Page 1

Document Number DGA1100-MAN/E

ORBISPHERE A1100 Family of

Oxygen Electrochemical Sensors

USER MANUAL

May 2011, Revision E

Page 2

Page 3

Table of Contents

Section 1 General Information.........................................................................................................3

1.1 Disclaimer ....................................................................................................................................3

1.2 Contact information...................................................................................................................... 3

1.3 Safety information ........................................................................................................................3

1.3.1 Use of hazard information ................................................................................................... 3

1.3.2 Service and repairs ............................................................................................................. 3

1.3.3 Precautionary labels............................................................................................................4

1.4 Product recycling information....................................................................................................... 5

1.5 Product disposal .......................................................................................................................... 7

1.6 Restriction of hazardous substances (RoHS) .............................................................................. 8

Section 2 Technical Specifications ................................................................................................9

2.1 Sensor weight and dimensions ....................................................................................................9

2.2 ORBISPHERE family of A1100 oxygen sensors .........................................................................9

2.3 Sensor configurations for standard applications ........................................................................ 10

2.4 Sensor membrane specifications...............................................................................................11

2.4.1 Oxygen sensors (Table 1)................................................................................................. 11

2.4.2 Oxygen sensors (Table 2)................................................................................................. 12

Section 3 Introduction ..................................................................................................................... 13

3.1 What you have received ............................................................................................................ 13

3.1.1 A1100 electrochemical sensor ..........................................................................................13

3.1.2 Protection caps .................................................................................................................13

3.1.3 Sensor recharge kit ...........................................................................................................14

3.2 Sensor components ...................................................................................................................15

3.3 Basic principle of operation........................................................................................................ 16

Section 4 Installation........................................................................................................................17

4.1 Sensor preparation .................................................................................................................... 17

4.2 Sensor installation...................................................................................................................... 22

4.2.1 Sensor positioning information..........................................................................................22

4.2.2 Sensor insertion ................................................................................................................ 23

4.2.3 Sensor removal................................................................................................................. 23

4.3 Mounting accessories ................................................................................................................24

4.3.1 External pressure sensor..................................................................................................24

4.3.2 Weld-on stainless steel socket.......................................................................................... 24

4.3.3 The 32003 insertion/extraction valve ................................................................................25

4.3.4 The 33095 sensor housing................................................................................................26

4.3.5 Tuchenhagen Varivent® in-line access unit...................................................................... 26

4.3.6 ORBISPHERE flow chambers .......................................................................................... 26

4.3.7 Multi-parameter flow chamber........................................................................................... 28

Section 5 Maintenance and Troubleshooting ............................................................................ 29

5.1 Maintenance .............................................................................................................................. 29

5.1.1 Maintenance schedule ...................................................................................................... 29

5.1.2 Prerequisites for sensor maintenance............................................................................... 29

5.1.3 Membrane replacement and sensor head cleaning..........................................................30

5.2 Troubleshooting .........................................................................................................................40

Section 6 Accessories and Spare Parts......................................................................................41

6.1 Accessories................................................................................................................................ 41

6.2 Flow chambers and installation devices ....................................................................................41

6.3 Sensor spare parts.....................................................................................................................42

6.4 Recharge kits for A1100 and A110E sensors ............................................................................ 42

6.5 Other spare parts .......................................................................................................................43

1

Page 4

Table of Contents

2

Page 5

Section 1 General Information

1.1 Disclaimer

The information in this manual has been carefully checked and is believed to be accurate.

However, Hach Lange assumes no responsibility for any inaccuracies that may be contained in

this manual. In no event will Hach Lange be liable for direct, indirect, special, incidental, or

consequential damages resulting from any defect or omission in this manual, even if advised of

the possibility of such damages. In the interest of continued product development, Hach Lange

reserves the right to make improvements in this manual and the products it describes at any

time, without notice or obligation.

Copyright © 2010 by Hach Lange. All rights reserved. No part of the contents of this manual

may be reproduced or transmitted in any form or by any means without the written permission of

Hach Lange.

1.2 Contact information

Manufacturing site:

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

1.3 Safety information

Please read the entire manual before unpacking, setting up, or operating this sensor.

Pay particular attention to all warning and caution statements. Failure to do so could result in

serious injury to the operator or damage to the equipment.

To the ensure the protection provided by this equipment is not impaired, do not use or install

this equipment in any manner other than that which is specified in this manual.

1.3.1 Use of hazard information

WARNING

A warning is used to indicate a condition which, if not met, could cause serious personal injury

and/or death. Do not move beyond a warning until all conditions have been met.

CAUTION

A caution is used to indicate a condition which, if not met, could cause minor or

moderate personal injury and/or damage to the equipment. Do not move beyond a

caution until all conditions have been met.

European HQ:

HACH LANGE GmbH

Willstätterstraße 11

40549 Düsseldorf

GERMANY

Tel. +49 211 52 880

Fax +49 211 52 88143

Note: A note is used to indicate important information or instructions that should be considered

before operating the equipment.

1.3.2 Service and repairs

None of the sensor’s components can be repaired by the user. Only personnel from Hach

Lange or its approved representative(s) is (are) authorized to attempt repairs to the sensor and

only components formally approved by the manufacturer should be used.

Any attempt at repairing the sensor in contravention of these principles could cause damage to

the sensor and corporal injury to the person carrying out the repair. It renders the warranty null

and void and could compromise the correct working of the sensor and the electrical integrity or

the CE compliance of the sensor.

If you have any problems with installation, or using the sensor please contact the company that

sold it to you. If this is not possible, or if the results of this approach are not satisfactory, please

contact the Customer Service department of Hach Lange.

3

Page 6

General Information

1.3.3 Precautionary labels

Read all labels and tags attached to the sensor. Personal injury or damage to the sensor could

occur if not observed.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol indicates the need for protective hand wear.

Electrical equipment marked with this symbol may not be disposed of in European public

disposal systems. In conformity with European local and national regulations, European

electrical equipment users must now return old or end-of-life equipment to the manufacturer

for disposal at no charge to the user.

Products marked with this symbol indicates that the product contains toxic or hazardous

substances or elements. The number inside the symbol indicates the environmental protection

use period in years.

4

Page 7

1.4 Product recycling information

ENGLISH

Electrical equipment marked with this symbol may not be disposed of in

European public disposal systems after 12 August 2005. In conformity with

European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of-life equipment to the

manufacturer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment

manufacturer or supplier for instructions on how to return end-of-life

equipment for proper disposal.

DEUTSCH

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in Europa nach dem 12.

August 2005 nicht mehr über die öffentliche Abfallentsorgung entsorgt werden. In

Übereinstimmung mit lokalen und nationalen europäischen Bestimmungen (EU-Richtlinie

2002/96/EC), müssen Benutzer von Elektrogeräten in Europa ab diesem Zeitpunkt alte bzw. zu

verschrottende Geräte zur Entsorgung kostenfrei an den Hersteller zurückgeben.

Hinweis: Bitte wenden Sie sich an den Hersteller bzw. an den Händler, von dem Sie das Gerät

bezogen haben, um Informationen zur Rückgabe des Altgeräts zur ordnungsgemäßen

Entsorgung zu erhalten.

General Information

FRANCAIS

A partir du 12 août 2005, il est interdit de mettre au rebut le matériel électrique marqué de ce

symbole par les voies habituelles de déchetterie publique. Conformément à la réglementation

européenne (directive UE 2002/96/EC), les utilisateurs de matériel électrique en Europe doivent

désormais retourner le matériel usé ou périmé au fabricant pour élimination, sans frais pour

l'utilisateur.

Remarque: Veuillez vous adresser au fabricant ou au fournisseur du matériel pour les

instructions de retour du matériel usé ou périmé aux fins d'élimination conforme.

ITALIANO

Le apparecchiature elettriche con apposto questo simbolo non possono essere smaltite nelle

discariche pubbliche europee successivamente al 12 agosto 2005. In conformità alle normative

europee locali e nazionali (Direttiva UE 2002/96/EC), gli utilizzatori europei di apparecchiature

elettriche devono restituire al produttore le apparecchiature vecchie o a fine vita per lo

smaltimento senza alcun costo a carico dell’utilizzatore.

Nota: Per conoscere le modalità di restituzione delle apparecchiature a fine vita da riciclare,

contattare il produttore o il fornitore dell’apparecchiatura per un corretto smaltimento.

DANSK

Elektriske apparater, der er mærket med dette symbol, må ikke bortskaffes i europæiske offentlige

affaldssystemer efter den 12. august 2005. I henhold til europæiske lokale og nationale regler

(EU-direktiv 2002/96/EF) skal europæiske brugere af elektriske apparater nu returnere gamle eller

udtjente apparater til producenten med henblik på bortskaffelse uden omkostninger for brugeren.

Bemærk: I forbindelse med returnering til genbrug skal du kontakte producenten eller

leverandøren af apparatet for at få instruktioner om, hvordan udtjente apparater bortskaffes

korrekt.

5

Page 8

General Information

SVENSKA

Elektronikutrustning som är märkt med denna symbol kanske inte kan lämnas in på europeiska

offentliga sopstationer efter 2005-08-12. Enligt europeiska lokala och nationella föreskrifter

(EU-direktiv 2002/96/EC) måste användare av elektronikutrustning i Europa nu återlämna gammal

eller utrangerad utrustning till tillverkaren för kassering utan kostnad för användaren.

Obs! Om du ska återlämna utrustning för återvinning ska du kontakta tillverkaren av utrustningen

eller återförsäljaren för att få anvisningar om hur du återlämnar kasserad utrustning för att den ska

bortskaffas på rätt sätt.

ESPANOL

A partir del 12 de agosto de 2005, los equipos eléctricos que lleven este símbolo no deberán ser

desechados en los puntos limpios europeos. De conformidad con las normativas europeas

locales y nacionales (Directiva de la UE 2002/96/EC), a partir de esa fecha, los usuarios

europeos de equipos eléctricos deberán devolver los equipos usados u obsoletos al fabricante de

los mismos para su reciclado, sin coste alguno para el usuario.

Nota: Sírvase ponerse en contacto con el fabricante o proveedor de los equipos para solicitar

instrucciones sobre cómo devolver los equipos obsoletos para su correcto reciclado.

NEDERLANDS

Elektrische apparatuur die is voorzien van dit symbool mag na 12 augustus 2005 niet meer

worden afgevoerd naar Europese openbare afvalsystemen. Conform Europese lokale en

nationale wetgegeving (EU-richtlijn 2002/96/EC) dienen gebruikers van elektrische apparaten

voortaan hun oude of afgedankte apparatuur kosteloos voor recycling of vernietiging naar de

producent terug te brengen.

Nota: Als u apparatuur voor recycling terugbrengt, moet u contact opnemen met de producent of

leverancier voor instructies voor het terugbrengen van de afgedankte apparatuur voor een juiste

verwerking.

POLSKI

Sprzęt elektryczny oznaczony takim symbolem nie może być likwidowany w europejskich

systemach utylizacji po dniu 12 sierpnia 2005. Zgodnie z europejskimi, lokalnymi i państwowymi

przepisami prawa (Dyrektywa Unii Europejskiej 2002/96/EC), użytkownicy sprzętu elektrycznego

w Europie muszą obecie przekazywać Producentowi stary sprzęt lub sprzęt po okresie

użytkowania do bezpłatnej utylizacji.

Uwaga: Aby przekazać sprzęt do recyklingu, należy zwrócić się do producenta lub dostawcy

sprzętu w celu uzyskania instrukcji dotyczących procedur przekazywania do utylizacji sprzętu po

okresie użytkownia.

PORTUGUES

Qualquer equipamento eléctrico que ostente este símbolo não poderá ser eliminado através dos

sistemas públicos europeus de tratamento de resíduos sólidos a partir de 12 de Agosto de 2005.

De acordo com as normas locais e europeias (Directiva Europeia 2002/96/EC), os utilizadores

europeus de equipamentos eléctricos deverão agora devolver os seus equipamentos velhos ou

em fim de vida ao produtor para o respectivo tratamento sem quaisquer custos para o utilizador.

Nota: No que toca à devolução para reciclagem, por favor, contacte o produtor ou fornecedor do

equipamento para instruções de devolução de equipamento em fim de vida para a sua correcta

eliminação.

6

Page 9

1.5 Product disposal

Note: The following only applies to European customers.

Hach Lange is committed to ensuring that the risk of any environmental damage or pollution

caused by any of its products is minimized as far as possible. The European Waste Electrical

and Electronic Equipment (WEEE) Directive (2002/96/EC) that came into force on August 13

2005 aims to reduce the waste arising from electrical and electronic equipment; and improve the

environmental performance of all those involved in the life cycle of electrical and electronic

equipment.

In conformity with European local and national regulations (EU Directive 2002/96/EC stated

above), electrical equipment marked with the above symbol may not be disposed of in

European public disposal systems after 12 August 2005.

General Information

Hach Lange will offer to take back (free of charge to the customer) any old, unserviceable or

redundant analyzers and systems which carry the above symbol, and which were originally

supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

In addition, Hach Lange will offer to take back (at cost to the customer) any old, unserviceable

or redundant analyzers and systems which do not carry the above symbol, but which were

originally supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

Should you wish to arrange for the disposal of any piece of equipment originally supplied by

Hach Lange, please contact your supplier or our After Sales Service department in Geneva for

instructions on how to return this equipment for proper disposal.

7

Page 10

General Information

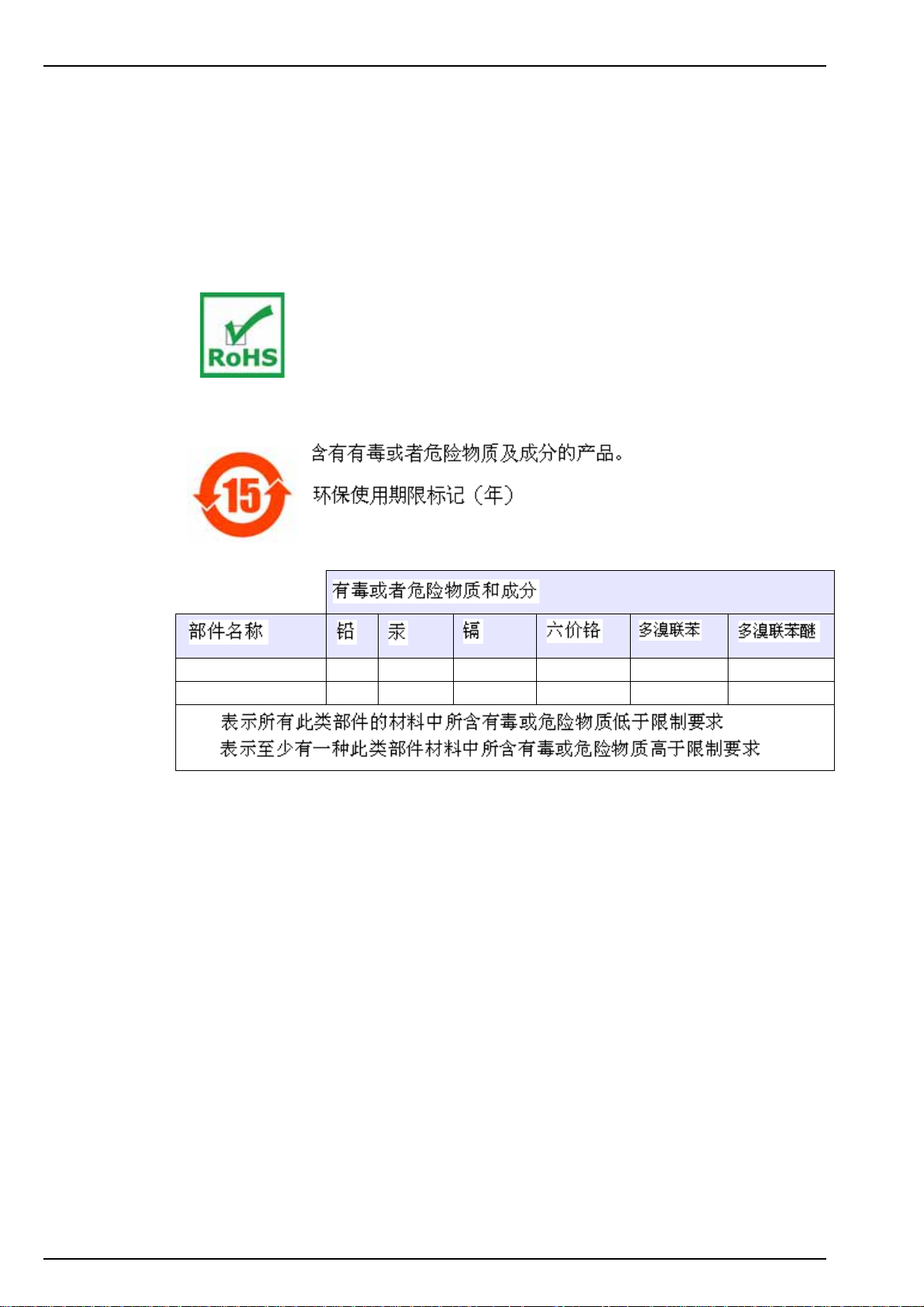

1.6 Restriction of hazardous substances (RoHS)

The European Union RoHS Directive and subsequent regulations introduced in member states

and other countries limits the use of six hazardous substances used in the manufacturing of

electrical and electronic equipment.

Currently, monitoring and control instruments do not fall within the scope of the RoHS Directive,

however Hach Lange has taken the decision to adopt the recommendations in the Directive as

the target for all future product design and component purchasing.

This product is compliant with the European Union RoHS Directive.

Note: The following only applies to exports of this product into the People’s Republic of China.

Connector socket X

Central tube X

O:

X:

8

Page 11

Section 2 Technical Specifications

Specifications are subject to change without notice.

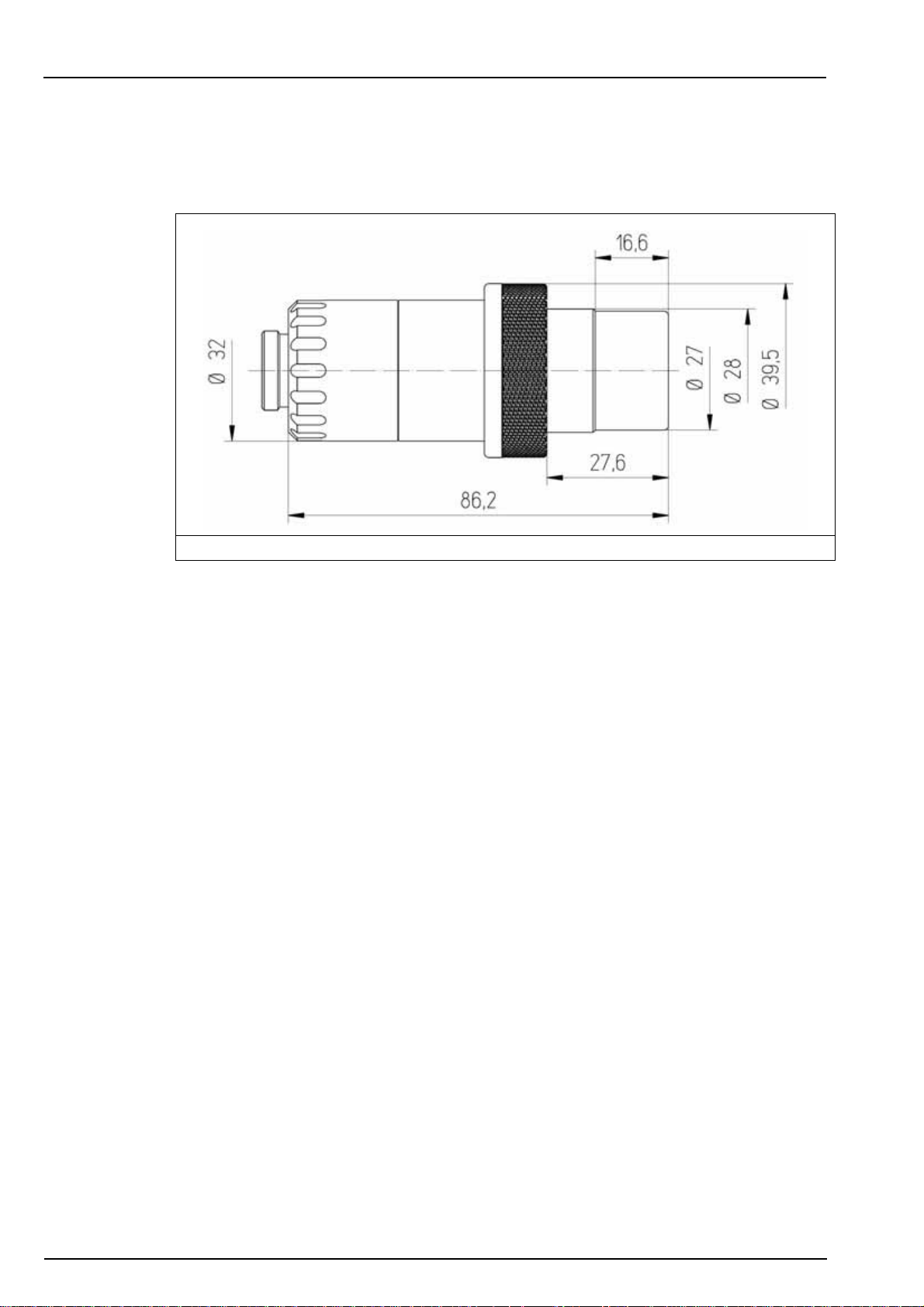

2.1 Sensor weight and dimensions

The sensor weight is approximately 300 grams.

Figure 1 Sensor dimensions

2.2 ORBISPHERE family of A1100 oxygen sensors

Model A1100 non-ATEX sensors

• Electrochemical oxygen sensor

• Stainless steel

• Maximum pressure 40 bar with default PPS collar (100 bar with stainless steel collar)

• Smart capability

Model A110E ATEX sensors

• Electrochemical oxygen sensor

• Ex II 1 G, Ex ia IIC T6

• Stainless steel or hastelloy

• Viton or kalrez o-rings

• Intrinsically safe

Note: Unlike the A1100 non-ATEX sensors, the intrinsically safe A110E ATEX sensors have no smart

capability to store calibration data. However, all A110E ATEX sensors have the ATEX conformity information

engraved on the sensor itself.

9

Page 12

Technical Specifications

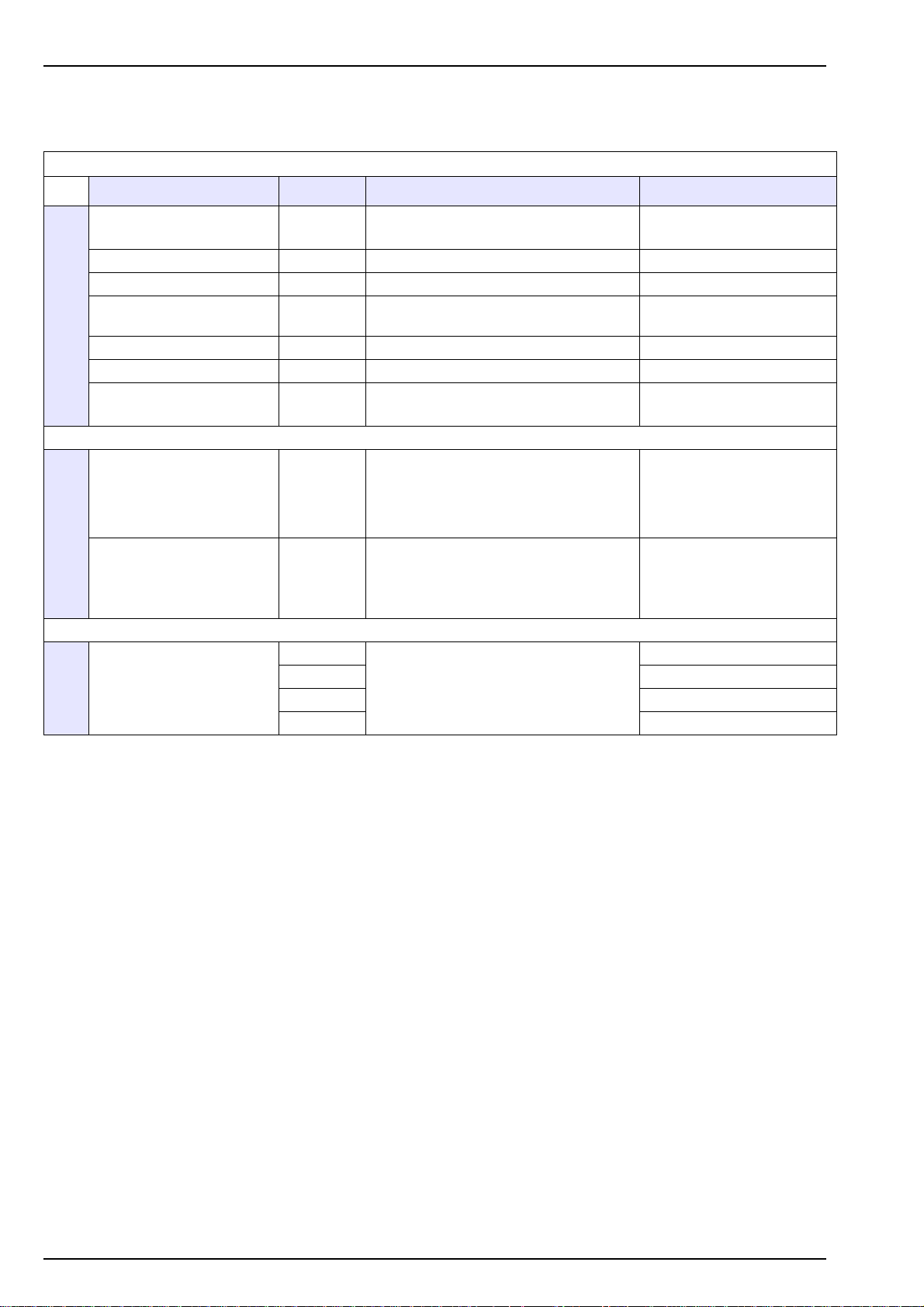

2.3 Sensor configurations for standard applications

Table 1 Sensor configurations for standard applications

Application Sensor Membrane Cartridge Protection Cap

Beer with 3650 Portable A1100-S00

Beer in-line A1100-S00 2952A-A 33051-SG

Wort in-line A1100-S00 29552A-A 33051-S0

Wort with 3650 Portable and

special flow cell 32007W.xxx

Beverage

3624 Probrix A1100-S00 2952A-A 33051-SG

3625 Package analyzer A1100-S00 2956A-A or 2952A-A 33051-SP

De-aerated water A1100-S00 2956A-A or 2952A-A

On-line dissolved oxygen

traces in pure water

Dissolved oxygen traces

with 3655 Portable

(Power - Electronics)

Pure water applications

ATEX

A1100-S00 29552A-A 33051-S0

A1100-S00 2956A-A 33051-S0

A1100-S00 2956A-A 33051-S0

A110E-SVS

A110E-SKS 33051-SG

A110E-HVS 33051-H0

A110E-HKS 33051-H0

2958A-A (optimized response time)

2952A-A (optimized maintenance interval)

2956A-A or 29552A-A

33051-SP

33051-S0

33051-SG (if exposed to CIP)

33051-SG

Note: Non-ATEX sensors are delivered with two protection caps as standard, one with a grille (33051-SP)

and one without (33051-S0). A third protection cap (33051-SG) is available as an option. ATEX Sensors are

delivered with one protection cap as standard.

10

Page 13

Technical Specifications

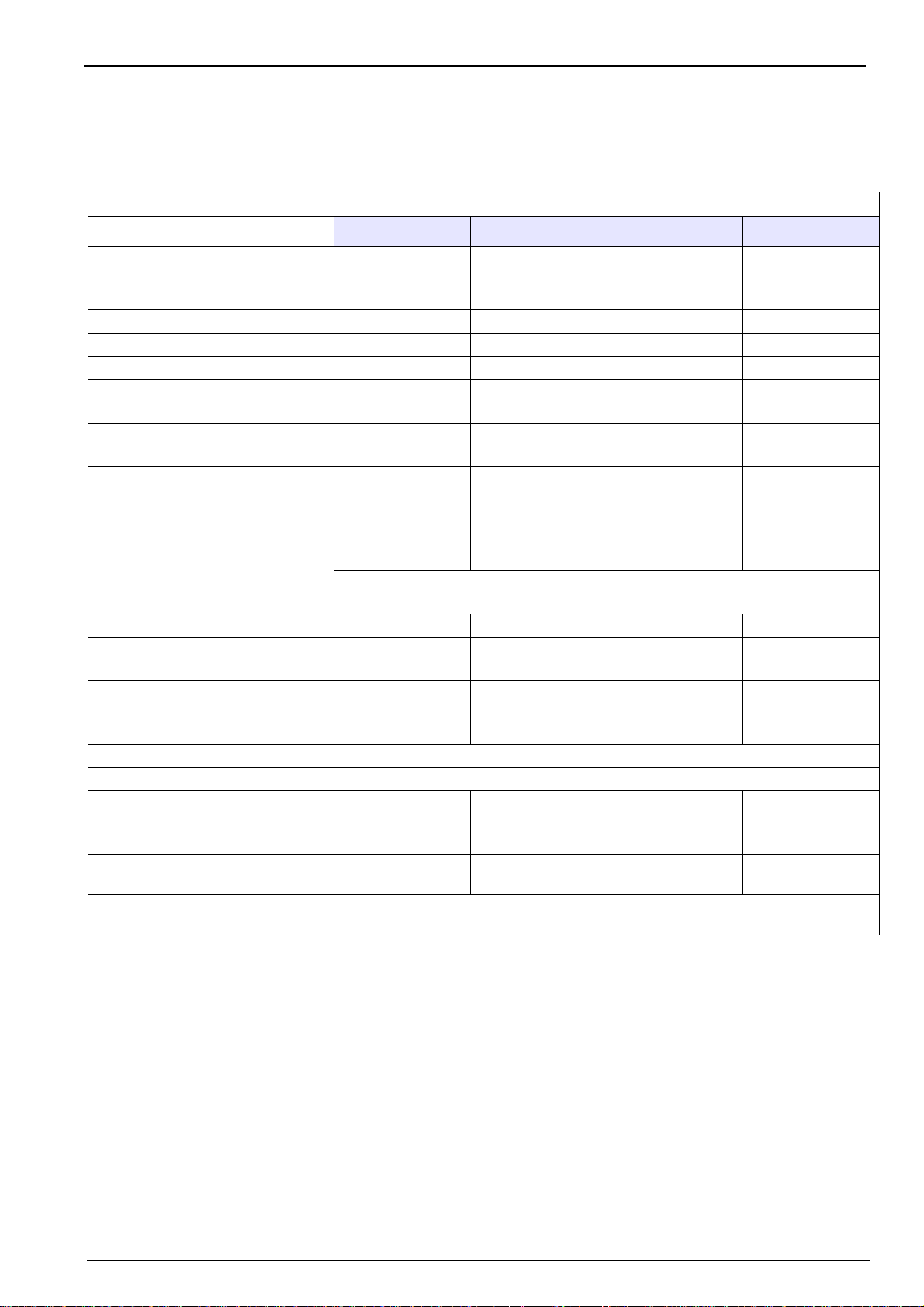

2.4 Sensor membrane specifications

2.4.1 Oxygen sensors (Table 1)

Table 2 Membrane specifications - Ox yg e n se n so rs (1 )

2956A-A 2958A-A 29552A-A 2952A-A

In line wort,

Air/O

injection,

2

Sewage treatment

PTFE Tefzel

Recommended applications

Corrosion control,

De-aerated water

Beverage,

Lab. applications

Material PFA Tefzel

®

Thickness [µm] 25 12.5 50 25

Calibration gas Air Air Air Air / Pure O

Dissolved measurement range

Gaseous measurement range

0 ppb to

20 ppm

0 Pa to

50 kPa

The greater of

±1% of reading

or ± 0.1 ppb

Accuracy

or ± 1 ppb

or ± 0.25 Pa

1

Accuracy is ± 0.1 ppb for 410, 510, 362x, 360x and 3655 instruments

2

Accuracy is ± 1 ppb for 366x and 3650 instruments

Integrated radiation dose limit [rads] 2 x 10

Expected current in air

@ 1 bar 25°C [µA]

Expected current in pure O

consumption in O2 saturated

O

2

water at 25°C [µg/hour]

[µA] 132 47 31.4 27

2

26.4 9.4 6.3 5.4

40 14 9.4 8

1

,

2

,

4

0 ppb to

40 ppm

0 Pa to

100 kPa

The greater of

±1% of reading

or ± 1 ppb,

or ± 2 Pa

8

10

0 ppb to

80 ppm

0 Pa to

200 kPa

The greater of

±1% of reading

or ± 2 ppb,

or ± 5 Pa

N/A 10

Temp. compensation range – 5 to 60° C

Temp. measuring range – 5 to 100° C

Response time

Recommended min. liquid flow rate

[mL/min]

Recommended min. linear flow rate

[cm/sec]

Recommended gaseous flow rate

[L/min]

1

2

2

7.2 sec. 9.5 sec. 90 sec. 38 sec.

180 120 50 50

200 100 30 30

0.1 to 3

Corrosion control,

In line beverage,

De-aerated water

0 ppb to

80 ppm

0 Pa to

200 kPa

The greater of

±1% of reading

or ± 2 ppb,

or ± 5 Pa

8

®

2

11

Page 14

Technical Specifications

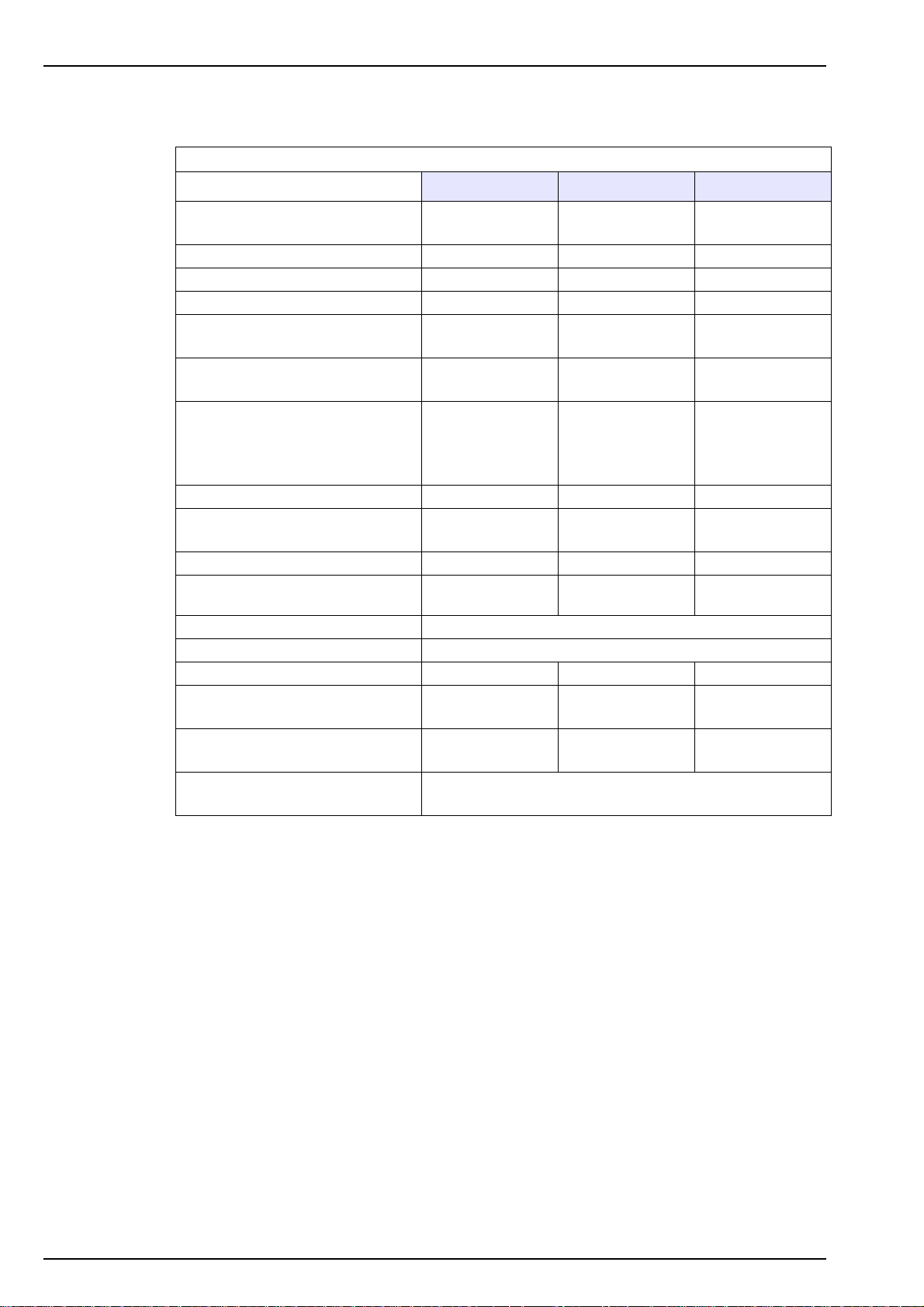

2.4.2 Oxygen sensors (Table 2)

Table 3 Membrane specifications - Oxygen sensors (2)

2935A-A 29521A-A 2995A-A

Recommended applications

Saturated to super

saturated levels

Material Halar

®

Saturated to super

saturated levels

®

Tefzel

In line hot wort

(up to 70°C)

Tedlar

Thickness [µm] 25 125 12.5

Calibration gas Air / Pure O

Dissolved measurement range

Gaseous measurement range

0 ppb to

400 ppm

0 Pa to

1000 kPa

The greater of

Accuracy

±1% of reading

or ± 10 ppb,

or ± 20 Pa

Integrated radiation dose limit [rads] N/A 10

Expected current in air

@ 1 bar 25°C [µA]

Expected current in pure O

consumption in O2 saturated

O

2

water at 25°C [µg/hour]

[µA] 4.7 3.8 0.9

2

0.9 0.7 0.2

1.4 1.3 0.3

Air / Pure O2 Pure O2

2

0 ppb to

400 ppm

0 Pa to

1000 kPa

The greater of

±1% of reading

or ± 10 ppb,

or ± 20 Pa

8

0 ppb to

2000 ppm

0 Pa to

5000 kPa

The greater of

±1% of reading

or ± 50 ppb,

or ± 100 Pa

10

Temp. compensation range – 5 to 60° C

Temp. measuring range – 5 to 100° C

Response time

Recommended min. liquid flow rate

1

2

[mL/min]

Recommended min. linear flow rate

2

[cm/sec]

Recommended gaseous flow rate

[L/min]

1

Response time at 25 °C for a 90% signal change

2

Liquid flow through an ORBISPHERE 32001 flow chamber, with protection cap and no grille

2.5 min. 18 min. 80 sec.

25 25 5

20 60 5

0.1 to 3

®

8

12

Page 15

Section 3 Introduction

3.1 What you have received

3.1.1 A1100 electrochemical sensor

The sensor may be delivered separately or as part of an ORBISPHERE system, depending on

the individual order.

The sensor (as illustrated in Figure 2 above) will be delivered fitted with a plastic screw-on

storage cap to protect the sensor head. This is held in place with a plastic collar.

A plastic screw-on base is also provided to protect the connection socket, and which also

provides a suitable stand for the sensor during maintenance procedures, and when not in use.

3.1.2 Protection caps

Non-ATEX sensors (A1100)

Two protection caps will be delivered with each sensor, one without a grille (part number

33051-S0) and one with a grille (part number 33051-SP).

A third protection cap (part number 33051-SG) is also available as an option and improves the

maintenance interval for beer or soft drinks process applications.

The three protection caps are illustrated below:

Figure 2 A1100 sensor with storage cap and base

Figure 3 Protection caps

ATEX sensors (A110E)

Only one protection cap will be delivered with each sensor (part number 33051-SG or

33051-H0).

13

Page 16

Introduction

3.1.3 Sensor recharge kit

A recharge kit (as illustrated in Figure 4 below) should have been ordered with the sensor as

this will be required to initially make the sensor operational. It is also required for sensor

cleaning and membrane replacement procedures.

Note: The recharge kit for oxygen has a blue sticker on the front of the box.

Figure 4 Sensor recharge kit

The kit contains:

• four recharge cartridges with pre-mounted membrane and electrolyte. The type of

membrane mounted in the cartridge will be specific to the kit ordered

• two anode cleaning tools

• a set of five cotton washers

• a set of five silicone discs (available in all 2956A-XXX recharge kits only)

• a set of replacement O-rings

• a set of Dacron

®

mesh patches.

14

Figure 5 Anode cleaning tool

The black anode cleaning tool (Figure 5) is used to clean the anode of any deposits or residue

that may have formed. It is doubled-ended so it can be used for two membrane replacement

processes, each end being used once.

Page 17

The cotton washers provide additional protection against the formation of deposits and residue

on the center electrode and anode, which prolongs the time period required between sensor

services.

The silicone discs are required for measurements in ultra-pure water or water containing

ammonia.

The Dacron

®

mesh patches provide protection to the membrane when using a protection cap

with grille.

For details of the part numbers for re-ordering, please refer to Recharge kits for A1100 and

A110E sensors on page 42.

3.2 Sensor components

The following illustration shows the assembled sensor with the storage cap and sensor collar

removed and the exploded view of the main sensor components. To remove the storage cap,

you will first have to unscrew and remove the sensor base.

Introduction

Figure 6 Sensor components

1 - Protection cap locking washer 4 - Cotton washer

2 - Protection cap (illustrated without grille) 5 - Silicone disc

3 - Cartridge containing electrolyte and membrane 6 - Sensor body

7 - Plastic base

Note: If a protection cap with grille is being used with the sensor, then a Dacron

between the protection cap and cartridge (components 2 and 3 in Figure 6 above).

®

mesh will be positioned

15

Page 18

Introduction

3.3 Basic principle of operation

In its simplest form, the electrochemical sensor consists of one center electrode (cathode) and

one counter electrode (anode) immersed in an electrolyte solution which is separated from the

gaseous or liquid sample by a gas permeable membrane. An electronic circuit is linked to the

anode and cathode. Through an applied voltage, current will flow between the anode and the

cathode.

A guard ring electrode surrounds the center electrode in order to reduce the influence of other

gases on the center electrode, and therefore improving analysis stability.

The sensor head is covered with a protection cap and, in some applications, a grille to protect

the membrane. Materials used for the components of the sensors differ with the application.

Gas penetrating through the membrane into the cell dissolves in the electrolyte. It undergoes a

reaction at the cathode, causing a measurable electric current to flow. This current is

proportional to the amount of gas entering the cell, which in turn is proportional to the partial

pressure of gas in the sample outside the cell.

The result is shown as gas concentration, which can then be displayed with a choice of several

measuring units, according to instrument setup.

The sensor also includes “smart sensor technology”, implemented using an RS485 interface.

The sensor electronics perform four functions:

• Apply constant voltage to the anode

• Measure the current flowing through the sensor

• Compensate for temperature variation in the gaseous or liquid sample

• Convert the cell’s electric current into an analog signal for sensor output

16

Page 19

Section 4 Installation

4.1 Sensor preparation

Your A1100 electrochemical sensor has been thoroughly cleaned and tested at the factory

before shipment. It has been shipped with a cartridge containing a membrane and electrolyte

pre-installed to protect the sensor head. This cartridge must be removed and replaced with a

new one prior to first use to make it fully operational. The new cartridge is included in the sensor

recharge kit (see additional details in Sensor recharge kit on page 14).

Non-ATEX sensors (A1100)

The sensor has been delivered with two protection caps, one with a grille and one without.

Ensure you use the correct protection cap for your application (see Table 1 on page 10 for

additional information).

ATEX sensors (A110E)

The sensor has been delivered with a single protection cap.

The following instructions detail the steps required to make the sensor operational. Should you

have any questions, your Hach Lange representative will be pleased to help.

CAUTION

Avoid all eye and skin contact with the electrolyte in the sensor and replacement

cartridge as it is corrosive and can cause burning. If eyes or skin come into cont act with

electrolyte, rinse immediately with water. In addition, the electrolyte can permanently

stain clothing so exercise care in han d li ng . It is highly recommended to wear protective

gloves and glasses during this process.

Note: It is advisable to perform this procedure with the plastic sensor base installed so as to avoid any

damage to the connection socket and also to provide a suitable stand for the sensor when required.

1. Hold the main body of the sensor and

unscrew the protection cap locking washer

by turning counter-clockwise. Remove it from

the sensor and put to one side.

2. Pull/twist off the protection cap and put to

one side.

17

Page 20

Installation

3. Hold the sensor with the membrane facing

down to avoid spilling any electrolyte, then

carefully unscrew the shipment cartridge.

Drain the old electrolyte into a sink and flush

away. Discard the shipment cartridge and

membrane.

4. Remove the cotton washer from the top of

the anode and discard.

5. Rinse the sensor head under a tap for 15

seconds, aiming the jet of water directly onto

the sensor head.

6. Do not dry the center electrode area, as the

gap between cathode and guard should be

left filled with water.

18

Page 21

Note: During this step, it is very important to ensure

your finger does not come into contact with the

cathode (golden surface) as it could leave greasy

deposits on the surface.

7. Take a silicone disc from the recharge kit,

hold it between thumb and forefinger and

position it on top of the anode.

Installation

Note: As in the previous step, it is very important to

ensure your finger does not come into contact with the

cathode (golden surface) as it could leave greasy

deposits on the surface.

8. Take a new cotton washer from the recharge

kit, hold it between thumb and forefinger and

position it on top of the silicone disc.

9. Place the recharge cartridge container on a

flat work surface and, keeping the container

upright to avoid spilling any of the electrolyte

inside, carefully unscrew the top.

10. Remove the packing component from the

center of the cartridge, making sure that the

O-ring on top of the cartridge remains in

place. If it comes away then replace it before

continuing.

11. If there are any visible bubbles in the

electrolyte, remove them using a stirring

motion with the packing component.

19

Page 22

Installation

12. Hold the container steady between thumb

and forefinger of one hand.

13. Lower the sensor into the container until the

top of the anode is covered with electrolyte.

14. Leave for a few seconds to ensure the cotton

washer has fully absorbed some of the

electrolyte and that it is no longer dry.

15. Gently screw the sensor clockwise into the

replacement cartridge, applying minimum

pressure to avoid any damage to the screw

threads.

16. Continue turning until the cartridge is

attached to the sensor, and the sensor is

automatically released from the container.

17. The empty container, the screw top and

packing component can be discarded.

Note: It is normal that some of the electrolyte will

overflow from the replacement cartridge and into the

plastic container.

20

Page 23

18. Rinse the sensor under a tap for about 5

seconds to remove any excess electrolyte,

then gently wipe with a soft tissue to ensure

all parts are completely dry.

19. Drain the overflow electrolyte from the

container into a sink and flush away.

20. Discard the used container.

Installation

21. If not using a protection cap with grille

proceed to step 24. Otherwise take a new

Dacron

recharge kit.

22. Place the mesh in the center of the

protection cap. It is very important that the

mesh is in the center of the protection cap

and covering the entire grille.

23. Lower the sensor onto the protection cap

making sure not to disturb the mesh.

24. Push the protection cap firmly into place,

making sure one of the four slots in the

protection cap fits over the small locking pin

(highlighted right). If it is necessary to turn

the protection cap to fit over the locking pin,

ensure you only turn it clockwise to avoid

unscrewing the cartridge.

®

mesh from the box of O-rings in the

21

Page 24

Installation

25. Finally, screw the protection cap locking

washer back into place in a clockwise

motion, and tighten finger tight.

4.2 Sensor installation

4.2.1 Sensor positioning information

Unless the sensor is part of the ORBISPHERE equipment that includes it, the sensor must be

installed in an ORBISPHERE socket or flow chamber, that allows contact with the sample fluid

to be analyzed.

The sensor and measuring instrument are connected by a cable and two 10-pin connectors.

The standard sensor cable length is 3 meters though extension cables of up to 1000 meters are

available. However, smart sensor technology is only available with distances of up to a

maximum of 750 meters.

Note: If the model 28117 pressure sensor is used, the maximum cable length is 50 meters.

Ensure that the sensor will be mounted:

• perpendicular to the pipe

• horizontal

• on a horizontal pipe section (or on flow-ascending vertical pipe)

• min. 15 meters away from pump's discharge side

• in a place where the sample flow is stable and rapid, and as far as possible from:

• valves

• pipe bends

• the suction side of any pumps

• a CO

Note: There may be situations where not all the above conditions can be met. If this is the case, or you

have any concerns, please consult your Hach Lange representative to appraise the situation and define the

best applicable solution.

injection system or similar

2

22

Page 25

4.2.2 Sensor insertion

Note: Check that the small O-ring at the bottom of the flow chamber is present during removal and

installation of the sensor, as it may stick to the sensor head and fall.

• Insert the sensor straight into the flow chamber or socket.

• Hand tighten the attaching collar.

• Connect the sensor cable.

• Check for leaks; replace O-rings if product leaks are visible.

Micro Volume Flow Chambers:

Installation

Note: Do not twist the sensor when inserting it into a micro volume flow chamber. This rotation may twist the

membrane holding ring, thus changing the membrane position. This can modify the membrane measuring

conditions, and affect measurement precision.

4.2.3 Sensor removal

• Shut off the sample flow and drain the sampling circuit of liquid or gas.

• Remove the sensor cable connected at the sensor end.

• Hold the sensor body in one hand to avoid rotation and unscrew the collar with the other

hand.

• Pull the sensor straight out of the socket or flow chamber.

• Check that both O-rings remain in place inside the flow chambers.

• Install sensor storage cap and sensor base (to protect the connection).

Figure 7 Sensor insertion

23

Page 26

Installation

4.3 Mounting accessories

4.3.1 External pressure sensor

The system can be fitted with an external pressure sensor. This enables a measurement of

fraction of gas under variable pressure conditions during gas phase measurement.

Note: Do NOT exceed the pressure range of the sensor. This would permanently deform the sensor

membrane, thus delivering incorrect pressure values in the future.

The external sensor connects to the ORBISPHERE measuring equipment with a 1 meter cable

and a 4 pin connector (an optional extension cable can be used, but total length should not

exceed 50 m.).

Two models are available, depending on application:

• 28117 Pressure sensor 0 - 5 bar absolute

• 28117C Pressure sensor 0 - 1 bar absolute

The external pressure sensor can be installed in the 32002.xxx multi parameter flow chamber. It

is held in place by a blue threaded collar. Tightness is assured by the O-ring on the sensor seat.

4.3.2 Weld-on stainless steel socket

The 29501 weld-on sensor socket can be used to install a sensor into a stainless steel pipe

(min.Ø 50 mm or 2”). When welding the socket to the pipe, check that setback between the

pipe’s inner diameter and the sensor tip does not exceed 4 mm (see diagram).

Figure 8 Weld-on sensor socket

24

Note: Be sure to remove the two O-rings from the socket before welding and leave the sensor’s stainless

steel cap screwed on during welding to prevent thread distortion.

Page 27

Recommendation:

To facilitate sensor removal and installation, we suggest installing the socket in a location where

the liquid can be drained quickly and easily. By creating a one meter long piece of pipe (shown

below) with shut off valves at both ends, just a small volume of liquid needs to be drained to

enable sensor removal. Also, a precise sensor and socket installation can be performed in the

workshop, and this assembly can be placed in the production line with minimal down time.

4.3.3 The 32003 insertion/extraction valve

Installation

Figure 9 Installation in-line

The ORBISPHERE 32003 insertion/extraction valve (illustrated below) allows for sensor

removal and installation without having to drain the fluid in the line. It can withstand a pressure

of up to 20 bars, with the sensor in place or not.

Sensor insertion is made by inserting the sensor into the housing and tightening the retaining

collar until it stops. As the retaining collar is tightened, the valve will open to allow the sample to

flow past the sensor head. Remove the sensor by unscrewing the collar and pulling the sensor

out. As the collar is unscrewed, the valve will automatically close to avoid any sample spillage.

Figure 10 ORBISPHERE model 32003 insertion/extraction valve

The diagram above right, shows the sensor in a sample line with the valve open allowing the

sample to run past the sensor head.

25

Page 28

Installation

4.3.4 The 33095 sensor housing

The ORBISPHERE 33095 sensor housing is also available for use with the A1100 sensor but

requires that the sample flow be turned off prior to insertion or removal of the sensor.

Sensor insertion is made by inserting the sensor into the housing and tightening the retaining

collar until it stops. Removal is made by unscrewing the collar and pulling the sensor out. Be

sure that the sample flow has been turned off before inserting or removing the sensor.

4.3.5 Tuchenhagen Varivent® in-line access unit

The following illustration shows the Tuchenhagen Varivent® In-Line Access Unit.

Figure 11 Tuchenhagen Varivent® in-line access unit

Purchasing a Tuchenhagen Varivent® in-line access unit, or an equivalent fitting with a 68 mm

flange diameter from the fitting manufacturer, is required to make use of the ORBISPHERE

model 32003 sensor housing device detailed above.

4.3.6 ORBISPHERE flow chambers

The ORBISPHERE 32001.xxx flow chambers are used to draw liquid and gaseous samples

past the sensor. They are available in several materials, depending on the application.

They connect to 6-mm or ¼" stainless steel tubing by means of two Swagelok™ fittings. If

necessary, copper or plastic tubing with low permeability can be substituted. Stainless steel

tubing is normally enough to hold the assembly in place, but for a more stable installation, a

large U-bolt can be used to mount the flow chamber to a support.

Dimensions of sensor and flow chamber assembly :

• Width: 50 mm

• Height: 210 mm

(add 100 mm for connection length)

26

Page 29

Table 4 Flow Chamber Orientation

Sample Orientation of flow chamber

Vertically, with connections down and

Gaseous or

liquid media

sensor up

- Center connection is the inlet

- Outer connection is the outlet

Installation

Gaseous media,

with occasional

liquid or vapor

Horizontally, to allow for drainage

- Center connection (inlet) must be up

- Outer connection (outlet) must be down

The connection diagram below is a recommended installation that allows for measuring and

calibrating without having to disconnect a line manually. "A" and "B" represent 3-way valves.

For measuring, calibration gas inlets and outlets are shut off. During calibration, the flow is

reversed to drive the remaining sample out. The calibration gas enters at the "sample out" port

and exits at the "sample in" port, as shown.

Figure 12 Flow chamber connections

27

Page 30

Installation

4.3.7 Multi-parameter flow chamber

Note: Suitable only for gaseous media.

The ORBISPHERE 32002.xxx multi parameter flow chamber can accommodate one or two

sensors and one sample pressure sensor. If only one gas sensor is used, the unused socket is

plugged with the stainless steel plugs provided (model 28123). The flow chamber is connected

to 6 mm or ¼" stainless steel tubing by two Swagelok™ fittings. If necessary, copper or plastic

tubing with a very low permeability can be substituted.

The flow chamber should be mounted in such a way that the sample outlet port is located at the

lowest point to allow condensation to escape with the outgoing gas. Attach the flow chamber to

a vertical support with the screws supplied. The pressure sensor must be on top.

Note: A user manufactured spacer (~15 mm thick) may be used between the flow chamber and support for

improved access for sensor removal.

28

Figure 13 32002.xxx Multi parameter flow chamber

Shown here with:

• gas sensor (right),

• pressure sensor (center),

• optional second sensor (left)

Page 31

Section 5 Maintenance and Troubleshooting

5.1 Maintenance

5.1.1 Maintenance schedule

The following table shows the recommended schedule for membrane replacement. The table

should only be used as a guideline, as maintenance intervals will vary depending on a number

of different parameters (e.g. water chemistry, CIP frequency, oxygen levels, sample

temperature, etc.).

Table 5 Maintenance schedule

Application Membrane type

Water applications (> 10ppb) 2956A Every 3 to 6 months

Pure water applications (power and electronics < 10 ppb) 2956A Every 3 to 6 months

Beer in-line 2952A Every 3 to 6 months

Wort in-line 29552A or 2995A Every 1 or 2 months

Portable or lab applications 2952A or 2958A Every 3 to 6 months

5.1.2 Prerequisites for sensor maintenance

The following table lists the prerequisites for a sensor maintenance:

Table 6 Prerequisites for sensor maintenance

Part No. Description

2959 Electrolyte for oxygen sensors, 50 ml. bottle.

29781 Cathode polishing powder (part no.29331) and cloth (part no. 2934).

32301 Electrochemical cleaning and regeneration center (see below)

40089 Tweezers, for maintenance kits

DG33303 Cleaning tool for sensor polishing

Important Note: If the sensor is being used in a high level hydrogen sample, this cleaning and

regeneration center is not required. In all other cases it is a prerequisite.

Membrane

replacement

The ORBISPHERE 32301 (illustrated below) is a very efficient cleaning and regeneration tool

for electrochemical sensors. This tool reverses the electrochemical process that is taking place

in the sensor cell during normal operation. This removes oxidation and at the same time

regenerates the surface of the electrodes. In addition, the regeneration center offers a continuity

tester for checking the sensor electronics.

29

Page 32

Maintenance and Troubleshooting

5.1.3 Membrane replacement and sensor head cleaning

A sensor recharge kit is required as it contains all the required components necessary for this

membrane replacement and sensor head cleaning process (see details in Sensor recharge kit

on page 14).

CAUTION

Avoid all eye and skin contact with the electrolyte in the sensor and replacement

cartridge as it is corrosive and can cause burning. If eyes or skin come into cont act with

electrolyte, rinse immediately with water. In addition, the electrolyte can permanently

stain clothing so exercise care in han d li ng . It is highly recommended to wear protective

gloves and glasses during this process.

Note: It is advisable to perform this procedure with the plastic sensor base installed so as to avoid any

damage to the connection socket and also to provide a suitable stand for the sensor when required.

1. Hold the main body of the sensor and

unscrew the protection cap locking washer

by turning counter-clockwise. Remove it from

the sensor and put to one side.

2. Pull/twist off the protection cap and put to

one side. If you are using a protection cap

with a grille, then remove the Dacron

from inside the cap and discard it.

®

mesh

30

Page 33

3. Hold the sensor with the membrane facing

down to avoid spilling any electrolyte, then

carefully unscrew the old cartridge. Drain the

old electrolyte into a sink and flush away.

Discard the old cartridge and membrane.

4. Remove the cotton washer and silicone disc

from the top of the anode and discard.

Maintenance and Troubleshooting

5. Rinse the sensor head under a tap for 15

seconds to remove any remaining electrolyte

and shake dry.

6. With a soft tissue gently clean around the

guard area (indicated right) and then wipe off

any excess moisture from the sensor to

ensure all parts are completely dry.

7. Repeat this rinse and dry process with the

protection cap.

8. Clean the anode using the cleaning tool

supplied.

9. Place the tool over the sensor head.

31

Page 34

Maintenance and Troubleshooting

10. Clean by rotating the cleaning tool over the

sensor head for a few seconds, in a

clockwise direction only.

11. Remove the tool and tap it face down on a

flat work surface to remove any powdery

deposit.

12. Check the sensor to ensure that all deposits

have been removed from the anode. If not,

repeat steps 10. and 11. until the anode

regains its bright silver appearance.

13. Rinse the sensor head under a tap for 15

seconds, aiming the jet of water directly onto

the sensor head.

14. Do not dry the center electrode area, as the

gap between cathode and guard should be

left filled with water.

15. Spread a little of the polishing powder

(29331) onto the clean polishing cloth (2934),

and add a few drops of water to form a grey,

milky liquid.

32

Page 35

16. Screw the polishing tool (DG33303) onto the

top of the sensor.

Maintenance and Troubleshooting

17. Polish the electrodes by moving the sensor

face in a circular direction against the liquid

in the polishing cloth for about 30 seconds.

18. Remove the polishing tool from the sensor.

19. Remove any polish deposits by rinsing the

sensor head under a tap for 30 seconds,

aiming the jet of water directly onto the

sensor head.

Important Note: If the sensor is used in high

level hydrogen sample, do not perform the

following steps but continue at step 29.

33

Page 36

Maintenance and Troubleshooting

20. Remove the plastic base from the bottom of

the sensor and connect the sensor to the

sensor cleaning and regeneration center

(32301).

21. Push the cleaning tool over the sensor head.

22. Pour enough electrolyte (2959) into the

cleaning tool until it completely covers all the

electrodes.

23. On the sensor cleaning and regeneration

center, turn the knob to the Anode position

and press the TIMER switch. A red warning

light will come on and remain on for 60

seconds while cleaning takes place.

24. At the end of the 60 second cleaning

process, check for an abundant stream of

bubbles should rise from the anode.If this

does not happen, press TIMER again.

Note: The development of bubbles is a sure sign of a

clean electrode.

25. On the sensor cleaning and regeneration

center, turn the knob to the Guard position

and press the TIMER switch. Again, watch

for the formation of bubbles and repeat the

cleaning process if necessary.

34

Page 37

26. On the sensor cleaning and regeneration

center, turn the knob to the Cathode position

and press the TIMER switch. Again, watch

for the formation of bubbles and repeat the

cleaning process if necessary.

27. When cleaning is complete, unplug the

sensor from the cleaning center and re-install

the plastic sensor base for the rest of the

procedure.

Maintenance and Troubleshooting

28. Remove any remaining electrolyte by rinsing

the sensor head under a tap for 60 seconds,

aiming the jet of water directly onto the

sensor head.

29. With the help of a pair of tweezers, remove

the old O-ring from the sensor body.

30. Replace the O-ring with a new one from the

recharge kit.

35

Page 38

Maintenance and Troubleshooting

Note: During this step, it is very important to ensure

your finger does not come into contact with the

cathode (golden surface) as it could leave greasy

deposits on the surface.

31. Take a silicone disc from the recharge kit,

hold it between thumb and forefinger and

position it on top of the anode.

Note: As in the previous step, it is very important to

ensure your finger does not come into contact with the

cathode (golden surface) as it could leave greasy

deposits on the surface.

32. Take a new cotton washer from the recharge

kit. Hold it between thumb and forefinger and

position it on top of the silicone disc.

33. Place the recharge cartridge container on a

flat work surface and, keeping the container

upright to avoid spilling any of the electrolyte

inside, carefully unscrew the top.

34. Remove the packing component from the

center of the cartridge, and make sure that

the O-ring remains in place on top of the

cartridge. If it comes away then replace it

before continuing.

35. If there are any visible bubbles in the

electrolyte, remove them using a stirring

motion with the packing component.

36

Page 39

36. Hold the container steady between thumb

and forefinger of one hand.

37. Lower the sensor into the container until the

top of the anode is covered with electrolyte.

38. Leave for a few seconds to ensure the cotton

washer has fully absorbed some of the

electrolyte and that it is no longer dry.

39. Gently screw the sensor clockwise into the

replacement cartridge, applying minimum

pressure to avoid any damage to the screw

threads.

Maintenance and Troubleshooting

40. Continue turning until the cartridge is

attached to the sensor, and the sensor is

automatically released from the container.

41. The empty container, the screw top and

packing component can be discarded.

Note: It is normal that some of the electrolyte will

overflow from the replacement cartridge and into the

plastic container.

37

Page 40

Maintenance and Troubleshooting

42. Rinse the sensor under a tap for about 5

seconds to remove any excess electrolyte,

then gently wipe with a soft tissue to ensure

all parts are completely dry.

43. Drain the overflow electrolyte from the

container into a sink and flush away.

44. Discard the used container.

45. If not using a protection cap with grille

proceed to step 48. Otherwise, take a new

Dacron

recharge kit.

46. Place the mesh in the center of the

protection cap. It is very important that the

mesh is in the center of the protection cap

and covering the entire grille (as illustrated

right).

47. Lower the sensor onto the protection cap

making sure not to disturb the mesh.

®

mesh from the box of O-rings in the

38

Page 41

48. Push the protection cap firmly into place,

making sure one of the four slots in the

protection cap fits over the small locking pin

(highlighted right). If it is necessary to turn

the protection cap to fit over the locking pin,

ensure you only turn it clockwise to avoid

unscrewing the cartridge.

Maintenance and Troubleshooting

49. Finally, screw the protection cap locking

washer back into place in a clockwise

motion, and tighten finger tight.

39

Page 42

Maintenance and Troubleshooting

5.2 Troubleshooting

Problem Probable cause Possible solution

Table 7 Troubleshooting

Sensor won't calibrate, even after

cleaning and/or membrane change.

"0000" O2 levels displayed.

Shorter than expected sensor operation

in relatively high dissolved O

concentration.

Unexpected or inaccurate dissolved O

readings.

Calibration is out of specification or

response time is too slow.

2

2

Instrument internal barometric pressure

sensor needs calibration.

Wet membrane interface. Wipe dry with a tissue and recalibrate.

S insensitivity" option enabled.

"H

2

Wrong reading scale "XXXX" selected

for display unit.

High O

deposits more quickly.

Air leak on product sample line.

High residual current.

Sensor incorrectly setup.

Temperature measurement incorrect.

Barometric pressure incorrect.

Cartridge incorrectly assembled on

sensor.

Sensor electrodes are dirty.

Sensor maintenance is required.

concentrations generate

2

Calibrate using a certified barometer. Do

not correct for sea level !

Disable from the menu on the

measuring instrument.

Change reading scale by selecting

"X.XXX, XX.XX or XXX.X" on the

instrument.

Install a less permeable membrane.

Turn off the analyzer when sensor is not

in a low O

Set flow rate to 100 ml/min. Wait until

stable, then slowly double the flow rate.

The stable value of dissolved O2 reading

must be the same as before. A variation

related to flow rate is a clear sign of an

air leak in the line.

Place sensor in de-aerated sample and

wait for low reading.

Check concentration against low

measurement limit (see tables in Sensor

membrane specifications on page 11).

If concentration is significantly higher

than low limit, try replacing the

membrane.

Check the sensor parameters on the

instrument.

Recalibrate the sensor.

Control the temperature with an external

reference.

Recalibrate the sensor.

Calibrate the barometric pressure

sensor using the instrument.

Recalibrate the sensor.

Verify the cartridge assembly is firmly

screwed onto the sensor and that the

membrane is tight.

Recalibrate the sensor.

Clean the sensor using the

ORBISPHERE 32301 cleaning and

regeneration center as explained in this

section.

Recalibrate the sensor.

Replace the membrane by installing a

new sensor cartridge as explained in

this section.

Recalibrate the sensor.

concentration.

2

40

Page 43

Section 6 Accessories and Spare Parts

6.1 Accessories

Table 8 Sensor accessories

Part N° Description

28117 Pressure sensor, 0-5 bar absolute

28117.C Pressure sensor, 0-1 bar absolute

6.2 Flow chambers and installation devices

Table 9 Flow chambers and installation devices

Part N° Description

29501.0 Sensor socket for welding to SS pipe, with EPDM O-ring

29501.1 Sensor socket for welding to SS pipe, with Viton O-ring

29508 Multi parameter flow chamber for headspace piercing device

32001.010 Flow chamber in stainless steel (316) with 6 mm fittings. Supplied with EPDM O-rings.

32001.011 Flow chamber in stainless steel (316) with ¼" fittings. Supplied with EPDM O-rings.

32001.012 Flow chamber in stainless steel (316) with 8 mm fittings. Supplied with EPDM O-rings.

32001.030 Flow chamber in Delrin with 6 mm fittings. Supplied with EPDM O-rings.

32001.031 Flow chamber in Delrin with ¼" fittings. Supplied with EPDM O-rings.

32001.040 Flow chamber in Hastelloy with 6 mm fittings. Supplied with EPDM O-rings.

32001.041 Flow chamber in Hastelloy with ¼" fittings. Supplied with EPDM O-rings.

32001.070 Flow chamber in Monel with 6 mm fittings. Supplied with EPDM O-rings.

32001.071 Flow chamber in Monel with ¼" fittings. Supplied with EPDM O-rings.

32001.110 Flow chamber in stainless steel (316) with 6 mm fittings. Supplied with Viton O-rings.

32001.111 Flow chamber in stainless steel (316) with ¼" fittings. Supplied with Viton O-rings.

32001.140 Flow chamber in Hastelloy with 6 mm fittings. Supplied with Viton O-rings.

32001.141 Flow chamber in Hastelloy with ¼" fittings. Supplied with Viton O-rings.

32001.151 Flow chamber in titanium with ¼" fittings (6 mm fittings not available in titanium) Supplied with Viton O-rings.

32001.170 Flow chamber in Monel with 6 mm fittings. Supplied with Viton O-rings.

32001.171 Flow chamber in Monel with ¼" fittings. Supplied with Viton O-rings.

32001.181 Flow chamber in Kynar with ¼" fittings. Supplied with Viton O-rings.

32001.191 Flow chamber in PTFE with ¼" fittings. Supplied with Viton O-rings.

32002.010 Multi parameter flow chamber in stainless steel with 6 mm fittings. Supplied with EPDM O-rings.

32002.011 Multi parameter flow chamber in stainless steel with ¼" fittings. Supplied with EPDM O-rings.

32003 ProAcc sensor insertion device ; for use with Tuchenhagen adapter

32006 Flow chamber in stainless steel (316) for use with for model 28117 and 28117.C pressure sensors.

32007D Flow chamber in Delrin for the 3655 portable instrument, with one meter of tubing.

32007F

32007W.030

32007W.031

32009 Flow chamber in acrylic with 1/8" Swagelok fittings for small volume liquid phase measurements.

32011

32017 Flow chamber used with 29981 Pharmapack. Must be ordered separately.

Flow chamber in Delrin for the 3650 portable instrument. Includes check valve, 1 meter of inlet tubing, quarter

turn flow valve, and outlet metal U-tube (6mm outside diameter).

Flow chamber in Delrin with 6 mm stainless steel Swagelok fittings for use with liquids with suspended

particles. Supplied with EPDM O-rings.

Flow chamber in Delrin with ¼" stainless steel Swagelok fittings for use with liquids with suspended particles.

Supplied with EPDM O-rings.

Flow chamber in acrylic with 1/8" Swagelok fittings for small volume liquid phase measurements, with port for

32562 external temperature sensor.

41

Page 44

Accessories and Spare Parts

6.3 Sensor spare parts

Table 10 Sensor spare parts

Part N° Description

A1100-S00

A110E-SVS A110E oxygen sensor, ATEX, stainless steel, viton o-rings, cap with grille

A110E-SKS A110E oxygen sensor, ATEX, stainless steel, kalrez o-rings, cap with grille

A110E-HVS A110E oxygen sensor, ATEX, hastelloy, viton o-rings, cap without grille

A110E-HKS A110E oxygen sensor, ATEX, hastelloy, kalrez o-rings, cap without grille

28104 Stainless steel sensor collar

28105 PPS sensor collar

28129 Delrin storage cap (sensor storage cap)

32205 Sensor support (base) for 31xxx sensors

33051-S0 Stainless steel 28mm cap for ORBISPHERE A1100 family EC sensors (without grille)

33051-SG

33051-SP

33051-H0 Hastelloy 28mm cap without grille for ORBISPHERE A110E ATEX sensors.

33052 Kit of 5 dacron mesh for protection cap with grille model 33051-SG or 33051-SP

A1100 oxygen sensor, non-ATEX, stainless steel, maximum pressure 40 bar with default PPS collar (100 bar

with 28104 stainless steel collar), with smart capability

Stainless steel 28mm cap with grille for ORBISPHERE A1100 family EC sensors. For use in beer or soft-drinks

processes and ATEX configurations.

Stainless steel 28mm cap with grille for ORBISPHERE A1100 family EC sensors. For use with 3625 package

analyzer and 3650 instrument when measuring beer or soft-drinks.

6.4 Recharge kits for A1100 and A110E sensors

Table 11 Recharge kits for A1100 sensors

Part N° Description

2935A-A

29521A-A

2952A-A

29552A-A

2956A-A

2956A-A05

2958A-A

2995A-A

2956A-AV

2956A-AK

29552A-AV

29552A-AK

Recharge kit of 4 pre-filled cartridges with premounted 2935A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 29521A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 2952A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 29552A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 2956A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers, silicone discs and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 2956A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers, silicone discs and cleaning tools. Special low concentrate electrolyte

Recharge kit of 4 pre-filled cartridges with premounted 2958A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 2995A membranes for A1xxx oxygen sensors.

Includes o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 2956A membranes for A1xxx oxygen sensors.

Includes viton o-rings, cotton washers, silicone discs and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 2956A membranes for A1xxx oxygen sensors.

Includes kalrez o-rings, cotton washers, silicone discs and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 29552A membranes for A1xxx oxygen sensors.

Includes viton o-rings, cotton washers and cleaning tools

Recharge kit of 4 pre-filled cartridges with premounted 29552A membranes for A1xxx oxygen sensors.

Includes kalrez o-rings, cotton washers and cleaning tools

42

Page 45

Accessories and Spare Parts

6.5 Other spare parts

Table 12 Other spare parts

Part N° Description

28093.0 EPDM O-rings for pressure sensor 28117.X. 18.78 x 1.78mm. (5 pieces)

28093.2 Kalrez O-ring for pressure sensor 28117.X. 18.78 x 1.78mm. (1 piece)

28093.4 Nitril O-rings for pressure sensor 28117.X. 18.78 x 1.78mm. (5 pieces)

29006.0

29006.1

29006.2

29006.4

29037 Regeneration cell for 32301, electrochemical sensor cleaning and regeneration unit

2959 Electrolyte for oxygen sensors, 50 ml. bottle.

29781 Cathode polishing powder (part no.29331) and cloth (part no. 2934).

32301 Electrochemical cleaning and regeneration center

40089 Tweezers, for maintenance kits

DG33303 Cleaning tool for sensor polishing

EPDM O-ring set for standard flow chambers (32001, 32002, 32007, 32009) and 29501 sensor socket.

(34x2mm & 28x2 mm).

Viton O-ring set for standard flow chambers (32001, 32002, 32007, 32009) and 29501 sensor socket. (34x2

mm & 28x2 mm).

Kalrez O-ring set for standard flow chambers (32001, 32002, 32007, 32009) and 29501 sensor socket. (34x2

mm & 28x2 mm).

Nitril O-ring set for standard flow chambers (32001, 32002, 32007, 32009) and 29501 sensor socket. (34 x 2

mm & 28 x 2 mm).

43

Page 46

Accessories and Spare Parts

44

Page 47

Page 48

Loading...

Loading...