Page 1

DOC022.52.90424

BIOGAS Titration Manager

08/2012, Edition 1A

User Manual

© HACH Company, 2012. All rights reserved. Printed in France.

Page 2

Table of contents

Section 1 Specifications................................................................................................. 4

Section 2 General Information .......................................................................................6

2.1 Safety notes................................................................................................................ 6

2.1.1 Use of Hazard information ................................................................................ 6

2.1.2 Precautionary Labels ........................................................................................6

2.1.3 Chemical and Biological Safety ........................................................................ 7

Section 3 Installation ...................................................................................................... 8

3.1 Unpacking the instruments.......................................................................................... 8

3.2 Operating environment................................................................................................ 8

3.3 Power connections......................................................................................................9

3.4 Interfaces .................................................................................................................. 10

3.5 Installation of burettes and reagents......................................................................... 10

Kapitel 4 Startup............................................................................................................12

4.1 Power the instrument on and off ............................................................................... 12

4.2 Language selection................................................................................................... 12

4.3 Display Contrast........................................................................................................12

Kapitel 5 Standard Operations..................................................................................... 14

5.1 Overview ................................................................................................................... 14

5.1.1 Use of alphanumerical keypad........................................................................14

5.1.2 General screen description.............................................................................15

5.2 Main menu ................................................................................................................ 16

5.3 Reagent menu .......................................................................................................... 16

5.4 Electrode menu.........................................................................................................18

5.5 Cell menu.................................................................................................................. 19

5.6 Setup Menu............................................................................................................... 20

5.6.1 Configuration menu ........................................................................................ 20

5.6.2 Customize the Titration Manager.................................................................... 23

5.7 Manual printouts........................................................................................................ 26

5.8 Edit data....................................................................................................................26

5.8.1 Edit method data.............................................................................................26

5.8.2 Edit reagent data ............................................................................................ 27

5.8.3 Edit electrode data.......................................................................................... 27

5.8.4 Automatic printouts.........................................................................................28

5.9 Store, send and recall data.......................................................................................29

5.9.1 The data log.................................................................................................... 29

5.9.2 The reagent calibration log ............................................................................. 33

5.9.3 The electrode calibration log...........................................................................33

5.10 Program instructions ............................................................................................... 34

5.10.1 Enter a new electrode................................................................................... 34

5.10.2 Enter a new reagent ..................................................................................... 38

5.10.3 Enter a new method...................................................................................... 40

2

Page 3

Table of contents

5.11 Run analyses...........................................................................................................42

5.11.1 Introduction....................................................................................................42

5.11.2 Run an elecrode calibration...........................................................................45

5.11.3 Run a reagent calibration ..............................................................................45

5.11.4 Run a method................................................................................................46

5.11.5 Run a sequence ............................................................................................46

5.11.6 Run a direct measurement ............................................................................46

Section 6 Maintenance ..................................................................................................48

6.1 Cleaning the instrument.............................................................................................48

6.2 Fuse replacement......................................................................................................48

6.3 Servicing....................................................................................................................48

Section 7 Troubleshooting............................................................................................50

7.1 Troubleshooting.........................................................................................................50

Section 8 Replacement Parts and Accessories ..........................................................52

8.1 Burette stands ...........................................................................................................52

8.2 Spare parts ................................................................................................................52

8.3 Polypropylene titration vessels ..................................................................................52

8.4 Notebook keyboards..................................................................................................52

8.5 Combined pH/Reference electrodes – Acid/Base titrations.......................................52

8.6 4-7-10 Series pH Standards ......................................................................................52

8.7 Electrode Maintenance Solutions ..............................................................................53

8.8 Titrant Solutions.........................................................................................................53

Section 9 Contact Information......................................................................................54

3

Page 4

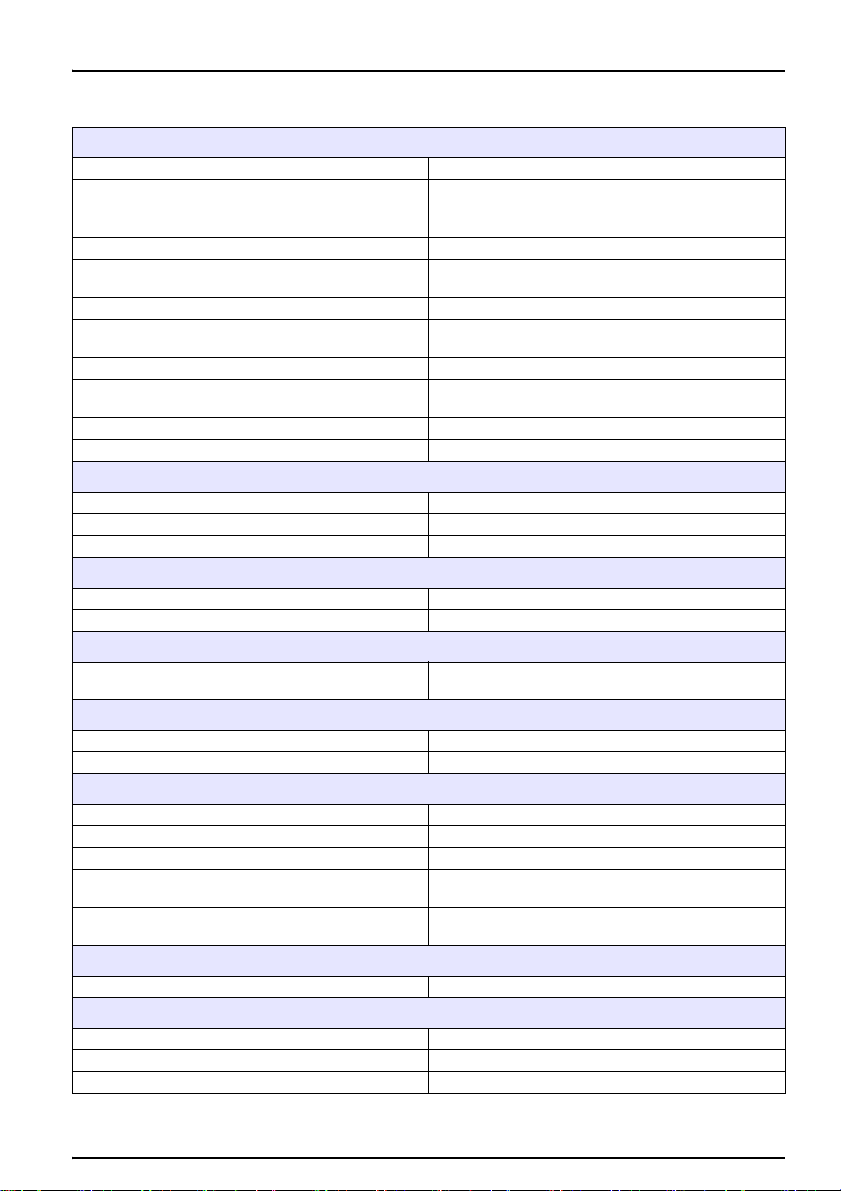

Section 1 Specifications

Specifications are subject to change without notice.

Methods

End point titration 1 to 3 pre-set

Auto determination of 1 to 4 inflection points with

Inflection point titration

Titration stops at pH, mV, mL, IP number

Titrant addition techniques

Titrant calibration

pH electrode calibration

Direct pH/mV measurements With recording on stable reading.

Back titration with manual

reagent addition

Sequencing of up to 3 methods

Coupling of 2 methods in one beaker

Measuring ranges - Resolution

pH value -9 to 23 pH - 0.001 pH

mV value ±2000 mV - 0.1 mV

Temperature -10 °C to +100 °C (14 to 212 °F) - 0.1 °C

Printout

Automatic. GLP compliant

3 levels of detail

Results

In each method, calculation of up to 4 results and 2

user-defined equations

Units

All standard units for samples/results

User-defined result units

Storage capacity

Global password protection for programming access

Non-volatile memory for storage of the last 60 results

10 user programmable methods

Libraries with more than 30 electrodes and 20 titrants

pre-identified

Embedded operating procedures for burette and

reagent exchange operations

Sample list

Up to 20 data with alphanumeric ID

Electrode stand - stirring

Magnetic stirrer 22 reproducible speeds (0 to 1100 rpm) in 50 rpm steps

Propeller connection

Beaker volume 5 to 400 mL

programmable IP acceptation windows.

IP detection using 1st and 2nd derivative curve.

Incremental dynamic, incremental monotonic and

continuous dynamic.

Up to 5 points using IUPAC standards or 4-7-10 Series

buffers with error recognition on buffer used.

4

Page 5

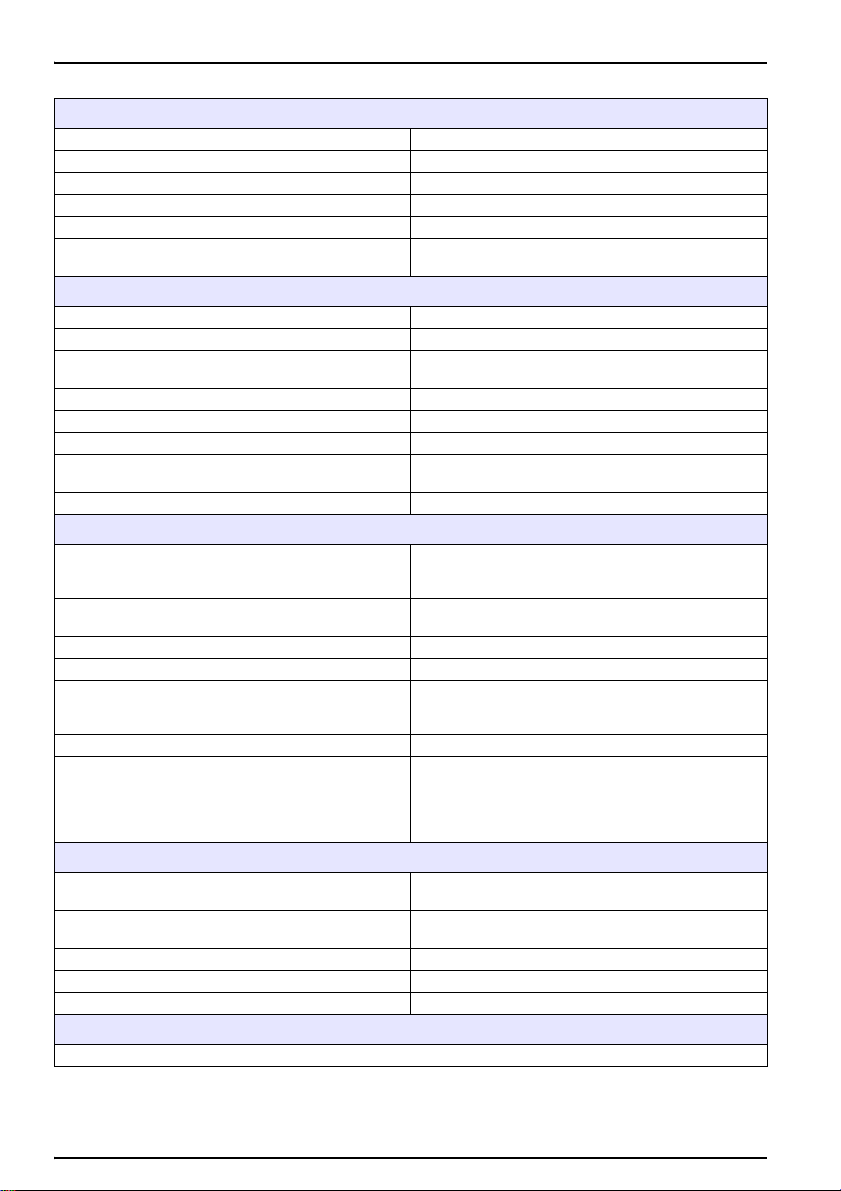

Specifications

Burette

1 embedded burette stand

Burette volumes available 1, 5, 10, 25, 50 mL

Burette motor 18000 steps

Complies with ISO/FDIS 8655-3

UV-protected encapsulated glass syringe

Embedded operating procedures

Inputs/outputs

1 indicator electrode inputs

1 reference electrode input

Selectable polarised input from -1 mA to +1 mA in 1 µA

steps, DC or AC

Differential input

Temperature input

0-5 V TTL output

Serial connections

PS/2 port for PC keyboard and/or barcode reader

General specifications

Casing

Languages

Dimensions (H x W x D) 380 x 230 x 450 mm (1.25 x 0.75 x 1.48 ft) (excl. tubing)

Weight 5 kg (excluding reagent bottles)

Power requirements

Mains fuses T1A L250V, slow blow (2 fuses)

Secondary fuses

Environmental operating conditions

Environmental operating conditions (working)

Environmental operating conditions (storage)

Altitude 2000 m

Level of pollution: 2

Transitory overvoltage: class II

Limited Warranty

The warranty period for instruments is 2 years from the date of shipment.

burette exchange, air bubble removal (Flush)

Fill, Empty function

Printer/PC, balance, sample changer and additional

titrator for use with TitraMaster 85 PC Software

Fully splashproof.

Graphic 128 x 128 dot LCD protected from spillages.

Soft-touch alphanumeric keypad (silicone)

English, German, Danish, French, Italian, Spanish,

Swedish

115 VAC (±10 %) or 230 Vac (±10 %)

50...60 Hz - 45 VA

On/Off power switch

T4 A, 230 V (1 fuse)

The secondary fuse is mounted on the printed circuit

board. If necessary, contact a manufacturer‘s Service

engineer for replacement of the fuse, as the instrument

casing must be opened.

5 to 40 °C (41 to 104 °F), max. 80 % relative humidity

(without water condensation)

-20 to 60 °C (-4 to 140 °F), max. 80 % relative humidity

(without water condensation)

5

Page 6

Section 2 General Information

2.1 Safety notes

Please read this entire manual before unpacking, setting up, or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use or install this

equipment in any manner other than that specified in this manual

2.1.1 Use of Hazard information

DANGER

Indicates a potentially or imminently hazardous situation that, if not avoided, results in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation that, if not avoided, may result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation that, if not avoided, could result in damage to the instrument. Information that requires spe-

NOTICE

cial emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol, if noted on the instrument, will be included with a danger or

caution statement in the manual.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems after 12 August of 2005. In conformity with European local and national regulations (EU

Directive 2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for

instructions on how to return end-of-life equipment, producer-supplied electrical

accessories, and all auxiliary items for proper disposal.

6

Page 7

General Information

2.1.3 Chemical and Biological Safety

DANGER

Potential danger with contact with chemical/biological substances.

Working with chemical samples, standards and reagents can be dangerous.

Make yourself familiar with the necessary safety procedures and the correct handling of the chemicals before use

and read and follow all relevant safety data sheets.

Normal operation of this device may require the use of chemicals or samples that are biologically

unsafe.

• Observe all cautionary information printed on the original solution containers and safety data

sheets prior to their use.

• Dispose of all consumed solutions in accordance with the local and national regulations and

laws.

• Select the type of protective equipment suitable to the concentration and quantity of the

dangerous material being used.

DANGER

The BIOGAS Titration Manager has been developed to meet the requirements of volumetric titration applications.

It is therefore aimed at experienced users who have the knowledge required to operate the instrument and implement the security instructions enclosed. Please remember that the BIOGAS Titration Manager must not, under

any circumstances, be used to perform tests on living beings.

WARNUNG

The BIOGAS Titration Manager may not be used in dangerous environments.

The manufacturer and its suppliers reject any express or indirect guarantee for use with high-risk activities.

Follow the following safety information, in addition to any local guidelines in force.

Safety information for the correct use of the instrument:

• Do not vibrate or jolt the instrument.

• Do not open the instrument.

• Guarantee is voided if the instrument is not used in accordance with the guidelines present in

this document.

ACHTUNG

The manufacturer is not responsible for damages resulting from misapplication or misuse of this product and

rejects the regulation of such damages, including direct, indirect and consequential damages, and in full

accordance with applicable law. The user is solely responsible for the identification of critical applications and risks

and taking appropriate measures to protect processes during a possible equipment malfunction.

7

Page 8

Section 3 Installation

DANGER

Only qualified personnel should conduct the tasks described in this section of the manual.

3.1 Unpacking the instruments

The BIOGAS Titration Manager comes packaged with the following items:

• BIOGAS Titration Manager, one burette, zero version

• B525, Burette Stand, 25 mL, red cover with connection tubing

• Accessories for Titration Manager burette stand

• Set of Cables for Tiration Workstation (w/o serial PC Printer cable)

• Cell kit

• Titration Vessel, PP, 40-100 mL (pack of 10 pcs of 956-265)

• Titration Vessel, PP, 22-45 mL (pack of 10 pcs of 956-178)

• User Manual BIOGAS

• Basic User Manual BIOGAS, multilingual

• Method Guide for FOS/TAC (organic acids (FOS) and total inorganic carbon (TAC)), En-Ger

• Installation form (Fr-Eng-Ger)

Note: If any of these items are missing or damaged, contact the manufacturer or a sales

representative immediatly.

3.2 Operating environment

The following conditions are necessary to ensure correct instrument operation and accurate results:

• Place the instrument firmly on an even surface. Do not push any objects under the instrument.

• Maintain an ambient temperature of 5 to 40 ºC (41 to 104 ºF) for proper instrument operation.

• The relative humidity should be less than 80 %; moisture should not condense on the

instrument.

• Leave at least a 15 cm (6 in.) clearance at all sides for air circulation to avoid overheating of

electrical parts.

• Do not operate or store the instrument in extremely dusty, damp or wet locations.

• Keep the surface of the instrument and all accessories clean and dry at all times. Splashes or

spills on the instrument should be cleaned up immediately.

Protect the instrument from temperature extremes, including heaters, direct sunlight and other heat sources.

NOTICE

8

Page 9

Installation

I

O

1

E1E1E2E2

TEMPTEMP

GNDGND

5V OUTV OUT

ININ

T 1A 250VT 1A 250V

TTLTTL

100-240V100-240Vacac

50-60Hz 45VA50-60Hz 45VA

SACSAC AUX.AUX.

REFREFPt-PtPt-Pt

LINE FUSE T1A L250VLINE FUSE T1A L250V

BALANCEBALANCE

PROPELLERPROPELLER

PC/PRINTERPC/PRINTERSLAVESLAVE

30201163020116

Conforms to Conforms to

UL STD 61010A-1 UL STD 61010A-1

Certified to Certified to

CSA STD C22.2 No. 1010.1CSA STD C22.2 No. 1010.1

MADE IN FRANCEMADE IN FRANCE RADIOMETER ANALYTICAL SASRADIOMETER ANALYTICAL SAS

716R999N999716R999N999

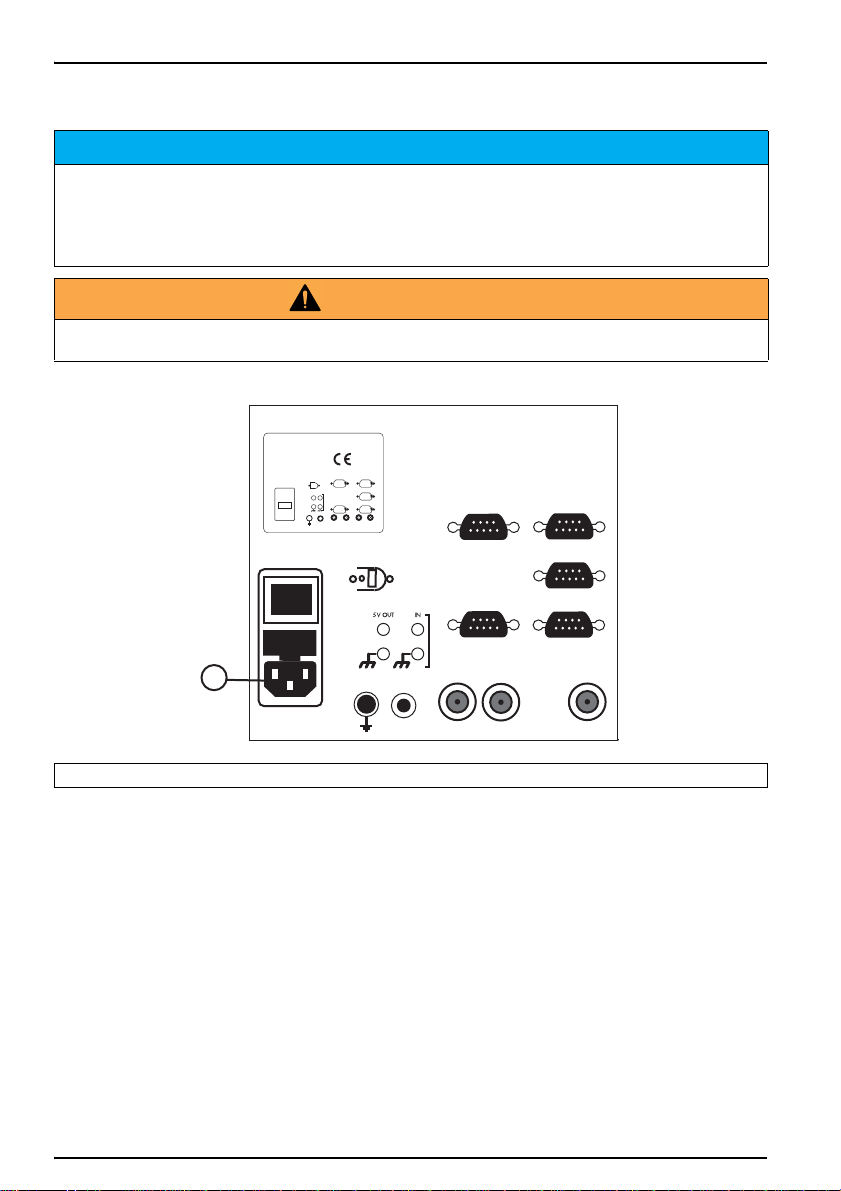

3.3 Power connections

Use only a grounded socket for the connection of this device to the power supply. If you are not sure if the sockets are grounded, have this checked by a qualified electrician. The power plug serves in addition to the power

supply to isolate the device quickly from the power source where necessary. During the disconnection from the

power source it must be made sure that the correct power plug is pulled (for example by labeling the sockets).

This is recommended for long-term storage and can prevent potential dangers in the event of a fault. Therefore

make sure that the socket to which the device is connected is easy to reach by each user at all times.

WARNING

Electrical dangers and fire hazard.

Only use the supplied power cable.

Figure 1 Power connection

NOTICE

1 Power connection

1. Plug the power cable into the back of the instrument (Figure 1).

2. Insert the plug of the power cable into a grounded mains socket (100–240 V~ / 50–60 Hz).

3. Switch the power button to "On" to turn on the instrument (Figure 2, position 13).

9

Page 10

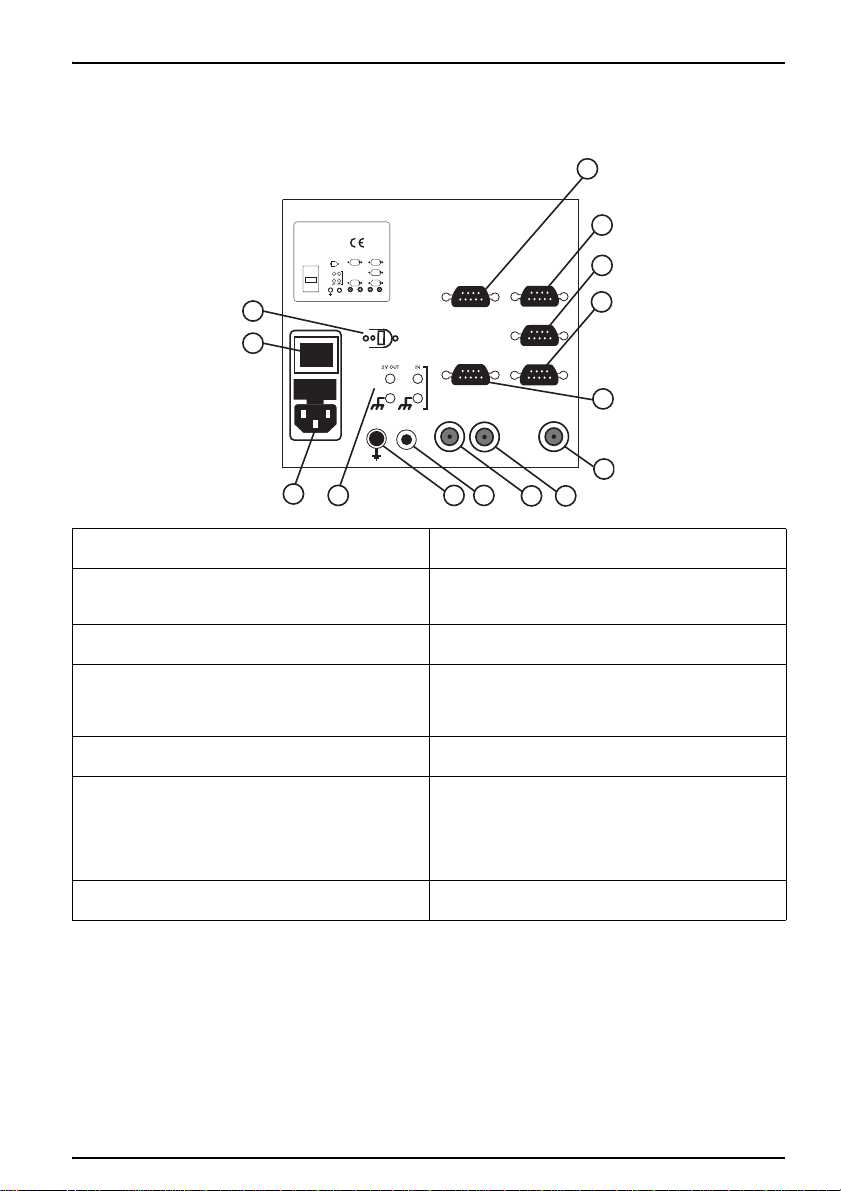

3.4 Interfaces

I

O

1

2

3

4

5

6

78

91011

12

14

13

E1E1E2E2

TEMPTEMP

GNDGND

5V OUTV OUT

ININ

T 1A 250VT 1A 250V

TTLTTL

100-240V100-240Vacac

50-60Hz 45VA50-60Hz 45VA

SACSAC AUX.AUX.

REFREFPt-PtPt-Pt

LINE FUSE T1A L250VLINE FUSE T1A L250V

BALANCEBALANCE

PROPELLERPROPELLER

PC/PRINTERPC/PRINTERSLAVESLAVE

30201163020116

Conforms to Conforms to

UL STD 61010A-1 UL STD 61010A-1

Certified to Certified to

CSA STD C22.2 No. 1010.1CSA STD C22.2 No. 1010.1

MADE IN FRANCEMADE IN FRANCE RADIOMETER ANALYTICAL SASRADIOMETER ANALYTICAL SAS

716R999N999716R999N999

Figure 2 Interfaces

Installation

1 RS232 socket. Not used.

2PC/PRINTER RS232 socket.

PC, cable A95X501

Printer, cables A95P201.

3 RS232 socket. Not used.

4 BALANCE RS232 socket.

Due to the large variety of balance and models,

cables are made on demand, please contact your

local supplier.

5SAC RS232 socket.

Sample changer, cable A95A202

6E1 BNC socket.

Combined pH or ISE electrodes w/wo

temperature sensor,

Single pH or ISE electrodes,

Single or combined metal electrodes (Redox

measurements)

7REF BNC socket.

Reference electrodes

3.5 Installation of burettes and reagents

Refer to:

• BIOGAS Titration Manager Installation form, Catalog Number: D26T044

• BIOGAS Titration Manager Reference Manual, Catalog Number: D21T087,

Section 5 Glossary, keywords «Installing burette» and «Installing reagent»

8Pt-Pt BNC socket.

Double metal electrodes

9TEMP Cinch socket.

Temperature sensors

10 Banana socket. Single metal electrodes for

grounding only

11 Red and black banana sockets

TTL 0 ±5 V input.

Red and black banana sockets

TTL 0 ±5 V output.

12 Power connection socket.

Line cord A95S001/A95S002

13 power button: On/Off switch

14 Socket for propeller stirrer (Catalog Number:

904-480).

10

Page 11

Installation

11

Page 12

Kapitel 4 Startup

4.1 Power the instrument on and off

1. Connect the power cable to a power socket.

2. Switch on the instrument via the power switch on

Note: Always wait about 20 seconds before turning the

instrument on again, otherwisethe electronic and

mechanical systems will be damaged.

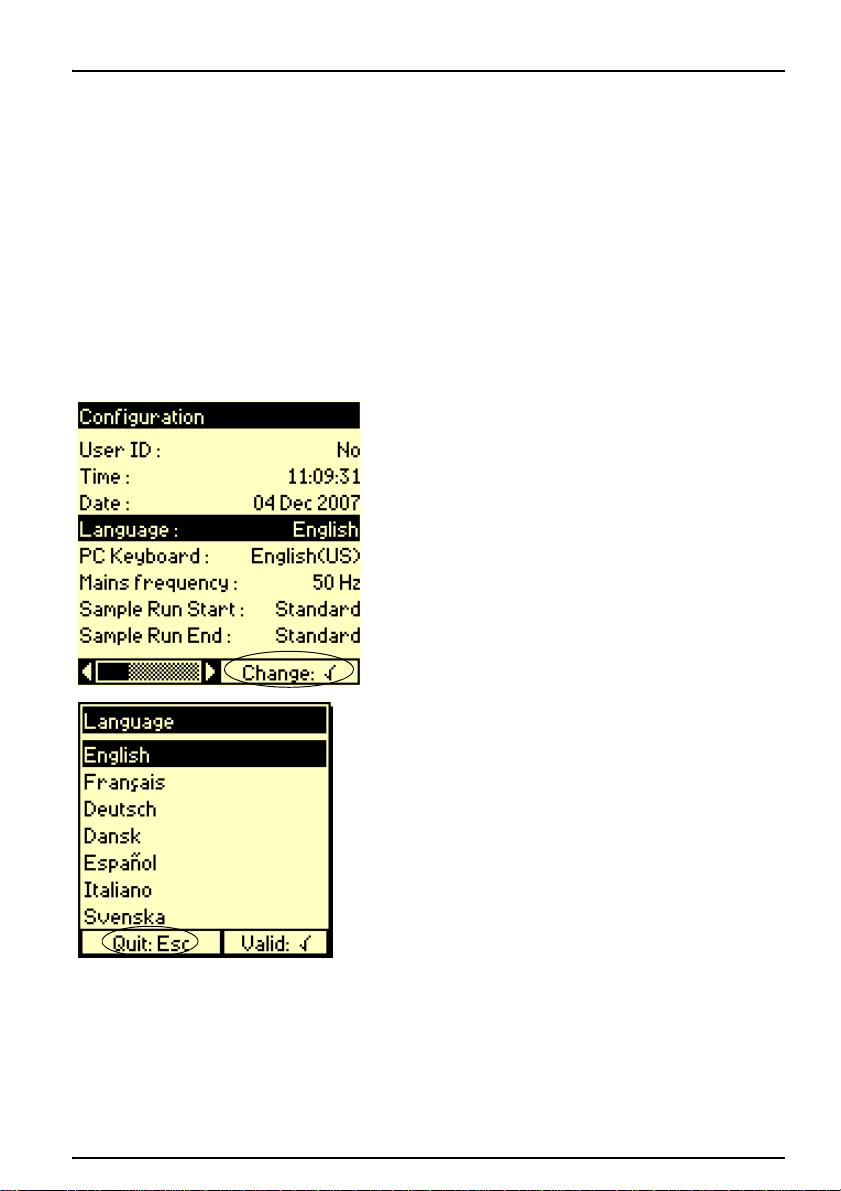

4.2 Language selection

1. Press Stop for 3 seconds in the Main menu.

2. Press 1 to enter the Configuration menu.

3. Select the Language line with the arrow keys and

the back.

The Main menu is displayed.

The Setup menu is displayed.

confirm.

4.3 Display Contrast

4. Select the desired language and confirm.

Note: Esc allows you to leave the screen without

changing the language.

The instrument functions in the selected language until

the option is changed.

If required, you can adjust the contrast of the display:

1. Select the Main menu.

2. Press 0 to increase the brightness, or press 7 to

decrease the brightness.

12

Page 13

Startup

13

Page 14

Kapitel 5 Standard Operations

5.1 Overview

The interface of the BIOGAS Titration Manager has

been specially designed to clearly guide you through

every step of the programming and running of the

analyses, whether you are a supervisor or a routine

user.

An important part of this interface is to check and control

the presence of different elements necessary to run the

defined application.

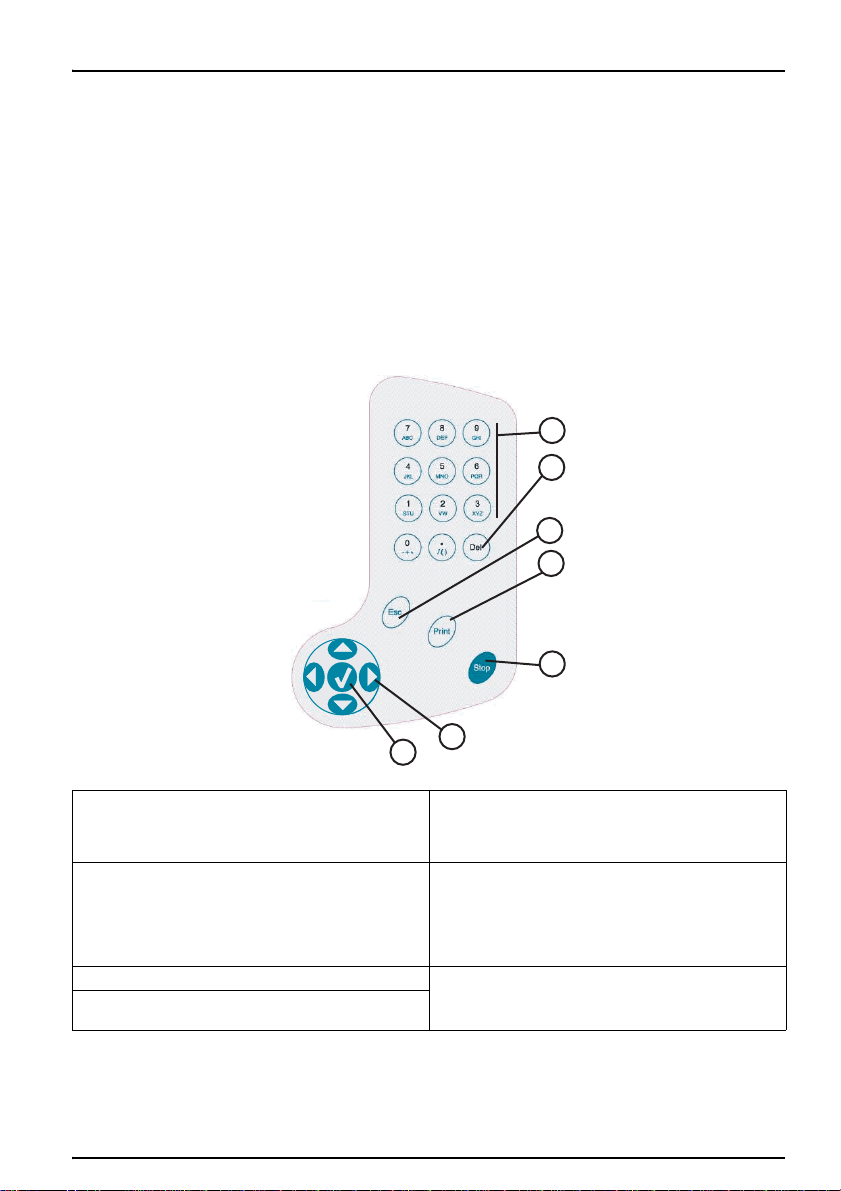

5.1.1 Use of alphanumerical keypad

Figure 3 Alphanumerical keypad

1

2

3

4

1 Alphanumeric keypad to enter data and parame-

ters on the same principle as mobile telephones.

These keys can also be used for quick access to

the different menus.

2 Del key: deletes the character on which the

cursor is positioned.

Operator may end the analysis before the max.

titration time or the max. volume have been

reached, if he considers his analysis finished.

Calculations are performed.

3 Esc key: returns to the previous screen.

4Print key: prints the data concerning the screen

displayed.

5

6

7

5 Stop key: stops an analysis or a burette function.

Press this key for 3 seconds in the Main window

to gain access to the setup parameters.

6 RIGHT, LEFT, UP, DOWN arrow keys are used

to move to different options within the menus.

7 Validation/Confirm key : confirms a data entry, a

message or a function asked for by the user.

14

Page 15

Standard Operations

1

3

2

4

5

6

7

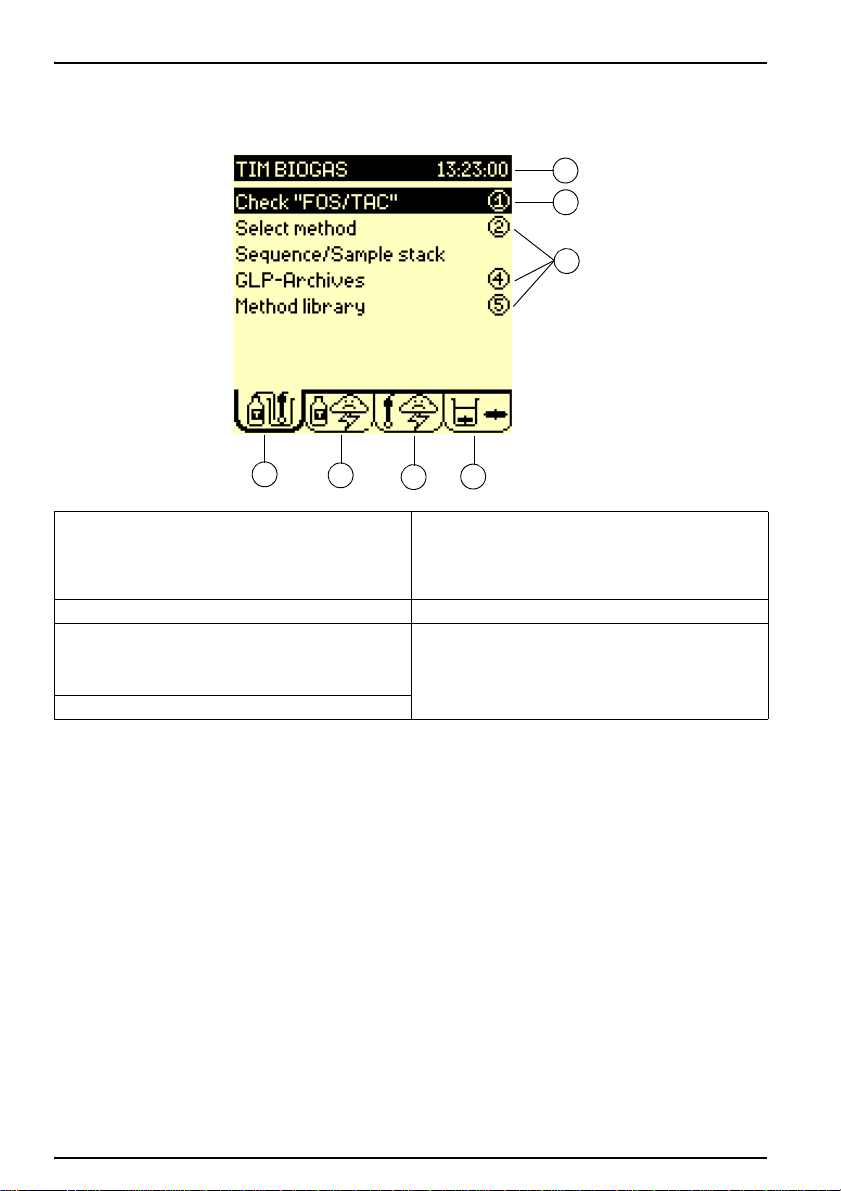

5.1.2 General screen description

Figure 4 General screen description:

1 Title bar.

Indicates the instrument name and the actual

time. You will be shown how to personalise the

name and adjust the time further on in the

manual.

2 Selected line 6 Electrode tab

3 Menu options.

Press the corresponding number for quick access

to the different menus. For example, press 5 to

enter the Method library

4 Method tab

5 Reagent tab

7 Cell tab

Note: The UP and DOWN keys allow you to select a

line. To enter an option, select the line, and press the

validation key. You can also press the corresponding

numerical key.

15

Page 16

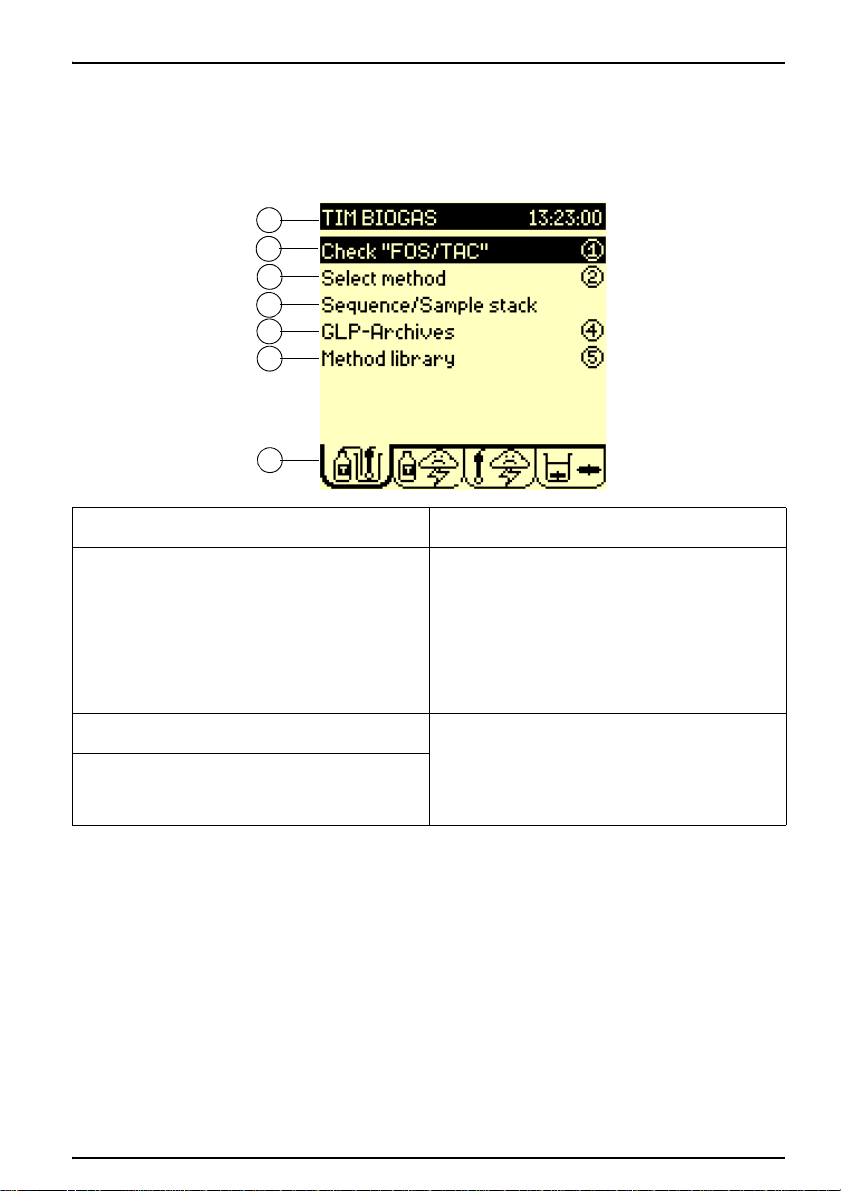

5.2 Main menu

1

3

2

4

5

6

7

Figure 5 Main menu

Standard Operations

When the instrument is switched on the Main window

is displayed.

1 Title bar: indicates the instruments name and the

current time.

2 Check or Run: check or run the selected method

/sequence. The method can be run when 2 sunny

icons are displayed in the Reagents and

Electrodes tabs.

Note: If a cloudy/stormy icon is displayed,

activate the "Check" command. The

Titration Manager will automatically guide

you through the necessary operations

required to solve the problem(s).

3 Select method: select method and view the main

parameters of that method.

4 Sequence/sample stack: if a Sample Changer is

used and declared in the Configuration menu,

program the sample stack. Select or edit the

sequence.

5.3 Reagent menu

5GLP-Archives: access GLP tables and visualise

the stored method sample results.

6 Method library: supervisor use only: create, edit,

reset and delete methods to correspond to your

specific needs.

7 Method icon: Animated icon indicates when a

method/sequence is running.

Press the RIGHT arrow key in the Main menu to

move to the Reagent menu.

16

Page 17

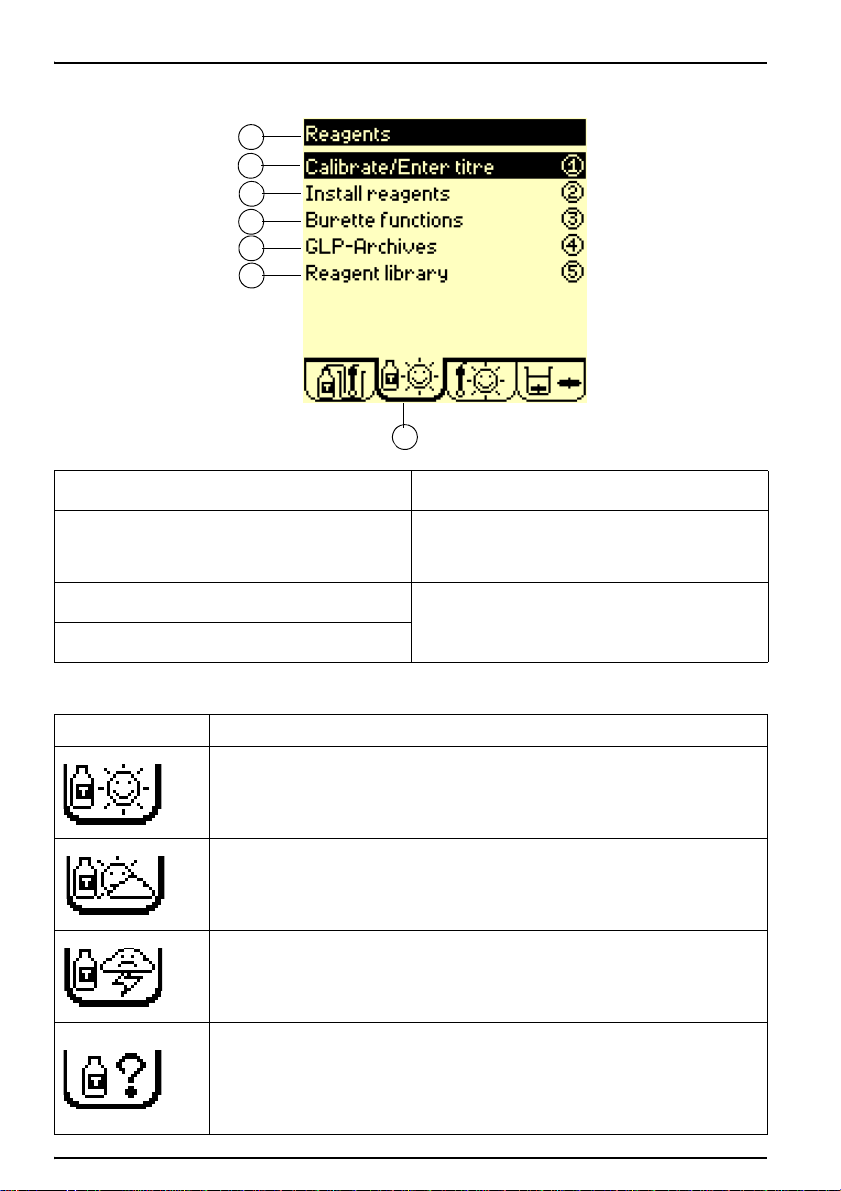

Standard Operations

1

3

2

4

5

6

7

Figure 6 Reagents menu

1 Title bar: indicates the name of the window.

2 Calibrate/Enter titre: determine the

concentration of the titrant (titre) by running a

calibration or a calibration sequence or by

entering the titre manually.

3 Install reagents: install or replace reagents in a

method or a sequence.

4 Burette functions: fill, empty, flush, rinse and

replace burette.

Icon Description

Sunny icon:

The reagent calibration or manual entry of the titre has been performed for all the reagents present in the system. Everything is just right!

Cloudy icon:

The reagent calibration of one of the reagents in the system should be performed within

12 or 24 hours.

Stormy icon:

The reagent calibration of one of the reagents in the system has elapsed.

At least one of the reagents present in the system has not been installed.

Question mark:

There is a problem in the editing of the reagent system. You need to be in Supervisor

mode to solve the problem. Check the sequence/method parameters of the reagent or

the electrode.

Check the sequence or method, (press 1 in the Main window). The instrument indicates

the possible errors and prompts you to correct them until ? disappears.

5GLP-Archives: access GLP tables and visualise

the last reagent calibration results.

6 Reagent library- supervisor use only: create,

edit, reset and delete reagents to correspond to

your specific needs.

7 Reagent icon: Reagent status icon indicates the

state of the reagent system. Four types of icons

can be displayed. See table on the next page.

Table 1 Reagent icons

17

Page 18

5.4 Electrode menu

1

3

2

4

5

6

Figure 7 Electrode menu

Standard Operations

Press twice the RIGHT arrow key in the Main menu to

move to the Electrode menu.

1 Title bar: indicates the name of the window.

2 Calibrate electrode: run a calibration or a

calibration sequence using the installed

electrodes.

3 Display measurement: displays mV and/or pH

and/or temperature at a connected electrode of

the electrode system.

4GLP-Archives: access GLP tables and visualise

the last electrode calibration results.

5 Electrode library- Supervisor use only: create,

edit, reset and delete electrodes stored in the

instrument.

6 Electrode icon: Electrode status icon indicates

the state of the electrode system. Four types of

icons can be displayed. See table on the next

page.

Table 2 Electrode icons

Icon Description

Sunny icon:

The calibration has been performed on the electrode present in the system. Everything

is just right!

Cloudy icon:

The electrode calibration of the electrode present in the system should be performed

within 12 or 24 hours.

Stormy icon:

The calibration date has elapsed for the electrode present in the system.

If acceptance limits have been set for the calibration: at least one calibration result lies

outside the programmed acceptance limits.

18

Page 19

Standard Operations

1

3

2

4

Icon Description

Question mark:

There is a problem in the editing of the electrode system. You need to be in Supervisor

mode to solve the problem. Check the sequence/method parameters of the reagent or

the electrode.

Check the sequence or method, (press 1 in the Main window). The instrument indicates

the possible errors and prompts you to correct them until ? disappears.

5.5 Cell menu

Figure 8 Cell menu

Table 2 Electrode icons

Press three times the RIGHT arrow key in the Main

menu to move to the Electrode menu.

1 Title bar: indicates the name of the window.

2 Internal stirring: command stirrer On/Off (see

Apply internal stirring).

19

3Speed: select the internal stirring speed, from

100 to 1100 rpm by steps of 50 rpm.

4Cell icon: animated icon indicates when the

magnetic stirrer or propeller is operating.

Apply internal stirring

1. Select Internal stirring = ON,

2. In the field Speed, select a stirring speed.

Apply external stirring

1. Connect the Stirring Propeller, part no. 904-480,

to the Titration Manager (see Figure 2 on page

10, position 14).

Line 1 is automatically replaced by External

stirring.

2. Select External stirring = ON.

Page 20

5.6 Setup Menu

1

2

5.6.1 Configuration menu

Figure 9 Configuration menu

Standard Operations

3. Adjust stirring by turning the stirring propeller

knob.

Note: You can consult the corresponding table

between the position (1 to 9) and the stirring

speed by selecting the field Speed setting.

1. Press Stop for 3 seconds in the Main window to

move to the Setup menu.

2. Enter the Supervisor code to differentiate

between the Routine mode and the Supervisor

mode.

• In Routine mode, the user is able to select

and run methods.

• In Supervisor mode, the user can create,

edit, select and run methods. A Supervisor

code is also used to protect your parameters from any unwanted changes.

Note: Continue without entering a Supervisor code.

1. Press 1 to enter the Configuration menu.

1 Use the UP and DOWN arrow keys to select the

parameter.

2 Horizontal scroll bar. The position of the bar

indicates the first screen in the Configuration

menu. Use the RIGHT arrow key to move to the

next screen

Note: The position of the bar indicates the

last screen in the Configuration menu

20

Page 21

Standard Operations

2. Press the RIGHT arrow key to move to the next

screen in the Configuration menu.

3. Press the UP arrow key to scroll in the

Configuration menu.

21

4. Press the LEFT arrow key to return to the first

screen in the Configuration menu.

Page 22

5.6.1.1 Date and time

Standard Operations

1. Select Time in the Configuration menu.

2. Enter the hours (from 00 to 23).

3. Press the RIGHT arrow key.

4. Enter the minutes (from 00 to 59).

5. Press the RIGHT arrow key.

6. Enter the seconds (from 00 to 59).

Note: The LEFT arrow key allows you to return

to the previous screen to modify an entered

value.

7. Press the validation key (as indicated on the

screen).

8. Select Date.

9. Enter the day (from 00 to 31).

10. Press the RIGHT arrow key.

11. Press the UP/DOWN arrow keys to select the

month.

22

Page 23

Standard Operations

5.6.2 Customize the Titration Manager

5.6.2.1 PC keyboard entry

Figure 10 PC Keyboard connection

12. Press the RIGHT arrow key.

13. Enter the year (from 2000 to 2069).

14. Press the validation key (as indicated on the

screen).

You can assign a name to your BIOGAS Titration

Manager, which will be permanently displayed in the

title bar of the Main menu.

1. Connect a PC keyboard to the 6-pin plug

situated on the left hand side of the instrument

(see Figure 10).

23

2. Select PC keyboard in the Configuration

menu.

3. Select English (US).

Note: This allows you to use a QWERTY

keyboard.

4. Press Esc to return to the SETUP menu.

5. Press 3 (Customize).

6. Select the Station parameter by pressing the

validation key.

7. Use the keyboard to enter the desired name.

8. Select the line HACH LANGE GmbH.

This line is used to enter information concerning

the workplace, user(s) name(s), location,

address etc.

Page 24

5.6.2.2 Alphanumerical keypad entry

Standard Operations

9. Enter the text using the PC keyboard (maximum

of 32 characters can be used).

Note: If the characters shown on the display do not

correspond to the ones typed on the keyboard,

redefine your keyboard type. To do this, press Esc

then 1 and select PC keyboard.

1. Press 3 (Customize) in the Setup menu.

2. Select the Station parameter by pressing the

validation key.

3. Example: To replace "TIM BIOGAS" by

"Chem.lab-1", proceed as follows:

a. Press 7 until the letter "C" appears, then

release the key. The cursor moves to the

next position.

b. Press 9 until the letter "h" appears.

c. Continue until you have entered

(em.lab-1).

24

Page 25

Standard Operations

4. To correct a typing error, proceed as follows:

a. Press the LEFT arrow key to position the

cursor on the letter "E".

b. Press 7 to enter the letter "A". The letter E

has been inserted between the letter "A"

and the letter "B".

c. Press Del to delete the "E".

d. Press the validation key to confirm the

entry.

5.6.2.3 Print data

25

1. Enter the Setup window: press Stop 3 seconds

in the Main menu.

2. Enter the Configuration menu: press 1.

3. Press the RIGHT arrow key to move to the

second page in the Configuration menu.

4. Select the Printer = On and confirm.

5. Select

Printer = 80 columns and

Format = Listing or

Page by Page.

6. Enter a User ID if required:

a. In Configuration menu, select User ID =

Yes .

b. You will be prompted to enter a user ID at

the start of a run method. This ID will

appear on the printouts.

7. Enter a Customize the printout if required:

a. In Configuration menu, press 3

(Customize).

b. Enter the name of your workstation (max. 4

lines of 32 characters) (see 5.6.2 on

Page 26

5.7 Manual printouts

Figure 11 Method library

Standard Operations

page 23). This information will appear as a

header at the start of the printout.

8. For automatic printout - select a condensed or

detailed printout.

• In the Printouts screen of the Edit

method/reagent/electrode, select Detailed

= High to obtain a full detailed printout,

• In the Printouts screen of the Edit

method/reagent/electrode, select Detailed

= Low for a condensed printout.

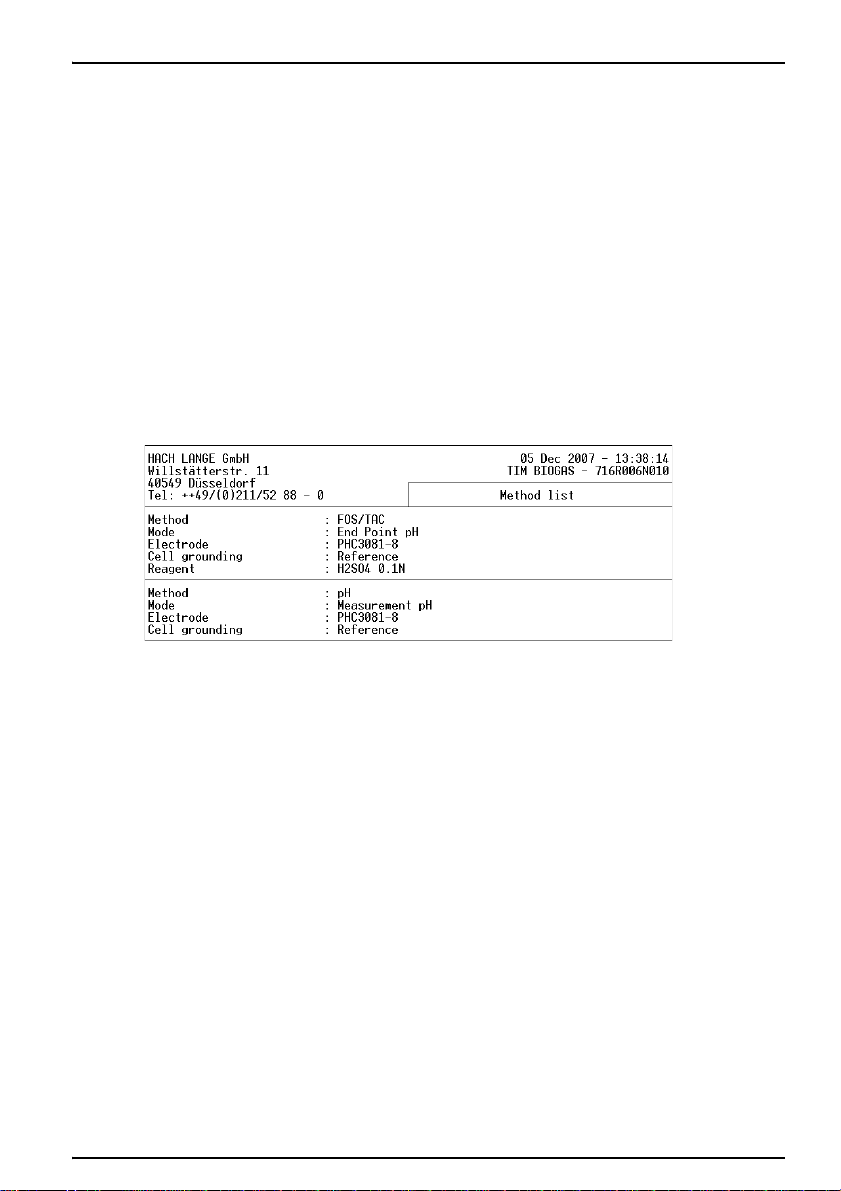

Method library

Press Print, in the Main window to give you an

overview of the methods available in the method list.

5.8 Edit data

5.8.1 Edit method data

Reagent library

Press Print, in the Reagents window to get an

overview of the reagents available in the reagent list.

Electrode library

Press Print, in the Electrodes window to get an

overview of the electrodes available in the electrode

list.

1. In the Main menu, press 5 Method library.

2. Press 2 to access. These are the parameters

entered in the Edit method screen.

3. Press Print to get an overview of the

parameters of the current programmed method.

26

Page 27

Standard Operations

Figure 12 Method data

5.8.2 Edit reagent data

5.8.3 Edit electrode data

27

1. Press 5 Reagent library in the Reagent menu.

2. Press 2 to access. These are the parameters

entered in the Edit reagent screen.

3. Press Print to get an overview of the

parameters of the current programmed

reagent.

1. Press 4 Electrode library in the Electrode

menu

Page 28

5.8.4 Automatic printouts

Standard Operations

2. Press 2 to access. These are the parameters

entered in the Edit electrode screen.

3. Press Print to get an overview of the

parameters of the current programmed

electrode.

The Print key is inactive during a titration, pH/mV

measurement, electrode or reagent calibration.

The results obtained during a "Run" are printed

automatically (see 5.6.2.3 on page 25).

Depending on the option selected for Detailed in the

Edit method/reagent/electrode - Printout screens,

you will obtain different types of printouts.

28

Page 29

Standard Operations

1

2

3

4

5

Figure 13 Example of a printout for a titration

1Header: information entered in the Customize

screen of the Setup window.

2 Analysis ID: User ID and Sample ID entered at

the start of the titration (if option selected during

editing).

3 Title of report: entered in Printouts screen during

method editing.

5.9 Store, send and recall data

5.9.1 The data log

29

4 Calibration data: of the electrode and reagent

used to perform the titration.

5 Titration results: obtained at the end of the

analysis.

The last 60 results are saved in the archives.

Enter the Main window and press 4 GLP-Archives to

access.

Note: The RIGHT and LEFT arrow keys allow you to

move from one screen to the other.

Page 30

Standard Operations

Examples:

Result no. 1/9 = Mean and standard deviation

Mean and standard deviation calculated on "TAC"

test results.

Result no. 1/9 = Mean and standard deviation

Mean and standard deviation calculated on "Volume

A" test results.

Result no. 1/9 = Mean and standard deviation

Mean and standard deviation calculated on "Volume

B" test results.

30

Page 31

Standard Operations

Result no. 1/9 = Mean and standard deviation

Mean and standard deviation calculated on "FOS"

test results.

Result no. 1/9 = Mean and standard deviation

Mean and standard deviation calculated on

"FOS/TAC" test results.

31

Result no. 2/9 = Test no.1

"TAC" result for test no.1.

Page 32

Standard Operations

Result no. 2/9 = Test no.1

"Volume A" result for test no.1.

Result no. 2/9 = Test no.1

"Volume B" result for test no.1.

Result no. 2/9 = Test no.1

"FOS" result for test no.1.

32

Page 33

Standard Operations

5.9.2 The reagent calibration log

Result no. 2/9 = Test no.1

"FOS/TAC" result for test no.1.

The last performed (current) calibration of each

reagent is saved in the archives.

Enter the Reagent menu and press 4 GLP-Archives

to access.

5.9.3 The electrode calibration log

33

The last performed (current) calibration of each

electrode is saved in the archives.

Enter the Electrode menu and press 3

GLP-Archives to access.

Page 34

5.10 Program instructions

5.10.1 Enter a new electrode

Standard Operations

Note: Only the Supervisor is allowed to program the

menus, Electrode, Reagent, and Method.

To select the Supervisor mode:

1. Press Stop for 3 seconds in the Main menu.

2. Enter the Supervisor code (see 5.6 on page 20).

3. Press 5 (Exit).

4. Select Return in mode = Supervisor.

For first time users, it is recommended to program the

instrument as follows:

1. Create the electrode(s) to be used to perform

the measurements.

2. Create the reagent(s) to be used during the

titration.

3. Create the method(s), which will consequently

use the electrode(s) and reagent(s) created in

the first two steps of programming.

4. Once you have finished programming, make

sure that NO question marks "?" are displayed

in the Reagent and Electrode tabs!

1. Enter the Elekctrode menu and press 4

(Electrode library).

34

Page 35

Standard Operations

2. Press 1 (New electrode).

3. Press the validation key in the Function field

4. Select the function of the electrode, refer to the

Table 3.

Table 3 Electrode functions

Electrode type Select function

pH single pH

pH combined w/wo temp. sensor pH pH

Single metal/redox mV (i=0)

Combined metal/redox w/wo temp. sensor mV (i=0)

ISE single mV (i=0)

ISE Combined w/wo temp. sensor mV (i=0)

Reference single Reference

Temperature sensor T°C

Ground metal Ground

Double metal mV (i>0)

5. Press the validation key in the ID field.

6. Select Other in the From field.

Note: The option From = Catalogue allows you

to create an electrode from a list of

preprogrammed electrodes.

7. Enter the identification (ID) of the electrode, (up

to 16 characters).

8. Press 1 twice.

9. Select the electrode Typ e, for electrodes with

pH or mV functions:

•Single pH - pH electrode (no reference

part),

• Combined pH - pH electrode with a refe-

rence part (with or without temperature

sensor),

• Single metal/redox - mV (i=0) function

electrode with a reference part,

• Combined metal/redox - mV (i=0) func-

tion electrode with a reference part (with or

without temperature sensor).

35

Page 36

Standard Operations

Note: When a combined electrode has been

defined, the instrument will prompt you to specify if it

has a built-in temperature sensor or not.

Note: When a single electrode has been defined,

the instrument will prompt you to define a reference

electrode in the Edit electrode screen.

10. When a combined or a reference electrode

has been defined, enter the potential (in mV) of

the reference element versus the Standard

Hydrogen Electrode (SHE).

This parameter enables to run calibration with

automatic buffer recognition when working with

different reference electrode systems. See the

table giving the potential at 25°C versus the

SHE of a few "reference elements/filling

solution" couples (Ta b le 4 ).

Note: When a combined pH or a single pH

electrodes has been defined, enter the internal pH of

the electrode (pH int).

11. Press 1 to confirm.

12. Edit the electrode parameters.

Table 4 Potential versus SHE of Reference electrodes

Reference element filling solution

Hg/Hg

SCE: Saturated Calomel Electrode

Hg/Hg

NCE: Normal Calomel Electrode

Hg/Hg

Hg/Hg

Hg/HgO - 0.1 M KOH +174 mV XR400, XR430, XR440

Ag/AgCl - Saturated KCl +199 mV

Ag/AgCl - 3 M KCl +208 mV

Ag/AgCl - 1 M KCl +235 mV

Ag/AgCl - 0.6 M KCl (sea water) +250 mV

Red Rod - Saturated KCl +199 mV

- Saturated KCl

2Cl2

- 1M LiCl

2Cl2

- Saturated K2SO

2SO4

- 1 M H2SO

2SO4

4

4

Potential versus

SHE

+244 mV

+280 mV REF921

+651 mV

+616 mV

«Catalog list» electrodes

pHC4000, pHC4001, pHC4006, XC601,

REF401, REF421, REF451, XR100, XR110,

XR130, XR150, MC408Pt

REF601, REF621, XR200,

XR230, MC602Pt, MC6091Ag

XR300, XR820, XC100, XC111,

XC120, XC161, XC200, XC250

pHC3001, pHC3005, pHC3006, pHC3011,

pHC3081, pHC3185, REF321, REF361,

MC3051Pt, ISEC301F

pHC2001, pHC2002, pHC2003, pHC2005,

pHC2011, pHC2015, pHC2051, pHC2085,

pHC2401, pHC2441, pHC2501, pHC2601,

pHC2701, REF200, REF201, REF251,

REF261, MC2095Sb, MC201Au-8

36

Page 37

Standard Operations

5.10.1.1 Edit an electrode

1. Enter the Electrode menu and press 4

(Electrode library).

2. Press the validation key and select the

electrode to be edited from the list.

3. Press 2 Edit electrode.

Note: The RIGHT and LEFT arrow keys allow you to

move from one screen to the other.

4. Select whether the electrode should be

calibrated or not (Calibration request = Yes or

No).

Note: If Calibration request = No, the electrode

parameter edition is completed.

Note: Electrode address: indicates which Titration

Manager socket the electrode is connected to:

TIM / E1, Ref, Temp, GND or Pt-Pt.

5. Enter the Periodicity.

Indicates the maximum period of time between

two calibrations. If the period of time is

exceeded, pH measurements can no longer be

performed using this pH electrode. The

electrode must be calibrated.

6. Enter the Number of buffers.

Number of standards (1 to 5) to be used for the

calibration.

7. Select Tem pera ture .

• If a temperature sensor is in use, select

Probe.

• If the temperature is entered manually via

the numeric keypad, select Entered.

• If the calibration is to be performed at 25°C,

select Fixed 25°C.

Note: If you have selected Temperature = Probe, a

temperature sensor must have been selected in the

Parameters screen.

37

Page 38

5.10.1.2 Enter the electrode parameters

5.10.2 Enter a new reagent

Standard Operations

1. Select Calibrate request = yes

2. Enter the electrode definition parameters

3. Go to the last Edit electrode screen.

4. Press 1 and enter the Calibration parameters:

general parameters used during the calibration.

5. Press 2 and enter the Calibration solutions

parameters concerning the standards used for

the calibration.

6. Press 3 and enter the Results parameters

concerning acceptation criteria that you can set

on the results.

7. Press 4 and enter Printouts parameters

defining the calibration report to be printed.

1. Enter the Reagents menu and press 5

(Reagent library).

2. Press 1 New reagent and press the validation

key.

3. Select From = Other.

Note: The option From = Catalogue allows you to

create a reagent from a list of common used

reagents.

4. Select ID and press the validation key.

5. Enter the reagent name (up to 16 characters).

6. Enter the "approximate" titre of the reagent (5

characters) in the Targ et t itr e field.

7. Enter the units (mM, M, mN, N) indicated on the

reagent bottle. Use the following:

mM = mmol/l, M = mol/l, mN = meq/l or

N = eq/l).

Note: Once the units have been confirmed, they

are added to the reagent ID and target titre.

Note: If molar units are selected (mM or M), it is

necessary to enter the stoichiometric coefficients for

the chemical reaction in the Results screen.

8. Press 1 twice to create the reagent.

9. Edit the reagent parameters.

38

Page 39

Standard Operations

5.10.2.1 Edit a reagent

1. Enter the Reagent menu and press 5 (Reagent

library).

2. Press the validation key and select the reagent

to be edited from the list.

3. Press 2 Edit reagent.

Note: The RIGHT and LEFT arrow keys allow you to

move from one screen to the other.

4. Enter the unit: mM = mmol/l, M = mol/l,

mN = meq/l or N = eq/l). The unit is indicated on

the reagent bottle.

5. Select Titre = Enter or Calibrate.

• Select Enter if you already know the titrant

concentration and do not wish to perform a

calibration.

• Select Calibrate if you wish to perform a

calibration. Enter the calibration parameters.

6. Select the type of method for Mode. You have

the choice between End Point, Monotonic IP,

Dynamic IP or Continuous IP.

7. Select the measurement mode for the

calibration (pH, mV or mV at imposed current).

8. Enter the Periodicity.

Indicates the maximum period of time between

two calibrations. If the period of time has

elapsed, titrations can no longer be performed

using this titrant.

9. Enter the Number of tests.

This is the number of times the calibration

method will be repeated, i.e. the number of

beakers to prepare for the calibration.

10. Select Temp erat ure.

• If a temperature sensor is in use, select

Probe.

• If the temperature is entered manually via

the numeric keypad, select Entered.

• If the calibration is to be performed at 25°C,

select Fixed 25°C.

Note: If you have selected Temperature = Probe, a

temperature sensor must have been selected in the

Parameters screen.

Note: If you want a message to be displayed upon

starting the calibration, select Notification = Yes

then enter the message (3 lines of 32 characters

maximum).

39

Page 40

5.10.2.2 Enter the reagent parameters

5.10.3 Enter a new method

Standard Operations

1. Select Titre = Calibrate

2. Enter the Edit reagent menu and press 1

(Calibration parameters).

The Calibration parameters are general

parameters used during the calibration.

3. Press 2 (Standard).

The Standard parameters concerning the

standard solution used for the calibration.

4. Press 3 (Results).

The Results parameters concerning

stoichiometric coefficients for the chemical

reaction (if required).

5. Press 4 (Printouts).

Enter Printouts parameters defining the

calibration report to be printed.

1. Enter the Method menu and press 5 (Method

library).

2. Press 1 New method and press the validation

key.

3. Select ID and press the validation key.

4. Enter a method name (up to 16 characters).

5. Press 1 to confirm.

6. Edit the method parameters.

40

Page 41

Standard Operations

5.10.3.1 Edit a method

1. Enter the Method menu and press 5 (Method

library).

2. Press the validation key and select the method

to be edited from the list.

3. Press 2 Edit method.

Note: The RIGHT and LEFT arrow keys allow you to

move from one screen to the other.

4. Select the method mode. The modes available

are:

• Measurement (pH, mV or mV at imposed

current)

• End point (titration to a preset mV or pH

end point)

• Coupled (methods chained in a same bea-

ker)

• Continuous IP (Inflection point detection

with continuous addition of the titrant)

• Monotonic IP (Inflection point detection

with incremental addition of the titrant,

increments of equal size)

• Dynamic IP (Inflection point detection with

incremental addition of the titrant, increments of varying size)

5. Select the measurement mode:

• pH

• mV

• mV at imposed current.

6. Select Tem pera ture .

• If a temperature sensor is in use, select

Probe.

• If the temperature is entered manually via

the numeric keypad, select Entered.

• If the calibration is to be performed at 25°C,

select Fixed 25°C.

7. Enter the Number of tests, i.e. the number of

times the method is to be repeated.

8. Select the way the cell grounding of the

measuring electrode will be performed:

• Reference: reference electrode connected

to the Ref socket on the titration system.

• Metal: metal electrode connected to the

GND socket on the titration system. For tit-

rations in very resistant medium.

•Other: an electrode which does not belong

to the electrode system.

9. If you want a message to be displayed upon

starting the method, select Notification = Yes

then enter the message (3 lines of 32

characters maximum).

41

Page 42

5.10.3.2 Enter the method parameters

Standard Operations

10. Select Blank:

A blank or blank sample is usually a solvent

used to dissolve or dilute the sample. This blank

may contain traces of the species you are

analysing.

• Select Yes for Blank when you want to subtract the volume of titrant used to titrate the

solvent from the volume found for the dissolved or diluted sample.Enter the unit: mM

= mmol/l, M = mol/l, mN = meq/l or N =

eq/l). The unit is indicated on the reagent

bottle.

1. Enter the Edit method menu and press 1

(Method parameters).

The Method parameters are general

parameters concerning the electrode and

reagent used by the method.

2. Press 2 (Sample).

The Sample parameters concerning the

sample amount analysed.

3. Press 3 (Results).

The Results parameters defining the results

and stoichiometric coefficients for the chemical

reaction (if required).

4. Press 4 (Printouts).

The Printouts parameters defining the analysis

report to be printed.

5.11 Run analyses

5.11.1 Introduction

5.11.1.1 Working in Supervisor mode

When programming in “SUPERVISOR” mode, it is

recommended to work in stages. These stages

should be carried out in the order described below:

1. Define your electrode(s)

42

Page 43

Standard Operations

Icon Description

Identify electrodes (including temperature

sensors) to be used for the analysis.

Electrodes can be created from the following

lists, Catalogue, Other or Copy from. When

creating the electrode, define if electrode

calibration is required (or not), if yes specify the

“periodicity” of the calibrations and the pH

standards to be used. Refer to 5.9.3 The

electrode calibration log on page 33.

2. Define reagent

Identify reagents to be used for the analysis.

Reagents can be created from the following

lists, Catalogue, Other, Copy from. When

creating the reagent, define if reagent calibration

is required (or titre entered manually), if yes

specify the “periodicity” of the calibrations and

the calibration method. Refer to 5.10.2.2 Enter

the reagent parameters on page 40.

Note: If you are to perform a calibration, make sure

that the electrode(s) used for the calibration are the

same as those used in the method.

3. Create a new method or Edit a pre-programmed

one

Create the measurement or titration method to

be used for the analyses. Enter the parameters

required to calculate the results, Refer to

5.10.3.2 Enter the method parameters on page

42.

When you have finished programming, select

the method or pre-programmed application,

refer to Short-Form Reminder no. 3.

If a sample changer is to be used, define the

sample changer in the Configuration menu.

4. Check icons

The following icons indicate the exact state of your

working system.

Table 5 Icons

43

Sunny icon:

Everything is OK. Run the method or sequence.

Note: Sunny icons are required to run the method.

Cloudy icon:

Action required within 12 or 24 hours. For example electrode and/or reagent calibration.

Page 44

Icon Description

Stormy icon:

Electrode/reagent calibration date elapsed or reagent not installed.

Question mark:

It is a programming error, reagent and/or electrode is/are not defined in the selected

method. Revise the method programming.

Standard Operations

Table 5 Icons

Note: When Cloudy/Stormy/Question mark icons

appear, Press 1 Check. The Titration Manager will

automatically guide you through the operations

necessary to solve the errors encountered.

5. Run the method.

5.11.1.2 Working in Routine mode

In “ROUTINE” mode you are guided at every step,

thanks to the clear-text messages and the icons

present on the large graphic display.

A Routine operator has access to all the displays for

checking purposes.

When working in “ROUTINE” mode, it is necessary

to install your titration system according to the

selected method or sequence, prior to running a

method or sequence.

44

Page 45

Standard Operations

1. Press 2 (Select method) in the main menu.

If Question marks "?" are present in the

electrode and/or reagent tabs. Programming

error due to missing electrode/reagent

parameters.

Contact your supervisor.

2. Connect/Check electrode(s).

Refer to Short-Form Reminder no. 1.

Note: When installing/checking an electrode

system, do not forget to connect all the

electrodes to the Titration Manager and

disconnect all the electrodes that are not used

by the method.

3. Install/Check reagent.

Refer to Short-Form Reminder no. 2.

4. Select Start in the main menu to run the

analysis when Sunny icons are visible in the

electrode and reagent tabs.

5. Run an electrode calibration when a Stormy

icon appears in the electrode tab.

6. Run a reagent calibration when a Stormy icon

appears in the titrant tab.

7. If you are unable to display the "Run" command

due to the presence of Cloudy/Stormy icons in

the Reagent and Electrode windows, activate

the "Check" command.

The BIOGAS Titration Manager will

automatically guide you through the necessary

operations required to solve the problem(s).

5.11.2 Run an elecrode calibration

5.11.3 Run a reagent calibration

45

Refer to Short-Form Reminder no. 4.

1. Select the method.

2. Install the electrode group.

3. Enter the Electrode menu.

4. Select 1 Calibrate electrodes.

5. Press the validation key.

6. Select the electrode to be calibrated from the

proposed list.

7. Press 1 to start the calibration.

Refer to Short-Form Reminder no. 5.

1. Select the method.

2. Install the reagent to be calibrated.

3. Install the electrode group to be used to perform

the calibration.

4. Enter the Reagents menu.

5. Select 1 Calibrate/Enter titre.

Page 46

5.11.4 Run a method

5.11.5 Run a sequence

5.11.6 Run a direct measurement

Standard Operations

6. Press the validation key.

7. Select the reagent from the proposed list.

8. Press 1 to start the calibration.

Refer to Short-Form Reminder no. 6.

1. Select the method.

2. Install the electrode group to be used to perform

the analysis.

3. Install the reagent groups to be used to perform

the analysis.

4. Display the Main menu. and press 1 to start the

analysis.

Refer to Short-Form Reminder no. 7.

1. Install the electrode group to be used to perform

the analysis.

2. Install the reagent groups to be used to perform

the analysis.

3. Display the Main menu.

4. Press 3.

5. Press 1.

6. Prepare the sample stack.

7. Display the Main menu and press 1 to start the

analysis.

Refer to Short-Form Reminder no. 8.

1. Select the method.

2. Install the electrode group.

3. Display the Electrode menu.

4. Press 2 to start the measurement.

5. Select the electrode in the list.

Note: You can stop or start stirring by pressing 1.

46

Page 47

Standard Operations

47

Page 48

Section 6 Maintenance

6.1 Cleaning the instrument

The BIOGAS Titration Manager requires minimum maintenance. The exterior surface can be cleaned

with tepid water and wiped dry with a soft cloth.

Note: Never use another solvent.

6.2 Fuse replacement

WARNING

To avoid the risk of electric shock, disconnect the instrument from the power source before the fuse replacement

procedure is commenced.

1. Switch off the instrument.

2. Disconnect line cord.

3. Remove the fuse holder.

4. Replace the used fuses with two new fuses, slow blow, 1.0 A (5 x 20 mm), part no. 450-020.

5. Put the cap back in place.

Figure 14 Fuse replacement

6.3 Servicing

WARNING

Do not attempt to service this product yourself, except as noted in the User’s guide or Reference Manual.

Please contact the service department of the manufacturer or the distributor.

48

Page 49

49

Page 50

Section 7 Troubleshooting

7.1 Troubleshooting

If you have forgotten an operation while editing the method, icons visible in the Electrode and

Reagent windows indicate that an error(s) has occured.

To find out where the error has occured and to help you solve them, run the “Check” command in the

Main window. The BIOGAS Titration Manager will automatically guide you through the operations

required to solve the errors encountered.

50

Page 51

51

Page 52

Section 8 Replacement Parts and Accessories

8.1 Burette stands

Cat. Number

B505 Burette Stand, 5 mL, UV protected with connection tubing X51T026

B510 Burette Stand, 10 mL, UV protected with connection tubing X51T017

B525 Burette Stand, 25 mL, UV protected with connection tubing X51T026

B550 Burette Stand, 50 mL, UV protected with connection tubing X51T028

8.2 Spare parts

Cat. Number

Delivery tubing with anti-diffusion tip X31T069

Titrant bottle stopper GL45 assembly with desiccant & suction tubing X31T070

Titrant bottle stopper GL45 assembly with desiccant & suction tubing for B501 X31T110

Fuse, slow blow, 1.0A, (5 x 20 mm) 450-020

Magnetic stirrer rods x3 LYW 064

Cylinder graduated 5mL 50837

Maintenance Kit of 3 tubes for B5xx X31T115

8.3 Polypropylene titration vessels

Cat. Number

Titration Vessel, PP, 40-100 mL (pack of 50 pcs) 904-490

Titration Vessel, PP, 22-45 mL (pack of 50 pcs) 904-489

8.4 Notebook keyboards

Cat. Number

Notebook Keyboard 83-keys, PS/2 port, US version X16T005

Notebook Keyboard 83-keys, PS/2 port, French X16T006

8.5 Combined pH/Reference electrodes – Acid/Base titrations

Cat. Number

pHC3081-8 - Combined pH electrode, Ag/AgCl, with temperature probe E16M305

8.6 4-7-10 Series pH Standards

Cat. Number

pH 4 - pH 4.00 at 25 °C, 500 ml S11M012

pH 7 - pH 7.00 at 25 °C, 500 ml S11M013

pH 10 - pH 10.00 at 25 °C, 500 ml S11M014

52

Page 53

Replacement Parts and Accessories

8.7 Electrode Maintenance Solutions

Cat. Number

RENOVO N - Normal Cleaning Solution, 250 mL S16M001

RENOVO

KS400 - Pepsin in HCl Cleaning Solution, 250 mL C20C370

KS410 - Thiourea Solution, 250 mL, for junction cleaning C20C380

KS120 - KCl Solution, saturated with AgCl, 500 mL, for Ag/AgCl reference C20C310

GK ANNEX - Electrode Maintenance Kit for pH & reference electrodes S91M001

X - Xtra Strong Cleaning Solution, 250 mL S16M002

8.8 Titrant Solutions

Cat. Number

Sulfuric acid standard solution, 0.1 N, 1000 mL 20253

Hydrochloric acid standard solution, 0.1 N, 1000 mL 1481253

53

Page 54

Section 9 Contact Information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE

FRANCE S.A.S.

8, mail Barthélémy

Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.

ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177

707

Doradztwo: +48 717 177

777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

Repair Service in

Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

Repair Service in

Latin America, the

Caribbean, the Far

East, Indian

Subcontinent, Africa,

Europe, or the Middle

East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE

NEDERLAND B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vajnory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

54

Page 55

Contact Information

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum

“Petrovsky

fort”, R.803

RU-194044,

Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@

hach-lange.com

www.hach-lange.com

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

ΗΑCH LANGE

E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD .ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/

ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE

MAROC SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@

hach-lange.com

www.hach-lange.ma

55

Loading...

Loading...