Page 1

Catalog Number 58600-18

Hach sc100™ Controller

Installation Manual

2/04 3ed

© Hach Company, 2003, 2004. All rights reserved. Printed in the U.S.A. ds/dp

Page 2

Table of Contents

Section 1 Specifications ............................................................................................................................................... 3

Section 2 General Information ..................................................................................................................................... 4

2.1 Safety Information ..................................................................................................................................................... 4

2.1.1 Precautionary Labels .............. ... .... .................................................................................................................. 4

2.2 General Product Information ..................................................................................................................................... 4

Section 3 Installation..................................................................................................................................................... 5

3.1 Mechanical Installation .............................................................................................................................................. 6

3.1.1 Controller Dimension Illustrations .................................................................................................................... 6

3.1.2 Using the Optional Sun Shield.................................................... ... ... .... ... ........................................................ 8

3.1.3 Mounting the Controller.................................................................................................................................... 9

3.2 Electrical Installation............ ... .... ... ... ... .................................................................................................................... 11

3.2.1 Installation in Conduit..................................................................................................................................... 11

3.2.3 Wiring for Power at the Controller.................................................................................................................. 12

3.3.2 Connecting the Analog Outputs..................................................................................................................... 16

3.4 Connecting/Wiring the Sensor Cable ...................................... ................................................................................ 17

3.5 Connecting the Optional Digital Output................................................................................................................... 18

Section 4 Maintenance................................................................................................................................................ 20

4.1 Cleaning the Controller............................................................................................................................................ 20

4.2 Fuse Replacement ............................................... ... ... ... ... ....................................... ... .... .. ....................................... 20

Section 5 Replacement Parts ..................................................................................................................................... 21

Section 6 How to Order............................................................................................................................................... 22

Section 7 Repair Service............................................................................................................................................. 23

Section 8 Limited Warranty ........................................................................................................................................ 24

Section 7 Compliance Information ............................................................................................................................ 25

Index............................................................................................................................................................................ 27

2

Page 3

Section 1 Specifications

Specifications are subject to change without notice.

Component Description

Controller Operating Temperature

Controller Storage Temperature –20 to 70 °C (–4 to 158 °F); 95% relative humidity, non-condensing

Enclosure NEMA 4X/IP66 metal enclosure with a corrosion-resistant finish

Power Requirements

Pollution Degree/Installation Category II; II

Outputs

Relays

Controller Dimensions ½ DIN—144 x 144 x 150 mm (5.7 x 5.7 x 5.9 inches)

Controller Weight 1.6 kg (3.5 lb)

Microprocessor-controlled measuring uni t wi t h me asu re d value display,

temperature display, and menu-driven system

–20 to 60 °C (–4 to 140 °F); 95% relative humidity, non-conden sing with

load <7 W; 20 to 40 °C (–4 to 104 °F) with sensor load <25 W

sensor

100–230 V ac ±10%, 50/60 Hz;

Power: 11 W with 7 W sensor load, 35 W with 25 W sensor load

Two (Analog (4–20 mA)) outputs, maximum impedance 500 ohm. Optional digital

network connection. IrDA digital connection.

Three SPDT, user-configurable contacts rated 100–230 V ac, 5 Amp

resistive maximum

3

Page 4

Section 2 General Information

2.1 Safety Information

Please read this entire manual before unpacking, setting up, or operating this

equipment. Pay attention to all danger and caution statements. Failure to do so

could result in serious injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not

use or install this equipment in any manner other t han that specified in

this

manual.

Use of Hazard Information

DANGER: Indicates a potentially or imminently hazardous situation which, if not

avoided, could r esult in death or serious injury.

CAUTION: Indicate s a potentially hazardous situation that may result in minor or

moderate injury.

Note: Information that requires special emphasis.

2.1.1 Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to

the instrument could occur if not

observed

This symbol, if noted on the instrument, references the instruction manual for operation

and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the conne ct ion for Protectiv e Earth

(ground).

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

2.2 General Product Information

The controller enclosure is NEMA4X/IP66-rated and has a corrosion-resistant

finish designed to withstand corrosive environmental constituents such as salt

spray and hydrogen sulfide. The controller display shows the current reading plus

a secondary measurement such as temperature if connected to a single sensor,

or two readings with their corresponding secon dary measurement reading s when

two sensors are connected.

Installation instructions for the contro ller are presen ted in th is manu al. If a system

with a sensor and a controller has been purchased, complete information for

installation and operation is also presented in the sensor system manual.

4

Page 5

Section 3 Installation

DANGER: Only qualified personnel should conduct the installation tasks

described in this section of the manual.

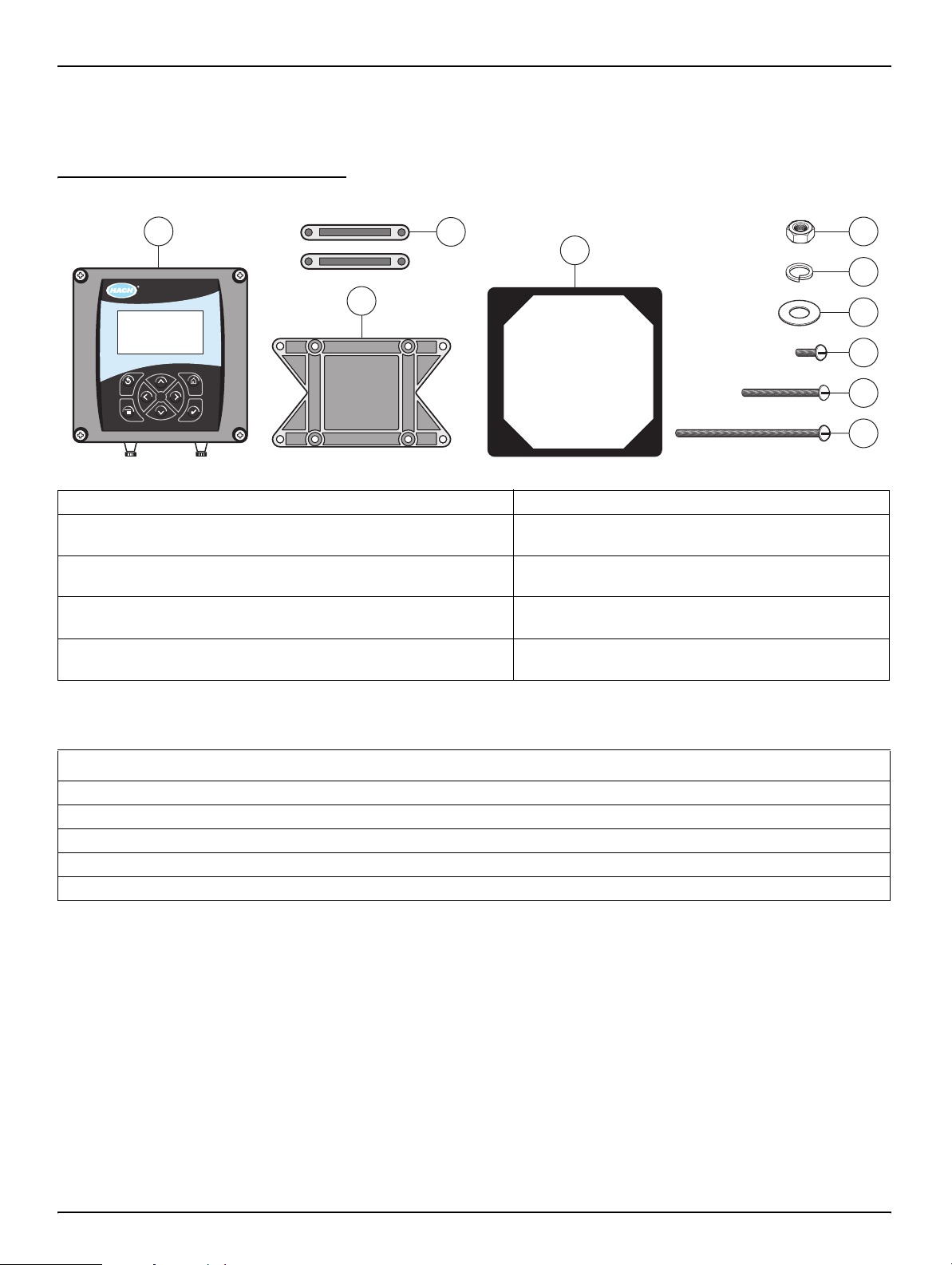

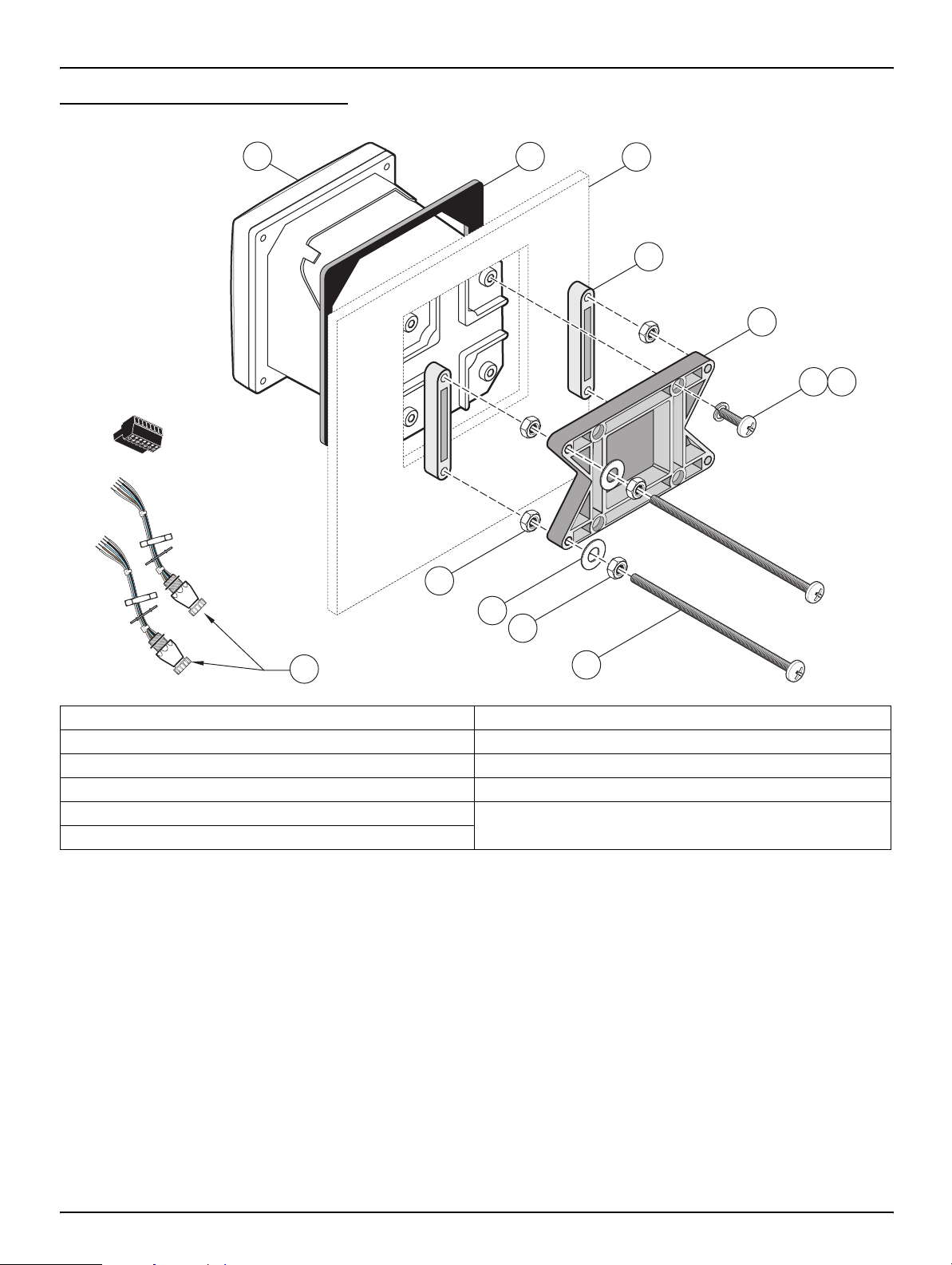

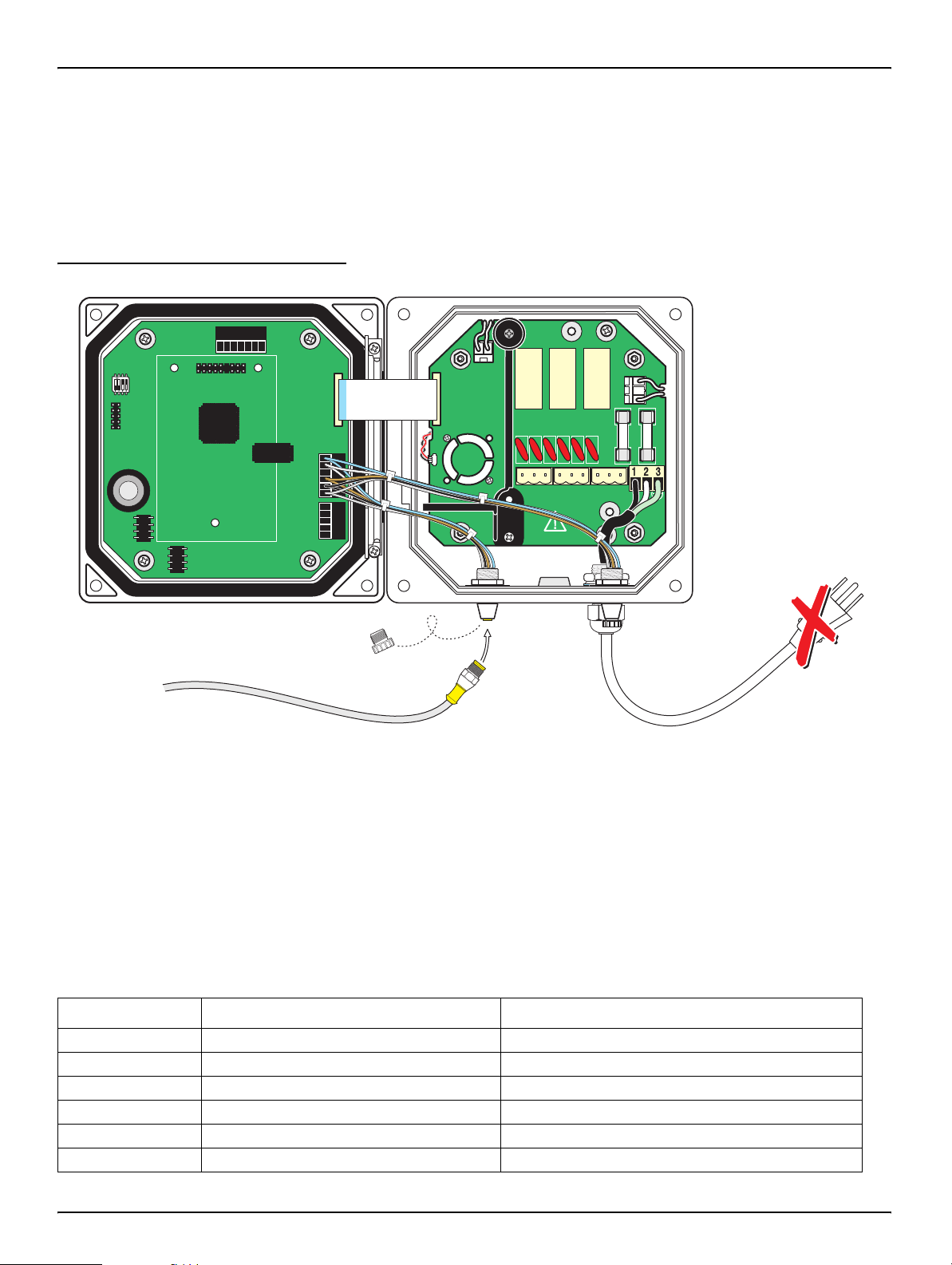

Figure 3-1 Components of a Basic System

1

sc100

1. Controller 6. Lock washer, ¼-inch I.D. (4), Cat. No . 8H1336

2. Mounting foot for panel mounting (2),

Cat. No. 1000B4F3222

3. Bracket f or panel and pipe mounting,

Cat. No. 1000C4F3217-101

4. Gasket for panel mounting, rubber,

Cat. No. 1000A4F3249-101

5. Hex nut, M6 (4), Cat. No. 5867300 10. Pan head screws (4), M6 x 1.0 x 150 mm,

3

2

4

7. Flat washer, ¼-inch I.D . (4),

Cat. No. 8H1346

8. Pan head screws (4), M6 x 1.0 x 20 mm,

Cat. No. 5867400

9. Pan head screws (4), M6 x 1.0 x 100 mm,

Cat. No. 5867500

No. 5867600

Cat.

5

6

7

8

9

10

Table 3-1 Customer Supplied Items

Item

14-AWG wire for electrical power connections in conduit or 115 or 230 V ac power cord plus a NEMA 4X-rated strain relief

High-quality, shielded instrumentation cable for connecting the analog outputs plus a NEMA 4X-rated strain relief.

Mounting hardware for the sensor (available from the manufacturer, order separately). See the sensor manual.

Sun shield for mounting configurations where the sun strikes the front of the display. See Figure 3-7 on page 8.

Common hand tools

5

Page 6

Installation

3.1 Mechanical Installation

Install in an environment that is protected from corrosive fluids.

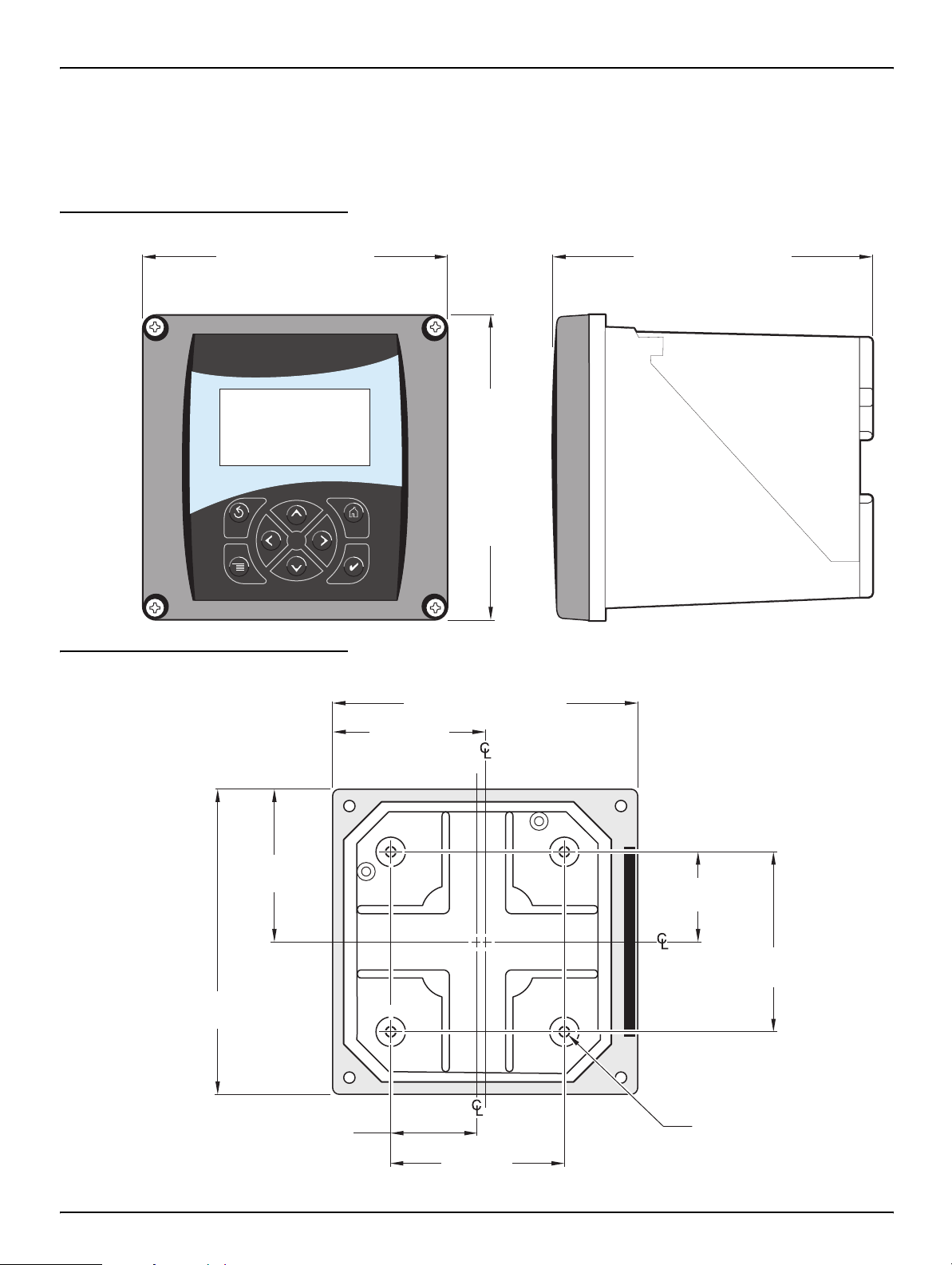

3.1.1 Controller Dimension Illustrations

Figure 3-2 Controller Dimensions

144.0 mm (5.67 inches) 150.0 mm (5.91 inches)

sc100

Figure 3-3 Controller Mounting Dimensions

144.02 mm (5.67 inches)

72.01 mm

(2.84 inches)

72.01 mm

(2.84 inches)

144.02 mm

(5.67 inches)

144.0 mm (5.67 inches)

40.14 mm

(1.58 inches)

80.27 mm

(3.16 inches)

40.14 mm (1.58 inches)

80.27 mm

(3.16 inches)

M6 x 1.0

6

Page 7

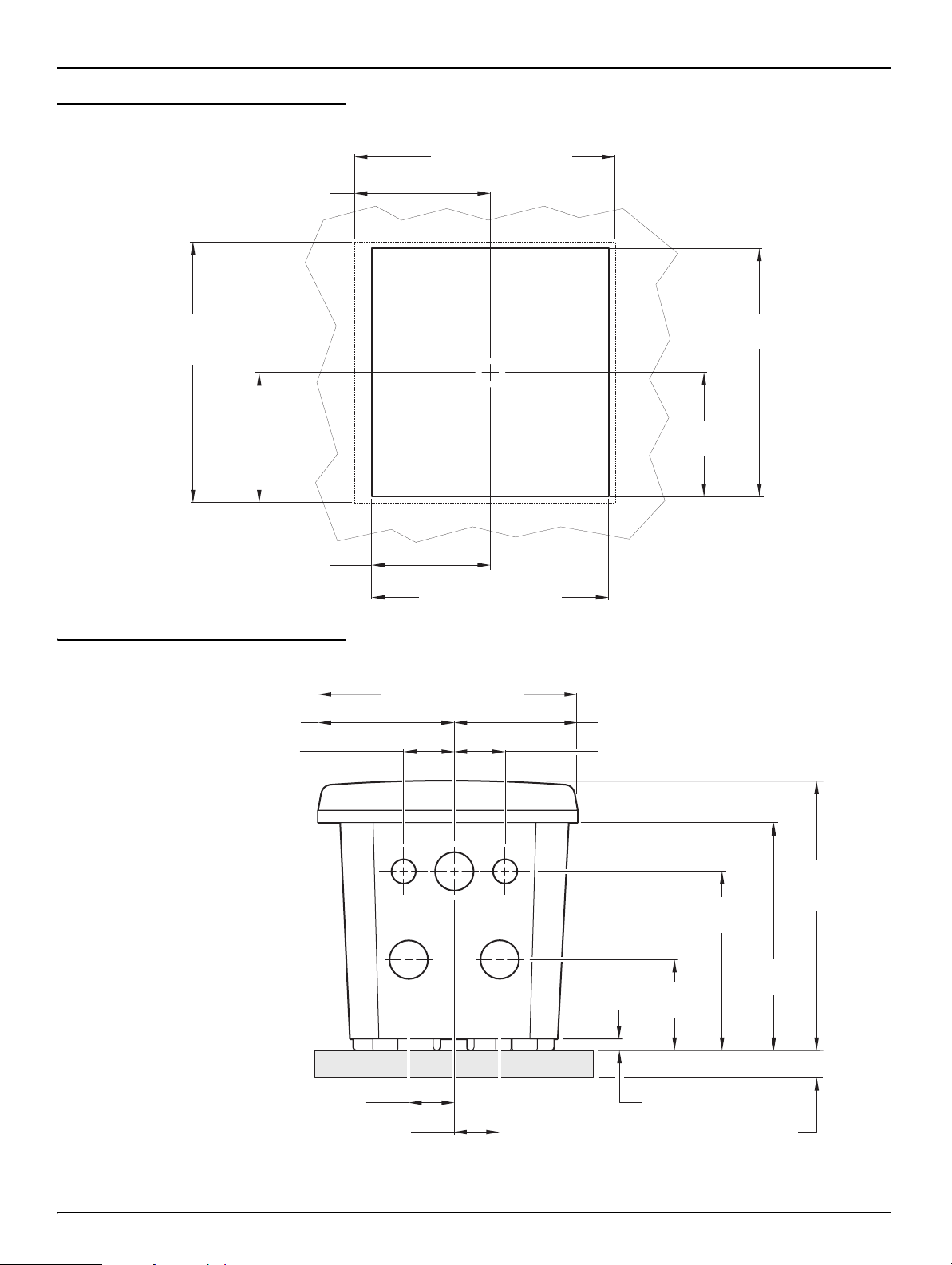

Figure 3-4 Panel Mount Cut-out Dimensions

75 mm (2.955 inches)

(ref only)

Installation

144 mm (5.67 inches)

(ref only)

144 mm

(5.67 inches)

(ref only)

72 mm

(2.835 inches)

(ref only)

66.67 mm (2.625 inches)

Figure 3-5 Conduit Hole Dimensions

75.07 mm (2.955 inches)

28.57 mm (1.125 inches)

135 mm

(5.31 inches)

67.4 mm

(2.65 inches)

133 mm (5.25 inches)

144 mm (5.67 inches)

68.96 mm (2.715 inches)

28.57 mm (1.125 inches)

25.4 mm (1.00 inch)

25.4 mm (1.00 inch)

99.31 mm

(3.91 inches)

50.8 mm

(2.00 inches)

6.35 mm (0.25 inch)

15.24 mm (0.60 inch)

(5.00 inches)

150 mm

(5.91 inches)

(ref only)

127 mm

7

Page 8

Installation

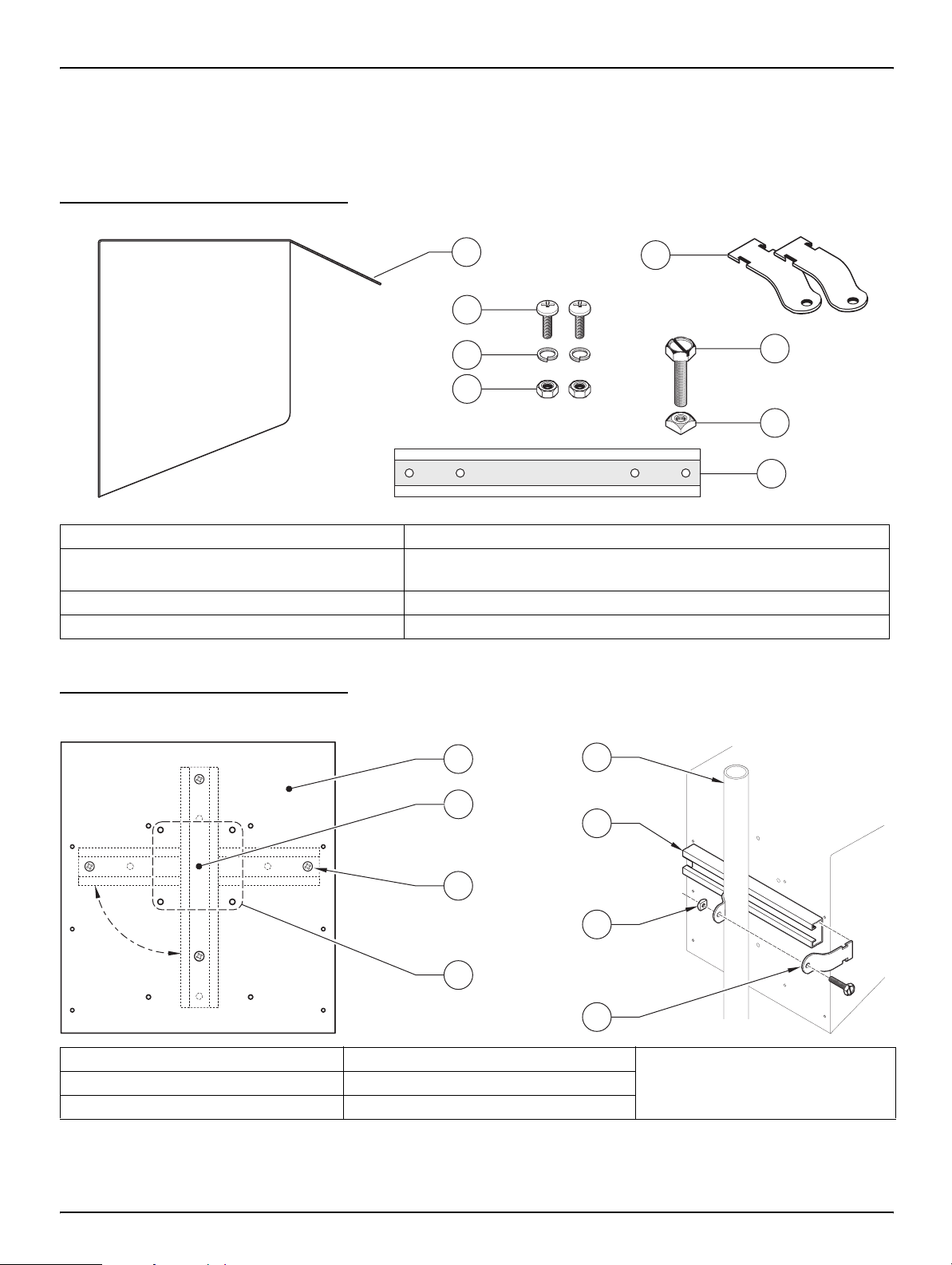

3.1.2 Using the Optional Sun Shield

The optional sun shield was designed to increase the readability of the display

by

screening it from direct sunlight. See Replacement Parts on page 21 for

ordering information.

Figure 3-6 Sun Shield Kit Components

1

2

3

4

1. Sun shield 5. Pipe mounting brackets (2), includes items 6 and 7, Cat. No. 9H1079

2. Pan head screws, M6 x 1.0 x 12 mm (6),

Cat. No. 200-1025

3. Lock washers, ¼-inch I.D. (2), Cat. No. 8H1336 7. Square nut, 5/16-inch (supplied with item number 5)

4. Hex nuts, M6 x 1.0 (2), Cat. No. 5867300 8. Uni-strut, 27 cm (10.5 inch) length, Cat. No. 276F1227

6. Hex/slotted head screw, 5/16-inch x 1.0-inch

(supplied with item number 5)

5

6

7

8

Figure 3-7 Mounting the Controller in the Sun Shield

1

2

3

4

1. Sun shield 4. Hole pattern for mounting controller 7. Pipe mounting bracket–slide into

2. Uni-strut (rotate 90° as required) 5. Pipe (vertical or horizontal as required)

3. Pan head screw, lock washer (2 each) 6. Hex/slotted head screw and square nut

5

2

6

7

uni-strut as shown. Secure the

fasteners to complete installation.

8

Page 9

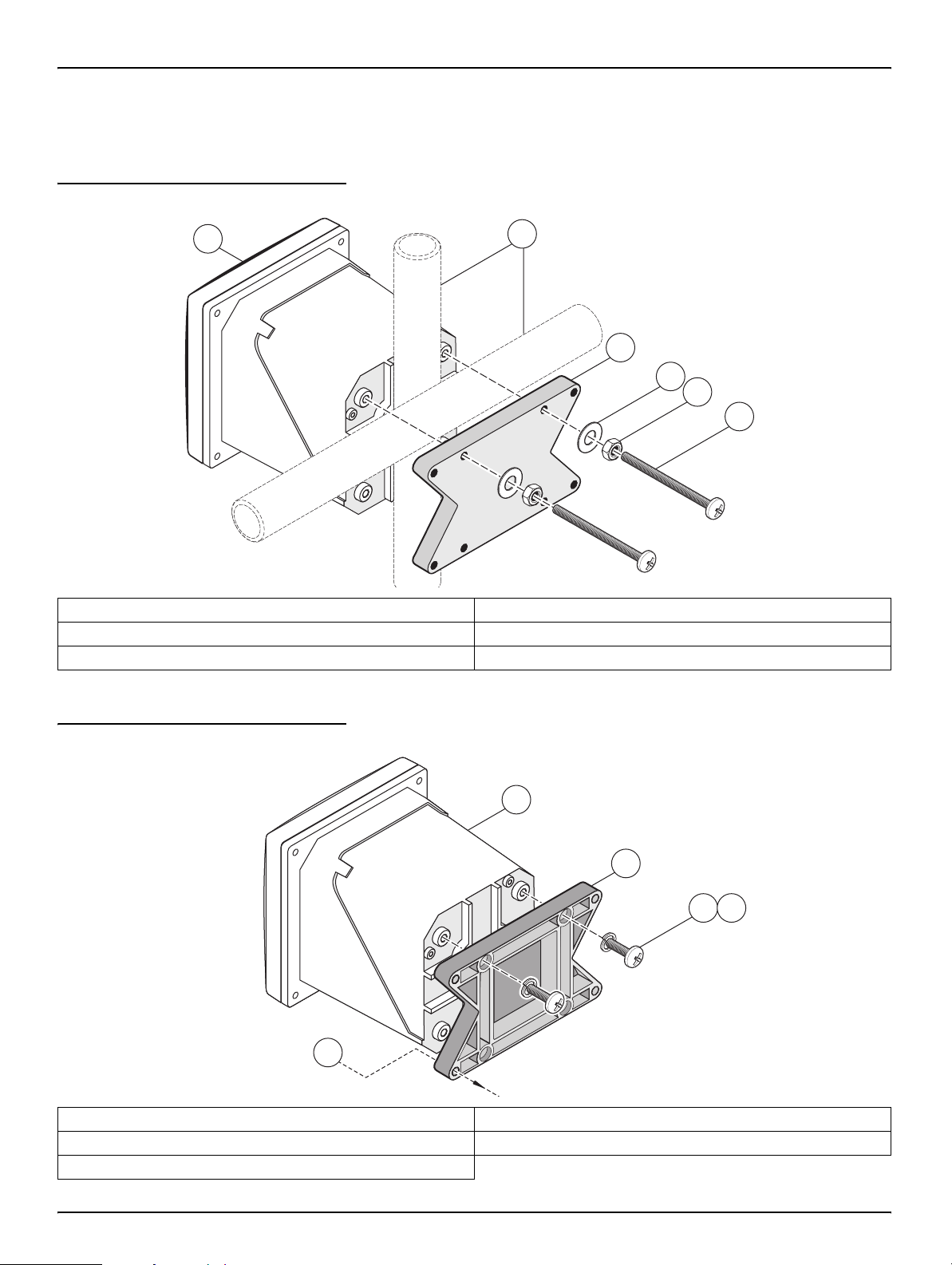

3.1.3 Mounting the Controller

Attach the controller to a rail or wall or mount it in a panel. Supplied mounting

hardware

Figure 3-8 Vertical or Horizontal Pipe Mounting the Controller

is shown in Figure 3-8, Figure 3-9, and Figure 3-10.

Installation

1

1. Controller 4. Flat washer, ¼-inch I.D. (4), Cat. No. 8H1346

2. Pipe (vertical or horizontal) 5. Hex nut, M6 (4), Cat. No. 5867300

3. Bracket, pipe mounting, Cat. No. 1000C4F3217-101 6. Pan head screw, M6 x 1.0 x 100 mm (4), Cat. No. 5867400

2

3

4

5

6

Figure 3-9 Wall Mounting the Controller

1

2

3

4

5

1. Controller 4. Pan head screw, M6 x 1.0 x 20 mm (4), Cat. No. 5867400

2. Bracket, Cat. No. 1000C4F3217-101 5. Customer-supplied hardware for wall mounting

3. Lock washer, ¼-inch I.D., Cat. No. 8H1336

9

Page 10

Installation

Figure 3-10 Panel Mounting the Controller

1

8

2

9

8

3

4

5

6

7

11

1. Controller 7. Lock washer, ¼-inch I.D., (4) Cat. No. 8H1336

2. Gasket, rubber, panel mount, Cat. No. 1000A4F3249-101 8. Hex nut (4), Cat. No. 5867300

3. Panel (maximum thickness is 9.5 mm (3/8 inch)) 9. Flat washer (4), Cat. No. 8H1346

4. Mounting Foot (2), Cat. No. 1000B4F3222 10. Pan head screw, M6 x 1.0 x 150 mm (4), Cat. No. 5867600

5. Mounting bracket, controller, Cat. No. 1000C4F3217-101 11. It may be necessary to remove the sensor connectors.

6. Pan head screw (4), Cat. No. 5867400

see procedure below.

10

To remove the sensor connectors bef ore inserting the controller enclosure into the

panel cut-out:

1. Disconnect the wires at terminal block J5, see Figure 3-20 on page 18.

2. Loosen and remove the nut securing the sensor connector inside the

enclosure. Remove the sensor connector and wires. Repeat step 1 and 2 for

the other sensor connector.

3. After the controller is in place in the panel, reinstall the senso r connectors and

reconnect the wiring to terminal J5 as shown in

Figure 3-20 on page 18.

10

Page 11

3.2 Electrical Installation

+

DATA

+

OUT 2

+

V

+

OUT 1

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

J1

J2

J4

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

S1

Installation

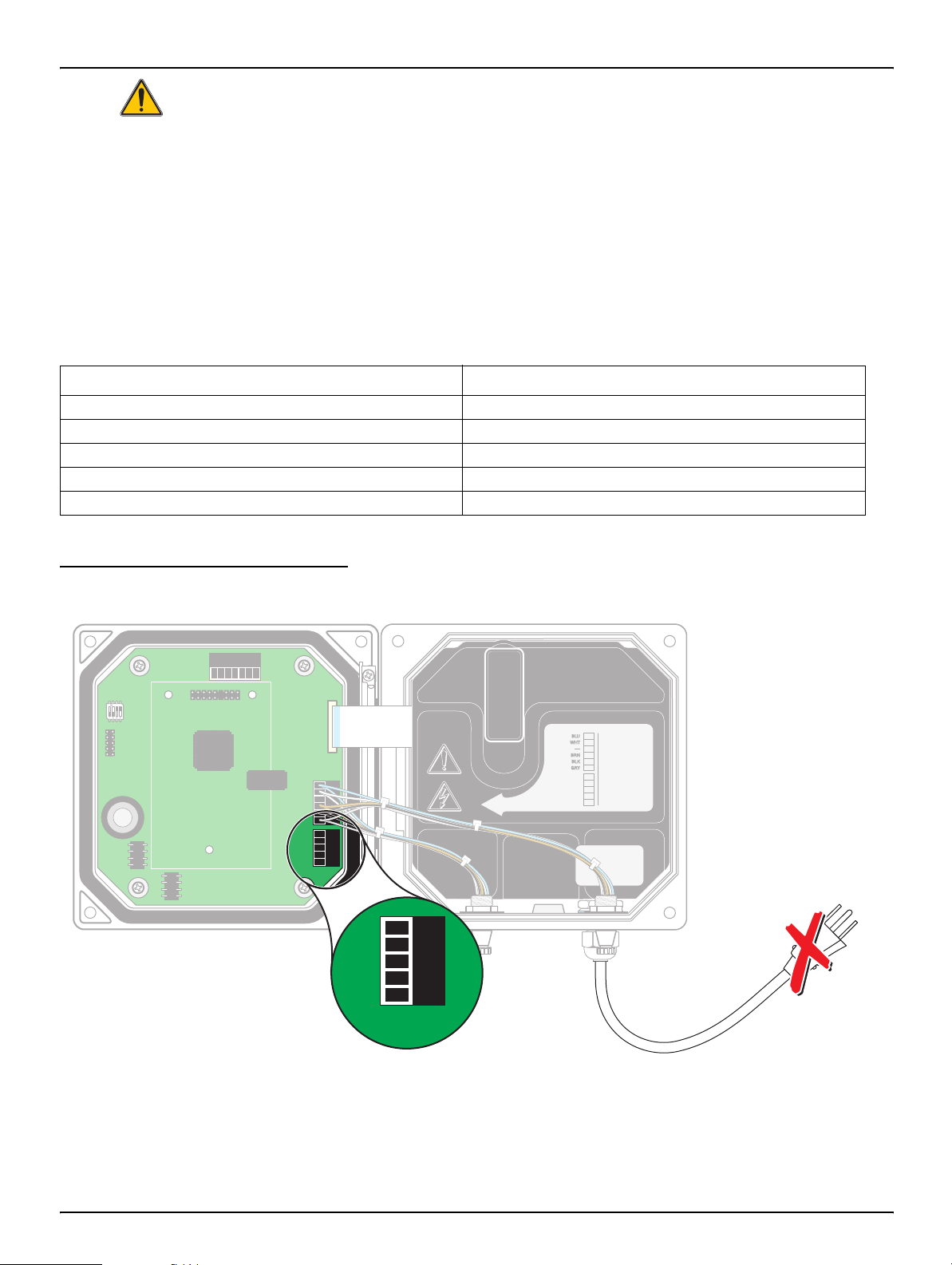

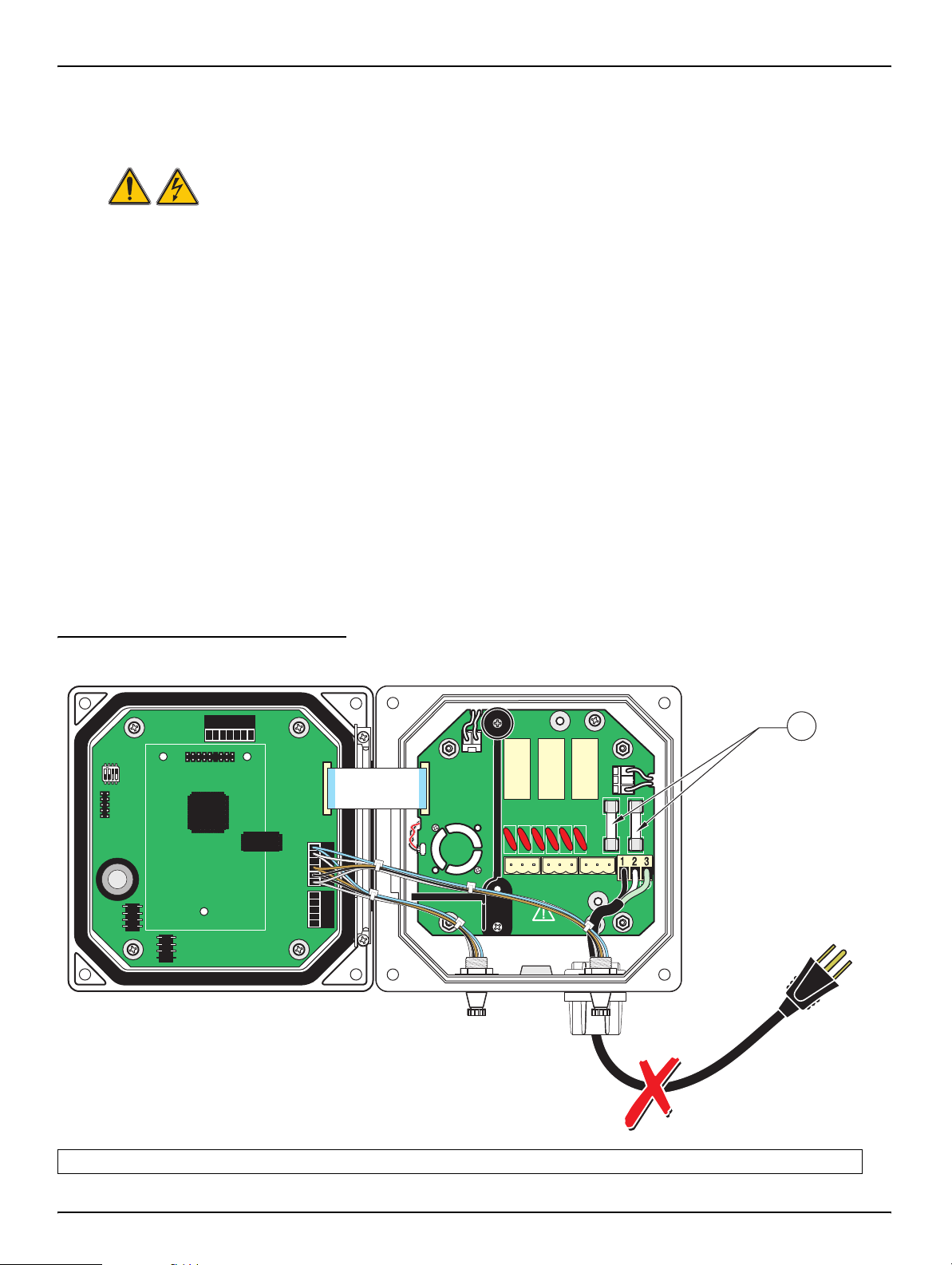

DANGER

The instrument must be installed

by qualified technical per s onn el

for adherence to all applicable

electrical codes.

High-voltage wiring for the controller is conducted behind the high voltage barrier

in the controller enclosure. The barrier must remain in place unless a qualified

installation technician is installing wiring for power, alarms, or relays. See

3-11 for barrier removal information.

3.2.1 Installation in Conduit

In hard-wired electrical applications, the power and safety ground service drops

for the instrument must be 18 to 12 AWG. See

relief and conduit opening sealing plug information. See section 3.2.3 on page 12

for wiring information.

3.2.2 Installation Using a Power Cord

A sealing-type strain relief to maintain the NEMA 4X/IP66 environmental rating

and a power cord less than 3

conductors (including a safety ground wire) can be used, see

on page 21. See Figure 3-12 on page 12 for strain relief and conduit opening

sealing plug assembly. See section 3.2.3 on page 12 for wiring information.

Figure 3-11 Removing Voltage Barrier

J1

S1

J2

U5

J4

U9

NETWORK

INTERFACE

CARD

J3

J5

J6

Figure

Figure 3-12 on page 12 for strain

meters (10 feet) in length with three 18-gauge

Replacement Parts

1

1

+

DATA

– DATA

2

SERVICE REQUEST

3

4

+

V

5

GND

6

1

+

OUT 2

– OUT 2

2

SHIELD/CHASSIS GND

3

4

+

OUT 1

5

– OUT 1

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

2

PCB

CONNECTOR

PROBES

ANALOG OUTPUTS

1. High voltage barrier 2. Unsna p the barrier latch then pull out to remove the barrier.

11

Page 12

Installation

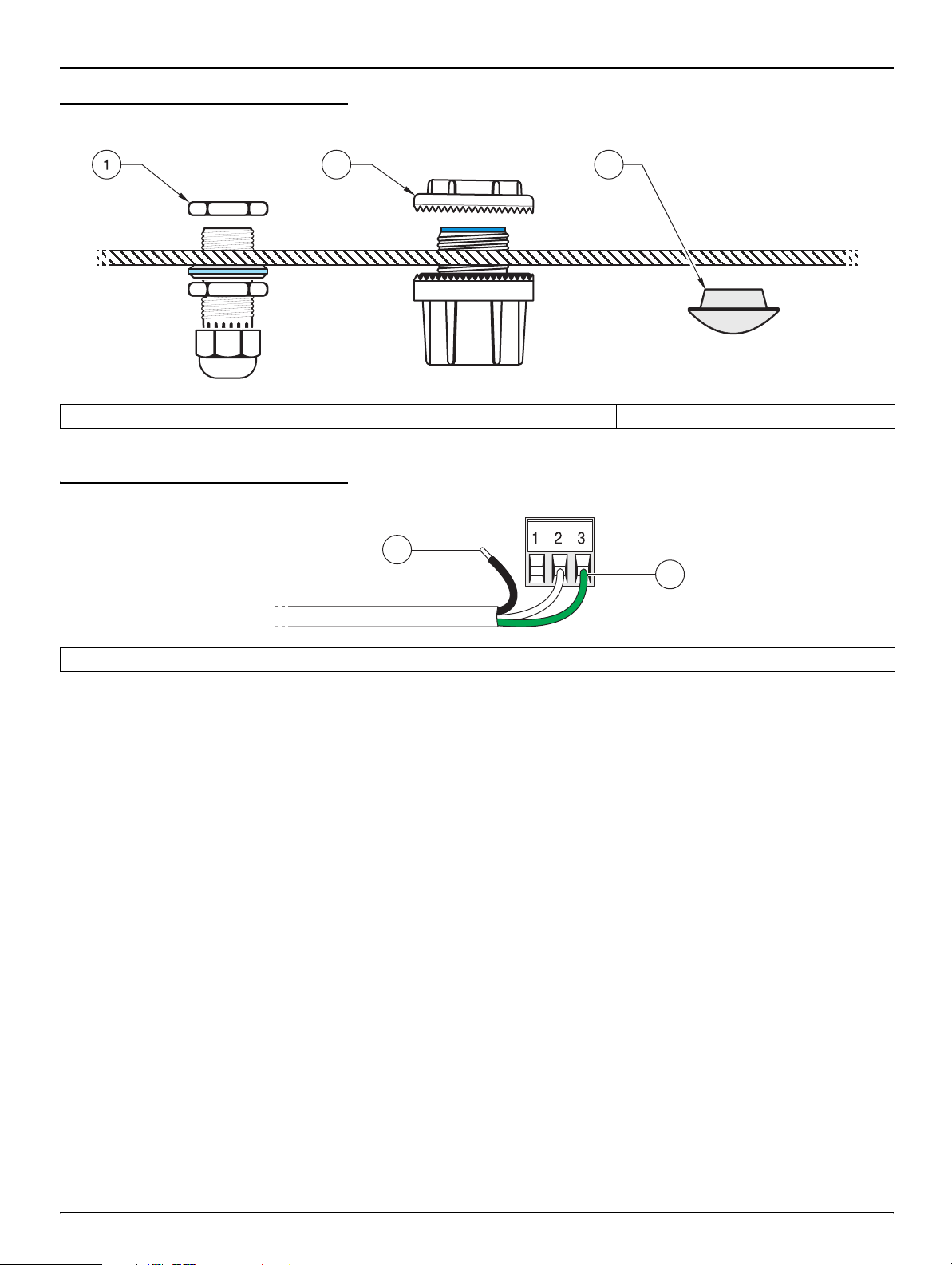

Figure 3-12 Using the Optional Stra in Reli ef and Conduit Plug

2

1. Power cord strain relief 2. Conduit strain relief 3. Conduit opening sealing plug

3

Figure 3-13 Proper Wire Preparation and Insertion

1

2

1. Strip ¼-inch of insulation. 2. Seat insulation against connector with no bare wire exposed.

3.2.3 Wiring for Power at the Controller

The instrument can be wired for line power by hard-wiring in conduit or by wiring

to a power cord. Regardless of the type of wire used, t he connections are m ade at

the same terminal. A local disconnect designed to meet local electrical code is

required and must be identified for all types of installation. See

Figure 3-16 on page 14 for suggest ed local disconnect configurations.

1. Obtain appropriate fittings with NEMA 4X/IP66 environmental rating.

2. Loosen the screws using a phillips-head screwdriver and open the hinged

controller cover.

3. Remove the high-voltage barrier (see Figure 3-11 on page 11).

4. Insert the wires through the strain relief fitting or conduit hub located in the

right-rear access hole in the bottom of the enclosure. Tighten the strain relief if

used, to secure the cord.

5. Properly prepare each wire (Figure 3-13) and insert each wire into the

terminal according to Table 3-2. Tug gently after each insertion to ensure the

connection is secure.

Figure 3-15 and

12

6. Seal any unused openings in the controller box with conduit opening sealing

plugs, see

Replacement Parts on page 21.

Page 13

Installation

RELAYB

7. Reinstall the high-voltage barrier and latch to secure.

Table 3-2 Power Wiring Information

Terminal Number Terminal Description Wire Color Code for North America Wire Color Code for Europe

1 Hot (L1) Black Brown

2 Neutral (N) White Blue

3 Protective Earth (PE) Green Green w/yellow tracer

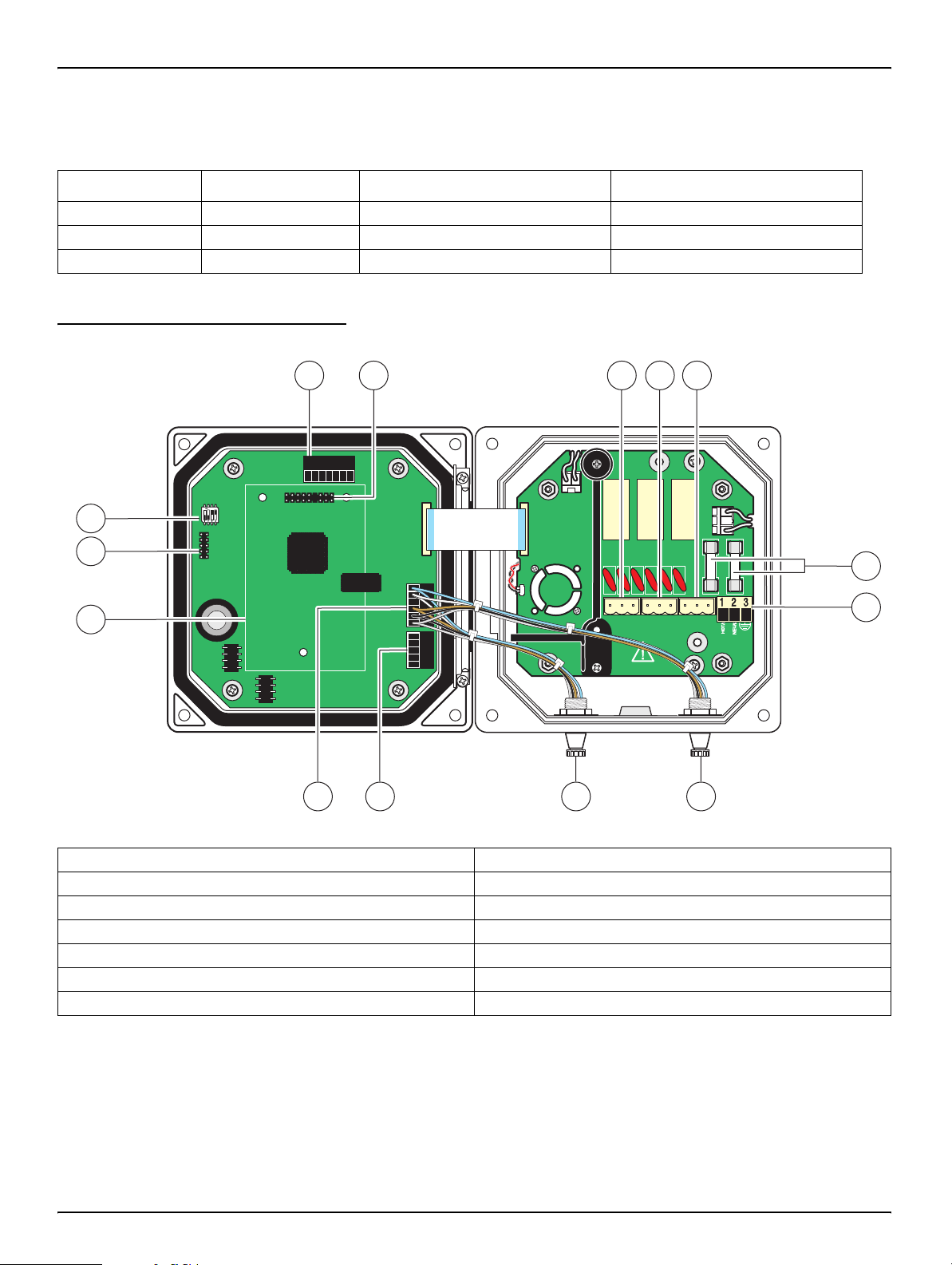

Figure 3-14 Wiring Connections

312

45

J1

J3

14

S1

J2

CARD

U5

U9

11 10

F1

J5

RELAYA

J6

NONO

F2

NCNCNC

NO

COMCOMCOM

RELAYCRELAYB

89

13

12

J4

NETWORK

INTERFACE

1. J1—Network connector 8. Sensor connector

2. J2—Header for optional network interface card 9. Sensor connector

3. J5—Relay A connector 10. J6—Analog output (4–20 mA) connector

4. J6—Relay B connector 11. J5—Sensor connector for hard-wiring

5. J7—Relay C connector 12. Position for network interface card

6. Fuses (F1, F2) 13. Service port

7. J8—ac Power connections 14. Sensor terminator selector/service port configuration

6

7

13

Page 14

Installation

Figure 3-15 Local Disconnect for Power Cord

J1

S1

J2

J3

1

CARD

U5

U9

J5

J6

F1

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

J4

NETWORK

INTERFACE

1. Power terminal 2. Power cord strain relief

Figure 3-16 Local Disconnect for Hard-wired Line Power

F2

2

J1

S1

J4

NETWORK

INTERFACE

J2

U5

U9

CARD

J3

J5

J6

F1

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

1. Power terminal 2. Conduit strain relief

1

F2

2

14

Page 15

3.3 Alarms and Relays

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYA

J1

J2

J4

S1

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

J5J5

The controller is equipped with three unpowered relays rated 100–230 V ac,

50/60

setup

3.3.1 Connecting the Relays

The relay connector accepts 18–12 AWG wire (as determined by load

application). Wire gauge less than 18 AWG is not recommended.

Installation

Hz, 5 amp resistive maximum. See the sensor manual for relay

details.

Danger: Relay loads must be

resistive. User must externally

limit current to the relays to

Amps by use of a fuse or

5

breaker.

Danger: ac power terminals are

designed for single wires. Do not

use more than one wire in each

terminal.

The controller contains three relays designed for use with high voltag e (greater

than 30V-RMS and 42.2V-PEAK or 60

information. The wiring is not designed for low voltage connections. Relay must

not be powered from t he same wiring used to powe r the cont roller . See the sensor

manual for relay setup

The Normally Open (NO) and Common (COM) relay contacts will be connected

when an alarm or other condition is active. The Normally Closed (NC) and

Common relay contacts will be connected when an alarm or other condition

is

inactive or when power is removed from the controller.

Figure 3-17 Alarm and Relay Connections

J1

S1

J4

NETWORK

INTERFACE

J2

U5

U9

CARD

J3

J5J5

J5

details.

3

2

1

V dc). Refer to Figure 3-17 for connection

J5 J6 J7

RELAY A RELAY B RELAY C

F1

F2

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

J6

Disconnect

Power

15

Page 16

Installation

+

DATA

+

OUT 2

+

V

+

OUT 1

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYA

J1

J2

J4

S1

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

J5J5

3.3.2 Connecting the Analog Outputs

Two isolated analog outputs (1 and 2) are provided, see Figure 3-18. Each out put

can be set to 0–20 or 4–20 mA, and can be assigned to represent the measured

parameter or secondary measurement such as temperature. Make connections

with twisted-pair shielded wire and connect the shield at the controlled component

end or at the control loop end. Do not connect the shield at both ends o f the cab le.

Use of non-shielded cable may result in radio frequency emission or susceptibility

levels higher tha n allowed. Maximum loop resistance is 500 ohm. Refer to the

sensor manual for output software setup.

Make wiring connections at the analyzer end as shown in Figure 3-18.

Table 3-3 Output Connections at Terminal Block J6

Recorder Wires Circuit Board Position

Output 2 + 1

Output 2 – 2

Shield 3

Output 1 + 4

Output 1 – 5

Figure 3-18 Analog Output Connections

J1

S1

J4

NETWORK

INTERFACE

CARD

J2

U5

J5J5

U9

J5

J6

J3

1

+

DATA

– DATA

2

SERVICE REQUEST

3

4

+

5

6

1

2

3

4

5

NCNCNC

NONO

COMCOMCOM

RELAYCRELAYBRELAYA

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

V

GND

F1

+

OUT 2

– OUT 2

SHIELD/CHASSIS GND

+

OUT 1

– OUT 1

NO

F2

PCB

CONNECTOR

PROBES

ANALOG OUTPUTS

1

2

3

4

5

J6

16

Page 17

3.4 Connecting/Wiring the Sensor Cable

The sensor cable is supplied with a k eyed quick-connect fitting for easy

attachment to

connector opening in case the sensor must be removed. Optional extension

cables may be purchased to extend the sensor cable length. If the total cable

length exceeds 100 M (300 ft), a termination bo x must be installed. See the

Replacement Parts section in the sensor manual for part number information.

Figure 3-19 Attaching the Sensor using the Quick-connect Fitting

J1

S1

J2

J3

the controller, see Figure 3-19. Retain the connecto r cap to seal the

Installation

J4

From Probe

NETWORK

INTERFACE

CARD

U5

J5J5

J5J5

U9

J5

J6

F1

F2

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

Modify the controller for sensor hard-wiring as follows:

1. Open the controller cover.

2. Disconnect and remove the existing wires between the quick connect and

terminal block J5, see

Figure 3-20 on page 18.

3. Remove the quick connect fitting and wires and install the threaded plug on

the opening to maintain the environmental rating.

Table 3-4 Wiring the Sensor at Terminal Block J5

Terminal Number Terminal Designation Wire Color

1 Data (+) Blue

2 Data (–) White

3 Service Request No Connection

4 +12 V dc Brown

5 Circuit Common Black

6 Shield Shield (grey wire in existing quick disconnect fitting)

17

Page 18

Installation

RELAY2

+

DATA

+

OUT 2

+

V

+

OUT 1

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAY3RELAY 2RELAY2RELAY 1

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

J1

J2

J4

NETWORK

INTERFACE

CARD

J3

J6

U5

U9

S1

J5

Figure 3-20 Hard-wiring the sensor

J1

S1

J4

NETWORK

INTERFACE

CARD

J2

U5

J5J5

J5

U9

J5

J6

J3

1

+

DATA

– DATA

2

SERVICE REQUEST

3

4

+

5

GND

6

1

+

2

3

4

+

5

– OUT 1

NCNCNC

NONO

COMCOMCOM

RELAY3RELAY 2

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

V

F1

OUT 2

– OUT 2

SHIELD/CHASSIS GND

OUT 1

NO

F2

PCB

CONNECTOR

PROBES

ANALOG OUTPUTS

RELAY1

Disconnect

Power

From Probe

1. Cut the connector from the sensor cable.

2. Reinstall the plug on the sensor access opening to maintain the

environmental rating.

3. Strip the insulation on the cable back 1-inch. Strip ¼-inch of each individ ual

wire end.

4. Wire as shown in Table 3-4.

5. Pass the cable through conduit and a conduit hub or a strain relief fitting and

an available access hole in the controller enclosure. Tighten the fitting.

6. Close and secure the cover.

3.5 Connecting the Optional Digital Output

At this time, the manufacturer supports ModBUS RS485, ModBUS RS232, and

ProfiBUS DP communication protocols . The optional digital output card is installed

in the location indicated in

user connection to the optional netw ork card. The terminal connection is based on

the selected network card. Ref er to the instructions supplied with t he network card

for more details.

Figure 3-21 on page 19. Terminal block J1 provides

18

Page 19

Table 3-5 Network Connections at Terminal Block J1

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAYCRELAYBRELAYA

J1

J2

J4

S1

NETWORK

INTERFACE

CARD

J3

J5

J6

U5

U9

J5J5J5J5

Installation

Terminal Number ModBUS RS485 2-wire ModBUS RS485 4-wire ModBUS RS232

1

1 D + RD + Rx A –

2 D – RD – — B1 +

3 — TD + Tx A2 –

4 — TD – — B2 +

5 Common Common Common Common

6 No connection No connection No connection No connection

7 Shield Shield Shield Shield

1. See Detail A.

Detail A RS232 Connections to Customer-supplied Computer 9-pin D Subminiature Connector

Common 5

Not used 4

Rx 3

Tx 2

Not used 1

9

8

7

6

ProfiBUS

Figure 3-21 Network Card Position in the Controller

1

J1

S1

J4

NETWORK

INTERFACE

2

CARD

J2

U5

U9

3

J3

J5J5J5J5

J5

J6

4

F1

F2

NCNCNC

NONO

NO

COMCOMCOM

RELAYCRELAYBRELAYA

1. J2—Network card header 2. Mounting hole (3) 3. Network card placement 4. J1 Terminal

19

Page 20

Section 4 Maintenance

RELAYB

4.1 Cleaning the Controller

With the enclosure securely closed, wipe the exterior with a damp cloth.

4.2 Fuse Replacement

The instrument contains two mains fuses. Failed fuses are an indication that an

equipment problem could exist. Problem resolution and fuse replacement should

be performed only by qualifie d service personnel. Refer to

following steps to replace the fuses:

1. Disconnect power to the controller (including power to relays if powered).

2. Open the hinged controller cover by completely loosening all four captive

screws in the cover.

3. Remove the high volta ge barrier; pull out on the lever of the captive fastener

then pull straight out on the barrier. Set the barrier aside for reinstallation.

4. Remove the fuses and install new fuses of th e same type and rating

(T,

1.6 A, 250 V, slow blow).

Figure 4-22 and the

Figure 4-22 Fuse Replacement

J1

S1

J4

NETWORK

INTERFACE

J2

U5

U9

CARD

5. Reinstall the high voltage barrier.

6. Close the controller cover and hand-tighten the four screws.

7. Reconnect power to the instrument.

J3

F1

J5

RELAYA

J6

NONO

F2

NCNCNC

NO

COMCOMCOM

RELAYCRELAYB

1

1. Fuses F1 and F2, T, 1.6 A, 250 V, slow blow

20

Disconnect

Power

Page 21

Section 5 Replacement Parts

Replacement Items

Item Cat. No.

Controller......................................................................................................................................................58600-00

Controller installation kit ...............................................................................................................................58672-00

Fuse, T, 1.6 A, 250 V, slow blow................................................................................................................... 52683-00

Instruction manual, English ..........................................................................................................................58600-18

Accessories

Sun shield.....................................................................................................................................................58690-00

Plug, conduit opening............................. ... .... ... ............................................................................................58687-00

Power cord with strain relief, 115 V ..............................................................................................................54488-00

Power cord with strain relief, 230 V .............................................................................................................54489-00

Strain relief, Heyco. ... ... .......................................... .... .......................................... .............................................16664

Digital output card for ModBUS RS232 communication...............................................................................59200-00

Digital output card for ModBUS RS485 communication...............................................................................59200-01

21

Page 22

Section 6 How to Order

U.S.A. Customers

By Telephone:

6:30 a.m. to 5:00 p .m. MST

Monday through Friday

(800) 227-HACH (800-227-4224)

By Fax:

(970) 669-2932

By Mail:

Hach Company

P.O. Box 389

Loveland, Colorado 80539-0389 U.S.A.

Ordering information by e-mail: orders@hach.com

Information Required

• Hach account number (if available) • billing address

• Your name and phone number • Shipping address

• Purchase order number • Catalog number

• Brief description or model number • Quantity

International Customers

Hach maintains a worldwide network of dealers and distributors. To locate the

representative neare st you, send an e-mail to: intl@hach.com or contact:

Hach Company World Headquarters; Loveland, Colorado, U.S.A.

Telephone: (970) 669-3050; Fax: (970) 669-2932

Technical and Customer Service (U.S.A. only)

Hach Technical and Customer Service Department personnel are eager to

answer questions about our products and their use. Specialists in analytical

methods, they are happy to put their talents to work for you.

Call 1-800-227-4224 or e-mail techhelp@hach.com

22

Page 23

Section 7 Repair Service

Authorization must be o btained from Ha ch Compan y before sending any items for

repair. Please contact the Hach Service Center serving your

In the United States:

Hach Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

(800) 227-4224 (U.S.A. only)

FAX: (515) 232-3835

In Canada:

Hach Sales & Service Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

(800) 665-7635 (Canada only)

Telephone: (204) 632-5598

FAX: (204) 694-5134

E-mail: canada@hach.com

location.

In Latin America, the Caribbean, the Far East, the

Indian Subcontinent, Africa, Europe, or the Middle East:

Hach Company World Headquarters,

P.O. Box 389

Loveland, Colorado, 80539-0389 U.S.A.

Telephone: (970) 669-3050

FAX: (970) 669-2932

E-mail: intl@hach.com

23

Page 24

Section 8 Limited Warranty

Hach Company warrants its products to the original purchaser against any defects that are due

to faulty material or workmanship for a period of *one year* from date of shipment unless

otherwise noted in the product manual.

The sc100 Controller is warranted for two years from the date of shipment.

In the event that a defect is disco vered during the warranty period, Hac h Company agrees that, at

its option, it will repair or replace the defective product or refund the purchase price, excluding

original shipping and handling charges. Any product repaired or replaced under this warranty

will be warranted only for the remainder of the original product warranty period.

This warranty does not apply to consumable products such as chemical reagents; or

consumable components of a product, such as, but not limited to, lamps and tubing.

Contact Hach Company or your distributor to initiate warranty support. Products may not be

returned without authorization from Hach Company.

Limitations

This warranty does not cover:

• Damage caused by acts of God, natural disaster, labor unrest, acts of war (declared or

undeclared), terrorism, civil strife or acts of any governmental jurisdiction

• Damage caused by misuse, neglect, accident or improper application or installation

• Damage caused by any repair or attempted repair not authorized by Hach Company

• Any product not used in accordance with the instructions furnished by Hach Company

• Freight charges to return merchandise to Hach Company

• Freight charges on expedited or express shipment of warranted parts or product

• Travel fees associated with on-site warranty repair

This warranty contains the sole express warranty made by Hach Company in connection with its

products. All implied warranties, including without limitation, the warranties of merchantability

and fitness for a particular purpose, are expressly disclaimed.

Some states within the United States do not allow the discla imer of implied warranti es and if this

is true in your state the above limitation may not apply to you. This warranty gives you specific

rights, and you may also have other rights that vary from state to state.

This warranty constitutes the final, complete, and exclusive statement of warranty terms and no

person is authorized to make any other warranties or representations on behalf of Hach

Company.

Limitation of Remedies

The remedies of repair, replacement or refund of purchase price as stated above are the

exclusive remedies for the breach of this warranty. On the basis of strict liability or under any

other legal theory, in no event shall Hach Company be liable for any incidental or consequential

damages of any kind for breach of warranty or negligence.

24

Page 25

Section 7 Compliance Information

Hach Co. certifies this instrument was tested thoroughly, inspected, and found to

meet its published specifications when it was shipped from the factory.

The Model SC-100 has been tested and is certified as indi cate d to the following

instrumentation standards:

Product Safety

UL 61010A-1 (ETL Listing # 65454)

CSA C22.2 No. 1010.1 (ETLc Certification # 65454)

Certified by Hach Co. to EN 61010-1 Amds. 1 & 2 (IEC1010-1) per

73/23/EEC, supporting test records by Intertek Testing Services.

Immunity

This equipment was tested for Industrial level EMC per:

EN 61326 (EMC Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use)

records by Hach Company, certified compliance by Hach Company.

per 89/336/EEC EMC: Supporting test

Emissions

Standards include :

IEC 1000-4-2:1995 (EN 61000-4-2:1995) Electrostatic Discharge Immunity

(Criteria B)

IEC 1000-4-3:1995 (EN 61000-4-3:1996) Radiated RF Electromagnetic Field

Immunity (Criteria A)

IEC 1000-4-4:1995 (EN 61000-4-4:1995) Electrical Fast Transients/Burst

(Criteria B)

IEC 1000-4-5:1995 (EN 61000-4-5:1995) Surge (Criteria B)

IEC 1000-4-6:1996 (EN 61000-4-6:1996) Conducted Disturbances Induced

by RF Fields (Criteria A)

IEC 1000-4-11:1994 (EN 61000-4-11:1994) Voltage Dip/Short Interruptions

(Criteria B)

Additional Immunity Standard/s include:

ENV 50204:1996 Radiated Electromagnetic Field from Digital Telephones

(Criteria A)

This equipment was tested for Radio Frequency Emissions as follows:

Per 89/336/EEC EMC: EN 61326:1998 (Electrical Equipment for

measurement, control and laboratory use—EMC requirements) Class “A”

emission limits. Supporting test records by Hewlett Packard, Fort Collins,

Colorado Hardware Test Center (A2LA # 0905-01) and certified compliance

by Hach Company.

Standards include :

EN 61000-3-2 Harmonic Disturbances Caused by Electrical Equipment

EN 61000-3-3 V oltage Fluct uation (Flick er) Disturbances Caused b y Electrical

Equipment

25

Page 26

Compliance Information

Additional Emissions Standard/s include:

EN 55011 (CISPR 11), Class “A” emission limits

Canadian Interference-causing Equipment Regulation, IECS-003, Class A

Supporting test records by Hewlett Packard, F ort Collins, Colorado Hardware Test

Center (A2LA # 0905-01) and certified compliance by Hach Company.

This Class A digital apparatus meets all requirements of the Canadian

Interference-cau sing Equipment Regulations.

Cet appareil numèrique de la classe A respecte toutes les exigences du

Rëglement sur le matÈriel brouilleur du Canada.

FCC PART 15, Class “A” Limits

Supporting test records by Hewlett Packard, Fort Collins, Colorado Hardware Test

Center (A2LA # 0905-01) and certified compliance by Hach Company.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and (2) this device must

accept any interfer ence receiv ed, including interf er ence that ma y cause undesired

operation.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable pr otection against harmful interf erence when th e equipment is

operated in a commercial en vir on men t. This e qu ipme nt ge nerates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense. The following techniques of re ducing the interference problems

are applied easily.

1. Disconnect the Model sc100 Controller from its power source to verify that it is

or is not the source of the interference.

2. If the Model sc100 Controller is connected into the same outlet as the device

with which it is interfering, try another outlet.

26

3. Move the Model sc100 Controller away from the device receiving the

interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

Page 27

Index

A

Alarms ......................................................................... 15

Analog Outputs

............................................................16

C

Cleaning

Controller

Compliance Information

Components

Customer Supplied

Controller

Enclosure Description

.............................................................. 20

.............................................. 25

................................................. 5

.............................................4

D

Digital Output ...............................................................18

E

Electrical Installation .................................................... 11

Conduit

Connecting/Wiring the Sensor Cable

Hard-wiring the Sensor

Power Cord

..................................................................11

.................... 17

......................................... 17

........................................................... 11

F

Fuse

Rating

....................................................................20

Replacement

......................................................... 20

H

hard-wired electrical applications ................................11

I

Installation ..................................................................... 6

Controller

Panel

Panel Mounting

Pipe Mounting

Wall Mounting

................................................................ 9

....................................................................... 7

..................................................... 10

......................................................... 9

......................................................... 9

M

ModBUS RS232 .................................................... 18, 21

ModBUS RS485

.......................................................... 21

O

Output

Connections

Outputs

........................................................................ 16

.......................................................... 16

P

Parts ............................................................................ 21

R

Relays ......................................................................... 15

Connecting

Specifications

Repair Service

Replacement

............................................................ 15

.......................................................... 3

............................................................. 23

............................................................... 21

S

Specifications ................................................................ 3

Sun Shield

..................................................................... 8

W

Wire preparation .......................................................... 12

27

Page 28

Visit http: //www.hach.com

Loading...

Loading...