Page 1

Operating instructions

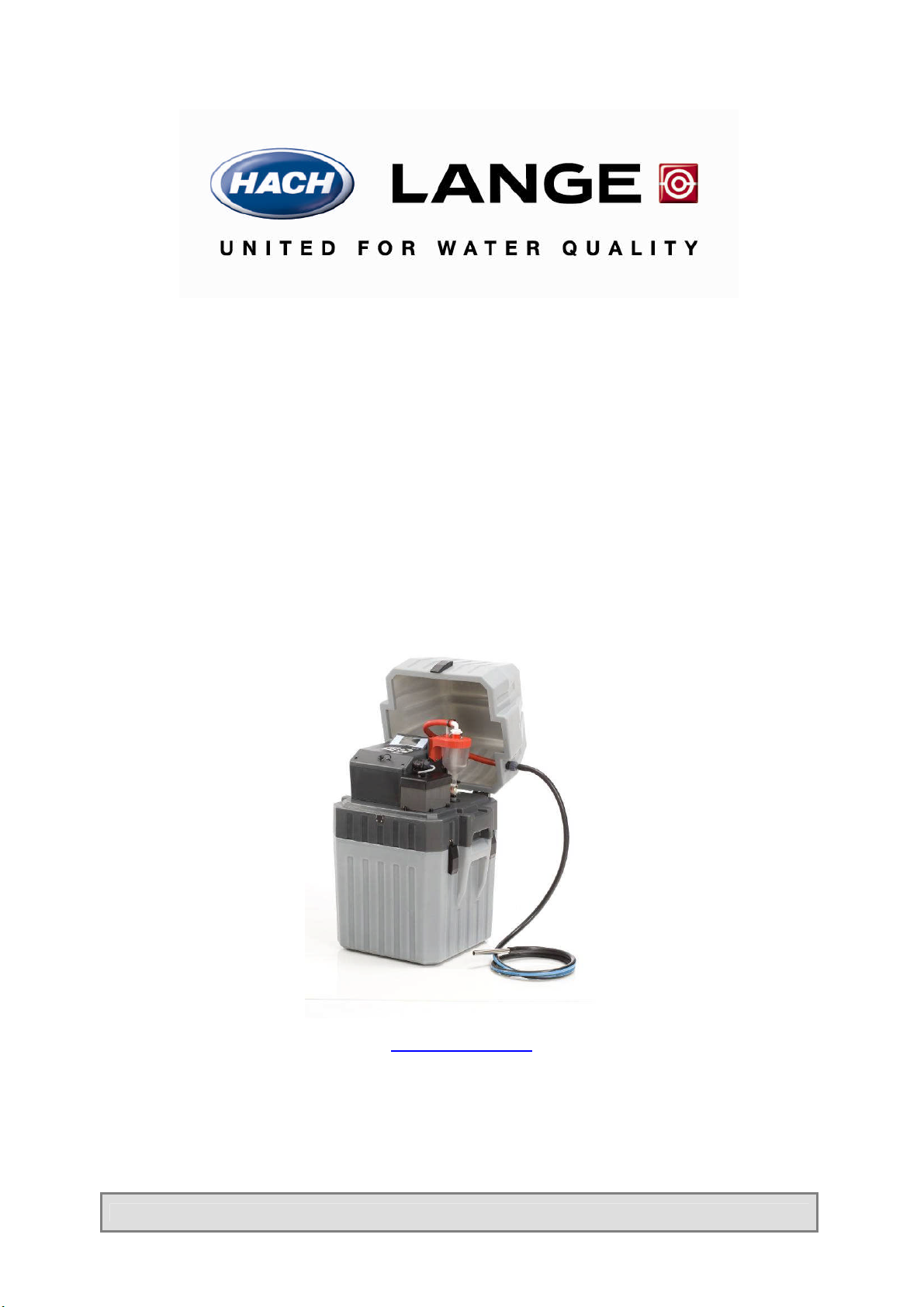

Water sampler

BÜHLER

2000

www.hach-lange.com

DOC023.52.90153 _BÜHLER_2000_BL1029_March09.doc

Page 2

Remarks

HACH LANGE GmbH is not liable for possible faults in this documentation. Any liability for direct or

consequential damages in connection with the delivery or the use of this device is excluded as far as it

is legal.

All rights, especially the rights for duplication, distribution and/or translation, are reserved to HACH

LANGE GmbH. Any reproduction, use or duplication of this manual, also in extracts, is prohibited by

law without the previous written agreement of HACH LANGE GmbH.

Subject to changes!

Access code for programming, system settings, key lock

Password:

Your password:

6299

Copyright by HACH LANGE GmbH © 1998 – 2009

Page 3

General information

MANUAL MODE

MEMORY

Table of contents

Table of contents .................................................................................................................................3

General information.................................................................................................................................4

Safety remarks.....................................................................................................................................4

Before putting into service ...................................................................................................................4

Permissible application........................................................................................................................4

Permissible operating and ambient conditions....................................................................................4

Redelivery for repair.............................................................................................................................5

Use of hazard information....................................................................................................................6

Precautionary labels ............................................................................................................................6

Characteristic features of the BÜHLER 2000 sampler ........................................................................9

Characteristic features of the BÜHLER 1029 sampler ......................................................................11

Sampler Bühler 1029 in combination with insulating box (Isobox) ....................................................12

Installing the apparatus......................................................................................................................13

Connections Bühler 2000 ..................................................................................................................14

Connections Bühler 1029 ..................................................................................................................14

Connector assignment – RS 232.......................................................................................................15

Connector assignment – input signals ............................................................................................15

Connector assignment – battery connection ..................................................................................15

Connector assignment – message ....................................................................................................16

Troubleshooting - general..................................................................................................................16

Sampling modes................................................................................................................................17

Sampling system................................................................................................................................19

Vacuum sampling system..................................................................................................................19

Troubleshooting – vacuum system....................................................................................................21

Programming .....................................................................................................................................22

EXAMPLES FOR STANDARD PROGRAMS .......................................................................................23

MAIN MENU (root):...............................................................................................................................30

CHANGE PROGRAM .......................................................................................................................31

START PROGRAM...........................................................................................................................34

...................................................................................................................................37

SETUP ..................................................................................................................................................38

MODEM SETTINGS..........................................................................................................................39

CHANGE SYSTEM SETTINGS ........................................................................................................41

EXTENDED PROGRAM SETTINGS ................................................................................................43

..............................................................................................................................................45

SERVICE MENU...................................................................................................................................47

APPENDIX A - Special programming................................................................................................50

SPECIAL DISPLAY/MALFUNCTION MESSAGES...........................................................................54

EXTENDED MALFUNCTION MESSAGES.......................................................................................55

EXTENDED MALFUNCTION MESSAGES.......................................................................................55

MESSAGES.......................................................................................................................................55

DIGITAL INPUTS / OUTPUTS ..........................................................................................................56

Rotating distributor.............................................................................................................................57

Troubleshooting - distributor..............................................................................................................58

Maintenance ......................................................................................................................................59

Spare parts / accessories......................................................................................................................62

Circuit diagram: mains connection BÜHLER 2000/1029...................................................................64

Warranty and liability..........................................................................................................................65

Contact...............................................................................................................................................66

Page 3 Manual BÜHLER 2000/1029

Page 4

General information

General information

We are glad that you have chosen this product.

When developing this device, we combined approved technique with innovative detail solutions.

Greatest importance has also been attached to the design of an apparatus which provides easy

access for connection and maintenance works.

Safety remarks

Disconnect the mains power connections before carrying out any connection, maintenance

or repair works.

Before putting into service

- Please read these operating instructions and special remarks thoroughly before putting the

device into service.

- Familiarize yourself with the safety and operating requirements in order to safeguard

personnel and equipment.

- The apparatus has been subjected to exhaustive quality inspections before dispatch.

- Any service and maintenance works required may only be carried out by trained service

personnel.

- Observe the local safety regulations and the rules for prevention of accidents.

- Observe the rules concerning the handling of hazardous substances.

- Do only use original spare parts or spare parts authorised by the manufacturer.

- No liability or claims under guarantee will be accepted in respect of any modifications or

conversions of the apparatus, other than those carried out by us or by persons authorised by

us or for which we have given express permission (in a written form)! This also refers to any

damage due to incorrect operation and/or improper use of the equipment.

Permissible application

The permissible application of the water sampler consists in the extraction of liquid, aqueous

substances, temperature range 0°C to 40°C. The device must only be installed in areas free from

explosion hazard and must only be used for sampling of non-explosive substances. Please refer to

the technical specifications in chapter “Specifications”. Other applications are not allowed!

Permissible operating and ambient conditions

- Sample extraction of liquid aqueous substances, temperature range: 0°C to 40°C.

- The sampler is designed for operation in non-hazardous areas (no explosion risk).

- The sampler can be operated at ambient temperatures from 0°C to +45°C.

- Sampling from pressurised lines is not possible.

- The device is weather-proof and suitable for outside operation.

Page 4 Manual BÜHLER 2000/1029

Page 5

General information

Redelivery for repair

Before returning any appliances to us, please pay attention to the following to avoid unnecessary cost

and repair delays:

- Redeliveries only after agreement by the supplier

- All appliances or parts returned to us for repair must be cleaned and free of any hazardous

substances whatsoever (acids, alkaline solutions, solvents, etc.) as in Germany official

regulations regarding waste stipulate that persons in possession of hazardous waste are

responsible for its disposal and that, at the same time, employers are responsible for

protecting their employees against hazardous materials.

- Any cleaning or disposal required to be carried out by us will be charged for accordingly.

All packing materials can be disposed of as usual.

Packing materials are: cardboard, wood, PS and PE.

If the packing is returned free of cost, we will take care of its disposal.

Page 5 Manual BÜHLER 2000/1029

Page 6

General information

Safety information

Use of hazard information

Please read this entire manual before unpacking, setting up

or operating this equipment. Pay attention to all danger and

caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is

not impaired, do not use or install this equipment in any

manner other than that specified in this manual.

DANGER

Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

Important Note: Information that requires special

emphasis.

Note: Information that supplements points in the main text.

Precautionary labels

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of

electrical shock and/or electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for

Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a fuse or current

limiting device.

Electrical equipment marked with this symbol may not be disposed of in European public

disposal systems after 12 August 2005. In conformity with European local and national

regulations (EU Directive 2002/96/EC), European electrical equipment users must now

return old or end-of life equipment to the Producer for disposal at no charge to the user.

Note: For all electrical products (marked or unmarked) which are supplied or produced

by Hach-Lange, please contact the local Hach-Lange sales office for instructions for

proper disposal.

Read all labels and tags attached to the instrument.

Personal injury or damage to the instrument could occur if

not observed.

Page 6 Manual BÜHLER 2000/1029

Page 7

Specifications

Device designation

Housing PE/PC(GF10)

Thermostatic control Insulated sample compartment (40 mm insulating layer)

Control Microprocessor control, foil keyboard, back-lit four-line LC-display

Data memory Non-volatile data memory: storage of sampling and malfunction data

Programming 6 user programs (can be edited freely)

Program start options Immediately, at a certain time, by an external signal

Program stop options End of sampling program after one program run, continuous operation

Pause mode Interruption of program at any time

Overfilling protection Adjustable from 1–999 samples/bottle

Interval setting 1 min. to 99 h 59 min. in steps of 1 minute

Pulse setting 1 to 255 pulses/sample

Manual sample extraction Possible at any time without interrupting the current program run

Program protection Up to 5 years after voltage loss

Interface RS 232

GSM modem / wireless

communication

Languages Multi-language, selectable

Signal inputs • 1x analogue: 4-20 mA, optional 0-20 mA,

Signal outputs / status

messages

Sampling method Vacuum system 20-350 ml

Single sample volume

accuracy

Suction height Max. 6,5 m (at 1013hPa)

Pumping speed >0,5 m/s at a suction height of up to at least 5 m (at 1013hPa); pump

Suction hose PVC, L=5 m, ID=9 mm (ID 16 mm at flow-proportional option).

Sampling modes Time-related, flow-dependent, flow-proportional (option), eventBottle variants 24 x 1 L PE (standard)

Bühler 2000

Option: freezer packs (200x10x8 mm)

Option: compressor cooling (12V/115V/230V)

like sample extractions, bottle changes, messages, external signals

Optional (in combination with PC software)

minimum voltage: 3,3 V (optocoupler)

• 5x digital:(flow, event, 3 inputs can be programmed freely

Max. 8 digital outputs, depending on device version; freely

programmable

< 2,8 %

capacity can be adjusted electronically

Max. hose length 30 m.

related, manual sample

13 L composite container

25 L composite container

4 x 5 L PE

16 x 1 L with freezer packs

Overall dimensions (Hxwxd)

787 x 510 x 468 mm

1030 x 548 x 470 mm with compressor cooling

Weight 22,4 kg 24x1 L version

34 kg 24x1 L version with compressor cooling (sampler incl. battery,

without suction hose, empty bottles)

Power supply 12 V/ 10 Ah lead gel battery (maintenance-free, sealed, leak proof)

115V or 230V mains-operation by means of battery charger in buffer

mode (float charge); power requirement max. 30 W

Number of samples Approx. 2000 samples per battery charge [determined at an ambient

temp. of 20° C, 1,5 m suction height, sampling interval of 1 min.] incl.

distributor advance

Ambient temperature 0 to + 45°C

Sample temperature 0 – 40°C

Page 7 Manual BÜHLER 2000/1029

Page 8

Specifications

Standards Device meets ISO 5667 standard

Wetted materials PVC, Silicone, PS, PE

Device designation

Thermostatic control Option: only in combination with insulating box (Isobox), freezer packs

Bottle variants Option:

Overall dimensions

Weight

BÜHLER 1029 (like BÜHLER 2000, however, with the following

modifications)

or compressor cooling (12V/115V/230V)

13 L composite container

25 L composite container

4 x 5 L PE bottle

24 x 1 L PE bottle

16 x 1 L bottle with freezer packs

(Hxwxd) sampler

442 x 452 x 222 mm

(Hxwxd) Insulating box – passive cooling

534 x 510 x 430 mm

(Hxwxd) Insulating box – active cooling

775 x 550 x 468 mm

11,6 kg sampler

11,5 kg insulating box – passive cooling (24x1 L)

24,0 kg insulating box – active cooling (24x1 L)

Page 8 Manual BÜHLER 2000/1029

Page 9

Installation

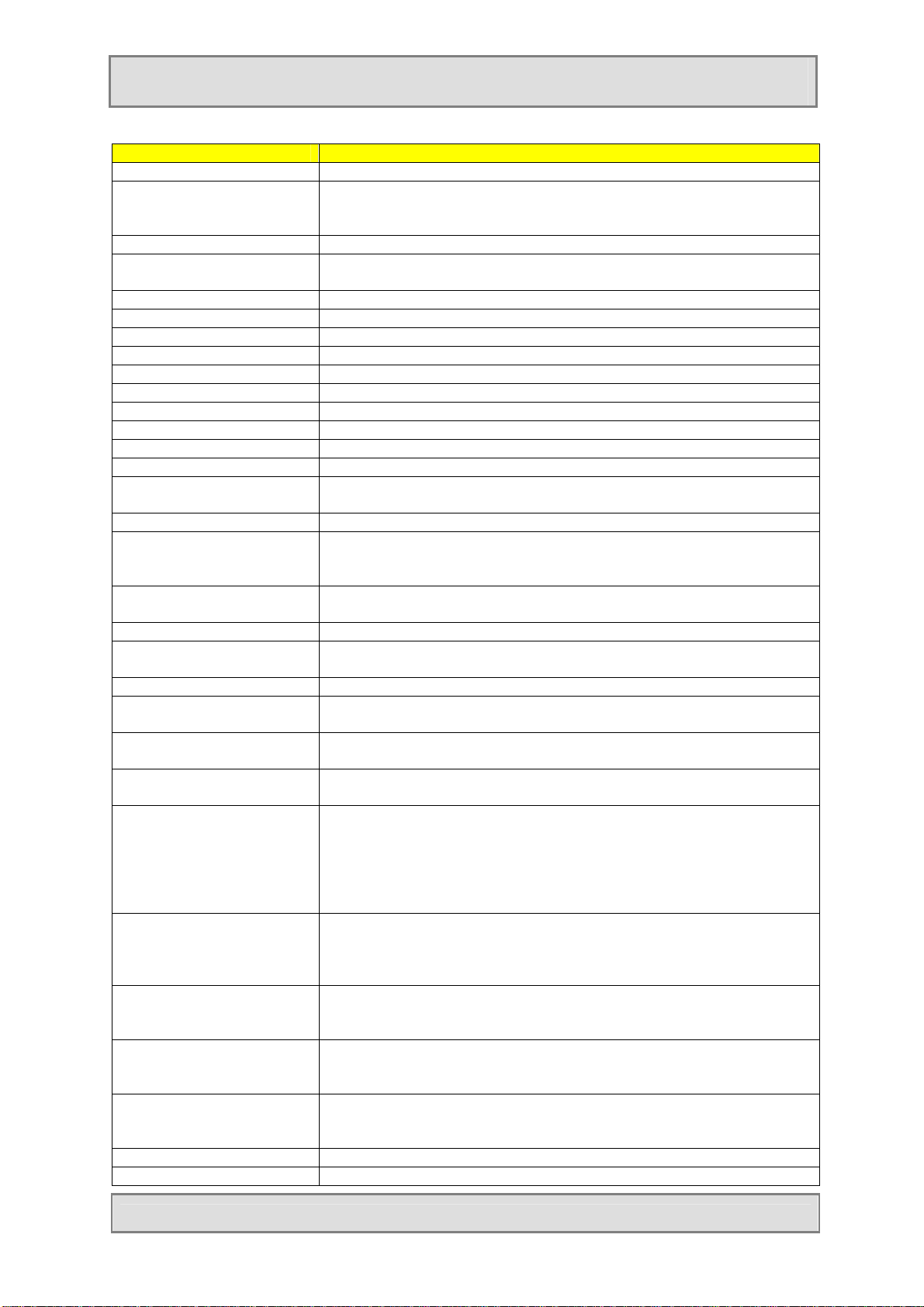

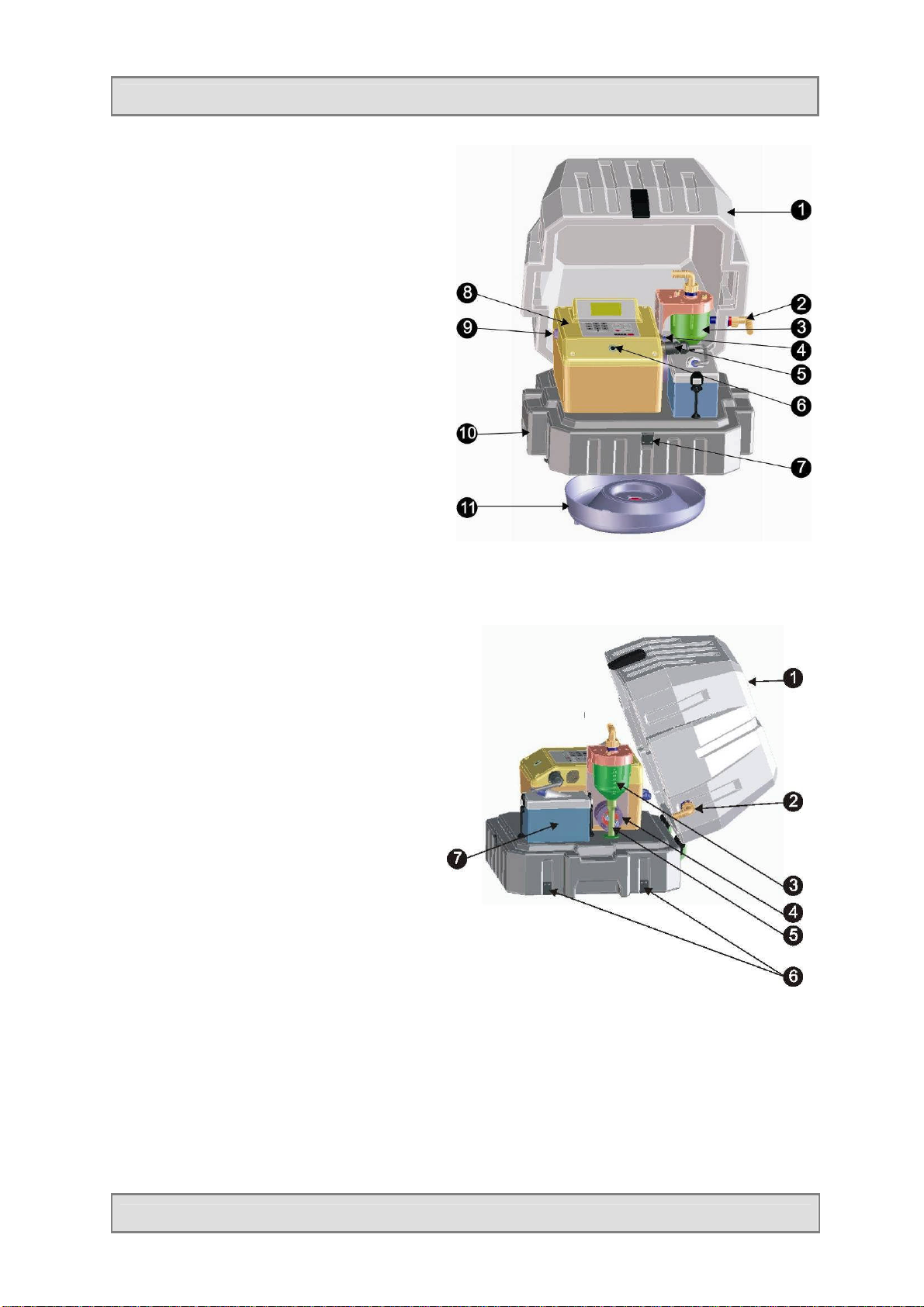

Characteristic features of the BÜHLER 2000 sampler

The device consists of the following component parts:

1. Sampler upper part

2. Snap-on lock of upper part

3. Intermediate bottom with distributor plate

4. Sampler lower part

5. Four snap-on locks at lower part (two on opposite

side)

6. Recessed grip

Lower part with inserted distributor plate

Opened lower part with bottles

Page 9 Manual BÜHLER 2000/1029

Page 10

Installation

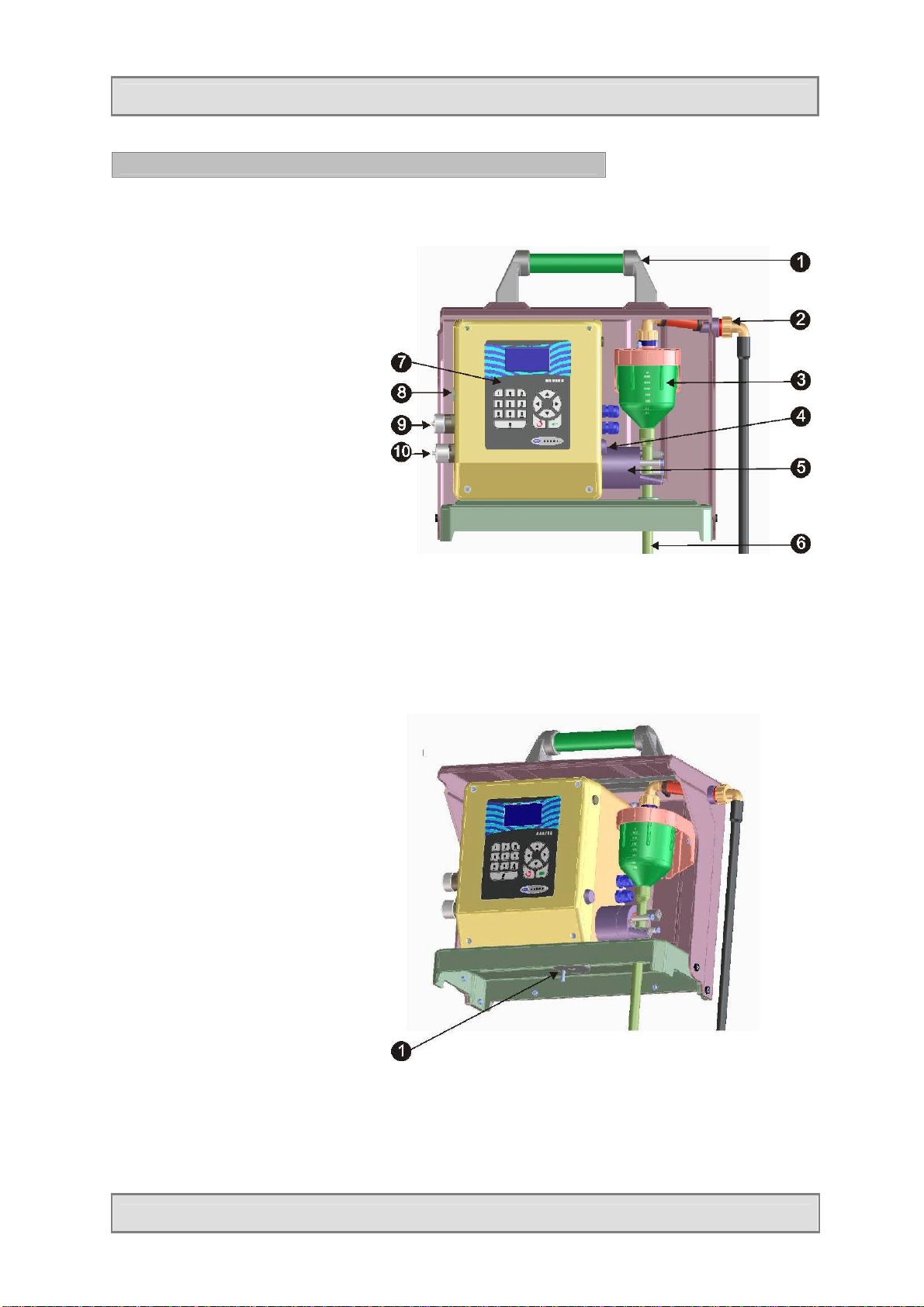

1. Lid

2. Suction hose connector ¾“

3. Metering vessel

4. Signal connector

5. Battery connector

6. RS 232 interface

7. Lid latch

8. Control unit with keyboard and display

9. ON / OFF switch

10. Intermediate bottom of housing

11. Distributor tray

1. Lid

2. Suction hose connector ¾“

3. Metering vessel

4. Pinch valve

5. Discharge hose

6. Latches of intermediate part

7. Storage battery

Page 10 Manual BÜHLER 2000/1029

Page 11

Installation

Characteristic features of the BÜHLER 1029 sampler

1. Handle

2. Suction hose connector

3. Metering vessel

4. ON / OFF switch

5. Dosing pinch valve

6. Discharge hose

7. Keyboard / display

8. Connector socket RS232

9. Connector socket of input signals

10. Connector socket of battery

charger

1. Distributor drive

Page 11 Manual BÜHLER 2000/1029

Page 12

Installation

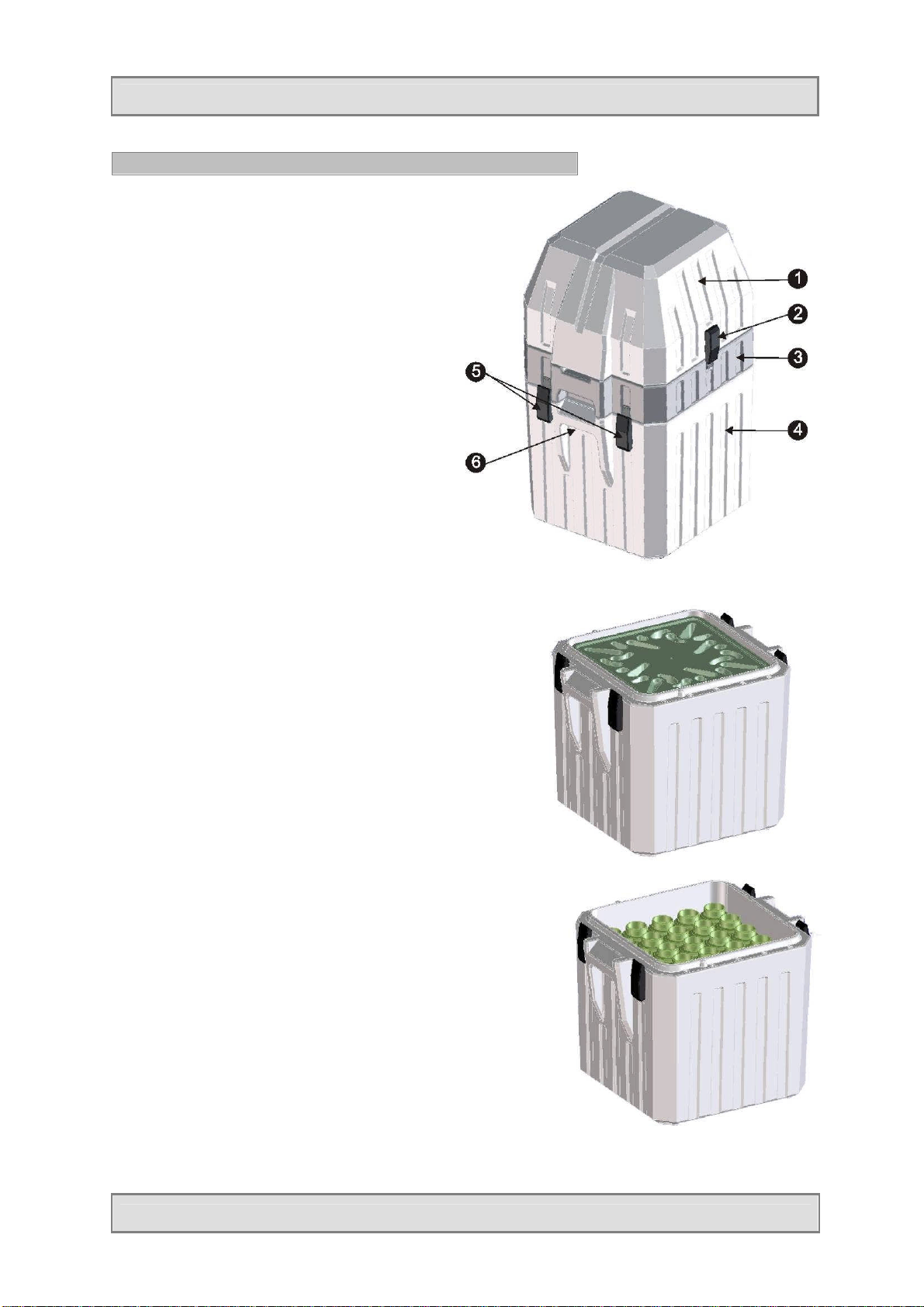

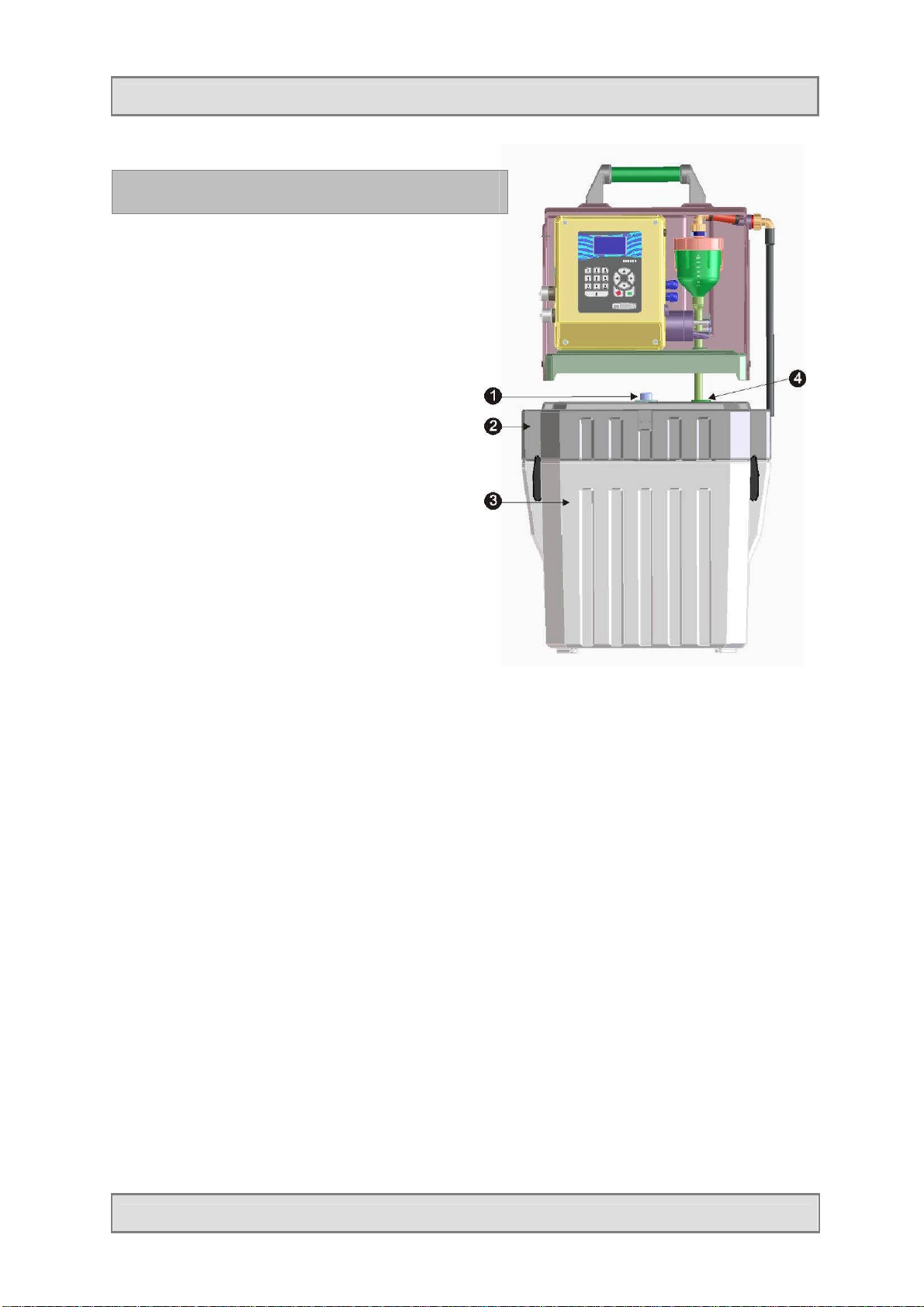

Sampler Bühler 1029 in combination with

insulating box (Isobox)

1. Distributor finger

2. Intermediate part with distributor plate

3. Lower part for bottles

4. Lead through for discharge hose of metering

vessel

Page 12 Manual BÜHLER 2000/1029

Page 13

Installation

Installing the apparatus

- We recommend to install the apparatus as close to the sampling point as possible. If installed

outside, the device should be positioned on a solid flat surface.

- The hose has to be laid with a constant fall from the sampler to the sampling point as lower

lying points can lead to deposits in the hose which may freeze in winter or result in crosscontaminations.

- To fix the suction hose, we recommend to use the extraction unit available as accessory.

- Immerse the end of the hose at the sampling point with the open end facing downstream

(direction of flow) so that coarse matter and fibres cannot be forced into the suction aperture

Mains connection / external power supply

A battery charger (option) is available to charge the battery.

Mains powered float charge option

The integral storage battery can be charged by means of the mains powered battery charger. In case

of a higher energy demand, the battery charger can be permanently connected to the mains, so that

the integral storage battery of the sampler is left permanently on charge (float charge).

Integral storage battery

A fully charged battery will, under ideal conditions, be sufficient for up to 2000 sample extractions.

Charging the storage battery

The integral battery is a maintenance-free sealed lead-acid battery.

Charge the storage battery for at least 14 -16 hours prior to the first use.

This charging time is also necessary if the storage battery is empty. To avoid a total discharge,

a protective mechanism is built-in which automatically switches off the device when the voltage

is too low.

The storage battery cannot be overcharged as the battery charger switches to compensation charge

as soon as the battery is fully charged.

For longer periods of non-use, top up the charge regularly (connect the battery to the charger).

In any case, avoid a total discharge as otherwise the storage battery will be damaged.

Switch on / off

The device is switched on and off by the ON / OFF switch.

Option: mains operation. In case of exclusive mains operation, the device is switched on by means

of the mains plug of the battery charger.

Hose connection

The inlet hose is connected at the side of the housing upper part (screw thread ¾“).

Signal connections

The signal connector (e.g. for a flow meter) is in front of the control.

Connection to a PC

The sampler is connected to a PC by means of an interface cable (art. No. BM900021) which is

connected to the RS232 connector.

Page 13 Manual BÜHLER 2000/1029

Page 14

Installation

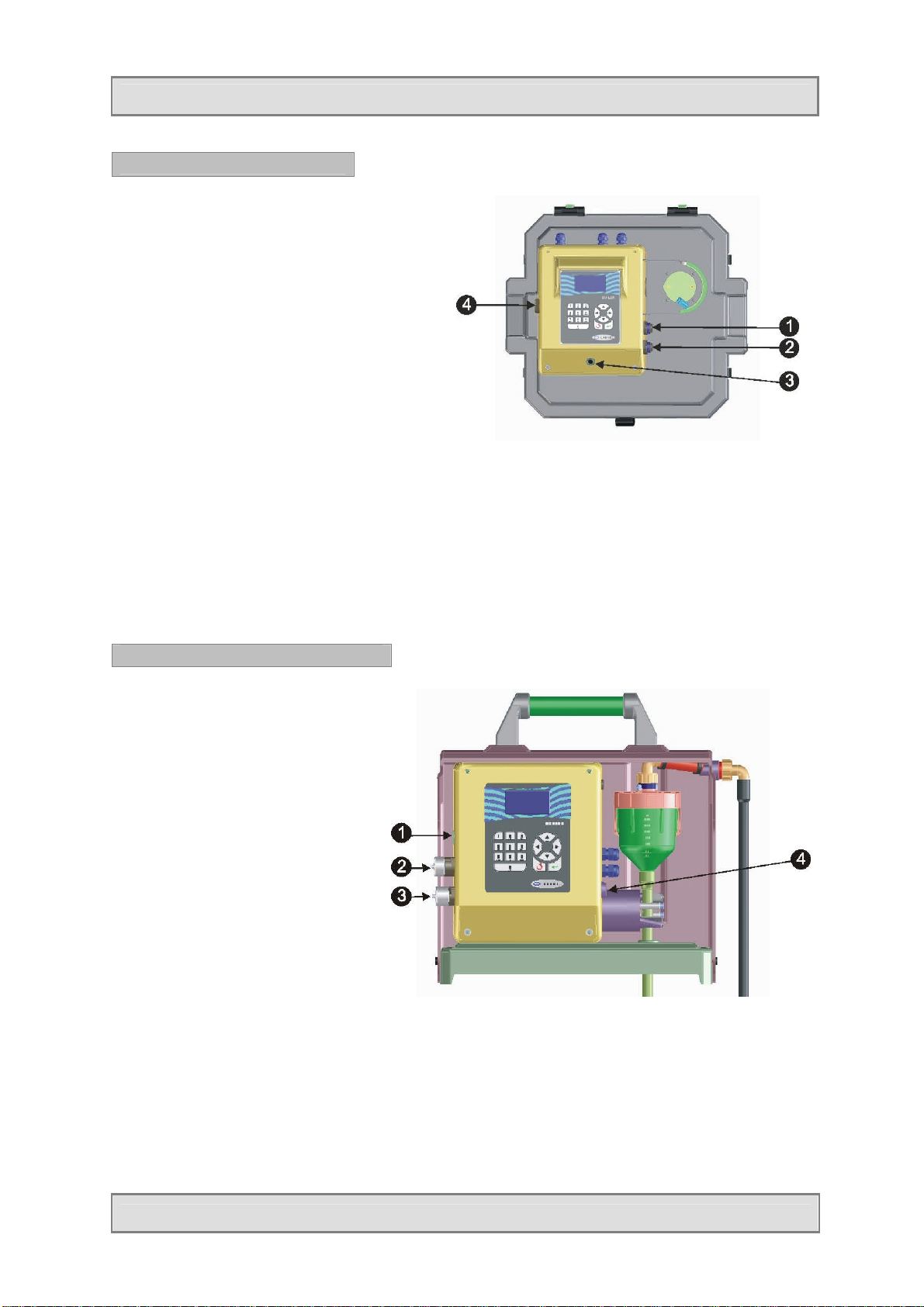

Connections Bühler 2000

1. Input signals connector

2. Battery connector 12V/10 Ah

3. RS 232 interface

4. ON / OFF switch

Connections Bühler 1029

1. RS 232 interface

2. Input signals connector

3. Battery charger connector

4. ON / OFF switch

Page 14 Manual BÜHLER 2000/1029

Page 15

Installation

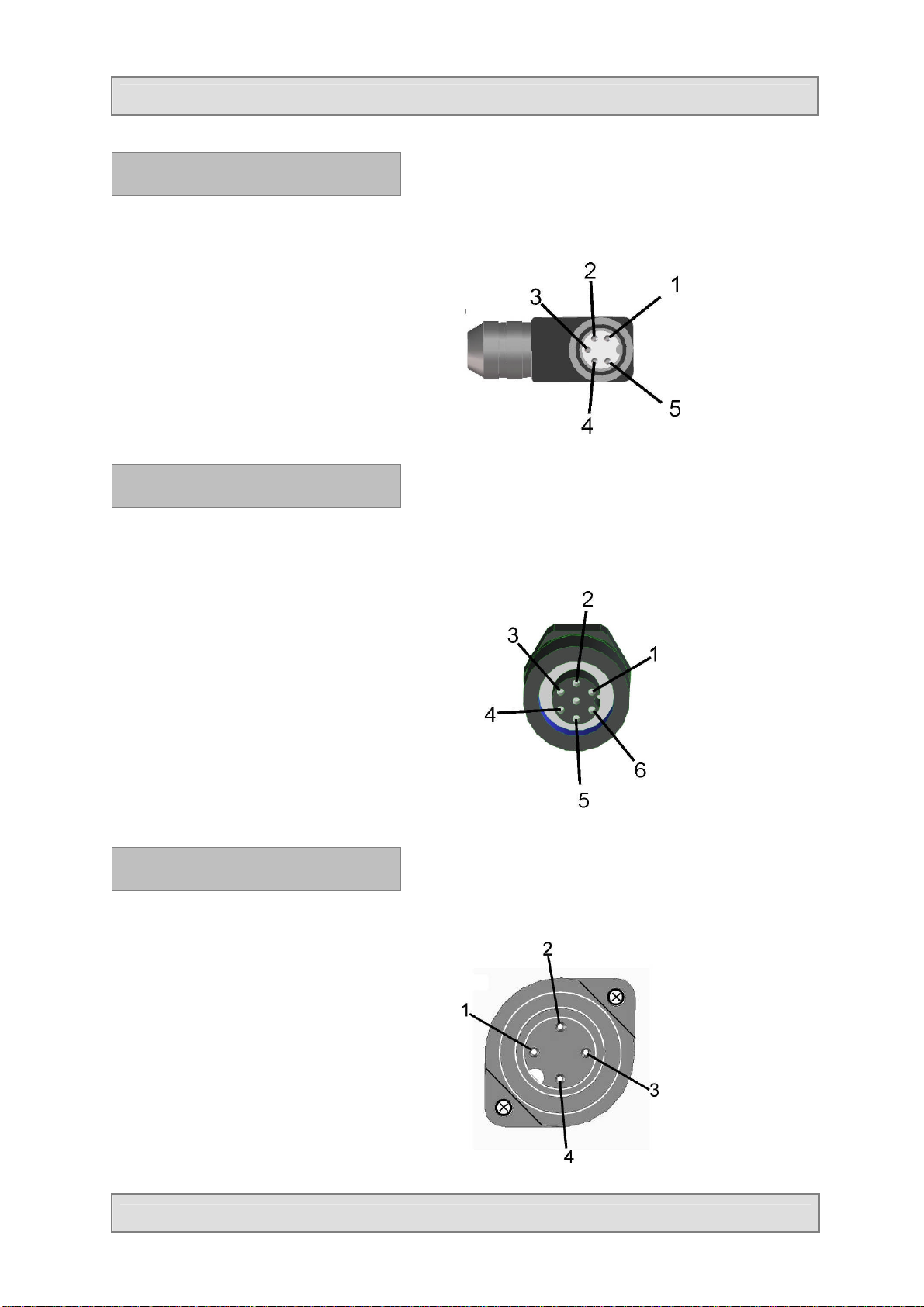

Connector assignment – RS 232

(plug)

1 = Rx

2 = Volt-free

3 = Tx

4 = Volt-free

5 = Gnd

Connector assignment – input

signals (plug)

Pin assignment:

1 = Flow analogue +

2 = Flow analogue 3 = COM

4 = Flow digital (pulse)

5 = Event

6 = Volt-free

Connector assignment – battery

connection (device)

Pin assignment:

1 = +

2 = 3 = Volt-free

4 = Volt-free

Page 15 Manual BÜHLER 2000/1029

Page 16

Installation

Connector assignment – message

• Message

Connection at relay as normally open or normally closed contact.

Troubleshooting - general

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type

and serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

Check all fuses and replace

them if necessary

Charge battery for at least 14

hours

No function

Fuse defective

Battery discharged

Exhaustive discharge of battery Replace battery

Page 16 Manual BÜHLER 2000/1029

Page 17

Operation

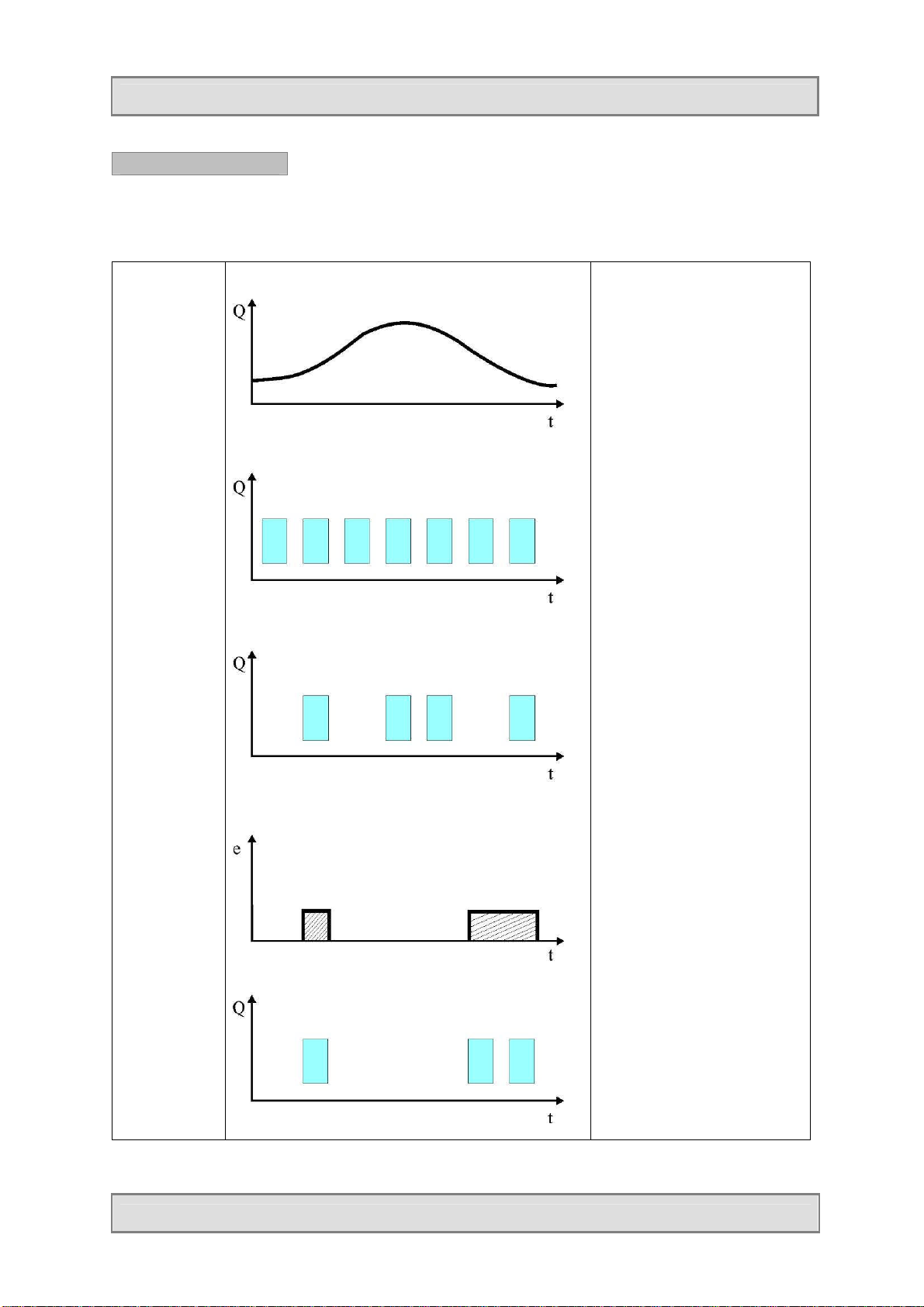

Sampling modes

Graphical representation of sampling modes TIME-FLOW-EVENT

Flow graph

Timeproportional

Flowdependent

Event signal

Eventproportional

A sample is extracted in fixed

time intervals (e.g. every 10

minutes) with a fixed sample

volume (e.g. 50 ml).

A sample is extracted in

variable time intervals

(depending on the flow (Q))

with a fixed sample volume.

The sampler is waiting for an

event (e.g. the exceeding of

a pH limit value). A sample is

extracted in fixed time

intervals (e.g. every 10

minutes) with a fixed volume

(e.g. 50 ml) as long as an

event is present.

Page 17 Manual BÜHLER 2000/1029

Page 18

Operation

Sampling modes

The following sampling modes can be programmed:

Sampling mode Description Example

Time-proportional In this sampling mode, the single

sample extractions as well as the

bottle change are effected in fixed

time intervals.

Flow-dependent

- digital

Flow-dependent

- analogue

In this sampling mode the sample

extraction is triggered by flow

pulses. The bottle change is

effected in fixed time intervals or

after a certain number of sample

extractions.

In this sampling mode samples are

extracted according to the analogue

flow signal (0-20 mA or 4-20 mA).

The sample extraction is started

when the programmed flow is

reached. Thus the interval between

the sample extractions varies

according to the flow signal. The

bottle change is effected in fixed

time intervals or after a certain

number of sample extractions.

Values to program:

sampling interval

e.g. 00:05 hh:mm

bottle filling time

e.g. 02:00 hh:mm

Values to program:

pulse divider

e.g. 100

(that means that a sample is extracted

after each 100th pulse).

Bottle filling time

e.g. 02:00 hh:mm

or

bottle change after X sample extractions

e.g. 100

Values to program:

Flow per sample extraction

e.g. 1 m³

Bottle filling time

e.g. 02:00 hh:mm

or

bottle change after X sample extractions

e.g. 100

Event-proportional In this sampling mode the sample

extraction is depending on an

external event signal (potential-free

make contact). The sample is only

extracted as long as the signal is

present. The sampling interval as

well as the bottle change is

programmed. The bottle is changed

at each new event signal.

If an event is longer than the

programmed bottle filling time, two

or more bottles will be filled for this

event.

Page 18 Manual BÜHLER 2000/1029

Values to program:

Sampling interval

e.g. 00:05 hh:mm

Bottle filling time

e.g. 02:00 hh:mm

Page 19

Operation

Sampling system

Vacuum sampling system

Metering vessel -structure-

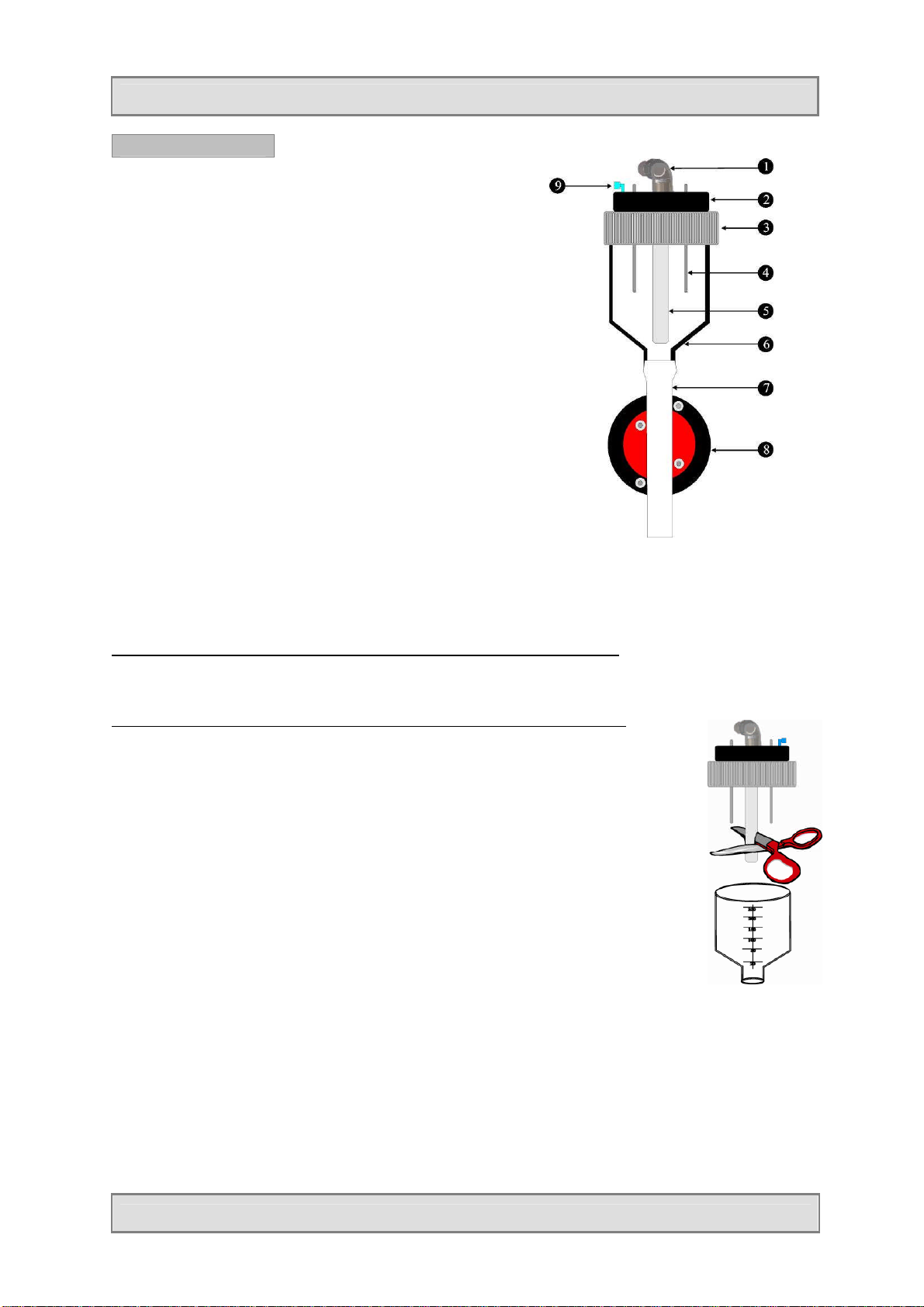

1. Hose connector

2. Flange

3. Screw cap

4. Electrodes

5. Volume control tube

6. Metering vessel

7. Silicone discharge tube

8. Motor-driven pinch-valve

9. Air connection

Cleaning:

- Glass metering vessel: unscrew the screw cap (3) and remove the flange. Now, the metering vessel

together with the silicone discharge tube (7) can be detached.

- Plastic metering vessel: Turn the plastic metering vessel anticlockwise (bayonet fitting) and remove.

Adjustment of sample shot volume at samplers with glass metering vessel:

To adjust the desired sample volume, loosen the knurled screw and displace the volume control tube

vertically.

Adjustment of sample shot volume at samplers with plastic metering vessel:

The sampler is always delivered with the volume control tube in full length.

To adjust the sample shot volume, the volume control tube (5) has to be cut

to length.

Procedure

1. There is a graduation in millilitres on the volume control tube.

2. Remove the metering vessel (6).

3. Cut the volume control tube to the desired length with scissors or a knife.

4. Reinstall the metering vessel (6) and tighten.

5. Check the sample volume by starting a manual sample extraction.

6. Now the device is ready for operation.

Remark: If you need to work with different sample volumes, you can cut to

size several tube pieces. As the volume control tube (5) is only

slipped on the hose connector (1), it is very easy to change the tube.

Page 19 Manual BÜHLER 2000/1029

Page 20

Operation

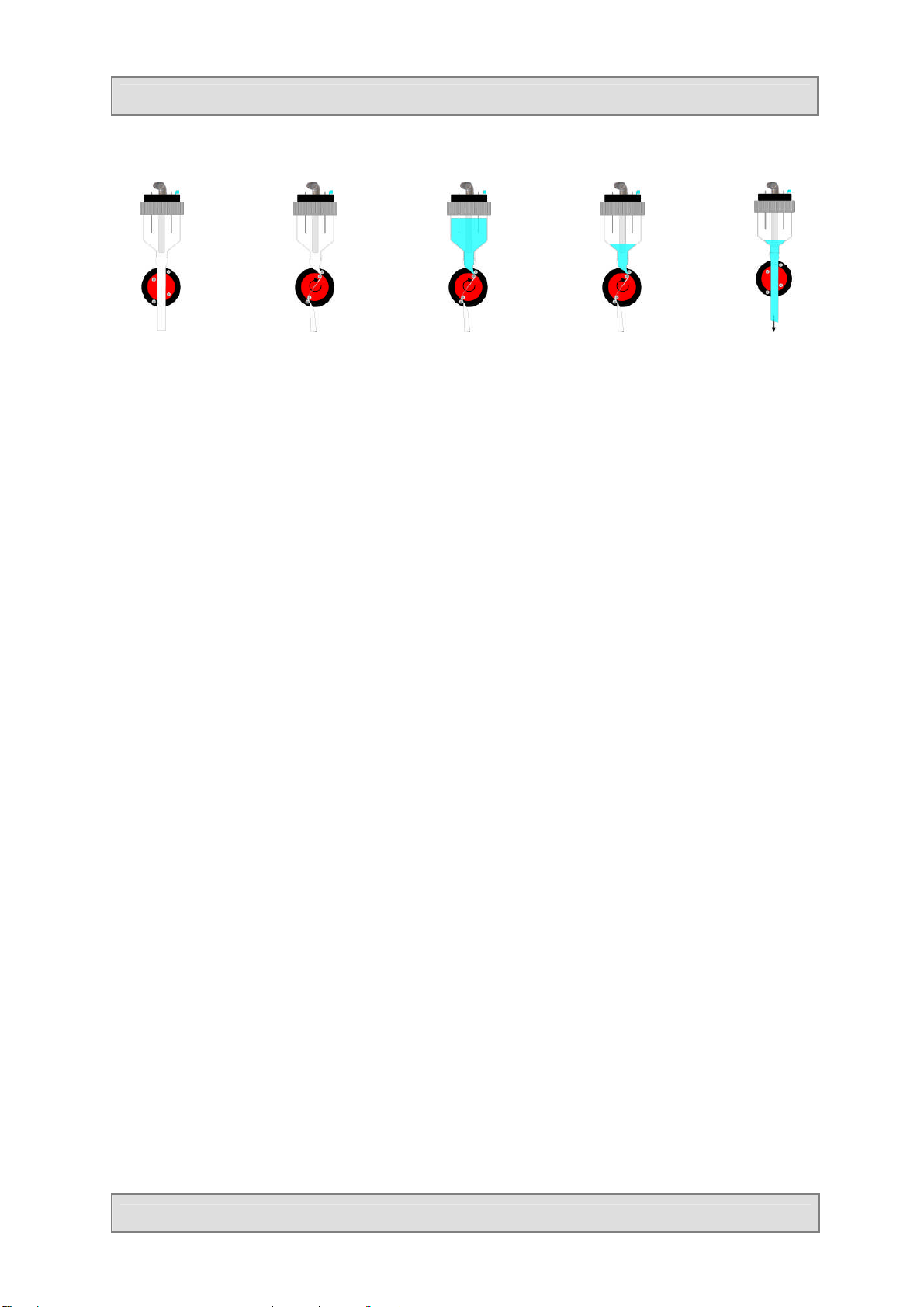

Operation principle:

1. Inoperative

position

Replacement of the silicone discharge hose

The silicone hose (BM69301) is only pushed over the lip of the metering vessel. A hose clamp is not

required. Humidify the hose a little bit, fix it at one point and push it over the lip.

Remark:

Do only use original spare parts from the manufacturer. The use of a wrong hose type can lead to

malfunctions at the system or may even damage the pinch valve!

Remark:

Conductivity of the sample medium

There are two conductive level electrodes in the metering vessel. Their sensitivity can be adjusted in the

service menu. In the factory the electrodes are adjusted to tap water (this adjustment does not have to

be changed under normal operating conditions). Minimum conductivity 50 μS/cm.

Please note that a wrong adjustment can lead to a flooding of the pneumatic system and to the

damage of component parts.

The sampler is not suitable for extraction of distilled water due to low conductivity.

2. Pinch-valve

closes

3. Metering

vessel is filled

up to the

electrodes

4. Dosing system

is aerated

5. Pinch

valve

opens and

sample

drains off

in bottle

Conductivity at 25°C

Rain water 50 μS/cm

Drinking water 500 μS/cm

Waste water 5000 μS/cm (5 mS/cm)

Seawater 50000 μS/cm (50 mS/cm)

ATTENTION:

Wrong operating conditions can lead to malfunctions or may even damage the apparatus. No liability or

claims under guarantee will be accepted in respect of any damage arising from the non-observance of

these operating instructions.

Page 20 Manual BÜHLER 2000/1029

Page 21

Operation

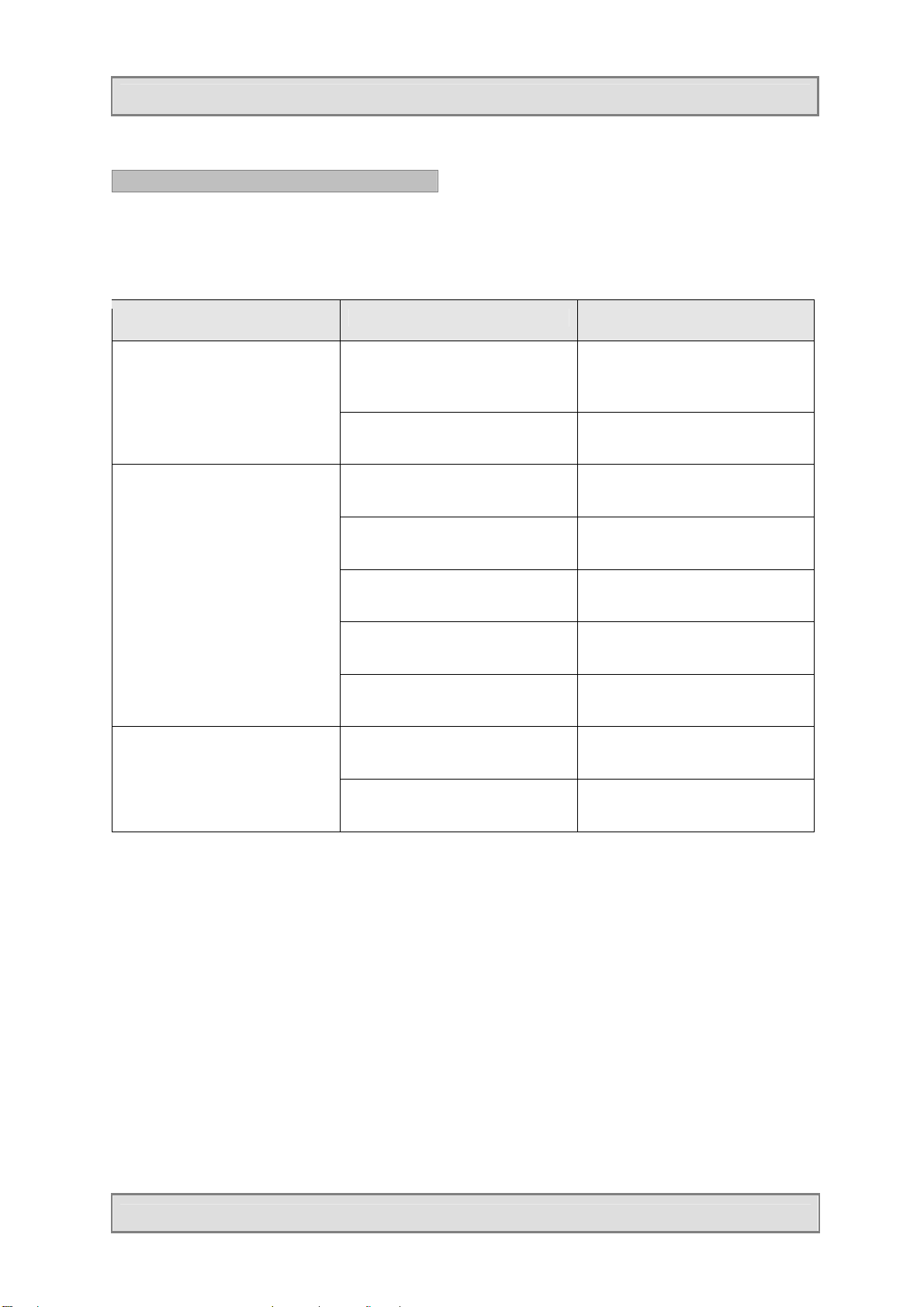

Troubleshooting – vacuum system

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

system flooded

Sampler does not extract

samples

pump

Adjustment of conductivity too

low. Distilled water has been

used as sample medium.

No contact to electrodes Check cable connection

System is leaking Check whether all hoses and

Pump/diaphragm defective Check pressure/vacuum of

Metering vessel not tight, no

vacuum

Filling level electrodes bridged Clean electrodes

Valve system/pinch valve does

not function correctly

Defective diaphragm Renew diaphragmNo pressure / vacuum at

Hoses are squeezed Check hoses

Contact service departmentElectrodes do not react,

connections are tight

pump

Check whether metering vessel

is tight (screw cap)

Check valve system/pinch valve

or contact service department

Page 21 Manual BÜHLER 2000/1029

Page 22

Operation

Programming

The menu structure is similar to the index of a computer hard disk and is

split up in main menus and submenus.

Assignment and function of keys:

The apparatus is interactively programmed by the user.

Function of the keys:

Display of help texts (in case of a selection

window the cursor has to be positioned on the

left digit of the selected value to activate the help

text)

Move from one to the next menu Arrow keys

Select the desired menu Enter key

Arrow key

Move within the menu Arrow keys

Selection within the menu Arrow keys

Confirm the choice (is automatically marked

with a √)

Entry of values Arrow keys

Confirm entered values Enter key

Return to higher menu level Back key

Entry of values Numerals 0 - 9

RESET (initialisation to factory settings) Back key

Example:

You want to change a setting, so first press the „ENT“ key.

The cursor is displayed flashing.

Now you can position the cursor on the desired setting by means of the arrow keys.

Enter key

Press key for at

least 10 seconds

Press the „ENT“ key again.

Your choice is now confirmed.

According to the program section you are in, an action is triggered or, if a program is edited, you are

automatically guided to the next menu.

Remark:

In general you can abort every action or step or return to a previous display by means of the back key.

Page 22 Manual BÜHLER 2000/1029

Page 23

Operation

EXAMPLES FOR STANDARD PROGRAMS

1. Programming of a „TIME-PROPORTIONAL“ sampling program

In this sampling mode, a sample is extracted as a function of a programmed time interval.

1.1.4

**********************

PROGRAM NO. 1

TIME

INTERVAL HRS. 0:06

FILLING TIME H 2:00

**********************

1.1.5

**********************

PROGRAM NO. 1

*CHANGE

DELAYED START

START

**********************

2.2.1

**********************

PASSWORD

****

**********************

Selection of the program number:

After having pressed the ENT key, a program number (1 to 6) can be

entered.

Confirm by pressing the ENT key.

Next menu: press the „DOWN“ arrow key.

PROGRAMMING

- Press the ENT key (cursor is displayed flashing)

- Press the „UP“ arrow key twice

- Confirm with ENT

Enter the valid password (factory-set code is 6299).

Remark:

This is only required if a password has been activated in „Setup“->

„System settings“. If not, just press the ENT key and you will get to

the next menu!

If the right password has been entered, you will automatically get to

the next menu.

3.4.1

**********************

MODE

EVENT

*TIME

FLOW ANAL. 0-20 mA

**********************

4.12.1

**********************

INTERVAL

00:10

**********************

5.2.2

**********************

BOTTLE FILLING

*TIME-RELATED

SAMPLE-RELATED

**********************

The selected sampling mode is marked with a star.

If the sampling mode shall be changed, press the ENT key and move

the cursor on the sampling mode TIME to create a time-proportional

program.

Confirm the input by pressing the ENT key.

Enter the sampling interval (hh:mm).

A sample is e.g. extracted every 10 minutes.

Select whether the bottle filling shall be

1. time-dependent or

2. depend on a pre-programmed number of

samples

Page 23 Manual BÜHLER 2000/1029

Page 24

Operation

**********************

6.2.1

**********************

FILLING TIME PER

BOTTLE

2:00H

**********************

5.2.5

**********************

BOTTLE VERSION

*SINGLE BOTTLE

2 x 5,0 L

2 x 10,0 L

**********************

5.2.12

**********************

REPEAT PROGRAM

YES

*NO

**********************

TIME-RELATED bottle filling:

Enter for how long each bottle shall be filled until the distributor

changes to the next bottle.

Example:

Interval: 10 min.

Filling time/bottle: 120 min.

Bottle volume: 2,5 L

That means 12 samples are extracted in 120 min. With a bottle

volume of 2,5 L, the maximum dosing volume per sample is

calculated as follows:

2500:12 200 ml.

If your sampler is equipped with a distributor, select here the

distributor/bottle variant.

If the program shall only run once, select NO.

Selecting „YES“ means continuous operation (the program is

always restarted).

Remark: In that case, the program will run endlessly. So, please

make sure that the bottles are emptied regularly

according to the programming as otherwise they will be

overfilled.

1.1.4

**********************

PROGRAM NO. 1

TIME

INTERVAL HRS. 0:06

FILLING TIME H 2:00

**********************

1.1.5

**********************

PROGRAM NO. 1

CHANGE

DELAYED START

*START

Each programming is completed with this menu to have the possibility to check the program settings of the just created program.

Program No. 1 has been programmed with a time-proportional

program.

To start the program, press the „DOWN“ arrow key.

The just created program can either be

• started immediately

• started with a delay or

• changed

Page 24 Manual BÜHLER 2000/1029

Page 25

Operation

**********************

2. Programming of a „FLOW-DEPENDENT“ sampling program

If this sampling mode is selected, the sampler has to be connected to a flow meter which either

supplies an analogue signal (0/4 - 20mA) or a digital pulse.

The sample extraction is carried out according to this „flow signal“.

The programming of each of the three modes (0 -20 / 4 - 20 / digital) is very similar. Only single

menus are different (depending on the selected settings). The programming of these menus is

depending on the context and thus results from it accordingly.

The following example shows the programming of:

- Flow analogue 0 - 20mA /time-related bottle filling / max. number of samples per bottle limited.

1.1.4

**************************

PROGRAM NO. 2

TIME

INTERVAL HRS. 0:06

FILLING TIME H 2:00

**************************

1.1.5

**********************

PROGRAM NO. 2

*CHANGE

DELAYED START

START

**********************

2.2.1

**********************

PASSWORD

****

**********************

Selection of the program number:

After having pressed the ENT key, a program number (1 to 6) can

be entered.

Confirm by pressing the ENT key.

Next menu: press the „DOWN“ arrow key.

PROGRAMMING

- Press the ENT key (cursor is displayed flashing)

- Press the „UP“ arrow key twice

- Confirm with ENT

Enter the valid password (factory-set code is 6299).

Remark:

This is only required if a password has been activated in „Setup“->

„System settings“. If not, just press the ENT key and you will get

to the next menu!

If the right password has been entered, you will automatically get

to the next menu.

3.4.1

**********************

MODE

EVENT

TIME

*FLOW 0-20 mA

4.10.1

**********************

SAMPLES PER HOUR

AT 20 mA

40

**********************

The selected sampling mode is marked with a star.

If the sampling mode shall be changed, press the ENT key and

move the cursor on the sampling mode FLOW to create a flowdependent sampling program.

Confirm the input by pressing the ENT key.

If „ANALOGUE“ (0/4-20mA) has been selected, enter here how

often samples shall be extracted at a maximum analogue flow

signal.

Example: - Flow analogue 0-20 mA

- At 20 mA 40 samples/hour shall be extracted.

- If there are on an average 10 mA for a period of

1 hour, 20 samples will be extracted.

Page 25 Manual BÜHLER 2000/1029

Page 26

Operation

**********************

5.2.2

**********************

BOTTLE FILLING

*TIME-RELATED

SAMPLE-RELATED

**********************

6.2.1

**********************

FILLING TIME PER

BOTTLE

2:00H

**********************

5.2.3

**********************

NO. OF SAMPLES PER

BOTTLE LIMITED?

*YES

NO

Select whether the bottle filling shall be

1. time-dependent or

2. depend on a pre-programmed number of samples.

At TIME-RELATED bottle filling:

Enter for how long each bottle shall be filled until the distributor

changes to the next bottle.

Example:

Interval: 10 min.

Filling time/bottle: 120 min.

Bottle volume: 2,5 L

That means 12 samples are extracted in 120 min. With a bottle

volume of 2,5 L, the maximum dosing volume per sample is

calculated as follows: 2500:12 200 ml.

In addition to the entry of a bottle filling time you can also limit the

number of samples per bottle.

6.5.1

**********************

MAX. NO. OF SAMPLES

PER BOTTLE

5

**********************

5.2.5

**********************

BOTTLE VERSION

*SINGLE BOTTLE

2 x 5,0 L

2 x 10,0 L

**********************

5.2.12

**********************

REPEAT PROGRAM?

YES

*NO

**********************

Enter the maximum number of samples per bottle.

If your sampler is equipped with a distributor, select here the

distributor/bottle variant.

If the program shall only run once, select NO.

Selecting „YES“ means continuous operation (the program is

always restarted).

Remark: In that case, the program will run endlessly. So,

please make sure that the bottles are emptied

regularly according to the programming as

otherwise they will be overfilled.

Page 26 Manual BÜHLER 2000/1029

Page 27

Operation

1.1.4

**********************

PROGRAM NO. 2

FLOW ANAL. 0-20 mA

SAMP./H AT 20 mA 40

FILLING TIME 2:00

**********************

1.1.5

**********************

PROGRAM NO. 2

CHANGE

DELAYED START

*START

**********************

Each programming is completed with this menu to have the

possibility to check the program settings of the just created

program.

Program No. 2 has now been programmed with a flow-

dependent program.

To start the program, press the „DOWN“ arrow key.

The just created program can either be

• started immediately

• started with a delay or

• changed.

Page 27 Manual BÜHLER 2000/1029

Page 28

Operation

**********************

***************

*******

3. Programming of an „EVENT-PROPORTIONAL“ sampling program

If this sampling mode is selected, the sampler is waiting for an external „event“ signal, e.g. from a

connected pH-meter. A sample is extracted according to the programming as long as the signal is

present. When the signal fades, the sampler waits for the next signal and then fills the next empty

bottle. Which „event“ sample has been filled into which bottle is recorded in the info memory.

1.1.4

**********************

PROGRAM NO. 3

TIME

INTERVAL HRS 0:06

FILLING TIME H 2:00

**********************

1.1.5

**********************

PROGRAM NO. 3

*CHANGE

DELAYED START

START

2.2.1

**********************

PASSWORD

****

**********************

Selection of the program number:

After having pressed the ENT key, a program number (1 to 6) can

be entered.

Confirm by pressing the ENT key.

Next menu: press the „DOWN“ arrow key.

PROGRAMMING

- Press the ENT key (cursor is displayed flashing)

- Press the „UP“ arrow key twice

- Confirm with ENT

Enter the valid password (factory-set code is 6299).

Remark:

This is only required if a password has been activated in „Setup“->

„System settings“. If not, just press the ENT key and you will get to

the next menu!

If the right password has been entered, you will automatically get

to the next menu.

3.4.1

**********************

MODE

*EVENT

TIME

FLOW 0-20 mA

**********************

4.12.1

**********************

INTERVAL

00:10

**********************

5.2.2

**********************

BOTTLE FILLING

*TIME-RELATED

SAMPLE-RELATED

The selected sampling mode is marked with a star.

If the sampling mode shall be changed, press the ENT key and

move the cursor on the sampling mode EVENT to create an

event-related sampling program.

Confirm the input by pressing the ENT key.

Enter the sampling interval (hh:mm).

A sample is e.g. extracted every 10 minutes.

Select whether the bottle filling shall be

1. time-dependent or

2. depend on a preprogrammed number of samples.

Page 28 Manual BÜHLER 2000/1029

Page 29

Operation

**********************

**********************

6.2.1

**********************

FILLING TIME PER

BOTTLE

2:00H

**********************

6.3.1

**********************

SAMPLES PER BOTTLE

1

5.2.5

**********************

BOTTLE VERSION

*SINGLE BOTTLE

2 x 5,0 L

2 x 10,0 L

At TIME-RELATED bottle filling:

Enter for how long each bottle shall be filled until the distributor

changes to the next bottle.

Example:

Interval: 10 min.

Filling time/bottle: 120 min.

Bottle volume: 2,5 L

That means 12 samples are extracted in 120 min. With a

bottle volume of 2,5 L, the maximum dosing volume per

sample is calculated as follows:

2500:12 200 ml.

At SAMPLE-RELATED bottle filling:

Enter the maximum number of samples per bottle. As soon as the

set number of samples has been extracted, sampling into the

respective bottle is terminated.

If your sampler is equipped with a distributor, select here the

distributor/bottle variant.

5.2.12

**********************

REPEAT PROGRAM ?

YES

*NO

**********************

1.1.4

**********************

PROGRAMM NO. 3

EVENT

INTERVAL HRS 00:06

BTL CHANGE EVENT

**********************

1.1.5

**********************

PROGRAM NO. 3

CHANGE

DELAYED START

*START

**********************

If the program shall only run once, select NO.

Selecting „YES“ means continuous operation (the program is

always restarted).

Remark: In that case, the program will run endlessly. So,

please make sure that the bottles are emptied

regularly according to the programming as

otherwise they will be overfilled.

Each programming is completed with this menu to have the

possibility to check the program settings of the just created

program.

Program No. 3 has now been programmed with an event-related

program.

To start the program, press the „DOWN“ arrow key.

The just created program can either be

• started immediately

• started with a delay or

• changed.

Page 29 Manual BÜHLER 2000/1029

Page 30

Operation

**********

************

**********************

**********************

**********************

MAIN MENU (root):

Display

1.1.1

**********************

Vxxxx

1.1.2

**********************

TUESDAY

03 FEBRUARY 2009

09 H 01 MIN 44 SEC

**********************

1.1.3

**********************

OPERATING VOLTAGE

13.8 V

1.1.4

**********************

PROGRAM NO. 1

TIME

INTERVAL HRS 0:06

FILLING TIME H 2:00

**********************

Description

Information menu „Version of firmware“

Information menu „Date/Time“

Time and date are changed in menu „SETUP“.

Information menu „Operating voltage“

Display of internal operating voltage (secondary voltage of power

pack).

Information/selection menu „Program“

In this menu the desired program is selected. The program selected

at the moment and its parameters are displayed. By pressing the

ENT key, the program No. can be changed and one of the 6 user

programs can be selected. The current

program settings of each program are shown.

Remark: This menu is displayed automatically after the last

step of each programming or program change.

Thus you can check immediately whether there are

any programming faults.

**********************

**********************

1.1.5

PROGRAM NO. 1

CHANGE

DELAYED START

*START

1.1.6

MANUAL SAMPLE

EXTRACTION

PROGRAMMING

A program (No. 01-06) selected in menu 1.1.4 can be

• started immediately

• started with a delay or

• changed.

MANUAL MODE

A single sample extraction into any bottle can be triggered

manually.

Page 30 Manual BÜHLER 2000/1029

Page 31

Operation

******

****************

1.1.8

**********************

SETUP

**********************

1.1.9

**********************

MEMORY

**********************

1.1.10

**********************

SERVICE MENU

**********************

CHANGE PROGRAM

SETUP

Enter general settings like

• Date, time

• Language

• Modem

• System settings

MEMORY

Here you can display or delete stored information like:

• Info memory (sampling protocol)

• Bottle memory

• Analogue signal

SERVICE MENU

In the service menu the single components and the inputs can be

tested. However, modifications should only be carried out by

specially trained service personnel.

1.1.5

**********************

PROGRAM NO. 1

*CHANGE

DELAYED START

START

**********************

2.2.1

**********************

PASSWORD

****

**********************

3.4.1

**********************

MODE

EVENT

*TIME

FLOW ANAL. 0-20 mA

A program (No. 01-06) selected in menu 1.1.4 can be

• started immediately

• started with a delay or

• changed.

To avoid manipulations to programs, a password has to be entered

first. The factory-set password is „6299“.

Remark: This is only required if a password has been activated

in „Setup“-> „System

settings“. If not, just press the ENT key and you will

get to the next menu!

(If you enter your own password, we recommend to note it down in

the manual as otherwise there is no more access!)

TIME-related sampling

By pressing the ENT key, the time-proportional sampling mode is

selected.

Page 31 Manual BÜHLER 2000/1029

Page 32

Operation

*****

*****************

3.4.1

**********************

MODE

*EVENT

TIME

FLOW ANAL. 0-20 mA

**********************

4.12.1

**********************

INTERVAL

00:10

**********************

3.4.1

**********************

MODE

TIME

*FLOW ANAL. 0-20 mA

FLOW ANAL. 4-20 mA

**********************

4.10.1

**********************

SAMPLES PER HOUR

AT 20 mA

40

**********************

EVENT-related sampling

By pressing the ENT key, the event-related sampling mode is

selected.

Enter the sampling interval in minutes for sampling modes „TIME“

or „EVENT“.

A sample is e.g. extracted every 10 minutes.

(If you edit a time or event program, the next menu is „BOTTLE

FILLING“)

FLOW ANALOGUE

By pressing the ENT key, the sampling mode „FLOW ANALOGUE“

(analogue signal 0/4 – 20 mA) is selected.

If „ANALOGUE“ (0/4-20mA) has been selected, enter here how

often samples shall be extracted at a maximum analogue flow

signal.

Example:

- Flow analogue 0-20 mA

- At 20 mA 40 samples/hour shall be extracted.

- If there are on an average 10 mA for a period of 1 hour, 20

samples will be extracted.

3.4.1

**********************

MODE

FLOW ANAL. 0-20 mA

FLOW ANAL. 4-20 mA

*FLOW DIGITAL

**********************

4.11.1

**********************

PULSE DIVIDER

25

**********************

5.2.2

**********************

BOTTLE FILLING

*TIME RELATED

SAMPLE RELATED

FLOW DIGITAL

By pressing the ENT key, the sampling mode „FLOW DIGITAL“ is

chosen.

Enter after how many input pulses (potential-free make contacts) a

sample shall be extracted in the sampling mode flow „DIGITAL“.

Example:

At a max. flow 1000 pluses/hour are delivered.

40 samples per hour shall be extracted. Thus the pulse divider

has to be set to 25.

Select whether the bottle filling shall be time-dependent or whether

it shall depend on a pre-programmed number of samples.

Page 32 Manual BÜHLER 2000/1029

Page 33

Operation

**********************

**********************

6.2.1

**********************

FILLING TIME PER

BOTTLE

2:00H

**********************

5.2.3

**********************

NO. OF SAMPLES PER

BOTTLE LIMITED?

*YES

NO

**********************

6.5.1

**********************

MAX. NO. OF SAMPLES

PER BOTTLE

TIME-related bottle filling

Enter for how long each bottle shall be filled until the distributor

changes to the next bottle.

Example:

Interval: 10 min.

Filling time/bottle: 120 min.

Bottle volume: 2,5 L

That means 12 samples are extracted in 120 min. With a bottle

volume of 2,5 L, the max. dosing volume per sample is

calculated as follows: 2500:12 200 ml.

TIME-related bottle filling

In addition to the entry of a bottle filling time you can also limit the

number of samples per bottle.

By means of this menu point a protection against overfilling at flow-

dependent sample extractions is guaranteed.

TIME-related bottle filling

Enter the max. number of samples per bottle.

5

**********************

6.3.1

**********************

SAMPLES PER BOTTLE

1

**********************

5.2.4

**********************

FILLING TIME PER

BOTTLE LIMITED?

*YES

NO

**********************

6.6.1

**********************

MAX. FILLING TIME

PER BOTTLE

2:00H

SAMPLE-related bottle filling

If a sample-related bottle filling has been selected, enter here the

number of samples per bottle.

SAMPLE-related bottle filling

In addition to the entry of a „MAX. NO. OF SAMPLES PER

BOTTLE“, you can also limit the „FILLING TIME PER BOTTLE“.

That means, after expiration of the entered time the distributor

changes to the next bottle.

SAMPLE-related bottle filling

Enter the max. filling time per bottle.

**********************

5.2.5

Select your distributor/bottle variant.

BOTTLE VERSION

12 x 1,0 L

*12 x 2,9 L

24 x 0,4 L

Page 33 Manual BÜHLER 2000/1029

Page 34

Operation

**********************

5.2.12

**********************

REPEAT PROGRAM?

YES

*NO

**********************

START PROGRAM

1.1.5

**********************

PROGRAM NO. 1

CHANGE

DELAYED START

*START

**********************

2.3.1

**********************

DELAYED START

01.01.2009

17:15

Selecting „YES“ means continuous operation (the program is

always restarted).

Remark: In that case, the program will run endlessly. So,

please make sure that the bottles are emptied regularly

according to the programming as otherwise they will be

overfilled.

START

After having pressed the ENT key, move the flashing

cursor on „START“ and confirm again with the ENT key. The

program is started immediately.

DELAYED START

Enter date and time of the delayed program start.

After having pressed the ENT key, the display shows the delayed

start time. The program will be activated automatically at the

entered date/time.

3.3.1

**********************

PROGRAM NO. 1

START 01.01./17:28

BOTTLE 1

< PAUSE WITH ENT >

**********************

3.3.2

**********************

01.01.2009 17:28:17

NEXT SAMPLE 5:43

NEXT BOTTLE 1:59

FLOW 12.2 mA

**********************

After the program has been started successfully, the following is

shown on the display:

1. The selected program

2. Start with date and time

3. The current bottle (or at special programs also e.g. pulse counter

and number of extracted samples)

The possibility to interrupt the program with ENT (pause mode).

Remark: During an active program you can have

displayed a lot of helpful information without

disturbing the program flow or stopping the

running program. You can scroll through the

menus described in the following with the

up/down arrow keys.

If the „down“ arrow key is pressed, date and time, time of the next

sample extraction and time of the next bottle change are displayed.

In time-proportional programs: display in min.

In flow analogue programs: display in %

In flow digital programs: display in pulses.

The flow can be displayed in L/s, cbm/h or mA (to be set in the

menu SETUP).

Page 34 Manual Bühler 2000/1029

Page 35

Operation

******************

****

3.3.3

**********************

01.01.2009 17:28:17

SAMPLES TOTAL

REQUESTED: 1

TAKEN: 0

3.3.4

**********************

01.01.2009 17:28:18

SAMP. CURRENT BTL

REQUESTED: 1

TAKEN: 0

**********************

3.3.5

**********************

PROGRAM NO. 1

INFO MEMORY

*********************

3.3.6

**********************

PROGRAM NO. 1

BOTTLE MEMORY

**********************

By pressing the „down“ arrow key again, the „total“ number of taken

and requested samples of the running program is displayed.

Display of the taken and the requested samples of the current

bottle.

By pressing the ENT key, the menu „INFO MEMORY“ is displayed.

Here you can have a look at the stored messages.

By pressing the ENT key the bottle memory is displayed as follows:

- Number of the bottle

- Date and filling period (from – to)

- Total filling time

- Taken and requested samples.

With the up/down keys you can scroll to each bottle.

3.3.7

**********************

INPUT SIGNALS

FILLING LEVEL 100

FLOW ANAL. 12.2 mA

EVENT 0 / FLOW DIG 0

**********************

3.3.9

**********************

PROGRAM NO. 1

ANALOGUE FLOW

SIGNAL

**********************

3.3.10

**********************

PROGRAM NO. 1

MANUAL SAMPLE

**********************

Display of „Input Signals“:

- Filling level (state of level electrodes. The indicated value has no

dimension!)

- Flow analogue

- Event input

- Flow digital

By pressing the ENT key, the stored mA-signal is shown. The

values displayed are hourly average values.

Here you can trigger manually a single sample extraction into any

bottle (bottle No. can be selected).

Page 35 Manual Bühler 2000/1029

Page 36

Operation

**********************

**********************

**********************

4.6.1

**********************

MANUAL SAMPLE:

BOTTLE 1

**********************

3.3.11

**********************

CHANGE BOTTLE TO

BOTTLE 2

*BOTTLE 3

BOTTLE 4

**********************

4.7.1

**********************

CONTINUING WITH

BOTTLE 3

3.3.12

**********************

PROGRAM NO. 1

PROGRAM SETTINGS

After having pressed the ENT key, you can either confirm the bottle

number already displayed or enter another bottle number. If a

different bottle number is entered, the distributor will change to the

previous bottle after the sample extraction.

This sample is stored in the memory as „manual sample“.

Here you can move the distributor to another bottle.

After having pressed the ENT key, you can select the desired bottle

number with the up/down keys. Thus the program is continued with

this bottle!

This menu is displayed after having pressed the ENT key for

confirmation.

By pressing the ENT key you can have a look at the settings of the

active (running) program.

Scroll with up/down keys.

To leave the menu, press the ESC key.

3.3.13

**********************

PROGRAM NO. 1

SYSTEM SETTINGS

**********************

3.3.1

**********************

PROGRAM NO. 1

START 7.01./17:08

BOTTLE 1

< PAUSE WITH ENT >

*********************

4.1.1

**********************

PROGRAM NO. 1

PAUSE STARTED

PLEASE WAIT

By pressing the ENT key you can have a look at the system

settings.

Scroll with up/down keys.

To leave the menu, press the ESC key.

PAUSE MODE

The pause mode is activated by pressing the ENT key.

Nevertheless the program continues to run according to the

programmed cycle, however, in the background.

During interruptions/pauses you can effect cleaning or maintenance

works.

This message is displayed if the device is in a non-completed cycle

when starting the pause mode. Only after termination of the cycle,

the pause mode can be started.

Page 36 Manual Bühler 2000/1029

Page 37

Operation

**********************

**********************

4.1.2

**********************

PROGRAM NO. 1

PAUSE (29:03)

*CONTINUE PROGRAM

3.3.1

**********************

PROGRAM NO. 1

START 7.01./17:08

BOTTLE 1

< PAUSE WITH ENT >

8.0.1

**********************

PROGRAM NO. 1

ABORT

*YES

NO

**********************

Now you are in the pause mode. The display shows the still

remaining pause time. After expiration of this time, the system will

return automatically to the running program.

The pause mode can be left at any time by pressing the ENT key.

Display shown after the pause mode has been left.

PROGRAM ABORTION

By pressing the ESC key, a running program can be aborted.

However, before the program is aborted, you have to confirm again

with „YES“.

Remark: If the device is in a non completed cycle when

aborting the program, a corresponding message is

displayed. As soon as the sampling cycle is

completed (may take some time), there is an

automatic return to the main menu level.

MANUAL MODE

1.1.6

**********************

MANUAL SAMPLE

EXTRACTION

**********************

2.5.1

**********************

MANUAL SAMPLE

BOTTLE: 1

**********************

MANUAL MODE

A single sample extraction into any bottle can be triggered

manually.

After having pressed the ENT key you can either:

- select the bottle number already displayed by pressing the

ENT key again

or

- enter a new bottle number for the extraction of the manual

sample.

Page 37 Manual Bühler 2000/1029

Page 38

Operation

*****************

*****

**********************

**********************

SETUP

1.1.8

**********************

SETUP

**********************

2.8.1

**********************

DATE TIME

18.01.2009

19:45

2.8.2

**********************

LANGUAGE

FRANCAIS

*ENGLISH

DEUTSCH

2.8.3

**********************

TYPE OF MODEM

*GSM (CELLULAR)

AT-COMPATIBLE

NO MODEM

„Setup“

Enter general settings like

• date, time

• language

• modem

• system settings

Set date and time.

Select the language.

If a modem is installed, enter here the modem type. Any

At-compatible modem or GSM modem can be used.

2.8.4

**********************

SYSTEM SETTINGS

CHANGE

**********************

Here you can change the system settings.

Remark: Modifications should only be carried out by specially

trained service personnel.

Wrong adjustments can lead to malfunctions or

may even damage the apparatus!

Page 38 Manual Bühler 2000/1029

Page 39

Operation

**********************

MODEM SETTINGS

2.8.3

**********************

MODEM

*GSM (CELLULAR)

AT-COMPATIBLE

NO MODEM

**********************

3.9.5

**********************

GSM-PIN

PIN:****

REPEAT: ****

**********************

3.9.1

**********************

INITIALIZE MODEM

*START

3.9.2

**********************

DEVICE

INDENTIFICATION

Select the type of modem.

Attention: Please make sure that the baud rate setting of CPU

and modem is identical!

Enter the corresponding GSM Pin No. and repeat it once to confirm.

Remark: The PIN check only serves for authorization. The PIN

cannot be changed here.

Start the initialization of the modem by pressing the ENT key.

If the system does not recognize the modem, an „error message“ is

displayed. If this is the case, check the installation and the

configuration of the modem (see modem manual).

For identification you can enter a name for the sampler by pressing

the ENT key.

The keyboard of the control unit is used in the same way as the

keys of a portable phone:

SAMPLER 1 >

**********************

3.9.3

**********************

SENDING OF SMS

ACTIVE:

*YES

NO

**********************

4.15.1

**********************

NUMBER FOR SMS:

49174356984 >

**********************

1 = 1 2 = abc2 3 = def3

4 = ghi4 5 = jkl5 6 = mno6

7 = pqrs7 8 = tuv8 9 = wxyz9

0 = - _@ .0

Select YES if the alarm messages shall be sent via SMS.

Press the ENT key to enter the SMS number.

If you entered a wrong number, press the left key to delete.

Remark: Enter the country code without 0 or + !

Page 39 Manual Bühler 2000/1029

Page 40

Operation

**********************

**********************

**********************

**********************

**********************

4.15.2

**********************

SEND SMS IN CASE OF:

SAMPLING (MAN)

*SAMPLING (PRG)

SAMPLING (REMOTE)

**********************

4.15.3

**********************

SEND TEST SMS

*NOW

3.9.4

**********************

SENDING OF FAX

ACTIVE:

*YES

NO

**********************

4.16.1

**********************

FAX NUMBER:

By pressing the ENT key all the messages which can be sent are

shown. With the up/down keys you can scroll. Press the ENT key

once to mark and to activate a message. If the ENT key is pressed

twice the marking is deleted again.

All messages marked with a star will be sent via SMS.

To check immediately whether the system is working correctly you

can send a test SMS.

Alternatively to the SMS you have the possibility to send the

messages to a fax apparatus.

Proceed as described above (SMS)!

Enter the fax number.

If you entered a wrong number, press the left key to delete.

4974719848144 >

4.16.2

**********************

FAX REPORT

SYSTEM SETTINGS

PROGRAM REPORT

*TEST PAGE

4.16.3

**********************

SEND PROGRAM

REPORT AUTOMAT.?

YES

*NO

5.7.1

**********************

APPEND INFO MEMORY

TO PROG. REPORT?

YES

*NO

Remark: Enter the country code without 0 or + !

To check immediately whether the system is working correctly you

can send a test fax message.

In addition to the alarm messages it is also possible to send the

program report (stored program data).

Possibility to send also the contents of the information memory.

Page 40 Manual Bühler 2000/1029

Page 41

Operation

**********************

6.10.1

**********************

DELETE INFO MEMORY

AT PROGRAM START?

YES

*NO

**********************

CHANGE SYSTEM SETTINGS

2.8.4

**********************

SYSTEM SETTINGS

CHANGE

**********************

3.10.1

**********************

PASSWORD

****

Select whether the info memory shall be deleted at the program

start.

Here you can change the system settings

Remark: Modifications should only be carried out by specially

trained service personnel.

Wrong adjustments can lead to malfunctions or may

even damage the apparatus!

This section is protected by a password. The factory-set password

is 6299 (the factory always activates the

password).

The password can also be changed.

**********************

4.17.1

**********************

PRE-PURGE

PRIOR TO SAMPLING

5.0 s

**********************

4.17.2

**********************

POST-PURGE

AFTER SAMPLING

0.0 s

**********************

4.17.3

**********************

AERATION TIME

5.0 s

DEACTIVATION:

To deactivate the password enter 0000 !

Set the purging time prior to each sample extraction. This is

recommended in order to remove possible deposits in the suction

aperture.

Set the purging time after each sample extraction (if the suction

hose is laid with a continuous fall, you can leave it at 000).

This purging is recommended if the suction hose is laid horizontally

in order to blow out remaining water.

Set the aeration time: time between filling level signal and opening

of pinch-valve in order to fill the sample into the bottle.

Page 41 Manual Bühler 2000/1029

Page 42

Operation

4.17.4

**********************

MAX. SUCTION TIME

60.0 s

**********************

4.17.6

**********************

PINCH-VALVE OPEN

3.0 s

**********************

4.17.7

**********************

PINCH-VALVE PAUSE

2.0 s

**********************

Limitation of suction time. After expiration of this time, the suction

process is terminated even if no water has been drawn off, that

means that there was no signal from the level electrodes. If this is

the case, a second attempt is made. That means after expiration of

the suction time, the line is purged again and water is drawn off. If

this second attempt fails, too, the message „ERROR SUCTION“ is

displayed which is resulting in a malfunction message (utilizable

signal if an optional relay is installed).

However, the sampler continues to function even after a

malfunction message. The program is not aborted for that

reason!

Possibility to correct the return time of the valve if it does not stand

straight. This is important for the pinch-valve to close correctly

during a sample extraction.

The pinch-valve first only opens 1/3. Here you can input the time

until it opens completely.

This is recommended if distributor variants are installed, as the

biggest part of the sample drains off more slowly. Apart from that,

the sample is discharged more gently.

4.17.9

**********************

CONDUCTIVITY

300

**********************

4.17.10

**********************

PUMPING CAPACITY

50 %

**********************

4.17.11

**********************

PINCH-VALVE POWER

60 %

**********************

Adjust the sensitivity of the conductivity electrodes.

However, this value has no dimension!

Make sure that the system is neither adjusted too insensitive (leads

to a flooding) nor too sensitive (there is a permanent signal and thus

no more sample extraction).

A lower value (e.g. 200) means more sensitive or quicker response

of the electrodes.

A higher value (e.g. 300) means more insensitive or slower

response of the electrodes.

Adjust the pumping capacity in %

The adjusted pumping capacity does not influence the suction

height but only the average suction speed when drawing-off the

sample.

The lower the pumping capacity, the longer the service life of the

pump.

Adjust the pinch-valve power in %.

Modifications should only be carried out by

service personnel!

Page 42 Manual Bühler 2000/1029

Page 43

Operation

**********************

**********************

4.17.12

**********************

VALVE SYSTEM

POWER

40 %

**********************

4.17.20

**********************

PULSE DURATION

FLOW DIGITAL

50 [ms]

4.17.21

**********************

FLOW UNIT

mA

m3/h

*L/s

5.9.1

**********************

FLOW

AT 20mA

Adjust the valve system power in %.

Modifications should only be carried out by service

personnel!

Input the required pulse duration of the digital flow signal. According

to our example, the signal would have to be present for 50 ms in

order to be utilizable for the control.

Select how flow shall be displayed after the program start.

Press the ENT key to scale the flow signal (l/s or m3/h).

Enter how the flow signal (mA) shall be scaled. To do this, just enter

the flow at 20 mA in L/s or m3/h. The scaling is done automatically

within the selected range.

1 L/s

**********************

EXTENDED PROGRAM SETTINGS

4.17.22

**********************

EXTENDED PROGRAM

SETTINGS ACTIVE

YES

*NO

**********************

4.17.23

**********************

PRG. SAMPLING DELAY

RANDOM TIME

*FIXED TIME

NONE

**********************

EXTENDED PROGRAM SETTINGS

The extended program settings offer a more extensive

programming.

The description of the individual functions can be found in appendix

-A-.

By selecting YES, the extended program functions are

activated and thus displayed and can be selected when

programming.

We recommend an activation only if really required as the structure

will get very complex!

Possibility to delay each sample extraction by the time entered.

• Fixed time: The sample extraction will always be

• Random time: If you enter e.g. 10 min., the sample

delayed by e.g. 5 min.

extraction will be delayed at random within

the range of 0 to 10 min.

Page 43 Manual Bühler 2000/1029

Page 44

Operation

**********************

**********************

****

******************

4.17.24

**********************

CALIBRATION OF

ANALOGUE SIGNAL

5.11.1

**********************

NON-CALIB. V 12.207

CALIB. VAL. 12.207

FACTOR: 1.0000

ENT=OK ESC=ABORT

**********************

4.17.25

**********************

INFO MEMORY

INFORMATION

SETTINGS

*RECORDING

CALIBRATION OF ANALOGUE SIGNAL

To display the calibration menu, press the ENT key.

Here you can calibrate the analogue signal by means of a reference

signal.

Use the arrow keys to set the values:

• up/down = rough adjustment (steps with 10)

• left/right = fine adjustment (steps with 1).

The „calibrated“ value is set immediately.

Press 0 to reset to factor 1.0000.

Confirm the values by pressing the ENT key!

Enter which data and how it shall be registered in the info memory.

5.14.1

**********************

RECORD:

*SAMPLING (MAN)

SAMPLING (PRG)

*SAMPLING (REMOTE)

**********************

5.13.1

**********************

DELETE INFO MEMORY

AT PROGRAM START?

YES

*NO

**********************

5.12.1

**********************

INFO MEMORY

SIZE: 1100

ENTRIES: 26

**********************

4.17.27

**********************

DIGITAL OUTPUTS

*OUTPUT 1

OUTPUT 2

OUTPUT 3

Info memory - Recording

By pressing the ENT key, a list of all possible messages is