Page 1

DOC022.97.80535

TL2350

07/2016, Edition 2

Manuel d'utilisation de base

Manual básico del usuario

Manual Básico do Usuário

Basic User Manual

基本用户手册

基本取扱説明書

기본 사용 설명서

คู่มือผู้ใช้เบื้องต้น

Page 2

English..............................................................................................................................3

Français......................................................................................................................... 24

Español.......................................................................................................................... 47

Português...................................................................................................................... 69

中文................................................................................................................................. 92

日本語........................................................................................................................... 111

한글............................................................................................................................... 132

ไทย.................................................................................................................................. 153

2

Page 3

Table of contents

Specifications on page 3 Startup on page 10

General information on page 4 Operation on page 11

Installation on page 8 Maintenance on page 20

User interface and navigation on page 9 Troubleshooting on page 21

Specifications

Specifications are subject to change without notice.

Specification Details

Measurement method Nephelometric

Regulatory Meets EPA Method 180.1

ASTM D7315 - Standard Test Method for Determination of Turbidity Above 1 Turbidity

Unit (TU) in Static Mode

ASTM D6655 - Standard Test Method for Determination of Turbidity Below 5 NTU in

Static Mode

Dimensions (W x D x H) 39.5 x 30.5 x 15.3 cm (15.6 x 12.0 x 6.02 in.)

Weight 3.0 kg (6.6 lb)

Enclosure IP30; indoor use only

Protection Class External power supply: Protection Class I; instrument: Protection Class II

Pollution degree 2

Installation category External power supply: Category II; instrument: Category I

Power requirements Instrument: 12 VDC, 3.4 A; power supply: 100–240 VAC, 50/60 Hz

Operating temperature 0 to 40 °C (32 to 104 °F)

Storage temperature –20 to 60 °C (–4 to 140 °F)

Humidity 5 to 95% relative humidity, non-condensing

Display 17.8 mm (7 in.) color touch screen

Light source Tungsten filament lamp

Measurement units NTU, EBC, Abs (absorbance), %T (% transmittance) and mg/L (degree)

Range NTU (Ratio on): 0–10,000 auto decimal

NTU (Ratio off): 0–40

EBC (Ratio on): 0–2450 auto decimal

EBC (Ratio off): 0–9.8

Absorbance1 (auto range): 0–1.0

Transmittance1 (%): 1.0–100

Degree (mg/L): 1–100

1

A filter assembly is necessary for absorbance or transmittance measurements

English 3

Page 4

Specification Details

Accuracy2, 3,

Resolution Turbidity: 0.001 NTU/EBC

Repeatability ±1% of reading or 0.01 NTU, whichever is greater (under reference conditions)

Response time Signal averaging off: 6.8 seconds

Stabilization time Ratio on: 30 minutes after start-up

Reading modes Single, continuous, Rapidly Settling Turbidity™, signal averaging on or off, ratio on or

Communication USB

Interface 2 USB-A ports for USB flash drive, external printer, keyboard and barcode scanner

Datalog Maximum 2000 total logs, includes reading log, verification log and calibration log

Air purge Dry nitrogen or instrument grade air (ANSI MC 11.1, 1975)

Sample cells Round cells 95 x 25 mm (3.74 x 1 in.) borosilicate glass with rubber-lined screw caps

Sample requirements 25 mm sample cell: 20 mL minimum

Certification CE, KC, RCM

Warranty 1 year (EU: 2 years)

4

Ratio on: ±2% of reading plus 0.01 NTU from 0–1000 NTU, ±5% of reading from

1000–4000 NTU, ±10% of reading from 4000–10,000 NTU

Ratio off: ±2% of reading plus 0.01 NTU from 0–40 NTU

Absorbance: ±0.01 Abs from 0–0.5 Abs at 455 nm, ±2% Abs from 0.5–1 Abs at 455 nm

Transmittance: 2% T from 10–100% T at 455 nm

Absorbance: 0.001 Abs

Transmittance: 0.1% T

Signal averaging on: 14 seconds (when 10 measurements are used to calculate the

average)

Ratio off: 60 minutes after start-up

off

0.1 scfm at 69 kPa (10 psig); 138 kPa (20 psig) maximum

Hose barb connection for 1/8-inch tubing

Note: Smaller sample cells (less than 25 mm) can be used when a cell adapter is used.

0 to 70 °C (32 to 158 °F)

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Additional information

Additional information is available on the manufacturer's website.

2

Turbidity specifications identified using USEPA filter assembly, recently prepared formazin

standard and matched 25-mm sample cells.

3

Intermittent electromagnetic radiation of 3 volts/meter or greater may cause slight accuracy

shifts.

4

Reference conditions: 23 ± 2 °C, 50 (± 10)% RH noncondensing, 100–240 VAC, 50/60 Hz

4 English

Page 5

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety

information.

D A N G E R

W A R N I N G

C A U T I O N

N O T I C E

Electrical equipment marked with this symbol may not be disposed of in European domestic or public

disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Certification

EN 55011/CISPR 11 Notification Warning

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

English

5

Page 6

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

Korean certification

업무용을 위한 EMC 등급 A 장치에 대한

사용자 지침

사용자안내문

A 급 기기 ( 업무용 방송통신기자재 )

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 , 가정

외의 지역에서 사용하는 것을 목적으로 합니다.

Product overview

C A U T I O N

Fire hazard. This product is not designed for use with flammable liquids.

The TL2350 laboratory turbidimeter measures the scattered light from water samples to determine

the turbidity value of the samples. In the ratio-on mode, the instrument uses multiple detectors at

different angles to correct for interferences and to increase the measurement range. In the ratio-off

mode, the instrument uses one detector at a 90-degree angle from the light source. The user can

calibrate the instrument and verify the calibration at regular intervals.

The user interface uses a touch screen display. A printer, USB flash drive or keyboard can connect

to the USB ports. Refer to Figure 1. The real-time clock with battery puts a time-date stamp on all of

the data that is transmitted or recorded (i.e., reading log, calibration log and verification log).

6

English

Page 7

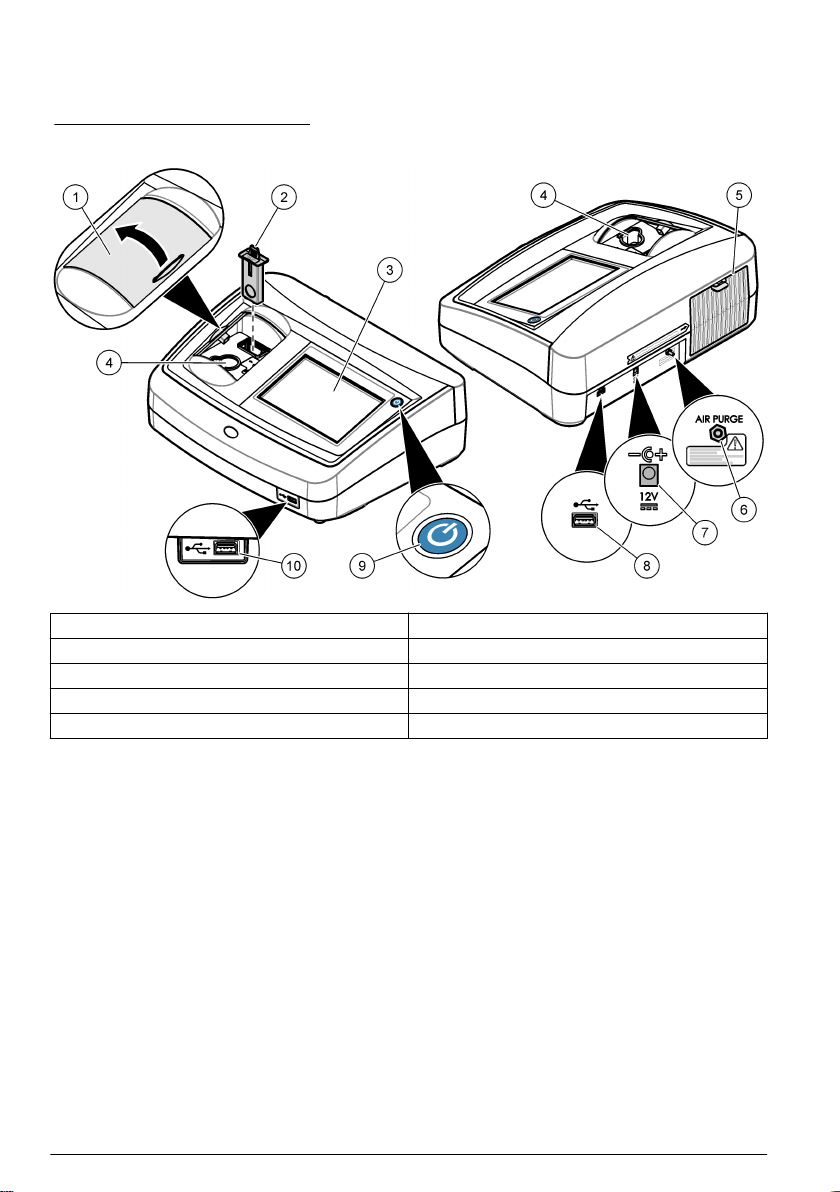

Figure 1 Product overview

1 Sample compartment lid 6 Air purge

2 EPA filter 7 Power connection

3 Touch screen display 8 USB port

4 Sample cell holder 9 Power button

5 Lamp cover 10 USB port

Product components

Make sure that all components have been received. Refer to Figure 2. If any items are missing or

damaged, contact the manufacturer or a sales representative immediately.

English

7

Page 8

Figure 2 Instrument components

1 Silicone oil 6 Gelex® secondary turbidity standardization kit

2 Oiling cloth 7 StablCal® Calibration kit

3 USEPA filter assembly 8 Power supply

4 TL2350 turbidimeter 9 Power cord

5 1-inch sample cells (30 mL) with caps (6x) 10 Dust cover

Installation

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

This instrument is rated for an altitude of 3100 m (10,710 ft) maximum. Use of this instrument at an

altitude higher than 3100 m can slightly increase the potential for the electrical insulation to break

down, which can result in an electric shock hazard. The manufacturer recommends that users with

concerns contact technical support.

Installation guidelines

Install the instrument:

• On a level surface

• In a clean, dry, well ventilated, temperature controlled location

• In a location with minimum vibrations that has no direct exposure to sunlight

• In a location where there is sufficient clearance around it to make connections and to do

maintenance tasks

• In a location where the power button and power cord are visible and easily accessible

Connect to external devices (optional)

Use the USB ports to connect the instrument to a printer, barcode handset scanner, USB flash drive

or keyboard. Refer to Figure 1 on page 7. The maximum length of a connected USB cable is 3 m

(9.8 ft). As an alternative to the touchscreen, use a keyboard to enter text into text boxes on the

display (e.g., passwords and sample IDs).

8

English

Page 9

User interface and navigation

The instrument display is a touch screen. Only use a clean, dry finger tip to navigate the functions of

the touch screen. Do not use writing tips of pens or pencils or other sharp objects to make selections

on the screen or damage to the screen will occur.

Refer to Figure 3 for an overview of the home screen.

Figure 3 Display overview

1 Sample ID and measurement number

2 User comments 8 Sidebar menu (refer to Table 1)

3 Instructions 9 Time and date

4 Turbidity value, unit and reading mode 10 Options button

5 Warning or error message 11 Read button

6 Calibration status icon and calibration curve 12 Home/Instrument information button

5

7 UP/DOWN navigation arrows

Table 1 Sidebar menu icons

Icon Description

Logs in or logs out an operator. To log in, select an operator ID and then push Login. To log out,

push Logout.

Login

Sample ID

Calibration

5

The measurement number increases by one each time a measurement is completed.

Note: When an operator is logged in, the Login icon changes to the icon selected for the operator ID (e.g., fish,

butterfly or soccer ball) and the text "Login" changes to the operator ID.

Selects the sample ID.

Starts a calibration.

English 9

Page 10

Table 1 Sidebar menu icons (continued)

Icon Description

Starts a verification.

Verification

Shows the reading log, calibration log and verification log. Refer to Show the recorded data

on page 19.

Data Log

Configures the instrument settings. Refer to Configure the instrument settings on page 11.

Setup

Shows the firmware information, instrument backup, instrument updates, signaling information and

factory service data.

Diagnostics

Sets a timer.

Timer

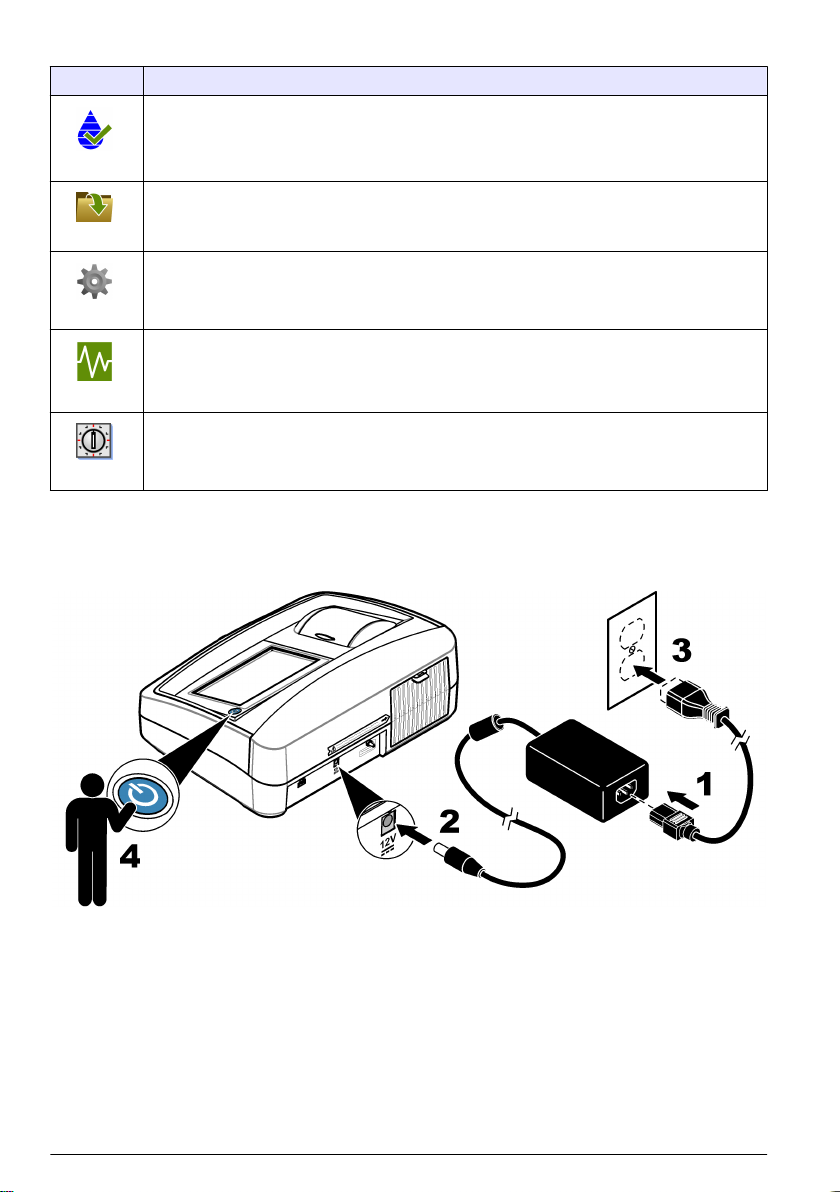

Startup

Refer to the illustrated steps that follow to supply power to the instrument and start the instrument.

The self-check will start.

10 English

Page 11

Operation

Configure the instrument settings

1. Push , then push Setup.

2. Select an option.

Option Description

Location Sets the location name of the instrument. The location is sent with measurements to the

Date & Time Sets the date format, the time format and the date and time. Enter the current date and

Security Enables or disables password protection for the settings and tasks in the security list.

Sound Settings Enables or disables the sound settings for individual events. To enable or disable all of

Peripherals Shows the connection status of attached devices such as a printer, USB memory (flash

Power

Management

USB drive. The location is not saved to the data log.

time. Date Format—Sets the date format. Options: dd-mm-yyyy (default), yyyy-mm-dd,

dd-mm-yyyy or mm-dd-yyyy. Time Format—Sets the time format. Options: 12 or

24 hours (default).

Security Password—Sets or changes the security (administrator) password

(10 characters maximum). Passwords are case sensitive. Security List—Sets the

security level for each setting and task in the security list.

• Off—All operators can change the setting or do the task.

• One key—Only operators with a one-key or two-key security level can change the

setting or do the task. Refer to Add operator IDs on page 12.

• Two keys—Only operators with a two-key security level can change the setting or do

the task.

Note: The Security setting is not set to on until Close is pushed.

the sound settings, select All and then push Setup.

drive) or keyboard.

Sets when the instrument is automatically set to sleep mode or off after a period of no

activity. Sleep Timer—Sets when the instrument is set to sleep mode. Options: OFF,

30 minutes, 1 (default), 2 or 12 hours.

Configure the measurement settings

Select the reading mode, measurement units, data log settings and more.

1. At the main reading screen, push Options>Reading Setup.

2. Select an option.

Option Description

Reading

Mode

Unit Selects the measurement units that show on the display and that are recorded to the data log.

Sets the reading mode to single, continuous or RST mode. Single (default)—The

measurement stops when the reading is stable. Continuous—The measurement continues

until the user pushes Done. RST—The Rapidly Settling Turbidity (RST) mode calculates and

continuously updates the turbidity reading of the sample to a confidence of 95%, based on the

accumulated trend of the real time measured values. The RST mode is best used on samples

that settle rapidly and continuously change in value. The reading is based on a correctly

prepared sample that is homogeneous at the beginning of the reading. It is best applied to

samples that are greater than 20 NTU. The sample must be mixed thoroughly by inversion

immediately before inserting it into the instrument. Signal Avg—The turbidity reading that

shows on the display is an average of the values measured during the time interval selected.

Options: For single measurement mode, 5 to 15 seconds. For continuous measurement mode,

5 to 90 seconds.

Options: NTU (default), EBC, Abs or %T.

English 11

Page 12

Option Description

Ratio Sets the ratio mode to on (default) or off. When set to off, an indicator shows on the reading

Bubble

Reject

Data Log

Setup

window.

Note: The ratio off mode is only valid for turbidity measurements that are less than 40 NTU.

Sets the bubble reject to on (default) or off. When set to on, high turbidity readings caused by

bubbles in the sample are not shown or saved to the data log.

Sets the data log settings. Auto Store—Measurement data is automatically recorded in the

reading log. Default: On. If Auto Store is off, push Options>Store to manually save a reading in

the data log. Send Data Format—Sets the output format of measurement data that is sent to

external devices (CSV, XML or BMP). Default: XML. Print Format—Sets the output format of

measurement data that is sent to a printer (Quick Print or Detailed Print (GLP)). Comments—

Lets users add comments to log entries. Auto Send—Measurement data is automatically sent

to all of the devices (e.g., printer and USB flash drive) that are connected to the instrument after

each measurement. Options: Off, new file or continue file: off—do not auto send data, new file—

send data and save it in a new file, continue file—send data and save all data in one file.

Add operator IDs

Add a unique operator ID for each person who will measure samples (30 maximum). Select an icon,

operator password and security level for each operator ID.

1. Push Login.

2. Push Options>New.

3. Enter a new operator ID (20 characters maximum), then push OK.

4. Push the LEFT and RIGHT arrows to select the icon for the operator ID (e.g., fish, butterfly or

soccer ball).

5. Push Operator Password, then enter a password for the operator ID.

Note: Passwords are case sensitive.

6. Push Security Level, then select the security level for the operator ID.

• Off—The operator cannot change the settings or do the tasks in the Security settings that have

a security level of one key or two keys.

• One key—The operator can change all the settings and do all the tasks in the Security settings

that have a security level of off or one key.

• Two keys—The operator can change all the settings and do all the tasks in the Security

settings.

Note: Before a security level can be selected, the Security setting must be set to on. Refer to Configure the

instrument settings on page 11.

7. Push OK>Close.

8. To edit an operator ID, select the operator ID and then push Options>Edit.

9. To delete an operator ID, select the operator ID and then push Options>Delete>OK.

Add sample IDs

Add a unique sample ID for each sample (1000 maximum). The sample ID identifies the sample

location or other sample specific information.

As an alternative, import sample IDs from a spreadsheet file to the instrument. Refer to the expanded

user manual on the manufacturer's website to import sample IDs.

1. Push Sample ID.

2. Push Options>New.

3. Enter a new sample ID (20 characters maximum).

4. Push OK.

12

English

Page 13

5. Select an option.

Option Description

Add Date/Time Adds the date and time that the sample was collected to the sample ID (optional). The date

Add Number Adds a measurement number to the sample ID (optional). Select the first number used for

Add Color Adds a colored circle to the sample ID icon (optional). The sample ID icon shows before the

and time entered for each sample ID show on the Sample ID menu.

the measurement number (0 to 999).

The measurement number shows in parenthesis after the sample ID on the home screen.

Refer to User interface and navigation on page 9.

sample ID on the home screen. Refer to User interface and navigation on page 9.

6. Push OK>Close.

7. To edit a sample ID, select the sample ID and then push Options>Edit>OK.

8. To delete a sample ID, select the sample ID and then push Options>Delete>OK.

Note: To delete all sample ID's, select the sample ID and then push Options>Delete All Sample IDs>OK.

Calibrate the turbidimeter with StablCal Standards

Calibrate the turbidimeter before it is used for the first time using the StablCal sealed vial standards

provided.

Calibrate the turbidimeter at least every 3 months or as specified by the regulating authority when

data is used for USEPA reporting.

The instrument is ready for calibration 60 minutes after start-up. Keep the instrument on 24 hours a

day if the instrument is used regularly.

Note: Unknown results may occur if standards other than the recommended calibration points are used. The

recommended calibration points (< 0.1, 20, 200, 1000, 4000 and 7500 NTU) provide the best calibration accuracy.

Use of standards other than StablCal, or user-prepared formazin, may result in less accurate calibrations. The

manufacturer cannot guarantee the performance of the instrument if calibrated with co-polymer

styrenedivinylbenzene beads or other suspensions.

Calibration notes

• Make sure that the instrument is in the same ambient conditions as where it is used.

• Make sure that the standards are at the same ambient temperature as the instrument before use.

• Use only the provided silicone oil. This silicone oil has the same refractive index as the vial glass

and masks minor glass differences and scratches.

• Store the oiling cloth in a plastic storage bag to keep the cloth clean.

• If power is lost during calibration, the new calibration data is lost and the last calibration data is

used.

• In Calibration mode, automatic range and signal averaging on are selected. When calibration is

completed, all operational modes go back to the last settings.

• All nephelometric (turbidity units of measure) calibrations are done at the same time.

• Ratio-on and Ratio-off calibration data is measured and recorded at the same time.

• Clean the USEPA filter assembly before doing a primary calibration, or at least every 3 months

(which is the USEPA-recommended primary calibration interval).

Configure the calibration settings

Change the calibration settings as necessary before the instrument is calibrated. The instrument

must be calibrated when the calibration curve is changed.

1. Push Calibration.

2. Push Options>Calibration Setup.

English

13

Page 14

3. Select the calibration curve range and type of calibration standard.

Option Description

StablCal RapidCal

(0–40 NTU)

StablCal (0–10000

NTU)

Formazin RapidCal

(0–40 NTU)

Formazin (0–10000

NTU)

Degrees (0–100 mg/L) Full-range calibration (20 mg/L, 100 mg/L and dilution water) with kaolin.

SDVB (0–10000 NTU) Full-range calibration (20 NTU, 200 NTU, 1000 NTU, 4000 NTU, 7500 NTU and

EU Pharm (0–30 NTU) Full-range calibration (<0.1 NTU, 3 NTU, 6 NTU, 18 NTU, 30 NTU).

Custom Calibration The user can enter a custom calibration for turbidity. The user selects the number

Calibration with 20-NTU StablCal standard (default).

Note: The dark current in the instrument is used as the zero point of the calibration

curve. The calibration curve is linear from 0-40 NTU, thus low turbidity

measurements are very accurate.

Full-range calibration (<0.1 NTU, 20 NTU, 200 NTU, 1000 NTU, 4000 NTU,

7500 NTU) with StablCal.

Calibration with 20-NTU formazin standard.

Note: The dark current in the instrument is used as the zero point of the calibration

curve. The calibration curve is linear from 0-40 NTU, thus low turbidity

measurements are very accurate.

Full-range calibration (20 NTU, 200 NTU, 1000 NTU, 4000 NTU, 7500 NTU and

dilution water) with formazin.

dilution water) with spherical styrene divinylbenzene.

of calibration standards and the value of each calibration standard. Use a custom

calibration when smaller sample cells are used with a sample cell adapter.

4. Select the remaining calibration options.

Option Description

Verify after Cal. Sets the instrument to start a verification immediately after the instrument is calibrated.

Calibration

Reminder

Reset to Factory

Calibration

When set to on, the verification standard is measured immediately after a calibration is

done. Default: ON. The value of the verification standard shows on the display as the

last standard during calibration.

Sets the time interval between calibrations. When a calibration is due, the display will

show a reminder and a question mark on the calibration icon at the top of the display.

Options: Off (default), 1 day, 7 days, 30 days or 90 days. When a calibration is done,

the calibration time is set to zero.

Sets the calibration settings to the factory defaults.

Prepare the StablCal standards

When received and at intervals:

1. Clean the exterior surface of the StablCal vials with laboratory glass cleaning detergent.

2. Rinse the vials with distilled or deionized water.

3. Dry the vials with a lint-free cloth.

Note: Never shake or invert the < 0.1 NTU standard. If the standard has been mixed or shaken, do not move the

vial for 15 minutes or more before using.

Note: Do not remove the caps from the sealed vials.

Make sure that the StablCal standards are at ambient instrument temperature before use (and no

greater than 40 °C (104 °F)).

Invert the standards (except < 0.1 NTU) before use. Refer to the user instructions that are supplied

with the StablCal standards.

14

English

Page 15

StablCal calibration procedure

1. Push Login and

select the applicable

Operator ID. If login is

not necessary, go to

step 3.

5. Hold the tab of the

USEPA filter assembly

so that the arrows point

toward the front of the

instrument. Push the

filter assembly fully in

the housing.

2. Push Login and

enter the password.

Push OK.

6. Push Calibration.

The standard values for

the selected calibration

curve (and verification

standard, if Verify after

Cal is on) show on the

display. To select a

different calibration

curve, refer to

Configure the

calibration settings

on page 13.

3. Remove the filter

assembly.

7. Get the StablCal

standard that shows on

the display. Clean the

vial with a soft, lint-free

cloth to remove water

spots and fingerprints.

4. Clean the lens of the

USEPA filter assembly.

Refer to Clean the filter

assembly on page 20.

8. Apply a small drop

of silicone oil from the

top to the bottom of the

vial.

9. Use the oiling cloth

to apply the oil equally

to the surface of the

vial. Remove most of

the oil. Make sure that

the vial is almost dry.

10. Carefully and

slowly invert the vial to

fully mix the standard

(do not invert the

<0.1 NTU vial). Be

careful not to add air

bubbles.

11. Put the vial in the

sample cell holder with

the triangle on the vial

aligned with the

reference mark on the

sample cell holder.

Push the lid closed until

a click is heard.

12. Push Read. Wait

1 minute for the

instrument to complete

the measurement.

English 15

Page 16

13. Open the lid and

remove the vial from

the sample cell holder.

14. Do steps 7–13 for

the other StablCal vials

(from lowest to highest

NTU standard). When

complete, the

measured values are

shown.

15. If Verify after Cal is

set to on, the value of

the verification standard

shows. Push Read to

measure the verification

standard.

16. Push Store to save

the new calibration

data.

Verification procedure

Use the verification procedure to measure the same Gelex or StablCal vial at regular intervals to

determine if the reading stays within the acceptance range. Use the Verification Setup menu to set a

reminder for the verification.

1. Push Login and

select the applicable

Operator ID. If login is

not necessary, go to

step 3.

5. Apply a small drop

of silicone oil from the

top to the bottom of the

vial.

16 English

2. Push Login and

enter the password.

Push OK.

6. Use the oiling cloth

to apply the oil equally

to the surface of the

vial. Remove most of

the oil. Make sure that

the vial is almost dry.

3. Push Verification.

The verification

standard value is

shown. Push

Options>Verification

Setup to change the

value of the verification

standard.

7. Put the vial in the

sample cell holder with

the triangle on the vial

aligned with the

reference mark on the

sample cell holder.

Push the lid closed until

a click is heard.

4. Clean the Gelex

vials with a soft, lint-free

cloth to remove water

spots and fingerprints.

8. Push Read. The

value and pass or fail

status shows. The data

is automatically stored

in the instrument.

Page 17

Turbidity measurement

For accurate turbidity readings use clean sample cells and remove air bubbles.

Measurement notes

Proper measurement techniques are important in minimizing the effects of instrument variation, stray

light and air bubbles. For accurate and repeatable measurements:

Instrument

• Make sure that the instrument is on a level, stationary surface that is free of vibration during the

measurement.

• The USEPA filter assembly is required for turbidity measurements reported for United States

Environmental Protection Agency (USEPA), National Primary Drinking Water Regulations

(NPDWR) or National Pollutant Discharge Elimination System (NPDES) permits.

• Turn the instrument on 30 minutes (Ratio on) or 60 minutes (Ratio off) before measurement. Keep

the instrument on 24 hours a day if the instrument is used regularly.

• Always close the sample compartment lid during measurement, calibration and verification.

• Remove the sample cell from the instrument and turn off the instrument if the instrument is stored

for an extended time period (more than a month).

• Keep the sample compartment lid closed to keep dust and dirt out.

Sample cells

• Always cap the sample cell to prevent spillage of the sample into the instrument.

• Always use clean sample cells in good condition. Dirty, scratched or damaged cells can result in

readings that are not accurate.

• Make sure that cold samples do not “fog” the sample cell.

• Store sample cells filled with distilled or deionized water and cap tightly.

• For the best accuracy, use a single sample cell for every measurement or a flow cell.

Note: As an alternative, matched sample cells may be used for measurements but do not provide as good of

accuracy or precision as a single indexed sample cell or flow cell. When using matched sample cells, align the

orientation mark on the sample cell with the reference mark on the sample cell holder.

Measurement

• Measure samples immediately to prevent temperature changes and settling. Before a

measurement is taken, always make sure that the sample is homogeneous throughout.

• Avoid sample dilution when possible.

• Avoid instrument operation in direct sunlight.

English

17

Page 18

Turbidity measurement procedure

To include an operator ID and sample ID with the measurement data, refer to Add sample IDs

on page 12 and Add operator IDs on page 12.

1. Push Login and

select the applicable

Operator ID. If login is

not necessary, go to

step 3.

5. Clean the sample

cells with a soft, lint-free

cloth to remove water

spots and fingerprints.

2. Push Login and

enter the password.

Push OK.

6. Apply a small bead

of silicone oil from the

top to the bottom of the

sample cells.

3. Push Sample ID.

Select the applicable

sample ID, then push

Select. The selected

sample ID shows on the

display.

7. Use the oiling cloth

provided to apply the oil

equally to the surface of

the sample cells.

Remove the excess oil.

Make sure that the

sample cells are almost

dry.

4. Rinse a clean,

empty sample cell two

times with the solution

to be measured and

drain to waste. Fill to

the line (about 30 mL)

with sample and

immediately put the cap

on the sample cell.

8. Gently and slowly

invert the sample cell to

fully mix the sample. Be

careful not to add air

bubbles.

9. Put the sample cell

in the sample cell

holder with the triangle

on the sample cell

aligned with the

reference mark on the

sample cell holder.

Push the lid closed until

a click is heard.

18 English

10. Push Read (or

Done if in continuous

mode). Wait for the

instrument to read the

sample.

Note: If auto store is

off, push Options >

Store to save the data.

Page 19

Data management

Show the recorded data

All the recorded data is kept in the data log. There are three types of data logs:

• Reading log—Shows the recorded measurements.

• Calibration log—Shows the calibration history.

• Verification log—Shows the verification history.

1. Push Data Log and select the applicable data log.

2. To show the details of a log entry, select the log entry and then push View Details.

Note: To add a comment to the log entry, push the comments icon.

3. To show only some of the data, push Filter, then select On. The Filter Settings window opens.

4. Select an option.

Option Description

Time Interval Selects only the data that was stored during a specific time interval.

Operator ID Selects only the data that was stored with a specific operator ID.

Sample ID Selects only the data from the Reading Log that was stored with a specific sample ID.

Send data to a connected device

The instrument can send data to a USB memory device or printer. For best results, use only USB

2.0 memory devices. The instrument makes a logger folder on the device and saves the data as

a .bmp, .csv or .xml file.

Use only the printers that are shown in the expanded version of this manual.

1. Connect a USB memory device or cable to a USB port on the instrument.

2. Connect the other end of the cable to the printer, if applicable.

3. Go to Setup>Peripherals. The connection status shows Connected. If the status shows Not

Connected, make sure to use the recommended devices.

4. Push Data Log and select the applicable log.

5. To send only some of the data, use the filter settings or select a single data point. Refer to Show

the recorded data on page 19.

6. Push Options>Send Data Log. Select single data point, filtered data or all data. Push OK.

The instrument sends the selected data to the connected devices.

Delete data from the data log

The instrument automatically deletes the oldest data record when the data log is full. The user can

also delete data manually. Make sure to save the data to an external device, then delete the data in

the data log.

1. Push Data Log and select the applicable log.

2. To delete only some of the data, use the filter settings. Refer to Show the recorded data

on page 19.

3. To delete the data, push Options>Delete Data. Select single data point, filtered data or all data.

Push OK.

The instrument deletes the selected data from the data log.

English

19

Page 20

Maintenance

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

Clean spills

C A U T I O N

Chemical exposure hazard. Dispose of chemicals and wastes in accordance with local, regional and

national regulations.

1. Obey all facility safety protocols for spill control.

2. Discard the waste according to applicable regulations.

Clean the instrument

Clean the exterior of the instrument with a moist cloth, and then wipe the instrument dry.

Clean the filter assembly

Note: Be careful not to push the lens out of the filter assembly.

1. Clean both sides of the lens of the filter assembly with glass cleaner, lens cleaner or isopropyl

alcohol, and a cotton-tipped swab or lens tissue.

2. Inspect the filter glass for scratches or other damage.

3. If a cloudy circle is seen around the edge of the filter, the filter material is delaminating. Replace

the filter assembly.

Replace the lamp

C A U T I O N

Wear protective eye wear when the lamp is turned on and the lamp cover is removed.

C A U T I O N

Burn hazard. The lamp must be cool before removal from the instrument.

Notes:

• Replace the lamp with the same size, style and electrical rating.

• Do not touch the lamp as oil from skin will damage the lamp. Clean the lamp with alcohol as

necessary.

• Either lamp lead can be put in either terminal block position.

• Turn the instrument on 30 minutes (Ratio on) or 60 minutes (Ratio off) before measurement or

calibration.

• Calibrate the instrument after the lamp is replaced.

To replace the lamp, refer to the documentation that is supplied with the lamp.

20

English

Page 21

Instrument utilities

1. Push Home to see the instrument model, version, serial number and location name.

2. Push Diagnostics.

3. Select an option.

Option Description

Factory Service For factory/service use only.

Instrument Backup Store—Saves a backup of all the instrument settings and log files to a USB flash drive.

Instrument Update Installs an instrument update on the instrument from a USB flash drive.

Service Time Shows the date entered for the last service date and for the next service date. When

Restore—Copies the instrument settings and log files from a USB flash drive to the

instrument. Overwrites all the instrument settings.

set to on, a service reminder shows on the display when service is due.

Troubleshooting

Message Solution

Startup

The self-check stopped.

Hardware error.

Next calibration is due! Calibrate the instrument. Refer to Calibrate the turbidimeter with StablCal

Next service is due! Contact technical support.

Next verification is due! Do a calibration verification. Refer to the expanded user manual on the

Reading

Hardware error / instrument

error

The calibration range is

exceeded.

The measurement range is

exceeded.

Calibration/Verification

Instrument error Examine the standards. Start the calibration or verification again.

Set the power to off, wait 20 seconds and then set the power to on again. If the

self check is not successful, record the error number and contact technical

support.

Error numbers: 0: RTC; 1: Touch IC; 3: Dark voltage—Close the door until a click

is heard. Start the instrument again. 4: Amplifier coefficient—Make sure that the

power supply is connected to an electrical outlet that has a protective earth

ground. 7: Lamp voltage—Make sure that the correct power supply is used. 8:

Transmission voltage drift—If the lamp was replaced, calibrate the instrument. If a

vial was in the sample compartment during the self-test at startup, remove the vial.

9: SDRAM; 10: NOR flash; 11: SPI flash; 12: Battery voltage; 13: Power supply

voltage—Make sure that the correct power supply is used.

Standards on page 13.

Note: The calibration reminder is set to on. Refer to Configure the calibration settings

on page 13.

Note: The service reminder is set to on. Refer to Instrument utilities on page 21.

manufacturer's website.

Note: The verification reminder is set to on.

Set the power to off, wait 20 seconds and then set the power to on again. If the

problem continues, contact technical support.

The measured turbidity is more than the calibration range of the instrument. Select

a calibration curve for the full measurement range. Refer to Configure the

calibration settings on page 13.

The measured turbidity is more than the measurement range of the instrument.

If calibration (or verification) is not successful, contact technical support.

English 21

Page 22

Message Solution

The standard is not stable. Use the correct calibration standards. Invert the standard until no bubbles or large

The standard value is out of

the measurement range.

The standard value is too

low.

The standard value is too

high.

Verification failed. Examine the verification standard. Calibrate the instrument. Refer to Calibrate the

Instrument update

Copy from USB Memory

failed

Instrument update file is

missing

Instrument update file is

corrupt

Not enough memory to

update the instrument

USB memory is not

connected.

Read/Write to USB flash drive

Cannot write to USB

memory

Cannot read from USB

memory

Restore backup

No instrument backup is

available.

Not able to restore the

backup

Security

Invalid password Enter the correct password. If the password is lost, contact technical support.

particles show.

Use the correct calibration standards. Invert the standards. Make sure to measure

the standards in ascending order.

The wrong calibration standard is in the vial compartment. Make sure that the

standard has not expired.

Put the correct calibration standard in the vial compartment. Make sure to invert

the standard.

The wrong calibration standard is in the vial compartment. Make sure that the

standard has not expired.

Put the correct calibration standard in the vial compartment.

turbidimeter with StablCal Standards on page 13.

If verification is not successful after calibration, contact technical support.

Remove large files from the USB flash drive that use too much space. Start the

instrument update procedure again.

Remove the instrument update files from the USB flash drive. Save the instrument

update files again to the USB flash drive.

Connect the USB flash drive to the instrument. Start the instrument update

procedure again.

Remove the instrument update files from the USB flash drive. Save the instrument

update files again to the USB flash drive.

Connect the USB flash drive to the instrument. Start the instrument update

procedure again.

Contact technical support.

Connect a USB flash drive to the instrument. Make sure that the file system

"FAT32" is installed on the USB flash drive.

Set the power to off, wait 20 seconds and then set the power to on again. Connect

the USB flash drive. Start the instrument update procedure again.

Connect a USB flash drive to the instrument. Make sure that the file system

"FAT32" is installed on the USB flash drive.

Set the power to off, wait 20 seconds and then set the power to on again. Look for

remaining space on the USB flash drive.

Set the power to off, wait 20 seconds and then set the power to on again. Connect

the USB flash drive to the instrument.

Connect a USB flash drive to the instrument. Make sure that the file system

"FAT32" is installed on the USB flash drive.

Set the power to off, wait 20 seconds and then set the power to on again. Connect

the USB flash drive. Start the instrument update procedure again.

22 English

Page 23

Message Solution

Send data

Connect a receiving device. Examine the device connections. Set the Auto Send setting to off. Refer to

Add sample IDs from list

No valid data found No sample ID file was found on the USB flash drive.

Not able to read sampling

date.

The instrument cannot read

the Sample ID

Problem/Error: Incorrect

date

Possible cause: The wrong

date format.

The sample ID list full. Data

has not been added.

Configure the measurement settings on page 11.

Make sure that the date and time format is dd.mm.yyyy hh:mm.

Examine the text strings. Refer to the expanded user manual on the

manufacturer's website.

Make sure that the date and time format is dd.mm.yyyy hh:mm.

Remove the sample IDs that are not used. Add a new sample ID.

English 23

Page 24

Table des matières

Caractéristiques à la page 24 Mise en marche à la page 32

Généralités à la page 25 Fonctionnement à la page 32

Installation à la page 29 Maintenance à la page 42

Interface utilisateur et navigation à la page 30 Dépannage à la page 44

Caractéristiques

Les caractéristiques techniques peuvent être modifiées sans préavis.

Caractéristique Détails

Méthode de mesure Néphélométrique

Réglementation Conforme à la méthode E.P.A. 180.1

ASTM D7315 - Méthode de test standard pour déterminer la turbidité au-dessus

d'une unité de turbidité (TU) en mode statique

ASTM D6655 - Méthode de test standard pour déterminer la turbidité en-dessous

de 5 NTU en mode statique

Dimensions (L x P x H) 39.5 x 30.5 x 15.3 cm (15.6 x 12.0 x 6.02 pouces)

Poids 3 kg

Boîtier IP30 ; usage en intérieur uniquement

Classe de protection Alimentation externe : classe de protection I ; instrument : classe de protection II

Niveau de pollution 2

Catégorie d’installation Alimentation externe : catégorie II ; instrument : catégorie I

Alimentation électrique Instrument : 12 V CC, 3,4 A ; alimentation : de 100 à 240 V c.a., 50/60 Hz

Température de

fonctionnement

Température de stockage –20 à 60 °C (–4 à 140 °F)

Humidité Humidité relative de 5 à 95 %, sans-condensation

Ecran Ecran tactile couleur de écran tactile couleur

Source de lumière Lampe à filament de tungstène

Unités de mesure NTU, EBC, Abs (absorbance), % T (% de transmittance) et mg/L (degré)

Plage NTU (mode de rapport activé) : décimale automatique de 0 à 10 000

0 à 40 °C (32 à 104 °F)

NTU (rapport désactivé) : 0–40

EBC (mode de rapport activé) : décimale automatique de 0 à 2 450

EBC (rapport désactivé) : 0–9,8

Absorbance1 (Réglage auto de la plage) : de 0 à–1,0

Transmittance1 (%) : de 1,0 à 100

Degré (mg/L) : de 1 à 100

1

Un ensemble de filtrage est nécessaire pour les mesures d'absorbance ou de transmittance.

24 Français

Page 25

Caractéristique Détails

Précision2, 3,

Résolution Turbidité : 0,001 NTU/EBC

Répétabilité ±1 % du relevé ou 0,01 NTU, selon l'écart le plus important (dans les conditions

Temps de réponse Moyenne pondérée du signal désactivée : 6,8 secondes

Temps de stabilisation Rapport activé : 30 minutes après le démarrage

Modes de mesure Signal unique, continu, RST (Rapidly Settling Turbidity™), moyennant activé ou

Communication USB

Interface 2 ports USB-A pour clé USB, imprimante externe, clavier et scanner de code à

Journal Datalog Total maximal d'entrées de journal de 2 000, comprenant un journal de mesure,

Purge d'air Azote sec ou air pour instruments (ANSI MC 11.1, 1975)

Cuves d'échantillon Cuves rondes 95 x 25 cm (3.74 x 1 po) verre au borosilicate avec bouchons à vis

Exigences relatives à

l'échantillon

Certification CE, KC, RCM

Garantie 1 an (UE : 2 ans)

4

Rapport activé : ±2 % du relevé plus 0,01 NTU de 0 à 1 000 NTU, ±5 % du relevé

de 1 000 à 4 000 NTU, ±10 % du relevé de 4 000 à 10 000 NTU

Rapport désactivé : ±2 % du relevé plus 0,01 NTU de 0 à 40 NTU

Absorbance : ±0,01 Abs de 0 à 0,5 Abs à 455 nm, ±2 % Abs de 0,5 à 1 Abs

à 455 nm

Transmittance : 2 % T de 10 à 100 % T à 455 nm

Absorbance : 0,001 Abs

Transmittance : 0,1% T

de référence)

Moyenne pondérée du signal activée : 14 secondes (lorsque 10 mesures sont

utilisées pour calculer la moyenne)

Rapport désactivé : 60 minutes après le démarrage

désactivé, mode de rapport activé ou désactivé

barres

un journal de vérification et un journal d'étalonnage.

0,1 scfm à 69 kPa (10 psig) ; 138 kPa (20 psig) maximum

Raccord de flexible à crans pour tube de 1/8e de pouce

revêtus de caoutchouc

Remarque : Des cuves pour échantillon plus petites (moins de 25 mm) peuvent être utilisées

lorsqu'un adaptateur pour cuves est utilisé.

cuve pour échantillon de 25 mm : 20 ml minimum

0 à 70 °C (32 à 158 °F)

Généralités

En aucun cas le constructeur ne saurait être responsable des dommages directs, indirects, spéciaux,

accessoires ou consécutifs résultant d'un défaut ou d'une omission dans ce manuel. Le constructeur

se réserve le droit d'apporter des modifications à ce manuel et aux produits décrits à tout moment,

sans avertissement ni obligation. Les éditions révisées se trouvent sur le site Internet du fabricant.

2

Spécifications de turbidité identifiées à l'aide d'un ensemble de filtre USEPA, d'un étalon de

formazine récemment préparé et de cuves pour échantillon de 25 mm correspondantes.

3

Un rayonnement électromagnétique intermittent de 3 volts/mètre ou plus peut causer de

légères imprécisions.

4

Conditions de référence : 23 (± 2) °C, 50 (± 10) % HR sans condensation, de 100 à 240 V c.a.,

50/60 Hz

Français 25

Page 26

Informations supplémentaires

Des informations supplémentaires sont disponibles sur le site Web du fabricant.

Consignes de sécurité

A V I S

Le fabricant décline toute responsabilité quant aux dégâts liés à une application ou un usage inappropriés de ce

produit, y compris, sans toutefois s'y limiter, des dommages directs ou indirects, ainsi que des dommages

consécutifs, et rejette toute responsabilité quant à ces dommages dans la mesure où la loi applicable le permet.

L'utilisateur est seul responsable de la vérification des risques d'application critiques et de la mise en place de

mécanismes de protection des processus en cas de défaillance de l'équipement.

Veuillez lire l'ensemble du manuel avant le déballage, la configuration ou la mise en fonctionnement

de cet appareil. Respectez toutes les déclarations de prudence et d'attention. Le non-respect de

cette procédure peut conduire à des blessures graves de l'opérateur ou à des dégâts sur le matériel.

Assurez-vous que la protection fournie avec cet appareil n'est pas défaillante. N'utilisez ni n'installez

cet appareil d'une façon différente de celle décrite dans ce manuel.

Interprétation des indications de risques

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée, entraîne des blessures graves,

voire mortelles.

D A N G E R

A V E R T I S S E M E N T

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée, peut entraîner des blessures

graves, voire mortelles.

Indique une situation de danger potentiel qui peut entraîner des blessures mineures ou légères.

Indique une situation qui, si elle n'est pas évitée, peut occasionner l'endommagement du matériel. Informations

nécessitant une attention particulière.

A T T E N T I O N

A V I S

Etiquettes de mise en garde

Lisez toutes les informations et toutes les étiquettes apposées sur l’appareil. Des personnes peuvent

se blesser et le matériel peut être endommagé si ces instructions ne sont pas respectées. Un

symbole sur l'appareil est référencé dans le manuel et accompagné d'une déclaration de mise en

garde.

Si l'appareil comporte ce symbole, reportez-vous au manuel d'utilisation pour consulter les

informations de fonctionnement et de sécurité.

Le matériel électrique portant ce symbole ne doit pas être mis au rebut dans les réseaux domestiques

ou publics européens. Retournez le matériel usé ou en fin de vie au fabricant pour une mise au rebut

sans frais pour l'utilisateur.

Certification

Avertissement EN 55011/CISPR 11

Ce produit appartient à la classe A. Dans un environnement domestique ce produit peut provoquer

des interférences radio auquel cas l'utilisateur peut être amené à prendre des mesures adéquates.

Règlement canadien sur les équipements causant des interférences radio, IECS-003, Classe

A :

26

Français

Page 27

Les données d'essai correspondantes sont conservées chez le constructeur.

Cet appareil numérique de classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC part 15, limites de classe A :

Les données d'essai correspondantes sont conservées chez le constructeur. L'appareil est conforme

à la partie 15 de la règlementation FCC. Le fonctionnement est soumis aux conditions suivantes :

1. Cet équipement ne peut pas causer d'interférence nuisible.

2. Cet équipement doit accepter toutes les interférences reçues, y compris celles qui pourraient

entraîner un fonctionnement inattendu.

Les modifications de cet équipement qui n’ont pas été expressément approuvées par le responsable

de la conformité aux limites pourraient annuler l’autorité dont l’utilisateur dispose pour utiliser cet

équipement. Cet équipement a été testé et déclaré conforme aux limites définies pour les appareils

numériques de classe A, conformément à la section 15 de la réglementation FCC. Ces limites ont

pour but de fournir une protection raisonnable contre les interférences néfastes lorsque l’équipement

fonctionne dans un environnement commercial. Cet équipement génère, utilise et peut irradier

l'énergie des fréquences radio et, s'il n'est pas installé ou utilisé conformément au mode d'emploi, il

peut entraîner des interférences dangereuses pour les communications radio. Le fonctionnement de

cet équipement dans une zone résidentielle risque de causer des interférences nuisibles, dans ce

cas l'utilisateur doit corriger les interférences à ses frais Les techniques ci-dessous peuvent

permettre de réduire les problèmes d'interférences :

1. Débrancher l'équipement de la prise de courant pour vérifier s'il est ou non la source des

perturbations

2. Si l'équipement est branché sur le même circuit de prises que l'appareil qui subit des

interférences, branchez l'équipement sur un circuit différent.

3. Eloigner l'équipement du dispositif qui reçoit l'interférence.

4. Repositionner l’antenne de réception du périphérique qui reçoit les interférences.

5. Essayer plusieurs des techniques ci-dessus à la fois.

Certification Coréenne

업무용을 위한 EMC 등급 A 장치에 대한

사용자 지침

사용자안내문

A 급 기기 ( 업무용 방송통신기자재 )

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 , 가정

외의 지역에서 사용하는 것을 목적으로 합니다.

Présentation du produit

A T T E N T I O N

Risque d’incendie. Ce produit n'est pas adapté à l'utilisation avec des liquides inflammables.

Le turbidimètre de laboratoire TL2350 mesure la lumière diffusée des échantillons d'eau pour

déterminer leur valeur de turbidité. Lorsque le mode Rapport est activé, l'instrument utilise plusieurs

détecteurs sous différents angles pour corriger les interférences et augmenter la plage de mesure.

Lorsque le mode Rapport est désactivé, l'instrument utilise un détecteur sur un angle de 90 degrés

par rapport à la source de lumière. L'utilisateur peut étalonner l'instrument et vérifier l'étalonnage à

intervalles réguliers.

Français

27

Page 28

L'interface utilisateur utilise un affichage à écran tactile. Une imprimante, une clé USB ou un clavier

peut être connecté aux ports USB. Reportez-vous à la Figure 1. L'horloge en temps réel à pile

affecte un horodatage à toutes les données transmises ou enregistrées (par ex., les journaux de

lecture, d'étalonnage et de vérification).

Figure 1 Présentation du produit

1 Couvercle du compartiment d'échantillon 6 Purge d'air

2 Filtre EPA 7 Branchement électrique

3 Ecran tactile 8 Port USB

4 Porte-cuve 9 Bouton d'alimentation

5 Cache du voyant 10 Port USB

Composants du produit

Assurez-vous d'avoir bien reçu tous les composants. Reportez-vous à la Figure 2. Si un élément est

absent ou endommagé, contactez immédiatement le fabricant ou un représentant.

28

Français

Page 29

Figure 2 Composants de l'instrument

1 Huile de silicone 6 Kit de standardisation de turbidité

2 Chiffon de huilage 7 Kit d'étalonnage StablCal

3 Ensemble de filtre USEPA 8 Alimentation

4 Turbidimètre TL2350 9 Cordon d'alimentation

5 Cuves à échantillon de 2,5 cm (30 mL) avec

bouchons (6x)

secondaire Gelex

10 Cache anti-poussière

®

®

Installation

A T T E N T I O N

Dangers multiples. Seul le personnel qualifié doit effectuer les tâches détaillées dans cette section du

document.

Cet instrument peut être utilisé jusqu'à une altitude de 3 100 m (10 710 pieds). Son utilisation à une

altitude supérieure à 2 000 m peut légèrement augmenter le risque de défaillance de l'isolation, et

entraîner un risque de choc électrique. Le fabricant conseille aux utilisateurs ayant des questions de

contacter l'assistance technique.

Conseils d'installation

Installez l'instrument :

• Sur une surface plane

• Dans un endroit propre, sec, bien ventilé et dont la température est sous contrôle

• Dans un endroit présentant le moins de vibrations possible et non exposé à la lumière directe du

soleil

• Dans un endroit offrant suffisamment d'espace autour de l'instrument pour effectuer les

connexions et les interventions de maintenance

• Dans un endroit où l'interrupteur et le cordon d'alimentation sont visibles et facilement accessibles

Français

29

Page 30

Branchement à des appareils externes (en option)

Utilisez les ports USB pour connecter l'instrument à une imprimante, un scanner manuel de codes à

barres, une clé USB ou un clavier. Reportez-vous à la Figure 1 à la page 28. La longueur maximale

d'un câble USB connecté est de 3 m. A la place des écrans tactiles, vous pouvez utiliser un clavier

pour entrer le texte dans les cases textuelles à l'écran (par ex., mots de passe et ID échantillon).

Interface utilisateur et navigation

L'écran de l'instrument est un écran tactile. Utilisez uniquement le bout du doigt propre et sec pour

parcourir les fonctions de l'écran tactile. N'utilisez pas la pointe d'écriture de stylos ou de crayons, ni

aucun autre objet pointu pour effectuer les sélections à l'écran au risque d'endommager l'écran.

Voir Figure 3 pour une vue d'ensemble de l'écran d'accueil.

Figure 3 Afficher une présentation

1 ID échantillon et nombre de mesures

2 Commentaires d'utilisateur 8 Menu latéral (voir Tableau 1)

3 Instructions 9 Heure et date

4 Valeur de turbidité, unité et mode de mesure 10 Bouton Options

5 Avertissement ou message d'erreur 11 Bouton Mesurer

6 Icône de statut d'étalonnage et courbe d'étalonnage 12 Bouton d'informations locales/d'instrument

5

Le nombre de mesures augmente de un chaque fois qu'une mesure est terminée.

5

7 Flèches de navigation HAUT/BAS

30 Français

Page 31

Icône Description

Connexion

ID échantillon

Etalonnage

Vérification

Journal des données

Setup

Diagnostics

Tableau 1 Icônes du menu latéral

Connexions ou déconnexions d'un opérateur. Pour se brancher, sélectionnez un

ID opérateur, puis appuyez sur Brancher. Pour débrancher, appuyez sur Débrancher.

Remarque : Lorsqu'un opérateur est connecté, l'icône de connexion est remplacée par l'icône

sélectionnée pour l'ID opérateur (par ex., un poisson, papillon ou un ballon de football) et le texte

« Connexion » est remplacé par l'ID opérateur.

Sélectionne l'ID échantillon.

Commence un étalonnage.

Commence une vérification.

Affiche les journaux de lecture, d'étalonnage et de vérification. Voir Affichage des

données enregistrées à la page 41.

Permet de configurer les paramètres de l'instrument. Voir Paramétrage de l'instrument

à la page 32.

Affiche les données spécifiques au micrologiciel, la sauvegarde de l'instrument, les

mises à jour de l'instrument, les informations de signalisation et les données sur la

réparation en usine.

Configure une minuterie.

Minuterie

Français 31

Page 32

Mise en marche

Reportez-vous aux étapes illustrées ci-dessous pour relier l'instrument à l'alimentation et démarrer

l'instrument. L'autodiagnostic démarre.

Fonctionnement

Paramétrage de l'instrument

1. Appuyez sur

, puis sur Configuration.

2. Sélectionnez une option.

Option Description

Emplacement Définit le nom d'emplacement de l'instrument. L'emplacement est enregistré avec les

Date et heure Définit le format de la date, le format de l'heure et la date et l'heure. Entrez la date et

Sécurité Active ou désactive la protection par mot de passe pour les paramètres et tâches qui

Paramètres

sonores

mesures sur la clé USB. L'emplacement n'est pas enregistré dans le journal de

données.

l'heure. Format date : définit le format de la date. Options : jj-mm-aaaa (par défaut),

aaaa-mm-jj, jj-mm-aaaa ou mm-jj-aaaa. Format temps : définit le format de l'heure.

Options : 12 ou 24 heures (par défaut).

figurent dans la liste de sécurité. Mot de passe de sécurité : définit ou modifie le mot

de passe de sécurité (administrateur) (de 10 caractères au maximum). Les mots de

passe sont sensibles à la casse. Liste de sécurité : définit le niveau de sécurité pour

chaque paramètre et tâche qui figurent dans la liste de sécurité.

• Désactivé : tous les opérateurs peuvent modifier le paramètre ou effectuer la tâche.

• Une clef : seuls les opérateurs dont le niveau de sécurité est une clef ou deux clefs

peuvent modifier le paramètre ou effectuer la tâche. Voir Ajout d'ID opérateur

à la page 33.

• Deux clefs : seuls les opérateurs dont le niveau de sécurité est deux clefs peuvent

modifier le paramètre ou effectuer la tâche.

Remarque : Le paramètre Sécurité n'est pas activé tant que vous n'avez pas appuyé

sur Fermer.

Active ou désactive les paramètres sonores pour les événements individuels. Pour

activer ou désactiver tous les paramètres sonores, sélectionnez Tous, puis appuyez sur

Configurer.

32 Français

Page 33

Option Description

Périphériques Affiche l'état de la connexion des périphériques associés comme une imprimante, une

Gestion de

l'alimentation

clé USB ou un clavier.

Définit quand l'instrument passe automatiquement en mode veille ou est désactivé après

une période d'inactivité. Minuteur en veille : définit quand l'instrument passe en mode

veille. Options : OFF, 30 minutes, 1 (par défaut), 2 ou 12 heures.

Configuration des paramètres de mesure

Sélectionnez le mode de mesure, les unités de mesure, les paramètres du journal de données et

plus encore.

1. Sur l'écran de mesure principal, appuyez sur Options>Réglage de la lecture.

2. Sélectionnez une option.

Option Description

Lecture

Mode

Unit

(Unité)

Rapport Permet d'activer (par défaut) ou de désactiver le mode de rapport. Lorsqu'il est désactivé, un

Rejet des

bulles d'air

Config.

données

Définit la mesure en mode unique, continu ou RST. Unique (par défaut) : la mesure s'arrête

lorsqu'elle est stable. Continu : la mesure continue tant que l'utilisateur n'a pas appuyé sur

Terminé. RST : le mode RST (Rapidly Settling Turbidity) calcule et met constamment à jour la

mesure de la turbidité de l'échantillon avec une précision de 95 %, en fonction de la tendance

accumulée des valeurs mesurées en temps réel. Le mode RST s'utilise au mieux sur les

échantillons qui se déposent rapidement et dont la valeur change en permanence. La mesure

se base sur un échantillon préparée correctement homogène au début de la mesure. Elle

s'applique le mieux aux échantillons de valeur supérieure à 20 NTU. L'échantillon doit

immédiatement être soigneusement mélangé par inversion avant d'être inséré dans

l'instrument. Moy. signal : la mesure de turbidité qui s'affiche à l'écran est une moyenne des

valeurs mesurées pendant l'intervalle de temps sélectionné. Options : pour le mode de mesure

unique, de 5 à 15 secondes. Pour le mode de mesure continu, de 5 à 90 secondes.

Sélectionne les unités de mesure qui s'affichent à l'écran et qui sont enregistrées dans le

journal des données. Options : NTU (par défaut), EBC, Abs ou % T.

indicateur s'affiche sur la fenêtre de lecture.

Remarque : Le mode de rapport désactivé n'est valide que pour des mesures de turbidité

inférieures à 40 NTU.

Permet d'activer (par défaut) ou de désactiver l'option Eliminer les bulles. Lorsque cette option

est activée, les mesures de turbidité élevées provoquées par des bulles dans l'échantillon ne

s'affichent pas ou ne sont pas enregistrées dans le journal des données.

Définit les paramètres du journal de données. Mémorisation automatique : les données de

mesure sont automatiquement enregistrées dans le journal de lecture. Valeur par défaut :

Activé. Si l'enregistrement automatique est désactivé, appuyez sur Options>Enregistrer pour

enregistrer manuellement une lecture dans le journal de données. Envoi du format de

données : définit le format de sortie des données de mesure qui sont envoyées aux

périphériques externes (CSV, XML ou BMP). Valeur par défaut : XML. Format d'impression :

définit le format de sortie des données de mesure qui sont envoyées à une imprimante

(Impression rapide ou Impr. détaillée (BPL)). Commentaires : permet aux utilisateurs d'ajouter

des commentaires aux entrées de journal. Envoi automatique : les données de mesure sont

automatiquement envoyées à l'ensemble des périphériques (par ex., imprimante et clé USB)

qui sont connectés à l'instrument après chaque mesure. Options : Désactivé, nouveau fichier

ou fichier continu : désactivé - ne pas envoyer automatiquement des données, nouveau fichier envoyer des données et les enregistrer dans un nouveau fichier, fichier continu - envoyer des

données et enregistrer toutes les données dans un fichier.

Ajout d'ID opérateur

Ajoutez un ID opérateur unique pour chaque personne qui mesure les échantillons (30 au

maximum). Sélectionnez une icône, un mot de passe opérateur et un niveau de sécurité pour

chaque ID opérateur.

1. Appuyez sur Connexion.

2. Appuyez sur Options>Nouveau.

Français

33

Page 34

3. Entrez un nouvel ID opérateur (20 caractères au maximum), puis appuyez sur OK.

4. Appuyez sur les flèches GAUCHE et DROITE pour sélectionner l'icône pour l'ID opérateur (par

ex., poisson, papillon ou ballon de football).

5. Appuyez sur Mot de passe utilisateur, puis entrez un mot de passe pour l'ID opérateur.

Remarque : Les mots de passe sont sensibles à la casse.

6. Appuyez sur Niveau de sécurité, puis sélectionnez le niveau de sécurité pour l'ID opérateur.

• Désactivé : l'opérateur ne peut pas modifier les paramètres ni effectuer aucune tâche sur les

paramètres de sécurité dont le niveau de sécurité comporte une ou deux clefs.

• Une clef : l'opérateur peut modifier tous les paramètres et effectuer toutes les tâches sur les

paramètres de sécurité dont le niveau de sécurité est désactivé ou comporte une clef.

• Deux clefs : l'opérateur peut modifier tous les paramètres et effectuer toutes les tâches sur les

paramètres de sécurité.

Remarque : Avant de sélectionner un niveau de sécurité, le paramètre de sécurité doit être activé. Voir

Paramétrage de l'instrument à la page 32.

7. Appuyez sur OK>Fermer.

8. Pour modifier un ID opérateur, sélectionnez-le puis appuyez sur Options>Modifier.

9. Pour supprimer un ID opérateur, sélectionnez-le puis appuyez sur Options>Supprimer>OK.

Ajout d'ID échantillon

Ajoutez un ID échantillon unique pour chaque échantillon (1000 au maximum). L'ID échantillon

identifie l'emplacement de l'échantillon ou d'autres informations spécifiques à l'échantillon.

Vous pouvez également importer dans l'instrument des ID échantillon à partir du fichier de feuille de

calcul. Reportez-vous au manuel de l'utilisateur complet sur le site Web du fabricant pour importer

des ID échantillon.

1. Appuyez sur Sample ID (ID d'échantillon).

2. Appuyez sur Options>Nouveau.

3. Entrez un nouvel ID échantillon (20 caractères au maximum).

4. Appuyez sur OK.

5. Sélectionnez une option.

Option Description

Ajouter

Date/Temps

Ajouter numéro Ajoute un nombre de mesure à l'ID échantillon (en option). Sélectionnez le premier

Ajouter couleur Ajoute un cercle coloré à l'icône d'ID échantillon (en option). L'icône d'ID échantillon

6. Appuyez sur OK>Fermer.

7. Pour modifier un ID échantillon, sélectionnez-le, puis appuyez sur Options>Modifier>OK.

8. Pour supprimer un ID échantillon, sélectionnez-le, puis appuyez sur Options>Supprimer>OK.

Remarque : Pour supprimer tous les ID échantillon, sélectionnez l'ID échantillon et appuyez sur

Options>Supprimer tous les ID d'échantillon>OK.

Ajoutez à l'ID échantillon la date et l'heure de collecte de l'échantillon (en option). La

date et l'heure entrées pour chaque ID échantillon s'affichent sur le menu

ID échantillon.

numéro utilisé pour le nombre de mesure (de 0 à 999).

Le nombre de mesure s'affiche entre parenthèses après l'ID échantillon dans l'écran

d'accueil. Voir Interface utilisateur et navigation à la page 30.

s'affiche avant l'ID échantillon dans l'écran d'accueil. Voir Interface utilisateur et

navigation à la page 30.

Calibation du turbidimètre avec les étalons StablCal

Calibrez le turbidimètre avant de l'utiliser pour la première fois à l'aide des étalons pour fiole scellée

StablCal fournis.

34

Français

Page 35

Étalonnez le turbidimètre au moins tous les 3 mois ou conformément aux spécifications des autorités

compétentes lorsque les données sont utilisées pour les rapports USEPA.

L'instrument est prêt pour l'étalonnage 60 minutes après le démarrage. Maintenez l'instrument en

marche 24 heures par jour s'il est utilisé régulièrement.

Remarque : Des résultats inattendus peuvent se produire si des étalons autres que les points d'étalonnage

recommandés sont utilisés. Les points d'étalonnage recommandés (< 0,1, 20, 200, 1 000, 4 000 et 7 500 NTU)

permettent d'obtenir une précision d'étalonnage optimale. L'utilisation d'étalons autres que les étalons StablCal ou

les étalons formazine préparés par l'utilisateur peut donner un étalonnage moins précis. Le fabricant ne peut pas

garantir les performances de l'instrument s'il est étalonné avec des perles de styrènedivinylbenzène de copolymère

ou d'autres suspensions.

Notes d'étalonnage

• Assurez-vous que l'instrument se trouve dans les mêmes conditions ambiantes que l'endroit dans

lequel il est utilisé.

• Assurez-vous que les étalons se trouvent à la même température ambiante que l'instrument avant

utilisation.

• N'utiliser que l'huile de silicone fournie. L'huile de silicone possède le même indice de réfraction

que le verre de la fiole et elle masque les différences et rayures mineures du verre.

• Rangez le chiffon de huilage dans un sachet de rangement en plastique pour le conserver propre.

• En cas de coupure de courant pendant l'étalonnage, les nouvelles données d'étalonnage sont

perdues et les données du dernier étalonnage sont utilisées.

• En mode d'étalonnage, la plage automatique et la moyenne des signaux sont sélectionnées. Une

fois l'étalonnage terminé, tous les modes de fonctionnement reviennent aux derniers paramètres

définis.

• Tous les étalonnages néphélométriques (unités de mesure de la turbidité) sont effectués en même

temps.

• Les données d'étalonnage sur rapport et hors rapport sont mesurées et enregistrées

simultanément.

• Nettoyez l'ensemble de filtre USEPA avant d'effectuer un étalonnage principal ou au moins tous

les 3 mois (l'intervalle d'étalonnage principal recommandé par l'USEPA).

Configuration des paramètres d'étalonnage

Modifiez les paramètres d'étalonnage selon les besoins avant l'étalonnage de l'instrument.

L'instrument doit être étalonné lorsque la courbe d'étalonnage est modifiée.

1. Appuyez sur Etalonnage.

2. Appuyez sur Options > Réglage de l'étalonnage.

3. Sélectionnez la plage de la courbe d'étalonnage et le type d'étalon.

Option Description

StablCal RapidCal

(de 0 à 40 NTU)

StablCal (0–10 000 NTU) Etalonnage complet (<0,1 NTU, 20 NTU, 200 NTU, 1 000 NTU, 4 000 NTU,

Formazin RapidCal (de

0 à 40 NTU)

Formazine

(0–10 000 NTU)

Degrés (0–100 mg/L) Etalonnage complet (20 mg/L, 100 mg/L et eau de dilution) avec kaolin.

SDVB (0–10 000 NTU) Etalonnage complet (20 NTU, 200 NTU, 1 000 NTU, 4 000 NTU, 7 500 NTU et

Etalonnage avec étalon StablCal de 20 NTU (par défaut)