Page 1

DOC022.52.90389

LICO 690 and LICO 620

USER MANUAL

07/2012 Edition 1A

© HACH-LANGE GmbH, 2012. All rights reserved. Printed in Germany.

Page 2

Page 3

Table of Contents

Section 1 Specifications ........................................................................................................................ 7

Section 2 General Information............................................................................................................... 9

2.1 Safety information............................................................................................................................... 9

2.1.1 Precautionary labels .................................................................................................................. 9

2.1.2 Safety around source lamps .................................................................................................... 10

2.1.3 Chemical and biological safety ................................................................................................ 10

2.2 Overview of product.......................................................................................................................... 10

Section 3 Installation............................................................................................................................ 13

3.1 Unpacking the instrument................................................................................................................. 13

3.2 Operating environment ..................................................................................................................... 13

3.3 Front and back view.......................................................................................................................... 14

3.4 Power connections ........................................................................................................................... 15

3.5 Interfaces.......................................................................................................................................... 16

3.6 Cuvette compartments and cuvette adapters................................................................................... 16

3.6.1 Cuvette compartments and adapter......................................................................................... 16

3.6.2 Installation of cuvette adapter Z............................................................................................... 17

Section 4 Start Up................................................................................................................................. 19

4.1 Switch on the instrument, startup process........................................................................................ 19

4.2 Language selection........................................................................................................................... 19

4.3 Self-check ......................................................................................................................................... 19

4.4 Sleep mode....................................................................................................................................... 20

4.5 Power off the instrument................................................................................................................... 20

Section 5 Standard programs.............................................................................................................. 21

5.1 Overview........................................................................................................................................... 21

5.1.1 Tips for using the touch screen................................................................................................ 21

5.1.2 Use of the alphanumeric keypad .............................................................................................21

5.1.3 Main menu ............................................................................................................................... 22

3

Page 4

Table of Contents

5.2 Instrument Setup...............................................................................................................................23

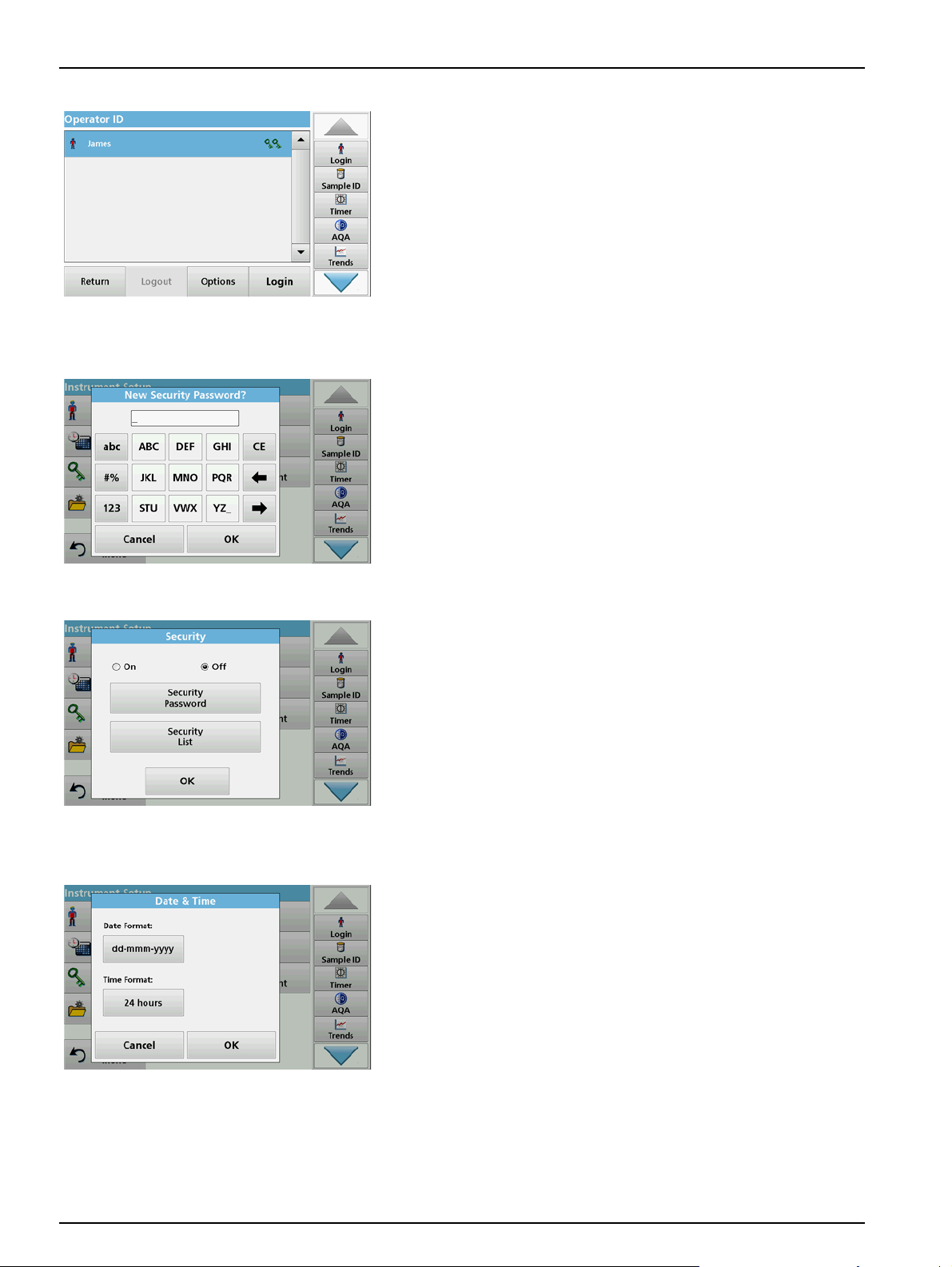

5.2.1 Operator ID...............................................................................................................................23

5.2.2 Sample ID.................................................................................................................................24

5.2.2.1 Sample ID with hand-held scanner method 1..................................................................25

5.2.2.2 Sample ID with hand-held scanner method 2..................................................................26

5.2.2.3 Import sample ID list........................................................................................................26

5.2.3 Security settings.......................................................................................................................27

5.2.3.1 Assign operator security level..........................................................................................28

5.2.3.2 Deactivate password .......................................................................................................30

5.2.4 Date and time...........................................................................................................................30

5.2.5 Sound settings..........................................................................................................................32

5.2.6 PC and printer ..........................................................................................................................32

5.2.6.1 Printer setup ....................................................................................................................33

5.2.6.2 Print data .........................................................................................................................34

5.2.6.3 Print data continuously ....................................................................................................34

5.2.6.4 Network setup..................................................................................................................35

5.2.7 Power Management .................................................................................................................38

5.3 Save, recall, send and delete data....................................................................................................38

5.3.1 Color values .............................................................................................................................38

5.3.1.1 Automatic/manual color value storage ............................................................................39

5.3.1.2 Recall color values from the measured data memory .....................................................39

5.3.1.3 Send color values from the measured data memory.......................................................41

5.3.1.4 Delete color values from the measured data memory.....................................................42

5.3.2 Control charts for data from the AQA Log................................................................................42

5.3.3 Data log (only LICO 690)..........................................................................................................43

5.3.3.1 Automatic/manual saving of single and multi-wavelength measurements ......................44

5.3.3.2 Recall single and multi-wavelength measurements from the measured data memory ...44

5.3.3.3 Send single and multi-wavelengths from the measured data memory............................46

5.3.3.4 Delete single and multi-wavelengths from the measured data memory..........................47

5.3.4 Wavelength scan and time course (LICO 690 only).................................................................47

5.3.4.1 Data storage from wavelength scan or time course ........................................................48

5.3.4.2 Recall stored data from wavelength scan or time course................................................48

5.3.4.3 Send data from wavelength scan or time course ............................................................49

5.3.4.4 Delete stored data from wavelength scan or time course ...............................................50

5.3.5 Trends ......................................................................................................................................50

5.4 Take and prepare samples................................................................................................................53

4

Page 5

Table of Contents

5.5 Color measurement .......................................................................................................................... 54

5.5.1 Take a color measurement ...................................................................................................... 55

5.5.1.1 Touch-sensitive areas in measurement mode................................................................ 55

5.5.1.2 Parameter setup options.................................................................................................56

5.5.1.3 Change the color scale after a measurement................................................................. 57

5.5.1.4 Change the measuring range after a measurement ....................................................... 58

5.5.2 Determination of the iodine color value....................................................................................58

5.5.3 Determination of the Hazen color value (Pt-Co or APHA method) .......................................... 58

5.5.4 Determination of the Gardner color value................................................................................ 59

5.5.5 Determination of the Mineral oil color value (ASTM D 1500 and ISO 2049)............................ 59

5.5.6 Determination of the Saybolt color number (ASTM D 156)...................................................... 59

5.5.7 Color determinations only by LICO 690................................................................................... 60

5.5.7.1 Color determination according to the European Pharmacopoeia (EP)........................... 60

5.5.7.2 Color determination according to the US Pharmacopoeia (USP)................................... 63

5.5.7.3 Color determination according to the Chinese Pharmacopoeia (CP) ............................. 64

5.5.7.4 Determination of the Klett color value............................................................................. 64

5.5.7.5 Determination of the AOCS Cc 13 e (Lovibond

5.5.7.6 Determination of the Yellowness Index (ASTM D 1925)................................................. 65

5.5.7.7 Determination of the Hess-Ives color number................................................................. 65

5.5.7.8 Determination of the ADMI color number........................................................................ 65

5.5.7.9 Determination of the Acid wash color ............................................................................. 66

5.5.7.10 Determination of the ICUMSA color index .................................................................... 66

5.6 Measurement of color differences (LICO 690 only).......................................................................... 67

5.6.1 Take a color difference measurement ..................................................................................... 67

5.6.1.1 View graph/table/values..................................................................................................69

5.6.2 Take a color difference measurement with stored reference values ....................................... 70

5.6.3 Add a reference to the reference list........................................................................................ 70

5.7 Photometry (LICO 690 only) ............................................................................................................. 71

5.7.1 Single Wavelength (absorbance, concentration and transmittance readings)......................... 71

5.7.1.1 Set up Single Wavelength mode..................................................................................... 71

5.7.1.2 Take single wavelength readings (single reading).......................................................... 73

5.7.2 Multi Wavelength mode – readings with more than one wavelength....................................... 73

5.7.2.1 Set the Reading mode at different wavelengths ............................................................. 73

5.7.2.2 Complete a reading in the Multi Wavelength mode ........................................................ 76

5.7.3 Time course of absorbance/transmittance............................................................................... 76

5.7.3.1 Time course setup parameters ....................................................................................... 76

5.7.3.2 Time course scan reading............................................................................................... 78

5.7.3.3 Analysis of time course data ........................................................................................... 78

5.7.4 Wavelength Scan mode – recording of absorbance and transmission spectrums .................. 79

5.7.4.1 Set up the wavelength scan............................................................................................ 80

5.7.4.2 Perform a wavelength scan ............................................................................................ 82

5.7.4.3 Work with reference scans.............................................................................................. 83

®

) scale.................................................. 65

5

Page 6

Table of Contents

Section 6 Advanced Operations ..........................................................................................................87

6.1 System Checks .................................................................................................................................87

6.1.1 Instrument Information .............................................................................................................87

6.1.2 Update the instrument software ...............................................................................................87

6.1.2.1 Software update with USB memory.................................................................................87

6.1.2.2 Software update with network connection.......................................................................88

6.1.3 Optical Checks .........................................................................................................................88

6.1.4 AQA Analytical Quality Assurance ...........................................................................................90

6.1.4.1 Standard Configuration....................................................................................................90

6.1.4.2 Perform AQA Standard Measurement.............................................................................91

6.1.5 Instrument backup....................................................................................................................92

6.1.6 Service menu ...........................................................................................................................93

6.1.7 Service time..............................................................................................................................93

6.1.8 Lamps operating time...............................................................................................................93

6.2 Toolbar ..............................................................................................................................................94

6.2.1 Log on ......................................................................................................................................94

6.2.2 Sample ID.................................................................................................................................94

6.2.3 Timer ........................................................................................................................................95

6.2.4 AQA..........................................................................................................................................95

6.2.5 Trends ......................................................................................................................................95

6.2.6 LICO Website...........................................................................................................................95

Section 7 Maintenance..........................................................................................................................97

7.1 Cleaning requirements ......................................................................................................................97

7.1.1 Spectrophotometer...................................................................................................................97

7.1.2 Screen ......................................................................................................................................97

7.1.3 Cuvettes/cells...........................................................................................................................98

7.2 Lamp replacement.............................................................................................................................98

7.3 Cell compartment (2) replacement..................................................................................................100

Section 8 Troubleshooting .................................................................................................................103

Section 9 Replacement Parts.............................................................................................................107

9.1 Accessories.....................................................................................................................................107

9.2 Replacement Parts..........................................................................................................................107

Section 10 Contact .............................................................................................................................109

Section 11 Warranty, liability and complaintsLimited warranty......................................................111

Index.....................................................................................................................................................113

6

Page 7

Section 1 Specifications

These are subject to change without notice!

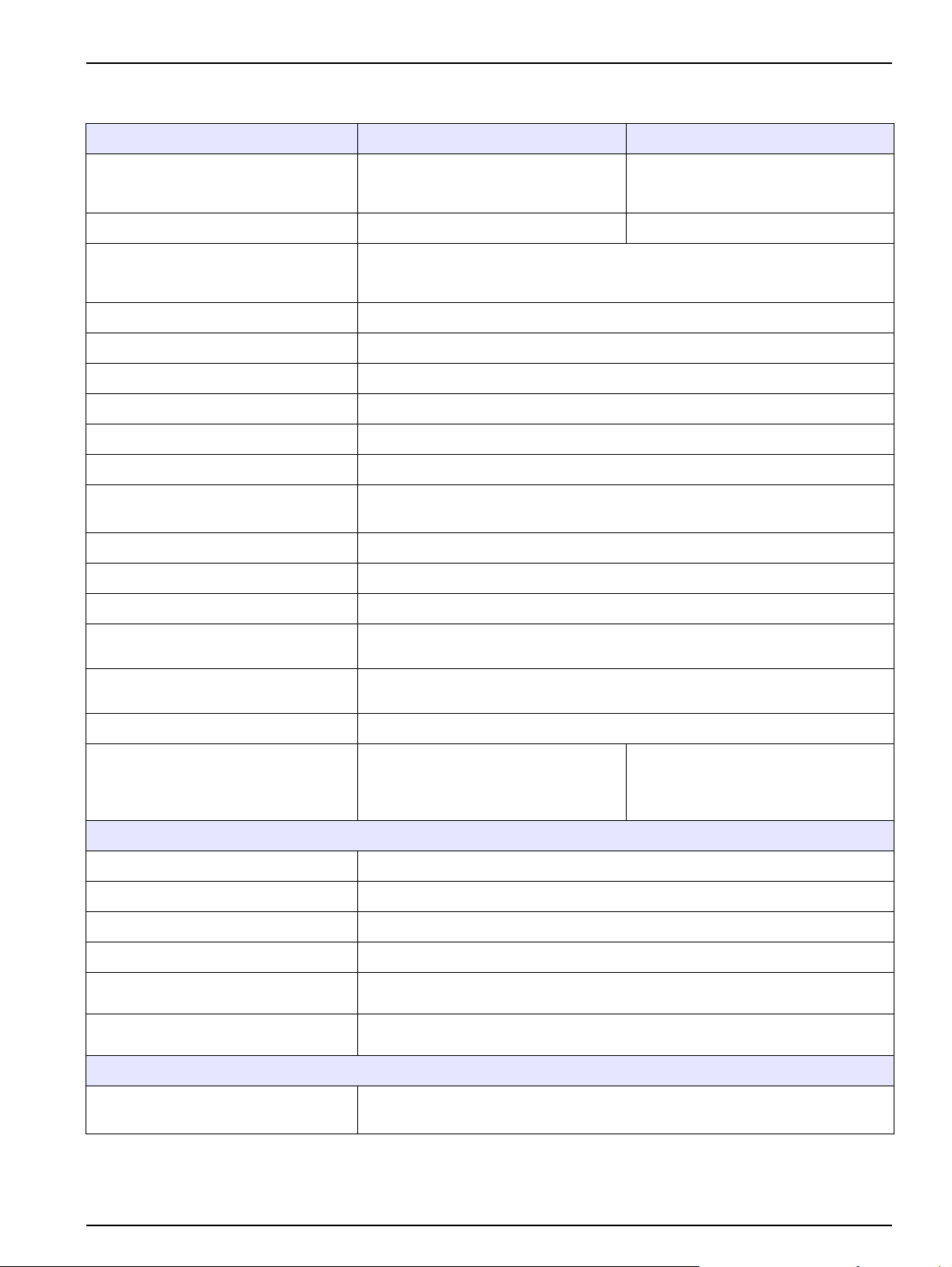

Performance specifications LICO 690 LICO 620

Color measurement, color difference

Display mode

Color measurement 26 color ratios 5 color ratios

Colorimetric evaluation

Source lamp Halogen lamp

Wavelength range 320–1100 nm

Wavelength Accuracy ± 1.5 nm (wavelength range 340–900 nm)

Wavelength reproducibility ≤ 0.1 nm

Wavelength resolution 1 nm

Wavelength calibration Automatic

measurement, absorbance and

concentration

All visual color ratios are calculated for standard light chart C and 2° standard

observers in accordance with DIN 5033. Colorimetric color values can be switched

to light type A, C, D65 and 2° or 10° standard observers.

Color measurement

Wavelength range for color

measurement

Scanning speed ≥ 8 nm/sec (in steps of 1 nm)

Spectral bandwidth 5 nm

Photometric measuring range ± 3 Abs (wavelength range 340–900 nm)

Photometric accuracy

Photometric linearity

Stray light < 0.1 % T at 340 nm with NaNO

Data log

Physical and environmental specifications

Width 350 mm (13.78 in)

Height 151 mm (5.94 in)

Depth 255 mm (10.04 in)

Earth 4200 g (9.26 lb)

Ambient operating requirements

Ambient storage requirements

Additional technical data

380–720 nm steps of 10 nm

5 mAbs at 0.0–0.5 Abs,

1 % at 0.50–2.0 Ext

< 0.5 % to 2 Abs

≤ 1 % at > 2 Abs with neutral glass at 546 nm

2

3000 color measurements,

100 color reference values,

1000 photometric measurements,

20 wavelength scans, 20 time scans

10–40 °C (50–104 °F), maximum 80 % relative humidity (without condensate

formation)

–40–60 °C (–40–140 °F), maximum 80 % relative humidity (without condensate

formation)

400 color measurements

Power connector via external power

supply

Input: 100–240 V/47–63 Hz

Output: 15 V/40 VA

7

Page 8

Specifications

Performance specifications LICO 690 LICO 620

Use only shielded cable with maximum length of 3 m:

2× USB type A

Interfaces

Housing rating IP40 (excluding interfaces and power supply)

Protection class Class I

1× USB type B

Use only shielded cable (for example STP, FTP, S/FTP) with maximum length of

20 m:

1× Ethernet

8

Page 9

Section 2 General Information

2.1 Safety information

Read through the entire user manual carefully before you unpack

the device, set up and put into operation. Pay attention to all

danger and caution statements. Failure to do so could result in

serious injury to the operator or damage to the equipment.

To make sure that the protection provided by this instrument is

not impaired, do not use or install this instrument in any manner

other than that specified in these operating instructions.

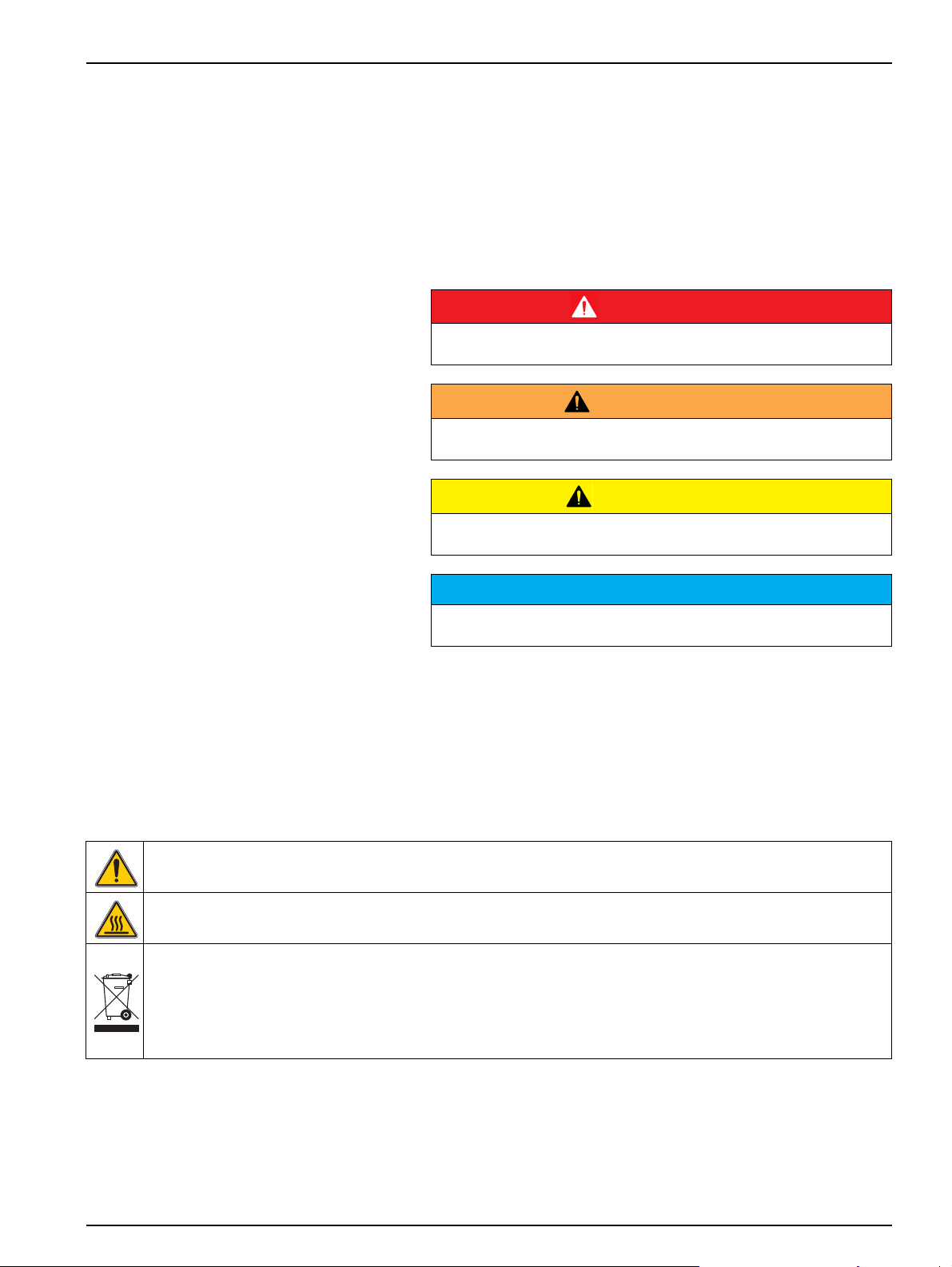

Indicates a potentially or imminently hazardous situation that, if not

avoided, results in death or serious injury.

Indicates a potentially or imminently hazardous situation that, if not

avoided, may result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or

moderate injury.

DANGER

WARNING

CAUTION

2.1.1 Precautionary labels

This symbol may be attached to the device and references the operation- and/or safety notes in the user manual.

This symbol on the device is an indication of hot surfaces.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the

manufacturer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment manufacturer or supplier for instructions on how to

return end-of-life equipment, manufacturer-supplied electrical accessories, and all auxiliary items for proper disposal.

NOTICE

Indicates a situation that, if it is not avoided, can lead to damage to

the device. Information that requires special emphasis.

Note: Information that supplements points in the main text.

Read all labels and tags attached to the instrument. Personal

injury or damage to the instrument could occur if not observed.

For symbols attached to the device, corresponding warning notes

are found in the user manual.

9

Page 10

General Information

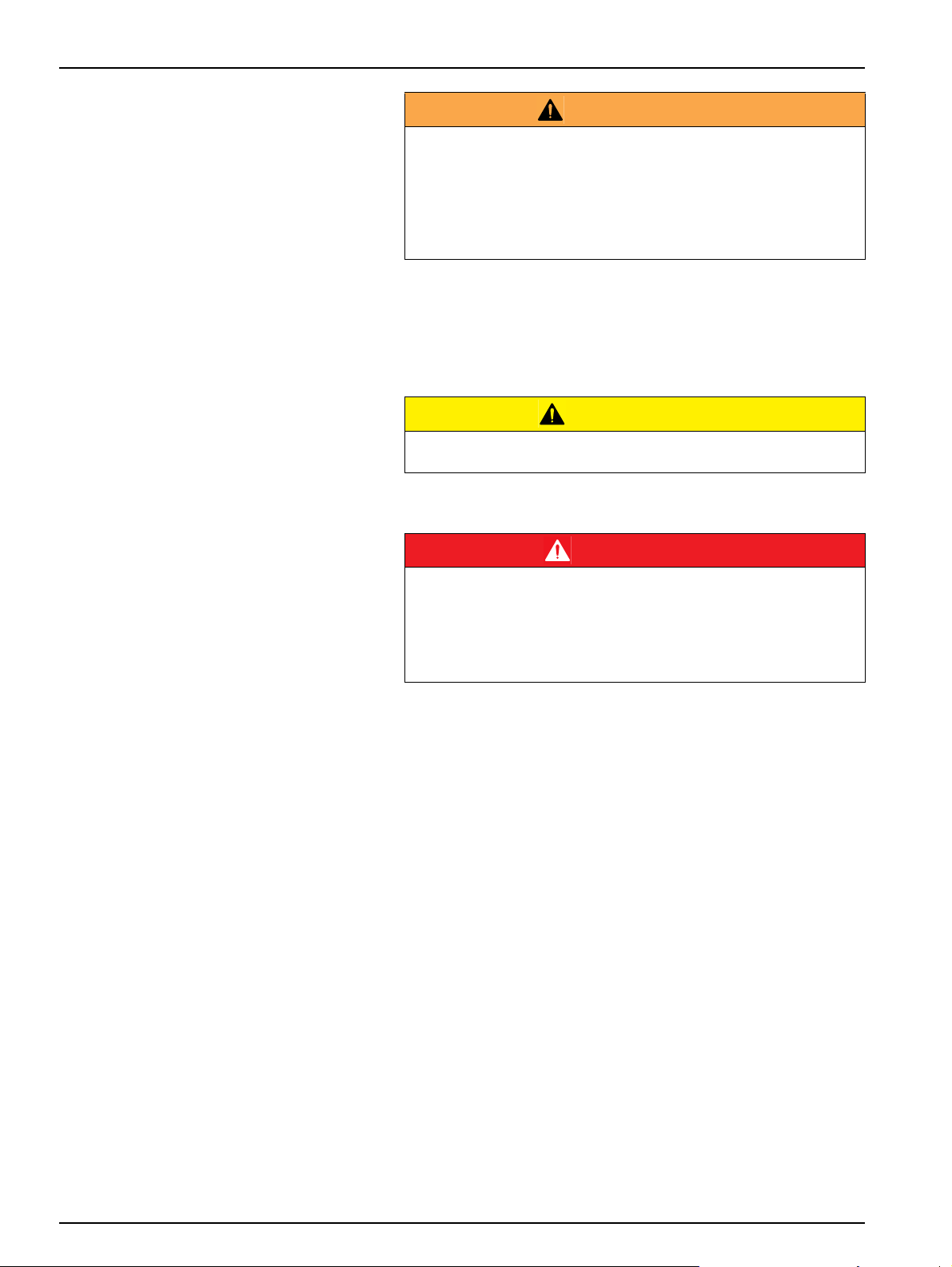

2.1.2 Safety around source lamps

2.1.3 Chemical and biological safety

WARNING

The manufacturer is not responsible for any damages due to

misapplication or misuse of this product including, without limitation,

direct, incidental and consequential damages, and totally excludes

such damages as permitted under applicable laws.

The user is solely responsible to identify critical application risks and

install appropriate mechanisms to protect processes during a possible

equipment malfunction.

The source lamp is operated at high temperatures.

To prevent electric shock, disconnect the instrument from the

power source before replacing the lamp.

CAUTION

Burn hazard. Allow the lamp(s) to cool for at least 30 minutes before

maintaining/replacing them.

2.2 Overview of product

DANGER

Potential danger with contact with chemical/biological substances.

Working with chemical samples, standards and reagents can be

dangerous.

Make yourself familiar with the necessary safety procedures and the

correct handling of the chemicals before use and read and follow all

relevant safety data sheets.

Normal operation of this device may require the use of chemicals

or samples that are biologically unsafe.

• Observe all cautionary information printed on the original

solution containers and safety data sheets prior to their use.

• Dispose of all consumed solutions in accordance with the

local and national regulations and laws.

• Select the type of protective equipment suitable to the

concentration and quantity of the dangerous material being

used.

The LICO 690 and LICO 620 instruments are VIS

spectral-photometers with wavelength ranges from 320 to

1100 nm. The instruments can perform a precise colorimetric

analysis in accordance with ISO/ASTM standards with a single

measurement and display the result in the form of classic color

systems such as iodine, Hazen or Gardner color values. The

instruments support multiple languages.

10

The LICO 690 is supplied with 26 color value calculations, while

the LICO 620 is supplied with five color value calculations (Iodine

color, Hazen color, Gardner color, Saybolt color and ASTM D

1500 color numbers).

Page 11

General Information

The LICO 690 contains the following programs and operating

modes in addition to the color measurement: single wavelength

mode, multi-wavelength mode, wavelength scan and time scan

mode. The digital measurements are displayed in the

dimensional units of concentration, absorbance or %

transmittance, making the LICO 690 universally suitable for lab

analysis.

11

Page 12

General Information

12

Page 13

Section 3 Installation

3.1 Unpacking the instrument

WARNING

Electrical and fire hazards.

Only use the supplied benchtop power supply LZV844.

Only qualified experts may perform the tasks described in this section

of the manual, while adhering to all locally valid safety regulations.

The following components are supplied as standard with the

LICO 690/620:

• LICO 690/LICO 620 spectrophotometer

• Dust cover

• USB dust cover, fitted as standard

• Table power supply with power cord

• Cuvette adapter Z, installed as standard

• Basic user manual

• CD-ROM with detailed operating instructions

3.2 Operating environment

Note: If any of these items are missing or damaged, please contact the

manufacturer or a sales representative immediately.

Observe the following points to allow the instrument to function

normally and give a long operating life.

• Position the instrument securely on a flat surface taking care

to remove any objects from under the device.

• The ambient temperature must be 10–40 °C (50–104 °F).

NOTICE

Protect the instrument from extreme temperatures from heaters,

direct sunlight and other heat sources.

• The relative humidity should be less than 80 %; moisture

should not condense on the instrument.

• Leave at least a 15 cm clearance at the top and on all sides

for air circulation to avoid overheating of electrical parts.

• Do not use or store the device in extremely dusty, humid or

wet places.

• Keep the surface of the instrument, the cell compartment and

all accessories clean and dry at all times. Immediately

remove splashes or spilt materials on or in the instrument

(refer to Section 7).

13

Page 14

Installation

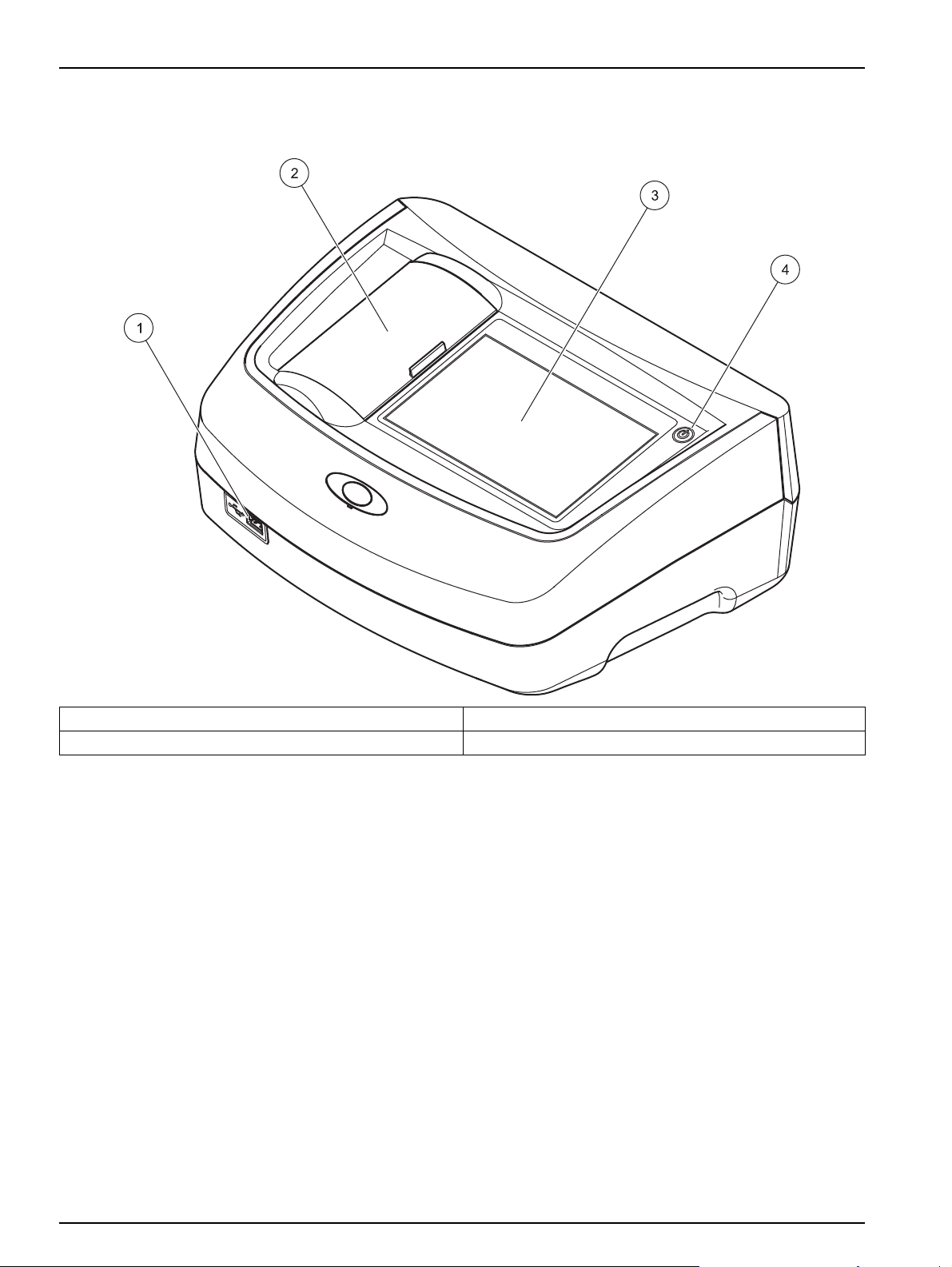

3.3 Front and back view

Figure 1 Front view

1 USB port type A 3 Touch screen

2 Cuvette compartment cover 4 On/off switch

14

Page 15

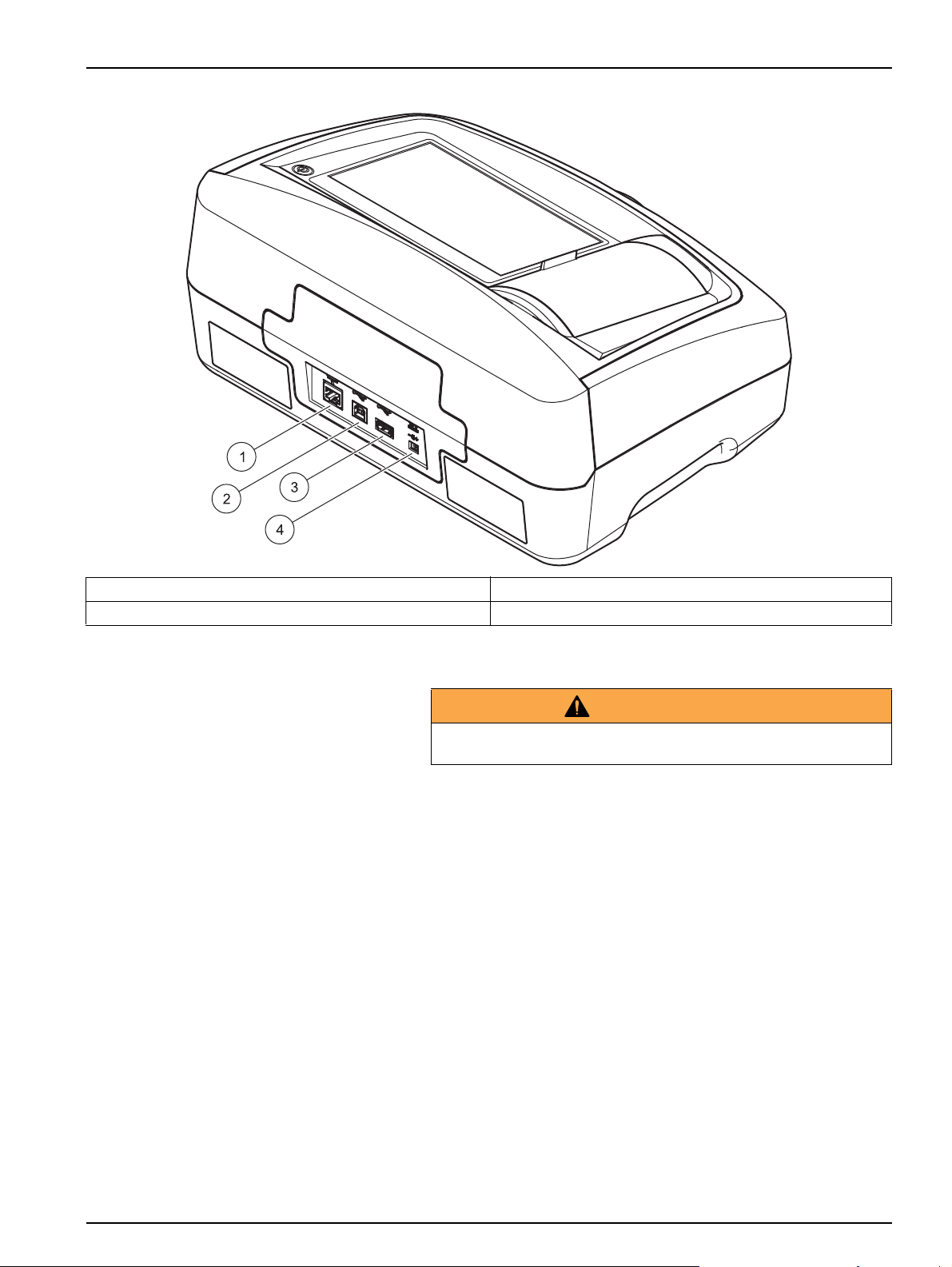

Figure 2 Back view

Installation

1 Ethernet port 3 USB port type A

2 USB port type B 4 Connection for benchtop power supply

3.4 Power connections

WARNING

Electrical and fire hazards.

Only use the supplied benchtop power supply LZV844.

1. Connect the power cable to the benchtop power supply.

2. Plug the benchtop power supply cable into the back of the

instrument (Figure 2, page 15).

3. Insert the power cable plug into a mains socket

(100–240 V~/47–63 Hz).

4. Turn on the power switch next to the screen to activate the

power supply (Figure 1, page 14).

Note: If you do not intend to use the instrument for a long period,

disconnect it from the power supply.

Note: Make sure the socket you are using is easily accessible.

15

Page 16

Installation

3.5 Interfaces

The instrument has three USB ports and one Ethernet port as

standard. They are located on the front and rear of the instrument

(Figure 1 Figure 2, page 15).

The USB type A ports are used for communications with a printer,

USB memory stick or keyboard. A USB memory stick can be

used to update the instrument software.

The USB type B port is used for communications with a PC. The

optional Hach Lange Online Data software must be installed on

the PC for this use.

A USB hub may be used to connect several accessories at a

time.

Note: USB cables must not be longer than 3m.

These USB ports permit data to be exported to a printer or PC

and also allow the instrument software to be upgraded (refer to

section 6.1.2, page 87). The Ethernet port supports real-time data

transfer in local networks, LIMS systems or SC controllers. Only

use a shielded cable (e.g. STP, FTP, S/FTP) with a maximum

length of 20 m for the Ethernet port.

Table 1 Interfaces

Interfaces Description

USB (Type A) This USB port can be used to connect a printer, a USB memory stick or a keyboard.

USB (Type B)

Ethernet

This USB port is intended only for the connection between the instrument and a PC (when the

relevant software is installed).

The Ethernet port is intended for data transfer to a PC without installed software or in a local

network . Only use a shielded cable (e.g. STP, FTP, S/FTP) with a maximum length of 20 m for

the Ethernet port.

3.6 Cuvette compartments and cuvette adapters

3.6.1 Cuvette compartments and adapter

Open the cuvette compartments by sliding the cuvette

compartment cover to the left.

The cover lowers to the side next to the cuvette compartments.

Note: If there are long intervals between uses, close the cuvette

compartment cover to protect the optics of the instrument from dust and

impurities.

The instrument has two cuvette compartments (Figure 3). Only

one cell type at a time can be used for a reading.

16

Cell compartment (1) for:

• 11 mm round cuvettes

Note: Insert cuvette adapter Z into the cuvette compartment (2).

Page 17

3.6.2 Installation of cuvette adapter Z

Installation

Cell compartment (2) for:

The following cell types can be used in cell compartment (2).

• Without cuvette adapter Z in the cuvette compartment (2),

you can insert 50 mm cuvettes.

• With cuvette adapter Z: 10 mm square cuvettes.

Note: These cuvettes must be inserted with cuvette adapter Z.

Note: In the event of severe contamination, you can replace the cuvette

compartment (2) (see chapter 7.3, page 100).

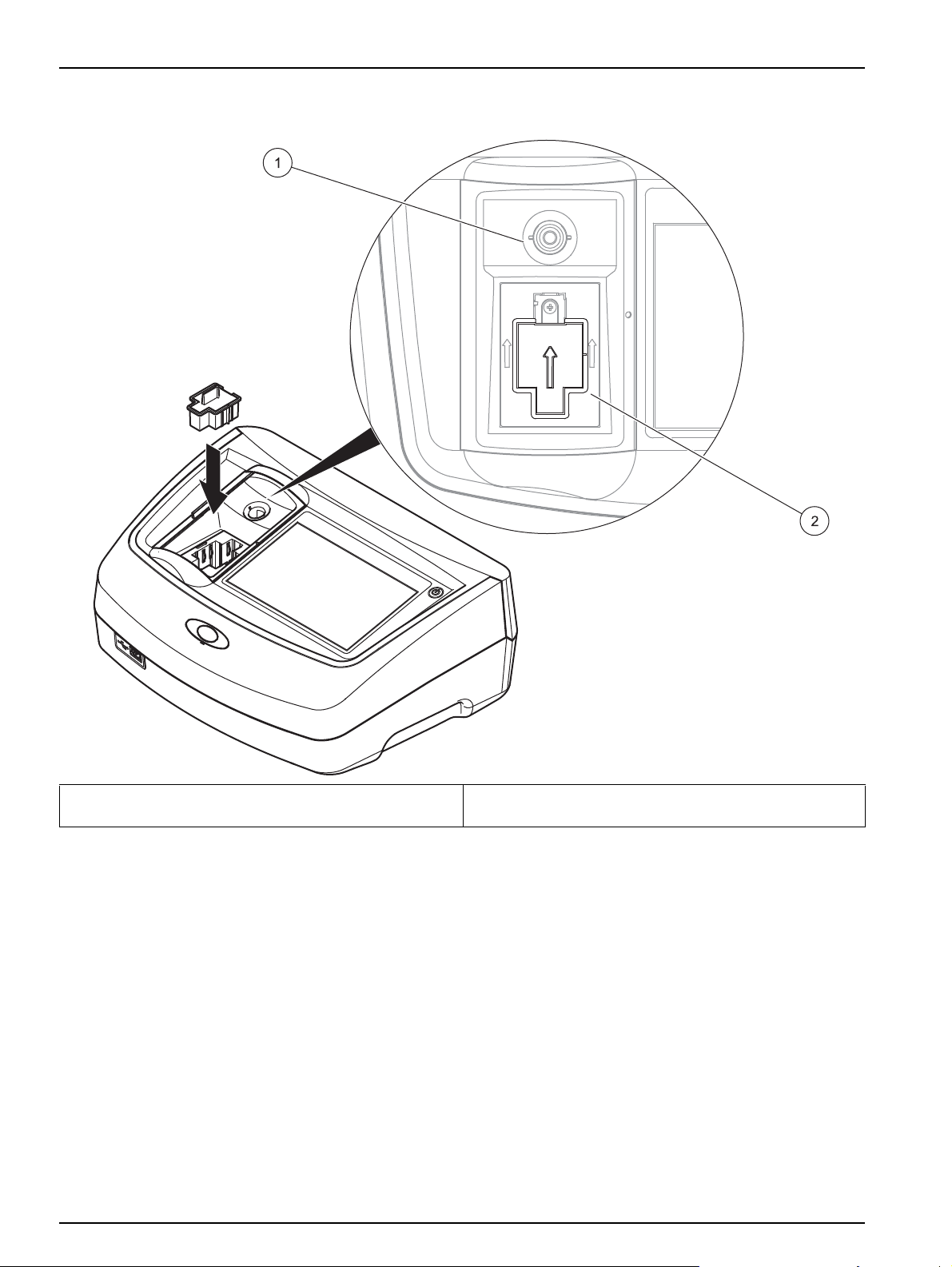

1. Open the cuvette compartment.

2. Insert cuvette adapter Z into the cuvette compartment (2) so

that the arrow on the cuvette adapter is pointing toward the

cuvette compartment (1) (Figure 3).

Note: The arrow on the cuvette adapter indi cates the direction of the

light beam path.

17

Page 18

Installation

Figure 3 Cuvette compartments and cuvette adapter Z

1 Cuvette compartment (1) for round cuvettes 2 Cuvette compartment (2) for square cuvettes, cuvette

adapter Z installed

18

Page 19

Section 4 Start Up

All screen displays in this operating manual correspond to the

LICO 690. The screen displays of the LICO 620 may differ.

4.1 Switch on the instrument, startup process

1. Connect the power cable to the mains outlet.

2. Switch on the instrument by pressing the power switch next

to the screen.

3. The instrument starts automatically with a startup process

lasting approximately 45 seconds. The screen displays the

manufacturer's logo. At the end of the startup process, a

startup melody is heard.

Note: Wait approximately 20 seconds before switching on again so as

not to damage the electronics and mechanics of the instrument.

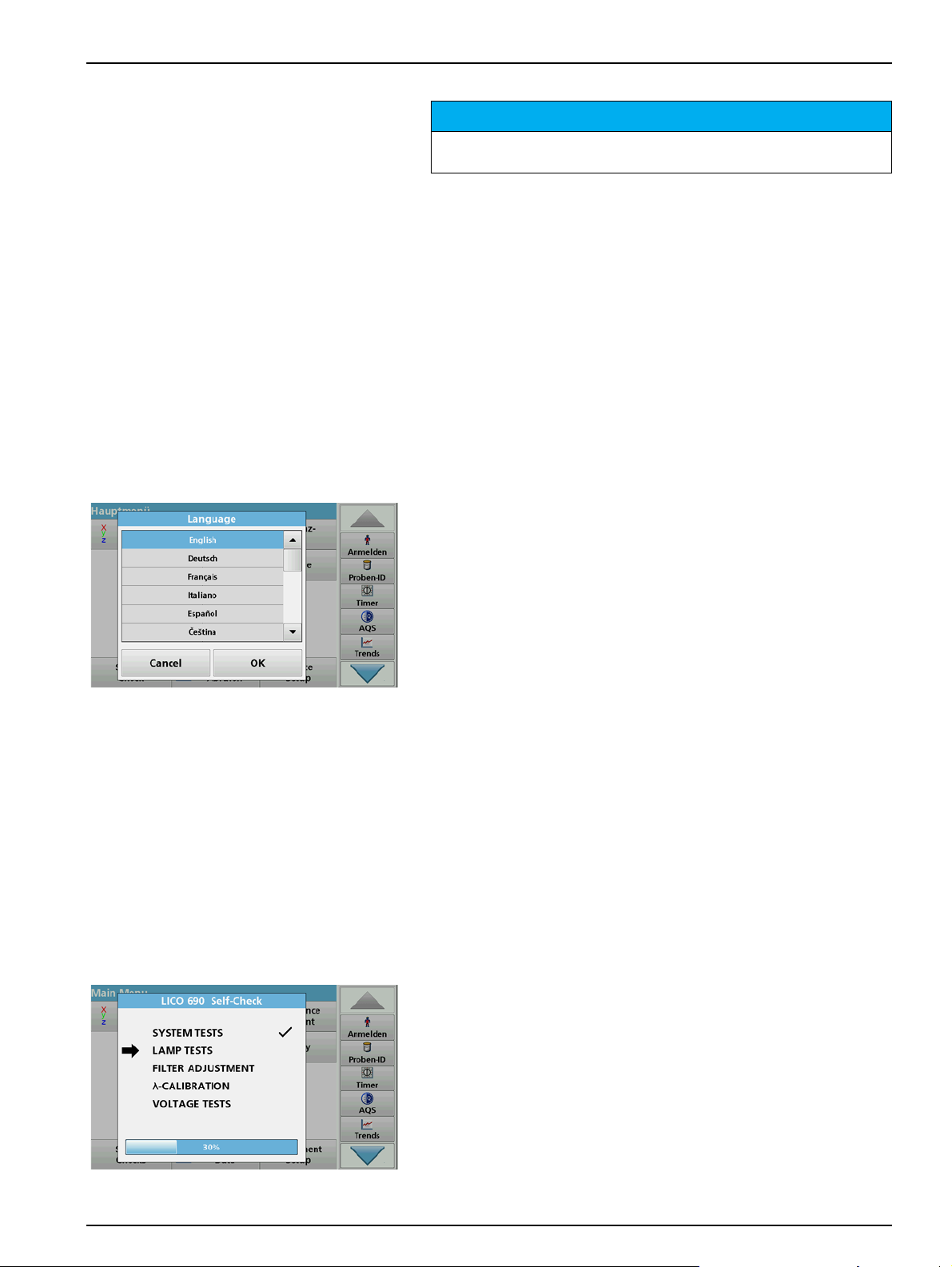

4.2 Language selection

NOTICE

4.3 Self-check

The software supports multiple languages. The first time the

instrument is switched on, the language selection screen will be

shown automatically after the startup process.

1. Select the required language.

2. Press OK to confirm the language selection. The self-check

will then start automatically.

Change the language setting

The instrument functions in the selected language until the option

is changed.

1. Turn the instrument on.

2. During the startup process, touch any point on the screen

and maintain contact until the option for selecting a language

is shown (approximately 45 seconds).

3. Select the required language.

4. Press OK to confirm the language selection. The self-check

will then start automatically.

Each time the instrument is powered up, a test program begins.

During the course of this program (approx. 25 seconds), system

tests, lamp tests, filter calibration, wavelength calibration and

voltage tests can be carried out. Each test that functions correctly

is marked accordingly.

Note: For error messages during the test program, refer to Section 8,

page 103.

19

Page 20

Start Up

4.4 Sleep mode

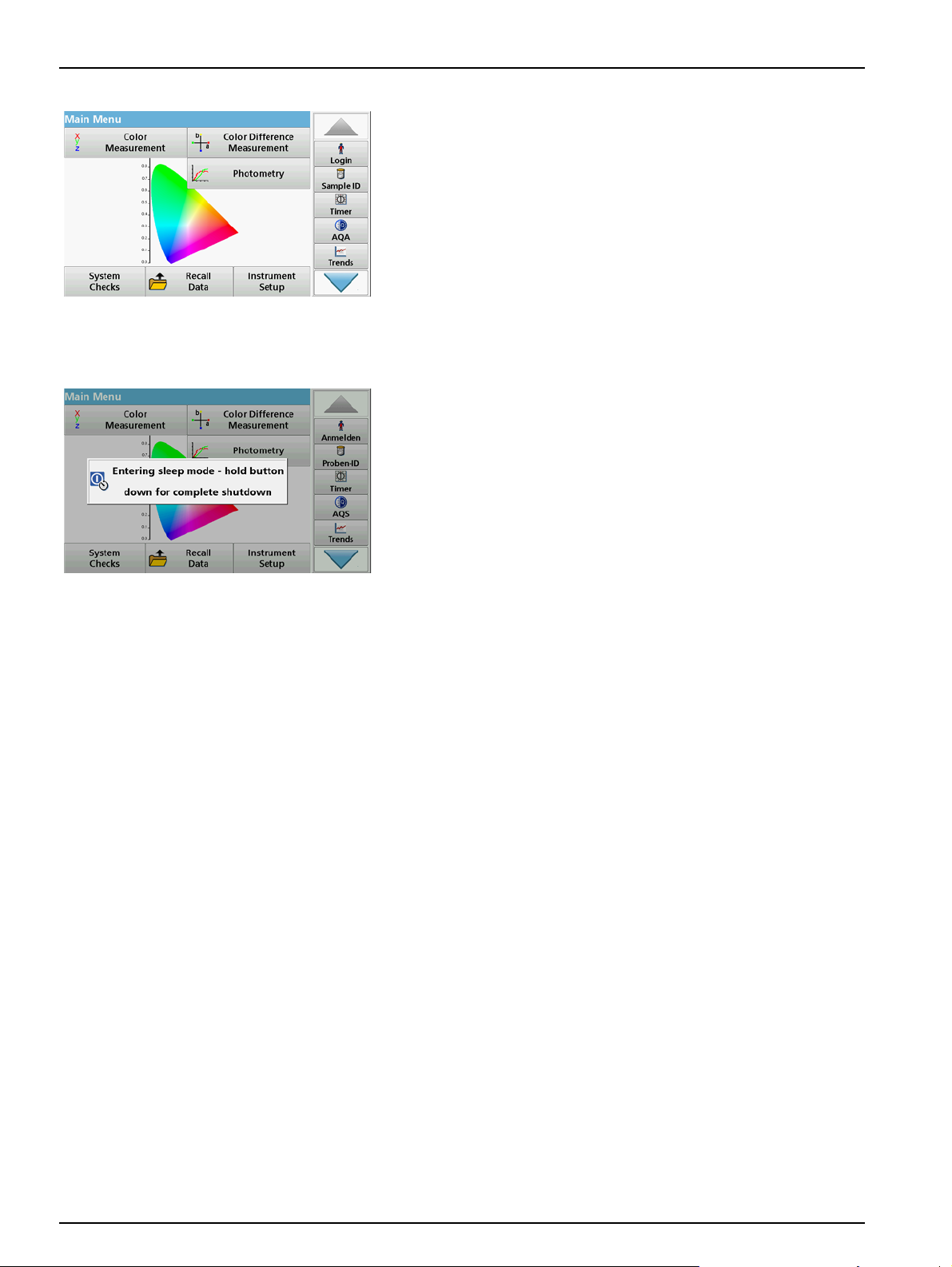

The Main Menu is displayed when diagnostics are completed.

Note: section 5.1.3, page 22 contains a detailed description of the main

menu.

The instrument can be put into sleep mode.

1. Briefly press the power switch next to the screen.

The "Sleep mode" message is shown. The screen will then

switch off automatically.

2. To switch on, press the power switch next to the screen.

The self-check will start automatically.

After that, the instrument is ready to use.

4.5 Power off the instrument

1. Press the power switch next to the screen for

approx. 5 seconds.

20

Page 21

Section 5 Standard programs

5.1 Overview

5.1.1 Tips for using the touch screen

The whole screen responds to touch. To choose an option, tap

with a fingernail, fingertip, an eraser or a specialised stylus. Do

not touch the screen with sharp objects, such as the tip of a

ballpoint pen.

• Do not place anything on top of the screen, to prevent

damage or scratching on the screen.

• Press buttons, words or icons to select them.

• Use scroll bars to move up and down long lists very quickly.

Press and hold the scroll bar, then move up or down to move

through the list.

• Highlight an item from a list by pressing it once. When the

item has been successfully selected, it will be displayed as

reversed text (light text on a dark background).

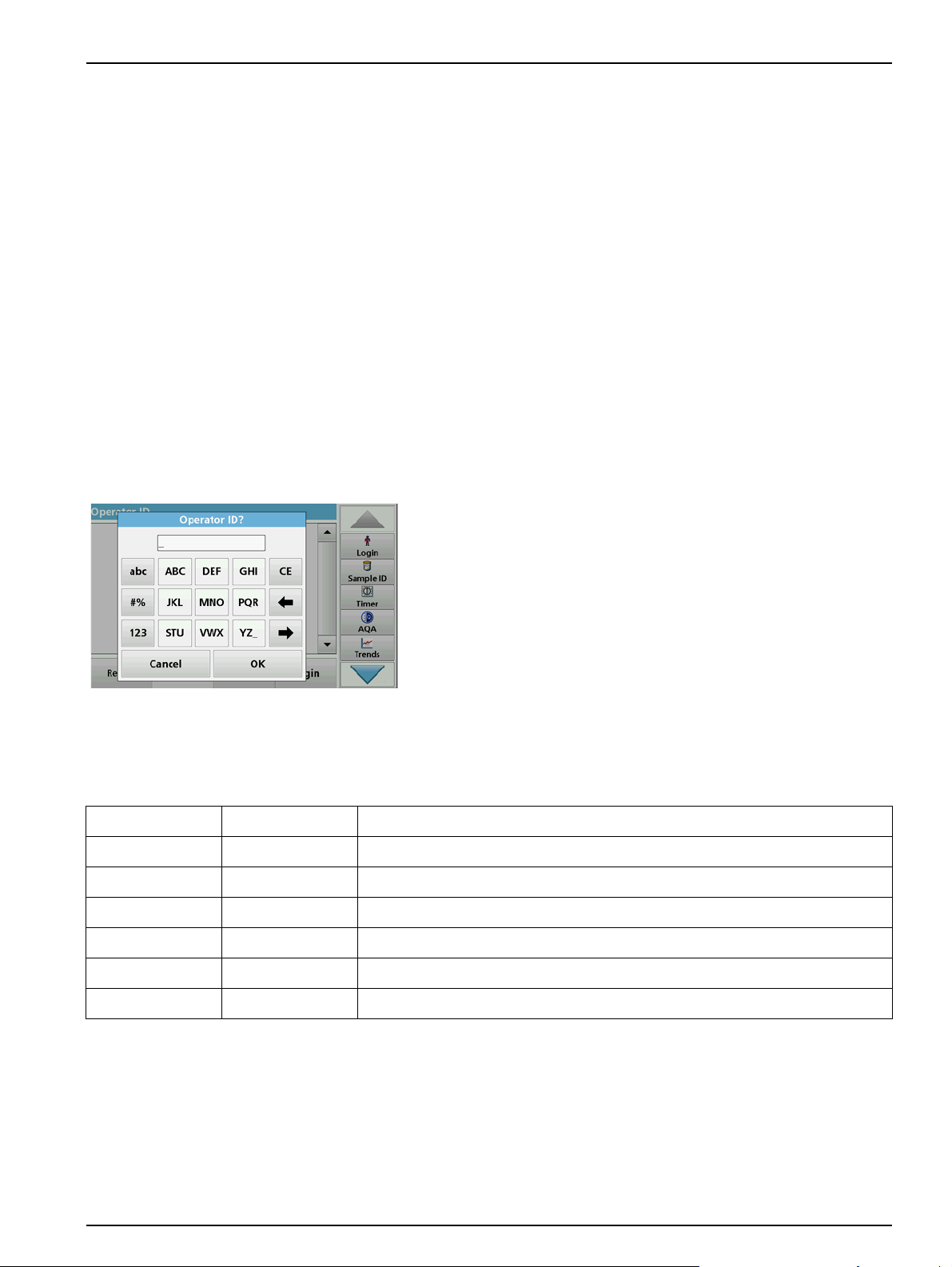

5.1.2 Use of the alphanumeric keypad

This display is used to enter letters, numbers and symbols as

needed when programming the instrument. Unavailable options

are disabled (grayed out). The icons on the right and left of the

screen are described in Table 2.

The central keypad changes to reflect the chosen entry mode.

Press a key repeatedly until the desired character appears on the

screen. A space can be entered by using the underscore on the

YZ_ key.

Press Cancel to cancel an entry, or press OK to confirm an entry.

Note: It is also possible to use a USB keyboard (with US keyboard

layout) or a hand-held USB barcode scanner (refer to Section 9,

page 107).

Table 2 Alphanumeric keypad

Icon / key Description Function

ABC/abc Alphabetic Toggles the character input mode between upper and lower case.

# % Symbols Punctuation, symbols and numerical sub- and superscripts may be entered..

123 Numeric For entering regular numbers..

CE Clear Entry Clear the entry.

Left Arrow Back Deletes the current character and goes back one position.

Right Arrow Next Navigates to the next space in an entry.

21

Page 22

Standard programs

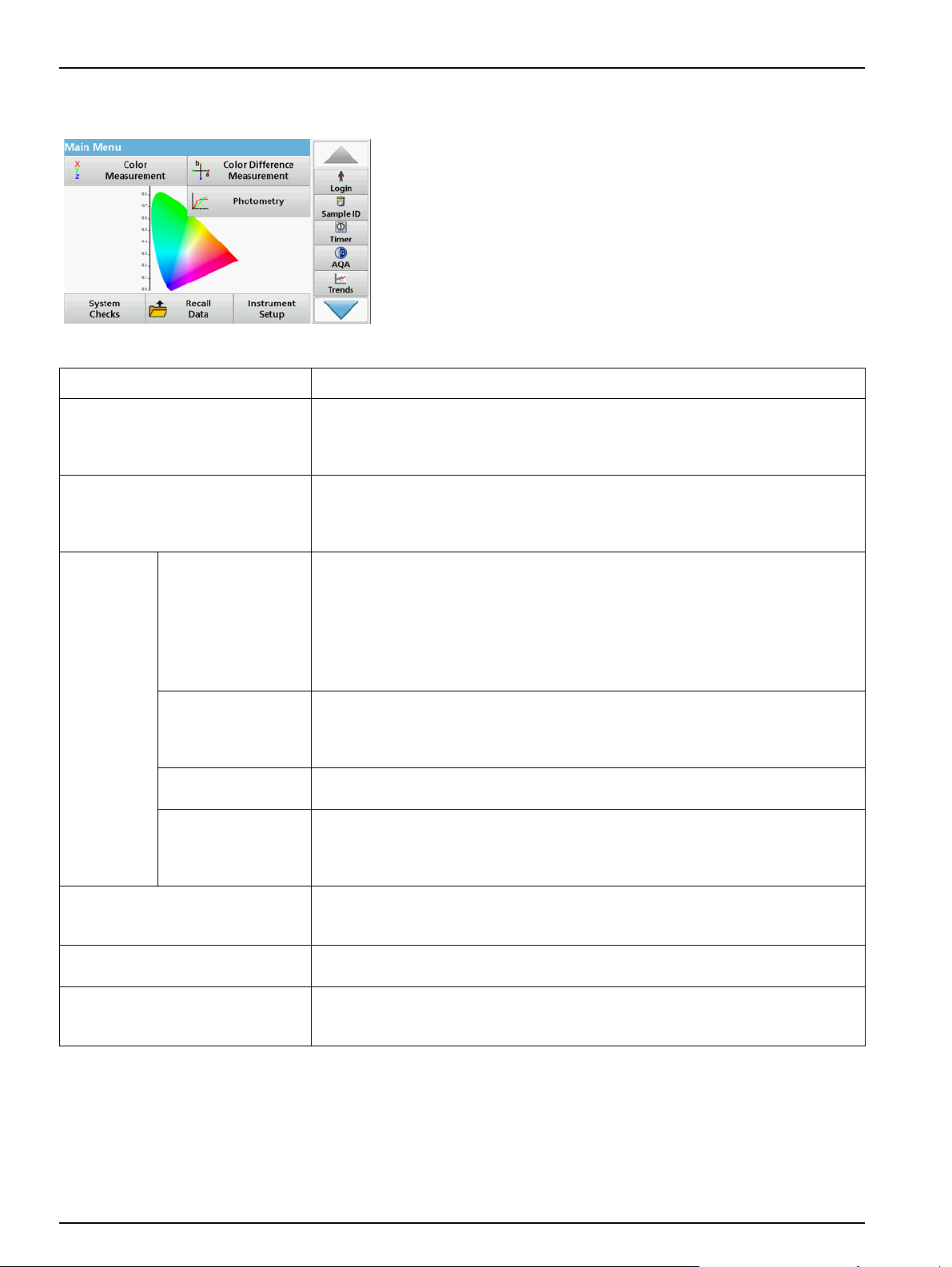

5.1.3 Main menu

Option Function

COLOR MEASUREMENT MODE is used to determine color values such as Hazen,

The

Color measurement

Color difference measurement

(only LICO 690)

Single Wavelength

Photometry

(only

LICO 690)

System Checks

Recall measurement data

Instrument Setup

Multi Wavelength

Time course

Wavelength Scan

Gardner and Saybolt. The LICO 690 also offers three-dimensional, absolute

colorimetric values, as well as the color scales of CIE L*a*b*, Hunter Lab or the

European Pharmacopoeia.

The mode for

quantitative color difference between a reference (R) and a sample (P) in the

three-dimensional color space (CIE L*a*b* or Hunter Lab). In this mode, an additional

reference memory for up to 100 references is available.

Single wavelength readings are:

Absorbance readings: The light absorbed by the sample is measured in absorbance

units.

Transmittance reading (%): Measures the percent of the original light that passes

through the sample and reaches the detector.

Concentration readings: A concentration factor can be entered to enable the

measured absorbance values to be converted into concentration values.

In the Multi Wavelength mode, absorbance (Abs) or percentage transmittance (%T) is

measured at up to four wavelengths and absorbance differences and absorbance

relationships are calculated. Simple conversions into concentrations can also be

carried out.

The time scan records the absorbance or % transmittance at a wavelength over a

defined time.

A wavelength scan shows how the light from a sample is absorbed over a defined

wavelength spectrum. This function can be used to determine the wavelength at

which the maximum absorbance value can be measured. The absorbance behavior is

displayed graphically during the scan.

The "System Check" menu contains a number of options, such as instrument

information, optical checks, instrument backup, service times, instrument update,

settings for analytical quality assurance and lamp history.

Saved data can be retrieved, filtered, sent to a printer, memory stick or PC and

deleted.

This menu is used to configure user-specific and/or process-specific settings:

operator ID, date and time, security settings, saved data, sound, PC and printer and

energy management.

A variety of modes may be selected from the Main Menu. The

following table briefly describes each menu option.

There is a toolbar on the right-hand side of the screen. Press to

activate the various functions.

Table 3 Main Menu options

COLOR DIFFERENCE MEASUREMENT is used to determine a

22

Page 23

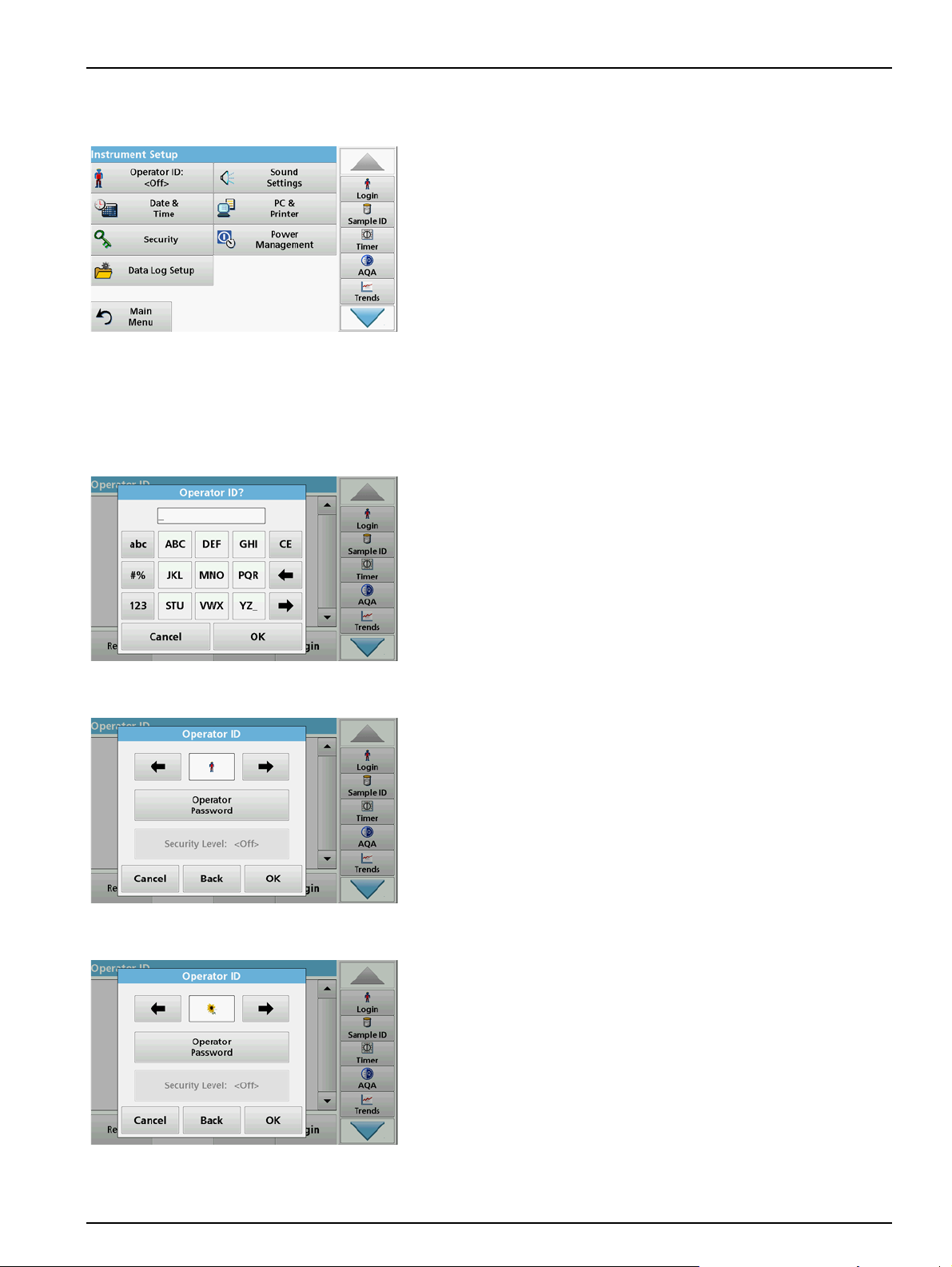

5.2 Instrument Setup

5.2.1 Operator ID

Standard programs

1. In the main menu, select the menu option Instrument setup.

A selection of functions appears in order to configure the

functions of the instrument.

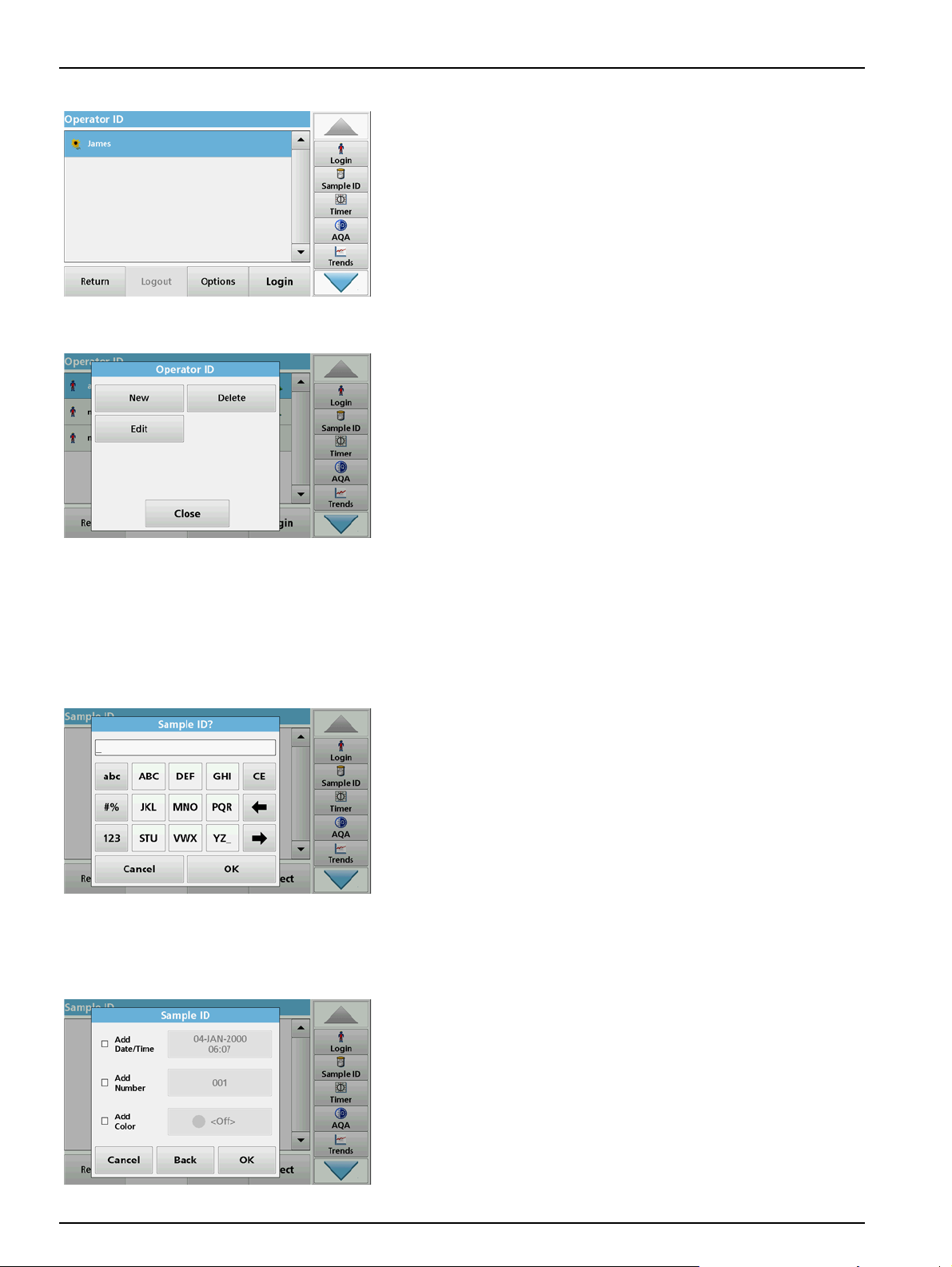

Use this option to enter up to 30 sets of operator initials (up to ten

characters each) into the instrument. This feature helps record

which operator measured each sample.

1. Press Operator ID in "Instrument setup".

2. Press Options > New to enter a new operator ID.

Note: If no operator ID has yet been entered, the alphanumeric

keyboard is immediately displayed.

3. Use the alphanumeric keypad to enter a new operator ID.

4. Press OK to confirm the entry.

5. Choose an icon for the operator ID using the Left Arrow and

Right Arrow.

6. Press Operator password to protect the operator ID with a

password.

7. Use the alphanumeric keypad to enter an operator password.

8. Press OK to confirm the entry.

9. Press Cancel to delete the complete entry for the operator

ID.

Press Back to reach to the input screen for operator ID.

Press OK to confirm the entry. The following screen is

displayed.

23

Page 24

Standard programs

10. With Back the device returns to the menu "Instrument

Setup".

Press Logout to log out of an active operator ID.

Press Login to activate a selected operator ID.

Press Options to enter, change or delete additional operator

IDs. The following screen is displayed.

11. Press New to enter another operator ID.

Press Delete to delete an operator ID.

Press Edit to edit an operator ID.

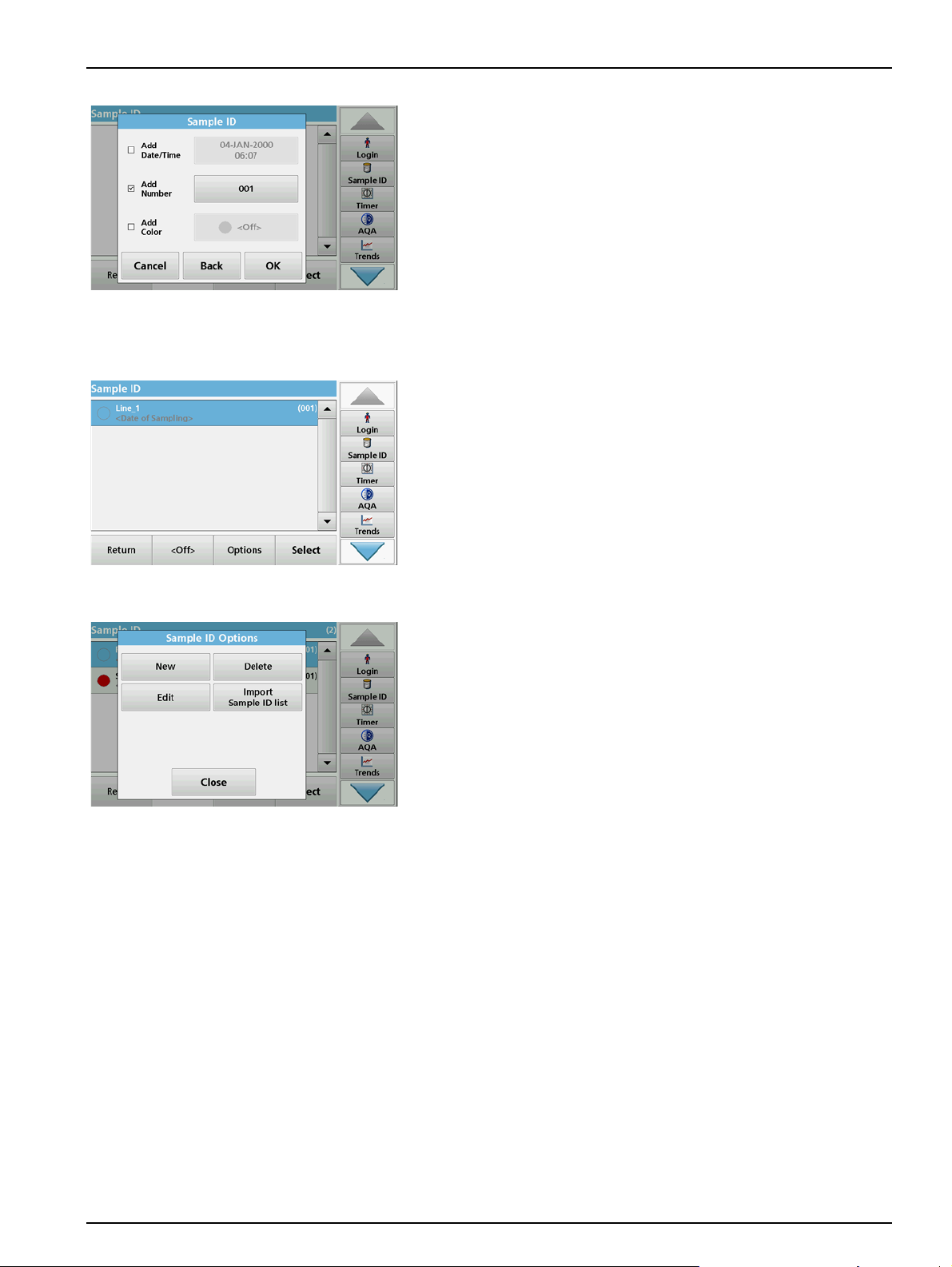

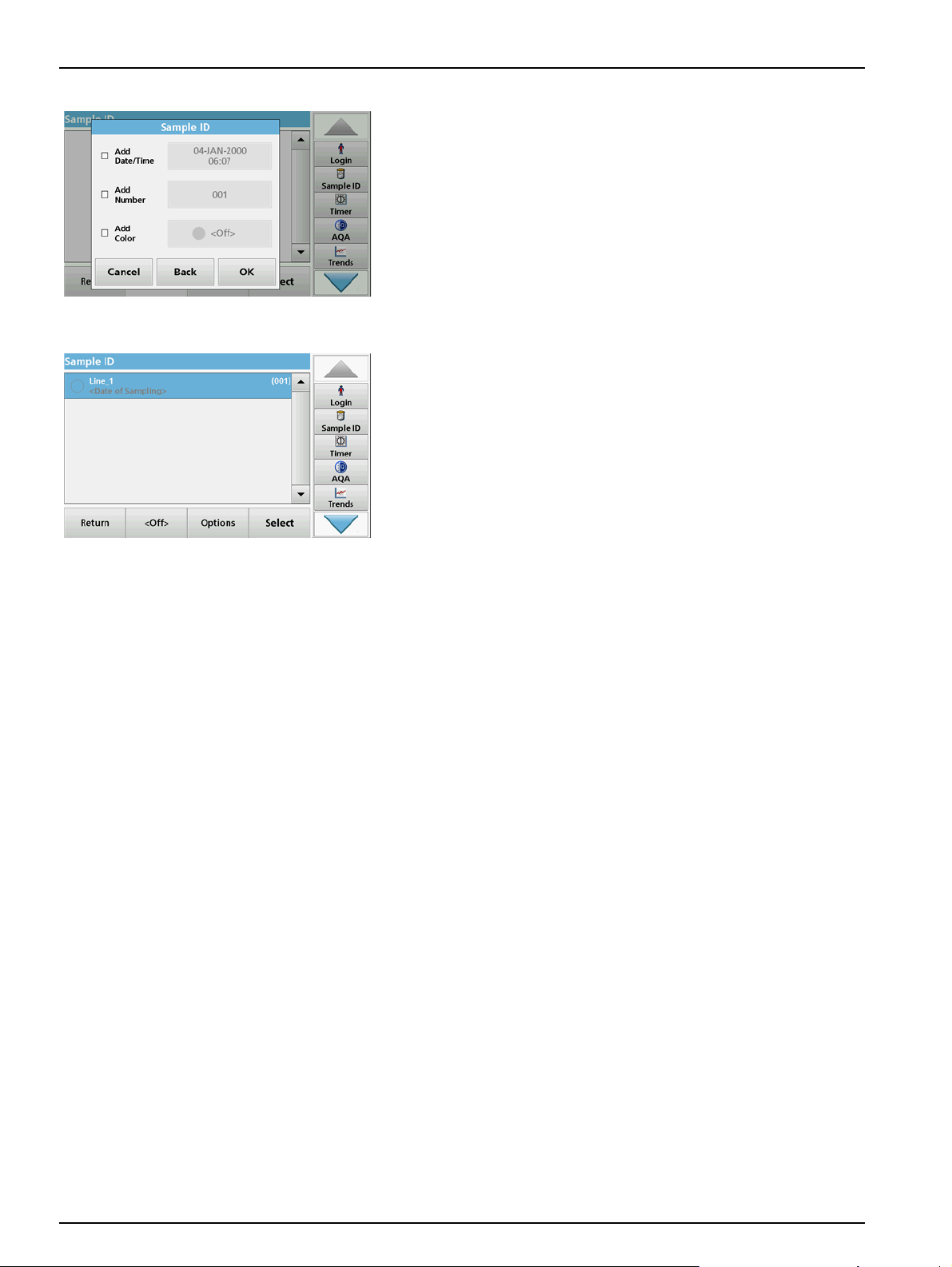

5.2.2 Sample ID

Use this option to enter up to 100 different sample designations

(up to 20 characters each) into the instrument. Sample IDs can

be used to specify the sample location or other sample specific

information, for example.

1. Press Sample ID in the toolbar on the right.

2. Press New to enter a new sample ID.

Note: If no sample ID has been entered yet, the alphanumeric

keyboard is immediately displayed.

3. Use the alphanumeric keypad to enter a new Sample ID.

Note: If a USB Barcode handset scanner (refer to section 5.2.2.1,

page 25) is connected, Sample IDs can also be scanned.

4. Press OK to confirm the entry.

5. Assign the current time and date, a sequential number or a

colour to the sample ID.

24

Page 25

Standard programs

6. To number the sample IDs sequentially (e. g. Inflow (01) etc.),

press Add Number.

• Use the arrow keys to specify the first number of the

sequence.

• Use the key between the arrow keys to enter the first

number of the sequence using the alphanumeric keypad.

7. Press OK to return to the "Instrument Setup" menu.

The Sample ID is activated. Each Sample ID is automatically

numbered in ascending order after a reading. The number is

shown in parentheses behind the Sample ID.

8. Press Back to return the instrument to the "Instrument Setup"

menu.

Press Off to switch off the active sample ID.

Press Select to activate the selected sample ID.

Use Options to enter, change or delete additional sample

IDs. The following screen is displayed:

9. Press New to enter another sample ID.

Press Delete to delete a sample ID.

Press Edit to edit a sample ID.

Select Import Sample ID List to import *.txt and *.csv files

via a USB stick or network; see section 5.2.2.3, page 26.

5.2.2.1 Sample ID with hand-held scanner method 1

1. Connect the hand-held scanner to the USB port.

Successful connection is indicated by a sound.

2. Press Sample ID > Options and NEW.

3. Read barcode with hand-held scanner.

25

Page 26

Standard programs

4. The sample ID can have the current date and time, a

sequential number and a colour allocated to it.

Select the required options or a colour.

5. Press OK to confirm the entry.

6. Press New again and repeat the process for each barcode.

5.2.2.2 Sample ID with hand-held scanner method 2

1. Read the sample ID in measurement mode with the

hand-held scanner and calibrate the cuvette.

The sample ID is saved togther with the measured value but

is not transferred to the list of sample IDs.

Note: To delete a sample ID, activate the ID by selecting it and pressing

Delete.

Note: A sample ID can be entered or changed in Reading Mode. To do

this, press Options > More > Instrument Setup. If a sample ID is

already assigned, select the "Sample ID" symbol.

5.2.2.3 Import sample ID list

1. Create an external sample ID list with a spreadsheet

program.

Four columns are permitted; column 1 contains the

sequential number, column 2 the sample designation,

columns 3 and 4 are optional.

Headings and comment lines must begin with #.

2. Create a folder named "Sample ID" on a USB stick or in your

established network.

26

3. Save the sample ID list with Save As in the format CSV or

UNICODE-TXT in the folder "Sample ID".

4. Connect the instrument to the USB stick or network.

All *.TXT and *.CSV files in the Sample ID folder will be

displayed for selection.

Page 27

5. Select the desired file with OK.

Standard programs

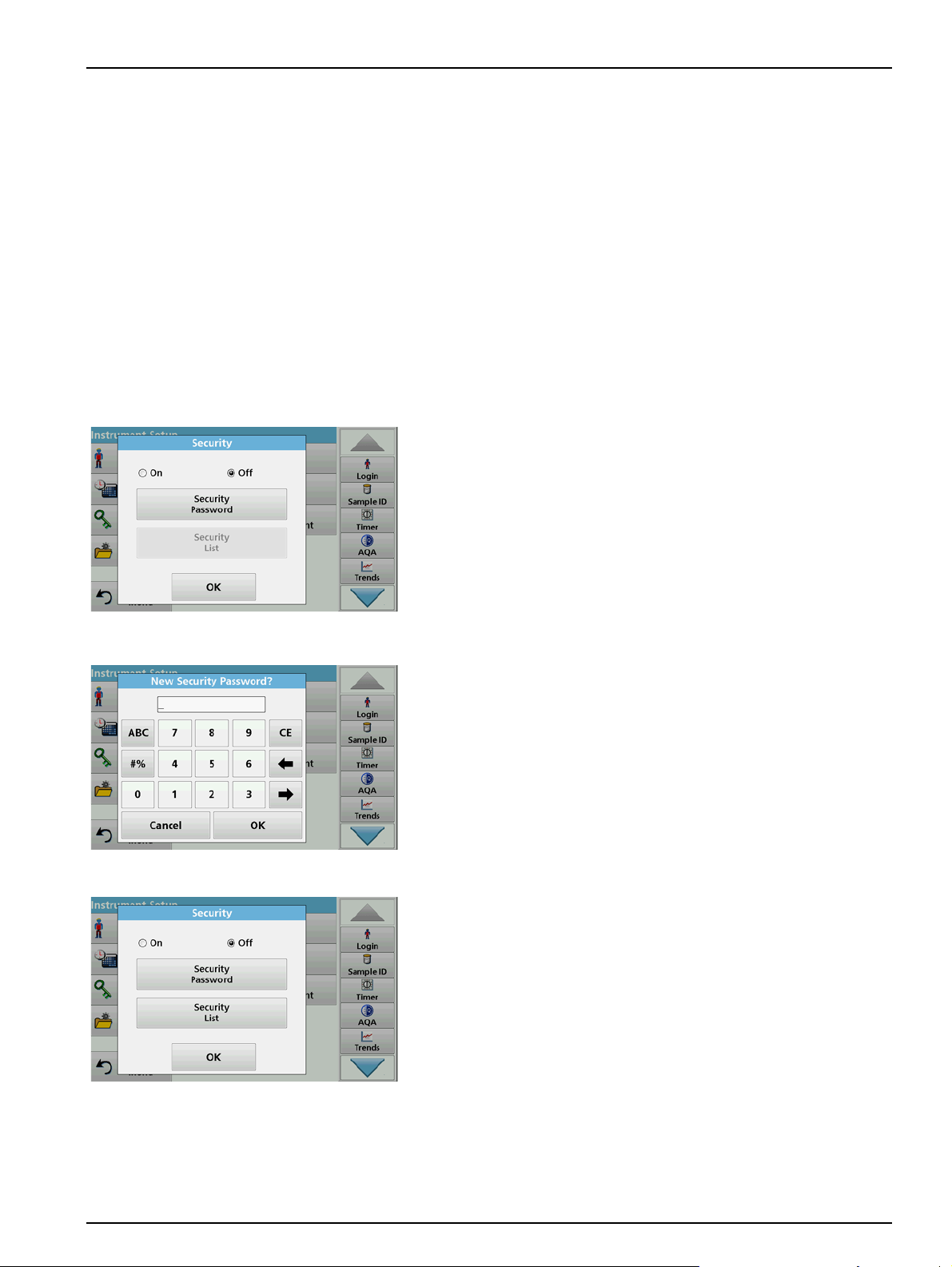

5.2.3 Security settings

6. Transfer the displayed sample ID list with

The "Security" menu contains a variety of security settings to

control access to various functions.

All functions can be allocated to three different security levels:

• not secured: every operator can make changes in this area.

• one key: every operator assigned this security level can

make changes to non-secured functions and functions with

one key.

• two keys: every operator assigned this security level can

make changes in all functions

1. Press Security in the "Instrument Setup" menu.

2. In order to open the Security List, assign a password as

security administrator. Press Security Password.

DONE.

3. Enter a new security password (up to 10 characters long) via

the alphanumeric keypad, and confirm with OK.

4. Press Security List to access various functions with security

level 1 or 2.

27

Page 28

Standard programs

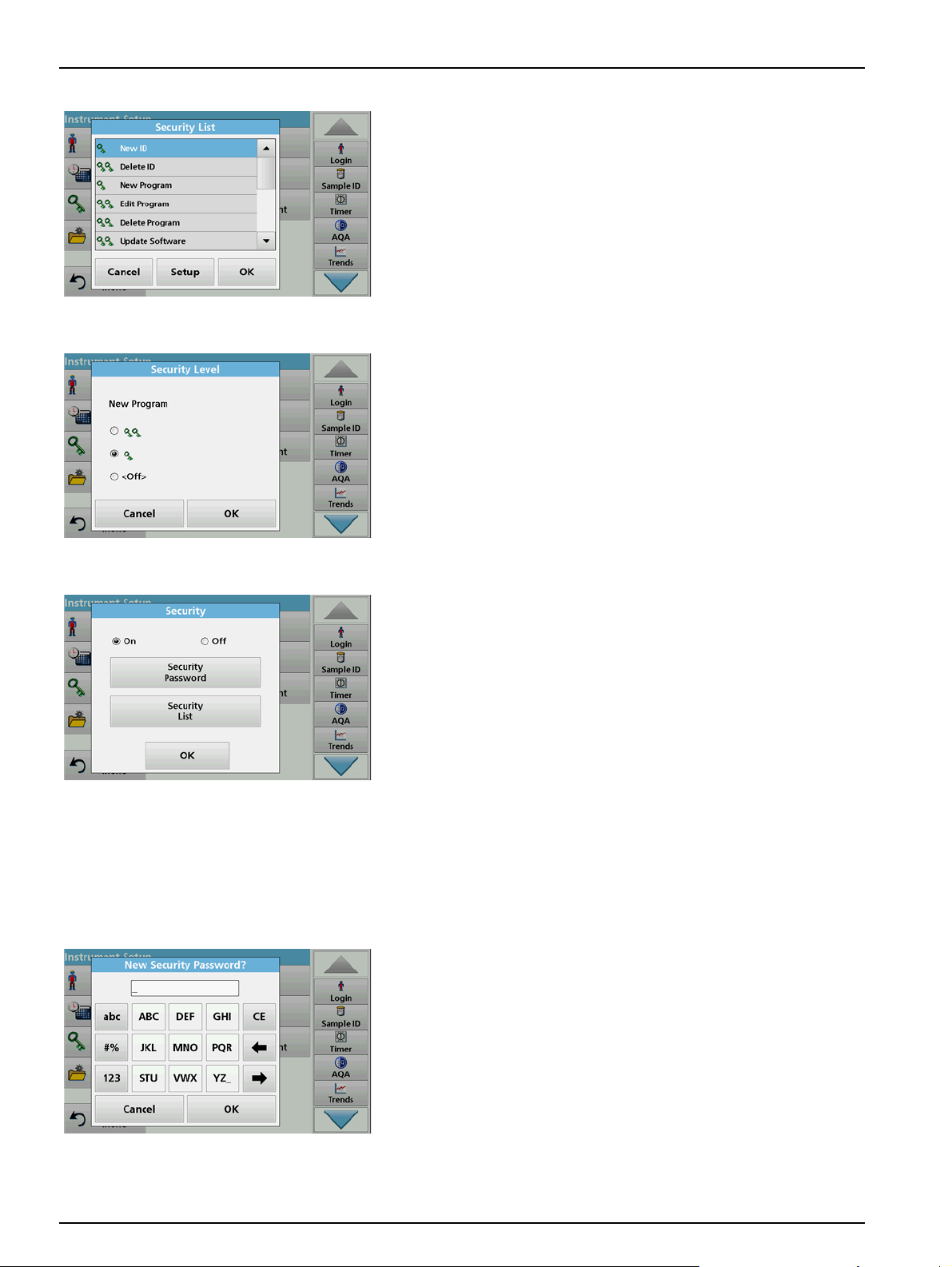

5. Select the required function and press Setup.

6. Select the required security level (two keys, one key or off)

and confirm using OK.

7. Press OK to return to the "Security" menu.

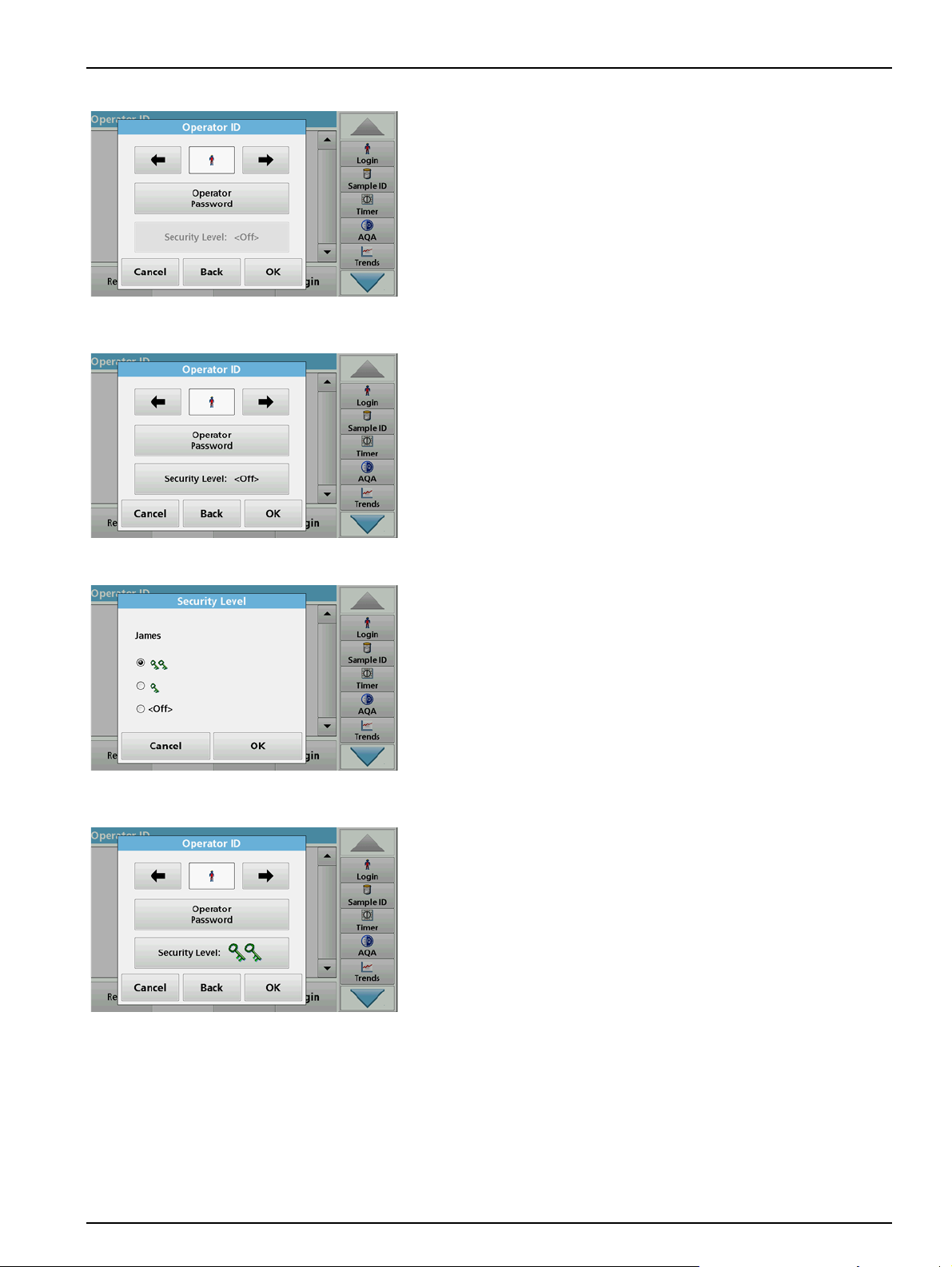

5.2.3.1 Assign operator security level

8. Press On to activate the new settings of the security list.

9. Press OK to return to the "Instrument Setup" menu.

Note: The alphanumeric keypad for entering the password appears

when a user tries to reach a locked setting.

Every operator with an operator ID can be assigned a security

level. This assignment is connected to the operator password.

Setup must be coordinated with the security administrator and

the operator.

1. Press Operator ID in "Instrument setup".

2. Enter the security password and confirm with OK.

3. Set up an operator ID (refer to section 5.2.1).

28

Page 29

Standard programs

4. Press Operator Password.

5. Enter the operator password and confirm with OK.

6. Press Security Level: <Off>.

7. Enter the security password and confirm with OK.

The current security level for the selected operator is shown.

8. Select the required security level for this operator ID and

confirm with OK.

9. Press OK.

29

Page 30

Standard programs

5.2.3.2 Deactivate password

The operator ID is displayed with the selected security level.

10. Activate the selected operator ID by pressing Login.

11. Enter the operator password.

12. Confirm with OK and return to "Instrument Setup".

1. Press Security in the "Instrument Setup" menu.

2. Enter the security password and confirm with OK.

5.2.4 Date and time

3. Press Off to deactivate the settings of the Security List.

4. Press OK and return to the "Instrument Setup" menu.

Note: Use this function to delete the former password or to enter a new

one.

1. Press Date and Time in "Instrument setup".

30

Page 31

2. Press Date Format for the date.

3. Press OK to confirm the entry.

4. Press Time Format for the time.

5. Press OK to confirm the entry.

Standard programs

6. Press OK to confirm the entry.

7. Enter the current date and time. Change the information

using the arrow keys.

8. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

31

Page 32

Standard programs

5.2.5 Sound settings

1. Press Sound Settings in "Instrument Setup".

The following options will be displayed:

• All: Activates/deactivates a sound with a variable volume for

every function, with the exception of the timer.

• Touch screen: Activates/deactivates a short sound with

variable volume every time the screen is touched.

• Reading done: Activates/deactivates a short sound with

variable volume when the reading is done.

•Timer: Sets short/long sound with variable volume when

timer has ended.

•Startup: Activates/deactivates a startup melody with variable

volume when the test program is started.

• Warning: Activates/deactivates a short sound with variable

volume if there is an error message.

• Shutdown: Activates/deactivates a short sound with variable

volume when shutting down.

5.2.6 PC and printer

2. Select the required action.

3. Press Setup and complete the required settings.

4. Press OK to confirm the entry.

5. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

As standard, the instrument has one Ethernet port and 2 USB

ports on the rear of the instrument, as well as one USB port on

the front (see Figure 1 and Figure 2, page 15). These interfaces

can be used for exporting data and graphics to a printer, updating

data and transferring data to a PC and in a network. They are

intended for connecting a USB memory, an external USB keypad

or a USB barcode hand-held scanner.

Note: With a USB hub, you can connect various accessory instruments

at the same time.

A USB memory stick is used to update data, refer to

section 6.1.2, page 87.

32

Note: A shielded USB cable must not be longer than 3m!

Page 33

5.2.6.1 Printer setup

Standard programs

1. Press PC & Printer in "Instrument Setup".

A list with information about the connections opens.

2. Press Printer.

3. Press Setup to display the Printer Setup screen.

Printer Setup:

• Resolution: Font size

• Paper: Paper size

• Network Printer: Automatic printer search or fixed input via IP

address.

Note: If an optional Thermal Printer is connected, the function "Auto

Send" on/off is available.

4. Press Resolution to select the print quality.

Select between:

• 100 dpi,

• 150 dpi and

• 300 dpi.

5. Press OK to confirm the entry.

Note: Press OK again to return to the "Instrument Setup" menu.

33

Page 34

Standard programs

5.2.6.2 Print data

6. Press Paper to select the paper size.

Select between:

• Letter,

• Monarch,

• Executive,

• A4.

7. Press OK to confirm the entry.

Note: Press OK again to return to the "Instrument Setup" menu.

1. In the main menu, press the Recall Data menu option.

2. Select the data source, where the data to be printed are

stored.

5.2.6.3 Print data continuously

A list is displayed. Data can be filtered. Refer to

section 5.3.1.2, page 39 for more information.

3. Press the Send Data symbol to transmit data (table, curve)

directly to the printer.

4. Highlight Single point, Filtered data or All data and press

OK to confirm.

Sending data... appears on the screen until the data is

printed.

If you would like to automatically print out all measured values

immediately after measurement, the use of a continuous form

printer is recommended, for example the 4" paper thermal printer

refer to Section 9, page 107.

1. Connect the thermal printer to a USB type A port.

2. Press PC and Printer in the "Instrument Setup" menu.

A list with information about the connections opens.

3. Highlight Printer.

34

4. Press Setup to display the Printer Setup screen.

5. Select Auto-Send: On to send all measured data

automatically to the Thermal printer.

Page 35

5.2.6.4 Network setup

Standard programs

The instrument supports communication in local networks. For

the setup of an Ethernet communication in networks, a special

configuration is required. The manufacturer recommends support

from a network administrator. Only use a shielded cable

(e.g. STP, FTP, S/FTP) with a maximum length of 20 m for the

Ethernet port. This section describes the setting options for the

photometer in relation to network communication.

The connection parameters must be configured for data transfer

to a PC or connection to a network.

1. Press PC & Printer in "Instrument Setup".

2. Press Network > Setup.

3. Press On and then LICO6xx IP: Automatic.

4. Press IP address.

An IP address is used to send data from a sender to a

pre-defined recipient.

• If the IP for the instrument is automatically assigned in

the network, no further settings are necessary. A

hostname can optionally be assigned.

• If the instrument address is fixed, the connection must be

configured.

5. To configure the IP address, press Fix.

6. Press IP address and enter the address.

35

Page 36

Standard programs

In conjunction with the IP address of an instrument, the subnet

mask establishes which IP addresses are located within the local

network.

7. Press Subnet Mask and enter the address.

A Gateway enables data communication in networks that are

based on varying protocols.

8. Press Default Gateway and enter the address.

9. Press OK to confirm the entry.

10. Press Network Server to determine the destination for the

data transmission.

11. Press Netdrive and run a netdrive setup.

Alternatively, select FTP and run FTP Setup.

The procedures are completely identical. As an example,

Netdrive Setup is described here.

36

Page 37

Standard programs

The target site can be defined by IP address or a server name.

12. Press IP-Address and enter the IP address or select Server

Name and enter a server name.

13. Press Data Folder and enter the target folder name.

Note: A folder with the selected name must exist on the target

system. Additionally, the folder must be shared with the operator,

using the corresponding password.

14. Press OK to confirm the entry.

User and password must be identical to the settings on the

target system.

15. Press User and enter the user designation.

16. Press OK to confirm.

17. Press Password and enter the password.

18. Press OK to confirm the entry.

19. Press Factory Default to restore the network configuration to

the factory defaults.

37

Page 38

Standard programs

5.2.7 Power Management

1. Press Power Management in "Instrument setup".

2. Press Sleep Timer and then OK.

3. Select the required time span after which the instrument will

go into energy-saving sleep mode if it is not used (refer to

section 4.4, page 20), and confirm with OK.

4. Press Power Off Timer and then OK.

5. Select the required time span after which the instrument will

automatically be powered off if it is not used, and confirm with

OK.

6. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

5.3 Save, recall, send and delete data

Up to 3000 color measured values (400 color measured values

for LICO 620) can be saved in the measured data memory.

In addition, the LICO 690 can store 100 reference color

measurements, 1000 single and multi-wavelength

measurements, 20 wavelength scans and 20 time scans.

A complete record of the analysis is stored, including the Date,

Time, Results, Sample ID and Operator ID.

5.3.1 Color values

Measurement results from the color measurement can be found

under Recall Data > Color Log.

38

Page 39

5.3.1.1 Automatic/manual color value storage

The data storage function indicates whether data is to be stored

automatically or manually (in the latter case, the user must decide

which data is to be saved).

1. Press Data Log Setup in the "Instrument Setup" menu.

2. Specify the output format of data to be exported using Send

3. Press OK to confirm the entry.

Standard programs

• With the Auto Store: On setting, the instrument

automatically saves all the calculated measured data

"after the measurement" or alternatively "after removing

the cuvette".

• With the Auto Store: Off setting, the instrument saves

no measured data automatically. In measurement mode,

select Options > Save to save the currently displayed

measured value.

Data Format. Select xml or csv.

The instrument then returns to "Instrument Setup".

Note: When the measured data memory of the device has reached its

maximum storage capacity, the oldest data record is automatically

deleted so that the new data can be saved.

5.3.1.2 Recall color values from the measured data memory

1. In the main menu, press the Recall Data menu option.

2. Press Color Log.

A listing of the stored data is displayed.

39

Page 40

Standard programs

3. Press Filter: On/Off.

The function Filter Settings is used to search for specific

items.

4. Activate On. The data can now be filtered using the following

selection criteria.

• Sample ID

• Operator ID

• Start Date

• Color Scale

or any combination of the four.

5. Press OK to confirm the selection.

The chosen items are listed.

6. Press View Details to get more information.

7. Press Options and Graph Data.

A graphic trend of all color values stored in the selected

period and color system is displayed. The trend shows a

visual impression of the measured process values, e.g.

during production supervision in the shift operation.

8. Press the arrow buttons on the right of the graph to move

the dotted cursor line inside of the trend graph to the different

measurement values. The color value of the marked

measurement is shown on the left vertical axis and the

date/time of this measurement is shown below the horizontal

axis.

40

Page 41

Standard programs

9. Press Control Limit.

10. Highlight On to change the Upper Control Limit and the

Lower Control Limit settings.

11. The measured points symbol changes the display of the

measured points.

5.3.1.3 Send color values from the measured data memory

Data is sent from the internal data memory as an XML file

(Extensible Markup Language) or as CSV files(Comma

Separated Value) to a USB mass storage device or to a network,

to a directory with the name ColorLog. The file can then be

processed using a spreadsheet program. The file name has the

following format: CL_Instrument Type_Serial

Number_Year-Month-Day_Hour_

Minute_Second.csv or CL_Instrument Type_Serial

Number_Year-Month-Day_Hour_

Minute_Second.xml.

To send data to a printer, refer to section 5.2.6.2, page 34.

1. Plug the USB memory stick into the USB-A port on the

instrument or connect the instrument to a network drive (see

section 5.2.6.4, page 35).

2. In the main menu, press the Recall Data option.

3. Select the data category to be transferred, e. g. Color Log.

A list of the selected measurement data is displayed.

41

Page 42

Standard programs

4. Press Options and then the PC & Printer icon.

5. Select the data to be sent.

The following options are available:

• Single point: only this selected reading will be sent

•Filtered data: only readings that correspond to the set

filters will be sent

• All data: all data in the selected data category will be

sent.

6. Press OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

5.3.1.4 Delete color values from the measured data memory

1. In the main menu, press the Recall Data menu option.

2. Press Color Log > Options > Delete.

3. Highlight Single point, Filtered data or All data and press

OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

5.3.2 Control charts for data from the AQA Log

1. In the main menu, press the Recall Data menu option.

42

Page 43

2. Press AQA Log.

A listing of the stored data is displayed.

3. Press Filter: On/Off.

4. Activate On.

5. Select a required parameter.

Standard programs

5.3.3 Data log (only LICO 690)

6. Press OK to confirm the selection.

The chosen items are listed.

7. Press Options > Control Chart.

The measured standard concentrations are displayed

graphically with the control limits and date.

Measurement results from the photometric measurements of

single and multi-wavelengths can be found under Recall Data

Data Log.

43

Page 44

Standard programs

5.3.3.1 Automatic/manual saving of single and multi-wavelength measurements

The data log function indicates whether data is to be stored

automatically or manually (in the latter case, the user must decide

which data is to be saved).

1. Press Data Log Setup in the "Instrument Setup" menu.

• With the Auto Store: On setting, the instrument

automatically saves all the calculated measured data

"after the measurement" or alternatively "after removing

the cuvette".

• With the Auto Store: Off setting, the instrument saves

no measured data automatically. In measurement mode,

Options > Save can be used to save the currently

displayed measured value.

2. Specify the output format of data to be exported using Send

Data Format. Select xml or csv.

3. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

Note: When the measured data memory of the instrument has reached

its maximum storage capacity, the oldest data record is automatically

deleted so that the new data can be saved.

5.3.3.2 Recall single and multi-wavelength measurements from the measured data memory

1. In the main menu, press the Recall Data menu option.

2. Press Data Log.

A listing of the stored data is displayed.

44

Page 45

Standard programs

3. Press Filter: On/Off.

The function Filter Settings is used to search for specific

items.

4. Activate On. The data can now be filtered using the following

selection criteria.

• Sample ID

• Operator ID

• Start Date

• Parameter (Single or multi-wavelength)

or any combination of the four.

5. Press OK to confirm the selection.

The chosen items are listed.

6. Press View Details to get more information.

7. Press Options and View Graph.

A graphic trend of all wavelength measurements stored in the

selected period is displayed. The trend shows a visual

impression of the measured process values, e.g. during

production supervision in the shift operation.

8. Press the arrow buttons on the right of the graph to move

the dotted cursor line inside of the trend graph to the different

measurement values. The absorbance of the selected

measurement is displayed on the left vertical axis, while the

date/time of this measurement is displayed below the

horizontal axis.

45

Page 46

Standard programs

9. Press Control Limit.

10. Highlight On to change the Upper Control Limit and the

Lower Control Limit settings.

11. The measured points symbol changes the display of the

measured points.

5.3.3.3 Send single and multi-wavelengths from the measured data memory

Data is sent from the internal data log as an XML (Extensible

Markup Language) file or as a CSV (Comma Separated Value)

file, to a directory with the name DataLog on a USB mass storage

device or a network drive. The file can then be processed using a

spreadsheet program. The file name has th format:

DL_Instrument Type_Serial Number_Year-Month-Day_Hour_

Minute_Second.csv or DL_Instrument Type_Serial

Number_Year-Month-Day_Hour_

Minute_Second.xml.

To send data to a printer, refer to section 5.2.6.2, page 34.

1. Plug the USB memory stick into the USB-A port on the

instrument or connect the instrument to a network drive (see

section 5.2.6.4, page 35).

2. In the main menu, press the Recall Data menu option.

3. Select the data category to be transferred, e.g. Data Log.

A list of the selected measurement data is displayed.

46

Page 47

Standard programs

4. Press Options and then the PC & Printer icon.

5. Select the data to be sent.

The following options are available:

• Single point: only this selected reading will be sent

• Filtered data: only readings that correspond to the set

filters will be sent

•All data: all data in the selected data category will be

sent.

6. Press OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

5.3.3.4 Delete single and multi-wavelengths from the measured data memory

1. In the main menu, press the Recall Data menu option.

2. Press Data Log > Options > Delete.

3. Highlight Single point, Filtered data or All data and press

OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

5.3.4 Wavelength scan and time course (LICO 690 only)

You can save 20 data records for the wavelength scan and 20

data records for the time course. The data must be stored

manually after it is displayed.

47

Page 48

Standard programs

5.3.4.1 Data storage from wavelength scan or time course

1. Press the Folder icon in the "Options" menu after a reading

is taken.

The Store Data list will be displayed.

2. Press Store to save the current scan to the highlighted

numbered line.

Note: Scans can be overwritten.

5.3.4.2 Recall stored data from wavelength scan or time course

1. In the main menu, press the Recall Data menu option.

a. Select Wavelength Scan or Time Course to recall data.

b. If you are already working in one of these programs,

press Options > More > Recall Data.

2. Select the required data.

3. Tap on Graph to display details.

Note: Press View List to return to "Recall Data".

48

Page 49

4. Press Tabl e to display details.

Note: Press View List to return to the "Recall Data" list.

5.3.4.3 Send data from wavelength scan or time course

There are two ways to recall sent data to a USB memory stick,

printer or PC with Hach Data Trans.

Option 1:

1. In the main menu, press the Recall Data menu option and

then Wavelength Scan or Time Course.

Standard programs

2. Press Options and then the PC & Printer icon to send the

data to a USB memory stick, to a printer or to a PC with Hach

Data Trans.

• When a printer is connected, select how to send the data

to the printer (graph, table or both graph and table).

• If a USB memory stick is connected, the files will be

automatically sent to the USB memory stick as xml or csv

files in the file folder "WLData (data of a wavelength

scan) or "TCData" (data of a time course).

The file name has the following format:

• Data from a wavelength scan:

"ScanData_LICO690_Serial NUmber_X.xml" or

"ScanData_LICO690_Serial Number_X.csv"

• Data of a time course:

"TCData_Serial Number_X.xml" or

"TCData_Serial Number_X.csv"

X = number of scans (1–20).

For further processing use a spreadsheet program.

Note: The message, "Data already present. Overwrite?" is displayed if

the files are already stored. Press OK to overwrite the stored data.

49

Page 50

Standard programs

Option 2:

1. Press Wavelength Scan or Time Course and then Options

> More > Send Data to send the data to a USB memory

stick or to a printer.

• When a printer is connected, select how to send the data

to the printer (graph, table or both graph and table).

• If a USB memory stick is connected, the files will be

automatically sent to the USB memory stick as xml or csv

files in the file folder "WLData (data from a wavelength

scan) or "TCData" (data from a time course).

The file name has the following format:

• Data from a wavelength scan:

"ScanData_LICO690_Serial Number_Year-Month-Day_

Hour_Minute_Second.xml" or

"ScanData_LICO690_Serial Number_Year-Month-Day_

Hour_Minute_Second.csv"

• Data from a time course:

"TCData_LICO690_Serial Number_Year-Month-Day_

Hour_Minute_Second.xml" or

"TCData_LICO690_Serial Number_Year-Month-Day_

Hour_Minute_Second.csv"

For further processing use a spreadsheet program.

5.3.4.4 Delete stored data from wavelength scan or time course

1. In the main menu, press the Recall Datamenu option and

thenWavelength Scanor Time Course.

A listing of the stored data is displayed.

2. Highlight any data to delete.

3. Press Delete in the "Options" menu and press OK to confirm.

5.3.5 Trends

You can use the Trends function to recall a load curve of the

saved measured values for each color value and sample location.

The concentration of the corresponding parameter is shown

graphically over time.

50

Page 51

Standard programs

1. Press Recall Data > Trends.

2. A list of all trend analyses is displayed.

3. Press Options and New to create a new trend.

Edit enables you to change the settings for an existing trend,

Delete enables you to delete an existing trend.

4. Define the trend settings according to sample ID, operator ID,

time interval and parameter.

51

Page 52

Standard programs

5. Use control limits to define the upper and lower limits that are

displayed in the graphic.

6. Select the required trend and confirm with Select.

7. The trend can be displayed in several formats, as a line or as

points.

8. Press Information to recall an overview of the parameter

information.

52

Page 53

5.4 Take and prepare samples

Standard programs

9. Press Add Data to include additional measured values in the

trend.

Take a representative sample from the product you wish to

measure in accordance with DIN EN ISO 15528 (or ASTM

D3925-02).

If the material shows any signs of turbidity, remove this turbidity

by filtration, centrifuging, heating, ultrasound treatment or other

suitable means.

Heat partly solid samples before measuring in order to dissolve

the solid material in the liquid. The preparation must not cause

any chemical changes in the sample.

Make sure that during the measurement there are no bubbles in

the sample.

For the color difference measurement, three cuvette types are

available that differ in terms of material (glass, PS and PMMA)

and path length (10 mm, 11 mm and 50 mm). Add approx. 2 cm

of the sample to the cuvette. The light beam passes through the

cuvette approx. 0.5 cm to 1.5 cm above the bottom of the cuvette.

The program calculates the iodine, Hazen, Gardner, Saybolt,

Klett and ASTM D 1500 color values automatically and displays

the color values. The cuvette type being used is taken into

consideration.

A dry thermostat is available for the round disposable glass

cuvettes with 11 mm. The dry thermostat heats up the cuvette to

any temperature between ambient temperature and 150 °C

(302 °F).

NOTICE

The samples must be clear and free of turbidity. If products in paste or

solid form cannot be measured directly, the product must be melted

before being transferred to the cuvettes/sample cells. Make sure the

cuvettes/sample cells do not contain any air bubbles.

• Always hold the cuvette/sample cell close to the top to make

sure that there are no fingerprints in the measurement zone

of the cuvette/sample cell. Use suitable transfer pipettes to

introduce samples into the cuvettes/sample cells.

• Slowly add samples to the cuvettes/sample cells to make

sure air bubbles do not form on the cuvette/sample cell wall

and in the sample. Air bubbles will cause false readings.

53

Page 54

Standard programs

5.5 Color measurement

• If air bubbles are entrapped, remove them by heat, vacuum,

ultrasonic treatment or other suitable means.

• Clean the outside of the cuvettes/sample cells thoroughly

before inserting them in the cell compartment.

NOTICE

Before using disposable cuvettes/sample cells made of PS

(Polystyrene) or PMMA (Polymethyl methacrylate), be sure that the

cuvettes/sample cells will not be destroyed by samples, otherwise the

cell compartment can be damaged.

Proper sample preparation is extremely important for accurate

color measurement. To make sure that an exact measurement is

taken, refer to the following sample preparation guidelines:

• Always clean the glass cuvettes/sample cells immediately

after use.

• Only use optically preferred samples for measurement. Make

sure the cuvettes/sample cells are clean and show no signs

of opaqueness.

• Slowly add the liquid to the cuvette in order to prevent the

formation of air bubbles in the sample.

• Chapter 5.4, Page 53 contains further information on

preparing and taking samples.

The color measurement mode is used to determine absolute

color values in the Hazen, Gardner, CIE L*a*b* or European

Pharmacopoeia color scales.

For each cuvette type (11 mm round cuvette and 10 and

50 mm square cuvettes), an independent calibration data record

is used.

It is possible to calibrate the instrument with one, two or three

types of cuvettes/sample cells and to use these different

cuvette/sample cell types in parallel.

To use the 10 mm square cuvette and 11 mm round cuvettes,

adapter Z must be inserted into the cuvette compartment (2). For

measurements with 50 mm square cuvettes, you must remove

the adapter.

54

Page 55

5.5.1 Take a color measurement

Standard programs

1. Press Color Measurement.

2. Insert a cuvette/sample cell with distilled water to calibrate.

Note: Always carry out the calibration very carefully, as a faulty

calibration can cause inaccurate results to be obtained.

3. The calibration starts automatically once the instrument has

detected the cuvette.

The type of cuvette/sample cell used and the exact progress

of calibration is shown in a separate window.

4. After calibration, the cuvette size used is displayed in the top

right.

Note: After calibration, you can measure the cuvette with distilled

water again as a sample.

The displayed measured values should match the uncolored color

indices (i.e. Hazen = 0, Gardner = 0.0, CIE L*a*b* = 100.0, 0.0, 0.0,

etc.)

5. Insert the test cuvette.

The measurement starts automatically.

The result of the color calculation is displayed.

Note: The bar on the right next to the result shows the result relative

to the measurement range.

6. For the next measurement, remove the cuvette and insert the

next sample cuvette, or press Measure to measure the same

sample again.