Page 1

DOC023.53.90137

AN-ISE sc ammonium and nitrate combination sensor

USER MANUAL

07/2010, Edition 1

© HACH Company, 2010. All rights reserved. Printed in Germany

Page 2

Page 3

Table of Contents

Section 1 Specifications..................................................................................................................... 5

1.1 Dimensions ........................................................................................................................................ 6

Section 2 General Information.......................................................................................................... 7

2.1 Safety information............................................................................................................................... 7

2.1.1 Hazard information in these operating instructions.................................................................... 7

2.1.2 Precautionary labels .................................................................................................................. 7

2.2 General information about the probe.................................................................................................. 8

2.3 Theory of operation............................................................................................................................. 9

Section 3 Installation.........................................................................................................................11

3.1 Unpack the probe ............................................................................................................................. 11

3.2 Unpacking the sensor cartridge........................................................................................................ 12

3.2.1 Assembling the storage container including sensor cartridge.................................................. 13

3.2.2 Removing the cartridge from the transport container............................................................... 14

3.3 Probe assembly................................................................................................................................ 15

3.4 Installation of the cleaning unit (optional) ......................................................................................... 17

3.5 Installation of the probe in the sample flow....................................................................................... 18

3.5.1 Position of the probe on the mount.......................................................................................... 19

3.5.2 Probe installation example....................................................................................................... 19

3.6 Connect the probe to the sc controller (non-hazardous location) with screw fittings........................ 20

Section 4 Operation........................................................................................................................... 21

4.1 How to use an sc controller .............................................................................................................. 21

4.2 Sensor setup..................................................................................................................................... 21

4.3 Sensor data logger ........................................................................................................................... 21

4.4 Sensor diagnostics menu ................................................................................................................. 21

4.5 Sensor setup menu........................................................................................................................... 22

4.6 Calibration/Matrix correction............................................................................................................. 25

4.6.1 Sensor code calibration ........................................................................................................... 26

4.6.2 Matrix correction via LINK2SC................................................................................................. 26

4.6.3 Matrix correction overview ....................................................................................................... 26

4.6.4 Performing the matrix correction.............................................................................................. 27

4.6.4.1 MATRIX 1 correction (1 point matrix correction)............................................................. 27

4.6.4.2 Value correction 1 ........................................................................................................... 28

4.6.4.3 Value correction 2 ........................................................................................................... 29

4.6.4.4 MATRIX 2 correction (2 point matrix correction)............................................................. 30

Section 5 Maintenance ..................................................................................................................... 31

5.1 Maintenance schedule...................................................................................................................... 31

5.2 Clean the sensor............................................................................................................................... 31

5.2.1 Polish the chloride electrode.................................................................................................... 31

3

Page 4

Table of Contents

5.3 Replace the sensor cartridge ............................................................................................................32

5.4 Storage..............................................................................................................................................34

Section 6 Troubleshooting ...............................................................................................................35

6.1 Error messages.................................................................................................................................35

6.2 Warnings ...........................................................................................................................................36

6.3 Troubleshooting ..............................................................................................................................37

6.3.1 Troubleshooting during operation.............................................................................................37

6.3.2 Troubleshooting during calibration ...........................................................................................38

Section 7 Replacement parts and accessories .......................................................................39

7.1 Replacement Parts............................................................................................................................39

7.2 Accessories.......................................................................................................................................39

7.3 Validation accessories.......................................................................................................................39

7.4 Corresponding documentation ..........................................................................................................39

Section 8 Contact ..............................................................................................................................41

Section 9 Limited warranty ..............................................................................................................43

Section 10 Certification.....................................................................................................................45

10.1 Certification .....................................................................................................................................45

Appendix A Modbus Register ........................................................................................................47

Index ......................................................................................................................................................49

4

Page 5

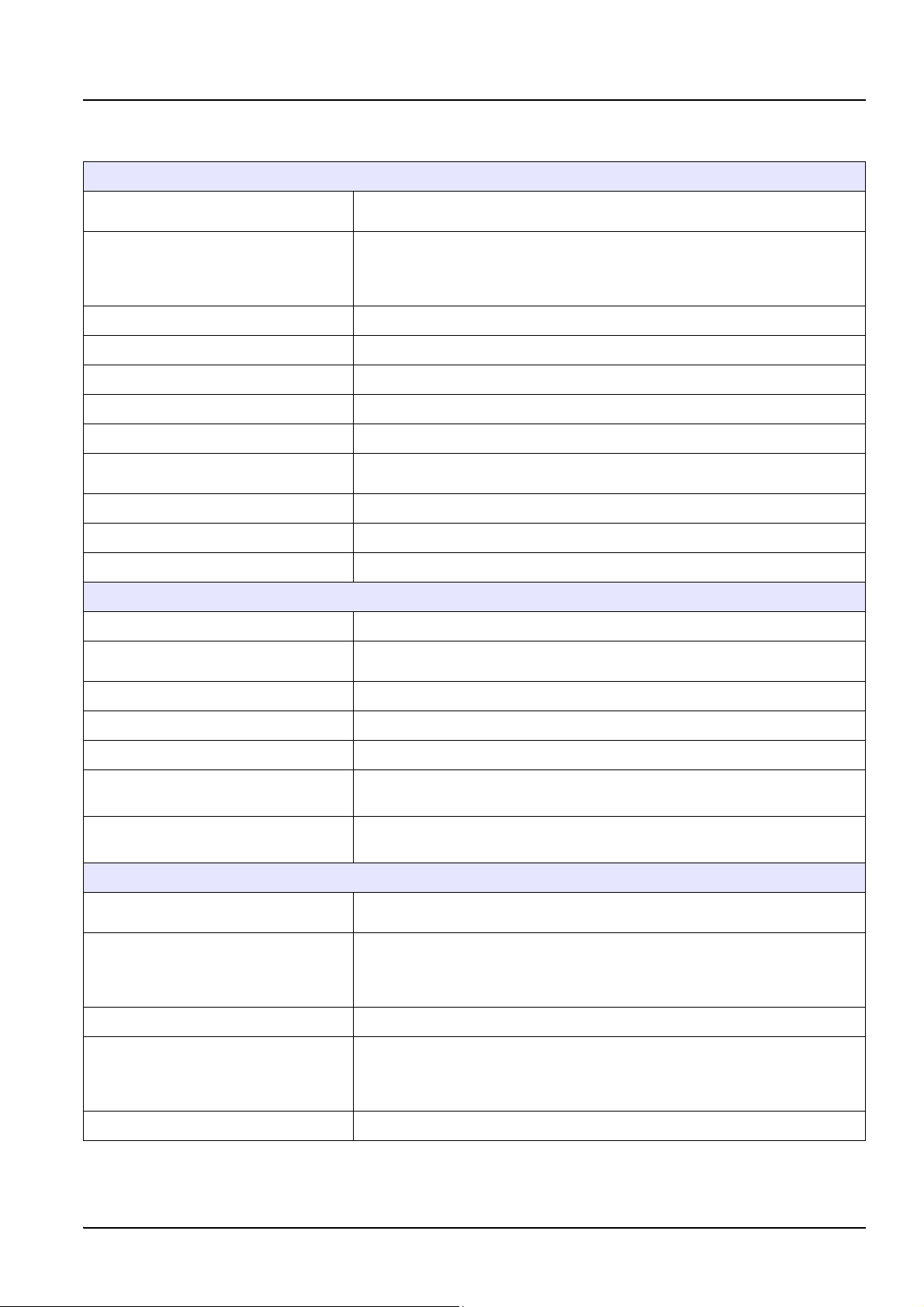

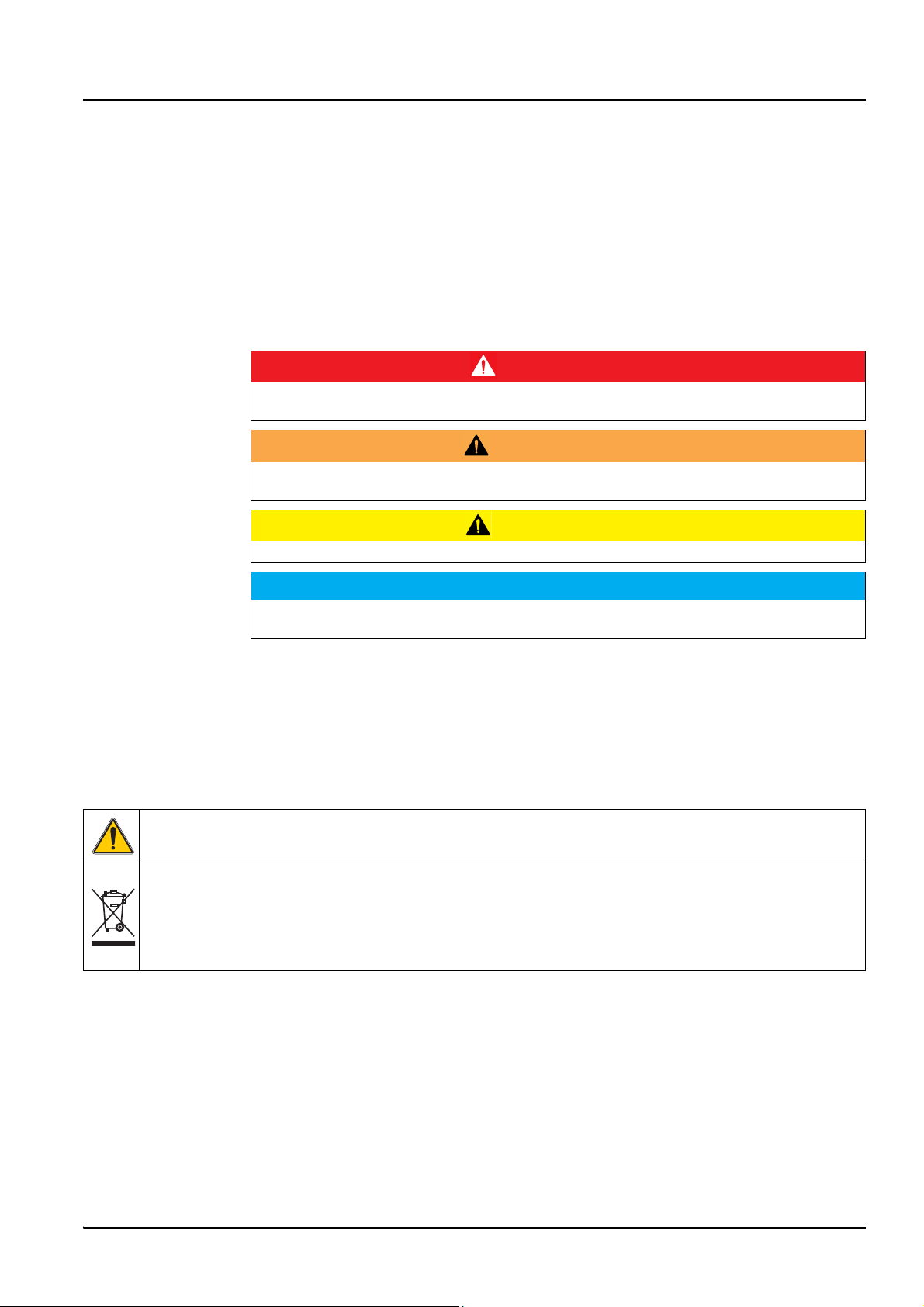

Section 1 Specifications

These are subject to change without notice.

General Information

Measuring method

Measuring range

Precision 5% of the measured value + 0.2 mg/L

Reproducibility 5% of the measured value + 0.2 mg/L1 (ammonium and nitrate)

Potentiometric measurement using ion-selective electrodes (ISE) for ammonium,

potassium, nitrate and chloride, reference system

0 to 1000 mg/L [NH

0 to 1000 mg/L [K+]

0 to 1000 mg/L [NO

0 to 1000 mg/L [Cl

–N]

4

–N]

3

–

]

1

(ammonium and nitrate)

Response time (90 %) < 3 minutes (5 to 50 mg/L NO

Measuring interval Continuous

pH range pH 5 to pH 9

Calibration methods

Power consumption 1 W

Power supply Via sc controller

Data transfer Via sc controller

Ambient data

Typical environment Used in the biological phase of municipal wastewater treatment

Storage temperature

Operating temperature Air: –20 to 45 °C (–4 to 113 °F)

Sample temperature +2 to 40 °C (35 to 104 °F)

Max. Flow velocity < 4 m/s

Max. sensor immersion

depth/pressure

Sensor code for sensor cartridge

1 and 2 point value correction or matrix correction

Sensor: –20 to 60 °C (–4 to 140 °F)

Sensor cartridge: 5 to 40 °C (41 to 104 °F)

Can be immersed at a depth of 0.3 to 3.0 m [1 to 10 ft];

maximum pressure: 0.3 bar (4.4 psi).

–N/NH4–N)

3

Max. Compressed air output during

cleaning unit operation

General information about the probe

Probe dimensions

Length of probe cable

Probe weight Approximately 2380 g (63.6 oz)

Wetted materials

Installation angle 45° +/– 15° vertical in flow direction

1

With standard solutions and ISE electrodes under laboratory conditions

3.1 bar (45 psi)

320 mm × 84.5 mm (12.6 × 3.3 in.) (Length × Ø)

Refer to Figure 1, Page 6.

Standard: 10 m [33.8 ft]

Extension cables are available as an option in the following lengths:

5, 10, 15, 20, 30, 50 m [16.4, 33.8, 49.2, 65.6, 98.4, 164 ft].

Maximum overall length: 100 m [328 ft]

Only for immersed installations:

Probe: stainless steel (1.4571), ASA + PC, silicon, PVC and PU

Sensor cartridge: PVC, POM, ABS, stainless steel (1.4571), NBR

Optional cleaning unit: TPE, PUR, stainless steel (1.4571)

5

Page 6

Specifications

1.1 Dimensions

Figure 1 Dimensions of stainless steel probe

6

Page 7

Section 2 General Information

2.1 Safety information

Please read the entire operating instructions before the instrument is unpacked, set up or

put into operation. Pay attention to all danger and caution statements. Failure to do so

could result in serious injury to the operator or damage to the equipment.

To make sure that the protection provided by this instrument is not impaired, do not use or

install this instrument in any manner other than that specified in these operating

instructions.

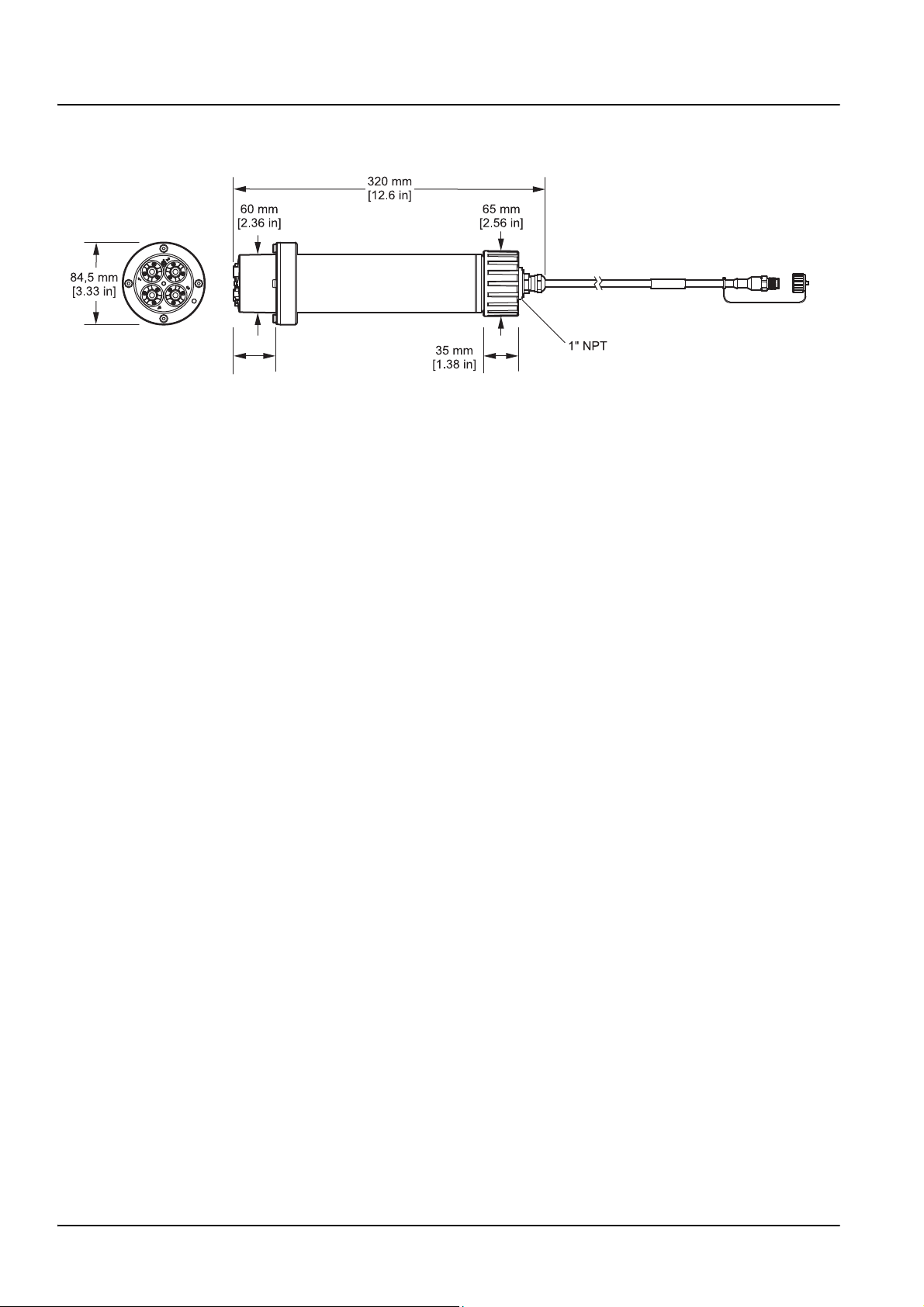

2.1.1 Hazard information in these operating instructions

DANGER

Indicates a potentially or imminently hazardous situation that, if not avoided, results in death or

serious injury.

WARNING

Indicates a potentially or imminently hazardous situatio

or serious injury.

n that, if not avoided, could result in death

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation that, if not avoided, could result in damage to the instrument. Information that

requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed. A symbol, if noted on the instrument, will be

included with a danger or caution statement in the operating instructions.

This symbol, if noted on the instrument, references the user manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the manufacturer

for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment manufacturer or supplier for instructions on how to

return end-of-life equipment, manufacturer-supplied electrical accessories, and all auxiliary items for proper disposal.

CAUTION

NOTICE

7

Page 8

General Information

4

1

2

3

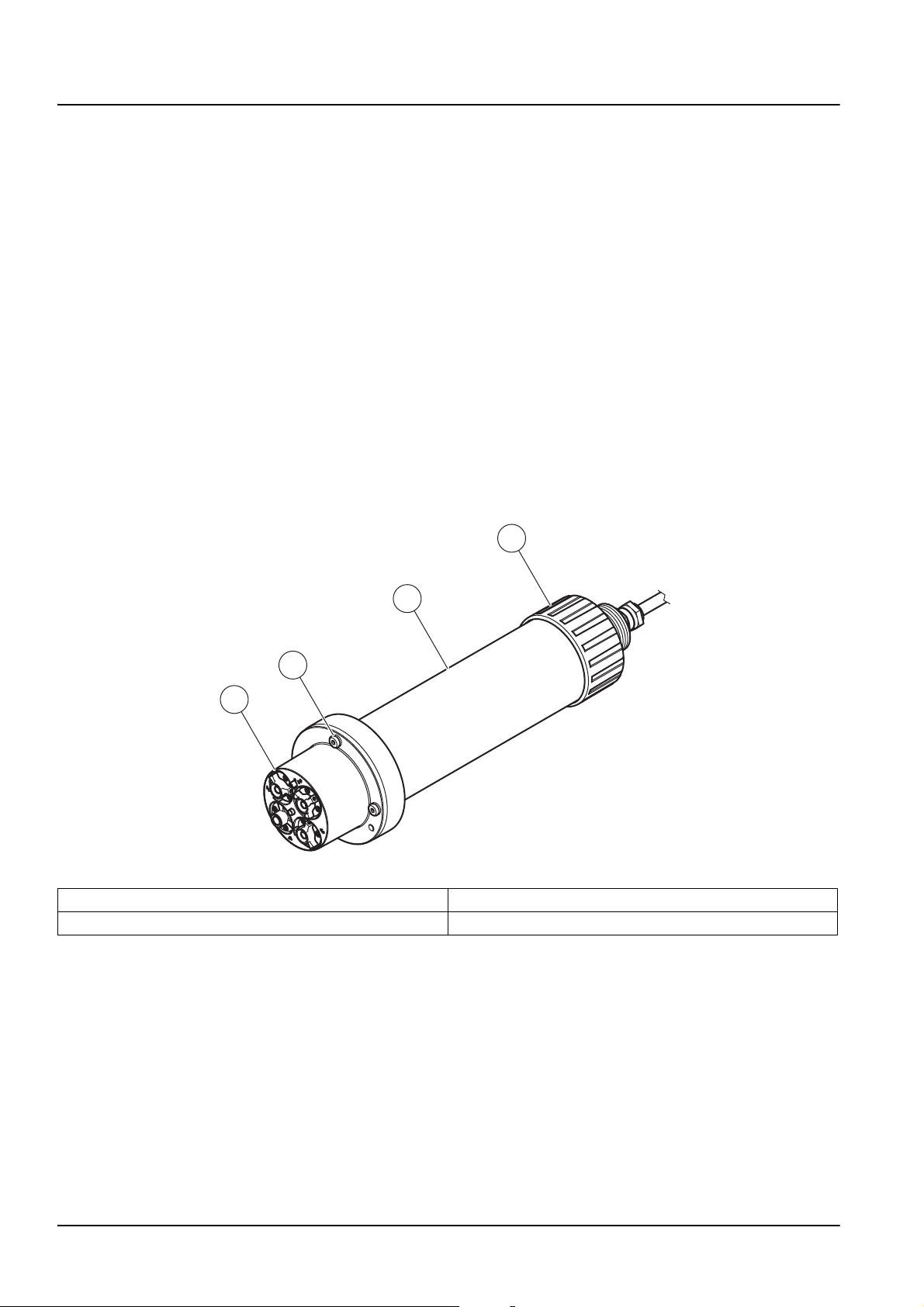

2.2 General information about the probe

The probe was developed for use in municipal wastewater applications.

The AN-ISE sc probe (please refer to Figure 2) with ion-selective electrodes (ISE probe) is

a continuously operating online process probe for directly measuring ammonium and

nitrate in reservoirs. It operates without reagents and requires no further processing of the

sample. The ammonium/nitrate ions are measured using an ion-selective electrode.

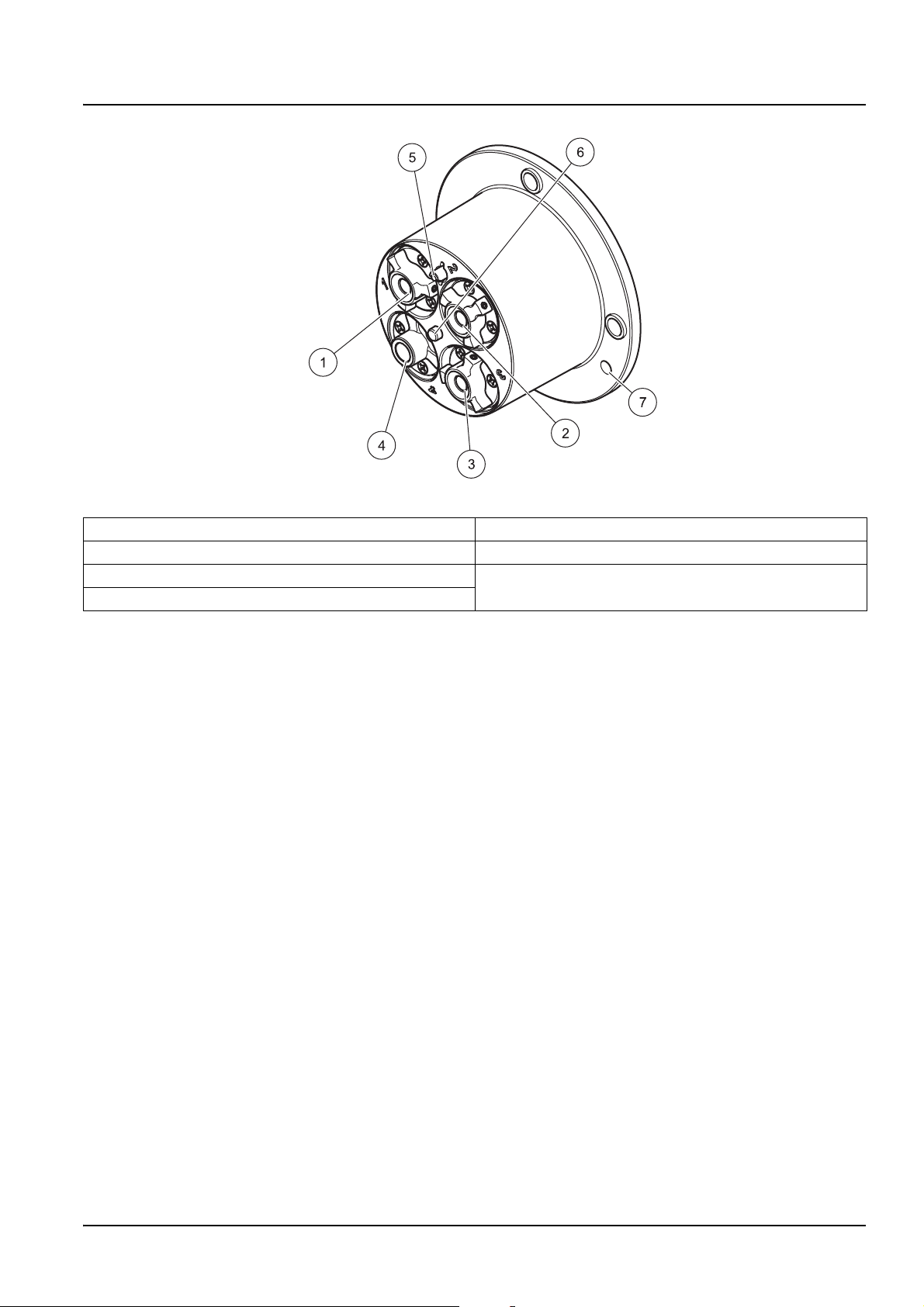

The only wearing part is the sensor cartridge (please refer to Figure 3, Page 9) (order

number LZY694). The sensor cartridge consists of the ion-selective electrodes for

ammonium and potassium (compensation electrode for ammonium) or nitrate and chloride

(compensation electrode for nitrate), a pHD reference system and a temperature sensor

for temperature compensation.

An additional cleaning unit designed for automatically cleaning the sensor cartridge

membranes can be ordered separately. Refer to the instruction sheet supplied with the

cleaning unit.

The manufacturer recommends using the High Output Air Blast system for the

compressed air supply (refer to 7.2 Accessories, page 39); this is a compressor in

weather-proof plastic housing.

Figure 2 AN-ISE sc probe

1 Sensor cartridge 3 Probe body

2 Fixing bolt for sensor cartridge 4 Union nut

8

Page 9

General Information

Figure 3 Sensor cartridge

1 Ammonium electrode 5 Reference system

2 Nitrate electrode 6 Temperature sensor

3 Potassium electrode 7 Marker hole for assembling the probe

4 Chloride electrode

2.3 Theory of operation

The AN-ISE sc probe uses the ion-selective electrode to measure ammonium ions (NH

and nitrate ions (NO

potassium, chloride and temperature are compensated for by means of the relevant

built-in electrodes. The reference system is designed using pH-differential technology and

is therefore particularly stable in terms of drift and contamination.

Ion-selective electrodes have a special membrane to which only a specific type of ion can

adhere. As a result an ion-specific potential forms on the membrane surface. To measure

a potential difference, a reference system is required that will not be affected by the

sample to be measured.

The CARTRICAL

individual electrodes against each other, but also the measuring electrodes with the

compensation electrodes and the reference; this is carried out at the factory.

–

) in a wastewater sample. Common interfering factors due to

3

TM

technology reduces cross sensitivity by calibrating not only the

+

)

4

9

Page 10

General Information

10

Page 11

Section 3 Installation

1

2

3

4

Only qualified personnel should conduct the tasks described in this section of the operating

manual.

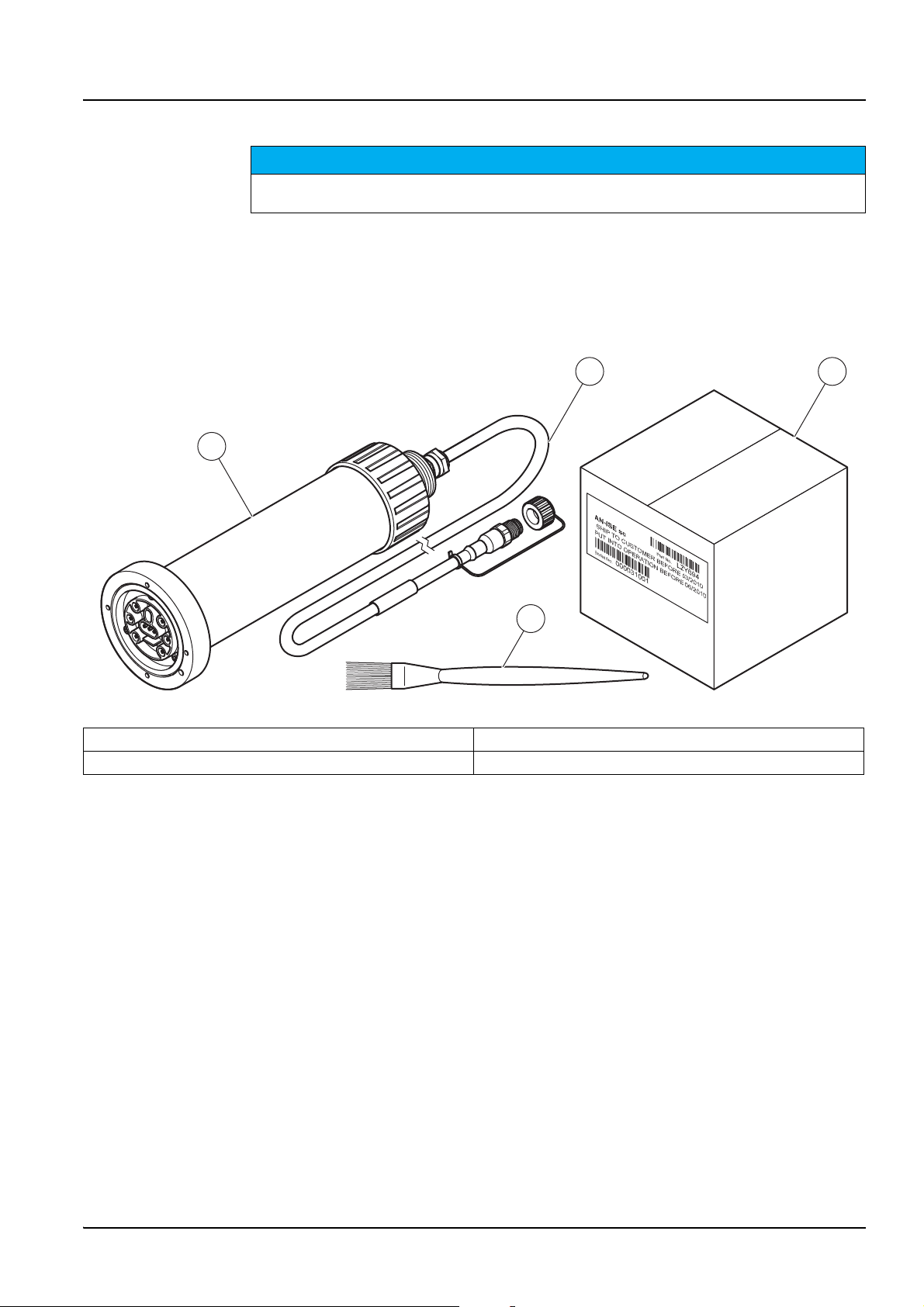

3.1 Unpack the probe

Remove the probe from the shipping container and inspect it for damage. Verify that all

items listed in Figure 4 are included. If any items are missing or damaged, contact the

manufacturer or distributor.

NOTICE

Figure 4 Product contents

1 Probe 3 Sensor cartridge packaging

2 Probe cable 4 Cleaning brush

11

Page 12

Installation

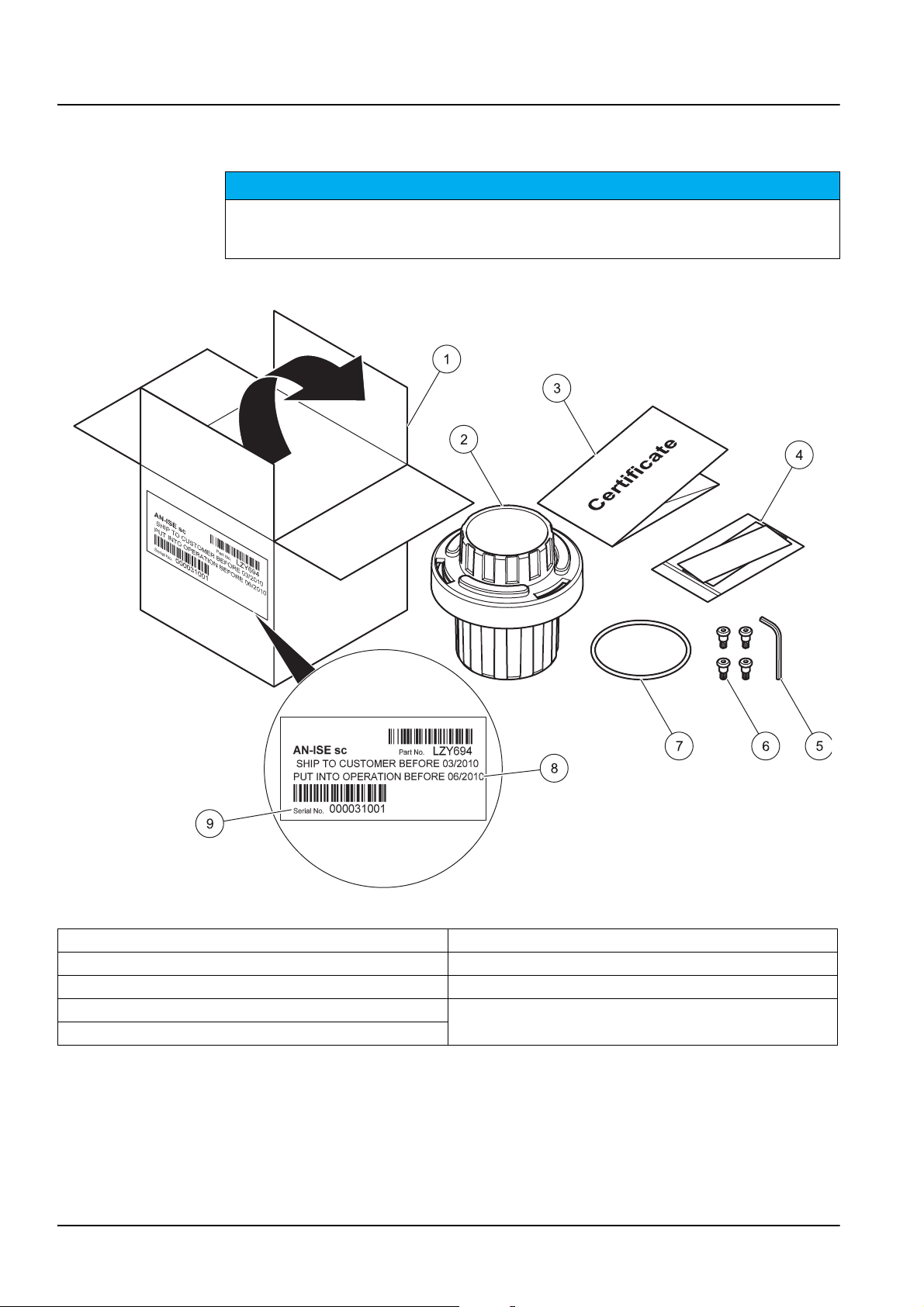

3.2 Unpacking the sensor cartridge

Avoid touching the membrane on the sensor cartridge or damage to the sensor may occur.

Make a note of the date on the sensor cartridge certificate. It is not an expiration date, but indicates

the optimum date to put the sensor cartridge into operation to ensure a maximum service life.

NOTICE

Figure 5 Storage container packaging

1 Sensor cartridge packaging 6 Socket head screws

2 Storage container for sensor cartridge 7 Black gasket

3 Test certificate for cartridge with sensor code 8 Latest date to put into operation

4 Polishing paper for chloride electrode 9 Serial Number

5 Socket head wrench

12

Page 13

2

3

4

5

1

3.2.1 Assembling the storage container including sensor cartridge

Installation

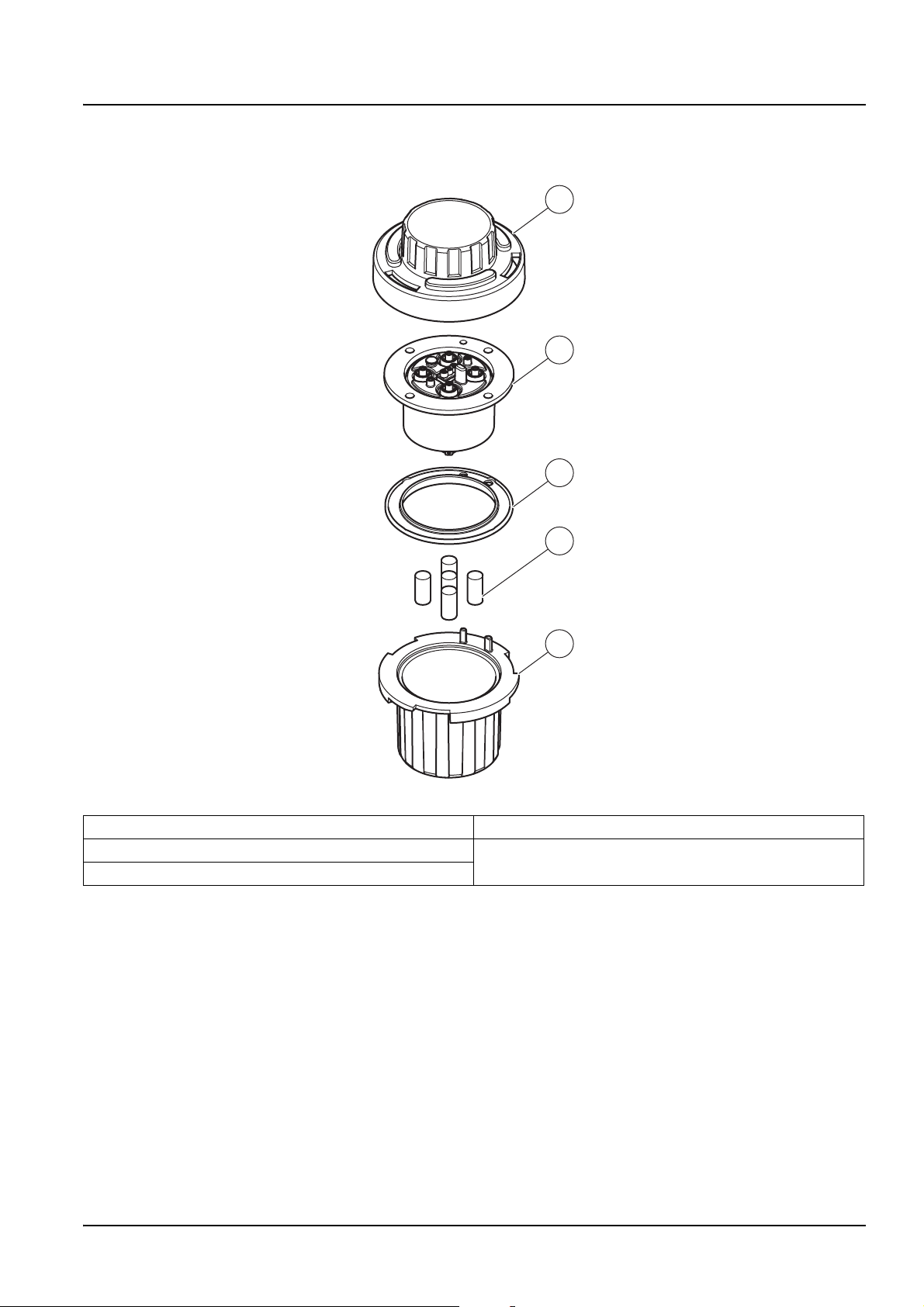

Figure 6 Storage container for sensor cartridge

1 Storage container 4 Sensor cartridge

2 Sponges soaked in storage solution 5 Lid with bayonet coupling

3 Black gasket

1

Save items 1, 2, 3 and 5 for subsequent storage of the sensor cartridge.

1

13

Page 14

Installation

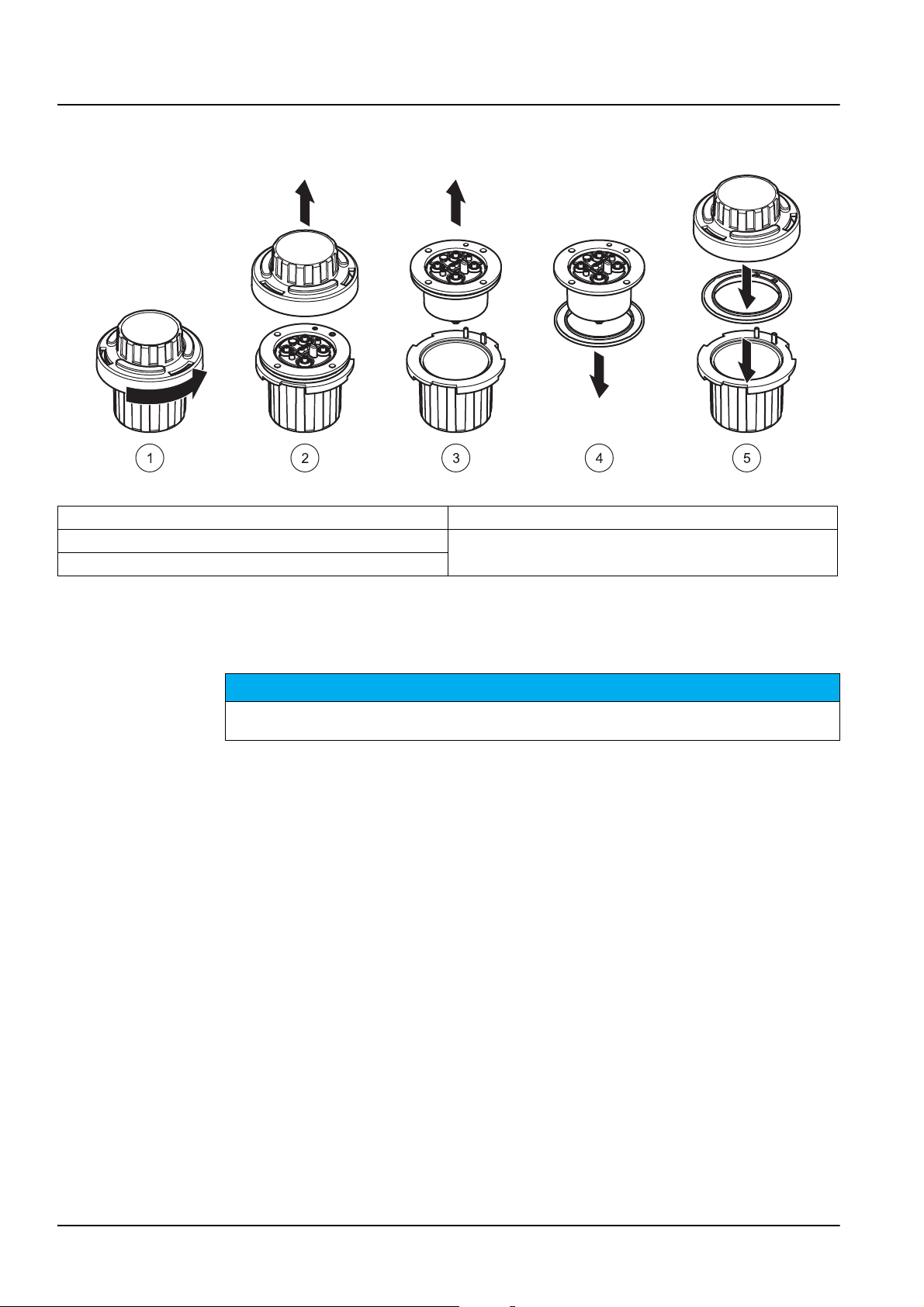

3.2.2 Removing the cartridge from the transport container

Figure 7 Opening the storage container

1 Release bayonet coupling 4 Remove black gasket

2 Remove lid 5 Insert black seal in storage container and close the lid.

3 Take out sensor cartridge

Note: This black gasket is not required for installation. It is advisable to keep the black gasket in

the sensor cartridge storage container.

NOTICE

The sensor cartridge must not be in contact with the air for more than 30 minutes. Make sure that

the electrodes do not dry out.

14

Page 15

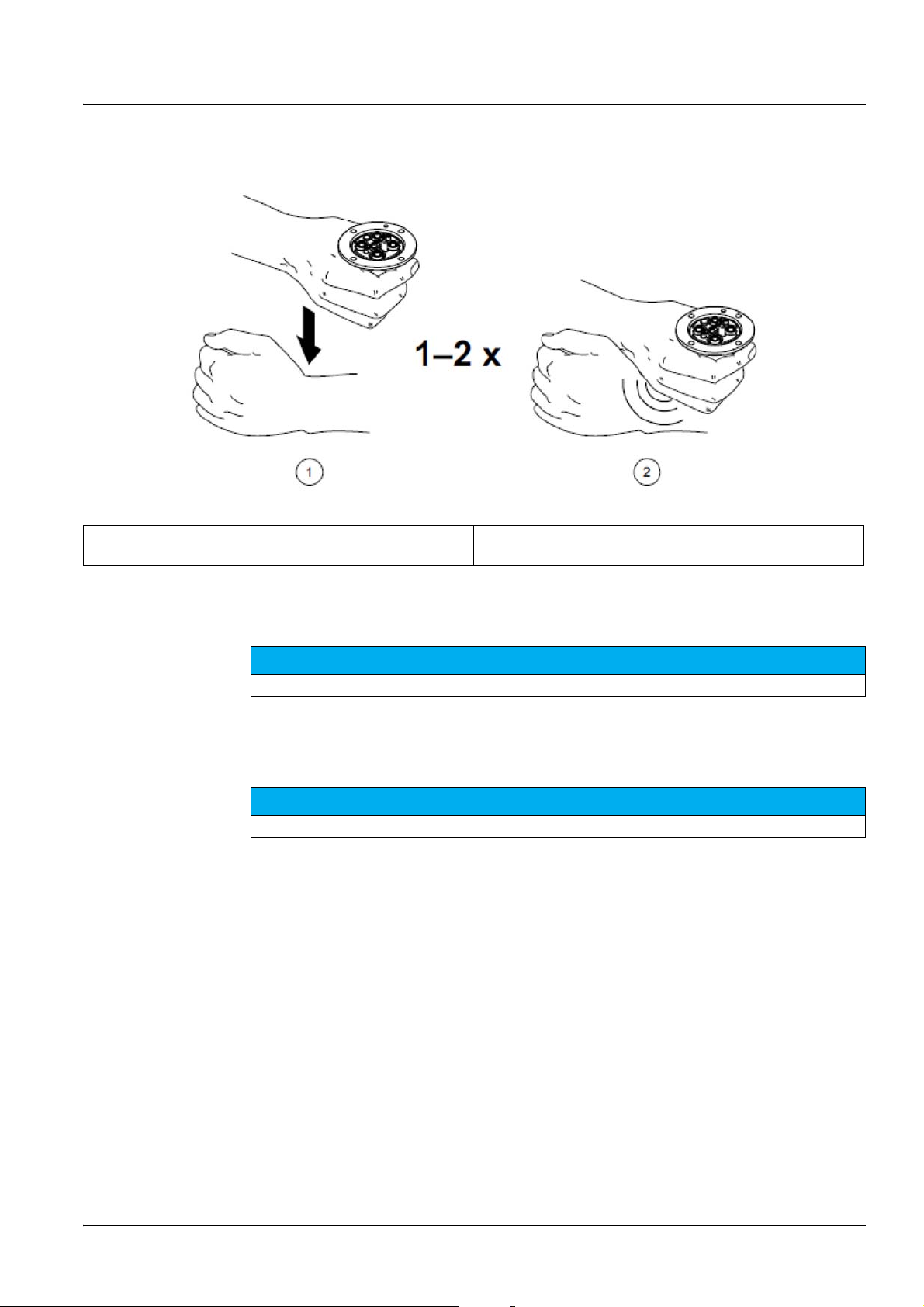

Please complete the following movement when you have unpacked the cartridge in order

to moisten the inside of the membranes.

Figure 8 Knocking the air out of the sensor cartridge

1 Hold the sensor cartridge in one hand with the

membranes facing downward.

Installation

2 Now hit sharply downward over your other hand.

3.3 Probe assembly

Avoid touching the membranes on the sensor cartridge or damage to the sensor may occur.

1. Place the black gasket Figure 10, Page 17 in the recess on the sensor body.

2. Make sure that the black gasket is correctly positioned.

The black gasket prevents sensor damage caused by moisture penetration.

NOTICE

NOTICE

15

Page 16

Installation

Figure 9 Sensor cartridge

1 Reference system cap 3 Front side with membranes

2 Rear side with contacts

NOTICE

The sensor cartridge must not be in contact with the air for more than 30 minutes.

The contacts in the sensor cartridge must be dry and must not become contaminated.

3. Align the marker hole on the sensor cartridge with the marker hole on the probe

adapter (refer to Figure 10, Page 17)

4. Place the 4 socket head screws in the corresponding screw holes and tighten gently

with the long side of the wrench. Then cross-tighten the screws by hand with the short

side of the wrench. Only use the screws supplied.

16

Page 17

Installation

Figure 10 Probe assembly

1 Socket head screw 5 Probe housing

2 Reference system cap 6 Union nut

3 Sensor cartridge 7 Marker hole

4 Black gasket 8 Socket head wrench

3.4 Installation of the cleaning unit (optional)

Please refer to the installation instructions for the cleaning unit for information on how to

install this on the probe.

Use the relay control on the sc controller to set the cleaning interval.

Select RTC (Real Time Clock) as the signal source. For details on more advanced relay

configuration, please refer to the User Manual for the relevant sc controller.

17

Page 18

Installation

3.5 Installation of the probe in the sample flow

NOTICE

Please handle the sensor cartridge carefully and avoid contact with the membranes when installing

the sensor.

There are mounts with separate installation instructions available for installation of the

probe, with or without a cleaning unit, to suit a number of different requirements.

Always observe the following prior to installation:

• The probe must be aligned with the bracket, as described in section 3.5.1, page 19.

• Position the probe at a distance of at least 200 mm (7.87 in.) from the tank wall.

• When the probe is attached with a chain mount, make sure that the probe cannot

strike the tank wall.

• Immerse the probe at an angle of approx. 45° ± 15°.

• Make sure that the probe is fully immersed.

• When using the cleaning unit refer to the supplied Instruction Sheet.

18

Page 19

3.5.1 Position of the probe on the mount

The probe must be attached in a specific position on the mount:

Figure 11 Installing the probe

1 Installation of the AN-ISE sc in the bracket. 45° adapter

and transition piece should be preassembled.

2 Aligning the probe using the colored reference system

cap. The salt bridge should be oriented upward (12 o'

clock, +/- 5°).

Installation

3 Attaching the aligned probe to the bracket using the

union nut

4 Removing the reference system cap

3.5.2 Probe installation example

Figure 12 Example of probe installation with rail mount

19

Page 20

Installation

3.6 Connect the probe to the sc controller (non-hazardous location) with screw fittings

The probe cable is supplied with a screw fitting with reverse polarity protection (refer to

Figure 13, Page 20). Retain the connector cap to seal the connector opening in case the

probe ever needs to be removed. Additional extension cables are available to increase the

probe cable length.

1. Unscrew the protective cap from the socket on the controller.

2. Insert the connector in the socket and hand-tighten the union nut.

Note: The middle connection on the sc1000 controller must not be used for probes as this is

reserved for the display module.

20

Figure 13 Connecting the probe to the sc controller with the screw fitting

Number Description Cable color

1 +12 VDC Brown

2 Ground Black

3 Data (+) blue

4 Data (–) White

5 Shield Shield (gray)

6 Guide

Page 21

Section 4 Operation

4.1 How to use an sc controller

The probe can be used with all sc controllers. Become familiarized with the controller's

functions before using the probe.

4.2 Sensor setup

When the sensor is connected for the first time, the sensor serial number is displayed as

the name of the sensor. To change the sensor name.

1. Open the MAIN MENU.

2. Select SENSOR SETUP and confirm.

3. Select the corresponding sensor and confirm.

4. Select CONFIGURE and confirm.

5. Select EDIT and confirm.

6. Edit the name and confirm to return to the CONFIGURE menu.

7. Check the sensor configuration and adjust as needed to meet requirements.

8. Go back to the MAIN MENU or the Measurement mode display.

4.3 Sensor data logger

Every sc-sensor provides a data memory and event memory within the sc controller. The

data memory is used to store measurement data at preset intervals; the event memory

stores events such as configuration changes, alarms and warning conditions. Both

memories can be read in CSV format (refer to the operating instructions for the sc

controller).

4.4 Sensor diagnostics menu

SENSOR STATUS

AN-ISE sc

ERROR LIST Displays all actual error codes.

ARNING LIST Displays all actual warnings.

W

21

Page 22

Operation

4.5 Sensor setup menu

SENSOR SETUP

AN-ISE sc

CALIBRATE

MATRIX CORR

NONE No MATRIX CORR. is activated

MATRIX 1 1 point matrix correction

NH4 + NO3 1 point matrix correction for ammonium and nitrate

NH4 1 point matrix correction for ammonium

NO3 1 point matrix correction for nitrate

NH4 + K 1 point matrix correction for ammonium and potassium

NO3 + CL 1 point matrix correction for nitrate and chloride

NH4+K NO3+CL 1 point matrix correction for ammonium, potassium, nitrate and chloride

TAKE SAMPLE IMMEDIATELY AND

ANALYSE IN LABORATORY

VALUE CORR. 1

NH4–N

NO3–N

VALUE POINT

AN-ISE SC NH4–N Enter the displayed ammonium value

AN-ISE SC K Enter the displayed potassium value

LAB NH4–N Enter the laboratory ammonium value

ENTRY COMPLETE Confirm the values entered

CORR-RESULT Display the correction results

VALUE CORR. 2 Perform 2 point value correction

NH4–N

NO3–N

VALUE POINT 1

AN-ISE SC NH4–N Enter the displayed ammonium value

AN-ISE SC K Enter the displayed potassium value

LAB NH4–N Enter the laboratory ammonium value

ENTRY COMPLETE Confirm the values entered

VALUE POINT 2

AN-ISE SC NH4–N Enter the displayed ammonium value

AN-ISE SC K Enter the displayed potassium value

LAB NH4–N Enter the laboratory ammonium value

ENTRY COMPLETE Confirm the values entered

CORR-RESULT Display the correction results

Matrix correction options.

The most recently used menu is displayed.

The currently active corrections are shown in Information.

Information window: When this window appears, the sample must be

taken immediately and then analyzed in the laboratory.

Perform 1 point value correction.

The most recently used menu is displayed.

The currently active corrections are shown in Information.

Select parameter for the 1 point value correction

Enter the values for the 1 point value correction

(below for the example of NH

Select parameter for the 2 point value correction

Enter the values for the 2 point value correction (first point) (below for

the example of NH

Enter the values for the 2 point value correction (second point) (below

for the example of NH

)

4

4

)

4

)

22

Page 23

4.5 Sensor setup menu (Continued)

SENSOR SETUP

FURTHER CORR. Other matrix correction options

None No FURTHER CORR. is activated

MATRIX 2 A 2 point matrix correction can be performed here

NH4

NO3

MEAS CONC 1 Saves the currently measured measurement for the first point

DATE Displays the date of the current correction of the first point

CONC. LABVALUE 1 Entry and display of reference value for the first point

MEAS CONC 2 Saves the currently measured measurement for the second point

DATE Displays the date of the current correction of the second point

CONC. LABVALUE 2 Entry and display of the reference value for the second point

HIST. CORR. Selection of one of the last corrections performed

SENSOR CODE The sensor code can be activated or entered here

INPUT Entry of the sensor code

AC TIVATION Activates the sensor code for the individual channels

NH4 + K Activate the sensor code for ammonium and potassium

NO3 + CL Activate the sensor code for nitrate and chloride

NH4+K NO3+CL

FACTORY CALIBRATION Activates factory calibration

ENTER CORR. The laboratory values of the last matrix correction can be changed

ENTER LABVALUE (displayed when MATRIX 1

or MATRIX 2 is performed)

AMMONIUM Enter the labatory value for ammonium

NITRATE Enter the laboratory value for nitrate

POTASSIUM Enter the laboratory value for potassium

CHLORIDE Enter the laboratory value for chloride

ENTRY COMPLETE Confirm the values entered

CORR-RESULT Display the correction results

NH4–N Displays whether or not the ammonium correction was successful

NO3–N Displays whether or not the nitrate correction was successful

K+ Displays whether or not the potassium correction was successful

CL Displays whether or not the chloride correction was successful

INFORMATION Information on the matrix correction used per parameter

NH4–N Matrix correction used for ammonium

NO3–N Matrix correction used for nitrate

K+ Matrix correction used for potassium

CL Matrix correction used for chloride

Parameter selection for the MATRIX2 correction.

Activate the sensor code for ammonium, potassium, nitrate and

chloride

Enter the laboratory values if MATRIX 1 or MATRIX 2 has been

selected

Operation

23

Page 24

Operation

4.5 Sensor setup menu (Continued)

SENSOR SETUP

CONFIGURE

EDIT NAME

MEAS UNITS Select either mg/L or ppm as the measurement unit

PARAMETERS Select NH4–N/NO3–N or NH4/NO

TEMP UNITS Selection of °C or °F as temperature unit

TEMP OFFSET Enter a temperature offset

RESPONSE TIME Entry of the response time (30 sec to 300 sec)

DATALOG INTRVL

K+ COMPENSATE

SET K+ CONC Only shown when K+ COMPENSATE is OFF

CL COMPNSATE

SET CL CONC Only shown when CL COMPNSATE is OFF

FACTORY CONFIG Resets the configuration on the factory setting

DIAG/TEST

SENSOR INFO Information on the connected sensor

SENSOR NAME Name of the connected sensor

EDIT NAME Serial number or name of the measurement location

SERIAL NUMBER Serial number of the connected sensor

SENSOR TYPE Instrument designation of the connected sensor

CODE VERS Software version

CAL DATA

NH4–N Matrix correction selected for ammonium

NO3–N Matrix correction selected for nitrate

K+ Matrix correction selected for potassium

CL Matrix correction selected for chloride

SIGNALS Signals and measurements of the individual measurement channels

AMMONIUM Display the signals and measurement results for ammonium

NITRATE Display the signals and measurement results for nitrate

POTASSIUM Display the signals and measurement results for potassium

CHLORIDE Display the signals and measurement results for chloride

REF. ELECTRODE Displays the signals and measurement results for the reference system

MV RAW Display the signals and measurement results for MV RAW

IMPED STATUS Display the signals and measurement results for impedance

Enter or edit the name.

Up to 10 alphanumeric characters

3

Select the data log interval (OFF, 30 sec, 1 min, 2 min, 5 min, 10 min,

15 min and 30 min), 5 min is the factory setting

Select automatic potassium compensation:

On

Off

0 = compensation OFF

+

0.1–2000 mg/L K

Select automatic chloride compensation:

On

Off

0 = compensation OFF

0.1–2000 mg/L CL = Fixed compensation value

Data of the selected MATRIX correction and information about slope

and offset of the individual channels, for example

= Fixed compensation value

24

Page 25

4.5 Sensor setup menu (Continued)

SENSOR SETUP

TEMP Display the signals and measurement results for temperature

HUMIDITY Display the signals and measurement results for humidity

RFID Display the signals and measurement results for RFID

CAL DAYS Display the age of the last matrix correction

AMMONIUM Display the age of the last m

NITRATE Display the age of the last m

SERVICE

TEST CARTRIDGE Perform a sensor check with the test cartridge

TEST CARTRIDGE FERTIG? DRÜCKE ENTER

TEST CARTRIDGE Display whether the individual sensor channels are OK or not

DIAG/TEST Displays whether or not DIAG/TEST is OK

GNDROD Displays whether or not GNDROD is OK

REF Displays whether or not REF channel is OK

NO3 Displays whether or not NO3 channel is OK

NH4 Displays whether or not NH4 channel is OK

ORP Displays whether or not ORP channel is OK

CL Displays whether or not CL channel is OK

+

K

TEMP Displays whether or not temperature channel is OK

CHANGE CARTR. Follow the menu process

CLEANING

Displays whether or not K channel is OK

Follow the menu process

atrix correction for ammonium

atrix correction for nitrate

Operation

for ammonium and nitrate

4.6 Calibration/Matrix correction

The four electrodes with the reference system of the compact sensor cartridge were

calibrated with one another at the factory using special standard solutions (CARTICAL

However, the membranes on the ion-selective electrodes are not 100% selective due to

other substances that may affect the measurement. Perform a matrix correction (refer to

4.6.4 on page 27) to compensate for other ions present on the ISE electrodes.

Potassium has the largest interference effect on the ammonium membrane, while chloride

has the largest effect on the nitrate membrane. The AN-ISE sc sensor compensates for

this with the aid of a built-in potassium/chloride electrode.

Cross sensitivities between ammonium, potassium/nitrate and chloride are automatically

eliminated. Solids do not interfere with the measurement. Due to matrix effects, correction

and validation cannot be performed with standard solutions. A matrix correction can be

carried out quickly and easily at any time.

A matrix correction may only be performed if the sensor has been immersed in the corresponding

wastewater matrix for over 12 hours. This is the minimum time required to adapt the ISE

membranes to the wastewater matrix.

NOTICE

TM

).

25

Page 26

Operation

4.6.1 Sensor code calibration

The sensor code is a calibration code and is delivered with the sensor cartridge certificate.

It contains the factory calibration described in section 4.6 on page 25 for the sensor

cartridge.

Instruments with automatic sensor code recognition (LXG440.99.0000x) read this

automatically and assume the Cartrical calibration.

Instruments without automatic sensor code recognition (LXG440.99.0001x) require the

sensor code to be entered during the initial setup and whenever a new sensor cartridge is

activated. If the sensor code certificate has been lost, please carry out factory calibration

(under the sensor code menu) as a temporary solution.

After activating the code, the sensor is fully calibrated but not yet adapted to the specific

matrix of the relevant application on a wastewater treatment plant. At least 12 hours must

elapse before a matrix correction is performed to allow the cartridge to adapt to the

specific matrix.

To change the sensor code:

1. Select

CODE>ENTER

2. Enter the sensor code.

3. Press

is set to zero.

All old calibration data are now overwritten with the new calibration data from the sensor

code. The sensor code data are checked by the system. If an error is indicated, check the

sensor code and if necessary repeat the entry of the sensor code.

SENSOR MENU>AN-ISE SC>CALIBRATE>FURTHER CORR.>SENSOR

ENTER to confirm and activate the sensor code. The day meter for the cartridge

4.6.2 Matrix correction via LINK2SC

The LINK2SC procedure offers a secure method of data exchange between process

probes and LINK2SC-compatible photometers using an SD memory card or via a local

area network (LAN). There are two different options are available:

a. The pure laboratory control measurement

b. A matrix correction that involves the measurement data generated in the

laboratory being used to correct the probe

During a pure control measurement, the measurement data is transferred from the prove

to the photometer where it is then archived together with the photometric reference data

that has been recorded.

During a matrix correction, the reference data generated in the laboratory is transferred to

the probe where is used for the correction.

The matrix correction process requires operating steps to be completed on the sc

controller and on a LINK2SC-compatible photometer.

Please refer to the LINK2SC user manual for a detailed description of the LINK2SC

procedure.

When using the LINK2SC software, sections 4.6.3 and 4.6.4 are not relevant.

4.6.3 Matrix correction overview

The AN-ISE sc sensor offers different options

(refer to Table 1) for correcting the sensor value with laboratory values (as a reference

value).

26

Page 27

The laboratory value of the water sample is entered as nitrate-nitrogen (NO3–N) or as

ammonium-nitrogen (NH

–N). This laboratory value replaces the prior value measured by

4

the sensor.

Tabl e 1 AN-ISE sc sensor correction options

Correction Option Application

A MATRIX 1 is the most commonly used correction option and performs a 1 point matrix

correction for ammonium and/or nitrate (4.6.4.1 on page 27). It is advisable to perform a MATRIX1 as

the first correction. The Matrix1 correction can be performed both with and without correction of the

MATRIX 1

VAL UE CO RR. 1

VAL UE CO RR. 2

MATRIX 2

HIST. CORR.

1

Examples of half a decade: The concentration of nitrogen nitrate shifts between 1 and 5 mg NO3–N or

between 5 and 25 mg/L NO3–N. (conc2 = (conc1 x 10)/2)

compensation electrodes (potassium or chloride); in most cases, it is sufficient to perform it without

correction of the compensation electrodes. A correction featuring potassium and chloride is only

necessary if a high level of accuracy is required. With a MATRIX1, a sample must be taken when the

correction is triggered and analyzed in the laboratory. The MATRIX1 is activated when the laboratory

value is entered.

Value correction 1 (correction at one concentration point) corresponds to a MA

with an alternative entry format.

Comparison values between AN-ISE sc and the laboratory can be collected over a period of around

a week with this correction. The correction can be performed at a later stage.

Value correction 2 (correction at 2 different concentration points) should be performed if dynamic

centration fluctuations are present over at least half a decade1 and a MATRIX1 or VALUE

con

CORR. 1 does not achieve a sufficiently accurate result.

Comparison values between AN-ISE sc and the laboratory can be collected over a period of around

a week with this correction. The correction can be performed at a later stage.

The MA

format and is recommended if there is a dynamic process with a large nitrate/ammonium fluctuation

over at least half a decade1. With a MATRIX2, a sample must be taken for both points when the

correction is triggered and analyzed in the laboratory. The MATRIX2 is activated when the laboratory

value is entered.

Return to one of the last matrix and value corrections performed if a correction has not produced

a successful result.

TRIX 2 correction corresponds to a VALUE CORR.2, but uses an alternative entry

Operation

TRIX1 correction

4.6.4 Performing the matrix correction

Note: Take laboratory value measurements or reference values promptly or, alternatively, take these

from the stabilized sample. This will prevent changes in sample concentration, as time is a factor in

comparative tests.

Refer to 7.3 Validation accessories, page 39 for recommended laboratory measurement

tests.

4.6.4.1 MATRIX 1 correction (1 point matrix correction)

Proceed as follows to perform MATRIX 1:

CALIBRATE

MATRIX CORR

FURTHER CORR.

INFORMATION

1. Select

2. Select

3. Select the parameters you wish to correct and confirm by pressing

options:

NH

NO

SENSOR MENU>AN-ISE SC>CALIBRATE>MATRIX CORR.

MATRIX 1 from the selection window and press ENTER.

+ NO3; NH4; NO3; NH4 + K;

4

+ Cl; NH4 + K NO3 + Cl.

3

ENTER. Selection

27

Page 28

Operation

MATRIX 1

TAKE SAMPLE

IMMEDIATELY

AND ANALYSE

IN LABORATORY

CALIBRATE

MATRIX CORR

FURTHER CORR.

ENTER LABVALUE

INFORMATION

The sensor saves the current values of the selected parameters at this point.

4. Take a water sample immediately from the closest point possible to the sensor. Filter

the sample as quickly as possible and carry out a prompt laboratory analysis of the

selected parameters, as the measurement value can change quickly.

When the laboratory value has been determined, proceed as follows:

5. Select

6. The laboratory values for the parameters can only be entered if the MATRIX1

correction has been selected beforehand. Once the laboratory values have been

entered, select

When the entered laboratory value is confirmed, the matrix correction is activated.

7. Once the correction is activated, the result

Note: This process must always be carried out in full to make sure the matrix correction is

completed successfully.

If a correction does not produce a successful result, calculations are made with the previous

correction.

4.6.4.2 Value correction 1

The one-point value correction VALUE CORR. 1 offers the option of retrospectively

CALIBRATE

MATRIX CORR

FURTHER CORR.

INFORMATION

performing a matrix correction at one point (

1. Take several samples with different concentrations on various days, preferably within

one week. Analyze the samples in the laboratory. During the time the samples are

being taken, the sample temperature should be around a maximum of 5 °C, as

temperature changes are not taken into account in the value correction.

SENSOR MENU>AN-ISE SC>CALIBRATE>ENTER LABVALUE

ENTRY COMPLETE to confirm.

CORR-RESULT is shown.

MATRIX1).

VAL UE POINT

AN–ISE SC NH4–N

AN–ISE SC K

LAB NH4–N

ENTRY COMPLETE

2. Make a note of the two values measured in the samples and displayed for the

parameters to be corrected (ammonium and potassium values, or nitrate and chloride

values)

3. Also note the laboratory values measured for ammonium or nitrate.

These three values form the correction point.

4. From the values taken, select a correction point that lies in the middle of the expected

concentration range.

5. Go to the sensor menu and select

confirm by pressing

6. Select the parameter (NH

ENTER.

–N or NO3–N) that requires correction.

4

7. Enter the three values for the sought correction point and confirm with

COMPLETE

Correction result

Note: If a correction does not produce a successful result, calculations are made with the previous

correction.

After successful completion of value correction, the corrected value is shown as the display value for

ammonium or nitrate the next time the menu is opened.

to activate the correction.

CORR-RESULT is shown.

CALIBRATE>MATRIX CORR>VALUE CORR. 1 and

ENTRY

28

Page 29

4.6.4.3 Value correction 2

The two-point value correction VALUE CORR. 2 makes it possible to perform a subsequent

CALIBRATE

MATRIX CORR

FURTHER CORR.

INFORMATION

2-point correction (

Note: Value correction 2 and MATRIX 2 are comparable from a calculation perspective.

1. Take several samples on various days with different concentrations, preferably within

a week, and perform an analysis of the samples in the laboratory. During the time the

samples are being taken, the sample temperature should be around a maximum of 5

°C, as temperature changes are not taken into account in the value correction.

Note: The VALUE CORR. 2 concentrations should be within a range of over half a decade. The

following formula can assist in the calculation of the half decade:

Operation

MATRIX2) to achieve higher accuracy for a larger concentration range.

VALUE POINT 1

AN–ISE SC NH4–N

AN–ISE SC K

LAB NH4–N

ENTRY COMPLETE

Conc2 >=

Conc1 × 10

2

2. Make a note of the two values measured with the sensor in the samples and displayed

for the parameters to be corrected (ammonium and potassium values, or nitrate and

chloride values).

3. Also note the laboratory value measured for ammonium or nitrate.

All three values form one of the two correction points.

4. Look for two correction points where the laboratory values are at least half a decade

apart and display typical operating conditions for the installation.

5. Go to the sensor menu and select

confirm with

6. Select the parameter (NH

Note: Only one parameter can be corrected at a time. If both need to be corrected, the procedure

must be performed again.

ENTER.

–N or NO3–N) that requires correction.

4

CALIBRATE>MATRIX CORR>VALUE CORR. 2 then

7. Enter the three values for the first correction point and confirm with ENTRY

COMPLETE

.

VALUE POINT 2

AN–ISE SC NH4–N

AN–ISE SC K

LAB NH4–N

ENTRY COMPLETE

8. To activate the correction, enter the three values for the second correction point and

confirm with

Correction result

Note: If a correction does not produce a successful result, calculations are made with the previous

correction. After successful completion of value correction, the corrected value is shown as the

display value for ammonium or nitrate the next time the menu is opened.

ENTRY COMPLETE.

CORR-RESULT is shown.

29

Page 30

Operation

4.6.4.4 MATRIX 2 correction (2 point matrix correction)

Proceed as follows to perform MATRIX 2:

AMMONIUM

CONC MEAS1

DATE

CONC. LABVALUE.1

MEAS CONC 2

DATE

CONC. LABVALUE 2

1. Select

2. Select

SENSOR MENU>AN-ISE SC>CALIBRATE>FURTHER CORR..

MATRIX 2 from the selection window and press ENTER.

3. Select the parameters requiring a two point matrix correction.

4. Select the point to be corrected first.

5.

SELECT MEAS CONC 1 or MEAS CONC 2

6. Take a water sample from the closest point possible to the sensor. Filter this sample

promptly and perform an immediate laboratory analysis of the selected parameters.

The measurement value can change very quickly:

When the laboratory value has been determined, proceed as follows:

7. Select

SENSOR MENU>ANISE SC>CALIBRATE>FURTHER CORR.>MATRIX 2

8. Select the parameters to be corrected with the laboratory value entry:

9. Enter the laboratory reference value and confirm.

The

MATRIX2 CORR. is activated when the entry is confirmed for both points.

30

Page 31

Section 5 Maintenance

Only qualified personnel should conduct the tasks described in this section of the operating

manual.

5.1 Maintenance schedule

NOTICE

Maintenance task 30 days

Clean the probe2 x

Replace the sensor cartridge

Check probe for damage x

Compare the measured value with a reference laboratory analysis and correct

the values as required via a matrix correction

1

Recommended: Weekly during the first month of operation

2

The frequency of cleaning depends on the application. Some applications may require cleaning to take place more or less

frequently.

3

In typical operating conditions, a different interval may be required depending on the specific application and local conditions.

4

Sensor cartridges are wear parts and are not covered by the instrument warranty.

3, 4

3

Note: Do not test the sensor with the usual NH4-N or NO3-N standard solutions as the ion strength

of normal solutions is not high enough.

1

x

12 months

x

5.2 Clean the sensor

NOTICE

Do not touch the membranes with fingers. Do not clean the sensor cartridge with sharp objects that

may cause scratches and do not use any chemical cleaning agent.

1. Clean the sensor cartridge with the soft brush supplied.

2. Clean the probe body (not the sensor cartridge) with a sponge or brush.

3. Rinse the sensor with clean, lukewarm water.

5.2.1 Polish the chloride electrode

Polish the chloride electrode if it looks heavily coated/contaminated.

After polishing, a new nitrate + chloride MATRIX1 correction should be performed after

12 hours.

Only use the LZY671 polishing paper supplied.

NOTICE

31

Page 32

Maintenance

Figure 14 Chloride electrode

5.3 Replace the sensor cartridge

The sensor cartridge is replaced as described below and in Figure 15, Page 33.

1. Replace the cartridge using menu point

CARTR.

2. Clean the probe and thoroughly dry the sensor cartridge and probe adapter.

3. Loosen the 4 socket head screws.

The sensor cartridge must point downward such that no water can run into the probe adapter. Pay

attention to the contacts between the probe and the sensor cartridge. The contacts have to remain

dry.

4. Pull the sensor cartridge out of the probe adapter and dispose of the old sensor

cartridge as per the applicable regulations.

5. Make sure that a new black gasket is installed every time the sensor cartridge is

replaced. Before the gasket is installed, clean the surface that faces the cartridge and

the groove for the gasket.

.

ANISE SC>DIAG/TEST>SERVICE>CHANGE

NOTICE

.

32

6. Insert the new sensor cartridge into the probe adapter. Observe the marker hole on

the sensor cartridge flange and the probe adapter.

7. Secure the sensor cartridge with the 4 socket head screws.

8. The sensor code (calibration data) is automatically read for instruments with automatic

recognition (LXG440.99.0000x). For instruments with non-automatic recognition

(LXG440.99.0001x), enter the new sensor code manually (refer to certificate).

Page 33

Maintenance

Figure 15 Replace the sensor cartridge

1 Socket head screw 5 Union nut

2 Sensor cartridge 6 Marker hole

3 Gasket 7 Socket head wrench

4 Sensor

33

Page 34

Maintenance

5.4 Storage

Take the probe out of the sample flow and clean thoroughly.

Short term storage

Keep the membranes and the reference system wet (DO NOT USE DISTILLED OR

DEMINERALIZED WATER). Drinking water is advised.

This will help avoid long response times when the probe is placed back in the sample flow.

Otherwise, the correct operation of the probe is no longer guaranteed.

Long term storage

NOTICE

Detach the cartridge and use the supplied storage container in the event of long-term storage.

Moisten the little sponge in the storage container with drinking water (DO NOT USE DISTILLED

OR DEMINERALIZED WATER) and make sure that the ISE membranes of the sensor cartridge

remain wet. Attach the reference system cap.

Check the membranes and ensure they are still moist every 2–4 weeks, depending on

environmental conditions.

Note: A storage container is supplied to keep the sensor cartridge moist. Keep sensor cartridge

capped within the storage container during short and long term storage. Refer to

Section 1 Specifications, Page 5 for storage temperatures.

Probe and sensor cartridge

Pay attention to the contacts betw

dry.

NOTICE

een the probe and the sensor cartridge. The contacts must be

34

Page 35

Section 6 Troubleshooting

6.1 Error messages

When the sensor is experiencing an error condition, the sensor reading on the

measurement screen will flash and the relays and analog outputs associated with this

sensor will be held. Errors are defined in Table 2.

Table 2 Error messages

Displayed errors Definition Resolution

NH4 mV RANGE! Ammonium mV value is out of measuring range

K+ mV RANGE! Potassium mV value is out of measuring range

NO3 mV RANGE! Nitrate mV value is out of measurement range

mV RANGE! Chloride mV value is out of measurement range

CL

REF1 mV RANGE! REF1 reference value is out of measuring range

REF2 mV RANGE!

TEMP RANGE Temperature value out of measurement range

NO CARTRIDGE No sensor cartridge connected

SENSOR CODE Sensor code calibration failed

HUMIDITY Humidity in the probe Inform service engineer

NH4-N CONC HIGH

NH4-N CONC LOW

NO3-N CONC HIGH

NO3-N CONC LOW

K+ CONC HIGH

K+ CONC LOW

CL CONC HIGH

CL CONC LOW

ORP electrode mV value is out of measuring

range

Ammonium concentration value exceeds

measuring range

Ammonium concentration value is below

measuring range

Nitrate concentration value exceeds measuring

range

Nitrate concentration value is below measuring

range

Potassium concentration value exceeds

measuring range

Potassium concentration value is below

measuring range

Chloride concentration value exceeds measuring

range

Chloride concentration value is below measuring

range

See 6.3.1 Troubleshooting during operation,

Page 37.

Connect sensor cartridge, see section 3.3,

page 15.

See 6.3.2 Troubleshooting during calibration,

Page 38

See 6.3.1 Troubleshooting during operation,

Page 37.

35

Page 36

Troubleshooting

6.2 Warnings

In the event of a sensor warning, all menus, relays and outputs continue to function as

normal but a warning symbol lights up.

Warnings may be used to trigger a relay and users can set warning levels to define the

severity. Warnings are defined in Table 3.

Table 3 Warnings

Displayed warnings Definition Resolution

RFID DATA Cartridge faulty, read process failed

NH4 mV RANGE!

K+ mV RANGE!

NO3 mV RANGE!

CL mV RANGE!

REF1 mV RANGE! 1st reference value is close to limit

REF2 mV RANGE! 2nd reference value is close to limit

TEMPERATURE Temperature is close to limit

CARTRIDGE OLD Sensor cartridge more than 1 year old Replace the sensor cartridge

NH4-N CONC HIGH

NH4-N CONC LOW

NO3-N CONC HIGH

NO3-N CONC LOW

K+ CONC HIGH

K+ CONC LOW

CL CONC HIGH

CL CONC LOW

AMMONIUM

OFFSET Ammonium offset is out of measuring range

SLOPE Ammonium slope is out of measuring range

POTASSIUM

OFFSET Potassium offset is out of measuring range

SLOPE Potassium slope is out of measuring range

NITRATE

OFFSET Nitrate offset is out of measurement range

SLOPE Nitrate slope is out of measurement range

CHLORIDE

OFFSET Chloride offset is out of measurement range

SLOPE Chloride slope is out of measurement range

Ammonium mV value is close to measuring range

limit

Potassium mV value is close to measuring range

limit

Nitrate mV value is close to measurement range

limit

Chloride mV value is close to measurement range

limit

Ammonium concentration value exceeds

measuring range

Ammonium concentration value is below

measuring range

Nitrate concentration value exceeds measuring

range

Nitrate concentration value is below measuring

range

Potassium concentration value exceeds

measuring range

Potassium concentration value is below

measuring range

Chloride concentration value exceeds measuring

range

Chloride concentration value is below measuring

range

Replace cartridge, check probe with test

cartridge

See 6.3.1 Troubleshooting during operation,

Page 37.

See 6.3.1 Troubleshooting during operation,

Page 37.

See 6.3.2 Troubleshooting during calibration,

Page 38.

36

Page 37

6.3 Troubleshooting

6.3.1 Troubleshooting during operation

Symptom Possible cause Corrective actions

Troubleshooting

Incorrect measurement

values

Incorrect measurement

values

Calibration too old; calibration was not suitable for

the particular case; big change in the wastewater

matrix

Strongly contaminated membranes and/or

reference electrode

Sensor membrane damaged

Reference element damaged

NO3 mV RANGE! (Nitrate mV value is out of

measurement range)

CL mV RANGE! (Chloride value is out of

measurement range)

REF1 RANGE! (measuring range exceeded on

1st reference value)

REF2 RANGE! (measuring range exceeded on

2nd reference value)

TEMPERATURE (Temperature value is out of

measurement range)

CARTRIDGE OLD (sensor cartridge more than

1 year old)

Dampness at the contacts of the sensor cartridge

Dampness inside the measuring probe/faulty

sensor electronics

Check the sensor electronics by using the test

cartridge (section 7.2, page 39).

1 Select SENSOR MENU>DIAG/TEST>

SERVICE>TEST CARTRIDGE>

Test Cartridge ready? Press ENTER

2 If all channels are confirmed with OK, the

sensor electronics are operational:

Test cartridge

OK

ENTER

Potassium concentrations too high (e.g.: >700

mg/L with small ammonium concentrations) or

chloride concentrations too high (e.g.: >1000 mg/L

with small nitrate concentrations)

Perform a suitable calibration.

See 4.6 Calibration/Matrix correction,

Page 25

Clean the sensor cartridge using a brush

and/or rinse the sensor cartridge with clean

water (without cleaning agents), and wipe the

sensor cartridge carefully with a soft, clean

cloth.

Clean all components (membranes/reference

electrode/temperature sensor).

Install the cleaning unit

Increase the cleaning interval

Check the sensor installation/

replace the sensor cartridge

Replace the sensor cartridge

Replace the sensor cartridge/check the

wastewater temperature

Replace the sensor cartridge

Dry the contact with a cloth or paper

Check the black gasket for damage and

make sure it is in the correct position.

Screw the 4 socket head screws tight.

If the test cartridge data are not within this

range or if the test cartridge check is not

successful, contact our service department.

Switch off potassium/chloride compensation

(in the configuration menu - then potentially

enter a fixed value for potassium/chloride)

37

Page 38

Troubleshooting

6.3.1 Troubleshooting during operation (Continued)

Symptom Possible cause Corrective actions

Air bubbles, depth of immersion

Unstable measurement

values

Dampness at the contacts of the sensor cartridge

Sensor membrane damaged

Reference element damaged

6.3.2 Troubleshooting during calibration

Symptom Possible cause Corrective actions

SENSOR CODE Sensor code entered incorrectly

AMMONIUM

Check the sensor installation

Check the cleaning unit configuration

Dry the contacts with a cloth or paper.

Check the black gasket for damage and

make sure it is in the correct position.

Screw the 4 socket head screws tight

Check the sensor installation/

replace the sensor cartridge

Using the certificate, check whether the

sensor code was entered correctly.

OFFSET

SLOPE

POTASSIUM

OFFSET

SLOPE

NITRATE

OFFSET

SLOPE

CHLORIDE

Error during the last ammonium correction, sensor

cartridge too old, contaminated, faulty

Error during the last potassium correction, sensor

cartridge too old, contaminated, faulty

Error during the last nitrate correction, sensor

cartridge too old, contaminated, faulty

Repeat the correction.

Use the previous correction.

Clean or replace the sensor cartridge.

Repeat the correction.

Use the previous correction.

Clean or replace the sensor cartridge.

Repeat the correction.

Use the previous correction.

Clean or replace the sensor cartridge.

OFFSET

SLOPE

38

Error during the last chloride correction, sensor

cartridge too old, contaminated, faulty

Repeat the correction.

Use the previous correction.

Clean or replace the sensor cartridge.

Page 39

Section 7 Replacement parts and accessories

7.1 Replacement Parts

Description Catalog Number

AN-ISE sc (probe with built-in 10-m cable and a pre-calibrated sensor cartridge) LXV440.99.000x1

AN-ISE sensor cartridge, calibrated

Cleaning brush LZY589

Black gasket LZY713

Cartridge screw set (4 screws and socket head wrench) LZY715

Protective cap for reference system LZY588

Cable clip for AN-ISE sc LZY717

1

Sensor cartridges are wearing parts that are not covered by the instrument warranty.

1

7.2 Accessories

Description Catalog Number

Cleaning Unit LZY706

Rail Mount Kit 6184900

Chain Mount Kit LZX914.99.12400

Stainless Steel Basin Edge Mounting LZX414.00.80000

High Output Air Blast compressor 115 V/50 Hz 6860003.99.0001

High Output Air Blast compressor 230 V/50 Hz 6860103.99.0001

Test cartridge LZY720

Polishing paper for chloride electrode LZY671

LZY694

7.3 Validation accessories

Description Catalog Number

Nitrate cuvette test (measurement range: 0.23–13.5 mg/L NO3–N/1–60 mg/L NO3) LCK 339

Nitrate cuvette test (measurement range: 5–35 mg/L NO

Chloride cuvette test (measurement range: 1–1000 mg/L Cl) LCK 311

Chloride test strips (measurement range: 30–600 mg/L Cl) 27449-40

Ammonium cuvette test (measurement range: 2–47 mg/L NH4–N/2.5–60.0 mg/L NH4) LCK 303

Ammonium cuvette test (measurement range 1–12 mg/L NH

Potassium cuvette test (measurement range: 5–50 mg/L K) LCK 228

–N/22–155 mg/L NO3)LCK 340

3

-N/1.3–15.0 mg/L NH4)LCK 305

4

7.4 Corresponding documentation

Description Catalog Number

Instruction sheet Cleaning Unit DOC273.99.90203

Instruction sheet Rail Mounting DOC273.99.90201

Instruction sheet Chain Mounting DOC273.99.90322

Compressor operating instructions ("HOAB") DOC023.53.00811

sc100 operating instructions DOC023.53.00032

sc1000 operating instructions DOC023.53.03260

39

Page 40

Replacement parts and accessories

40

Page 41

Section 8 Contact

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE

Rorschacherstrasse 30 a

CH-9424 Rheineck

Tel. +41 (0)71 886 91 11

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0)8 20 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Fax +48 717 174 088

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3

Sector 2

RO-021741 Bucureş

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

ti

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

41

Page 42

Contact

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

42

Page 43

Section 9 Limited warranty

Hach Company warrants its products to the original purchaser against any defects that are

due to faulty material or workmanship for a period of one year from date of shipment

unless otherwise noted in the product manual.

In the event that a defect is discovered during the warranty period, Hach Company agrees

that, at its option, it will repair or replace the defective product or refund the purchase price

excluding original shipping and handling charges. Any product repaired or replaced under

this warranty will be warranted only for the remainder of the original product warranty

period.

This warranty does not apply to consumable products such as chemical reagents; or

consumable components of a product, such as, but not limited to, lamps and tubing.

Contact Hach Company or your distributor to initiate warranty support. Products may not

be returned without authorization from Hach Company.

Limitations

This warranty does not cover:

• Damage caused by acts of God, natural disaster, labor unrest, acts of war (declared or

undeclared), terrorism, civil strife or acts of any governmental jurisdiction

• Damage caused by misuse, neglect, accident or improper application or installation

• Damage caused by any repair or attempted repair not authorized by Hach Company

• Any product not used in accordance with the instructions furnished by Hach Company

• Freight charges to return merchandise to Hach Company

• Freight charges on expedited or express shipment of warranted parts or product

• Travel fees associated with on-site warranty repair

This warranty contains the sole express warranty made by Hach Company in connection

with its products. All implied warranties, including without limitation, the warranties of

merchantability and fitness for a particular purpose, are expressly disclaimed.

Some states within the United States do not allow the disclaimer of implied warranties and

if this is true in your state the above limitation may not apply to you. This warranty gives

you specific rights, and you may also have other rights that vary from state to state.

This warranty constitutes the final, complete, and exclusive statement of warranty terms

and no person is authorized to make any other warranties or representations on behalf of

Hach Company.

Limitation of Remedies

The remedies of repair, replacement or refund of purchase price as stated above are the

exclusive remedies for the breach of this warranty. On the basis of strict liability or under

any other legal theory, in no event shall Hach Company be liable for any incidental or

consequential damages of any kind for breach of warranty or negligence.

43

Page 44

Limited warranty

44

Page 45

Section 10 Certification

10.1 Certification

FCC ID: YCB – LXG440

IC ID: 5879A – LXG440

This device complies with Part of the FCC and Industry Canada license exempt RSS

standard(s).

Operation is subject to the following two conditions:

1. this device may not cause interference, and

2. this device must accept any interference, including interference that may cause

undesired operation of the device."

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes :

1. l'appareil nedoit pas produire de brouillage, et

2. l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement."

Changes or modifications to this equipment not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following techniques can be

used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source

of the interference.

2. If the equipment is connected to the same outlet as the device experiencing

interference, connect the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

45

Page 46

Certification

46

Page 47

Appendix A Modbus Register

Tag N ame Register # Data Type Length R/W

AMMONIUM NH4-N 40001 Float 2 R 0/1500 AMMONIUM as NH4-N [mg/l]

AMMONIUM NH4 40003 Float 2 R 0/1932 AMMONIUM as NH4 [mg/l]

Nitrate NO3-N 40005 Float 2 R 0/1500 Nitrate as NO3-N [mg/l]

Nitrate NO3 40007 Float 2 R 0/6643 Nitrate as NO3 [mg/l]

Potassium 40009 Float 2 R 0/1500 Potassium [mg/l]

Chloride 40011 Float 2 R 0/1500 Chloride [mg/l]

TEMPERATURE [C] 40013 Float 2 R 0/60 TEMPERATURE [C]

TEMPERATURE [F] 40015 Float 2 R -54/180 TEMPERATURE [F]

Location 40025 String 8 R/W Location

MEAS UNITS 40033

SET PARAMETER 40034

TEMP UNITS 40035

TEMP ADJUST [C] 40036 Float 2 R/W -1.5/1.5 TEMP ADJUST [C]

TEMP ADJUST [F] 40038 Float 2 R/W -2.7/2.7 TEMP ADJUST [F]

Response Interval 40040

Logger Interval 40041

K+ compensation 40042

K+ subsitute value 40043 Float 2 R/W 0/1500

Chlorine

compensation

Cl subsitute value 40046 Float 2 R/W 0/1500

SERIAL NUMBER 40049 String 6 R/W SERIAL NUMBER

AC Code Version 40055 Float 2 R

BC Code Version 40057 Float 2 R

Structure DD 40059

Content DD 40060

Firmware DD 40061

Moist [%] 40062

Ammonium mV 40063 Float 2 R

40045

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

Unsigned

Integer

1 R/W U0/2 MEAS UNITS mg/l;ppm

1 R/W 0/1 NH4-N&NO3-N; NH4&NO3

1 R/W U25/26 °C; °F

1 R/W 10/1800 Response Interval

1R/W

1 R/W 0/1 K+ compensation on/off

1 R/W 0/1 Chlorine compensation on/off

1 R 0/255 Structure DD

1 R 0/255 Content DD

1 R 0/255 Firmware DD

1 R 0/100

Discrete

Range

0/1/2/3/4/

5/6/7

Min/Max

Range

0/3.402823

47E+38

0/3.402823

47E+38

-2000/2000

Description

Logger Interval

K+ subsitute value if

compensation is off

Cl subsitute value if

compensation is off

AC Code Version

BC Code Version

Moist [%] moisture in probe,

OK<5%

Ammonium mV

47

Page 48

Modbus Register

Tag Name Register # Data Type Length R/W

Ammonium Drift 40065 Float 2 R

Ammonium Noise 40067 Float 2 R

Nitrate mV 40069 Float 2 R

Nitrate Drift 40071 Float 2 R

Nitrate Noise 40073 Float 2 R

Potassium mV 40075 Float 2 R

Potassium Drift 40077 Float 2 R

Potassium Noise 40079 Float 2 R

Chloride mV 40081 Float 2 R

Chloride Drift 40083 Float 2 R

Chloride Noise 40085 Float 2 R

Reference mV 40087 Float 2 R

Reference Drift 40089 Float 2 R