Page 1

DOC024.98.93009

ORBISPHERE Model

6110 Package Analyzer

08/2013, Edition 3

Basic User Manual

Manuale dell'utente di base

Manuel d'utilisation de base

Manual básico del usuario

Manual Básico do Usuário

Základní uživatelská příručka

Basisgebruikershandleiding

Podstawowa instrukcja obsługi

Manual de bază al utilizatorului

Temel Kullanıcı Kılavuzu

Basishandbuch

基本用户手册

基本取扱説明書

Page 2

English..............................................................................................................................3

Deutsch..........................................................................................................................25

Italiano............................................................................................................................49

Français.........................................................................................................................72

Español..........................................................................................................................96

Português....................................................................................................................120

中文...............................................................................................................................144

日本語...........................................................................................................................163

Čeština.........................................................................................................................185

Nederlands.................................................................................................................207

Polski............................................................................................................................231

Română.......................................................................................................................255

Türkçe...........................................................................................................................278

2

Page 3

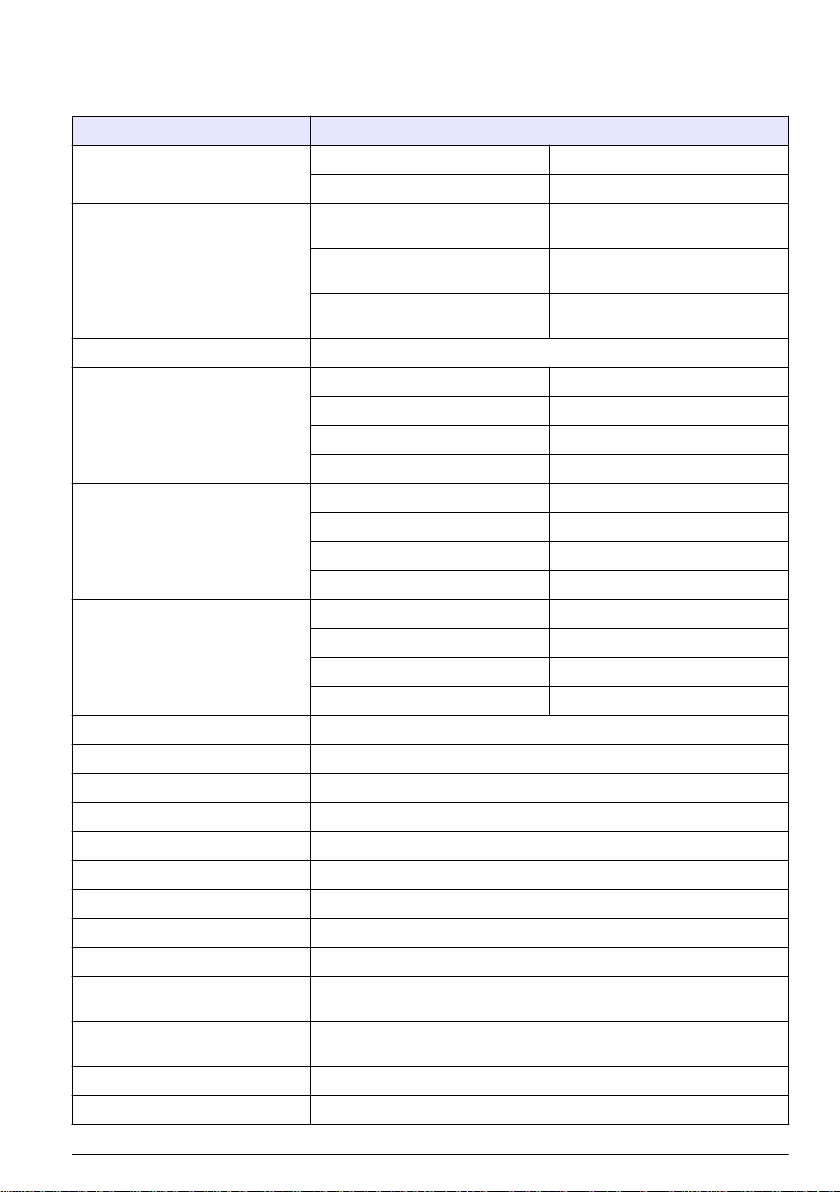

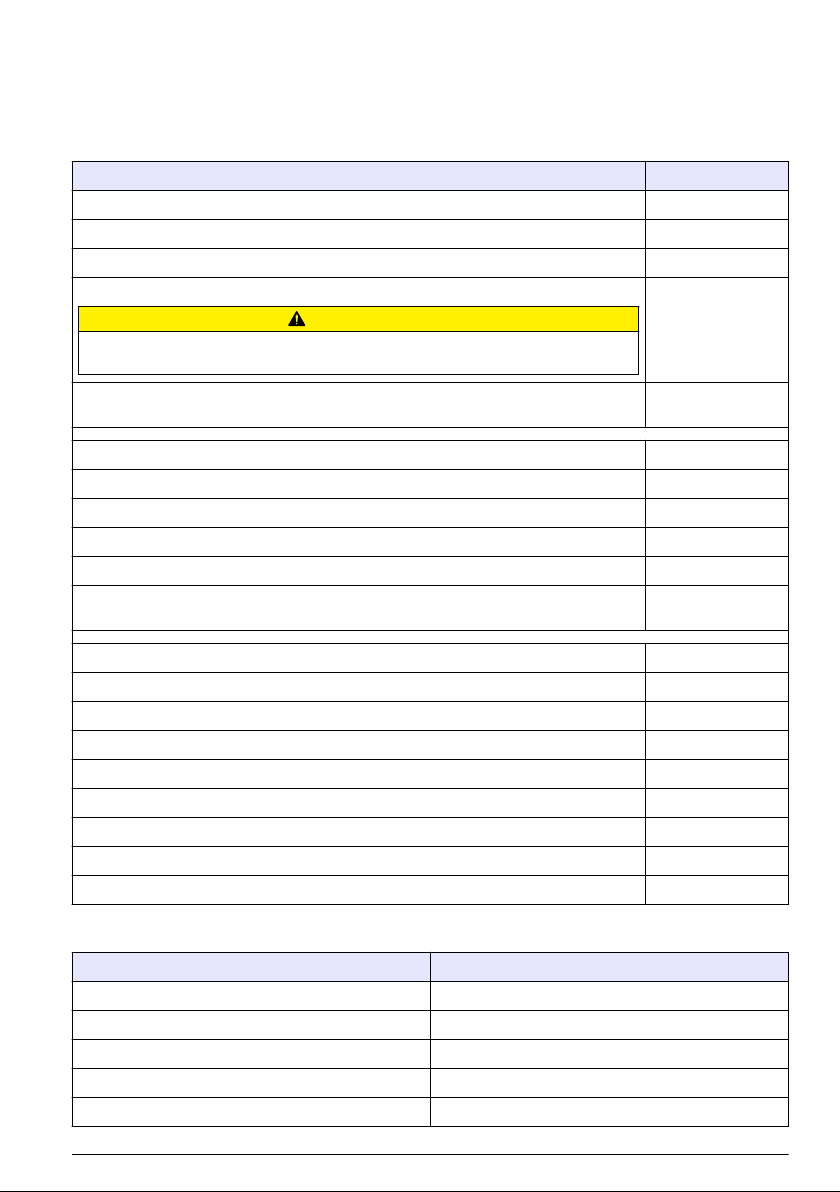

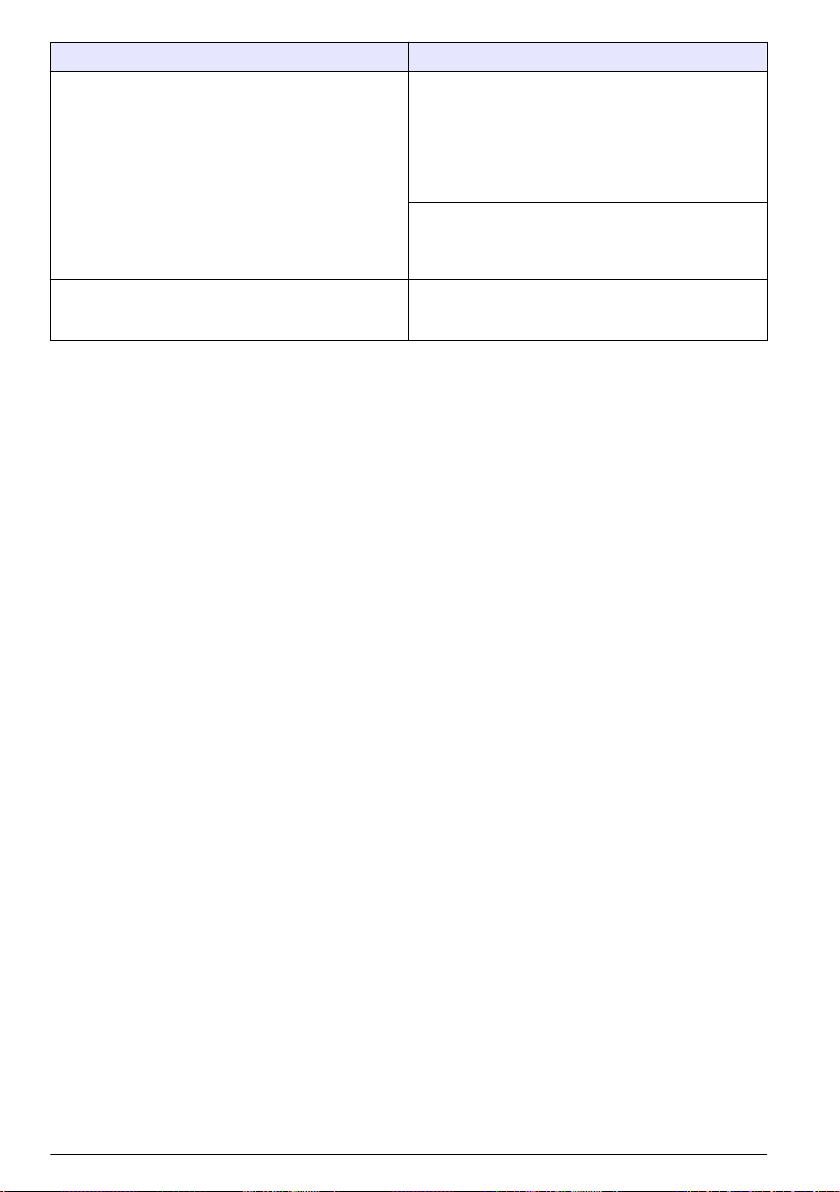

Specifications

Specifications are subject to change without notice

Specification Details

Measurement range O

Repeatability r

95

2

CO

2

Total Package Oxygen ± 5 μg/L ± 10% whichever is the

CO2 on equilibrated packages at T

= 10 to 25°C (50 to 77°F)

O

2

Typical analysis time About 4 minutes

Display units O2 concentration ppb or ppm

CO2 concentration V/V, g/kg, g/L or %W

Pressure bar, mbar, psia

Temperature °C, °F or K

Operating limits Package temperature -2 to 30°C (28 to 86°F)

Package pressure 1.4 to 6.8 bar absolute (20 - 99 psia)

Ambient temperature 0 to 40°C (32 to 104°F)

Relative humidity Up to 80%

Package setup Maximum package height 340 mm (13.39 ins)

Minimum package height 90 mm (3.54 ins)

Minimum volume 150 ml

Material Glass, PET or aluminum

Dimensions (L x W x H) 537 x 540 x 942 mm (21.1 x 21.3 x 37.1 ins)

Weight 55 kg (121 lbs)

Enclosure protection IP20

Power requirements 100-240 VAC ±10% @ 50-60 Hz

Power consumption Max. 250 VA

Purge gas CO2 with purity > 99.9% at 6 to 7 bar absolute (87 to 102 psia)

Purge gas consumption 0.4 mL/second (1.5 L/hour)

Forcing gas Air or N2 at 5.5 to 6 bar absolute (80 to 87 psia)

Forcing gas consumption 0.25 mL/minute in standby mode

European directives Low voltage 2006/95/EC

EMC 2004/108/EC

Electromagnetic compatibility

EN 61326: 2006

standards

Safety standard IEC/UL/CSA 61010-1

Laser product safety IEC/UL/CSA 60825-1

1 ppb - 12 ppm

0.75 - 5 V/V or 1.5 - 10 g/kg

greater

± 0.05 V/V or 0.10 g/kg ± 2%

whichever is the greater

± 2 ppb ± 10% whichever is the

greater

English 3

Page 4

Specification Details

Digital display TFT VGA (640 x 480) color display touch screen with backlight

Operating system Windows CE 4.2

Languages English, German, Spanish, Chinese, Japanese

Digital connections 1 x USB client, 1 x USB host, 1 x Ethernet

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

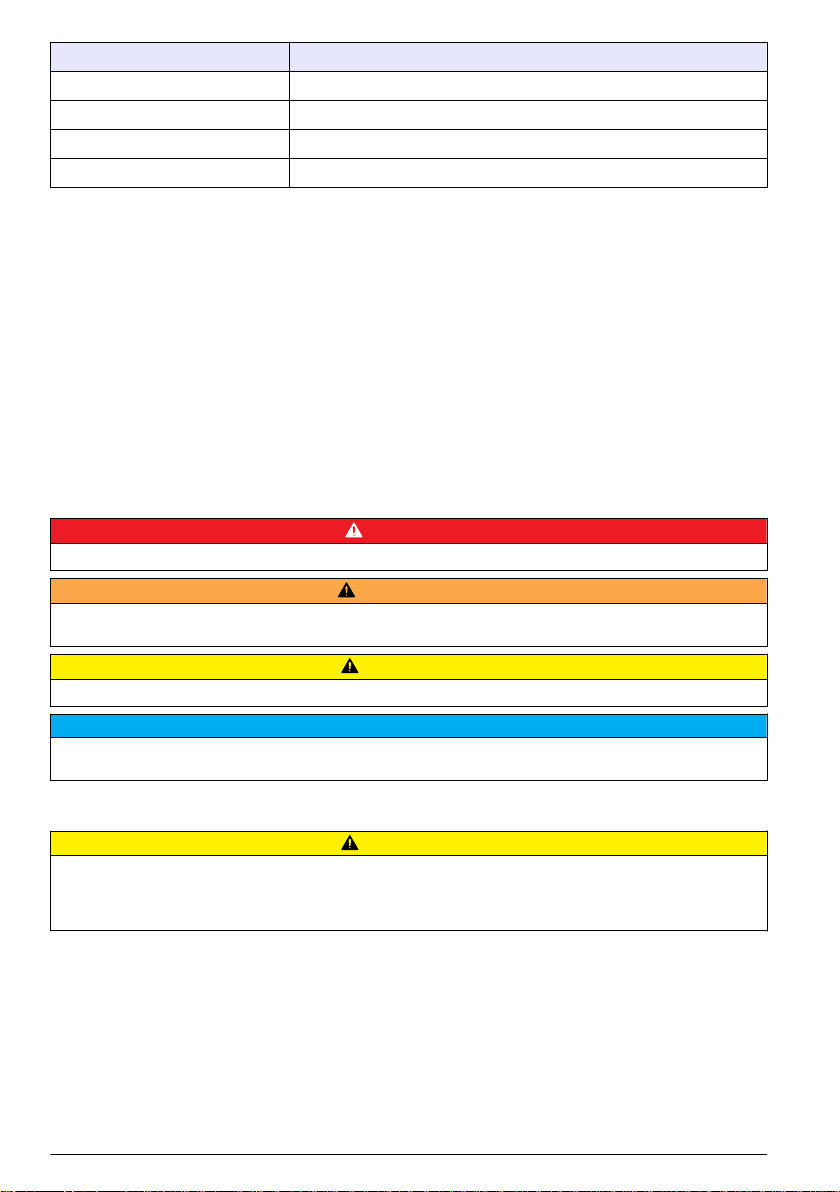

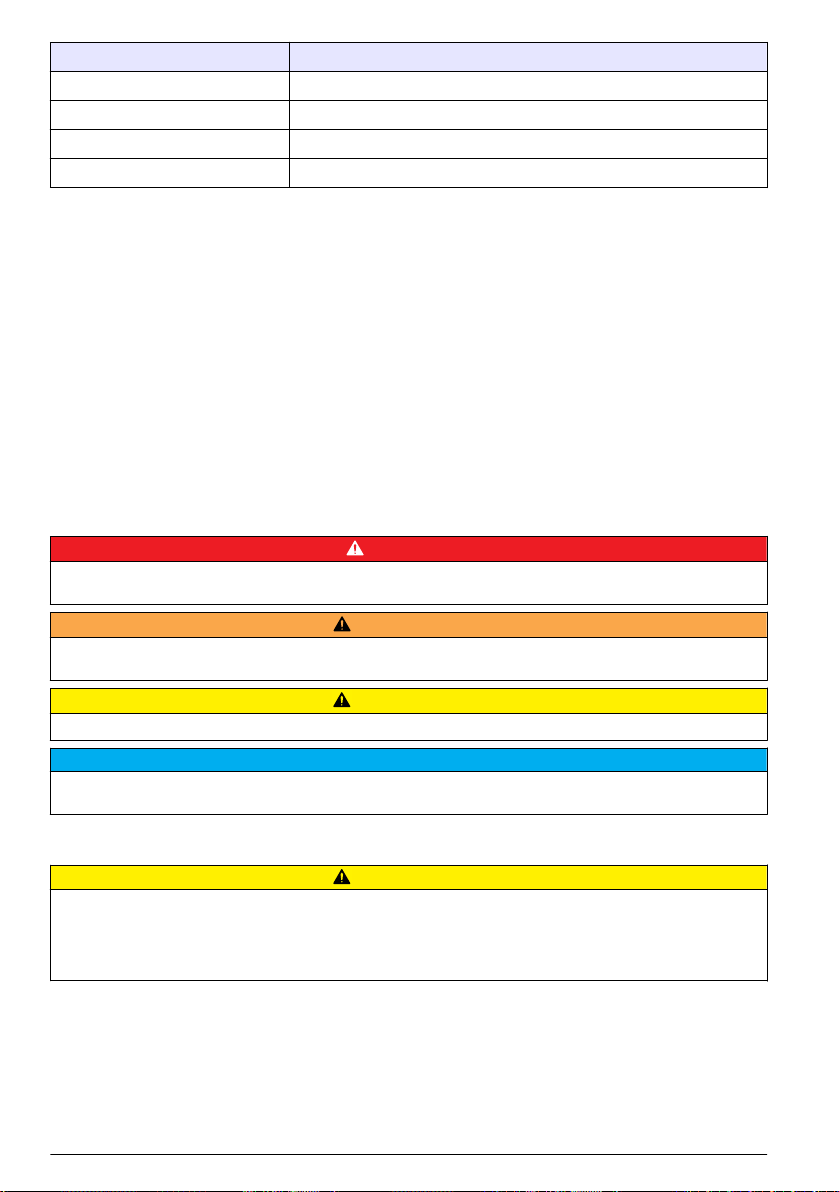

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

W A R N I N G

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

N O T I C E

Disclaimer

C A U T I O N

The manufacturer is not responsible for damages resulting from misapplication or misuse of this product and

rejects the regulation of such damages, including direct, indirect and consequential damages, and in full

accordance with applicable law. The user is solely responsible for the identification of critical applications and

risks and taking appropriate measures to protect processes during a possible equipment malfunction.

Use of antifoam

Antifoam is injected into the sample as part of the measurement process. Once a sample has

completed the measurement process it will therefore contain a small amount of antifoam. After

measurement, ensure the sample is disposed of in a sink (or similar) to avoid any risk of ingestion.

Class 1 laser

A Class 1 laser is installed in this instrument. Class 1 lasers are products where the radiant power of

the laser beam accessible (the accessible emission) is always below the Maximum Permissible

4

English

Page 5

Exposure value. Therefore, for Class 1 lasers the output power is below the level at which it is

believed eye damage will occur. Exposure to the beam of a Class 1 laser will not result in eye injury.

Class 1 lasers may therefore be considered safe. However, Class 1 laser products may contain laser

systems of a higher class but there are adequate engineering control measures to ensure that

access to the beam is not reasonably likely. This Class 1 laser product complies with 21 CFR

Chapter 1, subchapter J. It is evaluated and tested in accordance with EN 61010-1, Safety

Requirements for Electrical Equipment for Measurement and Control and Laboratory Use and

IEC/EN 60825-1, Safety of Laser Products.

CFL backlight

The CFL (compact florescent light) used for backlighting the screen display contains a small amount

of mercury. Please dispose of any used CFL’s in accordance with local, state or federal laws

concerning the disposal of products containing mercury.

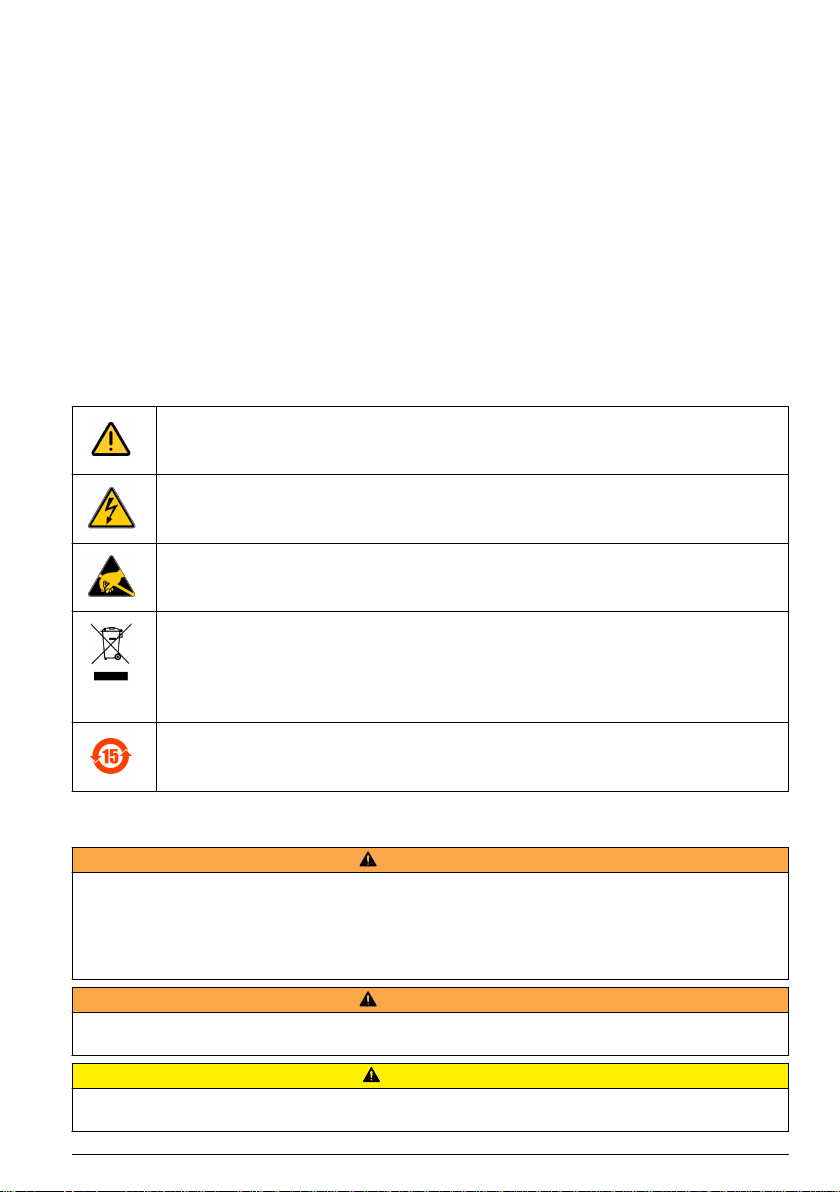

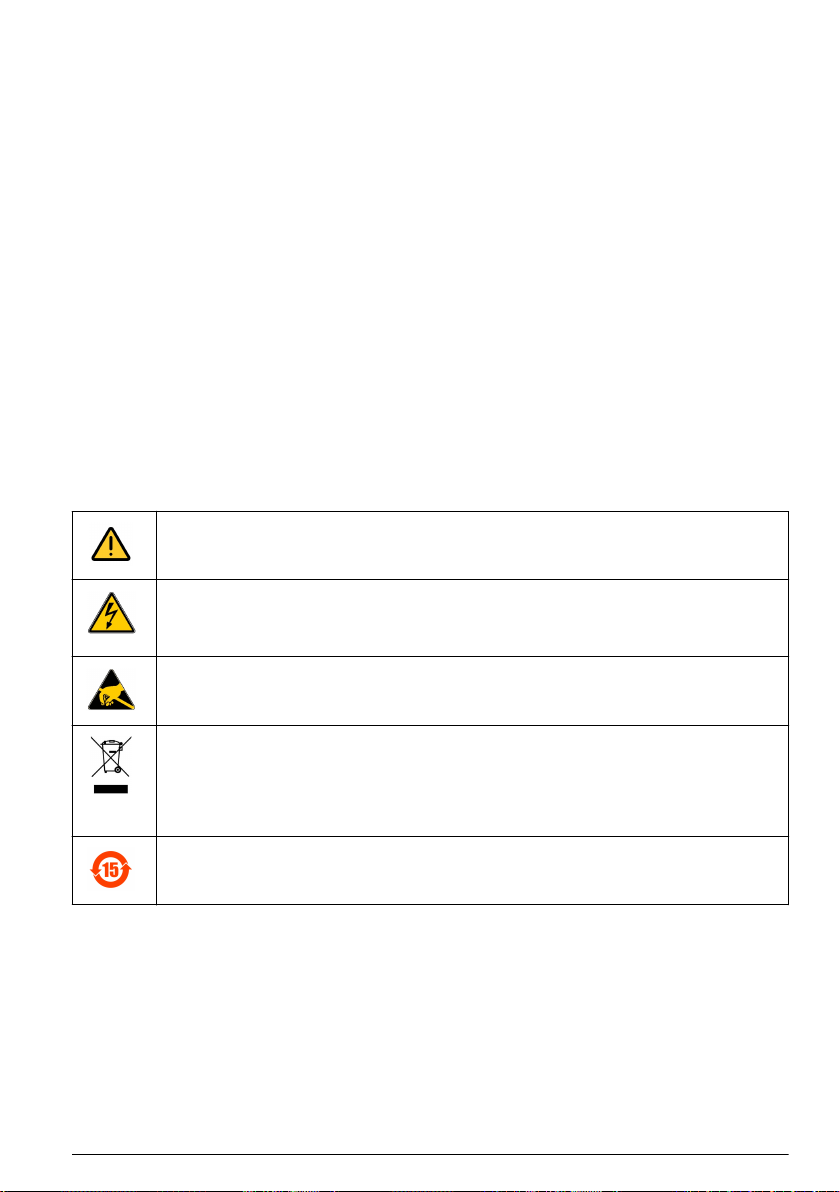

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary

statement.

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems. In conformity with European local and national regulations, European electrical equipment

users must now return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Installation

W A R N I N G

This section provides necessary information to install and connect the analyzer. The installation of the analyzer

should be performed in accordance with relevant local regulations, and only by personnel trained and

experienced in the installation of the 6110 analyzer. Disconnect the power supply of the analyzer before carrying

out any work inside the analyzer. Any work inside the analyzer should be performed exclusively by personnel

specialized and authorized to work on electrical installations. In addition, and in accordance with safety standards,

it must be possible to disconnect the power supply of the analyzer in its immediate vicinity.

Electrical danger and fire hazard. Only use the supplied power cable. Only qualified experts may perform the

tasks detailed in the installation section of this manual, while adhering to all locally valid safety regulations.

Proper ESD (electrostatic discharge) protocols must be followed to prevent damage to the product when working

with the electronic boards.

W A R N I N G

C A U T I O N

English 5

Page 6

D A N G E R

Risk of finger trapping. A silicon insert is located on the transparent front door to assist in lifting and lowering the

door when adding or removing packages for analysis. Under no circumstances must this silicon insert be

removed.

The instrument is heavy (55 kg) so extreme care must be taken when handling, to avoid damaging the instrument

or inflicting personal injury. It is highly recommended to use a pulley system (or similar) attached to the lifting

ring located on the top of the instrument when unpacking or moving it.

C A U T I O N

Positioning

C A U T I O N

The instrument is heavy (55 kg) so extreme care must be taken with handling to avoid damaging the instrument or

inflicting personal injury.

Hach Lange recommends installing the instrument on a sturdy laboratory table that can more than

support the 55kg weight. Place it on a clean flat surface, and convenient to the power source. The

display screen should be at head-height for easy viewing and operation.

Pre-installation

1. You will need the antifoam cartridge filled with the antifoam liquid as part of the installation

process. Prepare this before starting the installation using the instructions in Antifoam cartridge

preparation on page 7.

2. Make sure you have suitable standards available before performing any calibration.

3. Your A1100 electrochemical sensor has been thoroughly cleaned and tested at the factory before

shipment and installed in the instrument. It has been shipped with a cartridge containing a

membrane and electrolyte pre-installed to protect the sensor head. The sensor must be removed

from the instrument and the cartridge removed and replaced with a new one prior to first use to

make it fully operational. These steps are described in the A1100 cleaning procedure for

6110 TPA document supplied with the instrument. The new cartridge is included in the sensor

recharge kit, also supplied with the instrument.

Physical installation

An installation wizard will start automatically once power is connected to the instrument for the first

time.

1. Connect the instrument to a power source - see Power supply on page 7.

2. Turn the instrument ON. An instrument auto check routine will start automatically. As this is the

first time the instrument will have been powered up, the O2 sensor residual and the Antifoam

level LEDs will always be red. This is normal as the system has not yet been fully commissioned

and these can be ignored at this stage.

3. The wizard will start automatically. Press the Installation button to proceed.

4. At the end of the process select the auto-check option. See Instrument auto check on page 9

for a more detailed explanation of the auto-check process and results.

Post-installation

1. The instrument has been delivered with English as the default language. However, a USB

memory stick is supplied with other available languages (German, Spanish, Chinese, and

Japanese). If you wish to keep English as the preferred language please proceed to the next step

(Step 2 below), otherwise follow these instructions for installing a new language:

• Make sure that Microsoft ActiveSync® is installed on your PC (a copy is available as a free

download from the Microsoft web site).

6

English

Page 7

• Using the USB cable supplied with the installation kit, connect your PC to the instrument via

the USB client connector. ActiveSync® will start automatically. By default ActiveSync

®

proposes to set up a partnership with the instrument. This is not required, so select NO before

continuing.

• Insert the supplied USB memory stick into your PC.

• Inside the Setup folder, double click on the setup.exe executable file. Follow the on-screen

instructions on your PC and then on the instrument to install the preferred language software.

2. Set the security levels, user ID’s and passwords as described in Security and user management

on page 13.

3. Configure the instrument parameters as described in Configuration on page 10.

4. Perform a barometric sensor calibration as described in Barometric pressure sensor

on page 16.

5. Perform an O2 sensor calibration as described in Oxygen sensor on page 17. Wait until the

residual value of the sensor is low enough (controlled automatically by the instrument). This

operation may take around 1-2 hours depending on storage conditions.

Note: The other sensors are more stable and will not require calibration prior to use.

Power supply

W A R N I N G

Only use the supplied power cable. Removable power cables must not be replaced with inadequately

dimensioned power cables.

Check voltage requirement sticker on the rear panel of the instrument before connecting (100-240 VAC).

Connect the power cable supplied with the instrument to the socket at the rear of the

instrument (left in diagram) for AC power connection. To switch the instrument on and

off, press the rocker switch (right in the diagram) - I for On and O for Off.

Note: For optimum performance always keep the gas and power supplies to the instrument switched

on.

C A U T I O N

Emergency STOP button

The red STOP button is located on the right side of the instrument. Should the need arise to stop the

machine at any time during operation, press this button. An audible click can be heard as the button

locks in position. The instrument should then be disconnected from the power supply. Once

disconnected, unlock the button by turning it clockwise. The instrument can then be reconnected to

the power supply and restarted.

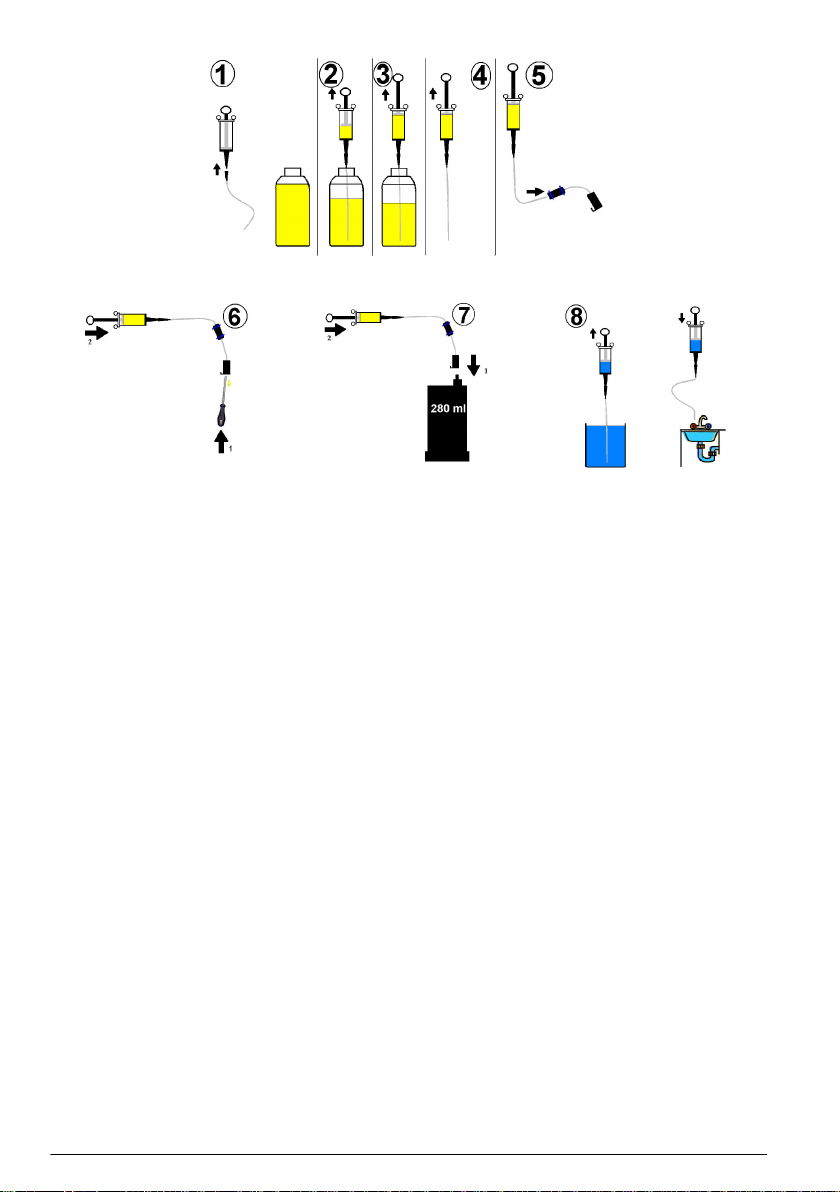

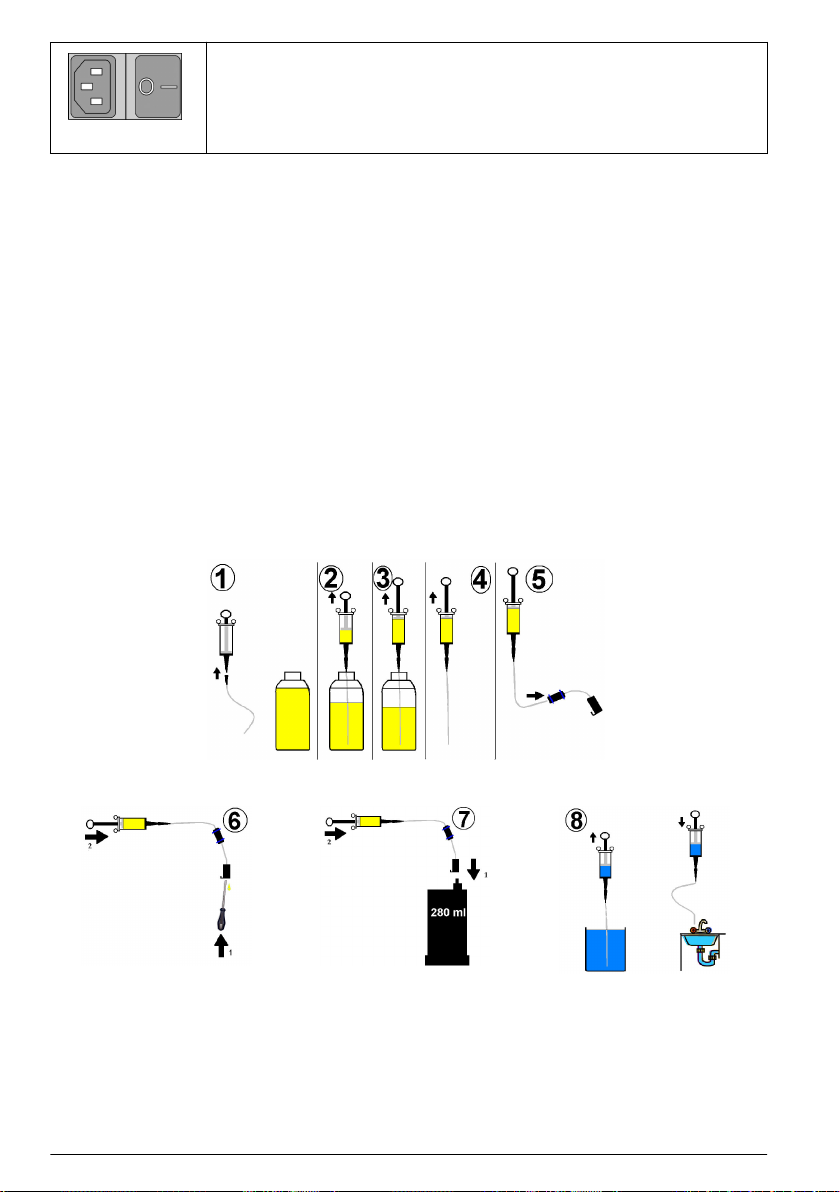

Antifoam cartridge preparation

An empty 280mL volume antifoam cartridge is delivered as part of the installation kit. A recharge

bottle of antifoam is part of the package along with the necessary tools to transfer the liquid to the

cartridge (100mL volume syringe, tubing and connectors).

Note: One antifoam recharge bottle should be enough to fill the cartridge at least 3 times and a cartridge

completely filled with antifoam is sufficient for approximately 3,000 measurements.

To optimize the performance and reliability of the instrument, it is strongly recommended to only use

the silicon antifoam supplied by Hach Lange (part number 33156). To fill the cartridge, proceed as

follows (numbers in the boxes correspond to the steps below):

English

7

Page 8

1. Connect the syringe to the tubing with the quick connector.

2. Unscrew the cap from the antifoam recharge bottle and put the tubing in, making sure it goes as

near to the bottom of the liquid as possible.

3. Pull on the syringe to extract the liquid until the syringe is full.

4. Remove the syringe and tubing from the recharge bottle.

5. Attach the end of the tubing from the syringe to the other piece of tubing using the quick fit

connector.

6. Remove any trapped air in the system by applying a small amount of pressure to the end of the

connector with a small screwdriver (or similar) to open the valve. Push slightly on the end of the

syringe until antifoam can be seen dripping out of the end of the connector. Remove the

screwdriver.

7. Attach the end of the second piece of tubing to the antifoam cartridge by pressing until the

connector clicks into place on the inlet valve. Then, push on the end of the syringe to empty the

contents into the cartridge. The syringe has a volume of 100mL and the cartridge a volume of

280mL, so repeat the process until the antifoam cartridge is full.

8. On completion, rinse out the syringe and all tubing with water. Screw the cap back onto the

antifoam container and store the tools and container in a cool dry place.

Note: After installation of the antifoam cartridge in the analyzer, it is critical that any air bubbles be cleared from

the antifoam circuit before taking any measurements. To do this, select the Antifoam system option from the

Actuator verification option in the Maintenance menu and follow the instructions as described in Antifoam

system on page 21. Select 50 injections and stop the process when the system constantly spits a small

stream of antifoam at each stroke denoting the antifoam circuit is free of air bubbles.

User interface

Switching ON and OFF

The instrument has a power switch located at the rear of the left side of the base. The LED on the

instrument measurement start button is illuminated when the instrument is powered ON.

Note: It is recommended to keep the instrument powered ON at all times, unless the instrument is to be moved to

another location, if it will not be used for a long period of time, or if maintenance procedures need to be carried out

inside the instrument.

8

English

Page 9

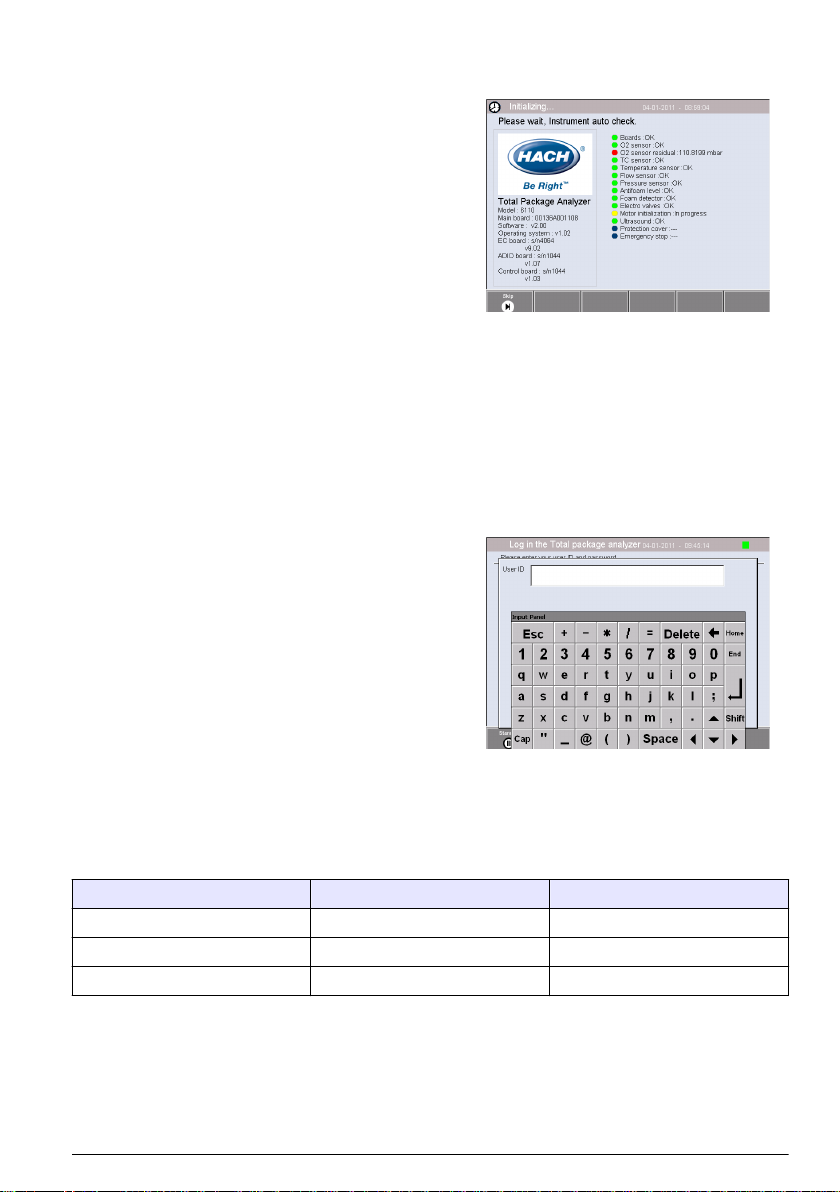

Instrument auto check

When the instrument is powered ON it goes through a number

of startup procedures to check all components are installed

and functioning correctly.

The right side of the screen lists each of the instrument

components that are being checked and a colored indicator to

the left of each component shows the current status:

• Green - the component is installed and working correctly

• Yellow - the component is in the process of being checked

• Red - there is a problem with that particular component

• Blue - the component has not yet been checked

If there are errors encountered on startup that mean the

instrument cannot function correctly a warning screen will be

displayed indicating the next course of action.

Note: Once the instrument is switched on you will need to wait until the oxygen sensor residual value reaches the

threshold of 0.1 mbar. This operation can take as much as two hours depending on the instrument and sensor

conditions prior to startup.

Touch screen

The front panel is a TFT VGA (640x480 pixels) color display and touch screen.

Data entry

When a text box (alphanumeric field) is selected for data entry,

a virtual keyboard appears on screen. This is used in a similar

way to a standard PC keyboard. When data entry is complete

press the Enter key on the right of the keyboard to confirm

input and exit the virtual keyboard.

Note: Use the Cap key at the bottom left of the keyboard to switch

between upper and lower case characters. This is important for casesensitive information such as passwords.

For convenience, selection through a possible large list of

items has been designed with a rolling list. Use the up and

down arrows at the side to navigate through the list or select

one item directly. Press Ok to confirm.

User identification

If access rights have been enabled (see Security management on page 13), it will be necessary to

log on as an authorized user to get access to the instrument. By default, three levels of user have

been defined for the instrument, and will be required on first access to the instrument:

Level ID Password

Administrator 000 123

Manager 001 123

Operator 002 123

After setting up your own user list, these three default entries should be removed.

To log on, press Login on the banner at the bottom of the screen. Enter a valid User ID and

Password combination in the boxes provided, and press Ok to continue. The details will be

displayed at the top left corner of the screen. Press the Ok button at the bottom left of the screen to

gain access to the menu.

English

9

Page 10

Note: For security purposes, when the session inactivity delay period has expired the user is logged off

automatically.

Instrument options

A banner is displayed at the foot of each screen showing the available options:

• Standby - Press this button to leave the instrument in operational mode if there is a long time

delay between measurements. The screen will go blank, but can be reactivated by tapping it. Once

reactivated, you will need to enter a valid user ID and password combination if this has been set

up.

• Configuration - Refer to Configuration on page 10

• Calibration - Refer to Calibration on page 15

• Measurement - Refer to Measurement process on page 17

• Analysis - Refer to Analysis on page 18

• Maintenance - Refer to Maintenance on page 19

Note: If any of the options are unavailable for any reason (e.g. access level not high enough), they will be greyed

out.

Instrument status indicator

A colored LED indicator on the top right of the screen will indicate the current status of the

instrument:

• Green - no problems have been detected

• Yellow - a problem has been detected but is not serious enough to stop measurements being

taken

• Red - there is a serious problem with the system which must be corrected before any

measurements can be taken

If multiple problems have been detected, the color of the LED will reflect the most severe error. If the

LED indicator is not green, pressing it on any screen will display a list of errors and warnings. To

make sure the instrument is working correctly, it is advisable to correct all errors and warnings before

continuing.

Configuration

Units and resolutions

For each value displayed by the instrument select the required unit from the drop-down list and press

Ok to continue. When all units have been assigned, press Ok on the main screen to save these

values and continue.

For each value displayed by the instrument select the required display resolution from a drop-down

list and press Ok to continue. A maximum of 4 digits and a decimal point can be displayed (i.e. 1234,

123.4, 12.34, or 1.234). This does not affect the actual resolution of data measured and stored, only

the data displayed on screen. When all display resolutions have been defined, press Ok on the main

screen to save these values and continue.

Package parameters

Package management

Add new package definitions (up to a maximum of 100), and edit or delete existing definitions. To edit

or delete a package, first select the package from the list displayed by touching the package name

on the screen, and then press either Edit or Delete as appropriate.

A new package will be created using the default package parameters. You will then need to select

the new package and edit it to define the new package parameters.

10

English

Page 11

1. Product tab

Option Description

Solubility Enter the type of beverage in the package.

Headspace Check this box for a fast measurement sequence that provides data from the

Equilibrated This is only available if Headspace (previous box) is checked. Check this box if you

Slow Decompress If checked, then after the measurement process has completed, a slow release of any

Formula Define up to five different formulae for computing a new parameter. The formula

headspace only.

require the additional total O2 and dissolved CO2 measurements taken from the

headspace.

remaining pressure will take place so the package can be handled safely.

definitions must already have been entered into the system (see Formula management

on page 12 for details).

2. Package tab

Option Description

Comment Enter a free-format alphanumeric text. This text will appear against the package description

Brimful volume Enter the volume of the package when full to overflowing.

Height Enter the overall height of the package. This information is used if you activate the

Tilt position Enter the tilt position of the package holder (optional). This should be 1, 2, or 3 and

Pck backstop Position of the package backstop (optional). The backstop is calibrated on a scale of zero

Package type Select the correct image for the type of package being measured (bottle, can, etc.). The

in the main package management screen.

Package size check option in Measurement output on page 12.

corresponds to the number on the tilt knob on the front of the instrument .

to seven.

setups for each icon are different, so it is important to select the correct one.

Note: The above reference values are also displayed at the start of the measurement process for the package,

so the operator can adjust the instrument accordingly (tilt position, etc.).

3. Alarms tab

Option Description

Alarm parameters Select the parameter to define the alarm settings, and enter the minimum and maximum

values allowable for each parameter listed. When the measurement value falls below

the minimum level or exceeds the maximum level for any parameter listed, an alarm will

be triggered.

4. Factors tab

Option Description

Factors Small adjustments can be made to the measurements listed by entering a factor. This defaults to

1.000 for all measurements to indicate no adjustment. If this is changed then the measurement

calculated by the instrument will be multiplied by this factor to give an adjusted measurement value.

English 11

Page 12

Formula management

This option allows you to add new formula definitions (up to a maximum of 40), and edit or delete

existing definitions. You can use up to 16 variables pre-defined by the instrument and 2 user defined

numerical variables that are set up manually at the end of each measurement.

1. New formula

Option Description

New Press the New button to create a new formula. The formula editor screen is displayed and used to

define the formula. The measurement values that can be used are listed down the left side of the

screen. The operators and operands are listed down the top right. In the bottom right of the screen

are a number of screen navigation options to assist in editing.

The colored indicator in the top right corner shows the validity of the formula as it is being created. It

is initially colored yellow but will turn red if the formula is invalid and green when valid. When the

indicator is red, the Ok button will be unavailable.

Use the Select button to select an existing formula to include in the new formula. The list of existing

formulae is displayed as a rolling list. When a valid formula has been entered, press the Ok button

to continue. You are then requested to assign a name to the new formula, after which an information

box is displayed showing the name of the user who created the formula and the date and time it was

created.

If required, add any free format alphanumeric text to identify the formula and press Ok to continue.

2. Edit or delete an existing formula

Option Description

Edit or

Delete

3. Display formula information

Option Description

Info This button can be used to display information about the selected formula, such as the operator who

To edit or delete a formula, first select the formula from the list displayed and then press

either Edit or Delete as appropriate. If Delete was selected, you will be asked to confirm

deletion before the formula is deleted from the list. If Edit was selected the formula editor

screen is displayed to allow you to change the definition of the formula.

created it, the date and time of creation (or the last edit), and any comments associated with it.

Instrument parameters

Measurement output

1. Define the parameters shown on the screen after and during the measurement process.

Option Description

Diagnostic

measurement view

Display diagnostic

results

Package size check If checked, the instrument will verify that the package size is the same as that

Warning messages If checked, any warning messages will be displayed during the package

12 English

Use this option to troubleshoot measurement problems. If this box is checked, then

instead of the standard measurement progress screens being displayed during the

measurement process, the measurement values are displayed instead.

Use this option to troubleshoot measurement problems. If this box is checked, then

instead of the standard measurement results screen being displayed at the end of

the measurement process, more detailed measurement values are displayed

instead.

defined in the height parameter for the package being measured. If different a

warning message will be displayed. The height detection resolution is 1 mm.

measurement process. If left unchecked, all warnings will be suppressed.

Page 13

Option Description

Normalization If checked, enter the temperature value for CO2 normalization. CO2 calculations will

Column selection From the drop down list, define the three measurements to display on the right side

then be made based on the temperature entered rather than the sample

temperature.

of the measurement results screen after the measurement process has completed.

When all details have been entered, select Ok to confirm.

Other parameters

1. Time and Date - Set the system date and time parameters and the display format. Select Ok to

confirm.

2. System information - Display the system information about the currently configured boards.

Select Exit to exit the screen.

Security and user management

Security management

When the instrument is started for the first time, security is disabled by default. To avoid any

unauthorized access, it is highly recommended that each user be entered into the system and given

appropriate access rights as soon as possible.

1. Configure parameters related to confidentiality. On completion, select Ok to confirm.

Option Description

Access rights

enabled

Auto logoff When checked, the user is logged out automatically when the set delay for inactivity is

Audit trail When checked, every action from a user is recorded in an audit file for traceability. These

Logout timer Enter a maximum time of inactivity (in minutes) for all users. Users are logged out

When checked (recommended), it is required to log on as a registered user to access the

menus. When disabled (default), all menus are access free and there will be no name

recorded against any actions in the log file. To set up valid users, refer to User

management on page 14.

reached (see Logout timer below). The instrument goes on standby.

actions cover the configuration, calibration, and maintenance options. The audit file is a

rolling buffer recording the last 1000 actions.

automatically when the period of inactivity exceeds this value and the Auto logoff

feature (above) is enabled.

English 13

Page 14

Option Description

Clear audit trail

file

Clear result file This option deletes the package measurement data.

This option deletes the audit file.

User management

1. The list of registered users (up to a maximum of 99) for this instrument are displayed. To have the

Delete and Edit options available, select one of the existing users.

Option Description

New To add a new user, all of the following fields must be entered, then select Ok to confirm:

• Name - Enter the user surname (3-15 characters)

• First Name - Enter the user first name (3-15 characters)

• ID - Enter an alphanumeric ID (1-10 characters)

• Password - Enter an alphanumeric password (3-15 characters)

• Security level - Select the security level from the drop-down list (see also the table below)

Edit or

Delete

Level Available options

Operator Measurement and Analysis

Supervisor Calibration, Measurement, Analysis and Maintenance

Manager Configuration, Calibration, Measurement, Analysis and Maintenance

Administrator Configuration, Calibration, Measurement, Analysis and Maintenance

To remove or modify an existing user, select the user in the user management screen and

select Edit or Delete as appropriate. To save all changes, press Ok or press the Exit button to

exit the screen without making any changes.

Audit trail

View the list of user actions performed on the instrument. The actions are listed chronologically with

the latest action always at the top of the list. When the maximum of 1,000 recorded actions is

reached, the oldest is deleted and replaced with the newest.

Scroll through the audit trail screens using the First, Previous, Next and Last buttons, or select the

Exit button to leave this option.

Note: To clear the audit trail file, use the option available in Security management on page 13.

Communication

This option sets the parameters required for exporting instrument data files to your PC or USB

storage device. Select from:

• Data download configuration (see Data download configuration on page 14)

• Ethernet configuration (see Ethernet configuration on page 15)

Data download configuration

Scroll through the list of available data files using the up/down arrow keys on the right, and select if

the file to be exported is in data or text format. By default, the text format is set to YES and the data

format to NO. Set both formats to NO if you do not require the file downloaded. Use the Invert

Selection button under each column to toggle between YES and NO. When the data formats have

been configured, select Ok to confirm.

Note: It is recommended to set the files to text format for easy loading into standard software applications on the

PC such as Microsoft Excel or similar. The data format is only required for Hach Lange service and support

personnel.

14

English

Page 15

To transfer the data files, plug an external mass storage device (such as a USB memory stick) into

the USB-A port at the rear left of the instrument. The instrument should automatically recognize the

presence of the device. The files are automatically copied and on completion a pop-up window will

inform you the process completed successfully and you can remove the device.

Remove the device and press YES in the pop-up window to continue, followed by EXIT in the main

window to complete the process. Insert the device into a USB port on your computer and download

the data using standard computer software.

Ethernet configuration

This option allows you to set up an Ethernet connection to download data from the instrument to a

PC. This can be to a web page (see Web browser configuration on page 15) using an HTTP

connection, or to an OPC client (see OPC client on page 15) using a DCOM connection. These

options allow you to perform several operations directly from your PC. To be able to use these

options, the instrument must be connected to the network.

At the bottom of the ethernet connection screen, check the data access box required.

Web browser configuration

Access the information by launching an internet browser on your PC and typing “http://” followed by

the device name assigned to the instrument. The home page will then be displayed. You will be

required to enter a valid username and password combination (defined in User management

on page 14). The initial screen will then be displayed. Click on Expand All to see all the available

options.

OPC client

OPC (Open Process Control) is a software interface standard that allows Windows PC programs to

communicate with industrial hardware devices. The OPC client software is installed on a PC and

communicates directly with the OPC server embedded in the 6110 instrument. To activate the link,

check the OPC option on the ethernet configuration screen.

The first time this option is selected, a registration key is required. This can be found on the case of

the supplied CD-ROM. Enter the registration key. Once validated, press the information button next

to the OPC checkbox to display the CLSID number. Enter the instrument ID (shown in the device

name box in the configuration screen) and the CLSID into the OPC client software on the PC to

establish the two-way network link to the instrument.

Scheduled operations

Define the sensor service and calibration schedule for all the sensors installed on the instrument.

• Manual Calibration - Select a sensor and check the activation flag as required. Set the desired

frequency from the options available. When set, the system will set a yellow status indicator

message to inform you when a sensor calibration is required.

• Verification - Define the verification frequency for selected sensors

• Routine maintenance - Define a service frequency for selected instrument maintenance options

• Service - Define a service frequency for selected instrument service options

Calibration

The calibration option is available for all of the internal sensors:

1. Barometric pressure sensor

2. Pressure sensor

3. Temperature sensor

4. CO2 sensor

5. Flow sensor

6. O2 sensor

Note: The above is the actual sequence that must be followed for any calibration (i.e. if you calibrate the CO

sensor, then the barometric sensor, pressure sensor and temperature sensor must be calibrated first and in that

order).

After selecting a sensor to calibrate, the details of the last calibration are displayed. This shows the

values recorded, and information about who performed the last calibration and when. The due date

2

English

15

Page 16

of the next calibration is also shown. A report is created on completion of any new calibration. The

last 10 reports can be viewed by selecting the Calibration reports option in the calibration screen.

Calibration schedule

The following table shows the recommended sensor calibration intervals based on an average of

500 package analyses per week. This proposed schedule can be modified according to operating

conditions.

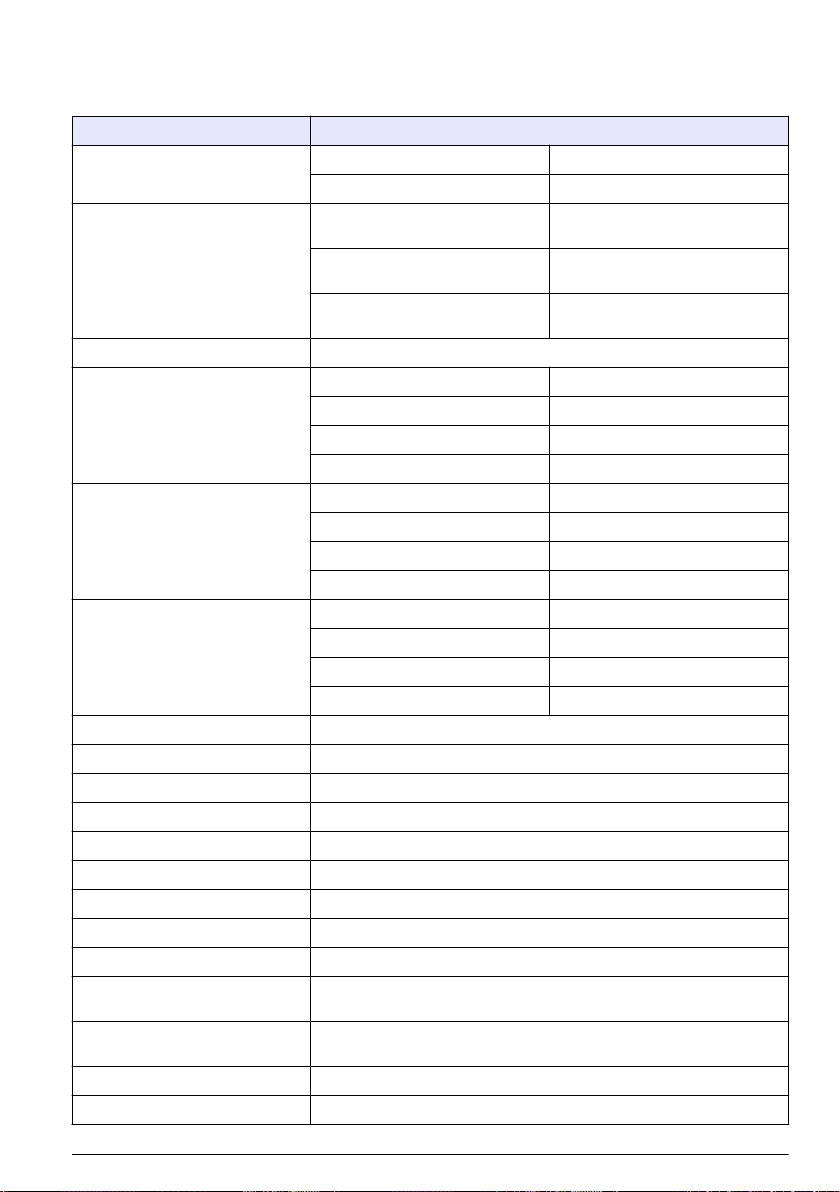

Sensor Interval Sensor Interval

Barometric pressure sensor 6 months O2 sensor 2 - 3 months

Flow meter 6 months CO2 sensor 6 months

Temperature sensor 6 months Pressure sensor 6 months

Barometric pressure sensor

1. A calibration screen is displayed showing the current values measured by the instrument.

2. Using a precision certified barometer, measure the barometric pressure in the location where the

instrument is used and compare with the current barometric pressure value displayed. If the

values are the same press Cancel, otherwise enter the new value in the New barometric value

box and press Validation to store the new setting.

Pressure sensor

1. A calibration screen is displayed showing the current values measured by the instrument.

2. Using a precision certified barometer, measure the barometric pressure in the location where the

instrument is being used. Provided a barometric pressure sensor calibration has recently been

performed this measurement should be the same as the value displayed in the Reference

pressure box. If this is the case press Enter, otherwise enter the measured barometric pressure

value in the Reference pressure box and press Enter.

3. Connect a precision certified pressure gauge (0-7 bar) to the gas out connection on the rear of

the instrument and measure the reference pressure. Enter this value in the Reference pressure

box and press Enter.

4. Press the Validation button at the bottom left of the screen to accept the new calibration and

complete the process.

Temperature sensor

1. A calibration screen is displayed and the instrument measures two temperature values and

checks the stability of the measurements. Provided the measurements are stable, you can

choose to accept or reject the new values. Press Validation to store the new setting.

Carbon dioxide sensor

A Verification option is also available for this sensor. The process is the same as a new calibration.

When verification is complete press the Ok button to exit. No report is produced for the verification

process. The CO2 sensor is calibrated using pure CO2 and air. CO2 is supplied by the purge gas and

air is provided by an internal pump that takes air directly from the atmosphere.

1. A calibration screen is displayed showing the gas purity data of the main gas. If the value is

incorrect, enter the correct value in the Gas purity box.

2. When the measurement stabilizes press the Validation First Point button. A new measurement

is then initialized and the internal air pump automatically activated.

16

English

Page 17

3. When the measurement stabilizes press the Validation Second Point button.

4. You now have the opportunity to accept the calibration, store the new values, and write the

details to the calibration report file. If the calibration cannot be performed, an error message will

be displayed giving the reason.

Flow sensor

1. A calibration screen is displayed and the instrument will then compute the measured flow in four

steps (at 0.200 mL/s, 0.400 mL/s, 0.800 mL/s and at 0.000 mL/s). The results are displayed on

screen.

2. After a few minutes, when the process is complete, the Validation button is highlighted. Press

this button to accept the calibration (you will need to confirm acceptance).

Oxygen sensor

The O2 sensor is calibrated in-situ with an air pump providing a continuous flow of fresh air in front of

the sensor head.

1. A calibration screen is displayed.

2. The value Ratio ideal membrane is a percentage of the current against the ideal current for the

membrane being used.

3. The value Variation shows the percentage of this measurement against the last sensor

calibration measurement.

4. The Calibration Status box at the bottom of the screen shows the current calibration process

with a bar graph below it to indicate the progress.

5. On completion, only if the calibration is valid will the Validation button be displayed. Press this

button to accept the calibration, store the new values, and write the details to the calibration

report file. If the calibration cannot be performed, an error message will be displayed giving the

reason.

Measurement process

Main screen

The initial screen displays standard information about the package to measure. You have the

possibility to change the user and the package type to be measured.

Start analysis

Note: Once a sample has completed the measurement process it will contain a small amount of antifoam.

Therefore, after measurement, ensure the sample is disposed of in a sink (or similar) to avoid any risk of ingestion.

For optimal operation, the base of the package holder should always have a layer of water for

improved transfer of the ultrasound energy to the liquid in the package. For the correct amount of

water, tilt the package holder forward by turning the tilt knob to position 3 (small can icon). Next, fill

the holder with water until the water level reaches the top without spilling over. Finally, put the holder

back to the correct tilt position for the package to be measured in readiness for the measurement

process.

Select the Start Analysis option to start the measurement process. The instrument will display

information regarding the measurement step being taken, instructions on any user involvement

required, and the measurement progress throughout the duration of the measurement process.

The first screen gives details of the package being analyzed and gives the user information on what

action to take. As instructed, raise the transparent front door in order to place the package in the

measuring chamber. As soon as the door is raised, the initialization screen is displayed with the next

set of instructions.

English

17

Page 18

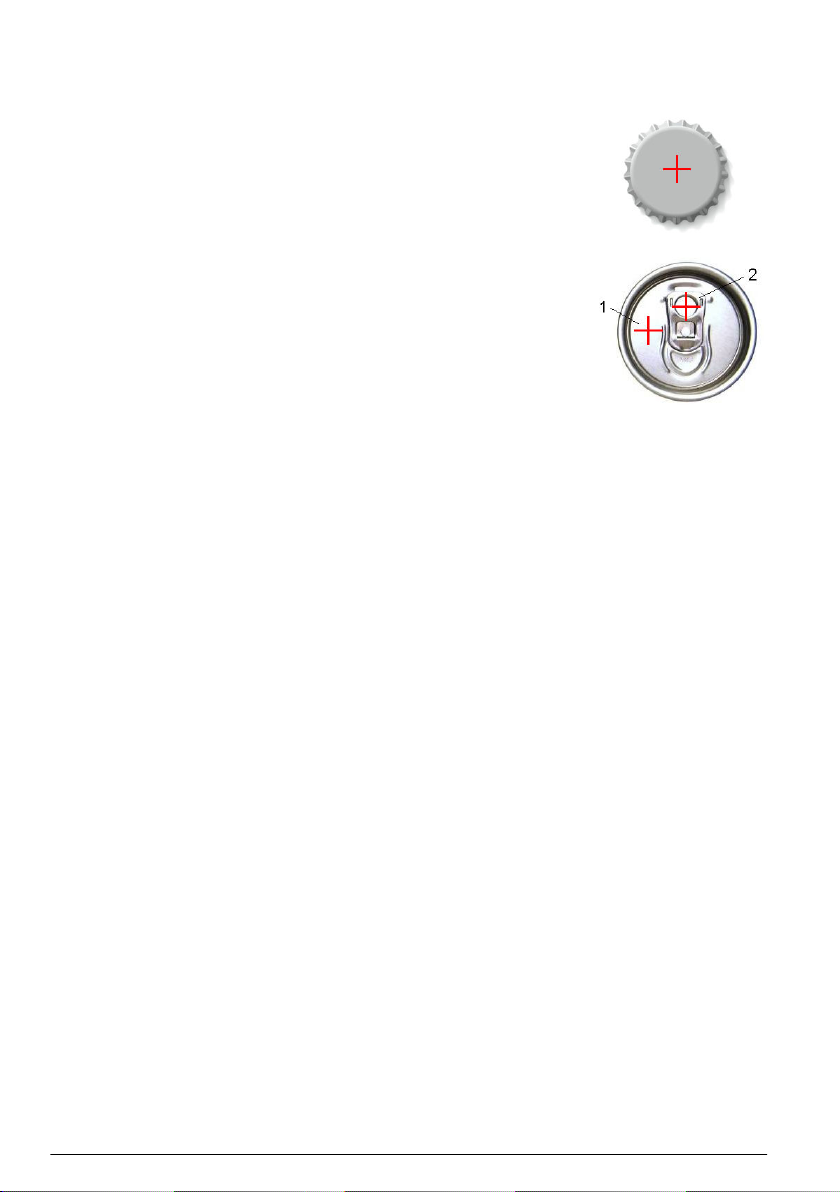

Place the package to be analyzed on the circular platform, and set the tilt position as defined for this

package by turning the black knob on the front. Two red laser beams are activated as the front door

is raised. Where the two red beams intersect is where the package will be pierced.

For bottles, position the package so that the two red beams intersect in the centre of

the bottle top (illustrated above left).

For cans, position the package so that the two red beams intersect at position 1

(illustrated above right). This is the recommended piercing position. Alternatively,

position the package so that the two red beams intersect at position 2. If piercing at

position 2, turn the ring pull 90° left or right, in order to clear the piercing position. Do

not pierce the can with the ring pull in the position illustrated.

Make sure that the package is also hard up against the backstop. This may require realigning the

backstop by turning the locking wheel counter clockwise and adjusting its position to that defined for

this package. Lock it in place by turning the locking wheel clockwise finger tight.

Once the package is secure against the backstop and the piercing position aligned with the two red

laser beams, close the front door.

Start the measurement process by pressing the illuminated START button on the front right side of

the instrument base. A progress bar is displayed at the bottom of the screen showing the elapsed

time to date, and the estimated time for measurement completion. This bar is updated on an ongoing basis. No user intervention or action is required until the measurement process has completed.

However, you do have the option to Abort the process at any point.

Once complete, the measurement results are displayed. The three columns of data displayed are

those that have been defined in Measurement output on page 12 and are color coded (green

signifies the measurements are within the defined limits for this package, and red signifies outside

the defined limits).

It is possible to add 2 numerical values and 5 comments to these results by entering them in the text

boxes displayed down the left. The numerical values will be required if they have been defined as

part of a formula (see Formula management on page 12).

Press the Continue button to return to the main measurement screen, or press the Info button to

display more detailed results in a tabular format.

Analysis

Open data

This option allows you to view the measurement data from the last 1000 measurements. The data

elements displayed are those defined in Table settings on page 18. Use the Previous and Next

buttons to scroll through the data. Select one of the lines of data and the Info button will be made

available. Press the Info button to see more details of the measurement in a new screen.

Use the Exit button to return to the main analysis menu.

Table settings

This options allows you to define up to 10 data elements that the instrument will display for each

measurement. More data is recorded, but only 10 values can be displayed on screen. Define for

each of the 10 columns the data to view from the drop-down list of available data elements. Select

Validation to accept and save the selected data elements.

18

English

Page 19

Maintenance

Schedule

The following table shows the recommended maintenance schedule for an average of 500 package

analyses per week. This proposed schedule should be modified according to operating conditions.

Action Interval

Clean instrument exterior Daily

Refill sonotrode base with water Daily

Check piercing tip is tight Daily

Check the purge gas supply, pressure and purity (CO2 99.9%)

C A U T I O N

On no account should the cylinder become empty while the instrument is switched on

as this can cause damage to the carbon dioxide sensor.

Daily

Run a reference sample (old beer) through the system to verify the CO2 sensor and the O

response/residual (< 20 ppb)

Goretex filter replacement (see Wizards on page 20) Weekly

Remove and clean instrument front door inside and out Weekly

Clean optical barrier windows Weekly

Clean the sonotrode surface of the package holder Weekly

Clean laser optics used to position the package Weekly

Refill the antifoam cartridge (see Antifoam cartridge preparation on page 7) Approximately every

O2 sensor cartridge replacement and calibration (see Wizards on page 20) Every 2-3 months

Piercing gasket replacement (see Wizards on page 20) Every 3 months

Piercing tip replacement (see Wizards on page 20) Every 6 months

Clean antifoam cartridge Every 6 months

Purge and clean antifoam system Every 6 months

Replace the display protection film Every 6 months

Replace the rim detector protection Every 6 months

Replace flow chamber O-ring Every 6 months

Replace the blue sample tubing Every 6 months

2

Daily

6 weeks

The following are performed by a Hach Lange service technician:

Action Interval

Sensor calibrations Twice a year

Replace needle valve Yearly

Replace antifoam cartridge internal membrane Yearly

Antifoam pump maintenance Yearly

Piercing module maintenance Yearly

English 19

Page 20

Wizards

This option gives an on-screen visual guide through a number of standard maintenance procedures

to perform on the instrument.

Installation

The installation wizard will be invoked automatically the first time the instrument is switched on to help you

complete the installation of the instrument.

Once the instrument has been successfully installed, the Skip installation wizard on device startup checkbox

should be checked to ensure a normal startup from there onwards.

Maintenance

It is recommended to use the maintenance wizards for maintenance of the instrument. Simply follow the onscreen instructions available for each of the options.

Antifoam

cartridge

replacement

EC sensor

maintenance

Goretex filter

replacement

Piercing tip

replacement

Antifoam pump

maintenance

A replacement cartridge can be used or the existing cartridge refilled with antifoam. If refilling

the existing cartridge, follow the instructions given in Antifoam cartridge preparation on page 7.

To ensure the performance and reliability of the instrument, it is strongly recommended to only

use the silicon antifoam supplied by Hach Lange (part number 33156).

Chemical reactions within the gas sensor requires that the oxygen sensor be serviced regularly

to restore its original sensitivity. A clear sign that a sensor maintenance is required is when

measurements are noticeably less stable than usual.

For EC sensor maintenance, please also refer to the instruction sheet entitled A1100 cleaning

procedure for 6110 TPA which is supplied with the instrument.

It is recommended to replace this filter every week.

It is recommended to replace these about every six months.

Note: When replacing the tip, use the mounting tool supplied with the installation kit and apply some Loctite

222 sealant (or similar) on the screw thread of the tip before mounting.

Refill or replace the antifoam cartridge as required.

®

Digital input verification

This option allows you to check all devices that provide digital inputs to the instrument

microprocessor. A black dot in the circle to the right of the option signifies that the sensor is

activated.

Actuator verification

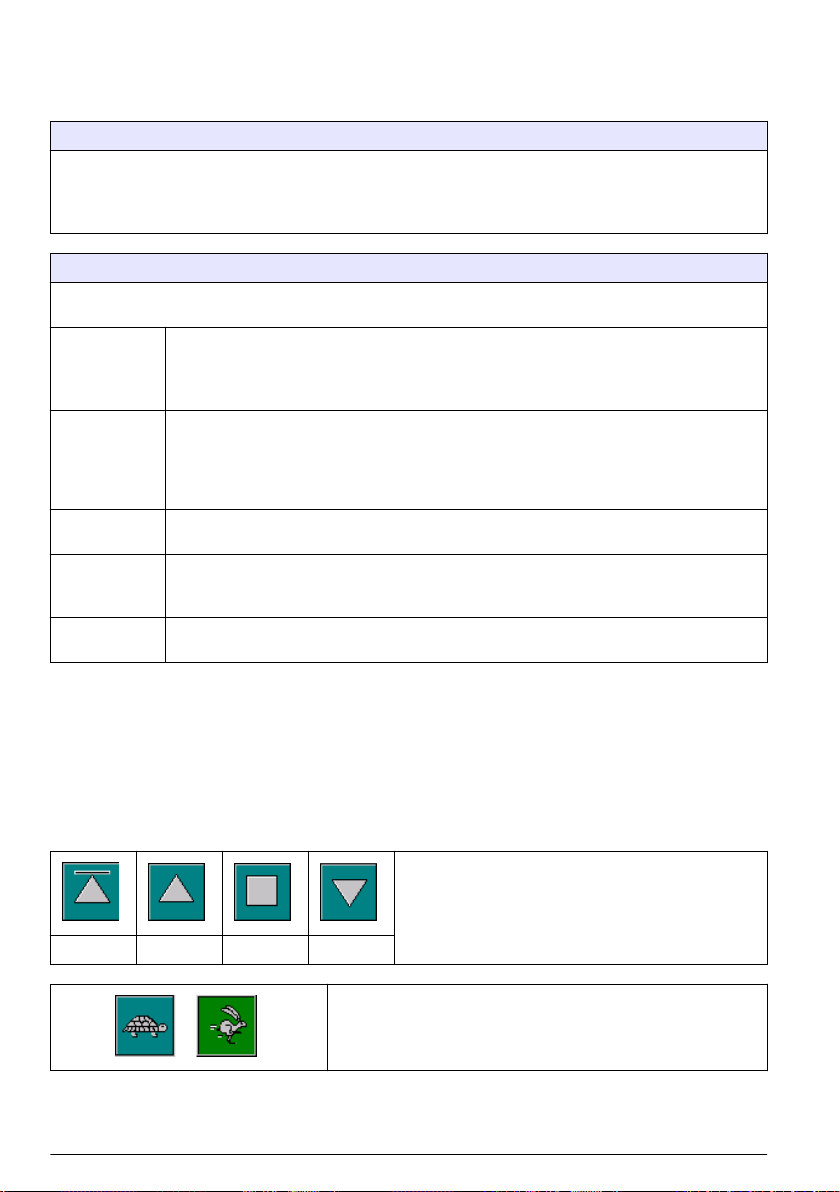

Manual displacement

Press on the icons to perform the required operation on

the piercing assembly.

The current position is displayed on the left side of the

Home Up Stop Down

20 English

It is advisable to check the displacement process using the two

different speed settings by pressing on these two buttons (tortoise

for slow and hare for fast).

screen as the assembly moves either up or down.

Page 21

Press on the icon with the up arrow to raise the needle back into the

home position.

Press on the icon with the down arrow to lower the needle without

moving the piercing assembly.

Ultrasound ON/OFF

With some water in the base of the package holder, test the system is working by moving your finger

across the base of the package holder and toggling the switch between ON and OFF. You should

sense a noticeable difference.

Lasers ON/OFF

Test the system is working by toggling the switch to ON and you should see the two red laser beams

intersecting on the package holder. Toggle the switch back to OFF and the laser beams should

disappear.

Antifoam system

Use this option to check the level of antifoam remaining, and to test that the antifoam injector system

is working. This option is useful to purge the system before an extended stand-by (several weeks) or

when performing start up procedures.

Enter the number of injections required and follow this procedure:

1. An antifoam priming beaker is available from the spares kit delivered with the instrument. Place

this on the ultrasonic base of the instrument, using the lasers to center it and lower the plastic

front door.

2. Activate the motor to lower the instrument head, allowing the needle to penetrate approximately

to the center of the beaker. Refer to Manual displacement on page 20 for details on lowering the

instrument head.

3. Press the Start injection button and you should hear the injector working. You should hear as

many clicks as you have defined for the injection number. In addition, the liquid should be seen

exiting from the tip of the needle.

4. On completion of the test press the Stop injection button and raise the instrument head to its

home position. Remove the beaker and rinse well with water. Store with the syringe and antifoam

container for next usage.

Analog value monitoring

This screen shows all the main analog signals related to the main components of the instrument.

Global system view

This option allows you check various components of the instrument. Check a component by pressing

on the button/schematic (which will turn to green) and observe the values being displayed.

Note: If the gas flow rate is manually changed, be aware that the automatic purge procedure (every 5 minutes) will

reset the gas flow rate back to 0.25 mL/s, which will have an impact on the values being observed.

System initialization

Selecting this option initiates the standard system startup process without having to power the

instrument off and on.

End application

Select this option to perform an orderly shut down of the instrument. On completion, the instrument

can be powered OFF.

English

21

Page 22

Service validation

This option lists the service due date for a number of options. As each service due date is passed,

the Service done button will be made available. Press this button after the service has been

performed to reset the service due date.

Measurement head initialization

Use this option to return the measurement head to the home position by pressing the Initialize

motor button.

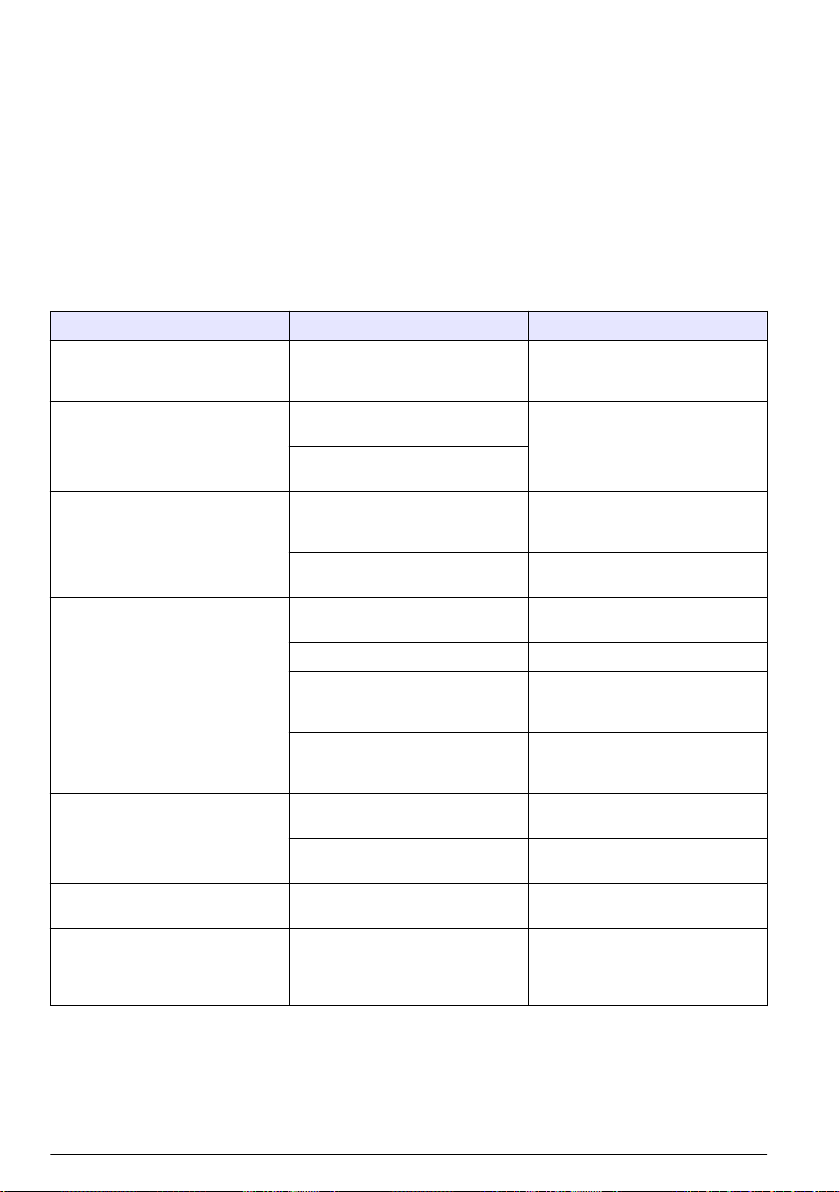

Troubleshooting

Error messages

Message Probable cause Solution

E1: Emergency STOP. Emergency STOP button pushed.

The measuring head has missed an

E2: Motor error.

E4: The front door has been

opened. The measurement process

has been stopped.

E10: Foam has been detected in the

gas path. The measurement

process is canceled.

E20: Not enough pressure in the

system. The measurement process

is canceled.

E40: Check gas supply, current

pressure: nn

E80: Rim detector is dirty. Please

clean it and restart the instrument.

obstacle.

Emergency STOP button pushed if

the motor is moving.

The front door has been opened

before the end of the measurement

process.

The front door is not closed

properly.

There is a problem with the

antifoam injection.

Incorrect tilt of the sonotrode. Check the tilt of the sonotrode.

There is no more antifoam.

The pressure in the package is

greater than the purge gas

pressure.

Problem of flow regulation during

the measurement.

The gas path is partially or totally

blocked.

Before filling the reference volume,

the pressure is lower than 1.5 bar.

The detector has become clogged

with old sample and dirt.

Release emergency STOP button

by turning it clockwise.

If necessary, initialize the motor.

Initialize the motor.

Close the front door.

Control the front door mechanism.

Try another measurement.

Check the antifoam level and refill if

necessary.

Prime the antifoam pump.

Increase the purge gas pressure.

Check the purge gas pressure.

Change the Goretex filter.

Control the antifoam injection.

Check the purge gas pressure.

Clean the two metal rods either side

of the piercing device with a damp

cloth. Turn the instrument off and

restart it.

22 English

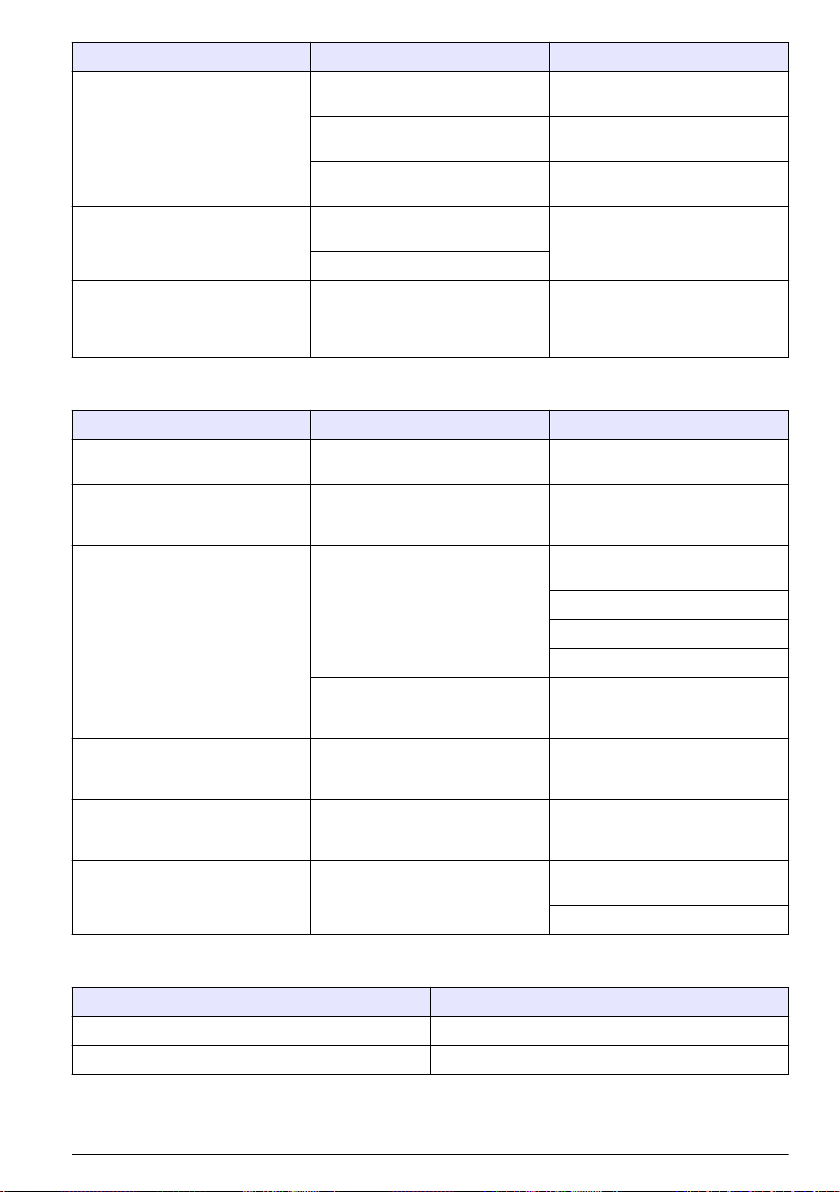

Page 23

Message Probable cause Solution

E100: Ultrasound error.

E200: Motor error - High limit.

E400: Problem to initialize the motor

displacement. The measurement is

aborted. Please restart the

instrument.

The ultrasound power supply is

OFF.

The emergency STOP button is not

released.

There is too much water in the

ultrasound generator.

The motor is above the reference

position.

An upper or lower limit is ON.

N/A

Check the ultrasound power supply.

Release emergency STOP button

by turning it clockwise.

Remove any excess water.

Go to the maintenance menu, move

the motor down and initialize it.

Turn the instrument off and restart

it.

Warning messages

Message Probable cause Solution

W1: Unstable reference pressure.

W2: Unmatched package size.

W4: Measurement timeout.

Accuracy of dissolved O2 not

guaranteed.

W20: Measurement process

incomplete. Insufficient initial

package pressure.

W40: Spontaneous degassing...

W80: Measurement process

incomplete. Insufficient package

pressure during ultrasound stage.

The variation of reference pressure

is too high.

The measured package height is

different from the value defined in

the package definition.

The measurement pressure is lower

than 3.5 bar.

Gas path not airtight.

The pressure in the package is too

low to continue with a

measurement.

A spontaneous degassing is

detected at the end of the first

expansion.

The measured pressure is too low

to compute the second phase of the

measurement.

Check the pressure stability of the

input reference gas.

Check the package size definition.

Check the black seal on the piercing

unit.

Check the purge gas pressure.

Check the forcing gas pressure.

Check the Goretex filter.

Check the airtightness of the gas

path between the piercing unit and

the measurement chamber.

Restart the measurement with

another package.

Restart the measurement with

another package.

Check foam intrusion in the gas

path.

Check Goretex filter.

Measurement problems

Observation Explanation

Negative TPO results. CO2 purge gas is not of the required purity of > 99.9%.

The instrument never reaches the threshold value. CO2 purge gas is not of the required purity of > 99.9%.

English 23

Page 24

Observation Explanation

Stop the analysis by pressing the emergency STOP

button.

Disconnect instrument from the power supply and

remove the bottle. Check that the piercing spike is in

place and not unscrewed. Release emergency STOP

The bottle goes up with the piercing head

No antifoam being injected

button by turning it clockwise and restart the

instrument.

Open the front door to stop the process. Remove the

bottle and check that the piercing spike is in place and

is not unscrewed. Close the front door and press the

Abort button on the screen.

Go to the antifoam section of the maintenance wizard

and prime the pumps until antifoam can be seen being

regularly injected into the antifoam priming beaker.

24 English

Page 25

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen

Spezifikation Details

Arbeitsbereich O

Wiederholbarkeit r

95

2

CO

2

Gesamtsauerstoff Gebinde ± 5 µg/L ± 10% je nachdem,

CO2 in ausgewogenen Gebinden

bei T = 10 bis 25°C (50 bis 77°F)

O

2

Typische Analysezeit Ca. 4 Minuten

Anzeigeeinheiten O2-Konzentration ppb oder ppm

CO2-Konzentration v/v, g/kg, g/L oder %W

Druck bar, mbar, psi

Temperatur °C, °F oder K

Betriebsgrenzwerte Gebindetemperatur -2 bis 30 °C (28 bis 86 °F)

Gebindedruck 1,4 bis 6,8 bar absolut (20 - 99 psi)

Umgebungstemperatur 0 bis 40 °C (32 bis 104 °F)

Relative Feuchtigkeit Bis zu 80 %

Gebinde Maximale Gebindehöhe 340 mm (13,39 Zoll)

Minimale Gebindehöhe 90 mm (3,54 Zoll)

Minimales Volumen 150 ml

Material Glas, PET oder Aluminium

Abmessungen (L x B x H) 537 x 540 x 942 mm (21,1 x 21,3 x 37,1 Zoll)

Gewicht 55 kg (121 lbs)

Schutzart IP20

Stromversorgung 100 - 240 V AC ±10%, 50 - 60 Hz

Stromverbrauch Max. 250 VA

Spülgas: CO2 mit einer Reinheit von > 99.9% bei 6 bis 7 bar absolut (87 bis 102 psi)

Spülgasverbrauch 0,4 ml/s (1,5 l/h)

Verdrängungsgas Luft oder N2 bei 5,5 bis 6 bar absolut (80 bis 87 psi)

Verdrängungsgasverbrauch 0,25 ml/m im Standby-Modus

Europäische Richtlinien Niederspannung 2006/95/EC

EMC 2004/108/EC

Elektromagnetische

EN 61326:2006

Kompatibilitätsstandards

Sicherheitsnorm IEC/UL/CSA 61010-1

Sicherheitsnorm für Laserprodukte IEC/UL/CSA 60825-1

1 ppb - 12 ppm

0,75 - 5 v/v oder 1,5 - 10 g/kg

welcher Wert größer ist

± 0.05 v/v oder 0,10 g/kg ± 2% je

nachdem, welcher Wert größer ist

± 2 ppb ± 10% je nachdem, welcher

Wert größer ist

Deutsch 25

Page 26

Spezifikation Details

Digitalanzeige TFT VGA (640 x 480) Farb-Touchscreen mit Hintergrundbeleuchtung

Betriebssystem Windows CE 4.2

Sprachen Englisch, Deutsch, Spanisch, Chinesisch, Japanisch

Schnittstellen 1 x USB-Client, 1 x USB-Host, 1 x Ethernet

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedineungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

G E F A H R

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

W A R N U N G

V O R S I C H T

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

H I N W E I S

Haftungsausschluss

V O R S I C H T

Der Hersteller ist nicht für die unsachgemäße oder falsche Verwendung des Produkts verantwortlich und haftet in

Übereinstimmung mit der geltenden Gesetzgebung folglich nicht für daraus entstehende direkte oder indirekte

Schäden bzw. Folgeschäden. Der Benutzer ist allein verantwortlich für die Erkennung kritischer Anwendungen

und Risiken sowie die Umsetzung angemessener Maßnahmen zum Schutz vor einem eventuellen fehlerhaften

Betrieb des Geräts.

Verwendung von Entschäumer

Der Probe wird während des Messvorgangs Entschäumer hinzugefügt. Aus diesem Grund enthält

eine Probe nach der Durchführung des Messvorgangs eine kleine Menge Entschäumer. Stellen Sie

sicher, dass die Probe nach der Messung in einem Ausgussbecken (oder ähnlichem) entsorgt wird,

um unter allen Umständen zu verhindern, dass das Getränk konsumiert wird.

26

Deutsch

Page 27

Laser Klasse 1

Dieses Gerät arbeitet mit einem eingebauten Laser der Klasse 1. Laser der Klasse 1 sind Produkte,

deren abgestrahlte Leistung des Laserstrahls (die zugängliche Strahlung) immer unter dem maximal

zulässigen Expositionsgrenzwert liegt. Daher liegt die Ausgangsleistung von Lasern der Klasse

1 unter dem Grenzwert, ab dem von Verletzungen des Auges auszugehen ist. Eine Exposition mit

einem Laser der Klasse 1 verursacht keine Augenverletzungen. Laser der Klasse 1 gelten daher als

sicher. Produkte der Laser-Klasse 1 können Lasersysteme einer höheren Klasse enthalten, bei

denen durch technische Maßnahmen sichergestellt wird, dass ein Zugang zum Strahl

unwahrscheinlich ist. Dieses Produkt der Laser-Klasse 1 entspricht 21 CFR Chapter 1, Subchapter J.

Es wurde nach EN 61010-1, Sicherheitsbestimmungen für elektrische Mess-, Steuer-, Regel- und

Laborgeräte und IEC/EN 60825-1, Sicherheit von Lasereinrichtungen bewertet und auf Konformität

mit diesen Normen geprüft.

CFL Hintergrundbeleuchtung

Die CFL (Kompaktleuchtstofflampe), die als Hintergrundbeleuchtung für die Bildschirmanzeige

verwendet wird, enthält eine kleine Menge Quecksilber. Bitte achten Sie bei der Entsorgung

gebrauchter CFLs darauf, die regionalen und staatlichen gesetzlichen Bestimmungen zur

Entsorgung quecksilberhaltiger Produkte einzuhalten.

Aufkleber mit Vorsichtshinweisen

Bitte lesen Sie alle auf dem Produkt angebrachten Etiketten und Hinweise. Die Nichtbeachtung kann

zu Verletzungen an Personen oder einer Beschädigung des Produkts führen. Im Handbuch werden

auf die am Gerät angebrachten Symbole in Form von Warnhinweisen verwiesen.

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen darf.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Elektrische Geräte, die dieses Symbol aufweisen, dürfen in Europa nicht als Haushaltsabfall

entsorgt werden. Den lokalen und nationalen europäischen Bestimmungen gemäß müssen

Benutzer von Elektrogeräten diese nun zur für den Benutzer kostenlosen Entsorgung an den

Hersteller zurückgeben.

Hinweis: Mit der Wiederverwertung, der stofflichen Verwertung oder anderen Formen der Verwertung von

Altgeräten leisten Sie einen wichtigen Beitrag zum Schutz unserer Umwelt.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Deutsch 27

Page 28

Installation

W A R N U N G

Der vorliegende Abschnitt liefert die für die Installation und das Anschließen des Analysators erforderlichen

Informationen. Das Gerät muss in Übereinstimmung mit den örtlich geltenden gesetzlichen Vorschriften

angeschlossen werden. Die Anschlussarbeiten dürfen ausschließlich von erfahrenem Personal, das über eine

entsprechende Qualifikation für den Anschluss von 6110 Analysatoren verfügt, ausgeführt werden. Unterbrechen

Sie die Stromversorgung des Geräts, bevor Sie Eingriffe im Inneren des Analysators vornehmen. Jegliche

Arbeiten im Inneren des Analysators dürfen ausschließlich von Personal durchgeführt werden, welches für

Arbeiten an elektrischen Anlagen ausgebildet und dafür zugelassen wurde. Zusätzlich und in Übereinstimmung

mit den Sicherheitsstandards muss es möglich sein, die Stromversorgung des Analysators in seiner unmittelbaren

Nähe zu unterbrechen.

Elektrogefahren und Brandgefahr Verwenden Sie nur das beiliegende Netzteil. Die in dem Abschnitt "Installation"

aufgeführten Arbeitsschritte müssen von einem qualifizierten Techniker und unter Berücksichtigung aller örtlich

geltenden Sicherheitsvorschriften durchgeführt werden.

Um Beschädigungen des Produkts während Arbeiten an den Platinen zu vermeiden, müssen geeignete ESDProtokolle (elektrostatische Entladung) befolgt werden.

Verletzungsgefahr durch Klemmen. Auf der transparenten Frontklappe wurde ein Silikoneinsatz montiert, um das

Anheben und Absenken der Klappe beim Laden und Entladen von Gebinden für die Analyse zu vereinfachen.

Dieser Silikoneinsatz darf unter keinen Umständen entfernt werden.

Da das Gerät schwer ist (55 kg), muss sehr vorsichtig damit umgegangen werden, um Beschädigungen am Gerät

und Verletzungen von Personen zu vermeiden. Es wird dringend empfohlen, beim Entpacken und Bewegen des

Instruments eine Seilrolle (oder Ähnliches) zu verwenden, die an dem Hebering auf der Oberseite des

Instruments befestigt wird, zu verwenden.

W A R N U N G

V O R S I C H T

G E F A H R

V O R S I C H T

Standort

V O R S I C H T

Da das Gerät schwer ist (55 kg), muss sehr vorsichtig damit umgegangen werden, um Beschädigungen am Gerät

und Verletzungen von Personen zu vermeiden.

Hach Lange empfiehlt, das Gerät auf einen stabilen Labortisch zu stellen, der ein höheres Gewicht

als 55 kg tragen kann. Die Stellfläche muss glatt und sauber sein und der Stromanschluss muss gut

erreichbar sein. Der Bildschirm sollte sich in Augenhöhe befinden, damit er gut abgelesen und

bedient werden kann.

Vor der Erstinbetriebnahme

1. Die Befüllung der Entschäumerkartusche mit Entschäumer gehört zu den Installationsschritten.

Bereiten Sie die Entschäumerkartusche vor der Installation des Geräts vor, beziehen Sie sich

dabei auf die Anweisungen in Vorbereitung der Entschäumerkartusche auf Seite 30.

2. Prüfen Sie vor der Ausführung einer Kalibrierung, ob Sie über geeignete Standardwerte verfügen.

3. Ihr elektrochemischer Sensor A1100 wurde vor dem Versand und der Installierung werkseitig

gründlich gereinigt und getestet. Er wurde mit einer Kartusche ausgeliefert, die eine vorinstallierte

Membran und Elektrolytflüssigkeit zum Schutz des Sensorkopfes enthält. Der Sensor und die

Kartusche müssen aus dem Instrument entfernt werden und die Kartusche muss vor der

Erstinbetriebnahme des Geräts durch eine neue ersetzt werden, um dessen volle

Funktionstüchtigkeit zu gewährleisten. Diese Schritte sind in dem Anweisungsblatt

A1100 cleaning procedure for 6110 TPA, das zum Lieferumfang des Geräts gehört,

beschrieben. Die neue Kartusche gehört zum Nachfüll-Kit des Sensors, das ebenfalls mit dem

Gerät geliefert wird.

28

Deutsch

Page 29

Geräteinstallation

Nach dem ersten Anschluss des Geräts an die Stromversorgung wird automatisch ein

Installationsassistent gestartet.

1. Schließen Sie das Gerät an eine Stromquelle an - siehe Stromversorgung auf Seite 29.

2. Schalten Sie das Gerät auf ON. Das Gerät führt jetzt routinemäßig einen Autotest durch. Bei der

ersten Inbetriebnahme des Geräts werden die Optionen O2 sensor residual und Antifoam level

immer rot gekennzeichnet. Die rote Kennzeichnung ist zu diesem Zeitpunkt normal, da das

System noch nicht vollständig in Betrieb genommen wurde. Sie kann folglich ignoriert werden.

3. Der Assistent startet automatisch. Drücken Sie die Schaltfläche Installation, um fortzufahren.

4. Wählen Sie nach Abschluss des Vorgangs die Option für den Autotest. Detaillierte Informationen

zum Autotest und den Ergebnissen finden Sie unter Geräteselbsttest auf Seite 31.

Erstinbetriebnahme

1. Das Gerät wird werkseitig für die Bedienersprache Englisch konfiguriert. Auf dem USB-Stick sind

aber andere Sprachen (Deutsch, Spanisch, Chinesisch und Japanisch) verfügbar. Wenn Sie die

Bedienersprache Englisch verwenden wollen, können Sie direkt zum nächsten Schritt (Schritt

2 unten) übergehen. Anderfalls führen Sie die folgenden Schritte aus, um eine neue

Bedienersprache zu installieren.

• Prüfen Sie, ob Microsoft ActiveSync® auf Ihrem PC installiert ist (bei Bedarf können Sie das

Programm kostenslos von der Microsoft-Webseite herunterladen).

• Schließen Sie Ihren PC mit dem USB-Kabel, das gemeinsam mit dem Installationskit

mitgeliefert wurde, über den USB-Anschluss an das Gerät an. ActiveSync® wird automatisch

gestartet. Als Default bietet ActiveSync® an, eine Partnerschaft mit dem Instrument

einzurichten. Das ist nicht erforderlich, wählen Sie deshalb NO, bevor Sie mit der

Erstinbetriebnahme fortfahren.