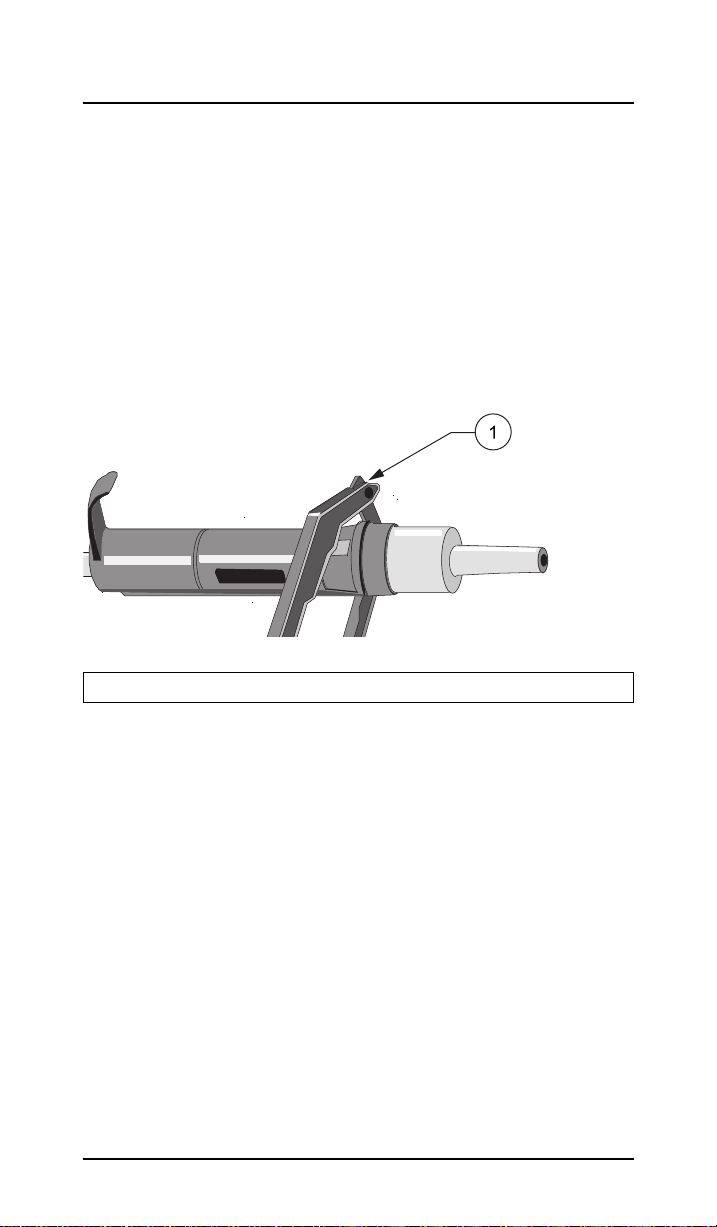

5.1 Opening the pipettes (0.2–1.0 mL)

1. Press the ejector button.

2. Insert the tip of the opening tool into the opening at the

end of the ejector button.

3. Pull out the ejector button and the tip ejector piston.

Figure 4 Opening the pipettes

19

Page 22

Maintenance

4. Remove the tip cone by turning it anticlockwise with the

enclosed tool.

5. Pull out the piston.

6. Remove the O-rings from the tip cone.

7. Clean the piston, the piston spring and the O-rings with a

clean, dry cloth.

8. Check the cylinder for foreign substances. Remember that

the cylinder does not have to be greased.

9. Grease the cleaned parts lightly with the accompanying

grease.

10. Reassemble the pipette.

20

Page 23

Maintenance

5.2 Opening the pipette (1–5 mL)

1. Remove ejector button and tip ejector as described above

(for 0.2–1.0 mL pipettes) section 5.1 on page 19.

2. Remove cover.

3. Remove cone and cylinder with the help of the tool by

pressing the two projections together. While pressing the

projections, push the tool towards the cone.

Figure 5 Opening the pipette

1 Service tool to open the pipette

4. Take apart, clean and grease as described above (for

0.2–1.0 mL pipettes) section 5.1 on page 19.

5. Reassemble in reverse sequence.

21

Page 24

Section 6 Calibration

The pipette is calibrated in the factory with distilled water at

22 °C/72 °F. No recalibration is needed for routine use. The

pipette can, however, be recalibrated for other temperatures

and solutions of different viscosities. An appropriately

sensitive analytical balance, a small beaker and distilled water

are needed to carry out the calibration.

Important Note: If either the handle or the piston is replaced,

the pipette must be recalibrated. If the O-rings or the tip cone

are replaced, the calibration should be checked.

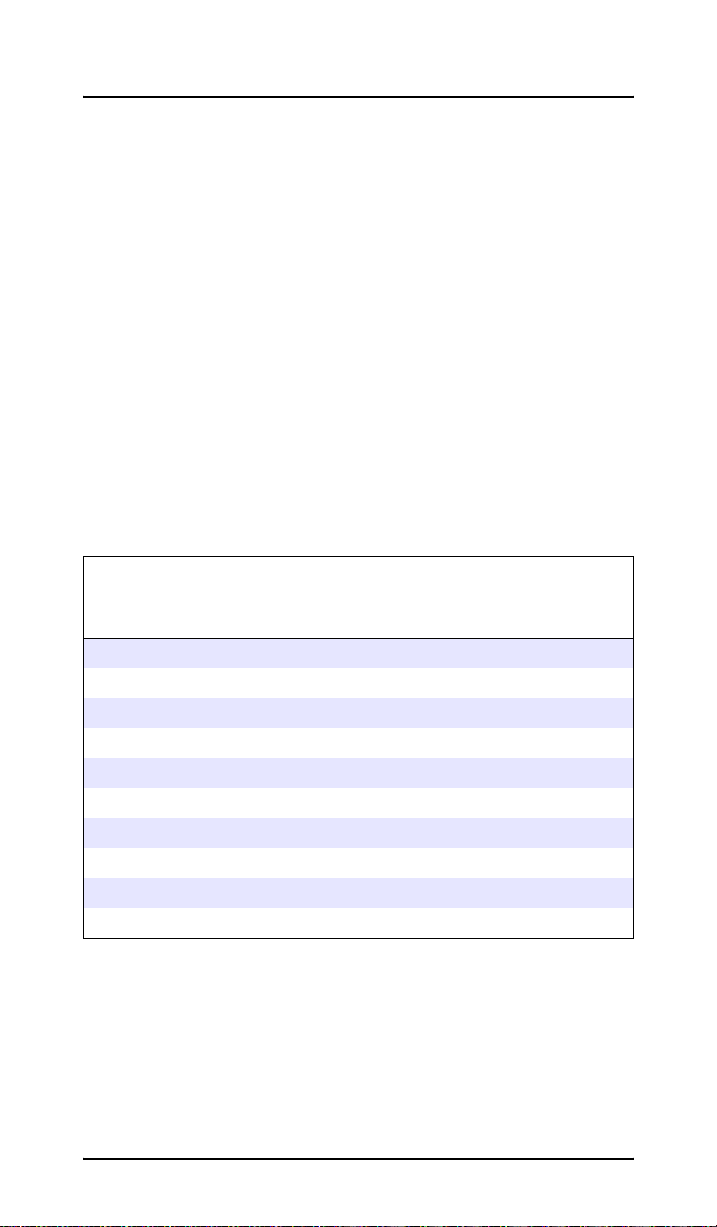

6.1 Checking the calibration

1. Set the pipette volume as follows in Table 1 Checking the

calibration:

Table 1 Checking the calibration

Pipette

(µL)

10 10 9.8–10.2

20 20 19.8–20.2

50 50 49.5–50.5

100 100 99.2–100.8

200 200 198.7–201.3

500 500 497.0–503.0

1000 1000 994.0–1006.0

2000 2000 1990.0–2010.0

200–1000 300 298–302

1000–5000 2000 1990–2010

Volume setting

permissible

weight range

(mg)

22

Page 25

Calibration

2. Use light pressure to place a tip on the tip cone, turning

the tip slightly.

3. Pipette distilled water into previously weighed beaker at

least five times. Determine each weight in mg to the first

decimal place and compare this with the weight shown

above. If the weight is not within this range, recalibrate the

pipette.

23

Page 26

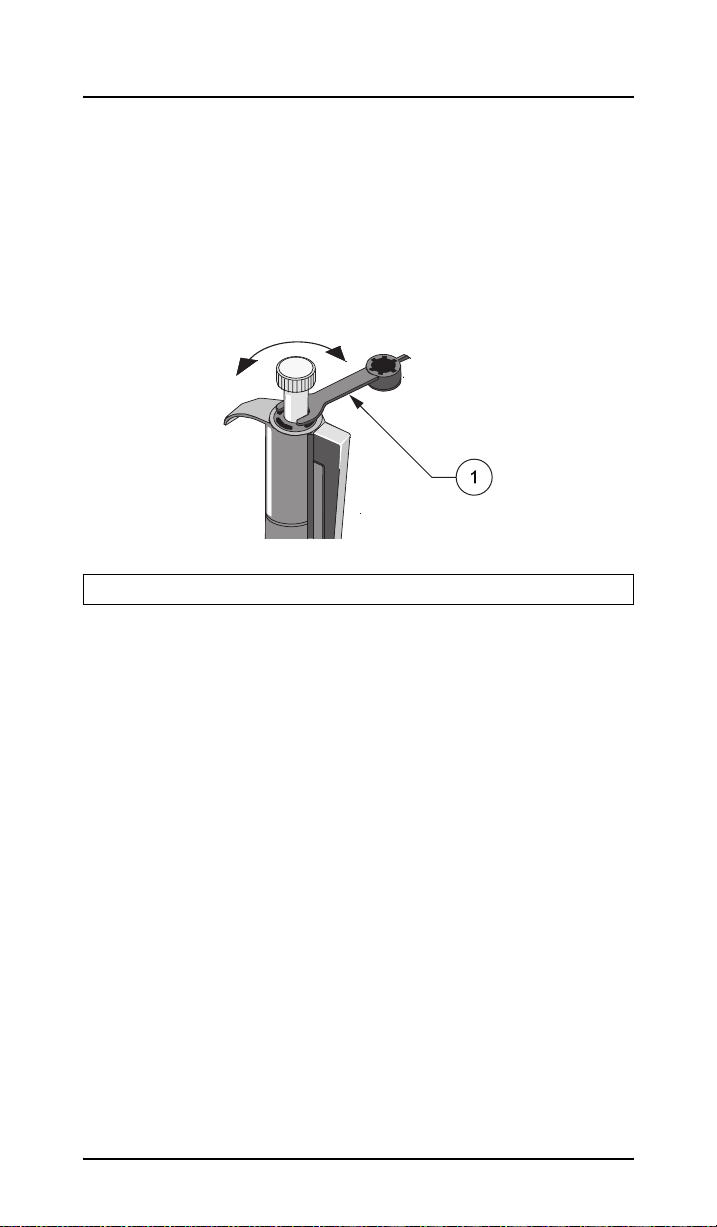

Section 7 Recalibration

The calibration is carried out with the supplied calibration key.

1. Place the calibration key in the holes of the calibration

groove at the top end of the handle.

2. Increase the volume by turning in clockwise direction or

reduce it by turning in anticlockwise direction.

Figure 6 Recalibration

1 Calibration key

3. Afterwards check the volume as described above

Section 6 Calibration on page 22.

Important Note: The pipette can only be calibrated within the

limits of the volume range for which it is meant to be used.

24

Page 27

Section 8 Troubleshooting

The following table is intended to help you to identify and

eliminate errors:

Table 2 Troubleshooting

Error Possible cause Response

Leakage

Inaccurate

pipetting

Tip not attached

properly

Foreign bodies

between cone and

tip

Foreign bodies

between O-ring and

piston

Insufficient grease

on the O-rings and

the piston

Defective O-rings Replace O-rings

Incorrect operation

Tip not firmly

attached

Calibration has

changed, e.g. due to

faulty operation

Fix tip firmly in place

Clean the cone and

attach a new tip

Clean and grease

the O-rings and the

piston in the cylinder.

Use the supplied

grease

Grease adequately

Use pipette as

described in the

manual

Attach tip firmly

Recalibrate

25

Page 28

Section 9 Warranty, liability

and complaints

The manufacturer warrants that the product supplied is free of

material and manufacturing defects and undertakes the

obligation to repair or replace any defective parts at zero cost.

The warranty period for these pipettes is 24 months.

With the exclusion of the further claims, the supplier is liable

for defects including the lack of assured properties as follows:

all those parts that can be demonstrated to have become

unusable or that can only be used with significant limitations

due to a situation present prior to the transfer of risk, in

particular due to incorrect design, poor materials or

inadequate finish will be improved or replaced, at the

supplier's discretion. The identification of such defects must be

notified to the supplier in writing without delay, however at the

latest 7 days after the identification of the fault. If the customer

fails to notify the supplier, the product is considered approved

despite the defect. Further liability for any direct or indirect

damages is not accepted.

If specific maintenance work defined by the supplier is to be

performed within the warranty period by the customer

(maintenance) and these requirements are not met, claims for

damages due to the failure to comply with the requirements

are rendered void.

Any further claims, in particular claims for consequential

damages cannot be made.

Consumables and damage caused by improper handling, poor

installation or incorrect use are excluded from this clause.

26

Page 29

Kapitel 1 Beschreibung der

Kolbenhubpipette

Abbildung 1 Pipettenbeschreibung

1 Kolbenknopf 4 Konus

2 Auswurftaste 5 Volumenanzeige

3 Spitzenabwerfer

27

Page 30

Beschreibung der Kolbenhubpipette

Die Kolbenhubpipette ist eine handliche, allgemein

verwendbare Mikroliterpipette zum Aufnehmen und Dosieren

von exakten Flüssigkeitsvolumina. Sie arbeitet nach dem

Prinzip der Luftverdrängung (Volumenhub) mit aufsetzbaren

Einmalspitzen. Das einstellbare Pipettiervolumen wird in einer

gut sichbaren Digitalanzeige am Pipettengriff dargestellt. Alle

Kolbenhubpipetten sind mit einem mechanischen

Spitzenabwurf-System ausgestattet.

1.1 Pipettenspitzen

Es wird empfohlen, nur Original HACH Pipettenspitzen bei der

Arbeit mit der Kolbenhubpipette einzusetzen. Die

Pipettenspitzen sind aus Polypropylen hergestellt und bei

121 °C autoklavierbar.

28

Page 31

Kapitel 2 Pipettenbedienung

2.1 Volumeneinstellung

(nur für variable Kolbenhubpipetten)

Das Pipettiervolumen wird über den Kolbenknopf am Griffende

eingestellt. Zur Vergrößerung des Volumens drehen Sie den

Kolbenknopf entgegen dem Uhrzeigersinn. Ein geringeres

Volumen stellen Sie durch Drehen des Kolbenknopfes im

Uhrzeigersinn ein. Stellen Sie sicher, dass das eingestellte

Volumen einrastet und die Zahlen der Volumenangabe an der

Digitalanzeige voll sichtbar sind.

Abbildung 2 Volumeneinstellung

Wichtiger Hinweis: Die angegebene Präzision und

Genauigkeit gilt nur für den auf der Pipette angegebenen

Volumenbereich. Stellen Sie keine Volumina außerhalb dieses

Bereiches ein. Drehen Sie die Volumeneinstellung nicht unter

Kraftanwendung über den angegebenen Bereich hinaus. Die

Pipette kann dadurch mechanisch zerstört werden.

2.2 Spitzenauswurf

Jede Kolbenhubpipette ist mit einem Spitzenauswurf-System

ausgestattet, um eine mögliche Kontamination zu verhindern.

Drücken Sie die Auswurftaste mit dem Daumen nach unten

und entfernen Sie die Spitze von dem Pipettenkonus.

29

Page 32

Pipettenbedienung

2.3 Pipettiertechniken

Die Bedienung der Pipette erfolgt über den Kolbenknopf am

Griffende.

Ein Maximum an Genauigkeit wird durch das Einhalten der

nachfolgenden Schritte erreicht:

1. Heben und Senken Sie den Kolbenknopf langsam und in

der gleichen Geschwindigkeit (besonders beim Pipettieren

von hochviskosen Flüssigkeiten).

2. Lassen Sie den Kolbenknopf nicht zurückschnappen.

3. Setzen Sie eine neue Spitze unter leichtem Druck und

einer leichten Drehung auf den Konus der

Kolbenhubpipette.

4. Stellen Sie sicher, dass die Pipettenspitze fest auf dem

Spitzenkonus sitzt und sich keine Fremdkörper zwischen

der Spitze und dem Konus befinden.

5. Durch mehrmaliges Füllen und Leeren der Spitzen mit der

jeweiligen Flüssigkeit die Spitzen benetzen.

6. Halten Sie die Pipette während der Flüssigkeitsaufnahme

nahezu senkrecht (maximal 10° entfernt von der

Senkrechten).

7. Die Temperatur der Pipetten und der Spitzen sollte mit der

Flüssigkeitstemperatur übereinstimmen.

30

Page 33

Kapitel 3 Standard-Technik

1. Drücken Sie den Kolbenknopf bis zum ersten Druckpunkt.

2. Die Pipettenspitze unter die Flüssigkeitsoberfläche

eintauchen (2–3 mm) und den Kolbenknopf langsam

loslassen. Nehmen Sie die Spitze aus der Flüssigkeit und

berühren Sie dabei den Rand des Gefäßes zum

Abstreifen von der überschüssigen Flüssigkeit.

3. Berühren Sie die Gefäßinnenseite mit der Spitze und

pipettieren Sie die Flüssigkeit durch leichtes,

gleichmäßiges Drücken des Kolbenknopfes bis zum

ersten Druckpunkt. Halten Sie die Pipette in dieser

Position. Nach ca. einer Sekunde drücken Sie den

Kolbenknopf bis zum zweiten Druckpunkt. Dadurch wird

die Spitze vollständig entleert.

4. Lassen Sie den Bedienungsknopf bis zur Grundstellung

zurückgehen.

Abbildung 3 Standard-Technik

a Grundstellung c zweiter Druckpunkt

b erster Druckpunkt

Wichtiger Hinweis: Nach Gebrauch Pipettenspitze wechseln!

31

Page 34

Kapitel 4 Pipettieren von

Vollblut

1. Tauchen Sie die Spitze in die Probe und drücken Sie den

Kolbenknopf bis zum ersten Druckpunkt. Stellen Sie

sicher, dass sich die Spitze unter der Oberfläche befindet.

2. Lassen Sie den Kolbenknopf langsam los, bis er sich in

der Ausgangsposition befindet. Die Spitze ist jetzt mit der

Probe gefüllt. Nehmen Sie die Spitze nicht aus der Probe.

3. Drücken Sie den Kolbenknopf bis zum ersten Druckpunkt

und lassen Sie ihn langsam wieder los. Wiederholen Sie

diesen Vorgang bis die Spitzenwand frei von Blut ist.

4. Drücken Sie den Kolbenknopf bis zum zweiten

Druckpunkt und entleeren Sie die Spitze vollständig.

Abbildung 4 Pipettieren von Vollblut

a Grundstellung c zweiter Druckpunkt

b erster Druckpunkt

32

Page 35

Kapitel 5 Tägliche Prüfung

Prüfen Sie die Pipette täglich vor Arbeitsbeginn oder nach

Arbeitsende auf Staub und äußere Verschmutzungen. Achten

Sie dabei besonders auf den Spitzenkonus. Reinigen Sie die

Pipette mit 70%-igem Alkohol. Setzten Sie zum Reinigen der

Pipette keine anderen Lösungsmittel ein.

33

Page 36

Kapitel 6 Wartungsarbeiten

Wird die Pipette täglich benutzt, ist mindestens zweimal pro

Jahr eine Wartung erforderlich. Die Wartung kann von Ihnen

im Labor durchgeführt werden oder senden Sie die Pipette an

HACH LANGE. Führen Sie die im folgenden beschriebenen

Arbeiten durch:

6.1 Öffnen der Pipetten (0,2–1,0 mL)

1. Drücken Sie die Auswurftaste nach unten.

2. Setzen Sie die Spitze des Öffnungs-Werkzeuges in die

Öffnung am Ende der Auswurftaste.

3. Ziehen Sie die Auswurftaste und den

Spitzenauswurfkolben ab.

34

Abbildung 5 Öffnen der Pipetten

Page 37

Wartungsarbeiten

4. Entfernen Sie den Spitzenkonus durch Drehen entgegen

dem Uhrzeigersinn mit dem beigefügten Werkzeug.

5. Ziehen Sie den Kolben heraus.

6. Entfernen Sie die O-Ringe von dem Spitzenkonus.

7. Reinigen Sie den Kolben, die Kolbenfeder und die

O-Ringe mit einem trockenen, sauberen Tuch.

8. Überprüfen Sie den Zylinder auf Fremdstoffe. Beachten

Sie, dass der Zylinder nicht gefettet werden muss.

9. Fetten Sie die gereinigten Teile leicht mit dem

beiliegenden Fett.

10. Setzen Sie die Teile wieder zusammen.

35

Page 38

Wartungsarbeiten

6.2 Öffnen der Pipette (1–5 mL)

1. Auswurftaste und Spitzenauswerfer wie für Pipette

0,2–1,0 mL Kapitel 6.1 auf Seite 34 beschrieben

entfernen.

2. Abdeckung entfernen.

3. Konus mit Zylinder durch Zusammendrucken der zwei

Haltenasen mit Hilfe des Werkzeuges entfernen. Beim

Zusammendrucken gleichzeitig das Werkzeug in Richtung

Konus schieben.

Abbildung 6 Öffnen der Pipetten

1 Werkzeug zum Öffnen der Pipette

4. Auseinandernehmen, Reinigen und Fetten wie für

Pipetten 0,2–1,0 mL Kapitel 6.1 auf Seite 34 beschrieben.

5. Zusammenbau in umgekehrter Reihenfolge.

36

Page 39

Kapitel 7 Kalibrierung

Die Pipette wurde werkseitig mit destilliertem Wasser bei

22 °C kalibriert. Für den Routinegebrauch ist keine

Rekalibrierung erforderlich. Die Pipette ist jedoch mit einer

Kalibriermöglichkeit zur Einstellung auf andere Temperaturen

und Lösungen verschiedener Viskositäten ausgestattet. Zur

Durchführung der Kalibrierung sind eine Analysenwaage mit

geeigneter Empfindlichkeit, ein kleines Becherglas und

destilliertes Wasser erforderlich.

Wichtiger Hinweis: Wurden der Handgriff oder der Kolben

gewechselt, muss die Pipette rekalibriert werden. Bei dem

Wechsel der O-Ringe oder des Spitzenkonus sollte die

Kalibrierung überprüft werden.

7.1 Prüfen der Kalibrierung

1. Stellen Sie das Volumen der Pipette wie in Tabelle 1

Pipettenkalibrierung beschrieben ein:

Tabelle 1 Pipettenkalibrierung

Pipette

(µL)

10 10 9,8–10,2

20 20 19,8–20,2

50 50 49,5–50,5

100 100 99,2–100,8

200 200 198,7–201,3

500 500 497,0–503,0

1000 1000 994,0–1006,0

2000 2000 1990,0–2010,0

200–1000 300 298–302

1000–5000 2000 1990–2010

Vol umen-

einstellung

erlaubter

Gewichtsbereich

(mg)

37

Page 40

Kalibrierung

2. Setzen Sie eine Spitze mit leichtem Druck und leichter

Drehung auf den Spitzenkonus.

3. Pipettieren Sie destilliertes Wasser in das vorher

gewogene Becherglas wenigstens fünf mal. Ermittlen Sie

jedes Gewicht mit einer Stelle nach dem Komma in mg

und vergleichen Sie dieses mit dem oben angegebenen

Wert. Liegt ein Wert nicht innerhalb des Bereiches, sollte

die Pipette rekalibriert werden.

38

Page 41

Kapitel 8 Rekalibrierung

Die Kalibrierung wird mit dem mitgelieferten Kalibrierschlüssel

durchgeführt.

1. Setzen Sie den Kalibrierschlüssel in die Löcher der

Kalibrierungsnute am oberen Ende des Handgriffes.

2. Erhöhen Sie das Volumen durch Drehen im Uhrzeigersinn

oder verringern Sie es durch Drehen entgegen dem

Uhrzeigersinn.

Abbildung 7 Rekalibrierung

1 Kalibrierschlüssel

3. Überprüfen Sie nach dem Einstellen das Volumen wie in

Kapitel 7 Kalibrierung auf Seite 37 beschrieben.

Wichtiger Hinweis: Die Pipette kann nur in dem für sie

vorgesehenen Volumenbereich kalibriert werden.

39

Page 42

Kapitel 9 Fehlersuche

Die folgende Tabelle gibt Ihnen Hinweise zu möglichen

Fehlern und deren Abhilfe

Tabelle 2 Fehlerbeschreibung

Fehler Möglicher Grund Lösung

:

Undichtigkeit

Ungenaues

pipettieren

Spitze nicht fest

aufgesetzt

Fremdkörper

zwischen Konus und

Spitze

Fremdkörper

zwischen O-Ring

und Kolben

Ungenügende

Fettung an den

O-Ringen und dem

Kolben

O-Ringe defekt O-Ringe wechseln

Falsche Bedienung

Spitze nicht fest

aufgesetzt

Kalibrierung hat sich

geändert z.B. durch

falsche Bedienung

Spitze fest aufsetzen

Reinigen des Konus

und aufsetzen einer

neuen Spitze

Reinigen und Fetten

der O-Ringe und des

Kolbens im Zylinder.

Verwenden Sie das

mitgelieferte Fett

Ausreichend fetten

Der Anleitung

gemäß arbeiten

Spitze fest aufsetzen

Rekalibrieren

40

Page 43

Kapitel 10 Gewährleistung,

Haftung und

Beanstandungen

Der Hersteller gewährleistet, dass das gelieferte Produkt frei

von Material- und Verarbeitungsfehlern ist und verpflichtet

sich, etwaige fehlerhafte Teile kostenlos instandzusetzen oder

auszutauschen.

Die Verjährungsfrist für Mängelansprüche beträgt bei diesen

Pipetten 24 Monate.

Für Mängel, zu denen auch das Fehlen zugesicherter

Eigenschaften zählt, haftet der Lieferer unter Ausschluss

weiterer Ansprüche wie folgt: Alle diejenigen Teile sind nach

Wahl des Lieferers unentgeltlich auszubessern oder neu zu

liefern, die innerhalb der Verjährungsfrist vom Tage des

Gefahrenüberganges an gerechnet, nachweisbar infolge eines

vor dem Gefahrenübergang liegenden Umstandes,

insbesondere wegen fehlerhafter Bauart, schlechter Baustoffe

oder mangelhafter Ausführung unbrauchbar werden oder

deren Brauchbarkeit erheblich beeinträchtigt wurde. Die

Feststellung solcher Mängel muss dem Lieferer unverzüglich,

jedoch spätestens 7 Tage nach Feststellung des Fehlers,

schriftlich gemeldet werden. Unterlässt der Kunde diese

Anzeige, gilt die Leistung trotz Mangels als genehmigt. Eine

darüber hinausgehende Haftung für irgendwelchen

unmittelbaren oder mittelbaren Schaden besteht nicht.

Sind vom Lieferer vorgegebene spezifische Wartungsarbeiten

innerhalb der Verjährungsfrist durch den Kunden selbst

durchzuführen (Wartung) und werden diese Vorgaben nicht

ausgeführt, so erlischt der Anspruch für die Schäden, die

durch die Nichtbeachtung der Vorgaben entstanden sind.

Weitergehende Ansprüche, insbesondere auf Ersatz von

Folgeschäden, können nicht geltend gemacht werden.

Verschleißteile und Beschädigungen, die durch

unsachgemäße Handhabung, unsichere Montage oder nicht

bestimmungsgerechten Einsatz entstehen, sind von dieser

Regelung ausgeschlossen.

41

Page 44

Gewährleistung, Haftung und Beanstandungen

42

Page 45

Section 1 Description de la

pipette à piston

Figure 1 Description de la pipette à piston

1 Bouton du piston 4 Cône

2 Bouton d'éjection 5 Indication du volume

3 Ejecteur de la pointe

43

Page 46

Description de la pipette à piston

La pipette à piston est une pipette à microlitre manuelle, à

usage multiple, destinée au prélèvement et au dosage de

volumes exacts de liquides. Elle fonctionne suivant le principe

du pistonnement à l'aide de pointes démontables à usage

unique. Le volume de pipetage réglable apparaît sur un

affichage bien visible, sur la poignée de la pipette. Toutes les

pipettes à piston sont équipées d'un système mécanique

d'éjection de la pointe.

1.1 Pointes de pipette

Nous conseillons de n'utiliser que des pointes de pipette

HACH d'origine sur la pipette à piston. Elles sont fabriquées

en polypropylène et résistent à 121 °C/250 °F en autoclave.

44

Page 47

Section 2 Utilisation de la

pipette

2.1 Réglage du volume

(uniquement pour les pipettes à piston variables)

Le volume de pipetage se règle par l'intermédiaire du bouton

du piston, sur l'extrémité de la poignée. Pour augmenter le

volume, tournez dans le sens anti-horlogique. A l'inverse, pour

diminuer le volume, tournez dans le sens horlogique.

Assurez-vous que le volume choisi est bien mémorisé et que

les chiffres qui l'indiquent apparaissent bien sur l'affichage

numérique..

Figure 2 Réglage du volume

Remarque importante : Pour que le dosage soit précis et

exact, il faut choisir un volume dans la gamme de volumes

propre à la pipette en question. Ne sélectionnez pas de

volume qui se situe en dehors de cette fourchette de valeurs.

Ne forcez pas le réglage du volume au-delà de la gamme de

volumes donnée ; vous risqueriez d'endommager le

mécanisme de la pipette.

2.2 Ejection de la pointe

Toute pipette à piston est pourvue d'un système d'éjection de

la pointe destiné à prévenir une éventuelle contamination.

Avec le pouce, enfoncez le bouton d'éjection et retirez la

pointe du cône de la pipette.

45

Page 48

Utilisation de la pipette

2.3 Techniques de pipetage

Pour contrôler la pipette, utilisez le bouton du piston situé à

l'extrémité de la poignée.

Pour un maximum de précision, respectez les consignes

suivantes :

1. Levez et abaissez le bouton du piston lentement et à

vitesse régulière (surtout si vous pipetez des liquides très

visqueux).

2. Ne laissez pas "sauter" le bouton du piston.

3. Placez une pointe neuve en appuyant et en tournant

légèrement le cône de la pipette à piston.

4. Assurez-vous que la pointe est solidement fixée dans le

cône et qu'il n'y a aucun corps étranger entre eux.

5. Amorcez les pointes en les remplissant et les vidant

plusieurs fois de suite avec le liquide concerné.

6. Durant le prélèvement, tenez la pipette le plus

verticalement possible (pas plus de 10° par rapport à la

verticale).

7. La pipette et la pointe doivent être à la même température

que le liquide.

46

Page 49

Section 3 Technique standard

1. Enfoncez le bouton jusqu'au premier point de poussée.

2. Plongez la pointe de la pipette sous la surface du liquide

(2–3 mm) et relâchez lentement le bouton du piston.

Retirez la pointe du liquide et effleurez le bord du récipient

pour ôter l'excédent le liquide.

3. Posez la pointe contre la paroi interne du récipient et

pipetez le liquide en appuyant légèrement et

régulièrement sur le bouton du piston jusqu'au premier

point de poussée. Maintenez la pipette dans cette

position. Après une seconde environ, enfoncez le bouton

jusqu'au second point de poussée pour vider

complètement la pointe.

4. Laissez revenir le bouton de commande en position

initiale.

Figure 3 Technique standard

a Position initiale c Second point de poussée

b Premier point de poussée

Remarque importante : Après usage, remplacez la pointe!

47

Page 50

Section 4 Pipetage de sang

complet

1. Plongez la pointe dans le réactif et enfoncez le bouton du

piston jusqu'au premier point de poussée. Assurez-vous

que la pointe de la pointe se trouve bien sous la surface.

2. Laissez remonter lentement le bouton du piston jusqu'à sa

position initiale. La pointe est à présent remplie de réactif.

Ne la retirez pas encore du réactif.

3. Enfoncez le bouton du piston jusqu'au premier point de

poussée et relâchez-le à nouveau lentement. Répétez

cette manoeuvre jusqu'à ce qu'il n'y ait plus de sang sur la

paroi de la pointe.

4. Enfoncez le bouton du piston jusqu'au second point de

poussée et videz complètement la pointe.

Figure 4 Pipetage de sang complet

a Position initiale c Second point de poussée

b Premier point de poussée

48

Page 51

Section 5 Contrôle quotidien

Contrôlez la pipette chaque jour avant le début du travail ou en

fin de journée. Vérifiez qu'elle ne porte ni poussières, ni

salissures extérieures. Faites tout particulièrement attention

au cône d'adaptation de la pointe. Nettoyez la pipette avec de

l'alcool à 70%. N'utilisez pas d'autre solvant.

49

Page 52

Section 6 Entretien

Si la pipette sert quotidiennement, elle doit être entretenue au

moins deux fois par an. Vous pouvez l'entretenir vousmême,

au laboratoire. Procédez par étapes, comme suit :

6.1 Pour ouvrir la pipette (0,2–1,0 mL)

1. Enfoncez le bouton d'éjection.

2. Introduisez la pointe de l'outil d'ouverture dans l'orifice

situé à l'extrémité du bouton d'éjection.

3. Otez le bouton et le piston d'éjection de la pointe.

50

Figure 5 Pour ouvrir la pipette

Page 53

Entretien

4. Retirez le cône d'adaptation de la pointe en le faisant

tourner dans le sens anti-horlogique, à l'aide de l'outil

fourni.

5. Retirez le piston.

6. Otez les joints toriques du cône d'adaptation de la pointe.

7. Nettoyez le piston, les ressorts de piston et les joints

toriques à l'aide d'un chiffon sec et propre.

8. Vérifiez qu'il n'y a pas de substance étrangère dans le

cylindre. Attention! le cylindre ne doit pas être graissé.

9. Graissez les parties nettoyées avec la graisse fournie.

10. Remontez les différentes pièces.

51

Page 54

Entretien

6.2 Pour ouvrir la pipette (1–5 mL)

1. Retirez le bouton d'éjection et l'éjecteur de la pointe

comme décrit pour la pipette 0,2–1,0 mL Section 6.1 a la

page 50.

2. Otez le couvercle.

3. Retirez le cône et le cylindre en pressant l'un vers l'autre

les deux ergots de butée à l'aide de l'outil. Tout en

pressant, faites glisser l'outil en direction du cône.

Figure 6 Pour ouvrir la pipette

1 L’outil pour ouvrir la pipette

4. Démontez, nettoyez et graissez comme expliqué pour la

pipette 0,2–1,0 mL Section 6.1 a la page 50.

5. Remontez en suivant les étapes dans l'ordre inverse.

52

Page 55

Section 7 Etalonnage

La pipette a été étalonnée en usine avec de l'eau distillée à

22 °C/72 °F. Un usage courant ne nécessite pas de

recalibrage. La pipette dispose toutefois d'une possibilité

d'adaptation à d'autres températures et viscosités. Pour

étalonner la pipette, il faut une balance de laboratoire de

sensibilité adéquate, un petit bécher et de l'eau distillée.

Remarque importante : En cas de remplacement de la

poignée ou du piston, il faut recalibrer la pipette. En cas de

remplacement des joints toriques ou du cône, il faut vérifier

l'étalonnage.

7.1 Vérification de l'étalonnage

1. Réglez le volume de la pipette comme expliqué

ci-dessous Tableau 1 Vérification de l'étalonnage :

Tableau 1 Vérification de l'étalonnage

Pipette

(µL)

10 10 9,8–10,2

20 20 19,8–20,2

50 50 49,5–50,5

100 100 99,2–100,8

200 200 198,7–201,3

500 500 497,0–503,0

1000 1000 994,0–1006,0

2000 2000 1990,0–2010,0

200–1000 300 298–302

1000–5000 2000 1990–2010

Réglage

du volume

Gamme

de masse autorisée

(mg)

53

Page 56

Etalonnage

2. Placez une pointe sur le cône en appuyant et en tournant

légèrement.

3. Pipetez de l'eau distillée au moins cinq fois dans le

bécher préalablement pesé. Notez chaque masse en mg,

en prenant une décimale, et comparez avec la valeur

précitée. Si une des valeurs se situe en dehors de la

fourchette de valeurs, la pipette doit être recalibrée.

54

Page 57

Section 8 Recalibrage

Pour l'étalonnage, utilisez la clef d'étalonnage fournie.

1. Introduisez la clef d'étalonnage dans les orifices des

rainures d'étalonnage situés à l'extrémité supérieure de la

poignée.

2. Augmentez le volume en tournant dans le sens horlogique

ou diminuez-le en tournant dans l'autre sens..

Figure 7 Recalibrage

1 Clef d'étalonnage

3. Vérifiez le réglage du volume de la manière expliquée

précédemment. Section 7 Etalonnage a la page 53

Remarque importante : La pipette ne peut être étalonnée

que dans la gamme de volumes qui lui est propre.

55

Page 58

Section 9 Recherche de

problèmes

Le tableau qui suit vous donne des indications sur les

problèmes possibles et la manière de les résoudre :

Tableau 2 Description de problèmes

Problème Cause possible Solution

Fixez la pointe

correctement

Nettoyez le cône et

placez une nouvelle

pointe

Nettoyez et graissez

les joints toriques et

le piston dans le

cylindre. Employez

la graisse fournie

Graissez

suffisamment

Remplacez les joints

toriques

Suivez le mode

d'emploi

Fixez la pointe

correctement

Recalibrez

Fuite

Pipetage incorrect

Pointe mal fixée

Corps étranger entre

le cône et la pointe

Corps étranger entre

le joint torique et le

piston

Graissage insuffisant

des joints toriques et

du piston

Joints toriques

défectueux

Mauvaise

manoeuvre

Pointe mal fixée

L'étalonnage s'est

modifié à cause, par

exemple, d'une

mauvaise

manoeuvre

56

Page 59

Section 10 Garantie,

responsabilité et

réclamations

Votre fabricant garantit que le produit livré est exempt de vices

de matériaux et d’usinage et s’engage à réparer ou à

remplacer gratuitement les éventuelles pièces erronées.

Le délai de prescription pour les réclamations concernant les

pipettes achetés est de 24 mois.

Le fournisseur est responsable des vices, comprenant

également l’absence de propriétés garanties, à l’exclusion de

toute autre demande, de la manière suivante : Le fournisseur

choisit de réparer gratuitement ou de remplacer toutes les

pièces qui, pendant la garantie à compter du jour du transfert

des risques, sont indubitablement inutilisables ou dont l’utilité

est nettement compromise à la suite d’un événement situé

avant le transfert des risques, notamment en raison de vices

de construction, de matériaux ou de finition. Le client est tenu

de notifier immédiatement par écrit au fournisseur la

constatation de tels vices, toutefois sept jours au plus tard

après la constatation du défaut. Dans le cas contraire, la

prestation est considérée comme acceptée en dépit du vice

constaté. Il n’existe pas de responsabilité supplémentaire pour

tout dommage direct ou indirect.

Si, pendant la garantie, conformément aux consignes

prescrites par le fournisseur, certains travaux de maintenance

spécifiques à la pipette sont à effectuer par le client

(maintenance) et que ces travaux ne sont pas effectués, le

client perdra tout droit à réparation des dommages dus au

non-respect de ces prescriptions.

Il est impossible de faire valoir des droits supplémentaires,

notamment des droits à réparation des dommages

consécutifs.

Les pièces d’usure et les dommages causés par une

manipulation, un montage ou une application non conformes,

sont exclus de cette clause.

57

Page 60

Garantie, responsabilité et réclamations

58

Page 61

Sección 1 Descripción de la

pipeta de émbolo

Figura 1 Descripción de la pipeta de émbolo

1 Disco de empuje 4 Cono

2 Pulsador de expulsión 5 Indicación del volumen

3 Expulsor de la punta

59

Page 62

Descripción de la pipeta de émbolo

La pipeta de émbolo es una pipeta de microlitro fácil de

manejar, de uso general, destinada a la toma y dosificación de

volúmenes exactos de líquido. Funciona según el principio de

la expulsión de aire y utiliza puntas desechables. El volumen

que se ha de pipetear aparece en un display bien visible, en el

mango de la pipeta. Todas las pipetas de émbolo están

equipadas con un sistema mecánico de expulsión de la punta.

1.1 Puntas de pipeta

Recomendamos utilizar únicamente puntas de pipeta HACH

originales al trabajar con la pipeta de émbolo. Las puntas de

pipeta son de polipropileno y pueden ser tratadas en

autoclave a 121 °C/250 °F.

60

Page 63

Sección 2 Utilización de la

pipeta

2.1 Ajuste del volumen

(solamente para las pipetas de émbolo variables)

El volumen a pipetear se fija con el disco de empuje situado

en el extremo del mango. Para aumentar el volumen, gire el

disco en sentido antihorario y, para reducirlo, gírelo en sentido

horario. Cerciórese de que el volumen seleccionado es

correcto (queda fijado en su sitio con un clic) y de que los

números que lo indican se ven bien en el display.

Figura 2 Ajuste del volumen

Nota importante: La precisión y exactitud especificadas son

únicamente válidas para el rango de volumen especificado en

la pipeta. No seleccionar un volumen que se encuentre fuera

de este rango. No girar con fuerza el disco de empuje para

fijar un volumen que se encuentra fuera del rango

especificado, ya que se podría estropear el mecanismo de la

pipeta.

2.2 Expulsión de la punta

Todas las pipetas de émbolo están equipadas con un sistema

de expulsión de la punta para impedir una posible

contaminación. Presione el pulsador de expulsión con el dedo

pulgar y retire la punta del cono.

61

Page 64

Utilización de la pipeta

2.3 Técnicas de pipeteado

Para manejar la pipeta utilice el disco de empuje que tiene en

el extremo del mango.

Para obtener la máxima precisión siga las siguientes

recomendaciones:

1. Suba y baje el disco de empuje lentamente y a una

velocidad uniforme (sobre todo al pipetear líquidos muy

viscosos).

2. No deje que el disco de empuje "salte" y vuelva a su

posición inicial.

3. Para colocar una punta nueva en el cono, presione

ligeramente y gire un poco la punta.

4. Cerciórese de que la punta está firmemente colocada en

el cono y de que no existen cuerpos extraños entre

ambos.

5. Humedezca las puntas llenándolas y vaciándolas varias

veces seguidas con el líquido en cuestión.

6. Mantenga la pipeta en posición casi vertical (no más de

10° respecto de la vertical) mientras el líquido está

entrando en la punta.

7. La temperatura de la pipeta y de la punta debe ser igual a

la del líquido.

62

Page 65

Sección 3 Técnica estándar

1. Presione el disco de empuje hasta el primer punto de

presión.

2. Introduzca la punta de la pipeta en el líquido (a una

profundidad de 2 ó 3 mm) y suelte lentamente el disco de

empuje. Saque la punta del líquido y toque con ella la

pared interior del recipiente para eliminar el exceso de

líquido.

3. Ponga la punta contra la pared interior del recipiente y

presione uniforme y ligeramente el disco de empuje hasta

alcanzar el primer punto de presión. Mantenga la pipeta

en esta posición. Al cabo de aprox. un segundo, presione

el disco de empuje hasta el segundo punto de presión; así

se habrá vaciado totalmente la punta.

4. Deje que el disco de empuje vuelva a su posición inicial.

Figura 3 Técnica estándar

a Posición inicial c Segundo punto de presión

b Primer punto de presión

Nota importante: ¡Cambiar la punta después del uso!

63

Page 66

Sección 4 Pipeteado de

sangre completa

1. Introduzca la punta en la muestra y presione el disco de

empuje hasta el primer punto de presión. Cerciórese de

que la punta está debajo de la superficie.

2. Suelte lentamente el disco de empuje hasta que se

encuentre en la posición inicial. La punta estará entonces

llena de muestra; no la saque de la muestra.

3. Presione el disco de empuje hasta el primer punto de

presión y, lentamente, vuelva a soltarlo. Repita esta

operación hasta que no quede sangre en la pared de la

punta.

4. Presione el disco de empuje hasta el segundo punto de

presión y vacíe totalmente la punta.

Figura 4 Pipeteado de sangre completa

a Posición inicial c Segundo punto de presión

b Primer punto de presión

64

Page 67

Sección 5 Control diario

Compruebe la pipeta cada día, antes de empezar a trabajar o

después de finalizado el trabajo, para verificar la posible

presencia de polvo y suciedad exterior. Preste especial

atención al cono de la punta. Limpie la pipeta con alcohol al

70%. No utilice ningún otro solvente.

65

Page 68

Sección 6 Mantenimiento

Si se utiliza la pipeta todos los días, el mantenimiento deberá

realizarse por lo menos dos veces al año; lo puede llevar a

cabo Usted mismo, en el laboratorio. Proceda de la manera

que se describe a continuación:

6.1 Abrir las pipetas (0,2–1,0 mL)

1. Presione el pulsador de expulsión.

2. Introduzca la punta de la herramienta de apertura en el

orificio situado en el extremo del pulsador de expulsión.

3. Saque el pulsador de expulsión y el émbolo de expulsión

de la punta.

66

Figura 5 Cómo abrir las pipetas

Page 69

Mantenimiento

4. Retire el cono de la punta girándolo en sentido antihorario

con la herramienta suministrada.

5. Saque el émbolo.

6. Retire las juntas tóricas del cono de la punta.

7. Limpie el émbolo, el muelle del émbolo y las juntas tóricas

con un paño seco y limpio.

8. Compruebe que no existen sustancias extrañas en el

cilindro. Tenga en cuenta que no hay que engrasar el

cilindro.

9. Engrase las partes limpias ligeramente con la grasa

suministrada.

10. Vuelva a ensamblar la pipeta.

67

Page 70

Mantenimiento

6.2 Abrir la pipeta (1–5 mL)

1. Retire el pulsador de expulsión y el expulsor de la punta

según lo descrito para las pipetas de 0,2–1,0 ml en la

Sección 6.1 en la página 66.

2. Retire la cubierta.

3. Retire el cono y el cilindro utilizando la herramienta,

apretando las dos guías. Al tiempo que presiona las

guías, deslice la herramienta hacia el cono.

Figura 6 Cómo abrir la pipeta

1 Herramienta para abrir la pipeta

4. Proceda a desmontar, limpiar y engrasar según lo descrito

para las pipetas de 0,2–1,0 ml en la Sección 6.1 en la

página 66.

5. Reensamblar en el orden inverso.

68

Page 71

Sección 7 Calibración

La pipeta se ha calibrado en fábrica con agua destilada a

22 °C/72 °F. Para el uso de rutina no se requiere recalibración.

No obstante, existe la posibilidad de recalibrar la pipeta para

otras temperaturas y soluciones de diferentes viscosidades.

Para realizar la calibración se necesitan una balanza analítica

con una sensibilidad adecuada, un vaso pequeño y agua

destilada.

Nota importante: En el caso de que se cambien el mango o

el émbolo, se deberá recalibrar la pipeta. Si se cambian las

juntas tóricas o el cono, se deberá verificar la calibración.

7.1 Comprobación de la calibración

1. Prefije el volumen de la pipeta según lo indicado en la

Tabla 1 Comprobación de la calibración:

Tabla 1 Comprobación de la calibración

Pipeta

(µL)

10 10 9,8–10,2

20 20 19,8–20,2

50 50 49,5–50,5

100 100 99,2–100,8

200 200 198,7–201,3

500 500 497,0–503,0

1000 1000 994,0–1006,0

2000 2000 1990,0–2010,0

200–1000 300 298–302

1000–5000 2000 1990–2010

Ajuste del volumen

Rango de peso

admisible

(mg)

69

Page 72

Calibración

2. Coloque una punta en el cono, presionando ligeramente y

girando un poco la punta.

3. Proceda a pipetear agua destilada, por lo menos cinco

veces, en el vaso previamente pesado. Determine cada

peso en mg, con una posición decimal, y compárelo con el

peso anteriormente citado. Si el peso está fuera del rango

de valores se deberá recalibrar la pipeta.

70

Page 73

Sección 8 Recalibración

La calibración se lleva a cabo con la llave de calibración

suministrada.

1. Coloque la llave en los agujeros de la ranura de

calibración situada en el extremo superior del mango.

2. Aumente el volumen girando en sentido horario o

redúzcalo girando en sentido antihorario.

Figura 7 Recalibración

1 Llave de calibración

3. Compruebe el ajuste del volumen de la forma descrita en

la Sección 7 Calibración en la página 69.

Nota importante: La pipeta solamente se puede calibrar

dentro de los límites del rango de volúmenes para el que está

prevista.

71

Page 74

Sección 9 Localización y

resolución de

fallos

La Tabla siguiente está prevista para ayudarle a identificar y

eliminar posibles fallos:

Tabla 2 Localización y resolución de fallos

Error Posible causa Solución

Fuga

Pipeteado

incorrecto

La punta no está

correctamente

colocada

Cuerpos extraños

entre el cono y la

punta

Cuerpos extraños

entre la junta tórica y

el émbolo

Grasa insuficiente

en las juntas tóricas

y el émbolo

Juntas tóricas

defectuosas

Funcionamiento

incorrecto

La punta no está

firmemente colocada

La calibración ha

cambiado, p.ej.

debido a un manejo

incorrecto

Fijar la punta

firmemente en su

sitio

Limpiar el cono y

colocar una punta

nueva

Limpiar y engrasar

las juntas tóricas y el

émbolo en el

cilindro. Utilizar la

grasa suministrada.

Engrasar

adecuadamente

Cambiar las juntas

tóricas

Utilizar la pipeta de

la forma descrita en

el manual

Fijar la punta

correctamente

Recalibrar

72

Page 75

Sección 10 Garantía,

responsabilidad y

reclamaciones

El fabricante garantiza que el producto suministrado se

encuentra libre de fallas de material y de fabricación y se

obliga a reparar o bien reemplazar gratuitamente las piezas

defectuosas.

El plazo prescriptivo para reclamos de falla en estos pipetas

es de 24 meses.

Para los defectos a los cuales pertenece también la ausencia

de las características aseguradas, el proveedor asume la

garantía del siguiente modo, bajo exclusión de mayores

responsabilidades: A opción del proveedor se han de reparar

o suministrar nuevamente sin coste alguno todas aquellas

piezas que se han vuelto inutilizables o cuya utilizabilidad se

ha perjudicado considerablemente y en forma comprobada a

causa de una circunstancia previa al traspaso de riesgo,

particularmente a causa de una falla de construcción, mala

calidad del material de construcción o bien un diseño

defectuoso, dentro del período de garantía y a partir del

momento de traspaso de riesgo. La determinación de tales

defectos debe notificarse por escrito en forma inmediata al

proveedor, a más tardar dentro de 7 días posteriores a la

detección del defecto. En caso que el cliente no proceda con

este aviso, se considera la prestación de servicio como

autorizada, sin considerar el defecto. No se aplica una

responsabilidad que supere los daños directos e indirectos.

En caso que el fabricante prescribiera dentro del período de

garantía la ejecución de trabajos de mantenimiento

específicos por parte del cliente y no se cumplieran estas

prescripciones, se termina la pretensión de garantía para

daños derivados por la no observación de las prescripciones.

No pueden reclamarse mayores pretensiones,

particularmente por daños consecutivos.

De esta regulación se consideran excluidas las piezas de

desgaste y los daños causados por un manejo inapropiado,

un montaje inseguro o bien una aplicación fuera del uso

previsto.

73

Page 76

Garantía, responsabilidad y reclamaciones

74

Page 77

Sezione 1 Descrizione della

pipetta a pistone

Figura 1 Descrizione della pipetta a pistone

1 Pulsante 4 Cono

2 Pulsante espulsore 5 Scala volume

3 Espulsore del puntale

75

Page 78

Descrizione della pipetta a pistone

La pipetta a pistone è una pipetta a microlitro estremamente

comoda ed universale concepita per eseguire il trasferimento

di volumi di liquido esatti. Essa funziona secondo il principio

dell’espulsione d’aria ed utilizza puntali monouso. Il volume da

pipettare è indicato su un visore chiaramente visibile posto

sull’impugnatura della pipetta. Tutte le pipette a pistone sono

dotate di un sistema meccanico per l’espulsione del puntale.

1.1 Puntali per pipette

Raccomandiamo di usare puntali per pipette HACH quando si

lavora con la pipetta a pistone. I puntali per pipette sono

fabbricati in polipropilene e possono essere autoclavati a

121 °C.

76

Page 79

Sezione 2 Uso della pipetta

2.1 Regolazione del volume

(solo per le pipette a pistone variabili)

Il volume della pipetta è regolato mediante il pulsante posto

sull’estremità dell’impugnatura. Girare il pulsante in senso

antiorario per aumentare il volume ed in senso orario per

ridurlo. Accertarsi che la regolazione del volume sia corretta

(clicca in posizione) e che il volume indicato sul visore sia

completamente visibile.

Figura 2 Regolazione del volume

Nota importante: la precisione ed accuratezza indicate si

riferiscono soltanto all'intervallo di volume specificato sulla

pipetta. Non regolare il volume su un valore esterno a tale

intervallo. Non usare la forza per girare il pulsante su un

volume esterno all'intervallo specificato. Così facendo infatti si

può danneggiare la pipetta.

2.2 Espulsione del puntale

Ogni pipetta a pistone è dotata di un sistema di espulsione del

puntale atto a prevenire eventuali contaminazioni. Con il

pollice premere il pulsante espulsore e rimuovere il puntale

dall’apposito cono.

77

Page 80

Uso della pipetta

2.3 Tecniche di pipettatura

La pipetta viene fatta funzionare con il pulsante posto

sull’estremità dell’impugnatura.

La massima accuratezza si ottiene eseguendo i seguenti

punti:

1. Muovere il pistone su e giù in maniera lenta e uniforme.

(soprattutto quando si pipettano liquidi altamente viscosi)

2. Non lasciare che il pulsante scatti indietro sulla posizione

originale.

3. Inserire un nuovo puntale nel cono esercitando una

leggera pressione e girando leggermente il puntale.

4. Accertarsi che il puntale sia saldamente posizionato nel

cono e che tra il puntale ed il cono non sia presente alcun

corpo estraneo.

5. Inumidire i puntali con il liquido riempiendoli e svuotandoli

ripetutamente.

6. Tenere la pipetta in posizione quasi verticale (a non più di

10° dalla verticale) mentre il liquido è aspirato nel puntale.

7. La temperatura della pipetta e del puntale deve

corrispondere a quella del liquido.

78

Page 81

Sezione 3 Tecnica standard

1. Premere il pulsante sul primo punto di pressione.

2. Immergere il puntale della pipetta sotto la superficie del

liquido (2–3 mm) e rilasciare lentamente il pulsante.

Estrarre il puntale dal liquido e con esso toccare la parete

interna del contenitore in modo da rimuovere il liquido in

eccesso.

3. Posizionare il puntale contro la parete interna del

contenitore e premere il pulsante in maniera leggera ed

uniforme fino a raggiungere il primo punto di pressione.

Tenere la pipetta in tale posizione. Dopo circa un secondo,

premere il pulsante fino a raggiungere il secondo punto di

pressione. Così facendo il puntale si svuota

completamente.

4. Lasciare che il pulsante torni sulla posizione di riposo.

Figura 3 Tecnica standard

a Posizione di riposo c Secondo punto di pressione

b Primo punto di pressione

Nota importante: dopo l’uso sostituire il puntale della pipetta!

79

Page 82

Sezione 4 Pipettare sangue

intero

1. Immergere il puntale nel campione e premere il pulsante

fino a raggiungere il primo punto di pressione. Accertarsi

che il puntale si trovi sotto la superficie.

2. Rilasciare lentamente il pulsante finché è nella posizione

iniziale. Il puntale è ora pieno di campione. Non togliere il

puntale dal campione.

3. Premere il pulsante fino a raggiungere il primo punto di

pressione e quindi rilasciarlo di nuovo lentamente.

Ripetere finché la parete del puntale è priva di sangue.

4. Premere il pulsante fino a raggiungere il secondo punto di

pressione e svuotare completamente il puntale.

Figura 4 Pipettare sangue intero

a Posizione di riposo c Secondo punto di pressione

b Primo punto di pressione

80

Page 83

Sezione 5 Controllo quotidiano

Controllare quotidianamente che la pipetta non presenti tracce

di polvere o sporco esterno prima di iniziare o finire il lavoro,

facendo particolare attenzione al cono del puntale. Pulire la

pipetta con alcool al 70%. Non usare alcun altro solvente per

pulire la pipetta.

81

Page 84

Sezione 6 Manutenzione

Se la pipetta è usata ogni giorno, la manutenzione deve

essere eseguita almeno due volte all’anno. La manutenzione

può essere eseguita nel proprio laboratorio. Eseguire le fasi

descritte qui di seguito:

6.1 Apertura delle pipette (0,2–1,0 mL)

1. Premere il pulsante espulsore.

2. Inserire la punta dello strumento apertore nell’apertura

sull’estremità del pulsante espulsore.

3. Tirare fuori il pulsante espulsore ed il pistone espulsore

del puntale.

82

Figura 5 Apertura delle pipette

Page 85

Manutenzione

4. Rimuovere il cono del puntale girandolo in senso

antiorario con lo strumento fornito a corredo.

5. Tirare fuori il pistone.

6. Togliere gli O-ring dal cono del puntale.

7. Pulire il pistone, la molla del pistone e gli O-ring con un

panno asciutto e pulito.

8. Controllare che sul cilindro non siano presenti sostanze

estranee. Ricordarsi che il cilindro non deve essere

ingrassato.

9. Ingrassare leggermente le parti pulite con il grasso fornito

a corredo.

10. Riassemblare la pipetta.

83

Page 86

Manutenzione

6.2 Apertura della pipetta (1–5 mL)

1. Rimuovere il pulsante espulsore e l’espulsore del puntale

come precedentemente descritto (per le pipette da

0,2–1,0 mL) sezione 6.1 a pagina 82.

2. Rimuovere il coperchio.

3. Rimuovere il cono ed il cilindro con l’aiuto dell’utensile

premendo le due sporgenze una verso l’altra. Premendo

le sporgenze, spingere l’utensile verso il cono.

Figure 6 Apertura della pipetta

1 Utensile di assistenza per l’apertura della pipetta

4. Smontare, pulire ed ingrassare come precedente descritto

(per le pipette da 0,2–1,0 mL) sezione 6.1 a pagina 82.

5. Riassemblare in sequenza inversa.

84

Page 87

Sezione 7 Calibrazione

La pipetta è calibrata in fabbrica con acqua distillata a 22 °C.

Per l’impiego di routine non è richiesta alcuna ricalibrazione.

La pipetta può tuttavia essere ricalibrata per altre temperature

e soluzioni di diversa viscosità. Per eseguire la calibrazione

sono necessari una bilancia analitica di sensibilità appropriata,

un piccolo bicchiere ed acqua distillata.

Nota importante: se vengono sostituiti l’impugnatura o il

pistone, la pipetta deve essere ricalibrata. Se vengono

sostituiti gli O-ring o il cono del puntale, la calibrazione deve

essere verificata.

7.1 Controllo della calibrazione

1. Impostare il volume della pipetta come segue in Tabella 1

Controllo della calibrazione:

Tabella 1 Controllo della calibrazione

Pipetta

(µL)

10 10 9,8–10,2

20 20 19,8–20,2

50 50 49,5–50,5

100 100 99,2–100,8

200 200 198,7–201,3

500 500 497,0–503,0

1000 1000 994,0–1006,0

2000 2000 1990,0–2010,0

200–1000 300 298–302

1000–5000 2000 1990–2010

Regolazione del

volume

Intervallo di peso

ammesso

(mg)

85

Page 88

Calibrazione

2. Posizionare il puntale sul rispettivo cono esercitando una

leggera pressione e ruotando leggermente il puntale.

3. Pipettare l’acqua distillata nel bicchiere precedentemente

pesato per almeno cinque volte. Determinare ciascun

peso in mg alla prima posizione decimale e confrontarlo

con il peso su indicato. Se il peso non rientra in questo

intervallo, ricalibrare la pipetta.

86

Page 89

Sezione 8 Ricalibrazione

La calibrazione è eseguita con la chiave di calibrazione fornita

a corredo.

1. Mettere la chiave di calibrazione nei fori della scanalatura

di calibrazione posta sull’estremità superiore

dell’impugnatura.

2. Aumentare il volume girando il senso orario o ridurlo

girando il senso antiorario.

Figura 7 Ricalibrazione

1 Chiave di calibrazione

3. Quindi controllare il volume come precedentemente

descritto Sezione 7 Calibrazione a pagina 85.

Nota importante: la pipetta può essere calibrata soltanto

entro i limiti dell’intervallo di volume a cui è destinata.

87

Page 90

Sezione 9 Diagnostica

La tabella seguente è concepita per aiutare ad identificare ed

eliminare eventuali errori:

Tabella 2 Diagnostica

Errore Causa possibile Risposta

Perdita

Pipettatura

inaccurata

Puntale non

correttamente

attaccato

Corpi estranei tra

cono e puntale

Corpi estranei tra

O-ring e pistone

Grasso insufficiente

sugli O-ring ed il

pistone

O-ring guasti Sostituire gli O-ring

Funzionamento

incorretto

Puntale non

saldamente

attaccato

La calibrazione è

cambiata, ad es. a

causa di un

funzionamento

difettoso

Fissare il puntale

saldamente in

posizione

Pulire il cono ed

attaccare un nuovo

puntale

Pulire ed ingrassare

gli O-ring ed il

pistone nel cilindro

usando il grasso

fornito

Ingrassare

adeguatamente

Usare la pipetta

come indicato nel

manuale

Attaccare

saldamente il

puntale

Ricalibrare

88

Page 91

Sezione 10 Garanzia,

responsabilità e

reclami

Il produttore garantisce che il prodotto fornito non presenta

difetti di materiale o di lavorazione e si impegna a riparare o a

sostituire gratuitamente eventuali componenti difettosi.

Il periodo di prescrizione per rivendicazioni dovute a reclami

corrisponde a 24 mesi per tutte le pipetta.

Il fornitore è responsabile per eventuali difetti, tra i quali rientra

la mancanza delle caratteristiche assicurate, fatta esclusione

di altre rivendicazioni: il fornitore è tenuto a riparare

gratuitamente o a sostituire – a sua scelta – tutti i componenti

che, entro il periodo di prescrizione, calcolato a partire dal

giorno del trapasso del rischio, risultino inutilizzabili o

utilizzabili solo con notevoli limiti e tale inutilizzabilità sia

imputabile a condizioni precedenti il trapasso del rischio, in

particolar modo struttura costruttiva difettosa, materiali

scadenti o produzione difettosa. Il fornitore va

immediatamente informato per iscritto del fato che si siano

rilevati tali difetti, comunque entro i 7 giorni successivi alla

constatazione del difetto. Se il cliente non esegue tale

comunicazione, la prestazione commerciale effettuata sarà

ritenuta accettata, nonostante la presenza di difetti. Si esclude

un'eventuale ulteriore responsabilità per danni potenziali o

imminenti.

Se, durante il periodo di prescrizione, il fornitore prescrive

operazioni di manutenzione da eseguirsi da parte del cliente

stesso (manutenzione) e tali operazioni non siano state

effettuate, decade il diritto di rivendicazione per i danni derivati

dalla non osservanza delle suddette prescrizioni.

Non sono rivendicabili ulteriori reclami, in particolari i reclami

inerenti il risarcimento per danni indiretti.

Le parti soggette ad usura ed eventuali guasti causati da un

utilizzo improprio, da montaggio inadeguato o da un uso non

corretto, sono esclusi dalle condizioni sopra riportate.

89

Page 92

Garanzia, responsabilità e reclami

90

Page 93

Page 94

Page 95

Page 96

Hach Company

PO Box 389

Loveland, CO 80539

Phone: 970/669-3050

Fax: 970/669-2932

orders@hach.com

www.hach.com

Great Britain

Hach Lange LTD

Pacific Way

Salford

Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

Austria

Dr. Bruno Lange Ges. MBH

Industriestraße 12

A-3200 Obergrafendorf

Tel. +43 (0)27 47 74 12

Fax +43 (0)27 47 42 18

info@hach-lange.at

www.hach-lange.at

France

Hach Lange

Hach SAS

33 Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

Spain

Hach Lange S.L.U.

C/Araba, 45. Apdo. 220

E-20800 Zarautz/Guipúzcoa

Tel. +34 9 43 89 43 79

Fax +34 9 43 13 02 41

info@hach-lange.es

www.hach-lange.es

Germany

Hach Lange GmbH

Willstätterstr. 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-0

Fax +49 (0)2 11 52 88-143

info@hach-lange.de

www.hach-lange.de

Switzerland

Dr. Bruno Lange AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

Belgium

Hach Lange SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Portugal

Hach Lange LDA

Rua dos Malhões

Edif. D. Pedro I

P-2770-071 Paço D'Arcos

Tel. +351 210 00 1750

Fax +351 210 00 8140

info@hach-lange.pt

www.hach-lange.pt

Italy

Hach Lange S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +33 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

1508010

Loading...

Loading...