Page 1

DOC022.53.90072

BODTrak™ II

USER MANUAL

02/2010,

Edition 2

© Hach Company, 2008, 2010. All rights reserved. Printed in China.

Page 2

Page 3

Table of contents

Section 1 Specifications .................................................................................. 5

Section 2 General information ....................................................................... 7

2.1 Safety information .......................................................................................7

2.1.1 Use of hazard information ................................................................ 7

2.1.2 Precautionary labels ......................................................................... 7

2.2 Theory of operation ..................................................................................... 8

2.2.1 Oxygen transfer to sample ............................................................... 8

2.2.2 Pressure sensor function .................................................................. 9

2.2.3 Removing carbon dioxide ................................................................. 9

Section 3 Installation ...................................................................................... 11

3.1 Component list .......................................................................................... 11

3.2 Electrical installation ................................................................................. 12

Section 4 Operation ........................................................................................13

4.1 Operational controls .................................................................................. 13

4.1.1 Channel selection keys ................................................................... 14

4.1.2 The arrow keys ...............................................................................14

4.1.3 The ON key .................................................................................... 14

4.1.4 The OFF key ................................................................................... 14

4.2 Bottle connections .................................................................................... 14

4.3 Setting the clock ....................................................................................... 15

4.4 RS232 Interface ........................................................................................ 15

4.5 Downloading test results ........................................................................... 16

4.5.1 Import data ..................................................................................... 16

4.5.2 Data format ..................................................................................... 17

4.5.3 Printing test results ......................................................................... 18

Section 5 BODTrak™ II procedures .......................................................... 19

5.1 General Information .................................................................................. 19

5.2 Simplified procedure .................................................................................20

5.3 Hach GGA (glucose/glutamic acid) procedure ..........................................22

5.4 Hach Standard Method procedure ............................................................ 24

5.5 Completion steps for all procedures ......................................................... 27

5.5.1 Determination of results .................................................................. 30

5.6 Typical curves ........................................................................................... 32

5.7 Special considerations .............................................................................. 33

5.7.1 Sample dilution ...............................................................................33

5.7.2 Sample seeding .............................................................................. 33

5.7.3 Sample temperature ....................................................................... 33

5.7.4 Toxic materials ...............................................................................33

5.7.5 Chlorine .......................................................................................... 34

5.7.6 pH effect .........................................................................................34

5.7.7 Supersaturation .............................................................................. 34

Section 6 Maintenance .................................................................................. 35

6.1 Cleaning the instrument ............................................................................ 35

6.1.1 Sample bottles ................................................................................ 35

3

Page 4

Table of contents

6.1.2 Stir bars and seal cups ....................................................................35

6.1.3 Bottle fences ...................................................................................35

Section 7 Troubleshooting ............................................................................37

7.1 High oxygen demand .................................................................................38

7.2 Nitrification .................................................................................................38

7.3 Excessive time lag .....................................................................................38

7.4 Sample temperature ..................................................................................38

7.5 Bottle leak ..................................................................................................39

Section 8 Replacement parts and accessories ......................................41

8.1 Replacement parts ....................................................................................41

8.2 Reagents ...................................................................................................41

8.3 Optional reagents ......................................................................................41

8.4 Accessories ...............................................................................................42

Section 9 Contact Information ......................................................................45

4

Page 5

Section 1 Specifications

Specifications are subject to change without notice.

Table 1 Specifications

General

Range Selectable, 0 to 35, 0 to 70, 0 to 350, 0 to 700 mg/L

3

Dimensions 28.9 x 26 x 9.8 cm (11

External power supply

Capacity Six 492 mL bottles

Shipping weight 4 kg (8.8 lb)

Operating temperature 20 ºC (68 ºF)

Storage temperature 0 to 40 ºC (104 ºF)

Input: 110 to 240 V, 50/60 Hz, Output: 24 V, UL CSA, and

TUV approved

Method performance specifications

On a standard containing 150 mg/L each of glucose and

glutamic acid, a single analyst using 6 BODTrak™ II

Precision

Drift Less than 3 mg/L BOD in 5 days

Resolution 1 mg/L BOD

instruments and testing 44 samples obtained a mean of

235 mg/L BOD with a 95% confidence limit of distribution

of 11 mg/L or a range of

224 to 246 mg/L BOD.

/8 x 10 ¼ x 3 7/8 inches)

Table 2 Certification

Certification

Hach Company certifies this instrument was tested thoroughly, inspected and found to meet

its published specifications when it was shipped from the factory. The BODTrak II has been

tested and is certified as indicated to the following instrumentation standards:

FCC Part 15, Sub-Part B, Class A Limits: Supporting test records by Intellistor, certified

compliance by Hach Company

Canadian Interference-Causing Equipment Regulation, ICES-003, Class A: Supporting

test records by Intellistor, certified compliance by Hach Company

EN 55011/CISPR 11(EMI) “B” Limits per 89/336/EEC EMC: Supporting test records by

Intellistor, certified compliance by Hach Company

EN 50082-1 (Immunity) per 89/336/EEC EMC: Supporting test records by Hach Company,

certified compliance by Hach Company. Standards include:

• IEC 801-2 and EN 61000-4-2 (ESD)

• IEC 801-3 and EN V50140 (RF & EM Field)

• IEC 801-4 and EN 61000-4-4 (Fast Transient)

• EN 61000-4-5 (Surge)

Warranty: US 1 year; EU 2 year

5

Page 6

Specifications

Table 2 Certification (continued)

Radio frequency interference

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations. This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Warning

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to correct

the interference at their own expense. Shielded cables must be used with this unit to ensure

compliance with the Class A FCC limits. Because this instrument operates on and

generates radio frequency energy, interference to radio and television reception may occur.

If such interference does occur, the operator should take the necessary steps to correct the

interference. The following techniques of reducing the interference problems are easily

applied:

• Disconnect power from the BODTrak II instrument to verify the instrument is

the source of the interference.

• If the BODTrak II is plugged into the same outlet as the device with which it is

interfering, try another outlet.

• Move the BODTrak II away from the device receiving the interference.

• Reposition the receiving antenna for the device receiving the interference.

• Try combinations of the above.

6

Page 7

Section 2 General information

2.1 Safety information

Please read this entire manual before unpacking, setting up or operating this

equipment. Pay attention to all danger and caution statements. Failure to do so

could result in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not

use or install this equipment in any manner other than that specified in this manual.

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or

moderate injury.

Important Note: Indicates a situation which, if not avoided, may cause damage to

the instrument. Information that requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to

the instrument could occur if not observed. A symbol, if noted on the instrument, will

be included with a danger or caution statement in the manual.

This symbol, if noted on the instrument, references the instruction manual for

operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of in

European public disposal systems after 12 August of 2005. In conformity with

European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of life equipment to the

Producer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxiliary items for proper disposal.

7

Page 8

General information

2.2 Theory of operation

Respirometric Biochemical Oxygen Demand (BOD) is a test done at 20 °C (68 °F)

in a controlled environment. The test period can be 5, 7 or 10 days, contingent on

the analysis or protocol. The BOD test measures the quantity of oxygen consumed

by bacteria that oxidize organic matter in a water sample. The test is used to

measure waste loadings at wastewater treatment plants and to examine the

efficiency of wastewater treatment.

BOD test results help find general oxygen uptake patterns. This lets operators

estimate plant operating efficiency and find correct treatment procedures.

Advantages to the BODTrak™ II as an alternative to the dilution method are:

• Minimal time to prepare a sample.

• Decreased total test time.

• The BODTrak II method gives results comparable to the diluton method (BOD5)

in 2 to 3 days.

• Calibration and dissolved oxygen measurement are not necessary.

• The BODTrak II test is easy to monitor.

• The sample is stirred constantly and kept in natural conditions. This makes the

BODTrak II results similar to occurrences found in a natural environment. The

dilution method supplies no additional oxygen to the sample. This causes a

higher percentage of oxygen depletion and possible retardation of biochemical

reactions.

• The BOD can be monitored at any time because the instrument continuously

shows the BOD result. Pressure changes in the closed BODTrak II system are

shown graphically in milligrams per liter (mg/L) on an LCD. The system supplies

360 uniform data points over the selected time period.

• The BODTrak II system continuously removes carbon dioxide from the system

so that the pressure difference monitored is proportional to the quantity of

oxygen used.

• Degassing can cause negative errors when heat is applied to a sample to

achieve experimental temperature. The BODTrak II adjusts for this occurrence.

The BODTrak II does not start the test until the temperature gets to equilibrium.

2.2.1 Oxygen transfer to sample

Bacteria in the sample use oxygen while consuming organic matter in the sample

bottles. The air in the bottle above the sample contains 21% oxygen and

replenishes the dissolved oxygen used by the bacteria. During the test period, stir

bars continually mix the sample in each bottle. This moves oxygen from the air to

the sample and helps simulate natural conditions.

8

Page 9

General information

2.2.2 Pressure sensor function

The BODTrak II is sealed to prevent external atmospheric pressure changes in the

test bottle. Pressure sensors monitor air pressure in the sample bottles. When

oxygen is consumed, the pressure in the bottle head space drops. The pressure

drop correlates directly to BOD.

2.2.3 Removing carbon dioxide

Carbon dioxide is made when microorganisms oxidize organic matter in the

sample. The carbon dioxide must be removed from the system so it does not

interfere with the measurement. Potassium hydroxide pellets put in the seal cup of

each sample bottle before the test remove the carbon dioxide.

9

Page 10

10

Page 11

Section 3 Installation

3.1 Component list

Compare each item below to the items in the shipment. If an item is missing or

damaged, refer to the manufacturer.

• BODTrak™ II instrument

• A UL/CSA approved 115 VAC power cord with a NEMA 5-15P style plug

• A 230 VAC harmonized power cord with a continental European plug

• Power supply, auto–switching between 115 V and 230 V

• 6 seal cups

• 6 BODTrak II amber sample bottles

• 6 BODTrak II magnetic stir bars

• Spatula scoop

• One package nutrient buffer solution pillows

• One container potassium hydroxide pellets

11

Page 12

Installation

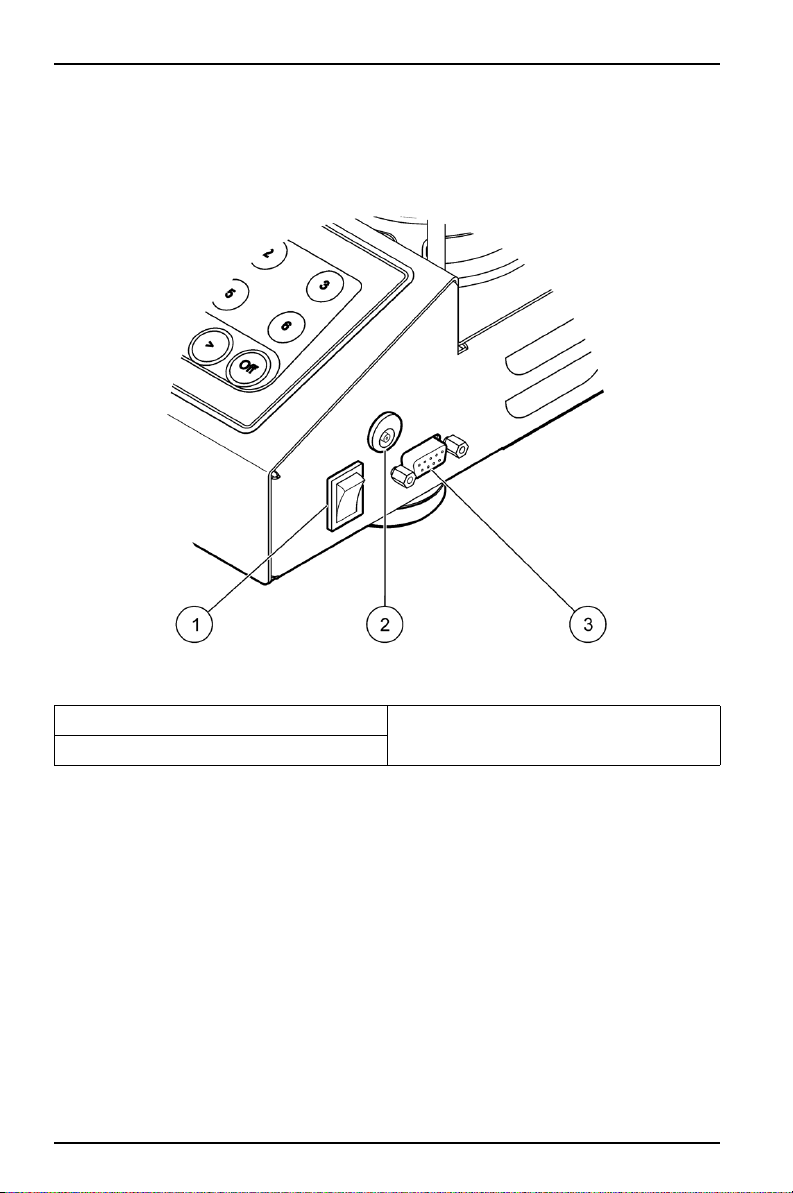

3.2 Electrical installation

The power adaptor supplies AC power to the IEC universal connector (Figure 1).

The power switch powers the instrument on and off.

Figure 1 External connections

1 Power switch 3 RS232 connector

2 IEC universal connector

12

Page 13

Section 4 Operation

4.1 Operational controls

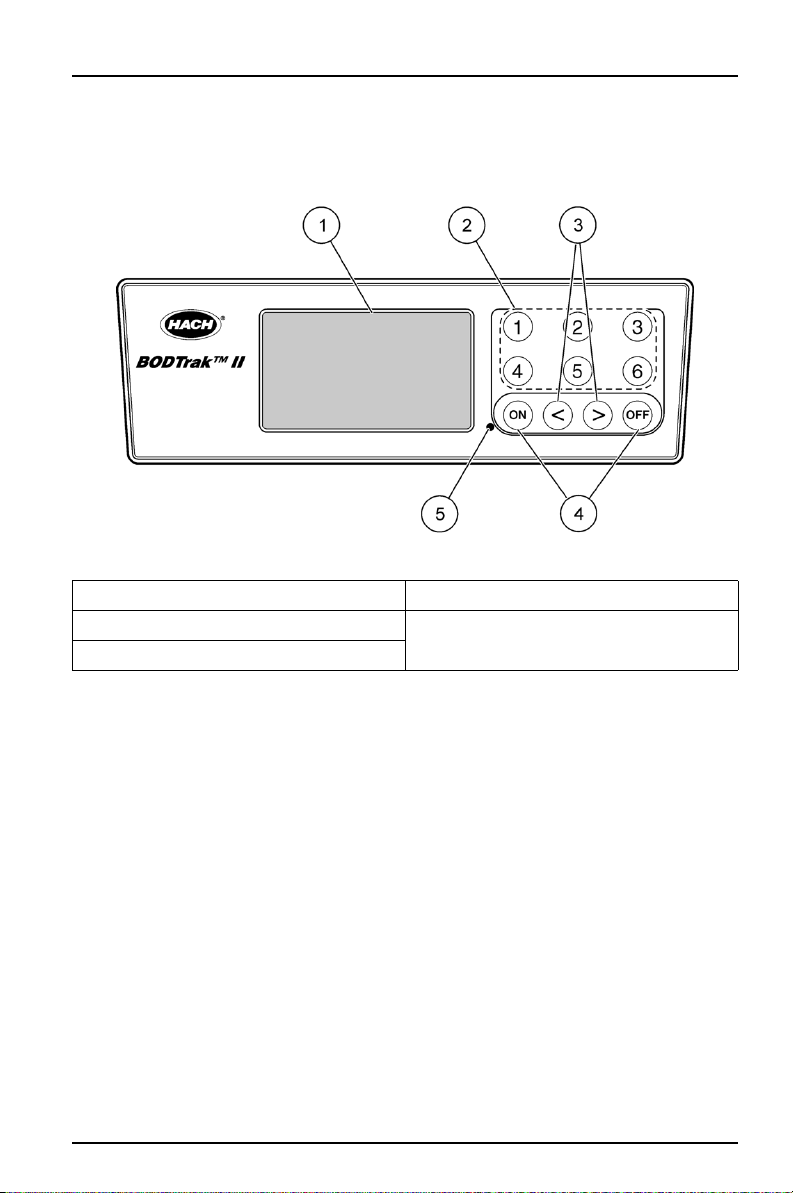

The BODTrak™ II operator controls are shown in Figure 2.

Figure 2 Operational controls

1 Display 4 ON/OFF keys

2 Channel selection keys 5 Power indicator

3 Arrow keys

1

The ON/OFF keys start and stop a test. They do not power the instrument on and off.

1

13

Page 14

Operation

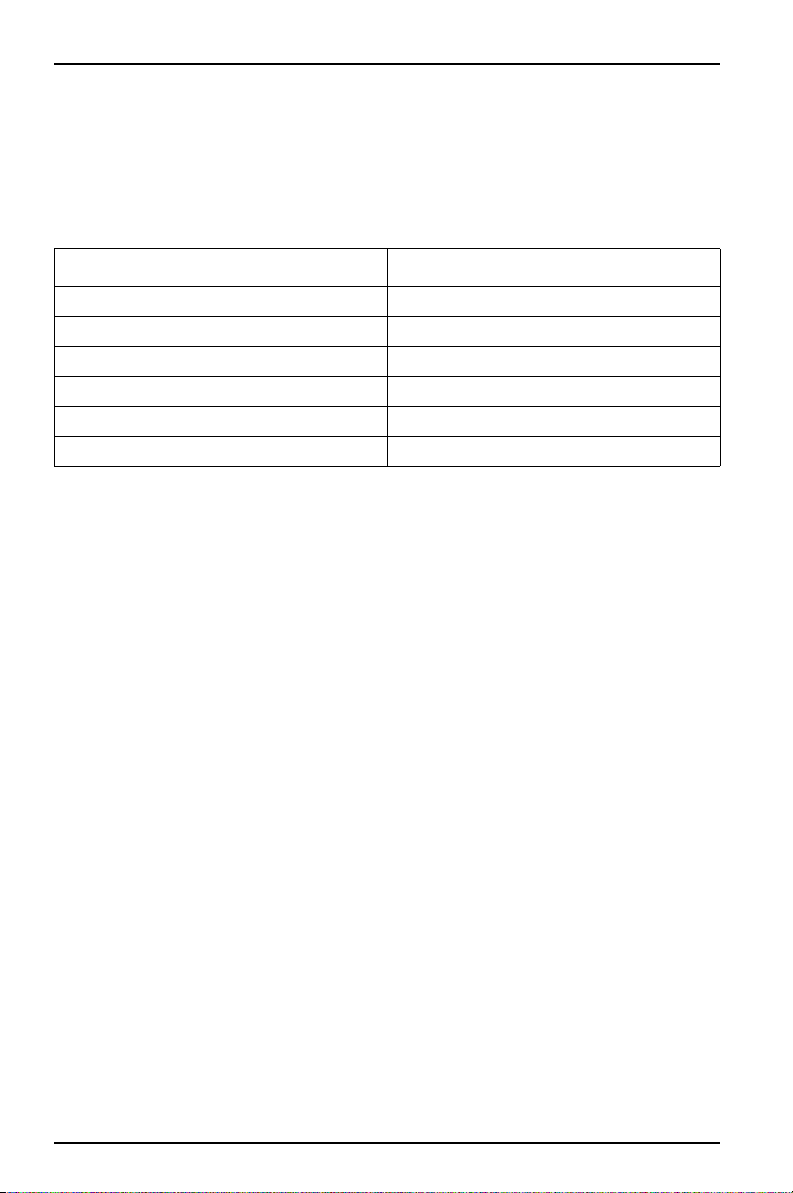

4.1.1 Channel selection keys

Push the related channel selection key to show data for one of the 6 bottles.

The channel selection keys are also used in the instrument setup menu to choose a

parameter to be edited (Table 3).

Table 3 Channel key setup parameters

Channel Parameter

1 Year (0-99)

2 Month (1-12)

3 Day (1-31)

4 Hour (0-24)

5 Minute (0-59)

6 Test Length (5, 7, or 10 days)

4.1.2 The arrow keys

The display shows a graph of BOD values on the vertical axis and time in days on

the horizontal axis. Push the left and right arrow keys to move the cursor along the

BOD curve to show the approximate coordinates (time, BOD) of the selected data

point.

The time interval and BOD value of the data point are shown in the lower right of

the display. The cursor is automatically placed at the most recently collected data

point in a channel display.

Push and hold the two arrow keys at the same time to go into the instrument setup

menu. The arrow keys are also used to change the time, date, test length and

range.

4.1.3 The ON key

To access the range selection menu, push the ON key from a channel display

screen. Then push and hold the ON key to start the test for the selected channel.

4.1.4 The OFF key

When a test is in DELAY or RUN modes, pushing and holding the OFF key

manually ends the test. The instrument will display END. The OFF key is also used

to exit the instrument setup menu or range selection menu. Any changes made

prior to exit will be saved.

4.2 Bottle connections

Each bottle position/channel has the applicable tube numbered with a plastic

sleeve. The bottle positions are numbered 1 though 6 with number 1 in the back left

corner of the chassis. Use the channel selection keys as a guide.

14

Page 15

Operation

4.3 Setting the clock

All channels must show END or CLEAR before the clock can be set. Push and hold

the two arrow keys at the same time until the instrument setup menu is shown.

Select the clock parameter to be adjusted by pushing the applicable channel key

(Table 3 on page 14). Use the arrow keys to edit the chosen parameter. Adjust

each parameter in the same manner. When all time adjustments are complete,

push the OFF key to save and go back to the data display screen.

4.4 RS232 Interface

All RS232 connections are made through the Serial I/O port (Figure 1 on page 12).

Connect the 9-pin D connector of a computer interface cable to the Serial I/O port

on the instrument. Connect the opposite end of the cable to the computer Serial I/O

port (Com 1 or Com 2).

The BODTrak II instrument is equipped as Data Communication Equipment (DCE).

The BODTrak II operates at 9600 baud with 8 data bits, no parity and one stop bit.

The computer or printer will not receive complete transmissions if the device cannot

continuously receive at 9600 baud.

Note: Use of the specified cable or an equivalent shielded cable is mandatory to meet Radio

Frequency Emissions requirements.

15

Page 16

Operation

4.5 Downloading test results

To transfer test results to a PC:

1. Choose

2. In the Connection Description window, type in a name for the connection and

choose an icon to represent it. Click

3. In the Connect To window, use the drop-down menu to choose the COM port

connected to the BODTrak II instrument. Click

4. Configure the COM port properties:

BPS = 9600, Data Bits = 8, Parity = None, Stop Bits = 1,

Flow Control = None.

5. Click

6. Choose

7. In the Capture Text window, click

Name the file and click SAVE.

8. In the Capture Text window click START.

9. Power on the BODTrak II. Push the applicable channel key for the data to be

downloaded.

10. Type GA in the HyperTerminal window, then push

complete when the screen stops adding new data.

11. Choose

12. Choose

13. To end the HyperTerminal session, choose FILE, EXIT.

14. Click

PROGRAMS, ACCESSORIES, COMMUNICATIONS, HYPERTERMINAL.

OK.

OK.

OK. The connect indicator will be shown.

TRANSFER, CAPTURE TEXT.

BROWSE to choose a specific save location.

ENTER. The transfer is

TRANSFER, CAPTURE TEXT, STOP.

CALL, DISCONNECT. The disconnected indicator will be shown.

YES to save the session and all instrument/port configuration settings.

4.5.1 Import data

To import the data from the captured text file:

1. Open a new or existing spreadsheet. Choose DATA, IMPORT EXTERNAL DATA,

IMPORT DATA.

2. Select the text file captured in HyperTerminal. Click

3. In the Text Import Wizard, choose Delimited as the file type, the start row in

the spreadsheet, and Windows (ANSI) as the file origin. Click NEXT.

4. Check the Space delimiter and Treat consecutive delimiters as one check

boxes. Click

NEXT.

5. Choose General as the Column data format then click

6. In the Import Data window, choose Existing worksheet. Choose the starting cell

then click

OK. The data will appear in your spreadsheet.

7. Choose File, Save As to save the spreadsheet.

The spreadsheet data cannot be edited or formatted in HyperTerminal or with the

BODTrak II.

16

IMPORT.

FINISH.

Page 17

Operation

4.5.2 Data format

When a result array is downloaded to HyperTerminal, all data from the test are sent

without pause. The data flow cannot be stopped or paused.

Figure 3 shows channel number, start date, start time, and the format of the

downloaded data. BOD values in mg/L follow. Only the first data points, of a

maximum of 360 equal distance points, are shown in this example. Each line ends

with a carriage return and a line feed. The end of the data stream is shown by a

message such as “Test Run to Completion” and a dollar symbol ($).

If small negative BOD values are seen at the start of a test, refer to Troubleshooting

on page 37.

BOD Log for Ch 1

Status: END

Full Scale: 700 mg/L

Tst length: 7 days

Start Date: 3/3/08

Time: 13:04

Days, Reading (mg/L)

0.00, 0

0.05, 10

0.11, 12

0.16, 12

0.22, 14

0.27, 14

0.33, 12

0.38, 8

0.44, 10

0.50, 12

0.55, 12

0.61, 14

-

-

Test Run to Completion

$

Figure 3 Downloaded test data

17

Page 18

Operation

4.5.3 Printing test results

The BODTrak II is compatible with the Citizen PD-24 printer, which is available as

an optional accessory (Section 8 on page 41). Connect the printer cable to the

serial port on the BODTrak II using the gender adapter provided with the printer.

Make sure the printer interface settings are correct (section 4.4 on page 15).

Power on the BODTrak II instrument. Push and hold the applicable channel number

for approximately 5 seconds at any time during a test. This moves the test results

from the BODTrak II to the printer. The instrument will send a copy of the graphical

display and a truncated data stream (127 data points).

18

Page 19

Section 5 BODTrak™ II procedures

5.1 General Information

There are three BODTrak II procedure variations. Choose the procedure that meets

the application requirements.

The Simplified procedure (section 5.2 on page 20) is recommended when sample

seeding, extra nutrients or buffers are not necessary. It is also recommended when

accuracy requirements are not stringent.

The Hach GGA (glucose/glutamic acid) procedure (section 5.3 on page 22) is

recommended for all accuracy and performance checks using seeded GGA. It is

also recommended when test accuracy is important.

The Hach Standard Method procedure (section 5.4 on page 24) is recommended

when samples are seeded or extra nutrients or reagents are added. Use this

procedure when following Standard Methods for the Examination of Water and

Wastewater, 21st Edition, Method 5210 D Respirometric Method.

All procedure variations are followed by completion steps for all procedures

(section 5.5 on page 27). It is possible to use a combination of these procedures

with one instrument, but in different bottles. Only one test length can be chosen.

Before starting the test:

Use the applicable sample volume tables for each procedure.

If power is interrupted when the instrument is in DELAY status, the test will stop and the

status will change to CLEAR when power returns. Start the test again.

If power is interrupted when the instrument is in RUN status, the test will resume when

power returns.

Keep deionized water overnight in an incubator at 20 ºC. Shake the deionized water to

saturate with air.

Settle the seed overnight in the BOD incubator at a temperature of 20 ºC. Be careful not to

disturb the settled solution. Pipet seed solution from the top.

Dilution is necessary if samples have BOD values more than 700 mg/L (5.7 on page 33).

At elevations higher than 5000 feet above sea level the 0 to 35 mg/L BOD range is

decreased to 0 to 25 mg/L BOD. Adjustment is not necessary for other test ranges.

Refer to section 5.7 on page 33 for special considerations including sample seeding and

pretreatment.

Use only BODTrak II stir bars and bottles. They are designed specifically for use with the

BODTrak II.

19

Page 20

BODTrak™ II procedures

5.2 Simplified procedure

Required apparatus:

BODTrak II bottle

Thermometer

Blender (optional)

Graduated cylinder

Required reagents:

1 nutrient buffer pillow

Table 4 Simplified sample volumes

BOD range mg/L Sample volume mL

0 to 35 420

0 to 70 355

0 to 350 160

0 to 700 95

1. Heat or cool the

sample to 19 to 21 ºC

(66 F to 70 ºF).

20

2. Homogenize the

sample in a blender if it

contains large settleable

or floatable solids.

3. Choose the correct

sample size for the

sample range (Table 4).

Measure the sample into a

graduated cylinder.

Page 21

BODTrak™ II procedures

4. Add the contents of 1

nutrient buffer pillow to the

graduated cylinder.

5. Transfer the contents of

the graduated cylinder to

a BODTrak II bottle.

Repeat steps 1 to 5 for

additional samples.

6. Continue to the

completion steps for all

procedures (section 5.5

on page 27).

21

Page 22

BODTrak™ II procedures

5.3 Hach GGA (glucose/glutamic acid) procedure

Required apparatus:

BODTrak II bottle

Graduated cylinder

Volumetric pipet and pipet filler

Tensette® pipet and pipet tips

Wash water bottle

Ampule breaker

Required reagents:

Deionized water

Hach GGA solution

1 nutrient buffer pillow

Before starting the test:

Use Hach BOD Standard Solution Ampules for Manometric Method (3000 mg/L Glucose,

3000 mg/L Glutamic acid).

On a standard containing 150 mg/L each of glucose and glutamic acid, a single analyst

using 6 BODTrak II instruments and testing 44 samples obtained a mean of 235 mg/L BOD

with a 95% Confidence Limit of Distribution of 11 mg/L or a range of 224 to 246 mg/L BOD

after 5 days.

Always prepare the seed blank before the GGA samples. Use the same amount of seed for

all GGA samples and seed blank.

Refer to section 5.7 on page 33 for special considerations.

Prepare seed blank

Use steps 1, 3 to 7.

Prepare sample

Use steps 1 to 7.

22

Page 23

BODTrak™ II procedures

Table 5 GGA sample volumes

BOD range

(mg/L)

0 to 350 8.0 10 to 35 160

Note: If seed strength is unknown, use 20 mL. Adjust seed volume as necessary to achieve

optimum GGA results. Use the same amount of seed for all GGA samples and seed blank.

GGA volume

(mL)

Seed volume

(mL)

Final Volume

(mL)

1. Add approximately

30 mL of deionized water

to a 200 mL graduated

cylinder.

4. Use a tensette pipet to

add the correct quantity of

seed to the graduated

cylinder (Table 5).

7. Continue to the

completion steps for all

procedures (section 5.5

on page 27).

2. Use a volumetric pipet

to transfer 8.0 mL of Hach

GGA solution to the

graduated cylinder.

Note: Skip this step when

preparing the seed blank.

5. Dilute to the sample to

160 mL using a deionized

water wash bottle.

3. Add the contents of 1

nutrient buffer pillow to the

graduated cylinder.

6. Transfer the prepared

sample from the

graduated cylinder to a

BODTrak II bottle.

Note: For additional GGA

samples, repeat steps 1 to 6.

23

Page 24

BODTrak™ II procedures

5.4 Hach Standard Method procedure

Required apparatus:

Thermometer

BODTrak II bottle

Blender (optional)

Graduated cylinder

Tensette pipet and pipet tips

Wash water bottle

Required reagents:

1 nutrient buffer pillow

Additional nutrient or buffer (optional)

Deionized water

Before starting the test:

Use the sample volume table to choose the correct sample size (Table 6).

If seeding samples, prepare a seed blank before preparing a sample. Treat the seed blank

the same as any other sample and omit step 5.

Refer to section 5.7 on page 33 for special considerations.

Table 6 Hach Standard Method sample volumes

BOD range

(mg/L)

Sample

volume (mL)

Seed volume

(mL)

Final volume

(mL)

Dilution

factor

0 to 35 370 10 to 35 420 1.14

0 to 70 305 10 to 35 355 1.16

0 to 350 110 10 to 35 160 1.45

0 to 700 45 10 to 35 95 2.11

Note: If seed strength is unknown, use 20 mL. Adjust seed volume as necessary to achieve

optimum results.

24

Page 25

BODTrak™ II procedures

1. Heat or cool the

sample to 19 to 21 ºC

(66 to 70 ºF).

4. Add the contents of 1

nutrient buffer pillow to the

graduated cylinder.

2. Homogenize the

sample in a blender if it

contains large settleable

or floatable solids.

5. If seeding the sample,

use a tensette pipet to add

the correct quantity of

seed to the graduated

cylinder (Table 6 on page

24).

3. Choose the correct

sample size for the

sample range (Table 6 on

page 24). Measure the

sample into a graduated

cylinder.

6. If necessary, add more

nutrient or buffer. Do not

add more than a total

volume of 50 mL (seed,

nutrient, buffer).

25

Page 26

BODTrak™ II procedures

7. Fill to the final test

range volume, if

necessary, with a

deionized wash water

bottle (Table 6 on page

24).

8. Transfer the prepared

sample from the

graduated cylinder to a

BODTrak II bottle.

Note: Repeat steps 1 to 8 for

additional samples.

9. Continue to the

completion steps for all

procedures (section 5.5

on page 27).

26

Page 27

BODTrak™ II procedures

5.5 Completion steps for all procedures

Required apparatus:

BODTrak II

Spatula scoop

BOD incubator

Seal cup

Stir bar

Required reagents:

2 potassium hydroxide pellets

1. Put a BODTrak II stir

bar into the bottle.

2. Put a seal cup into the

neck of the bottle.

3. Use a spatula scoop

to add 2 potassium

hydroxide pellets to the

seal cup. Repeat steps

1 to 3 for each sample

bottle.

27

Page 28

BODTrak™ II procedures

4. Put the bottles on the

BODTrak II chassis.

Connect the applicable

tube to the sample bottle

and tighten the cap.

7. Push and hold the left

and right arrow keys at

the same time to access

the instrument setup

menu.

Note: Set the time and date,

if necessary (section 4.3 on

page 15).

5. Put the instrument in

the incubator. The

incubator temperature

must be 20 ± 1 ºC

(68 ± 1 ºF).

Note: Instrument

performance has not been

tested at other

temperatures.

8. Push the Channel 6

key to access the test

length parameter. Use

the arrow keys to choose

a 5, 7 or 10 day test.

Note: The selected test

length is for all 6 channels.

6. Plug in and power on

the instrument. Make

sure all stir bars are

rotating. If not, lift the

bottle up and set down

again.

9. Push OFF to save

selections and exit the

menu.

28

Page 29

BODTrak™ II procedures

10.To start the test, push

the channel number

applicable to the bottle.

13.Push and hold the ON

key to start a test. A

graph will be displayed.

Note: To cancel a test push

and hold the OFF key.

Note: There is a built-in

1 hour instrument/sample

equilibration period before

data collection. The display

will show DELAY during this

period.

11.Push the ON key. The

range selection menu is

shown.

14.Do steps 10 through

13 again to set the test

range and start each of

the 6 channels. It is not

necessary to operate all

6 channels if less than 6

samples are available.

12.Use the arrow keys to

choose the test range.

Note: Use the left arrow key

for the 0 to 35 and

0 to 70 mg/L ranges. Use

the right arrow key for the

0 to 350 and 0 to 700 mg/L

ranges.

29

Page 30

BODTrak™ II procedures

5.5.1 Determination of results

After the end of the chosen test period (5, 7 or 10 days), END is shown on the

display. The procedure that is done dictates the determination of the results. The

results are determined based on the selected procedure: Simplified, Hach GGA or

Hach Standard Method.

5.5.1.1 Simplified sample results

The Simplified Procedure results are shown on the BODTrak II display. Push the

applicable channel selection key to show the results.

Note: If the sample was pre-diluted, apply a dilution factor to the instrument reading

(section 5.7.1 on page 33).

5.5.1.2 Hach GGA (glucose/glutamic acid) results

The seed blank and seeded GGA sample results are necessary for the Hach GGA

procedure results.

1. Push the channel selection key for the seed blank bottle. The results are

shown.

2. Push the channel selection key for the seeded GGA sample bottle. The results

are shown.

3. Calculate the results:

BOD mg/L = seeded GGA sample result - seed blank result

5.5.1.3 Hach Standard Method results

1. Push the channel selection key for the Hach Standard Method sample bottle.

The results are shown.

Note: Treat the seed blank the same as all other samples.

Note: If the sample was pre-diluted, apply a dilution factor to the instrument reading

(section 5.7.1 on page 33).

2. Find the dilution factor based on the selected range (Table 6 on page 24).

Example: If the sample range selected was 0 to 350 mg/L BOD, the dilution

factor is 1.45.

3. Calculate the corrected results:

BOD mg/L = BOD mg/L (instrument reading) x dilution factor

Example:

Instrument Reading = 200 mg/L, BOD dilution factor = 1.45

200 mg/L x 1.45 = 290 mg/L BOD (Corrected Result)

30

Page 31

BODTrak™ II procedures

BOD mg/L()ABx

SA

SB

--------

⎝⎠

⎛⎞

–=

BOD mg/L()290mg/L 120mg/L x

20mL

110mL

-------------------

⎝⎠

⎛⎞

–=

4. When samples are seeded, calculate the results using this equation and the

corrected results:

Where:

A = corrected BOD of the seeded sample

B = corrected BOD of the seed blank

SA = volume of seed in sample (sample can also be GGA)

SB = volume of seed in seed blank

Example:

A= 290 mg/L BOD

B= 120 mg/L BOD

SA= 20 mL

SB= 110 mL

BOD mg/L = 268 mg/L

31

Page 32

BODTrak™ II procedures

5.6 Typical curves

Typical curves through a 10 day test period are shown in Figure 4. For incorrect

curves refer to Figure 5 on page 37.

Figure 4 Typical curves

1 Typical with substrate variation 3 Typical with time lag

2 Typical

32

Page 33

BODTrak™ II procedures

5.7 Special considerations

5.7.1 Sample dilution

Unknown sample BOD effluent is typically in the 0 to 70 mg/L range. Unknown

sample BOD influent is typically in the 0 to 700 mg/L range. When the oxygen

requirement of a sample is more than 700 mg/L, dilute the sample with high-quality

distilled or deionized water.

Calculate the results to include the additional dilution factor. Example: If the BOD of

the sample is 1000 mg/L, dilute the sample 1:1 with distilled or deionized water. The

estimated BOD is now 500 mg/L. Use the sample volume specified in the table for

the 0 to 700 mg/L range of the chosen procedure. Multiply the instrument reading

result by 2. If using the Hach Standard Method procedure, continue with remaining

calculations.

5.7.2 Sample seeding

Some types of BOD samples do not contain sufficient bacteria to oxidize the

organic matter in the sample. Many industrial wastes are of this type. Some sewage

treatment plant effluents are chlorinated and essentially sterile. A BOD test cannot

be done in the absence of viable bacteria. To test such samples, seed each bottle

from a source known to contain a viable bacterial population.

Settled domestic wastewater plant influent or primary clarifier effluent are the

preferred sources of seed for most samples. Mixed liquor or undisinfected effluent

can be used for seed, but it is recommended to include a nitrification inhibitor.

Commercial seed sources are sometimes suitable. To prepare, see the instructions

from the manufacturer.

5.7.3 Sample temperature

Standard Methods for the Examination of Water and Wastewater, 21st Ed., 2005,

5210 D recommends an incubation temperature of 20 ±1 °C (68 °F) for the BOD

test. Put the BODTrak II instrument in an incubator that is adjusted to 20 ±1 °C. An

applicable BOD incubator is available from Hach (section 8.1 on page 41). Warm or

cool samples to 20 ± 1 °C.

Note: Instrument performance has not been validated at temperatures other than 20 °C.

5.7.4 Toxic materials

Industrial and chlorinated samples often contain toxic substances and require

special considerations when running BOD tests. Toxic materials in the sample will

cause decreased BOD values. Dilute the sample to minimize the toxic materials or

their effects. Refer to Standard Methods for the Examination of Water and

Wastewater, 21st edition, 5210 D.

33

Page 34

BODTrak™ II procedures

mL of Sodium Thiosulfate

mL used()mL sample to be dechlorinated()

100

-------------------------------------------------------------------------------------------------------------------

=

5.7.5 Chlorine

Any chlorine in the sample must be removed prior to testing. Keep the sample at

room temperature for 1 to 2 hours before a test to dissipate low chlorine

concentrations. If any chlorine remains after sitting for 2 hours or if the chlorine

concentration is high, add sodium thiosulfate to remove the chlorine:

1. In a 250 mL erlenmeyer flask add 100-mL of sample.

2. Add 10 mL of 100 g/L potassium iodide solution and

10 mL of 0.02 N sulfuric acid standard solution to the erlenmeyer flask.

3. Add 3 droppers of starch indicator solution and swirl to mix.

4. Titrate from dark blue to colorless with 0.025 N Sodium Thiosulfate standard

solution.

5. Calculate the quantity of sodium thiosulfate standard solution necessary to

dechlorinate the remaining sample:

6. Add the necessary quantity of 0.025 N sodium thiosulfate standard solution to

the sample and mix fully. After 10 to 20 minutes, do the BOD test.

5.7.6 pH effect

Low BOD test results occur when sample pH is outside the range of 6 to 8. Keep

this pH to simulate source sample conditions or adjust the pH to neutrality (buffered

at pH 7). Use 1.0 N (or weaker) sulfuric acid to neutralize caustic samples. Use 1.0

N (or weaker) sodium hydroxide to neutralize acidic samples. When samples are

pH adjusted, they should also be seeded.

5.7.7 Supersaturation

Equilibrate supersaturated cold samples (containing more than 9 mg/L dissolved

oxygen at 20 °C) to saturation:

1. Heat or cool the sample temperature to approximately 20 °C.

2. Half fill a sample bottle with sample.

3. Shake for 2 minutes or aerate with filtered compressed air for 2 hours.

34

Page 35

Section 6 Maintenance

DANGER

Only qualified personnel should conduct the tasks described in this section

of the manual.

6.1 Cleaning the instrument

Clean spills on the BODTrak™ II instrument with a soft cloth which has been

dampened with deionized or distilled water.

6.1.1 Sample bottles

After each test, empty the sample bottles and flush them thoroughly with hot water.

Use a brush, hot water and soap to remove residue. Residue creates a BOD. Flush

the bottles thoroughly with tap water and finally with distilled or deionized water to

remove all detergent.

6.1.2 Stir bars and seal cups

Clean the stir bars with hot water and soap. Use a brush to remove deposits. Flush

with tap water and finally with distilled or deionized water to remove all detergent.

Carefully empty and rinse the seal cups with water. Invert to dry.

6.1.3 Bottle fences

The bottle fences prevent tipping of the bottles and provide tubing management

during storage. For storage, put the tubing into the opening in the bottle fence.

Wind the tubing counter-clockwise and secure the bottle cap inside the fence.

35

Page 36

36

Page 37

Section 7 Troubleshooting

Incorrect BOD curves through a 10 day test period are shown in Figure 5. For

typical curves refer to Figure 4 on page 32.

Figure 5 Incorrect BOD curves

1 High oxygen demand 4 Initial sample temperature below

20 ºC or supersaturated with

oxygen

2 Nitrification 5 Bottle leak

3 Excessive time lag

37

Page 38

Troubleshooting

7.1 High oxygen demand

Samples that are above range (for example, a BOD over 350 mg/L when a 160-mL

sample is taken) will cause results as shown in Curve 1 (Figure 5 on page 37).

Dilute the sample (section 5.7 on page 33) or use a higher BOD range and a

different sample volume (Table 4 on page 20, Table 5 on page 23 or Table 6 on

page 24).

When the BOD range of a sample is unknown:

• Use the results from the Chemical Oxygen Demand (COD) test. An estimated

BOD value can be obtained by multiplying the COD by 0.68.

• Use the results from a series of BOD tests using the same sample but different

volumes.

• Or use dilution ratios to choose an applicable BOD range.

Typically, effluent is in the 0-70 mg/L range while influent is in the 0-700 mg/L

range. When the BOD of the sample is more than 700 mg/L, prepare a sample

dilution (section 5.7 on page 33).

7.2 Nitrification

The condition shown by Curve 2 is an example of nitrification (Figure 5 on page

37). Deviation from the typical curve (shown as the dashed line) is apparent by the

concave increase near the end of the test period.

Biological oxidation of organic nitrogen usually occurs after 5 days with typical

domestic waste. Nitrifying bacteria develop more slowly than other types of

bacteria.

However, some samples contain a high concentration of nitrifying bacteria and

nitrification results can occur sooner. Control nitrification problems with Hach

Nitrification Inhibitor. Dispense the inhibitor powder into an empty sample bottle and

then add the sample. With the Hach Dispenser cap, dispense 6 shots

(approximately 0.48 grams) into the empty bottle. Refer to replacement parts and

accessories (Section 8 on page 41).

7.3 Excessive time lag

Curve 3 (Figure 5 on page 37) shows a test that did not start with sufficient bacteria

during the incubation period. To do a test on a sample without sufficient bacteria,

seed the sample (section 5.7.2 on page 33).

Bacteria acclimation also causes conditions that could cause Curve 3. This

sometimes occurs with standards and added seed. Add more seed or choose a

different seed source.

7.4 Sample temperature

The initial negative results of Curve 4 (Figure 5 on page 37) show that the initial

sample temperature was below the specified range of 20 ± 1 ºC. A sample

supersaturated with oxygen will also display this type of curve (section 5.7.3 on

page 33 and section 5.7.7 on page 34).

38

Page 39

Troubleshooting

7.5 Bottle leak

Curve 5 (Figure 5 on page 37) shows a bottle leak. A bottle leak can also cause no

response from the system. If such a response occurs, check the seal cup and bottle

cap for contamination or damage.

39

Page 40

40

Page 41

Section 8 Replacement parts and

accessories

8.1 Replacement parts

Description Quantity Item Number

BODTrak™ II Instrument, 115/230 VAC 1 2952400

Bottle, BODTrak II, amber (6x) 1 714421

Power cord, 18/3 SVT 7.5’, 10A-125 VAC for North

American 115 VAC use

Power Cord, 8’, with continental European plug for 230

VAC u se

Power Supply 1 2952500

Computer cable for data transfer to PC 1 2959300

Seal Cup 1 2959500

Spatula scoop 1 1225700

Stir Bar, magnetic, BODTrak II 1 2959400

8.2 Reagents

Description Quantity Item Number

Respirometric BOD nutrient buffer pillows 1 2962266

Potassium hydroxide pellets 1 31425

1 2959200

1 2959100

8.3 Optional reagents

Description Quantity Item Number

Nitrification inhibitor, 35 g 1 253335

Dispenser cap for 35 g bottle (for use with nitrification

inhibitor)

Polyseed Inoculum (50x) 1 2918700

Potassium iodide solution, 100 g/L, 500 mL 1 1228949

Sodium Hydroxide standard solution, 1.0 N,

900 mL

Sodium Thiosulfate standard solution, 0.025 N, 1000

mL

Starch indicator solution, dropping bottle,

100 mL MDB

Sulfuric acid, ACS, 500 mL 1 97949

1 45901

1 104553

1 35253

1 34932

41

Page 42

8.3 Optional reagents (continued)

Description Quantity Item Number

Sulfuric acid, 0.02 N standard solution, 1000 mL 1 20353

Sulfuric acid, 1.0 N standard solution,

1000 mL

Voluette ampule standard for BOD, 3000 mg/L for

manometric, 10-mL/ampule, 16 ampules

1 127053

1 1486610

8.4 Accessories

Description Quantity Item Number

Ampule breaker kit for voluette ampules 1 2196800

Bottle, wash, 500 mL 1 62011

Bottle, polyethylene, with spigot, 4 L 1 1486817

Brush, cylinder, size 2 1 68700

Buret, straight stopcock, Teflon plug, 25 mL 1 1405940

Clamp, buret, double 1 32800

Cylinder, graduated, 10 mL 1 50838

Cylinder, graduated, 25 mL 1 50840

Cylinder, graduated, 50 mL 1 50841

Cylinder, graduated, 100 mL 1 50842

Cylinder, graduated, 250 mL 1 50846

Cylinder, graduated, 500 mL 1 58049

Cylinder, graduated, 1000 mL 1 50853

Flask, erlenmeyer 1 50546

Incubator, BOD, Model 205, 110 V 1 2616200

Incubator, BOD, Model 205, 220/240 V 1 2616202

Pipet, Tensette®, 0.1 to 1.0 mL 1 1970001

Pipet, Tensette, 1 to 10 mL 1 1970010

Pipet tips, 0.1 to 1.0 mL (50x) 1 2185696

Pipet tips, 0.1 to 1.0 mL (1000x) 1 2185628

Pipet tips, 1 to 10 mL (50x) 1 2199796

Pipet tips, 1 to 10 mL (250x) 1 2199725

Pipet filler, 3 valve 1 1218900

Pipet, serological, glass, 10 mL 1 53238

Printer, Citizen PD-24 with cable 1 2960100

Standard Methods for the Examination of Water and

Wastewater

Support stand, buret 1 32900

1 2270800

42

Page 43

Replacement parts and accessories

8.4 Accessories (continued)

Description Quantity Item Number

Thermometer, Mercury, -20 to 110 °C 1 56601

Thermometer, non-Mercury, -20 to 110 °C 1 2635702

Water Still, 120 V 1 2615900

Water Still, 220 V 1 2615902

Water System, Ultrapure, Millipore Direct -Q 3 1 2512100

DQ3 purification pack 1 2512201

43

Page 44

44

Page 45

Section 9 Contact Information

HACH Company World

Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) 227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

Repair Service in Latin

America, the Caribbean,

the Far East, Indian

Subcontinent, Africa,

Europe, or the Middle

East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE FRANCE

S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

Repair Service in

Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

45

Page 46

Contact Information

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 04 47

info@hach-lange.bg

www.hach-lange.bg

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Hegyalja út 7-13.

H-1016 Budapest

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Leonida, nr. 13

Sector 2

RO-020555 Bucuresti

Tel. +40 (0) 21 201 92 43

Fax +40 (0) 21 201 92 43

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

46

Loading...

Loading...