Page 1

DOC024.52.93009

ORBISPHERE Model 6110 Package Analyzer

User Manual

08/2013, Edition 5

Page 2

Page 3

Table of Contents

Section 1 General Information.........................................................................................................5

1.1 About this manual ........................................................................................................................ 5

1.2 Contact information...................................................................................................................... 5

1.3 Safety information ........................................................................................................................ 5

1.3.1 Use of hazard information................................................................................................... 5

1.3.2 Disclaimer ........................................................................................................................... 6

1.3.3 Safety precautions .............................................................................................................. 6

1.3.4 Service and repairs .............................................................................................................6

1.3.5 Class 1 LASER ...................................................................................................................6

1.3.6 Use of antifoam................................................................................................................... 7

1.3.7 CFL backlight ......................................................................................................................7

1.3.8 Precautionary labels............................................................................................................7

1.4 Product recycling information.......................................................................................................8

1.5 Product disposal ........................................................................................................................ 10

1.6 Restriction of hazardous substances (RoHS) ............................................................................11

Section 2 Specifications.................................................................................................................. 13

2.1 Technical specifications .............................................................................................................13

2.2 Instrument dimensions............................................................................................................... 14

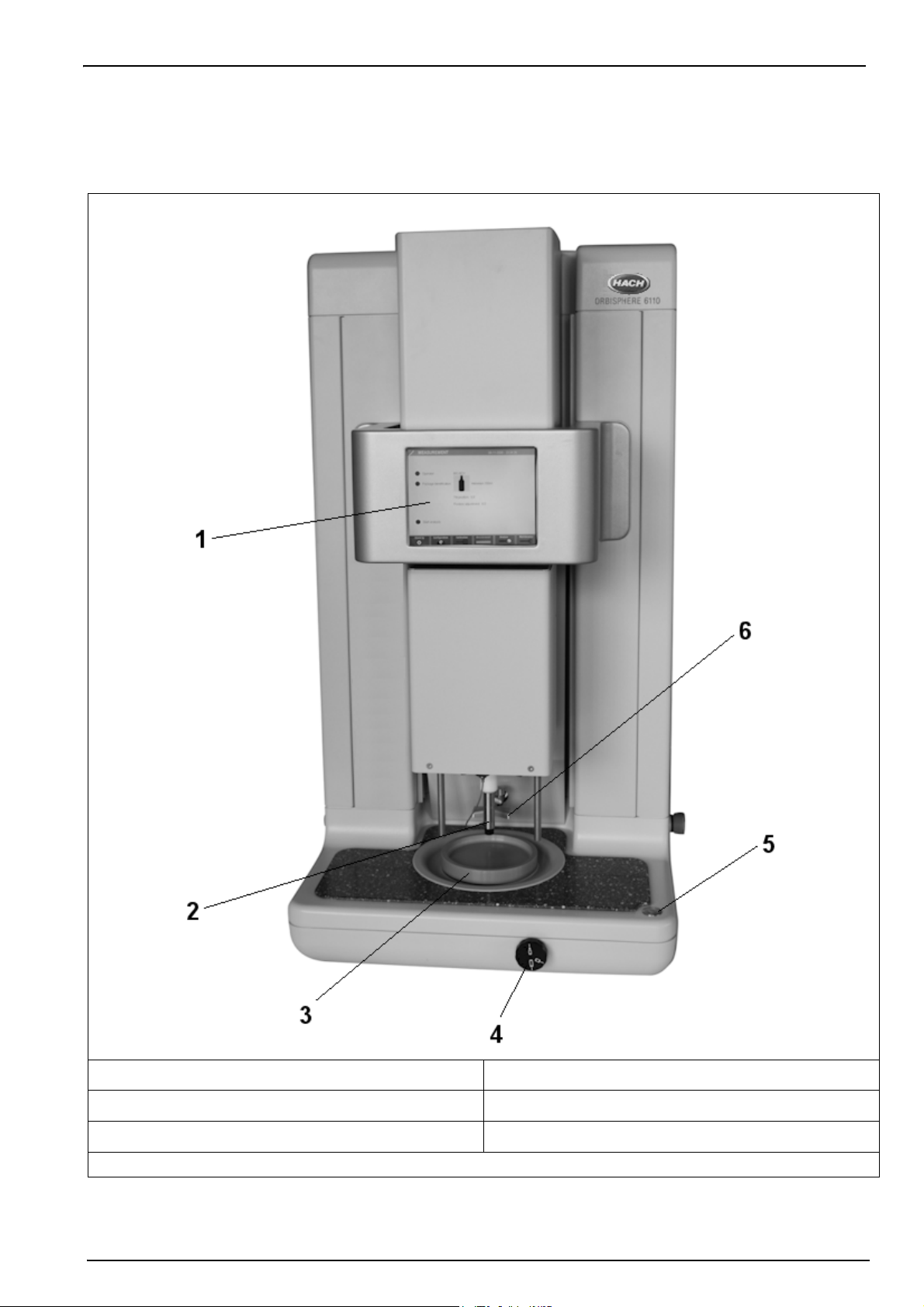

2.3 Main instrument components..................................................................................................... 15

2.3.1 Front view.......................................................................................................................... 15

2.3.2 Left side view .................................................................................................................... 16

2.3.3 Right side view.................................................................................................................. 17

2.4 Instrument switches and buttons ............................................................................................... 18

2.5 Operation overview ....................................................................................................................18

Section 3 Installation........................................................................................................................19

3.1 Unpacking .................................................................................................................................. 19

3.2 Main components.......................................................................................................................19

3.3 Positioning ................................................................................................................................. 20

3.4 Installation.................................................................................................................................. 20

3.4.1 Pre-installation .................................................................................................................. 20

3.4.2 Physical installation........................................................................................................... 21

3.4.3 Post-installation procedures..............................................................................................21

3.5 Additional installation information .............................................................................................. 22

3.5.1 Microsoft ActiveSync® configuration.................................................................................22

3.5.2 Power supply..................................................................................................................... 23

3.5.3 Emergency STOP button .................................................................................................. 23

3.5.4 Antifoam cartridge preparation.......................................................................................... 23

Section 4 User Interface and Startup...........................................................................................27

4.1 User interface.............................................................................................................................27

4.1.1 Turning the instrument ON and OFF.................................................................................27

4.1.2 Touch screen .................................................................................................................... 27

4.1.3 Data entry.......................................................................................................................... 27

4.1.4 Rolling lists........................................................................................................................28

4.1.5 Instrument options............................................................................................................. 28

4.1.6 Information and warning windows..................................................................................... 29

4.1.7 Instrument status indicator................................................................................................29

4.2 Instrument startup ...................................................................................................................... 30

4.2.1 Instrument auto check....................................................................................................... 30

4.2.2 User identification and access level.................................................................................. 31

4.3 Menu structure overview............................................................................................................32

Section 5 Configuration...................................................................................................................33

5.1 Configuration menu overview .................................................................................................... 33

5.2 Units and resolutions ................................................................................................................. 34

5.3 Package parameters..................................................................................................................35

1

Page 4

Table of Contents

5.3.1 Package management ......................................................................................................35

5.3.2 Formula management .......................................................................................................36

5.4 Instrument parameters ...............................................................................................................37

5.4.1 Measurement output .........................................................................................................37

5.4.2 Time and date ...................................................................................................................37

5.4.3 System information............................................................................................................38

5.5 Security and user management .................................................................................................38

5.5.1 Security management .......................................................................................................38

5.5.2 User management............................................................................................................. 38

5.5.3 Audit trail ...........................................................................................................................39

5.6 Communication ..........................................................................................................................39

5.6.1 Data download configuration.............................................................................................39

5.6.2 Ethernet configuration .......................................................................................................40

5.7 Scheduled operations.................................................................................................................43

5.7.1 Manual calibration ............................................................................................................. 43

5.7.2 Verification.........................................................................................................................43

5.7.3 Routine maintenance ........................................................................................................43

5.7.4 Service ..............................................................................................................................43

Section 6 Calibration........................................................................................................................45

6.1 Calibration menu overview.........................................................................................................45

6.2 Standards requirements.............................................................................................................45

6.3 Calibration schedule...................................................................................................................45

6.4 Barometric pressure sensor .......................................................................................................46

6.5 Pressure sensor .........................................................................................................................46

6.6 Temperature sensor...................................................................................................................47

6.7 Carbon dioxide sensor ...............................................................................................................47

6.8 Flow sensor................................................................................................................................48

6.9 Oxygen sensor ...........................................................................................................................48

Section 7 Measurement ...................................................................................................................49

7.1 Main screen................................................................................................................................50

7.1.1 User...................................................................................................................................50

7.1.2 Package ID........................................................................................................................50

7.1.3 Start analysis.....................................................................................................................50

7.2 Diagnostic measurement and results views...............................................................................53

7.2.1 Measurement view ............................................................................................................53

7.2.2 Results view ......................................................................................................................53

Section 8 Analysis ............................................................................................................................55

8.1 Analysis menu overview.............................................................................................................55

8.1.1 Open data..........................................................................................................................55

8.1.2 Table settings ....................................................................................................................55

Section 9 Maintenan ce.....................................................................................................................57

9.1 Schedule ....................................................................................................................................57

9.2 Purge gas cylinder......................................................................................................................57

9.3 Maintenance menu overview......................................................................................................58

9.3.1 Wizards .............................................................................................................................58

9.3.2 Digital input verification .....................................................................................................59

9.3.3 Actuator verification........................................................................................................... 60

9.3.4 Analog value monitoring....................................................................................................61

9.3.5 Global system view ...........................................................................................................62

9.3.6 System initialization........................................................................................................... 62

9.3.7 End application.................................................................................................................. 62

9.3.8 Service validation ..............................................................................................................62

9.3.9 Measurement head initialization........................................................................................62

2

Page 5

Table of Contents

Section 10 Troubleshooting ........................................................................................................... 63

10.1 Error and warning messages ...................................................................................................63

10.1.1 Error messages............................................................................................................... 63

10.1.2 Warning messages ......................................................................................................... 64

10.1.3 Red LED’s on startup screen .......................................................................................... 65

10.1.4 Measurement problems .................................................................................................. 66

Section 11 Spare Parts and Accessories .................................................................................... 67

Section 12 Material Safety Data Sheet s (MSDS)........................................................................ 69

12.1 Silicon antifoam (part number 33156)...................................................................................... 69

3

Page 6

Table of Contents

4

Page 7

Section 1 General Information

1.1 About this manual

The information in this manual has been carefully checked and is believed to be accurate.

However, Hach Lange assumes no responsibility for any inaccuracies that may be contained in

this manual. In no event will Hach Lange be liable for direct, indirect, special, incidental, or

consequential damages resulting from any defect or omission in this manual, even if advised of

the possibility of such damages. In the interest of continued product development, Hach Lange

reserves the right to make improvements in this manual and the products it describes at any

time, without notice or obligation.

Copyright © 2013 by Hach Lange. All rights reserved. No part of the contents of this manual

may be reproduced or transmitted in any form or by any means without the written permission of

Hach Lange.

1.2 Contact information

Manufacturing site:

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

1.3 Safety information

Please read the entire manual before unpacking, setting up, or operating this instrument.

Pay particular attention to all warning and caution statements. Failure to do so could result in

serious injury to the operator or damage to the equipment.

To ensure the protection provided by this equipment is not impaired, do not use or install this

equipment in any manner other than that which is specified in this manual.

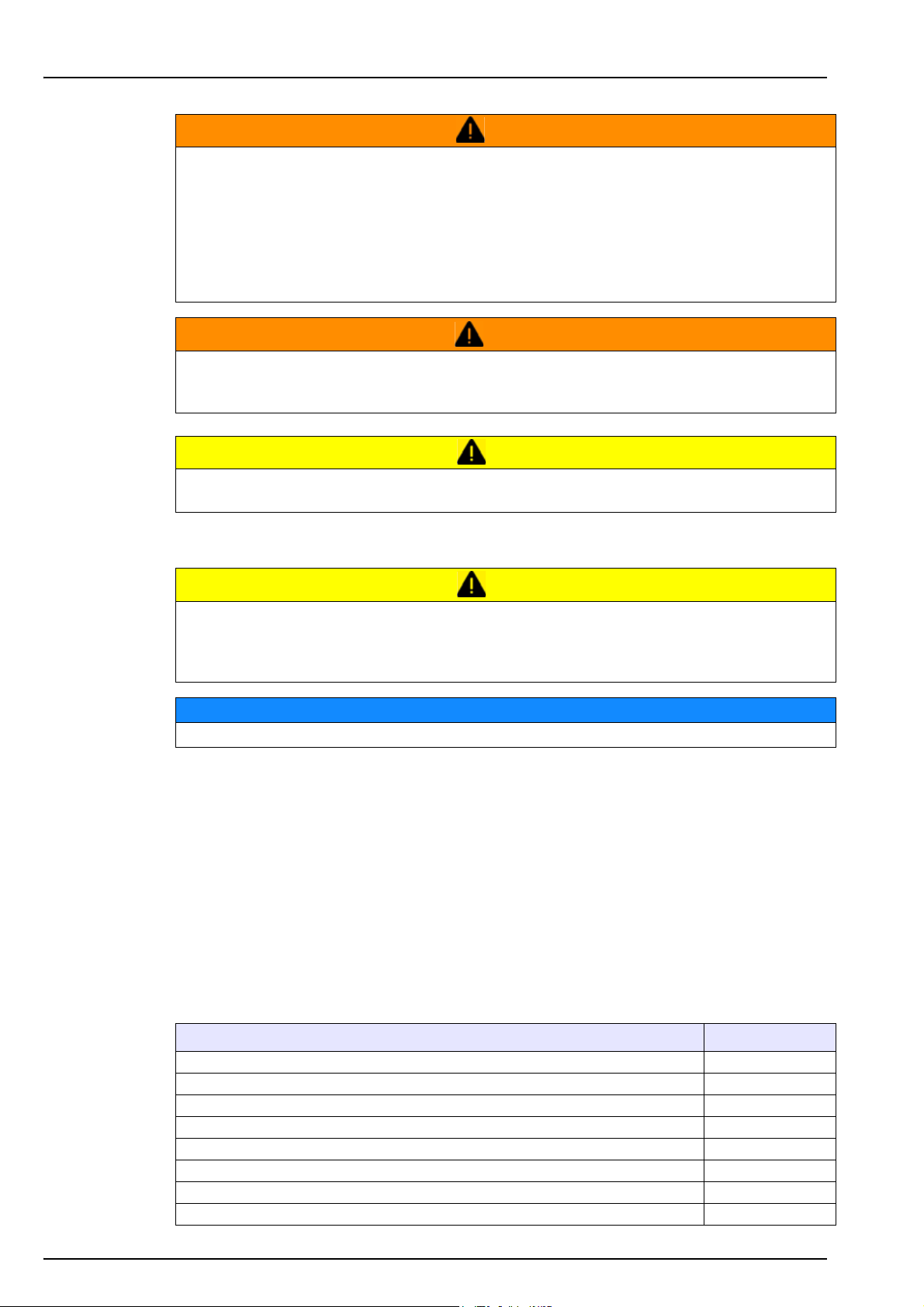

1.3.1 Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in

death or serious injury.

European HQ:

HACH LANGE GmbH

Willstätterstraße 11

40549 Düsseldorf

GERMANY

Tel. +49 211 52 880

Fax +49 211 52 88143

DANGER

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially or imminently hazardous situation that may result in minor or moderate

injury.

NOTICE

Indicates a situation which, if not avoided, may cause damage to the instrument. Information

that requires special emphasis.

5

Page 8

General Information

1.3.2 Disclaimer

The manufacturer is not responsible for damages resulting from misapplication or misuse of

this product and rejects the regulation of such damages, including direct, indirect and

consequential damages, and in full accordance with applicable law. The user is solely

responsible for the identification of critical applications and risks and taking appropriate

measures to protect processes during a possible equipment malfunction.

1.3.3 Safety precautions

CAUTION

DANGER

Risk of finger trapping.

A silicon insert is located on the transparent front door to assist in lifting and

lowering the door when adding or removing packages for analysis. Under no

circumstances must this silicon insert be removed.

WARNING

Electrical danger and fire hazard. Only use the supplied power cable. Only qualified experts

may perform the tasks detailed in the installation section of this manual, while adhering to all

locally valid safety regulations.

Removable power cables must not be replaced with inadequately dimensioned power cables.

1.3.4 Service and repairs

None of the instrument’s components can be serviced by the user. Only personnel from Hach

Lange or its approved representative(s) is (are) authorized to attempt repairs to the system and

only components formally approved by the manufacturer should be used. Any attempt at

repairing the instrument in contravention of these principles could cause damage to the

instrument and corporal injury to the person carrying out the repair. It renders the warranty null

and void and could compromise the correct working of the instrument and the electrical integrity

or the CE compliance of the instrument.

If you have any problems with installation, starting, or using the instrument please contact the

company that sold it to you. If this is not possible, or if the results of this approach are not

satisfactory, please contact the manufacturer’s Customer Service.

1.3.5 Class 1 LASER

A Class 1 LASER is installed in this instrument. Class 1 LASERS are products where the

radiant power of the LASER beam accessible (the accessible emission) is always below the

Maximum Permissible Exposure value. Therefore, for Class 1 LASERS the output power is

below the level at which it is believed eye damage will occur. Exposure to the beam of a Class 1

LASER will not result in eye injury. Class 1 LASERS may therefore be considered safe.

However, Class 1 LASER products may contain LASER systems of a higher Class but there are

adequate engineering control measures to ensure that access to the beam is not reasonably

likely.

WARNING

This Class 1 Laser product complies with 21 CFR Chapter 1, sub-chapter J. It is evaluated and

tested in accordance with EN 61010-1, Safety Requirements for Electrical Equipment for

Measurement and Control and Laboratory Use and IEC/EN 60825-1, Safety of Laser Products.

6

Page 9

1.3.6 Use of antifoam

Antifoam is injected into the sample as part of the measurement process. Once a sample has

completed the measurement process it will therefore contain a small amount of antifoam. After

measurement, ensure the sample is disposed of in a sink (or similar) to avoid any risk of

ingestion. Refer also to the material safety data sheet (MSDS) Silicon antifoam (part number

33156) on page 69 for additional antifoam safety information.

1.3.7 CFL backlight

The CFL (compact florescent light) used for backlighting the screen display contains a small

amount of mercury. Please dispose of any used CFL’s in accordance with local, state or federal

laws concerning the disposal of products containing mercury.

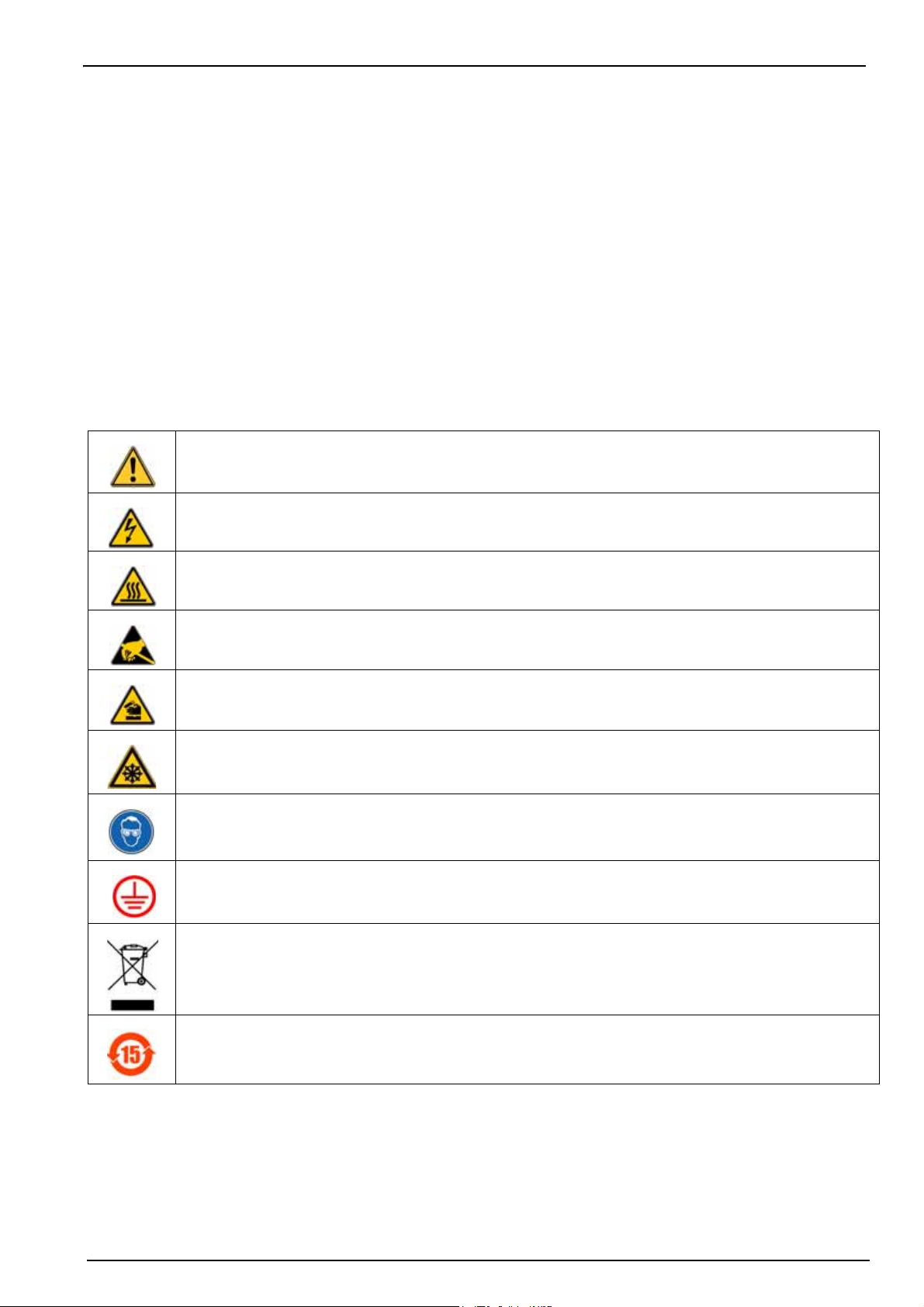

1.3.8 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed.

This symbol, when noted on a product, indicates a potential hazard which could cause serious personal injury

and/or death. The user should reference this instruction manual for operation and/or safety information.

General Information

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists and indicates that only individuals qualified to work with hazardous voltages should open

the enclosure or remove the barrier.

This symbol, when noted on the product, indicates that the marked item can be hot and should not be touched

without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic discharge

and indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that only individuals

qualified and trained to work with chemicals should handle chemicals or perform maintenance on chemical

delivery systems associated with the equipment.

This symbol, when noted on the product, indicates a laser device is used in the equipment.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for protective earth (ground).

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems. In

conformity with European local and national regulations, European electrical equipment users must now return

old or end-of-life equipment to the manufacturer for disposal at no charge to the user.

Products marked with this symbol indicates that the product contains toxic or hazardous substances or

elements. The number inside the symbol indicates the environmental protection use period in years.

7

Page 10

General Information

1.4 Product recycling information

ENGLISH

Electrical equipment marked with this symbol may not be disposed of in

European public disposal systems after 12 August 2005. In conformity with

European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of-life equipment to the

manufacturer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment manufacturer or

supplier for instructions on how to return end-of-life equipment for proper

disposal.

DEUTSCH

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in Europa nach dem 12.

August 2005 nicht mehr über die öffentliche Abfallentsorgung entsorgt werden. In

Übereinstimmung mit lokalen und nationalen europäischen Bestimmungen (EU-Richtlinie

2002/96/EC), müssen Benutzer von Elektrogeräten in Europa ab diesem Zeitpunkt alte bzw. zu

verschrottende Geräte zur Entsorgung kostenfrei an den Hersteller zurückgeben.

Hinweis: Bitte wenden Sie sich an den Hersteller bzw. an den Händler, von dem Sie das Gerät

bezogen haben, um Informationen zur Rückgabe des Altgeräts zur ordnungsgemäßen

Entsorgung zu erhalten.

FRANCAIS

A partir du 12 août 2005, il est interdit de mettre au rebut le matériel électrique marqué de ce

symbole par les voies habituelles de déchetterie publique. Conformément à la réglementation

européenne (directive UE 2002/96/EC), les utilisateurs de matériel électrique en Europe doivent

désormais retourner le matériel usé ou périmé au fabricant pour élimination, sans frais pour

l'utilisateur.

Remarque: Veuillez vous adresser au fabricant ou au fournisseur du matériel pour les

instructions de retour du matériel usé ou périmé aux fins d'élimination conforme.

ITALIANO

Le apparecchiature elettriche con apposto questo simbolo non possono essere smaltite nelle

discariche pubbliche europee successivamente al 12 agosto 2005. In conformità alle normative

europee locali e nazionali (Direttiva UE 2002/96/EC), gli utilizzatori europei di apparecchiature

elettriche devono restituire al produttore le apparecchiature vecchie o a fine vita per lo

smaltimento senza alcun costo a carico dell’utilizzatore.

Nota: Per conoscere le modalità di restituzione delle apparecchiature a fine vita da riciclare,

contattare il produttore o il fornitore dell’apparecchiatura per un corretto smaltimento.

DANSK

Elektriske apparater, der er mærket med dette symbol, må ikke bortskaffes i europæiske offentlige

affaldssystemer efter den 12. august 2005. I henhold til europæiske lokale og nationale regler

(EU-direktiv 2002/96/EF) skal europæiske brugere af elektriske apparater nu returnere gamle eller

udtjente apparater til producenten med henblik på bortskaffelse uden omkostninger for brugeren.

Bemærk: I forbindelse med returnering til genbrug skal du kontakte producenten eller

leverandøren af apparatet for at få instruktioner om, hvordan udtjente apparater bortskaffes

korrekt.

8

Page 11

General Information

SVENSKA

Elektronikutrustning som är märkt med denna symbol kanske inte kan lämnas in på europeiska

offentliga sopstationer efter 2005-08-12. Enligt europeiska lokala och nationella föreskrifter

(EU-direktiv 2002/96/EC) måste användare av elektronikutrustning i Europa nu återlämna gammal

eller utrangerad utrustning till tillverkaren för kassering utan kostnad för användaren.

Obs! Om du ska återlämna utrustning för återvinning ska du kontakta tillverkaren av utrustningen

eller återförsäljaren för att få anvisningar om hur du återlämnar kasserad utrustning för att den ska

bortskaffas på rätt sätt.

ESPANOL

A partir del 12 de agosto de 2005, los equipos eléctricos que lleven este símbolo no deberán ser

desechados en los puntos limpios europeos. De conformidad con las normativas europeas

locales y nacionales (Directiva de la UE 2002/96/EC), a partir de esa fecha, los usuarios

europeos de equipos eléctricos deberán devolver los equipos usados u obsoletos al fabricante de

los mismos para su reciclado, sin coste alguno para el usuario.

Nota: Sírvase ponerse en contacto con el fabricante o proveedor de los equipos para solicitar

instrucciones sobre cómo devolver los equipos obsoletos para su correcto reciclado.

NEDERLANDS

Elektrische apparatuur die is voorzien van dit symbool mag na 12 augustus 2005 niet meer

worden afgevoerd naar Europese openbare afvalsystemen. Conform Europese lokale en

nationale wetgegeving (EU-richtlijn 2002/96/EC) dienen gebruikers van elektrische apparaten

voortaan hun oude of afgedankte apparatuur kosteloos voor recycling of vernietiging naar de

producent terug te brengen.

Nota: Als u apparatuur voor recycling terugbrengt, moet u contact opnemen met de producent of

leverancier voor instructies voor het terugbrengen van de afgedankte apparatuur voor een juiste

verwerking.

POLSKI

Sprzęt elektryczny oznaczony takim symbolem nie może być likwidowany w europejskich

systemach utylizacji po dniu 12 sierpnia 2005. Zgodnie z europejskimi, lokalnymi i państwowymi

przepisami prawa (Dyrektywa Unii Europejskiej 2002/96/EC), użytkownicy sprzętu elektrycznego

w Europie muszą obecie przekazywać Producentowi stary sprzęt lub sprzęt po okresie

użytkowania do bezpłatnej utylizacji.

Uwaga: Aby przekazać sprzęt do recyklingu, należy zwrócić się do producenta lub dostawcy

sprzętu w celu uzyskania instrukcji dotyczących procedur przekazywania do utylizacji sprzętu po

okresie użytkownia.

PORTUGUES

Qualquer equipamento eléctrico que ostente este símbolo não poderá ser eliminado através dos

sistemas públicos europeus de tratamento de resíduos sólidos a partir de 12 de Agosto de 2005.

De acordo com as normas locais e europeias (Directiva Europeia 2002/96/EC), os utilizadores

europeus de equipamentos eléctricos deverão agora devolver os seus equipamentos velhos ou

em fim de vida ao produtor para o respectivo tratamento sem quaisquer custos para o utilizador.

Nota: No que toca à devolução para reciclagem, por favor, contacte o produtor ou fornecedor do

equipamento para instruções de devolução de equipamento em fim de vida para a sua correcta

eliminação.

9

Page 12

General Information

1.5 Product disposal

Note: The following only applies to European customers.

Hach Lange is committed to ensuring that the risk of any environmental damage or pollution

caused by any of its products is minimized as far as possible. The European Waste Electrical

and Electronic Equipment (WEEE) Directive (2002/96/EC) that came into force on August 13

2005 aims to reduce the waste arising from electrical and electronic equipment; and improve the

environmental performance of all those involved in the life cycle of electrical and electronic

equipment.

In conformity with European local and national regulations (EU Directive 2002/96/EC stated

above), electrical equipment marked with the above symbol may not be disposed of in

European public disposal systems after 12 August 2005.

Hach Lange will offer to take back (free of charge to the customer) any old, unserviceable or

redundant instruments and systems which carry the above symbol, and which were originally

supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

In addition, Hach Lange will offer to take back (at cost to the customer) any old, unserviceable

or redundant instruments and systems which do not carry the above symbol, but which were

originally supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

Should you wish to arrange for the disposal of any piece of equipment originally supplied by

Hach Lange, please contact your supplier or our After Sales Service department in Geneva for

instructions on how to return this equipment for proper disposal.

10

Page 13

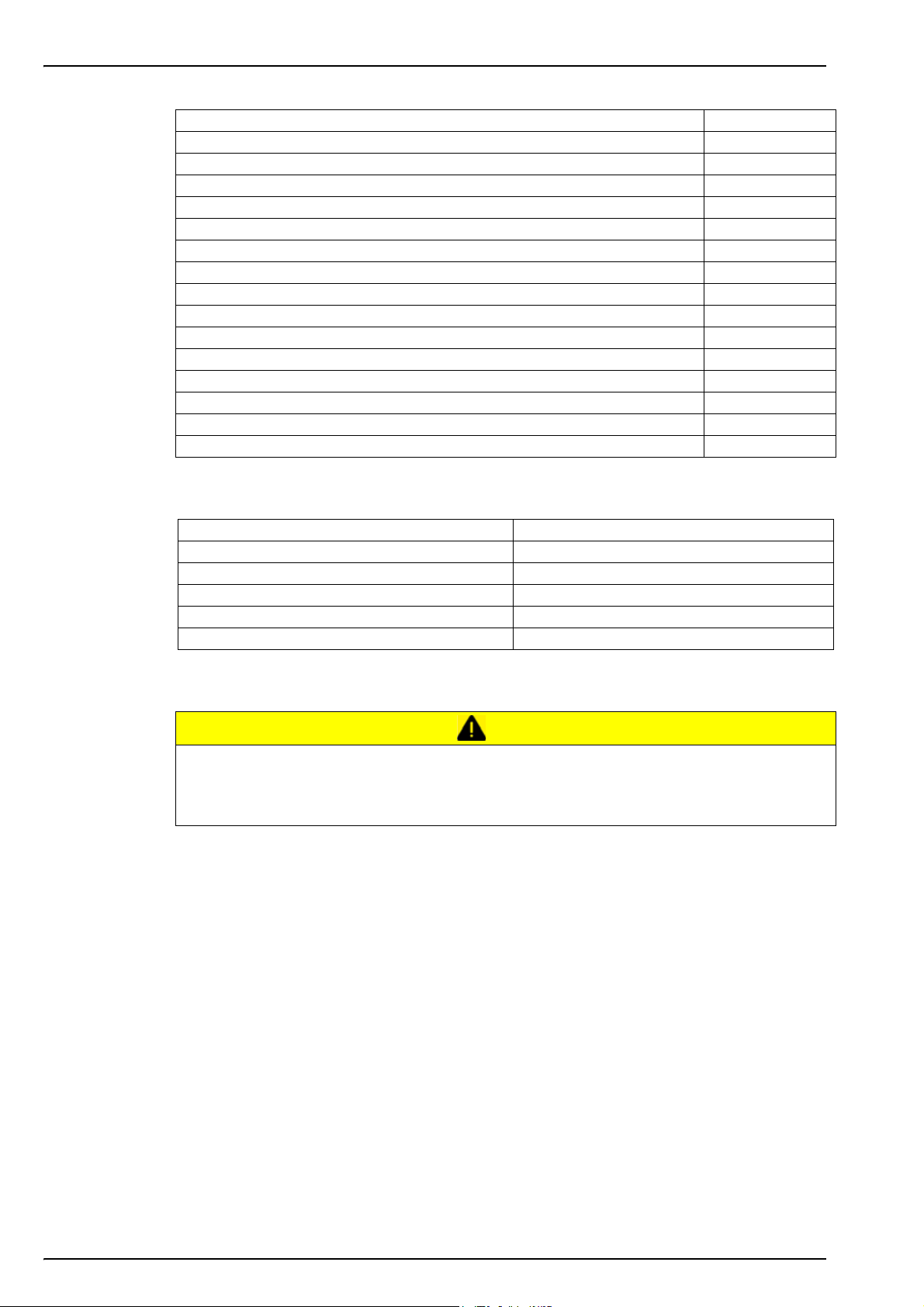

1.6 Restriction of hazardous substances (RoHS)

The European Union RoHS Directive and subsequent regulations introduced in member states

and other countries limits the use of six hazardous substances used in the manufacturing of

electrical and electronic equipment.

Currently, monitoring and control instruments do not fall within the scope of the RoHS Directive,

however Hach Lange has taken the decision to adopt the recommendations in the Directive as

the target for all future product design and component purchasing.

Note: The following only applies to exports of this product into the People’s Republic of China.

General Information

Backlit display O

Ultrasound head O

Brass spacers O

O:

X:

11

Page 14

General Information

12

Page 15

Section 2 Specifications

2.1 Technical specifications

Specifications are subject to change without notice.

Analysis

Measurement range

O

CO

2

2

1 ppb - 12 ppm

0.75 - 5 V/V or 1.5 - 10 g/kg

Total Package Oxygen ± 5 µg/L ± 10% whichever is the greater

on equilibrated

CO

Repeatability r

95

2

packages at T = 10 to 25°C

± 0.05 V/V or 0.10 g/kg ± 2% whichever is the greater

(50 to 77°F)

O

2

± 2 ppb ± 10% whichever is the greater

Typical analysis time About 4 minutes

concentration ppb or ppm

O

2

concentration V/V, g/kg, g/L or %W

CO

Display units

2

Pressure bar, mbar, psia

Temperature °C, °F or K

Package temperature -2 to 30°C (28 to 86°F)

Operating limits

Package pressure 1.4 to 6.8 bar absolute (20 - 99 psia)

Ambient temperature 0 to 40°C (32 to 104°F)

Relative humidity Up to 80%

Maximum package height 340 mm (13.39 ins)

Package setup

Minimum package height 90 mm (3.54 ins)

Minimum volume 150 ml

Material Glass, PET or aluminum

Enclosure

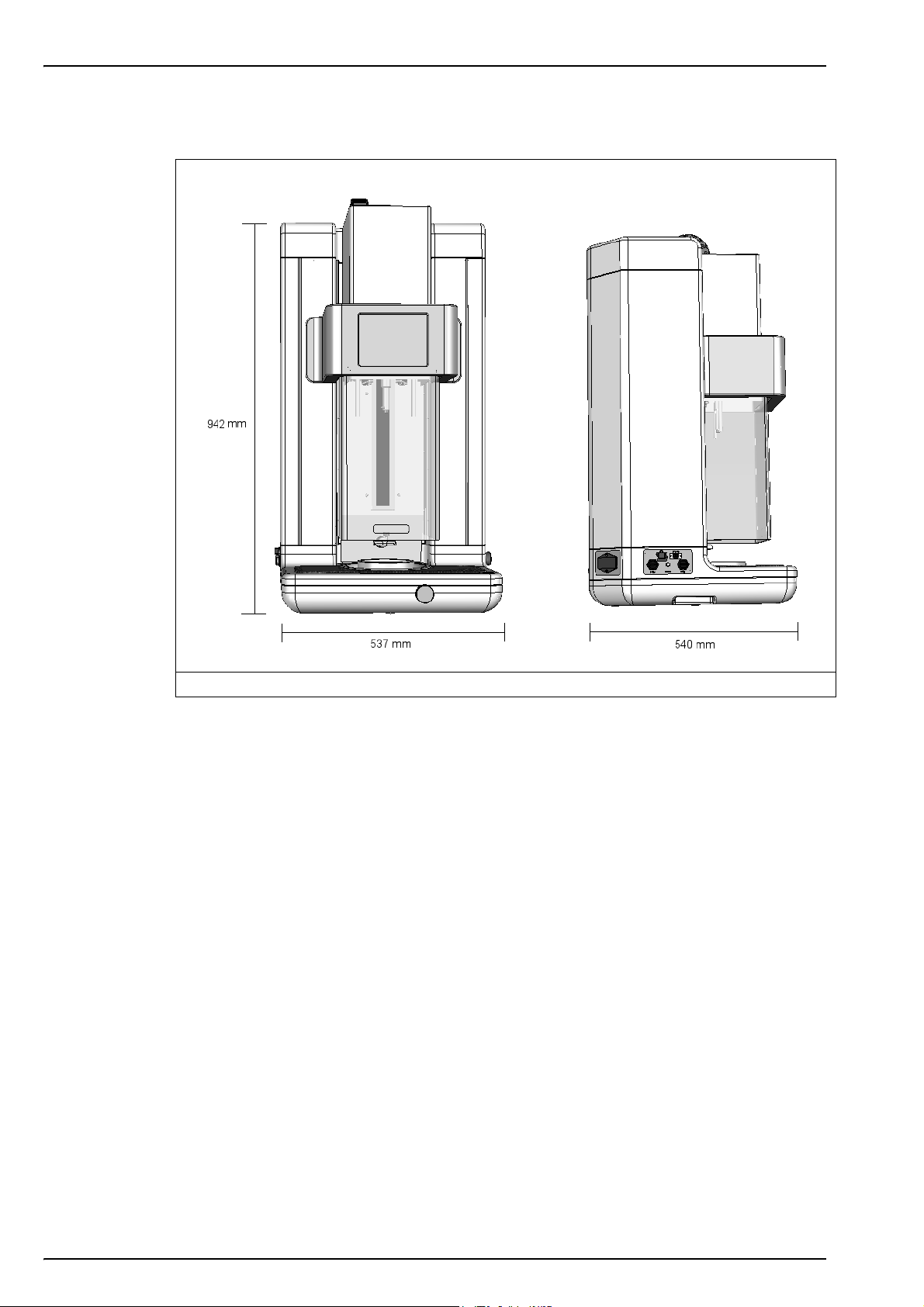

Dimensions (L x W x H) 537 x 540 x 942 mm (21.1 x 21.3 x 37.1 ins)

Weight 55 kg (121 lbs)

Enclosure protection IP20

Power requirements 100-240 VAC ±10% @ 50-60 Hz

Power consumption Max. 250 VA

Purge gas CO

with purity > 99.9% at 6 to 7 bar absolute (87 to 102 psia)

2

Purge gas consumption 0.4 mL/second (1.5 L/hour)

Forcing gas Air or N

at 5.5 to 6 bar absolute (80 to 87 psia)

2

Forcing gas consumption 0.25 mL/minute in standby mode

Compliance

European directives

Low voltage 2006/95/EC

EMC 2004/108/EC

Electromagnetic compatibility standards EN 61326: 2006

Safety standard IEC/UL/CSA 61010-1

Laser product safety IEC/UL/CSA 60825-1

Interface

Digital display TFT VGA (640 x 480) color display touch screen with backlight

Operating system Windows CE 4.2

Languages English, German, Spanish, Chinese, Japanese

Digital connections 1 x USB client, 1 x USB host, 1 x Ethernet

13

Page 16

Specifications

2.2 Instrument dimensions

Figure 1 Instrument dimensions

14

Page 17

2.3 Main instrument components

2.3.1 Front view

Specifications

1. Display panel 4. Knob to tilt package

2. Package piercing device 5. Measurement start button with LED

3. Package holder 6. Package backstop

Figure 2 Instrument components - front view

15

Page 18

Specifications

2.3.2 Left side view

1. Power socket 4. Ethernet connection

2. Power ON/OFF rocker switch 5. USB-B client 4-pin connector

3. USB-A connector for mass storage device

Figure 3 Instrument components - left side view

16

Page 19

2.3.3 Right side view

Specifications

1. Gas connection No. 1 (IN) - Forcing gas (Air or N2) 4. Gas connection No. 4 (OUT) - Pressure sensor calibration

2. Gas connection No. 2 (IN) - Purge gas (CO

3. Gas connection No. 3 (IN) - Reference gas (CO

99.9% purity) 5. Emergency STOP button

2

only)

2

Figure 4 Instrument components - right side view

17

Page 20

Specifications

2.4 Instrument switches and buttons

The mains power switch is located at the rear left of the instrument (No. 2 in Figure 3 on

page 16). To switch the instrument on and off, press the rocker switch to the

required position: “O” for Off and “I” for On.

The measurement button is located at the front right of the instrument (No. 5 in Figure 2

on page 15). Press this button to start a package measurement.

2.5 Operation overview

1. Piercing

The reference volume is filled with the purge gas and the whole of the gas sampling path is fully

purged. The purge stops when the rubber seal of the piercing device contacts the top of the

package. Once the package is pierced, a pump injects an antifoam solution into the headspace.

2. Oxygen in headspace and CO

2

The pressure is measured, then the regulating valve is opened and the gas contained in the

headspace flows over the O

headspace is obtained by integrating the volumes of O

The temperature is measured and combined with the pressure to calculate the CO

3. Liquid analysis (O

and the CO2 sensors at a given rate. The quantity of O2 in the

2

)

2

leaving the package per unit of time.

2

P/T value.

2

The gas flow is stopped and the ultrasonic sonotrode is activated. The regulating valve is then

opened and the gas escaping the liquid mixes with the gas of the headspace. The O

an exponential function to which coefficients can be included and the total O

contained in the

2

signal is

2

bottle is calculated by integrating this function.

Note: For faster measurements, the liquid analysis step can be skipped and the O

the headspace by setting specific parameters for the package (see Package parameters on page 35 for

additional details).

value calculated from

2

4. Headspace volume

At the end of the run, the gas flow is stopped and the valve is opened. The gas of the reference

volume expands in the headspace and the pressure reaches a new value. The headspace

volume is calculated with the ideal gas law principle.

5. End of measureme n t

The piercing head assembly is lifted out of the package. A short burst of gas purges the gas

sampling path to flush out any residual liquid or foam. The system returns to the standby mode

where the sensors are kept under a slight purge gas flow.

18

Page 21

Section 3 Installation

This section provides necessary information to install and connect the analyzer. The

installation of the analyzer should be performed in accordance with relevant local regulations,

and only by personnel trained and experienced in the installation of the 6110 analyzer.

Disconnect the power supply of the analyzer before carrying out any work inside the analyzer.

Any work inside the analyzer should be performed exclusively by personnel specialized and

authorized to work on electrical installations. In addition, and in accordance with safety

standards, it must be possible to disconnect the power supply of the analyzer in its immediate

vicinity.

Electrical danger and fire hazard. Only use the supplied power cable. Only qualified experts

may perform the tasks detailed in the installation section of this manual, while adhering to all

locally valid safety regulations.

Proper ESD (electrostatic discharge) protocols must be followed to prevent damage to the

product when working with the electronic boards.

WARNING

WARNING

CAUTION

3.1 Unpacking

The instrument is heavy (55 kg) so extreme care must be taken with handling to avoid

damaging the instrument or inflicting personal injury. It is highly recommended to use a

pulley system (or similar) attached to the lifting ring located on the top of the instrument when

unpacking. The instrument should always be moved and stored in a vertical position.

To avoid personal injuryIt is recommended to use a pulley system to rem.

Carefully remove the instrument and its accessories from the box and packing material,

referring to the packing list included to confirm that everything has been delivered. Please

visually inspect the instrument for shipping damage. If anything is missing or damaged, contact

the manufacturer or your dealer immediately.

You may want to retain the box and other packing material in case you later need to ship the

instrument. Please dispose safely and ecologically of the box and packing material (if not stored

for future use).

Please read through this manual thoroughly before carrying out the installation.

3.2 Main components

Factory supplied

CAUTION

NOTICE

Your 6110 Total Package Analyzer is shipped with the following components:

Equipment included Part No.

Instrument

6110 instrument including all sensors pre-installed

Installation kit

2.5 mm Allen key

Power supply cable

Protection film for screen

Protection for rim detector x4

Seal to package (6 items) 33117

19

Page 22

Installation

Solenoid valve 2/2 NC with O-ring 33122

Filter with Goretex membrane (52 items) 33124

Piercing tip x1 (for PET) DG33308

Piercing tip x2 (for metal) 33127

Piercing tip mounting tool 33159

Pneumatic tubing kit 33154

Antifoam recharge bottle 1L 33156

Antifoam cartridge (empty) 33157

Antifoam priming beaker 33161

Syringe for antifoam cartridge 33162

Sensor recharge kit 2956A-A

Outlet sample tube assembly DG33267

USB key 60930

USB client cable including connectors, length = 3m 32533.03

Sensor support (part of A1100-S00T) 32205

PPS sensor storage and calibration cap (part of A1100-S00T) 28129

Locally supplied

The following must be provided locally by the user:

Purge gas for O

Forcing gas for piercing device (Air or N

Reference gas for CO

Loctite® 222 sealant (or similar) For locking and sealing piercing tips

Precision certified barometer For calibrating the barometric pressure sensor

Precision certified pressure gauge (0-7 bar) For calibrating the pressure sensor

3.3 Positioning

The instrument is heavy (55 kg) so extreme care must be taken when handling, to avoid

damaging the instrument or inflicting personal injury. It is highly recommended to use a

pulley system (or similar) attached to the lifting ring located on the top of the instrument when

moving it.

Hach Lange recommends installing the instrument on a sturdy laboratory table that can more

than support the 55kg weight. Place it on a clean flat surface, and convenient to the power

source. The display screen should be at head-height for easy viewing and operation.

3.4 Installation

3.4.1 Pre-installation

and CO2 sensor (CO2) 6 to 7 bar (87 to 102 psia), purity > 99.9%

2

) 5.5 to 6 bar (80 to 87 psia)

2

sensor (optional) 5.5 to 6 bar (80 to 87 psia)

2

CAUTION

20

You will need the antifoam cartridge filled with the antifoam liquid as part of the installation

process. Prepare this before starting the installation using the instructions in Antifoam cartridge

preparation on page 23.

In addition make sure you have suitable standards available before performing any calibration,

see Standards requirements on page 45 for calibrating the instrument sensors.

Your A1100 electrochemical sensor has been thoroughly cleaned and tested at the factory

before shipment and installed in the instrument. It has been shipped with a cartridge containing

a membrane and electrolyte pre-installed to protect the sensor head. The sensor must be

removed from the instrument and the cartridge removed and replaced with a new one prior to

first use to make it fully operational. These steps are described in the A1100 cleaning

procedure for 6110 TPA document supplied with the instrument. The new cartridge is included

in the sensor recharge kit, also supplied with the instrument.

Page 23

3.4.2 Physical installation

An installation wizard will start automatically once power is connected to the instrument for the

first time.

1. Connect the instrument to a power source - see Power supply on page 23.

2. Turn the instrument ON. An instrument auto check routine will start automatically. As this is

the first time the instrument will have been powered up, the O2 sensor residual and the

Antifoam level LEDs will always be red. This is normal as the system has not yet been fully

commissioned and these can be ignored at this stage.

3. The wizard will start automatically. Press the Installation button to proceed.

4. At the end of the process select the auto-check option. See Instrument startup on page 30

for a more detailed explanation of the auto-check process and results.

3.4.3 Post-installation procedures

1. The instrument has been delivered with English as the default language. However, a USB

memory stick

Japanese). If you wish to keep English as the preferred language please proceed to the

next step (Step 2 below), otherwise follow these instructions for installing a new language:

a. Make sure that ActiveSync® is installed on your PC. If you do not have it installed on

your PC, please refer to Microsoft ActiveSync® configuration on page 22 for installation

details.

is supplied with other available languages (German, Spanish, Chinese, and

Installation

b. Connect your PC to the instrument via the USB client connector (No. 5 in Figure 3 on

page 16). ActiveSync® will start automatically. By default ActiveSync® proposes to set

up a partnership with the instrument. This is not required, so select NO before

continuing.

c. Insert the supplied

USB memory stick into your PC.

d. Inside the “Setup” folder, double click on the “setup.exe” executable file. Follow the

on-screen instructions on your PC and then on the instrument to install the preferred

language software.

2. Set the security levels, user ID’s and passwords as described in Security and user

management on page 38.

3. Configure the instrument parameters as described in Configuration on page 33.

4. Perform a barometric sensor calibration as described in Barometric pressure sensor on

page 46.

5. Perform an O

sensor calibration as described in Oxygen sensor on page 48. Wait until the

2

residual value of the sensor is low enough (controlled automatically by the instrument). This

operation may take around 1-2 hours depending on storage conditions.

Note: The pressure, flow, temperature and CO

prior to use.

sensors are more stable and will not require calibration

2

The instrument should now be ready for use.

If a problem should arise with the instrument, please refer initially to Troubleshooting on

page 63. If the problem cannot be overcome, please contact your Hach Lange representative

who will be happy to assist you.

21

Page 24

Installation

3.5 Additional installation information

3.5.1 Microsoft ActiveSync® configuration

This software must be installed on your PC when connecting to the instrument via the USB

client connector (No. 5 in Figure 3 on page 16). The latest version of ActiveSync® is available

as a free download from www.microsoft.com

Once successfully installed, ActiveSync® will

start automatically each time the instrument is

connected to the PC.

Note: By default ActiveSync® proposes to set up a

partnership with the instrument. This is not

required, so make sure this is set to NO (as

illustrated left) before continuing.

The ActiveSync® screen is then displayed

and an icon will appear in the taskbar at the

bottom of your screen.

When active the icon in the taskbar is colored green (as illustrated top left)

and when inactive, the icon is still visible but greyed out (as illustrated

bottom left).

22

Page 25

3.5.2 Power supply

Electrical danger and fire hazard. Only use the supplied power cable.

Removable power cables must not be replaced with inadequately dimensioned power cables.

Check voltage requirement sticker on the rear panel of the instrument before connecting

(100-240 VAC).

Installation

WARNING

WARNING

CAUTION

Connect the power cable supplied with the instrument to the socket

at the rear of the instrument (left in diagram) for AC power

connection.

To switch the instrument on and off, press the rocker switch (right in

the diagram) - “I” for On and “O” for Off.

Important Note: In order to get optimum performance from the instrument always keep the gas

and power supplies switched on.

3.5.3 Emergency STOP button

This is located on the right side of the instrument (No. 5 in Figure 4 on page 17). Should the

need arise to stop the machine at any time during operation, press this button. An audible click

can be heard as the button locks in position.

The instrument should then be disconnected from the power supply.

Once disconnected, unlock the button by turning it clockwise. The instrument can then be

reconnected to the power supply and restarted.

3.5.4 Antifoam cartridge preparation

An empty 280mL volume antifoam cartridge is delivered as part of the installation kit. A recharge

bottle of antifoam is part of the package along with the necessary tools to transfer the liquid to

the cartridge (100mL volume syringe, tubing and connectors).

Note: One antifoam recharge bottle should be enough to fill the cartridge at least 3 times and a cartridge

completely filled with antifoam is sufficient for approximately 3,000 measurements.

Important Note: To optimize the performance and reliability of the instrument, it is strongly

recommended to only use the silicon antifoam supplied by Hach Lange (part number 33156).

To fill the cartridge, proceed as follows (numbers in the boxes correspond to the steps):

23

Page 26

Installation

1. Connect the syringe to the tubing with the quick connector.

2. Unscrew the cap from the antifoam recharge bottle and put the tubing in, making sure it

goes as near to the bottom of the liquid as possible.

3. Pull on the syringe to extract the liquid until the syringe is full.

4. Remove the syringe and tubing from the recharge bottle.

5. Attach the end of the tubing from the syringe to the other piece of tubing using the quick fit

connector.

6. Remove any trapped air in the system by applying a small amount of pressure to the end of

the connector with a small screwdriver (or similar) to open the valve. Push slightly on the

end of the syringe until antifoam can be seen dripping out of the end of the connector.

Remove the screwdriver.

24

Page 27

Installation

7. Attach the end of the second piece of tubing to the antifoam cartridge by pressing until the

connector clicks into place on the inlet valve. Then, push on the end of the syringe to empty

the contents into the cartridge. The syringe has a volume of 100mL and the cartridge a

volume of 280mL, so repeat the process until the antifoam cartridge is full.

8. On completion, rinse out the syringe and all tubing with water. Screw the cap back onto the

antifoam container and store the tools and container in a cool dry place.

Important Note: After installation of the antifoam cartridge in the analyzer, it is critical that any

air bubbles be cleared from the antifoam circuit before taking any measurements. To do this,

select the Antifoam system option from the Actuator verification option in the Maintenance

menu and follow the instructions as described in Antifoam system on page 61. Select 50

injections and stop the process when the system constantly spits a small stream of antifoam at

each stroke denoting the antifoam circuit is free of air bubbles.

25

Page 28

Installation

26

Page 29

Section 4 User Interface and Startup

4.1 User interface

4.1.1 Turning the instrument ON and OFF

The instrument has a power switch located at the rear of the left side of the base (No. 2 in

Figure 3 on page 16). The LED on the instrument measurement start button (No. 5 in Figure 2

on page 15) is illuminated when the instrument is powered on.

Important Note: It is recommended to keep the instrument powered ON at all times, unless the

instrument is to be moved to another location, if it will not be used for a long period of time, or if

maintenance procedures need to be carried out inside the instrument.

4.1.2 Touch screen

The instrument front panel is comprised of a TFT VGA (640x480) color display touch screen

acting as display, touch pad and keyboard.

4.1.3 Data entry

When a text box (alphanumeric field) is selected for data entry, a virtual keyboard appears on

screen as illustrated below. This is used in a similar way to a standard PC keyboard.

Once values have been entered, press the (Enter) key on the right of the keyboard to

confirm input and exit the virtual keyboard.

Note: Use the Cap key at the bottom left of the keyboard to switch between upper and lower case

characters. This is important for case-sensitive information such as passwords.

27

Page 30

User Interface and Startup

4.1.4 Rolling lists

For convenience, selection through a possible large list of items has been designed with a

rolling list as in the example below. Use the up and down arrows at the side to navigate through

the list, or select one item directly. Press Ok to confirm.

4.1.5 Instrument options

A banner will be displayed at the foot of each screen showing the options available:

• Standby - Press this button to leave the instrument in operational mode if there is a long

time delay between measurements. The screen will go blank, but can be reactivated by

tapping it. Once reactivated, you will need to enter a valid user ID and password combination

if this has been set up (see User identification and access level on page 31).

• Configuration - Refer to Configuration on page 33

•Calibration - Refer to Calibration on page 45

• Measurement - Refer to Measurement on page 49

•Analysis - Refer to Analysis on page 55

• Maintenance - Refer to Maintenance on page 57

If any of the options are not available for any reason (e.g. access level not high enough), they

will be greyed out.

28

Page 31

4.1.6 Information and warning windows

At various stages, an information or warning message may be displayed to request confirmation

from the operator that his last action(s) must be applied, or that there is a problem that did not

enable the requested action to be performed.

Note: Warning messages can be suppressed by unchecking the warning messages parameter (see

Instrument parameters on page 37).

For a full list of all possible warning and error messages, and the recommended action to take,

please refer to the section entitled Troubleshooting on page 63.

User Interface and Startup

4.1.7 Instrument status indicator

A colored LED indicator on the top right of the screen will indicate the current status of the

system:

• A green indicator means that no problems have been found

• A yellow indicator means that a problem has been found, but is not serious enough to stop

measurements being taken

• A red indicator means that there is a serious problem with the system which must be

corrected before any measurements can be performed

If multiple problems have been detected, the color of the LED will reflect the most severe error

(red in the example below). If the LED indicator is not green, pressing it on any screen will

display a list of errors and warnings:

It is advisable to correct all of the errors listed before continuing, to ensure the instrument is

working correctly.

On completion of all startup checks you may be required to enter a valid identification number

and password (as described in User identification and access level on page 31) to continue.

Provided all startup checks were successful, the measurement screen will be displayed.

29

Page 32

User Interface and Startup

4.2 Instrument startup

Important Note: The following assumes that the instrument is already fully operational and has

been used for taking measurements. For first time startup of the instrument refer to Installation

on page 20 to ensure additional procedures have been completed successfully for the instrument

to start up without errors occurring during the auto check procedures.

4.2.1 Instrument auto check

When the instrument is powered ON it goes through a number of startup procedures to check all

components are installed and functioning correctly. A number of instrument parameters are also

displayed down the left side of the screen indicating the current software and board versions

installed:

Note: It is possible (but not recommended) to skip individual checks by pressing the Skip button when the

component has the yellow indicator against it to indicate the component check is in progress.

The right side of the screen lists each of the instrument components that are being checked,

and a colored indicator to the left of each component shows the current status:

• A green indicator means that the component is installed and working correctly

• A red indicator means that there is a problem with that particular component

• A yellow indicator means that the component is in the process of being checked

• A blue indicator means that the component has not yet been checked

If there are errors encountered on startup that mean the instrument cannot function correctly, a

warning screen will be displayed indicating the next course of action.

Important Note: Once the instrument is switched on you will need to wait until the oxygen

sensor residual value reaches the threshold of 0.1 mbar. This operation can take as much as two

hours depending on the instrument and sensor conditions prior to startup.

30

Page 33

4.2.2 User identification and access level

If access rights have been enabled, it will be necessary to log on as an authorized user to get

access to the instrument functionalities and settings (see Security and user management on

page 38 to set these up).

By default, three levels of user have been defined for the instrument, and will be required on first

access to the instrument:

Name First name ID Password Level

Administrator Administrator 000 123 Administrator

Manager Manager 001 123 Manager

Operator Operator 002 123 Operator

After setting up your own user list, these three default entries should be removed.

First press Login at the bottom of the screen to access the full login screen:

User Interface and Startup

Enter your identification and password in the boxes provided, and press Ok to continue. Your

details will be displayed at the top left corner of the screen. Then press the Ok button at the

bottom left of the screen to gain access to the main menu.

There are three user access levels:

Level Available options

Administrator Configuration, Calibration, Measurement, Analysis and Maintenance

Manager Configuration, Measurement, Analysis and Maintenance

Operator Measurement and Analysis

For security purposes, when the session inactivity delay period has expired (adjustable using

the option Security and user management on page 38), the user is logged off automatically.

31

Page 34

User Interface and Startup

4.3 Menu structure overview

32

Page 35

Section 5 Configuration

5.1 Configuration menu overview

33

Page 36

Configuration

This section describes the sequence of actions required to configure the instrument. The

following configuration options are available from the main screen:

• Units and resolutions

• Package parameters

• Instrument parameters

• Security and user management

• Communication

• Scheduled operations

5.2 Units and resolutions

Units

Define the units for all values displayed by the instrument:

• O2 concentration

• CO2 concentration

• Length

• Temperature

• Volume

• Pressure

• Quantities

For each parameter select the required unit from the drop-down list and press Ok to continue.

When all units have been assigned, press Ok on the main screen to save these values and continue.

Resolutions

Define the display resolution for all values displayed by the instrument. These are the same as listed for

units with the addition of Formula.

For each parameter select the required display resolution from a drop-down list. A maximum of 4 digits

and a decimal point can be displayed (i.e. 1234, 123.4, 12.34, or 1.234). This does not affect the actual

resolution of data measured and stored, only the data displayed on screen. Select the required resolution

from the list and press Ok to continue.

When all display resolutions have been defined, press Ok on the main screen to save these values and

continue.

Note: The instrument performance and specifically the sensitivity and accuracy of each measured

parameter is not affected by the choice of resolution. This is purely for screen display purposes. Refer to

Technical specifications on page 13 to view the accuracy of each measured parameter.

34

Page 37

5.3 Package parameters

5.3.1 Package management

Package management

Add new package definitions (up to a maximum of 100), and edit or delete existing definitions. To edit or

delete a package, first select the package from the list displayed by touching the package name on the

screen, and then press either Edit or Delete as appropriate.

New Create a new package. The new package will be created using the default package

parameters. You will then need to select the new package and edit these default parameters

to define the new package parameters.

Delete Confirm the deletion to delete the package from the list

Edit A new screen is displayed to allow you to change the definition of the package. Select each

tab in turn (detailed below) to define the package definitions.

Product tab

Solubility Enter the type of beverage in the package.

Headspace Check this box for a fast measurement sequence that provides data from the

Equilibrated This is only available if Headspace (previous box) is checked. Check this box if

Slow

Decompress

Formula Define up to five different formulae for computing a new parameter. The formula

Configuration

headspace only.

you require the additional total O

the headspace.

If checked, then after the measurement process has completed, a slow release of

any remaining pressure will take place so the package can be handled safely.

definitions must already have been entered into the system (see Formula

management on page 36 for details).

and dissolved O2 measurements taken from

2

Package tab

Comment Enter a free-format alphanumeric text. This text will appear against the package

description in the main package management screen.

Brimful volume Enter the volume of the package when full to overflowing.

Height Enter the overall height of the package. This information is used if you activate

the Package size check option in Instrument parameters on page 37.

Tilt position Enter the tilt position of the package holder (optional). This should be 1, 2, or 3

and corresponds to the number on the tilt knob on the front of the instrument (

4 in

Figure 2 on page 15).

Pck backstop Position of the package backstop (optional). The backstop is calibrated on a scale

of zero to seven.

Package type Select the correct image for the type of package being measured (bottle, can,

etc.). The setups for each icon are different, so it is important to select the correct

one.

Note: The above reference values are also displayed at the start of the measurement process for that

package, so the operator can adjust the instrument accordingly (tilt position, etc.).

Alarms tab

Alarm

parameters

Factors tab

Factors Small adjustments can be made to the measurements listed by entering a factor.

Select the parameter to define the alarm settings, and enter the minimum and

maximum values allowable for each parameter listed. When the measurement

value falls below the minimum level or exceeds the maximum level for any

parameter listed, an alarm will be triggered.

This defaults to 1.000 for all measurements to indicate no adjustment. If this is

changed then the measurement calculated by the instrument will be multiplied by

this factor to give an adjusted measurement value.

No.

35

Page 38

Configuration

5.3.2 Formula management

Formula management

This option allows you to add new formula definitions (up to a maximum of 40), and edit or delete existing

definitions. You can use up to 16 variables pre-defined by the instrument and 2 user defined numerical

variables that are set up manually at the end of each measurement.

When the option is selected a screen will be displayed listing all existing formulae.

New Press the New button to create a new formula. The formula editor screen is displayed (see

Figure 5 below) and used to define the formula. The measurement values that can be used

are listed down the left side of the screen and are defined as listed in Table 1 on page 37.

The operators and operands are listed down the top right. In the bottom right of the screen

are a number of screen navigation options to assist in editing.

The colored indicator in the top right corner shows the validity of the formula as it is being

created. It is initially colored yellow but will turn red if the formula is invalid and green when

valid. When the indicator is red, the Ok button will be unavailable.

Use the Select button to select an existing formula to include in the new formula. The list of

existing formulae is displayed as a rolling list.

When a valid formula has been entered, press the Ok button to continue. You are then

requested to assign a name to the new formula, after which an information box is displayed

showing the name of the user who created the formula and the date and time it was created.

If required, add any free format alphanumeric text to identify the formula and press Ok to

continue.

Edit or

Delete

Info This button can be used to display information about the selected formula, such as the

To edit or delete a formula, first select the formula from the list displayed and then press

either Edit or Delete as appropriate. If Delete was selected, you will be asked to confirm

deletion before the formula is deleted from the list. If Edit was selected the formula editor

screen is displayed to allow you to change the definition of the formula.

operator who created it, the date and time of creation (or the last edit), and any comments

associated with it.

36

Figure 5 Formula editor screen

Page 39

Table 1 Formula terms and definitions

Term Definition

O2 HS O

O2 liquid O

O2 total O

CO2 HS CO

CO2 liquid CO

CO2 total CO

CO2 PT Concentration of dissolved CO

CO2 True Concentration of the real dissolved CO

%CO2 HS CO

Vol HS (Pr) Volume of headspace

Vol package Volume of headspace + volume of liquid

Vol liquid Volume of liquid

Barometric Pr Barometric pressure

Pressure HS Headspace pressure after piercing

Temperature liquid Temperature of package liquid

Temperature EC Temperature of the O

User numval1

User numval2

in headspace

2

in liquid

2

in headspace + O2 in liquid

2

in headspace

2

dioxide in liquid

2

in headspace + CO2 in liquid

2

using headspace pressure obtained by a

2

pressure/temperature (PT) method after package shaking

purity during headspace analysis

2

sensor in the instrument

2

The values are defined in the Num 1 and Num 2 fields of the comments section on

the measurement results screen (see example measurement screen on page 52).

Configuration

(corrected with CO2 purity in the package)

2

5.4 Instrument parameters

5.4.1 Measurement output

Measurement output

Define the parameters shown on the screen after and during the measurement process.

Diagnostic

measurement

view

Display

diagnostic

results

Package size

check

Warning

messages

Normalization If checked, enter the temperature value for CO2 normalization. CO2 calculations will

Column

selection

When all details have been entered, select Ok to confirm.

Use this option to troubleshoot measurement problems. If this box is checked, then

instead of the standard measurement progress screens being displayed during the

measurement process, the measurement values are displayed instead (see example in

Measurement view on page 53).

Use this option to troubleshoot measurement problems. If this box is checked, then

instead of the standard measurement results screen being displayed at the end of the

measurement process, more detailed measurement values are displayed instead (see

example in Results view on page 53).

If checked, the instrument will verify that the package size is the same as that defined

in the height parameter for the package being measured. If different a warning

message will be displayed. The height detection resolution is 1 mm.

If checked, any warning messages will be displayed during the package measurement

process. If left unchecked, all warnings will be suppressed. For a full listing of possible

warnings, refer to Warning messages on page 64.

then be made based on the temperature entered rather than the sample temperature.

From the drop down list, define the three measurements to display on the right side of

the measurement results screen after the measurement process has completed (see

example in Figure 7 on page 52).

5.4.2 Time and date

Time / Date

Set the system date and time parameters and the display format. Select Ok to confirm.

37

Page 40

Configuration

5.4.3 System information

System information

Display the system information about the currently configured boards. Select Exit to exit the screen.

5.5 Security and user management

5.5.1 Security management

Note: When the instrument is started for the first time, security is disabled by default. To avoid any

unauthorized access, it is highly recommended that each user be entered into the system and given

appropriate access rights as soon as possible. Details are provided in this section.

Security management

Configure parameters related to confidentiality. On completion, select Ok to confirm.

Access rights

enabled

Auto logoff When checked, the user is logged out automatically when the set delay for inactivity

Audit trail When checked, every action from a user is recorded in an audit file for traceability.

Logout timer Enter a maximum time of inactivity (in minutes) for all users. Users are logged out

Clear audit trail

file

Clear result file This option deletes the package measurement data.

When checked (recommended), it is required to log on as a registered user to access

the menus. When disabled (default), all menus are access free and there will be no

name recorded against any actions in the log file. To set up valid users, refer to User

management below.

(Logout timer) is reached and the instrument goes on standby.

These actions cover the configuration, calibration, and maintenance options. Each

record holds the date and time of the action, the action ID and description, and the

operator name and ID. The audit file is a rolling buffer recording the last 1000 actions.

automatically when the period of inactivity exceeds this value and the Auto logoff

feature is enabled.

This option deletes the audit file.

5.5.2 User management

User management

When selected, the list of registered users (up to a maximum of 99) for this instrument are displayed.

Note: To have the Delete and Edit options available, select one of the existing users first.

New To add a new user, all of the following fields must be entered, then select Ok to add

Edit or Delete To remove or modify an existing user, select the user in the user management screen

Level Available options

Operator Measurement and Analysis

Supervisor Calibration, Measurement, Analysis and Maintenance

Manager Configuration, Calibration, Measurement, Analysis and Maintenance

Administrator Configuration, Calibration, Measurement, Analysis and Maintenance

the new user.

Name Enter the user surname (3-15 characters).

First Name Enter the user first name (3-15 characters)

ID Enter an alphanumeric ID (1-10 characters).

Password Enter an alphanumeric password (3-15 characters).

Security level Select the security level from the drop-down list. For a list of options

available at each level refer to Table 2 below.

and select Edit or Delete as appropriate. To save all changes, press Ok (you will be

required to confirm the changes) or press the Exit button to exit the screen without

making any changes.

Tabl e 2 Secu rit y lev e l table

38

Page 41

5.5.3 Audit trail

Audit trail

View the list of user actions performed on the instrument. The actions are listed chronologically with the

latest action always at the top of the list. When the maximum of 1,000 recorded actions is reached, the

oldest is deleted and replaced with the newest.

Scroll through the audit trail screens using the First, Previous, Next and Last buttons, or select the Exit

button to leave this option.

Note: To clear the audit trail file, use the option available in Security management.

5.6 Communication

This option sets the parameters required for exporting instrument data files to your PC or USB

storage device.

Select from:

• Data download configuration (see below)

• Ethernet configuration (see Ethernet configuration on page 40)

5.6.1 Data download configuration

Configuration

Scroll through the list of available data files using the up/down arrow keys on the right, and

select if the file to be exported is in data or text format. By default, the text format is set to YES

and the data format to NO. Set both formats to NO if you do not require the file downloaded.

Use the Invert Selection button under each column to toggle between YES and NO.

Note: It is recommended to set the files to text format for easy loading into standard software applications

on the PC such as Microsoft Excel or similar. The data format is only required for Hach Lange service and

support personnel.

When the data formats have been configured, select Ok to confirm.

The following files can be transferred:

• Audit trail: Audit trail.txt

• Calibration files: Calib Barometer.txt, Calib CO2.txt, Calib Flow.txt, Calib O2.txt,

Calib Pressure.txt and Calib Temperature.txt

• Liquid: Liquid.txt

• Package: Package.txt

• Result: Result.txt

• Configuration: Configuration.txt

• Formula: Formula.txt

• Raw data: Raw data.txt