Page 1

Operating instructions

Water sampler

BÜHLER

BU 4010/3010//4210/4410/6010

DOC028.52.90409_BÜHLER_April12.doc

Page 2

Remarks

HACH LANGE GmbH is not liable for possible f aults in this documentation. Any liability for direct or

consequential damages in connection with the delivery or the use of this device is excluded as far as it

is legal.

All rights, especially the rights for duplication, distribution and/or translation, are reserved to HACH

LANGE GmbH. Any reproduction, use or duplication of this manual, also in extracts, is prohibited by

law without the previous written agreement of HACH LANGE GmbH.

Subject to changes!

Access code for programming, system settings, key lock

Password:

Your password:

6299

Copyright by HACH LANGE GmbH © 1998 – 2012

Page 3

General Information

Table of contents

Table of contents ................................................................................................................................ 3

General information ............................................................................................................................. 4

Safety remarks ..................................................................................................................................... 4

Before putting into service ................................................................................................................... 4

Permissible application ........................................................................................................................ 4

Permissible operating and ambient conditions .................................................................................... 4

Redelivery for repair............................................................................................................................. 5

Use of Hazard Information ................................................................................................................... 6

Precautionary labels ............................................................................................................................ 6

Characteristics: sampler 4010 ........................................................................................................... 11

Characteristics: sampler 4210 ........................................................................................................... 12

Characteristics: sampler 4410 ........................................................................................................... 13

Characteristics: sampler 6010 ........................................................................................................... 14

Characteristics: sampler 3010 ........................................................................................................... 16

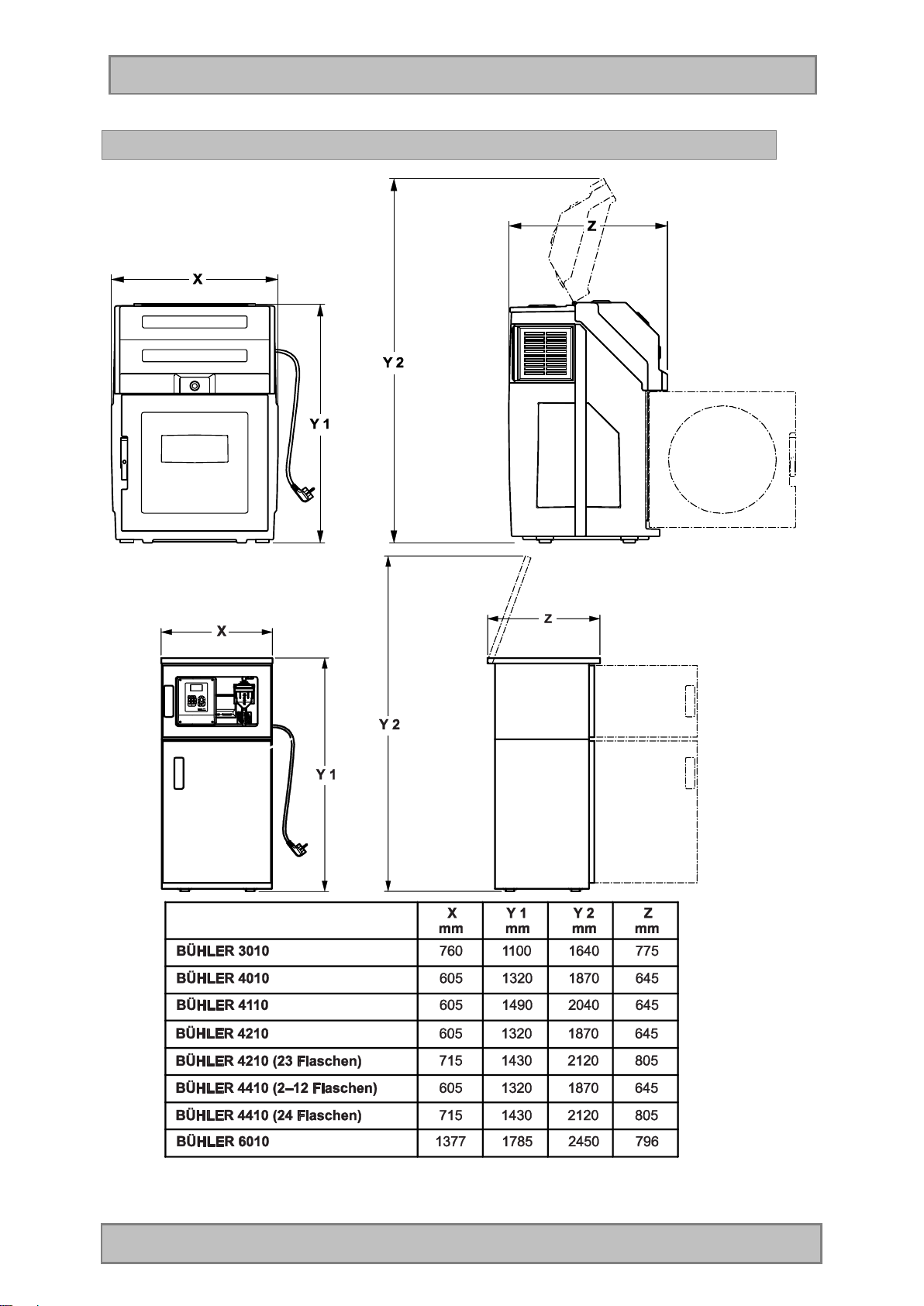

Dimensions of devices Bühler 4010, 4210, 4410 depending on the bottle variant (see technical

specifications) .................................................................................................................................... 17

Dimensions of devices Bühler 4010, 4210 depending on the bottle variant (see technical

specifications) .................................................................................................................................... 18

Dimensions of device Bühler 4410 depending on the bottle variant ................................................. 19

(see technical specifications) ............................................................................................................. 19

Dimensions of device Bühler 3010, depending on the bottle variant (see technical specifications) . 20

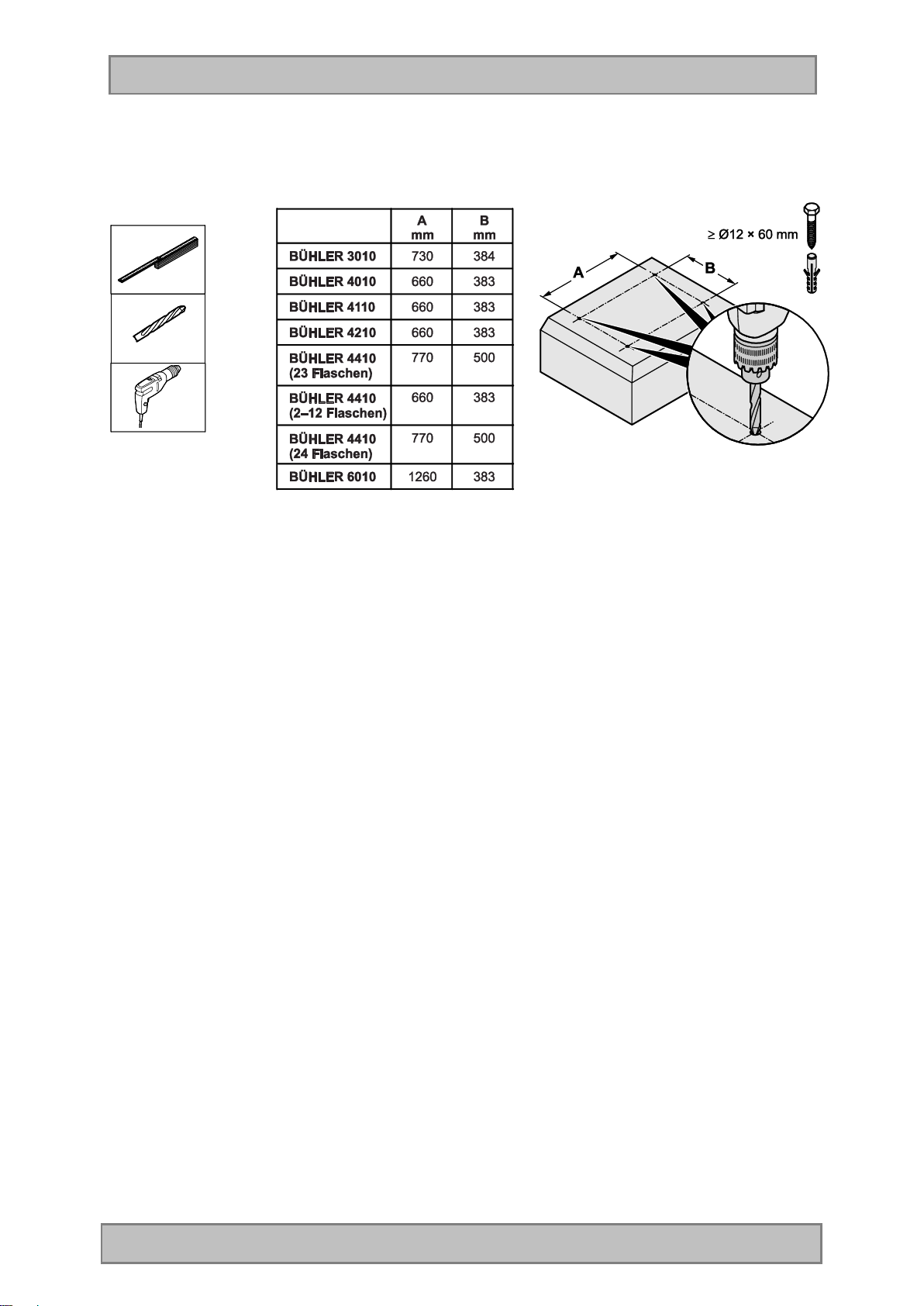

Installing the apparatus ...................................................................................................................... 21

Troubleshooting ................................................................................................................................. 23

Connections ....................................................................................................................................... 24

Terminal assignment – input signals ................................................................................................. 24

Sampling modes ................................................................................................................................ 25

Troubleshooting – vacuum sampling system .................................................................................... 30

Flow-proportional sampling system ................................................................................................... 31

Troubleshooting – flow-proportional sampling system ...................................................................... 33

Bypass sampling system ................................................................................................................... 34

Troubleshooting – bypass sampling system ...................................................................................... 35

Sample distribution at Bühler 4010/3010//6010 ................................................................................. 36

Troubleshooting – distributor 4010/3010//6010 ................................................................................. 37

Sample distribution at Bühler 4210 .................................................................................................... 37

Sample distribution at Bühler 4410 – variants: 12 / 24 bottles .......................................................... 38

Sample distribution at Bühler 4410 – variants: 2 / 4 bottles .............................................................. 40

Troubleshooting – distributor Bühler 4410 ......................................................................................... 41

Programming ..................................................................................................................................... 42

Maintenance ...................................................................................................................................... 45

Spare parts / accessories BÜHLER 3010, 4010, ............................................................................. 49

Spare parts sample distribution BÜHLER 3010, 4010 ...................................................................... 49

Circuit diagram terminal connections................................................................................................. 54

Warranty and liability.......................................................................................................................... 55

Contact ............................................................................................................................................... 56

Page 3 Manual BÜHLER BU4010ff

Page 4

General Information

General information

We are glad that you have chosen this product.

When developing this device, we combined approved technique with innovative detail solutions.

Greatest importance has also been attached to the design of an apparatus which provides easy

access for connection and maintenance works.

Safety remarks

Disconnect the mains power connections bef ore carrying out any connection, maintenance or

repair works.

Before putting into service

- Please read these operating instructions and special remarks thoroughly before putting the

device into service.

- Familiarize yourself with the safety and operating requirements in order to safeguard

personnel and equipment.

- The apparatus has been subjected to exhaustive quality inspections before dispatch.

- Any service and maintenance works required may only be carried out by trained service

personnel.

- Observe the local safety regulations and the rules for prevention of accidents.

- Observe the rules concerning the handling of hazardous substances.

- Do only use original spare parts or spare parts authorised by the manufacturer.

- No liability or claims under guarantee will be accepted in respect of any modifications or

conversions of the apparatus, other than those carried out by us or by persons authorised by

us or for which we have given express permission (in a written form)! This also refers to any

damage due to incorrect operation and/or improper use of the equipment.

Permissible application

The permissible application of the water sampler consists in the extraction of liquid, aqueous

substances, temperature range 0°C to 40°C. T he device must only be installed in areas free from

explosion hazard and must only be used for sampling of non-explosive substances. Please refer to

the technical specifications in chapter “Specifications”. Other applications are not allowed!

Permissible operating and ambient conditions

- Sample extraction of liquid aqueous substances, temperature range: 0°C to 40°C.

- The sampler is designed for operation in non-hazardous areas (no explosion risk).

- The sampler can be operated at ambient temperatures from -20°C to +43°C.

- Sampling from pressurised lines is not possible without optional accessories.

- The device is weather-proof and suitable for outside operation.

Page 4 Manual BÜHLER BU4010ff

Page 5

General Information

Redelivery for repair

Before returning any appliances to us, please pay attention to the following to avoid unnecessary cost

and repair delays:

- Redeliveries only after agreement by the supplier

- All appliances or parts returned to us for repair must be cleaned and free of any hazardous

substances whatsoever (acids, alkaline solutions, solvents, etc.) as in Germany official

regulations regarding waste stipulate that persons in possession of hazardous waste are

responsible for its disposal and that, at the same time, employers are responsible for

protecting their employees against hazardous materials.

- Any cleaning or disposal required to be carried out by us will be charged for accordingly.

All packing materials can be disposed of as usual.

Packing materials are: cardboard, wood, PS and PE.

If the packing is returned free of cost, we will take care of its disposal.

Page 5 Manual BÜHLER BU4010ff

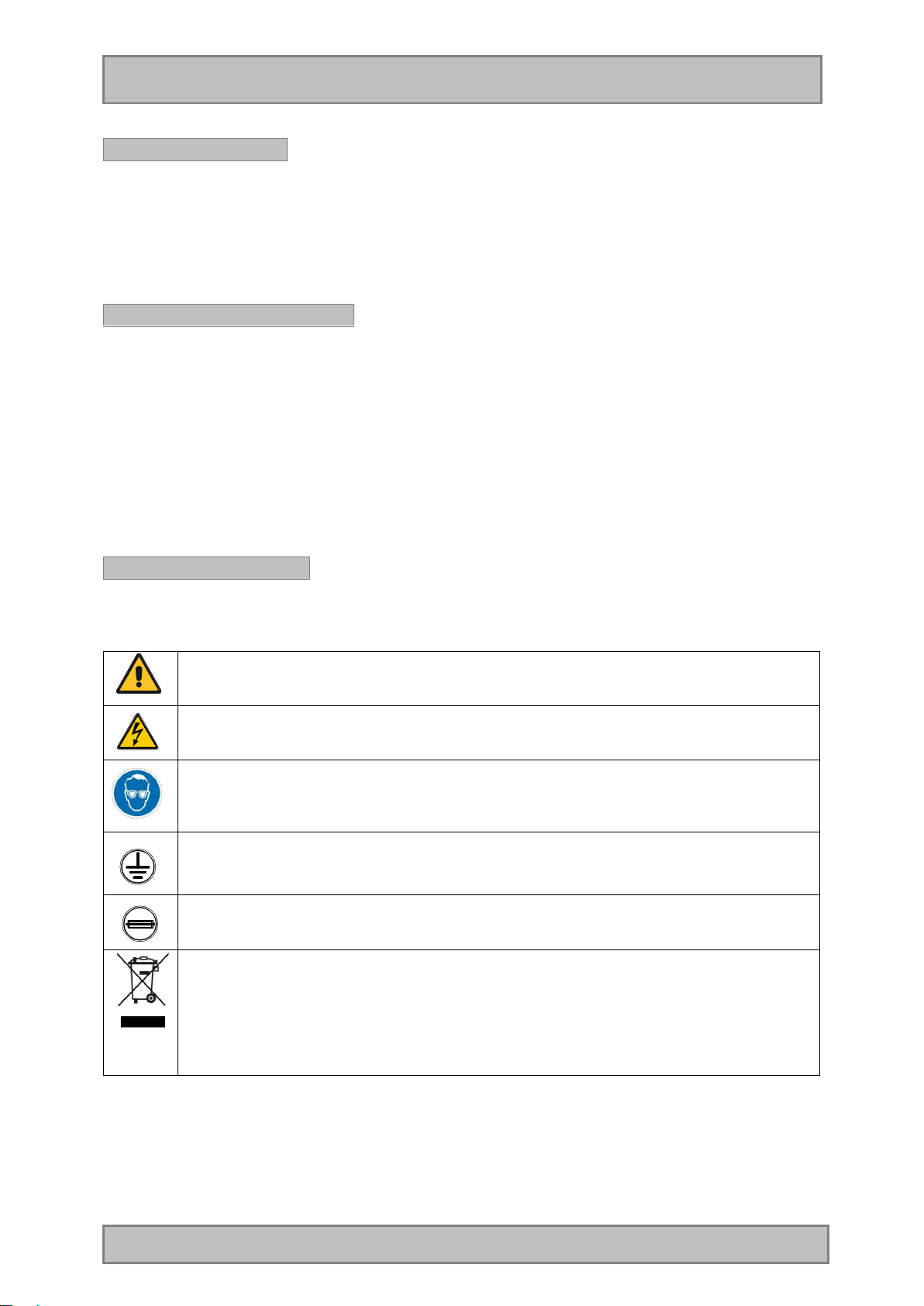

Page 6

General Information

Safety information

Please read this entire manual before unpacking, setting up

or operating this equipment. Pay attention to all danger and

caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is

not impaired, do not use or install this equipment in any

manner other than that specified in this manual.

Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or ser ious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

Important Note: Information that requires special

emphasis.

Note: Information that supplements points in the main text.

Precautionary labels

Read all labels and tags attached to the instrument.

Personal injury or damage to the instrument could occur if

not observed.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of

electrical shock and/or electrocution exists.

This symbol, when noted on the product, identifies the location of the connection for

This symbol, if noted on the product, indicates the need for protective eye wear.

Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a fuse or current

limiting device.

Electrical equipment marked with this symbol may not be disposed of in European public

disposal systems after 12 August 2005. In conformity with European local and national

regulations (EU Directive 2002/96/EC), European electrical equipment users must now

return old or end-of life equipment to the Producer for disposal at no charge to the user.

Note: For all electrical products (marked or unmarked) which are supplied or produced

Page 6 Manual BÜHLER BU4010ff

by Hach-Lange, please contact the local Hach-Lange sales office for instructions for

proper disposal.

Page 7

Installation

4010

Device designation

Housing Stainless steel with 40 mm insulation,

(material 1.4301/ SS304) / PS / PC (GF10)

Option:

(material 1.4571/ SS316Ti; SS304 EPOXY-coated;

SS316Ti EPOXY-coated)

Thermostatic control Self-contained cooling / heating with 4 settings, no-frost.

Temperature in sample compartment: 4°C (setting range: 0,0-9,9°C)

Control Microprocessor control, foil keyboard, graphical display (128*64 Pixel),

back lit

Data memory Non-volatile data memory: storage of sampling and malfunction data

like sample extractions, bottle changes, messages, external signals

Programming 12 user programs (can be edited freely)

Program start options Immediately, at a certain time, by an external signal

Program stop options End of sampling program after one program run, continuous operation

or x-runs

Pause mode Interruption of program at any time

Overfilling protection Adjustable from 1–999 samples/bottle

Interval setting 1 min. to 99 h 59 min. in steps of 1 minute

Pulse setting 1 to 9999 pulses/sample

Manual sample extraction Possible at any time without interrupting the current program run

Program protection Up to 5 years after voltage loss

Interface Mini-USB, RS422/485, RS 232

Communication Optional: TCP/IP RJ45 WEB board, 4-32GB SD/SDHC memorycard

Optional: Modbus or DP PROFIBUS connection

Languages Multi-language, selectable

Signal inputs • 2x analogue: 0/4-20 mA,

• 8x digital (flow, event, 1x free programmable)

Optional: expansion 4x digital, 3 free programmable and

8x Analogue Inputs 0-20mA / 0-10 V

Pulse-length min. 60 ms u. switch-level 7-24V, max. working

restistance 500 Ohm, signal-length max. 30 m

Signal outputs / status

messages

Sampling method -Vacuum system 20-350 ml, plastic vessel

Single sample volume

accuracy

Suction height Max. 8 m (at 1013 hPa and stagnant medium)

Pumping speed >0,5 m/s at a suction height up to at least 7,8 m (at 1013 hPa); pump

Suction hose PVC, L=7,5 m, ID=12 mm (ID 16 mm at flow-proportional option)

Sampling modes Time-related, flow-dependent, flow-proportional (option), event-related,

Bottle variants Plastic

Overall dimensions (Hxwxd)

Max. 8 digital outputs, 1x collective message

Optional: expansion 8x digital, 5 are free programmable

-Vacuum system 20-500 ml, optional

-Vacuum flow-proportional 5-350 ml, optional

-Bypass system 20-250 ml optional

< 2,8 % at standard vacuum system

capacity can be adjusted electronically.

Max. hose length 30 m

manual sample extraction

1 x 25 L, 1 x 50 L, 2 x 10 L

4 x 6,0 L, 4 x 10 L, 4 x 14 L, 4 x 20 L, 4 x 25 L

12 x 2,9 L, 24 x 1,0 L, 24 x 2,9 L

Glass

12 x 2,0 L, 24 x 1,0 L, 24 x 2 L

1.290 (1.890*)x 690 x 645 mm

for bottle variants: 1x25 L, 1x50 L, 2x10 L, 2x22 L, 4x6 L, 4x10 L,

4x14 L, 12x2 L, 12x2,9 L, 24x1 L

1400 (2015*) x 930 x 850 mm

for bottle variants: 4x20 L, 4x25 L, 24x2,9 L, 24x2 L, 36x1 L

Page 7 Manual BÜHLER BU4010ff

Page 8

Installation

Device designatio

n 4210

Device designation

4410

*) with opened top

Weight 100 kg with composite container; higher weight when using several

bottles and/or glass bottles

Power supply 230 V 50Hz

optional 115 V 50/60Hz

Power requirement Approx. 350 VA (with cooling)

Ambient temperature -20 - +43°C

Sample temperature 0 – 40°C

Standards Device meets ISO 5667 standard

Wetted materials PVC, Silicone, PS, PE, EPDM (optional: glass (Duran50) metering

vessel, sinker weight SS304)

(like 4010, with the following modifications)

Device type Fixed site sampler for sampling of faecal matter

Rinsing water inlet

Rinsing water outlet

Sampling method Vacuum system 20-500 ml

Sampling modes Time-related, flow-dependent, event-related, manual sample extraction

Bottle variants Plastic

Sample distribution Direct distribution with additional position for rinsing water. When using

Overall dimensions 1.290 (1.890*) x 690 x 645 mm

Weight 105 kg with composite container; higher weight when using several

Union nut R 3/4" (max. 2 bar)

Hose connector 25 mm

1 x 25 L, 4 x 14 L, 4 x 20 L

12 x 1 L, 23 x 1,0 L

Glass

12 x 1,0 L, 23 x 1,0 L

the rinsing function, the customer has to make sure that the rinsing

water can drain off freely

for bottle variants: 1x25 L, 4x14 L, 12x1 L

1400 (2015*) x 930 x 850 mm

for bottle variants: 4x20 L, 23x1 L

*) with opened top

bottles and/or glass bottles

(like 4010, with the following modifications)

Device type Self-emptying fixed site sampler for continuous operation without the

need of personnel (monitoring applications)

Emptying/rinsing Bottles are emptied, rinsed and re-filled on the same bottle position.

The rinsing head is installed above the bottle.

Bottle emptying for sample

collection

Hose inlet Hose connection at dosing unit (top)

Hose outlet Hose connection at dosing unit

Rinsing water inlet Union nut R 3/4" (max. 2 bar)

Rinsing water outlet Union nut R 1 1/4". When using the rinsing function, the customer has

Bottle variants Plastic

Overall dimensions (Hxwxd)

According to the device version: manual bottle emptying at 12 and 24-

bottle version or menu-driven emptying at 2 and 4-bottle version

Union nut R 3/4", hose ID 12 mm

Silicone hose 12x2, is only slipped over

to make sure that the rinsing water can drain off freely

2 x 10 L, 4 x 5 L, 4 x 10 L, 24 x 2 L (PPH)

Glass

12 x 1,6 L, 24 x 1,0 L, 24 x 2 L

• 1.290 (1930*) x 690 x 645 mm

Page 8 Manual BÜHLER BU4010ff

Page 9

Installation

Device designation

6010

double

-

housing

Device designation

3010

for bottle variants: 2 x 10 L, 4 x 5 L, 12 x 1,6 L

• 1400 (2175*) x 800 x 850 mm

for bottle variants: 4 x 10 L, 24 x 1 L, 24 x 2 L

*) with opened top

Weight 115 kg with bottle option 2x10 L PE; higher weight when using other

bottle or glass bottle options

(like 4010, with the following modifications)

Device type

Measuring pot inlet Hose nozzle ½“, hose ID 12 mm

Measuring pot outlet Hose nozzle ID 40 mm. The customer has to make sure that the water

Bottle variants Plastic

Overall dimensions (Hxwxd)

Weight Approx. 250 kg with composite container; higher weight when using

Power requirement Approx. 450 VA (with cooling + SC1000 controller), higher requirement

Device type Compact device in plastic housing, especially suitable for high ambient

Suction height Max. 7,5 m (at 1013 hPa and stagnant medium)

Pumping speed >0,5 m/s at suction height up to at least 6 m (at 1013h Pa); pump

Suction hose PVC, L=7,5 m, ID=10 mm (ID 16 mm at flow-proportional option).

Bottle variants Plastic

Sampling method Vacuum system 20-350 ml with plastic metering vessel

Ambient temperature -20°C to + 50°C (tropicalised)

Overall dimensions (Hxwxd)

Weight Approx. 70 kg with composite container, higher weight when using

Fixed site sampler in

in the measuring pot can drain off freely

1 x 25 L, 1 x 50 L, 2 x 10 L

4 x 6,0 L, 4 x 10 L, 4 x 14 L,

12 x 2,9 L, 24 x 1,0 L

Glass

12 x 2,0 L, 24 x 1,0 L

1.690 (2290*) x 1280 x 645 mm

*) with opened top

several bottles and/or glass bottles

when using the optional spiral pump

(like 4010, with the following modifications)

temperatures. Material: PE with 50 mm insulation / Styrosun / PC

(GF10)

capacity can be adjusted electronically

Max. hose length 30 m

1 x 25 L, 4 x 14 L, 12 x 2,9 L, 24 x 1,0 L

Glass

12 x 2,0 L, 24 x 1,0 L

1.100 (1.640*) x 760 x 745 mm

*) with opened top

several bottles and/or glass bottles

(measuring station)

Page 9 Manual BÜHLER BU4010ff

Page 10

Installation

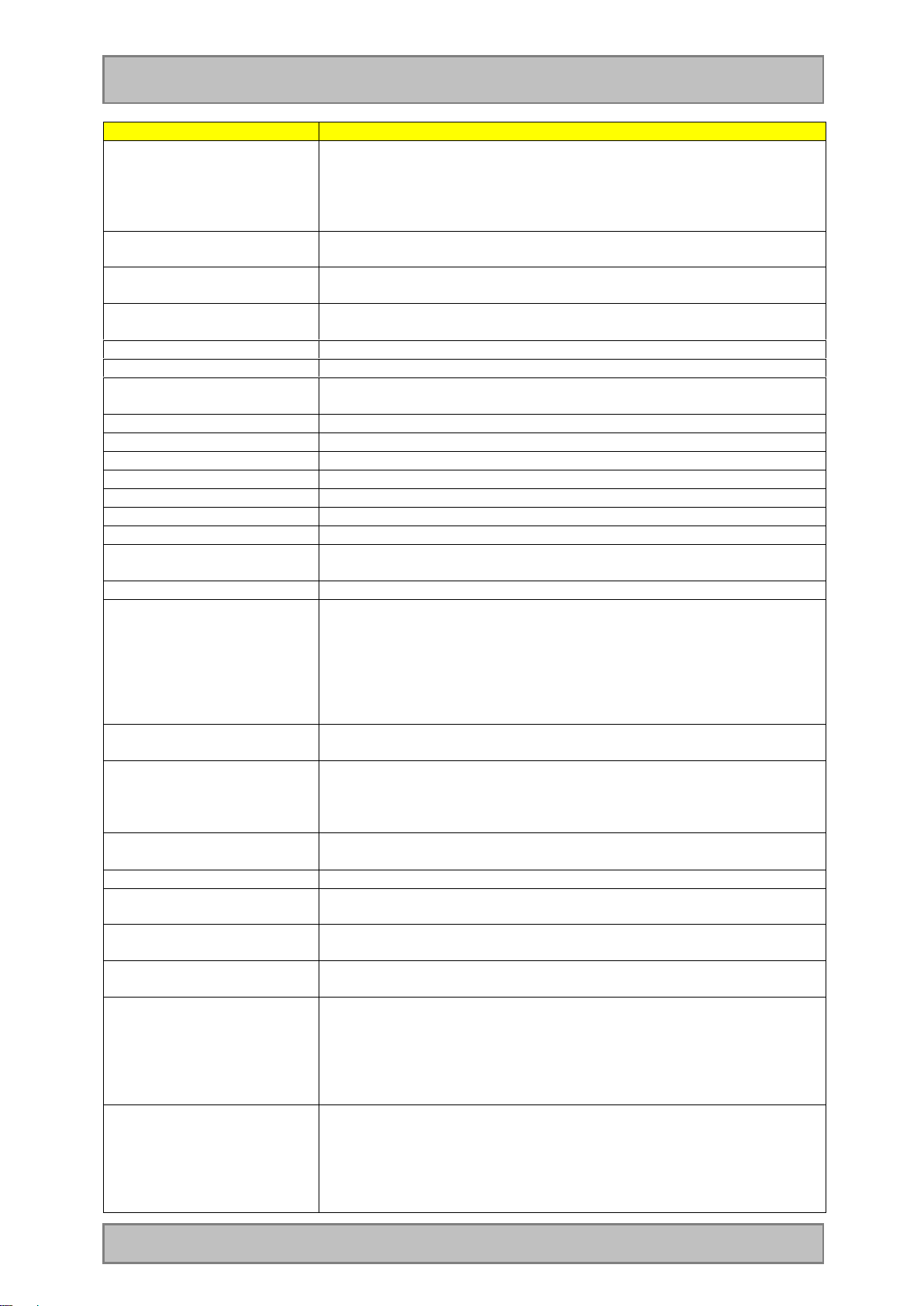

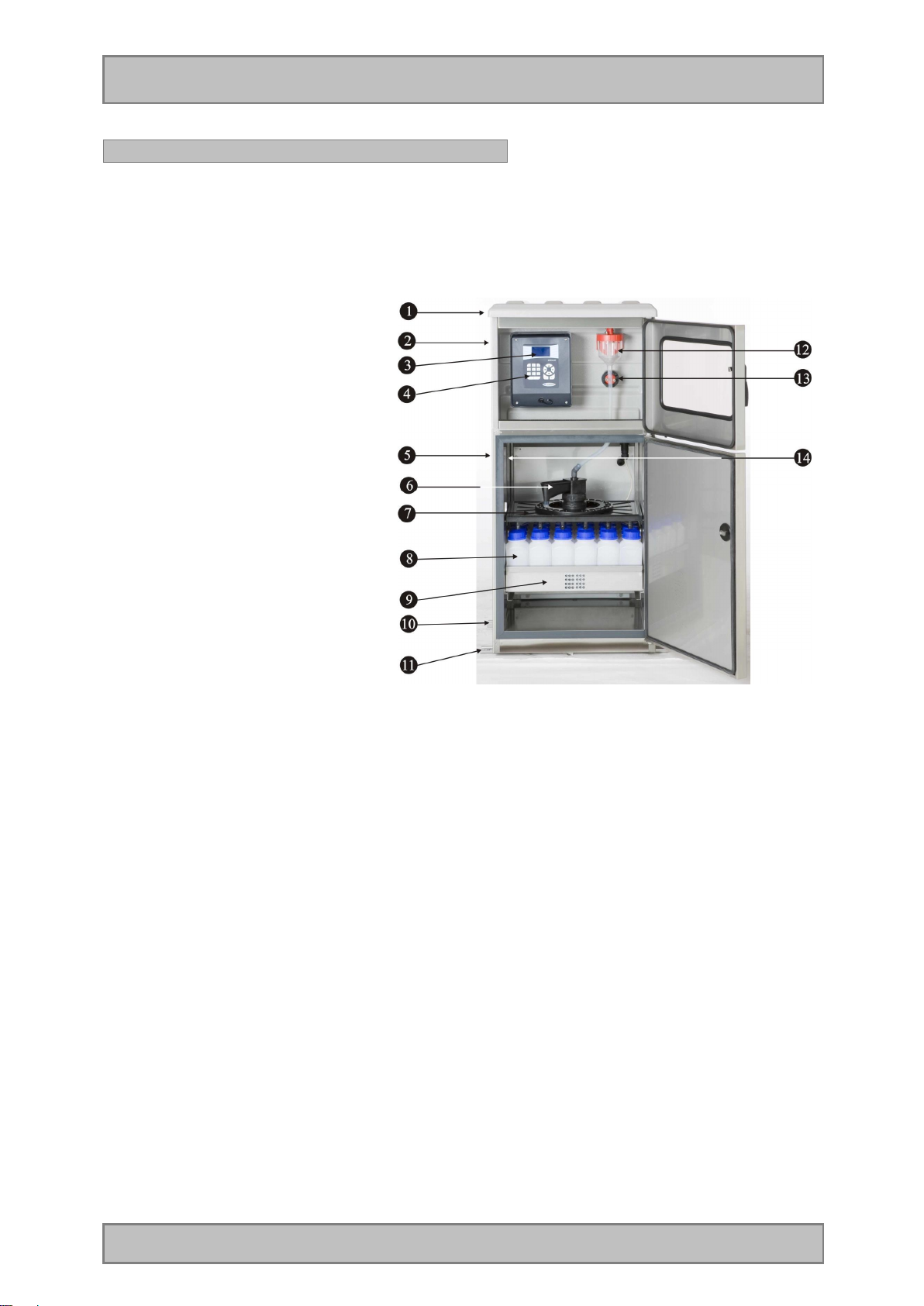

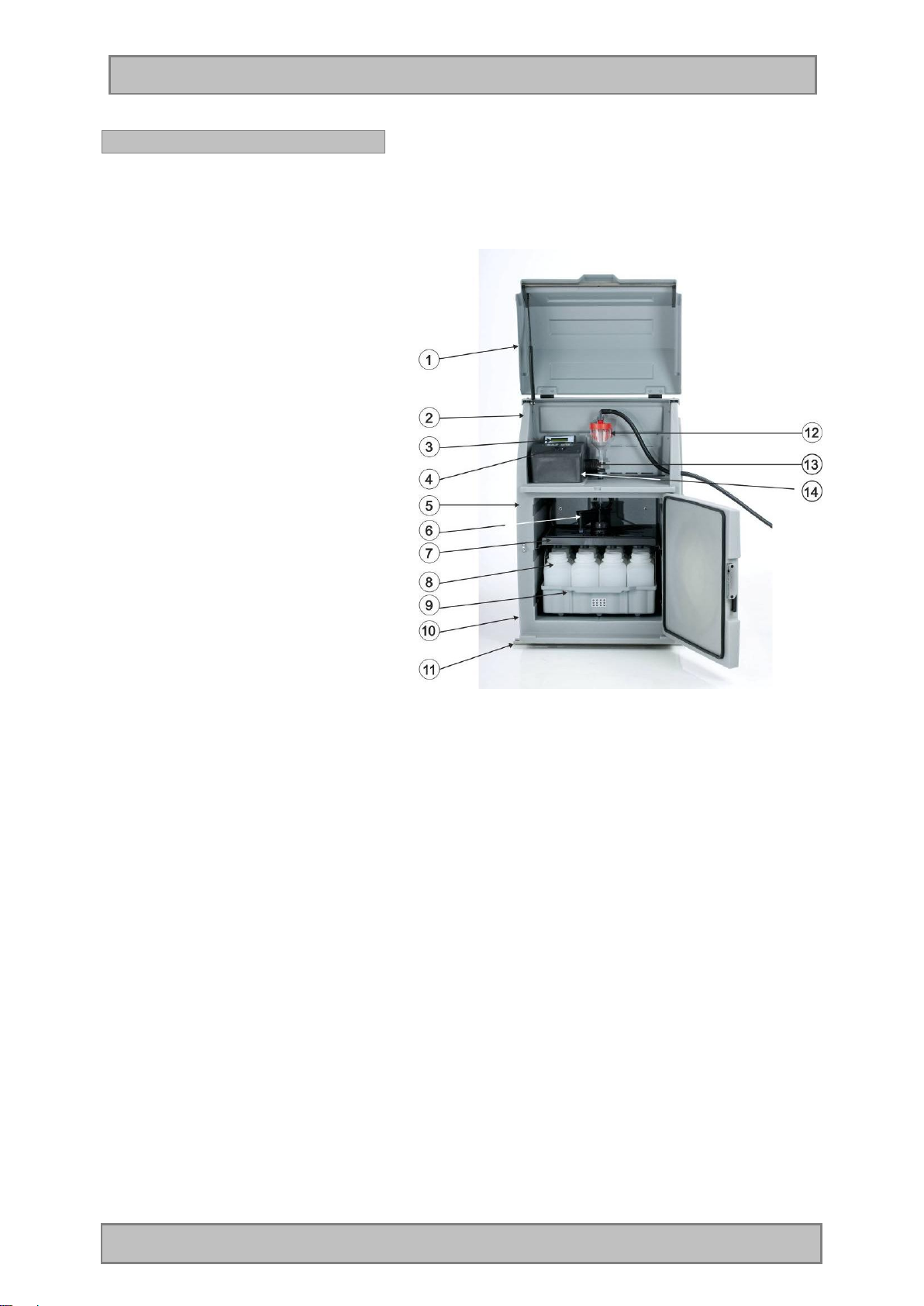

Characteristics: sampler 4010

The device consists of the following component parts:

1. Protective top (can be opened)

2. Upper part of housing

3. Back lit LC-display

4. Keyboard

5. Lower part of housing (cooled

sample compartment)

6. Motor-driven distributor

7. Distributor plate

8. Sample bottles

9. Carrying tray for bottles

10. Fixing bar

11. Fixing bar

12. Dosing unit

13. Pinch valve

14. Type plate

Remark: The illustrated sampler corresponds to a standard version with 12 bottles and

distributor plate.

According to the sampler version, some components such as dosing unit or

distributor/bottles can be different!

Remark: Please read the entire manual before unpacking, installing and operating this device.

Observe all danger and safety regulations. Non-observance can lead to serious

personal injury or to damage to the instrument.

DANGER The workings described in this chapter of the manual must only be carried our by

qualified personnel.

Page 10 Manual BÜHLER BU4010ff

Page 11

Installation

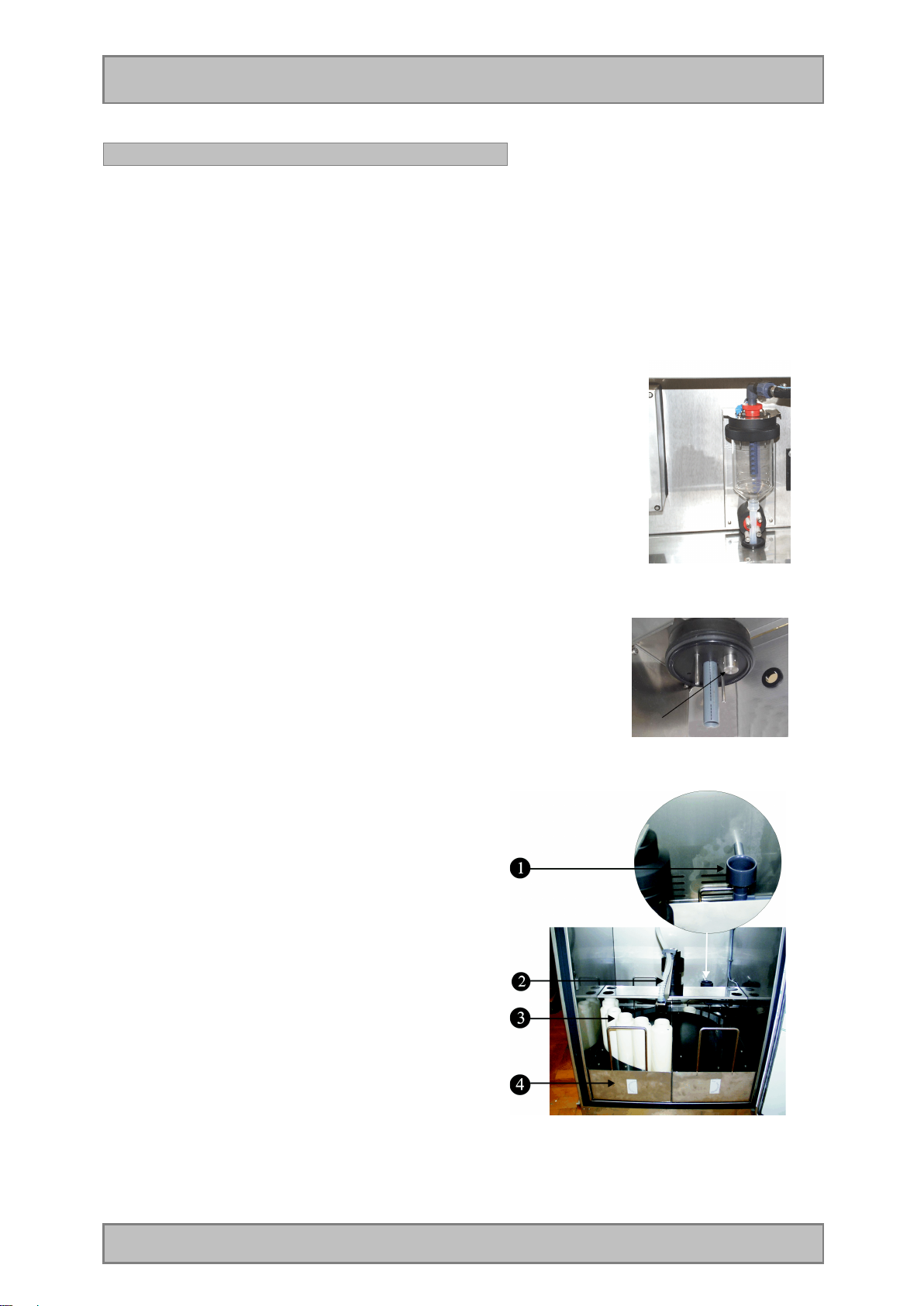

Characteristics: sampler 4210

Compared to the standard samplers, the special sampler for sampling of faecal matter is equipped

with a rinsing unit in the metering vessel and an additional outlet. Furthermore the sample is filled

directly into the bottles. The section from the metering vessel to the distributor outlet is rinsed.

Method of operation: The metering vessel is rinsed automatically after each sample extraction.

To do this, the distributor arm first moves on the discharge position and

then back on the bottle. Thus a sample contamination is avoided.

The picture shows the metering vessel with additional rinsing water

connection.

The rinsing head (arrow) can be seen after having removed the

metering vessel.

The picture shows the distributor unit:

1. Detailed view of discharge position when rinsing.

2. Distributor arm with direct dosing.

3. Sample bottles.

4. Bottle carrying tray.

Page 11 Manual BÜHLER BU4010ff

Page 12

Operation

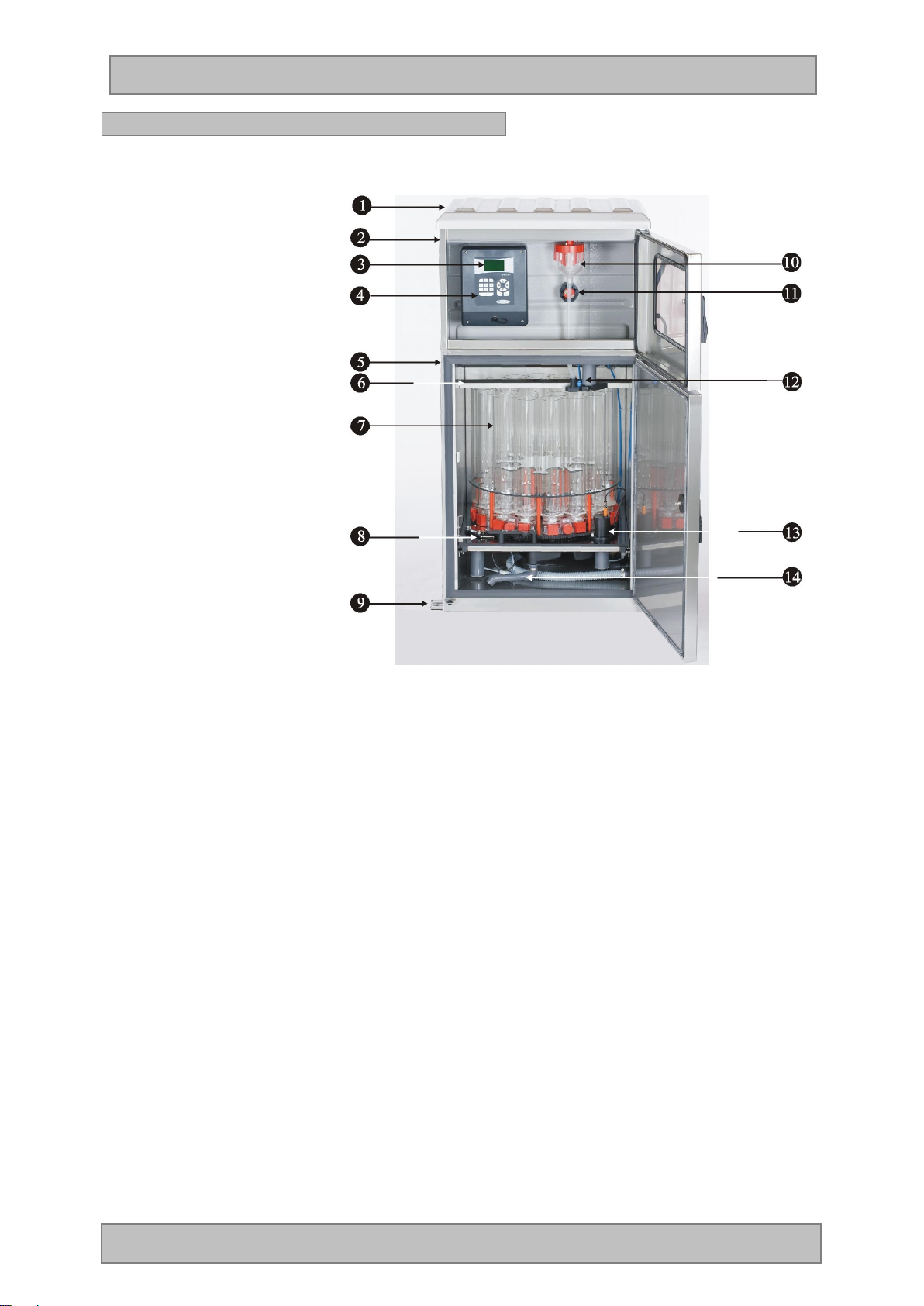

Characteristics: sampler 4410

1. Protective top (can be

opened)

2. Upper part of housing

3. Back lit LC-display

4. Keyboard

5. Lower part of housing

(cooled sample compart ment)

6. Type plate

7. Glass sample bottles

8. Distributor drive

9. Fixing bar

10. Dosing unit

11. Pinch valve

12. Combined dosing and

rinsing head

13. Automatic discharge valve

14. Swivelling sample discharge tube

Remark: The illustrated sampler corresponds to a standard version with 24 bottles.

According to the sampler version, some components such as dosing unit or

distributor/bottles can be different!

Page 12 Manual BÜHLER BU4010ff

Page 13

Operation

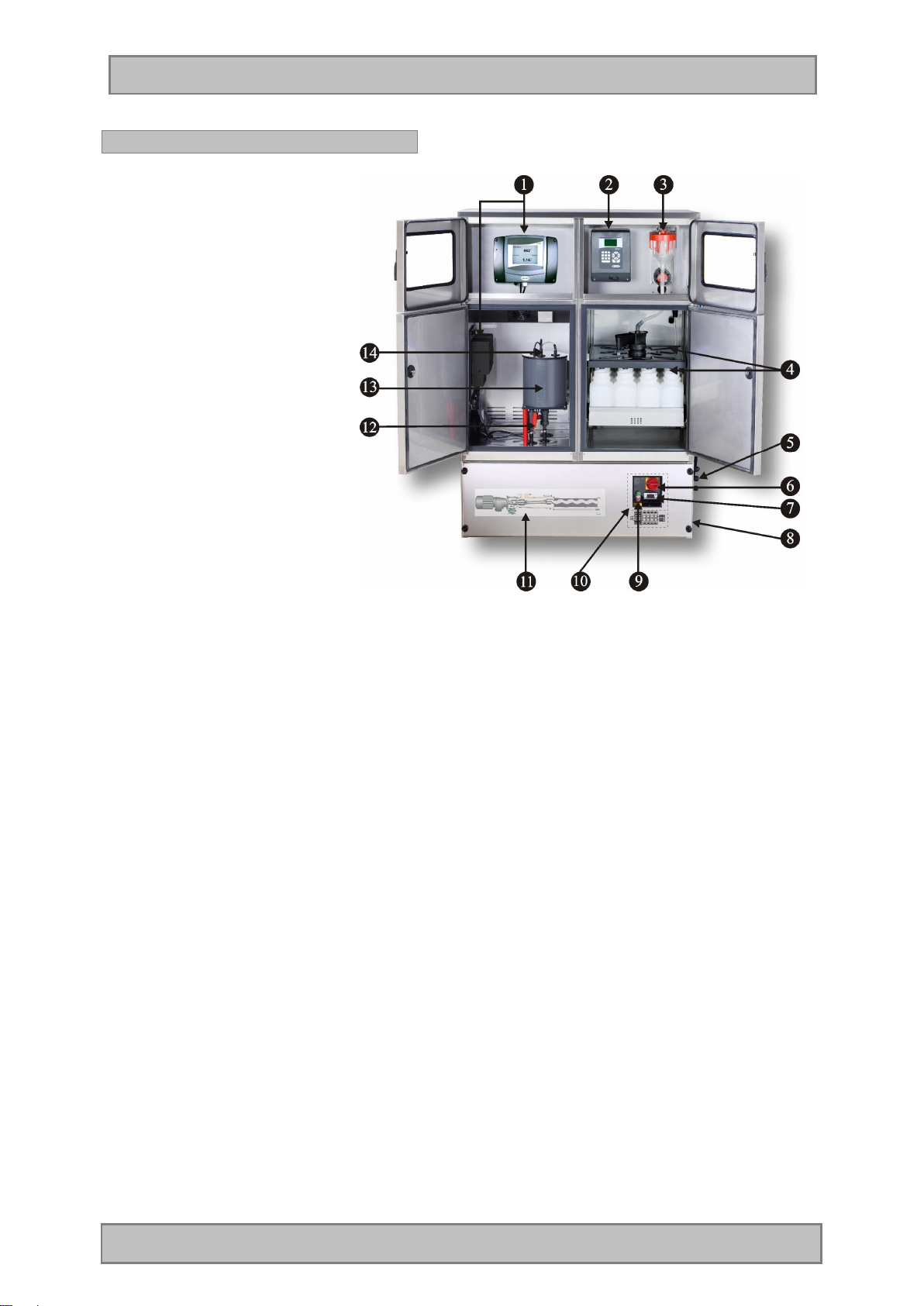

Characteristics: sampler 6010

1. Measuring unit with

transducers and display

2. Control

3. Dosing unit

4. Distributor

5. Cable feed through

(opt.: left side)

6. Main switch

7. Display of protection

against dry running

8. Water inlet and outlet

connection (opt.: left side)

9. Pump switch I/O

10. Terminal box

11. Pump (eccentric spiral

pump)

12. Water inlet and outlet of

measuring pot

13. Measuring pot

14. Fixture of electrodes/

measuring probes

Page 13 Manual BÜHLER BU4010ff

Page 14

Operation

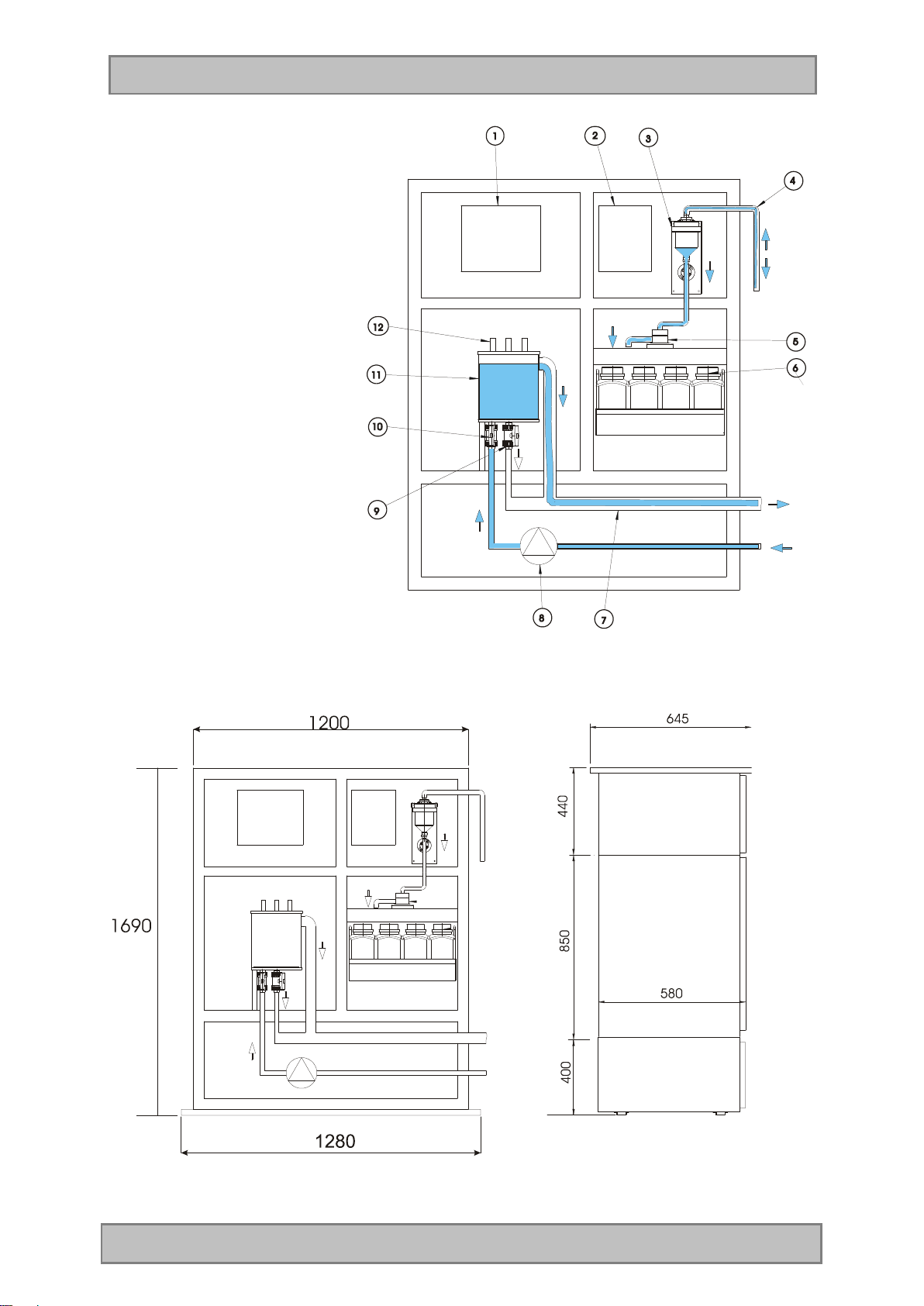

Schematic illustration

Water supply / water drain

1. Measuring transducer with

display

2. Sampler control

3. Dosing system

4. Feed tube of dosing system

5. Distributor

6. Bottles with tray

7. Measuring pot drain pipe

8. Pump (e.g. eccentric spiral

pump)

9. Outlet valve (manual/

automatic) for cleaning of

measuring pot

10. Supply valve for measuring

pot

11. Measuring pot with pressureless

overflow

12. Fixture of electrodes/

measuring probes

Overall dimensions: 1690 x 1280 x 645 mm (hxwxd)

Page 14 Manual BÜHLER BU4010ff

Page 15

Operation

Characteristics: sampler 3010

1. Protective top (can be opened)

2. Upper par t of housing

3. Back-lit LC-display with

keyboard

4. MiniUSB interface

5. Lower part of housing (cooled

compartment)

6. Motor-driven distributor

7. Distributor plate

8. Sample bottles

9. Bottle tray

10. Fixing bar

(illus. with option: mobile version)

11. Fixing bar

12. Dosing unit

13. Pinch valve

14. Type plate

Remark: The illustrated sampler corresponds to a standard version with 12 bottles and

distributor plate.

According to the sampler version, some components such as dosing unit or

distributor/bottles can be different!

Page 15 Manual BÜHLER BU4010ff

Page 16

Operation

Dimensions of devices

Page 16 Manual BÜHLER BU4010ff

Page 17

Operation

Page 17 Manual BÜHLER BU4010ff

Page 18

Operation

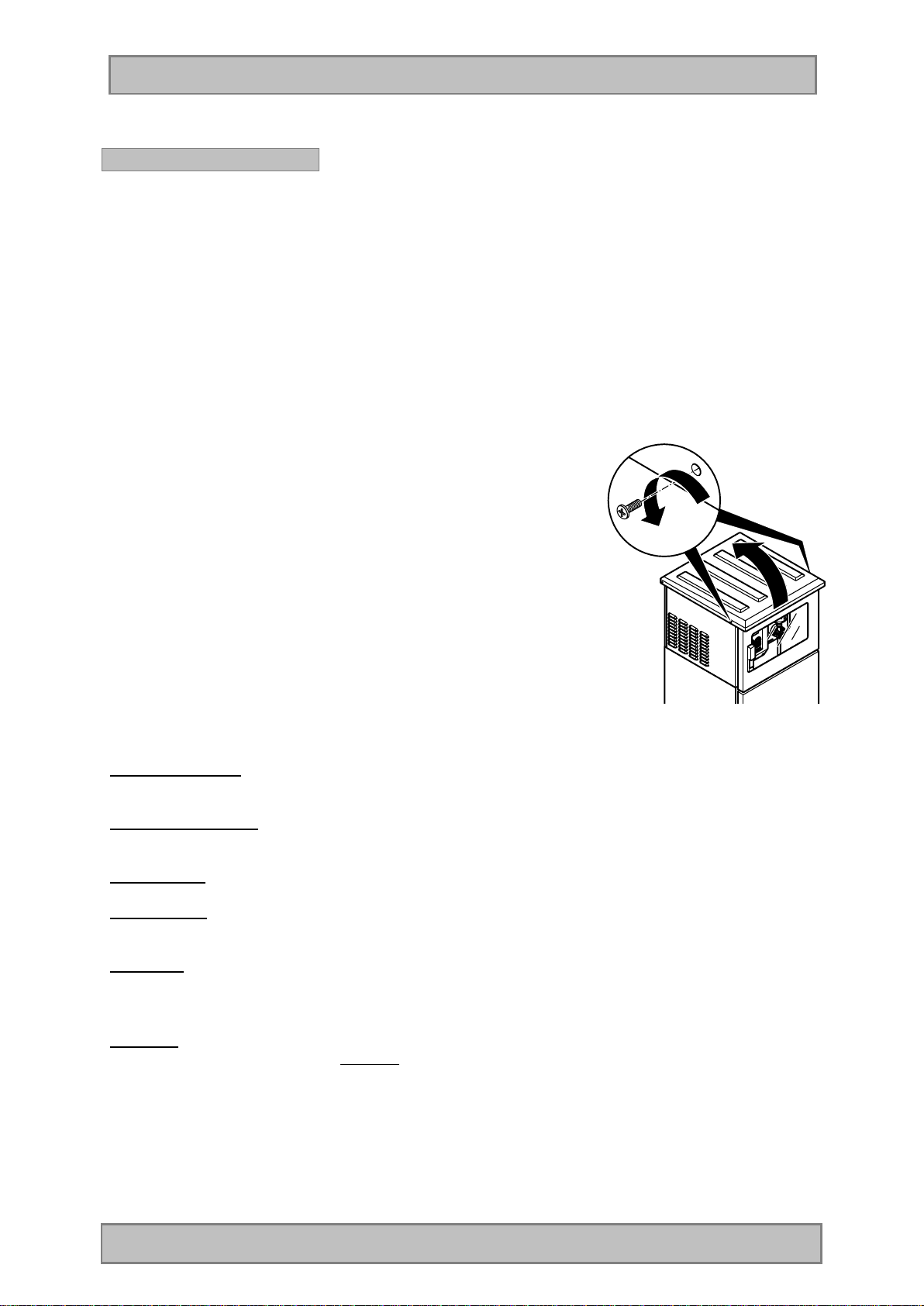

Installing the apparatus

- The workings described in this chapter of the manual must only be carried out by qualified

personnel.

- We recommend to install the apparatus as near as possible to the point of extraction. If installed

outside, the device should be fixed on a solid flat base (e.g. plinth). The fixing bars do already

have the necessary fixing holes.

- If the device is equipped with castors (mobile version), please make sure that the two lock-type

castors are locked during operation.

- For better deaeration / ventilation install the apparatus with a distance of approx. 10 cm to the wall.

- The hose has to be laid with a continuous fall from the apparatus to the point of extraction, without

fail. Lower lying points can lead to deposits in the hose which may freeze up in winter.

- To fix the suction hose, we recommend to use the extraction unit available as accessory.

- Fix the hose in such a way that the suction aperture lies in the direction of flow, so that coarse

matter and fibres cannot be forced into the suction aperture.

Remark: To open the top cover both front screws (left + right)

have to be removed. Then the top cover can be lifted

up to the point where the retention bars snap-in. To

close the cover again, the two retention bars have to

be lifted slightly.

After having closed the cover, the

two screws (left + right) have to be screwed in again.

Mains connection The device is equipped with a power supply lead.

The connecting data can be found in chapter “Technical Data”.

Connect/disconnect The device is connected/disconnected by means of the mains plug (except

devices with main switch).

Hose routing The apertures for the suction hose are on the left and on the right at the front.

Signal inputs The signal inputs (e.g. for flow meter) are located on the „fold-out“ plate and

can be connected according to the plan of terminal connections shown there.

Messages The relays required for messages (up to 4) can be fixed on the top hat rail. For

details please see the circuit diagram

Remark:

The apparatus must be cleaned regularly in accordance with the degree of contamination present. In

view of the quality of samples, we recommend to clean thoroughly especially the wetted parts like

dosing unit, electrodes, distributor, bottles and inlet hose. Failure to do so could result in damage or

destruction to the equipment, device that are not covered by warranty.

Page 18 Manual BÜHLER BU4010ff

Page 19

Operation

Replacement of fuses

1. Main fuse of device

(is installed on fold-out plate)

Fine-wire fuse 230V/T8A 5x20

To replace the fuse, pull out fuse holder,

open the cover and remove the fuse.

2. Fuse protection of CPU board

by an automatic fuse. The fuse is

reactivated by disconnecting the device

from the mains.

Troubleshooting

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

Sampler does not

function at all

Cooling system does

not function

- Mains connection

- Fuse defective

- Power supply

- Cooling system leaking

-Check mains cable

-Check all fuses and replace them

if necessary

-Check mains connection of

cooling machine

-Contact service department

Page 19 Manual BÜHLER BU4010ff

Page 20

Operation

Connections

Terminal assignment – input signals

Remark: Terminals K2 to K4 are optional depending on the device version.

BL3010

Page 20 Manual BÜHLER BU4010ff

Page 21

Operation

Sampling modes

The following sampling modes can be programmed:

Sampling mode Description Example

Time-

proportional

Flow-dependent

- digital

Flow-dependent

- analogue

In this sampling mode, the

single sample extractions as

well as the bottle change are

effected in fixed time intervals.

In this sampling mode the

sample extraction is triggered

by flow pulses. The bottle

change is effected in fixed time

intervals or after a certain

number of sample extractions.

In this sampling mode samples

are extracted according to the

analogue flow signal (0-20 mA

or 4-20 mA). The sample

extraction is started when the

programmed flow is reached.

Thus the interval between the

sample extractions varies

according to the flow signal.

The bottle change is effected in

fixed time intervals or after a

certain number of sample

extractions.

Values to program:

sampling interval

e.g. 00:05 hh:mm

Bottle filling time

e.g. 02:00 hh:mm

Values to program:

pulse divider

e.g. 100

(that means that a sample is

extracted after each 100th

pulse).

Bottle filling time

e.g. 02:00 hh:mm

or

bottle change after X sample

extractions e.g. 100

Values to program:

Flow per sample extraction

e.g. 1 m³

Bottle filling time

e.g. 02:00 hh:mm

or

bottle change after X sample

extractions e.g. 100

Flowproportional

Page 21 Manual BÜHLER BU4010ff

Samples are not extracted with

a fixed volume but within a

fixed time interval (e.g. every

10 minutes).For this kind of

sampling, the variable

automatic dosing system

(available as option) is

required. This system is only

working with an analogue flow

signal!

The sample volume adapts

•Analogue signal (4-20 mA or

optional 0-20 mA)

•The max. sample volume at

20 mA is fixed to 200 ml.

At an analogue signal of e.g.

10 mA, a 100 ml sample would

be extracted accordingly.

Sampling is effected in a fixed

time interval of e.g. 10

minutes.

Thus the sample extraction is

Page 22

Operation

Eventproportional

itself automatically

proportionally to the flow. This

is achieved by proportionally

scaling the mA signal and the

maximum sample volume. That

means, the sample volume is

automatically adjusted to the

mA

signal.

In this sampling mode the

sample extraction is depending

on an external event signal

(potential-free make contact).

The sample is only extracted as

long as the signal is present.

The sampling interval as well

as the bottle change are

programmed. The bottle is

changed at each new event

signal.

If an event is longer than the

programmed bottle filling time,

two or more bottles will be filled

for this event depending on the

programmed bottle filling time.

always proportional to the flow,

that means:

high flow = big sample

volume

low flow = small sample

volume.

Values to program:

Sampling interval

e.g. 00:05 hh:mm

Bottle filling time

e.g. 02:00 hh:mm

Page 22 Manual BÜHLER BU4010ff

Page 23

Operation

Vacuum sampling system

Metering vessel -structure-

1. Hose connector

2. Flange

3. Screw cap

4. Electrodes

5. Volume control tube

6. Metering vessel

7. Silicone discharge tube

8. Motor-driven pinch-valve

9. Air connection

Cleaning:

- Glass metering vessel: unscrew the screw cap (3) and remove the flange. Now, the metering

vessel together with the silicone discharge tube (7) can be detached.

- Plastic metering vessel: Turn the plastic metering vessel anticlockwise (bayonet fitting) and

remove.

Adjustment of sample shot volume at samplers with glass metering vessel:

To adjust the desired sample volume, loosen the knurled screw and displace the volume control tube

vertically.

Adjustment of sample shot volume at samplers with plastic metering vessel:

The sampler is always delivered with the volume control tube in full length.

To adjust the sample shot volume, the volume control tube (5) has to be cut

to length.

Procedure

1. There is a graduation in millilitres on the volume control tube.

2. Remove the metering vessel (6).

3. Cut the volume control tube to the desired length with scissors or a knife.

4. Reinstall the metering vessel (6) and tighten.

5. Check the sample volume by starting a manual sample extraction.

6. Now the device is ready for operation.

Remark: If you need to work with different sample volumes, you can cut to

size several tube pieces. As the volume control tube (5) is only

slipped on the hose connector (1), it is very easy to change the tube.

Page 23 Manual BÜHLER BU4010ff

Page 24

Operation

Operation principle:

1. Inoperative

position

Replacement of the silicone discharge hose

The silicone hose (BM69301) is only pushed over the lip of the metering vessel. A hose clamp is not

required. Humidify the hose a little bit, fix it at one point and push it over the lip.

Remark:

Do only use original spare parts from the manufacturer. The use of a wrong hose type can lead to

malfunctions at the system or may even damage the pinch valve!

Remark:

Conductivity of the sample medium

There are two conductive level electrodes in the metering vessel. Their sensitivity can be adjusted in

the service menu. In the factory the electrodes are adjusted to tap water (this adjustment does not

have to be changed under normal operating conditions). Minimum conductivity 50 μS/cm.

Please note that a wrong adjustment can lead to a flooding of the pneumatic system and to the

damage of component parts.

The sampler is not suitable for extraction of distilled water due to low conductivity.

Conductivity at 25°C

Rain water 50 μS/cm

Drinking water 500 μS/cm

Waste water 5000 μS/cm (5 mS/cm)

Seawater 50000 μS/cm (50 mS/cm)

ATTENTION:

Wrong operating conditions can lead to malfunctions or may even damage the apparatus. No liability

or claims under guarantee will be accepted in respect of any damage arising from the non-observance

of these operating instructions.

2. Pinch-valve

closes

3. Metering

vessel is filled

up to the

electrodes

4. Dosing system

is aerated

5. Pinch

valve

opens and

sample

drains off

in bottle

Page 24 Manual BÜHLER BU4010ff

Page 25

Operation

Troubleshooting – vacuum sampling system

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

Electrodes do not react,

system flooded

Sampler does not extract

samples

No pressure / vacuum at

pump

Adjustment of conductivity too

low. Distilled water has been

used as sample medium.

No contact to electrodes Check cable connection

System is leaking Check whether all hoses and

Pump/diaphragm defective Check pressure/vacuum of

Metering vessel not tight, no

vacuum

Filling level electrodes bridged Clean electrodes

Valve system/pinch valve does

not function correctly

Defective diaphragm Renew diaphragm

Hoses are squeezed Check hoses

Contact service department

connections are tight

pump

Check whether metering vessel

is tight (screw cap)

Check valve system/pinch valve

or contact service department

Page 25 Manual BÜHLER BU4010ff

Page 26

Operation

Flow-proportional sampling system

The characteristic features of the flow-proportional sampling are:

• fixed sampling interval (e. g. every 10 min) with

• variable sample volume (related to the mA-signal (flow))

At the variable dosing system, the sample volume is automatically changed according to the analogue

flow signal.

Example: - the selected range is 4 to 20 mA (option 0 – 20 mA)

- the maximum sample volume at 20 mA is fixed to 200 ml.

That means at an analogue signal of e.g. 10 mA, a 100 ml sample would

be extracted. Thus the sample extraction is always proportional to the flow.

This sampling mode supplies very good, representative results as even if flow is very low (e.g.

discharges at night) a sample extraction is still carried out in fixed time intervals.

For comparison a short description of the flow-dependent sampling mode:

The characteristic features of the flow-dependent sample extraction are:

• variable sampling interval (according to the mA-signal (flow)) with

• fixed sample volume (e.g. 100 ml)

In the flow-dependent sampling mode, a sample is e.g. always extracted after 10 m³, that means the

signal of the flow meter is totalized.

In case of very low flow quantities (e.g. discharges at night) it is possible that e.g. 2-3 hours pass until

the set 10 m³ are reached again and a sample is extracted.

Remark: That means if there is an accident (e.g. discharge of chemicals) during this period, there

will be no sample. However, a sample would have been very important for an analysis and

the taking of countermeasures.

Flow-proportional sampling system - structure

Structure:

1. Electrodes 2

2. Measuring tube

3. Electrodes 1

4. Connection for aeration

5. Dosingvessel

6. Pinsch Valve

7. Cleaning cap of gas drap

8. Inlet connection

Page 26 Manual BÜHLER BU4010ff

Page 27

Operation

Function of the VAR Flow-proportional sampling system

· Before the system can be used, it must be calibrated. In the automatic calibration cycles (5

cycles), the respective volumes must entered.

· At the flow-proportional (variable) sampling system the sample volume is directly entered in ml by

means of the keys at the control when editing a sampling program.

· After the program start the pinch valve is closed.

· A pressure (air produced by the diaphragm pump) is applied to the metering vessel via the air

connection. Thus the hose is purged.

· Now, the valve system switches to vacuum and the depression generated by the diaphragm pump

withdraws the air from the metering vessel. A vacuum is generated and leads to the drawing-off of

sample medium at the connected hose.

· The medium is sucked into the Dosingvessel over the Measuring tube (2).

· during inlet, the sample volume already will be measured in the measuring tube(2) and only the

requested volume remains in the vessel.

· After measuring is done, the system is ventilated by opening the air inlet (4) so that the water in

the suction hose can flow back to the extraction point.

· After a pre-programmed aeration time, the pinch valve (6) opens in two steps and the sample is

filled into a container.

Cleaning:

To clean the metering vessel (5), open the screw cap (glass) or turns to the left (plastic, bayonet

shutter), pull the silicone discharge hose to the front and remove the metering vessel.

The measuring tube (2) can be cleaned with a bottle brush BM60560 .

Page 27 Manual BÜHLER BU4010ff

Page 28

Operation

Troubleshooting – flow-proportional sampling system

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

Level electrodes do not react,

system is flooded

Sampler does not extract

samples

Pump does not produce

pressure/vacuum

Adjustment of conductivity is

too low. Distilled water is used

as sample medium

No contact to electrodes Check cable connections

System is leaking Check whether all hoses and

Pump/diaphragm defective Check pressure/vacuum of

Metering vessel not tight, no

vacuum

Level electrodes are bridged Clean electrodes

Valve system/pinch valve does

not work correctly

Diaphragm defective Replace diaphragm

Hoses are kinked Check hoses

Contact service department

connections are tight

pump

Check whether metering vessel

is tight (union nut)

Check valve system/pinch valve

or contact service dept.

Inaccurate sample volume

Page 28 Manual BÜHLER BU4010ff

System has been initialized or

hardware has been changed

Calibrate

Page 29

Operation

Bypass sampling system

Bypass metering vessel

This sampling method is suitable for use in bypass systems with flow-rates from 3 – 20 L/min.

- Patented motor-driven pinch valve which squeezes the dosing hose or the flow-through hose

below the metering vessel.

- No sensor, thus almost no wear.

- Front opening for ease of metering vessel cleaning

- The sample volume can be adjusted between 20 ml and 250 ml by displacing the filling tube

Metering vessel – structure -

1. Sample inlet

2. Hose connection for overflowing water

3. Flange

4. Screw cap

5. Filling level electrodes

6. Metering vessel

7. Adjustable tube – sample volume

8. Screw connection

9. Pinch valve 1 (sample outlet to distributor/bottles)

10. Silicone discharge tube

11. Pinch valve 2 (dosing)

12. Outlet hose

Method of operation

The desired volume can be adjusted between approx. 20 ml and 250 ml by means of the adjustable

tube. To adjust the desired sample volume, loosen the screw connection and displace the filling tube

upwards or downwards.

1. Continous flow

Inoperative Position

4. Pinch valve 2 is opened.

Water drains off up to the

level of the dosing tube.

2. Pinch valves 1+2 are closed 3. Water is filled up to the

electrodes

5. Pinch valve 1 is opened

and the sample is filled

into the bottle.

6. Inoperative Position

Page 29 Manual BÜHLER BU4010ff

Page 30

Operation

REMARK: The pinch valve (9) is in inoperative position always closed and will be opened 1x per

hour to avoid sticking of the silicon tube.

Replacement of dosing hose

The silicone hose (BM69301) is only pushed over the lip of the metering vessel. A hose clamp is not

required. Humidify the hose a little bit, fix it at one point and push it over the lip.

Remark: Conductivity of the sample medium

There are two conductive level electrodes in the metering vessel. Their sensitivity can

be adjusted progressively in the service menu. The factory adjusts the electrodes to

tap water (this adjustment does not have to be changed under normal operating

conditions).

Please note that a wrong adjustment can lead to a flooding of the pneumatic system and to the

damage of component parts.

ATTENTION: Wrong operating conditions can lead to malfunctions or may even damage the

apparatus. No liability or claims under guarantee will be accepted in respect of any

damage arising from the non-observance of these operating instructions.

Troubleshooting – bypass sampling system

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

Level electrodes do not

react, system is flooded

Sampler does not

extract samples

Metering vessel

overflowing (backflow)

-Adjustment of conductivity is too

low

-Failure on the power board

-Defective cable connection

-Wrong programming

-System is leaking

-No flow

-Inlet hose clogged

-Level electrodes bridged

-Wrong setting of parameters in

the service menu

-Outlet hose is clogged or

squeezed

-Pinch valve does not open

completely

-Check adjustment in service

menu

-Exchange power board

-Check cable connection

-Check programming

-Check whether the silicone

hoses are tight

-Check whether there is water

-Remove clogging

-Clean the electrodes

-Check entered values and, if

necessary, reset them to factoryset values by reinitialization

-Remove clogging

-Adjust position of pinch valve

Page 30 Manual BÜHLER BU4010ff

Page 31

Operation

Sample distribution at Bühler 4010/3010//6010

Ÿ Rotating distributor

- Motor-driven rotating distributor with encoder (pulse generator) which ensures:

- an exact sample discharge position as well as

- an automatic bottle position identification by means of a forked light barrier.

Remark: For reasons of operating safety, the distributor first always runs over position 1 again

when changing to the next bottle. Thus a correc t positioning even after a malfunction

(voltage loss) is always guaranteed.

Remark 2: When there are no pulses, the output is switched off and thus neither the motor

nor the gear will be damaged if the distributor is blocked.

ATTENTION: The distributor is driven by a geared motor. The distributor must under no

circumstances be turned by hand! In case of non-observance, the gear will be

damaged!

Page 31 Manual BÜHLER BU4010ff

Page 32

Operation

Troubleshooting – distributor 4010/3010//6010

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action Chapter

No function

Program cannot be

started

Distributor is

continuously turning

Wrong positioning of

distributor

Connections

Water penetrated in distributor

drive

Wrong distributor has been

entered

Forked light barrier defective

Pulse generator defective

Interfering pulses.

Pulse generator does not

function correctly

Check connections

Dismantle distributor

head and check for

water penetration.

Contact service

department

Correct entry

Contact service

department, return

defective part if

necessary

Contact service

department

Distributor

Programmin

g

Distributor

Distributor

Sample distribution at Bühler 4210

The picture shows the distributor unit:

1. Detailed view of discharge position when rinsing

2. Distributor arm with direct dosing

3. Sample bottles

4. Bottle carrying tray

Page 32 Manual BÜHLER BU4010ff

Page 33

Operation

Sample distribution at Bühler 4410 – variants: 12 / 24 bottles

Distributor

The distributor system is available in two variants:

- with 12 glass bottles, each 1,6 L

- with 24 glass bottles, each 2 L.

General view – complete distributor system with bottles:

1. 1,6 L or 2 L Duran50 glass bottle.

2. Drive unit with releasing mechanism, that means if the distributor is blocked, the drive unit is released.

Thus severe damage to the distributor is avoided.

3. Distributor drive unit.

4. Swivelling outlet tube for the manual emptying of the bottle.

5. Combined dosing/rinsing head. On this position the glass bottles are automatically emptied, rinsed

and filled again. For rinsing, the device has to be connected to a fresh water pipe. The emptying and

rinsing intervals can be set in the service menu.

6. Emptying mechanism. There is a silicone hose at the bottle outlet which is closed if non-operated by

means of a spring mechanism. To empty the bottle, the bottle outlet valve is opened and closed again

after rinsing by means of an eccentric unit.

7. Closing cylinder of bottle.

8. Lever to empty the bottle manually. To actuate the closing cylinder, the lever has to be turned to the

right. Now, the sample can be filled into a separate bottle.

9. Discharge tube for not needed samples and rinsing water with external hose connection to return this

water to the sewer.

Page 33 Manual BÜHLER BU4010ff

Page 34

Operation

Take out, empty or put in a bottle

To empty a bottle, to take it out for cleaning or to put it in again, the desired bottle can be moved to the

front position by means of the menu „Manual Mode“. This is also possible during a running program by

means of the pause mode. The active program does not have to be interrupted and continues to run

according to the programmed cycle, however, in the background. Detailed information can be found in

the chapter „Programming“.

Detailed view – distributor drive

Detailed view – dosing/rinsing head

Page 34 Manual BÜHLER BU4010ff

Page 35

Operation

Sample distribution at Bühler 4410 – variants: 2 / 4 bottles

1. Distributor

2. Rinsing water connection

3. Container

4. Locking device for telescopic drawer

5. Telescopic drawer

6. Discharge trough

1. Description

The motor-driven distributor unit consists of a distributor tie-bar, a drive unit with motor,

a light barrier and encoder as well as a distributor head with outlet tube.

There are 2 x 10 L PE containers (or 4 x 5 L PE containers) and each container is equipped with

a discharge valve at the bottom. In addition there is a rinsing valve for each bottle at the bottom

of the inner compartment.

2. Operating elements

The red screw cap of the distributor head can be unscrewed for cleaning.

Attention: Never turn the distributor by hand (geared motor)!

3. Method of operation

- The device is typically programmed in such a way that each container is filled for a period of 24

hours. Thus, a sample of the last 24 hours is available at any time.

- At each bottle change, the distributor passes a light barrier at position 1 to synchronize.

- After having passed the light barrier, the encoder pulses of the motor are counted to position the

outlet tube on bottle 2.

- After each program-related bottle change, the new bottle is automatically emptied and rinsed.

- To do this, the distributor first moves on the respective bottle.

- Thereafter the discharge valve at the bottom of the container is opened.

- After expiration of the emptying time (adjustable), the respective rinsing valve is opened (rinsing

time is adjustable, too) and the container is rinsed.

- After rinsing, the discharge valve closes and the device is ready for sampling again.

Page 35 Manual BÜHLER BU4010ff

Page 36

Operation

Troubleshooting – distributor Bühler 4410

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action Chapter

No function

Program cannot be

started

Wrong positioning of

distributor

Connections

Wrong distributor has been

entered

Interfering pulses.

Pulse generator does not

function correctly

Check connections Distributor

Correct entry

Contact service

department

Programming

Distributor

Page 36 Manual BÜHLER BU4010ff

Page 37

Operation

Programming

The menu structure is similar to a directory tree and is split up in

main menus and submenus.

Assignment and function of keys

The apparatus is interactively programmed by the user.

Function of keys:

Display of help texts. To activate the help

text when selecting a new display, first

Arrow key

press the arrow key pointing to the left.

Move from one to the next menu Arrow keys

Select the desired menu Enter key

Move within the menu Arrow keys

Selection within the menu or scrolling

within the data memory or bottle memory

Confirm the choice (is automatically

marked with a )

Arrow keys

Enter key

Entry/change of values Arrow keys

Confirmation of entered values Enter key

Return to higher menu level Back key

Initialization (reset) display

Back key +

Enter

Terminate sleep mode Back key

RESET / reset to factory settings Back key

Press both keys at the

same time

Press for at least

5 sec.

Keep pressed

when switching on

Page 37 Manual BÜHLER BU4010ff

Page 38

Operation

Navigation

The sampler can be operated by means of the control

unit. With the ARROW KEYS, the ENTER KEY and the

BACK KEY you can move from one screen to another.

An arrow on the display shows that there are further

selection possibilities (see illustration).

Example:

1. Press the “DOWN” arrow key two times to select the line DATA MEMORY.

2. Now press the ENTER KEY to display the data memory or to choose another

selection possibility.

Remark: The arrow pointing downward on the right side (bottom) of the display

indicates that there are further selection possibilities.

Menu variants:

The top line indicates that you can navigate to the right

or to the left by pressing the arrow keys.

The bottom line indicates with which key the action is

executed or terminated.

Here you can set a parameter. The top line shows

which value is to be set. The bottom line indicates the

possible range of values. The entry is possible directly

by means of the number keys or the digit is selected

with the right / left arrow keys and changed with the up

/ down arrow keys. The selected digit is displayed

inversely (cursor). Confirm the entry by pressing the

ENT key or abort it by pressing the BACK key (in this

case the initial value is not changed).

The arrows show that a digit can be changed.

Page 38 Manual BÜHLER BU4010ff

Page 39

Operation

Settings with selection menu

The cursor is positioned on the current selection line

(inversely) and can be moved up or down.

The arrow on the right side of the window indicates

that there are further entries which can be displayed

by scrolling up or down.

Depending on the menu, the display will show

in which direction you can scroll.

Definition of individual menu points

In the selection menus, additional program settings

are displayed. All the settings which have been

activated by pressing the ENTER key are marked

with a .

Page 39 Manual BÜHLER BU4010ff

Page 40

Operation

FUNTION

PROGRAMS

MANUAL SAMPLE

DATA MEMORY

DIAGNOSTICS/TEST

MAIN MENU STRUCTURE

The following list shows the main menu level with the menu points of the

submenus:

DISPLAY

DISPLAY

STATUS/STOP • INFO

• PAUSE

• STOP

START • IMMEDIATELY

• DATE/TIME

• WEEKDAY/TIME

CHANGE Time,Flow, Event

INTO CURRENT BOTTLE

EXTRACTION

INTO BOTTLE X

INFO MEMORY SET FILTER

BOTTLE PROTOCOL

COMPONENT TEST • DIAPHRAGM PUMP

• PINCH VALVE

• VALVE SYSTEM

• DISTRIBUTOR

• DIGITAL OUTPUTS

DIGITAL INPUTS FLOW DIGITAL 0 EVENT 0

DI3 DI4 DI5

DI6 DI7 DI8

ANALOG INPUTS ANALOGUE 1:

ANALOGUE 2:

ELECTRODES 1:

ELECTRODES 2:

PT 1000 SENSOR

VOLTAGE.:

VERSION INFO

Page 40 Manual BÜHLER BU4010ff

Page 41

Operation

SETTINGS

DATE/TIME

SYSTEM SETTINGS • LANGUAGE

SLEEP MODE

(Only portable sampler)

• DISTRIBUTOR

• MAX. SUCTION TIME

• PRE PURGE

• POST PURGE

• AERATION TIME

• PUMP POWER

• ANALOGUE SIGNAL

• DISPLAY

• PAUSE DURATION

• PROG. INPUT

• OUTPUTSIGNAL

• DATE/TIME

• WAKEUP WITH 5s ESC

• NO SLEEP MODE

PASSWORD • CHANGE PASSWORD

• CHANGE SETTINGS

• CHANGE PROGRAMS

SERVICE MENU Setting of base parameters

(to be done by a service

technician)

Password protected.

Page 41 Manual BÜHLER BU4010ff

Page 42

Operation

PROGRAMS

MANUAL SAMPLE

DATA MEMORY

Description of the menus

DISPLAY

STATUS/STOP

START

CHANGE PROGRAM No. [xx]

EXTRACTION

IN CURRENT BOTTLE

IN BOTTLE X

INFO MEMORY

BOTTLE MEMORY

DISPLAY

• INFO

• PAUSE

• STOP

• IMMEDIATELY

• DATE/TIME

• WEEKDAY/TIME

EXPLANATION / FUNCTION

Display of program details

Interruption of the running

program (max. 120 min.)

Stop /abort the program

Program start can be:

• immediately

• with date/time (dd:mm:yyyy

hh:mm)

• with weekday/time (day; hh:mm)

Change the program parameters

like mode of operation (time, flow,

event…), interval etc.

Selectable Modes:

• TIME

• FLOW DIGITAL

• FLOW ANALOGUE

• EVENT TIME

• EVENT DIGITAL

• EVENT ANALOGUE

Sample extraction into current

bottle

Sample extraction into selectable

bottle X

Data can be displayed with filter

Display of data of the single

bottles

Page 42 Manual BÜHLER BU4010ff

Page 43

Operation

DIAGNOSIS/TEST

SETTINGS

• DIAPHRAGM PUMP

• PINCH VALVE

COMPONENT TEST

• VALVE SYSTEM

• DISTRIBUTOR

• DIGITAL OUTPUTS

OUTPUTS TEMPCARD

DIGITAL INPUTS

ANALOG INPUTS

DISPLAY OF VERSION

DATE/TIME Setting of date / time

• LANGUAGE

• DISTRIBUTOR

• MAX. SUCTION TIME

SYSTEM SETTINGS

• PRE PURGE

• POST PURGE

• AERATION TIME

Functional check of the

components

Displays status of:

- Lower heating (OFF / ON)

- Cooling (OFF / ON)

- Upper heating (OFF / ON)

Display of

(DI=Digital Input):

- Flow digital Event (digital)

DI3 DI4 DI5

DI6 DI7 DI8

Display of:

- ANALOGUE 1

- ANALOGUE 2

- Electrodes 1

- Electrodes 2

- PT1000 temperature sensor

(option)

- Operating voltage

Display of the firmware version

Setting of device-specific

parameters

1.PRE Purge=purging of suction hose

before sampling

2. Post purge= active purging of

dosing vessel to adjust dosing volume

Page 43 Manual BÜHLER BU4010ff

Page 44

Operation

SLEEP MODE

PASSWORD

SERVICE

• PUMP POWER

• ANALOGUE SIGNAL

• DISPLAY

• PAUSE DURATION

• PROGR. INPUT

• OUTPUT SIGNAL

The program can be interrupted

for a period of 10-120 minutes

Inputsignal to start e.g. a program

Only active if the add-on board is

connected

• DATE/TIME

• WAKEUP WITH 5s ESC

ONLY FOR PORTABLE

SAMPLER

• NO SLEEP MODE

• CHANGE PASSWORD

• CHANGE SETTINGS

Setting / activation of the

password

• CHANGE PROGRAMS

Setting of base parameters (to be

done by a service technician)

(Password protected)

Page 44 Manual BÜHLER BU4010ff

Page 45

Operation

Examples of programs

Programming of a time-proportional sampling

program

Select PROGRAMS in the main menu

Select CHANGE

Select PROGRAM NO. 1 (out of 12).

Programs No. 2-12 can be selected by pressing the left

or right arrow key.

Press ENTER to edit the program.

Select the sampling mode TIME

(Sampling is effected in fixed time intervals)

Set the sampling interval

(time interval between the single sample extractions)

Page 45 Manual BÜHLER BU4010ff

Page 46

Operation

Set the BOTTLE FILL TIME

(here: each bottle is filled for 1 hour).

Terminate programming.

Now, the program can be started directly.

If selected "MORE SETTINGS ", the additional settings

are available:

- PROGRAMMING OK

(Set of selection and back to the START Menue)

- SERIAL SAMPLES

(samples/extraction)

means that each requested extraction consists of x-samples. This is useful

for a larger sample volume.

- BOTTLE SELECTION

(first Bottle / last Bottle)

The first and the last bottle can be defined for a cycle.

- PROGRAM PAUSE

(Prg.Pause=Timeshift of program start. Timeshift between end of program

x and start of next program. Moves the program cycle for continuous

operation with that time.

Page 46 Manual BÜHLER BU4010ff

Page 47

Operation

- QT-AUTOMATIC (Selection is only available for Flow program)

(Set of MIN. QT-TIME and/or MAX. QT-TIME)

- COMBINED EVENT SAMP.

(Combination of time- resp. Flow program with event; can be activated or

deactivated)

- PROGRAM SEQUENCE

(End of Prg1 can start Prog2....End of Prg.2 can start Prg x, last Prg.

starts Prg. 1 again or xx = endless run)

Program Start

After selection of the menu point “Start Program”, the

program to be started (1-12) has to be selected with the

left or right arrow key and has to be confirmed by

pressing the Enter key.

There are three resp. four possibilities to start the

program.

• IMMEDIATELY The program is started immediately.

• DATE/TIME The program start is effected on the selected date and at the

selected time. Format:dd:mm:yyyy hh:mm.

• WEEKDAY/TIME The program start is effected on the selected weekday and at

the selected time. Format: day; hh:mm

Page 47 Manual BÜHLER BU4010ff

Page 48

Operation

Program end

After having defined the start conditions, the program

end can be set as follows:

- AFTER 1 RUN Program is terminated after 1 run

- AFTER X RUNS Program is terminated after X runs

- CONTINUOUS OPERATION Program is continued indefinitely

Display of PROGRAM STATUS/STOP

Shows Status of programs. Programs can be paused or

stopped.

The status of all programs can be checked by pressing

the arrow keys (right/left).

When pressing the Enter key, the following is displayed:

ACTIVE = Program is started

or

INACTIVE = Program is not started

Page 48 Manual BÜHLER BU4010ff

Page 49

Operation

- INFO Display of information regarding the currently

running program: current bottle, samples

requested and samples taken, next sample

extraction or bottle change.

- PAUSE The program can be interrupted for a period of

10-120 minutes. The period can be entered in

the menu “SETTINGS”. The pause can be terminated manually or it is

automatically terminated after the entered xxx minutes.

- STOP The program can be stopped directly.

INFORMATION on program

After selection of INFO all details regarding the running

program are shown. The single screens can be displayed

by pressing the up/down arrow keys.

STOP -Stop Program

Active program can be stopped.

All running programs can be stopped at once as well.

Page 49 Manual BÜHLER BU4010ff

Page 50

Operation

Flow-proportional sample extraction

According to the output signal of your flow meter either

the operating mode flow analog or flow digital can be

selected in the program settings.

.

IMPORTANT: If an analogue signal (0/4-20 mA)

is used, it is absolutely necessary to

calibrate the input prior to the first use.

FLOW ANALOG

Calibrate the analog input 0/4-20 mA

The analog input can be calibrated in „SAMPLER

SETTINGS” ->FLOW SIGNAL. Just follow the menu

instructions.

1st step: connect 0/4 mA and confirm

2nd step: connect 20 mA and confirm

3rd step: Calibration ok, confirm

Remark: The analogue input is already calibrated to 0-20 mA in the factory.

FLOW ANALOG

The only difference between the programming of the

flow analog mode and the flow digital mode is the

definition of the sampling interval. Point of reference is

the maximum flow at 20 mA.

Event-proportional sample extraction

When selecting this sampling mode, the sampler is waiting

for an external “event” signal, e.g. from a connected pHmeter. A sample is extracted according to the programming

as long as the signal is present. When the signal is

deactivated the sampler waits for the next signal and then

fills the next empty bottle.

Which „event“ sample has been filled into which bottle

is recorded in the info memory.

In the event mode the sample extraction can be time or flow dependent. The

programming is effected as described before (sampling mode time, flow digital).

Page 50 Manual BÜHLER BU4010ff

Page 51

Operation

FREE PROGRAMMABLE INPUTS

Ø PROGR. INPUT

Ø ADDITIONAL INPUT 1

Ø ADDITIONAL INPUT 2

Ø ADDITIONAL INPUT 3

In the basic version 1 programmable input is available.

As an option with the "I / O expansion board" are another 3 Inputs available. Thus the sampler

can be controlled with a digital pulse (eg with external PLC).

Each INPUT (1-3) can be programmed out of the following list:

Ø NO FUNCTION

(turn off of the Input)

Ø PRG. START PULSE

(if selected, Program x will be started)

Ø PRG. STOP PULSE

(if selected, Program x will be stopped) (Back with ESC)

Ø PRG. RUN DURING PULSE

(During continuous signal, Program is running. If Signal drops down,

program stops.)

Ø DISTRIBUTOR PULSE

Pulse signal: <= 3sec means "next bottle"

>= 5 sec means "move to bottle 1"

Ø SAMPLE PULSE

Pulse means "take a sample"

Pulse signal must be > 50ms!

Remark: This feature is only available if no program is running. The unit is in

this case completely controlled externally (eg PLC)

Page 51 Manual BÜHLER BU4010ff

Page 52

Operation

OUTPUT SIGNALS

As an option are 5 Output signals available, which are

free configurable.

OUTPUTSIGNAL

Ø OUTPUT SIGNAL 1

Ø OUTPUT SIGNAL 2

Ø OUTPUT SIGNAL 3

Ø OUTPUT SIGNAL 4

Ø OUTPUT SIGNAL 5

Each Output signal (1-5) can be programmed out of the following list:

Ø PROGRAM ACTIVE

Selection of "PROGRAMS ACTIV" or "PROGRAM XX ACTIV"

Ø PROGRAM END

Ø Selection "PROGRAMS END" oder "PROGRAM XX END"

Ø ERROR

Selection: • GENERAL FAILURE

• FAILURE ELECTRODES

• ERROR SUCTION

• FAILURE DISTRIBUTOR

• MAX. SPL/BOTTLE

• mA FAILURE

• POWER FAILURE

• DOOR OPEN

• INTERNAL TEMPERATURE

• EMERGENCY CUTOFF

• SUCTION TIME

Ø SAMPLING ACTIVE

Ø BOTTLE CHANGE

Ø DISTRIBUTOR ON POS.1

Ø SIGNAL REVERSED

Ø SIGNAL OFF

("switch off" of the output signal)

Page 52 Manual BÜHLER BU4010ff

Page 53

Operation

Error

ERROR MESSAGES

code Text / meaning

1 Error distributor

2 Error suction

4 Error electrodes

5 End of voltage loss

6 Charge storage battery

7 Storage battery empty

10 Error analog signal A1

15 Emergency cutout

17 Storage battery defective

19 Error analog signal

LOG MESSAGES

Log code

1 Error

2 Program start

3 Program end prog. xx

4 Start program pause

5 End program pause

6 System start

9 Bottle change

10 Sample extraction

14 Voltage loss start

15 Start of event

16 End of event

18 Terminate sleep mode

19 Conductivity sample medium (resistance)

20 Temperature regulation

21 Bottle statistics

22 Single bottle statistics

23 Password for service menu

24 PT1000 temperature sensor / operating voltage

Meaning

28 Analog value A1 protocol

30

Overfill protection, Parameter 1= Drop sample

Parameter 2= Switch over to new bottle

Page 53 Manual BÜHLER BU4010ff

Page 54

Maintenance

Maintenance

The apparatus should be cleaned regularly in accordance with the degree of contamination present.

In view of the quality of samples, we recommend to clean thoroughly especially the wetted parts like

dosing unit, electrodes, distributor, bottles and inlet hose.

Remark:

There is a health hazard if the device is used in biologically or chemically contaminated areas. Please

take the necessary precautionary measures when cleaning or servicing the device.

Attention:

Disconnect the power connections before carrying out any maintenance or repair works. Repair works

must only be carried out by specially trained and authorised service personnel.

Remark: For cleaning of the metering vessel: see chapter „Operation – sampling systems“.

Pumping capacity: The pumping capacity (patented method) can be adjusted in the

service menu between 70 and 100 %.

Remark: The adjusted pumping capacity has no effect on the suction height

but only on the average suction speed when extracting the

sample. The lower the pumping capacity, the longer the life of the

pump

Page 54 Manual BÜHLER BU4010ff

Page 55

Spare parts / accessories

Spare

parts / access

o

ries BÜHLER

3010

,

4010,

Version with 1 container (1x25 L)

Version with 2 containers (2x10 L)

Version with 4 bottles (4x6,3 L)

Version with 4 containers ( 4 x 10 L)

Version with 4 containers ( 4 x 14 L)

Version with 12 bottles (12x2,9 L PE / 12x2,0 L glass)

Version with glass bottles

Version with 24 bottles (24x1 L)

A

rticle No.

Designation

Befestigungskomponenten Verteiler

2x10, 4x6, 12x2,9, 24x1

2x10, 4x6, 12x2,9, 24x1, 4x10, 4x14

2x10

BM60046 25 L composite container

BM40042 Slide-in plate for container positioning

BM60045 10 L PE container with cover

BM900499 Motor-driven distributor

BM40042 Slide-in plate for container positioning

BM60044 6,3 L bottle with cover

BM900499 Motor-driven distributor

BM900502 Distributor 4 x 10 L with tie bar

BM60081 10 L container

BM40212 Intermediate bottom sheet

BM900503 Distributor 4 x 14 L with tie bar

BM60334 14 L container

BM40 034 Bottle tray for 12 x 2,9 L bottles

BM60 034 2,9 L PE bottle

BM60 035 Cap for PE bottle

BM900499 Motor-driven distributor system for 12 bottles

BM30 013 2,0 L glass bottle

BM60161 Cap

BM40 035 Bottle tray for 24 x 1 L bottles

BM60 036 1,0 L PE bottle

BM60 037 Cap for PE bottle

BM900500 Motor-driven distributor system for 24 bottles

Version with glass bottles

BM30 012 1,0 L glass bottle

BM60144 Cap

Spare parts sample distribution BÜHLER 3010, 4010

BM900499 Distributor unit 12x2,9 L, 4x6 and 2x10 L with spout

BM900500 Distributor unit 24x1,0 L with spout

BM900502 Distributor unit 4x10 L with spout

BM900503 Distributor unit 4x14 L and 2x22 L with spout

BM900505 Distributor unit 4x20 L with spout

0050613

0001110

0040427

page 55 Manual BÜHLER BU4010ff

Halteschiene (2x erforderlich) für

Mutter M5 (8x erforderlich) für

Bodenblech für

Page 56

Spare parts / accessories

A

rticle No.

Designation

4x6

24x1

4x10 und 4x14

24x1

4x10 und 4x14

4x10

4x10

4x14

4x14

0040428

0040422

0040423

0050044-4

0069203

0069210

0050420

Spare parts – for all fixed site models -

BM900300 Suction hose ID12mm, length 7,5 m, with screw connection

BM900623 Suction hose ID10mm, length 7,5 m, with screw connection

BM900912 Saugschlauch ID12 mm, 7,5 m, mit Verschraubung u. Begleitheizung

BM900913 Saugschlauch ID10 mm, 7,5 m, mit Verschraubung u. Begleitheizung

BM69304 Suction hose ID 12 mm, running metre

Bodenblech für

Winkelschiene Tragewanne 24x1 rechts, für

Winkelschiene Tragewanne 24x1 links, für

Halteschiene für

Kantenschutzprofil für

Kantenschutzprofil für

Distanzleiste PVC für

,

,

BM69331 Suction hose ID 10 mm, running metre

BM50025 Stainless steel sinker weight, length 180 mm

BM900014 Extraction unit

BM900151 Interior lighting with door contact switch

BM900016 Mobile version consisting of:

•2 V2A castors

•2 V2A lock-type castors

•Fastening kit with:

4 V2A screws M12, 4 V2A nuts,

4 V2A plain washers, 4 plastic covers

BM30009 Plinth

BM900017 Mounting kit

Possible messages

BM900910 Hardwareerweiterung für MELDUNGEN (beinhaltet Steuererweiterung + 1

Melderelais)

BM900911 MELDERELAIS: Je Meldung ist je ein Melderelais erforderlich.

Insgesamt sind bis zu 8 Meldungen (Softwarekonfigurierbar)

(nur in Verbindung mit BM900910)

BM10038 Relay 12V, TS 35, change-over contact

BM10042 Fine-wire fuse T 8,0A 5x20

BM69403 Flat packing 25x15x2 EPDM

BM60050 Hose connector 3/4" x 13

Spare parts for vacuum sampling system

Article No. Designation

BM30004 Metering vessel 350 ml

page 56 Manual BÜHLER BU4010ff

Page 57

Spare parts / accessories

BM30005 Metering vessel 500 ml (only possible at standard vacuum system)

BM69401 O-ring 16x4, NBR (only at glass metering vessel)

BM69402 Quad-ring 81, 92x5, 33, NBR (only at glass metering vessel)

BM80044 Plastic metering vessel 350 ml

BM69452 Flat packing (only at plastic metering vessel)

BM60457 Folded paper filter (pneumatic unit)

BM69301 Silicone dosing tube 12x2

BM900897 Valve system for fixed site sampler

BM900908 Pinch valve