Page 1

DOC024.98.93002

ORBISPHERE Model 51x

Analyzer

05/2013, Edition 3

Basic User Manual

Manuale dell'utente di base

Manuel d'utilisation de base

Manual básico del usuario

Manual Básico do Usuário

Základní uživatelská příručka

Basisgebruikershandleiding

Alapvető felhasználói kézikönyv

Basishandbuch

Page 2

English..............................................................................................................................3

Deutsch..........................................................................................................................24

Italiano............................................................................................................................47

Français.........................................................................................................................69

Español..........................................................................................................................91

Português....................................................................................................................114

Čeština.........................................................................................................................136

Nederlands.................................................................................................................158

Magyar.........................................................................................................................180

2

Page 3

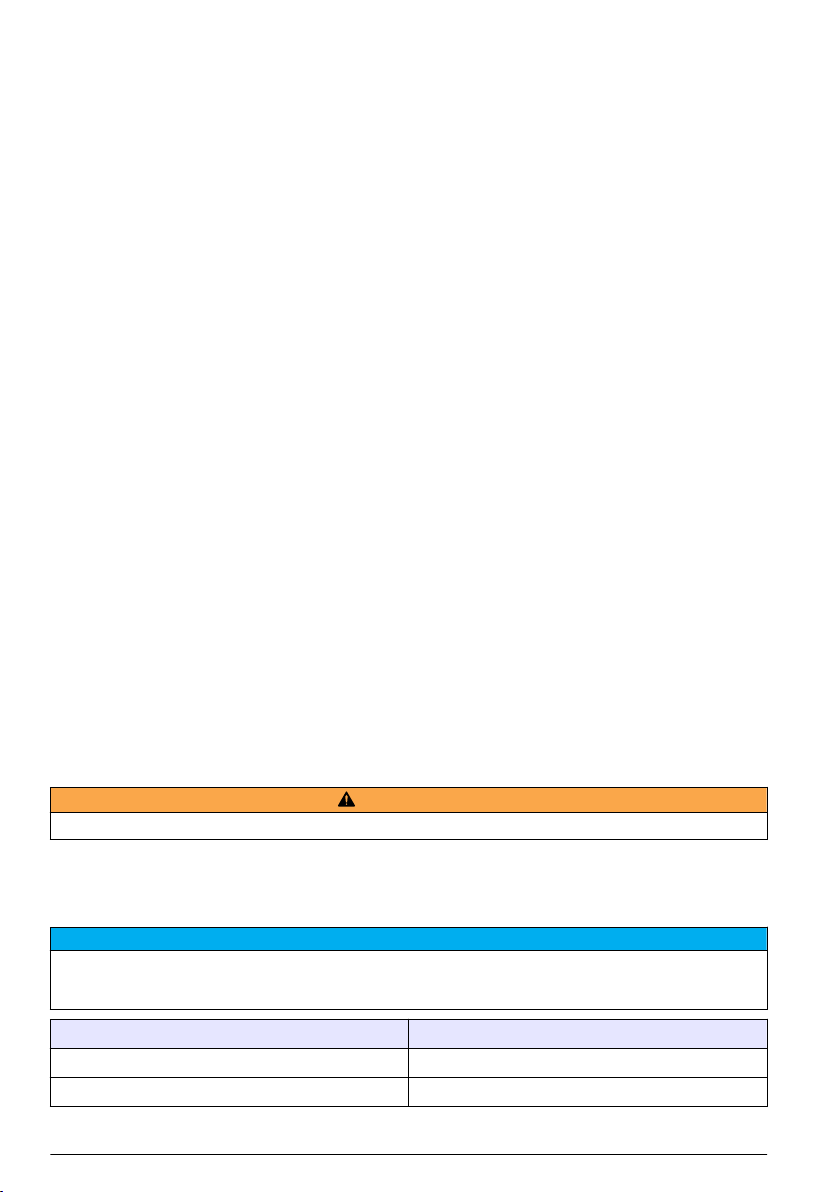

Specifications

Specifications are subject to change without notice.

Specification Details

Operating temperature -5°C to +40°C

Storage temperature -20°C to +70°C

Operating humidity 0 to 95% non condensing relative humidity

Operating altitude From 0 to 2,000 m. (6,550 ft.) above sea level

EN61326-1:2006 Directive 2004/108/EEC

EMC requirements

CE compliance EN61010-1: 2010 Directive 2006/95/EEC

Safety rating ETL, conforming to UL 61010-1 and CSA 22.2 No. 61010-1

Enclosure ratings

Power supply

Wall and panel mount

Power supply

Portable

Analog current output version

on the measurement board(s)

Analog voltage output version

on the measurement board(s)

Measurement alarm relays on

the measurement board(s)

Note: The wall mount instrument is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be required to take

adequate measures.

IP 65; Totally protected against dust; Protected against low pressure jets of

water from all directions.

Note: For portable models, IP 65 is applicable only when a cable is connected to the

ethernet socket.

NEMA 4X (wall mount only); Totally protected against dust; Protected against

pressure jets of water from all directions.

Universal 100 VAC to 240 VAC @ 50/60 Hz - 40VA 10 to 30 VDC - 30W

5V supplied through an external power supply 100-240 VAC @ 50/60 Hz - 1A

Optional battery pack with 4 hour autonomy (charges in about 6 hours). Battery

charge time can increase at T > 30°C.

4-20 mA (default) or 0-20 mA (configuration with software);

3 configurable outputs: Maximum load: 500 ohm; Sensitivity: 20μA;

Accuracy: ± 0.5% (between operating temperature limits)

0- 5 V output (hardware option);

3 configurable outputs; Minimum load: 10 KOhm; Sensitivity: 5 mV;

Accuracy: ± 0.5% (between operating temperature limits)

Three alarm relays per measurement board; 1A-30 VAC or 0.5A-50 VDC on a

resistance load.

Configurable to Normally Open [NO] or Normally Closed [NC] contacts by

changing the jumper positions.

W A R N I N G

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC

RMS

One system alarm relay; 1A-30 VAC or 0.5A-50 VDC on a resistance load.

Normally closed [NC] (NO relay also available) when instrument is turned on.

System alarm relay on the main

board

Options RS-485 or PROFIBUS-DP; USB client; USB host; Ethernet 10/100 Base-T

Wall and pipe mount instrument

(H x D x W)

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC

RMS

236.5 x 160 x 250 mm - weight 3.8 kg

9.31 x 6.30 x 9.84 ins. - weight 8.38 lbs

W A R N I N G

English 3

Page 4

Specification Details

Panel mount instrument

(housing) (H x D x W)

Portable

(H x D x W)

156 (123) x 250 x 220 (214) mm - weight 2.9 kg

6.14 (4.84) x 9.84 x 8.86 (8.43) ins. - weight 6.39 lbs

225 x 250 x 219 mm - weight 3.8 kg

8.86 x 9.84 x 8.62 ins. - weight 8.38 lbs

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

D A N G E R

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

C A U T I O N

N O T I C E

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed.

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

4 English

Page 5

This symbol, when noted on the product, indicates that the marked item can be hot and should not

be touched without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies the location of the connection for protective earth

(ground).

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems. In conformity with European local and national regulations, European electrical equipment

users must now return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxillary items for proper disposal.

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Installation

This section provides necessary information to install and connect the analyzer. The installation of

the analyzer should be performed in accordance with relevant local regulations.

D A N G E R

Electrocution Hazard. Do not connect AC power to a 5 VDC powered model.

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical connections.

W A R N I N G

W A R N I N G

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially wet locations a Ground Fault

Interrupt device must be used for connecting the equipment to its main power source.

Potential Electrocution Hazard. A protective earth (PE) ground connection is required for both 100-240 VAC and

5 VDC wiring applications. Failure to connect a good PE ground connection can result in shock hazards and poor

performance due to electromagnetic interferences. ALWAYS connect a good PE ground to the controller terminal.

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this section of the manual.

Install the device in a location and position that gives easy access to the disconnect device and its operation.

Potential Instrument Damage. Delicate internal electronic components can be damaged by static electricity,

resulting in degraded performance or eventual failure.

W A R N I N G

C A U T I O N

N O T I C E

N O T I C E

Portable mounting

Install the instrument on a laboratory table, on a clean flat surface in a safe area. Locate the

instrument convenient to the power source connectors, supplies and the PC. When carrying the

instrument, grip the top handle firmly, and gently place it on the working surface. Avoid putting the

English

5

Page 6

instrument on the floor. The instrument provides two folded legs hidden in the lower frame. Pull them

out to modify the display angle.

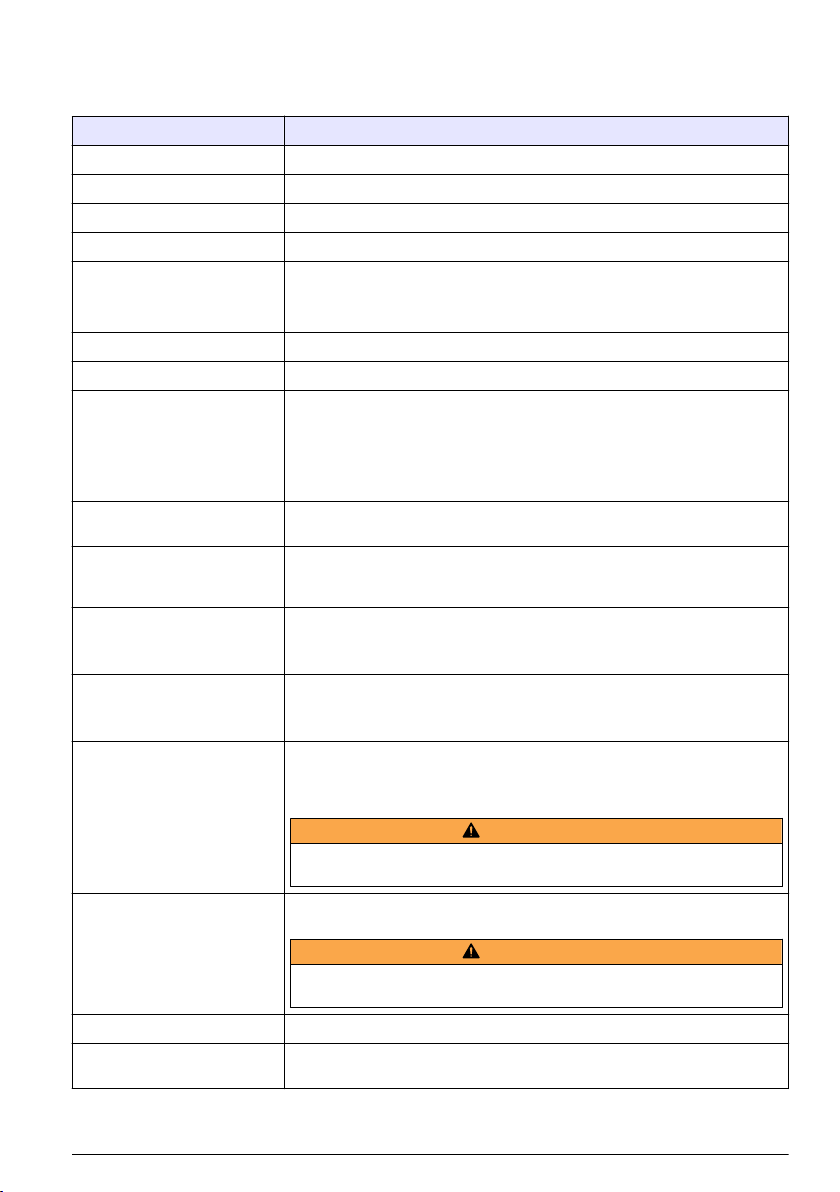

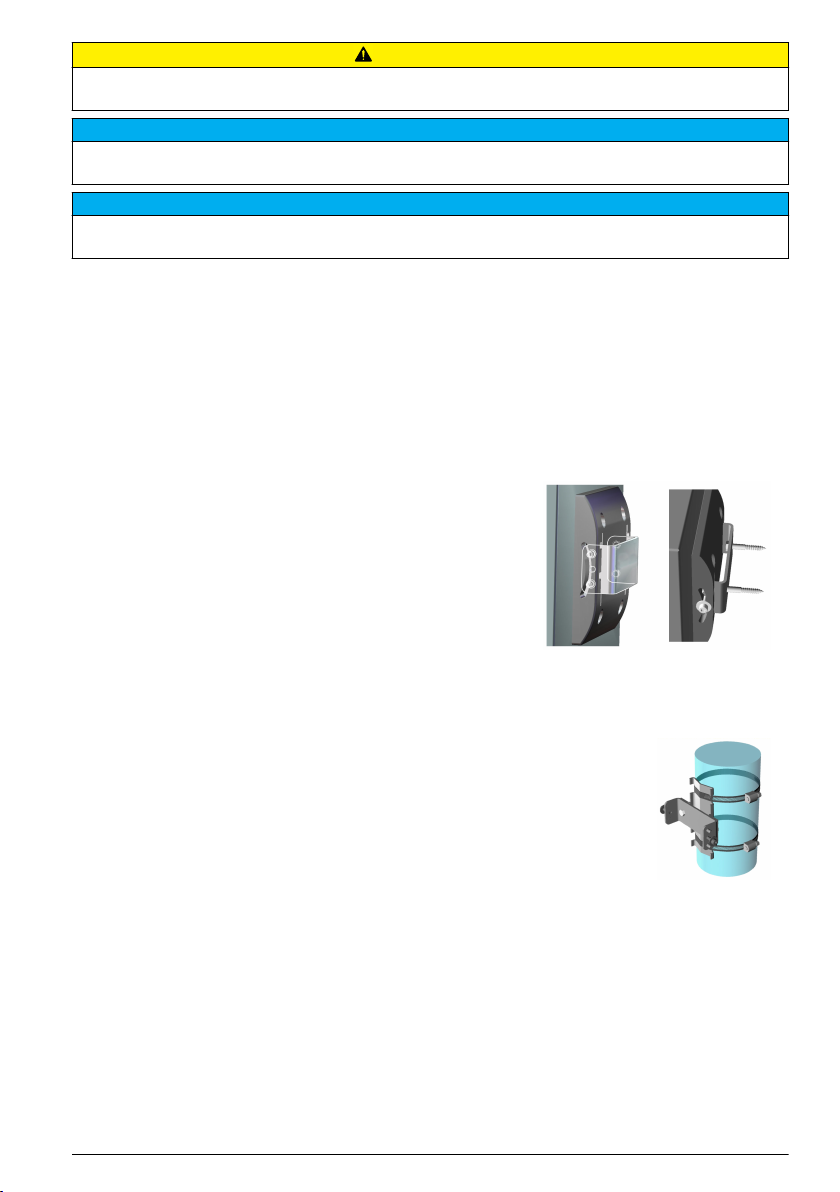

Wall mounting

1. Attach the U-bracket (provided) to the wall with two screws (not

provided).

2. Tilt the instrument slightly backwards to align the bracket pins and

the insertion slots, and slide the instrument onto the bracket as

shown.

3. Insert the 2 locking screws with washers through the side slots.

4. Adjust the instrument angle for better screen vision, and lock both

side screws.

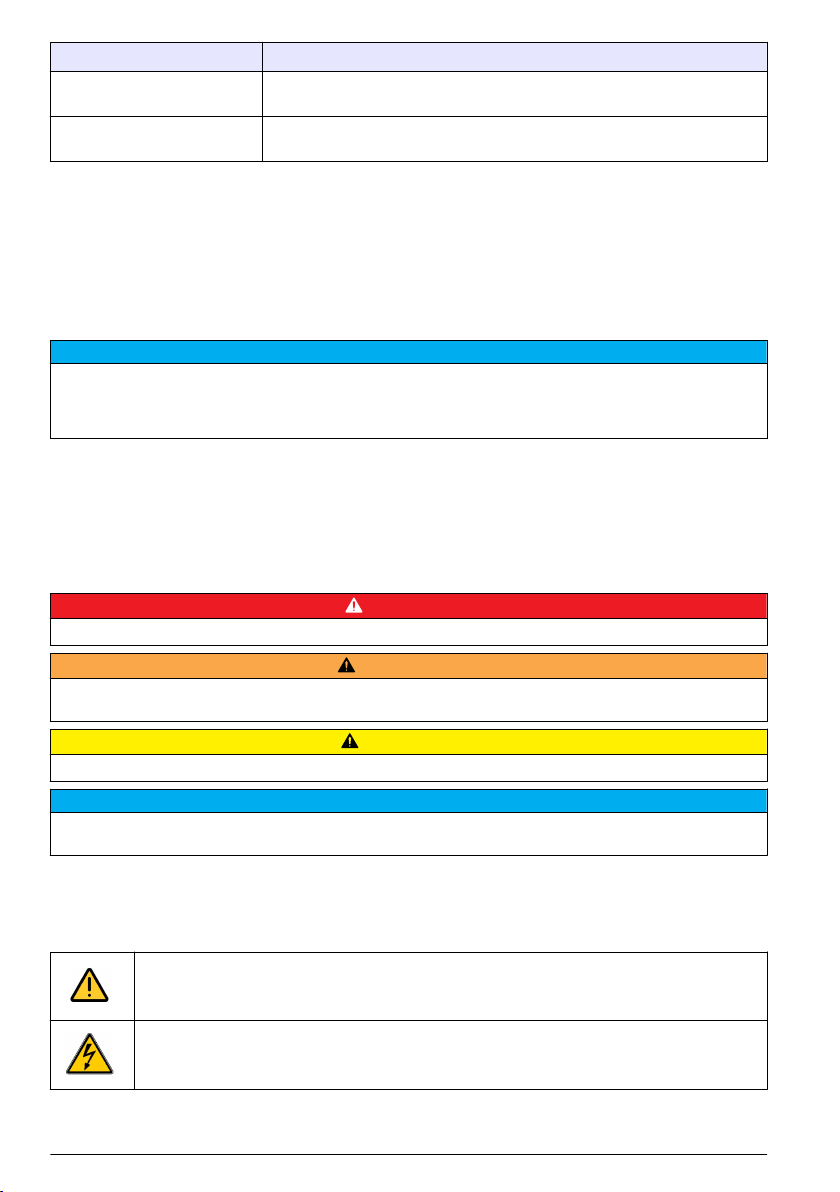

Pipe mounting

1. Assemble the pipe mount bracket to the U-bracket, using the two screws provided.

2. Attach this assembly to the pipe using two clamps (not provided).

3. Slide the instrument onto the bracket.

4. Insert the 2 locking screws with washers through the side slots.

5. Adjust the instrument angle for better screen vision, and lock both side screws.

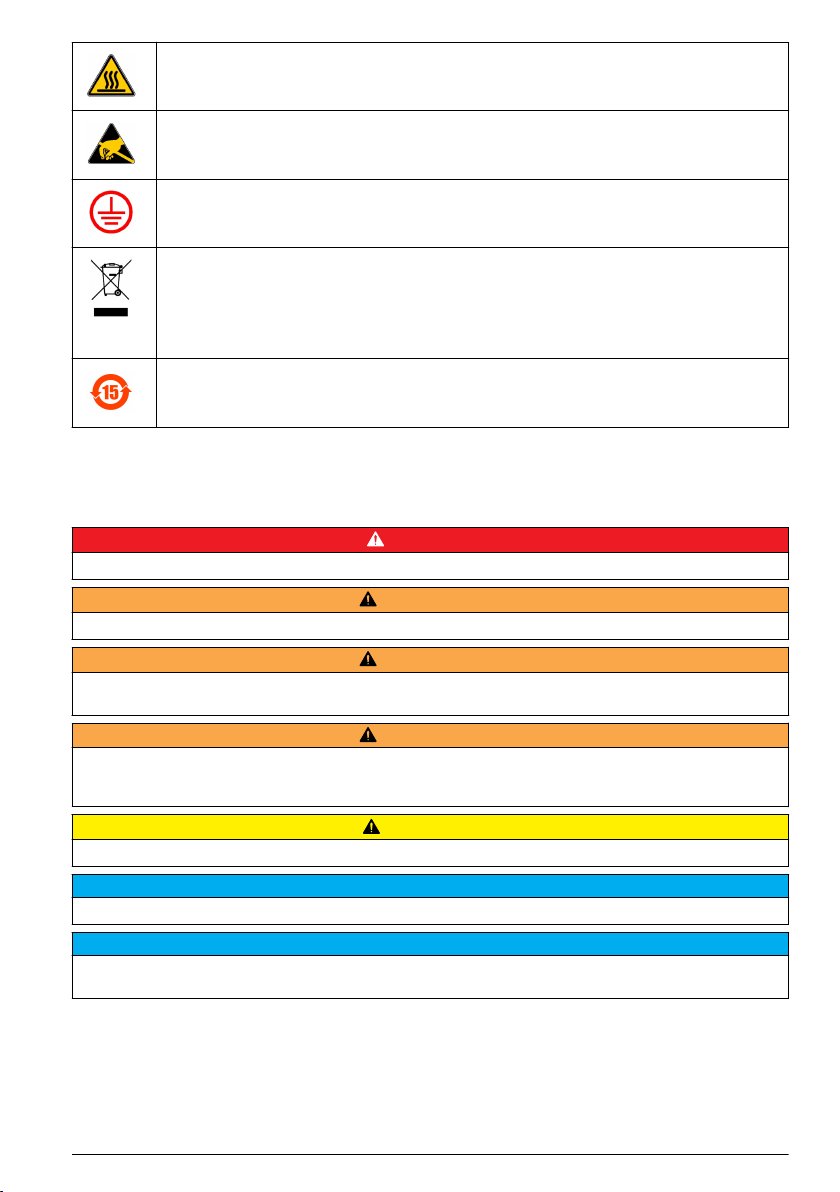

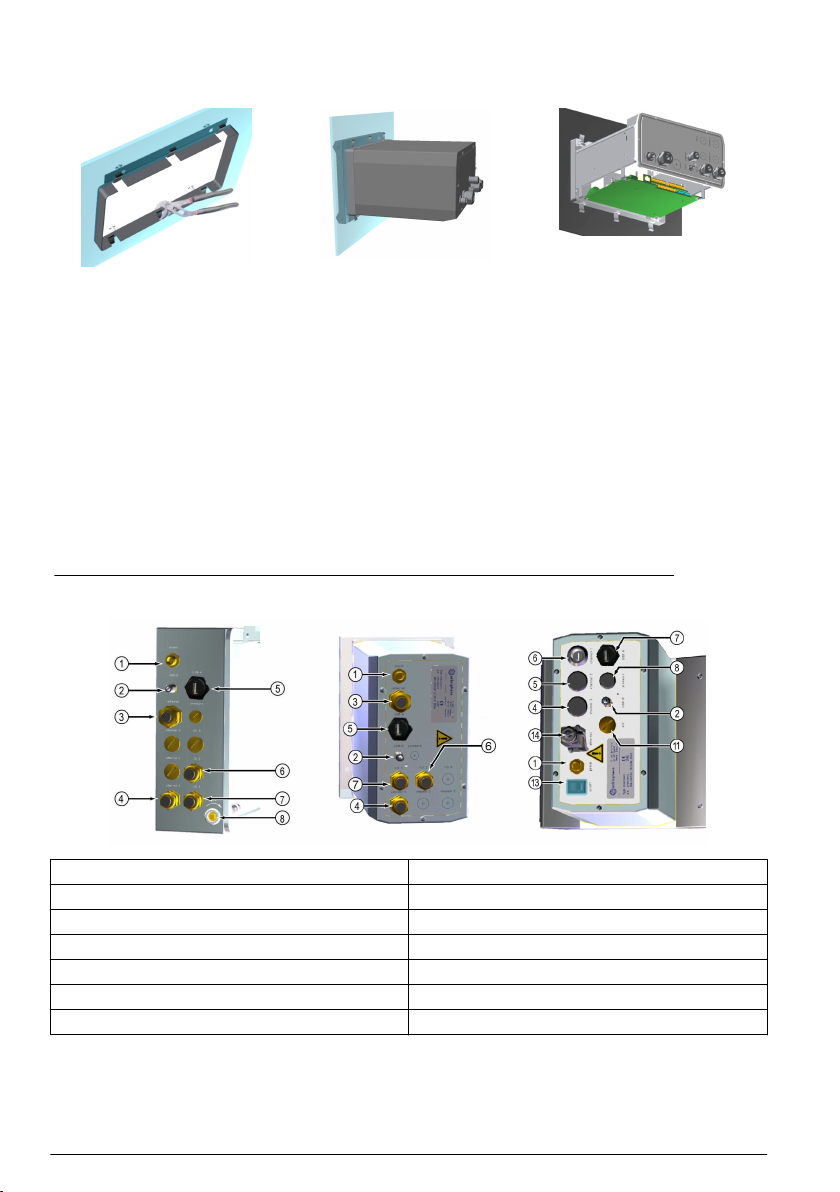

Panel mounting

1-3 4-5 6-7

1. Cut an opening in the panel to accommodate the bracket frame provided.

2. Install the provided frame in the opening.

3. Fold the 6 tabs over the panel lips, using adjustable joint pliers.

4. Slide the instrument in the bracket frame. The instrument should go over the four "T" pins. Rotate the 4 fast

locking screws on both sides of the front panel and slide it in.

5. Rotate the 4 fast locking screws 1/4 turn twice in the lock direction as indicated on the side of the front panel.

This locks the instrument in place on the four "T" pins.

6. To access the connections inside the instrument, remove the instrument housing (six screws on the back

panel, and slide the housing back out)

7. Pass the cables through the housing, then through the cable gland (if applicable) and then perform the

connections as detailed below.

6 English

Page 7

Instrument connections

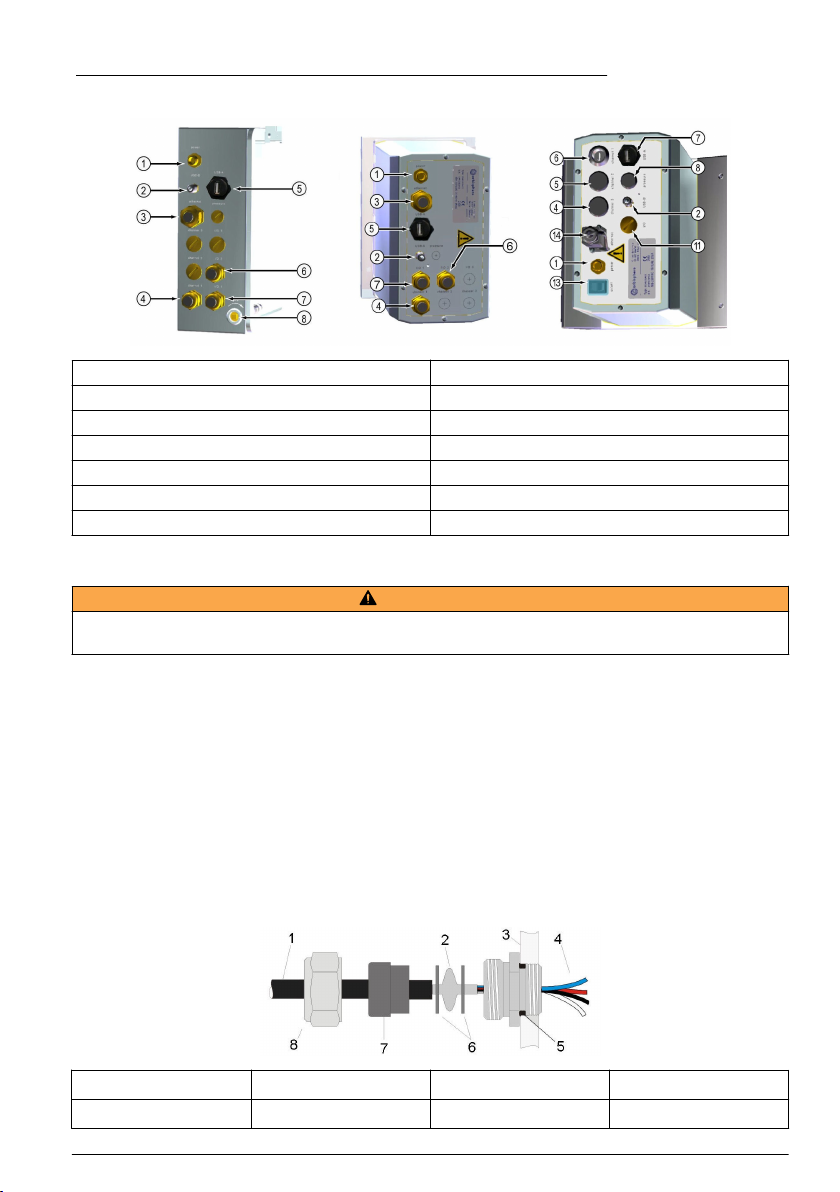

Figure 1 Connections - wall/pipe (left); panel (center); portable (right)

1 Power cable 8 External pressure sensor connection

2 USB-B client 4-pin connector 9 Input/Output 3 cable gland

3 Ethernet cable gland 10 Input/Output 2 cable gland

4 Sensor channel 3 connection 11 Input/Output 1 cable gland

5 Sensor channel 2 connection 12 Keylock (wall/pipe mount only)

6 Sensor channel 1 connection 13 On/Off power switch

7 USB-A host connector 14 Ethernet - Harting RJ Industrial connector

Connectors assembly instructions

W A R N I N G

Potential Electrocution Hazard. In order to maintain the NEMA/IP environmental ratings of the enclosure, use only

conduit fittings and cable glands rated for at least NEMA 4X/IP65 to route cables into the instrument.

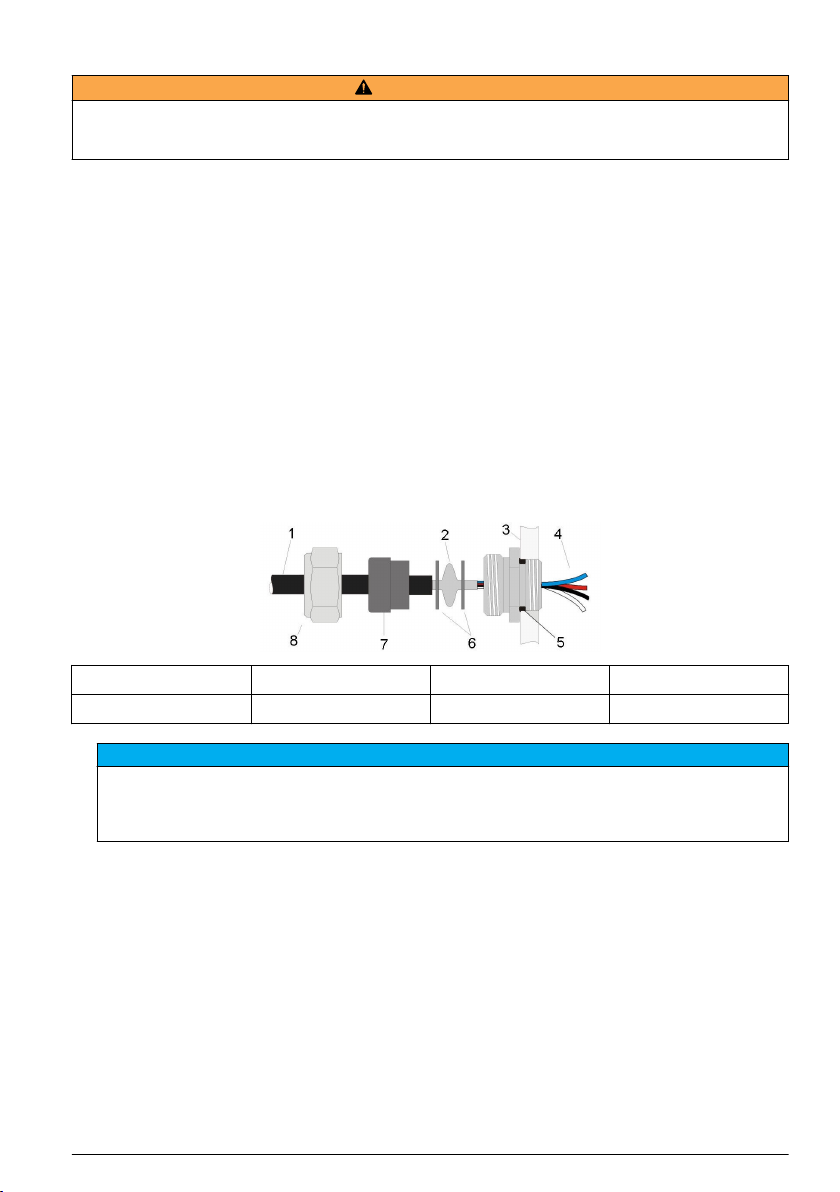

Cable gland wiring instructions

A waterproof cable gland is provided each time a cable must be connected inside the instrument.

The nickel-plated brass cable glands are EMC-types, designed so that the cable shields attach

directly to the instrument housing as a ground. Typical cable wiring instructions are detailed below.

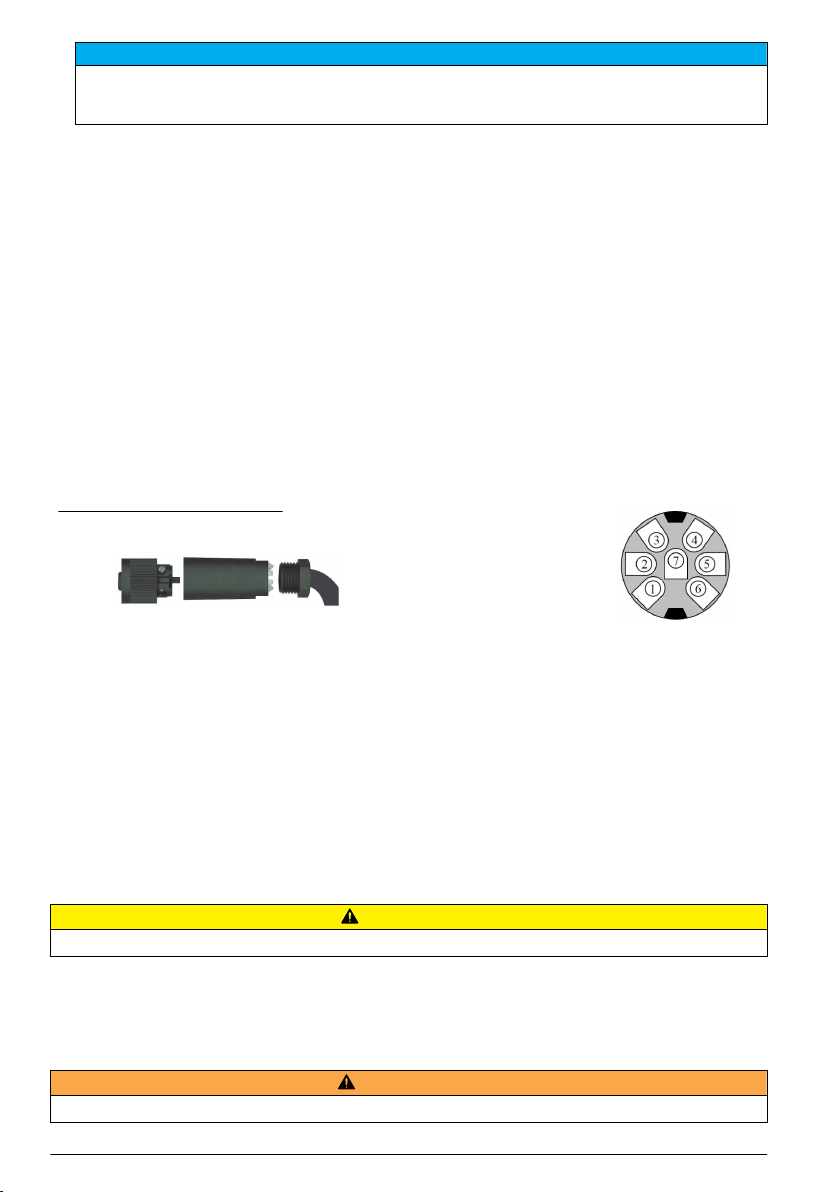

1. Unscrew the cable gland nut. Inside, the assembly is composed of a rubber gasket, and two

metal washers. Note that the ethernet gland on panel and wall mount instruments does not have

washers and the gasket is cut.

2. If wiring a sensor cable, the cable has already been prepared so simply remove the piece of

plastic protection from the exposed shielding. For other cables, strip off external insulation as

required, and 25 mm of shielding. Strip the wires about 8 mm from their ends.

3. Pass the cable through the nut, the rubber gasket, and the two washers.

4. Pinch the shield so that its entire circumference is pressed between the two washers and pass

the cable into the housing, blocking the cable gland.

1 Cable 3 Instrument 5 O-ring 7 Gasket

2 Shield 4 Wire 6 Washers 8 Gland nut

English 7

Page 8

N O T I C E

It is vitally important to ensure the shielding is pinched and secured between the two washers to ensure the

shielding attaches directly to the instrument housing as a ground. Failure to do this could cause damage to

the instrument, and for sensor cables give incorrect readings.

5. Reattach and tighten the cable gland nut.

6. Attach the wires to the corresponding terminal block connections.

Ethernet connector (portable instruments)

The Harting RJ Industrial® IP 67 Push Pull connector can be locked and unlocked using one hand

and minimal force. Only a few steps are necessary in order to quickly and reliably attach an Industrial

Ethernet cable to the Harting RJ Industrial® connector. Only a Harting cable should be used.

Connection to mains power supply

Power supply unit (portable instrument)

For portable instruments, an external power supply unit is supplied as standard. Connect the power

supply unit to the table instrument with the FIXCON® connector provided.

Power supply connection (low voltage instruments)

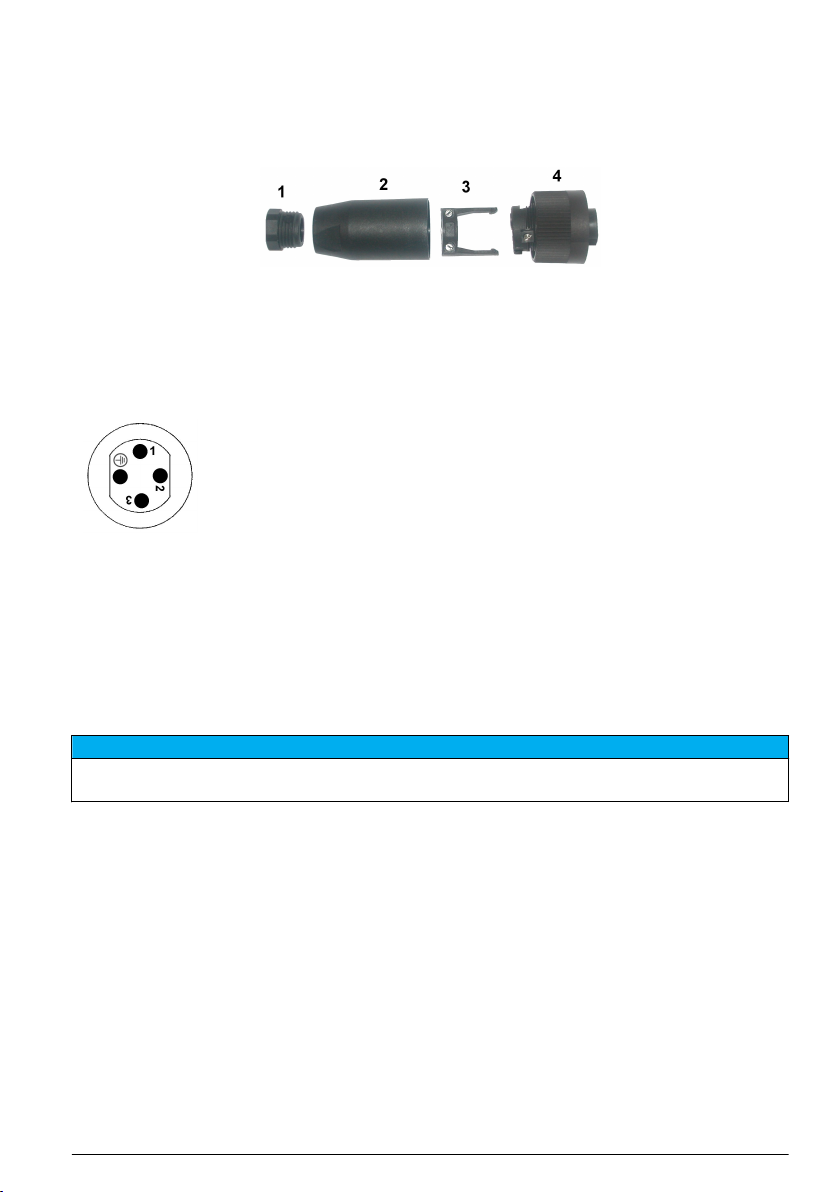

For low voltage instruments (10-30 VDC), connection to the mains power supply is with a 7-pin

BINDER connector (supplied).

Note: The connectors are grooved to avoid an incorrect fitting to the instrument.

Connect the power cable to the connector as follows:

Figure 2 BINDER connector

Pin Connections:

1. Not used

2. Power 10-30 VDC

3. Not used

4. Not used

5. Ground

6. Not used

7. Earth

Power supply connection (high voltage instruments)

High voltage instruments (100-240 VAC) have a 4-pin male connector pre-wired internally with a

male BINDER connector ready for mains connection. A compatible female connector is supplied with

the instrument.

If this female connector was supplied with a mains power plug already pre-attached (cable part

numbers 33031, 33032, 33033 and 33034) then the female connector can be plugged directly into

the instrument power connector. The two connectors are grooved to avoid an incorrect fitting. Tighten

the female connector to the instrument power connector finger-tight.

If no power cable was ordered with the equipment, a mains power plug must be connected to the

supplied female connector as described in the following procedure.

C A U T I O N

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this section of the manual.

User-supplied power cable specifications:

• 3-wire (live, neutral and earth)

• cable Ø ≥ 7mm; ≤ 9.5mm

• wire selection ≥ 1mm2, AWG18; ≤ 2.5mm2, AWG14

Potential Electrocution Hazard. Always disconnect power to the instrument when making electrical connections.

8 English

W A R N I N G

Page 9

Prepare the user-supplied power cable as follows:

1. Strip off 23 mm (0.9 ins.) of shielding from the power cable.

2. Cut back the live and neutral wires to 15 mm (0.6 ins.) in length but leave the earth wire as is.

3. Then strip off a small amount of external insulation from the three wires as required.

Wire the female connector as follows:

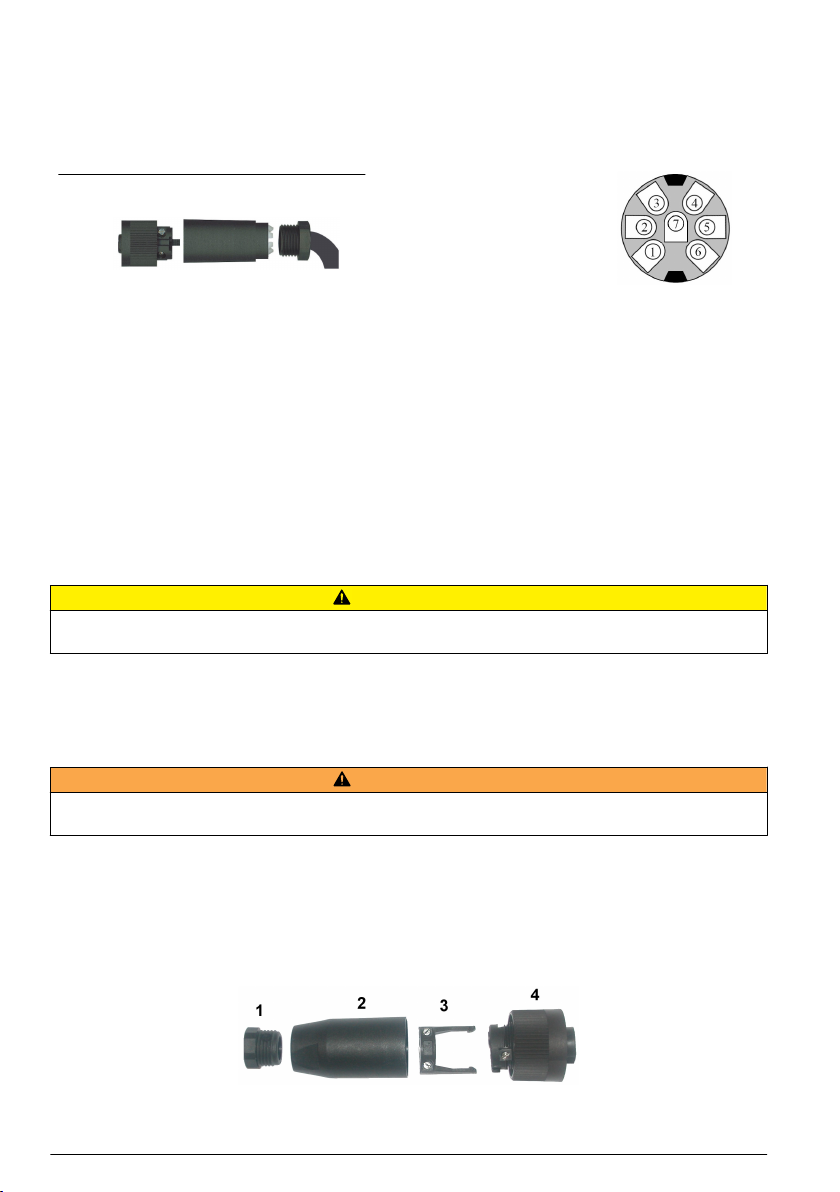

1. Take the narrow end of the connector (4) in one hand and the main body (2) in the other and

unscrew the two. Pull away the cable clamp (3) and unscrew the end plug (1) to reveal the four

parts that make up the connector.

2. Loosen the screws on the cable clamp (3) to allow enough room to pass the power cable through.

3. Pass the power cable through the end plug (1), the main body (2), and the cable clamp (3), and

then connect the three wires (live, neutral and earth) to the connector (4) as follows:

1. Live (brown)

2. Neutral (blue)

3. Not used

Earth - Earth (green and yellow)

Note: The numbers and earth symbol are stamped on the end of the connector. Ensure it is connected

correctly.

4. Slide the cable clamp (3) back onto the connector (4) and tighten the screws on the clamp to

secure the cable.

5. Screw the two parts (4) and (2) back together.

6. Secure the power cable by screwing the end plug (1) back in place.

7. The female connector can now be plugged directly into the instrument power connector. The two

connectors are grooved to avoid an incorrect fitting. Tighten the female connector to the

instrument power connector finger-tight.

Connections to electronic boards

N O T I C E

Potential Instrument Damage. Delicate internal electronic components can be damaged by static electricity,

resulting in degraded performance or eventual failure.

Note: Any loose connection wires should be bundled tightly together with the use of nylon cable ties.

Sensor cable

An ORBISPHERE cable is needed to connect the sensor(s) to the instrument. The portable

instruments have a Lemo 10 connector where a sensor cable has to be connected. The other

versions have a cable gland for cable passage, and the cable must be permanently connected to the

corresponding measuring board connector. Therefore the portable instruments require a standard

sensor cable, while the other versions require a sensor cable with free wires on the instrument end.

The free wires are connected to the connector J8 on the measuring board, as detailed later in this

chapter.

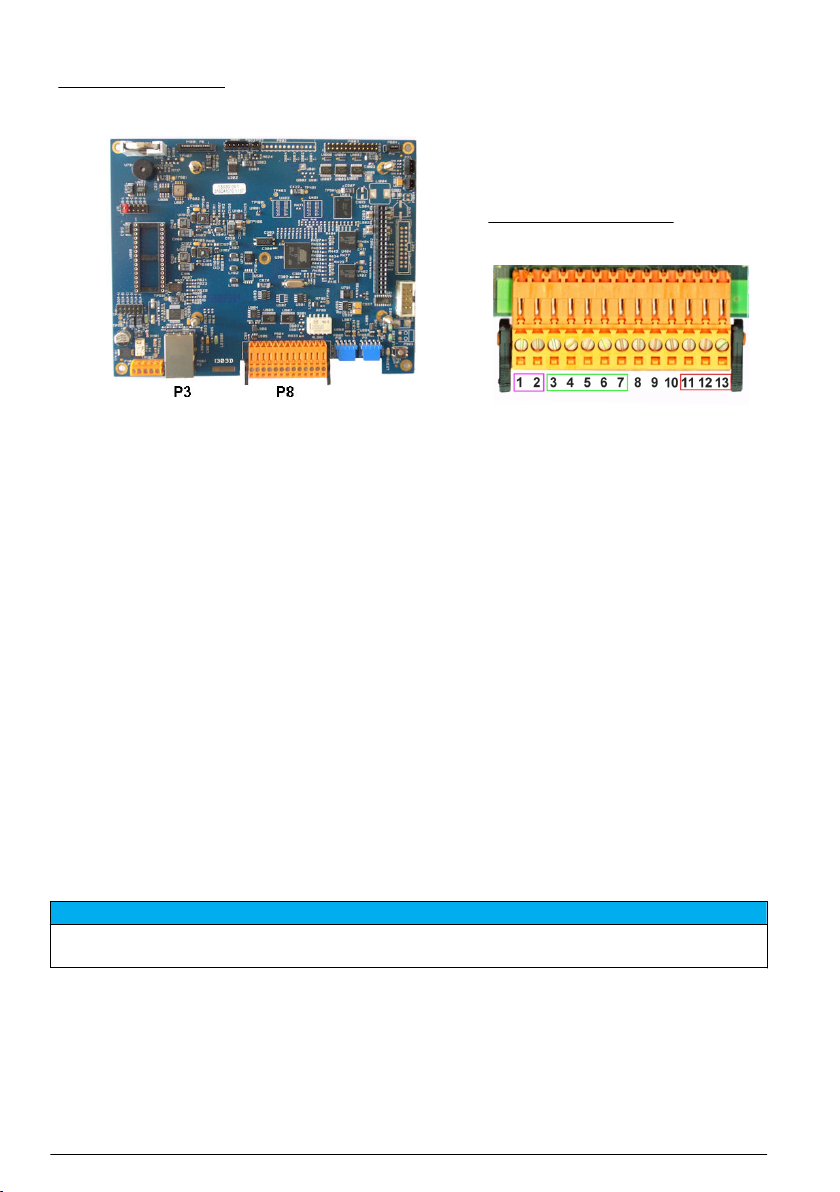

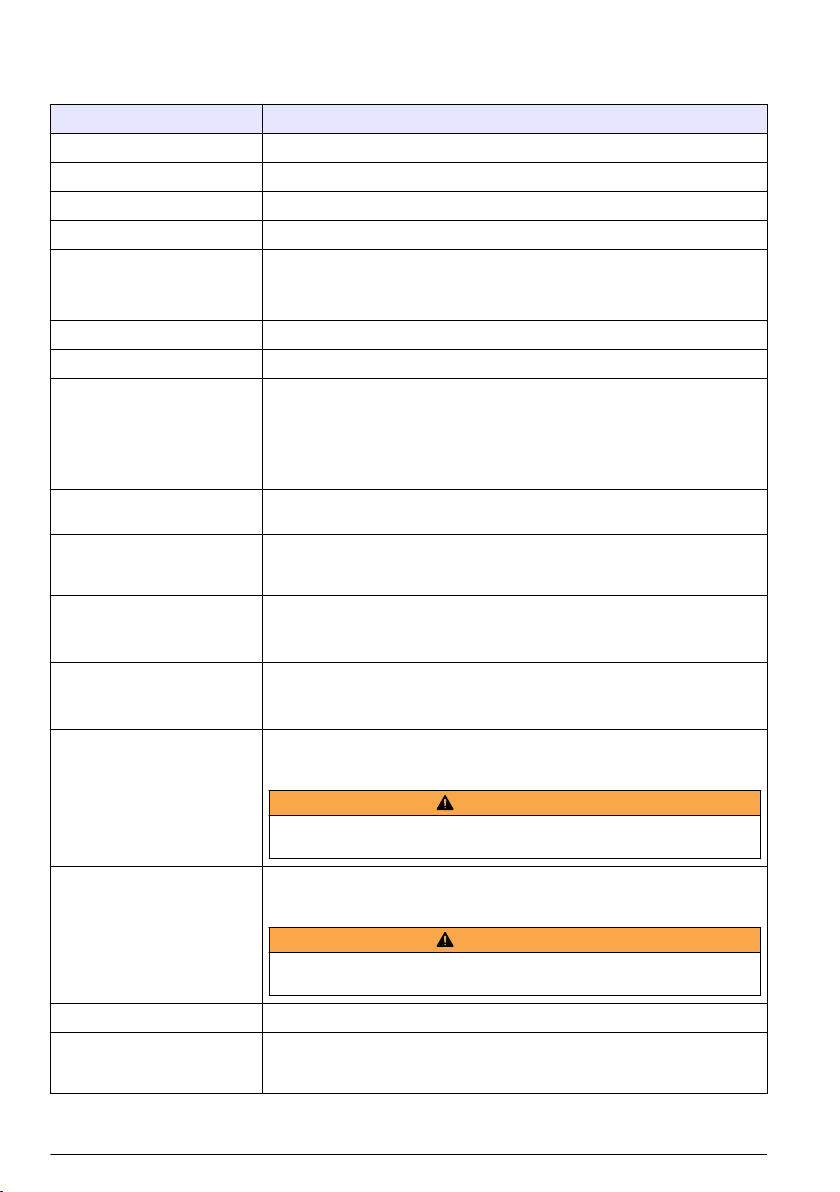

Electronic boards connectors

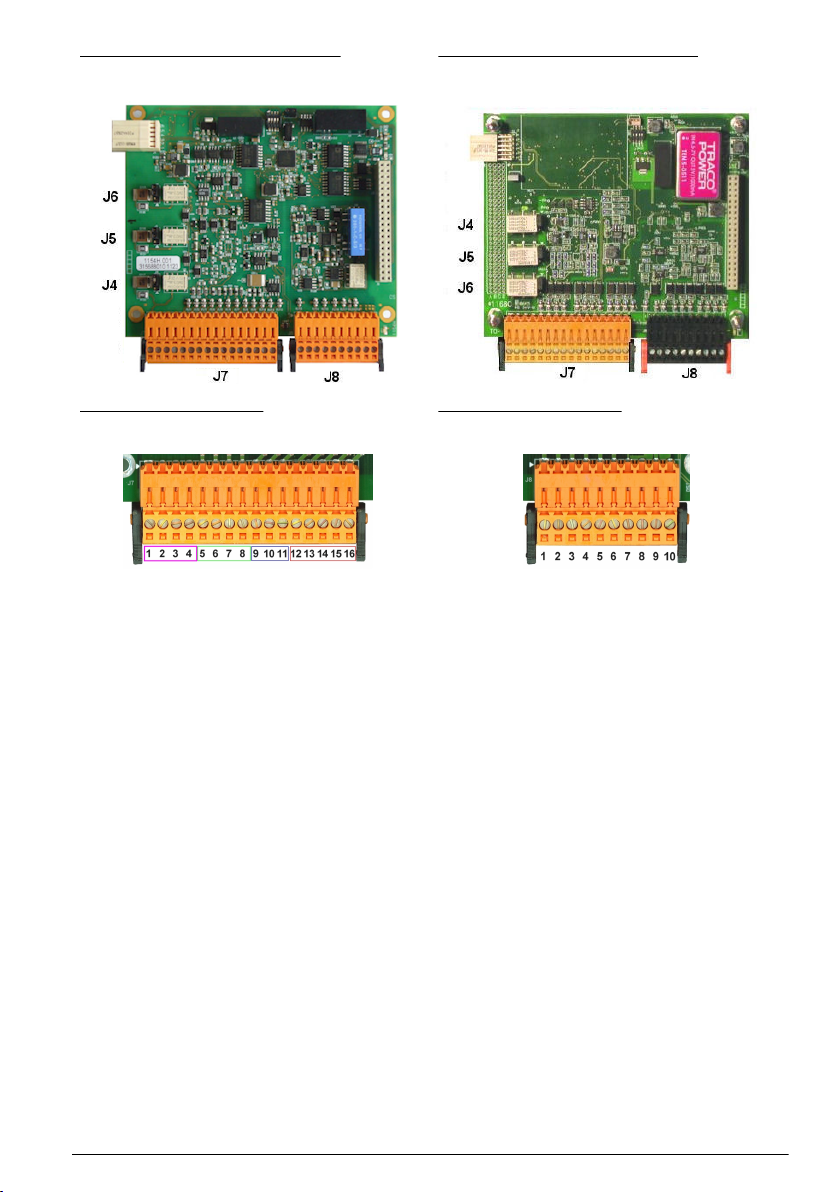

Connectors P8 on the main board (Figure 3 on page 10) and J7 and J8 on the measurement board

(Figure 5 on page 11 and Figure 6 on page 11) are made of two parts. Push down carefully the

black levers on either side of the connector and pull it out securely. Perform all connections with

these connectors unplugged. Once finished, attach the connectors to the boards by pushing them

firmly in place (levers up).

English

9

Page 10

Main board

Figure 3 Main board

Figure 4 Connector P8

Connector P8

The numbers listed below refer to the 13 available P8 connections (from left to right) in Figure 4.

1. RS-485 (signal A)

2. RS-485 (signal B)

3. PROFIBUS-DP (GND)

4. PROFIBUS-DP (+ 5 V)

5. PROFIBUS-DP (signal -)

6. PROFIBUS-DP (signal +)

7. PROFIBUS-DP (signal RTS)

8. Not used

9. Not used

10. Not used

11. System alarm relay (N.O.)

12. System alarm relay (N.C.)

13. System alarm relay (Common)

Connector P3

Ethernet RJ 45. Connect the wall and panel mount instruments to the local network by passing an

ethernet cable through the ethernet cable gland (gland location illustrated in Figure 1 on page 7) and

connecting to the P3 connector illustrated in Figure 3.

Note: For portable instruments, the ethernet connection is located on the back panel (see Instrument connections

on page 7). A waterproof Harting RJ industrial socket is provided to fit to a client network cable. Accessory adapter

and cable are available as an option.

Measurement board

The different measurement boards for the EC and TC sensors are illustrated in Figure 5 and

Figure 6. The type of board is easily identified by the color of the J8 connector. For EC boards this

connector is colored orange, and for TC boards it is colored black.

N O T I C E

It is extremely important that sensors are connected to the correct measurement board. Connecting a TC sensor

to an EC measurement board (and vice versa) will cause irreparable damage to the measurement board.

10 English

Page 11

Figure 5 EC measurement board Figure 6 TC measurement board

Figure 7 Connector J7 Figure 8 Connector J8

Connector J7 (inputs & outputs)

The numbers listed below refer to the 16 available J7 connections (from left to right) in Figure 7.

Measurement alarms relays:

1. Common

2. Output relay 1

3. Output relay 2

4. Output relay 3

Analog current (or voltage) outputs:

5. GND

6. Output 1

7. Output 2

8. Output 3

Digital inputs:

9. EC sensor: Not used

9. TC sensor: Hold input (short circuit to pin 12)

Analog inputs (when ext. press. sensor is directly

connected):

12. EC sensor: Not used

12. TC sensor: GND

13. Green: Input ext. press. sensor P+

14. White: Input ext. press. sensor P-

15. Red: Output ext. press. sensor +

16. Black: Ground (GND)

Note: On multi channel systems, the external pressure sensor must be wired to the channel 1 measurement board, but the signal is

used to compensate all channels.

10. Not used

11. Not used

Analog inputs (when ext. press. sensor extension,

Part N° 32548.xx, is used):

12. EC sensor: Not used

12. TC sensor: GND

13. Green: Input ext. press. sensor P+

14. Yellow: Input ext. press. sensor P-

15. White: Output ext. press. sensor +

16. Brown: Ground (GND)

English 11

Page 12

Connector J8 (sensor)

The numbers listed below refer to the 10 available J8 connections (from left to right) in Figure 8. The

colors indicated are the wire colors in the sensor cable.

Note: Remember, this connector is colored orange for EC sensors and black for TC sensors.

A1100 EC sensor 31xxx EC sensor 31xxxS smart EC

sensor

1. Guard electrode Guard electrode Guard electrode GND for power Yellow Brown

2. RS485A+ Not used I2C-SCL V2 signal Pink Red

3. Thermistor A Thermistor A Thermistor A Solenoid Grey Orange

4. Anode electrode Anode electrode Anode electrode Relay coil Red Yellow

5. RS485B Not used I2C-SDA +12V power Purple Green

6. Thermistor B Thermistor B Thermistor B +24V power White Blue

7. GND Not used GND V3 signal Black Purple

8. + 5V Not used + 5V GND for signal Green Grey

9. Cathode electrode Cathode electrode Cathode electrode -5V power Blue White

10. Not used Not used Not used Temperature Brown Black

TC sensor Sensor

cable

wall or

panel

LEMO

10 cable

portable

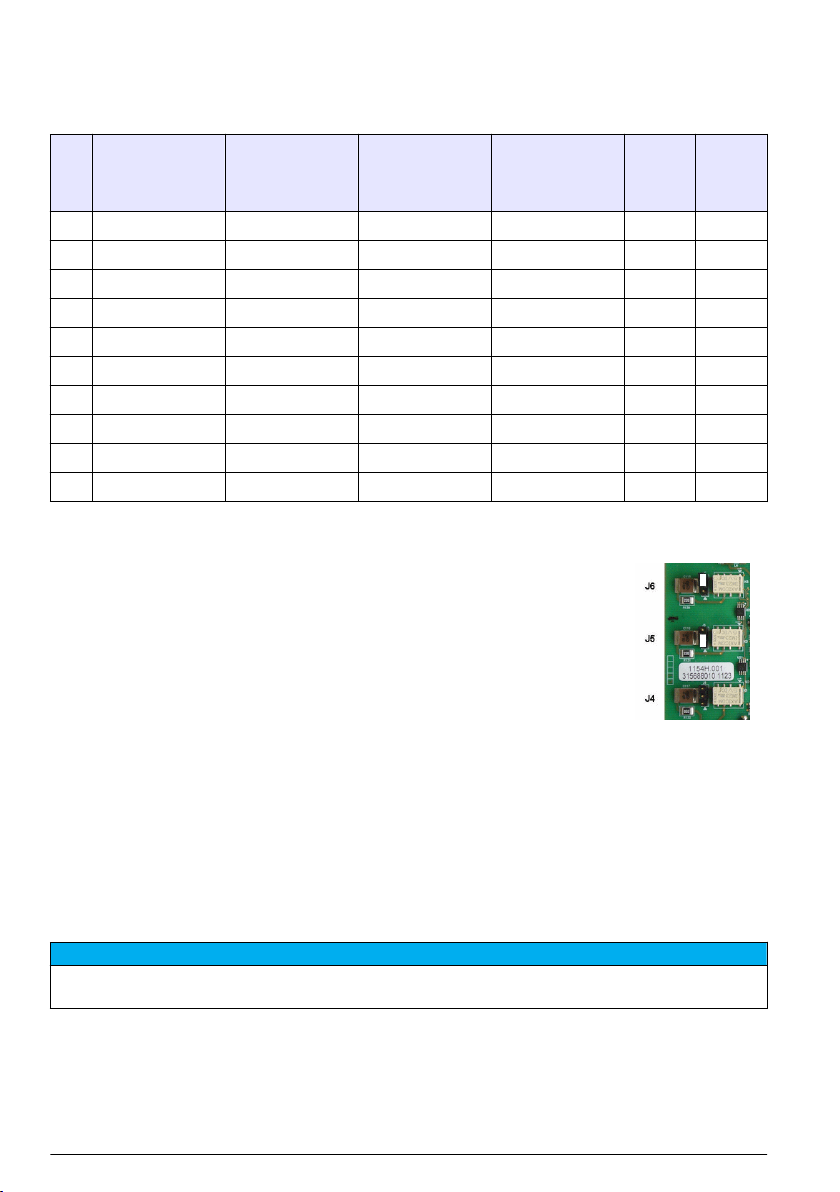

Measurement alarm relays

The three output relays are located on the measurement board.

They can be individually configured to Normally Open (NO) or to Normally Closed (NC) by

physically moving the jumper on each relay. The illustration is for the EC measurement

board (the positions are different for the TC measurement board):

• Upper relay is set to NC

• Middle relay is set to NO

• Lower relay is shown with no jumper

Note: For all measurement boards, J4 is relay 1, J5 is relay 2 and J6 is relay 3

Sensor installation

EC sensors

For EC sensor installation, servicing, and maintenance ensure you follow the instructions in the

Sensor Installation and Maintenance manual that was supplied with the instrument.

TC sensors

For TC sensor installation, servicing and maintenance ensure you follow the instructions in the TC

Sensor Installation and Maintenance manual that was supplied with the instrument. Pay particular

attention to the installation and connection of the purge gas supply.

N O T I C E

Do not place the TC sensor into a liquid sample until a constant supply of dry purge gas has been connected, as

liquid could condense inside the measuring chamber and cause damage to the thermal conductor chip.

To ensure the continuation of purge gas while the sensor is in contact with the sample, it is highly

recommended to use a backup purge gas cylinder with an automatic changeover valve that activates

when the first cylinder is empty.

The use of an ORBISPHERE Model 29089 gas regulator (or similar) is also recommended to deliver

a constant, pressure regulated supply of dry purge gas to the sensor, filtered to 40 μm.

12

English

Page 13

In addition, and to prevent any damage to the sensor electronics, the use of a purge safety backup

unit (ORBISPHERE Model 32605) is highly recommended to ensure the supply of purge gas remains

uninterrupted to the sensor in the event of a mains power outage.

The above ORBISPHERE accessories are explained in more detail in the TC Sensor Installation

and Maintenance manual.

User interface

Instrument controls

The instrument front panel provides:

• A touch screen acting as display, touch pad and keyboard.

• A LED, showing when the instrument is on.

Turning instrument On and Off

The instrument portable versions have a power switch located on the back panel. There is no power

switch for the wall or panel instruments. The mains must be disconnected to turn the instrument off.

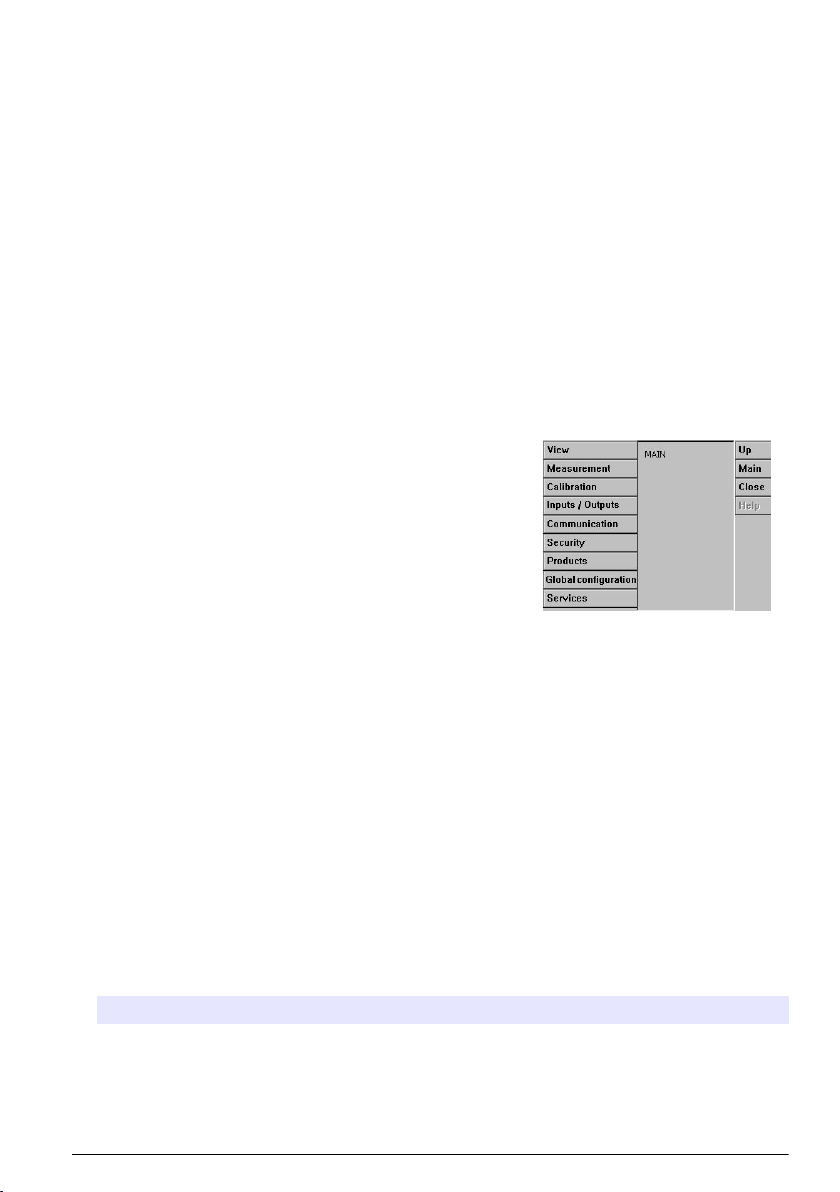

Menu navigation

Pressing the “menu” button in the header bar calls the main menu. The

display is made of three columns:

• The left shows the menu options

• The center shows a tree view of the position inside the menu

structure

• The right has the following generic controls:

• Up - Return to previous menu (one step back)

• Main - Jump directly to main menu

• Close - Close the menu and go back to the measurement display.

• Help - Help topics concerning current menu

Virtual keyboard

When a value or text is to be edited a virtual keyboard will appear on screen and can be used like a

standard keyboard. Press CAP to access special keys. When input is complete press the Enter key

to confirm and exit the virtual keyboard. During editing, the edited field name is displayed along with

units where applicable.

Security menu

Note: When the instrument is started for the first time security is disabled. It is highly recommended that each user

be entered into the system and given appropriate access rights as soon as possible to avoid any unauthorized

access.

Configure security

Define access levels for all users . This requires a user access level 4.

1. Select Configuration from the Security menu.

Option Description

Access rights When enabled only registered users can access the menus. When disabled (default)

Max session time The user is logged out automatically when the time limit is reached.

all menus are freely accessible and no ID is recorded against any action in the log file.

English 13

Page 14

Option Description

User action logging When enabled every action from a logged on user is recorded in a user log file.

User action log file The log file is a rolling buffer recording recent actions. Press Clear to empty the log

file.

User management

Select Access table from the Security menu to show the list of registered users (a maximum of

99 users allowed). They are listed by name, ID, password and access level.

Pressing on an empty line or the Add button displays a window to add a new user. User name, ID,

password (minimum 4 characters) and access level (1 to 4) are required.

Pressing on a registered user displays a window for editing or deleting that user.

View menu

Numeric view

This is the default view and shows the numeric measurement value identified for each gas

measurement channel available, a graphic showing measurement value evolution during the set time

frame, and sample temperature. The display is refreshed after each measurement cycle which can

be configured to suit user requirements. Select Configure from the View menu followed by Conf.

numeric view to customize the display.

Statistic view

This feature offers statistical data to match with Total Quality Management tools to better analyze

how a process behaves. The statistics are calculated from the data in the measurement file and

values updated each time a new measurement is added.

Diagnostic view

The diagnostic view contains important information but is only really useful for troubleshooting

purposes.

Measurement menu

Instrument configuration

TPO or TPA calculation (portable instrument)

The TPO (Total Package Oxygen) and TPA (Total Package Air) features are available on the

portable instrument for an EC sensor measuring oxygen. To initiate these options, the instrument

must be configured in Sample mode and the TPO or TPA calculation must be enabled. The operator

also needs to ensure the package is shaken for about 5 minutes before measuring, and to know the

total volume of the package and the total volume of the contents of the package.

Continuous mode or sample mode (portable instrument)

Continuous mode is typically used for process measurement, whereas sample mode is aimed at lab

measurements of small volume individual samples such as cans, bottles, etc. The measurement

mode is a parameter defined for the entire instrument, not for each channel.

Continuous or sample mode selection

1. Select Config. instrument from the Measurement menu:

Option Description

Measurement mode Continuous mode for on line process.

14 English

Sample mode for lab sample analysis (portable instruments only).

Page 15

Option Description

Pressure Select the barometric pressure units.

Temperature Select the temperature units.

Sample mode measurements (portable instrument)

1. Press the start/stop function key (on the header bar) to initiate the sample measurement.

The text In progress and the measurement value are displayed sequentially. The measurement

process stops when the stop criteria selected are fulfilled.

2. The measurement process is stopped when:

• The stop criteria is fulfilled, typically when the gas concentration reaches the set threshold

• The start/stop function key has been pressed

• The Maximum time criteria is reached

• An error has occurred (e.g. sensor out)

3. When the sample measurement stops because the stop criteria are fulfilled, the gas

concentration and temperature are no longer refreshed. They indicate the measurement when the

stop criteria was reached. If the channel was configured for TPO or TPA calculation, enter the

parameters.

4. If the sample mode is stopped for another reason (user abort, max. time, or measurement error),

the aborted message is displayed.

TPO and TPA parameters (portable instrument)

1. Overflow volume: Total package size

2. Net content volume: Volume of liquid in the package

3. Press the Compute button to calculate the TPO or TPA. The parameters can be changed and the

value recalculated if necessary.

TPO values are displayed in ppm, TPA values in mL.

4. To store the measurement, press the OK button.

Stop criteria configuration (portable instrument)

Available in Sample measurement mode, this setting allows configuration of the stop criteria for

each channel.

Note: The parameters available for configuration depend on the type of stop criteria being defined.

1. Select Menu / Main / Configure chan x and press the Stop criteria button.

Option Description

Above

threshold

Below

threshold

Stability The stop criteria is met when the variation of the gas concentration is smaller than the

Time The stop criteria is met when the elapsed time reaches the Max. time parameter.

The stop criteria is met when the gas concentration is greater than the parameter entered

in Threshold

The stop criteria is met when the gas concentration is lower than the parameter entered in

Threshold

parameter entered in Variation

Note: The number of samples taken into account to compute the Variation can be

adjusted using the parameter Depth.

English 15

Page 16

Option Description

Max. time The parameter Max. time is the maximum time allowed to reach the target. If Time is not

Time filter The time filter allows you to filter the stop criteria. The sample mode is stopped when the

the type of stop criteria, then when this delay has elapsed, the measurement stops and the

message aborted is displayed.

stop criteria is fulfilled for a time greater than the parameter Time Filter.

As an example, if criteria is set to Above threshold and Time Filter is set to 10 sec. the

measurement stops when the gas concentration is above the threshold for more than

10 seconds.

Measurement configuration

1. EC sensor

Option Description

Membrane Sensor’s membrane number selection.

Medium Liquid or gas phase.

Gas unit type Partial, Fraction, Dissolved.

Gas unit The list of available units depends on unit type selected above.

Note: This is the gas concentration measured by the EC sensor. When a composite unit

is selected (e.g. ppm » ppb) the unit will change depending on the range of the value to

display.

Liquid When medium is liquid, select water or a liquid with a different solubility (if available).

Display

resolution:

Thermal cutoff: To protect the sensor, the thermal cutoff function allows for setting a sample high

Maximum resolution depends on gas, membrane and unit. A maximum of 5 digits can be

displayed. Decimals can be limited to 0, 1, 2 or 3 decimals for easier reading. That does

not affect the actual resolution of data measured and stored, but only the data displayed.

temperature limit. If exceeded (during a Cleaning In Place cycle for example) the

electrical signal to the sensor is cut off, the measurement session is suspended and the

system displays a HOT alarm message. The system resumes when temperature drops

to 90% of the specified cutoff temperature.

• Thermal cut off options: Disabled / enabled.

• Thermal cut off temperature: To be set according to conditions.

2. TC sensor

The measurement configuration for a TC sensor is the same as for an EC sensor with the

addition of one extra selection criteria:

• Purge gas: From the drop-down list, select the purge gas being used for the TC sensor.

Measurement alarms configuration

Set the thresholds for the low/high concentration levels according to the application.

1. Select the Alarms button on the Measurement configuration screen:

Option Description

Low Low 2nd stage for too low concentration alarm.

Low 1st stage for too low concentration alarm.

High 1st stage for too high concentration alarm.

High High 2nd stage for too high concentration alarm.

16 English

Page 17

Option Description

Hysteresis The hysteresis is used to prevent relay flickering when the measurement is just at the alarm

Delay The delay in seconds, before alarms go on whenever concentration values go above ”High

levels. Set this to a minimum but enough to eliminate flickering. For example, if the High Alarm

is set to 40 ppb and the Hysteresis is set to 10% then the High Alarm is activated once the

measurement reaches 40 ppb but only deactivated once it drops below 36 ppb. With the Low

Alarm the opposite is true in that if the Low Alarm is set to 20 ppb and the Hysteresis set to 10%

then the Low Alarm is activated when the measurement drops below 20 ppb and deactivated

when it rises above 22 ppb.

alarms” or below “Low alarms”. Set this to a minimum value, but enough to avoid alarms for

non-representative peaks beyond the set level.

Measurement filter configuration

The filters are aimed at “flattening” the measurement curve in situations where the process shows

atypical peak values that could otherwise hamper the interpretation of measurement readings. The

filter is applied on the last set of measurements each time a measurement is taken.

1. Select the Filter button on the Measurement configuration screen:

Option Description

State Set the filters to Enabled or Disabled.

Type If enabled set the filter to Mean or Median.

Depth Number of measurements that make up a set.

Central depth Number of measurements to be used to determine the average.

2. Example: With a depth of 7 and central depth of 5, the 7 values are sorted and the highest (7.0)

and lowest (0.9) eliminated. The average of the center 5 is calculated as 3.88:

0.9 1.1 4.0 4.3 4.4 5.6 7.0

Mean is the mathematical average of the last set (depth) of measurement values.

Median allows for eliminating atypical peak measurement values and averaging the

remaining ones. The calculation sorts the last measurement set (depth) by values, then

ignores the highest and lowest values and averages the remaining values (central depth).

Advanced configuration

1. EC sensor

Option Description

Enable pressure sensor Check as appropriate.

Enable negative concentration Check as appropriate.

TPO enable (portable instruments in Sample

mode measurement only)

TPA enable (portable instruments in Sample

mode measurement only)

TPA K coefficient If TPA is enabled, enter the TPA K coefficient if different

2. TC sensor

Option Description

Enable ext. pressure

sensor

Check as appropriate.

Check if TPO calculation is required.

Check if TPA calculation is required.

from the displayed value.

English 17

Page 18

Option Description

Enable negative

concentration

Continuous purge during

thermal cut off

Offset and slope

corrections

Liquid to gas factor Enable correction as appropriate. If checked, the percentage correction factor

Check as appropriate.

If thermal cutoff has been enabled (see Measurement configuration

on page 16), then check this box to ensure that a continuous purge of the TC

sensor takes place while the measurement session is suspended due to the

thermal cutoff temperature value being exceeded.

Note: To manually set the TC sensor into a continuous purge mode, press the

Continuous Purge button that is available from the Services - Diagnostic Channel x - Amplifiers menu.

Enable correction as appropriate. If enabled, the correction values for offset and

slope must be entered. These values cannot be negative.

must be entered. This value cannot be negative.

Note: If you believe you need to enable these corrections, it is advisable to

contact a Hach Lange Service Representative first.

Interferences configuration

These options are available to take into account the influence of some components or gases in the

sample during measurement. All available interference corrections are disabled by default.

The following interference corrections are available:

• For oxygen measurements - CO2, H2S, Chlorine, Salt, H

• For hydrogen measurements - Temperature, H2O, He, O

• For nitrogen measurements - Temperature, H2O, O2, H

Note: If you believe you need to enable any of the above, it is advisable to contact a Hach Lange Service

Representative first.

2

2

2

Measured data storage

There is one measurement file per channel which contains the data generated by the measurement

cycle.

1. Storage modes in continuous measurement mode:

Option Description

No storage Storage is disabled.

Store once When the volatile memory is full (10,000 positions), the recording of measurement stops.

Rolling buffer When the volatile memory is full, the latest measurement set replaces the oldest one

continuously (first-in, first-out).

2. Storage modes in sample measurement mode:

Option Description

Only final measurement The measurement when the stop criteria are met is saved (one per

Only when sample mode started The measurements when the sample mode is started are saved.

All measurements All the measurements are stored continuously.

sample).

Calibration

Calibrations can only be performed once the instrument has been installed and configured.

18

English

Page 19

Note: The temperature sensor is factory calibrated and can only be changed by a Hach Lange representative.

Definitions

To calibrate the gas to measure (main gas), the user usually puts the sensor in the main gas without

any interfering gas.

Calibrations can only be performed once the instrument has been installed, configured and each

channel has been set up. You must also ensure that you have the correct access rights to access the

calibration menu.

Select sensor calibration from the calibration menu, then select the channel to calibrate.

There are two types of gas sensor calibration available, depending on the gas being measured and

the type of sensor being used:

1. In Air: For Oxygen and Ozone with an EC sensor.

2. Direct value: Any gas with either an EC or TC sensor. This calibration exposes the sensor to a

gas with a known partial pressure, or a liquid sample with a known gas concentration.

EC gas sensor calibration

Calibration of the measured gas

1. Before initiating a calibration process, the calibration parameters must be set by pressing on the

Modify button. The last calibration parameters are memorized, so this step can be ignored if the

correct parameters are already set.

Option Description

Calibration mode

Medium Select liquid or gas (direct calibration only)

Concentration unit type Partial, fraction or dissolved (dissolved is for calibration in a liquid only)

Concentration unit The list of available units depends on unit type selected above.

Liquid Select as appropriate, available when liquid has been selected in medium

Value Enter the gas concentration according to the value in the calibration media, when

Hold during calibration On by default, this stops any output from the instrument during the calibration

Interference enabled If selected, this takes into account the influence of interferences during calibration.

2. Press OK to start calibration

• A calibration screen will be displayed showing current measurement data which is continually

refreshed.

• The value “% ideal current” is a percentage of the current against the ideal current for the

membrane type selected. If this percentage is not within the accepted range, an error message

is displayed and the calibration process fails. A warning message can be displayed when this

value is close to the boundaries, but when calibration can be accepted.

• The message is first displayed in the result box. The dialog box with the error message or the

warning is displayed when the finish button is pressed.

• The value “% last calibration” shows the ratio between the current measurement and the

previous sensor calibration.

• The value “% variation” indicates the variation during the last 3 measurements, which is the

stability of the measurements. A variation as low as possible is needed for a precise

calibration.

• Direct value: Any gas

• In Air (default): For O2 or O

(above).

direct value is used.

process to avoid sending invalid information to any connected device.

By default the same interference as during measurement is selected.

3

English

19

Page 20

• The display shows the actual calibration parameters, and the actual readings (temperature,

barometer, current).

O2 sensor calibration

The O2 sensor needs to be calibrated after each sensor service. Wait at least 30 minutes after

mounting a new membrane before re-calibrating. The sensor is in contact with either:

• Air at atmospheric pressure (In Air)

• O2 at known concentration (Direct value). The gas can be dissolved or not.

In air calibration

This calibration procedure places the O2 sensor in water-saturated air, to provide a known oxygen

reference against which to calibrate.

Dry the sensor thoroughly, before placing the sensor storage cap under tap water. Shake off any

excess water, but leave a few drops inside the cap. Verify that the screw-on protection cap is in place

on the sensor head. If you use a Dacron mesh inside the protection cap, make sure it is dry before

attempting to calibrate. Then, loosely place the storage cap back on the sensor, holding it in place

with a few turns of its collar.

Set the calibration parameters accordingly and press calibrate.

Direct calibration

This procedure calibrates the oxygen sensor against a liquid sample containing a known level of

dissolved O2 flowing through the sample line.

The instrument displays the sensitivity of the sensor as a percentage of the sensitivity determined

when calibration was last performed.

Set the calibration parameters accordingly and press calibrate.

O3 sensor calibration

The sensor is either in contact with:

• Air at atmospheric pressure (In Air)

• O3 at known concentration (Direct Value). The gas can be dissolved or not.

The procedure is the same as for the O2 sensor. In the case of the "In air" calibration, the sensor

measures O2 during calibration. The O3 coefficient is deduced taking into account how the sensor

behaves in O2. As a different voltage is used at the anode to measure O2 and O3, the O

measurement takes a long time to stabilize. To facilitate the follow up after an "O3 in air" calibration,

3

negative values can be displayed.

H2 sensor calibration

W A R N I N G

Potential Fire and Explosion Hazard. Handle H2 gas with great care!

The recommended method is at known concentration (Direct Value). The gas can be pure H2 or a

mixture of H2 with an inert gas (e.g. a mixture of H2/N2). The known concentration is entered by the

user in the calibration parameter window. The sensor is in contact with the calibration gas (Direct

Value) in gas phase at atmospheric pressure.

Make sure the H2 concentration used for calibration is within the acceptable range for the membrane. Hach Lange

recommends the following calibration gas/inert gas combinations for calibrating with the following membranes.

See the Sensor Maintenance Manual for further details on membrane specifications:

N O T I C E

20 English

Membrane Recommended calibration gas

2956A 1% H2 / 99% N

2952A 10% H2 / 90% N

2

2

Page 21

Membrane Recommended calibration gas

2995A 100% H

29015A 100% H

2

2

TC gas sensor calibration

Calibration of the measured gas

1. Before initiating a calibration process, the calibration parameters must be set by pressing on the

Modify button. The last calibration parameters are memorized, so this step can be ignored if the

correct parameters are already set. Similarly, if only the calibration value has changed, then this

can be updated directly instead of pressing the Modify button.

Option Description

Gas Phase Select liquid or gas (direct calibration only)

Gas unit type Partial, fraction or dissolved (dissolved is for calibration in a liquid only)

Gas unit The list of available units depends on unit type selected above.

Liquid Select as appropriate.

Value Enter the gas concentration according to the value in the calibration media.

Hold during calibration On by default, this stops any output from the instrument during the calibration

Automatic calibration

stop

Interference enabled If selected, this takes into account the influence of interferences during

2. Press OK to start calibration

• A calibration screen will be displayed showing current measurement data which is continually

refreshed.

• The value “% ideal current” is a percentage of the current against the ideal current for the

membrane type selected. If this percentage is not within the accepted range, an error message

is displayed and the calibration process fails. A warning message can be displayed when this

value is close to the boundaries, but when calibration can be accepted.

• The message is first displayed in the result box. The dialog box with the error message or the

warning is displayed when the finish button is pressed.

• The value “% last calibration” shows the ratio between the current measurement and the

previous sensor calibration.

• The value “% variation” indicates the variation during the last 3 measurements, which is the

stability of the measurements. A variation as low as possible is needed for a precise

calibration.

• The display shows the actual calibration parameters, and the actual readings (temperature,

barometer, current).

process to avoid sending invalid information to any connected device.

If selected, when the stability criteria is reached, the calibration process stops

automatically.

calibration. By default the same interference as during measurement is

selected.

Barometric pressure calibration

Note: The barometric pressure sensor has been factory calibrated but should be periodically verified with a

precision certified barometer. This is only necessary if measuring in gas phase with fraction units (%, ppm).

The upper box shows the barometric pressure as measured by the instrument.

Using a precision certified barometer measure barometric pressure in the location where the

measuring instrument is used. Compare the values anf if they are the same press Cancel, otherwise

enter the new barometric pressure value in the lower box and press Validation to validate the new

setting.

English

21

Page 22

External pressure calibration (optional sensor)

Two point calibration (recommended)

1. Connect a certified absolute pressure gauge to the sample line, and use a certified precision

barometer.

2. The two point calibration starts with barometric pressure for the lower point. Expose the external

pressure sensor to the atmosphere.

3. Enter the barometric pressure read on the barometer in the upper window and validate P1.

4. Expose the external pressure sensor to line pressure, making sure it is exposed to the same

pressure as the certified absolute pressure gauge.

5. Enter the absolute pressure value read on the certified absolute pressure gauge in the lower box,

and validate P2.

Note: Any pressure can be used for P1 and P2, but for an accurate calibration P1 and P2 should be as different

as possible.

One point calibration

1. Connect a certified absolute pressure gauge to the sample line.

2. Expose the external pressure sensor to line pressure, making sure it is exposed to the same

pressure as the certified absolute pressure gauge.

3. Enter the absolute pressure value read on the certified absolute pressure gauge in the lower box,

and validate P1.

Note: Any pressure can be used for P1, but for one point it should be as close as possible to the sample

pressure.

Services menu

There are a number of options available from this menu with the key options detailed below.

Calibration timer

The instrument can automatically remind the user when the next sensor calibration is due. Select the

measurement channel, select Enable and enter a delay in days. The next calibration date is updated

when the sensor is calibrated.

Service timer

The instrument can automatically remind the user when the next sensor service is due. Select

Enable and enter a delay in days. The next service date is updated when the button Service done is

pressed after a service.

Language selection

Select the language from a list and restart the instrument to apply the change.

Clock

Update the time and date information.

Other menus

For information on setting up relays and analog outputs refer to the full user manual (Inputs/Outputs

menu).

For information on setting up RS485, PROFIBUS-DP, USB and HTTP/TCP-IP links refer to the full

user manual (Communications menu).

For information on setting up products and global configurations refer to the full user manual

(Products and Global Configuration menus).

22

English

Page 23

Maintenance

Instrument maintenance

C A U T I O N

Personal Injury Hazard. Any instrument maintenance should be carried out by a qualified Hach Lange Service

Technician. Please contact your local representative should you feel any maintenance or instrument adjustments

are required.

English 23

Page 24

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen.

Spezifikation Details

Betriebstemperatur -5°C bis +40°C

Lagerungstemperatur -20°C bis +70°C

Betriebsfeuchtigkeit 0 bis 95% relative Feuchtigkeit ohne Kondensbildung

Betriebshöhe Von 0 bis 2.000 m über dem Meeresspiegel

EN61326-1:2006 EU-Richtlinie 2004/108/EEC

EMC-Anforderungen

CE-Konformität EN61010-1: 2010 EU-Richtlinie 2006/95/EEC

Sicherheitsbestimmungen ETL, entspricht UL 61010-1 und CSA 22.2 Nr. 61010-1

Gehäuse

Stromversorgung

Wand- bzw. Paneelmontage

Stromversorgung

Tragbar

Analoger Stromausgang,

Version auf der Messkarte(s)

Analoger pannungsausgang,

Version auf der Messkarte(s)

Alarmrelais Messung auf der

Messkarte(s)

Hinweis: Das Instrument für die Wandmontage ist ein Produkt der Klasse A. In

Haushaltsumgebungen kann dieses Produkt Funkstörungen verursachen, die dazu führen

können, dass der Benutzer Gegenmaßnahmen ergreifen muss.

IP 65; Gesamtschutz gegen Staub; Geschützt gegen Wasserstrahlen mit

niedrigem Druck aus allen Richtungen.

Hinweis: Für tragbarenversionen ist IP 65 nur anwendbar, wenn ein Kabel an den EthernetSockel angeschlossen ist.

NEMA 4X (nur Wandmontage); vollkommen gegen Staub geschützt; gegen

Wasserstrahldruck aus allen Richtungen geschützt.

Universell 100 Vac bis 240 Vac @ 50/60Hz - 40VA; 10 bis 30 Vdc - 30W

5V über eine externe Stromversorgung 100Vac-240Vac bei 50/60Hz - 1A

Optional Batterie-Pack mit 4 Stunden Autonomie (Ladung in etwa 6 Stunden).

Ladezeit der Batterie kann bei T > 30° C erhöhen.

4-20 mA (Default) oder 0-20 mA (Konfigurierung mit Software);

3 konfigurierbare Ausgänge: Max. Last: 500 Ohm; Empfindlichkeit: 20μA

Genauigkeit: ± 0,5% (innerhalb der Temperaturgrenzwerte für den Betrieb)

0- 5 V Ausgang (Hardwareoption);

3 konfigurierbare Ausgänge; Min. Last: 10 KOhm; Empfindlichkeit: 5 mV

Genauigkeit: ± 0,5% (innerhalb der Temperaturgrenzwerte für den Betrieb)

Drei Alarmrelais pro Messkarte; 1A-30 Vac oder 0,5A-50 Vdc an Widerstand.

Konfigurierbar als Einschaltglied [NO] oder Ausschaltglied [NC] durch

Änderung der Position der Jumper..

W A R N U N G

Potenzielle Stromschlaggefahr. Angeschlossen an sichere niedrige

Spannung <33 VAC RMS

Ein Relais Systemalarm; 1A-30 Vac oder 0,5A-50 Vdc an Widerstand.

Ausschaltglied [NC] (NO-Relais ebenfalls lieferbar) wenn das Instrument

Systemalarmrelais auf dem

Mainboard

Optionen RS-485 oder PROFIBUS-DP; USB-Client; USB-Host; Ethernet 10/100 Base-T

Instrumente für Wandmontage

und Rohrmontage

(H x T x B)

eingeschaltet wird.

W A R N U N G

Potenzielle Stromschlaggefahr. Angeschlossen an sichere niedrige

Spannung <33 VAC RMS

236,5 x 160 x 250 mm - Gewicht 3,8 kg

9,31 x 6,30 x 9,84 ins. - Gewicht 8,38 lbs

24 Deutsch

Page 25

Spezifikation Details

Instrument für Paneelmontage

(Gehäuse) (H x T x B)

tragbar

(H x T x B)

156 (123) x 250 x 220 (214) mm - Gewicht 2,9 kg

6,14 (4,84) x 9,84 x 8,86 (8,43) ins. - Gewicht 6,39 lbs

225 x 250 x 219 mm - Gewicht 3,8 kg

8.86 x 9.84 x 8.62 ins. - Gewicht 8,38 lbs

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedineungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

G E F A H R

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

W A R N U N G

V O R S I C H T

H I N W E I S

Deutsch 25

Page 26

Aufkleber mit Vorsichtshinweisen

Bitte lesen Sie alle auf dem Produkt angebrachten Etiketten und Hinweise. Die Nichtbeachtung kann

zu Verletzungen an Personen oder einer Beschädigung des Produkts führen.

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen darf.

Dieses Symbol auf dem Produkt weist darauf hin, dass Bauteil heiß sein kann und mit unvorsichtig

berührt werden darf.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Dieses Symbol auf dem Produkt weist auf die Position des Schutzleiters (Erde) hin.

Elektrische Geräte, die dieses Symbol aufweisen, dürfen in Europa nicht als Haushaltsabfall

entsorgt werden. Den lokalen und nationalen europäischen Bestimmungen gemäß müssen

Benutzer von Elektrogeräten diese nun zur für den Benutzer kostenlosen Entsorgung an den

Hersteller zurückgeben.

Hinweis: Für die Rückgabe von Altgeräten, Zubehör und Zusatzausstattungen für eine Entsorgung/Recycling

wenden Sie sich bitte an den Gerätehersteller oder Lieferanten, der Ihnen genaue Anweisungen dazu geben wird.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Installation

Der vorliegende Abschnitt enthält Informationen für die Installation und das Anschließen des Geräts.

Die Installation des Geräts sollte in Übereinstimmung mit den vor Ort geltenden gesetzlichen

Vorschriften erfolgen.

G E F A H R

Stromschlaggefahr. Schließen Sie den Wechselstromanschluss nicht an ein mit 5 VDC gespeistes Modell an.

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn elektrische

Anschlüsse durchgeführt werden.

Potenzielle Stromschlaggefahr. Wenn dieses Gerät im Freien oder an potenziell feuchten Standorten eingesetzt

wird, muss ein FI-Schutzschalter zum Anschluss an die Netzversorgung verwendet werden.

Potenzielle Stromschlaggefahr. Bei 100-240 VAC- und 5 VDC-Anwendungen muss ein Erdungsschutzleiter (PE)

angeschlossen werden. Ohne ausreichenden Erdungsschutz besteht Stromschlaggefahr, und das Gerät kann

wegen elektromagnetischer Störungen nicht richtig funktionieren. Schließen Sie IMMER einen

Erdungsschutzleiter an der Steuerungsklemme an.

26 Deutsch

W A R N U N G

W A R N U N G

W A R N U N G

Page 27

V O R S I C H T

Verletzungsgefahr. Nur qualifiziertes Personal sollte die in diesem Kapitel des Handbuchs beschriebenen

Aufgaben durchführen.

Installieren Sie das Gerät an einem Standort und in einer Position, wo es zur Bedienung und zum

Abschalten/Abklemmen gut zugänglich ist.

Möglicher Geräteschaden Empfindliche interne elektronische Bauteile können durch statische Elektrizität

beschädigt werden, wobei dann das Gerät mit verminderter Leistung funktioniert oder schließlich ganz ausfällt.

H I N W E I S

H I N W E I S

Tragbaremontage

Installieren Sie das Instrument auf einem Labortisch, es in einem sicheren Bereich auf eine flache

Oberfläche. Positionieren Sie das Instrument in der Nähe einer Steckdose, der Zufuhrleitung und des

PCs. Halten Sie das tragbare Instrument beim Tragen sicher und stellen Sie es vorsichtig auf den

Arbeitstisch. Stellen Sie das Instrument nicht auf den Boden. Das tragbare Instrument weist zwei

klappbare beine auf, die im unteren Rahmen versteckt sind. Ziehen Sie sie heraus, um den Winkel

der Anzeige.

Wandmontage

1. Bringen Sie den (mitgelieferten) U-Bügel mit zwei Schrauben (nicht

mitgeliefert) an der Wand an.

2. Kippen Sie das Instrument leicht zurück, um die Stifte des Bügels

mit den Aufnahmeschlitzen auszurichten, und schieben Sie das

Instrument wie gezeigt auf den Bügel.

3. Setzen Sie die beiden Sperrschrauben mit den Scheiben durch die

seitlichen Schlitze ein.

4. Stellen Sie den Winkel des Instruments so ein, dass die

bestmögliche Ablesung des Bildschirms erzielt wird, und ziehen Sie

dann die beiden seitlichen Schrauben fest.

Rohrmontage

1. Montieren Sie den Rohrmontagebügel am U-Bügel mit den beiden mitgelieferten

Schrauben.

2. Befestigen Sie diese Bauteile dann mit den beiden Klemmschellen an dem Rohr

(gehören nicht zum Lieferumfang).

3. Schieben Sie das Instrument auf den Bügel.

4. Setzen Sie die beiden Sperrschrauben mit den Scheiben durch die seitlichen Schlitze

ein.

5. Stellen Sie den Winkel des Instruments so ein, dass die bestmögliche Ablesung des

Bildschirms erzielt wird, und ziehen Sie dann die beiden seitlichen Schrauben fest.

Deutsch 27

Page 28

Paneelmontage

1-3 4-5 6-7

1. Schneiden Sie eine Öffnung in den mitgelieferten.

2. Installieren Sie den mitgelieferten Rahmen in der Öffnung.

3. Falten Sie die 6 Zapfen mit einer Zange über die Lippen des Paneels.

4. Schieben Sie das Instrument in den Bügelrahmen. Das Instrument sollte über die 4 "T"-Stifte gehen. Drehen

Sie die 4 Befestigungsschrauben auf beiden Seiten des Frontpaneels und schieben Sie es hinein.

5. Drehen Sie die 4 Befestigungsschrauben zweimal um 1/4 Umdrehung in Sperrrichtung, wie auf der Seite des

Frontpaneels gezeigt. Dadurch rastet das Instrument über den vier "T"-Stiften ein.

6. Entfernen Sie für den Zugang zu den Anschlüssen im Inneren des Instruments das Gehäuse des Instruments

(6 Schrauben auf der Rückseite, und schieben Sie das Gehäuse zurück).

7. Führen Sie die Kabel durch das Gehäuse, dann durch den Kabeldurchlass (falls anwendbar) und nehmen Sie

die Anschlüsse vor, die im Folgenden detailliert beschrieben werden.

Anschlüsse des Instruments

Abbildung 1 Anschlüsse - Wand / Rohr (links); Paneel (Mitte); Tragbaren (rechts)

1 Stromkabel 8 Anschluss Außendrucksensor

2 USB-B-Client 4-Pin-Anschluss 9 Kabeldurchlass Eingang/Ausgang 3

3 Ethernetkabeldurchlass 10 Kabeldurchlass Eingang/Ausgang 2

4 Sensor Kanal 3-Verbindung 11 Kabeldurchlass Eingang/Ausgang 1

5 Sensor Kanal 2-Verbindung 12 Schloss (nur Wand- bzw. Rohrmontage)

6 Sensor Kanal 1-Verbindung 13 Schalter On/Off Power

7 Steckverbindung USB-A Host 14 Ethernet - Harting RJ Industrial-Anschluss

28 Deutsch

Page 29

Anweisungen zur Montage der Steckverbindungen

W A R N U N G

Potenzielle Stromschlaggefahr. Um die NEMA/IP-Umweltbedingungen des Gehäuses zu wahren, benutzen Sie

zur Verlegung von Kabeln im Geräteinnern nur Rohranschlussstücke und Kabeldurchführungen, die mindestens

NEMA 4X/IP65 erfüllen.

Anweisungen zur Verkabelung des Kabeldurchlasses

Jedes Mal, wenn ein Kabel im Inneren des Instruments angeschlossen werden muss, wird ein

wasserdichter Kabeldurchlass mitgeliefert. Die vernickelten Messing-Kabeldurchlässe entsprechen

dem EMC-Typ und sind so konzipiert, dass die Abschirmung des Kabels direkt an das Gehäuse des

Instruments als Masse angeschlossen wird. Im Folgenden werden die Anweisungen für den

typischen Anschluss des Kabels angegeben.

1. Schrauben Sie die Mutter des Kabelanschluß ab. Im Inneren besteht die Baugruppe aus einer

Gummiwährung und zwei Metallschlitten. bedenke Sie, dass der Ethernet an den Instrumenten

für die Paneel- und die Wandkarte keine Scheiben aufweisen und, dass die Dichtung

eingeschnitten ist.

2. Beim Verkabeln eines Sensorkabels ist das Kabel bereits vorbereitet; entfernen Sie daher einfach

den Kunststoffschutz von der ausgesetzten Abschirmung. Ziehen Sie bei den anderen Kabeln die

äußere Isolierung wie erforderlich und 25 mm der Abschirmung ab. Entfernen Sie ca. 8 mm der

Isolierung an den Enden der Leiter.

3. Führen Sie das Kabel durch die Mutter, die Gummidichtung und die beiden Scheiben.

4. Pressen Sie die Abschirmung zusammen, so dass der Gesamtumfang zwischen die beiden

Scheiben geklemmt wird, führen Sie das Kabel in das Gehäuse und blockieren Sie den

Kabeldurchlass.

1 Kabel 3 Instrument 5 O-ring 7 Dichtung

2 Abschirmung 4 Drahte 6 Unterlegscheiben 8 Kabelführung Mutter

H I N W E I S

Es ist ausgesprochen wichtig, dass die Abschirmung zusammengepresst und zwischen den beiden Scheiben

gesichert wird, um sicherzustellen, dass die Abschirmung direkt an das Gehäuse des Instruments als Masse

angeschlossen ist. Anderenfalls kan das Instrument beschädigt werden und die Sensorkabel können falsche

Werte anzeigen.

5. Bringen Sie die Mutter des Kabeldurchlasses wieder an und ziehen Sie sie an.

6. Schließen Sie die Kabel an die entsprechenden Anschlüsse des Anschlussblocks an.

Steckverbindung Ethernet (tragbares Instrument)

Die Steckverbindung Harting RJ Industrial® IP 67 Push Pull kann mit einer Hand leicht gesperrt und

entsperrt werden. Für das schnelle und sichere Anschließen eines Kabels Industrial Ethernet an die

Steckverbindung Harting RJ Industrial® sind nur wenige Schritte erforderlich. Es sollten

ausschließlich Harting-Kabel verwendet werden.

Anschluss an die Stromversorgung

Stromversorgungseinheit (tragbares Instrument)

Tragbare Instrumente werden standardmäßig mit einem externen Netzteil geliefert. Das Netzteil mit

dem FIXCON®-Steckverbinder (Lieferumfang) an das Tischgerät anschließen.

Deutsch

29

Page 30

Anschluss der Stromversorgung (Niederspannungsinstrumente)

Bei den Niederspannungsinstrumenten (10-30 Vdc) der Stromversorgung erfolgt der Anschluss über

einen BINDER-Stecker mit 7 Kontaktstiften (mitgeliefert).

Hinweis: Die Steckverbindungen weisen Kehlen auf, um ein falsches Einstecken in das Instrument zu verhindern.

Schließen Sie das Stromkabel wie folgt an die Steckverbindung an:

Abbildung 2 Steckverbindung BINDER

Kontaktstifte:

1. Nicht verwendet

2. Strom 10-30 Vdc

3. Nicht verwendet

4. Nicht verwendet

5. Masse

6. Nicht verwendet

7. Erde

Anschluss der Stromzufuhr (Hochspannungsinstrumente)

Hochspannungsinstrumente (100-240 VAC) werden für den Stromanschluss über einen BINDERStecker vorverkabelt. Wie im Folgenden gezeigt wird eine Steckkupplung an den Stecker

angeschlossen mitgeliefert.

Falls das Instrument mit einem an die Steckkupplung angeschlossenen Stecker für die

Stromversorgung geliefert wird (Kabel Bauteilnummer 33031, 33032, 33033 und 33034), kann das

Instrument direkt an die Stromversorgung angeschlossen werden. Die beiden Steckverbindungen

weisen Kehlen auf, um ein falsches Anschließen zu vermeiden. Befestigen Sie die Buchse handfest

an dem Leistungssteckverbinder des Instruments.

Wenn gemeinsam mit dem Instrument kein Leistungskabel bestellt wurde, muss ein Leistungsstecker

wie im Folgenden beschrieben an die beiliegende Buchse angeschlossen werden.

V O R S I C H T

Verletzungsgefahr. Nur qualifiziertes Personal sollte die in diesem Kapitel des Handbuchs beschriebenen

Aufgaben durchführen.

Spezifikation für vom Benutzer gelieferte Stromkabel:

• 3-adrig (Phase, Nullleiter und Erde)

• Kabel Ø ≥ 7mm; ≤ 9.5mm

• Kabelauswahl ≥ 1mm2, AWG18; ≤ 2.5mm2, AWG14

W A R N U N G

Potenzielle Stromschlaggefahr. Stellen Sie stets die Spannungsversorgung am Gerät ab, wenn elektrische

Anschlüsse durchgeführt werden.

Bereiten Sie das Stromkabel (nicht mitgeliefert) wie folgt vor:

1. Ziehen Sie 23 mm der Abschirmung des Stromkabels ab.

2. Schneiden Sie den Phasenleiter und den Nullleiter 15 mm ab und lassen Sie den Erdungsleiter

so, wie er ist.

3. Entfernen Sie die Isolierung der drei Leiter so weit wie erforderlich.

Verkabeln Sie die Steckkupplung wie folgt:

30

Deutsch

Page 31

1. Nehmen Sie das schmale Ende der Steckverbindung (4) in eine Hand und den Hauptkörper (2) in

die anderen und schrauben Sie sie auseinander. Ziehen Sie die Kabelklemme (3) ab und

schrauben Sie das Steckerende (1) ab, um zu den vier teilen gelangen, aus denen die

Steckverbindung besteht.

2. Lösen Sie die Schrauben der Kabelklemme (3), so dass das Stromkabel hindurchgeführt werden

kann.

3. Führen Sie das Stromkabel durch das Steckerende (1), den Hauptkörper (2) und die

Kabelklemme (3) und schließen Sie dann die drei Leiter (Phase, Nullleiter und Erdung) wie folgt

an die Steckverbindung (4) an:

1. Phase (braun)

2. Nullleiter (blau)

3. Nicht verwendet

Erde - Erde (grün und gelb)

Hinweis: Die Ziffern und das Erdungssymbol sind am Ende der Steckverbindung aufgedruckt. Stellen Sie

sicher, dass der Anschluss richtig vorgenommen worden ist.

4. Schieben Sie die Kabel (3) zurück auf die Steckverbindung (4) und sichern Sie das Kabel.

5. Schrauben Sie die beiden Teile (4) und (2) wieder zusammen.

6. Sichern Sie das Stromkabel durch Anschrauben des Steckerendes (1).

7. Die Buchse kann jetzt direkt an den Leistungsstecker des Instruments angeschlossen werden.

Die beiden Steckverbindungen weisen Kehlen auf, um ein falsches Anschließen zu vermeiden.

Befestigen Sie die Buchse handfest an dem Leistungsstecker des Instruments.

Anschlüsse an Elektronikkarten

H I N W E I S

Möglicher Geräteschaden Empfindliche interne elektronische Bauteile können durch statische Elektrizität

beschädigt werden, wobei dann das Gerät mit verminderter Leistung funktioniert oder schließlich ganz ausfällt.

Hinweis: Alle losen Verbindungskabel sollten mit Kabelbindern aus Kunststoff zusammengefasst werden.

Kabel des Sensors

Für den Anschluss des Sensors an das Instrument ist ein ORBISPHERE-Kabel erforderlich. Die

tragbarenversionen weisen eine Steckverbindung Lemo 10 auf, an die ein Sensorkabel

angeschlossen werden muss. Die anderen Versionen weisen eine Kabelführung auf und das Kabel

muss permanent an die Steckverbindung der entsprechenden Messkarte angeschlossen werden.

Daher machen die tragbarenversionen ein Standardsensorkabel erforderlich, während die anderen

Versionen ein Sensorkabel mit freien Drähten am Instrumentenende erforderlich machen. Die freien

Drähte werden wie im weiteren Verlauf dieses Kapitels beschrieben an die Steckverbindung J8 auf

der Messkarte angeschlossen.

Anschlüsse der Elektronikkarten

Die Steckverbindungen P8 auf dem Mainboard (Abbildung 3 auf Seite 32) und J7 und J8 auf der

Messkarte (Abbildung 5 auf Seite 33 und Abbildung 6 auf Seite 33) bestehen aus zwei Teilen.

Drücken Sie vorsichtig die schwarzen Hebel auf den beiden Seiten der Steckverbindung und ziehen

Sie sie sicher heraus. Nehmen Sie alle Anschlüsse vor, während diese Steckverbindungen

ausgesteckt sind. Bringen Sie anschließend die Steckverbindungen wieder an den Karten an und

stecken Sie sie sicher ein (Hebel nach oben).

Deutsch

31

Page 32

Mainboard

Abbildung 3 Mainboard

Abbildung 4 Steckverbindung P8

Steckverbindung P8

Die unten aufgeführten Zahlen beziehen sich auf die 13 verfügbaren Steckverbindungen P8 (von rechts nach

links) in Abbildung 4.

1. RS-485 (Signal A)

2. RS-485 (Signal B)

3. PROFIBUS-DP (GND)

4. PROFIBUS-DP (+ 5 V)

5. PROFIBUS-DP (Signal -)

6. PROFIBUS-DP (signal +)

7. PROFIBUS-DP (signal RTS)

8. Nicht verwendet

9. Nicht verwendet

10. Nicht verwendet

11. Systemalarmrelais (N.O.)

12. Systemalarmrelais (N.C.)

13. Systemalarmrelais (gemein)

Steckverbindung P3

Ethernet RJ 45. Schließen Sie das Instrument für die Wand- oder Paneelmontage an das lokale

Netzwerk an. Führen Sie dazu ein Ethernetkabel durch die Ethernet-Kabelführung (die Position der

Kabelführung ist in Abbildung 1 auf Seite 28 dargestellt) und schließen Sie die Steckverbindung an

die Steckverbindung P3 (siehe Abbildung 3) an.

Hinweis: Bei den tragbaren Instrumenten befindet sich der Ethernet-Anschluss auf der Rückwand (siehe

Anschlüsse des Instruments auf Seite 28). Für den Anschluss des Kabels für ein Client-Netzwerk ist ein

wasserdichter Harting RJ-Sockel vorhanden. Als Option sind außerdem ein Adapter und ein Kabel verfügbar.

Messkarte

Die verschiedenen Messkarten für die EC- und TC-Sensoren werden auf Abbildung 5 und

Abbildung 6 unten illustriert. Der Typ der Karte kann leicht an der Farbe der J8-Steckverbindung

identifiziert werden. Bei EC-Karten ist die Steckverbindung orange und bei TC-Karten ist sie