Page 1

DOC023.97.80521

SC1500 Controller

01/2019, Edition 7

User Manual

Manuel de l'utilisateur

Manual del usuario

用户手册

Page 2

English..............................................................................................................................3

Français......................................................................................................................... 23

Español.......................................................................................................................... 45

中文................................................................................................................................. 67

2

Page 3

Table of contents

Specifications on page 3 Operation on page 20

General information on page 4 Maintenance on page 20

Installation on page 6 Troubleshooting on page 21

Startup on page 20 Accessories on page 21

Specifications

Specifications are subject to change without notice.

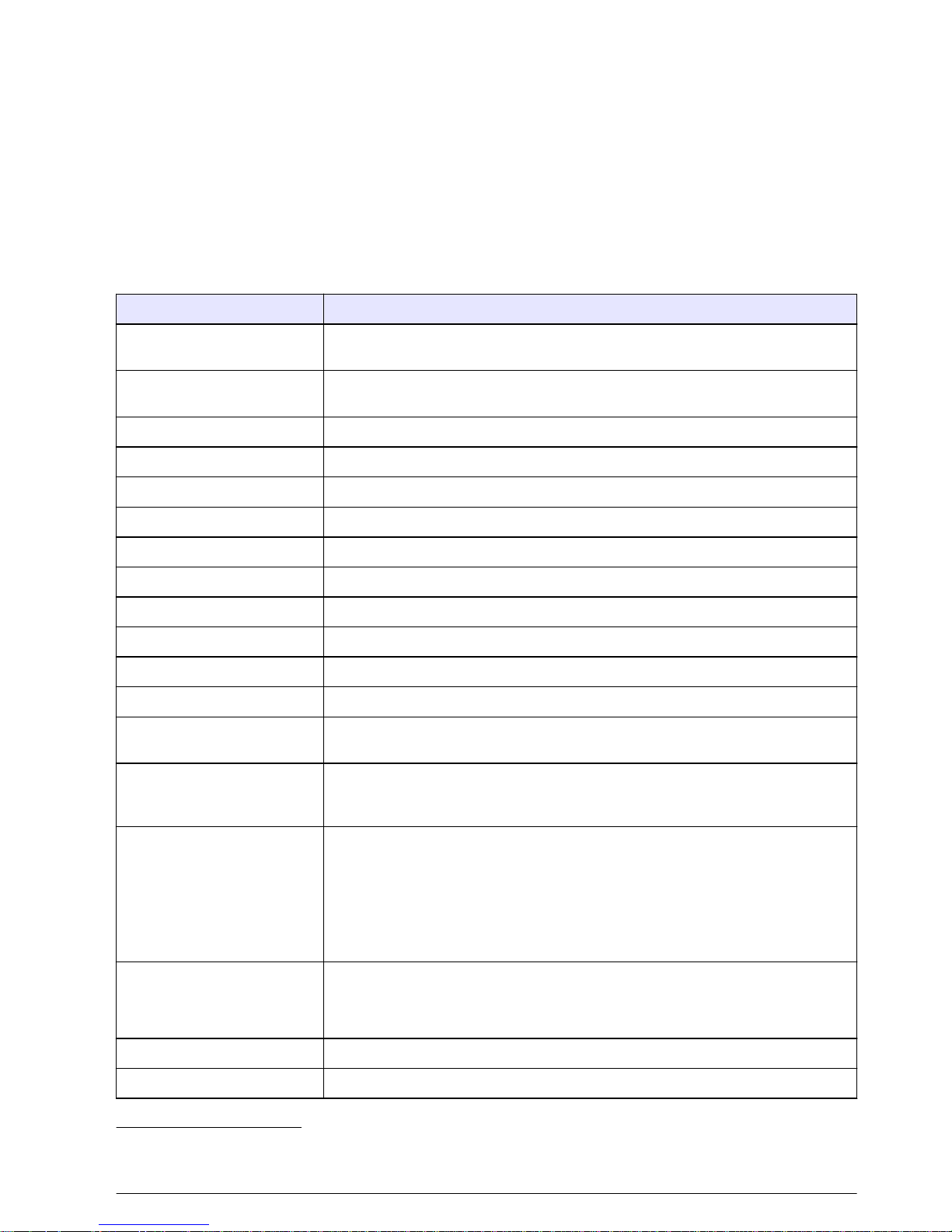

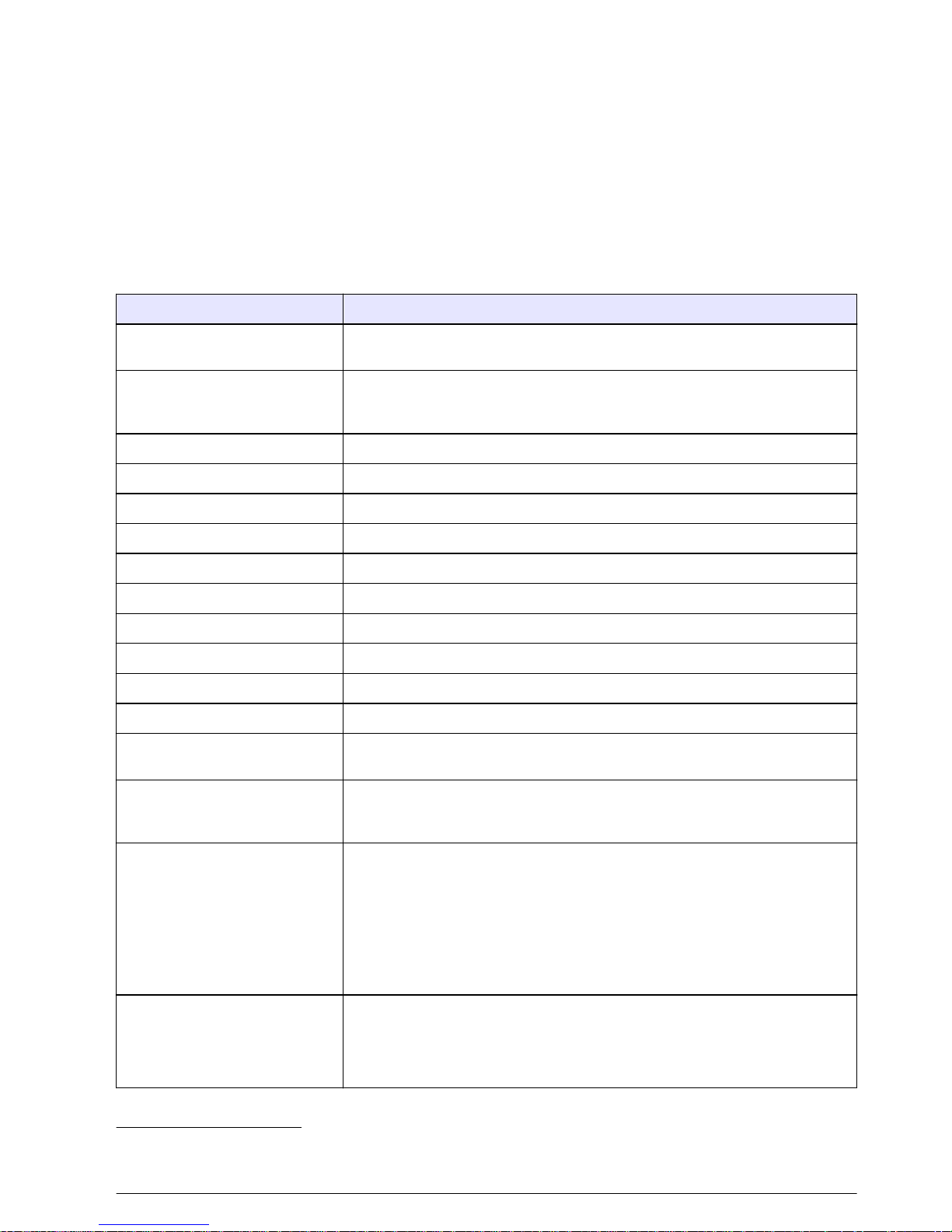

Specification Details

Dimensions (W x D x H) Controller: 315 x 120 x 242 mm (12.28 x 4.68 x 9.5 in.)

USB box: 79.5 x 55.1 x 159.5 mm (3.13 x 2.17 x 6.28 in.)

Enclosure Controller: Metal with corrosion-resistant surface, NEMA 4X/IP65 rating

USB box: ABS/polycarbonate, NEMA 4X/IP65 rating

Weight Approximately 5 kg (11 lb). Weight varies by model.

Pollution degree 2

Over voltage category II

Protection class I

Power requirements 100 to 240 VAC ± 10 VAC, 50/60 Hz, 1000 VA maximum

Fuse F1 and F2: M 3.5 A L, 250 V or T 3.15 A L, 250 V; F3 and F4: T 8 A H, 250 V

Operating temperature –20 to 55 °C (–4 to 131 °F)

Storage temperature –20 to 70 °C (–4 to 158 °F)

Humidity 95% relative humidity, non-condensing

Altitude 2000 m (6561 ft)

Measurement device

connections

Two, four or six device connectors and two AC power outlets

1

Network connections Two Ethernet connectors (10/100 Mbps), switch function, M12 female D-coding

connector

One USB connector in a USB box

Relay card (optional) Four relays on each relay card, change over contacts (SPDT)

Maximum switching voltage: 250 VAC, 125 VDC

Maximum switching current: 5 A

Note: Make sure to install the 5 A external breaker.

Maximum switching power: 1500 VA, 250 VAC; 625 W, 125 VDC

Wire gauge: 1.5 mm2 (15 AWG) maximum

Analog output card (optional)

Four 4–20 mA analog outputs on each analog output card, 500 Ω maximum

Wire gauge: 1.5 mm2 (15 AWG) maximum

The manufacturer recommends that signal cables with a shield are used.

Certification cTUVus compliant, CE compliant, DIN EN 61326 surge protection

Warranty 1 year (EU: 2 years)

1

The AC power outlets only supply power when the instrument has the optional 100 to 240 VAC

power supply.

English 3

Page 4

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

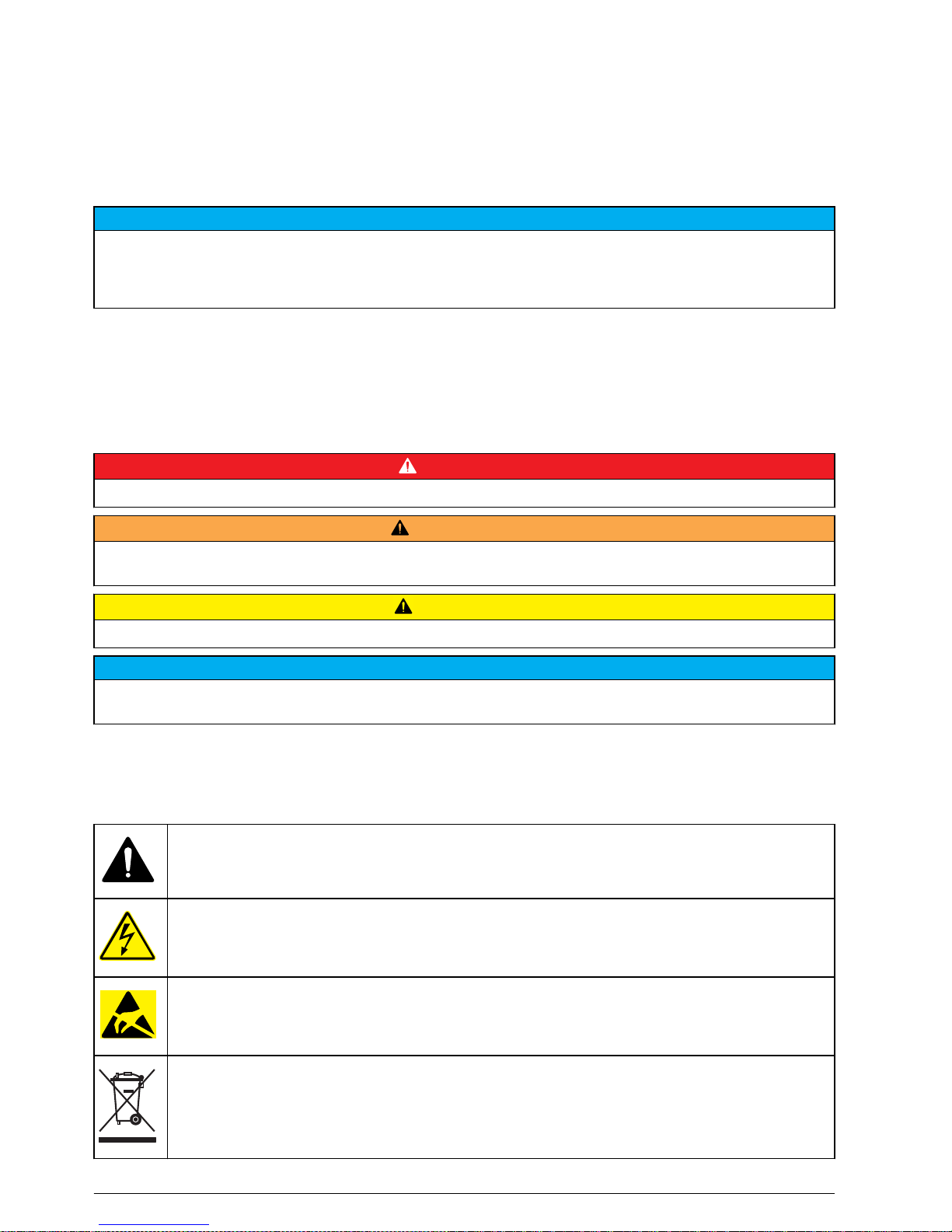

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential

injury. If on the instrument, refer to the instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

This symbol indicates the presence of devices sensitive to Electro-static Discharge (ESD) and

indicates that care must be taken to prevent damage with the equipment.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public

disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

4 English

Page 5

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol indicates that the marked item requires a protective earth connection. If the instrument is

not supplied with a ground plug on a cord, make the protective earth connection to the protective

conductor terminal.

Product overview

N O T I C E

Network and access point security is the responsibility of the customer that uses the wireless instrument. The

manufacturer will not be liable for any damages, inclusive however not limited to indirect, special, consequential

or incidental damages, that have been caused by a gap in, or breach of network security.

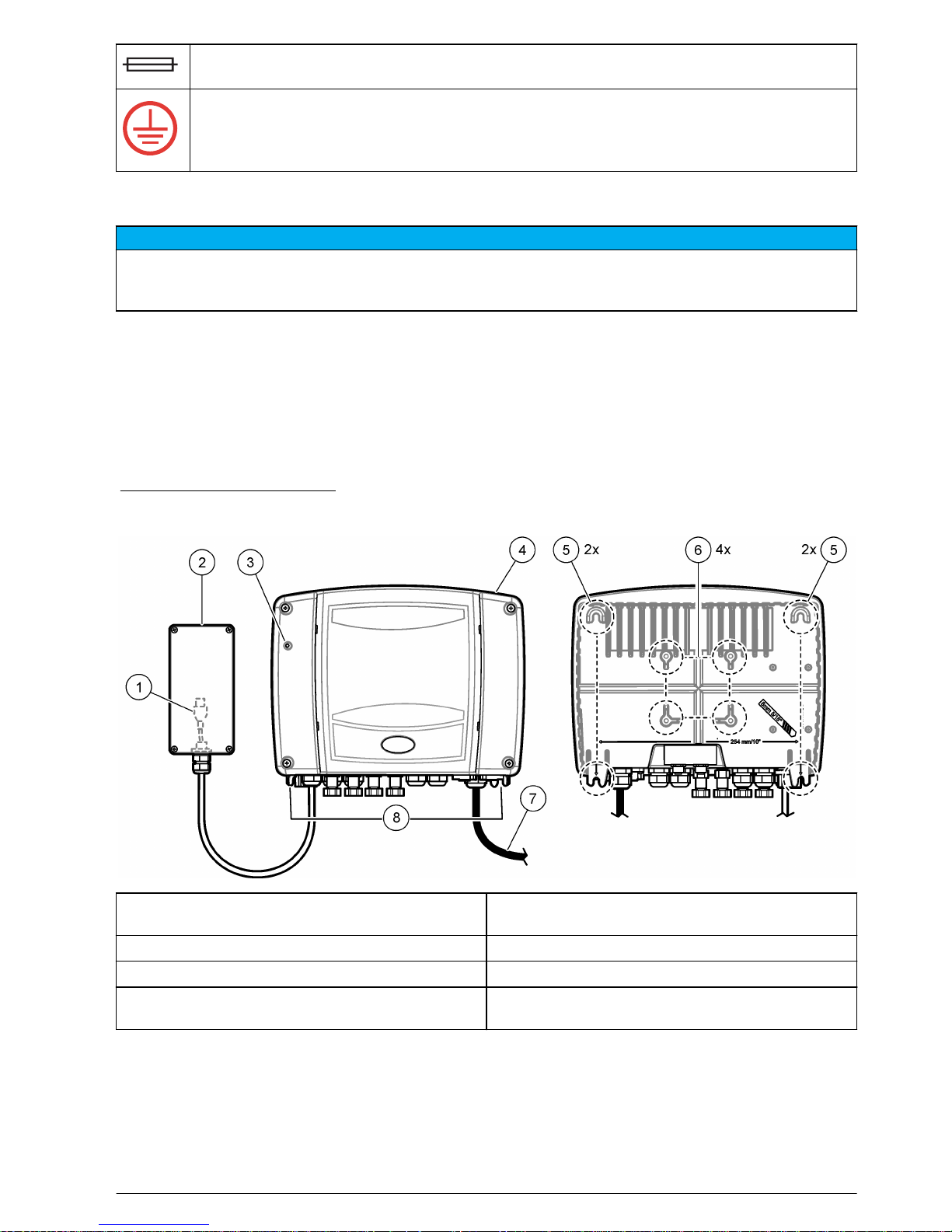

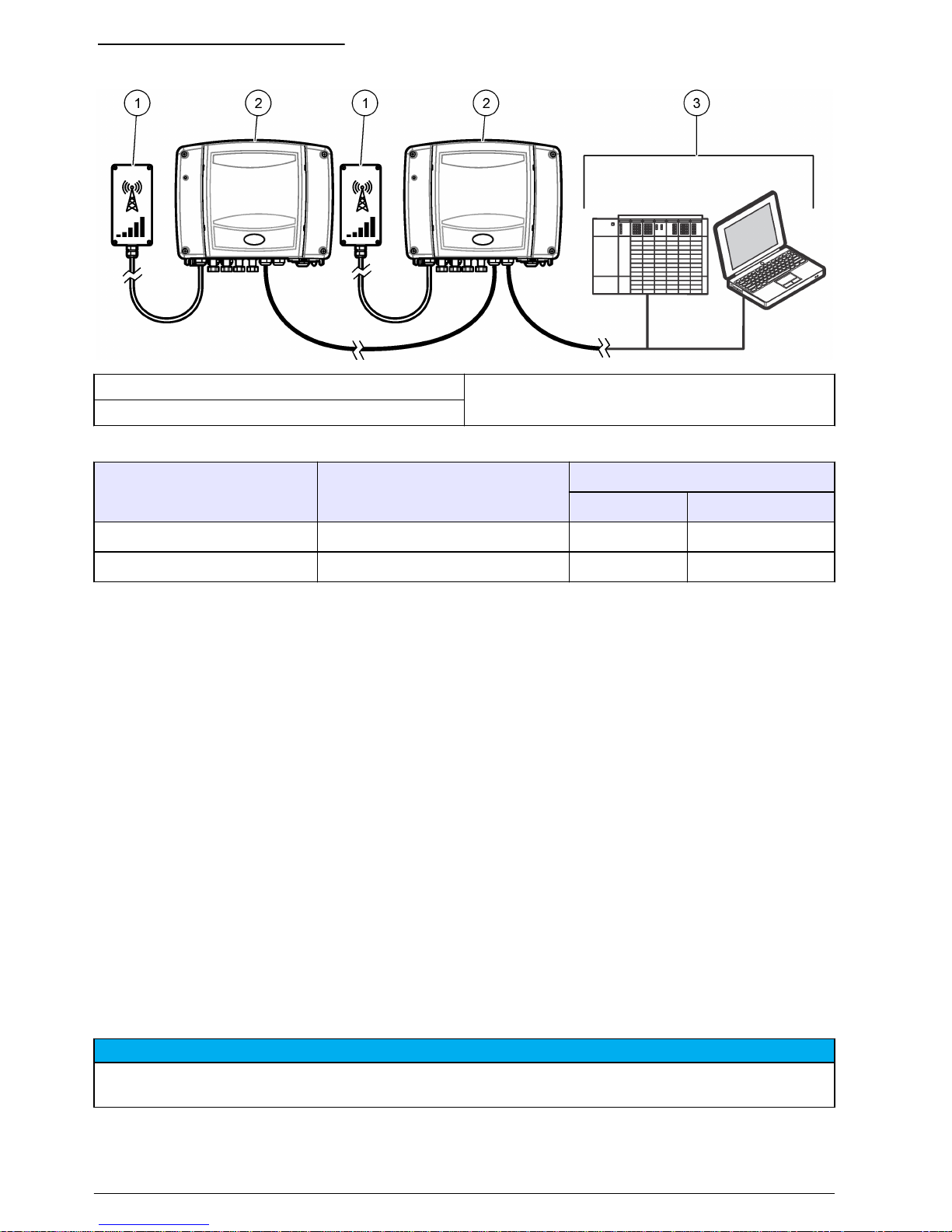

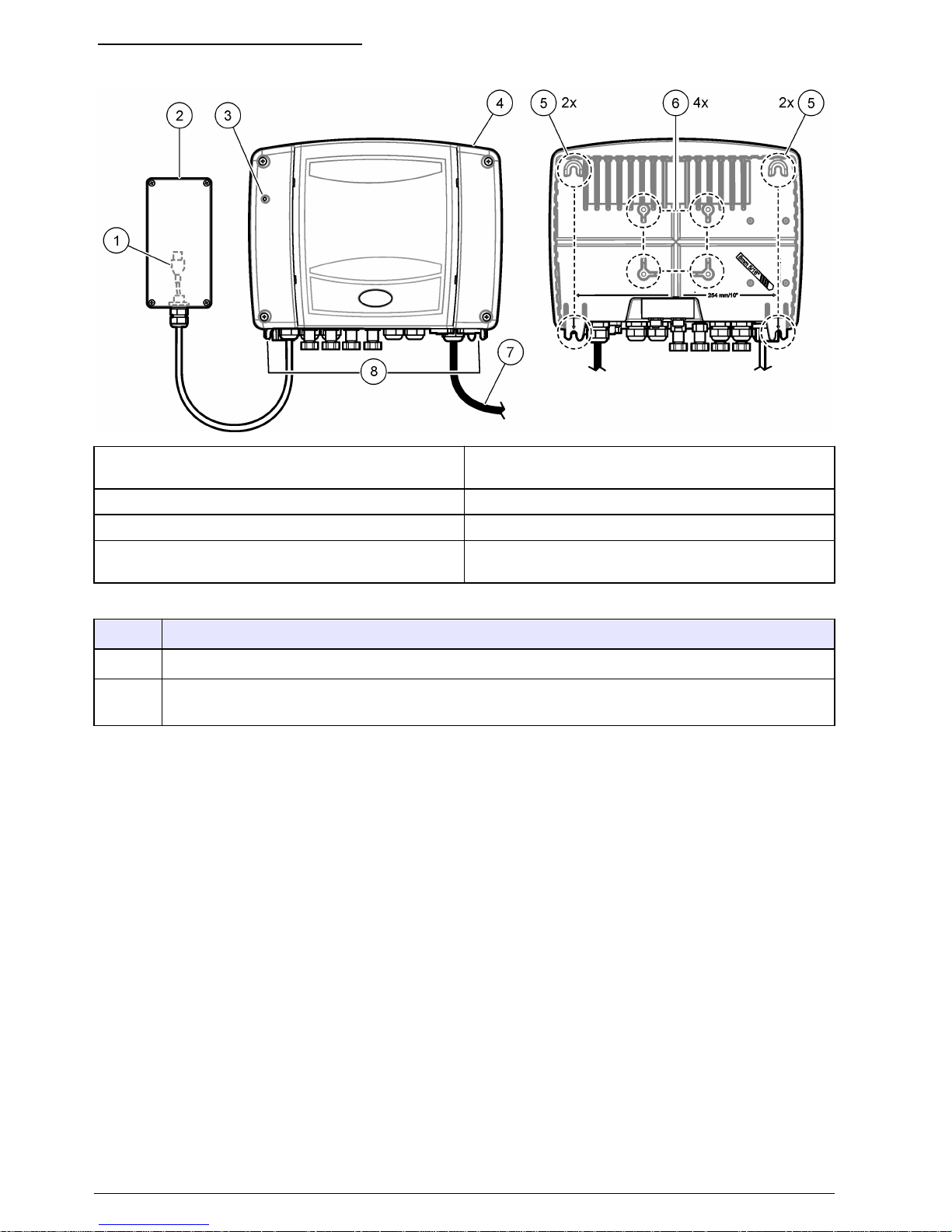

The sc1500 is a controller for digital analytical devices (e.g., sensors and analyzers). Refer to

Figure 1.

The controller is available with optional relays and analog outputs (4–20 mA). The optional relays are

used to control external devices (e.g., control devices and alarm devices). The optional analog

outputs are used to supply measurement values to external devices.

The controller is configured and operated with a mobile application on a customer-supplied iOS® or

an Android® device with an internet browser that is connected to the internet. The controller

communicates on a LAN, Wi-Fi or cellular network.

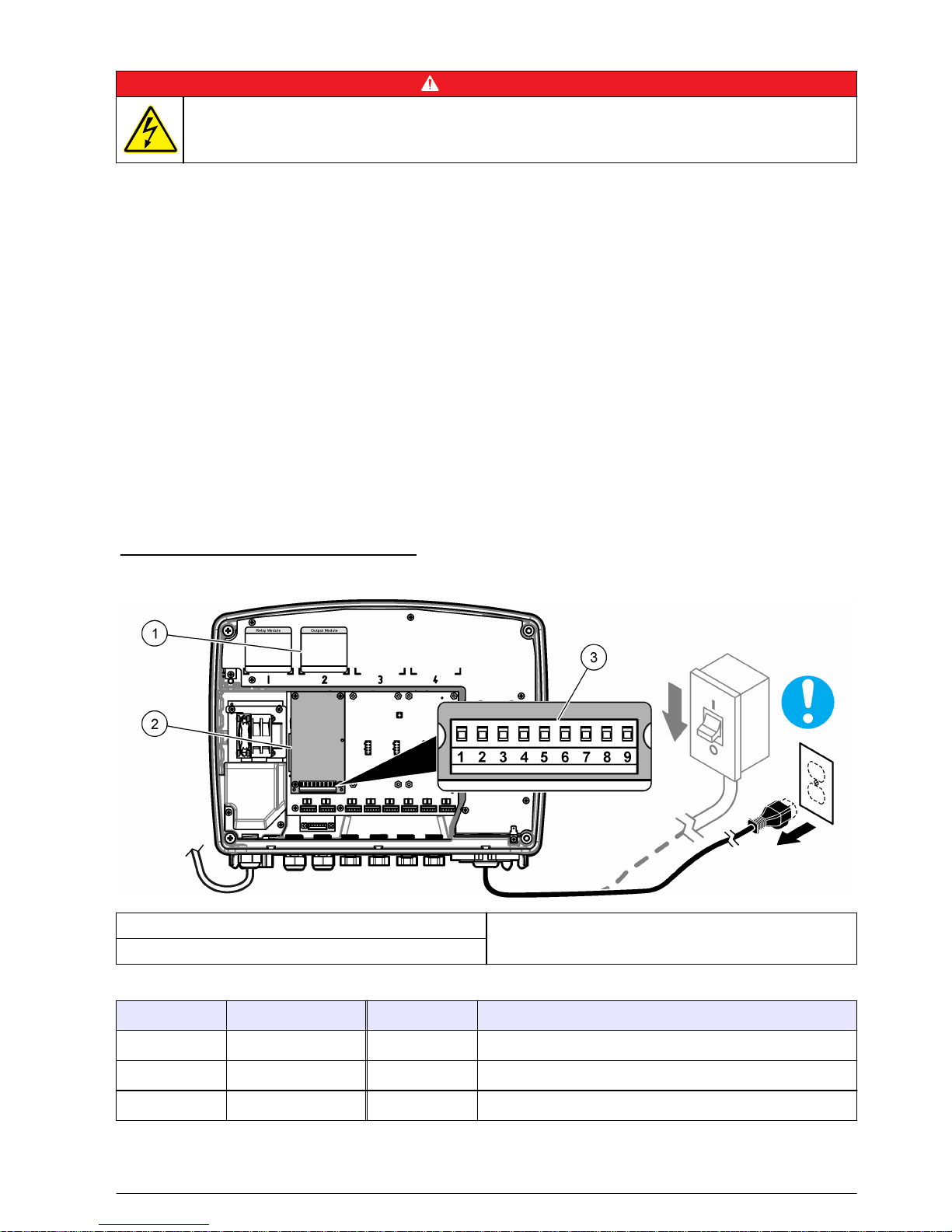

Figure 1 Product overview

1 USB connector (refer to Connect to a cellular

network on page 18)

5 Wall mounting slots

2 USB box 6 Pole mounting holes

3 Status indicator light (refer to Table 1) 7 Power cord (or conduit hub)

4 sc1500 controller 8 Electrical connectors and fittings (refer to Figure 6

on page 9)

English 5

Page 6

Table 1 Status indicator light

Color Status

Green Normal operation

Red There is a communications problem between the controller and one or more of the attached

measurement devices. Refer to Troubleshooting on page 21.

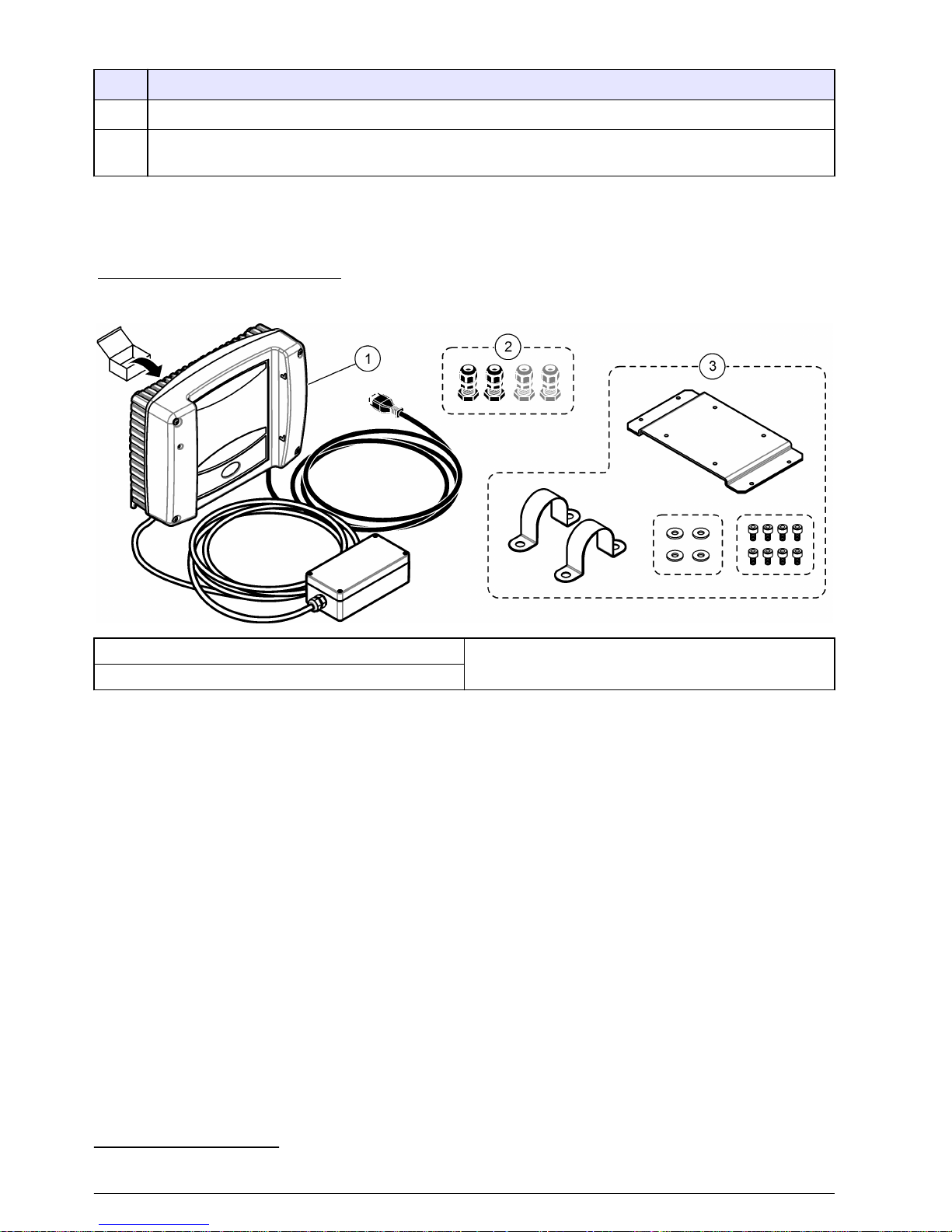

Product components

Make sure that all components have been received. Refer to Figure 2. If any items are missing or

damaged, contact the manufacturer or a sales representative immediately.

Figure 2 Product components

1 sc1500 controller 3 Pole mounting hardware for USB box

2

2 Strain relief fittings (quantity varies)

Installation

Mechanical installation

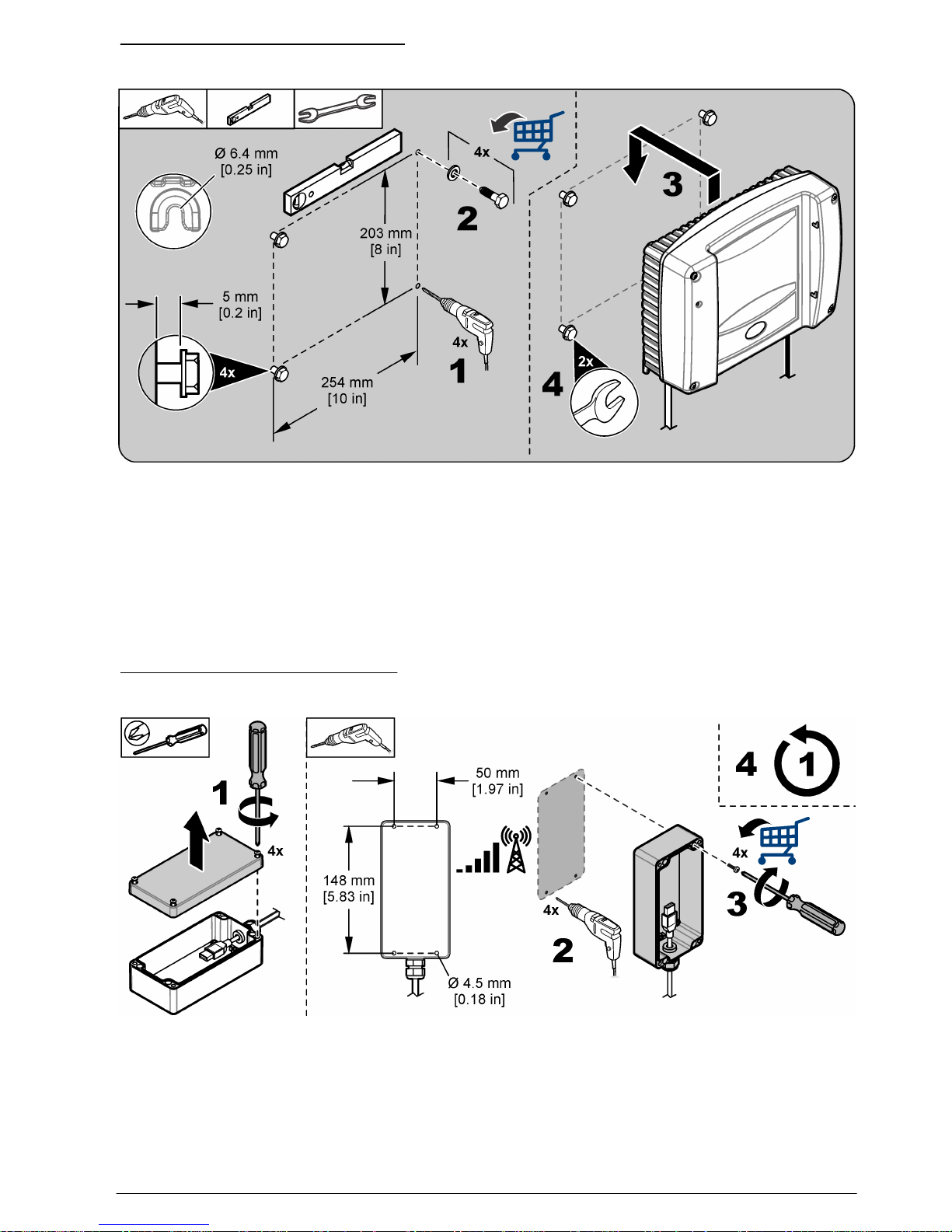

Install the controller

Attach the controller upright and level on a flat, vertical surface. Refer to the illustrated steps in

Figure 3. Install the controller in a location where the power disconnect device for the controller is

easily operated.

Mounting hardware is supplied by the user. Make sure that the wall mounting is able to hold 4 times

the weight of the equipment.

As an alternative, attach the instrument to a panel, vertical pole or horizontal pole. Refer to the

instruction sheet supplied with the optional mounting kit.

Note: The optional sunshield is recommended for all outdoor installations.

2

The pole mounting hardware is for a 40 mm (1.57 in.) diameter pole.

6 English

Page 7

Figure 3 Wall mounting—controller

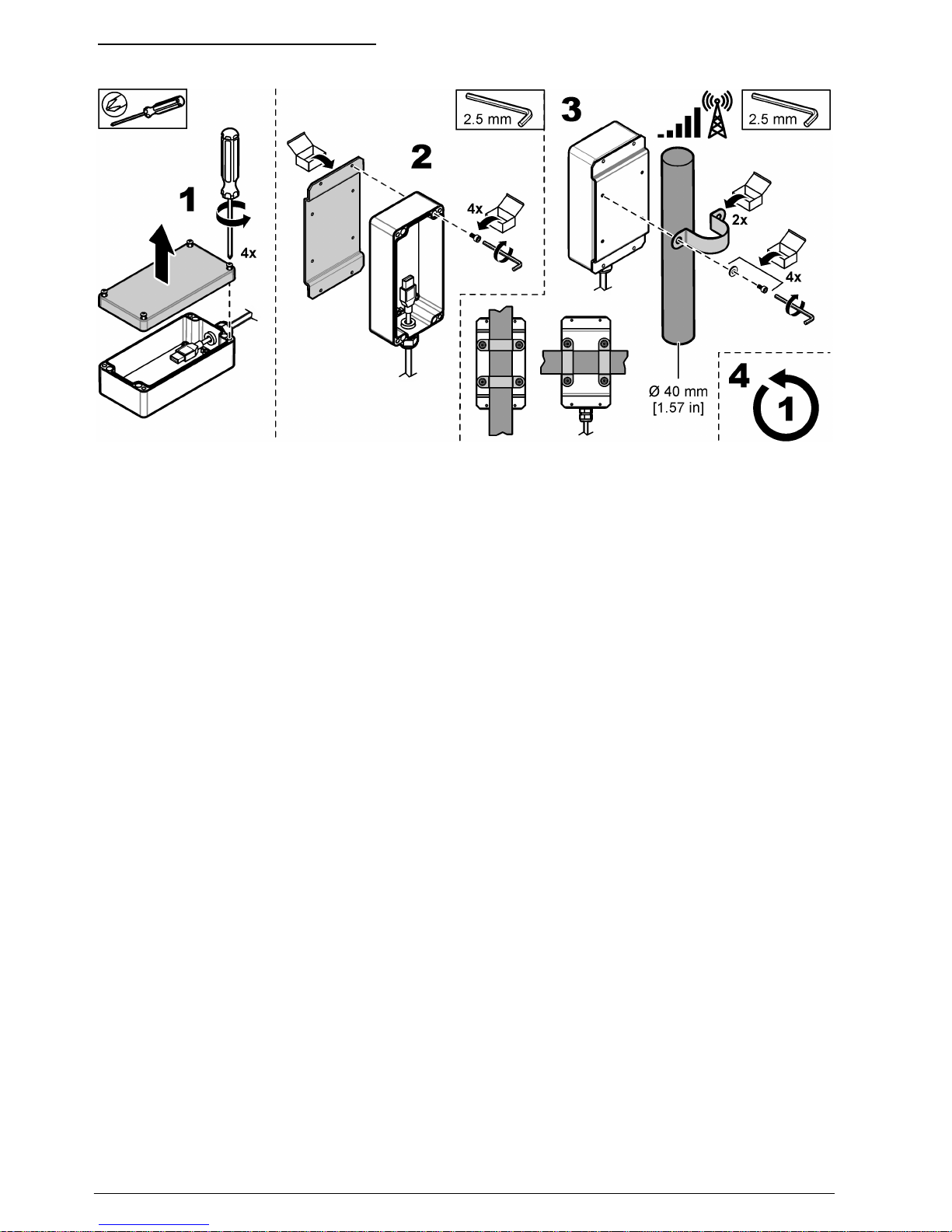

Install the USB box

Install the USB box in the location with the highest cellular signal strength. Use a mobile device with

the same cellular service provider as the sc1500 controller to find the location with the highest

cellular signal strength.

Install the USB box in a location where the power disconnect device for the controller is easily

operated.

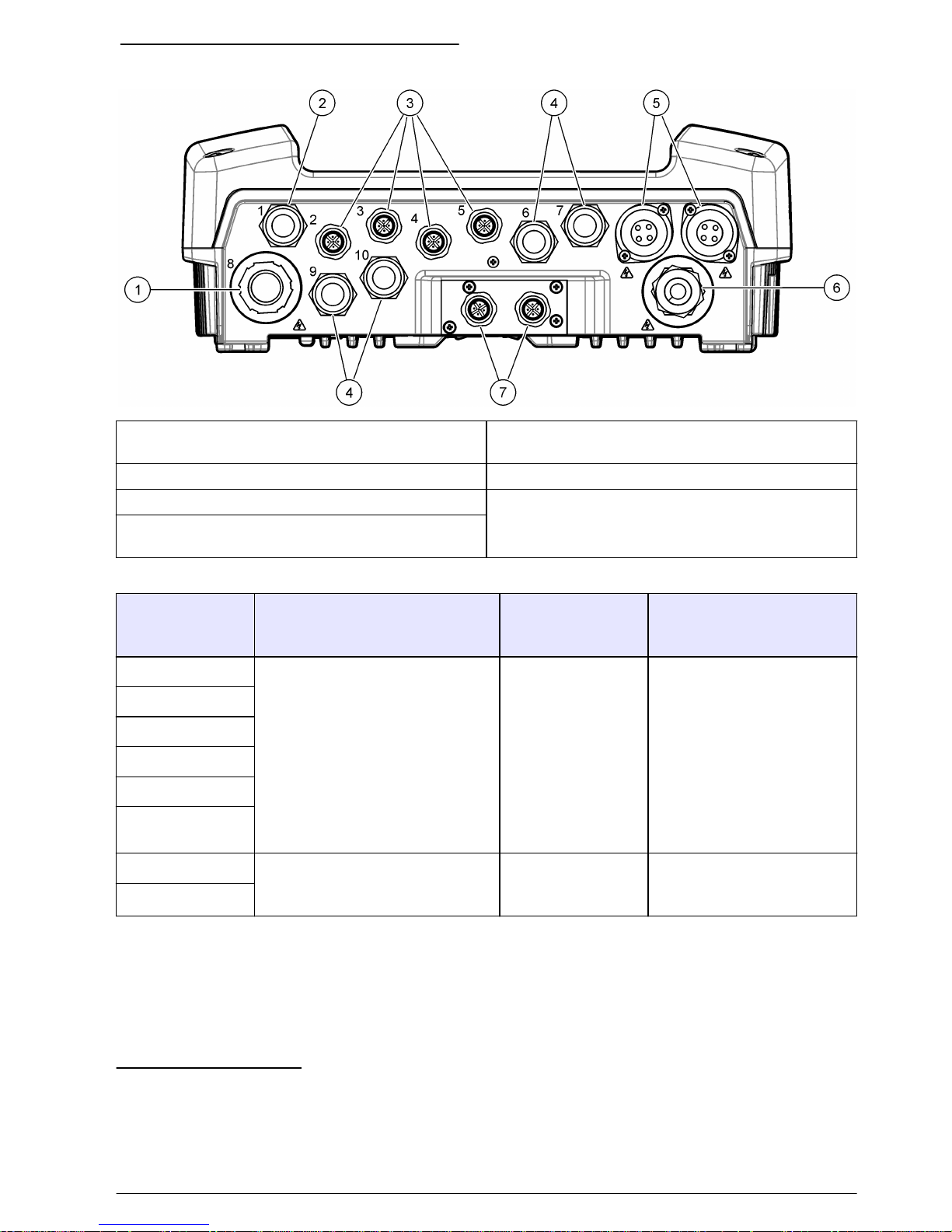

Attach the USB box to a wall, vertical pole or horizontal pole. Refer to the illustrated steps in Figure 4

or Figure 5. Pole mounting hardware for a 40 mm (1.57 in.) pole is supplied with the instrument. Wall

mounting hardware is supplied by the user.

Figure 4 Wall mounting—USB box

English 7

Page 8

Figure 5 Pole mounting—USB box

Electrical installation

Electrical connectors and fittings

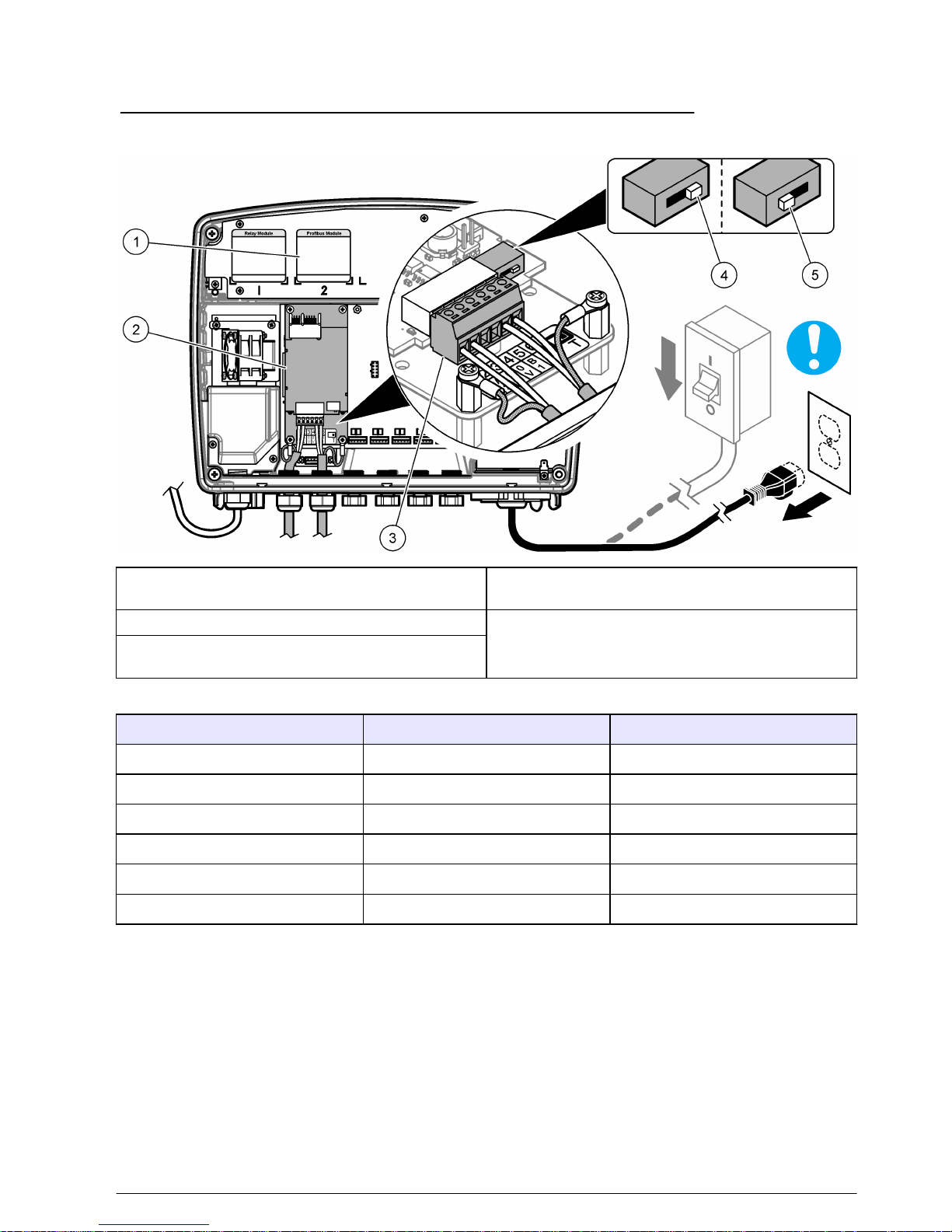

Figure 6 shows the electrical connectors and fittings on the instrument. Table 2 shows the connection

devices that can connect to the instrument. Only use the manufacturer-approved connection devices

from Table 2.

To keep the environmental rating of the enclosure, make sure that there is a plug in the strain relief

fittings that are not used and a connector cap on the unused connectors.

8

English

Page 9

Figure 6 Electrical connectors and fittings

1 Large strain relief fitting for relay—2.19 mm conduit

or 9 to 13.5 mm diameter cable

5 AC power outlets

4

2 USB box cable 6 Power cord (or conduit hub)

3 Device connectors

3

7 Ethernet connectors

5

4 Strain relief fittings for the analog output card or for

the Profibus card—5 to 6 mm diameter cable

Table 2 Manufacturer-approved connection devices

Devices Description Power

consumption per

device

Controller connection

A/N-ISE sc For devices with low power

consumption: 60 W maximum total

consumption is permitted.

< 3.5 W Use the device connector.

Refer to Figure 6, item 3.

LDO sc

SOLITAX sc

NITRATAX sc

SONATAX sc

pHD (pH and

Redox)

AMTAX sc For devices with high power

consumption: 1000 VA maximum

total consumption is permitted.

< 500 W Use the AC power outlets.

Refer to Figure 6, item 5.

PHOSPHAX sc

3

The quantity of device connectors and strain relief fittings varies with model.

4

The AC power outlets only supply power when the instrument has the optional 100 to 240 VAC

power supply.

5

Right M12 connector used for MODBUS TCP/IP. Left M12 connector used to daisy chain

controllers. Refer to Modbus TCP/IP expansion on page 19.

English 9

Page 10

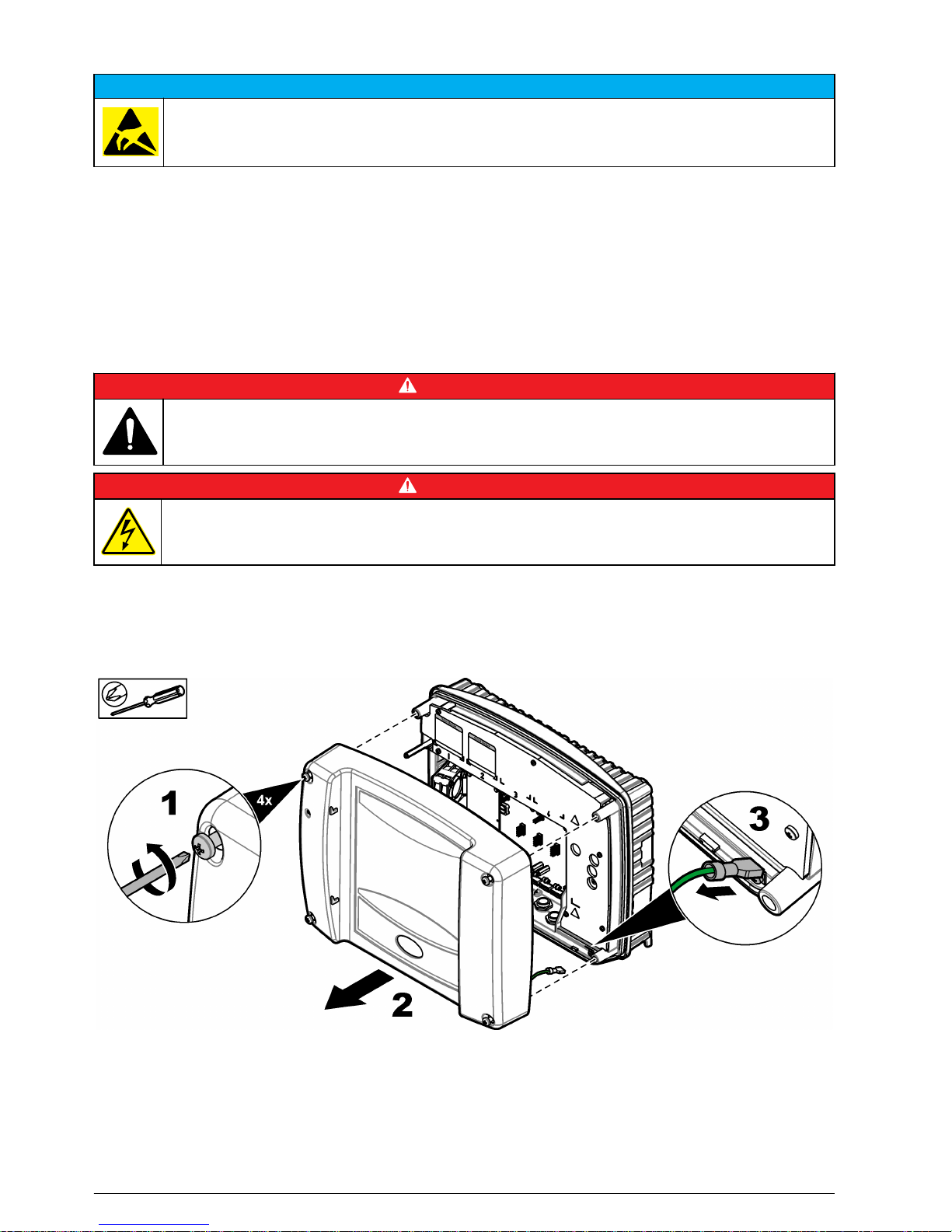

Electrostatic discharge (ESD) considerations

N O T I C E

Potential Instrument Damage. Delicate internal electronic components can be damaged by static

electricity, resulting in degraded performance or eventual failure.

Refer to the steps in this procedure to prevent ESD damage to the instrument:

• Touch an earth-grounded metal surface such as the chassis of an instrument, a metal conduit or

pipe to discharge static electricity from the body.

• Avoid excessive movement. Transport static-sensitive components in anti-static containers or

packages.

• Wear a wrist strap connected by a wire to earth ground.

• Work in a static-safe area with anti-static floor pads and work bench pads.

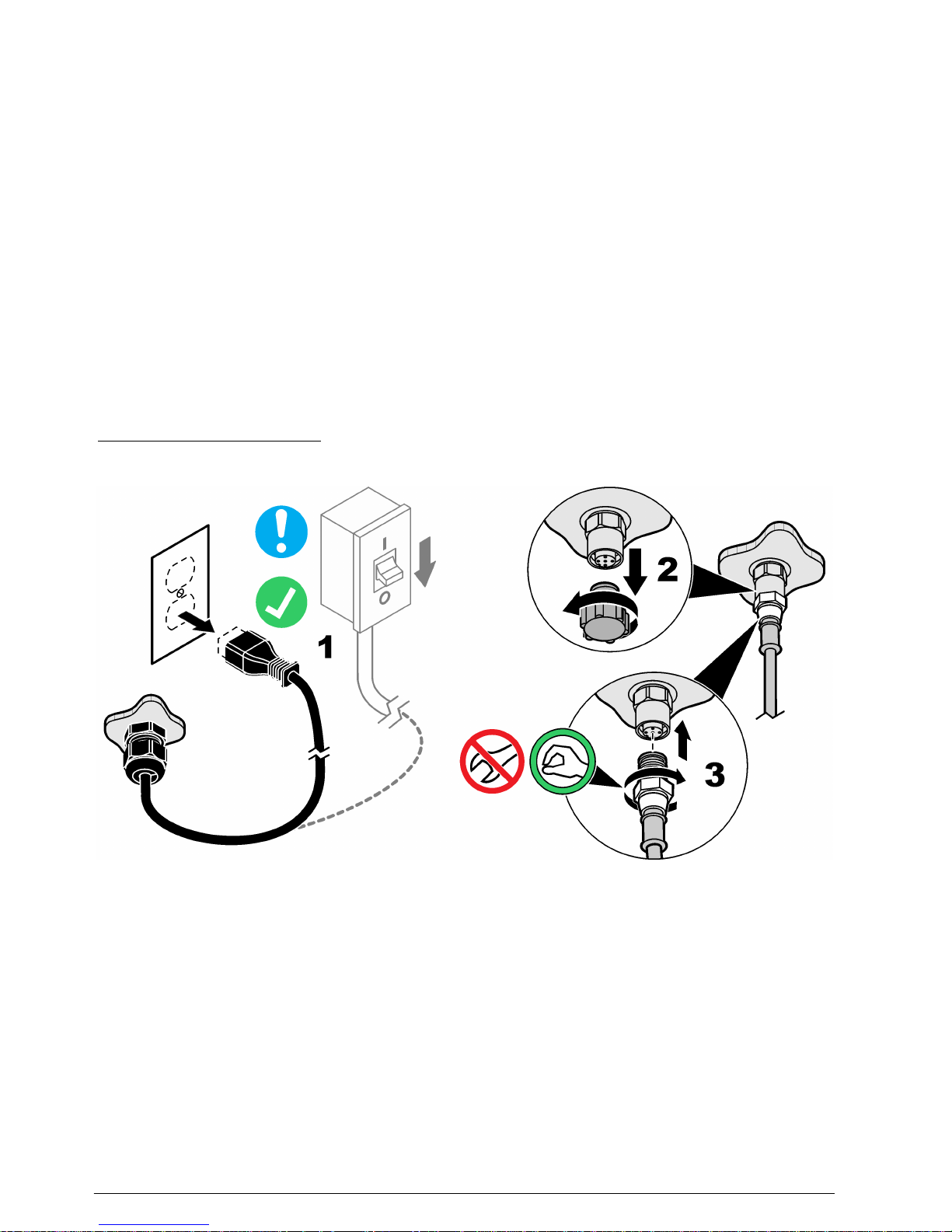

Power connections

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

D A N G E R

Electrocution hazard. Always remove power to the instrument before making electrical connections.

If the controller does not have an installed power cord, connect power with conduit or a power cord.

Refer to the sections that follow to connect power with conduit or a power cord.

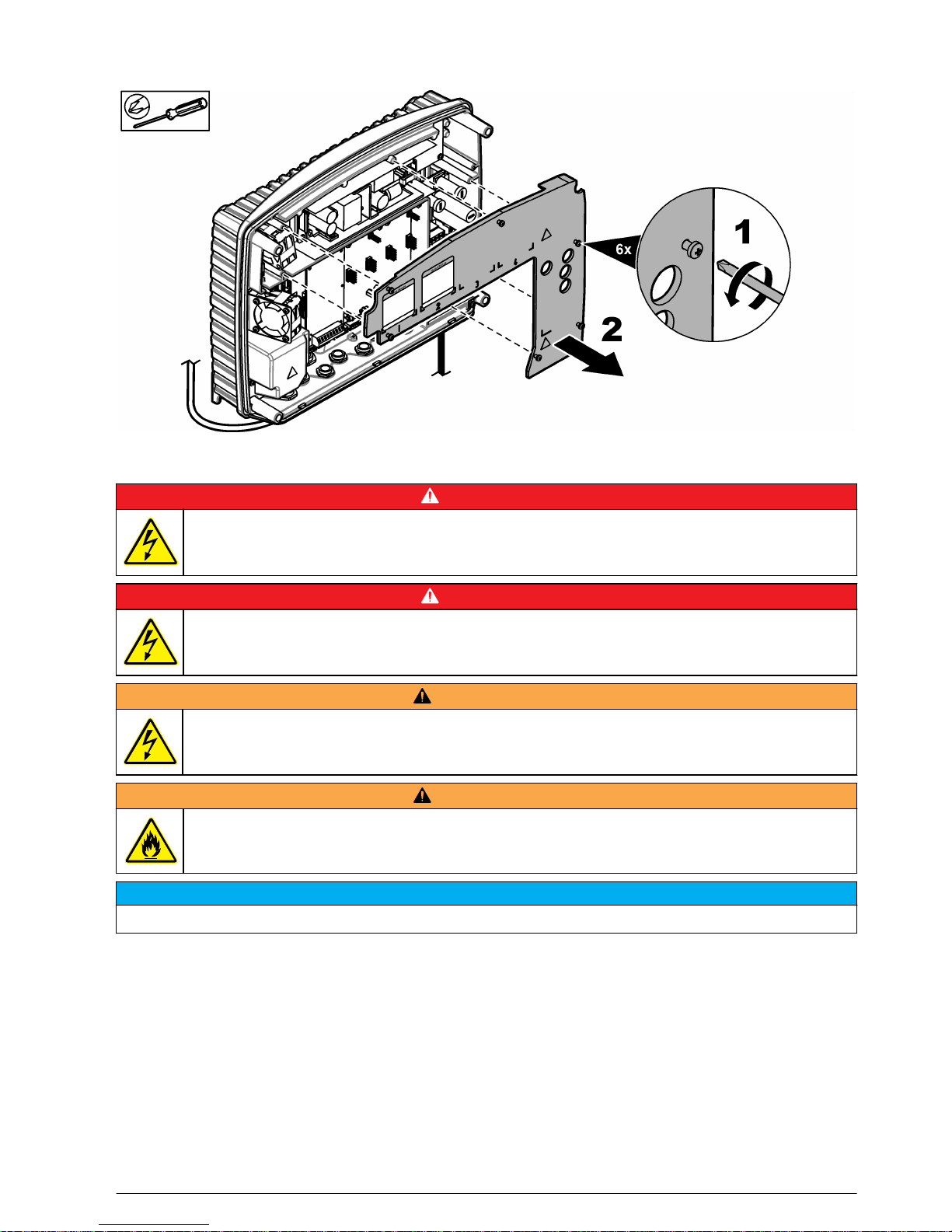

Remove the cover

Remove the cover as shown in the illustrated steps that follow.

High-voltage barrier

High-voltage wiring for the controller is located behind a high-voltage barrier in the controller

enclosure. Do not remove the barrier while power is supplied to the controller. Make sure that the

barrier is installed before power is supplied to the controller.

10

English

Page 11

Remove the high-voltage barrier

Remove the high-voltage barrier as shown in the illustrated steps that follow.

Wiring for power

D A N G E R

Electrocution hazard. Protective Earth Ground (PE) connection is required.

D A N G E R

Electrical shock and fire hazards. Make sure to identify the local disconnect clearly for the conduit

installation.

W A R N I N G

Potential Electrocution Hazard. If this equipment is used outdoors or in potentially wet locations, a

Ground Fault Interrupt device must be used for connecting the equipment to its mains power source.

W A R N I N G

Electrical shock and fire hazards. Make sure that the user-supplied power cord and non‐locking plug

meet the applicable country code requirements.

N O T I C E

Install the device in a location and position that gives easy access to the disconnect device and its operation.

Supply power to the instrument with conduit or a power cable. Make sure that a circuit breaker with

sufficient current capacity is installed in the power line. The circuit breaker size is based on the wire

gauge used for installation.

For installation with conduit:

• Install a local disconnect for the instrument within 3 m (10 ft) of the instrument. Put a label on the

disconnect that identifies it as the main disconnect device for the instrument.

• Make sure that the power and safety ground service drops for the instrument are 1.5 mm2 (15

AWG) (and the wire insulation is rated for 300 VAC or higher and 70 °C (158 °F) minimum.

• Connect equipment in accordance with local, state or national electrical codes.

English

11

Page 12

• Connect the conduit through a conduit hub that holds the conduit securely and seals the enclosure

when tightened.

• If metal conduit is used, make sure that the conduit hub is tightened so that the conduit hub

connects the metal conduit to safety ground.

For installation with a power cable, make sure that the power cable is:

• Less than 3 m (10 ft) in length

• Rated sufficient for the supply voltage and current.

• Rated for at least 70 °C (158 °F) and applicable to the installation environment

• Not less than 1.5 mm2 (15 AWG) with applicable insulation colors for local code requirements

• A power cable with a three-prong plug (with ground connection) that is applicable to the supply

connection

• Connected through a cable gland (strain relief) that holds the power cable securely and seals the

enclosure when tightened

• Does not have a locking type device on the plug

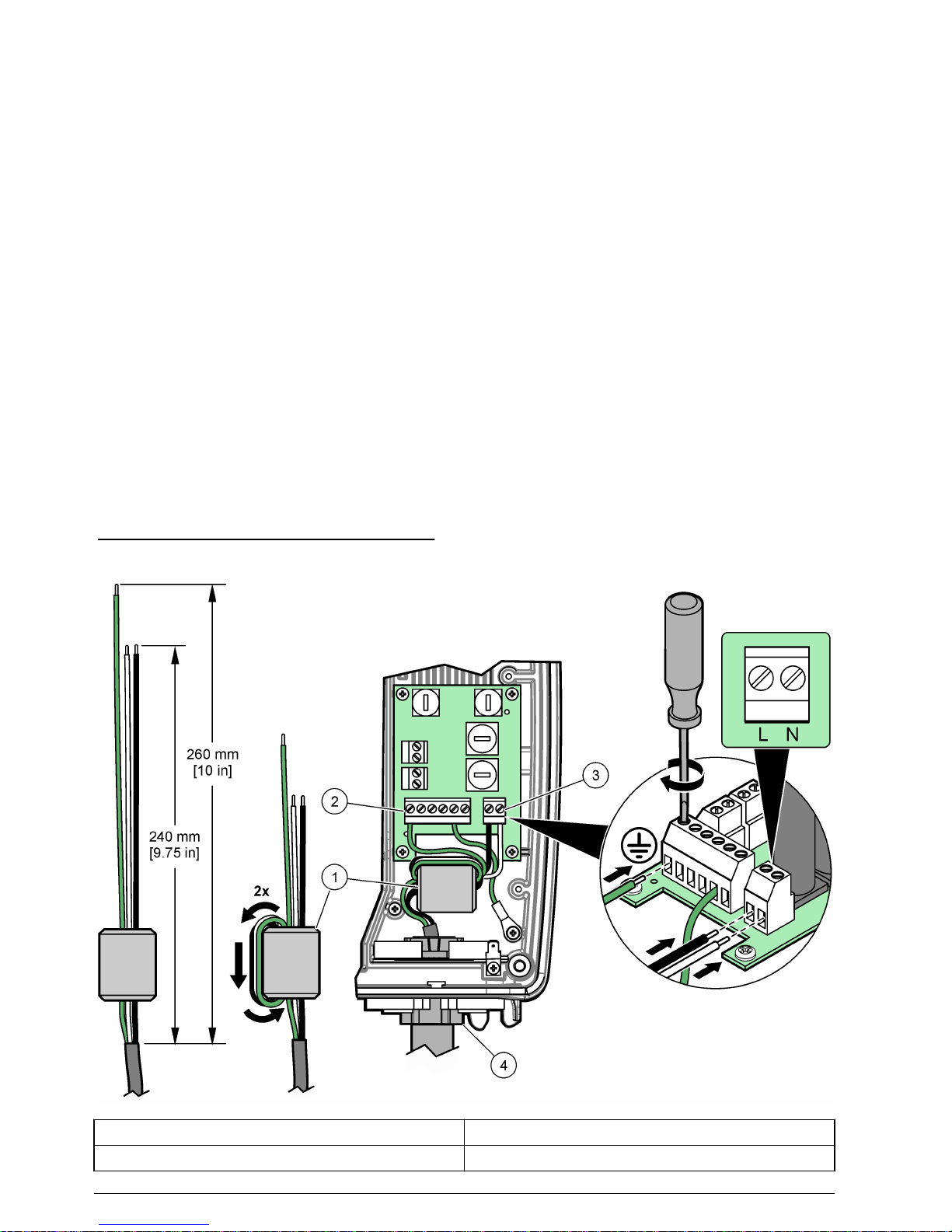

Connect conduit or a power cord

The controller can be wired for line power by hard-wiring in conduit or wiring to a power cord.

Regardless of the wire used, the connections are made at the same terminals.

Refer to Figure 7 and Table 3 to connect conduit or a power cord. Insert each wire into the

appropriate terminal until the insulation is seated against the connector with no bare wire exposed.

Tug gently after insertion to make sure that there is a secure connection.

After the power connections are made, install the high-voltage barrier.

Figure 7 Connect conduit or a power cord

1 Ferrite core 3 AC power terminal

2 Protective earth ground terminal 4 Conduit hub (or strain relief fitting for power cord)

12 English

Page 13

Table 3 Wiring information—AC power

Terminal Description Color—North America Color—EU

L Hot (L1) Black Brown

N Neutral (N) White Blue

Protective earth ground Green Green with yellow stripe

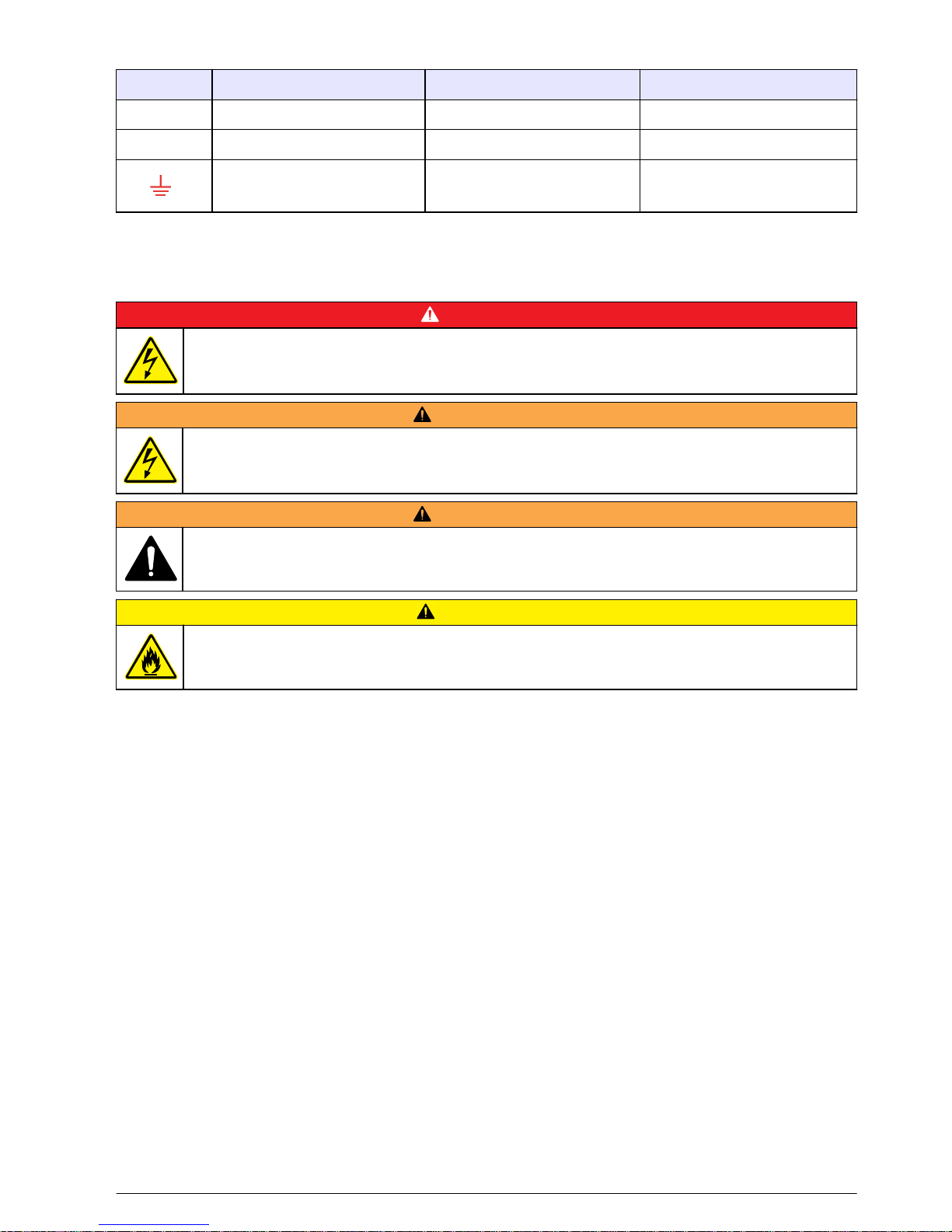

Expansion card connections

Connect the relays (optional)

D A N G E R

Electrocution hazard. Always remove power to the instrument before making electrical connections.

W A R N I N G

Potential Electrocution Hazard. Power and relay terminals are designed for only single wire termination.

Do not use more than one wire in each terminal.

W A R N I N G

Potential fire hazard. Do not daisy-chain the common relay connections or jumper wire from the mains

power connection inside the instrument.

C A U T I O N

Fire hazard. Relay loads must be resistive. Always limit current to the relays with an external fuse or

breaker. Obey the relay ratings in the Specifications section.

If the instrument has the optional relay card, the instrument has four non-powered, double-pole

relays. Each relay changes state when the selected trigger condition for the relay occurs.

The relay terminals are located behind a high-voltage barrier in the controller enclosure. Do not

remove the barrier while power is supplied to the relay terminals. Do not supply power to the relay

terminals when the barrier is not installed.

Connect each relay to a control device or an alarm device as necessary. Refer to the illustrated steps

that follow and Table 4 to connect the relays. Use the mobile application to select the trigger

condition for each relay.

Refer to Specifications on page 3 for the relay specifications. The relays are isolated from each other

and the low-voltage input/output circuitry.

The relay terminals accept 15 AWG wire (as determined by load application). Use wire with an

insulation rating of 300 VAC or higher. Wire gauge other than 15 AWG is not recommended.

The current to the relay contacts must be 5 A or less. Make sure to have a second switch available to

remove power from the relays locally in case of an emergency or for maintenance.

When switching large inductive loads (e.g., motors and pumps) or currents higher than 5 A, use an

auxiliary relay to extend the relay life.

Use the relays at either all high voltage (greater than 30 V-RMS and 42.2 V-PEAK or 60 VDC) or all

low voltage (less than 30 V-RMS and 42.2 V-PEAK, or less than 60 VDC). Do not configure a

combination of both high and low voltage.

English

13

Page 14

Relay terminal connections to the mains circuit in permanent connection applications must have

insulation rated for a minimum of 300 V, 70 °C (158 °F). Terminals connected to the mains circuit

with a power cord connection must be double insulated and rated 300 V, 70 °C (158 °F) at both the

inner and outer insulation levels.

Table 4 Wiring information—relays

Terminal Description Terminal Description

1 Relay 1, NC 7 Relay 3, NC

2 Relay 1, common 8 Relay 3, common

3 Relay 1, NO 9 Relay 3, NO

4 Relay 2, NC 10 Relay 4, NC

5 Relay 2, common 11 Relay 4, common

6 Relay 2, NO 12 Relay 4, NO

NC = normally closed; NO = normally open

14 English

Page 15

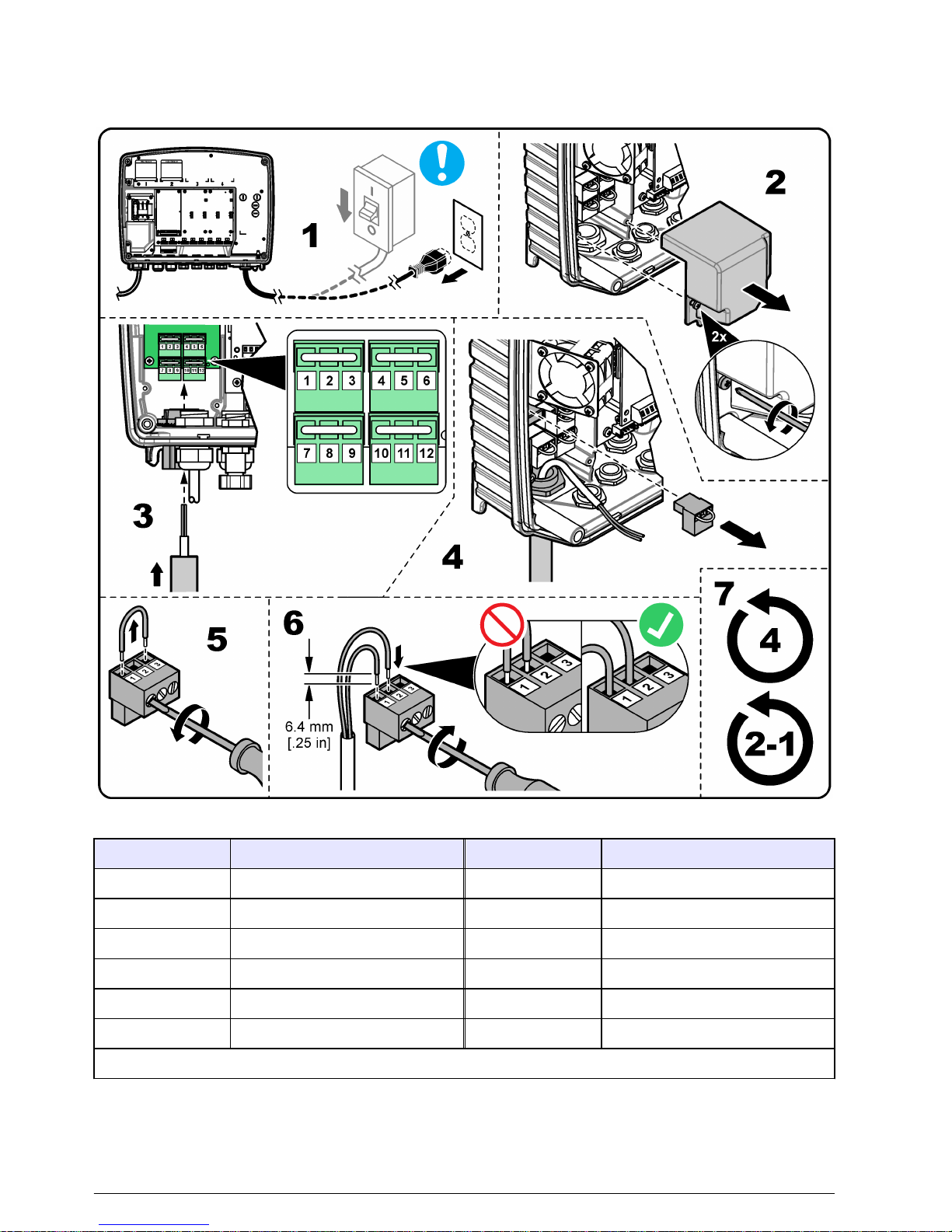

Connect the analog outputs (optional)

D A N G E R

Electrocution hazard. Always remove power to the instrument before making electrical connections.

If the instrument has the optional analog output card, the instrument has four 4–20 mA analog

outputs. Such outputs are commonly used for analog signaling or to control other external devices.

Connect each analog output to an external device as necessary. Refer to Figure 8 and Table 5 to

connect the analog outputs. Use the mobile application to configure each of the analog outputs to

agree with a measured parameter (e.g., pH or temperature).

Make connections with twisted-pair shielded wire and connect the shield to the shield terminal.

• Do not connect the shield at both ends of the cable.

• Use of non-shielded cable may result in radio frequency emission or susceptibility levels higher

than allowed.

• Maximum loop resistance is 500 Ω.

Notes:

• The analog output terminals accept 15 to 26 AWG wire.

• The analog outputs are isolated from the other electronics, but are not isolated from each other.

• The analog outputs are self-powered. Do not connect to a load with voltage that is independently

applied.

• The analog outputs cannot be used to supply power to a 2-wire (loop-powered) transmitter.

Figure 8 Connect the analog outputs

1 Wiring information—analog outputs 3 Analog output terminal

2 Analog output card

Table 5 Wiring information—analog outputs

Terminal Description Terminal Description

1 Output 1+ 6 Output 3–

2 Output 1– 7 Output 4+

3 Output 2+ 8 Output 4–

English 15

Page 16

Table 5 Wiring information—analog outputs (continued)

Terminal Description Terminal Description

4 Output 2– 9 Shield (connected to protective earth)

5 Output 3+

Connect the analog/digital inputs

D A N G E R

Electrocution hazard. Always remove power to the instrument before making electrical connections.

If the instrument has the optional input card, the instrument has four 4–20 mA inputs. Such inputs are

commonly used for looping in external devices' analog or digital signals.

Connect each external device to an input as necessary. Refer to Figure 9 to connect the inputs. Use

the mobile application to configure each of the inputs to agree with a measured parameter (e.g. flow).

Make connections with twisted-pair shielded wire and connect the shield to the shield terminal.

• Do not connect the shield at both ends of the cable.

• Use of non-shielded cable may result in radio frequency emission or susceptibility levels higher

than allowed.

Notes:

• The input terminals accept 15 to 26 AWG wire.

• The inputs are isolated from the other electronics, but are not isolated from each other.

Figure 9 Connect the inputs

1 Wiring information—inputs 3 Input terminal

2 Input card

For wiring information, refer to the SC1000 user manual, section 3.6.2 Input Card Connections.

Install the Profibus DP card

Refer to the applicable probe manual for operating instructions and instrument profiles. Refer to the

company web site for the latest GSD files and documentation.

To connect the Profibus DP card to the SC controller, refer to the SC controller Profibus

DP/V1 network card documentation. Install the Profibus card. Refer to Figure 10 and Table 6.

16

English

Page 17

After the plug-in expansion card is installed and connected, configure the card. Refer to the

documentation supplied with the Profibus DP card.

Figure 10 Profibus DP card (YAB103 since December 2013) connections

1 Wiring information—Profibus outputs 4 Network termination activated–last device on

network

2 Profibus DP card 5 Network termination deactivated–other devices on

network after this device

3 Terminal Block–Refer to Table 6 for terminal

assignments

Table 6 Profibus DP card (YAB103) terminal descriptions

Terminal Description Wire color

1 B2 out Red

2 A2 out Green

3 5 V Not used

4 0 V Not used

5 B1 in Red

6 A1 in Green

Remove an expansion card

Remove an expansion card if the probe connectors are blocked. Refer to the SC controller Profibus

DP/V1 network card documentation.

Note: The compact connectors are a very tight fit and the connections can easily break. Do not apply too much

force to remove the compact connectors.

1. Delete the card in the SC controller.

2. Remove power from the instrument.

3. Remove the probe module cover. Refer to Remove the cover on page 10

4. Disconnect all of the wires from the card.

English

17

Page 18

5. Remove the screws on the card.

6. Remove the card.

To replace and configure the card, provide the Profibus DP address and the cyclic Profibus DP

telegram to a Hach service technician.

Install the cover

Connect the ground wire for the cover to the controller, then install the instrument cover. Refer to

Remove the cover on page 10.

Make sure that the cover screws are tight to keep the environmental rating.

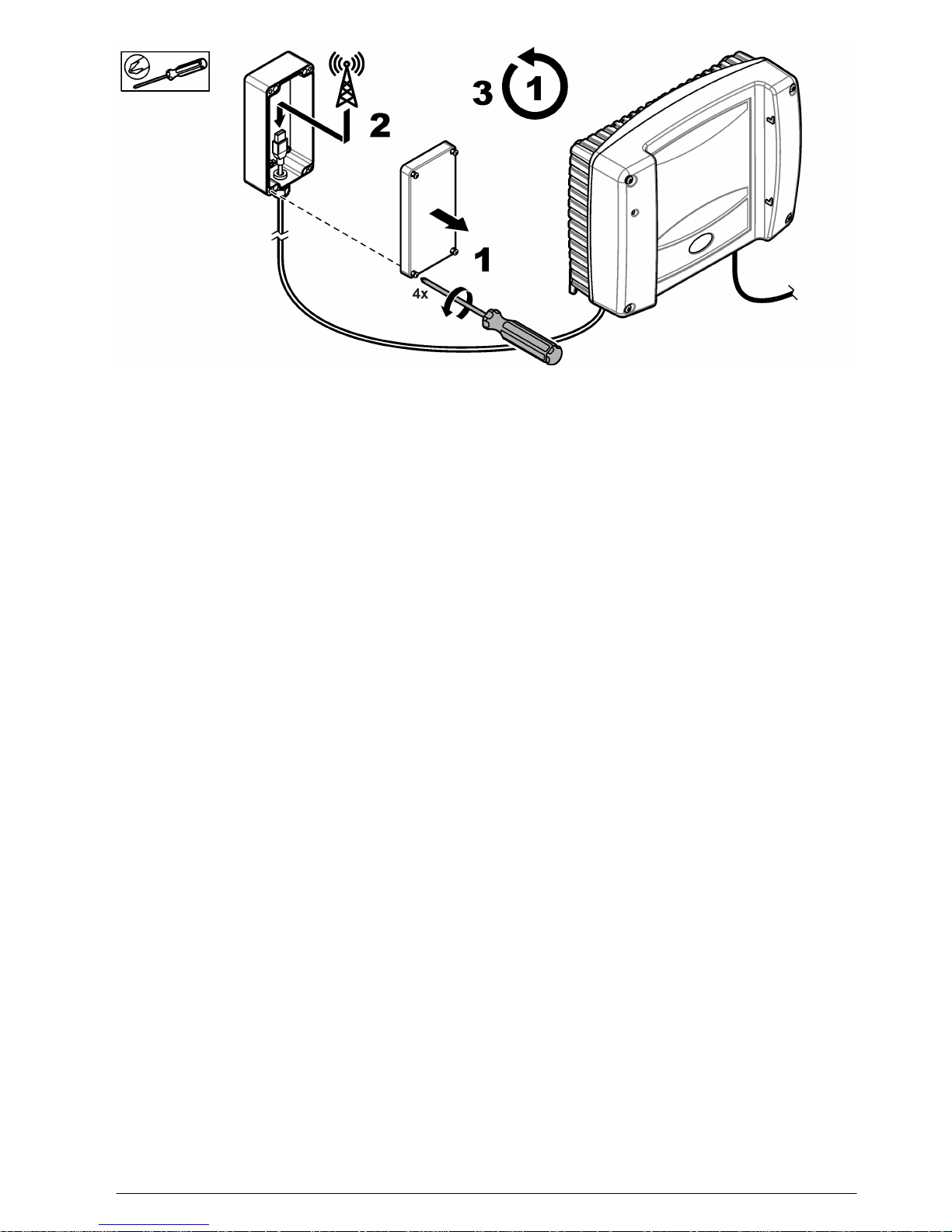

Connect measurement devices

Connect digital devices (e.g., sensors and analyzers) to the device connectors on the instrument.

Refer to Figure 11. Keep the device connector caps for future use.

Make sure that the device cables do not cause a trip hazard and do not have sharp bends.

If a measurement device has two cables, connect the second cable to an AC power outlet on the

instrument. Refer to Figure 6 on page 9. The voltage and current available at the AC power outlets is

the same as the power supplied to the instrument. Make sure that the power supplied is within the

power requirements of the device.

Note: The AC power outlets only supply power when the instrument has the optional 100 to 240 VAC power supply.

Figure 11 Connect a device

Connect to a cellular network

Connect the instrument to a cellular network with the USB connector in the USB box. Refer to the

illustrated steps that follow.

After the cover is installed, make sure that the screws are tight to keep the environmental rating.

18

English

Page 19

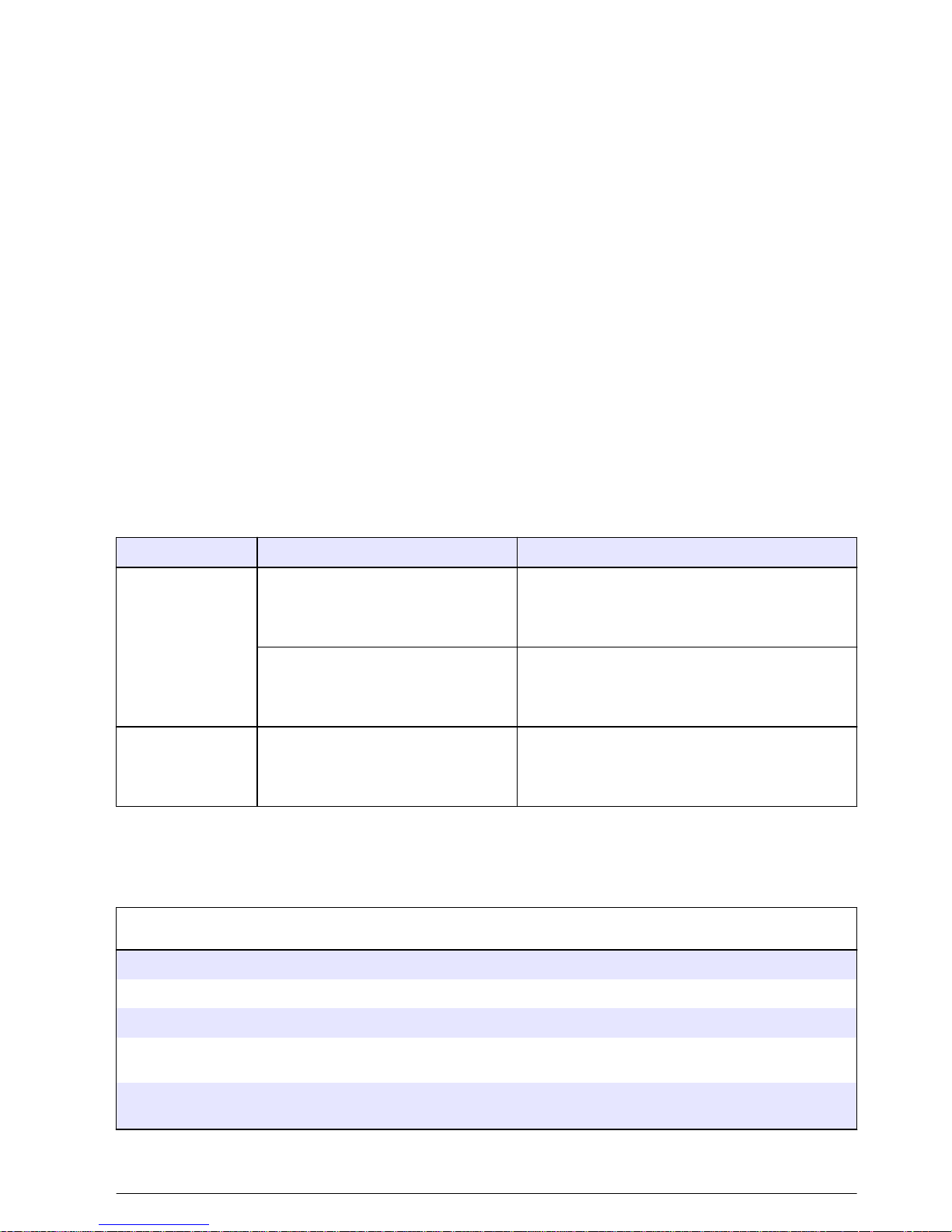

Modbus TCP/IP expansion

Modbus TCP/IP is a standard for industrial communications. The Modbus TCP/IP protocol connects

computers to measurement and control systems that use the TCP/IP protocol for data transmission.

This type of data transmission is known as machine to machine (M2M) communication.

The Modbus TCP/IP software module enables the controller to be integrated directly in

programmable logic controller (PLC) systems. PLC systems record and process the controller

measured data. The data analysis and the procedures caused by the results are programmed in the

PLC system.

Note: To use the Modbus TCP/IP software module, make sure that there is no Modbus card installed on the

controller.

Connect the controller to the external USB box. Refer to the documentation supplied with the USB

box. It is possible to daisy chain controllers. Refer to Figure 12. When a modem or WiFi stick is

connected at the USB box, this channel connects the controller to the internet. Thus, it is not possible

to connect the controller with the modem to the internet and to operate Modbus TCP with WiFi at the

same time; the USB box has only one USB slot. In such situation, Modbus TCP/IP can only operate

with the ethernet LAN connector (ethernet M12 connector). Table 7 shows the Internet and Modbus

TCP/IP possible connections combinations.

When only one controller is used, only the right M12 connector is used to connect to the PLC/internet

(left connector is not used). When daisy chain is used, always connect the right M12 connector with

the left M12 connector of the next controller. The daisy chained controller connected to PLC/internet

uses the right M12 connector for PLC/internet connection.

English

19

Page 20

Figure 12 Connection diagram

1 USB Box 3 PLC system

2 Controller

Table 7 Internet and Modbus TCP/IP connections combinations

LAN (M12 socket)

USB Box

WiFi Modem

Internet X X X

Modbus TCP/IP X X —

Startup

Connect the power cord to an electrical outlet with protective earth ground or set the circuit breaker

for the controller to on.

Operation

Use the MSM software to interact with the connected measurement devices. Contact Hach Technical

Support to get a Claros Mobile Sensor Management account for the first time.

Note: Refer to the manufacturer's website to find more information about the MSM software.

1. Open an internet browser, then enter the correct URL:

• US: https://us.fsn.hach.com

• EU: https://eu.fsn.hach.com

2. Enter login information to:

• Receive the status and measurement information about measurement devices.

• Configure and calibrate measurement devices.

• Get access to interactive, step-by-step maintenance guides.

Maintenance

N O T I C E

Do not disassemble the instrument for maintenance. If the internal components must be cleaned or repaired,

contact the manufacturer.

20 English

Page 21

Clean the instrument

Clean the exterior of the instrument with a moist cloth and a mild soap solution and then wipe the

instrument dry as necessary.

Fuse replacement

The fuse is a not a user-serviceable item. Contact technical support. A blown fuse can be an

indication that the instrument has a problem and that service is necessary.

Prepare for storage or shipping

Before long-term storage or shipping, prepare the controller as follows:

1. Use the mobile application to save all the important data on the controller to a storage device.

Note: All the factory and user settings are saved on the I/O cards in the controller.

2. Remove power to the controller.

3. Disconnect all the external devices that are connected to the controller.

4. Remove the USB box from the wall or pole.

5. Remove the controller from the wall, panel or pole.

6. Put the controller and USB box in a protective film or dry cloth. Keep the controller and USB box

in a dry location.

Troubleshooting

Problem Possible cause Solution

The status indicator

light flashes red.

There is a communication failure

between the controller and one or

more of the attached measurement

devices.

Make sure that the measurement device is

connected to the controller.

Damage has occurred to an attached

measurement device or the device

cable.

Examine the measurement device and the device

cable for damage. Make sure that the

measurement device is operational. If damage is

found, contact technical support.

The status indicator

light is off.

Power is not supplied to the controller

or there is a blown fuse.

Make sure that there is power to the controller.

If there is power, remove power to the controller

and identify if there is a blown fuse. If a blown fuse

is found, contact technical support.

Accessories

Note: Product and Article numbers may vary for some selling regions. Contact the appropriate distributor or refer to

the company website for contact information.

Description Item no.

GSM modem kit LZY971

Wi-Fi adapter US LZY996

Wi-Fi adapter EU LZY997

Panel mounting kit, sc1500, includes:

Bracket, strain relief fitting and digital extension cable

6169900

Pole mounting kit with sunshield, sc1500, includes:

Sunshield, ground base, pole, screw set and mounting plate

LZX957

English 21

Page 22

Accessories (continued)

Description Item no.

Wall mounting kit with sunshield, includes:

Sunshield, bracket, bolts (4x), nuts (4x) and washers (4x)

LZX958

Pole mounting hardware for sunshield, includes:

Mounting feet (8x), screws (4x), bolts (12x), washers (8x), nuts (4x) and anchors (4x)

LZX948

Power cable, China LZY393

Power cable, Great Britain LZY394

Power cable, European Union LZY395

Power cable, United States LZY396

Digital extension cable, measurement device, 10 m (32.8 ft) LZX849

Digital extension cable, measurement device, 20 m (65.6 ft) LZX851

22 English

Page 23

Table des matières

Caractéristiques à la page 23 Fonctionnement à la page 42

Généralités à la page 24 Maintenance à la page 42

Installation à la page 27 Dépannage à la page 43

Mise en marche à la page 42 Accessoires à la page 43

Caractéristiques

Les caractéristiques techniques peuvent être modifiées sans préavis.

Caractéristique Détails

Dimensions (l x P x H) Transmetteur : 315 x 120 x 242 mm (12,28 x 4,68 x 9,5 po)

Boîtier USB : 79,5 x 55,1 x 159,5 mm (3,13 x 2,17 x 6,28 po)

Boîtier Transmetteur : métal avec surface résistance à la corrosion, classification

NEMA 4X/IP65

Boîtier USB : ABS/polycarbonate, classification NEMA 4X/IP65

Poids Environ 5 kg (11 livres). Le poids varie en fonction des modèles.

Niveau de pollution 2

Catégorie de surtension II

Classe de protection I

Alimentation requise 100 à 240 V CA ± 10 V CA, 50/60 Hz, 1000 VA maximum

Fusible F1 et F2 : M 3,5 A L, 250 V ou T 3,15 A L, 250 V ; F3 et F4 : T 8 A H, 250 V

Température de fonctionnement -20 à 55 °C (-4 à 131 °F)

Température de stockage -20 à 70 °C (–4 à 158 °F)

Humidité 95 % d'humidité relative, sans condensation

Altitude 2000 m (6561 pieds)

Connexions d'un appareil de

mesure

Deux, quatre ou six connecteurs d'appareil et deux prises d'alimentation CA

1

Connexions réseau Deux connecteurs Ethernet (10/100 Mbit/s), fonction de commutation,

connecteur M12 femelle code D

Un connecteur USB dans un boîtier USB

Carte de relais (en option) Quatre relais sur chaque carte de relais, contacts inverseurs (SPDT)

Tension par découpage maximale : 250 V c.a., 125 V c.c.

Courant maximal de commutation : 5 A

Remarque : Veillez à installer le disjoncteur externe 5 A.

Puissance maximum de commutation : 1 500 VA, 250 V CA, 625 W, 125 V

CC

Calibre de fil : 1,5 mm2 (15 AWG) maximum

Carte de sortie analogique (en

option)

Quatre sorties analogiques 4-20 mA sur chaque carte de sortie analogique,

500 Ω maximum

Section de fil : 1,5 mm2 (15 AWG) maximum

Le fabricant recommande d'utiliser des câbles de signal blindés.

1

Les prises d'alimentation CA n'alimentent l'instrument que si l'alimentation facultative de 100 à

240 V CA est installée.

Français 23

Page 24

Caractéristique Détails

Certification Compatible cTUVus, compatible CE, protection contre surtensions DIN EN

61326

Garantie 1 an (UE : 2 ans)

Généralités

En aucun cas le constructeur ne saurait être responsable des dommages directs, indirects, spéciaux,

accessoires ou consécutifs résultant d'un défaut ou d'une omission dans ce manuel. Le constructeur

se réserve le droit d'apporter des modifications à ce manuel et aux produits décrits à tout moment,

sans avertissement ni obligation. Les éditions révisées se trouvent sur le site Internet du fabricant.

Consignes de sécurité

A V I S

Le fabricant décline toute responsabilité quant aux dégâts liés à une application ou un usage inappropriés de ce

produit, y compris, sans toutefois s'y limiter, des dommages directs ou indirects, ainsi que des dommages

consécutifs, et rejette toute responsabilité quant à ces dommages dans la mesure où la loi applicable le permet.

L'utilisateur est seul responsable de la vérification des risques d'application critiques et de la mise en place de

mécanismes de protection des processus en cas de défaillance de l'équipement.

Veuillez lire l'ensemble du manuel avant le déballage, la configuration ou la mise en fonctionnement

de cet appareil. Respectez toutes les déclarations de prudence et d'attention. Le non-respect de

cette procédure peut conduire à des blessures graves de l'opérateur ou à des dégâts sur le matériel.

Assurez-vous que la protection fournie avec cet appareil n'est pas défaillante. N'utilisez ni n'installez

cet appareil d'une façon différente de celle décrite dans ce manuel.

Interprétation des indications de risques

D A N G E R

Indique une situation de danger potentiel ou imminent qui entraînera la mort ou de graves blessures si elle n'est

pas évitée.

A V E R T I S S E M E N T

Indique une situation de danger potentiel ou imminent qui peut entraîner la mort ou de graves blessures si elle

n'est pas évitée.

A T T E N T I O N

Indique une situation de danger potentiel qui peut entraîner des blessures mineures ou modérées.

A V I S

Indique une situation qui, si elle n'est pas évitée, peut occasionner l'endommagement du matériel. Informations

qui doivent être soulignées.

Étiquettes de mise en garde

Lisez toutes les informations et toutes les étiquettes apposées sur l’appareil. Des personnes peuvent

se blesser et le matériel peut être endommagé si ces instructions ne sont pas respectées. Tout

symbole sur l'appareil renvoie à une instruction de mise en garde dans le manuel.

Ceci est le symbole d'alerte de sécurité. Respectez tous les messages de sécurité qui suivent ce

symbole afin d'éviter tout risque de blessure. S'ils sont apposés sur l'appareil, se référer au manuel

d'utilisation pour connaître le fonctionnement ou les informations de sécurité.

Ce symbole indique qu'il existe un risque de choc électrique et/ou d'électrocution.

24 Français

Page 25

Ce symbole indique la présence d'appareils sensibles aux décharges électrostatiques et indique que

des précautions doivent être prises afin d'éviter d'endommager l'équipement.

Le matériel électrique portant ce symbole ne doit pas être mis au rebut dans les réseaux domestiques

ou publics européens. Retournez le matériel usé ou en fin de vie au fabricant pour une mise au rebut

sans frais pour l'utilisateur.

Ce symbole, s'il figure sur le produit, indique l’emplacement d’un fusible ou d'un dispositif limiteur de

courant.

Ce symbole indique que l'élément marqué nécessite une connexion de protection à la terre. Si

l'appareil n'est pas fourni avec une mise à la terre sur un cordon, effectuez la mise à la terre de

protection sur la borne de conducteur de protection.

Présentation du produit

A V I S

La sécurité du réseau et du point d'accès relève de la responsabilité du client utilisant l'appareil sans fil. Le

fabricant ne peut être tenu pour responsable des dommages, y compris mais sans s'y limiter, indirects,

particuliers, fortuits ou accessoires occasionnés en raison d'une brèche dans la sécurité du réseau ou d'une

violation de la sécurité du réseau.

Le transmetteur sc1500 est destiné aux appareils d'analyse numérique, tels que les capteurs et les

analyseurs. Reportez-vous à la section Figure 1.

Le transmetteur est disponible avec des relais et des sorties analogiques en option (4-20 mA). Les

relais en option permettent de contrôler les appareils externes (p. ex., contrôle des appareils et des

appareils d'alarme). Les sorties analogiques servent à transmettre les mesures aux appareils

externes.

Le transmetteur est configuré et piloté par une application mobile sur un appareil iOS® ou Android

®

fourni par le client et disposant d'un navigateur Internet et d'une connexion à Internet. Le

transmetteur communique sur un réseau local (LAN), Wi-Fi ou cellulaire.

Français

25

Page 26

Figure 1 Présentation du produit

1 Connecteur USB (reportez-vous à Connexion à un

réseau cellulaire à la page 40)

5 Patte de fixation pour montage mural

2 Boîtier USB 6 Trous pour montage sur poteau

3 Voyant d'état (reportez-vous à Tableau 1) 7 Cordon d'alimentation (ou raccord de conduite)

4 Transmetteur sc1500 8 Connecteurs électriques et fixations (reportez-vous

à Figure 6 à la page 30)

Tableau 1 Voyant d'état

Couleur Etat

Vert Fonctionnement normal

Rouge Un problème de communication s'est produit entre le transmetteur et au moins l'un des appareils de

mesure connectés. Reportez-vous à la section Dépannage à la page 43.

Composants du produit

Assurez-vous d'avoir bien reçu tous les composants. Reportez-vous à la section Figure 2. Si des

éléments manquent ou sont endommagés, contactez immédiatement le fabricant ou un représentant

commercial.

26

Français

Page 27

Figure 2 Composants du produit

1 Transmetteur sc1500 3 Accessoires de montage sur poteau pour le boîtier

USB

2

2 Fixation avec protecteur de cordon (quantité

variable)

Installation

Installation mécanique

Installation du transmetteur

Fixez le transmetteur à la verticale et alignez-le sur une surface plane verticale. Reportez-vous aux

procédures présentées à la Figure 3. Installez le transmetteur à un endroit où le dispositif de

sectionnement du transmetteur est facilement accessible.

La visserie de montage est fournie par l'utilisateur. Vérifiez que le montage mural est capable de

supporter 4 fois le poids de l'équipement.

Sinon, fixez l'instrument sur un panneau, un poteau vertical ou horizontal. Reportez-vous à la feuille

d'instructions fournie avec le kit de montage en option.

Remarque : Le pare-soleil est facultatif, mais recommandé, pour toutes les installations extérieures.

2

Les accessoires sont destinés au montage sur un poteau de 40 mm (1,57 po) de diamètre.

Français 27

Page 28

Figure 3 Montage mural : transmetteur

Installation du boîtier USB

Installez le boîtier USB à un emplacement où le signal cellulaire est aussi fort que possible. Utilisez

un appareil mobile avec le même fournisseur de service cellulaire que le transmetteur sc1500 pour

identifier l'emplacement ayant la plus forte puissance cellulaire.

Installez le boîtier USB à un endroit où le dispositif de sectionnement du transmetteur est facilement

accessible.

Fixez le boîtier USB sur un mur, ou sur un poteau vertical ou horizontal. Reportez-vous aux

procédures illustrées dans la Figure 4 ou la Figure 5. Les accessoires de montage pour un poteau de

40 mm (1,57 po) sont fournis avec l'instrument. Le matériel de montage mural est fourni par

l'utilisateur.

Figure 4 Montage mural : boîtier USB

28 Français

Page 29

Figure 5 Montage sur poteau : boîtier USB

Installation électrique

Connecteurs électriques et fixations

La section Figure 6 illustre les connecteurs électriques et les fixations de l'instrument. La section

Tableau 2 montre les appareils de raccordement compatibles avec l'instrument. Utilisez uniquement

les appareils agréés par le fabricant indiqués dans le Tableau 2.

Afin d'assurer la classification environnementale du boîtier, assurez-vous que les fixations avec

protecteur de cordon qui ne sont pas utilisées soient bouchées et que les connecteurs inutilisés sont

protégés par un capot.

Français

29

Page 30

Figure 6 Connecteurs électriques et fixations

1 Connecteur large pour relais : conduite de 2,19 mm

ou câble de diamètre 9 à 13,5 mm

5 Prises d'alimentation CA

4

2 Câble du boîtier USB 6 Cordon d'alimentation (ou raccord de conduite)

3 Connecteurs d'appareil

3

7 Connecteurs Ethernet

5

4 Fixations avec protecteur de cordon pour la carte de

sortie analogique ou pour la carte Profibus, câble de

5 à 6 mm de diamètre

Tableau 2 Appareils de raccordement agréés par le fabricant

Appareils Description Consommation

électrique par

appareil

Raccordement au

transmetteur

A/N-ISE sc Pour les appareils à faible

consommation électrique, une

consommation totale de 60 W est

autorisée.

< 3,5 W Utilisez le connecteur de

l'appareil. Reportez-vous à la

Figure 6, repère 3.

LDO sc

SOLITAX sc

NITRATAX sc

SONATAX sc

pHD (pH et

Redox)

AMTAX sc Pour les appareils à faible

consommation électrique, une

consommation totale de 1 000 VA

est autorisée.

< 500 W Utilisez les sorties d'alimentation

secteur. Reportez-vous à la

Figure 6, repère 5.

PHOSPHAX sc

3

Le nombre de connecteurs d'appareil et de fixations avec protecteur de cordon varie en fonction

du modèle.

4

Les prises d'alimentation CA n'alimentent l'instrument que si l'alimentation facultative de 100 à

240 V CA est installée.

5

Connecteur M12 droit utilisé pour MODBUS TCP/IP. Connecteur M12 gauche utilisé pour la

connexion en guirlande des contrôleurs. Reportez-vous à la Extension Modbus TCP/IP

à la page 41.

30 Français

Page 31

Remarques relatives aux décharges électrostatiques (ESD)

A V I S

Dégât potentiel sur l'appareil Les composants électroniques internes de l'appareil peuvent être

endommagés par l'électricité statique, qui risque d'altérer ses performances et son fonctionnement.

Reportez-vous aux étapes décrites dans cette procédure pour éviter d'endommager l'appareil par

des décharges électrostatiques.

• Touchez une surface métallique reliée à la terre (par exemple, le châssis d'un appareil, un conduit

ou un tuyau métallique) pour décharger l'électricité statique de votre corps.

• Evitez tout mouvement excessif. Transportez les composants sensibles à l'électricité statique dans

des conteneurs ou des emballages antistatiques.

• Portez un bracelet spécial relié à la terre par un fil.

• Travaillez dans une zone à protection antistatique avec des tapis de sol et des sous-mains

antistatiques.

Branchements électriques

D A N G E R

Dangers multiples. Seul le personnel qualifié doit effectuer les tâches détaillées dans cette section du

document.

D A N G E R

Risque d'électrocution. Débranchez systématiquement l'alimentation de l'appareil avant d'effectuer

toute connexion électrique.

Si le transmetteur n'est pas fourni avec un cordon d'alimentation, utilisez une conduite ou un câble

d'alimentation pour le raccorder au secteur. Reportez-vous aux sections suivantes pour connecter

l'alimentation avec une conduite ou un câble d'alimentation.

Retrait du panneau

Retirez le panneau comme indiqué sur les étapes illustrées ci-dessous.

Français

31

Page 32

Barrière de protection haute tension

Les câbles haute tension du transmetteur sont situés derrière la barrière haute tension, dans le

boîtier du transmetteur. Ne retirez pas l'écran lorsque le transmetteur est sous tension. Assurez-vous

que l'écran est installé avant de mettre le transmetteur sous tension.

Retrait de l'écran de protection contre les hautes tensions

Retirez l'écran de protection contre les hautes tensions comme indiqué dans les étapes illustrées cidessous.

Câblage pour l'alimentation

D A N G E R

Risque d'électrocution. Un raccordement à la terre est nécessaire.

D A N G E R

Risques de choc électrique et d'incendie. Assurez-vous d'identifier clairement l'emplacement du

dispositif de déconnexion local pour l'installation du conduit.

A V E R T I S S E M E N T

Risque potentiel d'électrocution Si cet équipement est utilisé à l'extérieur ou dans des lieux

potentiellement humides, un dispositif de disjoncteur de fuite à la terre doit être utilisé pour le

branchement de l'équipement à sa source d'alimentation secteur.

A V E R T I S S E M E N T

Risques de choc électrique et d'incendie. Assurez-vous que le cordon et la fiche non verrouillable

fournis par l'utilisateur sont conformes aux normes du pays concerné.

A V I S

Installez l'appareil dans un emplacement et une position permettant d'accéder facilement à l'appareil débranché

et à son fonctionnement.

Alimentez l'instrument avec une conduite ou un câble d'alimentation. Assurez-vous qu'un disjoncteur

d'une capacité en courant suffisante est installé dans la ligne d'alimentation. Le calibre du disjoncteur

dépend du calibre des fils utilisés pour l'installation.

32

Français

Page 33

Pour une installation avec gaine :

• Installez un dispositif de coupure local pour l'instrument à moins de 3 m (10 pi) de cet instrument.

Placez une étiquette sur le dispositif de coupure signalant qu'il s'agit du dispositif de coupure

principal pour l'instrument.

• Assurez-vous que les raccordements de l'instrument aux dispositifs d'alimentation et de mise à la

masse de sécurité disposent des caractéristiques minimum de 1.5 mm2 (15 AWG) (et que l'isolant

des fils est prévu pour 300 V C.A. ou plus et 70 °C (158 °F).

• Raccordez l'équipement conformément aux codes électriques locaux ou nationaux.

• Insérez la conduite dans un raccord maintenant fermement la conduite et scellez le boîtier une fois

serré.

• En cas d'utilisation d'une conduite métallique, vérifiez le serrage du raccord. Le raccord doit relier

la conduite métallique à la masse de sécurité.

Pour l'installation avec un câble d'alimentation, assurez-vous que le câble d'alimentation présente les

caractéristiques suivantes :

• inférieur à 3 m (10 pi) de long ;

• a une valeur nominale adaptée à la tension et au courant fournis ;

• Résiste au moins à des températures allant jusqu'à 70 °C (158 °F) et est conforme aux conditions

de l'installation ;

• Pas moins de 1.5 mm2 (15 AWG) avec les couleurs d'isolation correspondant aux normes

applicables localement

• câble d'alimentation avec une fiche tripolaire (et prise de terre) conforme à la connexion de

l'alimentation ;

• connecté par un presse-étoupe (protecteur de cordon) qui le maintient en place et scelle le boîtier

lorsqu'il est serré ;

• ne présente pas de dispositif de verrouillage au niveau de la fiche

Connexion à un conduit ou câble d'alimentation

Le transmetteur peut être connecté à l'alimentation électrique par passage des câbles dans un

conduit ou par connexion à un câble d'alimentation. Quel que soit le câble utilisé, les connexions

sont effectuées au niveau des mêmes bornes.

Voir la Figure 7 et la Tableau 3 pour la connexion à un conduit ou un câble d'alimentation. Insérez

chaque câble dans la borne correspondante jusqu'à ce que l'isolant touche le connecteur, de sorte à

ne laisser aucune partie dénudée visible. Tirez légèrement après l'insertion afin de vérifier que le

branchement a été bien effectué.

Une fois les connexions électriques réalisées, installez l'écran de protection contre les hautes

tensions.

Français

33

Page 34

Figure 7 Connexion à un conduit ou câble d'alimentation

1 Bobine 3 Borne d'alimentation CA

2 Borne de mise à la terre pour protection 4 Raccord de conduite (ou fixation avec protecteur

pour le cordon d'alimentation)

Tableau 3 Informations de câblage : alimentation CA

Borne Description Couleur (Amérique du Nord) Couleur (UE)

l Phase (L1) Noir Marron

N Neutre (N) Blanc Bleu

Mise à la terre de protection Vert Vert avec des bandes jaunes

Connexions de la carte d'extension

Branchement des relais (en option)

D A N G E R

Risque d'électrocution. Débranchez systématiquement l'alimentation de l'appareil avant d'effectuer

toute connexion électrique.

A V E R T I S S E M E N T

Risque potentiel d'électrocution Les bornes d'alimentation et de relais sont conçues pour le

raccordement d'un seul fil. N'utilisez pas plus d'un fil à chaque borne.

34 Français

Page 35

A V E R T I S S E M E N T

Risque d'incendie potentiel Ne raccordez pas en guirlande les connexions relais standard ou le câble

volant à partir de la connexion secteur située dans l'appareil.

A T T E N T I O N

Risque d'incendie. Les charges de relais doivent être résistantes. Limitez toujours le courant vers les

relais avec un fusible ou un disjoncteur externe. Respectez les courants nominaux des relais indiqués

dans la section Spécifications.

Si l'instrument dispose de la carte de relais en option, il a quatre relais bipolaires non alimentés.

Chaque relais change d'état en présence de la situation de déclenchement sélectionnée pour ce

relais.

Les bornes du relais sont situées derrière un écran de protection contre les hautes tensions dans le

boîtier du transmetteur. Ne retirez pas l'écran lorsque les bornes du relais sont sous tension. Ne

mettez pas les bornes du relais sous tension avant d'installer l'écran de protection contre les hautes

tensions.

Connectez chaque relais sur un appareil de contrôle ou d'alarme en fonction des besoins. Reportezvous aux étapes illustrées suivantes et à la Tableau 4 pour connecter les relais. Utilisez l'application

mobile pour sélectionner la condition de déclenchement de chaque relais.

Les caractéristiques techniques des relais sont indiquées dans la section Caractéristiques

à la page 23. Les relais sont isolés les uns des autres, ainsi que du circuit basse tension des

entrées/sorties.

Les bornes de relais sont compatibles avec un fil de 15 AWG (comme l'indique l'application de

charge). Utilisez un fil d'une isolation nominale de 300 V ca ou plus. Un calibre de fil différent de

15 AWG est déconseillé.

Le courant vers les contacts de relais doit être de 5 A maximum. Veillez à ce qu'un second

interrupteur soit disponible pour couper le courant des relais localement en cas d'urgence ou à des

fins d'entretien.

En cas de commutation de charges inductives importantes (p. ex. moteurs et pompes) ou de

courants supérieurs à 5 A, utilisez un relais auxiliaire pour prolonger la durée de vie du relais.

Utilisez ces relais soit en haute tension (supérieure à 30 V eff et 42,2 V crête ou 60 Vc.c.), soit en

basse tension (moins de 30 V eff et 42,2 V crête ou moins de 60 Vc.c.). Ne configurez pas de

combinaison de haute et basse tension.

Les connexions des bornes au secteur dans les applications à connexion permanente doivent

présenter une isolation nominale supportant au minimum 300 V, 70 °C (158 °F). Les bornes reliées

au secteur à l'aide d'un cordon d'alimentation doivent présenter une double isolation supportant

300 V, 70 °C (158 °F) au niveau de l'isolation interne et externe.

Français

35

Page 36

Tableau 4 Informations de câblage : relais

Borne Description Borne Description

1 Relais 1, NF 7 Relais 3, NF

2 Relais 1, commun 8 Relais 3, (commun)

3 Relais 1, NO 9 Relais 3, NO

4 Relais 2, NF 10 Relais 4, NF

5 Relais 2, commun 11 Relais 4, commun

6 Relais 2, NO 12 Relais 4, NO

NF = normalement fermé ; NO = normalement ouvert

Branchement des sorties analogiques (en option)

D A N G E R

Risque d'électrocution. Débranchez systématiquement l'alimentation de l'appareil avant d'effectuer

toute connexion électrique.

36 Français

Page 37

Si l'instrument dispose de la carte de sortie analogique en option, il dispose alors de 4 sorties

analogiques de 20 mA. Ce type de sortie est généralement utilisé pour la transmission des signaux

de mesure ou pour le contrôle d'autres appareils externes.

Connectez chaque sortie analogique sur un appareil externe en fonction des besoins. Reportez-vous

à la Figure 8 et à la Tableau 5 pour réaliser le branchement des sorties analogiques. Utilisez

l'application mobile pour configurer chaque sortie analogique en fonction d'un paramètre mesuré (p.

ex., pH ou température).

Assurez les connexions avec un câble blindé à paires torsadées et connectez le blindage sur la

borne de blindage.

• Ne connectez pas le blindage aux deux extrémités du câble.

• L'utilisation d'un câble non blindé peut résulter en l'émission de fréquences radio ou en des

niveaux de susceptibilité plus élevés que permis.

• La résistance de boucle maximale est de 500 Ω.

Remarques :

• Les bornes de sortie analogiques sont compatibles avec des fils de 15 à 26 AWG

• Les sorties analogiques sont isolées des autres composants électroniques, mais elles ne sont pas

isolées les unes des autres.

• Les sorties analogiques sont auto-alimentées. Ne les connectez pas à une charge à tension

indépendante.

• Les sorties analogiques ne peuvent pas être utilisées pour alimenter un émetteur (à circuit bouclé)

à 2 fils.

Figure 8 Branchement des sorties analogiques

1 Informations de câblage : sorties analogiques 3 Borne de sortie analogique

2 Carte de sortie analogique

Tableau 5 Informations de câblage : sorties analogiques

Borne Description Borne Description

1 Sortie 1+ 6 Sortie 3–

2 Sortie 1– 7 Sortie 4+

3 Sortie 2+ 8 Sortie 4–

4 Sortie 2– 9 Blindage (mis à la terre)

5 Sortie 3+

Français 37

Page 38

Connexion des entrées analogiques/numériques

D A N G E R

Risque d'électrocution. Débranchez systématiquement l'alimentation de l'appareil avant d'effectuer

toute connexion électrique.

Si l'instrument dispose de la carte d'entrée en option, il dispose alors de 4 entrées de 4–20 mA. Ces

entrées sont couramment utilisées pour intégrer les signaux analogiques ou numériques des

appareils externes.

Connectez chaque appareil externe à une entrée selon les besoins. Reportez-vous à la Figure 9

pour la connexion des entrées. Utilisez l'application mobile pour configurer chaque entrée en fonction

d'un paramètre mesuré (p. ex., débit).

Assurez les connexions avec un câble blindé à paires torsadées et connectez le blindage sur la

borne de blindage.

• Ne pas connecter le fil blindé aux deux extrémités du câble.

• L'utilisation d'un câble non blindé peut résulter en l'émission de fréquences radio ou en des

niveaux de susceptibilité plus élevés que ceux autorisés.

Remarques :

• Les bornes d'entrée sont compatibles avec des fils de 15 à 26 AWG.

• Les entrées sont isolées des autres composants électroniques, mais elles ne sont pas isolées les

unes des autres.

Figure 9 Connexion des entrées

1 Informations de câblage : entrées 3 Borne d'entrée

2 Carte d'entrée

Pour les informations de câblage, reportez-vous au manuel d'utilisation SC1000, section

3.6.2 Connexions de la carte d'entrée.

Installation de la carte Profibus DP

Reportez-vous au manuel de la sonde pour obtenir les instructions d'utilisation et les profils

d'instrument. Consultez le site Web de la société pour obtenir les derniers fichiers GSD et la

documentation la plus récente.

Pour connecter la carte Profibus DP au transmetteur SC, reportez-vous à la documentation de la

carte réseau Profibus DP/V1 du transmetteur SC. Installez la carte Profibus. Reportez-vous aux

sections Figure 10 et Tableau 6.

38

Français

Page 39

Après avoir installé et connecté la carte d'extension enfichable, configurez la carte. Reportez-vous à

la documentation fournie avec la carte Profibus DP.

Figure 10 Connexions à la carte Profibus DP (YAB103 depuis décembre 2013)

1 Informations sur le câblage—Sorties Profibus 4 Borne de réseau activée—dernier périphérique sur

le réseau

2 Carte Profibus DP 5 Borne de réseau désactivée—autres périphériques

sur réseau après cet appareil

3 Bornier—Consultez le Tableau 6 pour les

affectations des bornes

Tableau 6 Description des bornes de la carte Profibus DP (YAB103)

Borne Description Couleur du fil

1 Sortie B2 Rouge

2 Sortie A2 Vert

3 5 V Non utilisé

4 0 V Non utilisé

5 Entrée B1 Rouge

6 Entrée A1 Vert

Retrait d'une carte d'extension

Retrait d'une carte d'extension lorsque les connecteurs de sonde sont bloqués. Reportez-vous à la

documentation de la carte réseau Profibus DP/V1 du transmetteur SC.

Remarque : Les connecteurs compacts offrent un contact ferme, et les connexions peuvent se casser facilement.

N'appliquez pas de force trop importante pour retirer les connecteurs compacts.

1. Supprimez la carte dans le transmetteur SC.

2. Coupez l'alimentation de l'instrument.

3. Déposez le couvercle du module de sonde. Reportez-vous à la section Retrait du panneau

à la page 31

4. Débranchez tous les fils de la carte.

Français

39

Page 40

5. Retirez les vis de la carte.

6. Retirez la carte.

Pour remplacer et configurer la carte, fournissez l'adresse Profibus DP et le télégramme

Profibus DP cyclique à un technicien de service Hach.

Installation du couvercle

Connectez le fil de terre du capot au transmetteur, puis installez le capot de l'instrument. Reportezvous à la Retrait du panneau à la page 31.

Assurez-vous que les vis du capot sont serrées pour assurer la classification environnementale.

Connexion des appareils de mesure

Connectez les appareils numériques (p. ex., capteurs et analyseurs) aux connecteurs d'appareil sur

l'instrument. Reportez-vous à la section Figure 11. Conservez les couvercles de connecteur

d'appareil pour une utilisation ultérieure.

Assurez-vous que les câbles de l'appareil ne risquent pas de créer un risque de chute et ne forment

pas d'angles droits ou pointus.

Si un appareil de mesure comporte deux câbles, connectez le deuxième câble à une prise

d'alimentation CA sur l'instrument. Reportez-vous à la section Figure 6 à la page 30. La tension et le

courant disponibles sur les prises d'alimentation CA sont identiques à l'alimentation fournie à

l'instrument. Assurez-vous que l'alimentation fournie corresponde à la valeur nominale de l'appareil.

Remarque : Les prises d'alimentation CA n'alimentent l'instrument que si l'alimentation facultative de 100 à

240 V CA est installée.

Figure 11 Connexion d'un appareil

Connexion à un réseau cellulaire

Connectez l'instrument à un réseau cellulaire au moyen du connecteur USB du boîtier USB.

Reportez-vous aux illustrations suivantes.

Une fois le capot installé, assurez-vous que les vis sont serrées pour assurer la classification

environnementale.

40

Français

Page 41

Extension Modbus TCP/IP

Le Modbus TCP/IP est un protocole standard pour les communications industrielles. Le protocole

Modbus TCP/IP connecte les ordinateurs aux systèmes de commande et de mesures qui utilisent le

protocole TCP/IP pour la transmission des données. Ce type de transmission de données est connu

sous le nom de communication de machine à machine (M2M).

Le module logiciel Modbus TCP/IP permet au contrôleur d'être intégré directement dans des

systèmes d'automate programmable industriel (API). Les systèmes API enregistrent et traitent les

données mesurées par le contrôleur. L'analyse des données et les procédures engendrées par les

résultats sont programmées dans le système API.

Remarque : Pour utiliser le module logiciel Modbus TCP/IP, assurez-vous qu'aucune carte Modbus n'est installée

sur le contrôleur.

Connectez le contrôleur au boîtier USB externe. Reportez-vous à la documentation fournie avec le

boîtier USB. Il est possible de raccorder des contrôleurs en guirlande. Reportez-vous à la Figure 12.

Lorsqu'une clé USB Wi-Fi ou un modem est connecté au boîtier USB, ce canal connecte le

contrôleur à Internet. Ainsi, il n'est pas possible de connecter le contrôleur à Internet avec le modem

et d'utiliser Modbus TCP avec une connexion Wi-Fi en même temps ; le boîtier USB ne dispose que

d'un seul port USB. Dans une telle situation, Modbus TCP/IP ne peut fonctionner qu'avec le

connecteur LAN Ethernet (connecteur M12 Ethernet). Le Tableau 7 présente les combinaisons de

connexions Internet et Modbus TCP/IP possibles.

Lorsqu'un seul contrôleur est utilisé, seul le connecteur M12 droit est utilisé pour se connecter à l'API

ou à Internet (le connecteur gauche n'est pas utilisé). Dans le cas d'une connexion en guirlande,

connectez toujours le connecteur M12 droit au connecteur M12 gauche du contrôleur suivant. Le

contrôleur en guirlande connecté à l'API ou à Internet utilise le connecteur M12 droit pour établir la

connexion.

Français

41

Page 42

Figure 12 Schéma de raccordement

1 Boîtier USB 3 Système API

2 Contrôleur

Tableau 7 Combinaisons de connexions Internet et Modbus TCP/IP

LAN (prise M12)

Boîtier USB

Wi-Fi Modem

Internet X X X

Modbus TCP/IP X X —

Mise en marche

Branchez le cordon d'alimentation sur une prise électrique raccordée la terre ou mettez le disjoncteur

du transmetteur en marche.

Fonctionnement

Utilisez le logiciel MSM pour interagir avec les appareils de mesure connectés. Contactez le support

technique Hach pour créer un compte Claros Mobile Sensor Management pour la première fois.

Remarque : Consultez le site Web du fabricant pour obtenir plus d'informations sur le logiciel MSM.

1. Ouvrez un navigateur Internet, puis saisissez l'URL correcte :

• Etats-Unis : https://us.fsn.hach.com

• Europe : https://eu.fsn.hach.com

2. Saisissez les informations de connexion pour :

• Recevoir les informations d'état et les relevés de vos instruments de mesure.

• Configurer et étalonner les instruments de mesure.

• Accéder aux guides de maintenance interactifs et détaillés.

Maintenance

A V I S

Ne pas démonter l'appareil pour entretien. Si les composants internes doivent être nettoyés ou réparés, contacter

le fabricant.

42 Français

Page 43

Nettoyage de l'instrument

Nettoyez l'extérieur de l'instrument avec un chiffon humide, puis essuyez l'instrument en ne laissant

aucune trace d'humidité.

Remplacement des fusibles

L'utilisateur ne peut pas remplacer les fusibles. Contactez l’assistance technique. Un fusible grillé

peut indiquer que l'instrument est défaillant et qu'une réparation est nécessaire.

Préparation pour le stockage ou le transport

Avant le stockage à long terme ou le transport du transmetteur, préparez-le comme indiqué cidessous :

1. Utilisez l'application mobile pour enregistrer toutes les données importantes du transmetteur sur

un périphérique de stockage.

Remarque : Tous les paramètres d'usine et de l'utilisateur sont enregistrés sur les cartes d'E/S du

transmetteur.

2. Mettez le transmetteur hors tension.

3. Déconnectez tous les appareils externes connectés au transmetteur.

4. Détachez le boîtier USB du mur ou du poteau.

5. Détachez le transmetteur du mur, panneau ou poteau.

6. Placez le transmetteur et le boîtier USB dans un film de protection ou un chiffon sec. Conservez

le transmetteur et le boîtier USB dans un lieu sec.

Dépannage

Problème Cause possible Solution

Le témoin lumineux

d'état clignote en

rouge.

Une rupture de communication s'est

produite entre le transmetteur et au

moins l'un des appareils de mesure

connectés.

Assurez-vous que l'appareil de mesure est

branché sur le transmetteur.

Un appareil de mesure ou son câble

est endommagé.

Recherchez les traces de dommages sur

l'appareil de mesure et son câble. Assurez-vous

que l'appareil de mesure est opérationnel. En cas

de dommages, contactez l'assistance technique.

Le témoin lumineux

d'état est éteint.

Le transmetteur n'est pas sous

tension ou un fusible est grillé.

Assurez-vous que le transmetteur est alimenté.

S'il est alimenté, mettez le transmetteur hors

tension et vérifiez les fusibles. Si vous un fusible

est grillé, contactez le service d'assistance

technique.

Accessoires

Remarque : Les numéros de référence de produit et d'article peuvent dépendre des régions de commercialisation.

Prenez contact avec le distributeur approprié ou consultez le site web de la société pour connaître les personnes à

contacter.

Description Article No.

Kit modem GSM LZY971

Adaptateur Wi-Fi USA LZY996

Adaptateur Wi-Fi UE LZY997

Kit de montage sur panneau, sc1500, inclut :

Support, fixation avec protecteur de cordon et rallonge numérique

6169900

Français 43

Page 44

Accessoires (suite)

Description Article No.

Kit de montage sur poteau avec pare-soleil, sc1500, incluant :

pare-soleil, base, poteau, vis et plaque de montage

LZX957

Kit de montage mural avec pare-soleil, incluant :

pare-soleil, support, boulons (4x), écrous (4x) et rondelles (4x)

LZX958

Matériel de montage sur poteau pour pare-soleil, incluant :

pieds de montage (8x), vis (4x), boulons (12x), rondelles (8x), écrous (4x) et ancrages

(4x)

LZX948

Câble d'alimentation, Chine LZY393

Câble d'alimentation, Grande-Bretagne LZY394

Câble d'alimentation, Europe LZY395

Câble d'alimentation, Etats-Unis LZY396

Rallonge numérique, appareil de mesure, 10 m LZX849

Rallonge numérique, appareil de mesure, 20 m LZX851

44 Français

Page 45

Tabla de contenidos

Especificaciones en la página 45 Funcionamiento en la página 64

Información general en la página 46 Mantenimiento en la página 64

Instalación en la página 49 Solución de problemas en la página 65

Puesta en marcha en la página 64 Accesorios en la página 65

Especificaciones

Las especificaciones están sujetas a cambios sin previo aviso.

Especificación Detalles

Dimensiones (An x Pr x Al) Controlador: 315 x 120 x 242 mm (12,28 x 4,68 x 9,5 pulg.)

Caja USB: 79,5 x 55,1 x 159,5 mm (3,13 x 2,17 x 6,28 pulg.)

Carcasa Controlador: metal con superficie resistente a la corrosión, grado de protección

NEMA 4X/IP65

Caja USB: ABS/policarbonato, grado de protección NEMA 4X/IP65

Peso Aproximadamente 5 kg (11 lb). El peso varía en función del modelo.

Grado de contaminación 2

Categoría de sobrevoltaje II

Clase de protección I

Requisitos de alimentación De 100 a 240 V CA ± 10 V CA, 50/60 Hz, 1000 VA como máximo

Fusible F1 y F2: M 3,5 A L, 250 V o T 3,15 A L, 250 V; F3 y F4: T 8 A H, 250 V

Temperatura de funcionamiento De –20 a 55 °C (de –4 a 131 °F)

Temperatura de

almacenamiento

De –20 a 70 °C (de –4 a 158 °F)

Humedad 95% de humedad relativa, sin condensación

Altitud 2000 m (6561 pies)

Conexiones para dispositivos

de medición

Dos, cuatro o seis conectores para dispositivos y dos salidas de alimentación

de CA

1

Conexiones de red Dos conectores Ethernet (10/100 mbps), función de conmutación, conector

con código D hembra M12

Un conector USB en una caja USB

Tarjeta de relés (opcional) Cuatro relés en cada tarjeta, contactos conmutados (SPDT)

Voltaje máximo de conmutación: 250 V CA, 125 V CC

Corriente máxima de conmutación: 5 A

Nota: Asegúrese de que instala el interruptor interno de 5 A.

Potencia máxima de conmutación: 1500 VA, 250 V CA; 625 W, 125 V CC

Diámetro del cable: 1,5 mm2 (15 AWG) como máximo

Tarjeta de salida analógica

(opcional)

Cuatro salidas analógicas de 4–20 mA en cada tarjeta de salida analógica,

500 Ω como máximo

Diámetro del cable: 1,5 mm2 (15 AWG) como máximo

El fabricante recomienda el uso de cables de señal blindados.

1

Las salidas de alimentación de CA solo suministran energía cuando el instrumento tiene la

fuente de alimentación opcional de 100 a 240 V CA.

Español 45

Page 46

Especificación Detalles

Certificación De conformidad con cTUVus, CE y DIN EN 61326 de protección contra

sobretensión

Garantía 1 año (EU: 2 años)

Información general

En ningún caso el fabricante será responsable de ningún daño directo, indirecto, especial, accidental

o resultante de un defecto u omisión en este manual. El fabricante se reserva el derecho a modificar

este manual y los productos que describen en cualquier momento, sin aviso ni obligación. Las

ediciones revisadas se encuentran en la página web del fabricante.

Información de seguridad

A V I S O

El fabricante no es responsable de ningún daño debido a un mal uso de este producto incluidos, sin limitación,

los daños directos, fortuitos o circunstanciales y las reclamaciones sobre los daños que no estén recogidos en la

legislación vigente. El usuario es el responsable de la identificación de los riesgos críticos y de tener los

mecanismos adecuados de protección de los procesos en caso de un posible mal funcionamiento del equipo.

Lea todo el manual antes de desembalar, instalar o trabajar con este equipo. Ponga atención a

todas las advertencias y avisos de peligro. El no hacerlo puede provocar heridas graves al usuario o

daños al equipo.

Asegúrese de que la protección proporcionada por el equipo no está dañada. No utilice ni instale

este equipo de manera distinta a lo especificado en este manual.

Uso de la información sobre riesgos

P E L I G R O

Indica una situación potencial o de riesgo inminente que, de no evitarse, provocará la muerte o lesiones graves.

A D V E R T E N C I A

Indica una situación potencial o inminentemente peligrosa que, de no evitarse, podría provocar la muerte o

lesiones graves.

P R E C A U C I Ó N

Indica una situación potencialmente peligrosa que podría provocar una lesión menor o moderada.

A V I S O

Indica una situación que, si no se evita, puede provocar daños en el instrumento. Información que requiere

especial énfasis.

Etiquetas de precaución

Lea todas las etiquetas y rótulos adheridos al instrumento. En caso contrario, podrían producirse

heridas personales o daños en el instrumento. El símbolo que aparezca en el instrumento se

comentará en el manual con una declaración de precaución.

Este es un símbolo de alerta de seguridad. Obedezca todos los mensajes de seguridad que se

muestran junto con este símbolo para evitar posibles lesiones. Si se encuentran sobre el instrumento,

consulte el manual de instrucciones para obtener información de funcionamiento o seguridad.

Este símbolo indica que hay riesgo de descarga eléctrica y/o electrocución.

46 Español

Page 47

Este símbolo indica la presencia de dispositivos susceptibles a descargas electrostáticas. Asimismo,

indica que se debe tener cuidado para evitar que el equipo sufra daño.

En Europa, el equipo eléctrico marcado con este símbolo no se debe desechar mediante el servicio

de recogida de basura doméstica o pública. Devuelva los equipos viejos o que hayan alcanzado el

término de su vida útil al fabricante para su eliminación sin cargo para el usuario.

Este símbolo, cuando aparece en un producto, identifica la ubicación de un fusible o de un limitador

de corriente.

Este símbolo indica que el objeto marcado requiere una toma a tierra de seguridad. Si el instrumento

no se suministra con un cable con enchufe de toma a tierra, realice la conexión a tierra de protección

al terminal conductor de seguridad.

Descripción general del producto

A V I S O

La seguridad de red y de punto de acceso es responsabilidad del cliente que utiliza el instrumento inalámbrico. El

fabricante no se hará responsable de ningún daño, incluyendo, sin limitación, daños indirectos, especiales,

fortuitos o circunstanciales provocados por el incumplimiento o la violación de la seguridad en la red.

El SC1500 es un controlador para dispositivos analíticos digitales (p. ej. sensores y analizadores).

Consulte la Figura 1.

El controlador está disponible con relés y salidas analógicas opcionales (4–20 mA). Los relés

opcionales se utilizan para controlar los dispositivos externos (p. ej., dispositivos de control y

dispositivos de alarma). Las salidas analógicas opcionales se usan para proporcionar valores de

medición a los dispositivos externos.

El controlador se configura y maneja a través de una aplicación móvil instalada en un dispositivo

iOS® o Android® del cliente con un navegador conectado a Internet. El controlador se comunica a

través de una red LAN, Wi-Fi o móvil.

Español

47

Page 48

Figura 1 Descripción general del producto

1 Conector USB (consulte Conexión a una red de

telefonía móvil en la página 62)

5 Ranuras para montaje en pared

2 Caja USB 6 Orificios para montaje en pértiga

3 Luz indicadora de estado (consulte la Tabla 1) 7 Cable de alimentación (o adaptador de conductos)

4 Controlador sc1500 8 Conectores y accesorios de conexión (consulte la

Figura 6 en la página 52)

Tabla 1 Luz indicadora de estado