Page 1

User Manual

Sodium (Na+) Ion Selective Probe: Model ISENa38101 or

ISENa38103

Safety information

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed. A symbol on the instrument is referenced in the

manual with a precautionary statement.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of-life equipment to the Producer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return end-of-life

equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

Specifications

Note: Specifications are subject to change without notice.

DOC022.52

.80027

Specifications Details

Probe type Digital, combination ion selective probe with a double junction, refillable

junction reference and a built-in temperature sensor

Electrode resistance < 800 Mohms at 25 °C (77 °F)

Range 0.023 mg/L (1x10-6 M) to 23,000 mg/L (1 M) Na

Linear region 1.4 mg/L to 23,000 mg/L

Slope -59 mV/pNa (90 to 110% at 25 °C (77 °F) per Nernstian theoretical value)

Operating temperature range 0 to 50 °C (32 to 122 °F)

Storage temperature range 5 to 40 °C (41 to 104 °F)

Junction Double ceramic porous pin

Reference type Ag/AgCl

Fill solution 0.02M NH4Cl

Response time in linear region 1 to 2 minutes in sample concentration > 1.4 mg/L

Minimum sample volume 25 mL

Dimensions Diameter: 12 mm (0.47 in.)

Length: 175 mm (6.89 in.)

Cable length: 1 or 3 m (3.28 or 9.84 ft)

Cable connection M12 digital output and connector compatible with HQd meters

+

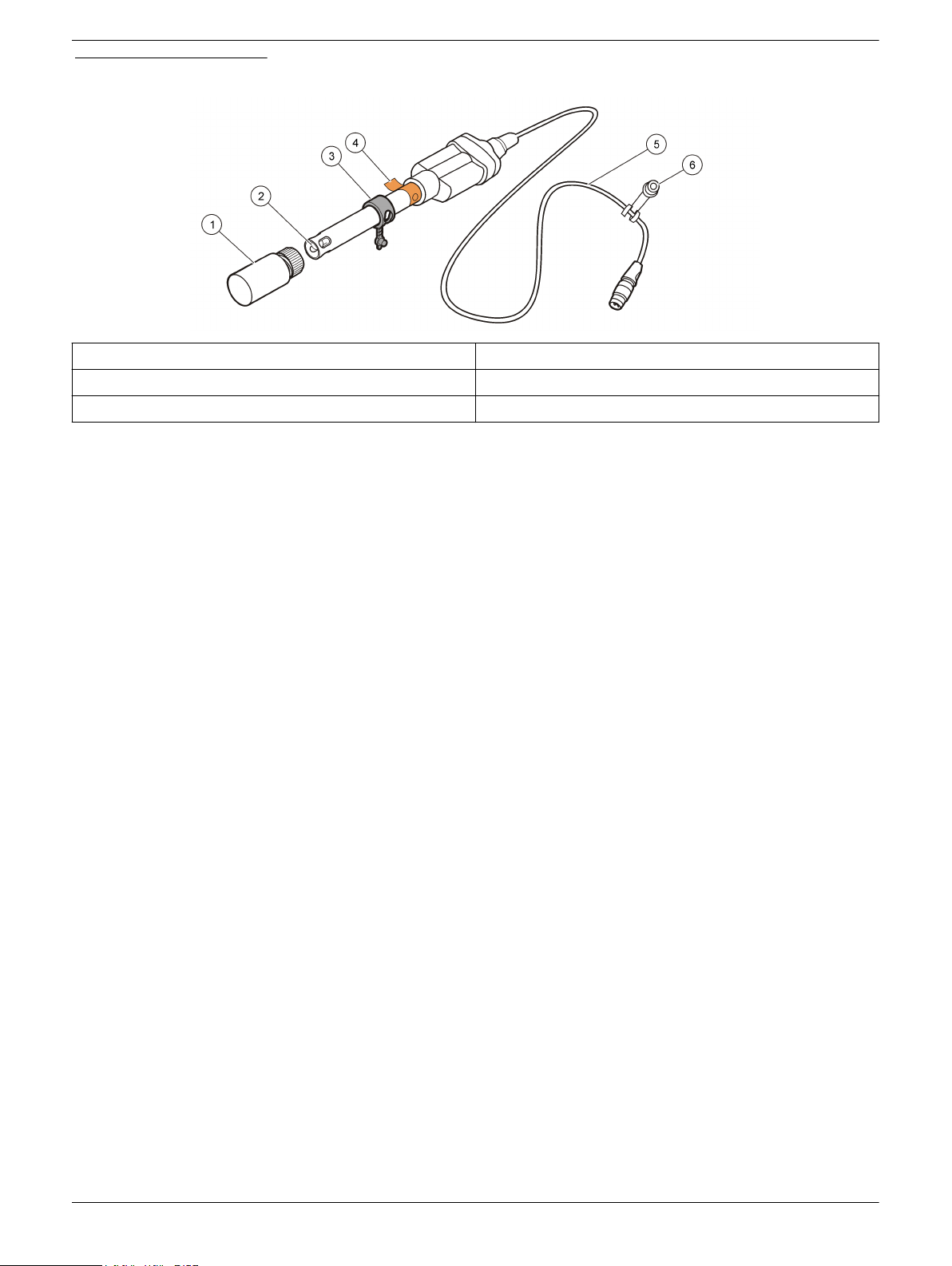

Product overview

The ISENa381 series probe is a refillable, combination sodium probe with a built-in

temperature sensor (Figure 1). The ISENa38101 or ISENa38103 probe is available with a

1 or 3 m (3.28 or 9.84 ft) cable and is intended for laboratory use. The probe measures

absolute mV values in wastewater, drinking water and general applications. The probe

measures sodium concentration in water samples. A 59 mL bottle of 0.02 M NH4Cl

Electrode Filling Solution is included with the probe.

1

Page 2

Figure 1 Probe overview

1 Probe soaker bottle 4 Protective tape and filing-hole

2 Reference junction, glass bulb and temperature sensor 5 1 or 3 meter (3.28 or 9.84 ft) cable

3 Filling-hole cap 6 Probe soaker bottle holder

Preparation for use

Prepare the probe for use before calibration or sample measurement.

1. Turn the probe soaker bottle cap counter-clockwise to loosen the cap.

2. Remove the soaker bottle from the probe.

3. Rinse the reference junction and glass bulb with Ionic Strength Adjustor (ISA) rinse

solution (refer to Prepare the ISA rinse solution on page 11

cloth.

4. Remove the protective tape from the filling hole before initial use (refer to Figure 1

on page 2). Dispose of the protective tape.

5. Add filling solution to the probe as necessary (refer to Fill the probe on page 11).

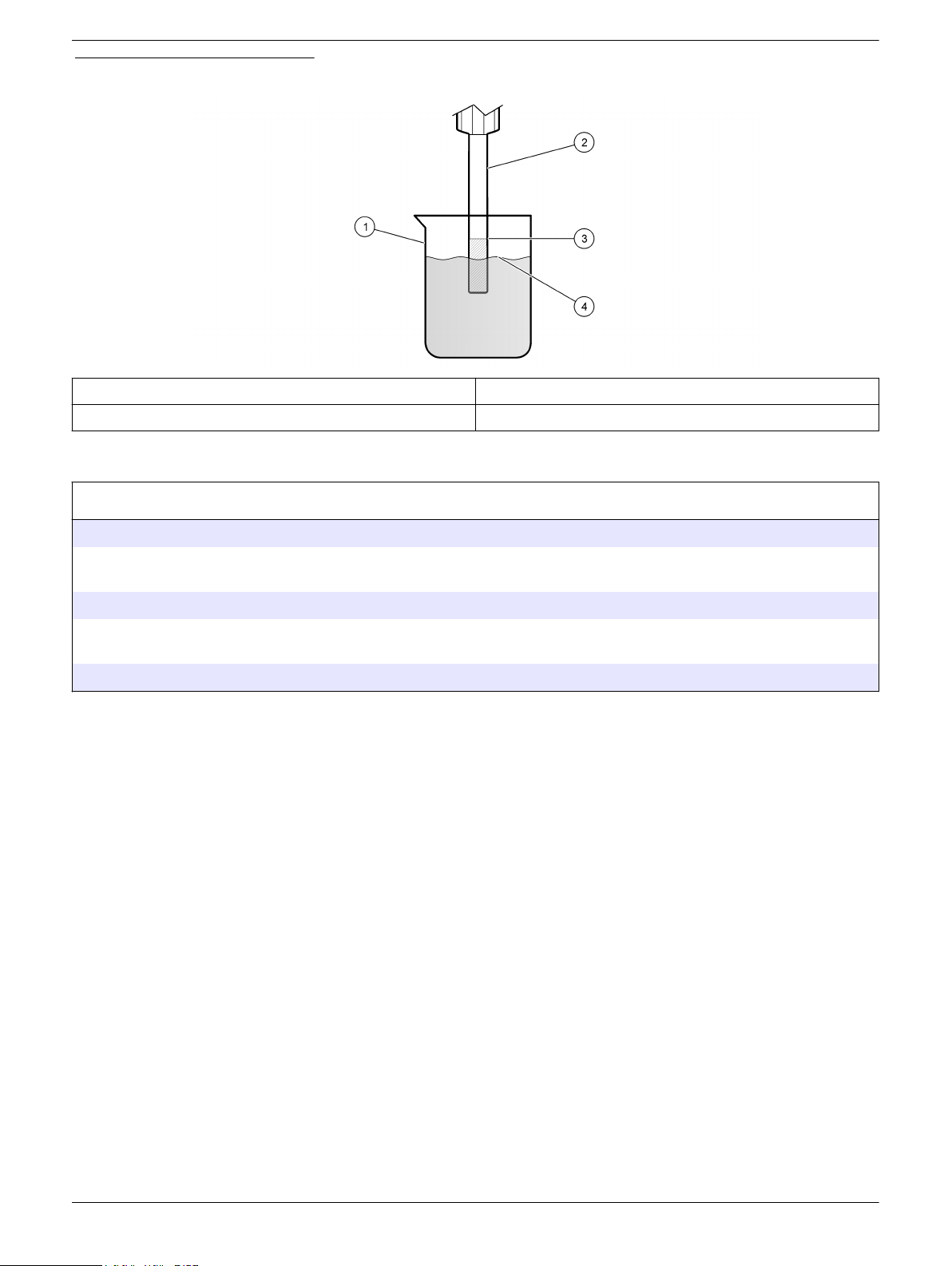

The filling solution must be above the standard solution or sample level during

measurement (Figure 2).

6. Make sure that the filling hole is open during measurement for the proper flow of the

filling solution.

Note: After long-term storage, the probe must be conditioned in 25 mL of 100 mg/L Na

standard solution with the contents of one Sodium ISA powder pillow for at least 30 minutes

prior to use. If probe stabilization is slow after storage, condition the probe for up to one hour in

25 mL of 100 mg/L Na+ standard solution with the contents of one Sodium ISA pillow.

). Blot dry with a lint-free

+

2

Page 3

Figure 2 Measurement method

1 Container 3 Filling solution level

2 Probe body 4 Standard solution or sample level

Calibration

Before calibration:

The probe must have the correct service-life time stamp. Set the date and time in the meter before the probe is attached.

It is not necessary to recalibrate when moving a calibrated probe from one HQd meter to another if the additional meter is

configured to use the same calibration options.

To view the current calibration, push , select View Probe Data, then select View Current Calibration.

If any two probes are connected, push the UP or DOWN arrow to change to the single display mode in order to show the

Calibrate option.

Prepare the probe for use (refer to Preparation for use on page 2

).

Calibration notes:

Stir the standards and samples at a slow and steady rate to prevent the formation of

•

a vortex.

• Additional standard sets along with the minimum number of calibration points can be

selected on the Calibration Options menu.

• Push Skip to omit a standard from the calibration routine. The display will not show

Skip until the minimum number of standards is met.

• Begin with the lowest concentration during calibration. This reduces carry-over

contamination to give the best results.

• For measurements below 1 ppm (10-5 M), use plastic lab-ware.

• Note the temperatures of the standards during calibration. Keep temperatures

between calibration standards within ±2 ºC for optimal results.

• The calibration is recorded in the electrode and the data log. The calibration is also

sent to a PC, printer or flash memory stick if connected.

• Air bubbles under the sensor tip when submerged can cause slow response or error

in measurement. If bubbles are present, gently shake the probe until bubbles are

removed.

• If a calibration error occurs, refer to Troubleshooting on page 12.

3

Page 4

Calibration procedure:

1. Connect the

probe to the

meter. Make sure

that the cable

locking nut is

securely

connected to the

meter. Turn the

meter on.

6. Add a stir bar

and put the probe

in the first

standard solution

in the set. Make

sure that the

reference

junctions are

fully

immersed in the

solution. Do not

put the probe on

the bottom or

sides of the

container. Shake

the probe from

side to side in the

sample to refresh

the reference

junction.

2. In three

separate beakers

or appropriate

containers,

prepare 10,

100 and

1000 mg/L Na

+

standard solution

or use appropriate

standards that are

above and below

your application

range as the

standard set.

7. Put the beaker

on an

electromagnetic

stirrer and stir at a

moderate rate.

Check for air

bubbles and

remove them if

necessary.

3. Add the

contents of one

Sodium ionic

strength

adjustment (ISA)

powder pillow per

25 mL to each

standard.

8. Push Read.

The display will

highlight the

standard value

and proceed to

the next standard

value. The display

will show

"Stabilizing" and a

progress bar as

the reading

stabilizes. The

display shows the

standard value

when the reading

is stable.

4. Push

Calibrate. The

display shows the

current standard

value that is to be

read from the

standard solution

set.

9. Repeat steps

5-8 for the other

Na+) standard

solutions in the

set.

5. Rinse the

probe with ISA

rinse solution

(refer to Prepare

the ISA rinse

solution

on page 11).

Never use

deionized water..

Blot dry with a lintfree cloth. Do not

touch the tip of the

probe.

10. Push Done to

view the

calibration

summary. The

display will not

show Done until

the minimum

number of

calibration points

have been

collected.

4

Page 5

11. Push Store to

accept the

calibration and

return to the

measurement

mode.

Measurement—direct method

Before measurement:

The probe must have the correct service-life time stamp. Set the date and time in the meter before the probe is attached.

If complete traceability is required, enter a sample ID and operator ID before measurement. Refer to the HQd meter manual

for more information.

Regular calibration is required for the best measurement accuracy (refer to Calibration on page 3).

Prepare the probe for use (refer to Preparation for use on page 2).

Measurement notes:

•

Stir the standards and samples at a slow and steady rate to prevent the formation of

a vortex.

• Stabilization times with smaller concentration changes generally will be longer and

can be minimized by proper stirring and conditioning. Experiment to determine the

proper stir rate if necessary.

• Note the temperatures of the samples during measurement. Temperatures of

calibration standards and samples should be kept within ±2 °C of each other for

optimal results.

• Data is automatically stored in the data log when Press to Read or Interval is

selected in the Measurement Mode. When Continuous is selected, data will only be

stored when Store is selected.

• Between measurements, rinse the probe with deionized water. Blot dry with a lint-free

cloth. For faster stabilization between measurements, put the probe in 100 mg/L

sodium standard (containing Sodium ISA) that is similar in concentration to the

samples to be analyzed.

• Air bubbles under the sensor tip when submerged can cause slow response or error

in measurement. If bubbles are present, gently shake the probe until bubbles are

removed.

• If a measurement error occurs, refer to Troubleshooting on page 12.

5

Page 6

Measurement procedure:

1. Connect the

probe to the

meter. Make sure

that the cable

locking nut is

securely

connected to the

meter. Turn the

meter on.

6. Push Read.

The display will

show "Stabilizing"

and a progress

bar as the probe

stabilizes in the

sample. The

display will show

the lock icon when

the reading

stabilizes.

2. Prepare a

minimum of 25 mL

of the sample(s) in

beakers or

appropriate

containers. Add

the contents of

one Sodium ionic

strength

adjustment (ISA)

powder pillow per

25 mL to each

sample.

7. Repeat steps

2 - 6 for additional

measurements.

3. Rinse the

probe with ISA

rinse solution

(refer to Prepare

the ISA rinse

solution

on page 11).

Never use

deionized water..

Blot dry with a lintfree cloth. Do not

touch the tip of the

probe.

8. When

measurements

are done, store

the probe (refer to

Storage

on page

12).

4. Add a stir bar

and put the probe

in the sample.

Make sure that the

reference

junctions are fully

immersed in the

solution. Do not

put the probe on

the bottom or

sides of the

container. Shake

the probe from

side to side in the

sample to refresh

the reference

junction.

5. Put the beaker

on an

electromagnetic

stirrer and stir at a

moderate rate.

Check for air

bubbles and

remove them if

necessary.

Run a check standard

The run check standard feature validates instrument performance between sample

measurements. Use the run check standard feature for periodic or user-defined interval

measurements of a traceable standard solution. Set the criteria for check standards from

the ISENa381 Settings menu.

Note: Access control must be off or a valid password must be entered before any of the check

standard method options can be changed.

1. Push

2. Select Run Check Standard.

Note: Select the correct probe if two probes are connected to the meter.

3. Prepare the standard solution shown on the display. Add one powder pillow per

25 mL of standard solution.

6

. The Full Access Options menu is shown.

Page 7

Interferences

4. Put the probe in the standard solution and push Read. The display will show

"Stabilizing" and a progress bar as the reading stabilizes. The display shows the

value of the check standard and either Check Standard Passed or Check Standard

Failed.

5. If the display shows Check Standard Passed, the check standard measurement is

within the accepted limits set by the administrative user. Select Done to continue with

the sample measurement.

6. If the display shows Check Standard Failed, the measurement is outside of

accepted limits set by the administrative user and a recalibration is recommended. If

the acceptance criteria is set to Cal Expires on Failure: Yes, the display shows the

calibration icon and a question mark until the probe is recalibrated. To correct the

probe calibration and status indicator, calibrate the probe (refer to Calibration

on page

3).

The glass membrane responds to sodium as well as other ions. Typically, probe response

to another ion increases the potential, and causes a positive error. The response to other

ions can be semi-quantitatively determined through the Nikolsky equation, an extended

Nernst equation:

E = E° + (RT/(zF)) ln [aNa + KNax × ax]

Where:

• ax = the activity of the interfering ion

• KNax = the selectivity coefficient for the interfering ion relative to sodium

If the probe is exposed to high levels of interferences, soak the probe in 1 M sodium

chloride to help remove the absorbed ions from the glass membrane. The major

interferences are silver and hydrogen ions. Hydrogen ion concentration is decreased by

the ISA, which raises the pH.

If the samples are highly acidic, or have a high buffer capacity, check that the sample pH

is above 9 after adding ISA. If necessary, add ammonium hydroxide (NH4OH) to the

calibration standards and samples in equal proportions to raise the pH. The ammonium

hydroxide (NH4OH) will not affect the measurement due to the low selectivity coefficient

of NH

The ions that interfere in sodium determinations are given for molar concentrations of all

ions. The smaller the value of the selectivity coefficient, the lower the interference.

Approximate values of selectivity constants (K) are ordered from highest to lowest in

Table 1.

Interference Selectivity coefficient

Ag+ (>1000) H+ (20) - reduced by ISA addition

Li+ (0.01) K+ (0.001)

Ti+ (0.0002) —

Advanced operation

Parameter-specific settings can be changed through the Full Access Options menu.

Details about menu navigation, available options and how to change them are given in

the screens, tables and procedures throughout this section.

4

+

ion.

Table 1 Interferences

7

Page 8

The settings that can be changed are shown in Table 2.

Table 2 Parameter-specific settings

Setting Options

Measurement Options

Calibration Options

Check Standard Options

Change measurement options

Methods are groups of default or user-defined settings relevant to specific applications. If

the meter is set to the default method and the Modify Current Settings option is chosen, a

prompt for a new name is shown after the changes are entered. The settings are saved

with this name to distinguish them from the default method settings, which cannot be

changed. A saved method can be used instead of multiple adjustments to the individual

settings. Changes made to a user-defined method are automatically saved with the

existing name. Multiple methods can be saved for the same probe on each meter.

• Units

Significant digits

•

• Auto stabilization

• Stability criteria

• Upper and lower range limits

• Standard set

• Calibration units

• Minimum calibration points

• Slope limit

• Calibration reminder

• Standard

• Check standard reminder

• Acceptance criteria

1. Make sure a probe is connected to the meter.

2. Push and select ISENa381 Settings.

3. Select Modify Current Settings.

4. Select Measurement Options and update the settings:

Option Description

Units Sets the preferred unit for ISE measurements—mg/L (default), µg/L, g/L,

g/kg, mol/L, mmol/L, mol/kg, %, ppm or ppb.

Note: The mV units are shown when the detailed display is selected.

Significant Digits Sets the significant digits shown—2, 3 (default) or 4.

Auto

Stabilization

Sets auto stabilization—on (default) or off.

The default stability drift rate is 1.0 mV/min.

8

Page 9

Option Description

Stability Criteria When Auto Stabilization is off, sets the stability criteria—0.1 to

9.9 mV/min.

Lower stability criteria will require longer stabilization times, but the

•

measurement will be more precise.

• Higher stability criteria will require shorter stabilization times, but the

measurements may be less precise.

Measurement

Limits

5. If prompted, enter a name for the new method settings. Additional changes made to

the settings of an existing method are automatically saved with the same method

name.

6. Push EXIT until the meter returns to the measurement mode.

Change calibration options

1. Make sure a probe is connected to the meter.

2. Push

3. Select Modify Current Settings.

4. Select Calibration Options and update the settings:

Option Description

Std Set Sets the temperature compensated standard sets that are used for

Sets the measurement limits—Lower limit (default: 0.023 mg/L) or Upper

limit (default: 14.00 mg/L).

The measurement limits can be set to match the acceptable values for

the sample. When the measurement is above the upper limit setting or

below the lower limit setting, the meter shows an "Out of limits" message.

This message is an alert to a potential problem with the process

conditions.

and select ISENa381 Settings.

calibration—

10, 100 or 1000 mg/L

•

• 100 or 1000 mg/L

Standard set values are shown on the Calibration Options screen.

Custom standard sets are characterized at 25 °C (77 °F). Custom

standard values are not temperature compensated. Select the Custom

buffer to make a custom standard. Up to five standard values can be

made (refer to Table 3).

Note: Only the minimum calibration points must be measured for Done to

be shown on the calibration screen.

Chemical Form Sets the chemical form.

Calibration

Units

Std Set Values When Std Set is set to Custom, sets the standard set values (refer to

Minimum Cal

Points

Slope Limit Sets the slope limit—1 to 15% (acceptable slope criteria, default = 10%).

Sets the preferred unit for ISE Calibration—mg/L (default), µg/L (available

only for custom calibration set), g/L, g/kg, mol/L, mmol/L, mol/kg, %, ppm

or ppb.

Table 3).

Up to five standard values can be made. Each standard value can include

a standard set value, Custom or No Standard.

Sets the minimum number of calibration points necessary before a

calibration can be completed—2 or 3.

The slope must fall within set limits for successful calibration.

9

Page 10

5. Select Calibration Reminder and update the settings:

Option Description

Reminder

Repeat

Expires Calibration expires after the selected time—Immediately, Reminder + 30 min

Meter will make an audible sound when a calibration is due and repeat the

sound at the selected interval—Off (default), 2 h, 4 h, 8 h, 2 d, 5 d or 7 d.

(default), Reminder + 1 h, Reminder + 2 h or Continue Reading.

Note: The meter cannot be used to read samples after calibration has

expired unless Continue Reading is selected.

6. If prompted, enter a name for the new method settings. Additional changes made to

the settings of an existing method are automatically saved with the same method

name.

7. Push EXIT until the meter returns to the measurement mode.

Table 3 Custom buffer sets

Buffer set values Option Description

Std1

Std2

Std3

Std4

Std5

10.0 mg/L Pre-set temperature compensated standard values.

100.0 mg/L

1000.0 mg/L

2299.0 mg/L (0.1 M NaCl)

Custom Custom standard value. Custom standard values are not temperature

No standard Standard is undefined when this option is selected.

Change check standard options

1. Make sure a probe is connected to the meter.

2. Push and select ISENa381 Settings.

3. Select Modify Current Settings.

4. Select Check Standards Options and update the settings:

Option Description

Standard Sets the check standard—10, 100, 1000 mg/L, 0.1 M NaCl or Custom.

Standard Units When Standard is set to Custom, sets the preferred unit for ISE check

Standard Value When Standard is set to Custom, enter the standard value using the

compensated.

The standard value is shown on the Check Standards Options screen.

standard—mg/L (default), µg/L, g/L, g/kg, mol/L, mmol/L, mol/kg, %, ppm or

ppb.

up/down arrow keys.

10

5. Select Check Standard Reminder and update the settings:

Option Description

Reminder Sets the check standard reminder—On or Off (default).

The meter automatically shows the check standard screen if Reminder is On.

Allow Defer Allows the postponement of check standard reminders—Yes or No.

Measurement of the check standard can be delayed if Allow Defer is set to Yes.

Page 11

Maintenance

Clean the probe

6. Select Acceptance Criteria and update the settings:

Option Description

Acceptance Limits Sets the tolerance limits for check standard—1% to 20%.

Cal Expires on Failure Recalibration required if check standard fails—Yes or No.

The calibration expires if the check standard fails and Cal Expires is

set to Yes.

7. If prompted, enter a name for the new method settings. Additional changes made to

the settings of an existing method are automatically saved with the same method

name.

8. Push EXIT

Clean the probe when:

• Drifting/inaccurate readings occur as a result of contamination on the glass sensor or

the probe being left dry for extended periods of time.

• Slow stabilization time occurs as a result of contamination on the glass sensor.

• The slope is out of range as a result of contamination on the glass sensor.

For general contaminants:

until the meter returns to the measurement mode.

1. Rinse the probe with ISA rinse solution and blot dry with a lint-free cloth.

2. Soak the glass bulb for 12 to 16 hours in Hach Electrode Cleaning Solution.

3. Rinse or soak the probe for 1 minute in 25 mL of 100 mg/L sodium standard (that

contains Sodium ISA).

4. Soak the probe in pH 4 buffer for up to 20 minutes, then rinse with deionized water.

5. Calibrate and test the probe again using the measurement procedures.

Fill the probe

To add filling solution to the probe:

1. If the filling hole is closed, remove the filling-hole cap from the filling hole (refer to

Figure 1 on page 2).

2. Remove the cap from the tip of the filling solution bottle.

3. Hold the bottle so that the tip is down. Put the tip of the bottle in the filling hole.

4. Slowly squeeze the bottle and fill the probe completely.

Note: Fill the probe completely for the best performance.

5. If the probe will not be used immediately, store the probe (refer to Storage

on page 12).

6. Keep the filling solution bottle and cap for later use.

Note: If the dispensing tip becomes clogged, remove the dispensing tip and soak the tip in

warm water. Dry thoroughly and assemble.

Prepare the ISA rinse solution

To prepare the ISA rinse solution, add one Sodium Ionic Strength Adjustor (ISA) powder

pillow (0.4 g) to every 25 mL of deionized water. Put the ISA rinse solution in a rinse

bottle.

Prepare the storage solution

To prepare the storage solution, add one Sodium Ionic Strength Adjustor (ISA) powder

pillow (0.4 g) to 25 mL of 100 mg/L Na+ standard solution.

11

Page 12

Storage

For the best probe performance, do not let the reference junction dry out.

Short-term storage

1. Put the filling-hole cap in the filling hole (Figure 1 on page 2).

2. Store the probe in a 25 mL of 100 mg/L Na+ standard solution with one Sodium Ionic

Strength Adjustor (ISA) powder pillow (0.4 g).

Long-term storage

1. Put the filling-hole cap in the filling hole (refer to Figure 1 on page 2).

2. Rinse the probe with ISA rinse solution (refer to Prepare the ISA rinse solution

on page 11). Never rinse with deionized water. Dry the probe with a lint-free cloth.

3. Fill the probe soaker bottle half full with 0.02 M NH4Cl Electrode Filling Solution..

4. Loosen the soaker bottle cap and put the soaker bottle on the probe.

5. Turn the soaker bottle cap clockwise to tighten the soaker bottle cap.

6. Make sure that the solution in the soaker bottle completely covers the glass bulb and

reference junction holes.

7. Before use after long-term storage, condition the probe in 25 mL of 100 mg/L Na+

standard solution with one Sodium ISA pillow (0.4 g) for at least 8 hours.

Troubleshooting

Message or symptom Possible cause Action

Software not updated To download the most current version of the

software, refer to the applicable product page on

the manufacturer's website.

Probe not supported

HQd meter does not support

IntelliCAL® probe

Probe not connected properly Disconnect, then connect the probe. Tighten the

Software not updated To download the most current version of the

Connect a probe or probe

requires service

mV reading is the same for all

solutions

Standard not recognized error Soaker bottle not removed Remove the soaker bottle.

Large number of methods stored on

probe

Damaged probe Make sure that there is connectivity with another

Soaker bottle not removed Remove the soaker bottle.

Electrical issue Contact a Technical Support Representative.

Refer to the HQd Series meter manual for

specific instructions for the meter model.

Contact a Technical Support Representative.

locking nut.

software, refer to the applicable product page on

the manufacturer's website.

Refer to the HQd Series meter manual.

Continue to let probe connect. Do not disconnect

probe.

probe or meter to confirm isolated issue with

probe. Contact a Technical Support

Representative.

12

Incorrect or contaminated standard

solution

Contaminated filling solution Replace the filling solution.

Use fresh standard solution as specified in the

method.

Page 13

Message or symptom Possible cause Action

Tape not removed from the filling hole Remove the tape.

Contaminated glass sensor Clean the probe (refer to Clean the probe

on page

Contaminated filling solution Drain and replace the filling solution with fresh

solution.

11).

Slow stabilization time

Slope out of range (refer to

Check probe response

on page 14)

Filling-hole cap is closed Open the filling-hole cap while in use.

Low sample temperature or

temperature difference between

samples

Air bubbles around inner reference

electrode

pH is too low Make sure the pH is greater than 9 after each

Ionic strength adjustor (ISA) not used Add ISA to each sample and standard.

Insufficient conditioning Condition for at least 8 hours in storage solution.

Damaged probe Contact a Technical Support Representative.

Incorrect standards Calibrate using freshly prepared standards.

Contaminated glass sensor Clean the probe and recalibrate.

Air bubbles around inner reference

electrode

Contaminated glass bulb Clean the probe (refer to Clean the probe

Clogged reference Rinse the reference junction with ISA rinse

Check the sample temperature. The lower the

temperature or the greater the difference of

temperatures between samples, the longer the

response time.

Gently tap the probe with hand or shake the

probe downward to remove any air bubbles.

ISA addition.

Gently tap the probe with hand or shake the

probe downward to remove any air bubbles.

on page 11).

solution thoroughly and shake the probe

downward to remove any air bubbles.

Drifting/inaccurate readings

Improper storage

conditions/dehydrated glass bulb

Stabilization criteria not optimized for

the application

Magnetic stirrers may generate

sufficient heat to change solution

temperature.

Filling-hole cap is closed Open the filling-hole cap while in use.

Damaged probe Contact a Technical Support Representative.

Electromagnetic Forces (EMF) such as

voltaic cells, thermoelectric devices,

electrical generators, resistors and

transformers

Colloidal and/or particulates in the

filling solution

Air bubbles around inner reference

electrode

Clean or condition the probe and attempt another

calibration. The probe may not function correctly

if the probe has been left dry for extended

periods of time. To re-condition the glass sensor

and reference junctions, allow the probe to soak

in storage solution (that contains Sodium ISA) for

at least 8 hours before use.

Adjust the stabilization criteria in the

Measurement Options menu.

Put a piece of insulating material between the

stirrer and beaker.

Do not use in areas where EMF is present.

Replace the filling solution, calibrate and retest.

Gently tap the probe with hand or shake the

probe downward to remove any air bubbles.

13

Page 14

Message or symptom Possible cause Action

Out of range Measurement value is outside of range Make sure that the sample is within the range of

the probe.

Out of limits

Temperature out of range

Check standard value is outside of

limits set in the current method

Measurement value is outside of

measurement limits set in the current

method.

Calibration temperature value is

outside of range

Measured temperature is outside the

range of the probe

Check standard temperature value is

outside of range

Make sure that the standard is within the limits of

the current method.

Make another method that expands the

acceptable limits.

Make sure that the sample is within the limits of

the current method.

Make a new method with an expanded range.

Make sure that the sample temperature is within

the range of the probe.

Make sure that the temperature sensor is

working correctly.

Make sure that the standard temperature is

within the range of the probe.

Make sure that the temperature sensor is

working correctly.

Make sure that the check standard temperature

is within the range of the probe.

Check probe response

To check the probe response, measure the probe potential (in mV) of two Sodium

Standard Solutions one decade apart in concentration that are above and below the

expected sample concentration. For example, use 10 and 100 mg/L Sodium Standard

Solutions. The two solutions should have potentials (difference in mV readings) that are

59 mV (±3 mV) apart at 25 °C. Both solutions should be above 1.4 mg/L Na+.

Check accuracy of sample reading

To check the accuracy of the sample reading, add a spike of Standard Sodium Solution

with the volumetric pipet. Refer to Table 4

and formulas to calculate the percent of

recovery.

Typically a percent of recovery of 100% ±5% is a good indication that the instrument,

technique and the sample do not contribute to measurement errors.

Table 4 Spike reference

Measured sample concentration Volume of standard at add Concentration of standard

1 to 2 mg/L 0.5 mL 100 mg/L

3 to 6 mg/L 1.0 mL 100 mg/L

7 to 15 mg/L 0.3 mL 1000 mg/L

15 to 30 mg/L 0.5 mL 1000 mg/L

30 to 60 mg/L 1.0 mL 1000 mg/L

Percent recovery

Use the following formulas to calculate the percent recovery when the sample volume is

25 mL.

E = (C x V1) / V

2

R = (A / (E + S)) x 100

Where:

14

S = mg/L of Na+ in sample (before spike)

•

• C = concentration of standard used for spiking (mg/L)

Page 15

• V1 = spike volume (mL)

V2 = spike volume (mL) + 25 mL sample volume

•

• E = expected concentration of spike (mg/L)

• R = percent recovery

• A = actual reading on meter after spike (mg/L Na+)

15

Page 16

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

©

Hach Company/Hach Lange GmbH, 2010, 2013. All rights reserved. Printed in U.S.A.

05/2013, Edition 3

Loading...

Loading...