Page 1

DOC024.52.93001

ORBISPHERE Model 410 Analyzer

User Manual

05/2013, Edition 10

Page 2

Page 3

Table of Contents

Section 1 General Information.........................................................................................................5

1.1 Disclaimer ....................................................................................................................................5

1.2 Contact information...................................................................................................................... 5

1.3 Safety information ........................................................................................................................ 5

1.3.1 Use of hazard information...................................................................................................5

1.3.2 Safety precautions .............................................................................................................. 6

1.3.3 Service and repairs .............................................................................................................6

1.3.4 Precautionary labels............................................................................................................ 7

1.3.5 Intended use of this equipment...........................................................................................7

1.4 Product recycling information.......................................................................................................8

1.5 Product disposal ........................................................................................................................ 10

1.6 Restriction of hazardous substances (RoHS)............................................................................ 11

Section 2 Specifications.................................................................................................................. 13

2.1 Technical specifications .............................................................................................................13

2.2 Hardware description ................................................................................................................. 14

2.3 Model identification system........................................................................................................ 14

2.4 Security level table..................................................................................................................... 15

2.5 Default parameters ....................................................................................................................16

Section 3 Installation........................................................................................................................17

3.1 Unpacking .................................................................................................................................. 17

3.2 Installation check list .................................................................................................................. 18

3.3 Wall mount and pipe mount instruments.................................................................................... 19

3.3.1 Instrument dimensions......................................................................................................19

3.3.2 Wall mounting ...................................................................................................................20

3.3.3 Pipe mounting ................................................................................................................... 20

3.3.4 Connection panel (bottom of instrument).......................................................................... 21

3.4 Panel mount instrument ............................................................................................................. 22

3.4.1 Instrument dimensions......................................................................................................22

3.4.2 Mounting ...........................................................................................................................23

3.4.3 Connection panel (bottom of instrument).......................................................................... 24

3.5 Connectors assembly instructions ............................................................................................. 25

3.5.1 Cable gland wiring instructions .........................................................................................25

3.5.2 USB-B client adapter cable...............................................................................................26

3.6 Connection to mains power supply ............................................................................................ 26

3.6.1 Power supply connection (low voltage instruments) ......................................................... 26

3.6.2 Power supply connection (high voltage instruments)........................................................ 27

3.7 Connections to electronic boards...............................................................................................28

3.7.1 Sensor cable ..................................................................................................................... 28

3.7.2 Electronic boards connectors............................................................................................ 29

3.7.3 Main board connections....................................................................................................29

3.7.4 Measurement board..........................................................................................................30

3.8 Measurement alarm relays ........................................................................................................ 31

3.9 Sensor installation......................................................................................................................32

3.9.1 EC Sensors.......................................................................................................................32

3.9.2 TC Sensors .......................................................................................................................32

3.10 Define working language ......................................................................................................... 32

3.11 Define security levels ............................................................................................................... 32

Section 4 User Interface..................................................................................................................33

4.1 Instrument .................................................................................................................................. 33

4.2 Touch screen .............................................................................................................................33

4.2.1 Function keys on the header bar.......................................................................................34

4.2.2 Menu navigation................................................................................................................ 35

4.2.3 Rolling list..........................................................................................................................35

4.2.4 Virtual keyboard ................................................................................................................35

1

Page 4

Table of Contents

4.2.5 Identification and authorization level .................................................................................36

4.2.6 Warning windows ..............................................................................................................36

4.3 Main menu structure...................................................................................................................37

Section 5 View Menu ........................................................................................................................39

5.1 Selection of the view style..........................................................................................................40

5.2 Configuration of the view styles..................................................................................................41

Section 6 Measurement Menu........................................................................................................43

6.1 Instrument configuration.............................................................................................................44

6.2 Measurement configuration........................................................................................................44

6.3 Measured data storage ..............................................................................................................47

Section 7 Calibration Menu.............................................................................................................49

7.1 Definitions...................................................................................................................................51

7.2 EC gas sensor calibration ..........................................................................................................51

7.2.1 O

7.2.2 O

7.3 TC gas sensor calibration...........................................................................................................53

7.4 Calibration errors (EC and TC sensors).....................................................................................54

7.5 Barometric pressure calibration..................................................................................................54

7.6 Calibration reports......................................................................................................................54

sensor calibration.........................................................................................................52

2

sensor calibration.........................................................................................................52

3

Section 8 Inputs/Outputs Menu.....................................................................................................55

8.1 Configure snooze .......................................................................................................................56

8.2 View inputs/outputs ....................................................................................................................56

8.3 Relays ........................................................................................................................................56

8.4 Analog outputs ...........................................................................................................................57

8.5 Analog output characteristics .....................................................................................................61

Section 9 Communication Menu....................................................................................................65

9.1 RS-485 simple mode configuration ............................................................................................66

9.1.1 Data available....................................................................................................................67

9.1.2 Example of use..................................................................................................................69

9.2 PROFIBUS-DP communication (optional)..................................................................................70

9.2.1 Installation .........................................................................................................................70

9.2.2 Input/Output data...............................................................................................................71

9.3 USB-A port (host).......................................................................................................................74

9.4 HTTP/TCP-IP .............................................................................................................................75

9.4.1 Overview ...........................................................................................................................75

9.4.2 PC interface.......................................................................................................................75

9.5 Data file transfer through the USB-B port (client).......................................................................77

9.5.1 PC software installation.....................................................................................................77

9.5.2 Microsoft synchronization software ...................................................................................77

9.5.3 Upload report files .............................................................................................................77

Section 10 Security Menu................................................................................................................79

10.1 Access rights management......................................................................................................79

10.2 Configure security ....................................................................................................................80

10.3 User management....................................................................................................................80

10.4 User action log file....................................................................................................................80

Section 11 Products Menu ..............................................................................................................81

Section 12 Global Configuration Menu........................................................................................83

Section 13 Services Menu...............................................................................................................85

13.1 Sensor diagnostics...................................................................................................................87

13.2 Language selection ..................................................................................................................88

13.3 Clock ........................................................................................................................................88

2

Page 5

Table of Contents

13.4 Screen......................................................................................................................................88

13.5 Buzzer...................................................................................................................................... 88

13.6 Boards info............................................................................................................................... 88

13.7 Batteries................................................................................................................................... 89

13.8 Software download ..................................................................................................................89

13.9 End application ........................................................................................................................89

Section 14 Maintenance and Troubleshooting.......................................................................... 91

14.1 Instrument maintenance .......................................................................................................... 91

14.2 Troubleshooting .......................................................................................................................91

14.3 List of events and alarms ......................................................................................................... 92

14.4 Storage, handling and transportation....................................................................................... 92

Section 15 Part Lists........................................................................................................................ 93

15.1 Accessories..............................................................................................................................93

15.2 Spare parts ..............................................................................................................................93

Section 16 Glossary .........................................................................................................................95

16.1 Gas units.................................................................................................................................. 95

16.2 Generic terms and definitions .................................................................................................. 95

3

Page 6

Table of Contents

4

Page 7

Section 1 General Information

1.1 Disclaimer

The information in this manual has been carefully checked and is believed to be accurate.

However, Hach Lange assumes no responsibility for any inaccuracies that may be contained in

this manual. In no event will Hach Lange be liable for direct, indirect, special, incidental, or

consequential damages resulting from any defect or omission in this manual, even if advised of

the possibility of such damages. In the interest of continued product development, Hach Lange

reserves the right to make improvements in this manual and the products it describes at any

time, without notice or obligation.

Copyright © 2006-2013 by Hach Lange. All rights reserved. No part of the contents of this

manual may be reproduced or transmitted in any form or by any means without the written

permission of Hach Lange.

1.2 Contact information

Manufacturing site:

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

1.3 Safety information

Please read the entire manual before unpacking, setting up, or operating this analyzer.

Pay particular attention to all warning and caution statements. Failure to do so could result in

serious injury to the operator or damage to the equipment.

To ensure the protection provided by this equipment is not impaired, do not use or install this

equipment in any manner other than that which is specified in this manual.

1.3.1 Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in

death or serious injury.

European HQ:

HACH LANGE GmbH

Willstätterstraße 11

40549 Düsseldorf

GERMANY

Tel. +49 211 52 880

Fax +49 211 52 88143

DANGER

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially or imminently hazardous situation that may result in minor or moderate

injury.

NOTICE

Indicates a situation which, if not avoided, may cause damage to the instrument. Information

that requires special emphasis.

5

Page 8

General Information

1.3.2 Safety precautions

Always remove power from the controller before performing maintenance activities.

Potential Electrocution Hazard. Always disconnect power to the instrument when

making electrical connections.

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially

wet locations a Ground Fault Interrupt device must be used for connecting the

equipment to its main power source.

DANGER

WARNING

WARNING

WARNING

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC RMS.

CAUTION

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this

manual.

NOTICE

Install the device in a location and position that gives easy access to the disconnect device

and its operation.

NOTICE

Potential Instrument Damage. Delicate internal electronic components can be

damaged by static electricity, resulting in degraded performance or eventual failure.

• The power cord plug connection is also used as a main power switch.

• The instrument must be connected to an electrical system which complies with

applicable local regulations.

• All the cables connected to the instrument must be fire resistant, type UL94V-1

• The operator must read and understand this manual before using the instrument .

• The instrument will not be used as a safety device. It does not provide a security

function in a hazardous process.

1.3.3 Service and repairs

None of the analyzer’s components can be serviced by the user. Only personnel from Hach

Lange or its approved representative(s) is (are) authorized to attempt repairs to the system and

only components formally approved by the manufacturer should be used. Any attempt at

repairing the analyzer in contravention of these principles could cause damage to the analyzer

and corporal injury to the person carrying out the repair. It renders the warranty null and void

and could compromise the correct working of the analyzer and the electrical integrity or the CE

compliance of the analyzer.

6

Page 9

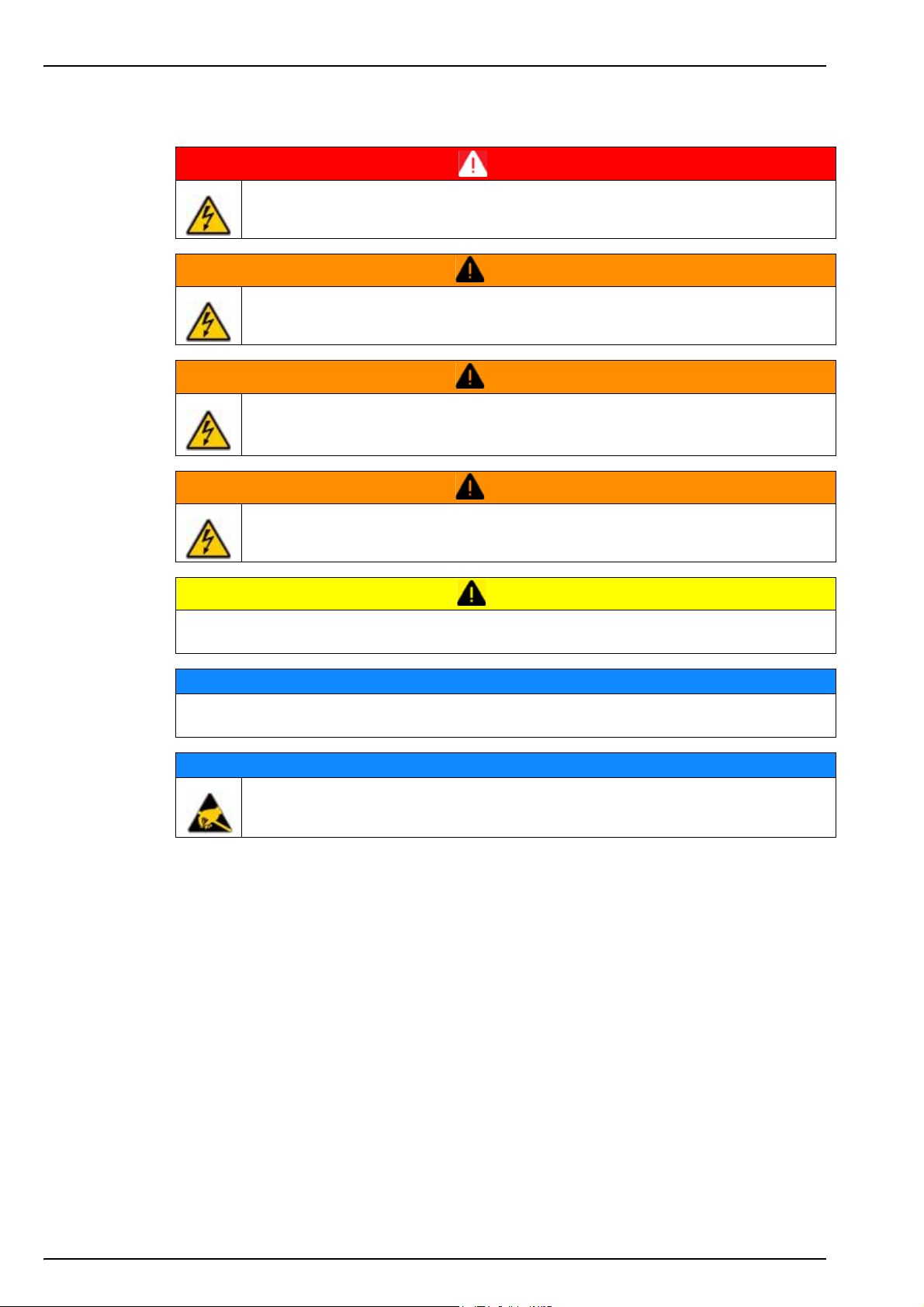

1.3.4 Precautionary labels

Read all labels and tags attached to the analyzer. Personal injury or damage to the analyzer

could occur if not observed.

This symbol, when noted on a product, indicates a potential hazard which could cause serious personal injury

and/or death. The user should reference this instruction manual for operation and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists and indicates that only individuals qualified to work with hazardous voltages should open the

enclosure or remove the barrier.

This symbol, when noted on the product, indicates that the marked item can be hot and should not be touched

without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic discharge and

indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that only individuals

qualified and trained to work with chemicals should handle chemicals or perform maintenance on chemical delivery

systems associated with the equipment.

General Information

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for protective earth (ground).

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems. In

conformity with European local and national regulations, European electrical equipment users must now return old

or end-of-life equipment to the manufacturer for disposal at no charge to the user.

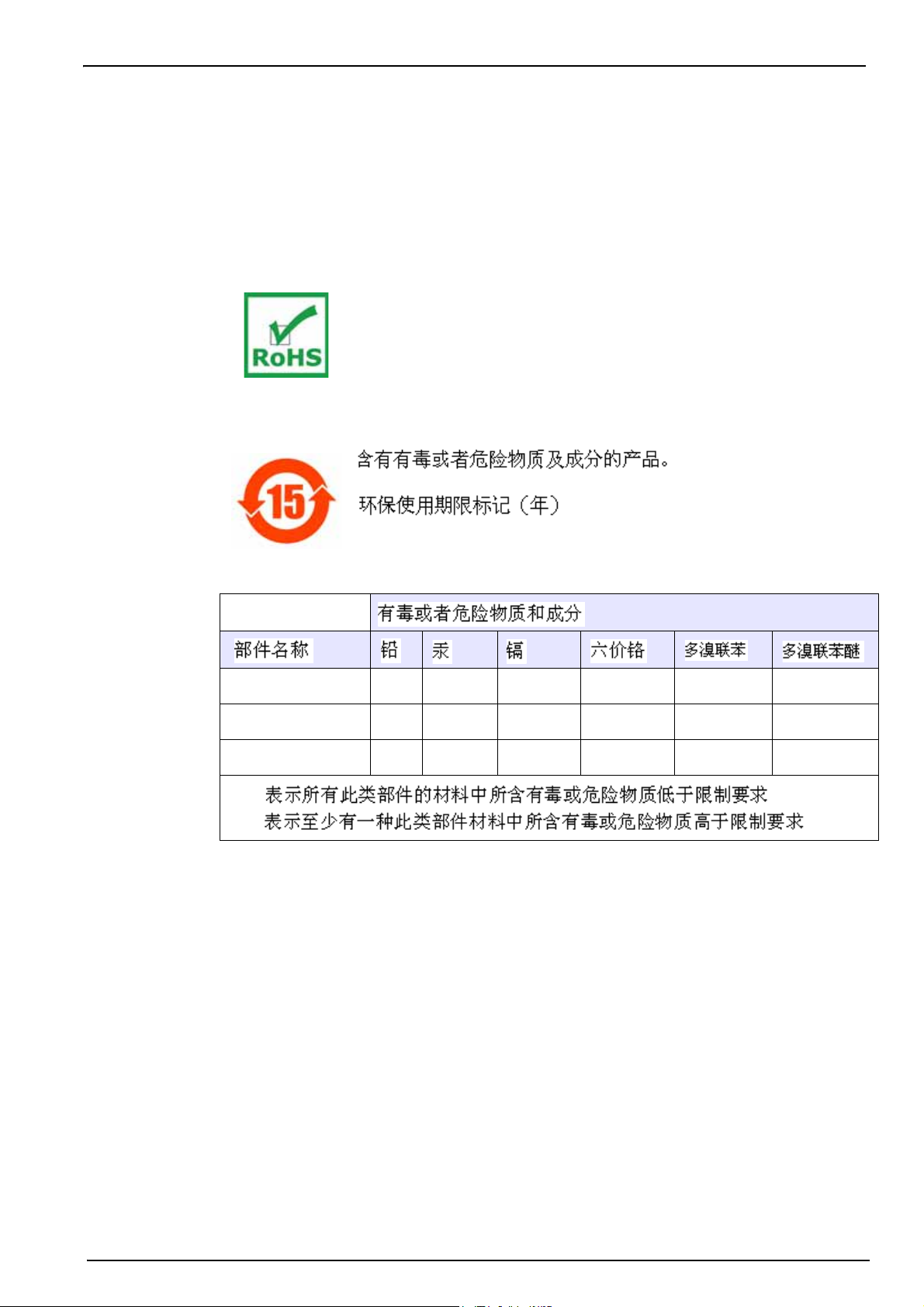

Products marked with this symbol indicates that the product contains toxic or hazardous substances or elements.

The number inside the symbol indicates the environmental protection use period in years.

1.3.5 Intended use of this equipment

This high accuracy ORBISPHERE instrument is designed for the measurement of oxygen,

ozone or carbon dioxide, for process and laboratory analysis in applications such as beverage,

life sciences, power generation and the electronics industry.

ORBISPHERE 410 analyzers are available as wall or pipe mount, and rack mount versions. The

ORBISPHERE 410 uses a patented gas phase (or dissolved gas) ORBISPHERE sensor.

Note: A "Normal sensor" or "Smart Sensor" can be connected to the measurement board. A "Smart sensor"

is a sensor with a non-volatile memory which allows storage of parameters (calibration coefficient, dates,

etc.). When a smart sensor is connected, these parameters are read by the instrument software. The

sensor can be calibrated in the lab and installed on site afterwards.

NOTICE

Use of the instrument outside of the environmental conditions described in Technical

specifications on page 13 may cause damage to the instrument but without endangering the

user.

7

Page 10

General Information

1.4 Product recycling information

ENGLISH

Electrical equipment marked with this symbol may not be disposed of in

European public disposal systems after 12 August 2005. In conformity with

European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of-life equipment to the

manufacturer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment

manufacturer or supplier for instructions on how to return end-of-life

equipment for proper disposal.

DEUTSCH

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in Europa nach dem 12.

August 2005 nicht mehr über die öffentliche Abfallentsorgung entsorgt werden. In

Übereinstimmung mit lokalen und nationalen europäischen Bestimmungen (EU-Richtlinie

2002/96/EC), müssen Benutzer von Elektrogeräten in Europa ab diesem Zeitpunkt alte bzw. zu

verschrottende Geräte zur Entsorgung kostenfrei an den Hersteller zurückgeben.

Hinweis: Bitte wenden Sie sich an den Hersteller bzw. an den Händler, von dem Sie das Gerät

bezogen haben, um Informationen zur Rückgabe des Altgeräts zur ordnungsgemäßen

Entsorgung zu erhalten.

FRANCAIS

A partir du 12 août 2005, il est interdit de mettre au rebut le matériel électrique marqué de ce

symbole par les voies habituelles de déchetterie publique. Conformément à la réglementation

européenne (directive UE 2002/96/EC), les utilisateurs de matériel électrique en Europe doivent

désormais retourner le matériel usé ou périmé au fabricant pour élimination, sans frais pour

l'utilisateur.

Remarque: Veuillez vous adresser au fabricant ou au fournisseur du matériel pour les

instructions de retour du matériel usé ou périmé aux fins d'élimination conforme.

ITALIANO

Le apparecchiature elettriche con apposto questo simbolo non possono essere smaltite nelle

discariche pubbliche europee successivamente al 12 agosto 2005. In conformità alle normative

europee locali e nazionali (Direttiva UE 2002/96/EC), gli utilizzatori europei di apparecchiature

elettriche devono restituire al produttore le apparecchiature vecchie o a fine vita per lo

smaltimento senza alcun costo a carico dell’utilizzatore.

Nota: Per conoscere le modalità di restituzione delle apparecchiature a fine vita da riciclare,

contattare il produttore o il fornitore dell’apparecchiatura per un corretto smaltimento.

DANSK

Elektriske apparater, der er mærket med dette symbol, må ikke bortskaffes i europæiske offentlige

affaldssystemer efter den 12. august 2005. I henhold til europæiske lokale og nationale regler

(EU-direktiv 2002/96/EF) skal europæiske brugere af elektriske apparater nu returnere gamle eller

udtjente apparater til producenten med henblik på bortskaffelse uden omkostninger for brugeren.

Bemærk: I forbindelse med returnering til genbrug skal du kontakte producenten eller

leverandøren af apparatet for at få instruktioner om, hvordan udtjente apparater bortskaffes

korrekt.

8

Page 11

General Information

SVENSKA

Elektronikutrustning som är märkt med denna symbol kanske inte kan lämnas in på europeiska

offentliga sopstationer efter 2005-08-12. Enligt europeiska lokala och nationella föreskrifter

(EU-direktiv 2002/96/EC) måste användare av elektronikutrustning i Europa nu återlämna gammal

eller utrangerad utrustning till tillverkaren för kassering utan kostnad för användaren.

Obs! Om du ska återlämna utrustning för återvinning ska du kontakta tillverkaren av utrustningen

eller återförsäljaren för att få anvisningar om hur du återlämnar kasserad utrustning för att den ska

bortskaffas på rätt sätt.

ESPANOL

A partir del 12 de agosto de 2005, los equipos eléctricos que lleven este símbolo no deberán ser

desechados en los puntos limpios europeos. De conformidad con las normativas europeas

locales y nacionales (Directiva de la UE 2002/96/EC), a partir de esa fecha, los usuarios

europeos de equipos eléctricos deberán devolver los equipos usados u obsoletos al fabricante de

los mismos para su reciclado, sin coste alguno para el usuario.

Nota: Sírvase ponerse en contacto con el fabricante o proveedor de los equipos para solicitar

instrucciones sobre cómo devolver los equipos obsoletos para su correcto reciclado.

NEDERLANDS

Elektrische apparatuur die is voorzien van dit symbool mag na 12 augustus 2005 niet meer

worden afgevoerd naar Europese openbare afvalsystemen. Conform Europese lokale en

nationale wetgegeving (EU-richtlijn 2002/96/EC) dienen gebruikers van elektrische apparaten

voortaan hun oude of afgedankte apparatuur kosteloos voor recycling of vernietiging naar de

producent terug te brengen.

Nota: Als u apparatuur voor recycling terugbrengt, moet u contact opnemen met de producent of

leverancier voor instructies voor het terugbrengen van de afgedankte apparatuur voor een juiste

verwerking.

POLSKI

Sprzęt elektryczny oznaczony takim symbolem nie może być likwidowany w europejskich

systemach utylizacji po dniu 12 sierpnia 2005. Zgodnie z europejskimi, lokalnymi i państwowymi

przepisami prawa (Dyrektywa Unii Europejskiej 2002/96/EC), użytkownicy sprzętu elektrycznego

w Europie muszą obecie przekazywać Producentowi stary sprzęt lub sprzęt po okresie

użytkowania do bezpłatnej utylizacji.

Uwaga: Aby przekazać sprzęt do recyklingu, należy zwrócić się do producenta lub dostawcy

sprzętu w celu uzyskania instrukcji dotyczących procedur przekazywania do utylizacji sprzętu po

okresie użytkownia.

PORTUGUES

Qualquer equipamento eléctrico que ostente este símbolo não poderá ser eliminado através dos

sistemas públicos europeus de tratamento de resíduos sólidos a partir de 12 de Agosto de 2005.

De acordo com as normas locais e europeias (Directiva Europeia 2002/96/EC), os utilizadores

europeus de equipamentos eléctricos deverão agora devolver os seus equipamentos velhos ou

em fim de vida ao produtor para o respectivo tratamento sem quaisquer custos para o utilizador.

Nota: No que toca à devolução para reciclagem, por favor, contacte o produtor ou fornecedor do

equipamento para instruções de devolução de equipamento em fim de vida para a sua correcta

eliminação.

9

Page 12

General Information

1.5 Product disposal

Note: The following only applies to European customers.

Hach Lange is committed to ensuring that the risk of any environmental damage or pollution

caused by any of its products is minimized as far as possible. The European Waste Electrical

and Electronic Equipment (WEEE) Directive (2002/96/EC) that came into force on August 13

2005 aims to reduce the waste arising from electrical and electronic equipment; and improve the

environmental performance of all those involved in the life cycle of electrical and electronic

equipment.

In conformity with European local and national regulations (EU Directive 2002/96/EC stated

above), electrical equipment marked with the above symbol may not be disposed of in

European public disposal systems after 12 August 2005.

Hach Lange will offer to take back (free of charge to the customer) any old, unserviceable or

redundant analyzers and systems which carry the above symbol, and which were originally

supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

In addition, Hach Lange will offer to take back (at cost to the customer) any old, unserviceable

or redundant analyzers and systems which do not carry the above symbol, but which were

originally supplied by Hach Lange. Hach Lange will then be responsible for the disposal of this

equipment.

Should you wish to arrange for the disposal of any piece of equipment originally supplied by

Hach Lange, please contact your supplier or our After Sales Service department in Geneva for

instructions on how to return this equipment for proper disposal.

10

Page 13

1.6 Restriction of hazardous substances (RoHS)

The European Union RoHS Directive and subsequent regulations introduced in member states

and other countries limits the use of six hazardous substances used in the manufacturing of

electrical and electronic equipment.

Currently, monitoring and control instruments do not fall within the scope of the RoHS Directive,

however Hach Lange has taken the decision to adopt the recommendations in the Directive as

the target for all future product design and component purchasing.

This product is compliant with the European Union RoHS Directive.

Note: The following only applies to exports of this product into the People’s Republic of China.

General Information

Locking system X

Spacer X

External connectors X

O:

X:

11

Page 14

General Information

12

Page 15

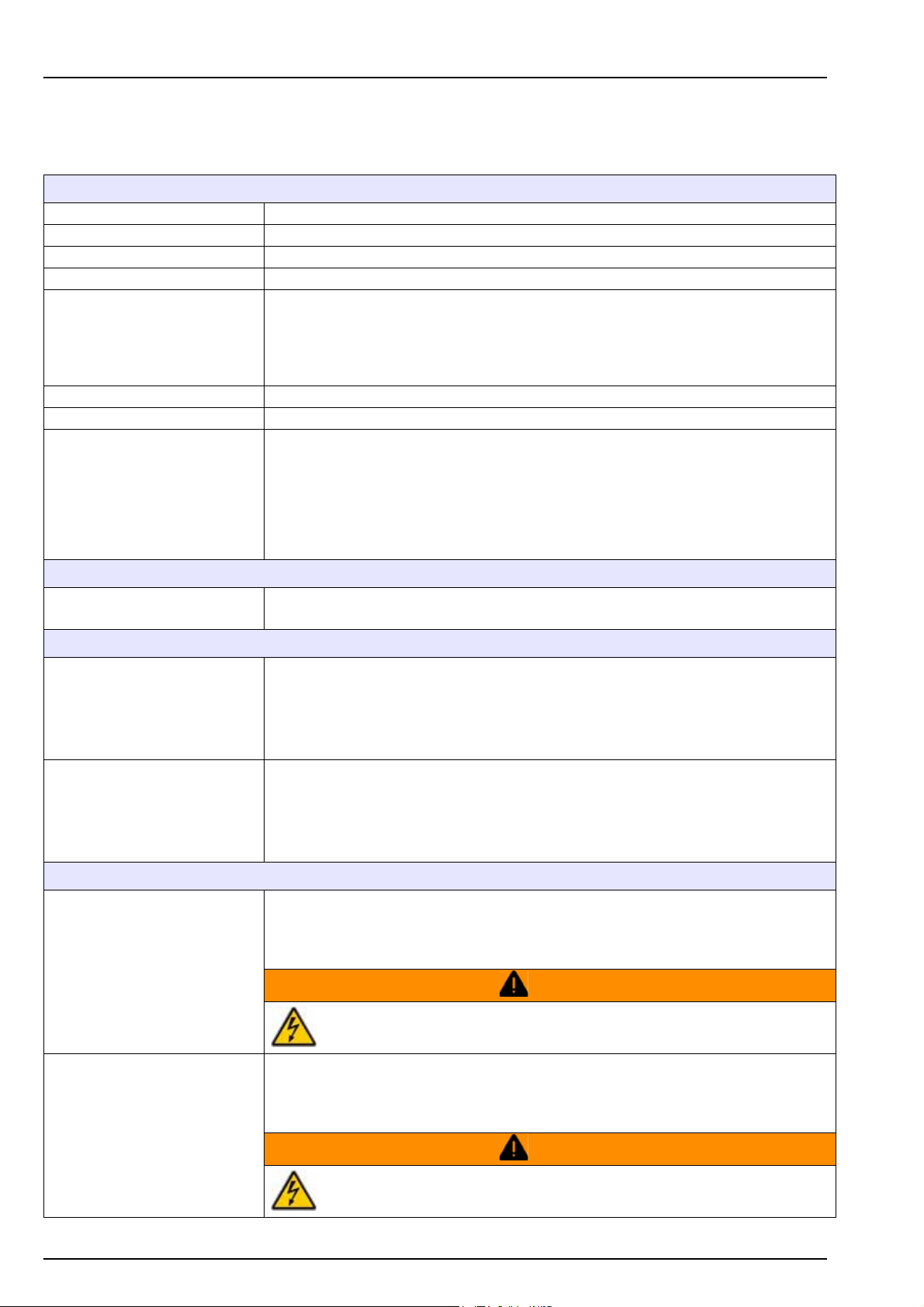

Section 2 Specifications

Specifications are subject to change without notice.

2.1 Technical specifications

OPERATING CONDITIONS

Operating temperature limits -5°C to +50°C

Storage temperature limits -20°C to +70°C

Operating humidity limits 0 to 95% non condensing relative humidity

Operating altitude From 0 to 2,000 m. (6,550 ft.) above sea level

EN61326-1:2006 Directive 2004/108/EEC

EMC requirements

CE compliance EN61010-1: 2010 Directive 2006/95/EEC

Safety rating ETL, conforming to UL 61010-1 and CSA 22.2 No. 61010-1

Enclosure ratings

Power supply

Analog current output version on

the measurement board

Analog voltage output version on

the measurement board

Measurement alarm relays on the

measurement board

Note: The wall mount instrument is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be required to take

adequate measures.

IP 65

Totally protected against dust.

Protected against low pressure jets of water from all directions.

NEMA4X (wall mount only)

Totally protected against dust.

Protected against pressure jets of water from all directions.

POWER SUPPLY

Universal 100 VAC to 240 VAC @ 50/60Hz - 40VA

10 to 30 VDC - 30W

ANALOG OUTPUTS

4-20 mA (default) or 0-20 mA (configuration with software)

3 configurable outputs

Maximum load: 500 ohm

Sensitivity: 20µA

Accuracy: ± 0.5% (between operating temperature limits)

0- 5 V output (hardware option)

3 configurable outputs

Minimum load: 10 KOhm

Sensitivity: 5 mV

Accuracy: ± 0.5% (between operating temperature limits)

DIGITAL OUTPUTS

Three alarm relays

1A-30 VAC or 0.5A-50 VDC on a resistance load

Configurable to Normally Open [NO] or Normally Closed [NC] contacts by changing the

jumper positions.

WARNING

System alarm relay on the main

board

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC RMS.

One "instrument system alarm" relay per instrument

1A-30 VAC or 0.5A-50 VDC on a resistance load

Normally closed [NC] (NO relay also available) when instrument is turned on. Opens when

a system alarm is detected, and when it does not receive any signal.

WARNING

Potential Electrocution Hazard. Connect only safety low voltage < 33 VAC RMS.

13

Page 16

Specifications

COMMUNICA TION

RS-485 or PROFIBUS-DP (optional)

Options

Thermal cut off Prevents ageing of sensors when exposed to high temperatures

Wall and pipe mount

(H x D x W)

Panel mount: Face (housing)

(H x D x W)

USB client

USB host

Ethernet 10/100 Base-T

GENERAL

SIZE AND WEIGHT

236.5 x 160 x 250 mm - weight 3.8 kg

9.31 x 6.30 x 9.84 ins. - weight 8.38 lbs

156 (123) x 250 x 220 (214) mm - weight 2.9 kg

6.14 (4.84) x 9.84 x 8.86 (8.43) ins. - weight 6.39 lbs

2.2 Hardware description

The instrument hardware is made of one main board, and one measurement board for the

measurement channel (= the sensor).

The main board includes the controls for power, display, the touch screen, the barometric

sensor, the alarms, and communication ports. The measurement board performs measurements

and executes commands from the main board. It holds the "Analog output" and "Relays" that

send information to external systems.

A hardware watchdog is activated at program start up, to check that the system is not frozen

(i.e. infinite loop, system crash, etc.). If the watchdog is not refreshed by the software every

minute, the measurement display, the relays and the analog output are frozen up to 2 minutes.

Then the reset shuts down the instrument for 10 seconds and the start-up procedure is

performed. At the same time all the hardware (sensor, measurement board) are reset.

2.3 Model identification system

The analyzer identification number and the instrument serial number are located on the label on

the back panel, and can be found on order confirmation and invoice papers.

A Oxygen EC sensor

C Ozone EC sensor

D Carbon dioxide TC sensor

W Wall

P Panel

1 100-240 VAC

410/

/ 000

2 10-30 VDC

C 0/4-20 mA

V 0-5 V

0 RS-485

1 PROFIBUS-DP / RS-485

0 Standard

K Korean language

14

Page 17

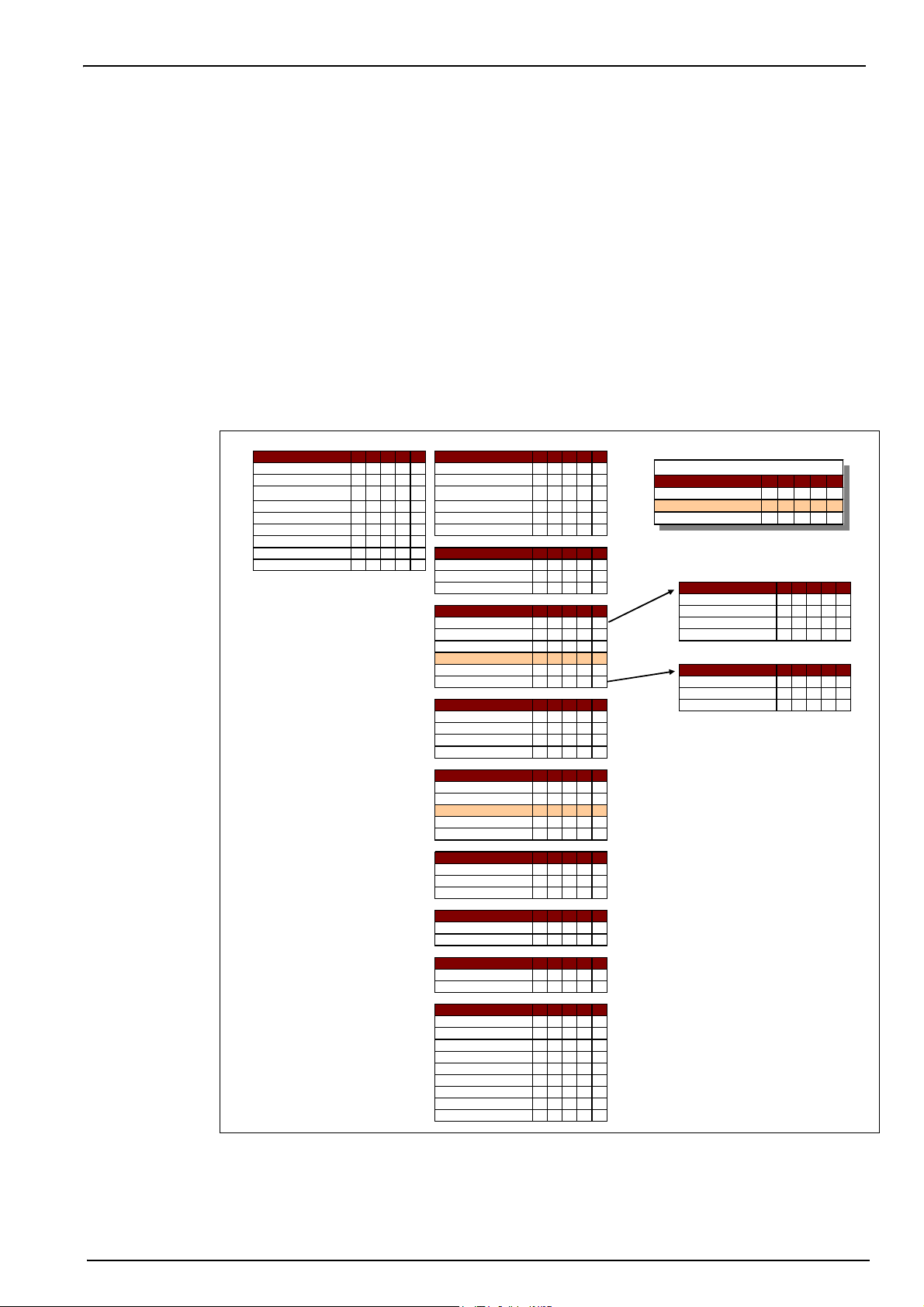

Example: 410 / A / W1C0 0000

Main 01234View 01234

iew XXXXX Numeric

Measurement XXXXX Graphic

Calibration X X X Statistical XXXXX

Inputs/outputs X X X Event

Communication X X Diagnostic

Securit

y

X X Configure

Products X X X

Global config X X Measurement 01234

Services X X Config instrument

Config channel

Measurement file

Gas senso

r

01234

Calibration

Calibration 01234

erification

Gas senso

r

Configuration

Interfernces

Reports

Baromete

r

External pressure

Amplifiers

Reports 0 1234

Reports

Senso

r

Interferences

Inputs/Outputs 01234 Baromete

r

Snooze

iew

Relays

Analog outputs

Communication 01234

RS 485

RS 485 simple

Profibus DP

USB-

A

HTTP / TCPIP

Securit

y

01234

Configuration

Access tabl

e

iew log file

Products 01234

Select product

Modify produc

Global config 01234

Save config

Select config

Services 01234

Diagnostic

Language

Clock

Screen

Buzzer

Boards info

Batteries

Soft download

More

Security level : 01234

vailable

Optional

Not available

Diagram Legend:

• Analyzer model 410

• For oxygen measurement

• Wall mounted

• 100-240 VAC

• 0/4 20 mA analog output

• RS-485

• Standard software (English, French, German, Italian, Spanish, Russian, Japanese, Chinese)

2.4 Security level table

A cross means that the user who has this user security level can access this function or setting

(see User management on page 80).

Note: When not shown, the sub-levels carry the same security level as the level above.

Specifications

V

Note: For the USB-A option in the Communication Menu, level 4 access is required to import the access

table data.

XXXXX

XXXXX

XXXXX

XXXXX

XX

XX

XX

XX

XXX

V

V

tXX

XXX

XX

XX

XXX

XX

XXX

XX

XX

XX

XX

XX

XX

XX

XX

XXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

A

V

X

X

X

X

X

XXX

XX

XX

XXX

XXX

XX

XXX

XXX

XXX

XX

15

Page 18

Specifications

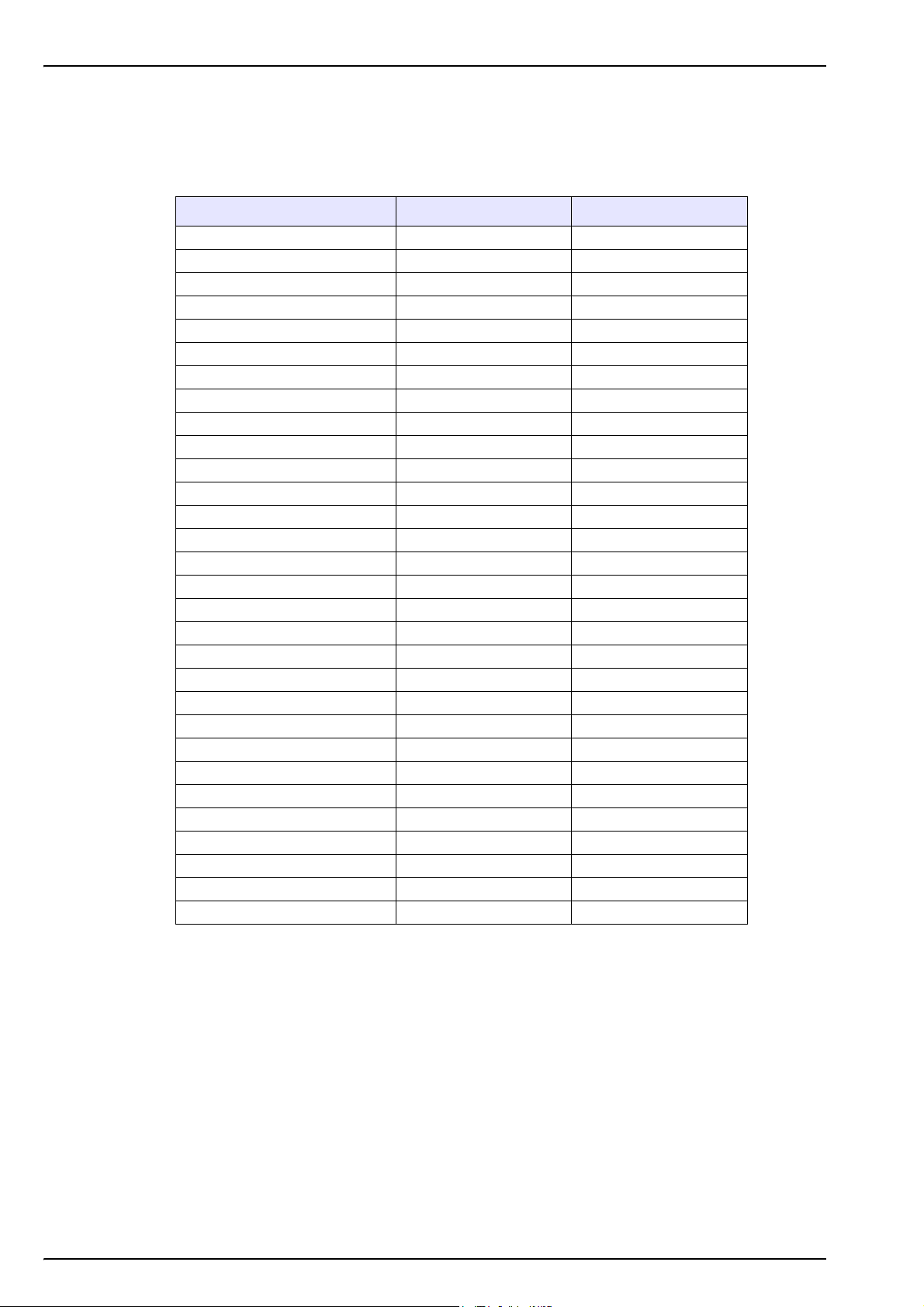

2.5 Default parameters

The table below indicates the factory default configurations. The instrument has these settings

when started for the first time.

Parameter Default settings Customer settings

Security Disabled

Measurement

Measurement mode Continuous

Data filter Disabled

Sample phase Liquid

Units ppm-ppb

Display resolution XX.X

Storage mode Rolling buffer

Sensor Membrane 2956

Temp unit °C

Pressure unit bar

Calibration

Mode in air (O

Hold Enabled

Analog outputs

Range 4-20 mA (0-5V)

Output Gas measurement

Extended mode Disabled

Characteristics Linear mode

Alarm relays Disabled

Thermal cutoff Enabled

Thermal cutoff temp 65°C

Calibration timer Disabled

Service timer Disabled

Buzzer

Screen tap Enabled

Alarm sound Disabled

Display

Minigraph Enabled

Temperature Disabled

, O3)

2

16

Page 19

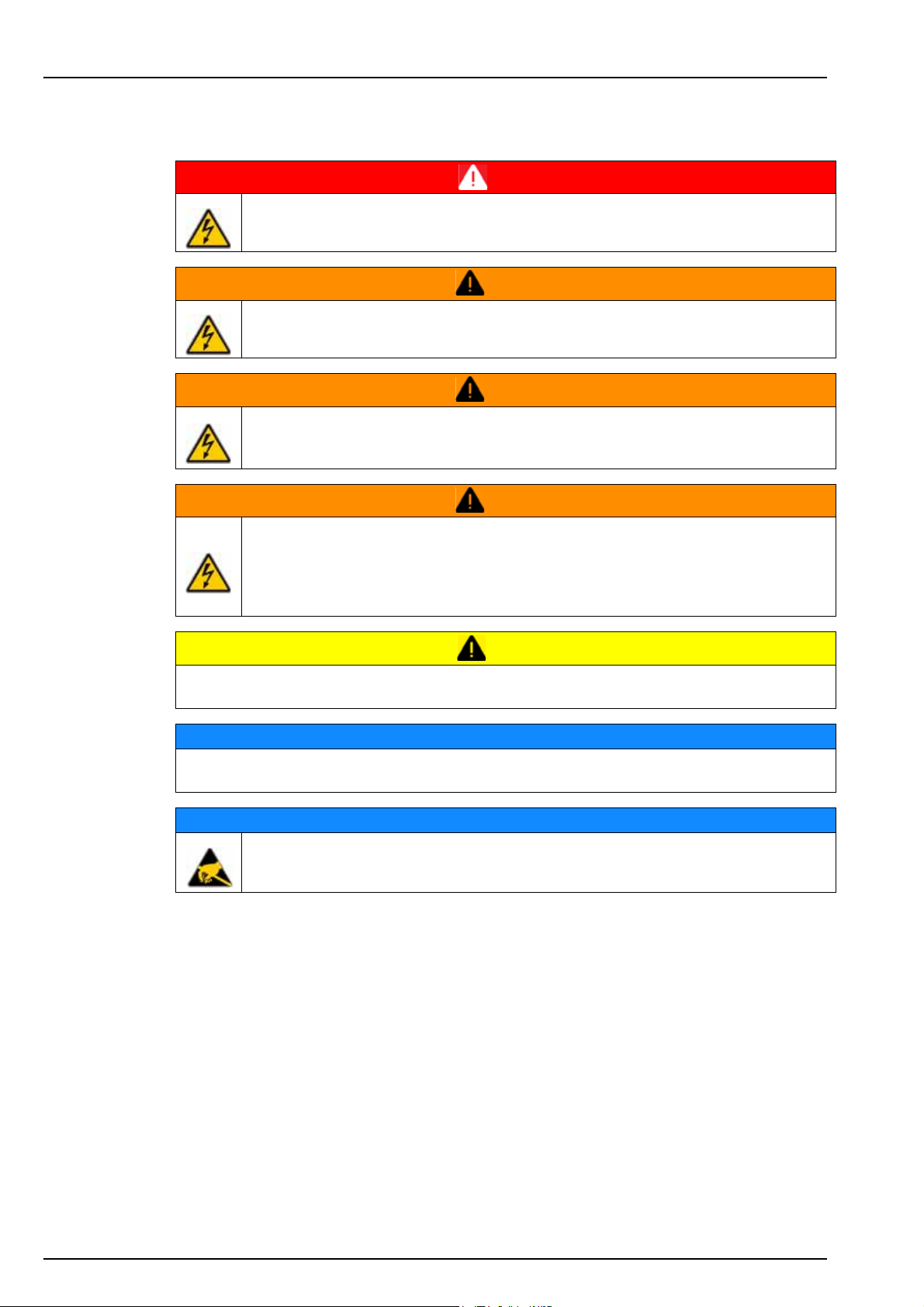

Section 3 Installation

This section provides necessary information to install and connect the analyzer. The installation

of the analyzer should be performed in accordance with relevant local regulations.

Electrocution Hazard. Do not connect AC power to a 5 VDC powered model.

Potential Electrocution Hazard. Always disconnect power to the instrument when

making electrical connections.

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially

wet locations a Ground Fault Interrupt device must be used for connecting the

equipment to its main power source.

DANGER

WARNING

WARNING

WARNING

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this

section of the manual.

Install the device in a location and position that gives easy access to the disconnect device

and its operation.

3.1 Unpacking

Remove carefully the instrument and its accessories from the box and packing material,

referring to the packing list included to confirm that everything has been delivered.

Potential Electrocution Hazard. A protective earth (PE) ground connection is

required for both 100-240 VAC and 5 VDC wiring applications. Failure to connect a

good PE ground connection can result in shock hazards and poor performance due

to electromagnetic interferences. ALWAYS connect a good PE ground to the

controller terminal.

CAUTION

NOTICE

NOTICE

Potential Instrument Damage. Delicate internal electronic components can be

damaged by static electricity, resulting in degraded performance or eventual failure.

Please visually inspect the instrument for shipping damage. If anything is missing or damaged,

contact the manufacturer or your dealer immediately.

You may want to retain the box and other packing material in case later you need to ship the

instrument (see Storage, handling and transportation on page 92). Please dispose safely and

ecologically of the box and packing material (if not stored for future use).

Please read through this manual thoroughly before carrying out the installation.

17

Page 20

Installation

3.2 Installation check list

To complete the installation, proceed to the following actions:

1. Follow the installation instructions in this section carefully

2. On completion, verify once more that everything is properly connected

3. Turn the instrument on

4. Set the language

5. Set the security levels, users ID’s and passwords

6. Perform a barometric sensor calibration

7. Perform the gas sensor(s) calibration

8. Perform calibration for the interferences

9. Adjust the settings for correction factors and interferences

The instrument should now be ready for operation. If a problem should arise, please refer

initially to Troubleshooting on page 91. If the difficulty cannot be overcome, please contact your

Hach Lange representative who will be happy to assist you.

18

Page 21

3.3 Wall mount and pipe mount instruments

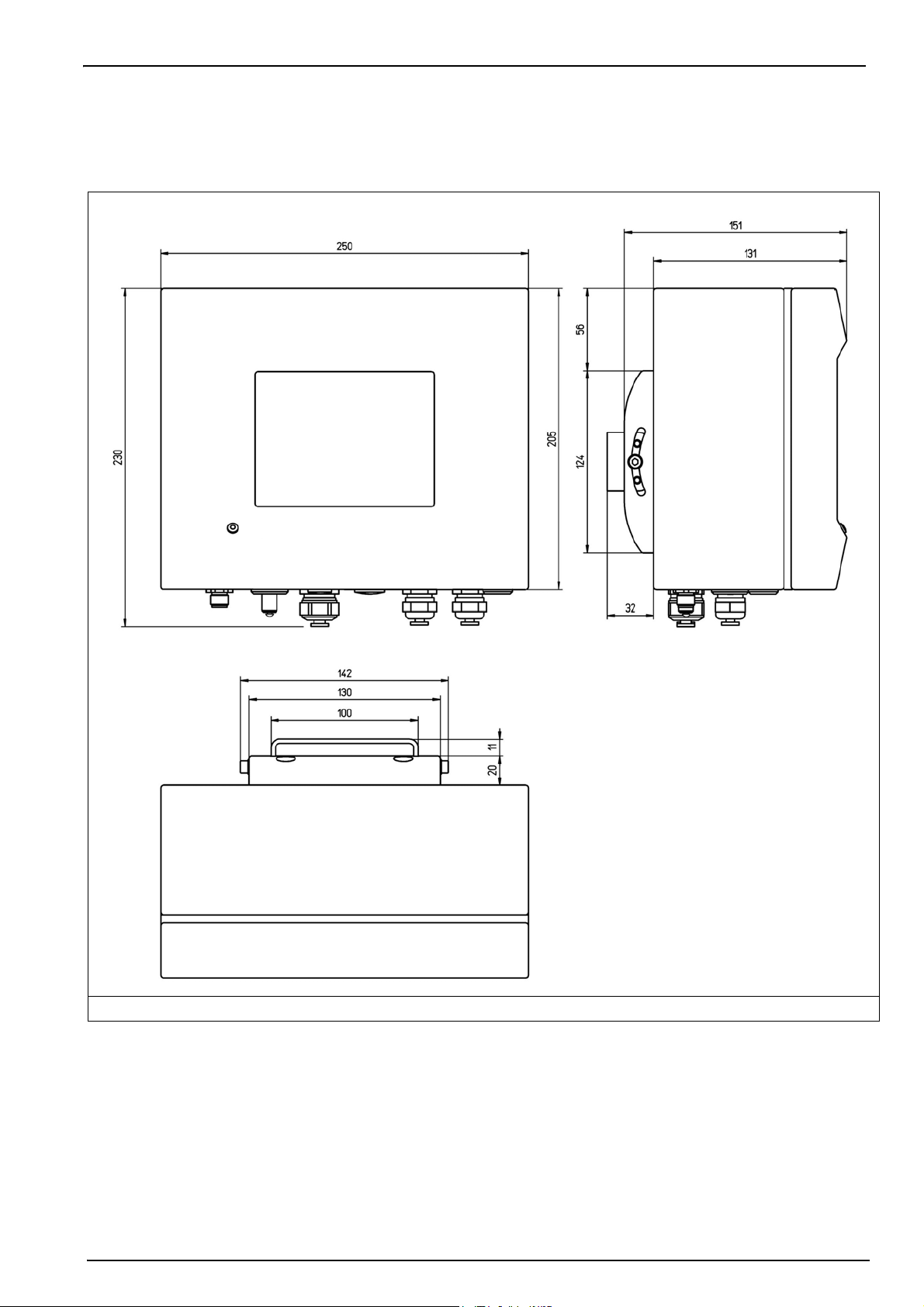

3.3.1 Instrument dimensions

Installation

Figure 1 Wall and pipe mount instrument dimensions (in millimeters)

19

Page 22

Installation

3.3.2 Wall mounting

Attach the U bracket provided to

the wall with two screws (not

provided).

Tilt the instrument slightly

backwards to align the bracket

pins and the insertion slots, and

slide the instrument onto the

bracket as shown.

Insert the 2 locking screws with

washers through the side slots.

Adjust instrument angle for better

screen vision, and lock both side

screws.

3.3.3 Pipe mounting

Figure 2 Wall mount bracket

Assemble the pipe mount bracket to the

U-bracket, using the two screws provided

Attach this assembly to the pipe using two

clamps (not provided) as shown on the left

The rest of the procedure is similar to the wall

mount version, pictured above.

Slide the instrument onto the bracket.

Insert the 2 locking screws with washers

through the side slots.

20

Figure 3 Pipe mount diagram

Adjust the instrument angle for better screen

vision, and lock both side screws.

Page 23

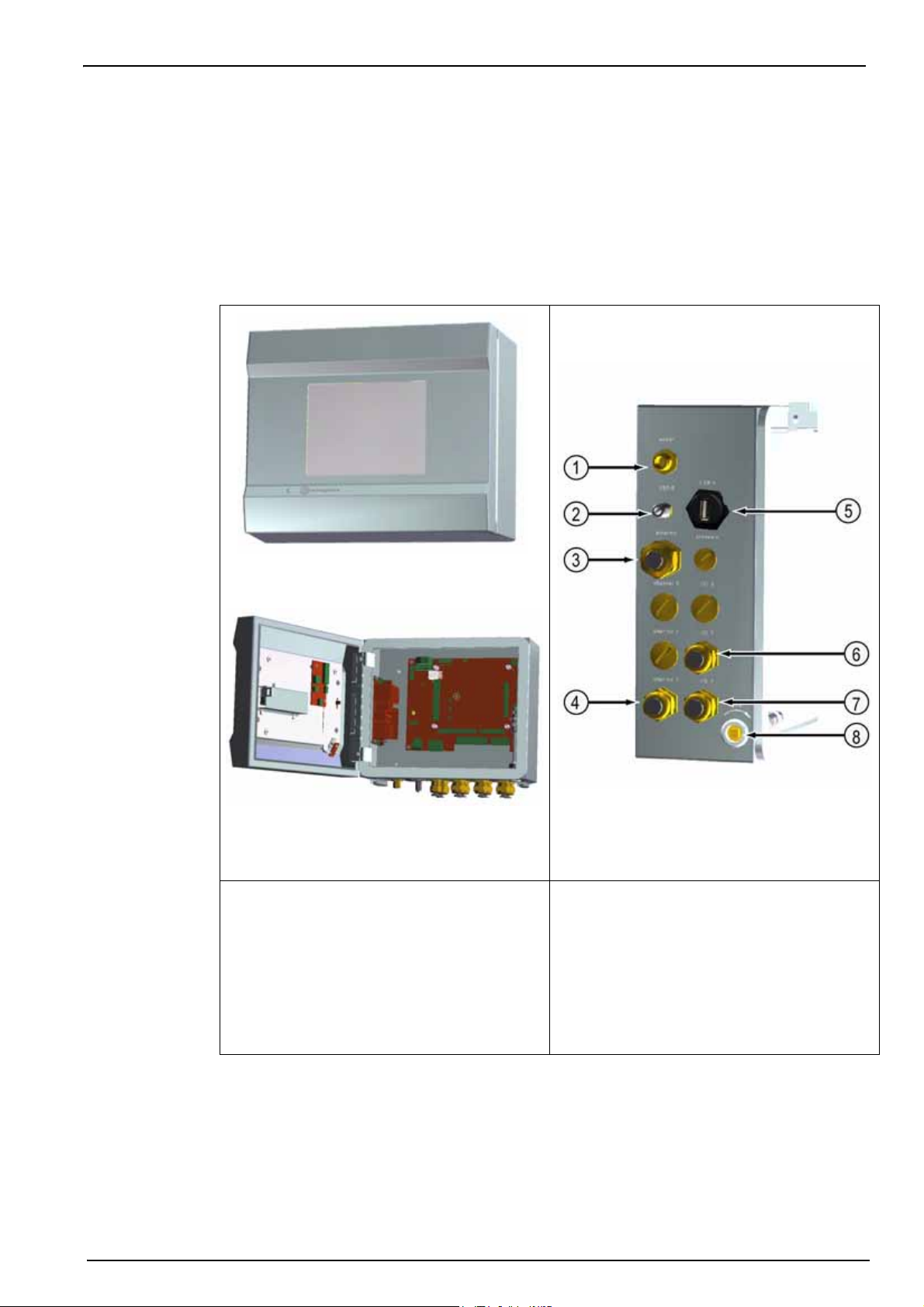

3.3.4 Connection panel (bottom of instrument)

Front panel door

A square key is provided to open the instrument front panel locks. The two locks are located on

the right side of the instrument on the top and bottom panels (bottom panel indicated with the

number 8 in Figure 4 below).

The front panel can be easily pivoted to the left as shown below. To retain the instrument

waterproof tightness, make sure the seal is clean and in good condition before closing the front

panel.

Installation

1. Power cable. The type of connection will

vary depending on the instrument

specification (see Connection to mains

power supply on page 26)

2. USB-B client 4 pin connector. Use the

adapter cable (see USB-B client adapter

cable on page 26)

3. Ethernet cable gland

Figure 4 Wall and pipe mount connection

panel

4. Sensor cable gland

5. USB-A host connector for mass storage

device

6. Input/Output 2 cable gland

7. Input/Output 1 cable gland

8. Keylock (bottom panel)

21

Page 24

Installation

3.4 Panel mount instrument

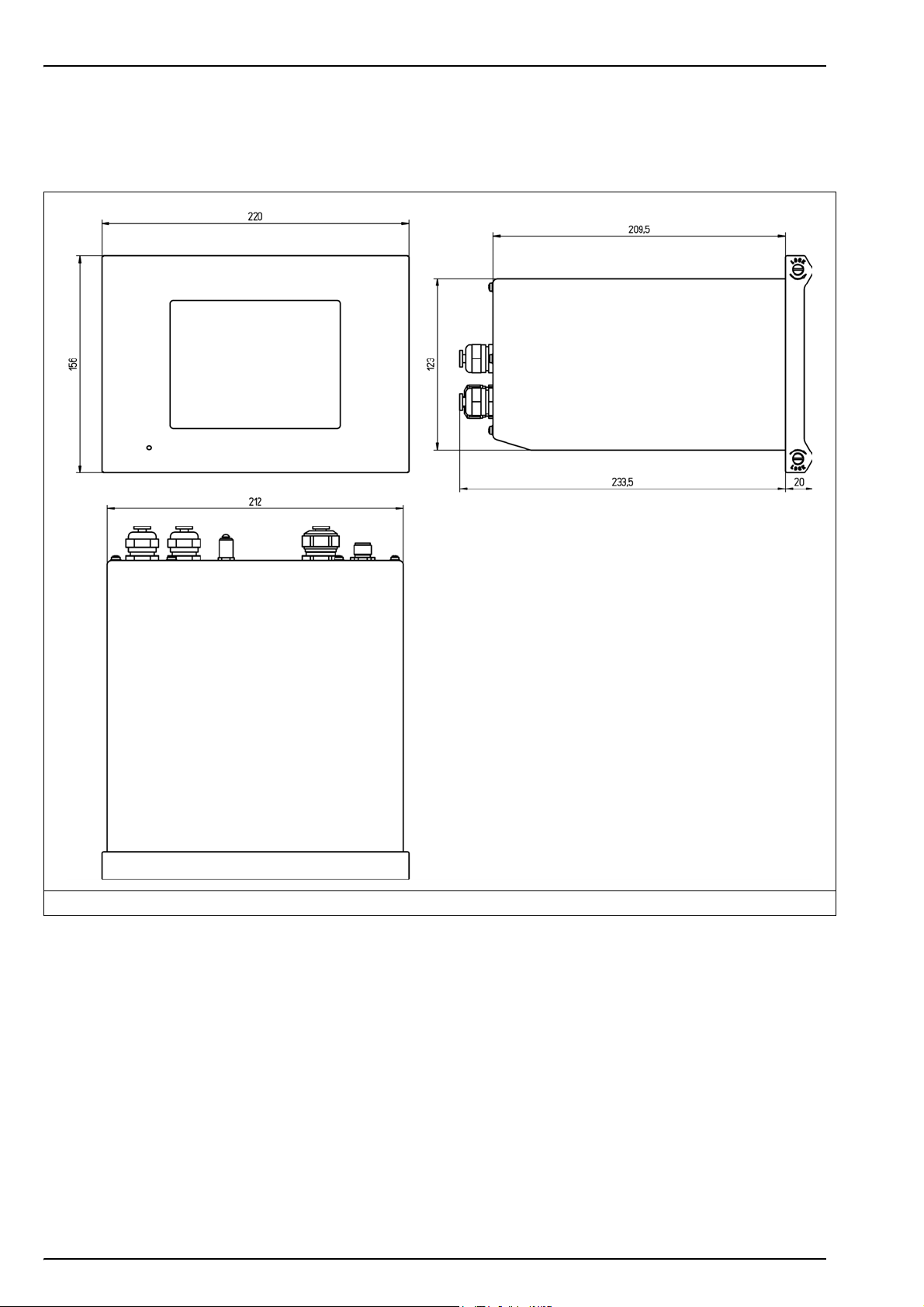

3.4.1 Instrument dimensions

22

Figure 5 Panel mount instrument dimensions (in millimeters)

Page 25

3.4.2 Mounting

Installation

1. Cut an opening in the panel to accommodate

the bracket frame provided (this is the same

size as previous generations of ORBISPHERE

type 3600 instruments).

Figure 7 Opening dimensions

Figure 6 Panel mount bracket frame

2. Install the provided frame in the opening

3. Fold the 6 tabs over the panel lips, using

adjustable joint pliers.

4. Slide the instrument in the bracket frame. The

instrument should go over the four “T” pins.

Rotate the 4 fast locking screws on both sides of

the front panel and slide it in.

5. Rotate the 4 fast locking screws 1/4 turn twice in

the lock direction as indicated on the side of the

front panel. This locks the instrument in place on

the four “T” pins.

6. To access the connections inside the

instrument, remove the instrument housing (six

screws on the back panel, and slide the housing

back out)

7. Pass the cables through the housing, then

through the cable gland (if applicable) and then

perform the connections as detailed below.

Note: Do not forget to pass the cable through the housing

before passing it through the cable gland on the back

panel.

23

Page 26

Installation

Alternative instrument mounting procedure

When it is not convenient to work from the back of the panel, the instrument can be connected

before fitting in the panel.

1. Install the panel support frame in the panel opening

2. Slip the cables through the panel opening

3. Remove the instrument cover

4. Slip the cables through the instrument cover

5. Slip the cables through the instrument back panel cable glands

6. Connect the cables to the instrument electronic boards

7. Tighten the cable glands

8. Reinstall the instrument cover

9. Install the instrument in the panel opening

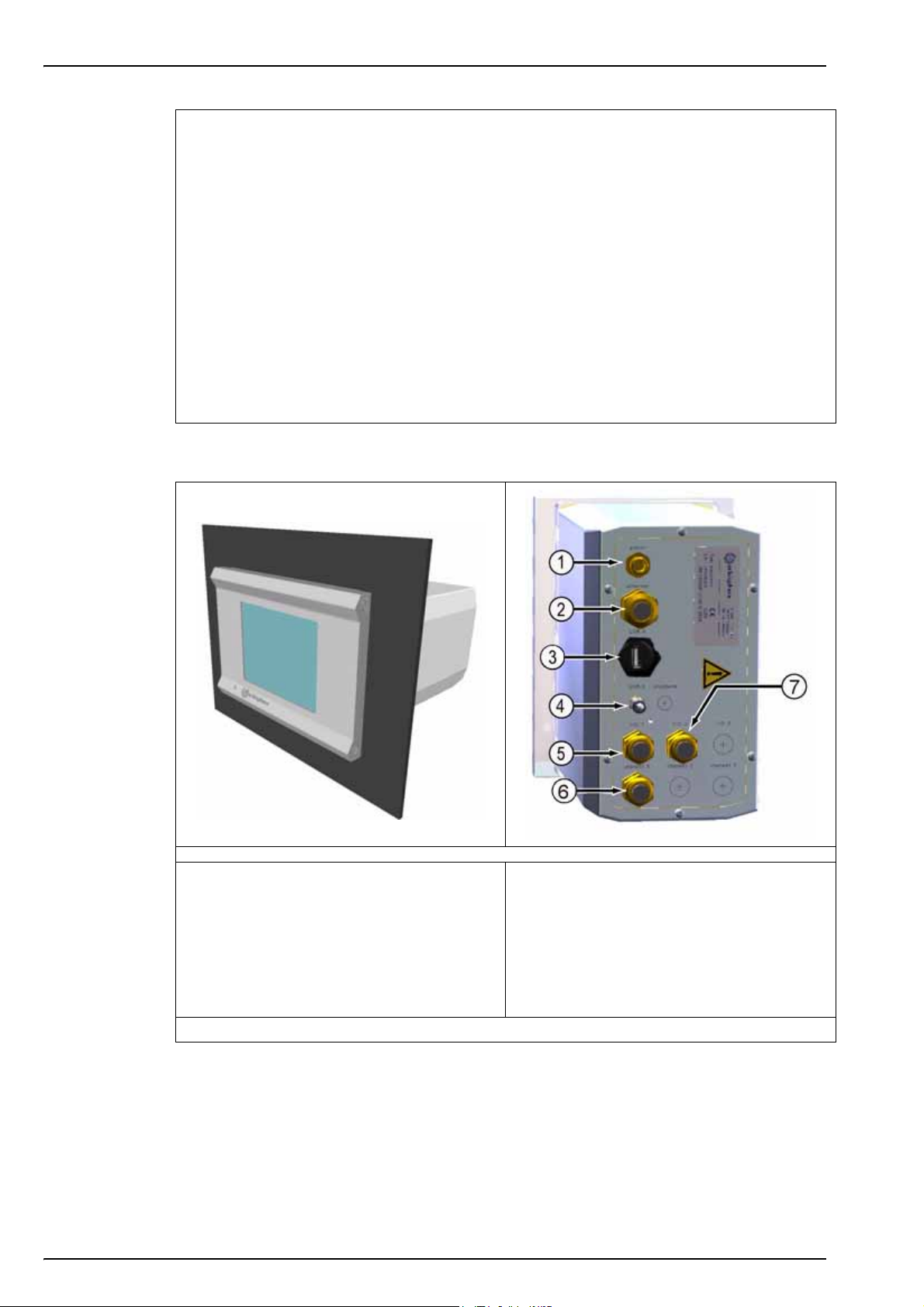

3.4.3 Connection panel (bottom of instrument)

24

1. Power cable. The type of connection will

vary depending on the instrument

specification (see Connection to mains

power supply on page 26)

2. Ethernet cable gland

3. USB-A host connector for mass storage

device

Figure 8 Panel mount connection panel

4. USB-B client 4 pin connector. Use the

adapter cable (see USB-B client adapter

cable on page 26)

5. Input/Output 1 cable gland

6. Sensor cable gland

7. Input/Output 2 cable gland

Page 27

3.5 Connectors assembly instructions

Potential Electrocution Hazard. In order to maintain the NEMA/IP environmental

ratings of the enclosure, use only conduit fittings and cable glands rated for at least

NEMA 4X/IP65 to route cables into the instrument.

3.5.1 Cable gland wiring instructions

A waterproof cable gland is provided each time a cable must be connected inside the

instrument. The nickel-plated brass cable glands are EMC-types, designed so that the cable

shields attach directly to the instrument housing as a ground. Typical cable wiring instructions

are detailed below.

Installation

WARNING

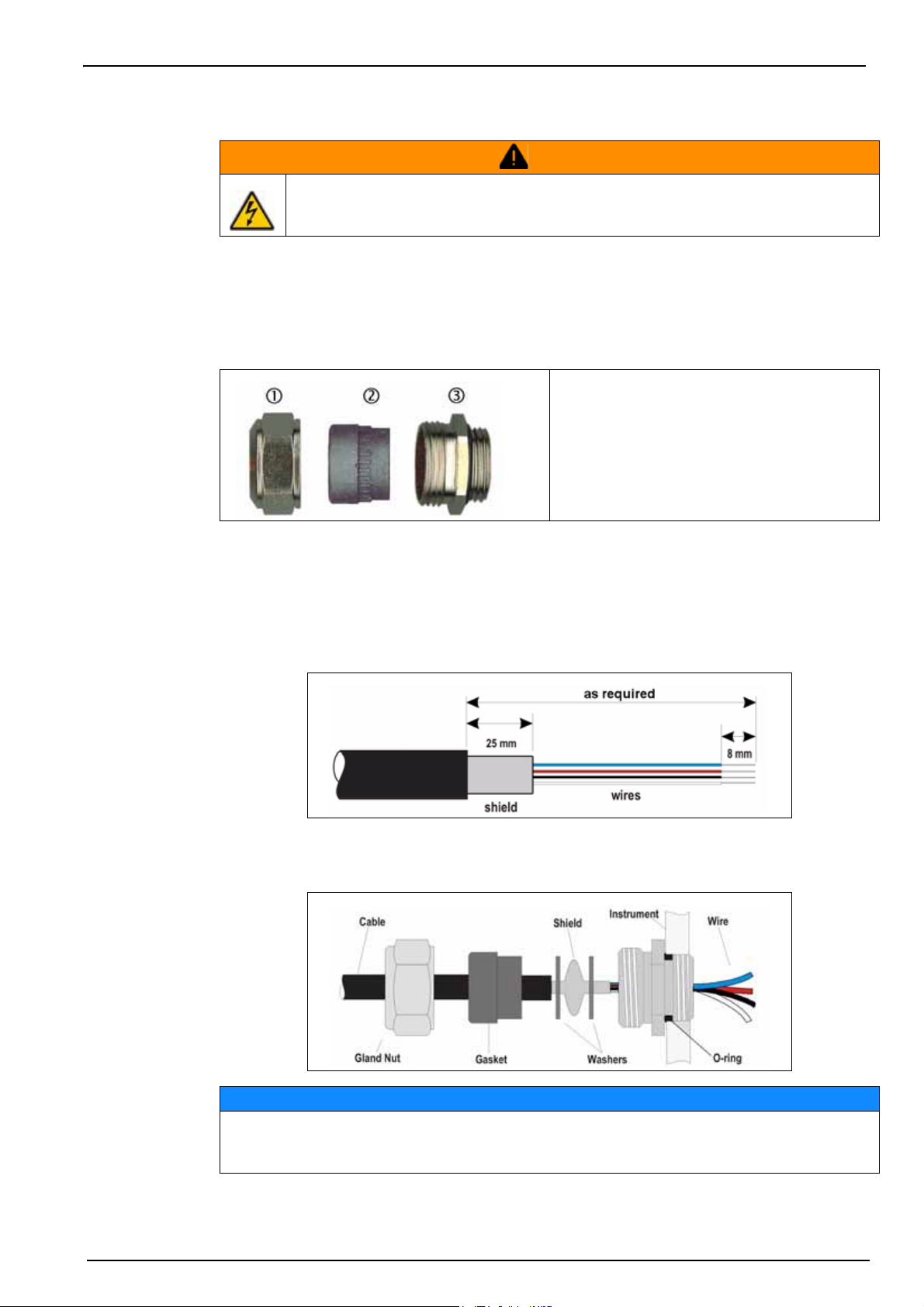

Gland parts (washers not shown):

1. Nut

2. Rubber gasket (seal)

3. Gland fitting with O-ring (attached to

instrument housing)

1. Unscrew the cable gland nut. Inside, the assembly is composed of a rubber gasket, and two

metal washers. Note that the ethernet gland on panel and wall mount instruments does not

have washers and the gasket is cut.

2. If wiring a sensor cable, the cable has already been prepared so simply remove the piece of

plastic protection from the exposed shielding.

For other cables, strip off external insulation as required, and 25 mm of shielding. Strip the

wires about 8 mm from their ends (see illustration below).

3. Pass the cable through the nut, the rubber gasket, and the two washers

4. Pinch the shield so that its entire circumference is pressed between the two washers and

pass the cable into the housing, blocking the cable gland

NOTICE

It is vitally important to ensure the shielding is pinched and secured between the two washers

to ensure the shielding attaches directly to the instrument housing as a ground. Failure to do

this could cause damage to the instrument, and for sensor cables give incorrect readings.

5. Reattach and tighten the cable gland nut

6. Attach the wires to the corresponding terminal block connections

25

Page 28

Installation

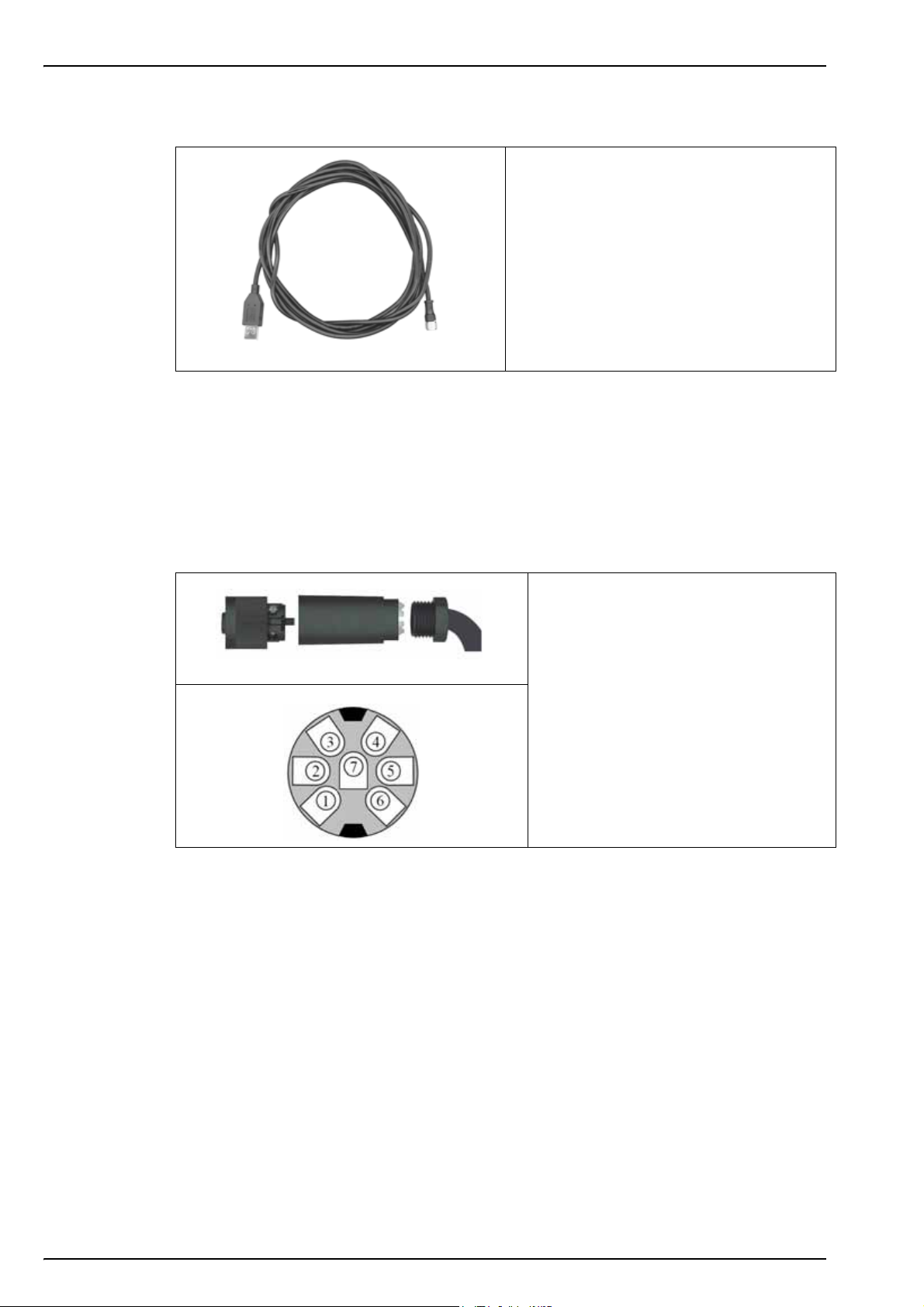

3.5.2 USB-B client adapter cable

This supplied cable is needed to connect the

instrument to a PC.

Connect to the instrument, and connect the

USB connector to the USB outlet on the

user’s PC.

Figure 9 USB-B adapter cable

3.6 Connection to mains power supply

3.6.1 Power supply connection (low voltage instruments)

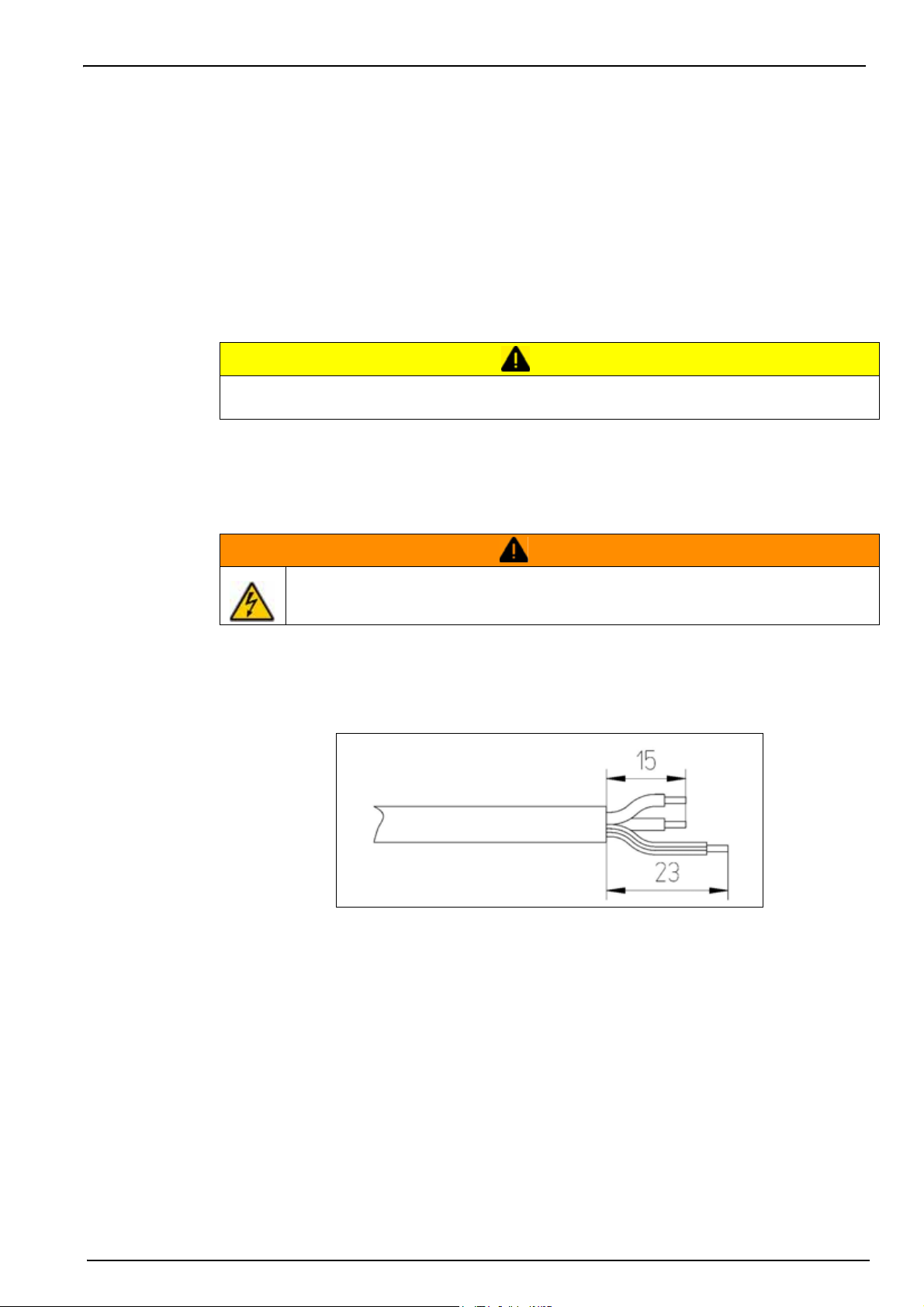

For low voltage instruments (10-30 VDC), connection to the mains power supply is with a 7-pin

BINDER connector (supplied).

Note: The connectors are grooved to avoid an incorrect fitting to the instrument.

Connect the power cable to the connector as follows:

Pin Connections:

Figure 10 BINDER connector

2) Power 10-30 VDC

5) Ground

7) Earth

1 + 3 + 4 + 6) Unused

26

Page 29

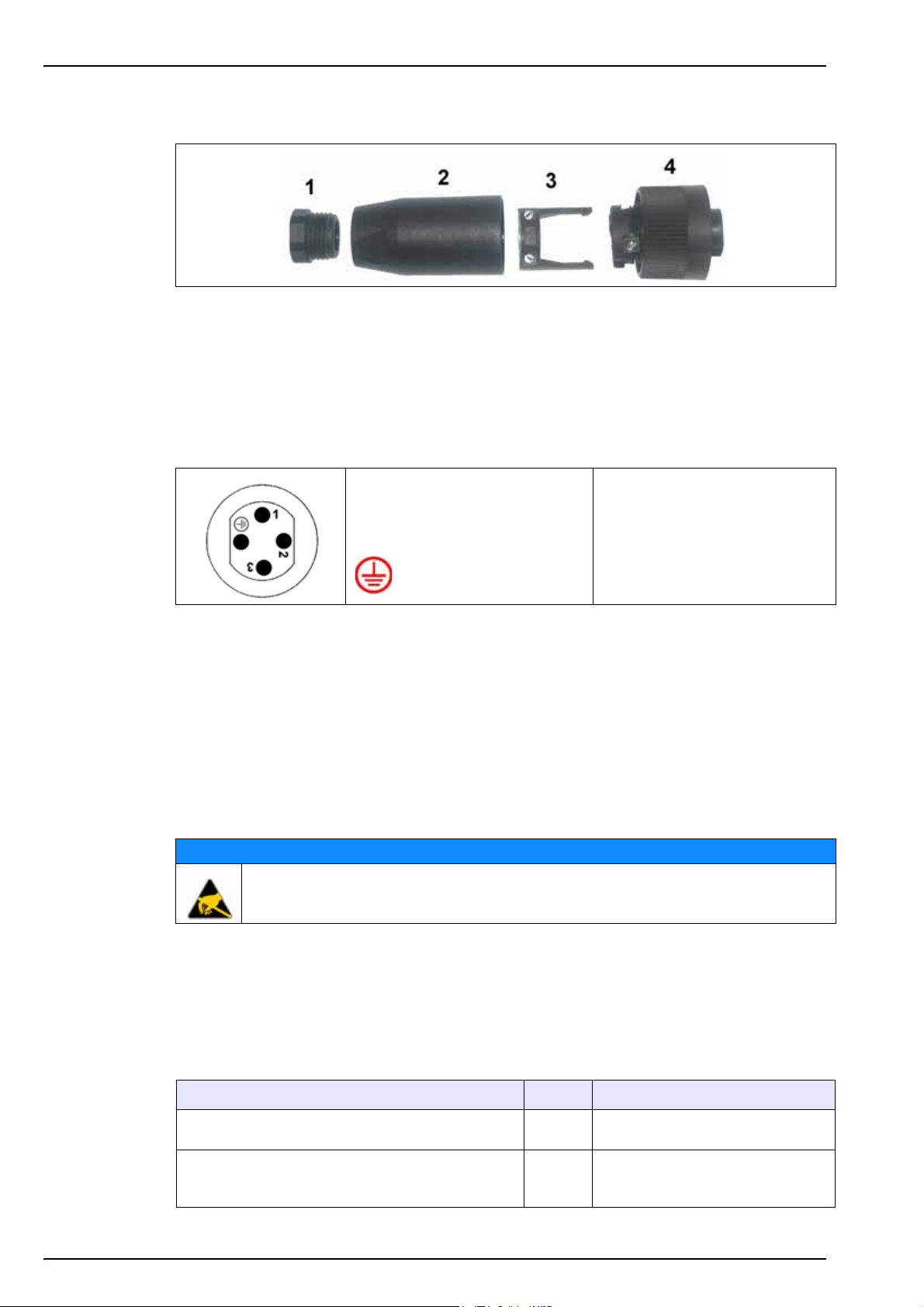

3.6.2 Power supply connection (high voltage instruments)

High voltage instruments (100-240 VAC) have a 4-pin male connector pre-wired internally with a

male BINDER connector ready for mains connection. A compatible female connector is supplied

with the instrument.

If this female connector was supplied with a mains power plug already pre-attached (cable part

numbers 33031, 33032, 33033 and 33034) then the female connector can be plugged directly

into the instrument power connector. The two connectors are grooved to avoid an incorrect

fitting. Tighten the female connector to the instrument power connector finger-tight.

If no power cable was ordered with the equipment, a mains power plug must be connected to

the supplied female connector as described in the following procedure.

CAUTION

Personal Injury Hazard. Only qualified personnel should conduct the tasks described in this

section of the manual.

User-supplied power cable specifications:

• 3-wire (live, neutral and earth)

• cable

• wire selection ≥ 1mm

ø ≥ 7mm; ≤ 9.5mm

2

, AWG18; ≤ 2.5mm2, AWG14

Installation

WARNING

Potential Electrocution Hazard. Always disconnect power to the instrument when

making electrical connections.

Prepare the user-supplied power cable as follows:

Strip off 23 mm (0.9 ins.) of shielding from the power cable. Cut back the live and neutral wires

to 15 mm (0.6 ins.) in length but leave the earth wire as is. Then strip off a small amount of

external insulation from the three wires as required:

27

Page 30

Installation

Wire the female connector as follows:

1. Take the narrow end of the connector (4) in one hand and the main body (2) in the other

and unscrew the two. Pull away the cable clamp (3) and unscrew the end plug (1) to reveal

the four parts that make up the connector.

2. Loosen the screws on the cable clamp (3) to allow enough room to pass the power cable

through.

3. Pass the power cable through the end plug (1), the main body (2), and the cable clamp (3),

and then connect the three wires (live, neutral and earth) to the connector (4) as follows:

1) Live (brown)

2) Neutral (blue)

3) Not used

Earth (green and yellow)

4. Slide the cable clamp (3) back onto the connector (4) and tighten the screws on the clamp

to secure the cable.

5. Screw the two parts (4) and (2) back together.

6. Secure the power cable by screwing the end plug (1) back in place.

7. The female connector can now be plugged directly into the instrument power connector. The

two connectors are grooved to avoid an incorrect fitting. Tighten the female connector to the

instrument power connector finger-tight.

3.7 Connections to electronic boards

Potential Instrument Damage. Delicate internal electronic components can be

damaged by static electricity, resulting in degraded performance or eventual failure.

Note: The numbers and earth

symbol are stamped on the end of

the connector. Ensure it is connected

correctly.

NOTICE

Note: Any loose connection wires should be bundled tightly together with the use of nylon cable ties.

3.7.1 Sensor cable

An ORBISPHERE cable is needed to connect the sensor to the instrument. There is a cable

gland for cable passage, and the cable must be permanently connected to the measuring board

connector. A sensor cable is required with free wires on the instrument end. The free wires are

connected to the connector J8 on the measuring board, as detailed later in this chapter.

All versions with a cable gland for sensor cable

passage

Adapter to connect a N°32505 cable (connector on

both sides) to the instruments without a Lemo 10

socket on the back panel.

28

Instrument Sensor Sensor cable

EC

EC Part N° 32517.mm

10 wire shielded. Part N° 32501.mm

(connector on sensor side only)

Page 31

3.7.2 Electronic boards connectors

Connectors P8 on the main board, and connectors J7 and J8 on the measurement board are

made of two parts. Push down carefully the black levers on either side of the connector and pull

it out securely. Perform all connections with these connectors unplugged. Once finished, attach

the connectors to the boards by pushing them firmly in place (levers up).

3.7.3 Main board connections

Installation

Figure 12 Connector P8

Figure 11 Main board

Figure 13 Connector P3

Connector P8:

1. RS-485 (signal A)

2. RS-485 (signal B)

3. PROFIBUS-DP (GND)

4. PROFIBUS-DP (+ 5 V)

5. PROFIBUS-DP (signal -)

6. PROFIBUS-DP (signal +)

Connector P3

Ethernet RJ 45. Connect the instrument to the local network by passing an ethernet cable

through the ethernet cable gland (location illustrated in Figure 4 on page 21 for the wall mount

and Figure 8 on page 24 for the panel mount). Connect to the P3 connector illustrated above.

7. PROFIBUS-DP (signal RTS)

8. Not used

9. Not used

10. Not used

11. System alarm relay (N.O.)

12. System alarm relay (N:C.)

13. System alarm relay (Common)

29

Page 32

Installation

3.7.4 Measurement board

The different measurement boards for the EC and TC sensors are illustrated in Figure 14 and

Figure 15 below. The type of board is easily identified by the color of the J8 connector. For EC

boards this connector is colored orange, and for TC boards it is colored black.

It is extremely important that sensors are connected to the correct measurement board.

Connecting a TC sensor to an EC measurement board (and vice versa) will cause irreparable

damage to the measurement board.

The colors indicated are the wire colors in the sensor cable.

NOTICE

Figure 14 EC Measurement board

Figure 16 Connector J7

Connector J7 (inputs & outputs)

Measurement alarms relays

1. Common

2. Output relay 1

3. Output relay 2

4. Output relay 3

Note: Relays N.O. or N.C. depends on the jumper

position on the relays (see Measurement alarm

relays on page 31).

Figure 15 TC Measurement board

Figure 17 Connector J8

Analog current (or voltage) outputs

5. GND

6. Output 1

7. Output 2

8. Output 3

Digital inputs

9. EC sensor: Not used

TC sensor: Hold input (short circuit to pin

12)

30

10. Not used

11. Not used

Page 33

Connector J8 (sensor)

Note: Remember, this connector is colored orange for EC sensors and black for TC sensors.

A1100 EC sensor 31xxx EC sensor

1)

Guard electrode

2)

RS485A+

3)

Thermistor A

4)

Anode electrode

5)

RS485B-

6)

Thermistor B

7)

GND

8)

+ 5V

9)

Cathode electrode

10)

Not used

Note: To change the type of sensor (e.g. from a 31xxx sensor to a 31xxxS smart sensor) contact your local

Hach Lange representative.

Guard electrode

Not used

Thermistor A

Anode electrode

Not used

Thermistor B

Not used

Not used

Cathode electrode

Not used

3.8 Measurement alarm relays

31xxxS smart EC

sensor

Guard electrode

I2C-SCL

Thermistor A

Anode electrode

I2C-SDA

Thermistor B

GND

+ 5V

Cathode electrode

Not used

TC sensor

GND for power

V2 signal

Solenoid

Relay coil

+12V power

+24V power

V3 signal

GND for signal

-5V power

Temperature

Installation

Cable

sensor

Yellow

Pink

Grey

Red

Purple

White

Black

Green

Blue

Brown

Figure 18 Output Relays

The three output relays are located on the measurement

board (see also Figure 14 and Figure 15 on page 30).

They can be individually configured to Normally Open (NO) or

to Normally Closed (NC) by physically moving the jumper on

each relay. The picture example on the left is for the EC

measurement board (the positions are different for the TC

measurement board):

• Upper relay is set to NC

• Middle relay is set to NO

• Lower relay is shown with no jumper, to show the 3 pins.

Note: For all measurement boards, J4 is relay 1, J5 is relay 2 and J6

is relay 3

31

Page 34

Installation

3.9 Sensor installation

3.9.1 EC Sensors

For EC sensor installation, servicing, and maintenance ensure you follow the instructions in the

Sensor Installation and Maintenance manual that was supplied with the instrument.

3.9.2 TC Sensors

For TC sensor installation, servicing and maintenance ensure you follow the instructions in the

TC Sensor Installation and Maintenance manual that was supplied with the instrument. Pay

particular attention to the installation and connection of the purge gas supply.

Do not place the TC sensor into a liquid sample until a constant supply of dry purge gas has

been connected, as liquid could condense inside the measuring chamber and cause damage

to the thermal conductor chip.

To ensure the continuation of purge gas while the sensor is in contact with the sample, it is

highly recommended to use a backup purge gas cylinder with an automatic changeover valve

that activates when the first cylinder is empty.

NOTICE

The use of an ORBISPHERE Model 29089 gas regulator (or similar) is also recommended to

deliver a constant, pressure regulated supply of dry purge gas to the sensor, filtered to 40 µm.

In addition, and to prevent any damage to the sensor electronics, the use of a purge safety

backup unit (ORBISPHERE Model 32605) is highly recommended to ensure the supply of purge

gas remains uninterrupted to the sensor in the event of a mains power outage.

The above ORBISPHERE accessories are explained in more detail in the TC Sensor

Installation and Maintenance manual.

3.10Define working language

See Language selection on page 88.

3.11 Define security levels

By default, access rights are disabled meaning no username/password combinations are

required to access the instrument menus. See User management on page 80 to set up new

users.

32

Page 35

Section 4 User Interface

4.1 Instrument

The instrument front panel provides these user interfaces:

• A touch screen acting as display, touch pad and keyboard. Contrast can be adjusted.

• A LED, showing when the instrument is on.

• A buzzer which sounds each time the screen is touched, and when an event alarm is set.

Turning instrument On and Off

There is no power switch on the instrument. The mains must be disconnected to turn the

instrument off. The LED indicates when the instrument is on.

Measurement window

The main (numeric) measurement window continuously displays:

• Sensor numeric values

• Measured sensor trends (for the last 10 minutes to last hour)

• Measured sensor data alarm limits and other events

• Temperature

4.2 Touch screen

The user interface on the front panel is a 320x240 pixels display with touch screen. To make

navigation user friendly, the interface software is Windows CE based, providing easy selection

through menus.

Figure 19 Numeric view

Touching some items on the display calls a related function, similar to a shortcut.

All the measurement, configuration, calibration and "standard

service" routines can be called by pressing buttons and menu

bars on screen.

Measurement display shows one measurement slope.

Display can be configured to only show a sensor

measurement, or to show a parametrized graphic

representation of the last measurements.

33

Page 36

User Interface

4.2.1 Function keys on the header bar

Shortcut to the user login window. Pressing this button for more than

2 seconds calls the ID and password window (see Identification and

authorization level on page 36).

• Closed padlock indicates that the touch screen is locked.

• Open padlock indicates that the instrument is in view mode only,

• When a user is logged in, this box show the authorization level of

This icon is used for adjusting the display brightness to improve

visibility. It is available all the time to any user, regardless of the user

security level. This icon is a shortcut to the backlight adjustment

window. See Screen on page 88

Short cut to the data storage window. Number shows the number of

measurement currently stored in volatile memory.

but no user is logged in (level 0).

this user as 1, 2, 3 or 4 (4 being the highest, see User

management on page 80).

normal - snooze

• No storage

• Store at once: When the buffer is full (1,000 positions), the

recording of measurement stops.

• Rolling buffer: When the buffer is full, the latest measurement set

replaces the oldest one (first-in, first-out)

In the event of an alarm, the “snooze” button stops the instrument

buzzer and returns all the relays in the instrument to their normal

state during the "snooze time". The icon indicates if the alarms is on

“snooze” or not. This "snooze" is configurable (see Configure

snooze on page 56).

Current date and time. This is also a shortcut to the date and time

setting window.

Call the contextual menu. This menu is in the header bar and its

content is related to the view displayed.

34

Opens the main menu page for easy navigation through all available

menus.

Page 37

4.2.2 Menu navigation

User Interface

Pressing the “menu” button in the header bar calls the main

menu. The display is made of three columns:

• The left column is the menus, or submenus (greyed out

options are not available)

• The center column shows a tree view of actual position

inside the menu structure

Figure 20 Main menu window

4.2.3 Rolling list

• The right column has the generic controls detailed below.

Return to previous menu (one step back)

Jump directly to main menu

Close the menu and go back to measurement view display. If the

menu button is pressed again, the menu returns to its previous state

(tree structure is saved)

Help topics concerning current menu

For convenience, selection through a possible large list of

items has been designed with a rolling list, like in this

example. Use the up and down arrow to navigate, or select

directly one item and press OK.

Figure 21 Rolling list

4.2.4 Virtual keyboard

Figure 22 Virtual editing

example

When a text box (alphanumeric field) has to be edited and is

pressed, a virtual keyboard appears on screen. It can be used

as a PC keyboard (pressing CAP gives access to special

keys).

Once values have been entered, press the Enter key to

confirm and exit the virtual keyboard.

During the editing, the edited field name is displayed, along

with units where applicable.

keyboard

35

Page 38

User Interface

4.2.5 Identification and authorization level

Once the access rights have been set, (User management on

page 80) it is necessary to log in as an authorized user to get

access to the instrument functionalities and settings.

Press the closed padlock for two seconds to open the

identification window. The user identification and password

must be entered to access functionalities authorized by the

security level of the given user (5 levels available. See User

management on page 80).

Figure 23 Identification

Note: To get to level 0, press the unlock button and OK, without entering any ID or password.

4.2.6 Warning windows

Figure 24 Warnings

window

For security, when the session inactivity delay period has

expired (adjustable, via Configure security on page 80), the

user is logged off automatically.

At various stages, a warning message may be displayed to

request confirmation from the operator that his last action(s)

must really be saved or cleared, or that there is a problem that

did not enable the requested action, such as during

instrument calibration (example shown left).

36

Page 39

4.3 Main menu structure

This is the structure of the main menu which is used to control every functionality of the

instrument. These submenus are detailed in the following sections of this Operator Manual.

User Interface

Figure 25 Main menu structure

37

Page 40

User Interface

38

Page 41

Section 5 View Menu

Figure 26 View menu

39

Page 42

View Menu

5.1 Selection of the view style

Numeric view

This is the default view. Display shows the numeric measurement value identified for the gas

measurement channel, a graphic showing measurement value evolution during the set time

frame, and sample temperature.

This display can be configured to suit individual conditions and convenience.

Diagnostic view

The diagnostic view contains useful information for troubleshooting purposes. The amount of information

displayed depends on the gas being measured and the channel configuration.

Statistic view

This feature offers statistical data that matches with Total Quality management tools. Statistics is a tool

to better analyze how a process behave. The 410 statistics window gives some useful information.

The statistics are calculated from the data in the measurement file. The values are updated each time a

new value is added to this file. Therefore the changes made in the configuration window are considered

only once a new value is added.

Cp process capability

Cp is an index used to assess the width of the process spread in comparison to the width of the

specification. It is calculated by dividing the allowable spread by the actual spread.

• A Cp of one indicates that the width of the process and the width of the specification are the

same.

• A Cp of less than one indicates that the process spread is greater than the specification. This

means that some of the data lies outside the specification.

• A Cp of greater than one indicates that the process spread is less than the width of the

specification. Potentially this means that the process can fit inside the specification limits

CPk process variability

Cpk takes into account the center of the data relative to the specifications, as well as the variation in

the process.

• A Cpk value of one indicates that the tail of the distribution and the specification are an equal

distance from the overall average.

• A Cpk of less than one means that some of the data is beyond the specification limit.

• A Cpk greater than one indicates that the data is within the specification.

• The larger the Cpk, the more central and within specification the data.

CPm process repeatability

Capability index that takes into account variation between the process average and the target. If the

process average and the target are the same value, Cpm will be the same as Cpk. If the average

drifts from the target, Cpm will be less than Cpk.

Skewness

negative

An asymmetric frequency distribution is skewed to the left if the lower tail

is longer than the upper tail, and skewed to the right if the upper tail is

longer than the lower tail. Distributions of positive-valued random

variables values are often skewed right.

40

positive

Figure 27 Skewness

Page 43

Kurtosis

Kurtosis is a parameter that describes the shape of a random variable’s

probability distribution.

The graphs on the left illustrate the notion of kurtosis. The lower curve

has higher kurtosis than the upper curve. It is more peaked at the center,

and it has fatter tails

Figure 28 Kurtosis

5.2 Configuration of the view styles

Numeric view configuration

List of parameters that can be adjusted to customize the numeric view display:

• Display temperature: no, channel temperature

• Display mini graph: yes/no

• Display time base: yes/no

• Upper bound: Adjust graph upper limit

• Lower boun d: Adjust graph lower limit

• Time base: Adjust graph time span

• Grid button: Set up the graph to display the x or y axes, the grid, or the thresholds

• Auto Scale update: Automatically set the graph upper and lower bounds to best fit the actual values

displayed.

• Clean button: Clear the slope displayed. The slope restarts from the left side.

View Menu

Statistic view configuration

Scope:

• Number of values: Statistic calculation range (from 10 to 1,000 values). Number of value taken in

consideration in the log file since last value stored. The recorded values with alarms are not

considered for calculation, but are part of the log file.

Histogram:

• Upper limit: Select High or High High alarm value, or a custom value.

•Lower limit: Select Low or Low Low alarm value, or a custom value.

Capability:

• Upper limit: Select High or High High alarm value, or a custom value.

•Lower limit: Select Low or Low Low alarm value, or a custom value.

41

Page 44

View Menu

42

Page 45

Section 6 Measurement Menu

Figure 29 Measurement menu

43

Page 46

Measurement Menu

6.1 Instrument configuration

Continuous mode description

Continuous mode is typically used for process measurement.

Continuous mode cycle

• Every 2 sec. measurements are refreshed on the display

• The relays and the analog outputs are updated

• Measurements are continuously stored in memory (volatile and non volatile memory) according to

individual settings

Measurement mode is locked on Continuous for on line process. Select the units for barometric

pressure and temperature.

6.2 Measurement configuration

EC sensor

• Sensor’s membrane number selection

•Medium: Liquid or gas phase.

• Gas unit type: Partial, Fraction, Dissolved.

• Gas unit: The list of available units depends on unit type selected above.

Note: This is the gas concentration measured by the EC sensor. When a composite unit is selected (e.g.

ppm-ppb) the unit will change depending on the range of the value to display.

•Liquid: When medium is liquid, select water or a liquid with a different solubility (if available).

• Display resolution: Maximum resolution depends on gas, membrane and unit. A maximum of 5

digits can be displayed. Decimals can be limited to 0, 1, 2 or 3 decimals for easier reading. That does

not affect the actual resolution of data measured and stored, but only the data displayed.

• Thermal cutoff: To protect the sensor, the thermal cutoff function allows for setting a sample high

temperature limit. If exceeded (during a Cleaning In Place cycle for example) the electrical signal to

the sensor is cut off, the measurement session is suspended and the system displays a “HOT” alarm

message. The system resumes when temperature drops to 90% of the specified cutoff temperature.

• Thermal cut off options: Disabled / enabled.

• Thermal cut off temperature: To be set according to conditions.

TC sensor

The measurement configuration for a TC sensor is the same as for an EC sensor with the addition of one

extra selection criteria:

• Purge gas: From the drop-down list, select the purge gas being used for the TC sensor.

44

Page 47

Measurement Menu

Measurement alarms configuration

Set the thresholds for the low/high concentration levels, according to the application. Each alarm type