Page 1

User Manual

PHC725

Safety information

DOC022.52.80432

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed. A symbol on the instrument is referenced in the

manual with a precautionary statement.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to the user.

Specifications

W A R N I N G

Chemical exposure hazard. Obey laboratory safety procedures and wear all of the

personal protective equipment appropriate to the chemicals that are handled. Refer to the

current safety data sheets (MSDS/SDS) for safety protocols.

C A U T I O N

Personal injury hazard. Glass components can break. Handle with care to prevent cuts.

Specifications are subject to change without notice.

Specifications Details

Probe type Digital combination glass pH probe with refillable electrolyte and built-in temperature sensor

Body material Glass

pH range pH 0 to 14

pH resolution User-selectable stabilization time and resolution—Fast: 0.1, Fast: 0.01, Medium: 0.01, Slow:

0.01 or Slow: 0.001

pH accuracy ±0.01 pH

Sodium (alkalinity) error <0.3 pH at pH 13 in 0.1 M NaOH

Slope –59 mV/pH (85 to 115% at 25 °C (77 °F) per Nernstian theoretical value)

Isopotential point pH 6.00

Temperature compensation 30 kΩ NTC thermistor

Temperature accuracy ±0.3 °C (±0.54 ° F)

Operating temperature –10 to 100 °C (14 to 212 °F)

Storage temperature 5 to 40 °C (41 to 104 °F)

Junction type Annular porous ring

Reference type Red Rod

1

Electrolyte Refillable, saturated KCl

1

Page 2

Specifications Details

Storage solution Saturated KCl

Minimum sample depth 14 mm (0.55 in.)

Dimensions Body diameter: 12 mm (0.47 in.)

Body length: 103 mm (4.1 in.)

Total length: 200 mm (7.87 in.)

Cable length: 1 m (3.28 ft)

Cable connection M12 digital output and connector compatible with HQd meters

1

Radiometer Analytical’s Red Rod technology: Encapsulation of reference elements with a red protection tube.

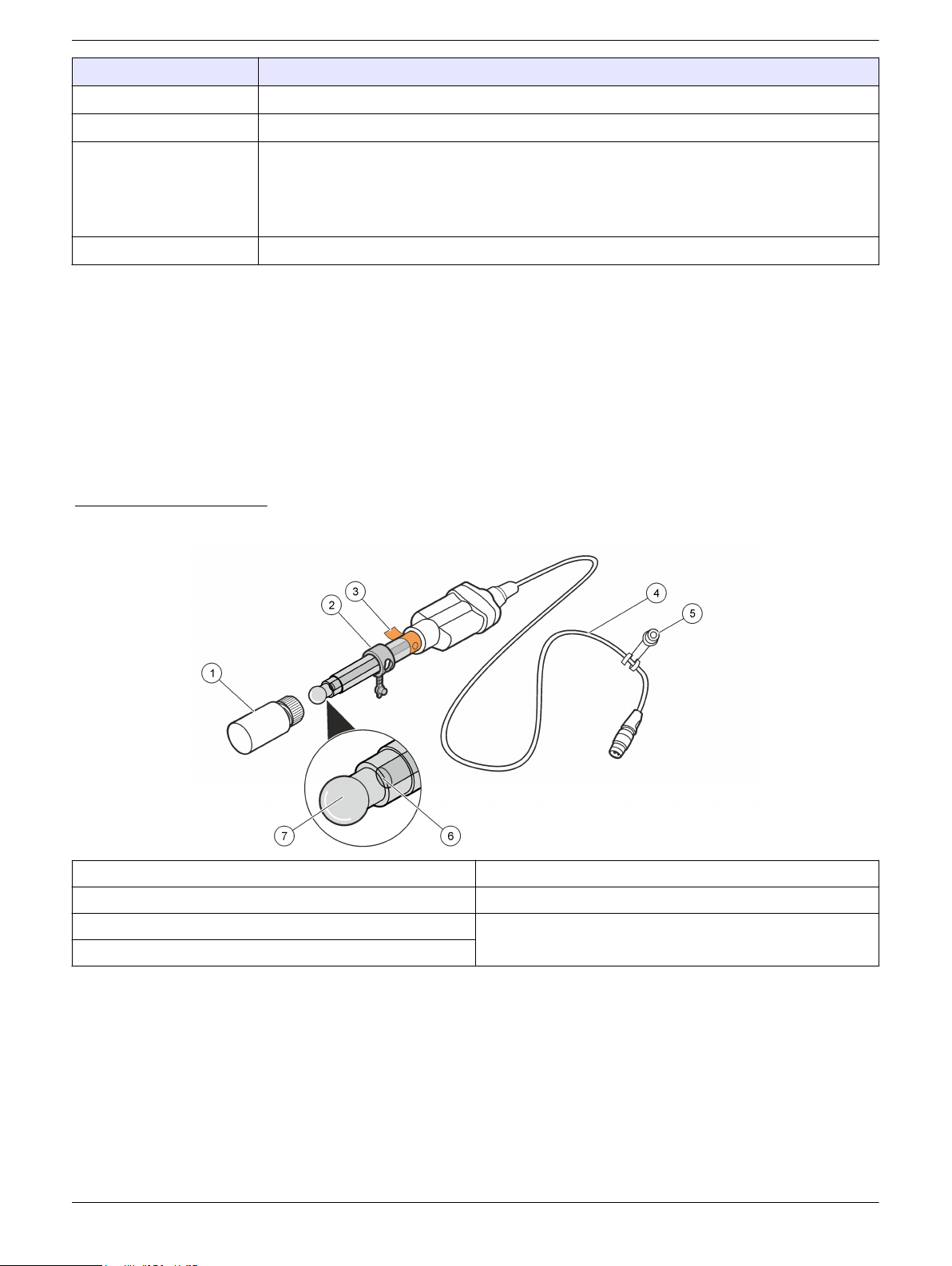

Product overview

The probe is a digital pH combination electrode with refillable electrolyte, a glass body

and an integrated temperature sensor. The probe is for laboratory use and measures pH

in general aqueous samples.

Note: Do not use the probe with organic solvents, emulsions, samples with high solids content or

high alkaline sample types.

A 59-mL bottle of reference electrolyte filling solution (saturated KCl solution) is included

with the probe. Refer to Figure 1.

Figure 1 Probe overview

1 Probe soaker bottle 5 Probe soaker bottle holder

2 Filling-hole cap 6 Reference junction

3 Protective tape and filling-hole 7 Glass bulb and temperature sensor

4 Cable, 1 meter (3.28 ft)

Preparation for use

Prepare the probe before a calibration or a sample measurement.

1. Turn the probe soaker bottle cap counter-clockwise to loosen the cap.

2. Remove the soaker bottle from the probe.

3. Fully rinse the reference junction and the glass bulb with deionized water to remove

all of the storage solution or possible salt particles. Dry with a no-lint cloth.

4. Remove the protective tape from the filling hole before initial use (refer to Product

overview on page 2). Discard the protective tape.

2

Page 3

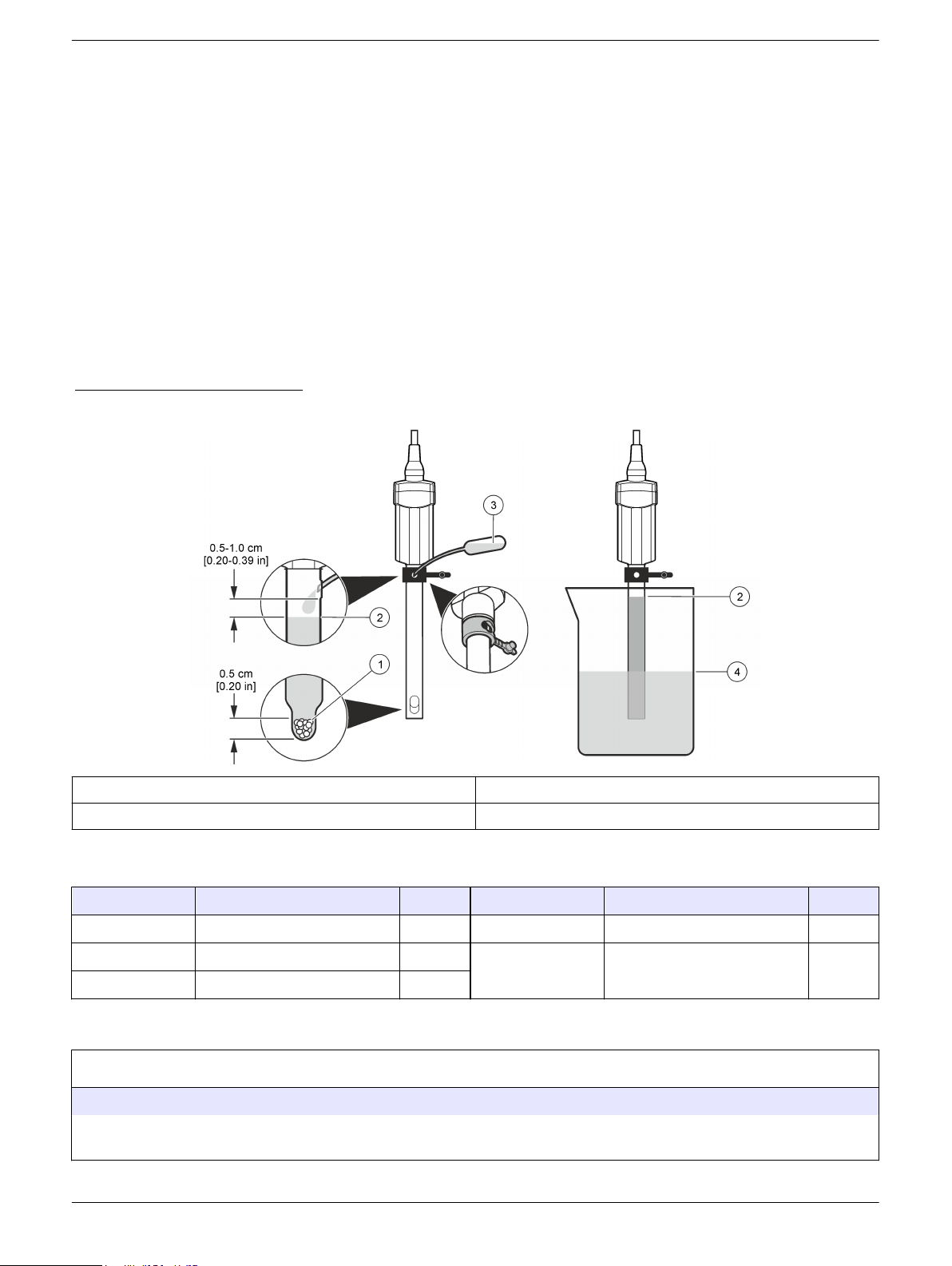

5. Add the filling solution to the probe as necessary (refer to Fill the probe

on page 11). The filling solution must be above the standard solution or the sample

level during measurement or calibration (Figure 2).

6. For Red Rod probes, make sure that there is approximately 0.5 cm (0.2 in.) of KCl

crystals in the filling solution in the probe. Refer to Table 1. For measurements at

temperatures higher than 60 °C (140 °F), add KCl crystals through the filling hole.

Refer to Table 1 to calculate the quantity of KCl crystals to add. The quantity of

necessary KCl crystal increases linearly from 60 to 100 °C.

7. For Red Rod probes, make sure that the KCl crystals move freely through the liquid

when the probe is inverted. If necessary, shake the probe to loosen the crystals.

8. Make sure that the filling hole is open during measurement for the correct flow of the

filling solution.

Note: For the best stabilization time, condition the probe for 2 hours in pH buffer 4.01 before use, if

the probe was not used for 3 weeks or more. In low ionic strength (LIS) samples, condition the

probe for a maximum of 5 minutes in the sample before use. In all other cases a condition before

use is not necessary.

Figure 2 Filling solution level

1 KCl crystals

2 Filling solution level 4 Standard solution or sample level

1

Red Rod probes only

1

3 Filling solution

Table 1 KCl crystal level for Red Rod pH probes

Temperature Amount of KCl crystals Add Temperature Amount of KCl crystals Add

60 °C (158 °F) 0.5 g (0.5 cm) 0 g 90 °C (194 °F) 0.875 g 0.375 g

70 °C (158 °F) 0.625 g 0.125 g 100 °C (212 °F) 1.0 g (1.0 cm) 0.5 g

80 °C (176 °F) 0.750 g 0.25 g

Calibration

Before calibration:

The probe must have the correct service-life time stamp. Set the date and the time in the meter before the probe is attached.

It is not necessary to calibrate again if a calibrated probe is moved from one HQd meter to another. Make sure that the

additional meter is configured to use the same calibration options.

3

Page 4

Before calibration:

To view the calibration data, push , then select View Probe Data>View Current Calibration.

If two probes are connected, push the UP or DOWN arrow to change to the single display mode to show the Calibrate option

(available only on HQ40d and HQ440d meters).

Prepare the probe for use (refer to Preparation for use on page 2).

Calibration notes:

• Use buffers that are two pH units apart.

• Select additional standard sets with the minimum number of calibration points in the

Calibration Options. For a two-point calibration, select: one buffer with a pH above

and one buffer with a pH below the sample pH. For a one-point calibration, select the

buffer nearest to the sample pH.

• The calibration is recorded in the probe and the data log. Send the calibration to a

PC, a printer or a flash memory stick if connected.

• Air bubbles under the sensor tip can cause a slow response or an error in the

measurement. If there are bubbles under the sensor tip, carefully shake the probe to

remove the bubbles.

• Make sure that the filling hole is open and above the sample solution level.

• Use a laboratory stirrer or shake the probe from side to side in the solution to refresh

the reference junction.

• The meter display shows "Stabilizing" and a progress bar as the probe stabilizes in

the standard. The display shows the buffer and the temperature corrected pH value

when the measurement is stable.

• The calibration and sample measurement conditions must be as similar as possible

(e.g., the temperature of the solution, the stir procedure, the stir rate and the position

of the probe).

• If a calibration error occurs, refer to Troubleshooting on page 12.

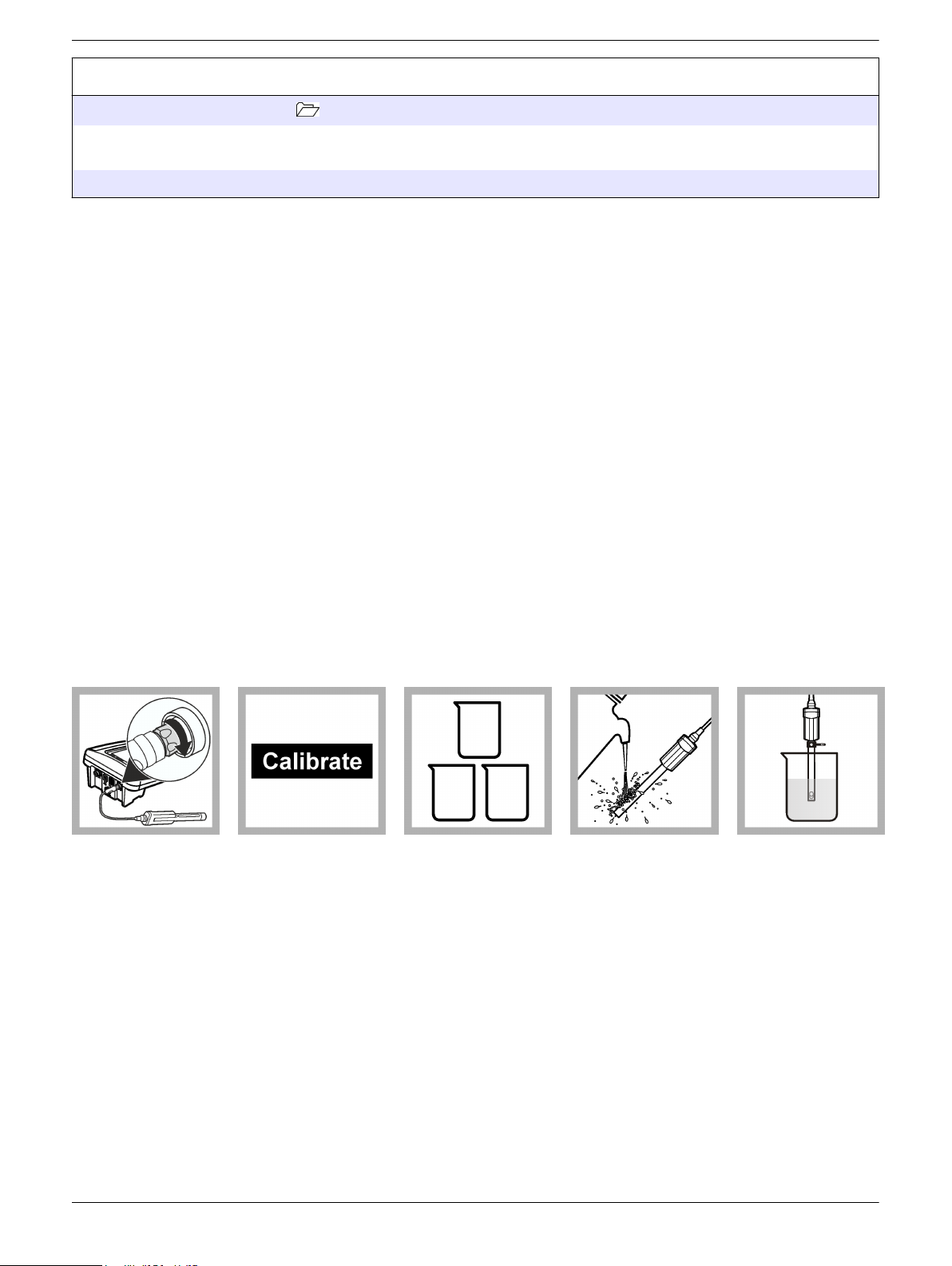

1. Connect the probe

to the meter. Make

sure that the cable

locking nut is correctly

connected to the

meter. Set the meter

to on.

Calibration procedure:

2. Push Calibrate.

The display shows the

buffers that are

necessary for

calibration.

3. Prepare the fresh

buffers in separate

beakers or applicable

containers.

4. Rinse the probe

with deionized water.

Dry with a no-lint

cloth.

5. Put the probe in

the pH buffer solution

and stir lightly. Make

sure to fully put the

reference junction into

the standard.

4

Page 5

6. Push Read. Wait

until the reading

stabilizes.

7. Do steps 4–6

again to collect the

minimum number of

calibration points

specified in the

calibration options.

Sample requirements

8. Push Done to view

the calibration

summary.

Note: The display will

not show "Done" until

the minimum number

of calibration points is

collected.

9. Push Store to

accept the calibration

and go back to the

measurement mode.

N O T I C E

Some probes are not compatible with specific sample types. Probe damage can occur.

• Samples must be aqueous. The probe can also make measurements in partially

aqueous or some water-miscible solvents. Read the results with caution because the

full pH scale changes when the solvent system changes.

• Probes with a Red-Rod reference system are compatible with solutions that contain

silver complexing or binding agents (e.g., TRIS, proteins and sulfides), as they have

an encapsulated reference system.

• Proteins can collect on the sensing element. Make sure that the probe stays clean

when these types of samples are measured.

• Do not use the probe in solutions that are out of the temperature range of the probe.

Refer to Specifications on page 1.

• For low ionic strength (LIS) or high purity samples, use an LIS chamber or a flow cell

to prevent sample contamination.

Measurement

Before measurement:

The probe must have the correct service-life time stamp. Set the date and the time in the meter before the probe is attached.

If the complete traceability is necessary, enter a sample ID and an operator ID before the measurement. Refer to the HQd

meter manual for more information.

A regular calibration is necessary for the best measurement accuracy (refer to Calibration on page 3).

Prepare the probe for use (refer to Preparation for use on page 2).

Measurement notes:

• Data is automatically stored in the data log when Press to Read or Interval is

selected in the Measurement Mode. When Continuous is selected, data is only

stored when Store is pushed.

• Air bubbles under the sensor tip can cause a slow response or an error in the

measurement. If there are bubbles under the sensor tip, carefully shake the probe to

remove the bubbles.

• For the best stabilization time, condition the probe for several minutes in the sample

or in a solution comparable to the sample in terms of pH and ionic strength before the

initial sample measurement.

5

Page 6

• Do not put the probe on the bottom or sides of the container.

• Make sure that the filling hole is open and above the sample solution level.

• Use a laboratory stirrer or shake the probe from side to side in the solution to refresh

the reference junction.

• The meter display shows "Stabilizing" and a progress bar as the probe stabilizes in

the sample. The display shows the lock icon when the measurement is stable.

• If a measurement error occurs, refer to Troubleshooting on page 12.

Measurement procedure:

1. Connect the probe

to the meter. Make

sure that the cable

locking nut is correctly

connected to the

meter. Set the meter

to on.

6. Do steps 3–5

again to make more

measurements.

2. Condition the

probe in the sample.

7. When

measurements are

done, put the probe in

storage (refer to

Storage

on page 11).

Run Check Standard

3. Rinse the probe

with deionized water

and then with the

sample. Dry with a

no-lint cloth.

4. Put the probe in

the sample and stir

lightly. Make sure to

fully put the reference

junction into the

sample.

5. Push Read. Wait

until the reading

stabilizes.

The Run Check Standard feature validates the instrument performance between sample

measurements. Use the Run Check Standard feature for a periodic or a user-defined

interval measurements of a traceable standard solution. Set the criteria for check

standards from the PHC725 Settings menu.

Note: Access control must be set to off or a valid password must be used to change the Run Check

Standard options.

1. Push . The Full Access Options menu shows.

2. Select Run Check Standard.

Note: Select the correct probe if two probes are connected to the meter.

3. Use the standard solution shown on the display.

4. Rinse the probe with deionized water. Dry the probe with a no-lint cloth.

5. Put the probe in the standard solution. Make sure that the reference junction is fully in

the standard. Move the probe up or down or lightly shake the probe to remove air

bubbles.

6

Page 7

6. Push Read. The display shows "Stabilizing" and a progress bar as the reading

stabilizes. The display shows the value of the check standard and Check Standard

Passed or Check Standard Failed.

7. If the display shows Check Standard Passed, the check standard measurement is in

the accepted limits. Select Done to continue the sample measurement.

8. If the display shows Check Standard Failed, the measurement is out of the accepted

limits. A calibration is recommended. Make sure that the limits are set correctly at the

PHC725 Settings menu. If the acceptance criteria is set to "Cal Expires on Failure:

Yes", the display shows the calibration icon and a question mark until the probe is

calibrated again. To correct the probe calibration and status indicator, calibrate the

probe (refer to Calibration on page 3).

Advanced operation

This section gives instructions about menu navigation and available options. Change

parameter-specific settings through the Full Access Options menu.

The settings that can be changed are shown in Table 2.

Setting Options

Table 2 Parameter-specific settings

Measurement Options

Calibration Options

Check Standard Options

Units

• Resolution

• Upper and lower range limits

• Buffer set

• Buffer set values (if Custom Buffer Set selected)

• Reminder

• Minimum Cal points

• Slope limit

• Standard (temperature compensated buffer or custom at 25 °C (77 °F))

• Reminder

• Acceptance criteria

• Standard value at 25 °C (77 °F) (if custom standard selected)

• pH

• mV

Change measurement options

Methods are groups of default or user-defined settings related to specific applications. If

the meter is set to the default method, a prompt for a new name method shows. The

settings are saved with this name to identify them from the default method settings, which

cannot be changed. Use a saved method as an alternative of many adjustments to the

individual settings. Changes made to a user-defined method are automatically saved with

the existing name. Save different methods for the same probe on each meter.

1. Make sure that a probe is connected to the meter.

2. Push and select PHC725 Settings.

3. Select Modify Current Settings.

4. Select Units. Select pH (default) or mV.

Note: Use the mV option to find the probe offset in a pH 7 buffer or to measure the slope. Both

units show when the Detail Display mode is selected.

7

Page 8

5. Select Measurement Options and update the settings:

Option Description

Resolution Set the resolution:

• 0.1 pH—Fast

• 0.01 pH—Fast (default)

• 0.01 pH—Medium

• 0.01 pH—Slow, or

• 0.001 pH—Slow

The resolution has an effect on the number of decimal digits and the

stabilization time. More stabilization time is necessary for higher resolution

measurements. Slower stabilization times give higher accuracy

measurements.

Measurement

Limits

Set the measurement limits—Lower limit (default: 0.00 pH) or Upper limit

(default: 14.00 pH).

Set the measurement limits to agree with the permitted values for the

sample. When the measurement is above the upper limit setting or below

the lower limit setting, the meter shows an "Out of limits" message. This

message is an alert to a possible problem with the process conditions.

6. If prompted, enter a name for the new method settings. Other changes made to the

settings of an existing method are automatically saved with the same method name.

7. Push EXIT until the meter goes back to the measurement mode.

Change calibration options

1. Make sure that a probe is connected to the meter.

2. Push and select PHC725 Settings.

3. Select Modify Current Settings.

4. Select Calibration Options and update the settings:

Option Description

Buffer Set Sets the temperature compensated buffer set for calibration:

Buffer Set

Values

Minimum Cal

Points

Slope Limit Sets the slope limit—1% to 20% (acceptable slope criteria, default = 15%).

• Color Coded—4.01, 7.00, 10.01 (default)

• IUPAC—4.01, 7.00, 10.01, 12.45

• DIN—4.65, 9.23

• IUPAC—4.01, 6.86, 10.01, 12.45

• IUPAC—4.01, 6.86, 9.18, 12.45

• IUPAC—4.01, 7.00, 9.18, 12.45

• Custom Buffer Set (refer to Table 3)

Custom buffer sets are characterized at 25 °C (77 °F).

Buffer set values show on the Calibration Options screen.

Note: Measure only the minimum calibration points specified in Minimum

Cal Points to complete a calibration.

Sets the buffer values if Custom Buffer Set is selected (refer to Table 3).

Sets the minimum number of calibration points that are necessary to

complete a calibration—1 (default), 2 or 3.

Set the slope between the set limits for a correct calibration.

8

Page 9

5. Select the Calibration Reminder and update the settings:

Option Description

Reminder

Repeat

Expires Calibration expires after the selected time—Immediately, Reminder +

The meter makes a sound when a calibration is necessary and at the

selected interval—Off (default), 2 h, 4 h, 8 h, 2 d, 5 d or 7 d.

30 min, Reminder + 1 h, Reminder + 2 h or Continue Reading.

Note: The meter cannot read samples after calibration has expired unless

Continue Reading is selected.

6. If prompted, enter a name for the new method settings. Other changes made to the

settings of an existing method are automatically saved with the same method name.

7. Push EXIT until the meter goes back to the measurement mode.

Table 3 Custom buffer sets

Buffer set

values

Std1 to

Std5

Option Description

1.09 pH—25 °C Pre-set temperature compensated buffer values.

1.68 pH—25 °C

4.01 pH—25 °C

4.65 pH—25 °C

6.86 pH—25 °C

7.00 pH—25 °C

9.18 pH—25 °C

9.23 pH—25 °C

10.01 pH—

25 °C

12.45 pH—

25 °C

Custom Buffer Custom buffer value.

No Buffer Select this option for undefined standards.

Note: It is necessary for selected standards to be different by a minimum of 2 pH units. For example, if

1.09 pH is selected for the first standard, the second standard must be different by at least 2 pH.

Standards that do not meet this minimum will show gray on the screen and will not be selectable.

Range = 2.000 pH to 14.000 pH.

Custom buffer values are not temperature compensated. Custom buffers must be read at

25 °C (77 °C).

Change check standard options

1. Make sure that a probe is connected to the meter.

2. Push

3. Select Modify Current Settings.

and select PHC725 Settings.

9

Page 10

4. Select Check Standards Options and update the settings:

Option Description

Standard Sets the temperature compensated buffer value for check standard—

• 4.01 pH—25 °C

• 4.65 pH—25 °C

• 6.86 pH—25 °C

• 7.00 pH—25 °C

• 9.18 pH—25 °C

• 9.23 pH—25 °C

• 10.01 pH—25 °C

• 12.45 pH—25 °C

• Custom

The standard value shows on the Check Standard Options screen.

No temperature compensation for custom buffers.

Standard

Value

When the Standard is set to Custom, enter the standard value with the

up/down arrow keys.

5. Select Check Standard Reminder and update the settings:

Option Description

Reminder Repeat Sets the time interval for the check standard reminder—Off, 30 minutes,

2 h, 4 h, 8 h, 12 h or 24 h.

Allow Defer Lets the postponement of check standard reminders—Yes or No.

Maintenance

Clean the probe

6. Select Acceptance Criteria and update the settings:

Option Description

Acceptance Limits Sets the tolerance limits for check standard—0.005 pH (default) to

1.000 pH.

Cal Expires on Failure Recalibration is necessary if check standard fails—Yes or No.

7. If prompted, enter a name for the new method settings. Other changes made to the

settings of an existing method are automatically saved with the same method name.

8. Push EXIT until the meter goes back to the measurement mode.

Clean the probe when there is contamination on the sensor. Symptoms of contamination

are:

• Readings are not accurate or consistent.

• The stabilization time is slow.

• A calibration error occurs.

• Contamination is visible on the probe (e.g., dirt).

1. Rinse the probe with deionized water. Blot dry with a no-lint cloth.

2. Soak the glass bulb of the probe in the applicable cleaning agent. Refer to Table 4.

Note: Remove KCl salt build-up from the probe with warm deionized water.

3. Rinse or soak the probe for 1 minute in deionized water.

4. Soak the probe in pH 4 buffer for 20 minutes.

5. Rinse the probe with deionized water.

6. Blot dry with a no-lint cloth.

10

Page 11

Table 4 Cleaning agent

Contaminant Cleaning agent Soak time

General contaminants Electrode cleaning solution 12–16 hours

Mineral deposits 0.1 N HCl solution 10–15 minutes

Fats, grease and oils Warm, mild detergent solution 2 hours (maximum)

Protein deposits Pepsin cleaning solution 3 hours (maximum)

Inorganic buildup EDTA solution 3 hours (maximum)

Replace the filling solution

Replace the filling solution and KCl crystals (if applicable) when either occurs:

• The filling solution becomes contaminated.

• The KCl crystals in a Red Rod probe no longer move freely through the liquid when

the probe is inverted.

1. Use a syringe or small pipette to remove as much filling solution from the probe as

possible.

2. For Red Rod probes, if KCl crystals are still in the probe:

a. Fill the probe half full with the filling solution.

b. With a finger over the filling hole, shake the probe until the crystals become

loose.

c. If the crystals will not loosen, fill the probe with filling solution. Put the probe into a

warm water bath for approximately 10 minutes (up to 60 °C (140 °F)).

d. Do step 1 again.

3. For Red Rod probes, add approximately 0.5 cm (0.2 in.) of KCl crystals to the probe

through the filling hole. For measurements at temperatures more than 60 °C (140 °F),

more crystals are necessary. Refer to Preparation for use on page 2.

4. Fill the probe. Refer to Fill the probe on page 11.

Fill the probe

Storage

Add filling solution to the probe when the filling solution level is low (refer to Preparation

for use on page 2) or is replaced (refer to Replace the filling solution on page 11). Refer

to Specifications on page 1 for the applicable filling solution.

1. If the filling hole is closed, remove the filling-hole cap from the filling hole (refer to

Product overview on page 2).

2. Remove the cap from the tip of the filling solution bottle.

3. Hold the bottle so that the tip is down. Put the tip of the bottle in the filling hole.

4. Slowly squeeze the bottle and fully fill the probe.

Note: Fully fill the probe for the best performance.

5. Put the probe into storage if not used immediately (refer to Storage on page 11).

6. Keep the filling solution bottle and cap for later use.

Note: If the dispensing tip becomes clogged, remove the dispensing tip and soak the tip in

warm water. Fully dry and assemble the tip.

Short-term and long-term storage

For the best probe performance, do not let the reference junction become dry.

Note: Keep the probe in a sample for a maximum of 2 hours if the sample pH is not too high.

11

Page 12

1. Put the filling-hole cap in the filling hole (refer to Product overview on page 2).

2. Rinse the probe with deionized water. Dry the probe with a no-lint cloth.

3. Fill the probe soaker bottle half full with the applicable Storage Solution (refer to

Specifications on page 1) .

4. Loosen the soaker bottle cap and put the soaker bottle on the probe.

5. Turn the soaker bottle cap clockwise to tighten the soaker bottle cap.

6. Make sure that the solution in the soaker bottle fully covers the glass bulb and the

reference junction.

Rehydration

If the glass bulb becomes dry:

1. Soak the probe tip in the 4.01 and 7.00 buffers each for 5 minutes.

2. Rinse the probe with deionized water. Blot dry with a no-lint cloth.

3. Calibrate the probe.

Troubleshooting

Message or symptom Possible cause Action

Probe not supported Software not updated To download the most current version of the software,

refer to the applicable product page on the

manufacturer's website.

Refer to the HQd Series meter documentation for more

information.

HQd meter does not sense the

IntelliCAL® probe

Connect a probe or probe

requires service

pH reading and/or mV reading

is same for all solutions

Standard not recognized error Soaker bottle not removed Remove the soaker bottle.

Probe not connected correctly Disconnect, then connect the probe. Tighten the locking

Software not updated To download the most current version of the software,

Large number of methods stored

on probe

Damaged probe Make sure that there is connectivity with another probe or

Soaker bottle not removed Remove the soaker bottle.

Electrical issue Contact technical support.

Incorrect buffer or contamination

in the buffer solution

Contamination in the filling

solution

Contact technical support.

nut.

refer to the applicable product page on the

manufacturer's website.

Refer to the HQd Series meter documentation for more

information.

If the probe has a large number of stored methods, more

time is necessary for connection. Do not disconnect the

probe, continue to let the probe connect.

meter to confirm isolated issue with probe. Contact

technical support.

Use fresh buffer solution as specified in the method.

Drain and replace the filling solution with fresh solution.

12

Page 13

Message or symptom Possible cause Action

Slow stabilization time Tape not removed from the

filling-hole

Contamination in the glass

sensor

Contamination in the filling

solution

Filling hole closed Make sure that the filling hole is open and above the

Poor contact between reference

junction and solution

LIS sample Soak the probe in the sample for 10 to 15 minutes before

Low sample temperature or

temperature difference between

samples

Air bubbles around inner

reference electrode

Dehydrated glass bulb Rehydrate the probe. Refer to Storage on page 11.

Not sufficient electrolyte flow

Remove the tape.

Clean the probe. Refer to Clean the probe on page 10.

Drain and replace the filling solution with fresh solution.

solution level.

Shake the probe in the solution from side to side to

refresh the reference junction.

the initial measurement or use a LIS chamber or flowthrough cell.

Examine the sample temperature. The lower the

temperature or the higher difference of temperatures

between samples, the longer the stabilization time will

be.

Carefully tap the probe with hand or shake the probe

downward to remove any air bubbles.

1

Open the sleeve junction.

pH probe too old (membrane

Replace the probe.

degradation)

Calibration errors Calibration not done correctly Calibrate again with fresh pH buffers.

Contaminated glass sensor Clean the probe. Refer to Clean the probe on page 10.

Slope exceeds the criteria for %

of theoretical (as defined in the

method slope limit)

1. Adjust the slope limits by changing the PHC725

calibration settings and method.

2. Calibrate again the probe.

3. Make a check standard to examine the performance

of the probe.

13

Page 14

Message or symptom Possible cause Action

Drifting/Inaccurate readings Contaminated glass bulb Clean the probe. Refer to Clean the probe on page 10.

CO2 absorption (for low ionic

strength or high purity sample)

Clogged reference Make sure that the filling hole is not covered. Rinse the

Improper storage conditions/

Dehydrated glass bulb

Colloidal and/or particulates in

the filling solution

Air bubbles around inner

reference electrode

Not sufficient electrolyte flow

Not sufficient stirring Stir the standards and samples at a slow and steady rate

Out of range Measurement value is out of

range

Out of limits Check Standard value is out of

limits in the current method

1

Use the LIS chamber for LIS/high purity samples to

prevent sample contamination.

reference junction holes with deionized water. Carefully

tap the probe with hand or shake the probe to remove air

bubbles. If there are salt crystals around the junction,

soak the electrode tip in a 60 ºC (140 ºF) water bath for

10 minutes.

Clean or condition the probe and calibrate again. The

probe can not operate correctly if the probe was left dry

for a long time. Rehydrate the probe. Refer to Storage

on page 11.

Replace the filling solution, calibrate and test again.

Carefully tap the probe with hand or shake the probe to

remove air bubbles.

Open the sleeve junction.

to prevent the formation of a vortex.

Make sure that the sample is in the range of the probe.

Make sure that the standard is in the limits of the current

method.

Do another method that expands the acceptable limits.

Measurement value is out of

measurement limits in the current

method

Temperature out of range Temperature value is out of

range

Measured temperature is out the

range of the probe

Check standard temperature

value is out of range

1

Only applicable for probes with sleeve junction.

Make sure that the sample is in the limits of the current

method.

Make a new method with an expanded range.

Make sure that the sample temperature is in the range of

the probe.

Make sure that the temperature sensor works correctly.

Make sure that the standard temperature is in the range

of the probe.

Make sure that the temperature sensor works correctly.

Make sure that the check standard temperature is in the

range of the probe.

Consumables and accessories

Description Quantity Item Number

Electrode filling solution, saturated KCl 59 mL 25118059

Electrode filling solution, saturated KCl 500 mL 25118049

KCl crystals (Radiometer Analytical) 15 g S21M001

Hach Electrode Cleaning Solution 500 mL 2965249

EDTA standard solution, 0.20N 500 mL 102149

Soaker bottle 1 5192900

14

Page 15

Consumables and accessories (continued)

Description Quantity Item Number

LIS chamber assembly 1 5189900

Color-coded pH standards (buffers)

pH 4.01 ±0.02 at 25 °C (77 °F), 500 mL 1 2283449

pH 7.00 ±0.02 at 25 °C (77 °F), 500 mL 1 2283549

pH 10.01 ±0.02 at 25 °C (77 °F), 500 mL 1 2283649

pH 4.01 ±0.02 at 25 °C (77 °F), 4 L 1 2283456

pH 7.00 ±0.02 at 25 °C (77 °F), 4 L 1 2283556

pH 10.01 ±0.02 at 25 °C (77 °F), 4 L 1 2283656

pH 4.01 ±0.02 at 25 °C (77 °F), 20 L 1 2283461

pH 7.00 ±0.02 at 25 °C (77 °F), 20 L 1 2283561

pH 10.01 ±0.02 at 25 °C (77 °F), 20 L 1 2283661

IUPAC series certified pH standards (buffers)

pH 4.005 ±0.010 at 25 °C (77 °F), 500 mL 1 S11M002

pH 6.865 ± 0.010 at 25 °C (77 °F), 500 mL 1 S11M003

pH 7.000 (Radiometer Analytical) ±0.010 at 25 °C (77 °F), 500 mL 1 S11M004

pH 9.180 ± 0.010 at 25 °C (77 °F), 500 mL 1 S11M006

pH 10.012 ± 0.010 at 25 °C (77 °F), 500 mL 1 S11M007

pH 12.45 ± 0.05 at 25 °C (77 °F), 500 mL 1 S11M008

Technical grade pH standards (buffers)

pH 4.65 at 25 °C (77 °F), 500 mL 1 S11M010

pH 9.23 at 25 °C (77 °F), 500 mL 1 S11M011

1

Certified standards ship with certificates for traceability to Standard Reference Materials

1

15

Page 16

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

©

Hach Company/Hach Lange GmbH, 2014. All rights reserved. Printed in Germany. 01/2014, Edition 1

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

Loading...

Loading...