Page 1

DOC024.98.93023

ORBISPHERE Model K-

M1100 Sensor and Model

410 Analyzer

12/2013, Edition 8

Basic User Manual

Manuale dell'utente di base

Manuel d'utilisation de base

Manual básico del usuario

Základní uživatelská příručka

Grundlæggende brugervejledning

Basisgebruikershandleiding

Podstawowa instrukcja obsługi

Основно ръководство за потребителя

Alapvető felhasználói kézikönyv

Начальное руководство пользователя

Temel Kullanıcı Kılavuzu

Osnovno uputstvo za upotrebu

Basishandbuch

Peruskäyttöohje

Page 2

English..............................................................................................................................3

Deutsch..........................................................................................................................24

Italiano............................................................................................................................47

Français.........................................................................................................................70

Español..........................................................................................................................93

Čeština.........................................................................................................................116

Dansk............................................................................................................................139

Nederlands.................................................................................................................161

Polski............................................................................................................................184

Suomi............................................................................................................................209

български...................................................................................................................230

Magyar.........................................................................................................................254

Русский........................................................................................................................277

Türkçe...........................................................................................................................302

Српски.........................................................................................................................325

2

Page 3

Specifications

Specifications are subject to change without notice.

Specification Details

EN61326-1:2006 Directive 2004/108/EEC

EMC requirements

CE compliance EN61010-1: 2010 Directive 2006/95/EEC

Safety rating ETL, conforming to UL 61010-1 and CSA 22.2 No. 61010-1

Enclosure ratings

Analog outputs

Measurement alarm relays on the

measurement board

Note: The wall mount instrument is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be required to take

adequate measures.

IP 65; Totally protected against dust; Protected against low pressure jets of

water from all directions.

NEMA 4X (wall mount only); Totally protected against dust; Protected

against pressure jets of water from all directions.

3 Smart 0/4 – 20 mA (500 Ohms), programmable as linear or tri-linear,

configurable to send diagnostics or alarm information.

Three alarm relays; 1A-30 VAC or 0.5A-50 VDC on a resistance load

Configurable to Normally Open [NO] or Normally Closed [NC] contacts by

changing the jumper positions

W A R N I N G

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC

RMS

System alarm relay on the main

board

One system alarm relay; 1A-30 VAC or 0.5A-50 VDC on a resistance load

Normally closed [NC] (NO relay also available) when instrument is turned on

W A R N I N G

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC

RMS

Digital communication

Data storage

Sample temperature

Sample pressure 1 to 20 bar absolute (14.5 to 290 psia)

Sample types

Measurement range

Repeatability

Reproducibility

Accuracy

RS485, Profibus DP (optional), Ethernet, USB-client to download data from

a computer, USB-host to download data with a USB memory stick

Rolling buffer or store once mode for up to 1,000 measurements

Holds calibration records for the last 10 calibrations

Measurement from -5 to 50°C (23 to 122°F)

Sensor resistant to temperature from -5 to 100°C (23 to 212°F)

K1100 sensor: Water only

M1100 sensor (low range): Water and beer

M1100 sensor (high range): Water, beer, wine, wort and carbonated drinks

Low range sensors: 0 to 2,000 ppb (dissolved)

High range sensors: 0 to 40 ppm (dissolved)

Low range sensors: ± 0.4 ppb or 1%, whichever is the greater

High range sensors: ± 0.015 ppm or ± 2% whichever is the greater

Low range sensors: ± 0.8 ppb or 2%, whichever is the greater

High range sensors: ± 0.02 ppm or ± 3% whichever is the greater

Low range sensors: ± 0.8 ppb or 2%, whichever is the greater

High range sensors: ± 0.02 ppm or ± 3% whichever is the greater

English 3

Page 4

Specification Details

Limit of detection (LOD)

Response time (90%)

Display resolution 0.1 ppb

Calibration

Calibration sample

Ambient temperature -5 to 50°C (23 to 122°F)

Humidity 0 to 95% non-condensing relative humidity

Power supply

Wall and pipe mount instrument

(H x D x W)

Panel mount instrument

(housing) (H x D x W)

M1100 12 mm (PG 13.5) sensor

(L x W)

K1100 and M1100 28 mm sensor

(L x W)

Calibration device Weight 0.7 kg

Low range sensors: 0.6 ppb

High range sensors: 0.015 ppm

Low range sensors: < 10 seconds in gas phase; < 30 seconds in liquid

phase

High range sensors: < 10 seconds in gas phase; < 50 seconds in liquid

phase

Low range sensors: Single point calibration (zero)

High range sensors: Two at cap replacement (zero and air), one during use

(air)

Low range sensors: Standard 99.999% N2 (quality 50) or equivalent oxygen

free gas

High range sensors: Standard 99.999% N2 (quality 30) or equivalent oxygen

free gas, air

Universal 85-264 VAC @ 50/60 Hz, 25 VA

10-36 VDC, 25 W

236.5 x 160 x 250 mm - weight 3.8 kg

9.31 x 6.30 x 9.84 ins. - weight 8.38 lbs

156 (123) x 250 x 220 (214) mm - weight 2.9 kg

6.14 (4.84) x 9.84 x 8.86 (8.43) ins. - weight 6.39 lbs

246 x 47 mm - weight 0.6 kg

9.69 x 1.85 ins - weight 1.32 lbs

143.50 x 49 mm - weight 0.74 kg

5.65 x 1.93 ins - weight 1.63 lbs

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

4

English

Page 5

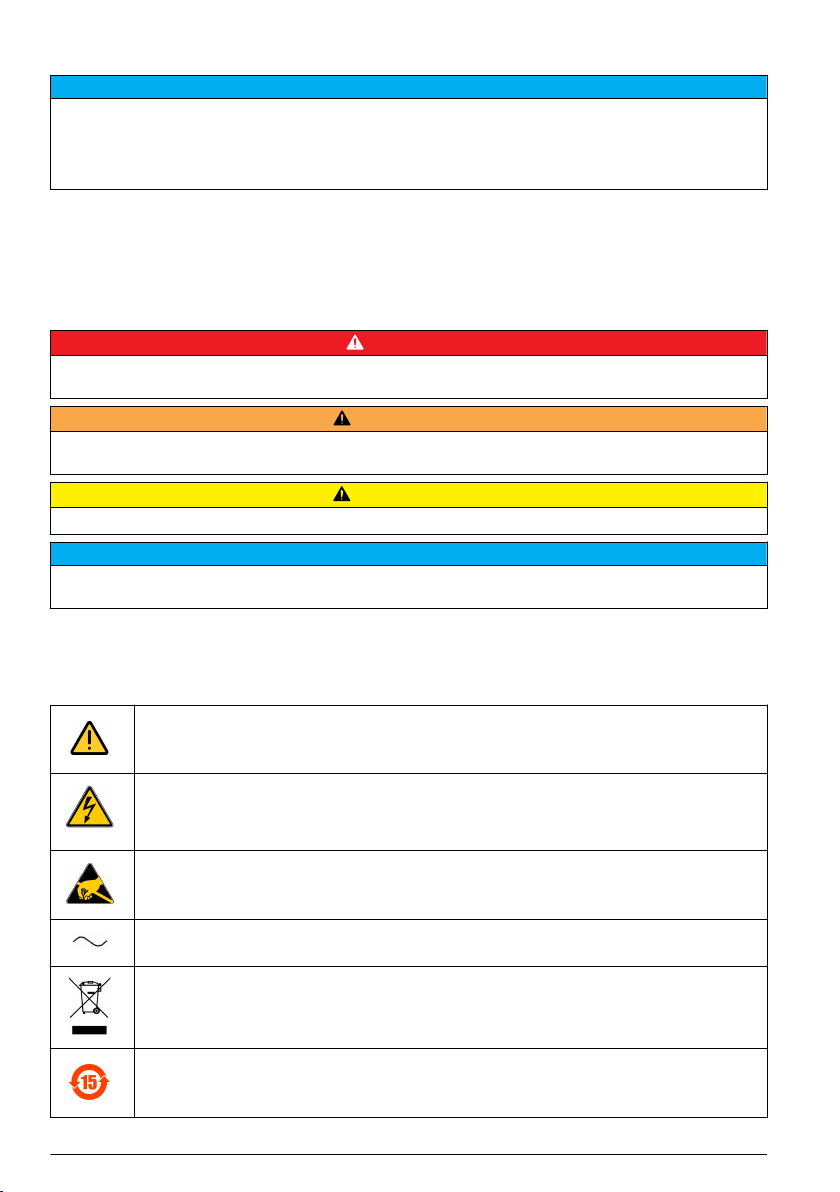

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

W A R N I N G

C A U T I O N

N O T I C E

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary

statement.

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on a product, indicates the instrument is connected to alternate current.

Electrical equipment marked with this symbol may not be disposed of in European domestic or

public disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no

charge to the user.

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Installation

This section provides necessary information to install and connect the analyzer. The installation of

the analyzer should be performed in accordance with relevant local regulations.

D A N G E R

Electrocution Hazard. Do not connect AC power to a 5 VDC powered model.

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical connections.

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially wet locations a Ground Fault

Interrupt device must be used for connecting the equipment to its main power source.

W A R N I N G

W A R N I N G

English 5

Page 6

W A R N I N G

Potential Electrocution Hazard. A protective earth (PE) ground connection is required for both 100-240 VAC and

5 VDC wiring applications. Failure to connect a good PE ground connection can result in shock hazards and poor

performance due to electromagnetic interferences. ALWAYS connect a good PE ground to the controller terminal.

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this section of the manual.

Install the device in a location and position that gives easy access to the disconnect device and its operation.

Potential Instrument Damage. Delicate internal electronic components can be damaged by static electricity,

resulting in degraded performance or eventual failure.

C A U T I O N

N O T I C E

N O T I C E

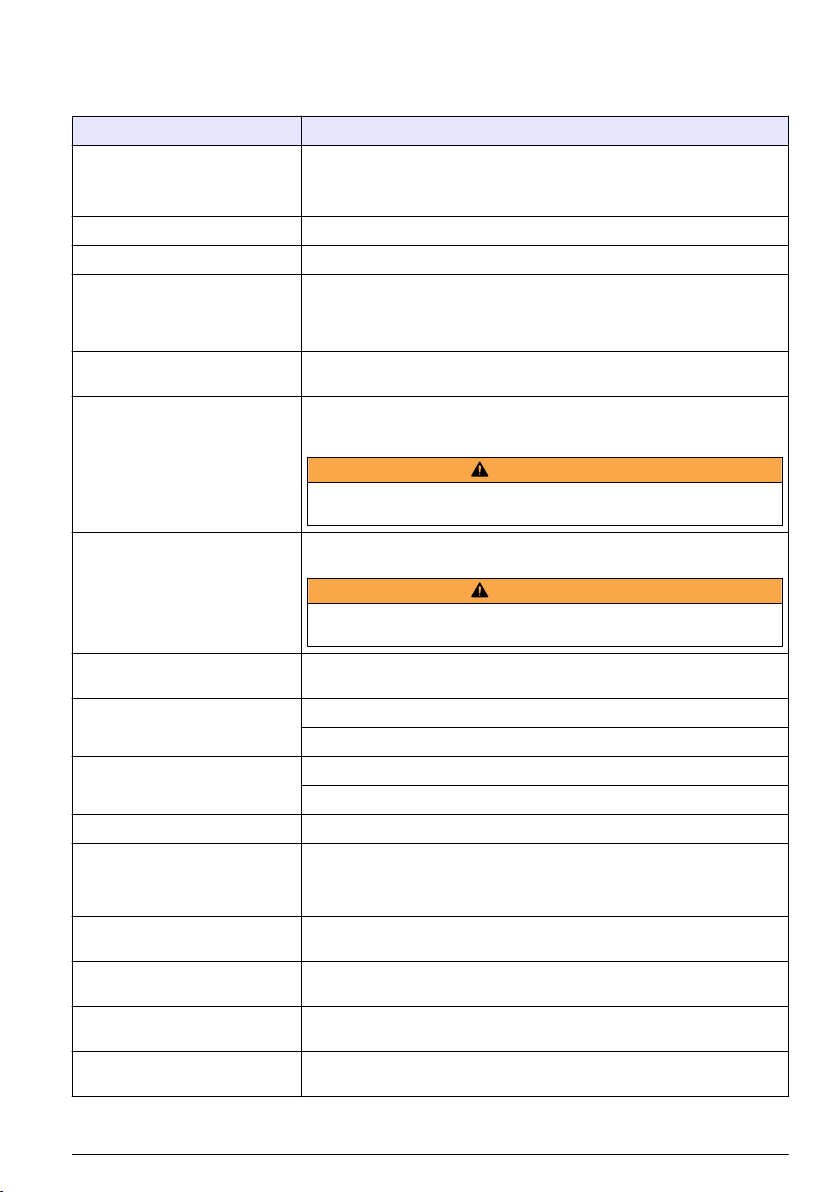

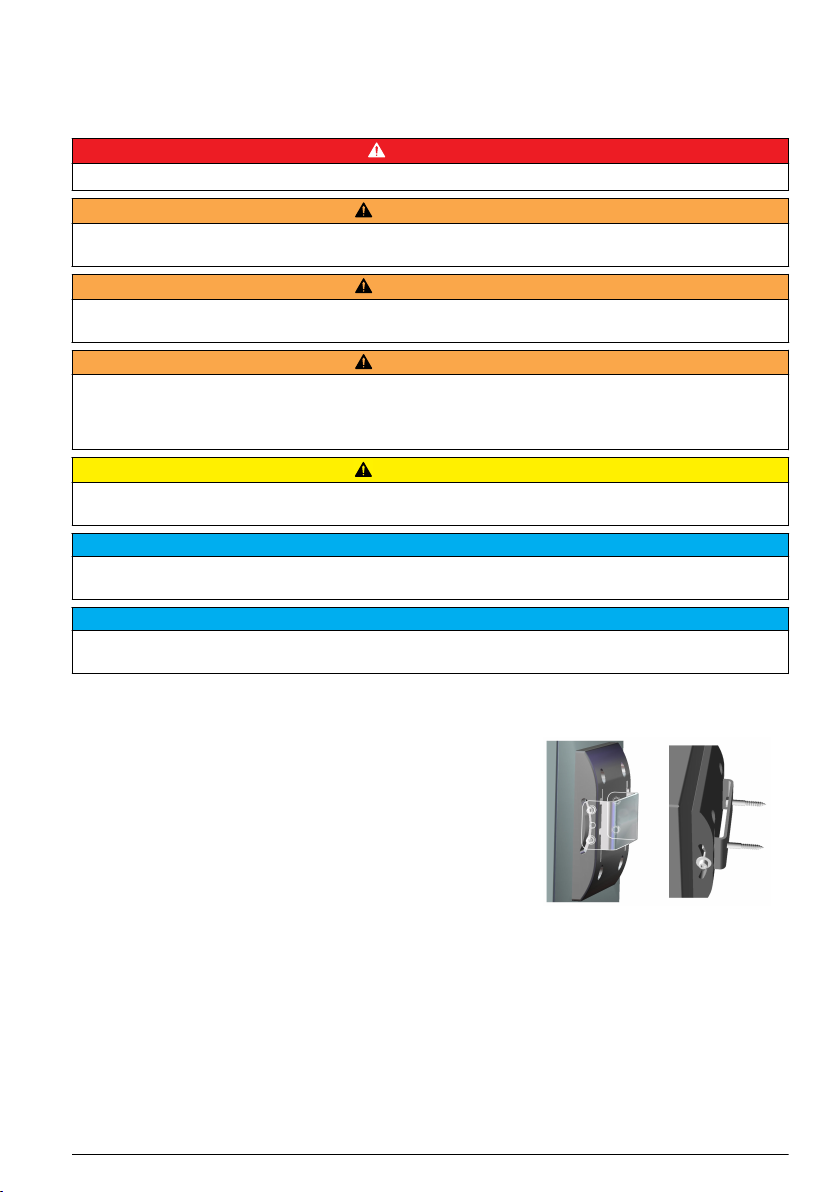

Wall mounting

1. Attach the U-bracket (provided) to the wall with two screws (not

provided).

2. Tilt the instrument slightly backwards to align the bracket pins and

the insertion slots, and slide the instrument onto the bracket as

shown.

3. Insert the 2 locking screws with washers through the side slots.

4. Adjust the instrument angle for better screen vision, and lock both

side screws.

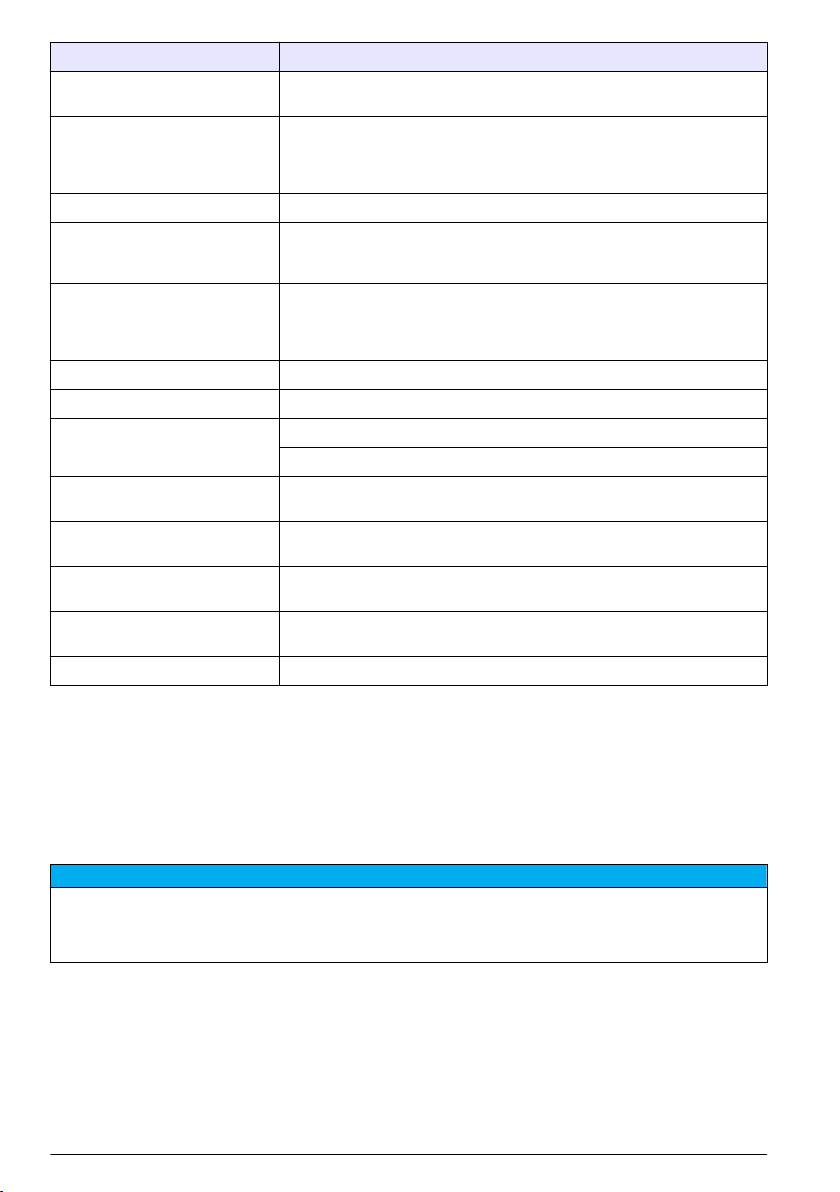

Pipe mounting

1. Assemble the pipe mount bracket to the U-bracket, using the two screws provided.

2. Attach this assembly to the pipe using two clamps (not provided).

3. Slide the instrument onto the bracket.

4. Insert the 2 locking screws with washers through the side slots.

5. Adjust the instrument angle for better screen vision, and lock both side screws.

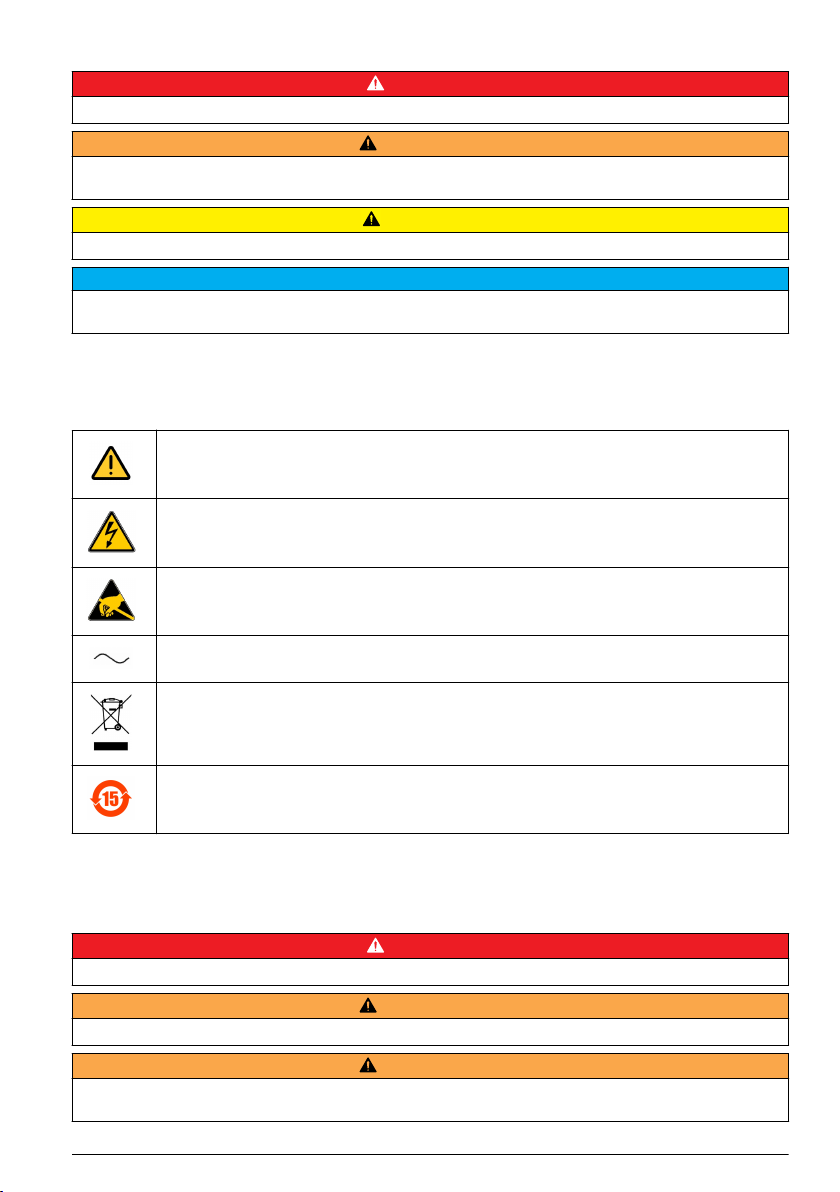

Panel mounting

1-3 4-5 6-7

6 English

Page 7

1. Cut an opening in the panel to accommodate the bracket frame provided.

2. Install the provided frame in the opening.

3. Fold the 6 tabs over the panel lips, using adjustable joint pliers.

4. Slide the instrument in the bracket frame. The instrument should go over the four "T" pins. Rotate the 4 fast

locking screws on both sides of the front panel and slide it in.

5. Rotate the 4 fast locking screws 1/4 turn twice in the lock direction as indicated on the side of the front panel.

This locks the instrument in place on the four "T" pins.

6. To access the connections inside the instrument, remove the instrument housing (six screws on the back

panel, and slide the housing back out)

7. Pass the cables through the housing, then through the cable gland (if applicable) and then perform the

connections as detailed below.

Instrument connections

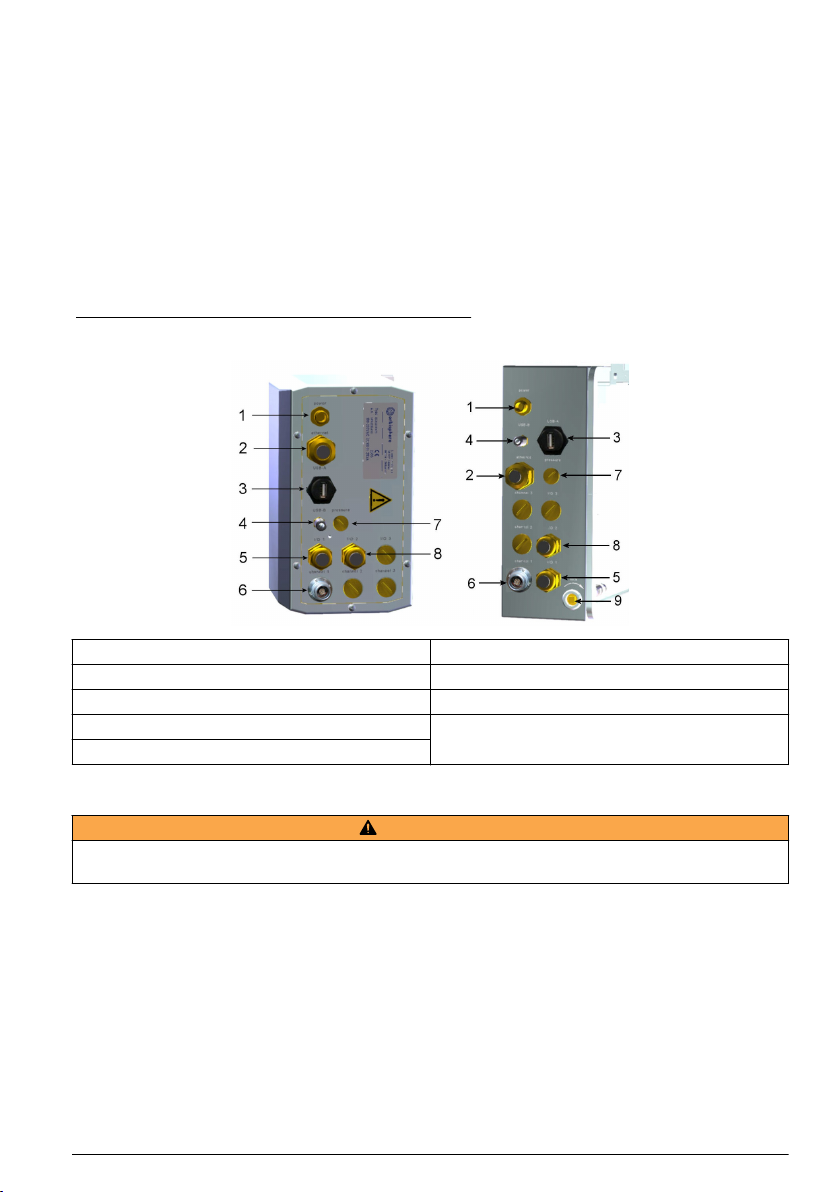

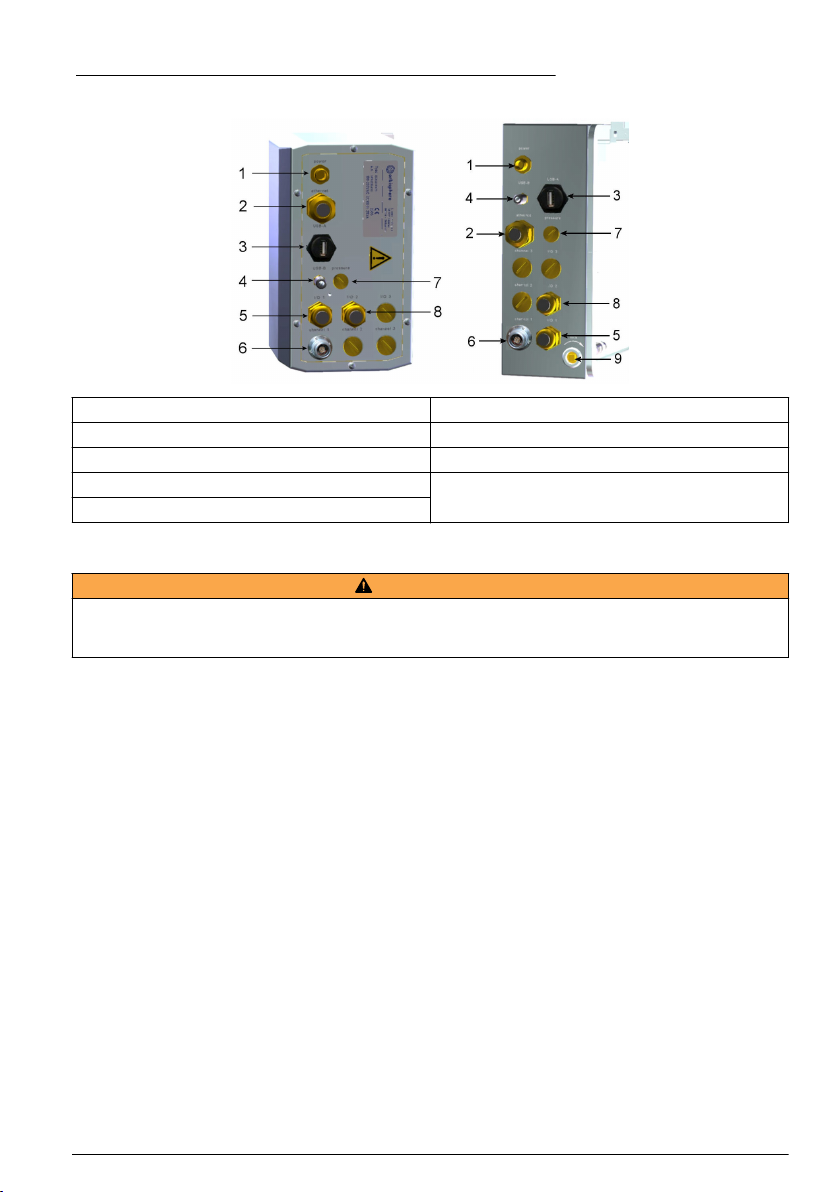

Figure 1 Connections - panel (left); wall/pipe (right)

1 Power cable 6 Sensor connection

2 Ethernet cable gland 7 External pressure sensor connection

3 USB-A host connector 8 Input/Output 2 cable gland

4 USB-B client 4-pin connector 9 Keylock (wall/pipe mount only)

5 Input/Output 1 cable gland

Connectors assembly instructions

W A R N I N G

Potential Electrocution Hazard. In order to maintain the NEMA/IP environmental ratings of the enclosure, use only

conduit fittings and cable glands rated for at least NEMA 4X/IP65 to route cables into the instrument.

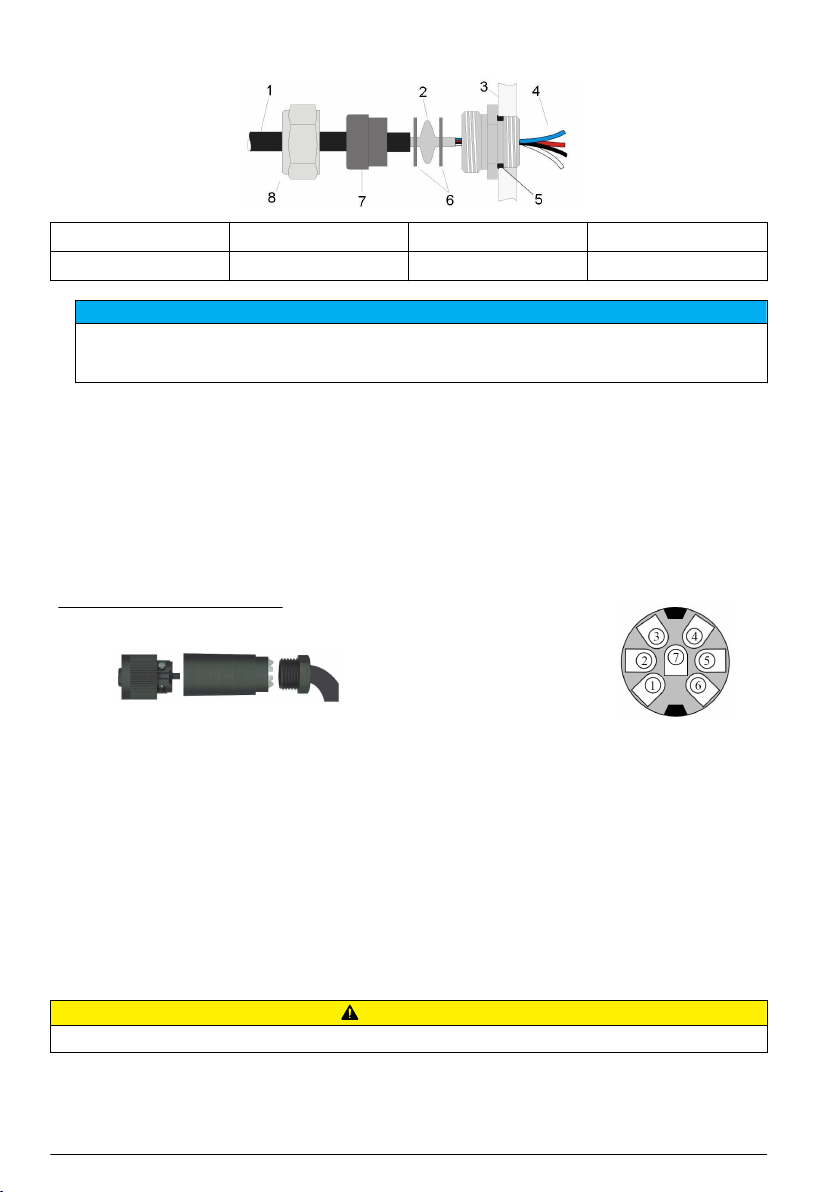

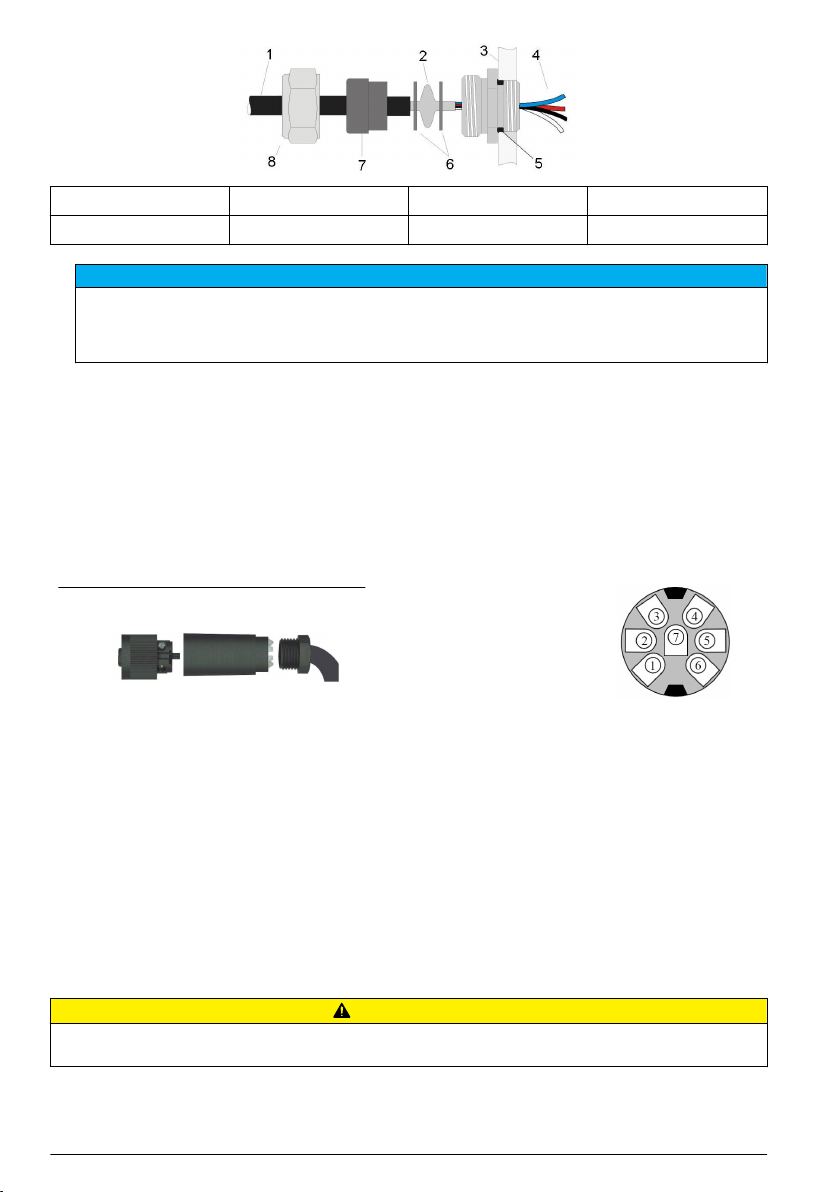

Cable gland wiring instructions

A waterproof cable gland is provided each time a cable must be connected inside the instrument.

The nickel-plated brass cable glands are EMC-types, designed so that the cable shields attach

directly to the instrument housing as a ground. Typical cable wiring instructions are detailed below.

1. Unscrew the cable gland nut. Inside, the assembly is composed of a rubber gasket, and two

metal washers. Note that the ethernet gland on panel and wall mount instruments does not have

washers and the gasket is cut.

2. If wiring a sensor cable, the cable has already been prepared so simply remove the piece of

plastic protection from the exposed shielding. For other cables, strip off external insulation as

required, and 25 mm of shielding. Strip the wires about 8 mm from their ends.

3. Pass the cable through the nut, the rubber gasket, and the two washers.

English

7

Page 8

4. Pinch the shield so that its entire circumference is pressed between the two washers and pass

the cable into the housing, blocking the cable gland.

1 Cable 3 Instrument 5 O-ring 7 Gasket

2 Shield 4 Wire 6 Washers 8 Gland nut

N O T I C E

It is vitally important to ensure the shielding is pinched and secured between the two washers to ensure the

shielding attaches directly to the instrument housing as a ground. Failure to do this could cause damage to

the instrument, and for sensor cables give incorrect readings.

5. Reattach and tighten the cable gland nut.

6. Attach the wires to the corresponding terminal block connections.

Connection to mains power supply

Power supply connection (low voltage instruments)

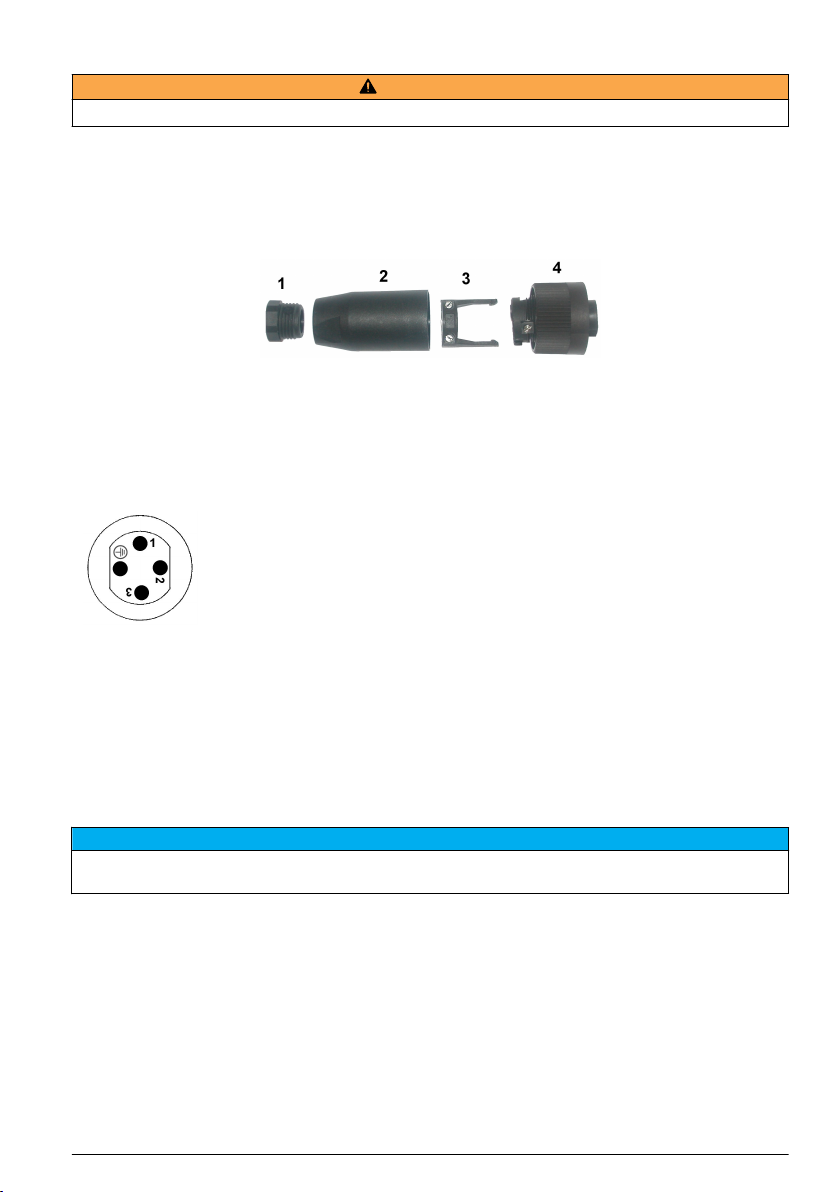

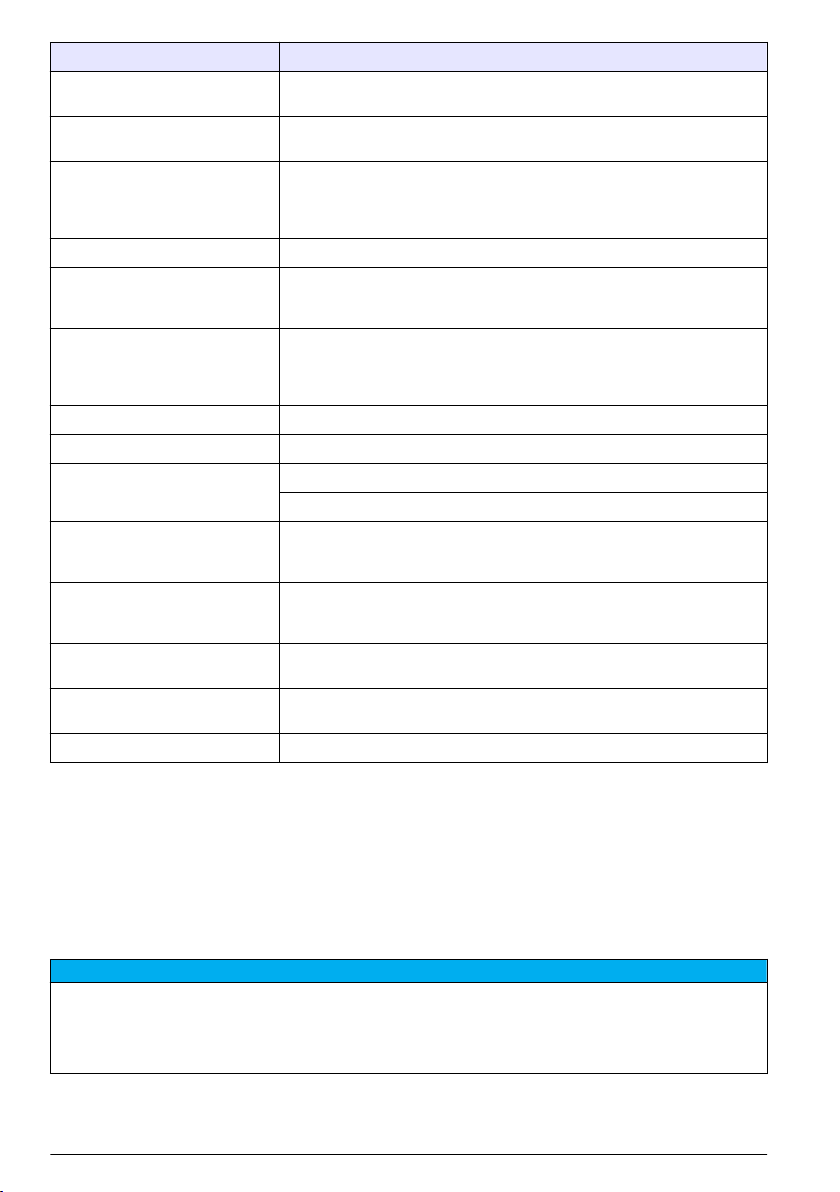

For low voltage instruments (10-30 VDC), connection to the mains power supply is with a 7-pin

BINDER connector (supplied).

Note: The connectors are grooved to avoid an incorrect fitting to the instrument.

Connect the power cable to the connector as follows:

Figure 2 BINDER connector

Pin Connections:

1. Not used

2. Power 10-30 VDC

3. Not used

4. Not used

5. Ground

6. Not used

7. Earth

Power supply connection (high voltage instruments)

High voltage instruments (100-240 VAC) have a 4-pin male connector pre-wired internally with a

male BINDER connector ready for mains connection. A compatible female connector is supplied with

the instrument.

If this female connector was supplied with a mains power plug already pre-attached (cable part

numbers 33031, 33032, 33033 and 33034) then the female connector can be plugged directly into

the instrument power connector. The two connectors are grooved to avoid an incorrect fitting. Tighten

the female connector to the instrument power connector finger-tight.

If no power cable was ordered with the equipment, a mains power plug must be connected to the

supplied female connector as described in the following procedure.

C A U T I O N

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this section of the manual.

User-supplied power cable specifications:

• 3-wire (live, neutral and earth)

• cable Ø ≥ 7mm; ≤ 9.5mm

8

English

Page 9

• wire selection ≥ 1mm2, AWG18; ≤ 2.5mm2, AWG14

W A R N I N G

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical connections.

Prepare the user-supplied power cable as follows:

1. Strip off 23 mm (0.9 ins.) of shielding from the power cable.

2. Cut back the live and neutral wires to 15 mm (0.6 ins.) in length but leave the earth wire as is.

3. Then strip off a small amount of external insulation from the three wires as required.

Wire the female connector as follows:

1. Take the narrow end of the connector (4) in one hand and the main body (2) in the other and

unscrew the two. Pull away the cable clamp (3) and unscrew the end plug (1) to reveal the four

parts that make up the connector.

2. Loosen the screws on the cable clamp (3) to allow enough room to pass the power cable through.

3. Pass the power cable through the end plug (1), the main body (2), and the cable clamp (3), and

then connect the three wires (live, neutral and earth) to the connector (4) as follows:

1. Live (brown)

2. Neutral (blue)

3. Not used

Earth - Earth (green and yellow)

Note: The numbers and earth symbol are stamped on the end of the connector. Ensure it is connected

correctly.

4. Slide the cable clamp (3) back onto the connector (4) and tighten the screws on the clamp to

secure the cable.

5. Screw the two parts (4) and (2) back together.

6. Secure the power cable by screwing the end plug (1) back in place.

7. The female connector can now be plugged directly into the instrument power connector. The two

connectors are grooved to avoid an incorrect fitting. Tighten the female connector to the

instrument power connector finger-tight.

Connections to electronic boards

N O T I C E

Potential Instrument Damage. Delicate internal electronic components can be damaged by static electricity,

resulting in degraded performance or eventual failure.

Note: Any loose connection wires should be bundled tightly together with the use of nylon cable ties.

Connectors P8 on the main board (Figure 3 on page 10) and J7 on the measurement board

(Figure 5 on page 11) are made of two parts. Push down carefully the black levers on either side of

the connector and pull it out securely. Perform all connections with these connectors unplugged.

Once finished, attach the connectors to the boards by pushing them firmly in place (levers up).

English

9

Page 10

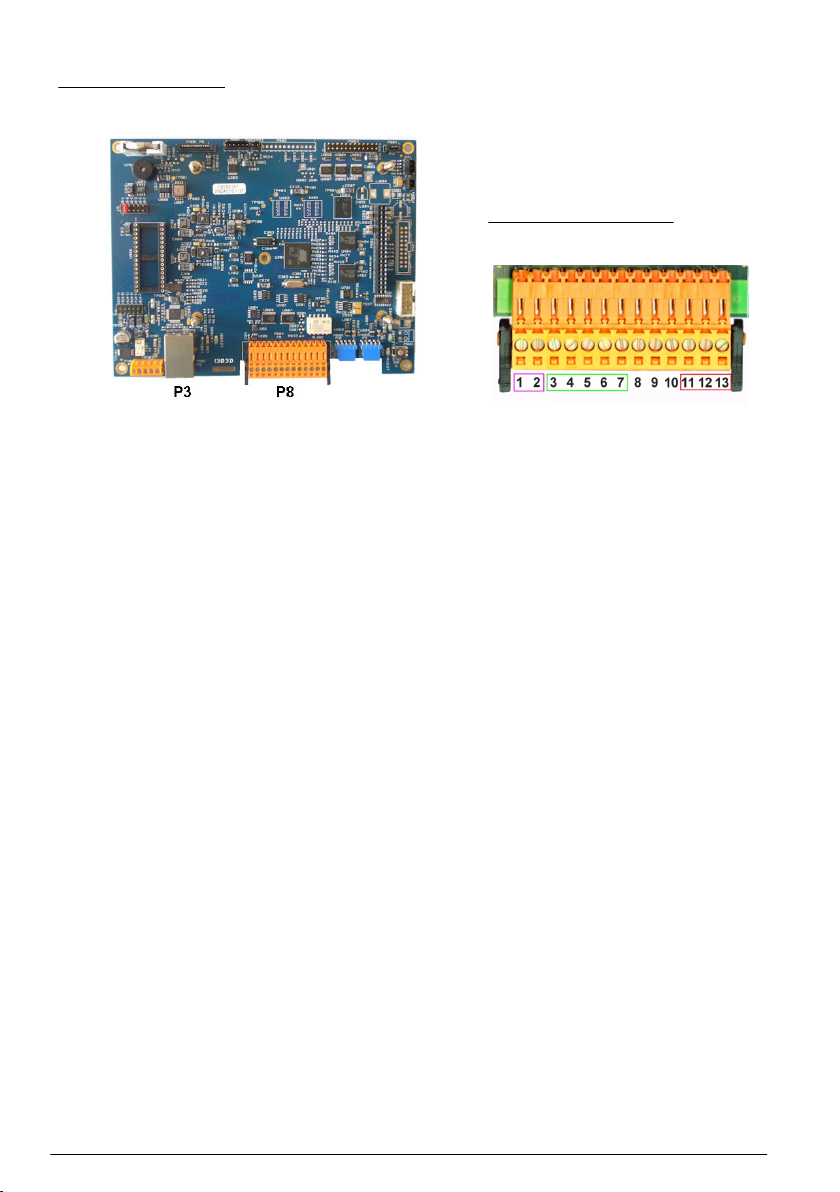

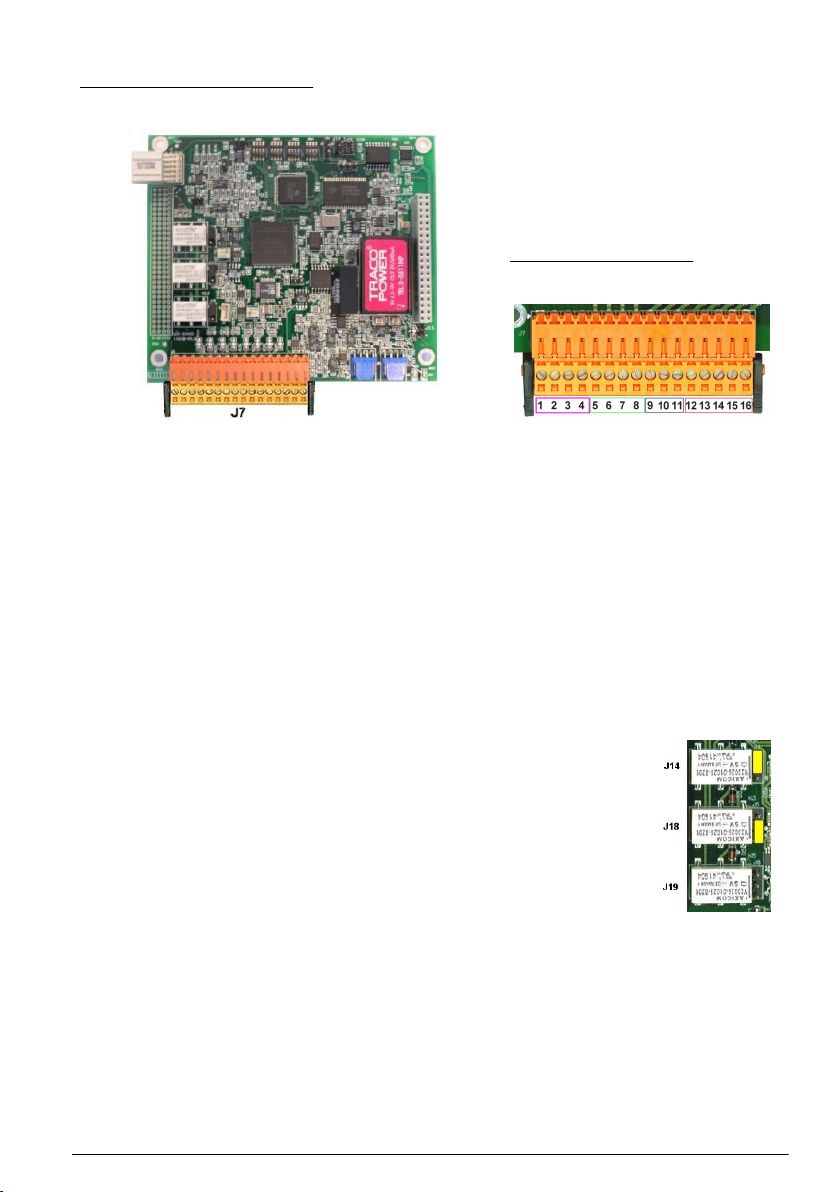

Main board

Figure 3 Main board

Figure 4 Connector P8

Connector P8

The numbers listed below refer to the 13 available P8 connections (from left to right) in Figure 4.

1. RS-485 (signal A)

2. RS-485 (signal B)

3. PROFIBUS-DP (GND)

4. PROFIBUS-DP (+ 5 V)

5. PROFIBUS-DP (signal -)

6. PROFIBUS-DP (signal +)

7. PROFIBUS-DP (signal RTS)

8. Not used

9. Not used

10. Not used

11. System alarm relay (N.O.)

12. System alarm relay (N.C.)

13. System alarm relay (Common)

Connector P3

Ethernet RJ 45. Connect the instrument to the local network by passing an ethernet cable through

the ethernet cable gland (gland location illustrated in Figure 1 on page 7) and connecting to the

P3 connector illustrated in Figure 3.

10

English

Page 11

Measurement board

Figure 5 Measurement board

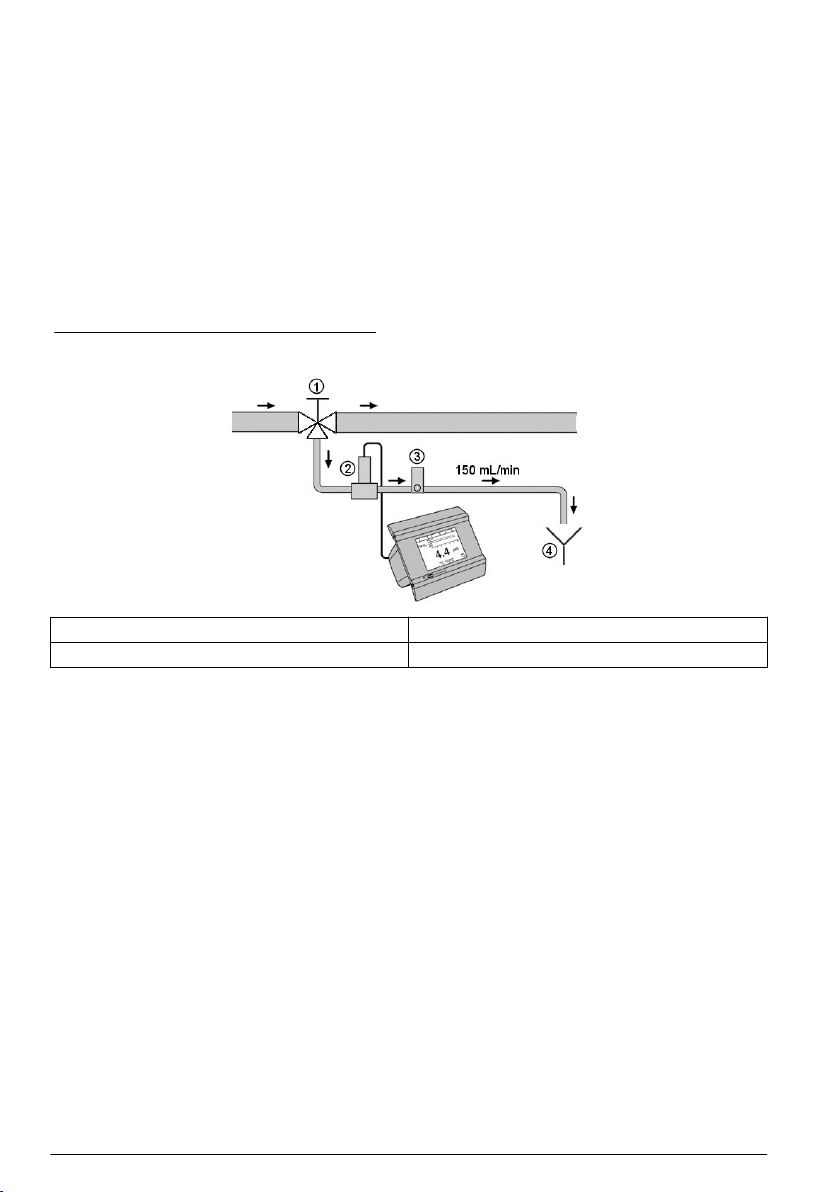

Figure 6 Connector J7

Connector J7 (inputs & outputs)

The numbers listed below refer to the 16 available J7 connections (from left to right) in Figure 6.

Measurement alarms relays:

1. Common

2. Output relay 1

3. Output relay 2

4. Output relay 3

Digital inputs:

9. to 16. Not used

Analog current outputs:

5. GND

6. Output 1

7. Output 2

8. Output 3

Measurement alarm relays

The three output relays are located on the measurement board.

They can be individually configured to Normally Open (NO) or to Normally Closed (NC) by

physically moving the jumper on each relay. On the illustration:

• Upper relay is set to NC

• Middle relay is set to NO

• Lower relay is shown with no jumper

Note: J14 is relay 1, J18 is relay 2, J19 is relay 3

Sensor installation

Sensor positioning

The sensor must be installed in a socket or flow chamber that allows contact with the sample fluid to

be analyzed. The sensor and measuring instrument are connected by a cable. The standard sensor

cable lengths are 3, 5, 10, 15 and 20 meters. Ensure that the sensor will be mounted:

• perpendicular to the pipe

• on a horizontal pipe section (or on flow-ascending vertical pipe)

• minimum of 15 meters away from the pump's discharge side

English

11

Page 12

• in a place where the sample flow is stable and rapid, and as far as possible from:

• valves

• pipe bends

• the suction side of any pumps

• a CO2 injection system or similar

Note: There may be situations where not all the above conditions can be met. If this is the case, or you have any

concerns, please consult your Hach Lange representative to appraise the situation and define the best applicable

solution.

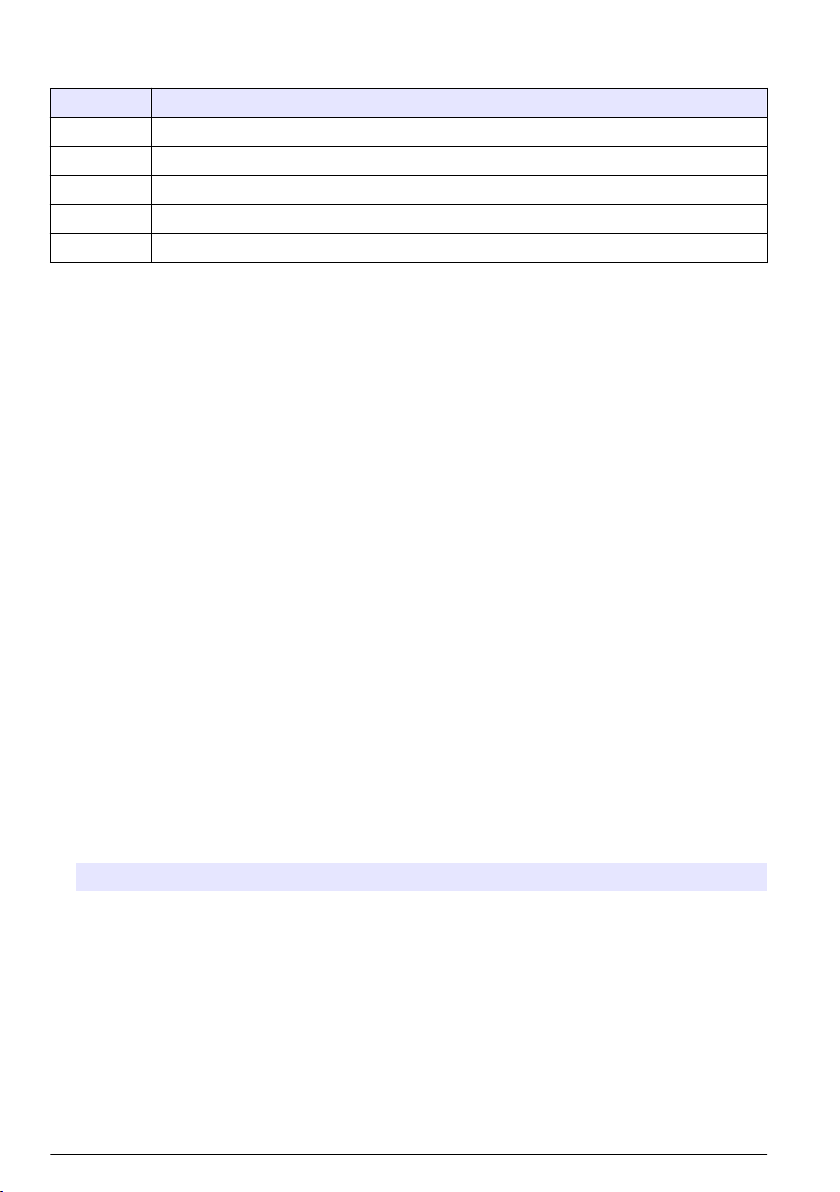

Recommended sample flow rate

For optimal response time, the recommended sample flow rate for both the K1100 and

M1100 sensors is 150 mL/min. Control the flow with the outlet valve on the flow meter (No. 3 in

Figure 7) to avoid foam developing inside the flow chamber which could lead to erroneous oxygen

measurement values.

Figure 7 Typical measurement schematic

1 Valve to redirect sample for measurement 3 Flow meter with outlet valve

2 Sensor and flow chamber combination 4 Drain

User interface

Instrument controls

The instrument front panel provides:

• A touch screen acting as display, touch pad and keyboard.

• A LED, showing when the instrument is on.

Turning instrument On and Off

There is no power switch on the instrument. The mains must be disconnected to turn the instrument

off.

Measurement window

The main (numeric) measurement window continuously displays:

• Sensor measured values

• Measured sensor trends (for the last 10 minute to last hour)

• Measured sensor data alarm limits and other events

12

English

Page 13

• Temperature

Touch screen

The user interface on the front panel is a touch screen providing easy selection through menus. All

the measurement, configuration, calibration and standard service routines can be called by pressing

buttons and menu bars on screen.

The display can be configured to only show a sensor measurement, or to show a parameterized

graphic representation of the last measurements.

Menu navigation

Pressing the “menu” button in the header bar calls the main menu. The

display is made of three columns:

• The left shows the menu options

• The center shows a tree view of the position inside the menu

structure

• The right has the following generic controls:

• Up - Return to previous menu (one step back)

• Main - Jump directly to main menu

• Close - Close the menu and go back to the measurement display.

• Help - Help topics concerning current menu

Virtual keyboard

When a value or text is to be edited a virtual keyboard will appear on screen and can be used like a

standard keyboard. Press CAP to access special keys. When input is complete press the Enter key

to confirm and exit the virtual keyboard. During editing, the edited field name is displayed along with

units where applicable.

Security menu

Note: When the instrument is started for the first time security is disabled. It is highly recommended that each user

be entered into the system and given appropriate access rights as soon as possible to avoid any unauthorized

access.

Configure security

Define access levels for all users . This requires a user access level 4.

1. Select Configuration from the Security menu.

Option Description

Access rights When enabled only registered users can access the menus. When disabled (default)

Max session time The user is logged out automatically when the time limit is reached.

User action logging When enabled every action from a logged on user is recorded in a user log file.

User action log file The log file is a rolling buffer recording recent actions. Press Clear to empty the log

Access rights management

Each user has a unique ID and password used to:

• Allow or deny a user to perform specific actions

• To trace all actions by "ID" in a log file

all menus are freely accessible and no ID is recorded against any action in the log file.

file.

English

13

Page 14

Once the ID and password are entered the user is allowed to perform actions according to the

"Access level" that has been attributed by the Manager:

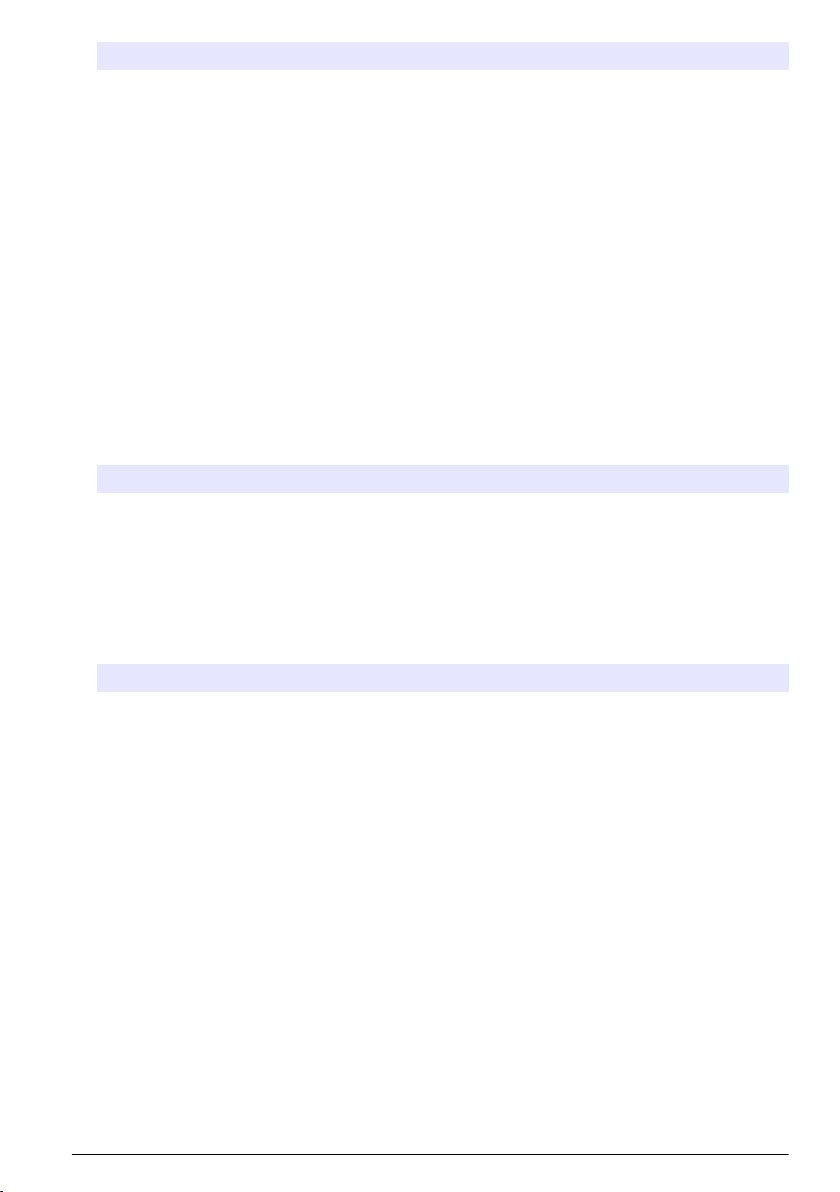

Access level Typical rights

0 View parameters, change views

1 + Start / Stop measurements

2 + Calibration

3 + Modify parameters

4 + Modify table "User Access level" + Enable/Disable "Access right"

At startup all menus are locked and a valid ID and password combination is required to get access

beyond the standard measurement view.

User management

Select Access table from the Security menu to show the list of registered users (a maximum of

99 users allowed). They are listed by name, ID, password and access level.

Pressing on an empty line or the Add button displays a window to add a new user. User name, ID,

password (minimum 4 characters) and access level (1 to 4) are required.

Pressing on a registered user displays a window for editing or deleting that user.

View menu

Numeric view

This is the default view and shows the measurement value, sample temperature value, and a graph

showing the measurements during the set time frame. The display is refreshed after each

measurement cycle which can be configured to suit user requirements.

The K1100 and M1100 low range sensors measure dissolved oxygen up to a maximum value of

2,000 ppb. The K1100 and M1100 high range sensors measure dissolved oxygen up to a maximum

value of 40 ppm. Should the measured concentration go above the maximum value for the sensor

then the measurement cycle is increased to 60 seconds and an Out of range message will be

displayed. An arrow symbol to the right indicates if the value is increasing, decreasing, or remaining

constant.

Once the measured value falls below the maximum value, the measurement cycle returns to the predefined interval.

Numeric view configuration

1. Select Configure from the View menu followed by Conf. numeric view to customize the display:

Option Description

Display temperature Selct Channel temperature to display the sample temperature.

Display mini graph Check the box to display the graph.

Display time base Check the box to display the time base.

Upper bound Adjust graph upper limit.

Lower bound Adjust graph lower limit.

Time base Adjust graph time span.

Grid button Set up the graph to display the x or y axes, grid, or alarm thresholds.

14 English

Page 15

Option Description

Auto scale update button Automatically set the graph upper and lower bounds to best fit the actual values

Clean button Clear the graph being displayed and restart.

displayed.

Statistic view

This feature offers statistical data to match with Total Quality Management tools to better analyze

how a process behaves. The statistics are calculated from the data in the measurement file and

values updated each time a new measurement is added.

Diagnostic view

The diagnostic view contains important information but is only really useful for troubleshooting

purposes.

Measurement menu

Instrument configuration

1. Select Config. instrument from the Measurement menu:

Option Description

Measurement mode Locked on Continuous mode.

Pressure Select the barometric pressure units.

Temperature Select the temperature units.

Measurement configuration

1. Select Configure channel from the Measurement menu:

Option Description

Sensor Displays the sensor model.

Medium Select Liquid or Gas

Gas unit type Select Partial, Fraction, or Dissolved.

Gas unit When a composite unit is selected the unit will change depending on the range of the

value to display. The list of available units depends on the gas unit type selected.

Liquid For the K1100 sensor this option is locked on Water. For the M1100 low range sensor,

choose between Water and Beer. For the M1100 high range sensor, choose between

Water, Beer, Wort, Wine and Carbonated drink.

Display resolution A maximum of 5 digits can be displayed. Decimals can be limited to 0, 1, 2 or 3 for

easier reading. The resolution affects only the data displayed, not the resolution of data

measured and stored.

English 15

Page 16

Option Description

T cut off If this temperature is exceeded the measurement session is suspended and the system

T cut off value Set to 5°C above the sample temperature.

displays a HOT alarm message. The system resumes when the temperature drops to

90% of the specified temperature. It is recommended to Enable this feature to maximize

sensor life and system performance.

Measurement advanced configuration

Note: The offset feature described below should be used for minor measurement adjustments only, and not as an

alternative to a sensor calibration. Make sure your sensor has been correctly calibrated before applying this feature.

1. Select the Advanced button on the Measurement configuration screen:

Option Description

Offset enabled Check this box to enable the user measurement offset option. If checked enter an

Offset value Enter an offset value to manually adjust the measurement value. If the gas unit type

Measurement This field cannot be updated. It shows the current measurement value with the offset

Target value Enter a target measurement value. The offset value is automatically computed so the

Compute offset Select this button to recompute the offset value at any time during the measurement

Out of range

protection

Measurement

interval

Ext. pres. sensor The external pressure sensor option is not available.

offset value or a target value:

or gas unit (defined in the Measurement configuration screen) are changed the

offset value is automatically reset to zero.

applied.

displayed measurement value will be equal to the target value.

process. The offset value will be computed based on the current and target

measurement values.

Check this box to enable the out of range protection (recommended). When enabled

and the measured value exceeds the instrument specification, the measurement

interval will be increased to 1 minute to protect the lifetime of the sensor spot. If

disabled, the lifetime of the spot can be negatively impacted if the sensor is exposed

to high oxygen concentrations for long periods of time.

Set the value to between 2 and 60 seconds to define the interval for refreshing the

measurement value on the display.

Measurement alarms configuration

Set the thresholds for the low/high concentration levels according to the application.

1. Select the Alarms button on the Measurement configuration screen:

Option Description

Low Low 2nd stage for too low concentration alarm.

Low 1st stage for too low concentration alarm.

High 1st stage for too high concentration alarm.

High High 2nd stage for too high concentration alarm.

16 English

Page 17

Option Description

Hysteresis The hysteresis is used to prevent relay flickering when the measurement is just at the alarm

Delay The delay in seconds, before alarms go on whenever concentration values go above ”High

levels. Set this to a minimum but enough to eliminate flickering. For example, if the High Alarm

is set to 40 ppb and the Hysteresis is set to 10% then the High Alarm is activated once the

measurement reaches 40 ppb but only deactivated once it drops below 36 ppb. With the Low

Alarm the opposite is true in that if the Low Alarm is set to 20 ppb and the Hysteresis set to 10%

then the Low Alarm is activated when the measurement drops below 20 ppb and deactivated

when it rises above 22 ppb.

alarms” or below “Low alarms”. Set this to a minimum value, but enough to avoid alarms for

non-representative peaks beyond the set level.

Measurement filter configuration

The filters are aimed at “flattening” the measurement curve in situations where the process shows

atypical peak values that could otherwise hamper the interpretation of measurement readings. The

filter is applied on the last set of measurements each time a measurement is taken.

1. Select the Filter button on the Measurement configuration screen:

Option Description

State Set the filters to Enabled or Disabled.

Type If enabled set the filter to Mean or Median.

Depth Number of measurements that make up a set.

Central depth Number of measurements to be used to determine the average.

Mean is the mathematical average of the last set (depth) of measurement values.

Median allows for eliminating atypical peak measurement values and averaging the

remaining ones. The calculation sorts the last measurement set (depth) by values, then

ignores the highest and lowest values and averages the remaining values (central depth).

Example: With a depth of 7 and central depth of 5, the 7 values are sorted and the highest (7.0)

and lowest (0.9) eliminated. The average of the center 5 is calculated as 3.88:

0.9 1.1 4.0 4.3 4.4 5.6 7.0

Measurement interferences

These options are available to take into account the influence of some components or gases in the

sample during measurement. All available interference corrections are disabled by default.

1. Select the Interferences button on the Measurement configuration screen:

Option Description

Chlorinity/Salinity Select Chlorinity, Salt or All disabled.

Chlorinity/Salinity conc. For chlorinity or salt, it is required to enter the actual concentration in the sample.

Measured data storage

There is one measurement file which contains the data generated by the measurement cycle. The

measurement file is updated in volatile memory and regularly copied in non-volatile memory (file

back-up). At start up the measurement file in volatile memory is updated with the file from the nonvolatile memory.

English

17

Page 18

Note: Data stored in volatile memory is lost when instrument is powered off; non-volatile memory is permanent. In

case of an accidental power off event the instrument resumes measurement storage after the last measurement

stored in flash.

1. Select Measurement file from the Measurement menu:

Option Description

Storage mode Select No storage if data storage is not required. Select Store once to start

RAM time The delay between two recordings of measurement data.

FLASH time The delay between two data file transfers from volatile memory into non-volatile

Save in flash now Press this button to store measurement data in flash immediately. After pressing

Auto save in flash Check this box to save measurements in flash automatically. Measurements are

Purge data Clear all data in the volatile and non-volatile memories.

Start logging

measurements

Open data Opens a table showing the measurments stored in the volatile memory (RAM).

recording measurements. When the volatile memory is full the recording of

measurement stops. Select Rolling buffer for continuous recording of

measurements. When the volatile memory is full the latest measurement set

replaces the oldest one (first-in, first-out)

memory. The last data file erases the previous one. This option is only available if

the Auto save in flash box is checked.

this button, press OK to initiate the process. A warning screen appears informing

you that the operation can take up to 30 seconds. Press Yes to continue or No to

abort.

saved at regular time intervals as defined in the FLASH time box.

Only available in Store once mode, this option starts or stops the measurement

recording session. Measurement recording ends automatically when the buffer is

full.

Calibration

Calibrations can only be performed once the instrument has been installed and configured.

Note: The temperature sensor is factory calibrated and can only be changed by a Hach Lange representative.

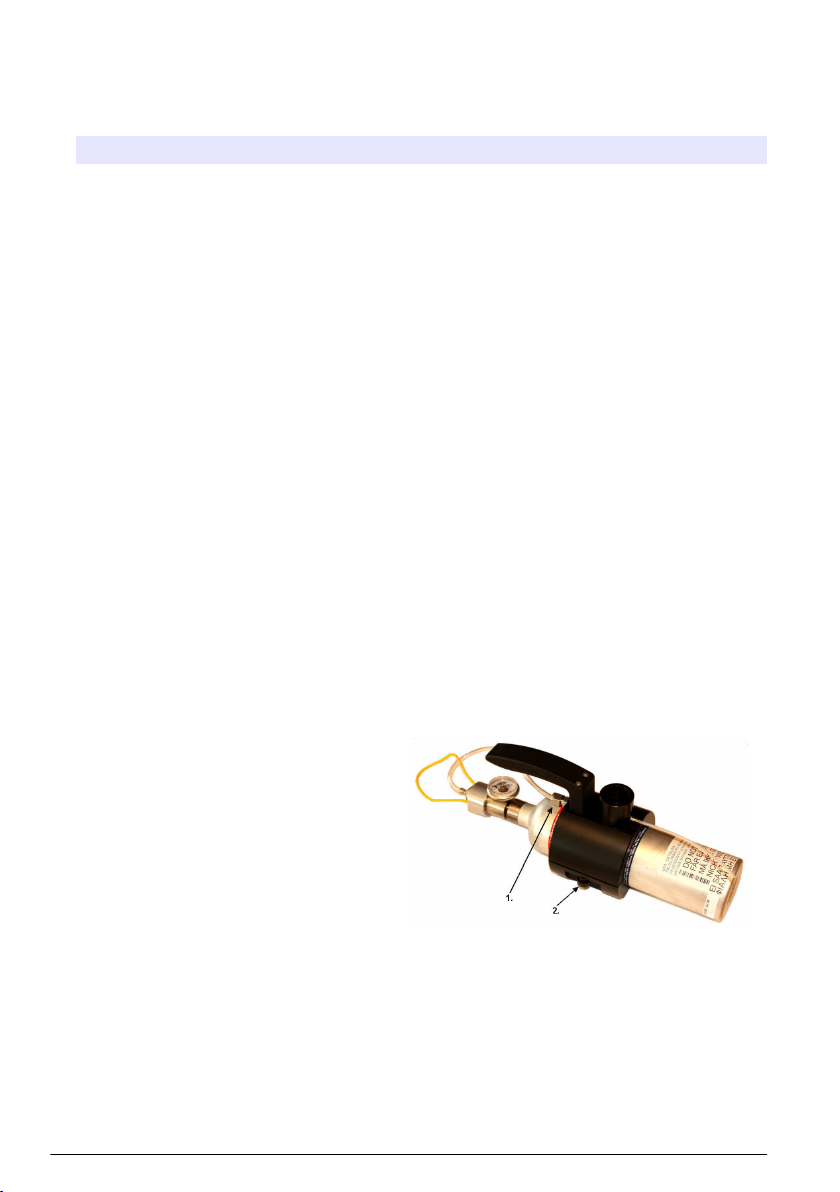

Portable calibration device

The portable calibration device (part number 33088)

is ideal for calibrating the sensor close to its location

in the sample. The device is designed to hold a one

liter gas cylinder but is fully compatible for use with

other kinds of gas cylinders.

When using other types of gas cylinders, simply

connect the gas supply to the Swagelok™ connector

(No. 1), and make sure that the inlet gas pressure

does not exceed 2 bars absolute.

The gas bottle is not supplied and must be

purchased locally.

To ensure the calibration works correctly the calibration gas bottles must be of 99.999% (50) quality

or better. Bottles containing 34 liters of compressed gas with a 5/8-18 UNF (C10) fitting are

compatible with the hand-held calibration device and recommended for this purpose. Empty gas

bottles are easily removed from the device. Simply unscrew the small screw (No. 2) a few turns, slide

18

English

Page 19

the bottle out of the holder, and unscrew the bottle from the pressure reducer. Follow this same

procedure in reverse order to install a new bottle.

Sensor calibration

The sensor can be calibrated manually on an ad hoc basis. By default, the mode is set to zero

calibration with auto-end.

For higher level concentrations (above 1% oxygen which corresponds to about 400 ppb dissolved

O2) a high level adjustment can be performed using a gas mixture containing more than 1% oxygen,

or a known line sample. However, this should not be done without first ensuring the zero point is

accurate. This can be achieved by performing a zero calibration first.

Low range sensors: (K1100-L and M1100-L spots)

There are two calibration modes available - zero or high level adjustment. The sensor is factory

calibrated at zero. During use, the zero calibration is the best calibration to guarantee the sensor

specifications. After a spot replacement, a zero calibration is recommended.

High range sensors: (K1100-H and M1100-H spots)

There are three calibration modes available - zero, high level adjustment or in 100% humid air. The

sensor is factory calibrated at zero and in 100% humid air. During use, humid air calibration is the

best calibration to guarantee the sensor specifications. After a spot replacement, a zero calibration

and a 100% humid air calibration are recommended.

Initial sensor calibration

The sensor has been calibrated at the factory prior to shipment and is ready for use upon delivery.

However, if the sensor has not been used for a period of more than six months since delivery or if the

sensor spot has been replaced or changed in any way, then a sensor calibration will be required.

1. From the Main menu, select Calibration followed by Gas sensor and then Configuration. Make

sure the parameters are set as follows:

Option Description

Auto-calibration Not available for this sensor.

Manual-calibration Make sure that the Auto-End box is checked.

Hold during calibration Make sure this box is checked.

Interferences enabled during

calibration

Zero calibration bottle Make sure this is disabled by unchecking the box as it is not relevant

2. Exit from the configuration screen by pressing OK.

3. Select Calibration and perform a manual zero calibration as described in Zero calibration

on page 21. For high range sensors perform an additional 100% humid air calibration as

described in 100% humid air calibration (high range sensors only) on page 21.

Make sure this is disabled by unchecking the box.

for this sensor.

Manual calibration

Manual calibrations can be made at any time by following these steps:

1. Remove the sensor from the sample line.

2. Rinse the sensor head with clean water.

3. Wipe the sensor head with a clean soft tissue to remove any excess moisture.

4. If using the supplied calibration device insert the sensor into the sensor holder on top of the

calibration device. If not using the calibration device insert the sensor into the flow chamber.

5. Flow the calibration sample through the calibration device or flow chamber as applicable. If using

the calibration device fully open the valve on the pressure reducer to give a gas flow rate of

0.1 L/min. If you are not using the supplied calibration device with pressure reducer the maximum

allowable inlet pressure must be no more than 2 bar absolute.

English

19

Page 20

6. Configure the calibration as described in Calibration configuration on page 20.

7. Start the calibration as described in Zero calibration on page 21, 100% humid air calibration

(high range sensors only) on page 21 or High level adjustment on page 21 depending on the

preferred calibration method.

Calibration configuration

Note: This option can also be invoked by pressing the Modify button in either the Zero calibration or High level

adjustment calibration screens.

1. From the Main menu, select Calibration followed by Gas sensor and then Configuration.

Option Description

Auto-calibration Not available for this sensor.

Manual-calibration When Auto-End is enabled a manual calibration will complete automatically when

Hold during

calibration

Interferences

enabled during

calibration

Zero calibration

bottle

Stop parameters If this button is pressed you can view or change the existing values or restore the

the parameters defined in Stop parameters are reached. Press on Configure to set

the manual calibration parameters. If the calibration fails, the previous calibration

parameters remain unchanged and a warning message displayed.

If checked this keeps the last measured value and stops updating the outputs during

the calibration or verification process. This avoids sending invalid information to any

connected device. At the end of a calibration, this hold remains on for a further

10 minutes to allow the system to stabilize.

This option enables the Chlorine or Salt interference during calibration. This option

must be used if there is chlorine in the calibration solution and if the chlorine

interference correction is enabled during measurement.

Make sure this is disabled by unchecking the box as it is not relevant for this sensor.

default values. It is highly recommended to leave these parameters at their default

values. These values apply to manual calibrations with the Auto-End parameter

enabled.

Configure manual calibration

1. Set the parameters for a manual sensor calibration:

Option Description

Calibration mode Select Zero calibration or High level adjustment. If using a high range sensor you also

Cal. sample Set to In line sample, Gas bottle or Factory parameters. If factory parameters is

Medium This is automatically set to Liquid if in line sample has been selected as the calibration

Gas unit type Either Partial or Dissolved are available for an in line sample. If gas bottle was selected

Gas unit The list of available units depends on unit type selected above.

20 English

have the option of 100% humid air calibration.

Note: If zero calibration or 100% humid air calibration is selected, no other parameters

are required. The following are only required for high level adjustment.

selected, the Ksv value is displayed but can be changed.

These additional parameters are required if in line sample or gas bottle has been

selected as the calibration sample:

sample, or Gas if gas bottle has been selected.

this is set to Fraction.

Page 21

Option Description

Liquid This defaults to Water for the K1100 sensor and Beer for the M1100 sensor.

Reference value Enter the reference value for calibration.

Zero calibration

With this method, the sensor should be removed from the sample and exposed to pure N2 gas. It is

recommended to use the specially designed portable calibration device for this purpose.

Press Start to start the calibration.

A screen is displayed showing the measured values and length of time the sensor has been under

calibration. These values are continually refreshed.

The value % last calibration is an informational message showing the difference between the

current and previous sensor calibrations.

The Signal within range and Stability reached boxes indicate whether the calibration is within

acceptable limits. When both boxes indicate YES, press Finish to accept the new calibration. If one

or both boxes continue to show NO you can still perform a calibration but it is not recommended

and the calibration should be aborted by pressing the Cancel button.

In the case of a calibration failure, attempt a second calibration after about 5 minutes. If the second

attempt also fails, then refer to your Hach Lange representative for advice.

Note: If the Auto-End parameter is enabled then the calibration will be considered successful when the parameters

defined in Stop parameters are met.

If you have not accepted or cancelled the calibration after an elapsed time of 10 minutes then the

process will time-out.

100% humid air calibration (high range sensors only)

With this method, the sensor should be removed from the sample and exposed to air saturated with

humidity. Do this by putting a drop of water in the calibration cap before installing the cap on the

sensor. Press Start to start the calibration. The process is then the same as for the Zero calibration

described previously.

High level adjustment

Note: Before using this option, ensure a zero calibration has been successfully completed first.

This calibration exposes the sensor to a gas or a liquid sample with a known gas concentration. You

also have the option to reset the sensor’s calibration parameters to factory settings (from drop-down

list for Cal. sample).

Press Start to start the calibration. The process is then the same as for the Zero calibration

described previously.

Barometric pressure calibration

Note: The barometric pressure sensor has been factory calibrated but should be periodically verified with a

precision certified barometer. This is only necessary if measuring in gas phase with fraction units (%, ppm).

The upper box shows the barometric pressure as measured by the instrument.

Using a precision certified barometer measure barometric pressure in the location where the

measuring instrument is used. Compare the values anf if they are the same press Cancel, otherwise

enter the new barometric pressure value in the lower box and press Validation to validate the new

setting.

Services menu

There are a number of options available from this menu with the key options detailed below.

Calibration timer

The instrument can automatically remind the user when the next sensor calibration is due.

• To enable the timer, select Enable and enter a delay in days.

English

21

Page 22

• The display shows the current instrument date and time, next calibration due date and time, and

the remaining days.

The next calibration date is updated when the sensor is calibrated.

Service timer

The sensor attached to your instrument will require periodic servicing and maintenance. The

instrument can automatically remind the user when the next sensor service is due.

• To enable the timer, select Enable and enter a delay in days.

• The display shows the current instrument date and time, the next sensor service due date and

time, and the remaining days.

After a service press the Service done button to update the next service date.

Language selection

Select the language from a list and restart the instrument to apply the change.

Clock

Update the time and date information.

Other menus

For information on setting up relays and analog outputs refer to the full user manual (Inputs/Outputs

menu).

For information on setting up RS485, PROFIBUS-DP, USB, HTTP/TCP-IP and attached PRINTER

links refer to the full user manual (Communications menu).

For information on setting up products and global configurations refer to the full user manual

(Products and Global Configuration menus).

Maintenance

Instrument maintenance

C A U T I O N

Personal Injury Hazard. Any instrument maintenance should be carried out by a qualified Hach Lange Service

Technician. Please contact your local representative should you feel any maintenance or instrument adjustments

are required.

Sensor maintenance

The sensor spot needs to be replaced about once a year. The procedure is very simple and takes no

more than a couple of minutes.

Equipment required

Note: Check the Ksv factor of the new spot on the maintenance kit box. If this is different to the Ksv value displayed

in the factory parameter (see Configure manual calibration on page 20) update the factory parameter to the new

value.

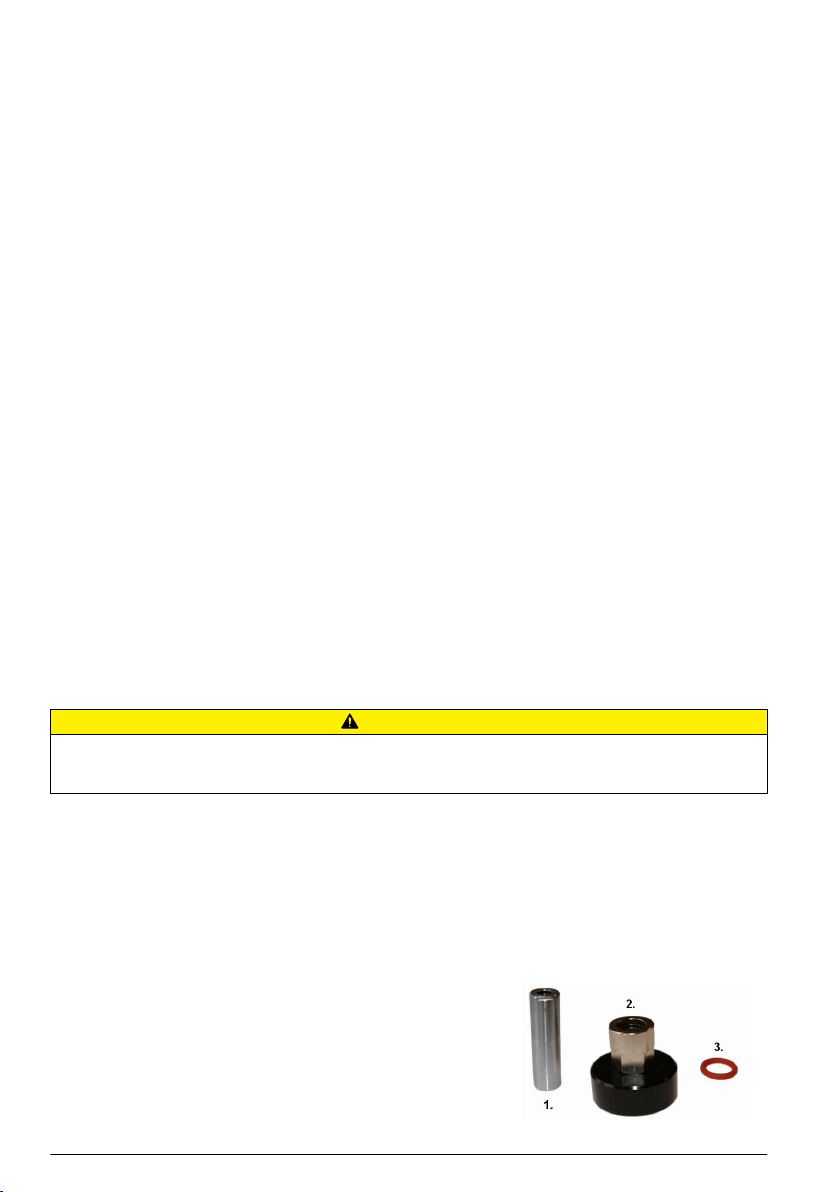

A replacement sensor spot

1.

2. The maintenance tool delivered with the sensor

3. O-ring supplied with the sensor spot

22 English

Page 23

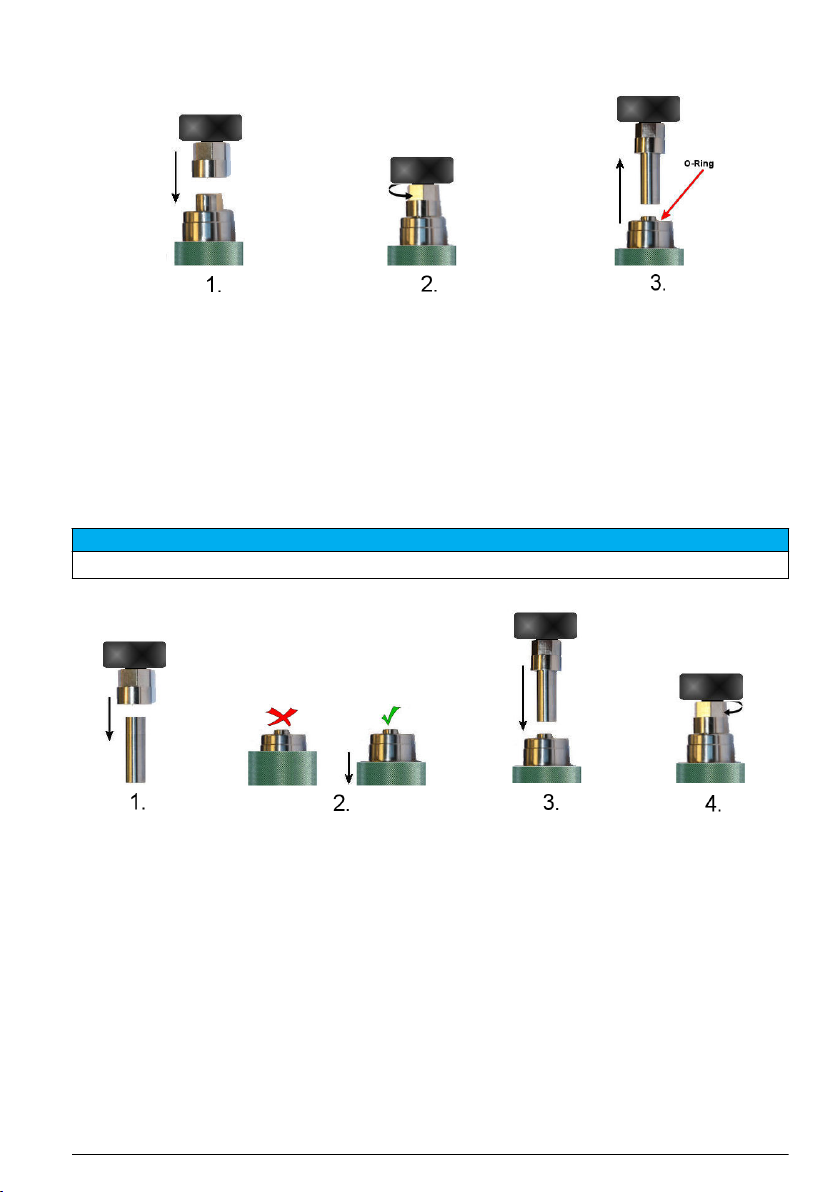

Sensor spot removal

1. Push the maintenance tool (square sides upmost) as far down as possible over the old sensor spot. Continue

to push down on the tool and turn gently until the square sides of the tool and the square slots of the sensor

spot engage. The tool should then drop into position.

2. Turn the tool counter-clockwise to unscrew the old sensor spot.

3. When unscrewed completely simply lift out the old sensor spot. Pull off the maintenance tool and discard the

old sensor spot.

Note: Check the O-ring. If it appears damaged in any way then using a pair of tweezers remove and replace it with the new O-ring

from the maintenance kit.

Sensor spot replacement

N O T I C E

Avoid scratching or damaging the sensor spot (the black surface on the sensor head) during this process.

1. Push the maintenance tool (square sides upmost) as far down as possible over the new sensor spot.

Continue to push down on the tool and turn gently until the square sides of the tool and the square slots of the

sensor spot engage. The tool should then drop into position.

2. Make sure the sensor collar is as far down as it will go, so that the top of the collar is aligned with the base of

the sensor head.

3. Take the combined maintenance tool and sensor spot and place it in the end of the sensor.

4. Turn the tool clockwise to screw in the new sensor spot, finger tight. Do not over-tighten. Once secure, pull off

the maintenance tool.

English 23

Page 24

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen.

Spezifikation Details

EN 61326-1:2006 EU-Richtlinie 2004/108

EMV-Anforderungen

CE-Konformität EN61010-1: 2010 EU-Richtlinie 2006/95/EEC

Sicherheitsbestimmungen ETL, entspricht UL 61010-1 und CSA 22.2 Nr. 61010-1

Gehäuse

Analoge Ausgänge

Messungsalarmrelais auf der

Messkarte

Hinweis: Das Instrument für die Wandmontage ist ein Produkt der Klasse A. In

Haushaltsumgebungen kann dieses Produkt Funkstörungen verursachen, die dazu

führen können, dass der Benutzer Gegenmaßnahmen ergreifen muss.

IP 65; Gesamtschutz gegen Staub; Geschützt gegen Wasserstrahlen mit

niedrigem Druck aus allen Richtungen.

NEMA 4X (nur Wandmontage); Gesamtschutz gegen Staub; Geschützt

gegen Wasserstrahlen aus allen Richtungen.

3 Smart 0/4 - 20 mA (500 Ohm), programmierbar als linear oder tri-linear,

konfigurierbar für das Senden von Diagnose- oder Alarminformationen.

Drei Alarmrelais; 1 A-30 V AC oder 0,5 A-50 V DC an einer Widerstandslast

Konfigurierbar als Einschaltglied [NO] oder Ausschaltglied [NC] durch

Änderung der Position der Jumper.

W A R N U N G

Potenzielle Stromschlaggefahr! Nur an Sicherheitsniederspannung <

33 V AC RMS anschließen

Systemalarmrelais auf dem

Mainboard

Nur ein Systemalarmrelais; 1 A-30 V AC oder 0,5 A-50 V DC an einer

Widerstandslast

Ausschaltglied [NC] (NO-Relais ebenfalls lieferbar) wenn das Instrument

eingeschaltet wird.

W A R N U N G

Potenzielle Stromschlaggefahr! Nur an Sicherheitsniederspannung <

33 V AC RMS anschließen

Digitale Kommunikation

Datenspeicherung

Probentemperatur

Probendruck 1 bis 20 bar absolut (14,5 bis 290 psia)

Probentypen

Messbereich

Wiederholbarkeit

RS485, Profibus DP (optional), Ethernet, USB-Client zum Herunterladen

von Daten von einem Computer, USB-Host zum Herunterladen von Daten

mit einem USB-Speicherstick

Endlosspeicher oder Einmalspeichermodus für bis zu 1.000 Messwerten

Speichert Daten für die letzten 10 Kalibrierungen

Messungen von -5 bis 50°C (23 bis 122°F)

Sensor temperaturbeständig von -5 bis 100°C (23 bis 212°F)

K1100 Sensor: Nur Wasser

M1100 Sensor (Niedrigbereich) Wasser und Bier

M1100 Sensor (Hochbereich) Wasser, Bier, Wein, Maische und

kohlendioxidhaltige Getränke

Sensoren für den Niedrigbereich: 0 bis 2.000 ppb (gelöst)

Sensoren für den Hochbereich: 0 bis 40 ppm (gelöst)

Sensoren für den Niedrigbereich: ± 0,4 ppb oder 1% je nach größerem Wert

Sensoren für den Hochbereich: ± 0,015 ppb oder ± 2%, je nach größerem

Wert

24 Deutsch

Page 25

Spezifikation Details

Reproduzierbarkeit

Genauigkeit

Nachweisgrenze (LOD)

Reaktionszeit (90%)

Anzeigeauflösung 0,1 ppb

Kalibrierung

Kalibrierungsprobe

Umgebungstemperatur -5 bis 50°C (23 bis 122°F)

Relative Luftfeuchtigkeit 0 bis 95% relative Feuchtigkeit (nicht kondensierend)

Stromversorgung

Instrument für die Wand- und

Rohrmontage

(H x T x B)

Instrument für die

Schalttafelmontage

(Gehäuse) (H x T x B)

M1100 12 mm (PG 13.5) Sensor

(L x B)

Sensor K1100 und M1100 28 mm

(L x B)

Kalibriergerät Gewicht 0,7 kg

Sensoren für den Niedrigbereich: ± 0,8 ppb oder 2% je nach größerem Wert

Sensoren für den Hochbereich: ± 0.02 ppb oder ± 3%, je nach größerem

Wert

Sensoren für den Niedrigbereich: ± 0,8 ppb oder 2% je nach größerem Wert

Sensoren für den Hochbereich: ± 0.02 ppb oder ± 3%, je nach größerem

Wert

Sensoren für den Niedrigbereich: 0,6 ppb

Sensoren für den Hochbereich: 0,015 ppm

Sensoren für den Niedrigbereich: < 10 Sekunden in der gasförmigen Phase;

< 30 Sekunden in der flüssigen Phase

Sensoren für den Hochbereich: < 10 Sekunden in der gasförmigen Phase; <

50 Sekunden in der flüssigen Phase

Sensoren für den Niedrigbereich: Einzelpunktkalibrierung (Null)

Sensoren für den Hochbereich: Zwei beim Austausch der Kappe (Null und

Luft), eine während der Benutzung

Sensor für den Niedrigbereich: Standard 99,999% N2 (Qualität 50) oder ein

vergleichbares sauerstofffreies Gas

Sensor für den Hochbereich: Standard 99,999% N2 (Qualität 30) oder ein

vergleichbares sauerstofffreies Gas, Luft

Universal 85-264 V AC @ 50/60 Hz, 25 VA

10-36 V DC, 25 W

236,5 x 160 x 250 mm - Gewicht 3,8 kg

9,31 x 6.30 x 9.84 ins. - Gewicht 8,38 lbs

156 (123) x 250 x 220 (214) mm - Gewicht 2,9 kg

6,14 (4,84) x 9,84 x 8,86 (8,43) Zoll - Gewicht 6,39 lbs

246 x 47 mm - Gewicht 0,6 kg

9,69 x 1,85 Zoll n- Gewicht 1,32 lbs

143,50 x 49 mm - Gewicht 0,74 kg

5,65 x 1,93 Zoll - Gewicht 1,63 lbs

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Deutsch

25

Page 26

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

Warnaufkleber

Bitte lesen Sie alle Aufkleber und Schilder, die am Produkt angebracht sind. Die Nichtbeachtung

kann zu Verletzungen von Personen oder Beschädigungen des Produkts führen. Im Handbuch

werden auf die am Gerät angebrachten Symbole in Form von Warnhinweisen verwiesen.

G E F A H R

W A R N U N G

V O R S I C H T

H I N W E I S

26 Deutsch

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen sollte.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Dieses Symbol weist darauf hin, dass das Instrument an Wechselstrom angeschlossen werden

muss.

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in der Europäischen Union nicht

als Haushaltsabfall oder in öffentlichen Abfallentsorgungssystemen entsorgt werden. Altgeräte

können ohne zusätzliche Kosten für den Verbraucher an den Hersteller für die Entsorgung

zurückgegeben werden.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Page 27

Installation

Der vorliegende Abschnitt enthält Informationen für die Installation und das Anschließen des Geräts.

Die Installation des Geräts sollte in Übereinstimmung mit den vor Ort geltenden gesetzlichen

Vorschriften erfolgen.

G E F A H R

Stromschlaggefahr. Schließen Sie den Wechselstromanschluss nicht an ein mit 5 VDC gespeistes Modell an.

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn elektrische

Anschlüsse durchgeführt werden.

Potenzielle Stromschlaggefahr. Wenn dieses Gerät im Freien oder an potenziell feuchten Standorten eingesetzt

wird, muss ein FI-Schutzschalter zum Anschluss an die Netzversorgung verwendet werden.

Potenzielle Stromschlaggefahr. Bei 100-240 VAC- und 5 VDC-Anwendungen muss ein Erdungsschutzleiter (PE)

angeschlossen werden. Ohne ausreichenden Erdungsschutz besteht Stromschlaggefahr, und das Gerät kann

wegen elektromagnetischer Störungen nicht richtig funktionieren. Schließen Sie IMMER einen

Erdungsschutzleiter an der Steuerungsklemme an.

Verletzungsgefahr. Nur qualifiziertes Personal sollte die in diesem Kapitel des Handbuchs beschriebenen

Aufgaben durchführen.

Installieren Sie das Gerät an einem Standort und in einer Position, wo es zur Bedienung und zum

Abschalten/Abklemmen gut zugänglich ist.

Möglicher Geräteschaden Empfindliche interne elektronische Bauteile können durch statische Elektrizität

beschädigt werden, wobei dann das Gerät mit verminderter Leistung funktioniert oder schließlich ganz ausfällt.

W A R N U N G

W A R N U N G

W A R N U N G

V O R S I C H T

H I N W E I S

H I N W E I S

Wandmontage

1. Bringen Sie den (mitgelieferten) U-Bügel mit zwei Schrauben (nicht

mitgeliefert) an der Wand an.

2. Kippen Sie das Instrument leicht zurück, um die Stifte des Bügels

mit den Aufnahmeschlitzen auszurichten, und schieben Sie das

Instrument wie gezeigt auf den Bügel.

3. Setzen Sie die beiden Sperrschrauben mit den Scheiben durch die

seitlichen Schlitze ein.

4. Stellen Sie den Winkel des Instruments so ein, dass die

bestmögliche Ablesung des Bildschirms erzielt wird, und ziehen Sie

dann die beiden seitlichen Schrauben fest.

Deutsch 27

Page 28

Rohrmontage

1. Montieren Sie den Rohrmontagebügel am U-Bügel mit den beiden mitgelieferten

Schrauben.

2. Befestigen Sie diese Bauteile dann mit den beiden Klemmschellen an dem Rohr

(gehören nicht zum Lieferumfang).

3. Schieben Sie das Instrument auf den Bügel.

4. Setzen Sie die beiden Sperrschrauben mit den Scheiben durch die seitlichen Schlitze

ein.

5. Stellen Sie den Winkel des Instruments so ein, dass die bestmögliche Ablesung des

Bildschirms erzielt wird, und ziehen Sie dann die beiden seitlichen Schrauben fest.

Paneelmontage

1-3 4-5 6-7

1. Schneiden Sie eine Öffnung in den mitgelieferten.

2. Installieren Sie den mitgelieferten Rahmen in der Öffnung.

3. Falten Sie die 6 Zapfen mit einer Zange über die Lippen des Paneels.

4. Schieben Sie das Instrument in den Bügelrahmen. Das Instrument sollte über die 4 "T"-Stifte gehen. Drehen

Sie die 4 Befestigungsschrauben auf beiden Seiten des Frontpaneels und schieben Sie es hinein.

5. Drehen Sie die 4 Befestigungsschrauben zweimal um 1/4 Umdrehung in Sperrrichtung, wie auf der Seite des

Frontpaneels gezeigt. Dadurch rastet das Instrument über den vier "T"-Stiften ein.

6. Entfernen Sie für den Zugang zu den Anschlüssen im Inneren des Instruments das Gehäuse des Instruments

(6 Schrauben auf der Rückseite, und schieben Sie das Gehäuse zurück).

7. Führen Sie die Kabel durch das Gehäuse, dann durch den Kabeldurchlass (falls anwendbar) und nehmen Sie

die Anschlüsse vor, die im Folgenden detailliert beschrieben werden.

28 Deutsch

Page 29

Anschlüsse des Instruments

Abbildung 1 Anschlüsse - Paneel (links); Wand / Rohr (rechts)

1 Stromkabel 6 Sensoranschluss

2 Ethernetkabeldurchlass 7 Anschluss Außendrucksensor

3 Steckverbindung USB-A Host 8 Kabeldurchlass Eingang/Ausgang 2

4 USB-B-Client 4-Pin-Anschluss 9 Schloss (nur Wand- bzw. Rohrmontage)

5 Kabeldurchlass Eingang/Ausgang 1

Anweisungen zur Montage der Steckverbindungen

W A R N U N G

Potenzielle Stromschlaggefahr. Um die NEMA/IP-Umweltbedingungen des Gehäuses zu wahren, benutzen Sie

zur Verlegung von Kabeln im Geräteinnern nur Rohranschlussstücke und Kabeldurchführungen, die mindestens

NEMA 4X/IP65 erfüllen.

Anweisungen zur Verkabelung des Kabeldurchlasses

Jedes Mal, wenn ein Kabel im Inneren des Instruments angeschlossen werden muss, wird ein

wasserdichter Kabeldurchlass mitgeliefert. Die vernickelten Messing-Kabeldurchlässe entsprechen

dem EMC-Typ und sind so konzipiert, dass die Abschirmung des Kabels direkt an das Gehäuse des

Instruments als Masse angeschlossen wird. Im Folgenden werden die Anweisungen für den

typischen Anschluss des Kabels angegeben.

1. Schrauben Sie die Mutter des Kabelanschluß ab. Im Inneren besteht die Baugruppe aus einer

Gummiwährung und zwei Metallschlitten. bedenke Sie, dass der Ethernet an den Instrumenten

für die Paneel- und die Wandkarte keine Scheiben aufweisen und, dass die Dichtung

eingeschnitten ist.

2. Beim Verkabeln eines Sensorkabels ist das Kabel bereits vorbereitet; entfernen Sie daher einfach

den Kunststoffschutz von der ausgesetzten Abschirmung. Ziehen Sie bei den anderen Kabeln die

äußere Isolierung wie erforderlich und 25 mm der Abschirmung ab. Entfernen Sie ca. 8 mm der

Isolierung an den Enden der Leiter.

3. Führen Sie das Kabel durch die Mutter, die Gummidichtung und die beiden Scheiben.

4. Pressen Sie die Abschirmung zusammen, so dass der Gesamtumfang zwischen die beiden

Scheiben geklemmt wird, führen Sie das Kabel in das Gehäuse und blockieren Sie den

Kabeldurchlass.

Deutsch

29

Page 30

1 Kabel 3 Instrument 5 O-ring 7 Dichtung

2 Abschirmung 4 Drahte 6 Unterlegscheiben 8 Kabelführung Mutter

H I N W E I S

Es ist ausgesprochen wichtig, dass die Abschirmung zusammengepresst und zwischen den beiden Scheiben

gesichert wird, um sicherzustellen, dass die Abschirmung direkt an das Gehäuse des Instruments als Masse

angeschlossen ist. Anderenfalls kan das Instrument beschädigt werden und die Sensorkabel können falsche

Werte anzeigen.

5. Bringen Sie die Mutter des Kabeldurchlasses wieder an und ziehen Sie sie an.

6. Schließen Sie die Kabel an die entsprechenden Anschlüsse des Anschlussblocks an.

Anschluss an die Stromversorgung

Anschluss der Stromversorgung (Niederspannungsinstrumente)

Bei den Niederspannungsinstrumenten (10-30 Vdc) der Stromversorgung erfolgt der Anschluss über

einen BINDER-Stecker mit 7 Kontaktstiften (mitgeliefert).

Hinweis: Die Steckverbindungen weisen Kehlen auf, um ein falsches Einstecken in das Instrument zu verhindern.

Schließen Sie das Stromkabel wie folgt an die Steckverbindung an:

Abbildung 2 Steckverbindung BINDER

Kontaktstifte:

1. Nicht verwendet

2. Strom 10-30 Vdc

3. Nicht verwendet

4. Nicht verwendet

5. Masse

6. Nicht verwendet

7. Erde

Anschluss der Stromzufuhr (Hochspannungsinstrumente)

Hochspannungsinstrumente (100-240 VAC) werden für den Stromanschluss über einen BINDERStecker vorverkabelt. Wie im Folgenden gezeigt wird eine Steckkupplung an den Stecker

angeschlossen mitgeliefert.

Falls das Instrument mit einem an die Steckkupplung angeschlossenen Stecker für die

Stromversorgung geliefert wird (Kabel Bauteilnummer 33031, 33032, 33033 und 33034), kann das

Instrument direkt an die Stromversorgung angeschlossen werden. Die beiden Steckverbindungen

weisen Kehlen auf, um ein falsches Anschließen zu vermeiden. Befestigen Sie die Buchse handfest

an dem Leistungssteckverbinder des Instruments.

Wenn gemeinsam mit dem Instrument kein Leistungskabel bestellt wurde, muss ein Leistungsstecker

wie im Folgenden beschrieben an die beiliegende Buchse angeschlossen werden.

V O R S I C H T

Verletzungsgefahr. Nur qualifiziertes Personal sollte die in diesem Kapitel des Handbuchs beschriebenen

Aufgaben durchführen.

Spezifikation für vom Benutzer gelieferte Stromkabel:

• 3-adrig (Phase, Nullleiter und Erde)

30

Deutsch

Page 31

• Kabel Ø ≥ 7mm; ≤ 9.5mm

• Kabelauswahl ≥ 1mm2, AWG18; ≤ 2.5mm2, AWG14

W A R N U N G

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn elektrische

Anschlüsse durchgeführt werden.

Bereiten Sie das Stromkabel (nicht mitgeliefert) wie folgt vor:

1. Ziehen Sie 23 mm der Abschirmung des Stromkabels ab.

2. Schneiden Sie den Phasenleiter und den Nullleiter 15 mm ab und lassen Sie den Erdungsleiter

so, wie er ist.

3. Entfernen Sie die Isolierung der drei Leiter so weit wie erforderlich.

Verkabeln Sie die Steckkupplung wie folgt:

1. Nehmen Sie das schmale Ende der Steckverbindung (4) in eine Hand und den Hauptkörper (2) in

die anderen und schrauben Sie sie auseinander. Ziehen Sie die Kabelklemme (3) ab und

schrauben Sie das Steckerende (1) ab, um zu den vier teilen gelangen, aus denen die

Steckverbindung besteht.

2. Lösen Sie die Schrauben der Kabelklemme (3), so dass das Stromkabel hindurchgeführt werden

kann.

3. Führen Sie das Stromkabel durch das Steckerende (1), den Hauptkörper (2) und die

Kabelklemme (3) und schließen Sie dann die drei Leiter (Phase, Nullleiter und Erdung) wie folgt

an die Steckverbindung (4) an:

1. Phase (braun)

2. Nullleiter (blau)

3. Nicht verwendet

Erde - Erde (grün und gelb)

Hinweis: Die Ziffern und das Erdungssymbol sind am Ende der Steckverbindung aufgedruckt. Stellen Sie

sicher, dass der Anschluss richtig vorgenommen worden ist.

4. Schieben Sie die Kabel (3) zurück auf die Steckverbindung (4) und sichern Sie das Kabel.

5. Schrauben Sie die beiden Teile (4) und (2) wieder zusammen.

6. Sichern Sie das Stromkabel durch Anschrauben des Steckerendes (1).

7. Die Buchse kann jetzt direkt an den Leistungsstecker des Instruments angeschlossen werden.

Die beiden Steckverbindungen weisen Kehlen auf, um ein falsches Anschließen zu vermeiden.

Befestigen Sie die Buchse handfest an dem Leistungsstecker des Instruments.

Anschlüsse an Elektronikkarten

H I N W E I S

Möglicher Geräteschaden Empfindliche interne elektronische Bauteile können durch statische Elektrizität

beschädigt werden, wobei dann das Gerät mit verminderter Leistung funktioniert oder schließlich ganz ausfällt.

Hinweis: Alle losen Verbindungskabel sollten mit Kabelbindern aus Kunststoff zusammengefasst werden.

Die Steckverbindungen P8 auf dem Mainboard (Abbildung 3 auf Seite 32) und J7 auf der

Messkarte (Abbildung 5 auf Seite 33) bestehen aus zwei Teilen. Drücken Sie vorsichtig die

schwarzen Hebel auf den beiden Seiten der Steckverbindung und ziehen Sie sie sicher heraus.

Nehmen Sie alle Anschlüsse vor, während diese Steckverbindungen ausgesteckt sind. Bringen Sie

anschließend die Steckverbindungen wieder an den Karten an und stecken Sie sie sicher ein (Hebel

nach oben).

Deutsch

31

Page 32

Mainboard

Abbildung 3 Mainboard

Abbildung 4 Steckverbindung P8

Steckverbindung P8

Die unten aufgeführten Zahlen beziehen sich auf die 13 verfügbaren Steckverbindungen P8 (von

rechts nach links) in Abbildung 4.

1. RS-485 (Signal A)

2. RS-485 (Signal B)

3. PROFIBUS-DP (GND)

4. PROFIBUS-DP (+ 5 V)

5. PROFIBUS-DP (Signal -)

6. PROFIBUS-DP (signal +)

7. PROFIBUS-DP (signal RTS)

8. Nicht verwendet

9. Nicht verwendet

10. Nicht verwendet

11. Systemalarmrelais (N.O.)

12. Systemalarmrelais (N.C.)

13. Systemalarmrelais (gemein)

Steckverbindung P3

Ethernet RJ 45. Schließen Sie das Gerät an das lokale Netzwerk an. Führen Sie dazu ein

Ethernetkabel durch die Ethernet-Kabelführung (die Position der Kabelführung ist in Abbildung 1

auf Seite 29 dargestellt) und schließen Sie die Steckverbindung an die Steckverbindung P3 (siehe

Abbildung 3) an.

32

Deutsch

Page 33

Messkarte

Abbildung 5 Messkarte

Abbildung 6 Steckverbindung J7

Steckverbindung J7 (Eingänge und Ausgänge)

Die unten aufgeführten Zahlen beziehen sich auf die 16 verfügbaren Steckverbindungen J7 (von

rechts nach links) in Abbildung 6.

Messungsalarmrelais:

1. Gemein

2. Ausgangsrelais 1

3. Ausgangsrelais 2

4. Ausgangsrelais 3

Digitale Eingänge:

9. bis 16. Nicht verwendet

Analoge Strom- Ausgänge:

GND

6. Ausgänge 1

7. Ausgang 2

8. Ausgang 3

Messungsalarmrelais

Die drei Ausgangsrelais befinden sich auf der Messkarte.

Sie können einzeln als Einschaltglied (NO) oder als Ausschaltglied (NC) konfiguriert

werden, indem der Jumper für das entsprechende Relais umgesetzt wird. In der

Abbildung:

• Das oberes Relais ist als Ausschaltglied konfiguriert.

• Das mittlere Relais ist als Ausschaltglied konfiguriert

• Das untere Relais wird ohne Jumper gezeigt.

Hinweis: J14 ist Relais 1, J18 ist Relais 2, J19 ist Relais 3

Sensorinstallation

Sensor positionieren

Der Sensor muss in einen Sockel oder in eine Flusskammer eingesetzt werden, die einen Kontakt

mit der zu analysierenden Probenflüssigkeit gestatten. Der Sensor und das Messinstrument sind

über ein Kabel miteinander verbunden. Die Standardlängen des Sensorkabels sind 3, 5, 10, 15 und

20 Meter. Stellen Sie sicher, dass der Sensor wie folgt montiert wird:

• senkrecht zum Rohr

Deutsch

33

Page 34

• in einem horizontalen Abschnitt des Rohrs (oder an einem vertikalen Rohr mit aufsteigendem

Fluss)

• mindestens 15 Meter von der Auslassseite der Pumpe entfernt

• an einer Stelle, an der der Fluss stabil und schnell ist, und so weit wie möglich entfernt von:

• Ventilen

• Rohrbögen

• den Ansaugseiten von Pumpen

• einem CO2-Einspritzsystem oder ähnlichen Vorrichtungen

Hinweis: In einigen Situation könnte es nicht möglich sein, alle vorgenannten Bedingungen zu erfüllen. Bitte

wenden Sie sich in diesem Fall an Ihren Hach-Lange-Vertreter, um die Situation zu bewerten und die beste

anwendbare Lösung zu finden.

Empfohlene Probenflussrate

Für optimale Reaktionszeiten wird eine Mindestflussrate für die Probe von 150 ml/min für beide

Sensoren (K1100 und M1100) empfohlen. Regulieren Sie den Fluss mithilfe des Ablassventils an

dem Flussmesser (Nr. 3 in Abbildung 7), um die Entwicklung von Schaum in der Flusskammer zu

vermeiden, da es dadurch zu falschen Sauerstoffmesswerten kommen kann.

Abbildung 7 Schematische Darstellung einer typischen Messung