Page 1

DOC023.52.00025

AMTAX sc, AMTAX indoor sc

USER MANUAL

04/2013, Edition 7A

AMTAX sc, AMTAX indoor sc

© HACH-LANGE GmbH, 2006–2010; 2012, 2013. All rights reserved. Printed in Germany. sd/sk

Page 2

Page 3

Table of Contents

Section 1 Specifications ..........................................................................................................5

Section 2 General Information ................................................................................................9

2.1 Safety information ........................................................................................................................ 9

2.1.1 Use of hazard information ................................................................................................... 9

2.1.2 Precautionary labels ........................................................................................................... 9

2.1.3 Change instrument labels .................................................................................................10

2.2 Product overview ....................................................................................................................... 10

Section 3 Installation .............................................................................................................13

3.1 Basic installation overview ......................................................................................................... 13

3.2 Unpack the instrument ............................................................................................................... 14

3.3 Mechanical installation ............................................................................................................... 14

3.3.1 Mount the instrument ........................................................................................................ 14

3.3.1.1 Wall mount ............................................................................................................... 14

3.4 Initial instrument setup ............................................................................................................... 17

3.4.1 Open the enclosure ........................................................................................................... 17

3.4.2 Remove the shipping transport locks ................................................................................ 19

3.4.3 Installation of the collecting tray ........................................................................................ 21

3.4.4 Connect the humidity sensor ............................................................................................ 22

3.4.5 Determine the appropriate installation option ................................................................... 23

3.5 Electrical installation .................................................................................................................. 24

3.5.1 Electrostatic Discharge (ESD) Considerations ................................................................. 25

3.5.2 Enclosure breakouts ......................................................................................................... 25

3.5.3 Insert tubing and/or cables ................................................................................................ 26

3.5.4 Connect the Filter Probe to the analyzer .......................................................................... 26

3.5.5 Connect the optional heated drain .................................................................................... 27

3.6 Installation of reagents ............................................................................................................... 29

3.7 Gas-sensitive electrode ............................................................................................................. 31

3.7.1 Installation of the electrode and electrolyte ....................................................................... 31

3.7.1.1 Fill the electrode with electrolyte .............................................................................. 31

3.8 Supply power to the analyzer ..................................................................................................... 33

3.9 Connect the data network .......................................................................................................... 34

Section 4 System Start Up .....................................................................................................35

4.1 Initializing the instrument ........................................................................................................... 35

Section 5 Operation ...............................................................................................................37

5.1 Sensor diagnostics menu ........................................................................................................... 37

5.2 Sensor setup menu .................................................................................................................... 37

5.2.1 System setup menu .......................................................................................................... 42

5.3 Calibration process .................................................................................................................... 42

5.4 Cleaning process ....................................................................................................................... 42

5.5 Measurement process ............................................................................................................... 43

Section 6 Maintenance ...........................................................................................................45

6.1 General maintenance ................................................................................................................. 45

6.1.1 Clean the analyzer ............................................................................................................ 45

6.1.1.1 Cleaning interval ......................................................................................................46

6.1.2 Replace the fan filter ......................................................................................................... 46

6.1.3 Fuse replacement ............................................................................................................. 47

6.2 Reagent replacement ................................................................................................................. 47

6.3 Routine maintenance schedule .................................................................................................. 48

6.4 Scheduled maintenance ............................................................................................................ 49

3

Page 4

Table of Contents

6.5 Replace the membrane cap, electrolyte and electrode ..............................................................49

6.6 Validation (Analytical quality assurance) ....................................................................................52

6.7 Shut the analyzer down ..............................................................................................................54

6.7.1 Shut the analyzer down for an extended period ................................................................54

6.8 Modify from single channel to dual channel ...............................................................................55

Section 7 Troubleshooting ....................................................................................................57

7.1 Troubleshooting the controller ....................................................................................................57

7.2 Troubleshooting the analyzer .....................................................................................................57

7.2.1 LED status .........................................................................................................................57

7.2.2 Error messages .................................................................................................................57

7.2.3 Warnings ...........................................................................................................................60

7.3 Troubleshooting the Electrode ...................................................................................................62

Section 8 Replacement Parts and Accessorie ....................................................................65

8.1 Standards and reagents .............................................................................................................65

8.2 Analyzer accessories .................................................................................................................65

8.3 Mounting hardware and accessories ..........................................................................................66

8.4 Replacement parts .....................................................................................................................66

Section 9 Contact Information .............................................................................................73

Section 10 Warranty and liability ..........................................................................................75

Appendix A Plumbing and Connection Options .................................................................77

A.1 Safety information ......................................................................................................................77

A.1.1 Electrostatic Discharge (ESD) Considerations ..................................................................77

A.2 Connect a 2-parameter option ...................................................................................................78

A.2.1 Remove the T-fitting ..........................................................................................................79

A.3 Drain line considerations ............................................................................................................79

A.4 Tubing considerations ................................................................................................................79

A.5 Option 1 plumbing and connections ...........................................................................................80

A.6 Option 2 plumbing and cable connections .................................................................................82

A.7 Option 3 plumbing and connections ...........................................................................................84

A.8 Option 4 plumbing and connections ...........................................................................................86

A.9 Option 5 plumbing and connections ...........................................................................................88

A.10 Option 6 plumbing and connections .........................................................................................90

A.11 Option 7 plumbing and connections .........................................................................................92

A.12 Option 8a plumbing and connections .......................................................................................94

A.13 Option 8b plumbing and connections .......................................................................................96

A.14 Option 9a plumbing and connections .......................................................................................98

A.15 Option 9b plumbing and connections .....................................................................................100

A.16 Option 10a plumbing and connections ...................................................................................102

A.17 Option 10b plumbing and connections ...................................................................................104

A.18 Option 11a plumbing and connections ...................................................................................106

A.19 Option 11b plumbing and connections ...................................................................................108

Appendix B Fieldbus Communications .............................................................................111

B.1 Fieldbus control ........................................................................................................................111

B.2 Remote controlled measurement series ..................................................................................111

B.3 External trigger contact, Control by external signal .................................................................112

B.4 Modbus register information ....................................................................................................112

4

Page 5

Section 1 Specifications

Specifications are subject to change without notice.

Enclosure rating

AMTAX sc: IP55

AMTAX indoor sc: IP54

Enclosure material ASA/PC UV-resistant

Measuring method GSE (Gas-Sensitive Electrode)

–N

4

–N

4

–N

4

–N

4

Measuring range

0.02 to 5.0 mg/L NH

0.05 to 20 mg/L NH

1 to 100 mg/L NH

10 to 1000 mg/L NH

0.02 mg/L NH4–N (0.02 to 5.0 mg/L NH

Detection limit

0.05 mg/L NH

1 mg/L NH

10 mg/L NH

–N (0.05 to 20 mg/L NH4–N Measuring Range)

4

–N (1 to 100 mg/L NH4–N Measuring Range)

4

–N (10 to 1000 mg/L NH4–N Measuring Range)

4

≤ 1 mg/L: 3 % + 0.02 mg/L

>1 mg/L: 5 % + 0.02 (0.02 to 5.0 mg/L NH

Measuring accuracy

(with standard solution)

3 % + 0.05 mg/L (0.05 to 20 mg/L NH

3 % + 1.0 mg/L (1 to 100 mg/L NH

4.5 % + 10 mg/L (10 to 1000 mg/L NH

–N (0.02 to 5.0 mg/L NH4–N Measuring Range)

4

Repeatability

(with standard solution)

3 % + 0.02 mg/L NH

2 % + 0.05 mg/L (0.05 to 20 mg/L NH

2 % + 1.0 mg/L (1 to 100 mg/L NH

2 % + 10 mg/L (10 to 1000 mg/L NH

Measuring Range: 0.02 to 5 mg/L NH

–N: 3 measurements (shortest 15 minutes)

4

Response time (90 %)

0.02 to 0.2 mg/L NH

0.2 to 5 mg/L NH4–N: 1 measurement (5 minutes)

Measuring Ranges: 0.05 to 20 mg/L; 1 to 100 mg/L and 10 to 1000 mg/L NH

< 5 minutes

Adjustable measuring interval 5 to 120 minutes

–N Measuring Range)

4

-N Measuring Range)

4

–N Measuring Range)

4

–N Measuring Range)

4

–N Measuring Range)

4

–N Measuring Range)

4

–N Measuring Range)

4

–N Measuring Range)

4

–N

4

–N

4

Power supply

Power supply with power cable only using the sc1000 controller

(analyzer, Filter Probe sc and drain tubing: 115 V versions or 230 V versions)

Data transmission Data transmission with data cable on the sc1000 controller

Electrical power consumption 500 VA

Electrical fuse protection

Via sc1000 controller

Maximum of 2 analysis instruments for each sc1000 controller.

Outputs Relay, current outputs, bus interface via sc1000 controller

Operating temperature

Storage temperature

AMTAX sc: –20 to 45 °C (–4 to 113 °F); 95 % relative humidity, non-condensing

AMTAX indoor sc: 5 to 40 °C (41 to 104 °F); 95 % relative humidity, non-condensing

–20 to 60 °C (–4 to 140 °F); 95 % relative humidity, non-condensing

4 to 55 °C (39 to 131 °F); 95 % relative humidity, non-condensing (electrode)

Sample temperature 4 to 40 °C (39 to 104 °F)

Sample pressure With continuous sample preparation –30 mbar to +50 mbar at overflow vessel

Sample flow Range: 1.0 L/h–20.0 L/h

Sample quality Ultra filtrated or

comparable

Sample level Level of liquid in basin with filtration probe must be below analyzer

5

Page 6

Specifications

Permissible pH value of the sample 5 to 9

Permissible hardness range <= 50 °dH 8.95 mMol/L

Permissible chlorid range <= 1000 mg/L Cl

–

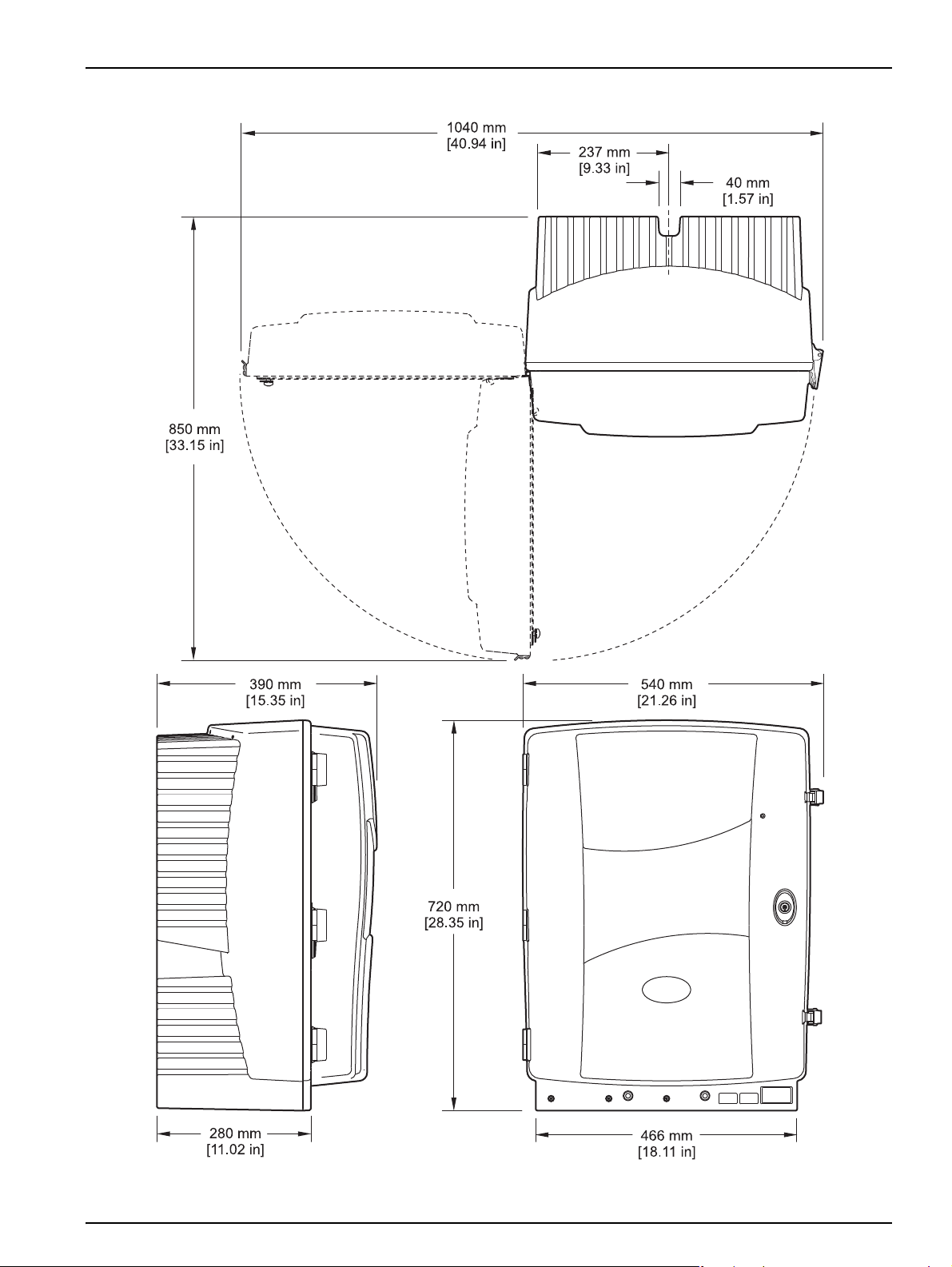

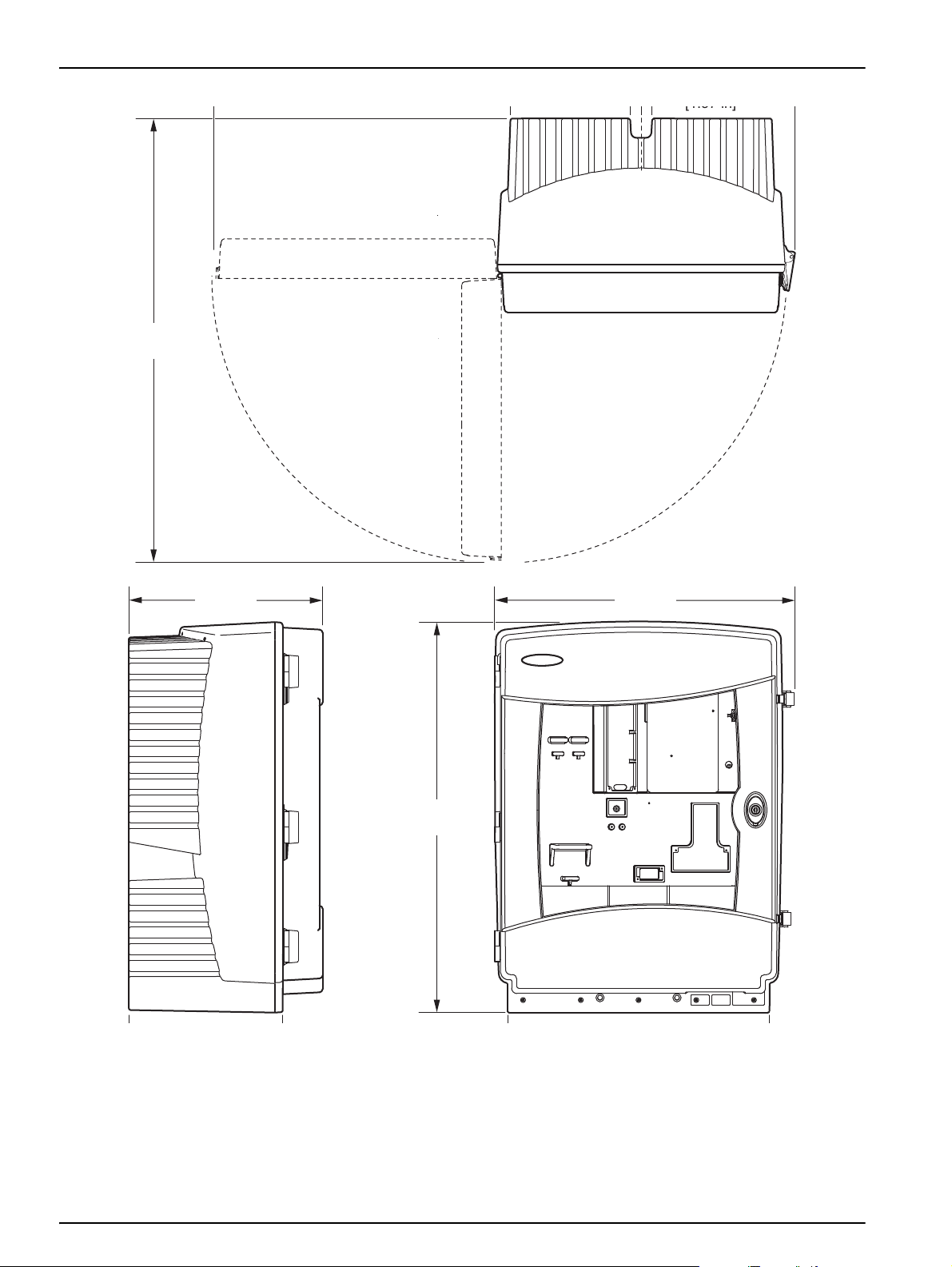

Dimensions (Figure 1, page 7,

Figure 1, page 7)

Data and power cable lengths 2 m (80 in.) (from edge of enclosure)

Weight

Certifications CE conform. Listed to UL and CSA safety standards by TUV.

AMTAX sc: (W × H × D) 540 × 720 × 390 mm (21,25 × 28,35 × 15,35 in.)

AMTAX indoor sc: (W × H × D) 540 × 720 × 370 mm (21,25 × 28,35 × 14.5 in.)

AMTAX sc: Approx. 31 kg, without Filter Probe sc and without chemicals

AMTAX indoor sc: Approx. 29 kg, without Filter Probe sc and without chemicals

6

Page 7

Specifications

Figure 1 Instrument dimensions AMTAX sc

7

Page 8

Specifications

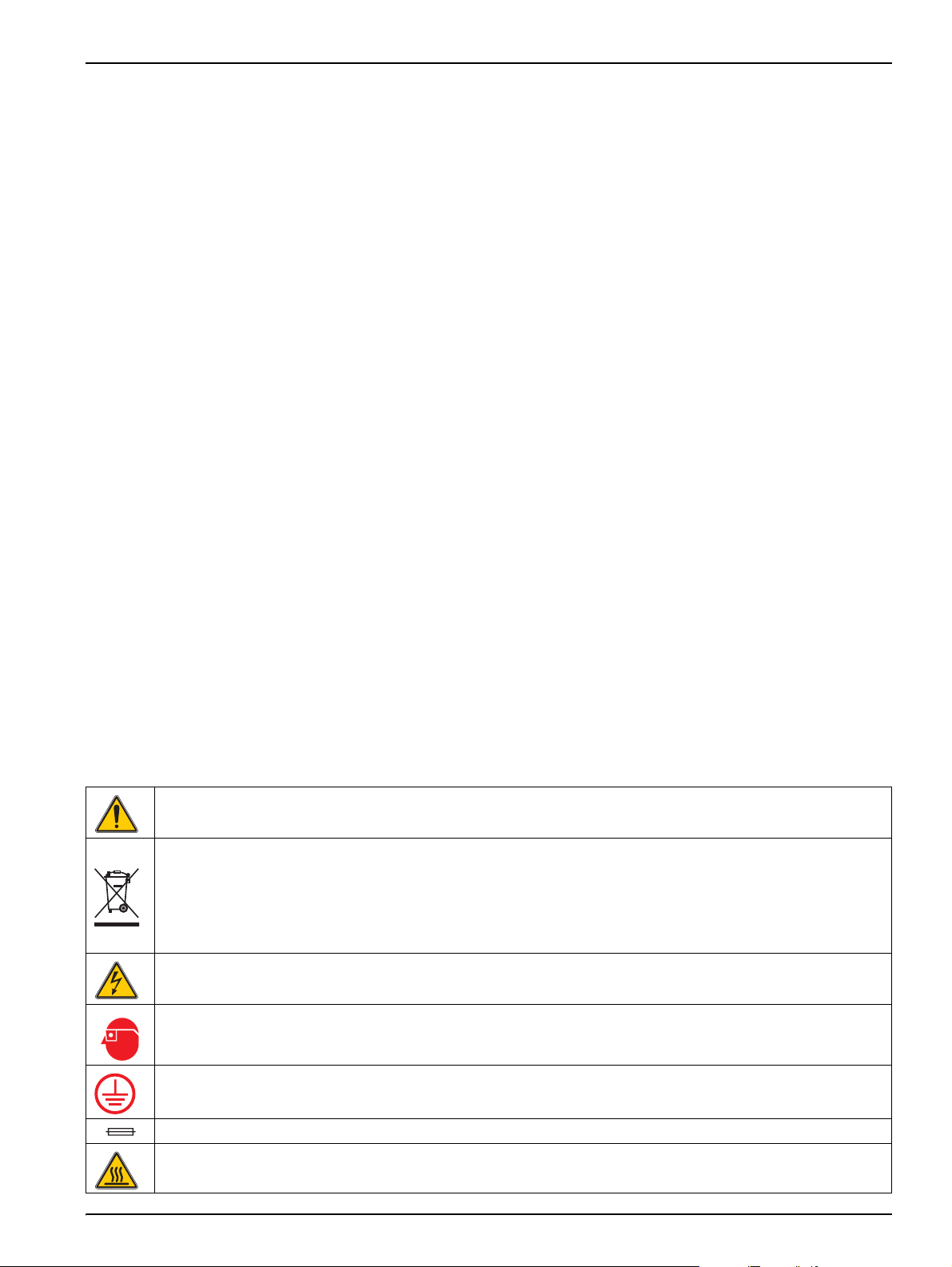

[1.57 in]

850 mm

[33.15 in]

720 mm

[28.35 in]

540 mm

[21.26 in]

370 mm

[14.57 in]

Figure 2 Instrument dimensions AMTAX indoor sc

8

Page 9

Section 2 General Information

2.1 Safety information

Please read this entire manual before unpacking, setting up or

operating this equipment. Pay attention to all danger and caution

statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner other

than that specified in this manual.

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

2.1.2 Precautionary labels

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC),

European electrical equipment users must now return old or end-of life equipment to the Producer for disposal at

no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories and all auxiliary items for proper disposal.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

Important Note: Indicates a situation which, if not avoided, may

cause damage to the instrument. Information that requires special

emphasis.

Note: Information that supplements points in the main text.

Read all labels and tags attached to the instrument. Personal injury

or damage to the instrument could occur if not observed. A symbol,

if noted on the instrument, will be included with a danger or caution

statement in the manual.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol, when noted on the product, indicated that the marked item can be hot and should not be touched

without care.

9

Page 10

General Information

18-32 kg (39.7-70.5 lbs)

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that only individuals

qualified and trained to work with chemicals should handle chemicals or perform maintenance on chemical delivery

systems associated with the equipment.

This symbol, when noted on the product, indicated the presence of devices sensitive to Electro-static Discharge

(ESD) and indicated that care must be taken to prevent damage with the equipment.

When carrying or transporting the instrument/instrument components and if the total weight is more than 18 kg,

make sure that suitable lifting equipment is used and/or that the instrument/instrument components are carried by

2 people.

2.1.3 Change instrument labels

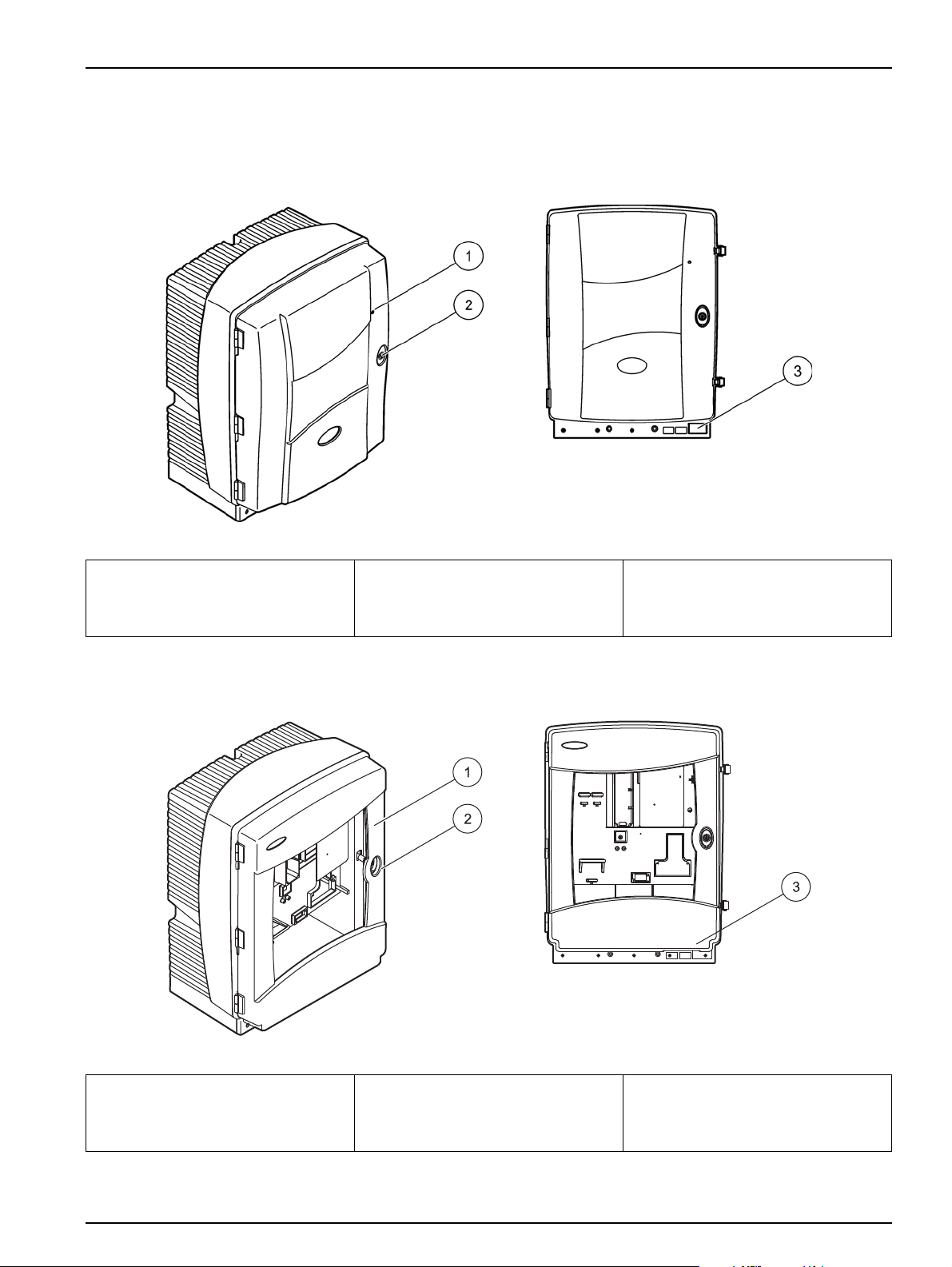

2.2 Product overview

Several safety labels (3 in the analytical section) are applied to the

instrument. If necessary, apply the correct language label over the

existing safety labels.

The AMTAX sc (Figure 3, Figure 4) measures the ammonium ions

present in treated aqueous solutions (waste water, process water

and surface water). The measured value is displayed in mg/L

NH

-N on the controller. The AMTAX sc must be used in

4

combination with the sc1000 controller. The sc1000 controller is

used to configure, power and output the measured values.

Conversion formula: NH

-N : NH

4

+

= 1 : 1.288

4

The AMTAX sc can operate using single or dual channel modes.

Operation with the Filter Probe sc is single channel only. The sc

analyzer can be converted from a single channel operation to dual

channel operation. Contact the manufacturer for more information.

10

Page 11

General Information

Dual channel operation is only possible with continuous sample

preparation, e.g. FILTRAX or Ultrafiltration. Sample preparation and

filtration must be provided before installing the analysis instrument.

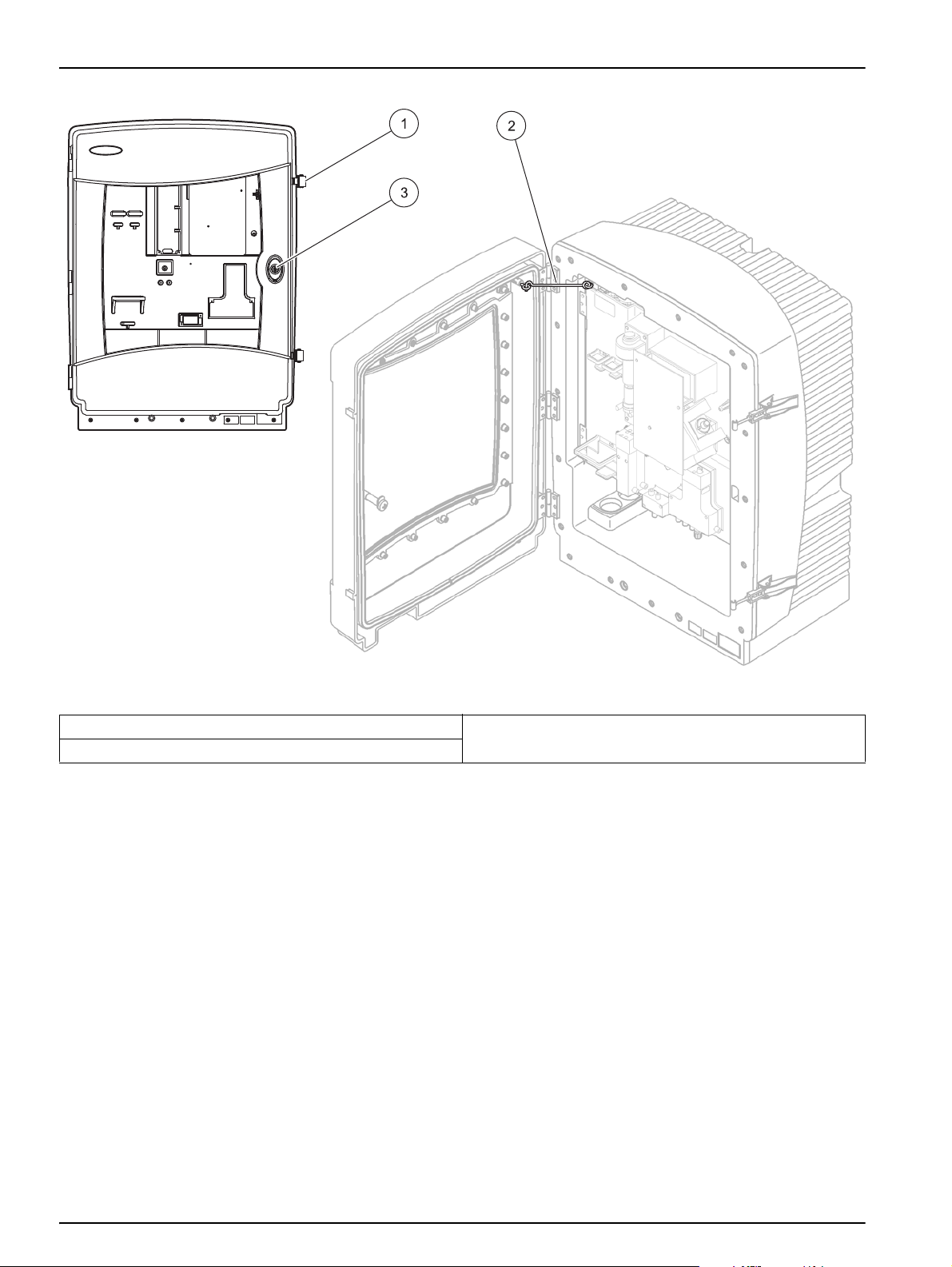

1 LED for operating state. Refer to

Table 9, page 57 for more

information.

Figure 3 AMTAX sc enclosure

2 Door lock 3 Rating plate with model number,

serial number, voltage and

frequency information and power

consumption information

1 LED for operating state. Refer to

Table 9, page 57 for more

information.

Figure 4 AMTAX indoor sc enclosure

2 Door lock 3 Rating plate with model number,

serial number, voltage and

frequency information and power

consumption information

11

Page 12

General Information

12

Page 13

Section 3 Installation

DANGER

Only qualified personnel should conduct the tasks described

in this section of the manual.

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

DANGER

Potential danger in the event of contact with

chemical/biological materials. Handling chemical samples,

standards and reagents can be dangerous. Familiarize

yourself with the necessary safety procedur es and t he corr ect

handling of the chemicals before the work and r ead and fo llow

all relevant safety data sheets.

Normal operation of this instrument may involve the use of

hazardous chemicals or biologically harmful samples.

• Observe all cautionary information printed on the original

solution containers and safety data sheet prior to their

use.

3.1 Basic installation overview

• Dispose of all consumed solutions in accordance with

national regulations and laws.

• Select the type of protective equipment suitable to the

concentration and quantity of the dangerous material at

the respective work place.

1. Unpack the instrument (section 3.2).

2. Mount the instrument (section 3.3, page 14).

3. Remove any transport locks (section 3.4.2, page 19).

4. Install the collecting tray and the humidity sensor (section 3.4.3,

page 21 and section 3.4.4, page 22).

5. Determine the appropriate installation option (section 3.4.5,

page 23).

6. Mount the Filter Probe sc or Filtrax, if necessary. Refer to the

appropriate manual for more information.

7. Connect the Filter Probe sc or Filtrax to the AMTAX sc, if

necessary. Refer to section 3.5.3, page 26 for the Filter Probe

sc. Refer to the Filtrax manual for more information.

8. Connect the Drain Heating Connection, if necessary.

9. Make all plumbing connections (Appendix A Plumbing and

Connection Options, page 77).

10. Install the reagents and prepare the Electrode and Electrolyte

(section 3.6, page 29 and section 3.7.1, page 31).

11. Connect the AMTAX sc to the sc1000 controller to supply

power to the system (section 3.8, page 33).

12. Connect the data network (section 3.9, page 34).

13

Page 14

Installation

3.2 Unpack the instrument

3.3 Mechanical installation

CAUTION

Pay attention to the weight (approximately 31 kg) of the

instrument. Do not try to carry the instrument without

assistance. Use only suitable lifting tackle for transport.

Open the shipping container while it is on its end and then slide the

analyzer out of the cardboard. The items supplied will vary

depending on the order. Standard items supplied for a minimal

configuration include:

• AMTAX sc and user manual

• Collecting tray

• Initial set of reagent and cleaning solutions

2 standard solutions and electrolyte / membrane caps

• Fastening bracket and angle bracket

• Accessories for tubing and flow-through variant

• Plug set

3.3.1 Mount the instrument

Select a suitable place to install the instrument. Plan the

mechanical installation before positioning posts or drilling holes.

Refer to Figure 1, page 7, Figure 2, page 8 for instrument

dimensions.

Make sure that the fastening has sufficient load bearing capacity

(approximately 160 kg). The wall plugs must be selected and

approved to suit the properties of the wall.

Plan cable and tubing routes to avoid sharp bends and tripping

hazards.

When connecting two analyzers (e. g. for measuring two

parameters with a FILTRAX or Ultrafiltration), plan where the

instruments are to be installed and consider the length of the

heated drain tubing (2 m).

The AMTAX sc can be mounted in three different ways:

• Wall Mount (section 3.3.1.1),

• Rail Mount; refer to the instruction sheet supplied with the

Rail Mounting Hardware.

• Stand Mount; refer to the instruction sheet supplied with the

Rail Mounting Hardware.

3.3.1.1 Wall mount

14

Refer to Figure 5, Figure 6 and following instructions to mount the

analyzer to a wall.

1. Align and install the fastening bracket to the wall.

2. Attach the angle bracket to the instrument using the

supplied screws.

3. Slide the bottom of the enclosure onto the fastening bracket.

Page 15

Installation

4. Attach the enclosure to the fastening bracket.

5. Attach the angle bracket on the enclosure to the wall.

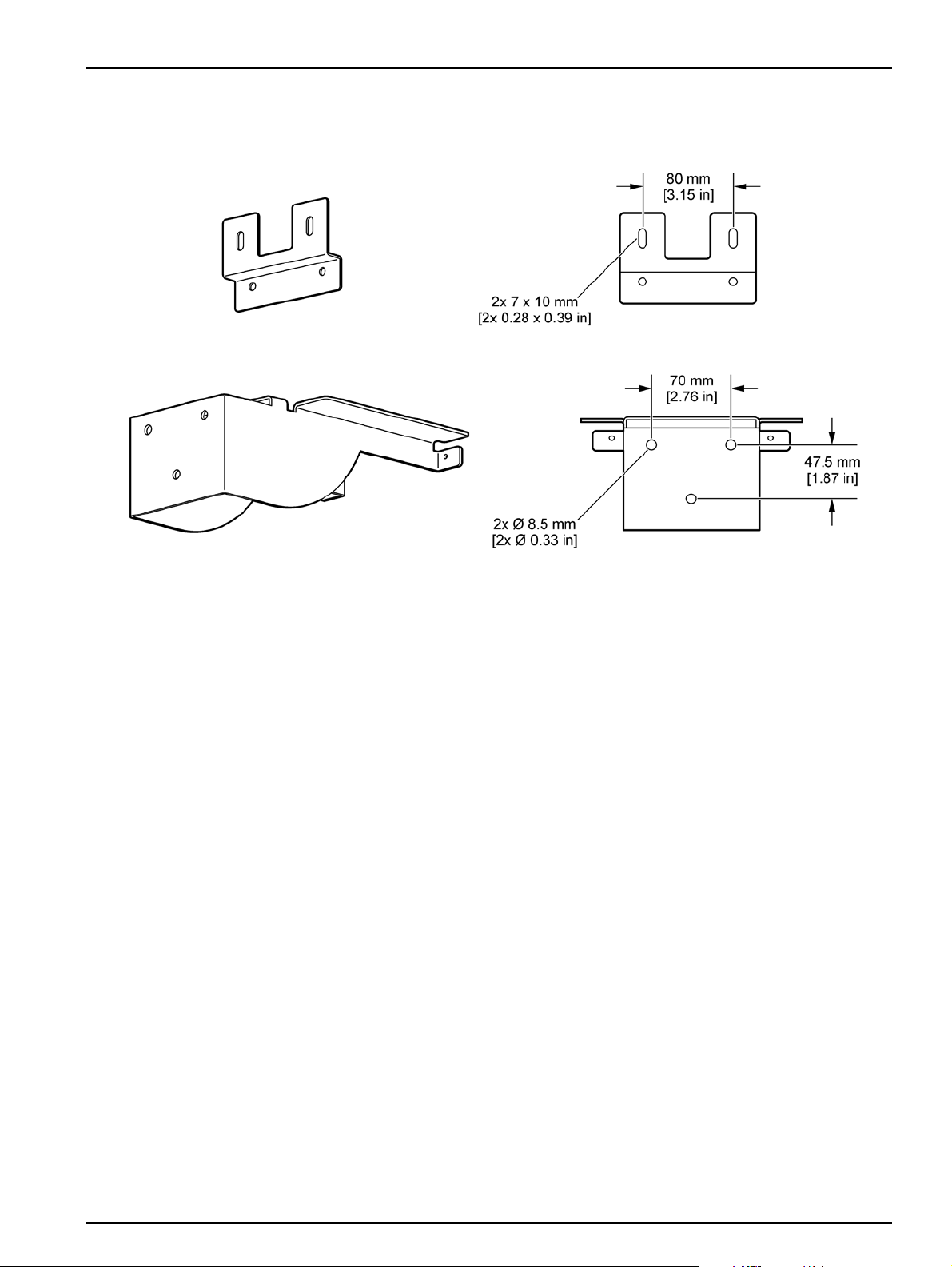

Figure 5 Bracket dimensions for wall mounting

15

Page 16

Installation

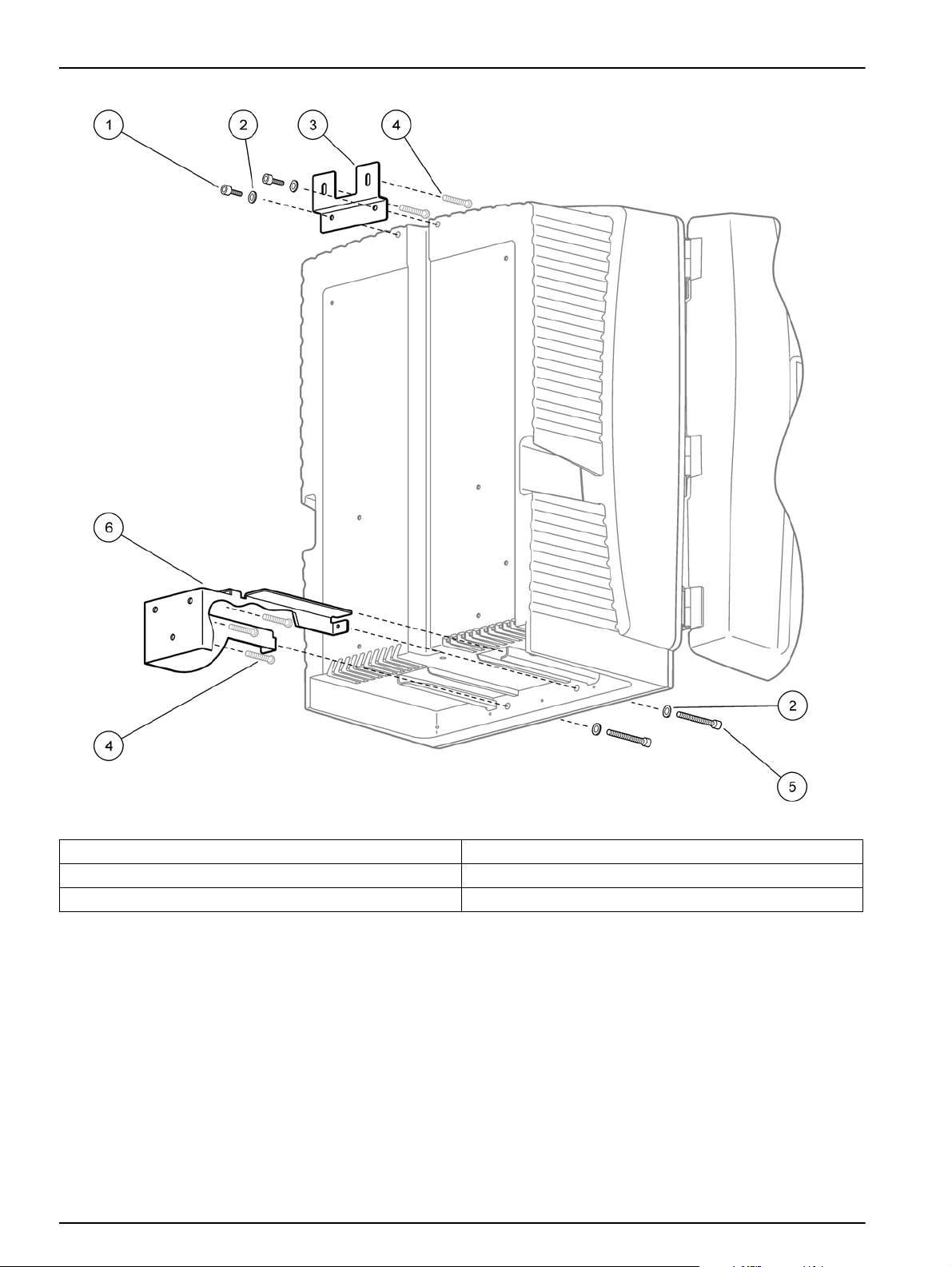

Figure 6 Wall mounting the analyzer

1 Socket head cap screw, M5 X 8 (2X) 4 Screw, customer supplied

2 Washer, M5 (4X) 5 Socket head cap screw, M5 X 40 (2X)

3 Angle bracket 6 Fastening bracket

16

Page 17

3.4 Initial instrument setup

3.4.1 Open the enclosure

Installation

DANGER

To reduce the risk of electrica l shock, mak e sure tha t no water

can enter the enclosure or come into contact with circuit

boards.

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

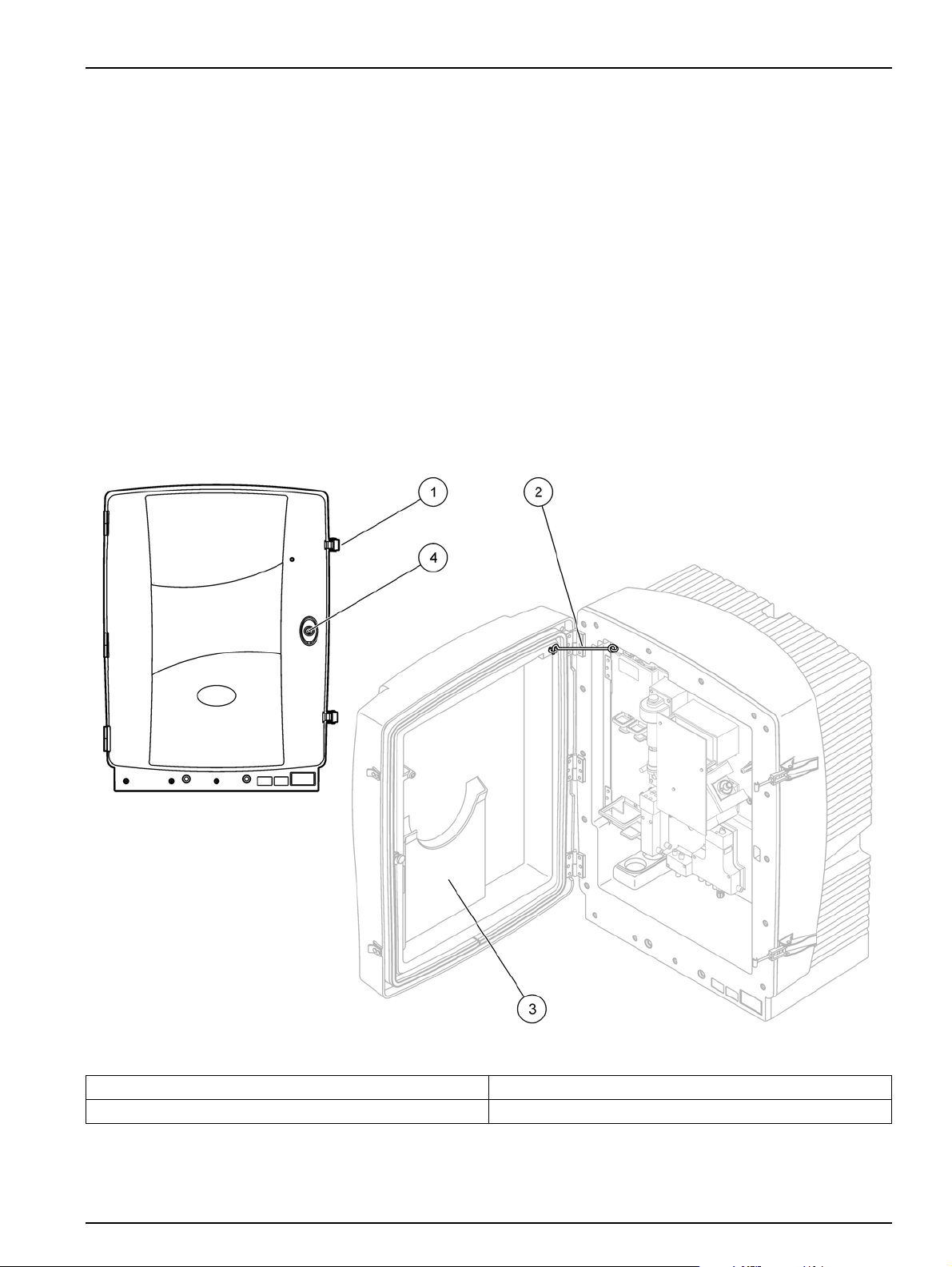

1. Unlock the instrument (item 4, Figure 7, item 3, Figure 8).

2. Open the side latches and release the door catch.

3. Open the door and secure the door using the hook or

completely remove the door.

Figure 7 Open the enclosure AMTAX sc

1 Latches 3 Pocket for user manual

2 Door hook 4 Lock with key

17

Page 18

Installation

Figure 8 Open the enclosure AMTAX indoor sc

1 Latches 3 Lock with key

2 Door hook

18

Page 19

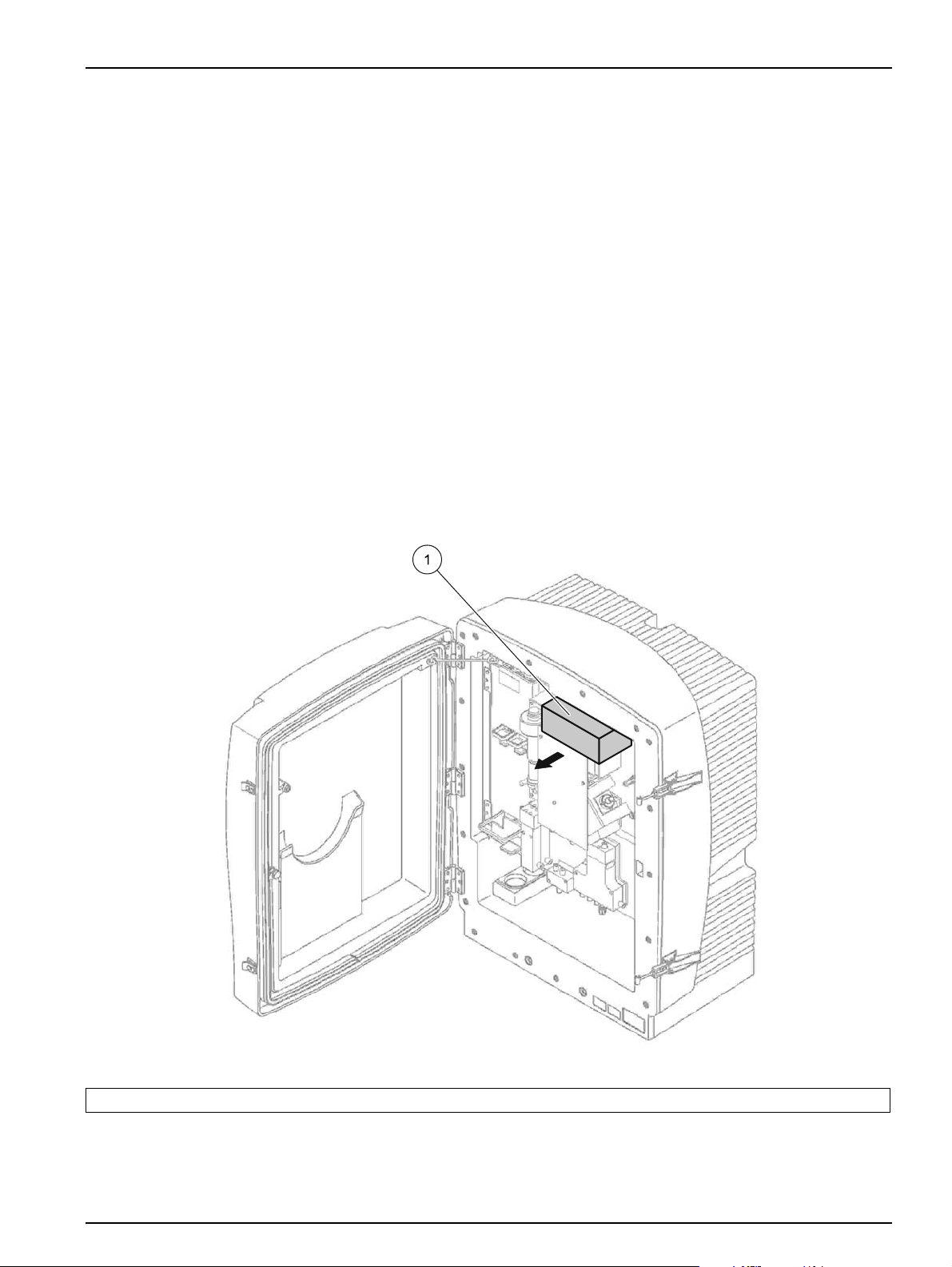

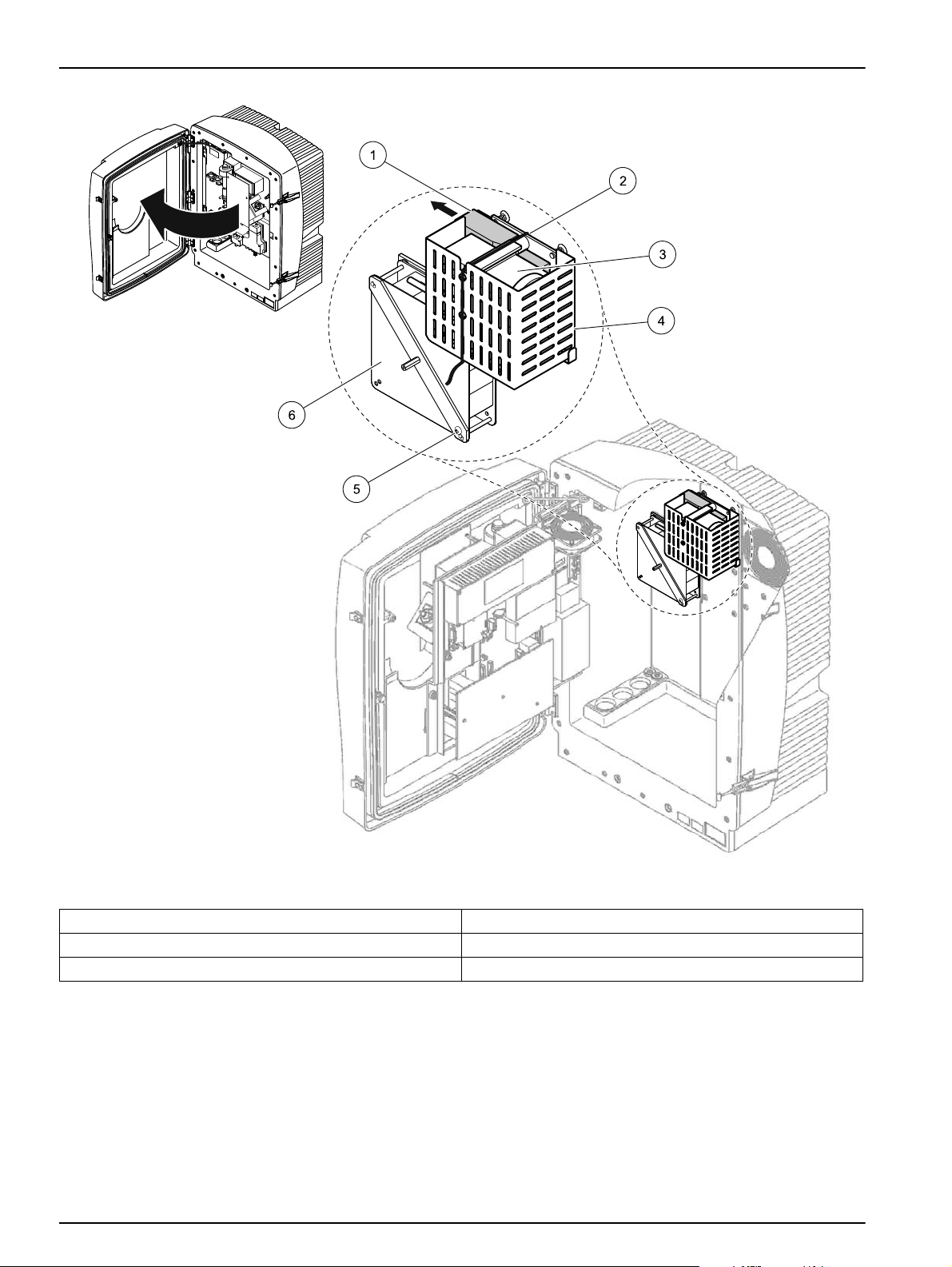

3.4.2 Remove the shipping transport locks

Prior to system start-up, the shipping transport locks must be

removed from the sc analyzer.

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

Important note: The electrode insulation for the measuring unit is

NOT a transport lock. Do NOT remove the cover on the measuring

unit.

1. Open the enclosure door and secure with the door hook.

2. Remove the transport lock on the analyzer panel (Figure 9).

Note: If the instrument is operated with a Filter Probe sc, it is equipped

with an internal compressor.

3. Remove the cable tie and pull out the compressor transport

lock to the left (Figure 10).

Note: Keep the transport locks for transporting and storage.

Installation

1 Transport lock

Figure 9 Remove the analyzer panel transport locks

19

Page 20

Installation

Figure 10 Compressor transport lock removal

1 Compressor transport lock 4 Protective cover for compressor

2 Cable tie 5 Fan locking screw

3 Compressor 6 Fan

1

The compressor, compressor transport lock and cable tie only apply to sc analyzers that operate using the Filter Probe sc.

1

20

Page 21

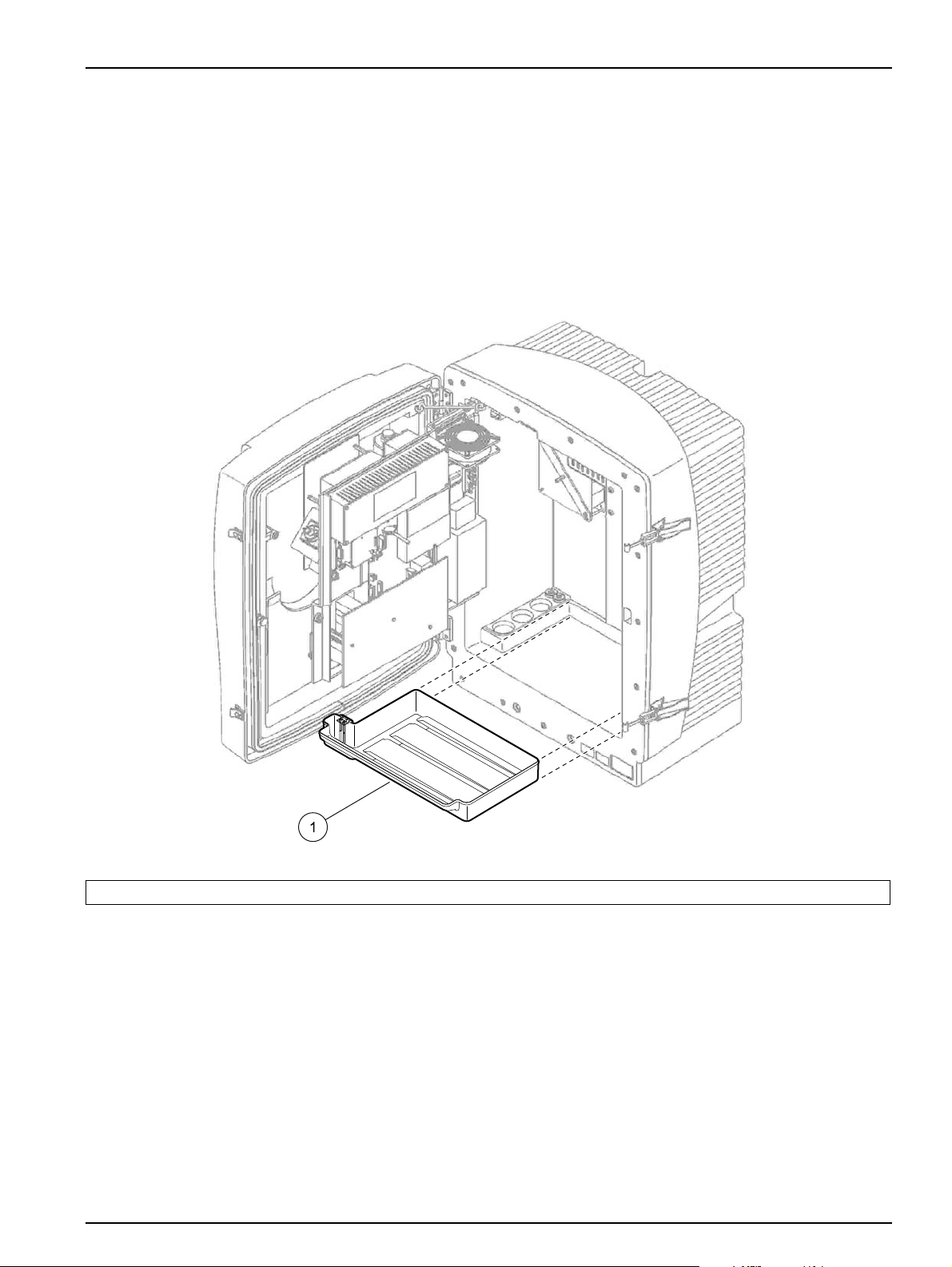

3.4.3 Installation of the collecting tray

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

1. Open the enclosure door and secure with the door hook.

2. Slide the collecting tray into the bottom of the enclosure

Installation

(Figure 11).

1 Collecting tray

Figure 11 Installation of the collecting tray

21

Page 22

Installation

3.4.4 Connect the humidity sensor

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

1. Remove power from the instrument.

2. Open the enclosure door and secure with the door hook.

3. Connect the humidity sensor wires to the terminal screws on

the collecting tray (Figure 12).

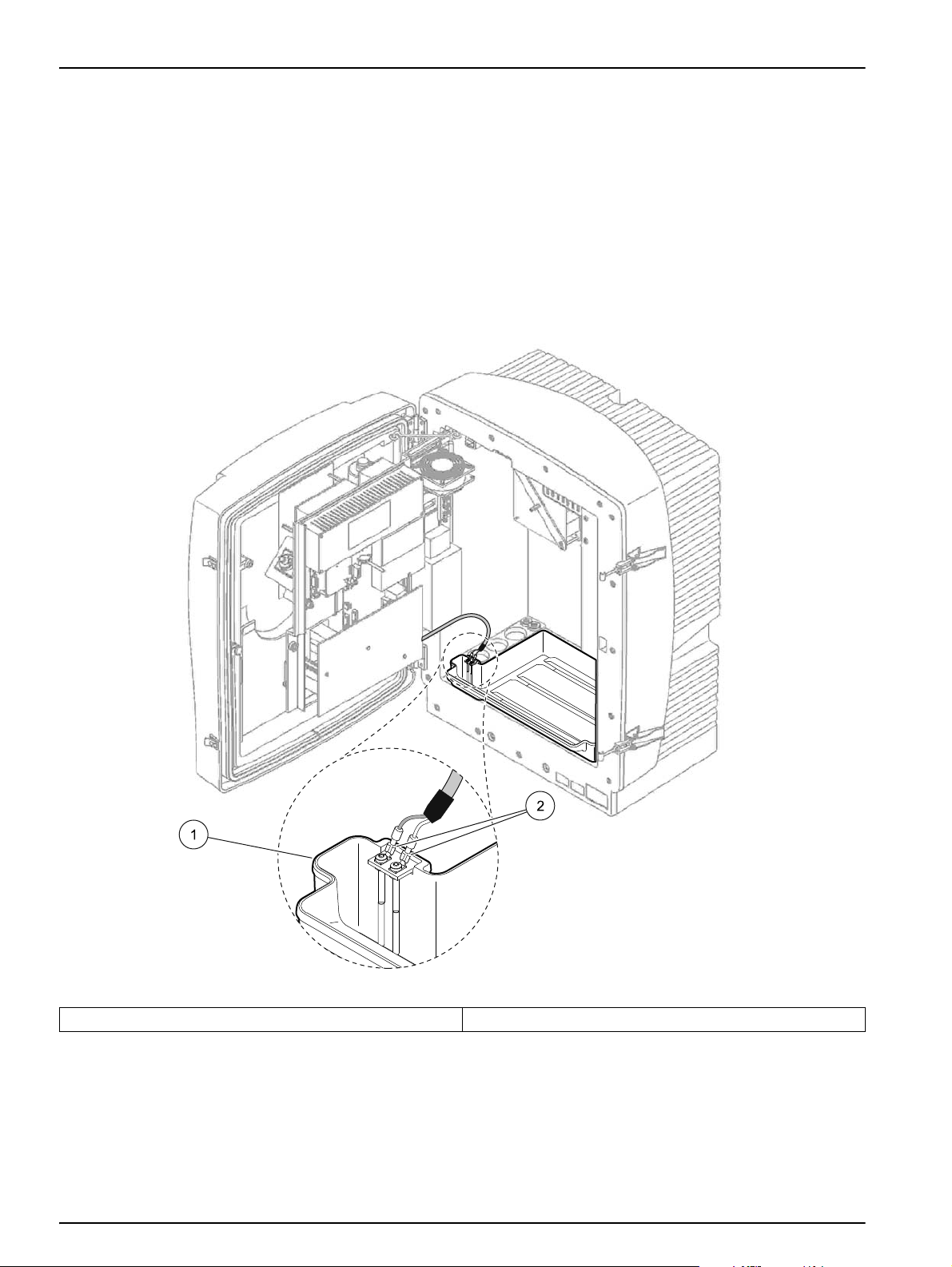

Figure 12 Connect the humidity sensor

1 Collecting tray 2 Humidity sensor connections

22

Page 23

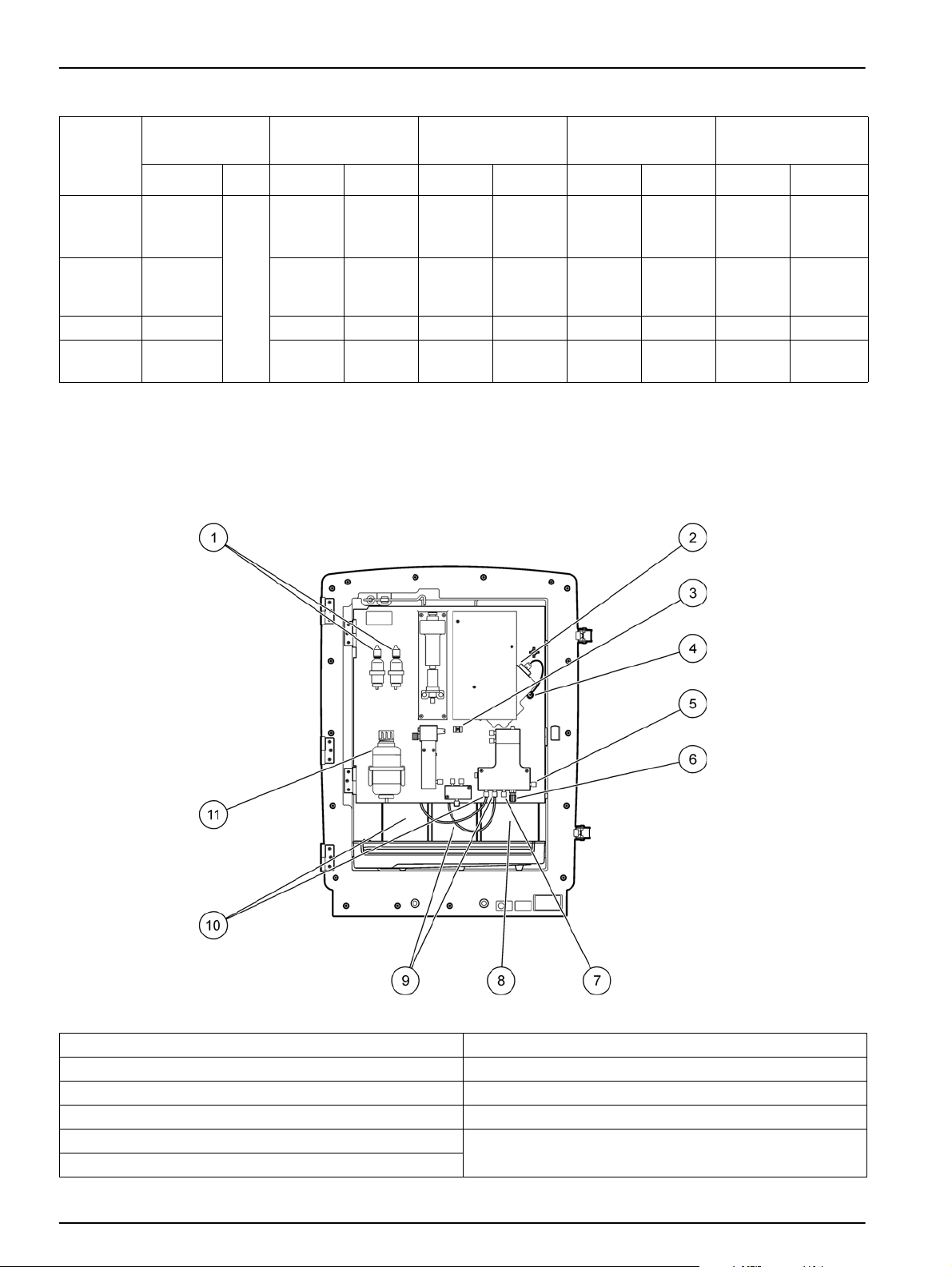

3.4.5 Determine the appropriate installation option

Before connecting tubing or cables, determine the option number

that corresponds the system configuration. Refer to Table 1. Based

on the option number, determine the sealing plug that will be used

to seal the enclosure openings, refer Table 2.

When the option number is determined, refer to Appendix A

Plumbing and Connection Options, page 77 for installation

information.

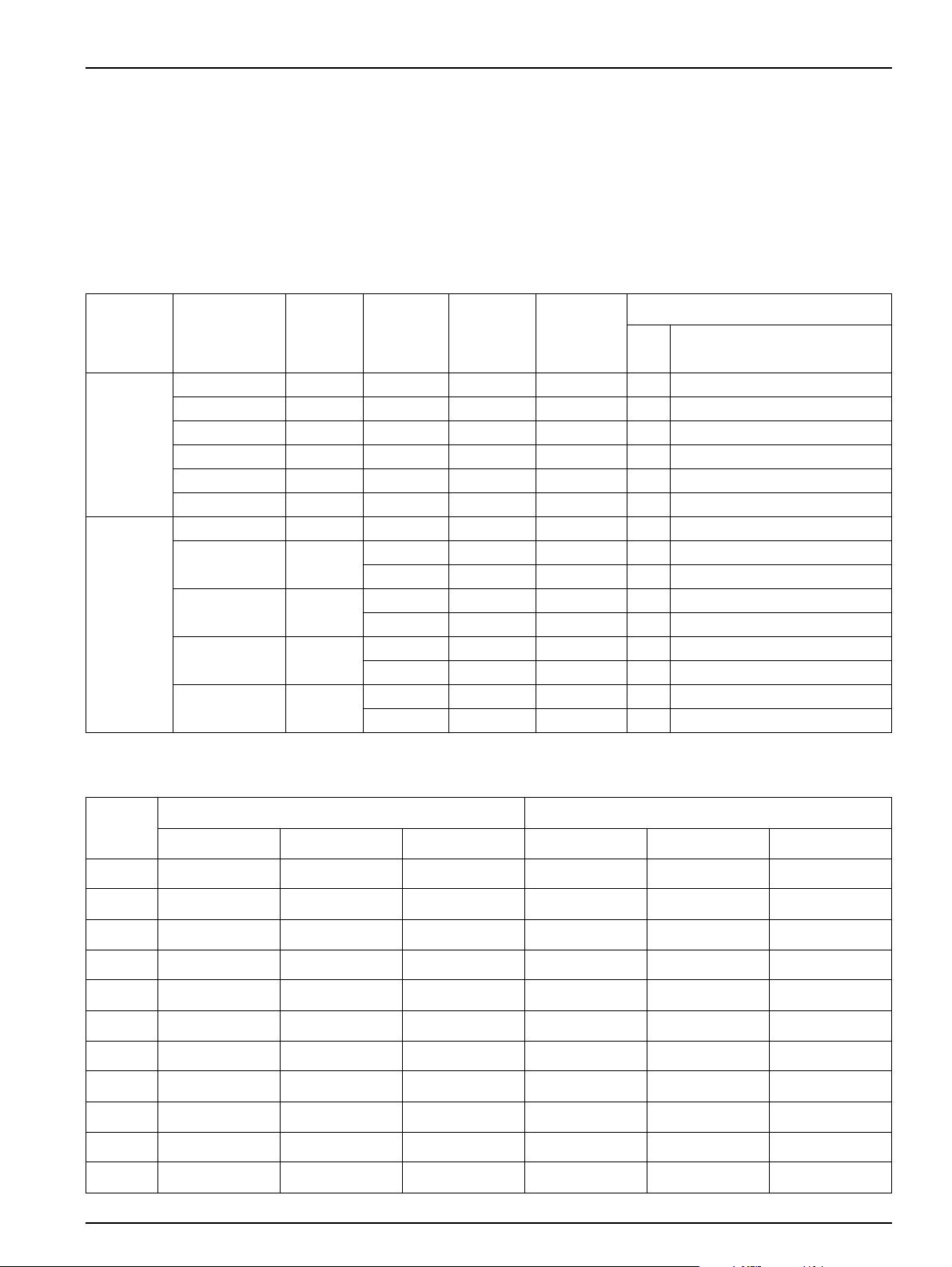

Table 1 System configuration options

Installation

Location Filtration Drain

Filter Probe sc Any 1 1 1 1 A.5 , page 80

Filter Probe sc Heated 1 1 1 2 A.6 , page 82

OUTDOOR

INDOOR

1

For 2-parameter options, refer to Connect a 2-parameter option, page 78.

FILTRAX Heated 1 1 1 3 A.7 , page 84

FILTRAX 2 heated 2 1 2 4 A.8 , page 86

2 FILTRAX Heated 1 2 1 5 A.9 , page 88

2 FILTRAX 2 heated 2 2 2 6 A.10 , page 90

Filter Probe sc Unheated 1 1 1 7 A.11 , page 92

FILTRAX Unheated

2 FILTRAX Unheated

Continuous

sample feed

2 continuous

sample feeds

Unheated

Unheated

Number of

analyzers

11 18 aA.12 , page 94

21 28 bA.13 , page 96

12 19 aA.14 , page 98

22 29 bA.15 , page 100

11 110 aA.16 , page 102

22 210 bA.17 , page 104

12 111 aA.18 , page 106

22 211 bA.19 , page 108

Sample

lines

(Ch1, Ch2)

Number of

parameter

Option

1

Refer to the following section

#

for more information:

Table 2 Sealing plug types

Analysis instrument 1 Analysis instrument 2

Option

Opening 1 Opening 2 Opening 3 Opening 1 Opening 2 Opening 3

1 Plug 2 Plug 3 Plug 3 — — —

2 Plug 2 Plug 1 Plug 3 — — —

3 Plug 1 Plug 1 Plug 3 — — —

4 Plug 1 Plug 1 Plug 3 Plug 1 Plug 1 Plug 3

5 Plug 1 Plug 1 Plug 1 — — —

6 Plug 1 Plug 1 Plug 1 Plug 1 Plug 1 Plug 3

7 Plug 2 Plug 3 Plug 3 — — —

8 Plug 1 Plug 3 Plug 3 Plug 3 Plug 3 Plug 3

9 Plug 1 Plug 1 Plug 3 Plug 3 Plug 3 Plug 3

10 Plug 3 Plug 3 Plug 3 Plug 3 Plug 3 Plug 3

11 Plug 3 Plug 3 Plug 3 Plug 3 Plug 3 Plug 3

23

Page 24

Installation

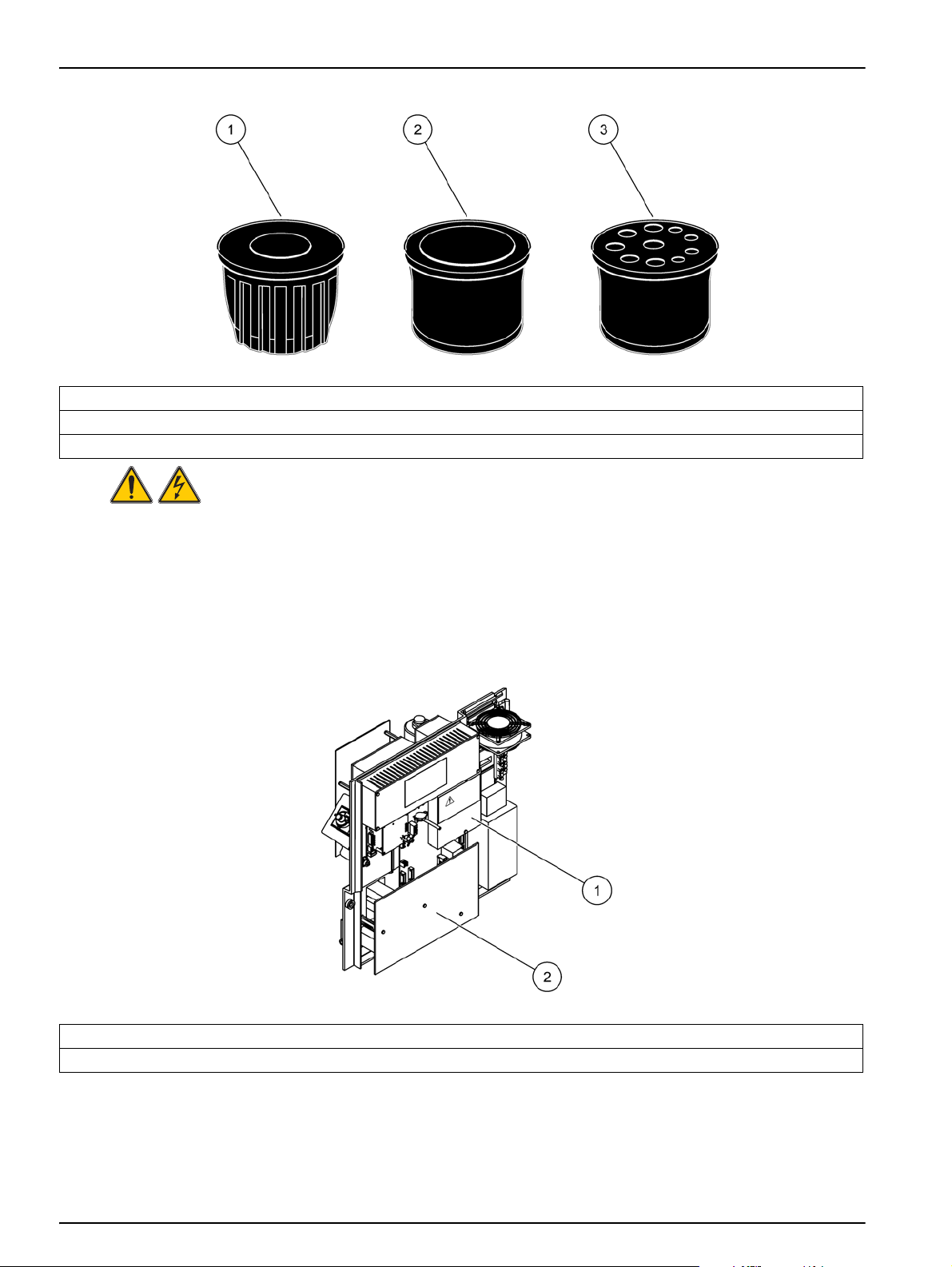

Figure 13 Sealing plug types

1 Sealing plug type 1

2 Sealing plug type 2

3 Sealing plug type 3

3.5 Electrical installation

DANGER

High voltage wiring connections are present under the

protective cover. The protective cover must remain in place

unless a qualified installation technician is installing wiring for

the Filter Probe sc or the heated drain.

See Figure 14 for protective cover removal.

Figure 14 Remove the protective covers

1 Protective cover for AC mains circuits (Back view)

2 Protective cover for main PCB

24

Page 25

3.5.1 Electrostatic Discharge (ESD) Considerations

Important Note: To minimize hazards an d ESD risks, maintenance

procedures not requiring power to the analyzer should be

performed with power removed.

Delicate internal electronic components can be damaged by static

electricity, resulting in degraded instrument performance or

eventual failure.

The manufacturer recommends taking the following steps to

prevent ESD damage to the instrument:

• Before touching any instrument electronic components (such

as printed circuit cards and the components on them)

discharge static electricity. This can be accomplished by

touching an earth-grounded metal surface such as the chassis

of an instrument or pipe or a metal conduit.

• To reduce static build-up, avoid excessive movement.

Transport static-sensitive components in anti-static containers

or packaging.

• To discharge static electricity and keep it discharged, wear a

wrist strap connected by a wire to earth ground.

Installation

3.5.2 Enclosure breakouts

• Handle all static-sensitive components in a static-safe area. If

possible, use anti-static floor pads and work bench pads.

There are four main enclosure openings to insert tubing and cables

(Figure 15).

1 Sample feed or refer to

Table 1, page 23 for

tubing options.

Figure 15 Enclosure breakouts

2 Refer to Table 1,

page 23 for tubing

options.

3 Refer to Table 1,

page 23 for tubing

options.

4 Power and data cables

25

Page 26

Installation

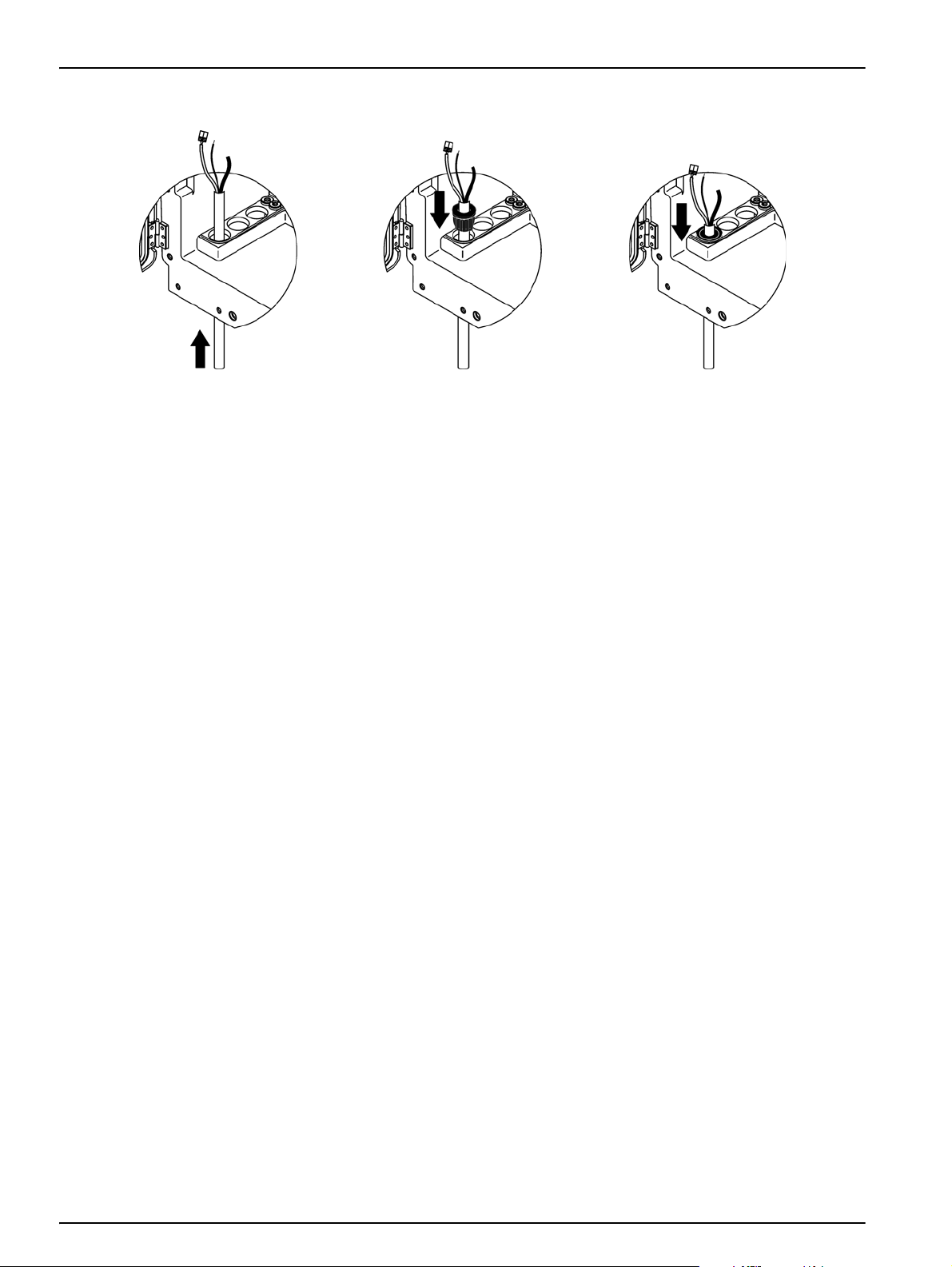

3.5.3 Insert tubing and/or cables

1 Guide the tubing or cables through

the enclosure openings

(Figure 15).

2 Push the plug from the top onto the

tubing or onto the cable.

3.5.4 Connect the Filter Probe to the analyzer

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

DANGER

Disconnect power from the sc analyzer at the sc1000 before

removing the protective covers in the an aly ze r.

Important Note: Make sure that for the use of a filter probe, the

level of the water in which the filtration probe is submersed, is

below the level of the analyzer.

1. Open the enclosure door and secure with the door hook.

2. Open the analyzer panel.

3. Remove the two screws from the protective cover and remove

the cover (item 1, Figure 14, page 24).

4. Connect the earth ground (green/yellow) wire (item 9,

Figure 16, page 28) from the Filter Probe sc to the ground

terminal (item 5, Figure 16, page 28).

3 Pull down the plug with the tubing

or the cables. Seal any unused

entry with Plug #3.

26

5. Connect the power connector to the appropriate terminal

connection (items 4 and 11, Figure 16, page 28).

6. Remove the three screws securing the bottom panel cover.

(item 2, Figure 14, page 24). Remove the panel.

7. Connect the data connector (item 10, Figure 16, page 28) to

the main board (item 12, Figure 16, page 28).

8. Install all covers and panels.

9. Connect the white air tubing (item 8, Figure 16, page 28) from

the Filter Probe sc to the air tubing connection on the analyzer

(Figure 16, page 28).

10. For sample and drain line connections refer to A.4, page79.

Page 27

3.5.5 Connect the optional heated drain

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

DANGER

Disconnect power from the sc analyzer at the sc1000 before

removing the protective covers in the analyzer.

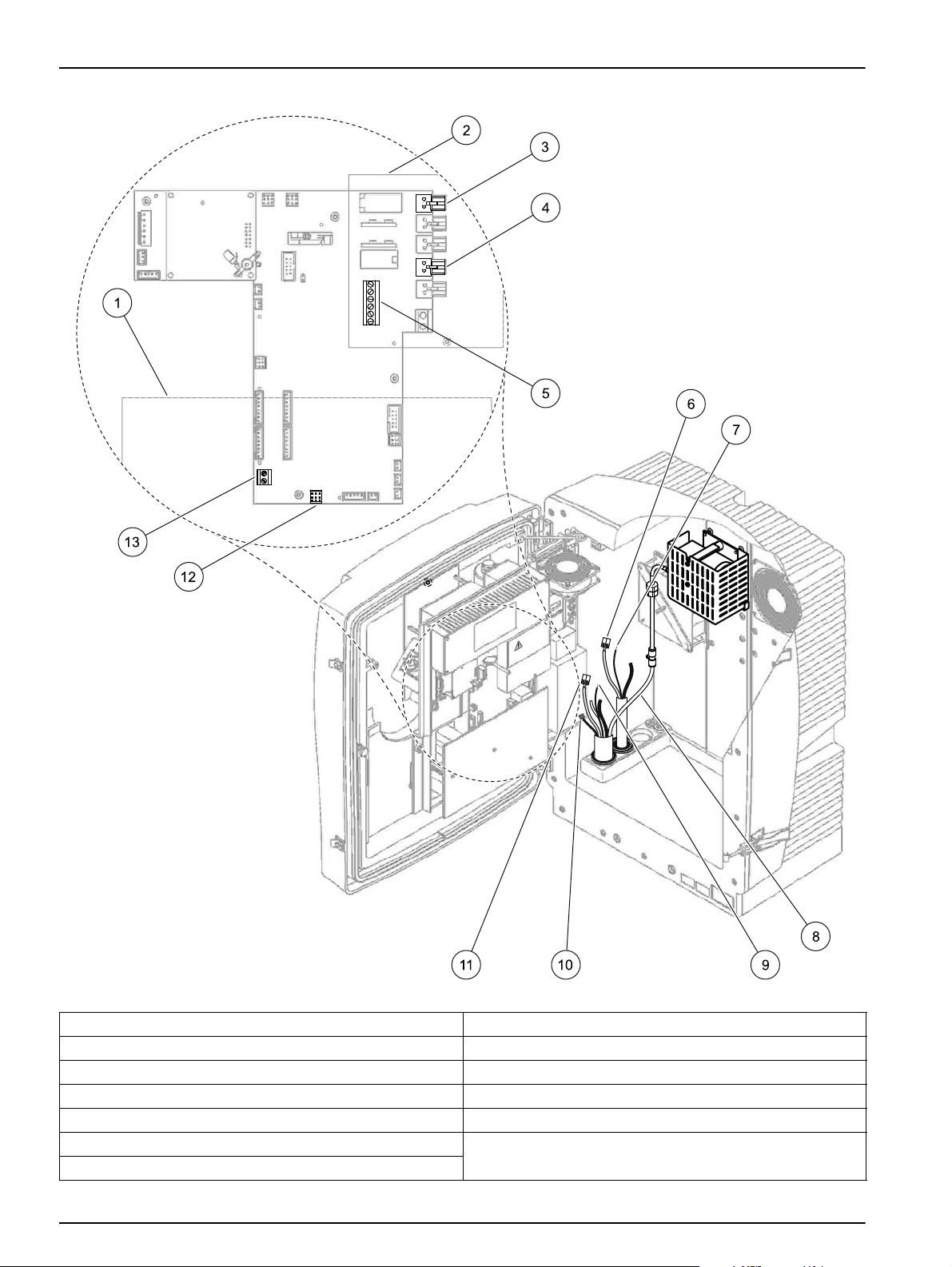

Refer to Figure 16 and the following procedure to connect the

heated drain.

1. Open the enclosure door and secure if necessary.

2. Open the analyzer panel.

3. Remove the protective cover (Figure 14, page 24).

4. Connect the earth ground wire (green/yellow) to the ground

5. Connect the cables for the heated drain (item 6, Figure 16,

6. Connect the drain tube as described in the appropriate Option

Installation

wire terminal strip.

page 28) to the terminal block (item 3, Figure 16, page 28).

Configuration, refer to sectionA.5, page80 for more

information.

7. Place the drain tube to the appropriate drain or basin.

8. Install all covers and panels.

27

Page 28

Installation

Figure 16 Connect the Filter Probe sc and optional heated drain

1 Bottom panel cover 8 Filter Probe sc air tube (white)

2 Protective cover 9 Filter Probe sc ground wire

3 Heated drain (optional) power connector 10 Filter Probe sc data cable connector

4 Filter Probe sc power connector 11 Filter Probe sc power cable connector

5 Ground wire terminal strip 12 Filter Probe sc data connector

6 Heated drain power cable connector 13 Remote control input (15–30 V DC) (Refer to

7 Heated drain ground wire

section B.3 , page 112)

28

Page 29

3.6 Installation of reagents

Installation

DANGER

Potential danger in the event of contact with

chemical/biological materials. Handling chemical samples,

standards and reagents can be dangerous. Familiarize

yourself with the necessary safety procedur es and t he corr ect

handling of the chemicals before the work and r ead and fo llow

all relevant safety data sheets.

Normal operation of this instrument may involve the use of

hazardous chemicals or biologically harmful samples.

• Observe all cautionary information printed on the original

solution containers and safety data sheet prior to their

use.

• Dispose of all consumed solutions in accordance with

national regulations and laws.

• Select the type of protective equipment suitable to the

concentration and quantity of the dangerous material at

the respective work place.

CAUTION

Avoid unnecessary contact with sample flows of unknown

concentration. This can produce hazards due to trace

chemicals, radiation or biological effects.

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

Important Note: Always lay the drain tubing so that there is a

continuous fall (minimum 3°), the outlet is clear (not pressurized)

and the drain tubing is not longer than 2 meters. For more

information refer to Appendix A, page 77.

Important Note: Incorrect use of the reagents can damage the

instrument. Carefully read the labels on the containers to make

sure that there are no mistakes.

The reagents and chemicals supplied are ready to use. The

reagents need to be placed in the analysis instrument and tubings

connected. Refer to Table 3 to determine the correct standards.

29

Page 30

Installation

Table 3 Reagents and measuring ranges

Reagent

CAL 1:

Standard 1

(low)

CAL 2:

Standard 2

(high)

Reagent orange BCF1009 28944-52 BCF1009 28944-52 BCF1009 28944-52 BCF1009 28944-52

Cleaning

solution

Lid color

EU US

transparent

light blue BCF1149 25147-54 BCF1011

gray LCW867 28942-46 LCW867 28942-46 LCW867 28942-46 LCW867 28942-46

gray

Measuring range 1

0.02–5 mg/L

EU US EU US EU US EU US

BCF1148 25146-54 BCF1010

Measuring range 2

0.05–20 mg/L

28941-54

(1 mg/L)

28943-54

(10 mg/L)

Measuring range 3

1–100 mg/L

BCF1020

BCF1021

28943-54

(10 mg/L)

58958-54

(50 mg/L)

Measuring range 4

10–1000 mg/L

BCF1012

BCF1013

28258-54

(50 mg/L)

28259-54

(500 mg/L)

1. Place the reagent containers in the instrument (Figure 17).

2. Insert the tubing in the reagent containers.

3. Screw the reagents to the supplied caps.

Figure 17 Chemicals and reagents in the AMTAX sc (Refer to Table 3, page 30 for more information)

1 Electrolyte solution replacement bottles 7 Sample line

2 Electrode assembly 8 Reagent

3 Fastener for membrane cap 9 Standard solution: High standard

4 Electrode panel connector 10 Standard solution: Low standard

5 Connection to cuvette 11 Cleaning solution

6 Drain

30

Page 31

3.7 Gas-sensitive electrode

Important Note: Before using the AMTAX sc for the first time, the

electrode has to be filled with the supplied electrolyte, see

section 3.7.1.1.

The ammonium in the sample is converted into (dissolved)

ammonia gas by adding sodium hydroxide solution. This dissolved

ammonia gas content will be converted into a measurable pH shift

in the electrode.

3.7.1 Installation of the electrode and electrolyte

The electrode body and the glass electrode are sold as a unit

(Refer to section 8.4, page 66). Use the electrode only in the

supplied enclosure. To prevent inaccurate readings or instrument

malfunction, do not use a different enclosure than that supplied by

the manufacturer.

3.7.1.1 Fill the electrode with electrolyte

CAUTION

Review all SDS/MSDS information and use recommended

safety measures to prevent exposure to potential chem ical

hazards.

Installation

Important Note: Never lubricate the membrane cap or the

electrode with grease, silicone oil or Vaseline. This will cause

damage to the Teflon membrane which will cause poor

performance.

Pre-requisites:

• The items required to fill the electrode are located in the bag

attached to the base of the enclosure.

• Before the electrolyte can be added to the electrode, open the

instrument enclosure and disconnect the electrode cable from

the analyzer panel.

31

Page 32

Installation

To fill the electrode with electrolyte:

Note: Use the electrolyte kit (see section 8.1, page 65) which contains a

bottle with the correct amount of electrolyte.

1 Pull the electrode plug.

Carefully slide the

electrode key (refer to

section 8.2, page 65)

under the electrode

assembly and pull to

remove. Do not apply

excessive pressure.

5 Carefully insert the

electrode into the body,

making sure the

electrode tip is not bent.

2 Carefully pull the

electrode straight out of

the electrode body.

Do not touch the

electrode with fingers.

6 Tighten the sealing cap. 7 Slide the electrode back

3 Secure the electrode in

the fastening clamp on

the front of the panel. Be

careful not to touch the

membrane.

into the cell, towards the

resistance of the o-ring

of the measuring

chamber, until it snaps

into place and reconnect

the electrode cable to

the panel.

4 Remove the cap from

the electrolyte and fill

the body with an entire

bottle of electrolyte

(11 mL). Gently tap the

side of the body to

remove any air bubbles.

Note: To prevent inaccurate

results, the electrolyte

volume should be between

4 mL and 11 mL. during

operation.

8 Place the bottles of

electrolyte into the

brackets on the analyzer

panel.

Close the enclosure

door.

Note: The electrode is

temperature sensitive. Keep

the enclosure door closed

during calibration and

measurements. Otherwise,

fluctuations in temperature

may cause measurement

errors.

32

Page 33

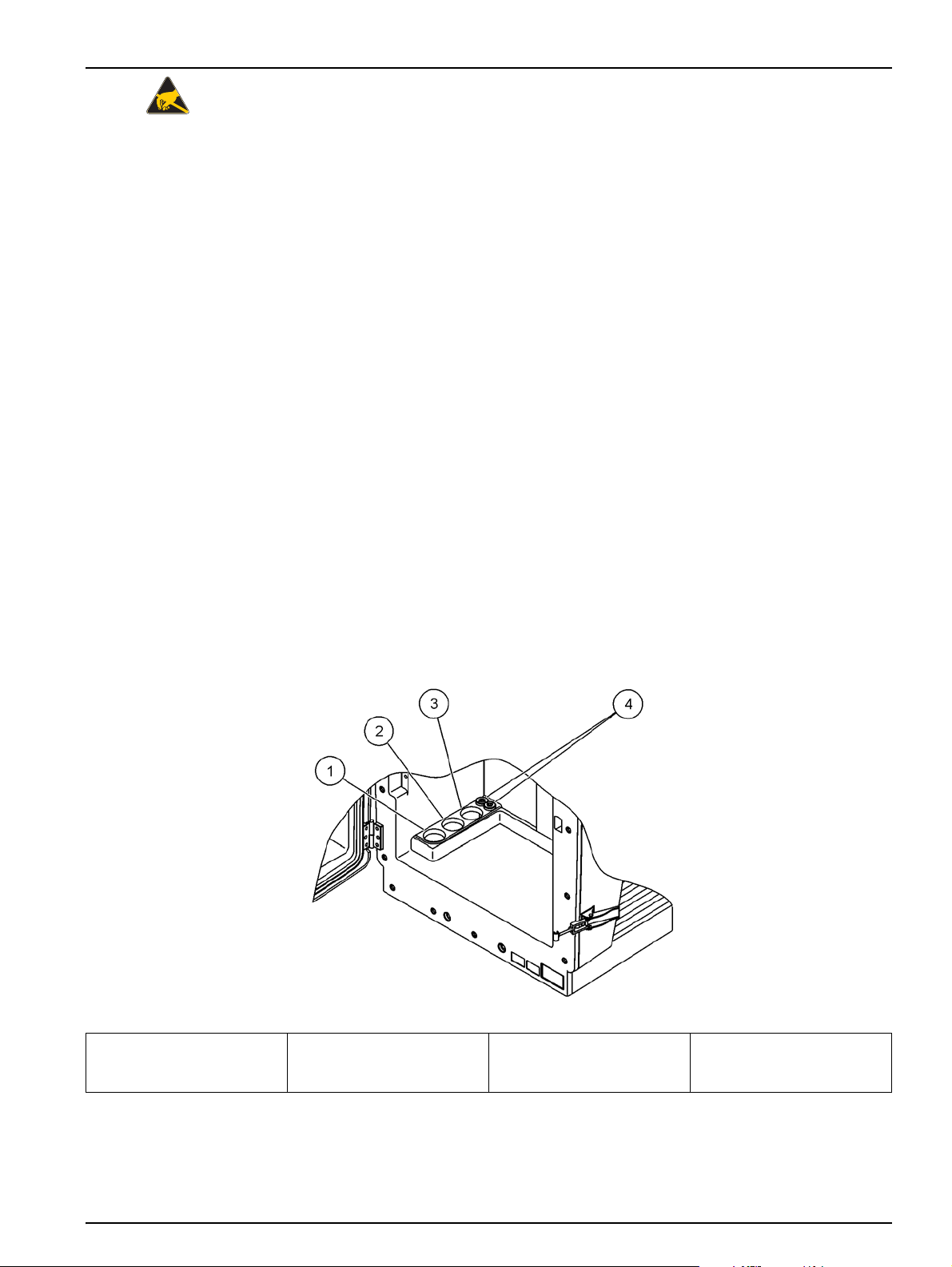

Figure 18 Electrode assembly

1 Electrode assembly 3 Sealing cap 5 Electrode body

2 Connector 4 Electrode 6 Membrane cap

Installation

3.8 Supply power to the analyzer

DANGER

Only connect the AMTAX sc to the sc1000 power supply

when the instrument is completely wired internally and it is

correctly earthed.

DANGER

Always connect a ground fault interrupt circuit (GFIC) or a

residual current circuit breaker (trigger current maximum at

30 mA) between the main power supply and the sc1000.

DANGER

Do not use the controller power sockets as general

mains sockets. They are only designed to provide power

for the analyzers.

Important Note: The power plug serves in addition to the power

supply to isolate the device quickly from the mains where

necessary.

Therefore make sure that socket to which the device is connected

is easy to reach by each user at all times.

Important Note: Unless the sc1000 that connects to the AMT AX sc

analyzer is already fitted with ac mains overvoltage (surge)

protection device, surge protection must be provided between the

mains connection of the sc1000 and the AMTAX sc analyzer if it is

demanded by the local regulation.

Only supply power to the instrument after all plumbing connections,

reagent installations and system start-up procedures have been

completed.

sc1000 power sockets can only be connected if a wide range

115/230 V power supply is built into the sc1000 controller. This

33

Page 34

Installation

does not work with 24 V versions of the sc1000 because it does not

provide the appropriate connectors for the analyzers.

Refer to the sc1000 manual for more information on

connecting power.

Please note the input voltage of the device. The device is available

in two non-adjustable voltage variants (115 V or 230 V).

The output voltage supplied by the controller at the outlets

corresponds to the mains voltage that is customary in the country in

question and to which the controller is connected.

A device designed for 115 V must not be connected to a controller

with a higher mains voltage.

1. Remove the power socket from the sc controller.

2. Connect the plug from the AMTAX sc to the power socket on

the sc controller.

Figure 19 Connect the AMTAX sc to the sc1000 power supply

1 Data connector

2 Power connectors

3.9 Connect the data network

34

Refer to the sc1000 controller user manual for more information on

connecting the data network (item 1, Figure 19).

Page 35

Section 4 System Start Up

4.1 Initializing the instrument

Important note: The instrument only can work correctly if it is at

operating temperature. Let the instrument warm up for a minimum

of an hour so the inside of the enclosure, chemicals and electrode

are at operating temperature.

1. Make sure the AMTAX sc is registered in the sc1000 system. If

necessary, initiate the controller to search for the analyzer.

Refer to the sc1000 user manual for more information.

When the analyzer is switched on for the first time, a menu for

the correct measurement range opens automatically.

Important Note: Use the correct standard solutions for the

selected range (Table 3 on page 30).

2. Configure the analyzer in the SENSOR SETUP menu and note

the settings. Refer to section 5.2 on page 37 for more

information. The factory settings (default setting) are

appropriate for most typical applications.

3. From SENSOR SETUP, select

AMTAX sc>MAINTENANCE>TEST/MAIN.

4. Select the PREPUMP ALL function and confirm.

5. Wait until the analyzer returns to the service state (displayed in

TEST/MAIN.>PROCESS) after the prepumping sequence is

completed.

6. Select REPLACE ELECTRO. from the maintenance menu to

activate the electrode and to start the calibration.

7. Confirm all menu points. The date for the electrode

maintenance counter will be updated automatically. The

instrument warms up the electrode and calibrate two times.

Then the analyzer starts the standard operation.

Important Note: After inserting a new electrode or restarting the

instrument, the values for the standard calibration change greatly,

but after approximately two days the mV-values for the standards

should increase slight with the evaporation of the elctrolyte. The

slope remains constant while both standard values increase

parallel.

35

Page 36

System Start Up

36

Page 37

Section 5 Operation

The AMTAX sc can only be operated with an sc1000 controller. For

further information, see the sc1000 User Manual.

An LED on the door indicates the current operating state. Refer to

the sc1000 User Manual and section 7.2.1, page 57.

Instrument, chemicals and electrode are temperature-sensitive. To

prevent incorrect measurements, only operate the instrument with

the door closed.

5.1 Sensor diagnostics menu

SELECT AMTAX sc (if more than one sensor or analyzer is attached)

AMTAX sc

ERROR LIST Displays all errors currently present in the sensor

WARNING LIST Displays all warnings currently present in the sensor

5.2 Sensor setup menu

SELECT AMTAX sc (if more than one sensor or analyzer is attached)

CALIBRATION (see 5.3, page 42)

CORR. FACTOR Displays the correction factor

LOCATION 1 Displays location1 which is adjusted in the CONFIGURE menu

GAIN CORR Adjusts the correction factor for channel 1

LOCATION2 Available with the 2-channel version.

GAIN CORR Available with the 2-channel version.

CALIBRATE Triggers an automatic calibration, then measuring mode

CAL.-CLEAN Triggers an automatic calibration with subsequent automatic cleaning, then measuring mode.

SETTINGS

SET OUTMODE

AUTOCAL

SET INTERVAL Time interval between two calibrations

START

DISCHARGE Number of measured values that are discarded after a calibration.

SEL ADJ METHOD Select the calibration method

ADVANCED

CONVENTIONAL

DEFAULT SETUP Resets to factory default settings.

CONFIGURE

LOCATION 1 Settings for location 1

EDIT NAME Enter the name for the measuring location as required.

SET PARAMETER Select output: ammonium or ammonium nitrogen

SELECT UNITS Select output: mg/L or ppm

QUANTITY CH 1

Value that is output during a calibration and the following discarded values.

HOLD = last measured value, SET TRANSFER = value to be entered.

Start time for the calibration (In case of more than one calibration per day: Enter start time for

the first calibration.)

Default calibration method for software version ≥ 1.60 (For best accuracy with lowest

measuring values.)

Calibration method for software version < 1.60 is available for compatiblility reasons (Not

selectable in the measuring range 0.02–5 mg/L.).

Number of measurements in succession ( = measurements on channel 1 +

DISCHARGE VAL 1 channel 1). Available with the 2-channel version.

37

Page 38

Operation

5.2 Sensor setup menu (continued)

CONFIGURE (continued)

DISCHARGE VAL 1

LOCATION 2 Settings for location 2

EDIT NAME Enter the name for the measuring location as required. Available with the 2-channel version.

SET PARAMETER Select output: ammonium or ammonium nitrogen. Available with the 2-channel version.

SELECT UNITS Select output: mg/L or ppm. Available with the 2-channel version.

QUANTITY CH 2

DISCHARGE VAL 2

MEASURING

SET INTERVAL

START BY BUS:

START BY BUS:

NUMBER OF MEAS.: Number of measurements after a bus activation.

DISCHARGE: Number of discharged values that precede the measurements.

AVERAGE: Number of measurements that are averaged. (Affects only the bus triggered measurements)

CLEANING

SET INTERVAL Number of hours between the cleanings

START

DISCHARGE Number of measured values that are discarded after a cleaning operation.

SET OUTMODE

CUVETTE TEMP.

TUBE HEATING

ON

OFF

REAG. WARNING

REAG. WARNING

WARNING Determines the level below which the reagent must drop to trigger the warning.

STAT. MODUL.WAR.

40 %, 30 %, 15 %

STATUS MODUL.ERR

14 %,10 %,8 %, OFF

Number of discarded values after switching from channel 1 to channel 2. Available with the

2-channel version.

Number of measurements in succession ( = measurements on channel 2 +

DISCHARGE VAL 2 channel 2). Available with the 2-channel version.

Number of discarded values after switching from channel 2 to channel 1. Available with the

2-channel version.

Enter measurement interval (Time interval between two measurements). ATTENTION with

filtration probe and 5 min operation: increased pump speed in the filtration probe, annual

filtration probe maintenance is necessary.

YES/NO; option whether the instrument is measuring continuously or measurements are

triggered by field-bus. "Fieldbus" must be activated under "TEST/MAINT". Instrument will

switch to 5 min interval when activated.

Start time for the cleaning (In case of more than one cleaning per day: Enter start time for the

first cleaning.)

Value that is output during a cleaning operation and the following discarded values.

HOLD = last measured value, SET TRANSFER = value to be entered.

Temperature for cuvette and electrode

Recommended: Select 45 °C at air temperature: up to 35 °C, 50 °C at air temperature: up to

40 °C, 55 °C at air temperature: up to 45 °C, at 55 °C reduced accuracy and shortened

electrode service life may occur.

Probe tube heating switches on at the start of the selected month when using the Filter

Probe sc.

Probe tube heating switches off at the end of the selected month when using the Filter

Probe sc.

On/Off

When On is selected: determines the warning output if the reagent levels are low

Warning is released: when a filter probe is installed and the status of filtration modules fall

below level

An error is generated: when a filter probe is installed and the status of filtration modules fall

below level. When switched to OFF, a deactivated sample detection will be switched to

"warning".

38

Page 39

5.2 Sensor setup menu (continued)

CONFIGURE (continued)

SAMPLE DETECTION

Determines instruments reaction when amount of available sample is too low. When

OFF/WARNING/ERROR

EXHAUST CONTROL

ON/OFF Determines instrument reaction when drain is blocked

ELECTROLYTE

WARNING/OFF

FALSE ELEC DATA

ERROR/OFF

DEFAULT SETUP Resets factor and settings to factory settings.

LAST CHANGE Indication of the last change of a setting in the configuration menu.

MAINTENANCE

INFORMATION

LOCATION 1 Indication of measuring location 1

LOCATION 2 Indication of measuring location 2 on two-channel version

TYPE Indication of instrument type

SENSOR NAME Indication of instrument name

SERIAL NUMBER Indication of serial number

RANGE Indication of measuring range

OPTION Indication of instrument option (filtration probe/1-channel/2-channel)

SOFTWARE PROBE Filtration probe software

SOFTW. AMTAX Instrument software

LOADER Detailed information on the software in the instrument

APPL Detailed information on the software in the instrument

STRUCTURE Detailed information on the software in the instrument

FIRMWARE Detailed information on the software in the instrument

CONTENT Detailed information on the software in the instrument

LANGUAGE List of languages that are supported by the installed language package.

CALIB. DATA

LOCATION1 Indication of measuring location 1

GAIN CORR Indicates the correction factor set for correcting the measured values at measuring location 1.

DATE Indicates the date of the last change to the correction factor.

LOCATION2 Available with the 2-channel version.

GAIN CORR Indicates the correction factor set for correcting the measured values at measuring location 2.

DATE Indicates the date of the last change to the correction factor.

mV ZERO Electrode signal at the zero point

mV STANDARD 1 Electrode signal with standard 1

mV STANDARD 2 Electrode signal with standard 2

mV SLOPE Electrode signal change per decade

LAST CALIBRAT. Time of the last calibration

mV ACTIVE Current electrode potential

instrument is in filter probe mode, deactivating the sample detection will switch a deactivated

"STATUS MODUL.ERR" to 14 %

Determines whether a warning is initiated when electrolyte level is low/ last change of

membrane is more than 90 days ago.

Determines whether an error is initiated when the mV-Zero value of the electrode is not within

a certain range (see list of errors)

Operation

39

Page 40

Operation

5.2 Sensor setup menu (continued)

MAINTENANCE (continued)

PROCESS Information what instrument is currently doing (measurement, calibration etc.)

REMAINING TIME Remaining time for current process, counting down to zero

LIST OF VALUES List of the last 10 measured values

MAINT. COUNTER Counter for reagent and consumables

OPERATING HOURS Indicates the instrument's operating hours.

REAGENT Displays the current level of the reagent.

CLEANING SOL. Displays the current level of the cleaning solution.

STANDARD SOL. Displays the current level of the standard.

REPLACE ELECTRO. Date of the last electrode change

CHANGE MEMBRAN Last electrode membrane and electrolyte change.

AIR FILTER PADS Days left until the next air filter change/clean.

PISTON PUMP Days left until the next pump piston and cylinder replacement (AMTAX piston pump)

REAGENT PUMP Number of pump strokes performed by the reagent metering pump

CLEANING PUMP Number of pump strokes performed by the cleaning metering pump

STATUS MODULES Only if filtration probe is registered: indicates the state of the modules.

CLEANING MODULS Only if filtration probe is registered: last filter module cleaning.

NEW MODULES Only if filtration probe is registered: last filter module replacement.

PUMP MEMBRANE

COMPRESSOR Only if filtration probe is registered: days left until the replacement of the air compressor.

ELECTROLYTE

TEST/MAINT Maintenance processes

SIGNALS

PROCESS Indication of what the instrument is doing.

REMAINING TIME Indication of the time left for the currently ongoing process

mV ACTIVE Current electrode potential (For electrode data ranges refer to Table 10, page 62).

CUVETTE TEMP. Current measuring cell temperature

ENCLOSURE TEMP Current temperature in the instrument

COOLING Current speed of the enclosure fan in %

HEATING Current enclosure heating power

PRESSURE ANALY Current pressure in the metering system of the valve block in mbar

HUMIDITY ANALY Indication of whether there is liquid in the collecting tray

STATUS MODULES Only if filtration probe is registered: shows status of filtration modules (0–100 %)

PRESSURE P. MIN

PRESSURE PROBE Only if filtration probe is registered: shows the actual minimum pressure at the filter modules

PROBE HEATING Only if filtration probe is registered: indication of switching state of sample tubing heating

HUMIDITY PROBE

DRAIN HEATING only in 1 or 2 channel mode: shows status of drain heating

PROCESS Indication of what the instrument is doing.

REMAINING TIME Indication of the time left for the currently ongoing process

SERVICE MODE

Only if filtration probe is registered: date of the last pump membrane replacement (filtration

probe sample pump).

counts down from 90 days. Negative values indicate that electrolyte change is overdue. Reset

by "CHANGE MEMBRANE" or "CHANGE ELECTRODE" process

Only if filtration probe is registered :shows the averaged minimum pressure at the filter

modules

Only if filtration probe is registered: indication of whether there is moisture in the probe

enclosure

Instrument can be adjusted to service mode (system free of liquids, thermal management and

compressor for filter probe (if installed) active

40

Page 41

5.2 Sensor setup menu (continued)

MAINTENANCE (continued)

Operation

SET OUTMODE

START Leave service mode, start measurement

REAGENT Resets the maintenance counter after reagent change

CLEANING SOLU. Resets the maintenance counter after changing the cleaning solution.

STANDARD SOL. Resets the maintenance counter after changing the standards.

AIR FILTER PADS Menu-based process for changing the air filter pads, resetting the maintenance counter

CHANGE MEMBRAN

REPLACE ELECTRODE Menu-based process for electrode change, sets new date in the maintenance counter

PISTON PUMP

REAGENT PUMP

CLEANING PUMP

PREPUMPING

PREPUMP ALL All liquids are pre-pumped in succession.

PREPUMP REAG. The reagent is pre-pumped.

PREPUMP CLEAN. The cleaning solution is pre-pumped.

PREPUMP

STANDARD

PREPUMPING

PROBE

PREPUMP SAMPLE Only if filtration probe is registered: sample is pumped from the filtration probe for 1 minute

MODULE CLEAN.

NEW MODULES Only if filtration probe is registered: last filter module replacement.

PUMP MEMBRANE

COMPRESSOR

CLEANING Trigger an automatic cleaning, then start measurement

FLUSHING

RESET ERROR Reset all error messages

CHANGE RANGE

UPDATE PROBE Enables the filtration probe software to be updated.

Elec. Type Change Not used at the moment

FIELDBUS

OPTION

VAL IDATION

Value that is output in the service state. HOLD = last measured value,

SET TRANSFER = Transfer value that is programmed on SC controller

Menu-based process for membrane-cap change of the electrode, sets new date in the

maintenance counter and resets electrolyte counter

Days left until the next pump piston and cylinder replacement (AMTAX piston pump), reset

after replacement of the pump

Number of pump strokes performed by the reagent metering pump, reset after replacement of

the pump

Number of pump strokes performed by the cleaning metering pump, reset after replacement

of the pump

The standards are pre-pumped.

Only if filtration probe is registered: The filtration probe and modules are bled and

pre-pumped.

Menu-based process for cleaning the filter modules, automatically resetting the maintenance

counter. With filtration probe.

Only if filtration probe is registered: shows the days left until the next change of pump

membrane (Filter Probe sc sample pump), Rest of the counter.

Only if filtration probe is registered: days left until the replacement of the air compressor.

Reset of the counter.

Pumps all liquids in succession. Put all tubings that go to reagents, standards and cleaning

solutions into deionised water and start FLUSHING prior to taking instrument out of operation

Software changes to another measuring range: ATTENTION, the appropriate standards must

be used!

ENABLED/DISABLED: Enable external control of instrument by Fieldbus. NOTE: When

instrument is put into SERVICE MODE by menu, the Fieldbus control is temporarily disabled.

Sets the instrument to filter-probe/ 1channel/ 2channel mode. Switching the options needs

modification of hardware!

Menu based process to measure external samples. When "Modification required" is

displayed: Disconnect sample tubing from overflow vessel, plug overflow vessel and put

sample tubing into external sample. After process: Unplug overflow vessel and reconnect

sample tube.

41

Page 42

Operation

5.2.1 System setup menu

5.3 Calibration process

For more information on System Setup (current outputs, relays and

network interfaces), refer to the sc1000 user manual.

Note: Make sure that all solutions are available to avoid incorrect

measurements.

1. To start an automatically calibration select

CALIBRATION>CALIBRATE>AUTOCAL>SET INTERVAL.

OR

1. To start a calibration manually select

CALIBRATION>CALIBRATE.

Note: Press START to confirm and start the calibration process.

After the next measurement and the 5 minutes waiting time, the

calibration will automatically start and proceed with all

necessary standards.

5.4 Cleaning process

Depending on the number of standards requiring calibration, a

cycle may take up to 40 minutes. After a successful calibration, the

instrument automatically returns to the measurements.

Note: When the instrument detects and displays a warning, the

measurement process will continue. Refer to section 7.2.3, pa ge 60 to

troubleshoot the warning.

Note: When the instrument detects and displays an error, the instrument

stops measuring. Refer to section 7.2.2, page 57 to troubleshoot the error.

For information about the cleaning interval refer to Table 4,

page 46.

Note: Make sure that the cleaning solution is available that the instrument

can work properly.

1. To configure an automatical cleaning interval select

CONFIGURE>CLEANING>SET INTERVAL.

OR

1. To start a manual cleaning cycle select

MAINTENANCE>CLEANING.

42

Note: Press START to confirm and start the cleaning process.

A cleaning cycle may take up to 10 minutes and then the

instrument returns automatically to the measuring mode.

Page 43

5.5 Measurement process

Operation

Note: Make sure that all solutions are available to avoid incorrect

measurements.

After start up, the instrument needs to warm up to automatically

initalize the measurment process. This process takes

approximately 15 minutes when the instrument temperature is

>15 °C (>59 °F).

Note: Lower instrument temperatures prolong the warming-up phase.

Note: From the service mode press START to confirm the inquiry to start

the measurement.

Note: The instrument calibrates before starting the measurment when the

last calibration is at least one day old.

An optimal measurement cycle may take 5 minutes.

43

Page 44

Operation

44

Page 45

Section 6 Maintenance

DANGER

Only qualified personnel should conduct the tasks described

in this section of the manual.

DANGER

Potential danger in the event of contact with

chemical/biological materials. Handling chemical samples,

standards and reagents can be dangerous. Familiarize

yourself with the necessary safety procedur es and t he corr ect

handling of the chemicals before the work and r ead and fo llow

all relevant safety data sheets.

Normal operation of this instrument may involve the use of

hazardous chemicals or biologically harmful samples.

• Observe all cautionary information printed on the original

• Dispose of all consumed solutions in accordance with

• Select the type of protective equipment suitable to the

solution containers and safety data sheet prior to their

use.

national regulations and laws.

concentration and quantity of the dangerous material at

the respective work place.

6.1 General maintenance

6.1.1 Clean the analyzer

CAUTION

The enclosure may tip forwards if it has not been fixed in

place. Only open the enclosure if the enclosure is properly

mounted.

• Regularly check the entire system for mechanical damage.

• Regularly check all connections for leaks and corrosion.

• Regularly check all cables for mechanical damage.

Clean the system with a soft, damp cloth. Use a commercially

available cleaning agent for stubborn soiling.

45

Page 46

Maintenance

6.1.1.1 Cleaning interval

The cleaning interval (Refer to section 5.2, page 37 for more

information.) is based on the hardness of the water in the sample

(see Table 4).

Note: The drain can block if the cleaning interval is too long for the

hardness of the sample.

Table 4 Cleaning interval

Water hardness Cleaning interval

ppm as CaCO

≤ 270 ≤ 15 ≤ 2.685 24 80

≤ 360 ≤ 20 ≤ 3.58 12 150

≤ 450 ≤ 25 ≤ 4.475 8 (pre-set) 220

≤ 540 ≤ 30 ≤ 5.37 6 290

≤ 630 ≤ 35 ≤ 6.265 3 570

>720 > 35 > 6.265 1 1700

3

in °dH

6.1.2 Replace the fan filter

in mMol/L

(alkaline earth ions)

The filter air pads must be cleaned or replaced regulary. Refer to

section 6.3, page 48 for more information.

The cooling fan must be stopped before completing any filter

maintenance.

To stop the cooling fan:

1. From the MENU select SENSOR SETUP>AMTAX SC and

press ENTER.

in hours

(or more often)

Consumption of cleaning

solution (includes calibration)

in mL/month

2. Select MAINTENANCE>TEST/MAINT>AIR FILTER PADS and

press ENTER.

3. Select START and press ENTER.

The process is started and the cooling fan stops.

Important Note: Open the instrument door to prevent overheating.

CAUTION

Avoid injury. Keep hands clear. Although the fan is stopped,

work carefully to avoid injury in case of failure.

To change the fan filter:

1. Open the analyzer enclosure and the analysis panel.

2. Press ENTER.

The instrument counts the remaining time in seconds down to

zero and goes to SERVICE STATE.

3. Change the air filter pads as described on the controller.

46

Page 47

6.1.3 Fuse replacement

Maintenance

4. Remove the fan locking screw and slide the retaining strap to

the top and remove (Figure 10, page 20). If necessary, press

the fan down to remove the retaining strap.

5. Slide the fan from the holding screws.

6. Clean the filter with soap and water and reposition.

7. Press ENTER.

8. Replace the fan. Make sure that the fan opening is positioned

downward. Attach the retaining strap (hold down the fan) and

install the fan locking screw.

9. Close the analyzer enclosure and the analysis panel.

10. Press ENTER.

The instrument will reset the maintenance counter and will start the

analyzer again.

The fuses for the power supply are found in the sc1000 controller.

Refer to the sc1000 User Manual for fuse replacement information.

6.2 Reagent replacement

The chemicals must be changed or renewed at regular intervals.

Refer to Table 5 for information on the life of the chemicals.

Table 5 Chemicals for the AMTAX sc

Chemical (section 8.1,

page 65)

Reagent 2500 mL for 3 month 2500 mL for 3 months 2500 mL for 2 months 2500 mL for 2 months

Standards (2 liters):

Cleaning and calibration

Electrolyte and

membrane cap

Measuring range 1

(0.02–5 mg/L)

0.5 and 2.5 mg/L for

2 month on daily

calibration

250 mL for 1 month on 3 cleanings and calibrations per day (default)

11 mL

Electrolyte for

1–1.5 months;

Membrane cap:

2–3 months

(depending on the

membrane soiling)

Measuring range 2

(0.05–20 mg/L)

1 and 10 mg/L for

3 months on daily

calibration

250 mL for 3 months on daily cleaning and calibration

11 mL

Replace with

membrane every

2–3 months

(depending on the

membrane soiling)

Measuring range 3

(1–100 mg/L)

10 and 50 mg/L for

3 months on daily

calibration

11 mL

Replace with

membrane every

2–3 months

(depending on the

membrane soiling)

Measuring range 4

(10–1000 mg/L)

50 and 500 mg/L for

3 months on daily

calibration

11 mL

Replace with

membrane every

2–3 months

(depending on the

membrane soiling)

47

Page 48

Maintenance

6.3 Routine maintenance schedule

The maintenance schedule is given for standard applications.

Deviant applications may cause different maintenance intervals.

Table 6 Routine maintenance schedule

3 months

Description

(Customer

task)

Visual check analytical compartment, manual cleaning if

necessary.

Check filter pads, clean/ replace if necessary, particularly on

fan side.

Check reagents, replace if necessary. X

Check cleaning solution, replace if necessary. X

Check maintenance counters. X

Check standard solutions, replace if necessary. X

Visual check of electrode, replace membrane cap and

electrolyte if necessary

1

X

1

X

1

1

1

1

1

X

6 months

(Service

task)

X

X

X

X

X

X

X

12 months

(Service

task)

24 months

(Service

task)

Check system for air impermeability. X

Function check of both fans. X

Function check heating for analyser enclosure. X

General function check. X

Read out and analyse event log. Read out and check data log

if necessary.

Check electrode (slope with intact membrane cap: –55mV to

–67mV), check every 6 months after 12 months of use.

(X)

X

2

X

Replace pump head for air pump. X

Check magnetic stir bar, replace if necessary. X

Replace reagent pump. X

Check cleaning pump and replace if necessary (check every

6 months after 12 months of use)

(X)

2

X

Check stirring motor, replace if necessary. X

1

Recommended maintenance interval, especially for reagents. The actual reagent and electrolyte (AMTAX sc) exchange

intervals depend on configuration.

2

Maintenance cycles are given for standard applications. Deviant applications may cause different maintenance intervals.

48

Page 49

Maintenance

6.4 Scheduled maintenance

Table 7 lists items, except the electrode, that need to be maintained

by service personnel ONLY. Contact the manufacturer for more

information.

Table 7 Repair maintenance items

Description When to replace Warranty

Reagent pump for sc analyzer (Valve pumps) 1 year 1 year

Pump head piston pump 10 mL

(Pre-greased cylinder and piston)

Switchable Compressor 115/230V 2 years recommended 2 years

Solenoid stirring bar 1 year 1 year

Check continuously after 1 year.

Electrode is OK, when slope

Electrode

with new membrane cap and

electrolyte is in the range of

–57 to –67 mV after 24 h of

membrane cap replacement.

1year 1year

1year

6.5 Replace the membrane cap, electrolyte and electrode

Important Note: Never lubricate the membrane cap or the

electrode with grease, silicone oil or Vaseline. This will cause

damage to the Teflon membrane which will cause poor

performance.

Note: The service life of the Teflon membrane will be reduced by tensides

or organic solvents in the waste water.

For optimal performace, replace the the membrane cap, electrolyte

and electrode regularly (refer to Table 6, page 48).