Page 1

DOC013.52.90205

BÜHLER 3010, 4010–6010

Short Manual

01/2011, Edition 2A

© HACH-LANGE GmbH, 2010–2011. All rights reserved. Printed in Germany

Page 2

Page 3

Table of contents

Section 1 Specifications ........................................................................................................................ 5

1.1 Dimensions ........................................................................................................................................ 6

Section 2 General information............................................................................................................... 7

2.1 Safety information............................................................................................................................... 7

2.1.1 Hazard information in this manual ............................................................................................. 7

2.1.2 Warning labels ........................................................................................................................... 7

2.2 General information ............................................................................................................................ 8

2.2.1 Areas of application ................................................................................................................... 8

2.2.2 Functional description................................................................................................................ 8

2.3 Scope of delivery ................................................................................................................................ 8

Section 3 Installation............................................................................................................................ 11

3.1 Mechanical installation...................................................................................................................... 12

3.1.1 Required tools.......................................................................................................................... 12

3.1.2 Select installation location........................................................................................................ 13

3.1.3 Unpacking................................................................................................................................ 14

3.1.4 Set up....................................................................................................................................... 15

3.2 Electrical connections ....................................................................................................................... 17

3.2.1 Electrical installation ................................................................................................................ 18

3.2.1.1 Prepare the electrical installation (3010)......................................................................... 18

3.2.1.2 Prepare the electrical installation (4010–6010)............................................................... 19

3.2.1.3 Wiring diagram (3010) ....................................................................................................20

3.2.1.4 Wiring diagram (4010–6010) .......................................................................................... 20

3.2.1.5 Complete the electrical installation (3010)...................................................................... 21

3.2.1.6 Complete the electrical installation (4010–6010)............................................................ 21

3.3 Commission the equipment .............................................................................................................. 22

3.3.1 Tube connection ...................................................................................................................... 22

3.3.2 Set the individual sample volumes........................................................................................... 25

3.3.2.1 Plastic dosing vessel....................................................................................................... 25

3.3.2.2 Glass dosing vessel........................................................................................................ 27

3.3.2.3 Dosing vessel for flow-proportional sampling ................................................................. 27

3.3.2.4 Bypass dosing vessel .....................................................................................................28

3.3.2.5 Flush water connection and drain (4210/4410)............................................................... 29

3.3.2.6 Water circuit diagram (6010)........................................................................................... 30

3.3.3 Preparing the sample containers (3010, 4010, 4110, 4210, 6010).......................................... 30

3.3.4 Connect the equipment to the mains ....................................................................................... 31

3

Page 4

Section 4 Operation ..............................................................................................................................33

4.1 Control unit operation........................................................................................................................33

4.1.1 Password..................................................................................................................................33

4.1.2 Programming............................................................................................................................33

4.1.2.1 Keyboard layout/function.................................................................................................33

4.2 Normal operation...............................................................................................................................35

4.2.1 Replace the sample bottles (3010, 4010, 4110, 4211).............................................................36

4.2.2 Sampling (4411 with 12 or 24 bottles)......................................................................................38

4.2.3 Sampling (4411 with 2 or 4 bottles)..........................................................................................42

Section 5 Maintenance and cleaning...................................................................................................47

5.1 Maintenance tasks ............................................................................................................................47

5.2 Cleaning ............................................................................................................................................47

5.2.1 Clean the housing and distribution unit ....................................................................................47

5.2.2 Clean the dosing vessel ...........................................................................................................49

5.3 Troubleshooting ................................................................................................................................51

5.3.1 Open the housing to change the fuse (3010)...........................................................................51

5.3.2 Open the housing to change the fuse (4010–6010).................................................................52

5.3.3 Change the fuse.......................................................................................................................52

5.3.4 Reassemble the housing (3010) ..............................................................................................53

5.3.5 Reassemble the housing (4010–6010) ....................................................................................54

5.4 Instrument decommissioning and storage.........................................................................................54

Section 6 Spare parts and accessories ..............................................................................................55

6.1 Spare parts........................................................................................................................................55

Section 7 Warranty and liability ...........................................................................................................59

Section 8 Contact information ............................................................................................................61

4

Page 5

Section 1 Specifications

Specifications are subject to change without notice.

Electrics

Power supply 230V/50Hz.,16A fuse

Power consumption approx. 350 VA

Environment

Medium temperature 0to+40°C [32to104°F]

Ambient temperature –20to+40°C [–4to104°F]

Delivery height < 8 m [26.2 ft}

General specifications

Maintenance requirements Maintenance-free

Weight See Figure 10, page 16 and Figure 11, page 16

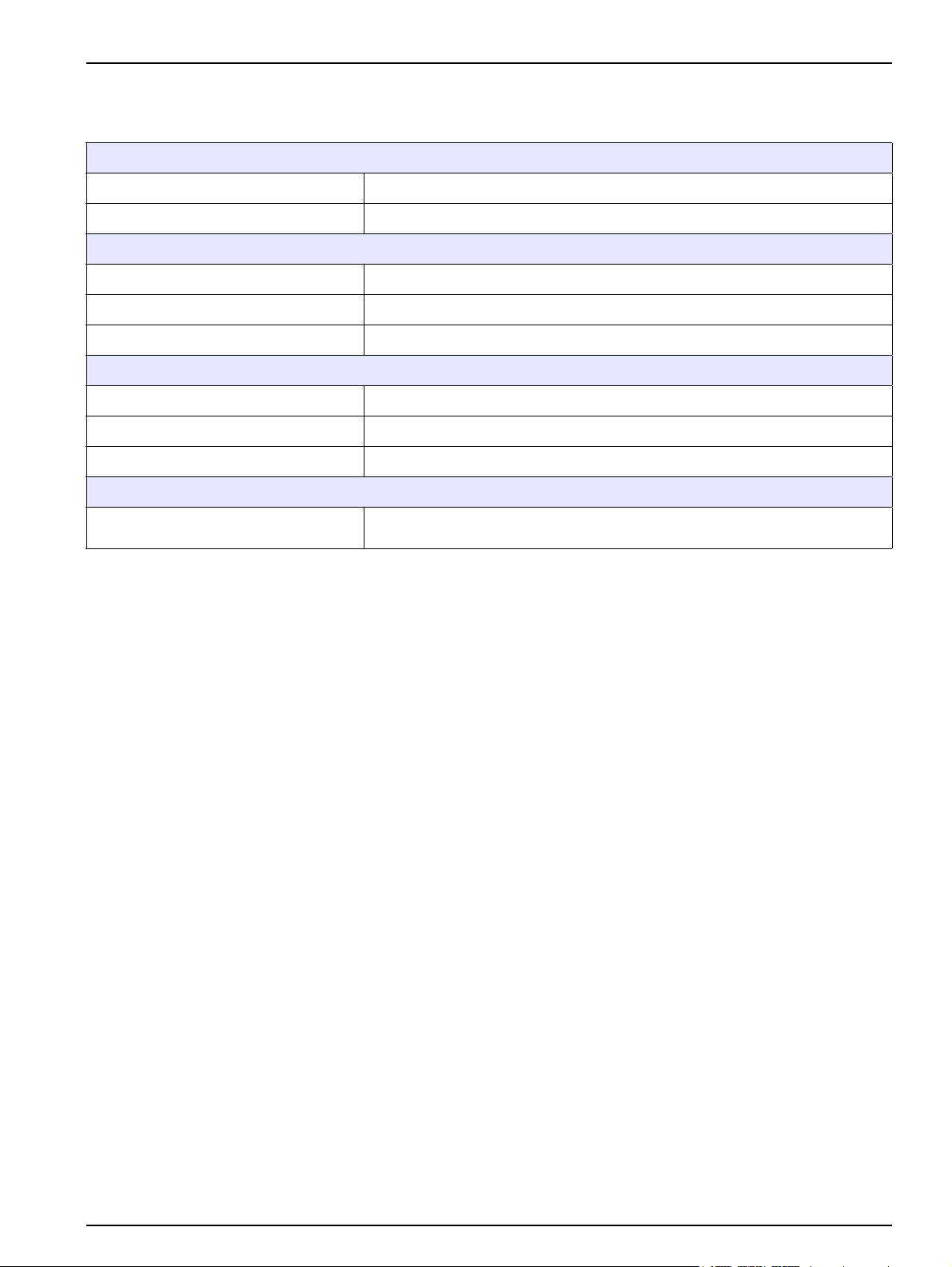

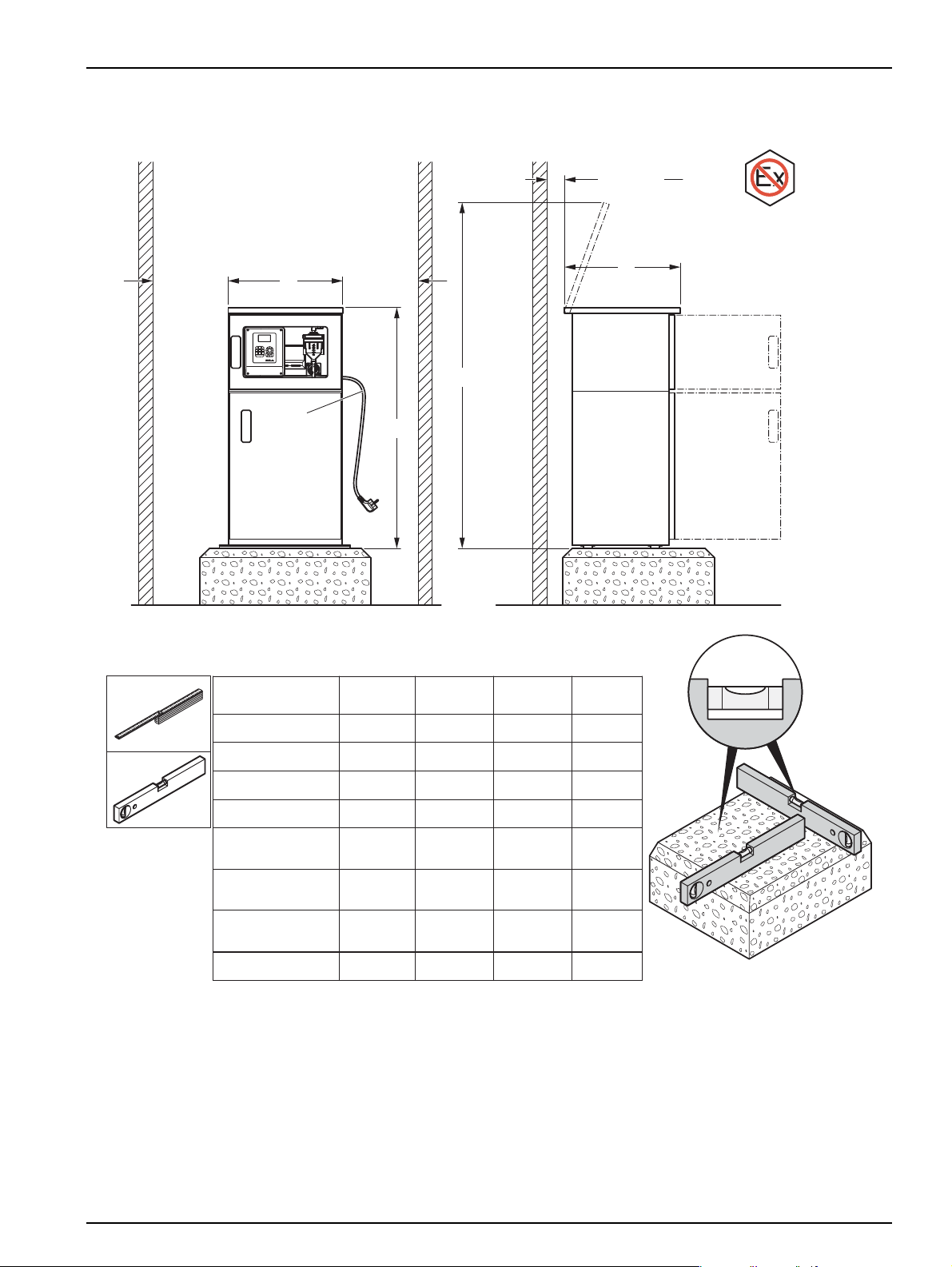

Dimensions (W × H × D) See Figure 1

Certification

Certification

CE, MCERTS (not 3010)

Sampling in accordance with ISO 5667-2/3-10

5

Page 6

Specifications

5

jkl6mno4ghi

8

tuv wxyz97pqrs

2

abc3def

1

0

Y1

X

Z

Y2

BÜHLER 3010

BÜHLER 4010

BÜHLER 6010

BÜHLER 4210

BÜHLER 4410 (2–12 Flaschen)

BÜHLER 4410 (24 Flaschen)

BÜHLER 4210 (23 Flaschen)

BÜHLER 4110

mm [in.]

Y1

1100 [43.3]

1325 [52.2]

1690 [66.5]

1325 [52.2]

1325 [52.2]

1415 [55.7]

1415 [55.7]

1475 [58.1]

mm [in.]

X

760 [30]

605 [23.8]

1200 [47.2]

605 [23.8]

605 [23.8]

715 [28.1]

715 [28.1]

605 [23.8]

mm [in.]

Y2

1640 [64.6]

1895 [74.6]

2260 [89]

1895 [74.6]

1895 [74.6]

2120 [83.5]

2120 [83.5]

2030 [79.9]

mm [in.]

Z

725 [28.5]

645 [25.4]

645 [25.4]

645 [25.4]

810 [31.9]

810 [31.9]

645 [25.4]

645 [25.4]

(23 bottles)

(2–12 bottles)

(24 bottles)

1.1 Dimensions

6

Figure 1 Dimensions

Page 7

Section 2 General information

2.1 Safety information

Please read this entire manual before the equipment is unpacked, set up or operated. Pay

attention to all danger and caution statements. Personal injury or damage to the

equipment could occur if they are not observed.

To ensure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

2.1.1 Hazard information in this manual

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation that, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially or imminently hazardous situation that could result in minor

or moderate injury.

Important note: Information that requires special emphasis.

Note: Information that supplements points in the main text.

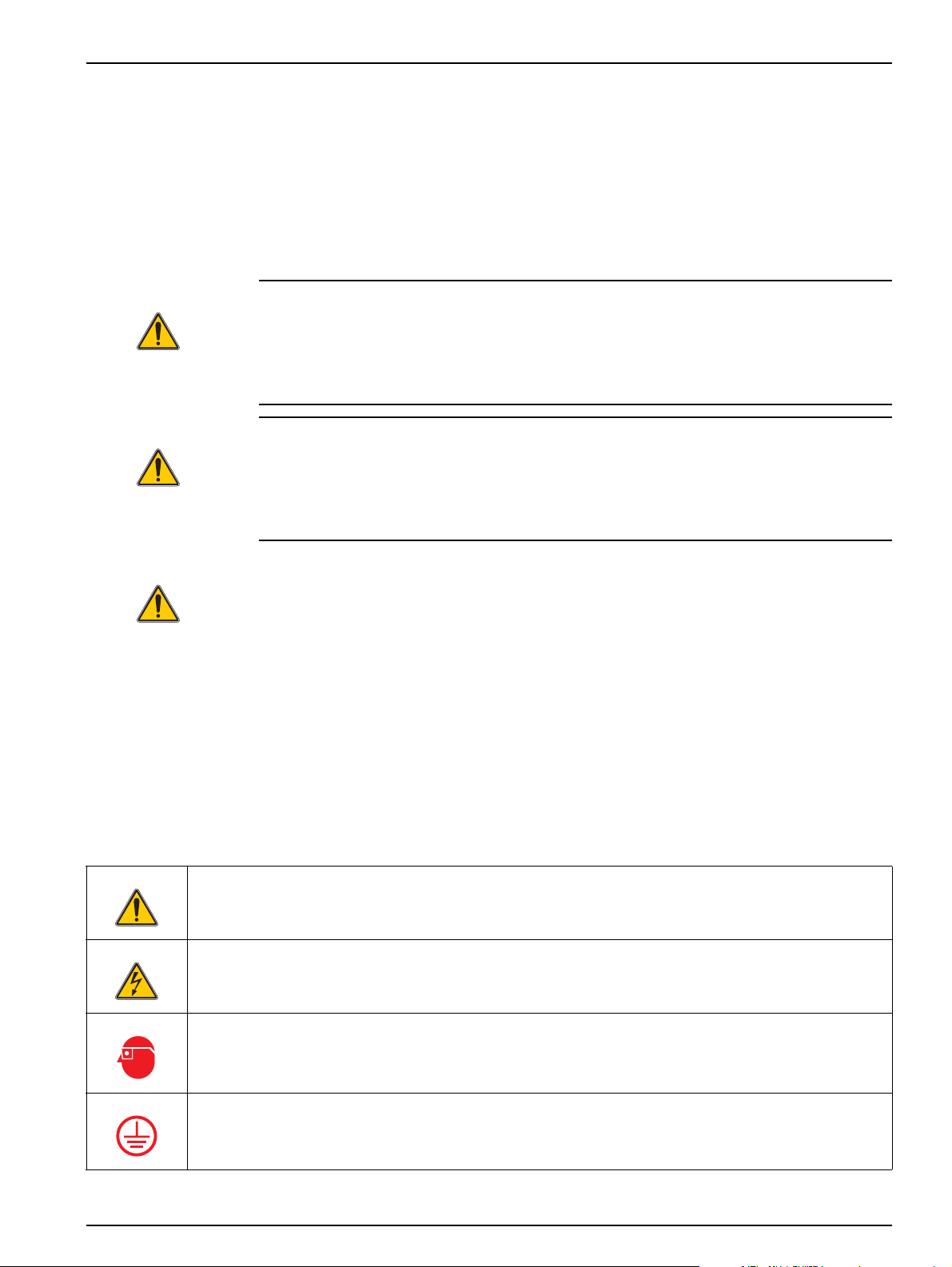

2.1.2 Warning labels

Read all labels and notices attached to the equipment. Personal injury or damage to the

equipment could occur if they are not observed. Any symbol on the equipment will appear

along with a caution statement in the manual.

This symbol, if noted on the instrument, references the user manual for operation and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol may appear on the product and indicates the need for protective eye wear.

This symbol may appear on the product and identifies the connection point for the protective ground.

7

Page 8

General information

When this symbol appears on the product, it identifies the location of a fuse or a current limiter.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the

manufacturer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment manufacturer or supplier for instructions on how

to return end-of-life equipment, manufacturer-supplied electrical accessories, and all auxiliary items for proper

disposal.

2.2 General information

2.2.1 Areas of application

The equipment is used for sampling aqueous liquids with a temperature between 0°C

and 40°C [32 to 104 °F].

2.2.2 Functional description

The equipment provides temporary storage for liquids of a specified volume so that they

can be analyzed.

2.3 Scope of delivery

The equipment is supplied with a tube and a short manual.

If you require further information, you can order the operating instructions (refer to

Section 6 Spare parts and accessories, page 55) from the manufacturer or you can

download it from the Internet.

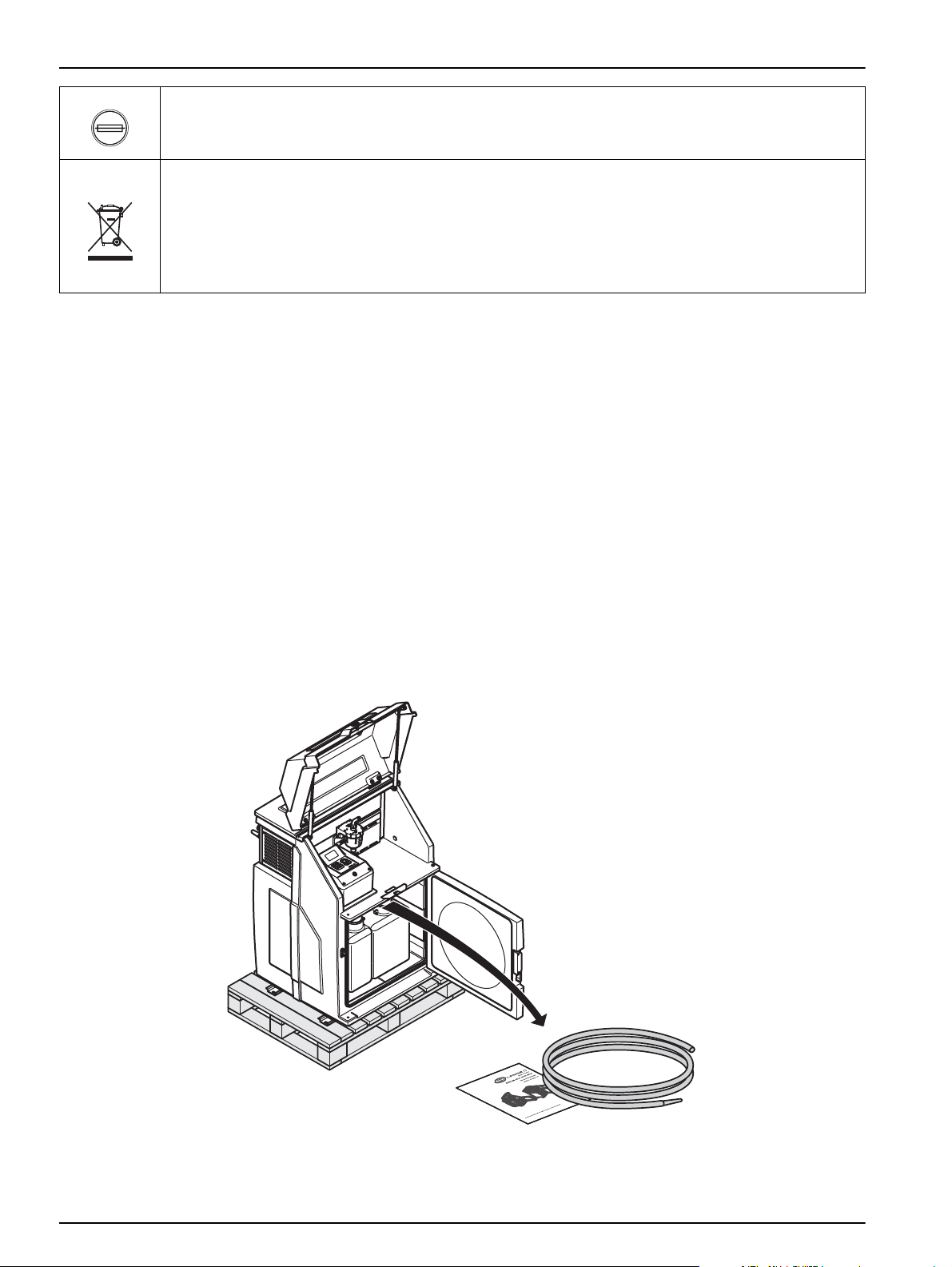

Figure 2 Scope of delivery (3010)

8

Page 9

General information

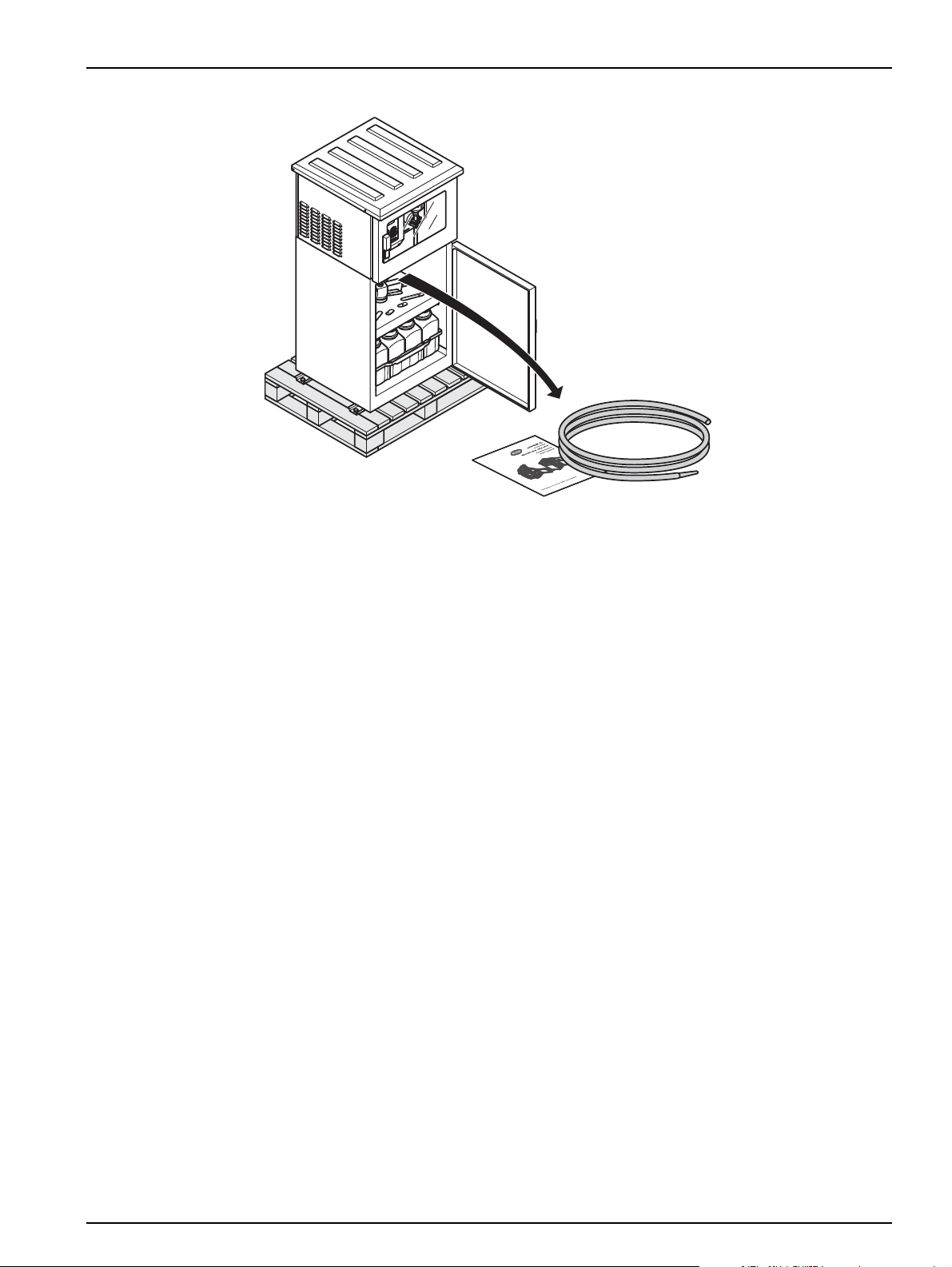

Figure 3 Scope of delivery (4010–6010)

9

Page 10

General information

10

Page 11

Section 3 Installation

DANGER

Only qualified experts should conduct the tasks described in this section.

DANGER

Select an appropriate installation location for the instrument.

Plan out the mechanical mount·before positioning poles or drilling holes. Make

sure the mount has a sufficient bearing capacity. The dowels must be selected and

authorized according to the condition of the wall.

The manufacturer shall accept no liability if the instrument is installed incorrectly.

Plan how to lay cables and tubes and their path in advance. Lay the tubes, data

cables and power cables without any bends and so they do not pose a tripping

risk.

Do not connect the electrical supply to the mains if the equipment has not been

wired and fused correctly.

Sufficiently protect the electrical power supply against short circuits.

For the external power supply, always connect a residual-current circuit

breaker·(trip current max.: 30 mA) between the mains and the system.

If the equipment is to be installed outdoors, switch the overload prot ection

between mains and system.

Products intended by the manufacturer for outdoor use offer a higher level of

protection against the penetration of liquids and dust. If these products are

connected to a mains outlet with a cable and plug·rather than a permanently

connected cable, the plug and outlet are much more susceptible to liquid and dust

penetration. The operator must sufficiently protect the plug and outlet against

liquid and dust penetration in accordance with local safety regulations. If the

instrument is to be used outdoors, it must be connected to a suitable outlet with a

protection type of at least IP44 (splash protectio n).

11

Page 12

Installation

17 mm

3.1 Mechanical installation

DANGER

Select an appropriate installation location for the instrument.

Plan out the mechanical mount·before positioning poles or drilling holes. Make

sure the mount has a sufficient bearing capacity. The dowels must be selected and

authorized according to the condition of the wall.

The manufacturer shall accept no liability if the instrument is installed incorrectly.

Plan how to lay cables and tubes and their path in advance. Lay the tubes, data

cables and power cables without any bends and so they do not pose a tripping

risk.

Note: For information on installation with optional accessories, refer to the relevant installation

instructions.

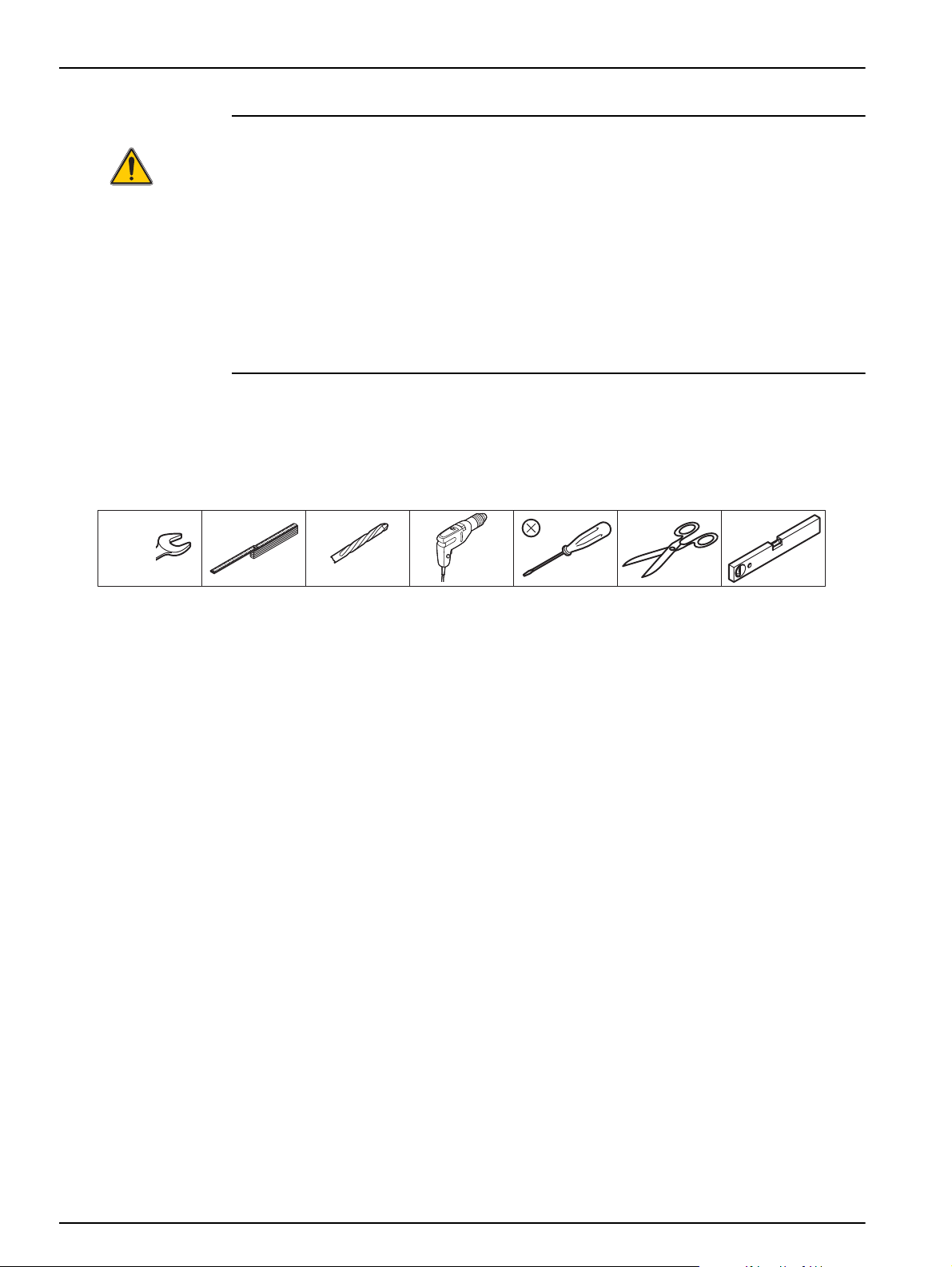

3.1.1 Required tools

Figure 4 Required tools

12

Page 13

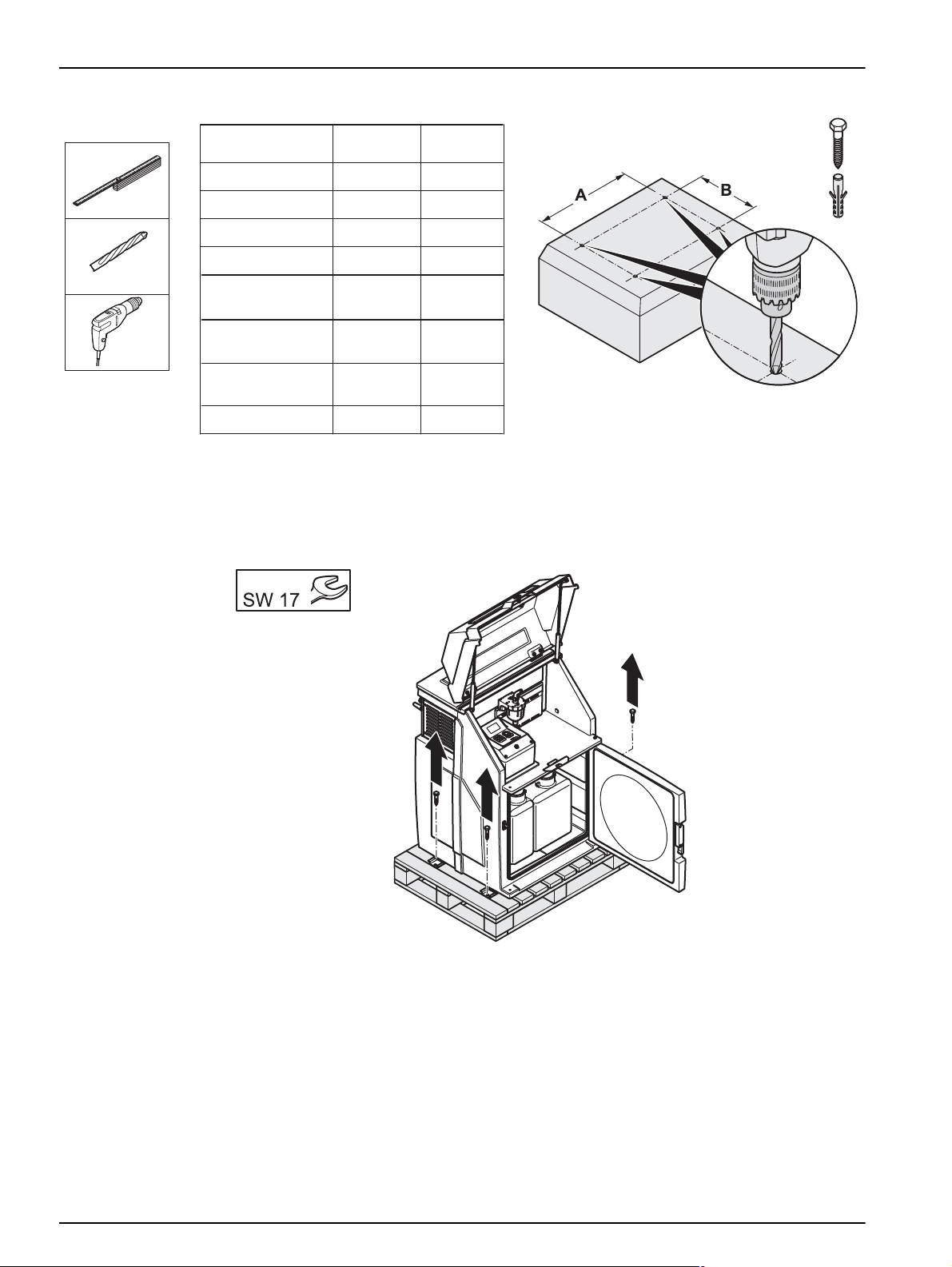

3.1.2 Select installation location

≥50mm

[2 in]≥

Z

Y2

5

jkl6mno4ghi

8

tuv wxyz97pqrs

2

abc3def

1

0

2500 mm

[100 in]

≥ 500 mm

[20 in]≥

≥ 500 mm

[20 in]≥

Y1

X

BÜHLER 4010

BÜHLER 3010

BÜHLER 4210

BÜHLER 4410

(2–12 Flaschen)

BÜHLER 4210

(23 Flaschen)

BÜHLER 4410

(24 Flaschen)

BÜHLER 4110

BÜHLER 6010

X

mm [in.]

605 [23.8]

760 [30]

605 [23.8]

715 [28.1]

605 [23.8]

715 [28.1]

605 [23.8]

1200 [47.2]

Y1

mm [in.]

1325 [52.2]

1100 [43.3]

1325 [52.2]

1415 [55.7]

1325 [52.2]

1415 [55.7]

1475 [58.1]

1690 [66.5]

mm [in.]

Y2

1895 [74.6]

1640 [64.6]

1895 [74.6]

2120 [83.5]

1895 [74.6]

2120 [83.5]

2030 [79.9]

2260 [89]

mm [in.]

Z

645 [25.4]

725 [28.5]

645 [25.4]

810 [31.9]

645 [25.4]

810 [31.9]

645 [25.4]

645 [25.4]

Ex

(2–12 bottles)

(24 bottles)

(23 bottles)

Installation

Figure 5 Select installation location

13

Page 14

Installation

³ Ø12×60mm

mm [in.]

A

730 [28.7]

660 [26]

660 [26]

660 [26]

660 [26]

770 [30.3]

770 [30.3]

1260 [49.6]

B

mm [in.]

384 [15.1]

383 [15.1]

383 [15.1]

383 [15.1]

383 [15.1]

500 [19.7]

500 [19.7]

383 [15.1]

BÜHLER 3010

BÜHLER 4010

BÜHLER 4110

BÜHLER 4210

BÜHLER 4410

(2–12 Flaschen)

BÜHLER 4410

(23 Flaschen)

BÜHLER 4410

(24 Flaschen)

BÜHLER 6010

(2–12 bottles)

(24 bottles)

(23 bottles)

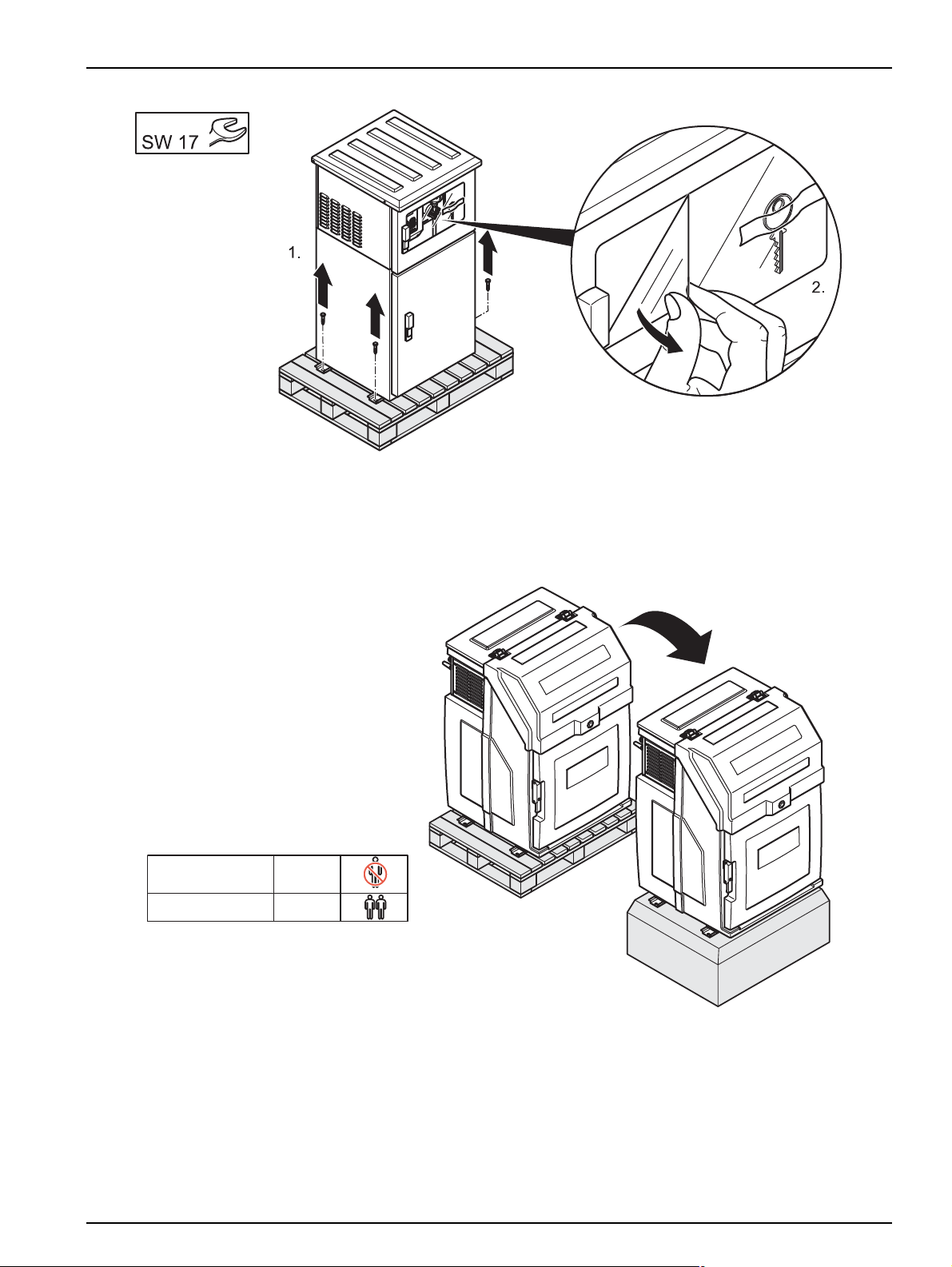

3.1.3 Unpacking

Figure 6 Prepare the installation location

14

Figure 7 Move the equipment from the transport pallet (3010)

Page 15

Figure 8 Move the equipment from the transport pallet (4010–6010)

BÜHLER 3010

kg

75

Installation

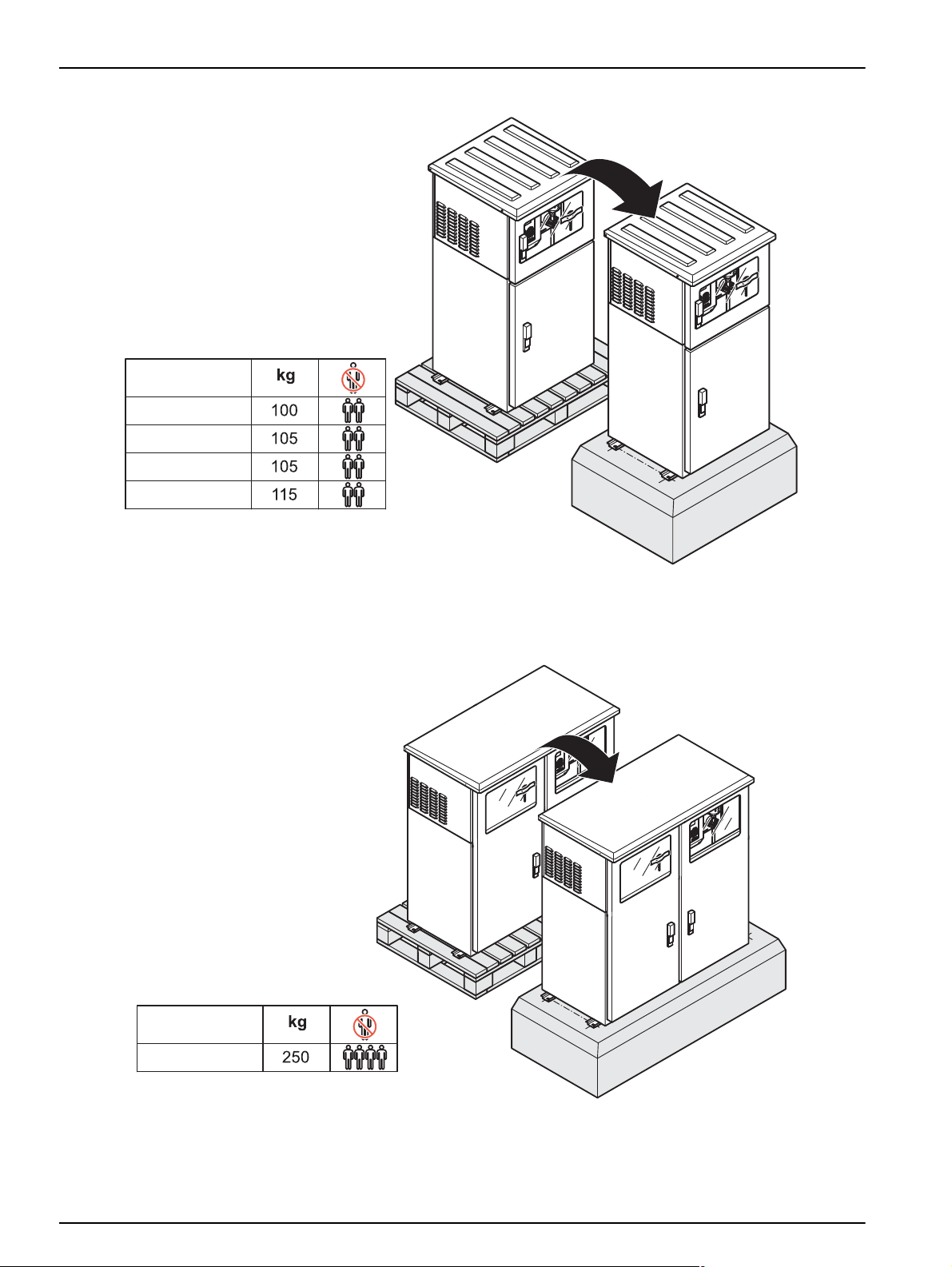

3.1.4 Set up

Figure 9 Set up the equipment (3010)

15

Page 16

Installation

BÜHLER 4010

BÜHLER 4210

BÜHLER 4410

BÜHLER 4110

BÜHLER 6010

Figure 10 Set up the equipment (4xx0)

16

Figure 11 Set up the equipment (6010)

Page 17

Installation

³ Ø12×60mm

>80Nm

³ 17 mm

Figure 12 Align and secure the equipment

3.2 Electrical connections

DANGER

Only qualified experts should conduct the tasks described in this section.

DANGER

Do not connect the electrical supply to the mains if the equipment has not been

wired and fused correctly.

Sufficiently protect the electrical power supply against short circuits.

For the external power supply, always connect a residual-current circuit

breaker·(trip current max.: 30 mA) between the mains and the system.

If the equipment is to be installed outdoors, switch the overload prot ection

between mains and system.

If the mains plug·of the power supply cable·is removed, a suitable double-pole

one-way switch must be installed immediately next to the display unit·with clear

labeling for the power supply.

Products intended by the manufacturer for outdoor use offer a higher level of

protection against the penetration of liquids and dust. If these products are

connected to a mains socket with a cable and plug·rather than a permanently

17

Page 18

Installation

connected cable, the plug and socket are much more susceptible to liquid and

dust penetration. The operator must sufficiently protect the plug and outlet against

liquid and dust penetration in accordance with local safety regulations. If the

instrument is to be used outdoors, it must be connected to a suitable outlet with a

protection type of at least IP44 (splash protection).

3.2.1 Electrical installation

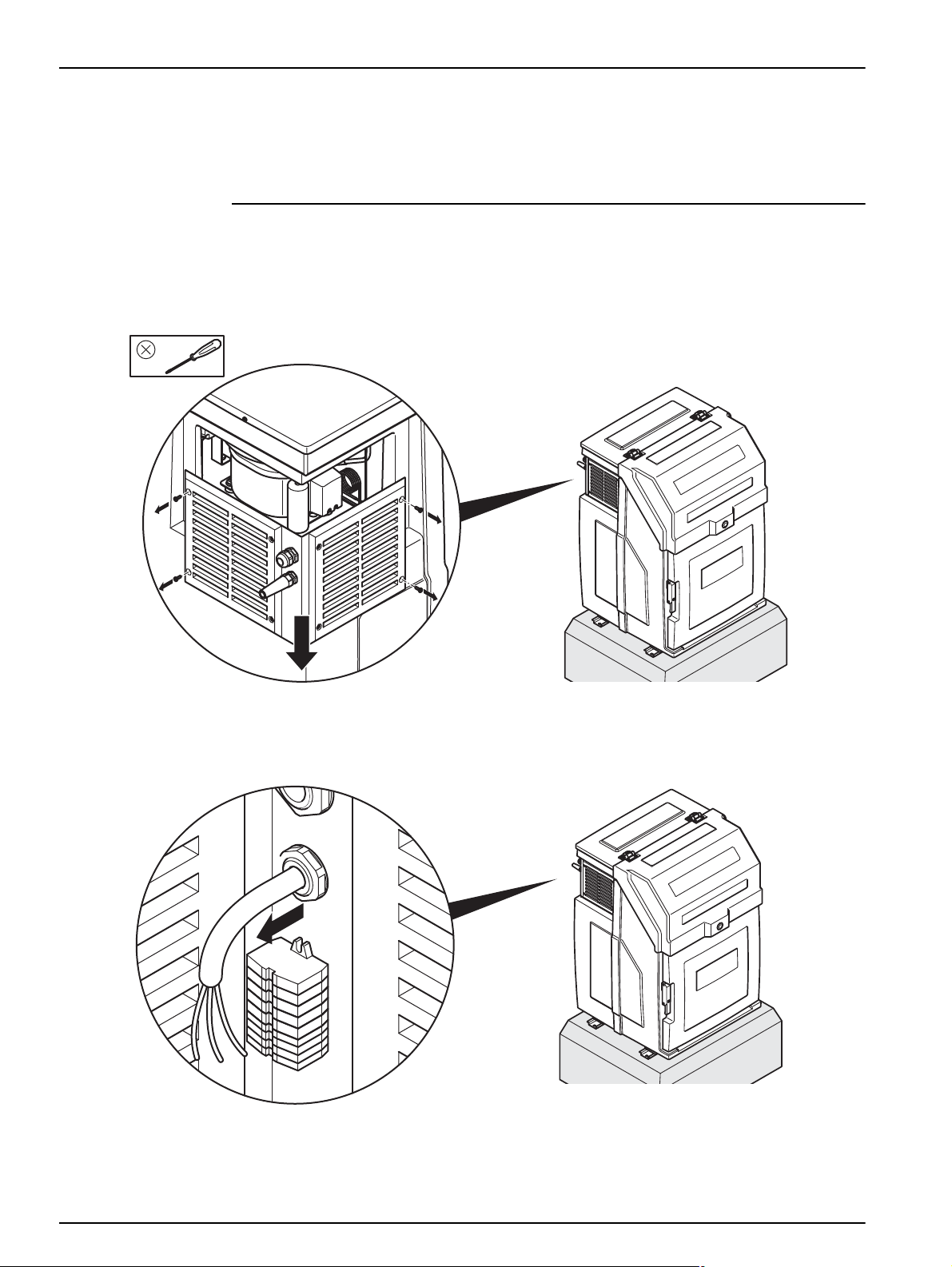

3.2.1.1 Prepare the electrical installation (3010)

Figure 13 Loosen the screws and remove the cover (3010)

Figure 14 Feed cable through (3010)

18

Page 19

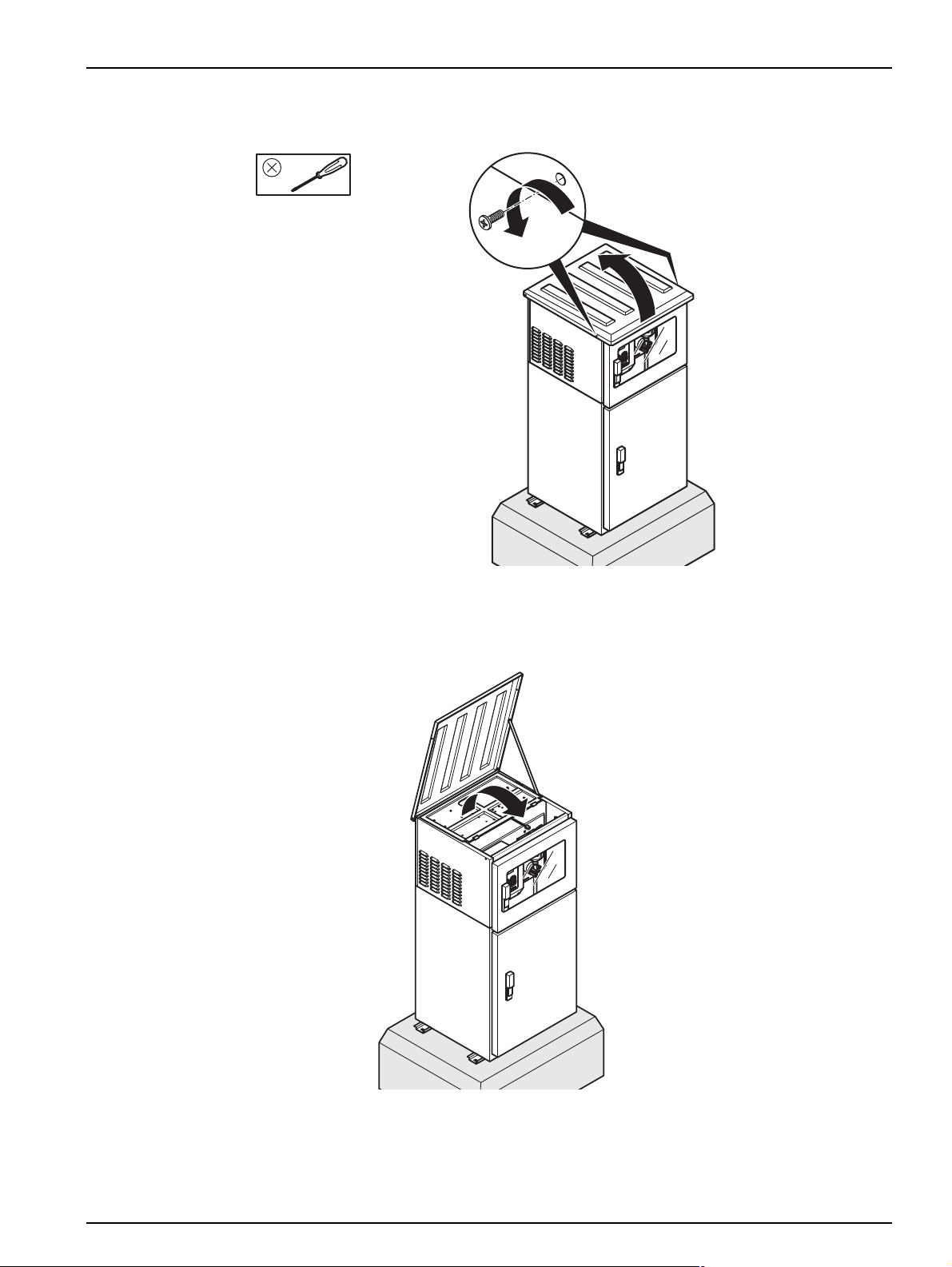

3.2.1.2 Prepare the electrical installation (4010–6010)

Installation

Figure 15 Loosen the lid screws and open the lid (4010–6010)

Figure 16 Lift up the cover (4010–6010)

19

Page 20

Installation

23456111214

14

12

11

pH

Q

In: DC 12 V

Out: AC 250V/2×8A

Kontaktbelegung: Relais

pH

Q

Pin assignment: relay

3.2.1.3 Wiring diagram (3010)

Figure 17 Wiring diagram (3010)

3.2.1.4 Wiring diagram (4010–6010)

20

Figure 18 Wiring diagram (4010–6010)

Page 21

3.2.1.5 Complete the electrical installation (3010)

Installation

Figure 19 Attach cover

3.2.1.6 Complete the electrical installation (4010–6010)

Figure 20 Shut the cover

If suction tube is not connected immediately, close the housing lid as described in

Figure 24, page 23 and Figure 25, page 24.

21

Page 22

Installation

3.3 Commission the equipment

3.3.1 Tube connection

Figure 21 Key storage location

22

Figure 22 Feed the suction tube though housing opening

Page 23

Installation

Figure 23 Screw in the union nut

Figure 24 Close the lid

23

Page 24

Installation

–20–+40 °C

[–4–+104 °F]

0–+40 °C

[+32–+104 °F]

>50µs

³ 1000 mm

[40 in]³

£ 8000 mm

[21.3 ft]£

£ 30.000 mm

[100 ft]£

ExH2S

Figure 25 Screw down the lid tightly

Position the tubes in accordance with the following installation diagram.

24

Figure 26 Installation diagram

Page 25

3.3.2 Set the individual sample volumes

3.3.2.1 Plastic dosing vessel

Installation

Figure 27 Release the plastic dosing vessel

Figure 28 Remove the plastic dosing vessel

25

Page 26

Installation

V-Probe [mL]

= 150 mL

Figure 29 Cut the dosing tube to set the sample volume

26

Figure 30 Reinstall the plastic dosing vessel

Page 27

3.3.2.2 Glass dosing vessel

100 mL = 100 mL

100 mL = 100 mL

Installation

Figure 31 Adjust the dosing pipe to set the sample volume

3.3.2.3 Dosing vessel for flow-proportional sampling

Figure 32 Calibrate the flow-proportional dosing vessel via the service menu

27

Page 28

Installation

DP = 0 [hPa, bar]

4–20 L/Min.

+mL

–mL

DP = 0 [hPa, bar]

Notüberlauf

Emergency overflow

Figure 33 The flow-proportional dosing vessel may only be used,

3.3.2.4 Bypass dosing vessel

if there is NO counter pressure

28

Figure 34 Set the sample volume of the bypass dosing vessel

Page 29

3.3.2.5 Flush water connection and drain (4210/4410)

Schlauchtülle: ¾”

Schlauch Ø (innen) 25 mm

Hose nozzle: ¾"

Hose: Ø (internal) 25 mm

Schlauch ID 25 mm

Schlauchtülle ¾”

Hose: Ø (internal) 25 mm

Hose nozzle: ¾"

Installation

Figure 35 Flush water connection and drain (4210)

Figure 36 Flush water connection and drain (4410)

29

Page 30

Installation

DP = 0 [hPa, bar]

Schlauchtülle: ½”

Schlauch: Ø (innen) 12 mm

Schlauchtülle: Ø (innen) 40 mm

Tube nozzle: ½"

Tube:

Tube nozzle:

Ø (internal) 40 mm

Ø (internal) 12 mm

3.3.2.6 Water circuit diagram (6010)

Figure 37 Water circuit diagram (6010)

3.3.3 Preparing the sample containers (3010, 4010, 4110, 4210, 6010)

30

Figure 38 Place the empty bottles in the housing

Page 31

Figure 39 Close the door

Installation

3.3.4 Connect the equipment to the mains

Make sure that:

• The equipment has been fully prepared for commissioning

• The values on the rating label correspond with those of the mains supply

• The correct plug has been attached or the direct wire has been implemented correctly

• The equipment can be put into operation without any risks

Figure 40 Rating label

31

Page 32

Installation

3m

[10 ft]

3m

[10 ft]

Figure 41 Possible connection configurations

32

Page 33

Section 4 Operation

4.1 Control unit operation

All the equipment functions are software-controlled.

4.1.1 Password

Password to program sampler and to change settings is:

4.1.2 Programming

The menu structure resembles the directory structure of a computer hard drive and is

divided into main menus and sub menus.

4.1.2.1 Keyboard layout/function

The equipment is programmed by the operator.

6299

Figure 42 Control panel

The key functions are configured as follows to enable highly intuitive operation:

Table 1 Key functions

Display help text

(in the case of selection fields,

the cursor must be placed on the left-hand side)

Move from one menu item to the next menu selection Arrow keys

Select the menu required Enter key

Move within a menu Arrow keys

Arrow key

33

Page 34

Operation

Table 1 Key functions (Continued)

Select from within a menu Arrow keys

Confirm the selection

(automatically marked with a )

Enter/change values Arrow keys

Confirm the entered values Enter key

Return to the next superordinate menu level Back key

Enter values

RESET (restore factory settings)

Press and hold Back for at least 10 seconds

Enter key

Numeric

keypad

Back key

Example: A setting needs to be changed.

1. Press Enter.

The cursor then flashes.

2. Use the arrow keys to move the cursor until it is in the required position.

3. Press Enter.

The selection is now confirmed and the program can be started.

34

Page 35

Figure 43 Start the program

Depending on the program range,

Operation

• an activity is started or

• the next menu item is automatically selected.

Note: The general rule:

If you press Back,

– the activity is cancelled or

– the navigation takes one step back in the menu.

4.2 Normal operation

The described normal operation applies to several models

(e.g.) 3010, 4010, 4011, 4110, 4210, 4411).

The 3010, 4011 and 4411 models are displayed as examples in the images.

35

Page 36

Operation

4.2.1 Replace the sample bottles (3010, 4010, 4110, 4211)

Figure 44 Open the door

36

Figure 45 Remove the full bottles

Page 37

Operation

Figure 46 Replace with empty bottles

Figure 47 Close the door

37

Page 38

Operation

4.2.2 Sampling (4411 with 12 or 24 bottles)

Figure 48 Press PAUSE to suspend the current program (4411 with 12 or 24 bottles)

Figure 49 Select to remove the sample (4411 with 12 or 24 bottles)

38

Page 39

Figure 50 Select bottle number (4411 with 12 or 24 bottles)

Operation

Figure 51 Swivel out the sample faucet (4411 with 12 or 24 bottles)

39

Page 40

Operation

Figure 52 Press the lever to open the sample faucet

(4411 with 12 or 24 bottles)

40

Figure 53 Swivel the lever back to close the sample faucet (4411 with 12 or 24 bottles)

Page 41

Operation

Figure 54 Swivel in the sample faucet (4411 with 12 or 24 bottles)

Figure 55 Select to continue the program (4411 with 12 or 24 bottles)

41

Page 42

Operation

4.2.3 Sampling (4411 with 2 or 4 bottles)

Figure 56 Select pause (4411 with 2 or 4 bottles)

Figure 57 Release the bottle holder (4411 with 2 or 4 bottles)

42

Page 43

Operation

Figure 58 Pull out the bottle holder and take sample (4411 with 2 or 4 bottles)

Figure 59 Select to remove sample (4411 with 2 or 4 bottles)

43

Page 44

Operation

Figure 60 Select the bottle number (4411 with 2 or 4 bottles)

44

Figure 61 Push the bottle holder back in and secure (4411 with 2 or 4 bottles)

Page 45

Figure 62 Select to continue program (4411 with 2 or 4 bottles)

Operation

45

Page 46

Operation

46

Page 47

Section 5 Maintenance and cleaning

DANGER

Only qualified experts should conduct the tasks described in this section.

WARNING

Please observe the following points for the use of chemicals and/or waste water:

Wear protective clothing:

– Laboratory coat

– Protective eyewear

– Rubber gloves

5.1 Maintenance tasks

The equipment is maintenance-free, therefore the operator does not need to carry out any

maintenance work.

5.2 Cleaning

5.2.1 Clean the housing and distribution unit

WARNING!

Manual rotation of the distribution unit can damage the dr ive.

Never rotate the distribution unit manually.

Clean the interior and exterior of the housing with a damp, lint-free cloth. Add commercial

household cleaner to the cleaning water as required.

47

Page 48

Maintenance and cleaning

Figure 63 NEVER rotate the distribution unit manually

48

Figure 64 Clean the distribution unit

Page 49

5.2.2 Clean the dosing vessel

Maintenance and cleaning

Figure 65 Release the dosing vessel

Figure 66 Remove the dosing vessel

49

Page 50

Maintenance and cleaning

Figure 67 Clean the dosing vessel

Figure 68 Insert the dosing vessel

50

Page 51

5.3 Troubleshooting

If the equipment does not function as required, check the fuse and replace if necessary.

5.3.1 Open the housing to change the fuse (3010)

Maintenance and cleaning

Figure 69 Open the lid and detach the cover (3010)

Figure 70 Remove the safety cover (3010)

51

Page 52

Maintenance and cleaning

5×20mm

8 A (träge)

(inactive)

5.3.2 Open the housing to change the fuse (4010–6010)

Open the housing lid as described in Figure 15, page 19 and Figure 16, page 19.

5.3.3 Change the fuse

Figure 71 Fuse support

If the error is not rectified, please contact the customer service of the manufacturer (refer

to Contact information, page 61).

52

Page 53

5.3.4 Reassemble the housing (3010)

Maintenance and cleaning

Figure 72 Install the safety cover (3010)

Figure 73 Close the housing (3010)

53

Page 54

Maintenance and cleaning

5.3.5 Reassemble the housing (4010–6010)

Close the housing lid as described in Figure 20, page 21, Figure 24, page 23 and

Figure 25, page 24.

5.4 Instrument decommissioning and storage

1. Remove all liquids and, if necessary, solid matter from the infeed and outfeed lines

and sample containers and clean as required.

2. Close all active programs.

3. Switch the equipment off.

54

Page 55

BM80070

BM69452

BM80044

350 mL

BM69301

12×2

BM69302

4×1,5

BM900715

Kunststoff - Dosiereinheit

Plastic dosing vessel

Section 6 Spare parts and accessories

6.1 Spare parts

Description Cat. no.

Short Manual (xx = language number) Doc013.xx.90205

Full User Manual (xx = language number) Doc023.xx.90144

Figure 74 Plastic dosing vessel

55

Page 56

BM900053

BM69401

BM69402

BM30004

350 mL

BM69301

12×2

BM69302

4×1,5

Glas - Dosiereinheit (350 mL)

BM900674

Glass dosing vessel (350 ml)

Spare parts and accessories

Figure 75 Glass dosing vessel (350 ml)

56

Page 57

BM30005

500 mL

BM69301

12×2

BM69302

4×1,5

BM69402

BM69401

BM900053

Glas - Dosiereinheit (500 mL)

BM900243

Glass dosing vessel (500 ml)

Spare parts and accessories

Figure 76 Glass dosing vessel (500 ml)

57

Page 58

Spare parts and accessories

Bypass - Dosiereinheit (Glas)

BM69402

BM30027

250 mL

BM69301

12×2

BM69317

20×2

BM900239

Bypass dosing vessel (glass)

Figure 77 Glass dosing vessel (flow)

58

Page 59

Section 7 Warranty and liability

The manufacturer warrants that the product supplied is free of material and manufacturing

defects and undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out within

6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of further claims, the supplier is liable for defects including the lack of

assured properties as follows: All those parts that, within the warranty period calculated

from the day of the transfer of risk, can be demonstrated to have become unusable or that

can only be used with significant limitations due to a situation present prior to the transfer

of risk, in particular due to incorrect design, poor materials or inadequate finish will be

improved or replaced, at the supplier's discretion. The identification of such defects must

be reported to the supplier in writing without delay, but no later than 7 days after the

identification of the fault. If the customer fails to notify the supplier, the product is

considered approved despite the defect. Further liability for any direct or indirect damages

is not accepted.

If equipment-specific maintenance and servicing work defined by the supplier is to be

performed within the warranty period by the customer (maintenance) or by the supplier

(servicing) and these requirements are not carried out, claims for damages are rendered

void due to the failure to comply with the requirements.

Any further claims, in particular claims for consequential damages, cannot be made.

Consumables and damage caused by improper handling, unsafe assembly or by incorrect

use are excluded from this provision.

Process instruments of the manufacturer are of proven reliability in many applications and

are therefore often used in automatic control loops to provide the most economical

operation possible for the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control

loop such that a malfunction in an instrument results in an automatic change over to the

backup control system, which is the most secure operating condition for the environment

and for the process.

59

Page 60

Warranty and liability

60

Page 61

Section 8 Contact information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Fax +48 717 174 088

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 4908300 Ext. 140

Fax +90312 4919903

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

61

Page 62

Contact information

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

62

Loading...

Loading...